Patents

Literature

1000results about How to "Uniform wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

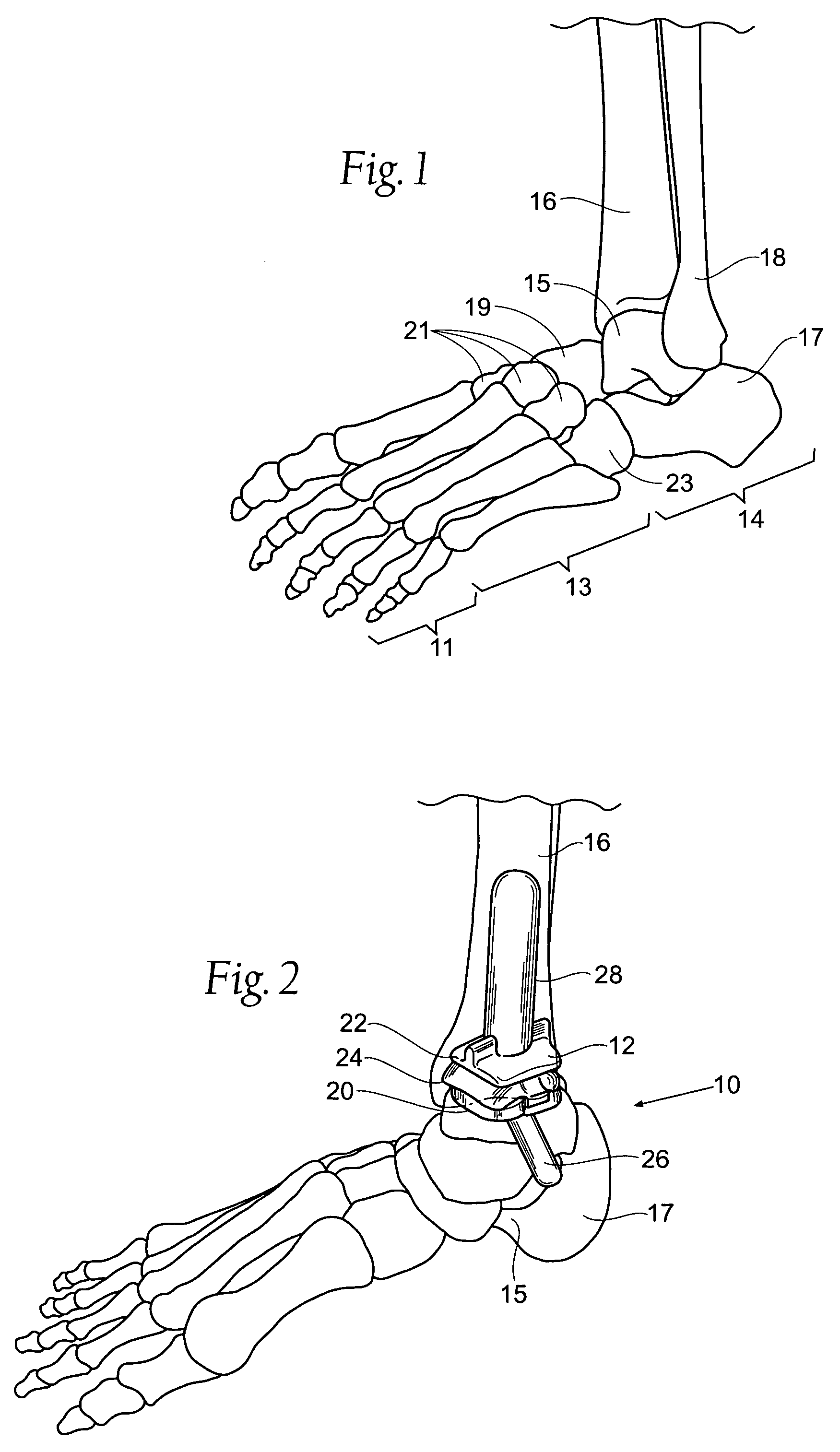

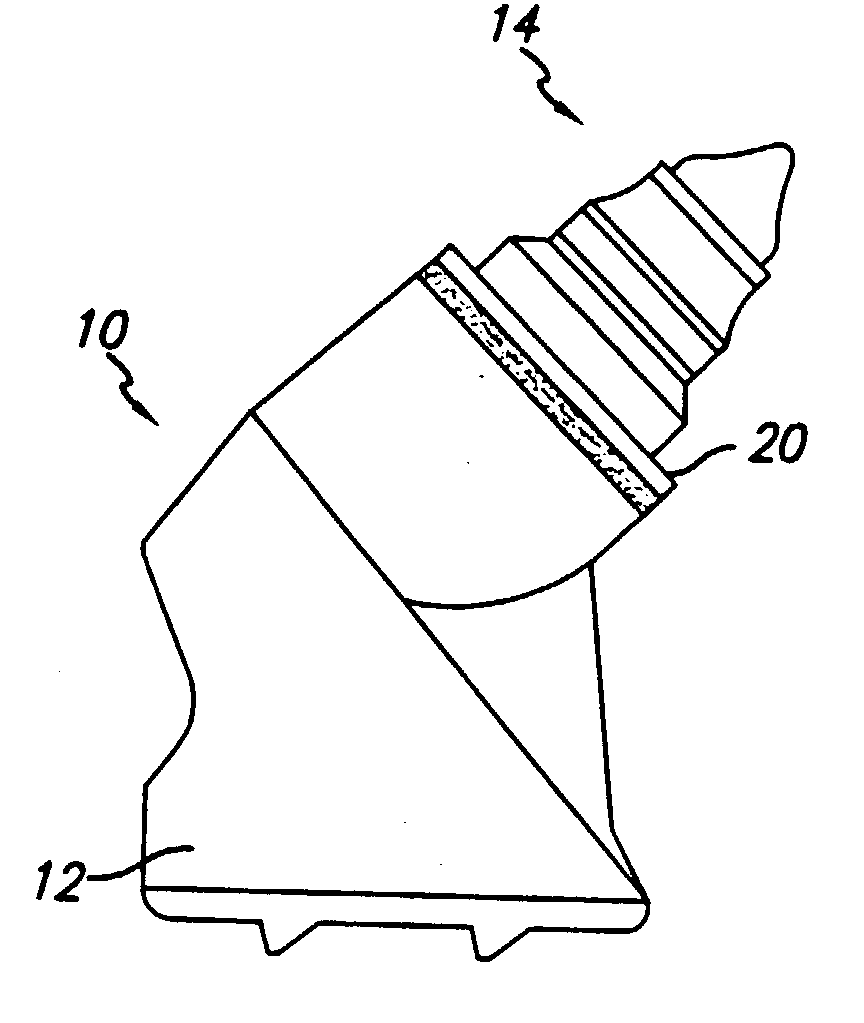

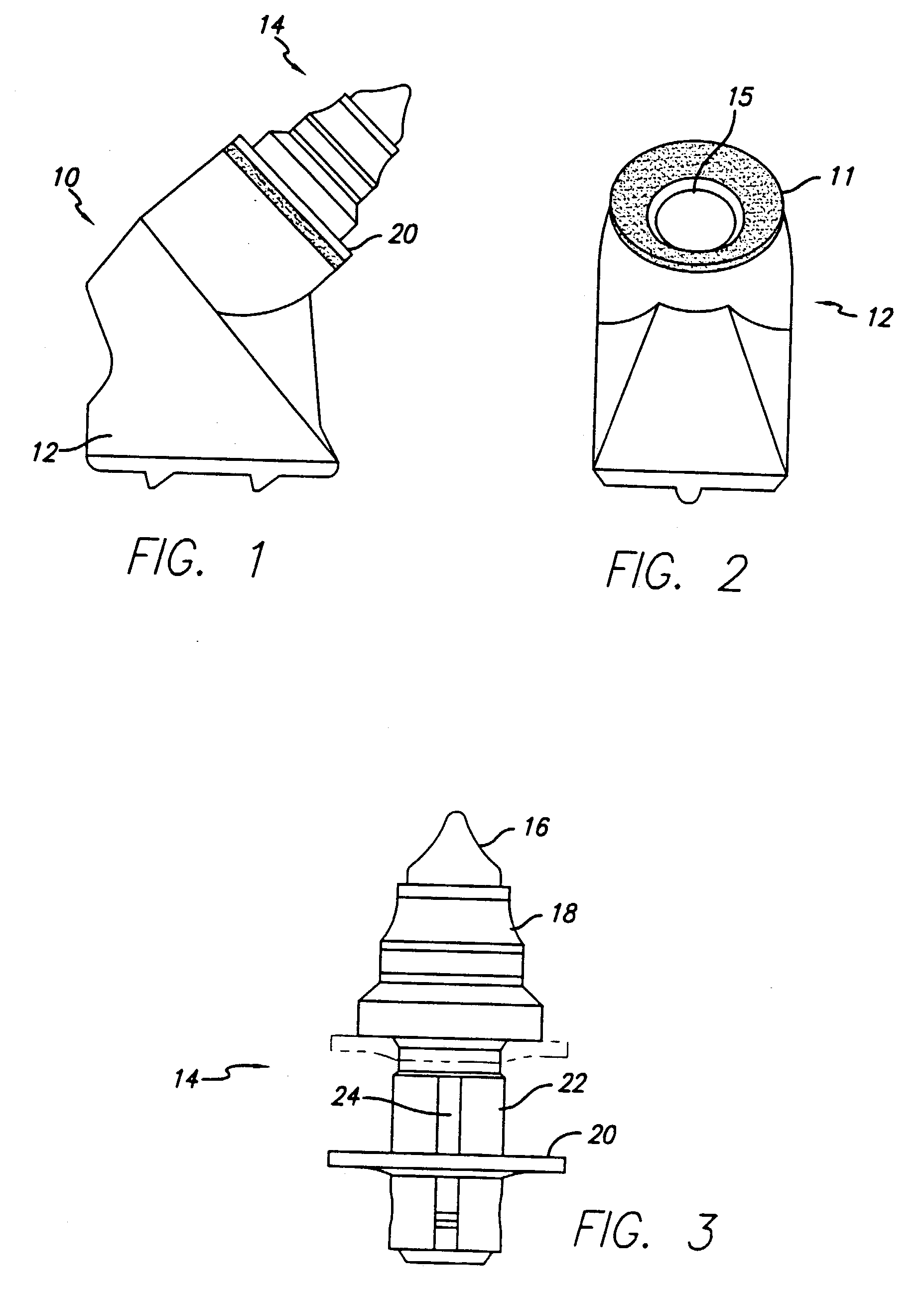

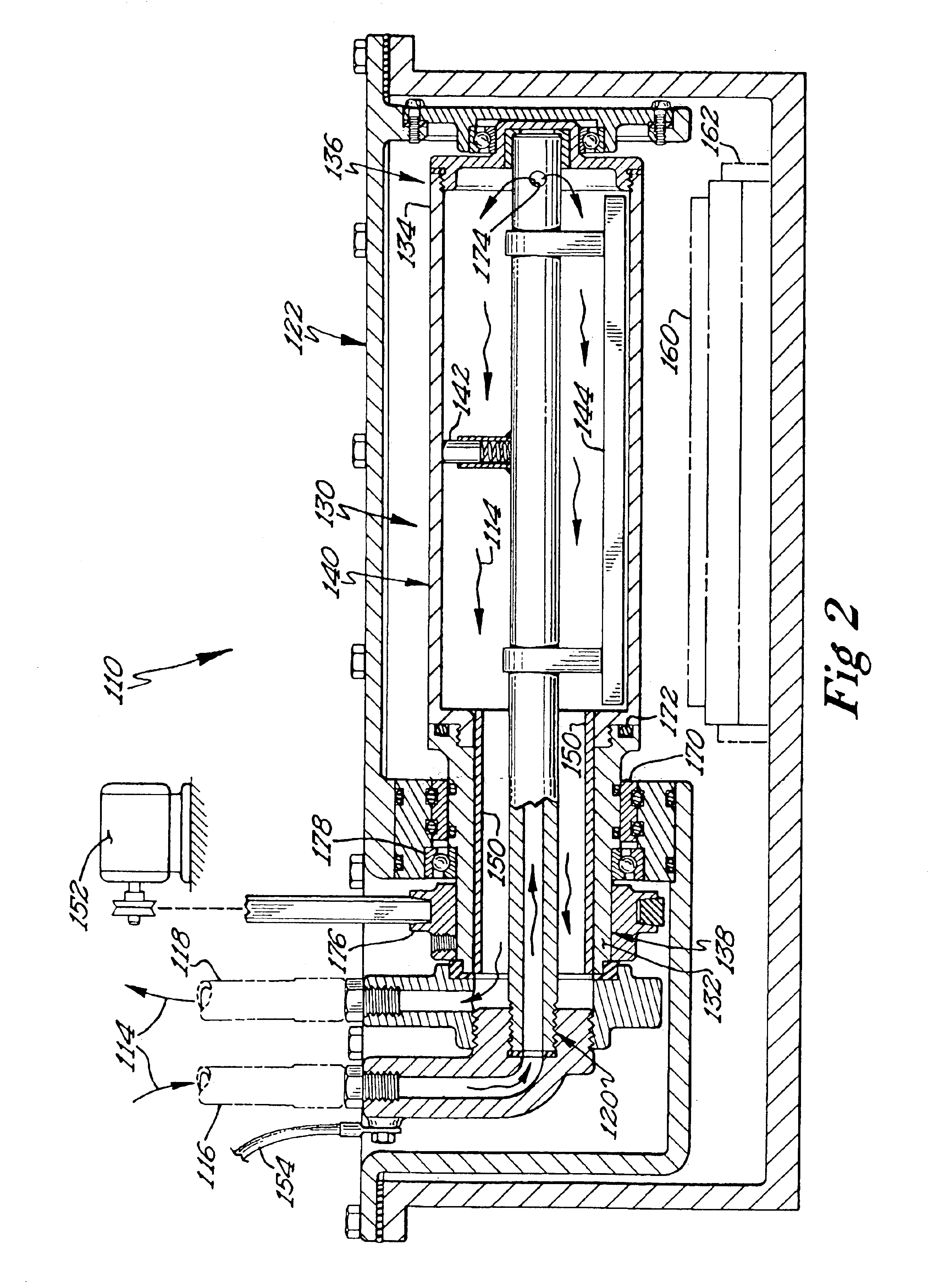

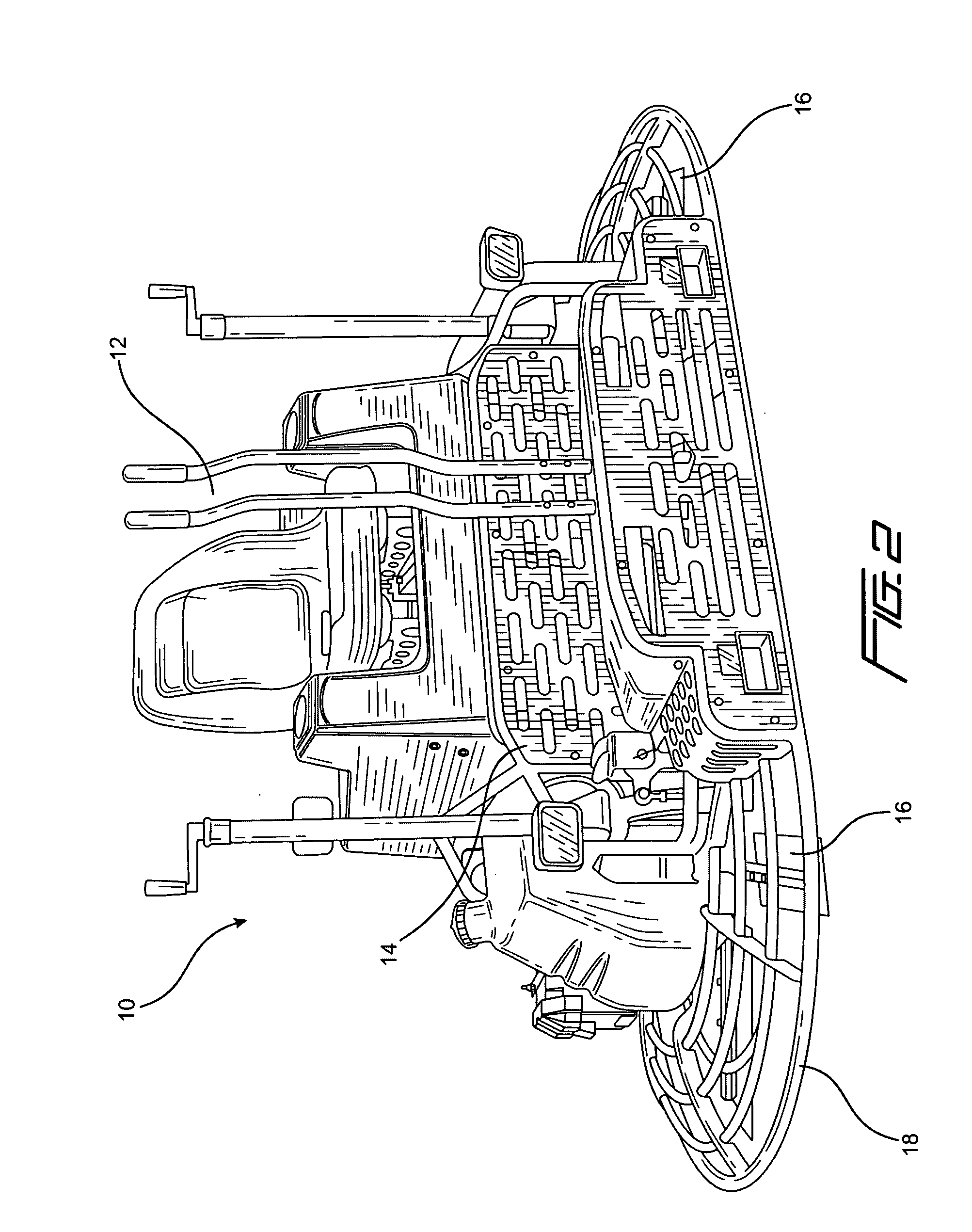

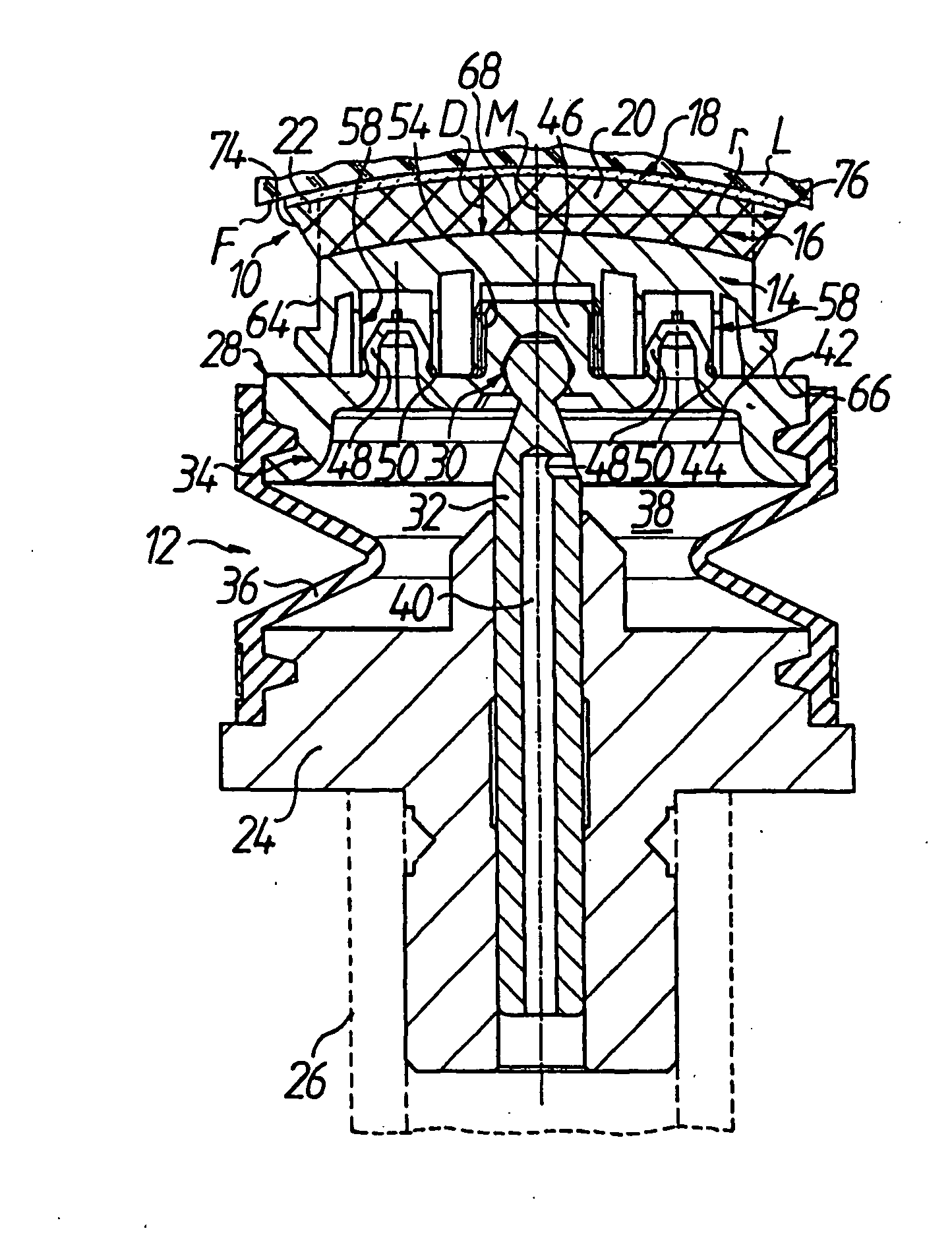

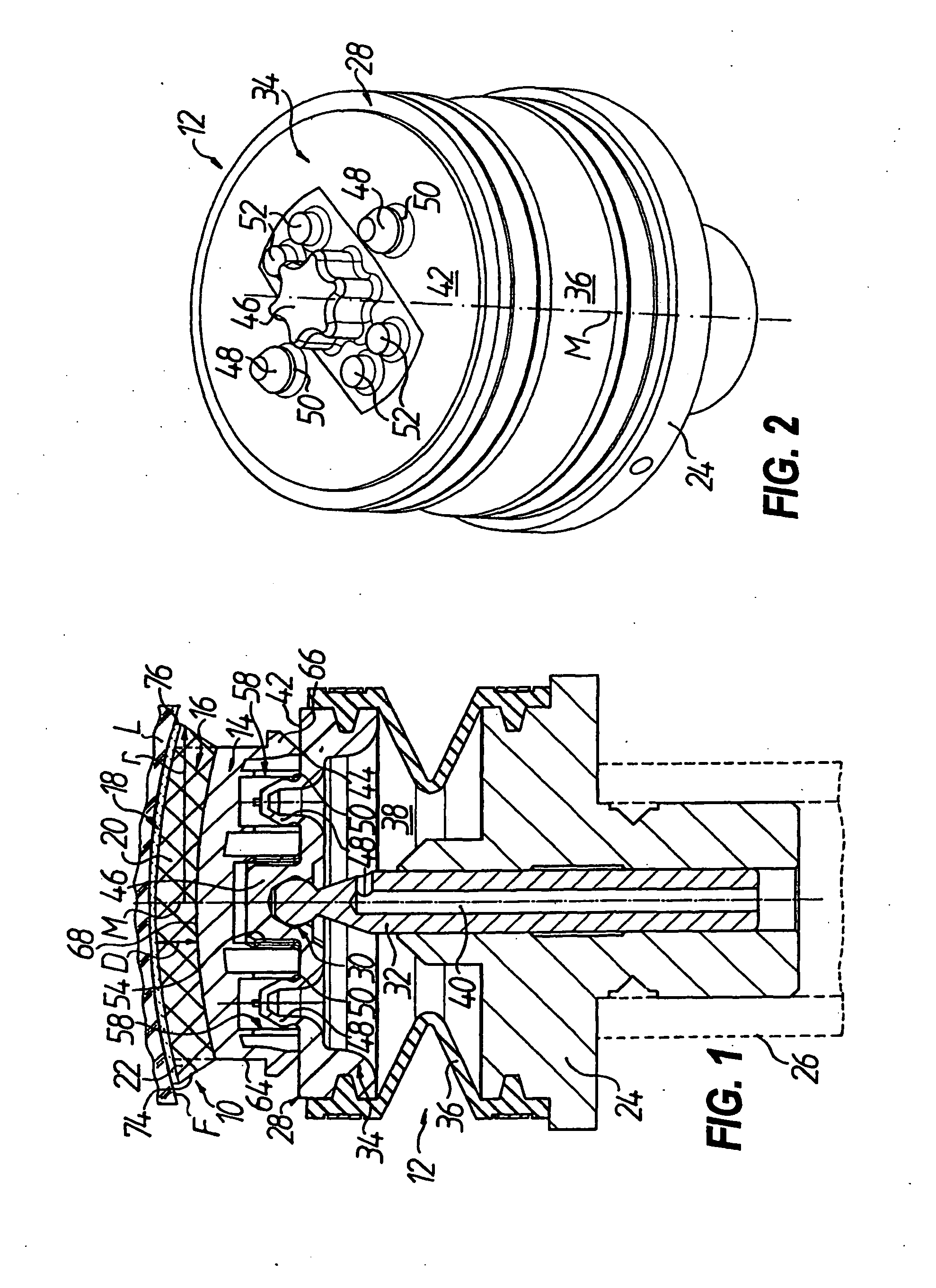

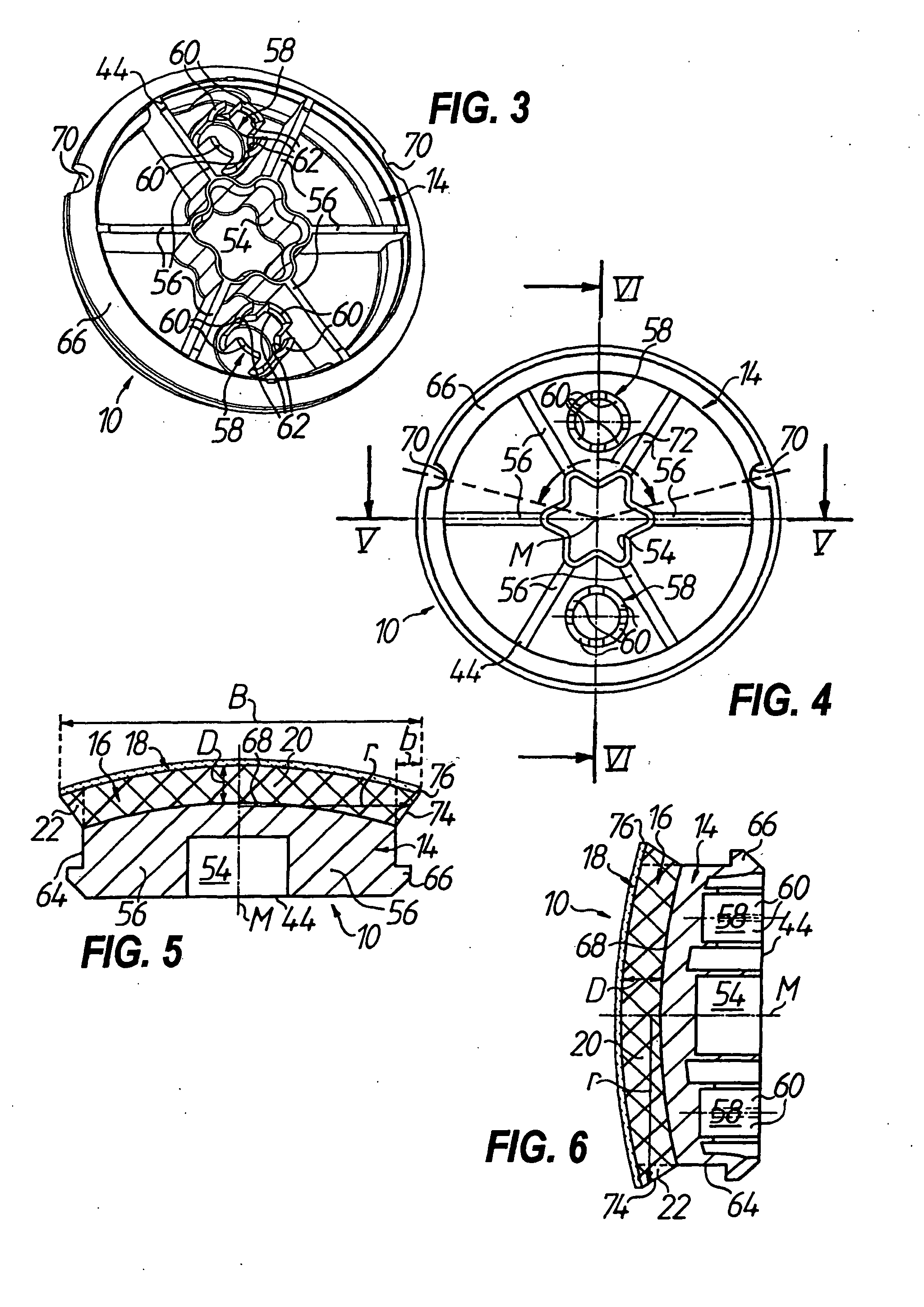

Ankle replacement system

ActiveUS20060229730A1Improved long-term resultPrecise positioningWrist jointsAnkle jointsCalcaneusAnkle joint replacement

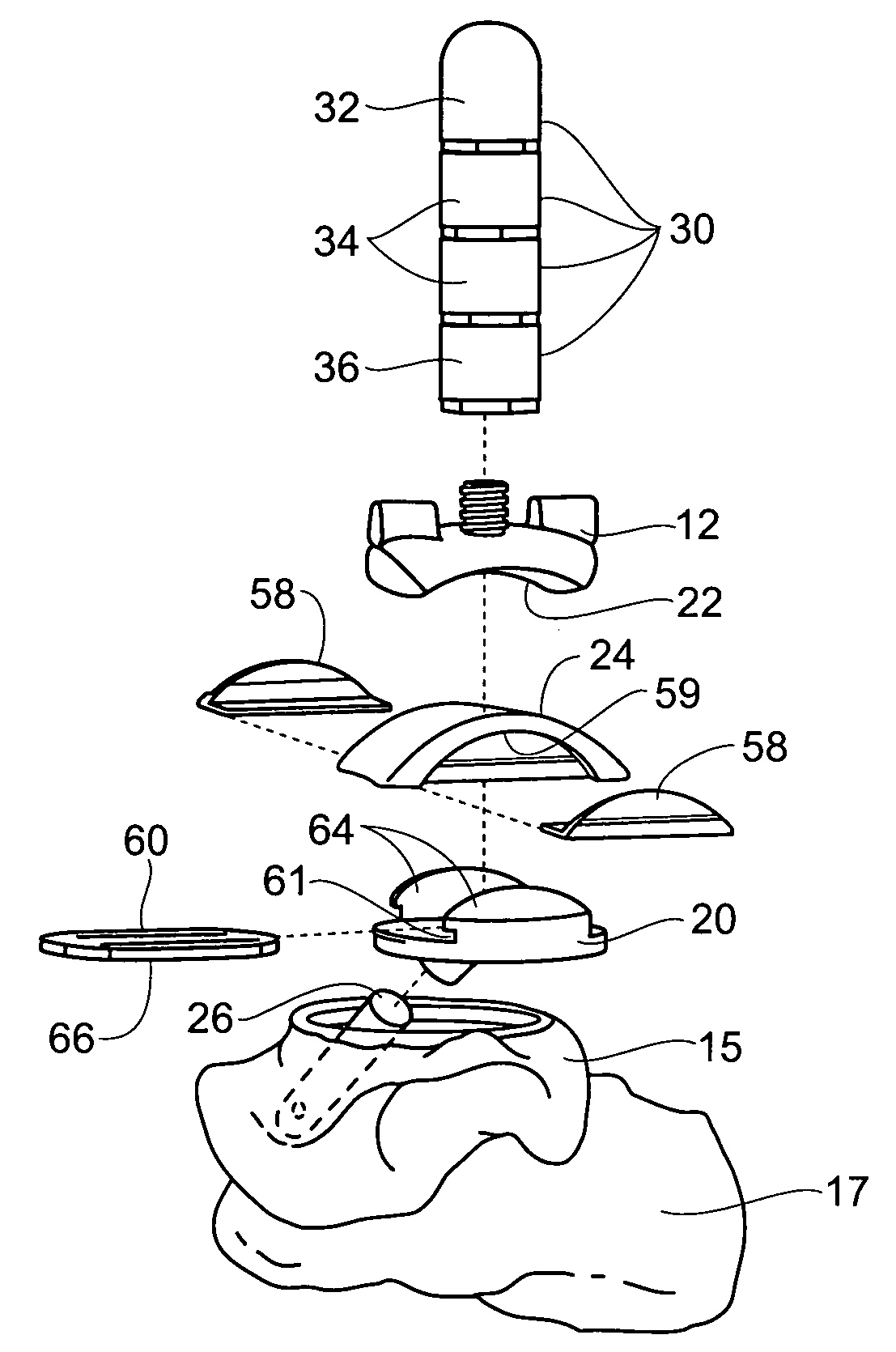

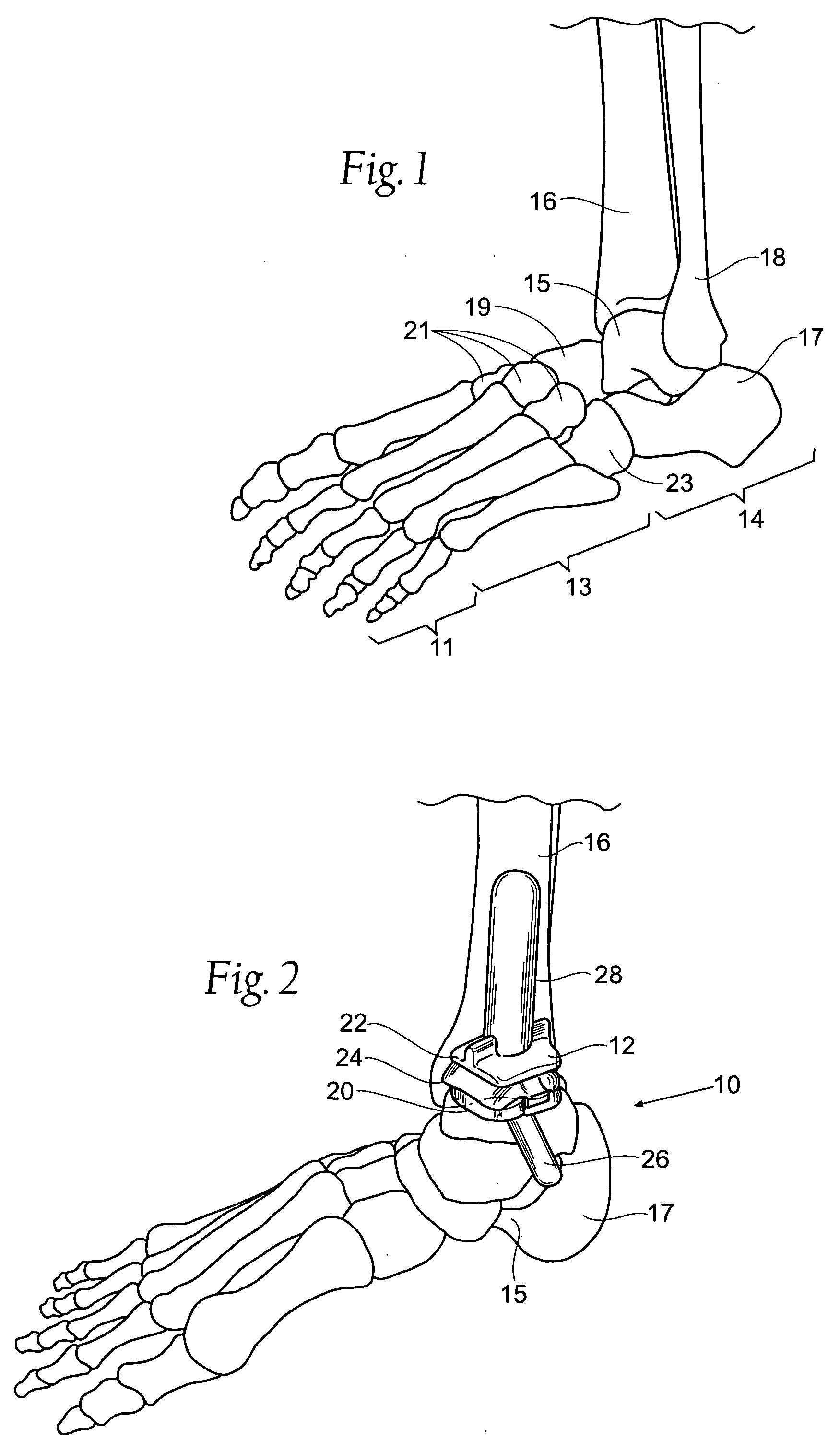

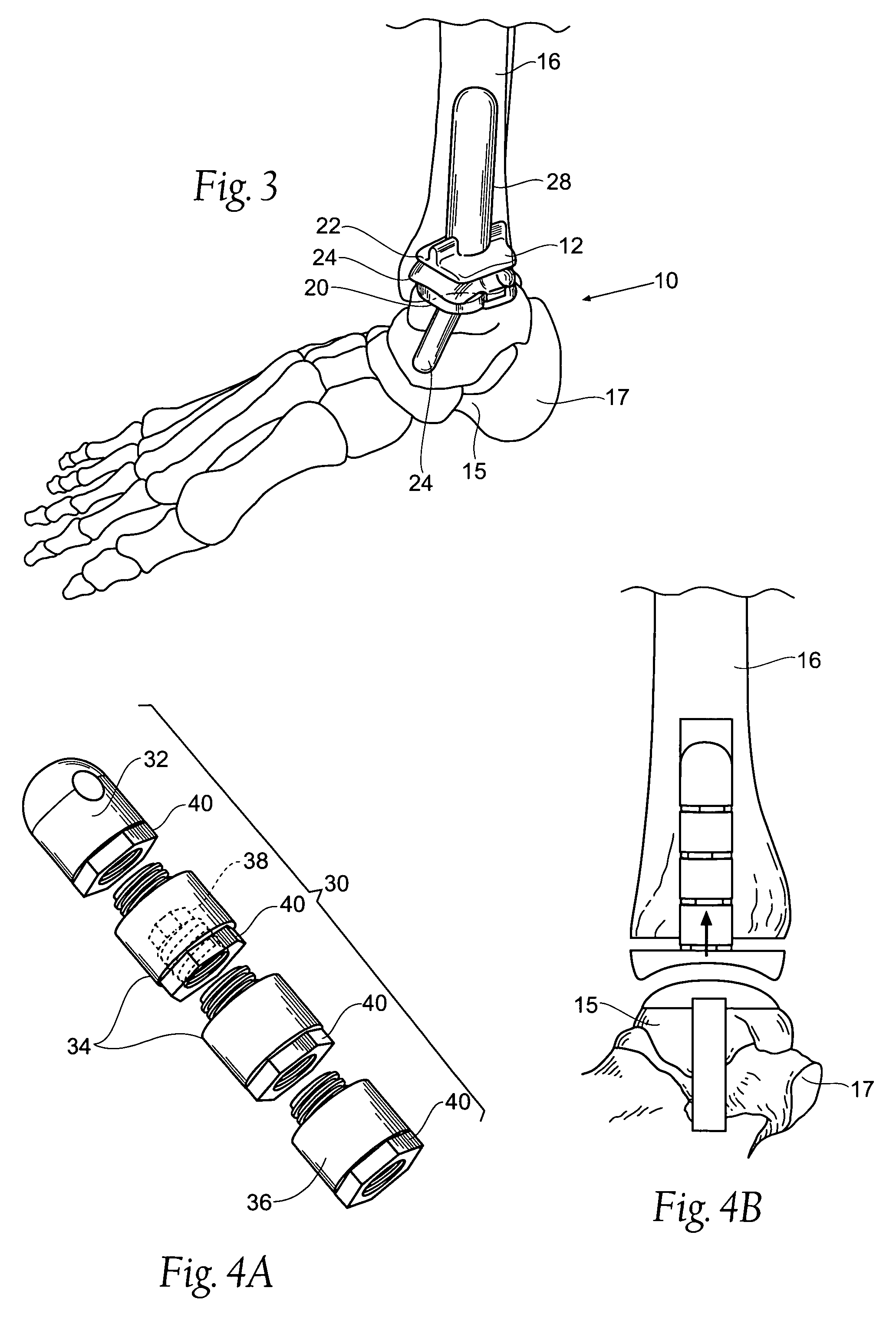

A prosthesis suited for orthopedic implantation possesses a multi-piece stem component that supports an artificial joint surface that can articulate with another artificial joint surface in various ways. The prosthesis can be assembled in a snap fit and / or interlocking fashion that provides positive locking means without the use of screws or other fasteners. The prosthesis can accommodate fitment of a plastic joint surface made, e.g., from ultra high molecular weight polyethylene. The prosthesis is well suited for use in an ankle replacement system that can be installed using minimally invasive intramedullary guidance established with respect to the major axis of the tibia by minimally invasive access through the calcaneus, through an incision in the bottom of the foot. The prosthesis makes possible the installation of a total ankle system using minimally invasive anterior access to the ankle joint for making bony cuts and to install prosthesis components.

Owner:INBONE TECH

Ankle replacement system

ActiveUS7534246B2Function maximizationMaximize longevityWrist jointsAnkle jointsArticular surfacesAnkle joint replacement

A prosthesis suited for orthopedic implantation possesses a multi-piece stem component that supports an artificial joint surface that can articulate with another artificial joint surface in various ways. The prosthesis can be assembled in a snap fit and / or interlocking fashion that provides positive locking means without the use of screws or other fasteners. The prosthesis can accommodate fitment of a plastic joint surface made, e.g., from ultra high molecular weight polyethylene. The prosthesis is well suited for use in an ankle replacement system that can be installed using minimally invasive intramedullary guidance established with respect to the major axis of the tibia by minimally invasive access through the calcaneus, through an incision in the bottom of the foot. The prosthesis makes possible the installation of a total ankle system using minimally invasive anterior access to the ankle joint for making bony cuts and to install prosthesis components.

Owner:INBONE TECH

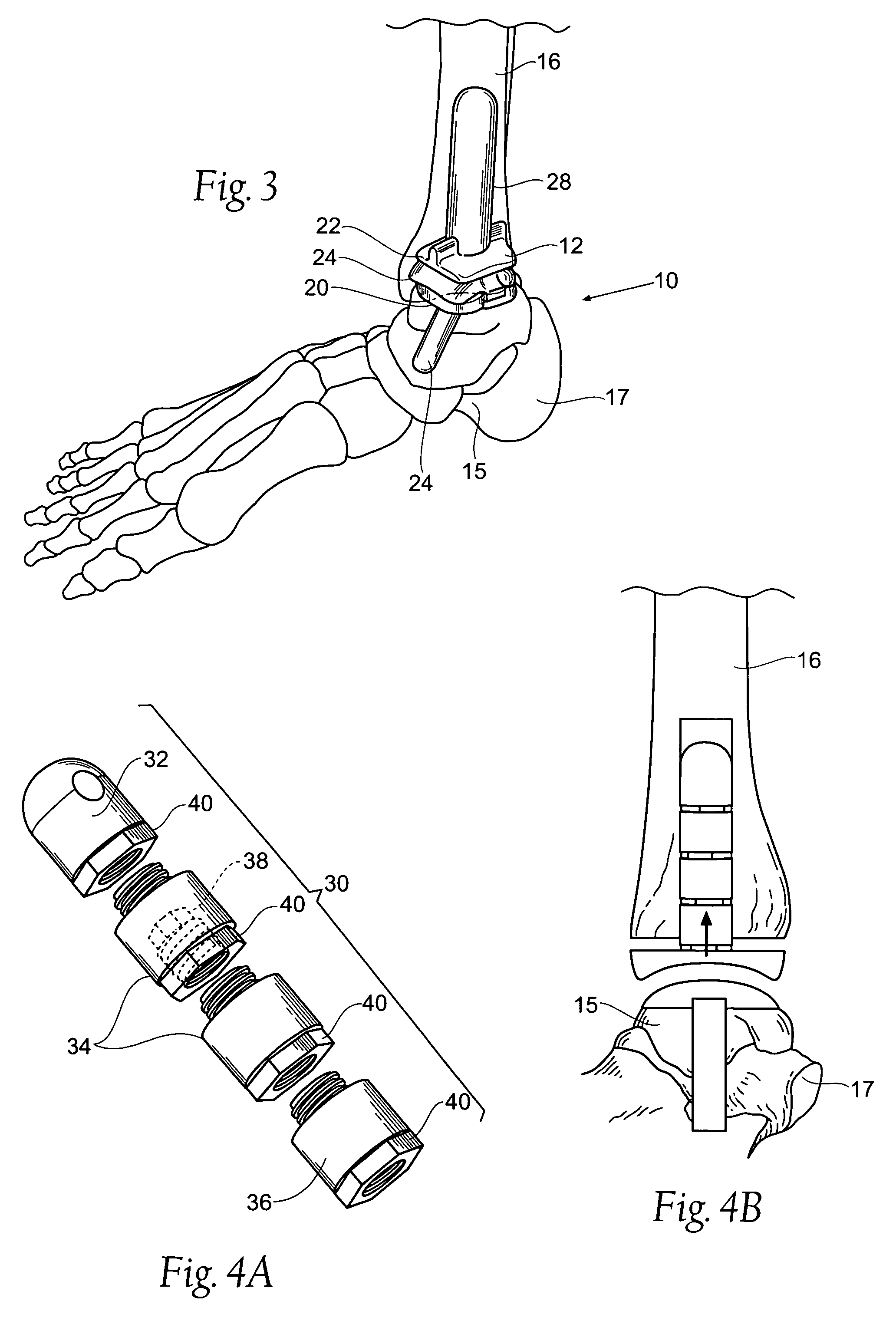

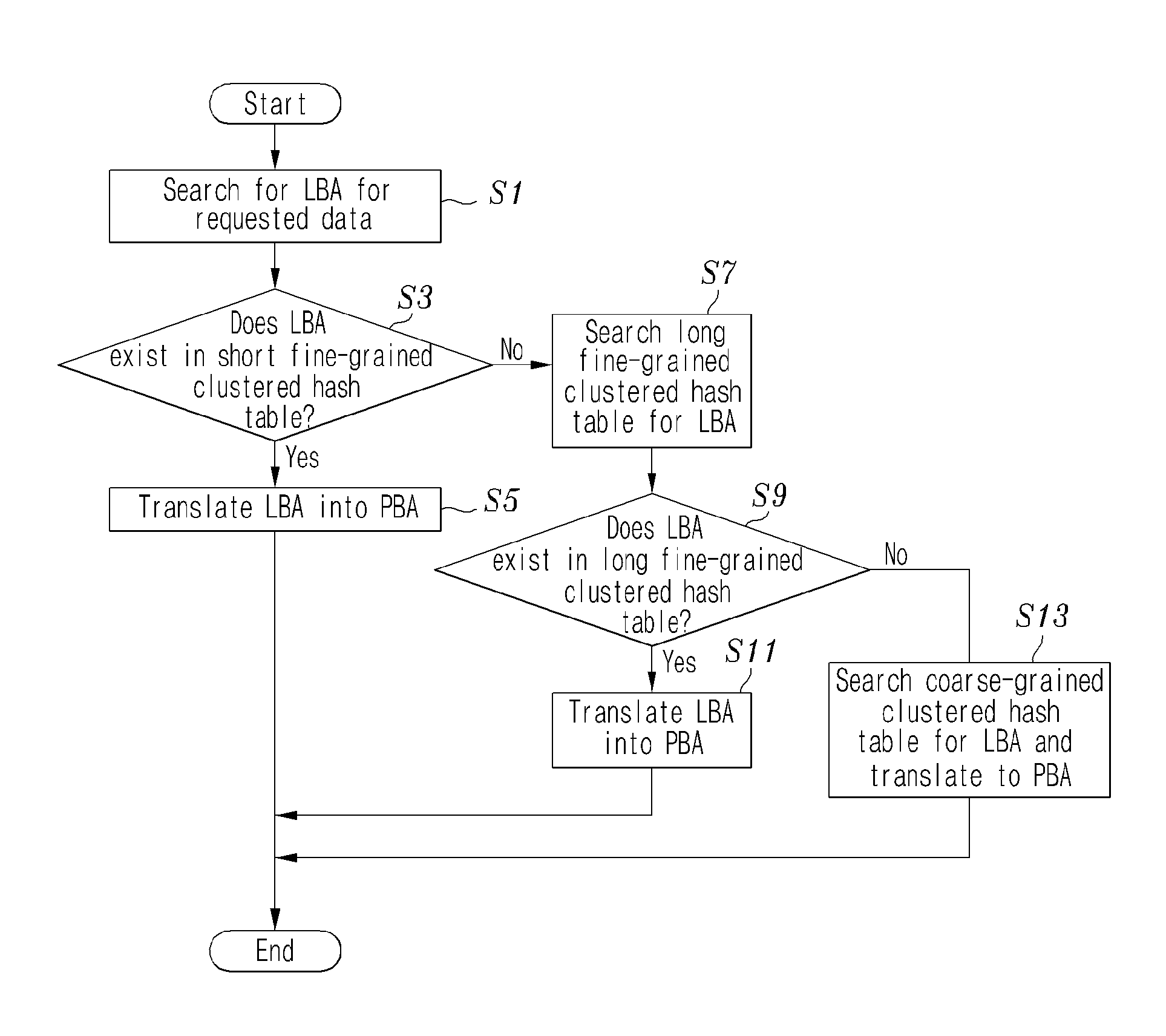

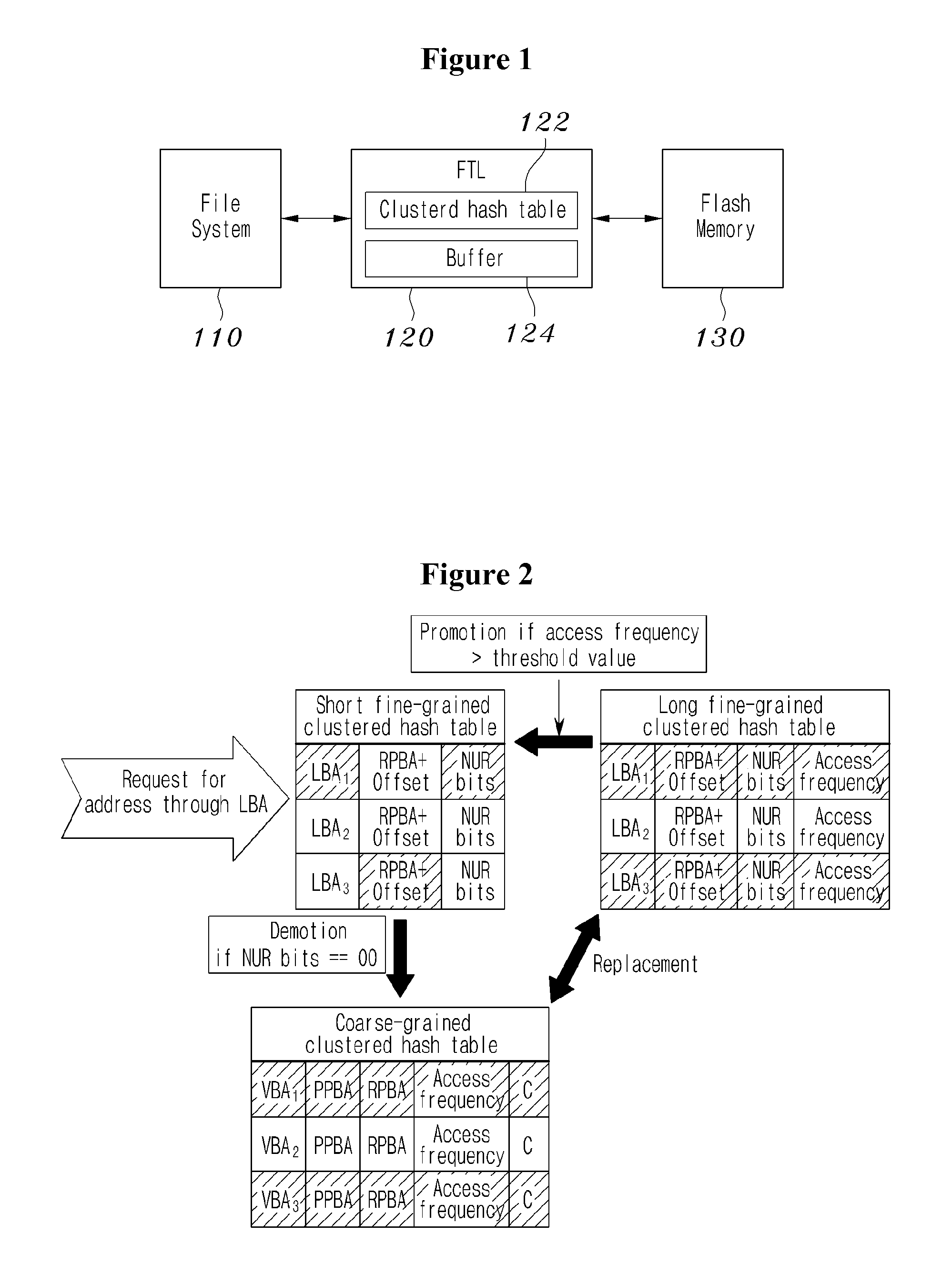

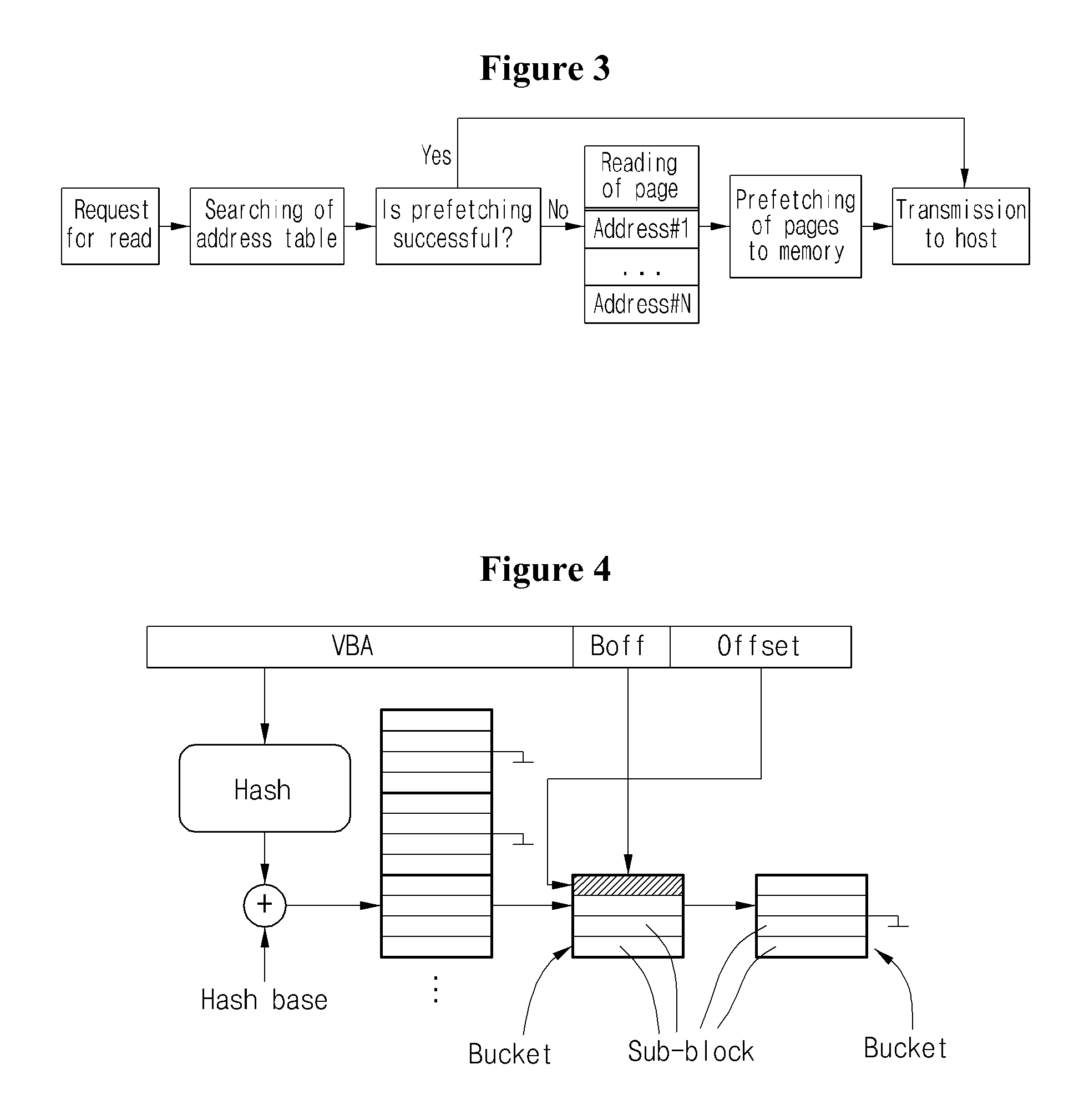

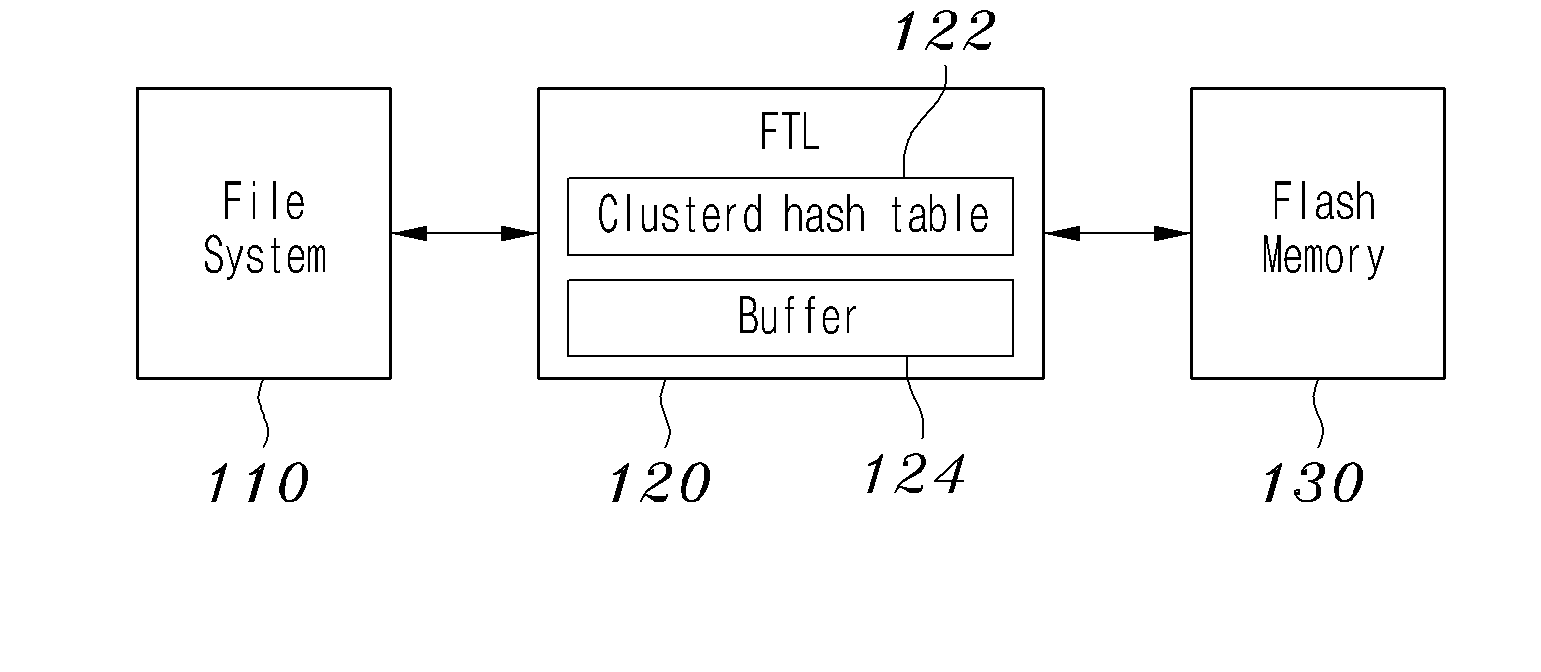

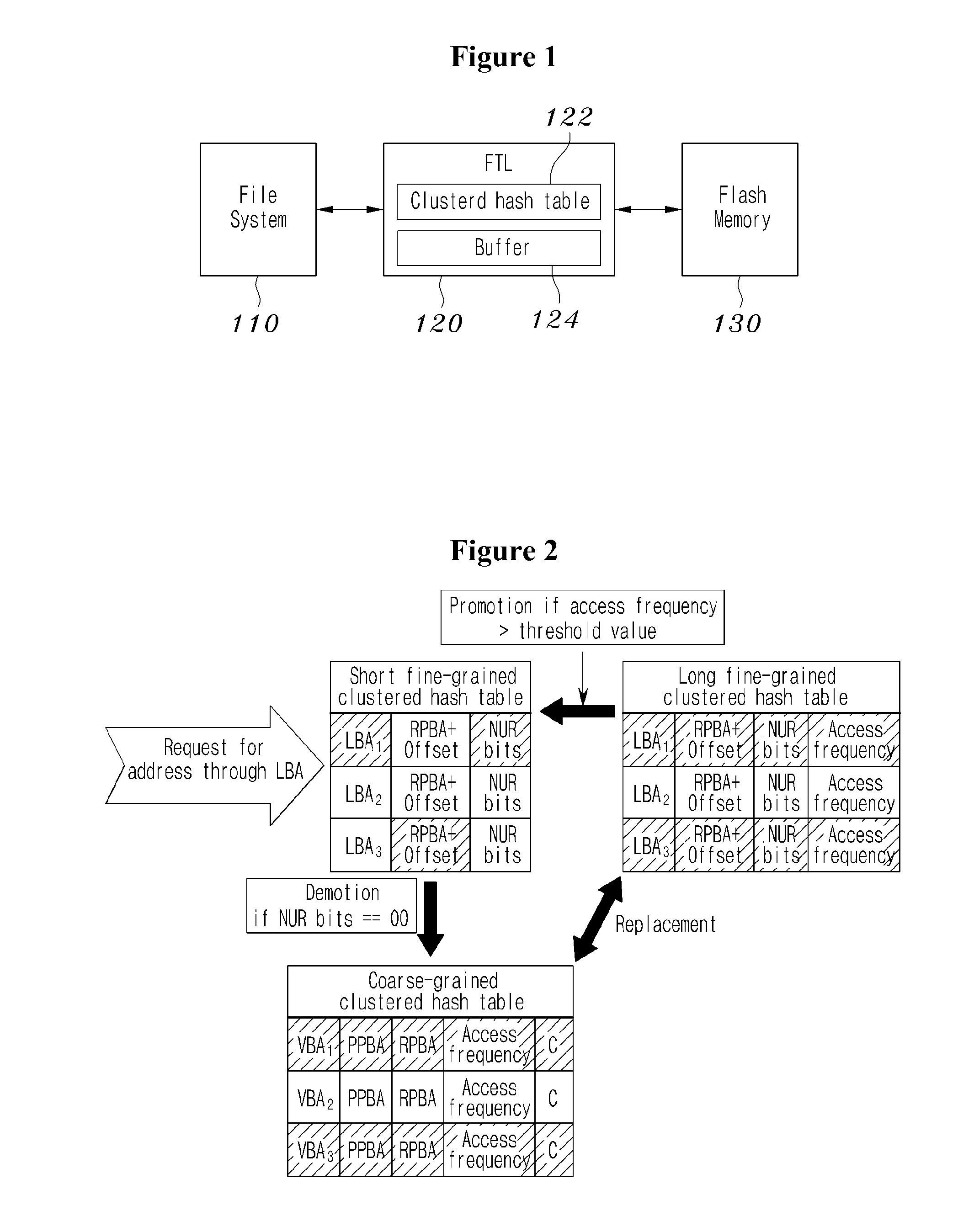

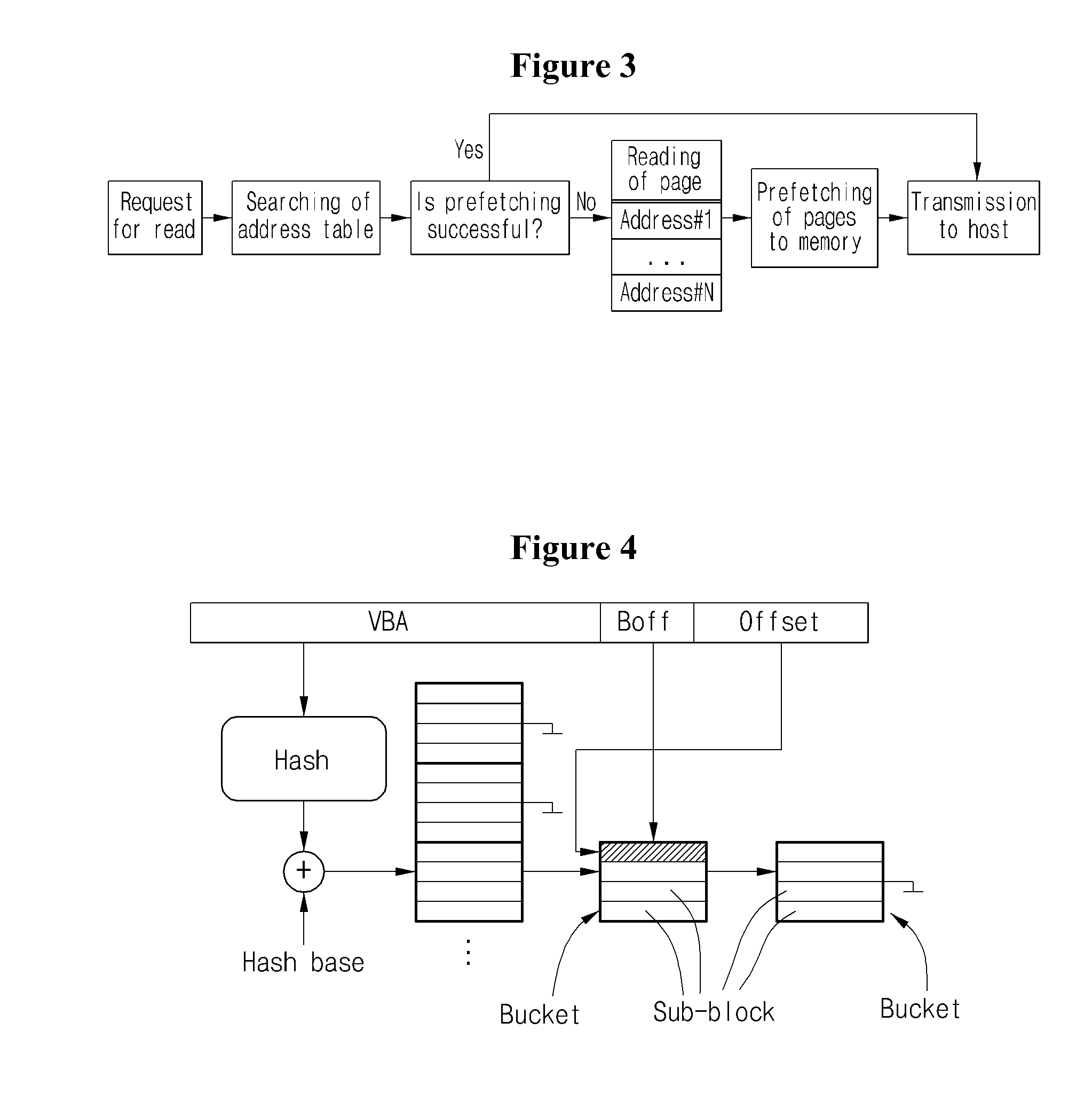

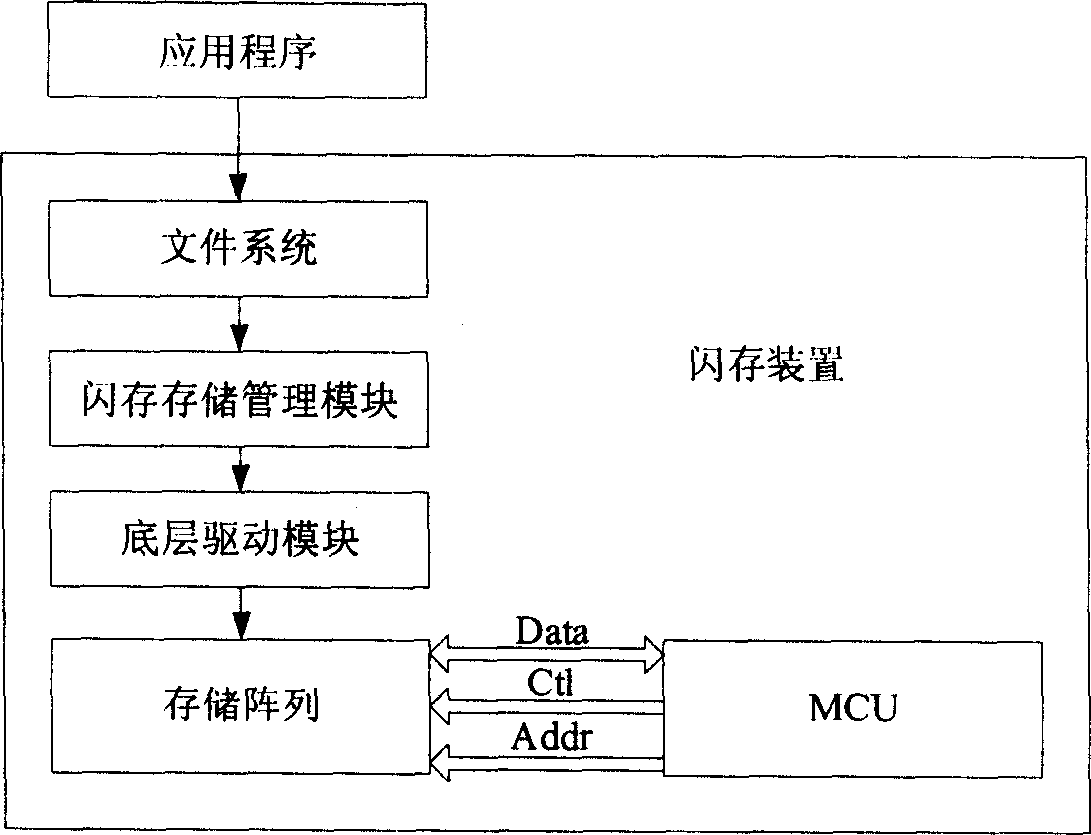

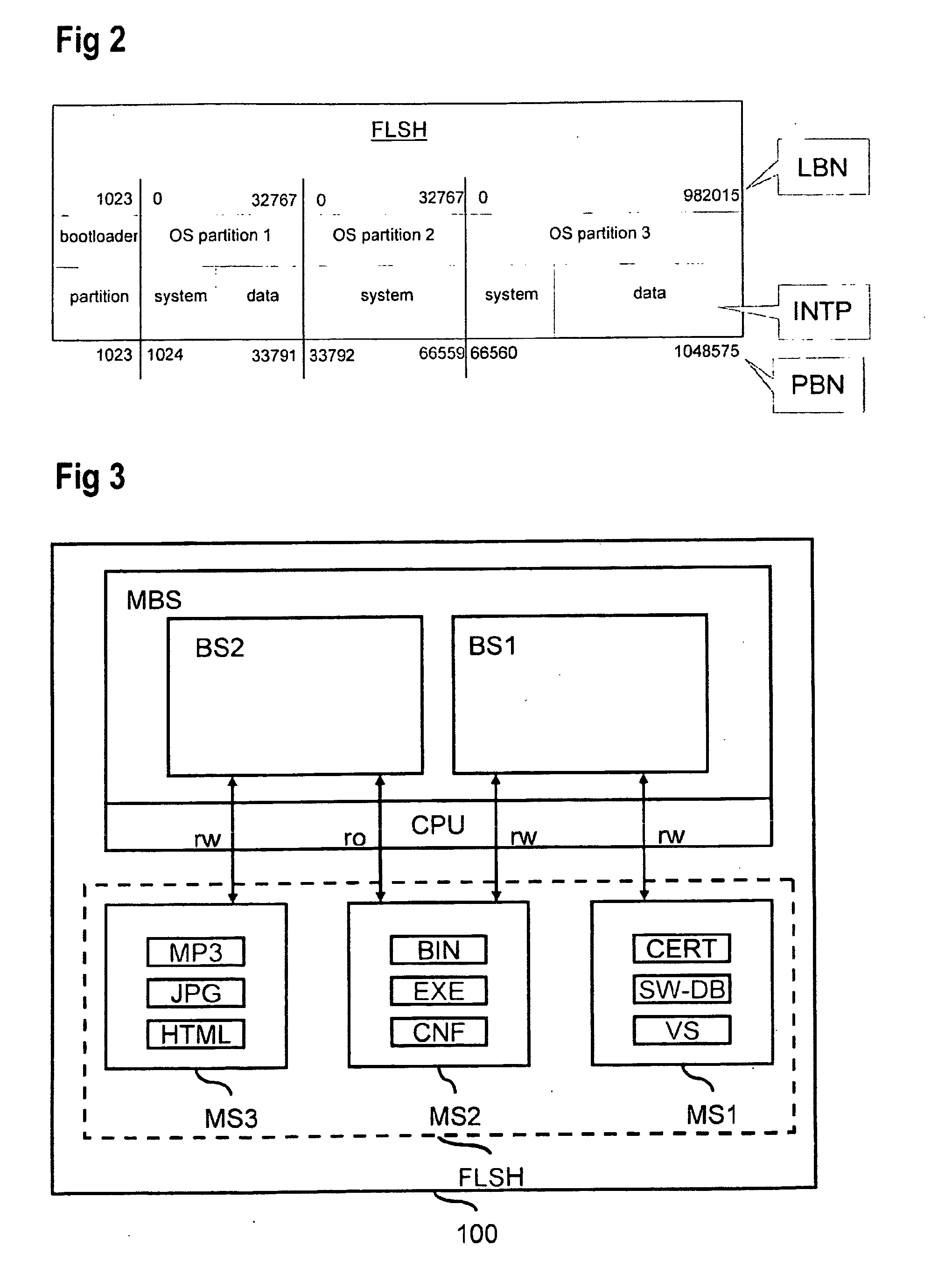

Efficient prefetching and asynchronous writing for flash memory

InactiveUS8024545B2Minimized in sizePerformance maximizationMemory architecture accessing/allocationMemory adressing/allocation/relocationFlash file systemFile system

Disclosed herein are a flash file system and an address translation method. The flash file system includes a file system, a Flash Translation Layer (FTL), and flash memory. The FTL receives Local Block Addresses (LBAs) from the file system, and translates the LBAs into Physical Block Address (PBAs. The flash memory receives the resulting PBAs. The FTL includes a memory block in which a multi-stage clustered hash table for mapping the LBAs to the PBAs is stored, and performs the address translation using the clustered hash table.

Owner:INHA UNIV RES & BUSINESS FOUNDATION +1

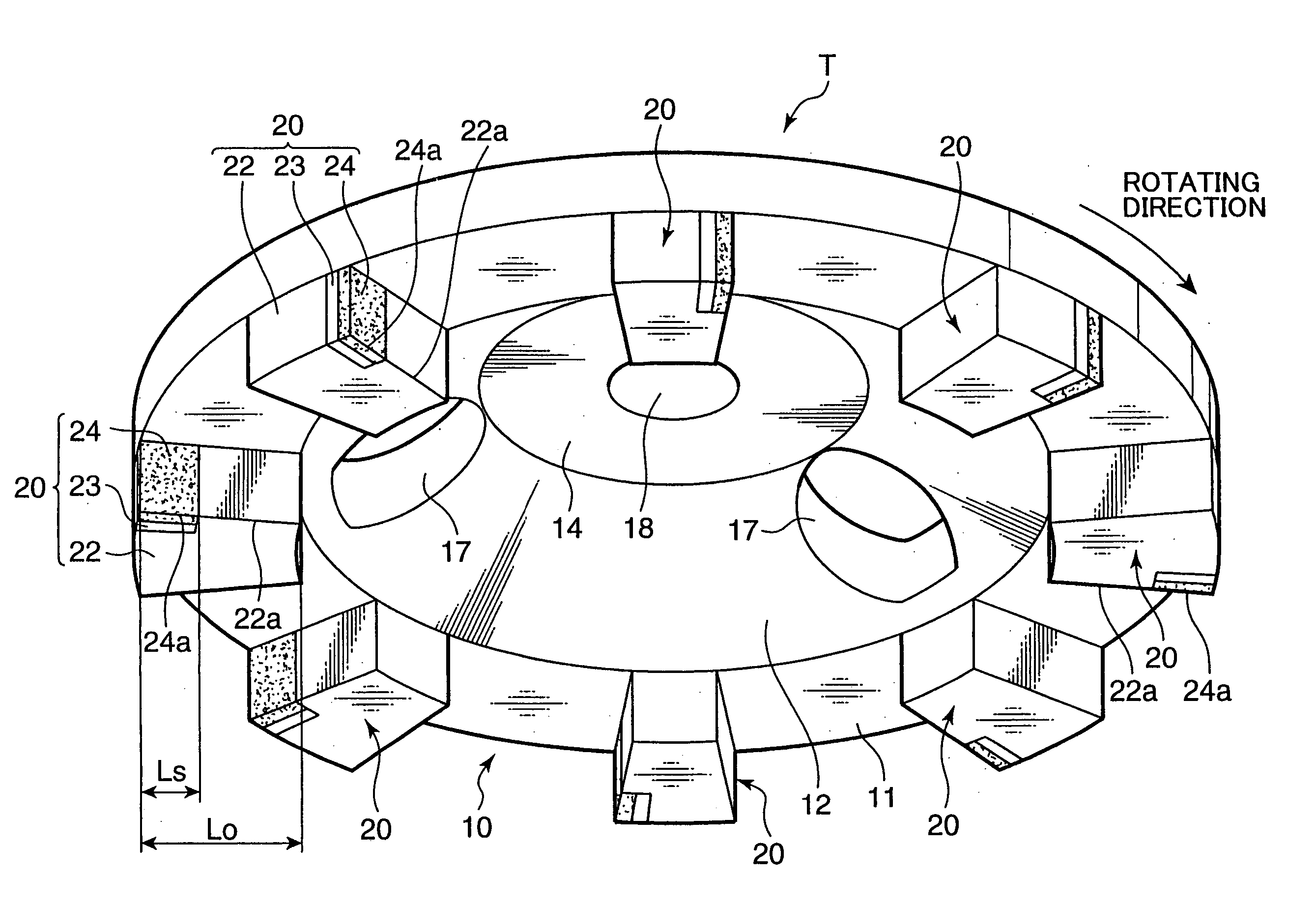

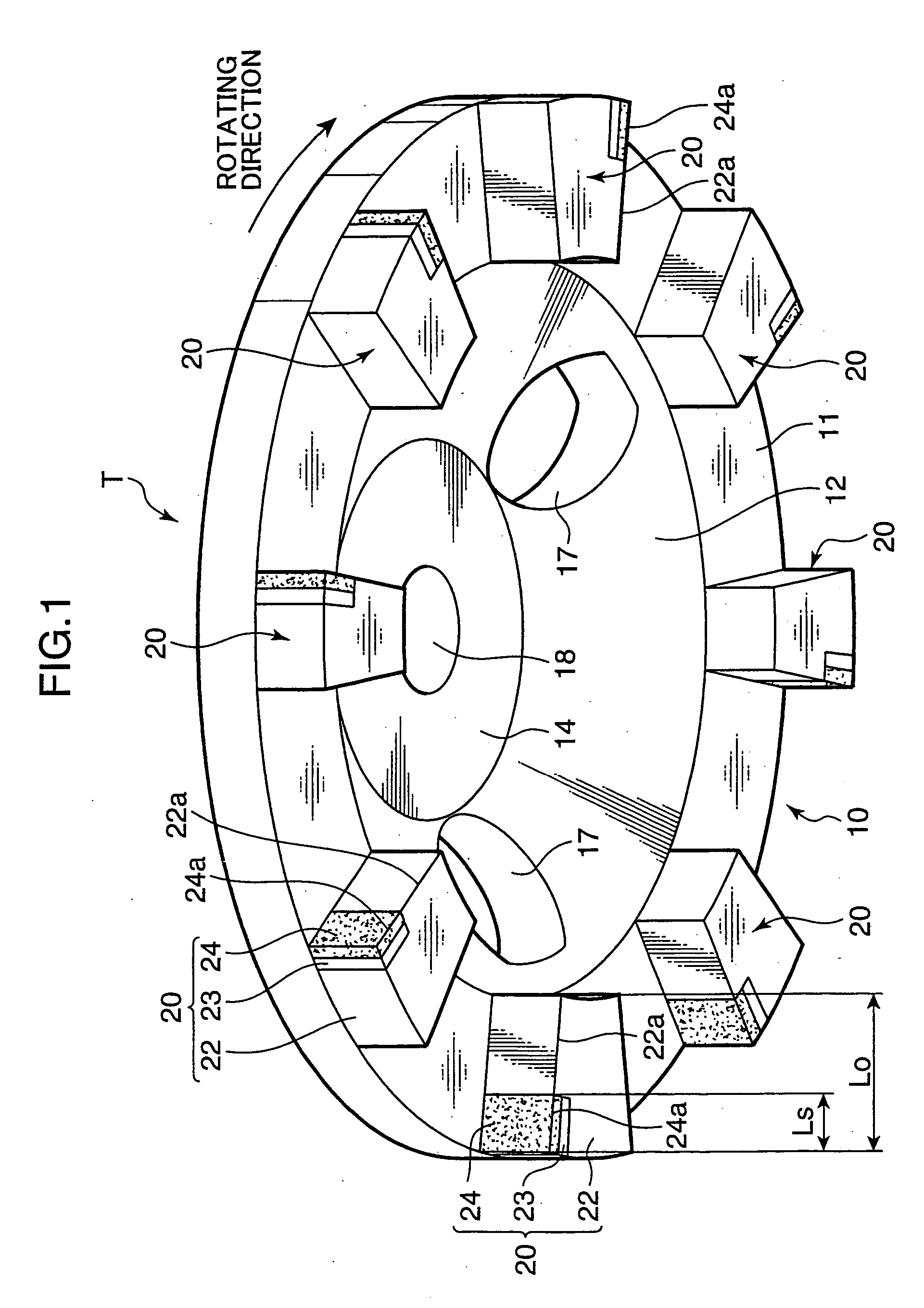

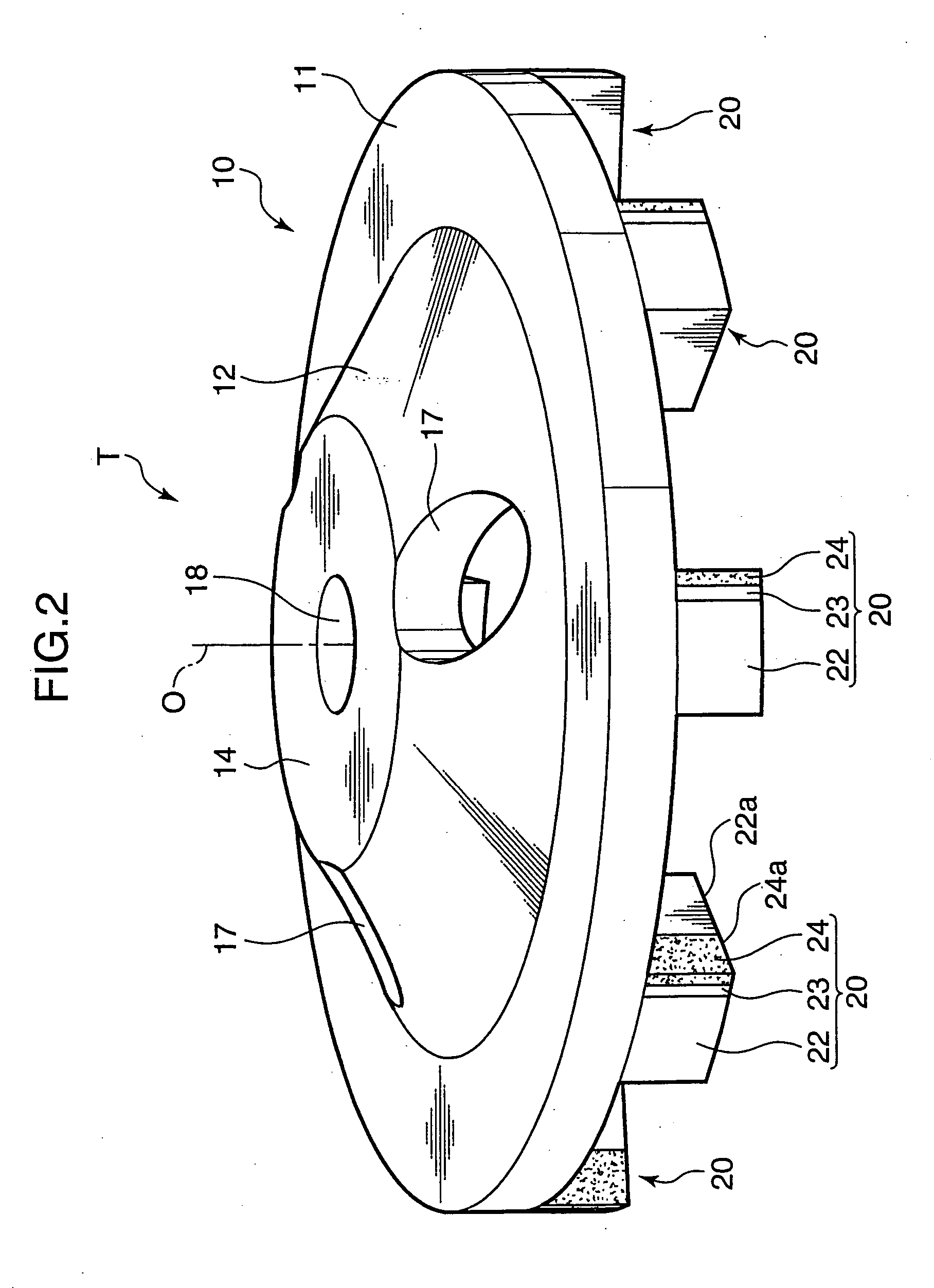

Rotary tool and its cutting part

InactiveUS20050164620A1Few or no effectsSharp cutting qualityRevolution surface grinding machinesMilling cuttersMetallurgy

A rotary tool (T) has a rotary segment (10) with an opposed surface opposed to a work surface and a plurality of cutting parts (20) arranged on the opposed surface. Some cutting parts (20) include tips (22a) made of a grinding tool segment obtained by binding abrasive grains by a metal binder and the other cutting parts (20) include tips (24a) made of a sintered material harder than the grinding tool segment, and the respective cutting parts (20) are arranged such that the tips (24a) are located at positions more outward than the tips (22a) with respect to radial directions of the rotary segment.

Owner:SANWA KENMA

Rotating cutter bit assembly having hardfaced block and wear washer

InactiveUS20030230926A1Effective protectionHigh hardnessDisloding machinesUnderground miningBearing surfaceWear resistant

A rotatable cutting bit, and rotatable cutting bit-bit holder assembly and washer that have increased wear resistance characteristics. The assembly incorporates a new holding washer design that has improved wear resistant characteristics between the cutter bit and top surface of the bit holder during operation. The cutter bit assembly includes a bit holder having a top surface, a generally flat washer, the top surface includes a top face forming a bearing surface for the cutting bit to enhance rotation of the cutter bit. The wear rate caused by the relative rotation between the rear face of the washer and top surface of the block face is reduced in the present invention. The top surface of the bit holder is hardfaced to limit and reduce wear. The improved wear resistance properties of the invention reduce the amount of necessary maintenance of rotary drums in the field resulting in reduce downtime and increase productivity.

Owner:KENNAMETAL INC

Efficient prefetching and asynchronous writing for flash memory

InactiveUS20090106486A1Minimized in sizePerformance maximizationMemory architecture accessing/allocationMemory adressing/allocation/relocationFlash file systemFile system

Disclosed herein are a flash file system and an address translation method. The flash file system includes a file system, a Flash Translation Layer (FTL), and flash memory. The FTL receives Local Block Addresses (LBAs) from the file system, and translates the LBAs into Physical Block Address (PBAs. The flash memory receives the resulting PBAs. The FTL includes a memory block in which a multi-stage clustered hash table for mapping the LBAs to the PBAs is stored, and performs the address translation using the clustered hash table.

Owner:INHA UNIV RES & BUSINESS FOUNDATION +1

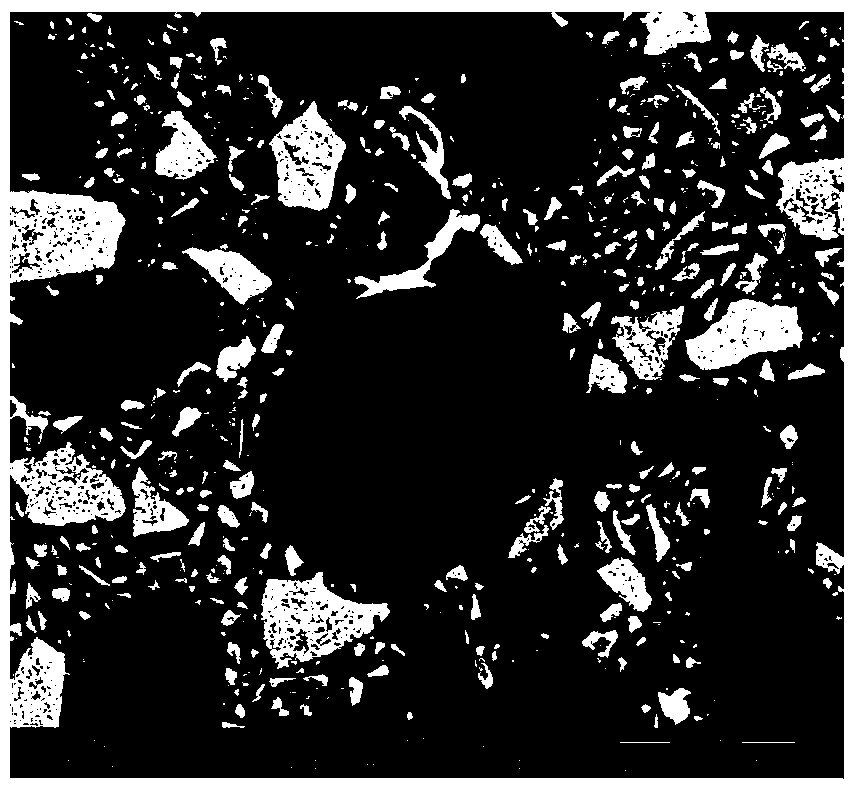

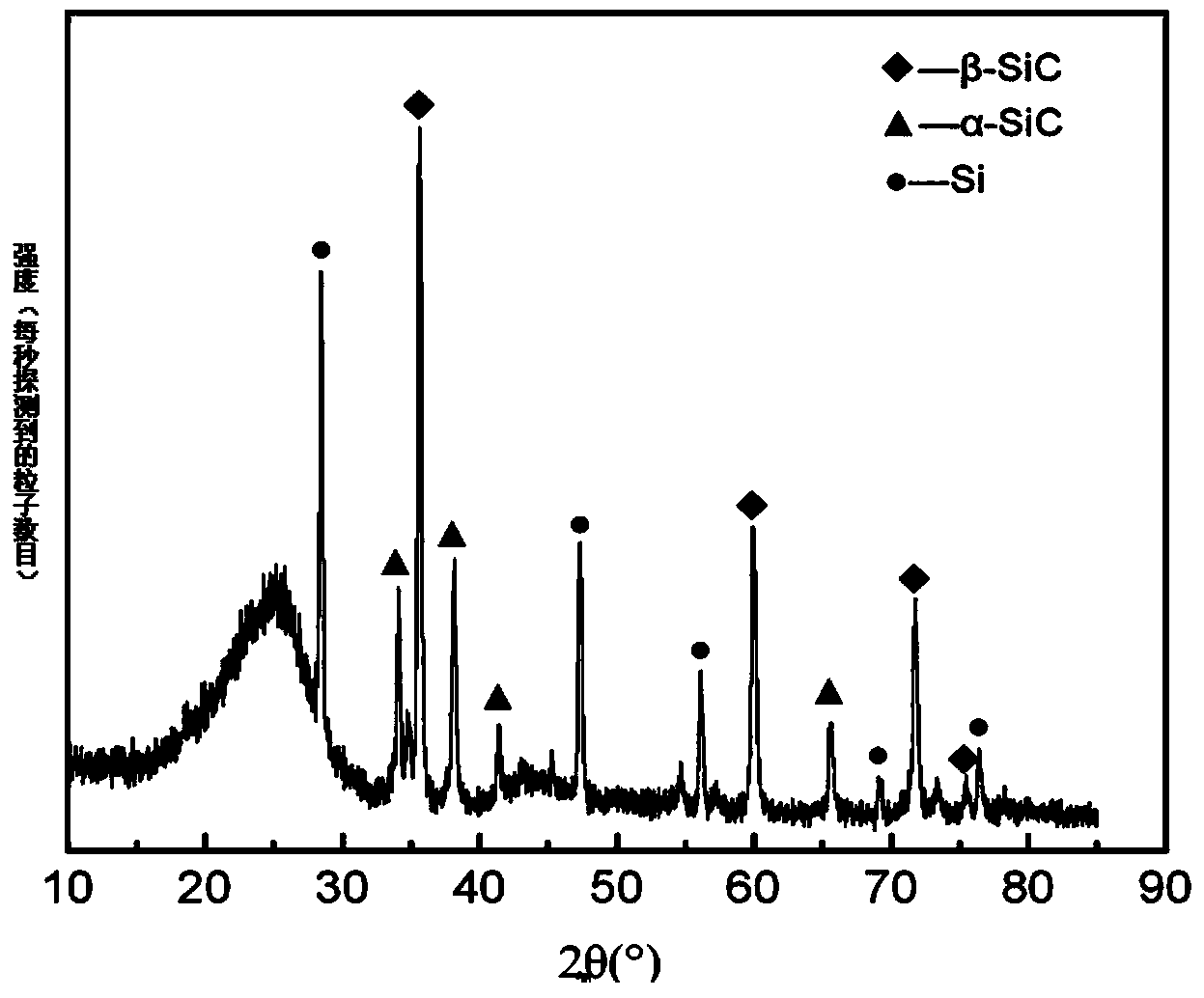

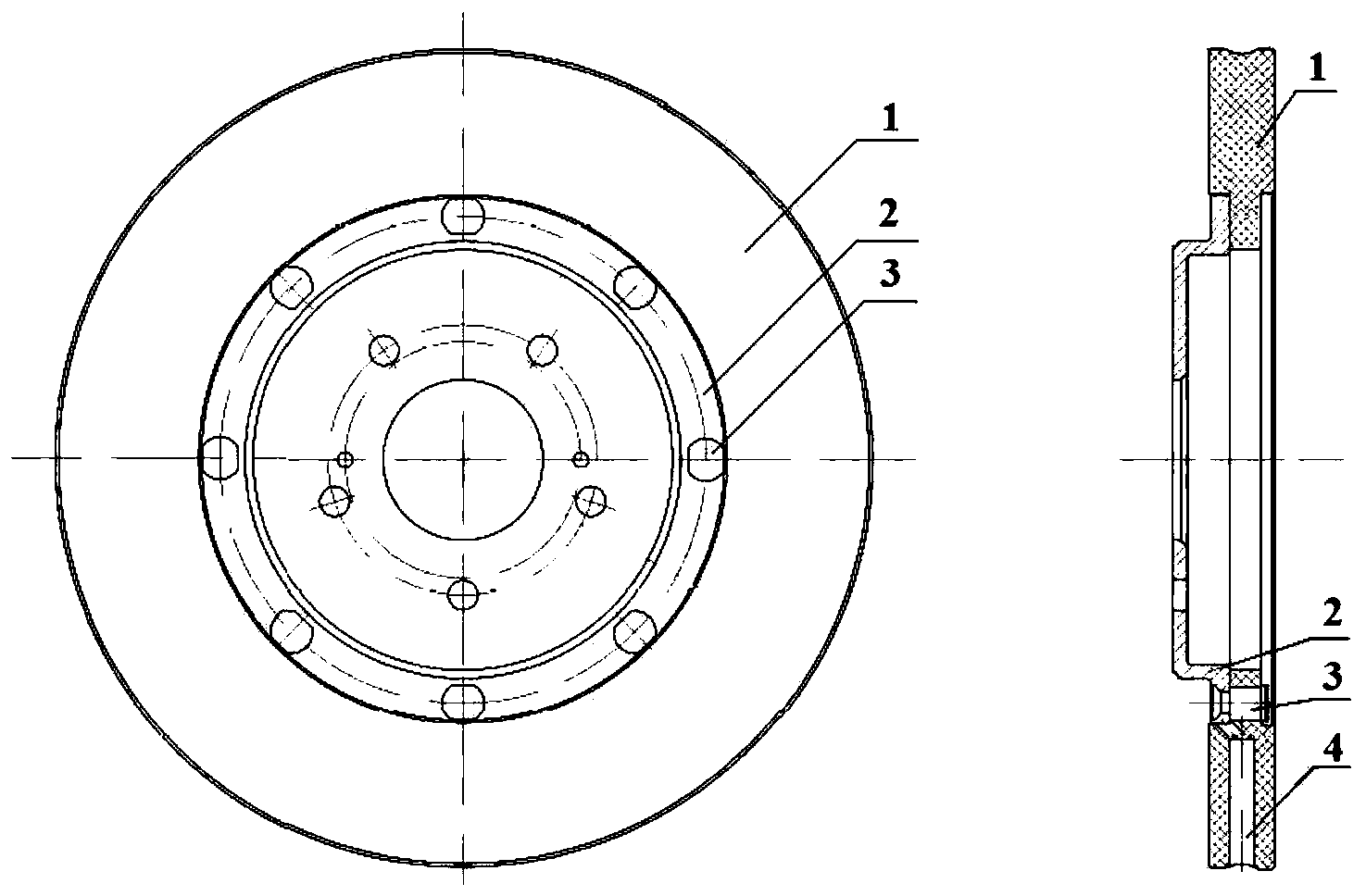

Carbon-ceramic composite brake disc and preparation method thereof

The invention relates to a carbon-ceramic composite brake disc and a preparation method thereof and belongs to the technical field of preparation of carbon-ceramic composites and brake discs. The carbon-ceramic composite brake disc comprises the following components by mass percent: 12% to 20% of short carbon fiber, 20% to 45% of matrix carbon, 30% to 55% of SiC and 2% to 6% of Si, wherein the short carbon fiber is 15-30mm in length. The method comprises the following steps: carbonizing a carbon fiber-reinforced blank body with the density of 0.9g / cm<3> to 1.3g / cm<3> so as to obtain a porous carbon / carbon (C / C) body; then performing dipping on the porous C / C body, cross-linking solidification and splitting decomposition so as to generate a SiC base body on the matrix carbon; performing the dipping, the cross-linking solidification and the splitting decomposition again until the density of an obtained C / C-SiC composite blank body reaches 1.6-1.9g / cm<3>; and performing silicon leaching treatment on the C / C-SiC composite blank body and anti-oxidation treatment and assembling, thus obtaining the carbon-ceramic composite brake disc. According to the method provided by the invention, the difficult problem that a metal brake disc is poor in thermal dissipation and abrasion resistance and heavy in weight in the prior art is effectively solved. The preparation method is simple; and the obtained carbon-ceramic composite brake disc is high in thermal stability, light in weight and resistant to abrasion, and cannot generate thermal vibration.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

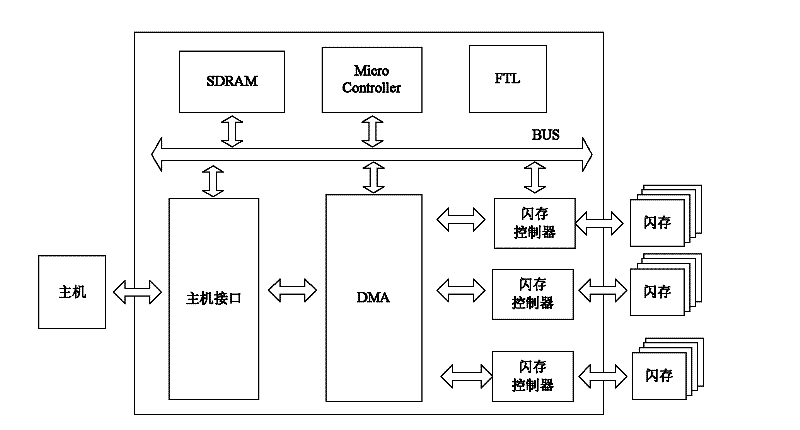

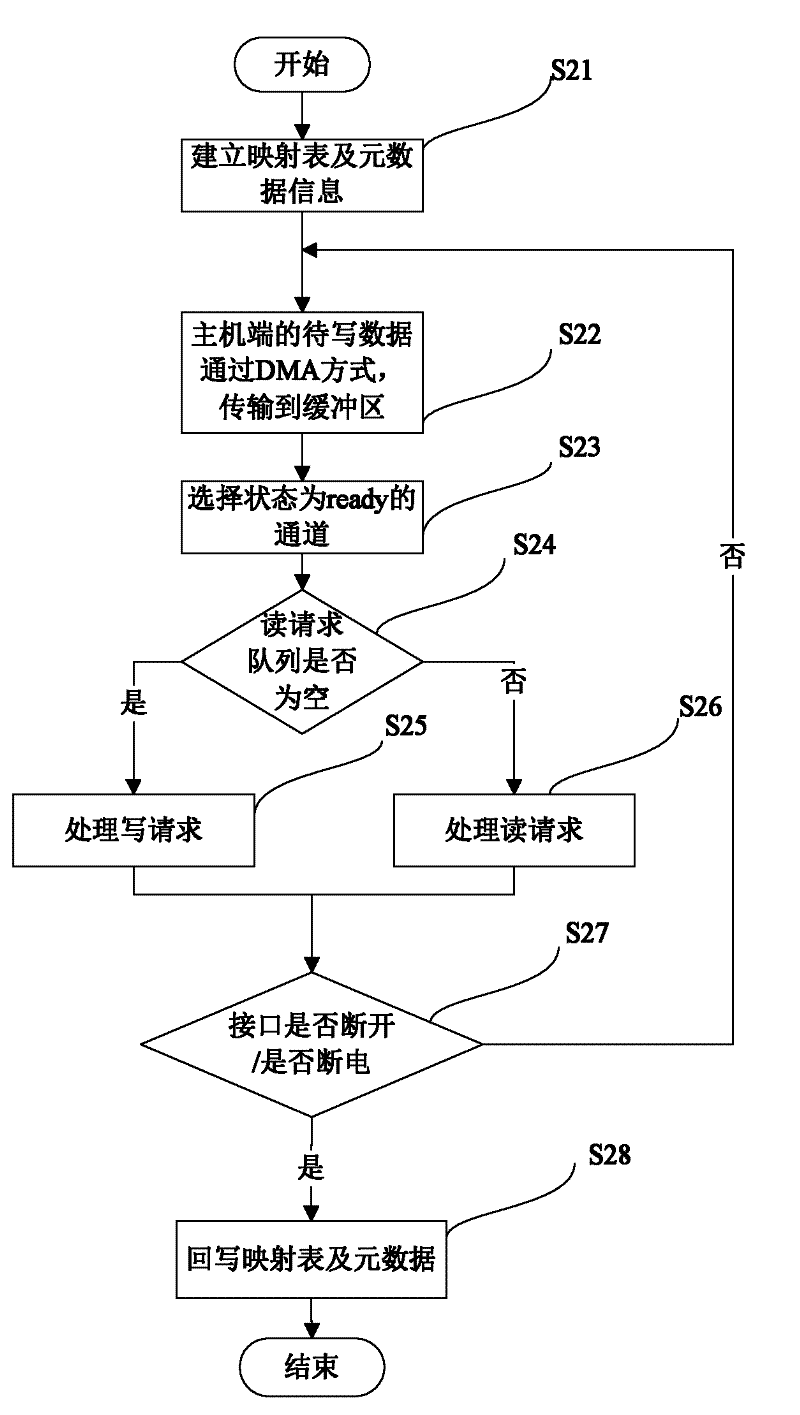

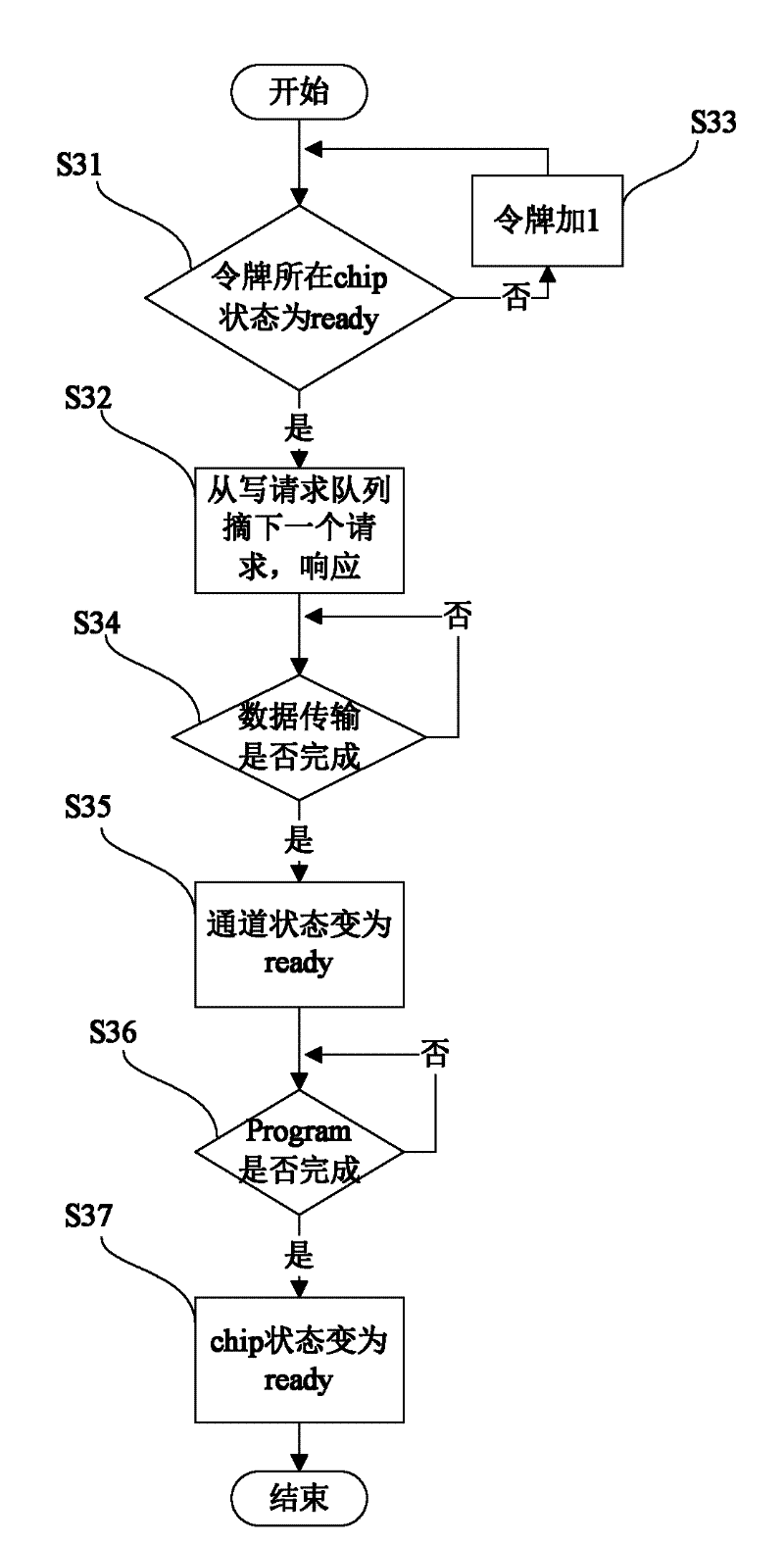

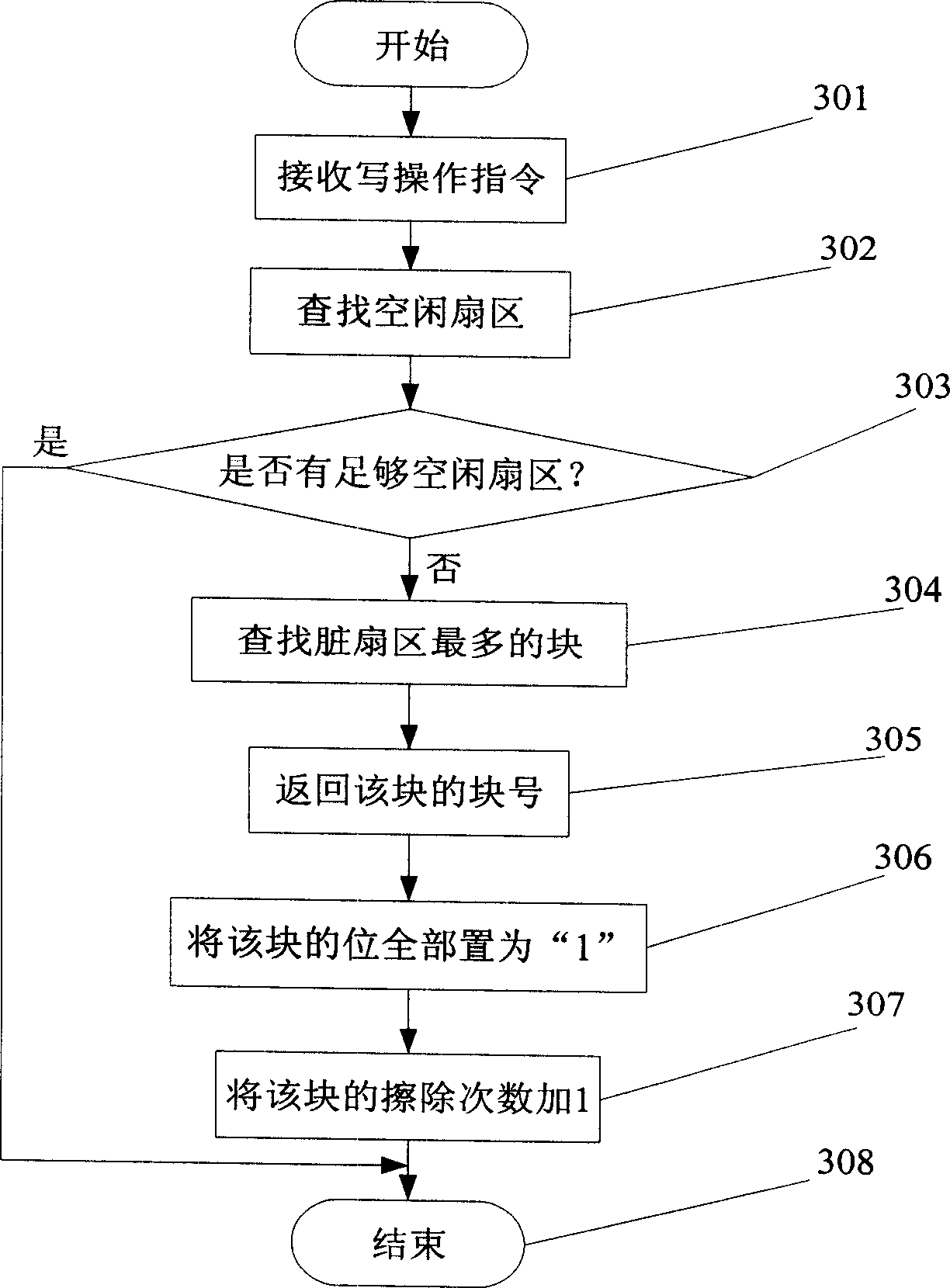

Method for controlling data reading and writing of multi-channel solid-state disc

ActiveCN102567257AFast transferUniform wearInput/output to record carriersDirect memory accessComputer science

The invention discloses a method for controlling data reading and writing of a multi-channel solid-state disc, comprising the steps of: (1) building a mapping table to store a mapping relationship of a solid-state disc logic address and a physical address, (2) transmitting a data to be written of a host terminal to a buffer area of a channel controller through a DMA (Direct Memory Access), (3) selecting a channel of which a channel state is ready, (4) finding out a reading request in a chip state which is ready from a reading request queue of the channel of which the state is ready and serving the reading request, (5) finding out a writing request in the chip state which is ready from a writing request queue if the reading request queue is null, writing the data of the buffer area into a free page of the chip, and then modifying corresponding relationship between a corresponding logic address and a physical address in the mapping table so as to finish writing operation. According to the method disclosed by the invention, fast transfer of an interface data is realized, and parallel communication among the channels and serial pipeline operation inside the channels are also realized. Abrasions among all the chips of SSD (solid state disks) are also uniform due to mode adoption of a token ring.

Owner:HUAZHONG UNIV OF SCI & TECH

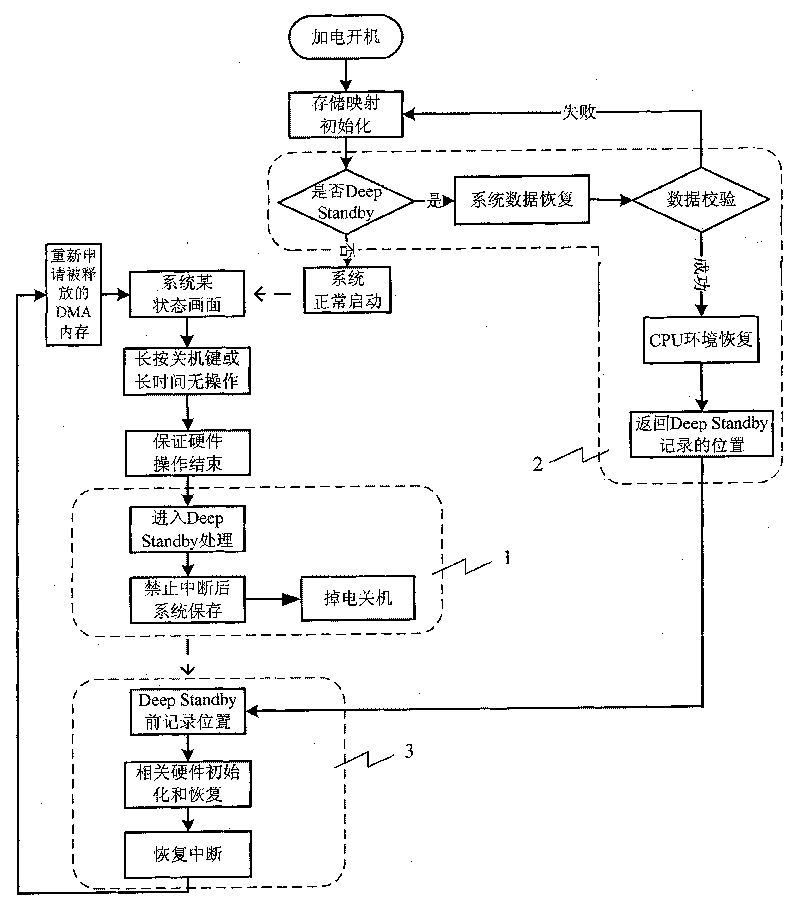

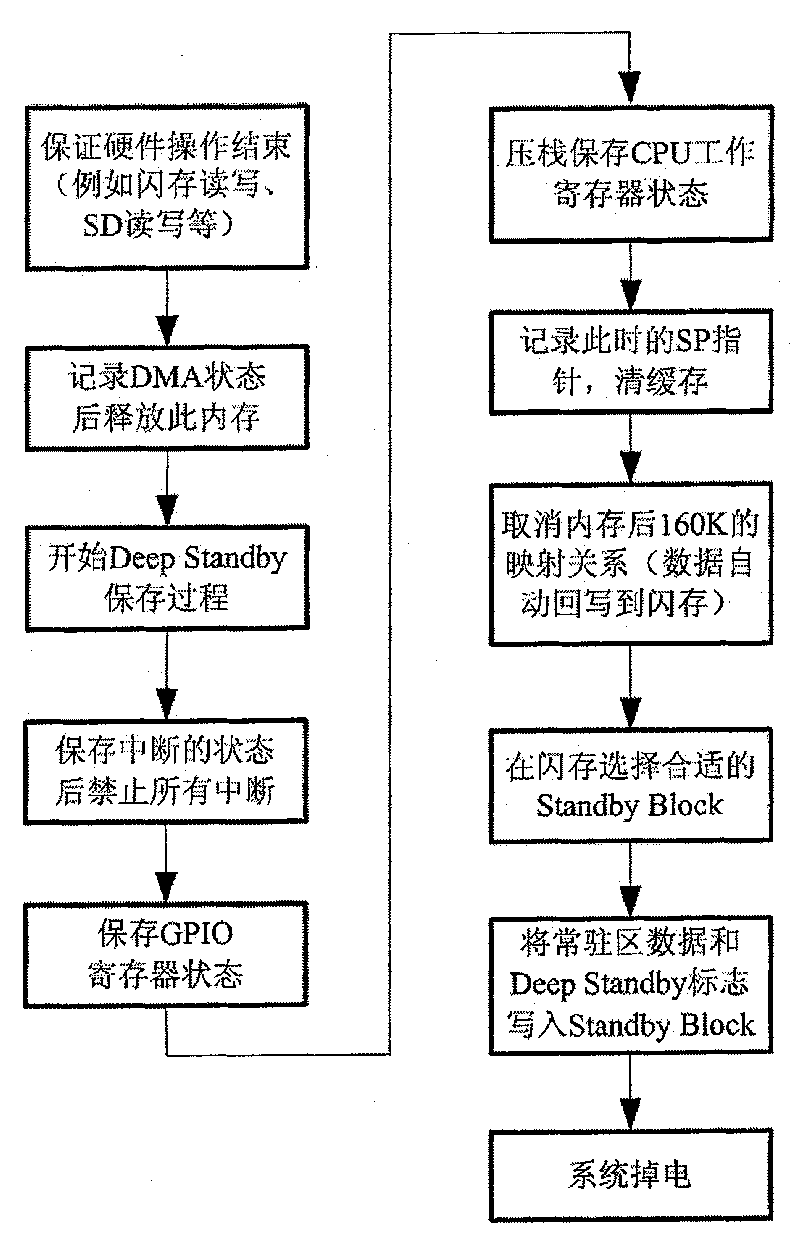

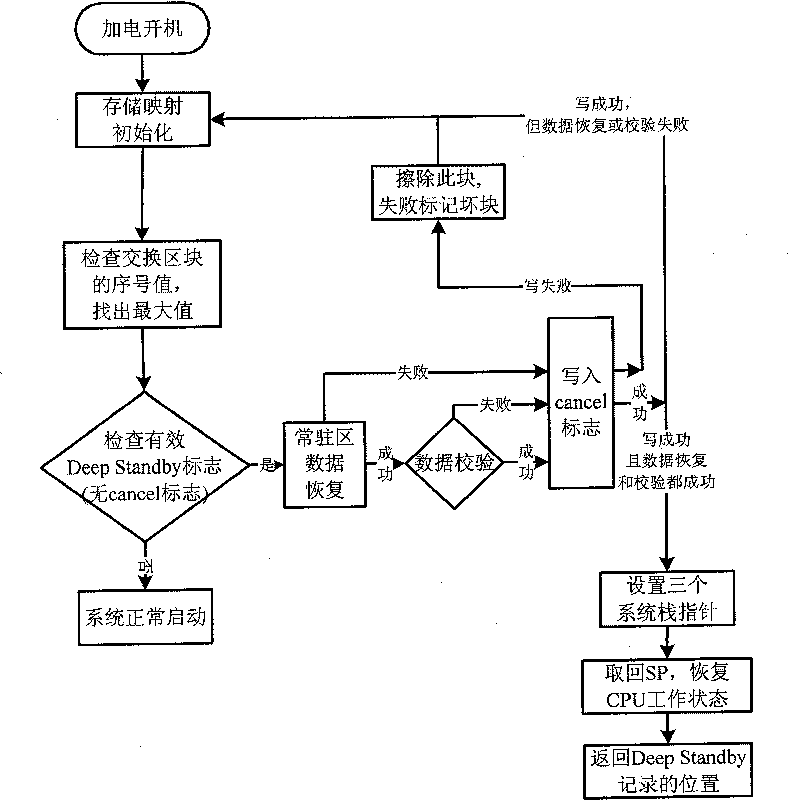

Deep-sleep method of embedded system

ActiveCN101710253AReduce standby power consumptionImprove boot speedEnergy efficient ICTPower supply for data processingElectricitySystem recovery

The invention provides a deep-sleep method of embedded system. The method mainly comprises the following processing steps: 1, in the system operating status, judging whether no operation is performed for long time to ensure that if so, the system preservation process is carried out after the hardware operation is ensured to be completed and then the system is closed to enter the deep-sleep mode, or receiving a system-closing signal; 2, starting the system, searching a deep-sleep block after the mapping and initializing of memory; after finding the effective deep-sleep sign, performing system data recovery process; and 3. after successfully recovering the system, performing the initializing of the related hardware, and returning to the state before the deep-sleep mode. By using the method of the invention, after the device is powered down or powered off and powered on again, the device can automatically return to the original interface to greatly reduce the power consumption of the stand-by system and save energy and electrical energy, thus prolonging the service time of the battery and ensuring the service life of the related hardware while largely increasing the startup speed of the system.

Owner:浙江金华凯宇电子科技有限公司

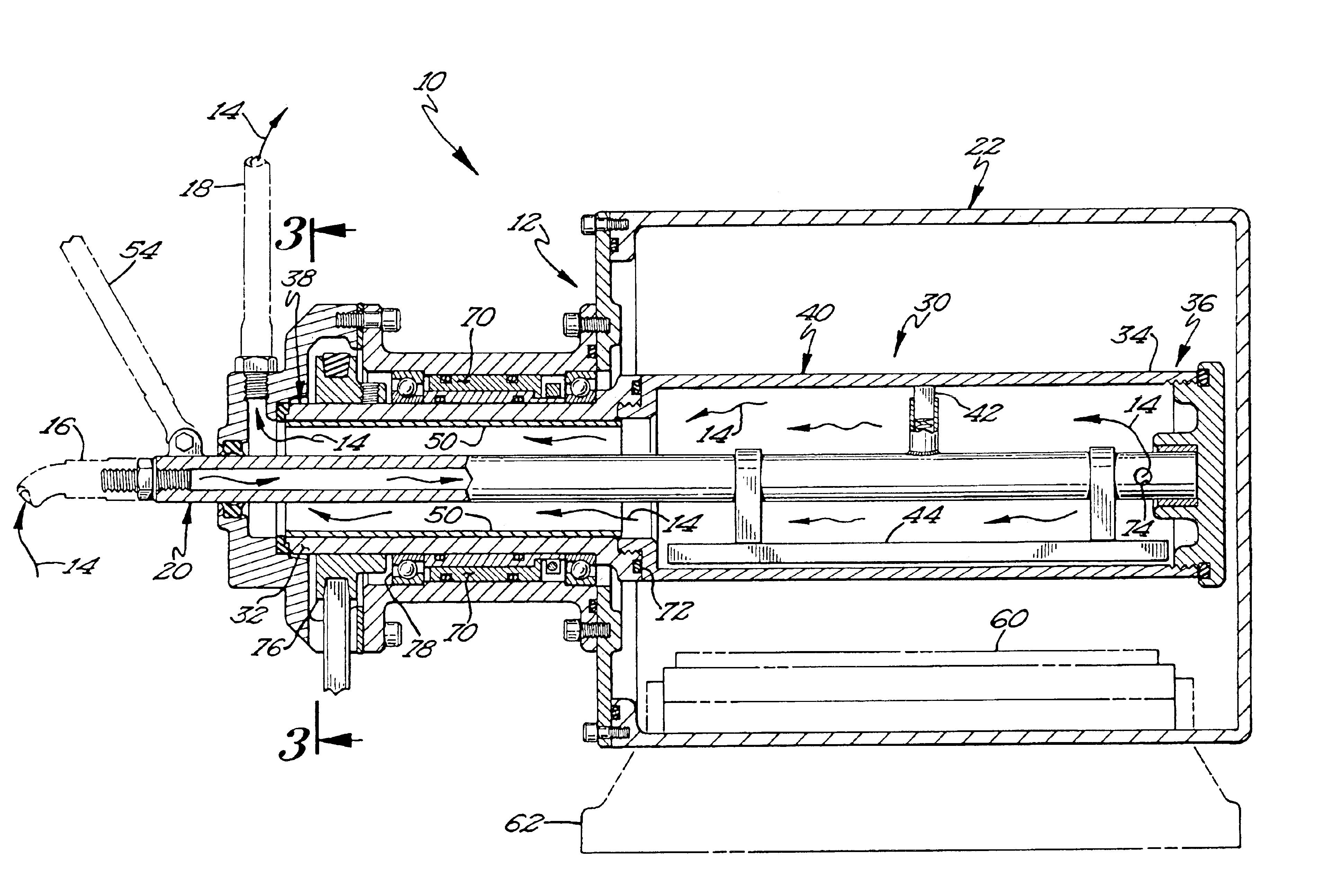

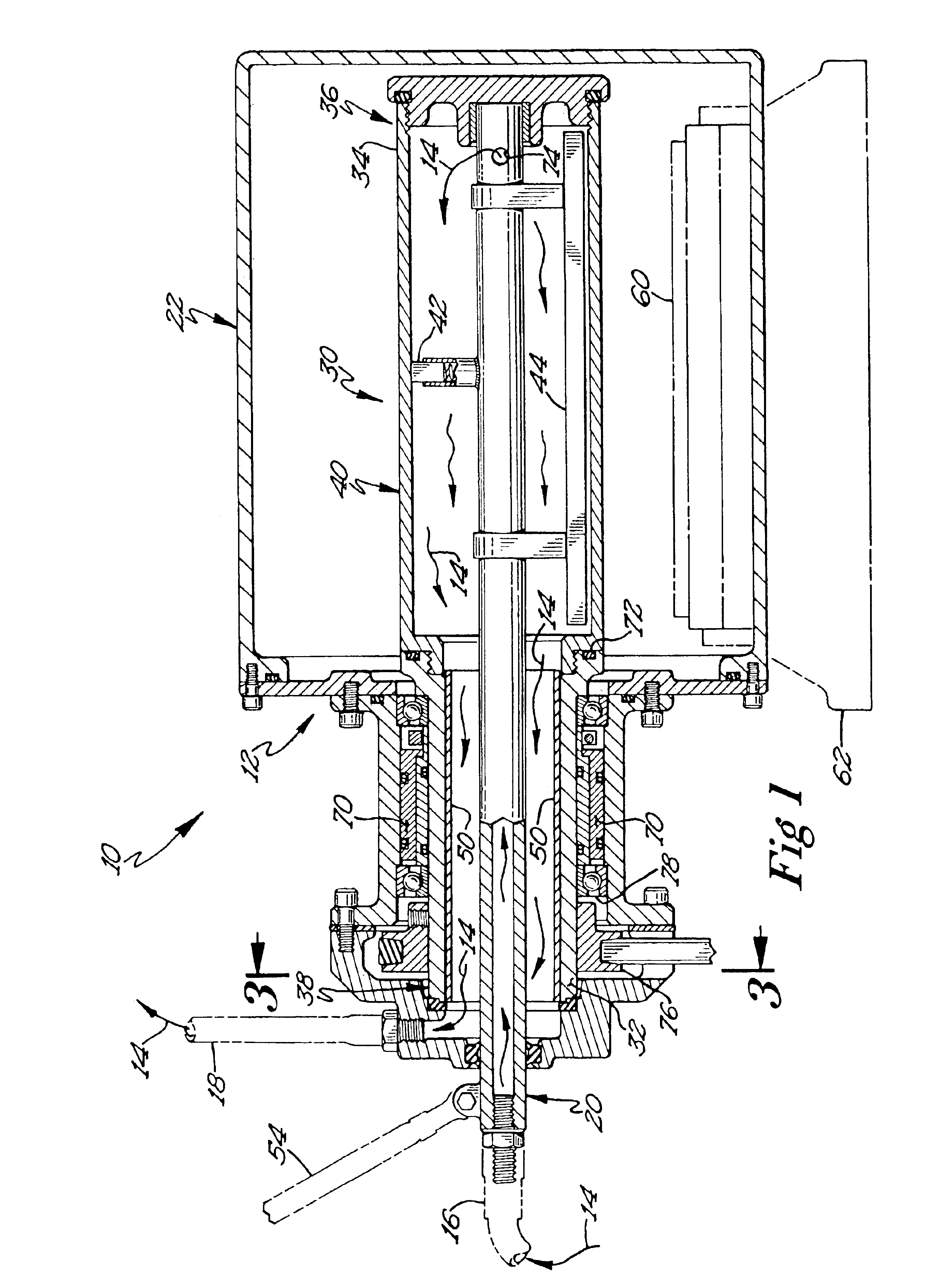

High-power ion sputtering magnetron

InactiveUS6841051B2Shields heat-sensitive partsAvoid noiseCellsElectric discharge tubesMagnetic heatingDrive shaft

Owner:BUEHLER AG

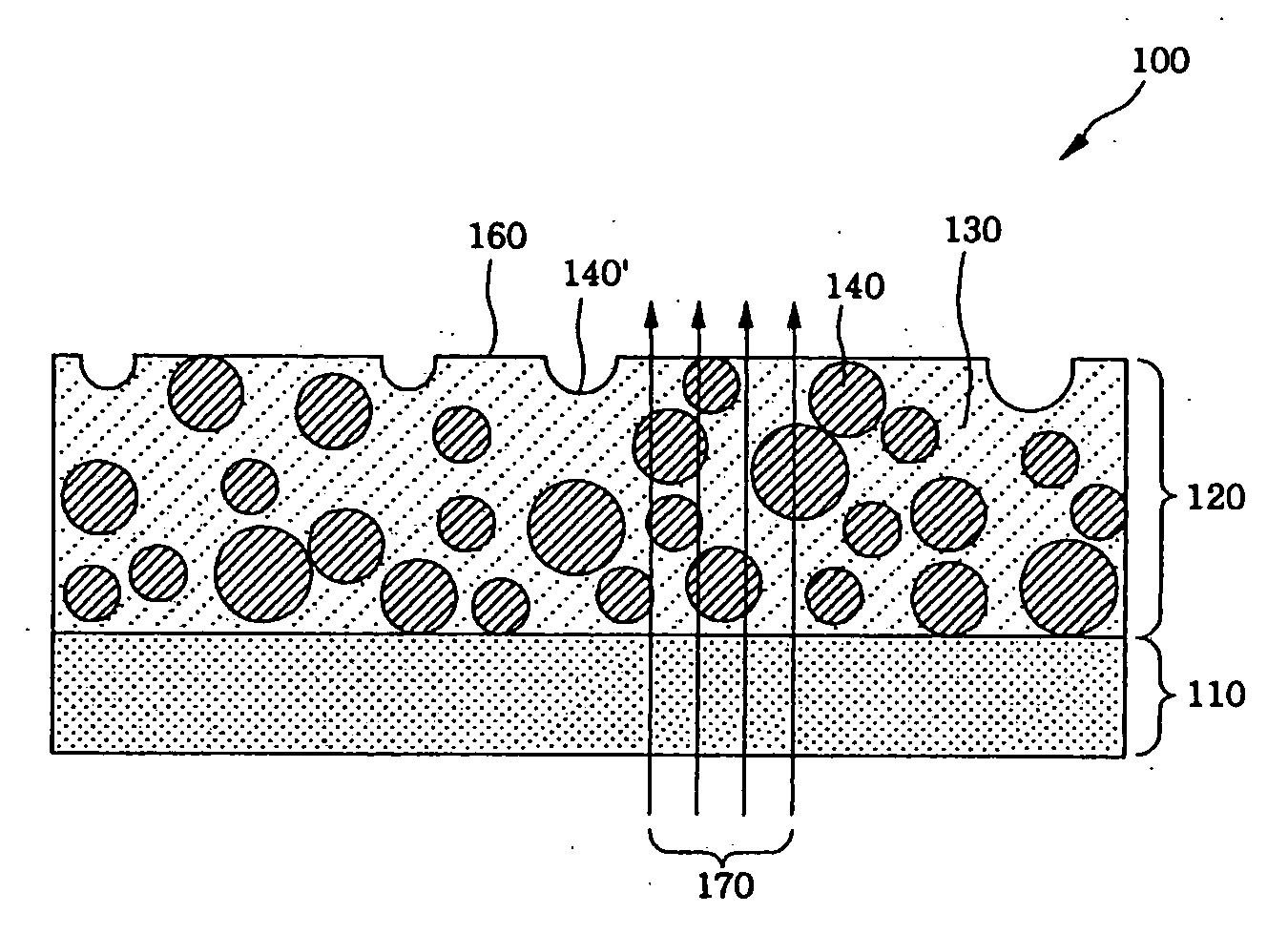

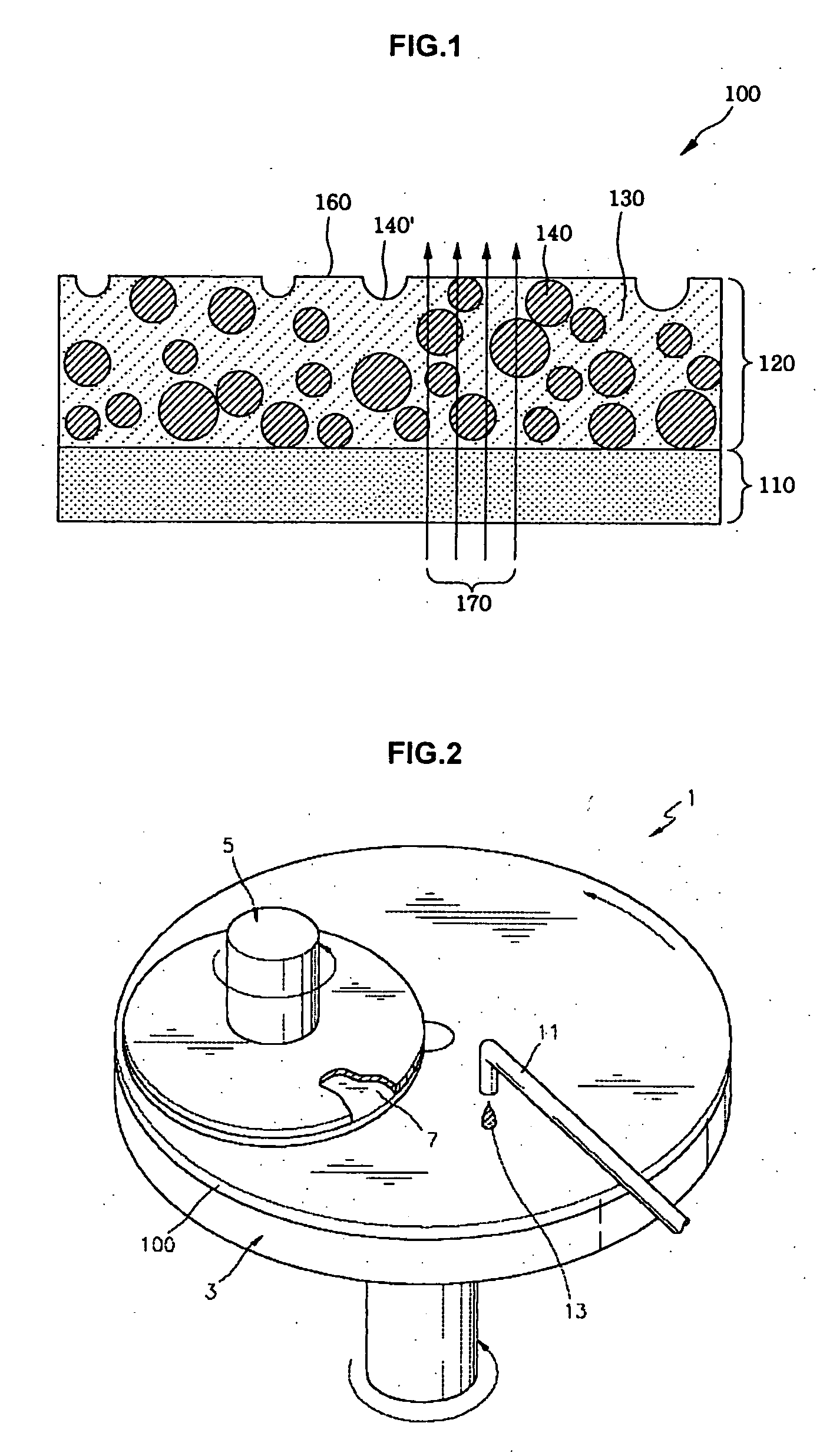

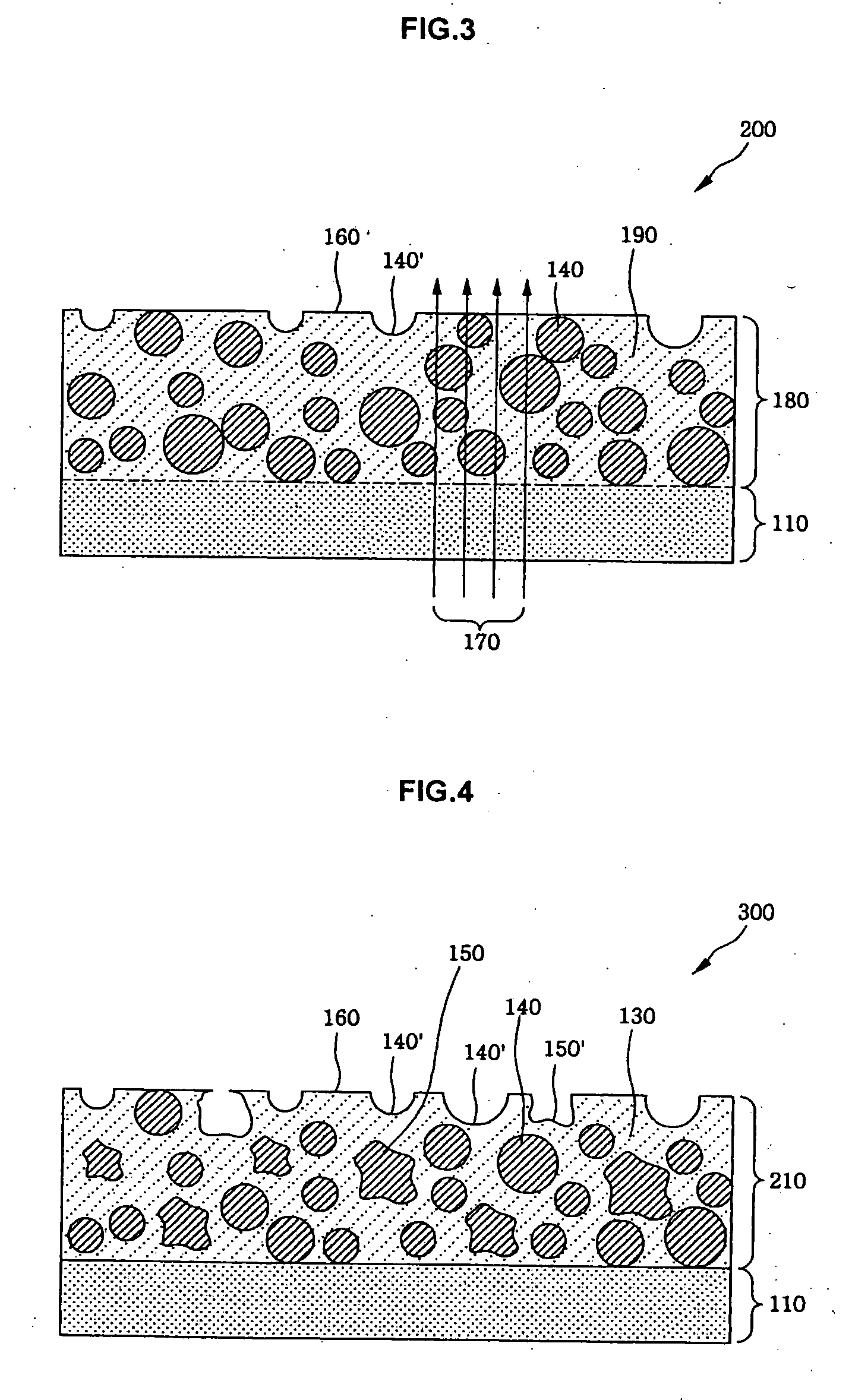

Polishing pad containing embedded liquid microelements and method of manufacturing the same

ActiveUS20060125133A1Easy to manufactureImprove accuracySemiconductor/solid-state device manufacturingFlexible-parts wheelsMaterials scienceLiquid phase

A polishing pad is provided. The polishing pad includes a polishing layer composed of a polymeric matrix and liquid microelements embedded in the polymeric matrix. Open pores defined by the embedded liquid microelements are distributed across a surface of the polishing layer. Due to the microstructural open pores uniformly distributed across a surface of the polishing pad, a polishing operation can be performed at high precision. The polishing pad shows constant polishing performance during the polishing operation, can be stably used, and does not cause a wafer to be scratched. In addition, a method of manufacturing the polishing pad is provided. Since all components used to manufacture the polishing pad are in a liquid phase, manufacturing can be easily performed.

Owner:KPX CHEM

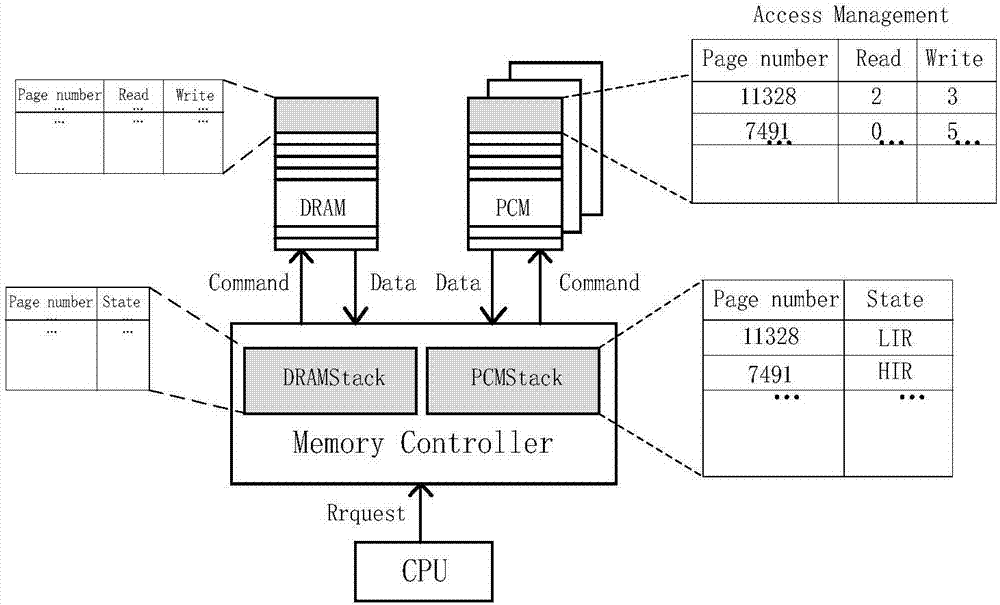

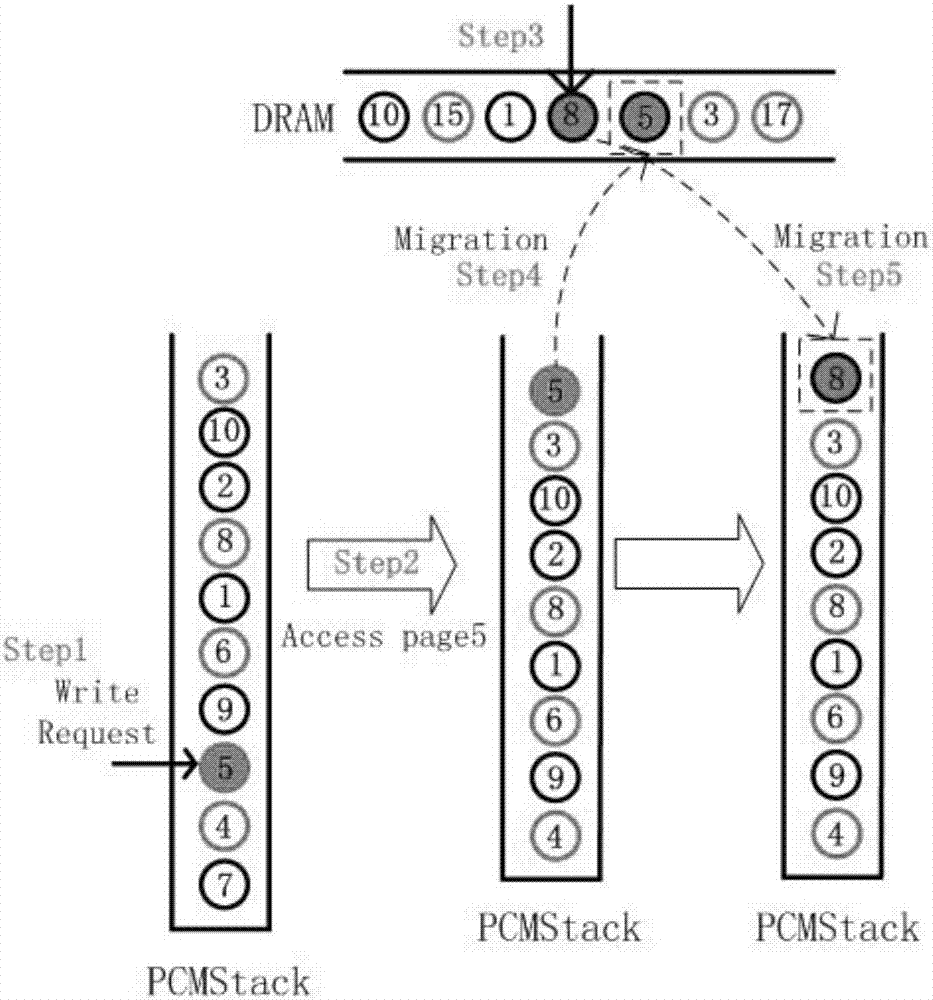

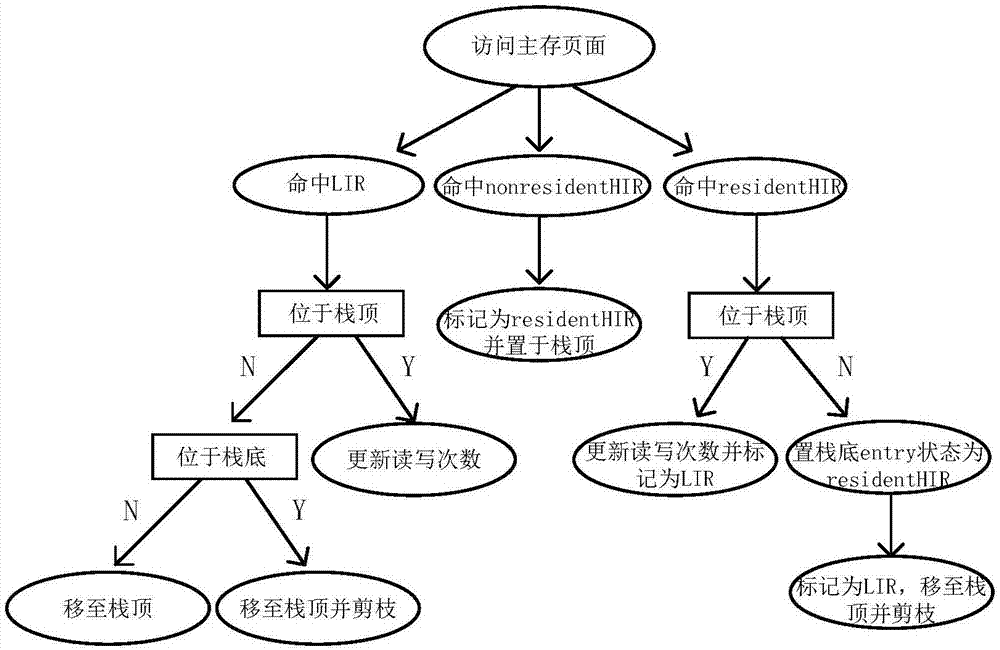

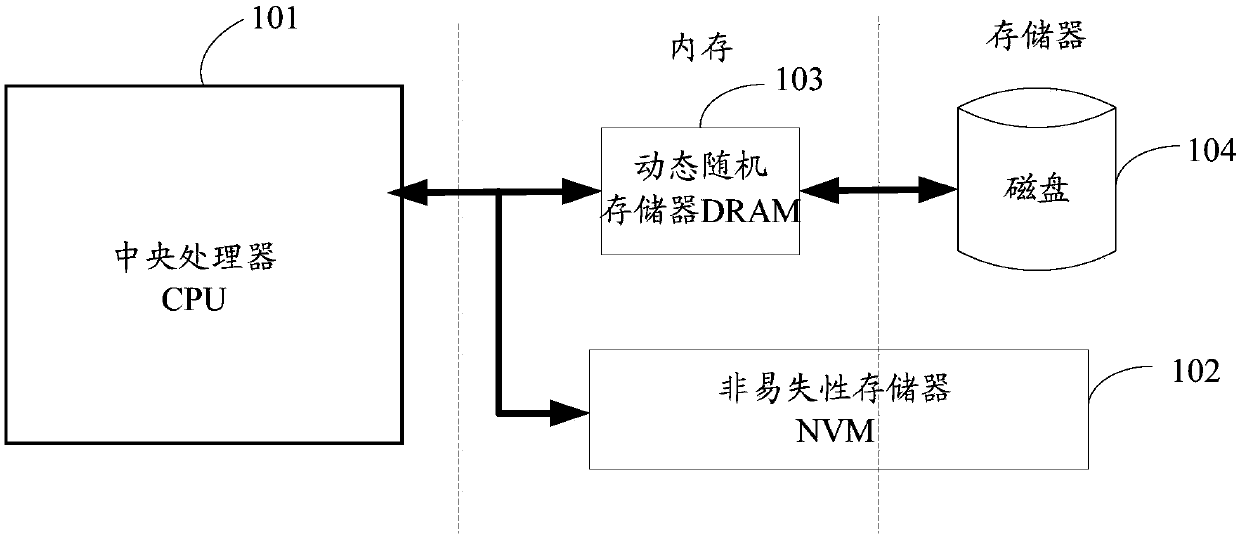

Hybrid main storage architecture based efficient dynamic page scheduling method

ActiveCN107193646AReduce the number of migrationsAccurateProgram initiation/switchingResource allocationAccess timeDynamic management

The invention discloses a hybrid main storage architecture based efficient dynamic page scheduling method applied to a memory controller of a horizontal storage architecture which comprises a first storage medium and a second storage medium. The hybrid main storage architecture based efficient dynamic page scheduling method comprises the steps of configuring an access list respectively in each storage medium; configuring a stack respectively for each storage medium in the memory controller; carrying out dynamic management fore recently accessed pages in the storage medium based on the page state records recorded in the stack and the reading-writing access time recorded in the access list, placing the pages with high writing hot-degree in the first storage medium, storing the frequently read pages in the second storage medium, wherein the first storage medium is a DRAM, and the second storage medium is NVM. The hybrid main storage architecture based efficient dynamic page scheduling method can master the historical access information more precisely to adapt to the application scenes with relatively weak locality, can greatly reduce frequent and ineffective page migration quantity between the hybrid memory mediums, and can improve the utilization rate and the access hit rate of a main memory.

Owner:PLA UNIV OF SCI & TECH

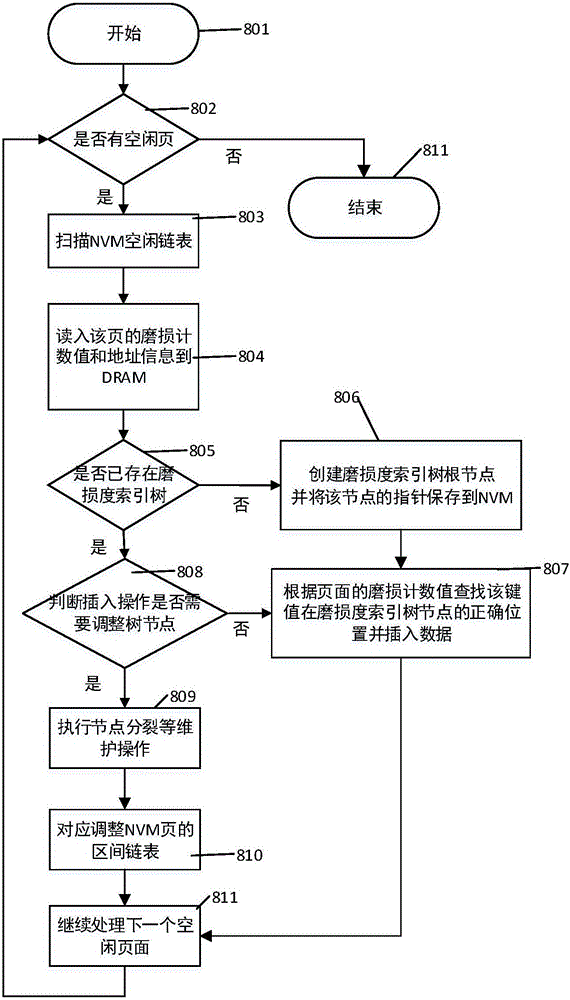

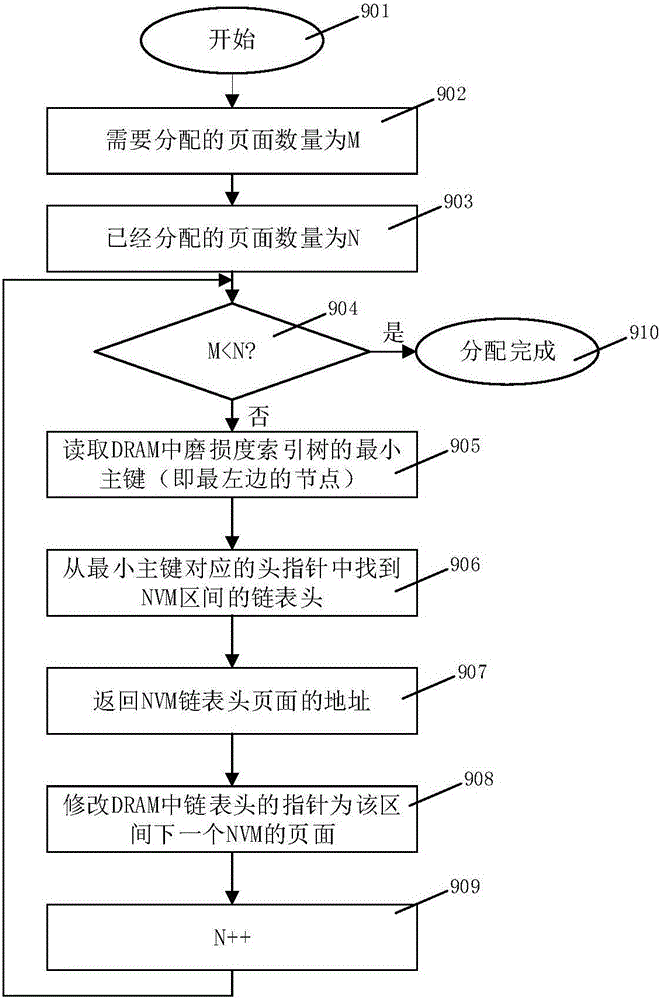

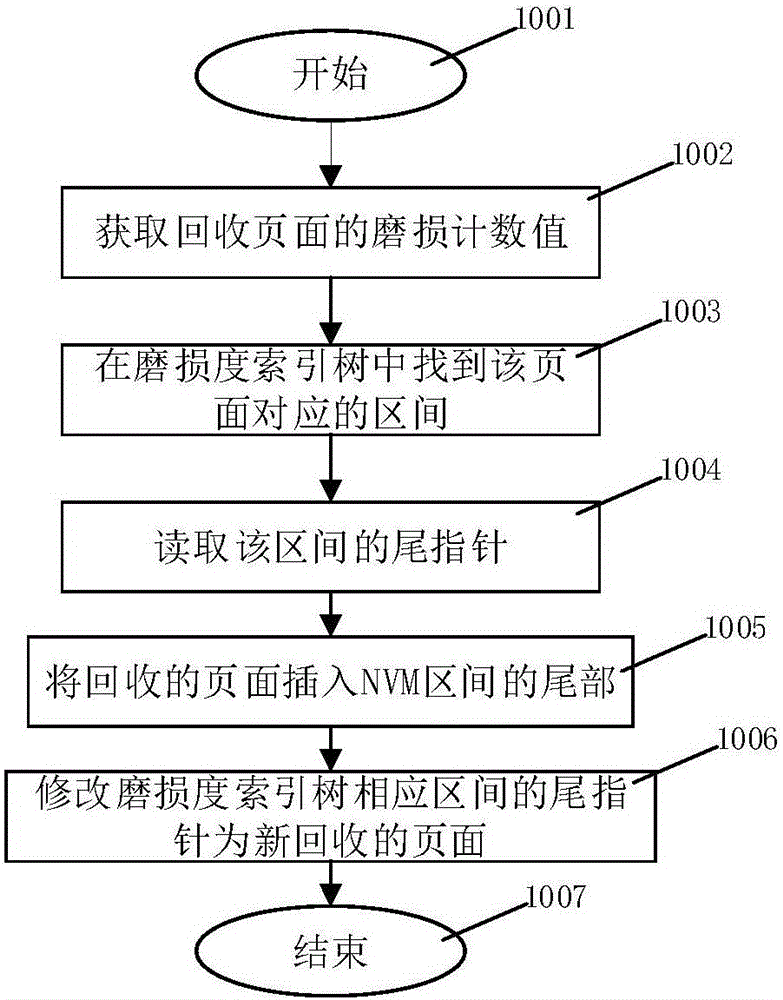

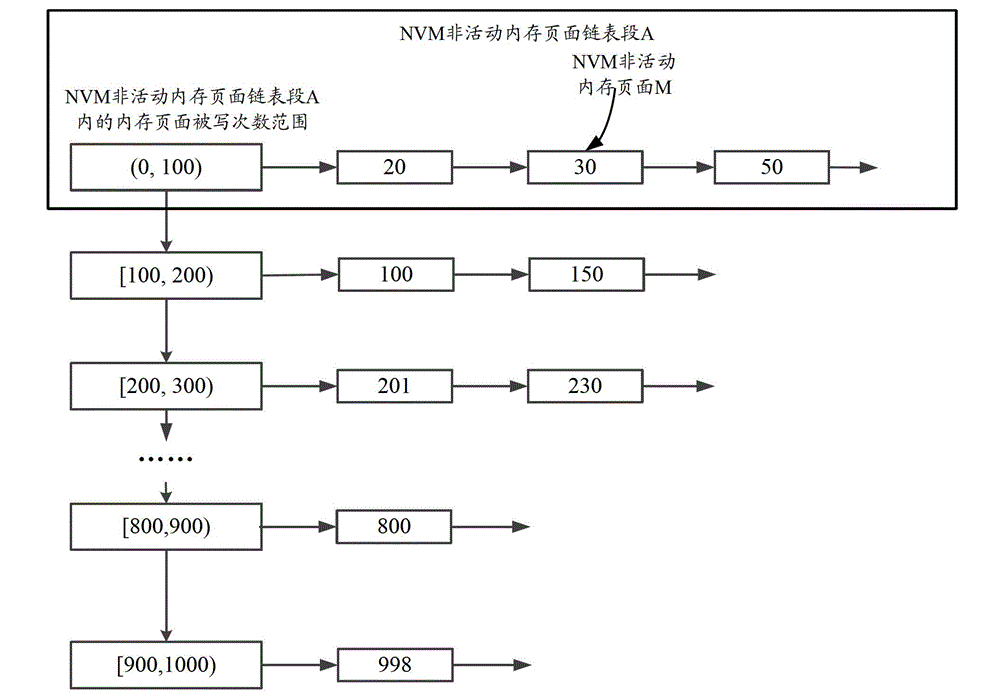

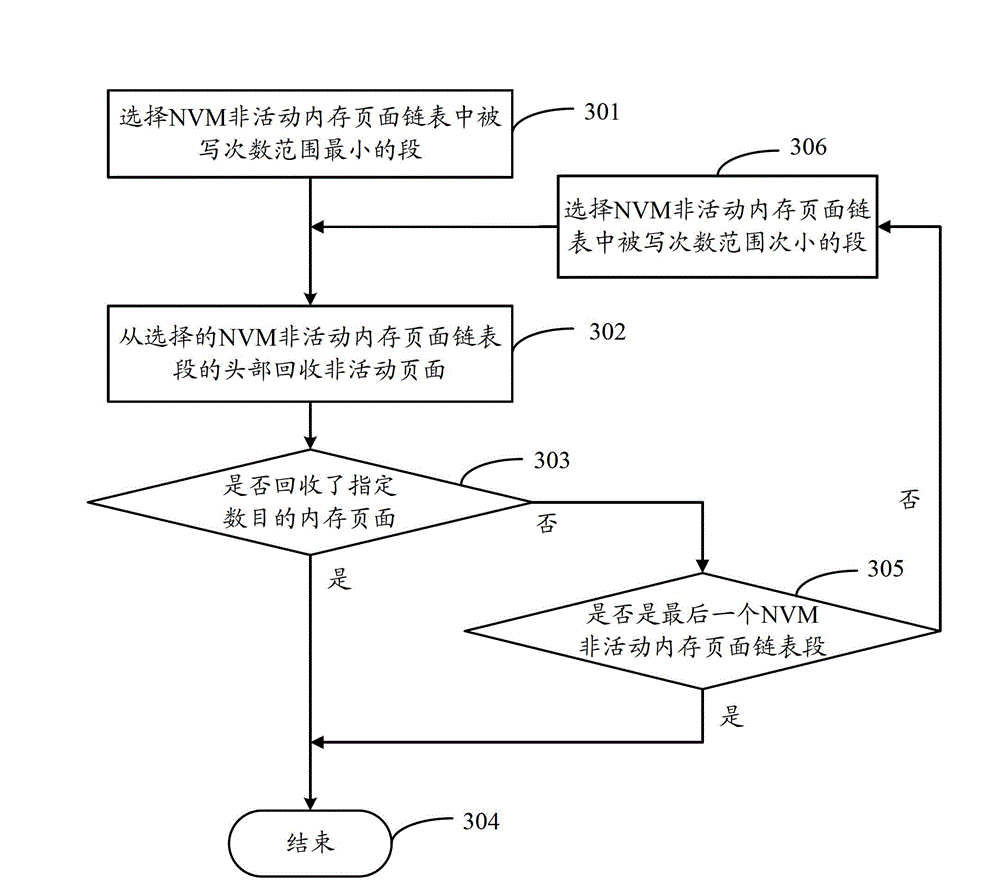

Efficient page organization and management method facing NVM (Non-Volatile Memory)

ActiveCN105930280ARealize distributionTake advantage ofMemory adressing/allocation/relocationParallel computingTerm memory

The invention discloses an efficient page organization and management method facing an NVM (Non-Volatile Memory). The efficient page organization and management method comprises the steps of: firstly, establishing and organizing index structures of idle pages in the NVM by a tree-shaped structure, and generating a wear degree index tree; then partitioning the idle pages in the NVM into a plurality of intervals according to sizes of wear count values, and connecting the idle pages inside each interval in a link list form to form an interval link list; storing all internal nodes of the wear degree index tree besides leaf nodes in a DRAM (Dynamic Random Access Memory) for rapid indexing; and enabling nodes on the last layer in the DRAM to point to the interval link lists of NVM pages. The efficient page organization and management method facing the NVM, which is provided by the invention, solves the problem of an NVM page organization and management method in the prior art, and enables pages with low write wear to be preferably selected, thereby fulfilling the aim of uniformly distributing write operations into each page as far as possible; meanwhile, when write wear leveling is ensured, high-performance NVM page distribution and recovery management is achieved; and a multi-core architecture is sufficiently utilized, and parallel distribution and recovery are achieved.

Owner:诸葛晴凤

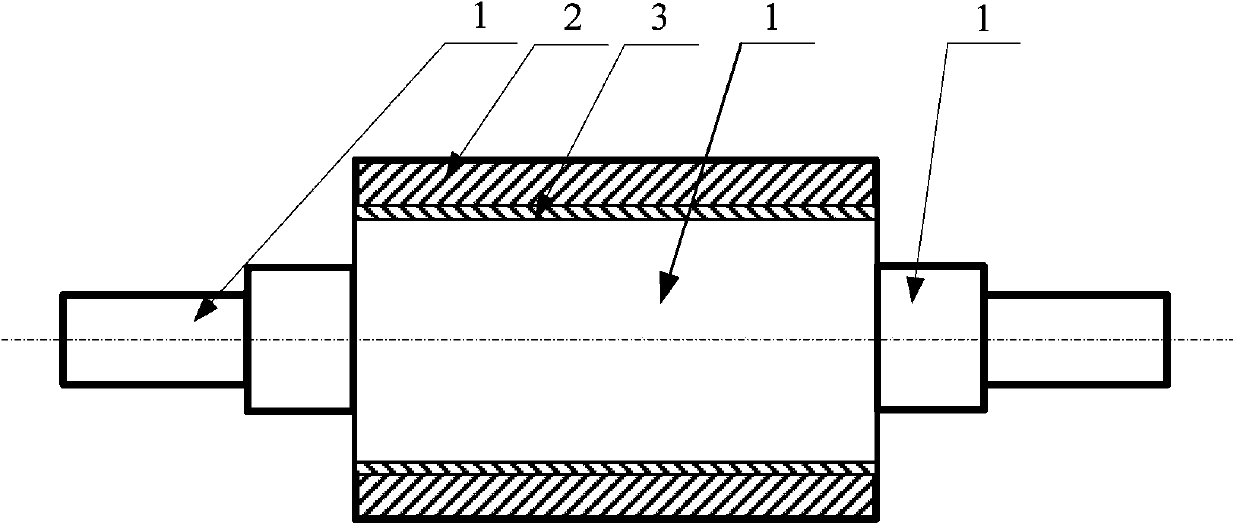

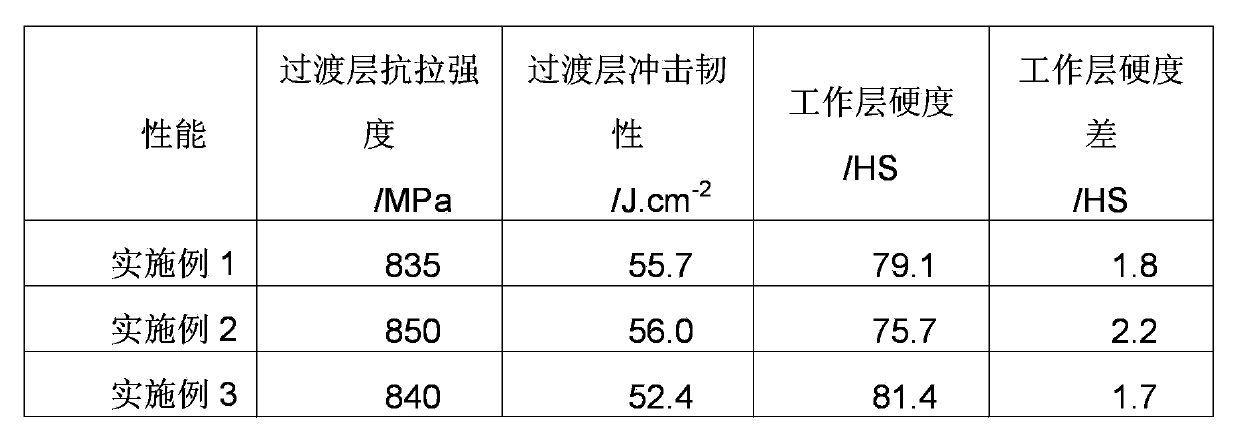

Overlaying repair method for worn roller

InactiveCN103418923AUniform hardnessHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantToughness

The invention discloses an overlaying repair method for a worn roller. The method is characterized by comprising the following process steps of turning the worn surface of the worn roller; overlaying a high-toughness transition layer on the turned surface; overlaying a wear-resistant working layer on the transition layer; performing heat treatment on the roller subjected to overlaying repair; and performing finish machining on the roller to enable the roller to reach the specified dimension and precision. Compared with the past production and manufacture process and production method, the production and manufacture cost is relatively low, the production and manufacture period is relatively short, and the roller subjected to overlaying repair is long in service life.

Owner:BEIJING UNIV OF TECH

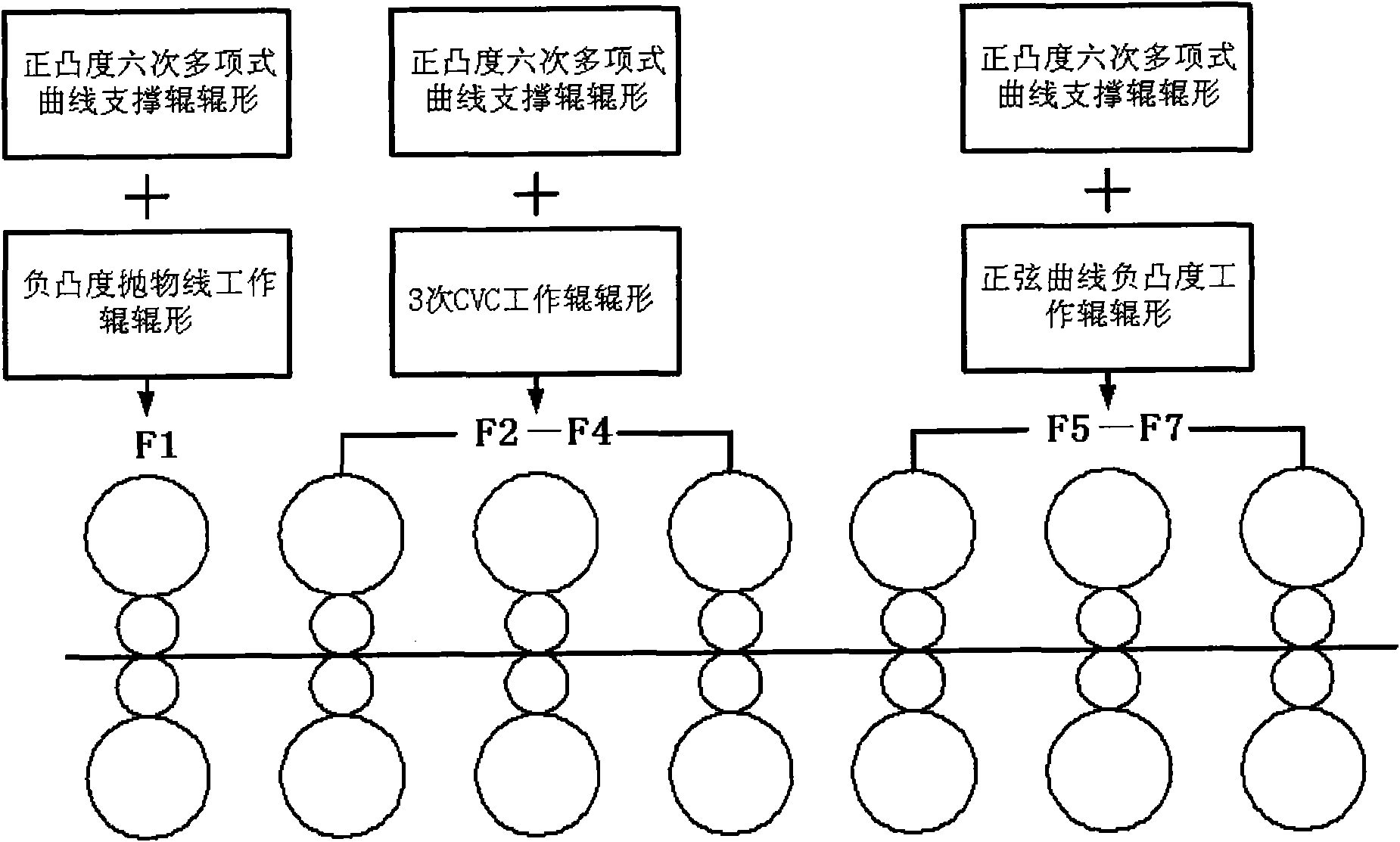

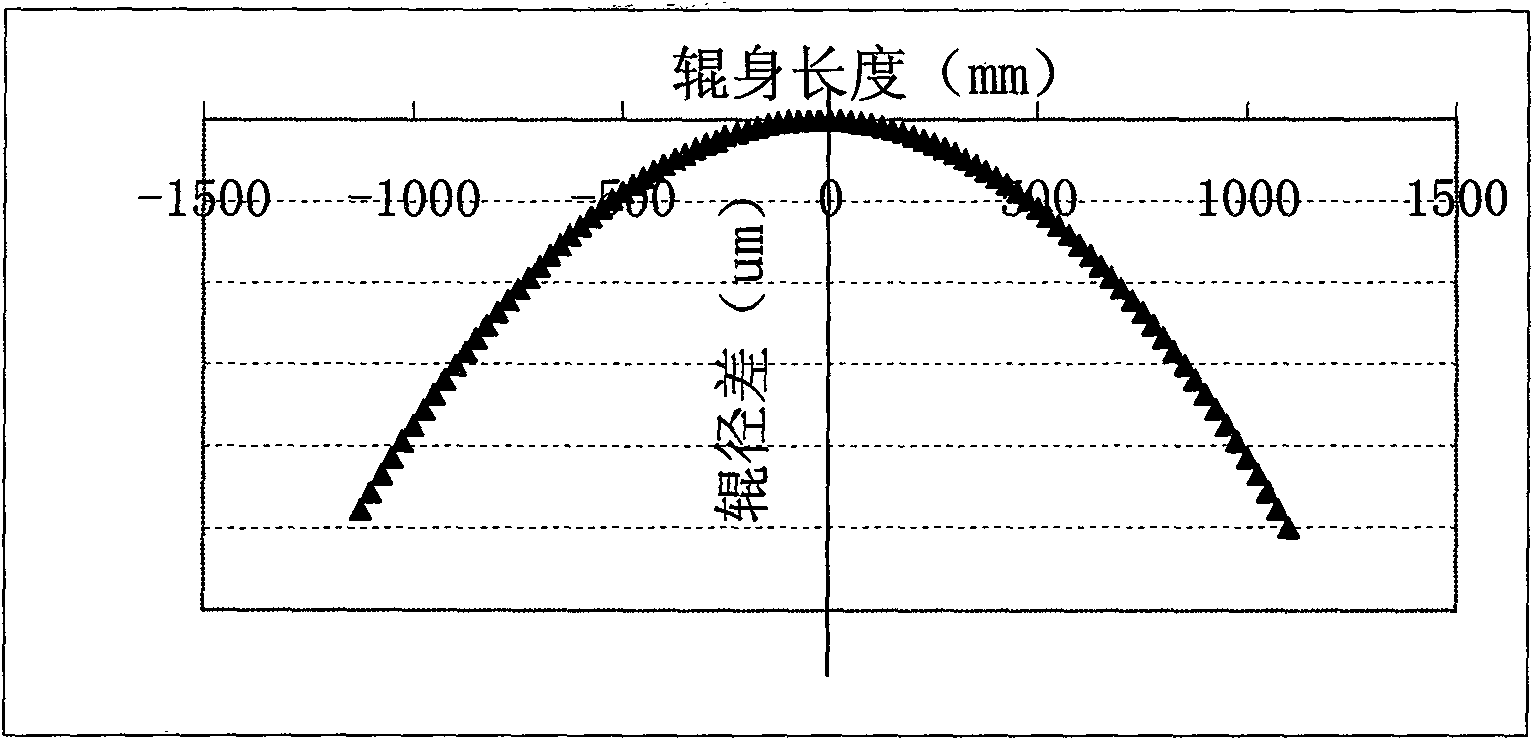

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

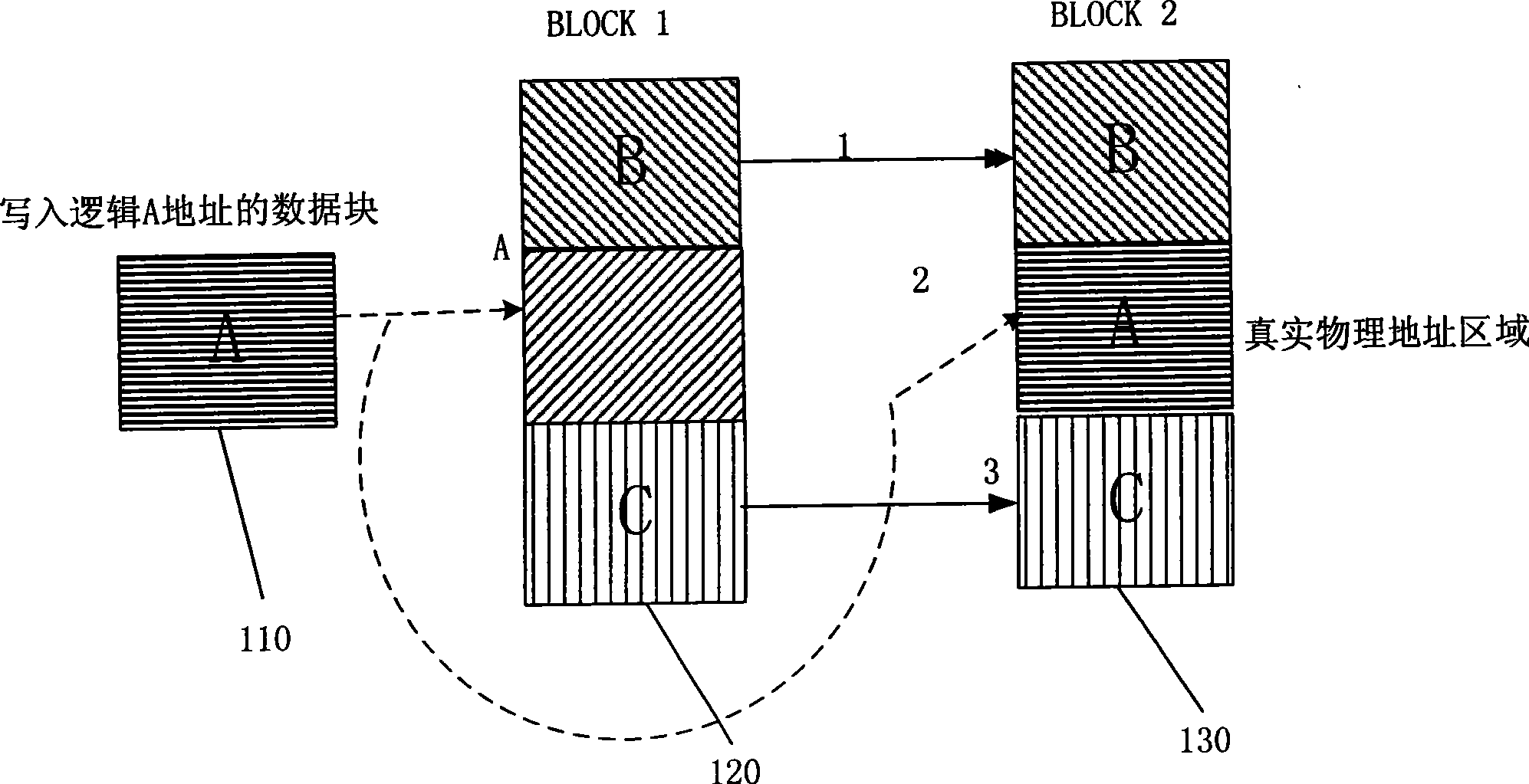

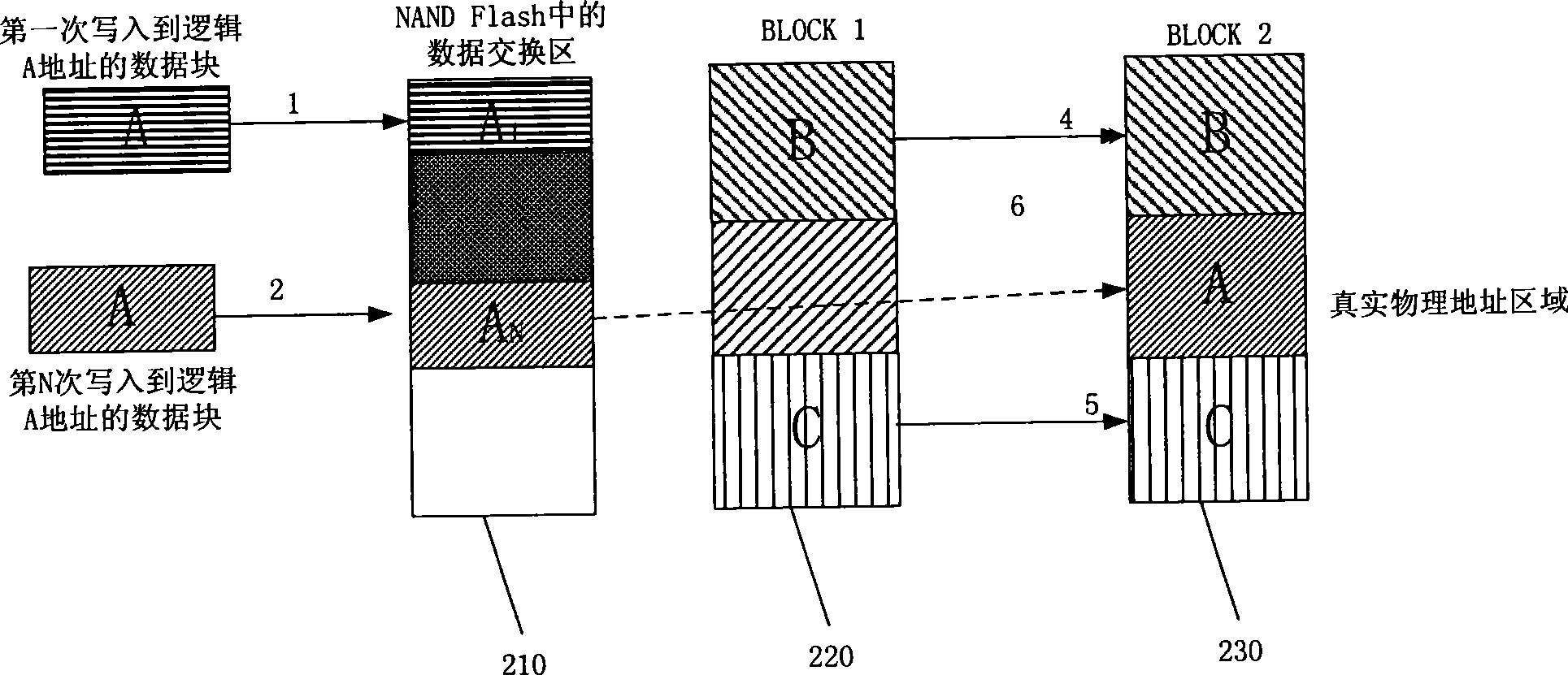

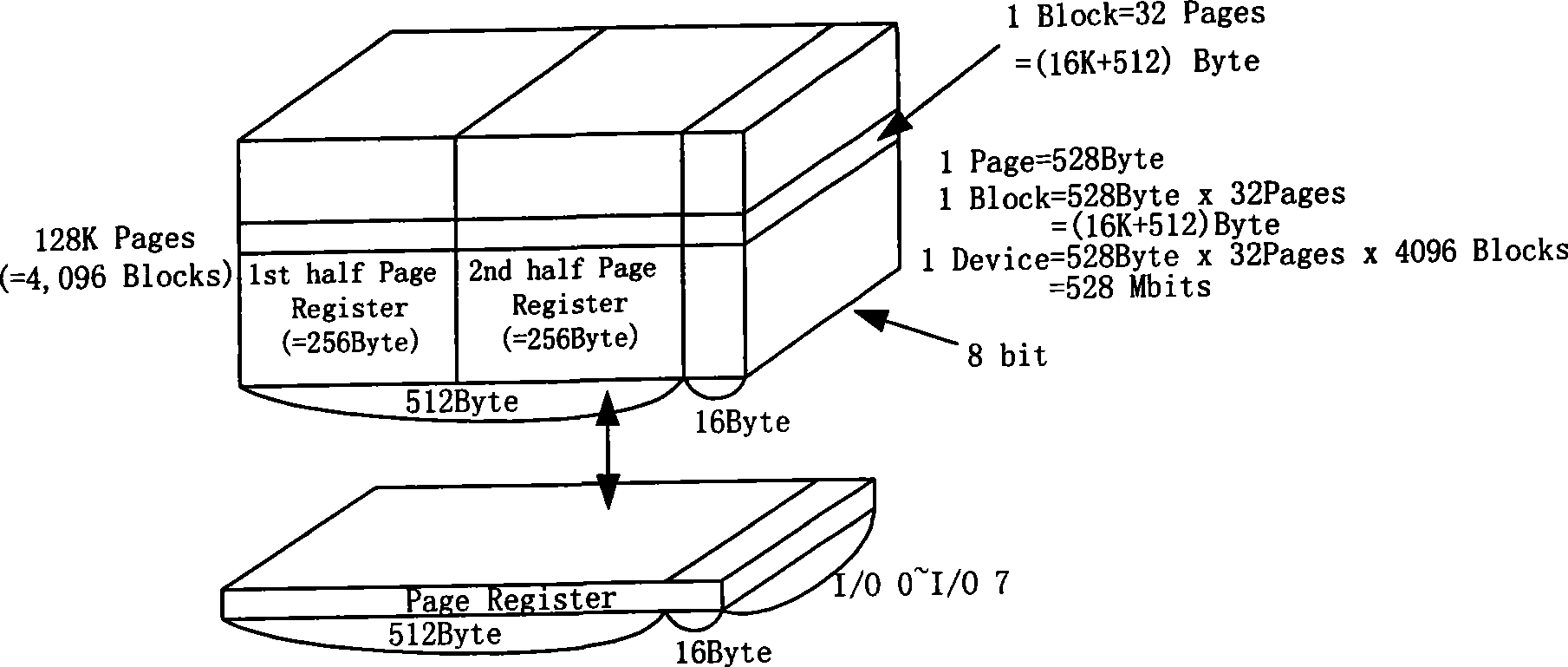

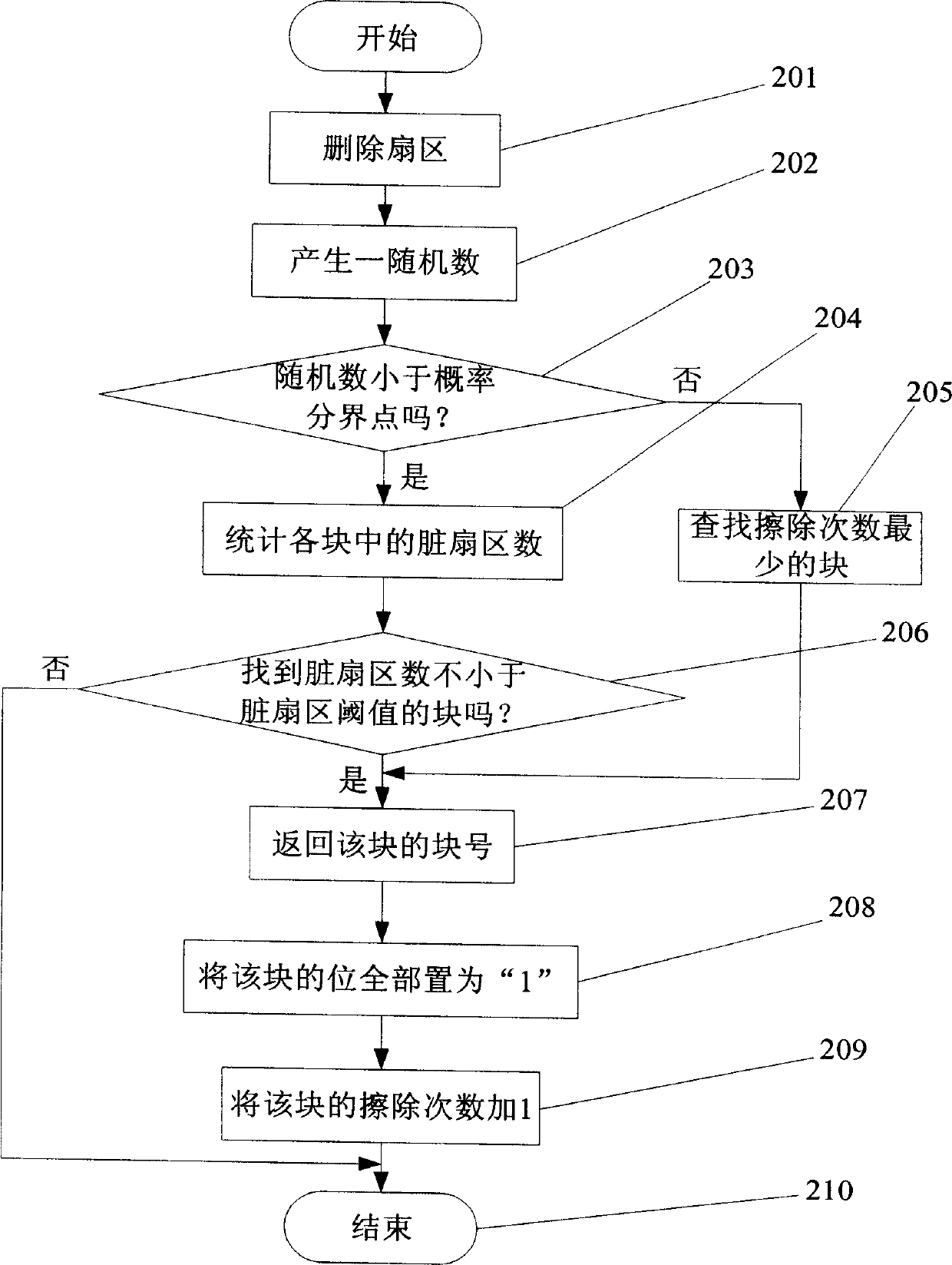

NAND flash memory optimizing and managing method based on data interchange zone

ActiveCN101382918AExtended service lifeImprove read and write speedMemory adressing/allocation/relocationFlash memory controllerMemory controller

The invention discloses a NAND Flash memory optimization management method based on a data exchange zone, which comprises the following steps: at least 2 blocks are set on the NAND Flash as the data exchange zone; a dynamic data effectiveness identification item is added for recording the aging degree of the data blocks in the data exchange zone; and the data block, before being modified during the setting period, is written into the real physical address of the flash memory after a logical address is re-mapped. By the management method, through the data exchange zone of a plurality of blocks set in the NAND Flash chip by a flash memory controller, the mid-process data during the read-write is stored by buffering, thus reducing the write-in frequency in the system document zone of the NAND Flash chip, increasing the read-write speed of the chip, as well as balancing the abrasion of the chip and prolonging the service life of the NAND Flash.

Owner:SLICONGO MICROELECTRONICS INC

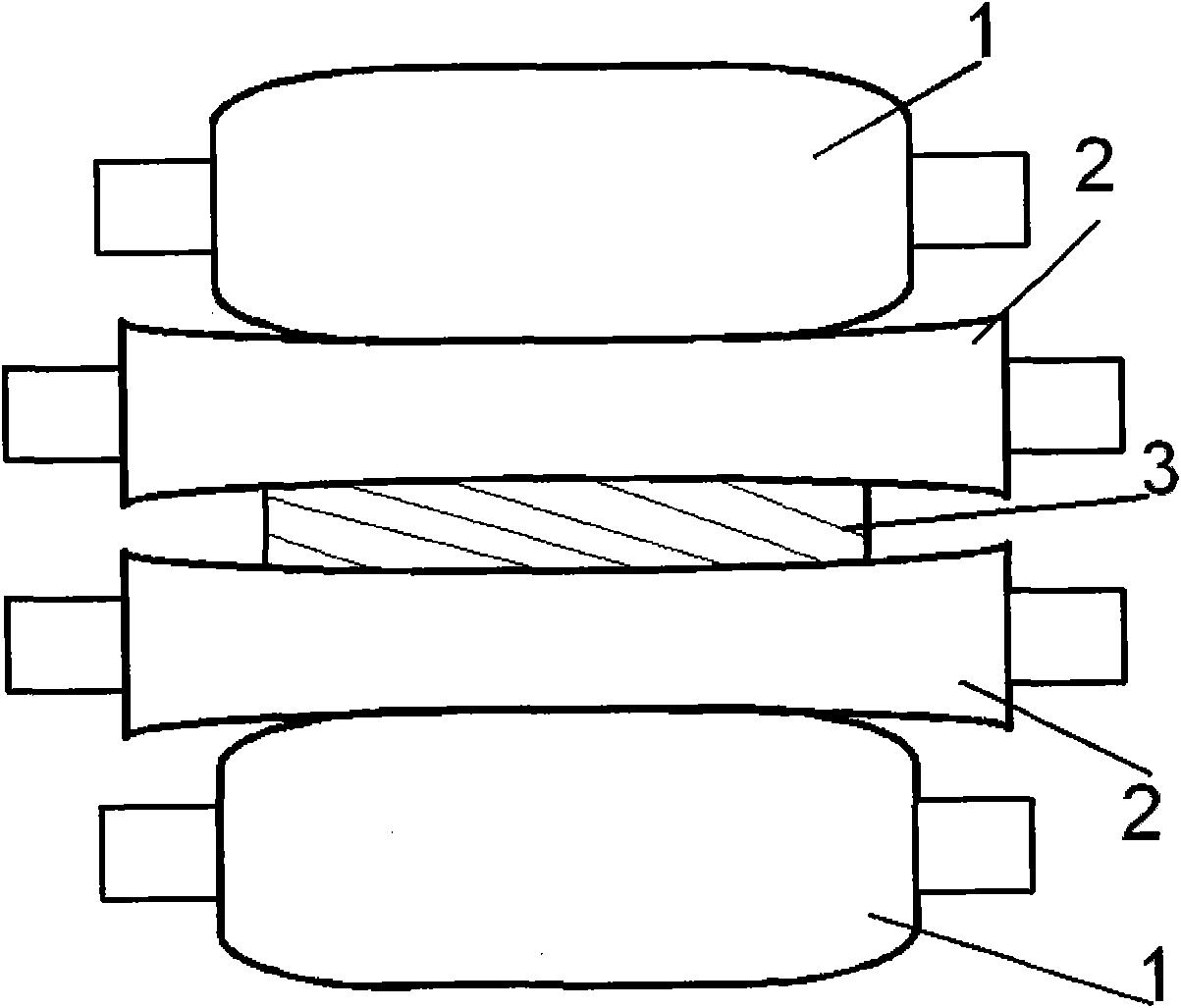

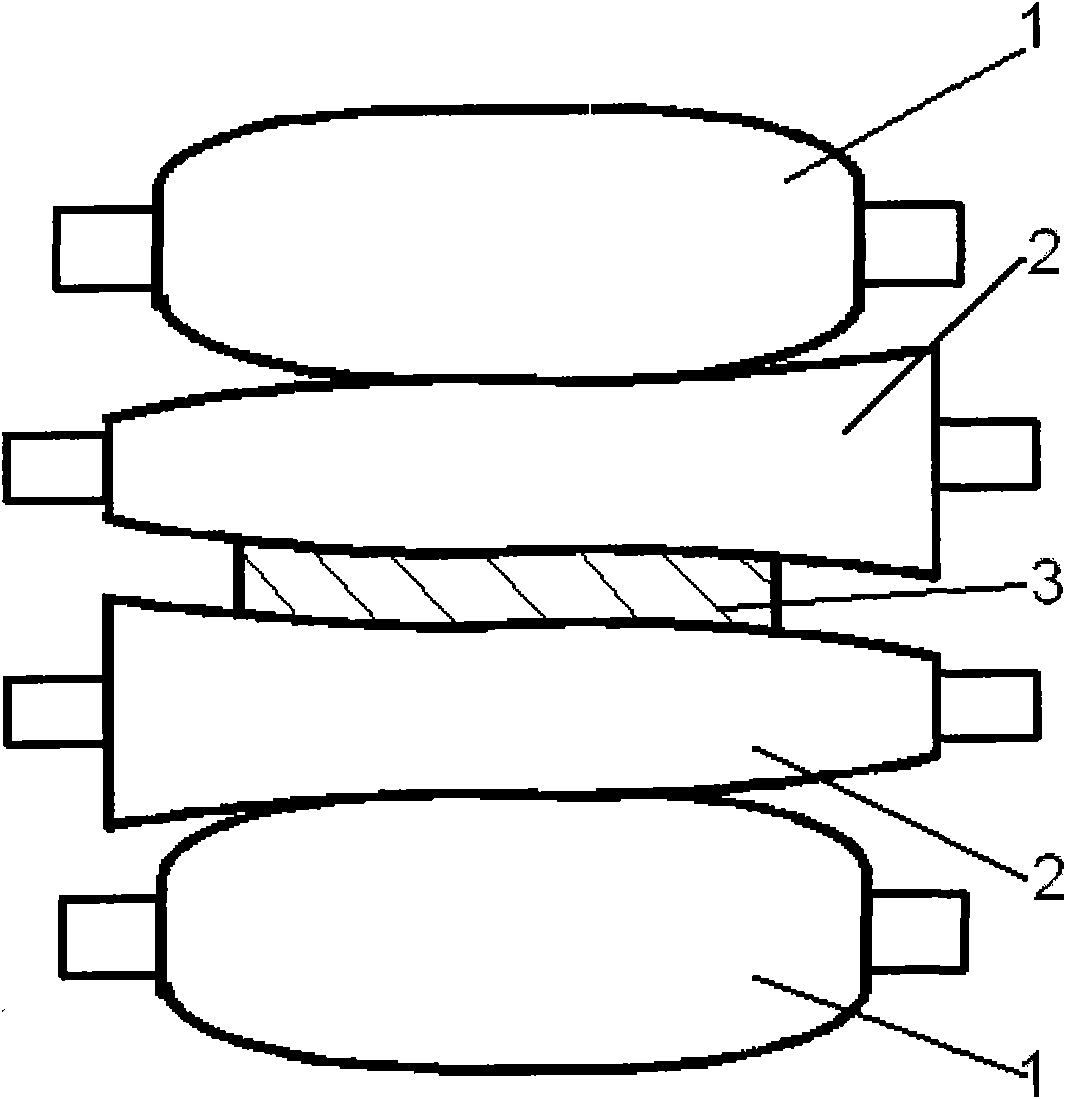

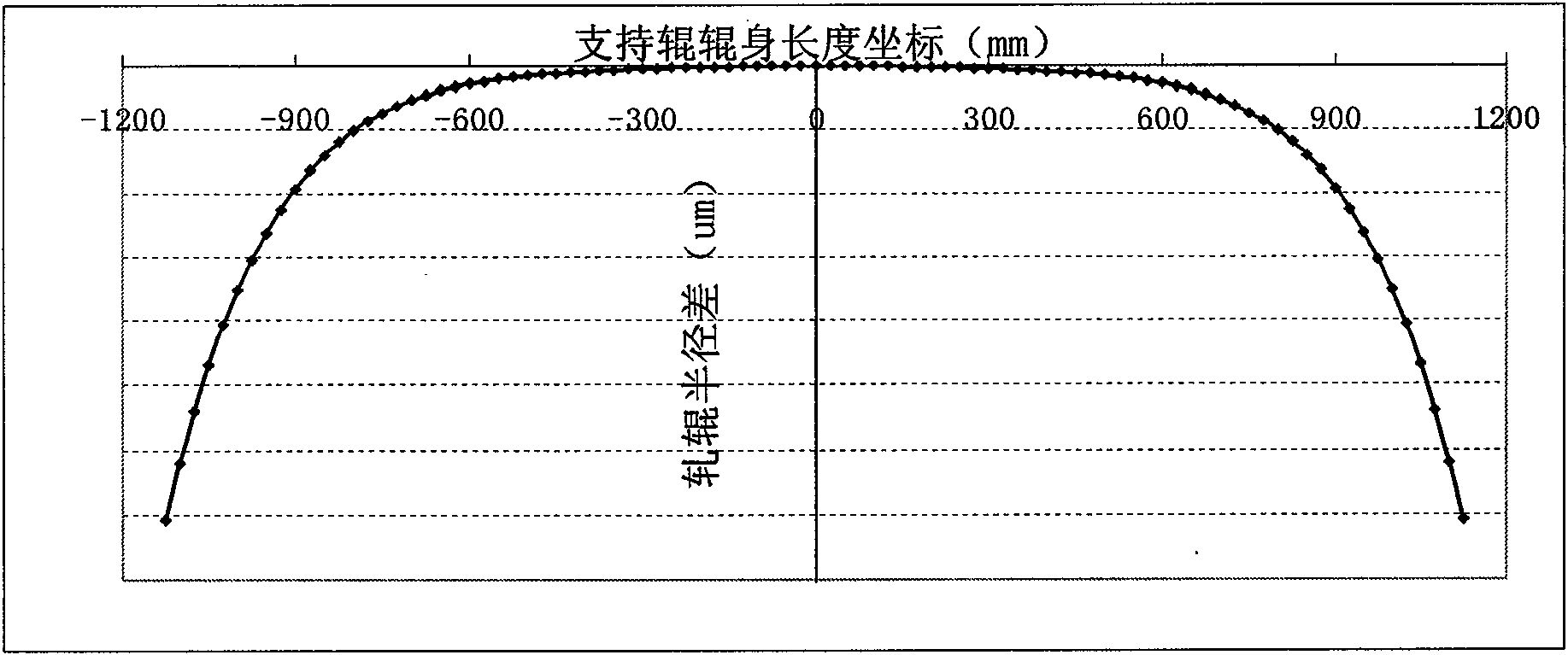

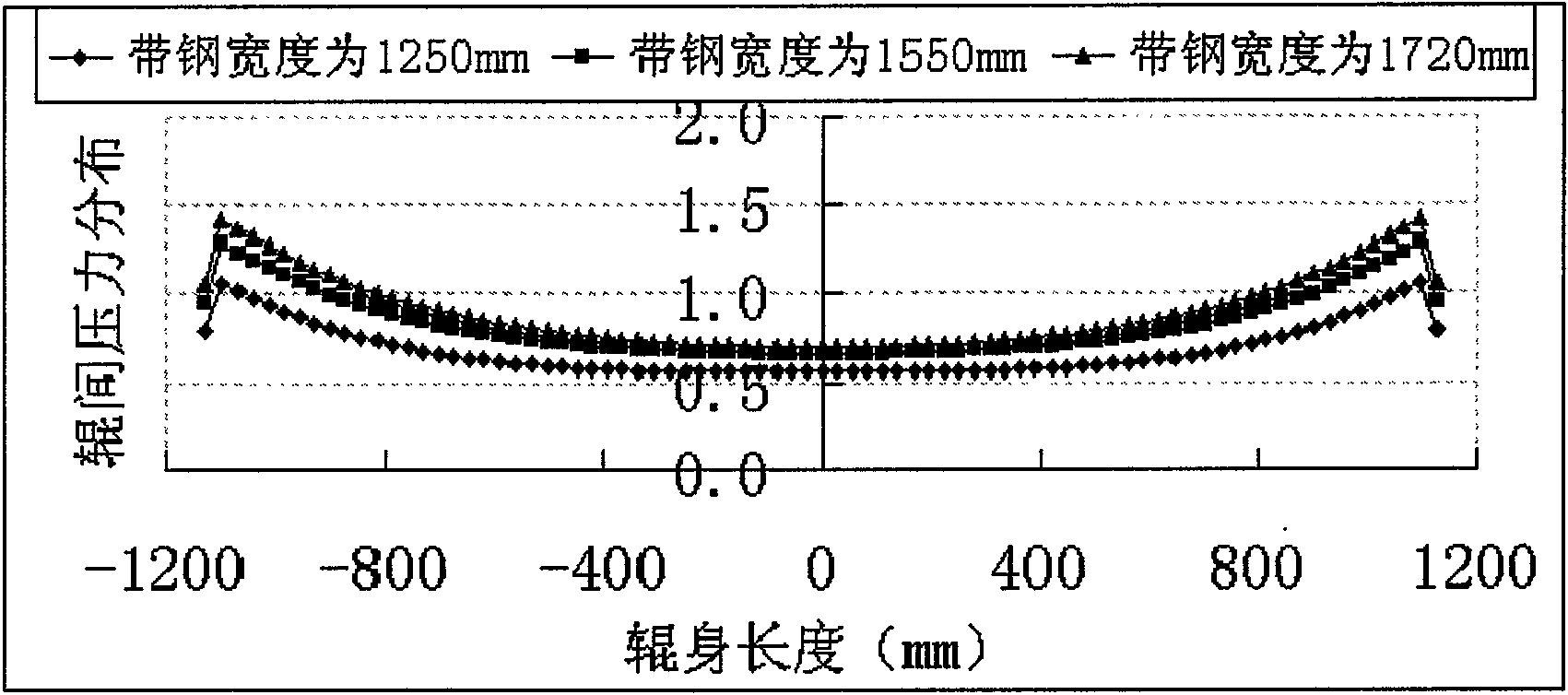

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

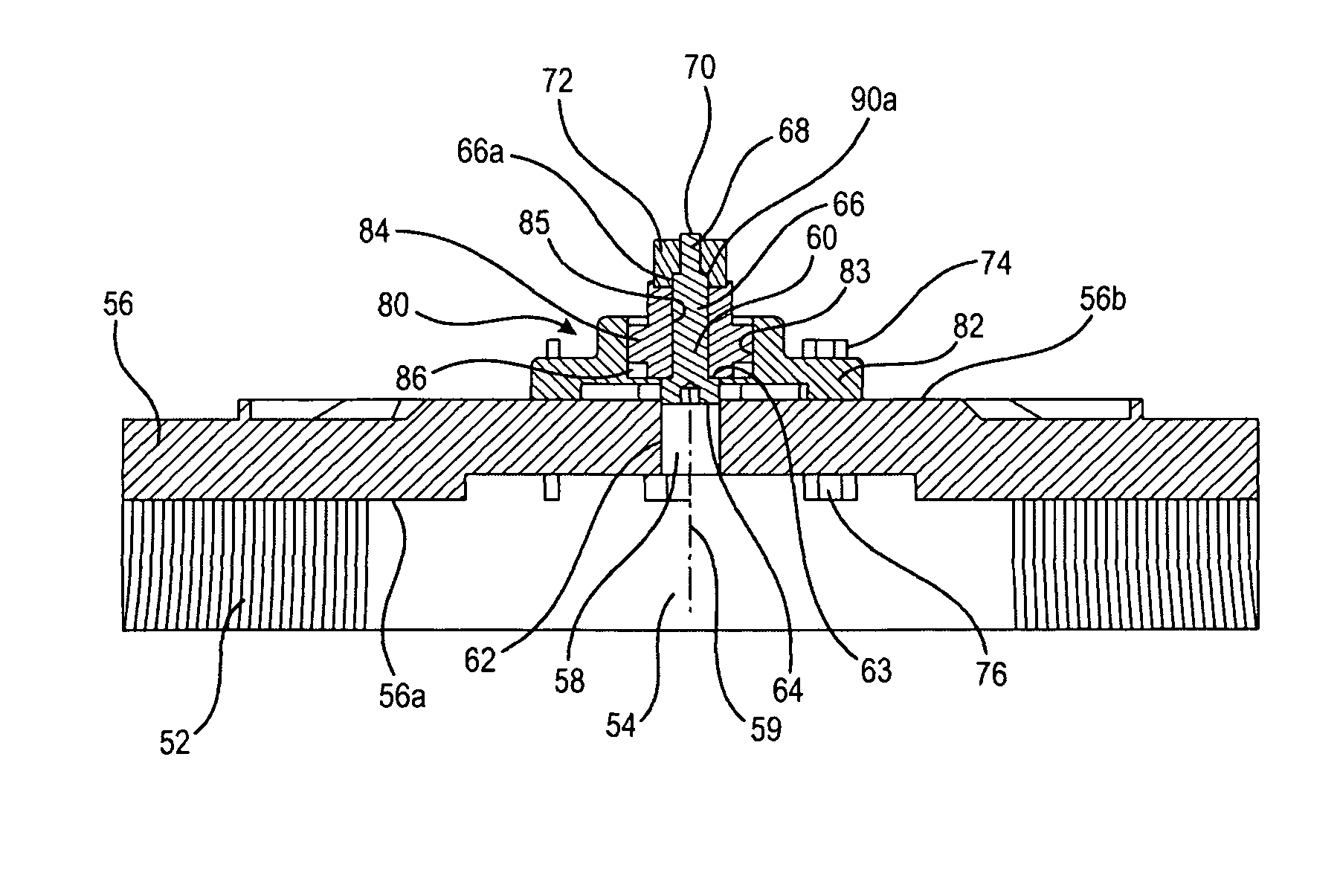

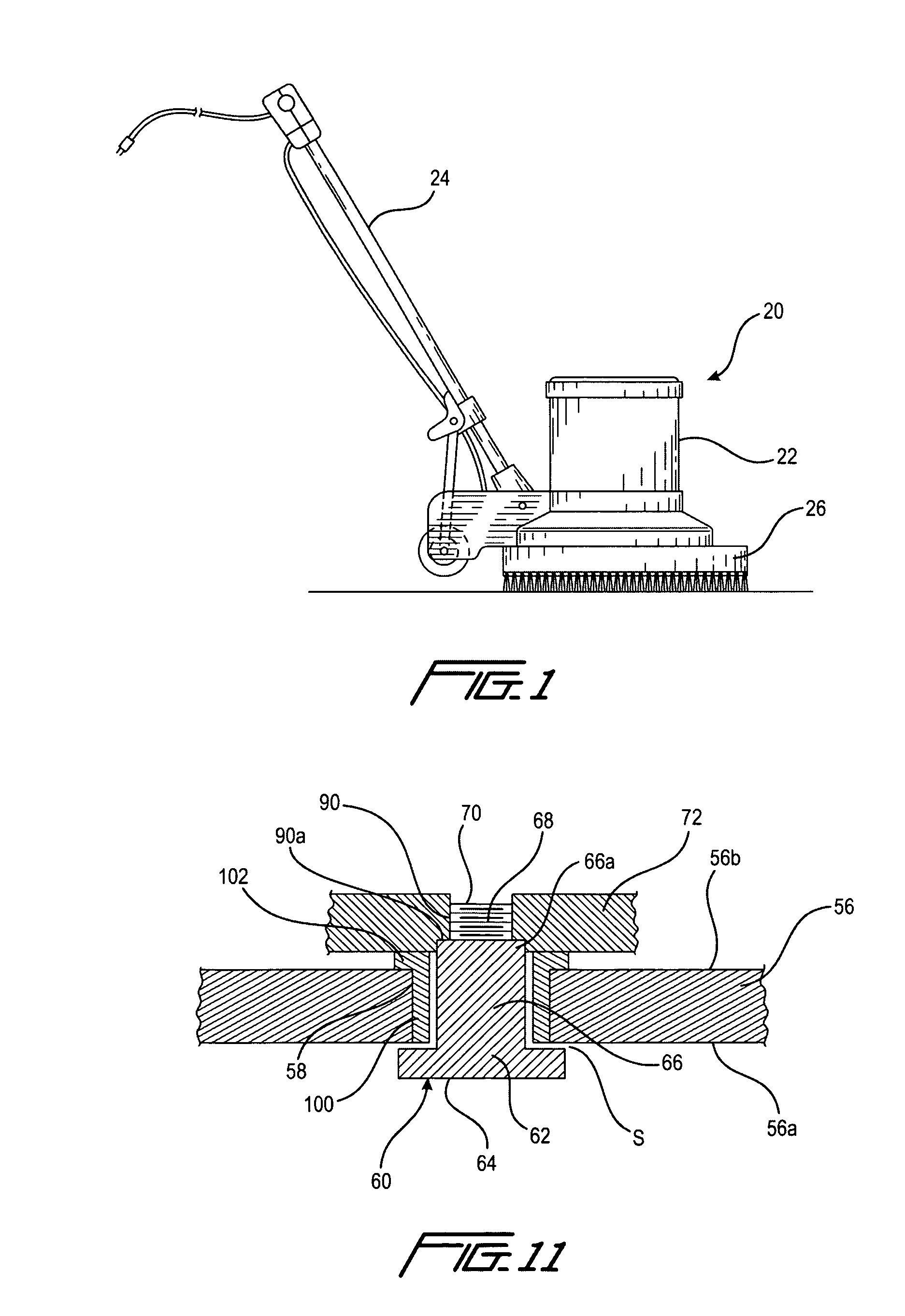

Mounting adapter for concrete surface processing tool

InactiveUS7815393B2Increase capacityFor quick replacementGrinding wheel securing apparatusCarpet cleanersMotor driveEngineering

A mounting assembly for rotatably mounting a surface processing tool holder on at least one motor driven rotatable arm of a surface processing apparatus, such that the tool can spin freely as the arm is driven by the motor, includes an elongate shank having a smooth surfaced, cylindrical portion intermediate its ends adapted for positioning within an aperture in the tool holder with one threaded end portion projecting through the aperture for attachment to an elongate mounting bar adapted for attachment to the arm. A bearing supported by the tool body and surrounding the smooth surfaced portion of the shank is rotatable relative to the shank. The mounting bar includes a threaded aperture for receiving the threaded end portion of the shank and the threaded aperture includes a counterbore for receiving the end portion of the smooth surfaced shank portion which is adjacent the threaded end portion.

Owner:WAGMAN METAL PRODS

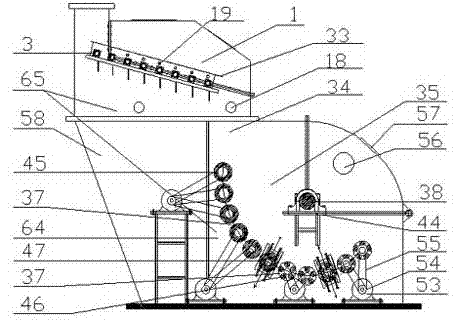

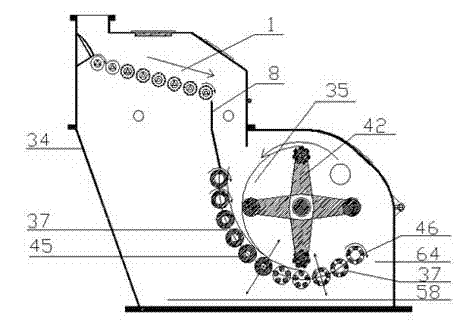

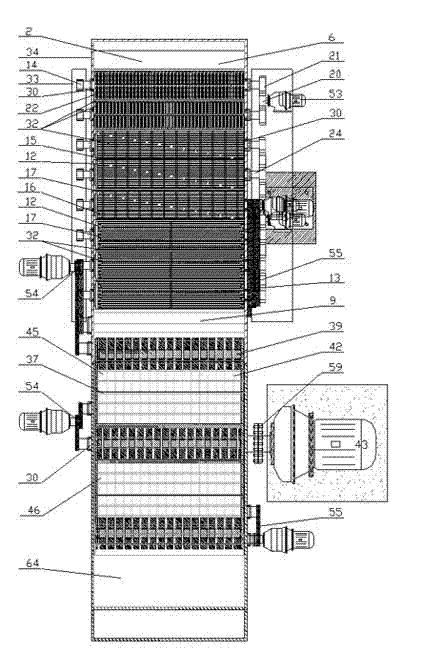

Sieving and crushing integrated machine

ActiveCN102896019AStrong impact resistanceReduces impact and wearSievingScreeningSystem structureProcess engineering

The invention discloses a sieving and crushing integrated machine. The sieving and crushing integrated machine comprises a machine housing, a sieving and distributing machine (1) arranged at an upper part of the machine housing, and a sieving and crushing machine (35) arranged at a lower part of the machine housing, wherein the sieving and distributing machine (1) comprises a charge hole (2), an arc-shaped distributing plate (6), an iron remover (11), a transmission device, a flange type sieve shaft (4) and a filter sieve shaft (5); the sieving and crushing machine (35) comprises a main rotor, an arc-shaped counterattack sieve roller set, a particle size adjusting device and a transmission device; and a charge hole (36) of the sieving and crushing machine is positioned below a discharge hole (9) of the sieving and distributing machine. The sieving and crushing integrated machine has the following creative effects: the original two-stage crushing and one-stage sieving mode is changed to be a one-stage sieving and one-stage crushing mode, so that a system structure is simplified; problems of material adhesion and blockage, high iron content, low sieving and crushing efficiency, high power consumption, non-uniform ring hammer wear, unadjustable particle size, high difficulty in overhauling and replacement of spare parts, inconvenience in operation and the like are solved; and the sieving and crushing integrated machine is a major innovation of sieving and crushing equipment technology.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

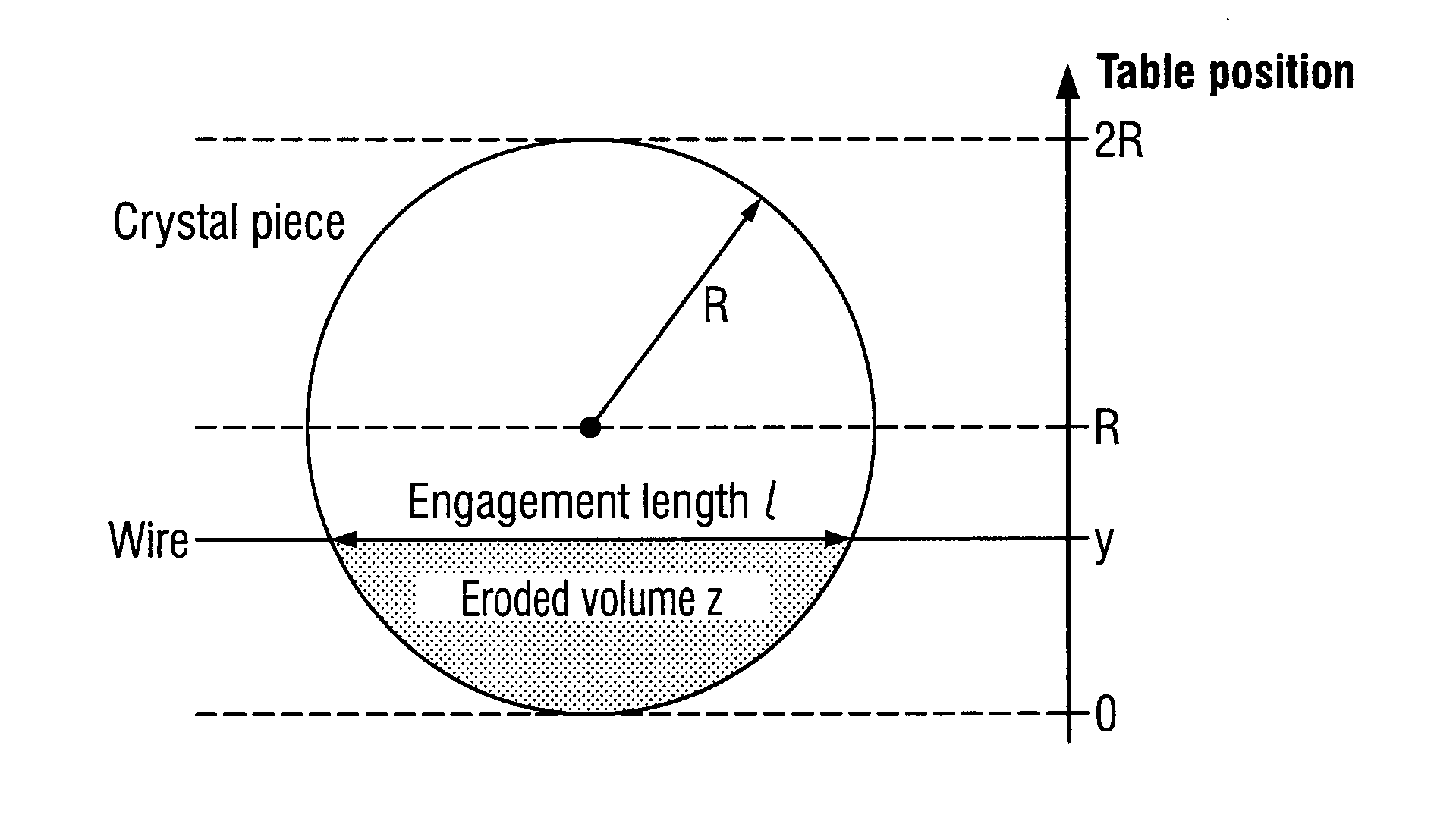

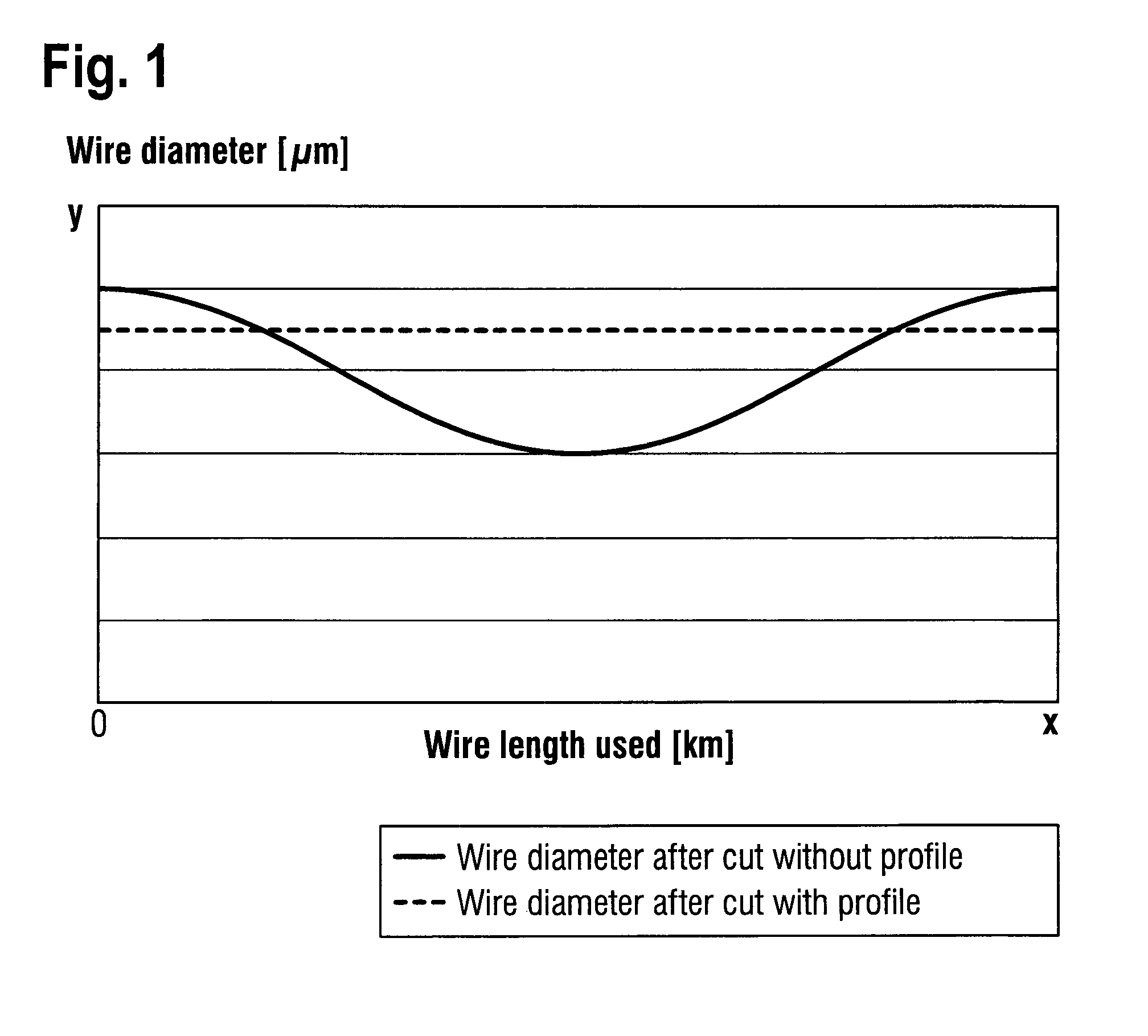

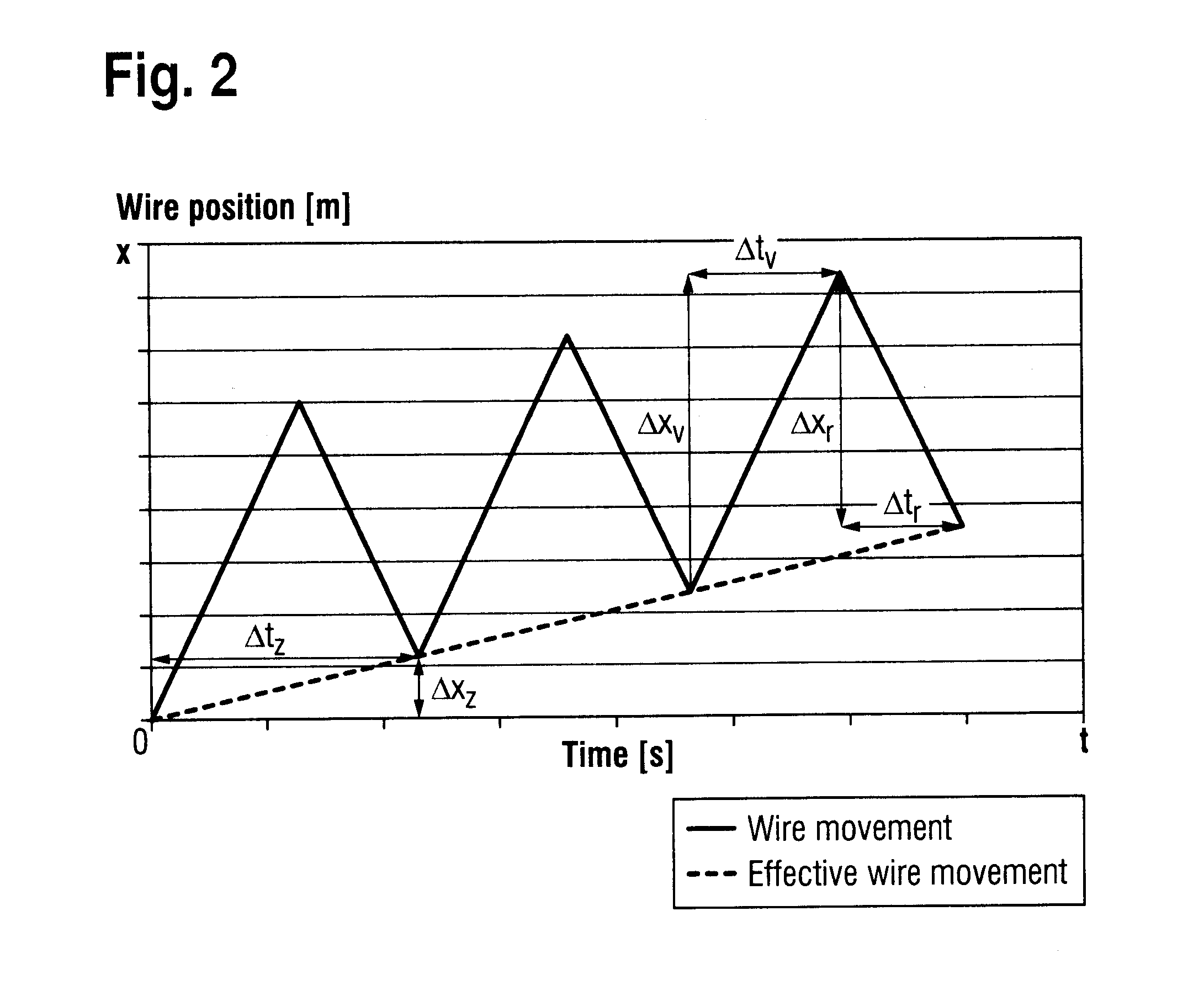

Method For Slicing A Multiplicity Of Wafers From A Workpiece

ActiveUS20080141994A1Uniform wearAvoid disadvantagesMetal sawing devicesMetal sawing accessoriesWire rodEngineering

A multiplicity of wafers are sliced from a workpiece which has a longitudinal axis and a cross section, the workpiece fastened on a table being fed by a relative movement directed perpendicularly to the longitudinal axis of the workpiece between the table and the wire gang of a wire saw, with a variable forward feed rate through the wire gang formed by a sawing wire moved with an effective speed, the effective speed of the sawing wire being regulated as a function of the forward feed rate and the workpiece cross section so as to result in uniform wear of the sawing wire.

Owner:SILTRONIC AG

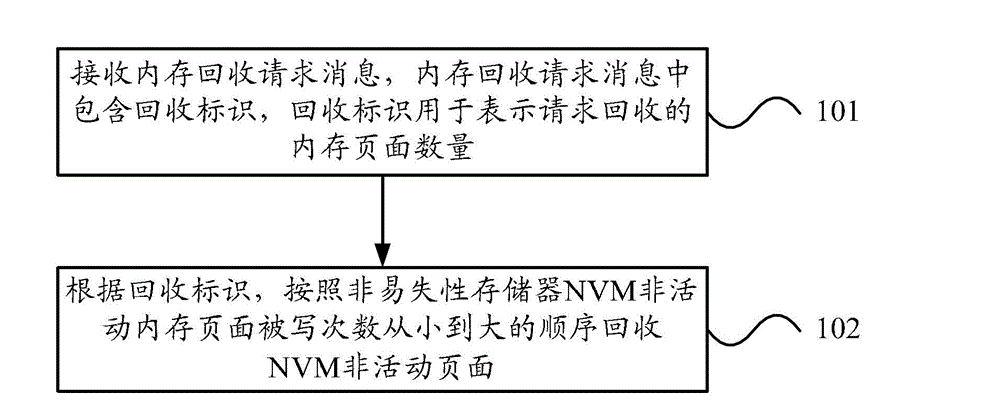

Internal memory recovery method and device

ActiveCN104008061AUniform wearImprove stabilityMemory architecture accessing/allocationMemory adressing/allocation/relocationInternal memoryRecovery method

Provided are a memory recycling method and device. The memory recycling method comprises: receiving a memory recycling request message, with the memory recycling request message containing a recycling identifier, the recycling identifier being used for indicating the number of memory pages which requested to be recycled; according to the recycling identifier, recycling inactive pages of a non-volatile memory (NVM) in order of the number of times the inactive memory pages of the NVM have been written, from small to large. In the memory recycling method and device in the embodiments of the present invention, by recycling the inactive pages of the NVM in order of the number of times the inactive memory pages of the NVM have been written, from small to large, it is realized that a page of which the number of times the inactive memory pages of the NVM have been written is relatively small is recycled first, and a page of which the number of times the inactive memory pages of the NVM have been written is relatively big is recycled later, thereby enabling the wear of the memory pages of the NVM to be balanced, and improving the stability and reliability of a memory unit.

Owner:HUAWEI TECH CO LTD +1

Dirty block recovery method for flash memory device

Owner:KONKA GROUP

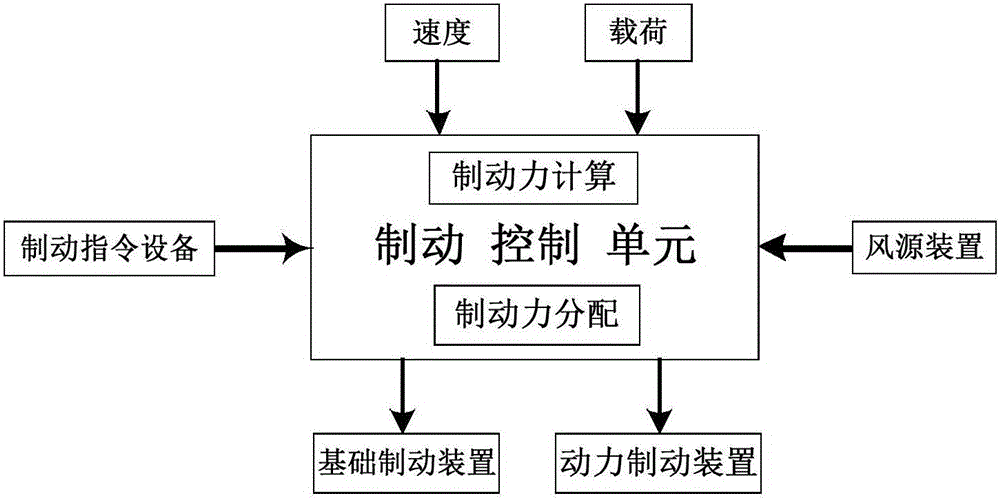

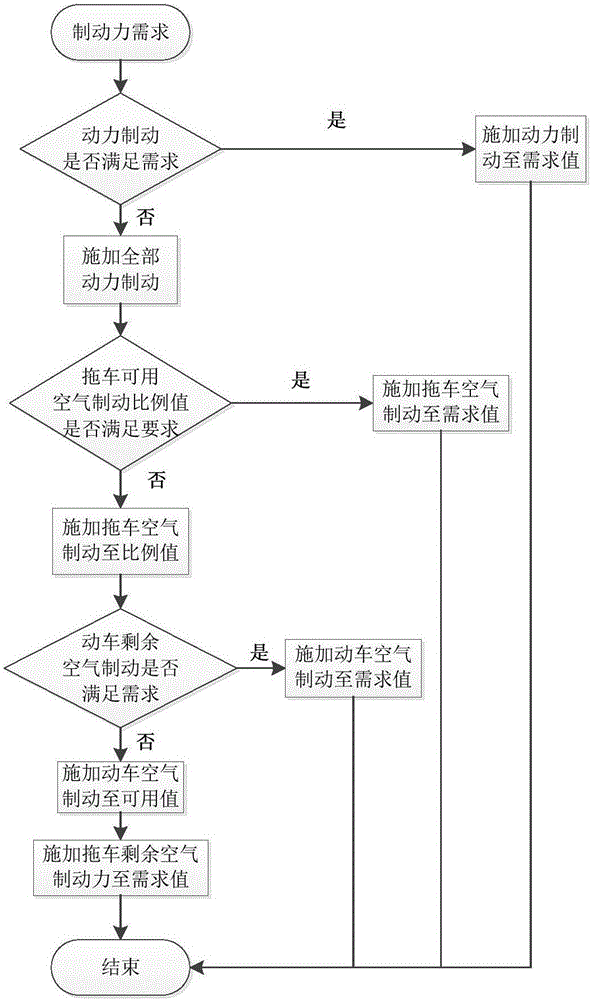

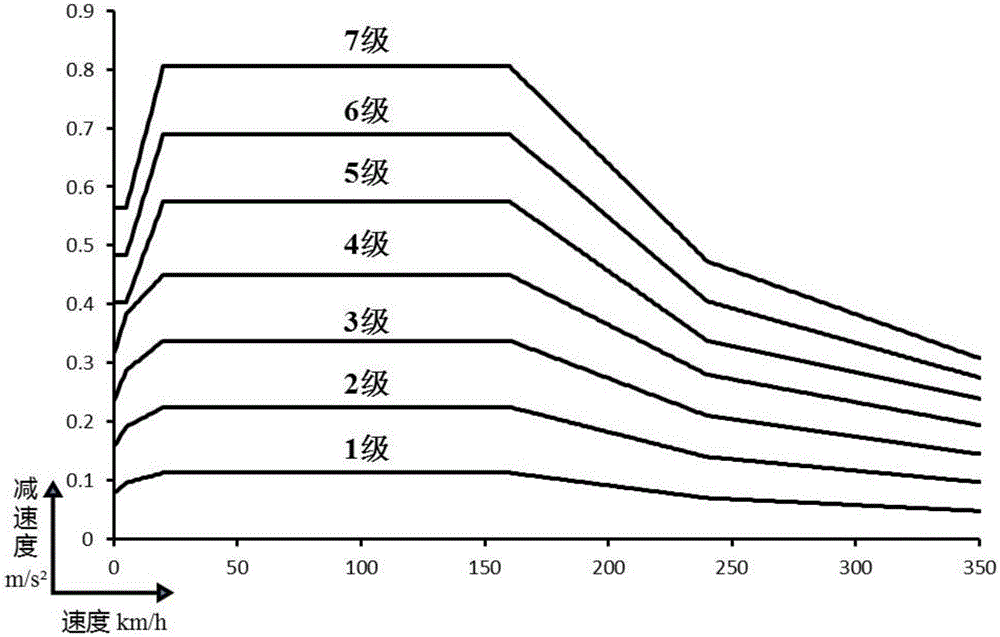

Brake system of CRH (China railway high-speed) and brake method thereof

ActiveCN106080217AImprove maintainabilityImprove economyBraking action transmissionElectrodynamic brake systemsBraking systemArresting gear

The invention provides a brake system of CRH (China railway high-speed) and a brake method thereof. The brake system of the CRH comprises brake instruction equipment, a brake control unit, a basic brake device, a power brake device, and an air source device, wherein the brake instruction equipment is used for sending out a brake instruction; the brake control unit is used for receiving the brake instruction, and distributing the brake power; the basic brake device is used for executing the air brake; the power brake device is used for executing the non-friction brake; the air source device is used for providing compressed air for the brake system and other air utilization equipment. The brake method is used for the brake system of the CRH. The brake control method has the advantages that by favorably distributing the brake force, when the power brake of the CRH is sufficiently utilized, and the air brake distribution of the CRH and a trailer is also performed; by properly setting the numbers of basic brake devices of CRH and trailer in the brake system, the brake force which is applied to each set of basic brake device is uniform; the overhauling, maintenance and economy of basic brake are favorably realized.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

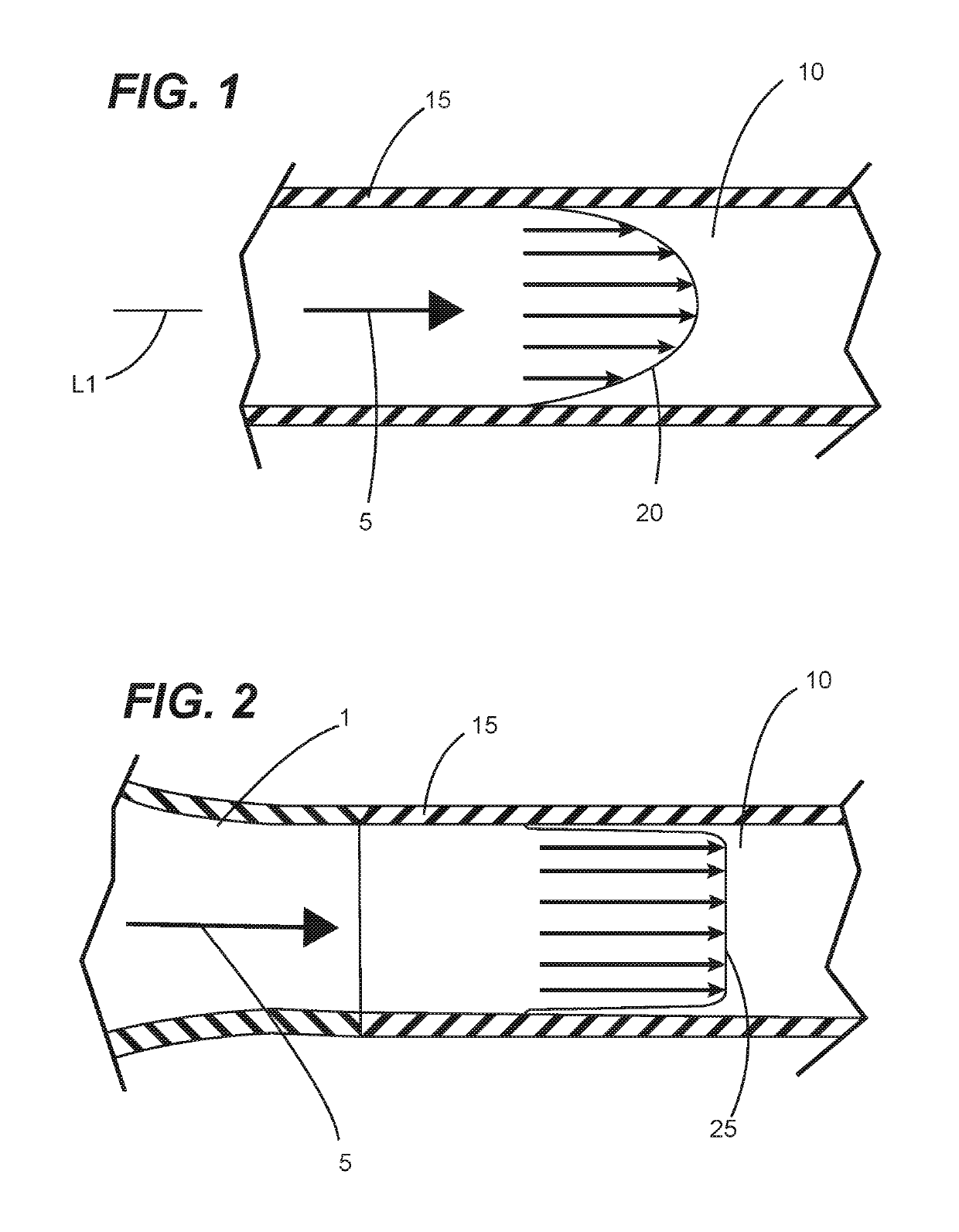

Material flow amplifier

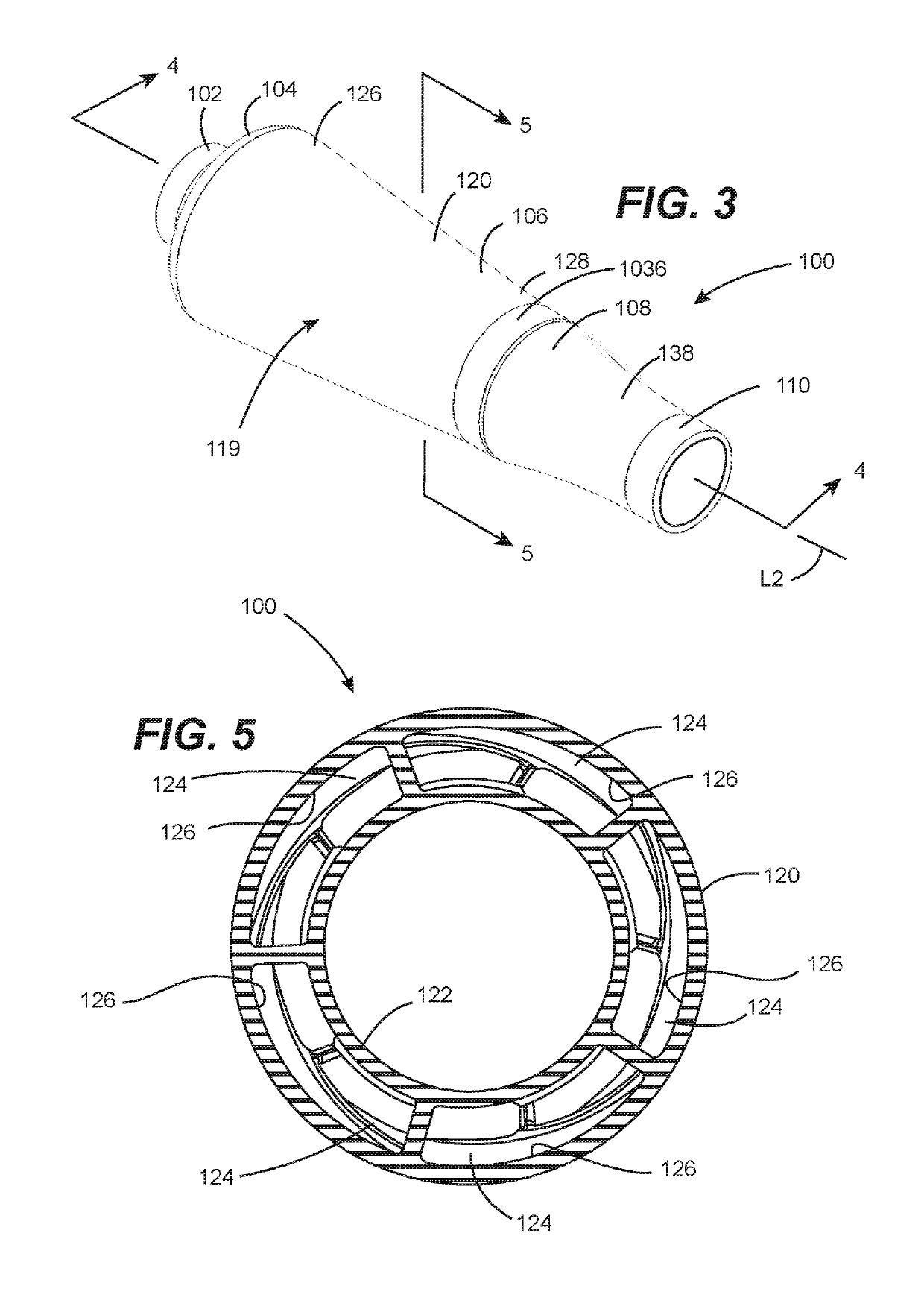

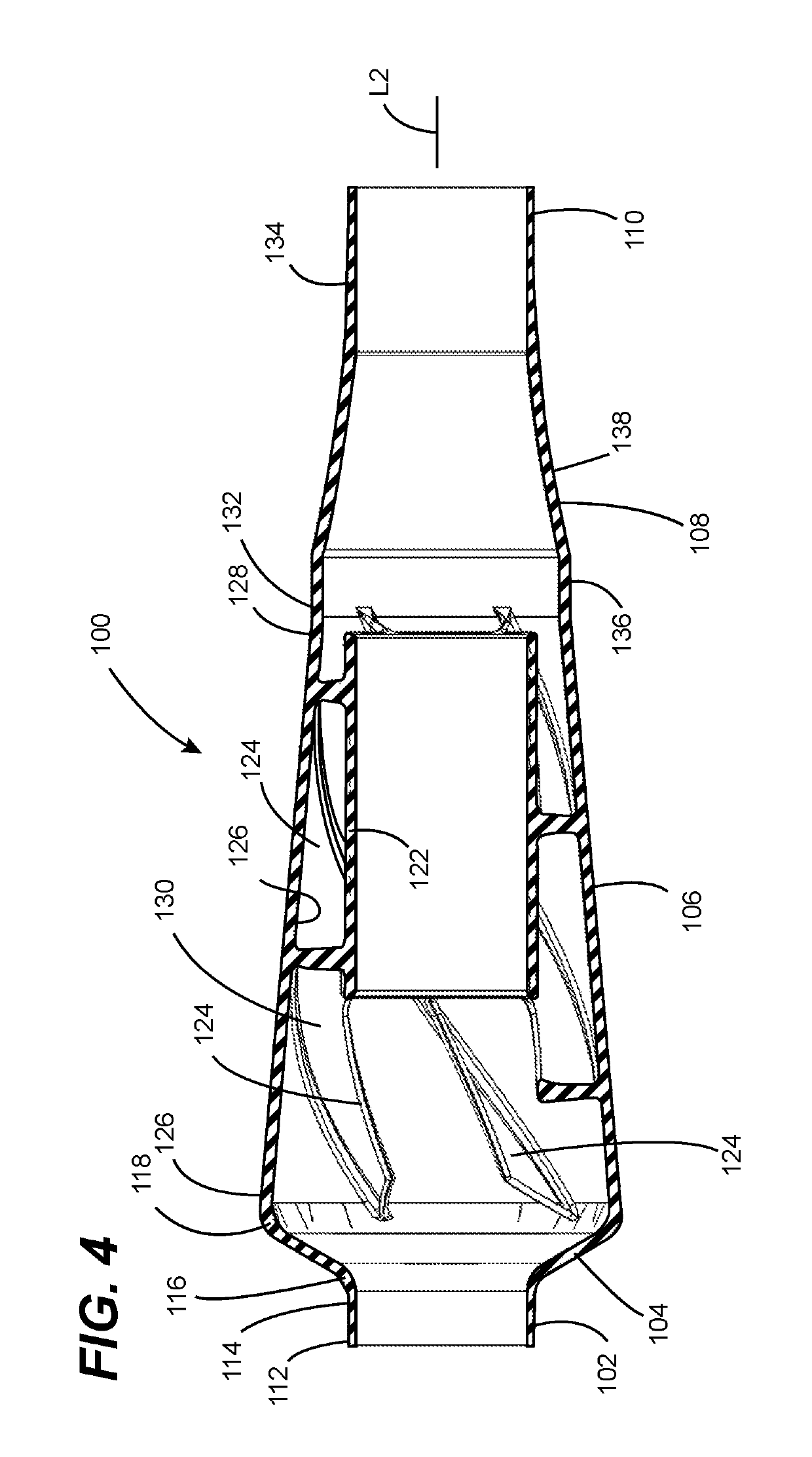

ActiveUS10458446B1Weakening rangeIncrease flow rateFlow mixersCircuit elementsParticulatesAudio power amplifier

Material flow amplifiers as disclosed herein overcome drawbacks associated with known adverse flow conditions (e.g., surface erosion and head losses) that arise from flow of certain types of materials (e.g., fluids, slurries, particulates, flowable aggregate, and the like) through a material flow conduit. Such material flow amplifiers provide for flow of flowable material within a flow passage of a material flow conduit (e.g., a portion of a pipeline, tubing or the like) to have a cyclonic flow (i.e., vortex or swirling) profile. Advantageously, the cyclonic flow profile centralizes flow toward the central portion of the flow passage, thereby reducing magnitude of laminar flow. Such cyclonic flow profile provides a variety of other advantages as compared to a parabolic flow profile (e.g., increased flow rate, reduce inner pipeline wear, more uniform inner pipe wear, reduction in energy consumption, reduced or eliminated slugging and the like).

Owner:VORTEX PIPE SYST LLC

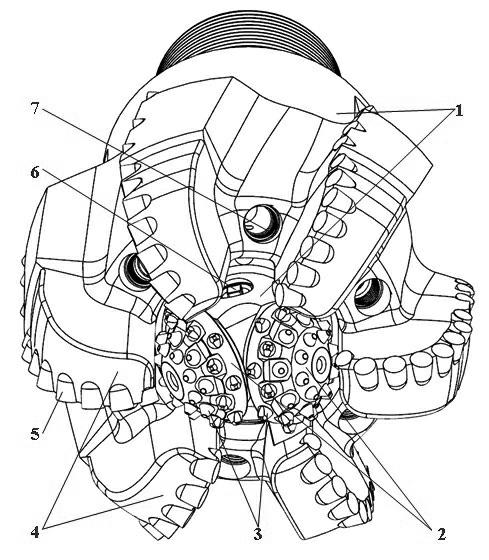

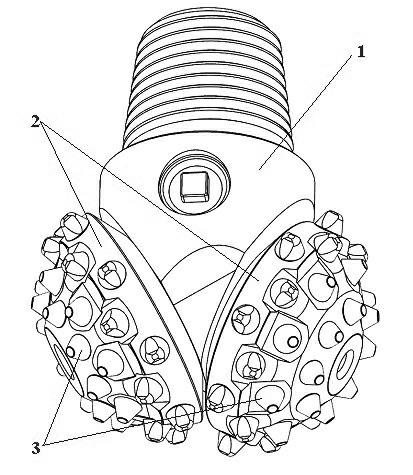

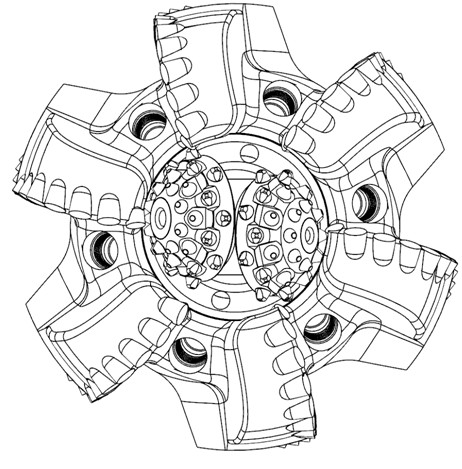

Composite bit with rotary cut rock-breaking function

ActiveCN102434105AExtended service lifeGood gauge effectDrill bitsConstructionsAgricultural engineeringPolycrystalline diamond

The invention discloses a composite bit with a rotary cut rock-breaking function, which comprises the composition of a rotary cut bit, a polycrystalline diamond compact (PDC) bit and a roller cone bit. The composite bit with the rotary cut rock-breaking function comprises a main body (1), a rotary cut bit roller cone (2), rotary cut bit cutting teeth (3), a PDC bit knife wing (4), PDC cutting teeth (5), an oil storage capsule (6) and a spray nozzle (7). The bit main body (1) comprises a roller cone shaft neck, a wiper block, a high-pressure mud channel and connecting screw threads. The composite bit with the rotary cut rock-breaking function has the advantages that the rotary cut bit cutting teeth in the composite bit impact, crush and cut rocks in rotary cut mode, central rock breaking efficiency is high, mechanical drilling speed is high, the composite bit has better dynamics performance, and the abrasion is even. Simultaneously, a bit bearing structure is improved, service life of the bit is prolonged while improvement of the rock-breaking efficiency is guaranteed, and the gauge protection effect is good. Different composite structures in the composite bit can achieve the effects of high central rock breaking efficiency, high mechanical drilling speed and good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Polishing disc for a tool for the fine machining of optically active surfaces particularly on spectacle lenses and method for its production

ActiveUS20080305723A1Rapid and accurate productionDegradation takes placeGrinding machine componentsFlexible-parts wheelsMachined surfaceEngineering

A polishing disc for a tool for the fine machining of optically active surfaces, particularly on spectacle lenses as workpieces, comprises a main body which has a center axis and on which there is fixed an intermediate layer which is softer than the main body and on which a polishing agent carrier rests. The intermediate layer has, with respect to the center axis, a radial inner region of substantially constant axial thickness and an adjoining radial outer region. The latter is formed or is fixed to the main body in a particular way so as to prevent the edge of the polishing disc from being imprinted on the machined surface of the workpiece in the form of very fine, scratch-like microstructures. Also proposed is a simple method which can be used to produce such a polishing disc.

Owner:SATISLOH AG

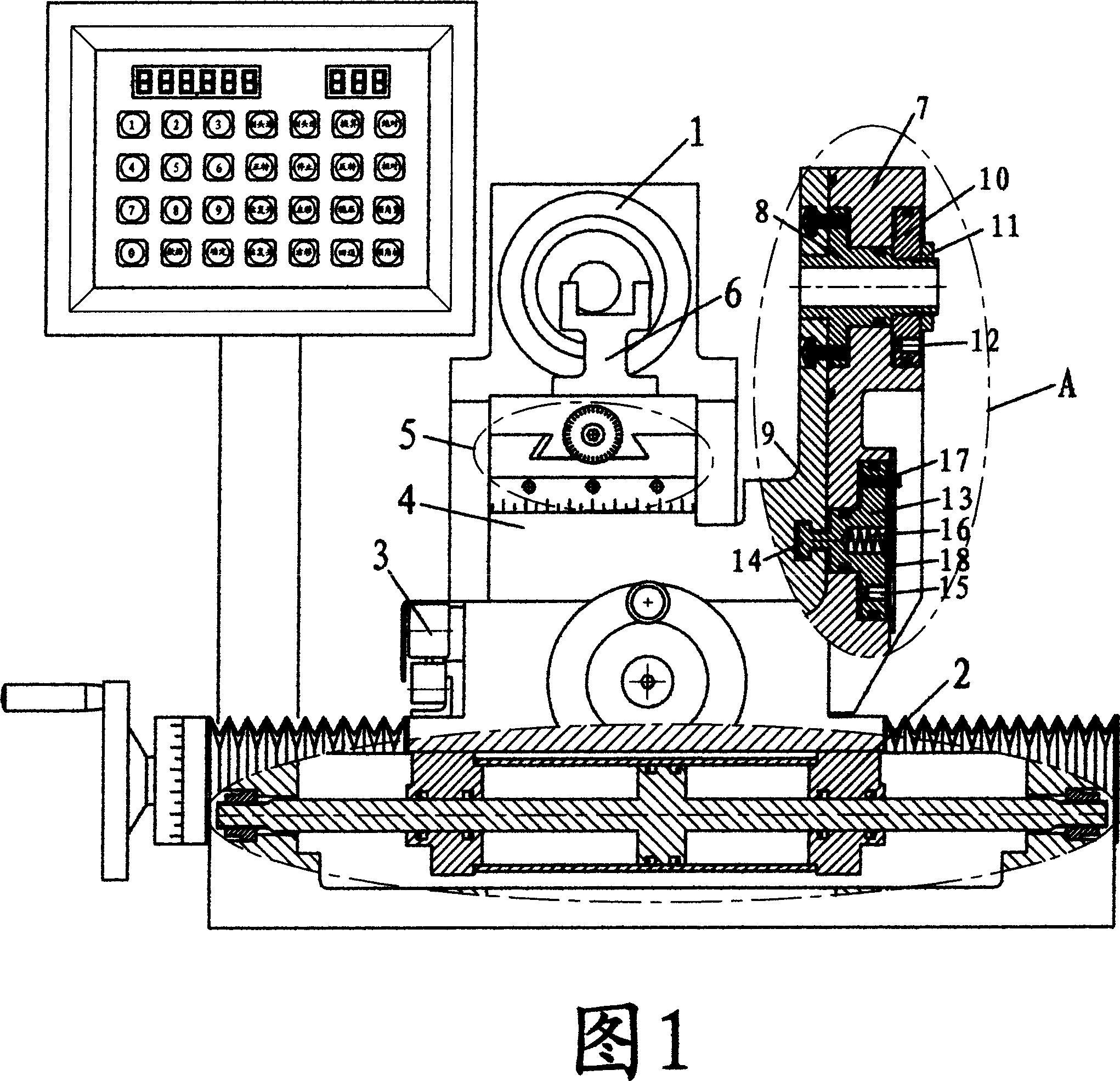

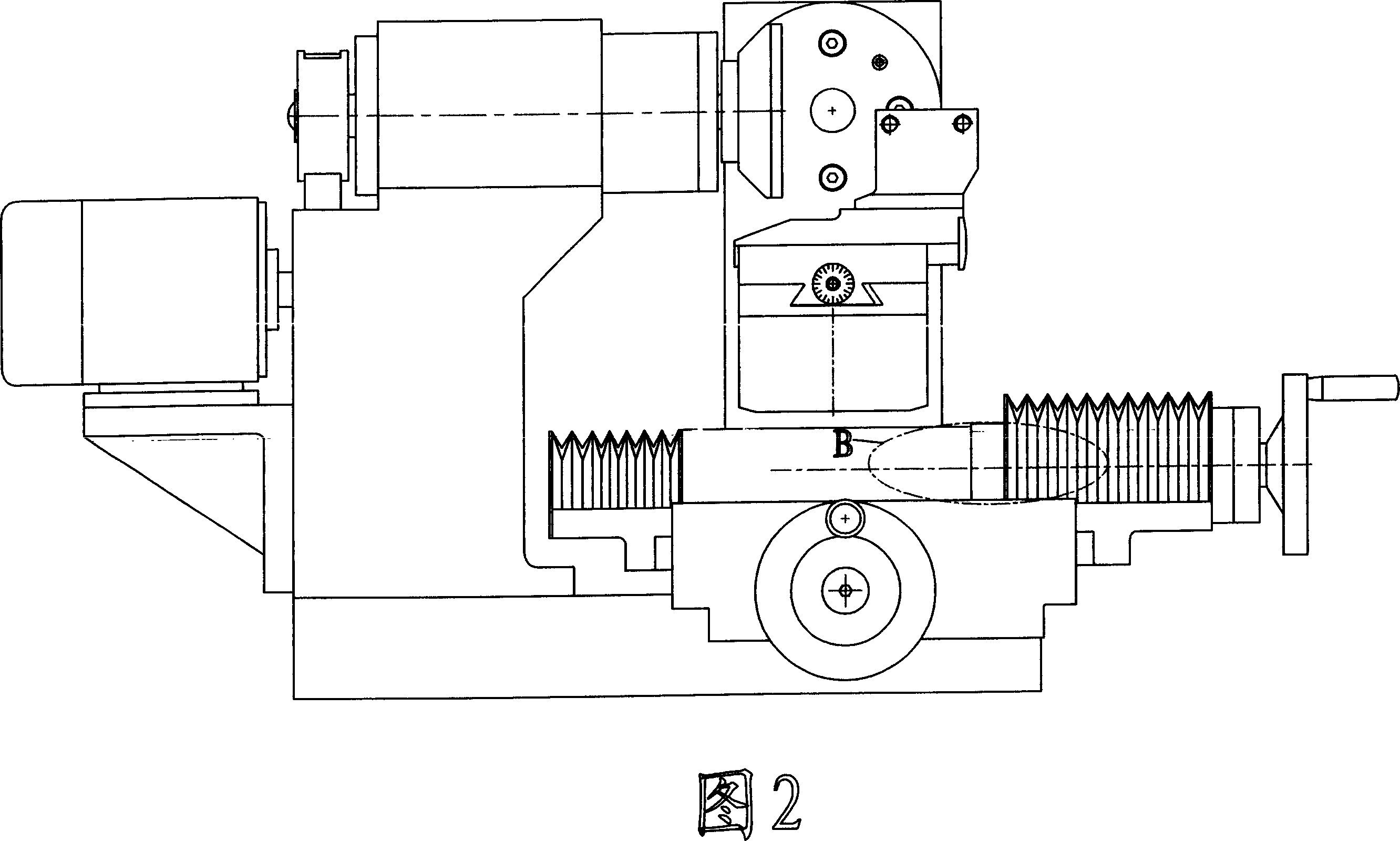

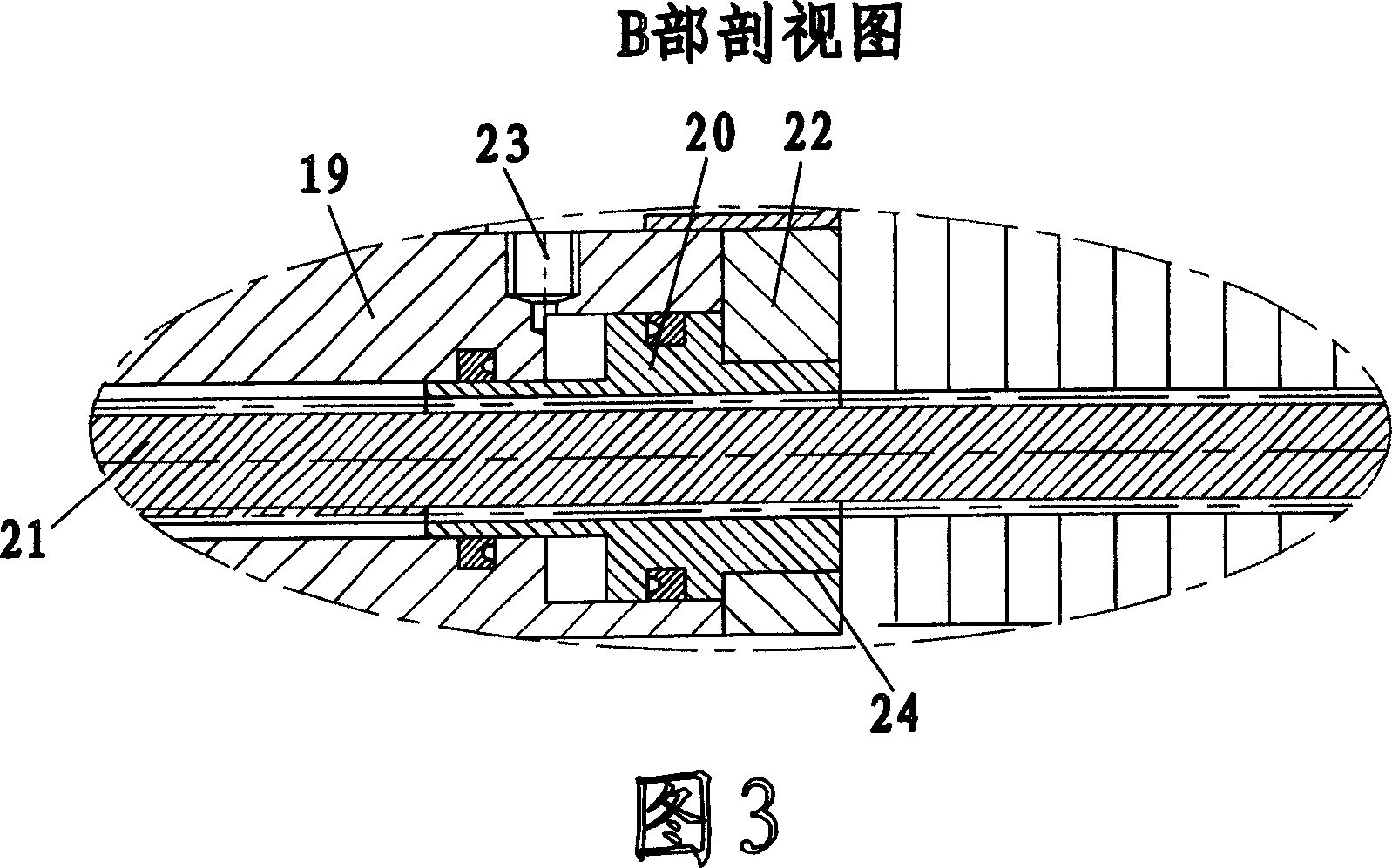

Knife tool arc edging device

InactiveCN101058160AUniform wearQuality improvementGrinding machine componentsOther manufacturing equipments/toolsEngineeringReturn work

The invention relates to a tool arc girnIt mainly comprises the body, the grinding head assembly, cross sledge, oblique angle, return working platform. It features in the grinding head and cross sledge connected to or installed on the body, oblique angle installed between the cross sledge and the return working platform which installs the sub crossing sledge with cutter carrier on it. The axial core of the oblique structure ranges within the 10 mm of the extended radius of the return shaft core and one half of the outer radius of the end surface of the sand wheel. It has strong rigidity, fine grinding quality, convenient adjustment, applicable for fine grinding.

Owner:林志贺

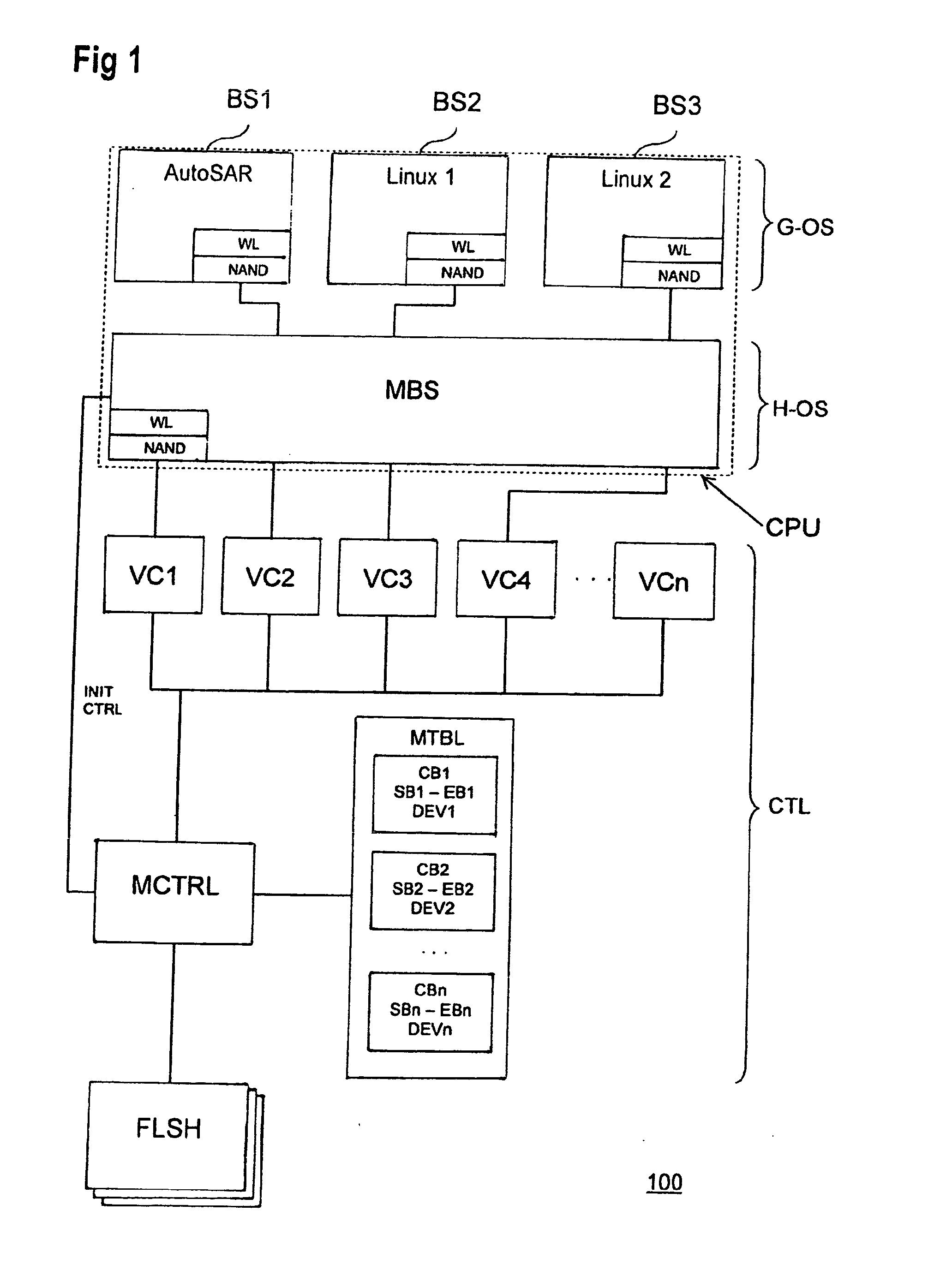

Memory controller for providing a plurality of defined areas of a mass storage medium as independent mass memories to a master operating system core for exclusive provision to virtual machines

ActiveUS20150006795A1Reduce loadImprove securityMemory architecture accessing/allocationMemory adressing/allocation/relocationMass storageOperational system

A computer system includes at least one processor, a first mass memory and a second mass memory. The computer system implements a master operating system core, a first operating system core and at least one second operating system core on the processor under control of the master operating system core. The memory controller provides the master operating system core with defined areas of a mass storage medium as a first mass memory and at least one second mass memory, each independent of one another, and controls mapping of the first mass memory and of the at least one second mass memory to the defined areas of the mass storage medium. The master operating system core allows the first operating system core and the at least one second operating system core to have exclusive access to at least one of the mass memories.

Owner:CONTINENTAL AUTOMOTIVE GMBH

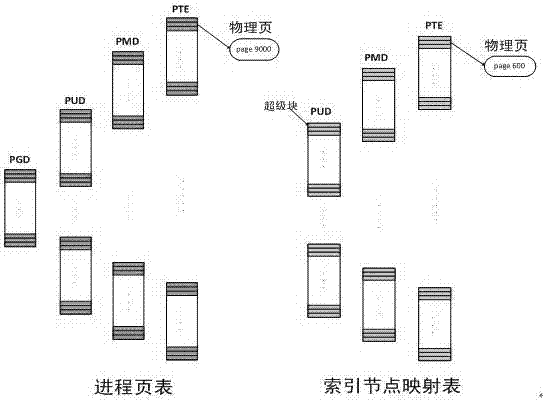

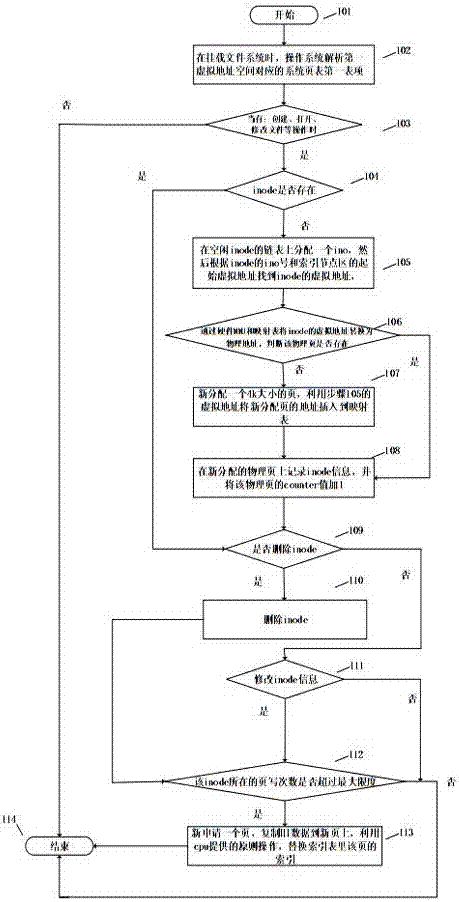

Metadata management method based on nonvolatile memory file system

InactiveCN107016100AWrite wear levelingAvoid write wearFile metadata searchingSpecial data processing applicationsArray data structureOperational system

The invention discloses a metadata management method based on a nonvolatile memory file system. The method comprises the steps that 1, file index nodes are organized into an index node region in an array mode, and each index node is provided with a fixed serial number; 2, according to a system page table format, a mapping table is built for the file index node region, and the highest pointer of the mapping table is stored into a super block of the file system; 3, each file index node obtains a corresponding virtual address of itself through an ino number and an initial virtual address of the index node region; when the file system is mounted, the operating system analyzes a first table item of the system page table corresponding to the first virtual address space; 4, the super block of the file system is checked, the highest pointer of the mapping table of the index node region is inserted into the first table item, and the mapping relation between the virtual address space and the physical address space in the index node region is built. The method has the advantages that the nonvolatile memory writing abrasion balance is ensured, and metadata can be rapidly accessed.

Owner:CHONGQING UNIV

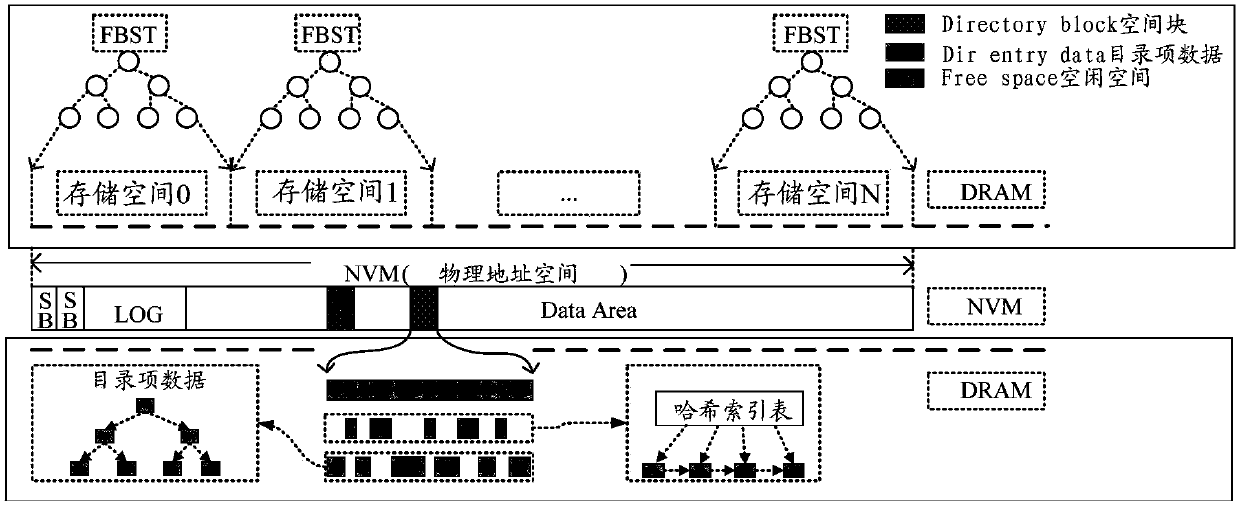

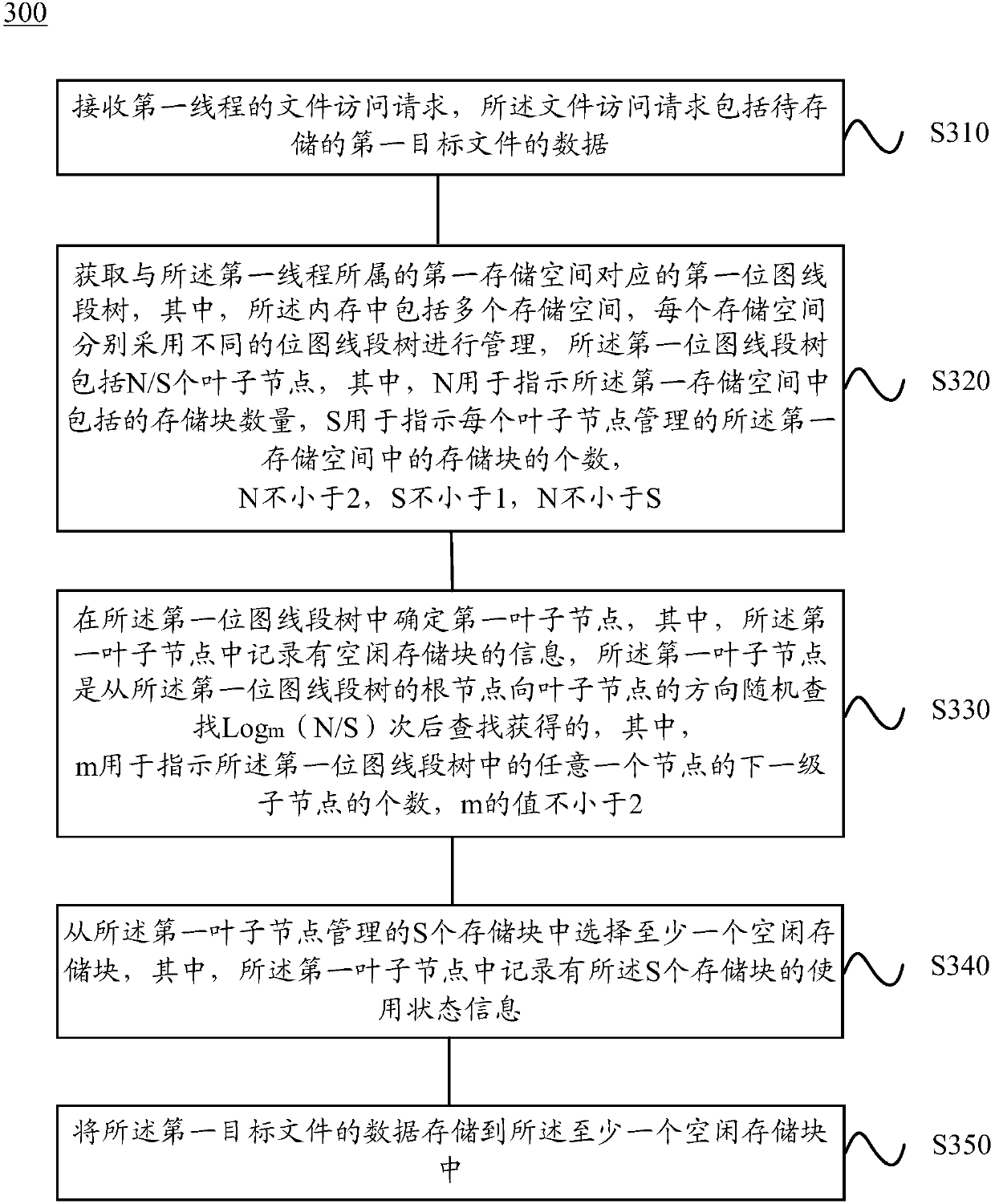

Memory space management method and apparatus

ActiveCN108628753AUniform wearExtended service lifeMemory adressing/allocation/relocationLine segmentBitmap

The invention provides a memory space management method and apparatus. The method comprises the steps of receiving a file access request of a first thread, wherein the file access request comprises data of a to-be-stored first target file; obtaining a first bitmap line segment tree corresponding to a first storage space which the first thread belongs to, wherein the first bitmap line segment treecomprises N / S leaf nodes, N is used for indicating the quantity of storage blocks comprised in the first storage space, and S is used for indicating the quantity of the storage blocks in the first storage space and managed by each leaf node; determining the first leaf node in the first bitmap line segment tree; selecting at least one idle storage block in the S storage blocks managed by the firstleaf node; and storing the data of the first target file in the at least one idle storage block. According to the memory space management method and apparatus, the idle storage blocks can be randomlyallocated, so that the wear balance of a memory is realized and the service life of the memory is prolonged.

Owner:HUAWEI TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com