Patents

Literature

653 results about "Tank pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

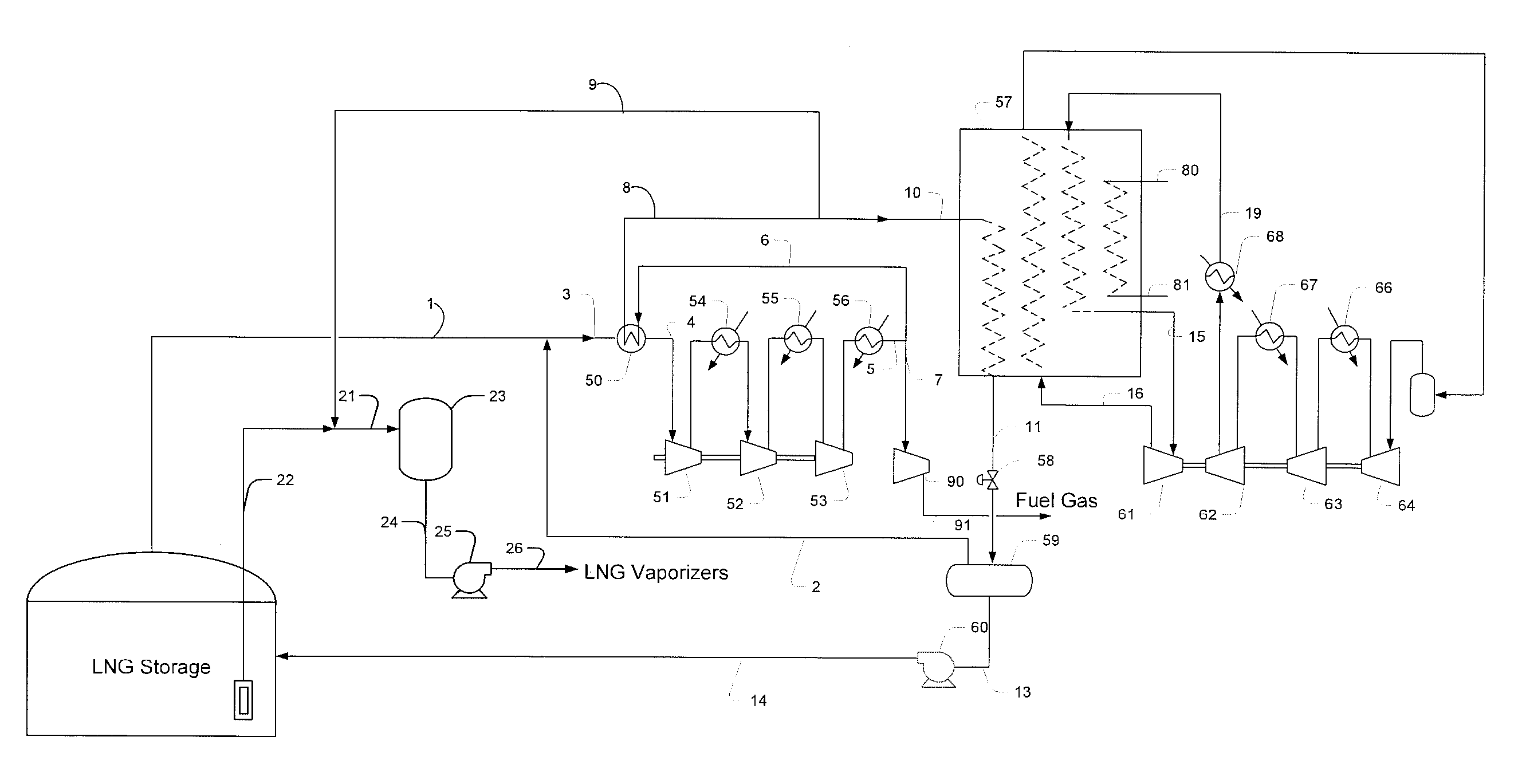

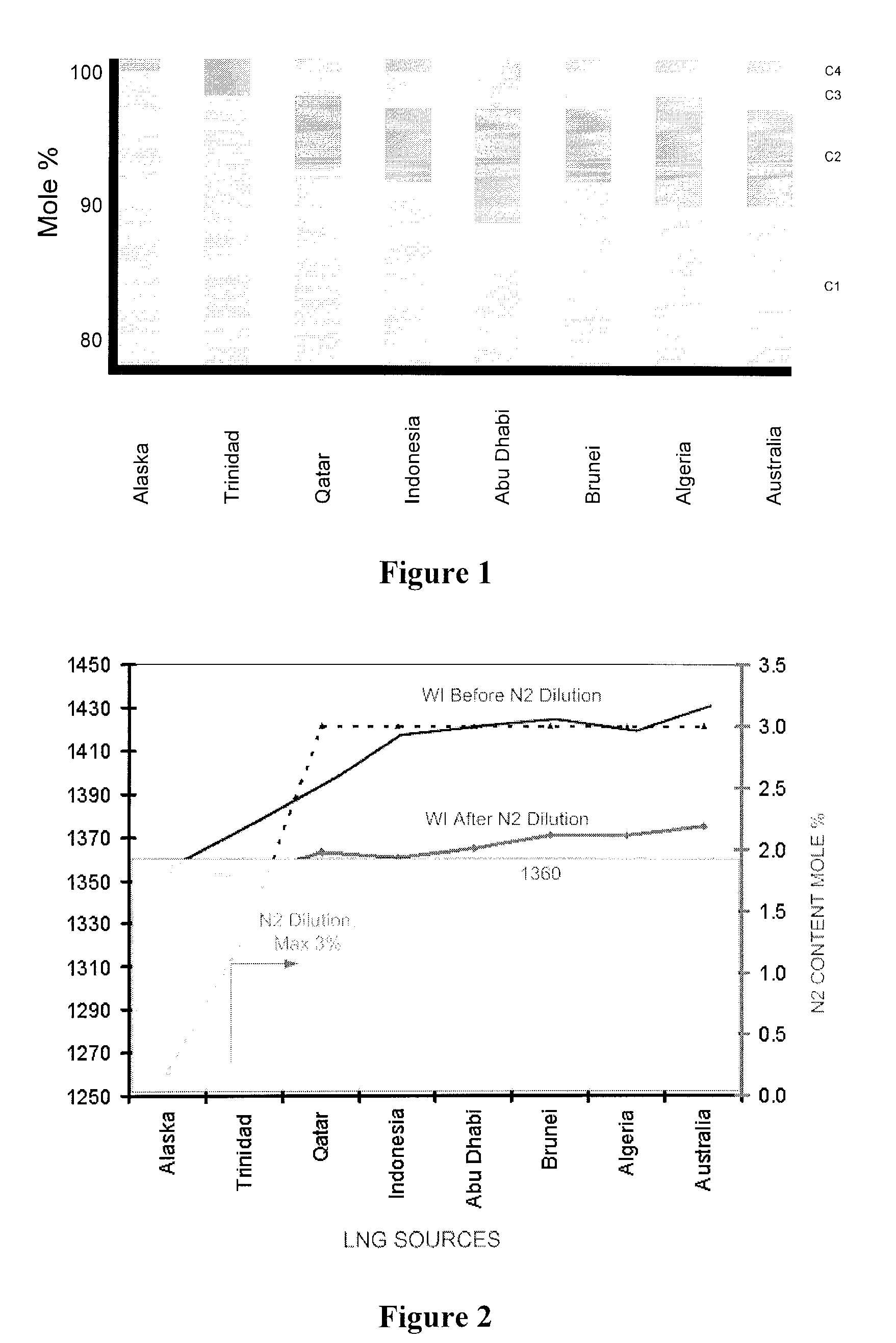

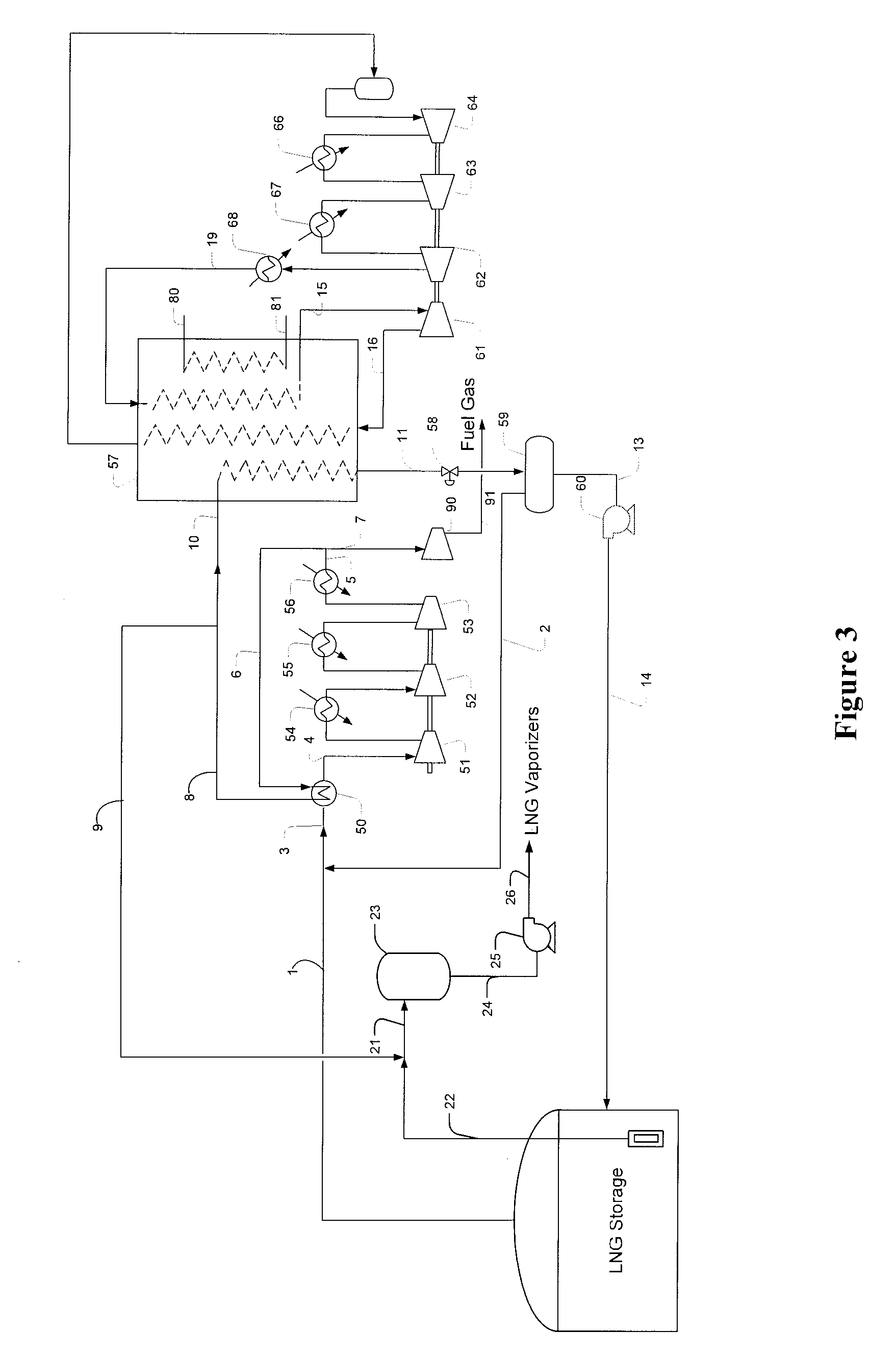

Methods and Configurations of Boil-off Gas Handling in LNG Regasification Terminals

InactiveUS20110056238A1Stable storage tank pressure controlStable controlSolidificationLiquefactionProcess engineeringWobbe index

A LNG storage and regasification plant includes a reliquefaction unit in which boil-off vapors from the storage tanks are re liquefied and recycled back to the LNG storage tanks for tank pressure and Wobbe index control. Preferably, LNG cold is used for reliquefaction and operational flexibility is achieved by feeding a portion of the pressurized boil-off gas to a fuel gas header and / or to be recondensed by the sendout LNG.

Owner:FLUOR TECH CORP

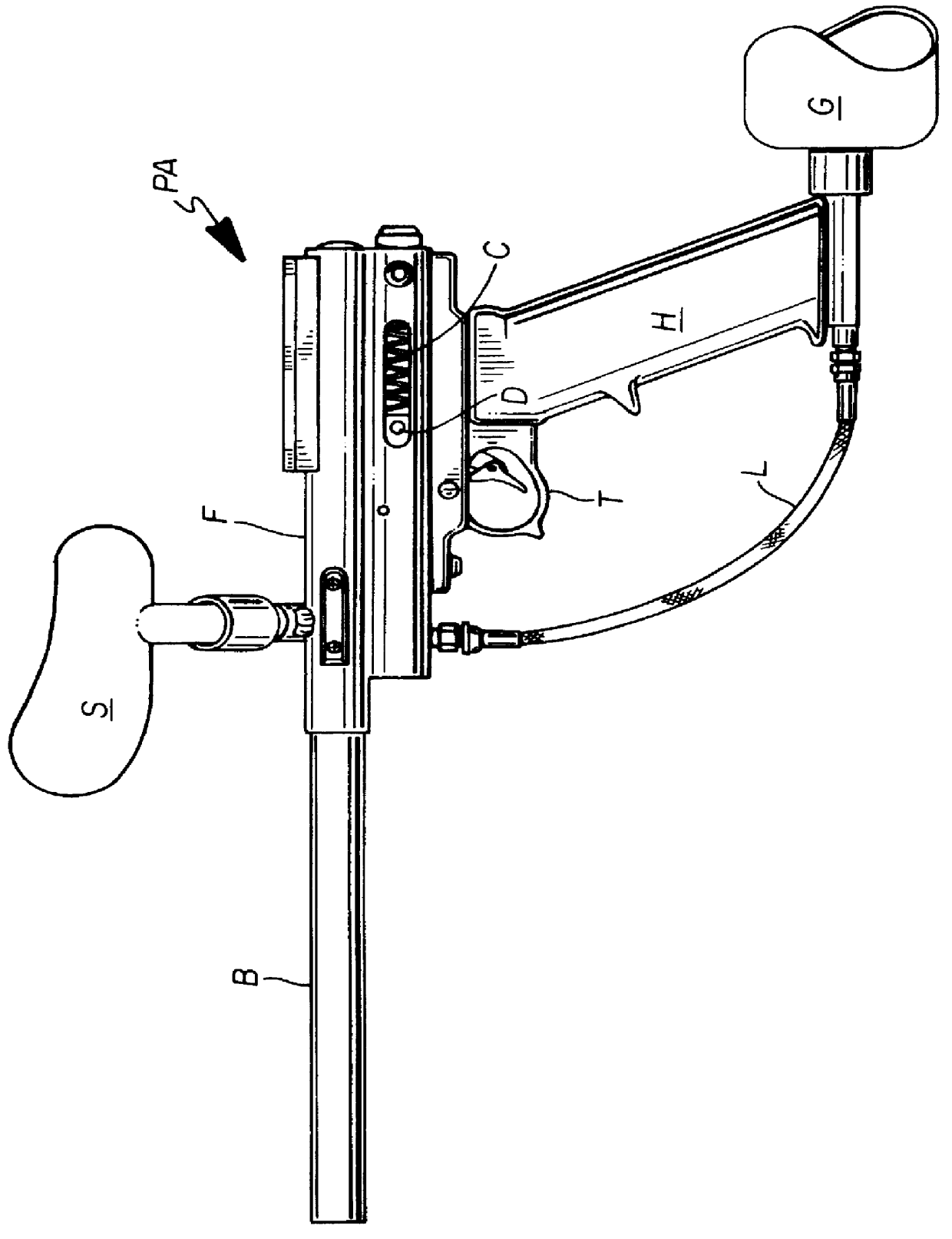

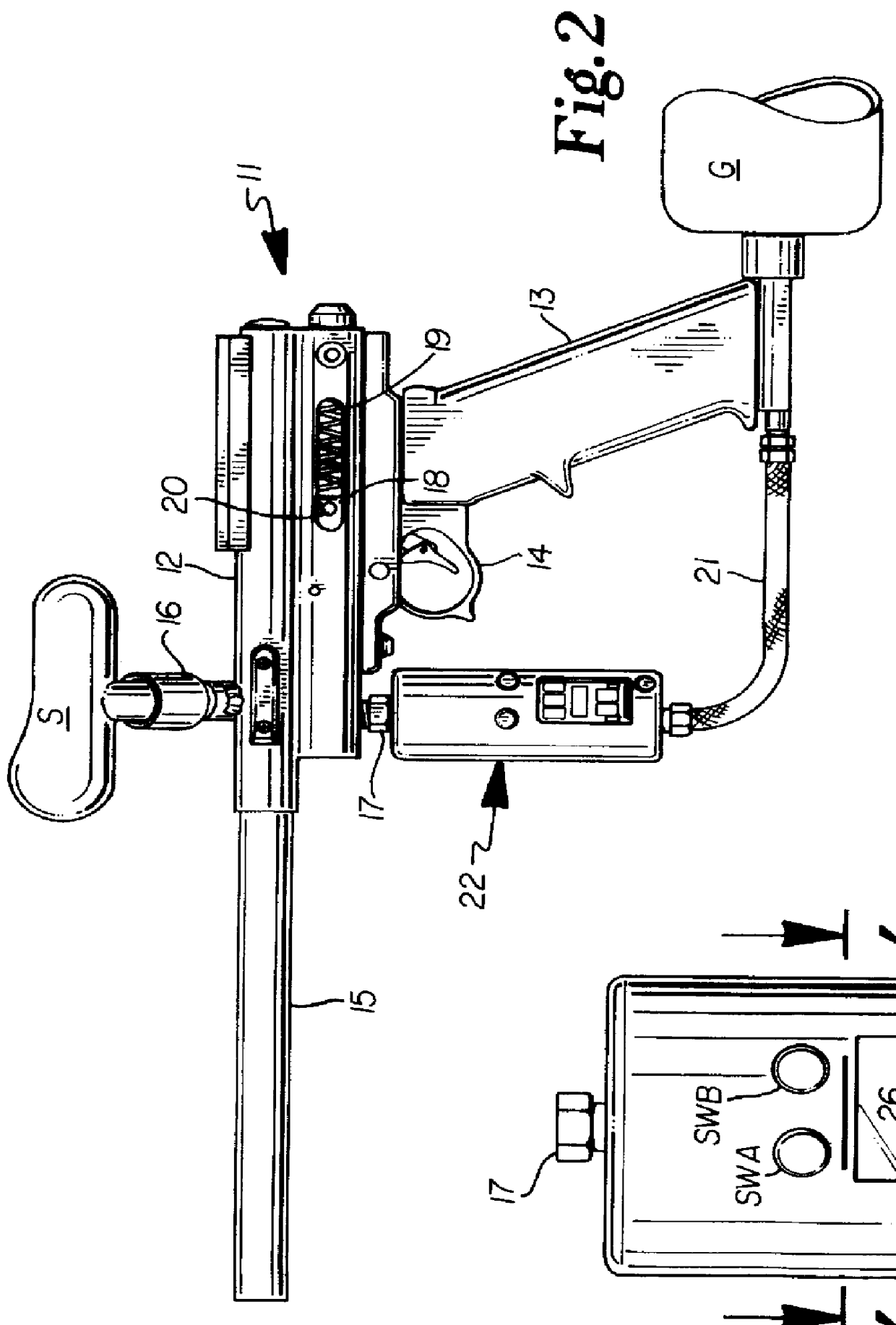

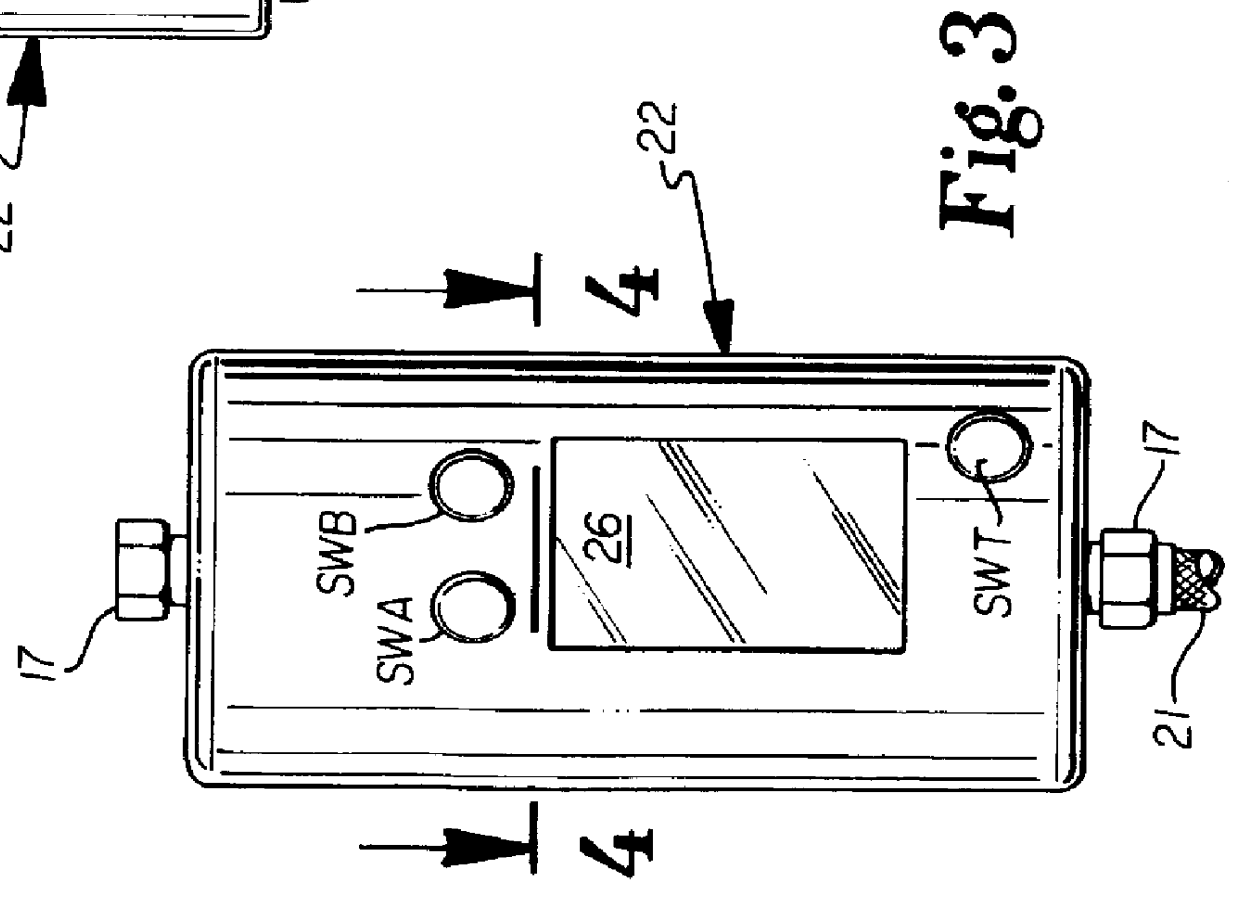

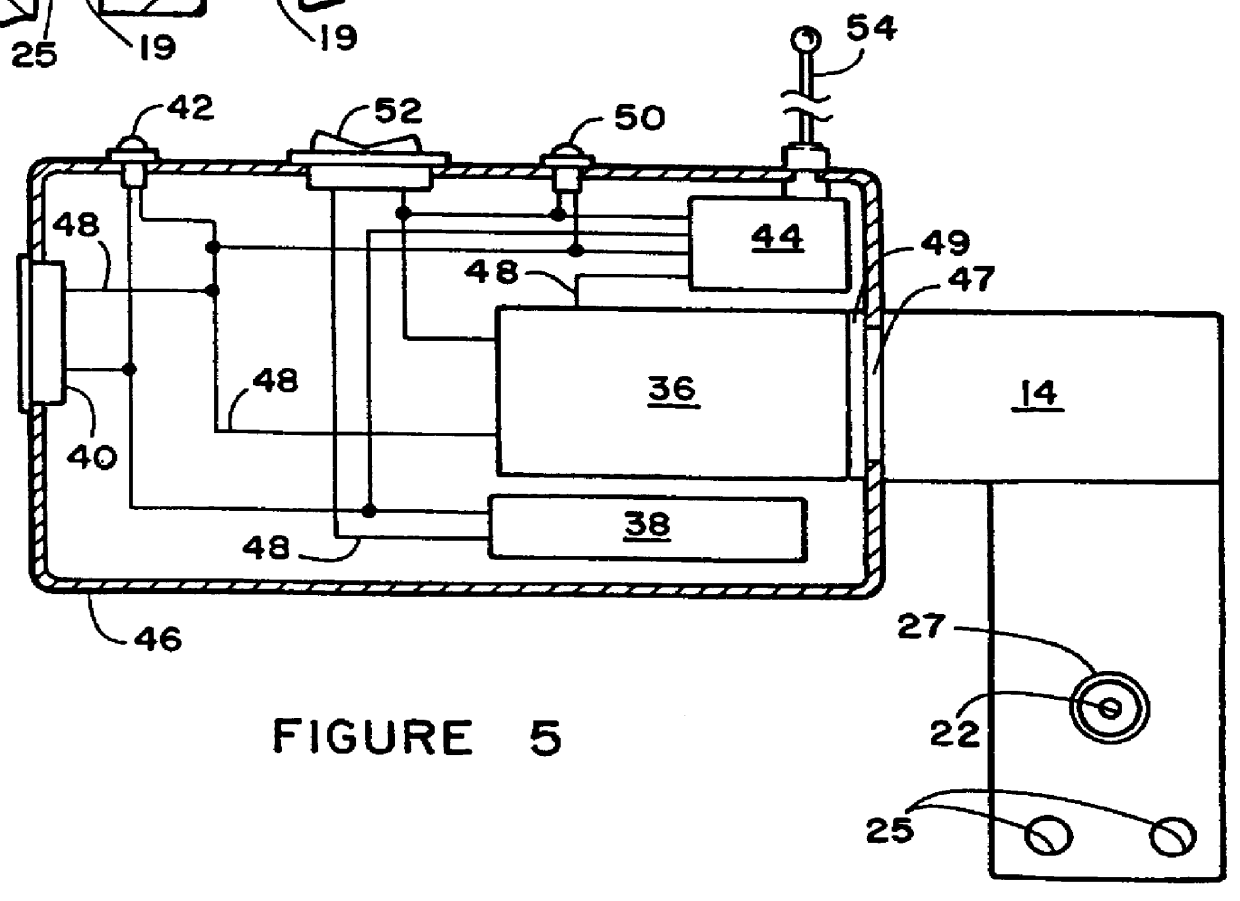

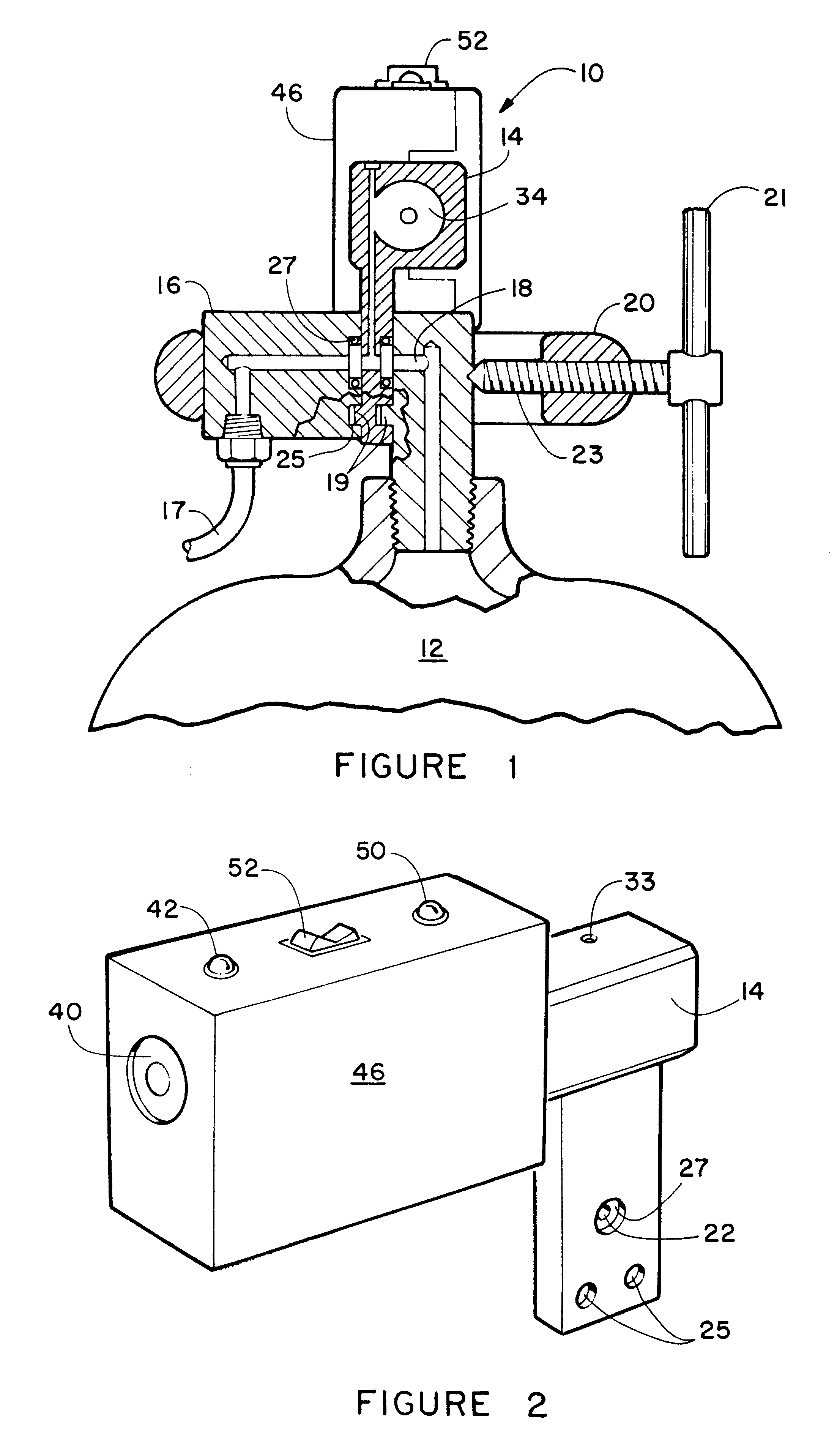

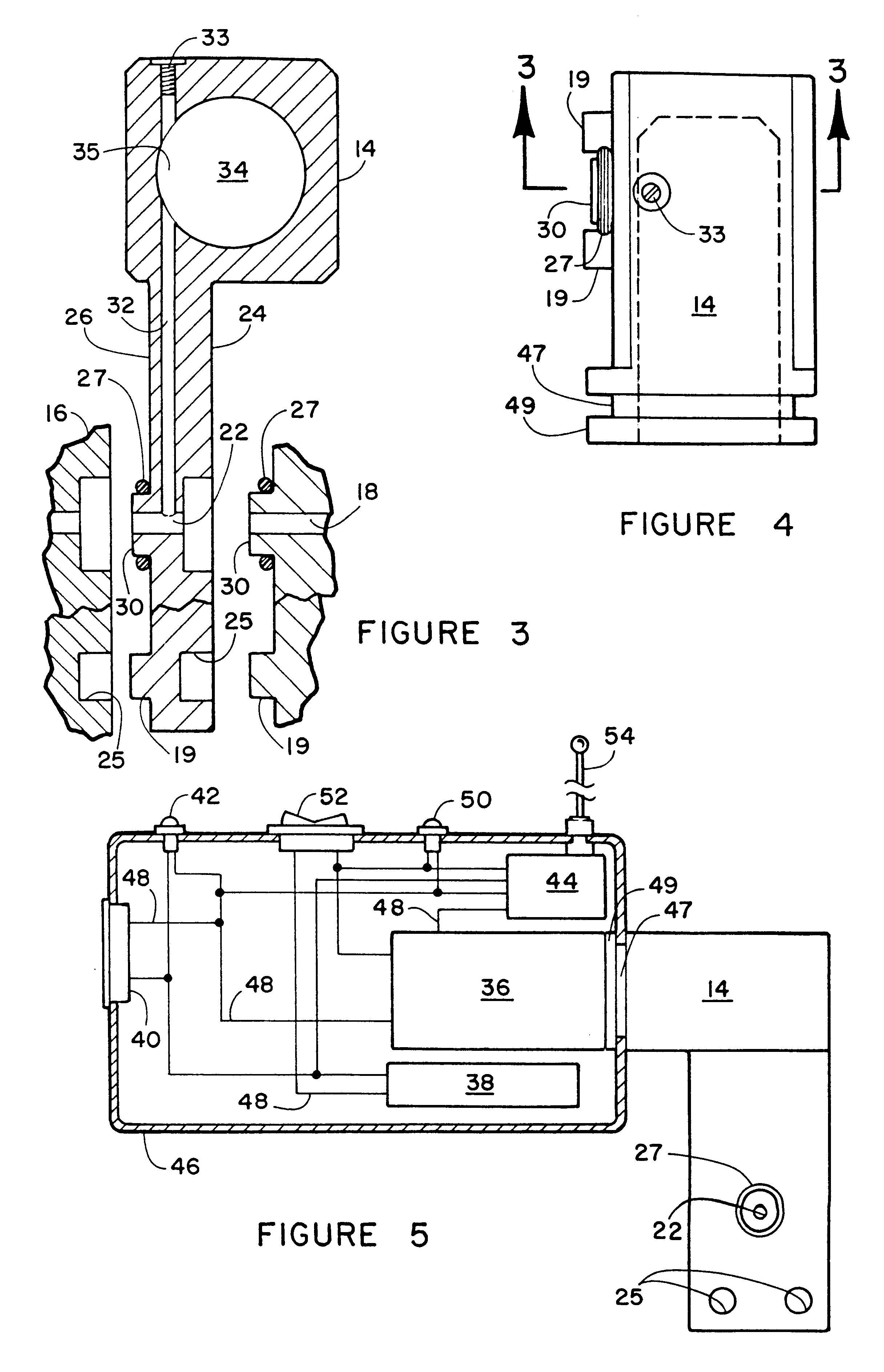

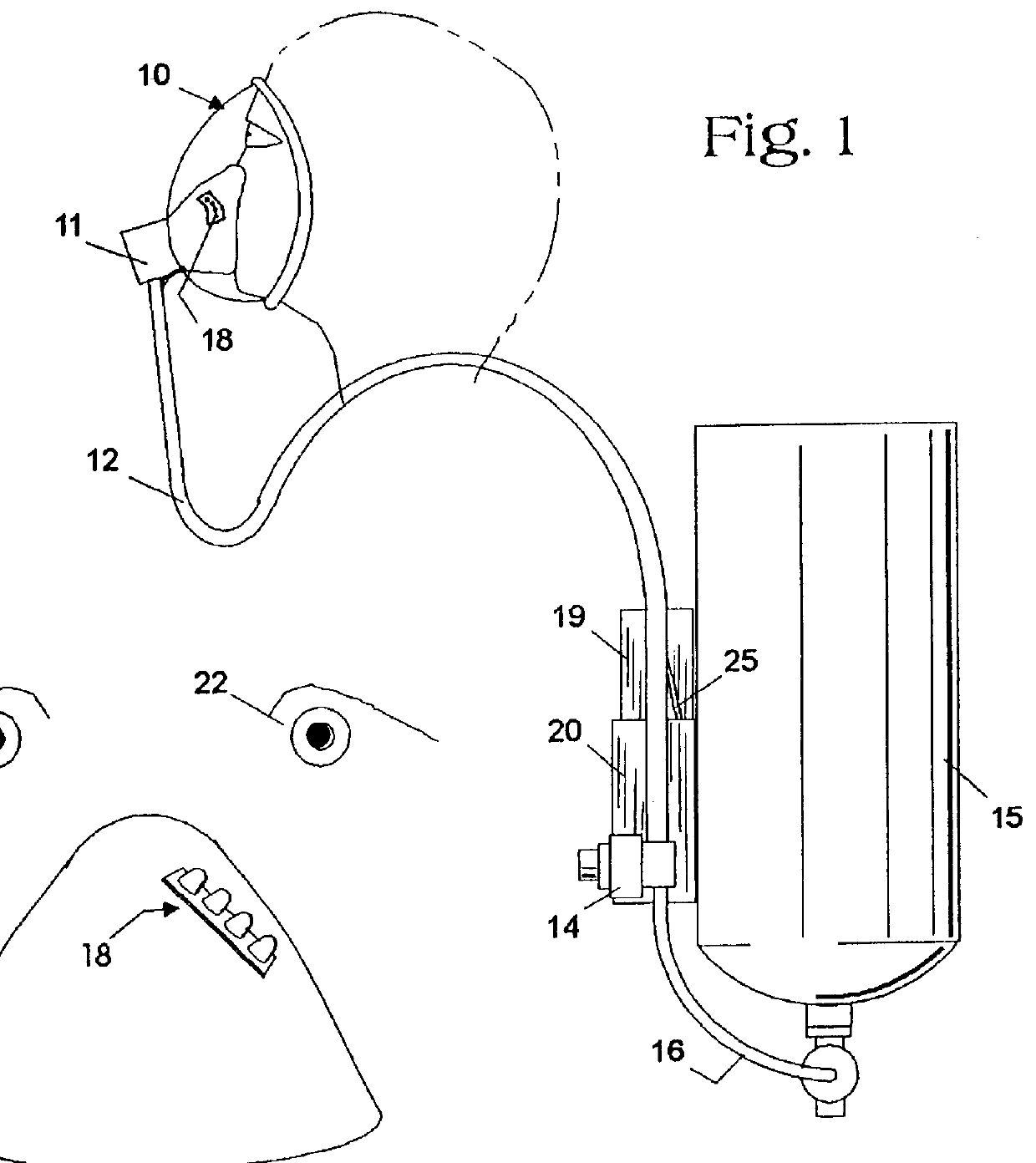

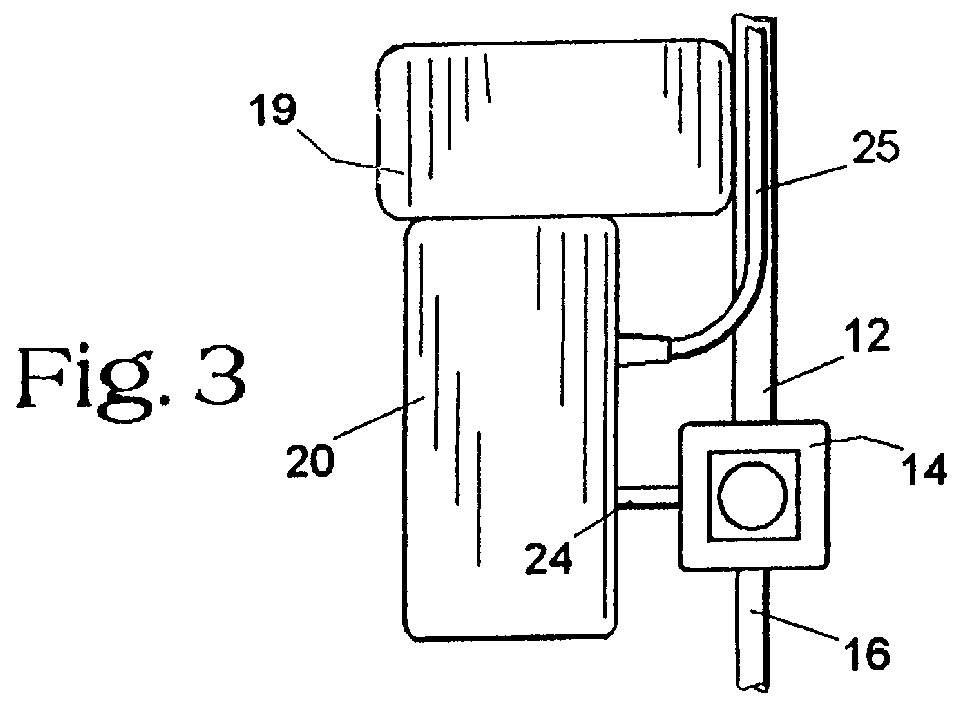

Paintball gun monitor

The invention and disclosure is directed to improvements for a pressure gun utilized to propel paint containing balls which will, when they strike, break and apply paint to a target or, as utilized in the sport of Paint or Splat Ball, an opposing player, to identify such person as having been hit and therefore out of the game. The improvements include both a retro-fit and a custom adapted monitor with visual readout for counting the number of balls which have been shot by sensing pressure drop, or through Hall effect sensing, or mechanical switch actuation; the latter two sensing propelling bolt movement. The monitor also includes a visual readout for reverse timing to show the player game time remaining and a tank pressure supply readout which will show the player remaining tank pressure. Through microprocessing of the information of shot count and time remaining or elapsed, a shooting rate is determinable. Both the retro-fit unit and the custom unit supply the same basic information to the microprocessor which then will calculate shot rate.

Owner:SEEFELDT WILLIAM J +1

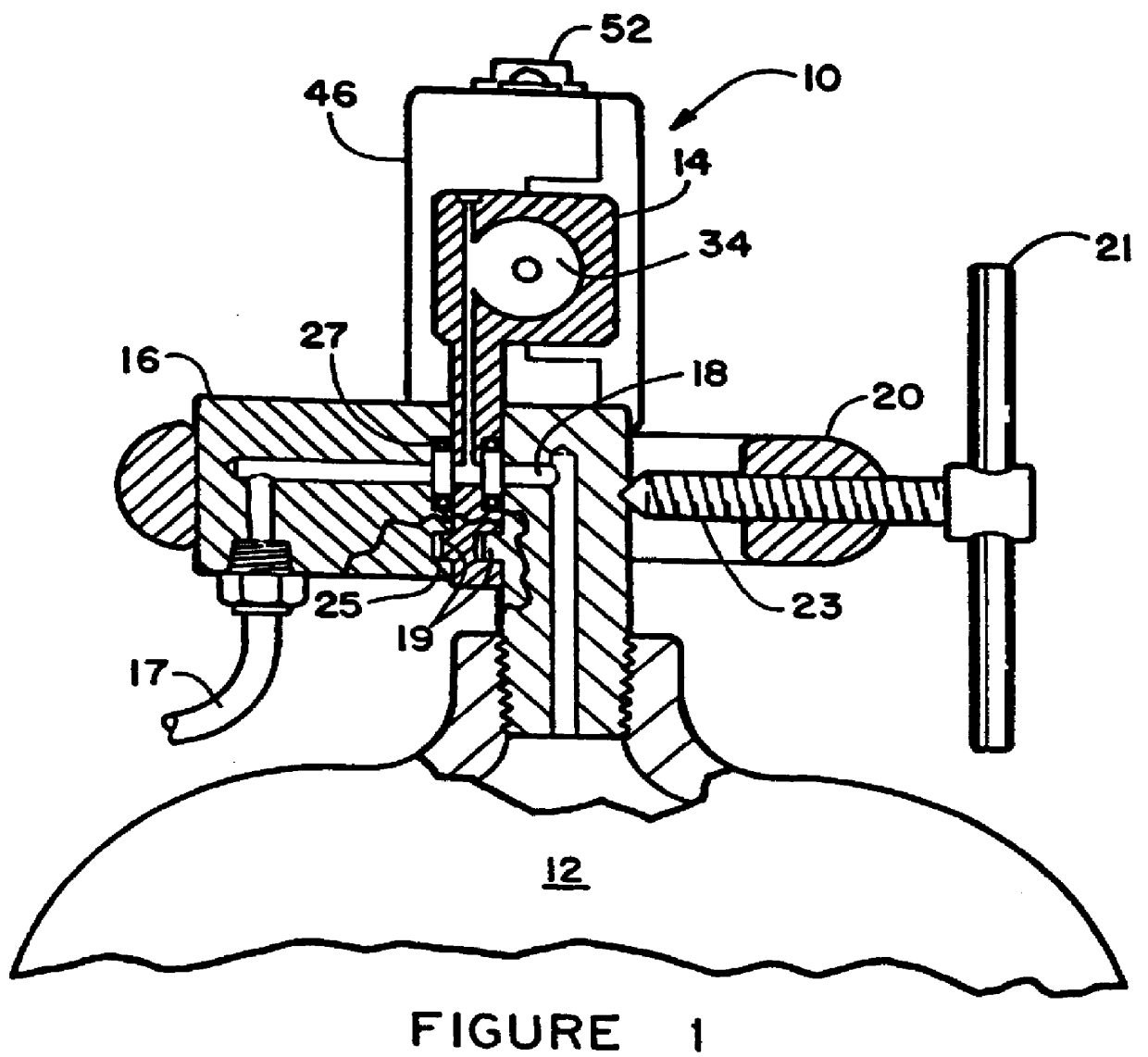

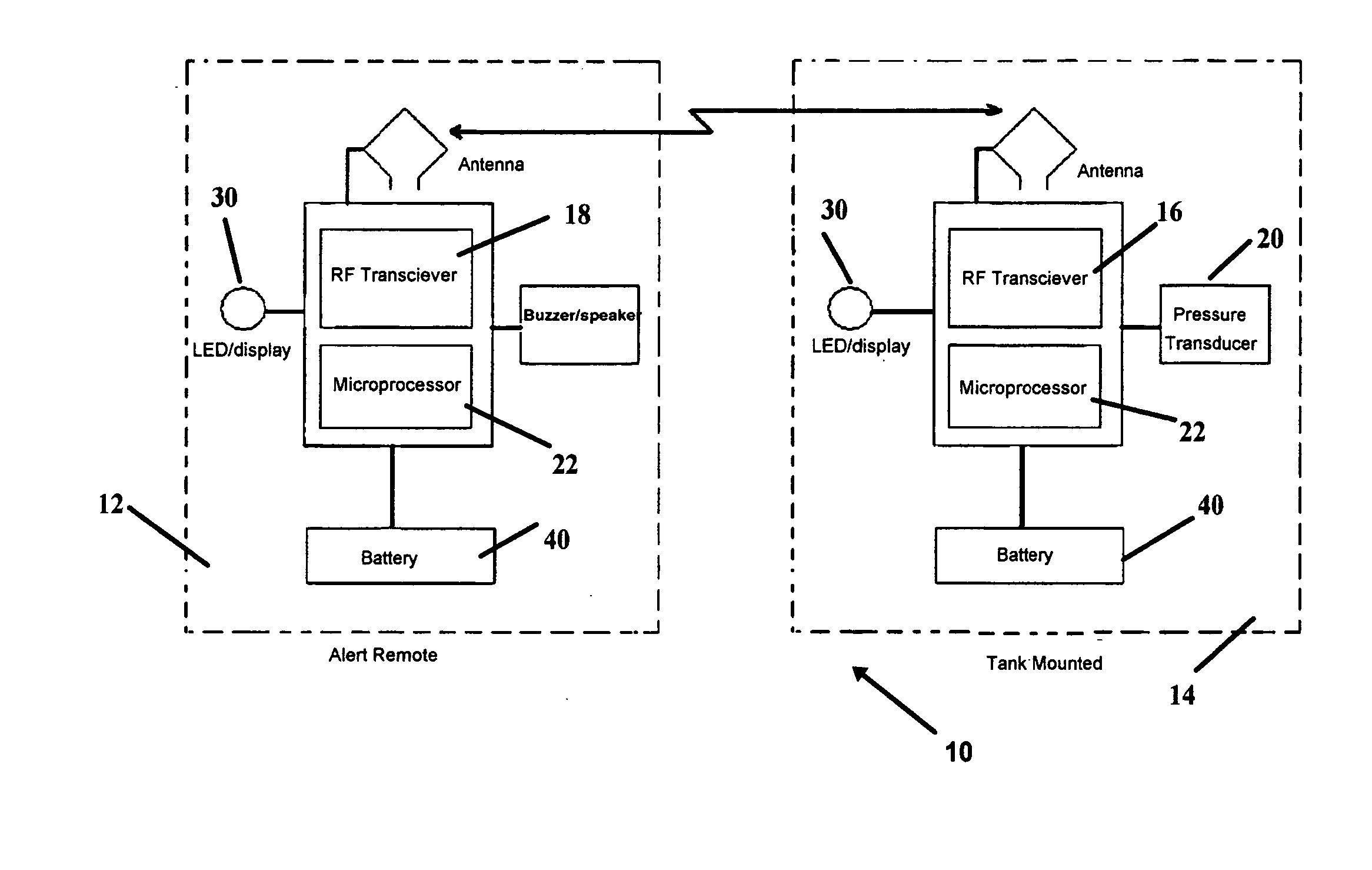

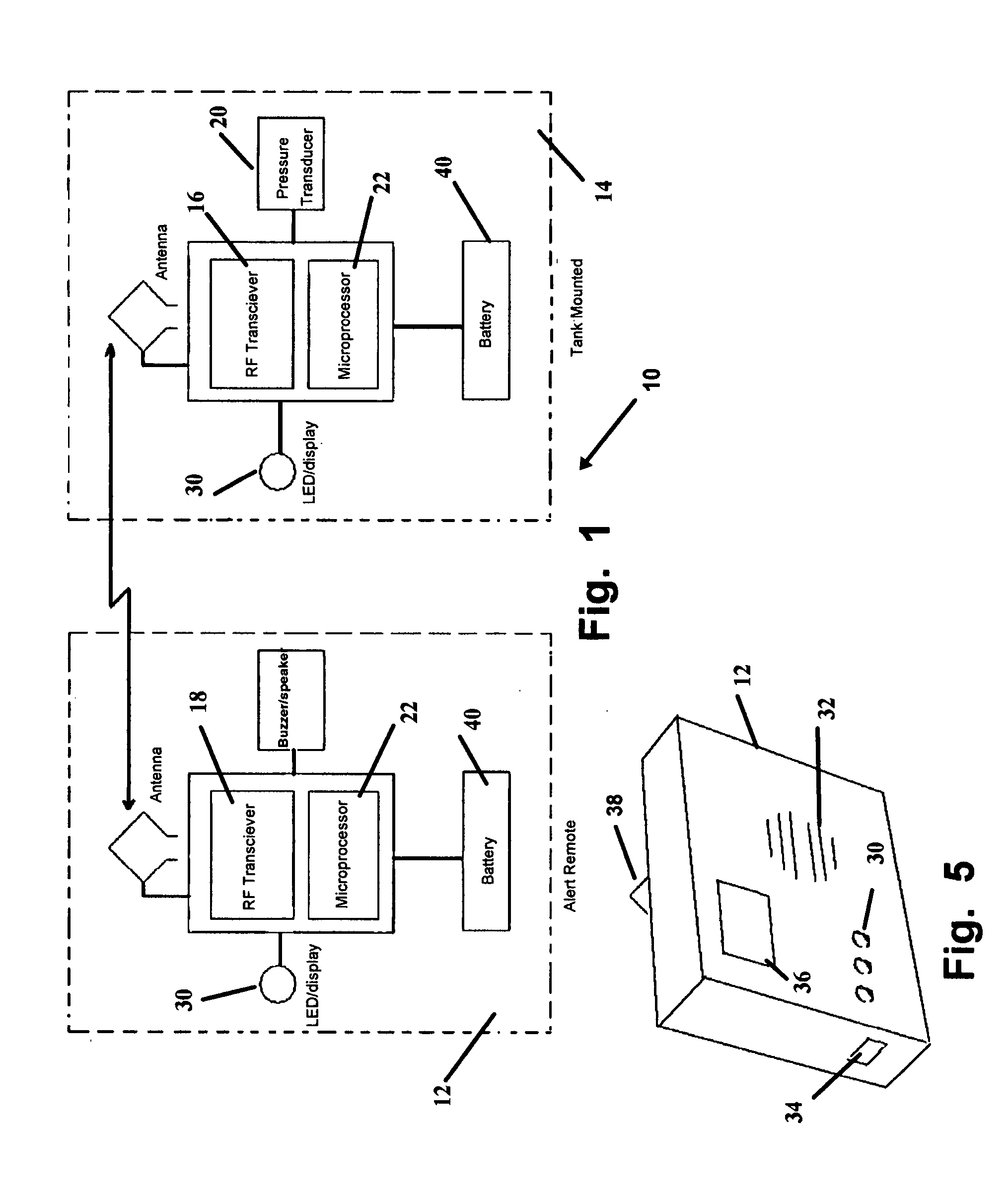

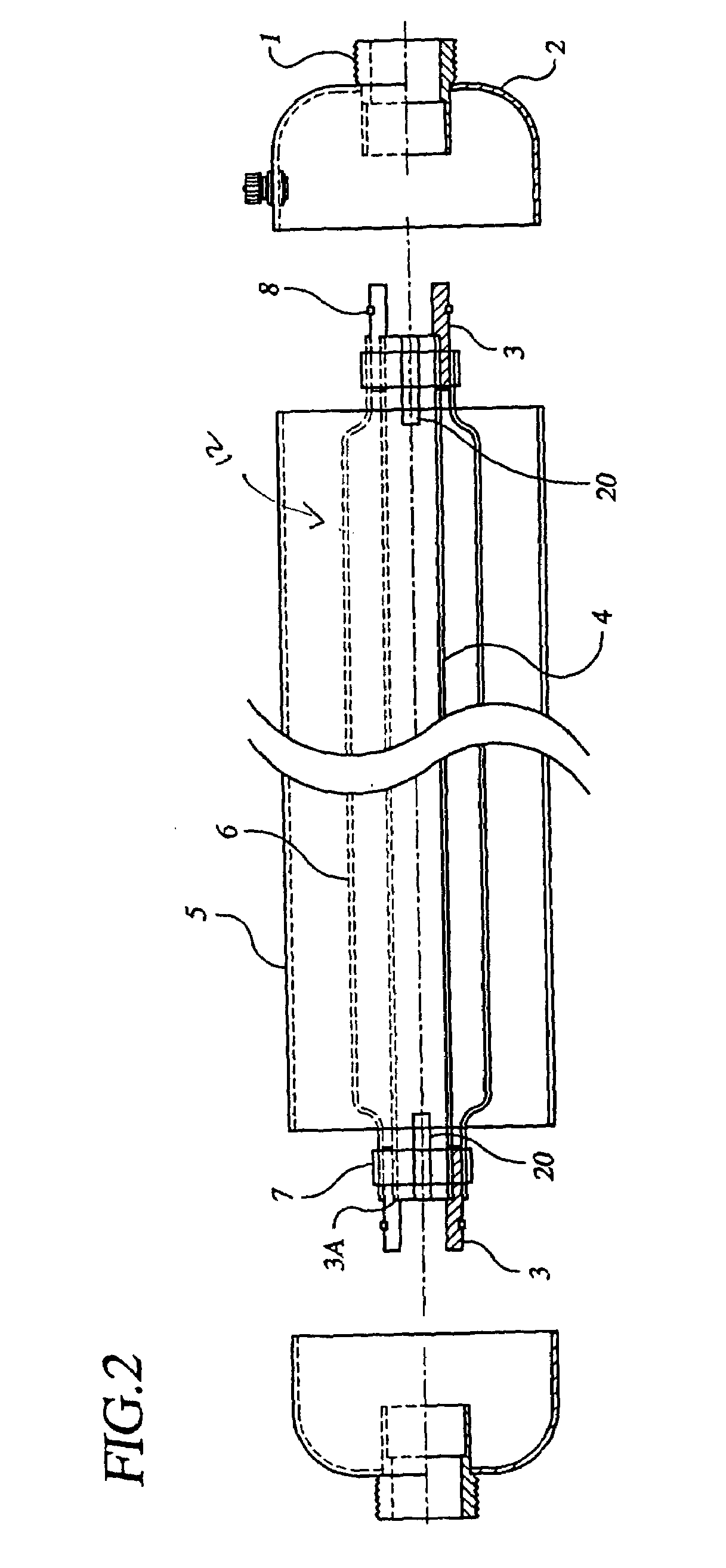

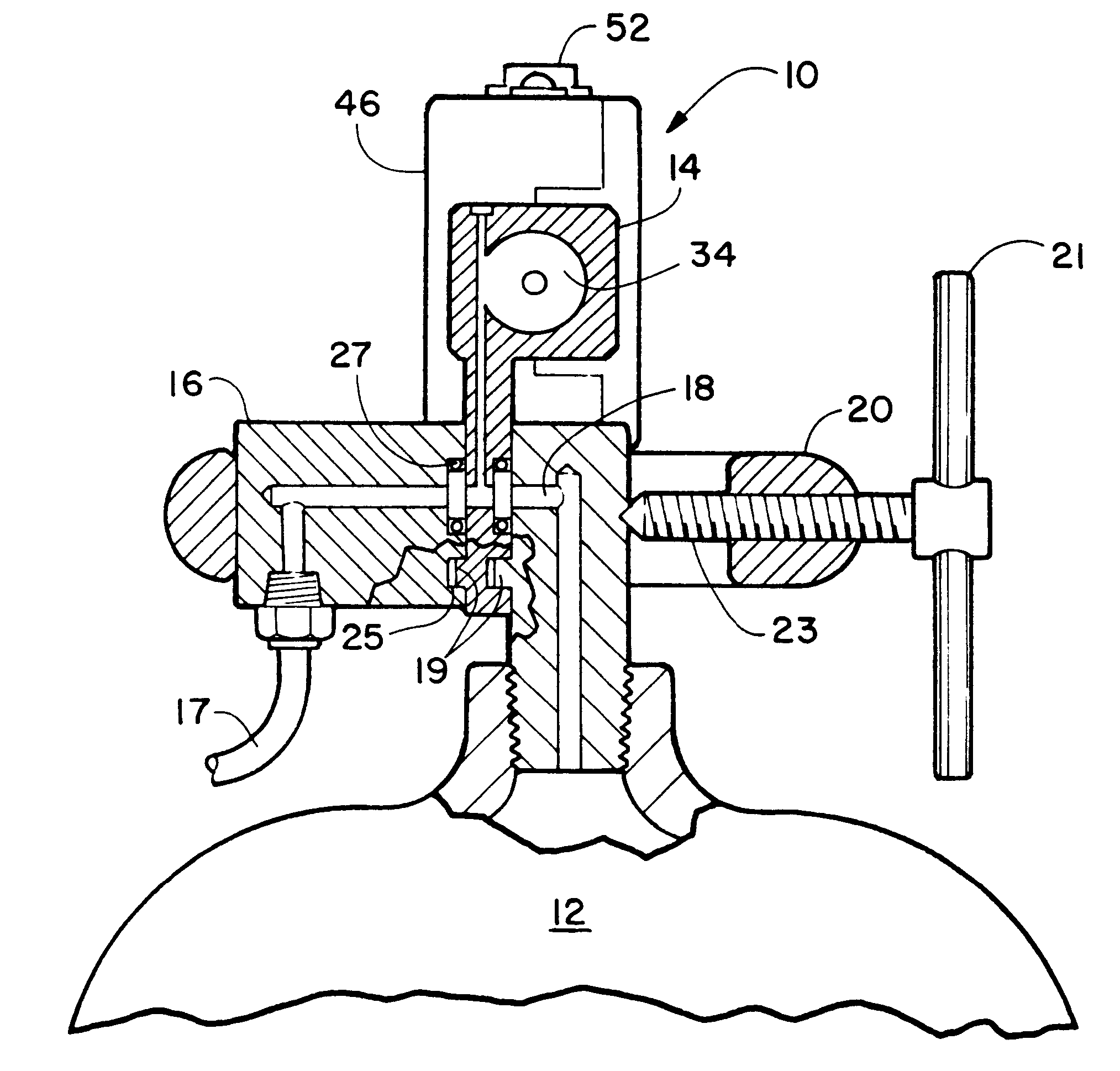

Pressure monitor and alarm for compression mounting with compressed gas storage tank

InactiveUS6137417AImprove securityReduce tank pressureValve arrangementsMeasurement of fluid loss/gain rateGas cylinderEngineering

A warning device configured for removable mounting in combination with a high pressure gas cylinder and a regulator used to regulate the high pressure gas supplied by the cylinder. The device compression mounts between the regulator and tank outlet on conventional portable oxygen and gas supply systems using a specially configured manifold. The device features one or a combination of alarms, from a group including audio, visual, electronic, and remotely transmitted alarms. These alarms are activated by a pressure switch monitoring the remaining supply in the gas cylinder through a conduit the manifold. The alarm signal from the device alerts the user, or a third party monitoring the user, of current tank pressure or will sound an alarm when remaining high pressure gas inside the gas cylinder drops below a predetermined level.

Owner:INGEN TECH

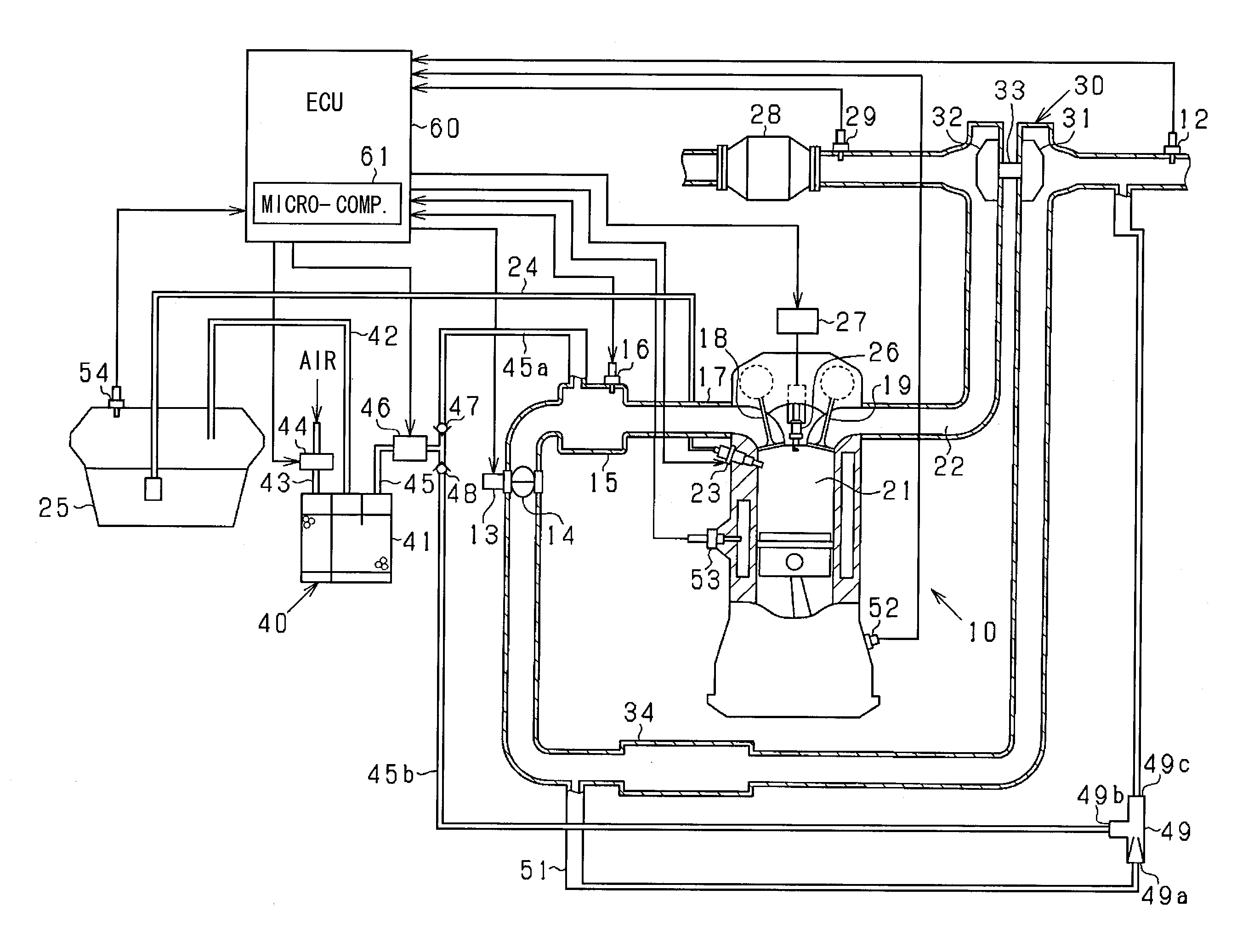

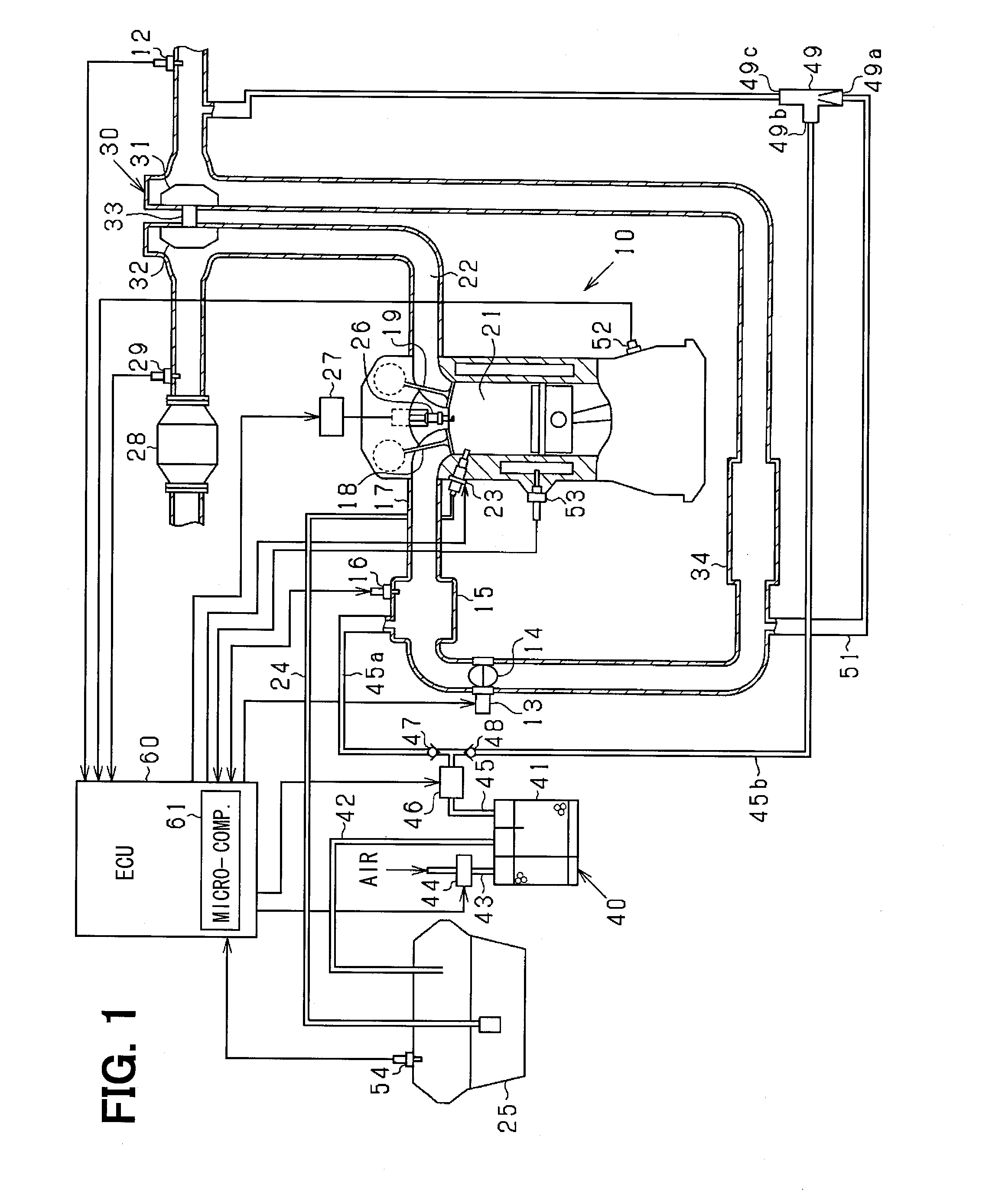

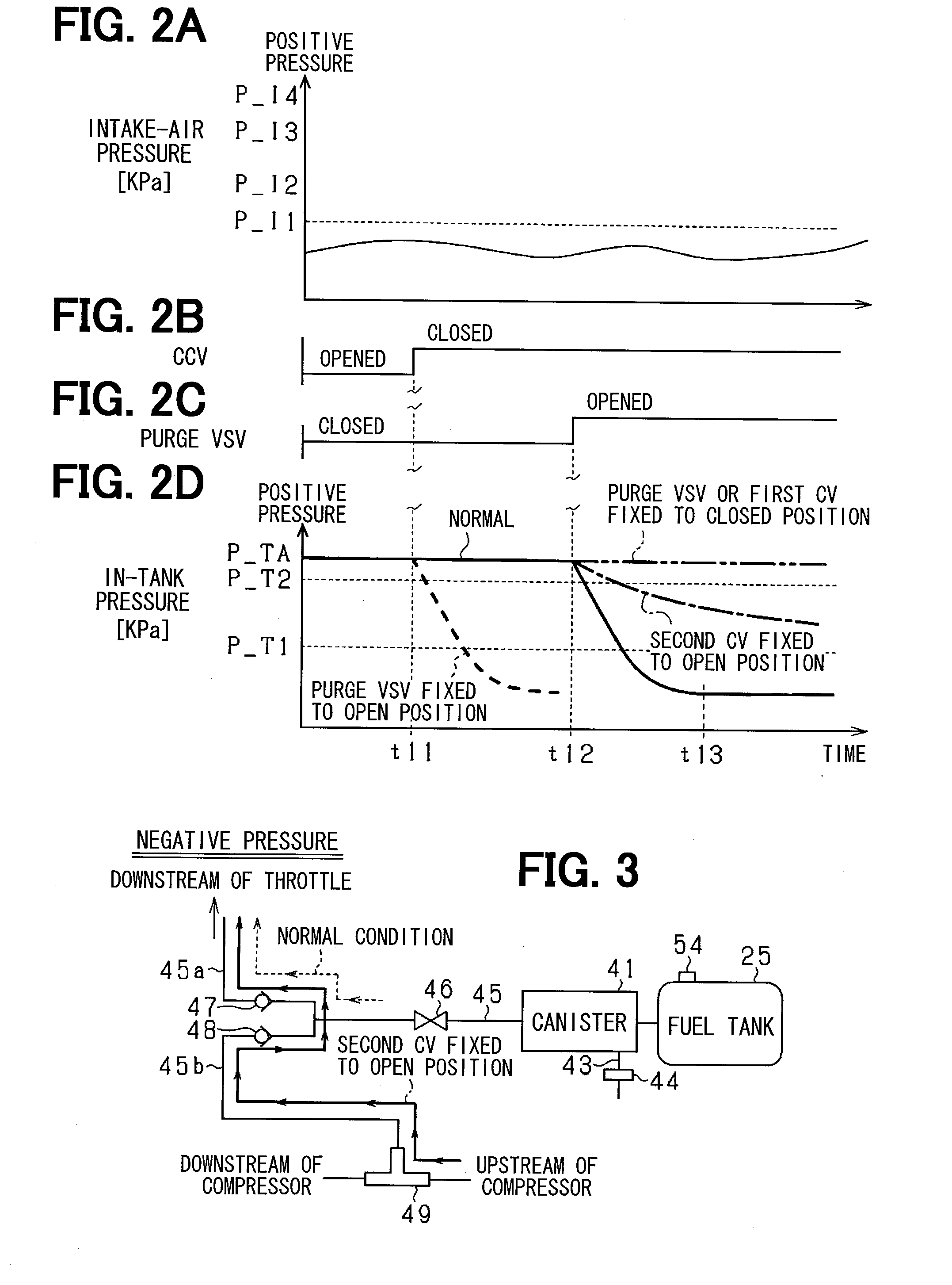

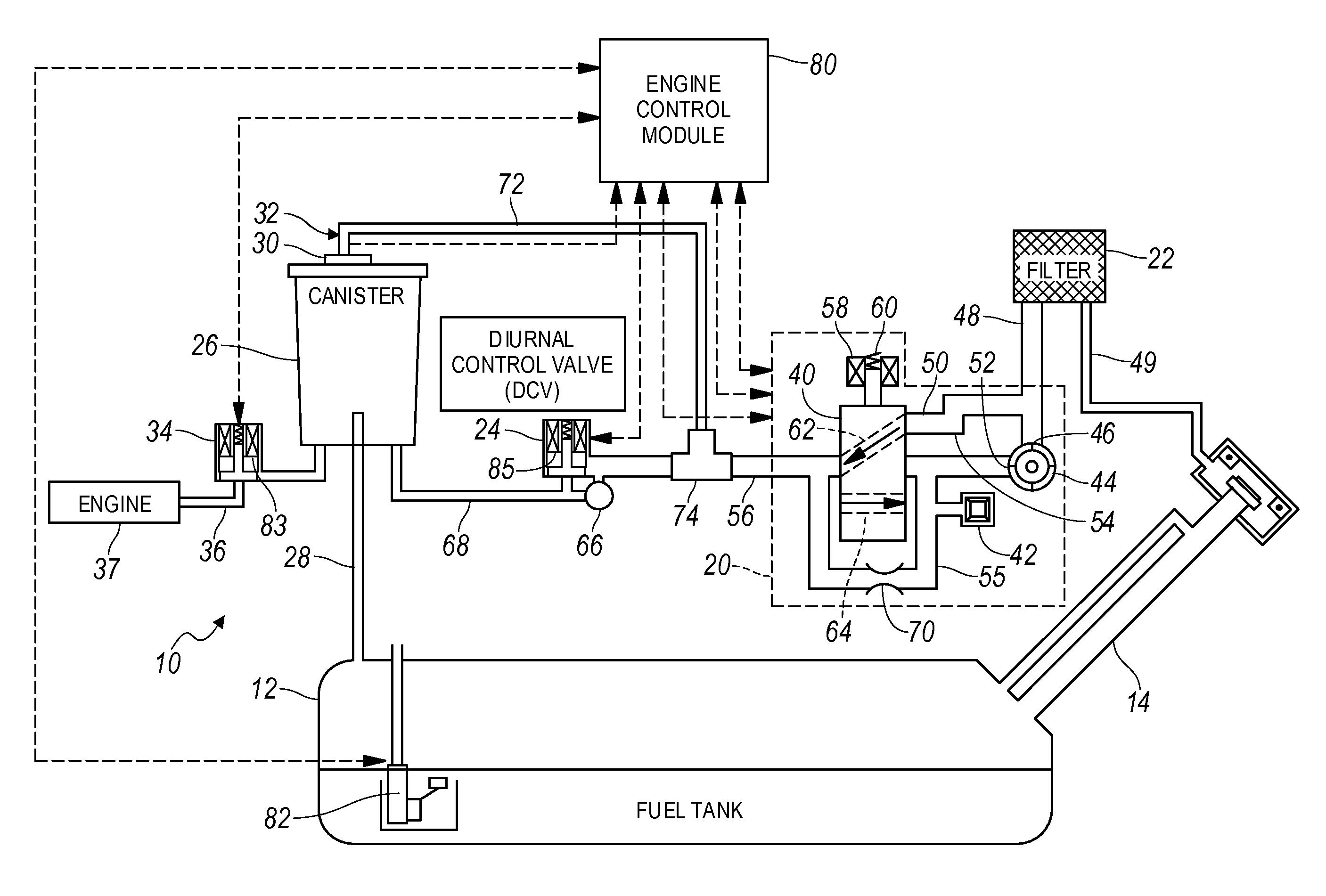

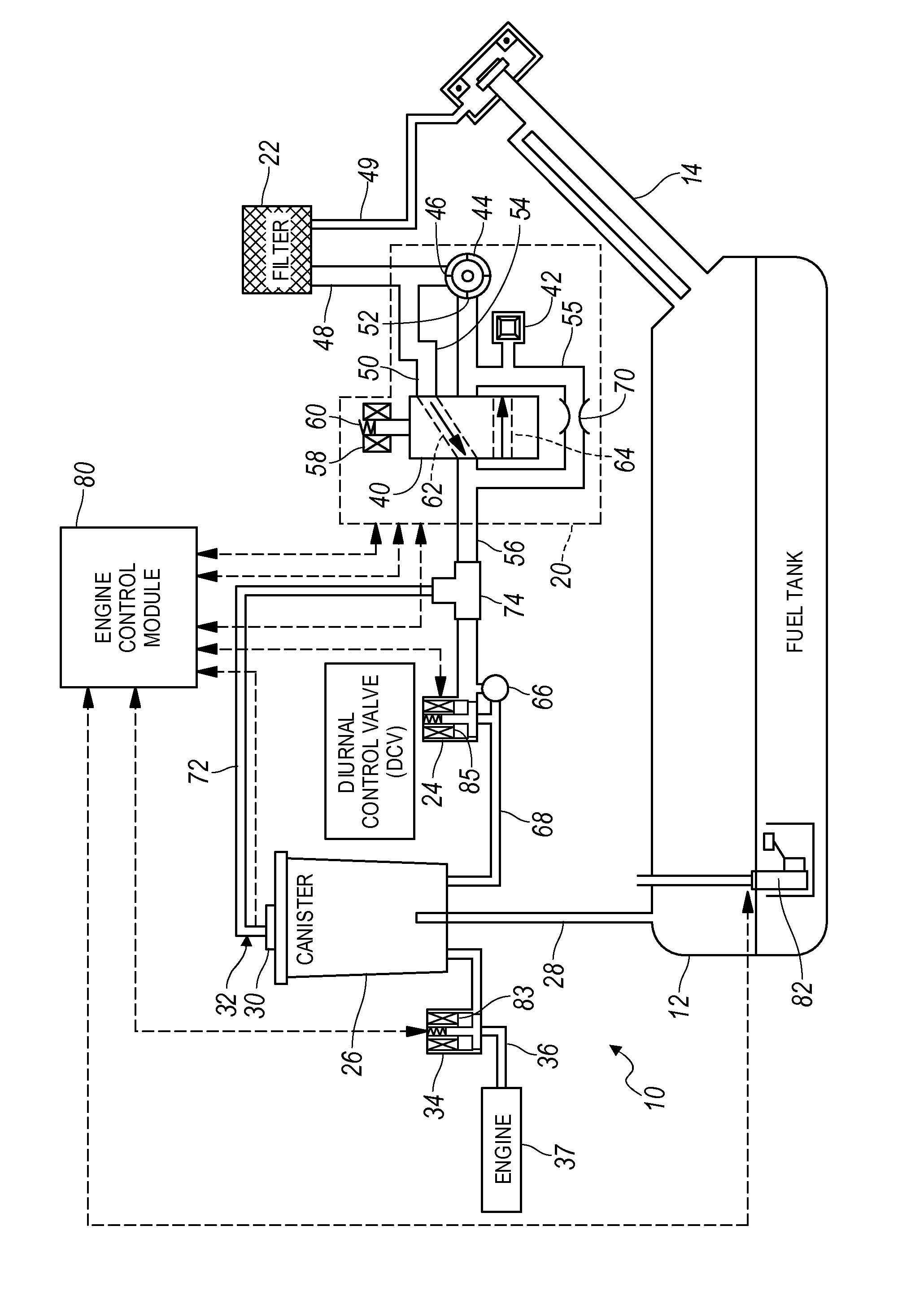

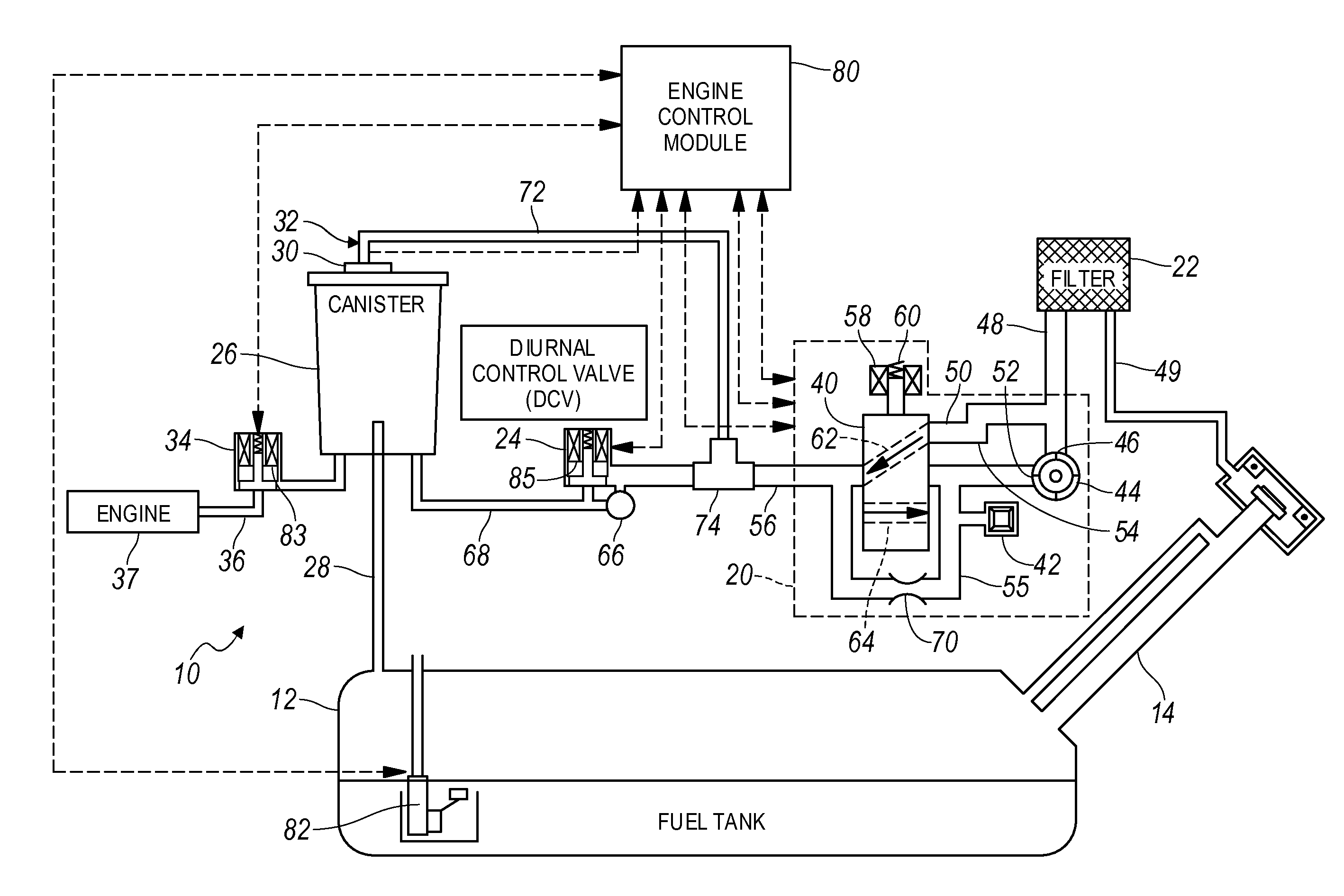

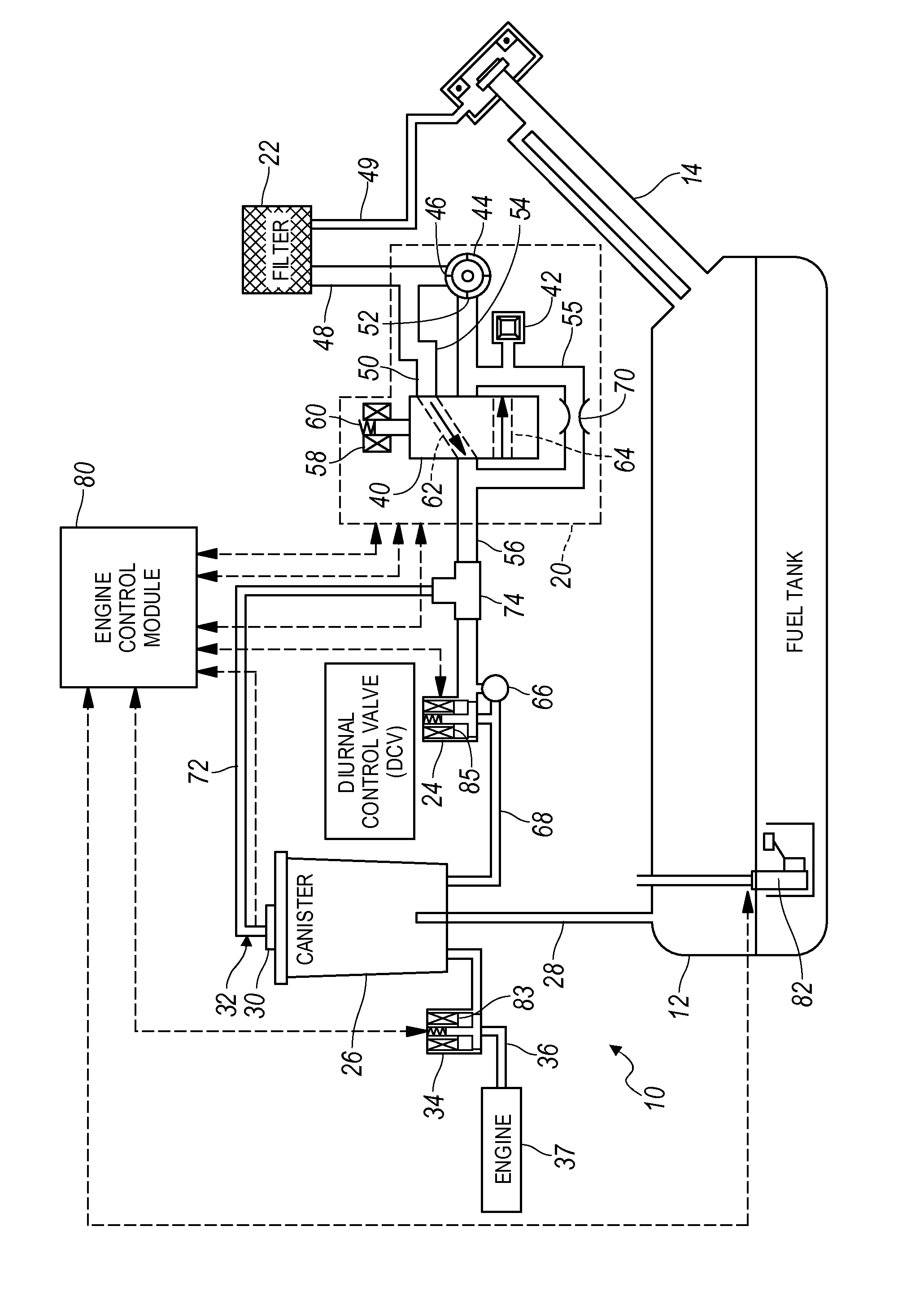

Vaporized-fuel processing system

ActiveUS20130199504A1Improve accuracyNon-fuel substance addition to fuelMachines/enginesFuel tankEngineering

A first purge passage is connected to an intake-air passage at a downstream side of a throttle valve. A second purge passage is connected to the intake-air passage at an upstream side of a supercharging device. A first and a second check valve are respectively provided in the first and second purge passages. A control unit determines to which operating condition (from a first to a third operating condition) engine operation corresponds, based on downstream-side and upstream-side pressure of the throttle valve. A change of in-tank pressure of a fuel tank is detected in a condition that an air-communication valve is closed but a purge control valve is opened. The control unit diagnoses which of the valves is not normally operated and whether such valve is fixed to a valve opened or a valve closed position, based on the change of in-tank pressure for each of engine operating conditions.

Owner:DENSO CORP

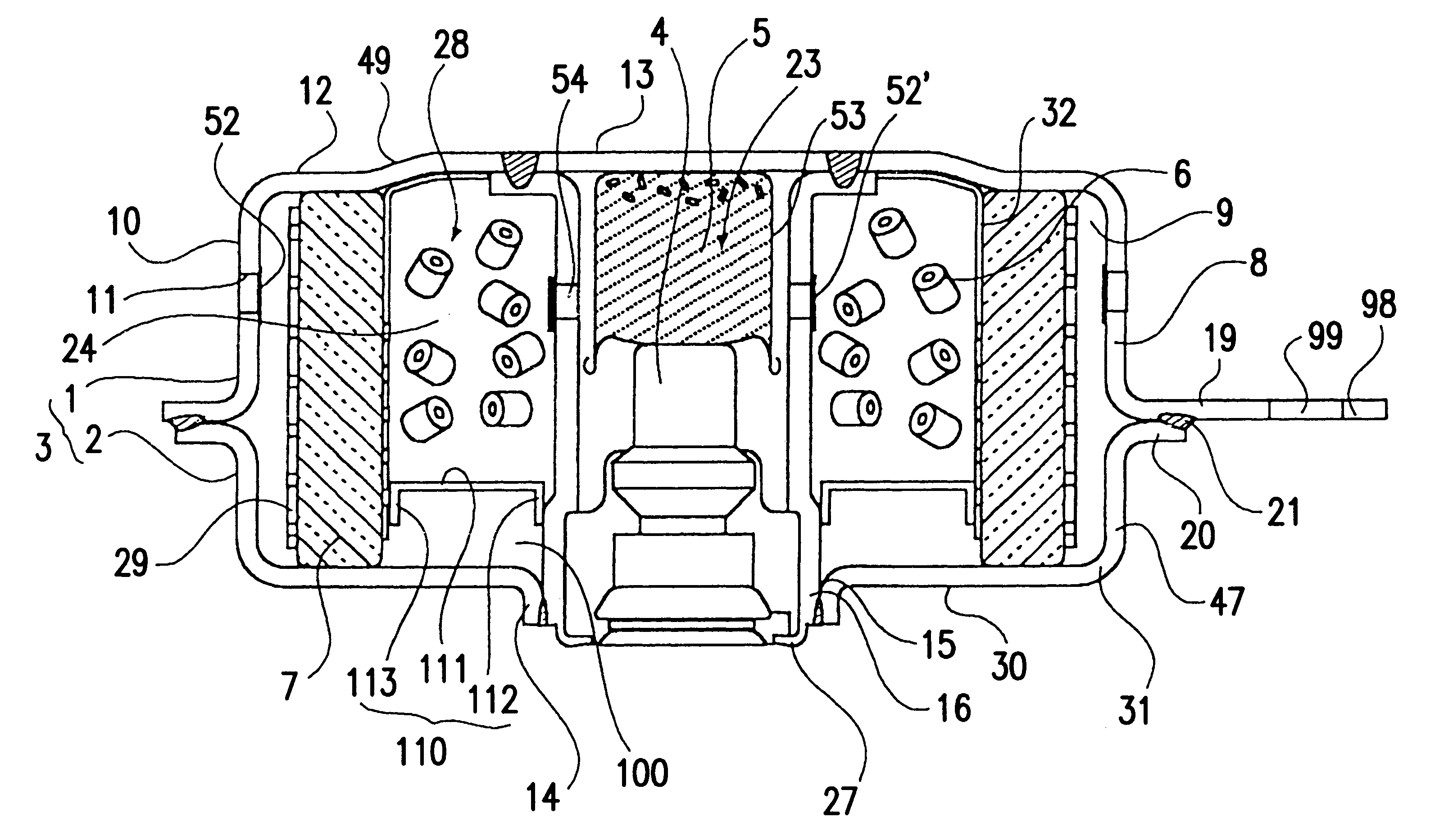

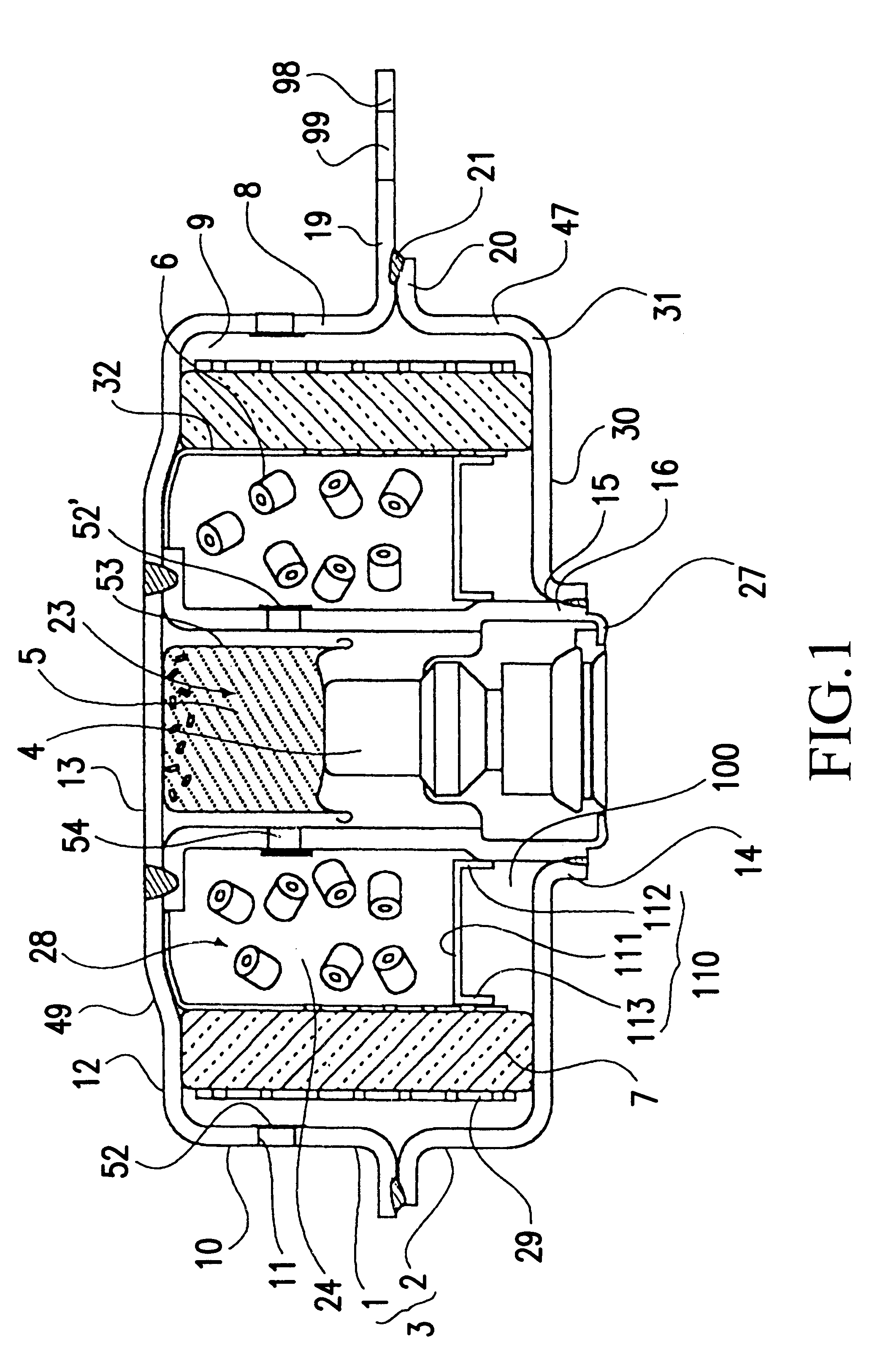

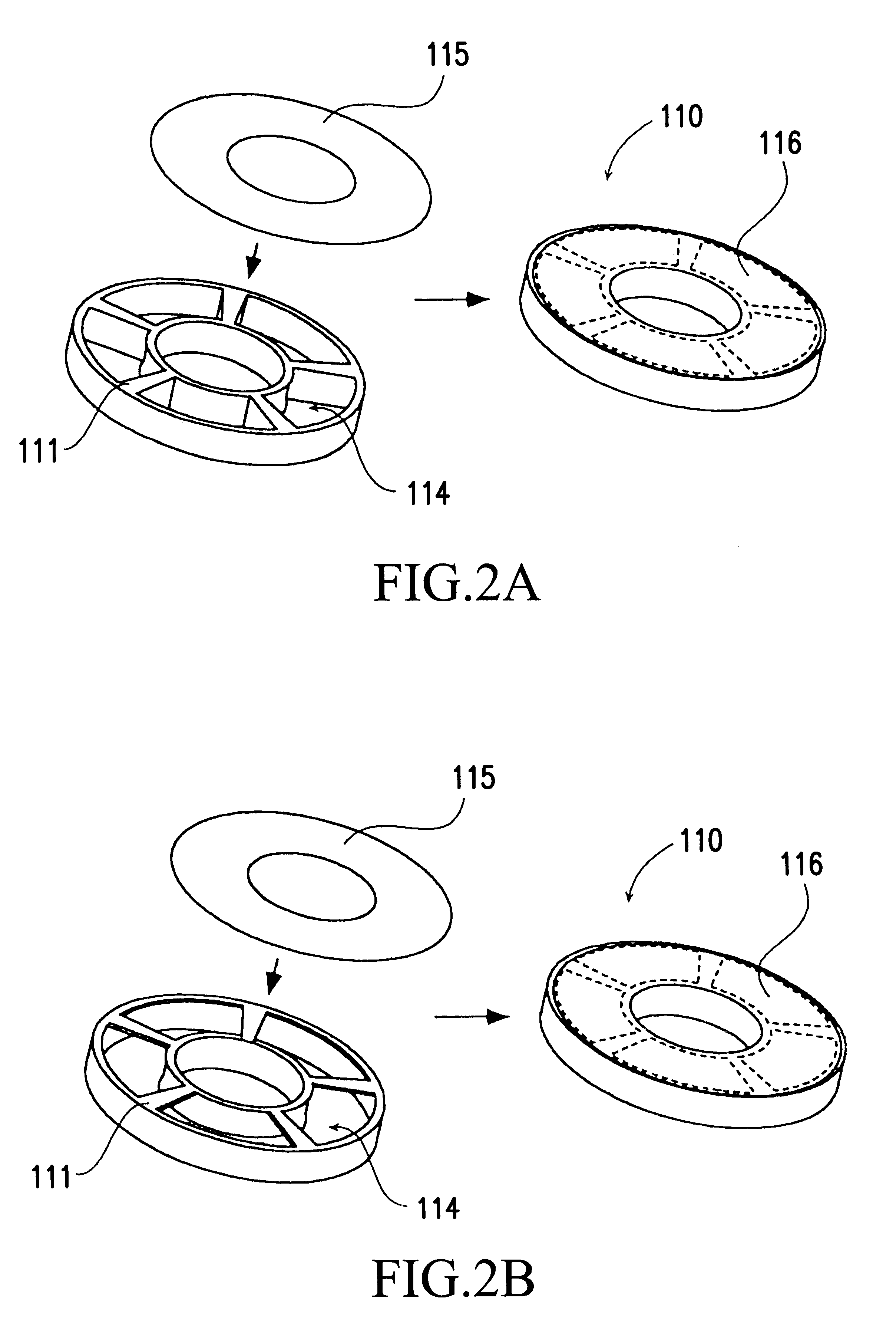

Airbag gas generator and an airbag apparatus

InactiveUS6540256B2Easy constructionImprove protectionPedestrian/occupant safety arrangementExplosivesGas-discharge lampCombustion

Owner:DAICEL CHEM IND LTD

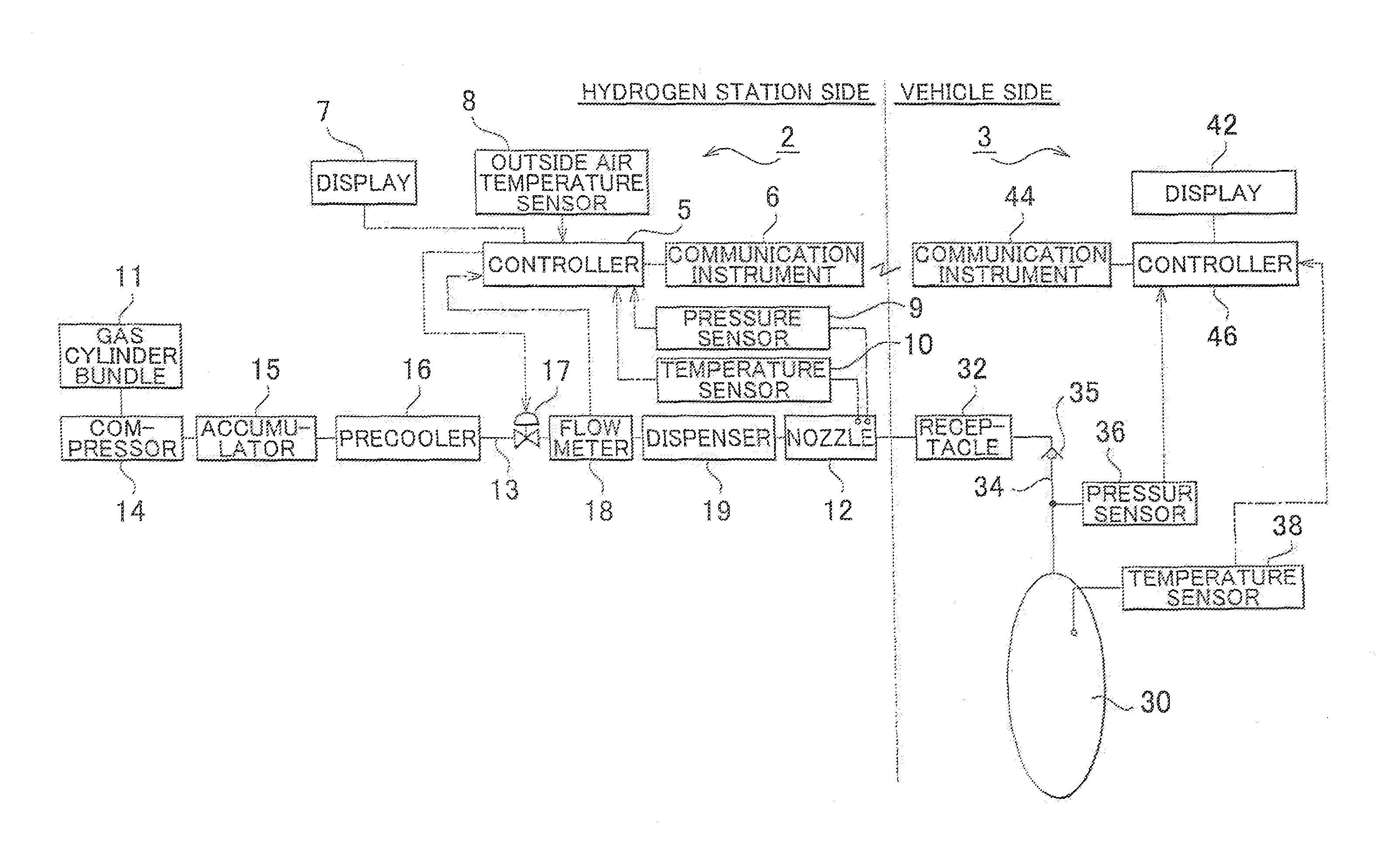

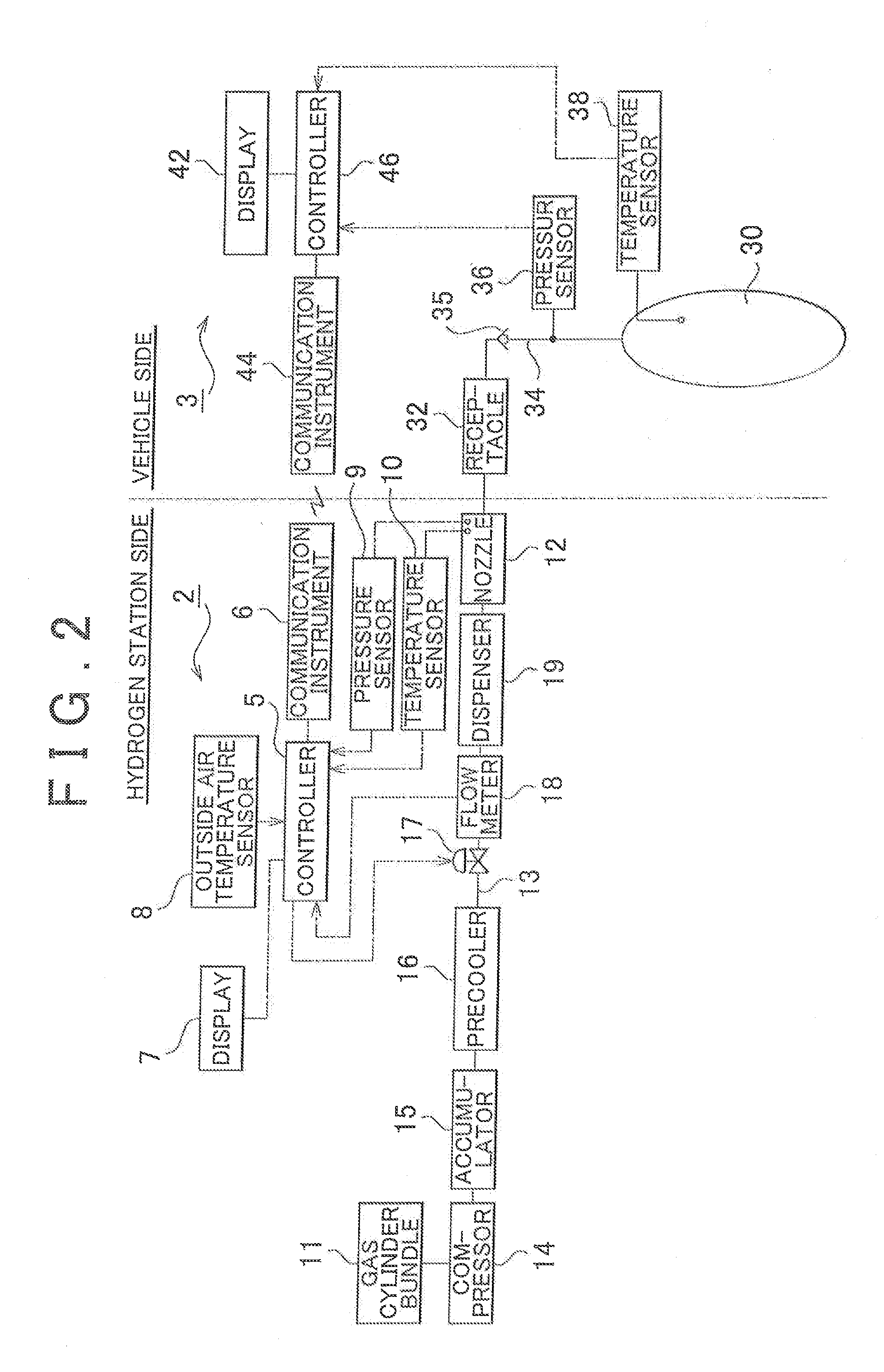

Gas filling method, gas filling system, gas station and mobile unit

ActiveUS20130037165A1Reduce loadShorten the time periodGas handling applicationsGas handling/storage effectsEngineeringProduct gas

A gap amount (62) between a liner (53) and a reinforcement layer (55) before filling gas into a tank (30) is calculated on the basis of a tank pressure and a tank temperature in the tank (30). It is predicted whether a load larger than or equal to an allowable amount acts on the liner (53) by the gas filling on the basis of the calculated gap amount (62). When it is predicted that the load larger than or equal to the allowable amount acts on the liner (53), a filling flow rate at which the gas is filled into the tank (30) is limited in comparison with a case where it is predicted that the load larger than or equal to the allowable amount does not act on the liner (53).

Owner:TOYOTA JIDOSHA KK

System and method for remote oxygen supply monitoring and calculation of replacement requirements

A device and method for remote monitoring of remaining gas supplies in compressed gas cylinders conventionally employed to supply patient oxygen. The device employs a pressure sampling component to communicate sequential electronic signals to a remote receiver of remaining pressure in the tank. Software and a microprocessor in the receiver continually calculate a future replacement time for the tank based on tank pressure depletion identified in the most recent pressure reading of the tank over the time duration from the next most recent pressure reading.

Owner:INGEN TECH

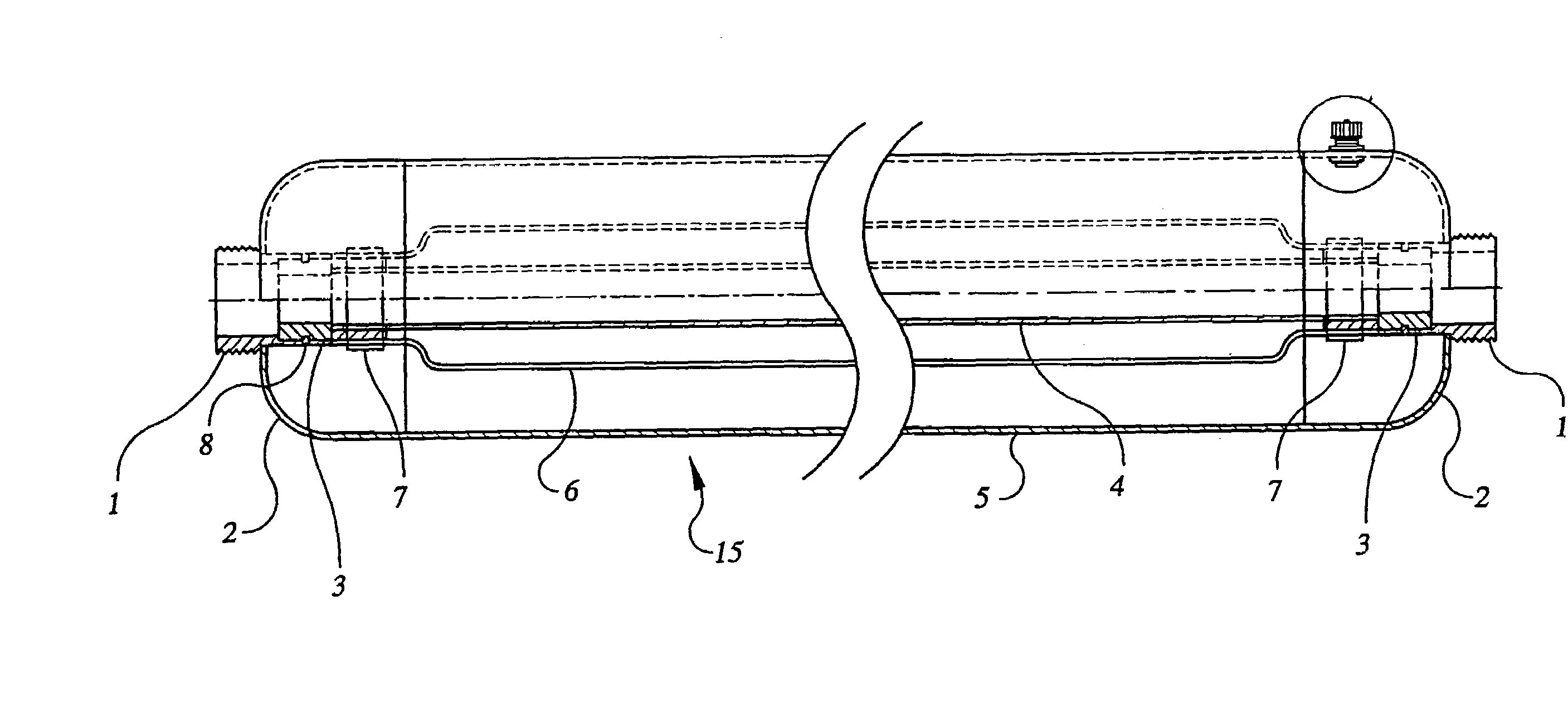

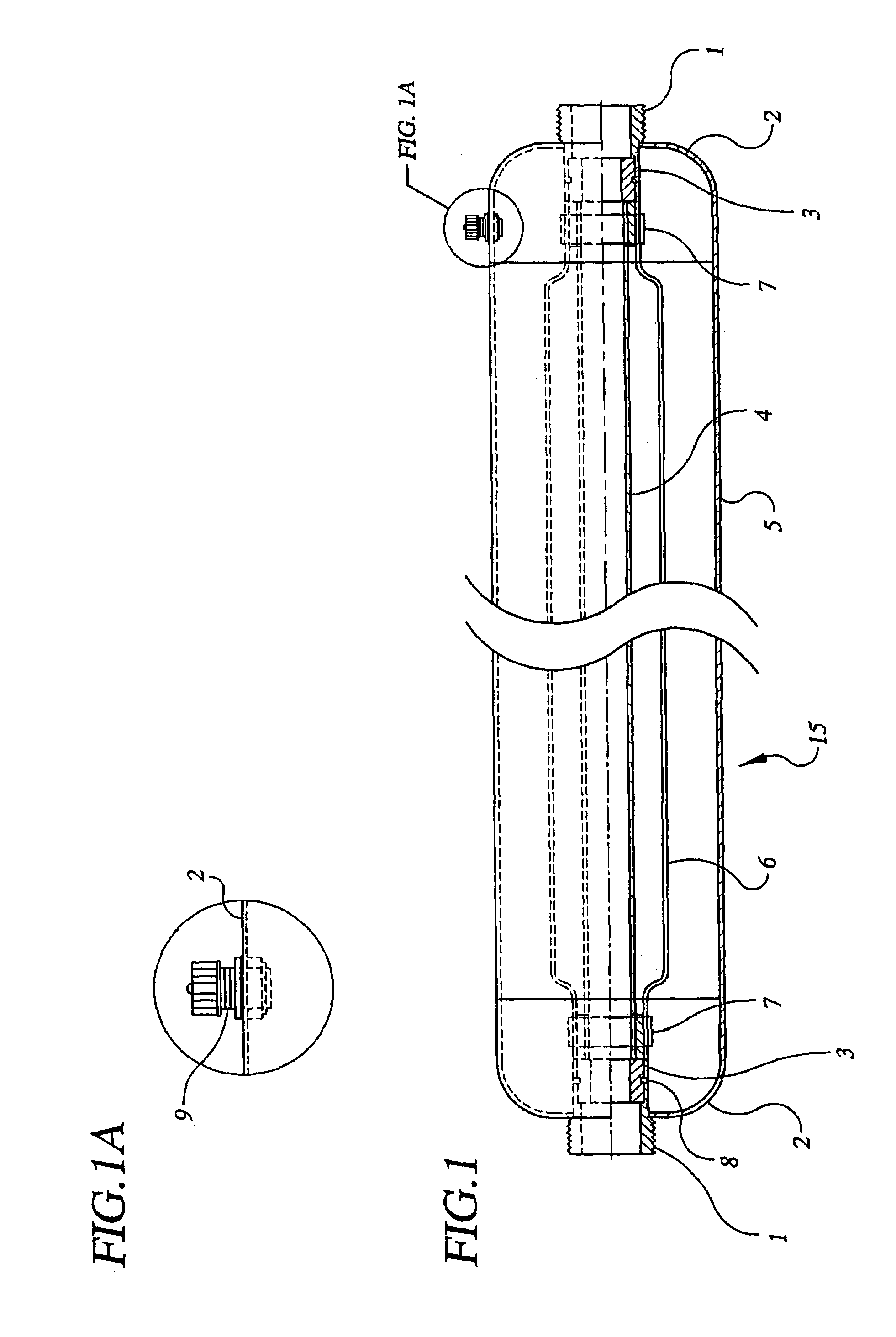

In-line flow through diaphragm tank

An in-line expansion tank. As fluid traverses a pipe within the tank, it may pass into and displace a diaphragm disposed outside of the pipe if the fluid pressure is greater than a tank pressure pushing the diaphragm against the pipe. When the fluid pressure decreases, the fluid passes from the diaphragm back into the pipe.

Owner:FLEXCON INDS

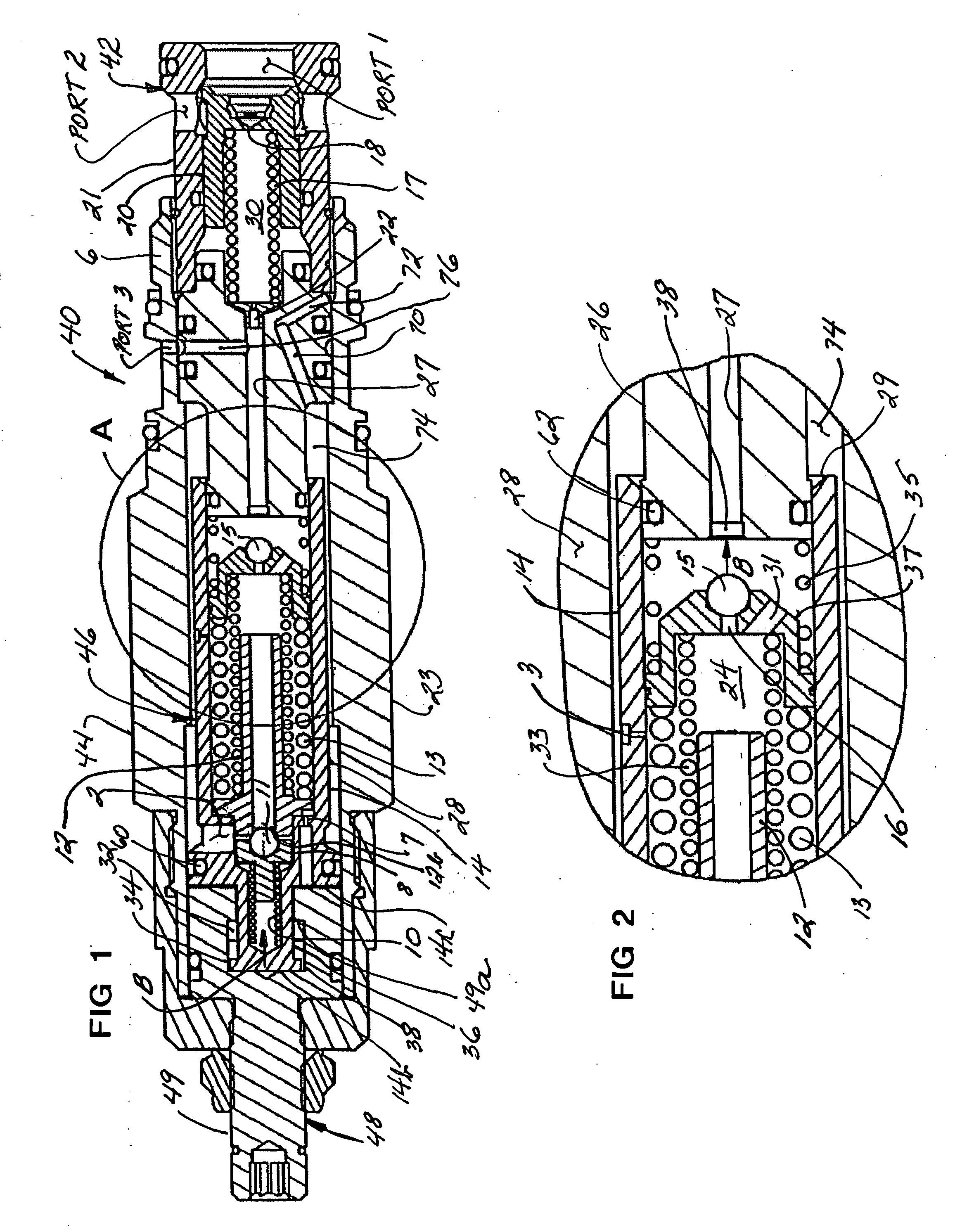

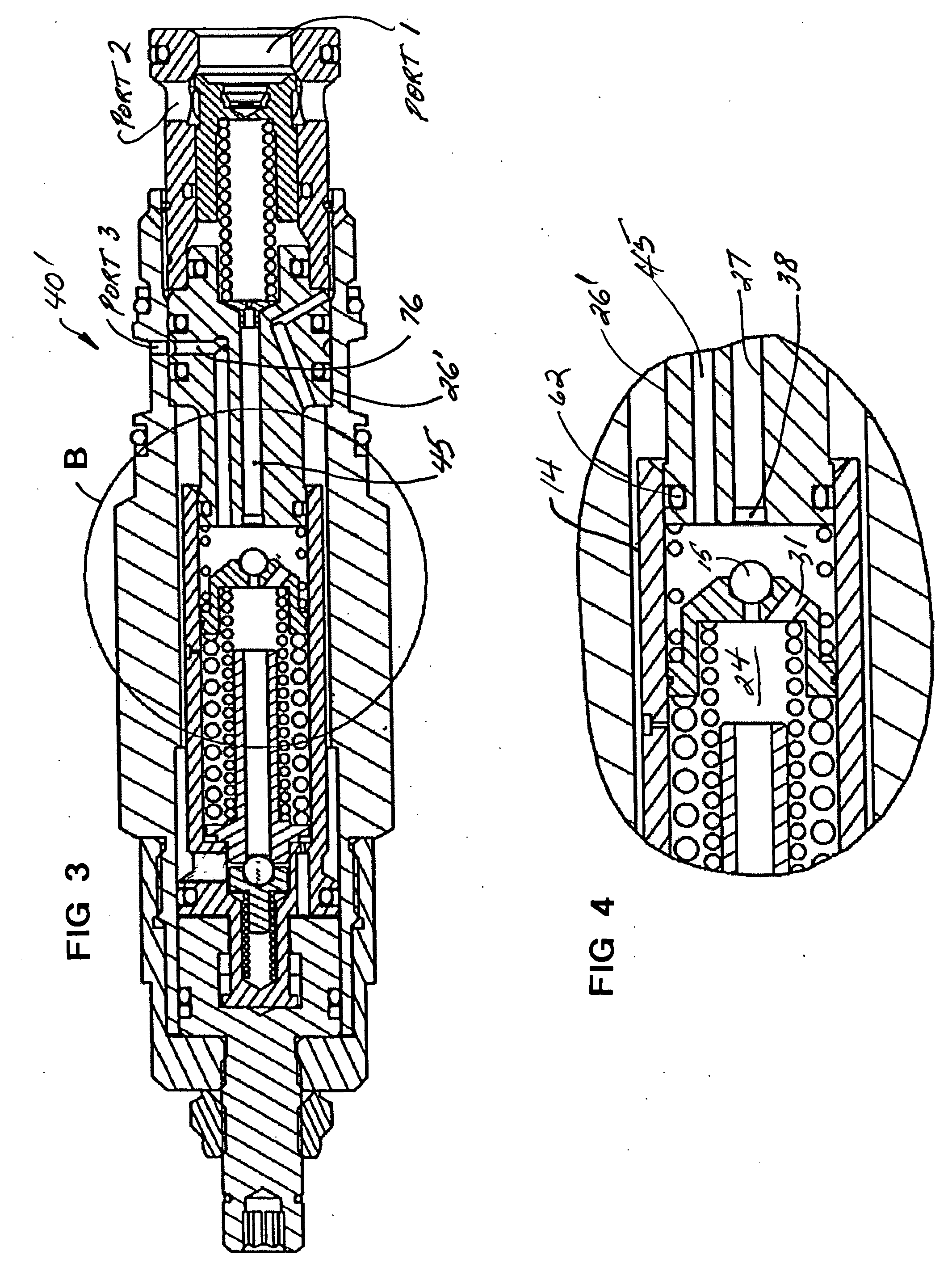

Fuel tank pressure control valve including an integrated sensor

A device for controlling fluid flow between an evaporative emission space of a fuel tank and a fuel vapor collection canister that includes a housing, a valve, a seal, an electric actuator, an electric transducer, and an electrical connector. The housing includes a first port, a second port, and a fluid flow path that extends between the first and second ports. The first port is adapted for receiving fluid flow from the evaporative emission space and is at a first pressure level. The second port is adapted for supplying fluid flow to the fuel vapor collection canister and is at a second pressure level. The valve is movable along an axis with respect to the housing between a first configuration, a second configuration, and an intermediate configuration between the first and second configurations. The first configuration permits substantially unrestricted fluid flow between the first and second ports. The second configuration prevents fluid flow between the first and second ports. The seal is located at an interface between the housing and the valve and includes an annular lip, which projects obliquely with respect to the axis in the first configuration of the valve. The electric actuator is disposed within the housing and is operatively coupled to the valve element. The electric transducer is disposed within the housing and is in fluid communication with the fluid flow path. The electric transducer senses the first pressure level. The electrical connector is disposed on the housing. The electrical connector includes a first set of terminals, which are in electrical communication with the electric actuator and a second set of terminals, which are in electrical communication with the electric transducer.

Owner:SIEMENS VDO AUTOMOTIVE CORP

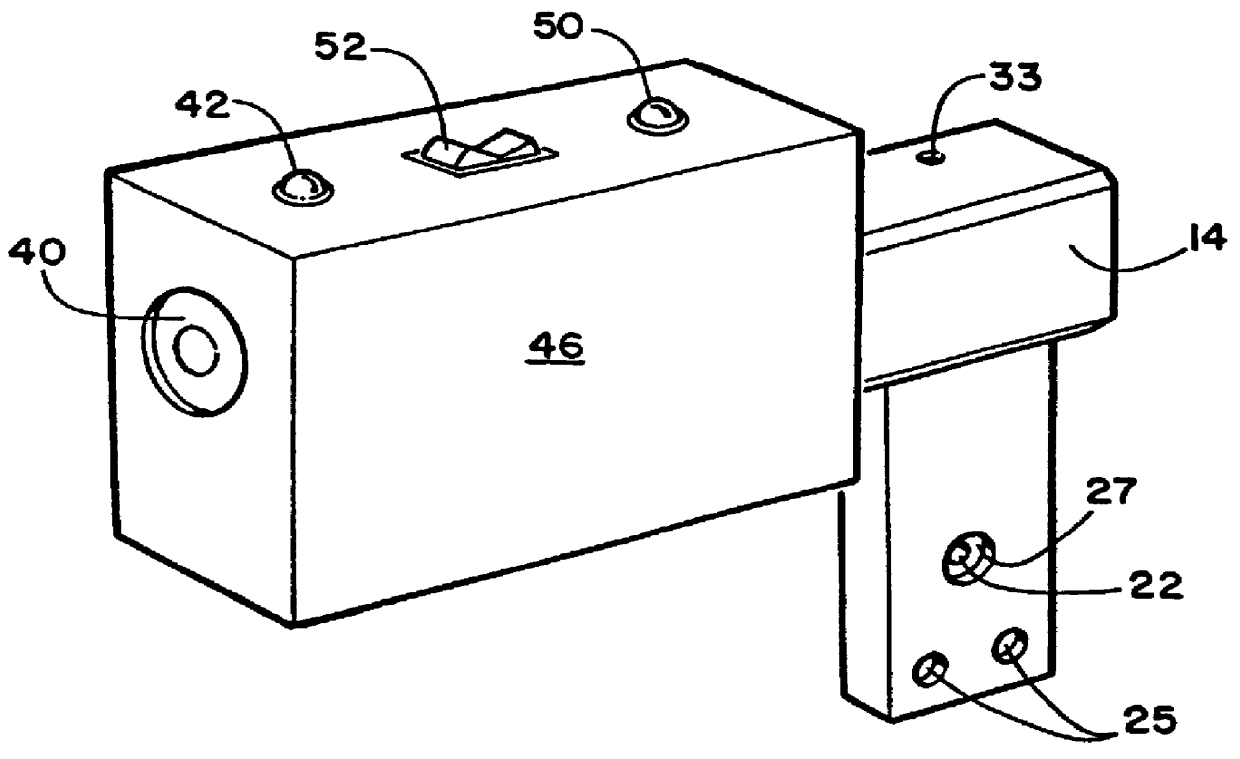

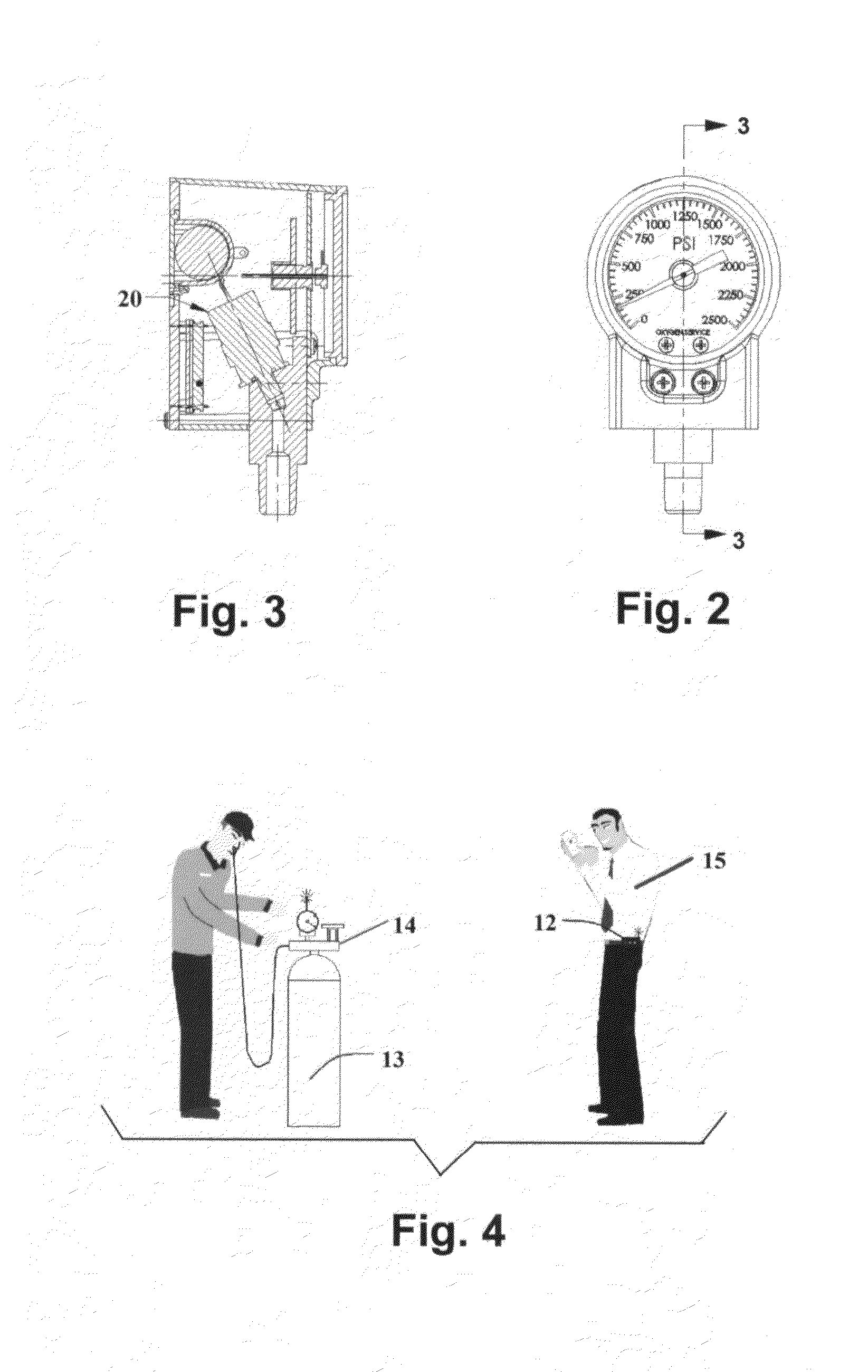

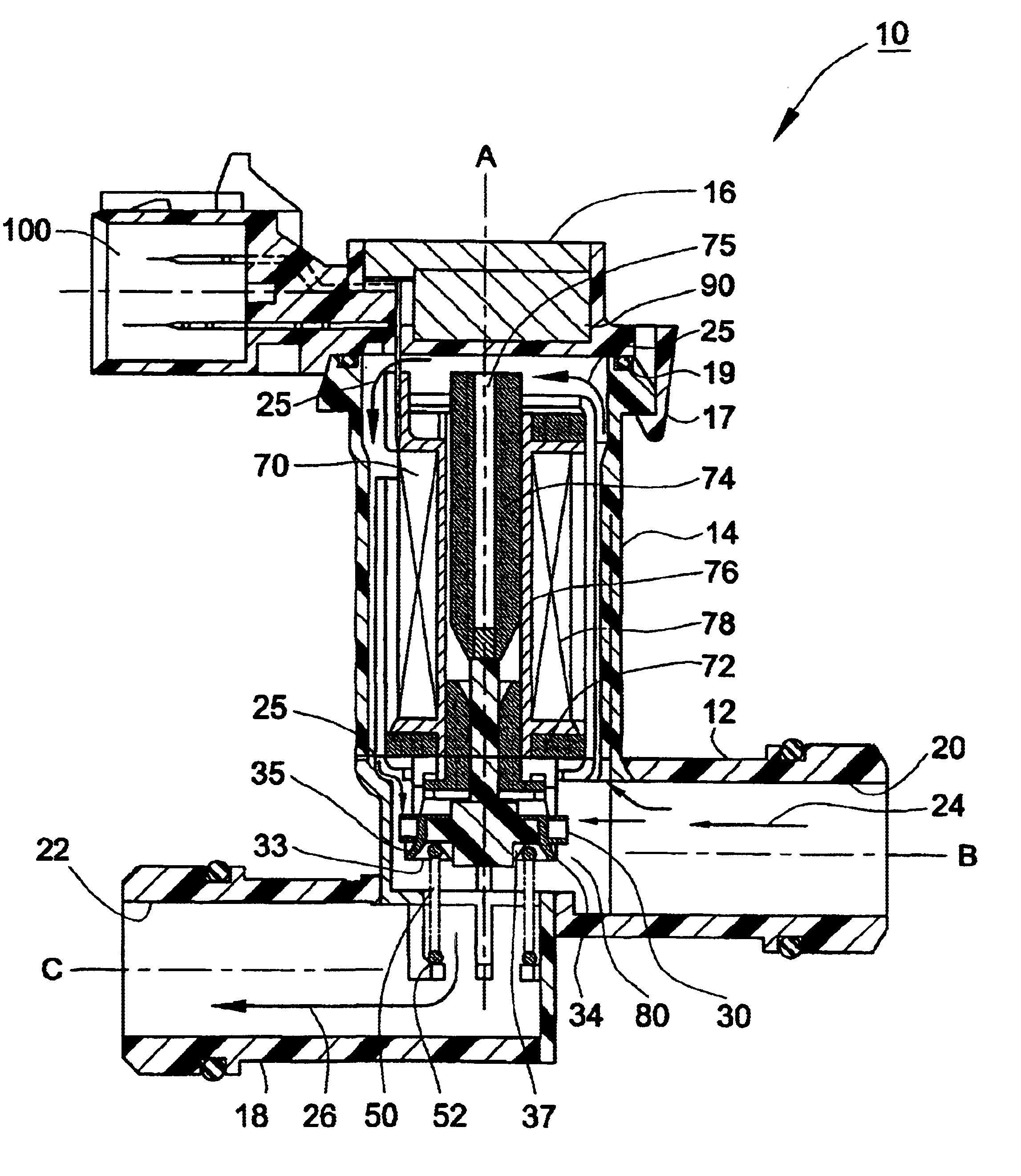

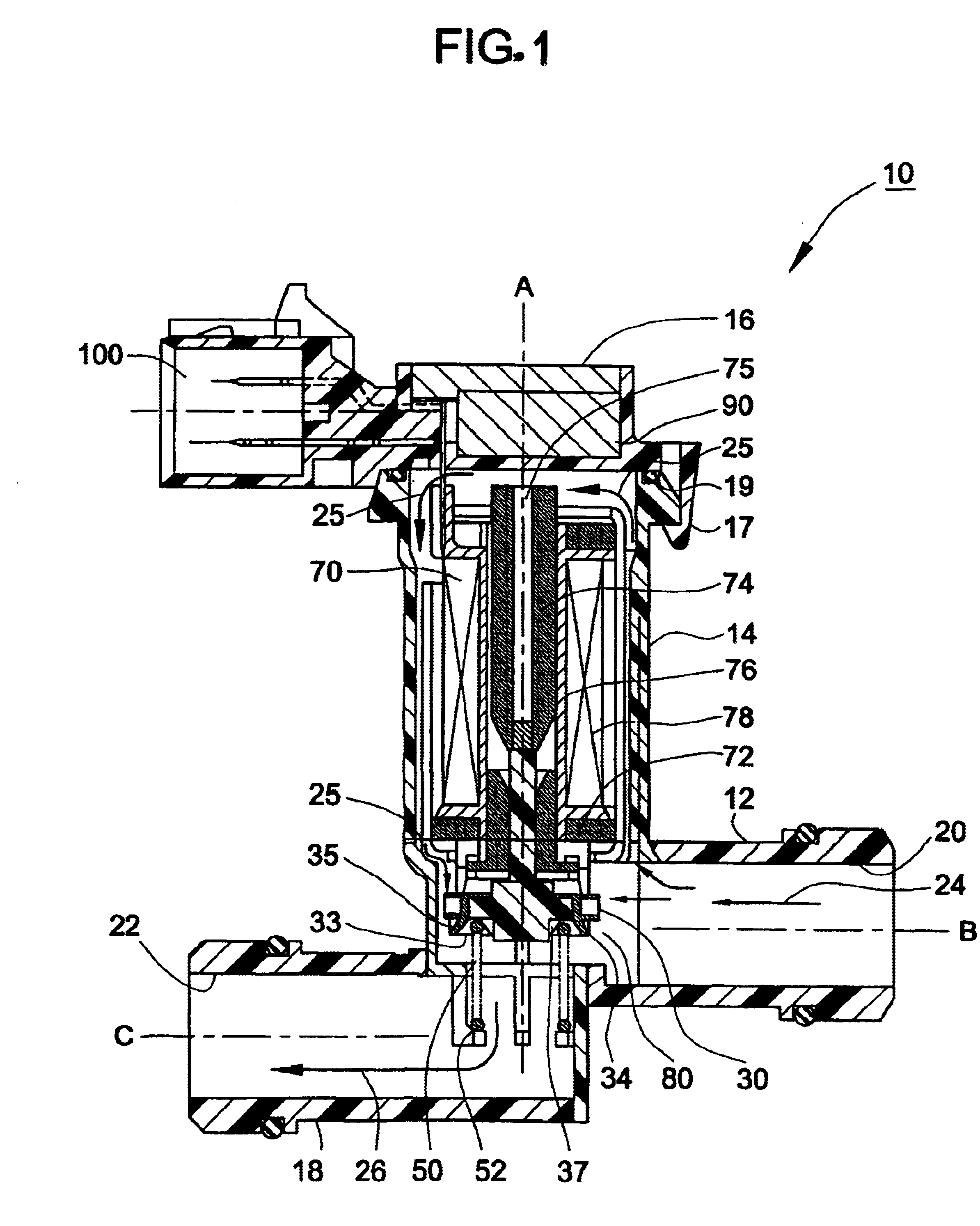

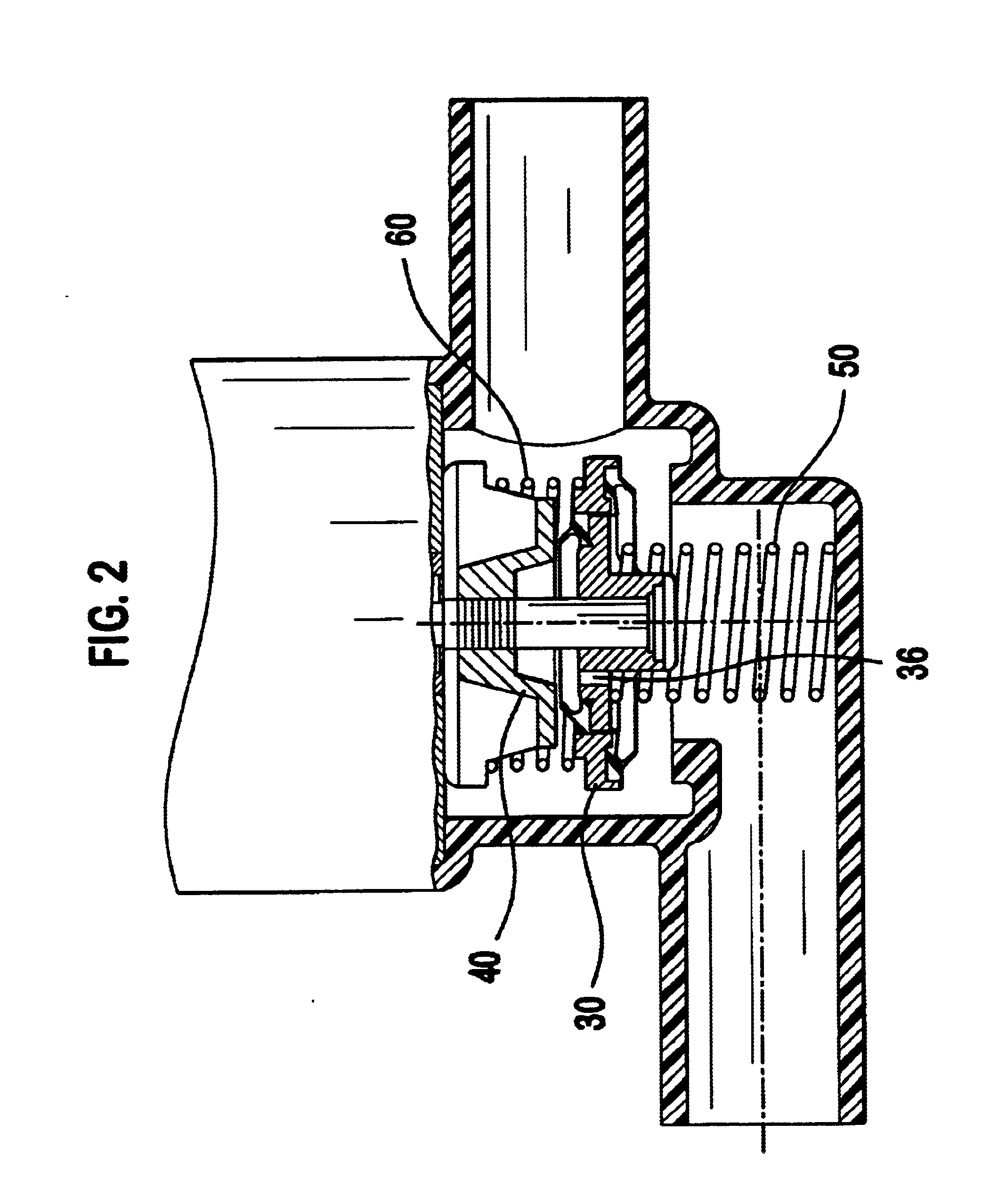

Gauge mounted pressure monitor and alarm for compression mounting with compressed gas storage tank

A warning device configured for removable mounting in combination with a high pressure gas cylinder and a regulator used to regulate the high pressure gas supplied by the cylinder. The device compression mounts between the regulator and tank outlet on conventional portable oxygen and gas supply systems using a specially configured manifold. The device features one or a combination of alarms, from a group including audio, visual, electronic, and remotely transmitted alarms. These alarms are activated by a pressure switch monitoring the remaining supply in the gas cylinder through a conduit the manifold. The alarm signal from the device alerts the user, or a third party monitoring the user, of current tank pressure or will sound an alarm when remaining high pressure gas inside the gas cylinder drops below a predetermined level.

Owner:INGEN TECH

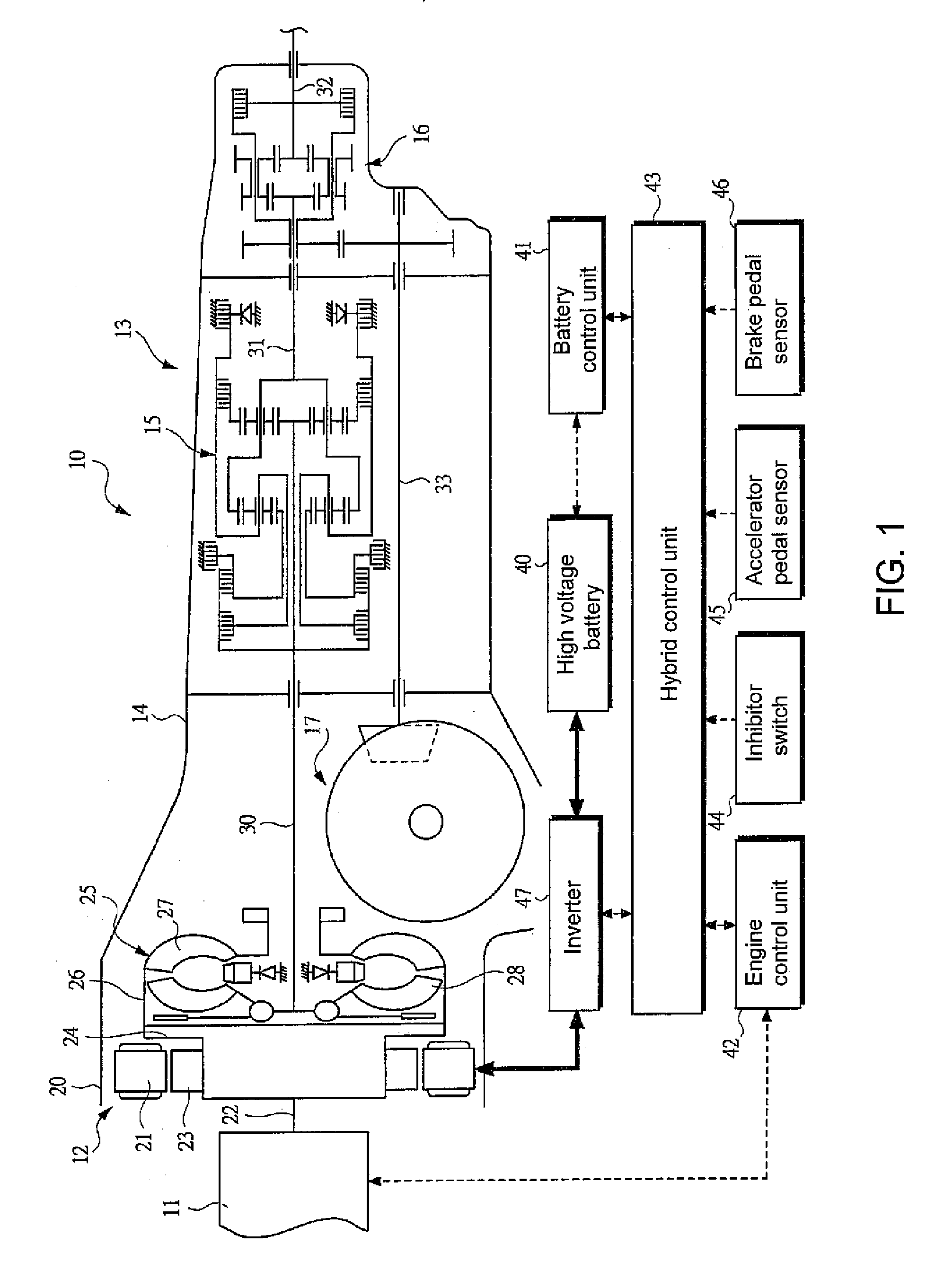

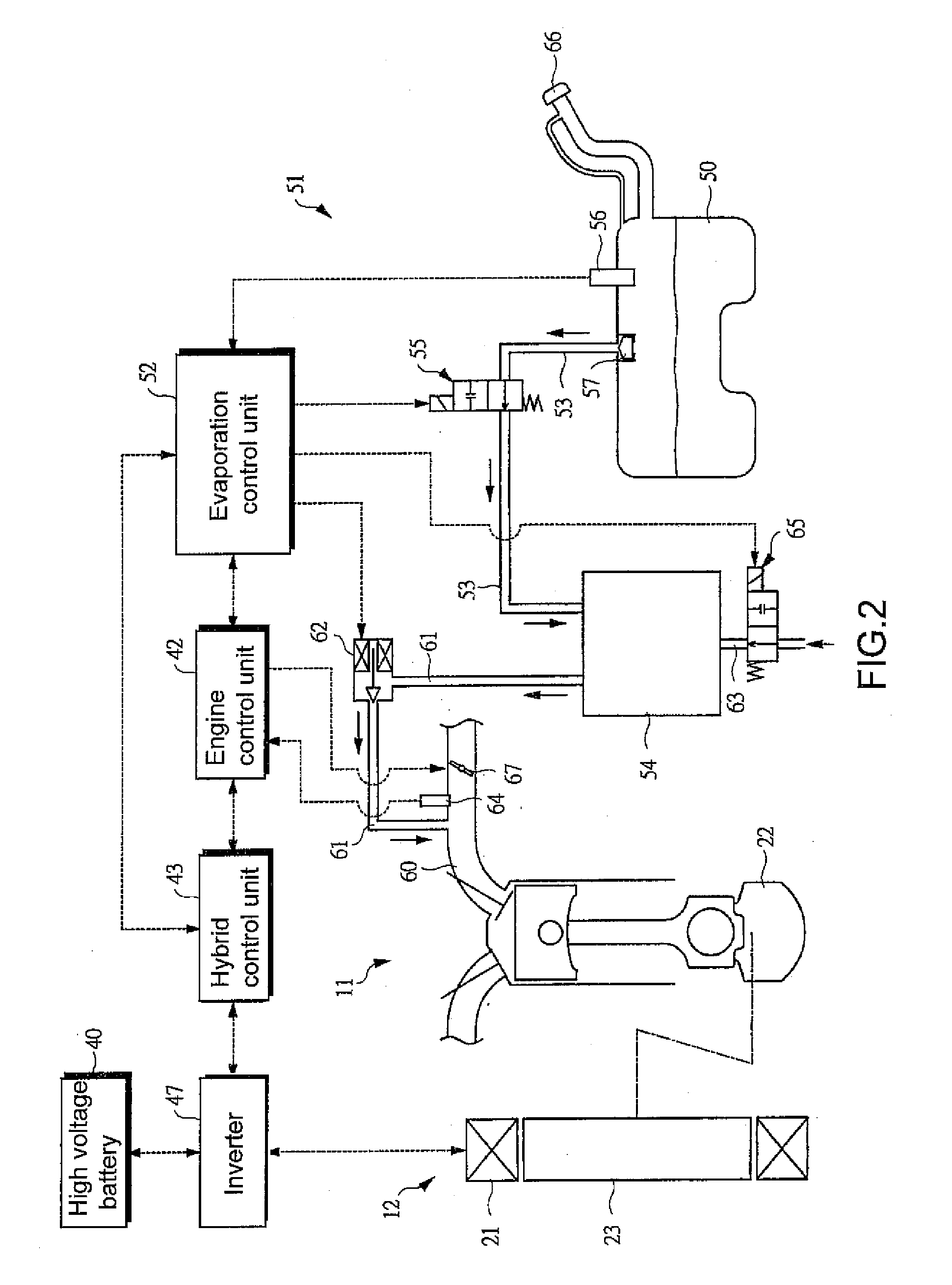

Diagnostic control device for a hybrid vehicle

InactiveUS7506639B2Vehicle testingRegistering/indicating working of vehiclesEvaporationHybrid vehicle

Owner:SUBARU CORP

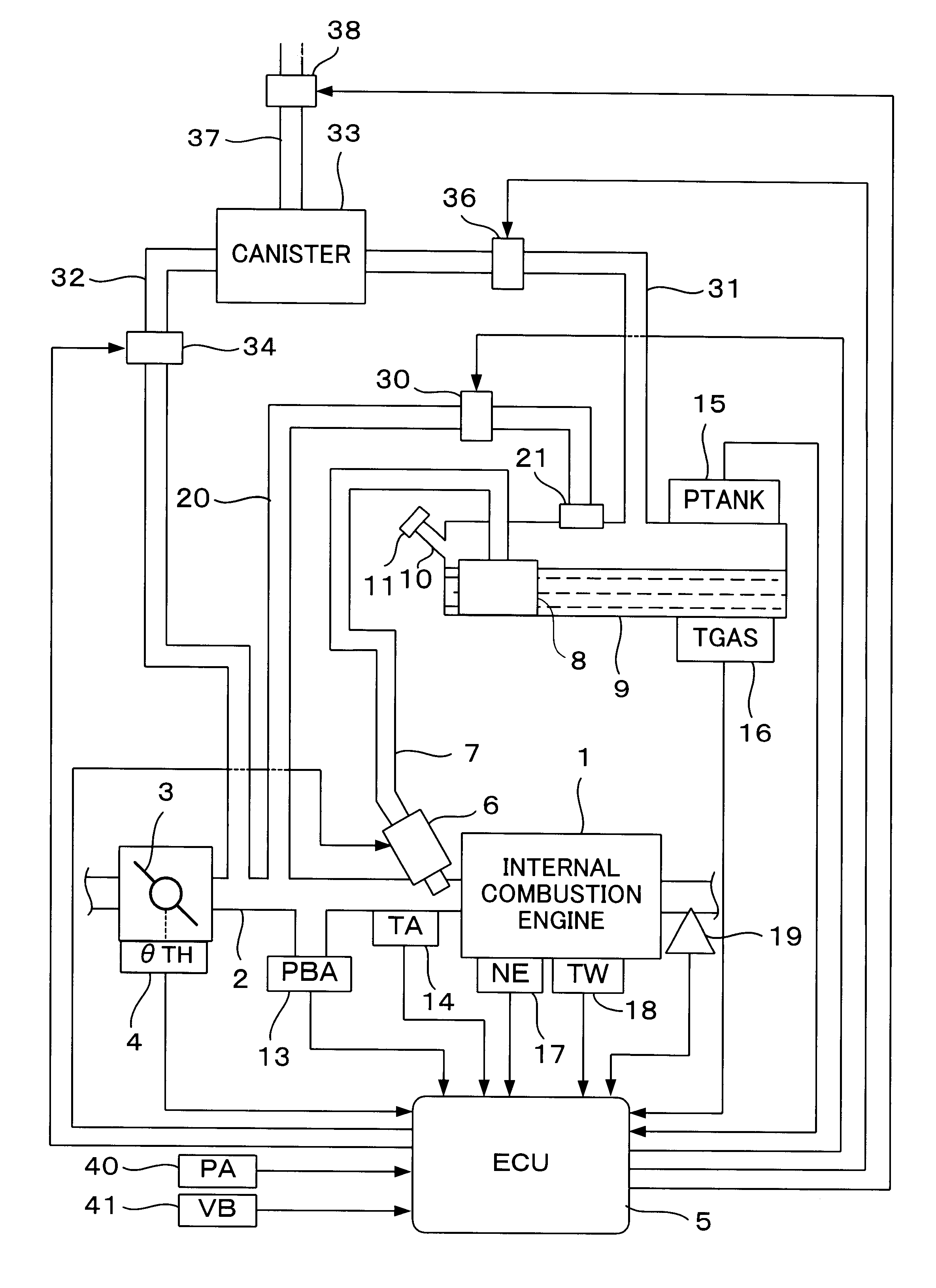

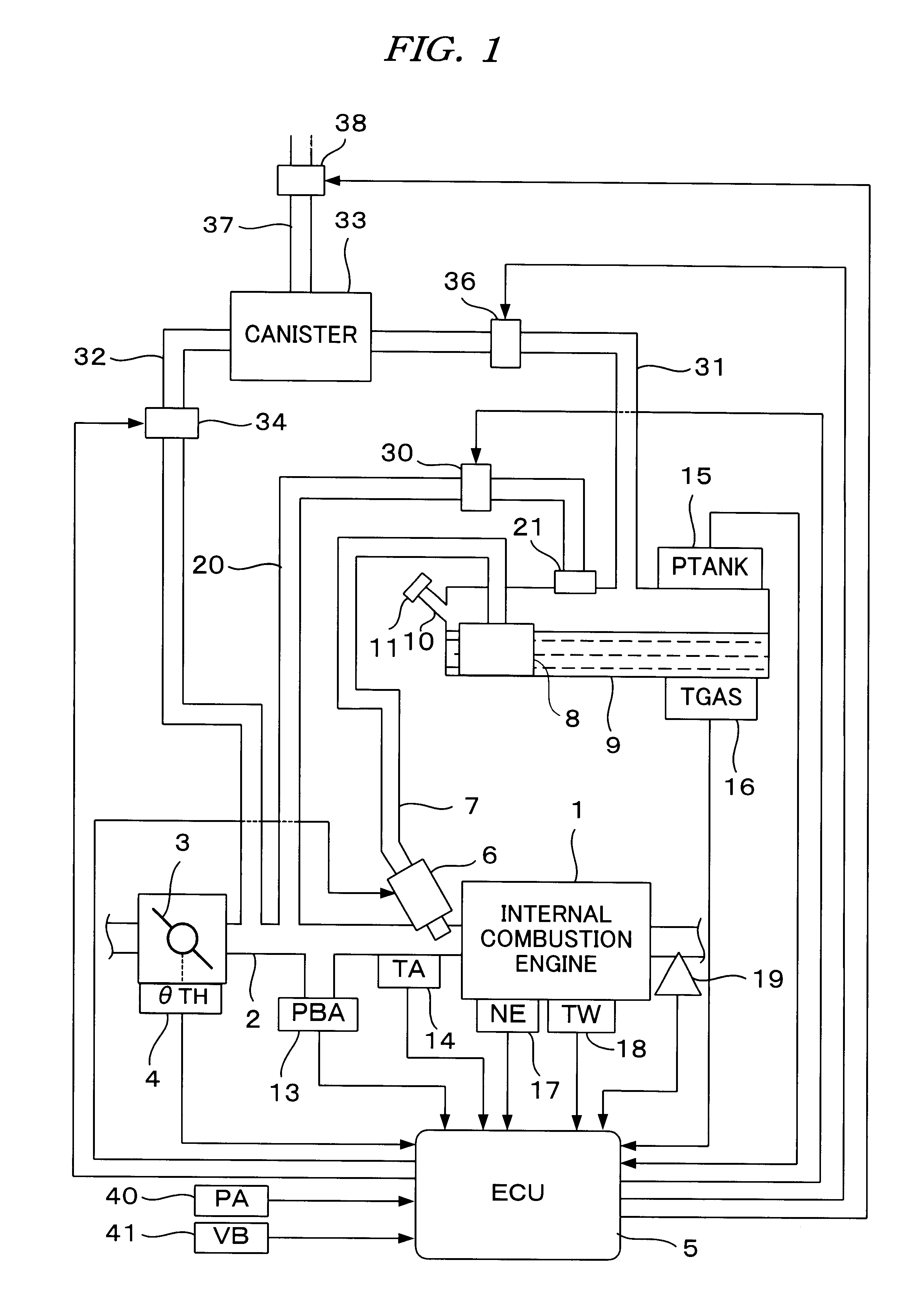

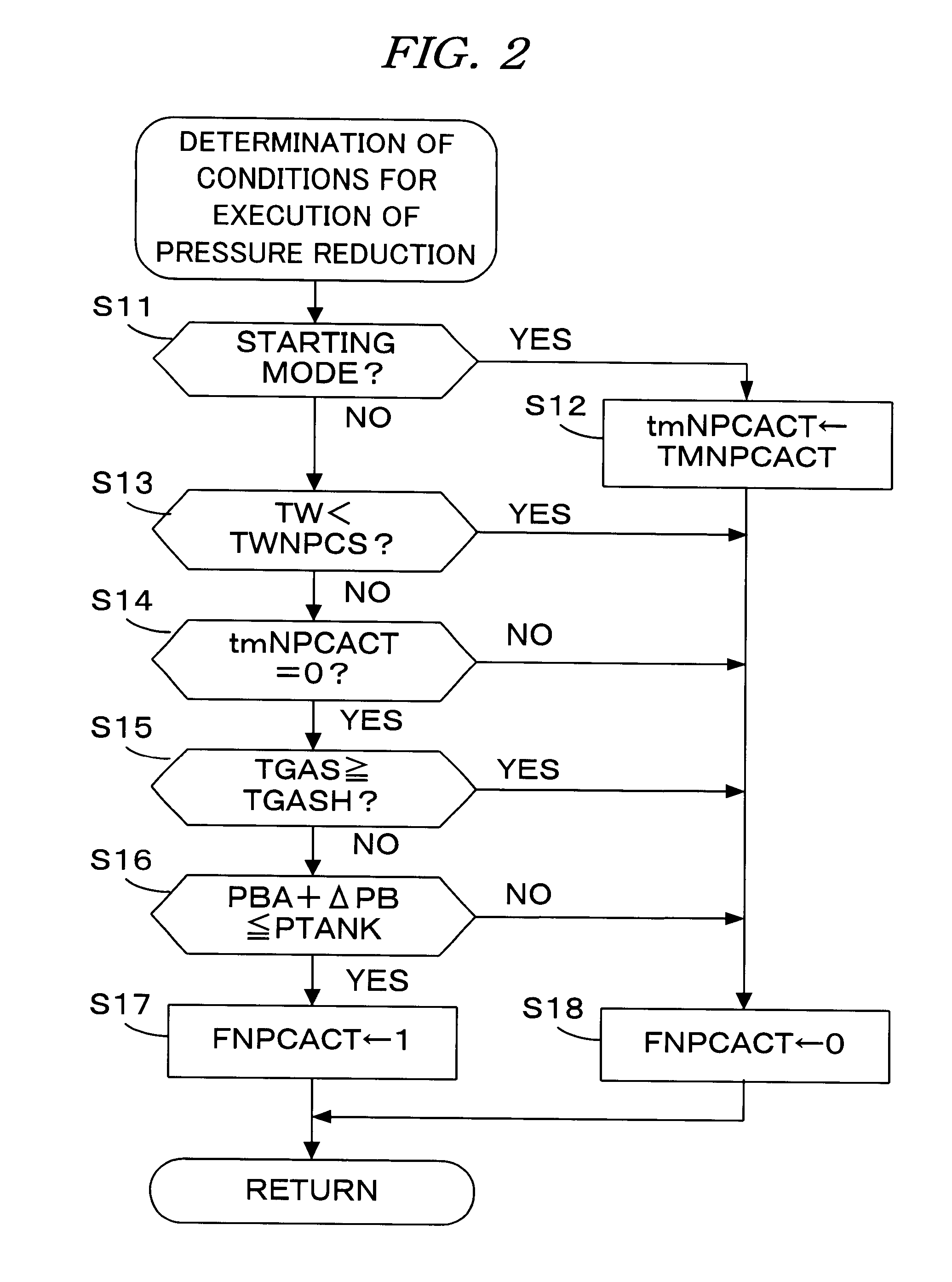

Evaporative emission control system for internal combustion engine

InactiveUS6305362B1Quick pressure reductionStorage capacityElectrical controlNon-fuel substance addition to fuelControl systemFuel tank

Disclosed herein is an evaporative emission control system which can properly control the ratio between a tank purge amount and a canister purge amount to realize quick pressure reduction in a fuel tank and ensuring the storage capacity of a canister in a well balanced fashion. A target pressure in controlling the pressure in the fuel tank at a negative pressure and a detected pressure in the fuel tank are compared with each other. When the difference between the target pressure and the detected pressure is large, tank purge is preferentially carried out to open a tank pressure control valve. When the detected pressure is in the vicinity of the target pressure, canister purge is preferentially carried out to purge the evaporative fuel stored in the canister.

Owner:HONDA MOTOR CO LTD

System and method for closing a tank valve

ActiveUS20130255636A1Reduce lossesReduce the amount requiredElectrical controlInternal combustion piston enginesRail pressureSolenoid valve

A method for closing a storage tank valve in response to leaks in a fuel line or fuel rail and emptying the tank of a vehicle when no leaks are detected is described. The method includes comparing a tank pressure to a fuel line or fuel rail pressure in order to detect leaks therein and further includes using a dedicated tank pressure sensor to measure the gaseous pressure of the storage tank, and thereby the amount of fuel remaining. In response to leaks in the fuel system, a controller may close an electronic solenoid valve, which reinforces a mechanical excess flow valve, to block the flow of fuel and prevent fuel loss from the gaseous storage tank.

Owner:FORD GLOBAL TECH LLC

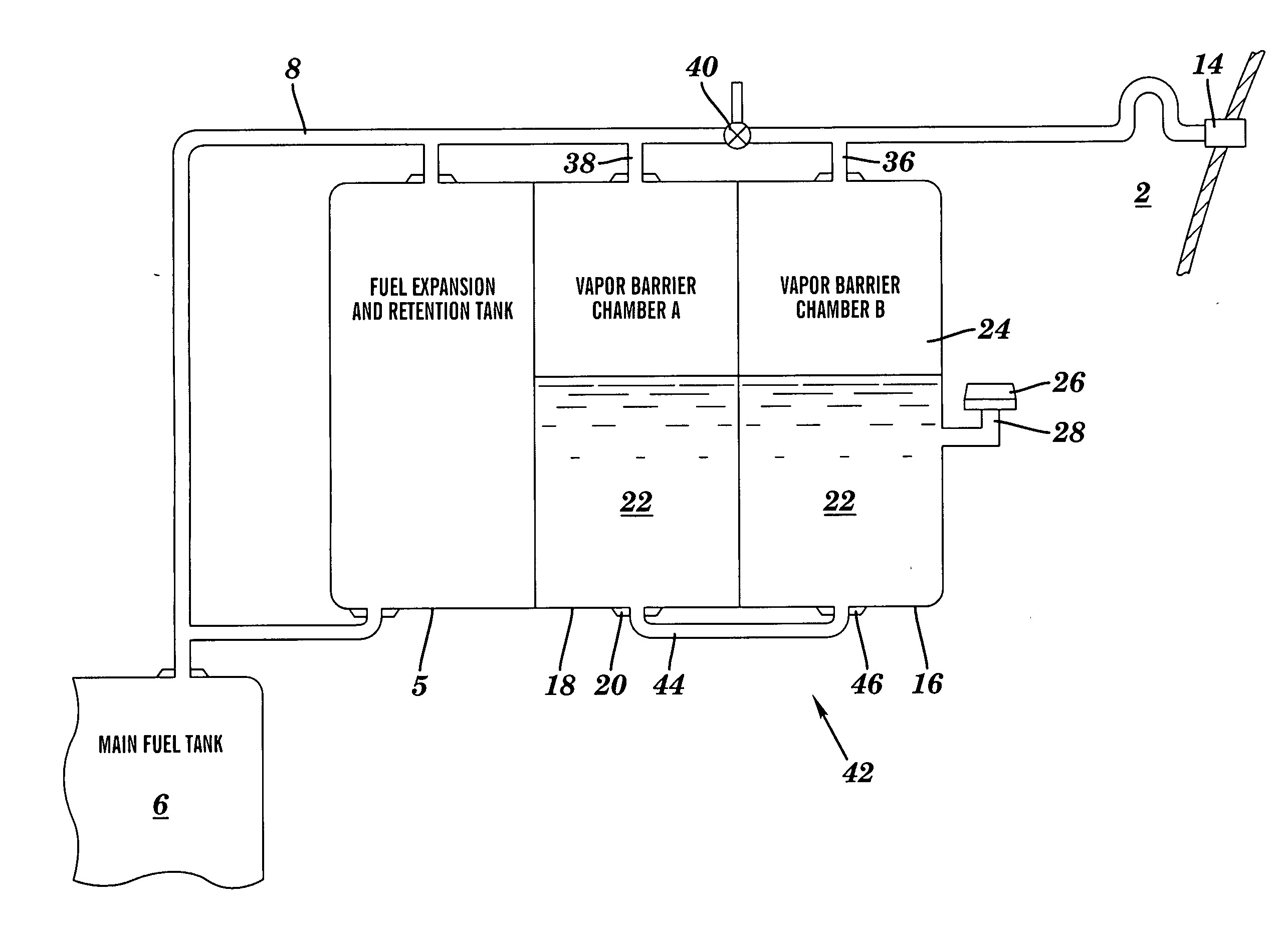

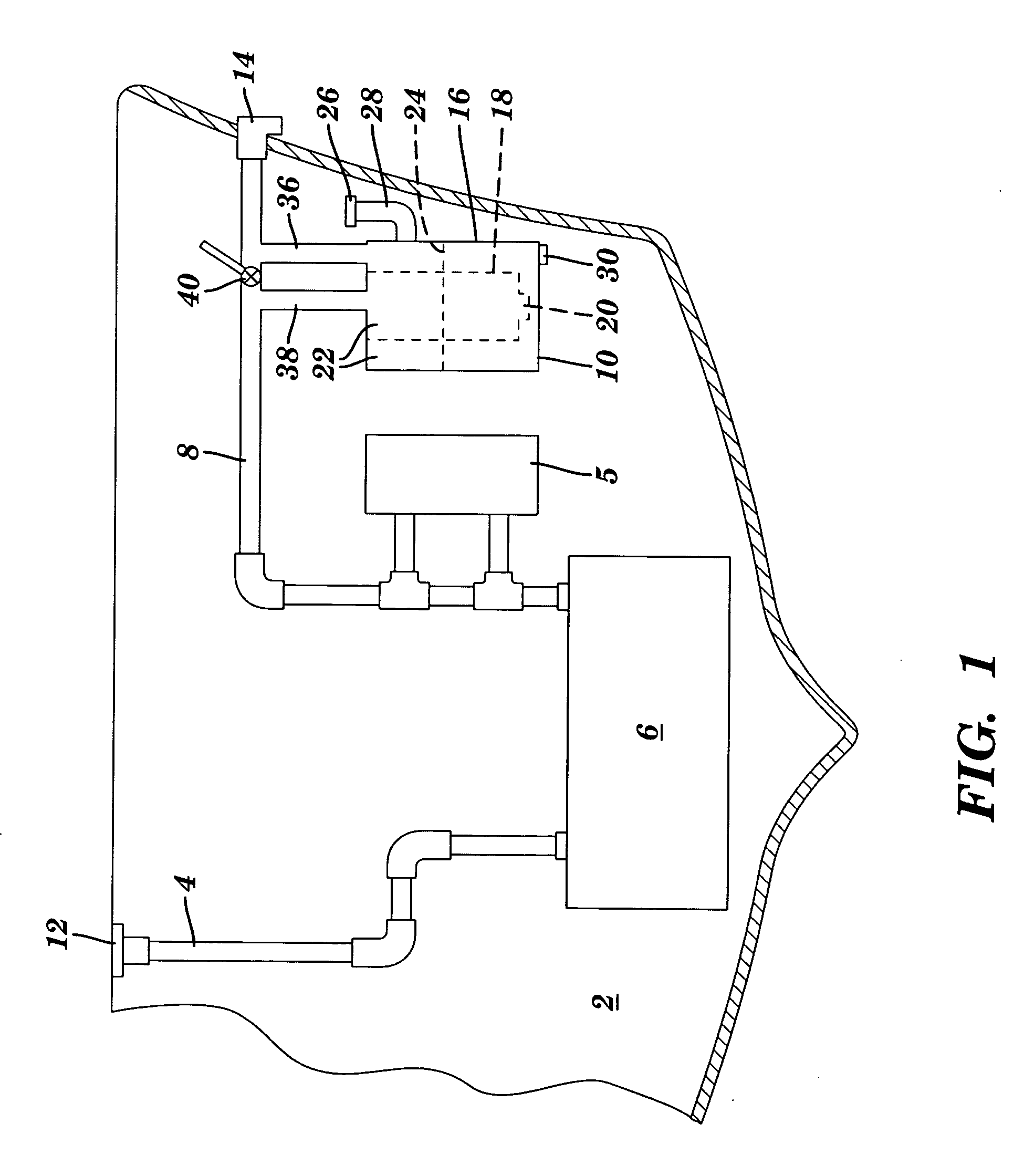

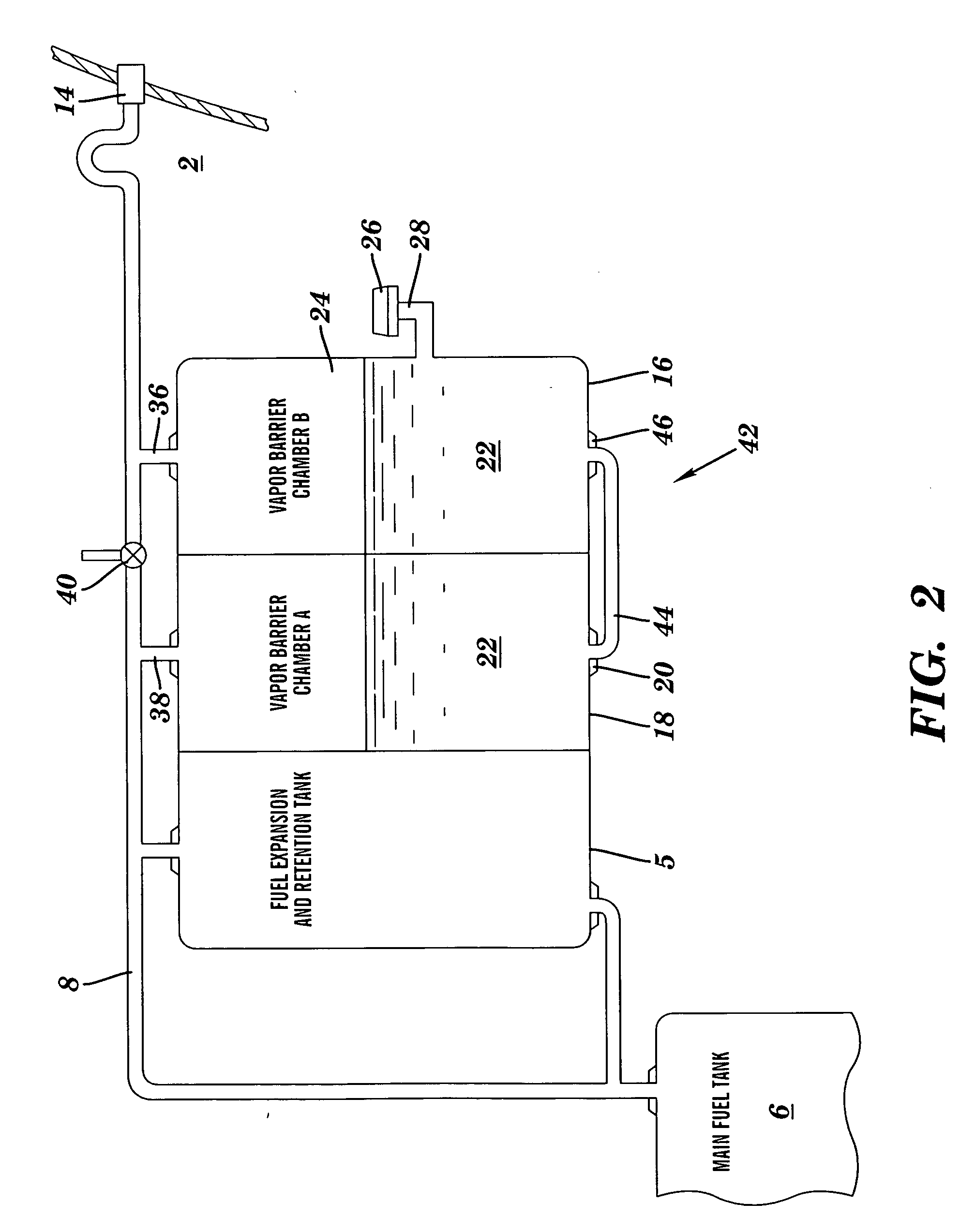

System and method for tank pressure compensation

ActiveUS20050199294A1Avoid flowNon-fuel substance addition to fuelLarge containersFuel vaporAutomotive engineering

A supplemental fluid tank, preferably having two chambers each partially containing a fluid, fluid communicated intermediate a fuel tank and vent to reduce fuel vapor emissions, particularly for a boat. More specifically, when fuel is used or cooled, pressure or volume, respectively, of the remaining fuel in the fuel tank is reduced in prior art systems. Accordingly, air is drawn into the fuel tank through the vent line and becomes saturated with fuel (i.e., fuel vapor). Conversely, when fuel in the fuel tank is warmed it expands and fuel vapor is forced out of the vent into the environment. An exemplary embodiment reduces entry of air in through the vent and escape of fuel vapor out of the vent using two intermediate chambers in fluid communication with each other, each preferably having a non-evaporative fluid (e.g., oil), to provide volume / pressure compensation of the fuel in the fuel tank.

Owner:VAITSES STEPHEN P

Checking functionality of fuel tank vapor pressure sensor

InactiveUS8342157B2Reliable checkEmission reductionNon-fuel substance addition to fuelMachines/enginesAtmospheric airFuel tank

A vehicle fuel emissions system includes a fuel tank, a tank pressure sensor indicating a pressure differential between the tank and a port communicating with the atmosphere, a pump for selectively producing vacuum in the tank, and a passage connecting the pump and a pressure sensor air reference port external to the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

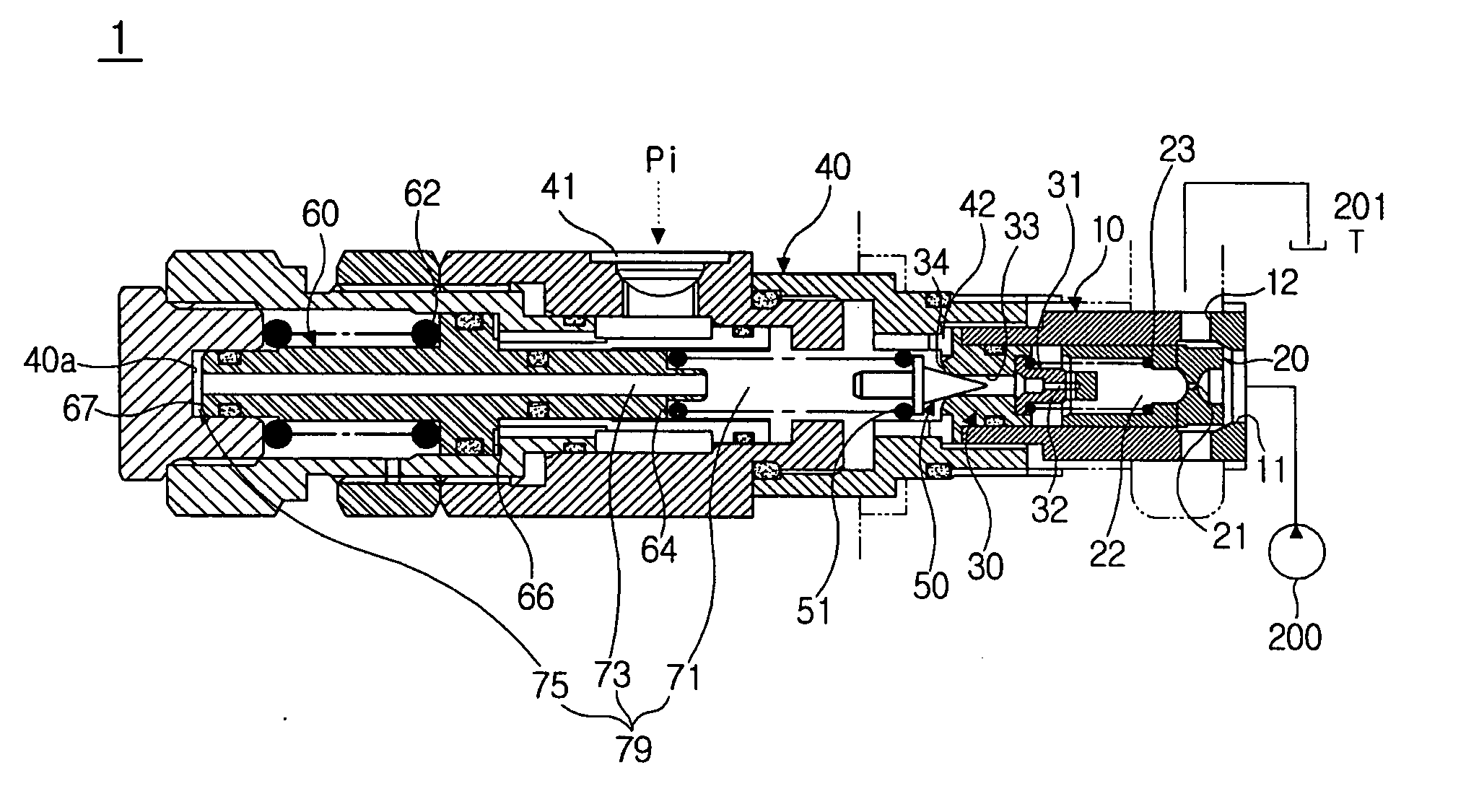

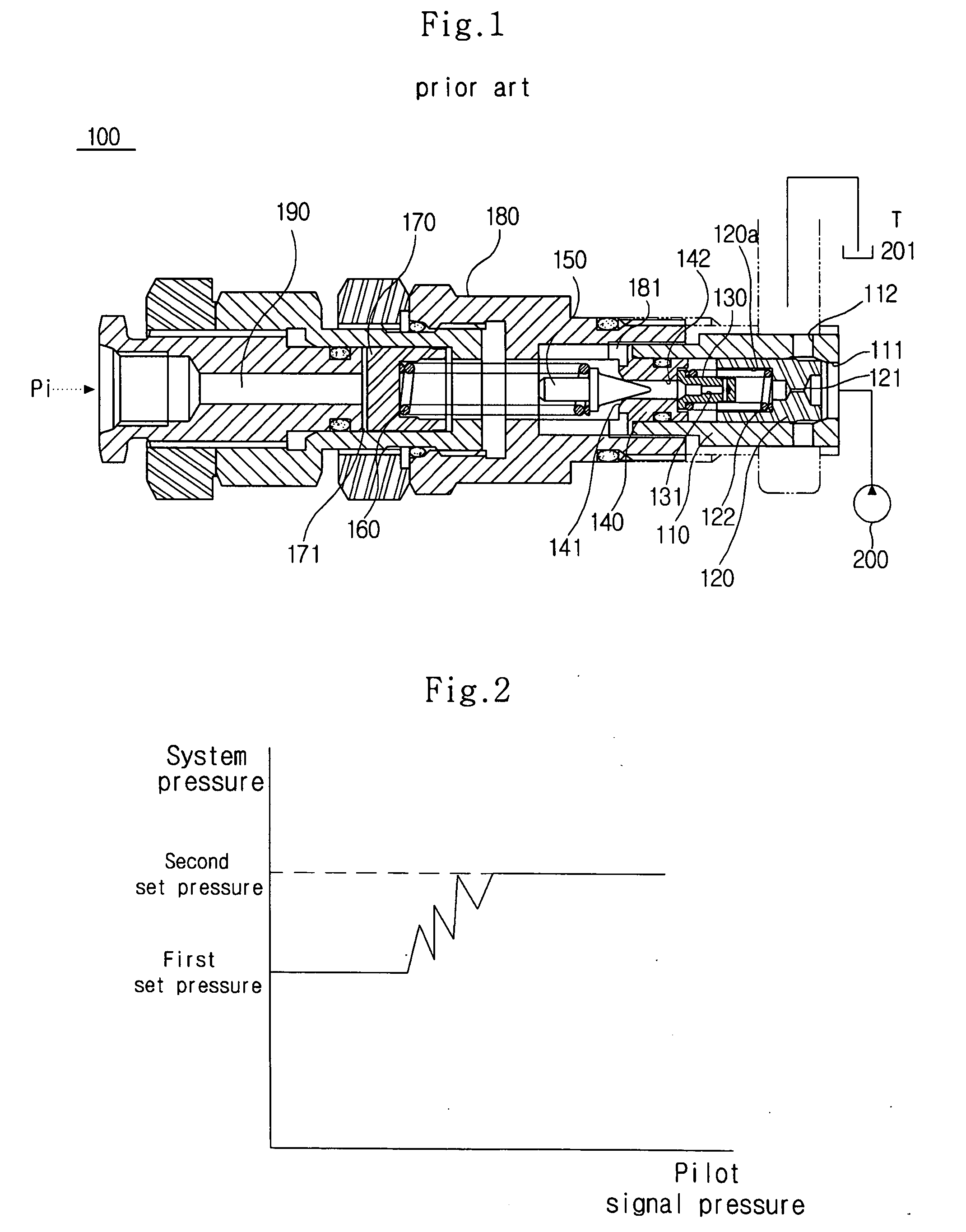

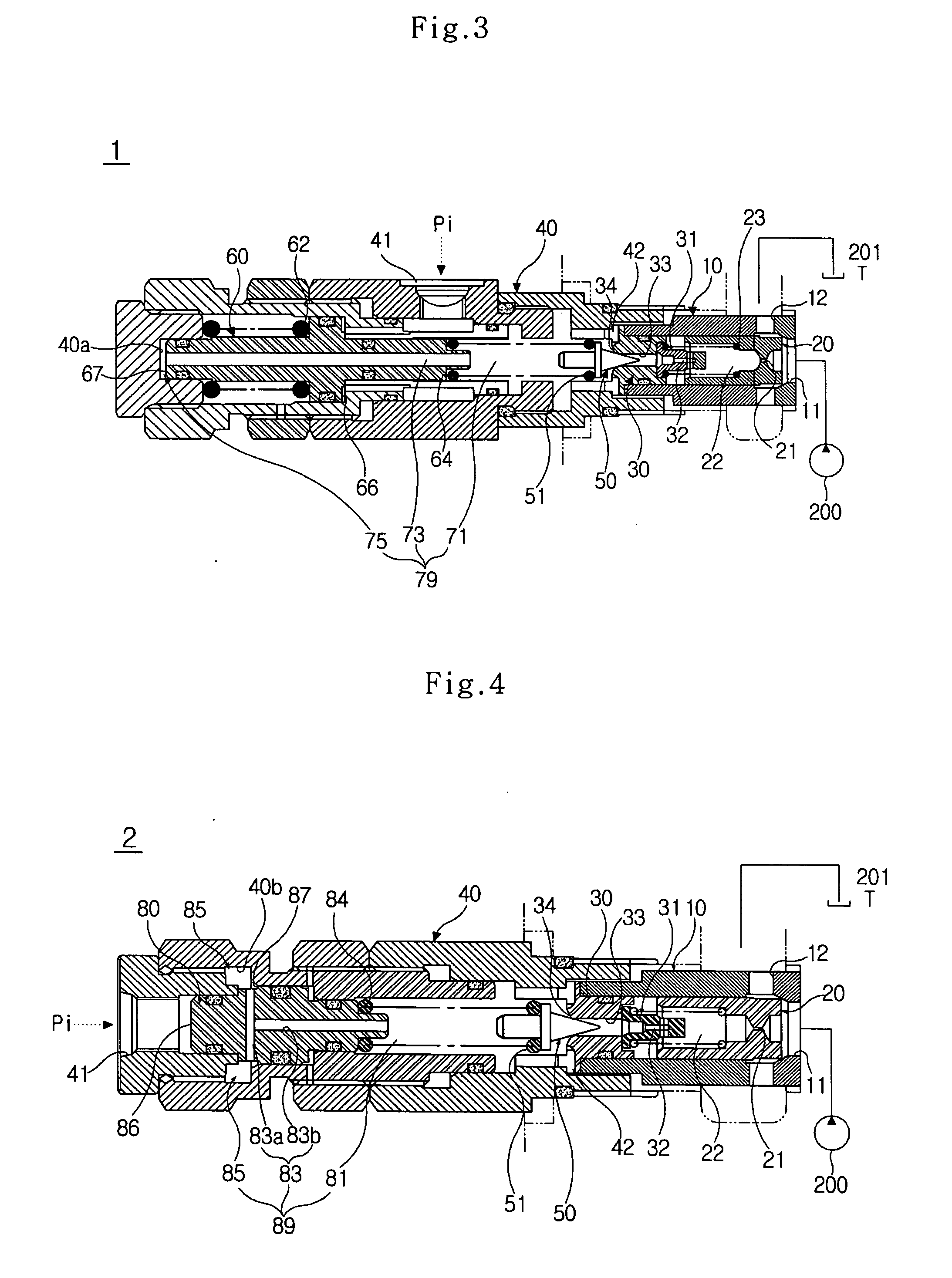

Pilot operated relief valve

ActiveUS20050183775A1Operating means/releasing devices for valvesServomotor componentsFuel tankSafety valve

Disclosed is a pilot operated relief valve, in which a balance system is provided to offset a tank pressure exerted on a piston, so that a setting pressure of a pilot poppet is not changed even when the tank pressure is changed, and thus a function of the relief valve can be stably performed. The pilot operated relief valve is comprised of a sleeve, a main poppet provided to be movable in the sleeve, a seat provided in the sleeve, a housing connected to a rear end of the sleeve, a pilot poppet provided to be movable in the housing, a piston moved by a pilot signal pressure, and the balance system offsetting the tank pressure exerted on the piston.

Owner:VOLVO CONSTR EQUIP

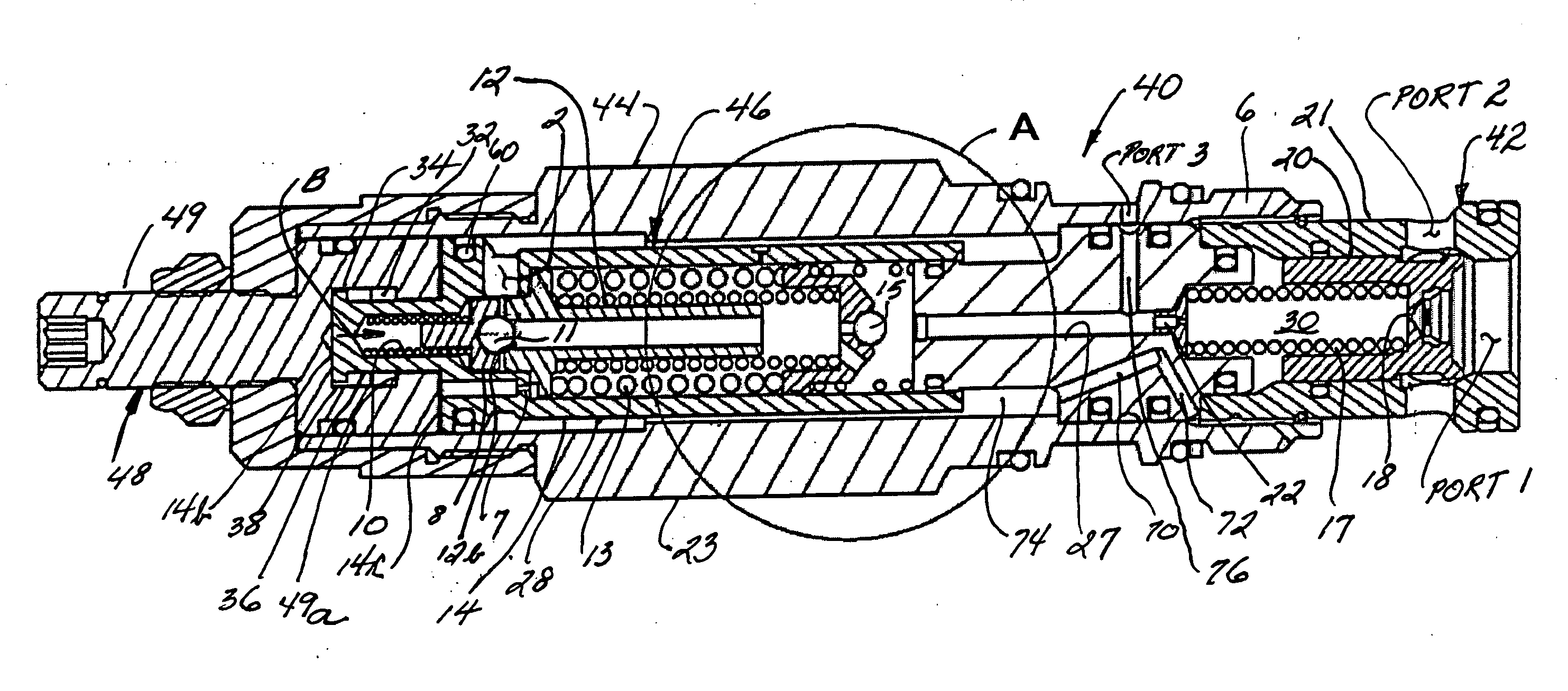

Soft ventable relief valve

InactiveUS20060201554A1Increase relief settingLow pressure settingOperating means/releasing devices for valvesEqualizing valvesPressure riseSystem pressure

A pilot operated pressure valve which limits the rate of pressure rise and substantially eliminates excessive system and tank pressure spikes. Because the pilot ball downstream of the damping orifice is held off the pilot seat in the normal starting condition by a pilot return spring, the main piston will open immediately when system pressure overcomes the low bias pressure of the main spring. A pilot pressure bypass port, which selectively deactivates the pilot chamber features, may also be included.

Owner:SUN HYDRAULICS LLC

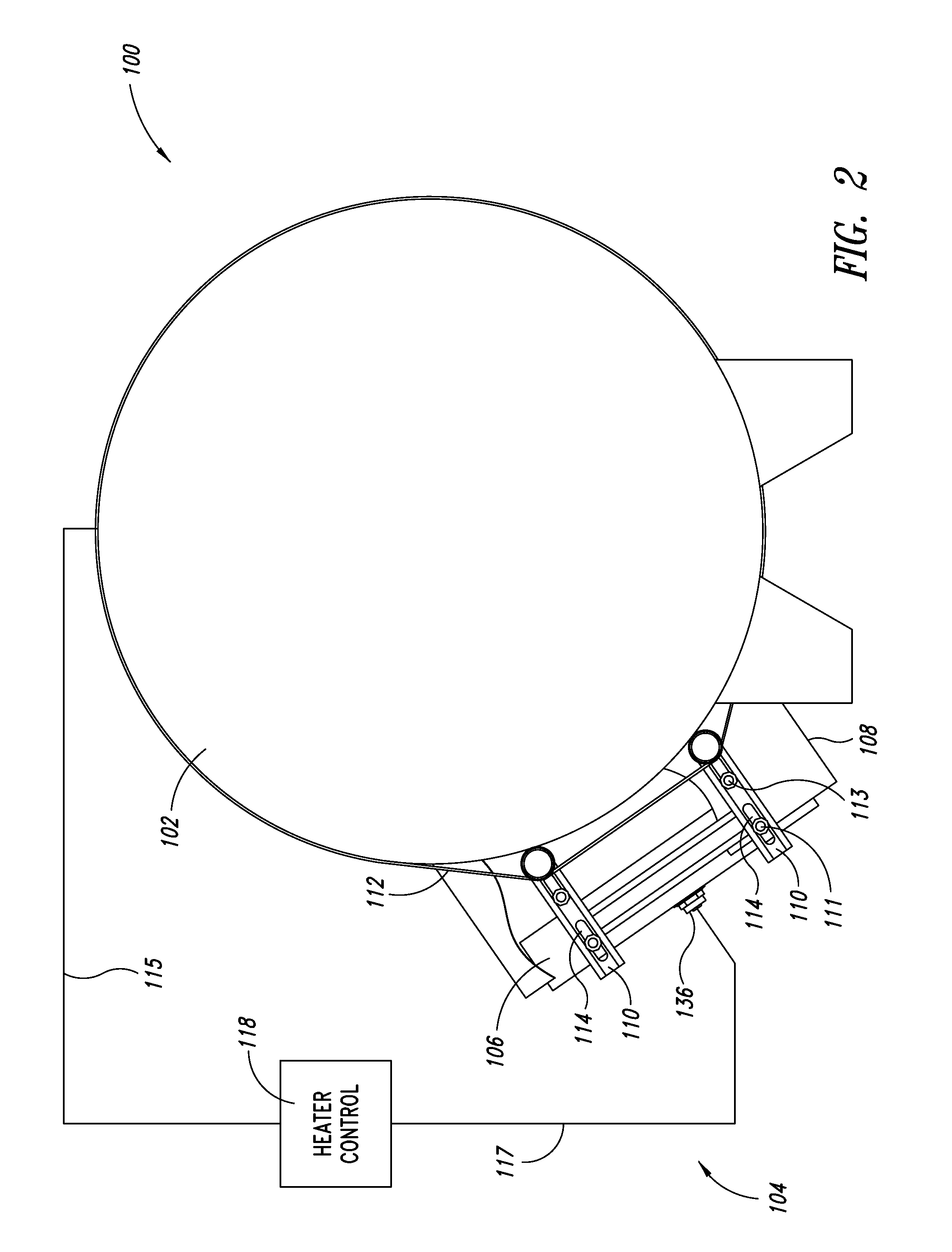

Heater for liquefied petroleum gas storage tank

ActiveUS20110311928A1Quick upgradeDomestic stoves or rangesContainer filling methodsFuel tankEngineering

A catalytic tank heater includes a catalytic heating element supported on an LPG tank by a support structure that holds the element in a position facing the tank. Vapor from the tank is provided as fuel to the heating element, and is regulated to increase heat output as tank pressure drops. The heating element is internally separated into a pilot heater and a main heater, with respective separate fuel inlets. The pilot heater remains in continual operation, but the main heater is operated only while tank pressure is below a threshold. Operation of the pilot heater keeps a portion of the catalyst hot, so that, when tank pressure drops below the threshold, and fuel is supplied to the main heater, catalytic combustion quickly expands from the area surrounding the pilot heater to the remainder of the catalyst.

Owner:ALGAS SDI INT

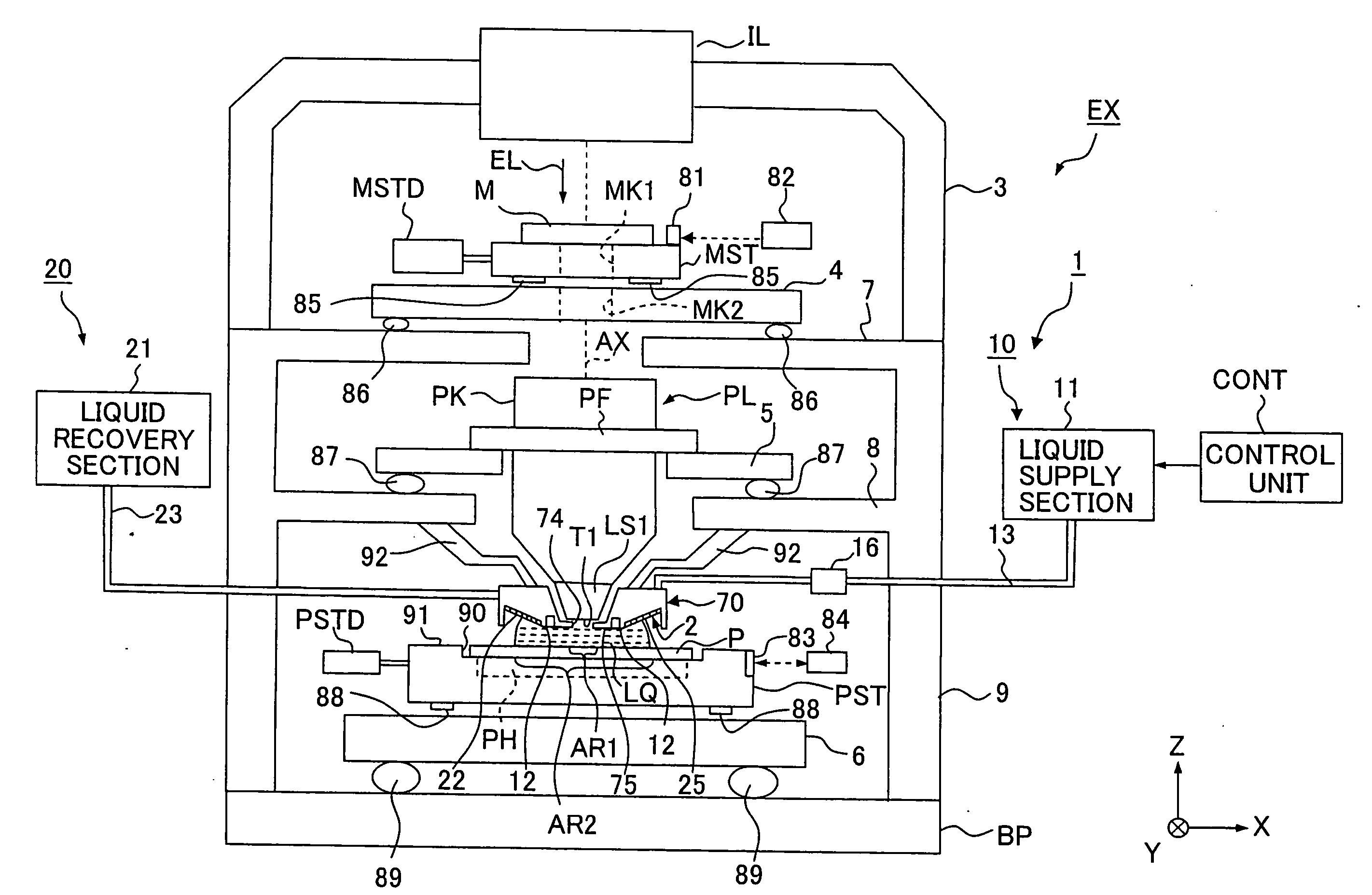

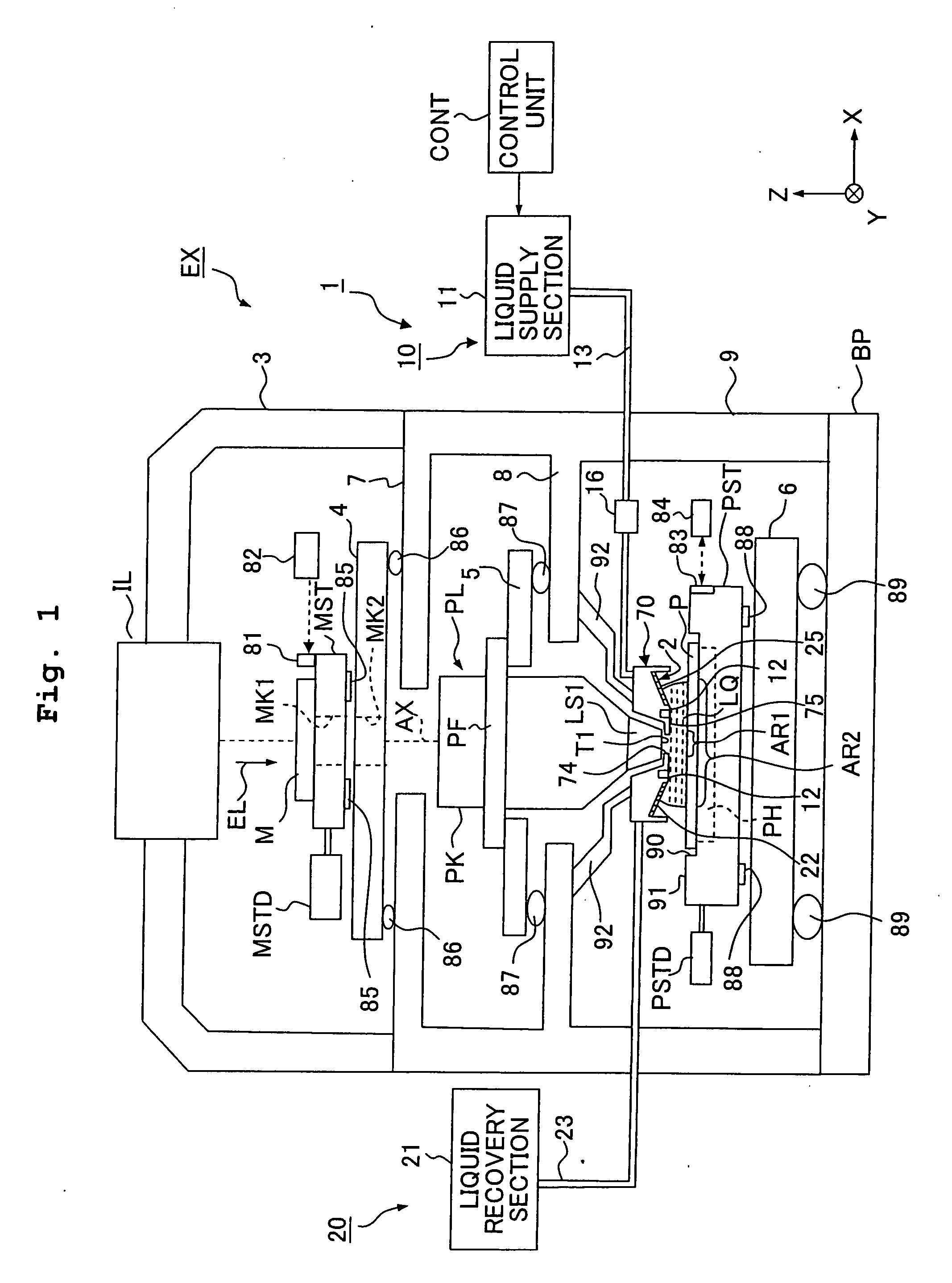

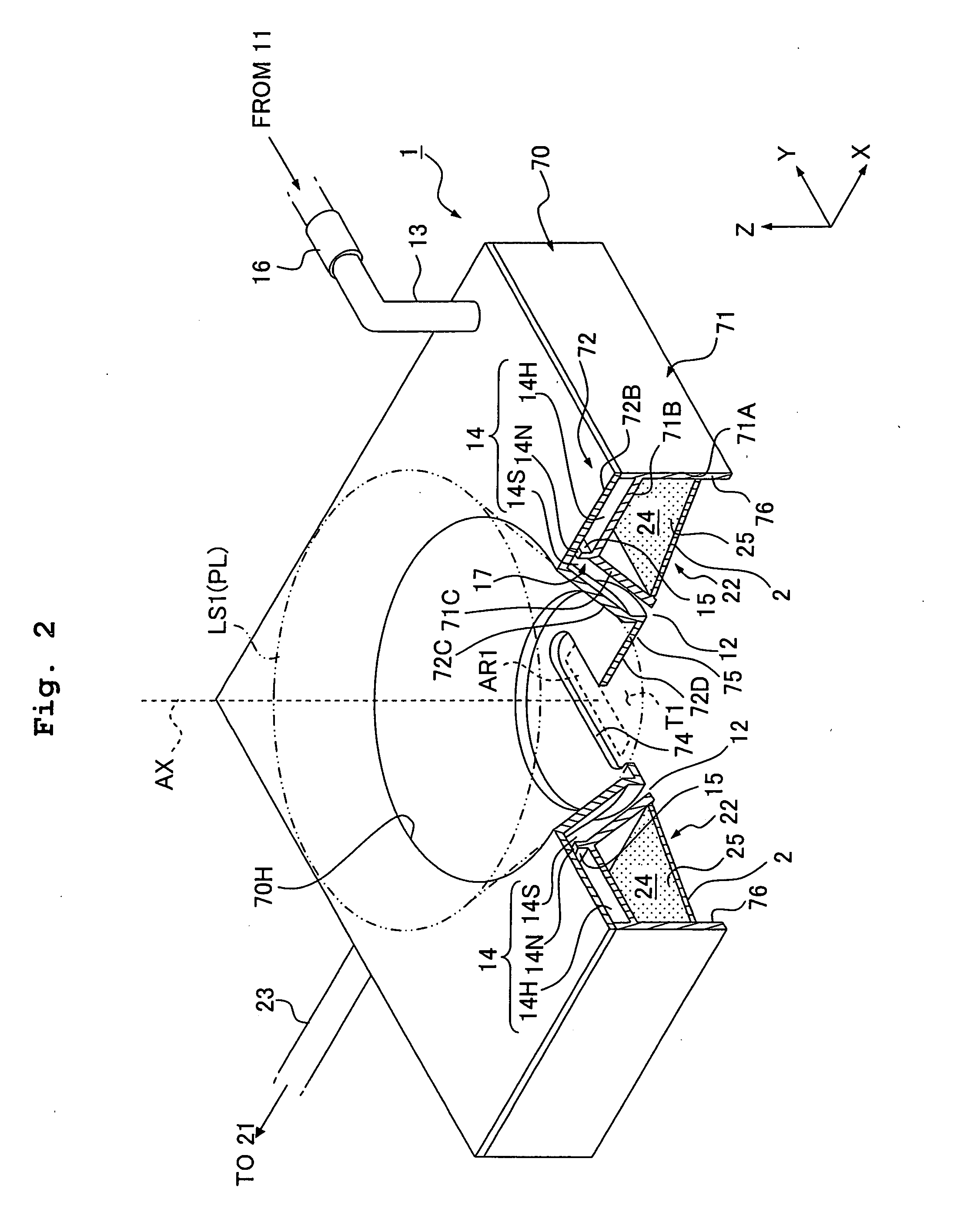

Exposure apparatus, exposure method, and method for producing device

InactiveUS20070195301A1Suppressing amount of movementSuppress large change of shapePhotomechanical apparatusPhotographic printingGas passingEngineering

A lithographic apparatus includes a substrate table to hold a substrate and a projection system to project a patterned radiation beam onto a target portion of the substrate. A liquid supply system at least partly fills a space between the projection system and the substrate with a liquid, and has a liquid confinement structure to at least partly confine the liquid within the space. An outlet removes a mixture of liquid and gas passing through a gap between the liquid confinement structure and the substrate. An evacuation system draws the mixture through the outlet, and includes a separator tank to separate liquid from gas in the mixture and a separator tank pressure controller, connected to a non-liquid-filled region of the separator tank, to maintain a stable pressure within the non-liquid-filled region.

Owner:NIKON CORP +1

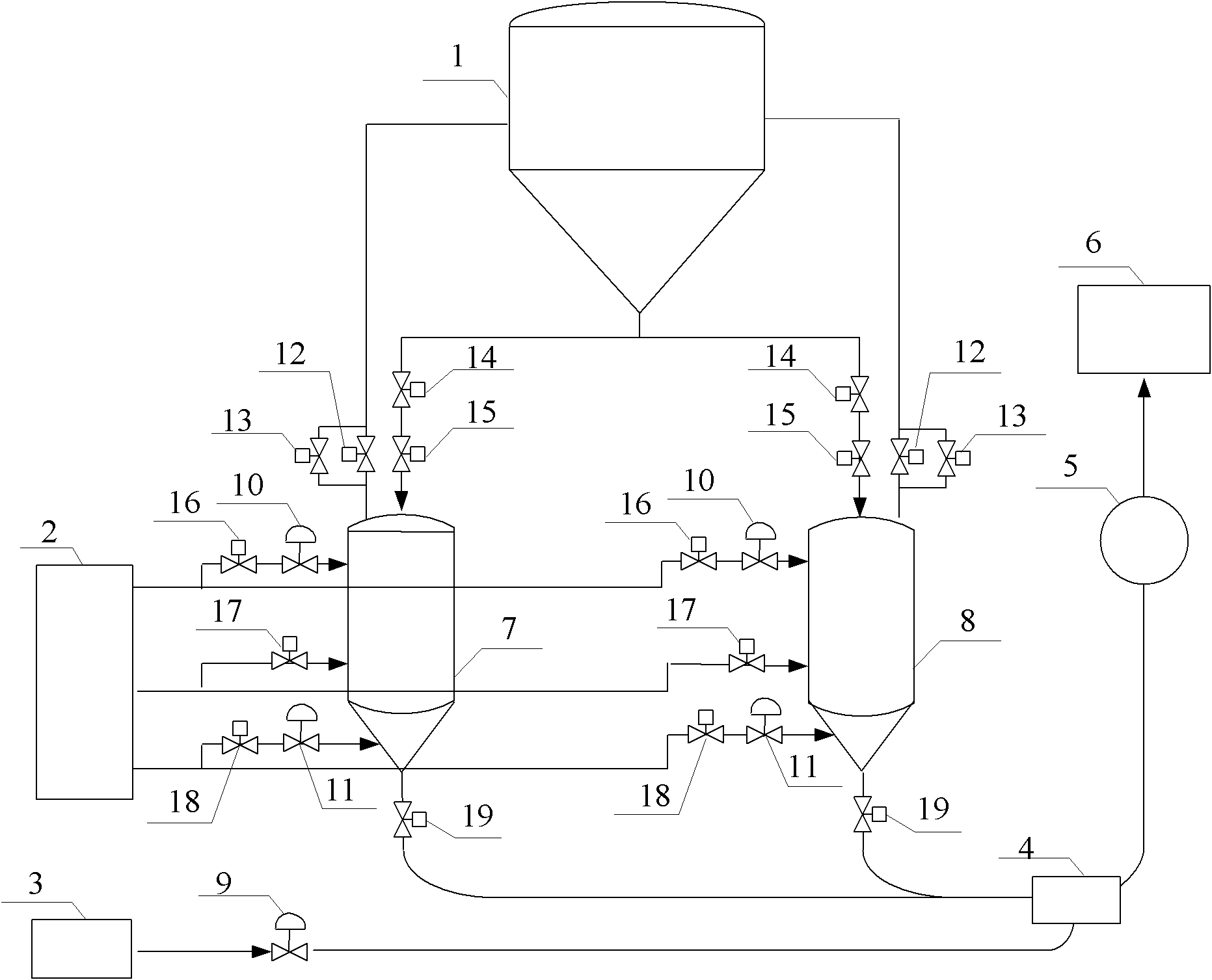

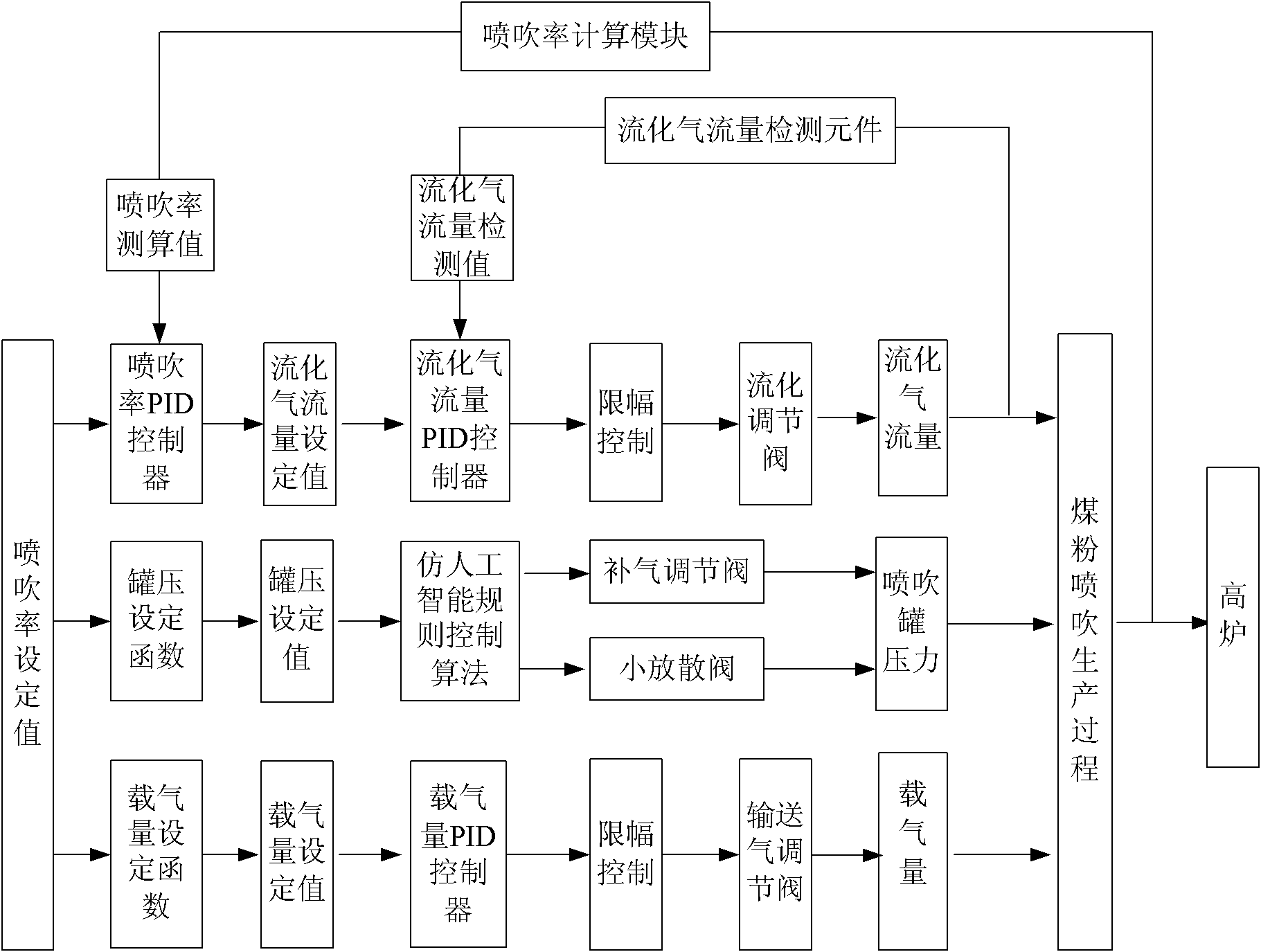

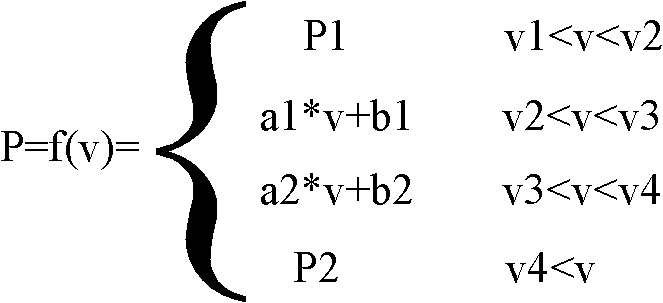

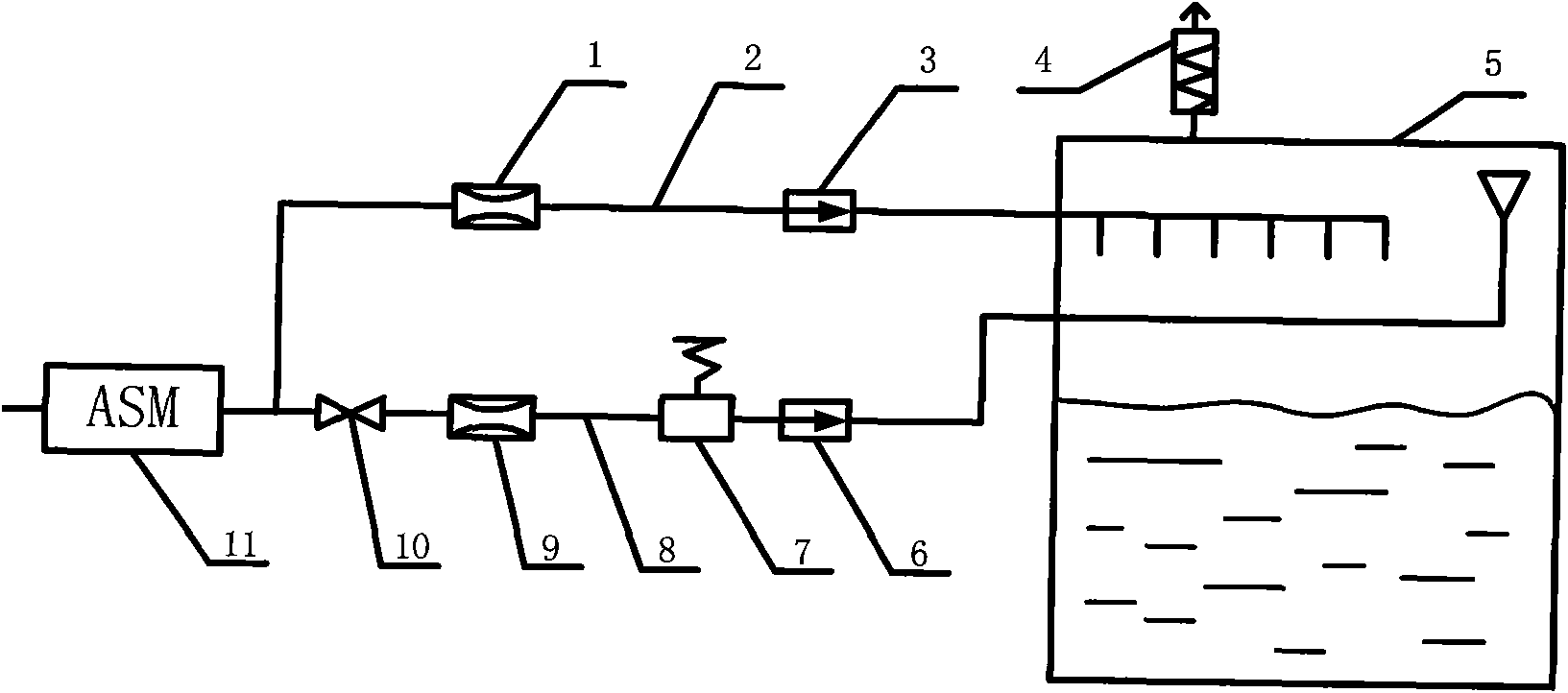

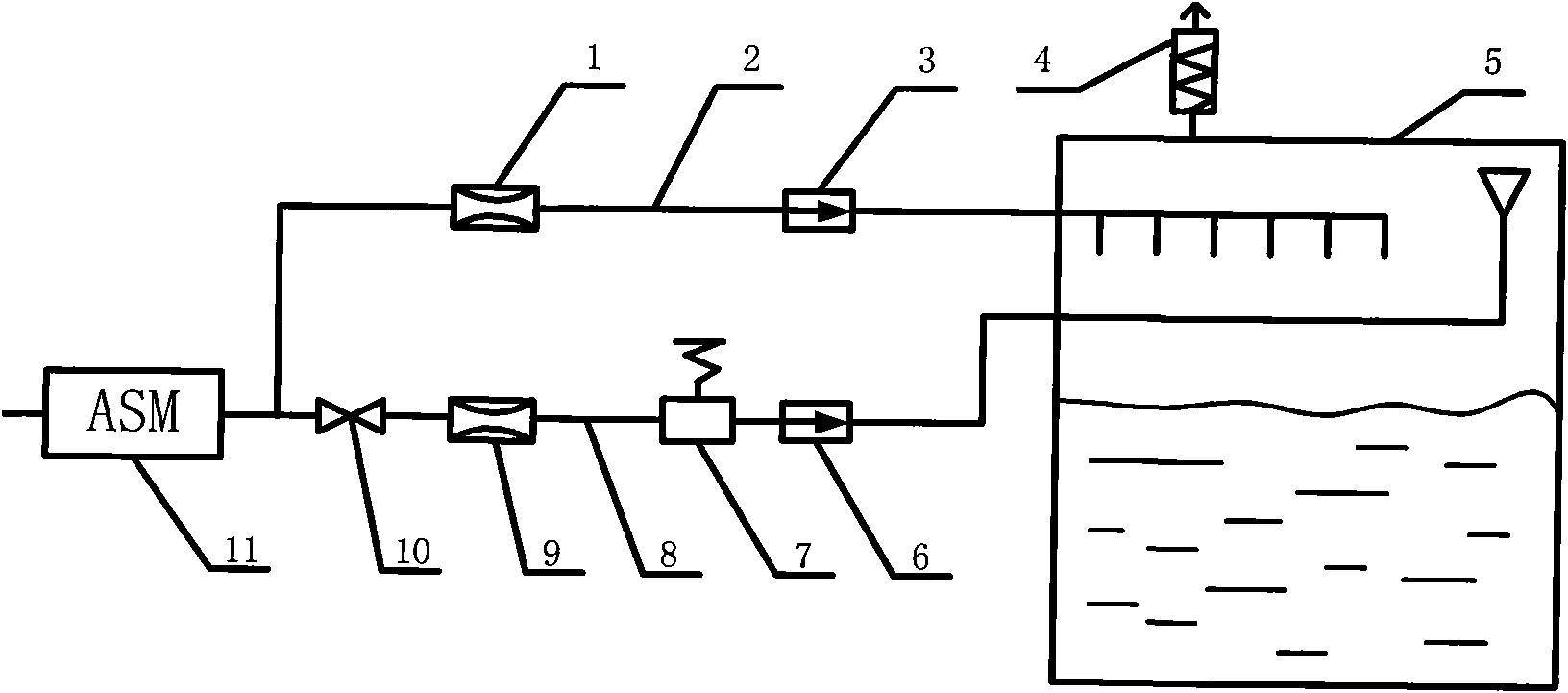

Coal injection system of blast furnace

InactiveCN101899542AAvoid interferenceFast and stable adjustmentBlast furnace componentsBlast furnace detailsEngineeringNitrogen pressure

The invention relates to a coal injection system of a blast furnace, which comprises a plurality of injection tanks, wherein the upper parts of the injection tanks are connected with a coal powder bin (1) through pipelines, charging dump valves (14) and blanking dump valves (15) for injection of materials in the tanks, and are respectively connected with the coal powder bin through pipelines, small bleeding dump valves (12) and large bleeding dump valves (13) for bleeding of the injection tanks at the same time; the middle parts of the injection tanks are respectively connected with a nitrogen pressure regulating station (2) through three connecting pipelines and valves in three ways, wherein one way is used for pressure complement of the injection tanks, one way is used for pressure recharging of the injection tanks, and the last way is used for fluidizing the coal powder in the injection tanks; and the lower parts of the injection tanks are respectively connected with a mixer (4) through pipelines and coal injection dump valves (19), and the mixer is connected with a dispenser (5) and each blast hole of a blast furnace (6) through pipelines. The invention can effectively prevent interference of furnace pressure fluctuation on the injection rate, prevent lagging and large fluctuation in the process of tank pressure regulation and ensure the fast, stable and uniform regulation of tank pressure.

Owner:WISDRI ENG & RES INC LTD

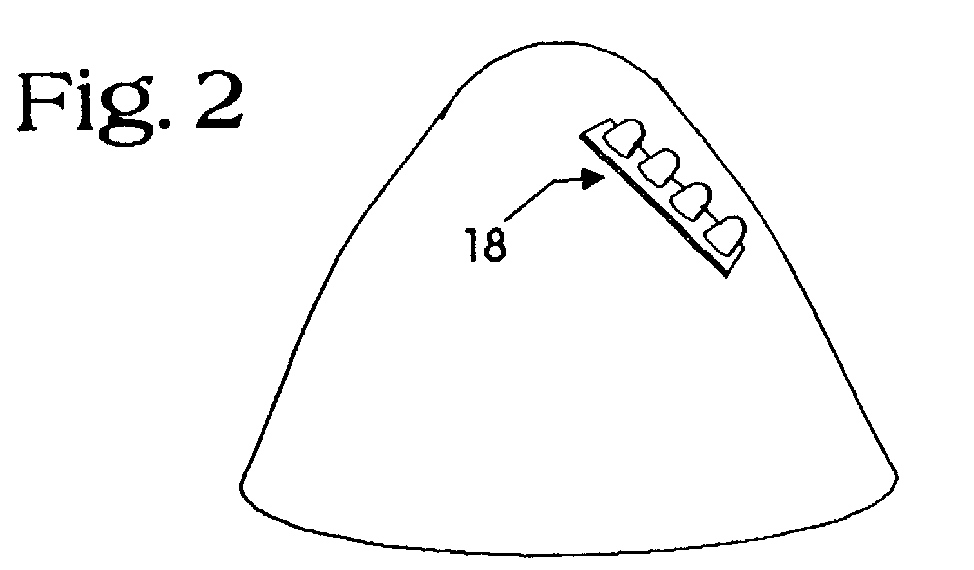

Pressure display for self contained breathing apparatus

A self contained breathing apparatus has a display of air pressure within the face mask in the field of vision of the user of the breathing apparatus. The display is four lights that indicate the four quarter-tanks of pressure, and the lights change to indicate the amount of air remaining. A transducer receives tank pressure and provides an electric signal. The air pressure is placed on a bourdon tube which rotates a disk in response to changes in pressure. One half of the disk includes a gradient, and a light source emits light through the gradient to be received by a light sensor. As the disk rotates, the gradient varies the amount of light received by the sensor, so the electrical output of the sensor varies.

Owner:AVON PROTECTION SYST

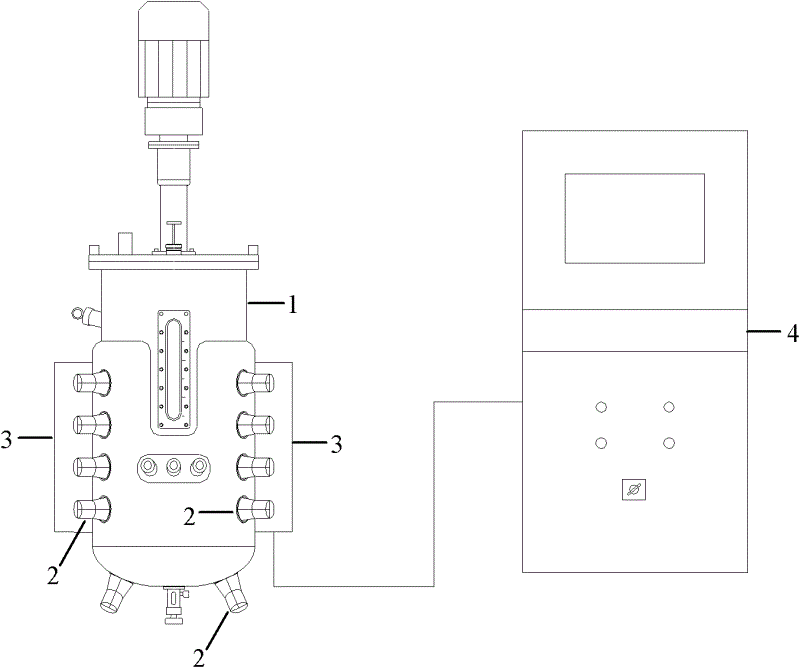

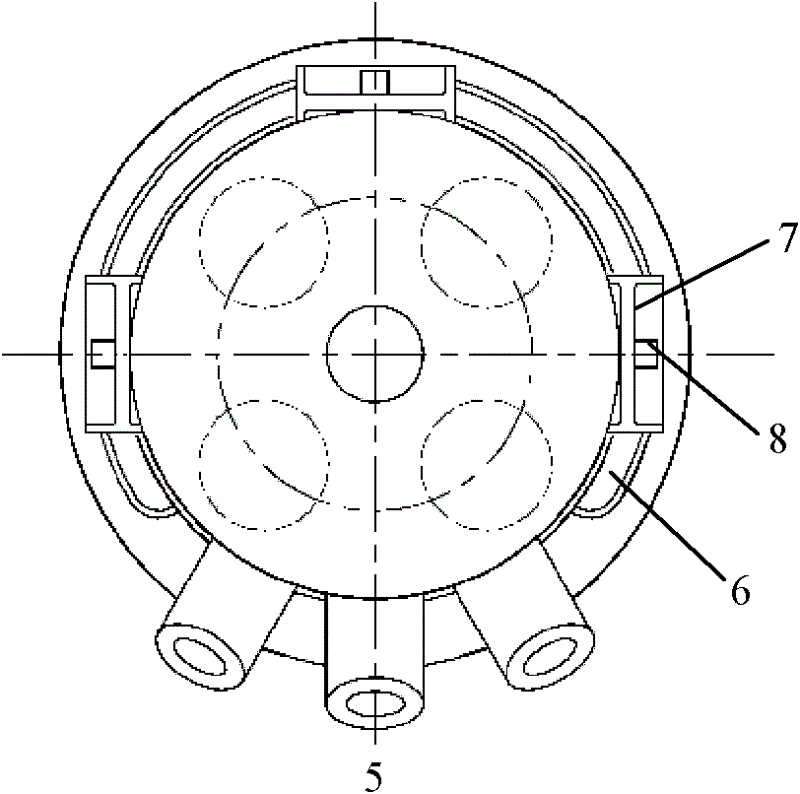

Ultrasound-enhanced bioreactor

ActiveCN102618440AOptimal growth and metabolismPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsOxygenData recording

The invention relates to an ultrasound-enhanced bioreactor, comprising a liquid state fermentation tank, an ultrasonic transducer, an ultrasonic generator and an ultrasonic fermentation control system, wherein the ultrasonic transducer is fixed on the side wall of the liquid state fermentation tank by bonding, the radiating surface of the ultrasonic transducer is fixed on the planar structure of the tank body of the liquid state fermentation tank by bonding. The ultrasonic fermentation control system comprises a biological fermentation process control unit and an ultrasonic control unit, wherein the biological fermentation process control unit is used for controlling the pH value, dissolved oxygen, temperature, rotating speed, air flow, tank pressure and supplementary material, and carrying out real-time monitoring on the whole fermentation process and conducting data recording and analysis; and the ultrasonic control unit is used for controlling the start of the ultrasonic transducer, the selection of ultrasonic frequencies, the selection of ultrasonic power and ultrasonic generation time in order to achieve optimum ultrasound-enhanced microbes and effects of growth metabolism of plant tissue cultures.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Checking Functionality of Fuel Tank Vapor Pressure Sensor

InactiveUS20110197862A1Reliable checkEmission reductionNon-fuel substance addition to fuelMachines/enginesAtmospheric airFuel tank

A vehicle fuel emissions system includes a fuel tank, a tank pressure sensor indicating a pressure differential between the tank and a port communicating with the atmosphere, a pump for selectively producing vacuum in the tank, and a passage connecting the pump and a pressure sensor air reference port external to the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

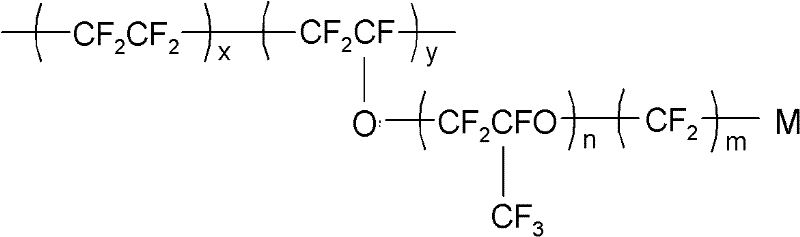

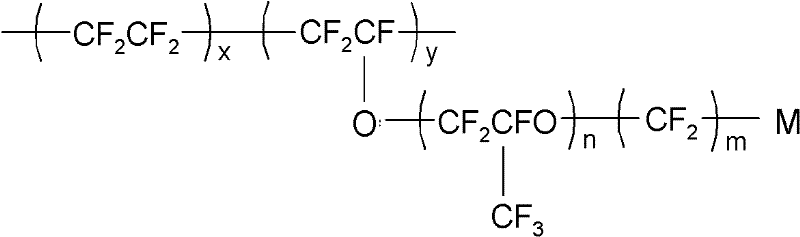

Ion exchange membrane with high current efficiency, and preparation method and application thereof

ActiveCN102336043AHigh mechanical strengthImprove current efficiencyCellsSynthetic resin layered productsCarboxylic acidIon-exchange resin

The invention relates to an ion exchange membrane with high current efficiency, and a preparation method thereof, and application of the ion exchange membrane to preparation of caustic soda in a chlor-alkali tank, and belongs to a compound membrane for producing alkali metal hydroxides and chlorine simultaneously in an ion membrane electrolytic tank. The ion exchange membrane with high current efficiency is characterized by being formed by compounding three layers of perfluorinated ion exchange resin base membranes and a reinforcing material; the three layers of perfluorinated ion exchange resin base membranes are sequentially a high-exchange-capacity sulfonic acid layer, a low-exchange-capacity sulfonic acid layer and a high-exchange-capacity carboxylic acid layer; and the reinforcing material is compounded on one side near the high-exchange-capacity sulfonic acid layer. The invention provides the ion exchange membrane which is high in current efficiency, mechanical strength and chemical stability, suitable for high and low alkali liquor concentration, and low in cost; the preparation method is simple; and in an electrolytic process, the electrolytic tank always keeps high current efficiency and low tank pressure; and products hydroxides have few impurities and are high in purity.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

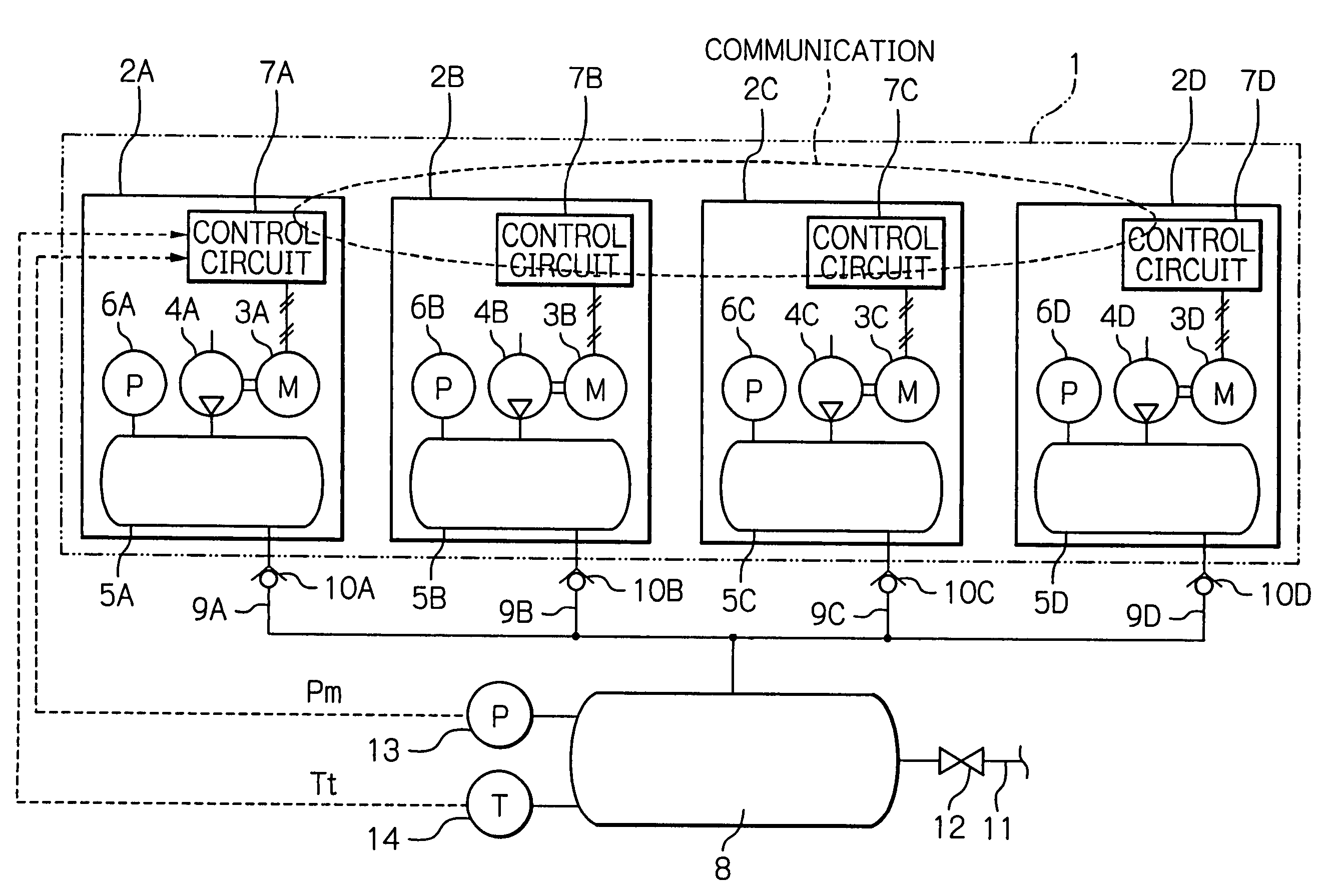

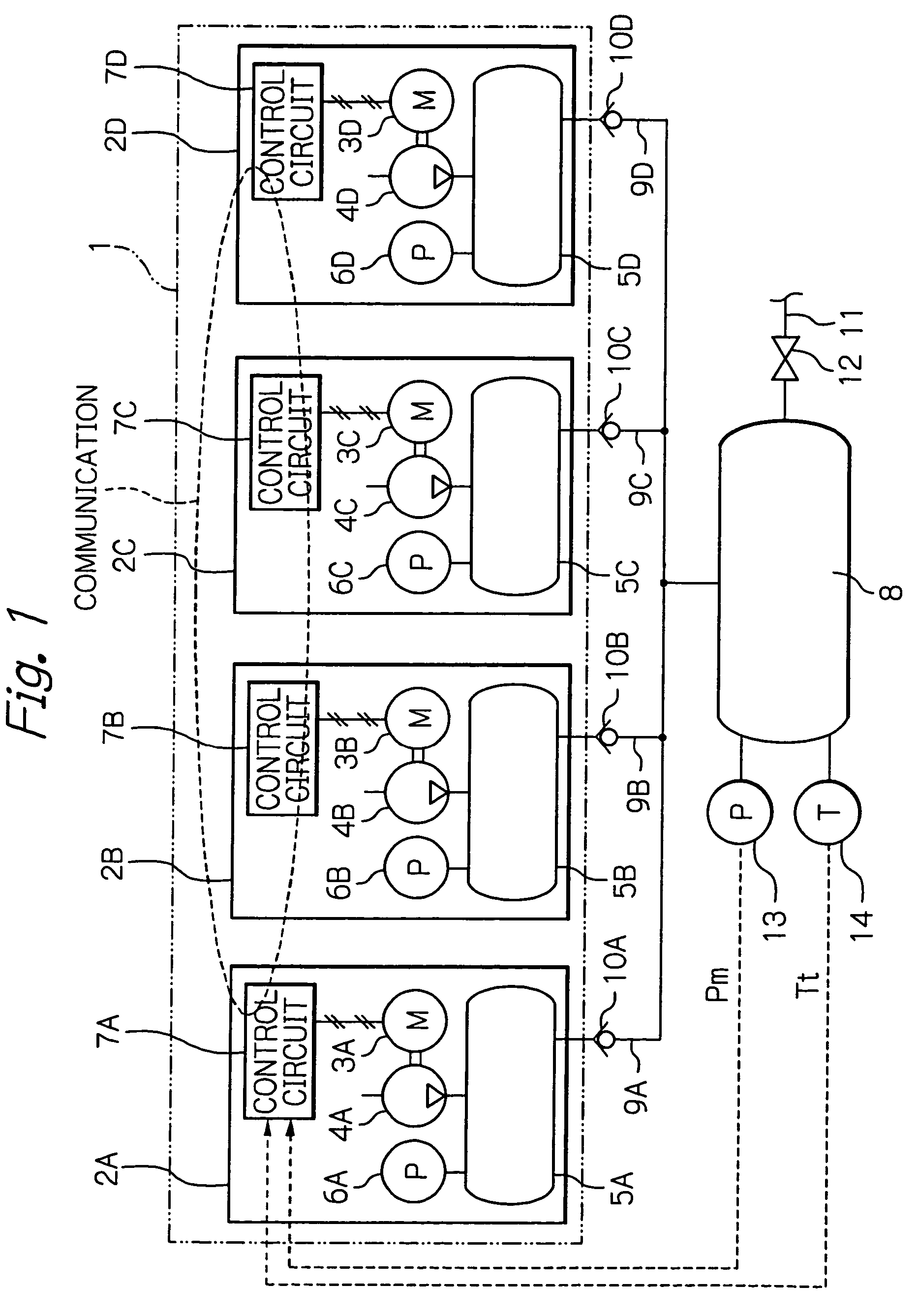

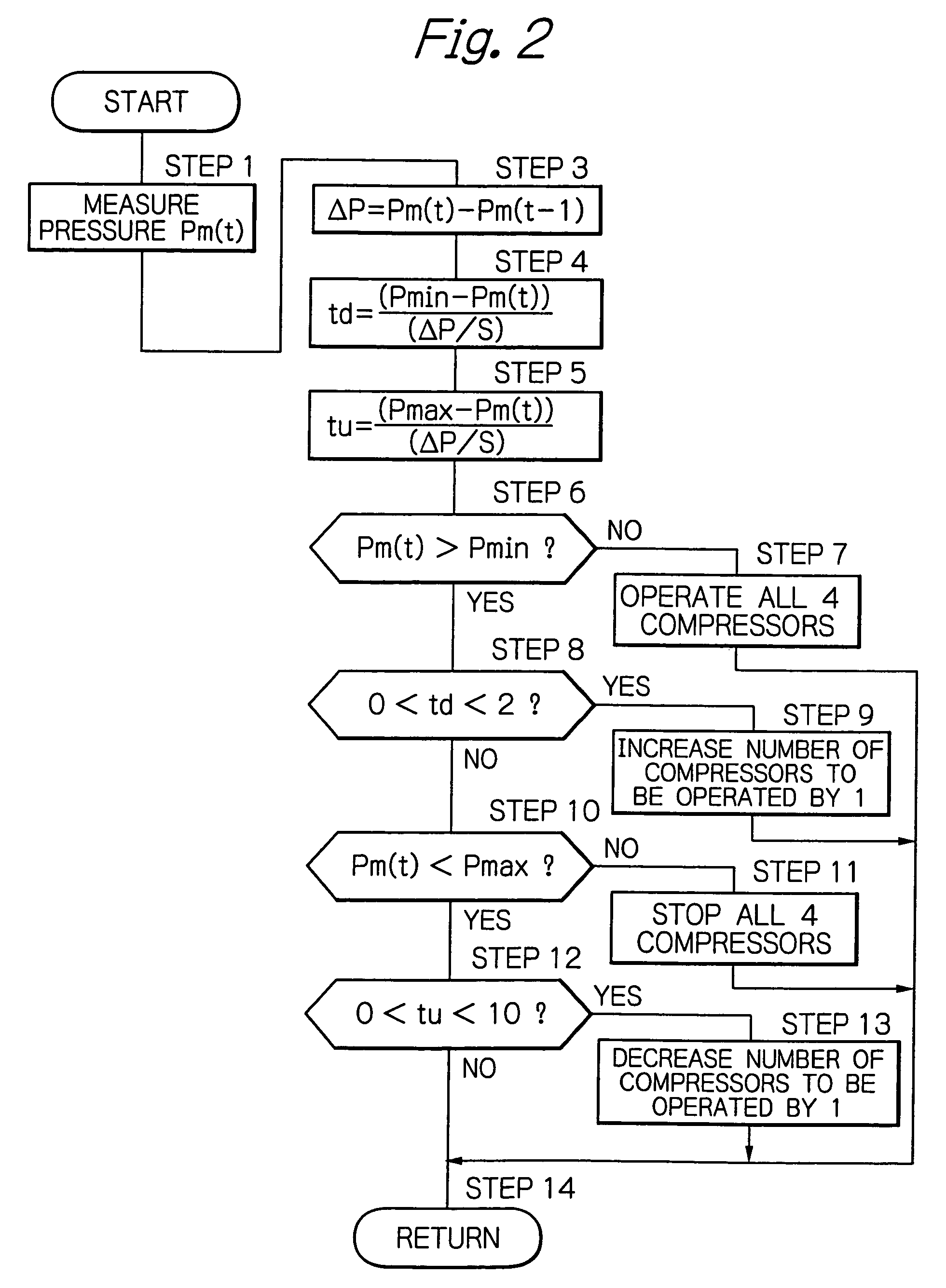

Control system for air-compressing apparatus

ActiveUS7722331B2Reduce power consumptionIncrease pressureFluid parameterPump controlControl systemEngineering

An air-compressing apparatus has four compressors individually supplying compressed air to a tank having a pressure sensor. The pressure sensor is connected to control circuits of the compressors. The control circuits compute times needed for the tank pressure to reach minimum and maximum pressures, respectively, of the tank by using the detected tank pressure and also using a tank pressure change value. The computed time values correspond to the consumption of compressed air. Thus, the control circuits can control the number of compressors to be operated according to the consumption of compressed air.

Owner:HITACHI LTD

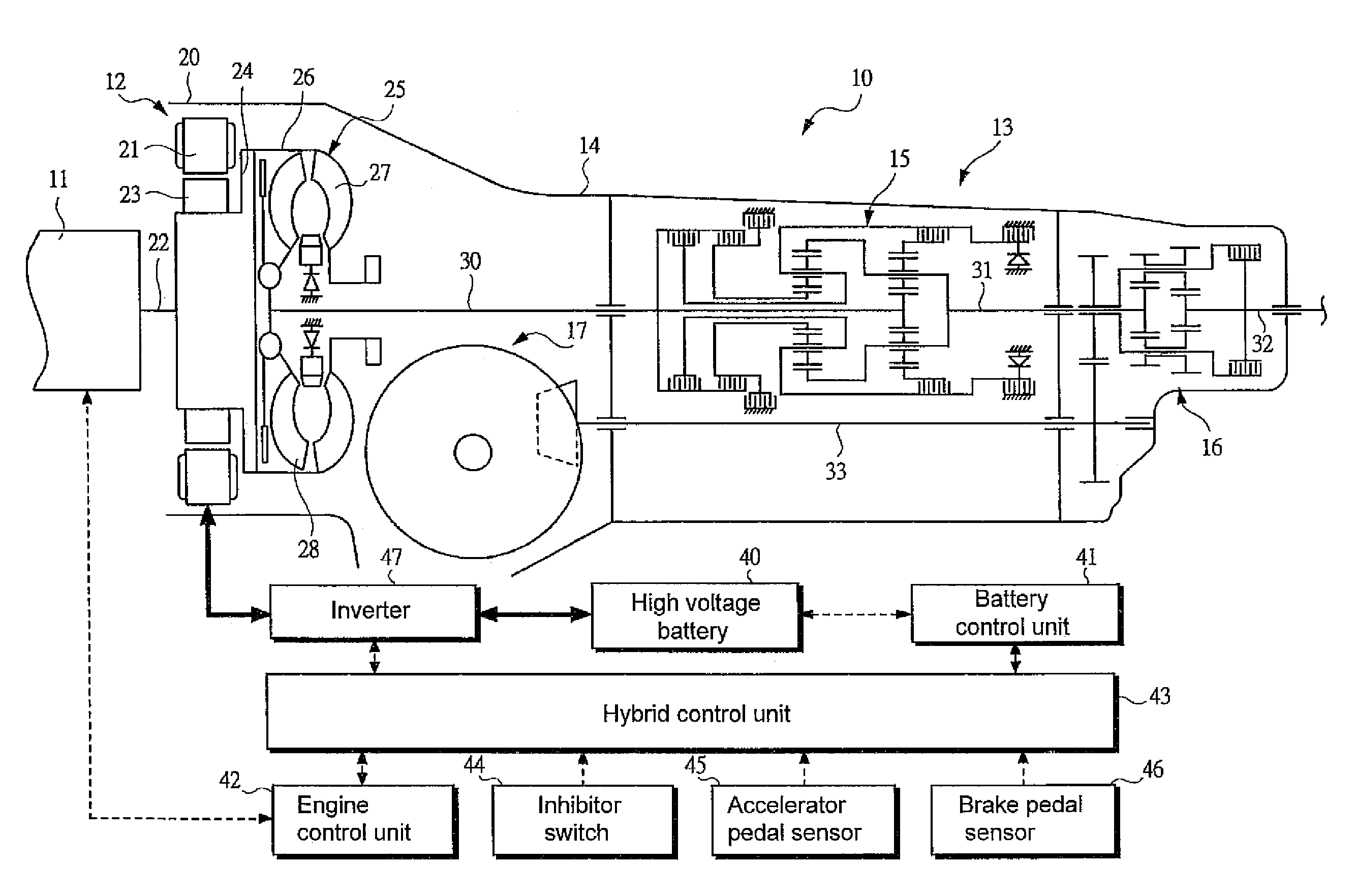

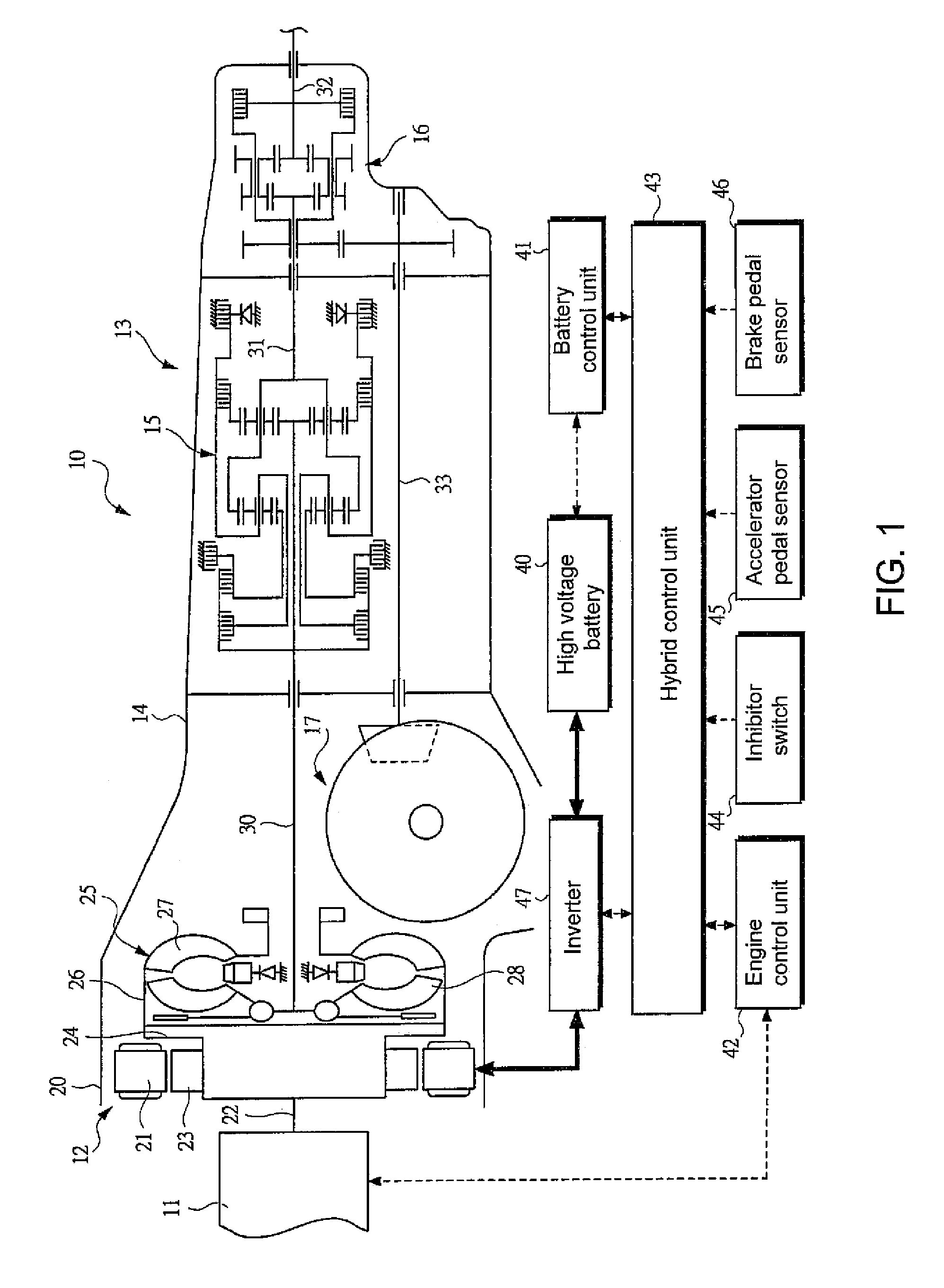

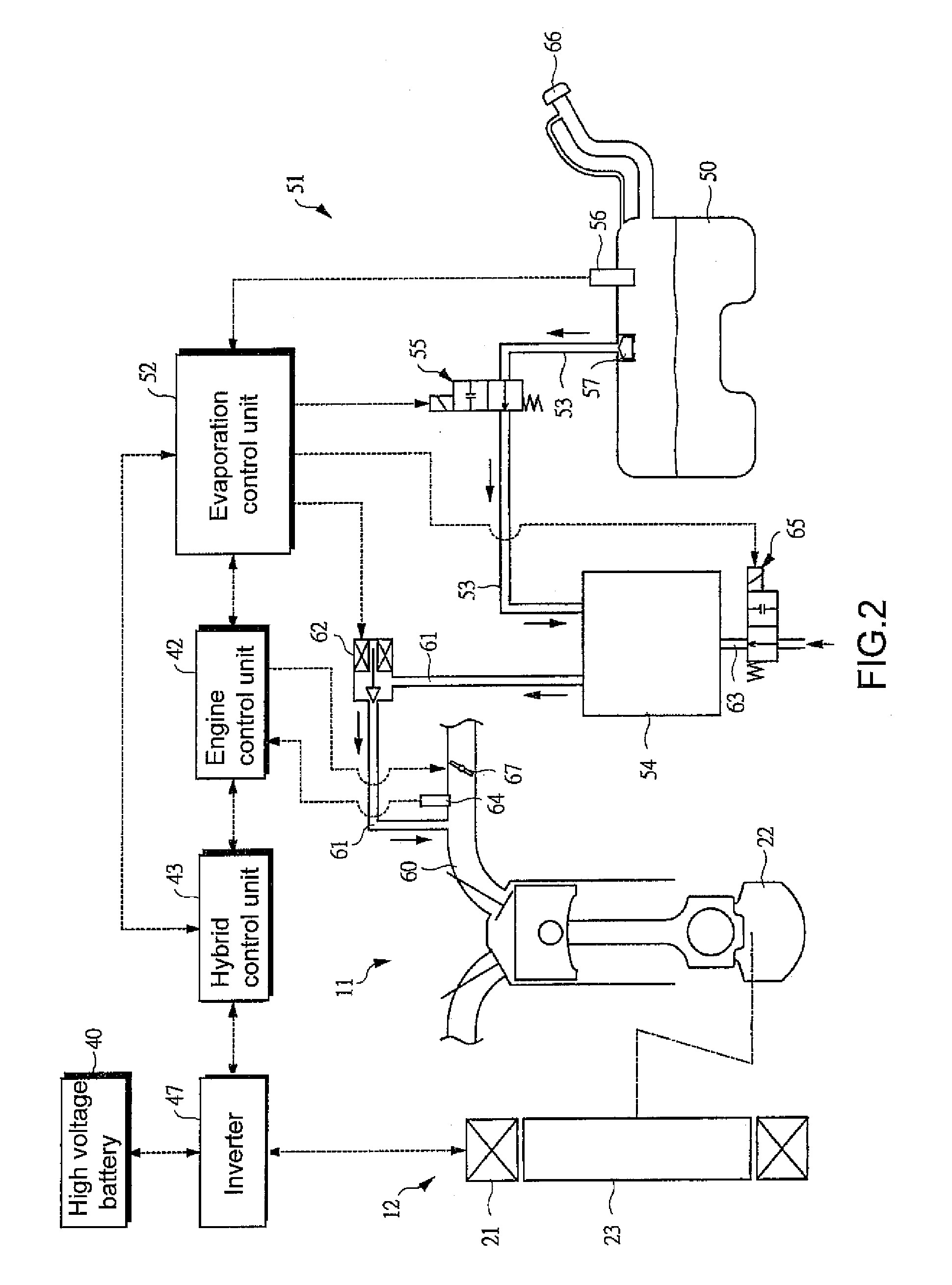

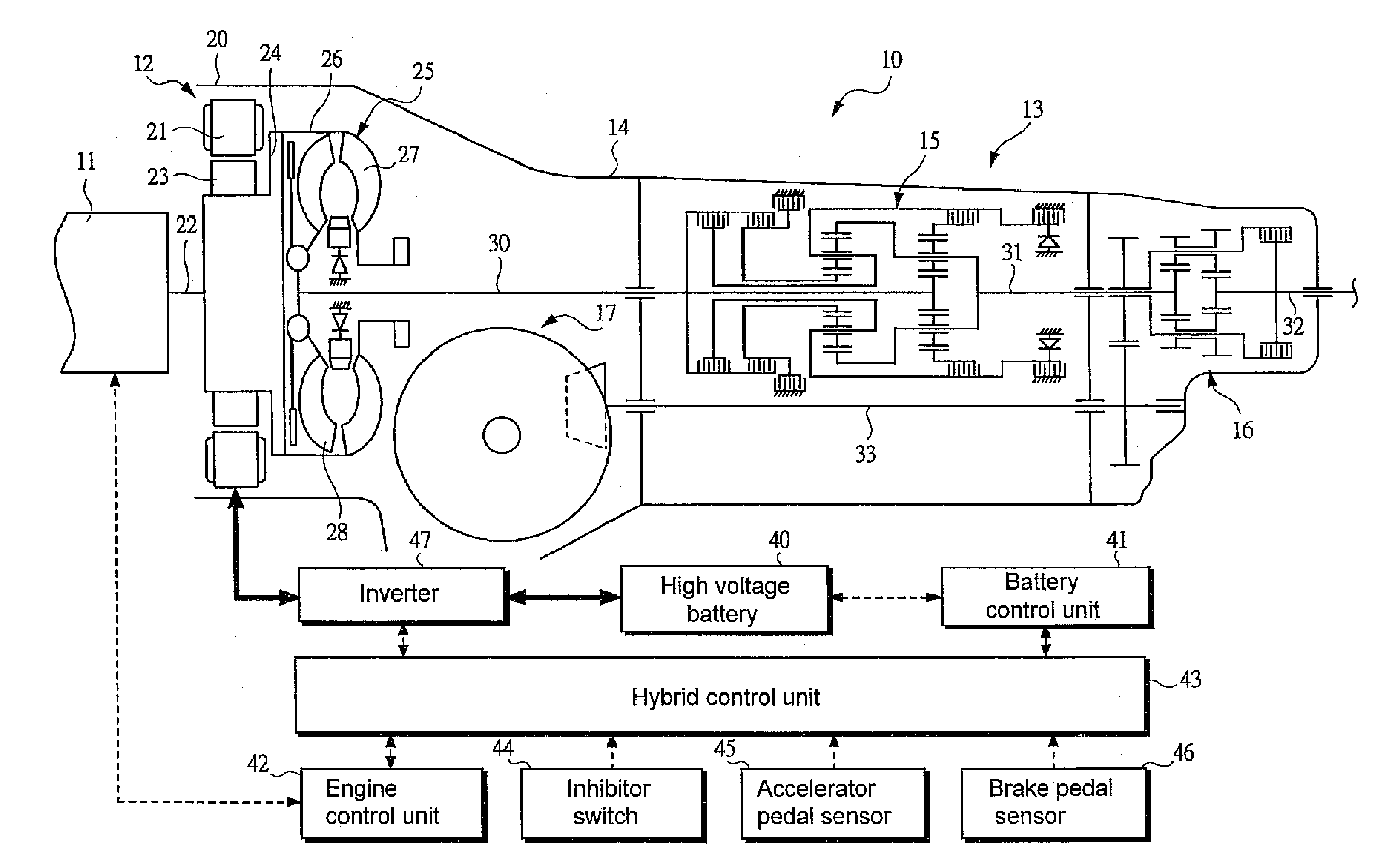

Diagnostic control device for a hybrid vehicle

InactiveUS20070267232A1Reduce troubleshooting timeShorten diagnostic timeVehicle testingRegistering/indicating working of vehiclesEvaporationHybrid vehicle

A diagnostic control device for a hybrid vehicle is provided for shortening the time required for a failure diagnosis of an evaporation purge system. After introducing the inlet-pipe's negative pressure into the evaporation purge system 51, the evaporation control unit 52 diagnoses failure states concerning the evaporation purge system 51 such as a leak by detecting changes in inner tank pressure over a prescribed time. In order to shorten such failure diagnosis control time, a motor generator 12 is driven to assist the engine when introducing the inlet-pipe's negative pressure into the evaporation purge system 51. With such assist-driving, it becomes possible to reduce engine load, therefore, the throttle valve 67 of the engine 11 can be controlled to be on the closed side, making it possible to create sufficient inlet-pipe's negative pressure. Through this, the pressure in the evaporation purge system 51 can be decreased quickly, which shortens the time for failure diagnosis in the evaporation purge system 51.

Owner:SUBARU CORP

Fermentation preparation method for edible fungus probiotics health-care drink

ActiveCN103932344AGood health valueHigh nutritional valueFood thermal treatmentLactobacillusBiotechnologyFruit juice

The invention provides a fermentation preparation method for an edible fungus probiotics health-care drink. The method comprises the following steps: adding proper amounts of sugar, albumen powder, inorganic salt, gelatinized corn steep liquor, fruit juice and water to obtain a mixture, wherein edible fungus mycelium homogenate or fruiting body powder is used as a raw material, filing a fermentation tank with the mixture, performing steam sterilization, cooling, and fermenting according to the following stages: (1) introducing sterile air into the fermentation liquor, wherein the tank pressure is 0.04-0.08MPa, inoculating a bacillus subtilis seed solution, wherein the compression-ventilation ratio is 0.5-1.0, the temperature is 26-30 DEG C, the stirring rotating speed is 150-220r / min, and fermenting for 24-36 hours; (2) raising the temperature to 34-40 DEG C, wherein the stirring rotating speed is 180-260r / min, and ventilating and fermenting for 8-16 hours; (3) stopping ventilating, closing all connected valves on the fermentation tank, raising the temperature to 46-50 DEG C, wherein the stirring rotating speed is 200-250r / min, and fermenting for 5-10 hours; and (4) inoculating a lactic acid bacteria seed solution, wherein the temperature is 40-44 DEG C, the stirring rotating speed is 150-200r / min, fermenting for 4-6 hours, reducing the temperature to 30-35 DEG C, inoculating a bifidobacterium seed solution, wherein the stirring rotating speed is 100-180r / min, and fermenting for 6-10 hours, so as to obtain a viable type health-care drink containing bacillus subtilis and lactic acid bacteria after the fermentation is ended.

Owner:湖北九公堂生物科技有限公司

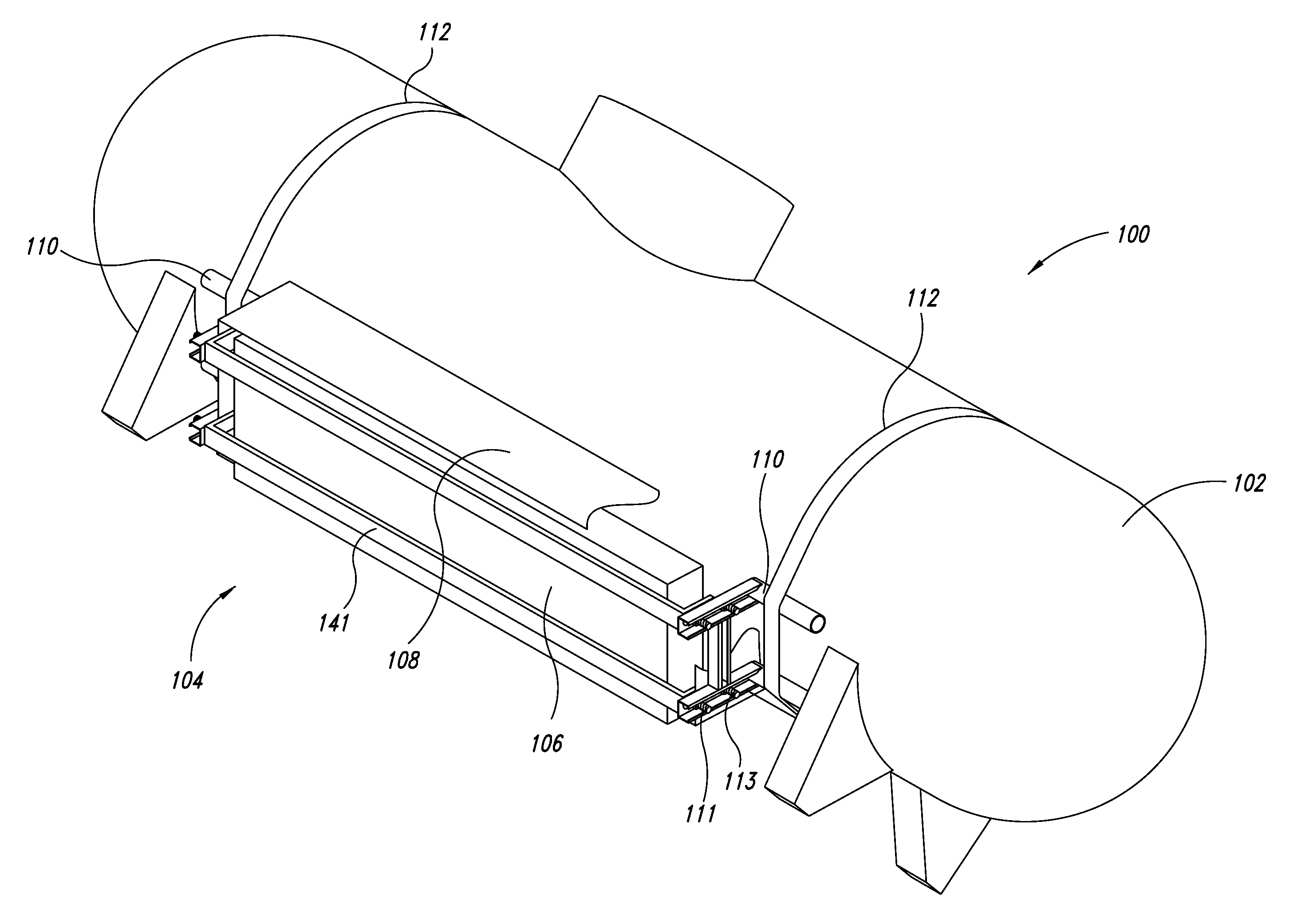

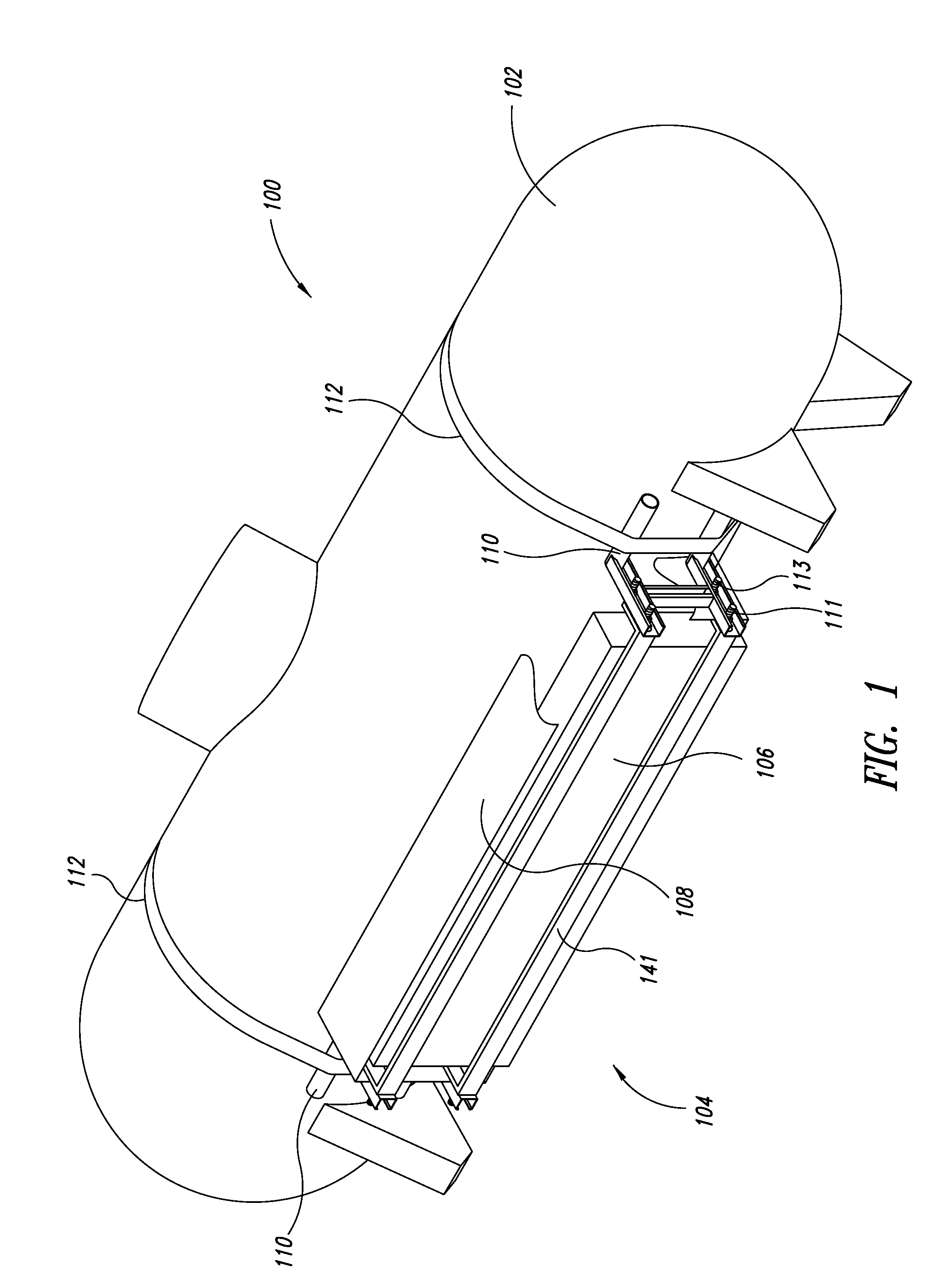

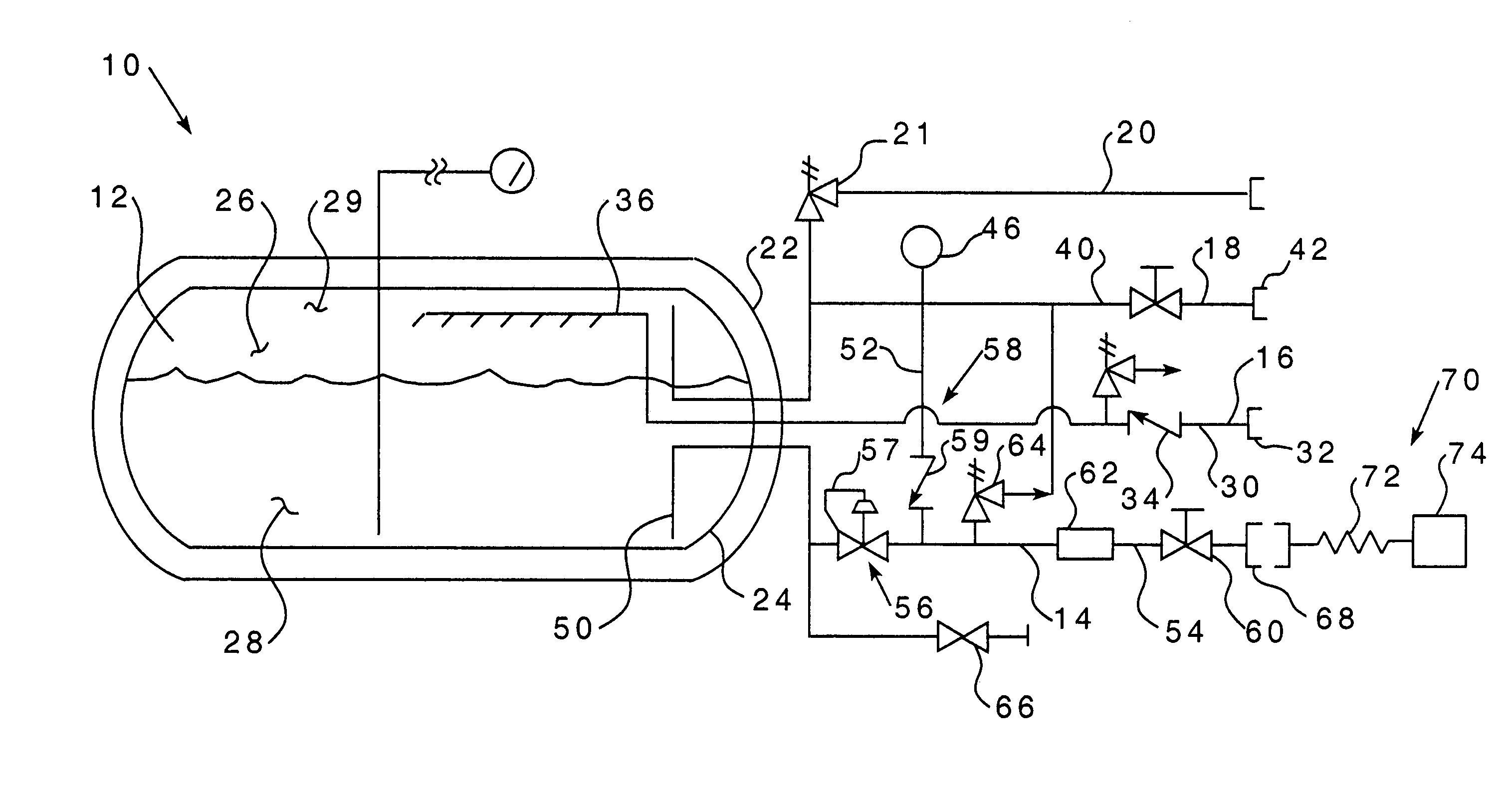

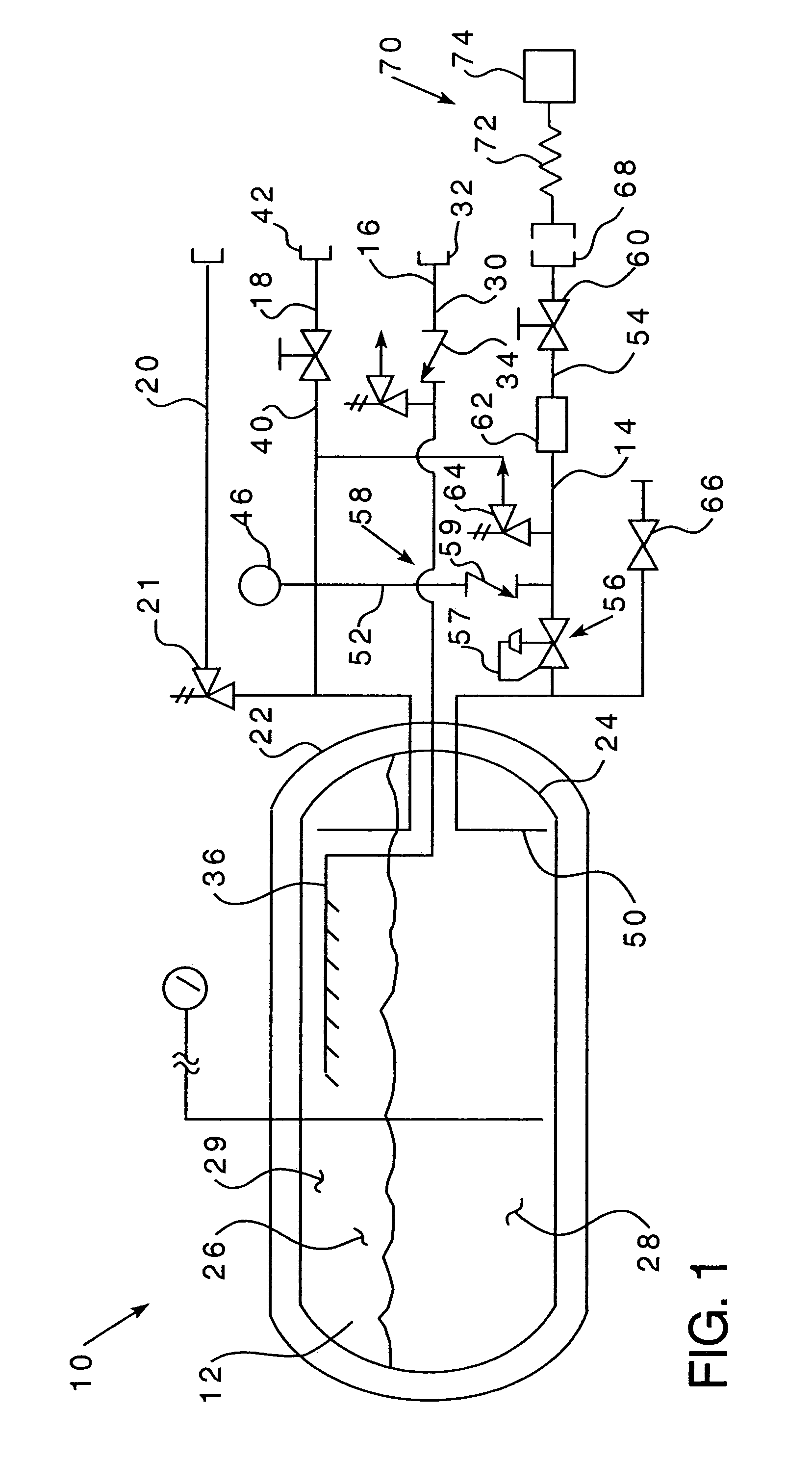

Pressure management system for liquefied natural gas vehicle fuel tanks

A storage and delivery device for a cryogenic liquid that includes a vessel assembly and a delivery line assembly. The vessel assembly has a liquid space and a vapor space. The delivery line assembly has a liquid line, a vapor line, and a delivery line. The liquid line is in fluid communication with the liquid space. The vapor line is in fluid communication with the vapor space. The liquid line has a flow control device located thereon and structured to control the flow of fluid through the liquid line. The liquid line flow control device is structured to close the liquid line when the vessel assembly is at a predetermined pressure.

Owner:TW CRYOGENICS

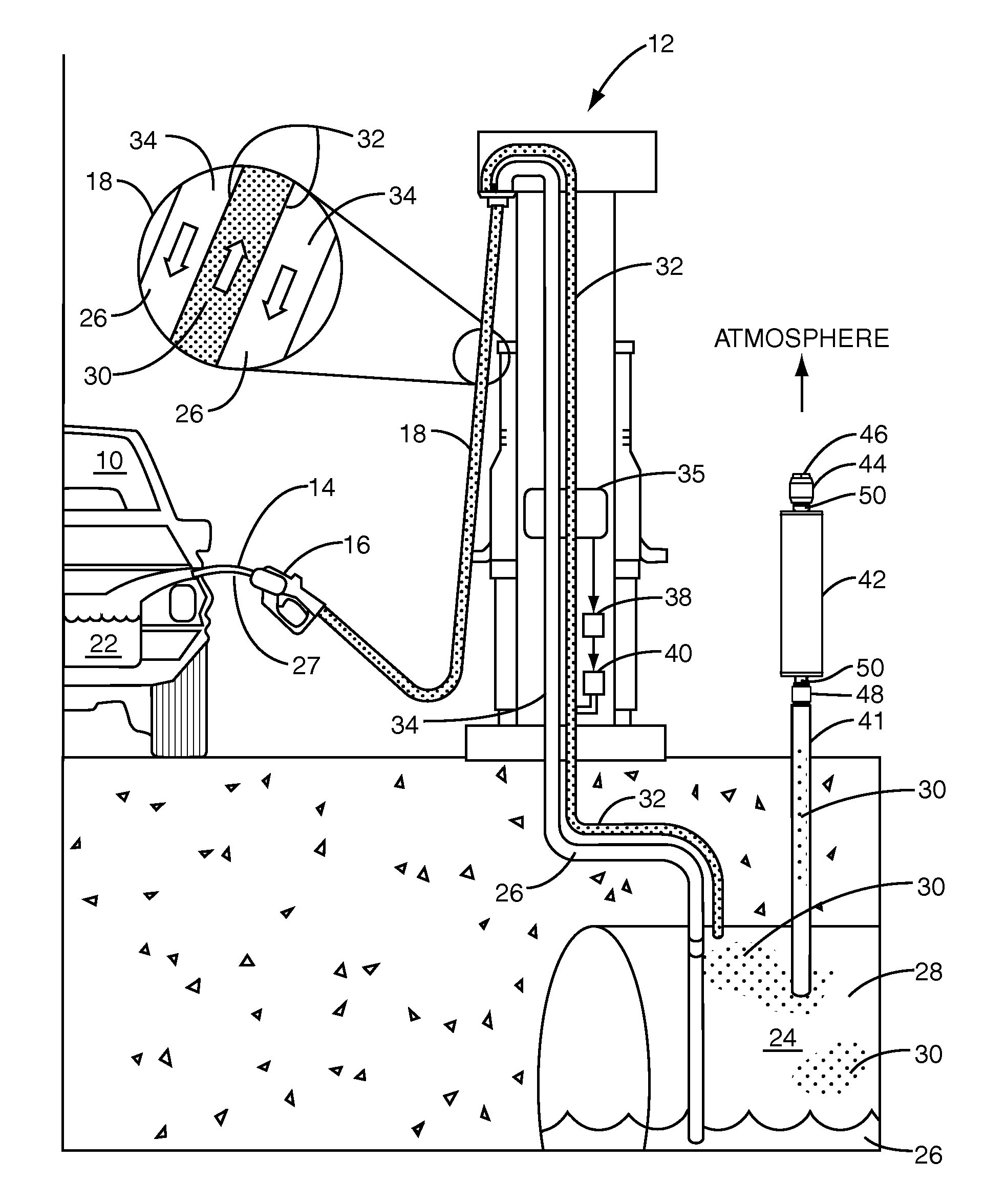

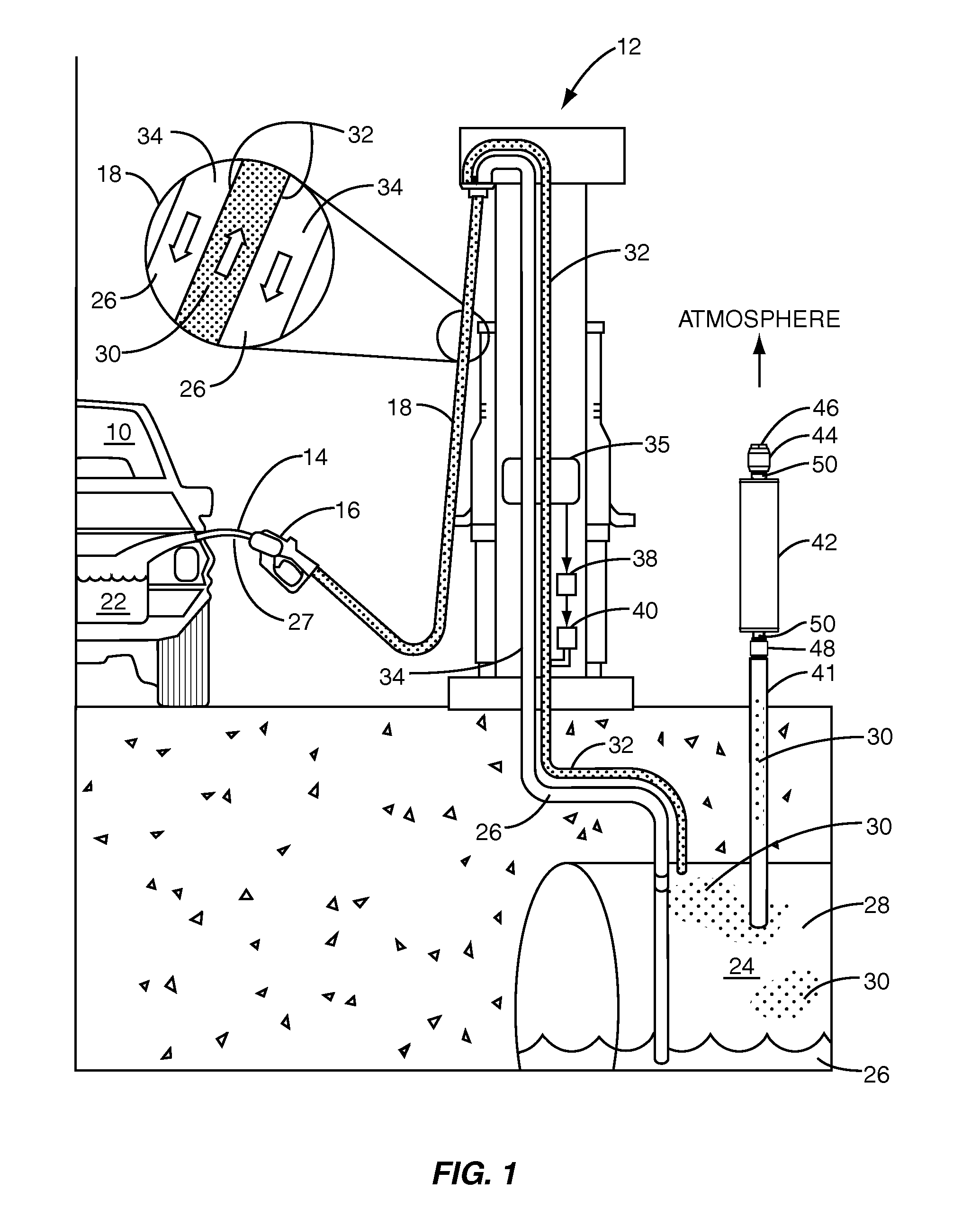

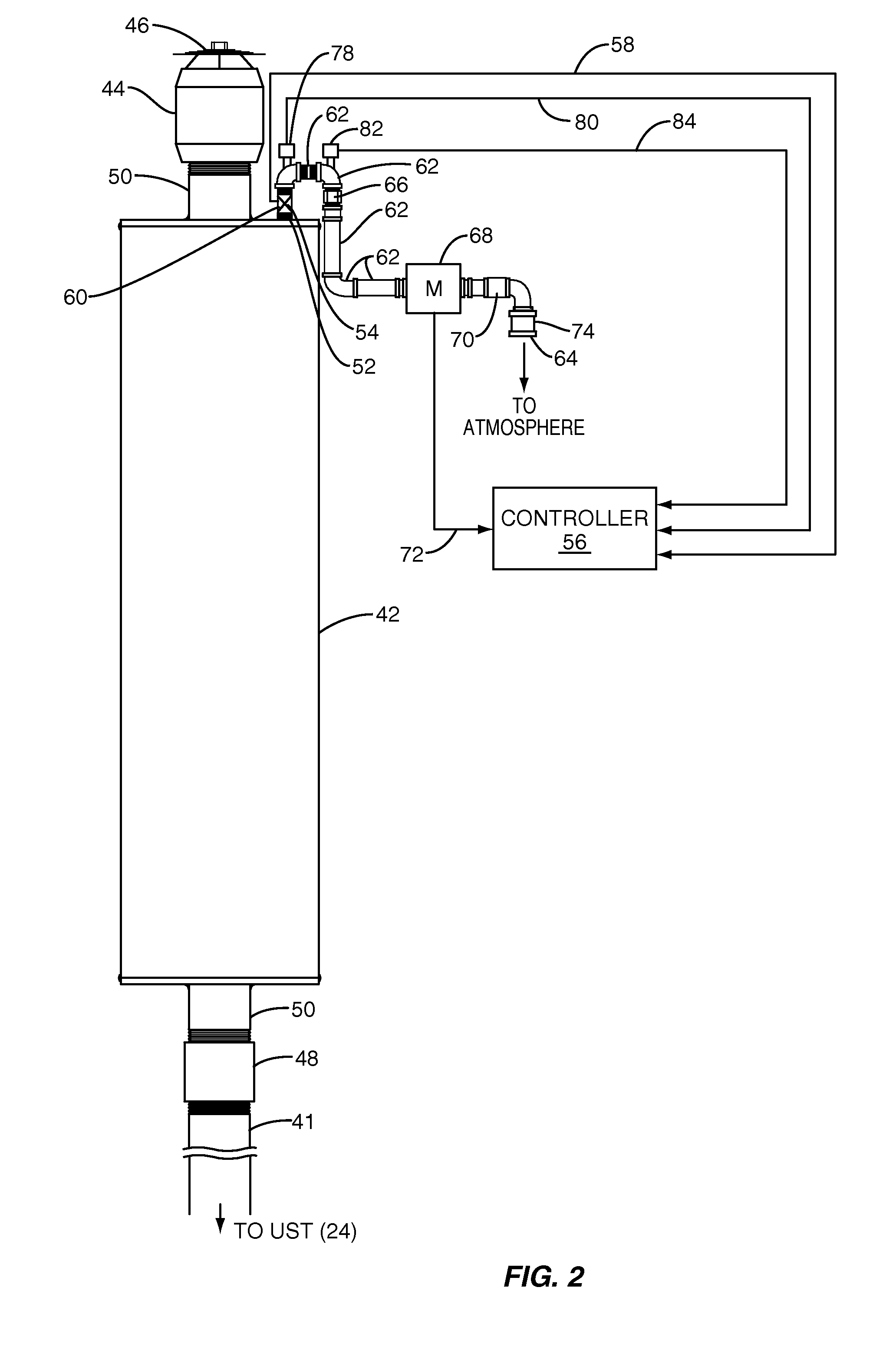

Fuel storage tank pressure management system and method employing a carbon canister

ActiveUS7566358B2Prevents excessive positive pressureAvoid emissionsCombination devicesGas treatmentPressure risePositive pressure

A carbon canister to adsorb hydrocarbons from a hydrocarbon air mixture in a UST system to prevent fugitive emissions due to overpressurization. The carbon canister has an inlet port at one end coupled to the UST system. An outlet port on the opposite end of the canister is connected to a flow-limiting orifice with a known calibrated flow rate that vents in a controlled fashion to the atmosphere. When UST pressure rises slightly above ambient pressure, fuel vapors and air from the UST system enters, via the inlet port, into the canister, where hydrocarbons are adsorbed onto the surface of the activated carbon. The cleansed air vents through the controlled flow outlet port to atmosphere, thereby preventing excessive positive pressure from occurring in the UST system. The activated carbon is purged of hydrocarbons by means of reverse air flow caused by negative UST pressures that occur during periods of ORVR vehicle refueling.

Owner:VEEDER ROOT

Fuel-tank inert gas control device

ActiveCN101891017ASimple structureLow costFuel tank safety measuresWeight reductionAviationFuel tank

The invention relates to a fuel-tank inert gas control device, which belongs to the field of aero-technology. The fuel-tank inert gas control device comprises a small flow limit hole, a small flow pipeline, a small check valve, a safety valve, a large check valve, a pressure reducer, a large flow limit hole, a large flow pipeline, and a block valve and the like, wherein in the two inert gas pipelines, one is used for controlling the normally-open feeding of the inert gas with low oxygen content and low flow under the action of the flow limit holes, and the other one is used for controlling the discontinuous feeding of the inert gas with high oxygen content and large flow according to the pressure demands of the fuel tank through the cooperation of the flow limit holes, the pressure reducer and the block valve. Through the cooperation among the flow limit holes and the pressure reducer and the like, the fuel-tank inert gas control device has the advantages of realizing the oxygen content and pressure controls of the inert gas in the fuel tank, and improving the working reliability. Meanwhile, the oxygen content control of the inert gas in the fuel tank has a larger margin and can reduce the requirements for oxygen content of the feed gas when the plane drops, so the fuel-tank inert gas control device can reduce the scale of the air separator, and reduce the cost and weight thereof.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com