Ultrasonic wire cutting saw for hard-fragile material processing

A wire cutting saw, hard and brittle material technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of low processing precision, high cost, increased processing cost, etc., and achieve simple and reasonable structure and high production efficiency. , The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

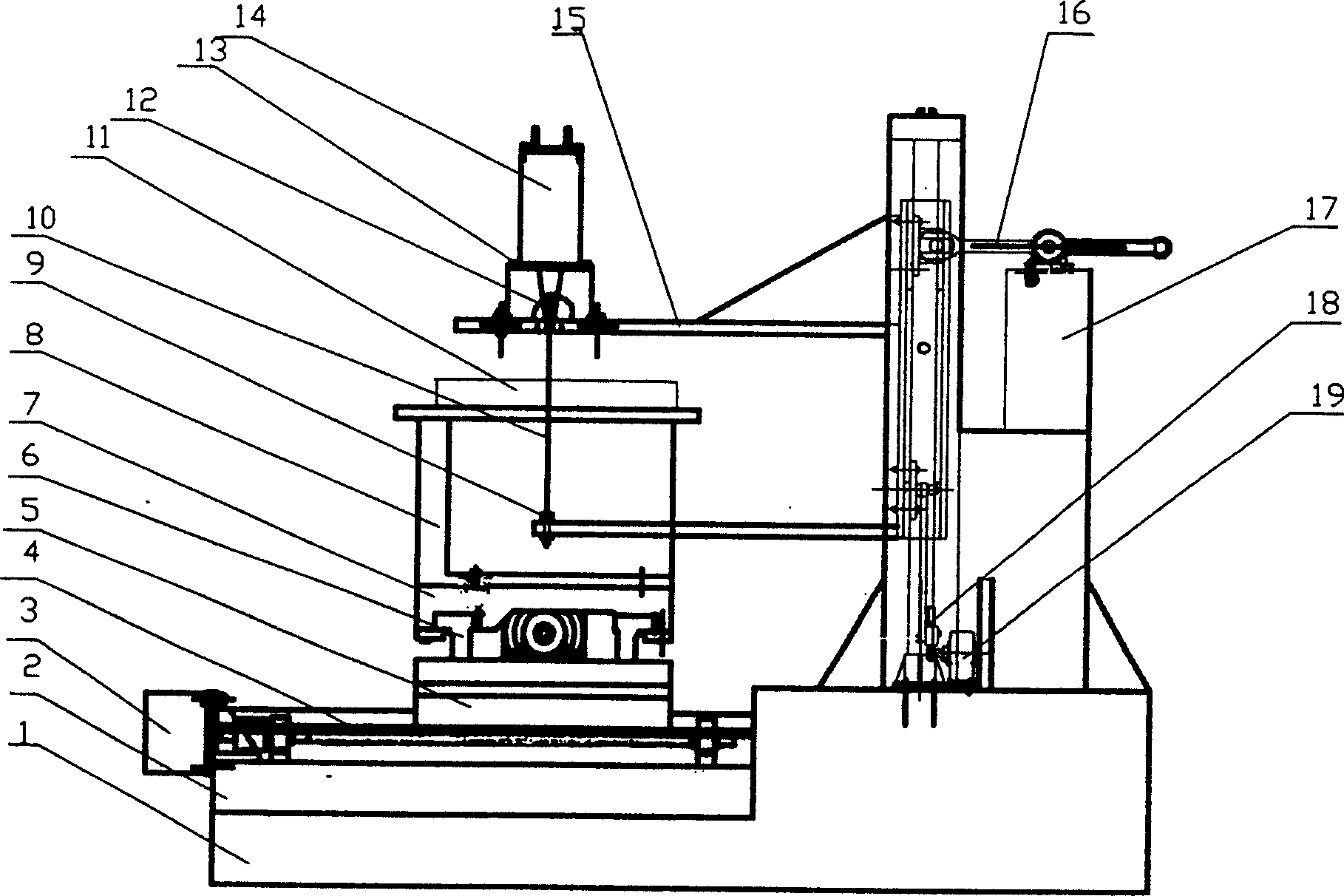

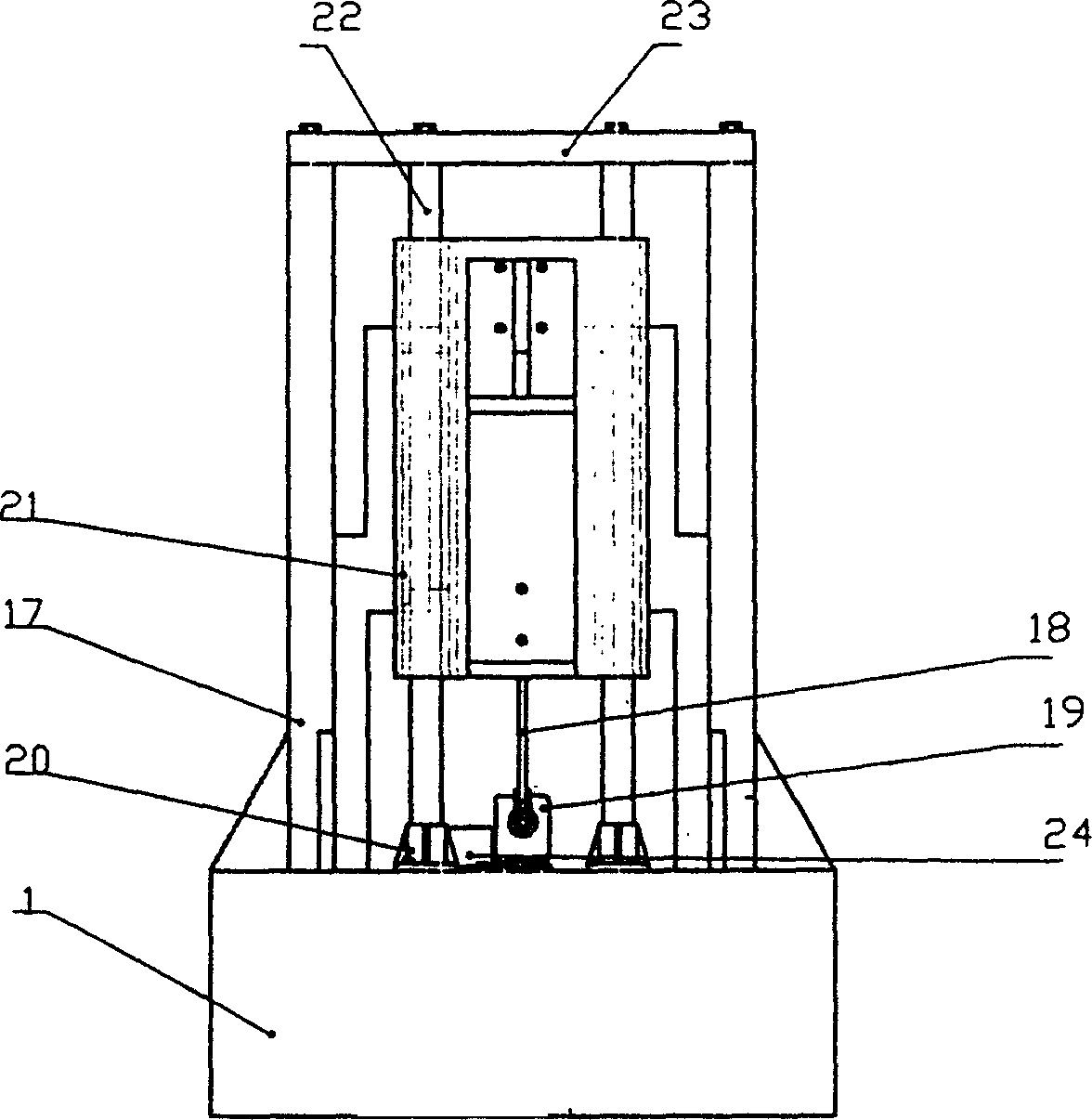

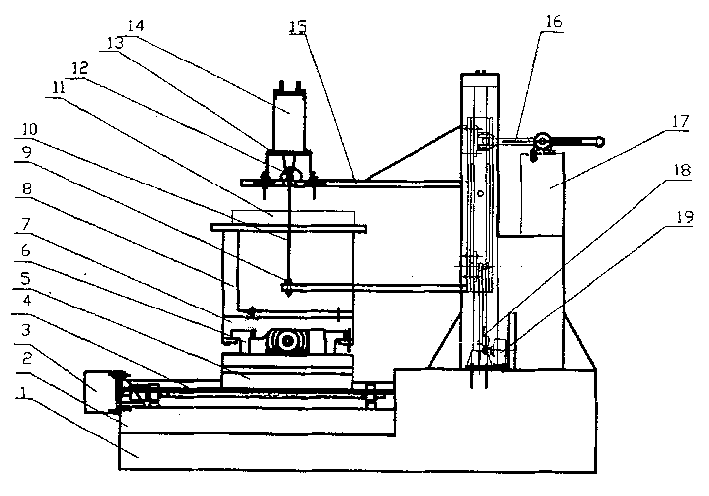

[0009] Such as figure 1 and figure 2 As shown, the technical scheme and working process of the present invention are further described in conjunction with the embodiments. An ultrasonic wire cutting saw for processing hard and brittle materials, comprising a bed 1, a longitudinal working slide 2, a longitudinal working slide 5, a workpiece support 8, an ultrasonic vibration device, a wire saw reciprocating mechanism, a vertical bed 17, Cooling system and electrical controls. The horizontal working slide 7 is set on the horizontal sliding base 6 through guide rails, the horizontal stepping motor is fixed on the horizontal sliding base 6, and is connected with the horizontal ball screw through a coupling, and the horizontal screw nut is connected with the horizontal working slide through screws. 7 is fixed, and the horizontal working slide table 7 is driven by a horizontal stepping motor to move left and right. The horizontal sliding table 6 is fixed on the longitudinal worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com