Knife tool arc edging device

An arc edge and tool technology, which is used in manufacturing tools, parts of grinding machine tools, grinding/polishing equipment, etc. problems, to achieve the effect of uniform grinding wheel wear, convenient size and position adjustment, and improve the quality of sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

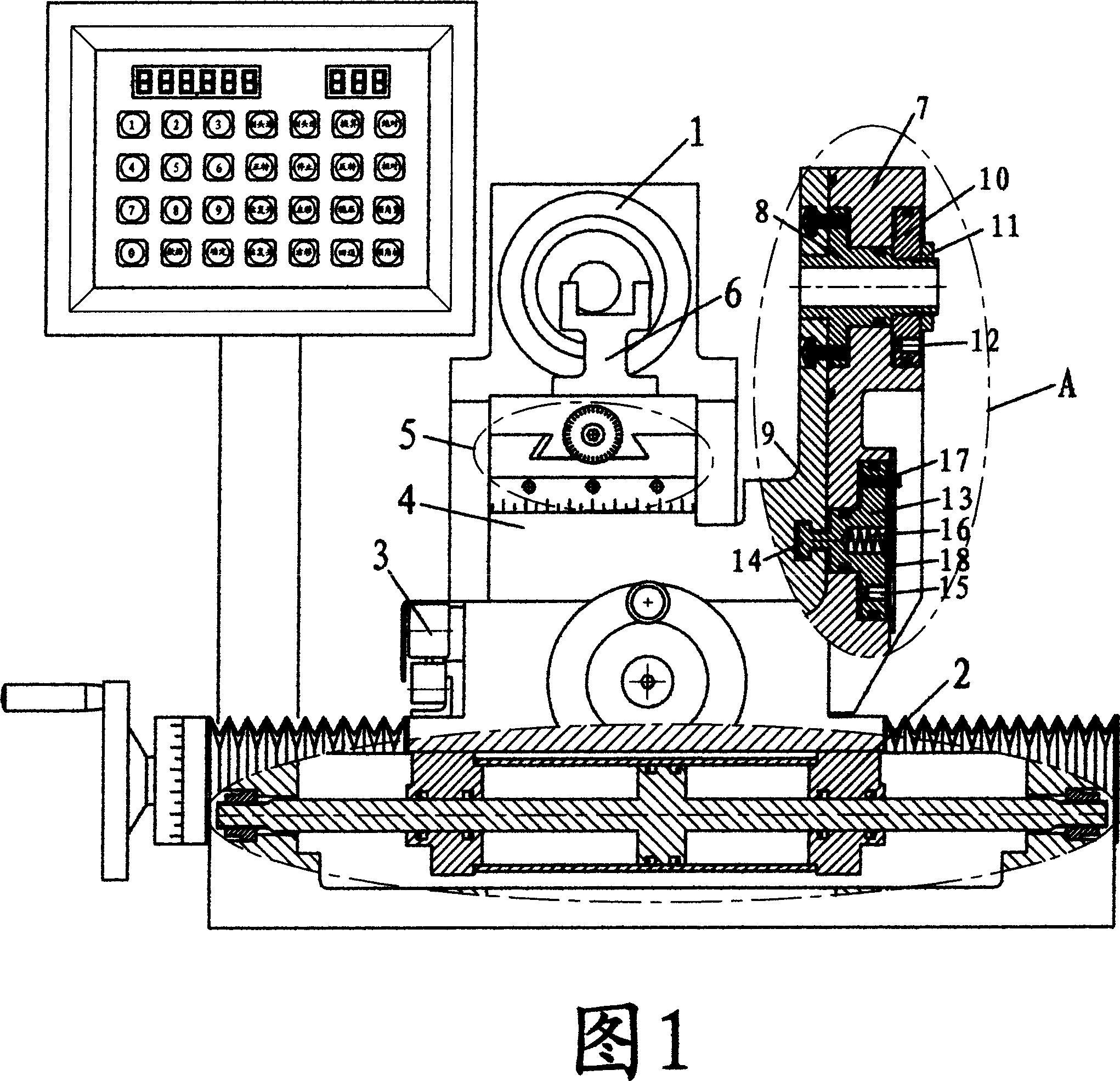

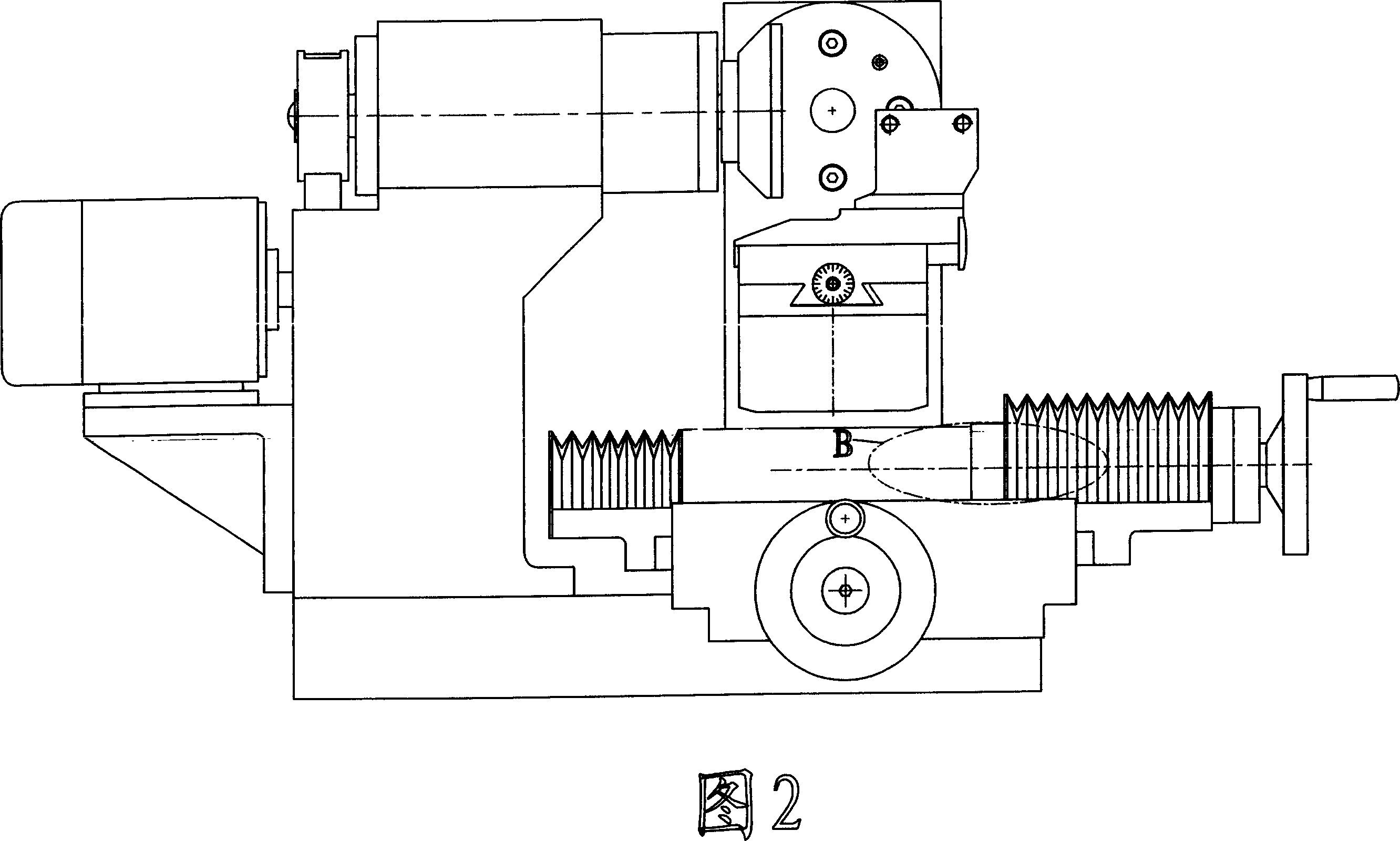

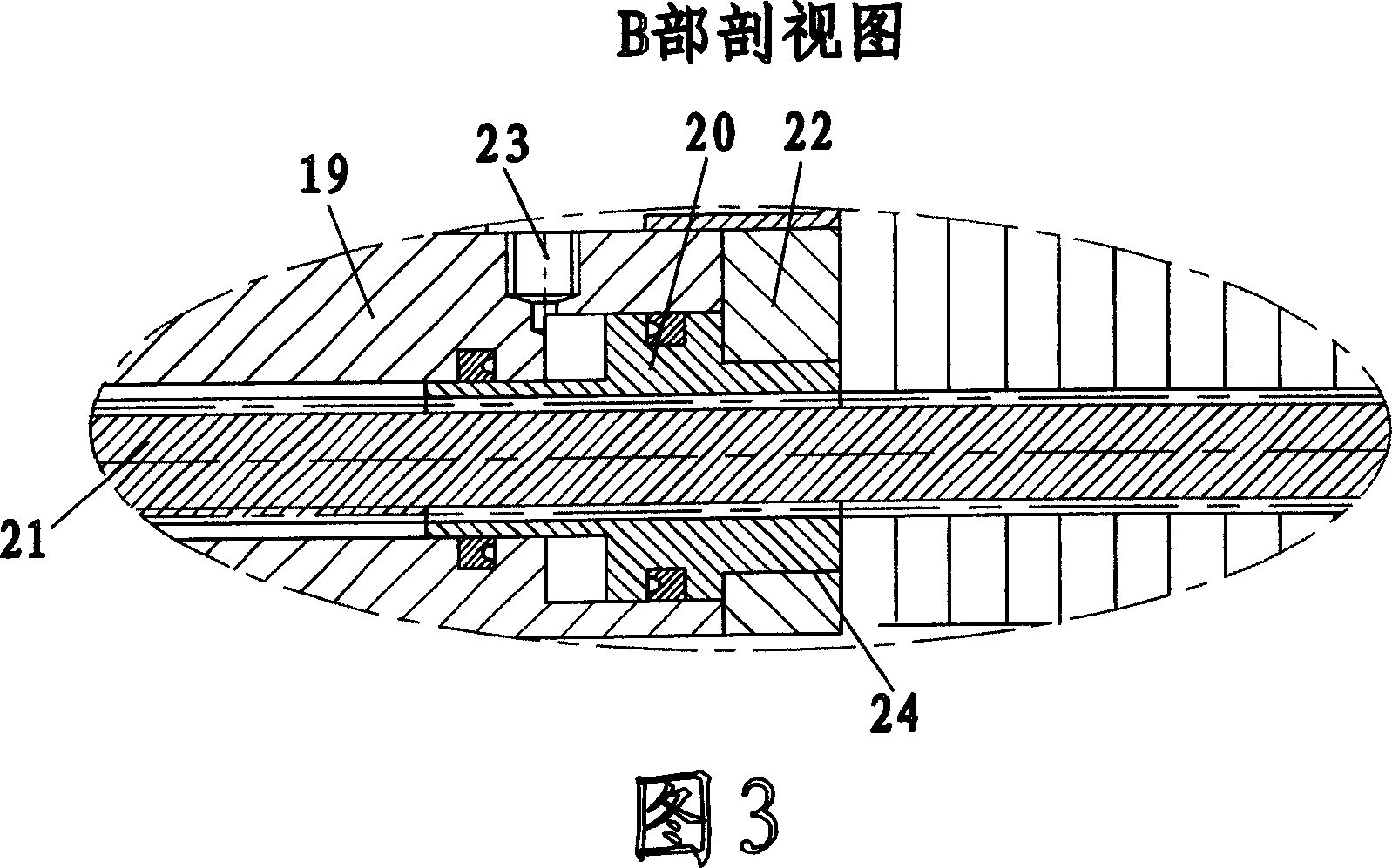

[0022] Shown with reference to Fig. 1, 2, present embodiment grinding head assembly (1) conjoined is installed on the body, and it can effectively improve the rigidity of grinding head. The cross slide adopts a rolling guide rail structure, which has a small friction coefficient, stable movement, and high precision, which is especially beneficial to steady-pressure feed and low-speed reciprocating movement. A biaxial cylinder (2) and a set of clutch screw mechanism are installed in the longitudinal axis slide seat of the cross slide seat; When cutting the blade, separate the screw nut, and then use the double-axis cylinder (2) to perform automatic reciprocating motion; when sharpening milling cutters and other tools, connect the ventilation pipes at both ends of the double-axis cylinder (2) to the outside air, and then close the The screw nut is used to drive the screw when the screw is directly rotated, so that it is easy to operate. A screw adjustment mechanism (B) and a gr...

Embodiment 2

[0026] With reference to shown in Fig. 5, present embodiment and the first embodiment structurally have increased lifting mechanism between the inclination block of inclination mechanism and the rotary table; Worm drive mechanism; In addition, the double-axis cylinder and the clutch screw mechanism installed on the vertical axis slide seat are replaced with the transmission mechanism of the stepper motor driving the rolling screw.

[0027] With reference to Fig. 5, shown in 6, the elevating mechanism of the present embodiment mainly consists of the inclination block (9) of the inclination mechanism, the base (25) of the rotary table, the gap adjustment block (26), the special nut bar (27), the special Bolt (28), bevel gear shaft (29), intermediate pin (30) form. The base of the rotary table (25) is processed with a dovetail protrusion in the direction of its axis of rotation, and the inclination block (9) of the inclination mechanism is processed with a dovetail groove matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com