Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

A measuring device and grinding force technology, applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., to achieve the effect of high rigidity, less links, and small hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

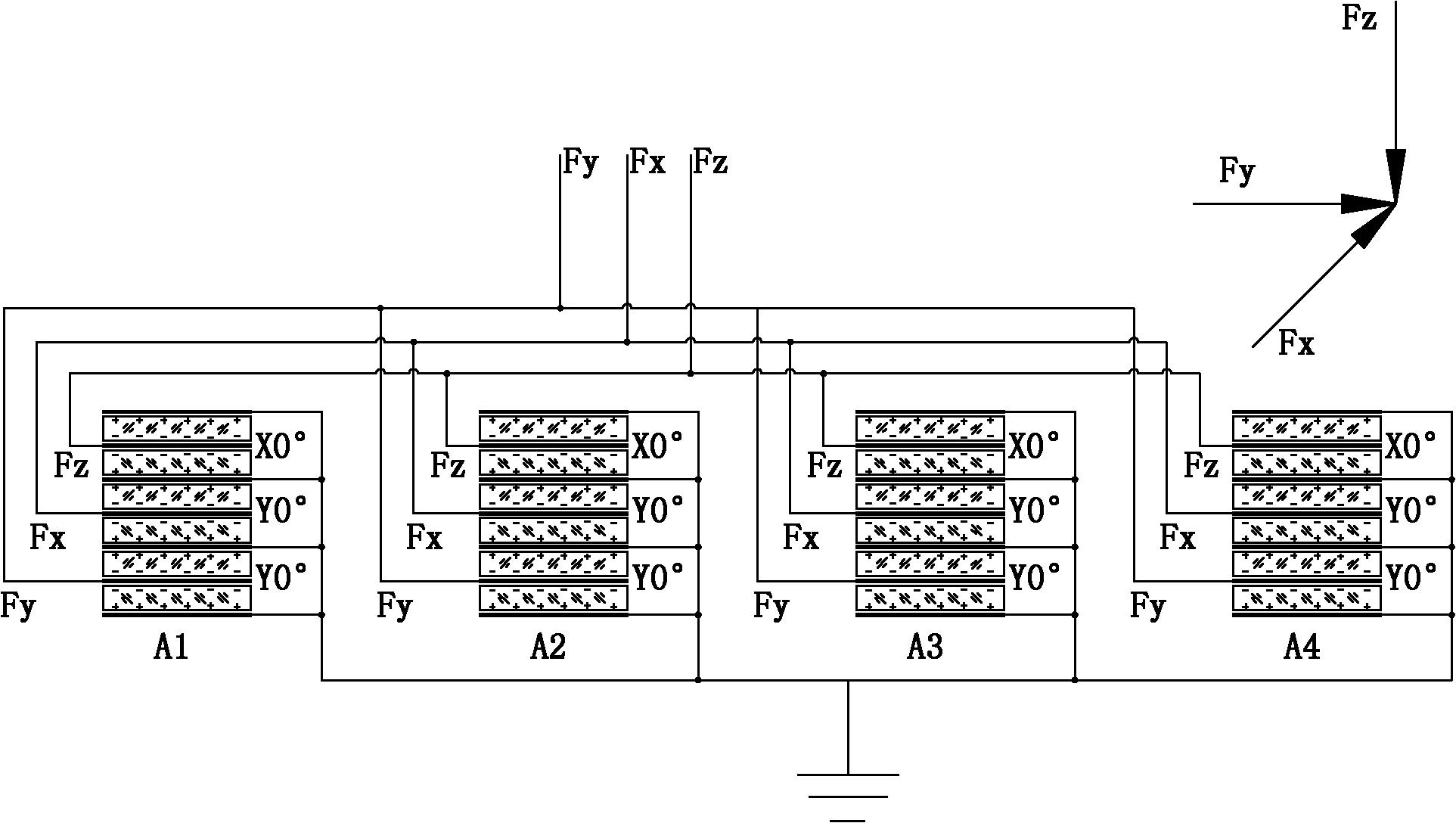

[0029] Example: The laboratory room temperature is 26°C, the sensitivities of the charge amplifier YE5850B are SX=7.93pc / kgf, SY=7.85pc / kgf, SZ=3.53pc / kgf respectively. It can be concluded from Table 1 that when Fz is loaded, the non-linear error is less than 0.2%, the repeatability error is less than 0.5%, and the cross-directional interference is less than 2%. The test results show that all the indicators have reached the standards stipulated by the International Production Engineering Research Association - Cutting Science and Technology Committee.

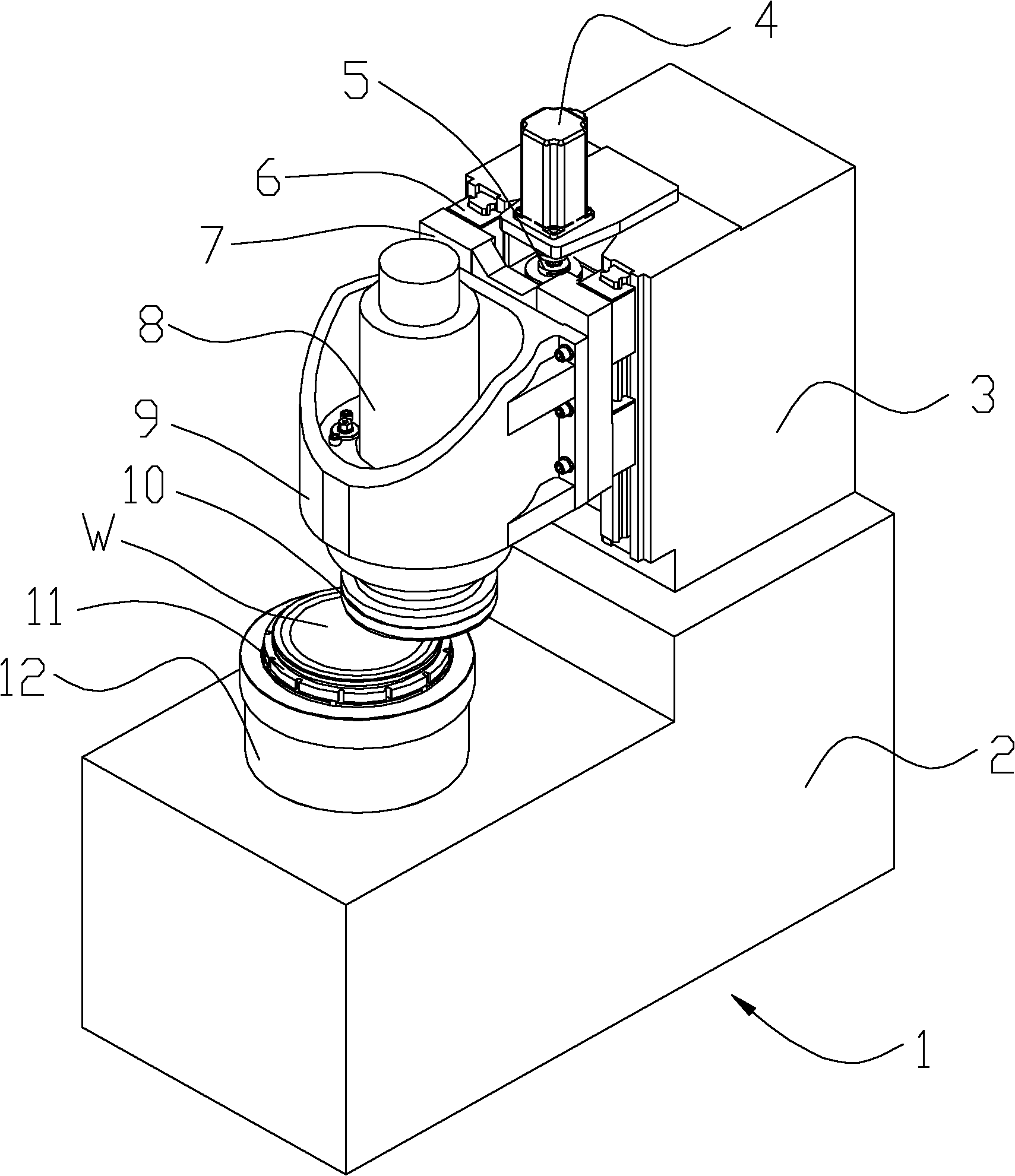

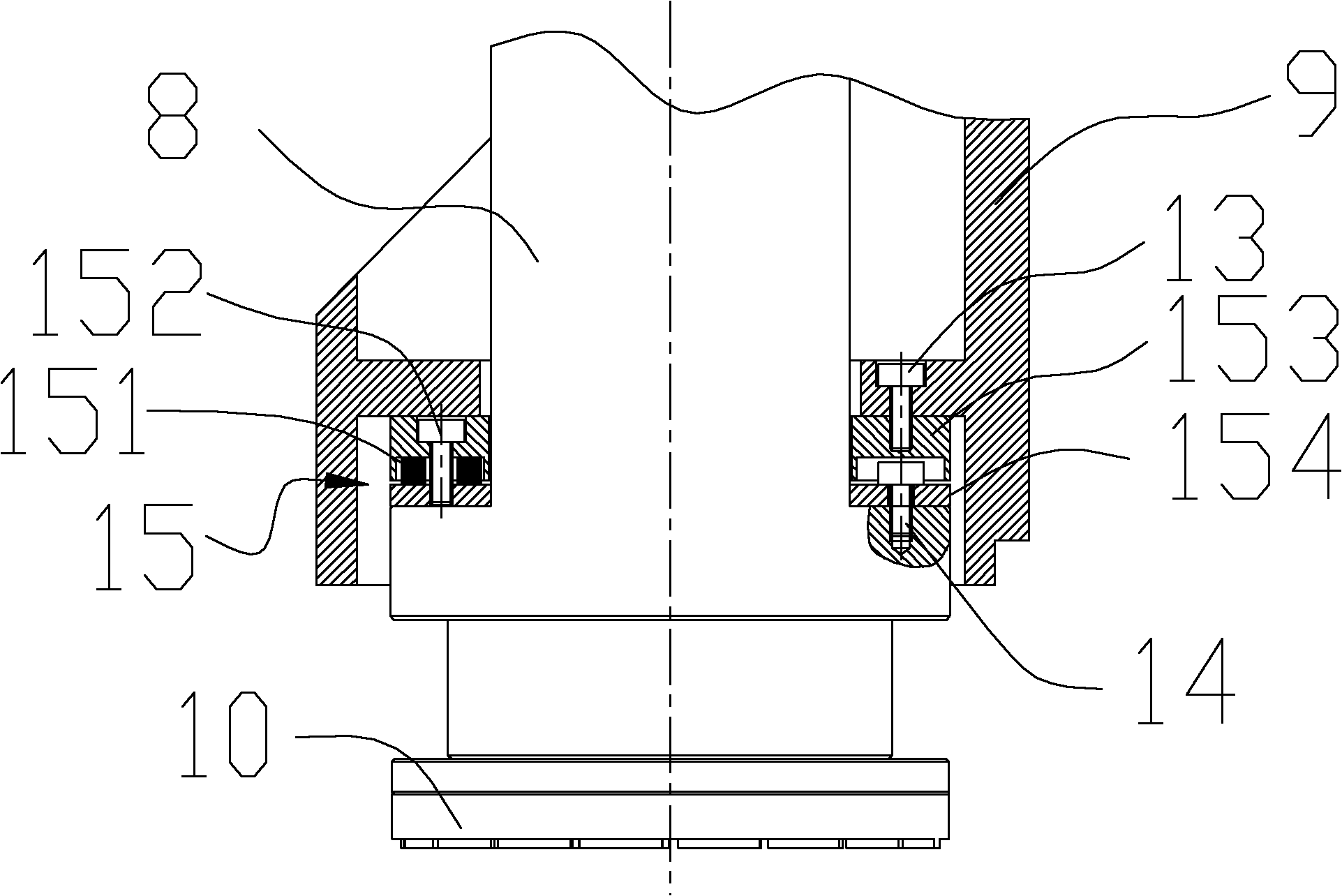

[0030] like Figure 4 As shown, when grinding a semiconductor wafer W, the grinding force is transmitted to the main shaft 8 through the grinding wheel 10, and then transmitted to the grinding force detection device 15 through the flange of the main shaft 8, and the corresponding radial force Fr and tangential force Ft are output respectively. and the charge signal of the axial force Fz are modulated and amplified by the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com