Patents

Literature

67 results about "Axis cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Axis cylinder See axon. axis cylinder an AXON. axis pl. axes [L., Gr.] 1. a line through a center of a body, or about which a structure revolves. 2. the second cervical vertebra. celiac axis celiac trunk. axis cylinder axon. dorsoventral axis one passing from the back to the belly surface of the body. electrical axis of heart the resultant of the ...

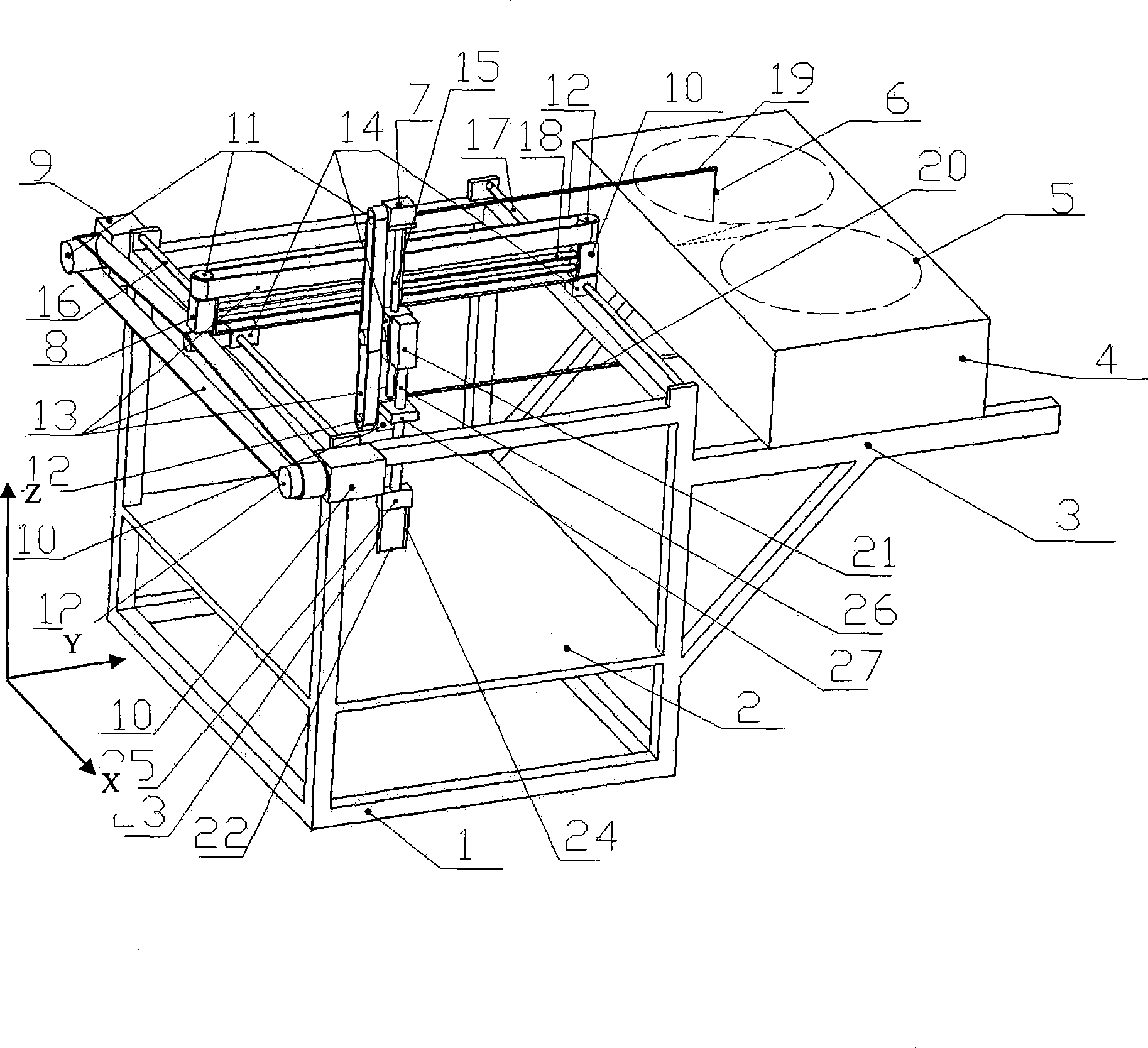

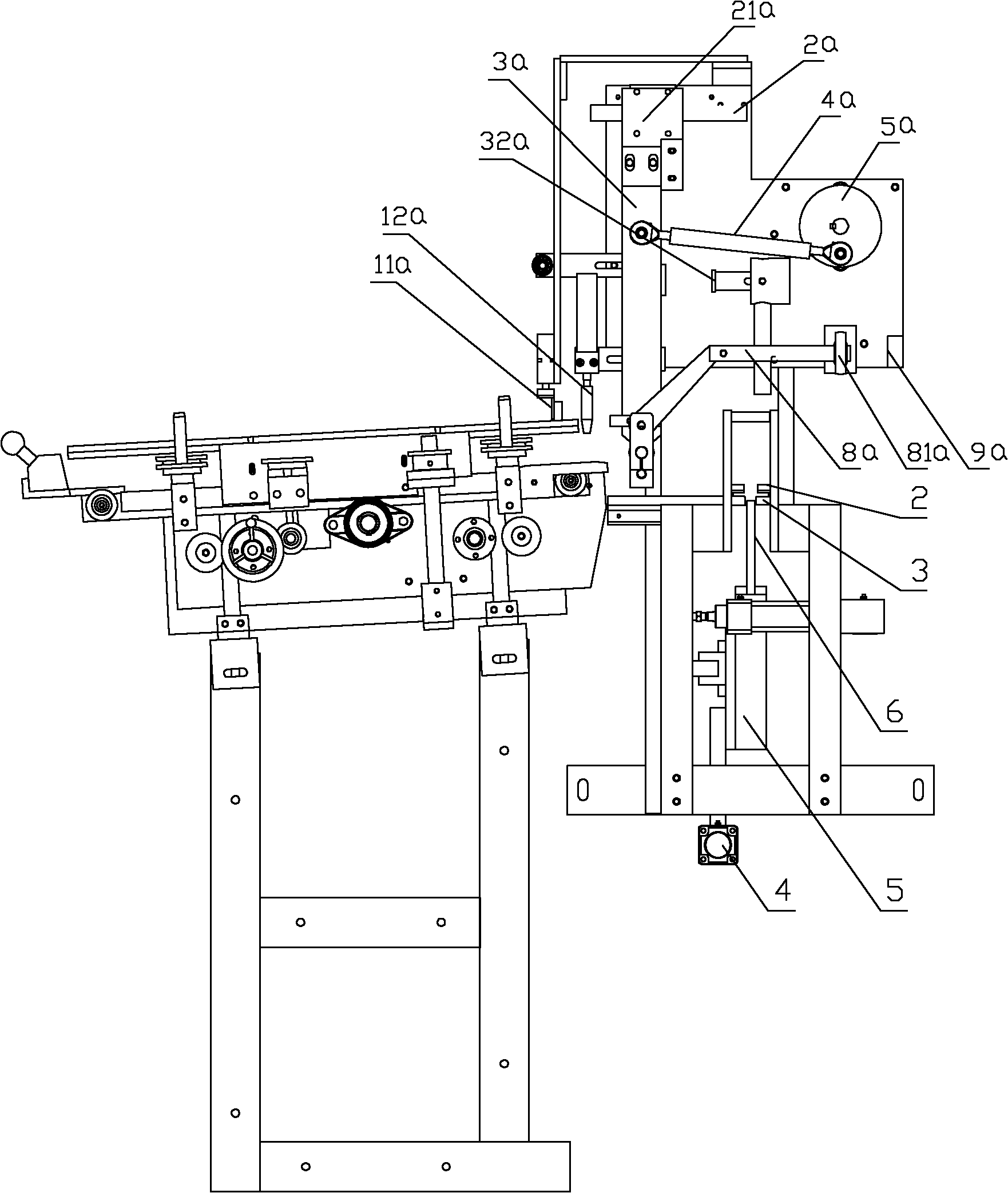

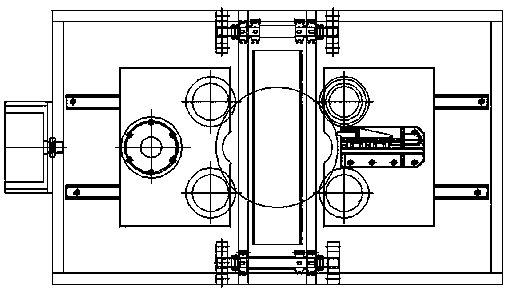

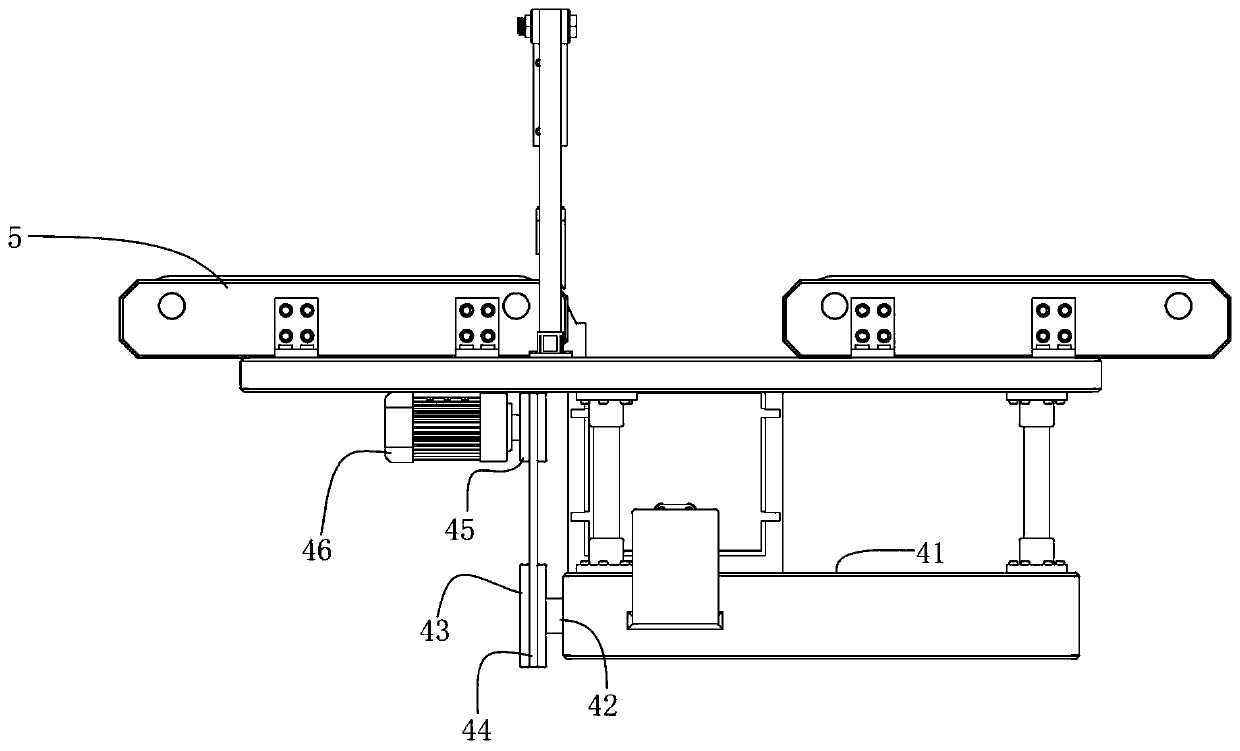

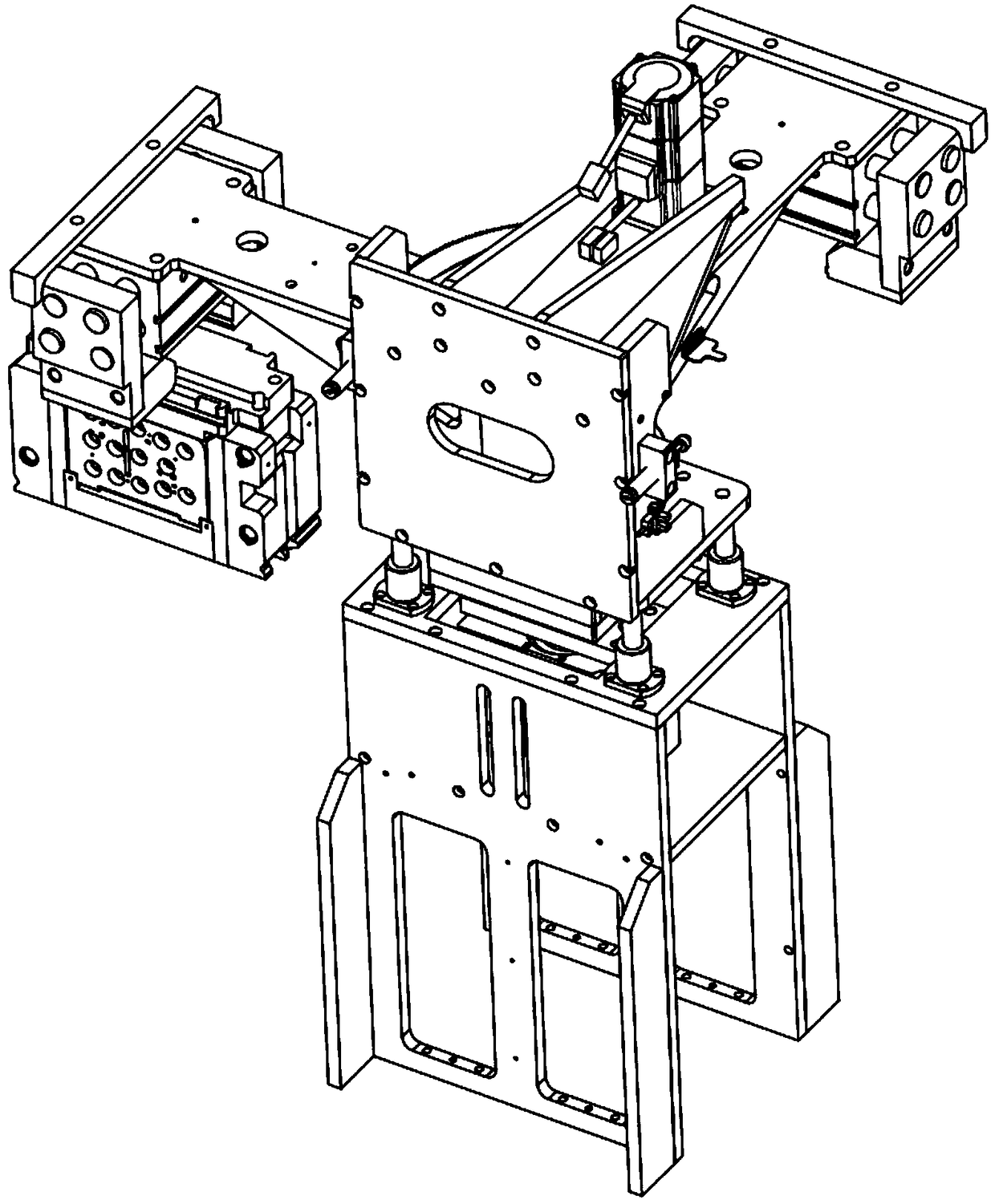

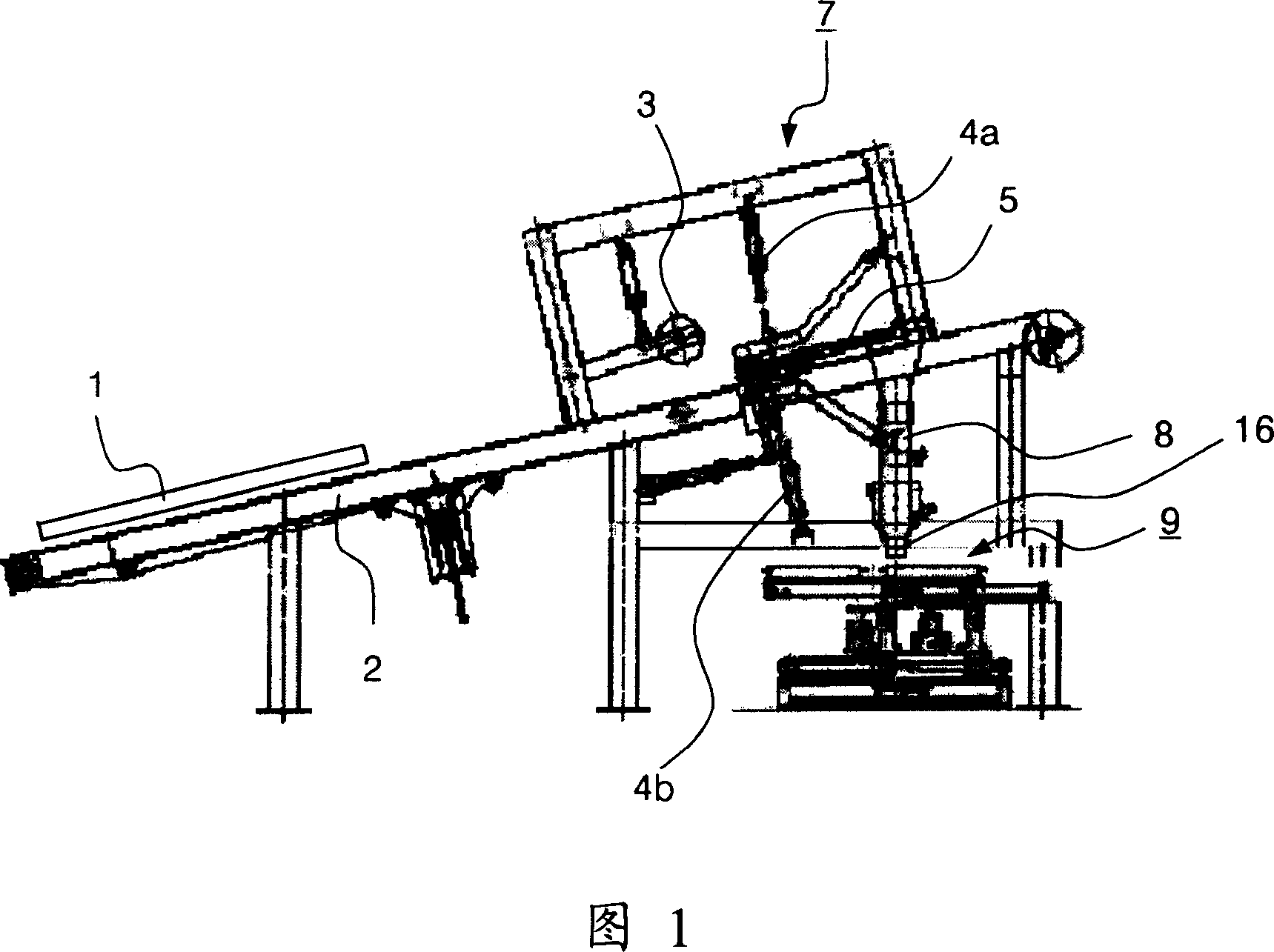

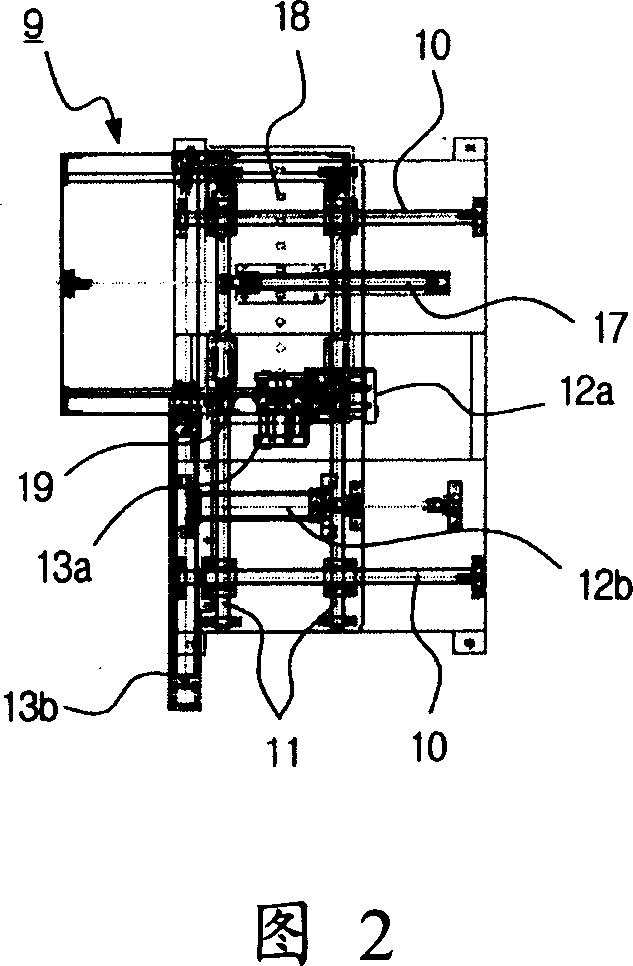

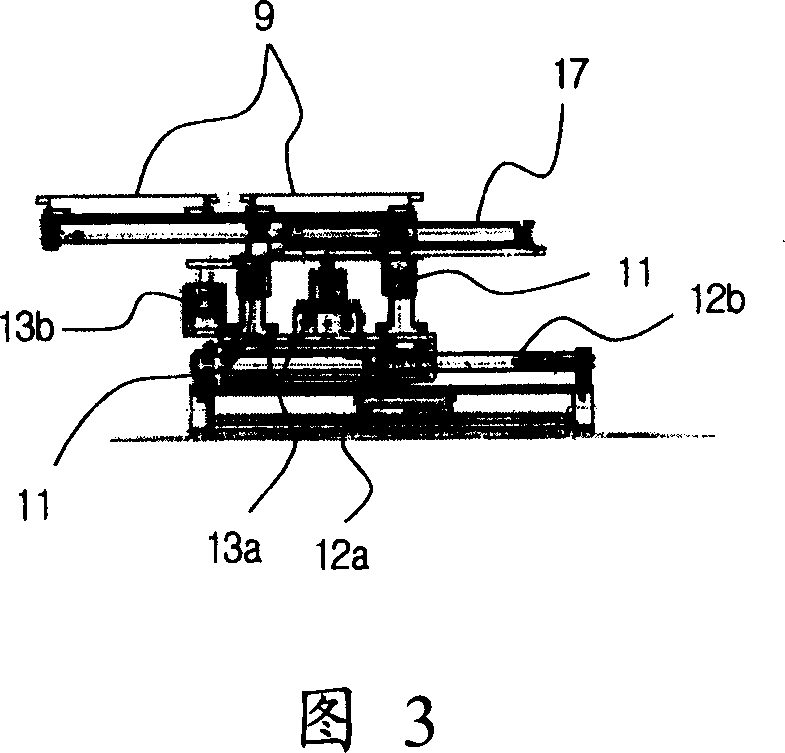

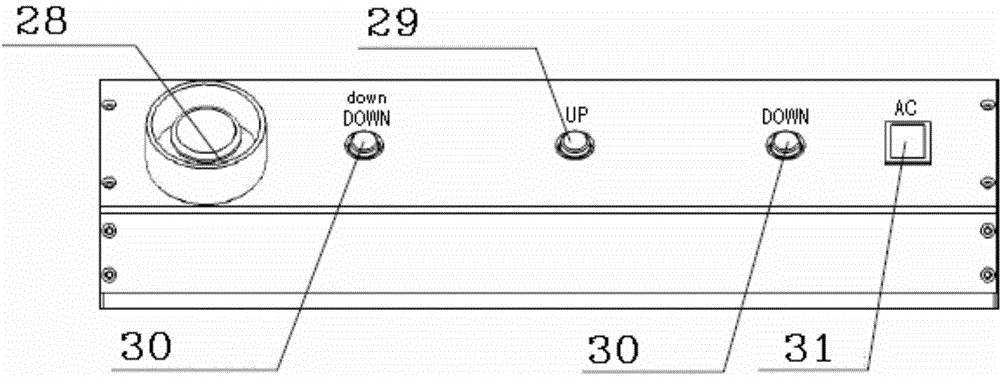

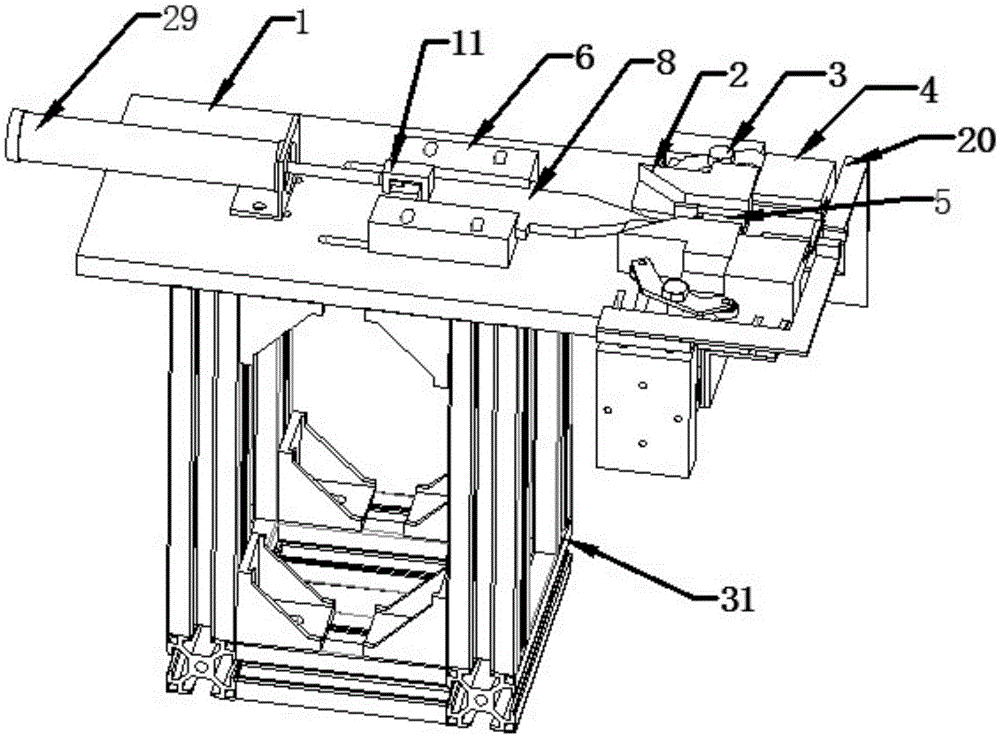

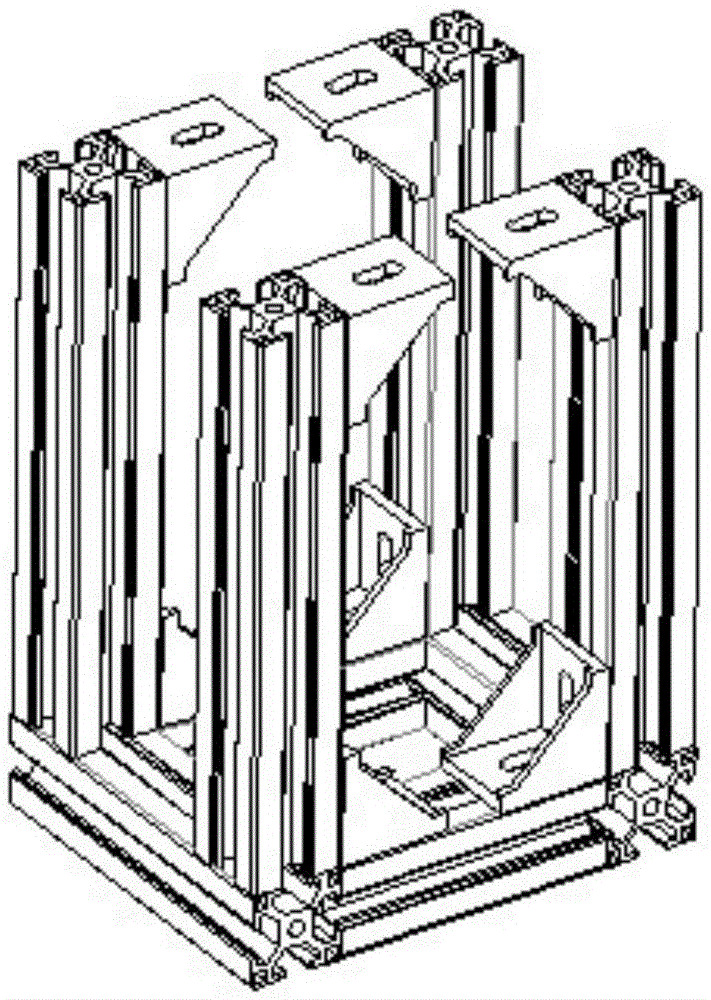

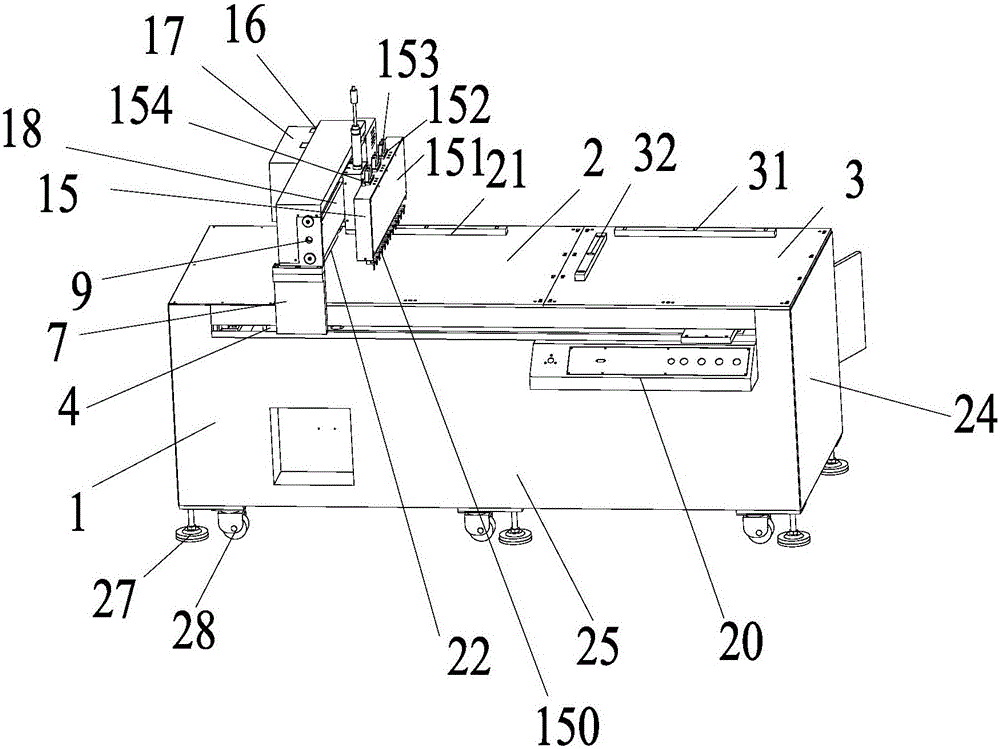

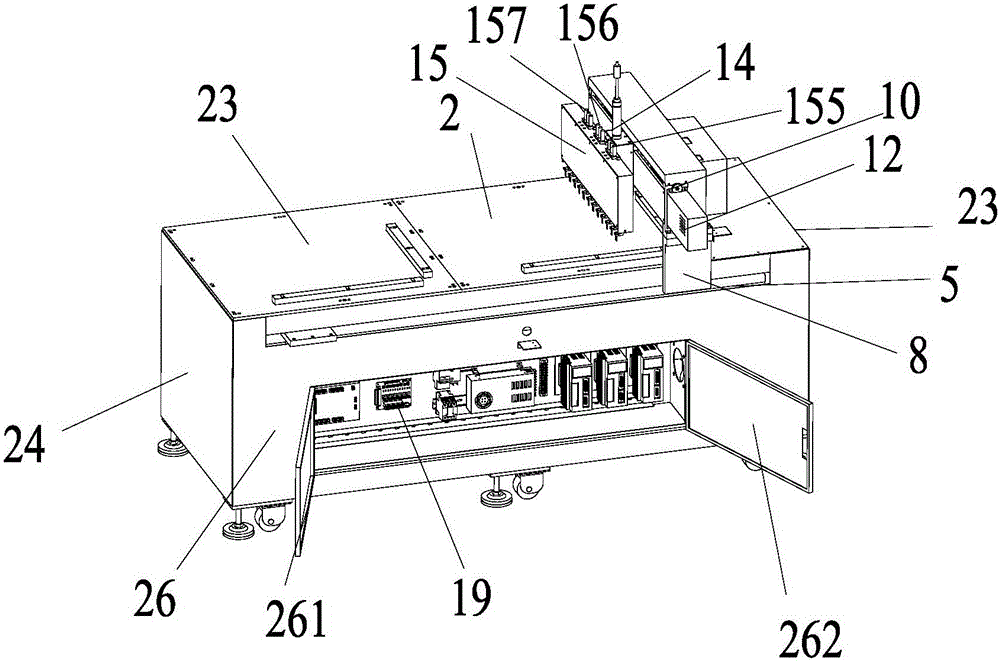

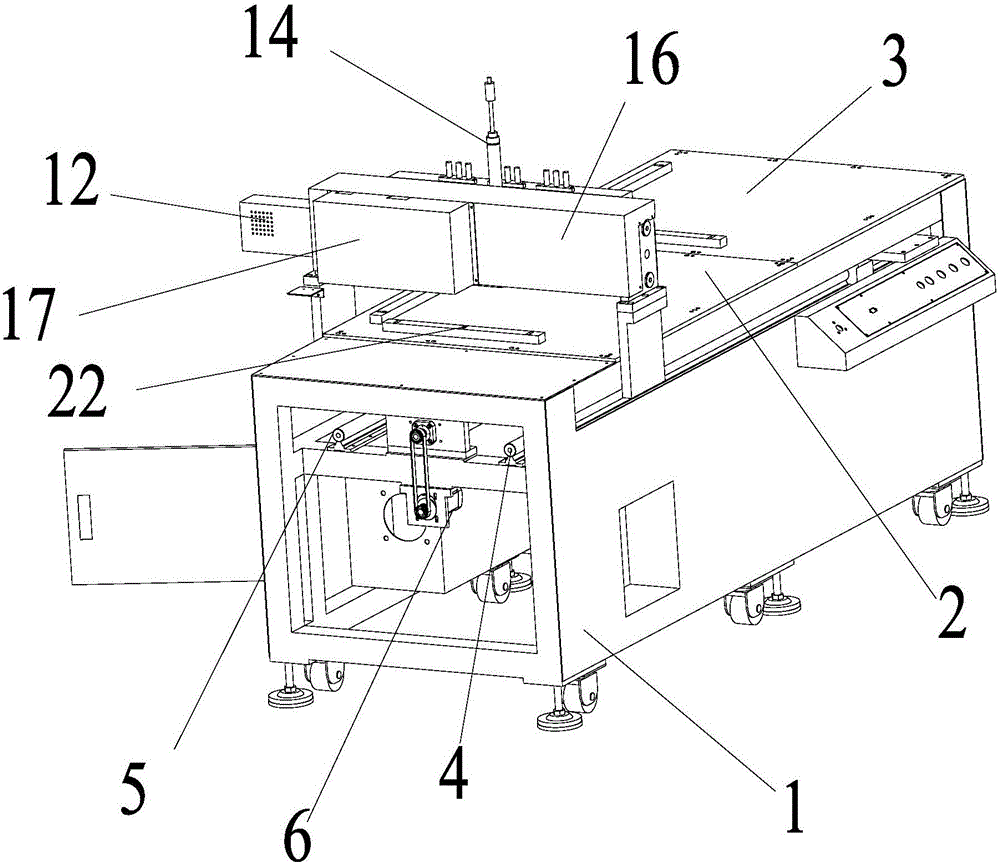

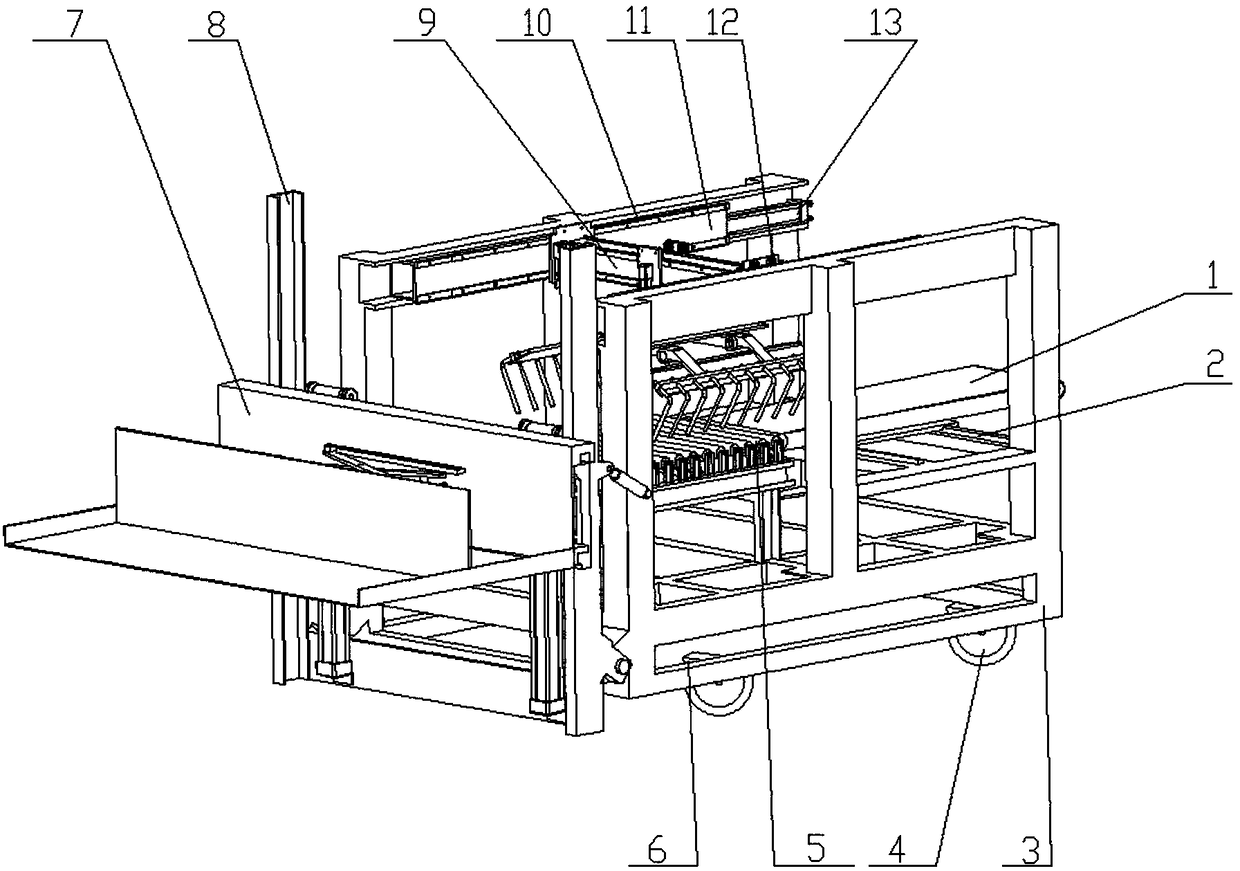

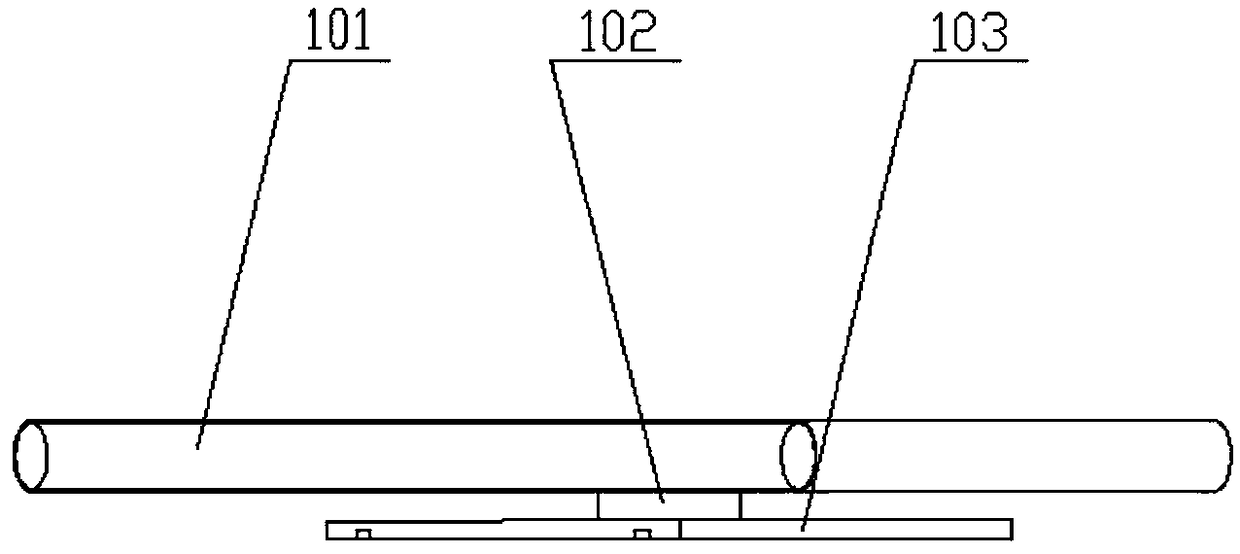

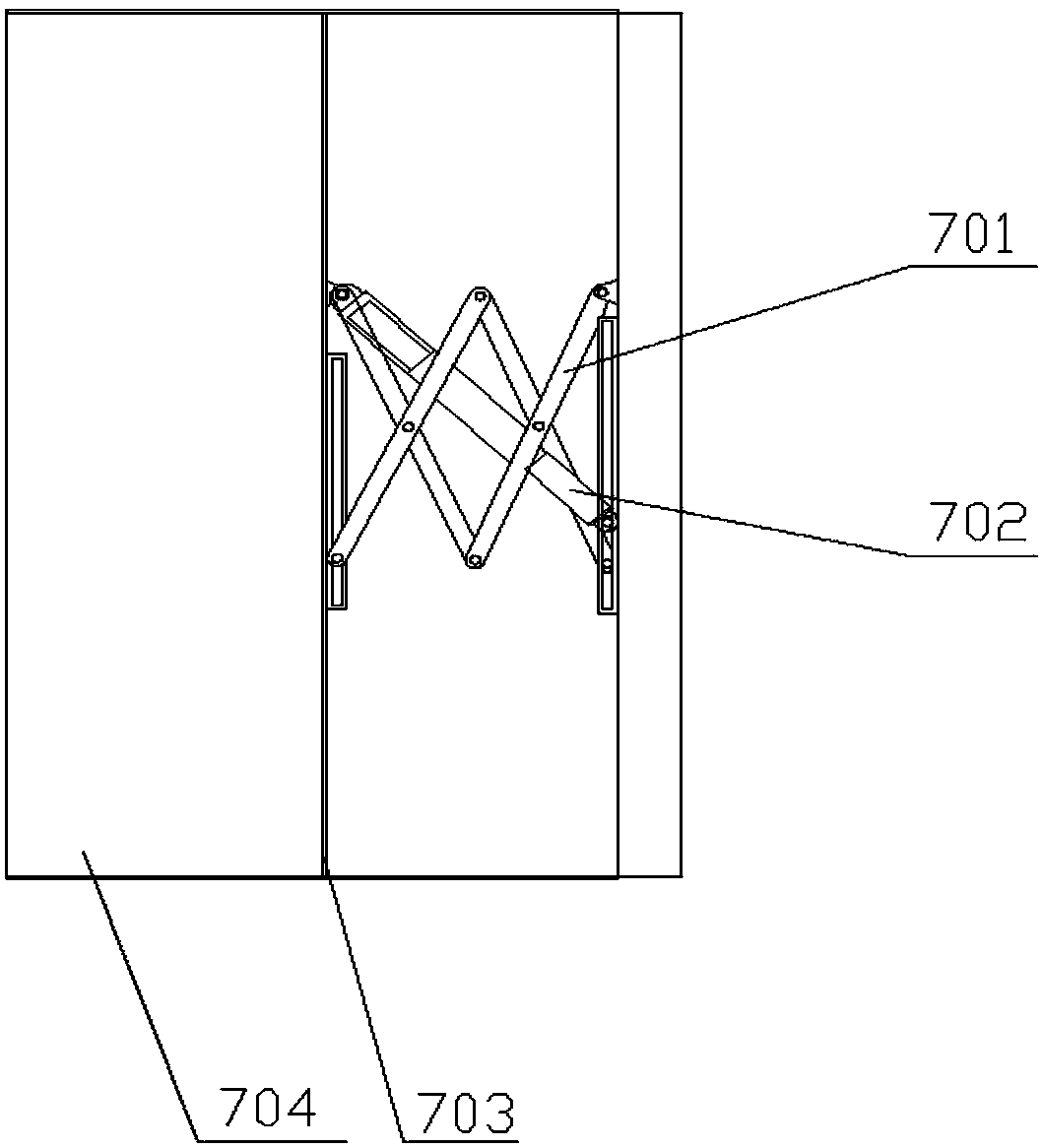

Lost foam wire cutting numerical control machining shaping mill

InactiveCN101474803AFast preparationAutomatic productionMetal working apparatusAxis cylinderNumerical control

A vanishing mould digital control linear cutting processing forming machine belongs to automatic machining device, and overcomes the problems of low forming speed and singular function of prior vanishing mould digital control linear cutting processing forming machine. The vanishing mould digital control linear cutting processing forming machine is composed of a mechanical part and a control part. The mechanical part comprises a frame, a tray, an X-axis motor, a Y-axis motor, a Z-axis motor, a X-axis left cylinder slide way, a X-axis right cylinder slide way, a Y-axis cylinder slide way, a Z-axis cylinder slide way, a main shaft motor and the main shaft. The right side of frame is fixed with a bracket. Two ends of Z-direction vertical girder are fixed with an upper cantilever and a lower cantilever. A baiting cutting line is connected between the end of upper cantilever and the end of lower cantilever. An installation plate is installed on the end of main shaft. The installation plate is fixed with a left supporting arm and a right supporting arm. A processing cutting line is connected between the end of left supporting arm and the end of right supporting arm. The vanishing mould digital control linear cutting processing forming machine of the invention has the advantages of compact structure, complete function, excellent economy and excellent practicality. The vanishing mould digital control linear cutting processing forming machine integrates the functions of baiting, blocking, etc. The manufacturing of vanishing moulds with middle or small quantity is quickly, economically and automatically / semi-automatically completed. The vanishing mould digital control linear cutting processing forming machine can also be used for manufacturing foam pad with middle or small quantity.

Owner:HUAZHONG UNIV OF SCI & TECH

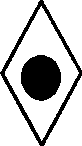

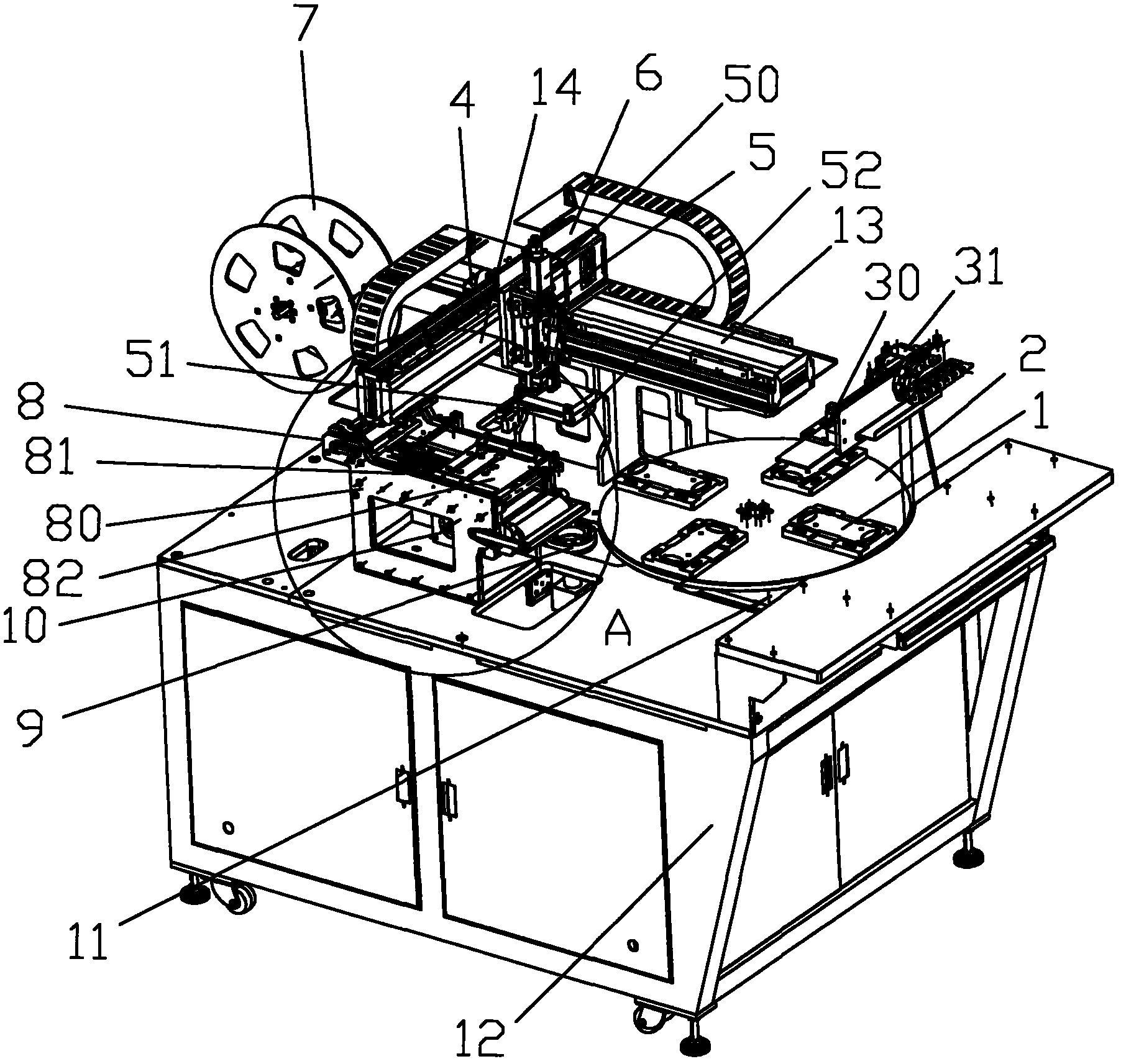

Labeling machine

InactiveCN102530336AReduce manual interventionSave human resourcesLabelling flat rigid surfacesLabelling machinesAxis cylinderEngineering

The invention provides a labelling machine which comprises a machine frame, a rotating bedplate, a material belt wheel disc, a material conveying device. a material pressing device and a material taking device, wherein the rotating bedplate is arranged at one end of the machine frame; the material belt wheel disc is arranged at the other end of the machine frame; the material conveying device and the material pressing device are arranged between the rotating bedplate and the material belt wheel disc; the material taking device is arranged on one side of the material belt wheel disc; a positioning jig for positioning a mobile phone screen is arranged on the rotating bedplate; the material conveying device comprises a sliding platform, a motor arranged below the sliding platform, and a sensor arranged between the sliding platform and the material belt wheel disc; and the material pressing device comprises a Y-axis slide track arranged on the machine frame, an X-axis slide track arranged on the Y-axis slide track, a Y-axis cylinder used for driving the X-axis slide track, a sliding suck head arranged on the X-axis slide track, and an X-axis cylinder used for driving the sliding suck head. The manual intervention is less in the manufacturing process, the human resources are saved, the working efficiency and the rate of good products are improved greatly, and the labor cost is saved.

Owner:杨传军

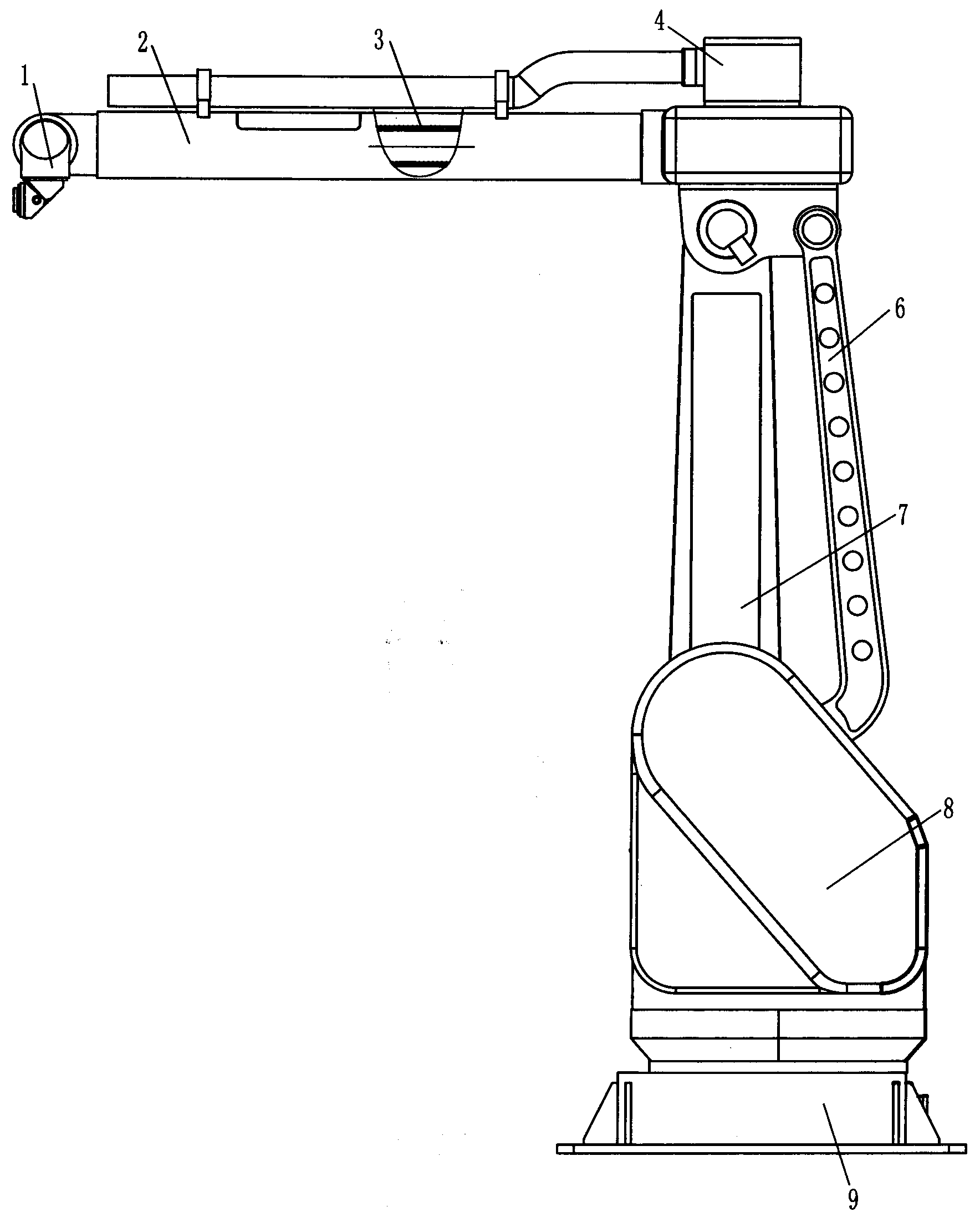

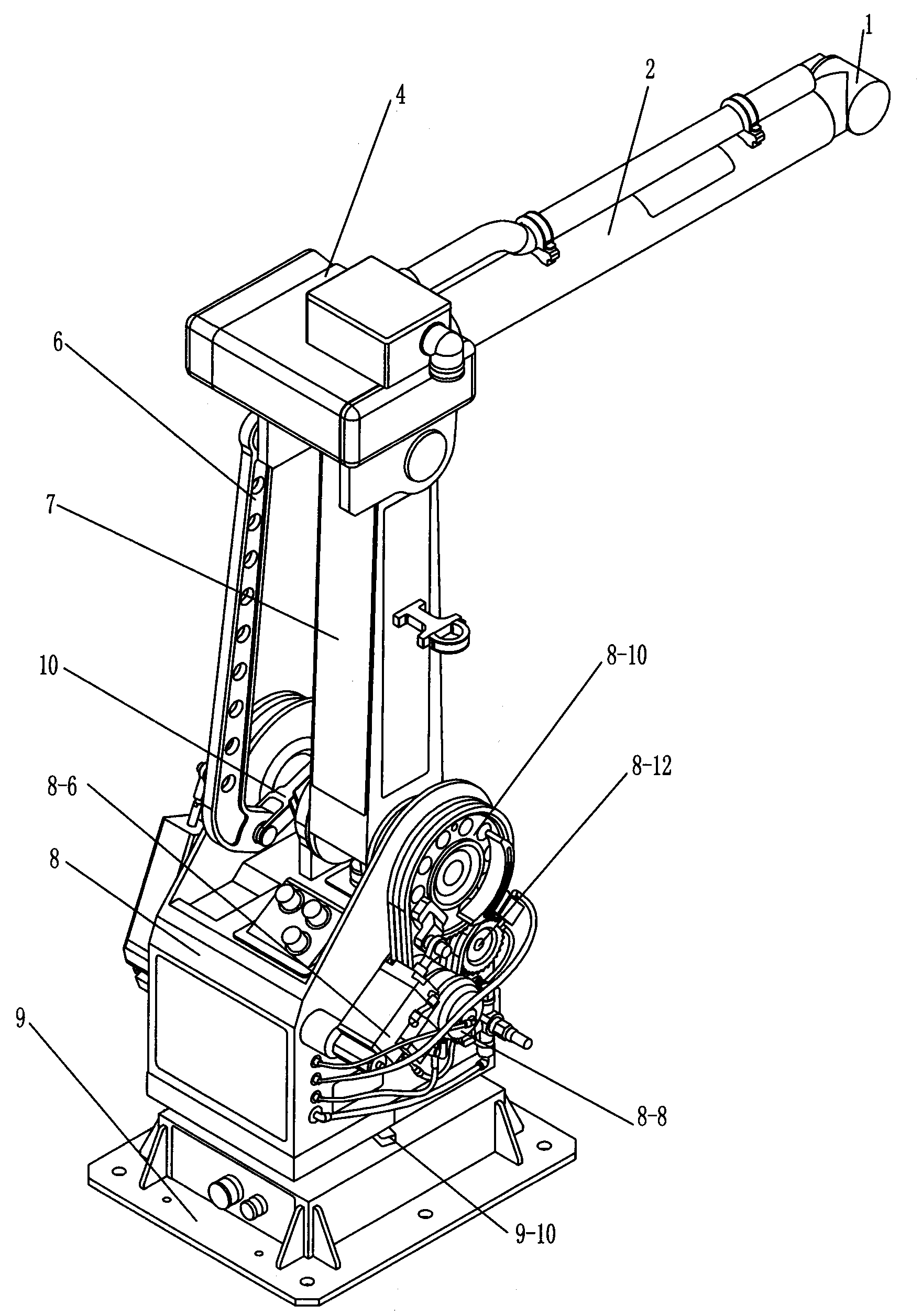

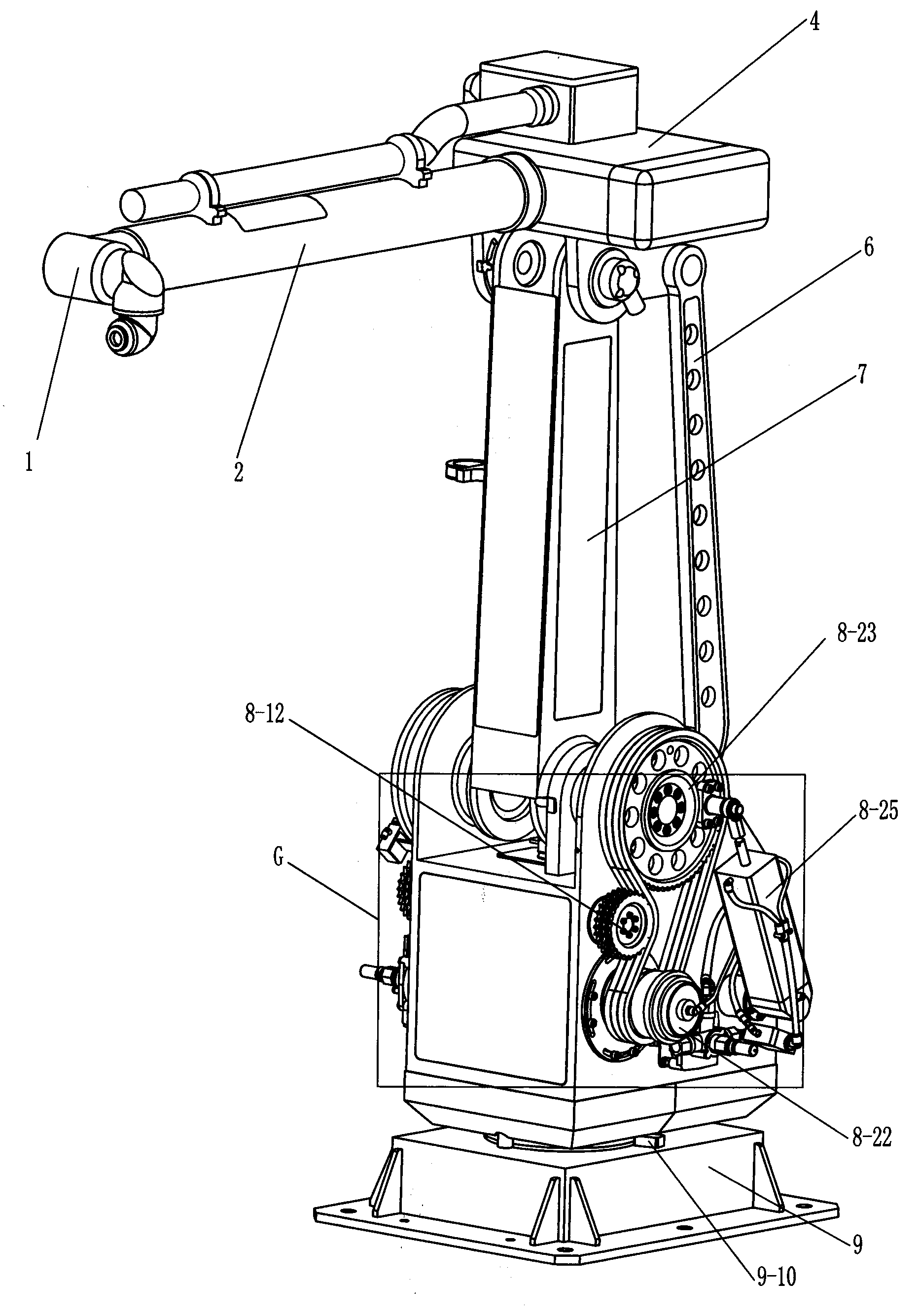

Professional glaze spraying six-axis robot

A professional glaze spraying six-axis robot belongs to the technical field of robot, and solves the problems of expensiveness, complicated operation and difficult maintenance of a foreign glaze spraying robot system in domestic application. The robot wrists are connected to a fourth, fifth and sixth axis motor through wrist transmission chains; the robot wrists, small arms and a fourth, fifth and sixth shaft seat assembly are orderly connected; the upper part of a big arm assembly is connected with the fourth, fifth and sixth shaft seat assembly through a bearing shaft seat one, and the part is connected with second and third axis large chain wheel assemblies; a second axis motor assembly drives the second large chain wheel assembly to rotate; a second axis cylinder assembly is fixed on a second and third axis box bodies and the second axis large chain wheel assembly; upper part of a third axis driving connecting rod through a bearing two is connected with the fourth, fifth and sixth shaft seats assemblies, and the lower part is connected with a third axis drive bracket through a bearing three; the third axis driving bracket is connected with the third large chain wheel assemblies; and the third axis motor assembly through a chain two drives the third large chain wheel assemblies to rotate. The invention is special for glaze spraying.

Owner:杭州钱江机器人有限公司

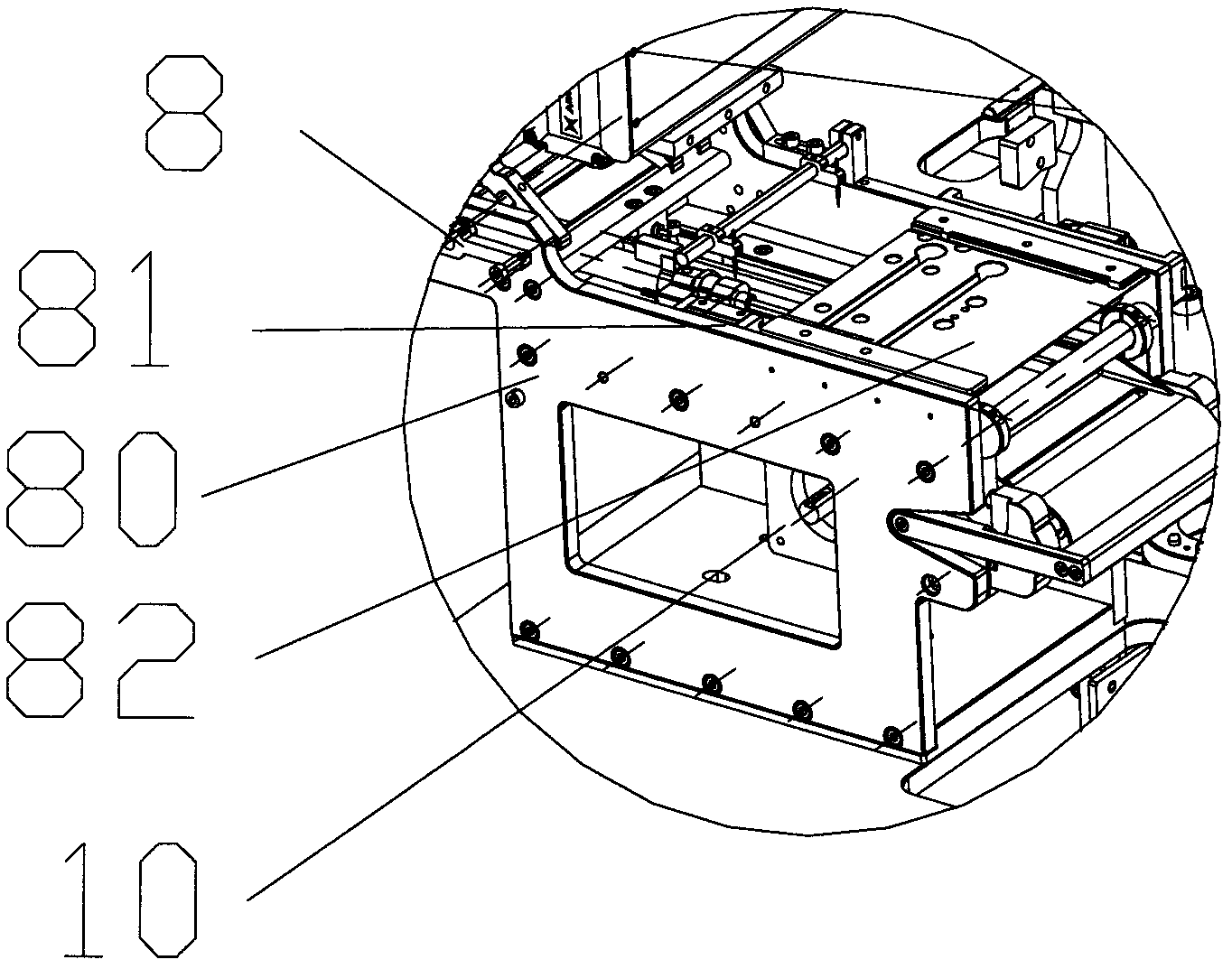

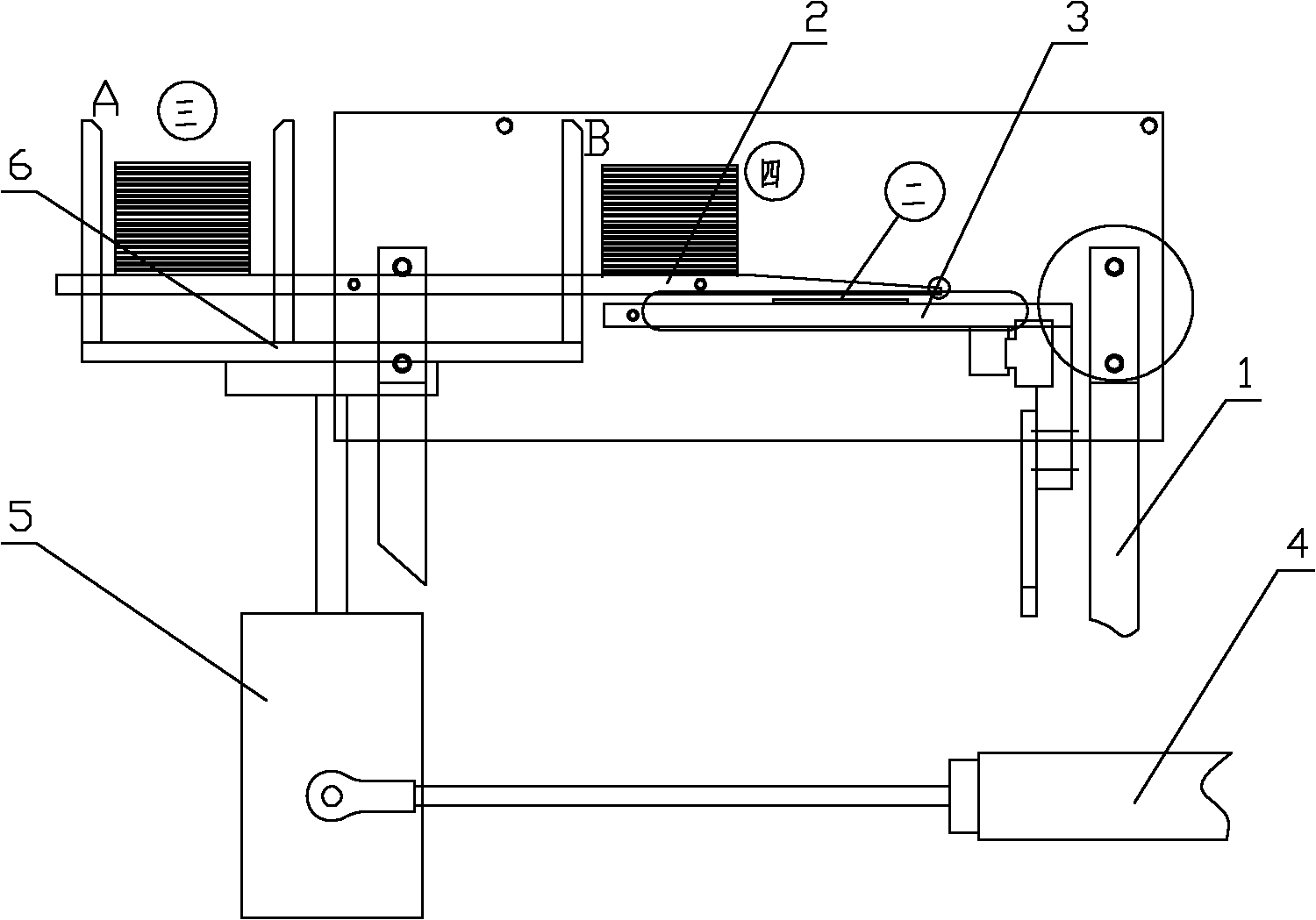

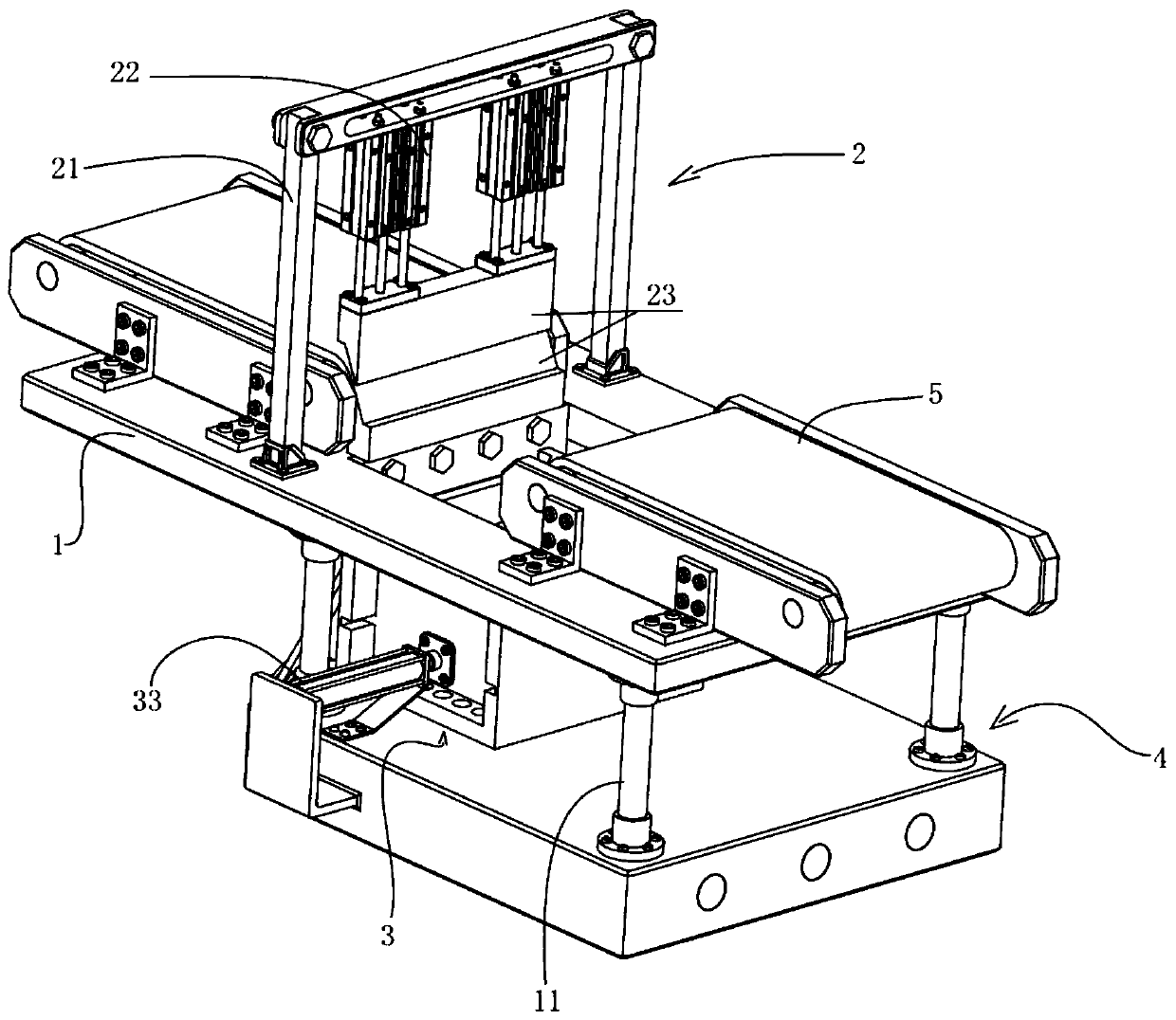

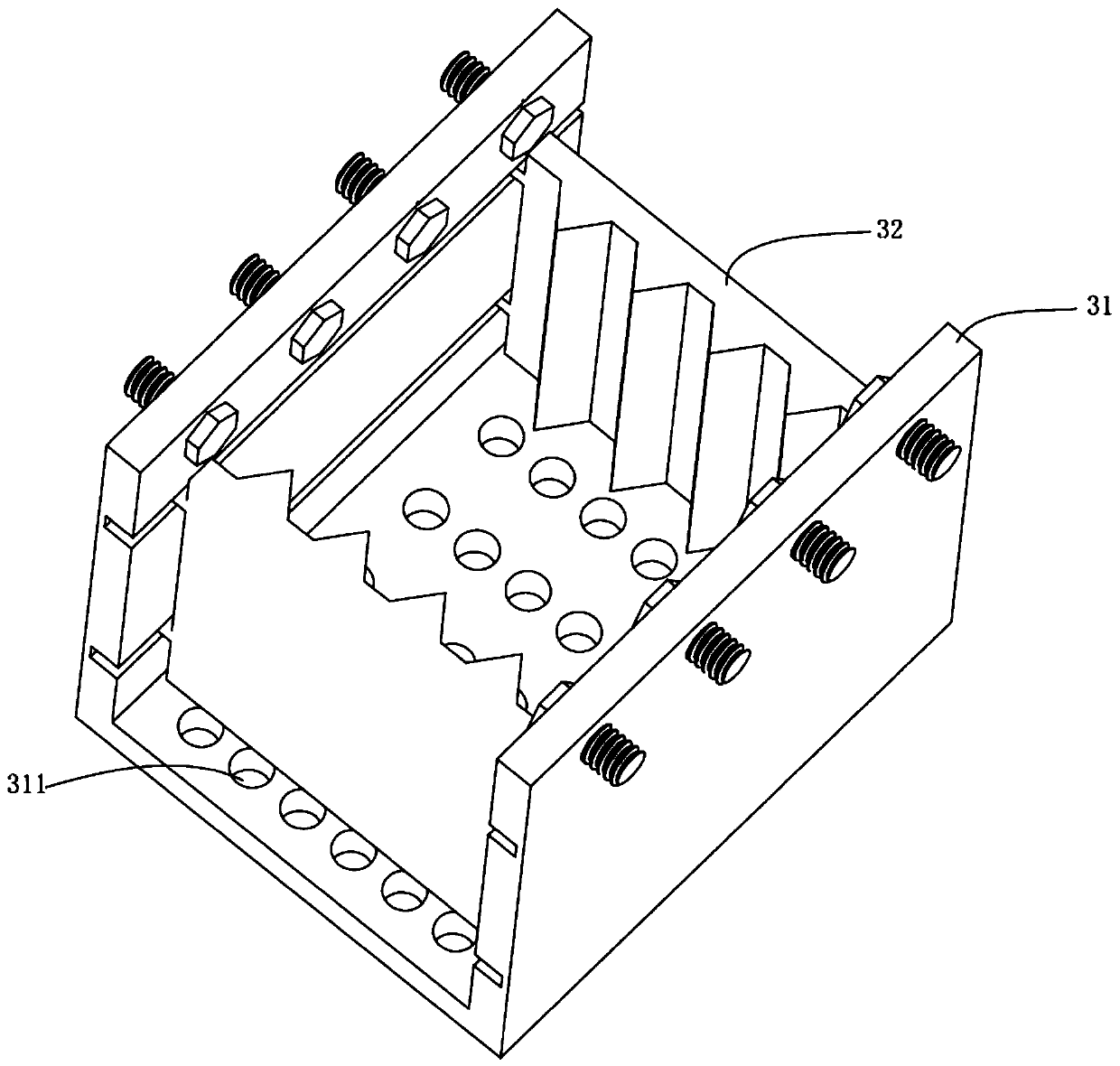

Odd-number polar plate group-collocating mechanism of flaker

InactiveCN102185152ASimple structureImprove efficiencyFinal product manufactureSecondary cells manufactureCollocationAxis cylinder

The invention discloses an odd-number polar plate group-collocating mechanism of a flaker. The odd-number polar plate group-collocating mechanism comprises a support, wherein a horizontal upper guide rail and a horizontal lower guide rail are arranged on the upper part of the support; a gap for a polar plate to pass through horizontally is formed between the upper guide rail and the lower guide rail; the lower part of the support is provided with an X-axis cylinder which is connected a Z-axis cylinder sliding up and down; the upper part of the Z-axis cylinder is provided with a push rod mechanism; the side part of the lower guide rail, in parallel with the upper plane of the lower guide rail, is provided with a horizontal panel for placing the polar plate; the side part of the horizontal panel is provided with a plate-pushing mechanism to push the polar plate on the horizontal panel to the gap between the upper guide rail and the lower guide rail; the support is provided with a plate suction mechanism above the horizontal panel; and the support is also provided with a plate delivering mechanism on the side part of the horizontal panel. Through the unique design of an up-and-down laminated structure with the upper and lower guide rails, the odd-number polar plate group-collocating mechanism ensures that a polar plate group and odd-number plates are successfully collocated into a polar group; besides, the supply of odd-number polar plates is achieved through the plate delivering mechanism and the plate suction mechanism. Therefore, the structure has the advantages of simple structure, high efficiency, orderly group collocation and the like.

Owner:广州市捷威专用设备有限公司

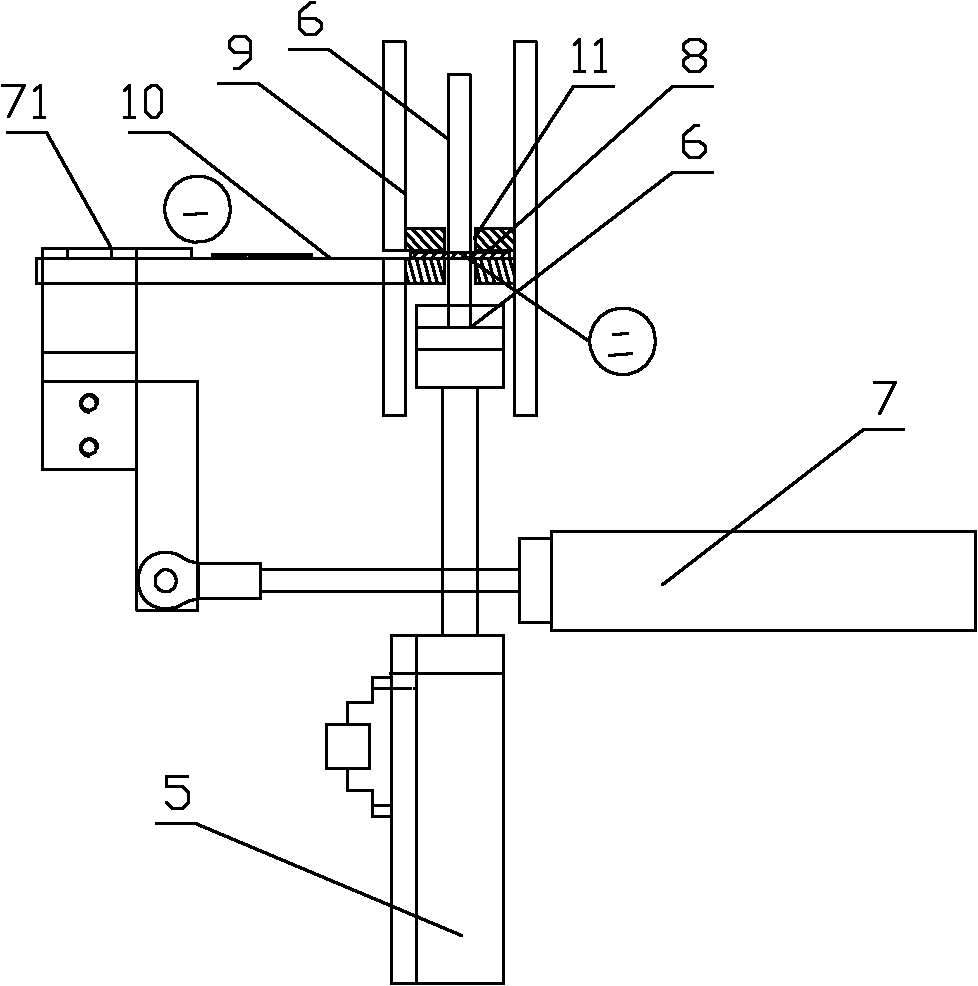

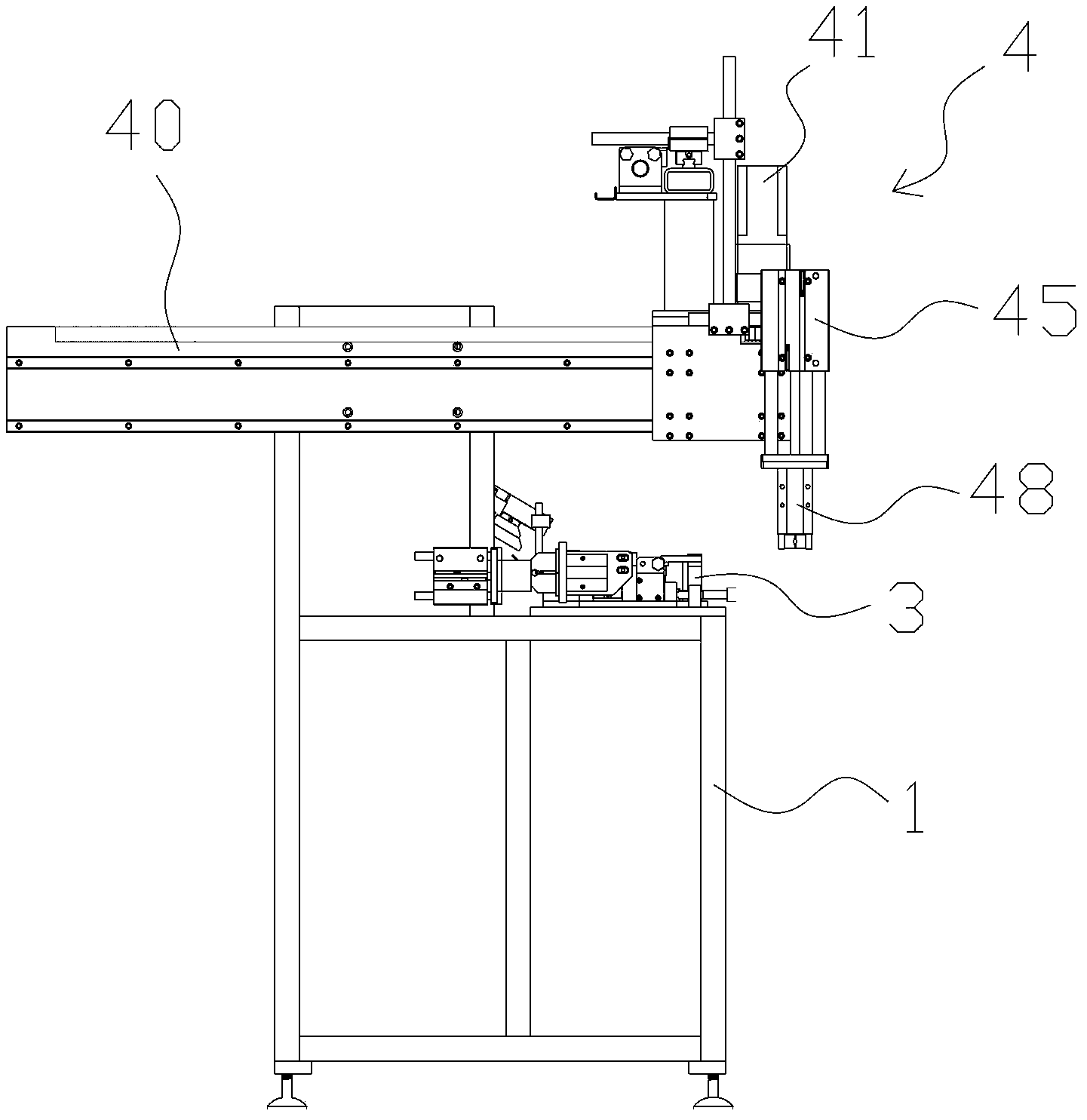

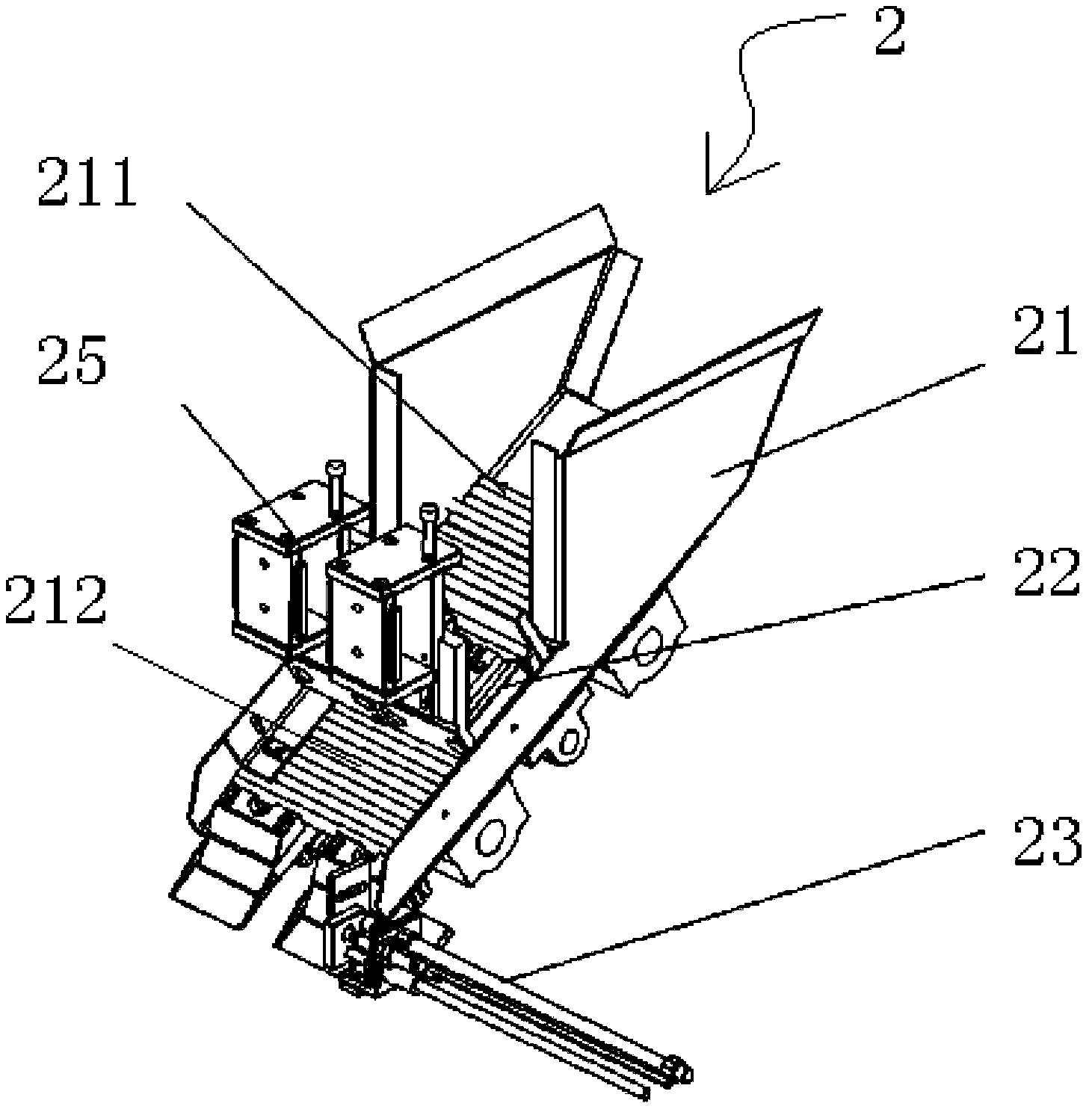

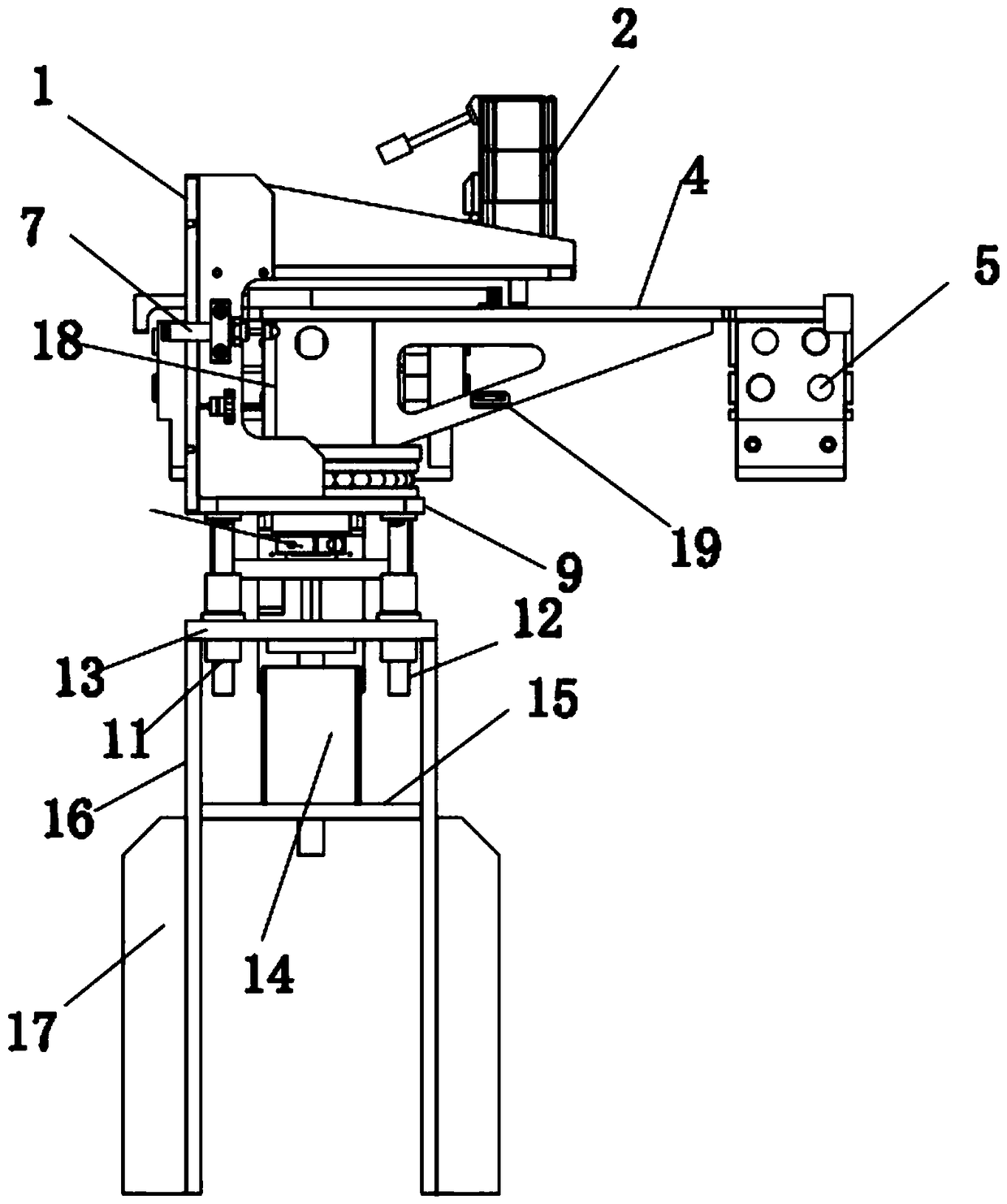

Pipe bending machine loading and unloading manipulator

ActiveCN103381452AIncrease productivityHigh degree of automationMetal-working feeding devicesPositioning devicesAxis cylinderEngineering

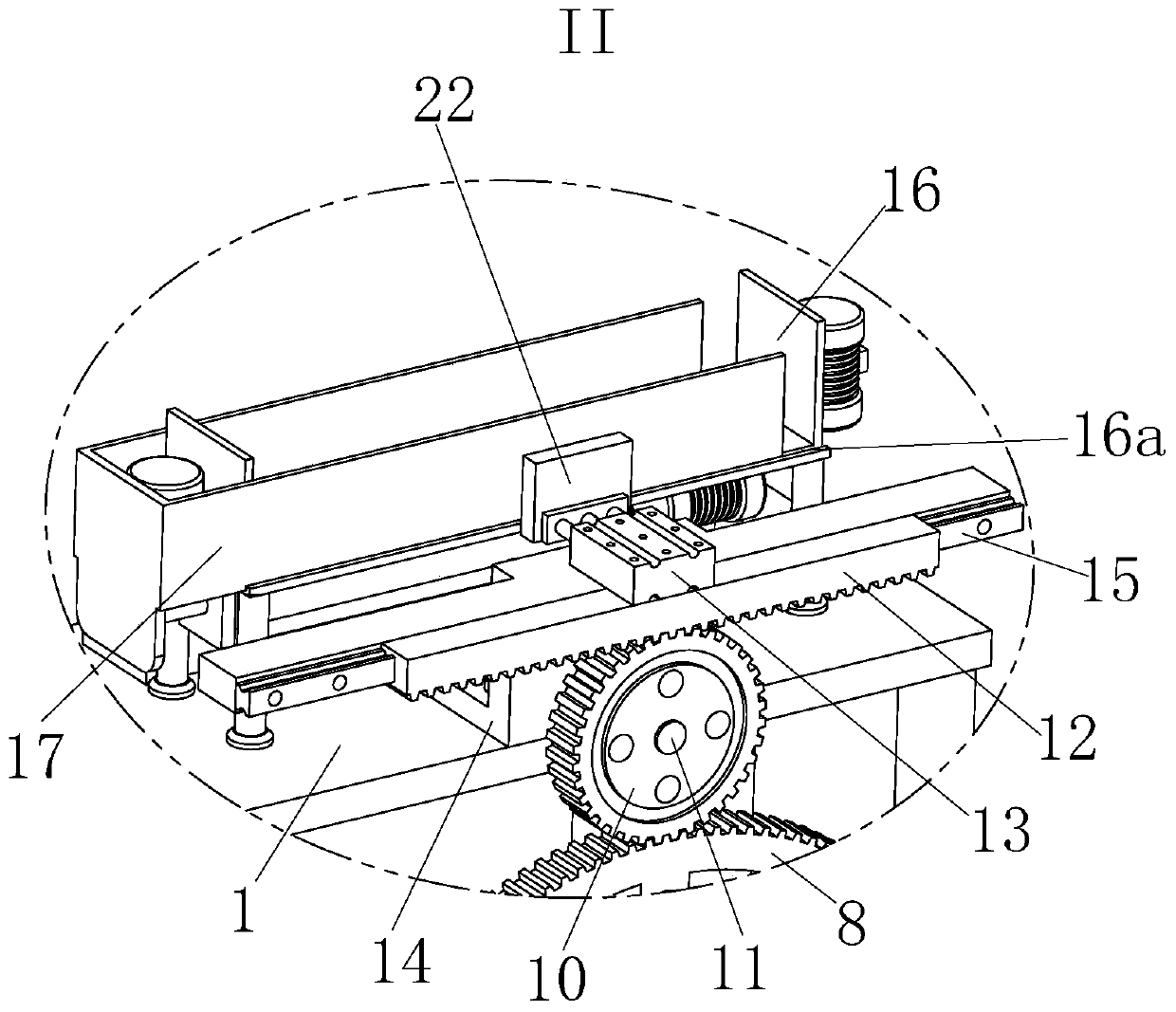

The invention discloses a pipe bending machine loading and unloading manipulator which comprises a machine body, a storage bin system, a loading system and an unloading system, wherein the loading system comprises a loading gripper device used for grabbing material output by a material ejection cylinder; the loading gripper device takes a rodless cylinder as power to realize switching between the grabbing position and the output position; the unloading system comprises an X-axis guide rail with racks, an X-axis servo gear motor, a dragging strip connected with the X-axis servo gear motor, a Y-axis guide rail, a Y-axis cylinder, and an air claw arm connected with the tail end of an ejector rod of the Y-axis cylinder; a Z-axis cylinder is arranged on the air claw arm; an air claw is arranged at the tail end of the Z-axis cylinder. The pipe bending machine loading and unloading manipulator effectively improves the production efficiency, is high in degree of automation and safe and reliable, and does not require manual operation, and the equipment has the characteristics of compact and firm structure, and low operation cost.

Owner:GUANGDONG CLAW ROBOT CO LTD

Deflashing device for flange of wheel

The invention discloses a deflashing device for a flange of a wheel. The deflashing device comprises a rack, a cylinder, a motor, clamping shafts, a V-shaped block, a gear rack, a supporting plate, a gear, knives, a knife rest, knife holders and the like. When the wheel on a production line reaches the approximate middle position of four clamping shafts, a sensor enables the wheel to stop moving, and a three-axis cylinder lifts the wheel to the middle height of the V-shaped block through the supporting plate; a clamping cylinder pushes a left sliding table to move towards the middle, and a right sliding table moves towards the middle under the action of the gear rack of the gear, so that a wheel workblank is synchronously clamped in the V-shaped block and located in the central position; the motor drives two clamping shafts on the left side to rotate through a chain and drives the wheel to rotate in a clamping state through friction force; and under the action of feed cylinders, both the knife A and the knife B move forward, and relative cutting movement is formed when the knives are contacted with the flange, so that the flange can be well deflashed.

Owner:CITIC DICASTAL

Lifting-clamping-type vacuum chuck clamp and use method thereof

PendingCN110271031AWon't fallImprove the efficiency of grabbing goodsGripping headsAxis cylinderPulp and paper industry

The invention belongs to the technical field of robot clamps and discloses a lifting-clamping-type vacuum chuck clamp and a use method thereof. The lifting-clamping-type vacuum chuck clamp is provided with a mounting frame; a chuck is fixed at the lower end of the mounting frame through bolts; a clamp connecting plate is fixed at the upper end of the mounting frame through bolts; the lower sides of the two ends of the clamp connecting plate are connected with triaxial cylinders through bolts; a guide rail frame is fixed at the lower ends of the three-axis cylinders through bolts; one-way air cylinders are fixed on the upper sides of the left and right ends of the guide rail frame through bolts; the lower ends of the output shafts of the two one-way air cylinders are connected with clamping plates through bolts; a triaxial camera cylinder is fixed in a mounting groove in the lower end of the mounting frame through bolts; the lower end of the output shaft of the triaxial camera cylinder is connected with a three-dimensional camera through bolts; and the three-dimensional camera penetrates through a rectangular through hole formed in the center of the chuck. According to the lifting-clamping-type vacuum chuck clamp, through the combined design of the air cylinder, the chuck and the clamping plates and the article recognition of the three-dimensional camera, the problems of incapability of cargo recognition and grabbing, damage and slow grabbing beat are solved.

Owner:SPEEDBOT ROBOTICS CO LTD

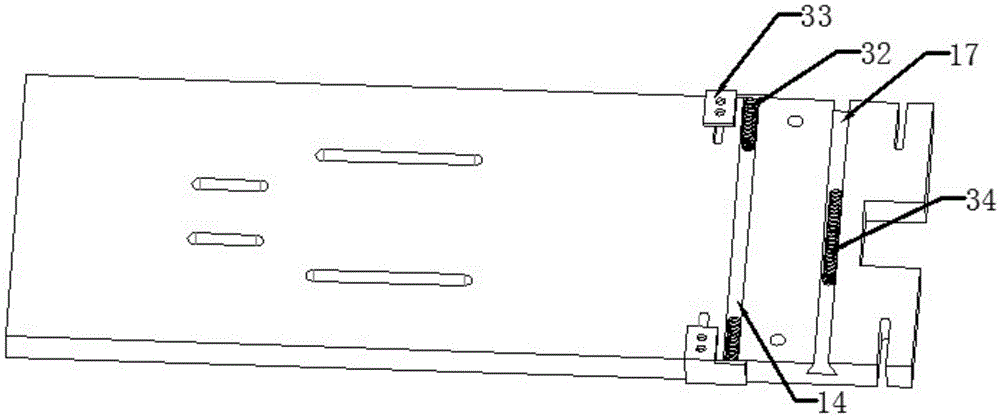

Testing tool and testing method of battery component with NFC

ActiveCN105807224AAdd test functionShorten the test cycleNear-field transmissionElectrical testingAxis cylinderTest battery

The present invention discloses a testing tool and testing method of a battery component with NFC. The testing tool comprises a working table whose upper end face is provided with an X-axis cylinder and a Y-axis screw rod, a Y-axis platform which is arranged on a Y-axis screw rod, the battery component with NFC arranged on the Y-axis platform, a testing component which is arranged on the working table and comprises a voltage and current transmitter for testing the battery, an NFC chip for testing NFC, and two pairs of spring contacts, and a controller, wherein one pair of spring contacts is connected to the voltage and current transmitter, and the other pair of spring contacts is connected to the NFC chip. According to the testing tool of the invention, the battery component with NFC is arranged on the Y-axis platform, thus the testing component tests the battery and NFC of the battery component with the NFC, thus the testing tool has the functions of battery testing and NFC, the battery component with NFC can complete the tests of different projects in one testing tool, and the testing cycle is shortened.

Owner:BYD CO LTD

Medical waste crushing device

InactiveCN110369461AAvoid entanglementImprove crushing effectSolid waste disposalGrain treatmentsAxis cylinderThumb opposition

The invention provides a medical waste crushing device comprising a baseplate, a cutting mechanism, an extrusion mechanism, a crushing mechanism and conveyor belts. The cutting mechanism comprises a bracket, three-axis cylinders and cutters, and the bracket is fixedly installed on the baseplate; the two three-axis cylinders are installed on the bracket by bolts, and one cutter is installed on thetwo three-axis cylinders by bolt; the other cutter is installed on the baseplate by bolts, wherein the cutting edges of the two cutters are in opposition to each other, and are arranged alternately; and the two conveyor belts are installed on the both sides of the baseplate separately. Medical waste is conveyed into the crushing mechanism through the two conveyor belts in a classified mode, and the cutters are driven by the two three-axis cylinders to move back and forth for cutting and crushing the medical waste; part of disposable medical waste is hard to crush by a rotating cutter, and thecrushing effect is improved; the medical waste is pretreated through the extrusion mechanism, and then crushed through the crushing mechanism so that the waste is crushed thoroughly.

Owner:淮北市儒伽医疗科技有限公司

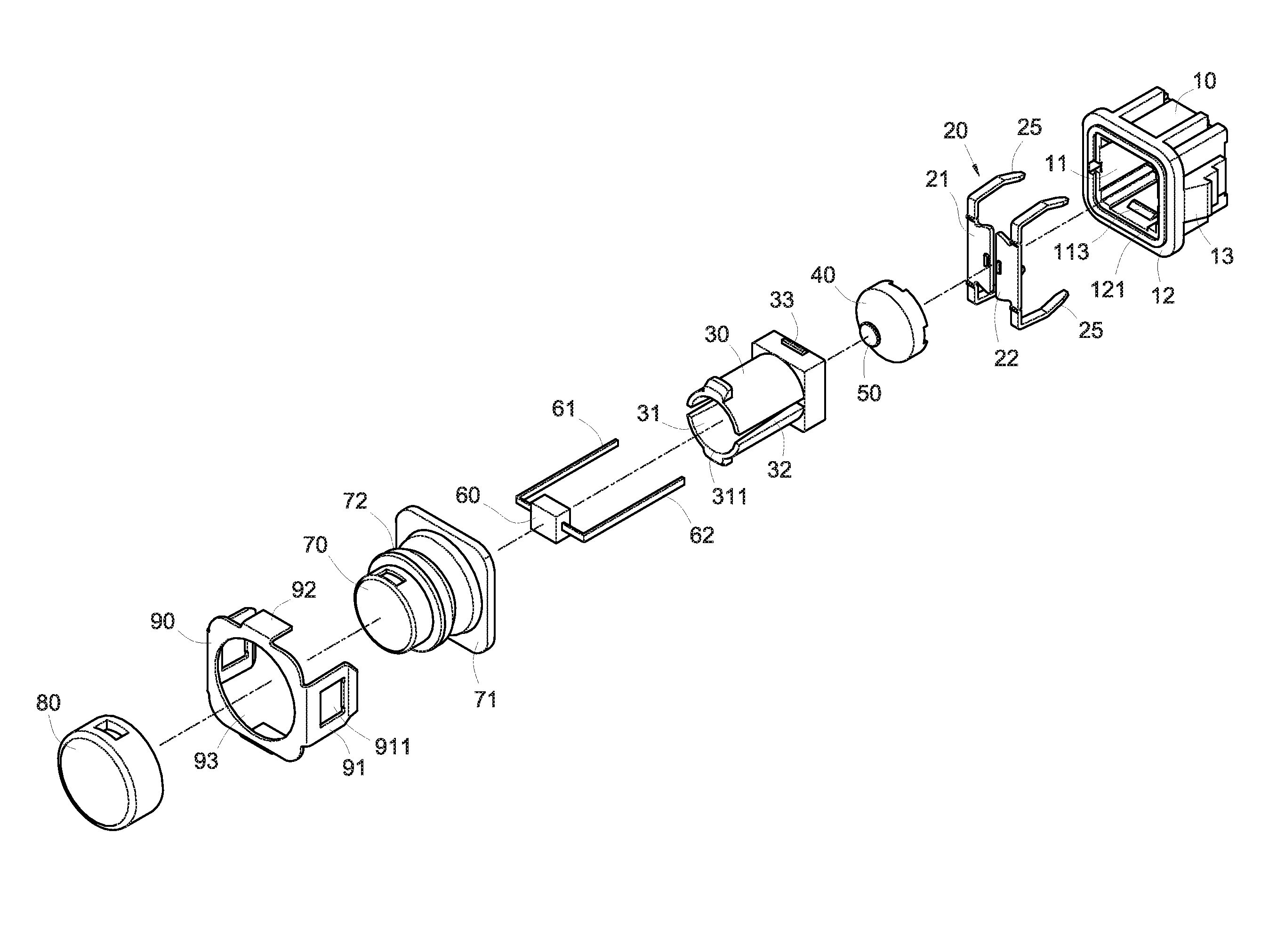

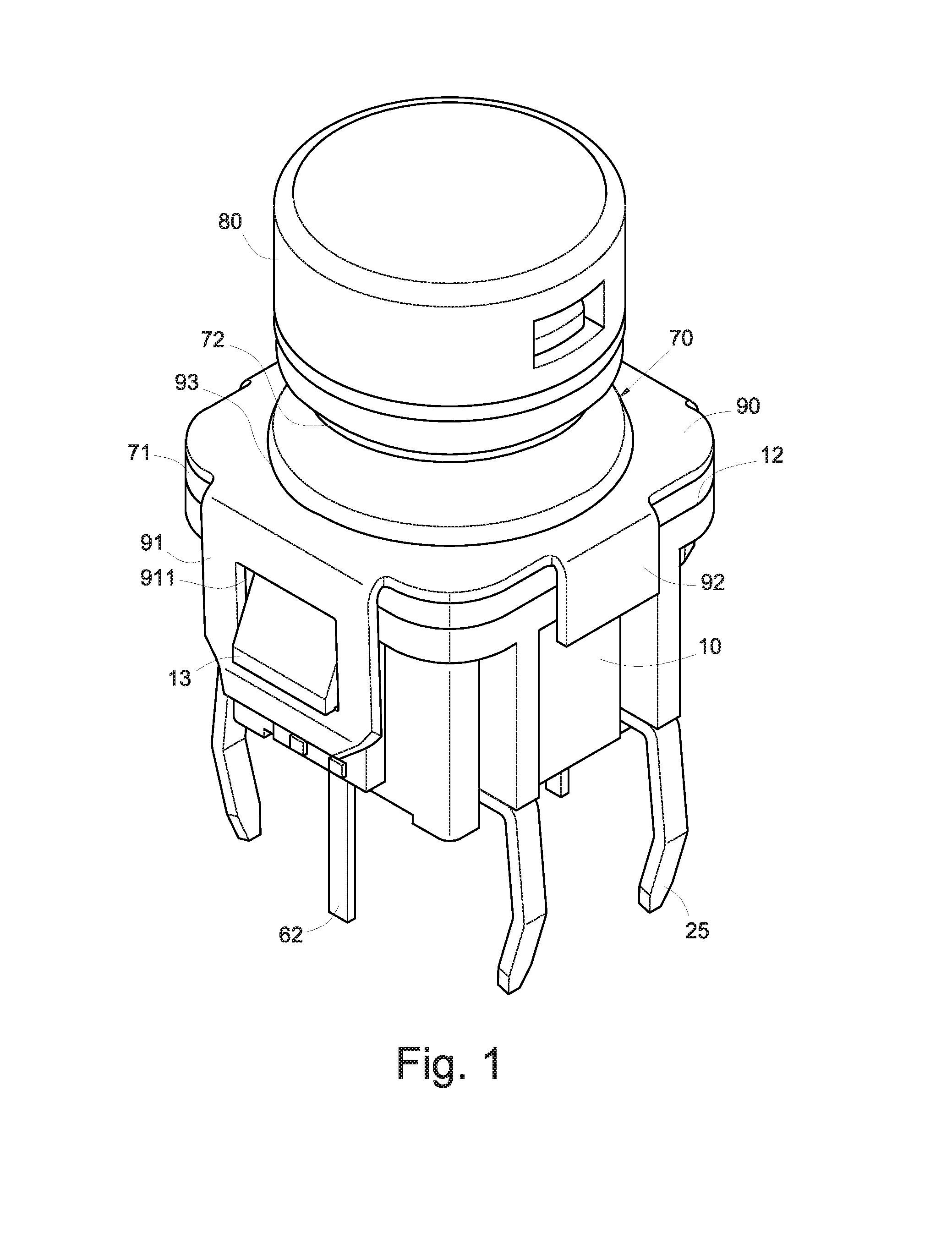

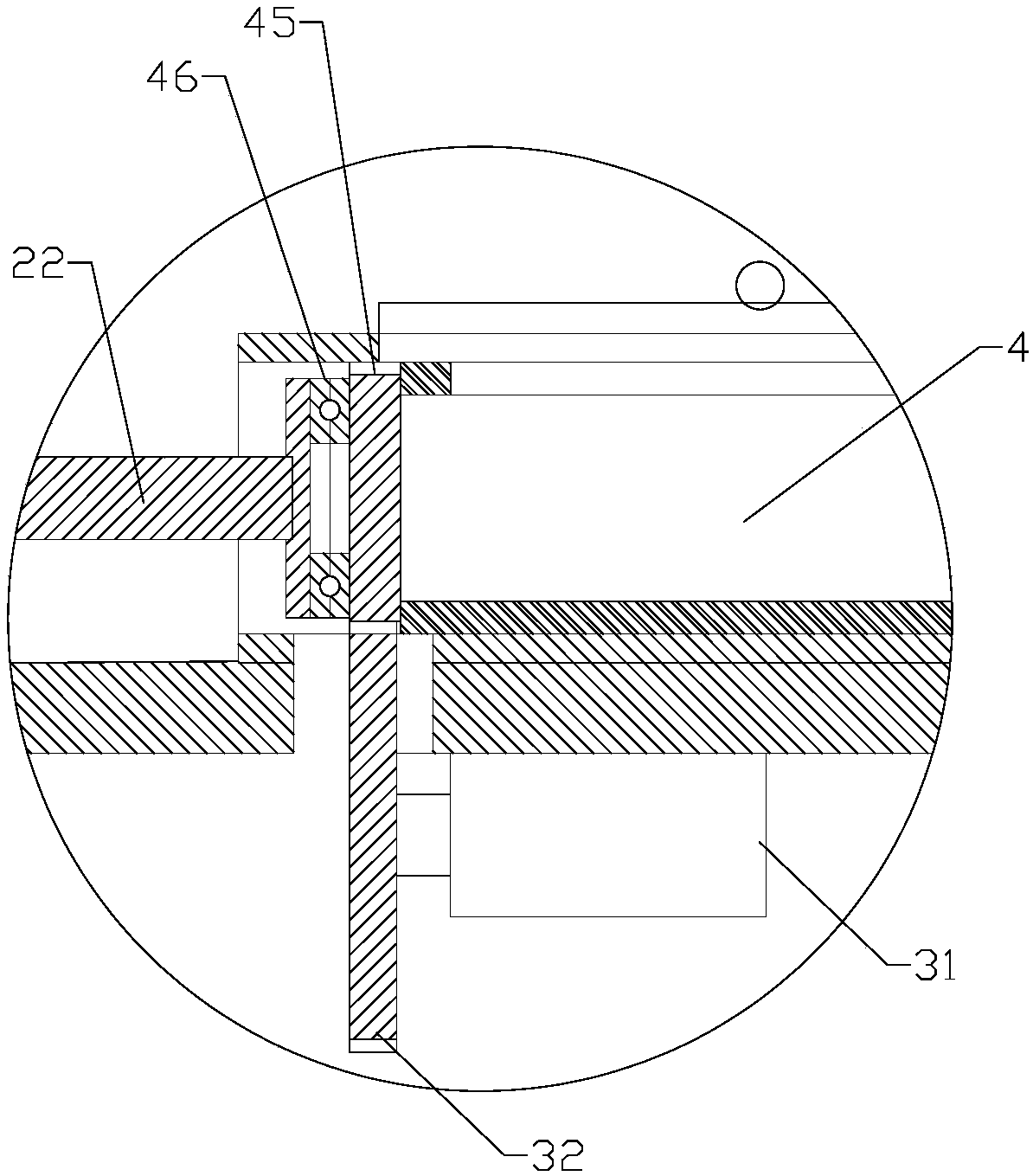

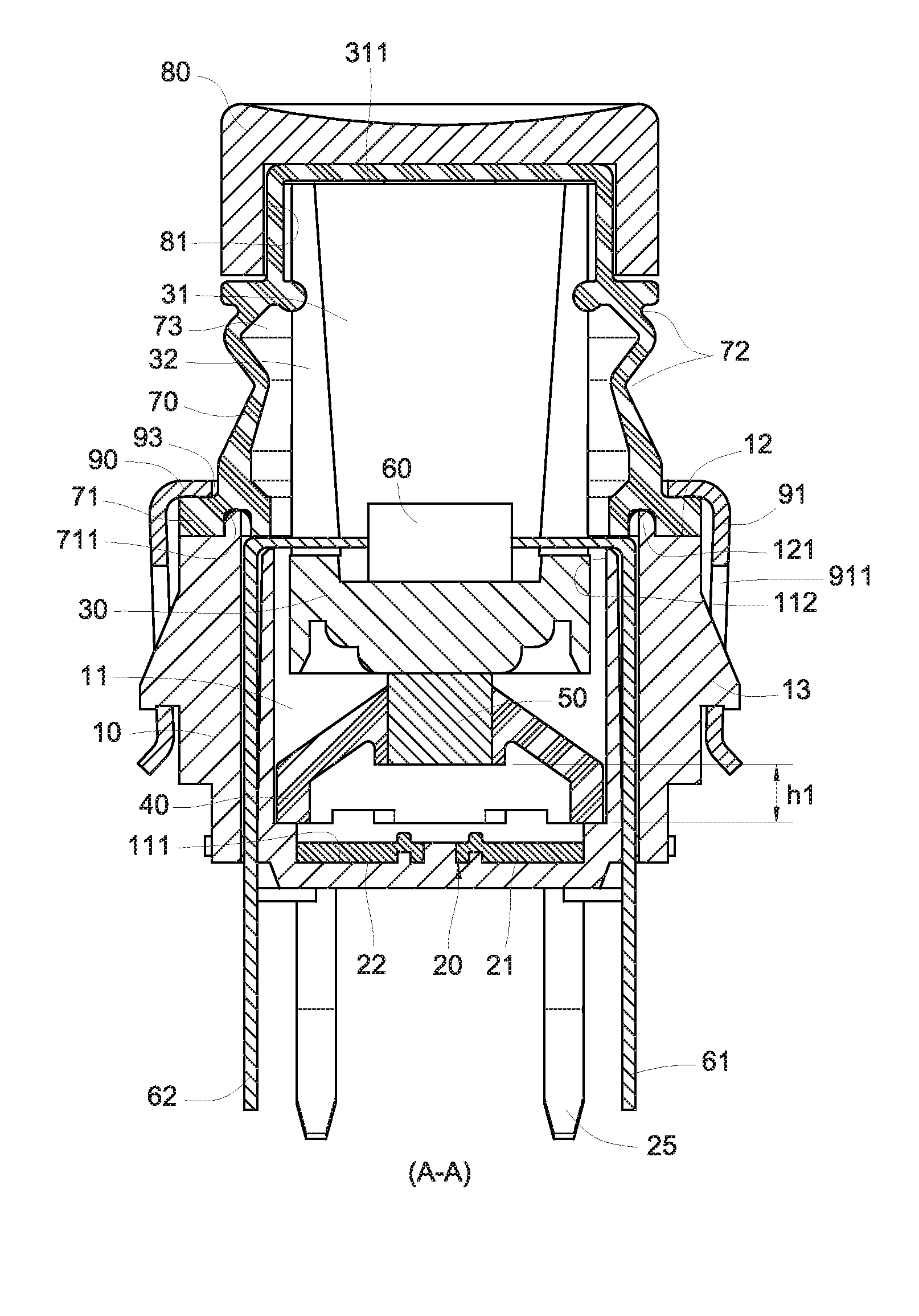

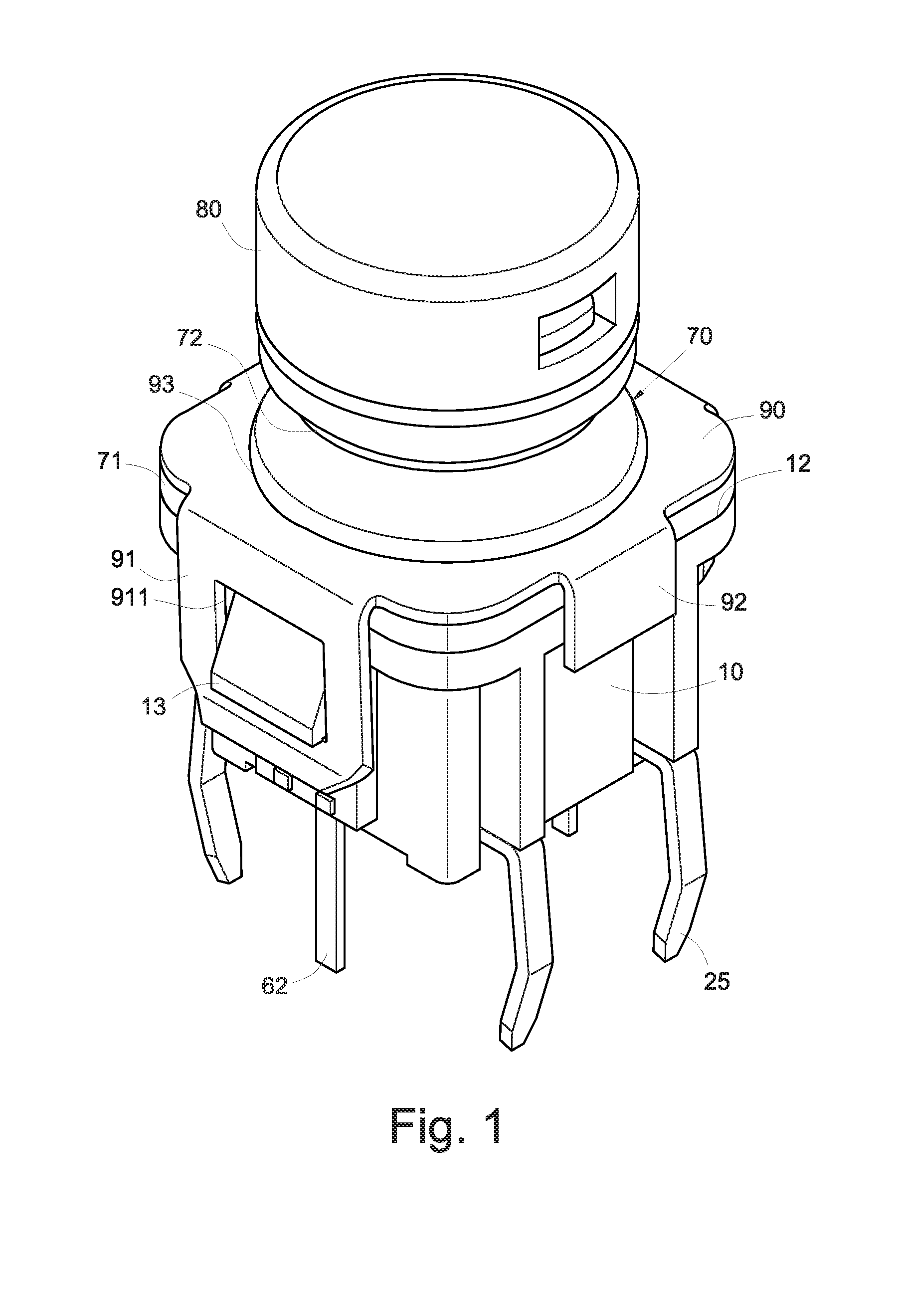

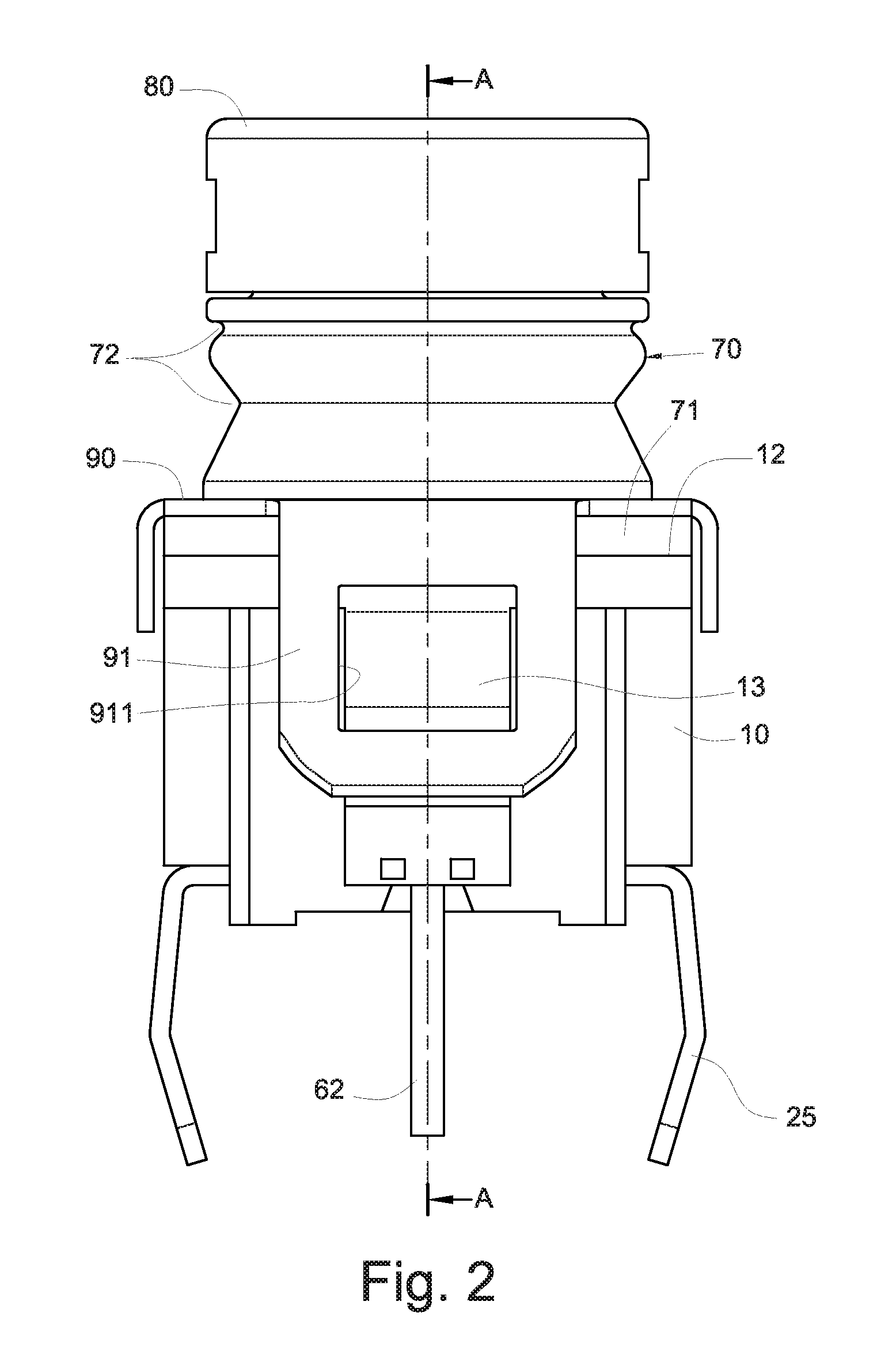

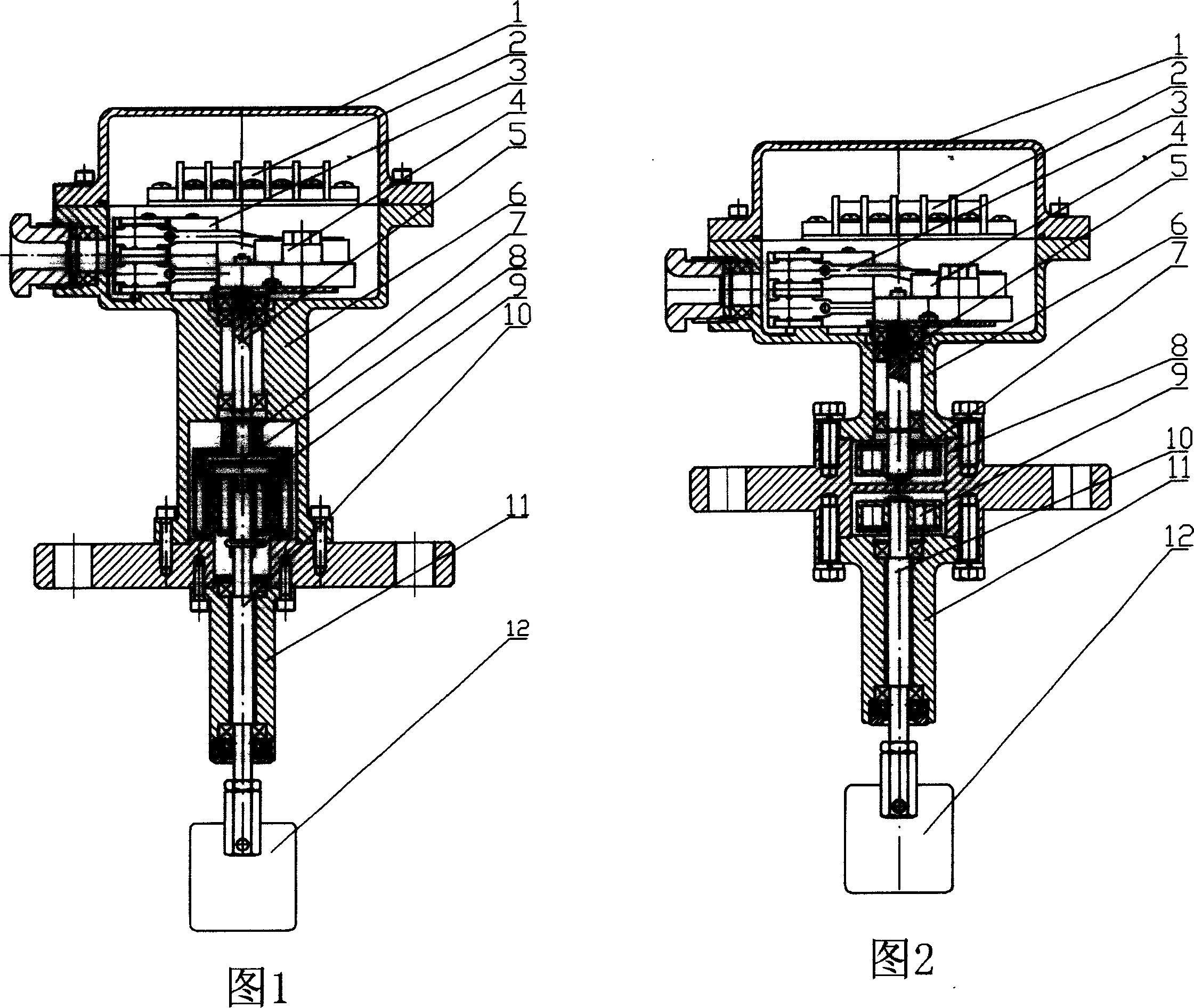

Electrically conductive structure of micro switch

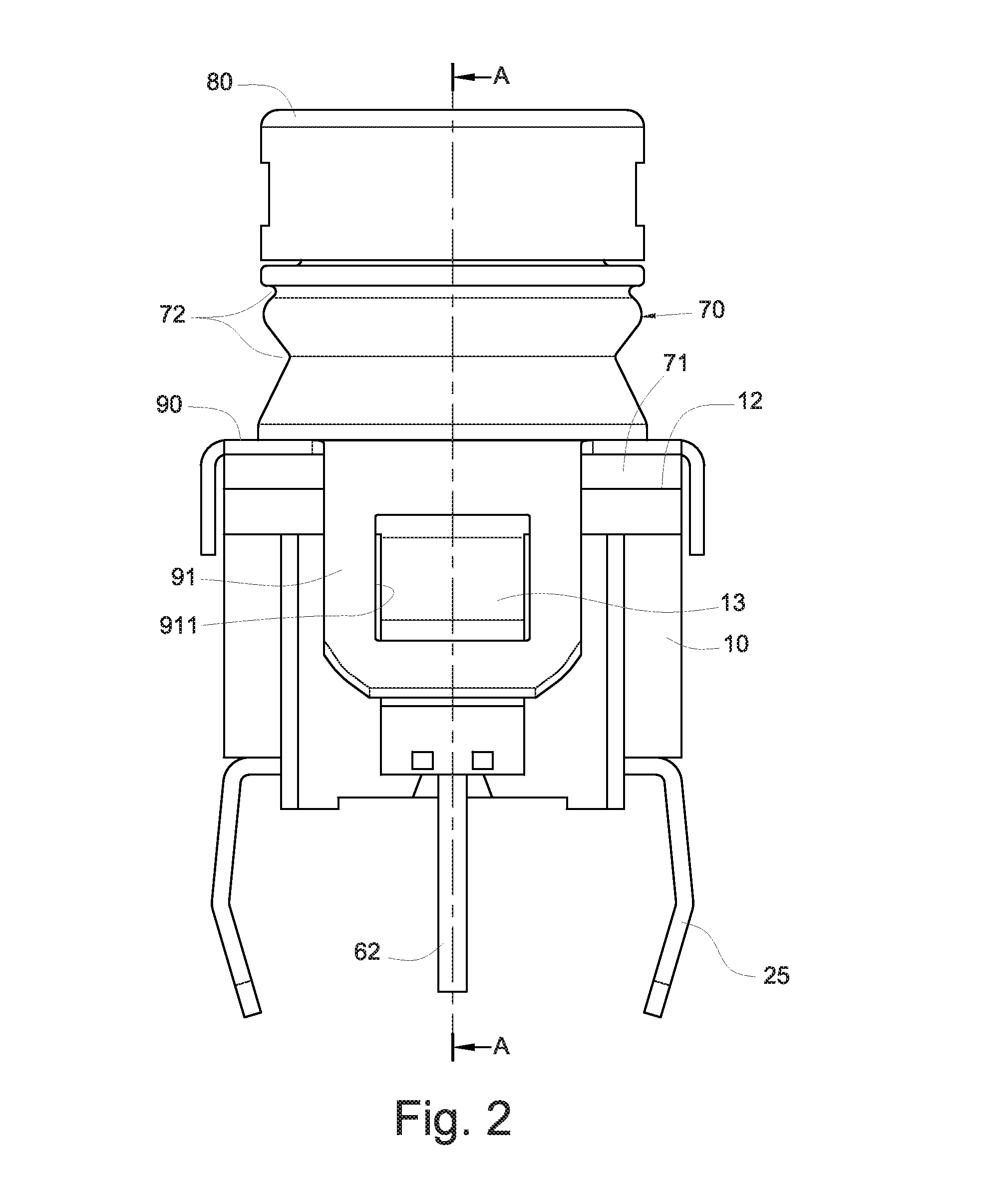

InactiveUS20130112535A1Increased Durability LifeExtended service lifeContacts enclosures/screensAxis cylinderReciprocating motion

An electrically conductive structure of a micro switch capable of letting users know about the reciprocal movement of a switch button, comprising a base, having an electrode module installed in a containing groove formed at the top of the base; an axis cylinder slidably installed in the containing groove; a conical sleeve made of a soft high temperature resisting material and disposed between the axis cylinder and the electrode module; a metal conductive bump formed at the top of the conical sleeve and driven by the axis cylinder to compress and release the conical sleeve to connect and disconnect the electrode module, and the axis cylinder moves reciprocally to produce a hand-pressing feeling, and the containing groove has as sheathe made of a soft high temperature resisting material to block external liquid from entering into the containing groove to improve the service life of the switch.

Owner:CHU CHING HSIUNG

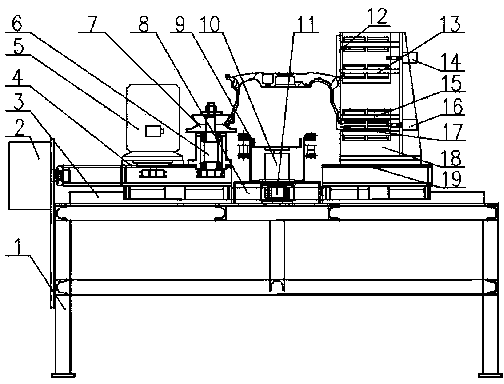

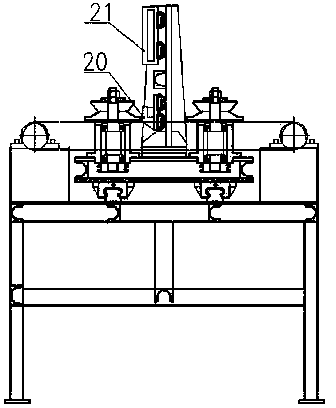

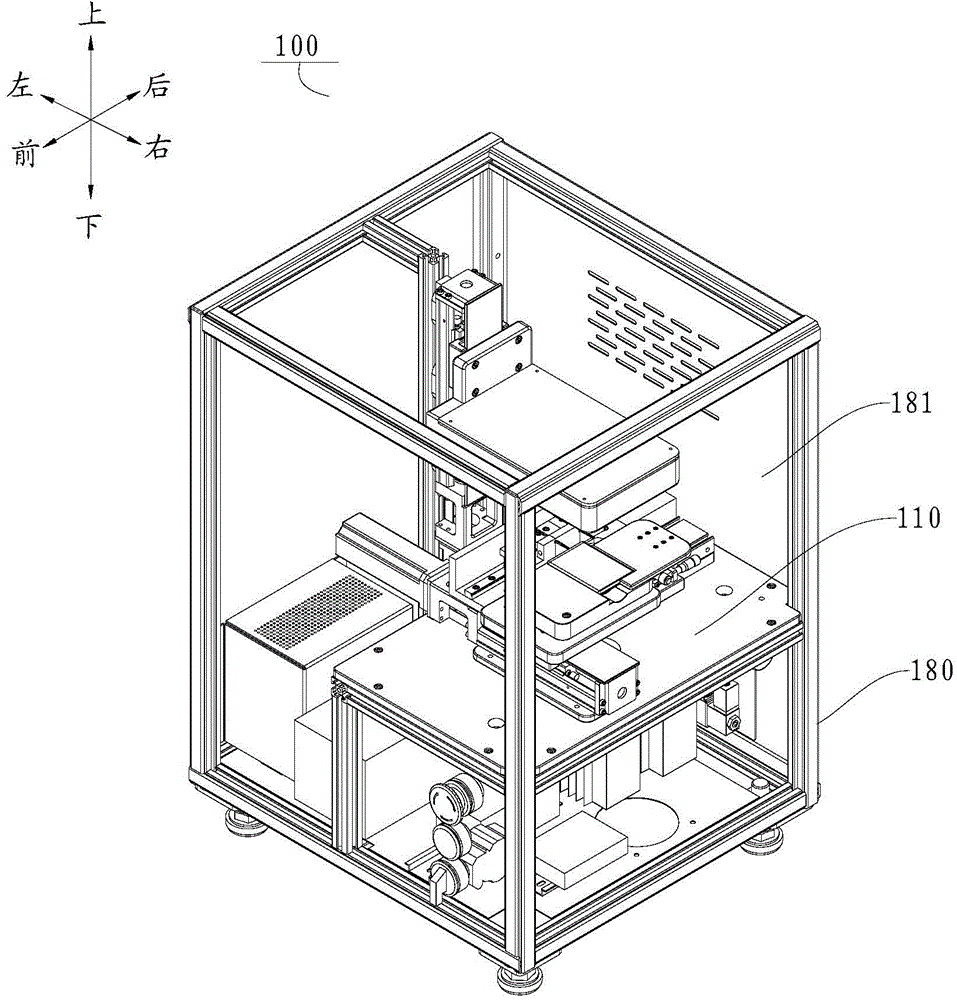

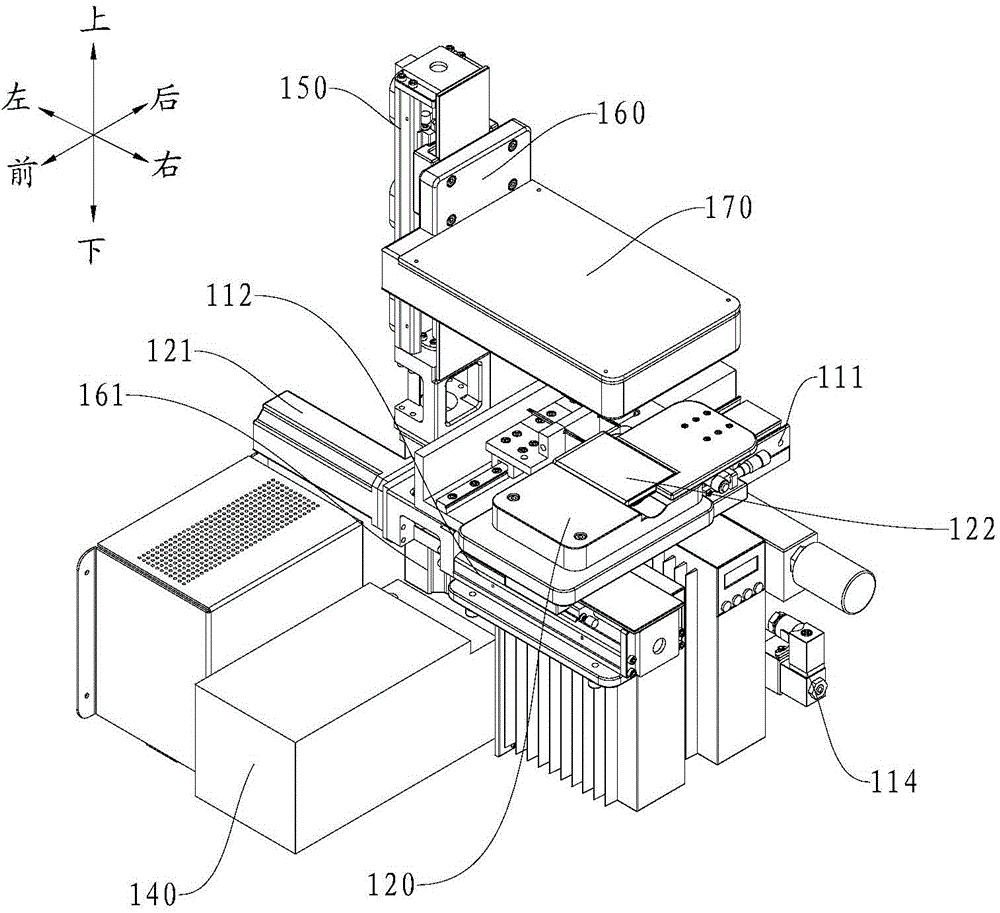

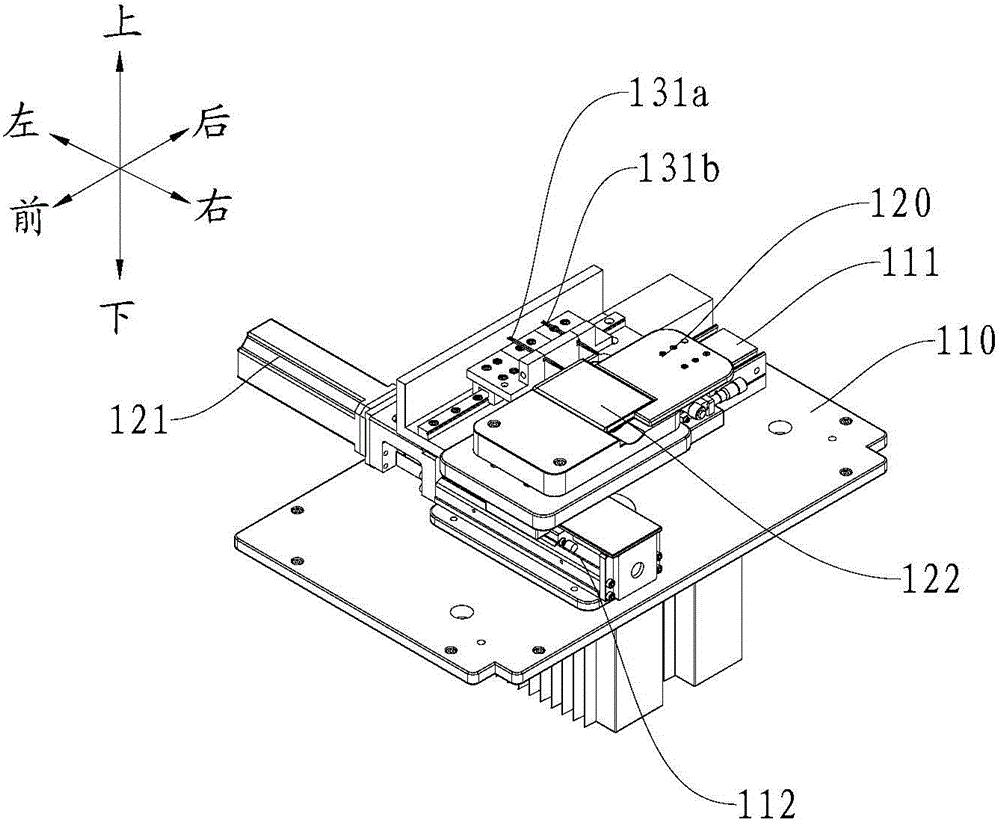

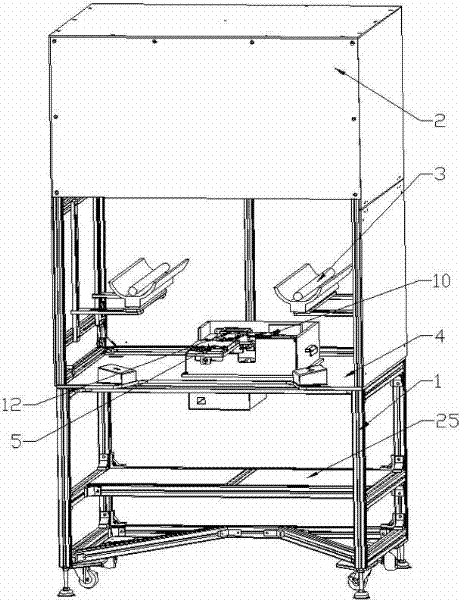

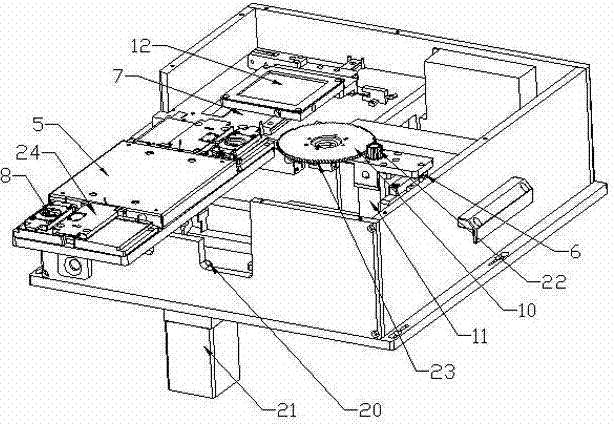

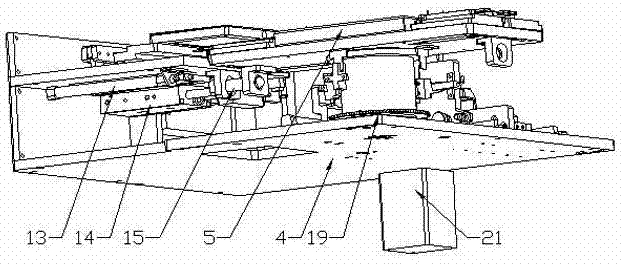

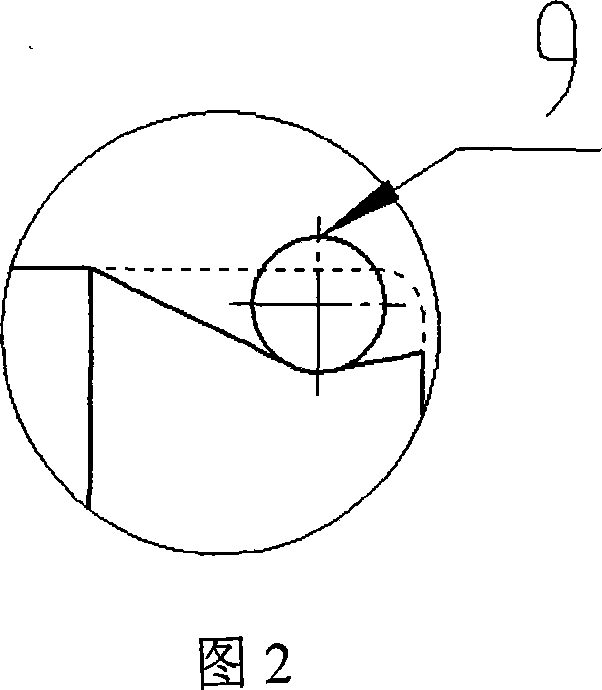

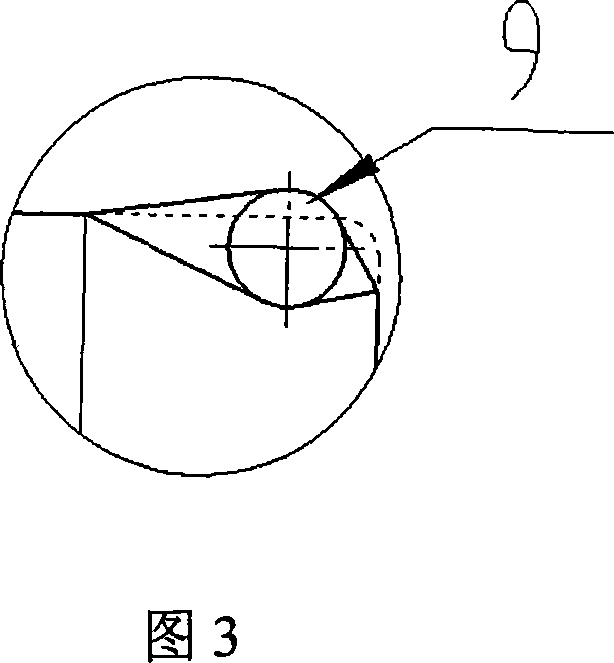

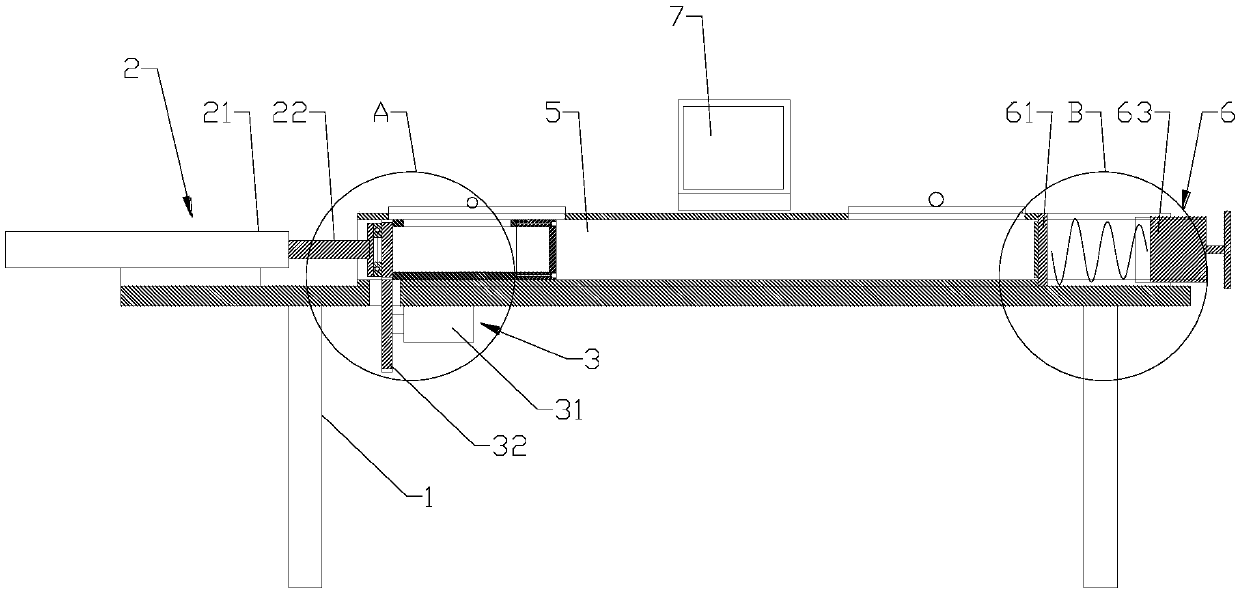

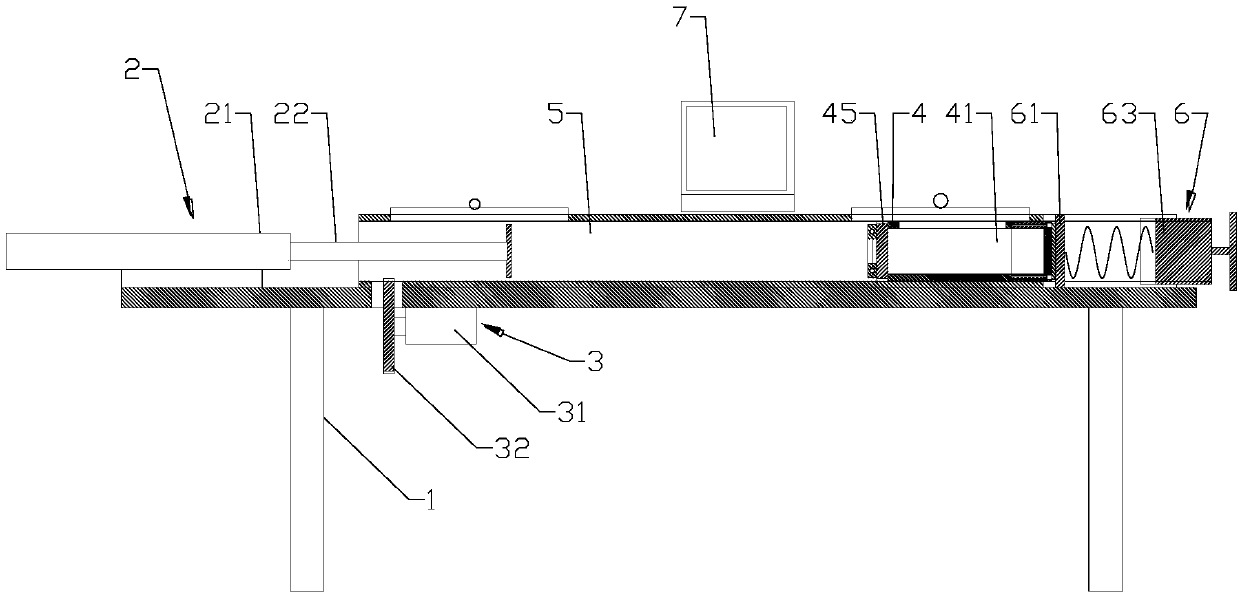

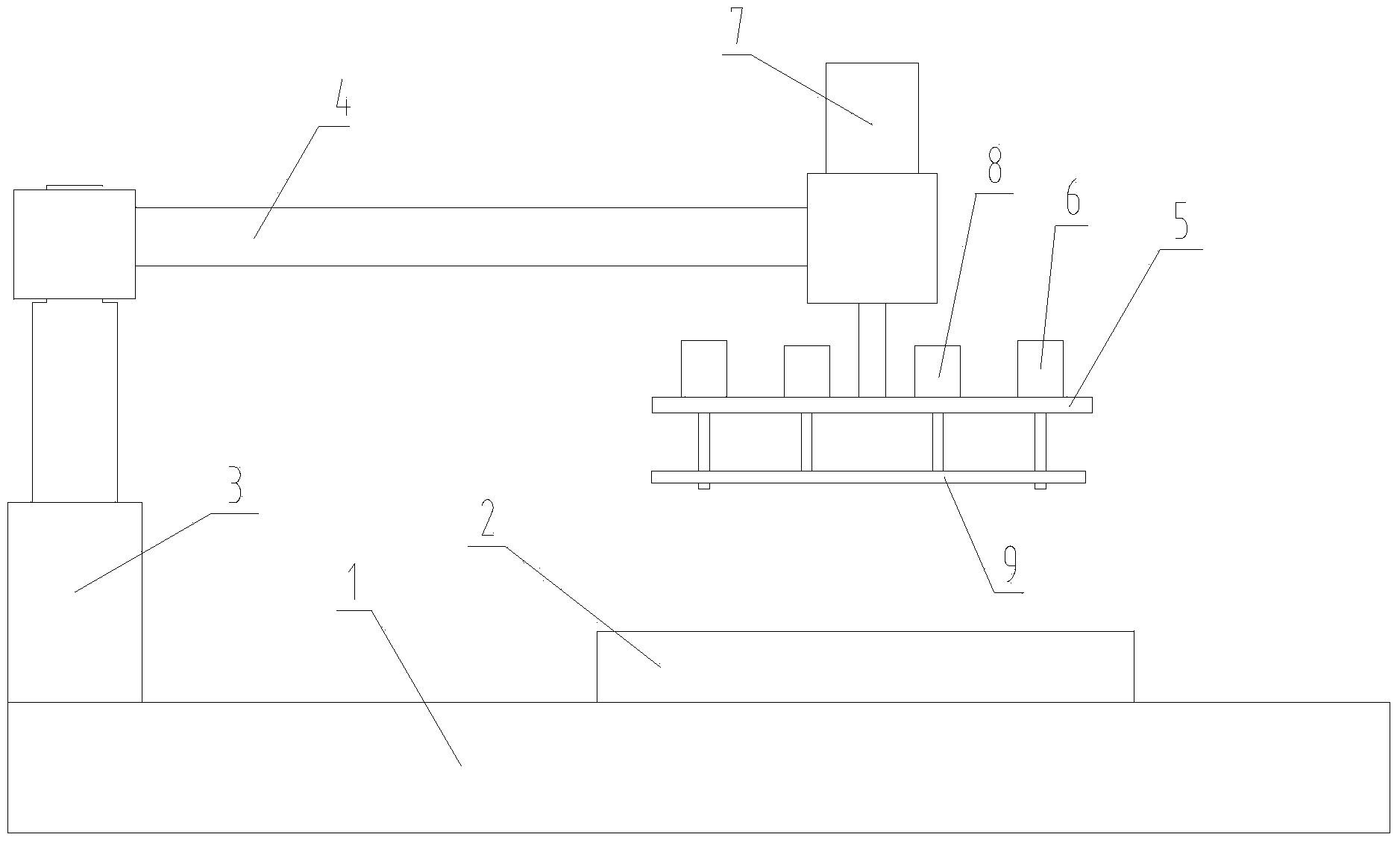

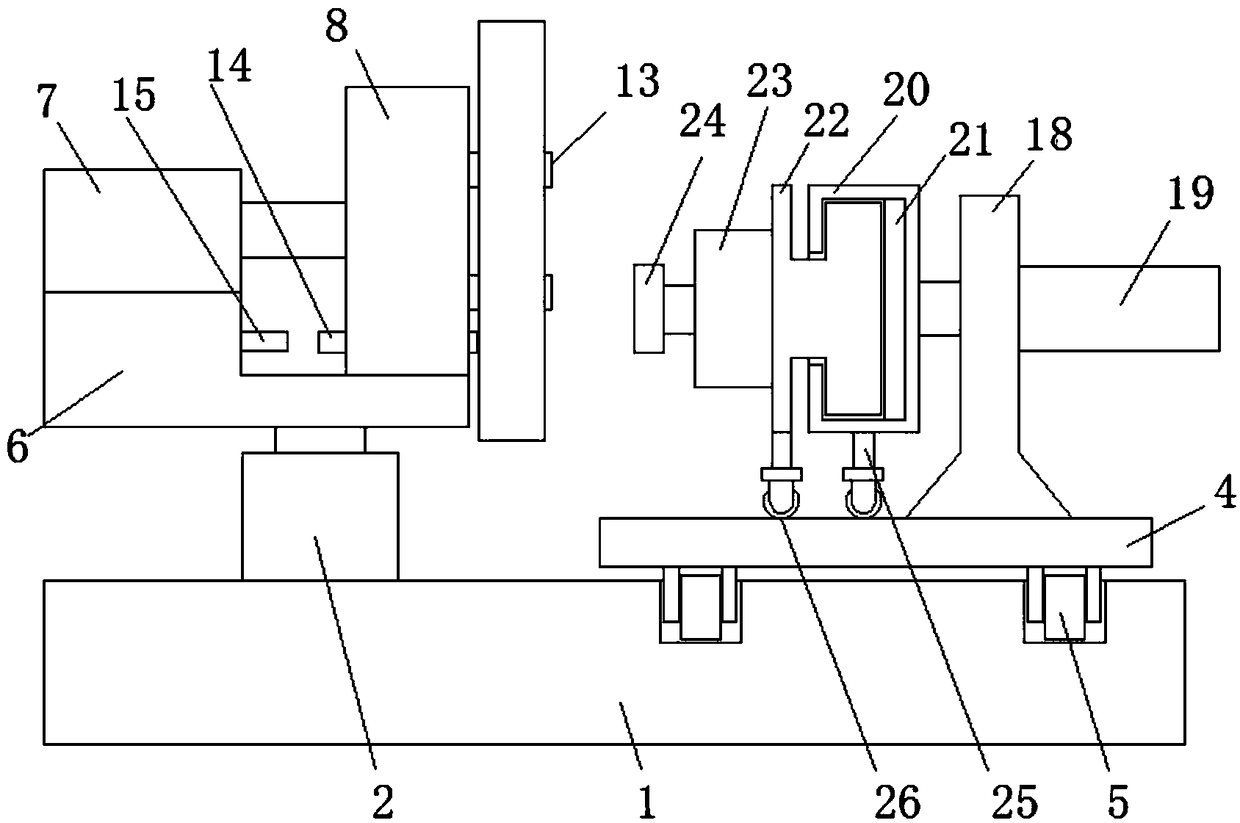

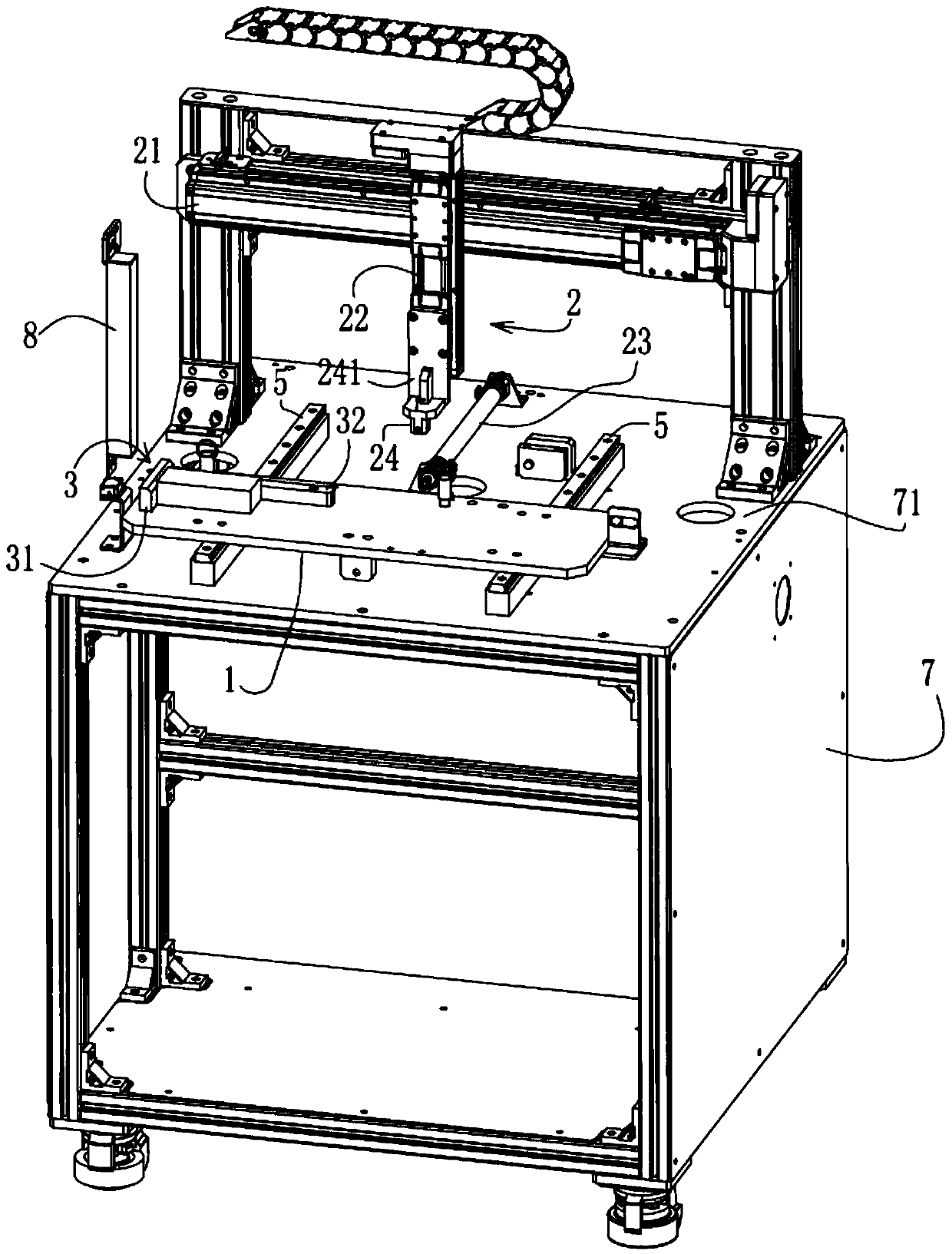

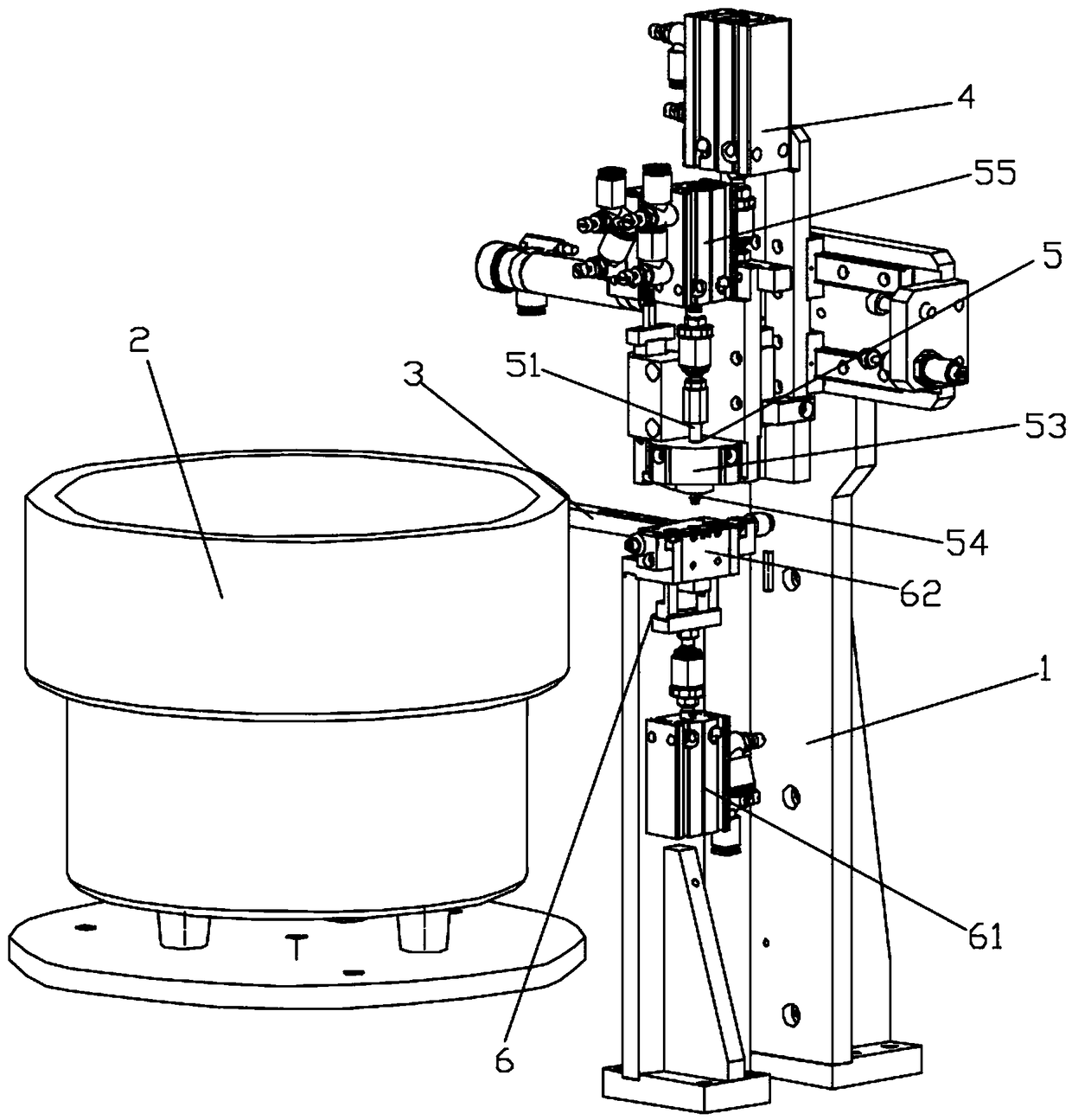

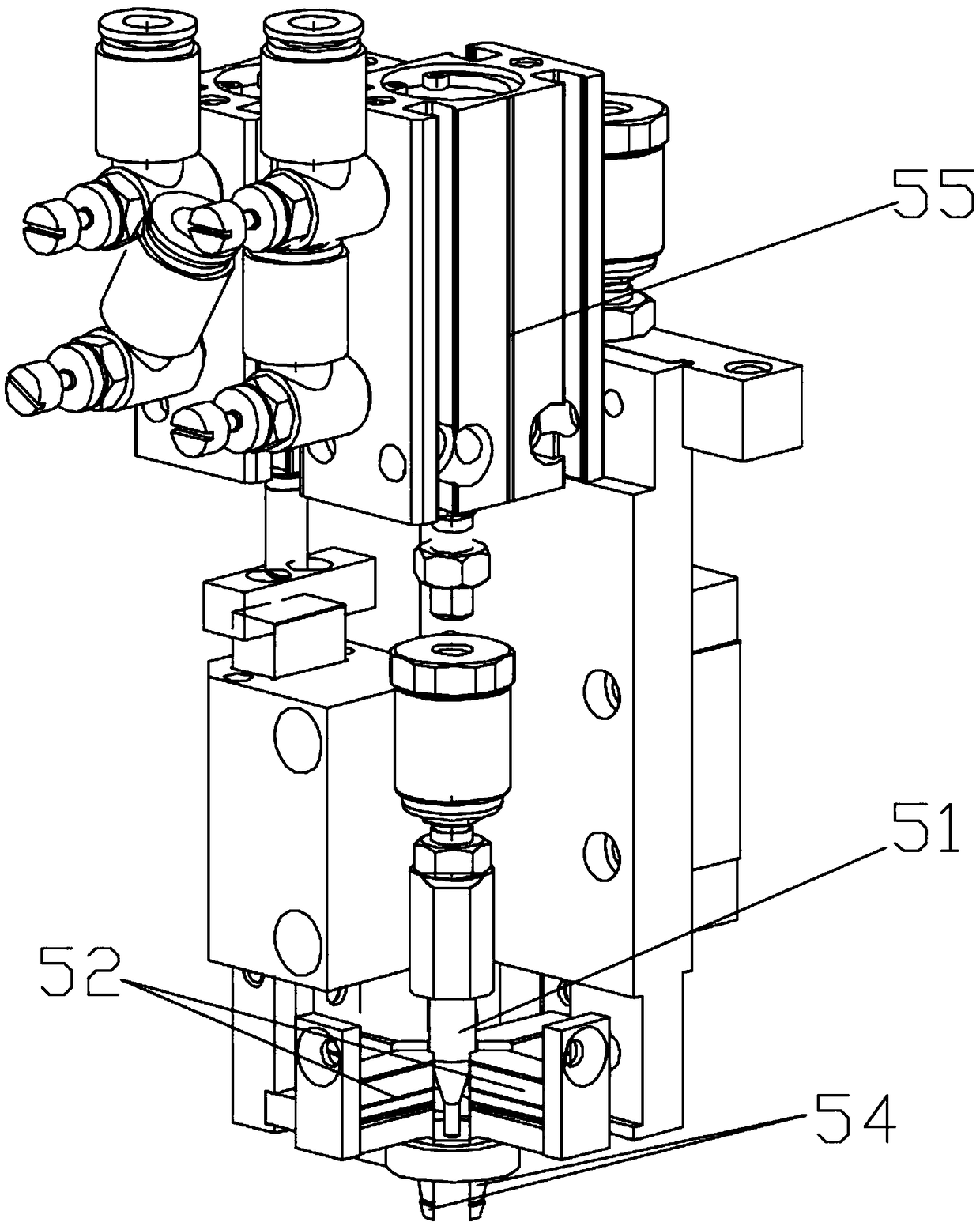

Lens testing focusing machine

The invention discloses and provides a lens testing focusing machine, which has high automatic degree, high testing accuracy and high working efficiency. The lens testing focusing machine comprises a frame (1), a lamp box (2), a focusing plate, a light distribution lamp (3), a reference plate (4) and a peripheral host, wherein the reference plate (4) is provided with a swinging platform (5), an X-axis focusing workbench and Y-axis testing workbench; two lens trays are arranged at opposite angles on the swinging platform; the X-axis focusing workbench is driven by an X-axis cylinder to move in the X-axis direction in a reciprocating way; the X-axis focusing workbench is provided with a focusing ring (10); the focusing ring (10) is driven by a focusing motor arranged on the X-axis focusing workbench to rotate; the focusing ring (10) is arranged on a support cylinder; the Y-axis testing workbench is provided with a white screen (12); and the lens trays are provided with sensors. The lens testing focusing machine can be widely applied to the field of lens processing.

Owner:珠海市运泰利自动化设备有限公司

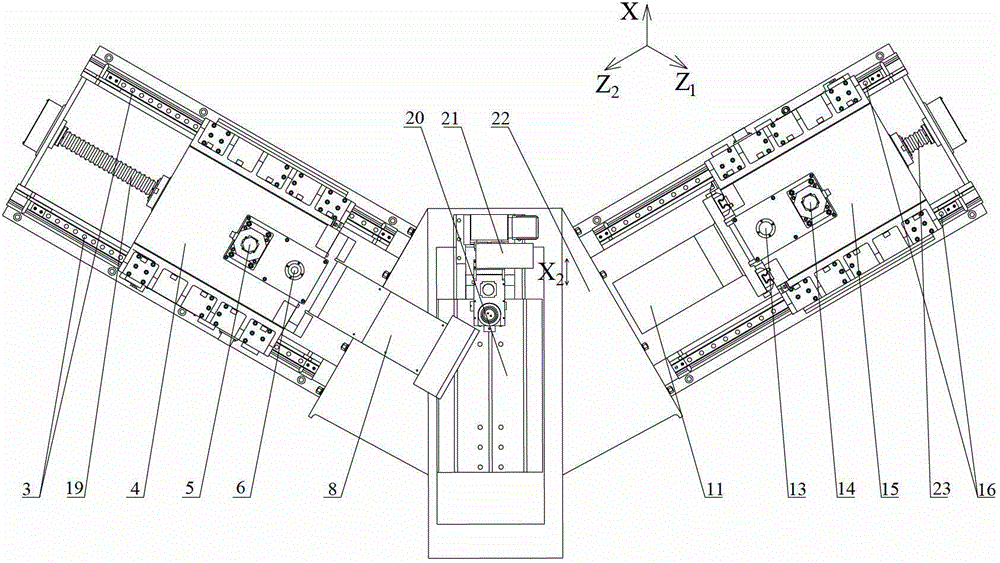

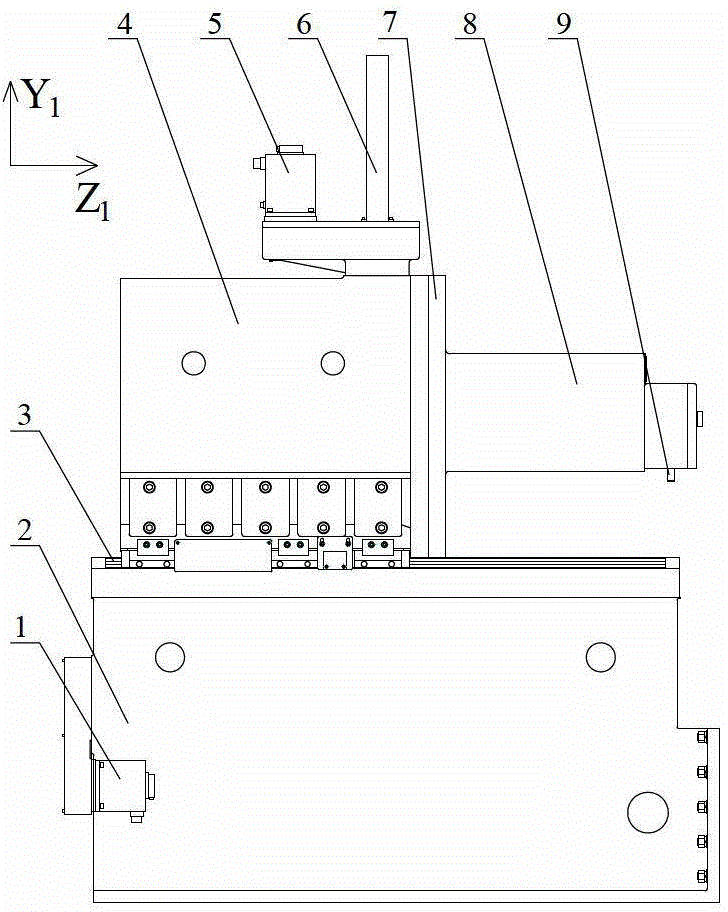

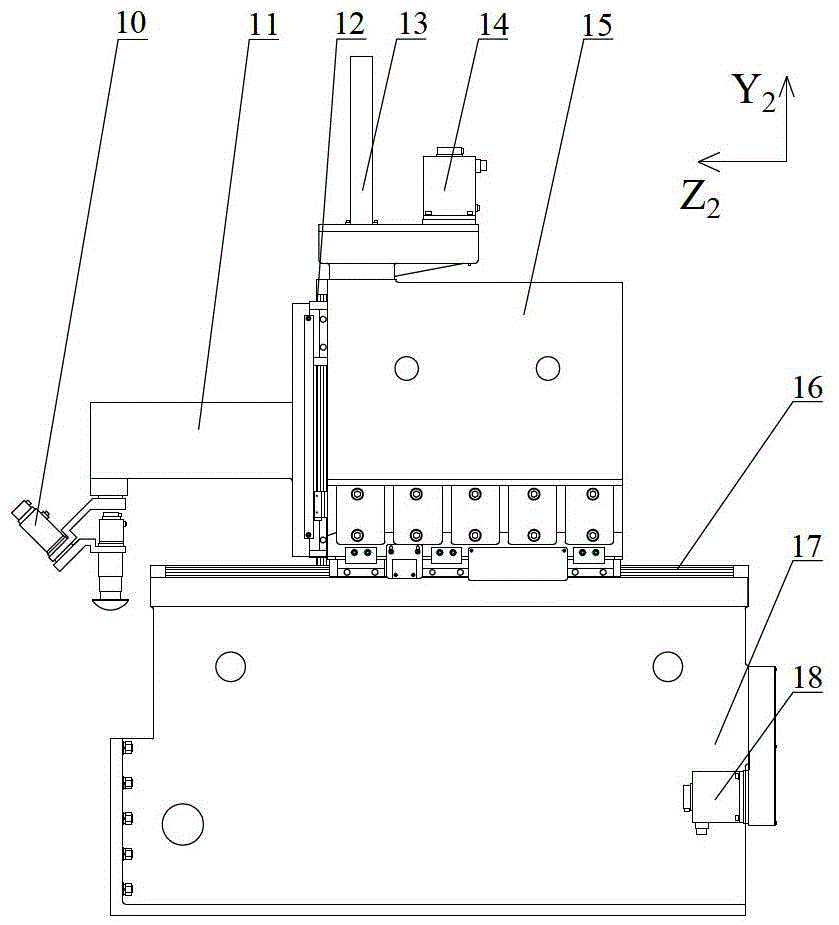

Grinding and polishing combined machining machine tool

ActiveCN102975097AShort tripAvoid mobilityOptical surface grinding machinesGrinding drivesAxis cylinderBall screw

A grinding and polishing combined machining machine tool relates to a precision grinder and a polishing machine tool. The grinding and polishing combined machining machine tool comprises a grinding device, a polishing device, a movable on-line trimming device and a workbench device; the grinding device and the polishing device are respectively arranged on one side of the workbench device; the grinding device is provided with a grinding device tool body base, a Z1-axis servo motor, a Z1-axis ball screw pair, a Z1-axis guide rail, a Y1-axis servo motor, a Y1-axis ball screw pair, a Y1-axis guide rail, a grinding device column, a spindle carrier and a grinding wheel; the polishing device is provided with a polishing device tool body base, a Z2-axis servo motor, a Z2-axis ball screw pair, a Z2-axis guide rail, a Y2-axis servo motor, a Y2-axis ball screw pair, a Y2-axis guide rail, a polishing device column, a polishing device suspension arm and an air bag grinding head; the movable on-line trimming device is provided with a trimmer, an X2-axis guide rail, an X2-axis cylinder and a rotary platform; and the workbench device is provided with a workbench, a workbench tool body, an X-axis guide rail, an X-axis ball screw pair and an X-axis servo motor.

Owner:XIAMEN UNIV

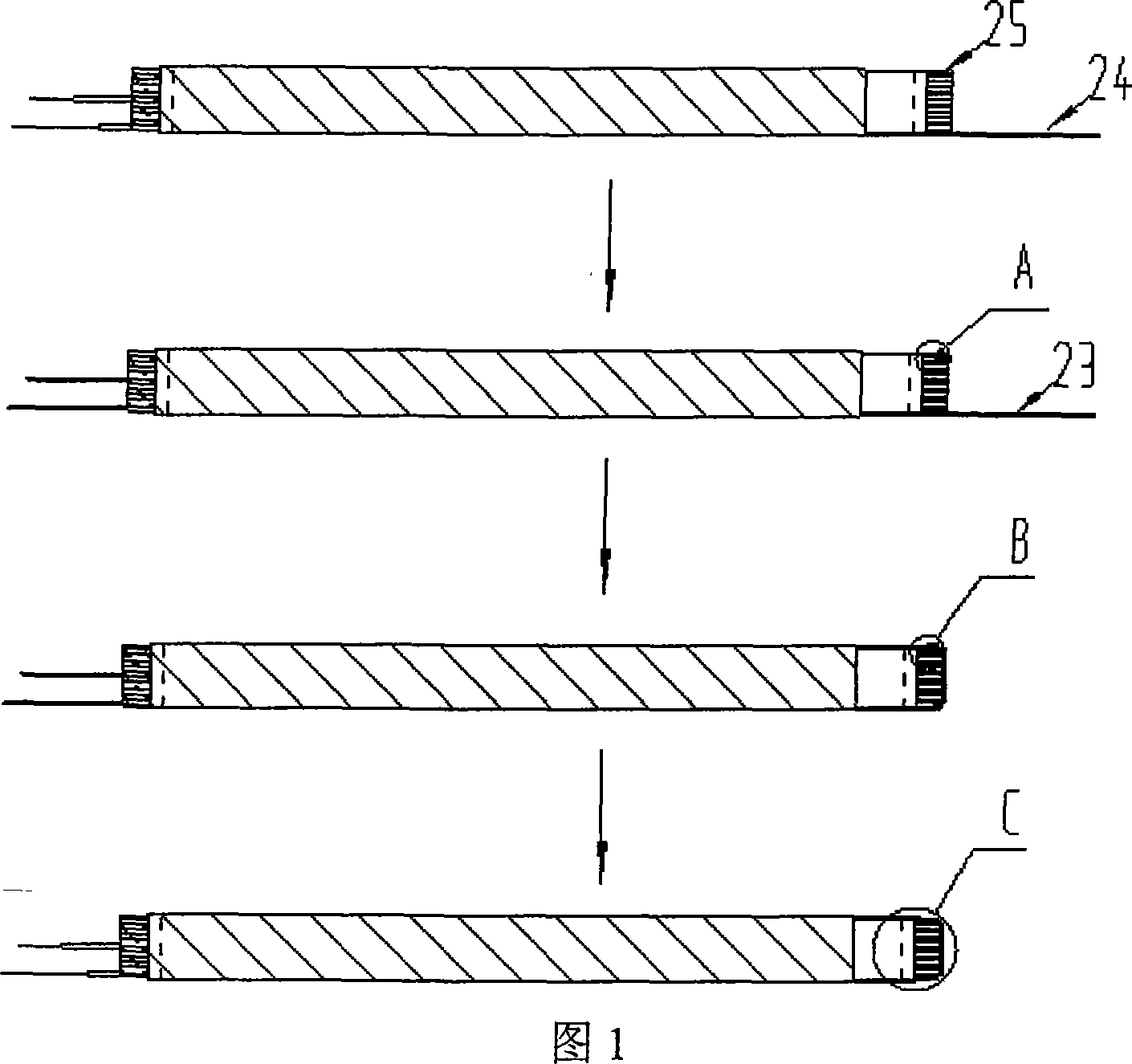

Method for packing the adhesive tape at the bottom of the lithium ion battery coil core and its device

ActiveCN101034763ATape works wellGood effectFinal product manufactureElectrolyte accumulators manufactureAxis cylinderIt equipment

The invention relates to a method to paste adhesive tape on the bottom of lithium ion battery coil core and its equipment, the method has the following steps: (1) according to the general pastes adhesive tape in the coil core base down surface, and parallel press a membrane press axis with 0.5-1 millimeter diameter on the upper surface of the base coil core membrane; (2) turn over the adhesive tape upward which glues on the core base down surface, and wrapping together with the membrane press axis; (3) smoothing draw out the membrane press axis from the one side. The equipment through traction cylinder, encapsulate cylinder and the press axis cylinder separately drive the rolling mechanism, press axis clamping fixture and so on to complete the setting of press axis and extracting press axis. Because of the membrane press axis protection, the membrane of the coil core base and the pole in the ture over upwards processing, the maintenance is good, cannot contusion and up turn, effectively guarantees the battery productquality.

Owner:TIANJIN JUYUAN NEW ENERGY TECH CO LTD

Injury experiment device for simulating brain deceleration injury in traffic accident

InactiveCN109545030AEffective simulationGood repeatabilityCosmonautic condition simulationsSimulatorsInjury causeAxis cylinder

The invention discloses an injury experiment device for simulating a brain deceleration injury in a traffic accident. The device comprises a rack and an acceleration device, a rotating driving device,an experiment box, a simulation track and a deceleration device. The experiment box is arranged on the simulation track. The acceleration device and the deceleration device are arranged at the starting line and the finishing line of the simulation track respectively, the acceleration device is used for driving the experiment box to move on the simulation track, the acceleration device is used fordecelerating the experiment box, and the experiment box is used for fixing an animal needed by an experiment. According to the injury experiment device for simulating the brain deceleration injury inthe traffic accident, the deceleration injury mechanism process can be independently simulated, the diffusible axis cylinder injury causing mechanism process can also be simulated, the brain deceleration injury causing process with the diffusible axis cylinder injury in the traffic accident can be effectively simulated, the repeatability is high, and the experiment result is accurate.

Owner:中国人民解放军陆军特色医学中心

Wheel hub drilling device with accurate positioning

InactiveCN104209552AThe overall structure is simple and reliableThe hole position is accurateWheelsBoring/drilling machinesAxis cylinderHydraulic cylinder

The invention provides a wheel hub drilling device with accurate positioning, and belongs to the field of wheel hub manufacturing equipment. The device comprises a base, wherein a positioning base is arranged on the base; one side of the base is provided with an axis cylinder; a rotating rod sleeves on the axis cylinder; the front end of the rotating rod is provided with a disk; a plurality of holes are formed in the disk; a motor is arranged on the surface of the disk; the motor is connected with a drill to penetrate through the hole on the disk; the front end of the rotating rod is provided with a hydraulic cylinder; a hydraulic rod on the hydraulic cylinder is connected with the disk to stretch the height of the disk so as to be suitable for the wheel hub with different thicknesses. The device is simple and reliable in structure; one drill is aligned with the hole on the wheel hub, the disk is pressed, the other drills begin drilling so as to ensure that the position of the hole on the wheel hub is exact, the positioning is accurate; multiple holes can be processed for the wheel hub, and the efficiency is high.

Owner:安徽省巢湖市宏顺机械铸造有限公司

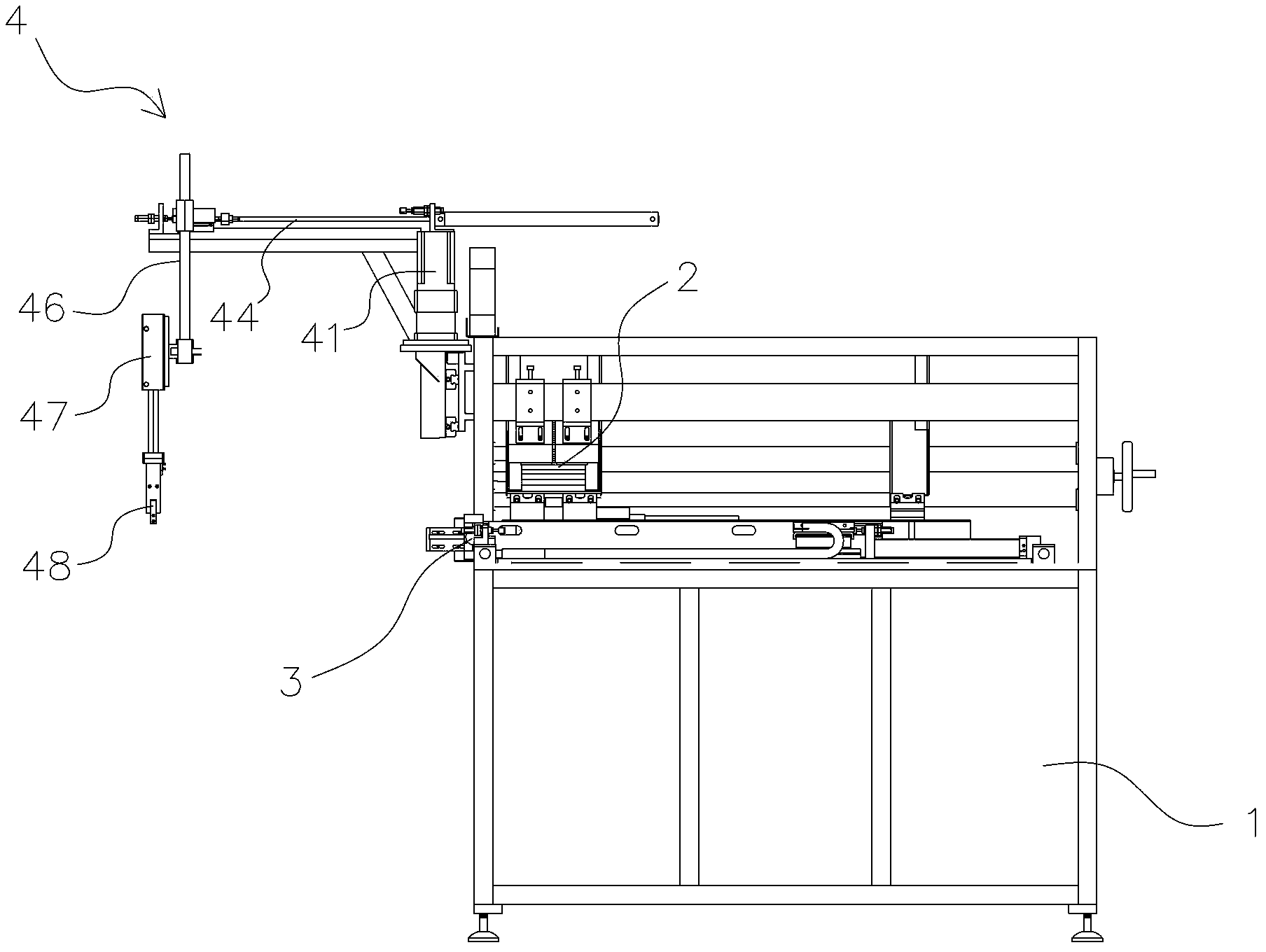

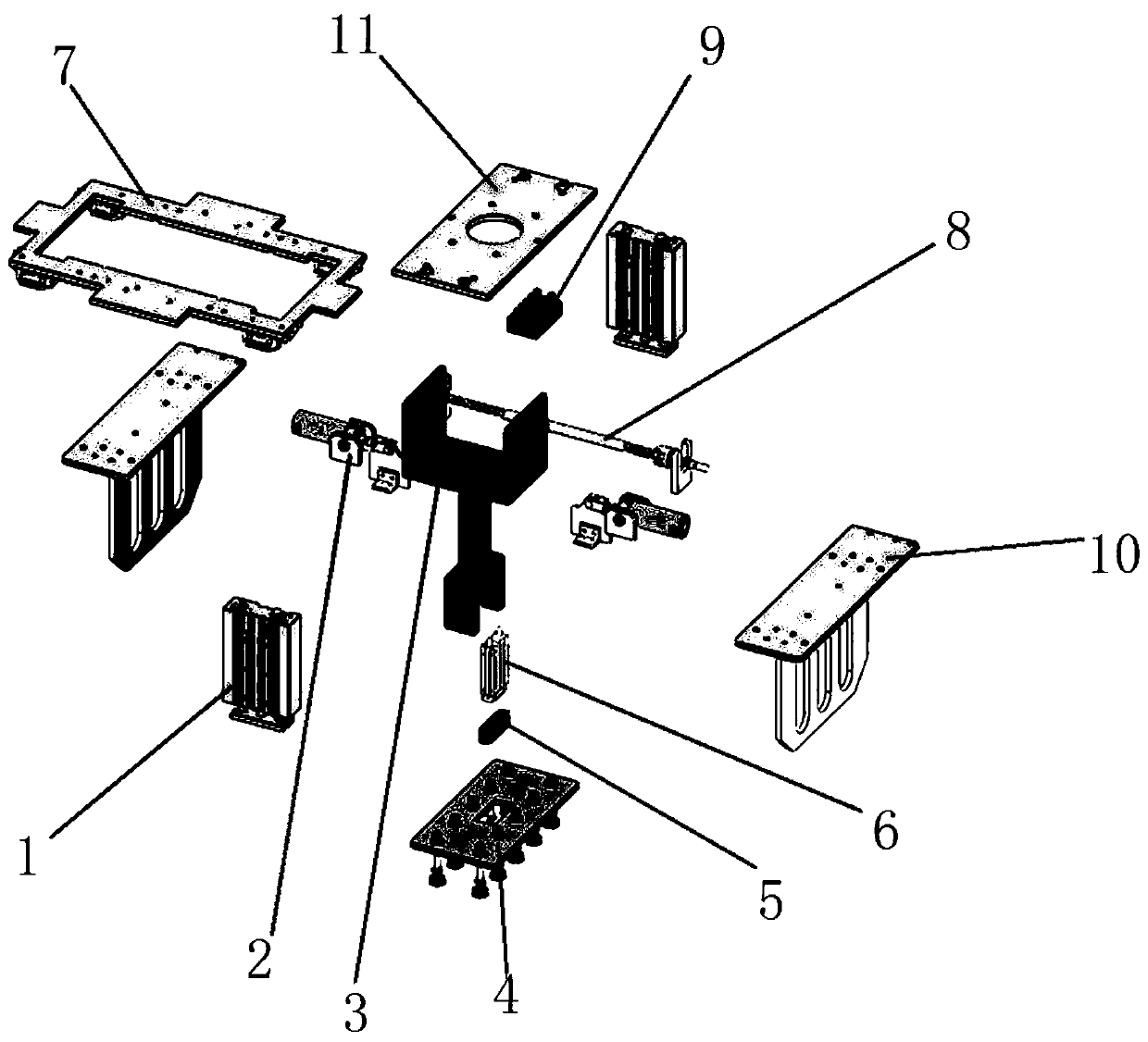

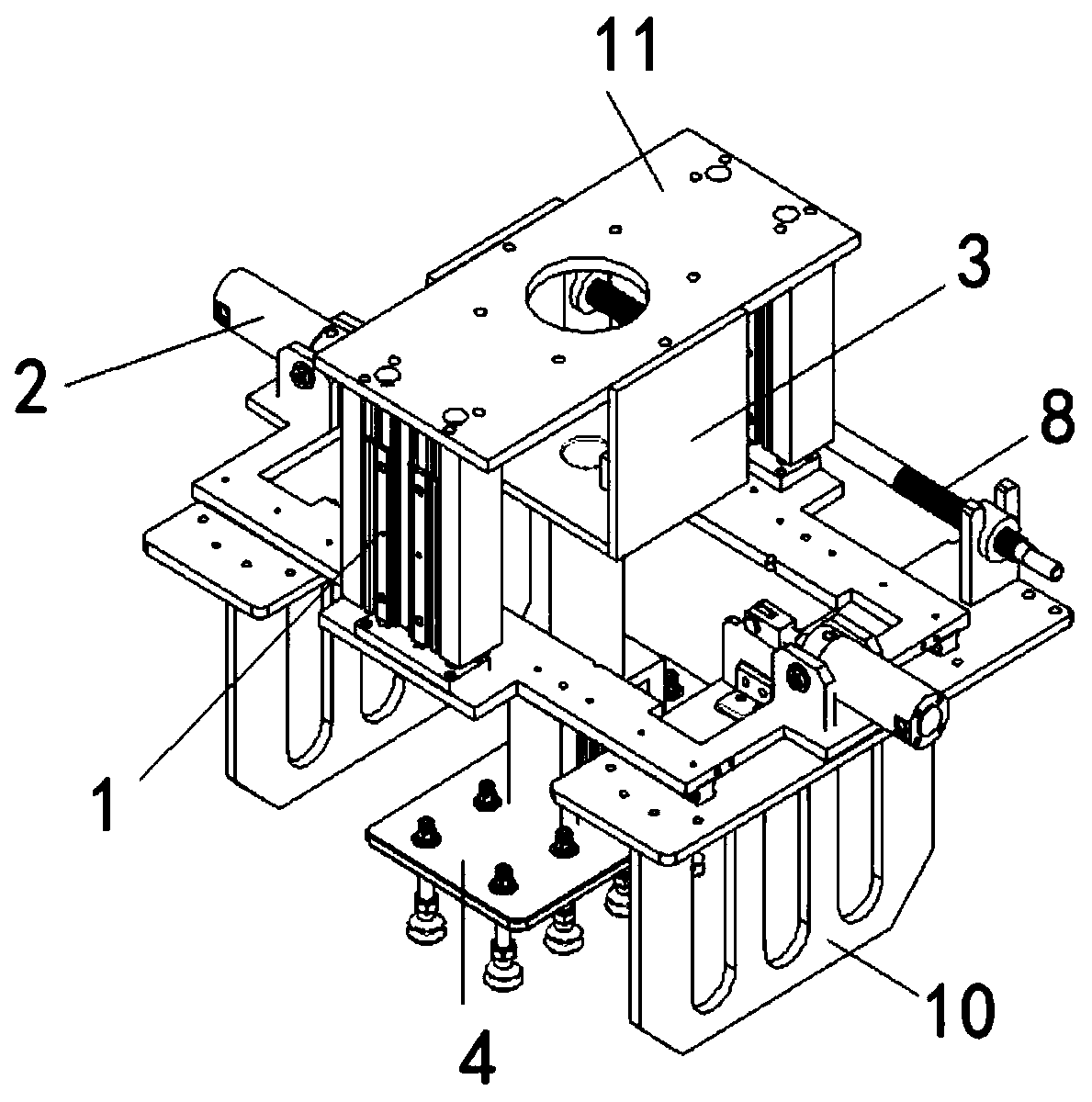

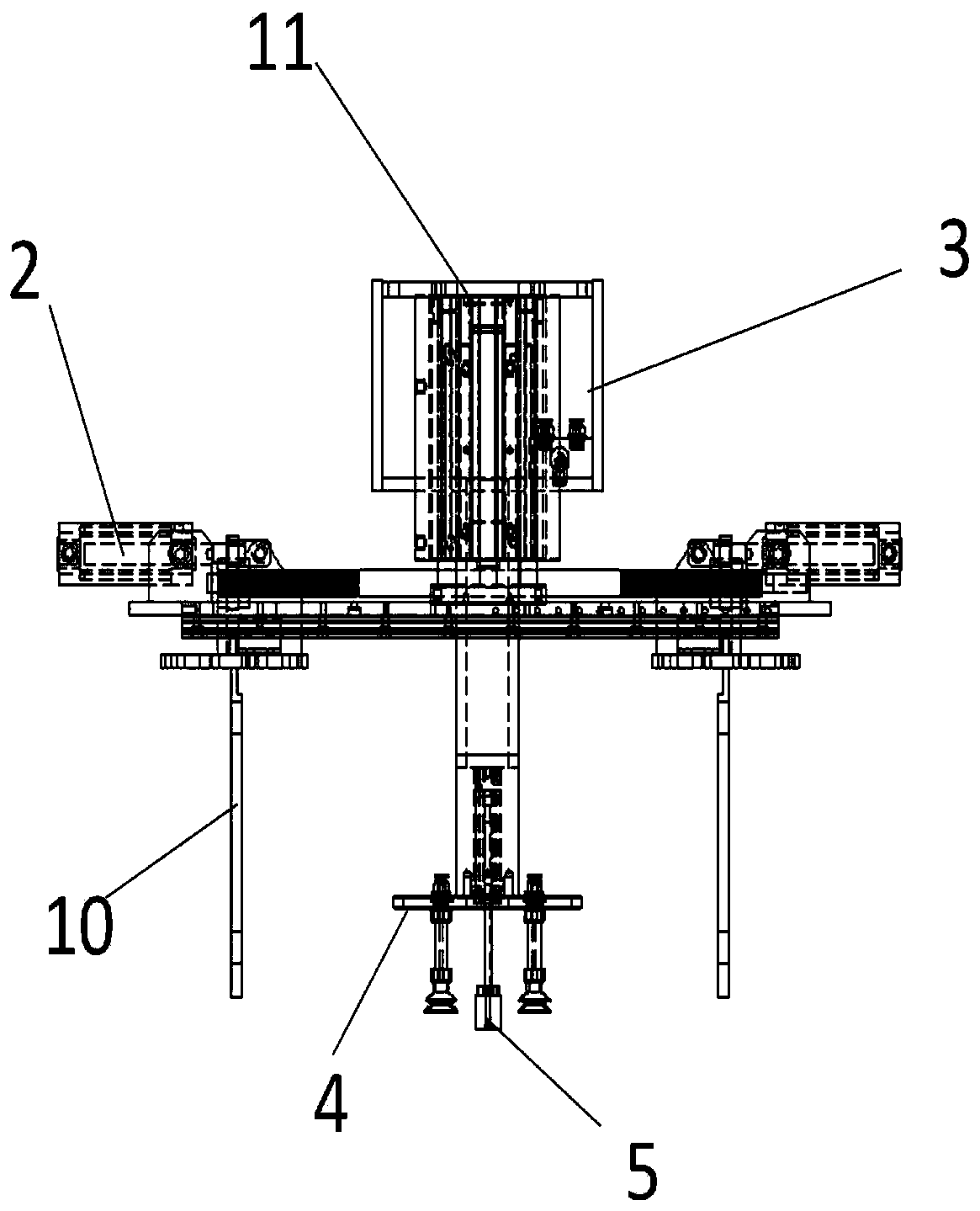

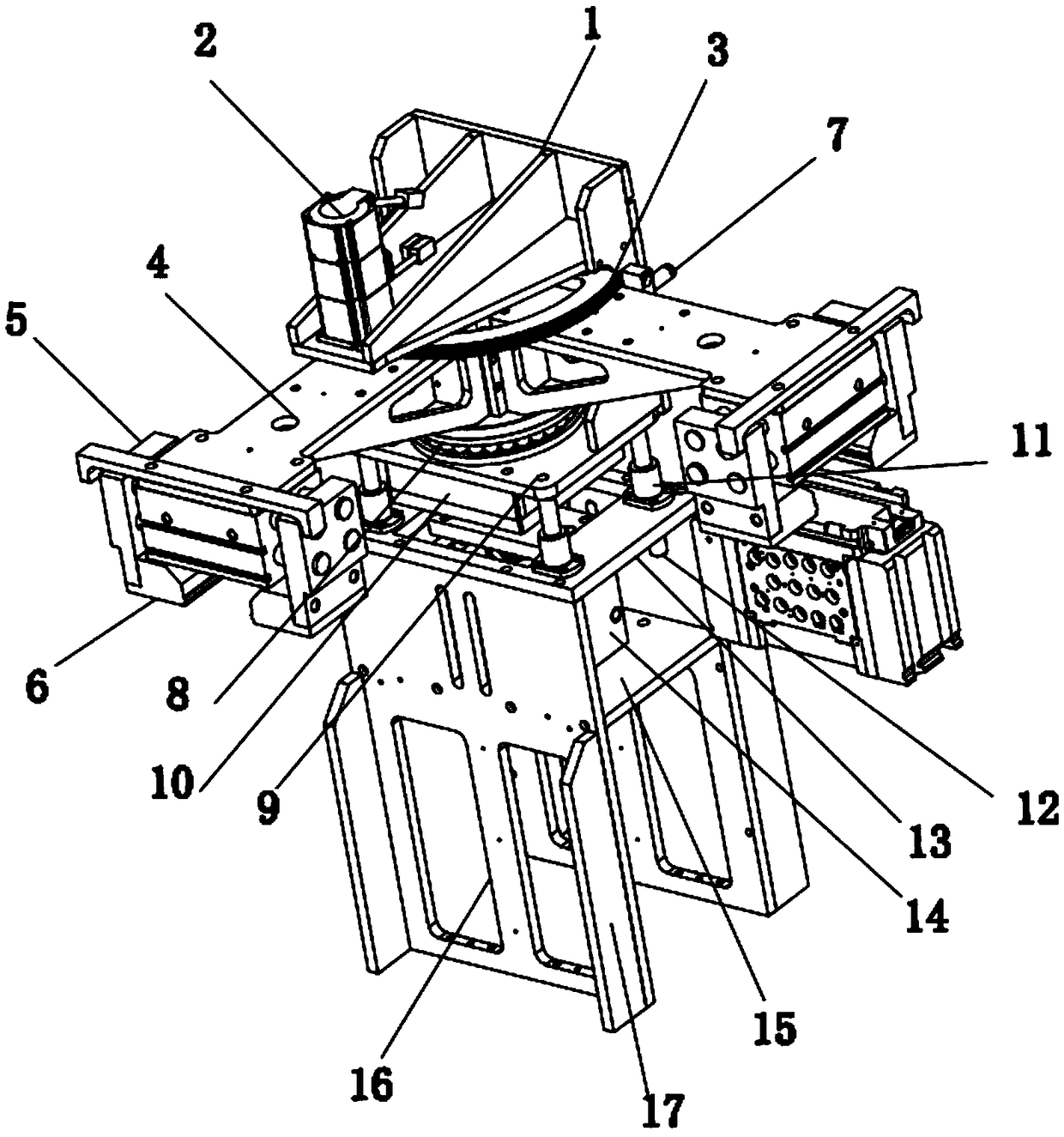

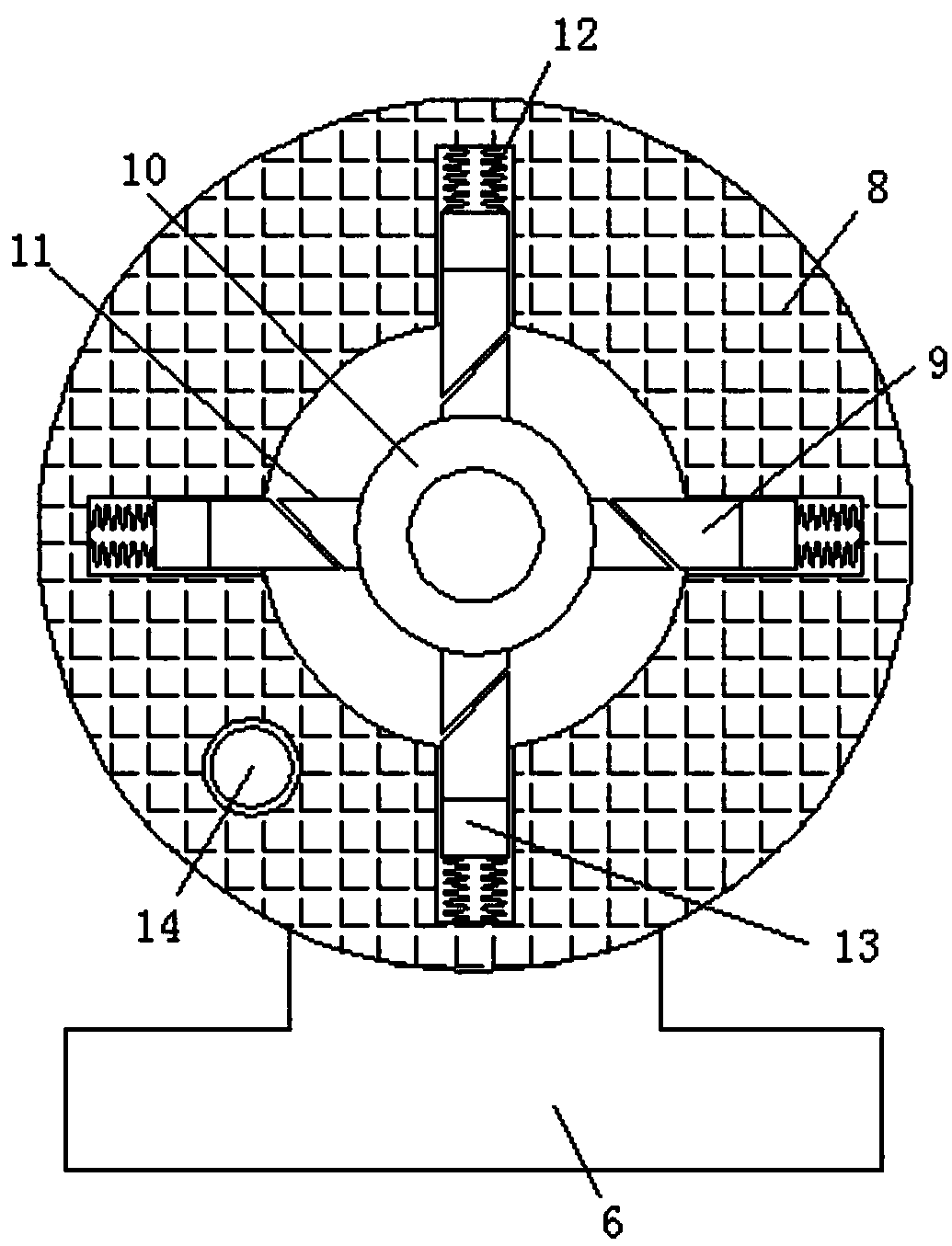

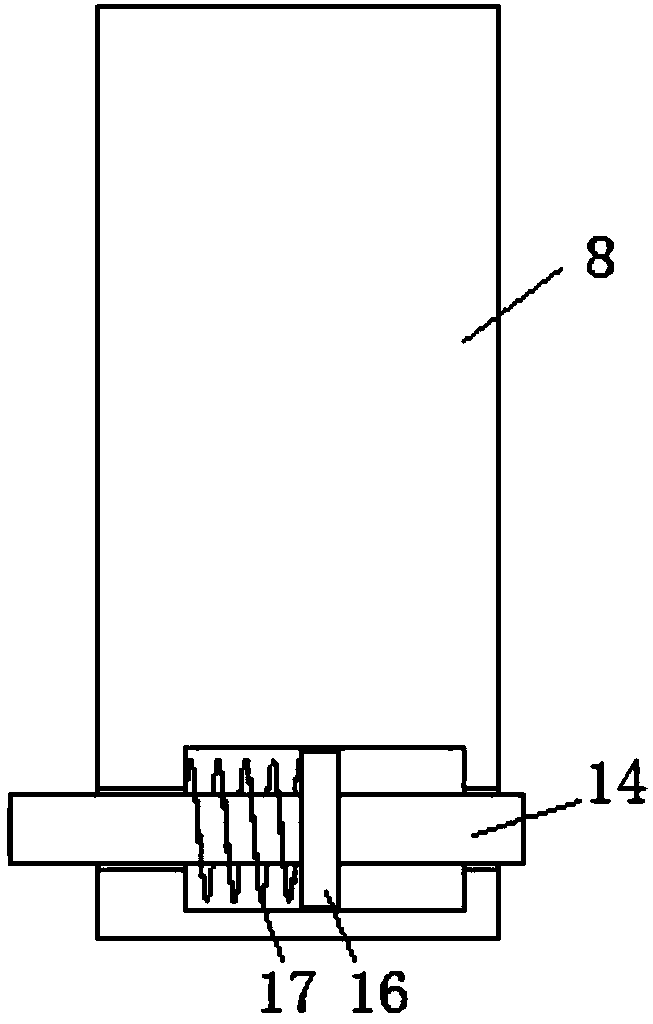

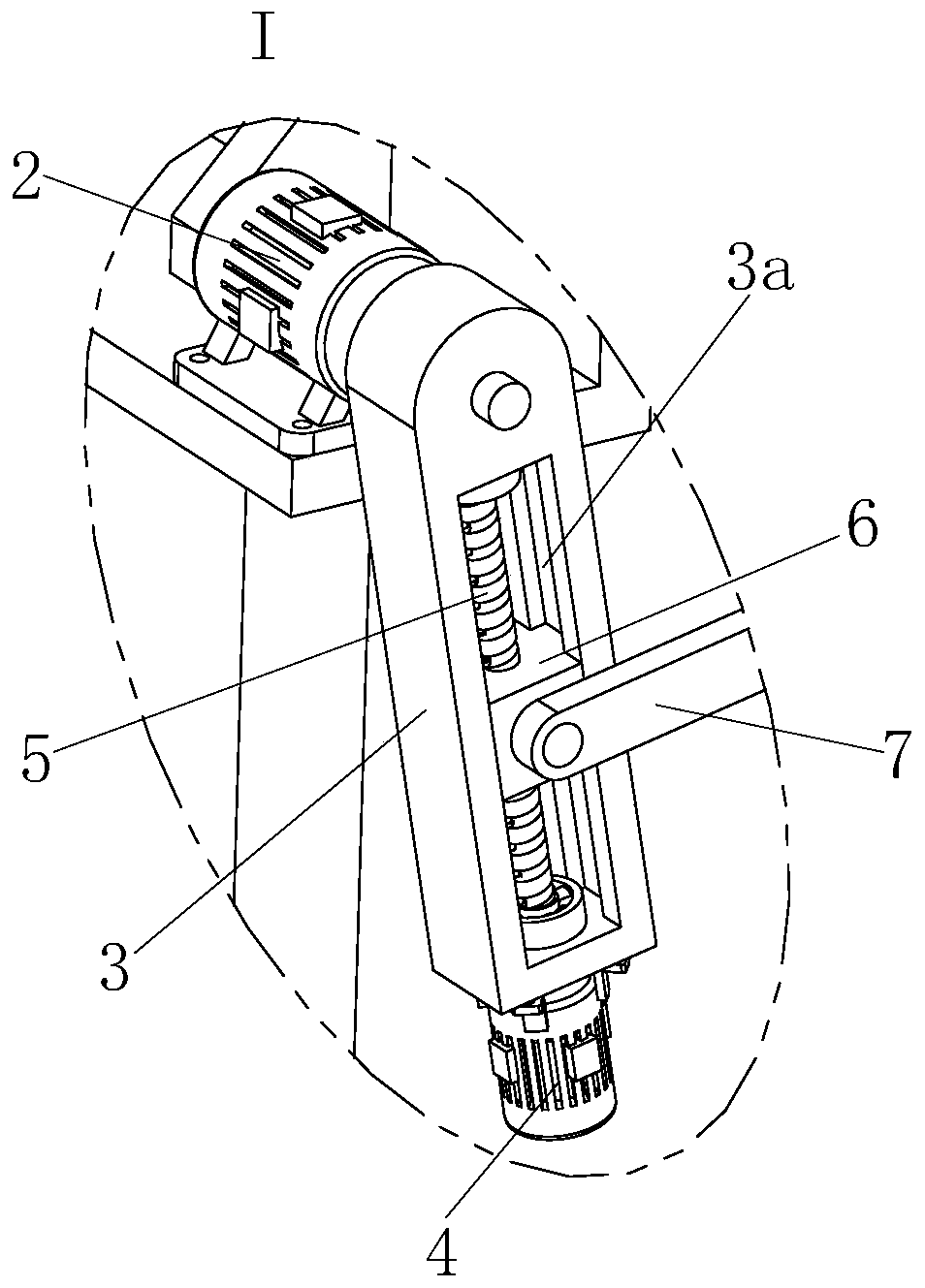

90-degree rotating taking mechanism

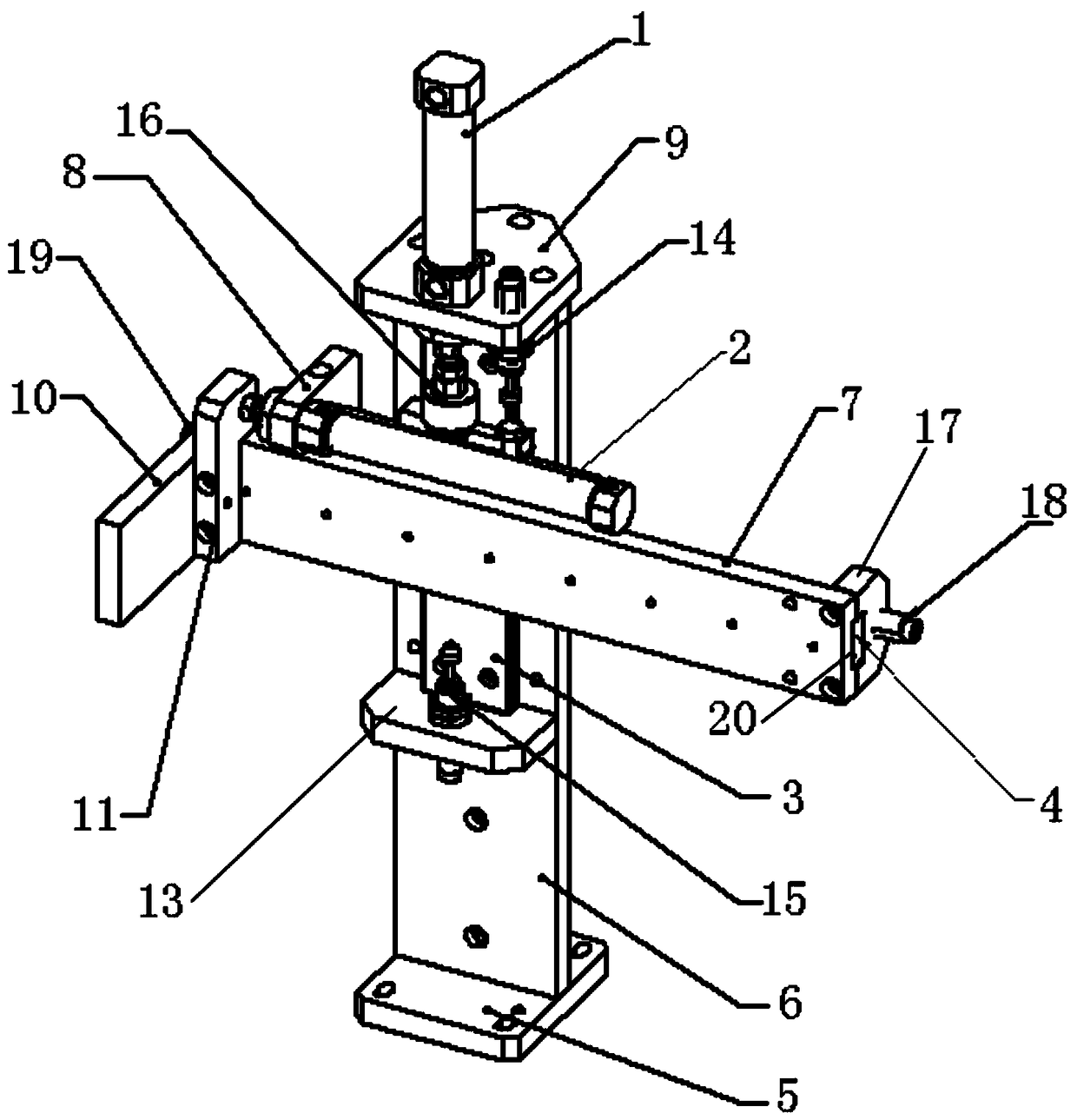

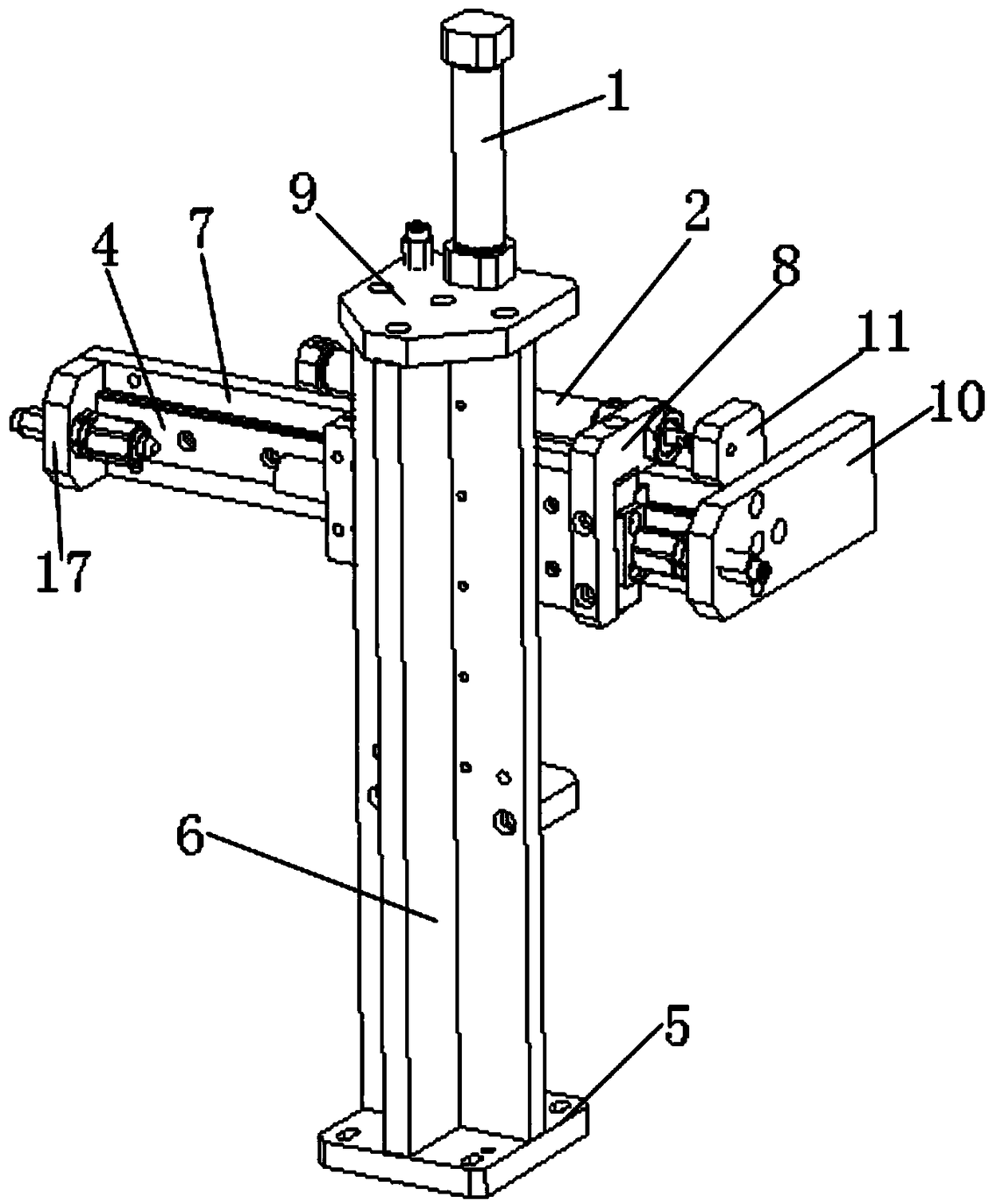

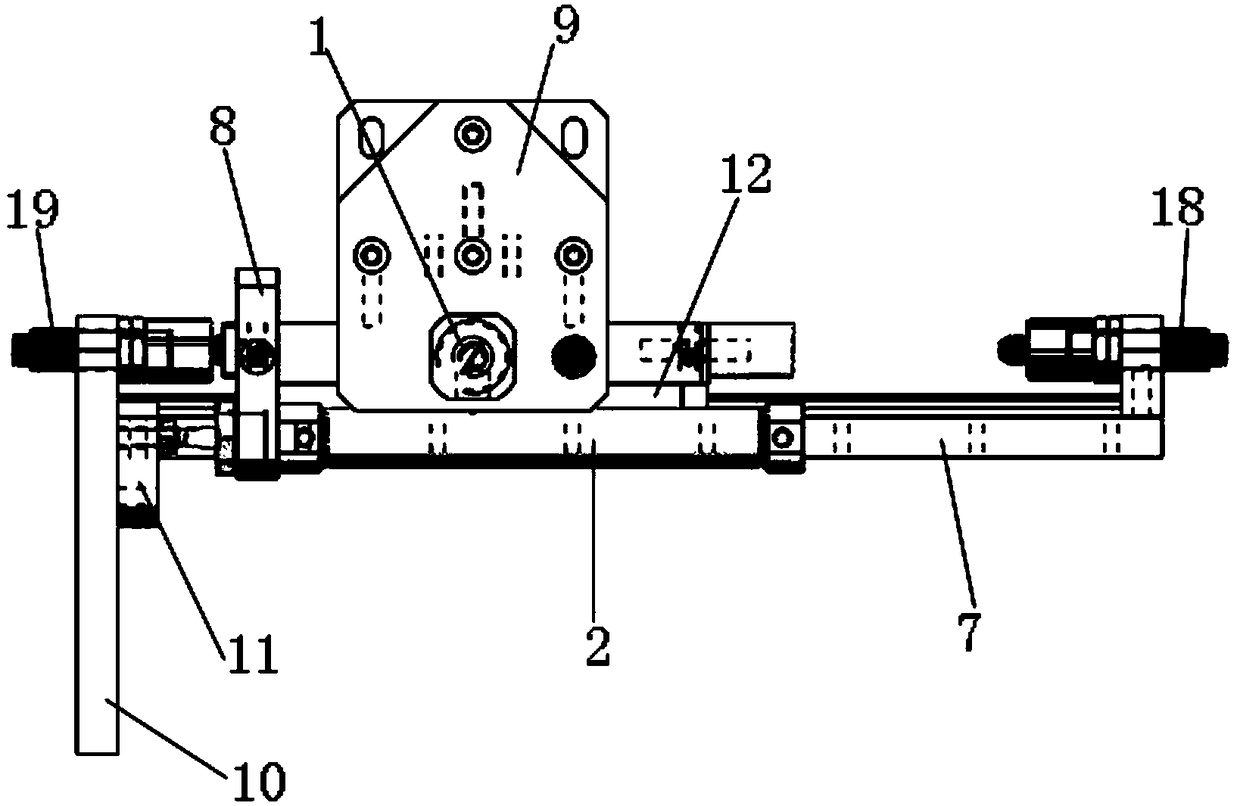

The invention discloses a 90-degree rotating taking mechanism comprising a servo fixing bracket (1), a servo motor (2), 90-degree gears (3), a taking arm assembly (4), a taking clamping jaw cylinder (5), a clamping jaw (6), oil pressure buffers (7), a turntable (8), a turntable fixing plate (9), a three-axis cylinder mounting plate (10), a linear guide sleeve (11), a guide rod (12), a bottom fixing plate (13), a three-axis cylinder (14), a supporting plate (15) and a base side vertical plate (16); and the servo motor is mounted on a servo motor mounting plate, the oil pressure buffers (7) aremounted on the two sides of a bracket vertical plate, and the two 90-degree gears (3) on the left and right are connected with the top of the taking arm assembly (4) to be fixed. The 90-degree rotating taking mechanism is reasonable in structural design, can improve the product clamping efficiency, and can ensure that fully-automated mass production of products is achieved.

Owner:SHENZHEN BOHUITE TECH CO LTD

Electrically conductive structure of micro switch

InactiveUS8772658B2Increased durabilityProlong lifeContacts enclosures/screensAxis cylinderReciprocating motion

An electrically conductive structure of a micro switch capable of letting users know about the reciprocal movement of a switch button, comprising a base, having an electrode module installed in a containing groove formed at the top of the base; an axis cylinder slidably installed in the containing groove; a conical sleeve made of a soft high temperature resisting material and disposed between the axis cylinder and the electrode module; a metal conductive bump formed at the top of the conical sleeve and driven by the axis cylinder to compress and release the conical sleeve to connect and disconnect the electrode module, and the axis cylinder moves reciprocally to produce a hand-pressing feeling, and the containing groove has as sheathe made of a soft high temperature resisting material to block external liquid from entering into the containing groove to improve the service life of the switch.

Owner:CHU CHING HSIUNG

Sample storing apparatus of rubber sample picking machine

Owner:HANKOOK TIRE WORLDWIDE

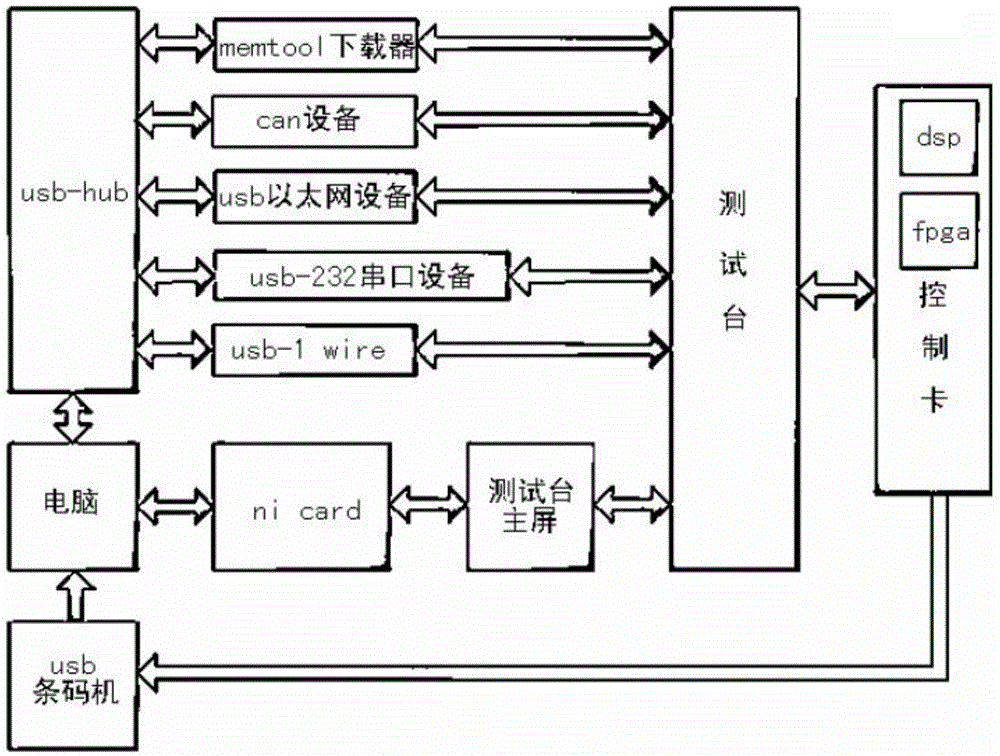

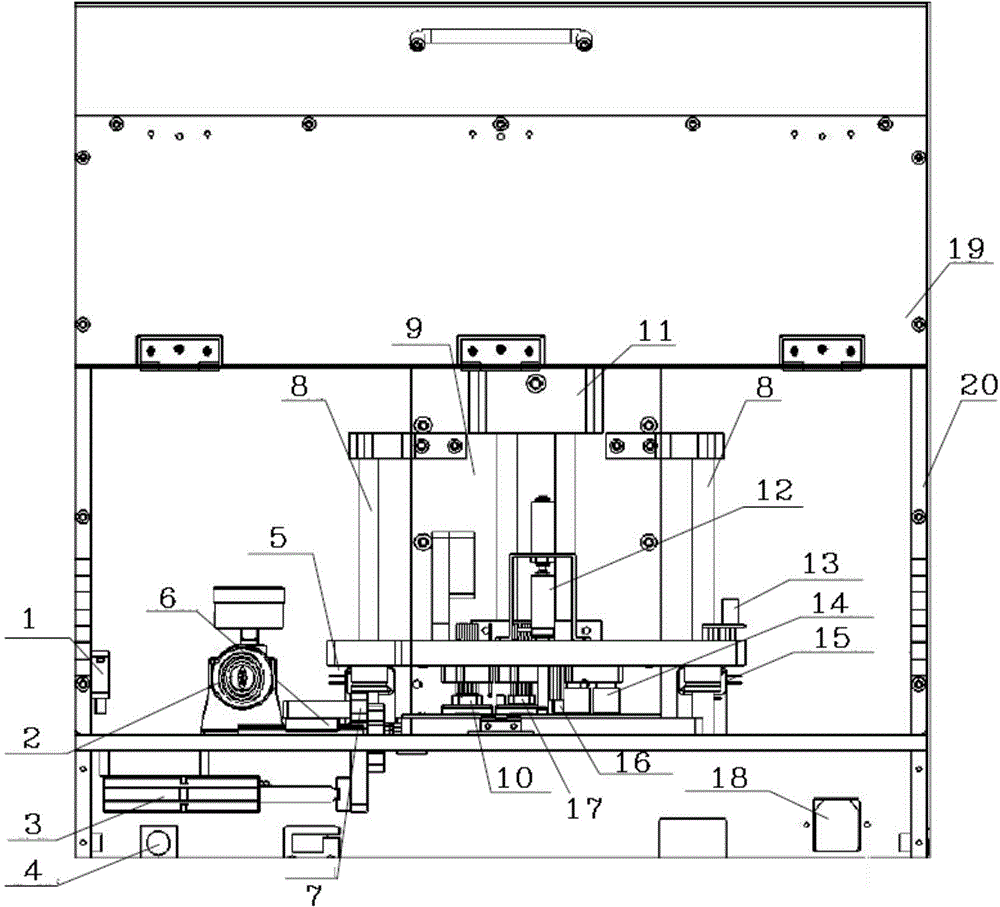

Control card test board

ActiveCN104834304AReduce manual operationsConvenient queryElectric testing/monitoringAxis cylinderSoftware engineering

The invention relates to a control card test board. An upper part of a rack is provided with a safety gate, and the inner side of the rack is a cavity, and is provided with a working bench. One side of the rack on the upper part of the working bench is provided with a safety gate cover detection switch, and the lower part of the side of the working bench close to the safety gate cover detection switch is fixedly provided with an X-axis cylinder. The input end of the X-axis cylinder is communicated with an air pressure input joint, and the output shaft of the X-axis cylinder is connected with an X-axis guide rail sliding block on the upper surface of the working bench, and is fixedly provided with an encoder user port module. The upper part of the working bench corresponding to the output end of the encoder user port module is provided with a supporting rack, which is fixedly provided with an X-axis cylinder rightward position-restricted switch and a Y-axis cylinder downward position-restricted switch. The middle position of the upper part of the rear part of the supporting rack is fixedly provided with a Y-axis cylinder, and the output end of the Y-axis cylinder is connected with a fixing installation bench, which is provided with various modules. The control card test board is advantageous in that the time consumption of the test is less, and the automation of the test can be realized completely, and then the burnout of the products caused by the human errors can be prevented, and therefore all functions can be tested, and the background records can be queried conveniently.

Owner:PHASE MOTION CONTROL NINGBO

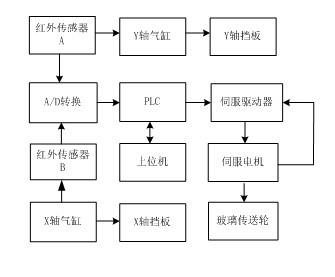

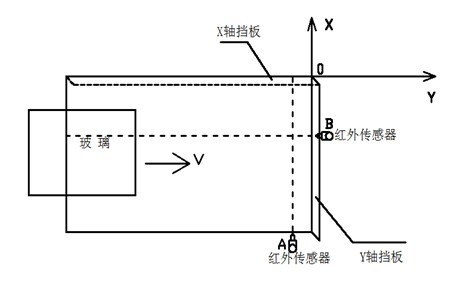

Positioning method used in sandwich glass production process

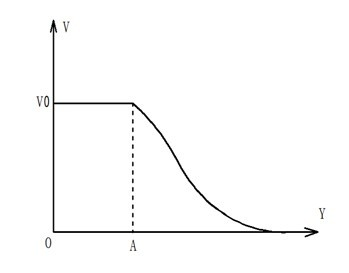

InactiveCN102092966AAutomatic fast and accurate positioningAvoid wastingAxis cylinderProduction line

The invention provides a positioning method used in a sandwich glass production process. The method comprises the following steps of: 1) conveying glass sheets onto a positioning device platform under the traction of a servo driving device; 2) driving the glass sheets to move in the Y axis direction by using the servo driving device, transmitting a signal to the servo driving device by using a sensor, controlling a glass transmission wheel to slow down and stop driving, raising a Y axis baffle plate after a Y axis cylinder receives the signal of the sensor, forcing the glass sheets to stop moving forward through mechanical force, and quickly lowering the Y axis baffle plate to the original place; 3) conveying the glass sheets in the X axis direction in a similar way as the conveying in the Y axis direction except that an X axis baffle plate does not move downwards to the original place; and 4) slowly erecting the Y axis baffle plate, and moving and adjusting the glass sheets in a direction opposite to the direction in the step 2) at the low speed so as to complete secondary positioning in the Y axis direction. The positioning method is applied to a sheet combining process for a sandwich glass production line, so that automatic, quick and accurate positioning of glass sheets is realized, waste of raw materials is avoided, and production cost is lowered.

Owner:GUANGDONG FUSHAN GLASS MACHINERY +1

Polishing device of clutch brake disc of washing machine

ActiveCN108907998AIncrease productivityGuaranteed polishing effectGrinding feed controlGrinding machinesAxis cylinderEngineering

The invention discloses a polishing device of a clutch brake disc of a washing machine, comprising a working base platform, of which the top is fixedly provided with a Z-axis cylinder and a Y-axis cylinder through a bolt; the top of one side of the working base platform is of an L-shaped structure; the Y-axis cylinder is installed in the vertical inner side of the working base platform; a slidingbase is vertically arranged above the working base platform; an output rod of the Y-axis cylinder is fixedly connected with one side of the sliding base; a track wheel is arranged at the bottom side of the sliding base; a track slot is arranged at the top side of the working base platform; the track wheel is slidingly connected in the track slot; an output rod of the Z-axis cylinder is fixedly connected with an L-shaped installation plate; a rotary motor I is installed at the top side of the L-shaped installation plate; and an output shaft of the rotary motor I is fixedly connected with a connecting round bar. The polishing device provided by the invention improves the production efficiency greatly, ensures the polishing effect of the clutch brake disc of the washing machine and meets theusing demands of people in production and life.

Owner:宁国市金泰金属制品有限公司

Magnetic pole detecting machine of linear motor

PendingCN110208694AQuick one-by-one detectionMeet actual testing needsElectrical measurement instrument detailsDynamo-electric machine testingAxis cylinderRange of motion

The invention provides a magnetic pole detecting machine of a linear motor. The detecting machine comprises a carrying platform and a detecting mechanism arranged at the upper side of the carrying platform. The carrying platform moves back and forth between an initial loading position and a detection position below the detecting mechanism. A positioning mechanism for locating a stator of a linearmotor is arranged on the carrying platform. In addition, the detecting mechanism also includes an X-axis electric cylinder, a Z-axis electric cylinder, a Y-axis cylinder and a magnetic pole sensor. The magnetic pole sensor is driven by the Z-axis electric cylinder to move up and down back and forth along the Z axis; the Z-axis electric cylinder and the magnetic pole sensor arranged on the Z-axis electric cylinder are driven by the X-axis electric cylinder to reciprocate left and right; and the Y-axis cylinder drives the carrying platform to reciprocate front and back along a slide rail arranged in a Y-axis direction. The motion range of the magnetic pole sensor covers the area of the positioning mechanism on the carrying platform. With the three-axis detecting mechanism and the magnetic pole sensor, the magnetic poles on the stator of the linear motor can be detected one by one, so that the actual detection requirement of industrial production is met.

Owner:昆山崴乐盟自动化设备有限公司

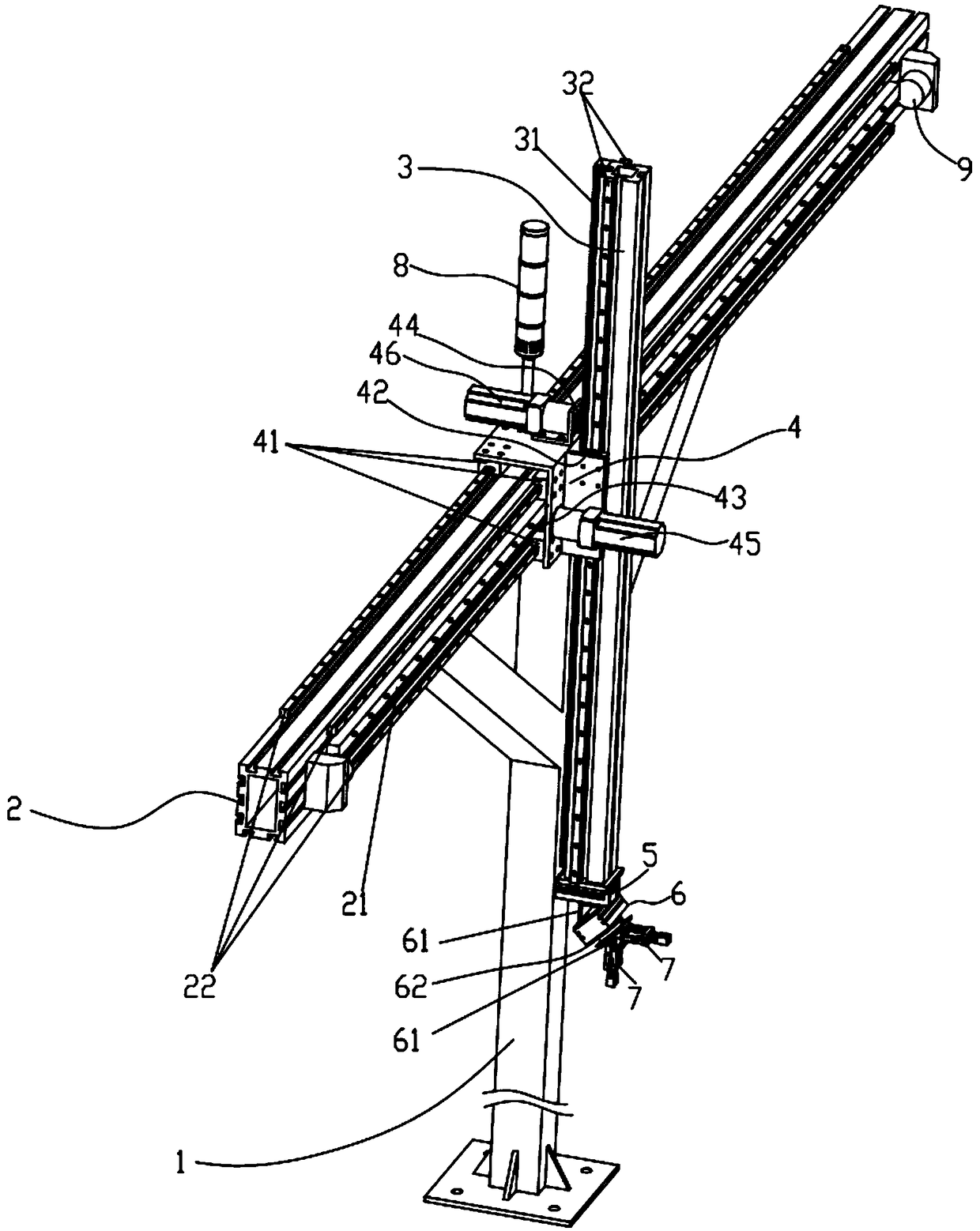

Material carrying truss

The invention relates to the technical field of material carrying, in particular to a material carrying truss. The material carrying truss comprises a stand column, an X-axis truss body, a Z-axis truss body, a moving base, a Y-axis cylinder, a steering base and two cylinder clamping claws; the X-axis truss body is provided with an X-axis rack and an X-axis guide rail; the Z-axis truss body is provided with a Z-axis rack and a Z-axis guide rail; the moving base is provided with an X-axis slider, a Z-axis slider, an X-axis gear, a Z-axis gear, an X-axis motor and a Z-axis motor, so that the moving base can perform X-axis reciprocating movement relative to the X-axis truss body, and the Z-axis truss body can perform Z-axis reciprocating movement relative to the moving base; the Y-axis cylinder is fixed to the end portion of the Z-axis truss body; the two ends of the steering base are each of a right-angle turning-connection structure; the two cylinder clamping claws are fixedly connectedwith the two right-angle sides of the other end of the steering base correspondingly; and a rotating disk mechanism is further arranged in the middle of the steering base. The material carrying trusscan achieve flexible carrying of materials in a three-dimensional space, and is simple and firm in structure, small in occupied space and low in cost.

Owner:广州市轻工高级技工学校

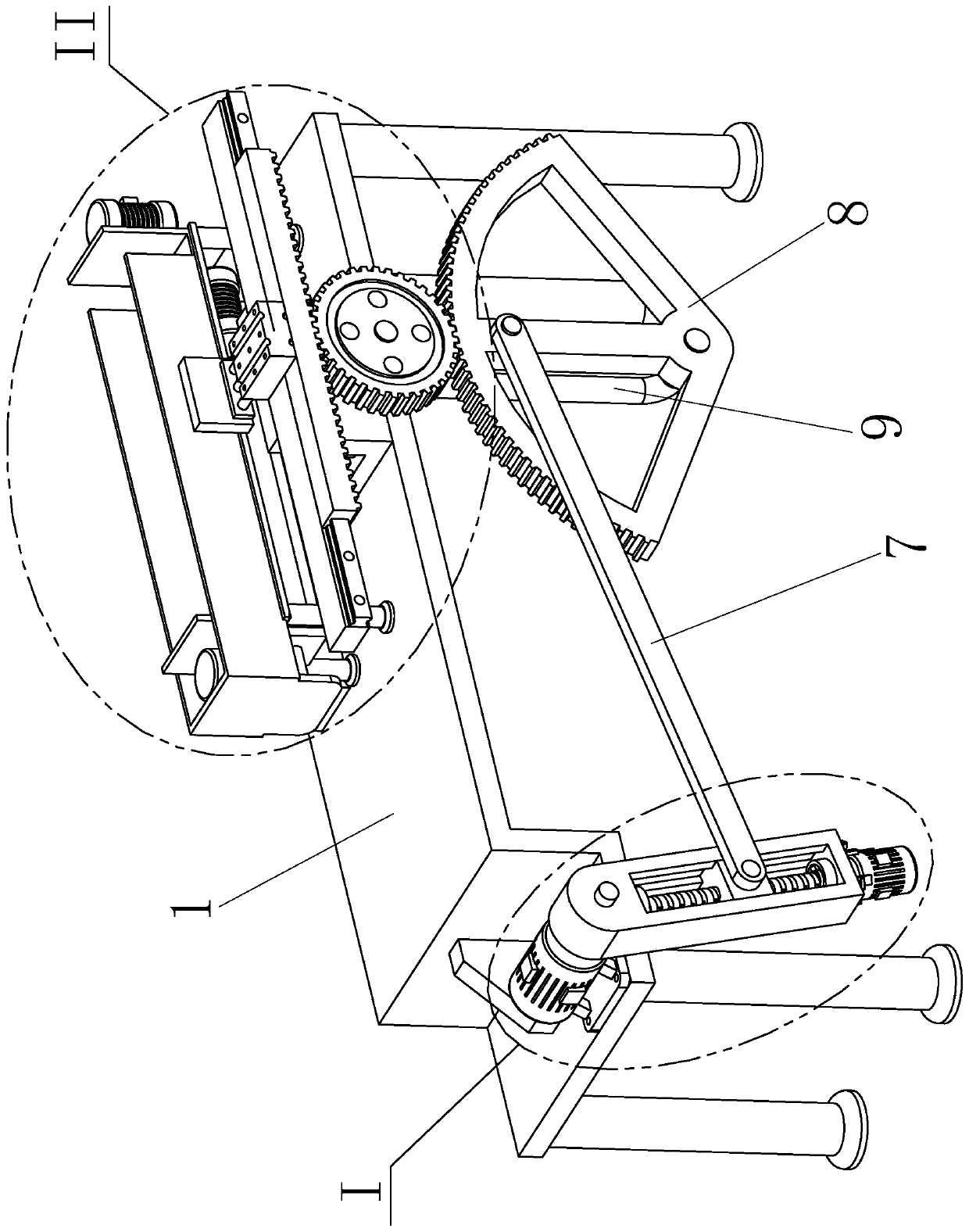

Down feather box packing device

PendingCN110540078ARealize highly automated case loadingEasy to useLoading/unloadingAxis cylinderGear wheel

The invention relates to a down feather box packing device. The down feather box packing device comprises a working table. A motor I is mounted on the left portion of the working table. A U-shaped frame box is mounted on the front side of the right portion of the working table. Packing boxes are arranged on the rear side of the right portion of the working table. The motor is connected with a rocking bar assembly. The rocking bar assembly is connected with a sector gear. The sector gear is engaged with a spur gear. The spur gear is engaged with a rack. A three-axis cylinder is fixedly mountedon the rack. The three-axis cylinder is connected with a push plate. A material control assembly is arranged on the U-shaped frame box. The down feather box packing device is fast and convenient to use. On the basis of vibrating down feathers in the U-shaped frame box, the down feather box packing device controls the three-axis cylinder to do reciprocating sliding in the horizontal direction and automatically pushes down feathers in each area of the U-shaped frame box into the corresponding packing boxes to achieve the high-automation box packing on the down feathers, and manpower is saved a lot relatively.

Owner:安徽文翔羽绒制品有限公司

Dual-axis automatic grabbing manipulator device

The invention discloses a dual-axis automatic grabbing manipulator device and belongs to the technical field of new energy and energy saving. The dual-axis automatic grabbing manipulator device comprises an up-down motion cylinder, a front-back movement cylinder, a Z-axis linear guide rail, an X-axis linear guide rail, a substrate, a substrate supporting plate, an X-axis guide rail fixing plate, an X-axis cylinder fixing plate, a Z-axis upper base plate, a grabbing fixing plate, an X-axis push plate and a sliding block. A Z-axis cylinder and the Z-axis guide rail cooperate to make up-down movement, a Z-axis up-down hydraulic buffer is used for limiting (fine adjustment of the distance is allowed), an X-axis cylinder and the X-axis guide rail cooperate to make front-back movement, an X-axisfront-back hydraulic buffer is used for limiting (fine adjustment of the distance is allowed), and the grabbing work in a fixed area is achieved through cooperation of the Z axis and the X axis. Thedual-axis automatic grabbing manipulator device is suitable for being used in a small space, and by adoption of the thin guide rails, the whole design is fully small, flexible and harmonious in proportion while good rigidity is achieved. The whole device is of a lightweight aluminum structure, so that the weight is light while rigidity of the whole structure is ensured.

Owner:苏州倍科自动化科技有限公司

Automatic arc-shaped grafting clip pushing method

ActiveCN105660196ARealize the role of righting and positioningRealize automatic push and clamp operationHorticultureAxis cylinderMechanical engineering

The invention provides an automatic arc-shaped grafting clip pushing method. The method is characterized by comprising the steps that 1, an arc-shaped grafting clip is horizontally placed on a slideway of sliding blocks by people, a steel wire ring of the grafting clip is supported by the plane of the slideway, and the lower half portion of the head of the grafting clip falls between the two sliding blocks; 2, a seedling final singling component acts firstly, a first double-axis cylinder and a second double-axis cylinder retract to enable two rubber mats to be aligned, a third double-axis cylinder and a fourth double-axis cylinder retract soon after to enable notches in the two rubber mats to be connected, so that seedling final singling is achieved, then the first double-axis cylinder, the second double-axis cylinder, the third double-axis cylinder and the fourth double-axis cylinder restore respectively, and seedling final singling mechanical arms are separated; 3, a push rod component moves forwards under the pushing of a single-axis cylinder, a groove in a push rod head of the push rod component pushes the steel wire ring of the grafting clip, and the oblique surfaces of the two sides of a push rod body and the sliding blocks interact to push the sliding blocks to move leftwards and rightwards; at the moment, acting force is transmitted to a guide slot block by the sliding blocks under the action of a corner, so that the guide slot block moves in a direction opposite to the moving direction of the sliding blocks.

Owner:尚古智造(山东)智能装备有限公司

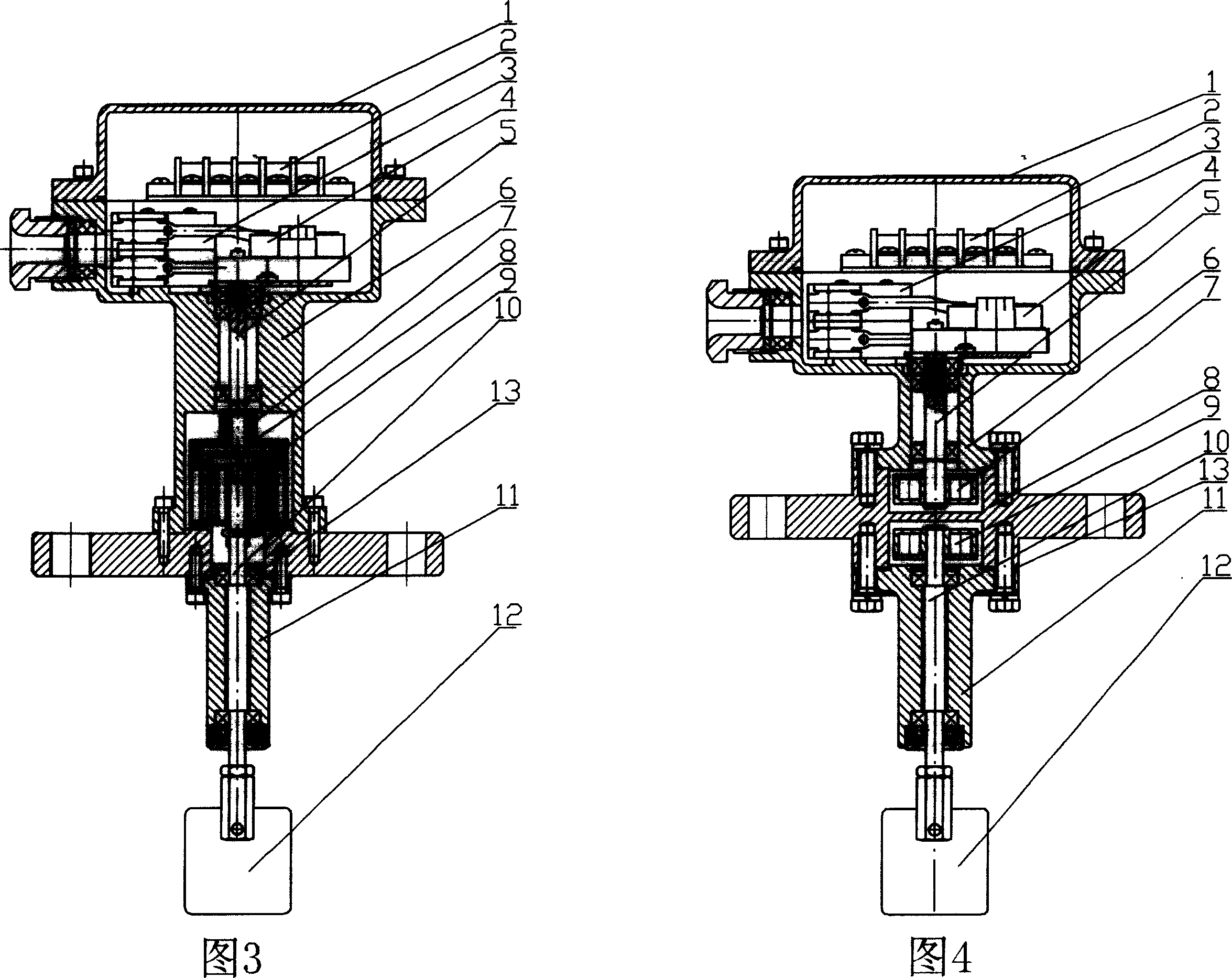

High temperature, high pressure, antistatic type impeding level controller

High-pressure, high-temperature anti-static resistance rotating material level controller relates to a material level controller, and the material level controller includes the cover, the electrical component, the axis A, the base, the drive component I, the separated set flange, the drive component II, the axis B, the axis cylinder, the detection plate component, and the antistatic component. Its cover connects with the base by thread, the electrical component connecting with the end of the axis A, and the drive component I connecting with the other end of the axis A to be fixed, and the drive component I drives the drive component II after the isolation of the separated set flange, the drive component II connecting with the end of the axis B to be fixed, and the axis cylinder is fixed on the separated set flange through bolt, the other end of the axis B connecting with the detection plate component, and between the axis cylinder and the separated set flange, there is the antistatic component. The invention is suitable for upper and lower threshold alarm of silo or dust clean equipment in the metallurgical, chemical, mining, power, road, food and environmental industries, with the characteristics of resisting high-temperature, high-pressure and antistatic.

Owner:张明

Mahjong automatic painting machine

InactiveCN105750160AImprove efficiencyLabor savingLiquid surface applicatorsCoatingsAxis cylinderEngineering

The invention relates to the technical field of automatic painting devices, in particular to a mahjong automatic painting machine which comprises a rack.A first working table and a second working table are arranged on the rack, a first transverse limiting block and a first longitudinal limiting block are arranged on the first working table, a second transverse limiting block and a second longitudinal limiting block are arranged on the second working table, a first Y-axis guide rod and a second Y-axis guide rod are arranged on two sides of the rack in Y-axis directions respectively and driven by a Y-axis motor, a first X-axis support is arranged on the first Y-axis guide rod, a second X-axis support is arranged on the second Y-axis guide rod, a first X-axis guide rod is arranged on the first X-axis support, a second X-axis guide seat is arranged on the second X-axis support, an X-axis guide rod is arranged between the first X-axis guide seat and the second X-axis guide seat and driven by an X-axis motor, an X-axis screw rod guide seat is arranged on the X-axis guide rod, a Z-axis cylinder is arranged on the X-axis screw rod guide seat, and a nine-gun box is arranged on the Z-axis cylinder.The mahjong automatic painting machine realizes automatic painting and is high in efficiency.

Owner:东莞市铭威机器人技术有限公司

Efficient stacker crane used inside van type truck

PendingCN108423444ASolve the difficulty of not being able to fill the vanAvoid difficultiesStacking articlesDe-stacking articlesAxis cylinderVehicle frame

The invention discloses an efficient stacker crane used inside a van type truck. The efficient stacker crane comprises a frame, return pulleys, a servo motor, a feeding device, a non-power roller, a feeding sliding rail, a conveying device, an X-axis beam, an X-axis cylinder, an X-axis rail, an X-axis roller, a lifting portable frame and a discharging device, wherein the return pulleys and the servo motor are fixed at the bottom of the frame, the feeding device is connected with the frame through the feeding sliding rail, the non-power roller is mounted on the inner side of the bottom of the frame, the X-axis beam is embedded into a groove of the frame, the X-axis cylinder drives the X-axis beam to slide relative to the frame, the feeding device slides on the X-axis rail on the X-axis beamthrough the X-axis roller, the lifting portable frame is fixed at the front end of the frame, and the discharging device is mounted on the lifting portable frame. According to the efficient stacker crane, positions are adjusted through a PLC (programmable logic controller) control system, so that the efficient stacker crane can solve the problem that a van type truck cannot be fully filled by a current stacker crane.

Owner:QINGDAO UNIV OF SCI & TECH

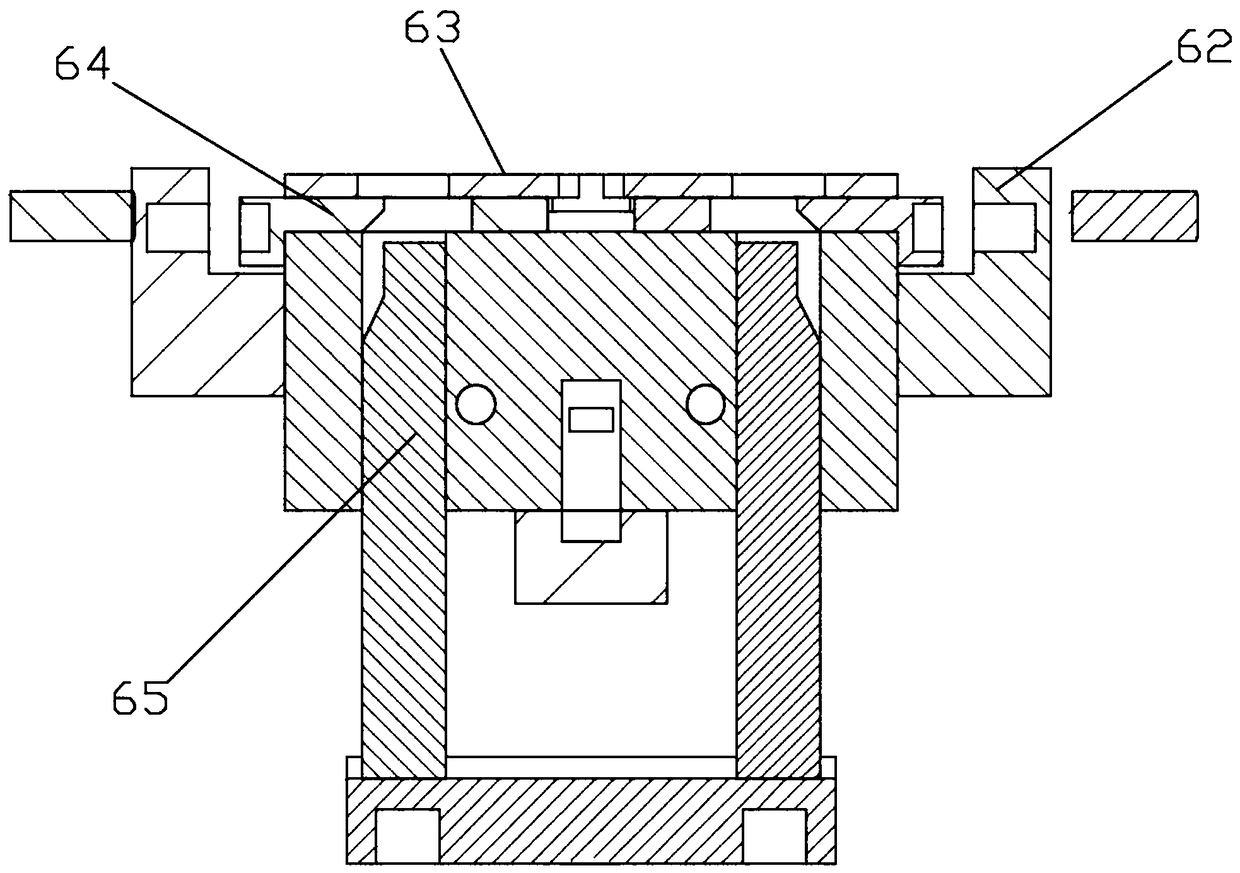

Mechanism for sleeving valve body with O-ring

InactiveCN109015518AImprove assembly efficiencyImprove assembly stabilityMetal-working hand toolsAxis cylinderSleeve valve

The invention relates to the field of ferrule assembly mechanisms, in particular to a mechanism for sleeving a valve body with an O-ring. The mechanism comprises a frame, a vibration plate, a flow channel, a two-axis mechanical arm, an O-ring expansion mechanism and an O-ring ejection mechanism, wherein the frame is equipped with the two-axis mechanical arm and the O-ring ejection mechanism, and an X-axis cylinder of the two-axis mechanical arm is fixed on the frame, and a Y-axis moving end of the two-axis mechanical arm is fixedly provided with the O-ring expansion mechanism for picking up and expanding the O-ring, and the O-ring expansion mechanism is located at the O-ring ejection mechanism. The flow channel on the vibration plate is connected to the O-ring ejection mechanism. The invention adopts the ejection mechanism to sequentially eject the O-rings transmitted from the flow channel one by one, and cooperates with the expansion mechanism through the two-axis mechanical arm to pick the O-ring that is ejected and expand the O-ring, and then sleeves the valve body with the O-ring, thus completing the assembly, and improving the assembly efficiency and stability of the valve body and the O-ring.

Owner:苏州博鲁克机器人系统工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com