Polishing device of clutch brake disc of washing machine

A polishing device and clutch technology, which are applied in the directions of grinding machine parts, grinding/polishing equipment, and workpiece feed motion control, can solve problems such as low work efficiency and poor polishing effect, and achieve guaranteed and fixed effects. Plus, the effect of less number of position adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

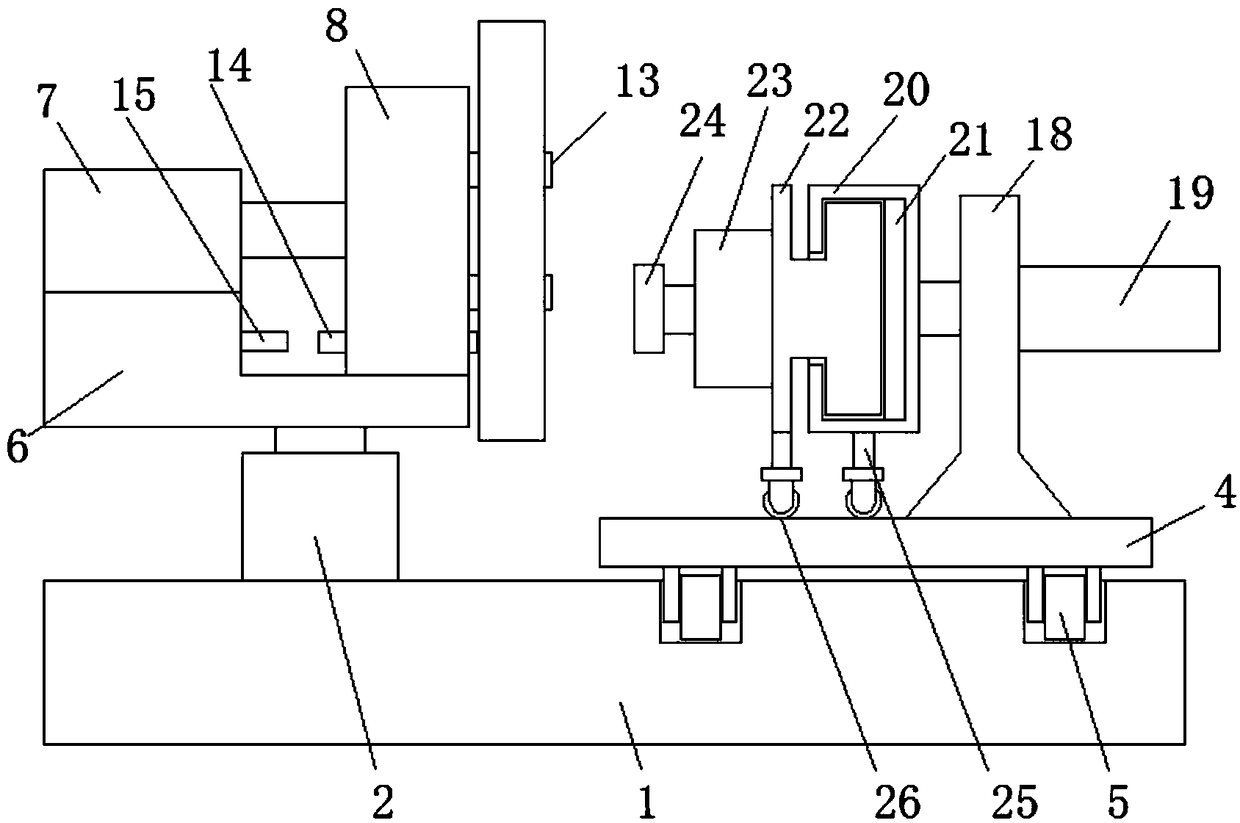

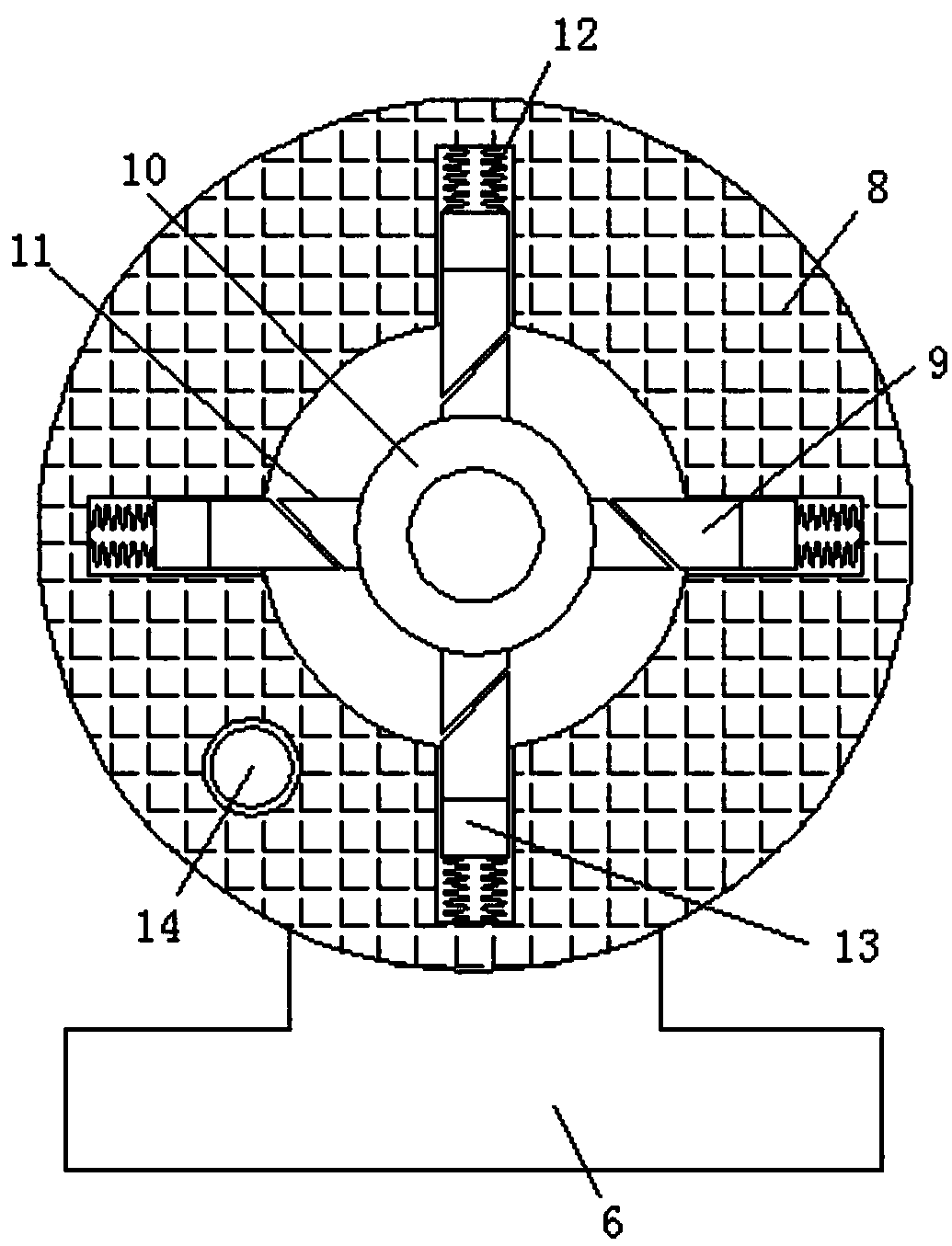

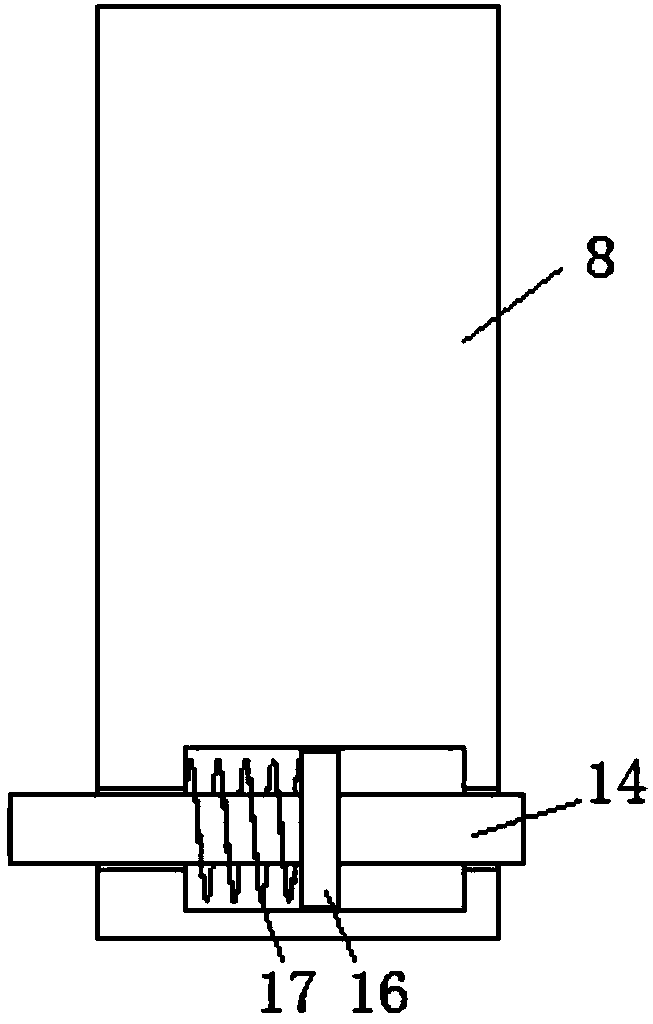

[0026] refer to Figure 1-4 , a washing machine clutch brake disc polishing device, including a working base 1, the top of the working base 1 is fixed with a Z-axis cylinder 2 and a Y-axis cylinder 3 by bolts, and the top of one side of the working base 1 is an L-shaped structure , and the Y-axis cylinder 3 is installed on the vertical inner side of the working base 1, and a sliding seat 4 is arranged vertically above the working base 1. The output rod of the Y-axis cylinder 3 is fixedly connected to one side of the sliding seat 4, and the sliding The bottom side of the seat 4 is provided with a track wheel 5, and the top side of the working base 1 is provided with a track groove, the track wheel 5 is slidably connected in the track groove, and the output rod of the Z-axis cylinder 2 is fixedly connected with an L-shaped mounting plate 6. The top side of the shape mounting plate 6 is equipped with a rotating motor-7, and the output shaft of the rotating motor-7 is fixedly conn...

Embodiment 2

[0028] Such as figure 1 with figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the grinding mechanism includes a Y-shaped mounting plate 18, which is fixedly installed on the top side of the sliding seat 4, and one part of the Y-shaped mounting plate 18 The X-axis cylinder 19 is fixedly installed on the side by bolts, and the output rod of the X-axis cylinder 19 is fixedly connected with the connecting cylinder 20. The side of the connecting cylinder 20 close to the clamp rod 13 is provided with a T-shaped groove, and the vertical of the T-shaped groove is A pressure sensor 21 is fixedly installed on the inner wall of one side, and an I-shaped mounting plate 22 is arranged in the T-shaped groove, and one end of the I-shaped mounting plate 22 extends to the side of the connecting cylinder 20 close to the clamp rod 13 and is fixedly installed with a second rotating motor. 23, the output shaft transmission of rotating motor two 23 is provided...

Embodiment 3

[0030] Such as figure 1 with figure 2 As shown, this embodiment is basically the same as Embodiment 1 or Embodiment 2. Preferably, auxiliary support rods 25 are fixedly welded to the bottom sides of the connecting cylinder 20 and the I-shaped mounting plate 22, and the bottom of the auxiliary support rods 25 Universal wheels 26 are provided at both ends, and the connecting cylinder 20 and the I-shaped mounting plate 22 are auxiliary supported respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com