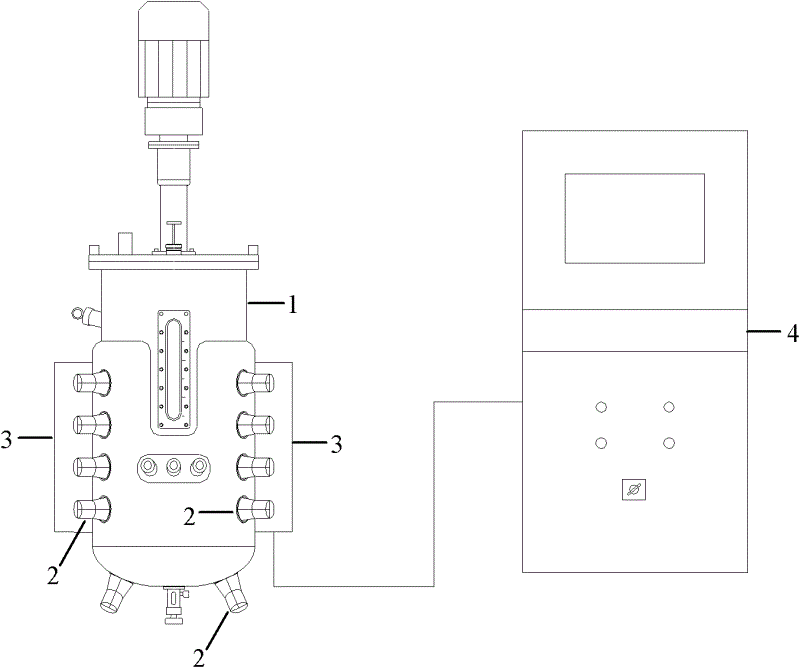

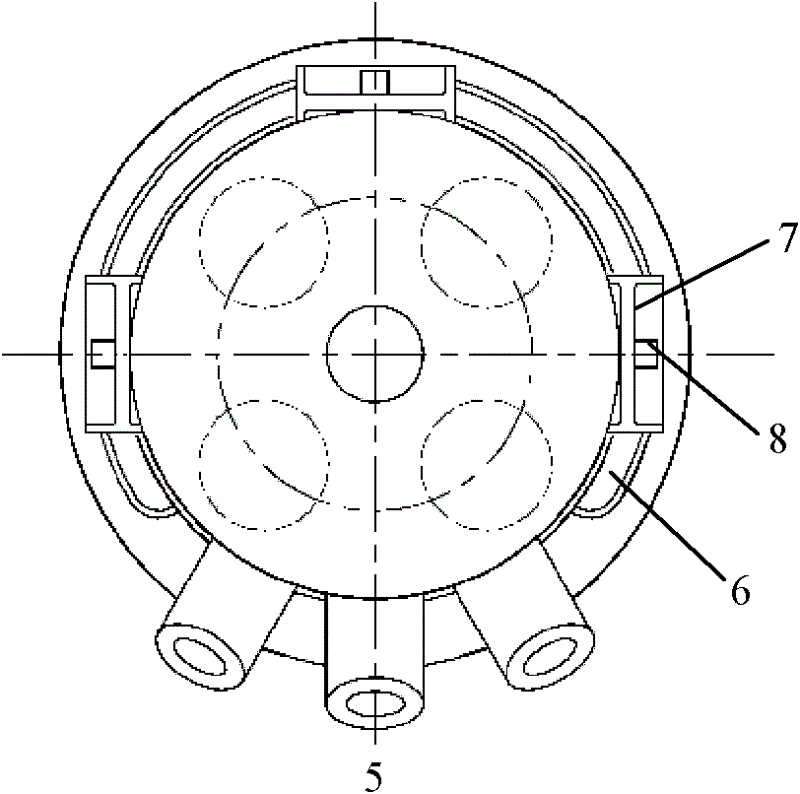

Ultrasound-enhanced bioreactor

A bioreactor, ultrasonic enhancement technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc., can solve the patent unreported, ultrasonic bioreactor equipment development research blank and other problems to achieve the effect of speeding up the biological reaction rate, shortening the fermentation period, and improving mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After fermentation and inoculation, open the ultrasonic control interface, select to open all ultrasonic transducer groups, select ultrasonic frequency 40K, ultrasonic power 100%, set ultrasonic time for 10 minutes, perform ultrasonic enhancement, and exit the ultrasonic control interface after the ultrasonic effect is over.

Embodiment 2

[0036] At 2h, 6h, and 12h of the fermentation process, open the ultrasonic control interface, select to open all ultrasonic transducer groups, select ultrasonic frequency 28K, ultrasonic power 80%, set ultrasonic time for 5 minutes, perform ultrasonic enhancement, and wait for ultrasonic action Exit the ultrasound control interface after finishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com