Patents

Literature

1300 results about "Wire saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wire saw is a saw that uses a metal wire or cable for cutting. Industrial wire saws are usually powered. There are also hand-powered survivalist wire saws suitable for cutting branches. Wire saws are classified as continuous (or endless, or loop) or oscillating (or reciprocating). Sometimes the wire itself is referred to as a "blade".

Wire saw

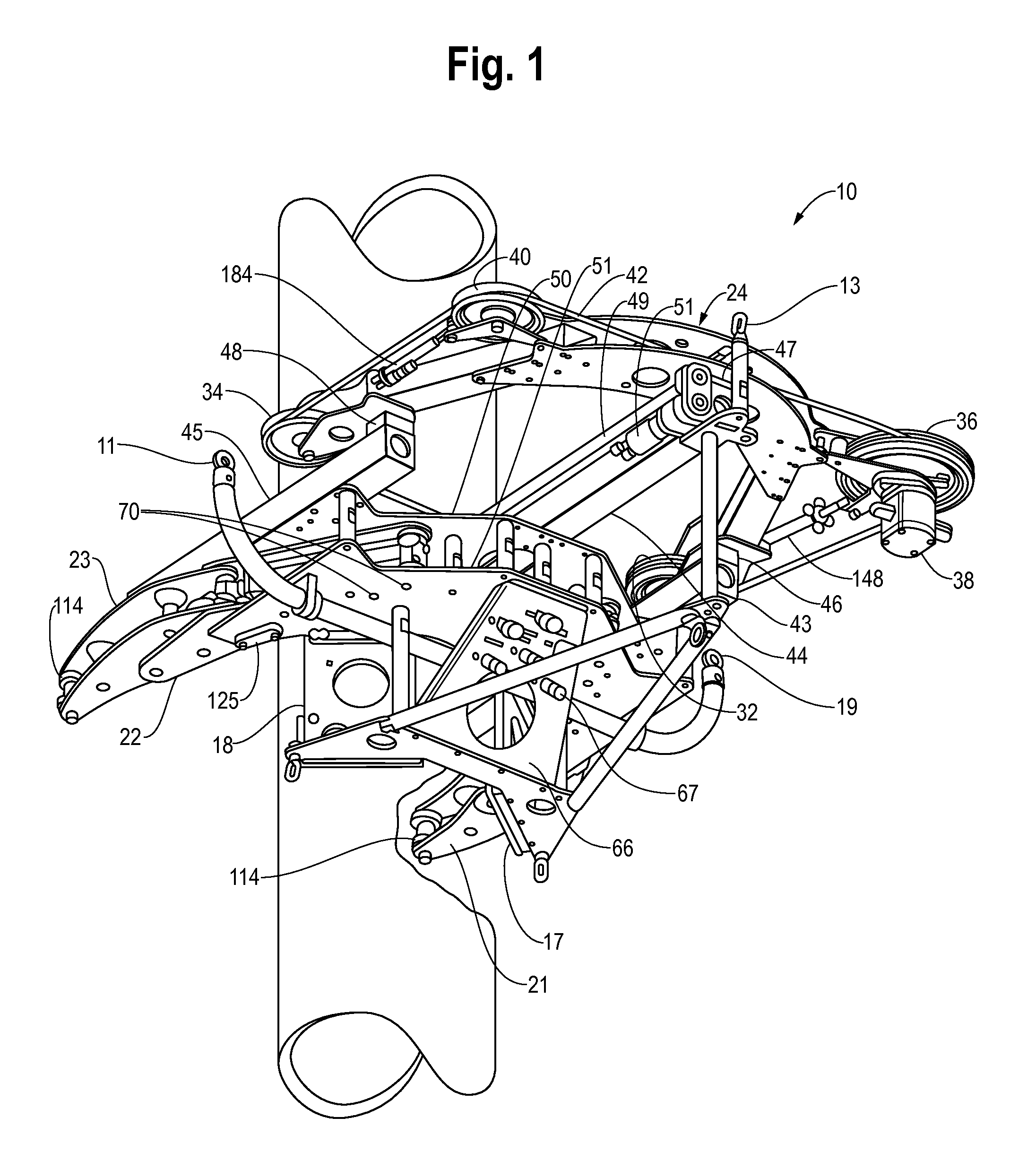

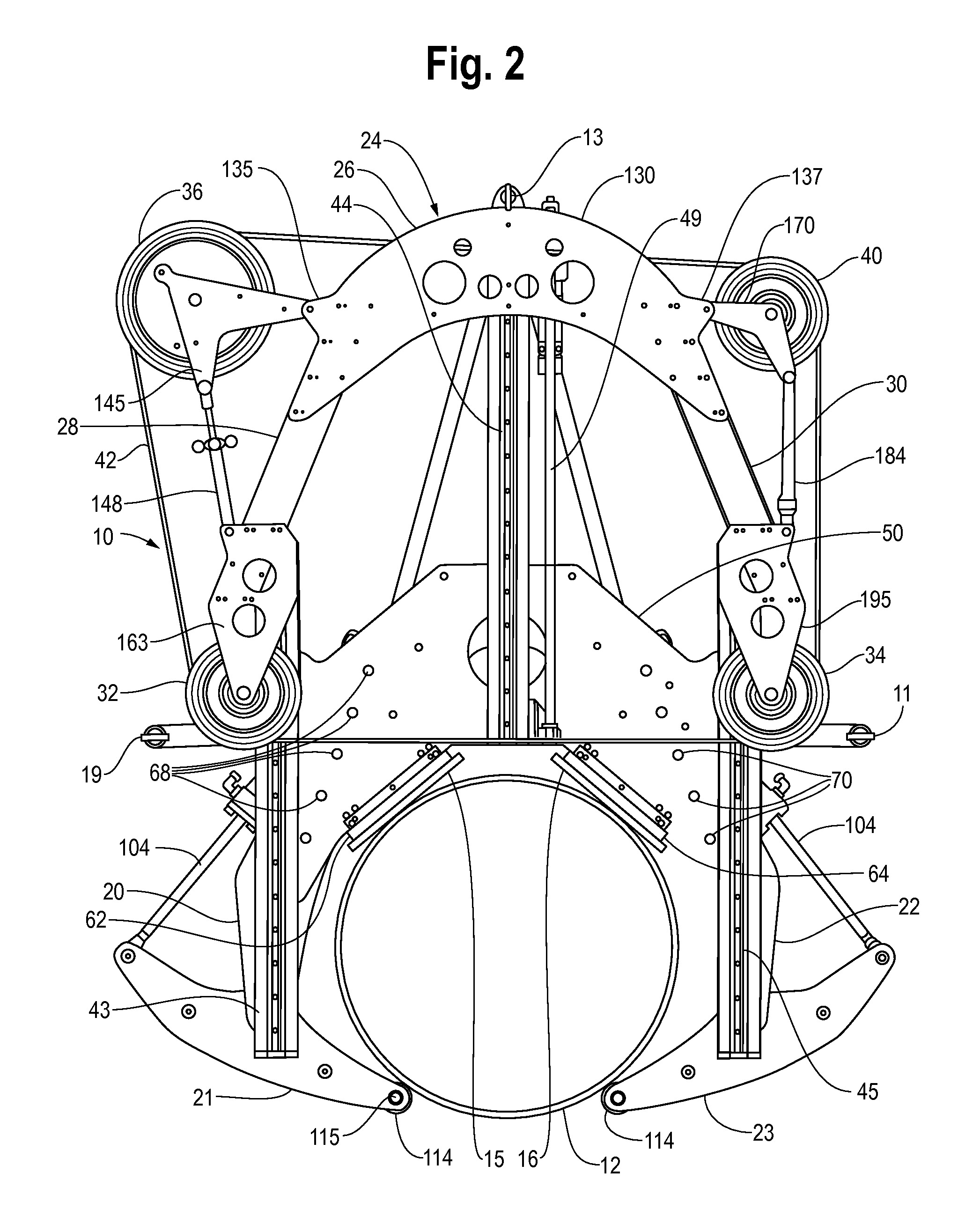

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

Superabrasive wire saw and associated methods of manufacture

InactiveUS6915796B2Improving particle retentionHigh material removal ratePigmenting treatmentOther chemical processesWire rodAlloy

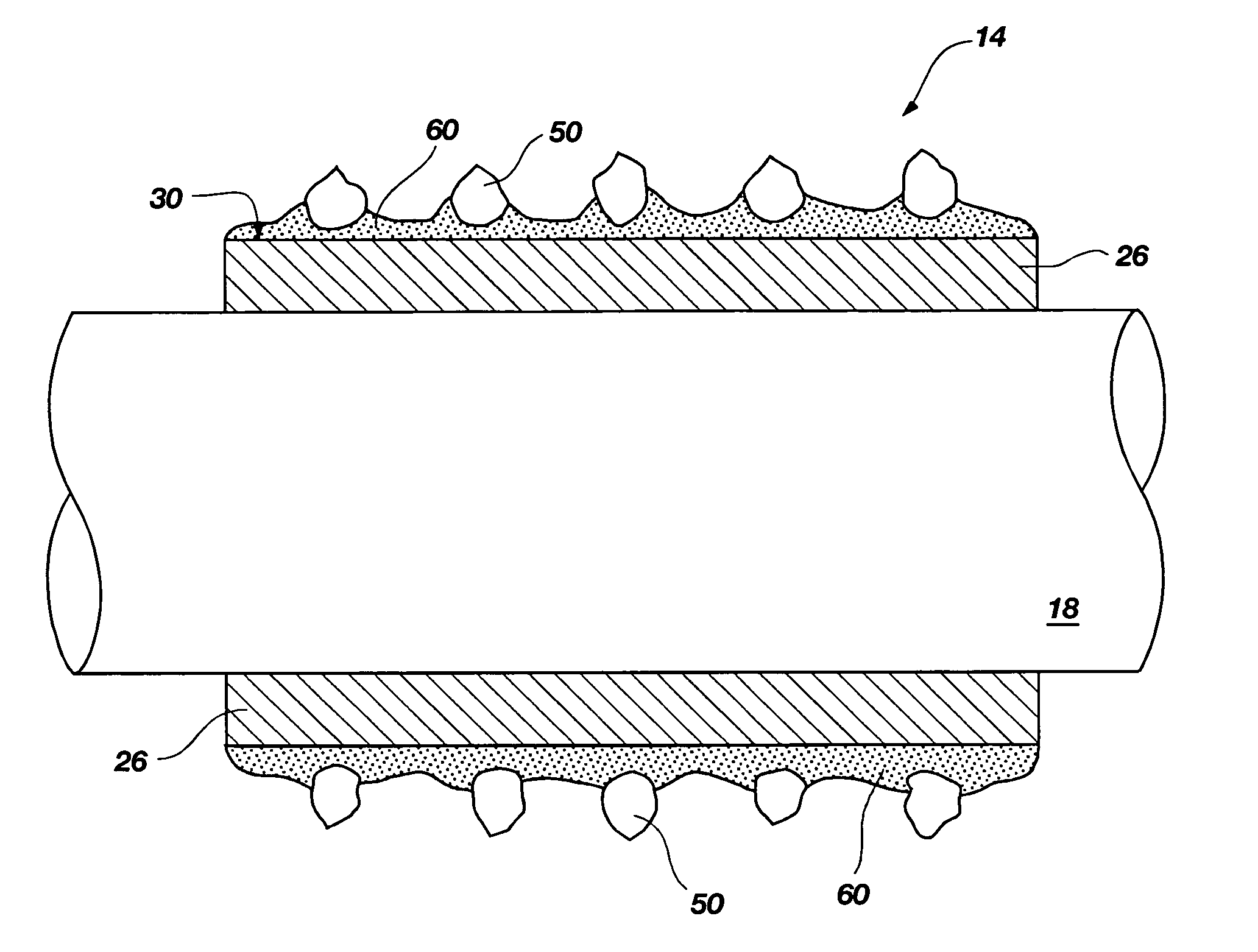

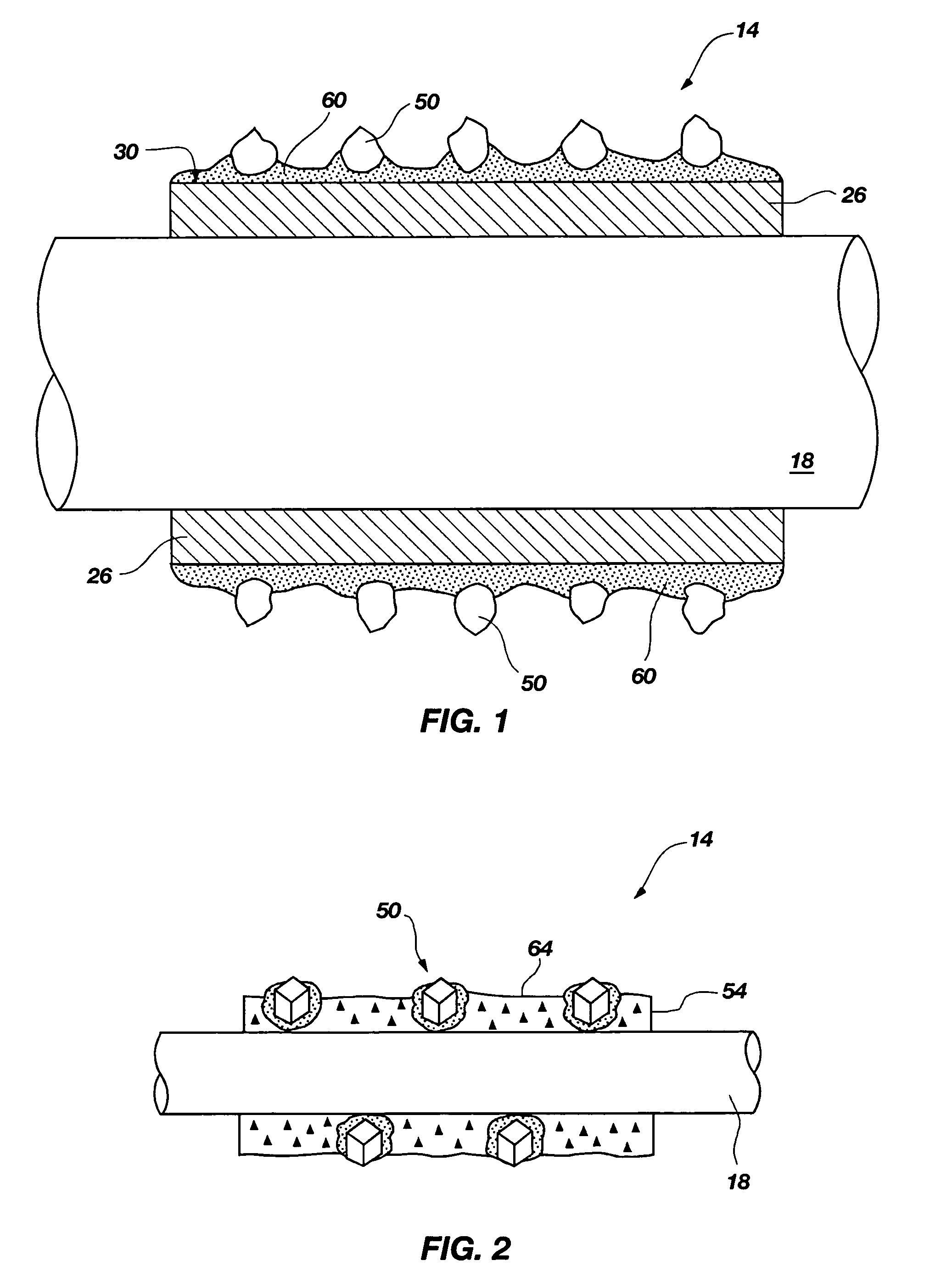

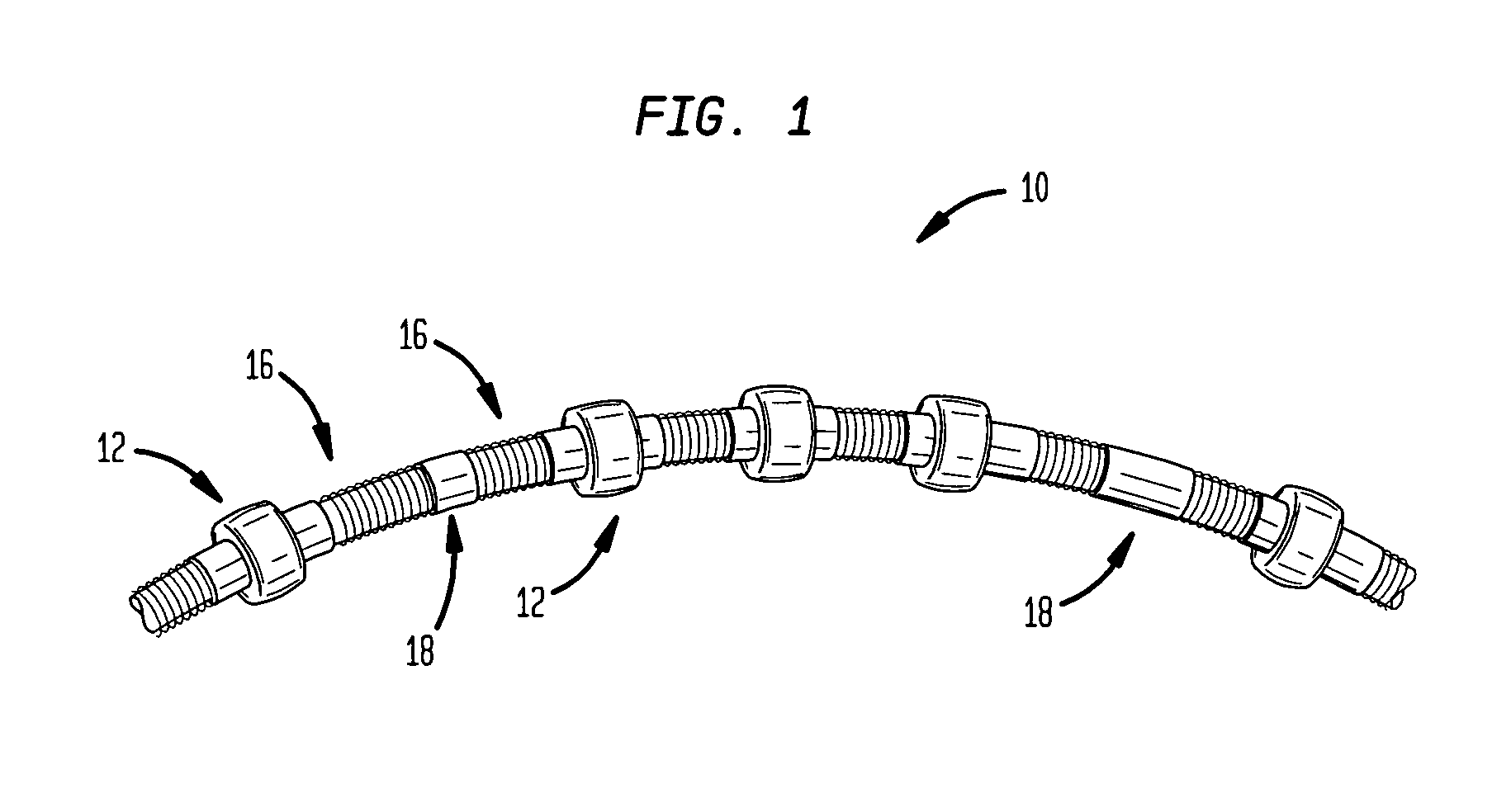

A superabrasive wire saw having a plurality of individual coated superabrasive particles attached to a wire with an organic binder is disclosed and described. The superabrasive particle can be coated with a solidified coating of a molten braze alloy that is chemically bonded to the superabrasive particle. The organic binder can optionally contain filler materials and / or an organometallic coupling agent to improve the retention of coated superabrasive particles. The resulting superabrasive wire saws can be produced having diameters of less than 0.5 mm which significantly reduce kerf loss. Various methods for making and using such a superabrasive wire saw are additionally disclosed and described.

Owner:SUNG CHIEN MIN

Reciprocating wire saw for cutting hard materials

InactiveUS7089925B1Low costIncrease valueBelt grinding machinesMetal sawing toolsEngineeringWire saw

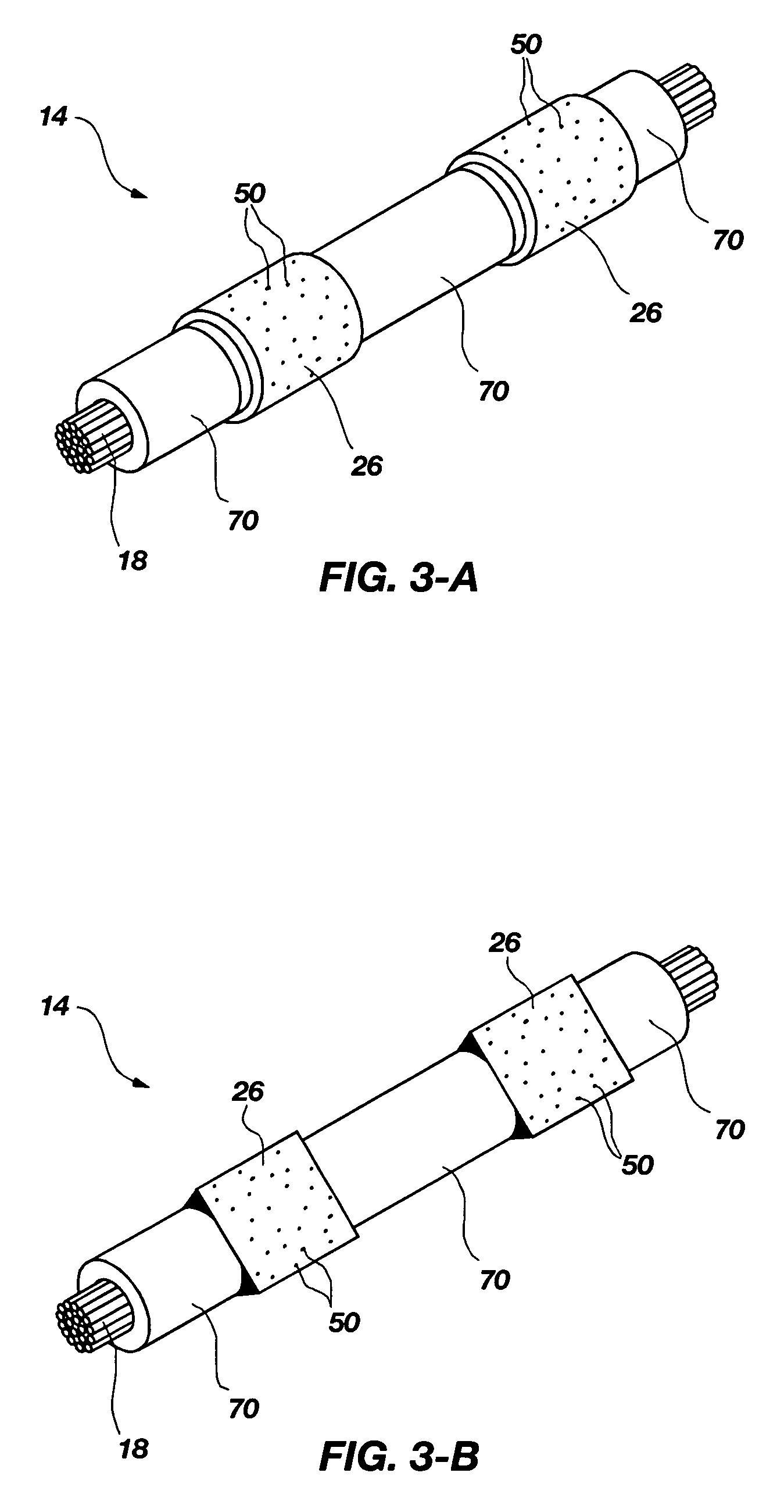

The present invention features a reciprocating wire saw particularly adapted or configured for cutting hard materials. In one aspect, the reciprocating wire saw comprises (a) a flexible wire; (b) a plurality of cutting segments fittable onto the flexible wire, wherein each of the cutting segments comprises an outer surface; and a (c) plurality of superabrasive particles braze bonded onto the outer surface of the cutting segments to form a cutting wire. In another aspect, the reciprocating wire saw comprises a plurality of superabrasive particles braze bonded directly to the wire itself to form a cutting wire. The cutting wire is unique in that it comprises a pre-determined superabrasive particle concentration and is configured to cut various materials, such as granite, in a reciprocating manner.

Owner:KINIK

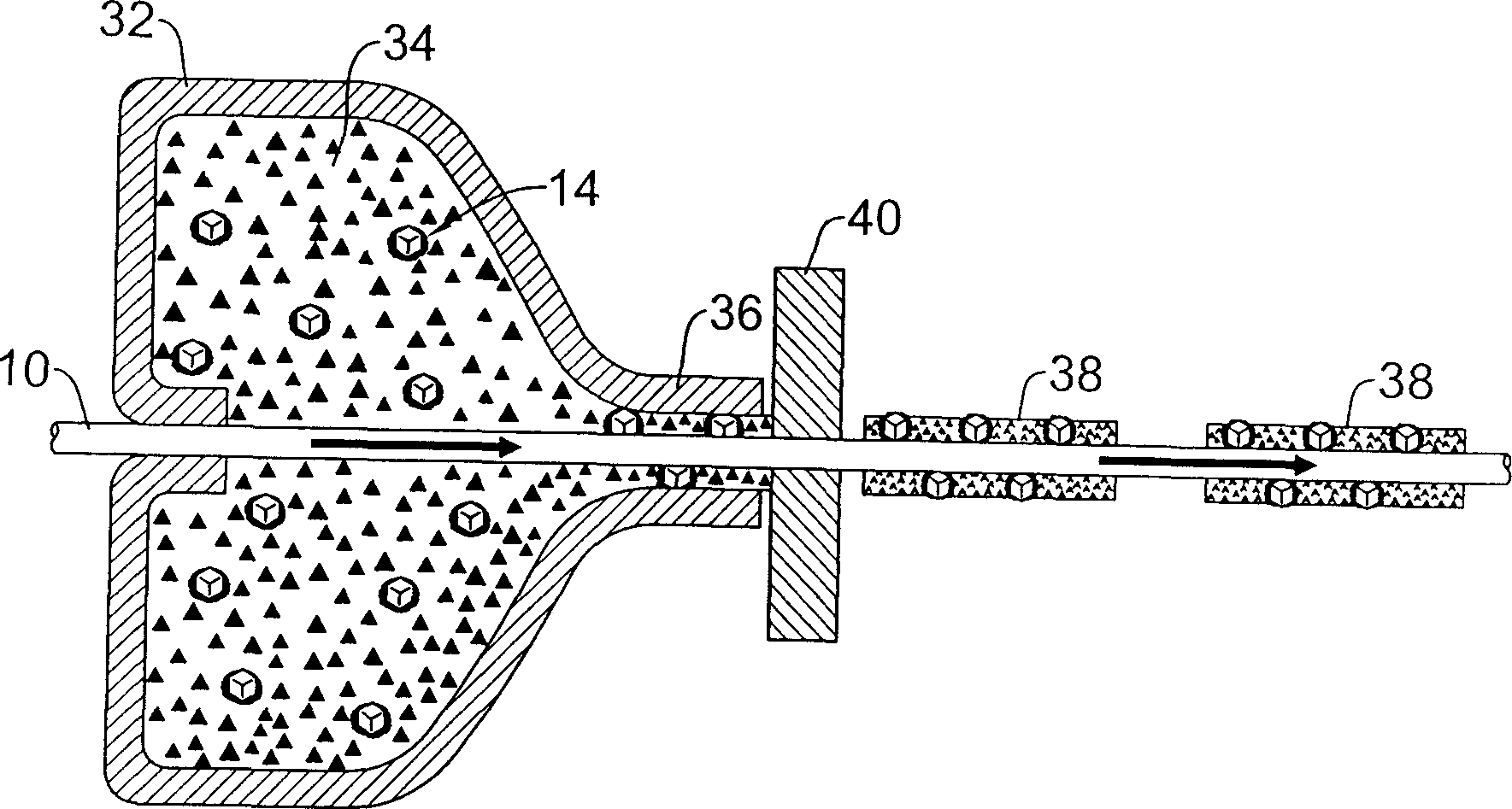

Wire-saw and its manufacturing method

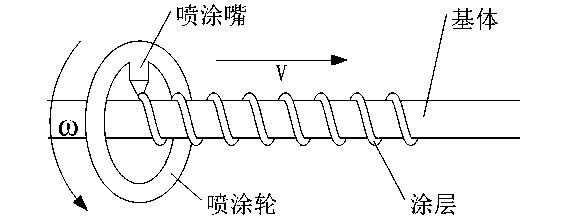

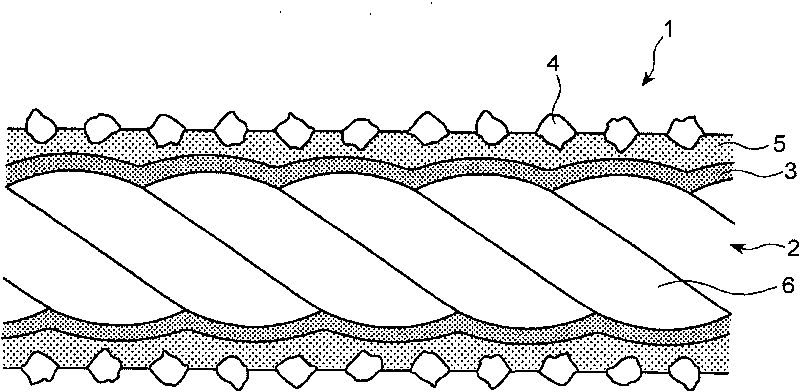

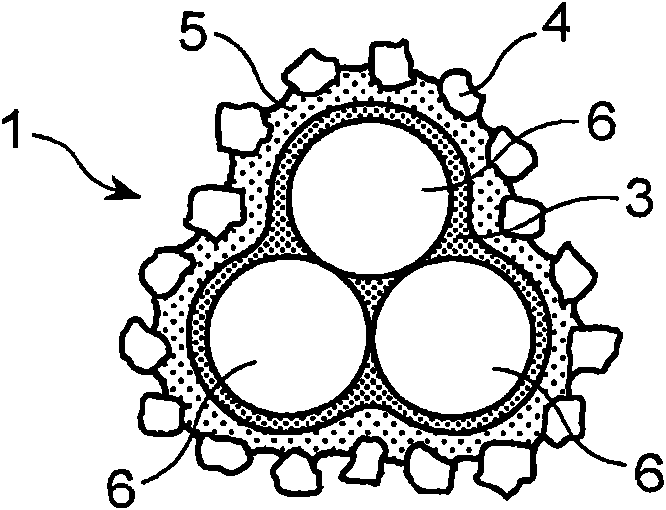

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

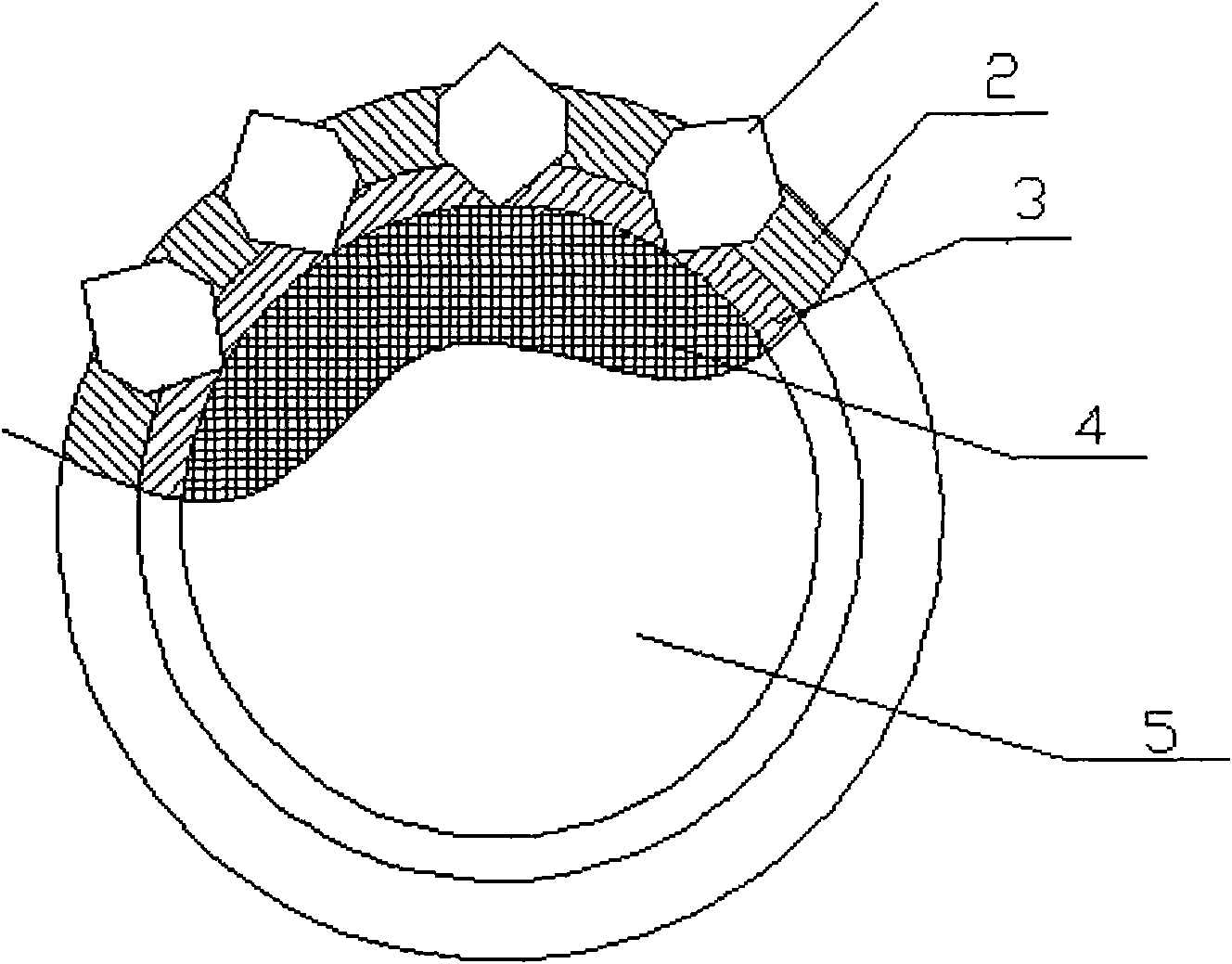

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

Wire Saw

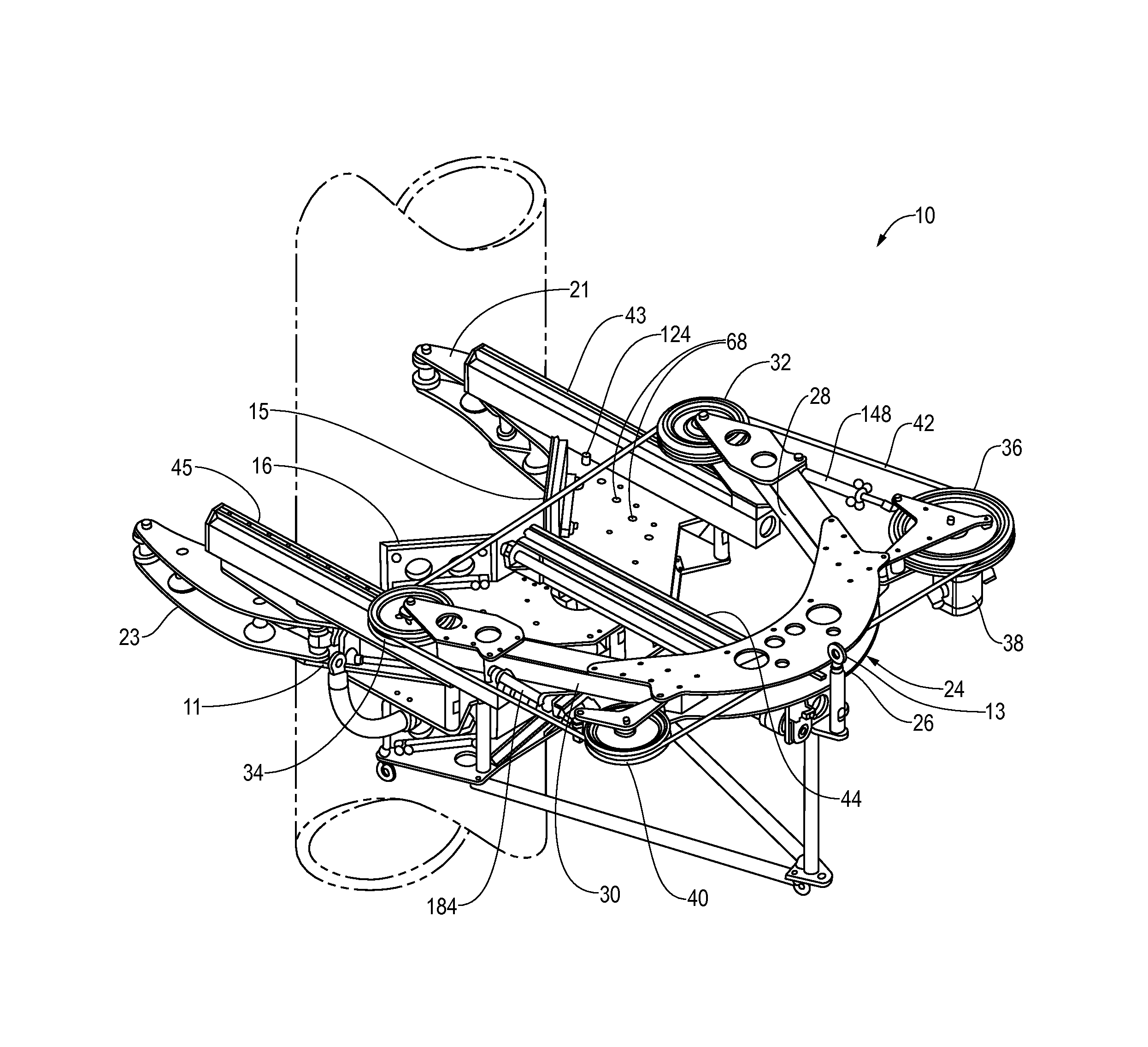

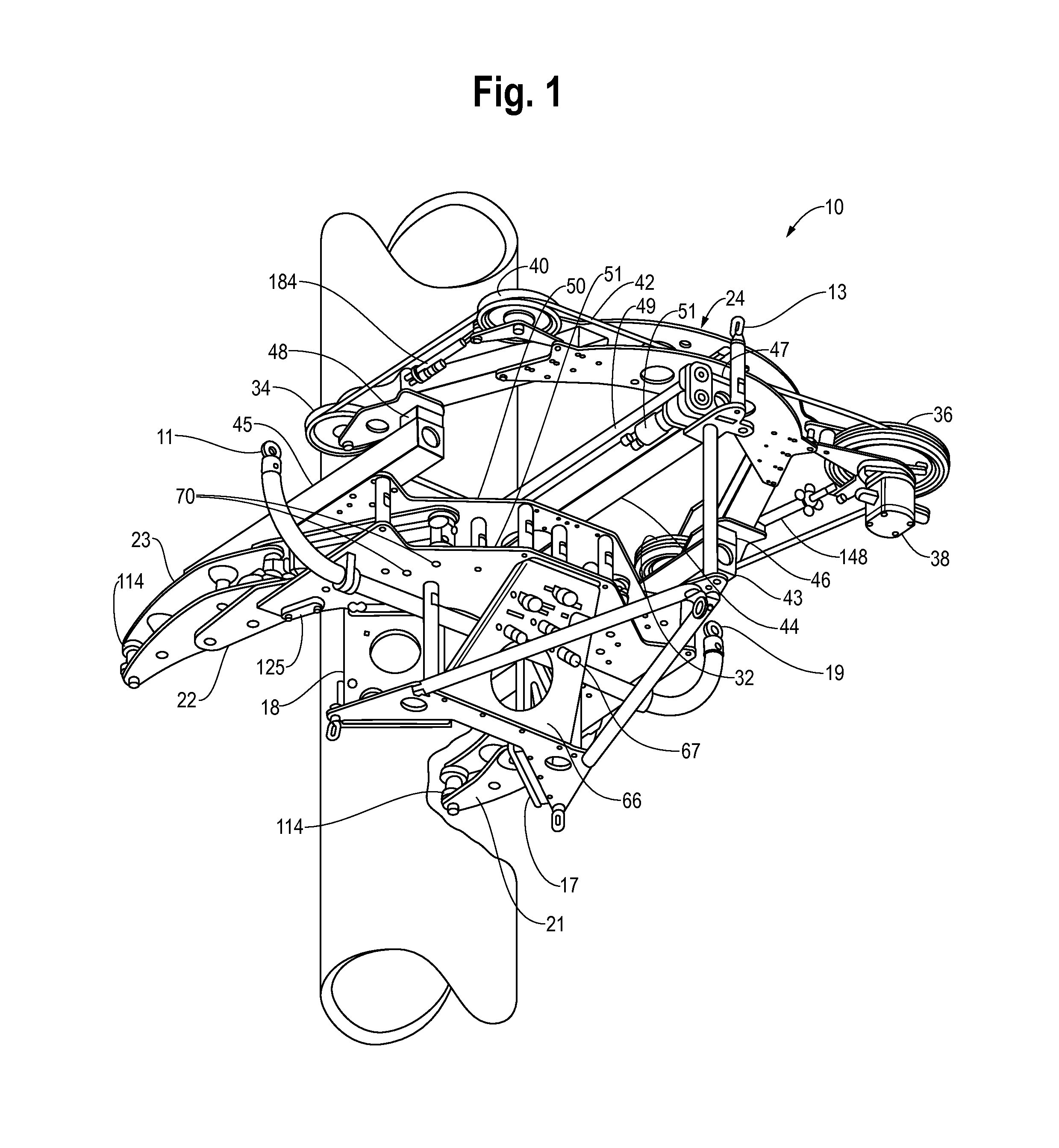

ActiveUS20100186564A1Avoid disconnectionIncrease frictionMetal sawing devicesAutomatic control devicesWire sawDiamond

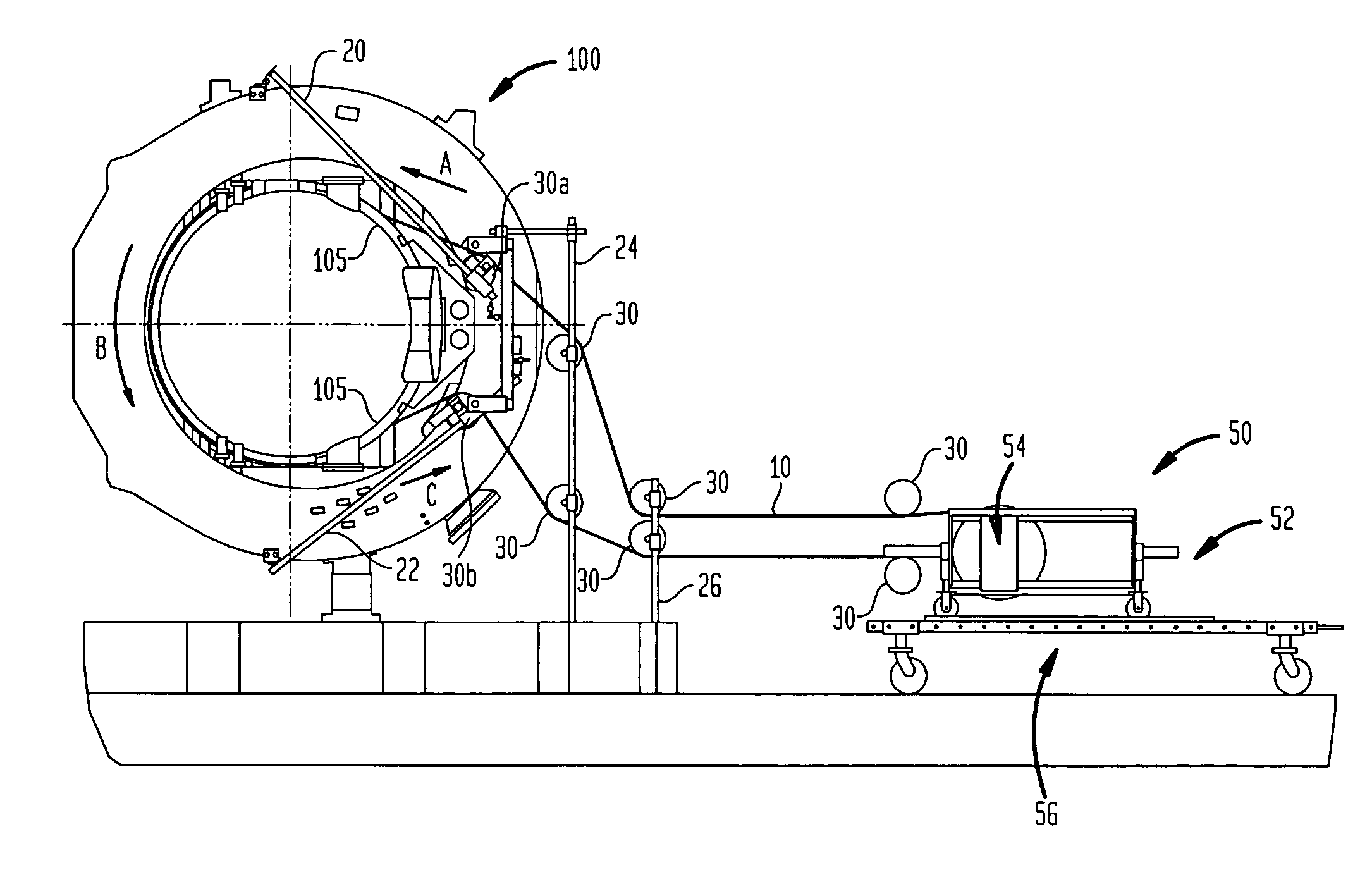

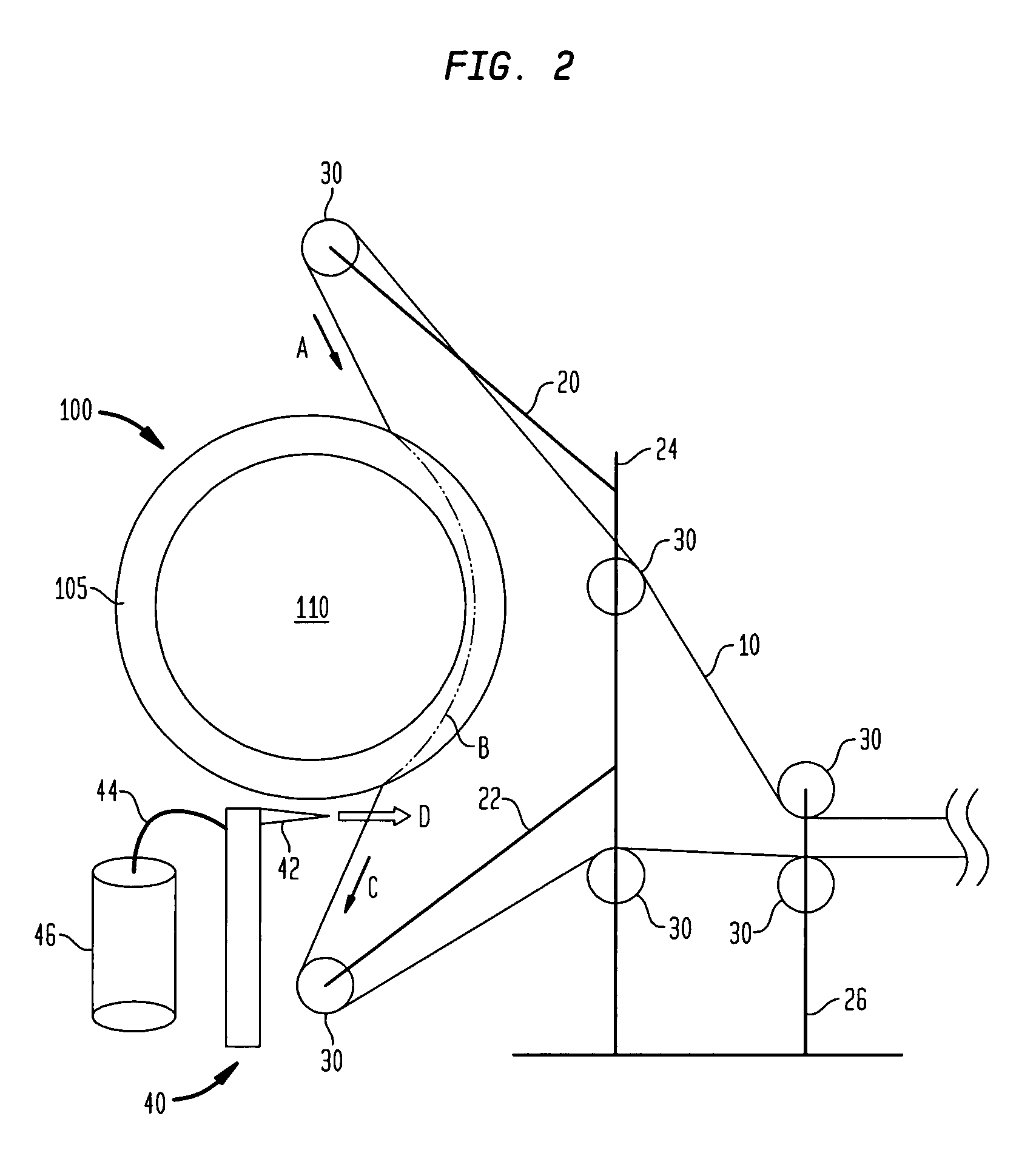

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

Method and apparatus for arthroscopic bone preparation

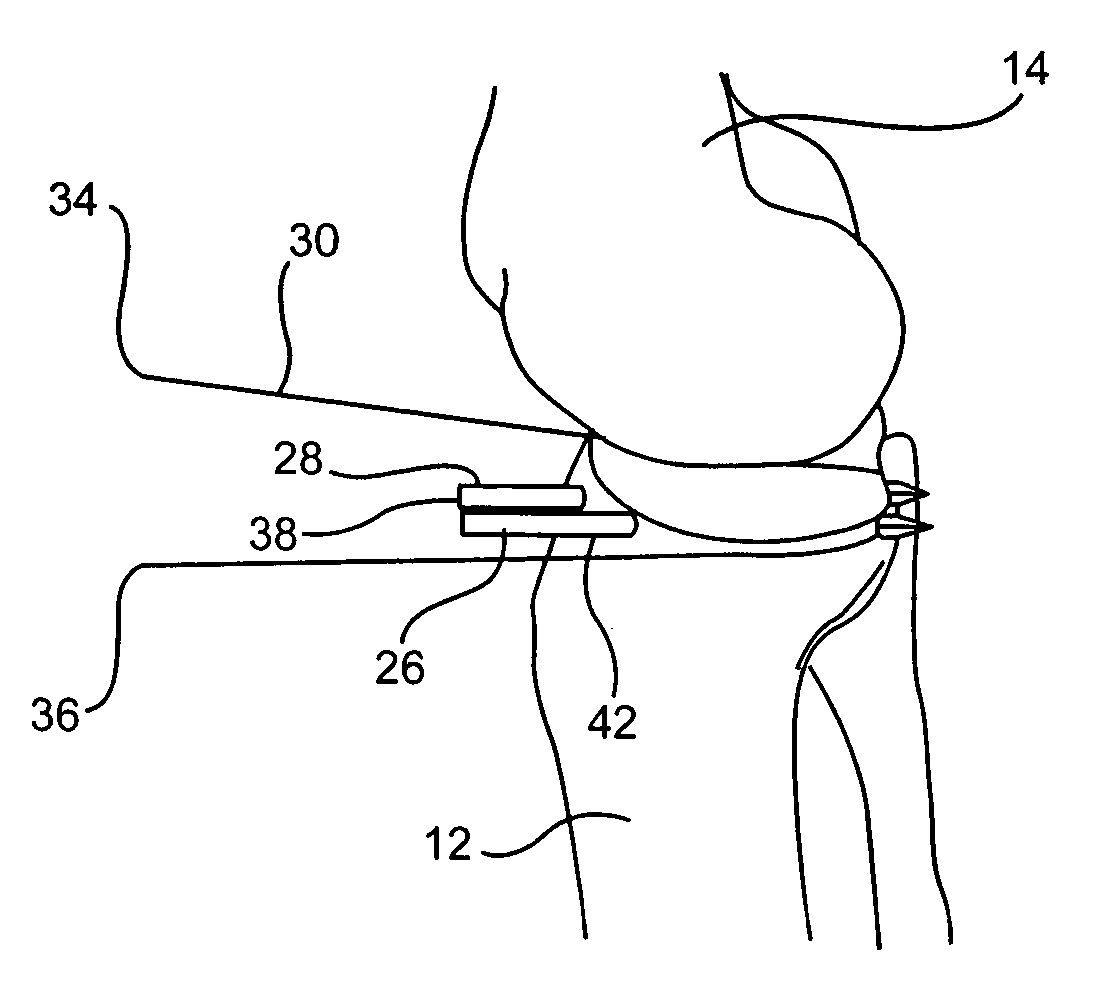

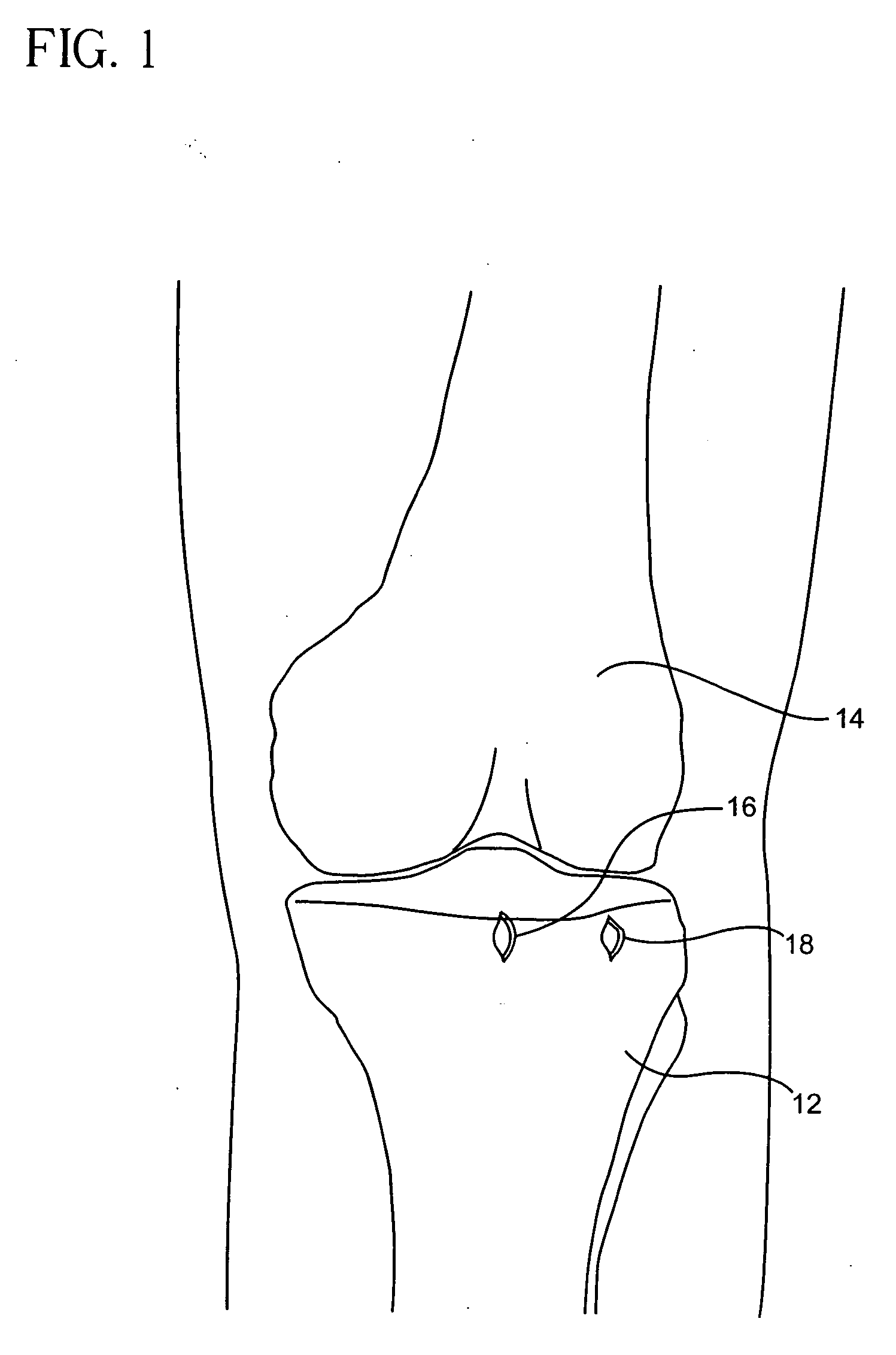

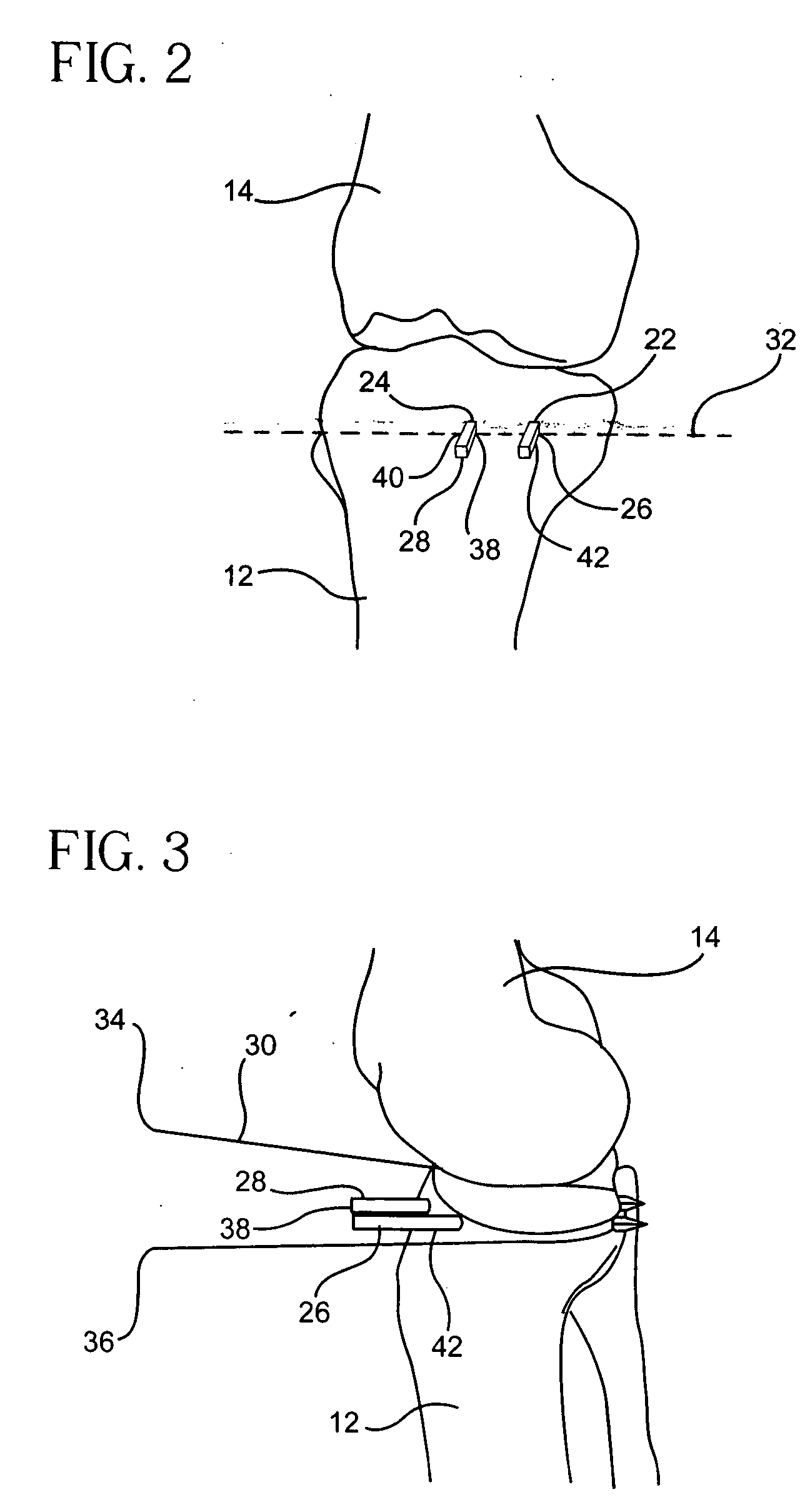

InactiveUS20050216023A1Shorten the timeReduce the risk of infectionJoint implantsNon-surgical orthopedic devicesArthroscopic procedurePlane of reference

A guide system for resecting a bone through incisions of the type utilized for arthroscopic procedures is provided. The guide system comprises a first alignment pin, a second alignment pin and a wire saw. The first alignment pin is configured to be inserted through a first incision into a bone in a first orientation. The second alignment pin is configured to inserted through a second incision into the bone in a second orientation. The first alignment pin and the second alignment pin are configured and oriented to define a resection plane of reference through which the bone is to be resected and the wire saw is configured to be inserted through the first and second incisions to be guided by the first and second alignment pins while being moved to resect the bone.

Owner:DEPUY PROD INC

Ultrasonic wire cutting saw for hard-fragile material processing

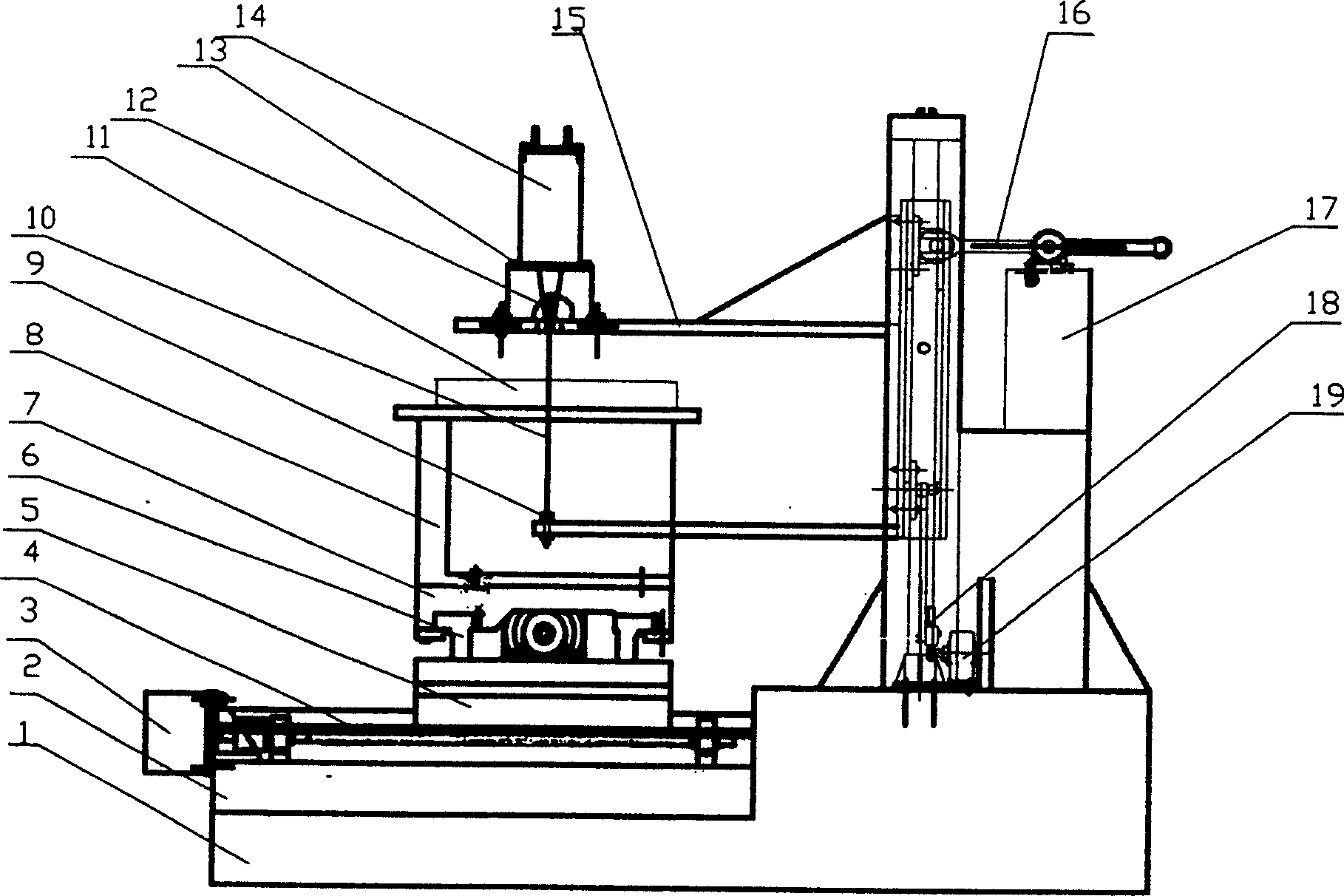

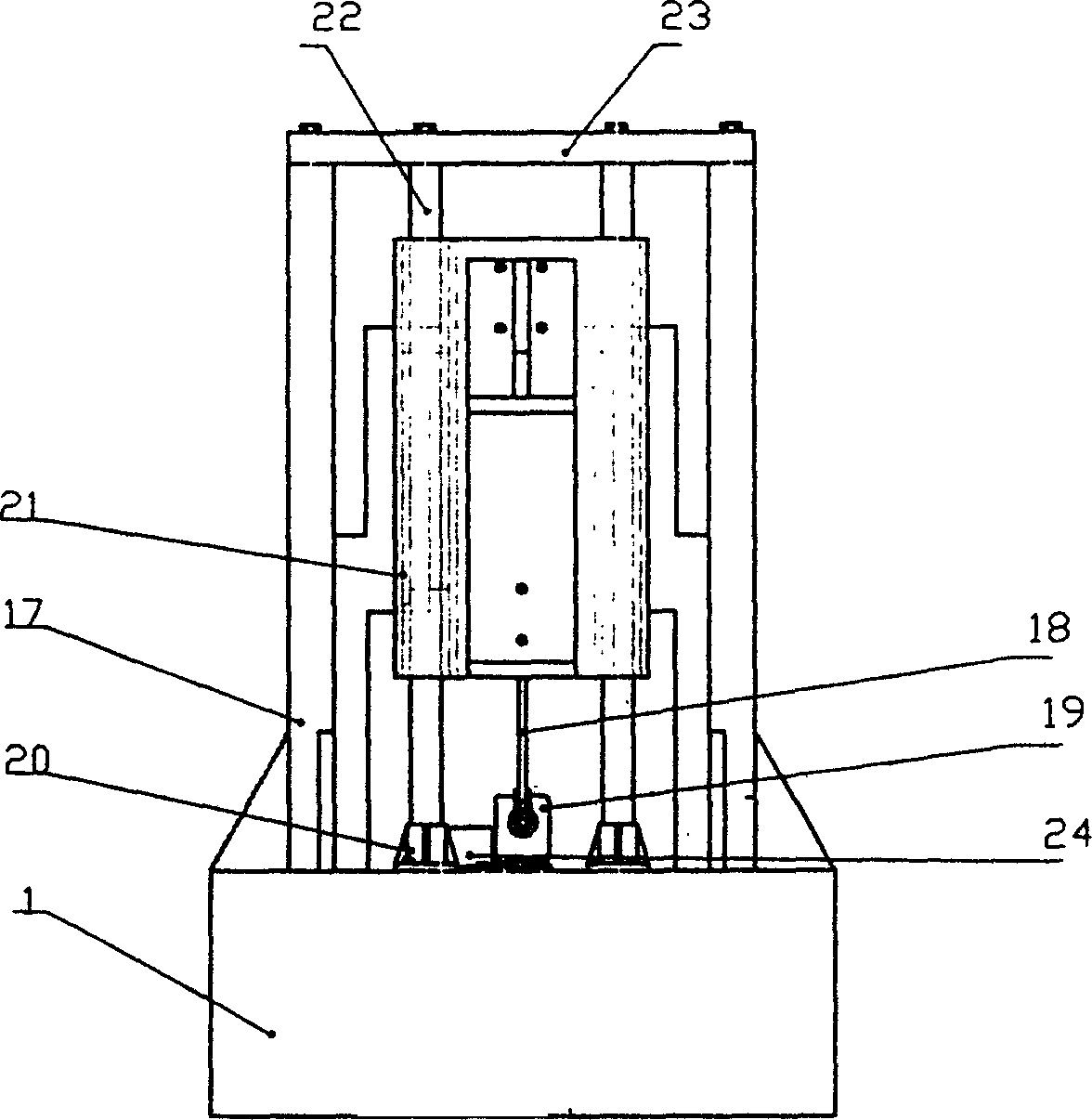

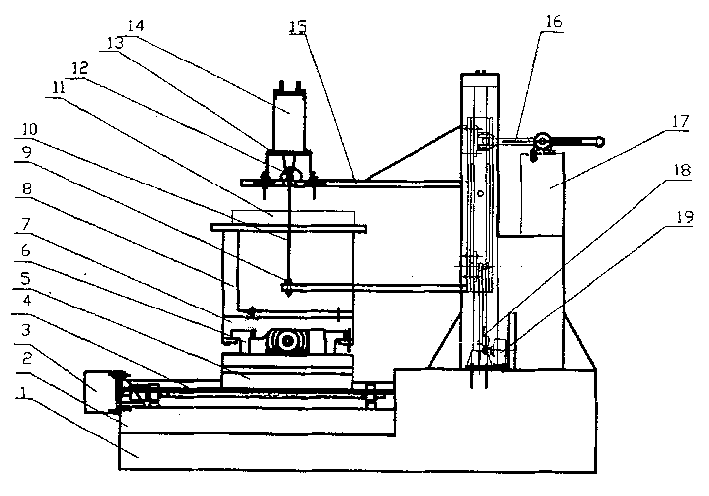

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

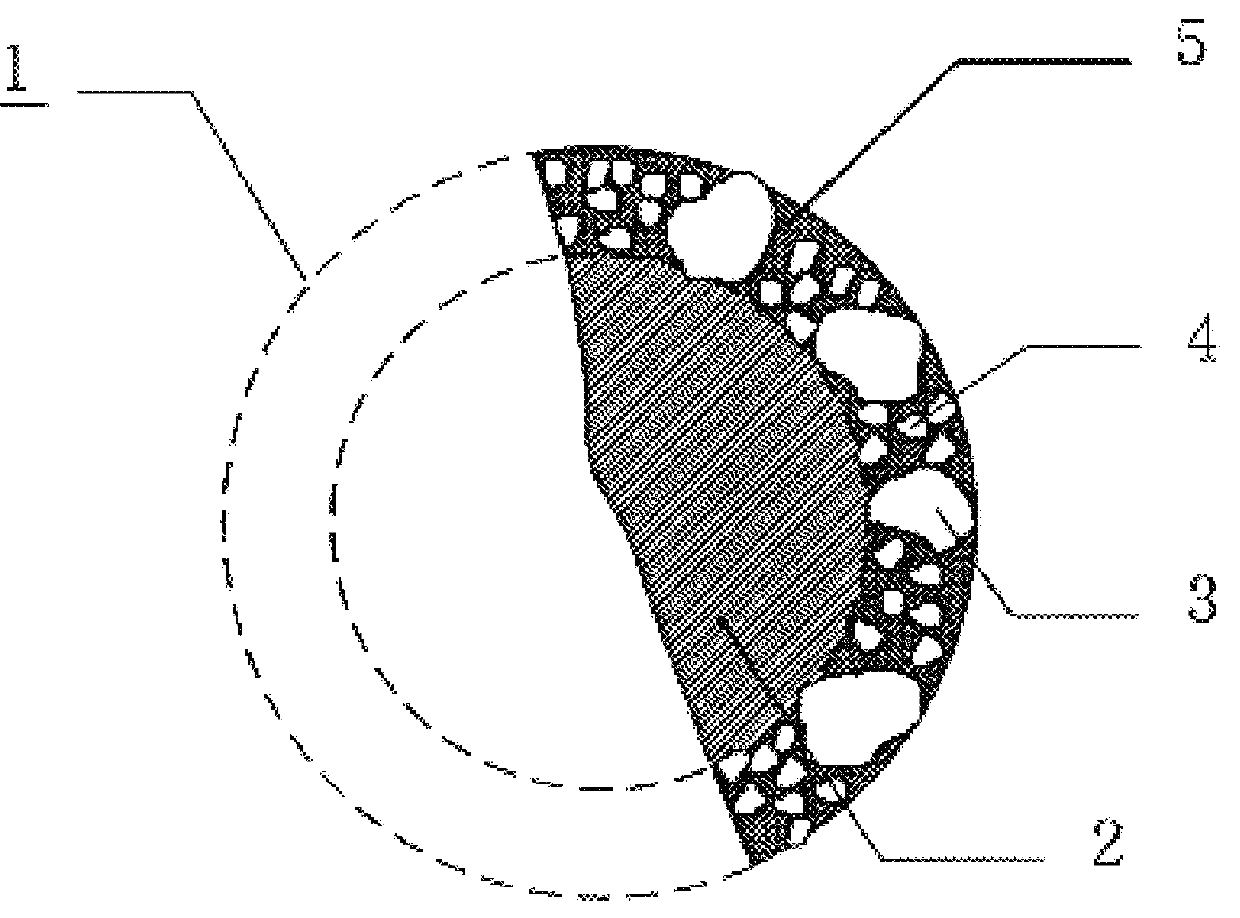

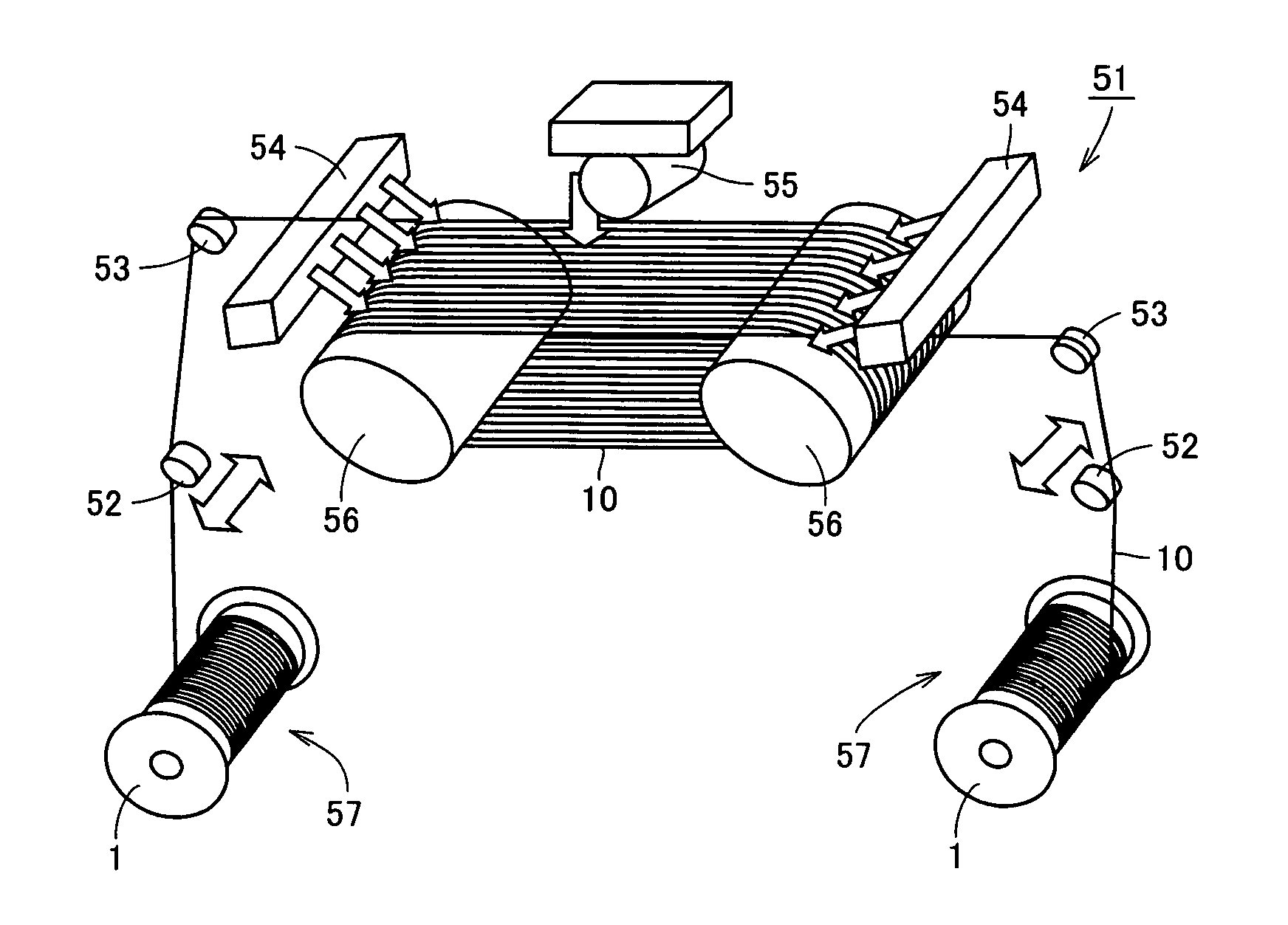

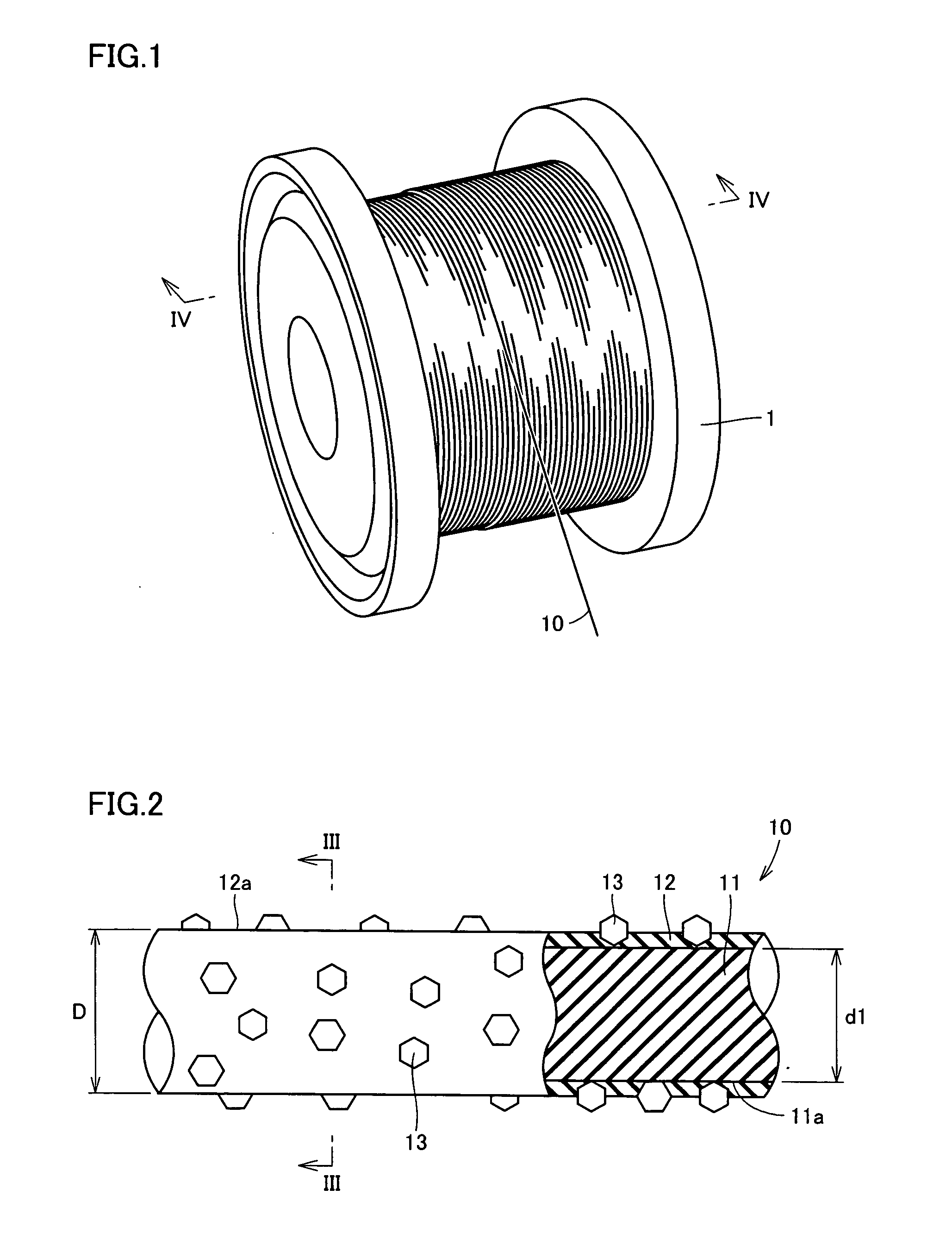

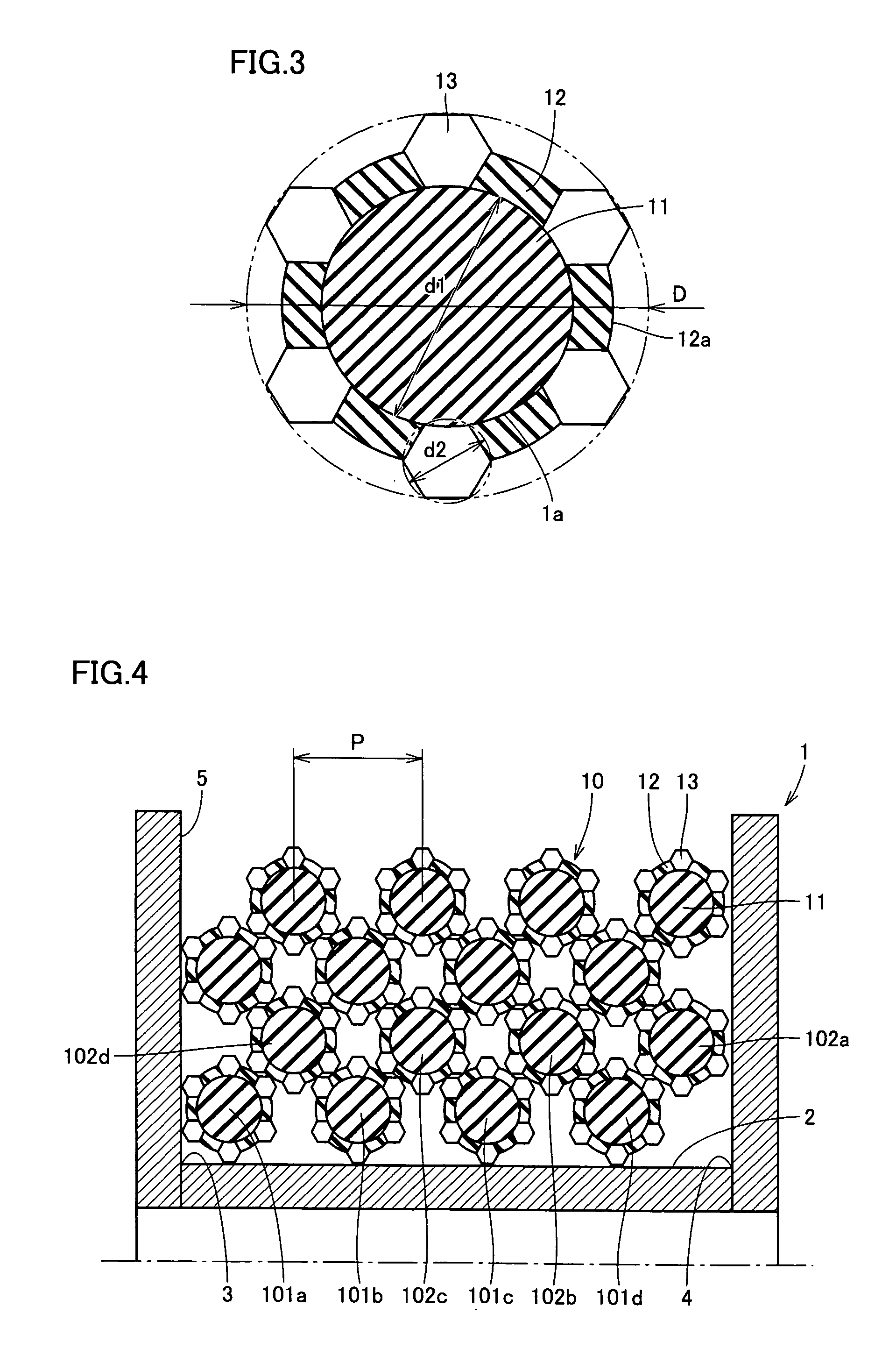

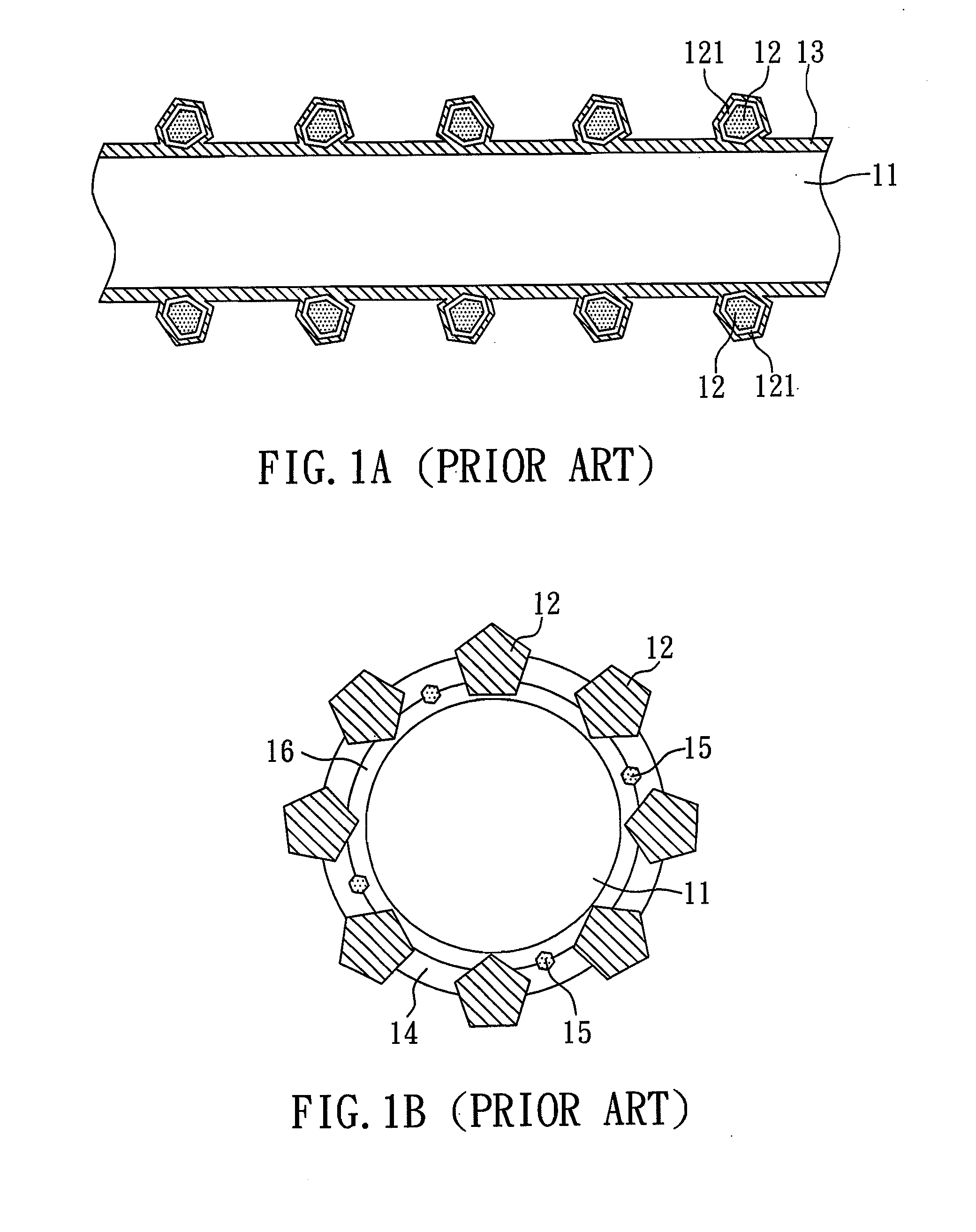

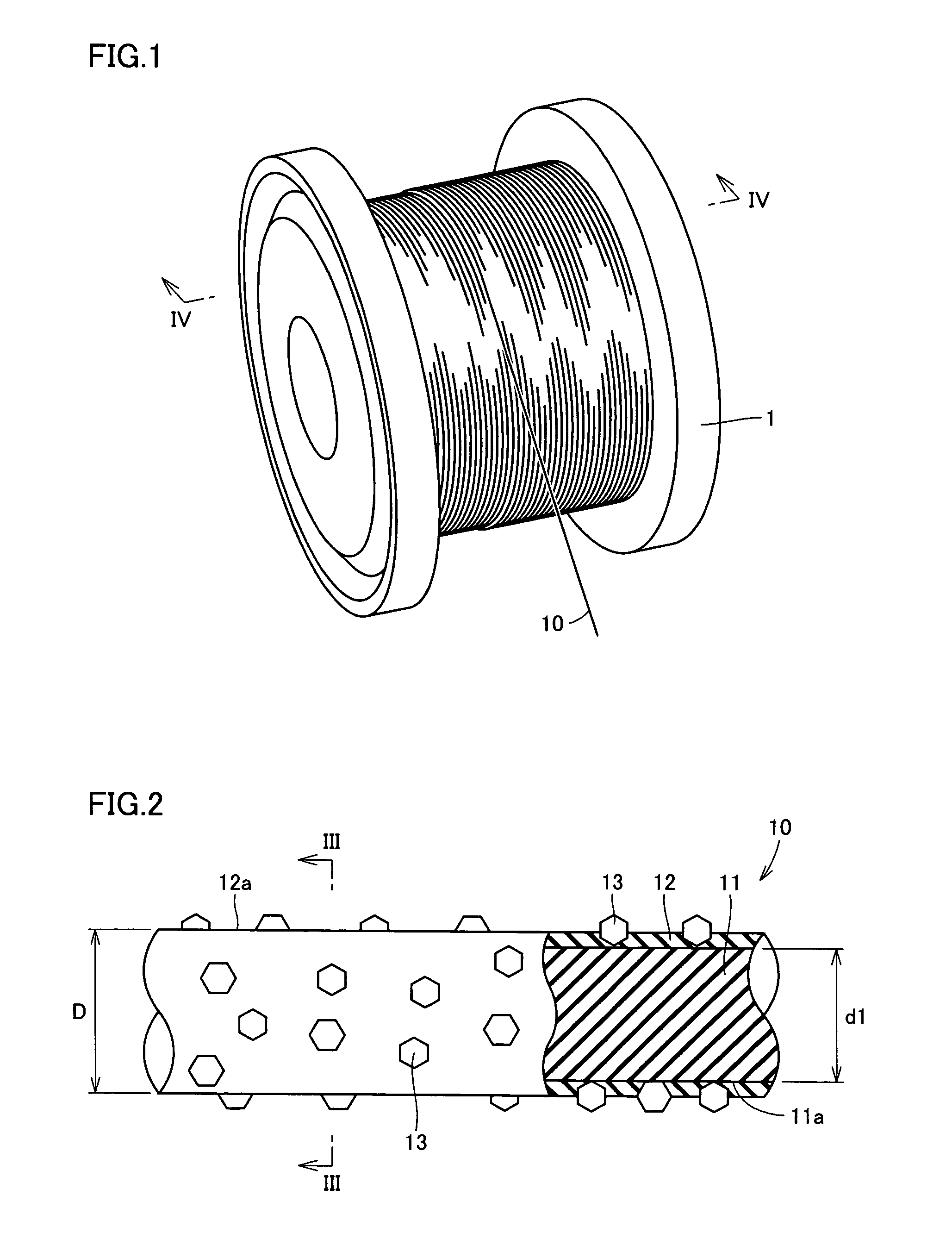

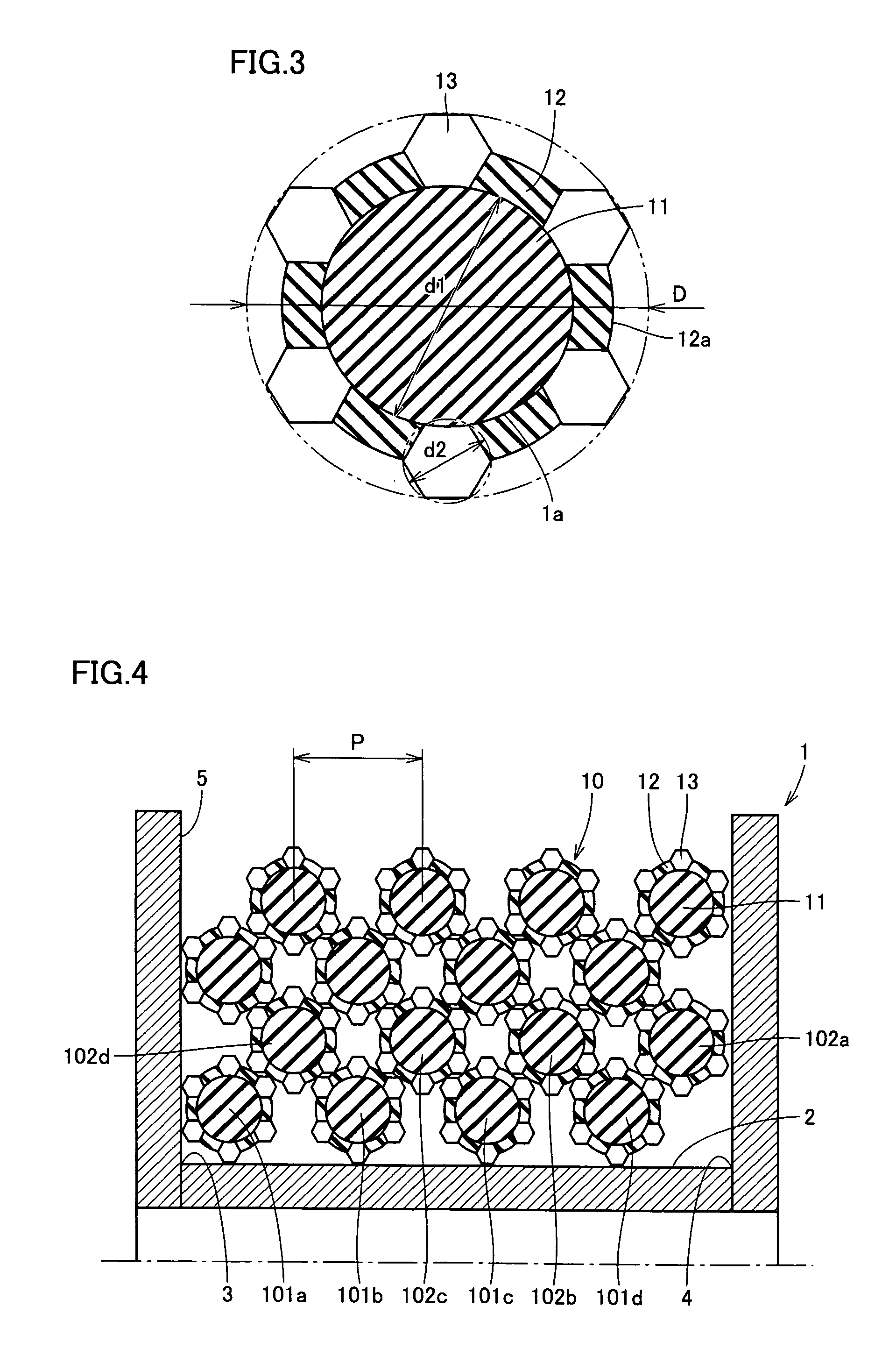

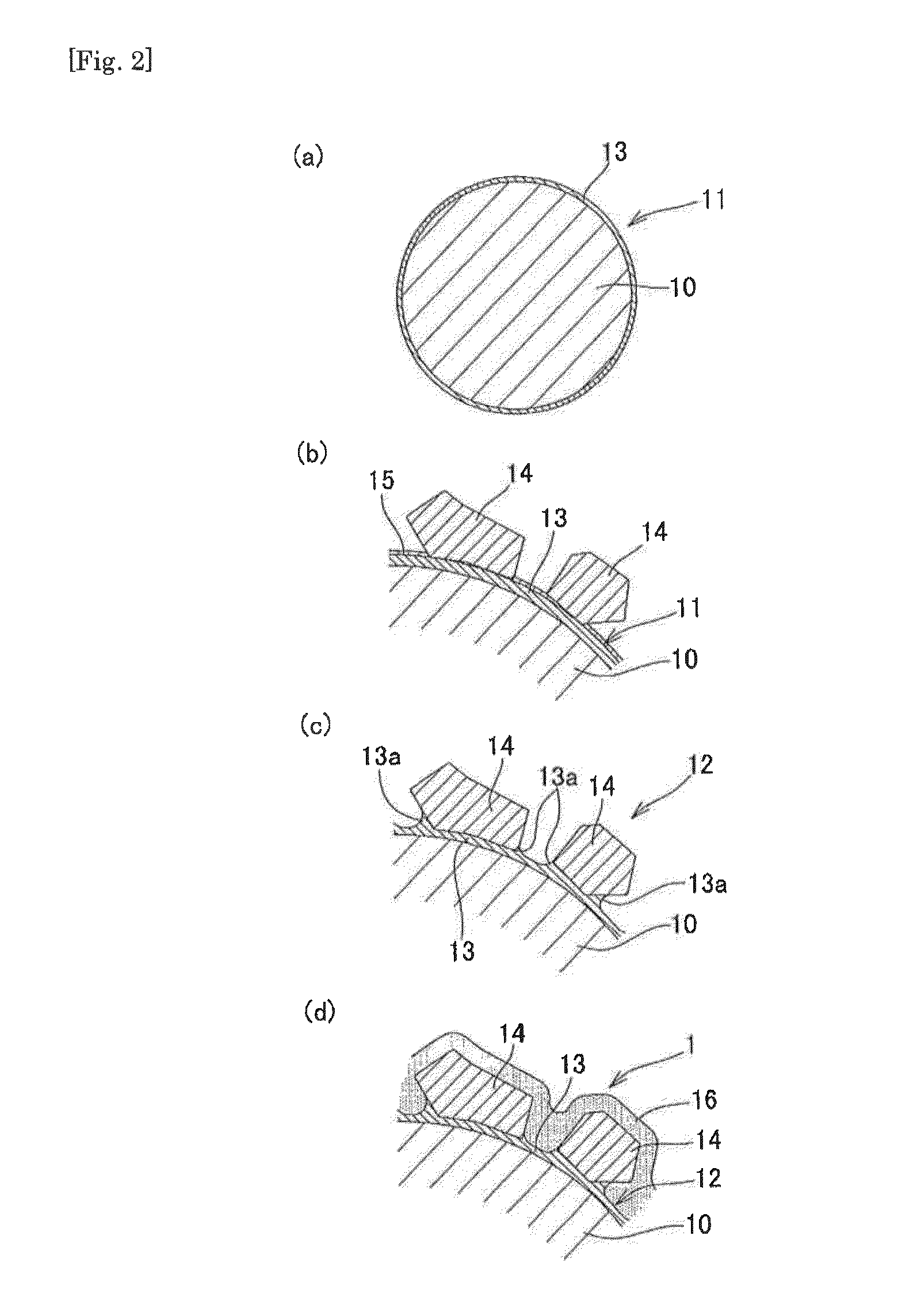

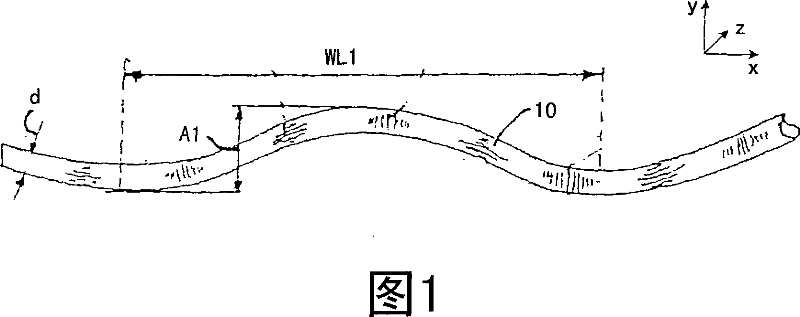

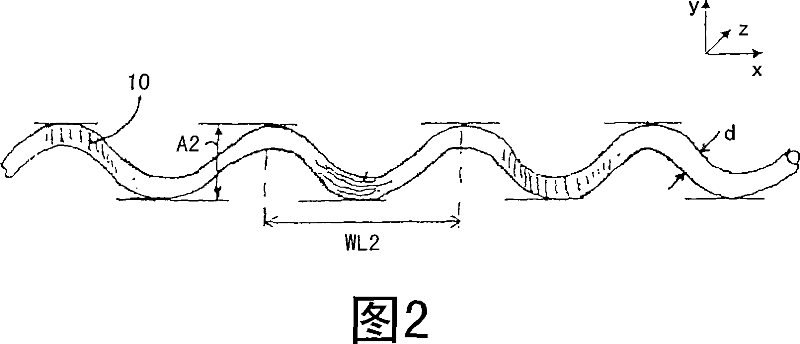

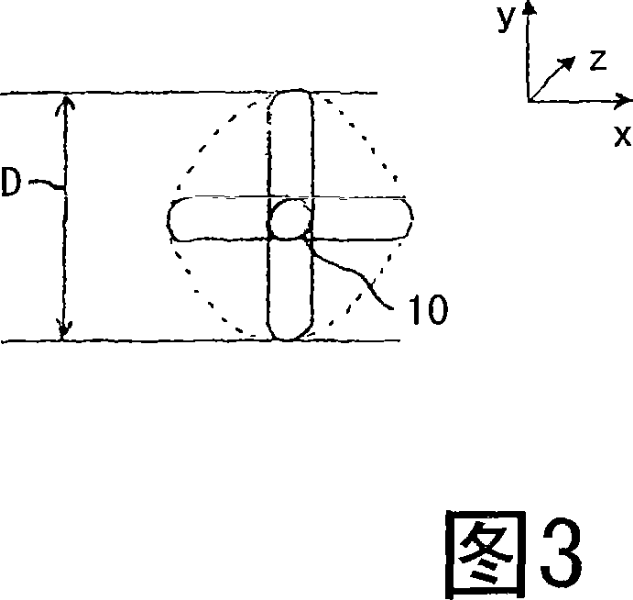

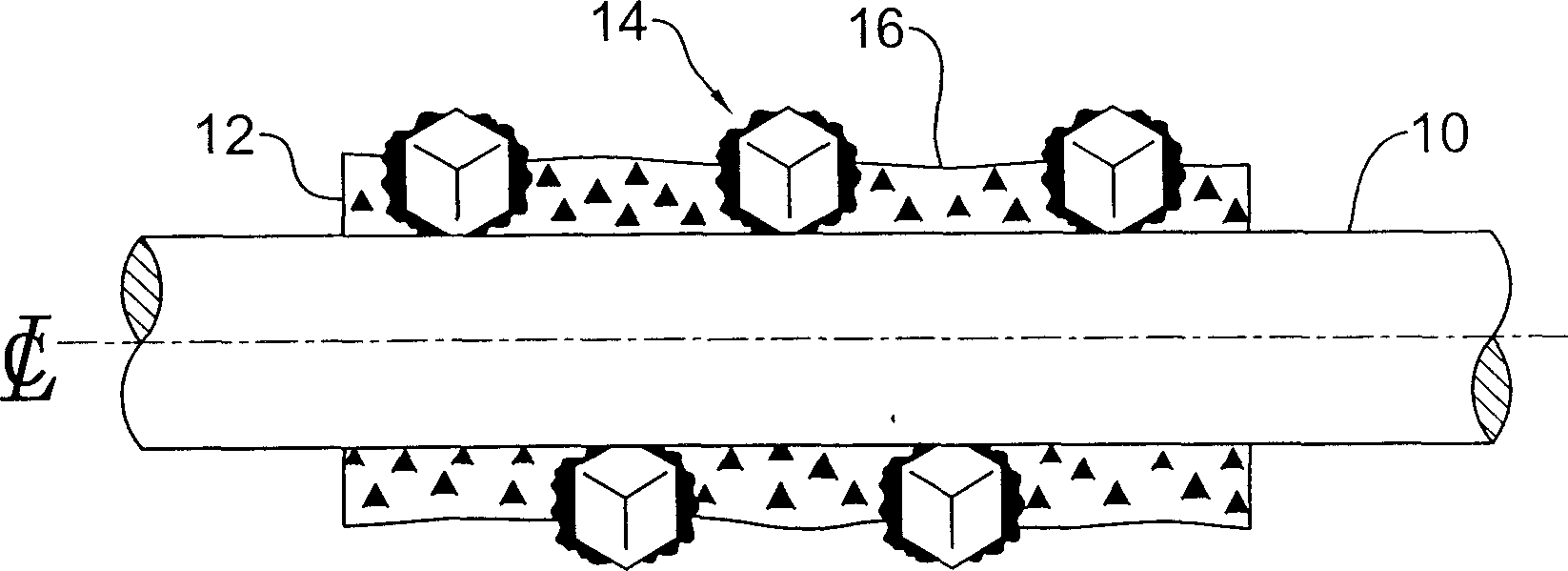

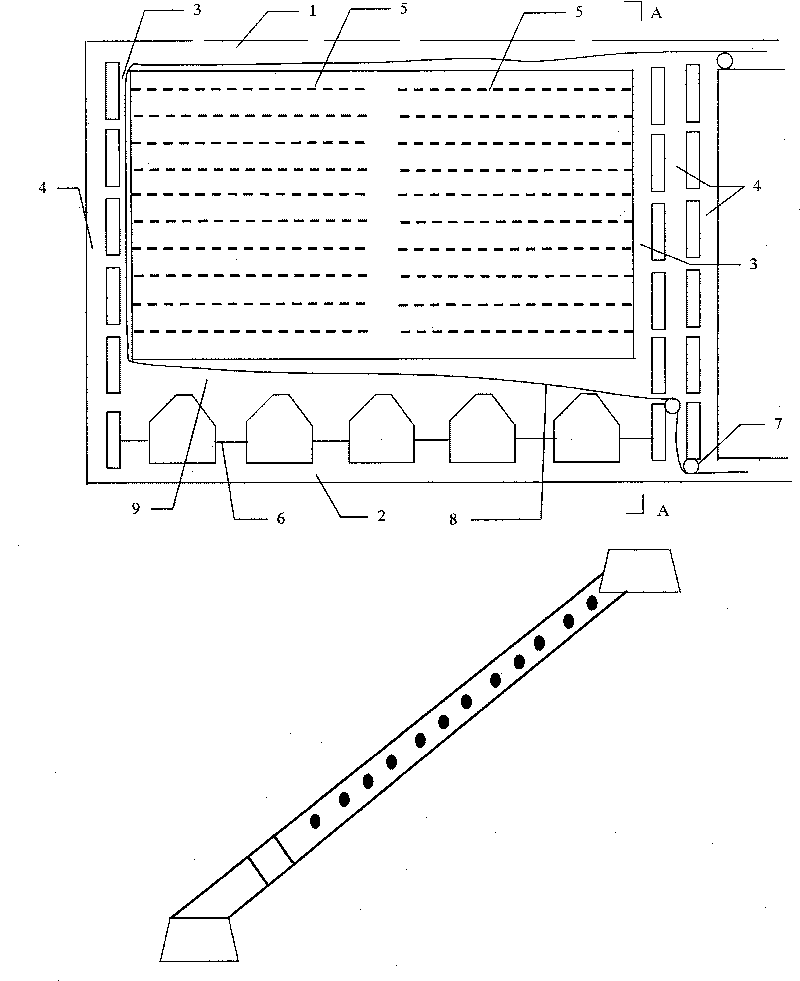

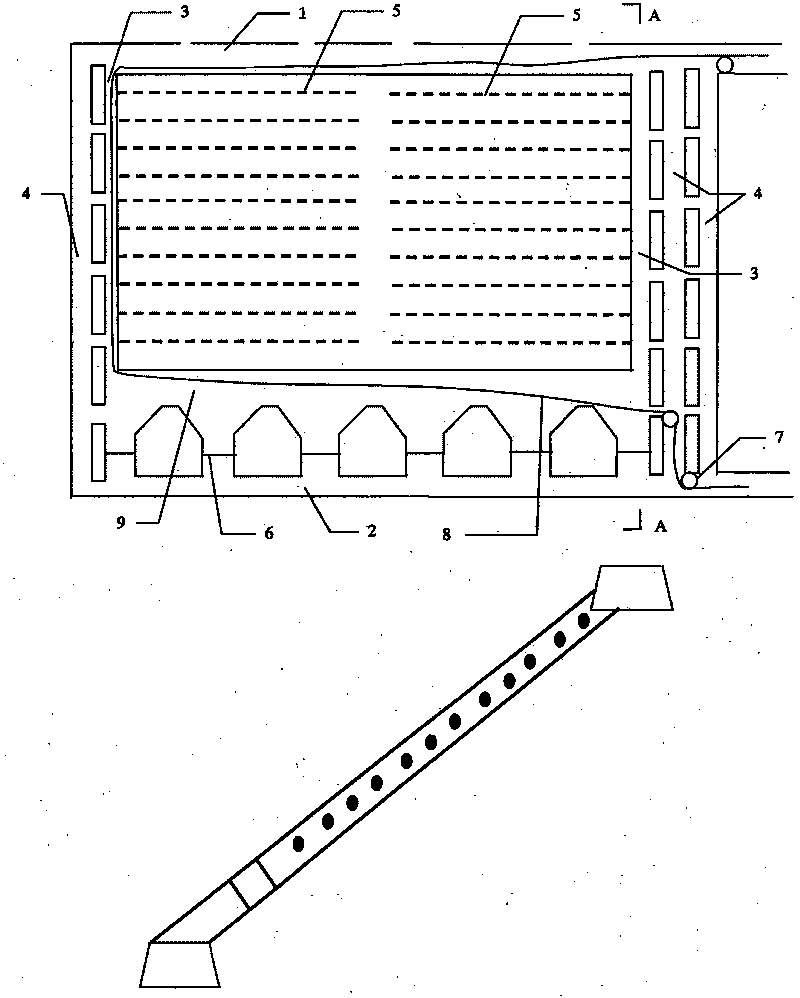

Super abrasive grain wire saw winding structure, super abrasive grain wire saw cutting device, and super abrasive grain wire saw winding method

InactiveUS20070023027A1Friction can be so intenseDamage to materialMetal sawing devicesEdge grinding machinesConductor CoilWire saw

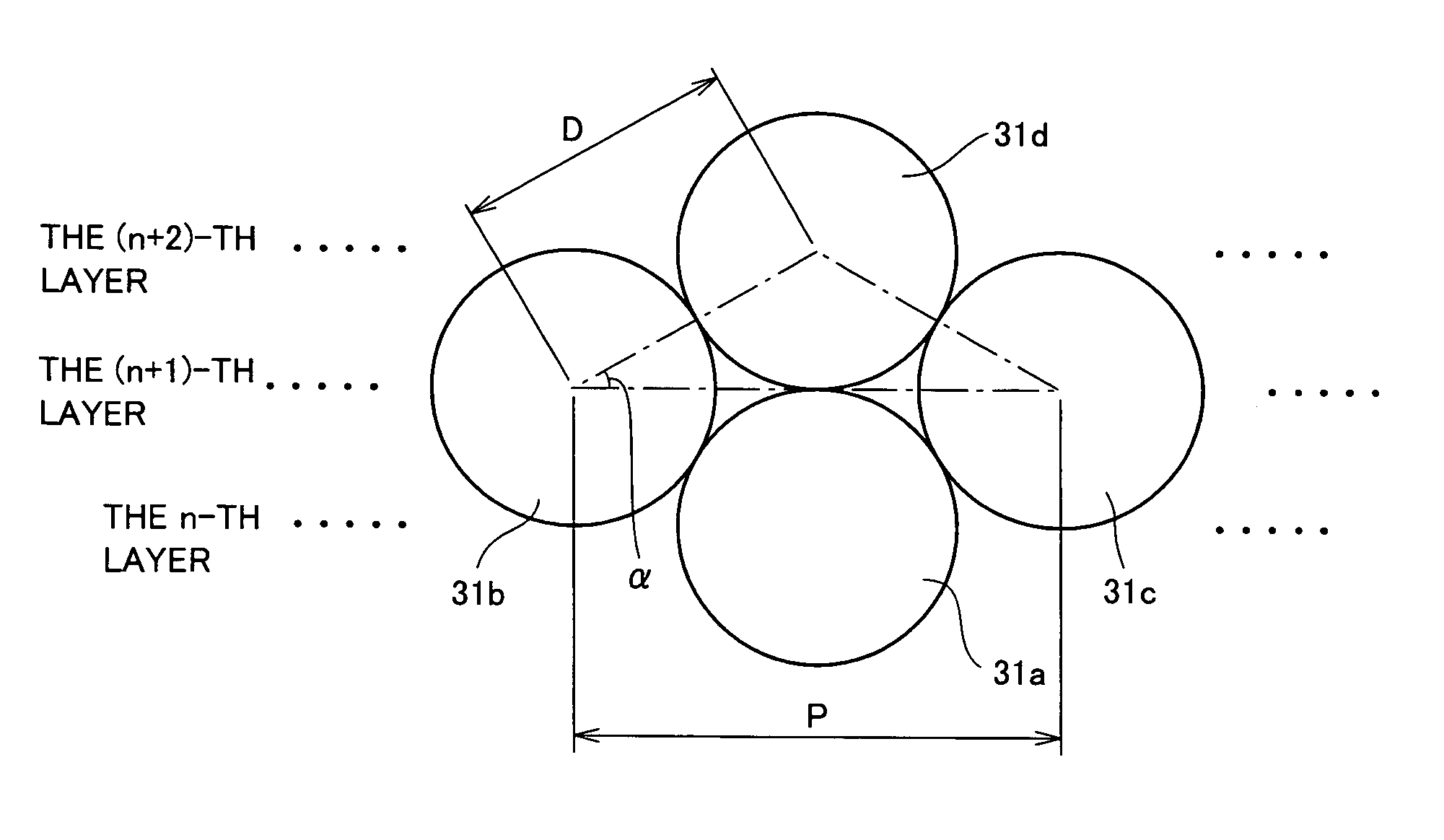

A superabrasive wire saw-wound structure includes a superabrasive wire saw (10) formed with an average diameter D and a reel (1). The superabrasive wire saw (10) includes a core wire (11), a bonding material (12) surrounding a surface of the core wire (11), and a plurality of superabrasive grains (13) bonded to the surface of the core wire (11) with the bonding material (12). The reel (1) includes a peripheral surface (2) having one end (3) and the other end (4). The superabrasive wire saw (10) which is to be unreeled successively toward a workpiece is wound around the peripheral surface (2) reciprocatingly between the one end (3) and the other end (4) to be multi-layered. A pitch P for winding the superabrasive wire saw (10) around the peripheral surface (2) between the one end (3) and the other end (4) satisfies a relation of D<P<2D. According to the present invention, there can be provided a superabrasive wire saw-wound structure, a cutting device with a superabrasive wire saw, and a method of winding a superabrasive wire saw which can reduce damage to a bonding material and falling of a superabrasive grain.

Owner:ALLIED MATERIAL

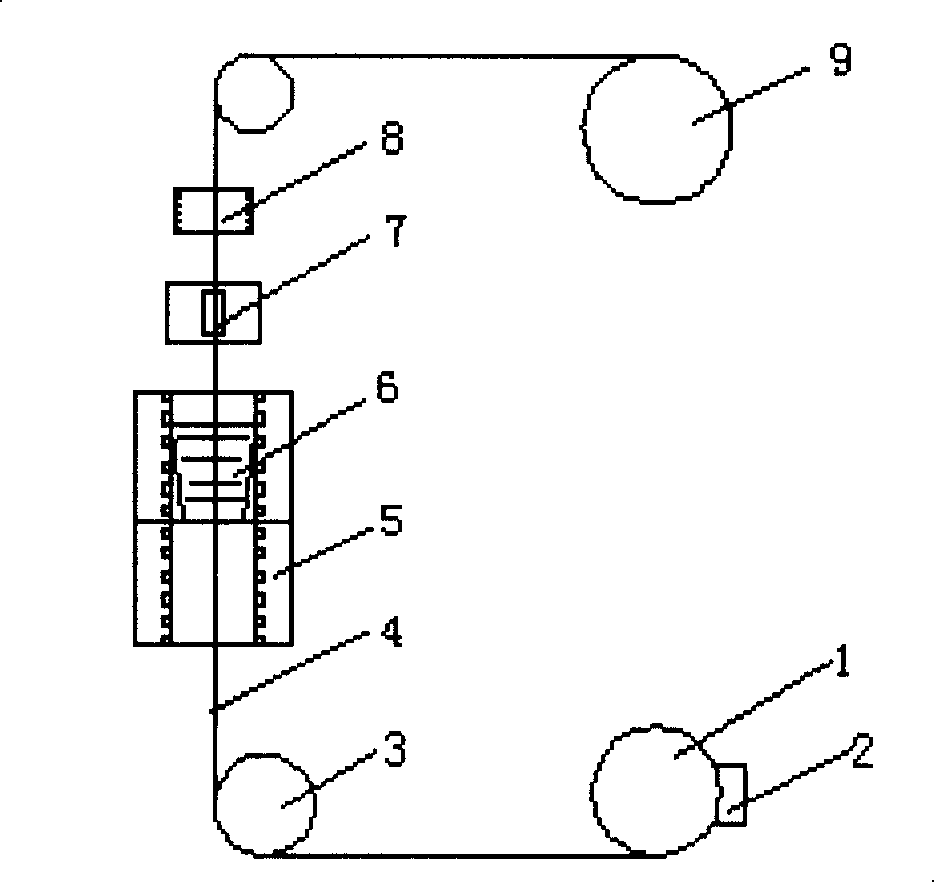

Wire saw for cutting hard and fragile materials and manufacturing method thereof

InactiveCN101564828AReduce sheddingImprove bindingAbrasion apparatusGrinding machinesCopper platingUV curing

The invention relates to a wire saw for cutting hard and fragile materials and a manufacturing method thereof. The wire saw is fixed with an grinding material on a core wire through a bonding agent and is characterized in that the bonding agent consists of an inner layer UV resin bonding agent and an outer layer heat reactive resin bonding agent; and the grinding material is evenly and continuously distributed in a monolayer mode around the core wire, partial grinding material is embedded in the UV resin bonding agent, other partial grinding material is exposed outside the heat reactive resin bonding agent to form an exit lip, and the rest part is enwrapped by the outer layer heat reactive resin. The grinding material adopts a diamond or CBN adopting surface metal plating; and the core wire adopts a copperized music wire. The manufacturing method is performed continuously and quickly according to the following steps: under the traction of a driving device, setting out the core wire continuously through a wire plate, surface preparation, cleaning, drying, coating with the inner layer UV resin bonding agent, grinding material cementation, UV curing, coating with the outer layer heat reactive resin bonding agent, thermocuring and drawing in a cable to form a plate. The wire saw and the method solve the problem of driving aspects before cured resin is completely cured, and can effectively solve the problem that the grinding material in the prior art is easy to agglomerate.

Owner:NANJING NORMAL UNIVERSITY

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

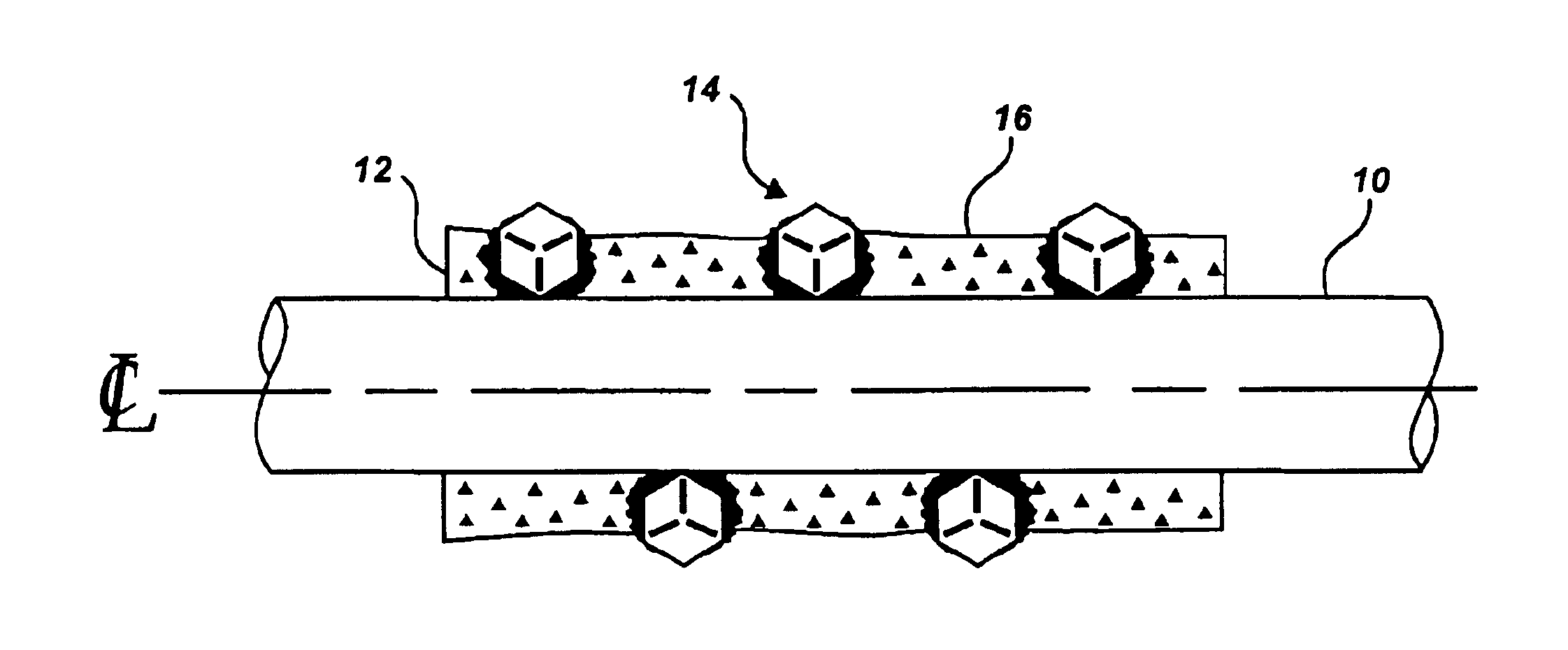

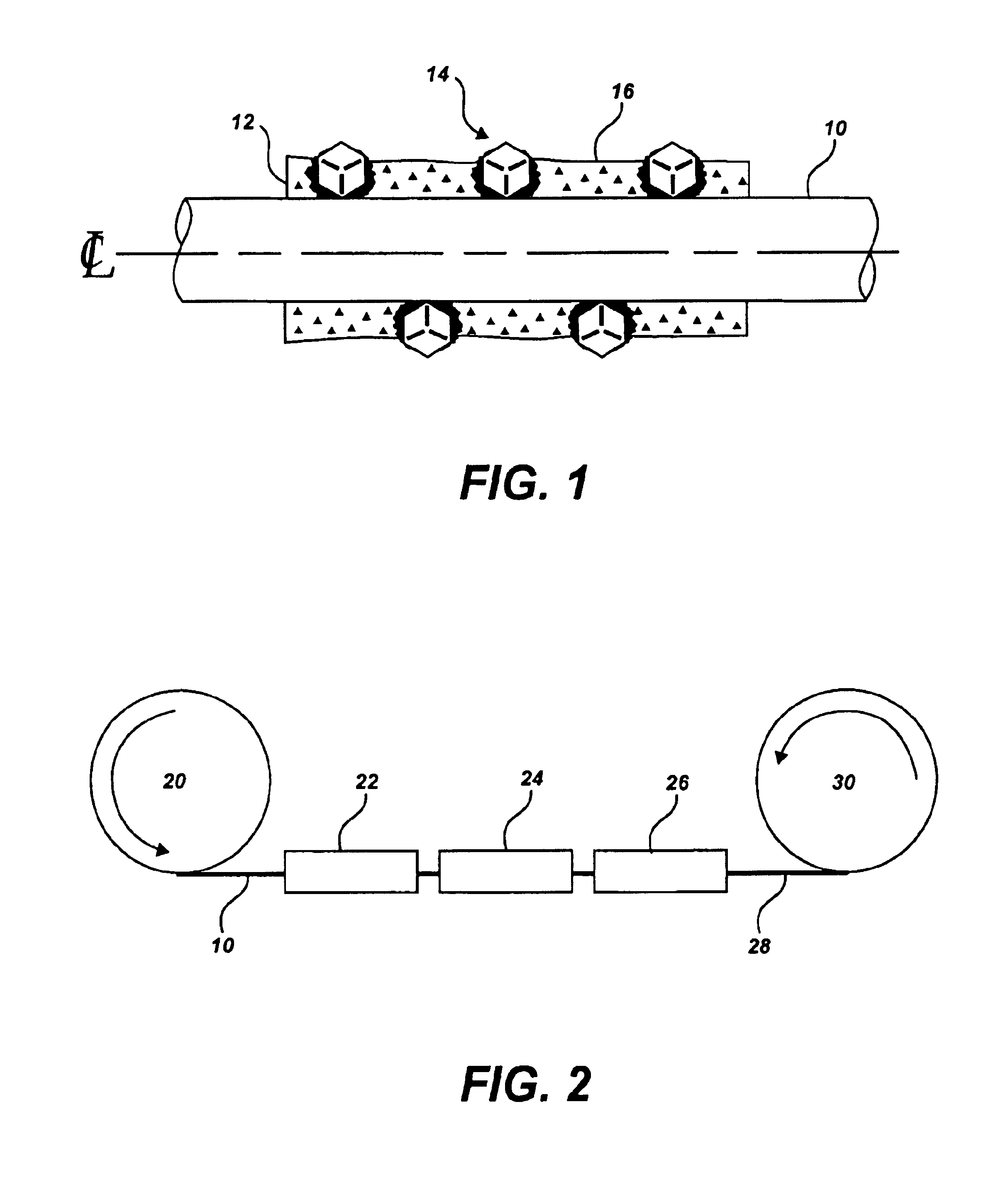

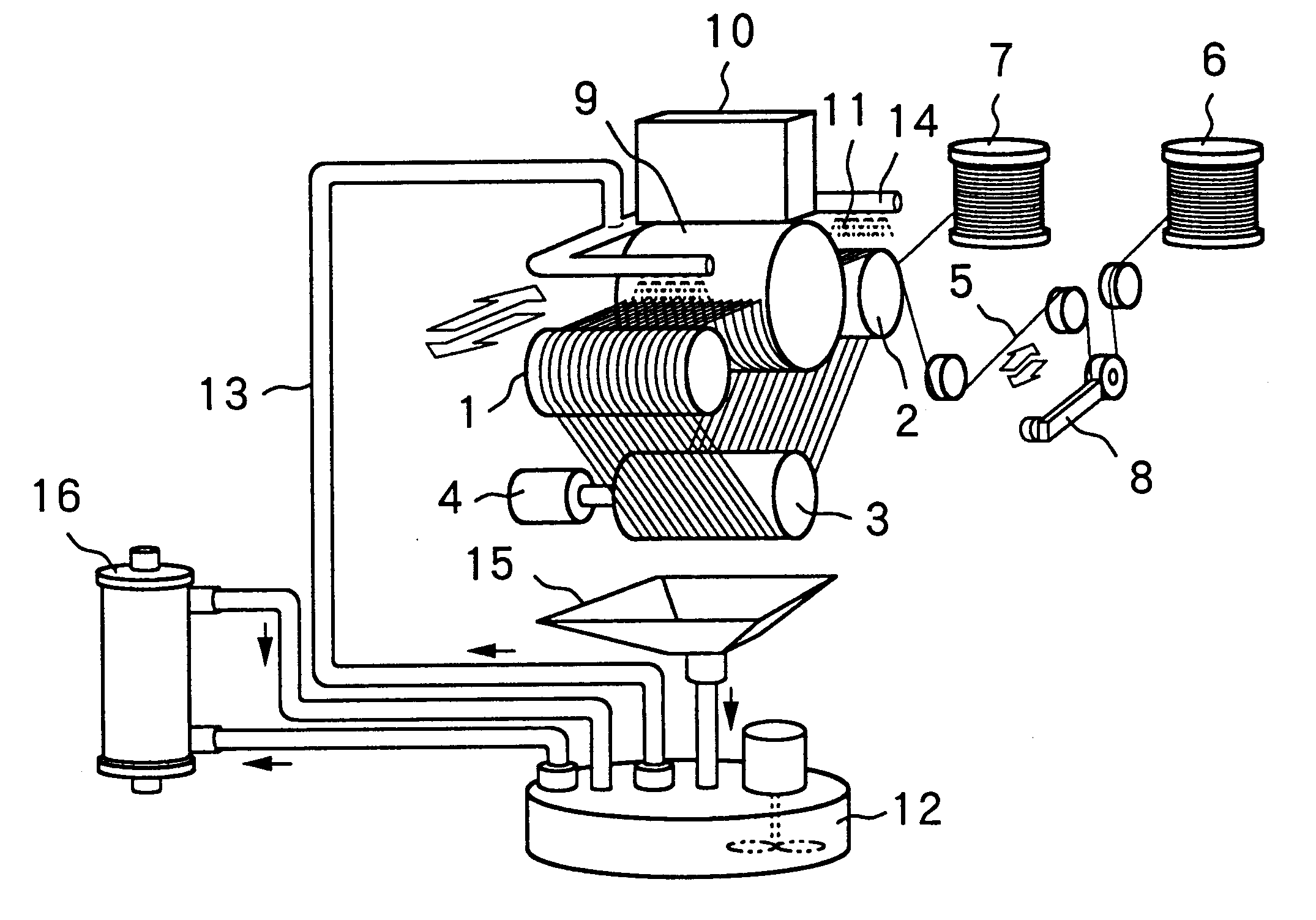

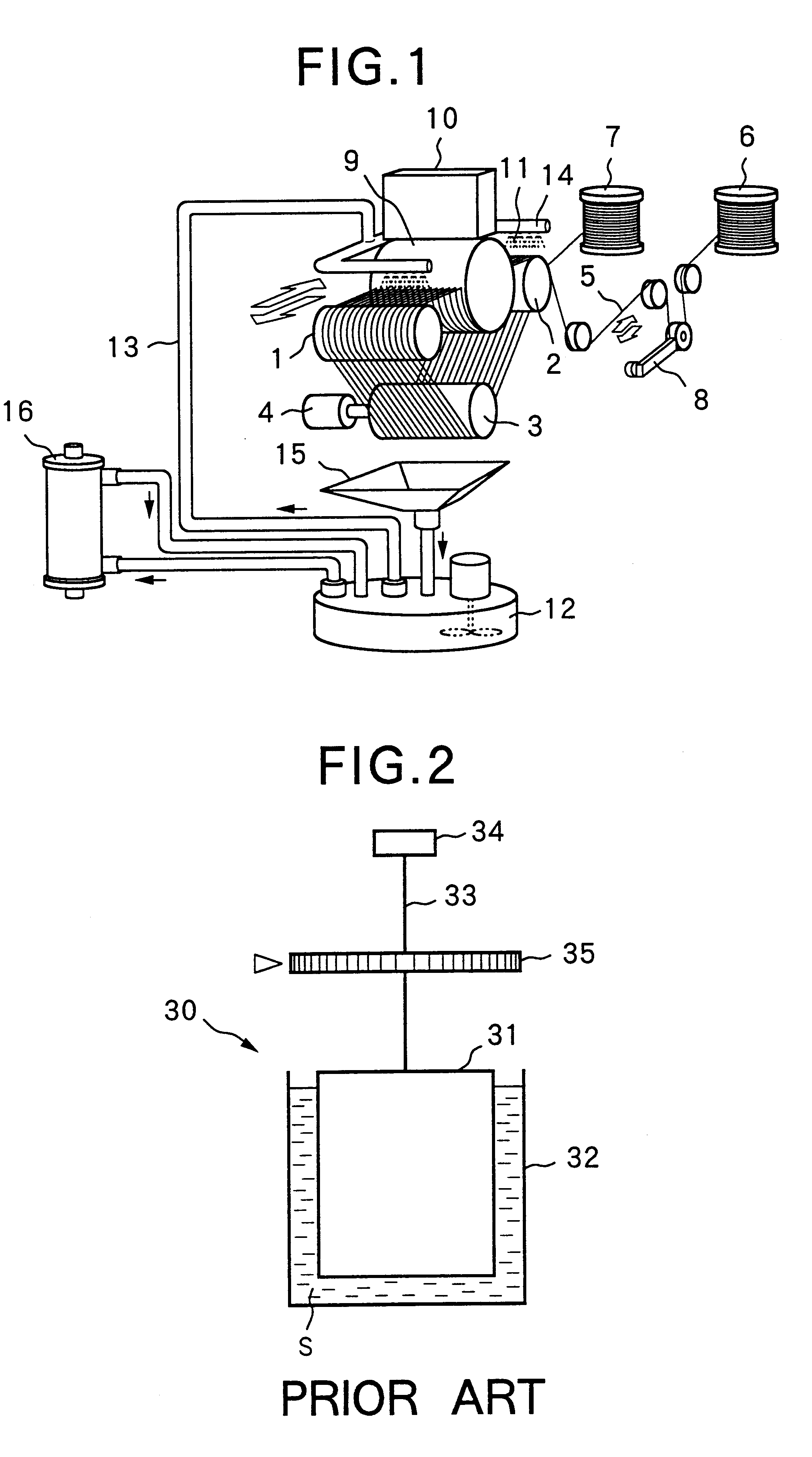

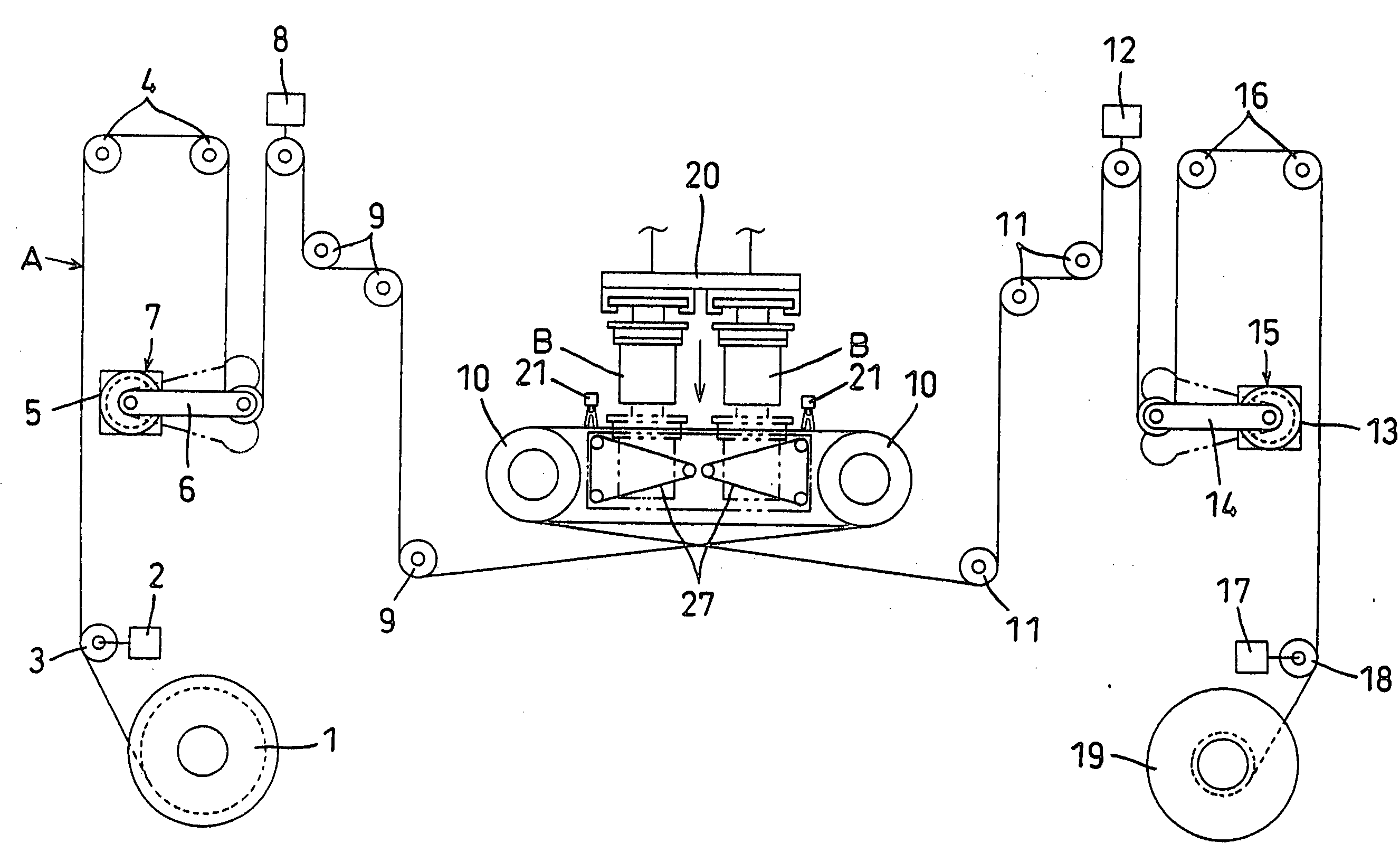

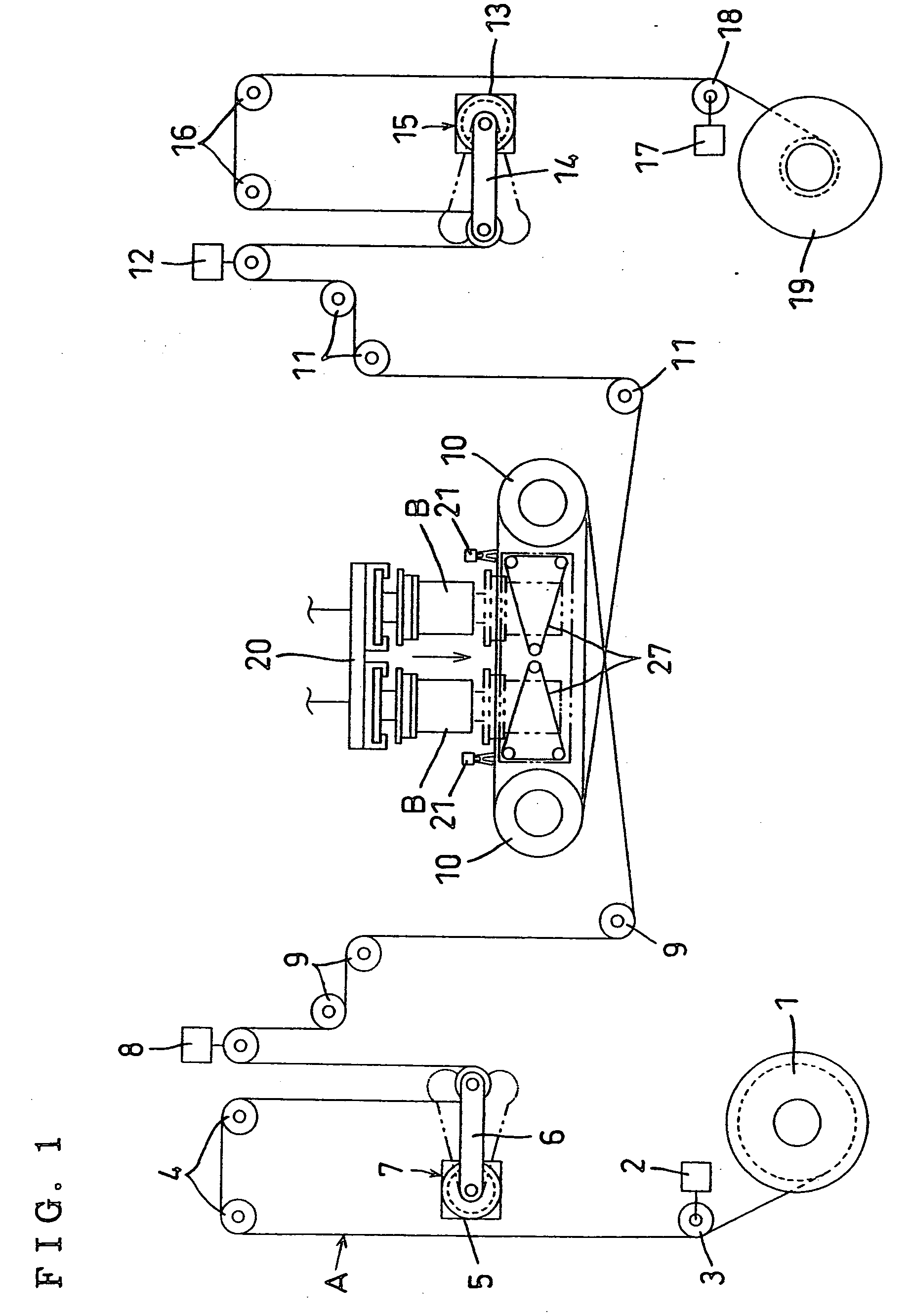

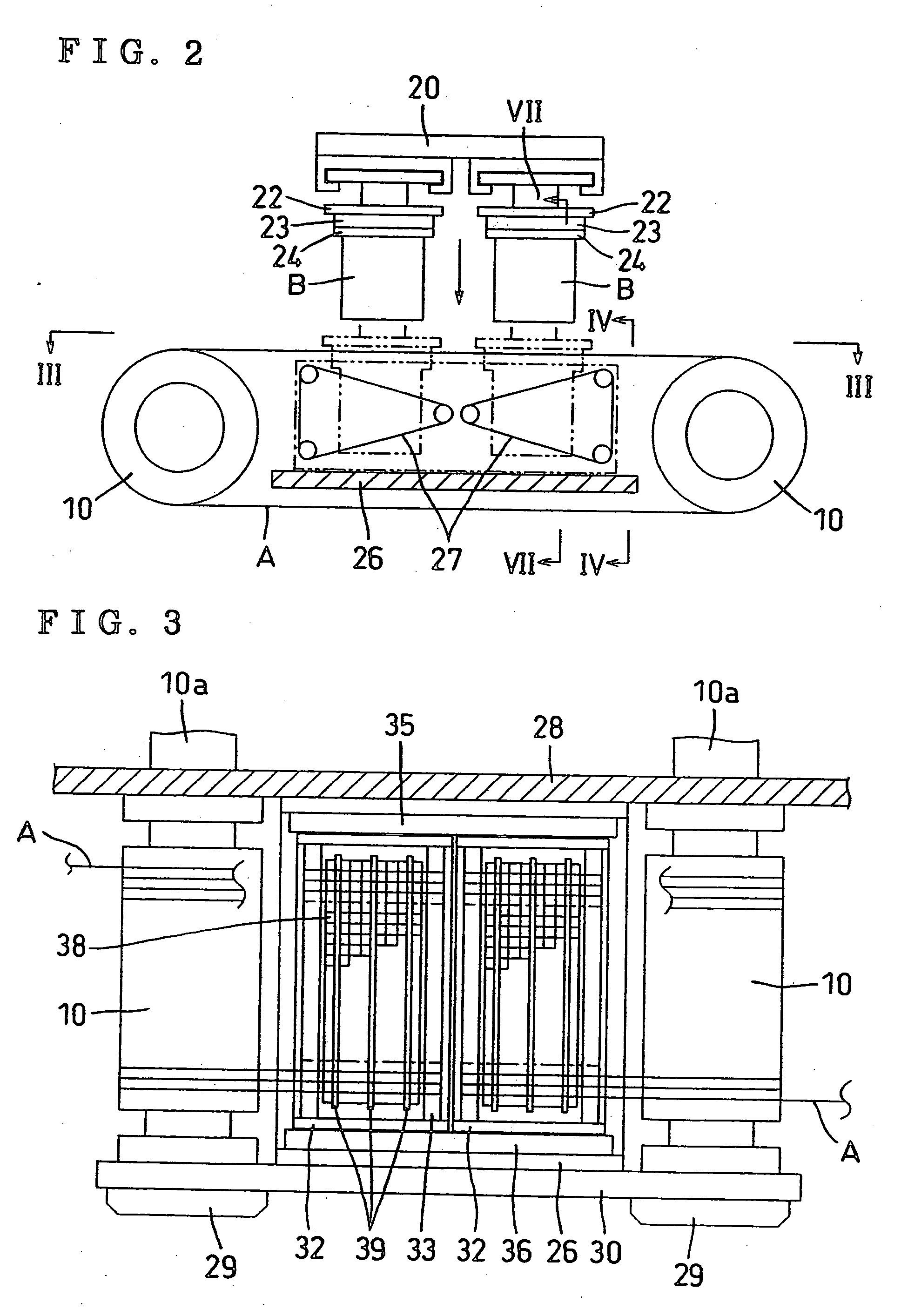

Wire saw and process for slicing multiple semiconductor ingots

InactiveUS6941940B1Improve throughputQuality improvementMetal sawing devicesSemiconductor/solid-state device manufacturingIngotSingle crystal

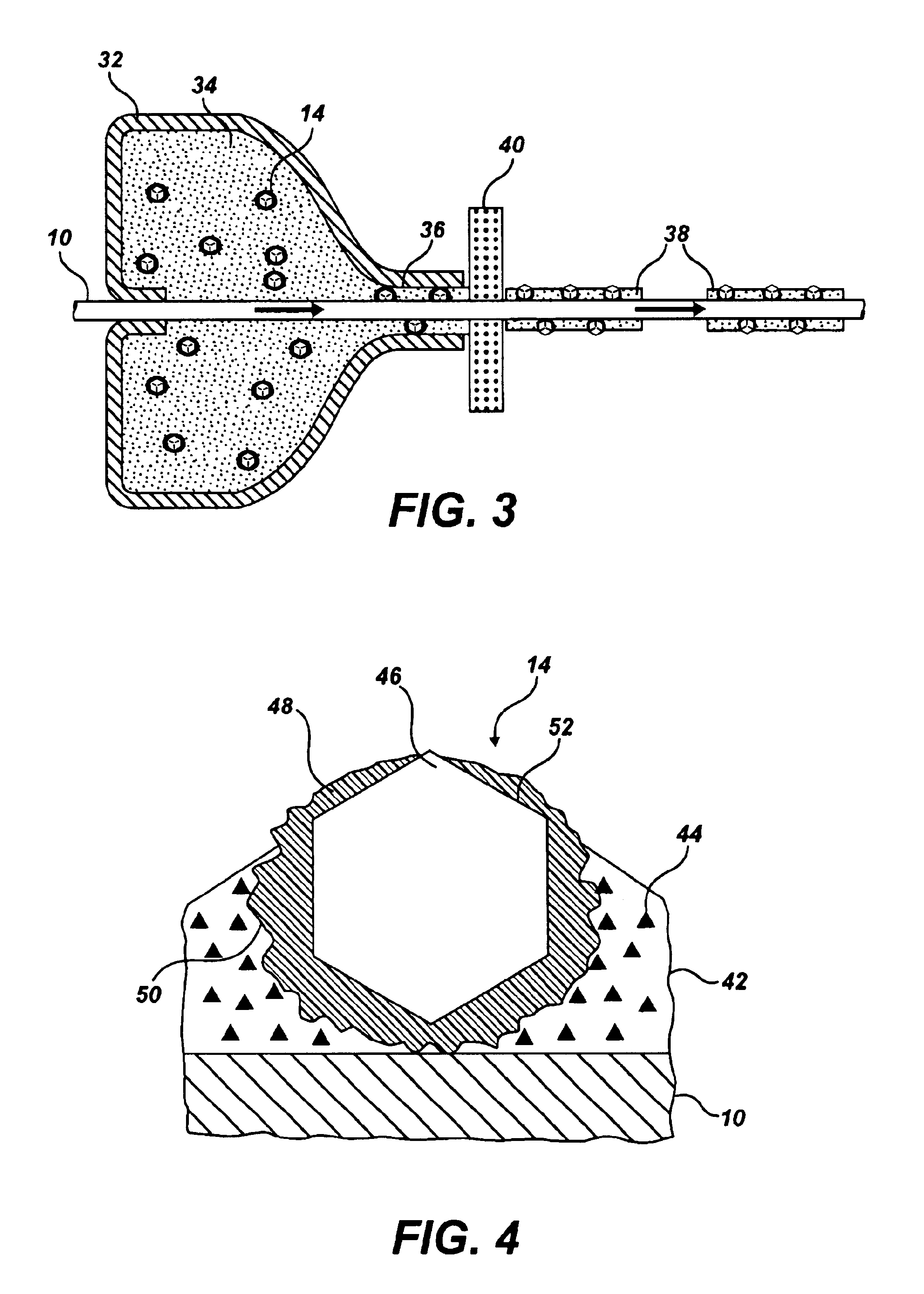

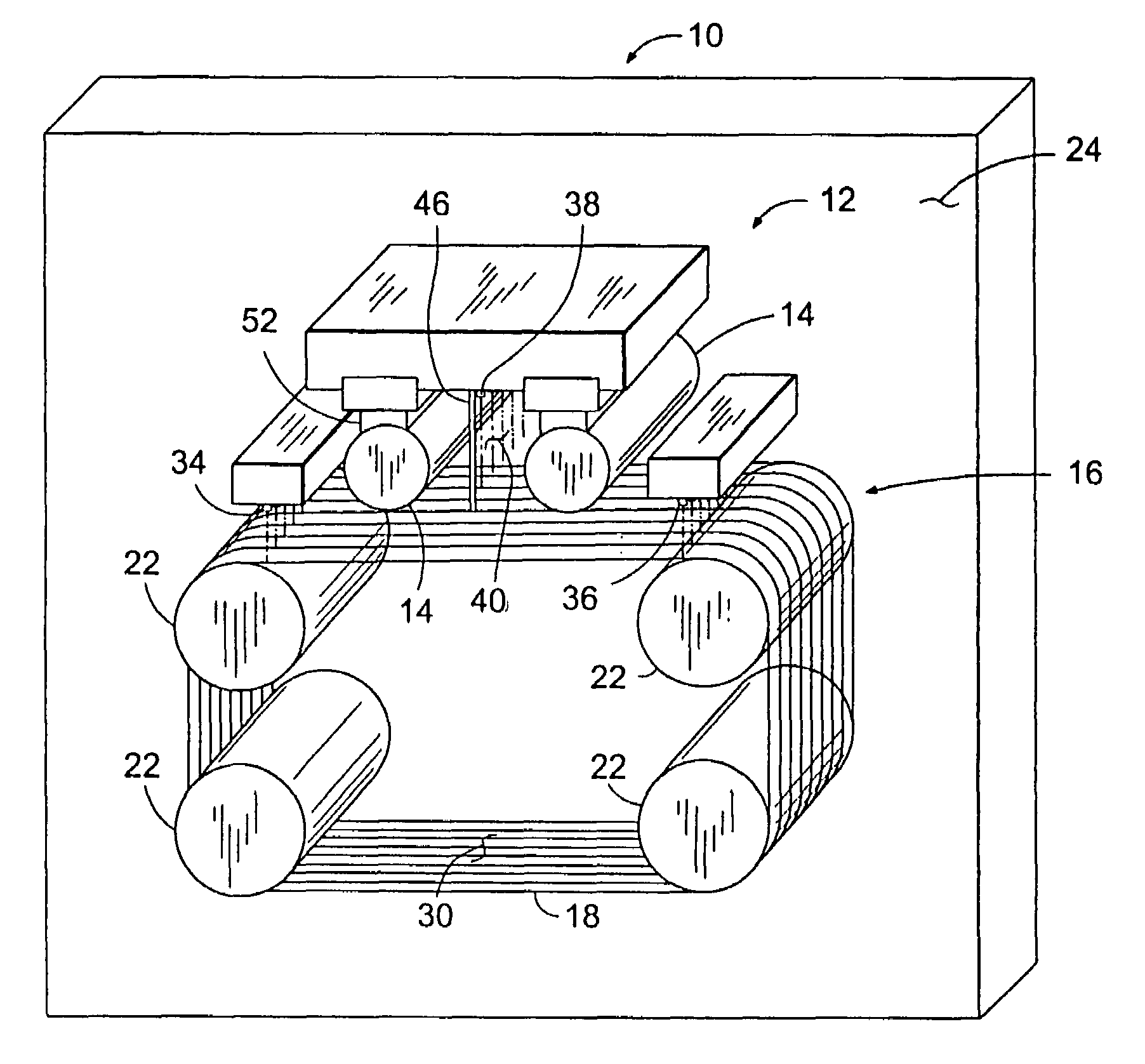

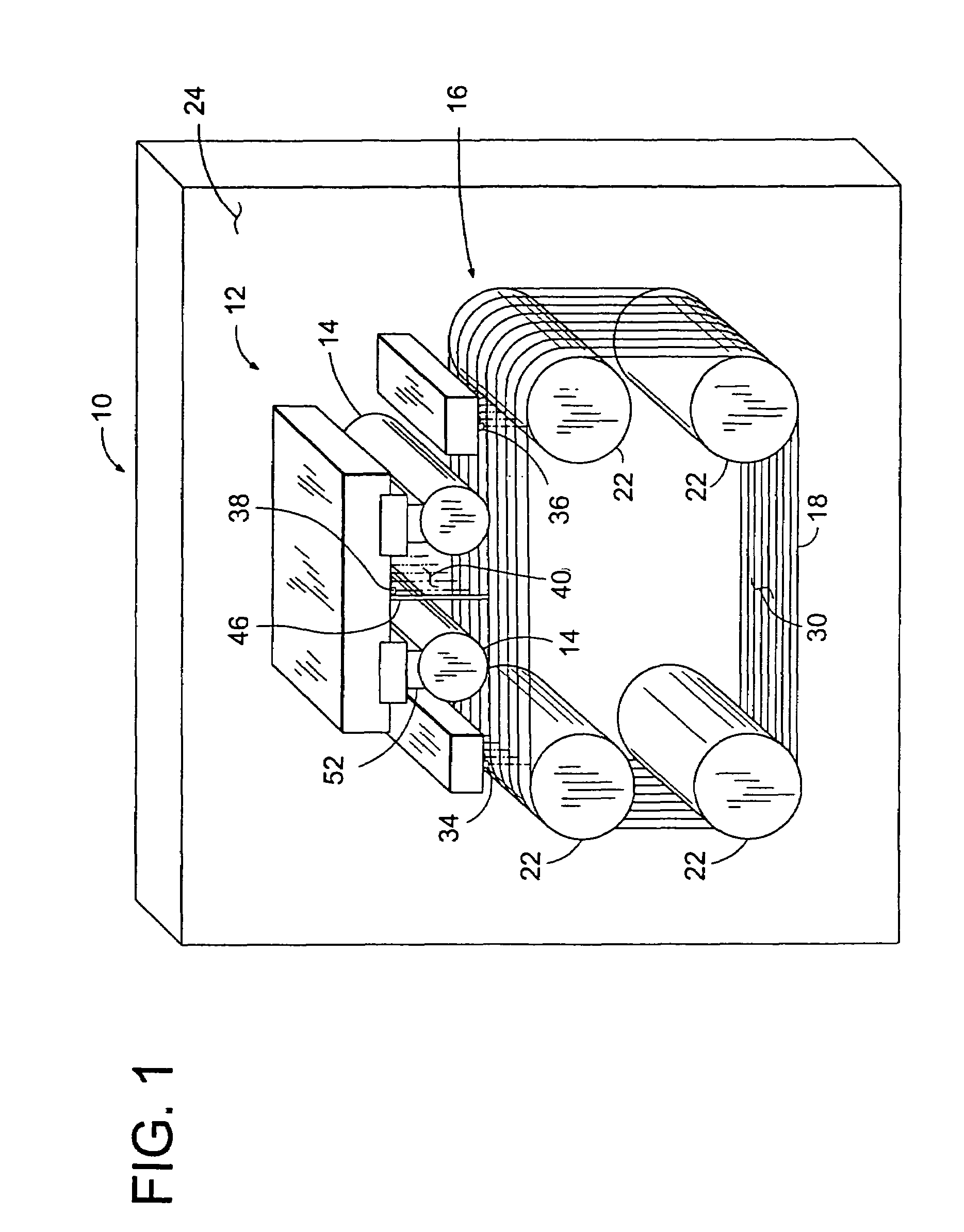

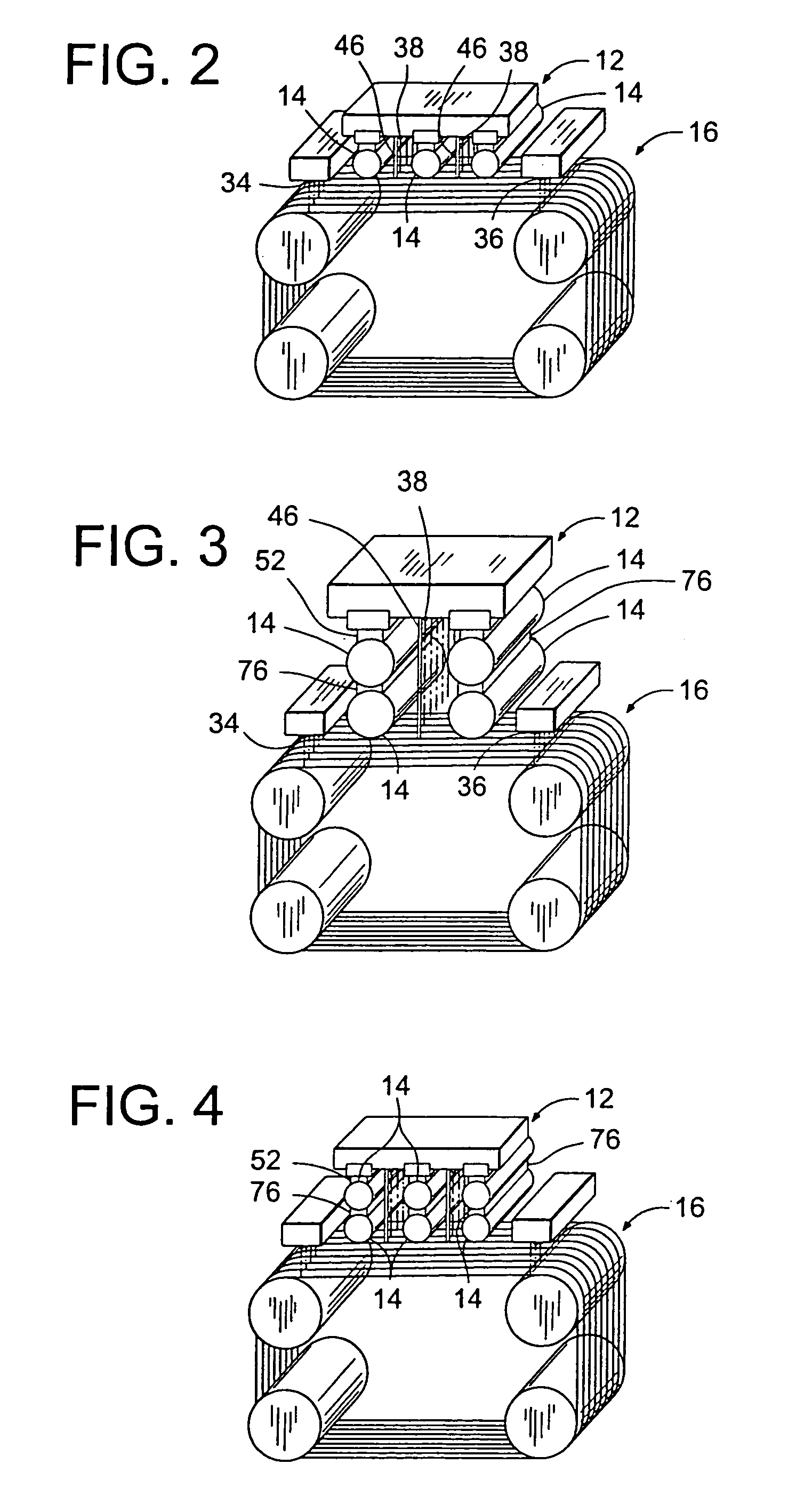

A wire saw (10) for simultaneously slicing multiple, generally cylindrical monocrystalline ingots (14) into wafers. The wire saw includes a cutting head (16), an ingot support (12), and multiple generally parallel lengths of cutting wire (18) defining a cutting web (30). A slurry delivery system includes nozzles (34, 36, and 38) positioned for dispensing slurry along the wire web generally at lateral sides of each ingot. A process for simultaneously slicing at least two generally cylindrical semiconductor ingots into wafers includes mounting at least two ingots to a common ingot support, moving the ingot support relative to the cutting web so that the two ingots simultaneously press against the cutting web at cutting regions, and dispensing a liquid slurry to at least three locations on the wire web including two outermost sides of the cutting regions and a location between each pair of ingots.

Owner:GLOBALWAFERS CO LTD

Cutting oil composition

InactiveUS6383991B1Good dispersionEasy to cleanWork treatment devicesAdditivesHydrogen atomChemical composition

The present invention relates to a cutting oil comprising (a) a polyether compound represented by the formula (I):wherein each of R1 and R2, which may be identical or different, is hydrogen atom or a hydrocarbon group having 1 to 24 carbon atoms, at least one of which is a hydrocarbon group; EO is oxyethylene group; AO is an oxyalkylene group having 3 or 4 carbon atoms; and each of m and n is 1 to 50, wherein a sum of m and n is from 4 to 100; a cutting oil composition comprising the above cutting oil and an abrasive; a cutting method using the above cutting oil composition; and a process of cleaning a wafer, comprising the steps of cleaning a wafer obtainable by cutting an ingot with a wire saw using the above cutting oil composition; heating the resulting waste water to a temperature equal to or higher than a cloud point of a polyether compound represented by the formula (I) contained in the waste water, to allow separation into an oil phase and an aqueous phase; and removing the oil phase comprising the polyether compound from the waste water. According to the present invention, there can be obtained excellent dispersibility of the abrasive, and excellent re-dispersibility, cutting performance and workability when sedimented, and the object to be cut obtained after cutting can be easily cleaned.

Owner:KAO CORP

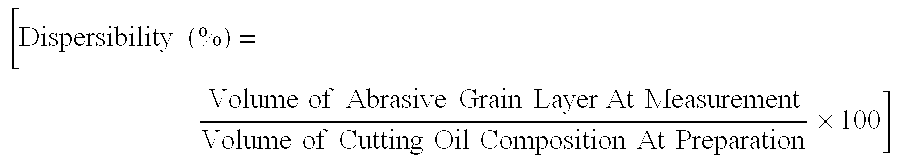

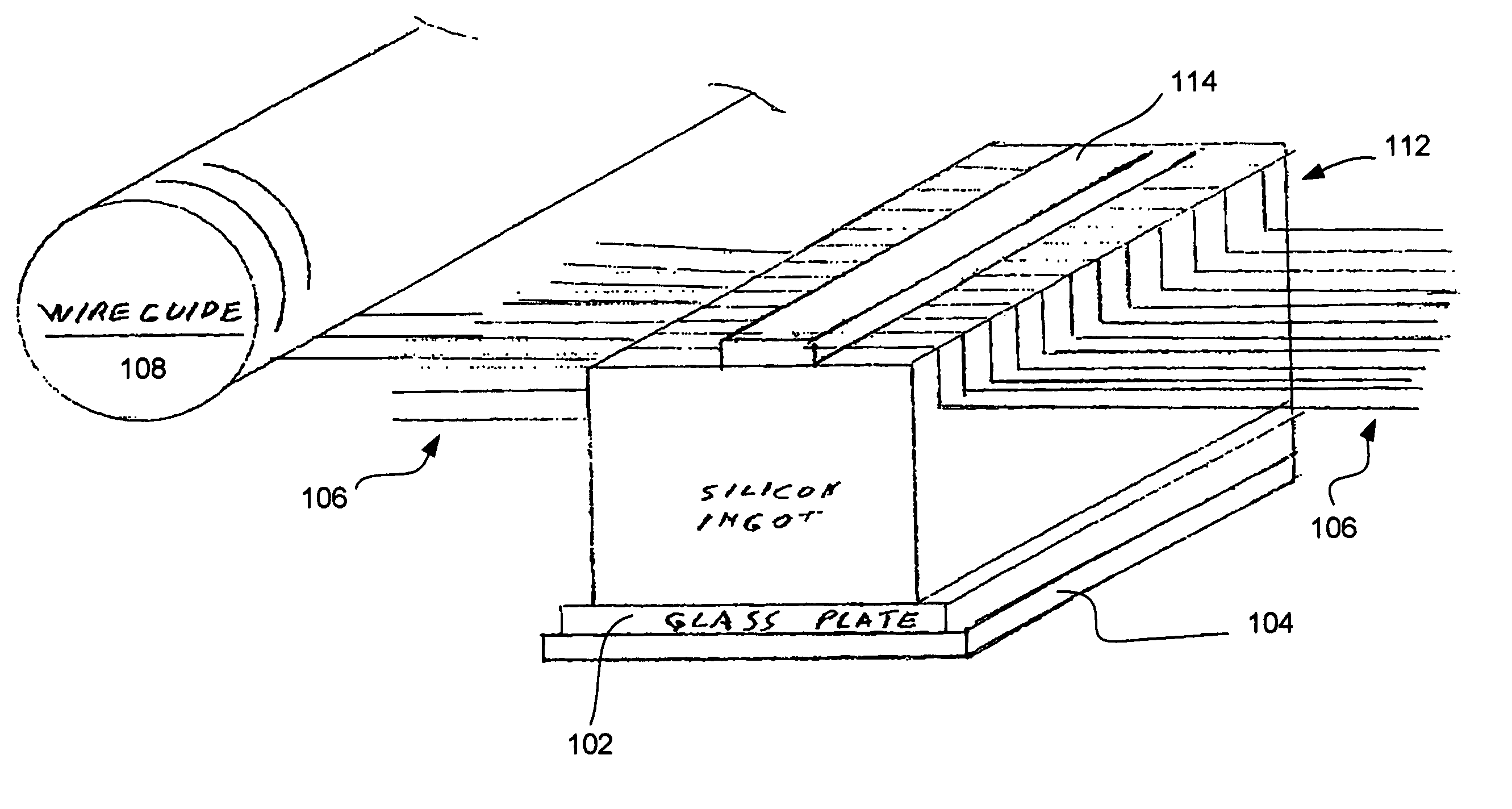

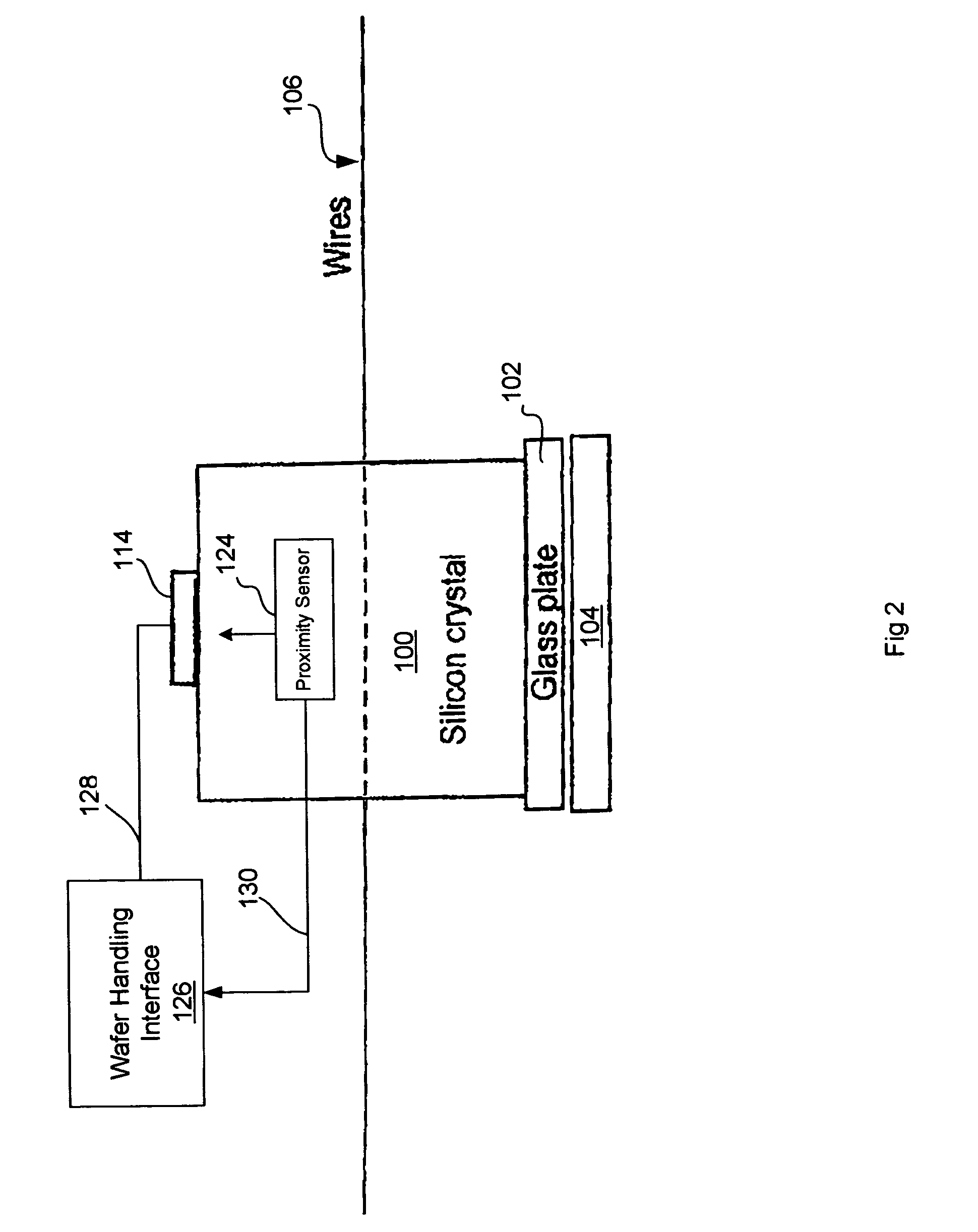

Method and apparatus for cutting ultra thin silicon wafers

InactiveUS7025665B2Uniform flatnessEasy to controlMetal sawing devicesBelt grinding machinesWaferingIngot

A wire saw and wafer stabilizing system are provided for holding wafer sections invariantly against vibration and unwanted movement during the sawing process. A stabilizing means is applied to the ends of partially defined wafer sections at an early stage when the wafer sections are partially cut through a silicon ingot or block of silicon material. The stabilizing means serves to stabilize the wafer sections immovably against vibration, oscillation, or unwanted contact during the subsequent sawing process. The stabilizing system also accelerates handling of the wafers after slicing is completed, facilitates the cleaning process, and allows for more rapid or automated placement of the wafers in cassettes. Wafers produced by the stabilizing system are characterized by a minimized total thickness variation, substantially uniform planarity, and substantially without bow or warp.

Owner:SOLAICX

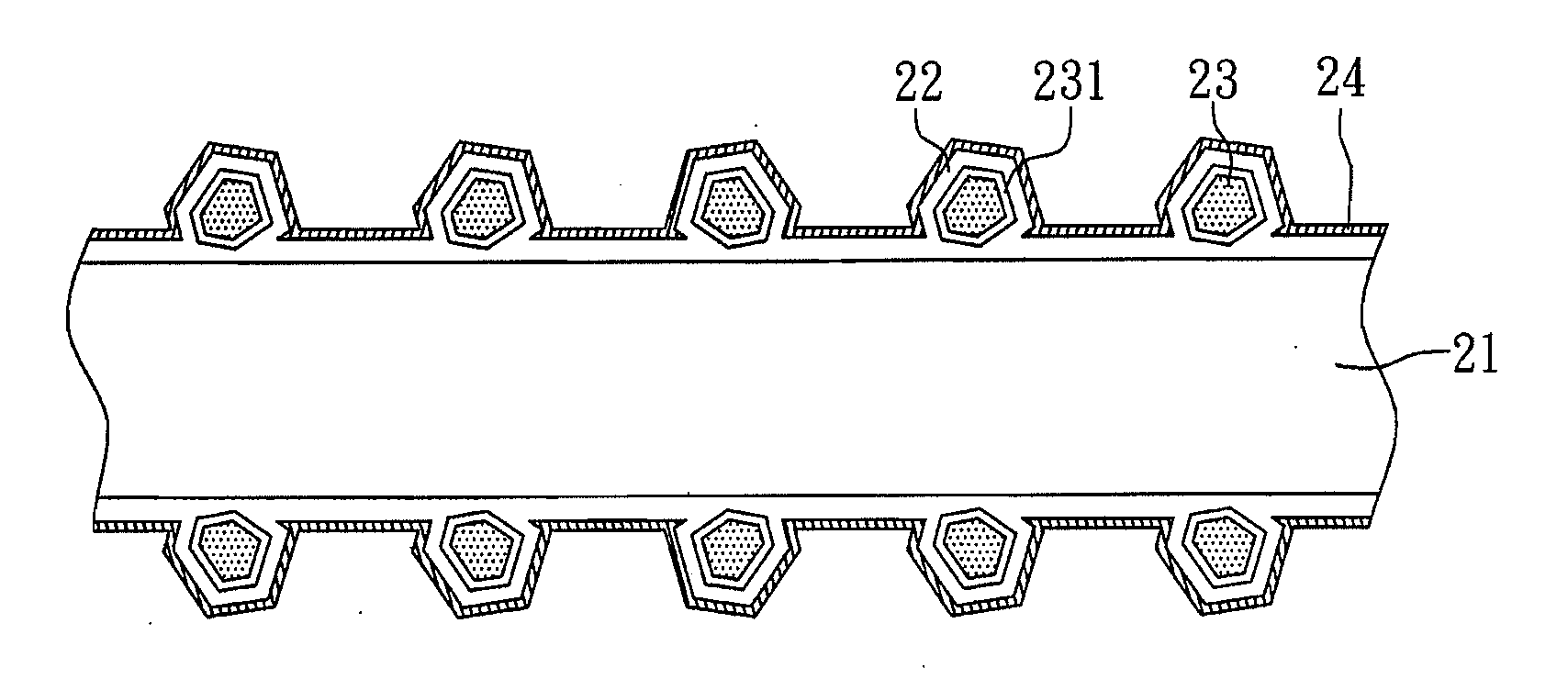

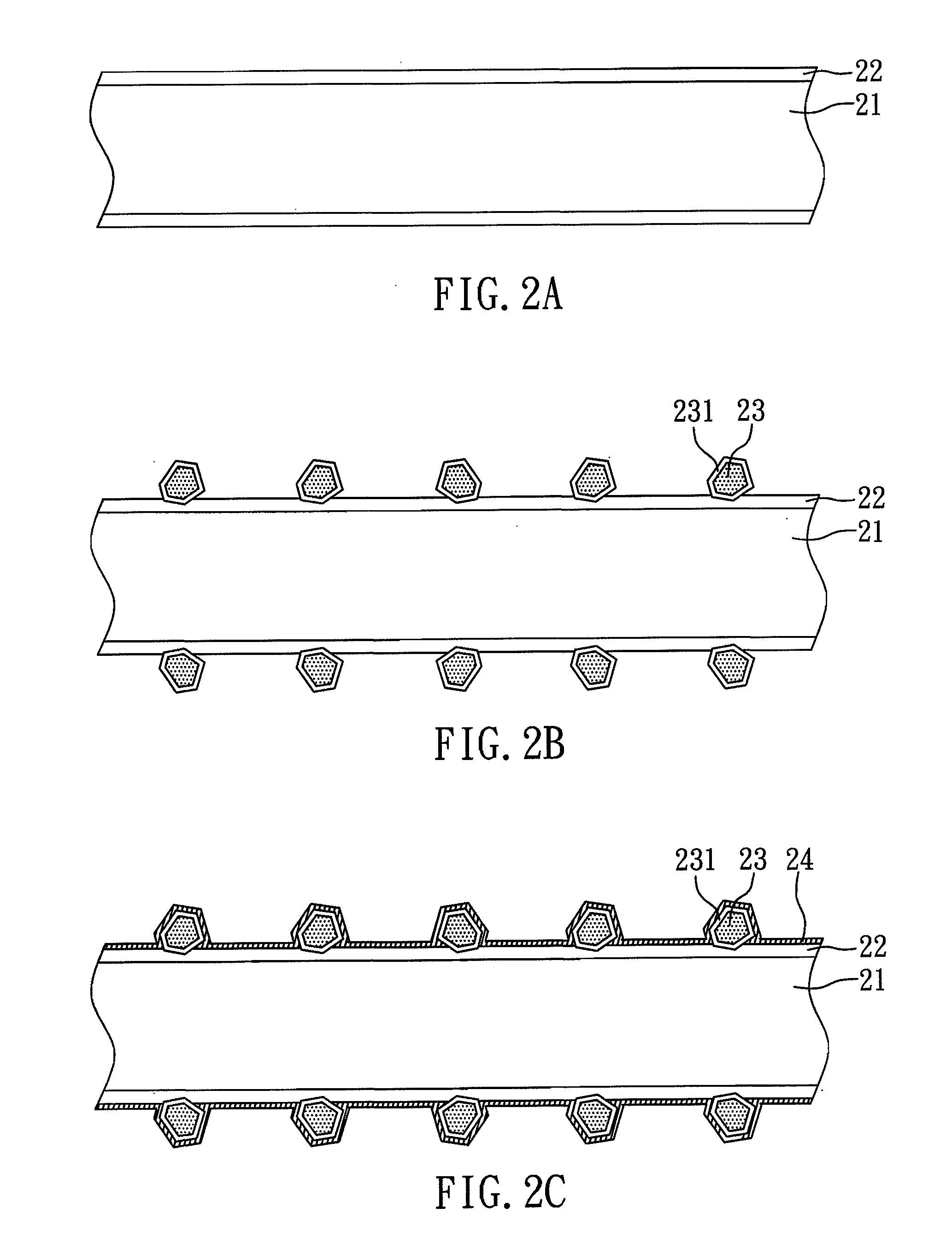

Wire saw and method for fabricating the same

The present invention relates to a wire saw and a method for fabricating the same. The method for fabricating a wire saw according to the present invention includes: providing a core wire; coating an intermediate layer over the core wire, and embedding a plurality of abrasives in the intermediate layer; and plating a metal protective layer over the abrasives. Accordingly, the present invention can resolve the conventional problem of abrasives in the plating bath aggregating during electroplating deposition, so as to enhance cutting quality and precision.

Owner:KINIK

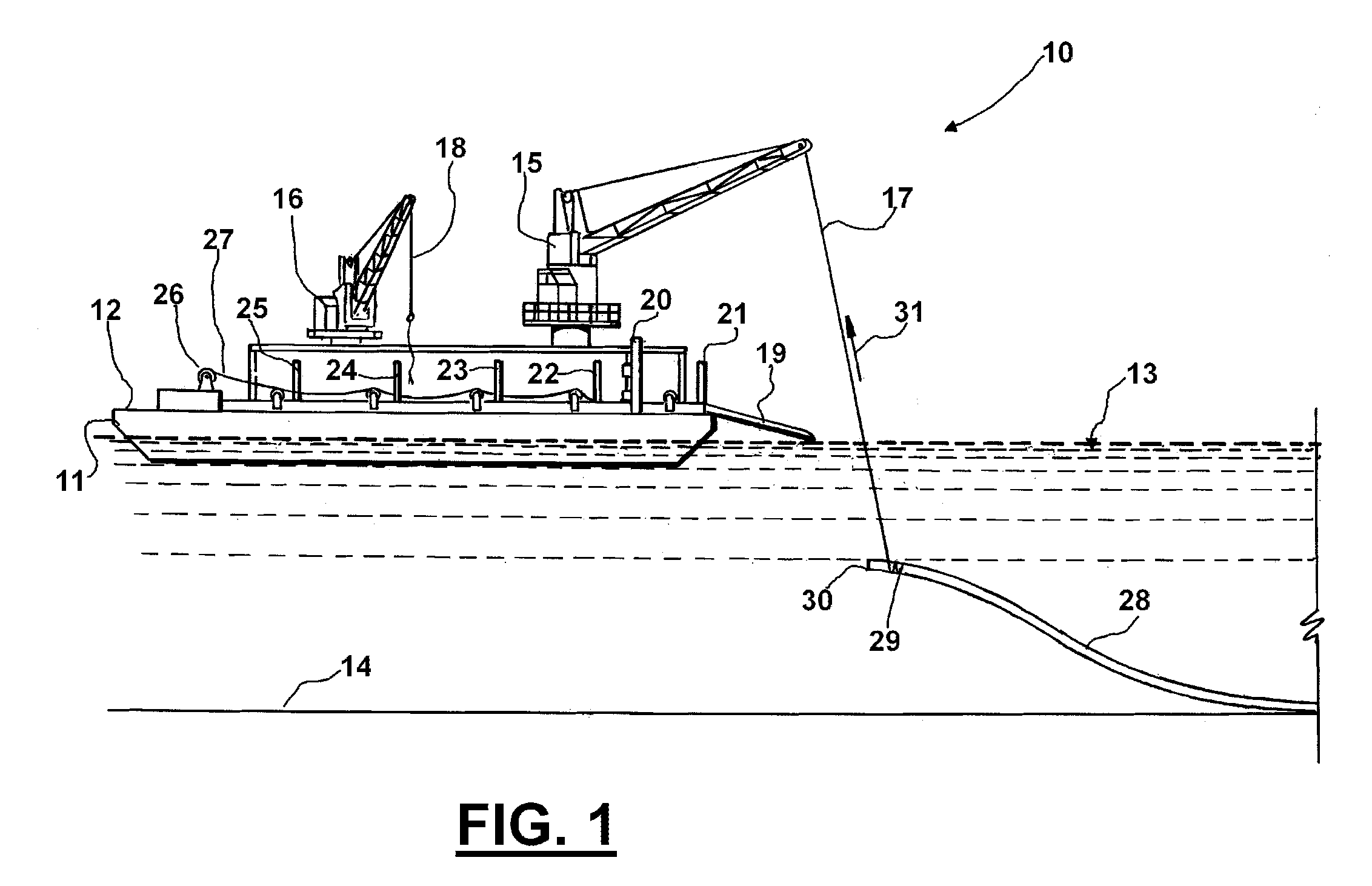

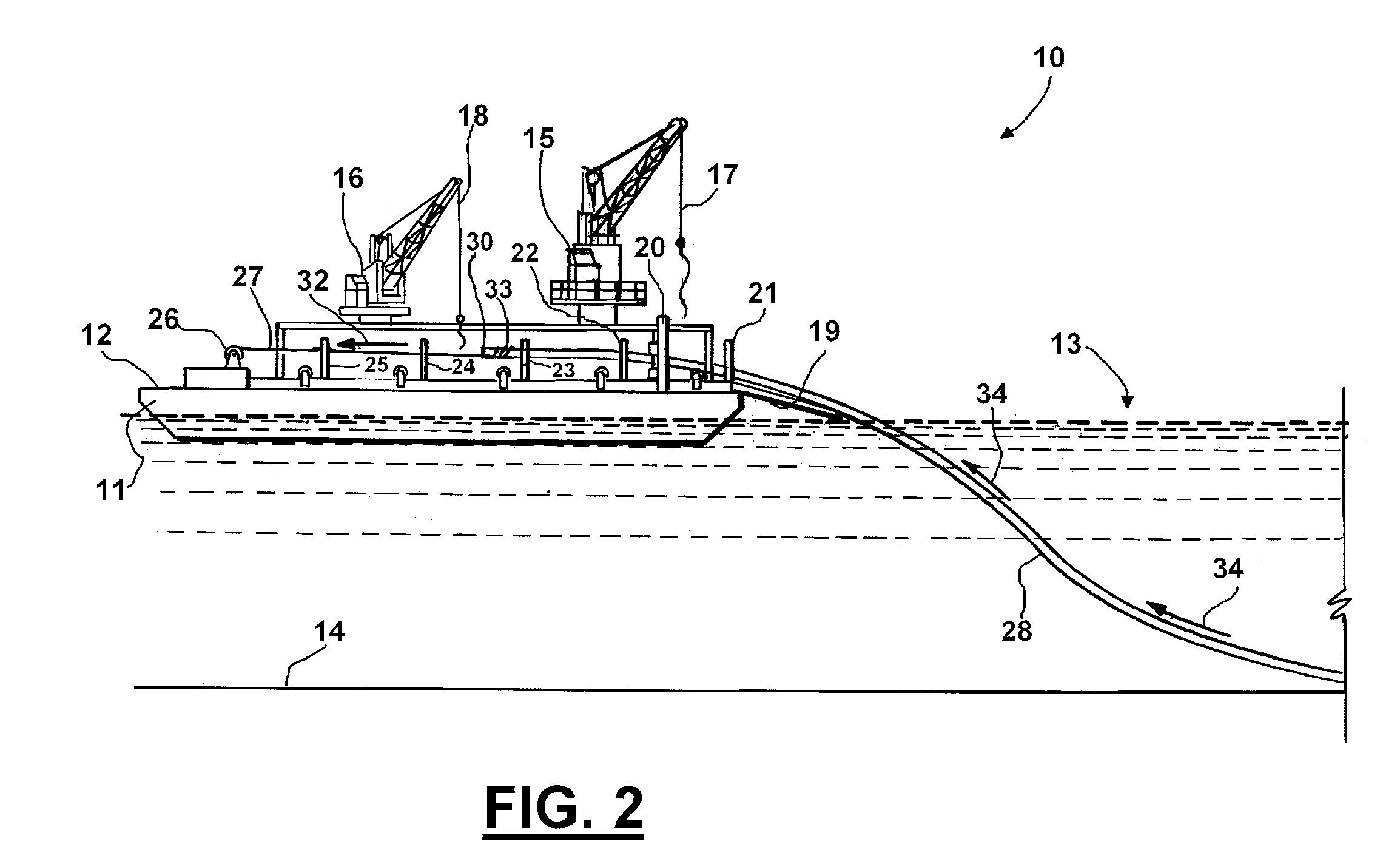

Method and apparatus for diamond wire cutting of metal structures

InactiveUS6881131B2Reduce breakageAbsorb energyMetal sawing devicesMetal sawing accessoriesNuclear reactorDiamond wire saw

A method and apparatus for diamond wire cutting of metal structures, such as nuclear reactor vessels, is provided. A diamond wire saw having a plurality of diamond beads with beveled or chamfered edges is provided for sawing into the walls of the metal structure. The diamond wire is guided by a plurality of support structures allowing for a multitude of different cuts. The diamond wire is cleaned and cooled by CO2 during the cutting process to prevent breakage of the wire and provide efficient cutting. Concrete can be provided within the metal structure to enhance cutting efficiency and reduce airborne contaminants. The invention can be remotely controlled to reduce exposure of workers to radioactivity and other hazards.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Super abrasive grain wire saw winding structure, super abrasive grain wire saw cutting device, and super abrasive grain wire saw winding method

A superabrasive wire saw-wound structure includes a superabrasive wire saw (10) formed with an average diameter D and a reel (1). The superabrasive wire saw (10) includes a core wire (11), a bonding material (12) surrounding a surface of the core wire (11), and a plurality of superabrasive grains (13) bonded to the surface of the core wire (11) with the bonding material (12). The reel (1) includes a peripheral surface (2) having one end (3) and the other end (4). The superabrasive wire saw (10) which is to be unreeled successively toward a workpiece is wound around the peripheral surface (2) reciprocatingly between the one end (3) and the other end (4) to be multi-layered. A pitch P for winding the superabrasive wire saw (10) around the peripheral surface (2) between the one end (3) and the other end (4) satisfies a relation of D<P<2D. According to the present invention, there can be provided a superabrasive wire saw-wound structure, a cutting device with a superabrasive wire saw, and a method of winding a superabrasive wire saw which can reduce damage to a bonding material and falling of a superabrasive grain.

Owner:ALLIED MATERIAL

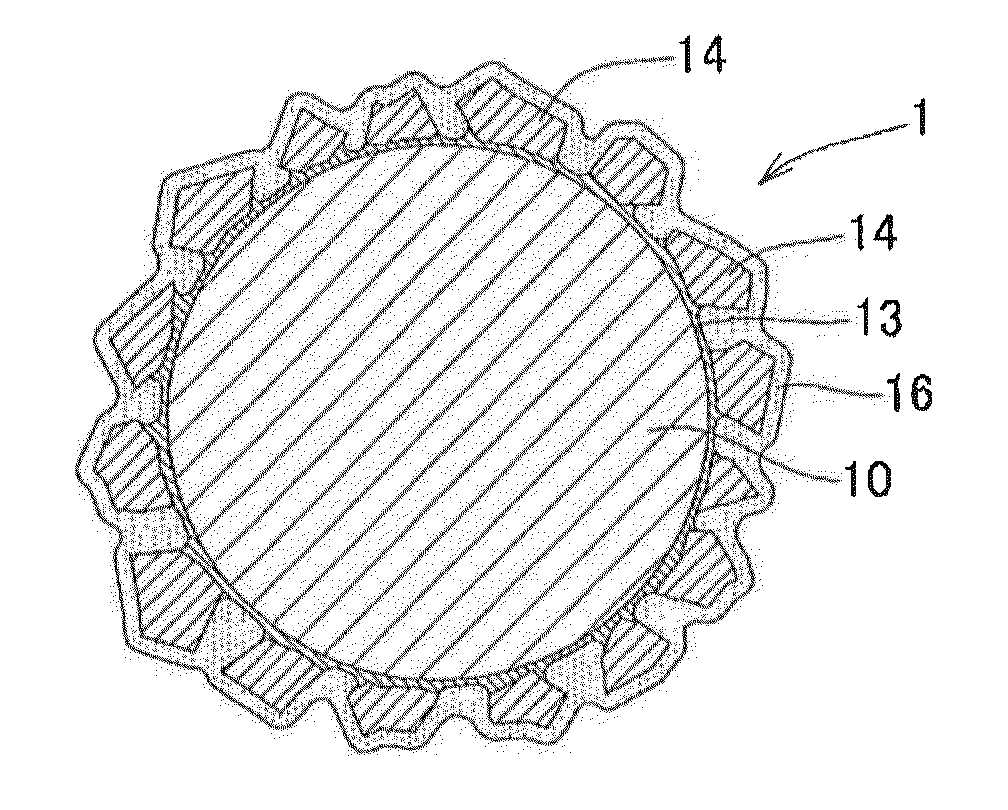

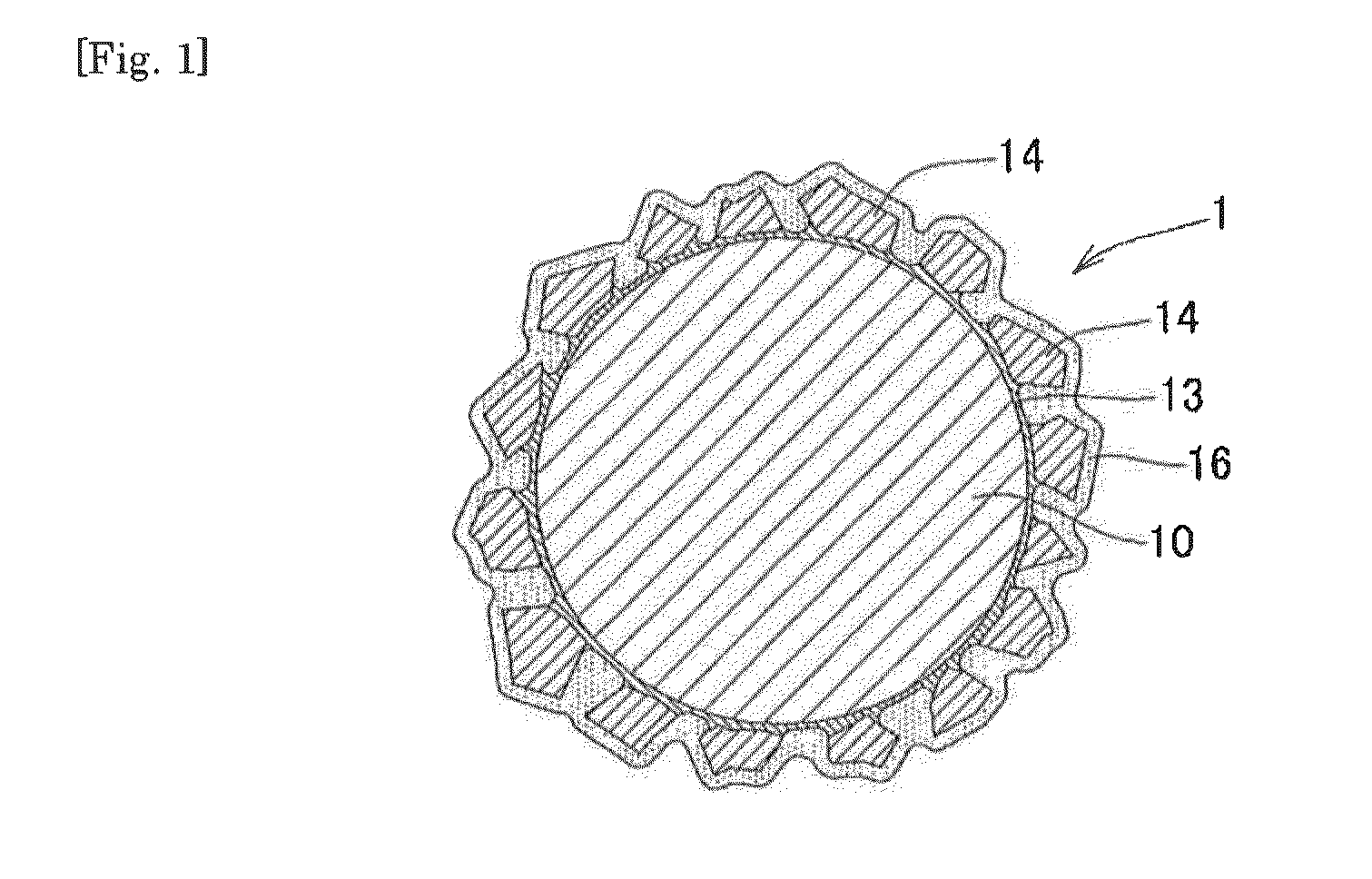

Super-abrasive grain fixed type wire saw, and method of manufacturing super-abrasive grain fixed type wire saw

InactiveUS20130032129A1Improve retentionFast productionMetal sawing tool makingAbrasion apparatusWire sawMetal

The super-abrasive grain fixed type wire saw is equipped with two layers consisting of a brazing material layer (13) and a metal plating layer (16), the aforementioned brazing material layer (13) serving to temporarily fix super-abrasive grains (14), and the aforementioned metal plating layer (16) serving to hold the super-abrasive grains (14). The thickness of the brazing material layer (13) is 10% or less of the average grain diameter of the super-abrasive grains (14). The brazing material layer (13) is formed on the surface of a wire (10) in advance. The super-abrasive grains (14) are dispersed and adhered in a single layer onto the brazing material layer (13). Subsequently, the surface of the brazing material layer (13) is melted and solidified, resulting in a super-abrasive-grains-temporarily-adhered wire (12) such that super-abrasive grains (14) are joined to the adhesion surface of the brazing material layer (13). Thereafter, the super-abrasive-grains-temporarily-adhered wire (12) is metal-plated.

Owner:NAKAMURA CHOKO

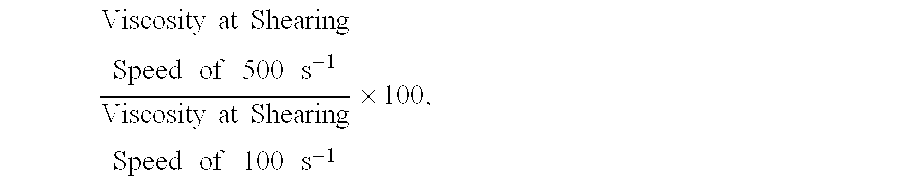

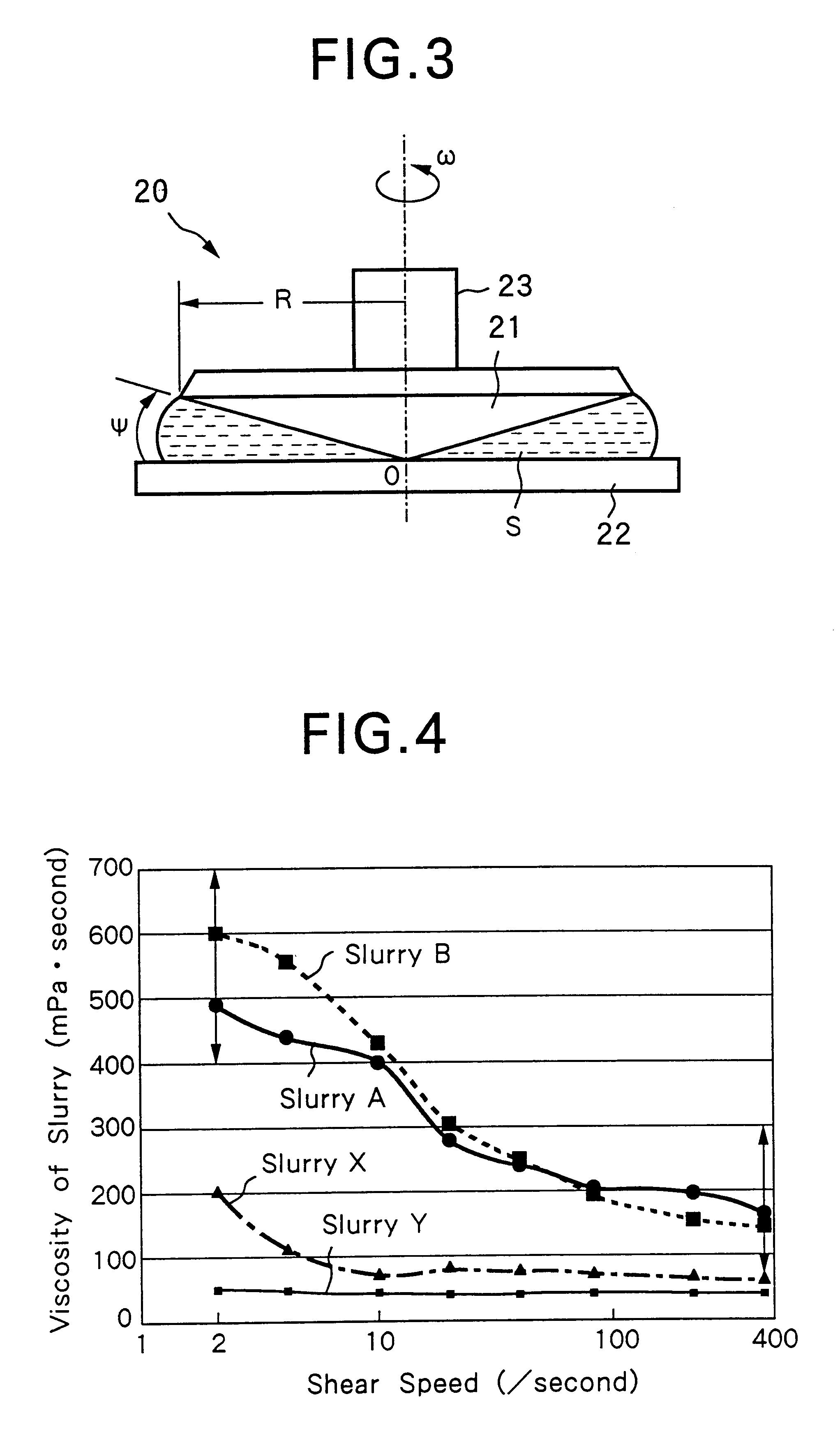

Slurry useful for wire-saw slicing and evaluation of slurry

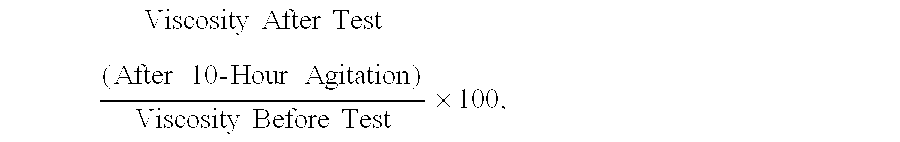

Slurry useful for wire-saw slicing has viscosity adjusted to 400-700 mPa.second at a shear speed of 2 / second and of 50-300 mPa.second at a shear speed of 380 / second. The viscosity of slurry is measured using a cone and plate type viscometer which can measure viscosity at different shear speeds. Since the slurry sufficiently flows into inner parts of grooves formed in an ingot and consumed for wire-saw slicing due to the viscosity controlled in response to the shear speed, the ingot can be efficiently sliced to wafers or discs.

Owner:SUPER SILICON KENKYUSHOKK +1

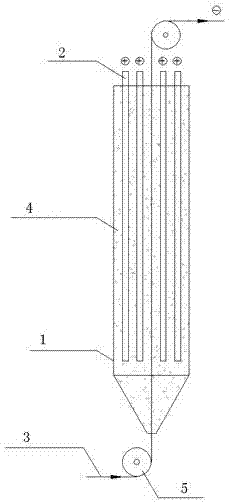

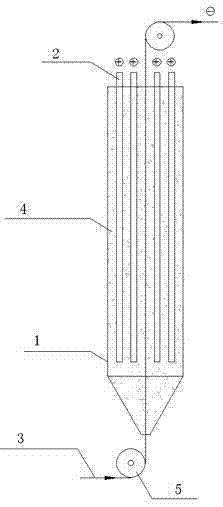

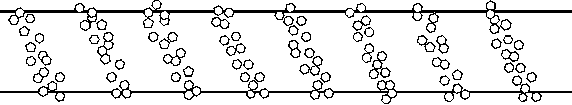

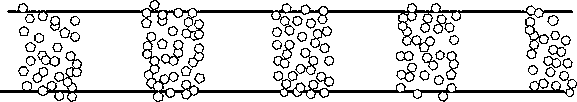

A sanding method for diamond wire saw

The invention relates to a sand feeding method for a diamond wire saw. The method comprises the following steps of: (1) preparing a diamond electroplating solution, wherein each litre of the electroplating solution comprises 10-20g of diamond, 100-240g of NiSO4, 40-100g of NiCl2, 10-50g of CoSO4 and 40-80g of H2BO3; (2) adding the electroplating solution to a sand feeding tower, wherein the sand feeding tower is in the shape of a column or polygon and is arranged vertically, and 2 to 8 Ni anodes are uniformly arranged on the inner wall of the sand feeding tower; and (3) making a bare metal wire penetrate into the bottom of the sand feeding tower and out of the tower top at a speed of 2-8 m / min; by adopting the bare metal wire as the cathode and Ni as the anode during the penetration of the bare metal wire, applying DC (Direct current) and plating diamond on the bare metal wire. The diamonds on the diamond wire saw prepared by the invention are uniformly distributed and are not accumulated.

Owner:NANJING SANCHAO ADVANCED MATERIALS

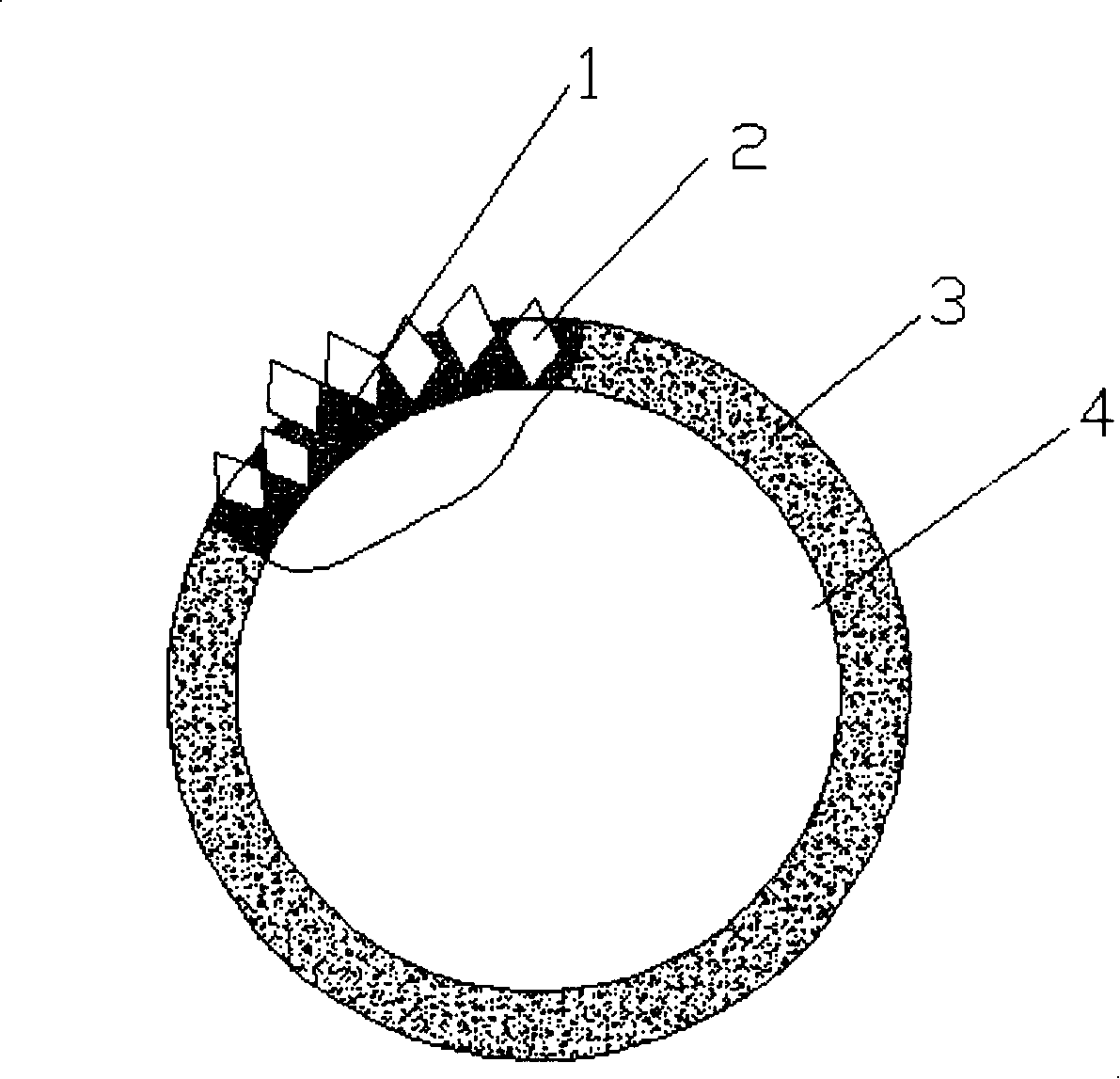

Method for preparing metal binding agent diamond scroll saw

InactiveCN101209505ATo achieve the purpose of cuttingImprove bindingMetal sawing tool makingMetal sawing toolsDiamond wire sawDiffusion reaction

The invention provides a preparation method and the product of a metal binder diamond wire saw, comprising the preparation steps of (1) steel wire surface, (2) plating auxiliary disposal of the steel wire, (3) burdening, (4) plating of steel wire and (5) post-processing. The thickness of the binder coating ranges from 1 / 2 to 2 / 3 of the grain diameter of the diamond. By a series of chemical and diffusion reaction, the surface of the steel wire is covered by a layer of uniform and firm coating 3; a diamond mill grain 2 is also uniformly held in a metal binding layer 1, thus achieving the cutting object.

Owner:ZHEJIANG UNIV OF TECH

Monofilament metal saw wire

ActiveCN101039771AEasy to manufactureImproved entrainment characteristicsMetal sawing devicesMetal sawing toolsMicrometerCrimp

Monofilament metal saw wire for a wire saw, wherein the saw wire being provided with a plurality of crimps. The crimps are arranged in at least two different planes, such that, when measured, between measuring rods of a micrometer, over a length comprising crimps in at least two different planes, a circumscribed enveloping D diameter of the saw wire is between 1.05 and 1.50 times a diameter d of the saw wire itself.

Owner:ARCELORMITTAL BIESEN & BERTENBERG +1

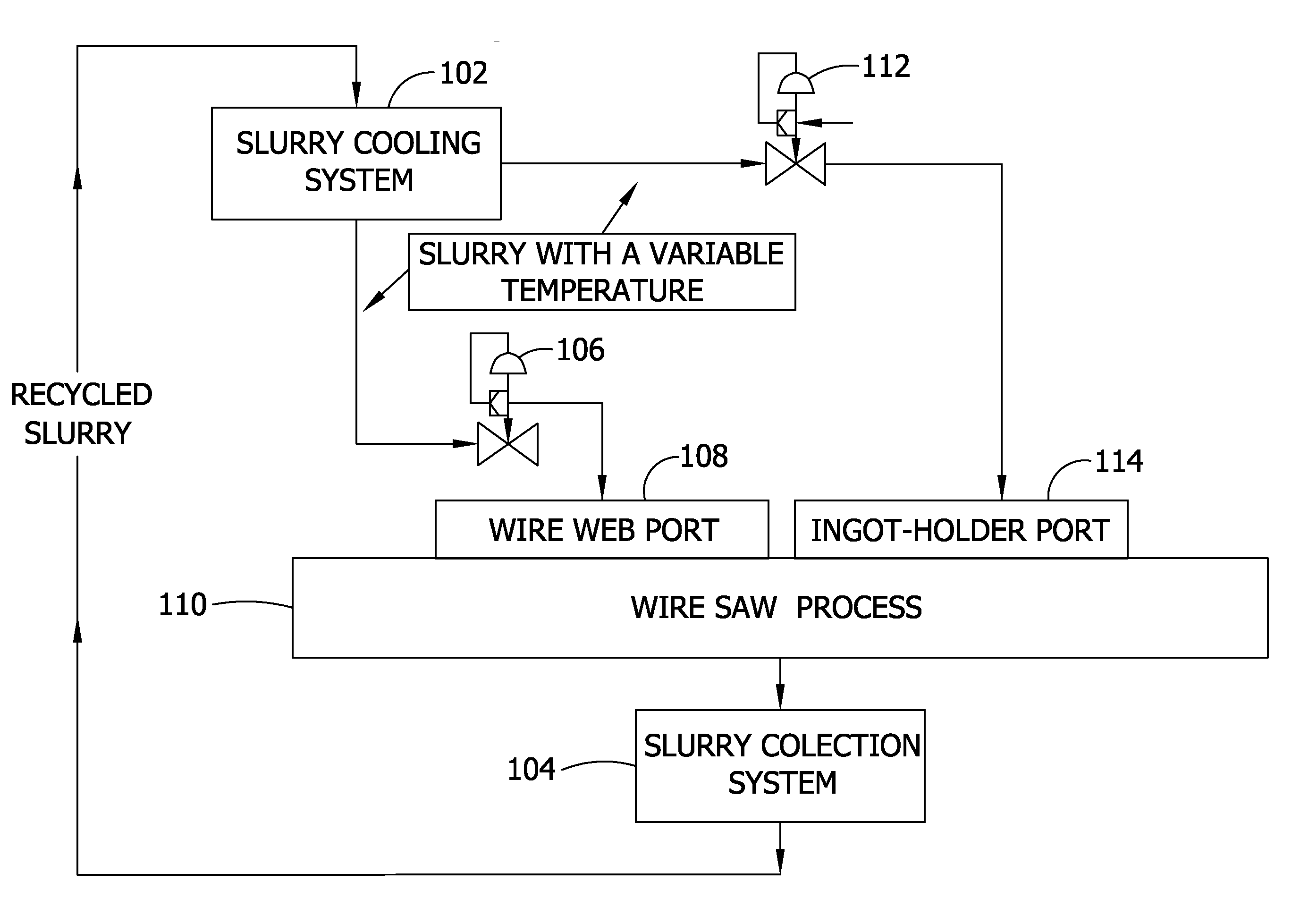

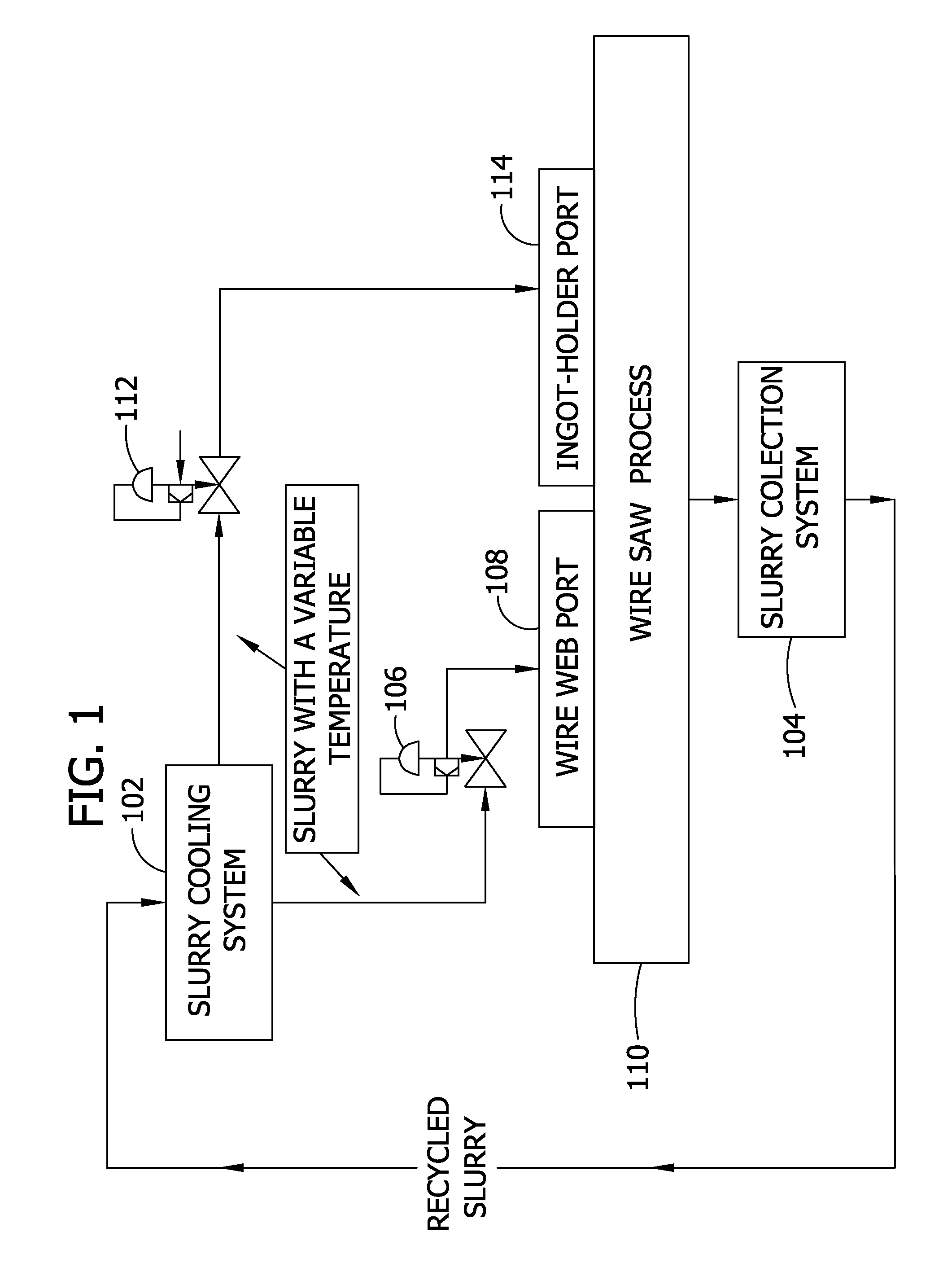

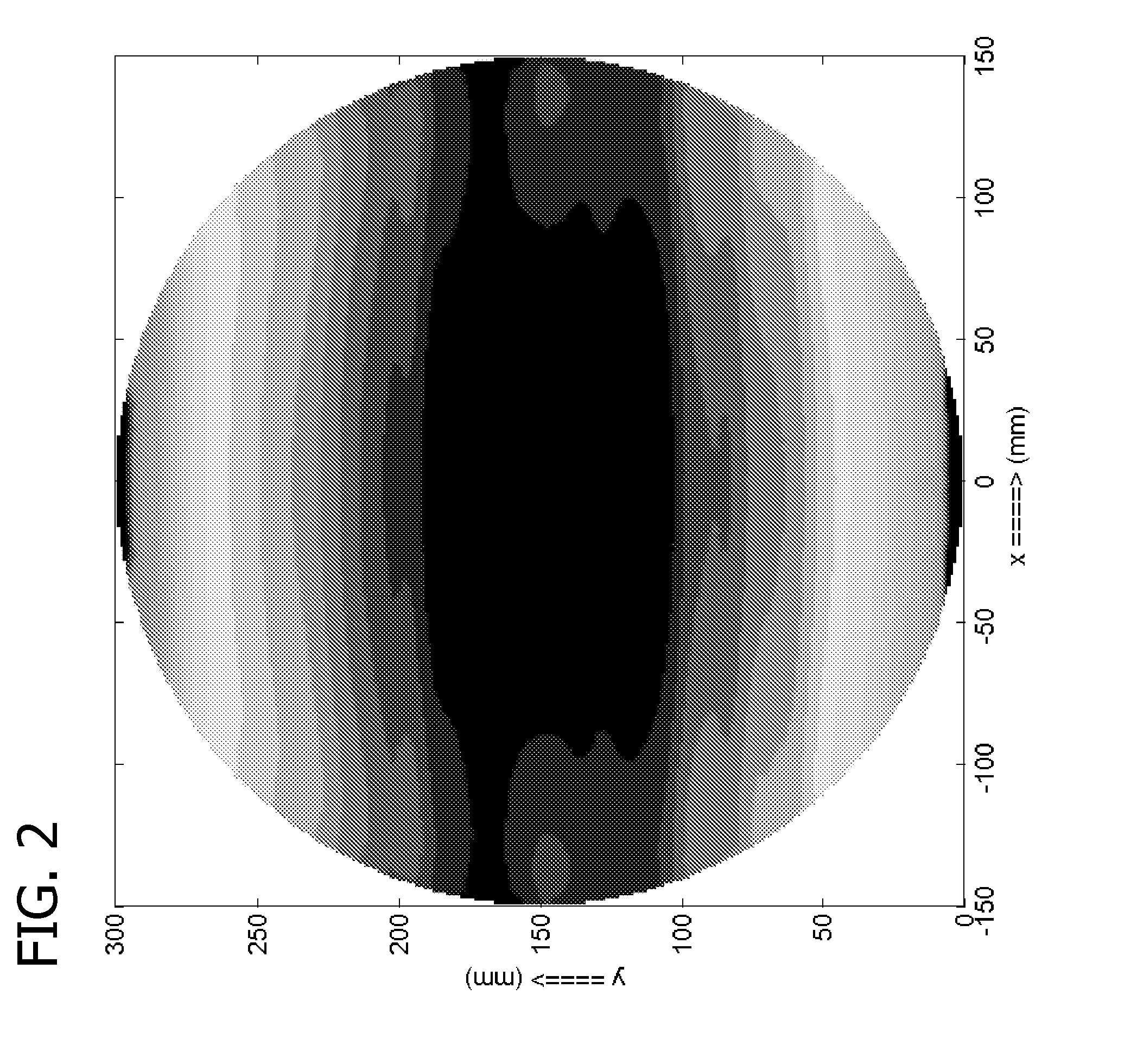

Wire saw ingot slicing system and method with ingot preheating, web preheating, slurry temperature control and/or slurry flow rate control

InactiveUS20070178807A1Reduce warpageBelt grinding machinesGrinding feed controlControl flowTemperature control

A system and method for slicing an ingot into wafers using the wire saw process. A slurry collection system collects and supplies slurry to a slurry handling system for controlling temperatures and / or flow rates of the slurry thereby providing slurry output at a controlled temperature and / or a controlled flow rate to slicing system for cutting the ingot, which may be preheated.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

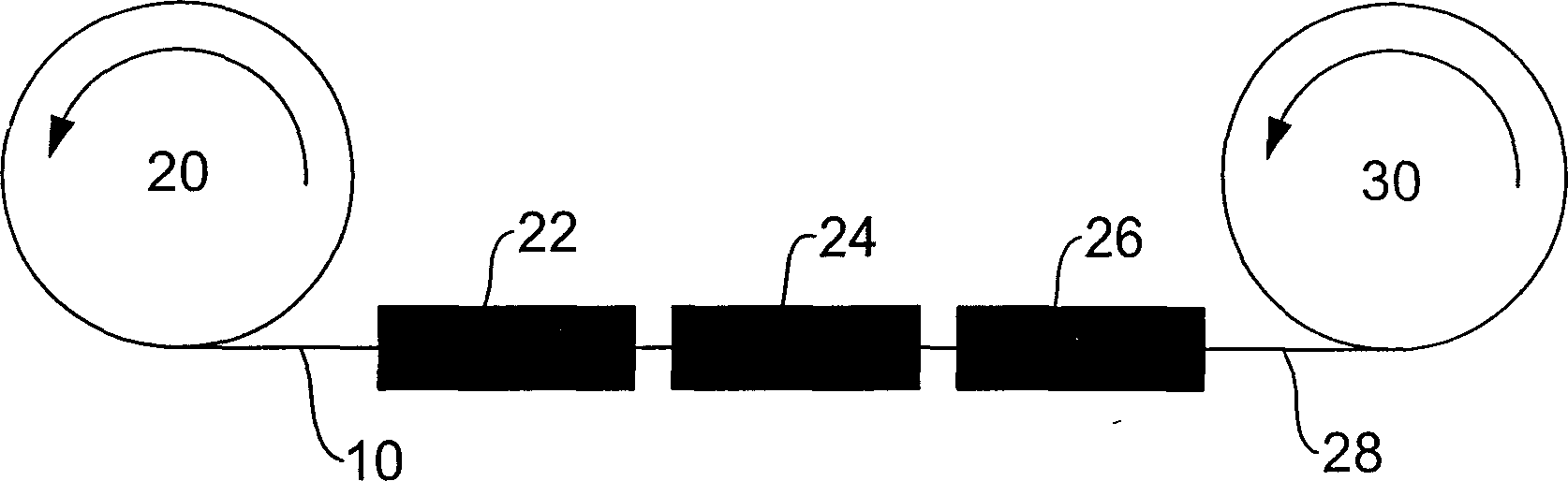

Cutting method by wire saw and cut workpiece receiving member in wire saw

InactiveUS20070131213A1Accurately cut outEnhance wafer cleansing performanceWorkpiece holdersBelt grinding machinesEngineeringAbutment

In a cutting method by a wire saw, in which a wire A at a wire array wound around work rollers 10 is made to reciprocate or travel in one direction at a high speed and numerous pieces of wafers are cut out in abutment of a workpiece B against the wire array, a receiving member 27 of a cassette type having numerous support wires 34 arranged at the same pitch as that of the wire at the wire array is disposed at a position immediately under the wire array for cutting the workpiece B; and wafers b cut out of the workpiece B by the wire A are contained in separation one from another between the support wires 34 in the receiving member 27. Thus, the wafers can be prevented from adhering to each other during a cutting operation, thus to be accurately cut, and further, the wafers can be prevented from being cracked during the cutting operation, thus to be efficiently separated one from another, so as to enhance wafer cleansing performance.

Owner:TAKATORI

Superabrasive wire saw and associated methods of manufacture

InactiveCN1852796AUnderstanding contributionAbrasion apparatusMetal sawing toolsChemical LinkageFilling materials

A superabrasive wire saw having a plurality of individual coated superabrasive particles (14) attached to a wire (10) with an organic binder (42) is disclosed and described. The superabrasive particle (46) can be coated with a solidified coating (48) of a molten braze alloy that is chemically bonded to the superabrasive particle (46). The organic binder ( 42) can optionally contain filler materials and / or an organometallic coupling agent to improve the retention of coated superabrasive particles (14). The resulting superabrasive wire saws (28) can be produced having diameters of less than 0.5 mm, which significantly reduce kerf loss. Various methods for making and using such a superabrasive wire saw are additionally disclosed and described.

Owner:RITEDIA CORPORATION

Method for mining coal of steeply inclined thin seam

InactiveCN101737047ALow costEasy dischargeUnderground miningBlastingMining engineeringEconomic benefits

The invention provides a method for mining coal of a steeply inclined thin seam on the basis of learning from a long-hole blasting coal mining method and a wire saw coal mining method, which is a long-hole blasting and wire saw coal mining method and relates to underground coal mining. The method comprises the following steps: long boreholes are arranged in a direction which is parallel to the cross pitch of the coal seam for coal blasting; after finishing blasting a work surface, making the coal slip out from a section coal bin and loading the coal for outward transport through a haulage drift; and when blasting to the vicinity of a tailgate through the long boreholes, stopping the blasting and utilizing a wire saw to mine remaining coal. The method has the advantages of no work surface support, rational tunnel arrangement, simple ventilation management, the capacity of realizing unmanned work surface mining, low cost, strong security, high coal mining rate, low worker labor intensity, good social and economic benefits and the like.

Owner:孙广义 +2

Electroplating diamond fretsaw with grinding materials controllably distributed and preparation method

ActiveCN103100987AReduce usageIncrease profitMetal sawing toolsGrinding devicesRegion selectionDiamond wire saw

The invention discloses an electroplating diamond fretsaw with grinding materials controllably distributed and a preparation method. The electroplating diamond fretsaw is composed of a steel wire base body and diamond grinding materials, and is characterized in that the diamond grinding materials on the fretsaw are electrically deposited on a surface of the steel wire base body according to a pre-arranged shape, and a chip removal groove is formed on a none-deposited-diamond surface of the grinding materials. The preparation method comprises the following critical steps: region selection and coating processing are conducted on the surface of the steel wire base body, and a reserved none-grinding-material surface of the steel wire base body is coated with a pre-arranged shape; sand-feeding process is conducted on surfaces of the steel wire base body, the steel wire base body enters an electroplating groove, and the diamond grinding materials are electrically deposited on an uncoated region of the base body; and coating removal processing is conducted on the surface of the steel wire base body, the steel wire base body enters a coating removal groove to remove the coating, and manufacturing of the diamond fretsaw is finished. The electroplating diamond fretsaw with the grinding materials controllably distributed and the preparation method have the advantages of being high in cutting efficiency, long in service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

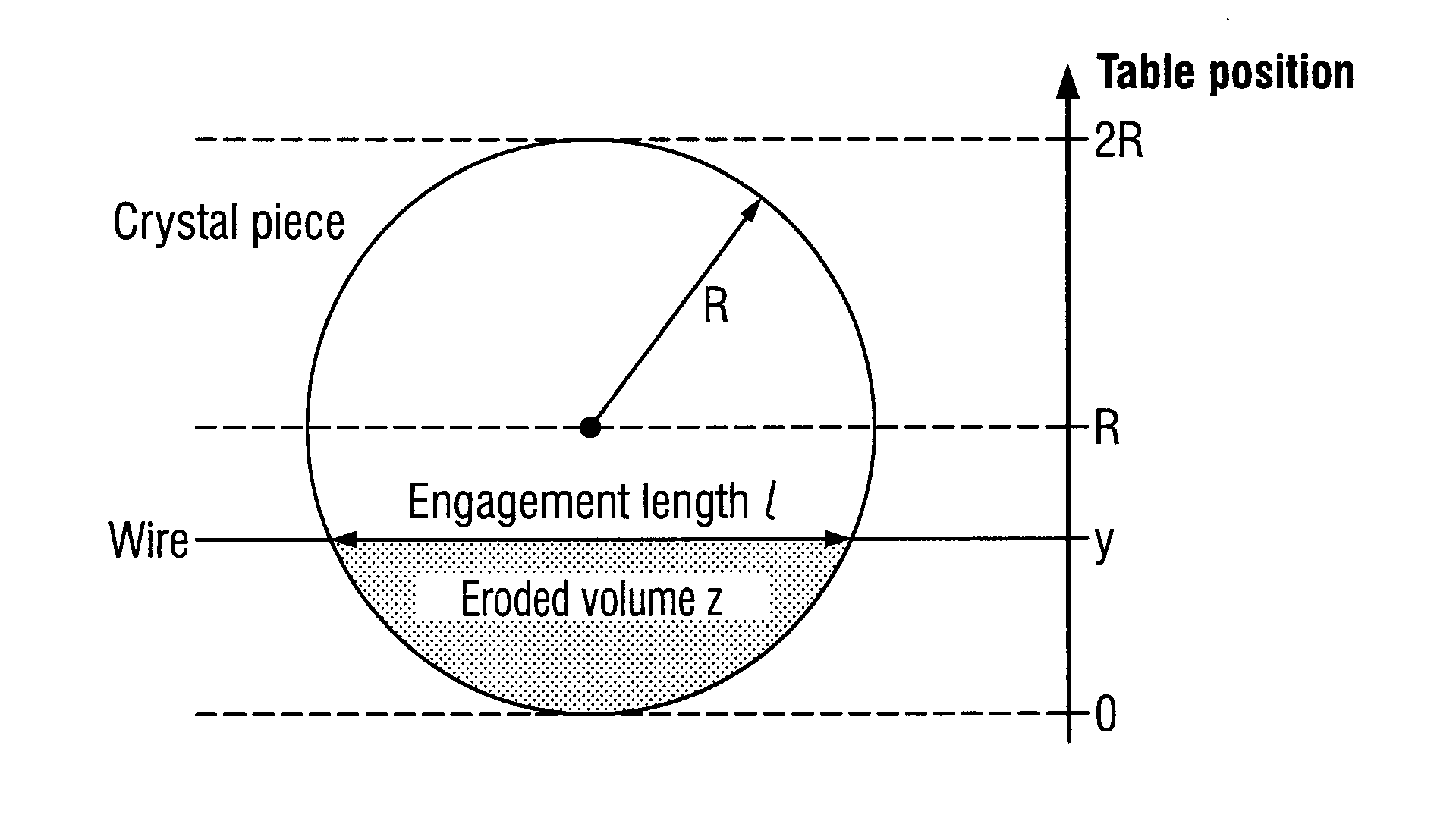

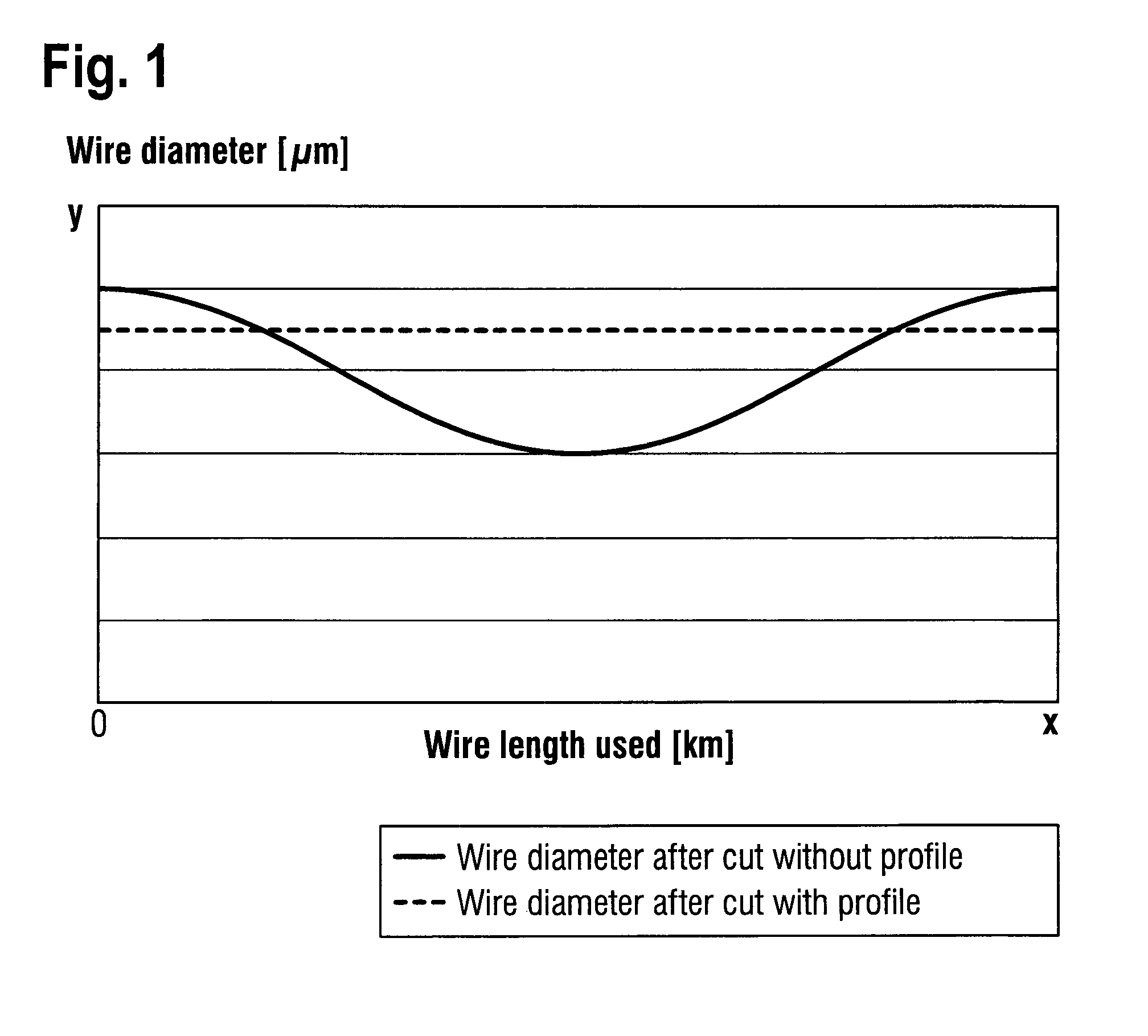

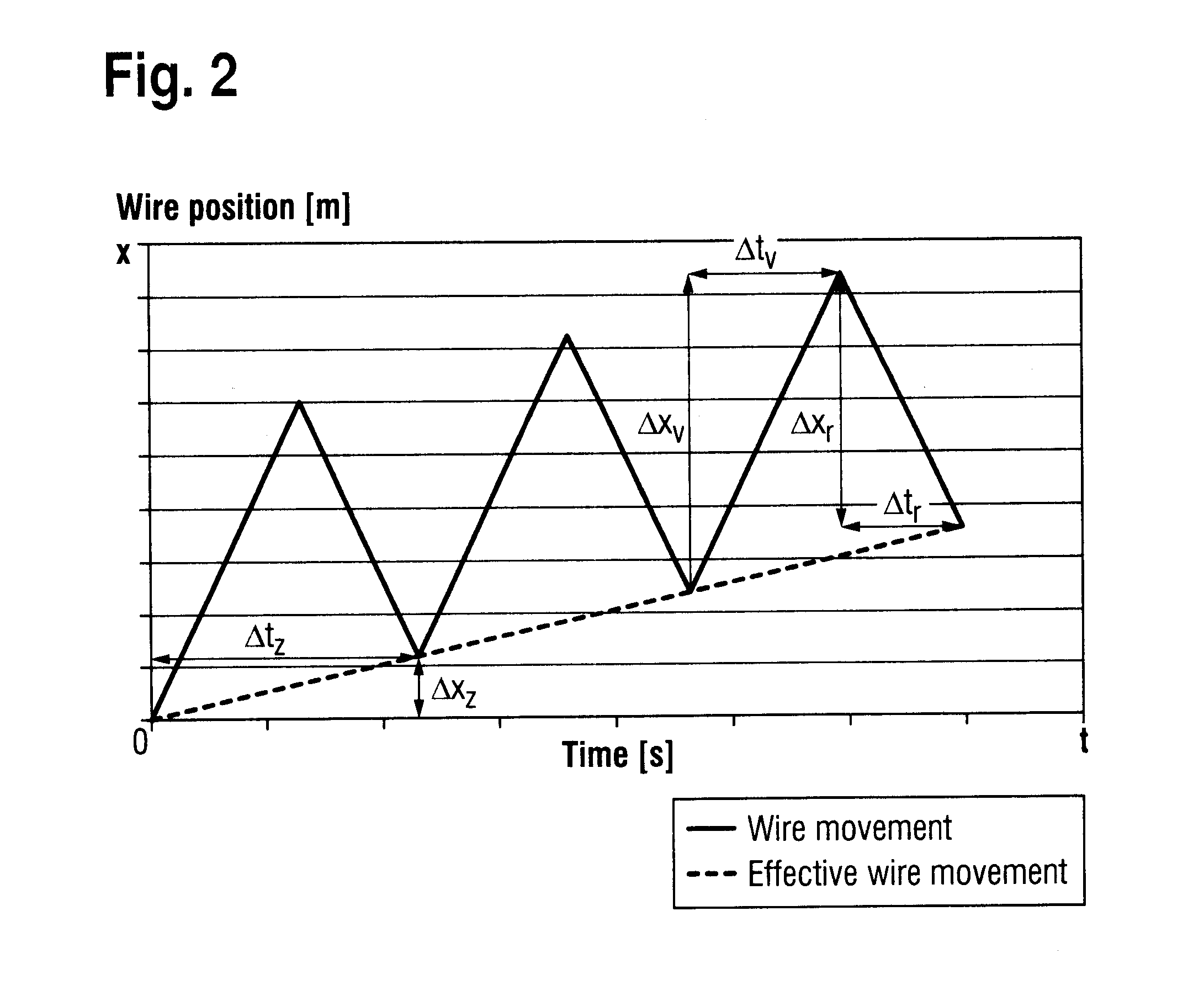

Method For Slicing A Multiplicity Of Wafers From A Workpiece

ActiveUS20080141994A1Uniform wearAvoid disadvantagesMetal sawing devicesMetal sawing accessoriesWire rodEngineering

A multiplicity of wafers are sliced from a workpiece which has a longitudinal axis and a cross section, the workpiece fastened on a table being fed by a relative movement directed perpendicularly to the longitudinal axis of the workpiece between the table and the wire gang of a wire saw, with a variable forward feed rate through the wire gang formed by a sawing wire moved with an effective speed, the effective speed of the sawing wire being regulated as a function of the forward feed rate and the workpiece cross section so as to result in uniform wear of the sawing wire.

Owner:SILTRONIC AG

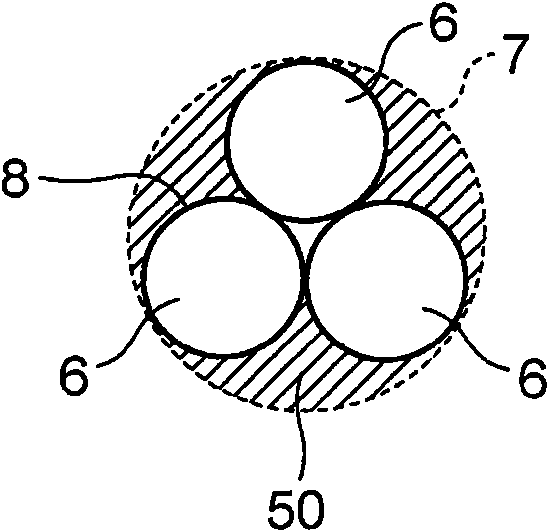

Resin bonder wire saw

InactiveCN101712135AGood flexibilityHigh bending fatigue mildGrinding machinesTwist drillsWire sawContour line

The invention discloses a resin bonder wire saw, which comprises a core wire consisting of a plurality of single wires (6) which are twisted together, a first resin layer (3) which has a first resin and covers the core wire, a second resin layer which has a second resin and covers the first resin layer (3) and adhesive particles (4) immobilized on the second resin layer (5), wherein the diameter of the circumcircle of the cross section of the single wires is equal to or more than 0.20 millimeters and equal to or less than 0.40 millimeters; and the area of the cross section of an area enclosed by the contour line of the single wires (6) and the circumcircle of the single wires is equal to or more than 30 percent of the area of the cross section of the circumcircle and is equal to or less than 55 percent of the area of the cross section of the circumcircle.

Owner:NORITAKE SUPER ABRASIVE CO LTD +1

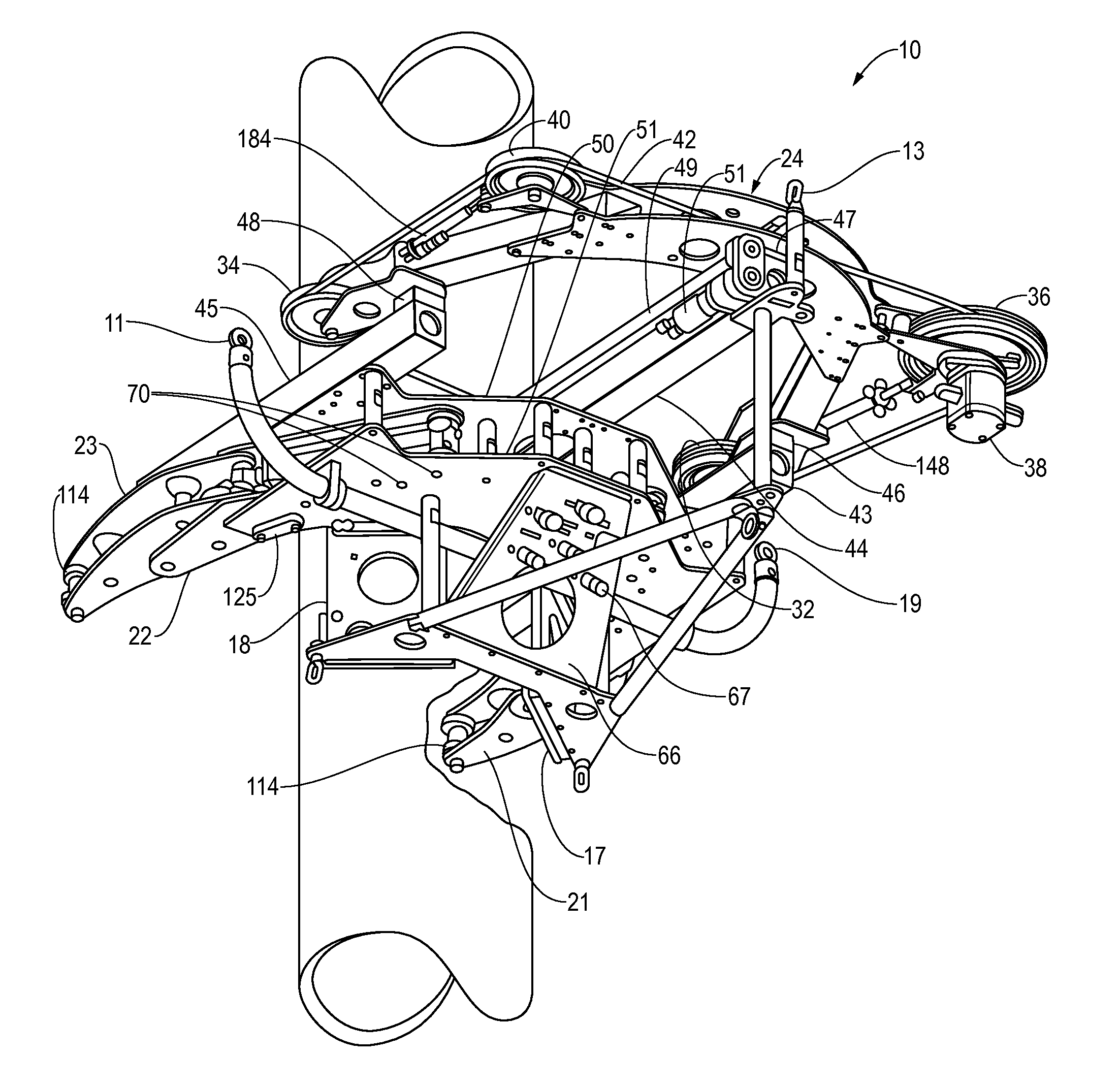

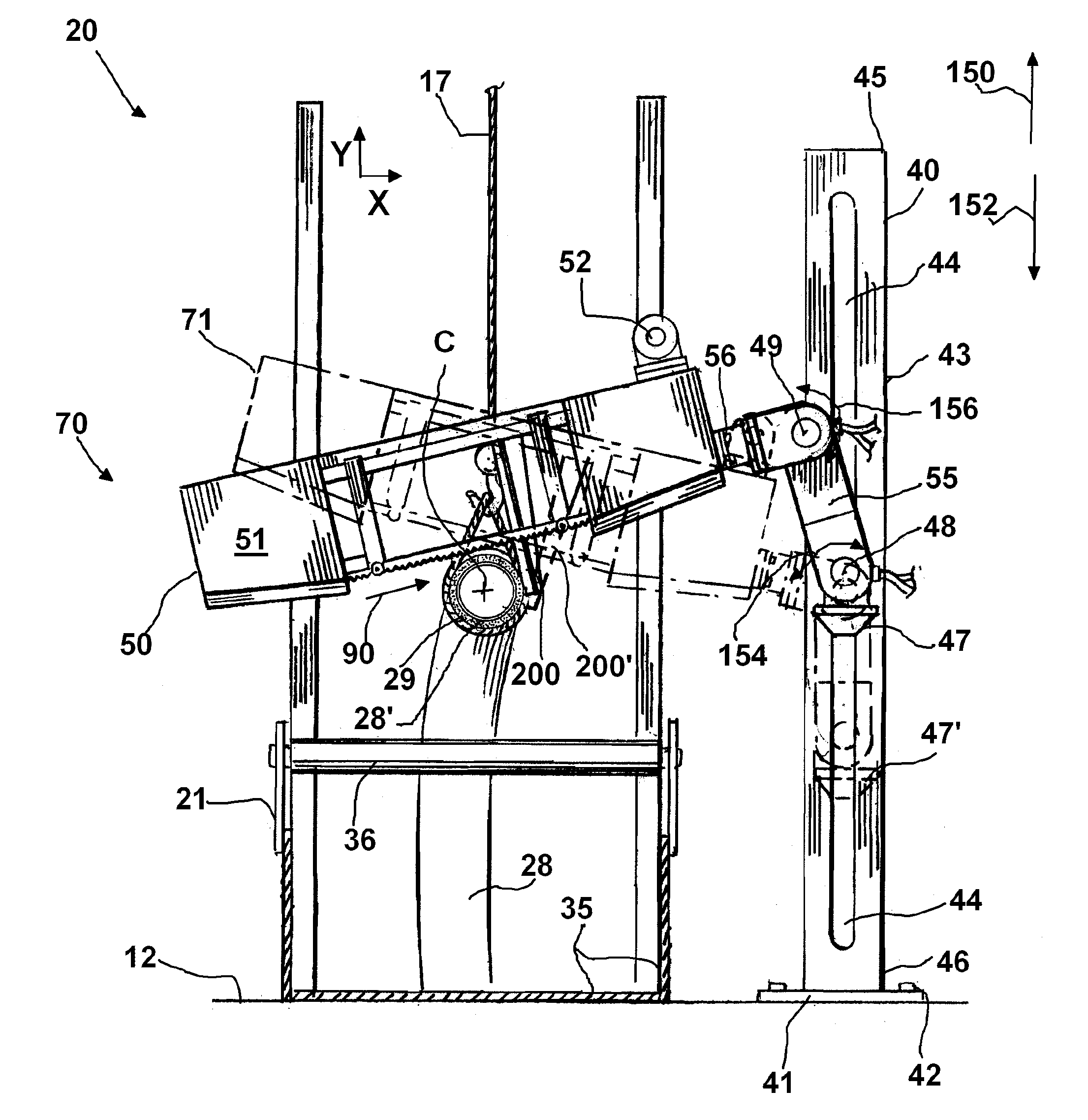

Articulating band saw and method

ActiveUS8475081B2Eliminate needImprove securityMetal sawing devicesPipe laying and repairDiamond wire sawActuator

An articulating band saw apparatus provides a frame that includes a vertically extending section having upper and lower end portions. An elevator moves between the upper and lower end portions of the frame. A first hydraulic actuator is supported on the elevator for movement therewith. A first arm provides arm end portions, the first arm supported by the first hydraulic actuator. An end of the first arm supporting a second hydraulic actuator that is spaced away from the first hydraulic actuator. The second hydraulic actuator supports a second arm. An endless band type saw is mounted on the free end of the second arm generally opposite the second actuator. The band saw is movable by articulation of the first and second actuators and resulting movement of the first and second arms. In one embodiment, the band saw is a diamond wire saw.

Owner:AES EOT EQUIP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com