Patents

Literature

491 results about "Tangential force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tangential force. Tangential force is a force which acts on a moving body in the direction of a tangent to the path of the body. It either decreases or increases the velocity of the moving body. 667 views · View 1 Upvoter.

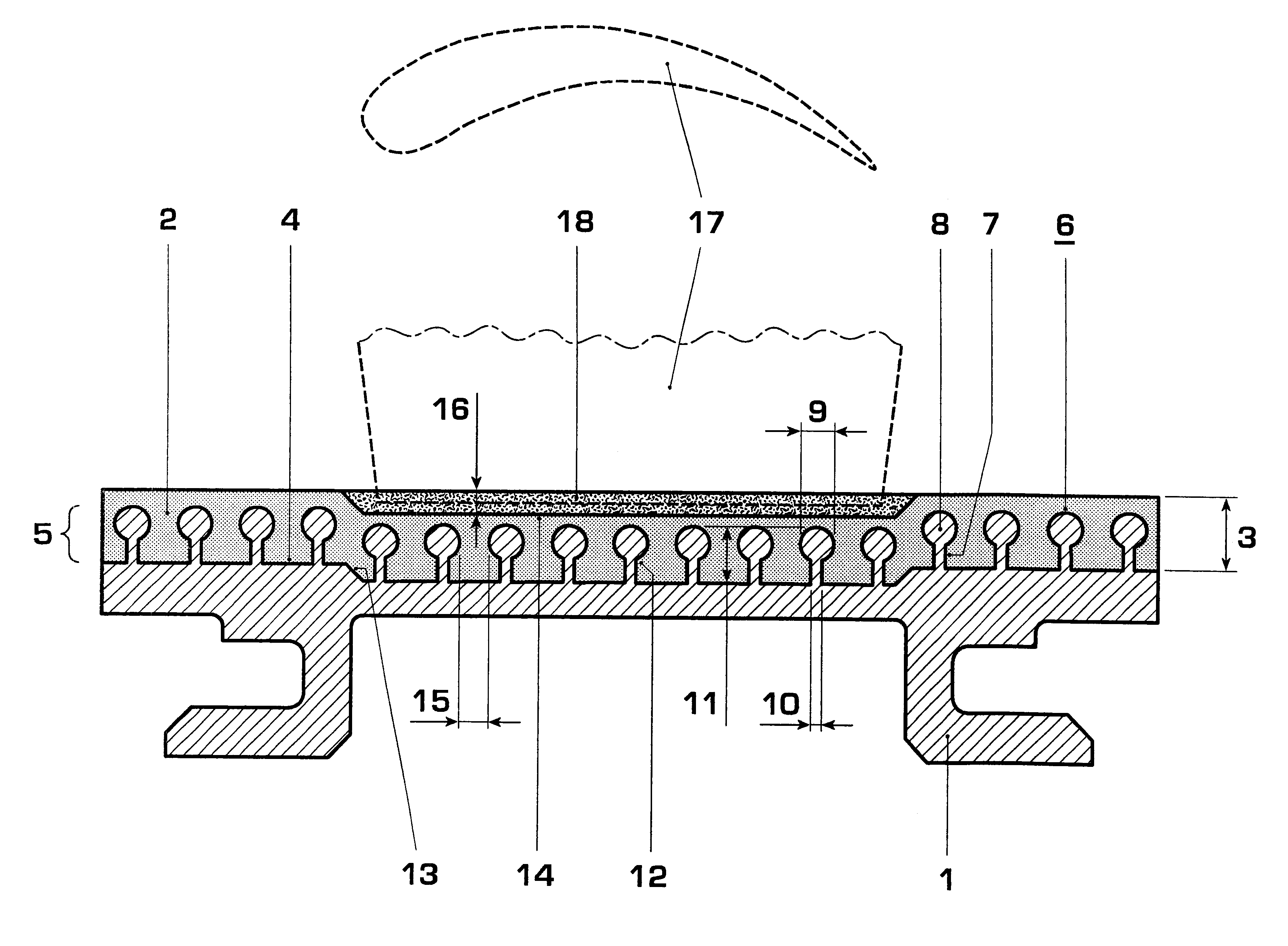

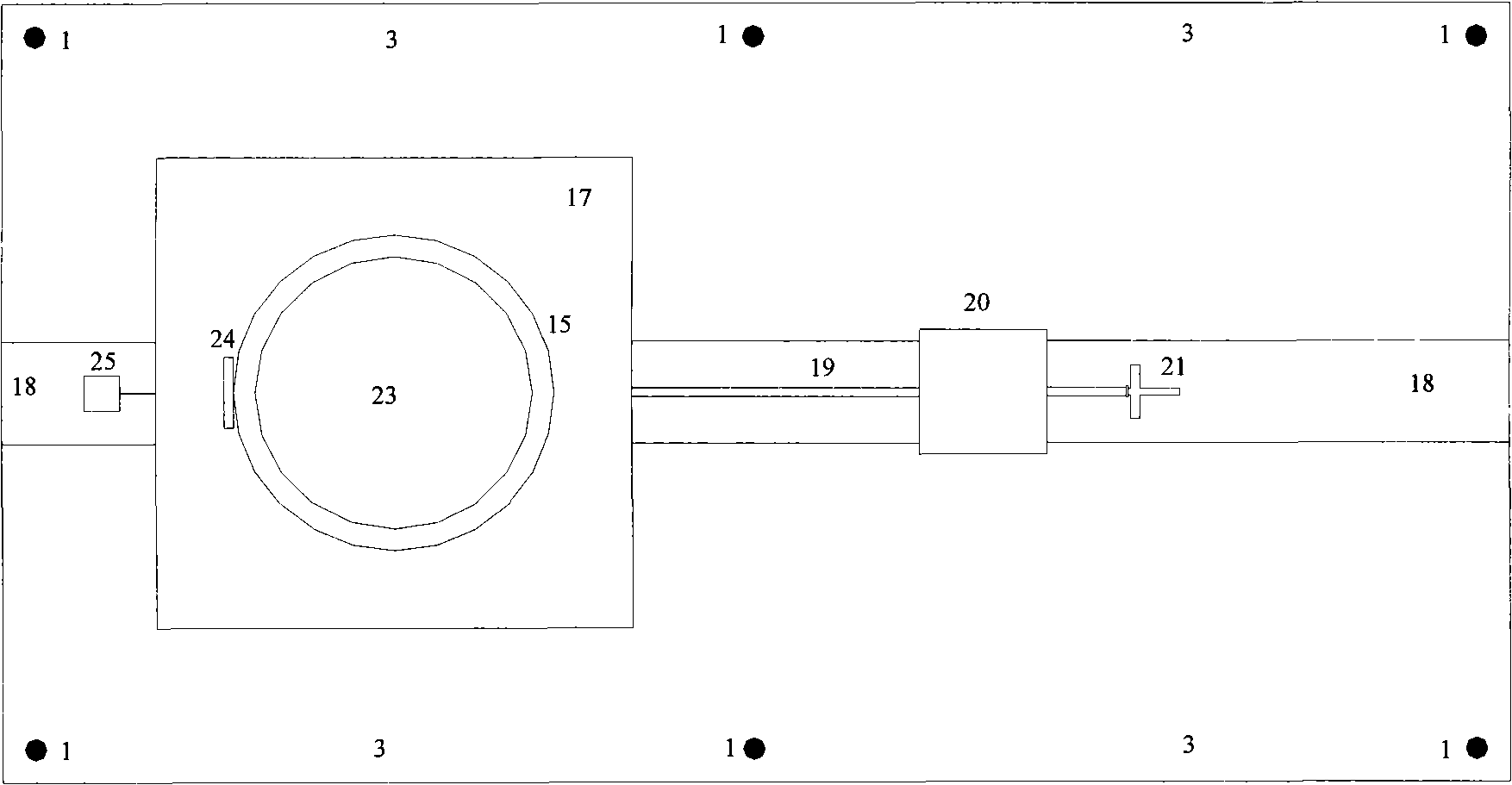

Protective helmet

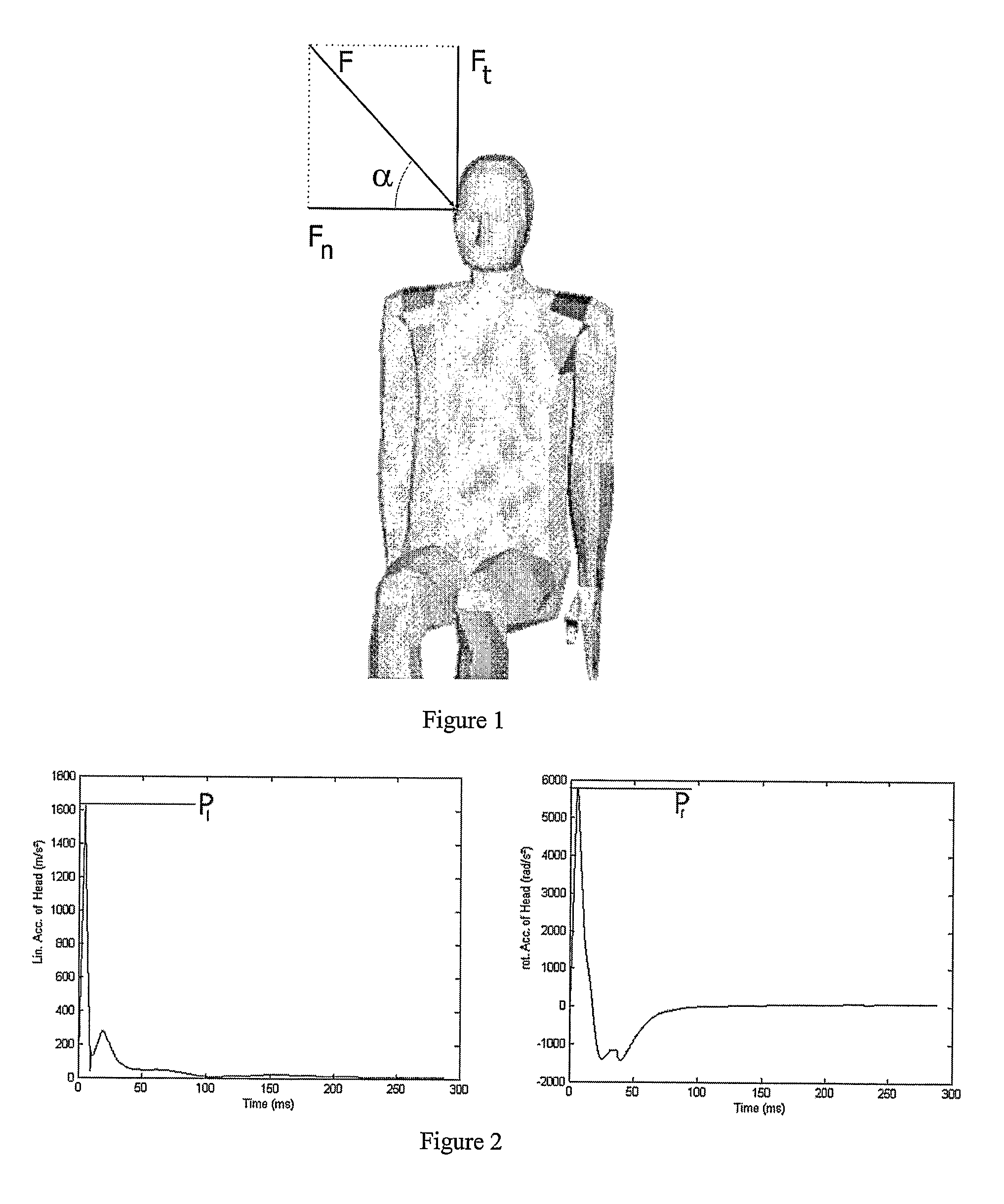

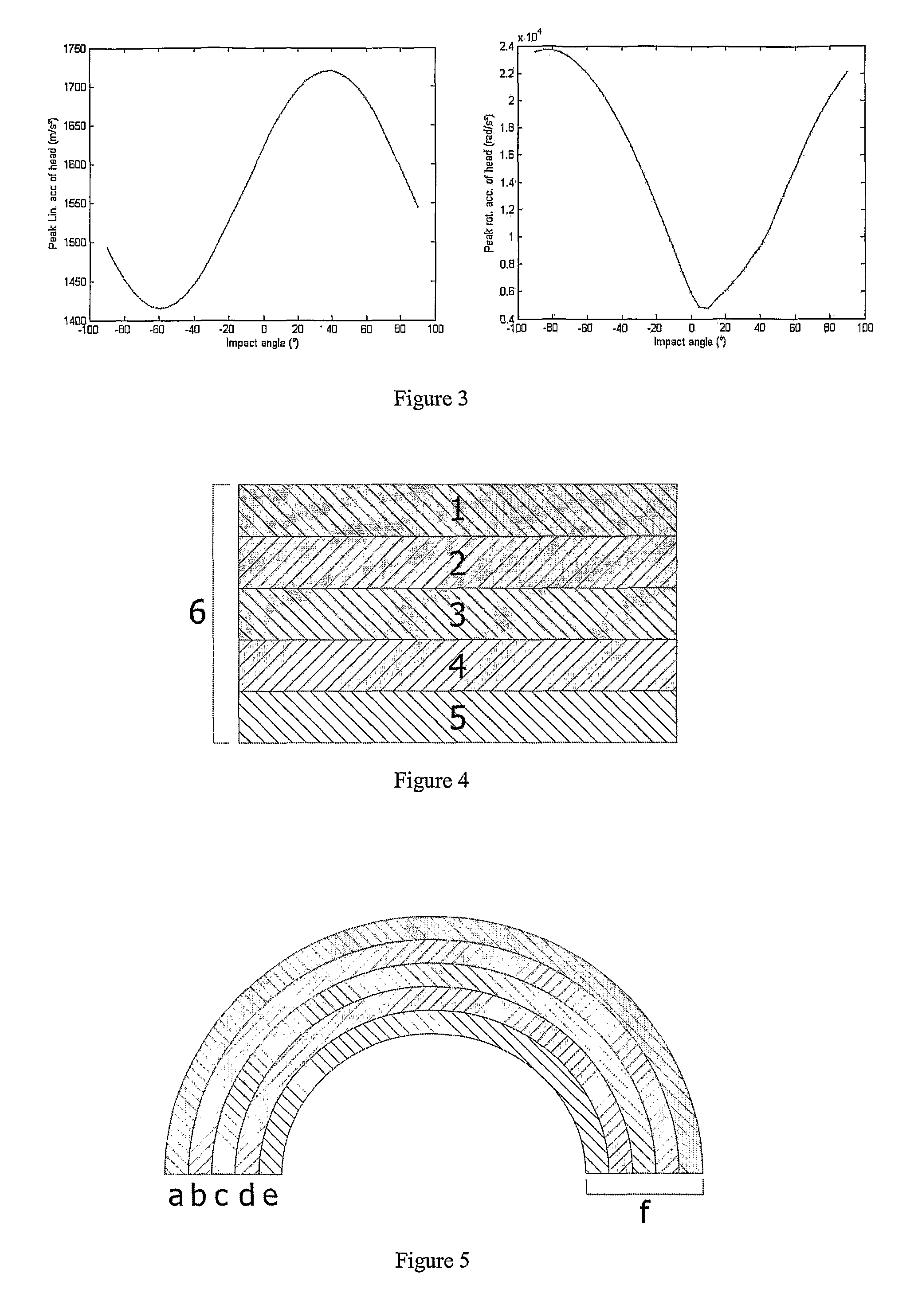

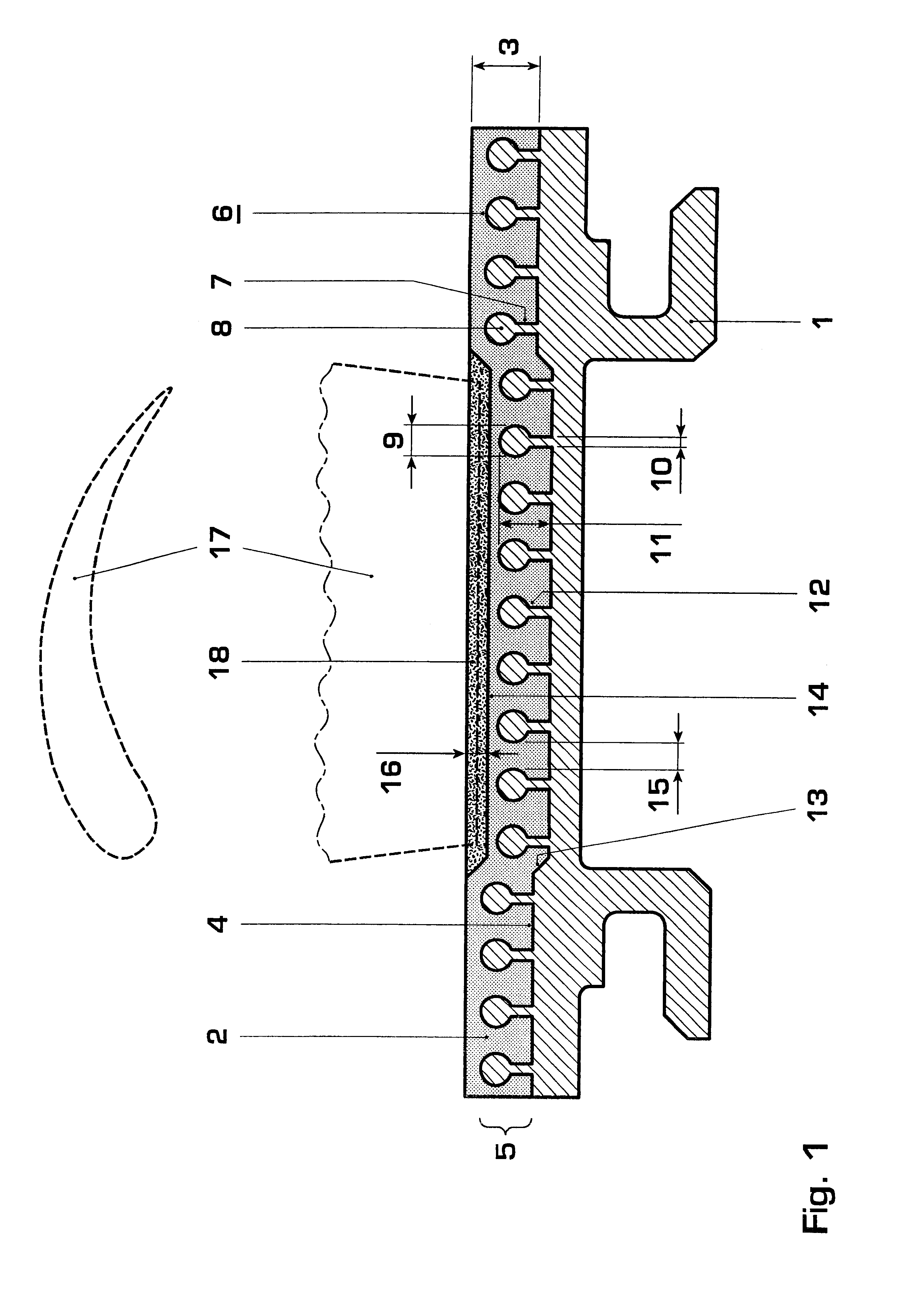

InactiveUS7930771B2Improve protectionReduce the risk of injuryHatsHeadwear capsTangential forceCell wall

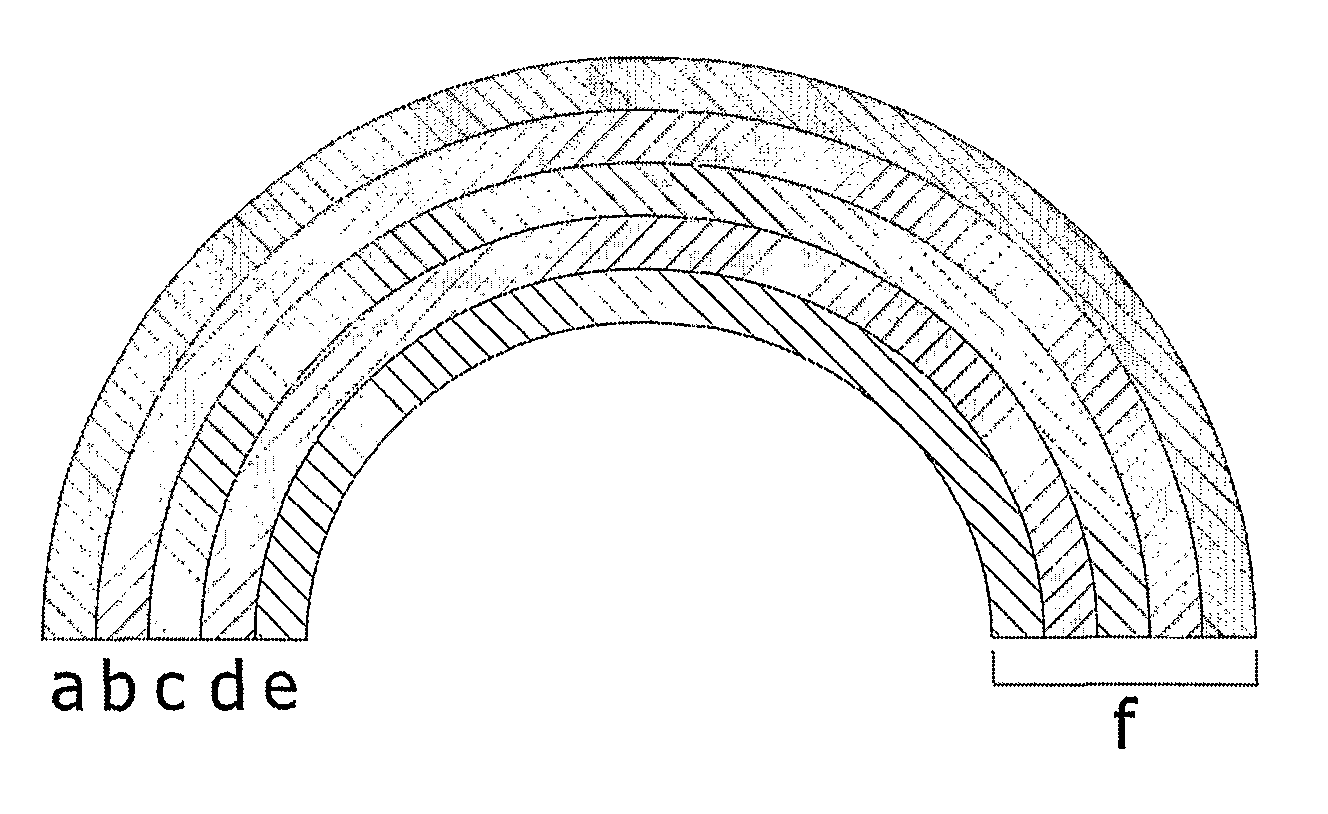

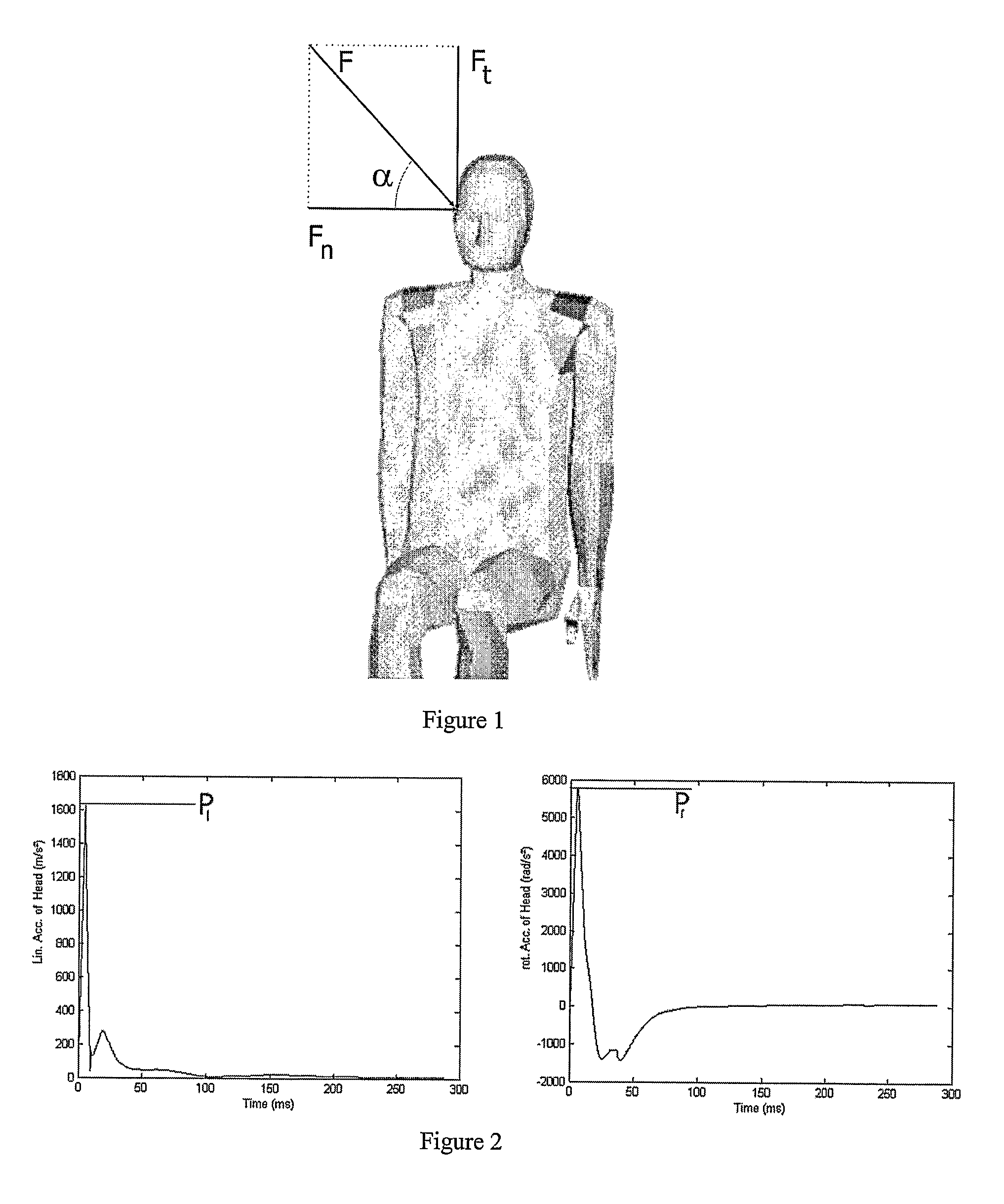

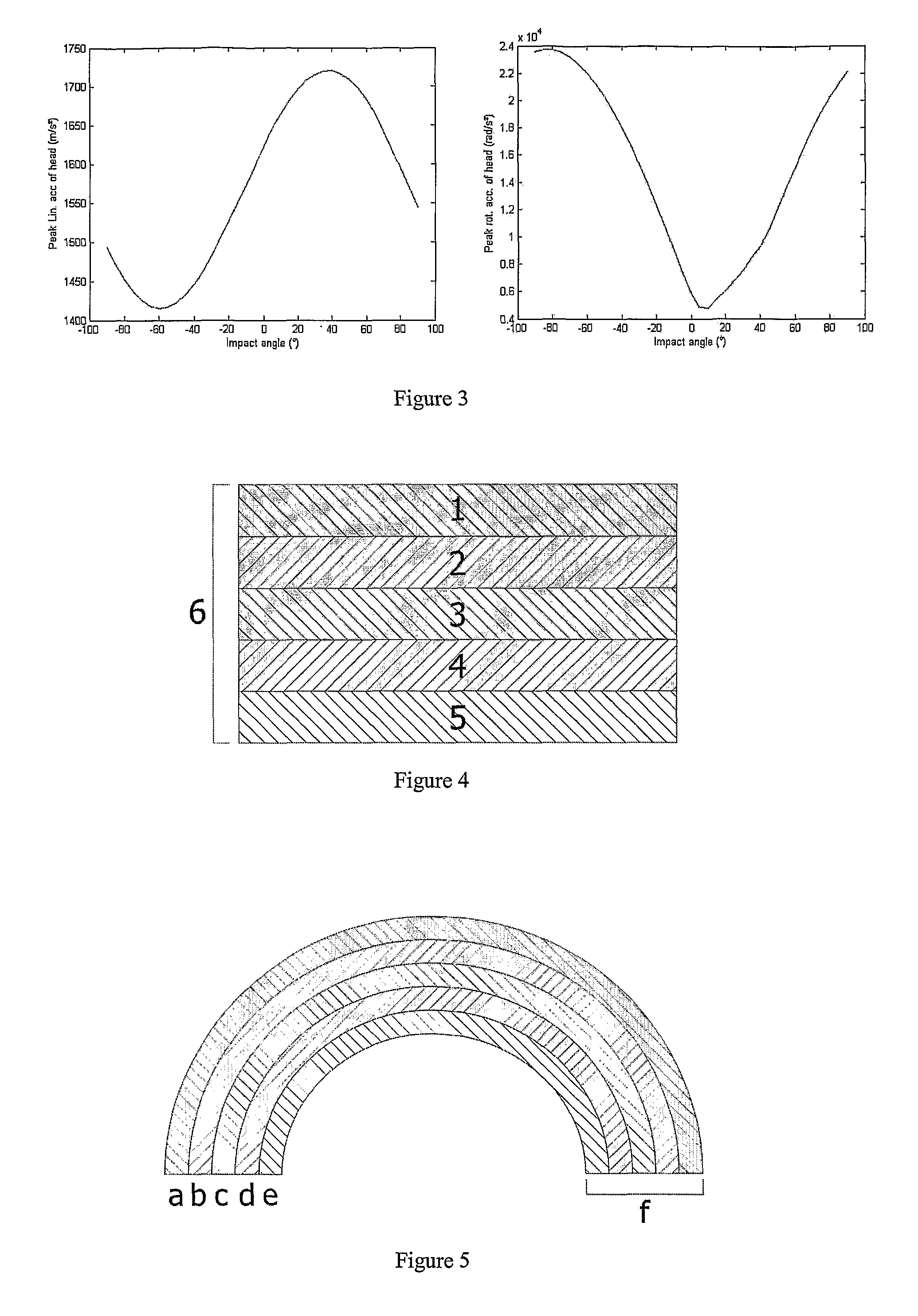

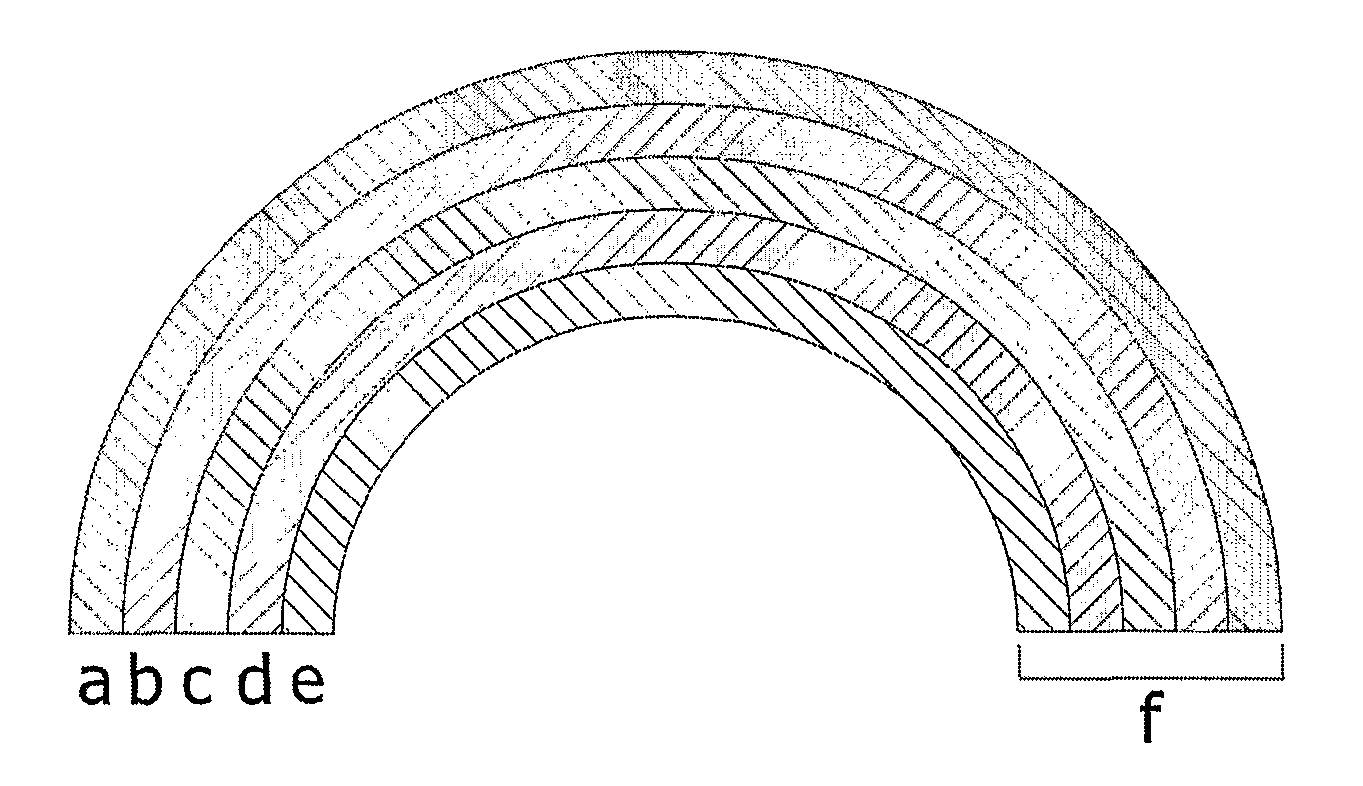

A protective helmet is described comprising: an outer layer (1); an inner layer (5) for contact with a head of a wearer; and an intermediate layer (3, 4) comprising an anisotropic cellular material comprising cells having cell walls, the anisotropic cellular material having a relatively low resistance against deformation resulting from tangential forces on the helmet. The anisotropic material can be a foam or honeycomb material. The foam is preferably a closed cell foam. The helmet allows tangential impacts to the helmet which cause less rotational acceleration or deceleration of the head of the wearer compared to helmets using isotropic foams while still absorbing a significant amount of rotational energy.

Owner:K U LEUVEN RES & DEV

Protective Helmet

InactiveUS20080066217A1Improve protectionReduce the risk of injuryHatsSport apparatusHoneycombTangential force

A protective helmet is described comprising: an outer layer (1); an inner layer (5) for contact with a head of a wearer; and an intermediate layer (3, 4) comprising an anisotropic cellular material comprising cells having cell walls, the anisotropic cellular material having a relatively low resistance against deformation resulting from tangential forces on the helmet. The anisotropic material can be a foam or honeycomb material. The foam is preferably a closed cell foam. The helmet allows tangential impacts to the helmet which cause less rotational acceleration or deceleration of the head of the wearer compared to helmets using isotropic foams while still absorbing a significant amount of rotational energy.

Owner:K U LEUVEN RES & DEV

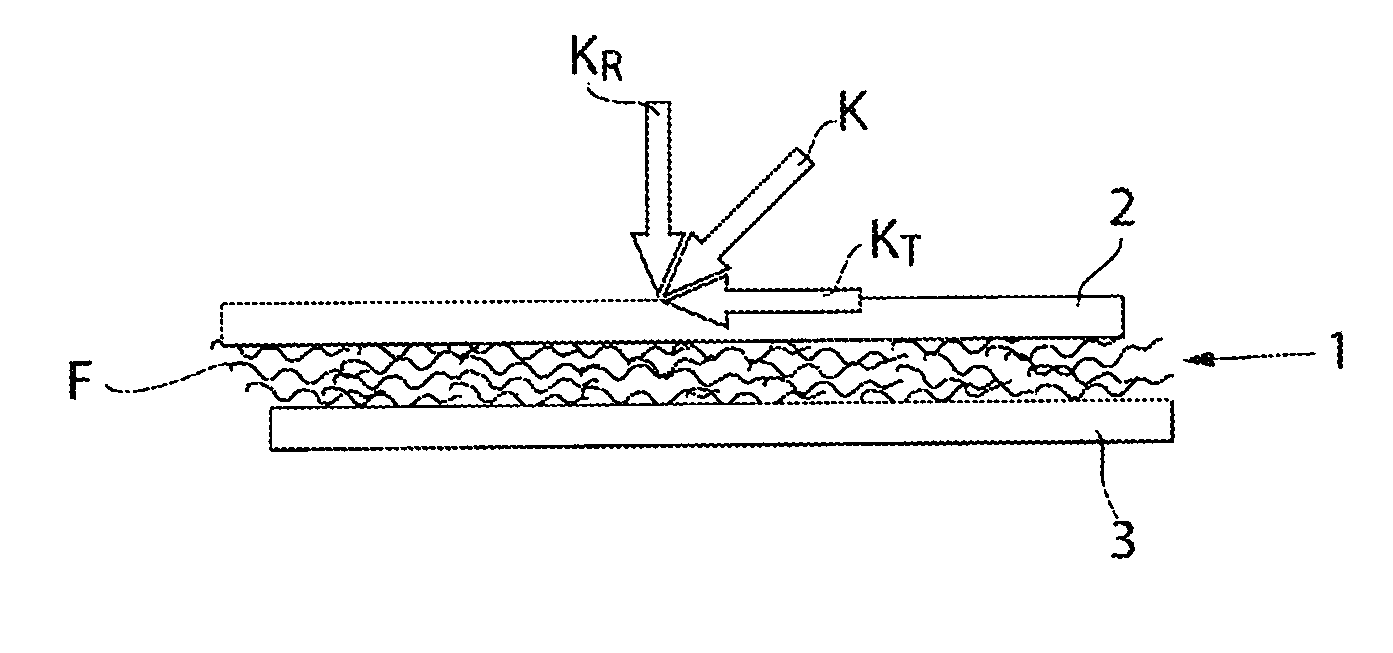

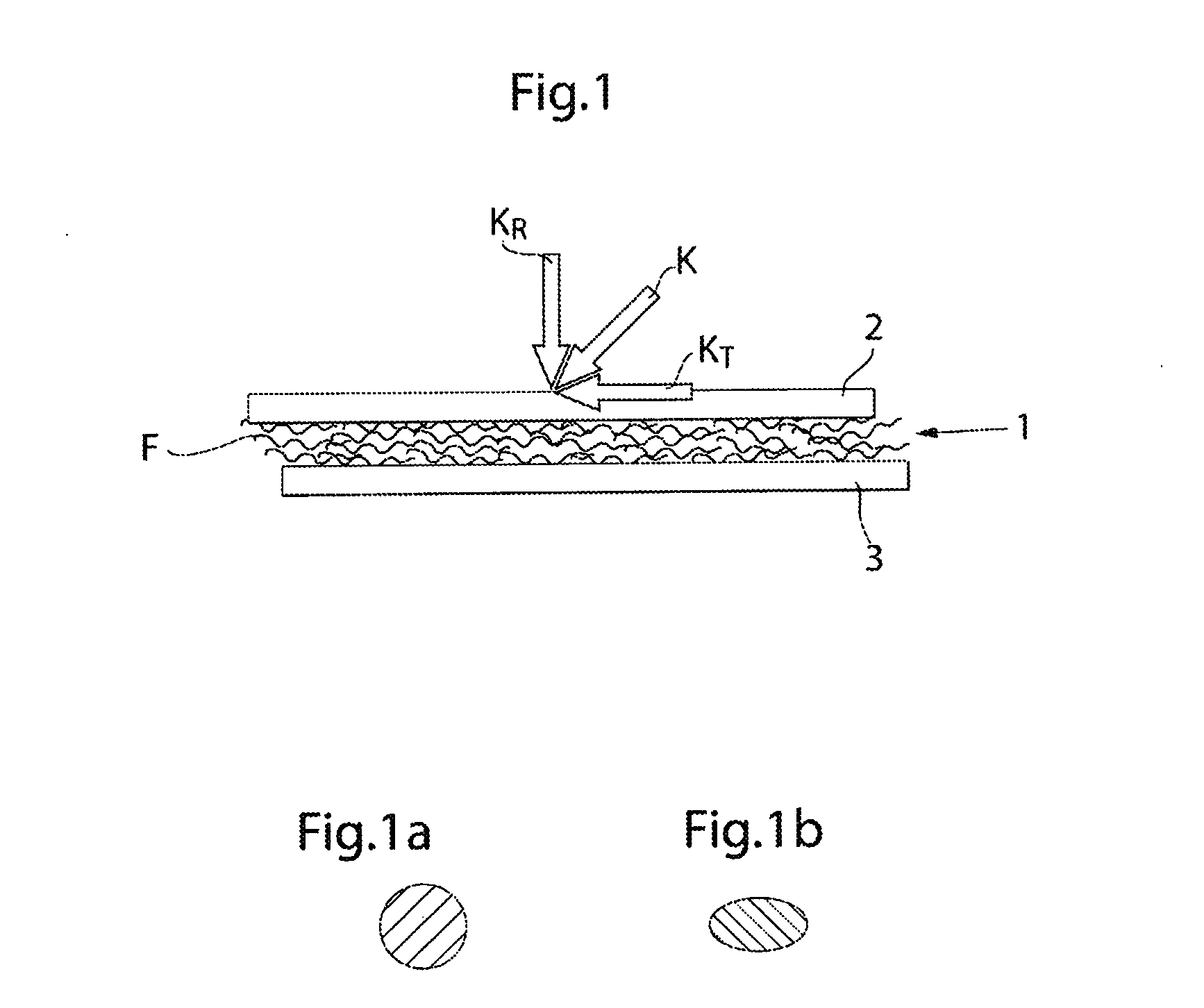

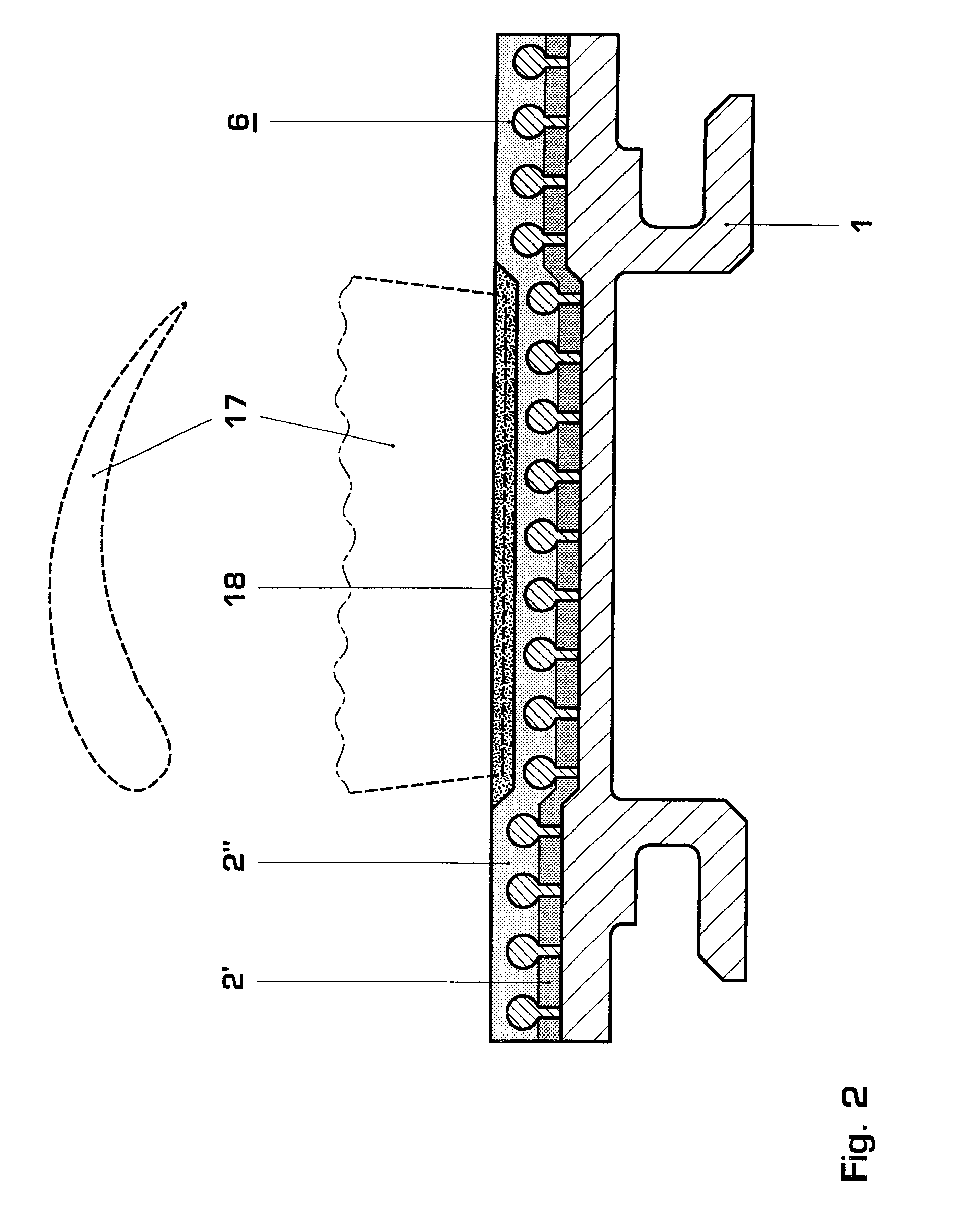

Intermediate Layer of Friction Decreasing Material

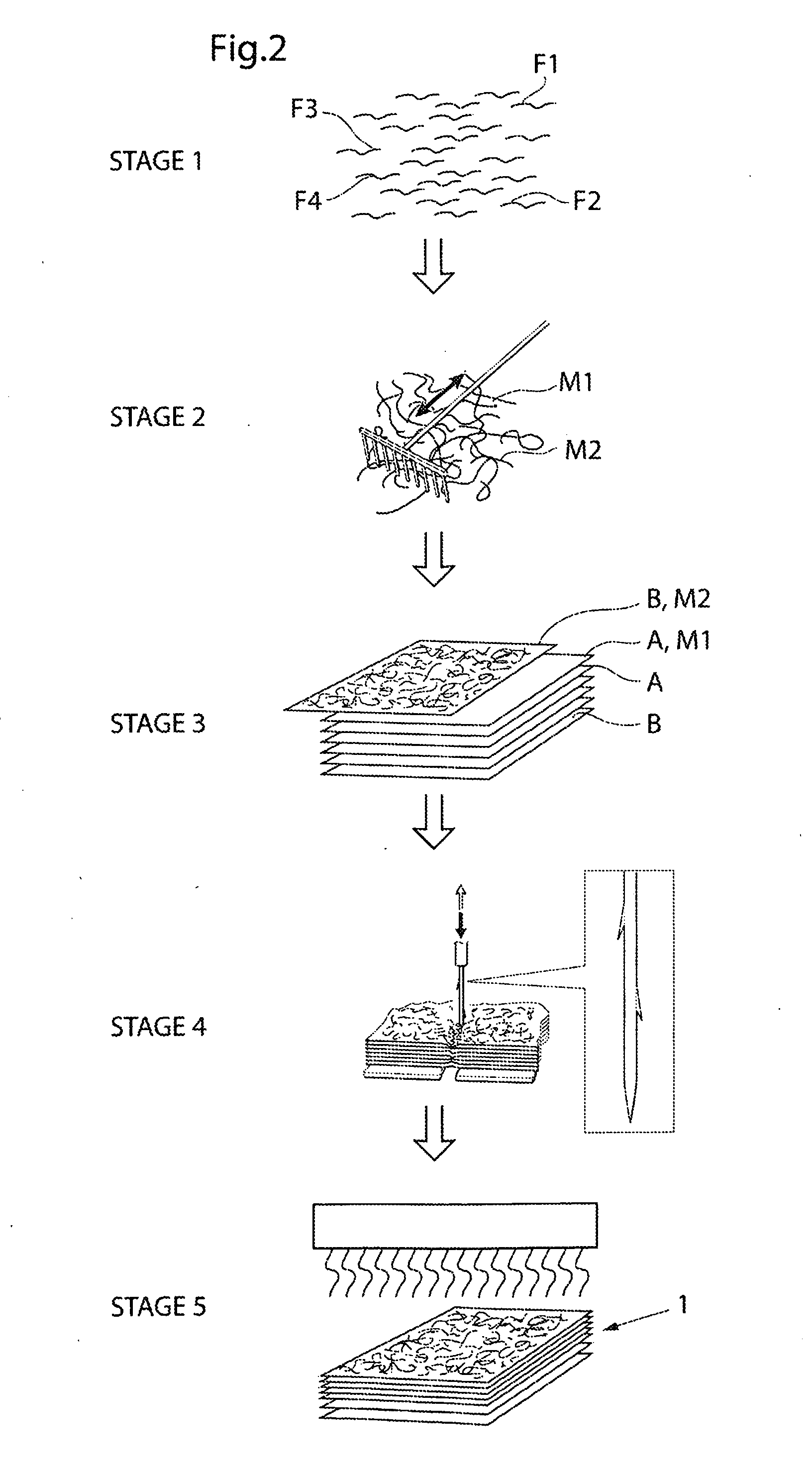

InactiveUS20130040524A1Efficient productionEasy to shapeReactive armourDynamic armourFiberTangential force

The invention according to the present invention relates to an intermediate layer (1) of friction decreasing material placed between two layers (2, 3). The intermediate layer (1) is adapted to create a sliding movement between the layers (2, 3) when a force (K) is applied and a tangential force component (KT) shears the layers. The friction decreasing material comprises fibers (F).

Owner:MIPS

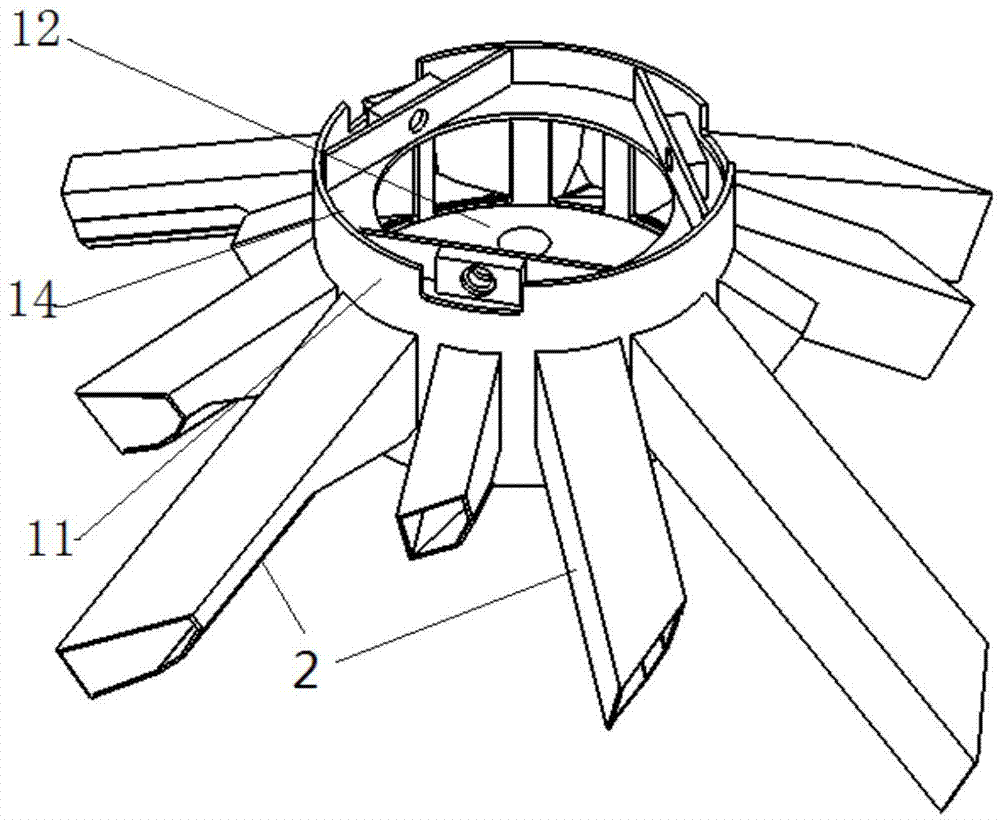

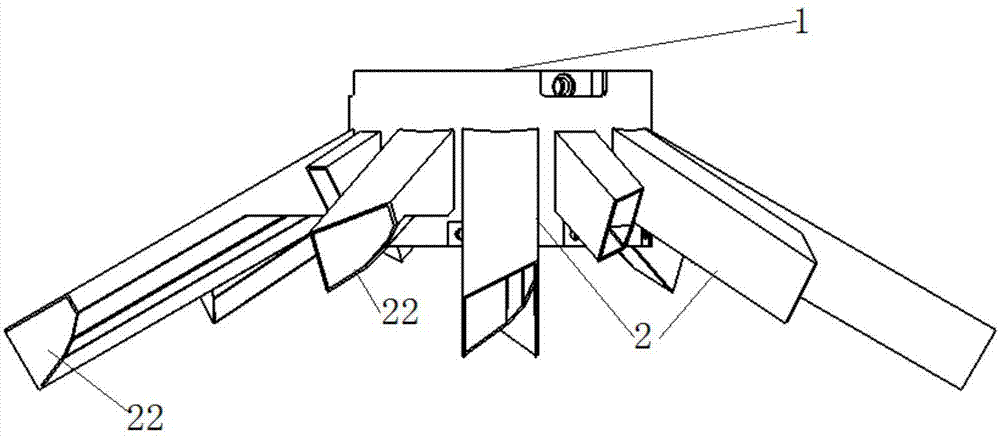

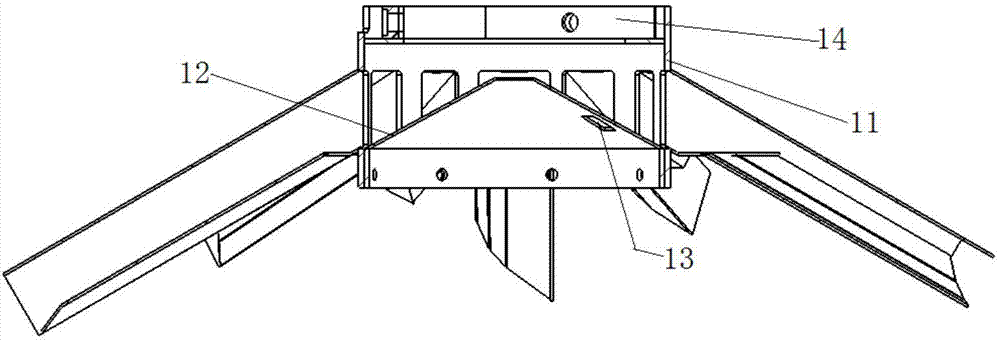

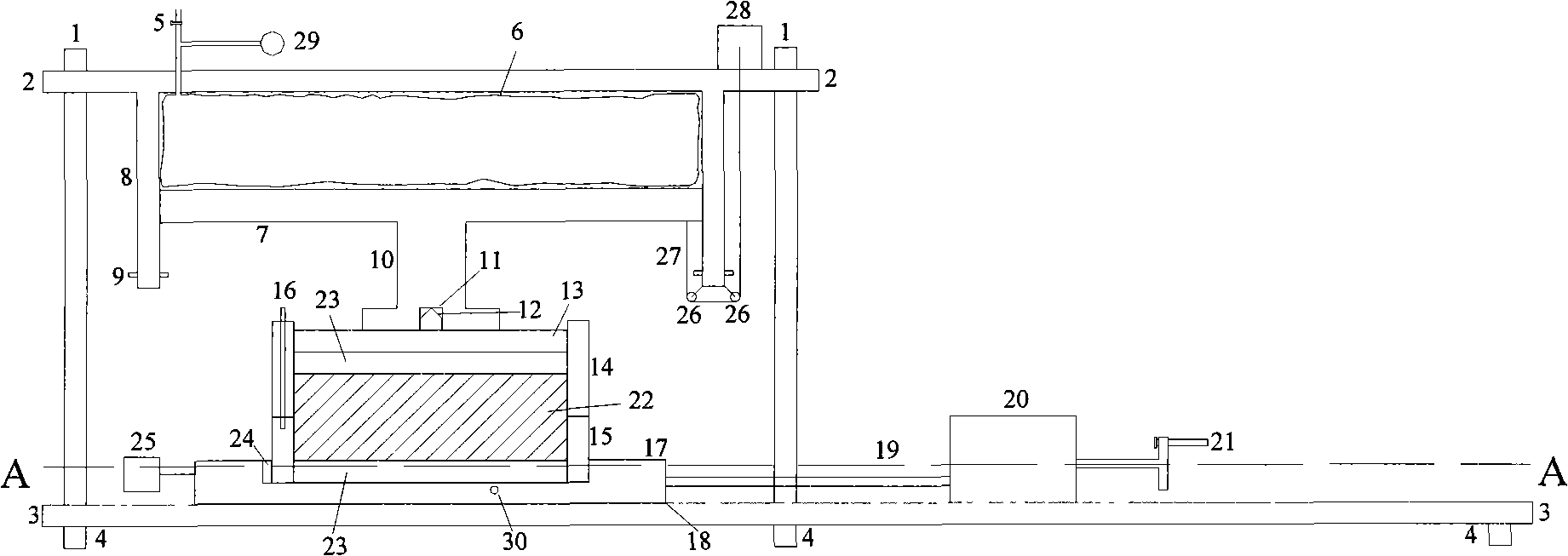

Rotating-type grain distributor and granary provided with grain distributor

InactiveCN104709729AGuaranteed safe storageReduce accumulationLoading/unloadingTangential forceEngineering

The invention discloses a rotating-type grain distributor and a granary provided with the grain distributor, and belongs to the technical field of granaries. The rotating-type grain distributor comprises a grain collecting barrel. The grain collecting barrel comprises a barrel wall and a barrel bottom. The outer side of the barrel wall of the grain collecting barrel is provided with two downward-inclined grain sliding pipes. The bottom face and one side face of each grain sliding pipe are curved surfaces which are of an integral structure. When the rotating-type grain distributor is used, the rotating-type grain distributor is arranged at a grain inlet of the granary, after grain enters the grain collecting barrel, the grain flows into the grain sliding pipes, and when the rotating-type grain distributor rotates, the grain sliding pipes rotate along with the rotating-type grain distributor. Due to the fact that the bottom face and one side face of each grain sliding pipe are curved surfaces which are of the integral structure, when the rotating-type grain distributor rotates, under the effect of centrifugal force and tangential force generated by the curved surfaces, the grain is scattered and flows out of the grain sliding pipes, and the grain falls onto a circular cross section of the granary. According to the rotating-type grain distributor, the impurity accumulation caused by automatic grading formed by concentrated falling of the grain is alleviated, and the safe storage of the grain is guaranteed.

Owner:BEIJING U PRECISION TECH

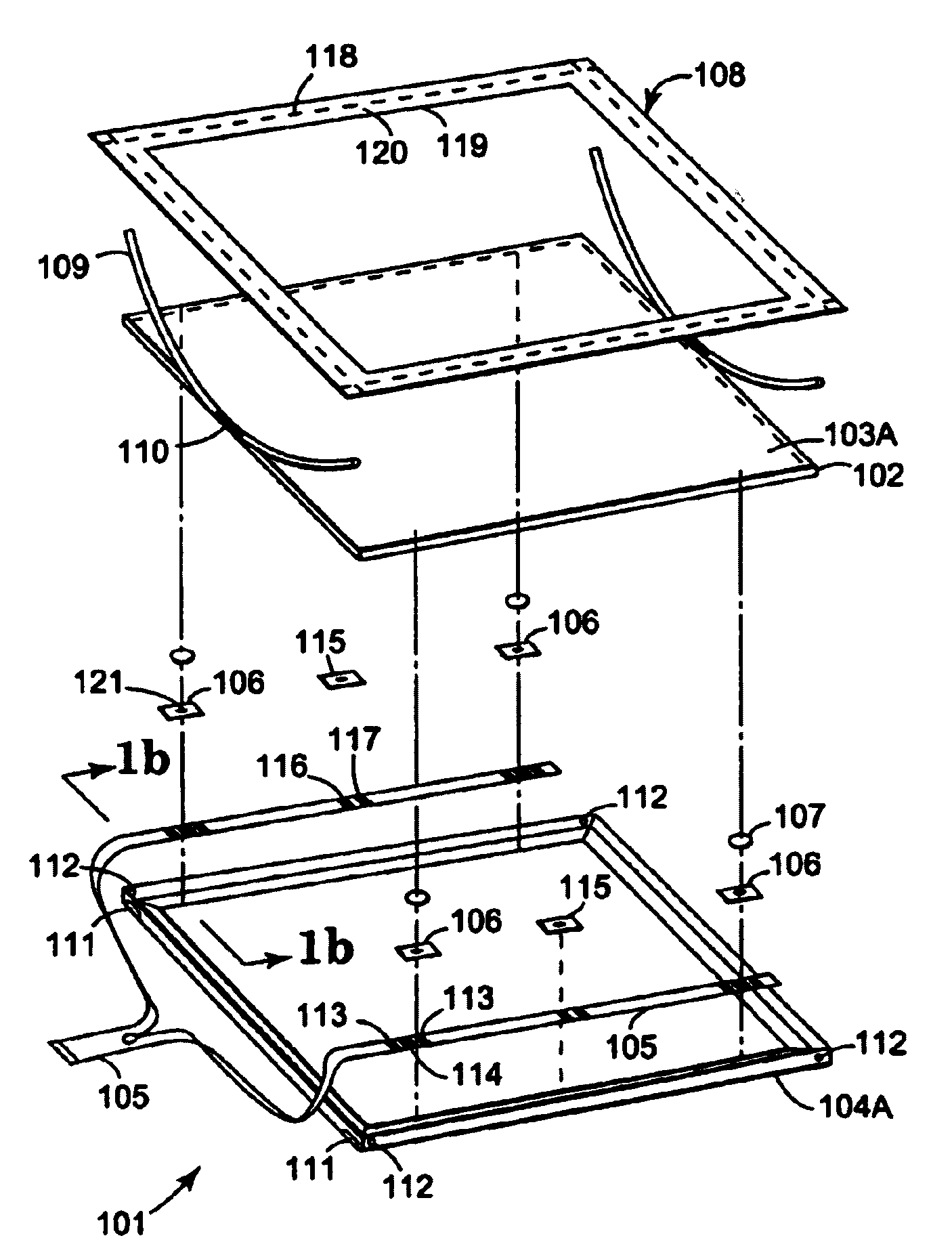

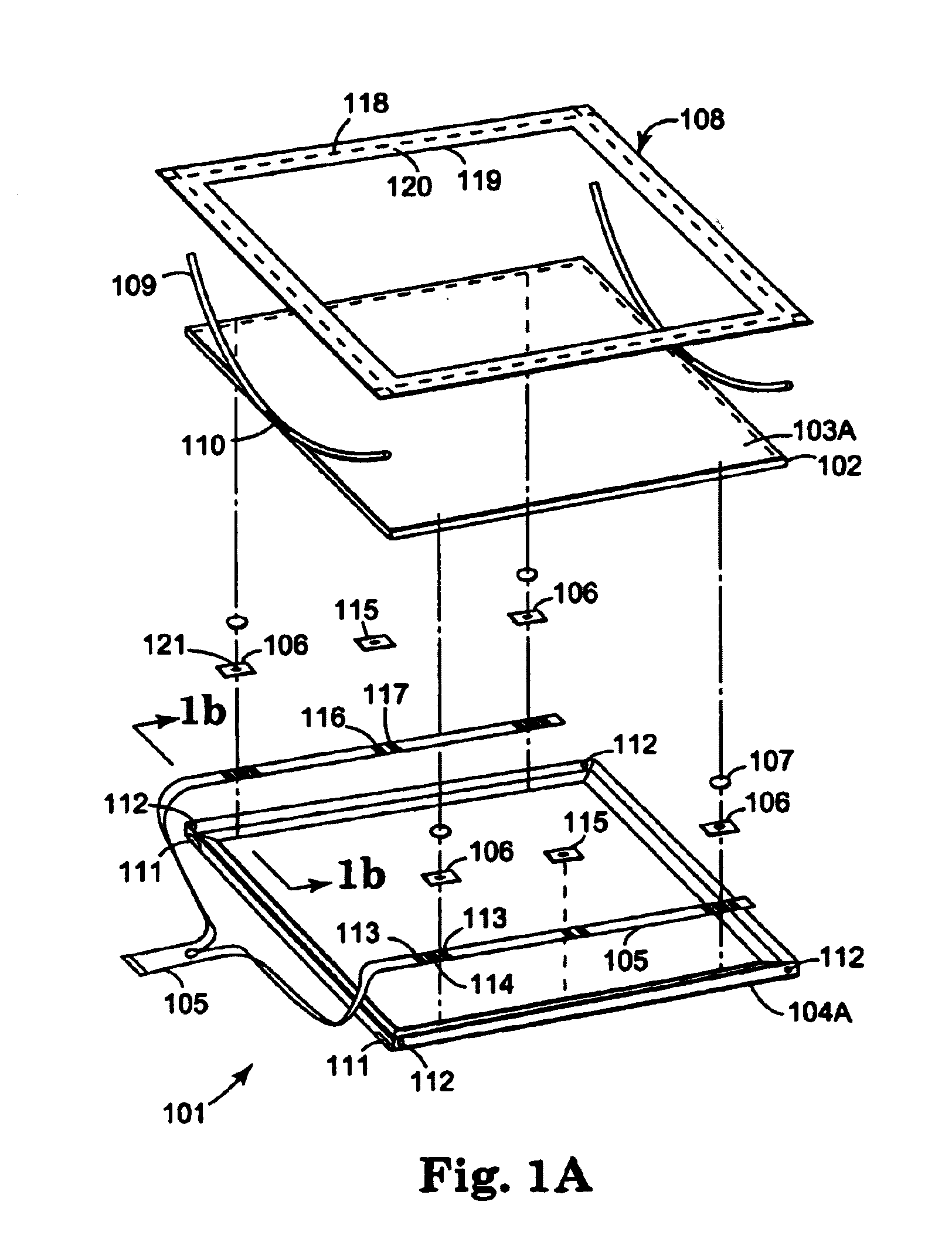

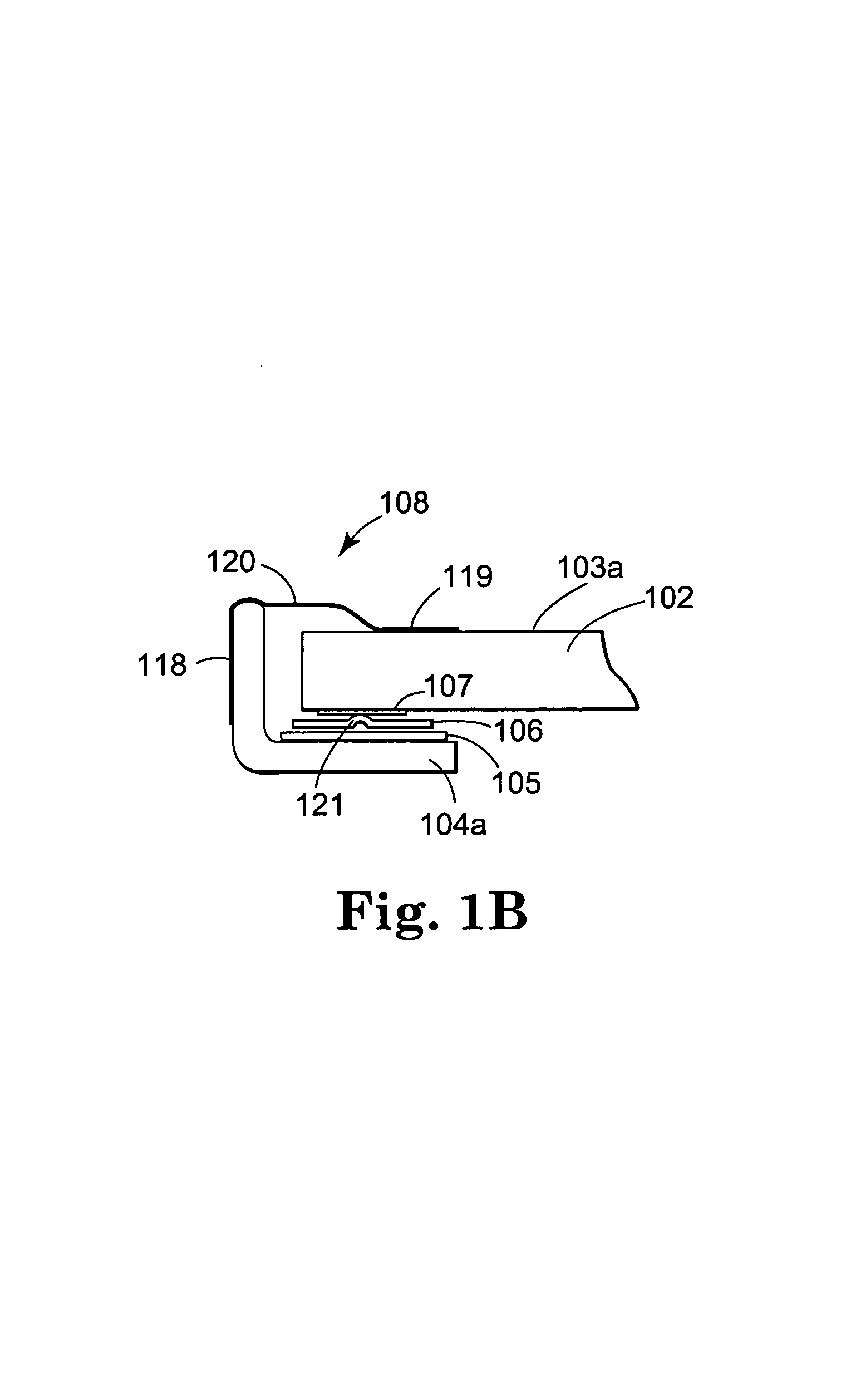

Tangential force control in a touch location device

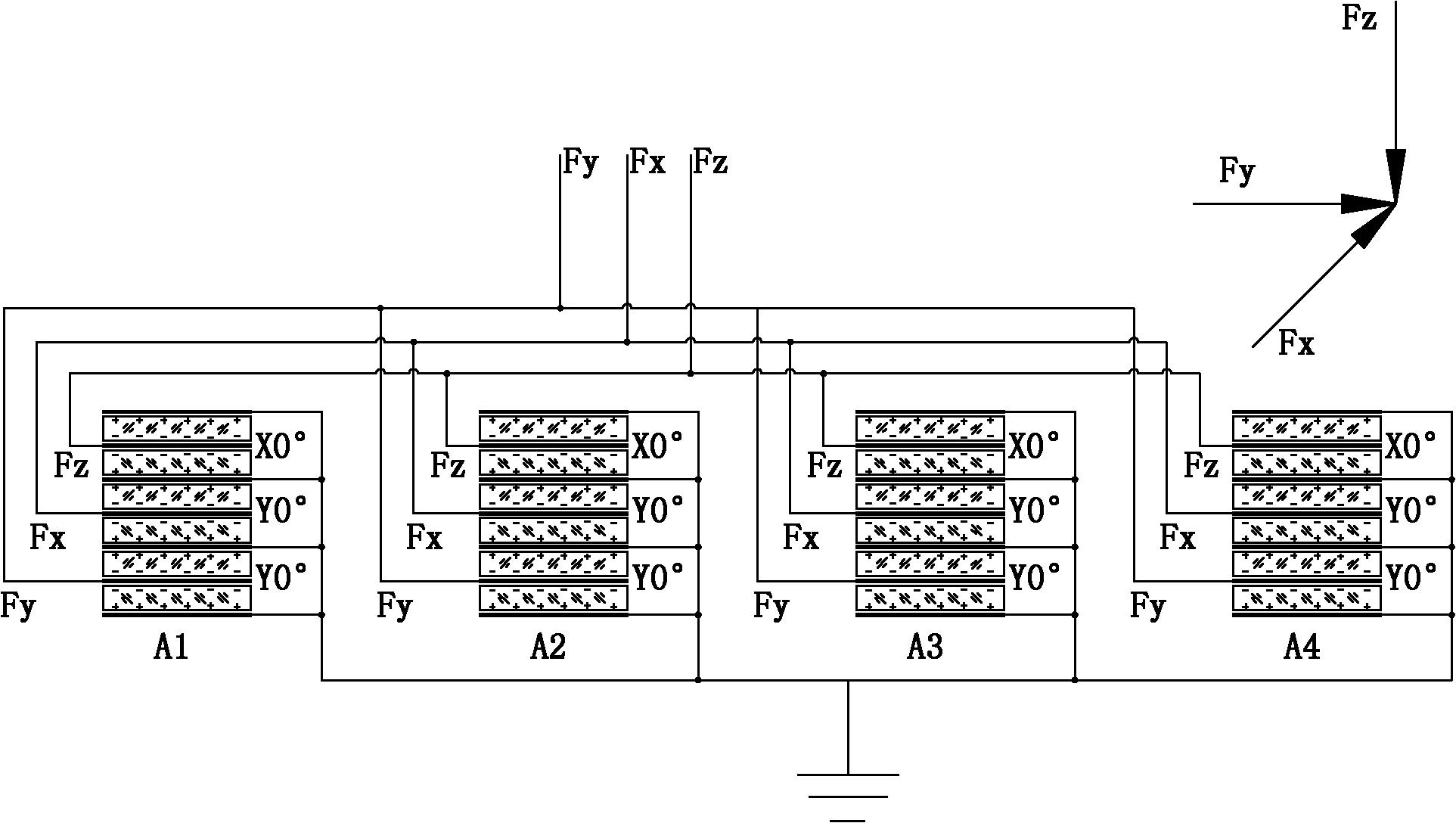

ActiveUS7183948B2Reduce transmissionEffective applicationElectronic switchingGraph readingTangential forceTangential contact

Various techniques are provided for reducing the impact of tangential forces on touch location in a touch location device. For example, in one aspect, shunt connections are provided that impede lateral motion of the touch surface structure at the level of the touch plane, thereby reducing to insignificant magnitude reactions to tangential force passing through the sensing connections. In another aspect, sensing connections incorporate elastic means so adjusted as to turn that connection's reaction to tangential touch force perpendicular to its axis of sensitivity. In another aspect, sensing connections incorporate sensing means so adjusted as to turn that connection's axis of sensitivity perpendicular to its reaction to tangential force.

Owner:3M INNOVATIVE PROPERTIES CO

Gas turbine seal

InactiveUS6652227B2High bonding strengthHigh overheatPump componentsReaction enginesCeramic coatingTangential force

The invention relates to a gas turbine seal, comprising a metallic component (1) with a durable or erosion-resistant ceramic coating (2) and an abradable ceramic layer (18) which is arranged thereon in locally delimited fashion, a bond layer (5) being arranged on the surface (4) of the metallic component (1), to which bond layer the durable or erosion-resistant ceramic coating (2) is applied as a covering layer. The invention is characterized in that the bond layer (5) comprises separate, adjacent spherical rivets (6) or mushroom-shaped rivets (6) which have a web (7) and a head (8). These rivets form individual metal islands with numerous undercuts (12), around which there is a continuous ceramic network. It is possible to produce very thick layers which have a good bond strength, the ceramic not being flaked away even in the event of introduction of radial / tangential forces, sickle-shaped contact or locally high overheating / frictional heat, and a good sealing action being achieved.

Owner:GENERAL ELECTRIC TECH GMBH

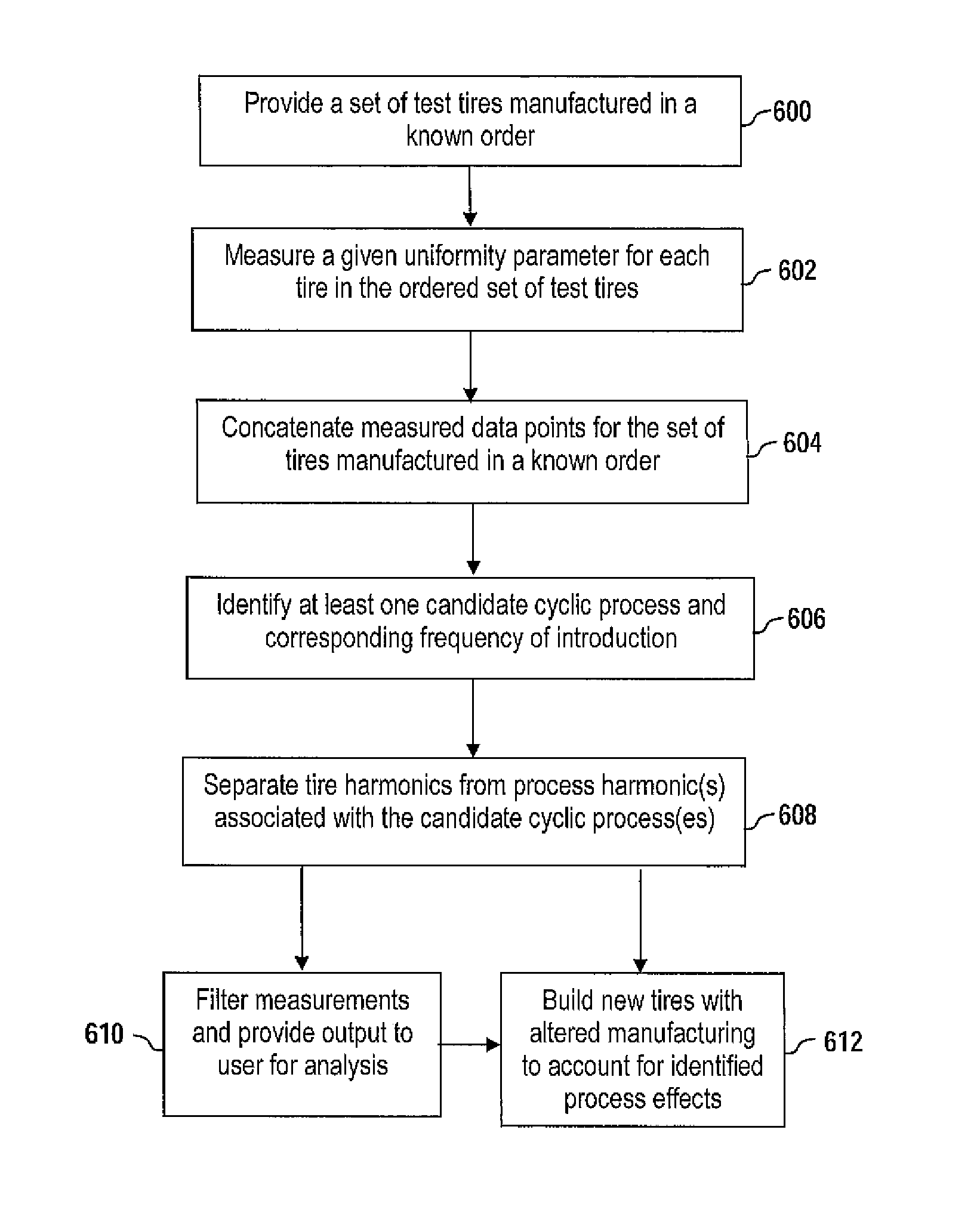

Improvement of tire uniformity through identification of process signatures

ActiveUS20120035757A1Improve uniformityOptimizing componentsTyresSpecial data processing applicationsTire uniformityCyclic process

A system and related method for improving tire uniformity includes providing a number (n) of test tires manufactured in a known order and identifying at least one candidate cyclic process effect with a corresponding frequency of introduction (f). A given uniformity parameter, such as radial or lateral run-out, balance, mass variation, radial lateral or tangential force variation, is measured for each tire in the test set, and measured data points are combined into a concatenated composite waveform. At least one process harmonic associated with each identified cyclic process effect is separated from the tire harmonics, for example, by Fourier transformation with identification of the process harmonics as positive integer multiples of the mth harmonic of the measured uniformity parameter where m=n / f. Once the process harmonics are extracted, filtered uniformity measurements can be provided or new tires can be built with the process effect minimized.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

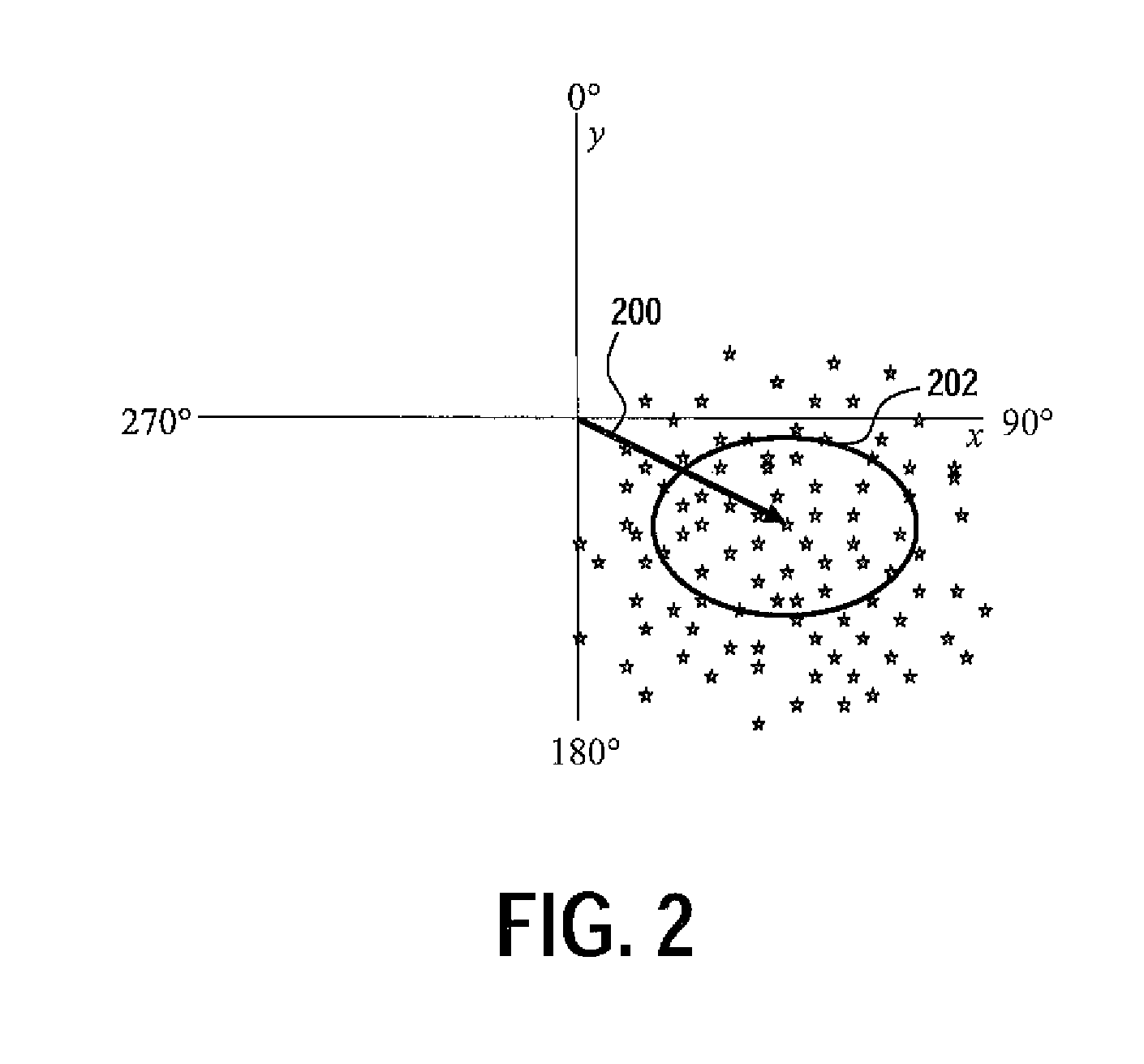

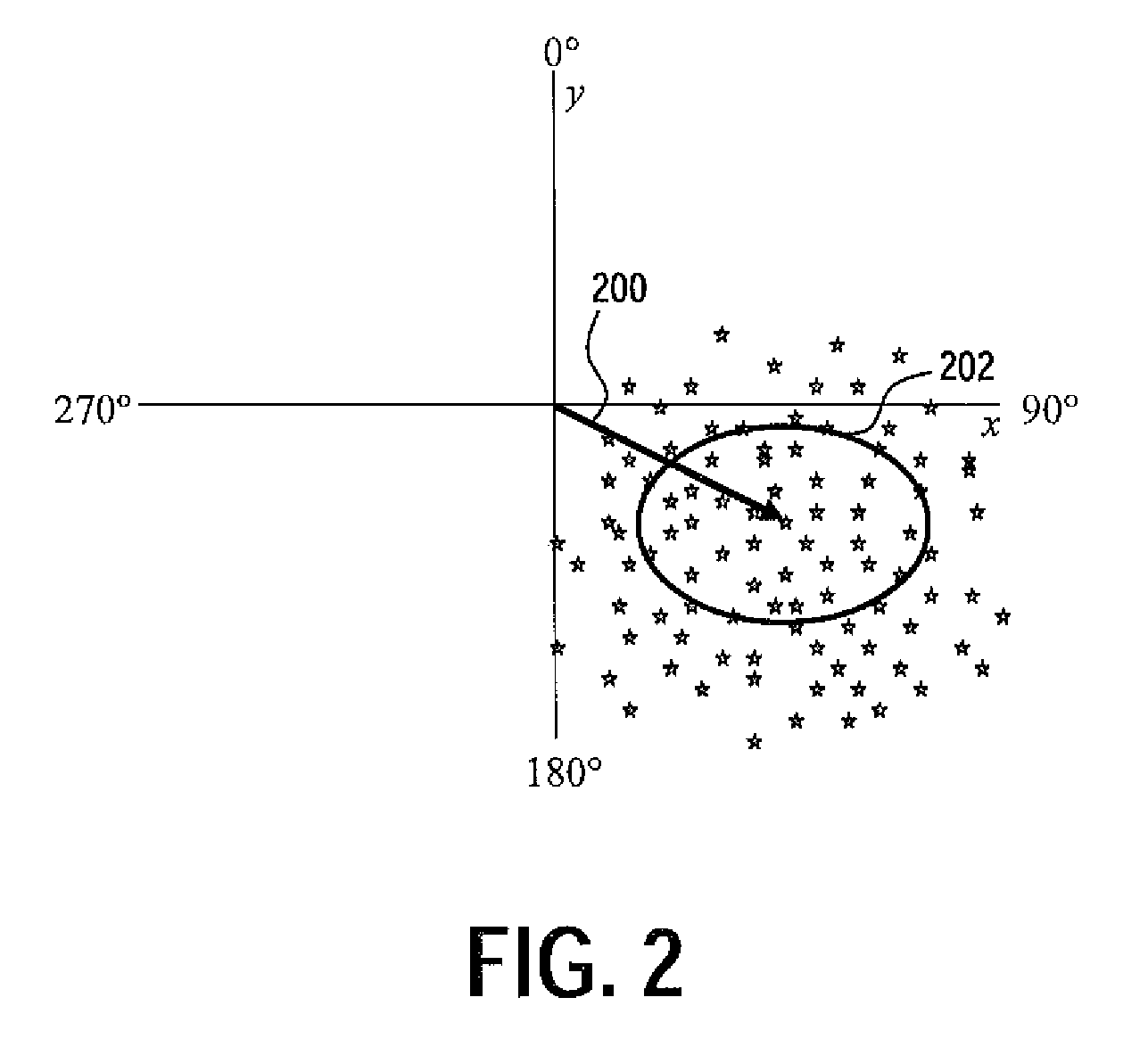

Tire uniformity through identification of process effects using singlet tire regression analysis

ActiveUS20130098148A1Improve uniformityDifferent from numberTyresRoads maintainenceTire uniformityRegression analysis

A system and related method for improving tire uniformity includes identifying at least one candidate process effect and a corresponding process harmonic number for each process effect. A given uniformity parameter, such as radial or lateral run-out, balance, mass variation, radial lateral or tangential force variation, is measured for each tire in a test set, such that the measurements contain tire harmonics as well as a process harmonics corresponding to each candidate process effect. Rectangular coordinate coefficients are electronically constructed for each said process harmonic, after which point the rectangular coordinates corresponding to each process harmonic are solved for (e.g., by using regression-based analysis). The magnitude of each said process harmonic is estimated, and a final magnitude estimate for each process harmonic can be determined by summarizing (e.g., by taking the average or median value) the respectively estimated magnitudes for each process harmonic across all test tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

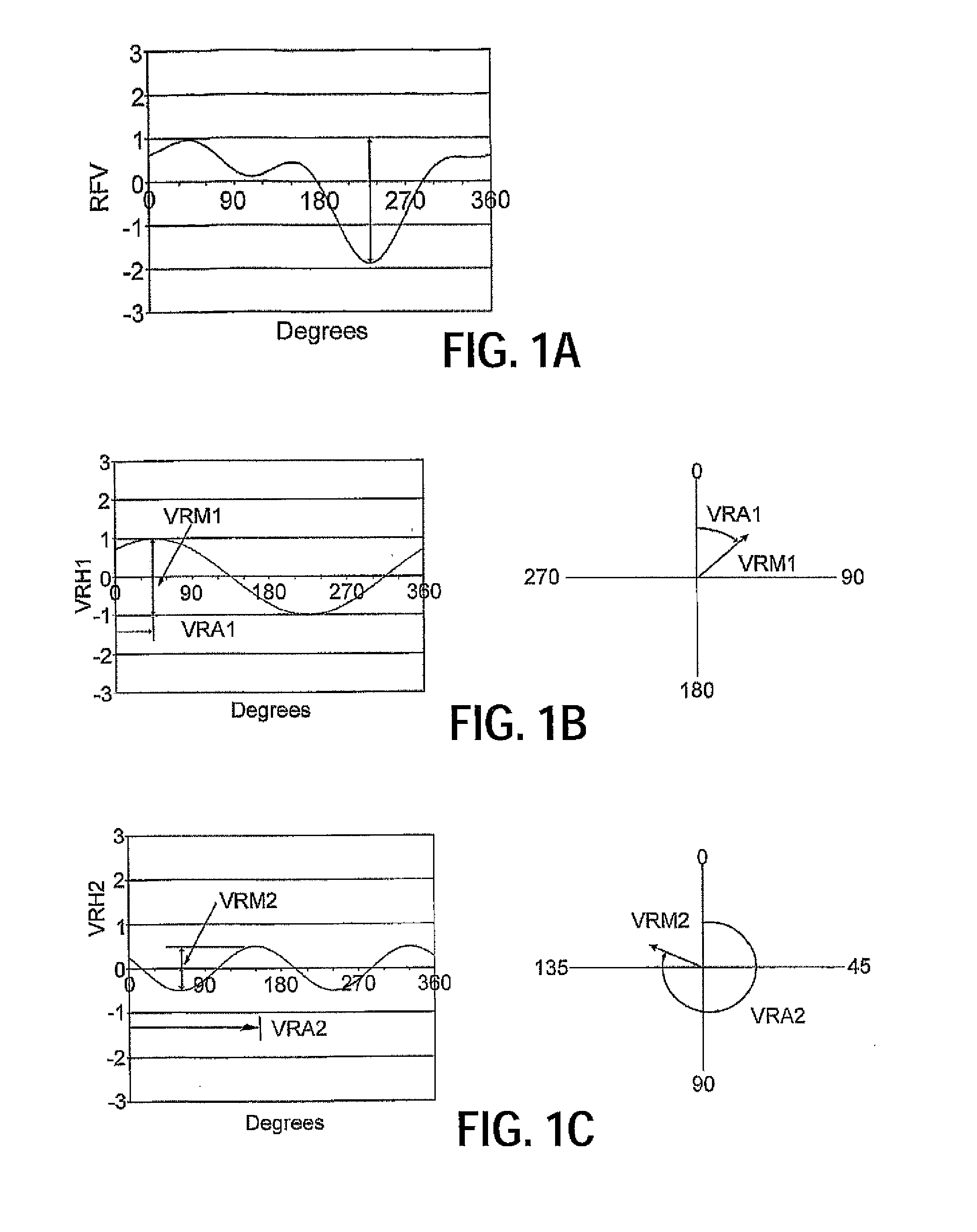

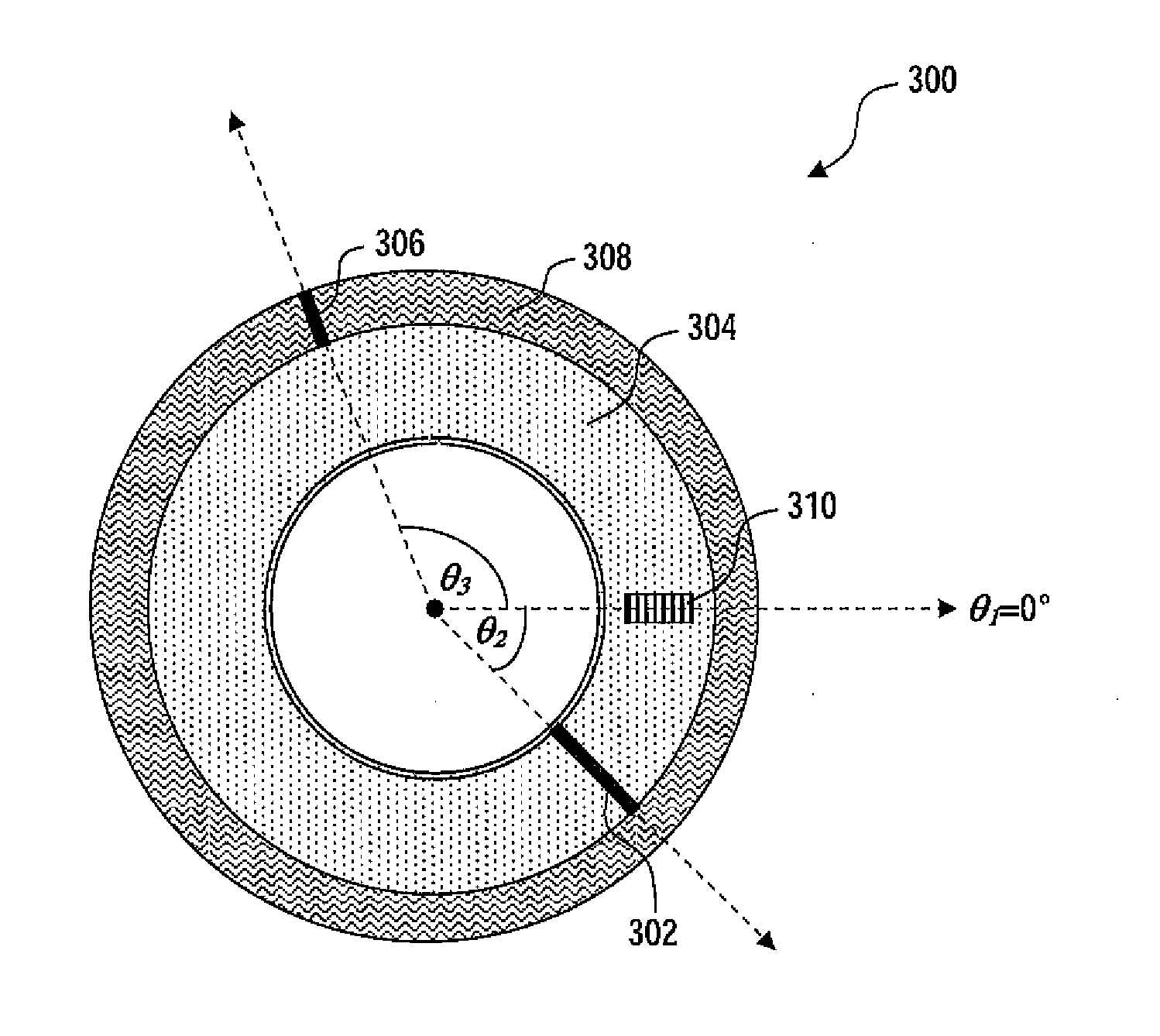

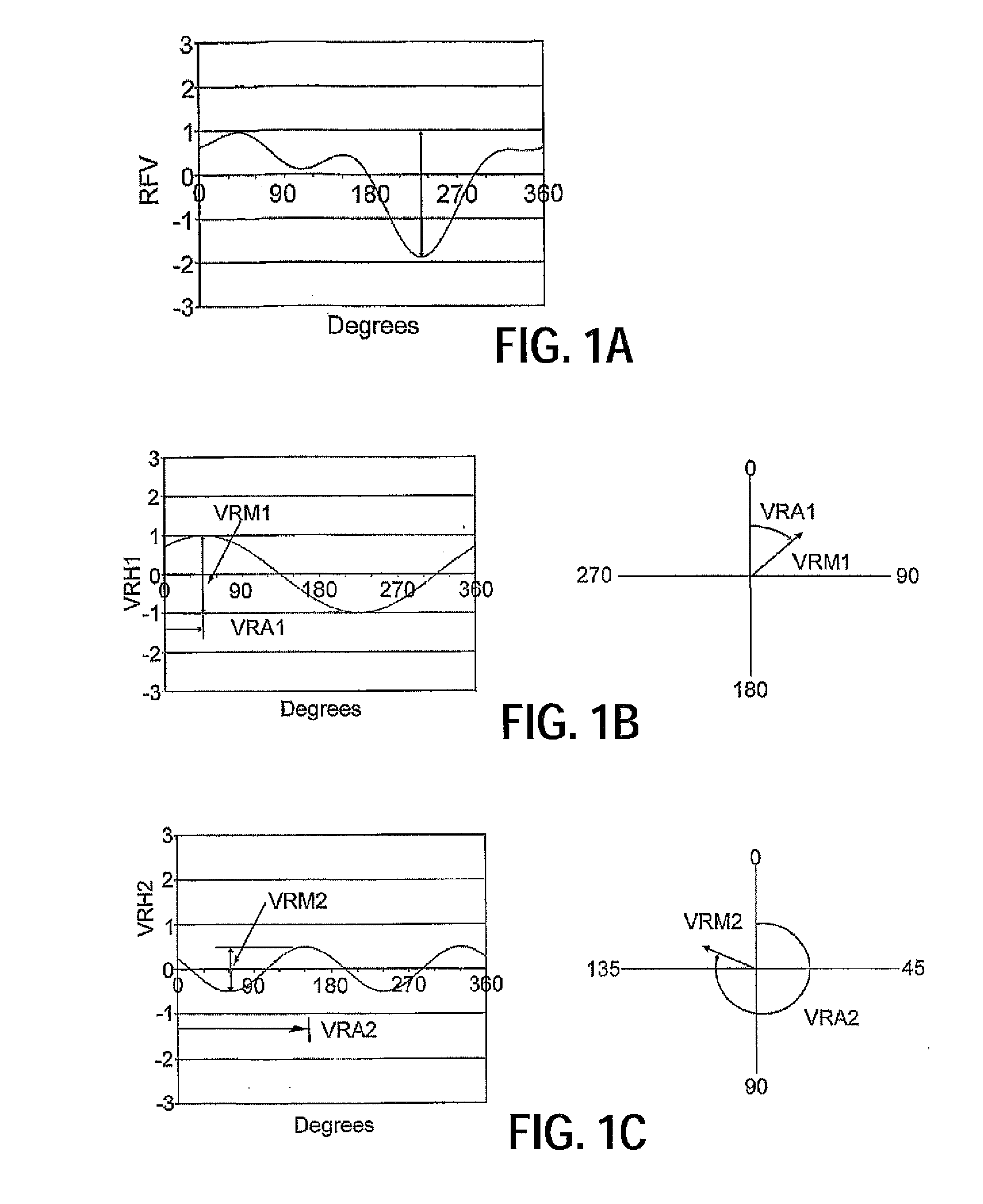

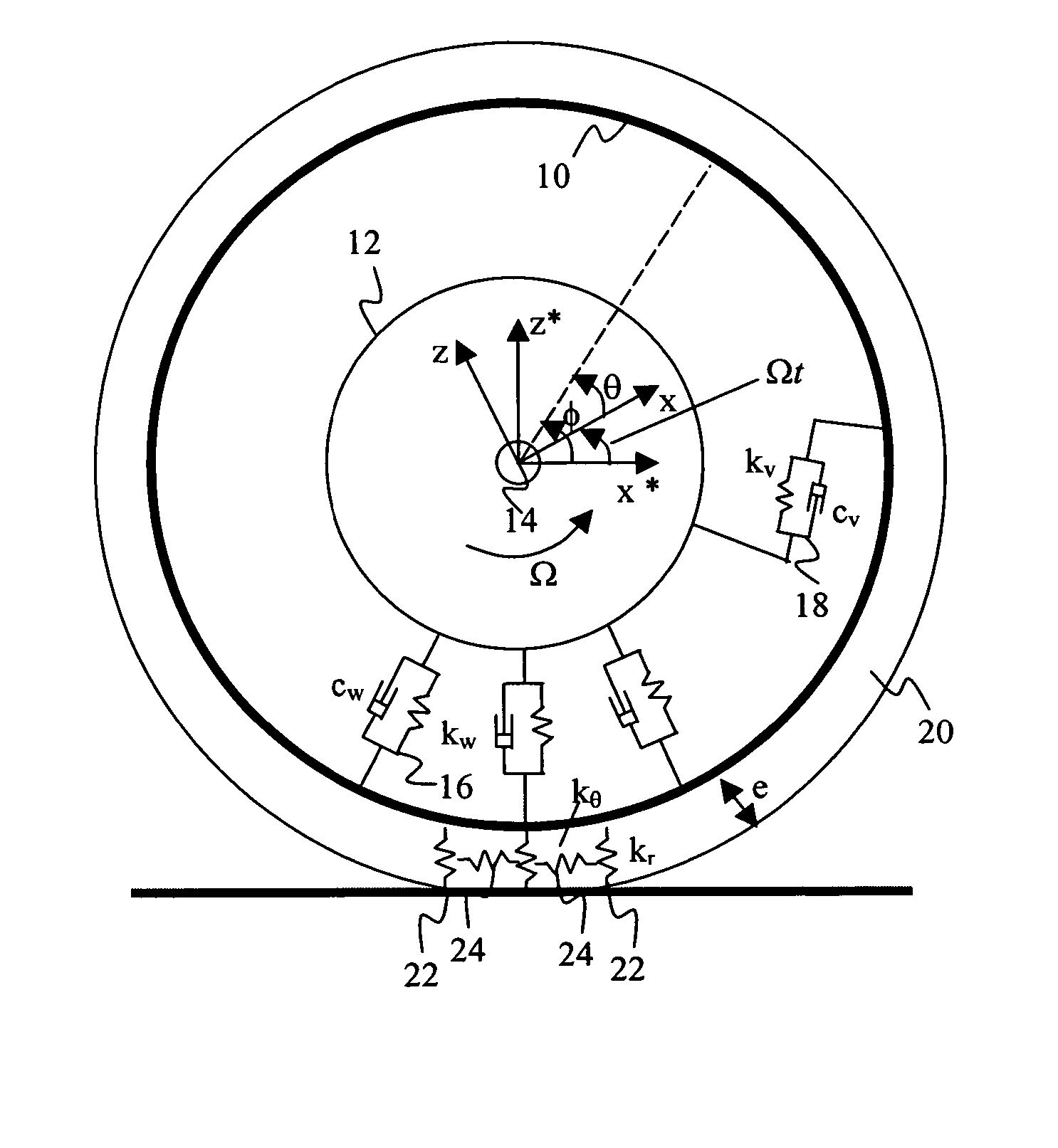

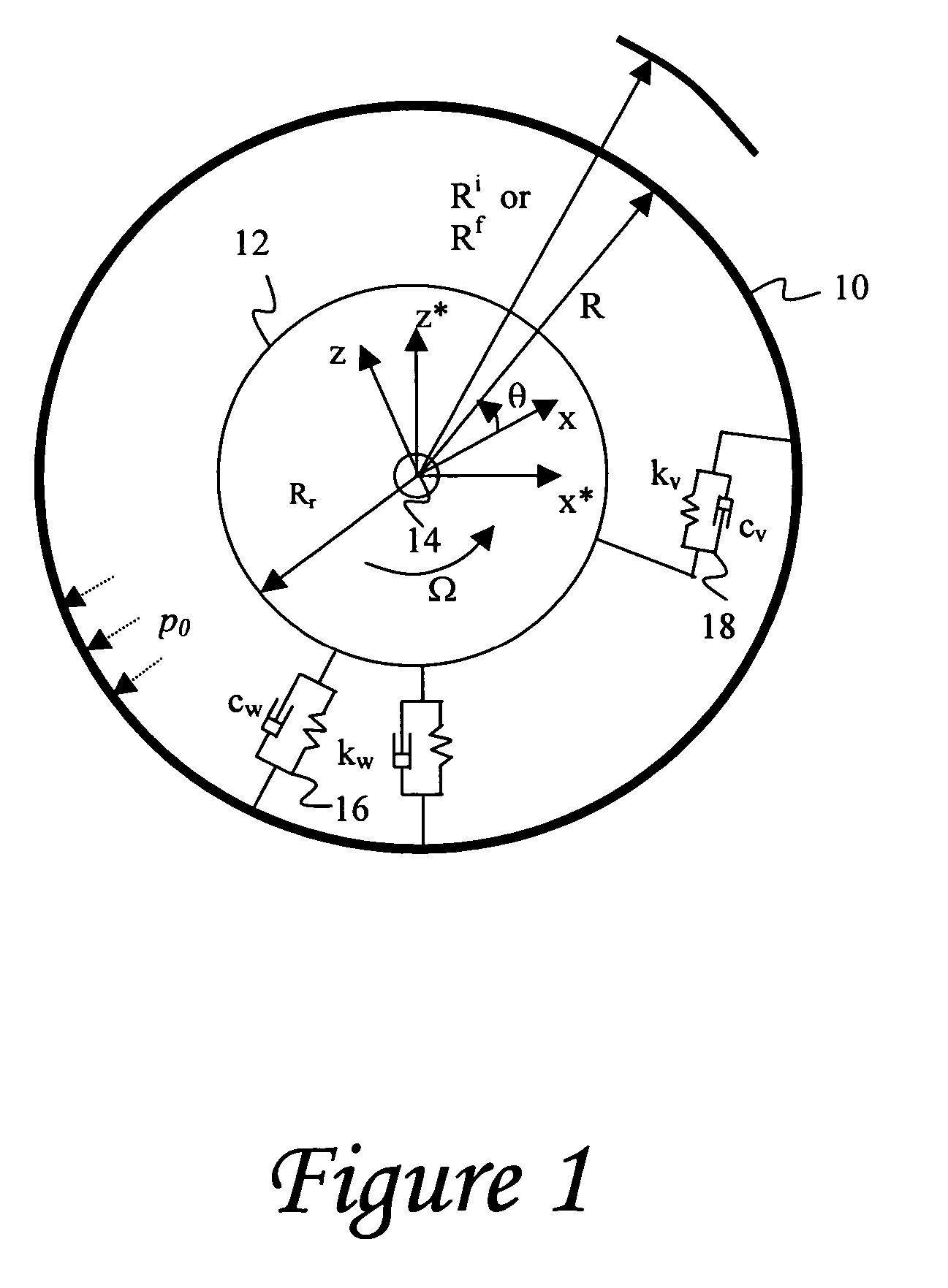

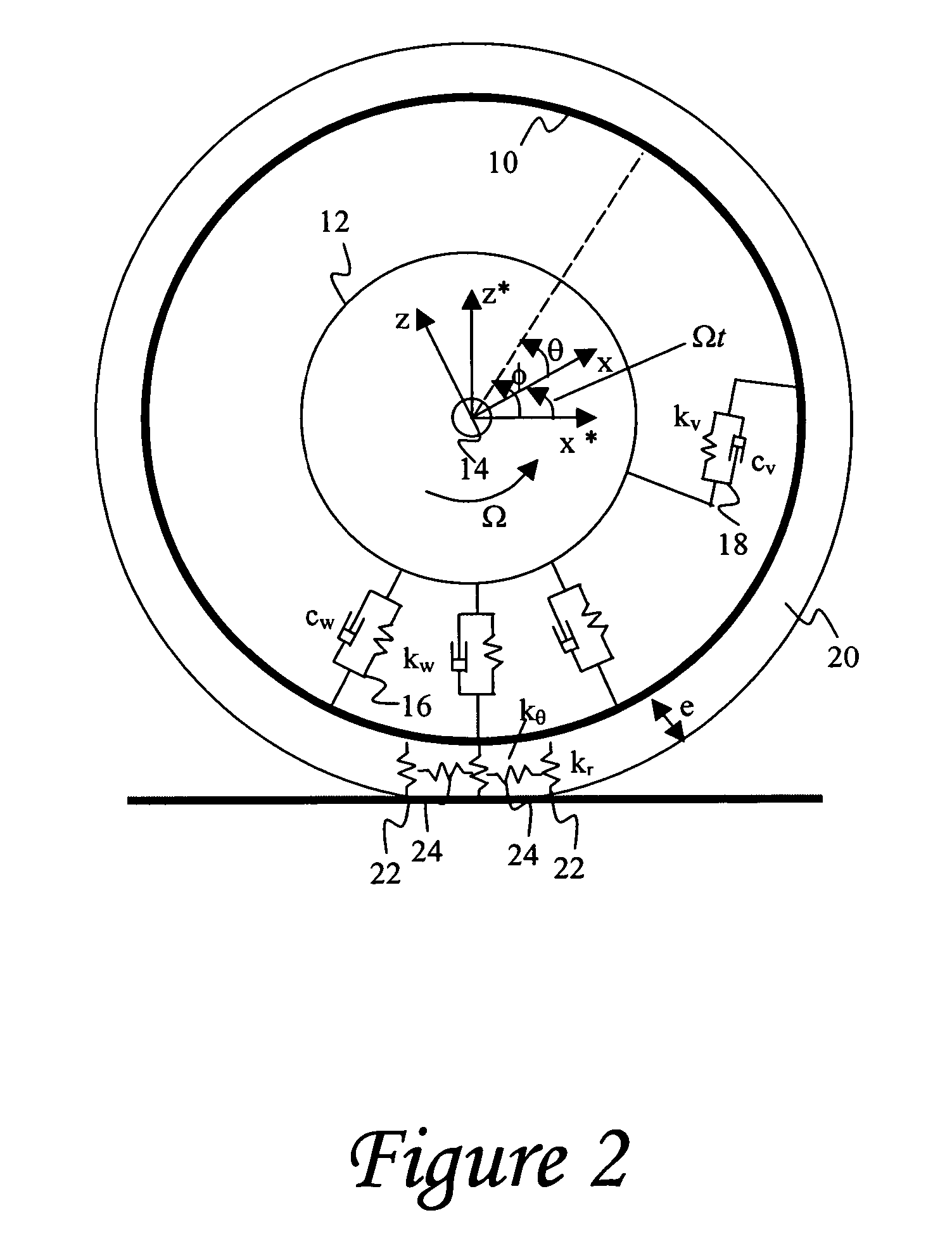

Prediction and control of mass unbalance and high speed uniformity

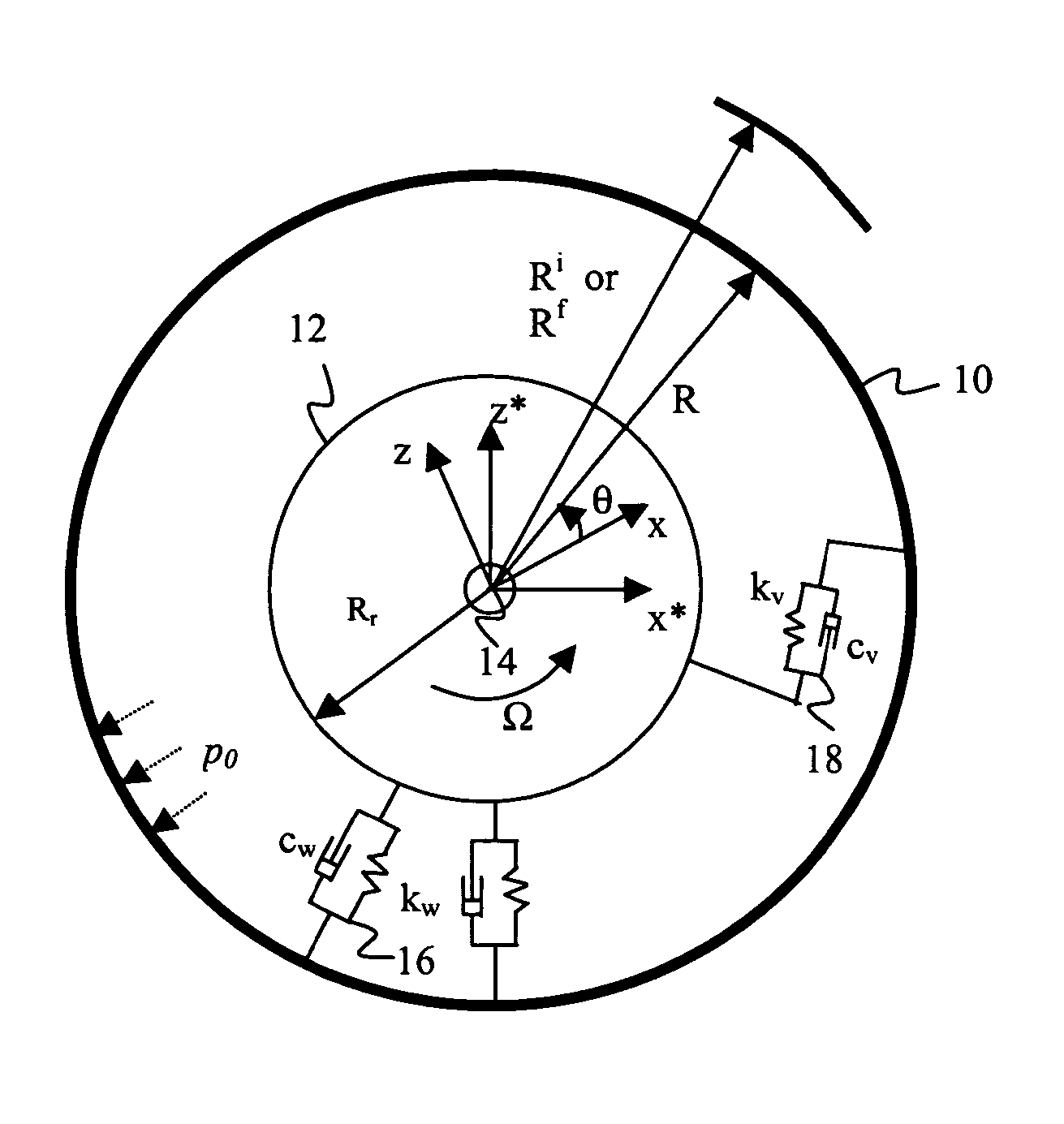

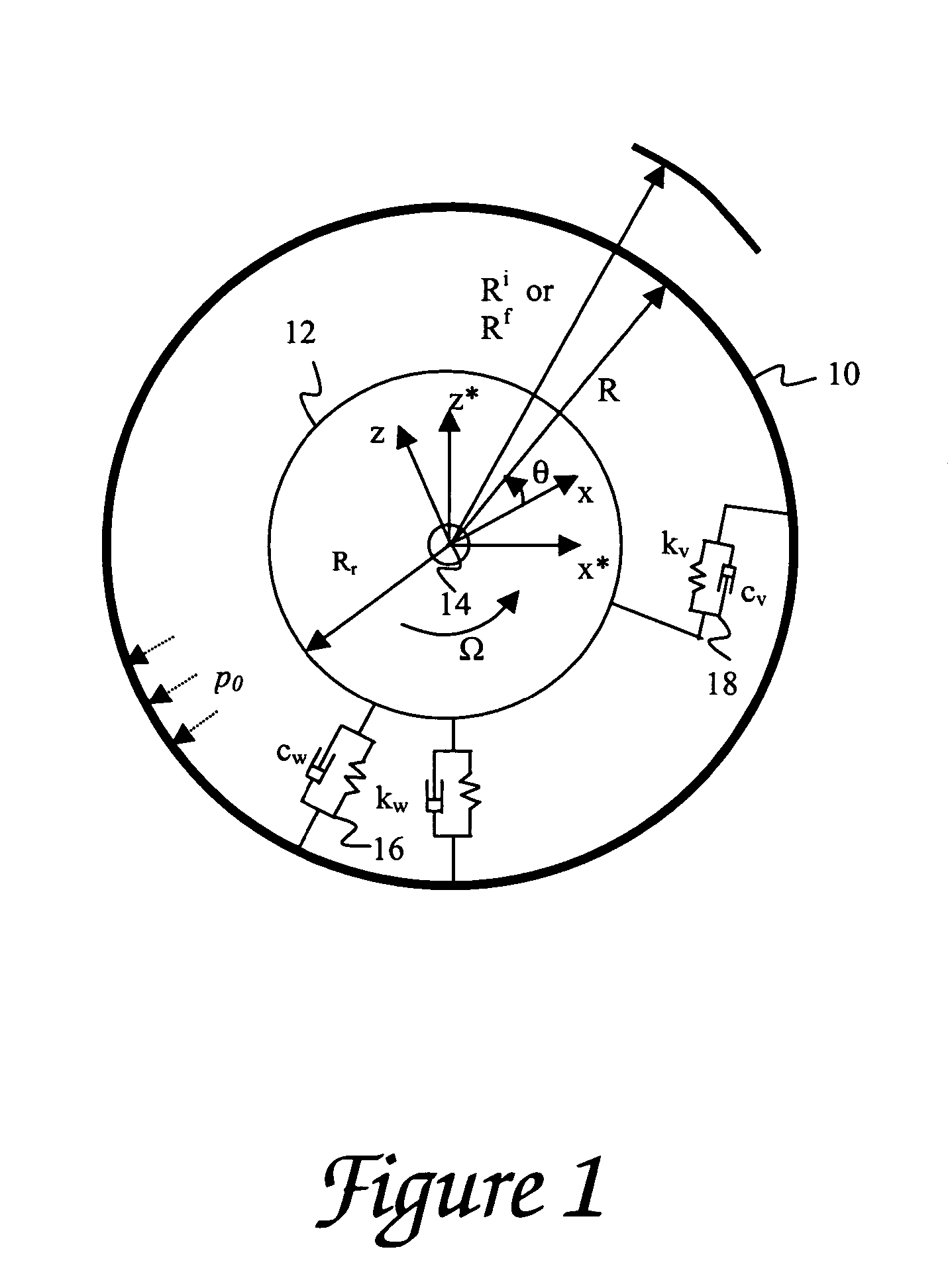

ActiveUS20050081614A1Little effectAdvanced technologyRoads maintainenceVehicle tyre testingLow speedHarmonic

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

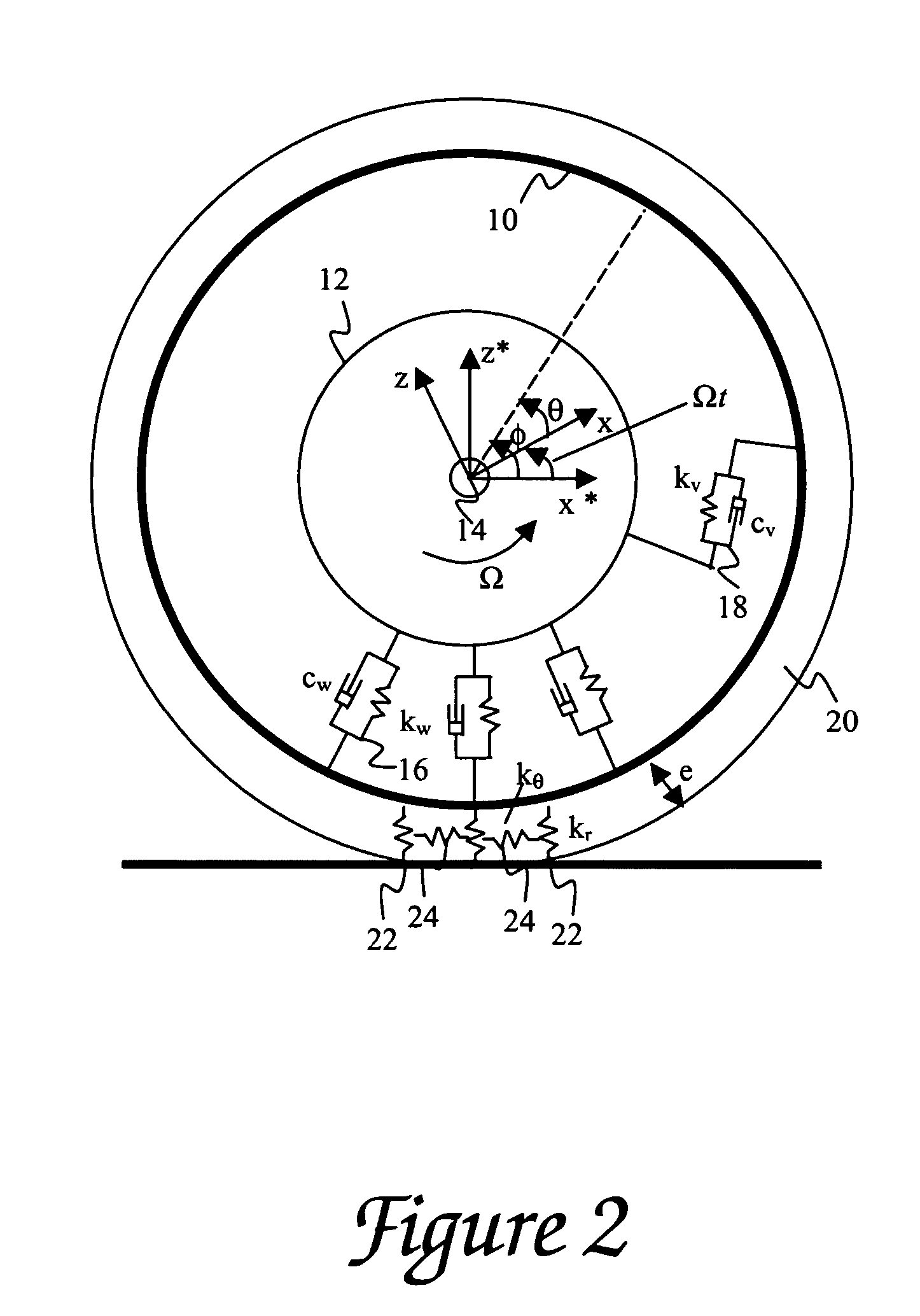

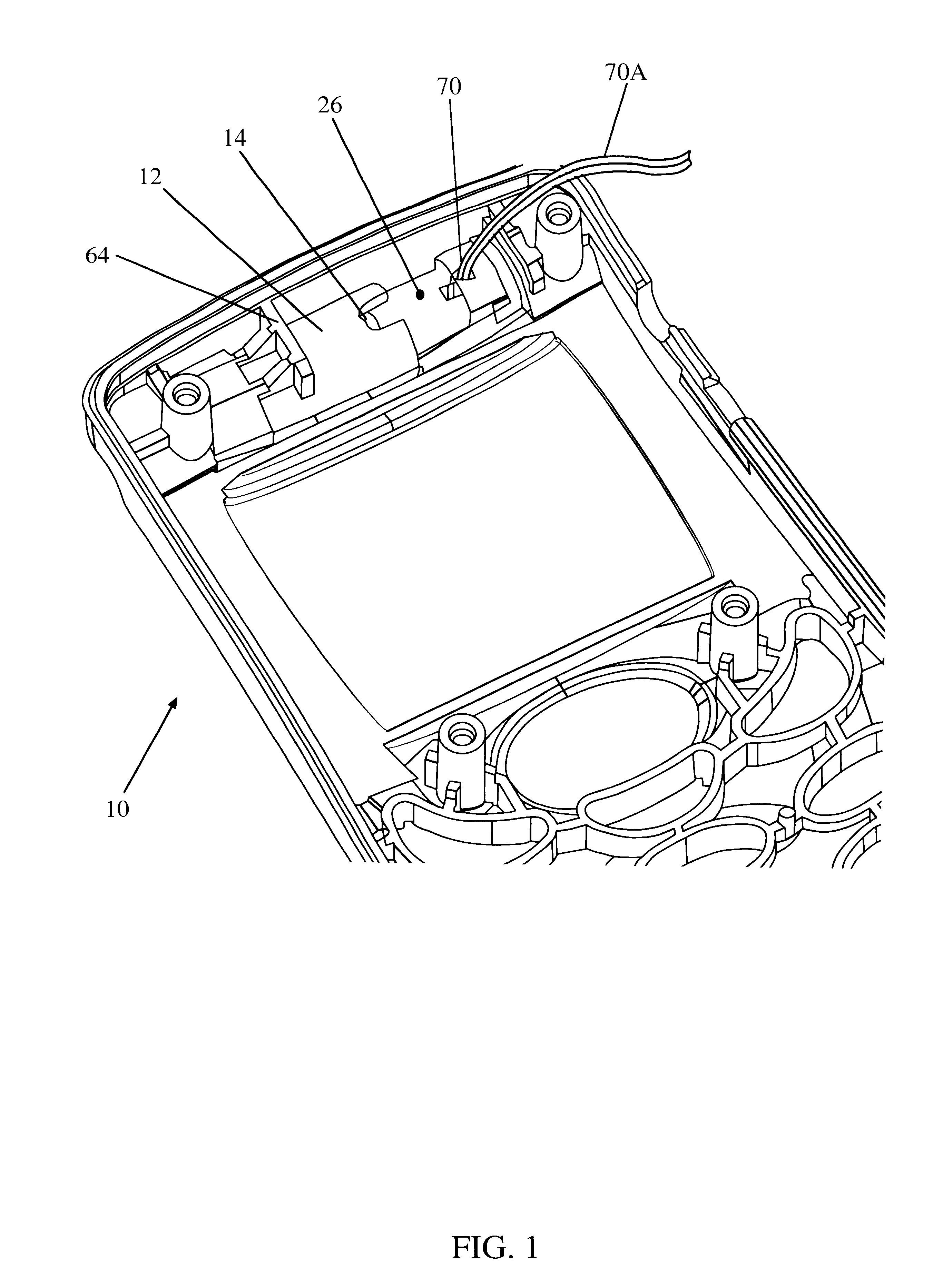

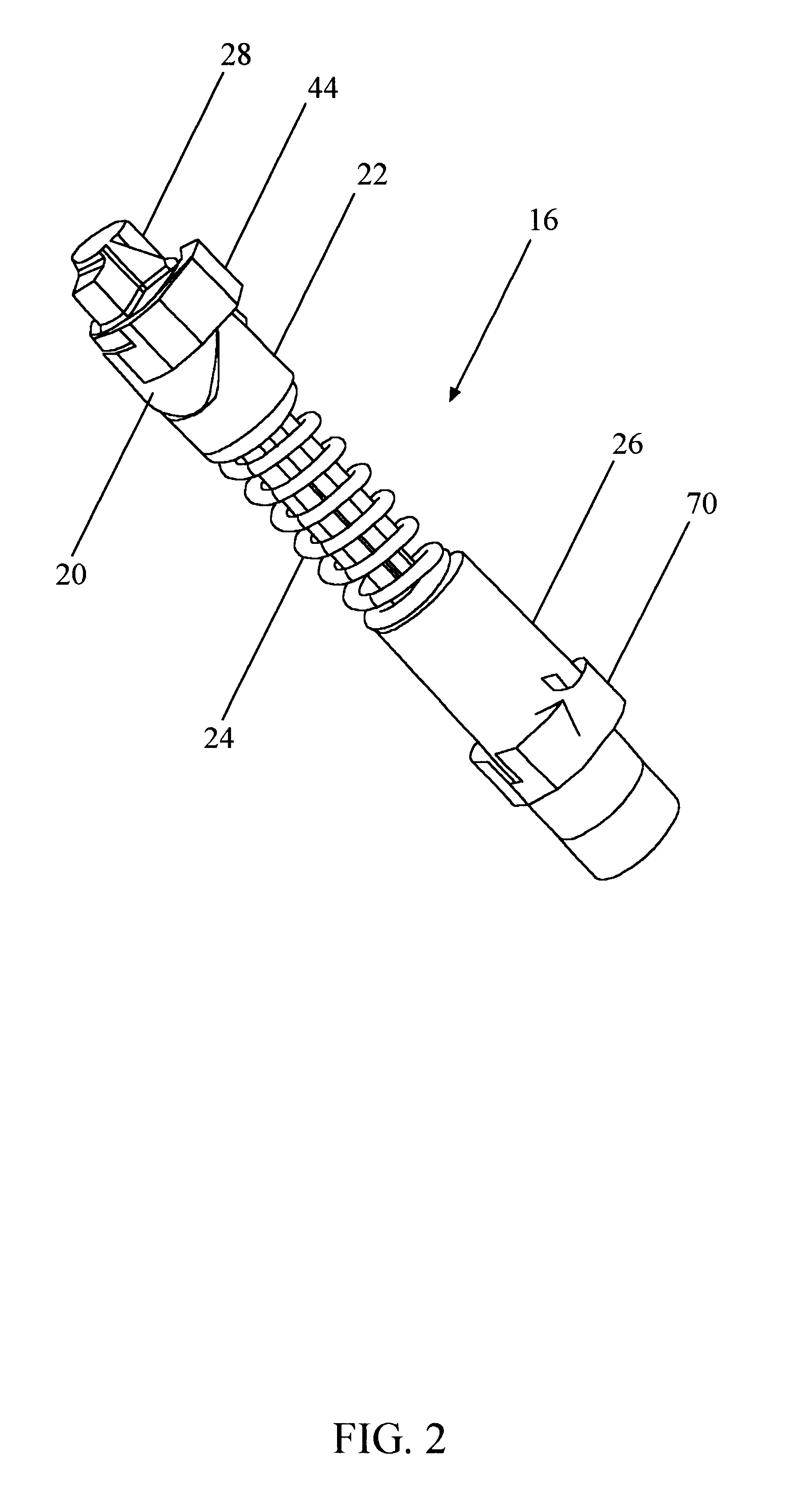

Preferential deflection hinge mechanism with an idler for foldable portable electronic devices

A space efficient and cost effective hinge clutch mechanism for facilitating the rotational positioning of a lid member of a portable electronic device relative to the housing the device. The clutch mechanism includes an elongated cam-shaft extending through a plurality of aligned components including a face cam member, a cam follower, and a compression spring and partially through a hollow retaining member. Rotation of the retaining member prevents the cam-shaft from being inadvertently with drawn. The clutch mechanism may be manually or automatically pre-assembled before insertion into the housing. An idler positioned adjacent to the retaining member serves as conduit for wires extending from the rotating lid member and the housing of the portable electronic device. The interaction of the cam and cam follower retains the lid in its fully open or fully closed positions until sufficient rotational force is exerted on the lid to overcome the tangential force of the spring.

Owner:QUALCOMM INC

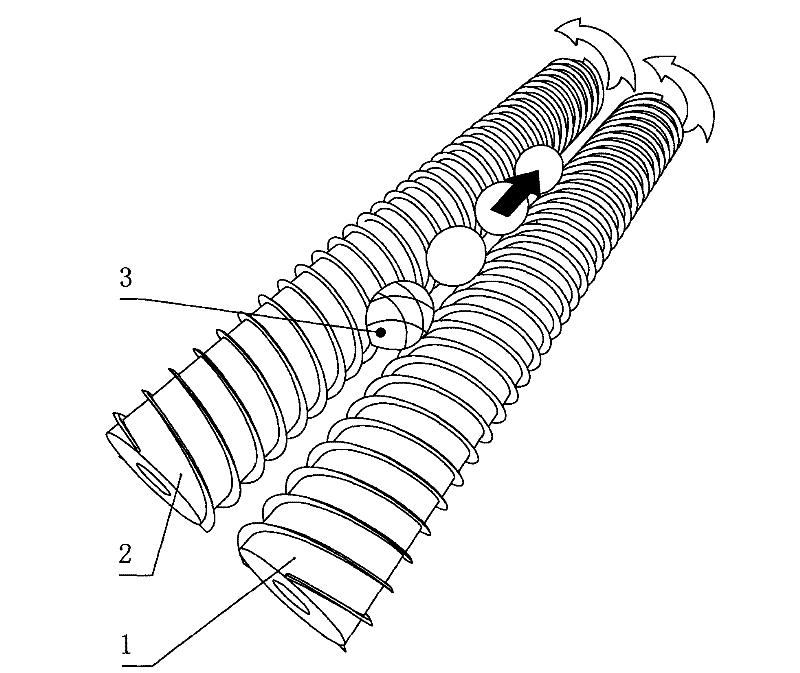

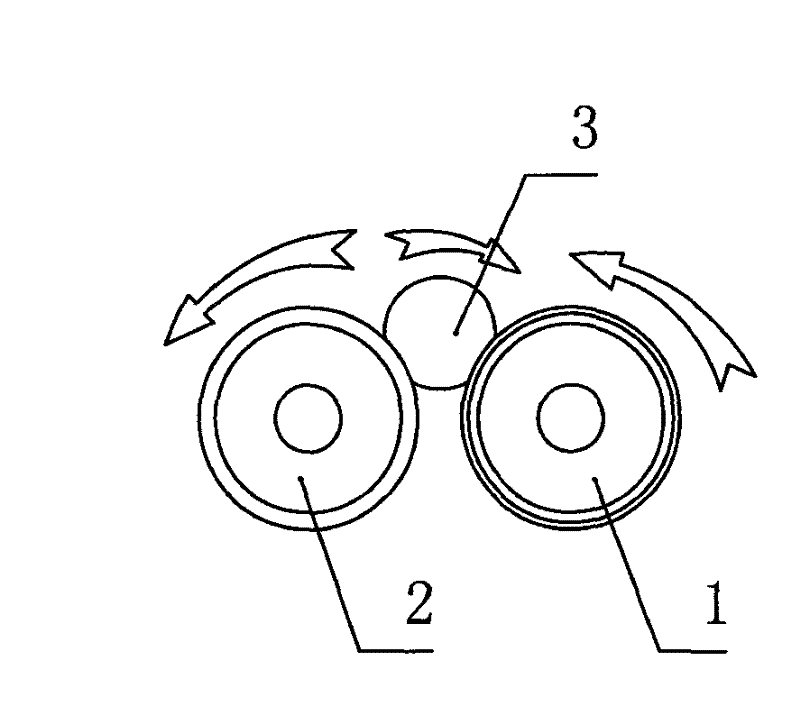

Method for stripping off green husk of nut through mechanized dry process

The invention discloses a method for stripping off green husks of nuts through a mechanized dry process and relates to a fruit processing technique, in particular to a processing technique for stripping off the green husks of the nuts. Crossed reticular knife marks are cut on the surfaces of fermented mature green nuts through two spiral knife rolls which have opposite spiral directions and rotate in the same direction at different speeds, and then the spiral knife rolls rotate to apply tangential force and axial force on the nuts to rotate and turn over the nuts so as to enable the green husks to be split and separated from the surfaces of the nuts. Since the spiral knife rolls have sharp edges, when the spiral knife rolls cut into the green husks, sap in the green husks is not squeezed out and is prevented from contaminating the exterior surfaces of the nuts during processing. Though the entire green husk stripping motions are equivalent to simulated manual stripping actions, the mechanized high-efficiency application of the green husk stripping action is realized. Therefore, the invention provides the effective method for stripping the green husks of the nuts through the dry process.

Owner:YUNNAN SARDE TECH +1

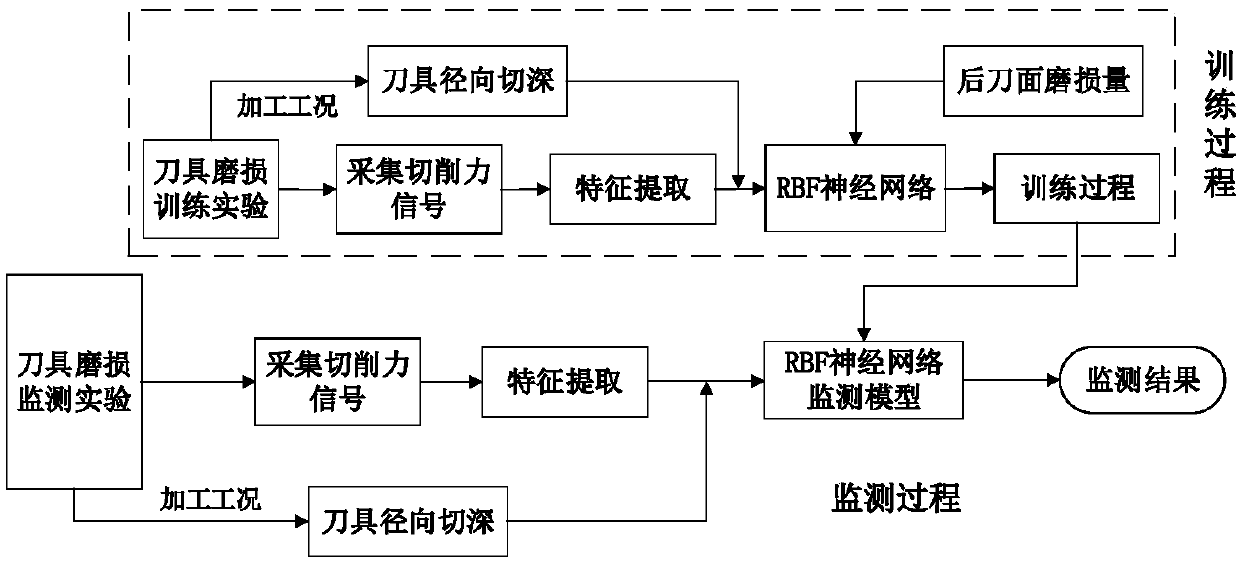

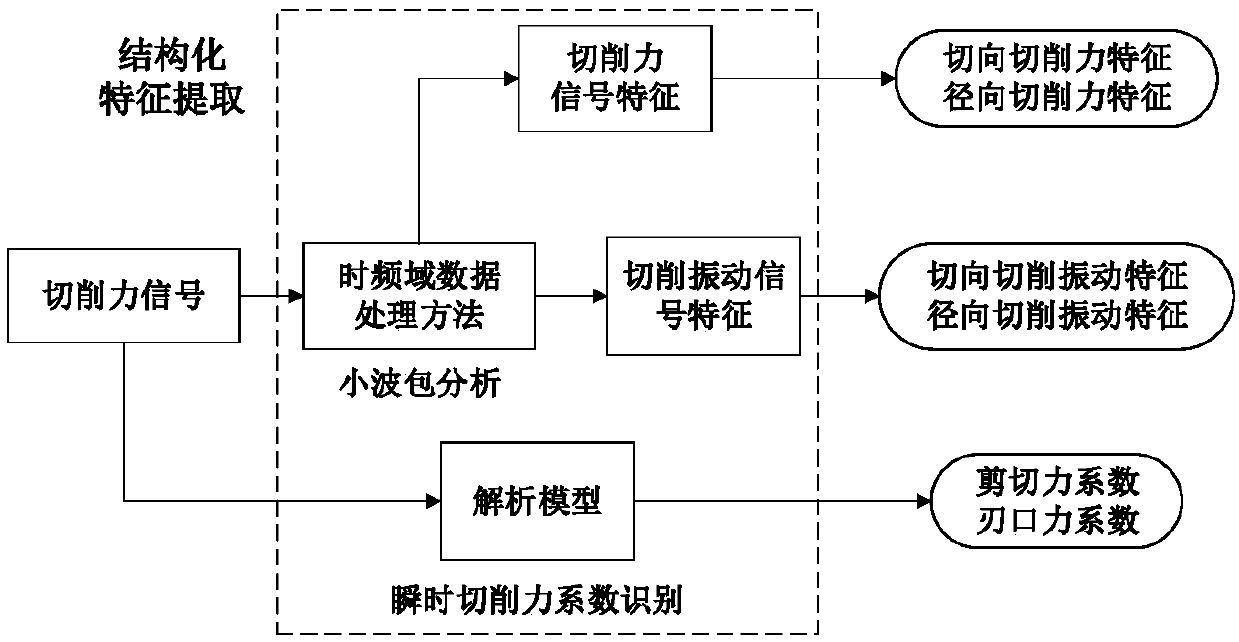

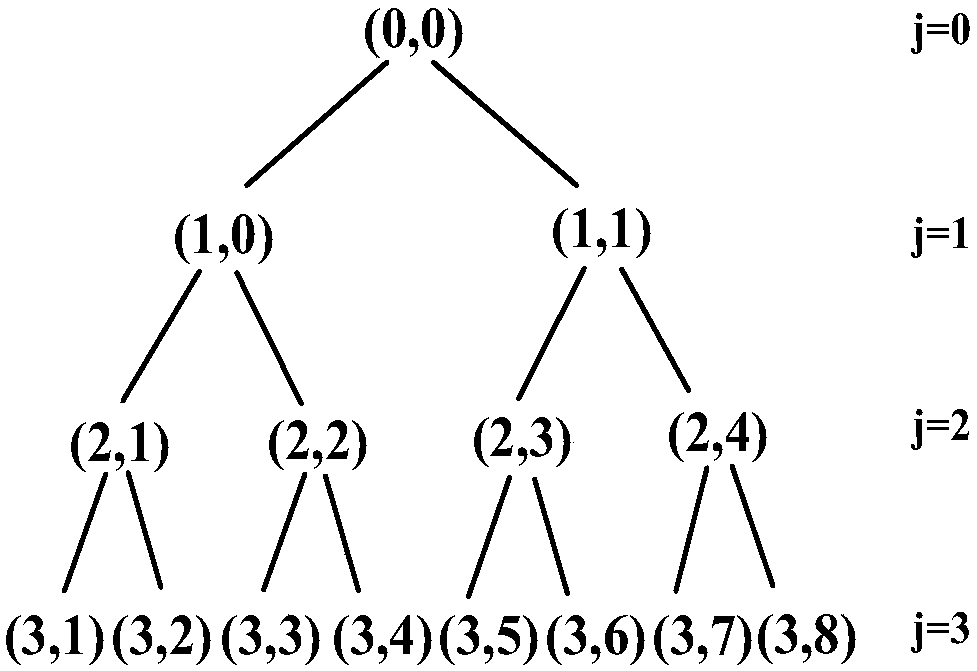

Cutter abrasion online monitoring method based on wavelet packet analysis and radial basis function (RBF) neural network

ActiveCN108356606AAchieve the effect of online monitoringIncrease costMeasurement/indication equipmentsHidden layerTangential force

The invention relates to a cutter abrasion online monitoring method based on wavelet packet analysis and a radial basis function (RBF) neural network. The method comprises the steps that shear force coefficients and cutting edge force coefficients of tangential force and radial force in different cutter abrasion states are calibrated by means of an instantaneous cutting force coefficient recognition method; and by analyzing the correlation between cutting force coefficients and cutter abrasion, the coefficients are taken as cutter abrasion characteristic parameters and input into a RBF neutralnetwork model after being subjected to normalization processing. An input layer of a RBF neutral network monitoring model training process comprises cutting force characteristics, cutting vibration characteristics, the shear force coefficients and the cutting edge force coefficients after being subjected to normalization processing; and an output layer comprises the cutter rear cutter surface abrasion capacity after being subjected to normalization processing; a hidden layer comprises neurons obtained through radial basis function iterative optimization; and it is verified that the RBF neuralnetwork monitoring model has the advantages of high response speed and high recognition precision through cutter abrasion monitoring experiments.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

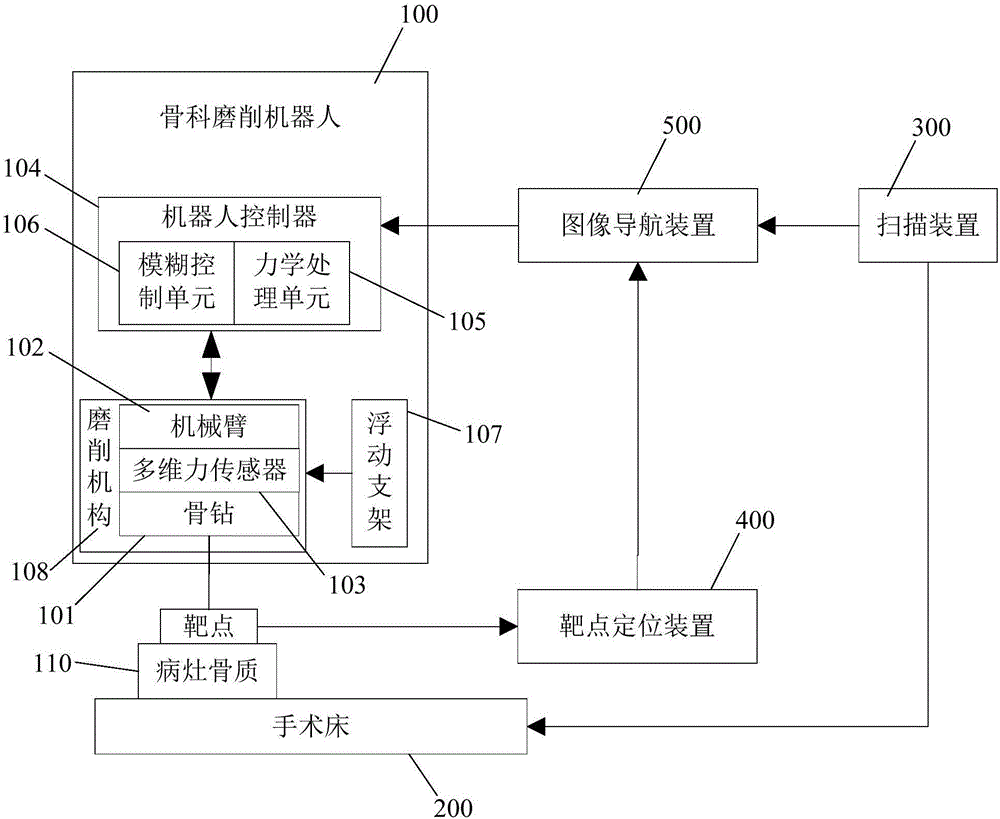

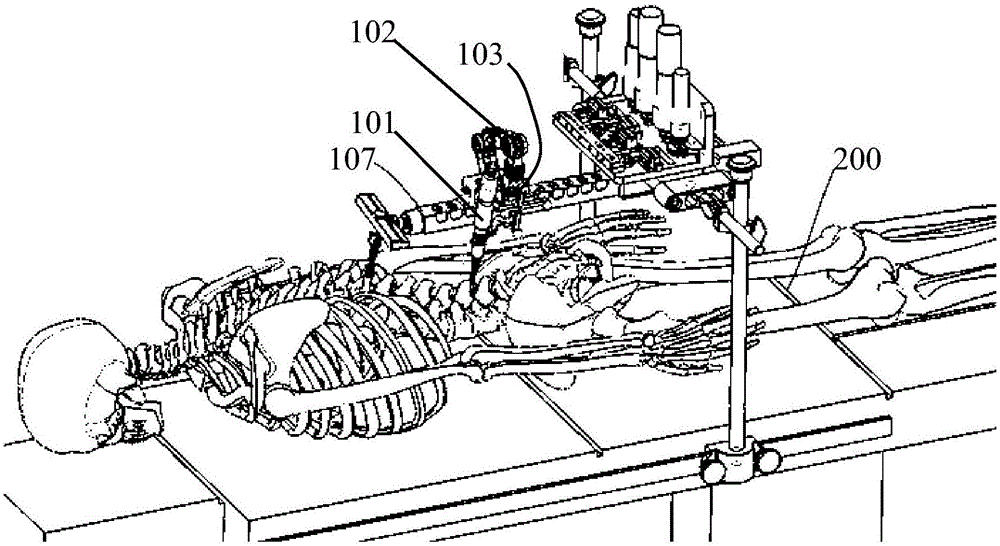

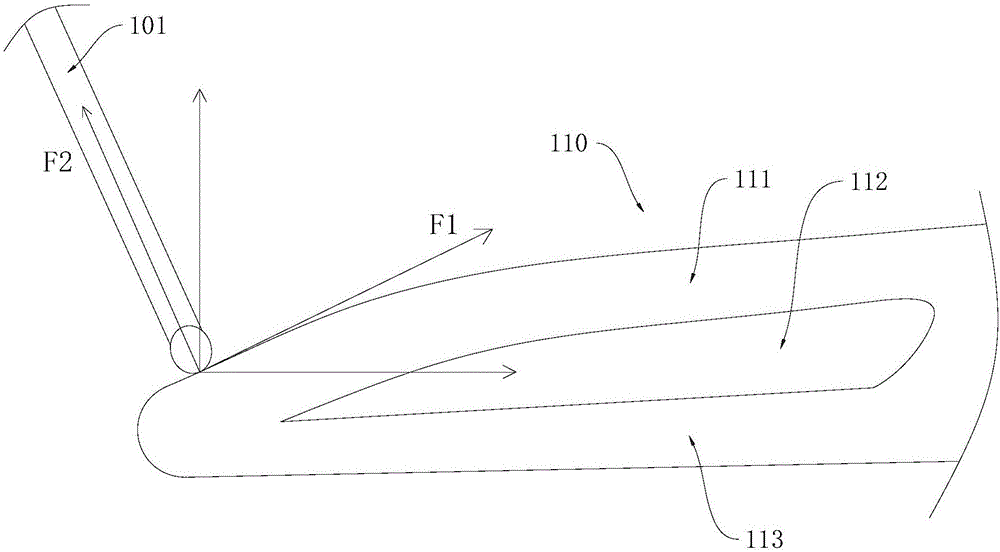

Bone grinding robot, and vertebral plate surgical robot control system and method

InactiveCN106725711AImprove processing speedHigh control precisionSurgical navigation systemsSurgical robotsSurgical robotControl system

The invention discloses a bone grinding robot which comprises a bone drill for grinding a focal bone, a mechanical arm for driving the bone drill to move, a multi-dimensional force sensor for collecting acting force generated by the bone drill during grinding of the focal bone, and a robot controller, wherein the bone drill, the mechanical arm and the multi-dimensional force sensor are electrically connected to the robot controller respectively; the robot controller is used for decomposing the acting force collected by the multi-dimensional sensor into tangential force along the tangent plane of the focal bone and axial force along the axis of the bone drill, controlling the moving posture of the mechanical arm so as to keep the tangential force at a preset value, and obtaining a grinding depth position of the bone drill for the focal bone according to a force value of the axial force. According to the bone grinding robot, the calculation processing process can be simplified, and the grinding depth can be judged, so that the surgical precision is improved, and the surgical accuracy and safety are improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

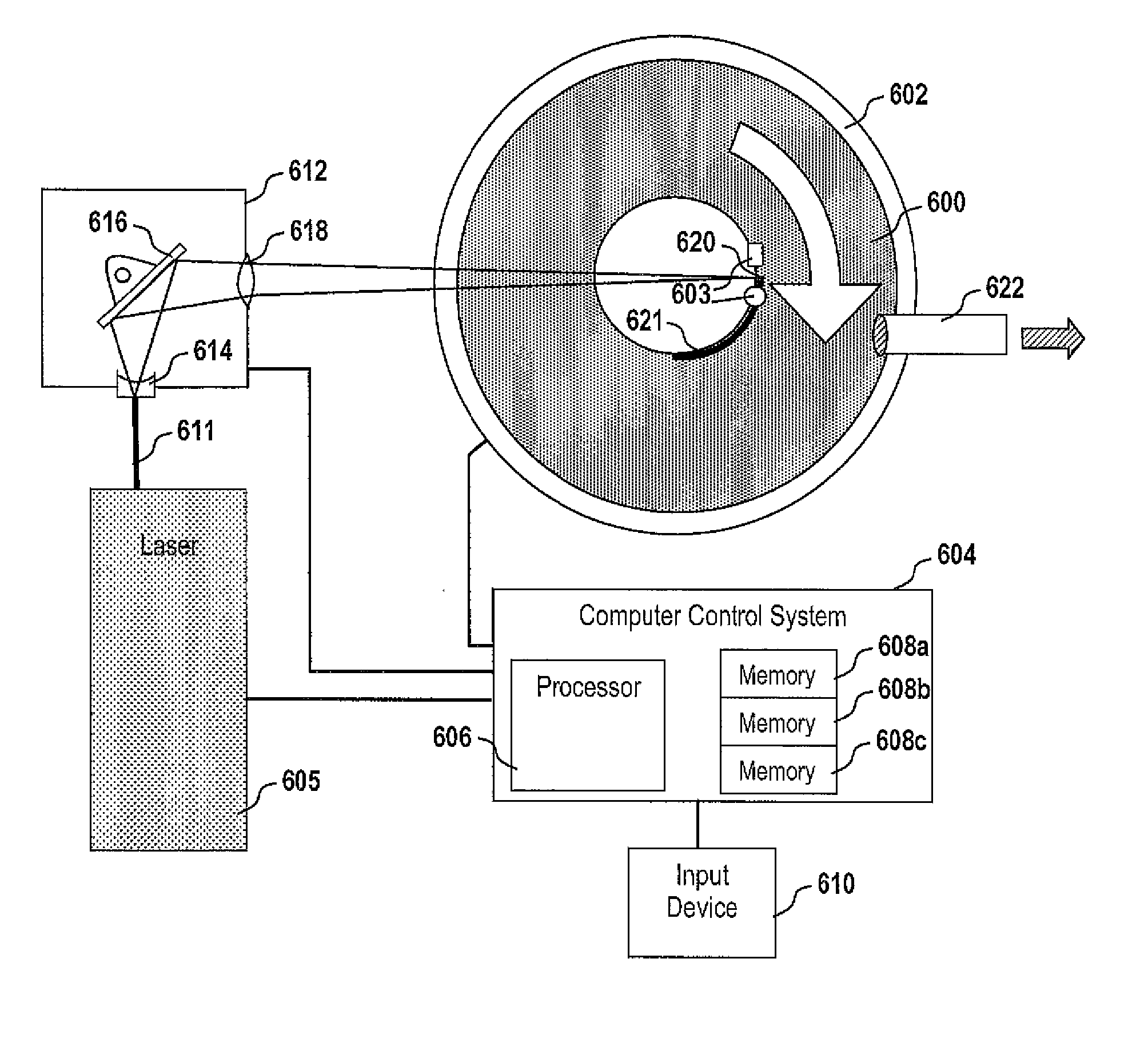

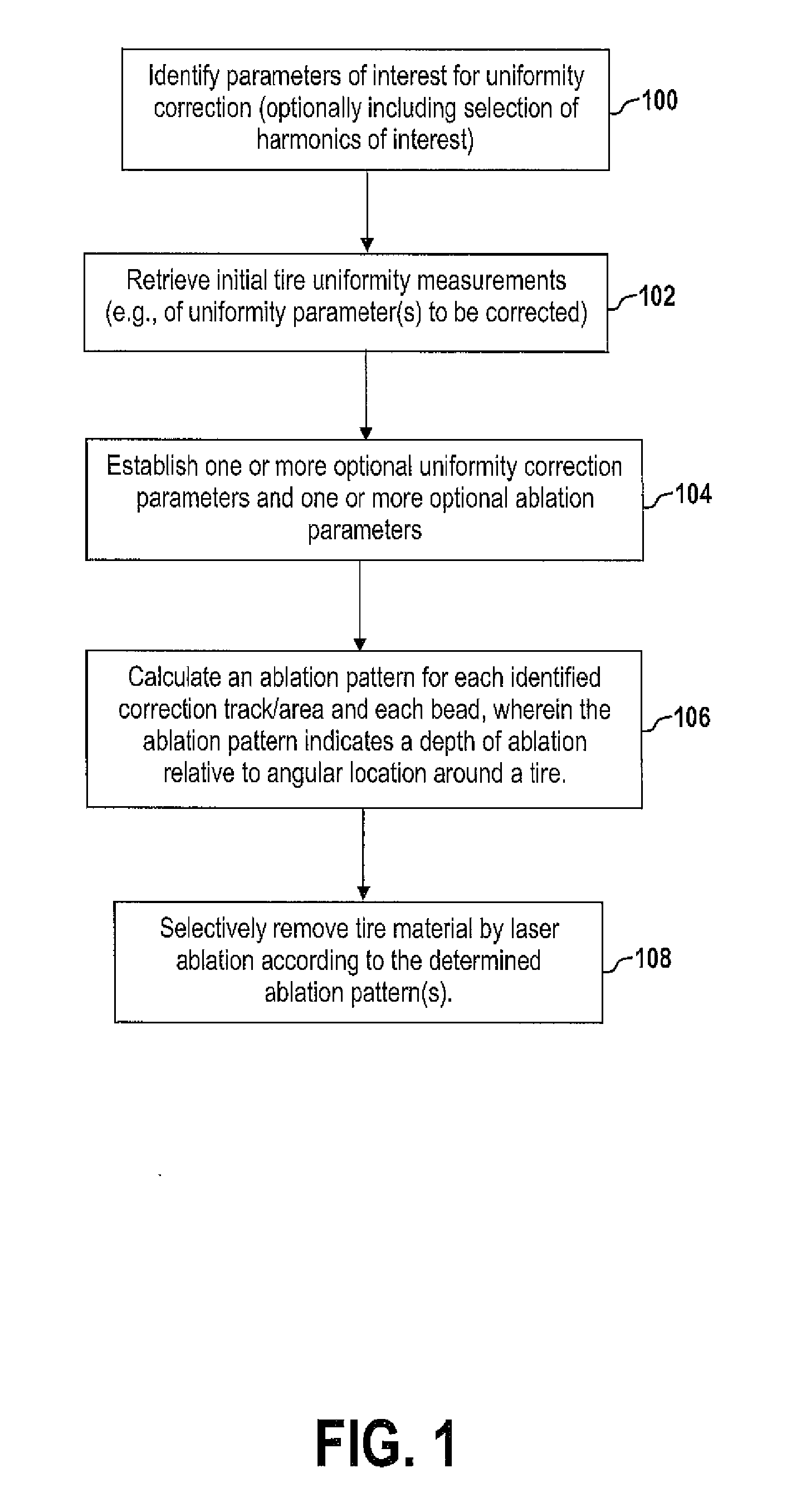

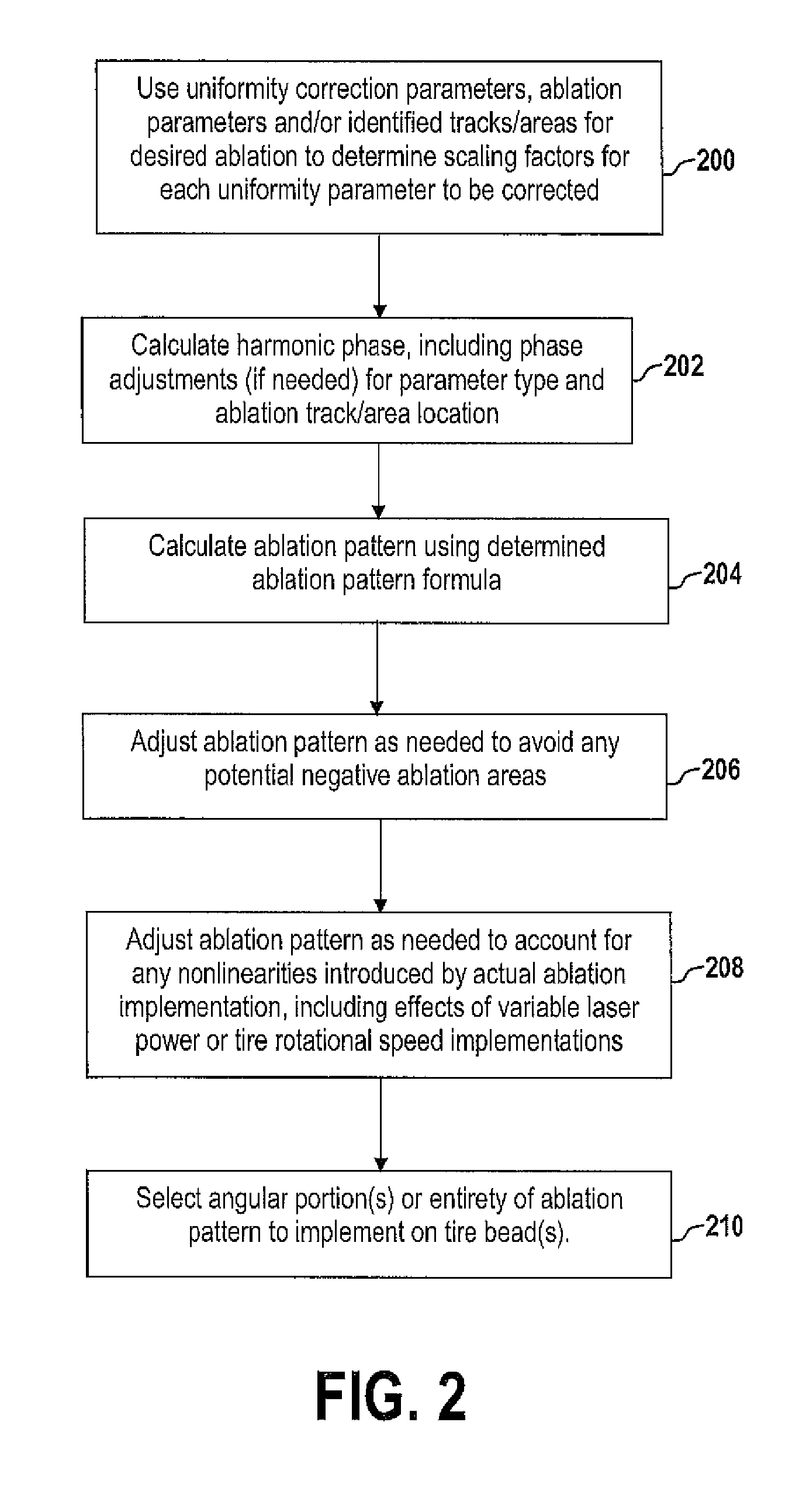

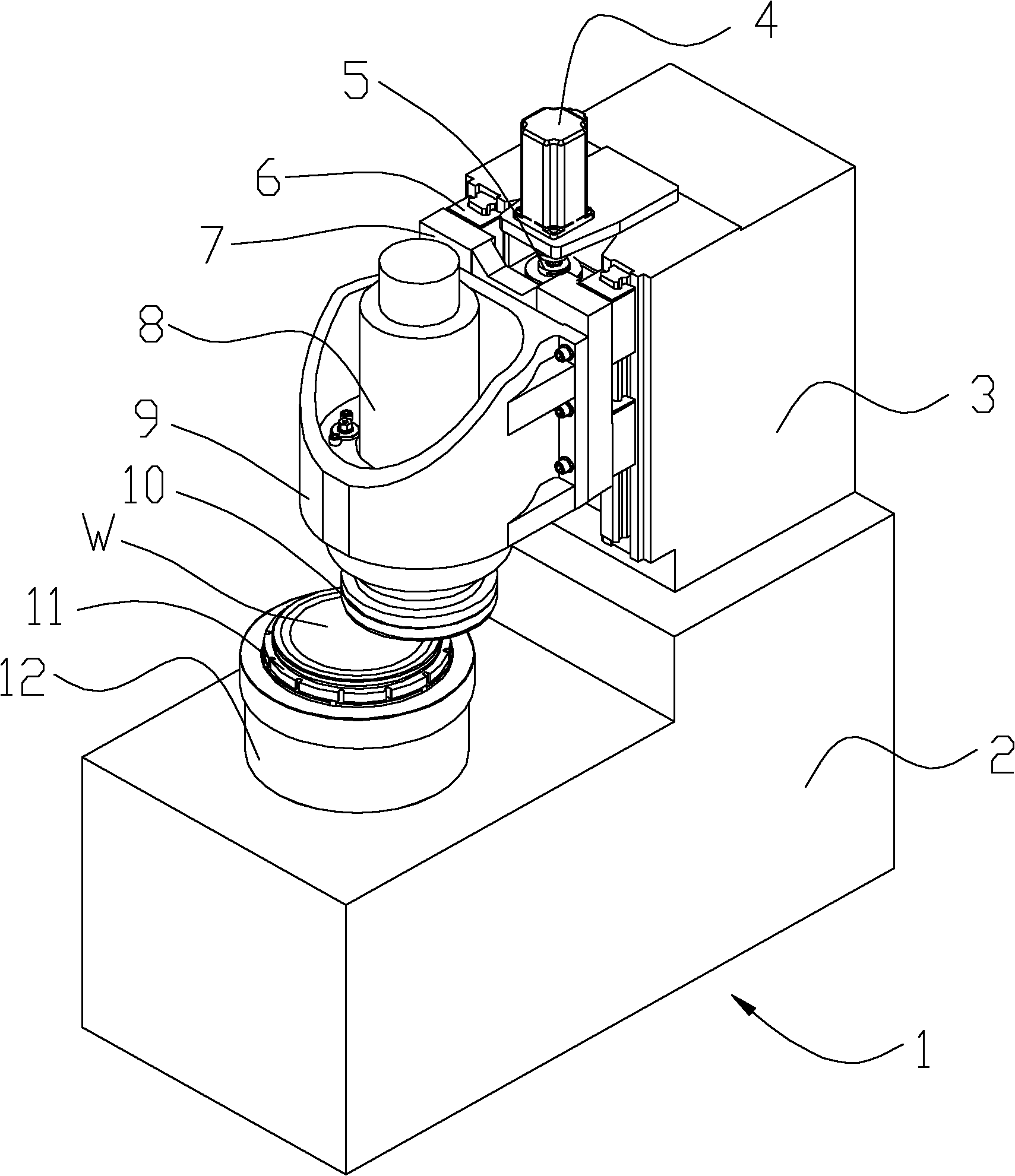

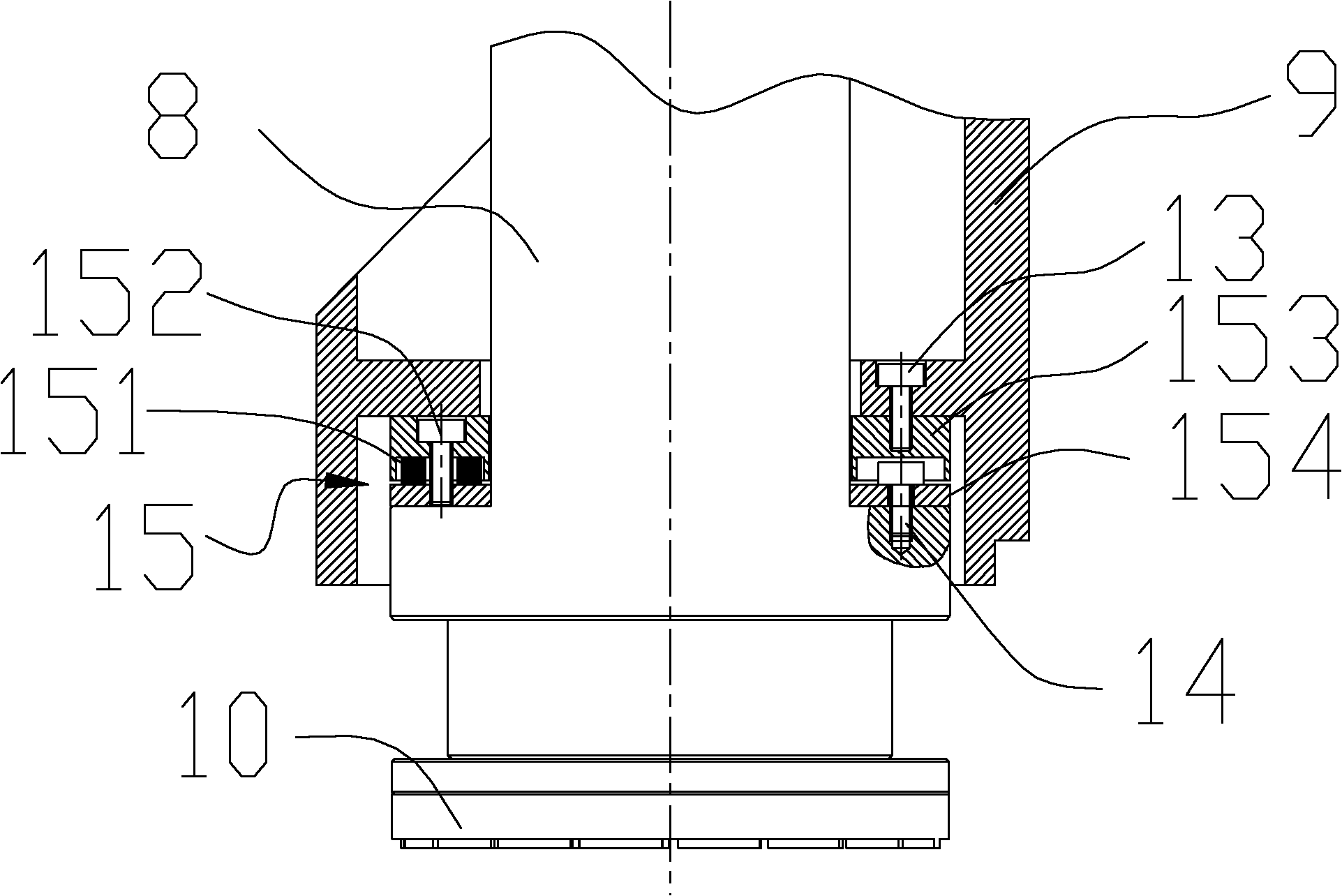

Uniformity correction by ablation at different track locations along a tire bead

A system and method for reducing the magnitude of one or more harmonics of one or more uniformity parameters in a cured tire involves selective removal of tire material at one or more track / area locations along first and second bead profiles. Selective removal may occur via ablation at the bead seat, low flange and / or high flange zones to correct for a selected number of harmonics of such parameters as radial, lateral and tangential force variation. Ablation patterns are calculated and implemented on first and second tire beads to achieve desired levels of force reduction at selected angular locations (within the expanse from 0-360 degrees along each tire bead). Ablation patterns may be calculated for implementation at fixed or varied tire rotational speeds and / or fixed or varied levels of laser power.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

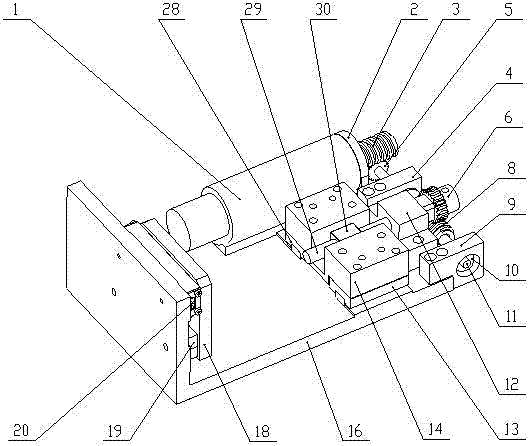

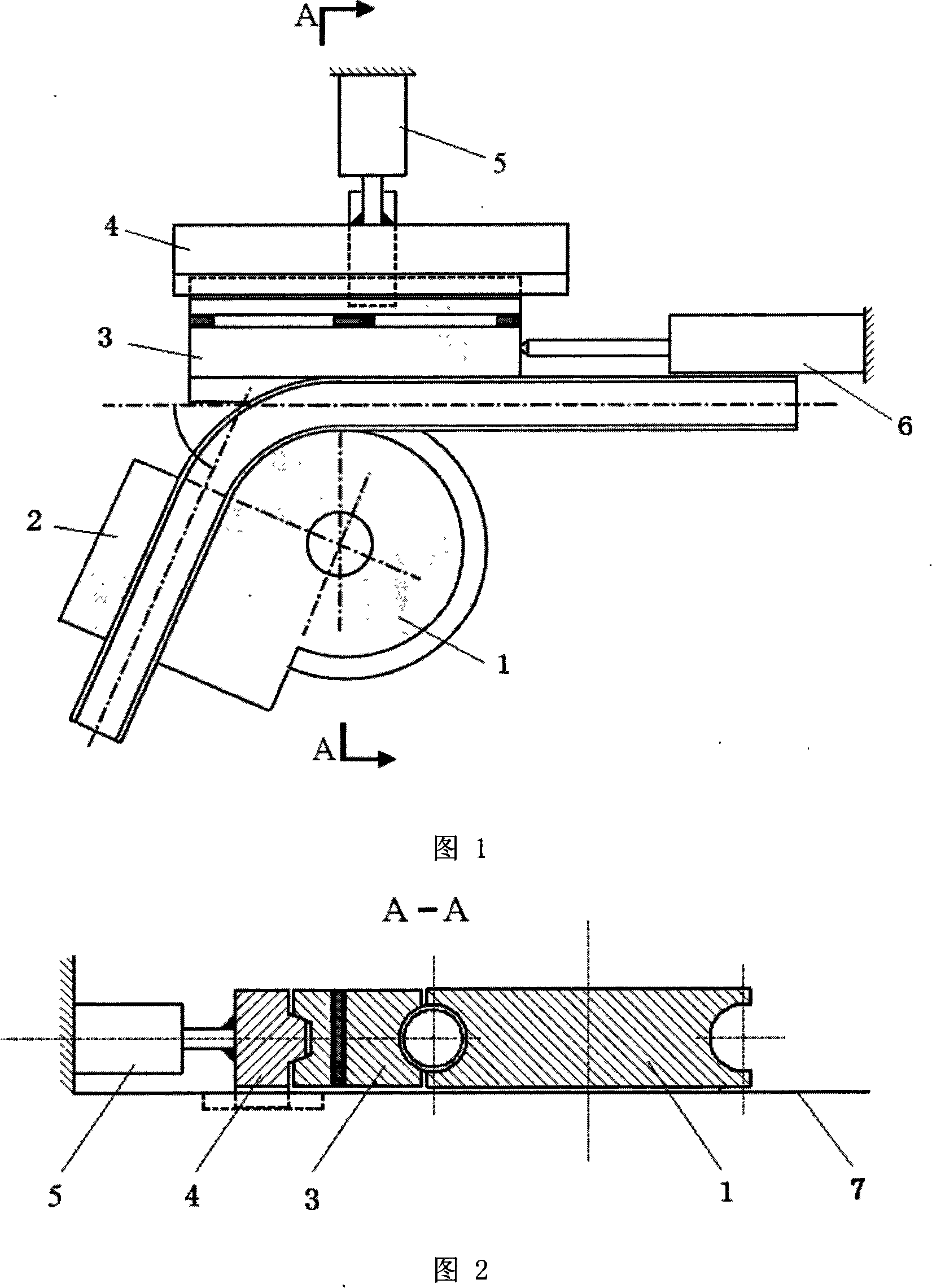

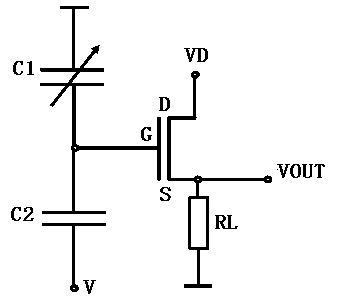

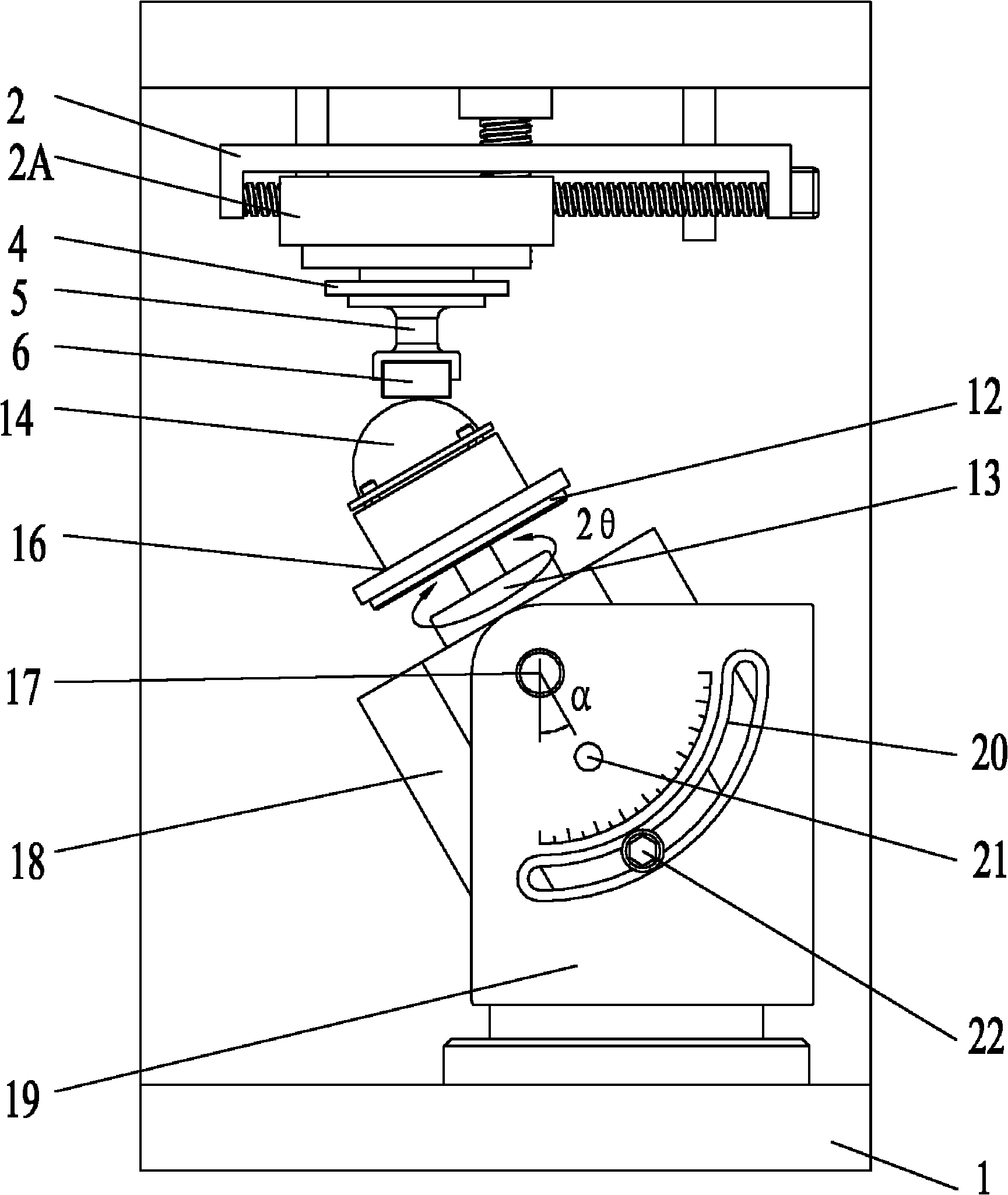

Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

ActiveCN102009387AImprove machining accuracyImprove processing qualityGrinding feed controlMeasurement deviceTangential force

The invention belongs to the ultraprecision machining field of the hard and brittle semiconductor crystalline materials and relates to a grinding force on-line measurement device used in the grinding process of the semiconductor wafer and a force-controlling grinding method. The invention discloses a semiconductor wafer grinding force on-line measurement device which is used as the feedback element of a grinding force adaptive control system. The grinding force measurement device adopts the piezoelectric measuring principle and contains a sensor part and a data processing unit, wherein the sensor part is used for the on-line measurement of the radial force Fr, the tangential force Ft and the axial force Fz; and the data processing unit is used to collect and analyze the grinding force data and perform feedback control to the feed speed and feed amount of the grinding wheel, thus the aim of on-line measurement can be achieved. The invention has the following advantages: the grinding force on-line measurement device has simple structure, and the modifications to the original equipment are less; the grinding force on-line measurement links are fewer, the response speed is fast, and the precision is high; and the grinding efficiency of the semiconductor wafer can be increased and the thickness of the damaged layer is reduced.

Owner:宁波知行半导体有限公司

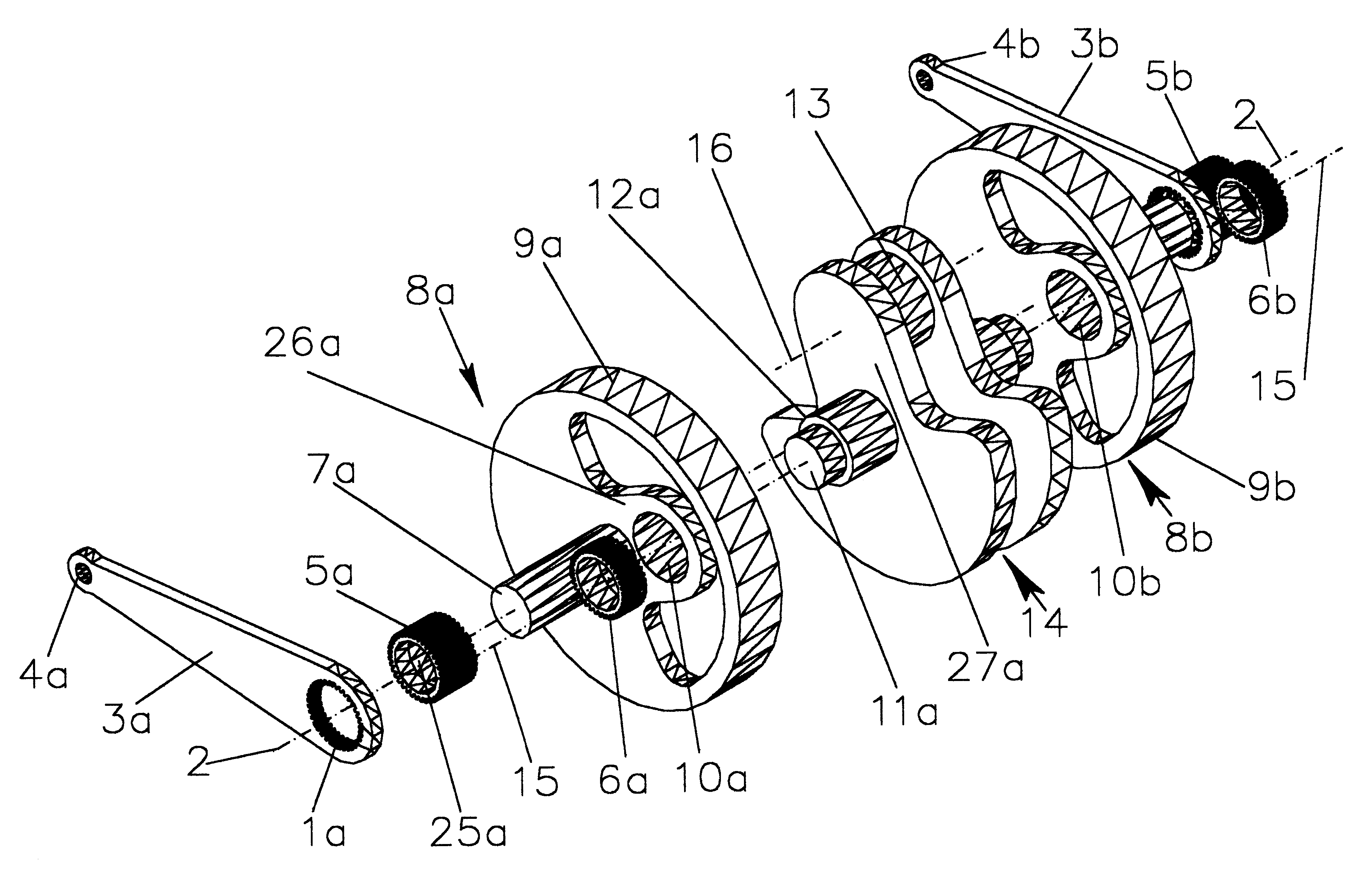

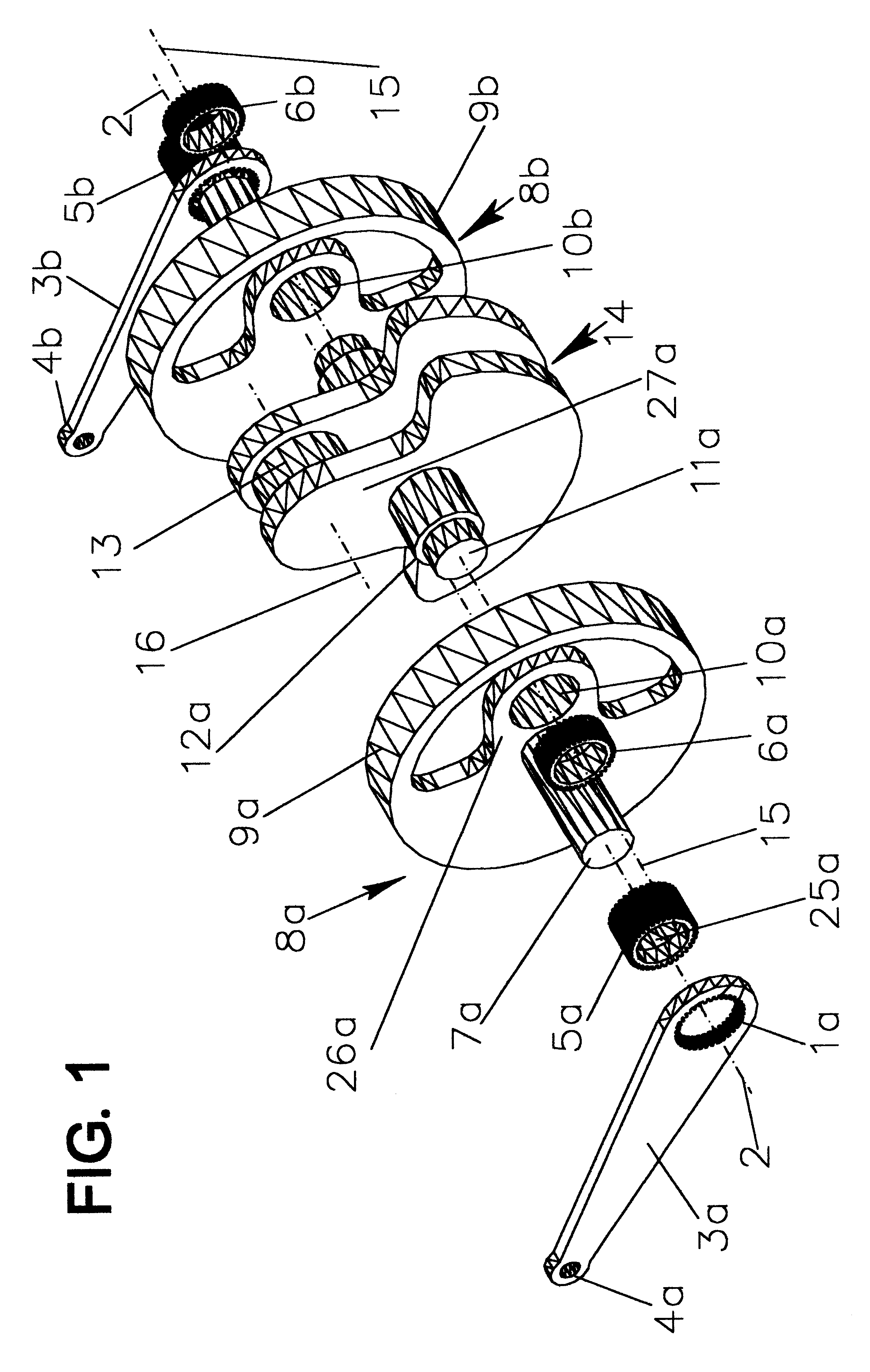

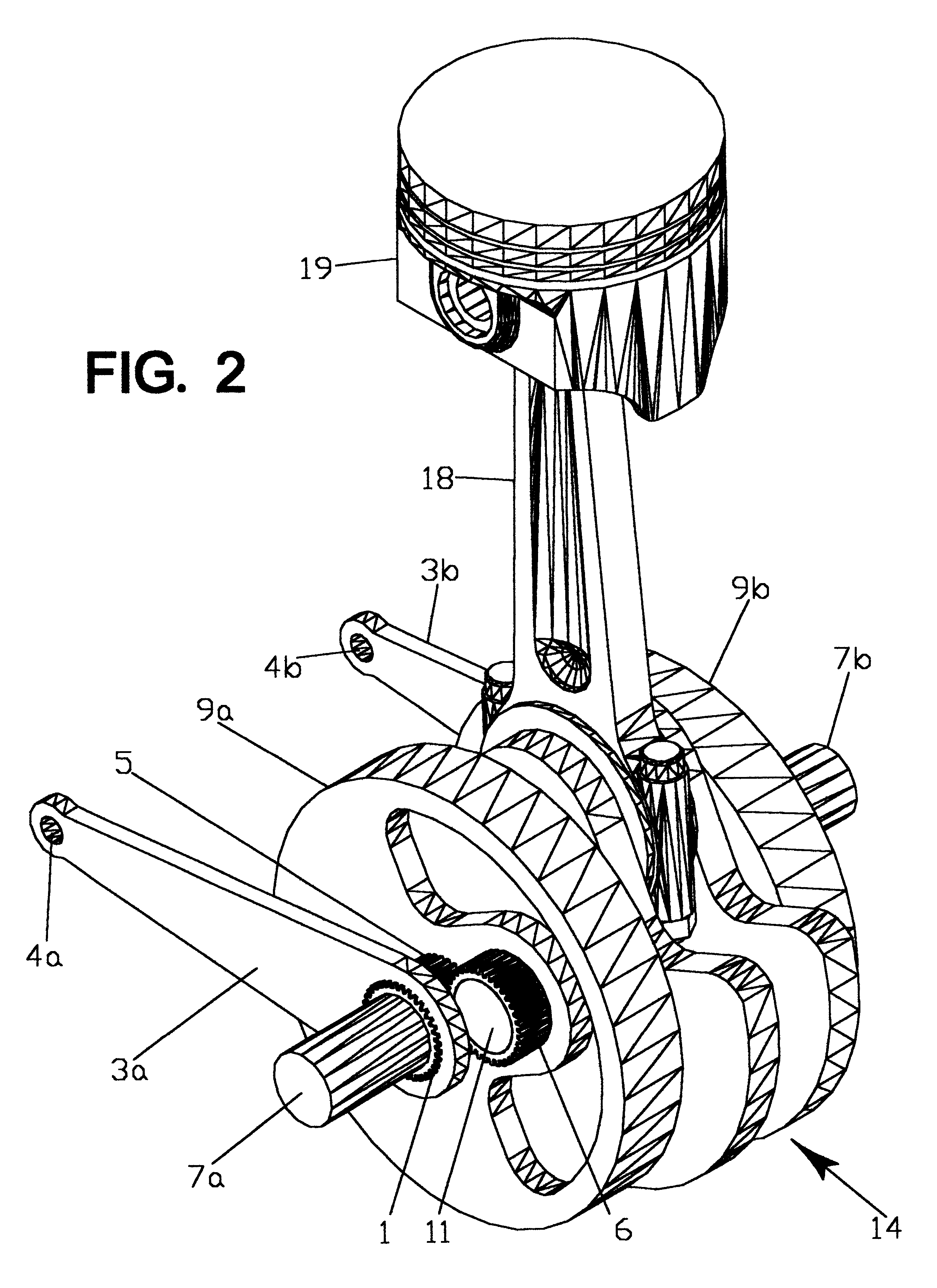

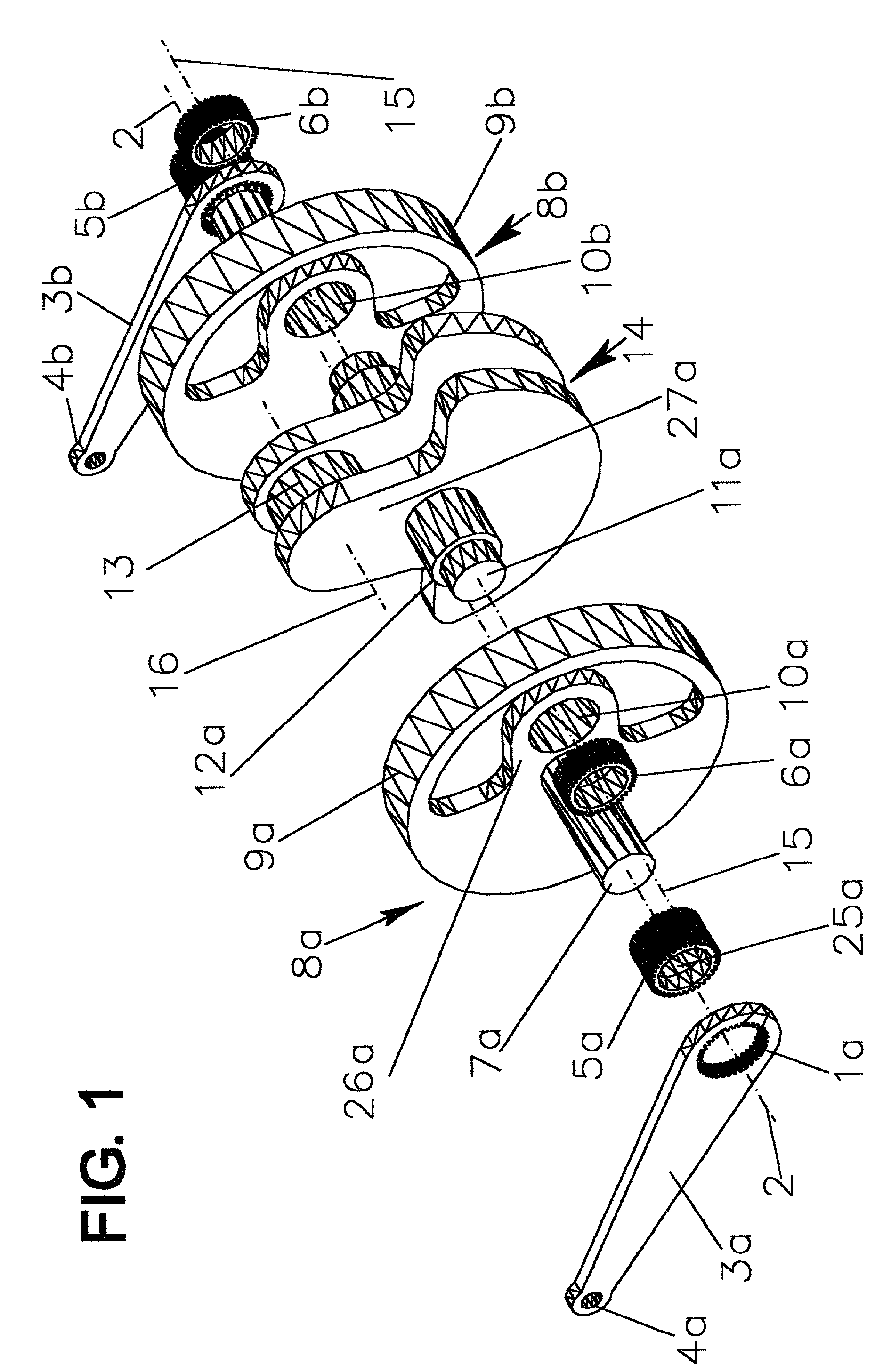

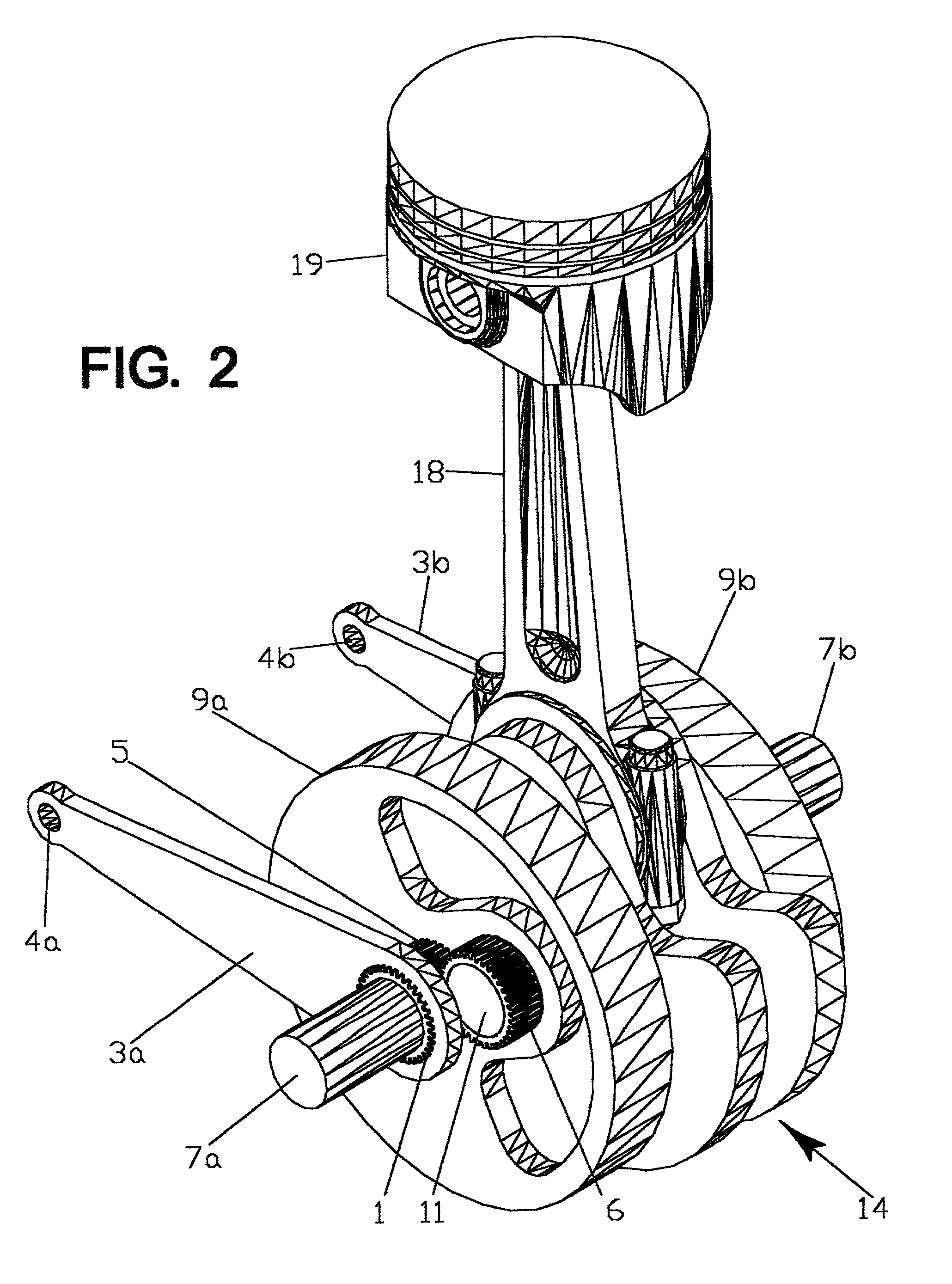

Cardioid cycle internal combustion engine

InactiveUS6526935B2Improve fuel efficiencyMore outputConnecting rodsMachines/enginesFuel efficiencyTangential force

Owner:SHAW RALPH

Tire uniformity through compensation between radial run out and stiffness variation

Methodology for characterizing non-uniformity forces at a tire spindle, such as low and high speed radial force variations and high speed tangential force variations include the steps of measuring radial run out and radial or tangential force variations at high and / or low speeds. From such measurements, the contribution of a predetermined type of stiffness variation (e.g. radial, tangential, extensional, bending) to respective radial and / or tangential force variations can be determined. Signature analysis statistical methods may also be utilized to characterize such tire non-uniform forces for different steps and reference physical angles of a tire construction process. Based on the characterization of such tire non-uniform forces, additional process steps may further correspond to tire grading and / or sorting processes, physical tire modification processes and tire manufacturing processes. Tire correction mechanisms and / or feedback control in a tire manufacturing process preferably yield tires having radial run out and stiffness variation parameters that are out of phase for one or more harmonics, thus yielding a reduction in the non-uniformity forces such as radial and tangential force variations at a tire spindle.

Owner:MICHELIN RECH & TECH SA

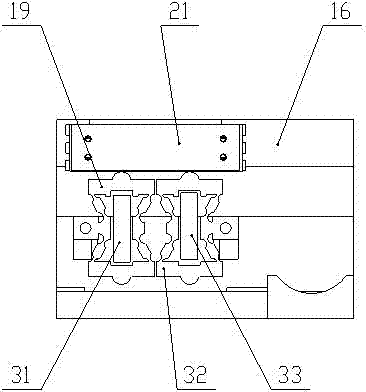

Airbag-loading potable weak and soft interlayer direct shear apparatus

InactiveCN101592575AApply evenlyContinuous and stable tangential forceMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesBall screwTangential force

The invention provides a simple, accurate and field airbag-loading potable soft and weak interlayer direct shear apparatus. In the direct shear apparatus, airbag loading is adopted to apply a normal force, and a piston system arranged on the upper part of a reaction frame can guarantee the verticality and application uniformity of the normal force when a sample produces shearing displacement; and a ball screw system applies a tangential force and linear guides under a sample seat can guarantee the horizontality of the application direction of the shearing force and the continuity and smoothness of the tangential force. A normal force applying system avoids bearing load, and airbag pressurization is accomplished by a potable pressurizing device and is high in precision, simple and easy to implement. A tangential force applying system uses a screw handle to apply force and the force application is steady and highly operable. Both the normal force applying system and the tangential force applying system are fixed, small in volume, high in reliability and convenient in on-site test. The test device can perform the quick shearing of field soft and weak interlayer and consolidated drained quick and slow shear tests and is simple, precise and high in operability.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

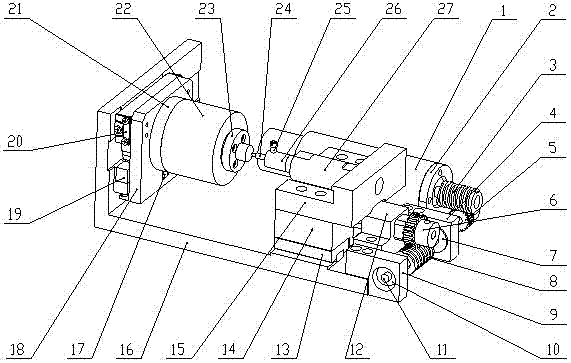

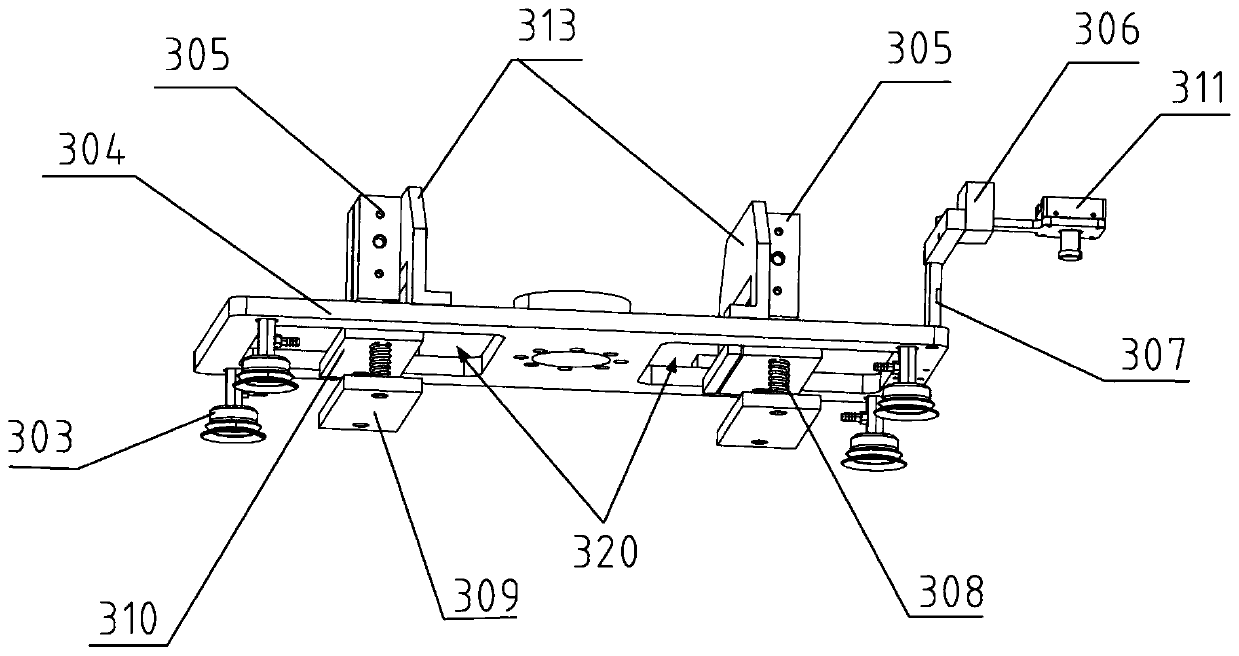

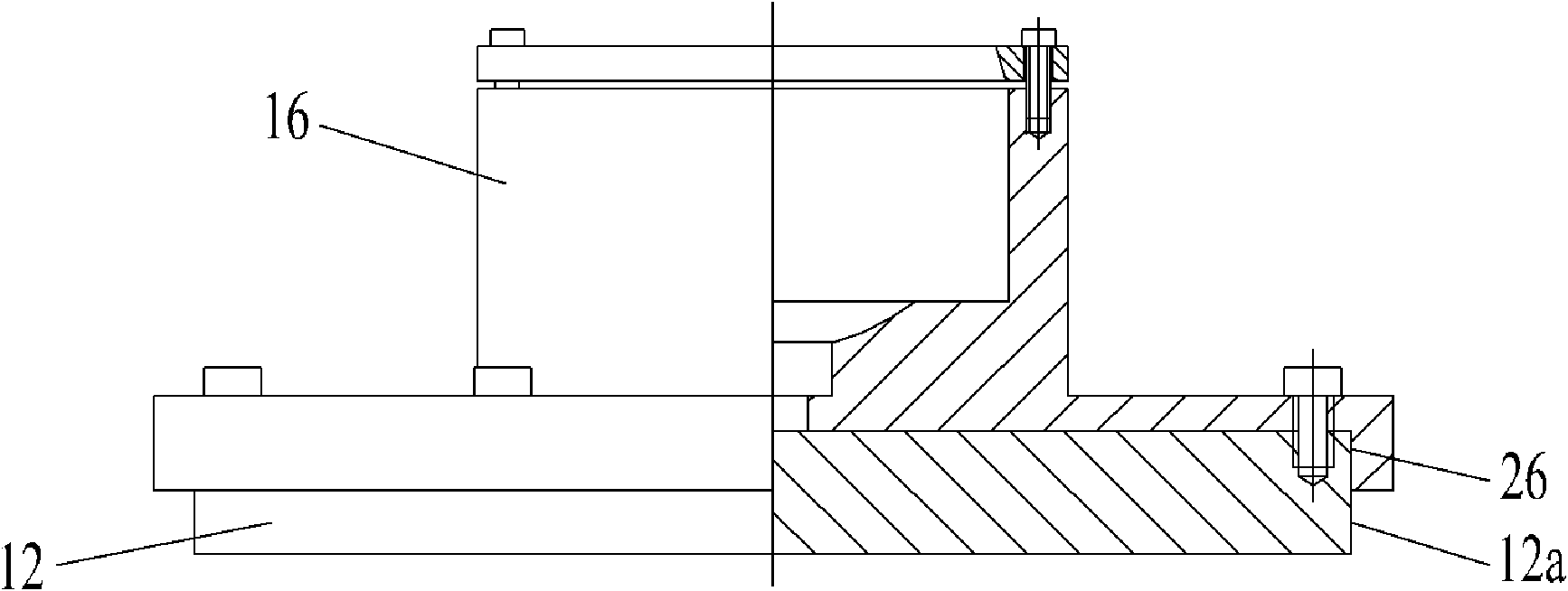

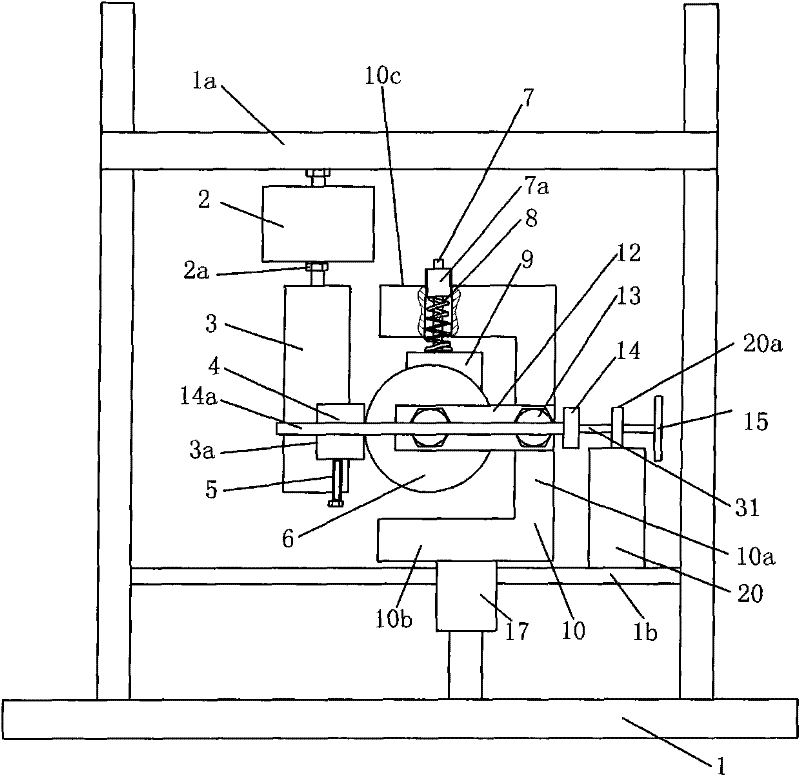

In-situ micro-nano indentation/scratch test platform and test method

ActiveCN104729911AOvercoming detectionOvercoming the lack of tangential forceInvestigating material hardnessMicro nanoScientific instrument

The invention relates to an in-situ micro-nano indentation / scratch test platform and a test method, and belongs to the field of electromechanical integrated precision scientific instruments. An X axis precision scratch unit and a Y axis large-stroke stick-slip drive scratch assembly are assembled at the tail of a base, a Z axis macro-movement adjusting mechanism is assembled at the middle of the base, a motor driving unit is assembled at the head of the base, a precision pressing driving and displacement signal detecting unit is installed on the Z axis macro-movement adjusting mechanism, and a precision three-axis force sensor used for detecting an indentation pressing force and a normal force and a tangential force of a scratch is installed on the X axis precision scratch unit. The in-situ micro-nano indentation / scratch test platform has the advantages of compact structure, miniaturization, integration, and capability of better ensuring the assembly precision, effectively improving the overall rigidity and dynamic properties and improving the overall test precision while overcoming the defect that an existing test platform cannot be used for quantitatively detecting the normal force and the tangential force in a scratch process.

Owner:JILIN UNIV

Tube bending forming processing device

InactiveCN101147934AImprove memory propertiesIncrease hydrostatic pressureShaping toolsHydraulic cylinderTangential force

The present invention discloses a bending forming processing equipment for pipe material. Said equipment includes the following several portions: bending die clamping die, pressing die, pressurizing plate, circumferential pressure-applying hydraulic cylinder, axial propulsion hydraulic cylinder and bending machine working table. The circumferential pressure-applying hydraulic cylinder pushing rod is rigidly connected with the pressurizing plate, the axial propulsion hydraulic cylinder pushing rod is flexibly connected with the pressing die end portion. The circumferential pressure-applying hydrautic cylinder can be used for driving said pressurizing plate to circumferentially apply pressure to the pipe material, and the axial propulsion hydraulic cylinder can be used for driving pressing die to apply tangential force to the pipe material, the bending die is fixed on the bending machine working table by means of bending centre, and bending die, pressing die and clamping die respectively have the groove fit with the outer diameter of said pipe material, the pressurizing plate is connected with the pressing die by means of dovelail groove, and the pressurizing plate also is connected with the bending machine working table by means of dovetail groove.

Owner:SHANGHAI JIAO TONG UNIV

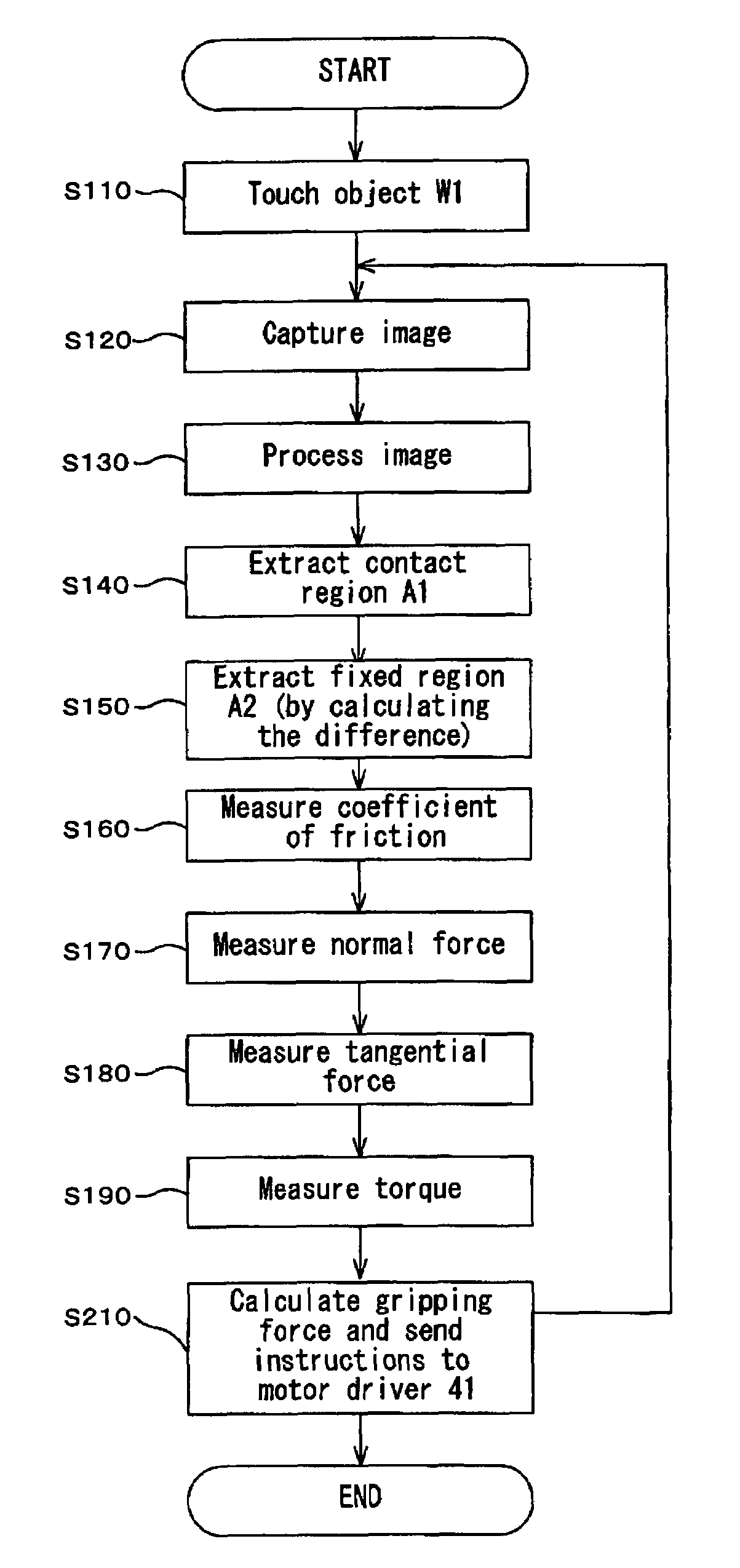

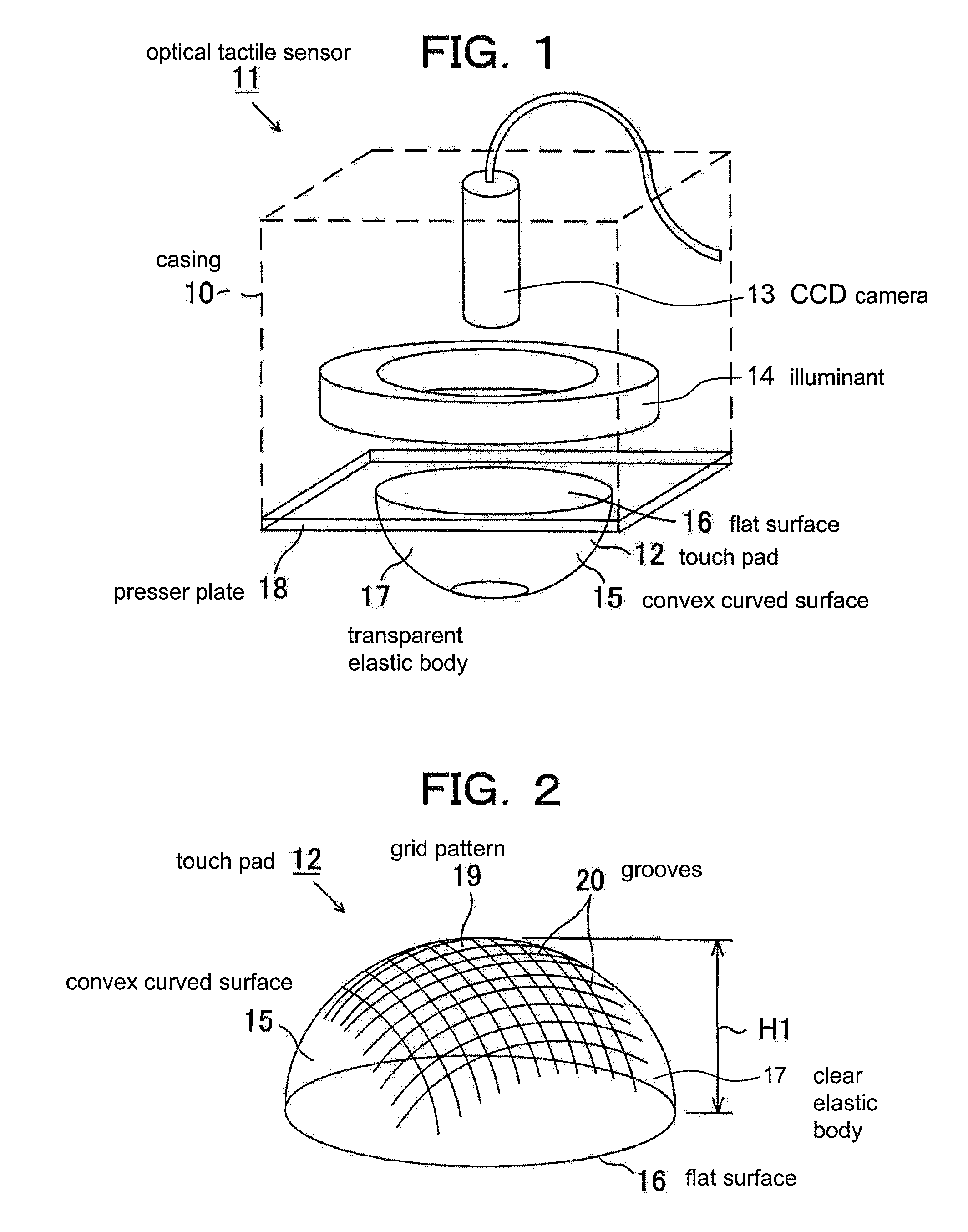

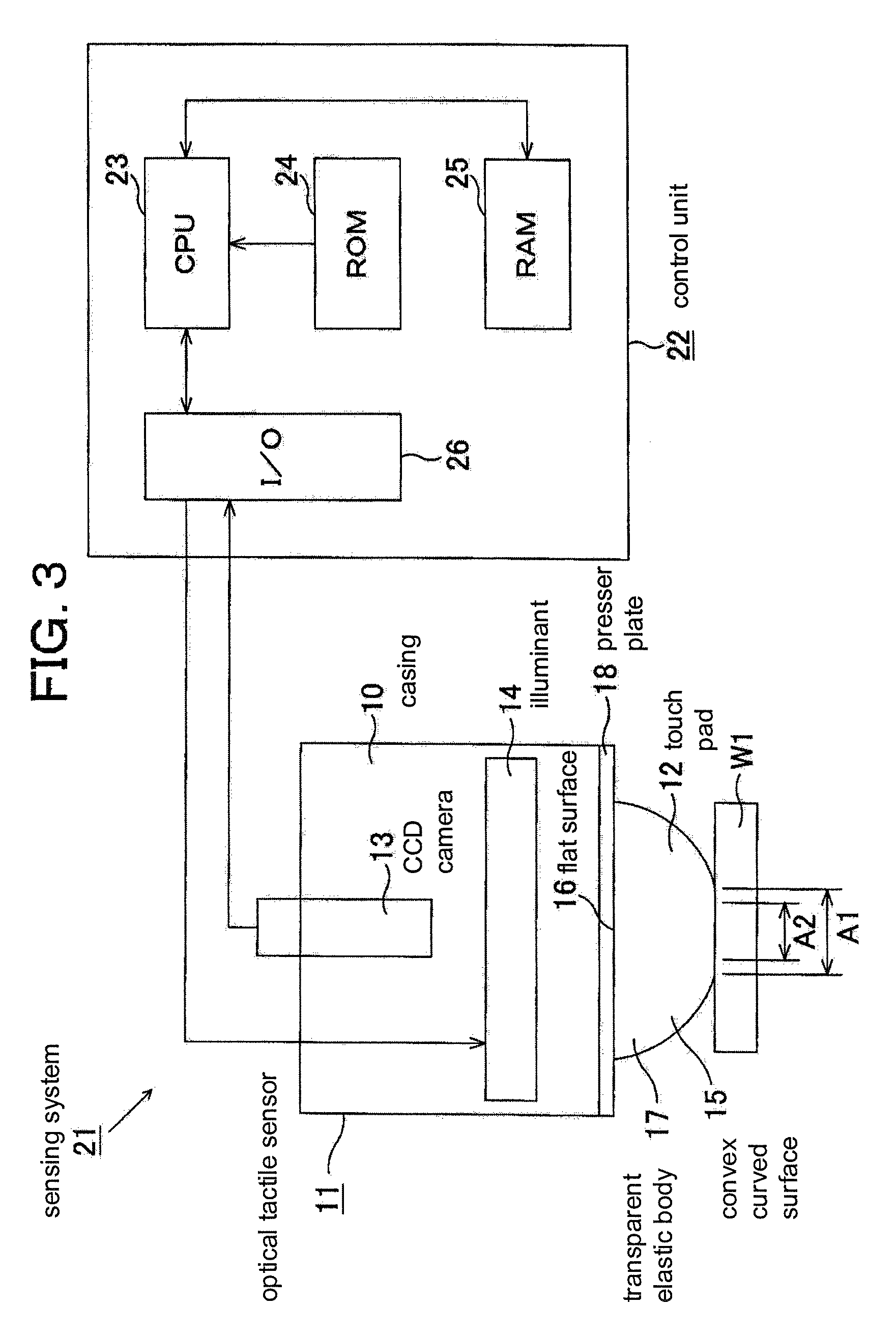

Control of object operating force, object gripping force and robot hands

ActiveUS7707001B2Small and simple structureA large amountForce measurementMeasurement arrangements for variableGrip forceRobot hand

An optical tactile sensor has a touch pad and a CCD camera for imaging behavior of the touch pad. A CPU processes image information from the CCD camera, extracts information on the size, shape, and center of gravity of a contact region, and extracts information on the size of a fixation region. The CPU obtains a normal force from the size of the contact region, obtains a tangential force from the shape of the contact region and the center of gravity of the contact region, and obtains a friction coefficient from the ratio of the size of the fixation region to the size of the contact region.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST

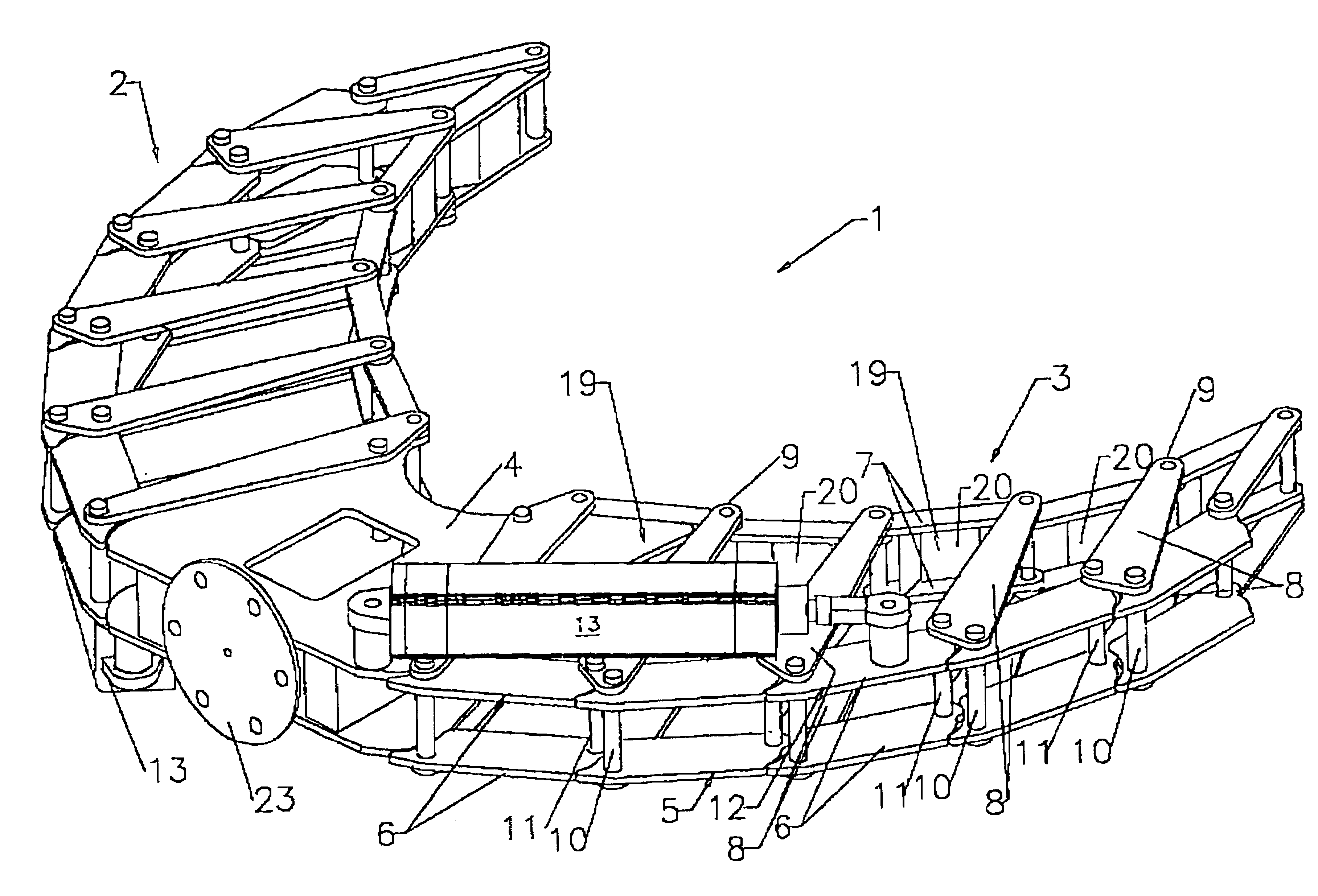

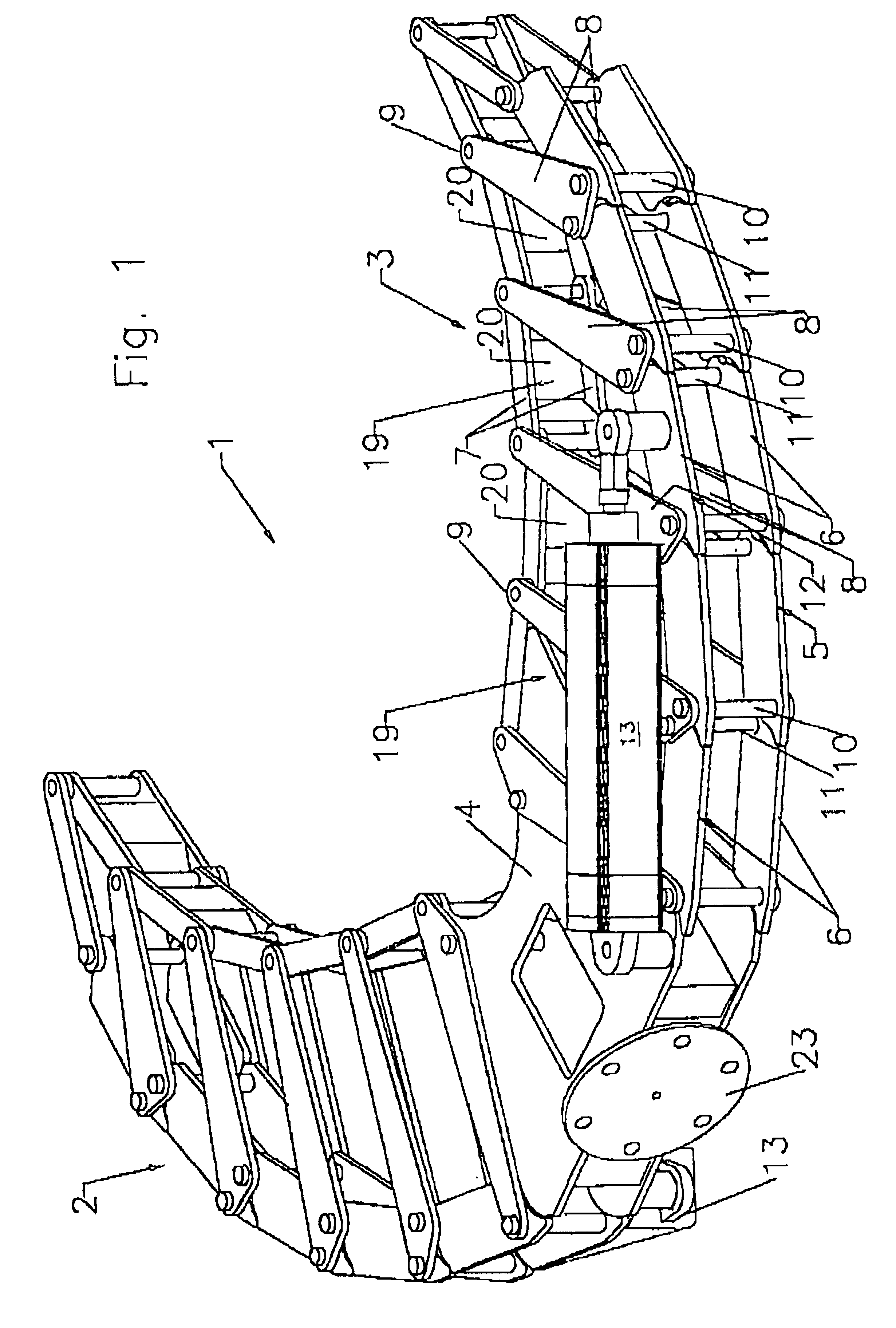

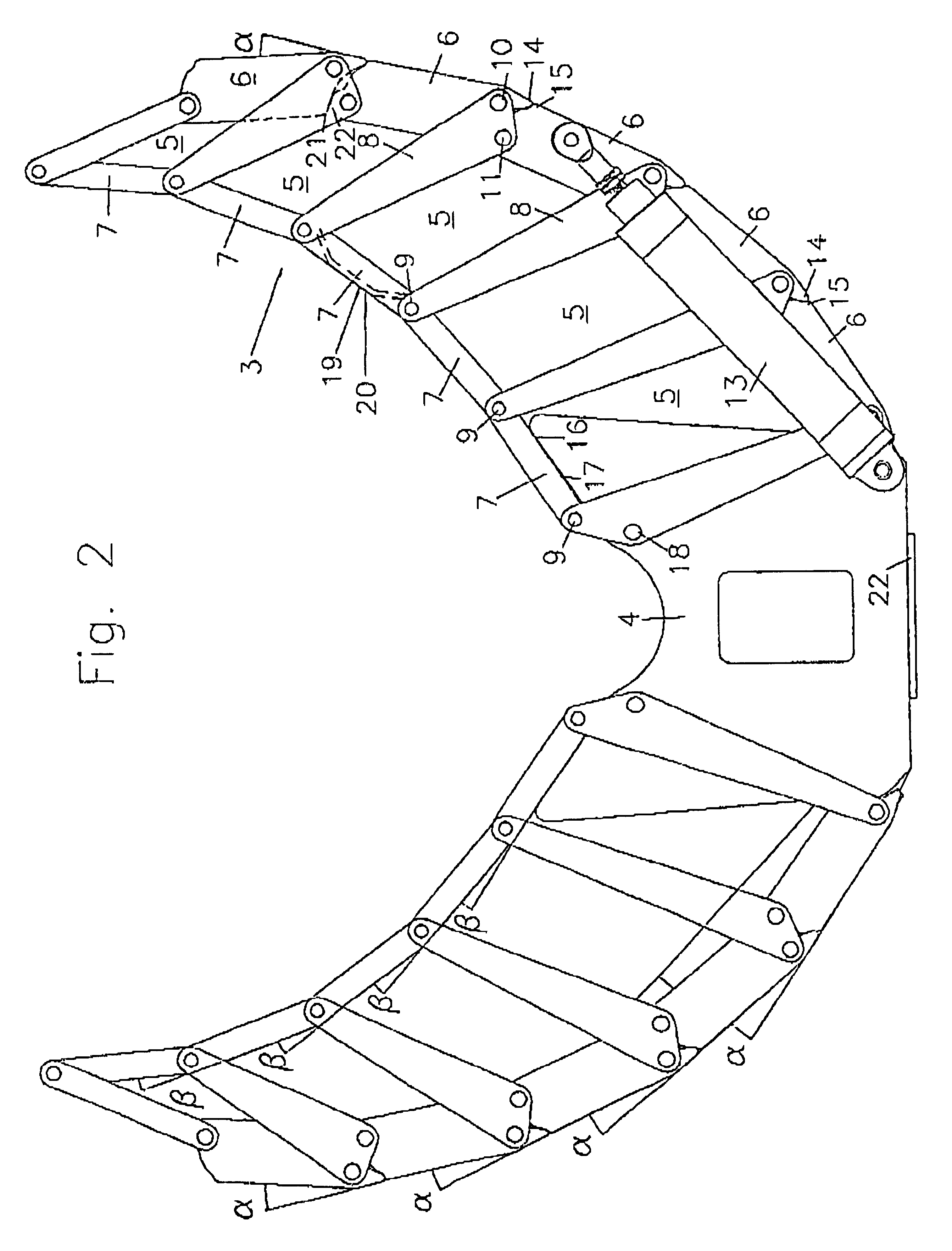

Gripper with segmented arms

InactiveUS6260902B1Meet the limit requirementsGripping headsThin material handlingTangential forceEngineering

A segmented gripper is provided, having two arms (2;3) which are operated for closing and opening movement in an operational plane. The arms are flexible in the way of a finger; i.e. the geometry is variable to adapt to the external shape of the article to be gripped. This is accomplished by providing a structure for the arms, wherein an outer row of pivotally connected links (6) is interconnected with an inner row of pivotally connected links (7), the interconnecting elements (8) being pivotally attached to the link connecting points of each row of links. The lengths of the interconnecting elements are successively decreasing towards the free end of each arm, so that the arm displays a claw-like configuration. The arms are pivotally attached on a support, so that when an actuating force is applied tangentially to the outer row of links, the arms are operated for a closing motion. When the exterior of an article is engaged by any of the inner links, continued tangential force causes the inner row of links to bend about the corresponding link connection point, the outer links peripherally overrunning the inner links by rotation of the interconnecting elements about the attachment points (9,10,11).

Owner:SYNNELIUS SUNE

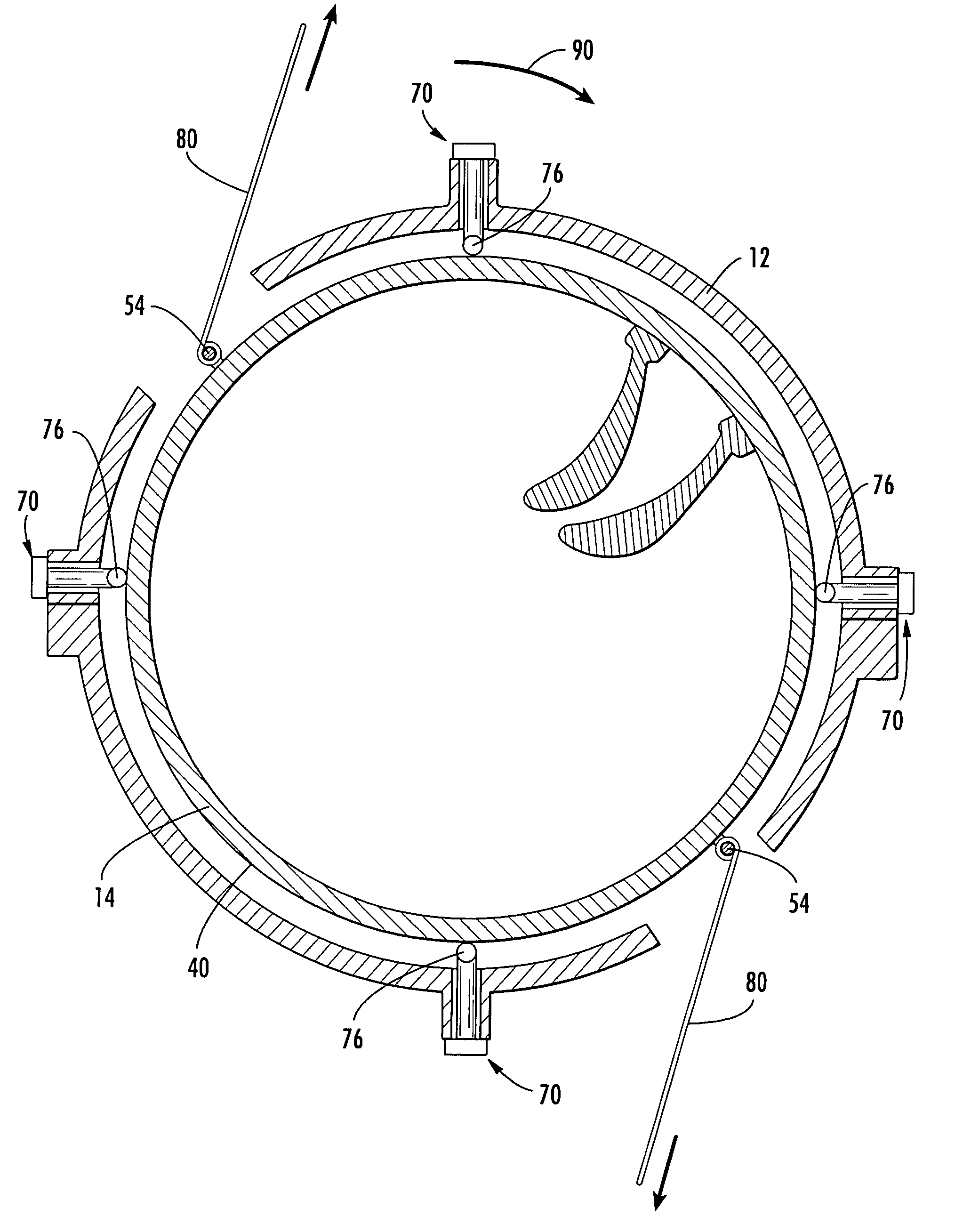

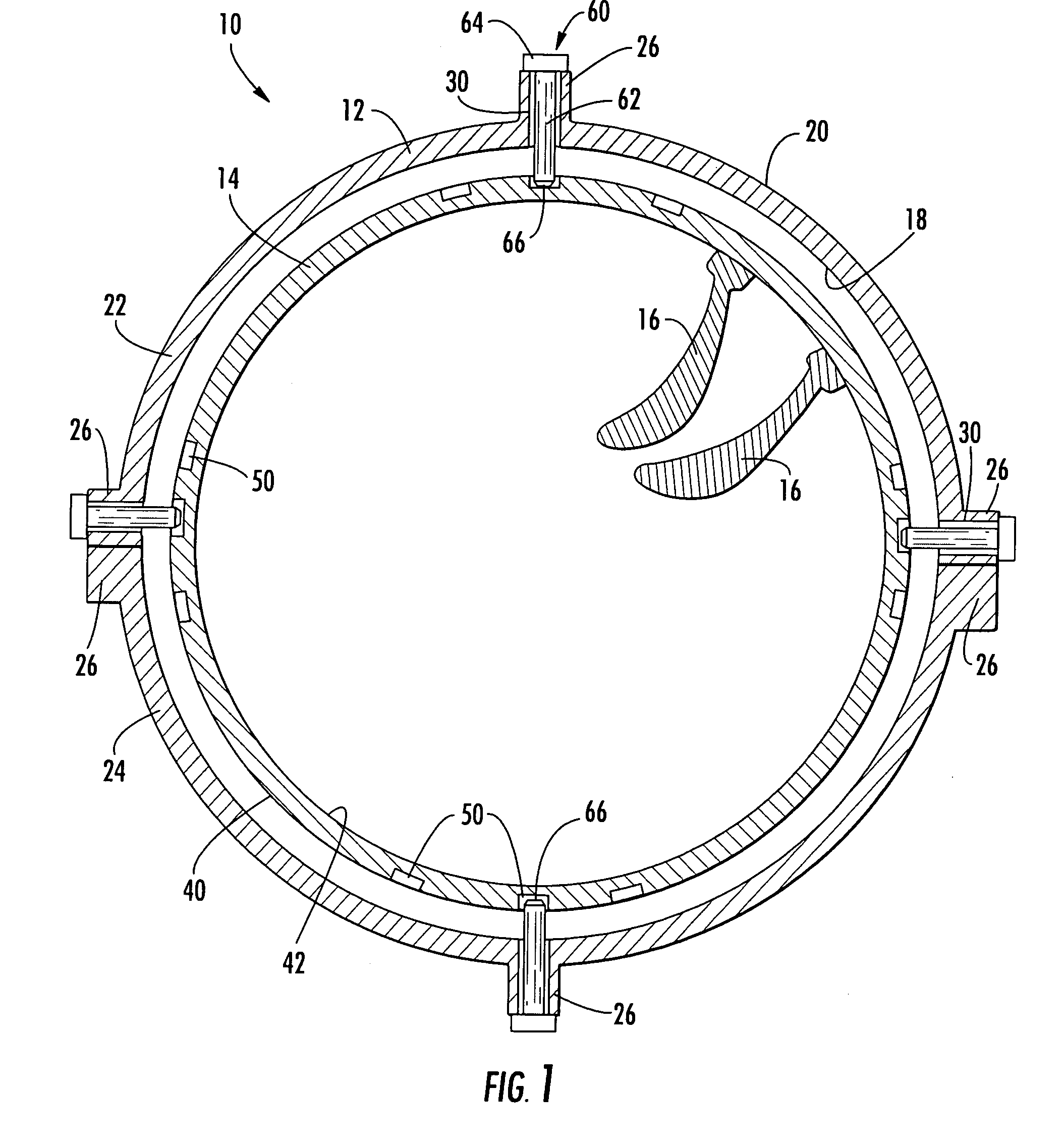

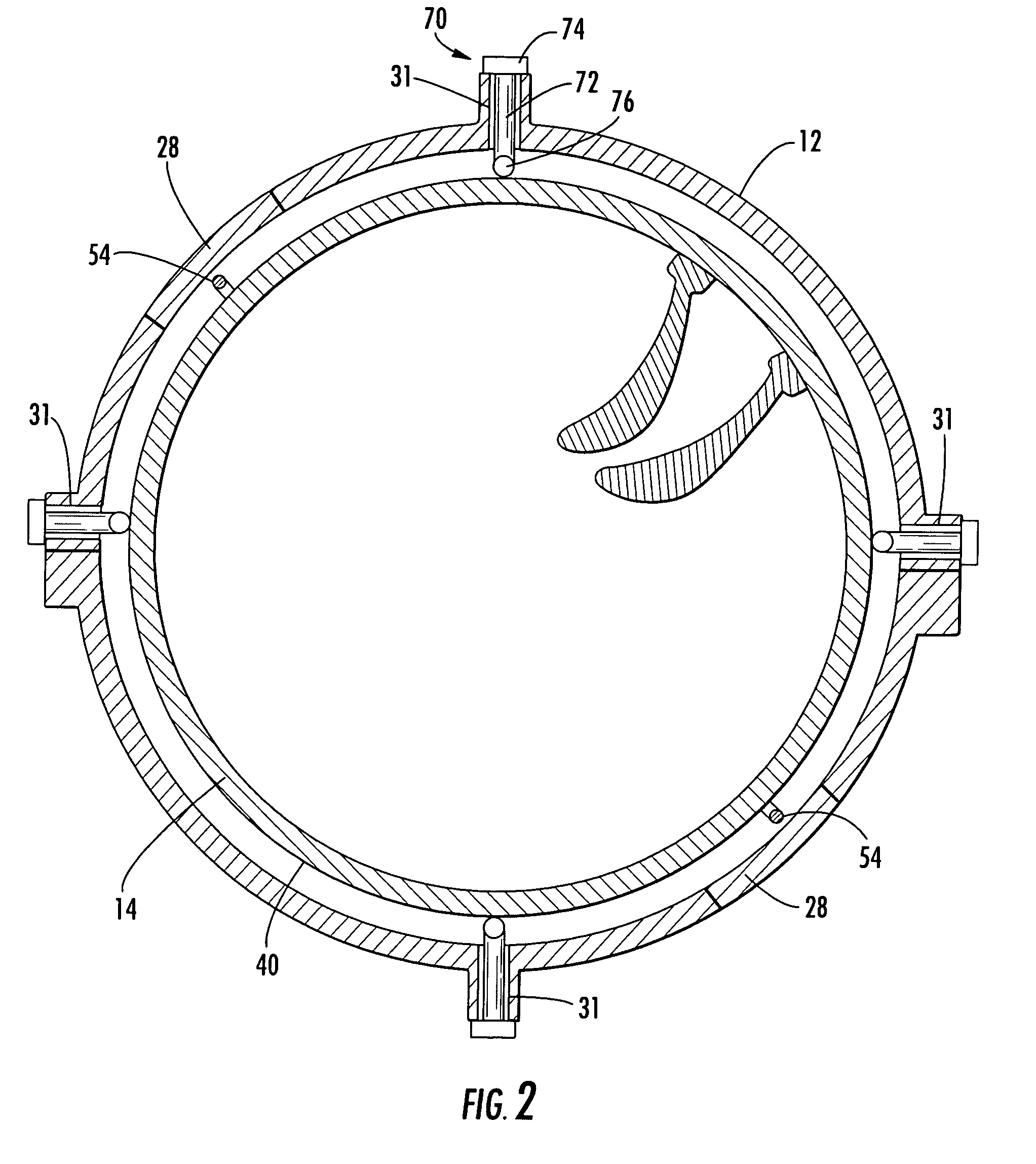

Turbine blade ring assembly and clocking method

Aspects of the invention relate to a method for clocking a row of stationary airfoils relative to an adjacent row of airfoils, and a turbine blade ring configured for use in such a method. The method according to aspects of the invention is advantageous because it can avoid extensive disassembly of the turbine in order to clock the blade ring. The method includes engaging the outer peripheral surface of a blade ring with a plurality of roller pins such that the weight of the blade ring is entirely supported by the roller pins. A tangential force is applied to the blade ring such that the blade ring rotates on the roller pins, thereby adjusting the position of the stationary airfoils affixed to the blade ring. Additional rotational adjustments can be made to the blade ring until the blade ring is clocked to the desired position.

Owner:SIEMENS ENERGY INC

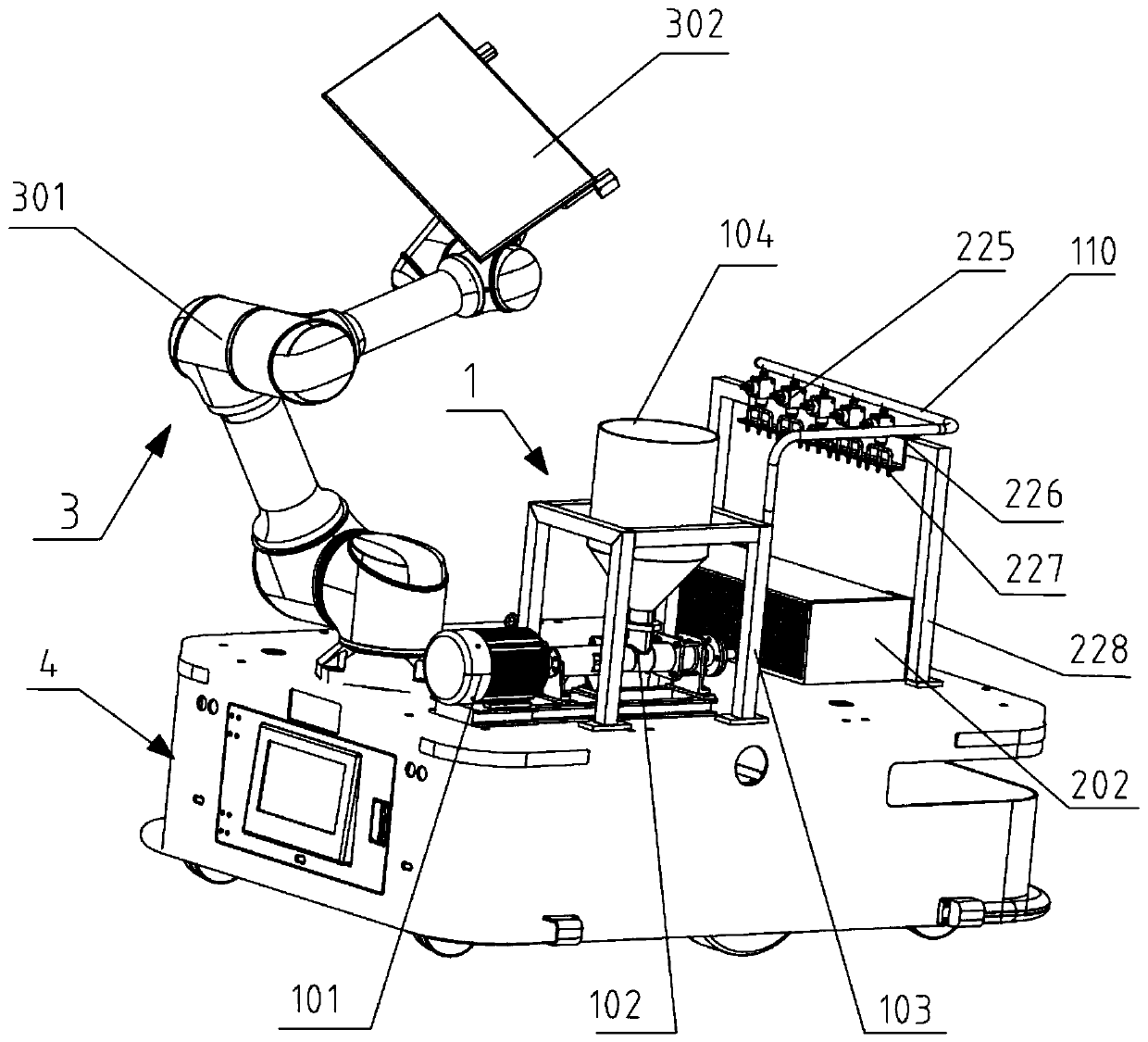

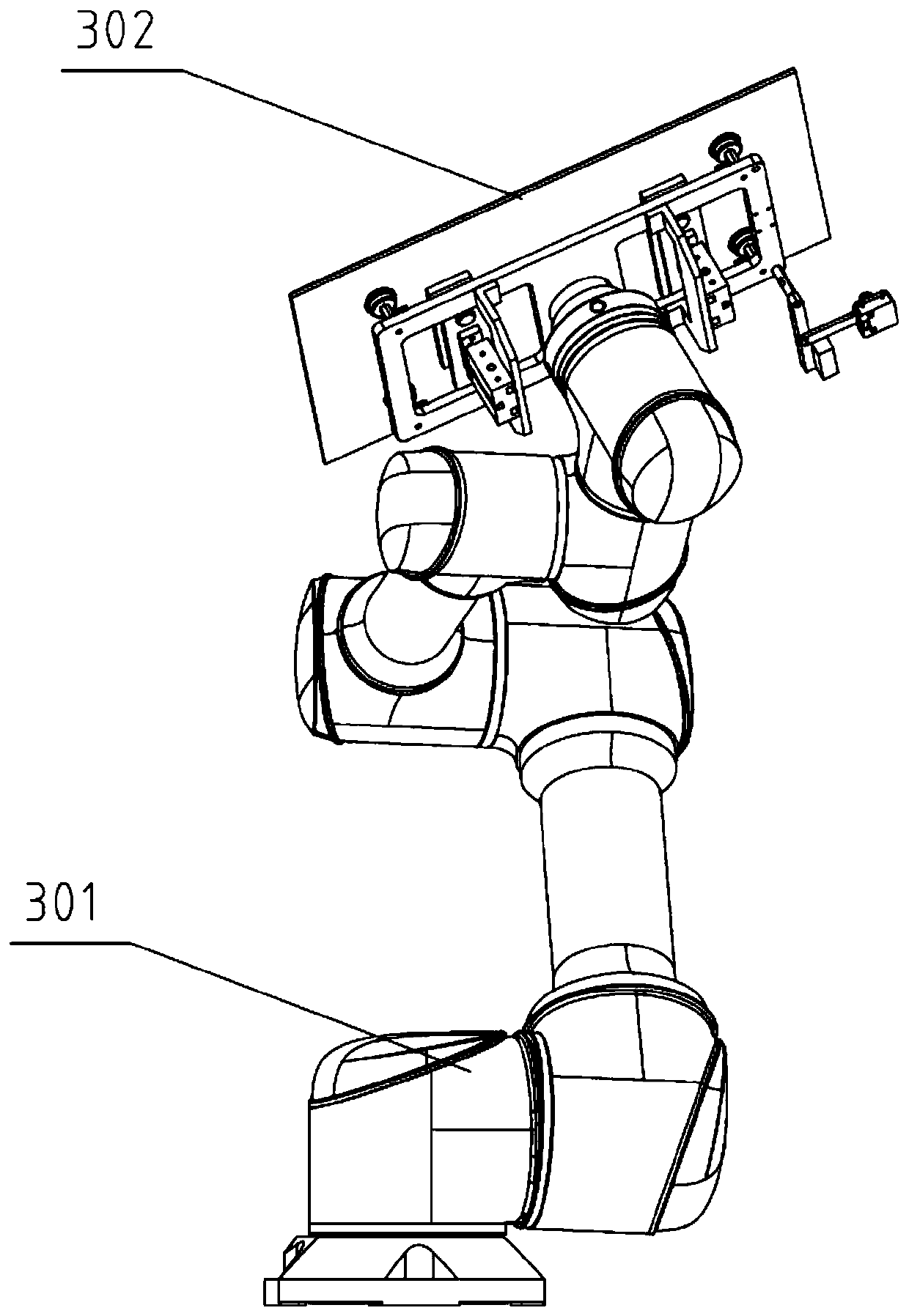

Tile laying device and tile laying robot

ActiveCN110552491APrevent damage from being knockedReduce hollowingBuilding constructionsTangential forceEngineering

The invention discloses a tile laying device and a tile laying robot. The tile laying device comprises a knocking mechanism, wherein the knocking mechanism comprises a flexible knocking part, a knocking driving part and an elastic element, the knocking driving part is arranged to be capable of driving the flexible striking part to stretch out and draw back to vertically knocking tiles laid on a to-be-operated surface, and the elastic element is arranged between the knocking driving part and the flexible knocking part and is used for providing elastic restoring force for the flexible knocking part when the soft striking part is used for knocking the ceramic tiles. When the striking driving piece of the tile laying device drives the flexible striking piece to knock the tiles, elastic restoring force is provided for buffering through the elastic element, so that the tiles can be prevented from being knocked and damaged, and the phenomenon of hollowing of the tiles is reduced; and in addition, due to the fact that the flexible striking piece vertically knocks the tiles, the phenomenon that tangential force is applied to the tiles, so that plane displacement of the tiles is caused is avoided, the height difference among the tiles can be effectively guaranteed particularly when the tiles are laid on the wall surface, and the tile laying quality is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

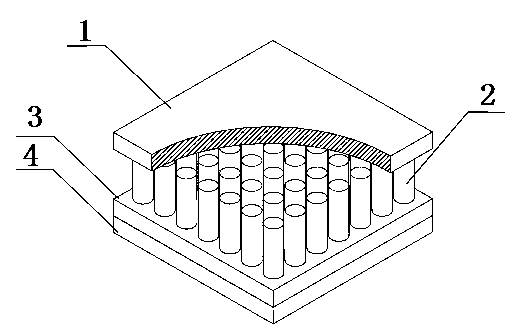

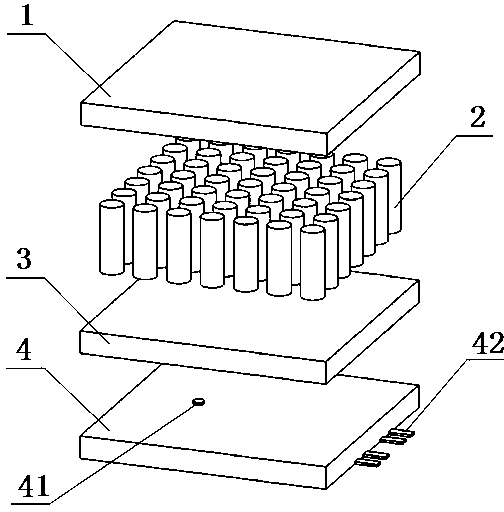

Flexible force sensor capable of measuring normal force and tangential force

InactiveCN104266780AIncrease the capacitance change valueCompact structureForce measurementCapacitanceElectricity

The invention provides a flexible force sensor capable of measuring the normal force and tangential force. The flexible force sensor comprises a flexible force sensing unit and a detection circuit unit electrically connected with the flexible force sensing unit. The flexible force sensing unit is composed of an upper flexible electrode plate layer, a lower flexible electrode plate layer and a flexible supporting layer located between the upper flexible electrode plate layer and the lower flexible electrode plate layer. The flexible supporting layer is composed of flexible supporting bodies with gaps and filling gas located in the gaps of the flexible supporting bodies. According to the flexible force sensor capable of measuring the normal force and tangential force, the flexible supporting layer is adopted to replace a traditional solid dielectric layer, the capacitance change value generated when stress is conducted on the sensor is effectively increased, and the force measuring sensitivity is improved remarkably.

Owner:宁波华铸环保科技有限公司

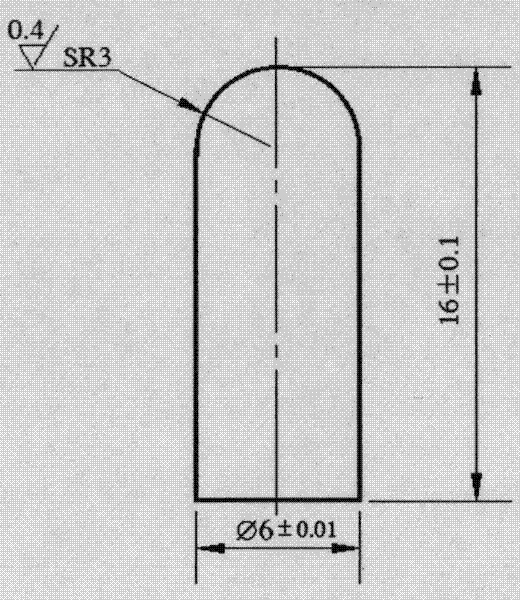

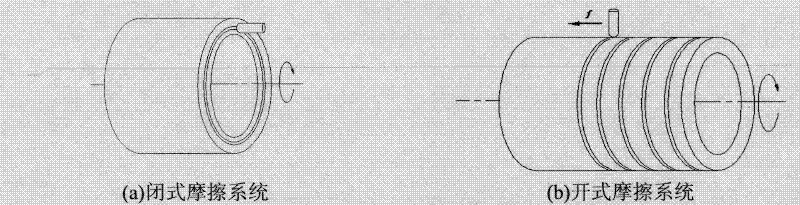

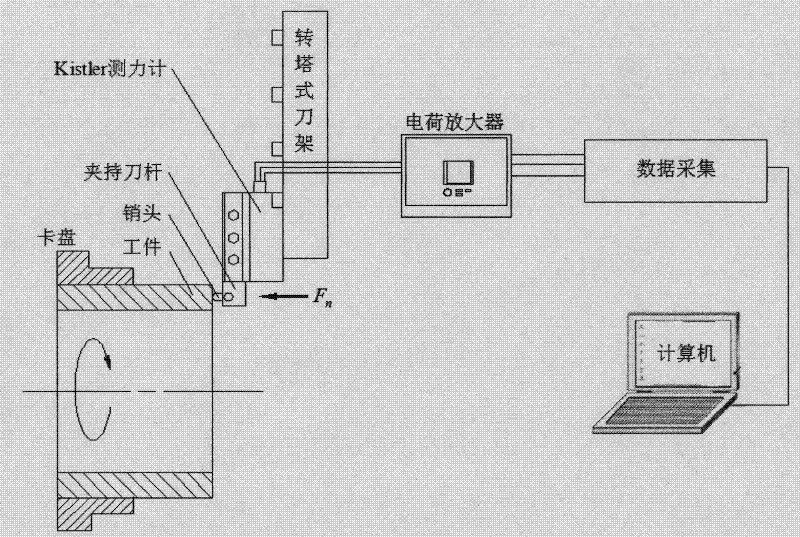

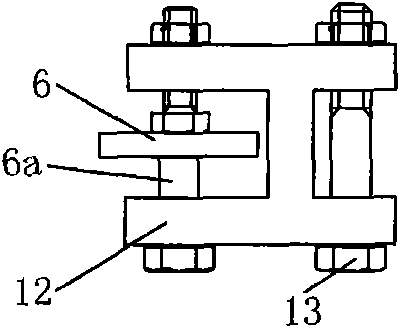

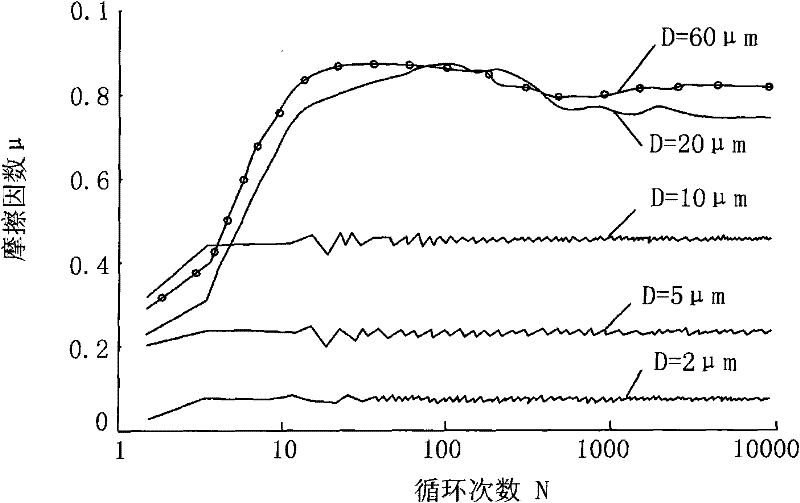

Method for testing cutting and bonding friction characteristics with point-contact opened-closed type pin-disc friction system

The invention relates to a method for testing cutting and bonding friction characteristics with a point-contact opened-closed type pin-disc friction system which is structured by a friction test platform transformed by a lathe. Aiming at the research requirements on the cutting friction problem and through the design of a pin-disc structure and the combination of lathe space motion trail, an opened-closed type system can be structured, and the cutting friction under an extreme working condition can be simulated; and an acting force of a contact interface can be measured by utilizing a Kistler piezoelectric force meter, a tangential force component caused by material elasticplastic deformation can be removed by combining a finite element simulation method, and thus a bonding friction factor can be obtained. The method disclosed by the invention is mainly used for testing and analyzing the friction characteristic of cutters in the cutting process. A main body of equipment is common equipment in a manufacturing laboratory, and has the advantages of good rigidity, simple structure, easy implementation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

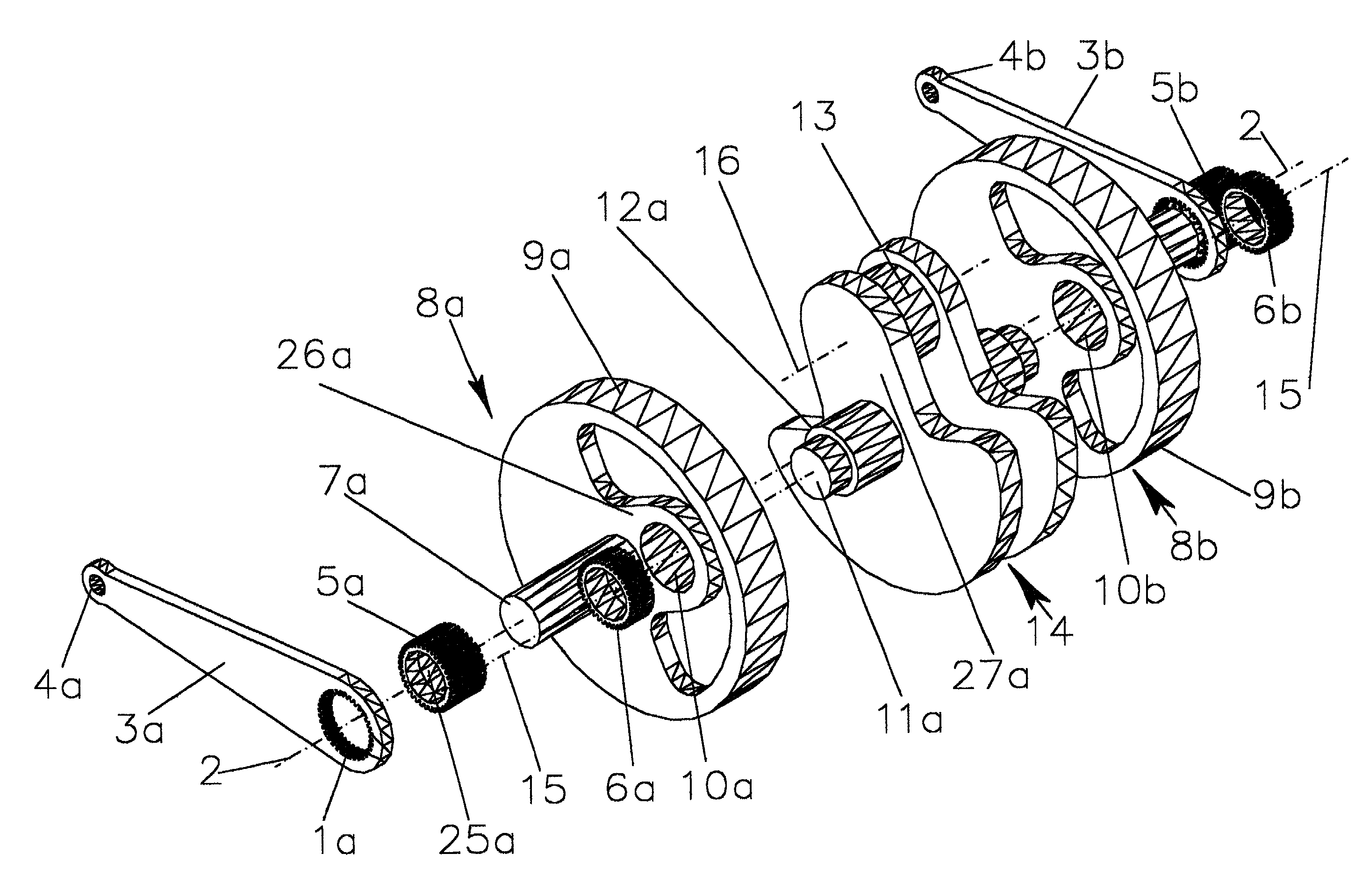

Cardioid cycle internal combustion engine

InactiveUS20020185101A1Improve fuel efficiencyMore outputConnecting rodsMachines/enginesFuel efficiencyTangential force

The cardioid cycle engine utilizes a centrally located output shaft which carries an orbiting crankshaft for each cylinder. The journals of the orbiting crankshafts trace a heart shaped pattern, hence the term "cardioid" cycle. The crankshafts are geared to rotate within the revolving output shaft in the same direction and at the same angular velocity as the output shaft. In the preferred embodiments the offsets of the two shafts are adjusted so that they are additive in the second quadrant of output shaft rotation. This configuration produces four strokes, variable in length and duration, in each 360° of output shaft rotation. The expansion stroke can exceed twice the intake stroke in length, and TDC can occur when the output shaft is well past the normal TDC position, allowing tangential force on the shaft when cylinder pressure is highest. Compression ratios can be varied over the full useable range while the engine is operating. When used as an engine, fuel efficiency and torque are increased, and when used as a compressor the peak torque loads are reduced.

Owner:SHAW RALPH

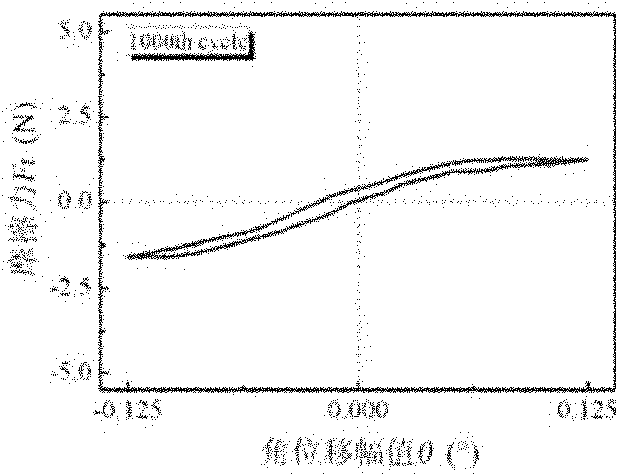

Test method and test device for torsional composite fretting friction wear

InactiveCN101963563AReal and effective analysisReal and effective testInvestigating abrasion/wear resistanceNormal loadFretting

The invention discloses a test method and a test device for torsional composite fretting friction wear. The method comprises the following steps that: a, an upper test piece is clamped on an upper fixture connected with a six-axis force / moment sensor, and a lower test piece is clamped by a lower fixture, wherein the lower fixture is fixed on an inclined rotary motor (13) shaft; b, a data acquisition control system controls the upper fixture and the upper test piece to move up and down and move left and right to make the upper fixture and the upper test piece contact and keep a set normal load Fn, and the data acquisition control system controls a rotary motor and the lower test piece to rotate in set parameters; and c, the six-axis force / moment sensor measures a tangential force, namely a frictional force Ft, the frictional force Ft is sent to the data acquisition control system, and the curve of the frictional force Ft and a rotary angle displacement amplitude theta is obtained through analysis to represent dynamic characteristics of torsional composite fretting. By the method, composite fretting damage of a component in complex stress is more really simulated; the precision of control and test is high; the repeatability of experimental data is good; and the automation degree is high.

Owner:SOUTHWEST JIAOTONG UNIV

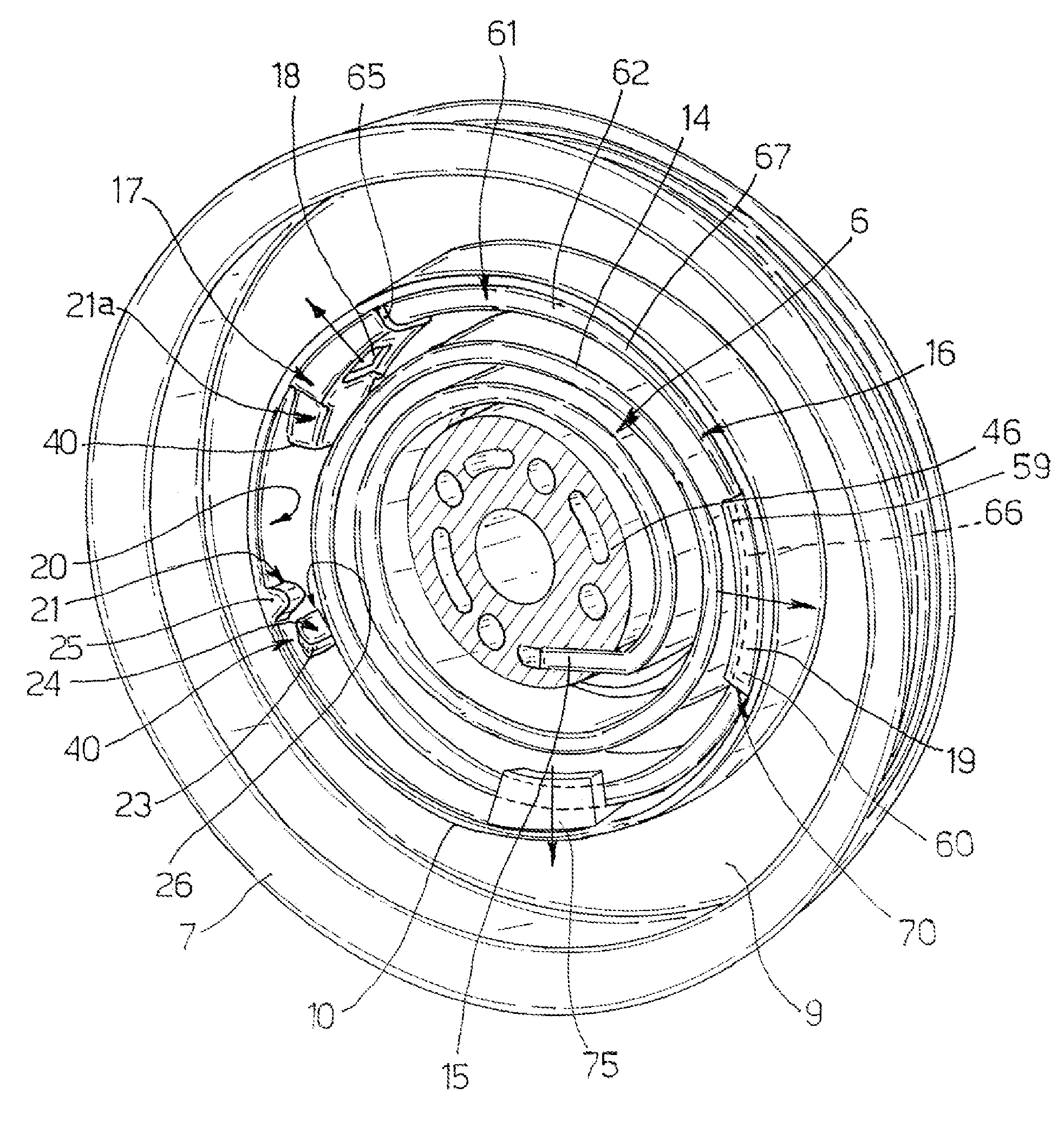

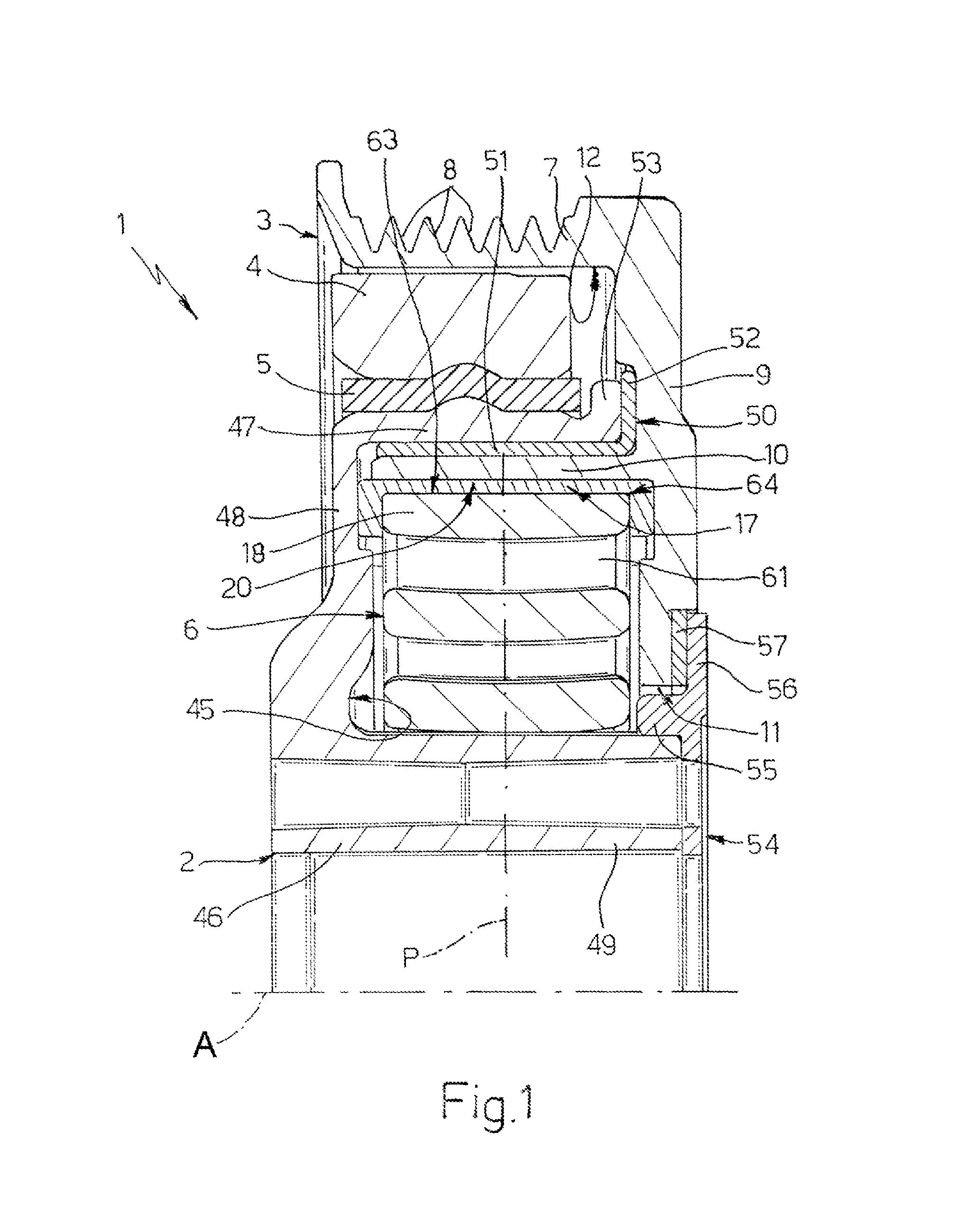

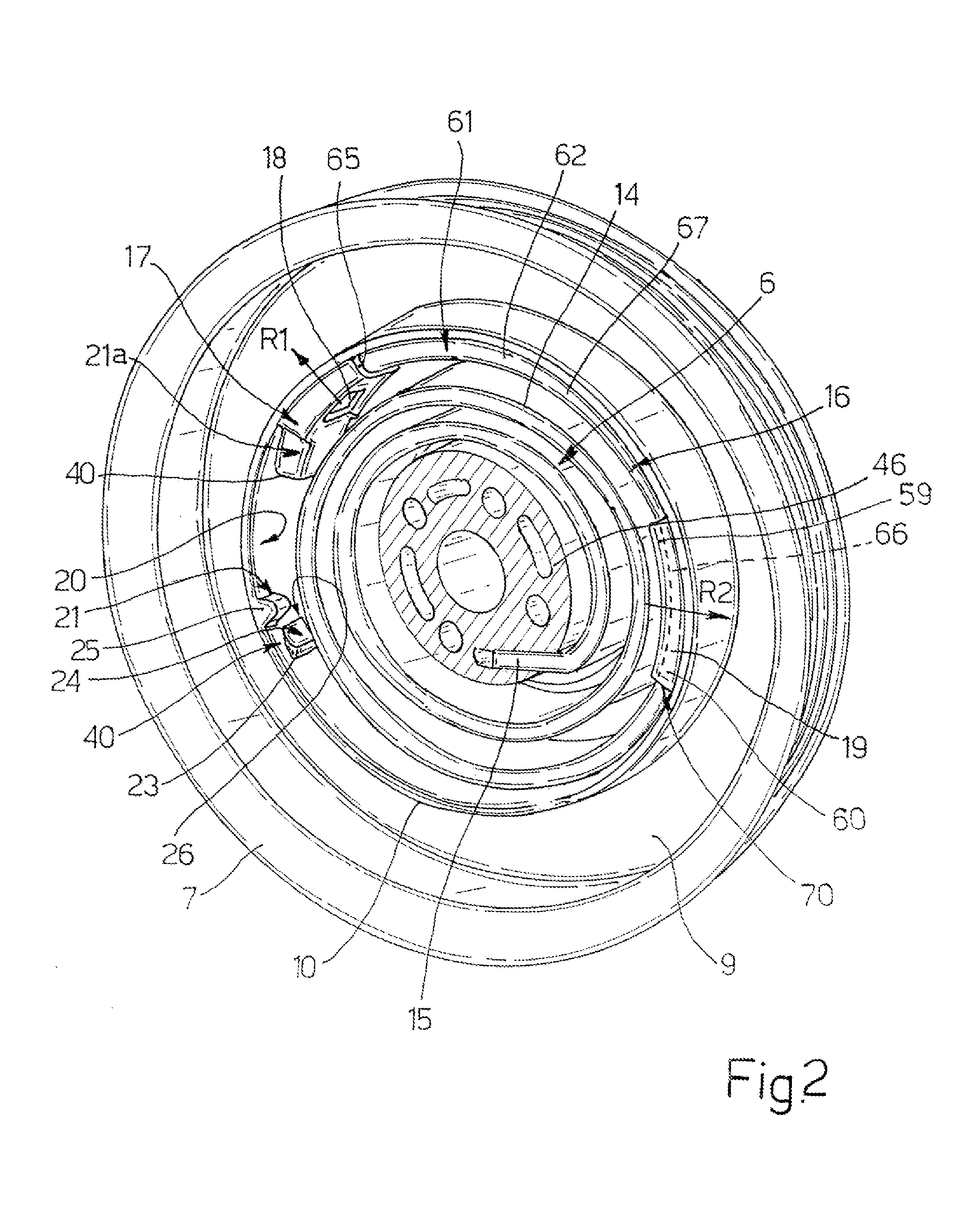

Pulley assembly

A pulley assembly for flexible motor vehicle transmission, comprising a supporting member rotatable about an axis, a pulley adapted to cooperate with a belt and connected to the supporting member to be rotatable about said axis with respect to the supporting member, a spiral spring interposed between the supporting element and the pulley and comprising a sliding portion elastically loaded in radial direction against a sliding wall carried by one of either the supporting members or the pulley for coupling by a tangential force transmission the hub to the supporting member. In particular, the sliding portion defines a first contact zone and a second contact zone in which is concentrated the contact pressure exchanged between the sliding portion and the sliding wall, the first and second contact zone being reciprocally and angularly distanced.

Owner:DAYCO EURO

Small-displacement reciprocating rolling friction abrasion test device

InactiveCN101750259AAuthentic, reliable and effective simulationAuthentic, reliable and effective analysisInvestigating abrasion/wear resistanceRolling resistanceTangential force

The invention relates to a small-displacement reciprocating rolling friction abrasion test device. A plane sample clamp is fixedly connected below a cross beam of a hydraulic friction test machine by a tangential force sensor; a rolling sample clamp is positioned at the right side of the plane sample clamp and is fixed on a vertical column of a support frame; a bottom plate of the clamp support frame is connected on a hydraulic piston of the hydraulic friction test machine; the right side of the clamp support frame is provided with a normal force; a screw at the right side of the normal force sensor is connected on a support nut by threads, and the end part of the screw is connected with a rotating disc; the support nut is fixed on a work platform surface of the hydraulic friction test machine by a support seat; and a U-shaped connecting piece at the left side of the normal force sensor is sheathed on the vertical column of the clamp support frame. The small-displacement reciprocating rolling friction abrasion test device can simulate the friction abrasion between a plane sample and a rolling body more really and reliably, is convenient to microscopically analyze the test result, and has high degree of automation, simple and convenient operation, high accuracy of control and test and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com