Patents

Literature

1629results about How to "Shorten the fermentation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

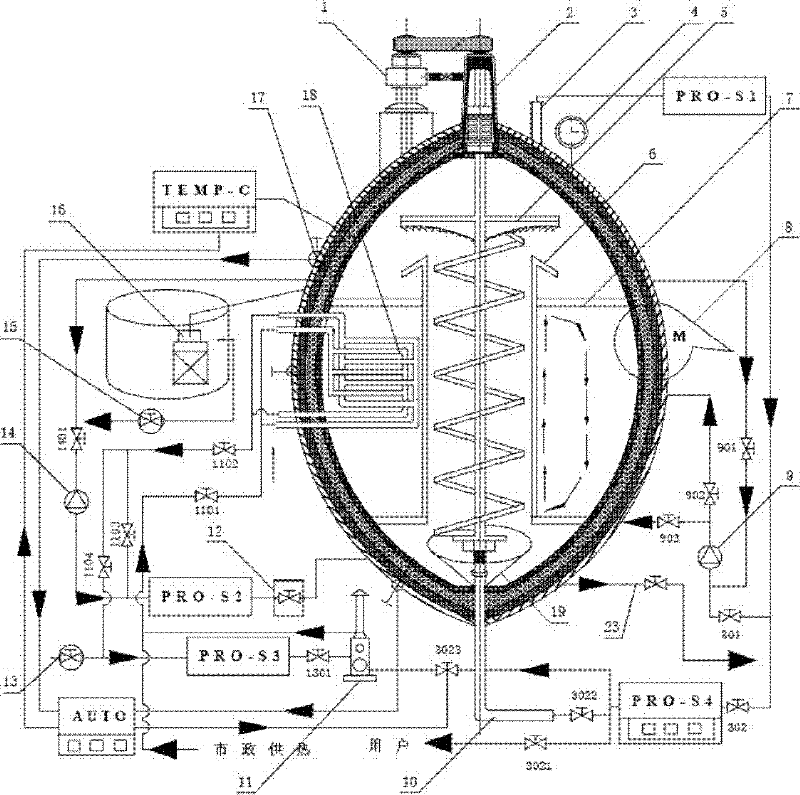

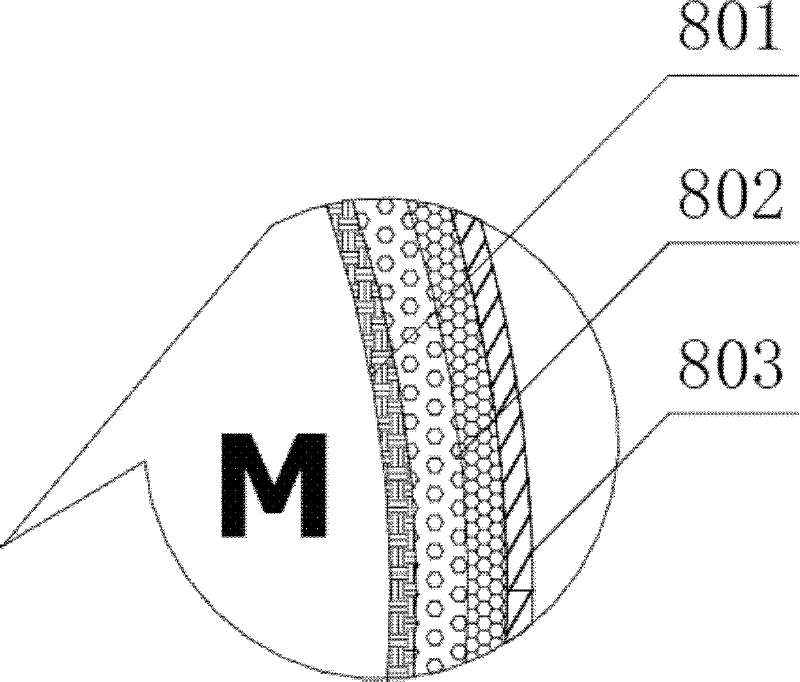

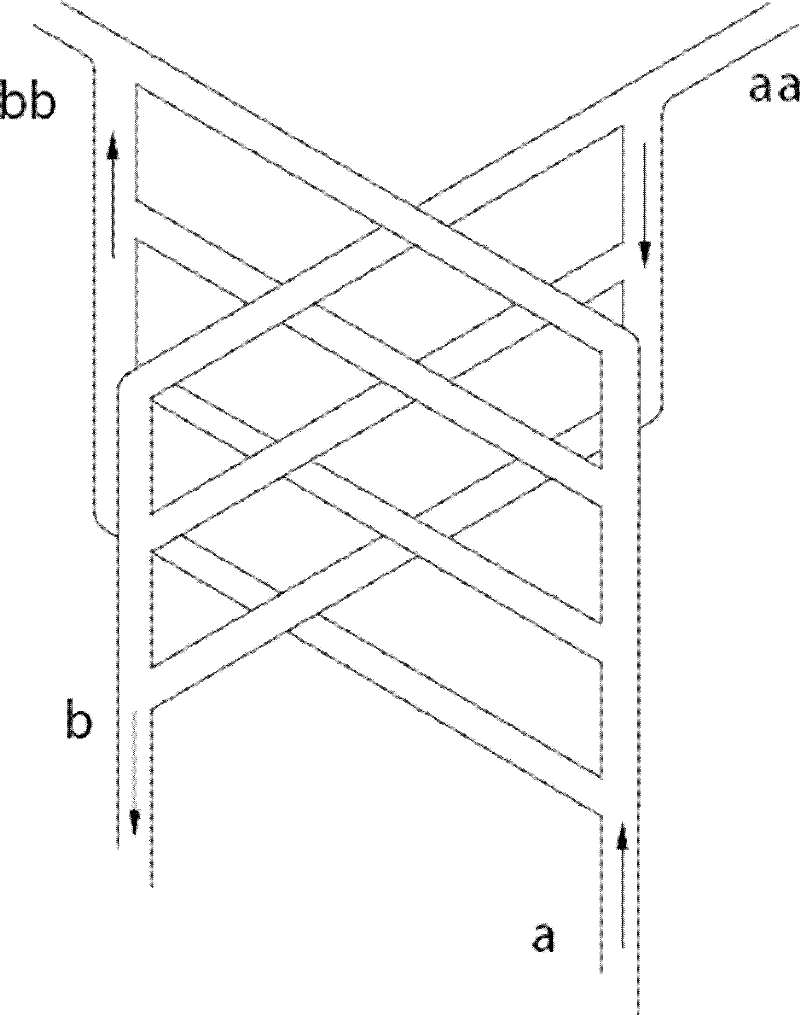

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

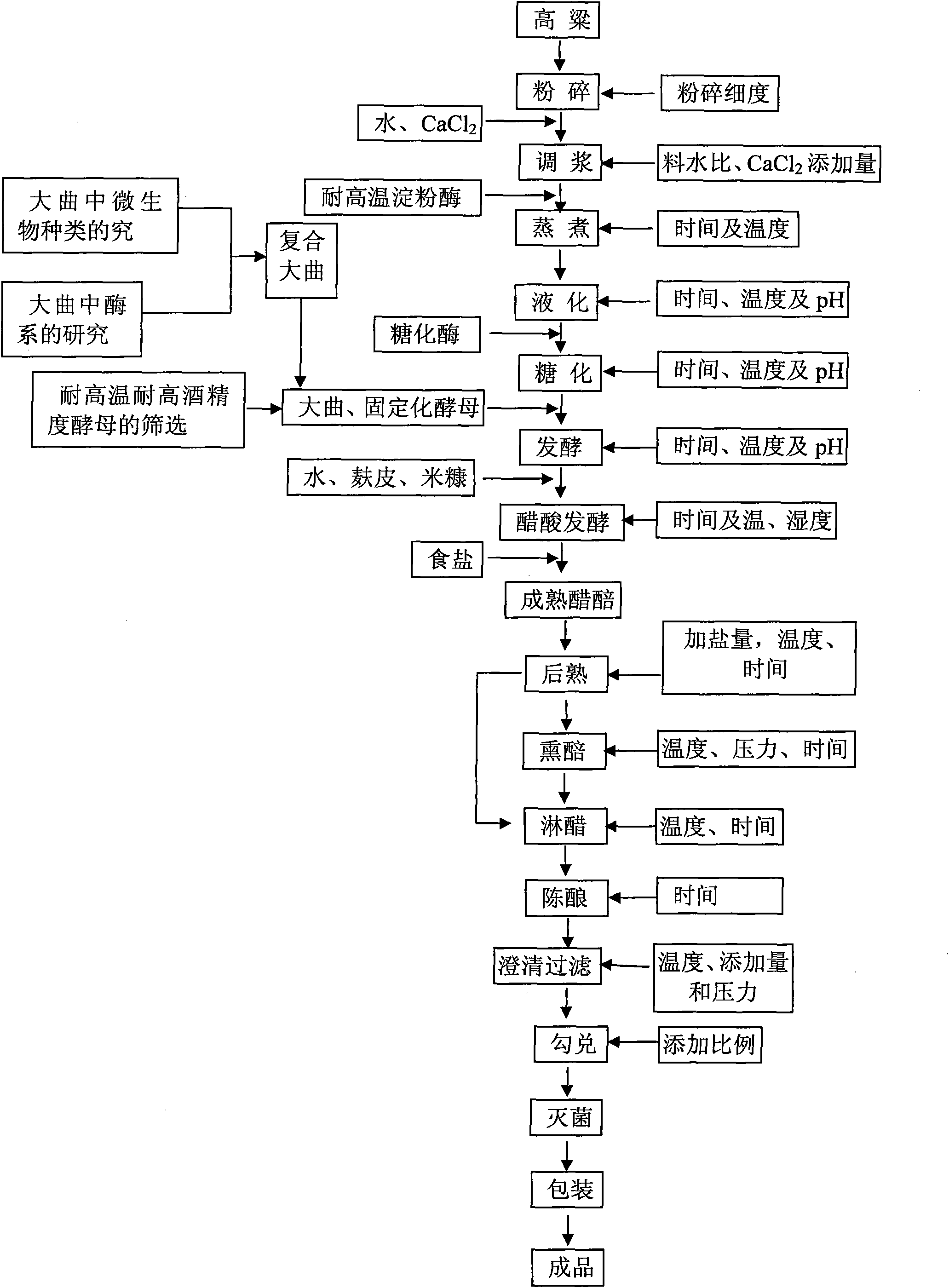

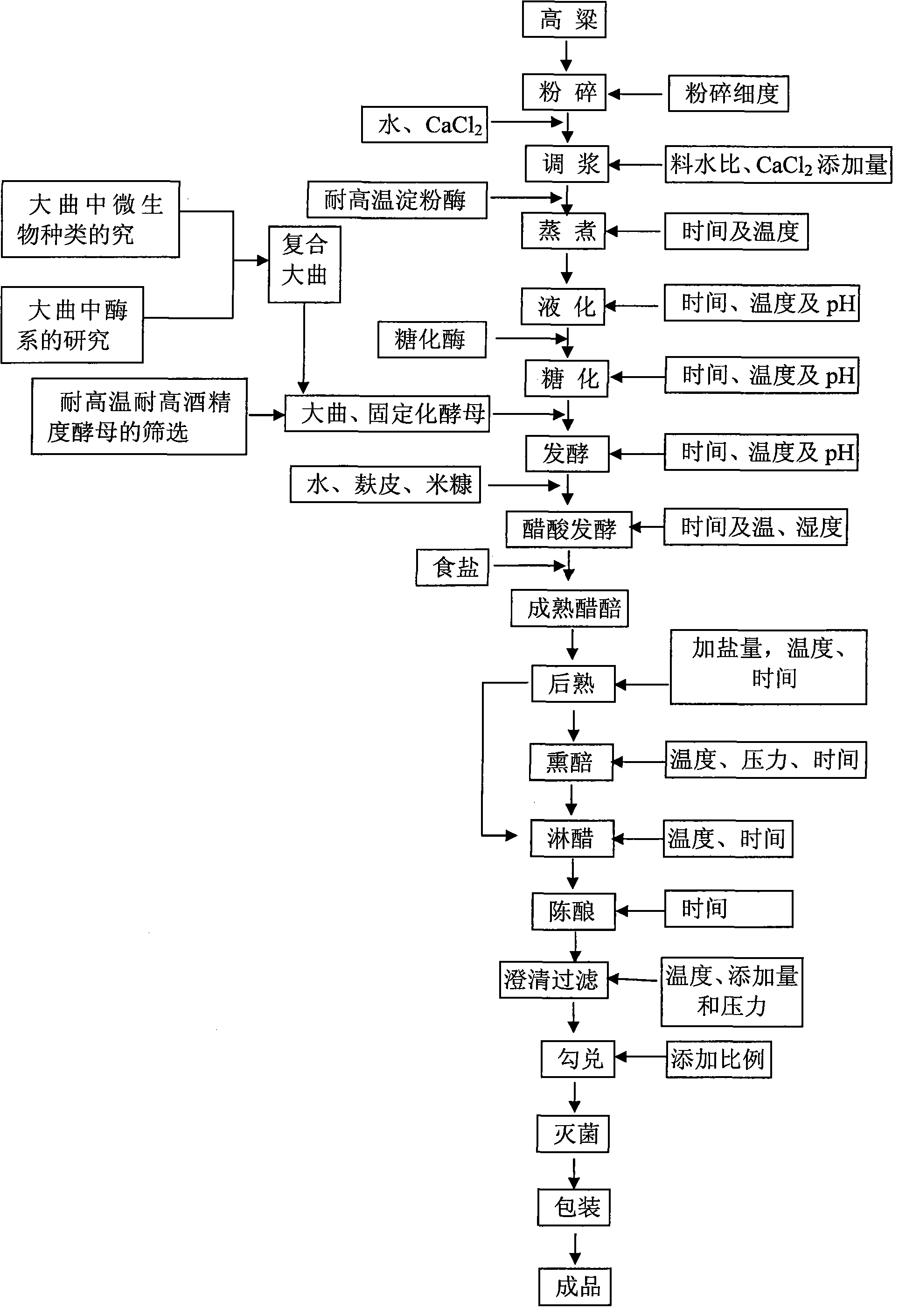

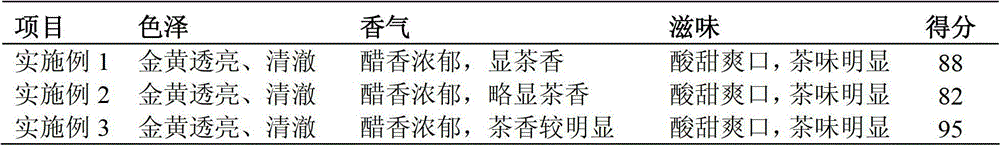

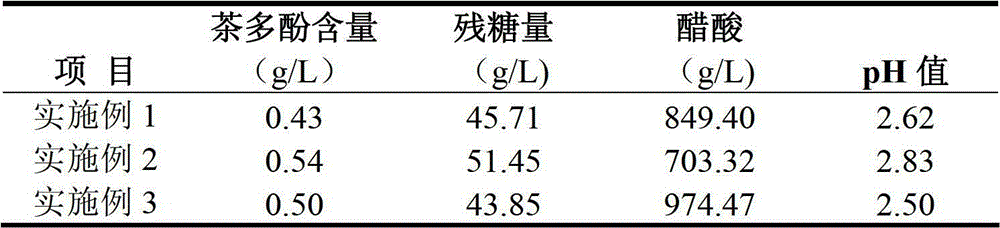

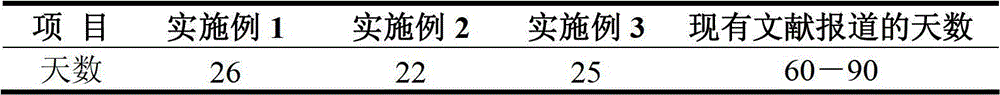

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

Tea vinegar beverage and method for preparing same

InactiveCN102860374AEasy to develop and produceLow costPre-extraction tea treatmentFiltrationSweetness

The invention discloses a tea vinegar beverage and a method for preparing the same. The tea vinegar beverage is prepared from fresh tea leaves by the steps of spreading, green killing, crushing, leaching, filtration, inoculation of microzyme, fermentation of acetic bacteria, filtration and sterilization. The tea vinegar beverage has a heavy fragrance of vinegar, a bright golden yellow liquor color, proper taste of sourness and sweetness and an obvious tea smell. According to the preparation method provided by the invention, the tea vinegar beverage is directly prepared by fermenting fresh tea leaves serving as the raw material, thereby enriching the variety of tea beverage products, contributing to the development and utilization of fresh tea leaves in China and enjoying a wide application prospect.

Owner:HUAZHONG AGRI UNIV

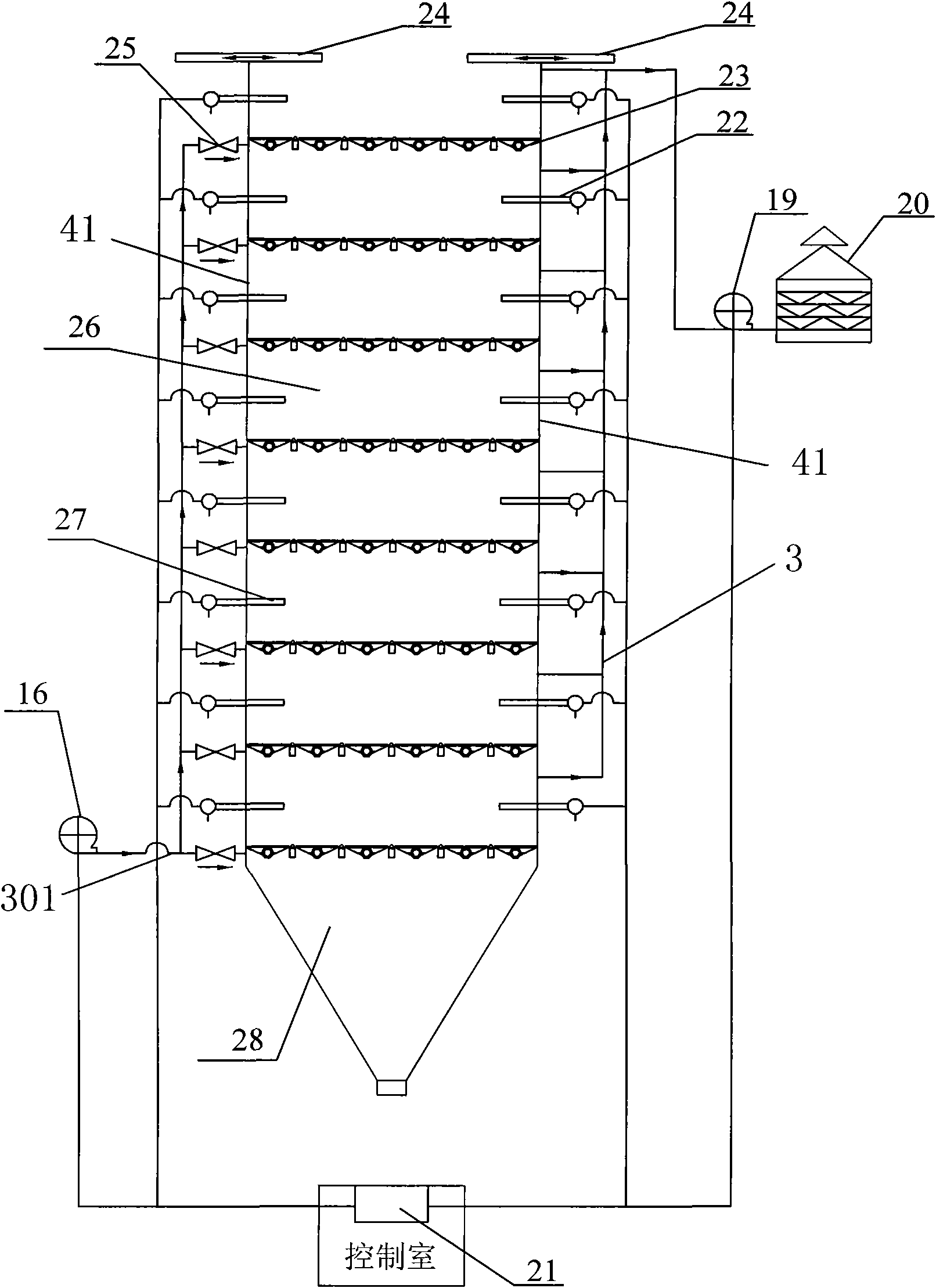

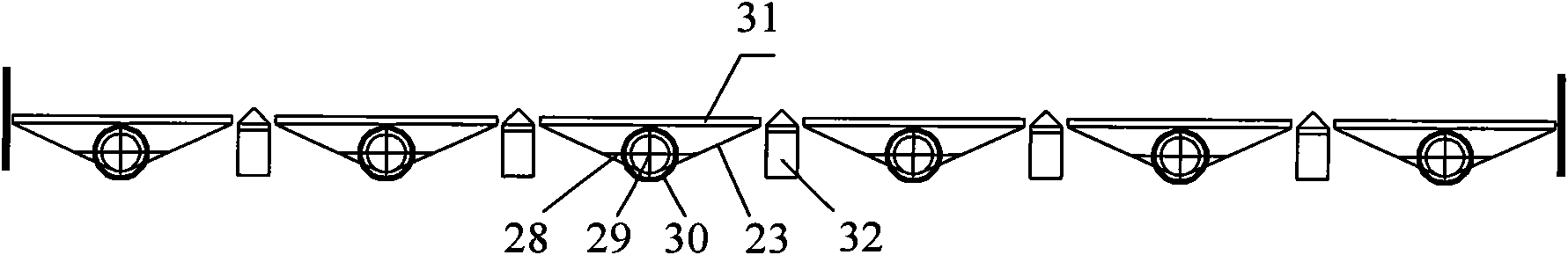

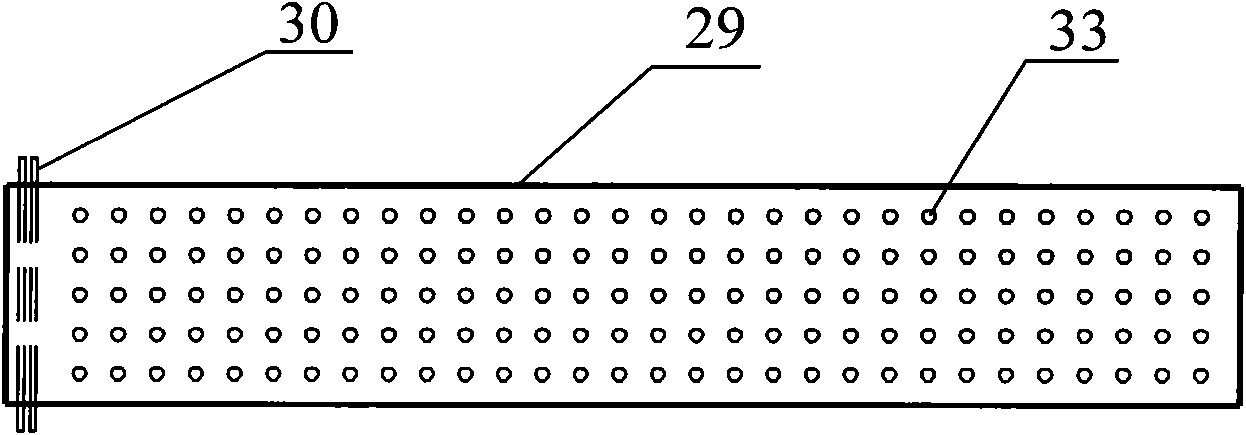

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

Ferment-fermented pickles and preparation method thereof

InactiveCN101720901AReduce pollutionShorten the fermentation cycleClimate change adaptationFood preparationSaline waterFood technology

The invention relates to pickles fermented by probiotic-containing food ferment and a preparation method thereof, in particular to pickles fermented by several kinds of pure lactobacillus ferment and a preparation method thereof, which belong to the technical field of foods. The preparation method comprises the following steps: (1) the processing of raw material vegetables, namely cleaning and draining; (2) the preparation of brine; (3) the preparation of ferment solution; (4) the bottling of the vegetables and the addition of the brine and the ferment solution; and (5) fermentation. The invention not only provides a new deep processing path of the food ferment containing probiotics, but also acquires new, conventional and healthy pickles.

Owner:丹尼斯克(中国)有限公司

Medlar and red date enzyme and preparation method thereof

InactiveCN104872674AKeep natural colorImprove biostabilityNatural extract food ingredientsFood ingredient functionsRipeningHigh pressure

The invention discloses a medlar and red date enzyme and a preparation method thereof, which belong to the technical field of enzyme preparation. Multi-strain composite fungi powder is adopted as a leavening agent; the medlar and the red date are adopted as main raw materials; dietary fiber, pectin hydrolyzate, seasoner extracting liquor, Chinese herbal medicine extracting liquor, enzyme stabilizer and other multifunctional auxiliary raw materials are scientifically compounded and modified; low-temperature processing technology such as ultrasonic cleaning, cryogenic grinding, microwave-assisted high-voltage pulse electric field processing and ultrasonic ripening are mainly adopted in the whole process, so that the natural colors, the flavor, the taste and the content of the active materials of the medlar and the red date are maintained furthest, the biological stability, the non-biological stability and the biological activity of the medlar and red date enzyme are obviously enhanced, the introduction of chemical addition agent is reduced, and the juicing rate of the medlar and the red date as well as the food safety of the enzyme are improved. Finally, the medlar and red date enzyme with high biological activity, strong stability, strong taste, flavor and appetite, long expiration date and edible safety is prepared.

Owner:NINGXIA JINSHANGQI BIOTECH

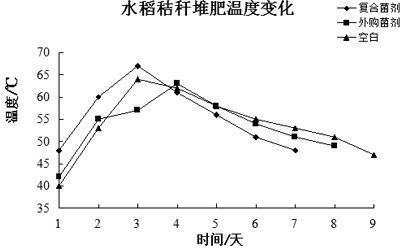

Microbial composite microorganism inoculant for producing biological organic fertilizer from decomposed organic wastes

InactiveCN101486597AReduce the level of odorPromote growthMicroorganismsOrganic fertilisersBiotechnologyCellulose

The invention relates to the range of microorganism fermentation inoculant, in particular to a microorganism composite fermentation inoculant which is used for digesting the compost of livestock manure, crop straws, mud, mushroom slag, decoction dregs, garden shearing substances, grass peat, castor bean meal, bone meal, and bean pulp meal rich in cellulose and organic matters as well as manufacturing a bio-organic fertilizer. 2 strains screened from a plurality of organic waste materials with high capability for digesting cellulose and high temperature resistance (70 DEG C) are scientifically and reasonably combined with 11 beneficial strains to prepare a microorganism composite fermentation inoculant which can not only digest organic materials, but also enhance the efficiency, quality and biological activity of the compost. The invention can be used in the high efficient and reasonable application of agricultural wastes and in the industry of waste disposal.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

High-efficiency ferment for fermenting bean pulp and bean pulp fermentation technology using the ferment

The invention relates to a high-efficiency ferment for fermenting bean pulp, belonging to the biologic enzymolysis fermentation technical field. The high-efficiency ferment is formed by mixing bacillus subtilis, bacillus licheniformis, lactobacillus acidophilus, lactobacillus casei, saccharomyces cerevisiae and candida utilis. The fermentation technology comprises the following steps: crushing the bean pulp and corn; activating the strains; uniformly mixing the bean pulp and the fermentation liquor using a mixer; packing the mixed bean pulp in fermentation bag; fermenting the packaged bean pulp and processing fermented bean pulp: drying-crushing-detecting-packaging-finished product. The technology is simple and the product quality is stable and the content of the anti-nutrient factor in the bean pulp is eliminated and obviously reduced, therefore the bean pulp is a safe plant protein feeder for infant animal with balanced nutrient, good quality and low price and help for health growth of the infant animal, in replace of animal protein feeder of bone powder, fish powder or the like.

Owner:MINXIONG BIOTECH CO LTD LONGYAN FUJIAN

Method for fermented-producing bacteria cellulose with pineapple peel juice by two-step method

InactiveCN101671708AEasy to produceReduce manufacturing costMicroorganism based processesFermentationMicrobiologyTwo step

The invention discloses a method for fermented-producing bacteria cellulose with pineapple peel juice by a two-step method. In the method, two stages, including multiplication of acetobacter xylinum and fermented production of bacteria cellulose, are separated from each other, sterile air is ceaselessly fed in at 22 to 28 DEG C in the process of fermentation and acetobacter xylinum is cultivated for 24 to 72 hours under 100 to 200rpm stirring, at this moment, the viable count of acetobacter xylinum is 10<8> to 10<9>cfu / ml, cells are subject to multiplication culture of bacteria to be in a synchronous growth period as far as possible, and the cells are then subject to shallow tray static cultivation in a fermentation medium for fresh juice of the pineapple peel so as to result in bacteria cellulose with the yield more than 17.5g / L. The method greatly shortens the production period of bacteria cellulose, makes full use of the pineapple peel and protects environmental, and in addition, the produced bacteria cellulose is compact and uniform in texture.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing quickly-fermented probiotic pickle by biological method

The invention discloses a method for preparing quickly-fermented probiotic pickle by the biological method, belongs to the field of deep processing of vegetables, and particularly relates to a method for producing pickle by compound bacteria powder. The method solves the technical problem about quick production of high-quality fermented pickle and includes main steps of firstly, adding raw materials and sealing: cutting vegetables and placing cut vegetables into a container, adding compound bacteria powder containing bacillus aceticus and brewer's yeast, and auxiliaries with salt, and sealing the container; secondly, fermenting: controlling the temperature at 23-36 DEG C for early fermenting, and controlling temperature at 15-25 DEG C for later fermenting, and keeping fermenting time within 20-40 hours; and thirdly, dewatering and flavoring: dewatering the pickle after fermenting, and adding seasoning to mix uniformly. The method is applicable to pickle production in different scale and has wide application prospect in the pickle production field, production time can be obviously shortened, and pickle products are rich in nutrition and pure in taste.

Owner:李绩

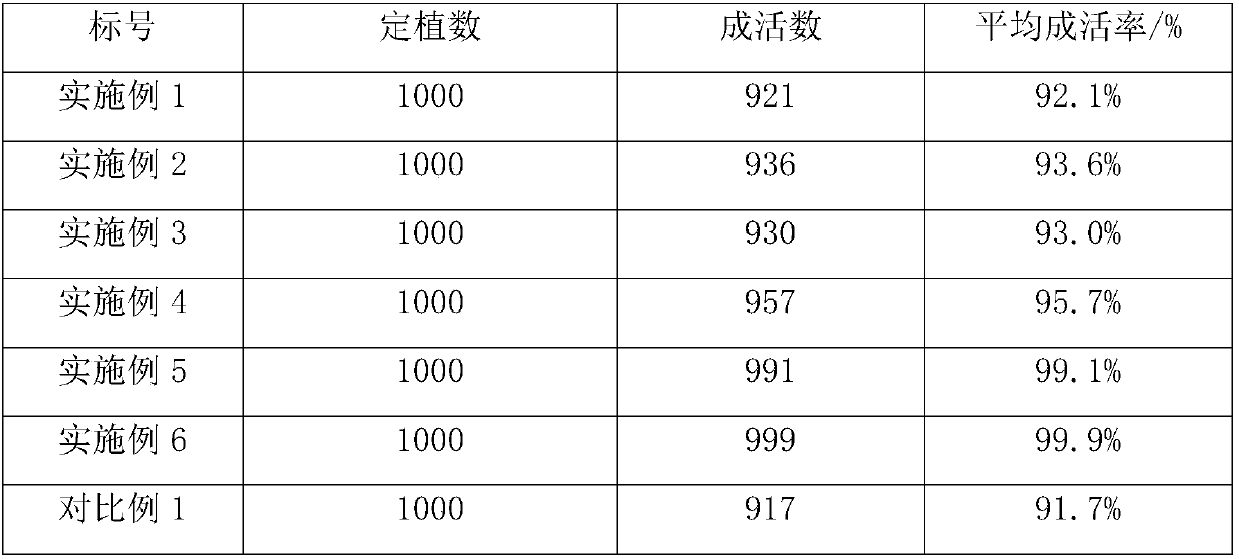

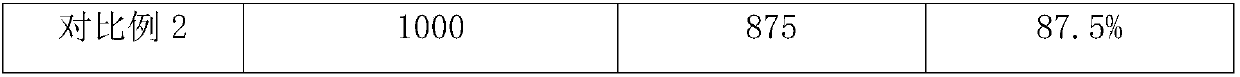

Organic cultivation substrate and methods for transforming saline alkali land and planting Lycium ruthenicum by using same

InactiveCN107698385AShorten the fermentation cycleImprove fermentation qualityExcrement fertilisersMicroorganism based treatmentAgricultural economyLycium ruthenicum

The invention provides an organic cultivation substrate and a preparation method thereof, and methods for transforming saline alkali land and planting Lycium ruthenicum by using the cultivation substrate. The invention aims to overcome disadvantages in the prior art. According to the invention, fermented agricultural and forest residues, a biological bacterium fertilizer and animal manure are utilized to develop a low-cost and highly-efficient organic cultivation substrate, so the saline alkali land is transformed, and the yield and the quality of the Lycium ruthenicum are improved at the sametime; and an important practical significance is realized for improving the comprehensive development and utilization level of the saline alkali land in China and promoting the sustainable development of agricultural economy in a saline alkali land area.

Owner:南京百世维康信息科技有限公司

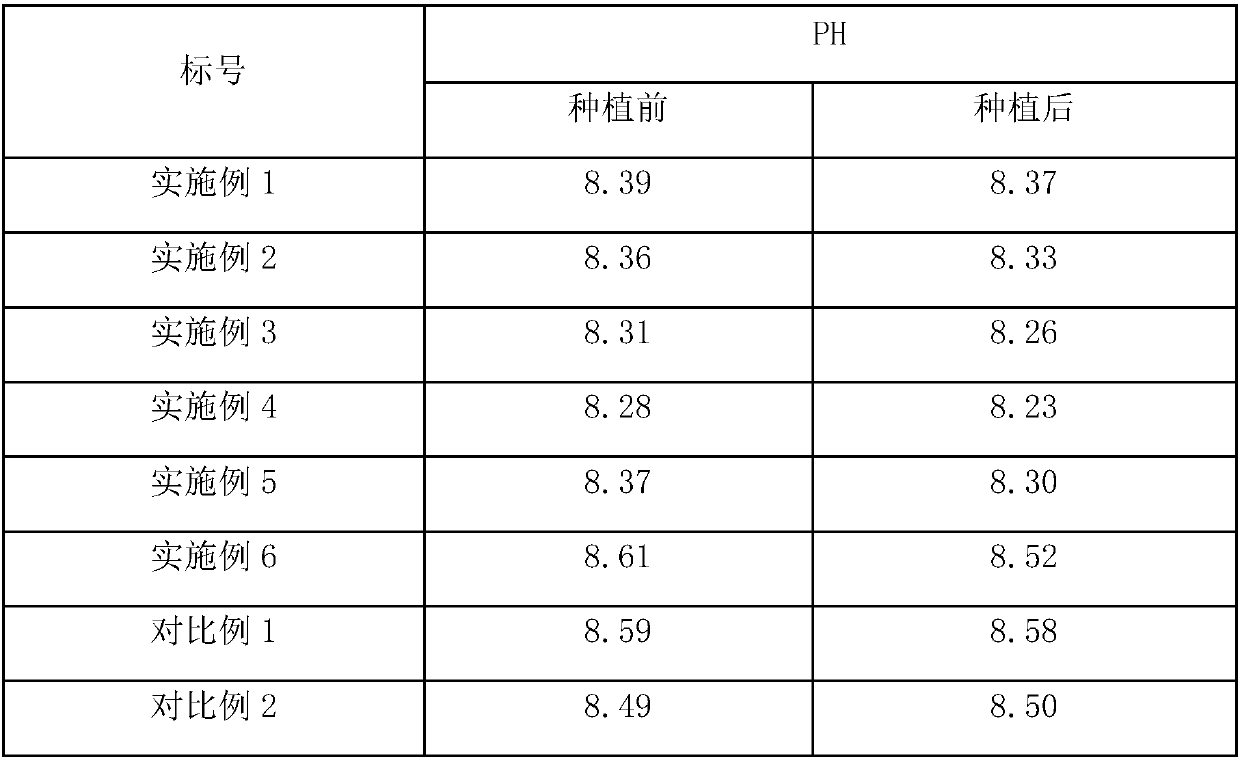

Brewing process of soy sauce

The invention discloses a brewing process of a soy sauce, which comprises the following steps: (1) preparation of soy sauce koji, namely, mixing cooked soybeans with wheat or flour, adding strains for preparing the soy sauce koji; and (2) fermentation, namely, mixing the soy sauce koji with a saline solution so as to obtain a soy sauce mash, and carrying out high-salt liquid-state fermentation, wherein the salinity of the soy sauce mash in the early stage of the fermentation is controlled at 14.0-15.5g / 100 ml, after the fermentation is performed for 45-75 days, the salinity of the soy sauce mash is adjusted to 18.0-19.0g / 100 ml, and fermentation goes on, so that soy sauce liquor is obtained. In the process, low-salt fermentation is performed before high-salt fermentation, so that the utilization rate of raw materials is improved, the fermentation cycle is short, and the productivity is greatly improved; and the obtained soy sauce has an outstanding fragrance and a delicious taste, and has no difference with a soy sauce prepared by using a traditional high-salt liquid-state fermentation method.

Owner:GUANGDONG CHUBANG FOOD

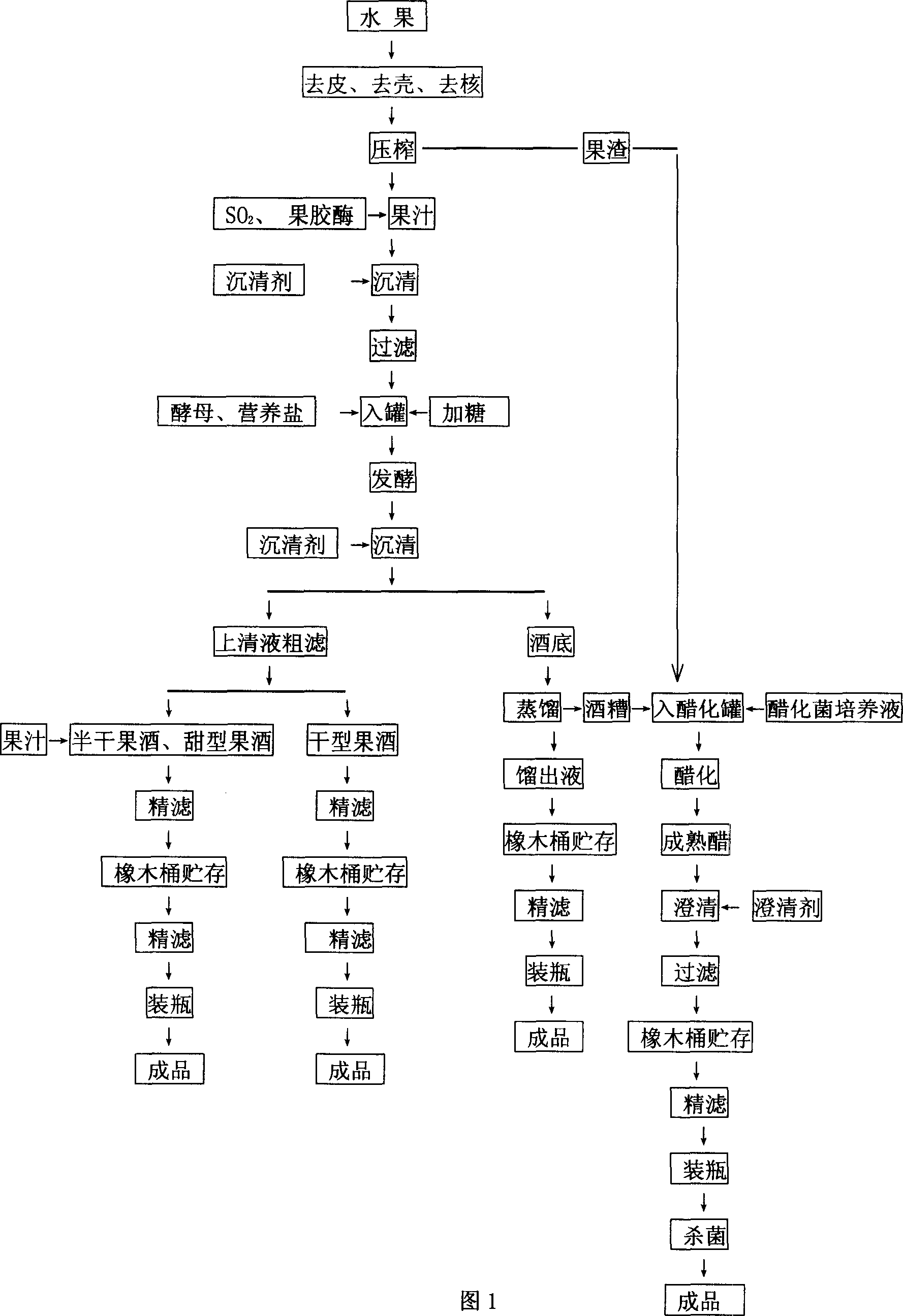

Brewage of fruit wine, vinegar and brandy

InactiveCN1530432AReduce emission lossRealize comprehensive utilizationAlcoholic beverage preparationVinegar preparationFruit wineYeast

A process for brewing fruit wine, fruit vinegar and fruit brandy includes such steps as fermenting fruit juice to obtain dry, semi-dry, or sweet fruit wine, distilling the fermented wine substrate to prepare fruit brandy, and using the distilled dregs and squeezed fruit dregs to prepare fruit vinegar. Its advantages are high utilization rate of fruit, low cost, and less pollution.

Owner:BAIWEIGUO BREWING INDAL XIAMEN CITY

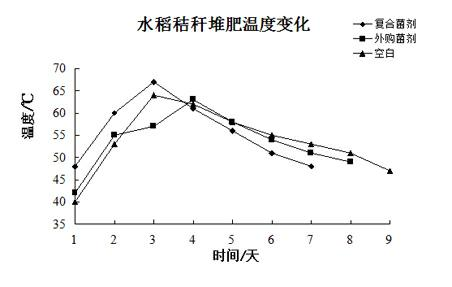

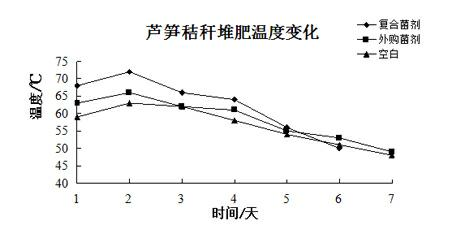

Efficient straw degrading composite fungicide and organic fertilizer preparing method thereof

ActiveCN102676492AFully degradedIncrease productivityBio-organic fraction processingMicroorganism based processesInsect pestFermentation

The invention relates to an efficient straw degrading composite fungicide (JFB-1) and an organic fertilizer preparing method thereof. The composite fungicide comprises composite bacteria and a carrier, wherein the carrier is wheat bran, and the composite bacteria include composite bacteria I, composite bacteria II, composite bacteria III and auxiliary bacteria. The composite bacteria I, II and III account for 1-1.5% of the weight of straws, wherein the composite bacteria I account for 20-25%, the composite bacteria II account for 45-50%, the composite bacteria III account for 30-35%, and the composite bacteria are added uniformly in compost fermentation so as to effectively improve the maturation speed and the quality of an organic fertilizer. The fungicide is fully mixed with straws of rice, asparagus and other crops to carry out compost fermentation, the straws can be degraded rapidly through the synergistic effect of the bacteria, the degradation efficiency is improved, the degradation time is shortened, and insect pests are effectively killed and are rapidly transformed into the organic fertilizer for improving soil. The efficient straw degrading composite fungicide can be used for effectively solving the problem of land occupation caused by landfill, or the problems of fire, traffic dangers, environment pollution and the like caused by burning.

Owner:SHANGHAI JIAO TONG UNIV

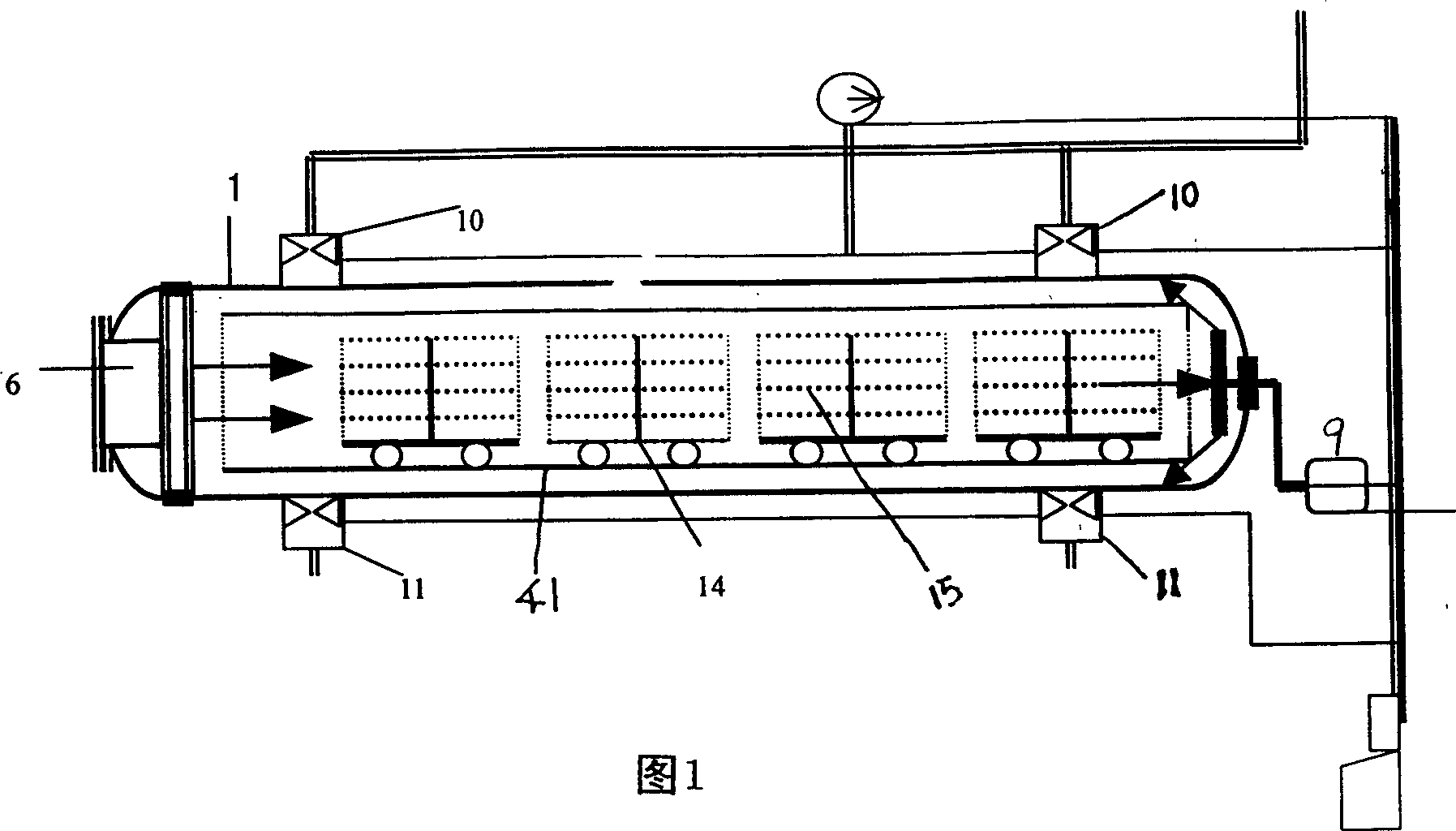

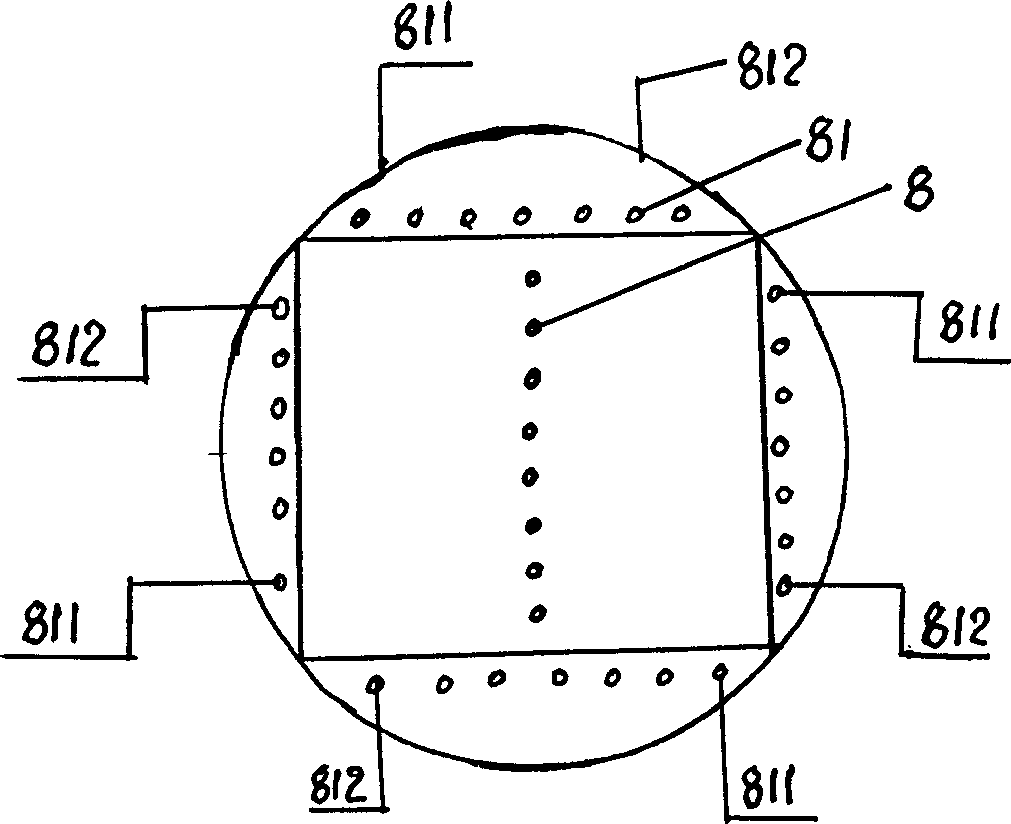

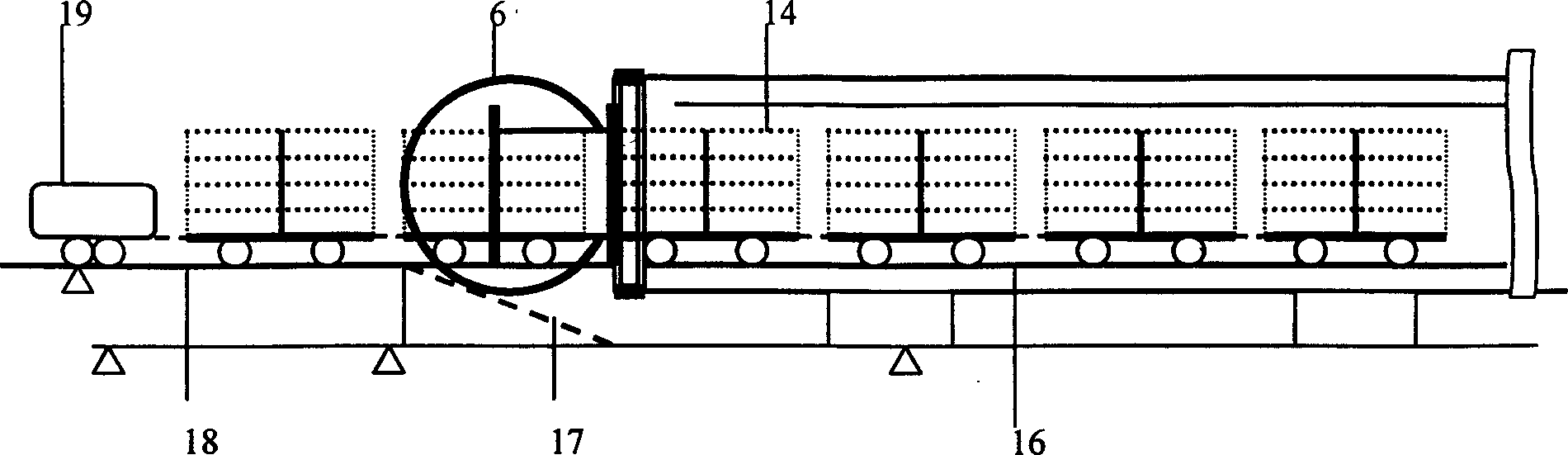

Gas-phase double-dynamic solid fermentation technology and fermentation apparatus

InactiveCN1434113ASimple structureImprove sealingBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseEngineering

The present invention relates to a gas-phase double-dynamic solid fermentation techinque, and is characterized by that the solid material to be fermented is placed into a double-dynamic environment with pressure pulsatino and circular flowing air to make solid fermentation. Its fermentation equipment includes a horizontal cylindrical tank with a quickly-opening door, in the interior of the tank arectangular spacing cylinder which is formed from four partition boards and whose section is quadratic is axially placed, and in the space of partition board and tank wall a cooling calandria parallel to the partition board is arranged, and the vertical centre of the spacing cylinder is equipped with horizontally-arranged several groups of cooling calandria.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

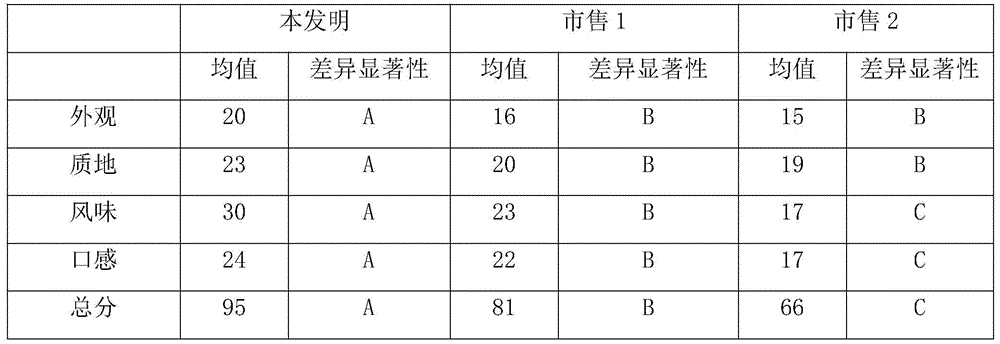

Technological process for preparing fermentation dehydrated beef using composite leaven

InactiveCN101248884AImprove organizational structureEnhance sensory effectFood preparationLactobacillusOrganoleptic

The invention provides a method for producing fermented beef jerky with compound leaven. The bacteria strain used in fermentation is lactobacillus casei and staphylococcus xylosus with volume ratio of 1:3 and volume of addition of 1-1.5%, the fermentation temperature is 20 DEG C, and the fermentation time is 5 days. The addition of lactobacillus casei reduces pH value of the product, improves safety, improves the texture of the product, and shortens fermentation period. At the same time, the addition of staphylococcus xylosus generates a large amount of flavoring substances during fermentation process, improves sensing effect of the product, and the final product has thick fragrance, good taste, and infinitive aftertaste. The inventive method is especially suitable for producing fermented beef jerky, as well as air dried sausage and sausage.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Light, simple and efficient cultivation method for cotton

InactiveCN102204469AOvercoming not perishableShorten the fermentation cycleHorticultureTransplantingFilling-in

The invention relates to a light, simple and efficiency cultivation method for cotton. Straw-like light seedling raising medium is filled in paper cylinder and pot or paper plug or nonwoven fabric bags for raising cotton seedlings, and mechanical sowing, transplanting and cotton harvesting can be performed. The light, simple and efficiency cultivation method has the characteristics of labor conservation, cost conservation, high yield and high efficiency, requires small investment, makes operation easy, avoids environment pollution and is a new method for large-scale cotton production with bright promotion and application prospects.

Owner:操宇琳

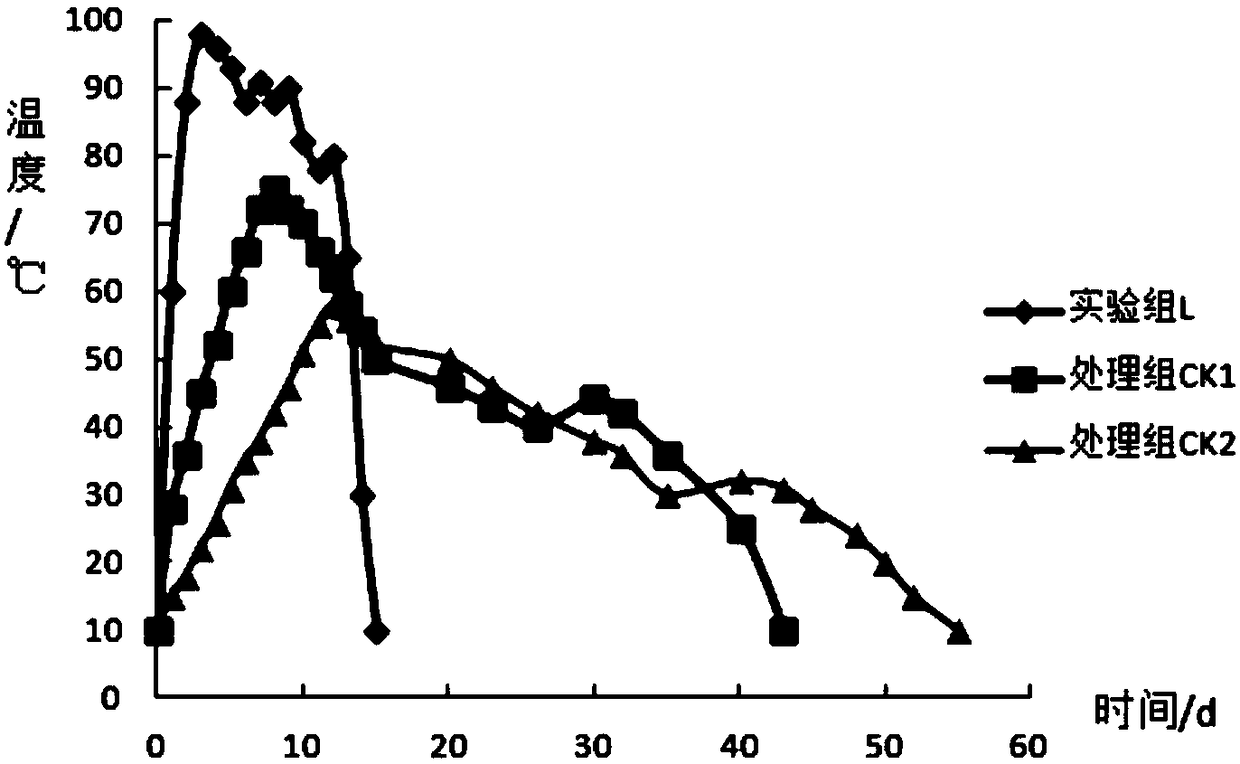

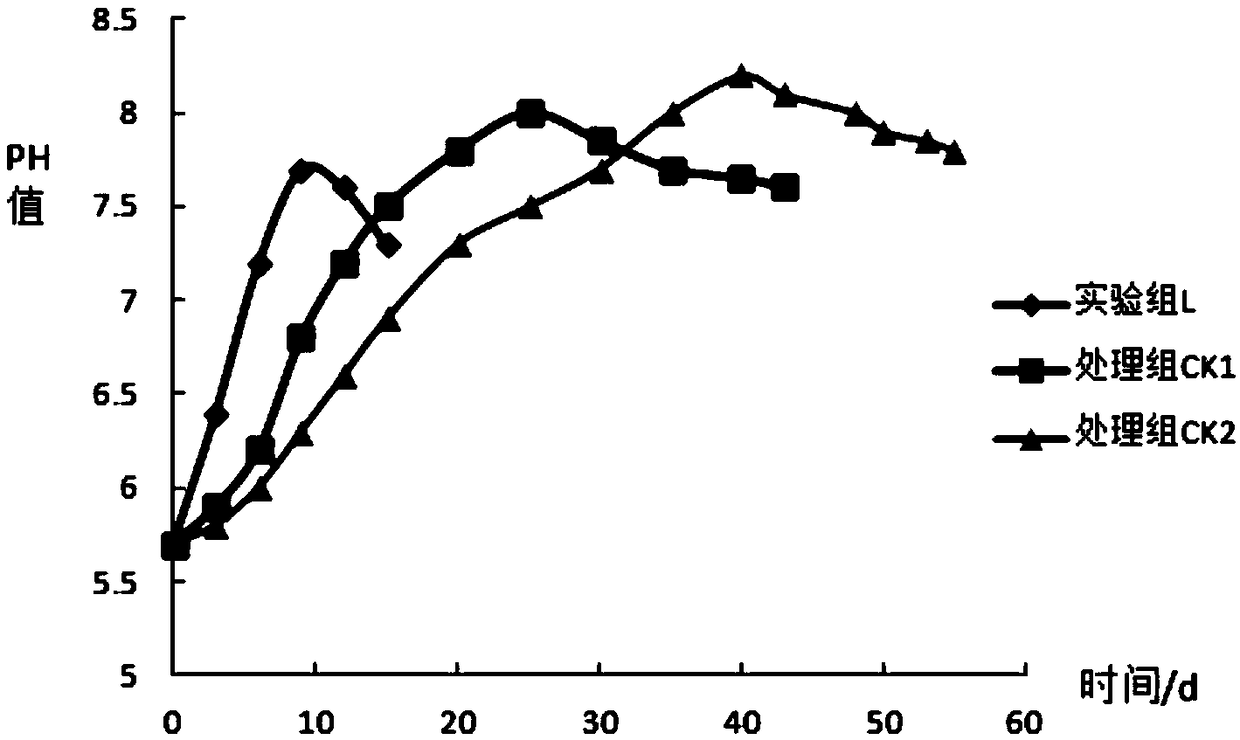

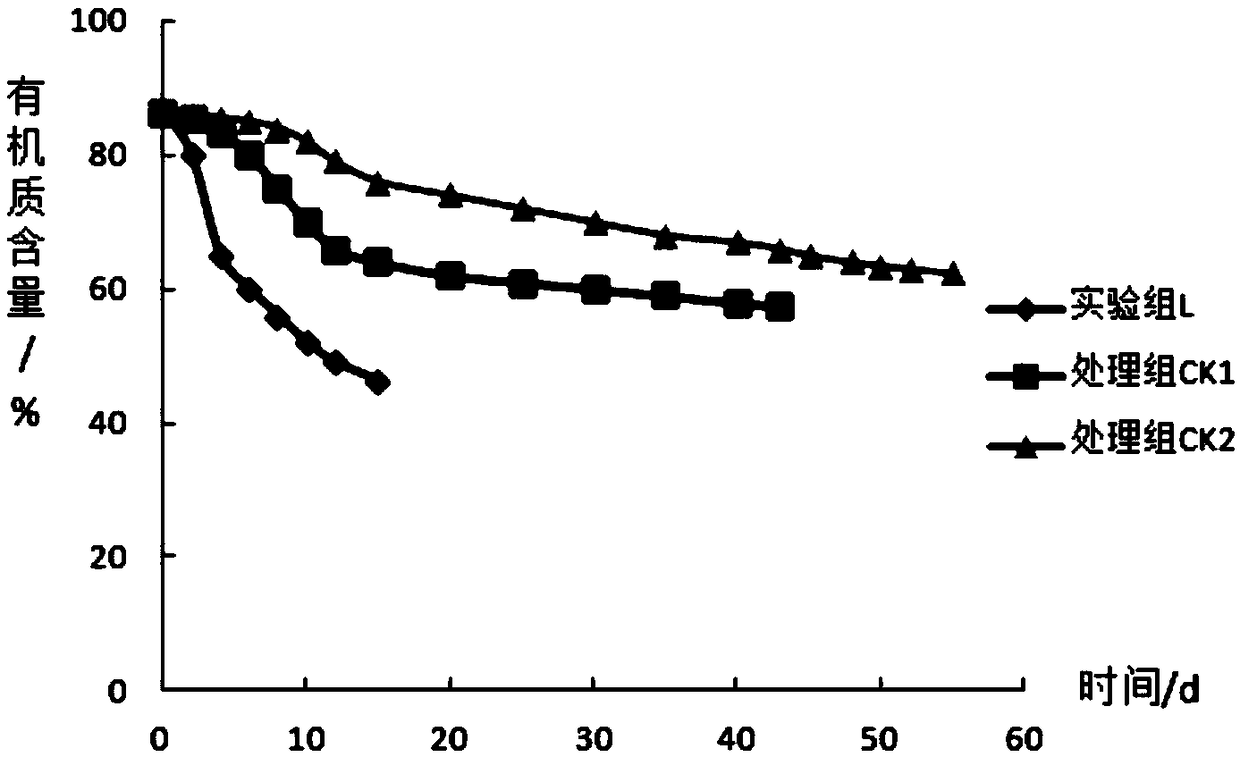

Ultrahigh temperature decomposition agent of straws and cattle manure, and preparation and application of decomposition agent

ActiveCN108624539APromote degradationFully degradedFungiBio-organic fraction processingBacillus licheniformisDecomposition

The invention discloses an ultrahigh temperature decomposition agent of straws and cattle manure, and a preparation and an application of the decomposition agent, and belongs to the field of decomposition agents. The decomposition agent is prepared by mixed fermentation and drying of the straw, the cattle manure and a complex decomposition inoculant, wherein the complex decomposition inoculant comprises 1-10 parts of thermophilic bacterium inoculant, 1-6 parts of bacillus licheniformis inoculant, 1-6 parts of aspergillus oryzae inoculant, 1-6 parts of lactobacillus plantarum inoculant, 1-6 parts of thermoactinomyces sacchari, and 1-6 parts of cold-proof brevibacterium inoculant. The decomposition agent, a composting method and the application of the decomposition agent solve the problems of slow temperature rise during composting and decomposition, low fermentation temperature, long fermentation time, incomplete decomposition, poor compost quality and the like in the fermentation of the existing complex inoculant, and the decomposition agent is quick in temperature rise during the composting and the decomposition, quick in heating-up, high in fermentation temperature, short in fermentation time, more thorough in decomposition and higher in quality.

Owner:河北木美土里科技有限公司

Production of alcohol from mixed bacterial population degradable fermented bastose substance

InactiveCN1896254AReduce degradationShorten the fermentation cycleBiofuelsMicroorganism based processesAlcohol productionCellulose degradation

Production of alcohol from mixed microbial pool degradable and fermented lignocellulose substance is carried out by crushing lignocellulose substance, soaking with H2SO4, bursting by steam, solid-liquid separating, adding nutritive liquid into solid-phase substance, sterilizing, adding distiller's yeast and cellulose degrading microbe into saccharifying fermentative substrate, degradation saccharifying-fermenting synchronously, distilling and rectifying to obtain final product. It is simple, has short saccharifying and fermenting period, higher raw material utilization rate and more alcohol yield and no feedback inhibition function.

Owner:HARBIN INST OF TECH

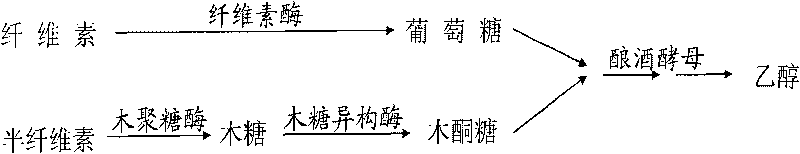

Method for producing ethanol by fermenting straws

ActiveCN101705255AOvercome stabilityOvercoming the deficiency of high residual xyloseBiofuelsMicroorganism based processesIsomerizationXylanase Y

The invention provides a method for producing ethanol by synchronizing saccharification, isomerization and fermentation of lignocellulose. In the method, cellulase, xylanase and xylose isomerase are used to enzymolyze the lignocellulose, and enzymolysis products are fermented to obtain the ethanol. The method adopts the synchronous saccharification, isomerization and fermentation of the lignocelluloses to produce the ethanol, and has the advantages of reducing the negative feedback inhibition of the enzymolysis products on the cellulase and the xylanase, increasing enzymolysis rate, shortening a fermentation period, reducing production cost and the like.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for fermentation-membrane separation combined production of long-chain dicarboxylic acid

ActiveCN104862348AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationAlkaneCandida viswanathii

The invention discloses a method for fermentation-membrane separation combined production of long-chain dicarboxylic acid and especially relates to a method for high yield production of dodecanedioic acid (DC12). The method comprises introducing a Candida viswanathii culture seed liquid into a liquid fermentation medium mixed solution which contains 5-40% (v / v) of C10-C18 n-alkane and 95-60% (v / v) of saccharic multielement substrate as a growth carbon source and has pH of 5.0-8.5, carrying out culture on the mixed solution under conditions of a temperature of 24-40 DEG C and ventilatory capacity of 0.1-3.0vvm for 42-194h, starting a fermentation-membrane separation combined device, returning the cells separated by the combined device into a fermentation cylinder, feeding the permeate liquid separated by the combined device into an extraction unit, preparing long-chain dicarboxylic acid, simultaneously, supplying a medium into the fermentation cylinder and carrying out fermentation. In n-dodecane transformation production of DC12, the method has an acid yield of 250g / L and an acid production rate of more than 1.6g / h.L, improves microbial density in fermentation, shortens a fermentation period, improves dicarboxylic acid production intensity and returns the unused n-dodecane into the fermentation unit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for quickly producing bio-organic fertilizer by using tobacco stalks and bio-organic fertilizer

InactiveCN103058725ARealize resourcesEfficient killingBio-organic fraction processingOrganic fertiliser preparationEcological environmentFlora

The invention discloses a method for quickly producing a bio-organic fertilizer by using tobacco stalks and the bio-organic fertilizer. The raw materials for producing the bio-organic fertilizer in the method comprise the following substances in percentage by weight: 30 to 70 percent of tobacco stalks subjected to steam explosion treatment, 20 to 50 percent of mixed accessories, 5 to 15 percent of conditioning agent and 1 to 5 percent of microbial flora; and the bio-organic fertilizer is prepared through an aerobic composting process, wherein the stacking C / N ratio is adjusted to be 25 to 35 / 1, the water content is adjusted to be 50 to 65 percent, the pH is controlled to be 5.0 to 8.5, the strip stamping height is 1.0 to 1.5 m, and the tobacco stalks are crushed, screened and packaged after reaching a maturity index. The method has the characteristics of fast treatment, high efficiency and fast maturity, and has an important practical significance for fully using wasted tobacco stalk resources, improving the ecological environment of tobacco planting areas and reducing environmental pollution. The bio-organic fertilizer has high organic content, has the effects of improving the soil structure and improving the soil fertility, and can be widely used for planting economic crops of tobaccos, vegetables and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

Method for quickly producing carotenoid by utilizing microaerobic fermentation of rhodobacter sphaeroides

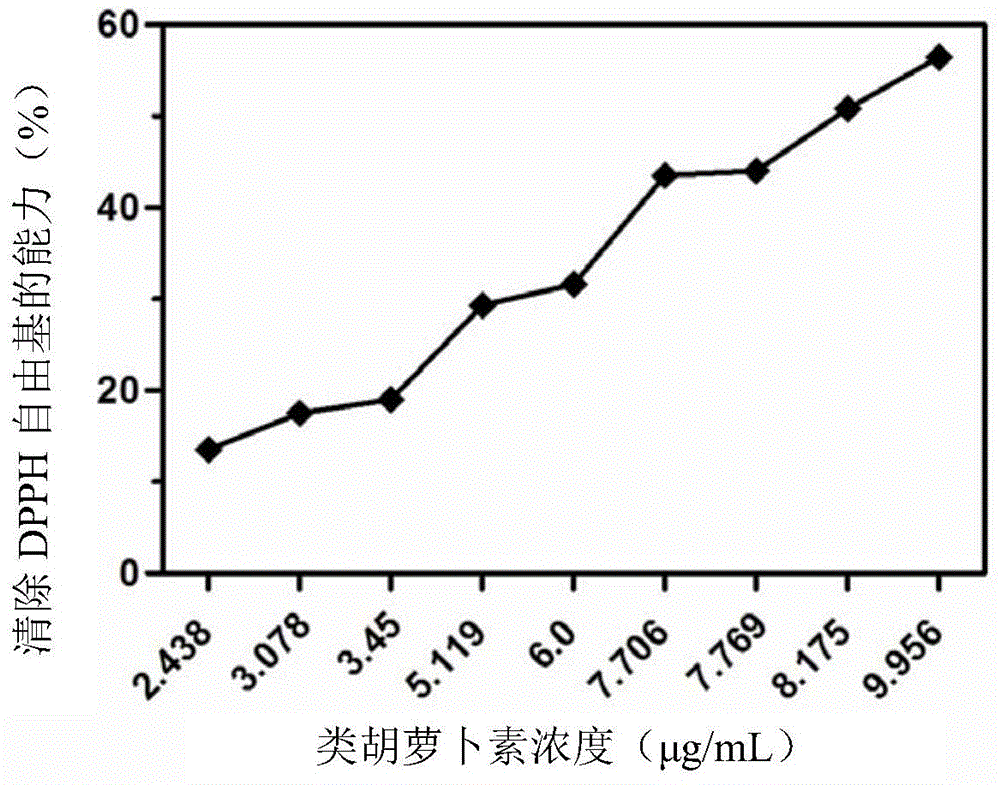

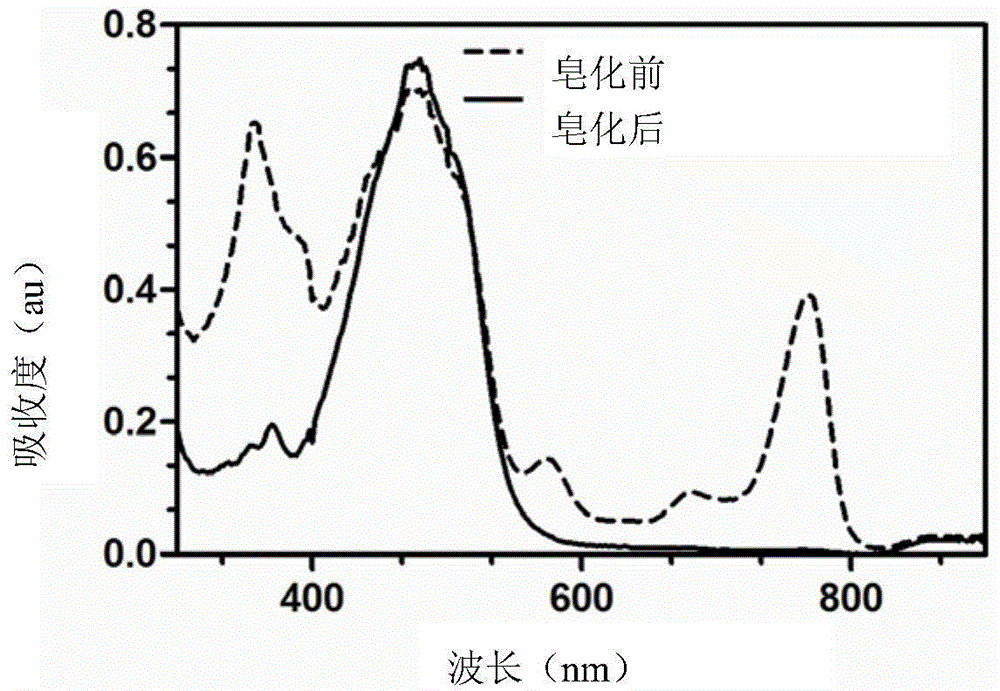

ActiveCN104805168AIncrease production capacityShort fermentation timeMicroorganism based processesFermentationDPPHFermentation

The invention discloses a method for quickly producing carotenoid by utilizing microaerobic fermentation of rhodobacter sphaeroides. The method comprises the following particular steps that the activated rhodobacter sphaeroides is inoculated to an MMS (methylmercuric sulfate) culture medium; aerobic culture is performed until OD600 (optical density 600) is 0.6-0.8; a culture condition is adjusted to be microaerobic; the carotenoid is induced to be quickly and greatly synthesized; and then extraction and purification are performed. The time for producing the carotenoid by the method is short and only 36h; the yield of thallus is up to 6g / L; the yield and the productivity of the carotenoid are 8.287mg / L and 1911mug / g respectively; the carotenoid has good capacity for removing DPPH (1,1-diphenyl-2-picryl-hydrazyl) radicals; and IC50 (half maximal inhibitory concentration) is about 8mug / mL.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

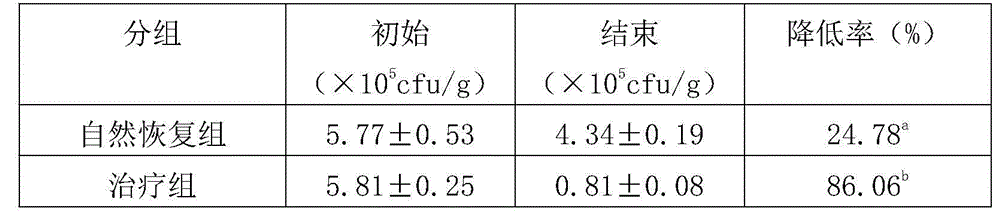

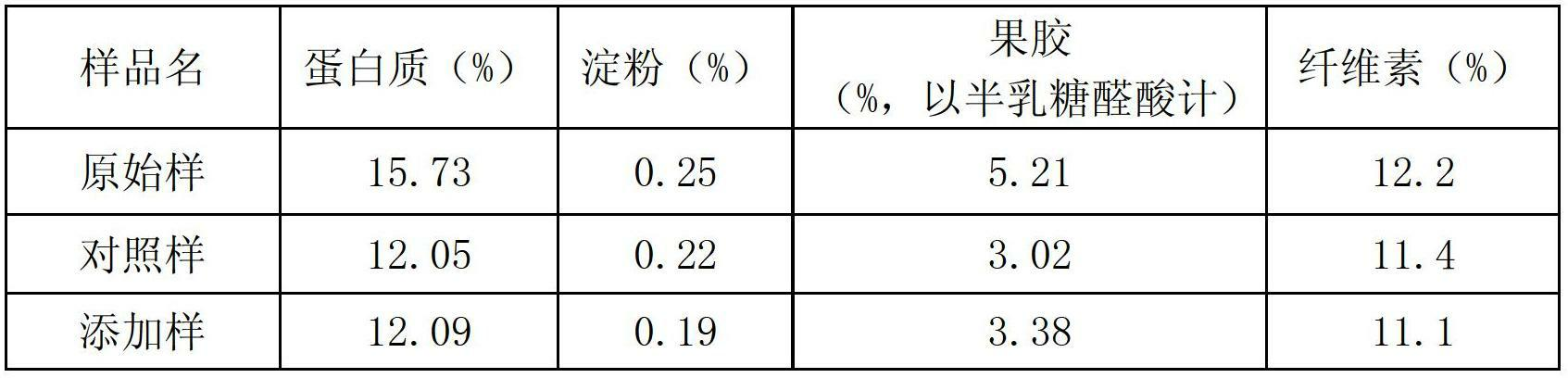

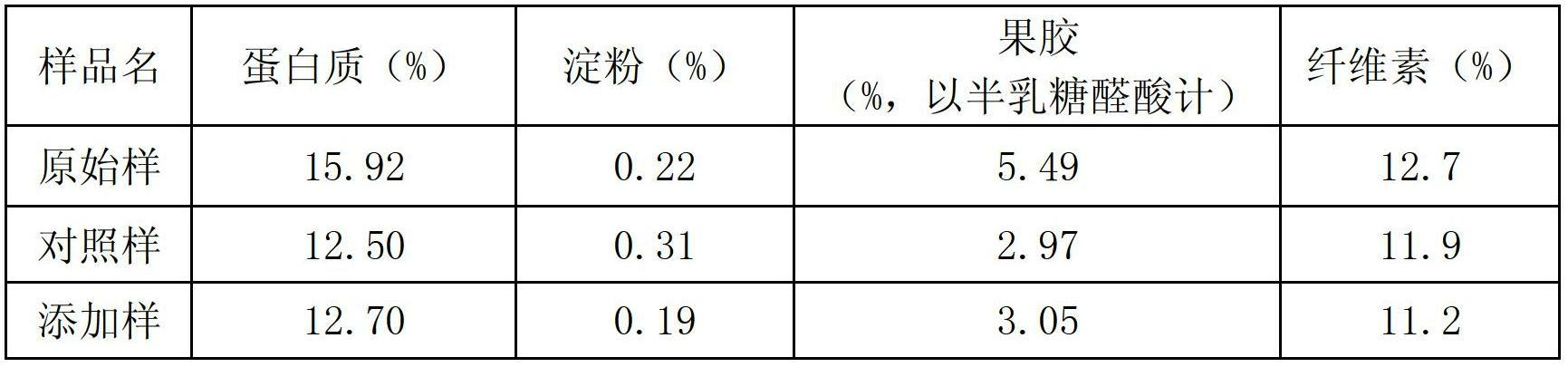

Microbial preparation for shortening tobacco fermentation period and application of microbial preparation

InactiveCN102660461AEfficient degradationLess irritatingBacteriaTobacco treatmentCelluloseNicotiana tabacum

The invention relates to a microbial preparation for shortening a tobacco fermentation period and application of the microbial preparation, and relates to the technical field of microorganism and tobacco processing. The microbial preparation comprises bacillus cereus and bacillus amyloliquefaciens from tobaccos, and the ratio of the live bacillus cereus to the live bacillus amyloliquefaciens is 10-200:1-50. The powdery microbial preparation is obtained by means of separation, culture and preparation and is dissolved into sterile water according to the proportion of 0.5-5%, formed water aqua is uniformly sprayed on tobaccos according to the proportion of 3-10%, and the tobaccos are artificially fermented for 10-40 days at the temperature ranging from 25 DEG C to 50 DEG C and the humidity ranging from 65%RH to 80%RH. Tests show that cellulose, protein, pectin and the like in the tobaccos can be degraded effectively, and the tobacco fermenting period is shortened to 10-40 days. Artificially fermented tobaccos are not obviously different from naturally alcoholized tobaccos in terms of quality, the tobacco fermenting period is shortened, and the quality of the tobaccos can be improved.

Owner:CHINA TOBACCO CHUANYU IND

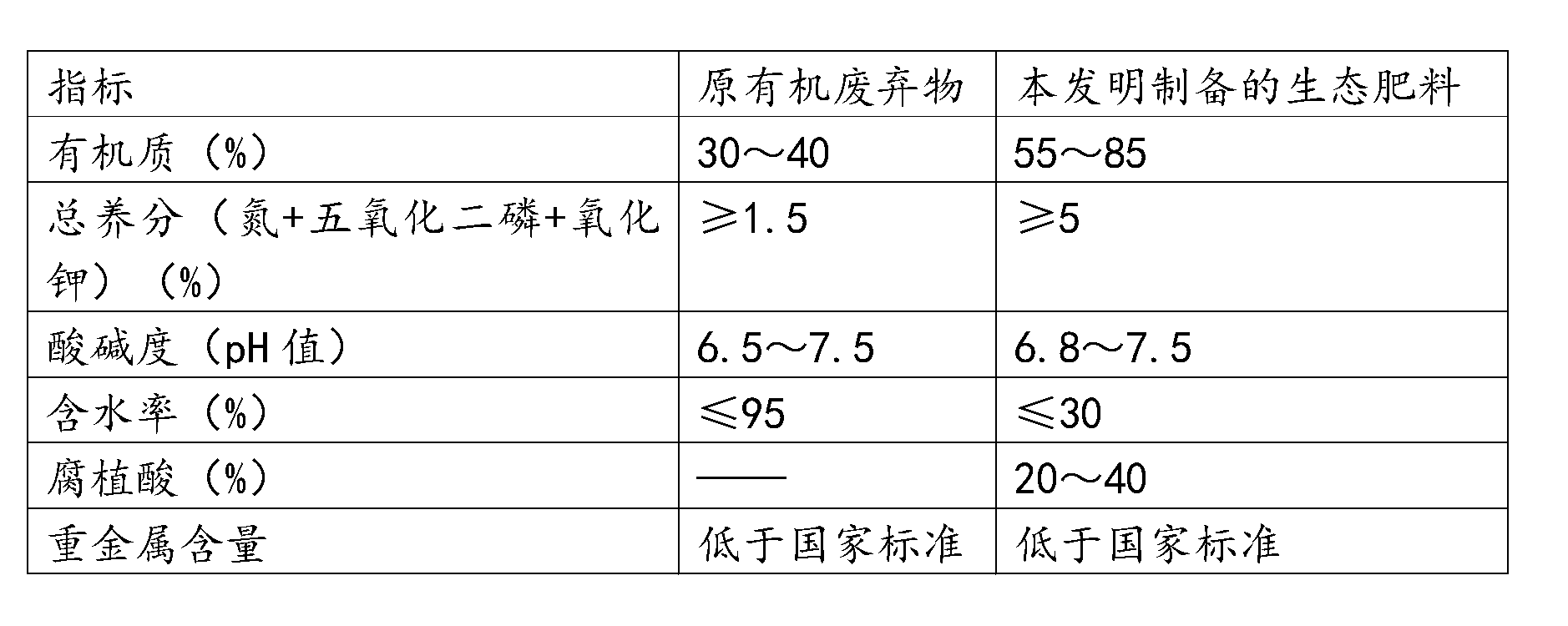

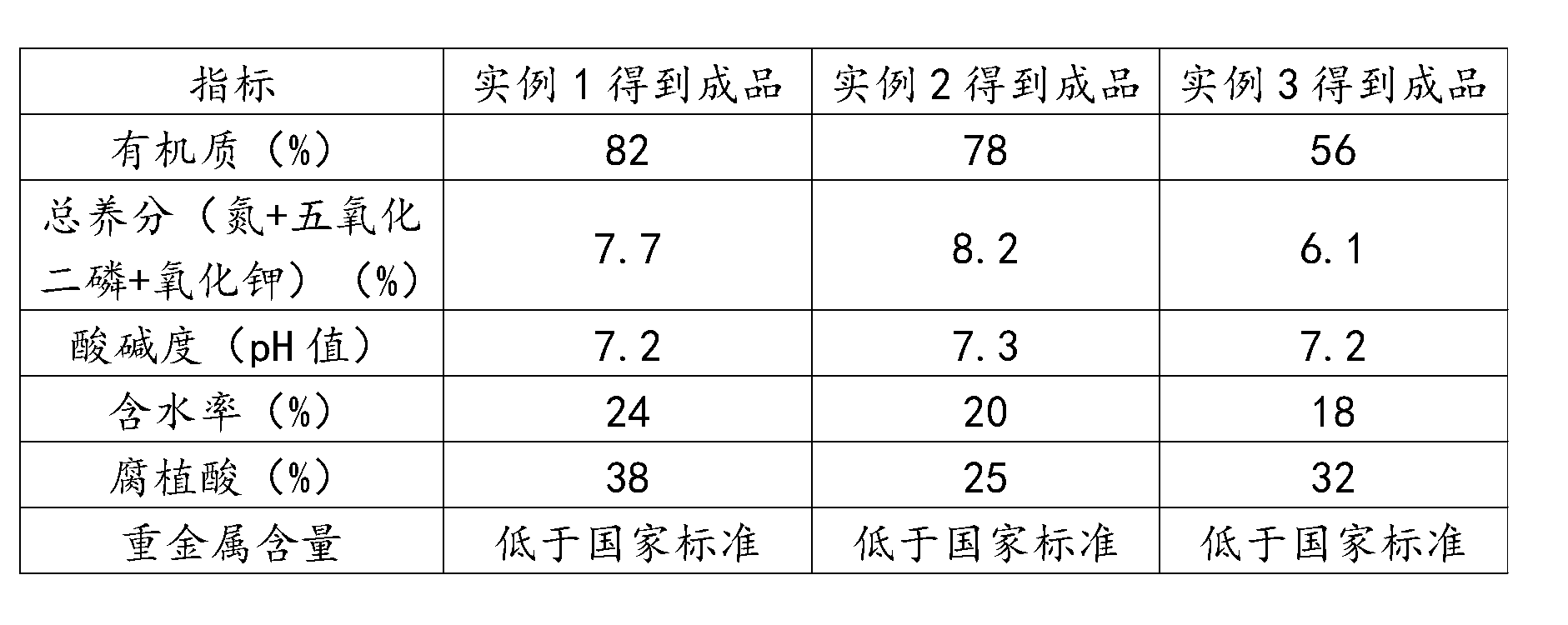

Method for preparing ecological organic fertilizer from organic waste

InactiveCN103183541ANo secondary environmental pollution problemsGood wall breaking effectBio-organic fraction processingOrganic fertiliser preparationResource utilizationMicrobial agent

The invention relates to a method for preparing an ecological organic fertilizer from organic waste. The method comprises the following steps of putting the organic waste of which the moisture content is within 95% into a subcritical water reaction kettle, adding biomass which is 0-10% of the organic waste, feeding NaOH to the reaction kettle to adjust the pH to 7.5-8.5; leading steam into the reaction kettle, adjusting the temperature to 150-300 DEG C and the pressure to 0.5-5.0MPa to react for 15-60 minutes; baking or dewatering the product until the moisture content is 50-65%; feeding a microbial agent which is 0.5-1% of weight of the product to the baked or dewatered product; evenly mixing and then piling, heating the pile to 60-70 DEG C after 2-3 days to be stable, and carrying out heat preservation at 55-65 DEG C to maintain for 5-7 days, and turning when the temperature exceeds 65 DEG C and preparing the product until the temperature is not changed. By adopting the method, the limitation of the traditional aerobic fermentation is broken through; pathogene can be thoroughly killed; no bad smell or heavy metal pollution appears; the treatment cost is reduced; the treatment efficiency is improved; and the highest target of resource utilization of the organic waste is achieved.

Owner:ROAD ENVIRONMENT TECH

Chinese beimao spore liquid culture fermentationi technology

A liquid fermentation process for the Chinese pilous spore includes such steps as getting bacterial spawn, Erlenmeyer flask culture of bacterial spawns, liquid seed culture, and liquid fermenting. Its advantags are high successful rate, low cost and no environmental pollution. The resultant mycelia can be used for medical or health-care product. The fermented liquid can be used as oral liquir or beverage.

Owner:安徽林苑虫草研究所

Method for improving content of ganoderma triterpenes in ganoderma liquid deep fermentation mycelium

InactiveCN104017852AIncrease dissolved oxygen concentrationImprove permeabilityFungiMicroorganism based processesBiotechnologyMycelium

The invention relates to a method for improving content of ganoderma triterpenes in ganoderma liquid deep fermentation mycelium, and the method is as follows: 1, taking a slant mycelium ganoderma strain, picking a sclertium for inoculating into a seed culture medium, after the inoculation, culturing for 7-14 days to obtain a seed culture liquid; 2, inoculating the cultured seed culture liquid into a fermentation medium according to the inoculum concentration of 5%-15%, after the inoculation, culturing for 3 to 10 days, adding 1vol%-5vol% of oleic acid in the fermentation culturing process to finally obtain ganoderma mycelium for further extract of the ganoderma triterpenes. The method has the advantages of being simple in process and effective, has application value in the industrial production, can successfully achieve significant improvement of yield of an expression product, shortens the fermentation cycle, improves the production efficiency, and has certain guidance and inspiration significance to optimize the fermentation process of other fungal mycelium.

Owner:SHANGHAI ACAD OF AGRI SCI

Method for producing specialized organic fertilizer for protected cultivation by silkworm excrement fermentation

InactiveCN102432356ASimple processShort fermentation cycleBio-organic fraction processingOrganic fertiliser preparationMicroorganismOrganic fertilizer

The invention discloses a method for producing a specialized organic fertilizer for protected cultivation by silkworm excrement fermentation, comprising the following steps of: inoculating active microorganisms to silkworm excrement, uniformly stirring, fermenting at high temperature, drying, granulating and sieving. According to the invention, silkworm excrement can be fully utilized to save resources and solve the pollution problem of waste silkworm excrement. The pH value of the silkworm excrement specialized organic fertilizer prepared in the invention ranges from 7.0 to 8.0, thus effectively solving the soil acidification problem frequently caused in protected cultivation. The organic fertilizer maintains original growth activating substances of silkworm excrement, contains a lot of beneficial microorganisms and more than 50% of organic matters, can be used to increase crop yield, improve crop quality and fertilize and improve soil, and is a good fertilizer for the production of nuisance free agricultural products.

Owner:ZHEJIANG UNIV

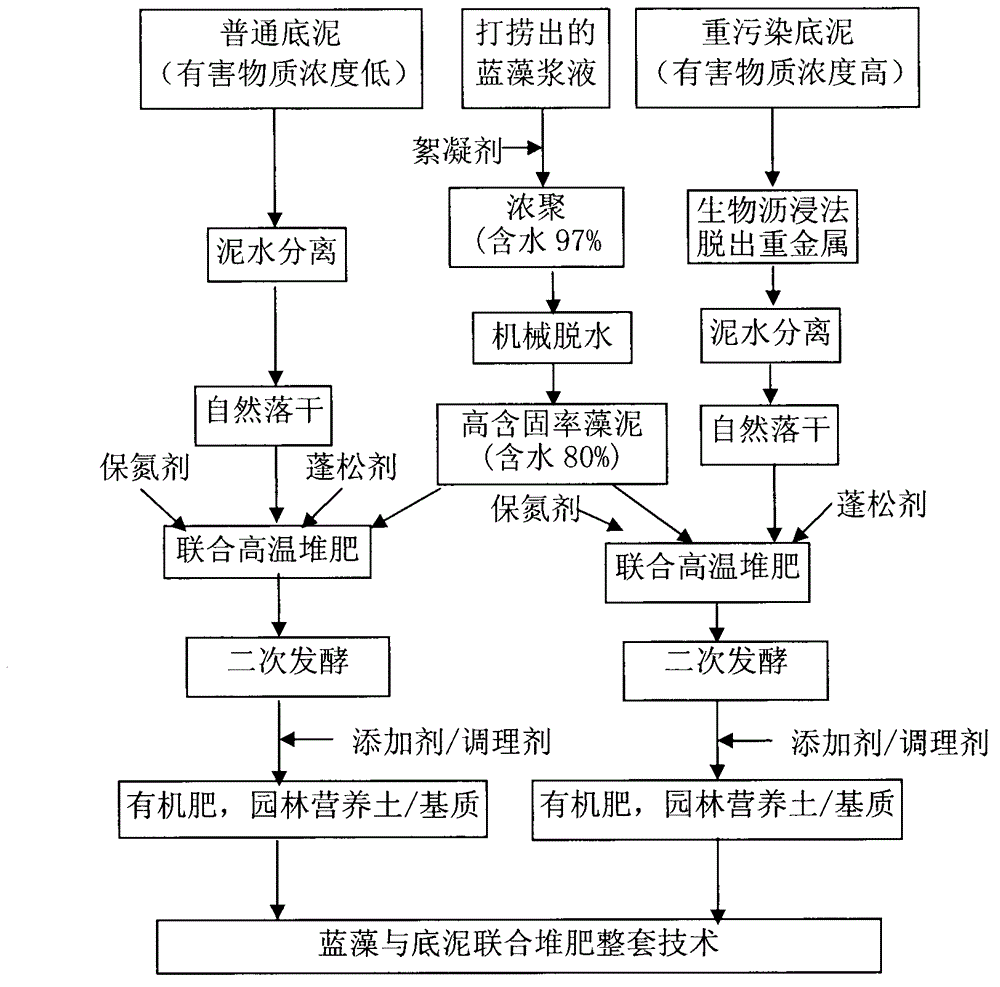

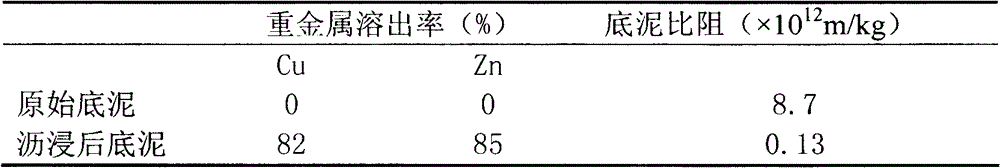

Method for co-composting of blue-green algae and polluted bottom sediment

InactiveCN102875210AComprehensive nutritionFull of nutritionBio-organic fraction processingOrganic fertiliser preparationBiological growthGreen algae

The invention relates to a technology for co-composting of blue-green algae and polluted bottom sediment, and belongs to the technical field of environmental engineering. The technology comprises the following steps: at first, heavy metal in the polluted bottom sediment is removed by adopting a bioleaching technology, then blue-green algae and the polluted bottom sediment are mixed, the physicochemical property of the mixture of the blue-green algae and the bottom sediment is regulated to the condition needed by growth of aerobic fermentation microorganisms through adopting conditioners such as straws, rice husks, bran, spent mushroom composts, dregs of decoctions, wood chips and the like by means of the characteristics of high water content of the blue-green algae and C / N ratio imbalance and the like, a certain quantity of nitrogen conserving agents is added, and then a forced ventilation fermentation manner is adopted in a compost factory, the temperature of the compost is increased to be more than 60 DEG C within an extremely short time, the high-temperature fermentation period is kept for about 15 days, and the compost is transferred in a secondary fermentation zone till the compost is decomposed thoroughly after the high-temperature fermentation period is ended. The technology achieves the cleanness of the polluted bottom sediment and large-scale treatment of the quick composting of blue-green algae and the polluted bottom sediment, and combines the harmlessness and the reclamation of the algae and the polluted bottom sediment organically.

Owner:NANJING AGRICULTURAL UNIVERSITY

Preparation method for capsicum thick broad-bean sauce

InactiveCN104207106ARealize large-scale productionClean thoroughlyFood preparationGlass fiberCapsicum annuum

A preparation method for capsicum thick broad-bean sauce employs the following steps: step 1, preparing cleaned fresh capsicum accounting for 70% by weight of raw materials; step 2, crushing fresh capsicum obtained in the step 1 for usage; step 3, mixing crushed capsicum obtained in the step 2 with broad bean accounting for 30%, pumping the mixture into a food-grade glass-fiber-reinforced-plastic fermentation tank by a pump and stirring uniformly; step 4, after uniform stirring is performed, controlling the temperature to be 28-38 DEG C, and performing fermentation, when the temperature is relatively low, conveying steam through a stainless steel pipe twinning round the tank body for keeping warm, guaranteeing the fermentation temperature, stirring once every 3-5 days during fermentation, stirring for 20 min in each stirring process, and fermenting for 5 months, so as to obtain a finished product; and step 5, opening a discharging port at the bottom of the tank and discharging the fermented finished product capsicum thick broad-bean sauce, performing product detection and packaging and warehousing. The preparation method realizes scalization, intensification and cleansing, and helps to save production field, reduce labor cost, shorten fermentation period and improve production efficiency.

Owner:遵义市名城酿造厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com