Patents

Literature

4256 results about "Husk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Husk (or hull) in botany is the outer shell or coating of a seed. It often refers to the leafy outer covering of an ear of maize (corn) as it grows on the plant. Literally, a husk or hull includes the protective outer covering of a seed, fruit, or vegetable. It can also refer to the exuvia of bugs or small animals left behind after moulting.

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

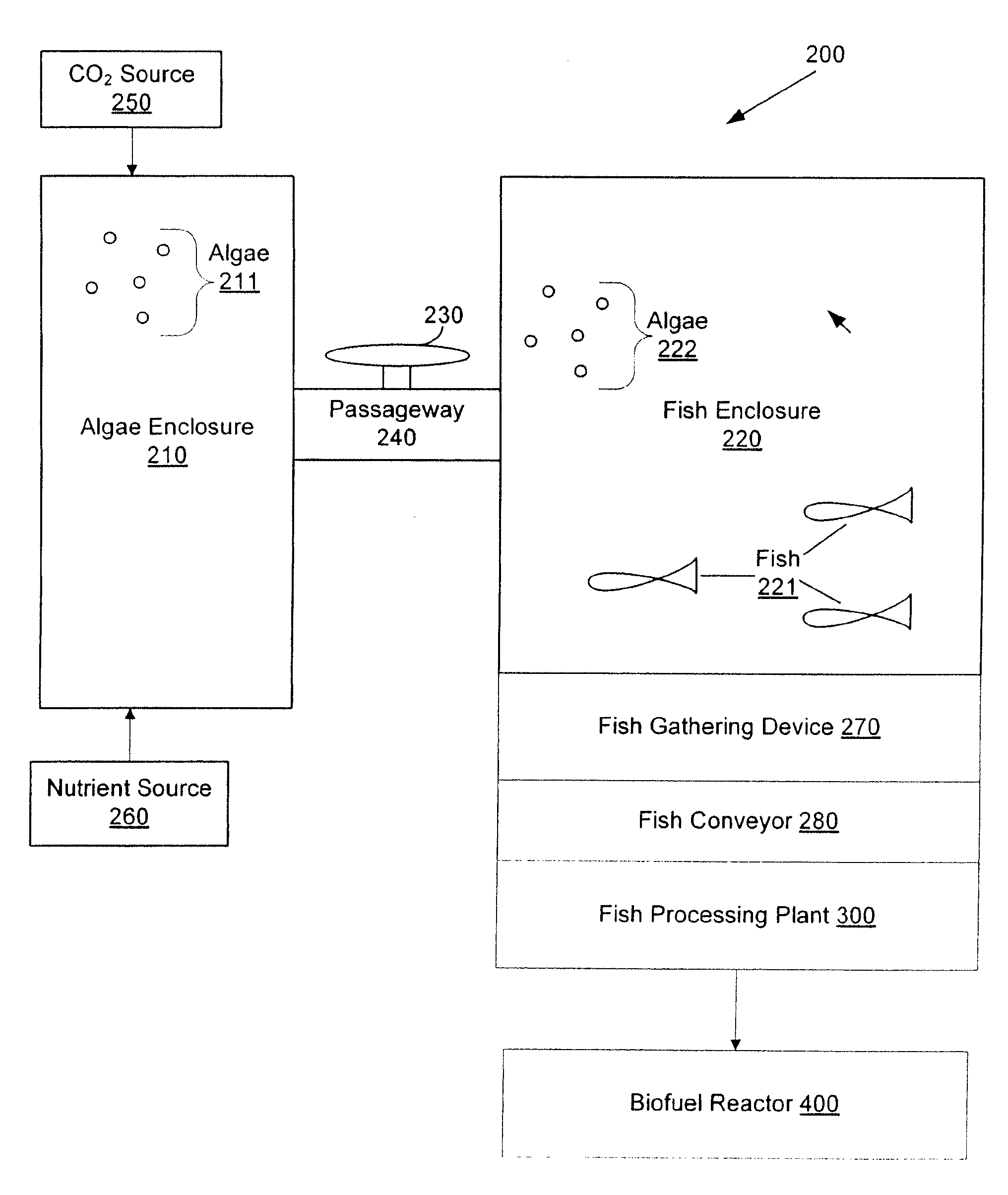

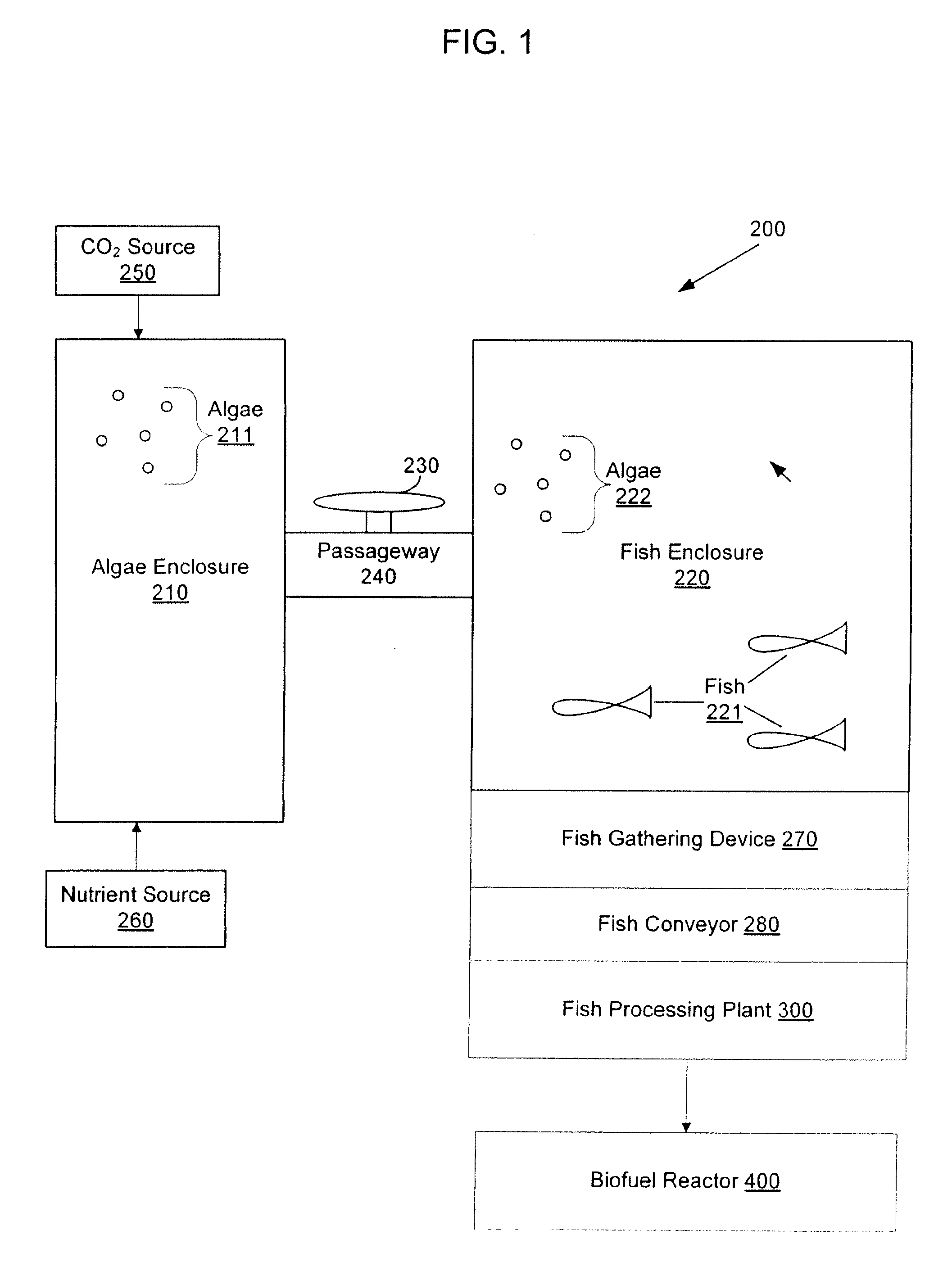

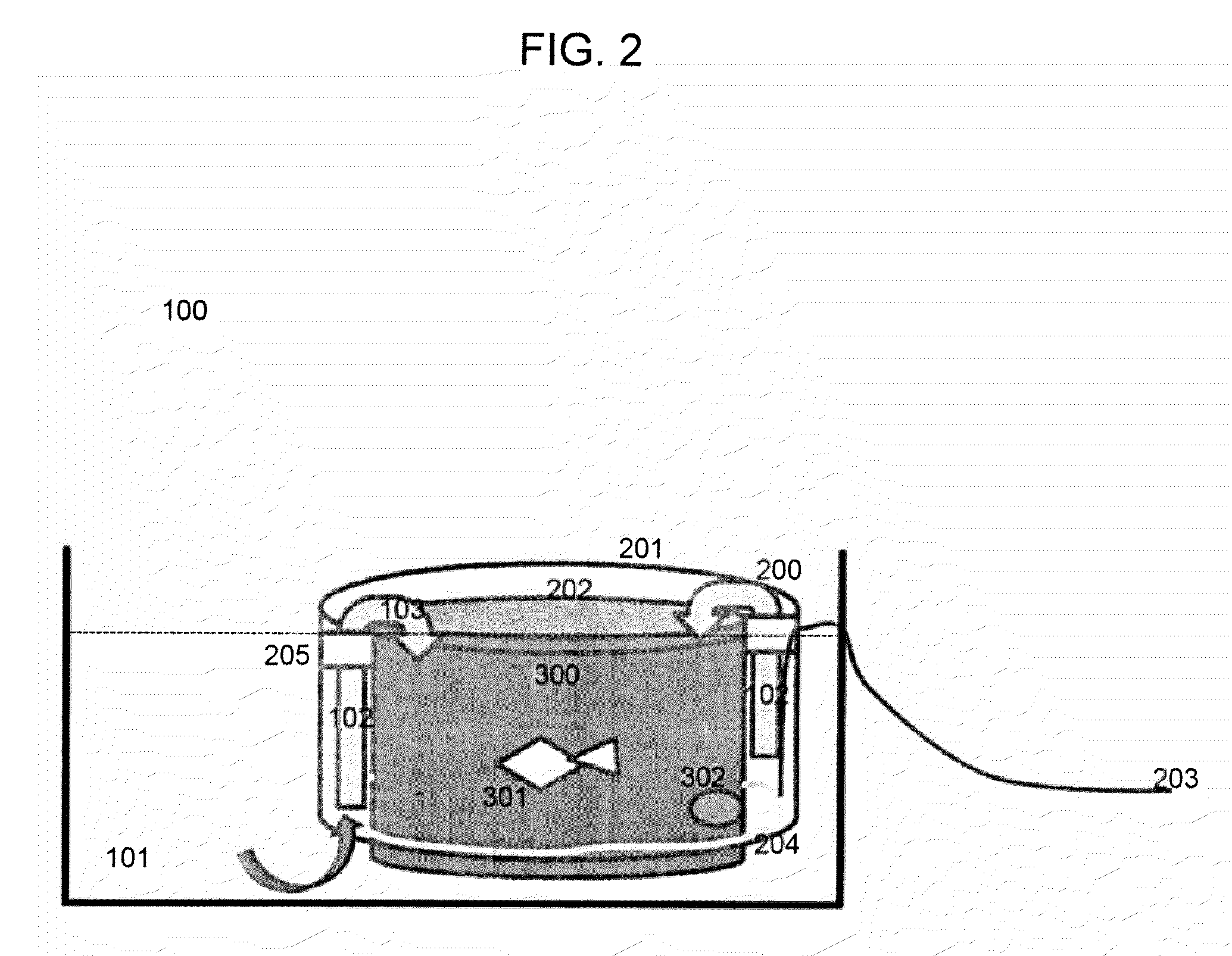

Systems and methods for producing biofuels from algae

The invention provides systems and methods for producing biofuel from algae that use cultured fish to harvest algae from an algal culture. The methods further comprise gathering the fish, extracting lipids from the fish, and processing the lipids to form biofuel. The multi-trophic systems of the invention comprises at least one enclosure that contains the algae and the fishes, and means for controllably feeding the algae to the fishes. The lipid compositions extracted from the fishes are also encompassed.

Owner:LIVEFUELS

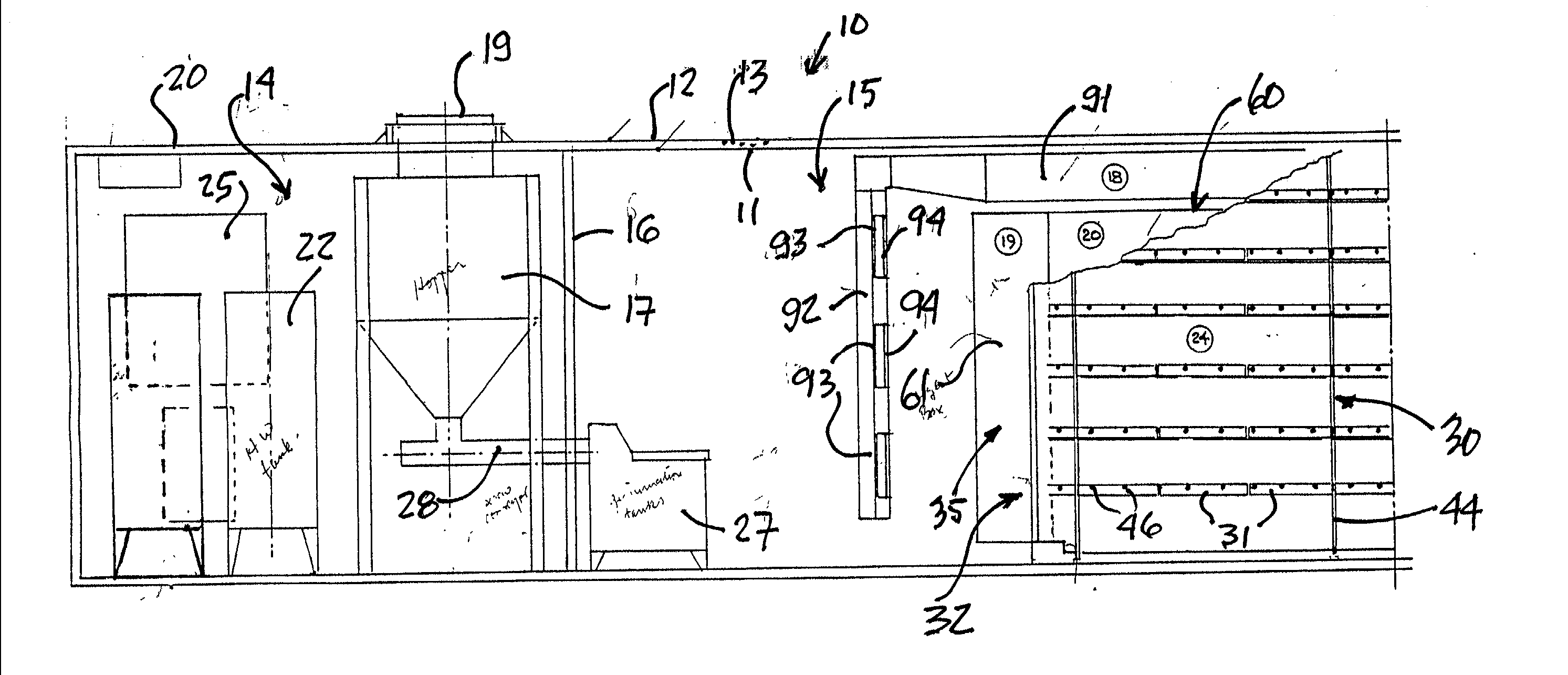

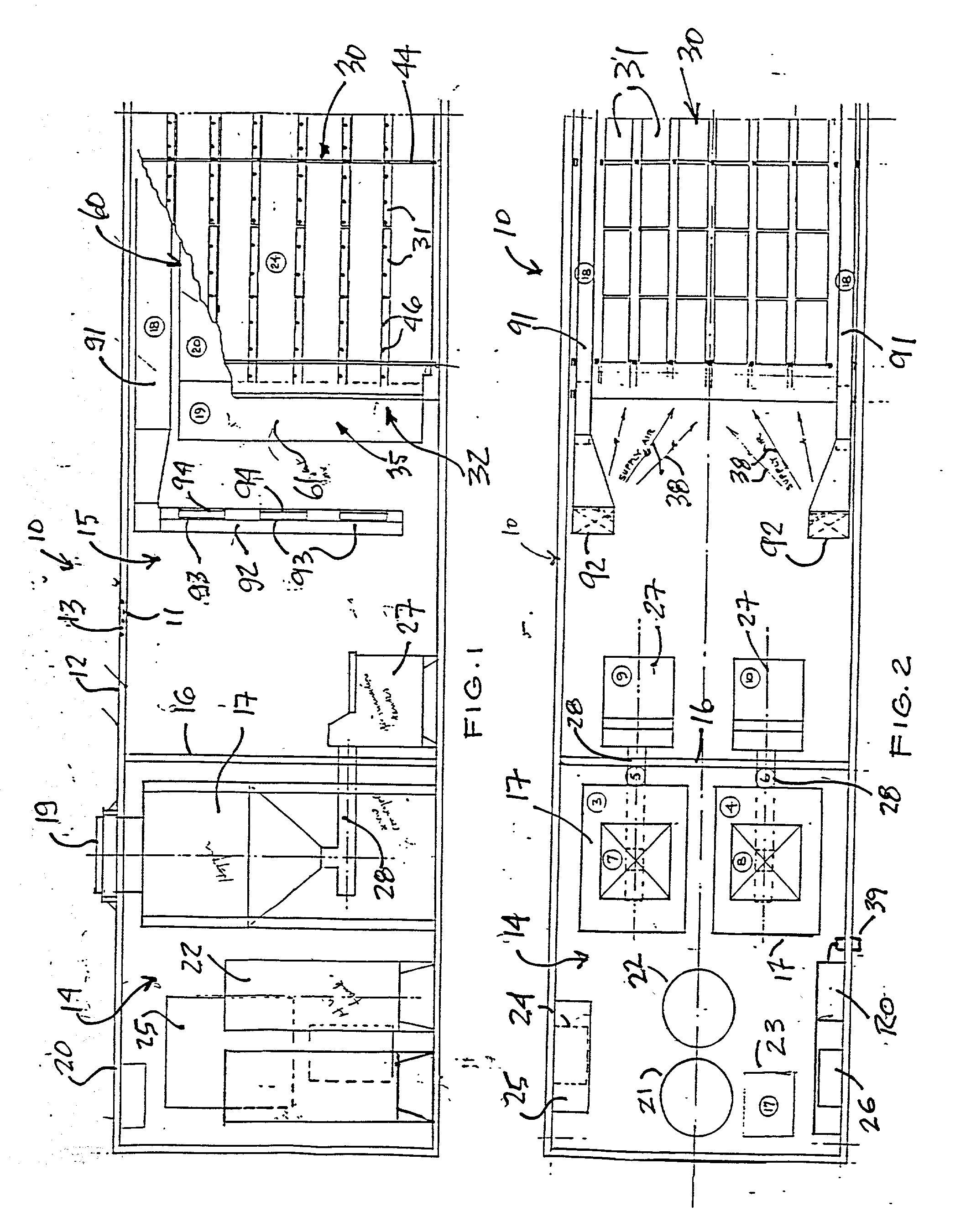

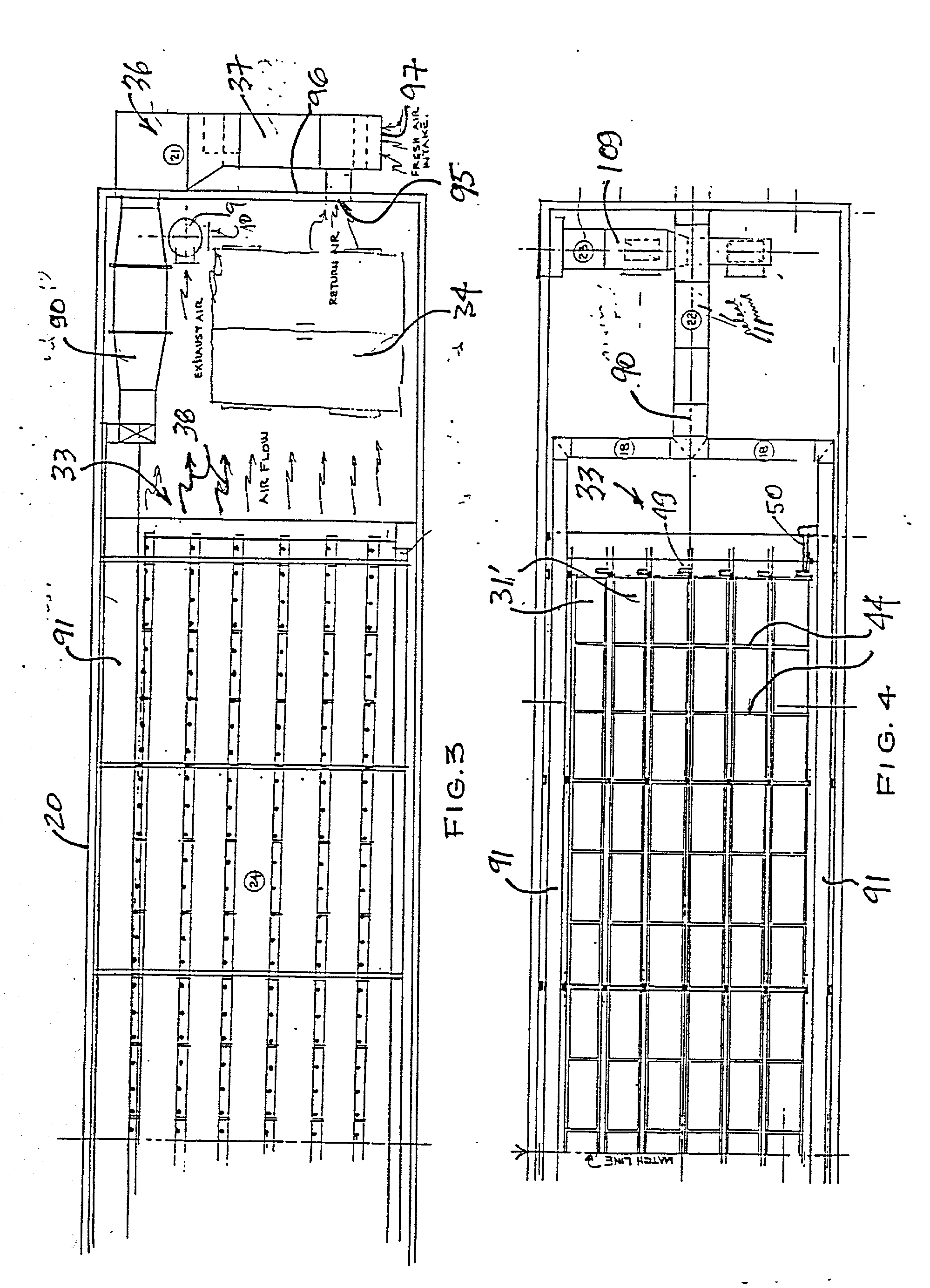

Hydroponic growing enclosure and method for the fabrication of animal feed grass from seed

InactiveUS20030101645A1Easy to useAgriculture gas emission reductionCultivating equipmentsAnimal feedSprouted Seeds

A self-contained hydroponic growing enclosure and method for the fabrication of animal feed grass from seed is described. The enclosure is a self-contained enclosure which is insulated and which can be transported or assembled on site and which is independent of outside climatic conditions. Seed is stored in an isolated portion of the enclosure and fed to germination tanks in predetermined quantities where the seeds are germinated for a predetermined period of time. The tanks are then drained of their iodine-treated water and the germinated seeds are placed in predetermined quantities onto trays which are placed at an inlet end of a racking system. Trays are removed with grown grass at a harvest outlet end of the racking system in the same sequence as they are placed at the inlet end, so that there is a continuous daily supply of feed grass. Light walls are provided on opposed sides of the racking system to illuminate the beds. Conditioned air is also convected through the racking system from the inlet end to the outlet harvest end and the air flow distributes carbon dioxide generated in an inlet end section by the germinating seed grain, over the entire growing beds. The beds are also sprayed with water and the air flow is reconditioned by an air conditioning unit, filtered to remove bacteria and recirculated through the racking system. More specifically, the production system uses feed-quality barley for growing in tray beds to produce approximately 2,200 pounds of feed grass per day in a 7-day cycle from seed to feed.

Owner:COLE ROBERT +1

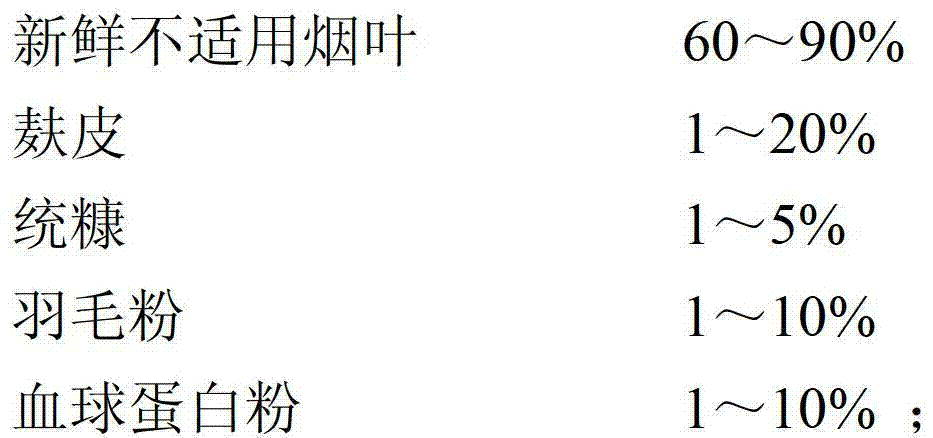

Method for processing inapplicable tobacco leaves by musca domestica larva to prepare biological protein feed

ActiveCN103109972ARealize resource utilizationIncrease profitAnimal feeding stuffAnimal scienceResource utilization

The invention discloses a method for processing inapplicable tobacco leaves by musca domestica larvae to prepare a biological protein feed, and belongs to the technical field of environmental protection. The method for processing the inapplicable tobacco leaves by the musca domestica larvae to prepare the biological protein feed comprises the steps of: crushing fresh inapplicable tobacco leaves until the grain size of the crushed leaves is 1-5mm; adding bran, mixture of rice chaff and husk, feather meal and spray-dried animal blood cells to prepare compost; and inoculating housefly eggs at the surface of the compost, cultivating the housefly eggs for 5 days at 25-35 DEG C, collecting the compost containing the musca domestica larvae, drying and preparing the biological protein feed. The method disclosed by the invention is strong in handling capacity, small in floor area, and low in energy consumption in the processing process, achieves the resource utilization of the inapplicable tobacco leaves, changes waste into precious resources, improves the environmental health, simultaneously produces the biologic protein feed, and has a good application prospect.

Owner:胡新军 +2

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

Preparation technique of big-leaf seed tea seed oil

InactiveCN101665742AAvoid the drawbacks of emulsification that is not easy to separateNot easy to blockFatty-oils/fats refiningFatty-oils/fats productionNutritive valuesHusk

The invention discloses a preparation technique of big-leaf seed tea seed oil. The preparation technique comprises the following steps: (1) squeezing the big-leaf seed tea seed oil: removing impurities, drying, husking, separating husks and kernels, softening, rolling embryos, braising, stir-frying and squeezing; and (2) refining the big-leaf seed tea seed oil: degumming raw oil, deacidifying, washing with water, dewatering, decolouring, deodorizing and filtering. The big-leaf seed tea seed oil prepared by the technique has the advantages of high oil output rate, superior oil quality, clear, bright and transparent colour, no bitter taste, pure fragrance and good mouth feel, and the nutritive value of the big-leaf seed tea seed oil is furthest protected. The big-leaf seed tea seed oil is not easy to be oxidized and deteriorate, has stable oil quality, safety, no toxicity, no side effect, and favorable properties of storage resistance and high-temperature resistance, is a better materialfor processing powdered oil, oleomargarin, salad oil and shortening oil and also can be used for cosmetics and medical oil.

Owner:陈军 +2

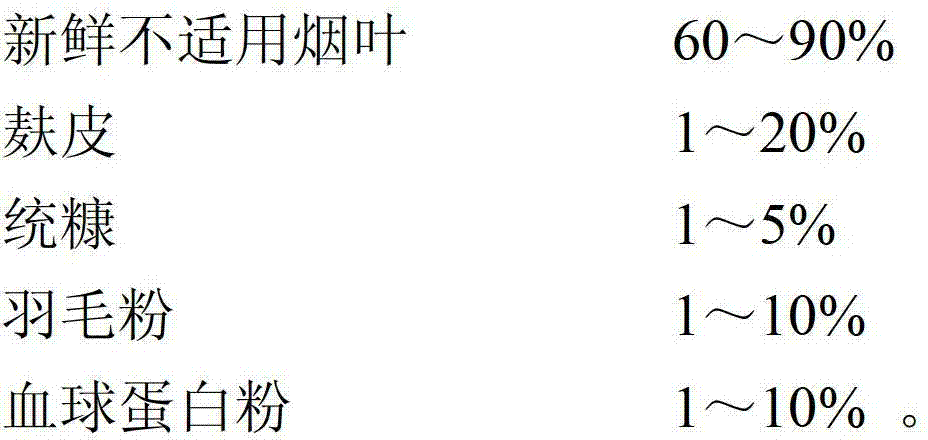

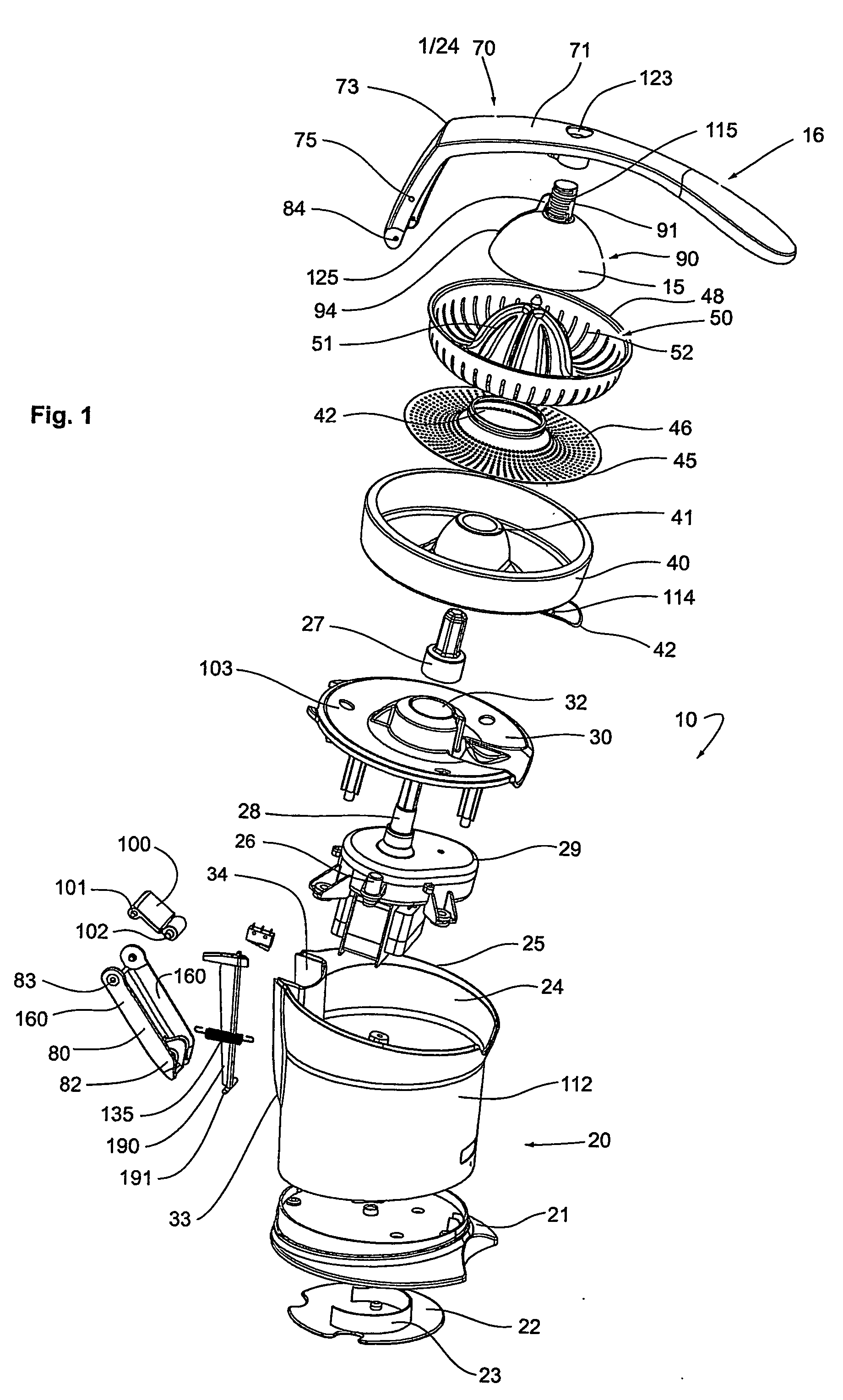

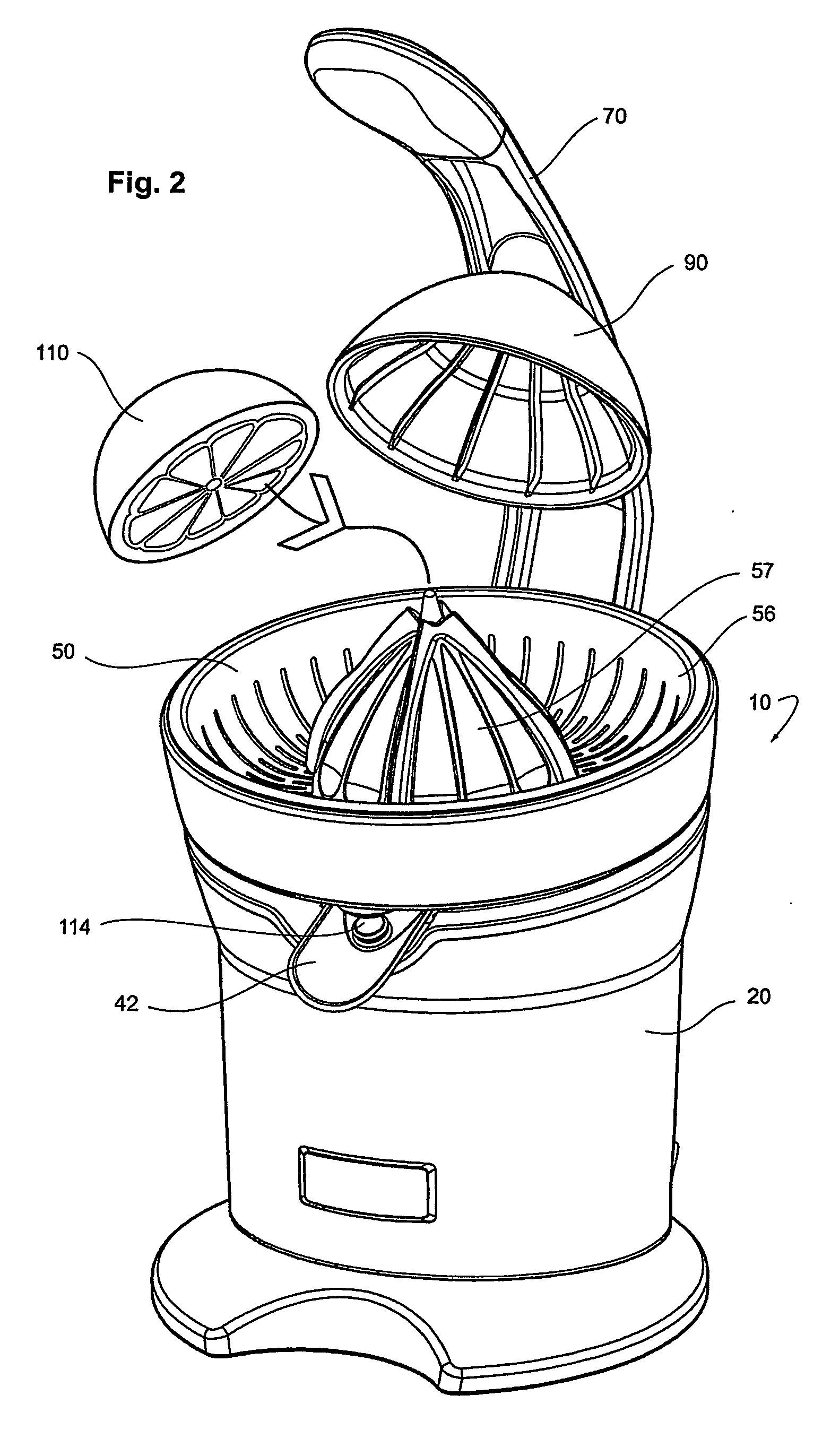

Citrus reamer and press

InactiveUS20070125244A1Simple and reliable processEfficient and versatileJuice extractionClosuresFruit juiceHusk

A reamer (50) for a citrus juicer (10) is formed from a plurality of ribs (53) including an upper profile and a lower profile. The ribs may be knife like to maximize juice extraction. Fruit may be brought into contact with the reamer by an actuating arm (70). The actuating arm preferably includes a four part linkage with a major pivot arm (80) and a minor pivot arm (85). In a motorized version, a housing (20) supports the reamer (50) and contains a motor and gear box (29). A juice collector (40) lies intermittent the housing (20) and the reamer (50), to collect the juice and optionally includes a filter (45) to remove pulp.

Owner:BREVILLE HLDG PTY LTD

Culture medium for Agaricus bisporus production and its application

InactiveCN1788540ARaw materials are easy to getReduce manufacturing costCuttersCutting implementsHuskCrop field

The present invention relates to bispore mushroom cultivating technology, and is especially one kind of bispore mushroom cultivating medium and its application. The cultivating medium consists of grass material 45í½55 wt%, dung material 35í½45 wt%, cake fertilizer 1í½8 wt%, urine 0.5í½1.0 wt%, gypsum powder 0.5í½1.5 wt%, calcium superphosphate 0.8í½1.5 wt%, lime powder 0.2í½1.5 wt%, calcium carbonate 0í½2.0 wt% and dichlorovos 0í½0.5 wt%. The grass material including rice straw, wheat straw, cotton seed husk, corn cob and corn stalk, and the dung material including cow dung, house dung and chicken dung account for at least 90 wt%. The cake fertilizer may be soybean cake, soybean powder, cotton seed cake and / or corn powder. The cultivating medium is used for cultivating bispore mushroom in tall stalk crop field and has biological conversion efficiency over 60 % and bispore mushroom yield over 25 kg / sq m.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

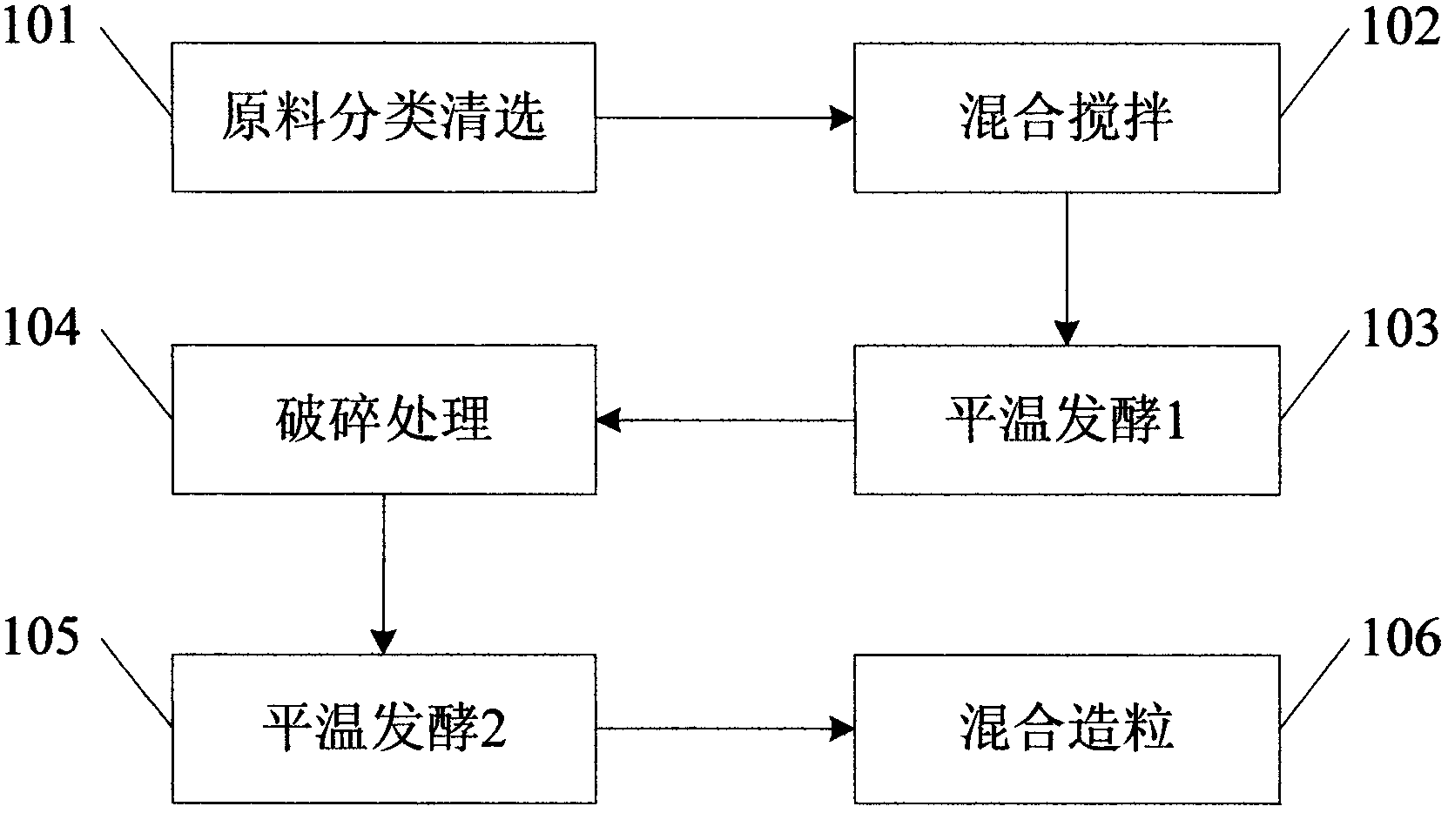

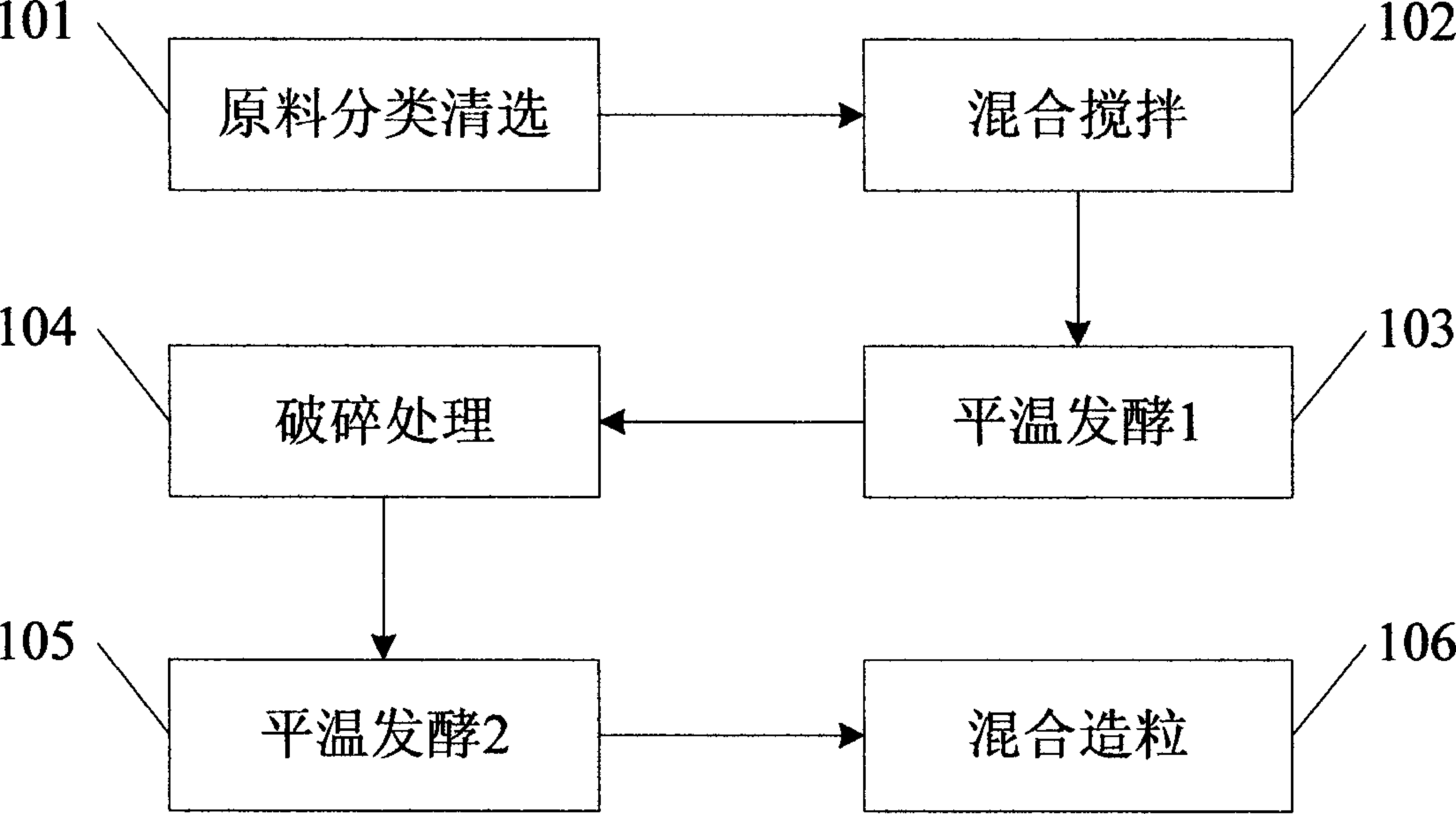

Microbial organic fertilizer and manufacture method of microbial organic fertilizer

ActiveCN102674996ASolve the problem of burning roots and seedlingsImprove survival rateBio-organic fraction processingClimate change adaptationFecesLivestock

The invention discloses an organic fertilizer, which comprises the following raw materials including livestock excrement, poultry excrement, organic matters, domestic garbage, meal cake, leaves, rice husks, straw, weeds, crop straw, fire ashes, nitrogen fertilizers, phosphoric fertilizers, potash fertilizers, trace elements, compound bactericides 1 and compound bactericides 2. The invention also discloses a manufacture method of the microbial organic fertilizer. The microbial organic fertilizer disclosed by the invention has the advantages that the technical problems are solved to realize the effect that the household garbage, the leaves, the weeds and the like are perfectly applied to the organic fertilizer, and the defects that in the existing organic fertilizer product, phenomena of root burning and seedling burning more or less exist, the fertilizer effect and the effect period are equivalent to that of chemical compound fertilizers, the soil improvement effect is poor, and the like are overcome.

Owner:石光忠

Culture medium of pleurotus eryngii and preparation thereof

InactiveCN101456772AShorten the growth cycleHigh biotransformation rateClimate change adaptationExcrement fertilisersSucroseOyster

The invention discloses a Pleurotus eryngii culture medium and a manufacturing method thereof. The culture medium comprises 75 to 80 percent of cottonseed hulls or wheat straws or straws or corncob, 5 to 12 percent of wheat bran or rice husks, 8 to 10 percent of dry fowl manure, 3 to 8 percent of cornmeal, 1 to 2 percent of hemihydrate gypsum, 0.5 to 1.5 percent of sucrose and 0.5 to 1.5 percent of quicklime, and is added with 0.1 to 0.3 percent of potassium dihydrogen phosphate and 0.1 to 0.2 percent of magnesium sulfate according to the total amount of the compositions, and various compositions are calculated by weight percentage. The cottonseed hulls or the wheat straws or the straws or the corncob and the dry fowl manure are stacked and retted before use; and the culture medium after cultivation of Pleurotus eryngii is subjected to on-the-spot returning treatment. By adoption of the technical proposal, the method can make branched oyster mushrooms organisms well grown, overcome the defect that the prior art has no culture medium specially prepared for branched oyster mushrooms, simplify the production process, shorten the growth period of the Pleurotus eryngii, and improve the bioconversion of the Pleurotus eryngii.

Owner:许忠

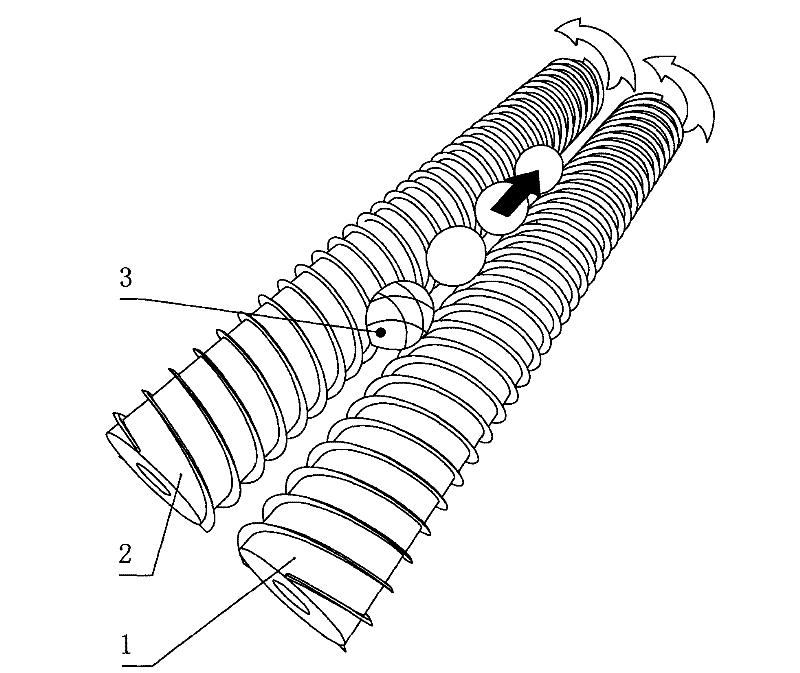

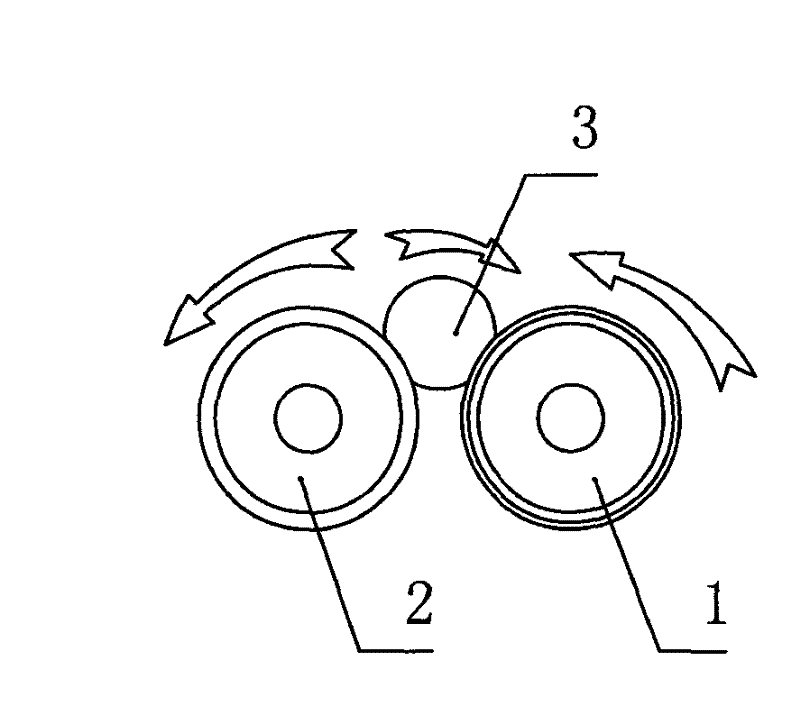

Method for stripping off green husk of nut through mechanized dry process

The invention discloses a method for stripping off green husks of nuts through a mechanized dry process and relates to a fruit processing technique, in particular to a processing technique for stripping off the green husks of the nuts. Crossed reticular knife marks are cut on the surfaces of fermented mature green nuts through two spiral knife rolls which have opposite spiral directions and rotate in the same direction at different speeds, and then the spiral knife rolls rotate to apply tangential force and axial force on the nuts to rotate and turn over the nuts so as to enable the green husks to be split and separated from the surfaces of the nuts. Since the spiral knife rolls have sharp edges, when the spiral knife rolls cut into the green husks, sap in the green husks is not squeezed out and is prevented from contaminating the exterior surfaces of the nuts during processing. Though the entire green husk stripping motions are equivalent to simulated manual stripping actions, the mechanized high-efficiency application of the green husk stripping action is realized. Therefore, the invention provides the effective method for stripping the green husks of the nuts through the dry process.

Owner:YUNNAN SARDE TECH +1

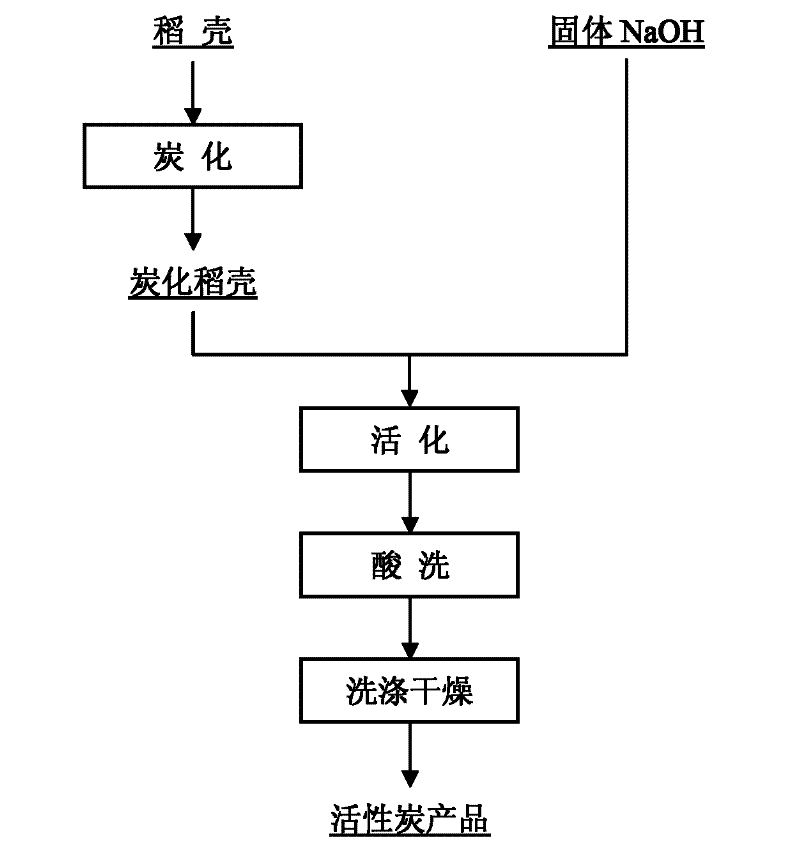

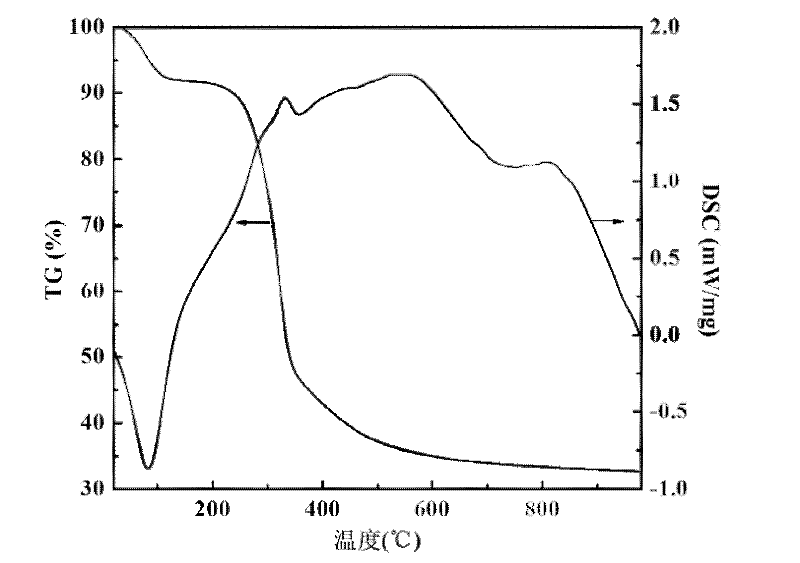

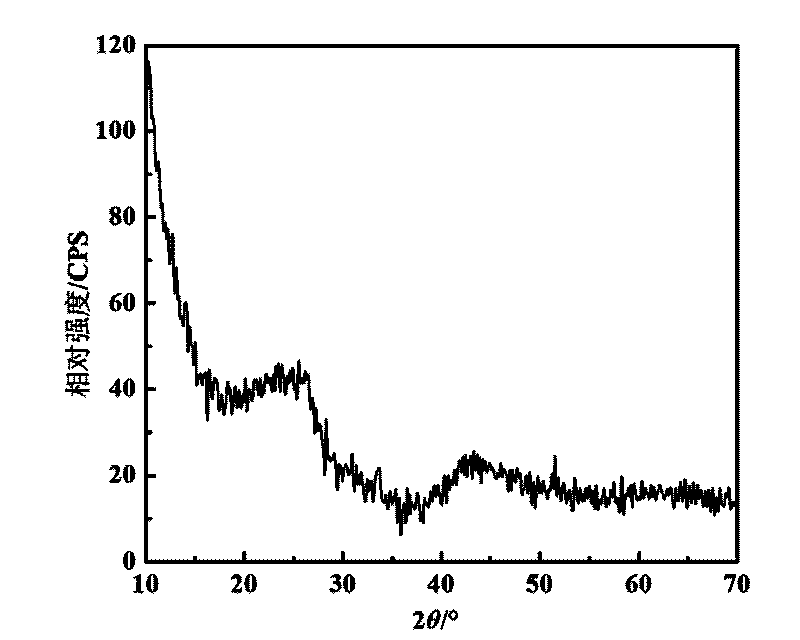

Method for preparing activated carbon

The invention relates to a method for preparing activated carbon. In the method, rice husks are taken as a raw material, NaOH is taken as an activator, and an activated carbon product is prepared through high temperature carbonization and activation, has high specific surface area, low ash content, a large number of distributed micropores, and high adsorption property, and is an ideal adsorption material, an ideal electrode material, an ideal hydrogen storage material and an ideal catalyst carrier. Alkaline solution is not required to be used for impregnation and activation, and the obtained product has a small particle size, has the characteristics of wide raw material source, low cost and simple process, is suitable for popularization, and has certain economic significance and environment-friendly significance.

Owner:CENT SOUTH UNIV

Method for producing table vinegar by adopting two-step acetic acid fermentation method

ActiveCN102433255AEfficient conversionKeep the flavorMicroorganism based processesVinegar preparationAlpha-amylaseTwo step

The invention discloses a method for producing table vinegar by adopting a two-step acetic acid fermentation method and belongs to the technical field of brewing of the table vinegar. According to the method, the problems of low alcohol intolerance, long fermentation period and low acetification rate for acetic acid fermentation in a traditional method are solved. The method comprises the following steps of: uniformly stirring sorghum flour, corn flour, rice meal and water; adding thermostable alpha amylase for liquefying; after liquefying, reducing the temperature, adding Daqu, saccharifyingkoji, red starter, saccharomyces cerevisiae and aroma-producing yeast and carrying out alcoholic fermentation to obtain liquor; adopting the two-step acetic acid fermentation method: firstly, mixing the liquor; adding acetic acid bacteria subjected to liquid amplification culture for carrying out primary acetic acid fermentation; when the alcoholic strength of brewing mass is reduced to 6-5DEG C,adding wheat bran and rice husk as accessories for mixing; inoculating fire fermented liquor for carrying out secondary acetic acid fermentation; sealing the liquor; smoking the liquor; spraying vinegar; filtering; and packaging to obtain a finished product. According to the method disclosed by the invention, the high-content alcohol can be effectively converted; the acid yield and the acetification rate in unit time are improved; and the flavor of the table vinegar produced by adopting a traditional solid acetic acid fermentation method is ensured.

Owner:山西金龙鱼梁汾醋业有限公司

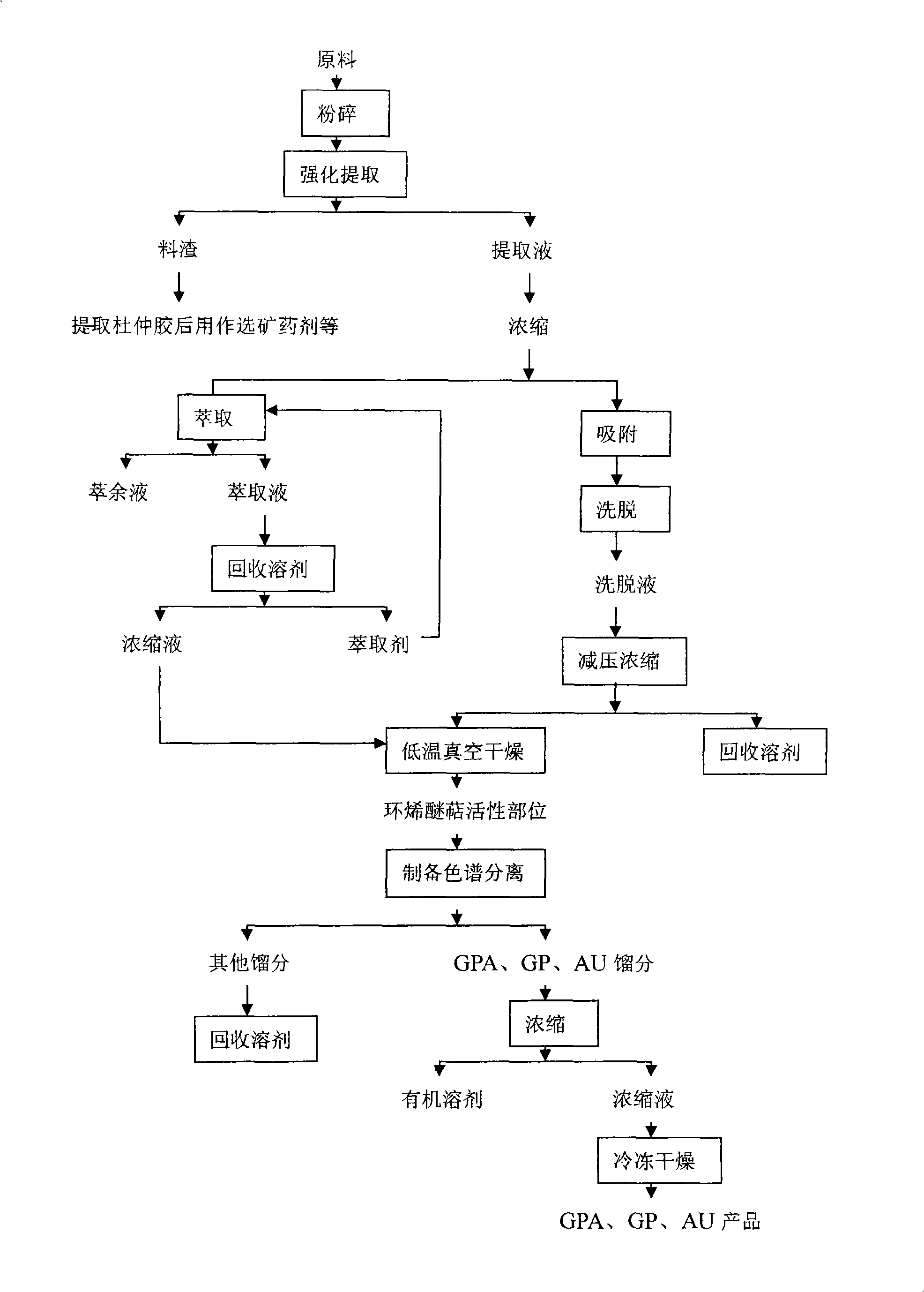

Method for extracting iridoid active site and monomer from eucommia bark

InactiveCN101260131AEasy to separateImprove product qualitySugar derivativesPlant ingredientsAucubinSorbent

The invention discloses a method for extracting active sites of iridoid, and extracting monomer geniposidic acid (GPA), geniposide(GP) and aucubin(AU) from eucommia, wherein raw materials are extracted by taking the eucommia(husk, leaf or seed) as materials and utilizing the conventional leaching method, the ultrasonic extraction method or the microwave extraction method, and an extracting solution is preliminarily purified by methods such as the solvent extraction and the adsorption separation of special adsorbents, etc., and thus the active sites of the iridoid(the total content of the iridoid is no less than 50 percent) is obtained, and GPA, GP and AU undergo the separation, low temperature condensation, refrigeration and drying by using the preparation high pass filter technique and taking an alcohol-water solution as the mobile phase to obtain monomers of GPA, GP and AU, contents of which are all no less than 90 percent. The preparation method disclosed by the invention utilizes novel process of the extraction and separation, and can simultaneously prepare a plurality of monomer products of the eucommia, and provides scientific foundations for the comprehensive development and utilization of the eucommia; moreover, the whole process does not use solvents harmful to human bodies, thereby realizing the green preparation.

Owner:JISHOU UNIVERSITY

Process for preparing high-purity nano silicon dioxide from rice husk

The method for preparing nano silicon dioxide by utilizing rice husk includes the following steps: firstly, preparing inorganic acid treatment agent whose concentration is 1-20 wt%, according to the weight ratio of 2-50:1 adding rice husk, boiling for 0.5-3 hr., washing with water, drying, combusting rice husk for 15-180 min, at 600-900 deg.C, pulverizing combusted product to obtain the invented nano silicon dioxide whose grain size is 30-80 nm and purity is 98-99.9%. The used treatment agent is HCl or H2SO4, etc. The combustion heat or the rice husk can be recovered, and can be used as heat source for drying treated rice husk and also can be used as heat source for other application including heating and bathing pool.

Owner:JILIN UNIV

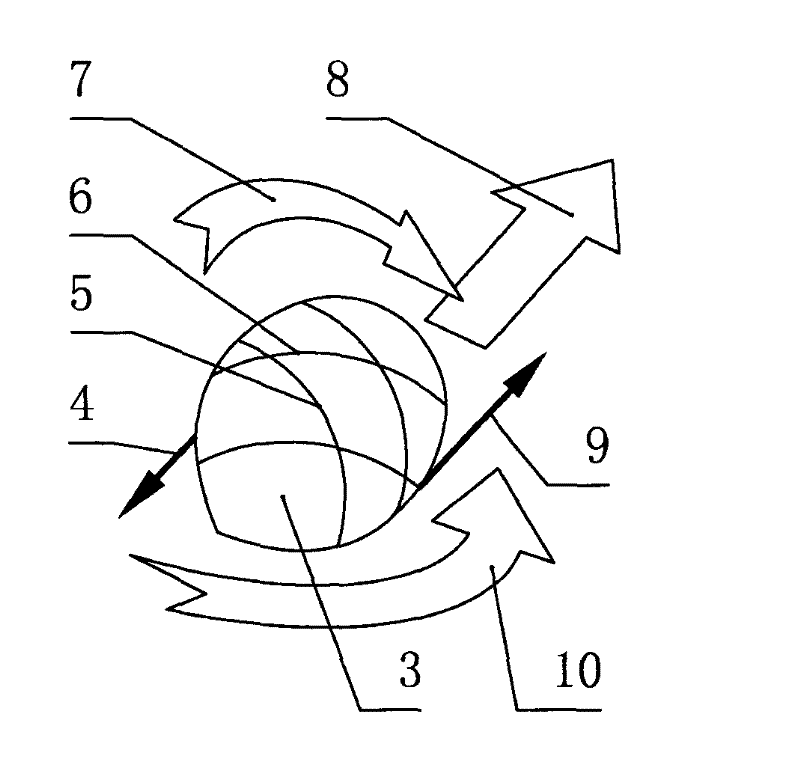

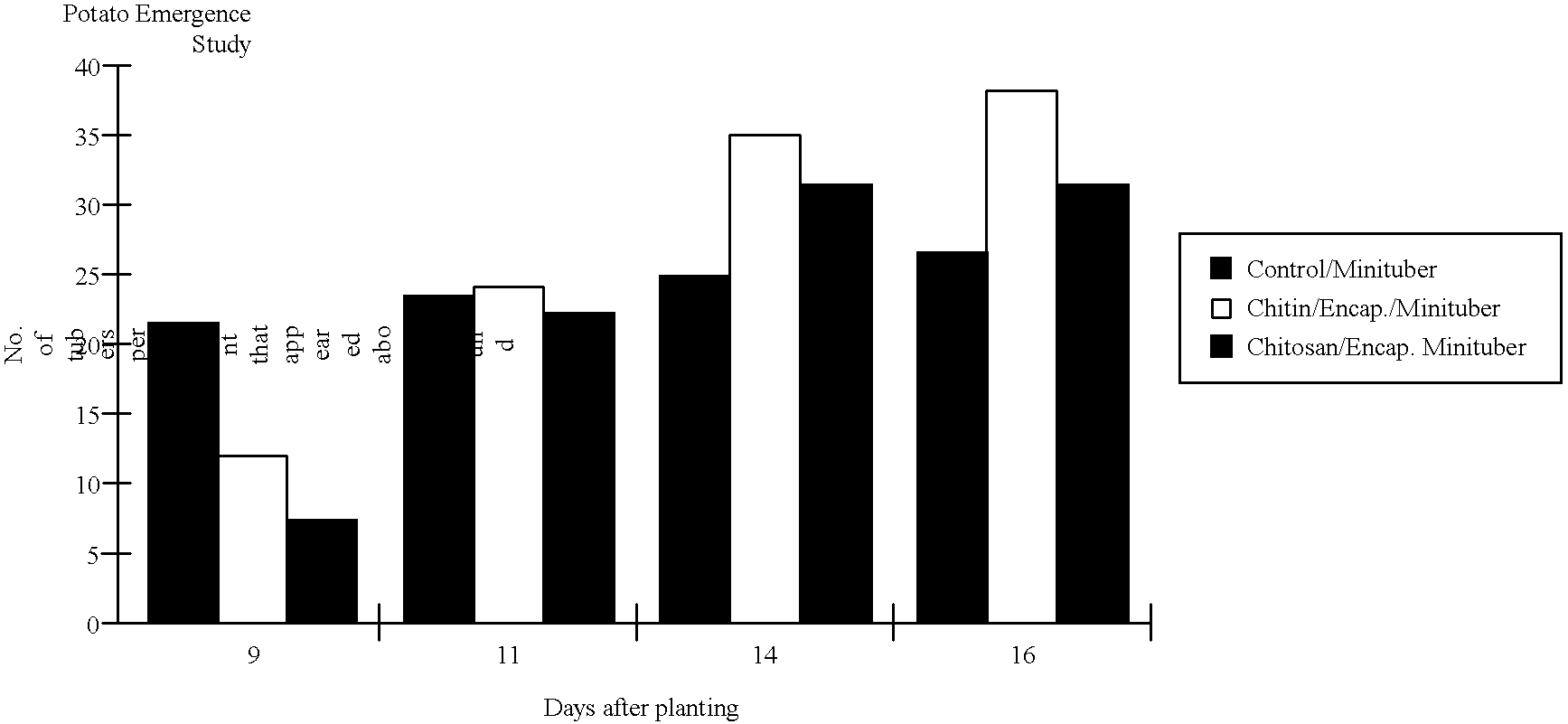

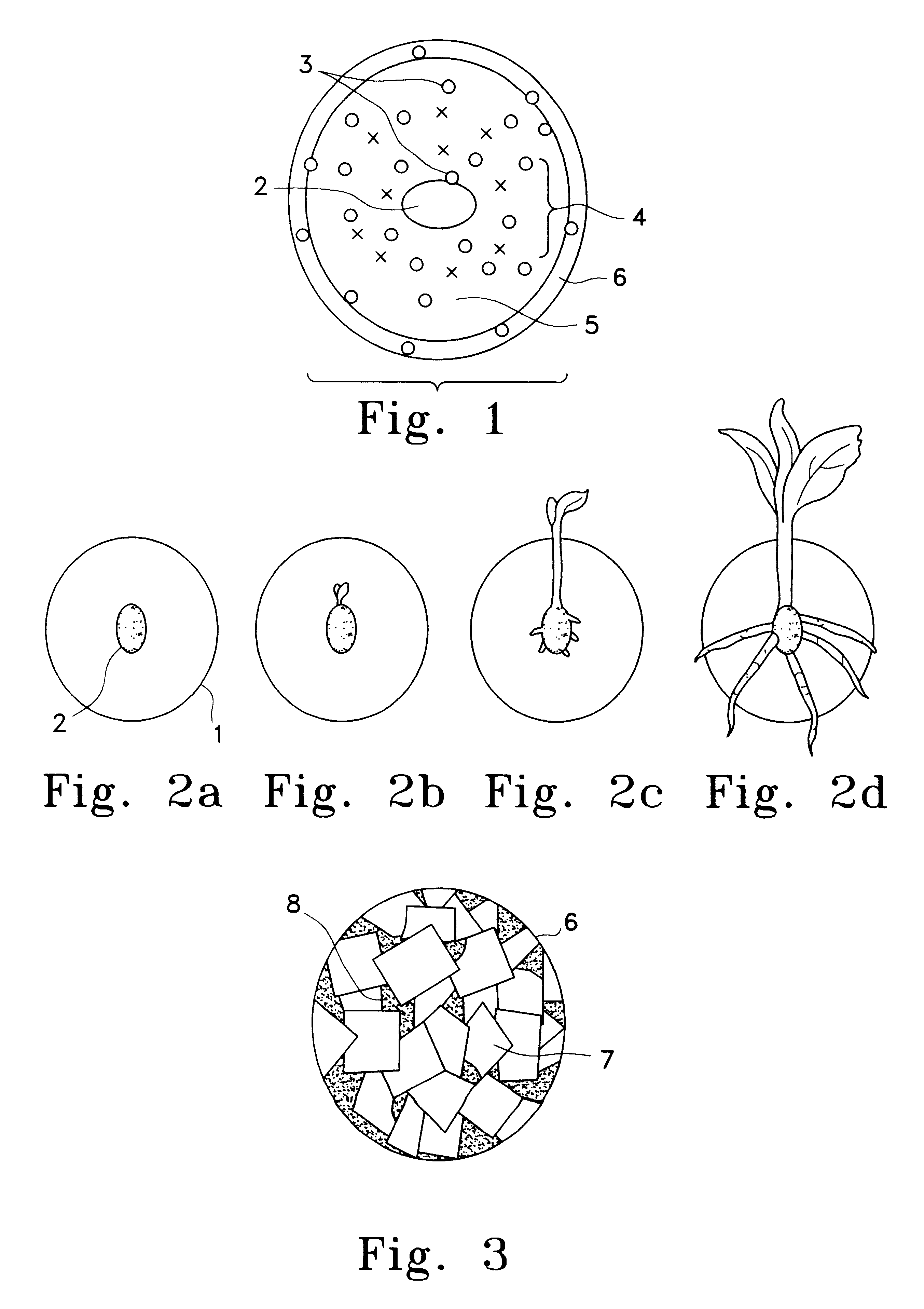

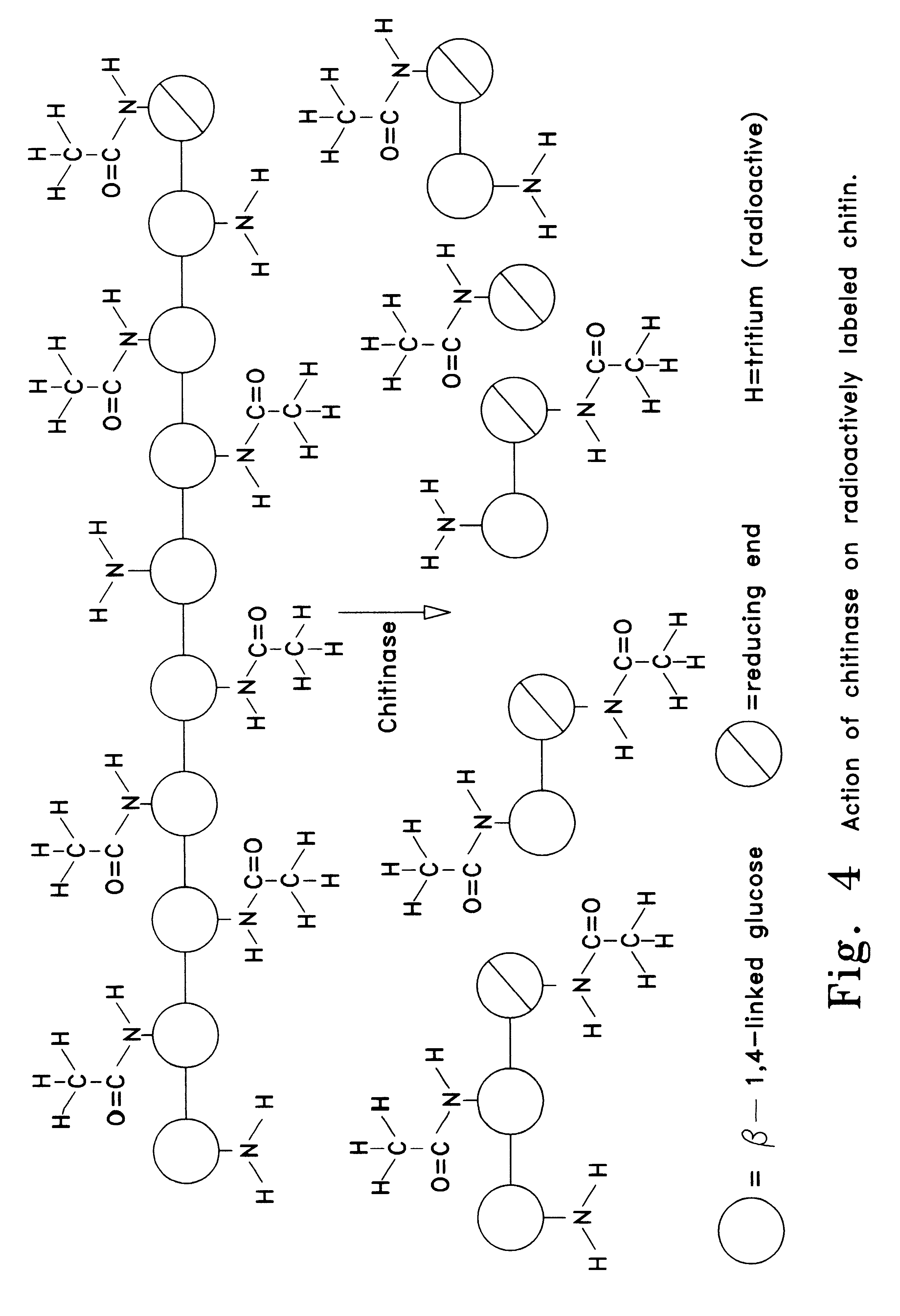

Tuber planting system comprising chitin or chitosan

InactiveUS6193988B1Increase emergenceHigh yieldBiocideDead animal preservationActivated carbonPropagule

A planting system involving a non-damaging stimulus (3) which is placed in the vicinity of a propagule (2) causes a naturally defensive substance (5) to be produced by the propagule. This substance may exist within an encapsulant (1) for a period of time so that the propagule may have enhanced disease control until it develops sufficiently to fend for itself. In one embodiment a large encapsulant surrounds a potato tuber. This encapsulant may include chitin to cause the release of chitinase through intermediate stimulants such as mRNA and activated carbon to absorb or release particular substances. The encapsulant is bound through the use of pentosan which acts with flaked chitin to achieve an outer casing and further protect the propagule both mechanically and chemically.

Owner:ENVIROGEN

Method for preparing high mode number waterglass and active carbon by rice hull ash

The invention relates to a method for preparing high-mode water glass and activated carbon from rice husk ash, which is characterized by comprising: micro-milling, heating of an alkali liquor, reaction, filtration, washing by boiling water, acid leaching, filtration and washing, drying, secondary activation, water washing, drying, and crushing. The method has the advantages that the method adopts the rice husk ash as a raw material to prepare the activated carbon, and the rice husk ash not only has low cost but also dose not contain harmful substances, so that the method fully and comprehensively utilizes rice husks, and not only achieves the aim of using waste materials as resources but also protects the environment.

Owner:NANCHANG UNIV

Conditioner-fertilizer composition for modifying and improving the structure of saline soils and/or alkaline soils

InactiveUS20050022570A1RestoresImprove propertiesCalcareous fertilisersAlkali orthophosphate fertiliserAlkali soilPhosphate

An effective conditioner-fertilizer of low and competitive cost particularly formulated for restoring or improving the cultivation properties and productivity of saline or alkaline soils, comprising: a) a chelating substance, for example sodium tripolyphosphate; b) a pH modifying or buffering substance, for example an inorganic acid; c) a surfactant, for example polyethylenglycols; and optionally, d) a plant nutrient substance, for example humic extracts which can advantageously derived from the pecan husk. The synergistic combination of polyphosphates, pH modifying and buffering substances and surfactants in the conditioner-fertilizer formulation significantly improves its effectiveness at a competitive cost. Other ingredients may also be added, for example, sodium lignosulphonate, calcium lignosulphonate and the like for modifying the physical structure of soils. The conditioner-fertilizer can be applied directly to the soil before plantation, mixed with the irrigation water or to the leaves during plant growth.

Owner:DUARTE MACDONALD ADALBERTO ENRIQUE

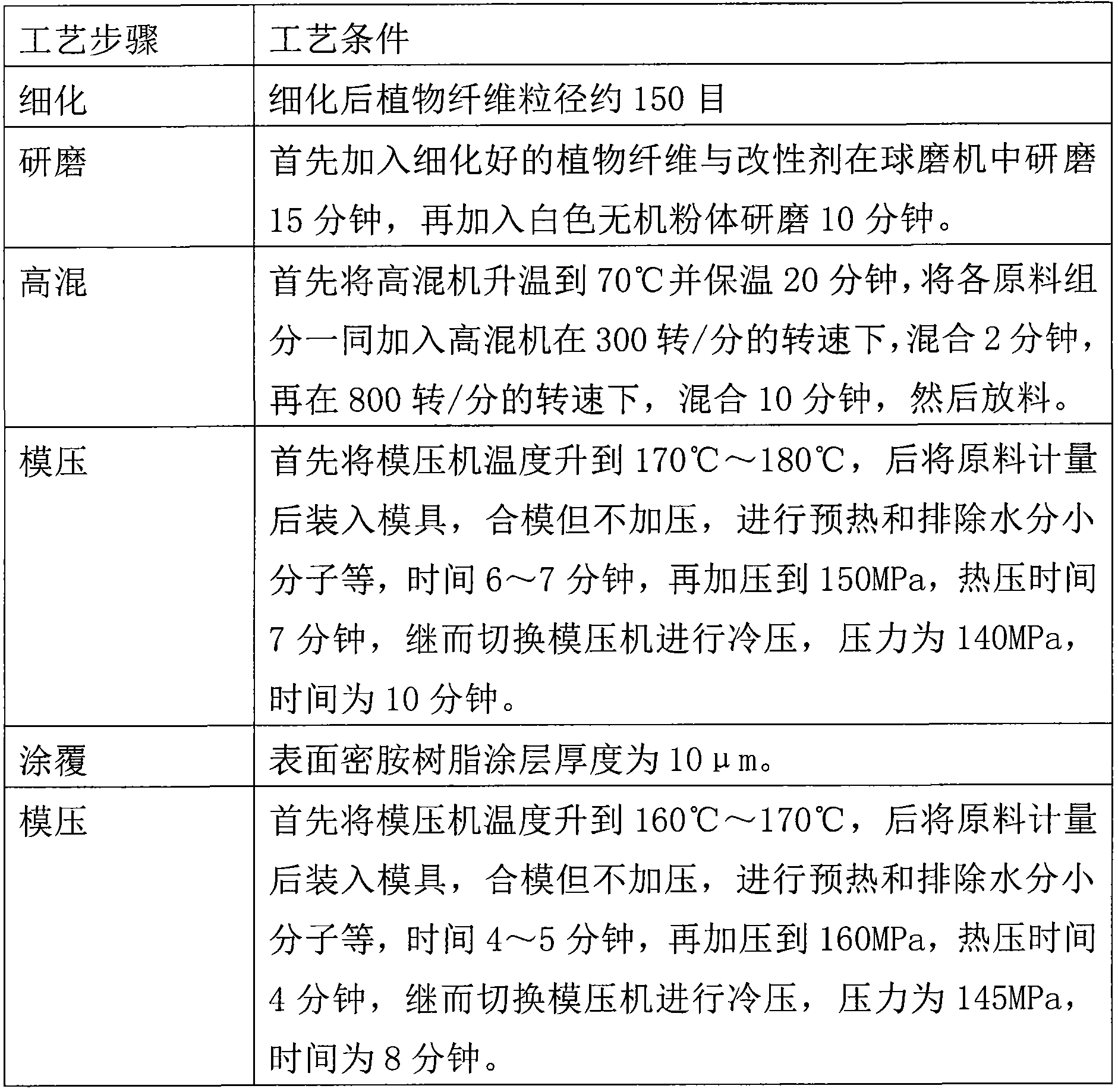

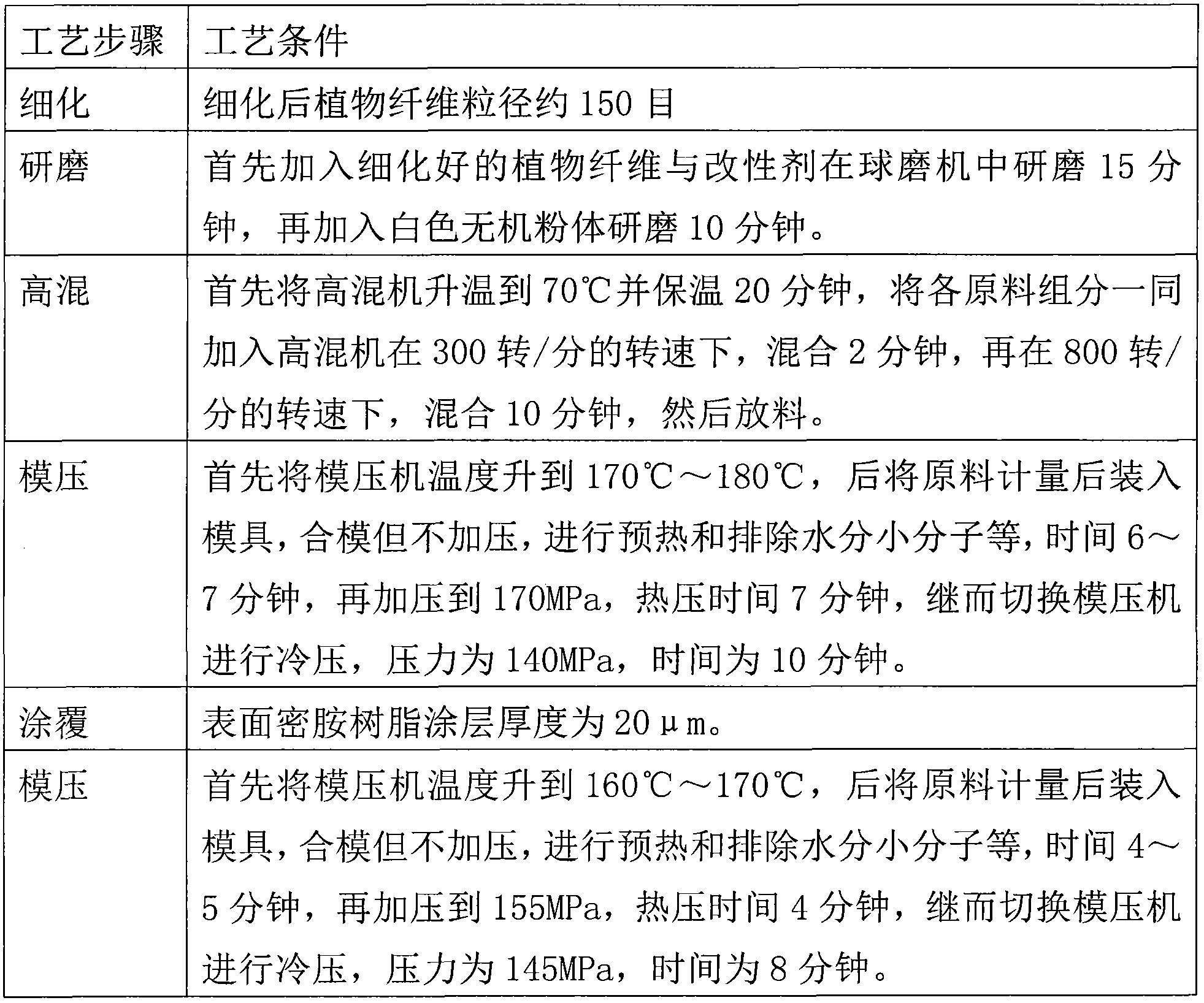

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

Method for preparing dietary fiber through solid-gas explosion

The invention belongs to the technical field of preparation of dietary fibers, and particularly relates to a method for preparing the dietary fibers by using grain seed husks, such as corn husks and the like as raw materials and utilizing a solid-gas explosion technology, which comprises the following steps of: regulating the water content of the grain seed husks to 50-300 percent, and then placing into a sealed gas explosion device; raising the pressure of the gas explosion device to 0.4-1.2Mpa within 5-25 minutes, and retaining the pressure for 10-120 seconds and then instantaneously depressurizing; and adding water into the processed grain seed husks for extraction, removing the starch and the protein therein, modifying, separating and removing impurities to obtain the dietary fibers. The method has the advantages of simple operation, convenient and rapid extraction, abundant raw material sources and low production cost and can simultaneously obtain two types of high-quality corn-husk dietary fiber products with high purity and large yield, and both the yield and the physiological activity of the products are markedly improved.

Owner:河南省农科院农副产品加工研究所

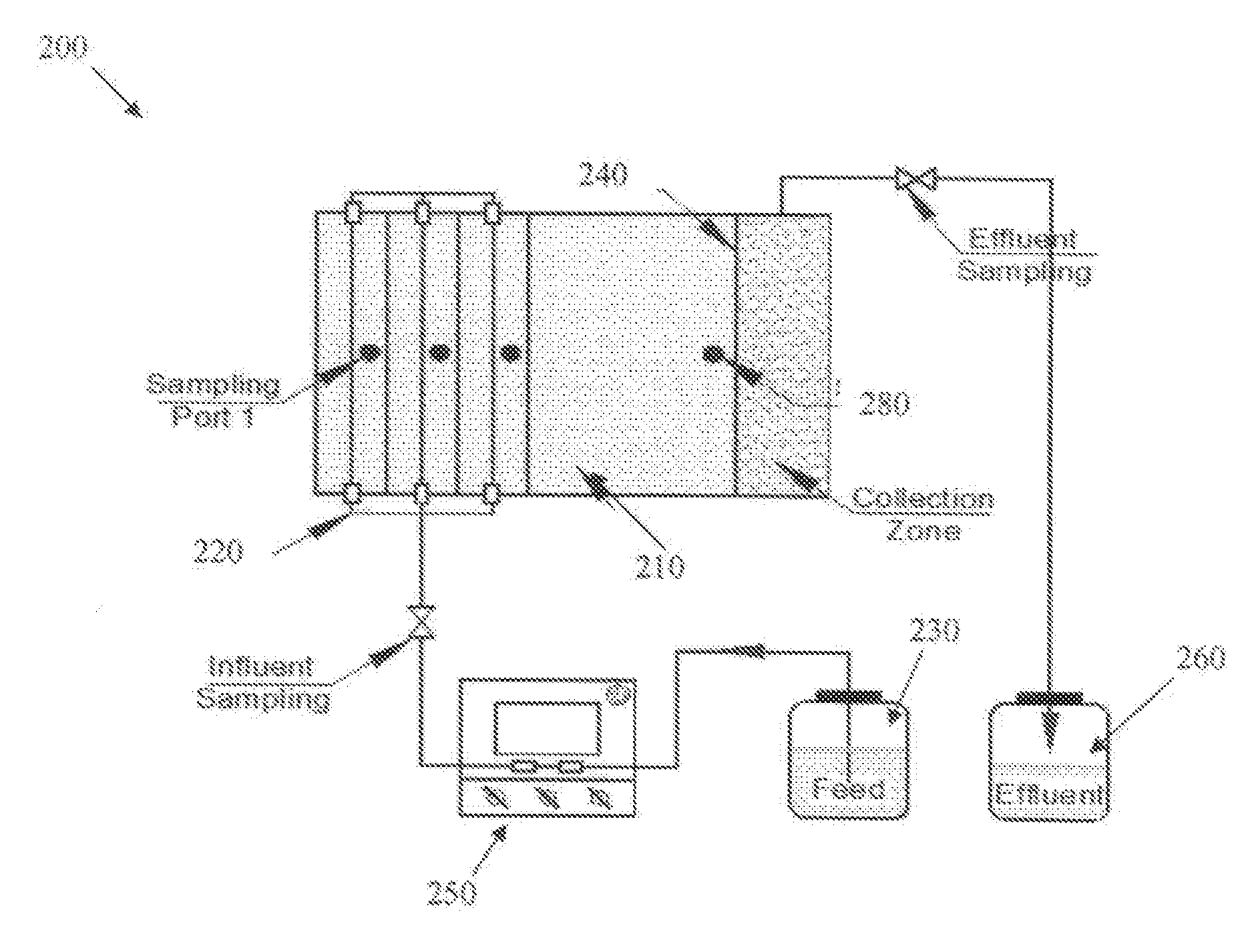

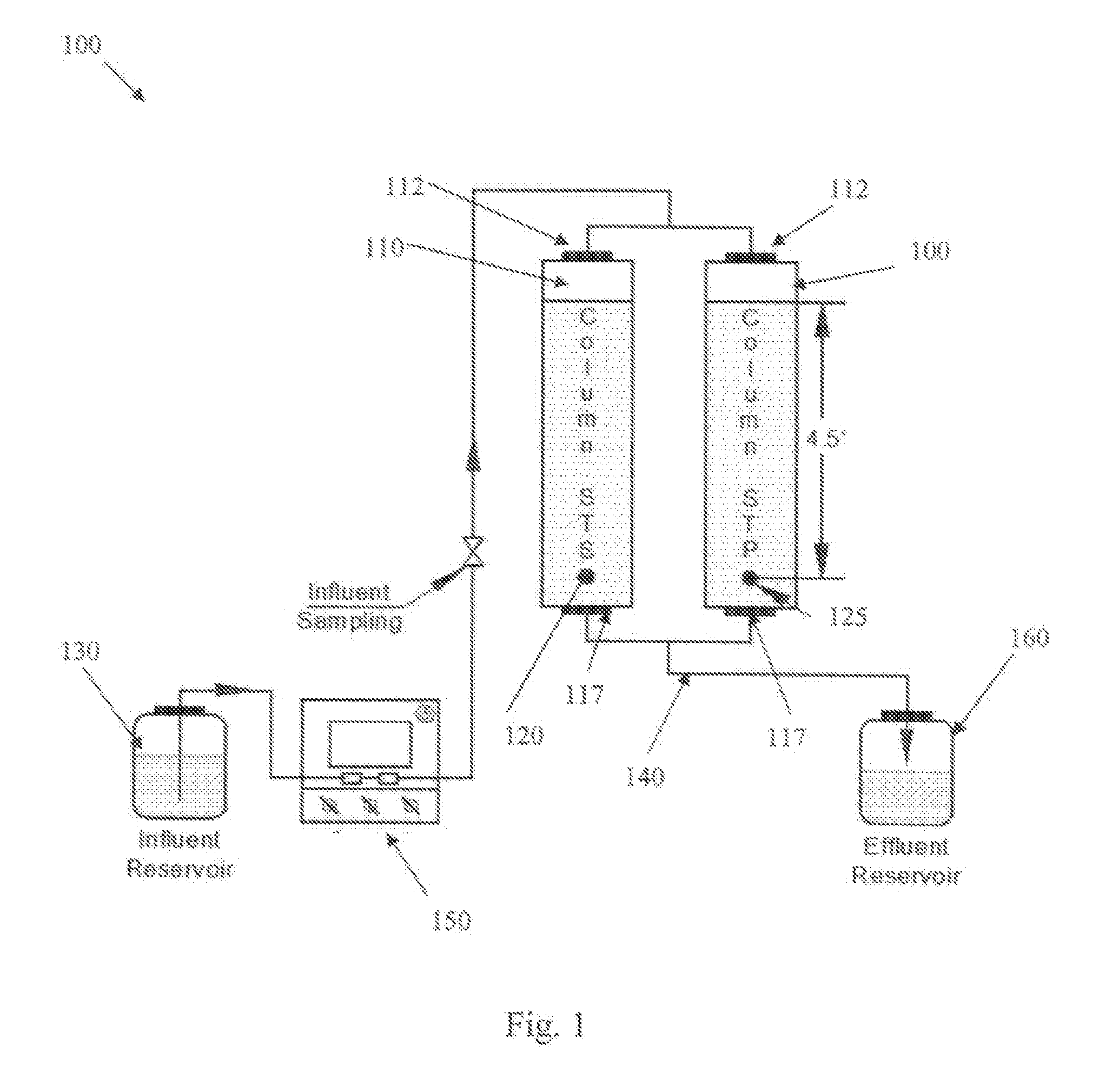

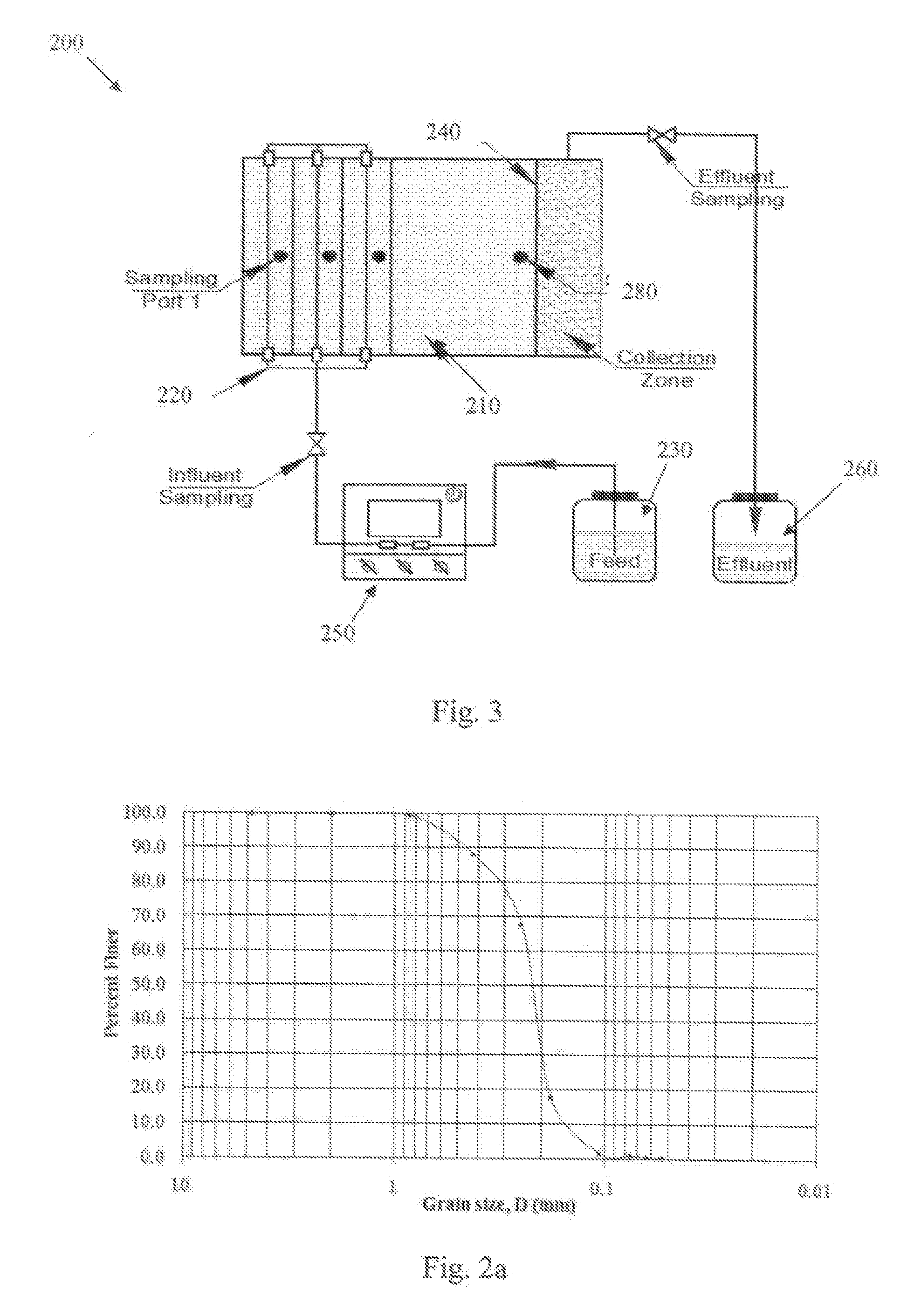

Passive Underground Drainfield For Septic Tank Nutrient Removal Using Functionalized Green Filtration Media

ActiveUS20100059437A1Improve sustainabilityImprove applicationWater cleaningContaminated soil reclamationSubsurface drainageOyster

Methods, systems and compositions for a green sorption media for bioretention soil amendments in drainfields for on-site waste water systems filled with the green sorption media to foster an anaerobic or anoxic environment saturated. The green sorption media includes one or more recycled materials, including tire crumb, sawdust, orange peel, coconut husks, leaf compost, oyster shell, soy bean hulls and one or more naturally occurring materials including peat, sands, zeolites, and clay. The wastewater filtration system for a passive drainfield includes the green sorption material mixture, a cell including baffled compartments and a riser, the cell filled with green sorption material mixture to provide an alternating cycle of aerobic and anoxic environments, an influent distribution system to distribute the influent over the cell, and a piping system arranged for dosing the cell to sustain the functionality of the green sorption material mixture to remove nutrient content in wastewater.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Preparation method of magnetic beads by extracting nucleic acid and application of method

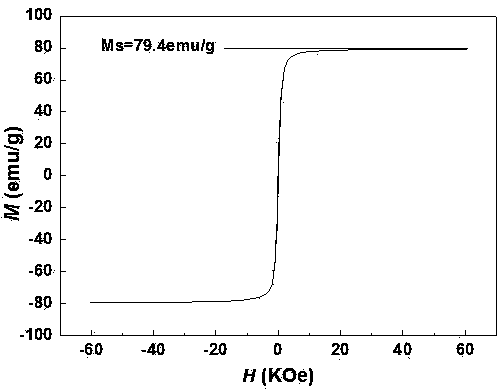

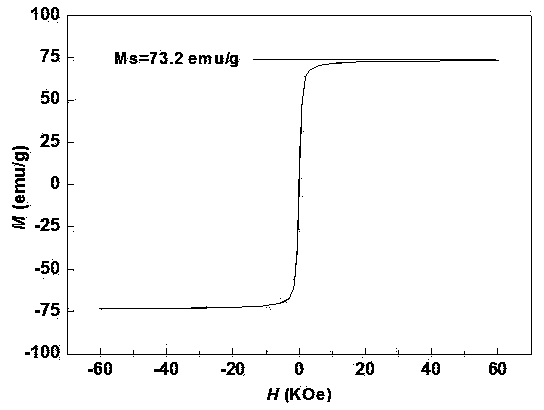

ActiveCN103908945AHigh saturation magnetizationImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMagnetic beadMagnetite Nanoparticles

The invention discloses a preparation method of magnetic beads by extracting nucleic acid. The surfaces of magnetic nanoparticles Fe3O4 are coated with silicon hydroxyl and then are dispersed into a 0.02% NaN3 aqueous solution; the prepared silicon-based magnetic bead is of a core-shell structure and comprises a Fe3O4 nanoparticle core and a SiO2 shell layer, wherein the outer surfaces of a plurality of Fe3O4 nano-particles are coated with the SiO2 shell layer; the silicon-based magnetic bead has the secondary particle size of 400nm-1 micron, measured by a nanometer laser particle analyzer, and has the saturation magnetization of 43.0-74.5emu / g after being subjected to ultrasonic dispersion for 1h; the prepared silicon-based magnetic bead can be widely applied to nucleic acid extraction and purification of biomaterials such as fresh animal tissues, animal tissue paraffin sections, plant leaves, seeds, whole blood, free serum, hairs, fingernails, stubs, saliva, bacteria or viruses. The method is simple in process flow, convenient to operate, and low in raw material cost and is suitable for being used in industrial mass production.

Owner:滁州市方舟医疗科技有限责任公司

Method for producing nano-scale white carbon black with rice hull ash

The invention relates to a method for preparing nanometer level white carbon black by rice husk ash. The method is characterized in that the process method comprises the following steps: the rice husk ash is treated by an alkaline method to prepare soluble glass; and a soluble glass solution is subjected to condensation, heat insulation, acidic reaction, aging, rinsing, filtering, preparing, homogenizing, spraying and drying, and airflow pulverization. The method has the technical effects that the method reduces cost, improves corrosion resistance, high hardness and high toughness of the material, and has simple preparation process flow, low production cost and good stability.

Owner:NANCHANG UNIV

Process for preparing silicon dioxide aerogel using rice husk ash as raw material

InactiveCN1449997ALarge specific surface areaReduce manufacturing costSilicaSolid waste disposalHYDROSOLSilicon dioxide

The method for preparing silicon dioxide aerogel utilizing waste material rice husk ash obtained by combusting rice husk includes the following steps: soaking the rice husk ash in organic alkaline aqueous solution, using inorganic acid to neutralize alkaline solution to produce silicon dioxide hydrosol, ageing said hydrosol, substituting water content in the hydrosol with organic solvent, then substituting organic solvent with liquid CO2, then supercritical CO2 drying so as to obtain white silicon dioxide aerogel whose specific surface area is 297.3 sq.m / g, apparent density is 0.532 g / cu.cm and internal microporous average pore size is 22.3 nano.

Owner:TSINGHUA UNIV

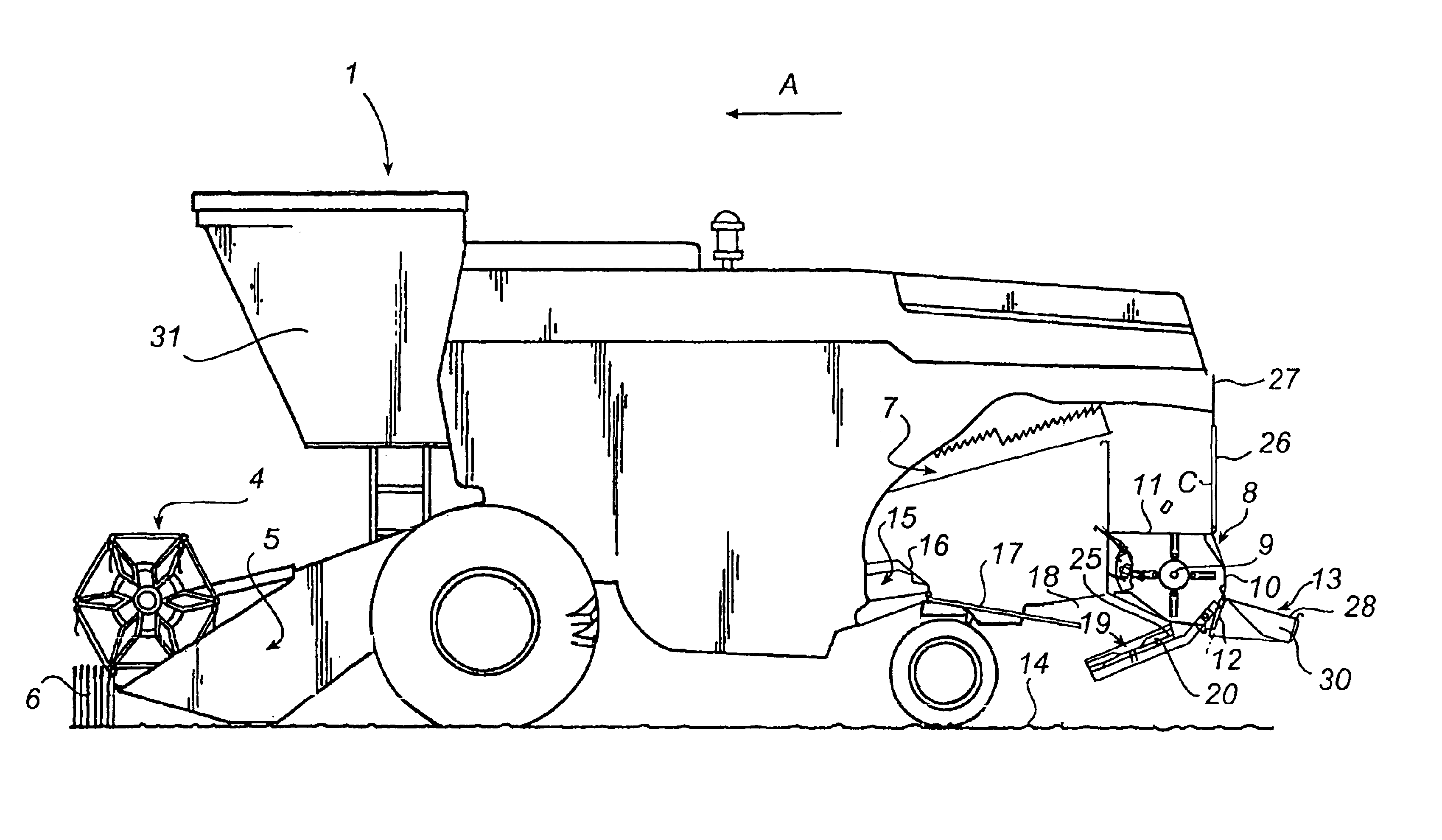

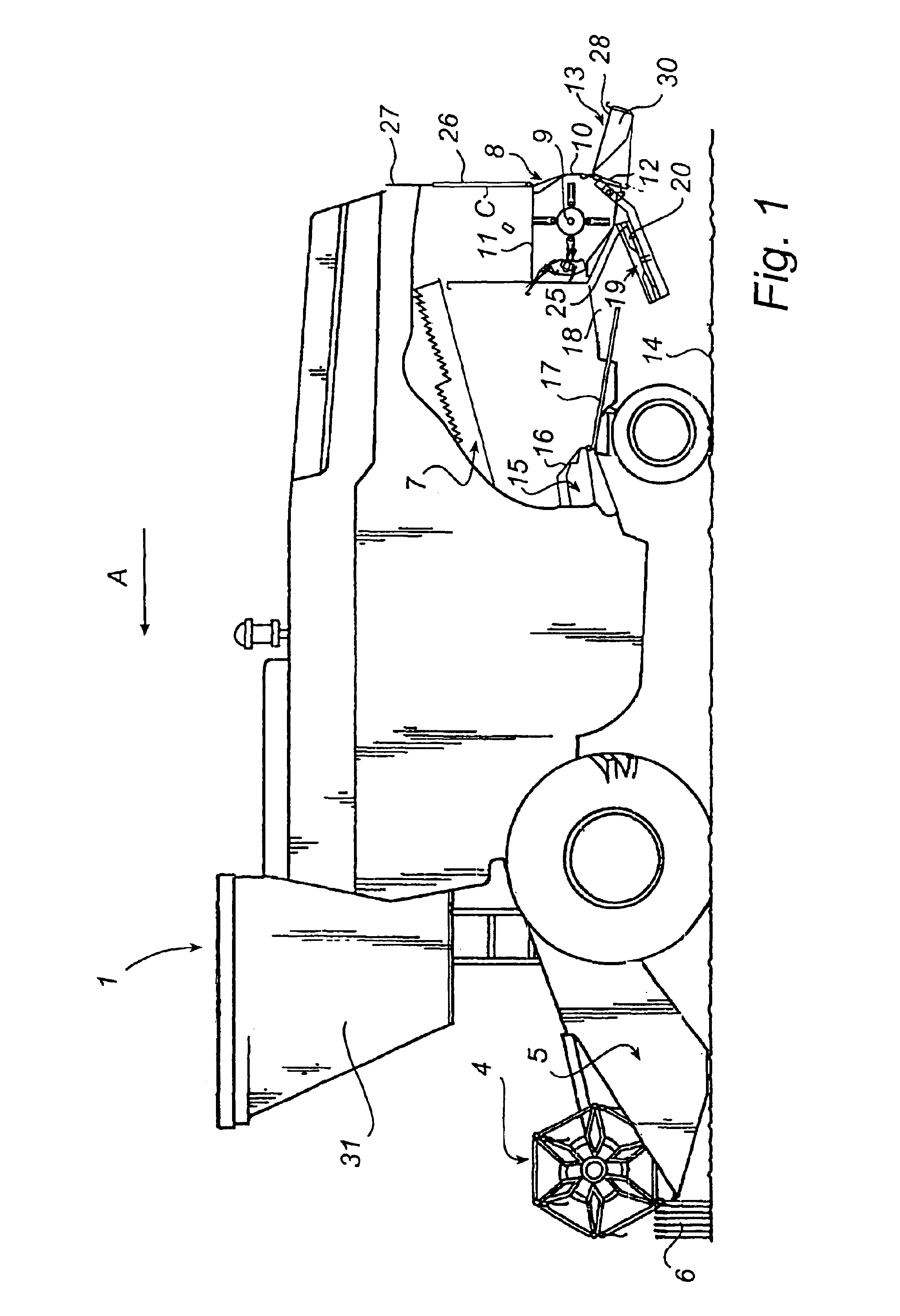

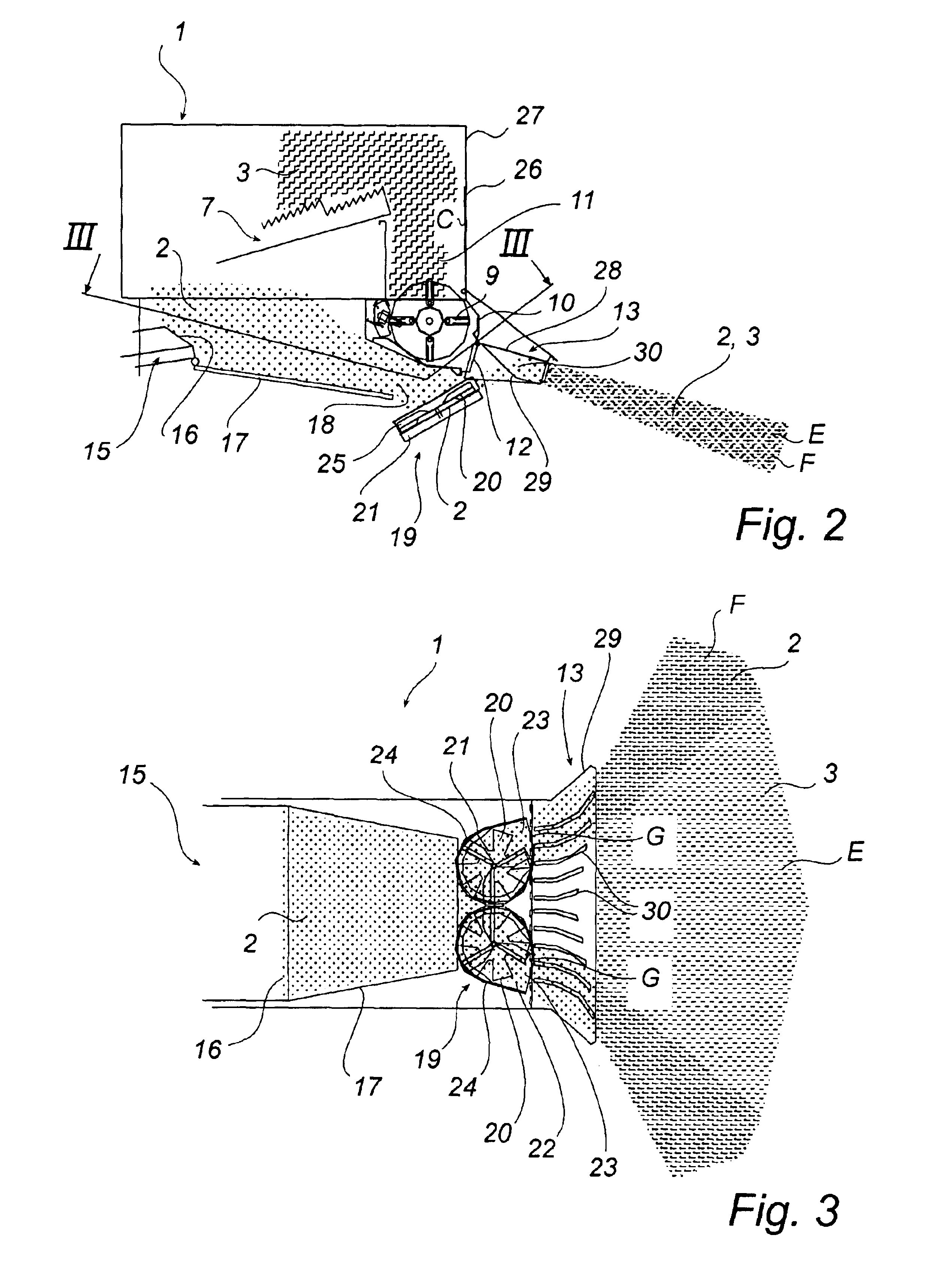

Harvester combine

A combine harvester has a husk discharge device mounted downstream from a sieving unit, and a blower mounted in a housing having at least one husk discharge opening, and a straw chopping device, which is located downstream from a straw shaking device and the husk discharge device and which has a rotary cutter mounted in a housing to chop the straw, the housing having an inlet for the unchopped straw and an outlet for the chopped straw. A guide means is located upstream of the straw chopping device, the guide means being displaceable between a first position for closing the inlet so as to effect bypassing of the straw chopping device and allowing deposition of the unchopped straw in the form of strings, and a second position in which is exposed the inlet to allow chopping of straw. A spreading device for spreading of the chopped straw received from the straw chopping device is connected to the outlet thereof and is formed with spreader wings. The husk discharge opening is arranged to be directed towards the spreading device, allowing husks to be blown into the device and spreading of the husks over the ground with the aid of the spreader wings.

Owner:REKORDVERKEN SWEDEN

Method for manufacturing bio-organic fertilizers

ActiveCN101618979AReduce feeding costsReduce farming pollutionBio-organic fraction processingAnimal housingBiotechnologyBran

The invention provides a method for manufacturing bio-organic fertilizers. Protease, saccharomycetes and lactobacillus are utilized for fermenting sawdust, straws, unite bran and pig manure to manufacture the organic fertilizer. The manufacturing procedures comprise the steps of: establishing of a pig house, selecting and matching raw materials, padding manufacturing, designing of a fermenting bed for feeding pigs, disinfecting culture gaps, post treatment of padding materials, disinfecting surfaces of padding materials after one batch of pig cultivation, turning over and mixing materials, supplying bacterium solution, and carrying out cultivation of pigs of next batch. The padding materials of the fermenting bed are cleared out of the pig house after being utilized for three years, adding bacterium solution and corn powder, stirring evenly, adjusting water content, pressing tightly, sealing, and fermenting for half of mouth, namely obtaining high-quality biological bacterial fertilizer. The method utilizes the bacterial solution to carry out fermentation of straws, sawdust, rice husks and pig manure, one part of the obtained mixture is ingested and absorbed by pigs, the unabsorbed part thereof is used as biological organic fertilizer for fully utilization, therefore, the method not only can reduce the feeding cost of the pig, but also can reduce culture pollution and provide high-quality biological organic fertilizers for the plant industry.

Owner:广东希普生物科技股份有限公司

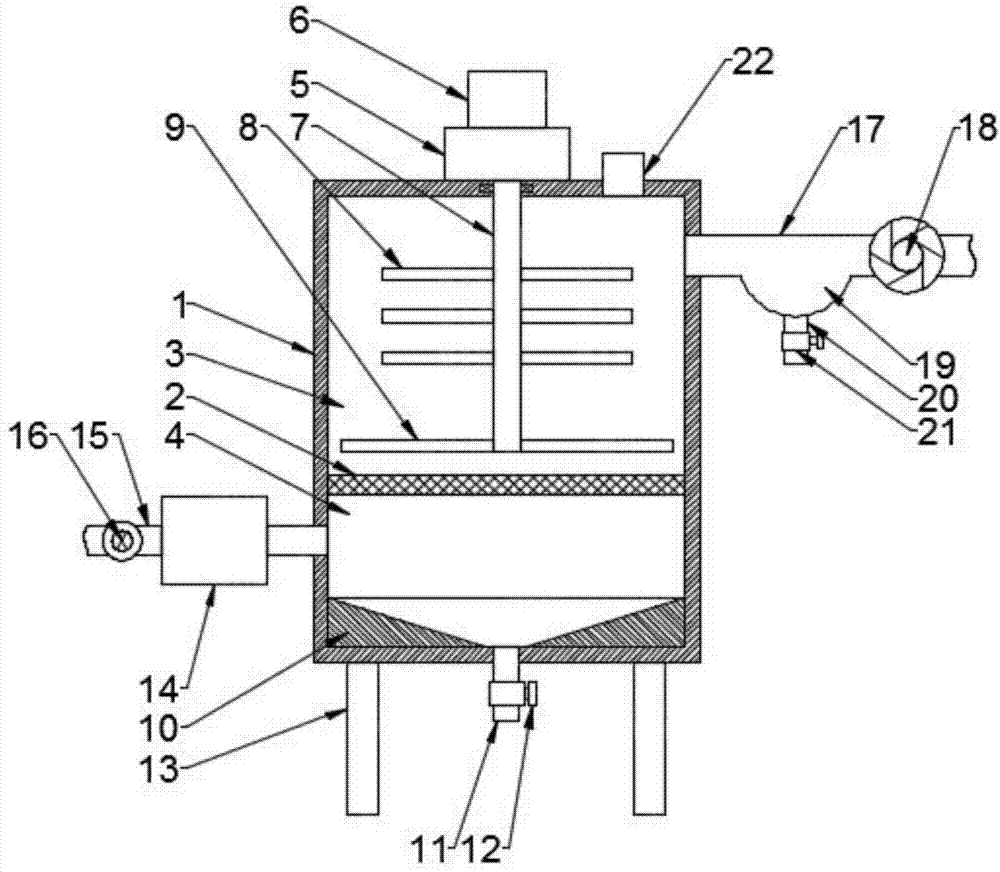

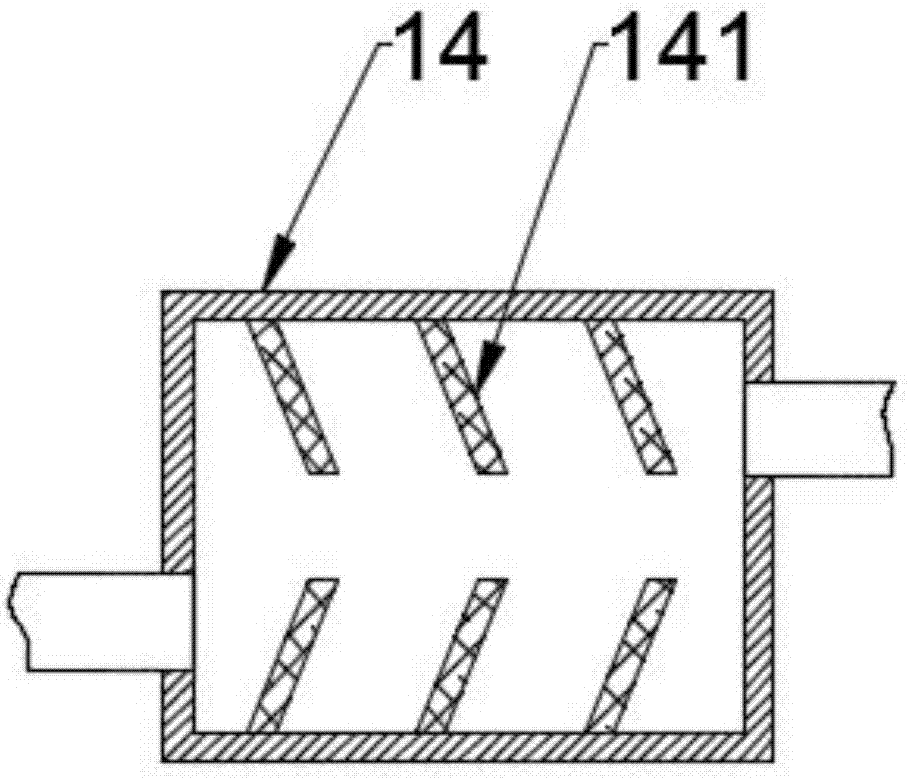

Grain dryer capable of winnowing grain husks

The invention discloses a grain dryer capable of gas-separating chaff, which includes a drying box. The bottom of the inner cavity of the drying box is provided with a screening net. The screening net separates the inner cavity of the drying box into a drying chamber and a discharge chamber. The drying cavity is equipped with a stirring rod. The middle part of the stirring rod is evenly provided with a number of stirring blades. The bottom end of the mixing rod is evenly provided with a number of scrapers in the circumferential direction. The top of the stirring rod passes through the top of the drying box. The wall of the drying chamber is rotatably connected to the reducer, and the reducer is fixedly connected to the motor shaft of the motor. The top of one side wall of the drying chamber is connected to the air outlet duct; the bottom wall of the discharge chamber is provided with a guide cover, and the discharge chamber is The bottom wall is connected to the main discharge pipe, and one side wall of the discharge chamber is connected to the heating box; the invention is provided with a stirring rod and a stirring blade mechanism to stir the grains, so that the grains are evenly heated and the stirring speed is accelerated; and the rising hot air flow can The chaff in the grain is screened, and then screened twice through the air outlet duct, so that the chaff is completely discharged and the grain particles remain.

Owner:合肥图腾龙企业管理事务所(有限合伙)

Compound forage for Mule ducks

ActiveCN1947551AImprove conversion rateSolve the problem of hair lossFood processingAnimal feeding stuffBiotechnologyAnimal Foraging

Owner:ZHEJIANG QUNDA FEED TECH CO LTD

Methods for improving the nutritional quality of residues of the fuel, beverage alcohol, food and feed industries

InactiveUS20060233864A1Improve nutritional qualityIncreased rate of weight gainBy-product recoveryFood processingBeet pulpIngested food

A method is provided for improving the nutritional quality of a fibrous by-product or residue of a food manufacturing process, wherein the fibrous by-product or residue is inoculated with at least one filamentous fungus, and the fibrous by-product or residue is fermented thereby to decrease dry matter content, increase protein content, and decrease fat content of the by-product or residue. Suitable byproducts or residues include spent brewer's grains, dried distiller's grains, dried distiller's solubles, distiller's dried grains with solubles, residues of the cereal processing industry, wheat bran, soybean hulls, citrus pulp, beet pulp, rice husks or hulls, bagasse, apple pommace, and combinations thereof. Enzymes produced during the fermentation may also be used as valuable coproducts such as animal feed supplements, or may be used in primary fermentations for the brewing and distilling industry.

Owner:ALLTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com