Patents

Literature

1514 results about "Expansion tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An expansion tank or expansion vessel is a small tank used to protect closed (not open to atmospheric pressure) water heating systems and domestic hot water systems from excessive pressure. The tank is partially filled with air, whose compressibility cushions shock caused by water hammer and absorbs excess water pressure caused by thermal expansion.

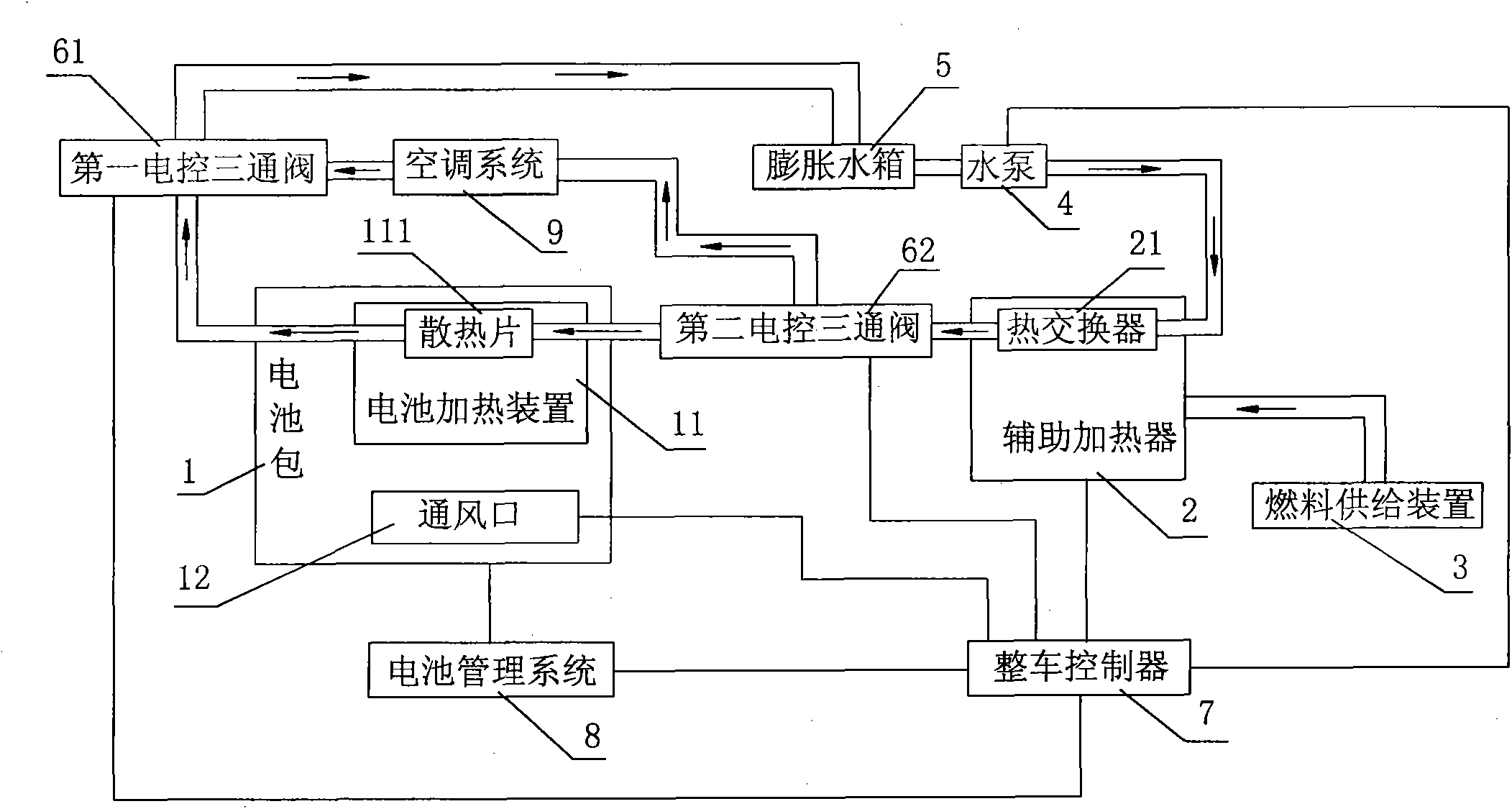

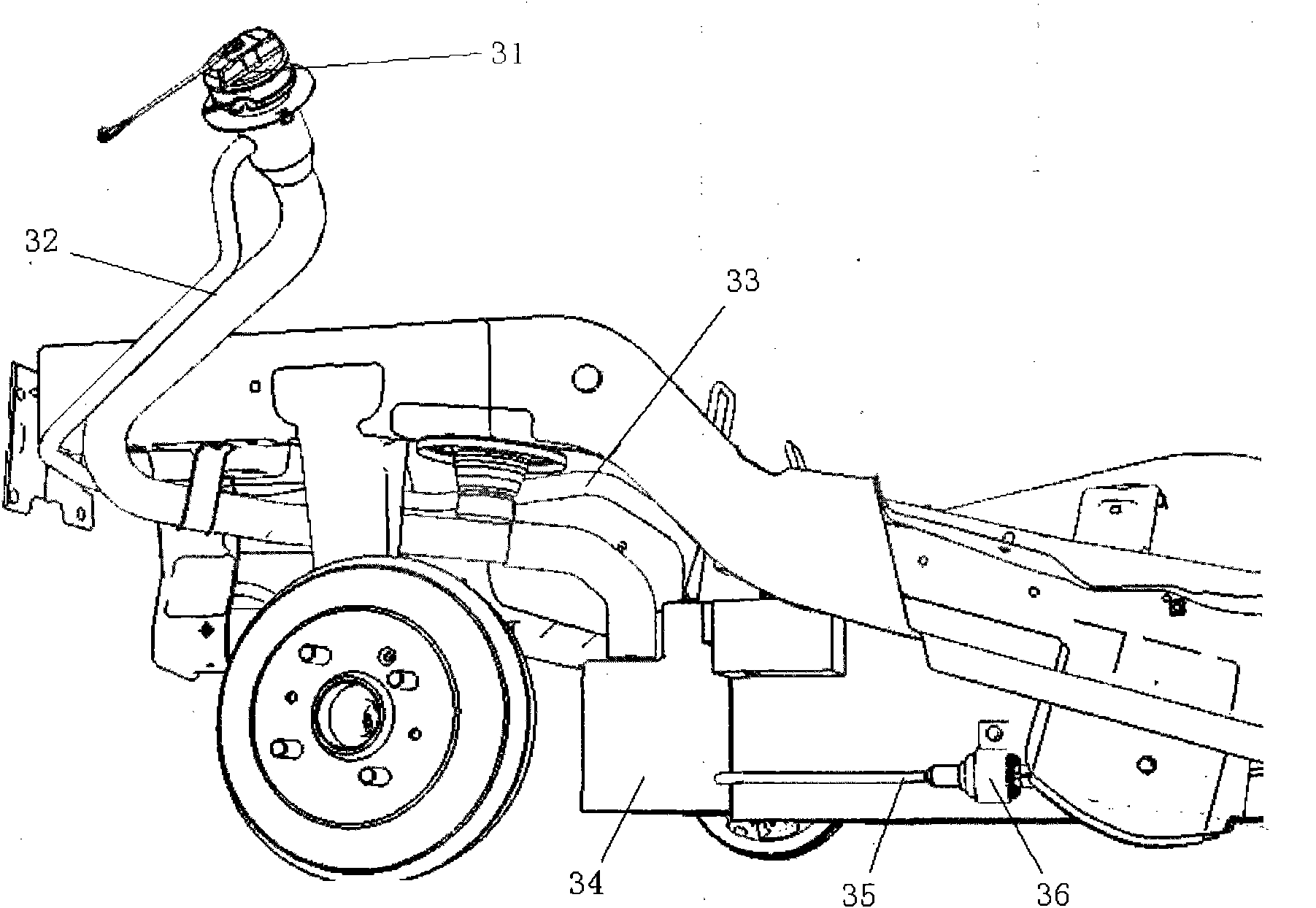

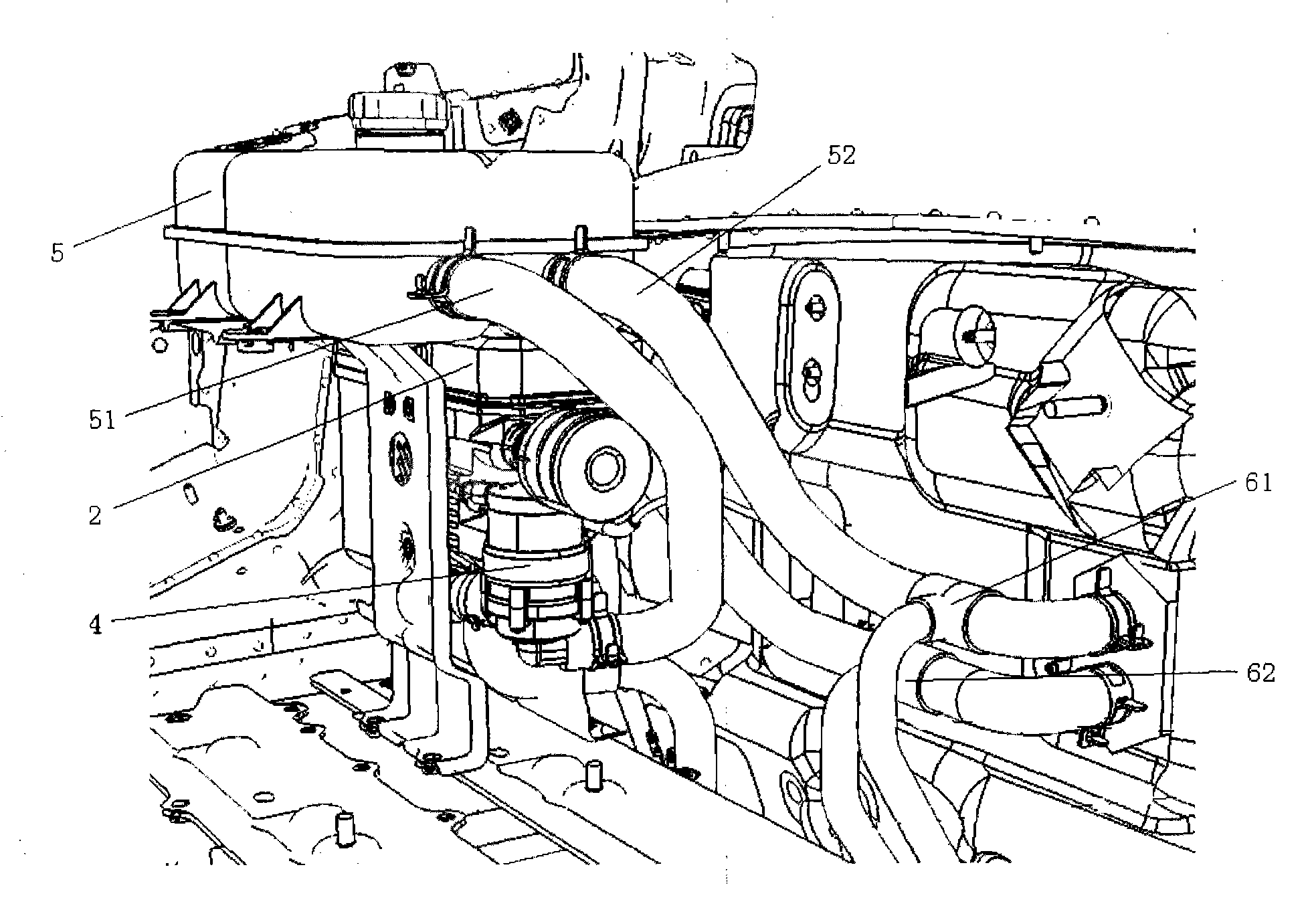

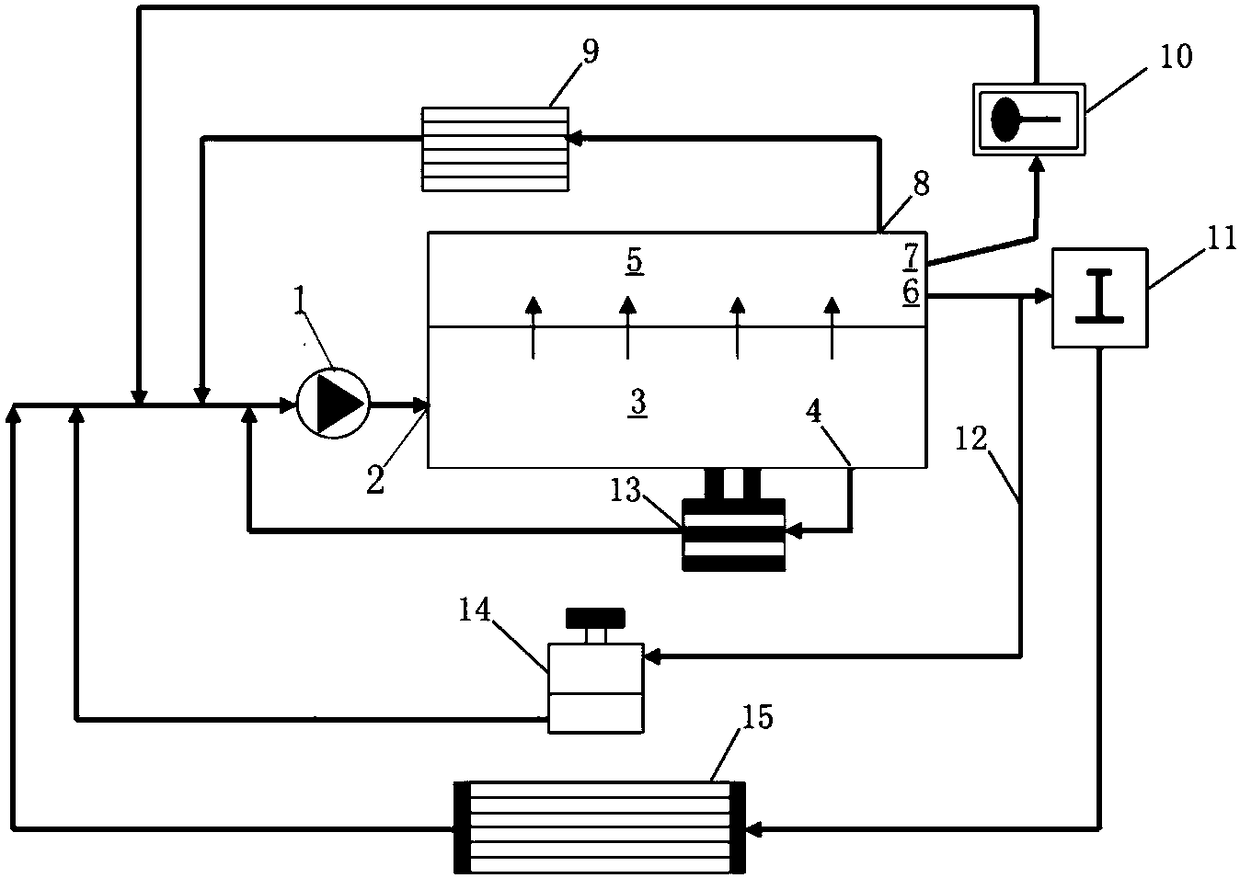

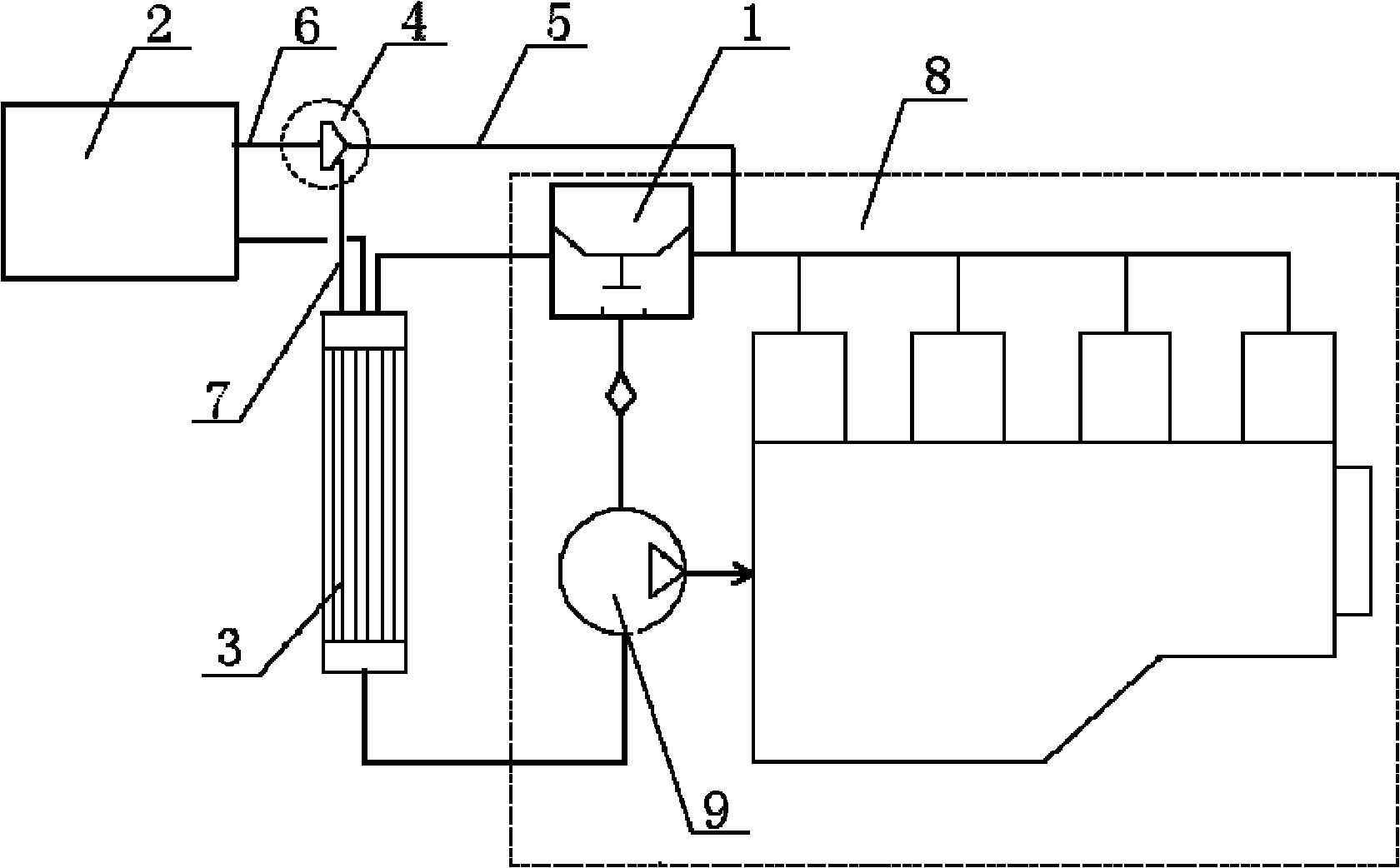

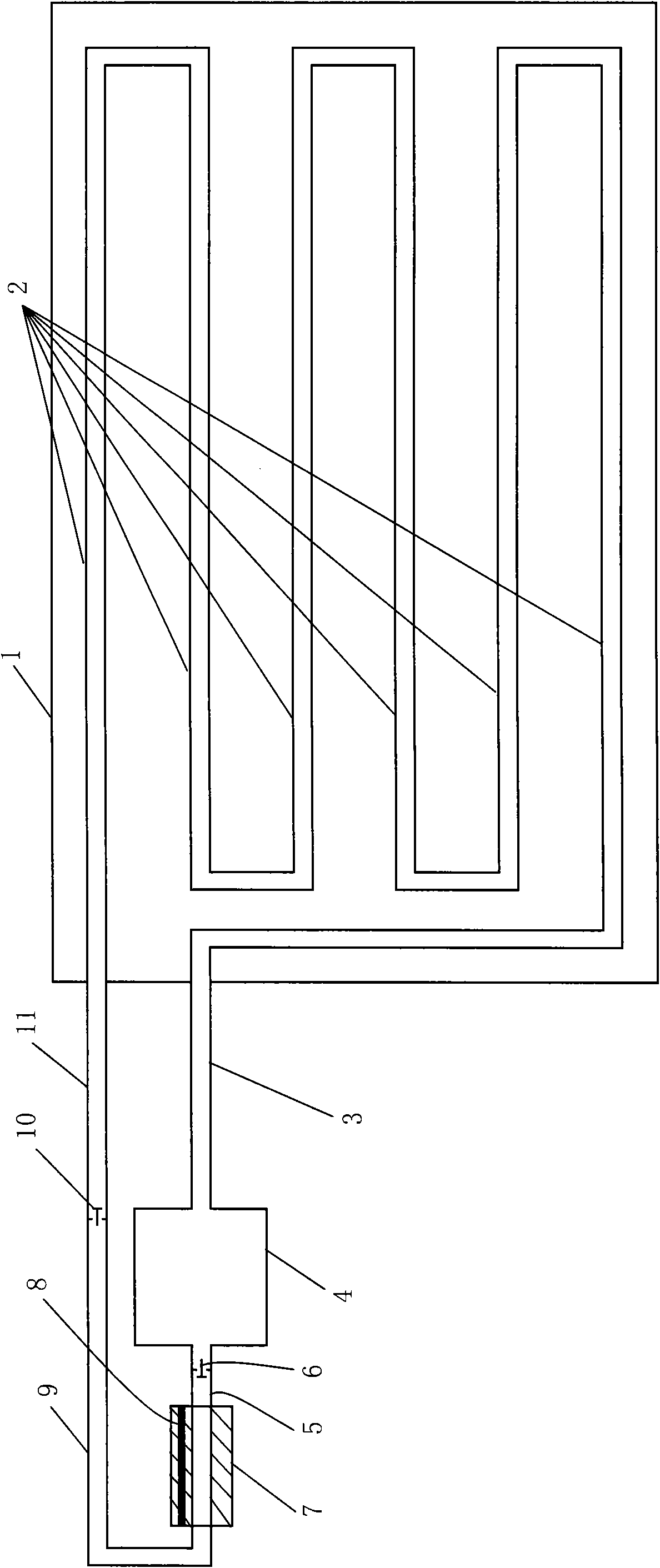

Heating system of power battery of pure electric automobile and control method thereof

ActiveCN101962000AGuaranteed to be heatedDoes not consume powerAir-treating devicesCell temperature controlExpansion tankPower battery

The invention aims to provide a heating system of a power battery of a pure electric automobile and a control method thereof, which are used for eliminating the influence of low temperature on the performance of the power battery of the pure electric automobile to ensure that the pure electric automobile can be used in severe cold areas in winter. The heating system comprises a battery heating device which is arranged in a battery pack, wherein the battery heating device is provided with a hollow radiating fin; and the radiating fin is provided with a water inlet and a water outlet. The heating system is characterized by also comprising an auxiliary heater, wherein the auxiliary heater is connected with a fuel supply device; a heat exchanger is arranged in the auxiliary heater; the water inlet of the heat exchanger is communicated with the water outlet of an expansion water tank by a water pump and a water pipe; the water outlet of the heat exchanger is communicated with the water inlet of the radiating fin by an electric control valve; the water outlet of the radiating fine is communicated with the water inlet of the expansion water tank; the electric control valve, the auxiliary heater and the water pump are connected with a vehicle controller and are controlled by the vehicle controller; and the vehicle controller is also connected with a battery management system.

Owner:奇瑞新能源汽车股份有限公司

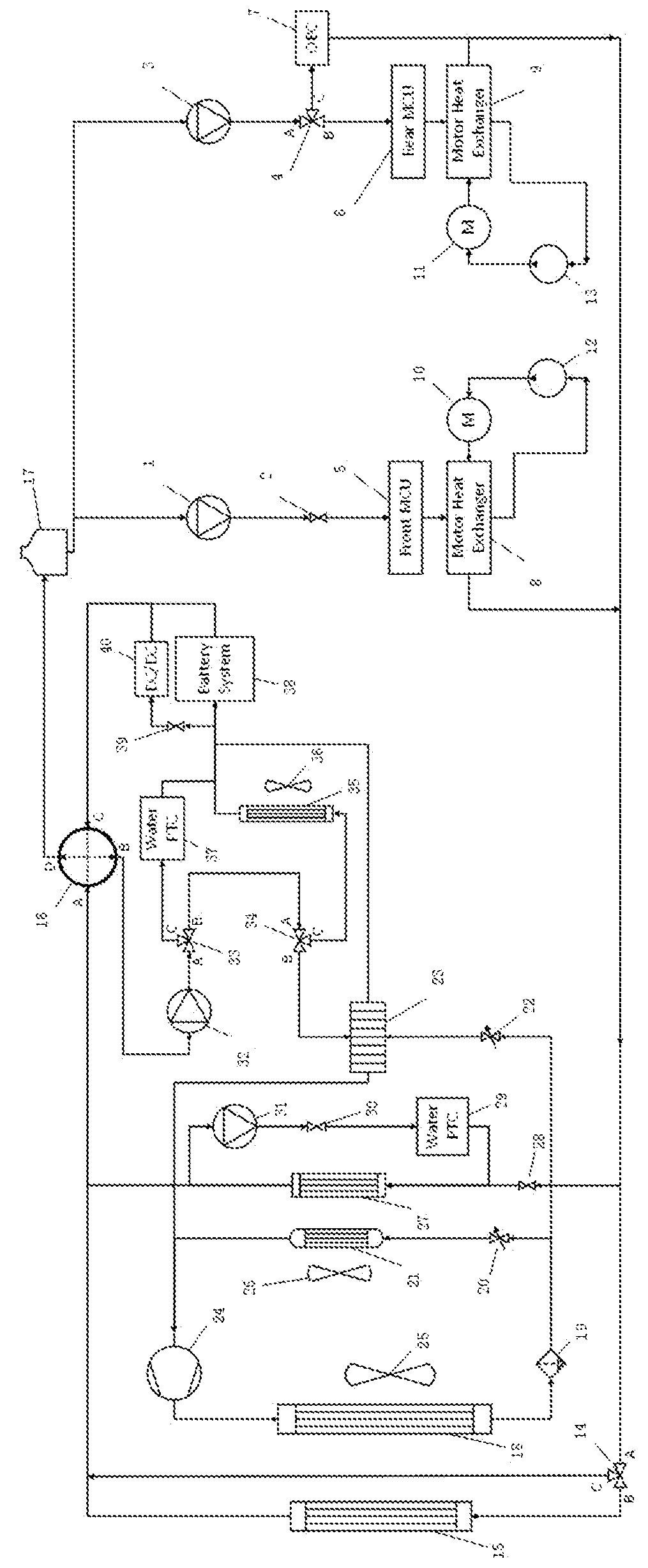

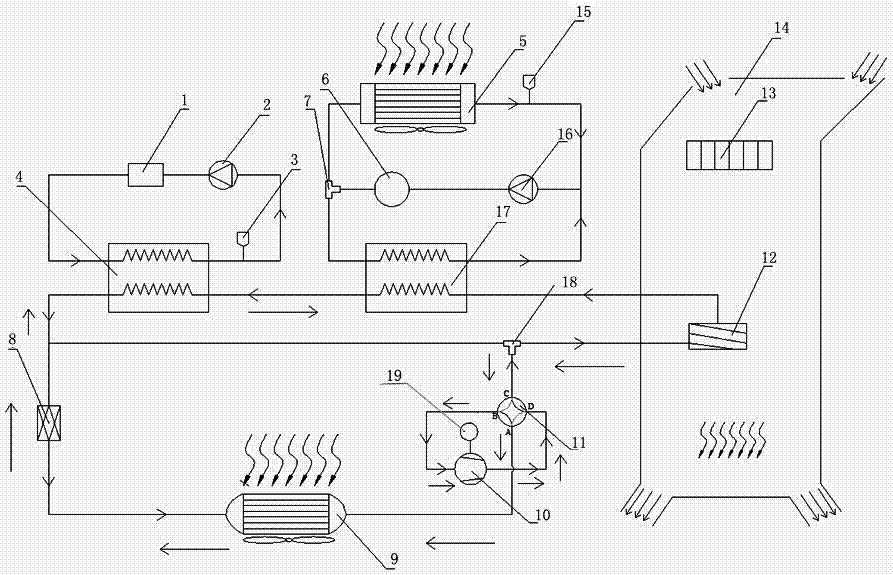

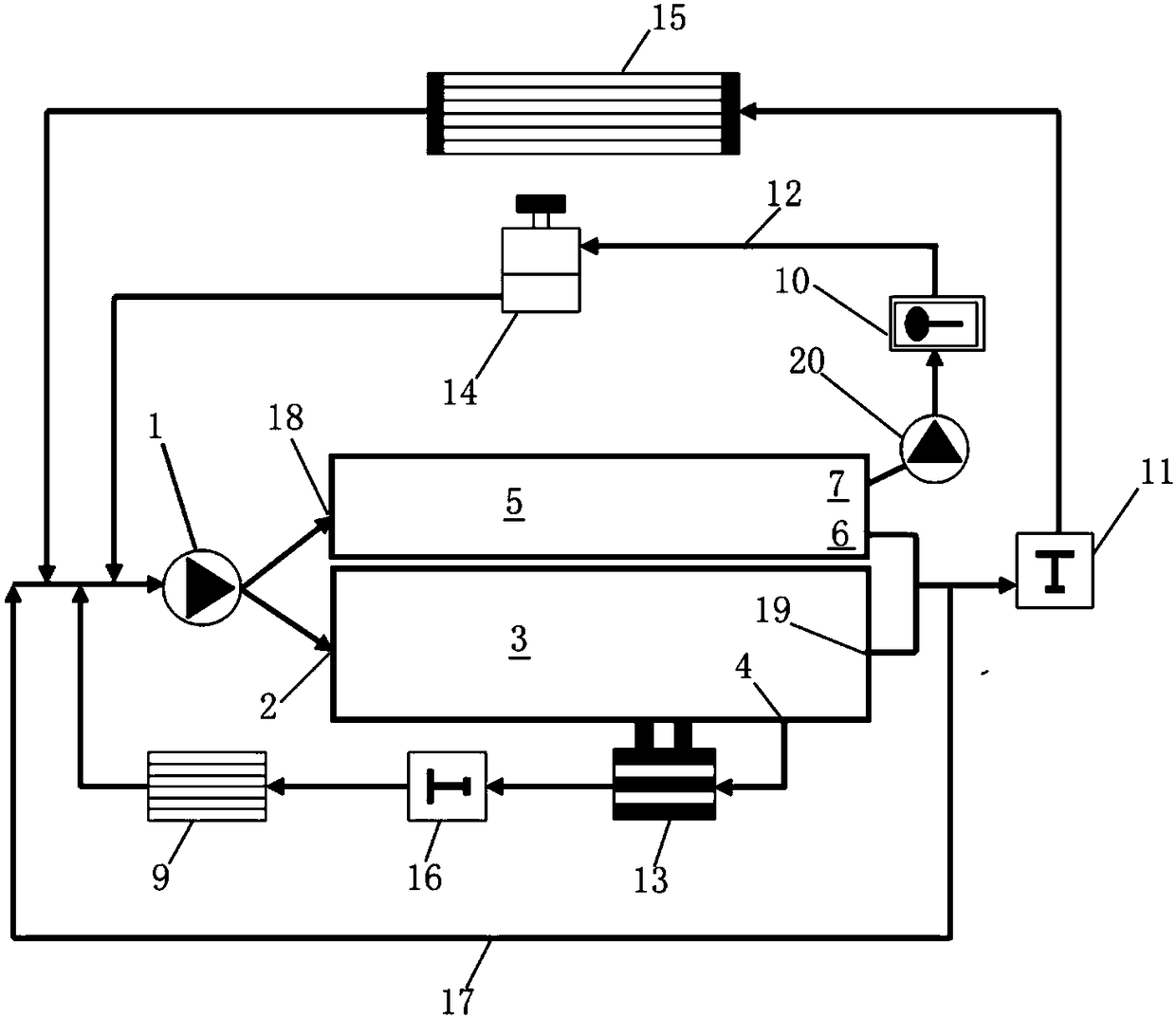

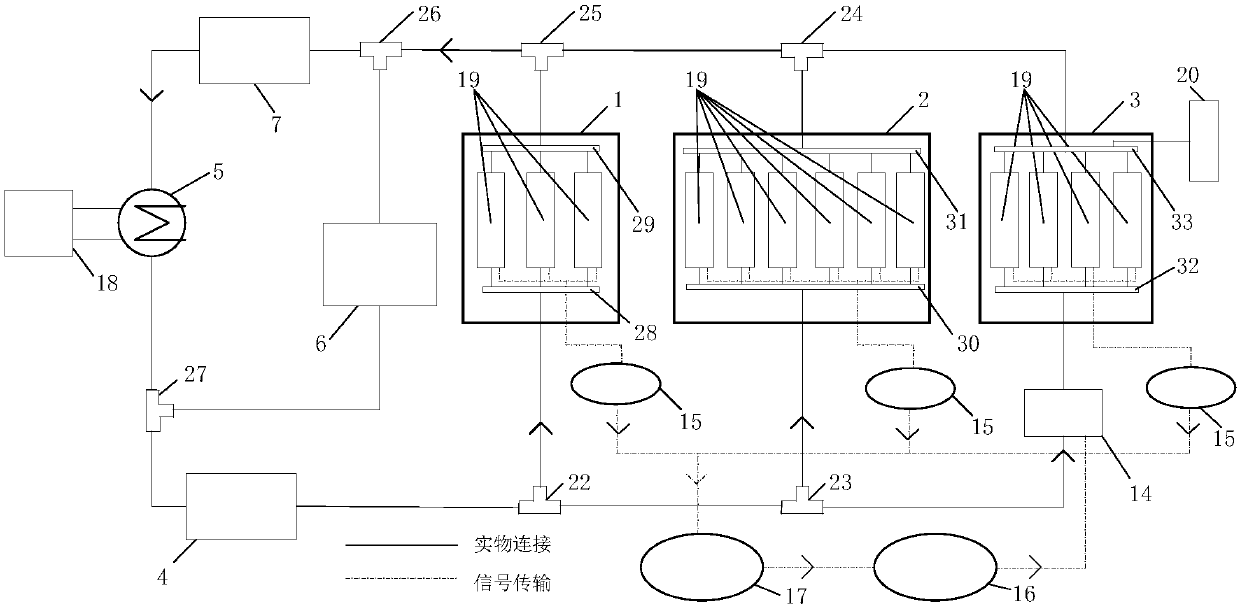

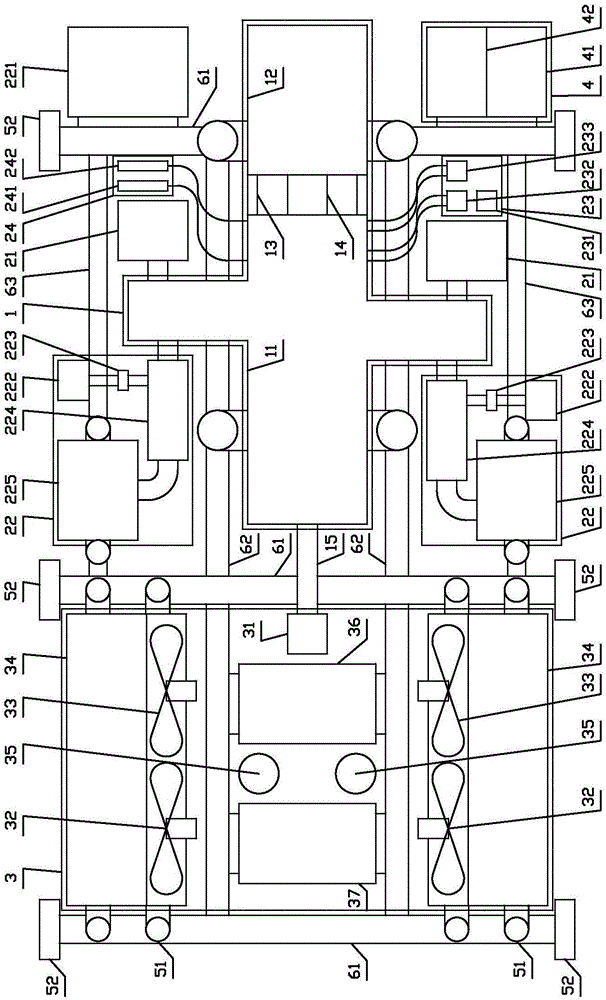

Intelligent multi-loop thermal management system for an electric vehicle

InactiveUS20180178615A1Meet different requirementsEasy to operatePower to auxillary motorsPropulsion by batteries/cellsIntelligent lightingExpansion tank

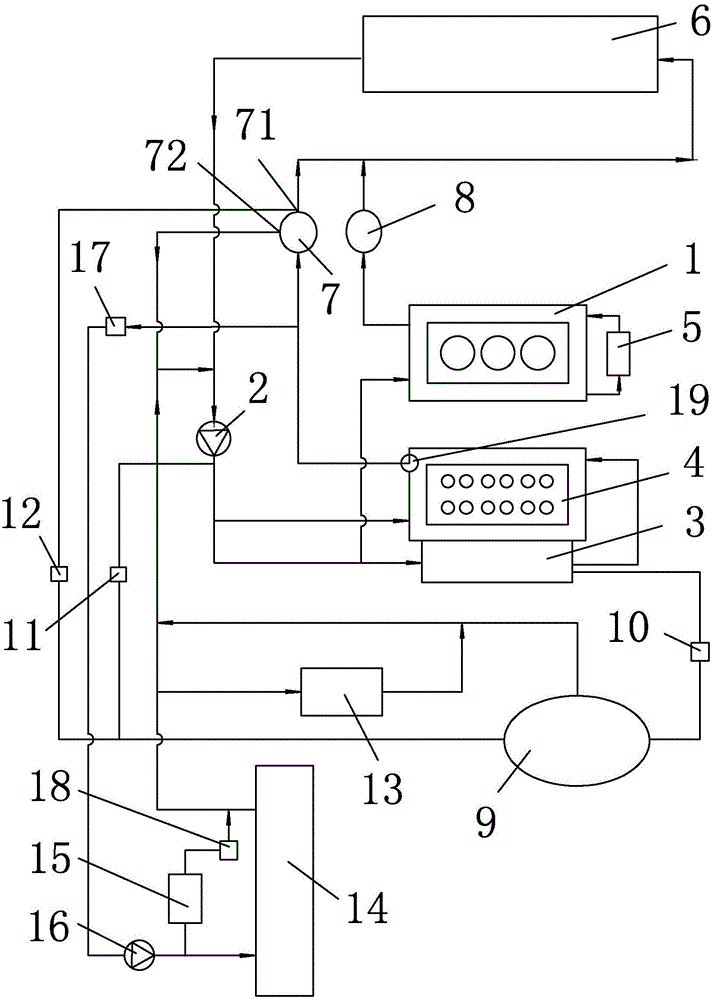

An intelligent multi-loop thermal management system for and electric vehicle has components including a battery pack, an electric-drive module, an on-board charger a DC / DC converter, a battery radiator, a battery refrigerator, a motor radiator, an electric water pump, an electric oil pump, an expansion tank, a PTC heater, a heat exchanger, an electric compressor, a condenser, an evaporator, a receiver drier, and a heater core. The system also includes an electric-drive module having a drive motor and a motor control unit. The components are thermally connected to each other by using a pipeline and a four-way valve, a three-way valve, a straight-through valve, and an electronic expansion valve that are disposed in the pipeline, to form a plurality of loops that separately performs thermal management and control the battery pack, the electric-drive module, and a passenger compartment air conditioner.

Owner:BORDRIN MOTOR CORP

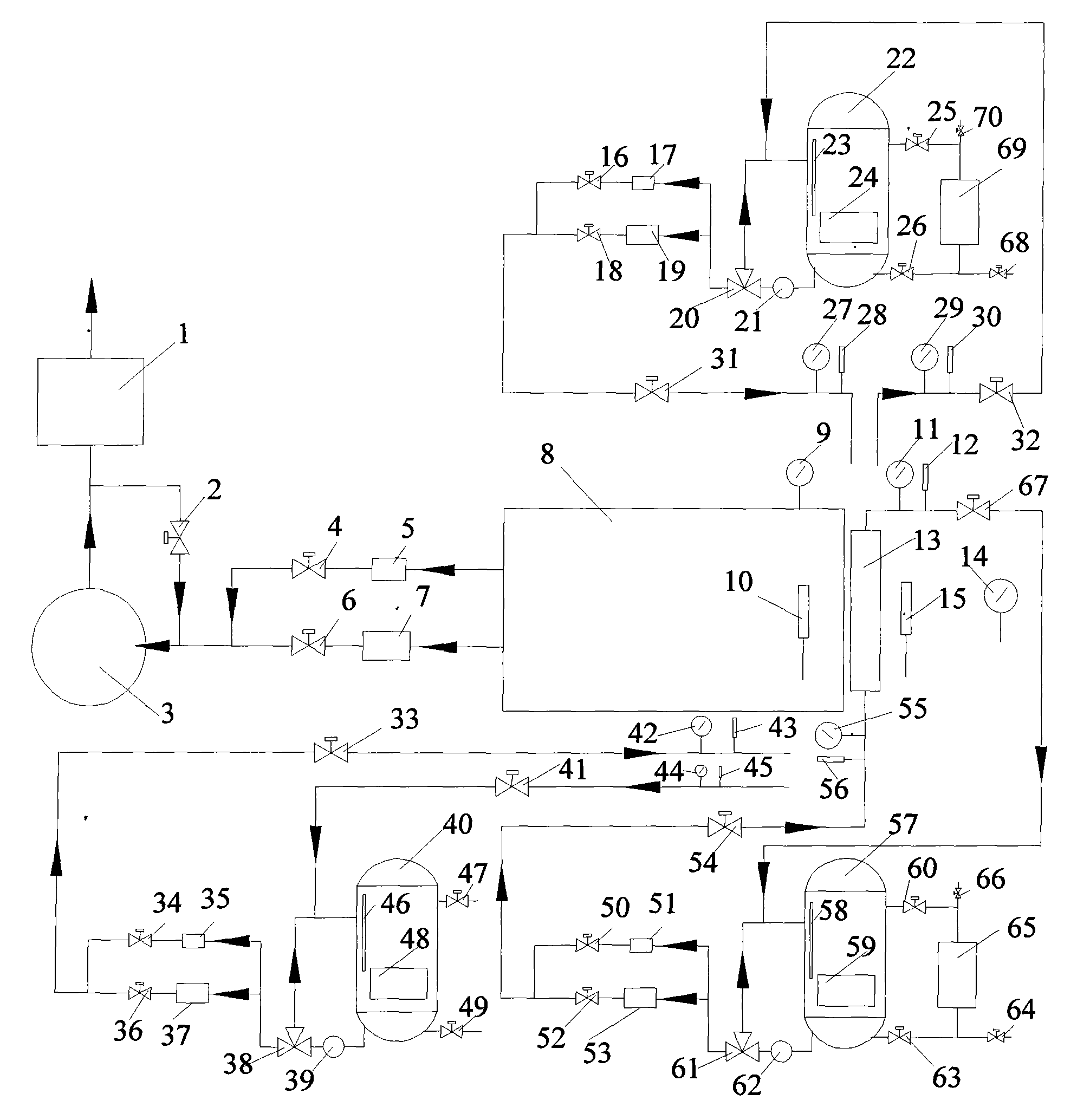

High-heat-discharge-quantity refrigerating and heating temperature control system for reaction kettle

ActiveCN103983041ACompact structureReasonable structureMechanical apparatusEfficient regulation technologiesExpansion tankVapor–liquid separator

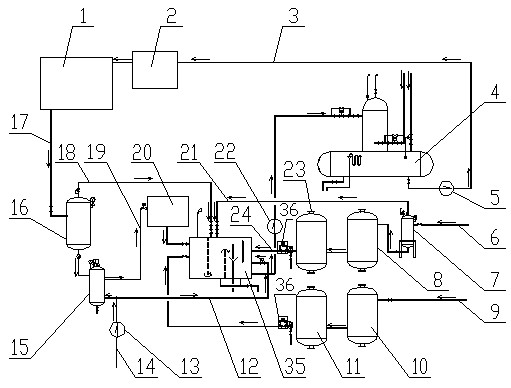

The invention relates to a high-heat-discharge-quantity refrigerating and heating temperature control system for a reaction kettle. The high-heat-discharge-quantity refrigerating and heating temperature control system comprises a reaction kettle, wherein one end of the reaction kettle is sequentially connected with a heating pipe, an electric proportioning regulating valve, a first cold storage tank and an evaporation heat exchanger through a fourth pipeline, the output end of the evaporation heat exchanger is sequentially connected with a first circulation pump, a first one-way valve, an expansion tank and an exhaust valve through a first pipeline, the exhaust valve is connected to the other end of the reaction kettle through a fifth pipeline, the two ends of the evaporation heat exchanger are connected with a refrigerating machine, the refrigerating machine is structurally characterized in that one end of the evaporation heat exchanger is sequentially connected in series with a gas-liquid separator, a compressor, an oil separator, a condenser, a drying filter, a second cold storage tank, an electromagnetic valve and an expansion valve through a third pipeline, the outer end of the expansion valve is connected with the other end of the evaporation heat exchanger through an eighth pipeline, the refrigerating machine is positioned between the electromagnetic valve and the second cold storage tank and is connected with the third pipeline through the second pipeline, and an electronic expansion valve is arranged on the second pipeline. The work reliability is good.

Owner:WUXI GUANYA REFRIGERATION TECH

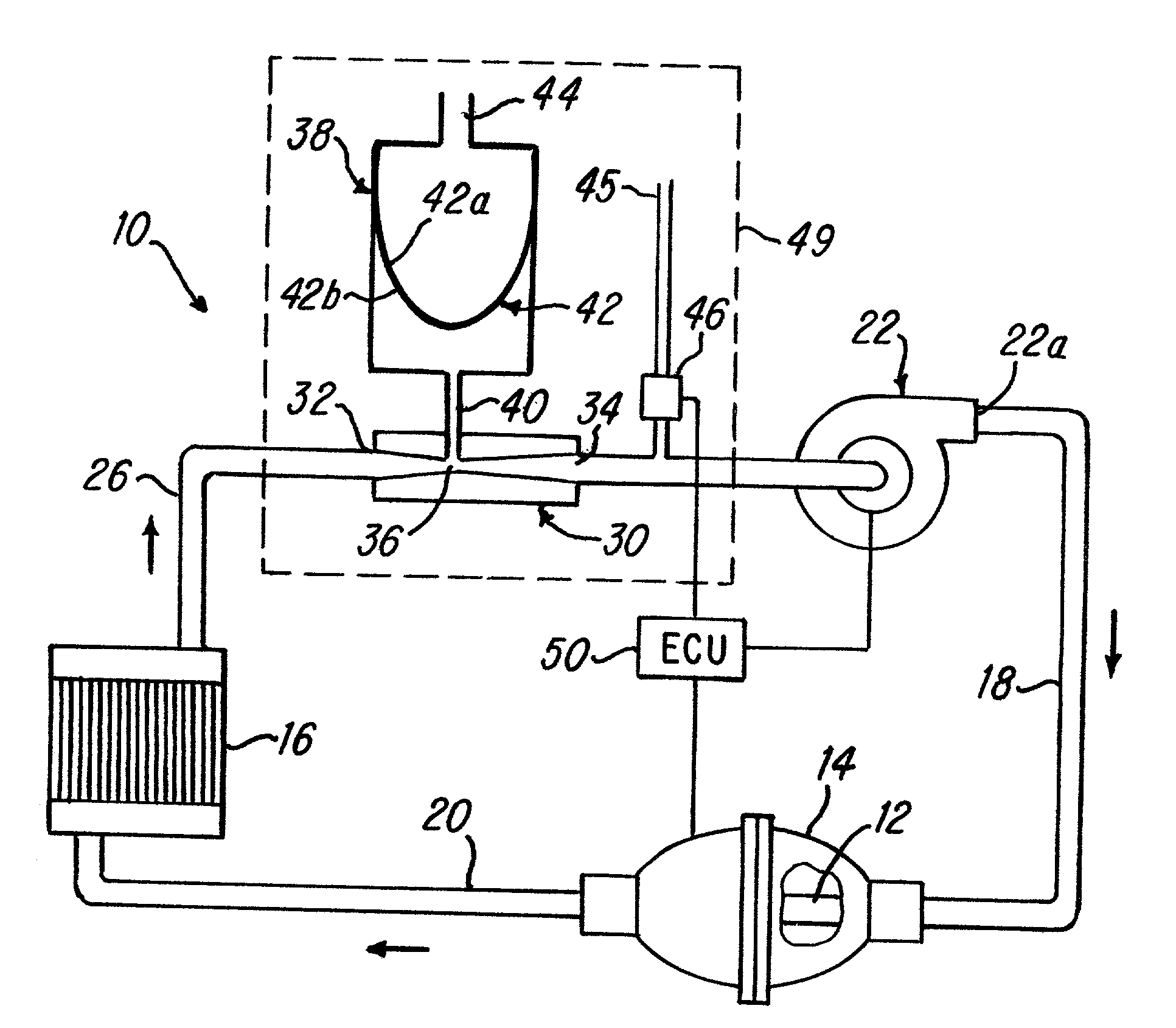

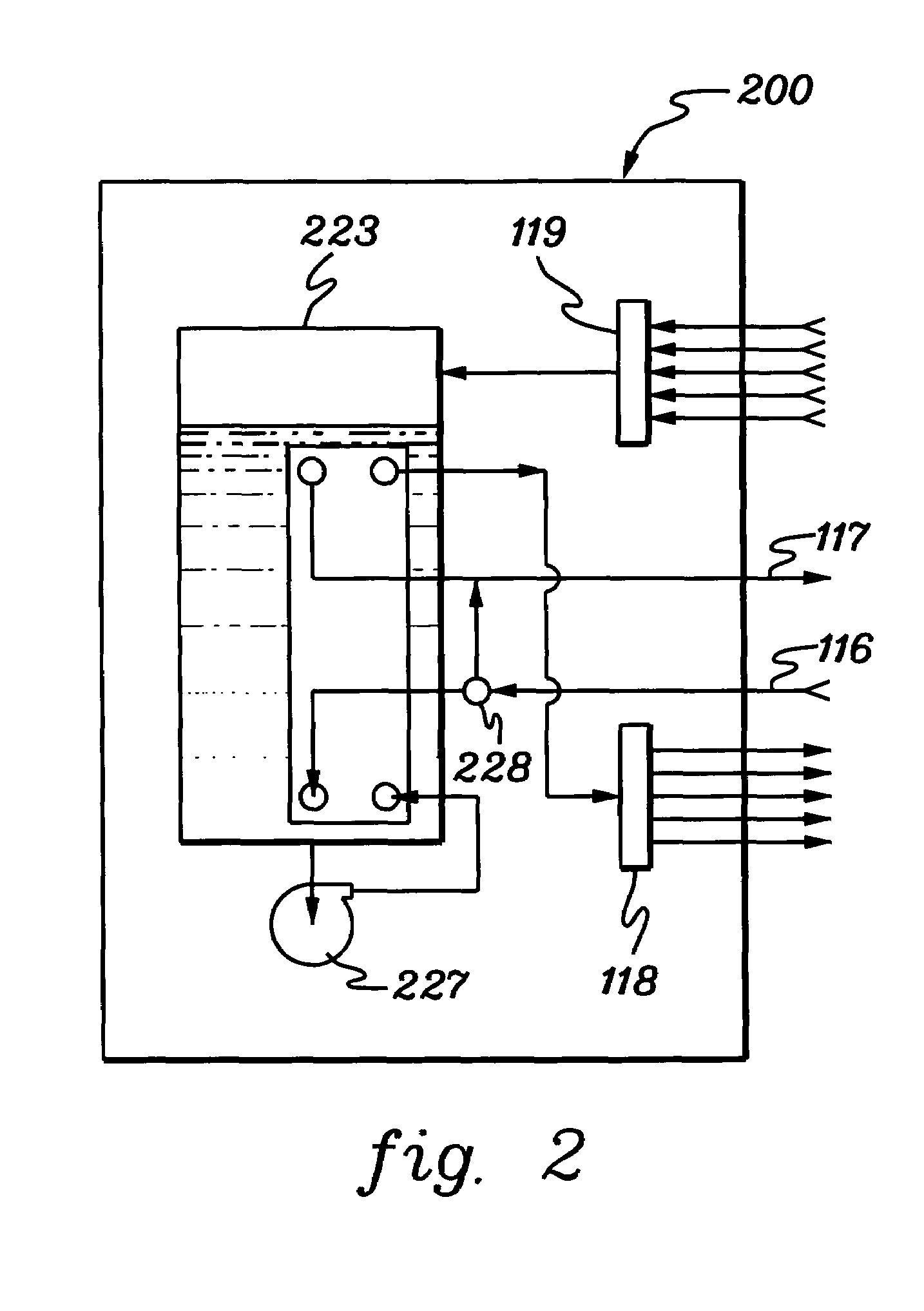

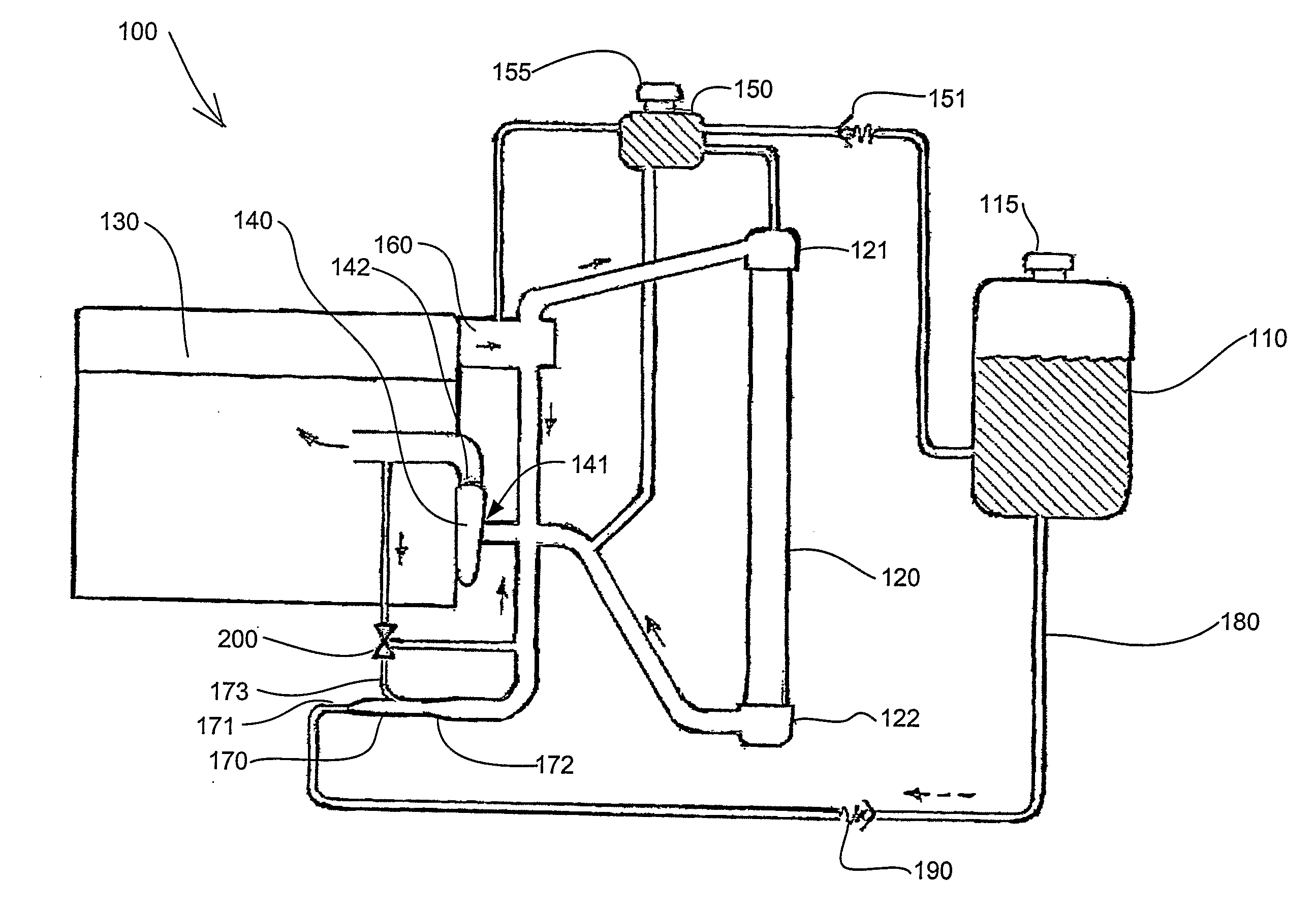

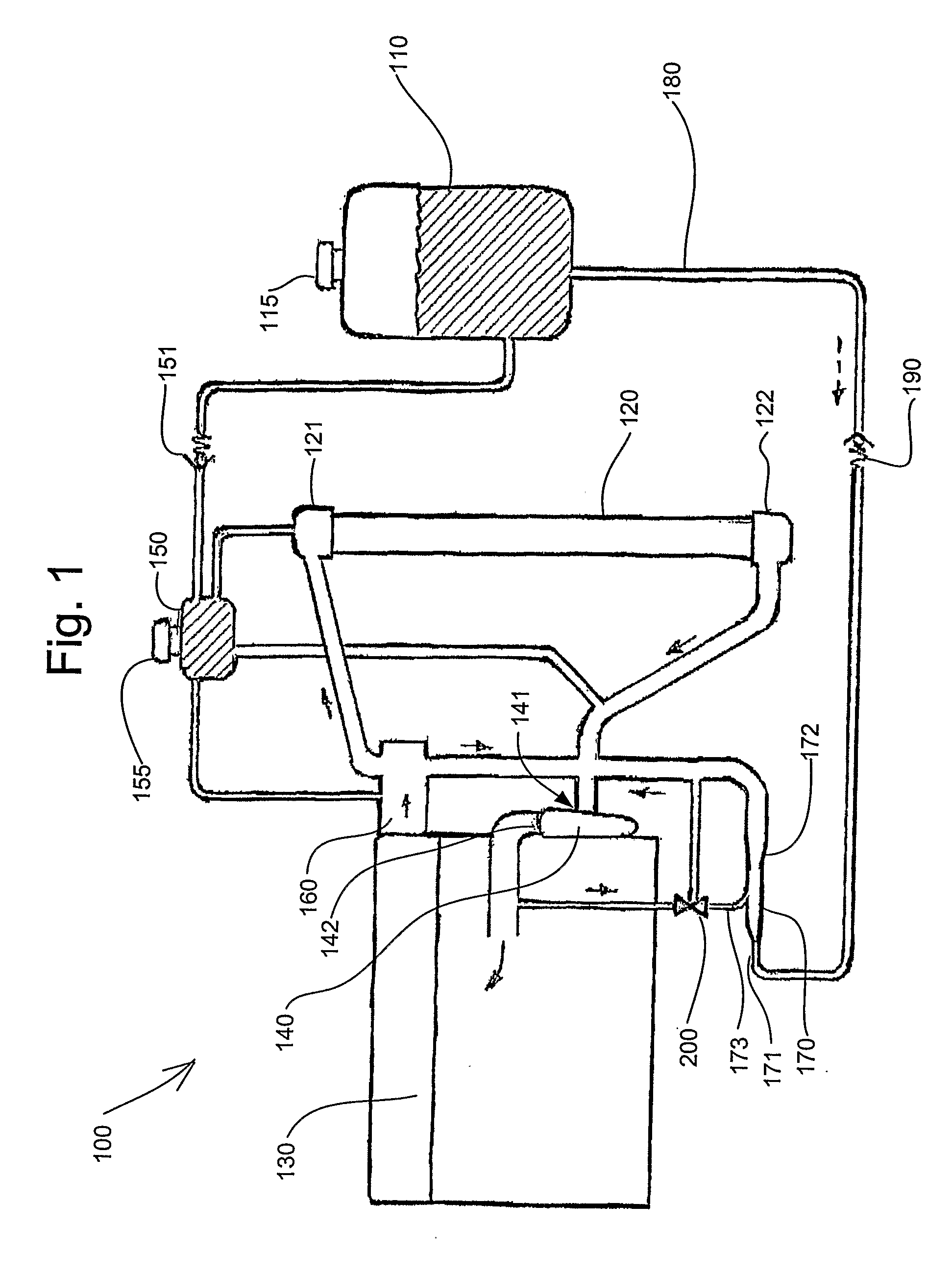

Method and system for cooling heat-generating component in a closed-loop system

A system and method for improving cooling of a heat-generating component in a closed-loop cooling system is shown. The system comprises a venturi having a throat which is coupled to an expansion tank that is exposed to atmospheric pressure in the embodiment being described. The venturi, when used with a pressure switch, can operate to determine a flow rate which can be used to generate a signal which in turn is used to activate or deactivate one or more of the components, such as the heat-generating component, in the system. Also shown is another embodiment wherein a circular venturi is provided to permit a venturi passageway to be defined about an axis of the pump in order to shorten the overall length of the pump and venturi combination.

Owner:TARK

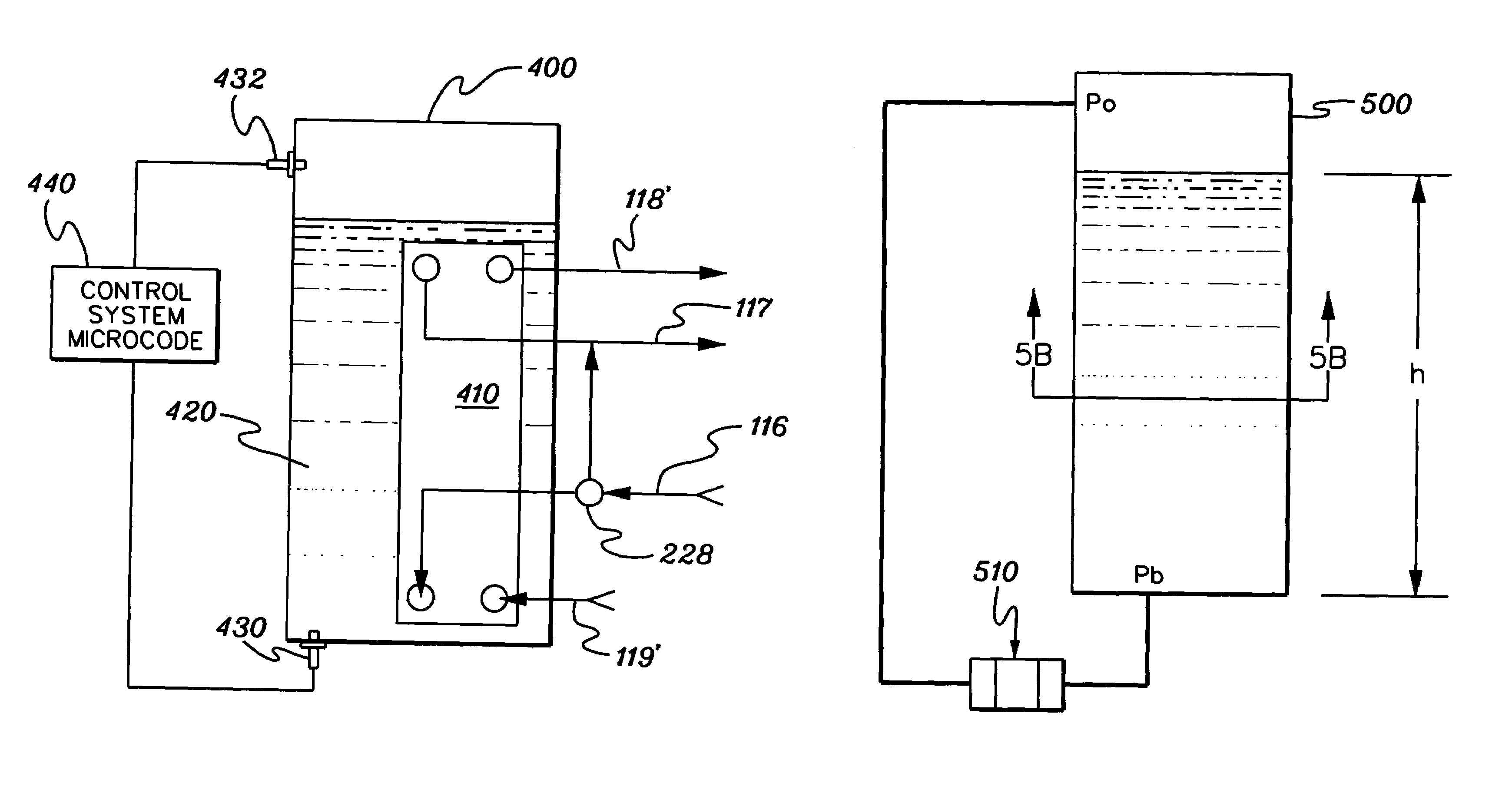

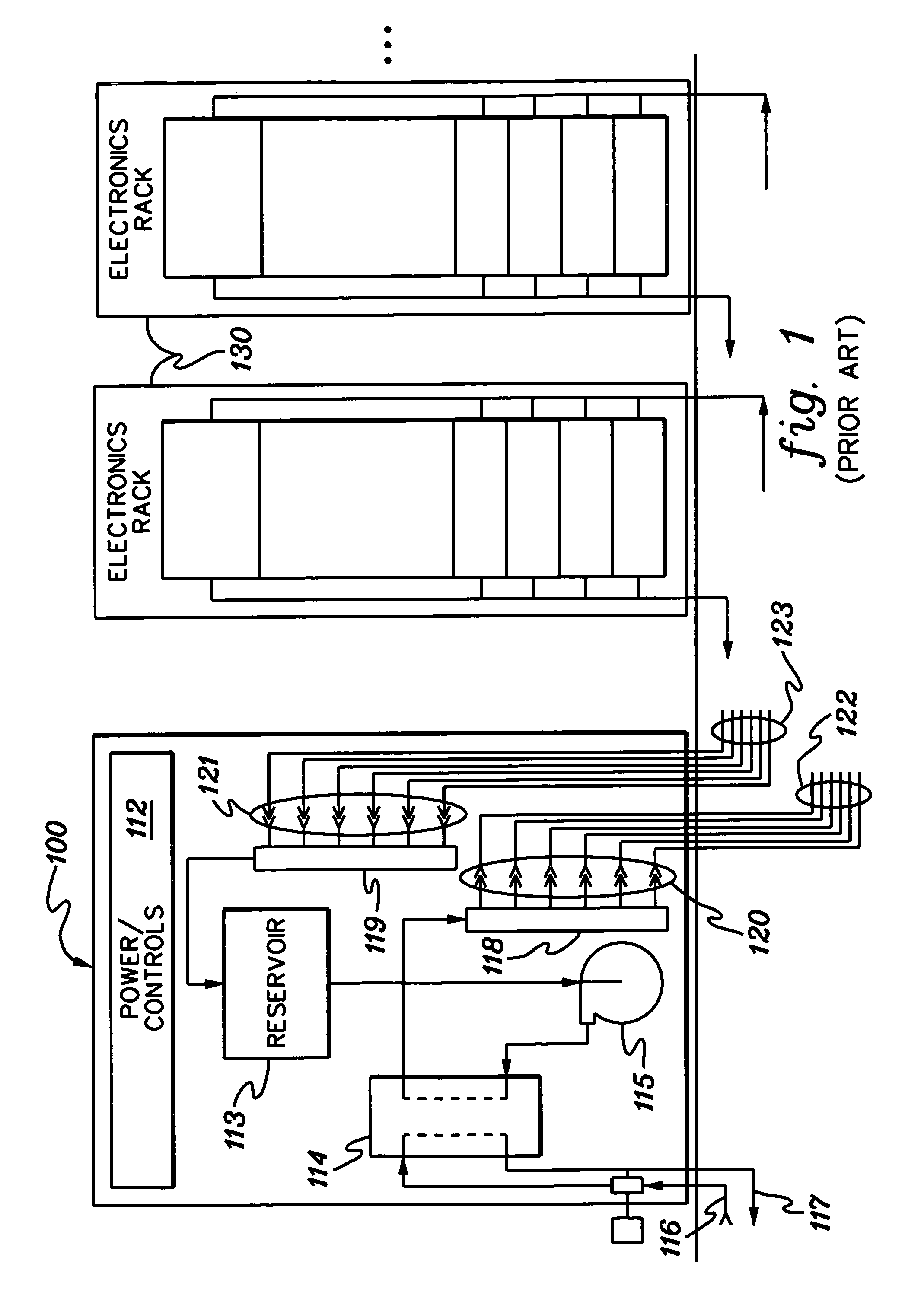

Method, system and program product for monitoring rate of volume change of coolant within a cooling system

InactiveUS7000467B2Detection of fluid at leakage pointDigital data processing detailsExpansion tankSystems design

Method, system and program product are provided for monitoring coolant within a cooling system designed to provide system coolant to one or more electronics subsystems. The monitoring technique includes employing at least one pressure transducer to obtain multiple pressure measurements related to an amount of coolant within an expansion tank of the cooling system, and determining a rate of volume change of coolant within the expansion tank employing the multiple pressure measurements. Successive pressure measurements can be taken at a known time interval to determine the rate of volume change of coolant within the expansion tank. An automatic determination can also be made on the immediacy of action to be taken for service of the cooling system based on the rate of volume change of coolant within the expansion tank.

Owner:IBM CORP

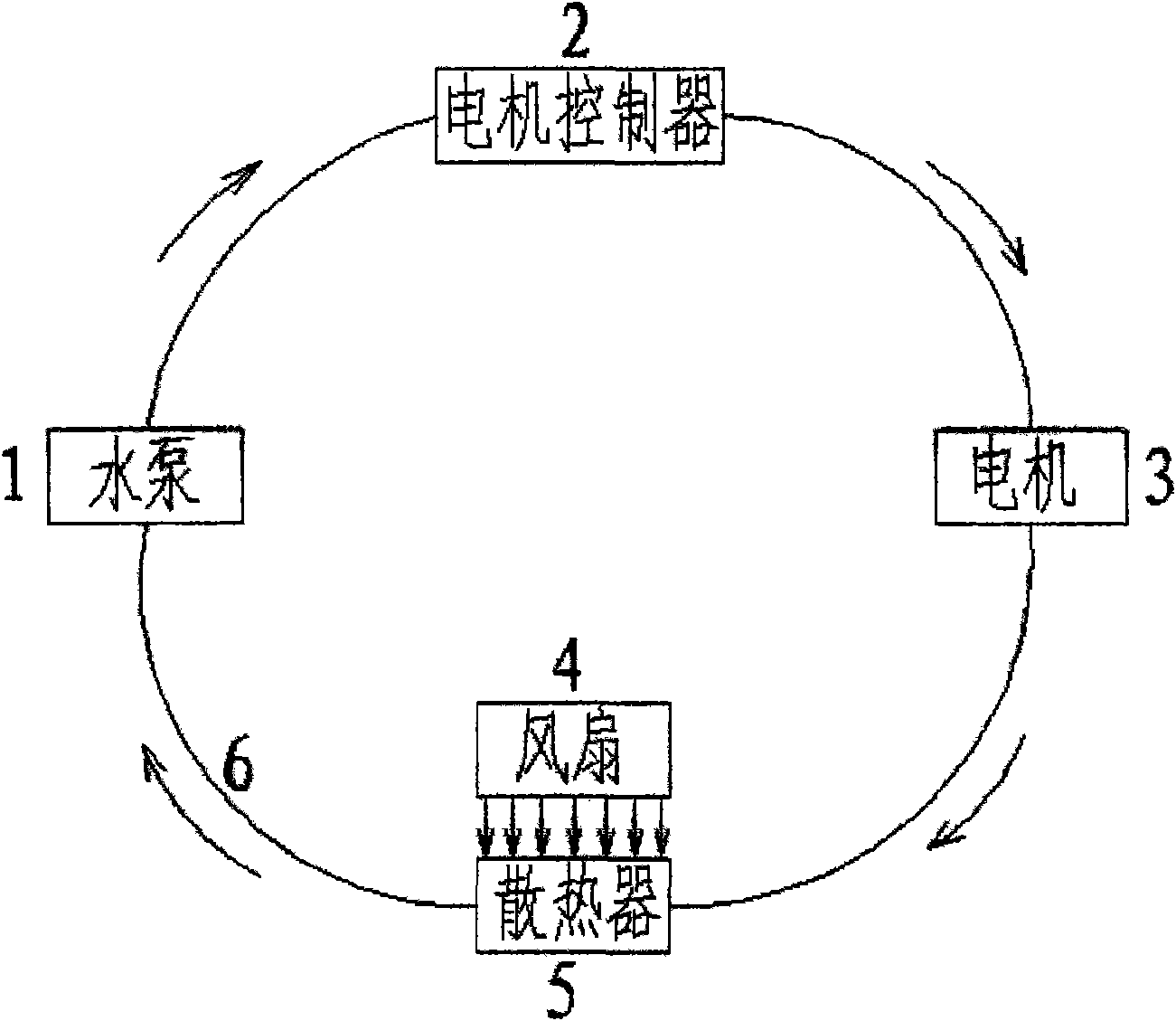

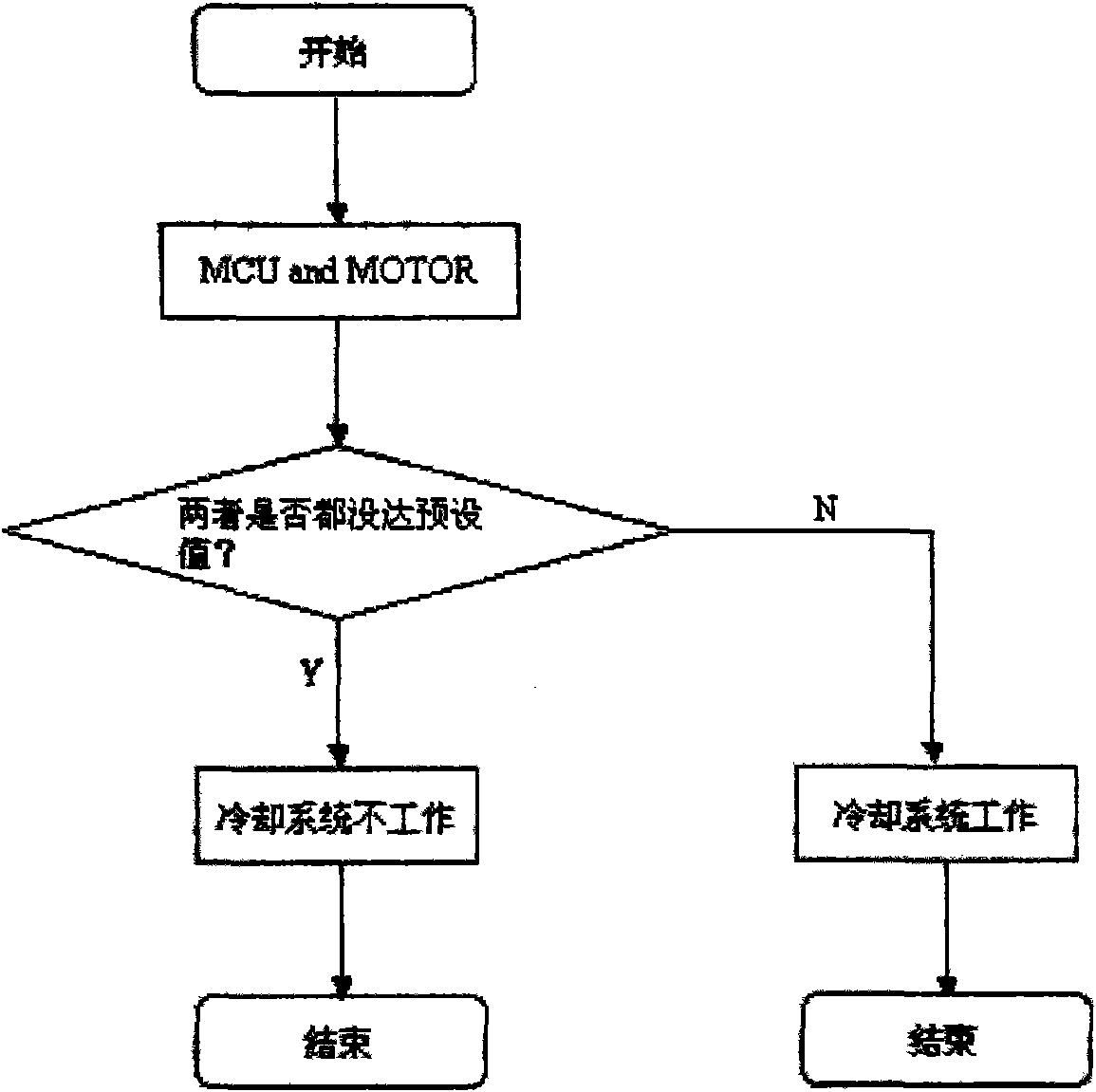

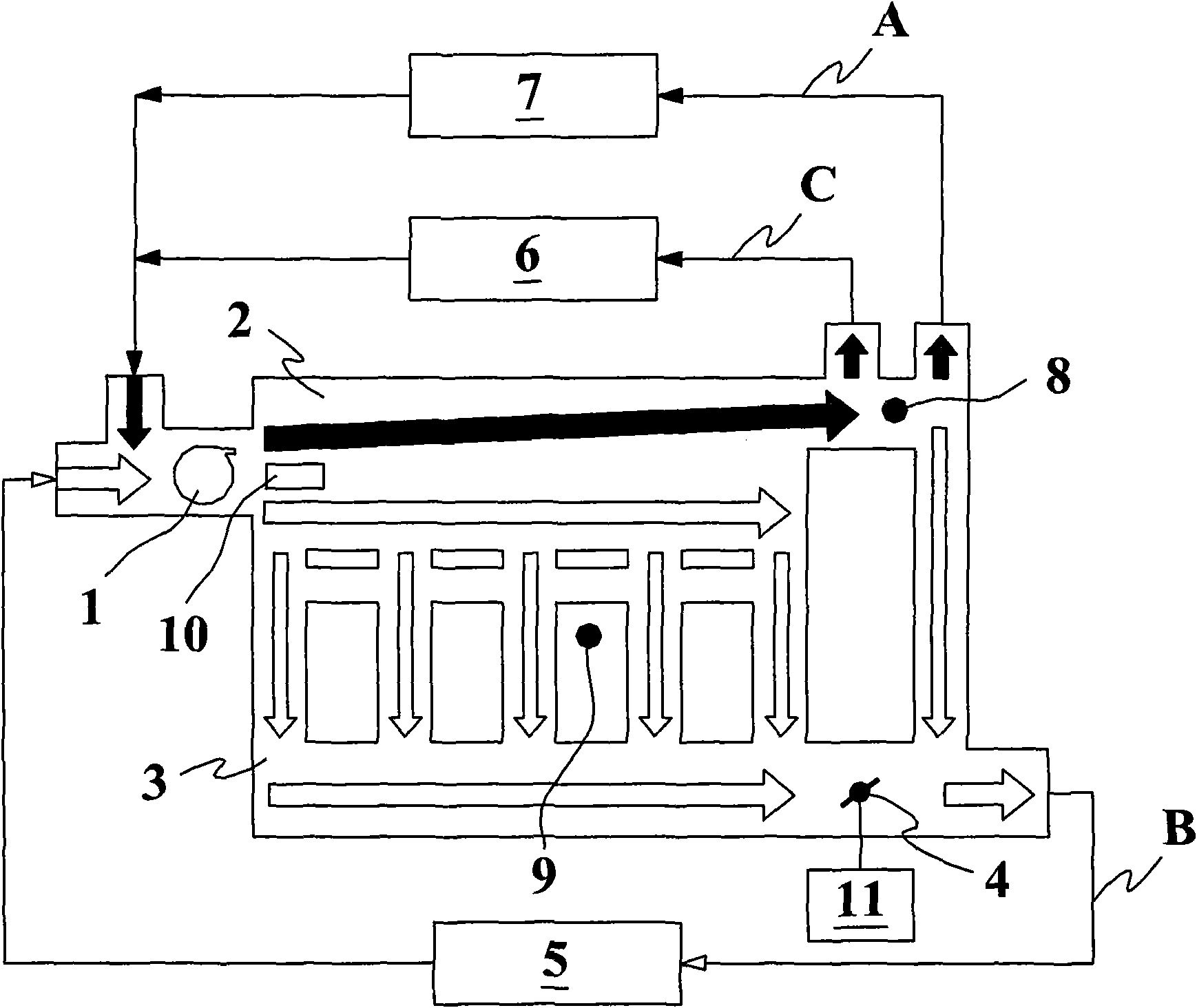

Electric automobile cooling system and control method thereof

InactiveCN101549637ASolve the cooling problemExtend your lifePropulsion coolingCold airExpansion tank

The invention provides an electric automobile cooling system, comprising an electric water pump (1), an electric machine controller (MCU) (2), an electric machine (3), a radiator (5), a fan (4), an expansion tank and hose (6); wherein the electric machine (3) and the electric machine controller (2) are arranged in the front cabin of the electric automobile. The electric water pump (1), electric machine controller (2), electric machine (3) and the hose for the radiator (5) are connected with each other to form a cooling circuit; the fan is arranged at the back part of the radiator and the headwind and the cold air driven by the fan exchange heat with the radiator. When one of the electric machine temperature and the electric machine controller temperature achieves the preset value, the cooling system starts to work. When the two temperatures are lower than the preset value, the cooling system stops to work. Therefore the service life of the electric water pump is prolonged and the reliability of the cooling system is increased.

Owner:CHERY AUTOMOBILE CO LTD

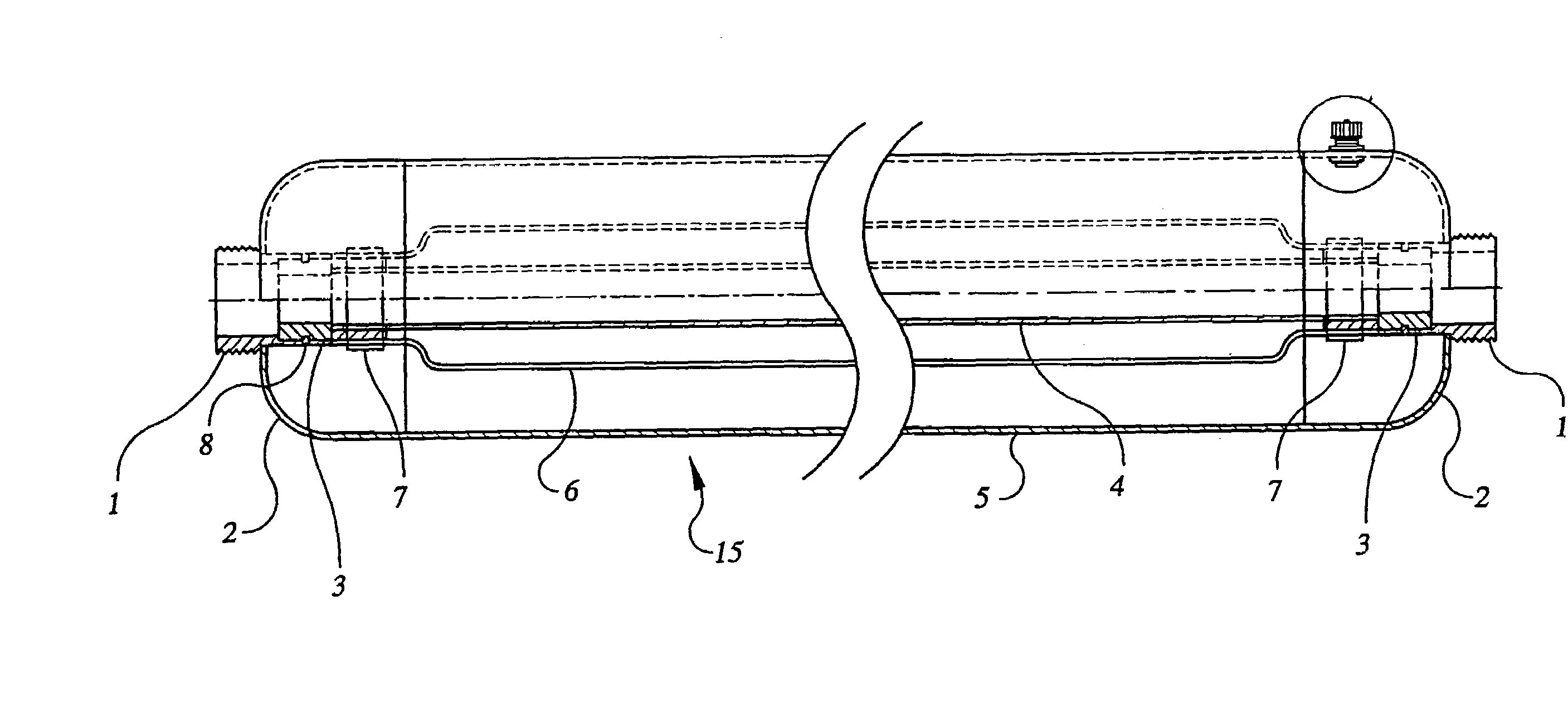

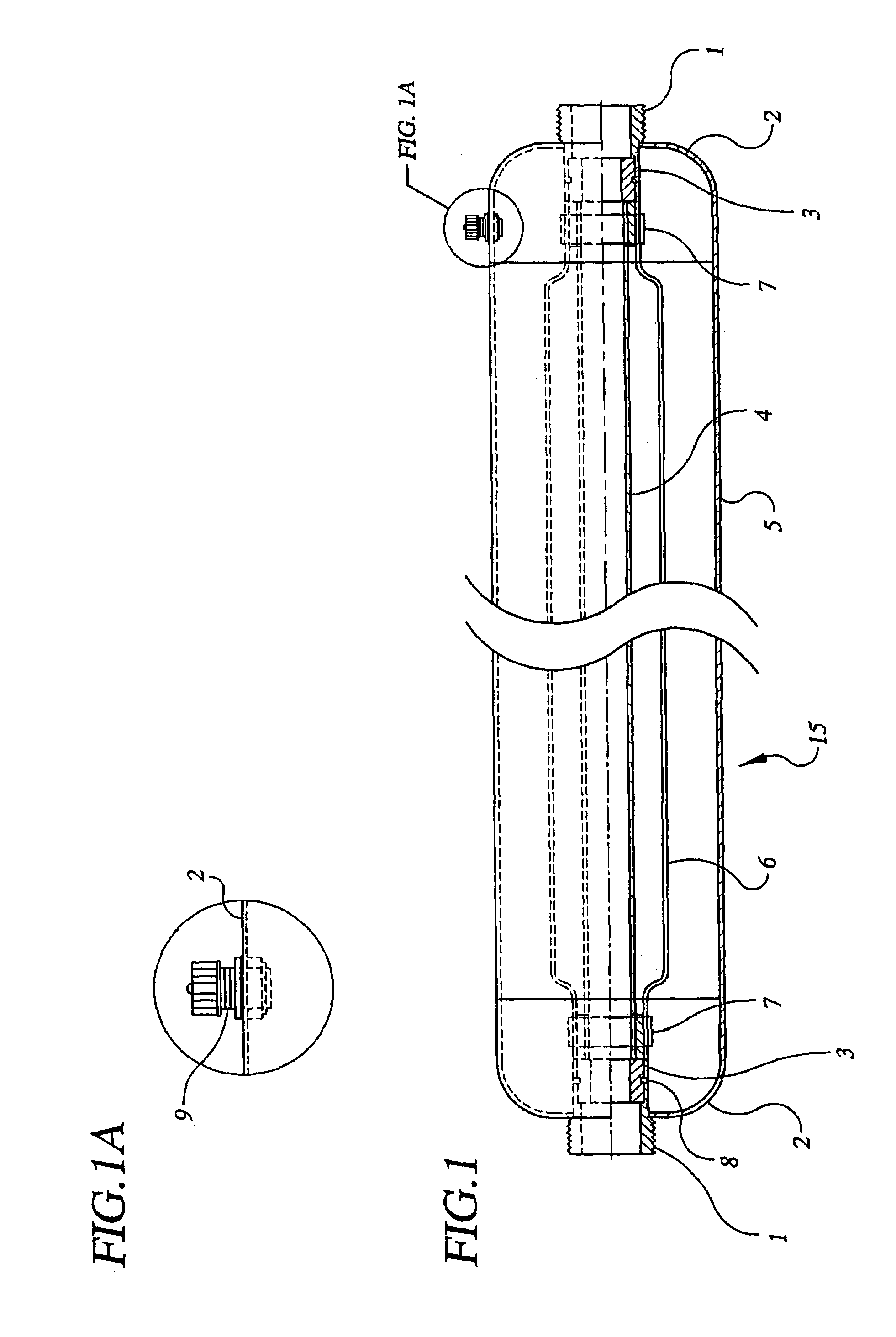

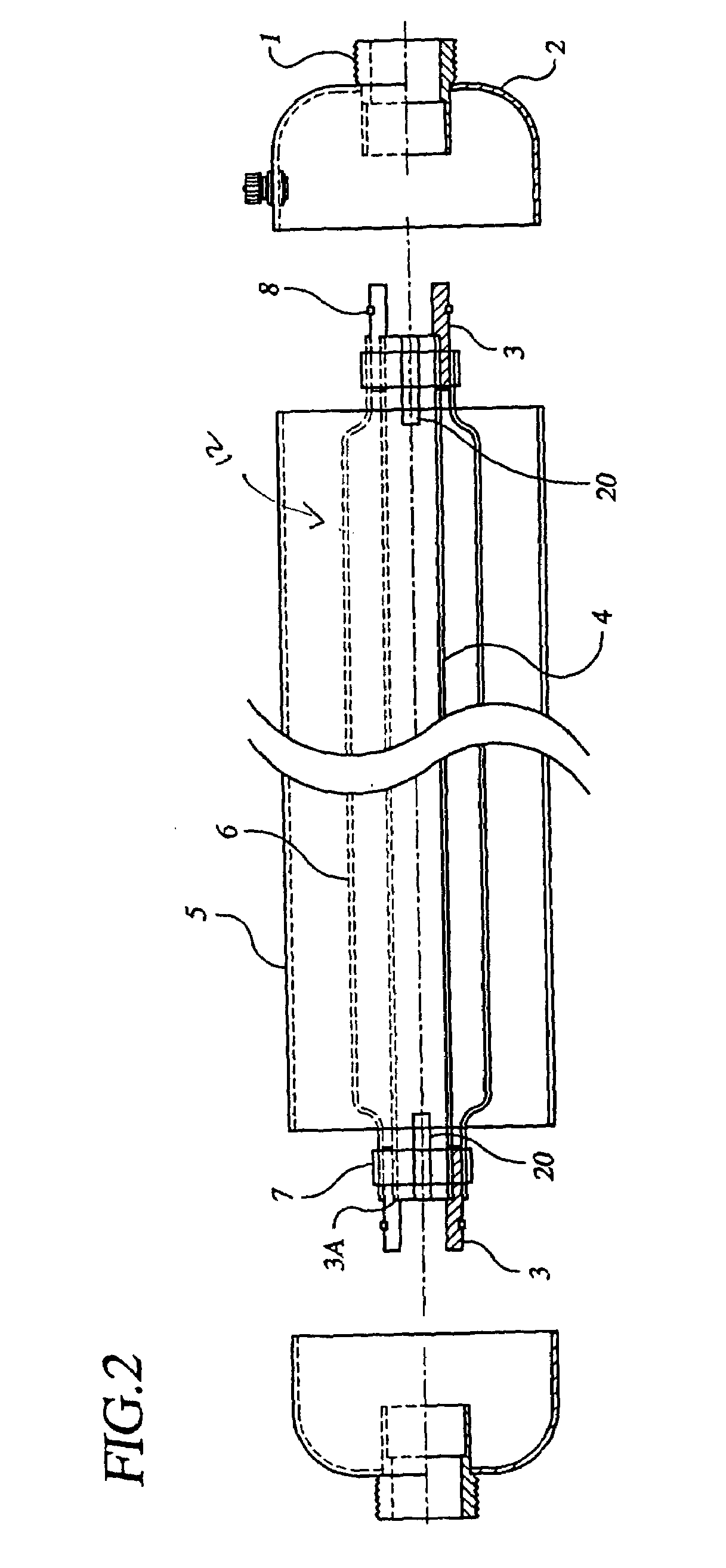

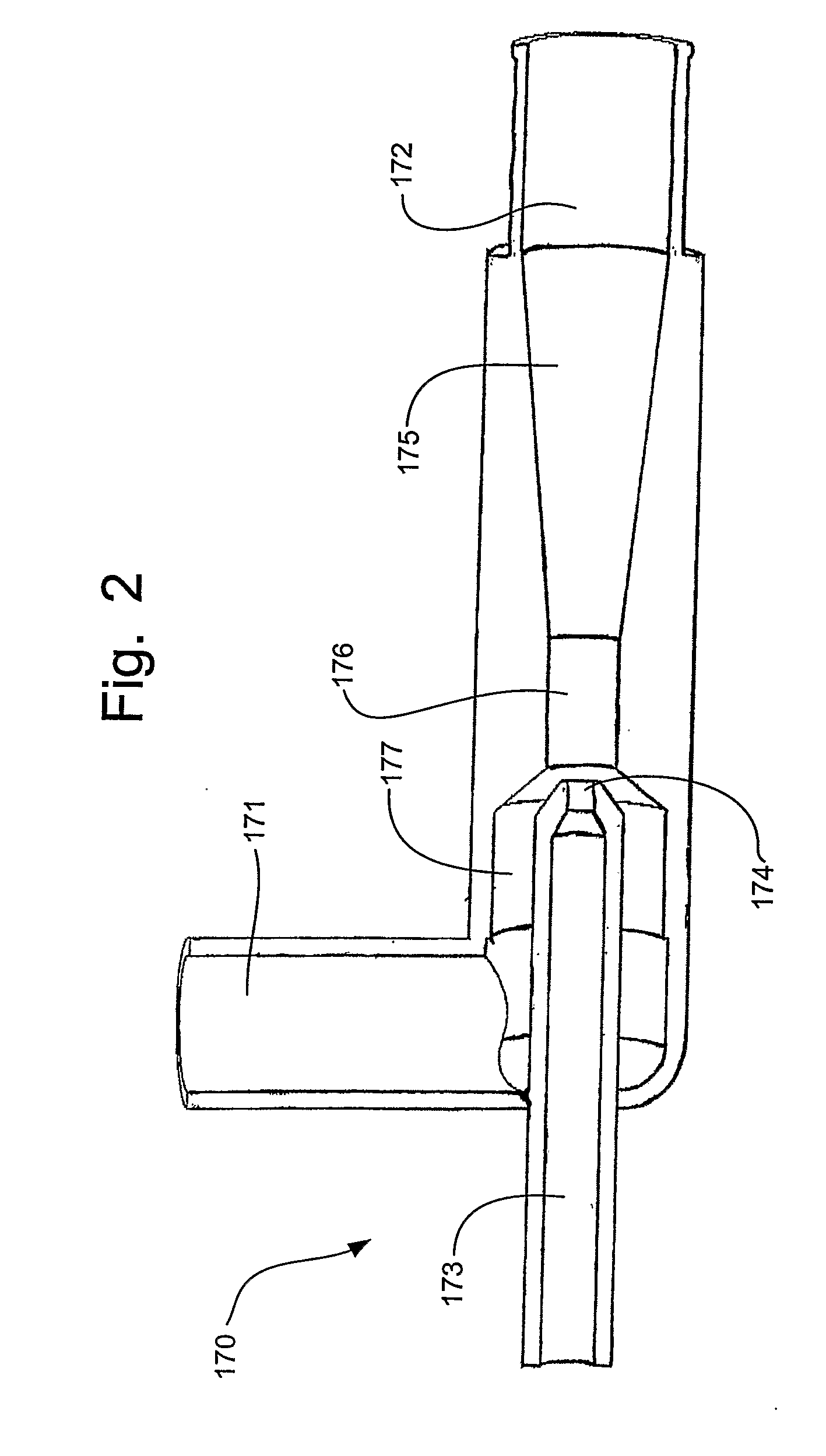

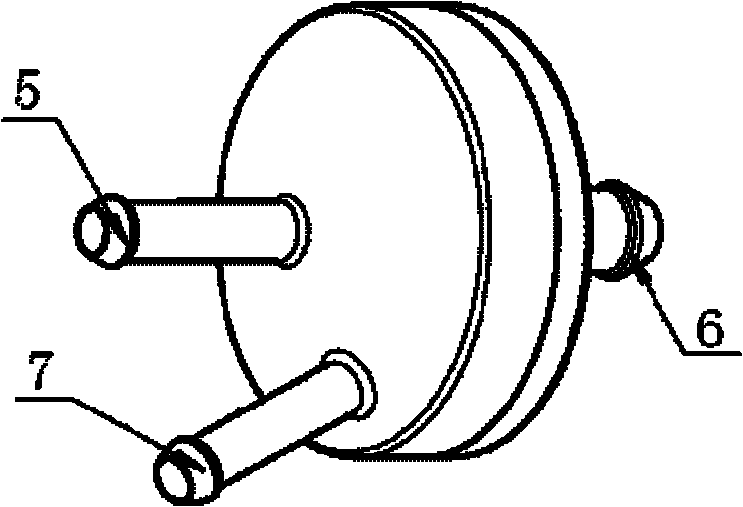

In-line flow through diaphragm tank

An in-line expansion tank. As fluid traverses a pipe within the tank, it may pass into and displace a diaphragm disposed outside of the pipe if the fluid pressure is greater than a tank pressure pushing the diaphragm against the pipe. When the fluid pressure decreases, the fluid passes from the diaphragm back into the pipe.

Owner:FLEXCON INDS

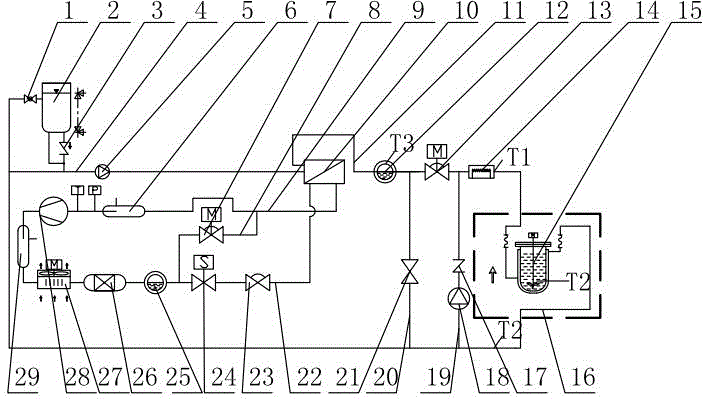

System for testing heat-transfer performance of gas-water-oil heat interchanger

InactiveCN101587027AEasy to operateReduce the human factorMaterial thermal conductivityStructural/machines measurementExpansion tankPilot system

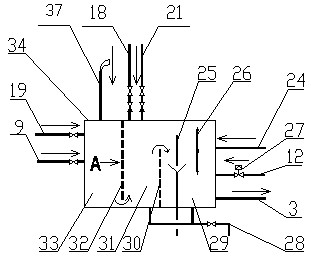

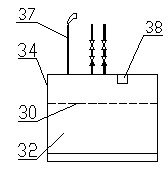

The invention relates to a system for testing heat-transfer performance of a gas-water-oil heat interchanger, and is composed of a steady air system, a cold water system, a hot water system and a oil system. The steady air system: a voltage-stabilizing case output end is connected with inlets between the first steady air flow gauge and the first steady air pneumatic butterfly valve or the second flow gauge and the second steady air pneumatic butterfly valve and high-pressure centrifugal fan, wherein, steady air bypass electric control valve is connected between the inlet and the outlet of the high-pressure centrifugal fan; the hot water system: an expansion water tank, an electric heater water tank and an outlet are connected to the water pump, and water enters into the heat interchanger to be measured through the bypass of the electric three-way valve, the water flow gauge and the electromagnetic valve, thereby forming a closed loop system; the cold water system: compared with the hot water system, the system does not have an expansion water tank; the oil loop system is a open and close type circulating system: the outlets of the expansion fuel tank and the fuel-tank are connected to the oil pump, oil enters into the heat interchanger to be measured through the bypass of the electric three-way valve, the oil flow gauge and the electromagnetic valve, thereby forming a closed circulation for testing the heat exchange performance of the oil-water, oil-gas heat interchanger.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

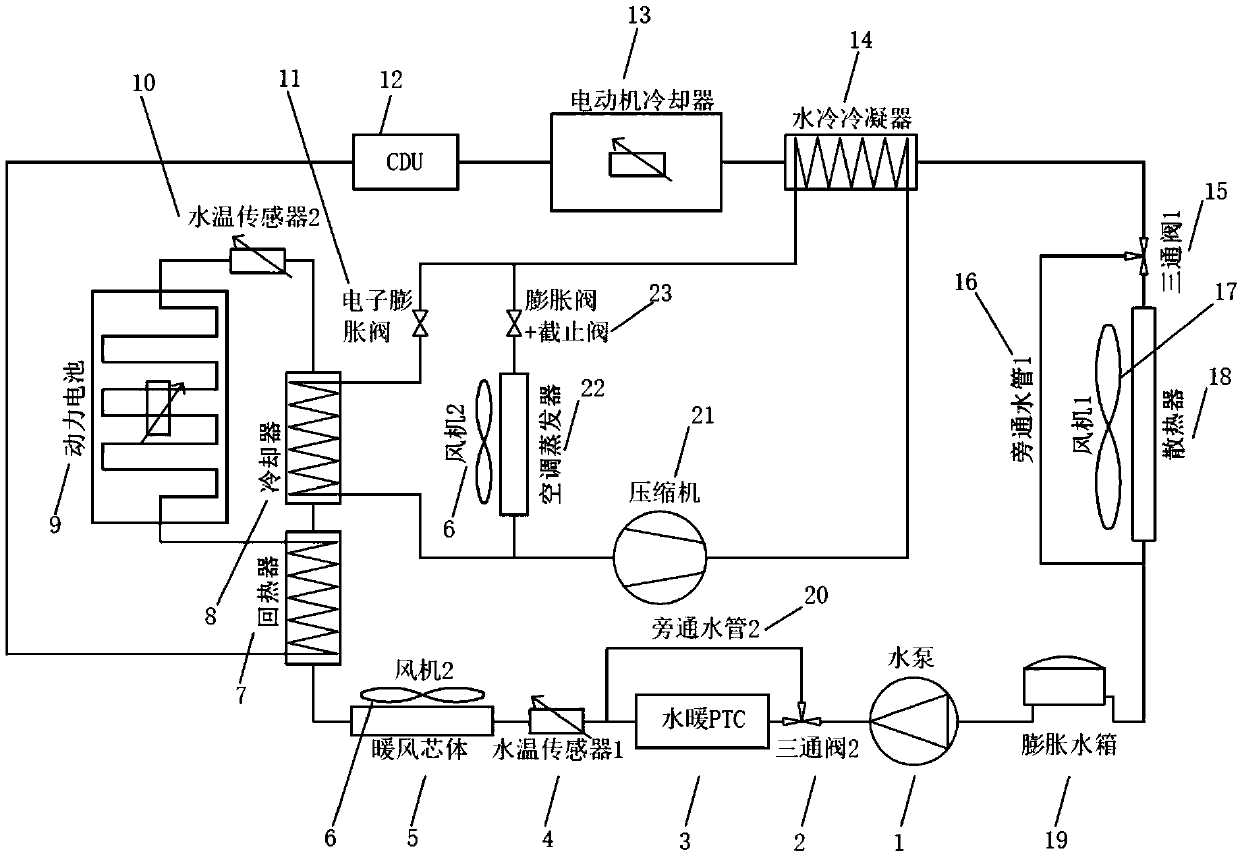

New energy automobile heat management system capable of utilizing waste heat fully

PendingCN109649119AReduce the temperatureAir-treating devicesVehicle heating/cooling devicesExpansion tankNew energy

The invention relates to a new energy automobile heat management system capable of utilizing waste heat fully. The system comprises a water pump, a water heating PTC, a warm air core, a heat regenerator, a cooler, a power battery, a CDU, a motor cooler, a water-cooling condenser, a heat radiator and an expansion water tank, two ends of the water heating PTC and the heat radiator are connected witha bypass water pipe, a refrigerating heat exchange unit is arranged between the cooler and the water-cooling condenser, and an air conditioning evaporator is arranged in the refrigerating heat exchange unit and parallelly connected with the coolers. Compared with the prior art, the system has the advantages that battery waste heat, motor waste heat and waste heat generated by work consumption ofa compressor can be utilized effectively for passenger cabin air conditioner heating, defrosting, demisting and battery heating , and power demand of the water heating PTC is lowered effectively, so that energy consumption of a heat management system is reduced, and driving mileage of a new energy automobile is increased.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

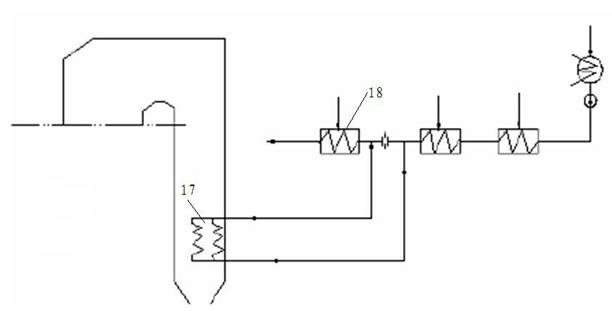

Exhaust gas waste heat recovery and emission reduction comprehensive application system for coal-fired boiler in thermal power plant

ActiveCN102305413AImprove dust removal efficiencyImprove performanceCombustion processIndirect carbon-dioxide mitigationAir preheaterExpansion tank

The invention discloses an exhaust gas waste heat recovery and emission reduction comprehensive application system for a coal-fired boiler in a thermal power plant. In the invention, along the flow direction of flue gas, an air preheater, a first low temperature economizer, a low temperature dust collector, a draught fan, a second low temperature economizer and a desulfuration island are sequentially arranged on a pipe between the boiler and a chimney, wherein, the inlet of the air preheater is respectively communicated with a cold primary air pipe and a cold secondary air pipe; the cold secondary air pipe is provided with a secondary air heater; the secondary air heater is communicated with the second low temperature economizer via a coal-water pipe; the coal-water pipe is provided with an expansion tank and a water pump; and the low temperature economizer is divided into two segments, wherein, one segment is used for heating condensed water, and the other section is used for heating the cold secondary air at the inlet of the air preheater by virtue of a water medium. The exhaust gas waste heat recovery and emission reduction comprehensive application system has the beneficial effects of maximally utilizing the gas waste heat, reducing heat consumption of a machine set, lowering energy consumption of equipment such as the dust collector, the draught fan, a blower and the like, reducing the power consumption rate of the thermal power plant, improving the economical efficiency of the thermal power plant, more efficiently saving the energy consumption, and benefiting construction of the lowcarbon society.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

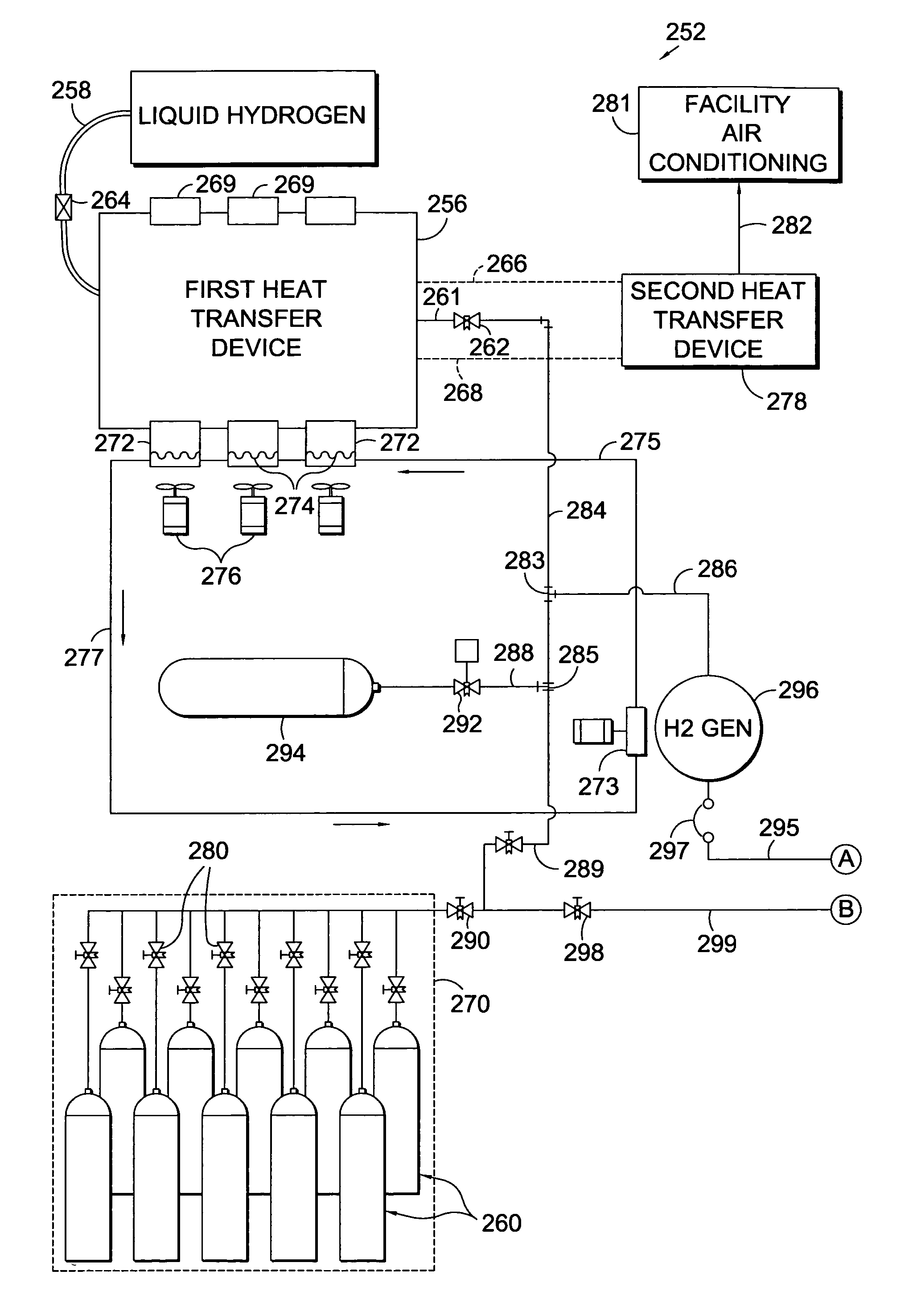

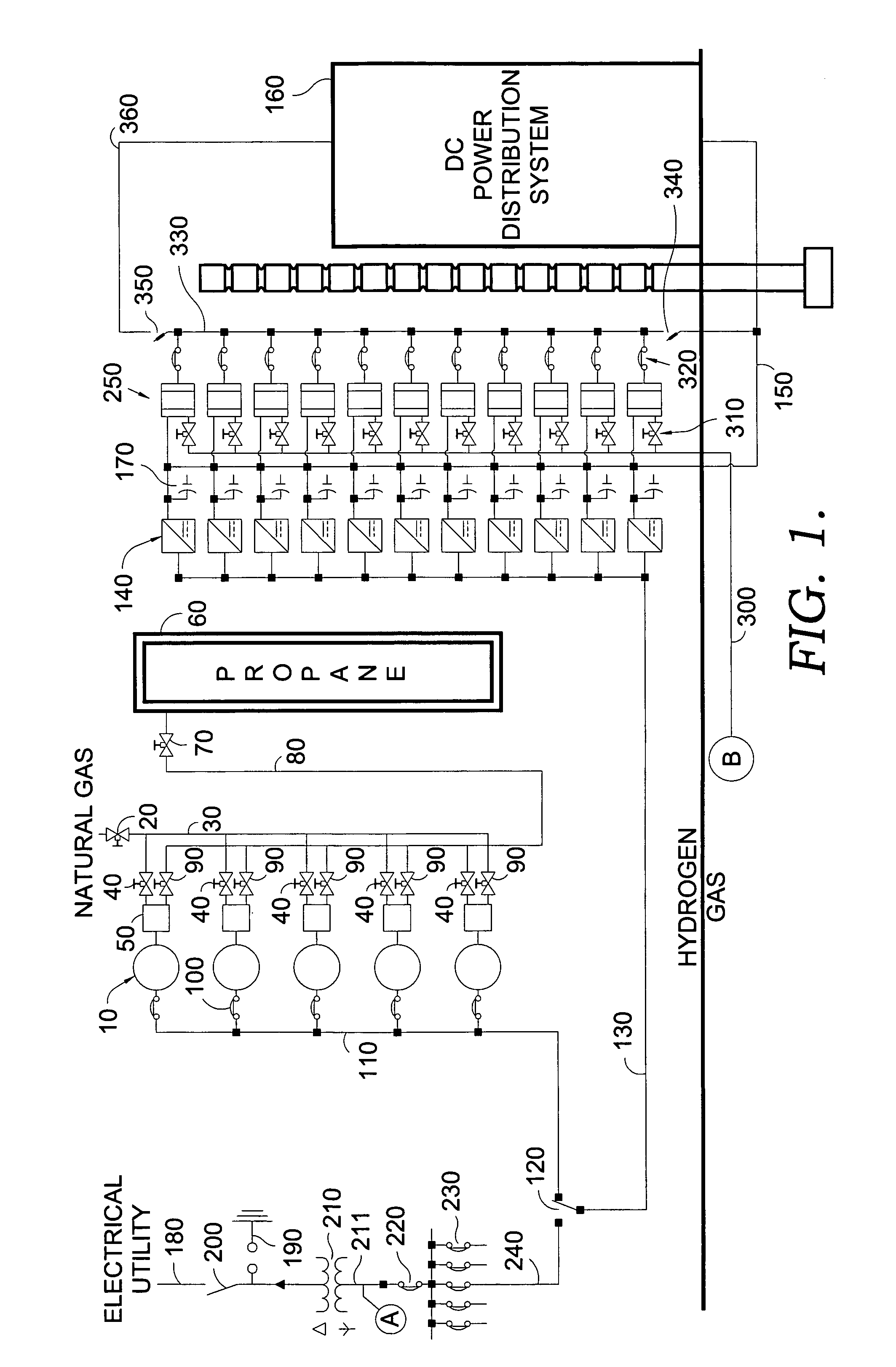

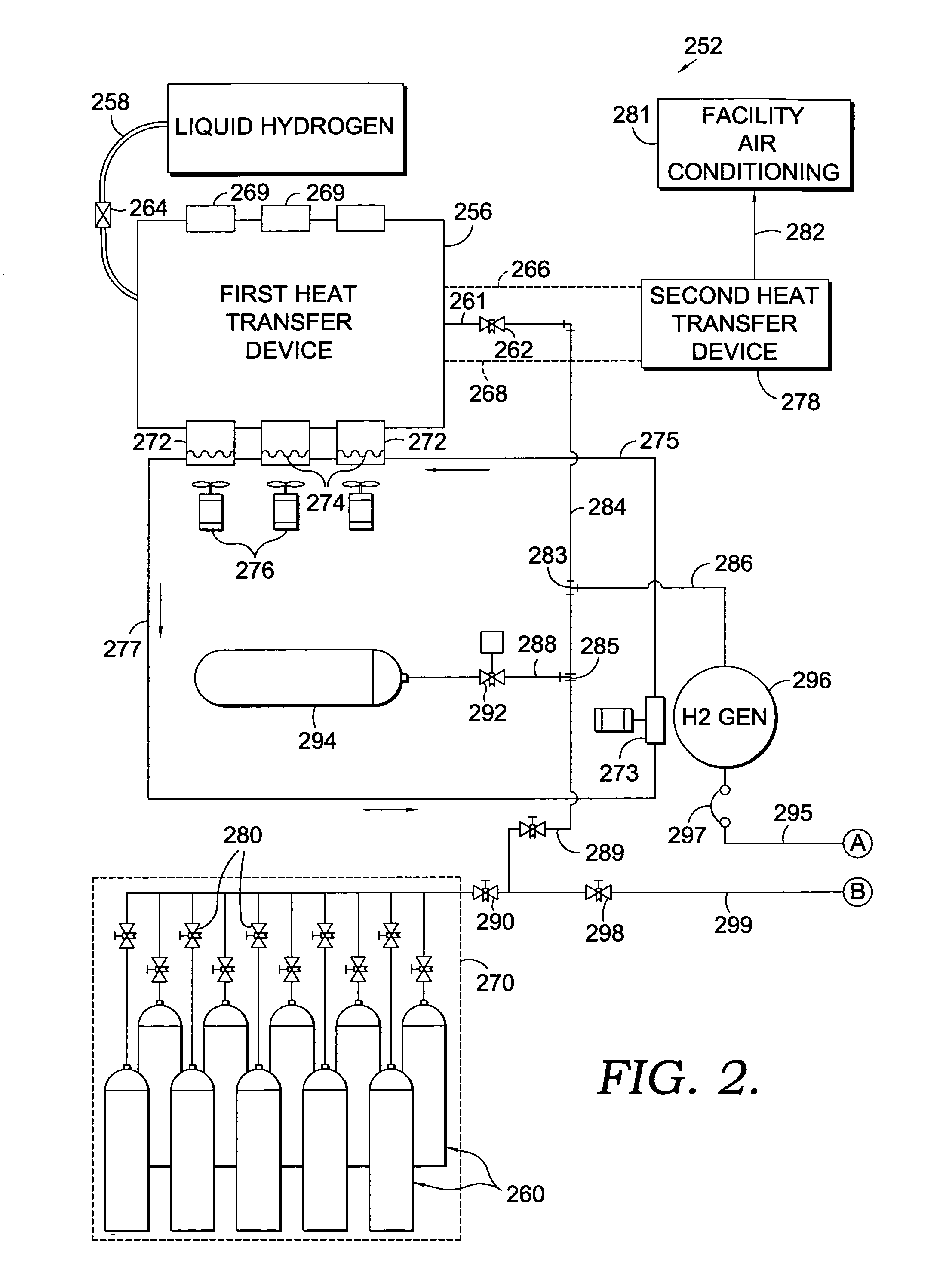

Power system for a telecommunications facility

ActiveUS7081687B2Internal combustion piston enginesFuel supply apparatusExpansion tankTelecommunications link

An energy generating system for a telecommunications facility includes a hydrogen fuel supply system. The hydrogen fuel supply system includes a source of liquid hydrogen which uses a high pressure expansion tank along with additional storage tanks. The system also incorporates first and second stage heat exchangers. The first stage exchanger is used to benefit from the endothermic reaction created when liquid hydrogen transforms into vapor. The cooling provided from this state change is transferred into a second medium which is delivered into a second stage heat transfer device and then used for air conditioning purposes. The system also includes a hydrogen generator which may be used to create AC power by combusting vaporous hydrogen.

Owner:T MOBILE INNOVATIONS LLC

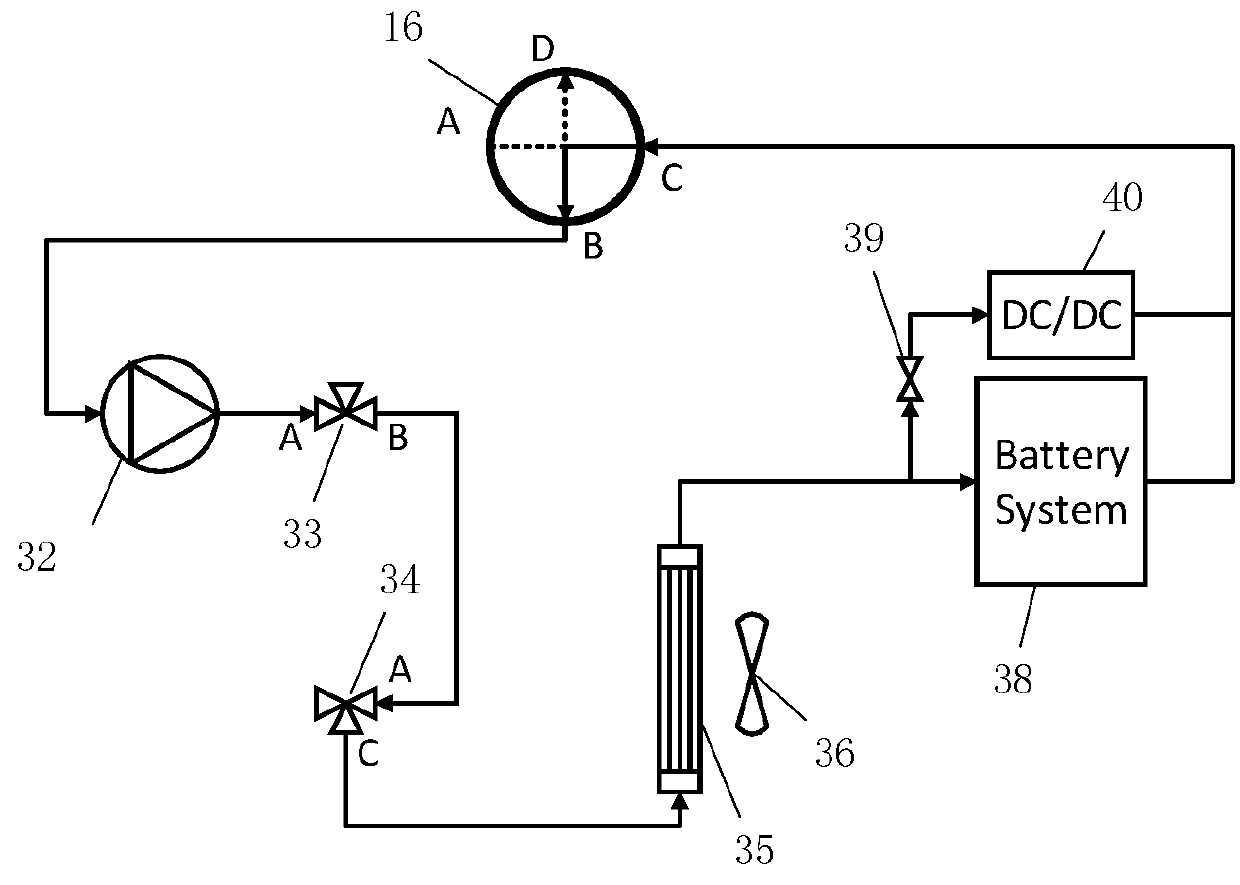

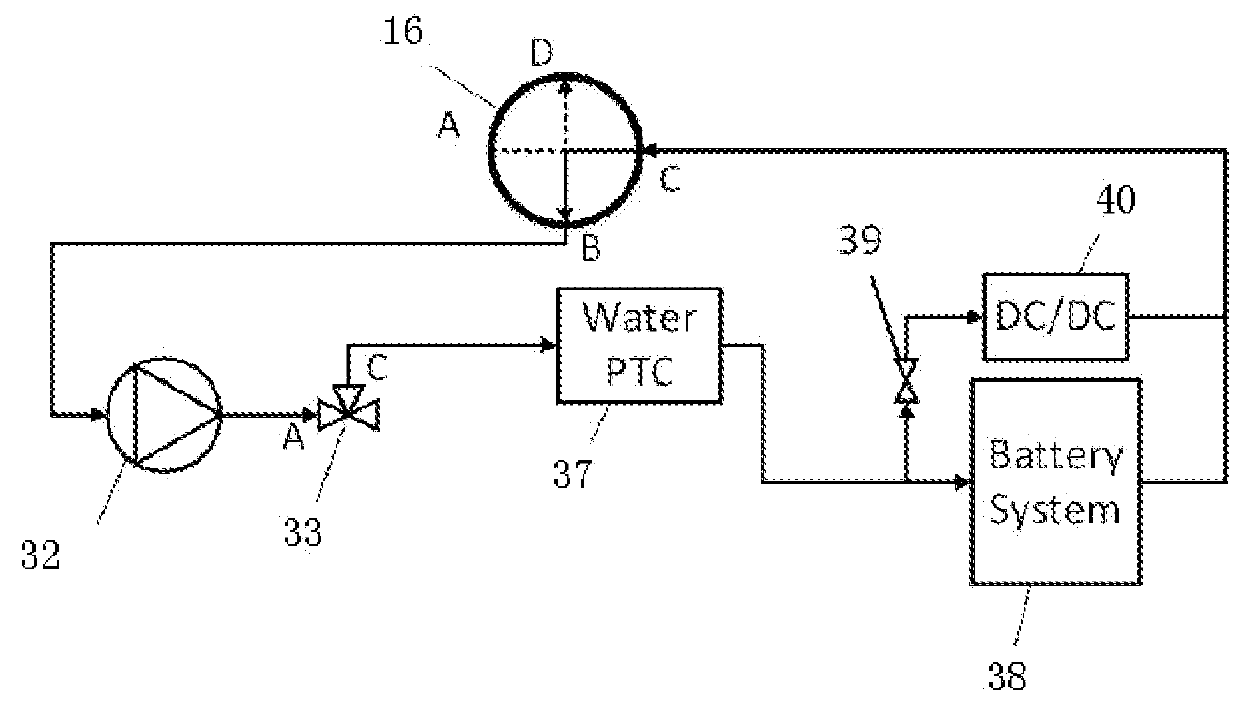

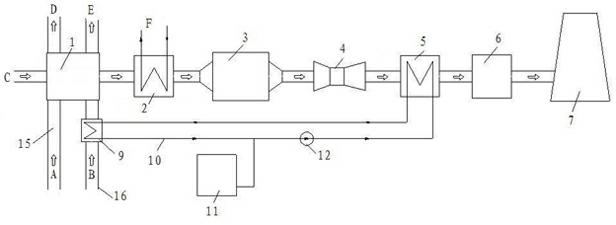

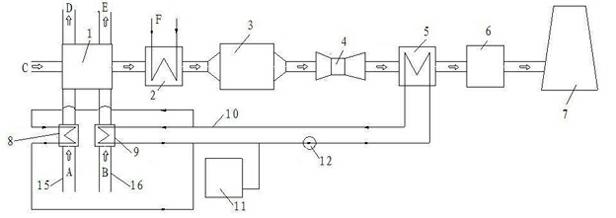

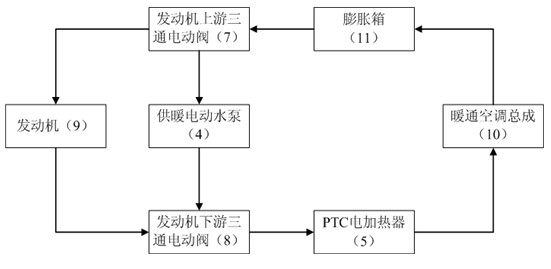

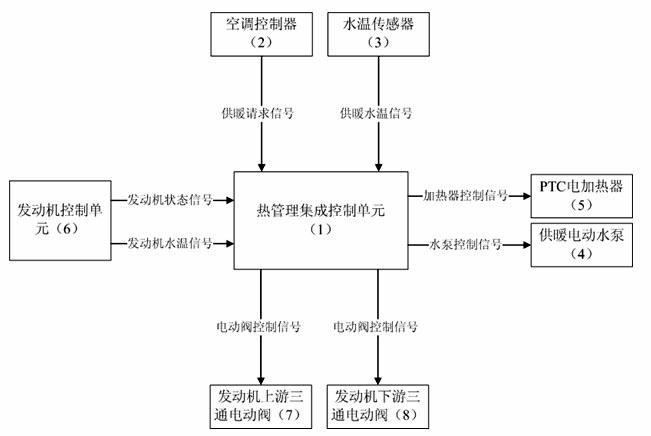

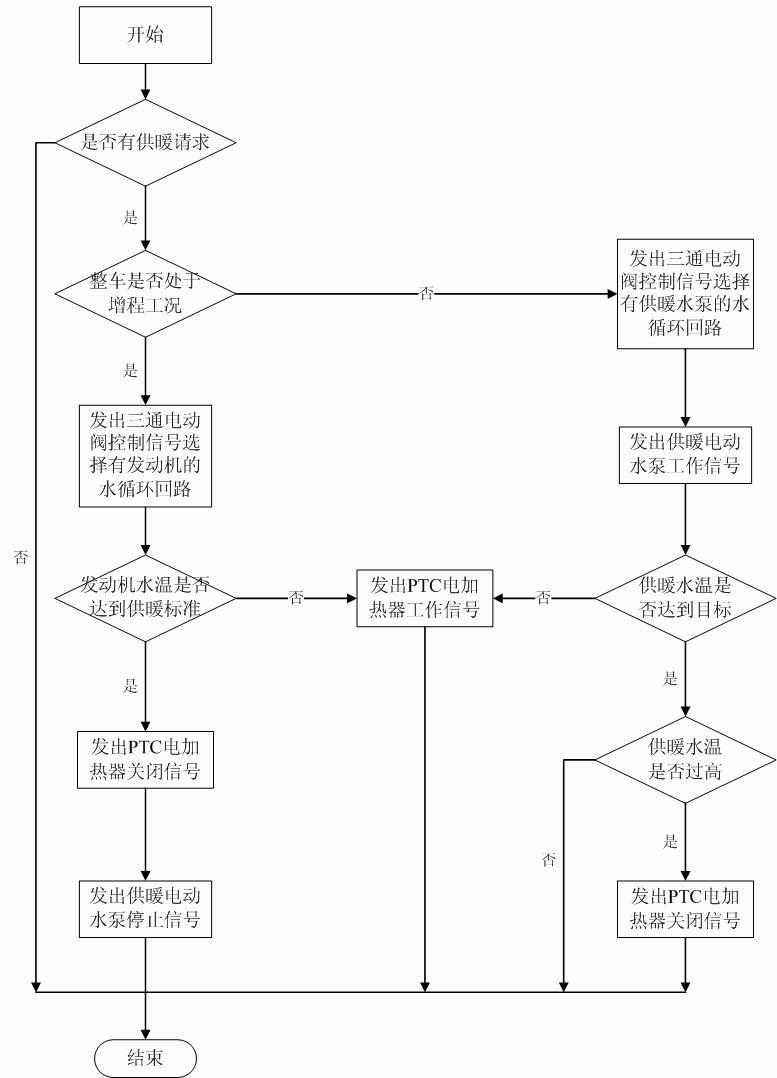

Air-conditioner heating system for extended range electric vehicle and control method of air-conditioner heating system

ActiveCN102529642AImprove battery lifeSave time at workAir-treating devicesVehicle heating/cooling devicesExpansion tankHeat management

The invention discloses an air-conditioner heating system for an extended range electric vehicle, which comprises a control circuit and two heating circulating water loops. The control circuit comprises a heat management integrated control unit, an air-conditioner controller, a water temperature sensor, a heating electric water pump, a PTC (positive temperature coefficient) electric heater and an engine control unit. The first heating circulating water loop starts from the heating electric water pump to sequentially pass through an engine lower three-way electric valve, the PTC electric heater, a heating ventilation air-conditioner assembly, an expansion tank and an engine upper three-way electric valve and returns to the heating electric water pump through water pipes. The second heating circulating water loop starts from an engine to sequentially pass through the engine lower three-way electric valve, the PTC electric heater, the heating ventilation air-conditioner assembly, the expansion tank and the engine upper three-way electric valve and returns to engine through water pipes. The invention further discloses a control method of the air-conditioner heating system for the extended range electric vehicle. Usable heat and power source in operation of the engine are effectively used by the air-conditioner heating system and the method, and electric quantity of batteries is saved while endurance mileage of the vehicle is increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Integrated thermal management system for electric vehicles

ActiveCN107444103AReduce consumptionAchieve warmingAir-treating devicesVehicle heating/cooling devicesExpansion tankStored energy

The invention discloses an integrated thermal management system for electric vehicles. The integrated thermal management system comprises a battery integrated thermal management system, a motor integrated thermal management system and a refrigeration and heating cycle system of a heat pump air conditioner, wherein the battery integrated thermal management system comprises a first water pump, a first phase change heat exchanger, a first expansion tank and a battery water-cooling coil; the motor integrated thermal management system comprises a second water pump, a second phase change heat exchanger, a second expansion tank, a radiator and a first motor water-cooling coil; and the refrigeration and heating cycle system of the heat pump air conditioner comprises a condenser, the heat pump air conditioner, an evaporator and a dryer. The battery integrated thermal management system and the motor integrated thermal management system are connected with the refrigeration and heating cycle system of the heat pump air conditioner through the first phase change heat exchanger and the second phase change heat exchanger. During a heating cycle, the first phase change heat exchanger and the second phase change heat exchanger transfer stored energy to the evaporator for preheating. During a refrigeration cycle, the evaporator transfers heat to the first phase change heat exchanger and the second phase change heat exchanger for storing energy. The integrated thermal management system for the electric vehicles shares the evaporator, decreases the number of evaporators and causes structure layouts inside the electric vehicles to be reasonable.

Owner:HEFEI UNIV OF TECH

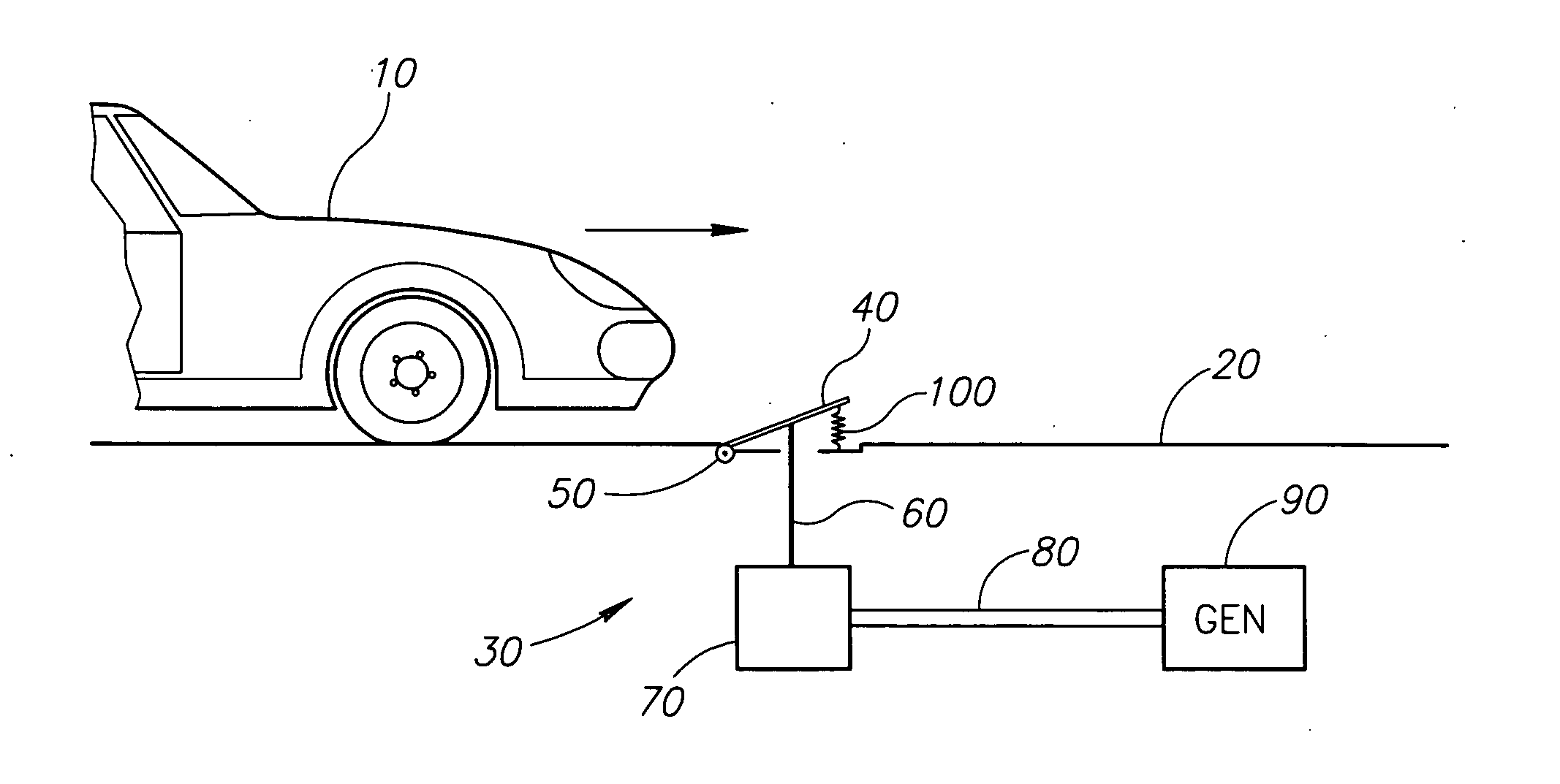

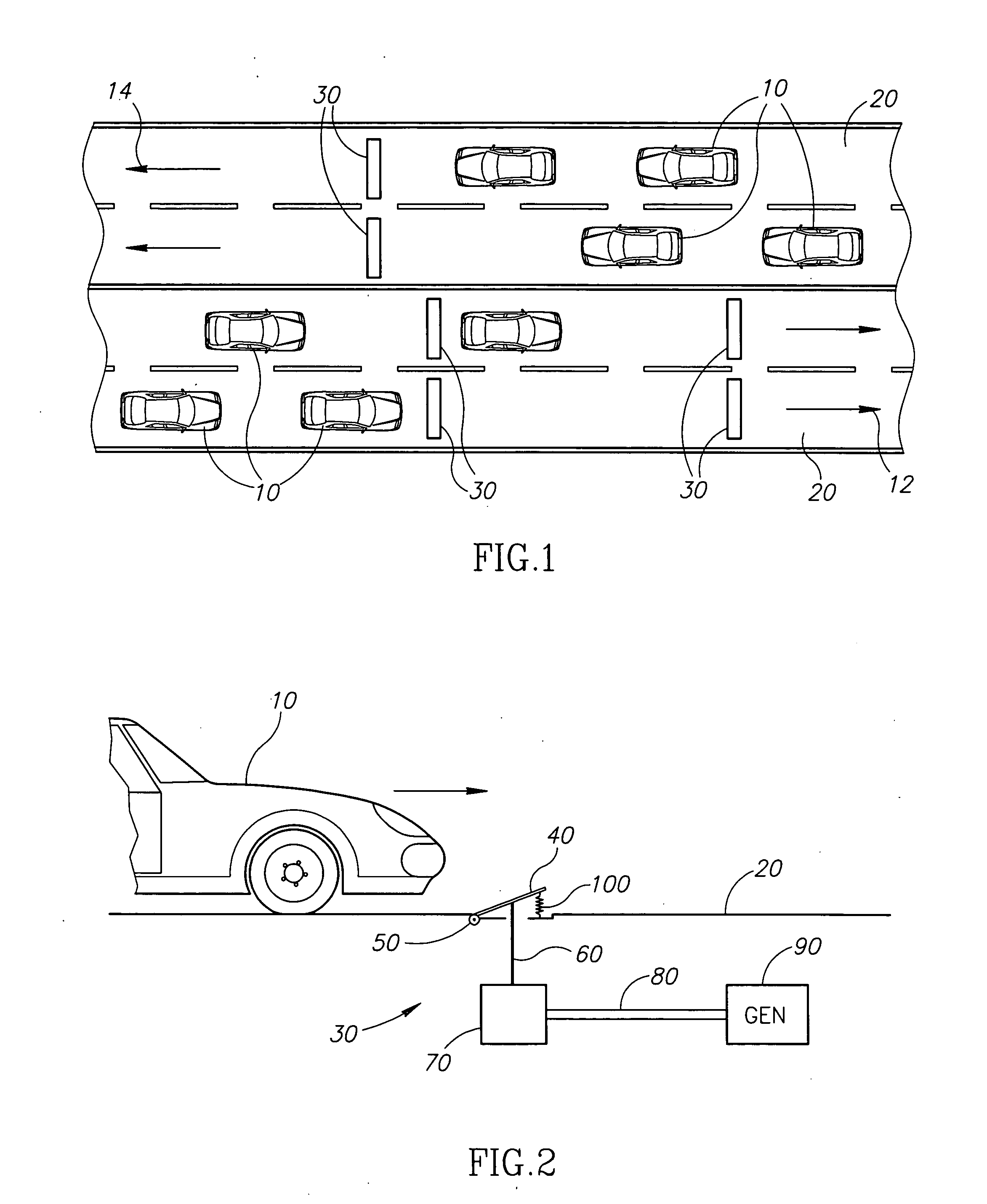

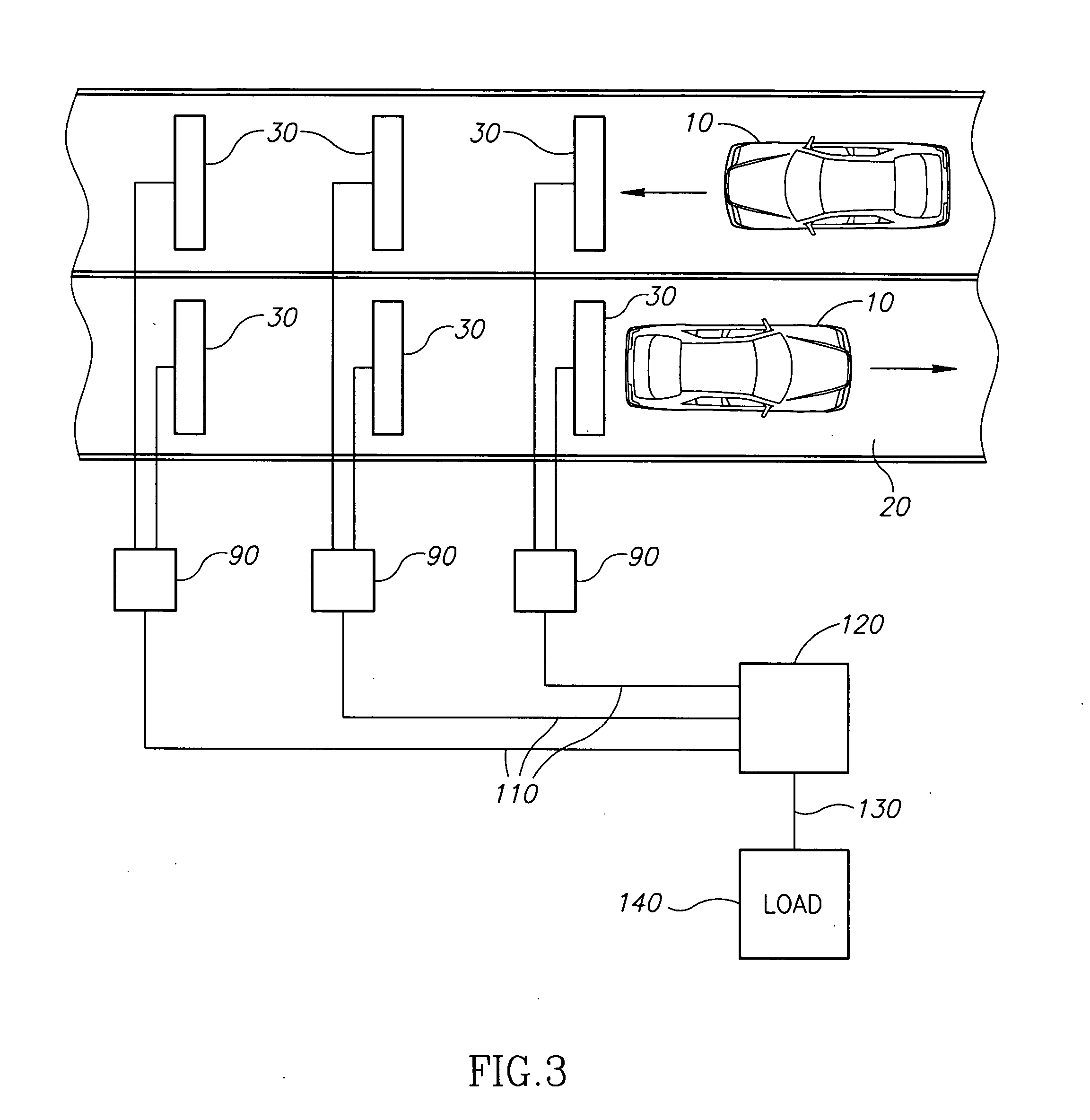

Hydraulic roadbed electricity generating apparatus and method

A roadbed generator provides a roadbed collector positioned within a roadbed. The roadbed collector engages passing vehicles collecting kinetic energy therefrom, which is converted to electrical energy that is collected and passed to a load for use. In one embodiment a roadbed collector is a piston positioned below a hinged surface plate that forms part of the roadbed. Passing vehicles drive the plate and piston down into a cylinder containing hydraulic fluid, driving the hydraulic fluid from the cylinder to a hydraulic generator. A return spring coupled to the surface plate force the plate back into an elevated position after a vehicle has passed on. In some embodiments an expansion tank interposed between the cylinder and generator forces fluid back into the cylinder causing the piston to move upwardly in preparation for engaging another vehicle.

Owner:ADAIR SARAH

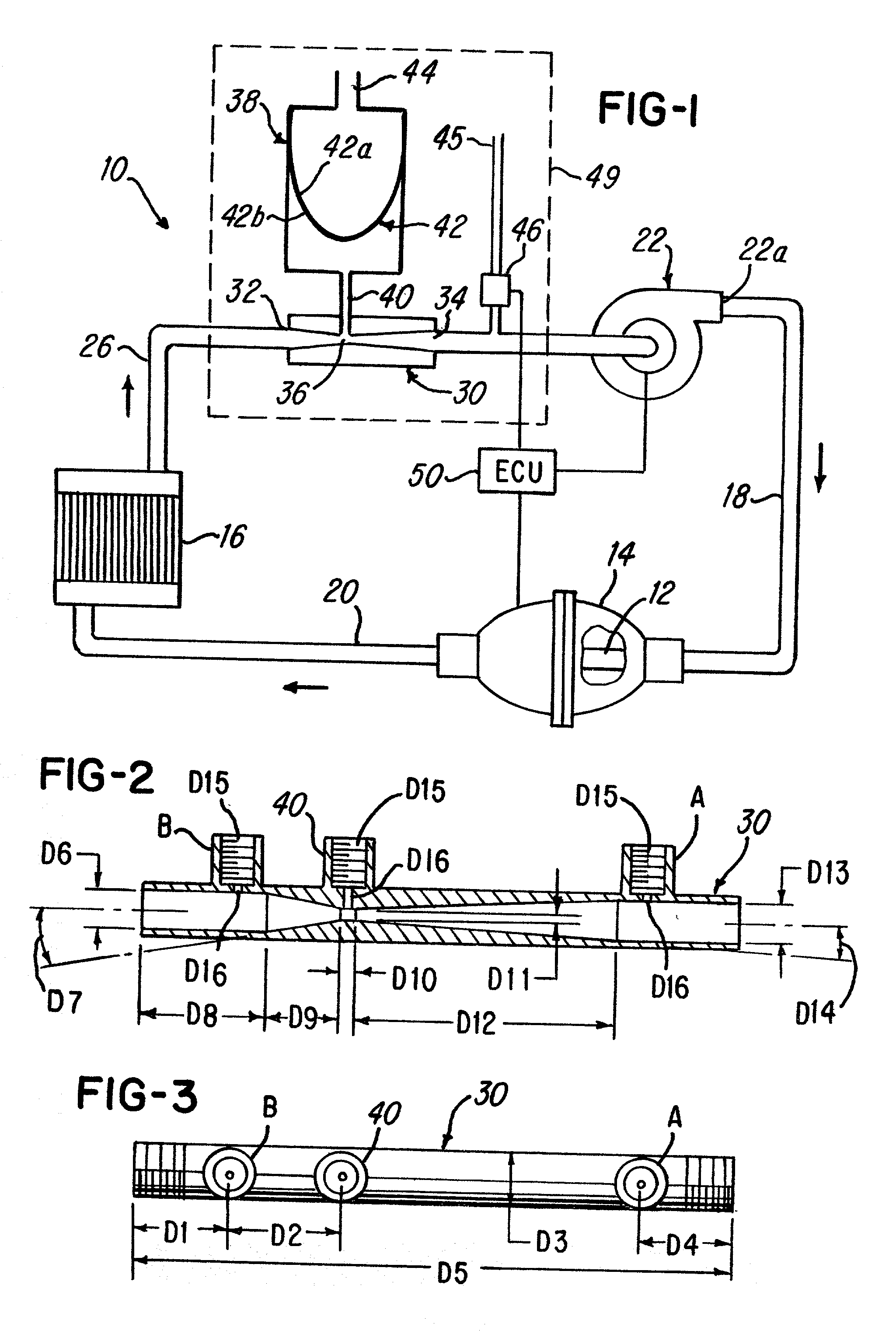

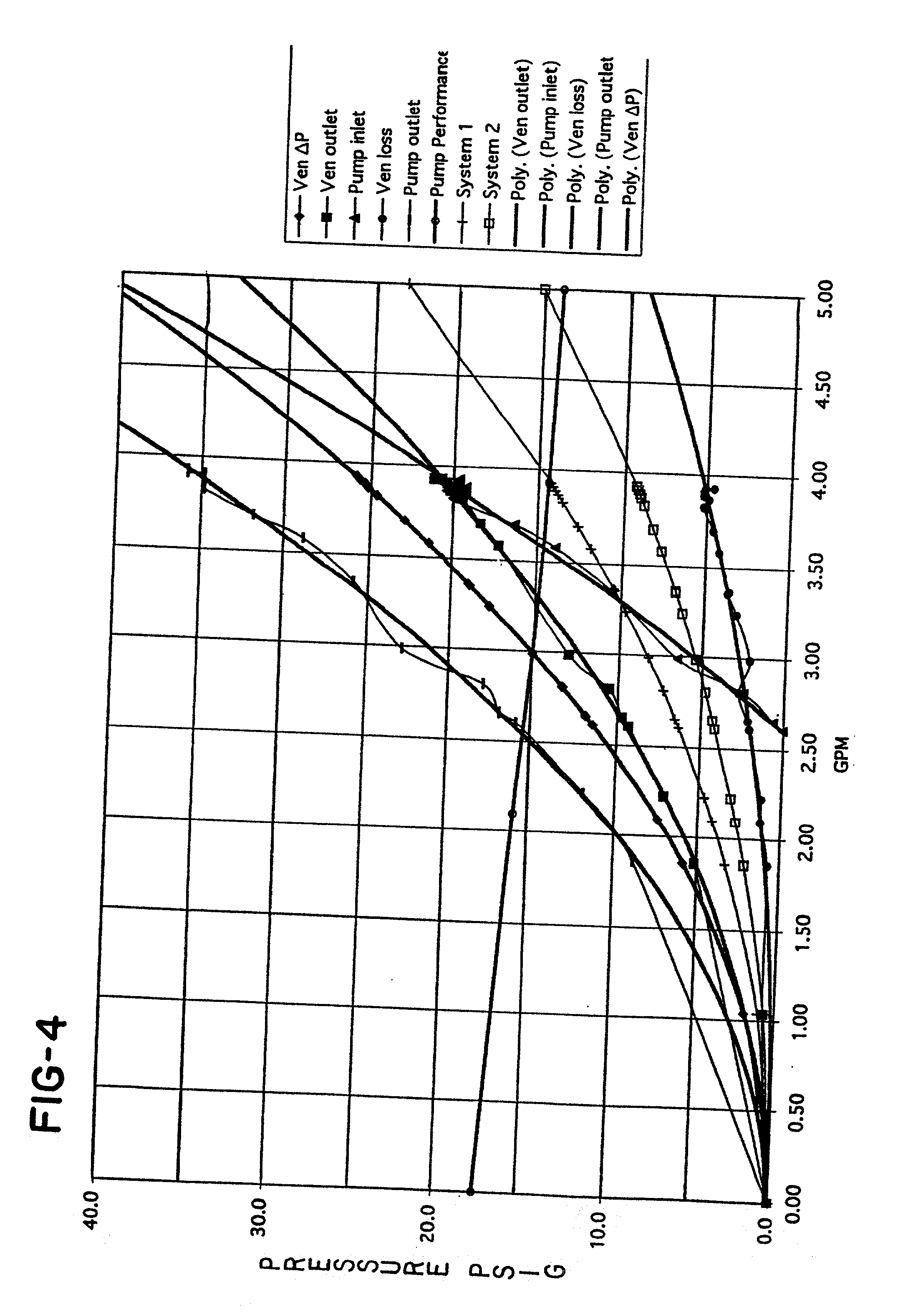

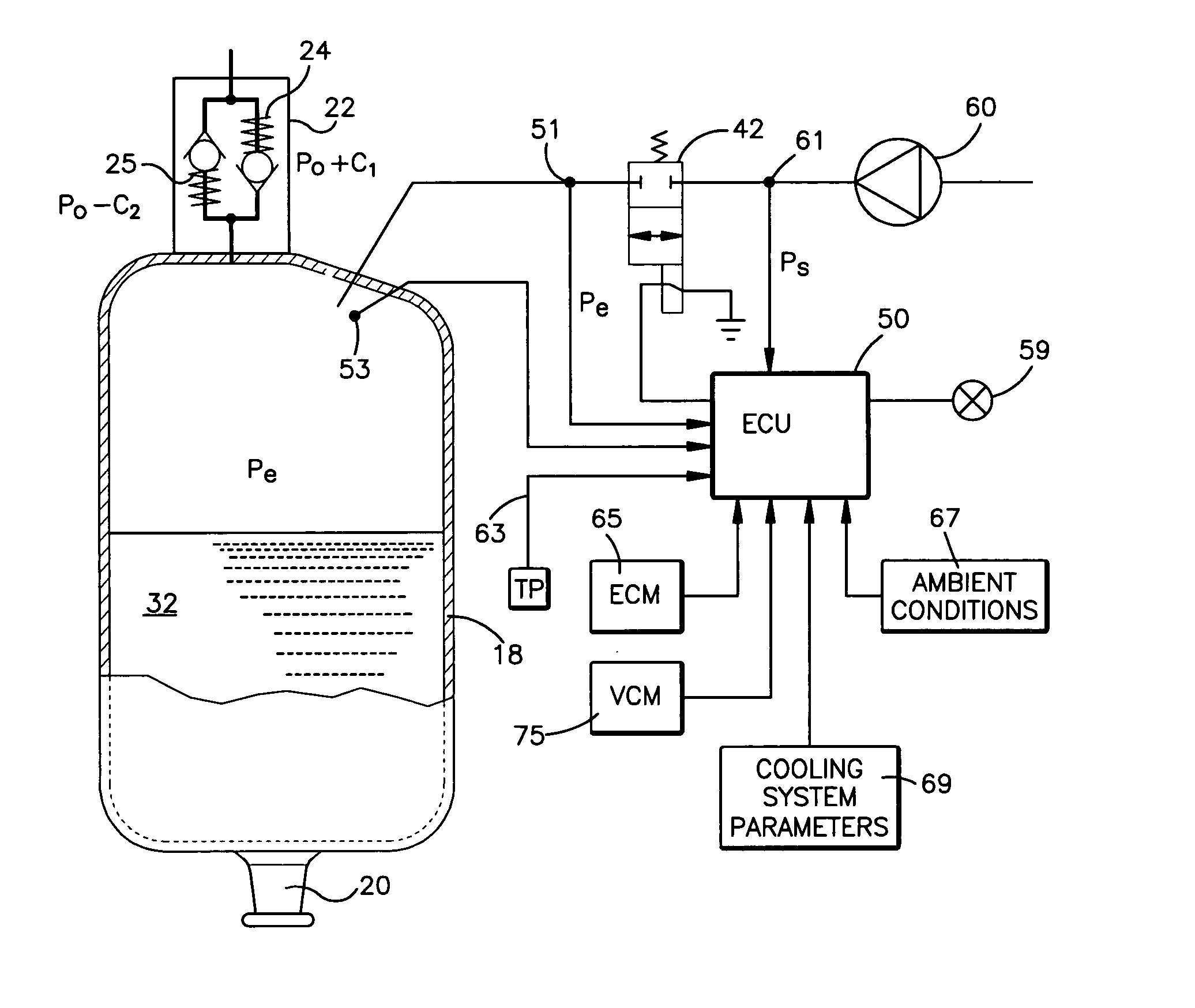

Engine cooling system

InactiveUS20050061264A1Inhibition of decayLiquid coolingCoolant flow controlExpansion tankAerospace engineering

An improved cooling system for a turbo charged internal combustion engine is disclosed. A conduit connects a pressurizing engine air intake to the cooling system to raise the pressure in the cooling system thereby enabling an increase of the maximum temperature which coolant in the cooling system can reach. An electronically controlled valve selectively places the expansion tank in communication with the pressurizing engine air intake to maintain a desired pressure in the tank and to prevent back flow of fluid into the engine air intake.

Owner:VOLVO TRUCKS NORTH AMERICA

Double-loop cooling system and method for engine

ActiveCN105298613AImprove powerImprove economyLiquid coolingCoolant flow controlExpansion tankThermostat

The invention relates to the field of engine cooling systems and aims at providing a double-loop cooling system and method for an engine. The double-loop cooling system for the engine comprises a cylinder block water jacket and a cylinder cover water jacket, and a main water pump; the cylinder cover water jacket comprises an upper cylinder cover water jacket and a lower cylinder cover water jacket, the two of which are connected with the main water pump; the double-loop cooling system for the engine further comprises an engine oil cooler connected in series with the cylinder block water jacket, a radiator connected with the main water pump, a cylinder cover thermostat connected with the upper cylinder cover water jacket and a lower cylinder cover water jacket, a cylinder block thermostat connected with the cylinder block water jacket and the radiator, an expansion tank connected with the main water pump, a first degassing valve connected with the upper cylinder cover water jacket and the expansion tank, a second degassing valve connected with the main water pump and the expansion tank, and a third degassing valve connected with the cylinder cover thermostat and the expansion tank; a water temperature sensor is arranged at an outlet of the lower cylinder cover water jacket. The double-loop cooling system for the engine is good in dynamic property, economical efficiency and discharge property of the engine, and is further capable of prolonging the service life of the engine.

Owner:宝鸡吉利发动机有限公司

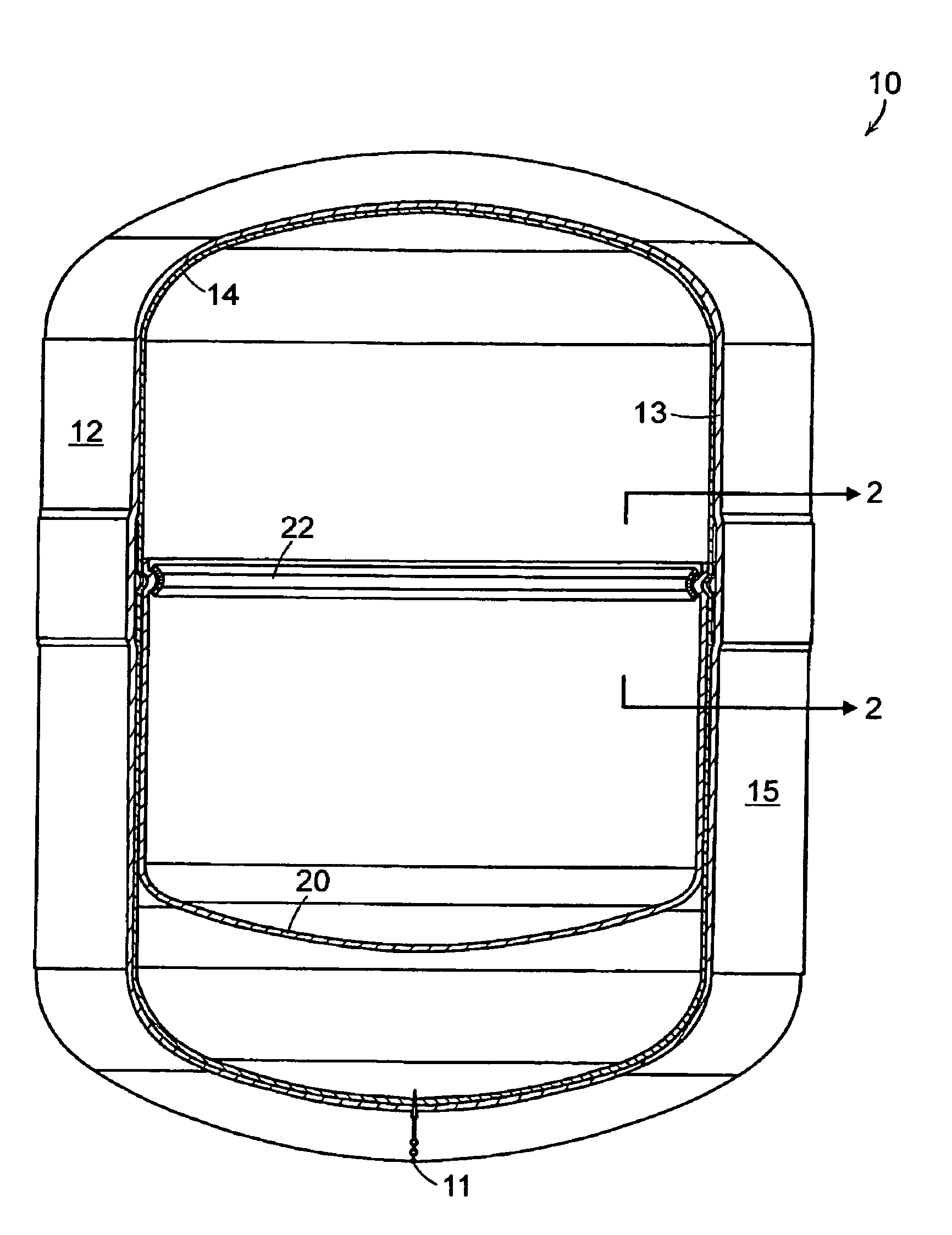

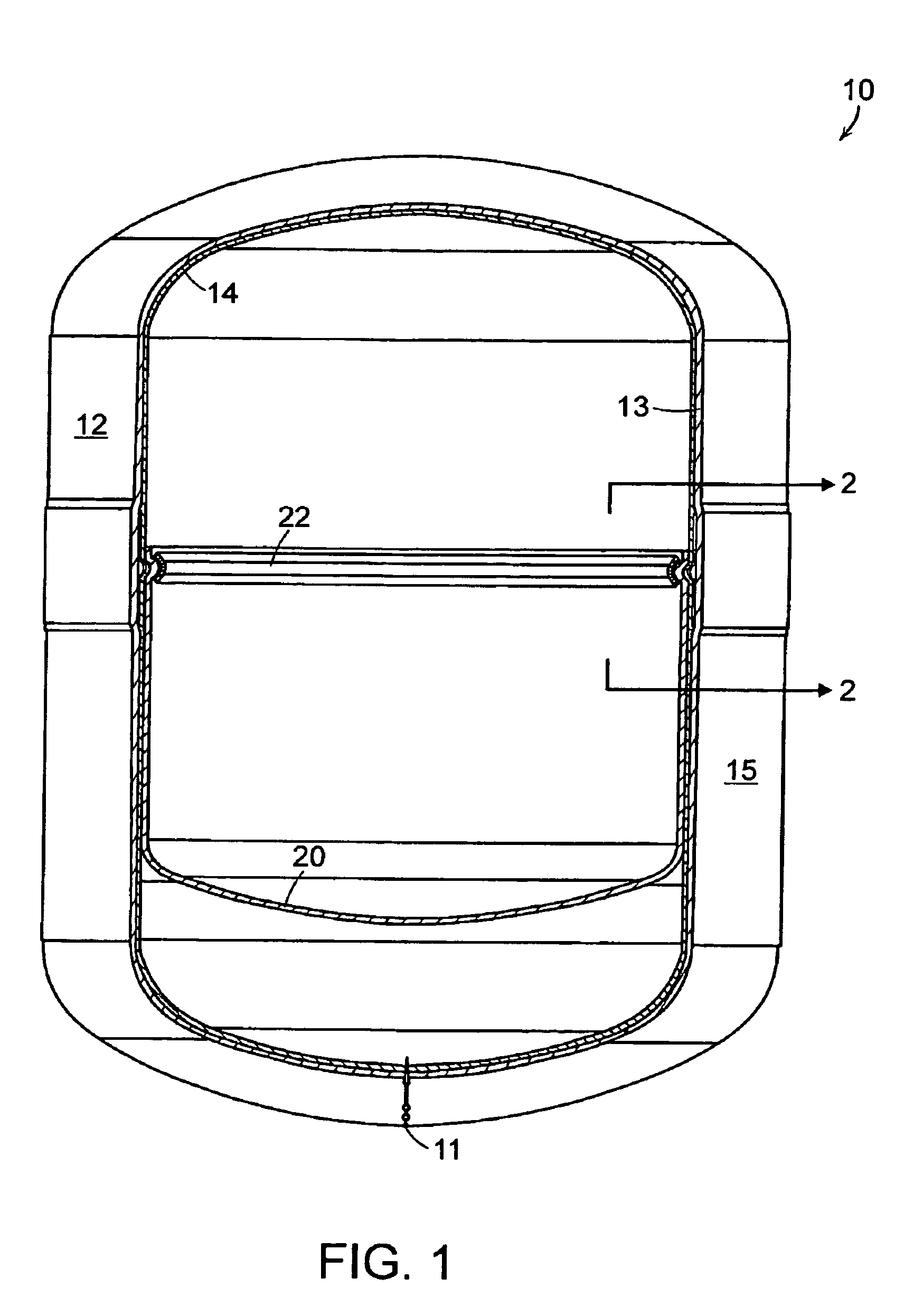

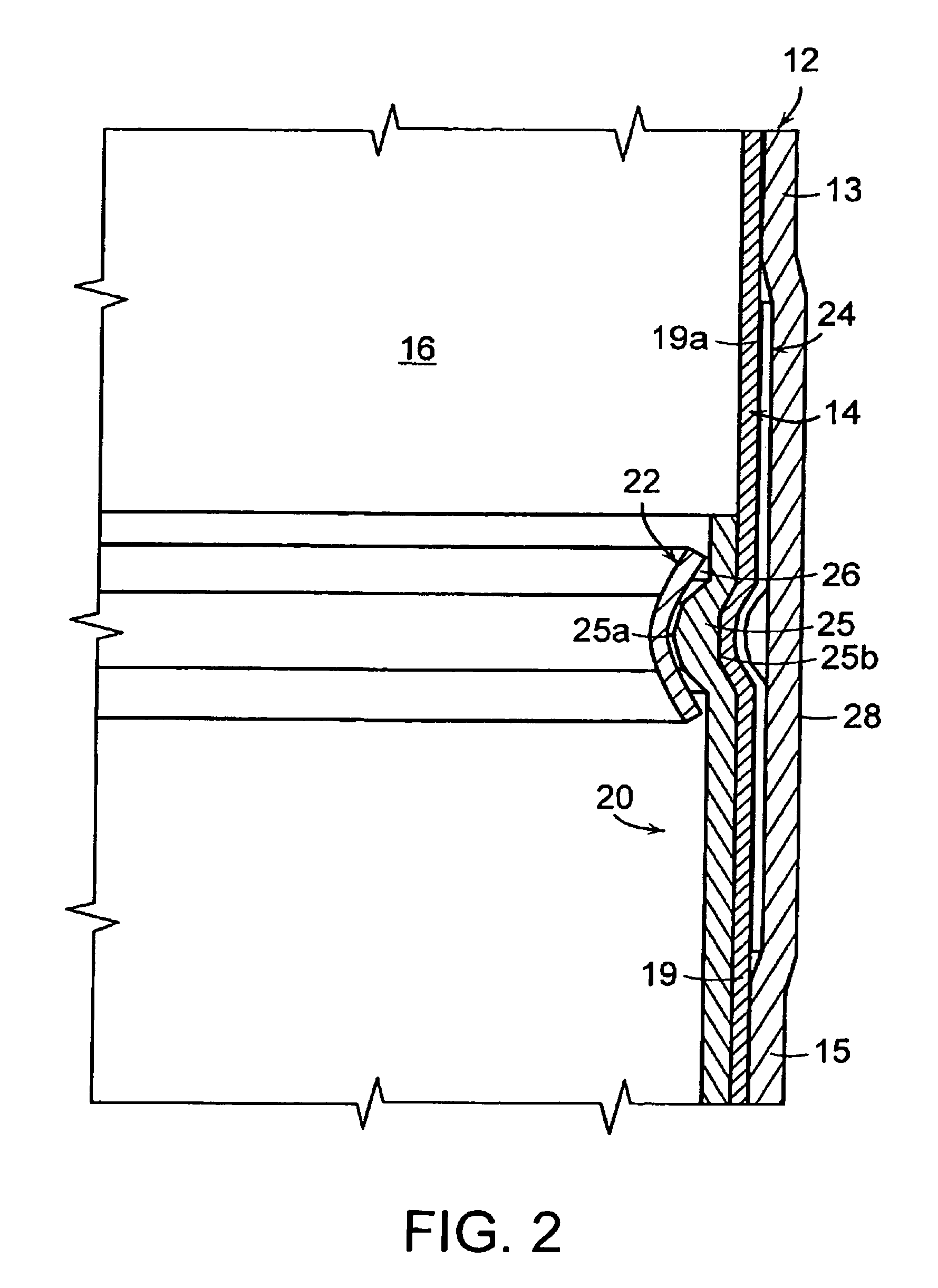

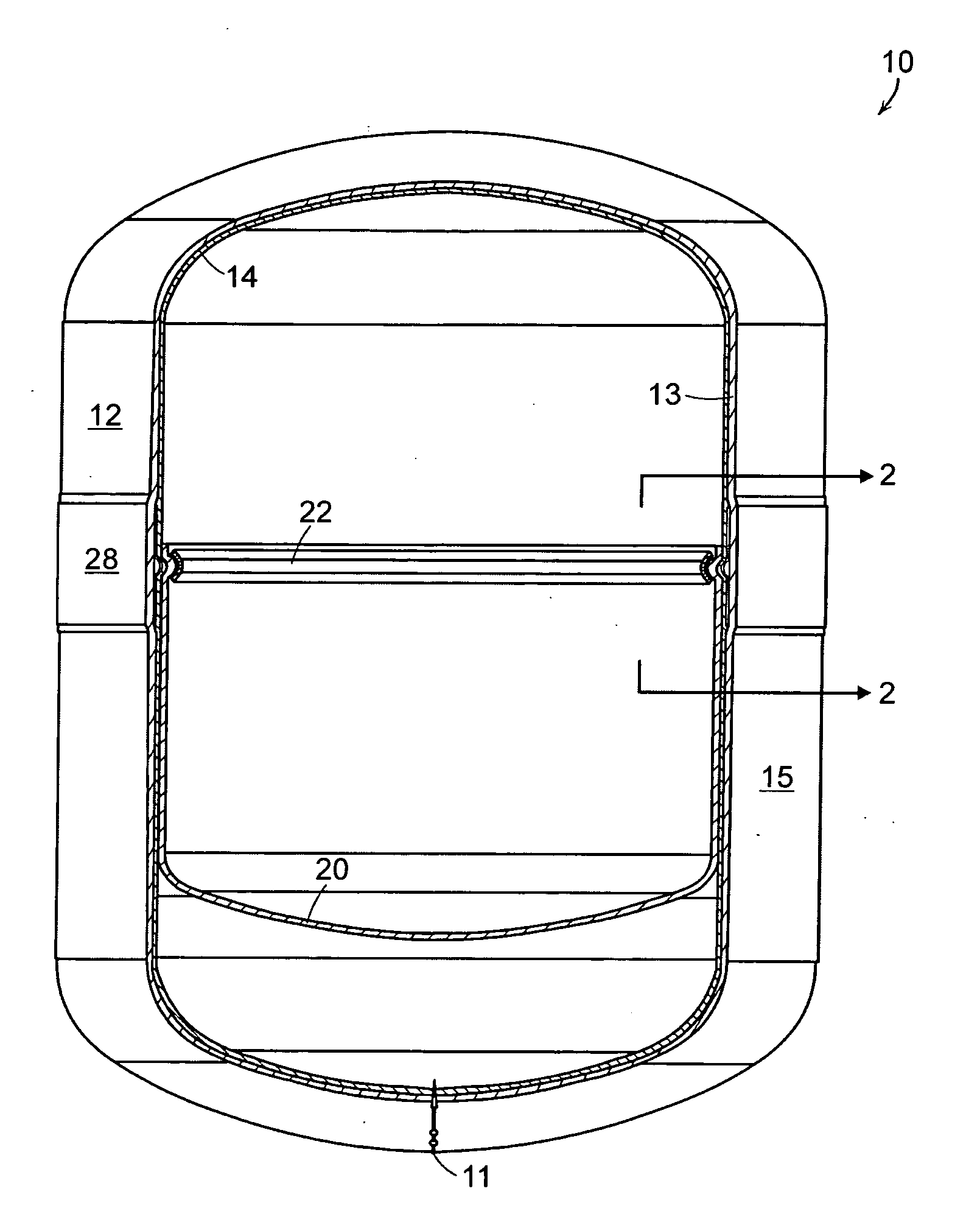

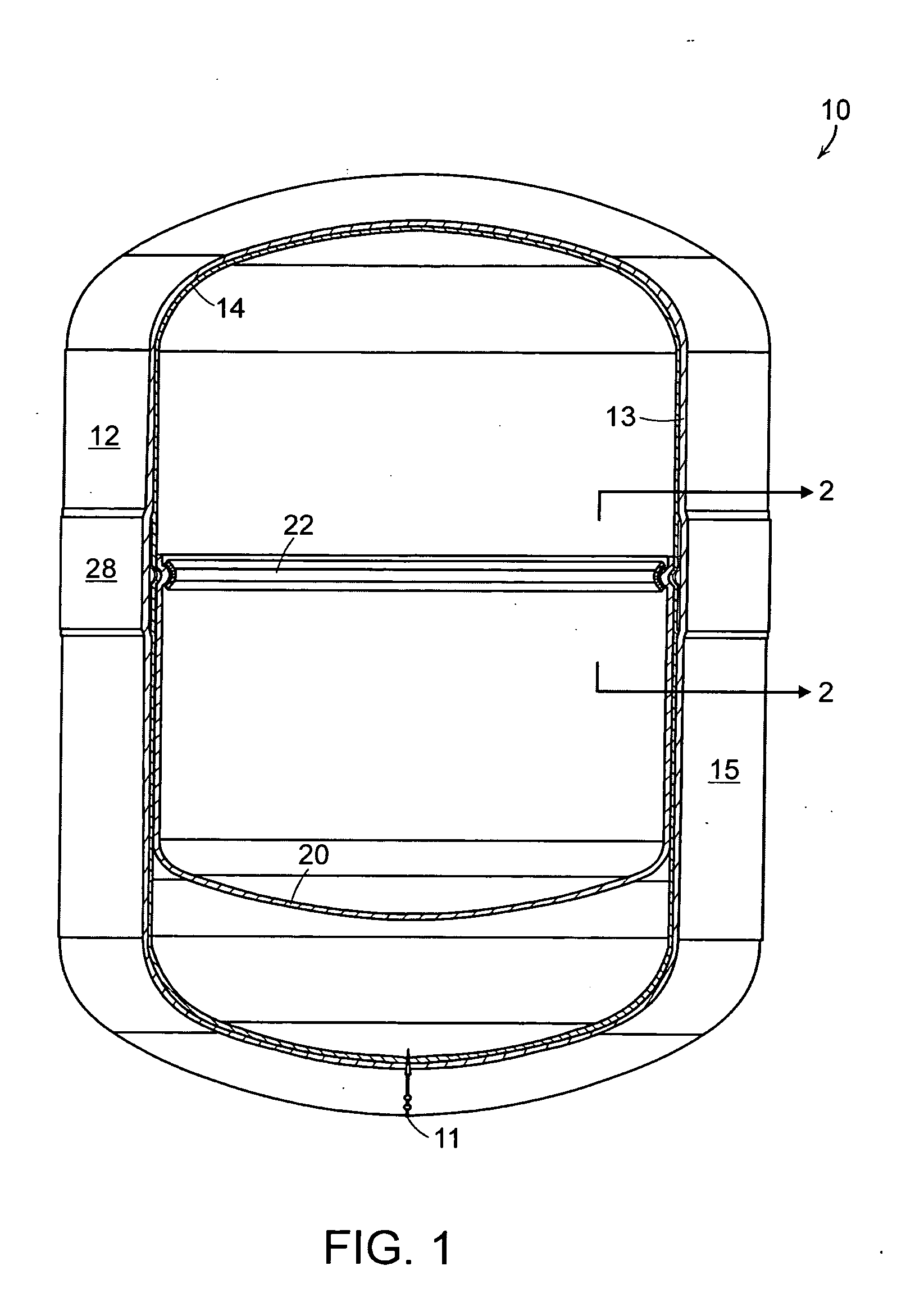

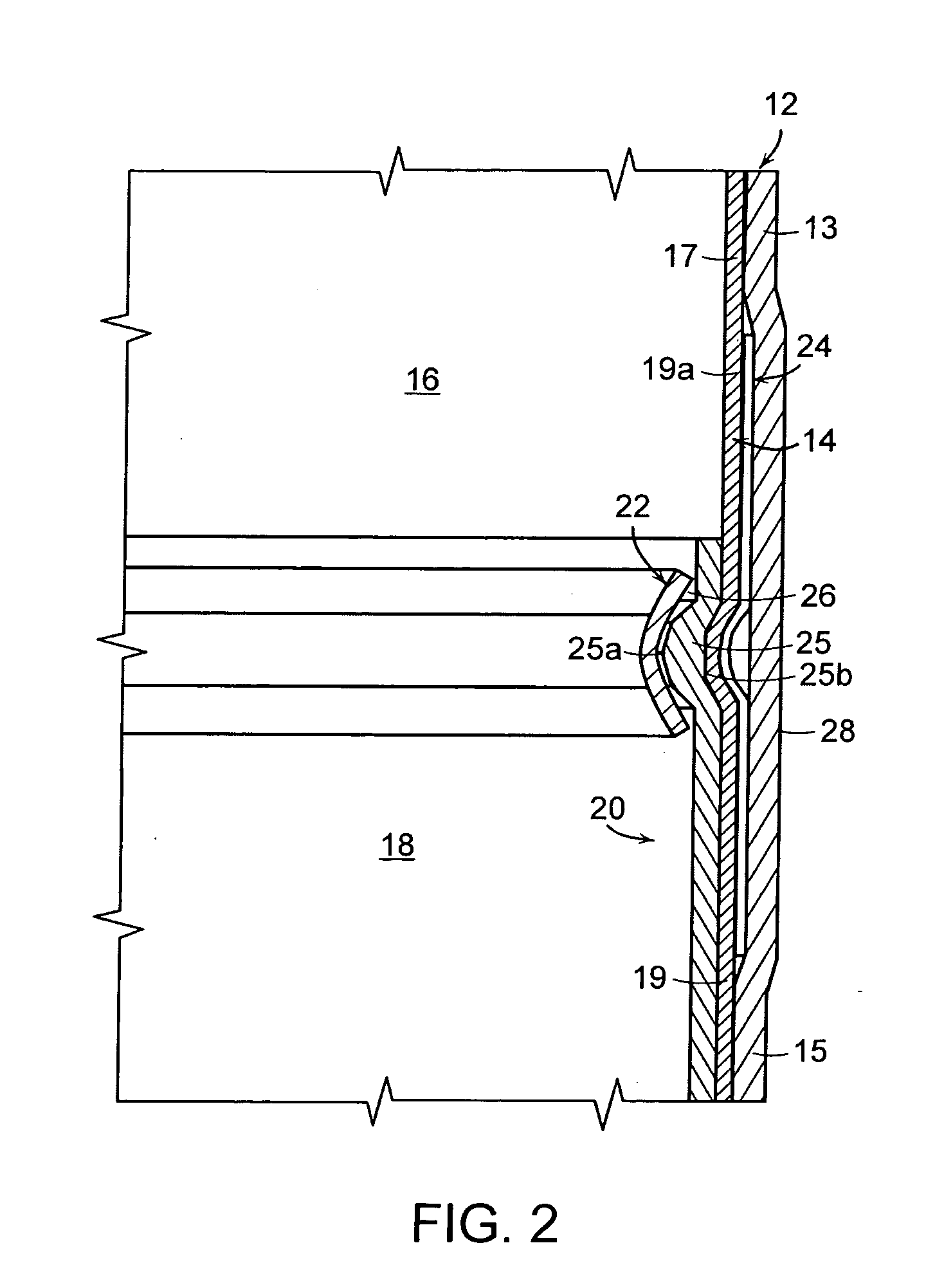

Non-metallic expansion tank with internal diaphragm and clamping device for same

ActiveUS7216673B2Reduce maintenance costsSolution to short lifeLighting and heating apparatusPipe elementsExpansion tankEngineering

A non-metallic, diaphragm-type tank assembly for use with a pressurized water system is disclosed. The tank assembly comprising a non-metallic outer body; a non-metallic inner shell assembly, including an upper portion and a lower portion, that is contained by the non-metallic outer body; and a diaphragm that is structured and arranged about the upper and lower portions of the inner shell assembly to separate said inner shell assembly into a water portion and a pressurized gas portion. Preferably, the diaphragm comprises a resilient, non-porous material and includes a bead portion comprising an annular ring that is convex on an inner side and concave on an outer side at its outer periphery. More preferably, the bead portion is removably secured to the overlapable end portion of the lower portion of the inner shell assembly by a clamping system that comprises an inner clamp hoop and an outer band. Specifically, the outer band can be mechanically crimped to compress and secure the second overlapable end portion and the bead portion of the diaphragm between the inner clamp hoop and the outer band to provide a watertight seal for the water portion.

Owner:AMTROL LICENSING INC

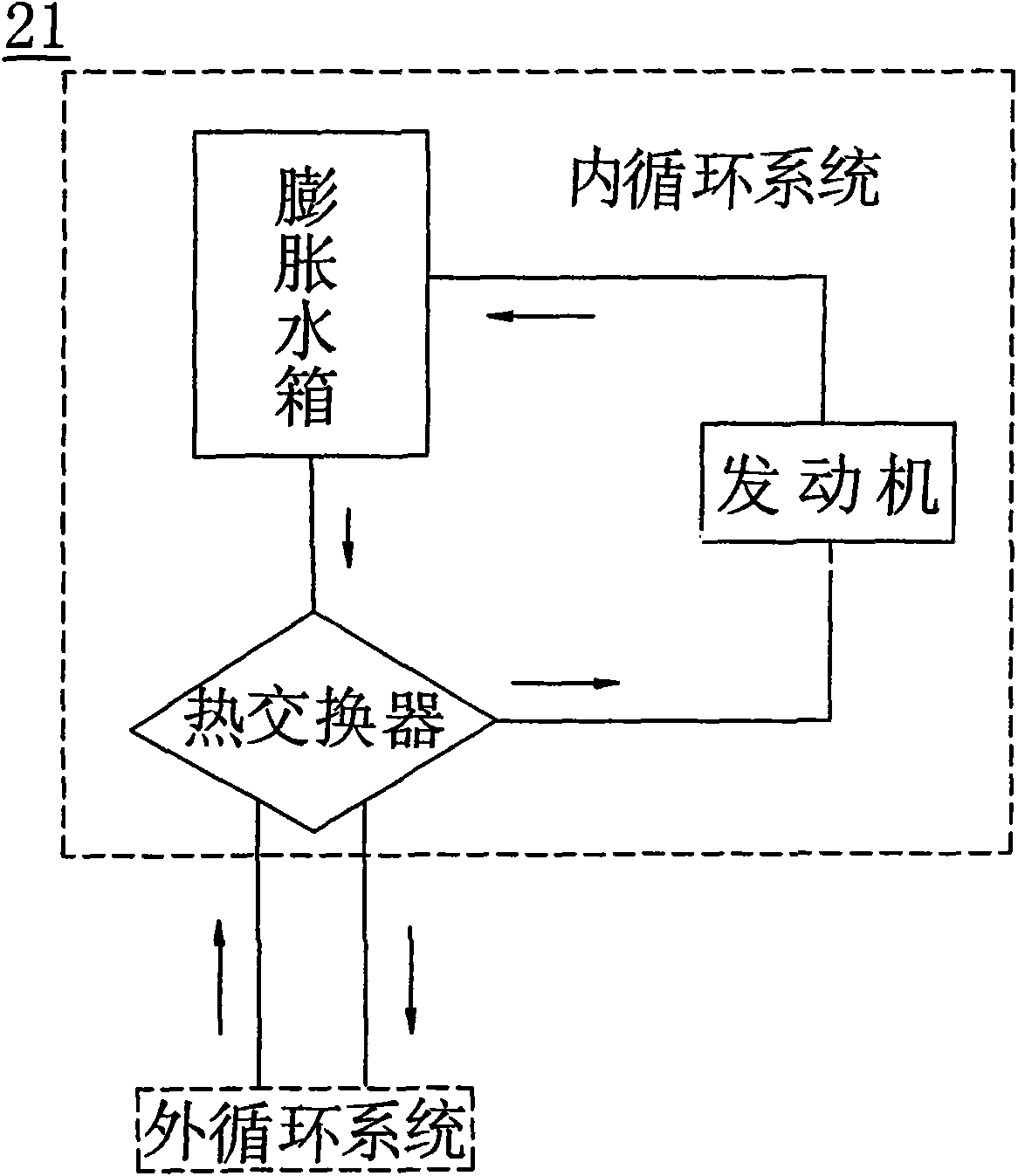

Cooling system

InactiveUS20090277401A1Increase pressureCoolant flow controlMachines/enginesExpansion tankThermostat

A cooling system for an engine is divided into an inner circuit and an outer circuit, said inner circuit including a radiator, a cooling pump, a thermostat housing, an ejector pump, cooling channels arranged inside the engine and ducting connecting said components. The ejector pump is arranged to draw coolant from the outer system and deliver it to the inner system. The outer system includes an expansion tank, ducting interconnecting the expansion tank and the ejector pump and ducting interconnecting the inner circuit and the expansion tank. A one-way valve is placed in the ducting interconnecting the expansion tank and the inner circuit.

Owner:VOLVO LASTVAGNAR AB

Automobile engine cooling system

ActiveCN108343500AReduce trafficTraffic restrictionsCoolant flow controlMachines/enginesExpansion tankCombustion

The invention provides an automobile engine cooling system which comprises a water pump, a cylinder cover water jacket, a cylinder body water jacket, a first thermostat, a heat radiator, an electronicwater pump, a supercharger, an expansion tank, an engine oil cooler, a second thermostat, a fan heater and an engine degassing pipeline, wherein the opening and closing of corresponding pipelines ofthe engine oil cooler and the fan heater are controlled by the second thermostat; after the supercharger is shut down, the electronic water pump carries out delay cooling; and the flow rate of each loop is about 30 L / min, so that the requirements of the engine oil cooler and the fan heater are met at the same time. With the adoption of the engine cooling system, the friction is reduced, oil consumption is reduced, the requirement on water pump performance is lowered, the combustion efficiency is improved, and the reliability of the supercharger is ensured.

Owner:HAIMA AUTOMOBILE CO LTD +1

An engine cooling system and a cooling method

InactiveCN102733921AReduce fuel consumptionIncrease fuel consumptionLiquid coolingCoolant flow controlExpansion tankFriction loss

The invention relates to an engine cooling system, comprising a radiator, an expansion water tank, a pump unit, and a water jacket of a cylinder cover and a water jacket of a cylinder body that are communicated with each other. An outlet of the pump unit is communicated with an inlet of the water jacket of the cylinder cover to input cooling liquid; the input cooling liquid is arranged to be two flow paths for respectively cooling the cylinder cover and the cylinder body of the engine, wherein the first flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder cover via the water jacket of the cylinder cover, and enters into an inlet of the pump unit after passing through the expansion water tank; the second flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder body via the water jacket of the cylinder body, and enters into the inlet of the pump unit after passing through the radiator. The invention also relates to an engine cooling method. By utilizing the engine cooling system and the cooling method, temperatures of the cylinder cover and the cylinder body can be controlled and maintained in a more reasonable way, and therefore a temperature of lubricating oil can be notably improved, friction loss can be lowered, fuel consumption can be more efficient, and emission can be lowered.

Owner:SAIC GENERAL MOTORS +1

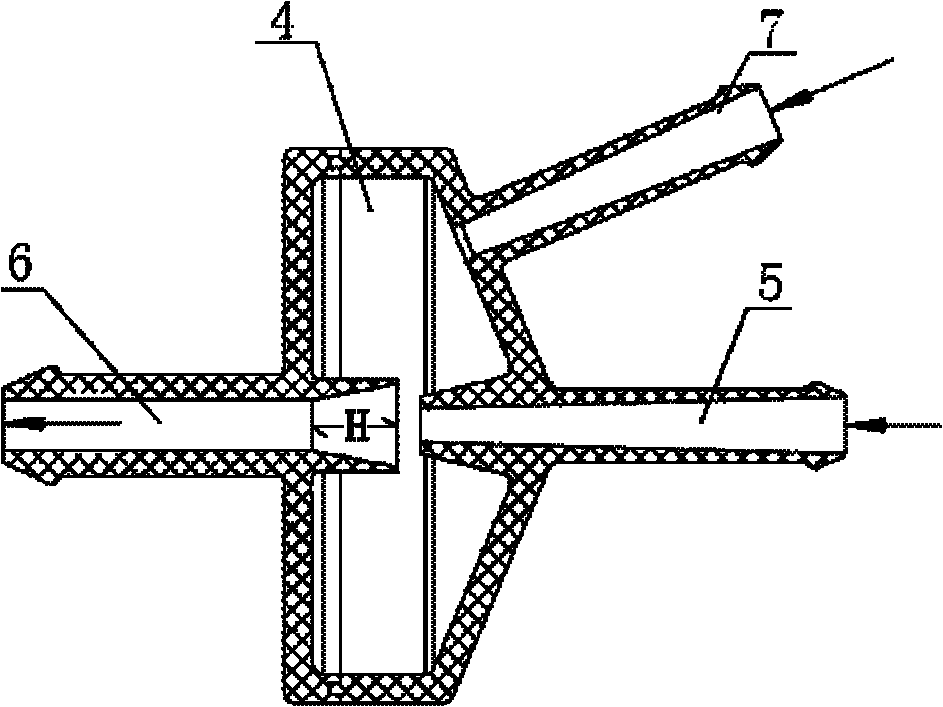

Engine cooling water system device with automatic exhaust function

InactiveCN102042073AEfficient exclusionMachines/enginesEngine cooling apparatusExpansion tankCooling effect

The invention discloses an engine cooling water system device with an automatic exhaust function. In the device, a Venturi tee pipe is arranged among an engine cooling water outlet pipe, an expansion tank and a water tank; a water inlet of a thermostat and an inlet pipe of the Venturi tee pipe are connected with an engine cooling water outlet pipe respectively; the water outlet pipe is connected with the expansion tank; a bypass pipe of the Venturi pipe, an water outlet pipe of the expansion tank and a water outlet pipe of the thermostat are connected with the water tank; an water outlet pipe of the water tank and a water distributing pipe of the thermostat are connected to a water pump, and a water outlet of the water pump is connected to an engine cooling water inlet; and an air inlet pipe and an air outlet pipe of the Venturi tee pipe form a Venturi pipe structure in the cavity of the Venturi tee pipe. No matter however the engine runs, steam bubbles and air bubbles in a cooling system can be exhausted automatically, an air cock in a cooling circulation system can be eliminated, so the cooling effect of the engine can be remarkably improved. Meanwhile, the corrosion of oxygen molecules to metal can be reduced after the air in a coolant is exhausted, so the service life of the engine can be prolonged.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

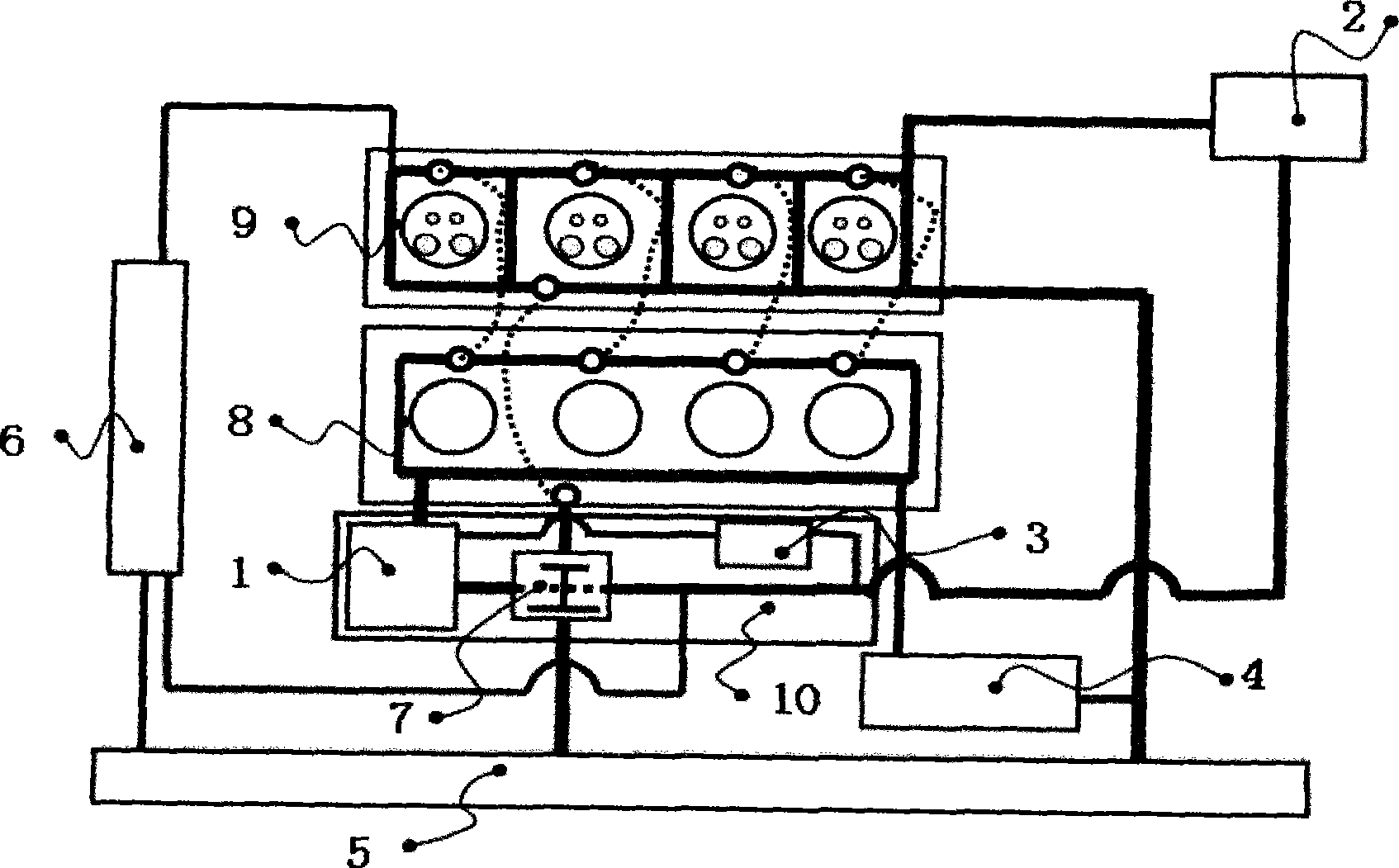

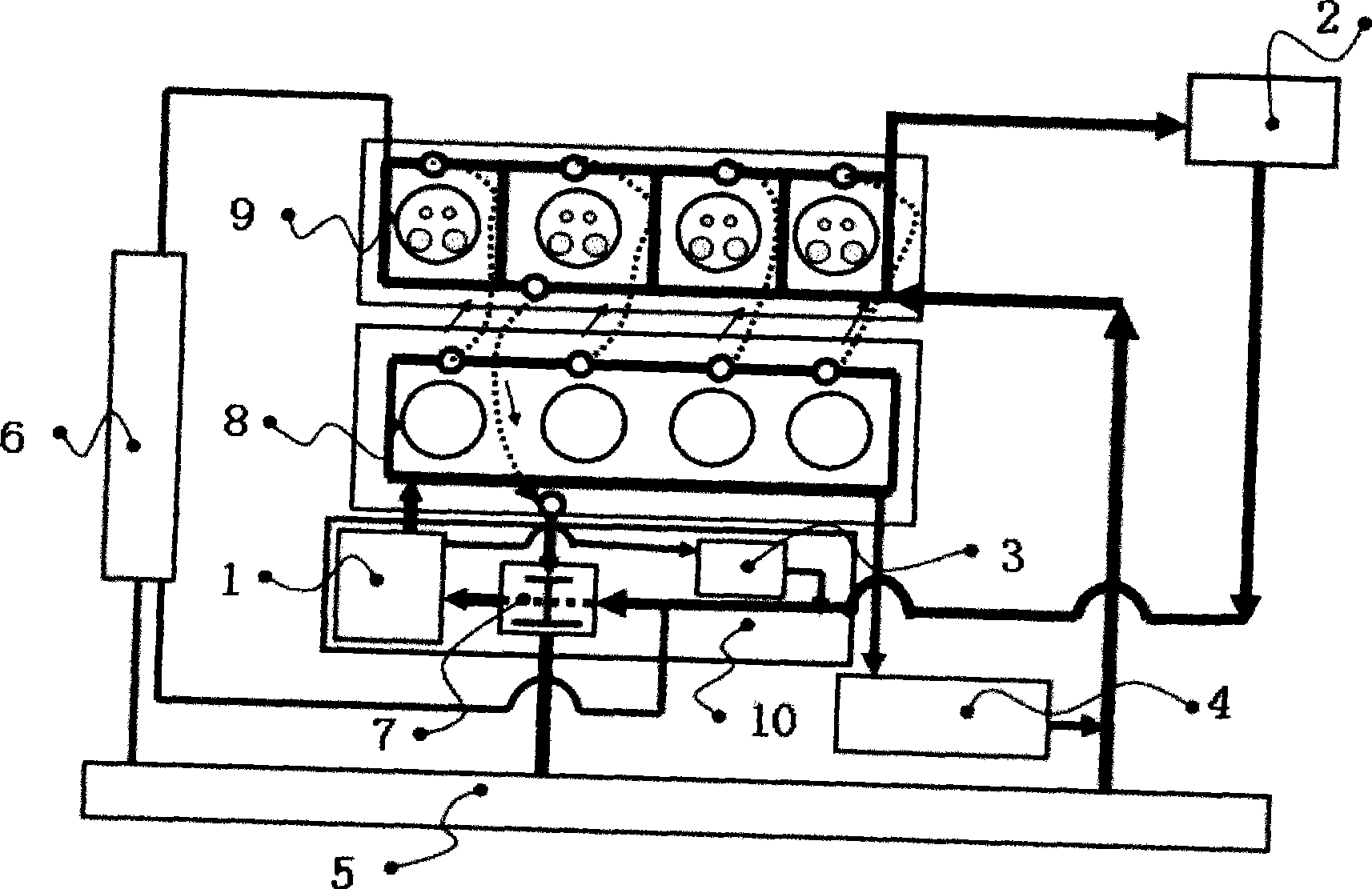

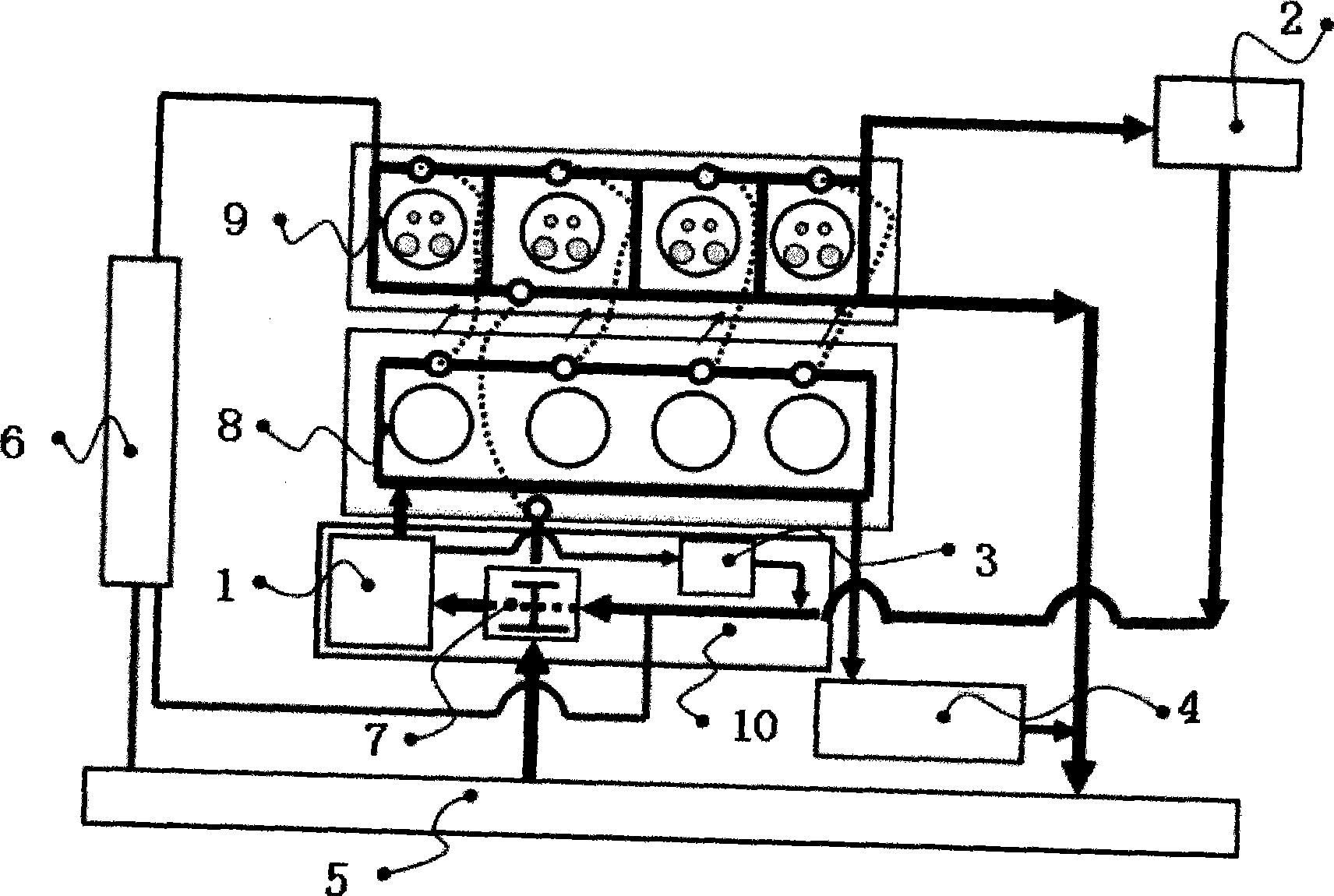

Cooling system of engine

ActiveCN101463752AReduce the temperatureImprove fuel economyCoolant flow controlMachines/enginesExpansion tankWax

The invention discloses an engine cooling system, comprising a pump (1), a heater unit (2), an oil cooler (3), an EGR cooler (4), a radiator (5), an expansion tank (6), a thermolator (7), a cylinder body water jacket (8), a cylinder head water jacket (9) and an integrated support (10), wherein, the pump (1), the oil cooler (3) and the thermolator (7) are mounted on the integrated support (10), and the thermolator (7) is a high purity wax thermolator which is arranged at a water inlet; cooling fluid entering the cylinder head water jacket (9) flows out through the back end of the cylinder head, two water outlets are arranged at two sides of the back end of the cylinder head, the water outlet at the air inlet side is connected with the radiator (5), the water outlet at the air outlet side is connected with the heater unit (2), a branch circuit of the heater unit is normally open, and the branch circuit of the heater unit is controlled by the thermolator (7). By increasing the initial operating temperature and lowering the temperature difference between the full operating temperature and the initial operating temperature, the engine cooling system of the invention can improve cooling effect, thus improving economical efficiency of engine gas fuel, and lowering discharge of harmful gases; in addition, the structural arrangement is more compact.

Owner:CHERY AUTOMOBILE CO LTD

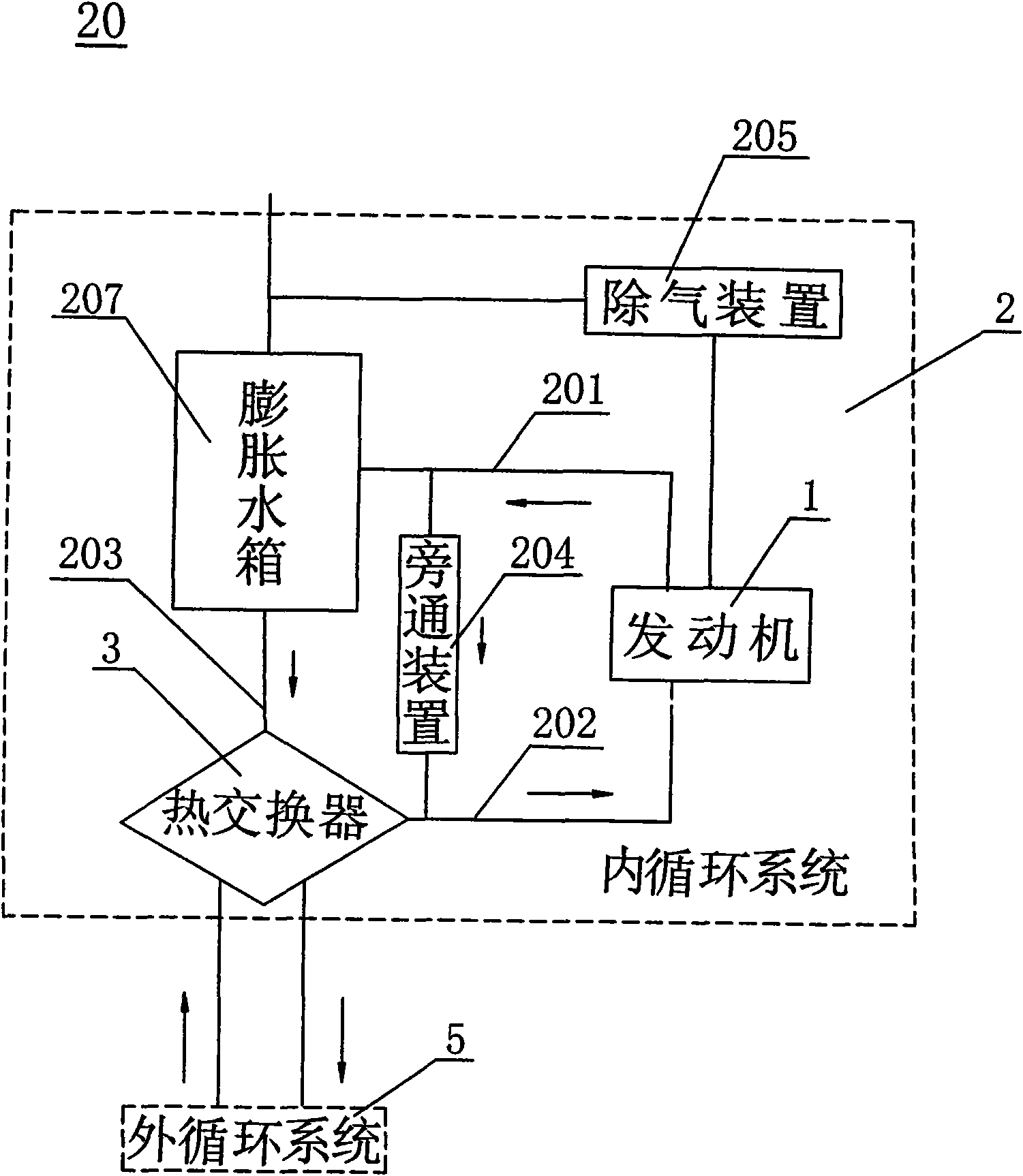

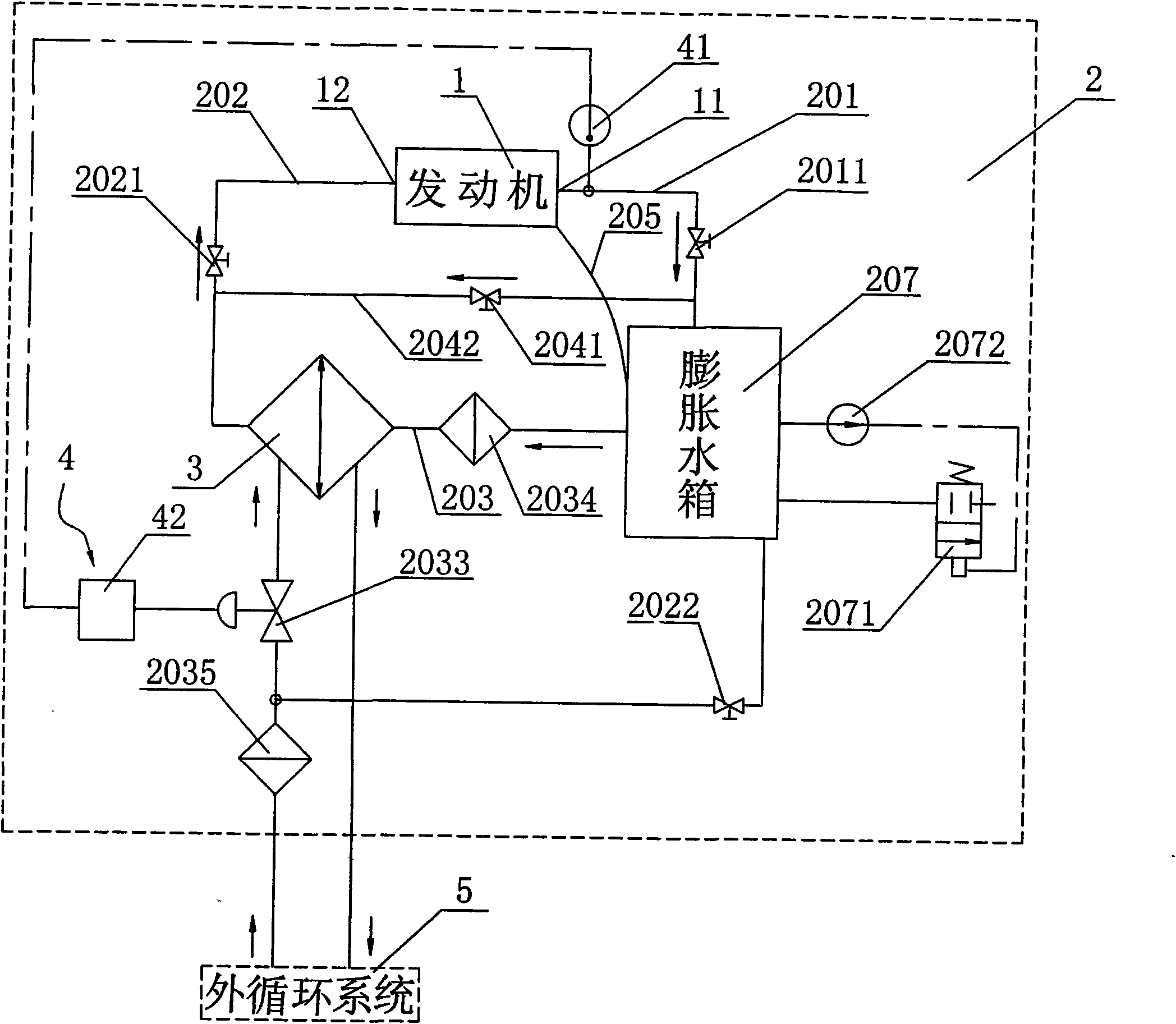

Cooling fluid temperature control system for testing engine performance

The invention relates to a cooling fluid temperature control system for testing engine performance. The cooling fluid temperature control system comprises a cooling fluid internal recycling system, a heat exchange device, a temperature monitoring and controlling device and a cooling fluid external recycling system, wherein the cooling fluid internal recycling system and the cooling fluid external recycling system are connected with the heat exchange device respectively; the cooling fluid internal recycling system is connected with an engine; the temperature monitoring and controlling device is connected with the cooling fluid internal recycling system, the heat exchange device and the cooling fluid external recycling system respectively; and the cooling fluid internal recycling system is a closed internal recycling system. A gas exhausting pipe is arranged on the conventional water temperature control system and communicates a cylinder cover water channel of the engine with a swelling water tank to ensure that the recycling water channel of the engine normally exhausts the gas; and the water inlet end and the water outlet end of the engine are additionally provided with bypass pipes and bypass valves to use water outlet pressure to compensate water inlet pressure so as to further reduce the difference of the water inlet pressure and the water outlet pressure, improve water inlet flow and water outlet flow and fulfill the aim that a cooling water system for engine tests simulates the operational states of the whole vehicle.

Owner:BEIQI FOTON MOTOR CO LTD

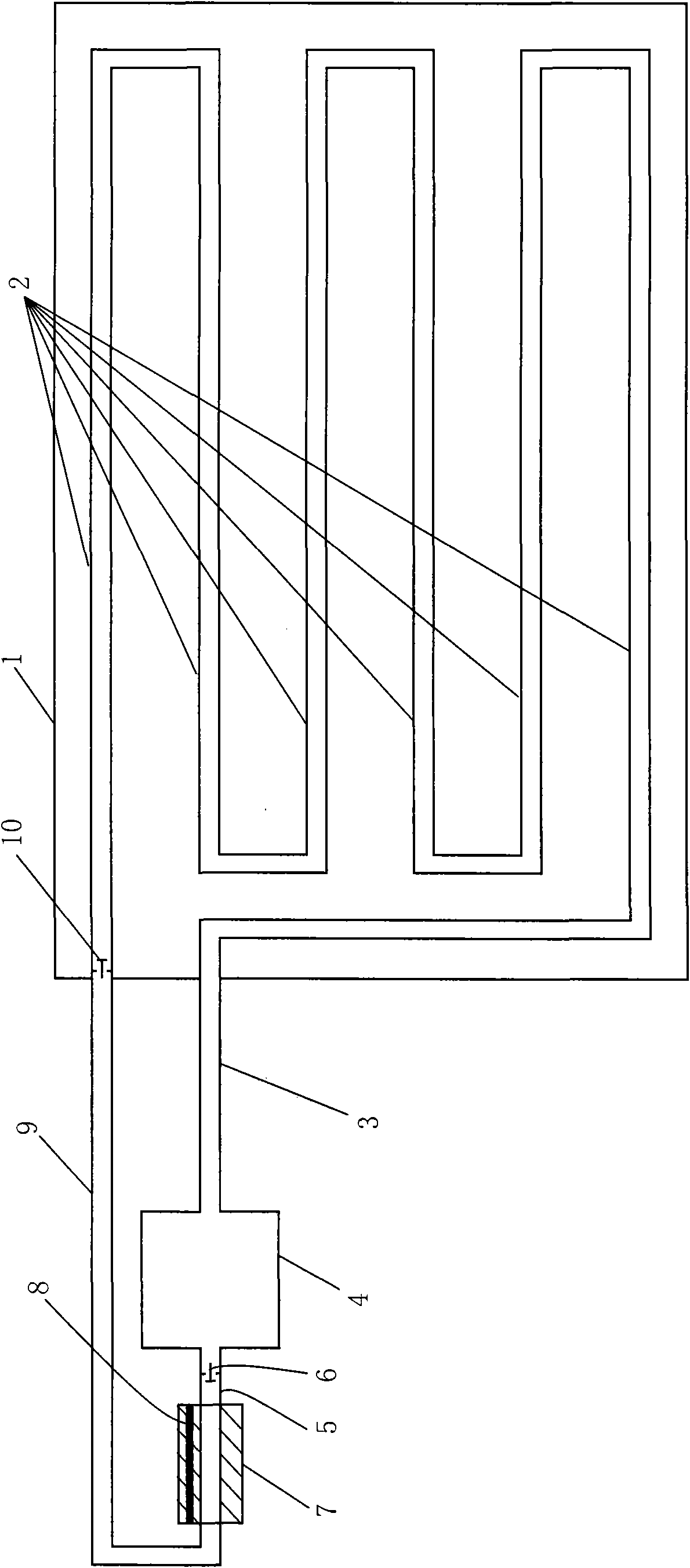

Hot water circular cushion for warming

InactiveCN101558946ARealize cyclic heat transferEven heat dissipationFluid mattressesBedsExpansion tankWater vapor

The invention relates to a hot water circular cushion for warming by using water vapor to push water to circularly flow for heat transmission, which comprises a hose, a cushion body, an expanding water tank, a start holding valve, tail-end holding valves, an electrical heating element and a hot water pipe. The hot water pipe is combined with the electrical heating element, and the flexible pipe is arranged in the cushion body. The hot water circular cushion for warming also comprises a vapor pipe and an exhaust connecting hose. One end of the hot water pipe is connected with one end of the vapor pipe, the other end of the vapor pipe is connected with one end of the hose, the other end of the hose is connected with one end of the exhaust connecting hose, the other end of the exhaust connecting hose is connected with one end of the expanding water tank, and the other end of the expanding water tank is connected with the other end of the hot water pipe through a connecting pipe to form a circular passage. The start holding valve is arranged on the connecting pipe, the tail-end holding valves are arranged on the optional positions of the hose and the exhaust connecting hose, and the direction of the start holding valve and the directions of the tail-end holding valves are the same. The volume in the hot water pipe is matched with the volume in the vapor pipe, and an inlet connecting hose is added between the vapor pipe and the hose. The temperature of the water entering the hose in the cushion body is not high by using the structure, and the water is very comfortable to use.

Owner:王彤宇

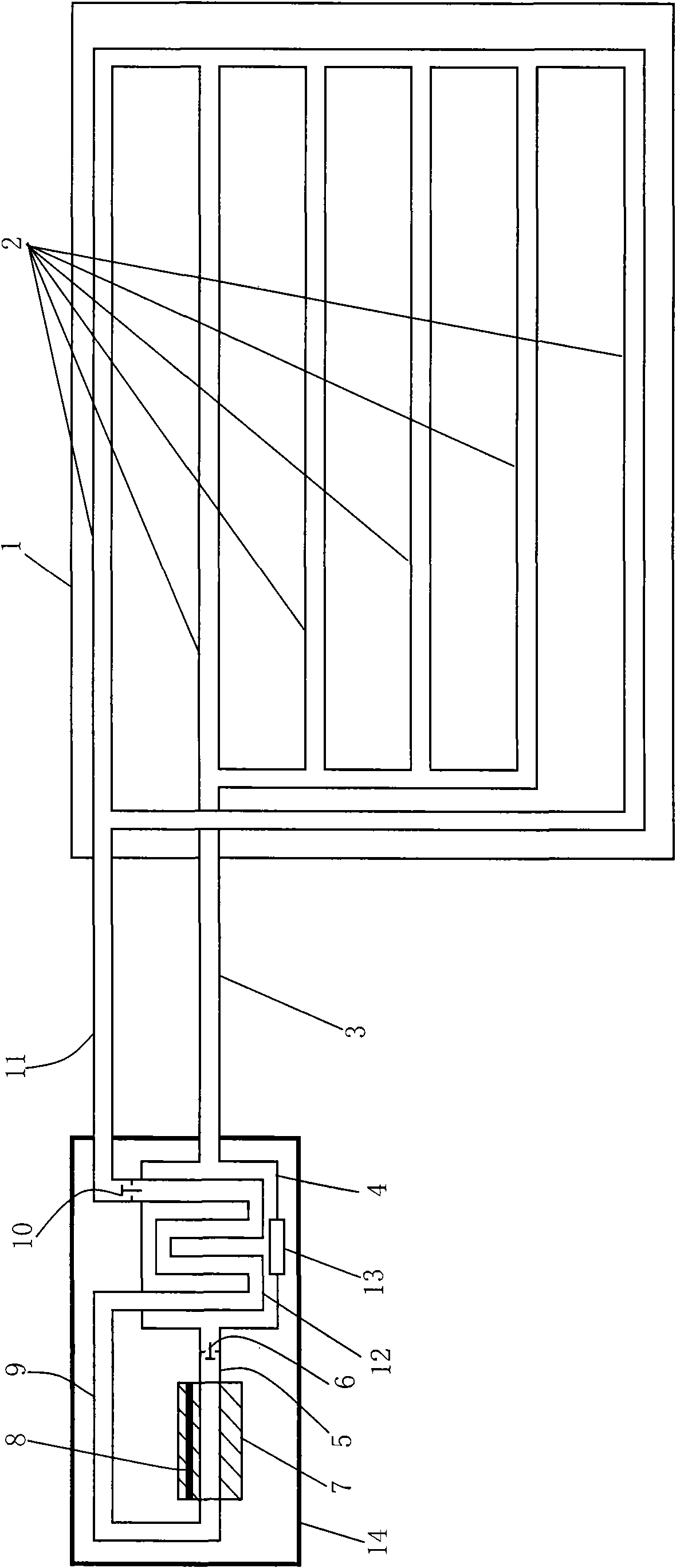

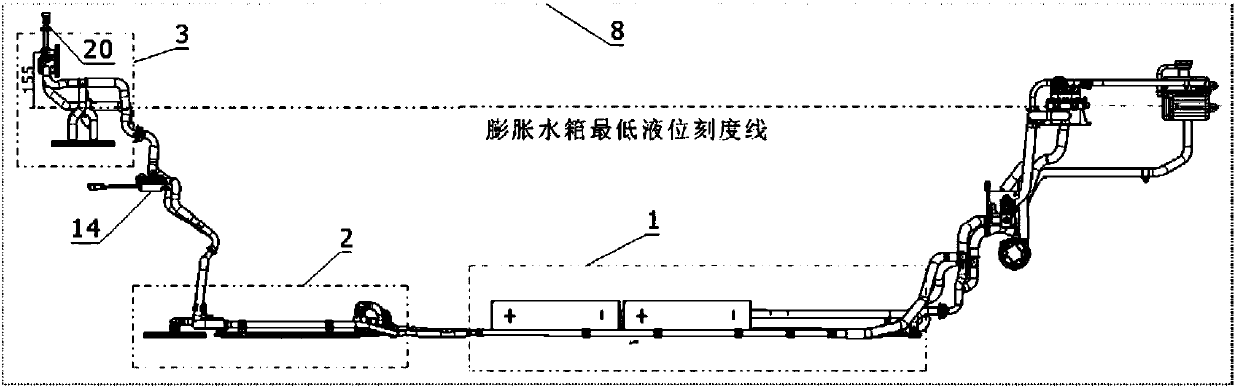

Three-pack power battery cooling and heating system of new energy automobile

ActiveCN107768774AImprove performanceEnsure safetySecondary cellsCell component detailsExpansion tankNacelle

The invention discloses a three-pack power battery cooling and heating system of a new energy automobile. A first battery pack and a second battery pack are arranged at the lower part of a chassis ofa vehicle body and are located at the lowest positions of the vehicle. A third battery pack is arranged in a trunk of the vehicle and is located at the highest position of the vehicle. A water coolingstructure in the third battery pack is provided with a normally closed exhaust valve at the highest position of the vehicle. A scale line at the lowest liquid position of an expansion water tank is lower than the normally closed exhaust valve. The water cooling structure composed of water cooling plates connected in parallel is arranged in each one of the battery packs. The water cooling structures connected in parallel in each battery pack are connected to a high-pressure water heater, a plate heat exchanger, the expansion water tank and an electronic water pump in a front cabin to form a loop. A damping hole is arranged in a joint of the water cooling plate. A thermal conductive pad and a thermal insulation pad are respectively arranged above and below the water cooling plate. A proportional control water valve is arranged at a main inlet of the third battery pack. According to the cell temperature difference control water valve opening degree, uniform temperatures between cells arerealized, the driving range of the whole vehicle is increased and the exhaust problem of the system is solved.

Owner:CHINA FIRST AUTOMOBILE

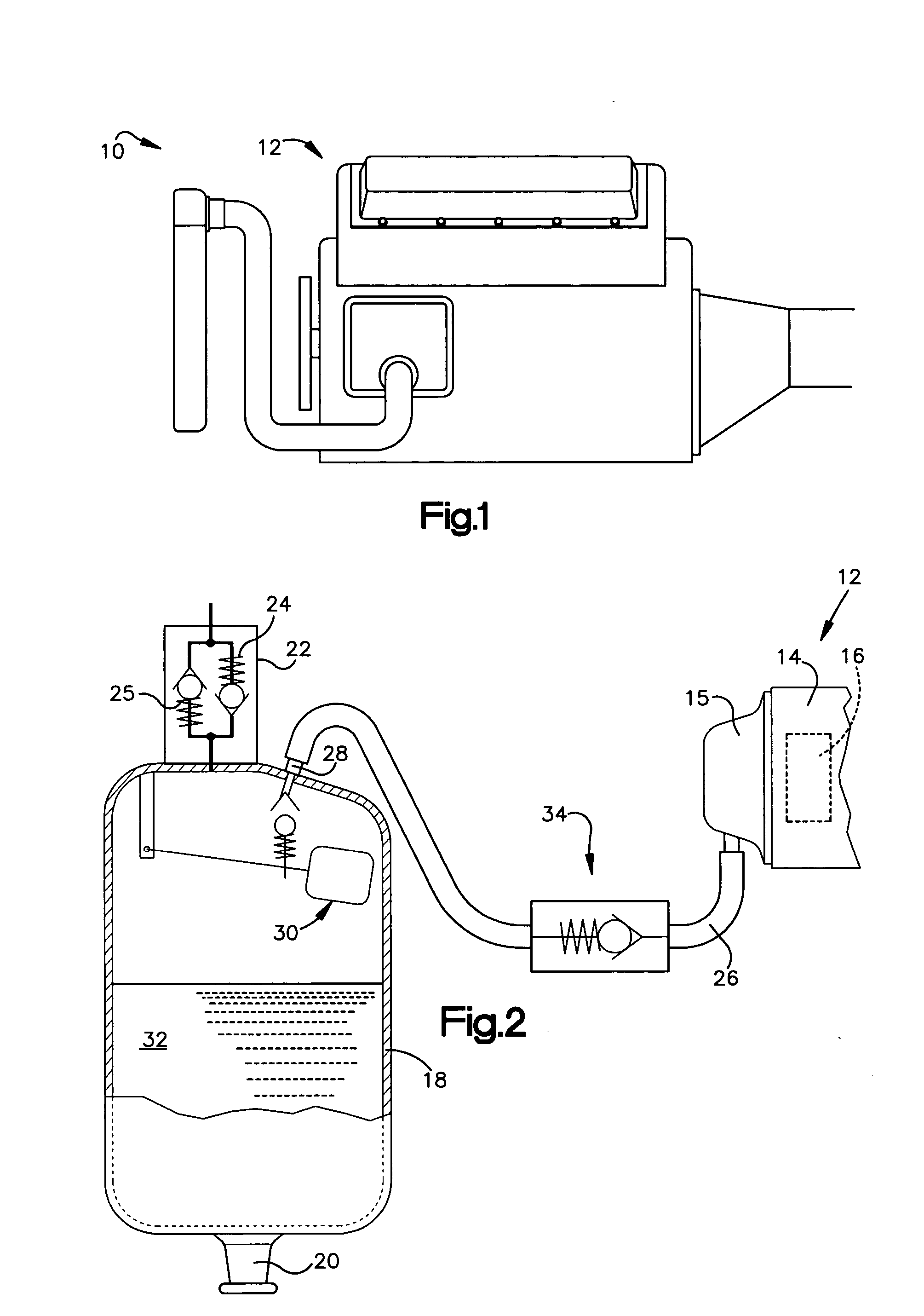

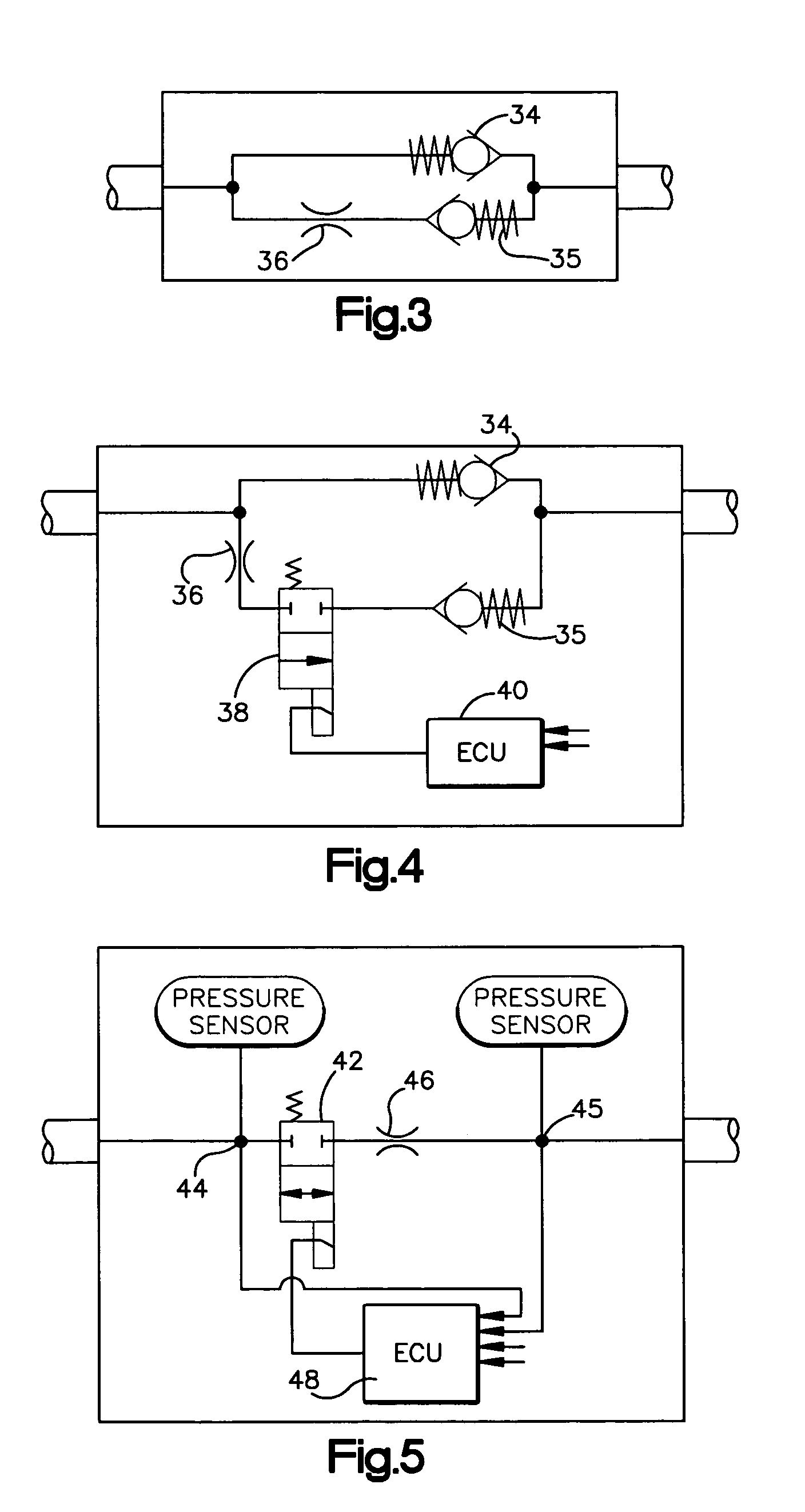

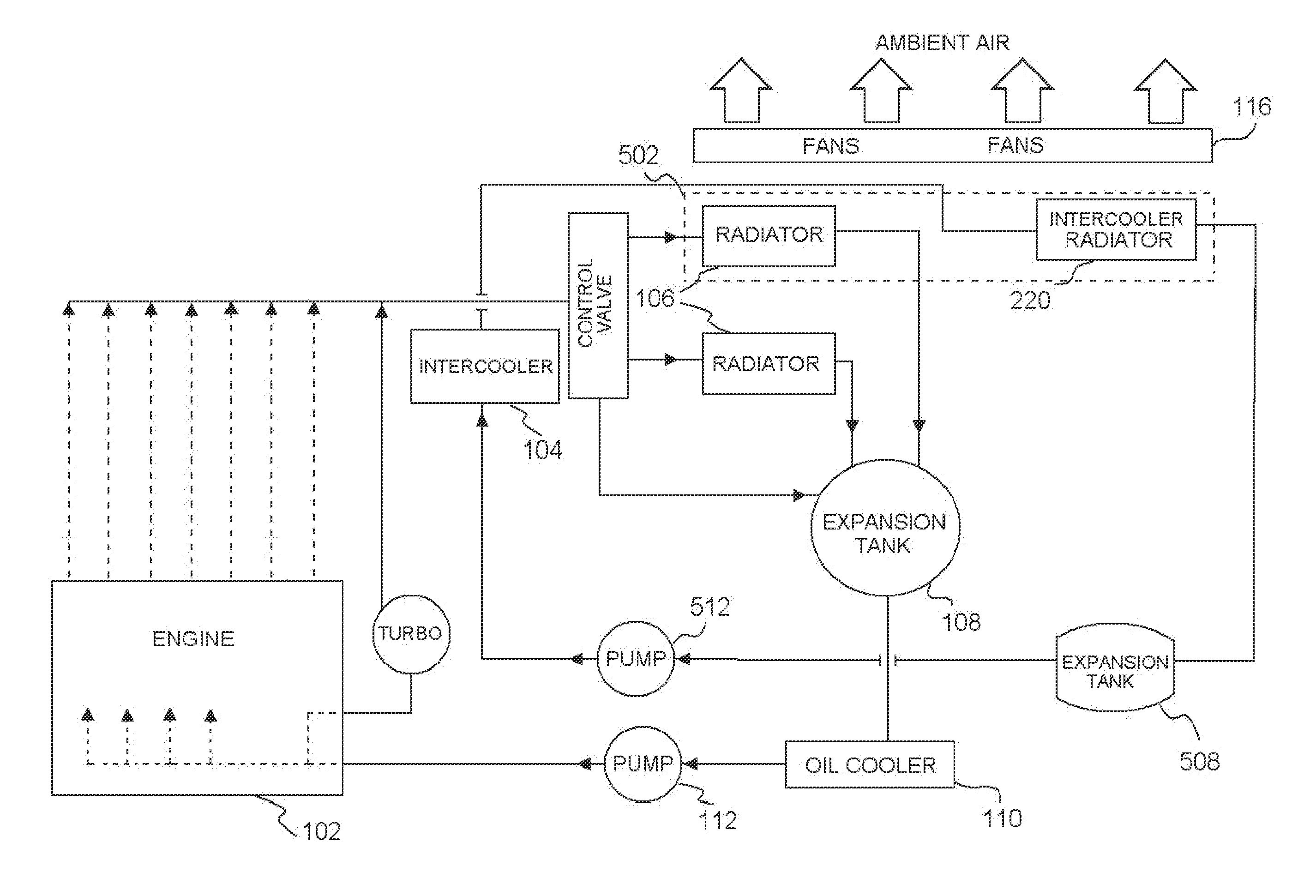

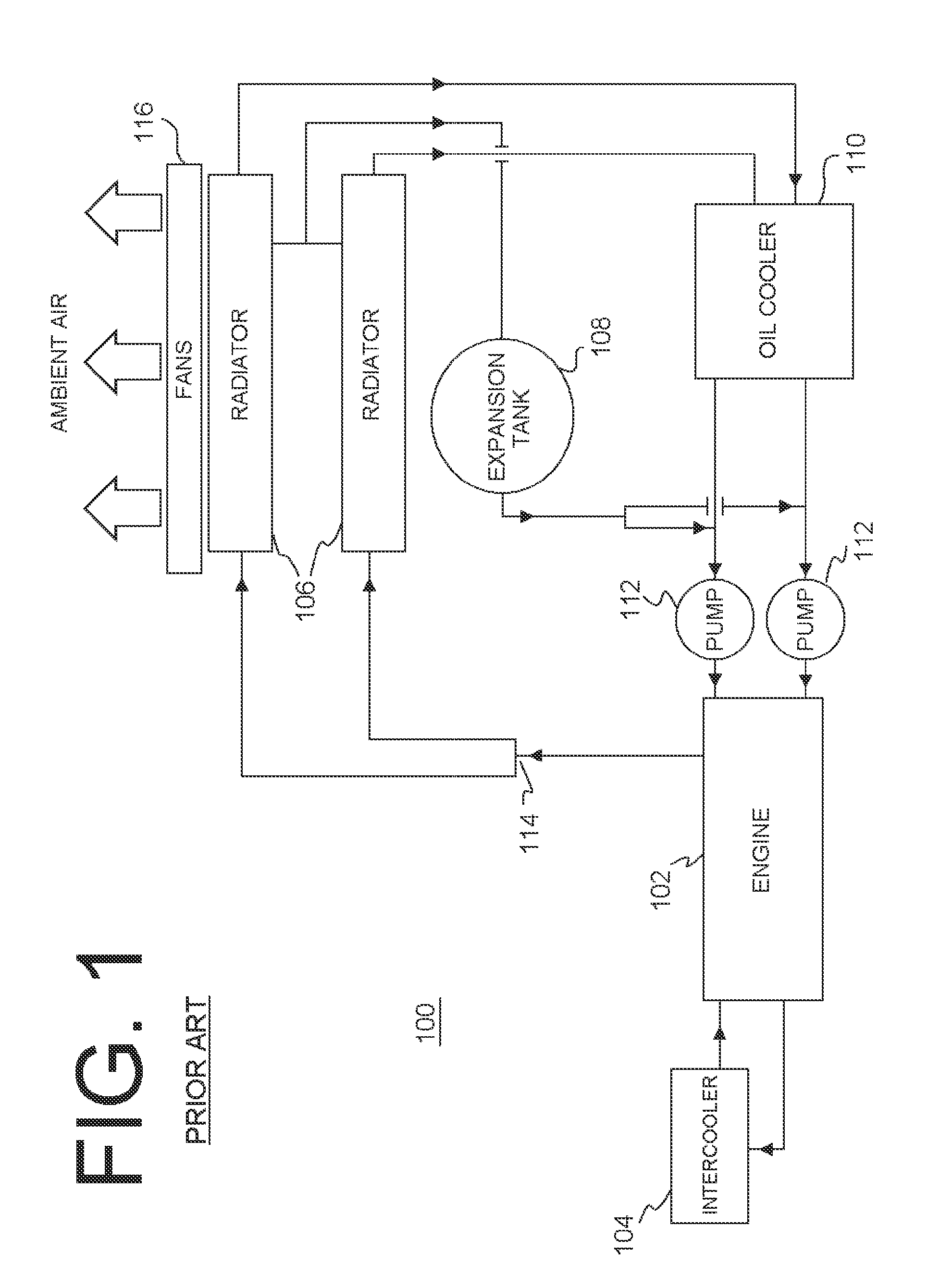

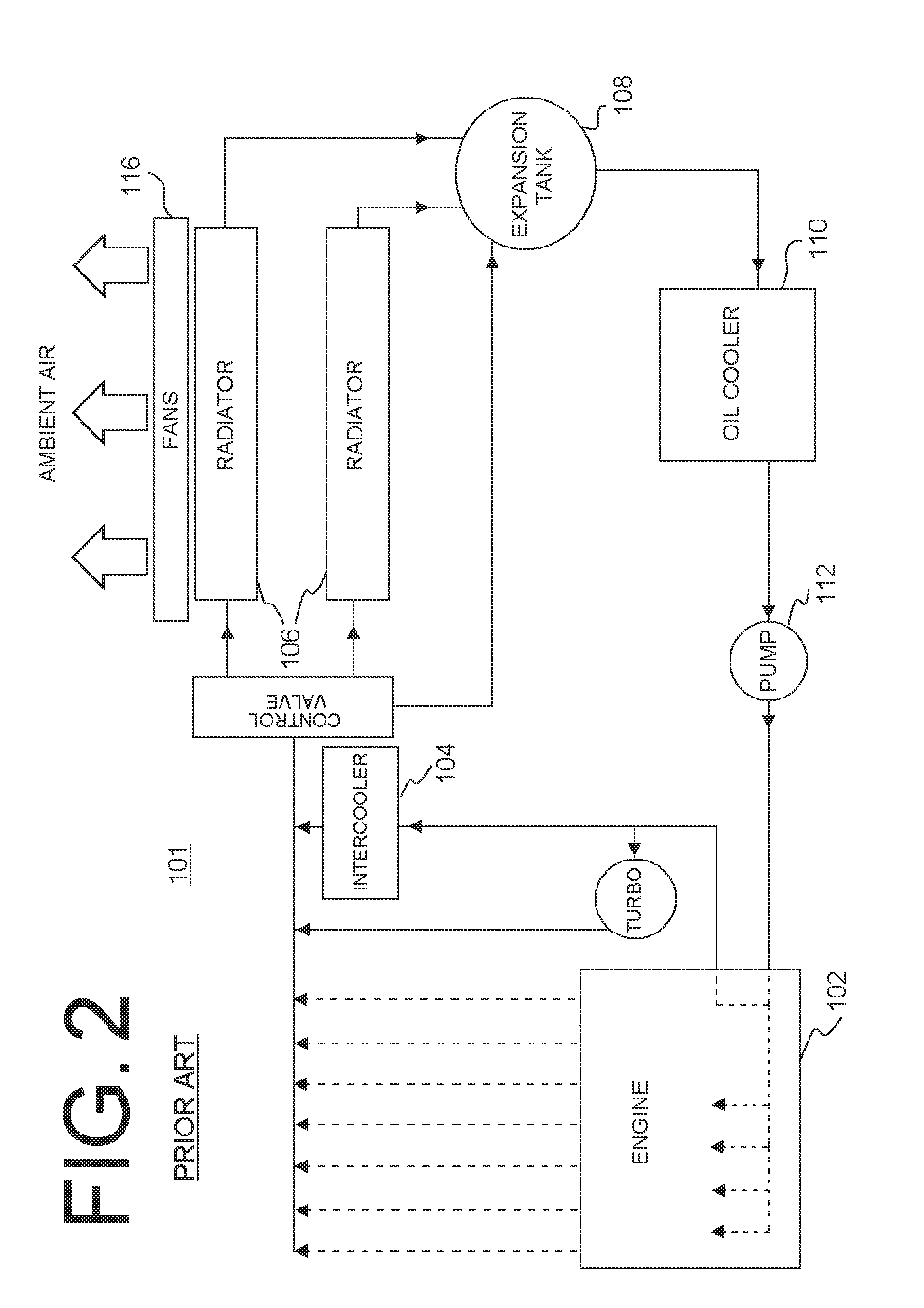

Split Cooling Method and Apparatus

A system and method for cooling an internal combustion engine. In one embodiment of the invention a cooling system for an internal combustion engine is disclosed, comprising an engine; an intercooler for receiving combustion air from a turbocharger, the intercooler comprising an air-to-liquid heat exchanger for exchanging heat between the combustion air and a liquid coolant; an intercooler radiator; at least one engine coolant radiator; an expansion tank; an oil cooler; and at least one pump, wherein the dedicated fan is controlled by a temperature switch or controller and wherein the at least one engine coolant radiator and the intercooler radiator are located on opposite sides of the engine.

Owner:NORFOLK SOUTHERN

Boiler water replenishing system capable of collecting waste heat and condensed water

ActiveCN102607014AHydration does not affectReduce consumptionFeed water supplyExpansion tankBoiler blowdown

The invention discloses a boiler water replenishing system capable of collecting waste heat and condensed water. A boiler blowdown pipe of a boiler is connected with a blowdown expansion tank, a steam outlet of the blowdown expansion tank is connected into a hot water tank through a blowdown flash steam pipe, a blowdown water pipe of the blowdown expansion tank is connected into a continuous-discharge heat exchanger which is further connected with a softened water feeding pipe, the softened water feeding pipe is connected with a water softening station through a water supply pump, the softened water feeding pipe for the continuous-discharge heat exchanger is connected with a boiler secondary energy saver prior to being connected into the hot water tank, and the hot water tank is connected with a hot water outlet pipe which is sequentially connected with a circulating pump, a heat deaerator and a boiler water feeding pump prior to being connected into a boiler water inlet. The boiler water replenishing system has the advantages that centralized use of the waste heat and the condensed water is achieved, steam consumption of the deaerator is reduced, waste heat absorption effect is enhanced, connection of the deaerator is simplified, pollution of the heat and the condensed water to the environment is reduced, and water replenishing for the boiler is unaffected when heat exchange equipment fails.

Owner:CHINA TOBACCO HENAN IND

Non-metallic expansion tank with internal diaphragm and clamping device for same

ActiveUS20060000839A1Reduce maintenance costsSolution to short lifeLighting and heating apparatusPipe elementsExpansion tankEngineering

A non-metallic, diaphragm-type tank assembly for use with a pressurized water system is disclosed. The tank assembly comprising a non-metallic outer body; a non-metallic inner shell assembly, including an upper portion and a lower portion, that is contained by the non-metallic outer body; and a diaphragm that is structured and arranged about the upper and lower portions of the inner shell assembly to separate said inner shell assembly into a water portion and a pressurized gas portion. Preferably, the diaphragm comprises a resilient, non-porous material and includes a bead portion comprising an annular ring that is convex on an inner side and concave on an outer side at its outer periphery. More preferably, the bead portion is removably secured to the overlapable end portion of the lower portion of the inner shell assembly by a clamping system that comprises an inner clamp hoop and an outer band. Specifically, the outer band can be mechanically crimped to compress and secure the second overlapable end portion and the bead portion of the diaphragm between the inner clamp hoop and the outer band to provide a watertight seal for the water portion.

Owner:AMTROL LICENSING INC

Bottom-arranged power integrated system for high-speed internal combustion motor train unit

ActiveCN106347378AReduce axle loadMeet the needs of high-speed passenger transportIC engine locomotivesIC reciprocating piston engine transmissionExpansion tankAir filter

The invention discloses a bottom-arranged power integrated system for a high-speed internal combustion motor train unit. The bottom-arranged power integrated system for the high-speed internal combustion motor train unit comprises a diesel generating set, a diesel auxiliary system, a cooling system, an electronic control system and a mounting frame, wherein the diesel generating set comprises a diesel and a generator; the generator and the diesel are fixed through a connecting flange; the diesel auxiliary system comprises an inlet air filter, an exhaust SCR aftertreatment system, a fuel system and an engine oil system which are arranged on two sides of the diesel generating set; the cooling system comprises a fixed hydraulic pump, a cooling device, an expansion water tank and a fixed hydraulic tank; the diesel generating set and the cooling device are fixed on the mounting frame through elastic rubber dampers; and the mounting frame is hung below a floor of a vehicle through an elastic rubber damper. While axle weight of the bottom-arranged power integrated system for the high-speed internal combustion motor train unit is reduced, passenger carrying space on the vehicle can be utilized to a maximum extent,, and therefore, requirements of high speed passenger transportation are met.

Owner:CRRC DALIAN INST CO LTD

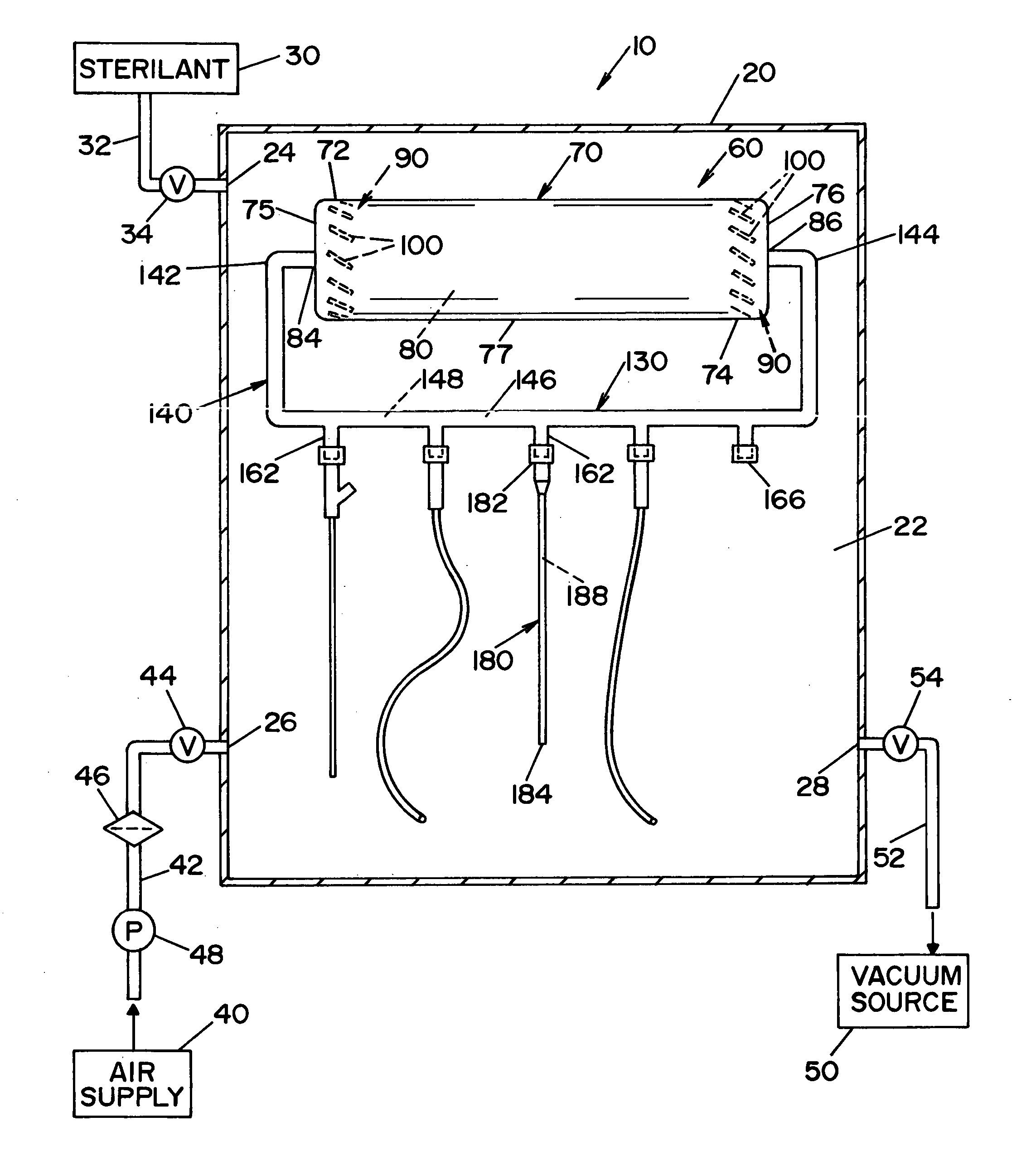

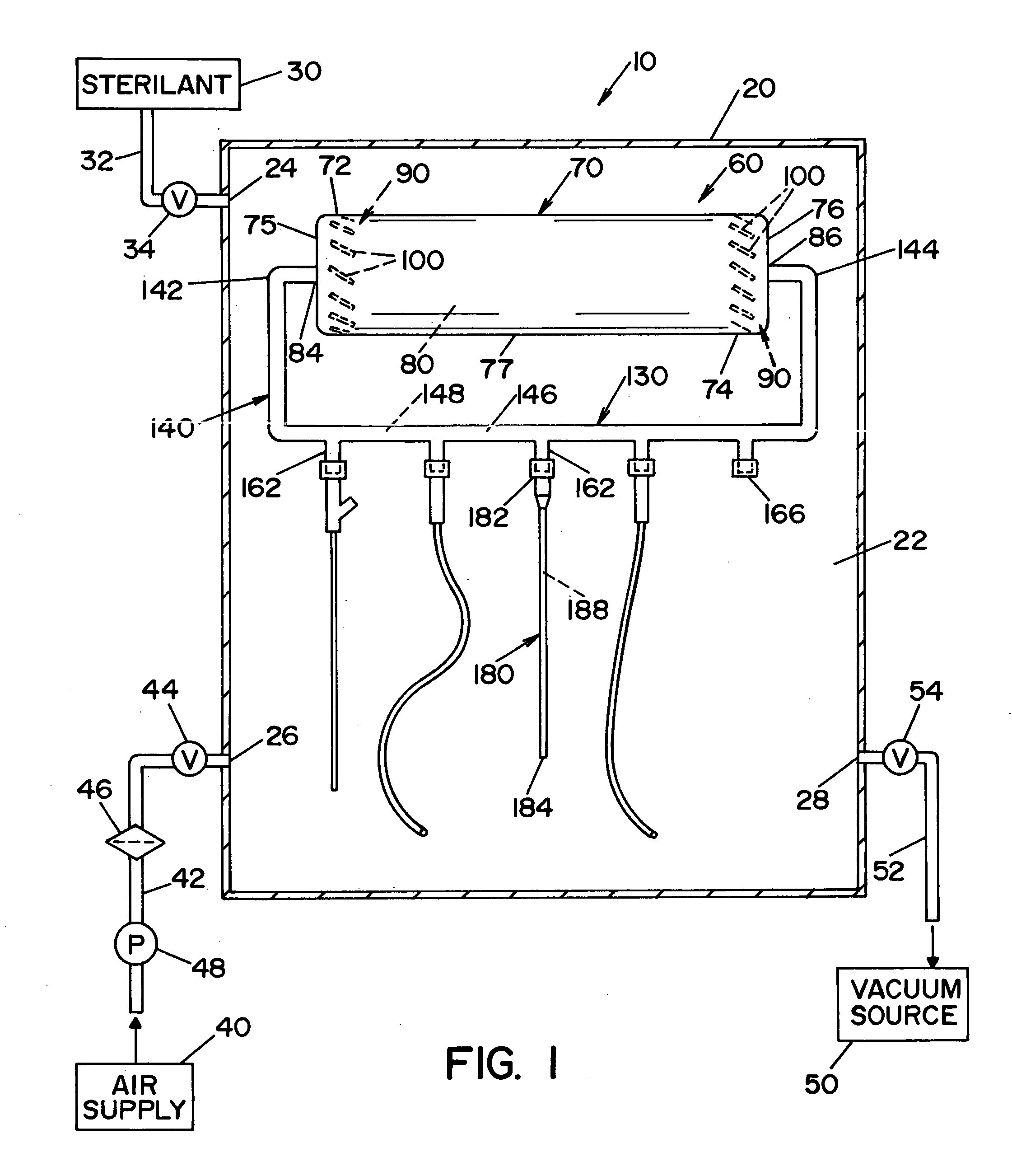

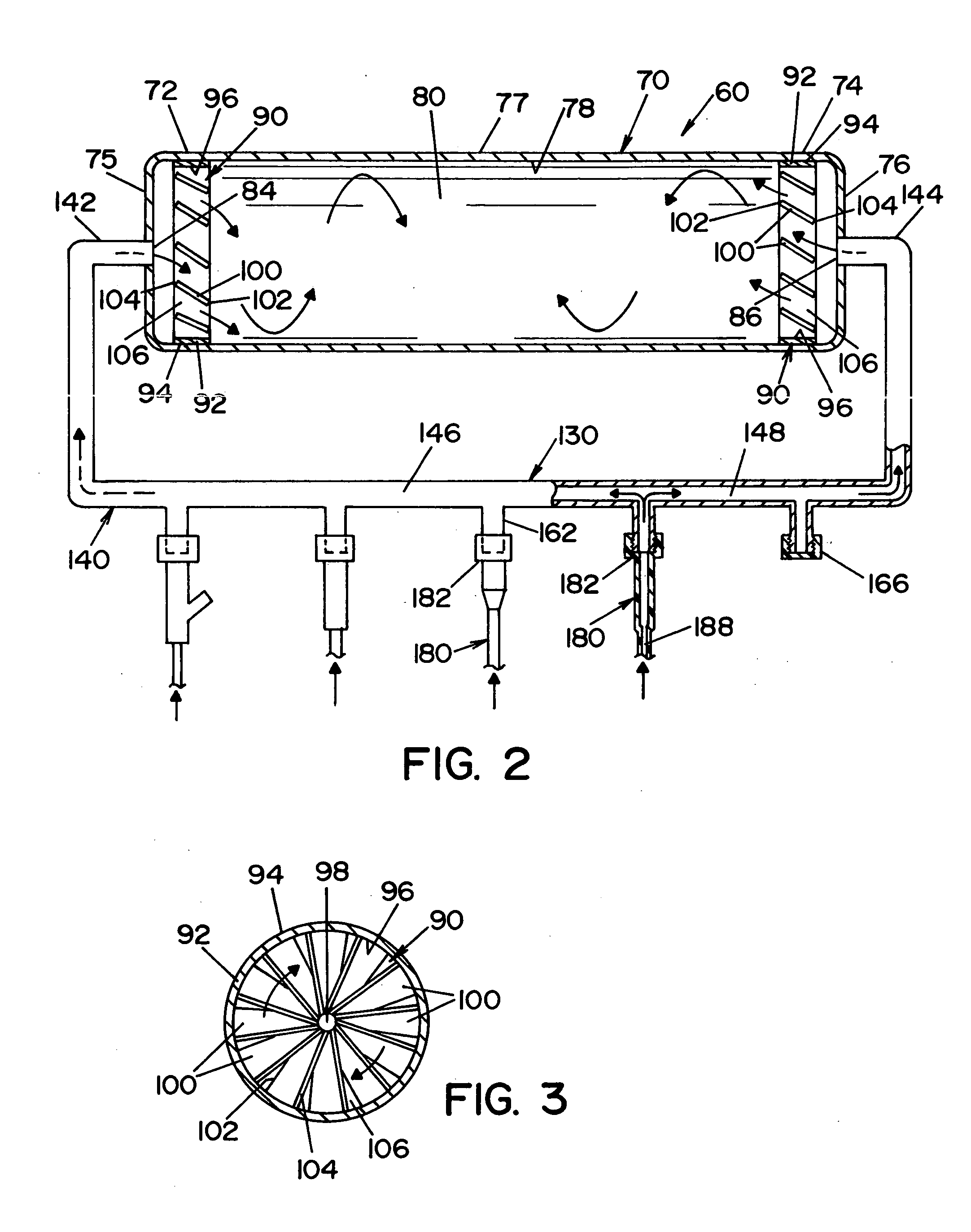

Sterilization device for sterilization of lumen devices

ActiveUS20050260097A1Apparent advantageEndoscopesLavatory sanitoryExpansion tankBiomedical engineering

An apparatus for the sterilization of lumen devices. The apparatus for sterilizing lumen devices is comprised of a chamber defining a region for sterilization, an expansion tank assembly, and a mixing member. The chamber is adapted to receive the expansion tank. The expansion tank is adapted to fluidly connect to at least one lumen device. The mixing member is disposed within the expansion tank to mix gaseous sterilant within residual gas that may include contaminants.

Owner:AMERICAN STERILIZER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com