Brewage of fruit wine, vinegar and brandy

A technology for brewing fruit wine and brandy, which is applied in the preparation of vinegar and alcoholic beverages, etc., can solve problems that cannot be solved by fruit production technology, and achieve the effects of filling market product vacancies, reducing costs, and shortening the fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

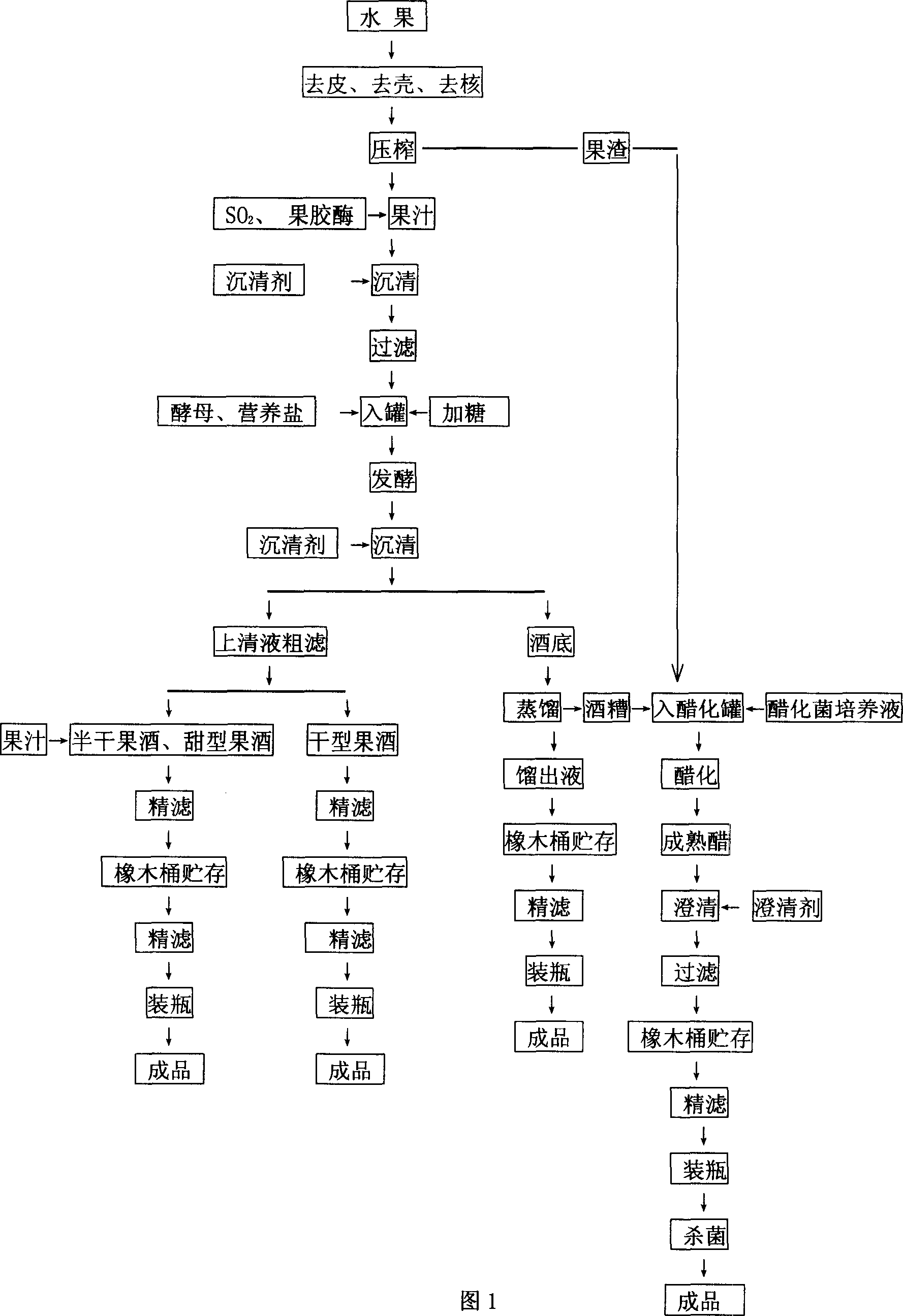

Image

Examples

Embodiment 1

[0032] Embodiment 1 selects pineapple as raw material

[0033] (1) Pineapple wine

[0034] (1) Clean the pineapple with a fruit washing machine, and extract the juice with a press;

[0035] (2) Add pectinase in the ratio of 2g / l to the fruit juice; add SO in the ratio of 50ppm / l 2 , after passing the small test, add clarifying agent in a certain proportion, and then clarify for about 2 days;

[0036] (3) Put it into the fermentation tank after filtering, adjust the sugar content to 150g / l, add nutrients: ammonium sulfate 1.5g / l, vitamin B 1 0.06g / l, at the same time add fruit wine active dry yeast at a ratio of 1.5g / l;

[0037] (4) The fermentation temperature is controlled at 15-16°C. When the sugar content drops to 70-80g / l, add sucrose and continue the fermentation. The fermentation time is 7-10 days;

[0038] (5) Add clarifying agent for clarification for 3 days, take the supernatant and coarsely filter it, and then fine filter it with a fine filter machine to obtain ...

Embodiment 2

[0050] (1) Orange fruit wine

[0051] (1) Remove the orange peel and squeeze the orange meat with a press

[0052] (2) The following steps are the same as the pineapple wine

[0053] (2) Orange brandy

[0054] The steps are the same as the pineapple brandy.

[0055] (3) Orange vinegar

[0056] (1) Put orange grains and orange pomace with alcohol content of 5-6% (orange pomace needs to be mixed with 15% bran, husk or wheat husk) into the vinegarization tank. The ratio of orange pomace to orange distiller's grains is 3:1.

[0057] (2) The following steps are the same as pineapple wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com