Patents

Literature

20585results about "Grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

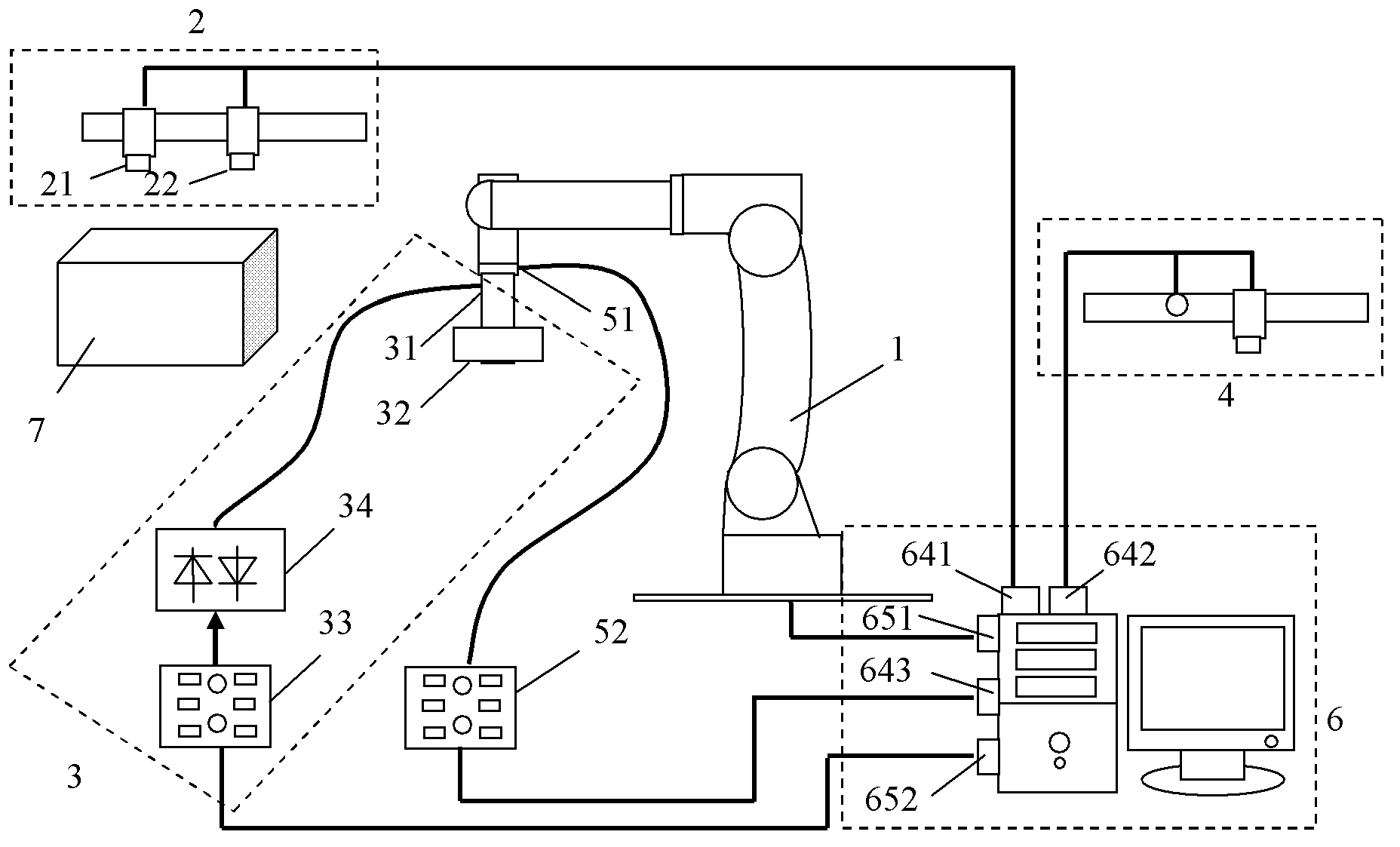

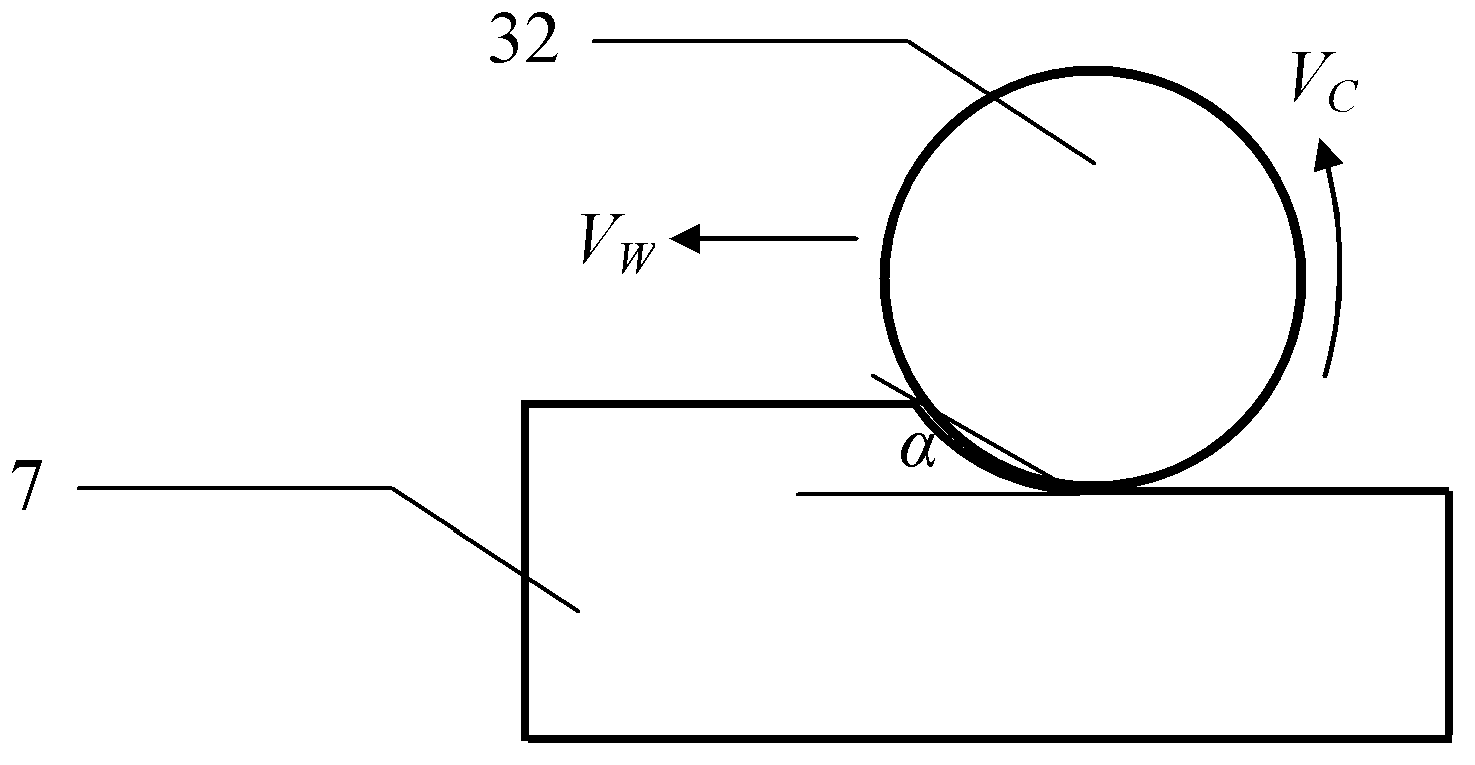

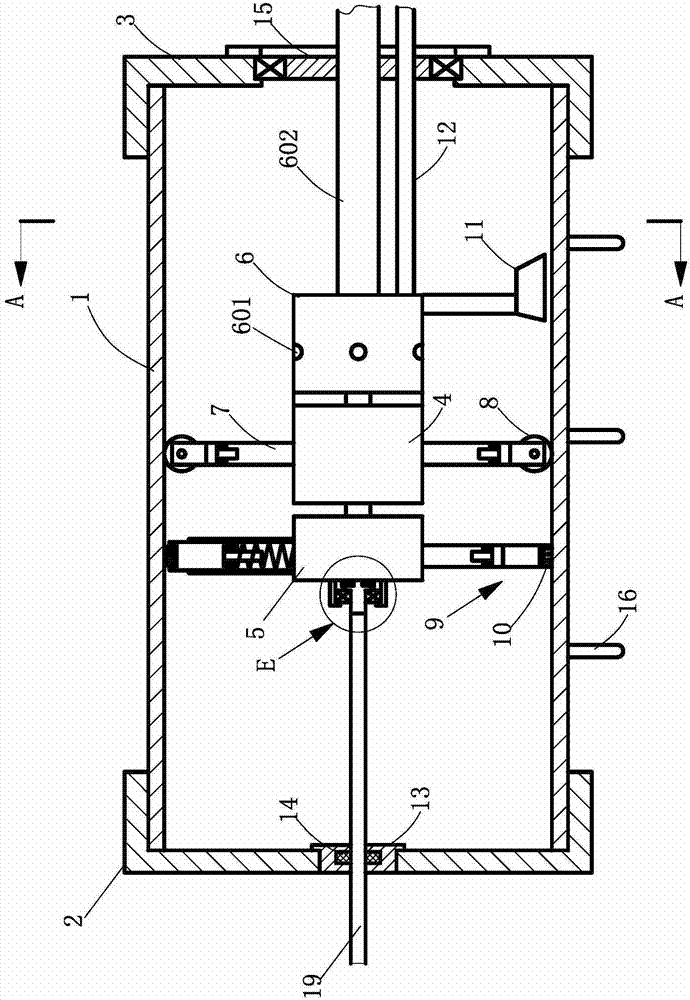

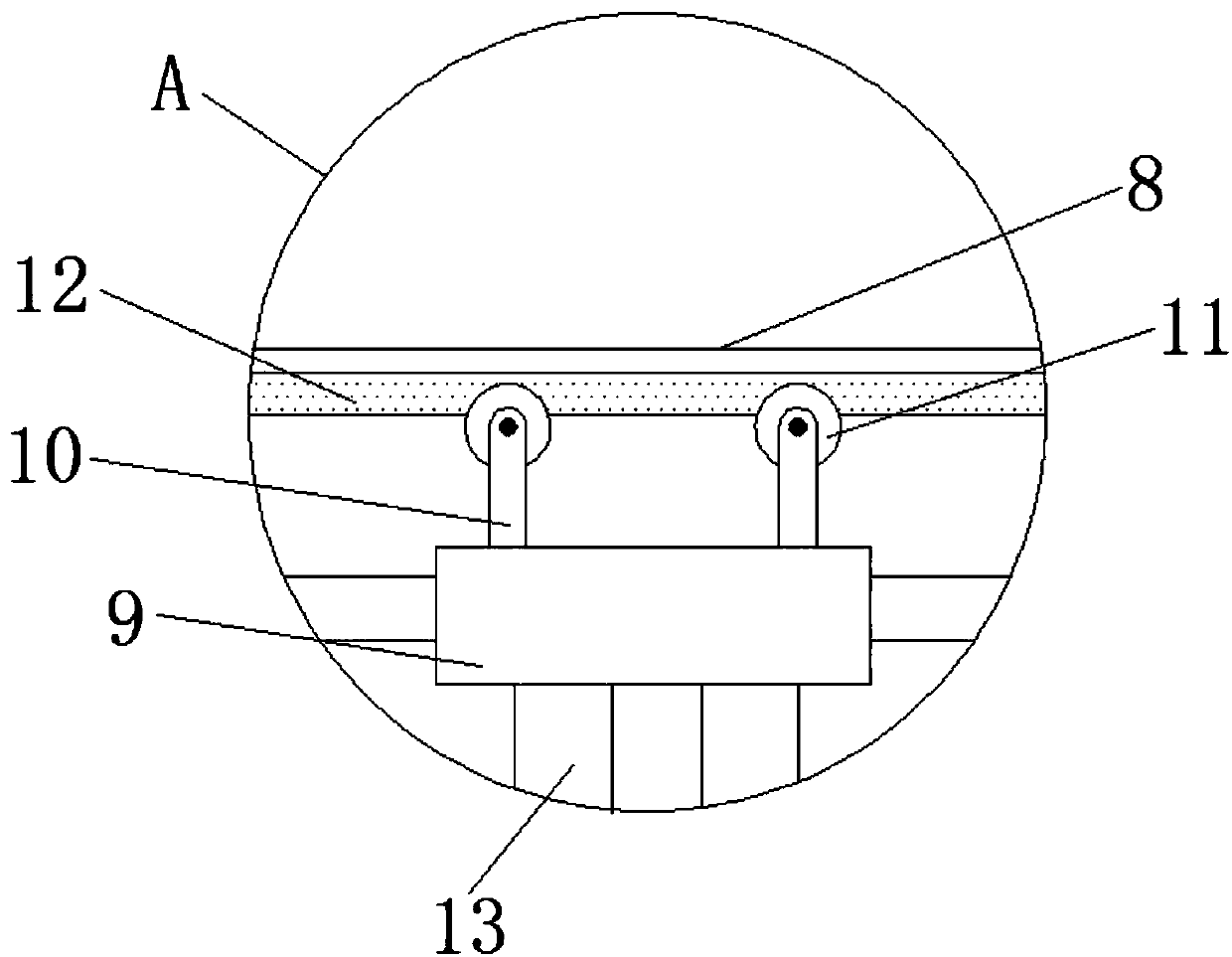

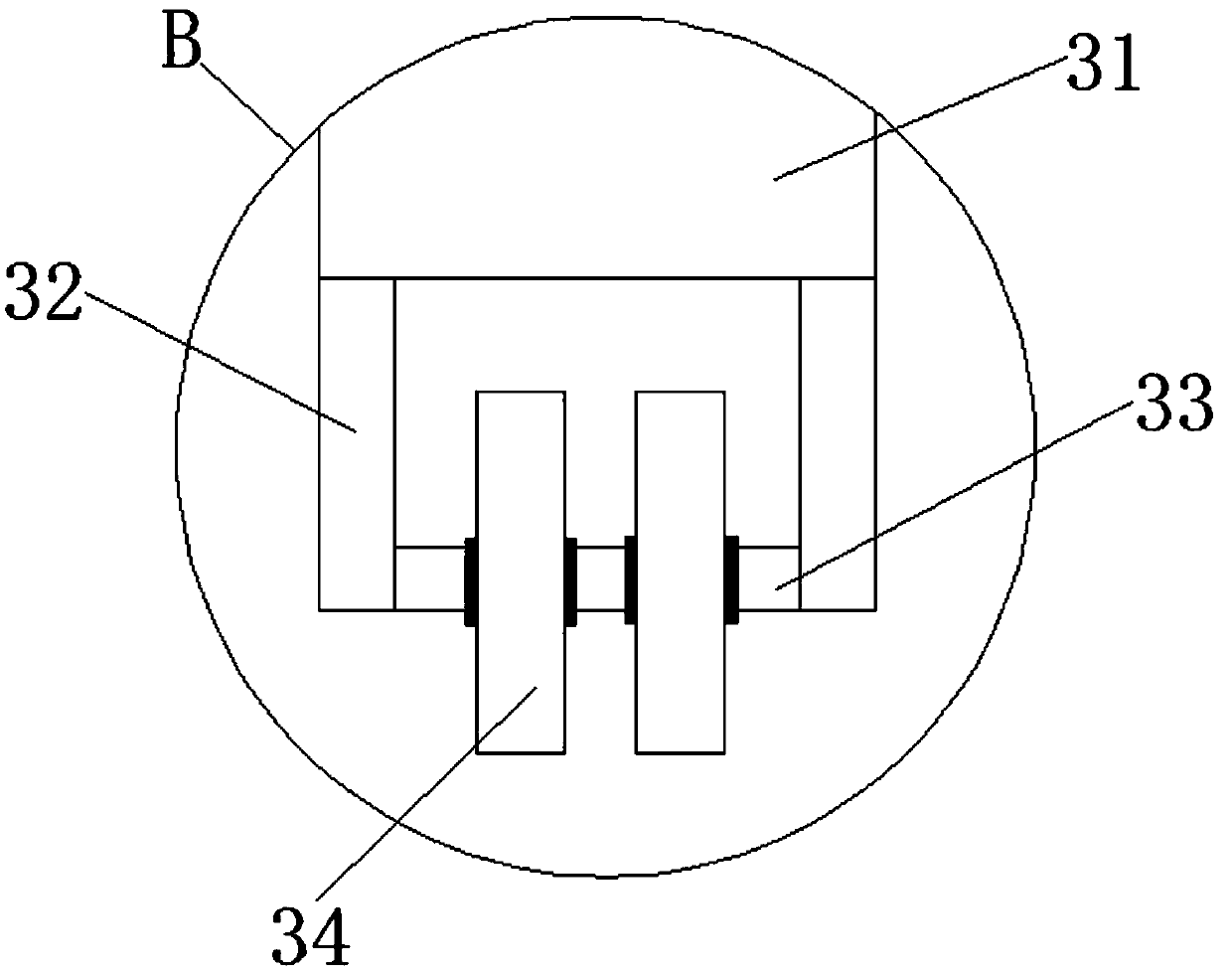

Robot grinding system based on feedback of sensor

The invention discloses and relates to a robot grinding system based on feedback of a sensor. The robot grinding system based on the feedback of the sensor is capable of detecting an contour of a workpiece and regulating grinding tracks in real time and comprises a robot (1), a workpiece contour detection unit (2), an electro-spindle unit (3), a grinding wheel wear detection unit (4), a grinding force detection unit (5) and a system control host (6). The robot grinding system based on the feedback of the sensor achieves automatic grinding on workpiece surface by detecting the grinding force between a grinding wheel and a workpiece, the three-dimensional measuring data of the outline of the workpiece and wear degree of the grinding wheel and controlling feed speed and rotating speed of the grinding wheel through a control algorithm.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

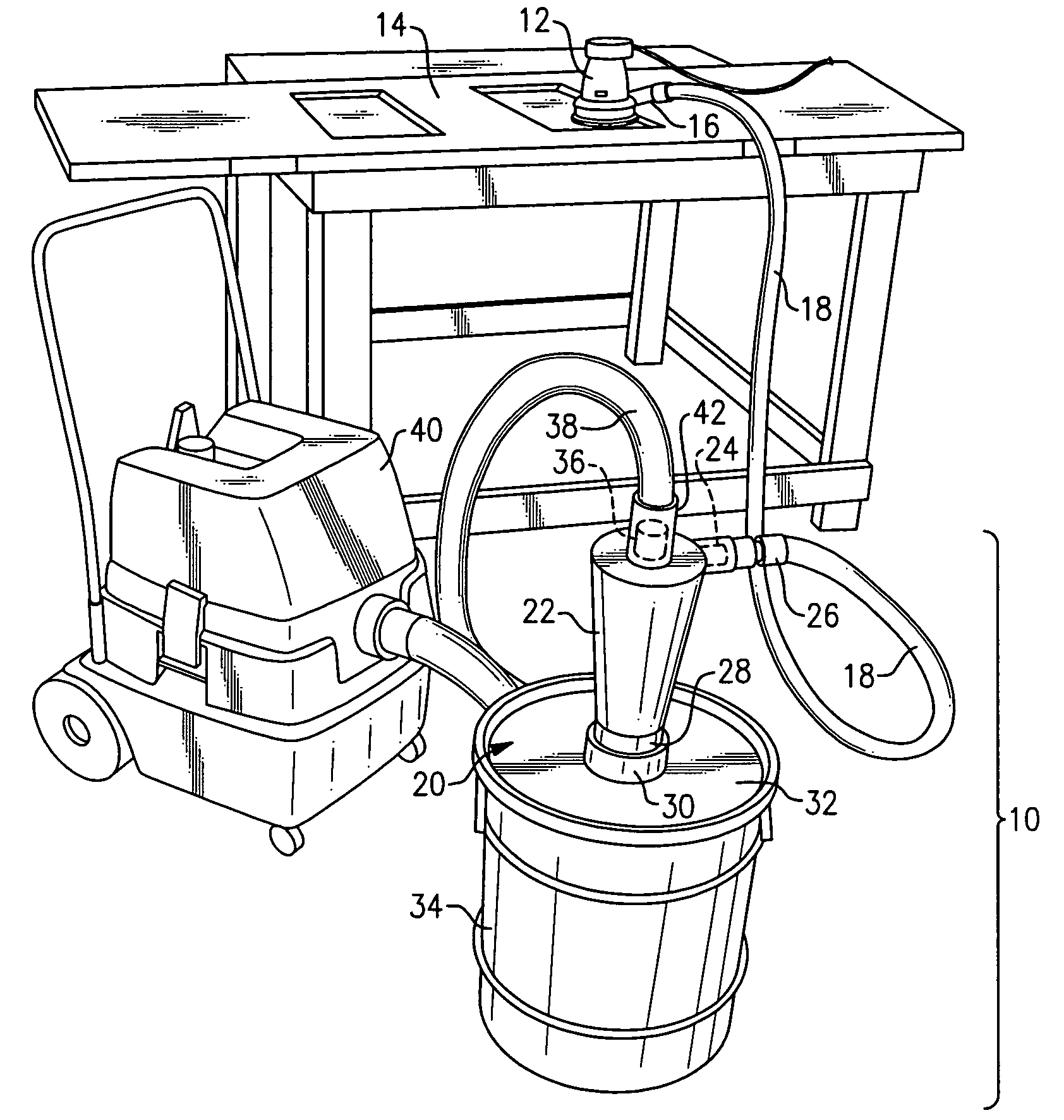

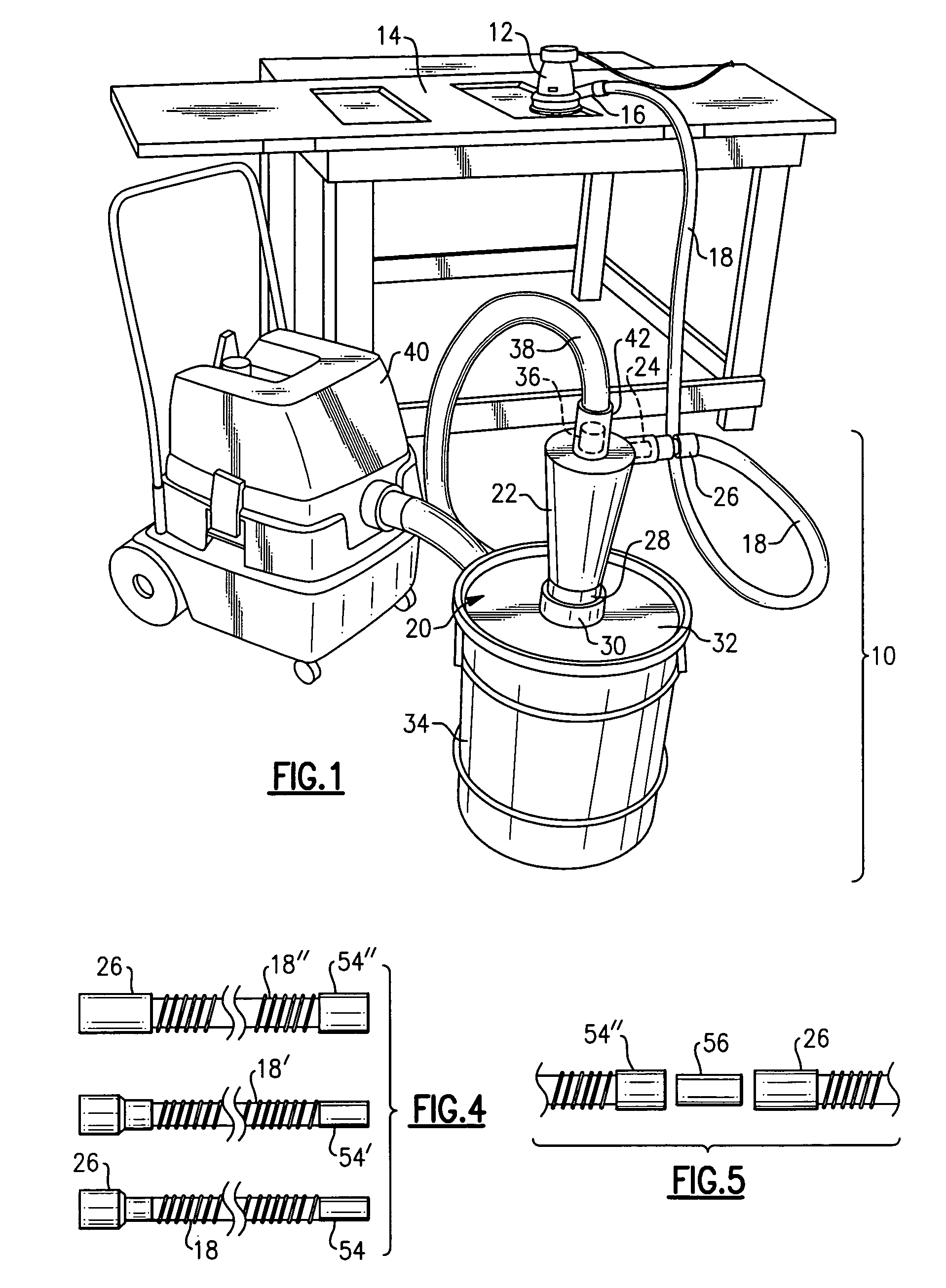

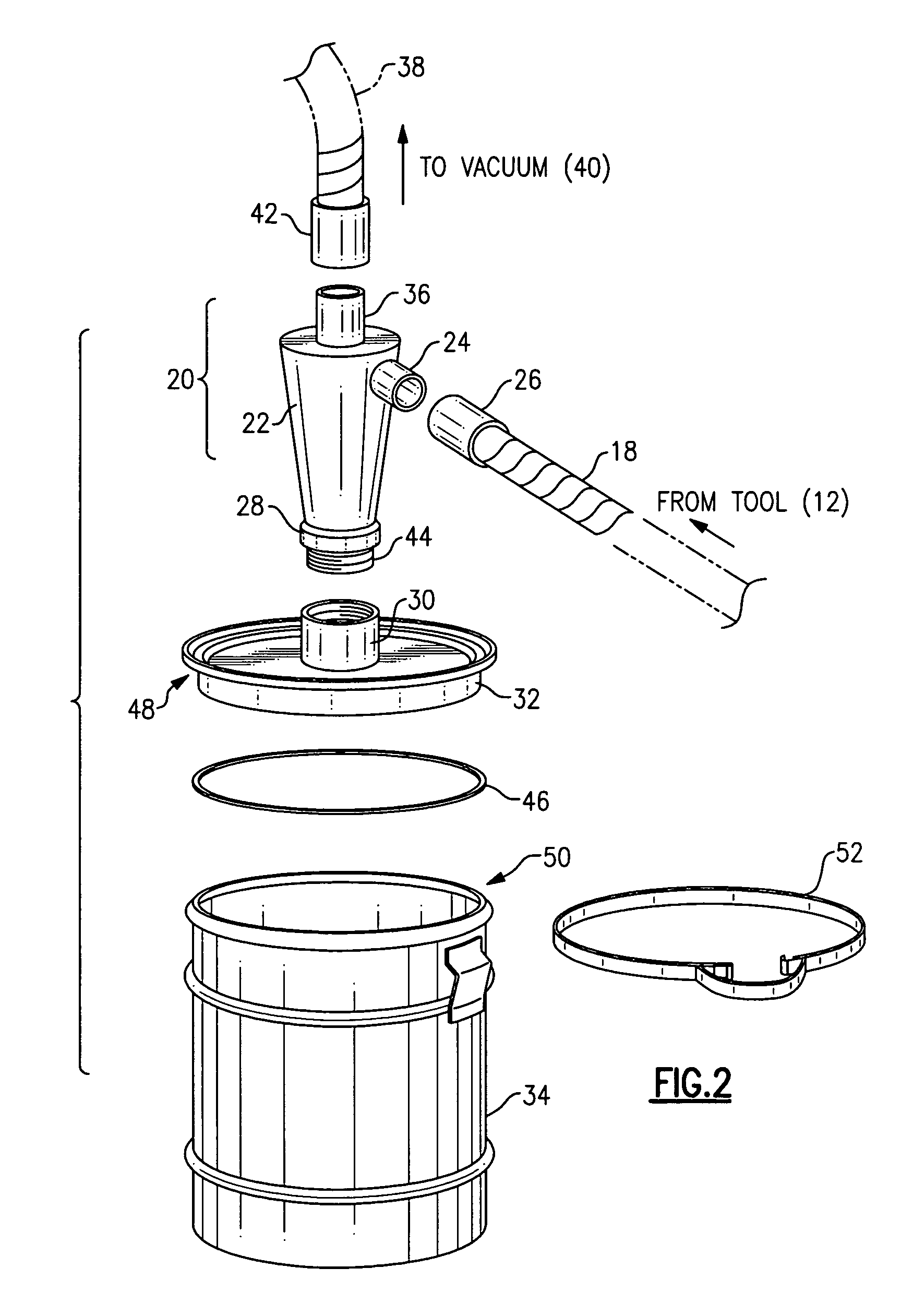

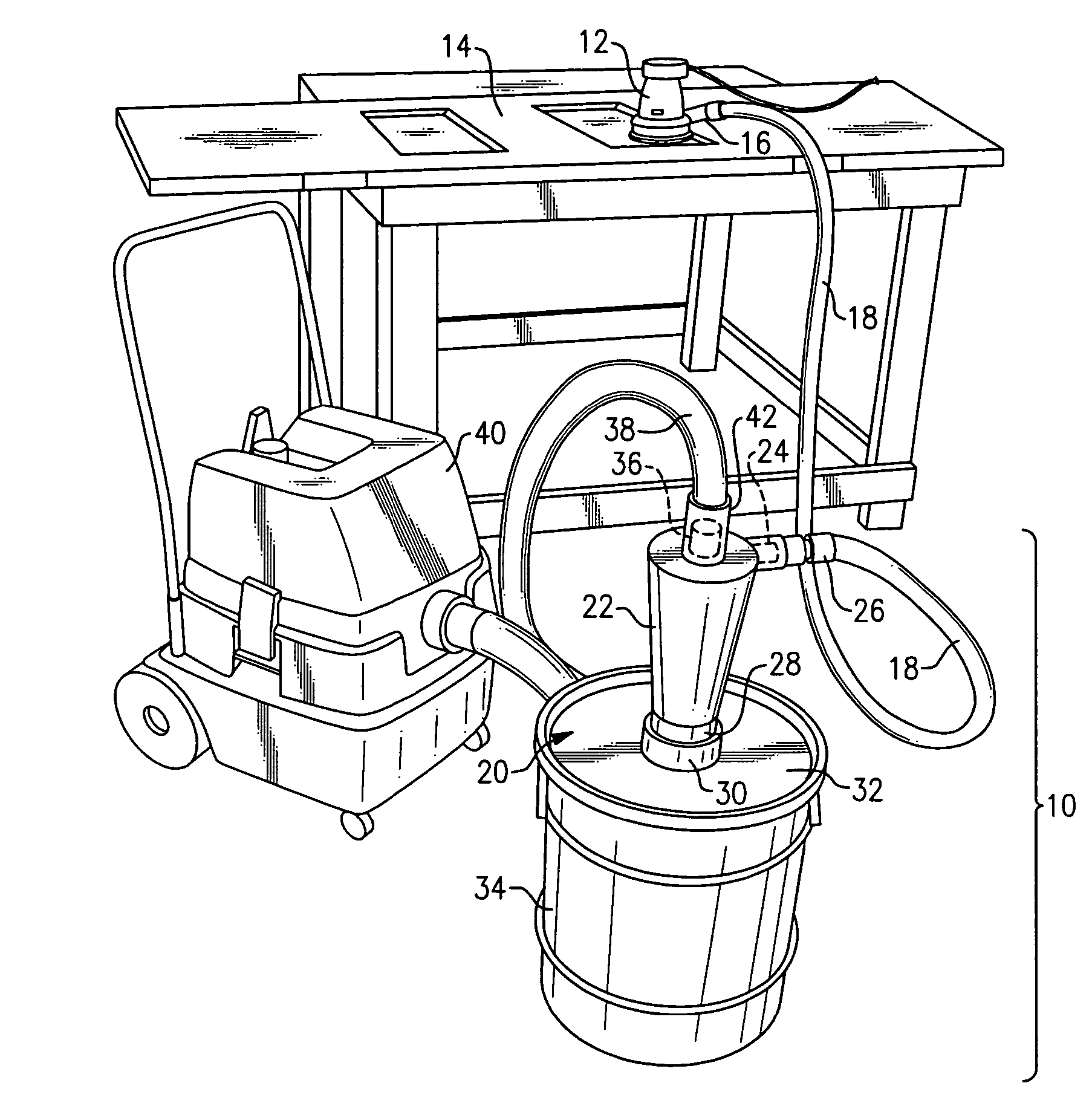

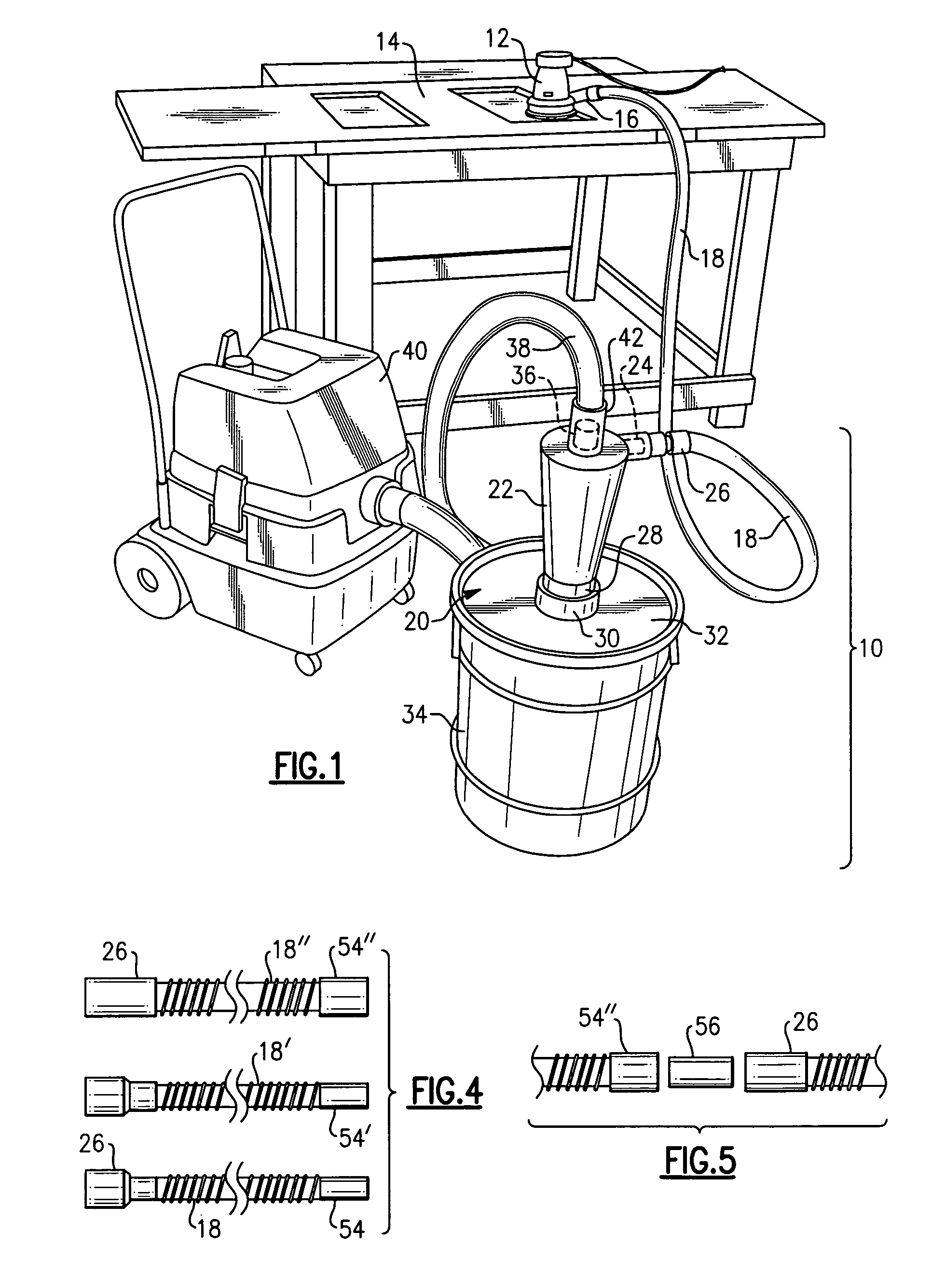

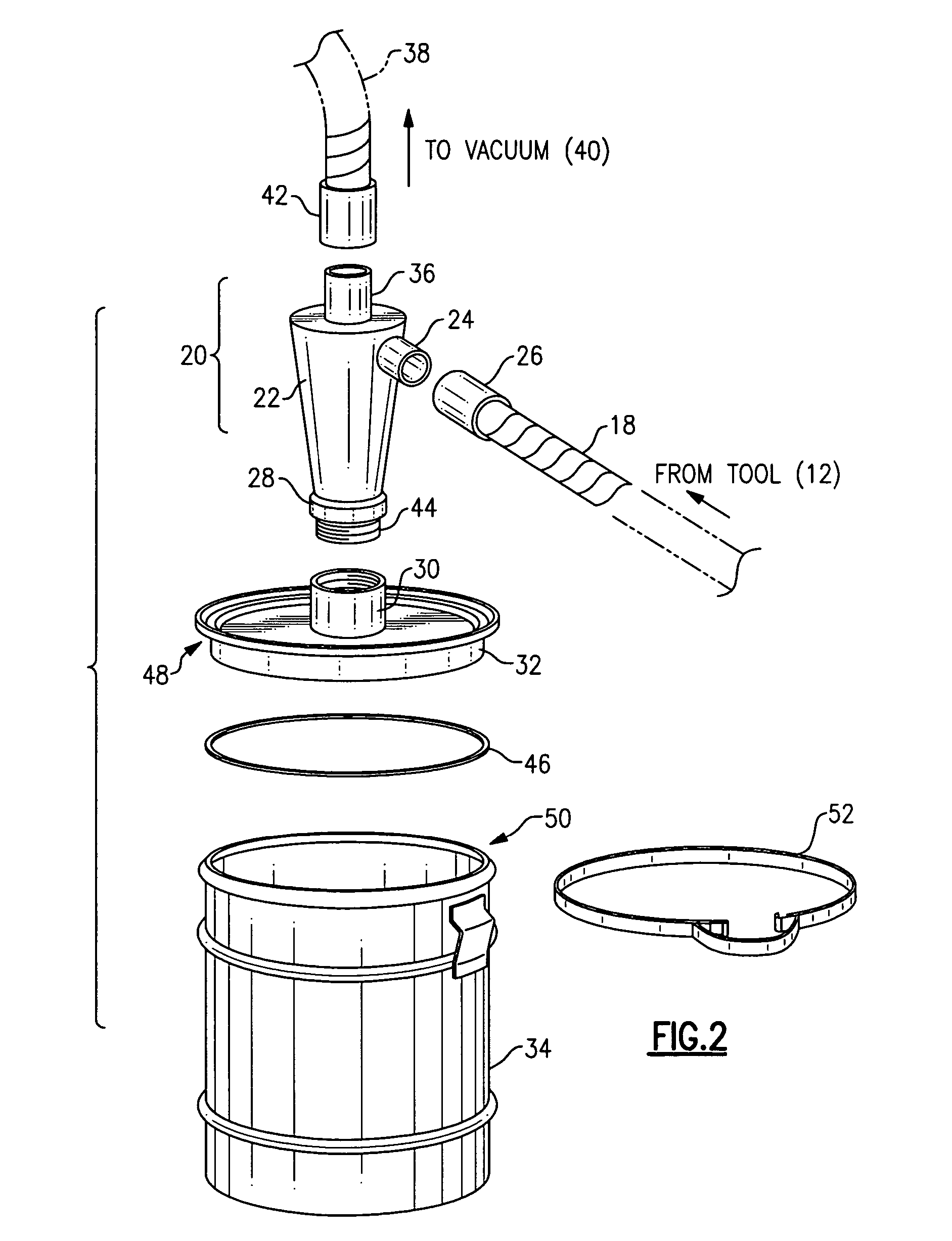

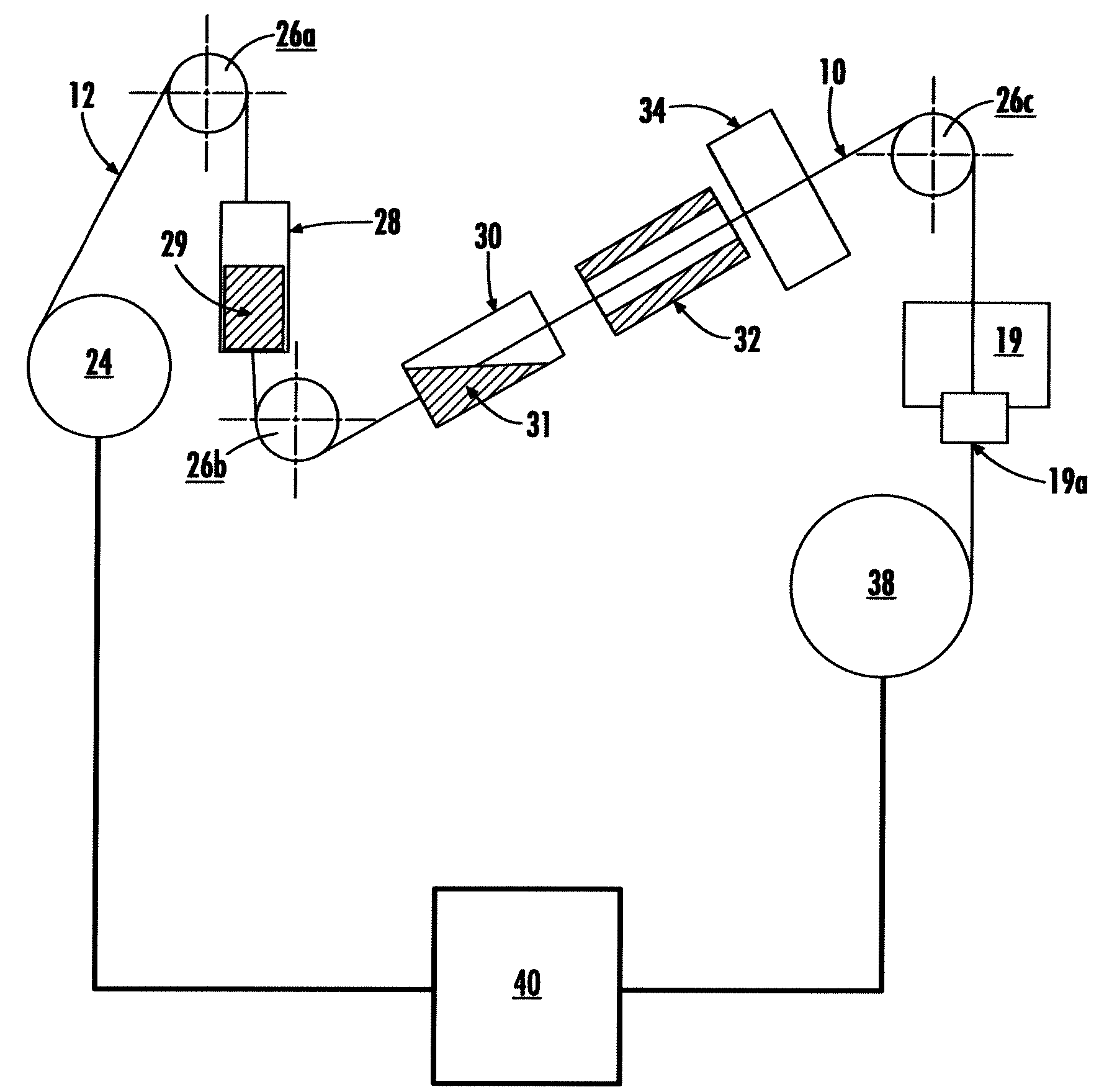

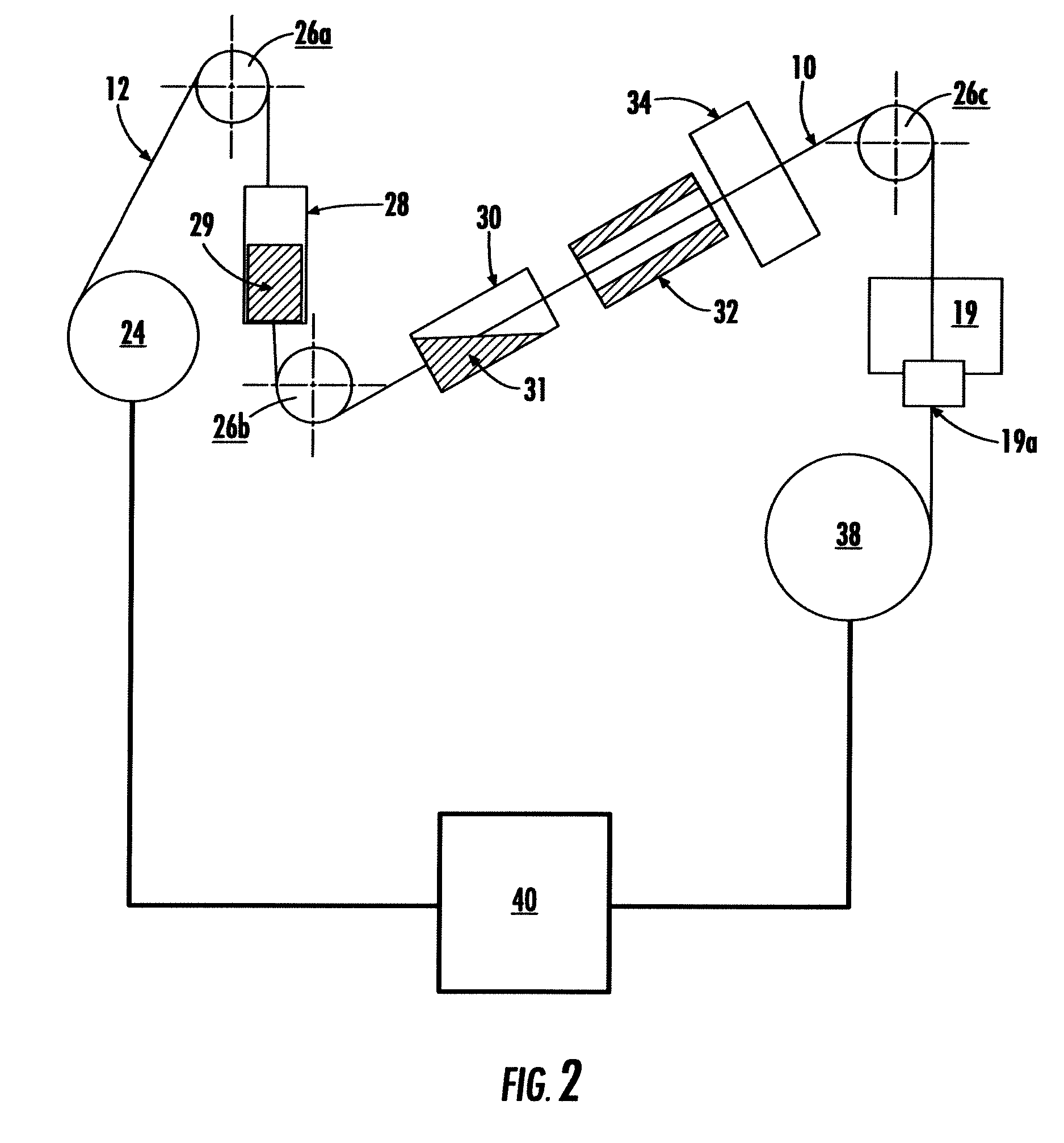

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

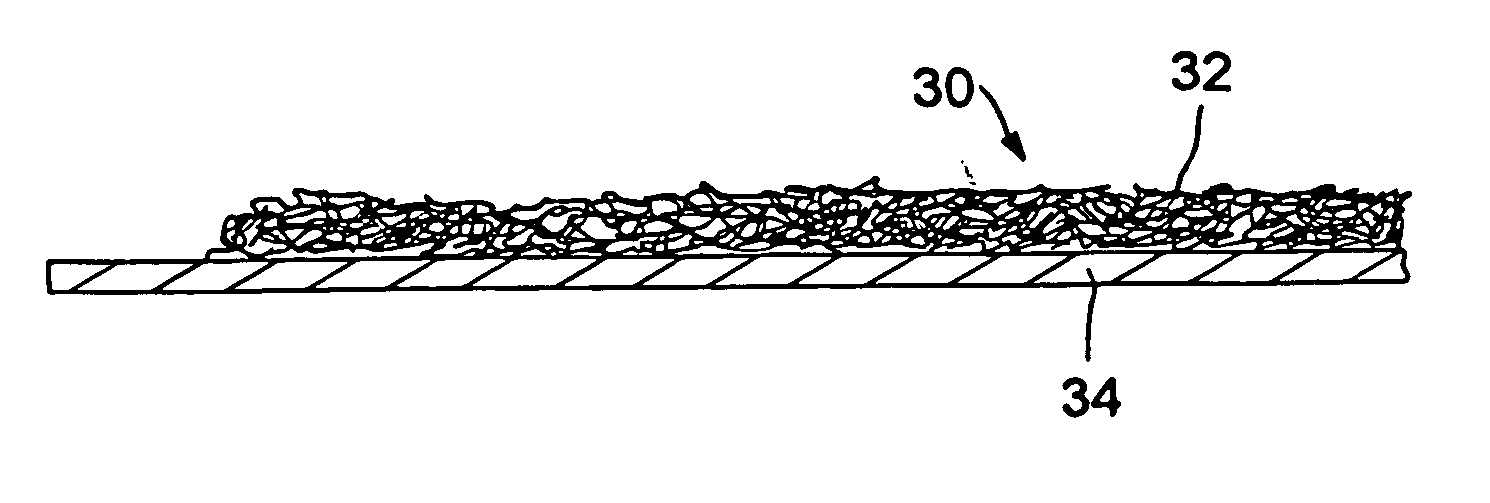

Disposable scrubbing product

InactiveUS20050129897A1Resists effect of waterMaintain stiffnessStampsWrappersEngineeringFibrous layer

The present invention discloses a disposable scrubbing product for use in household cleaning or personal care applications. The scrubbing product of the invention is a multi-layer laminate product and generally includes at least two distinct layers, an abrasive layer and an absorbent fibrous layer such as a layer tissue made from papermaking fibers, a layer of coform, an airlaid web, or combinations thereof. The abrasive layer is formed primarily of polymeric fibers in a disordered or random distribution as is typical of fibers deposited in meltblown or spunbond processes so as to form an open, porous structure. In one embodiment, multiple layers of an abrasive structure are releasably attached together. In this manner, the top or outermost layer may be removed after being used in order to expose an unused abrasive structure located below the discarded layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

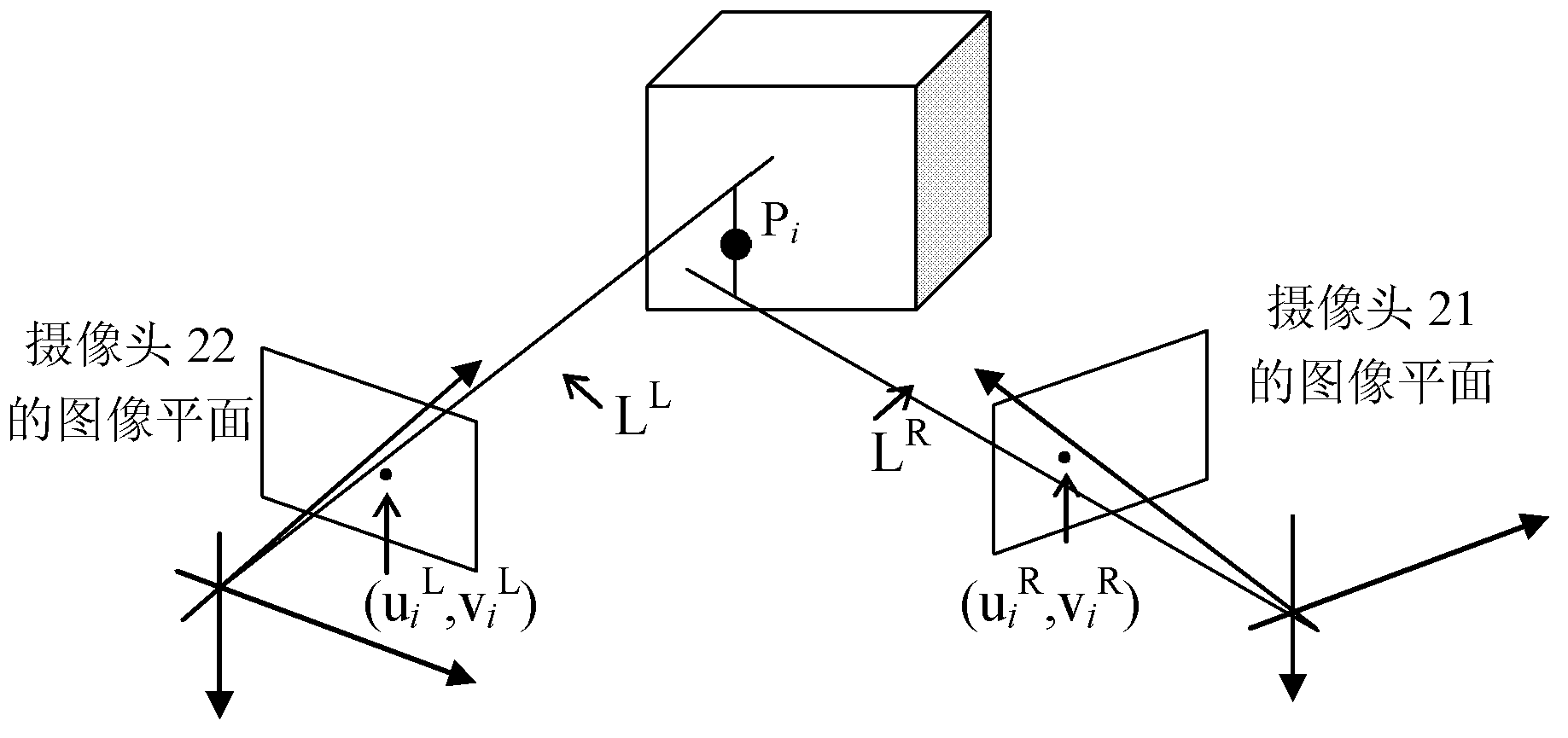

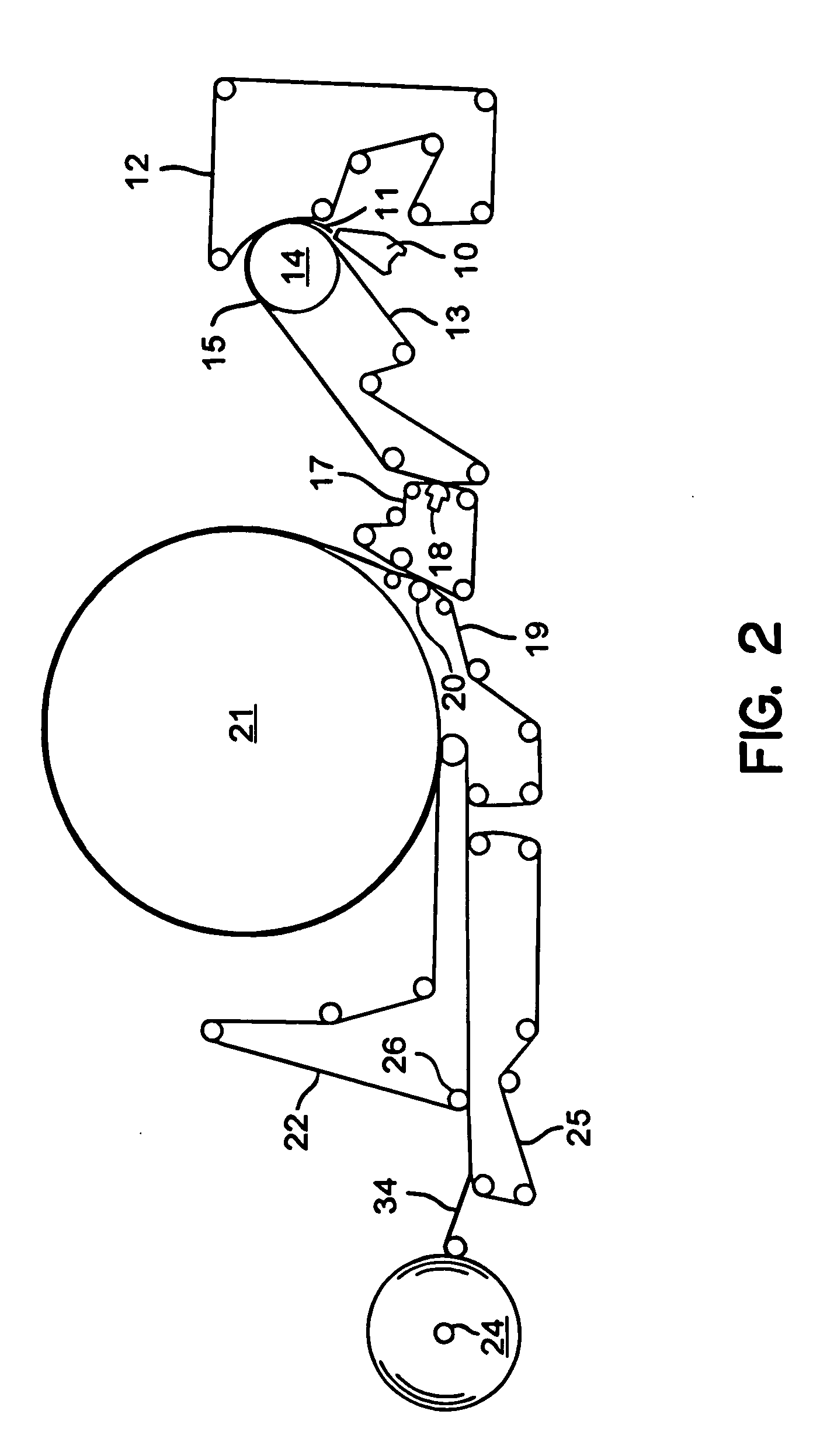

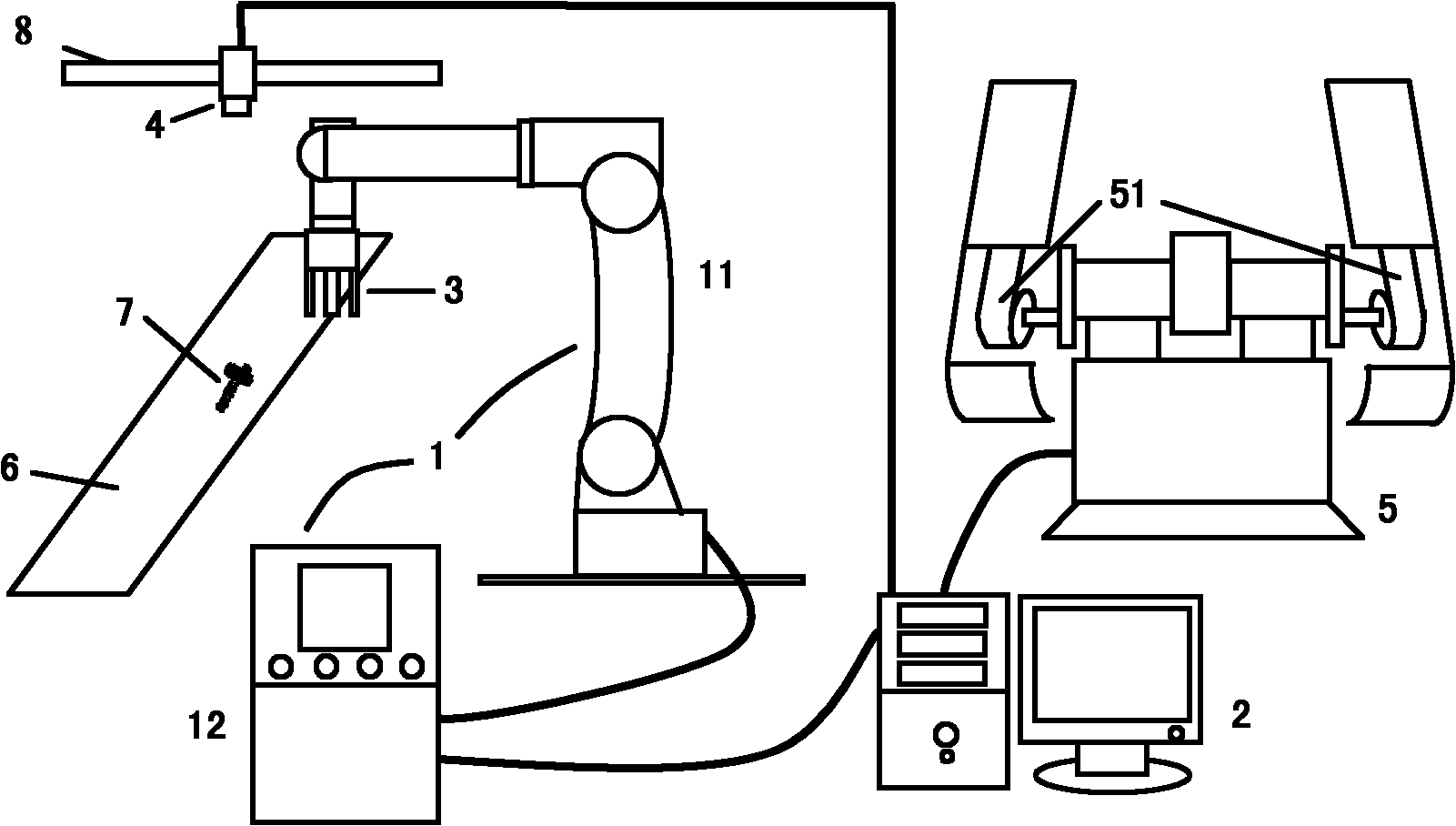

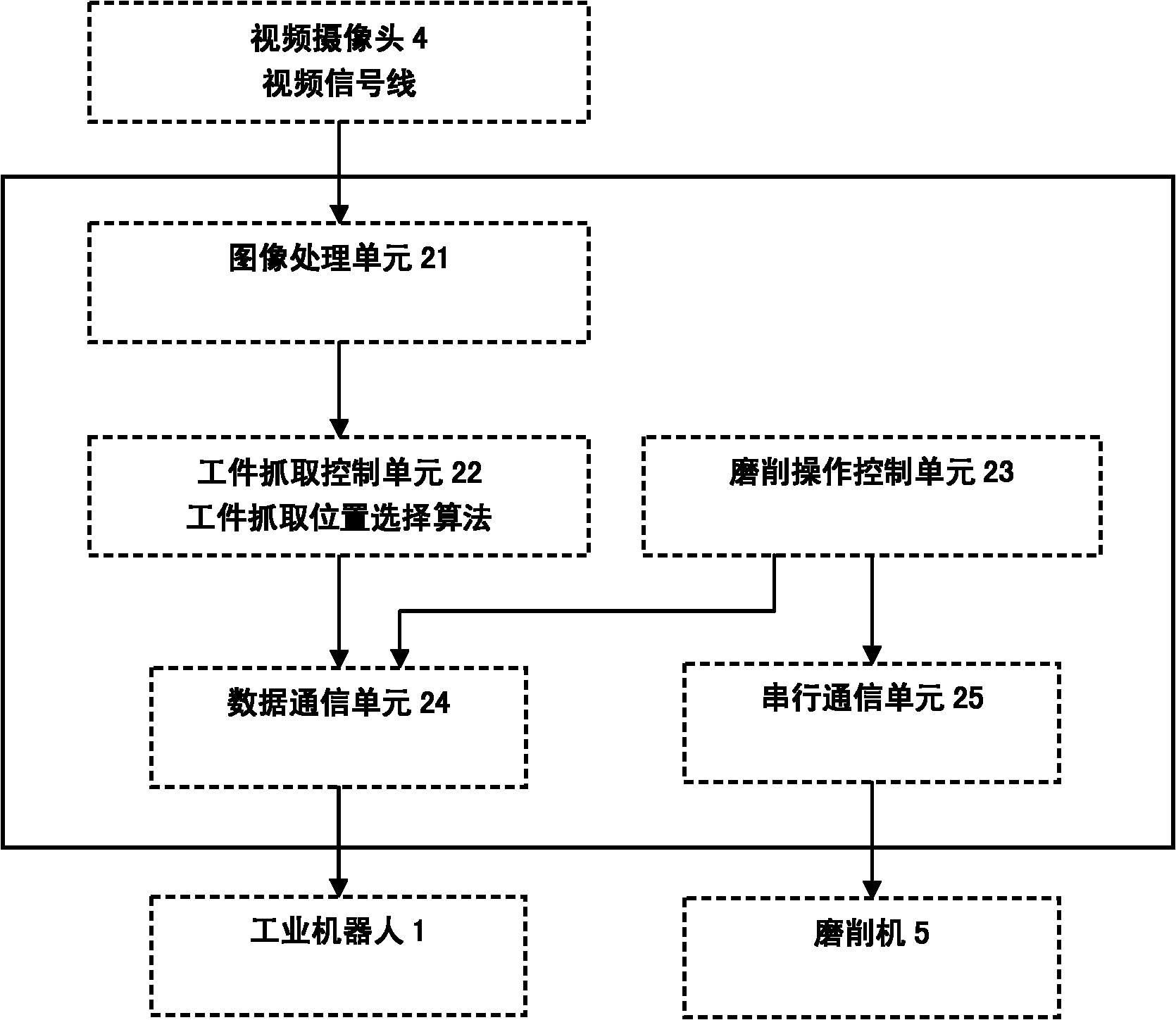

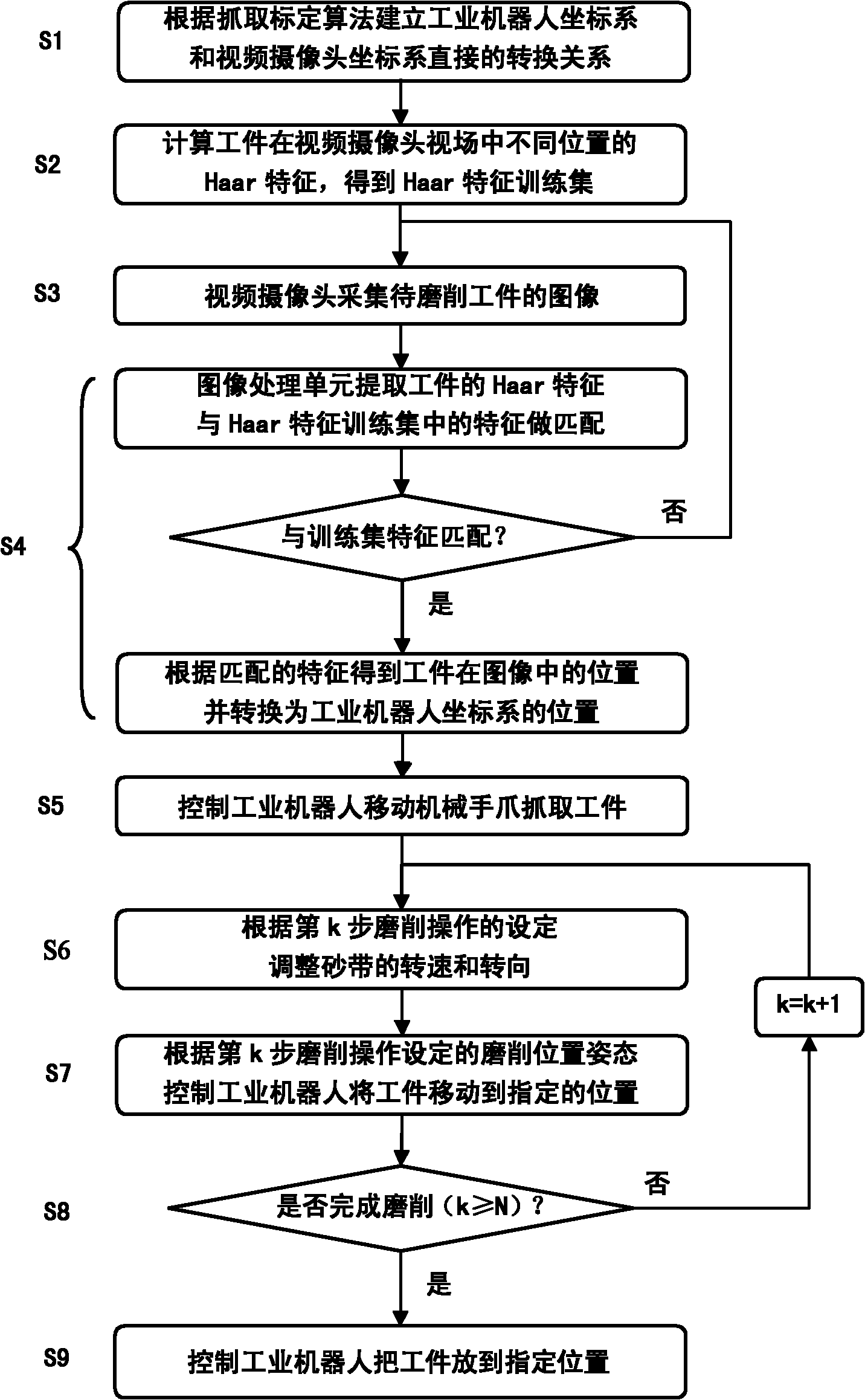

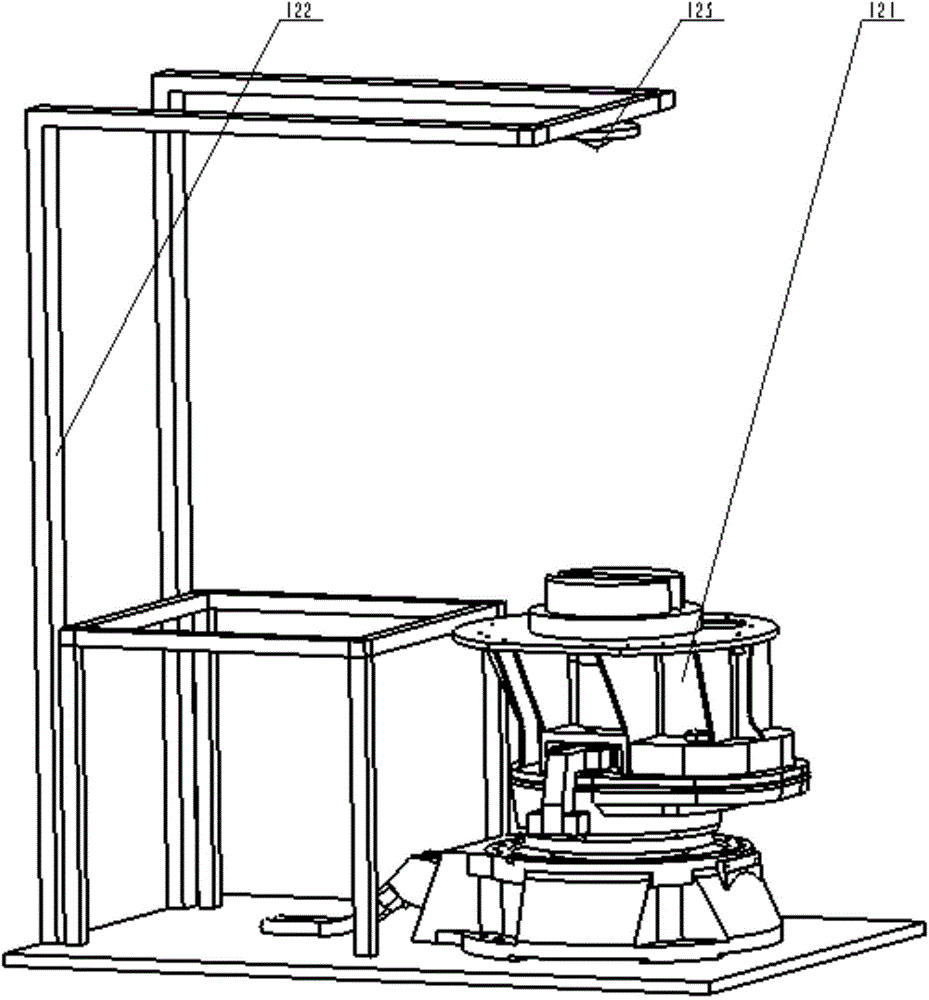

System and method for grinding industrial robot on basis of visual information

InactiveCN102120307AIncrease flexibilityImprove intelligenceGrinding feed controlAutomatic grinding controlVision basedIndustrial engineering

The invention relates to a system and a method for grinding an industrial robot on the basis of visual information. In the system, the image of a workpiece is collected by a video camera; the workpiece is positioned by computer recognition; the movement locus points of a mechanical arm from the current position to a fetching position are planned on line to control the mechanical arm to fetch the workpiece; and then, the revolving speed and the revolving direction of an abrasive belt are controlled by a preset operation step of grinding so as to control the industrial robot to move the workpiece to an appointed position and gesture for grinding and polishing the workpiece. In the system, the video camera collects the image of the workpiece in real time; the workpiece is identified and positioned by the computer to control the mechanical arm to fetch the workpiece; the movement of the industrial robot and the running state of a grinder in the workpiece grinding operation are controlled; the data end of a computer is connected with the data end of the control cabinet of the industrial robot; output locus points controls the industrial robot to move; and the data end of the computer is connected with the data end of the grinder to control the grinder to start and stop and control the revolving speed and the revolving direction of the abrasive belt.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Method of producing an integral resonator sensor and case

InactiveUS6944931B2Improve Sensing PerformanceIncrease the areaGrinding machine componentsWave amplification devicesAcousticsResonator

The present invention discloses an inertial sensor having an integral resonator. A typical sensor comprises a planar mechanical resonator for sensing motion of the inertial sensor and a case for housing the resonator. The resonator and a wall of the case are defined through an etching process. A typical method of producing the resonator includes etching a baseplate, bonding a wafer to the etched baseplate, through etching the wafer to form a planar mechanical resonator and the wall of the case and bonding an end cap wafer to the wall to complete the case.

Owner:CALIFORNIA INST OF TECH +1

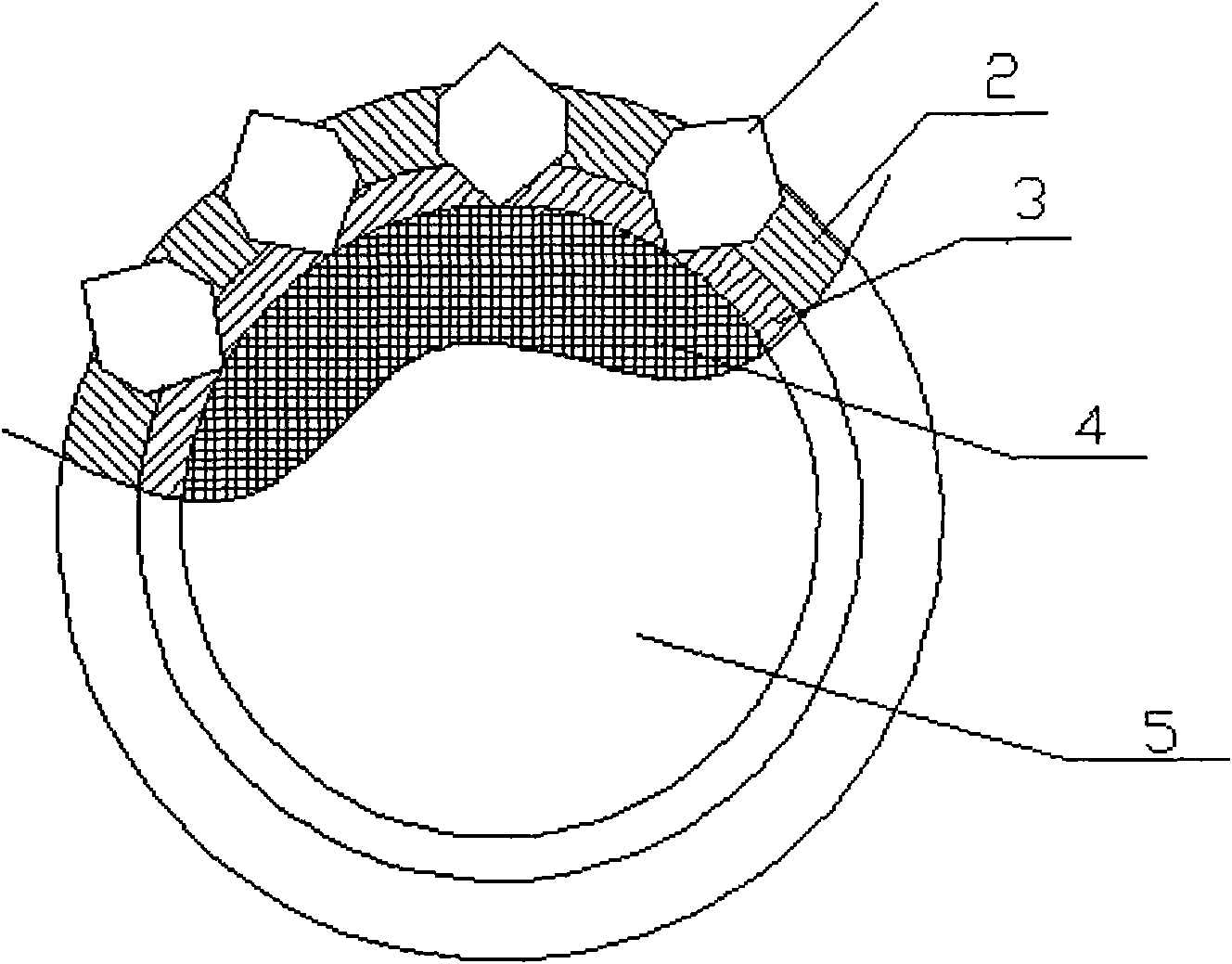

Wire-saw and its manufacturing method

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

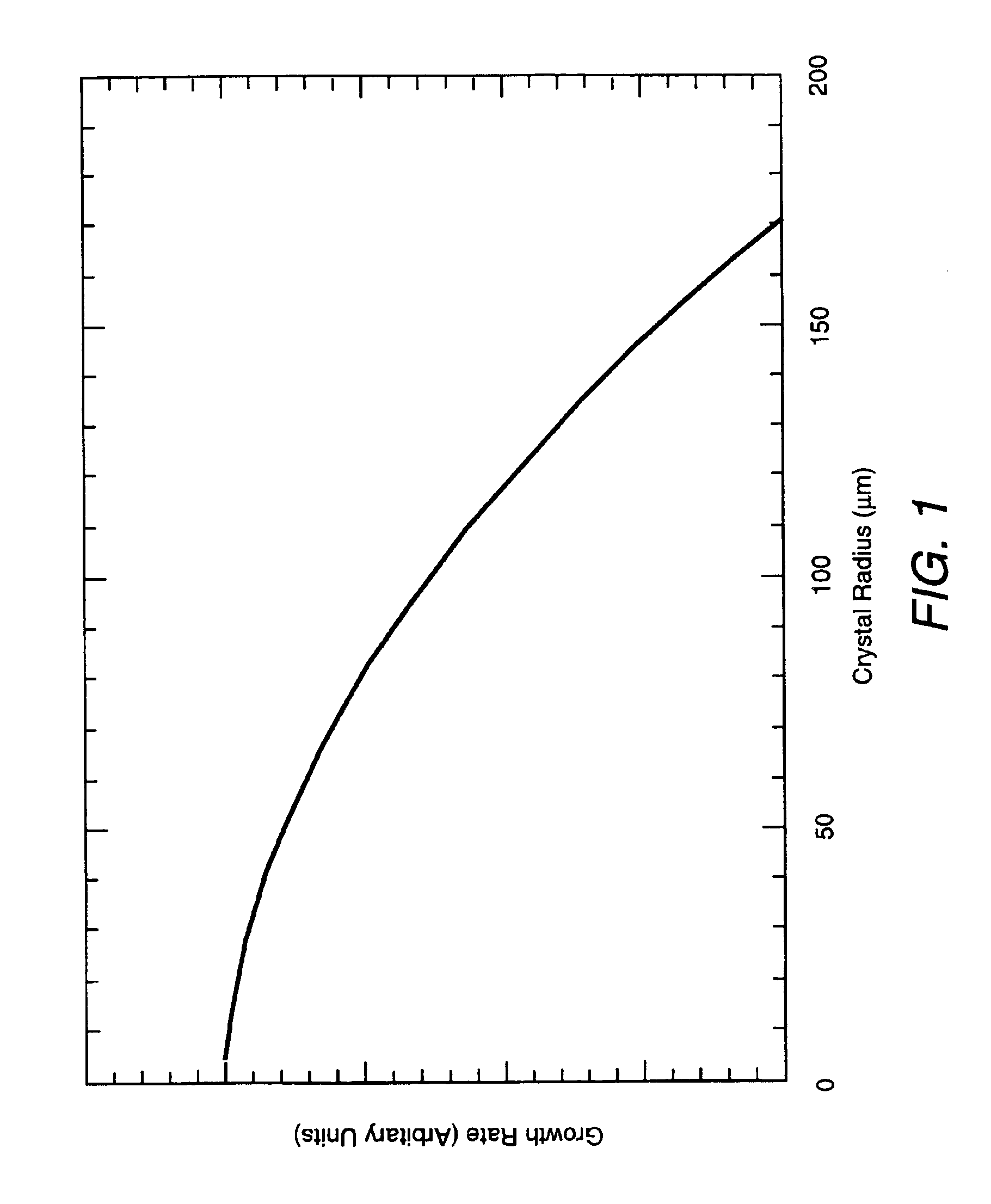

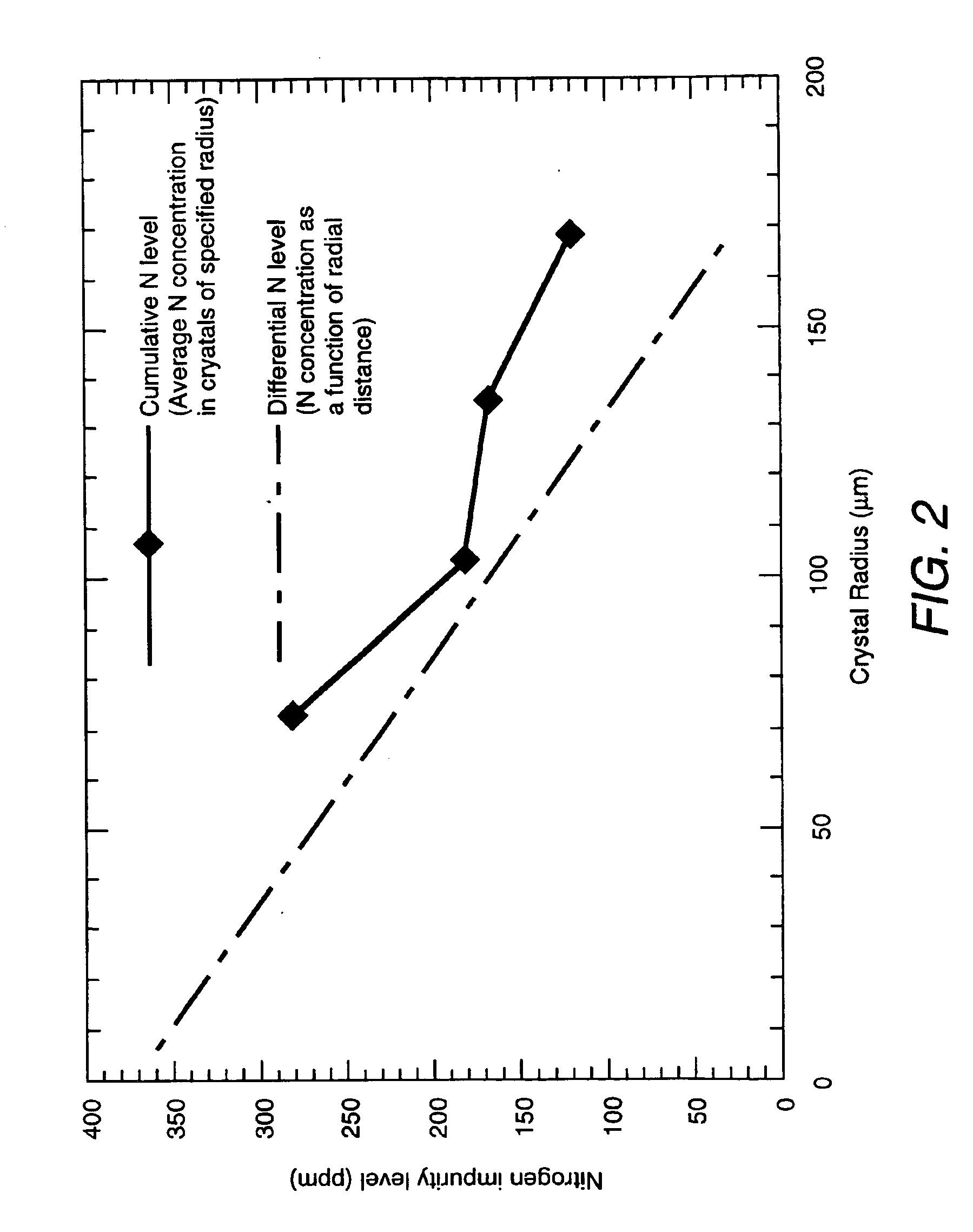

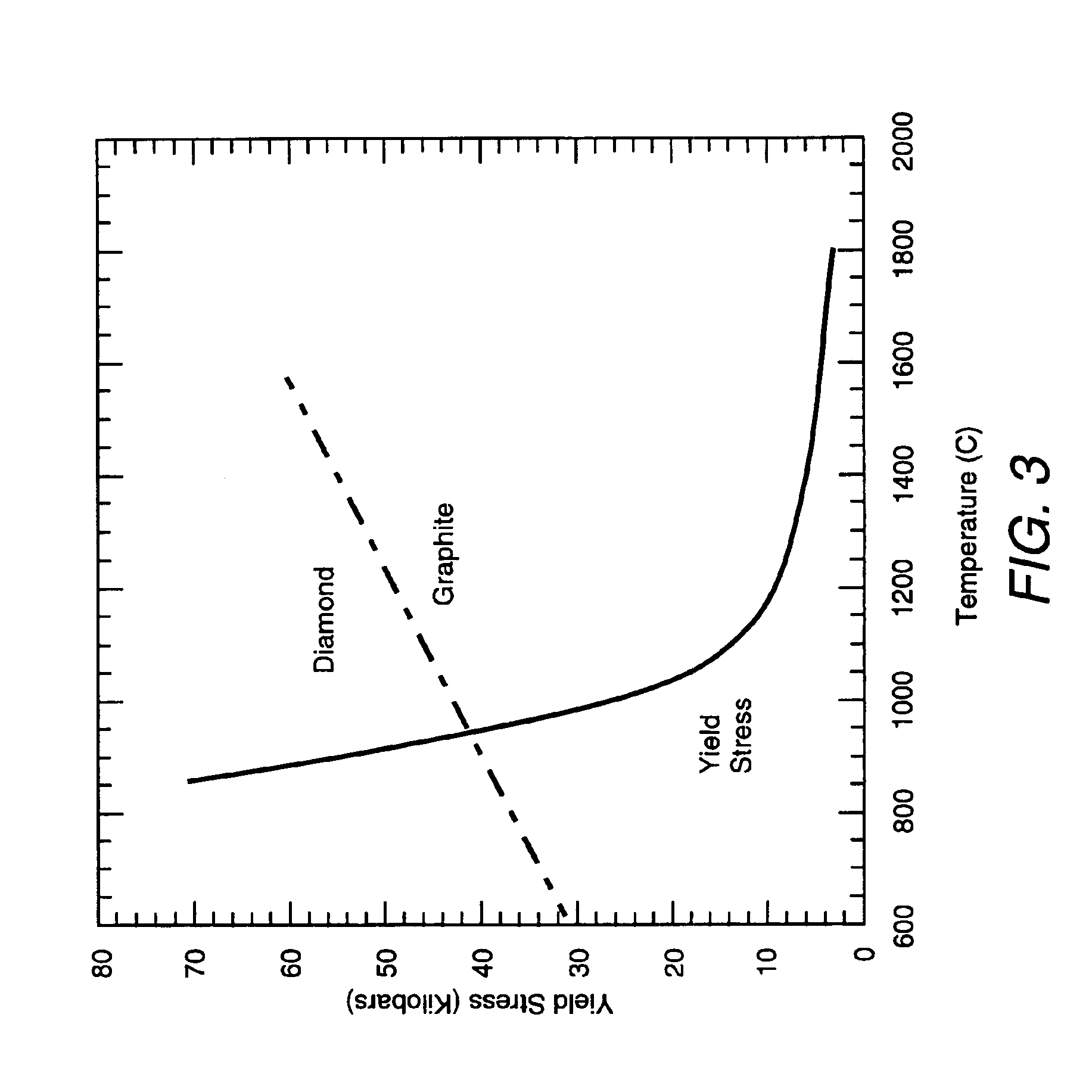

Surface impurity-enriched diamond and method of making

InactiveUS6887144B2Increases compressive fracture strengthHigh breaking strengthPolycrystalline material growthUltra-high pressure processesDopantMicrometer

An element-doped diamond crystal is disclosed herein. The crystal includes at least one dopant element which has a greater concentration toward or near an outermost surface of the crystal than in the center of the crystal. The concentration of the dopant element is at a local minimum at least about 5 micrometers below the surface. The concentration-profile of the dopant element for these diamond crystals causes an expansion of the diamond lattice, thereby generating tangential compressive stresses at the surface of the diamond crystal. These stresses beneficially increase the compressive fracture strength of the diamond.

Owner:DIAMOND INNOVATIONS INC

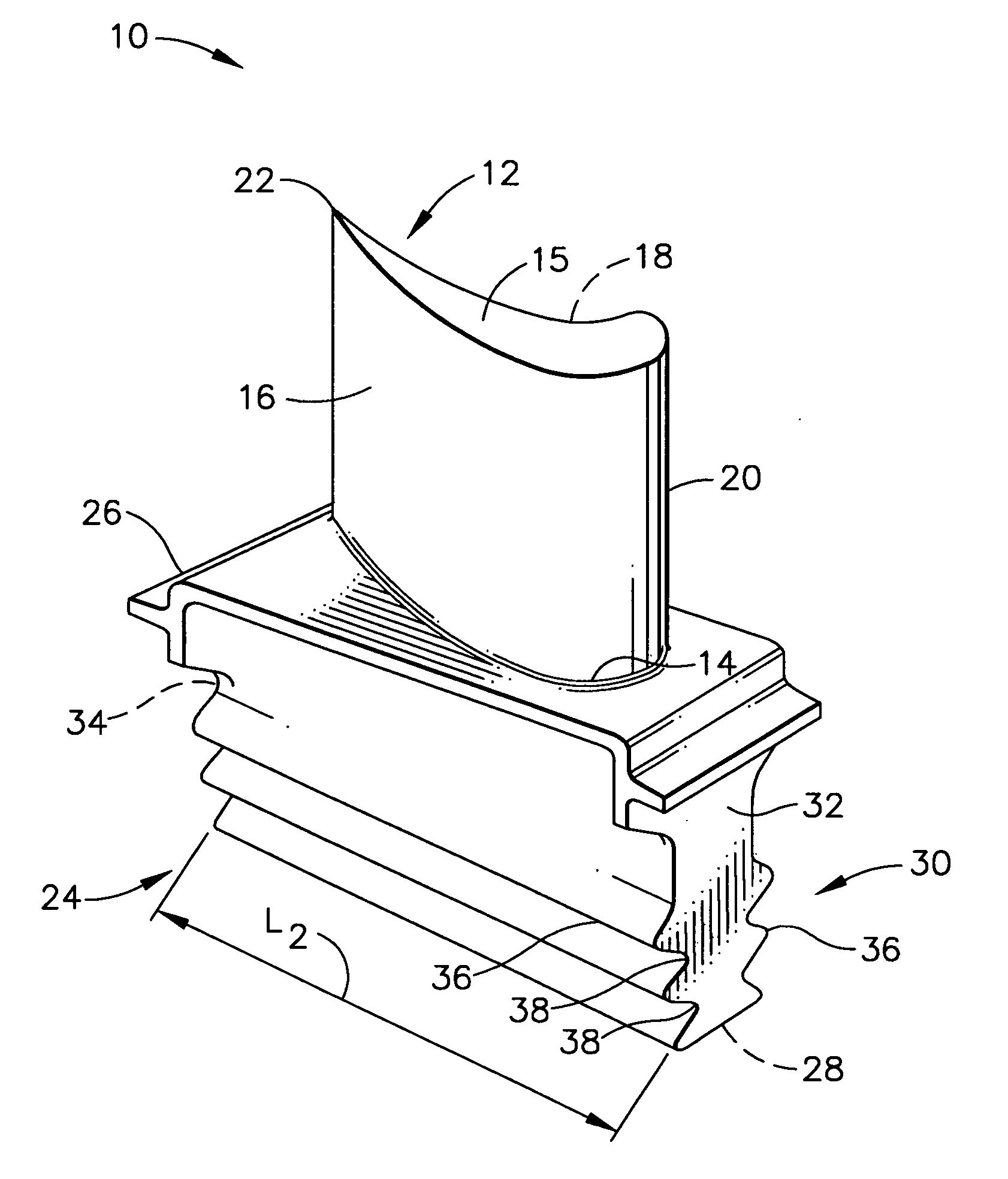

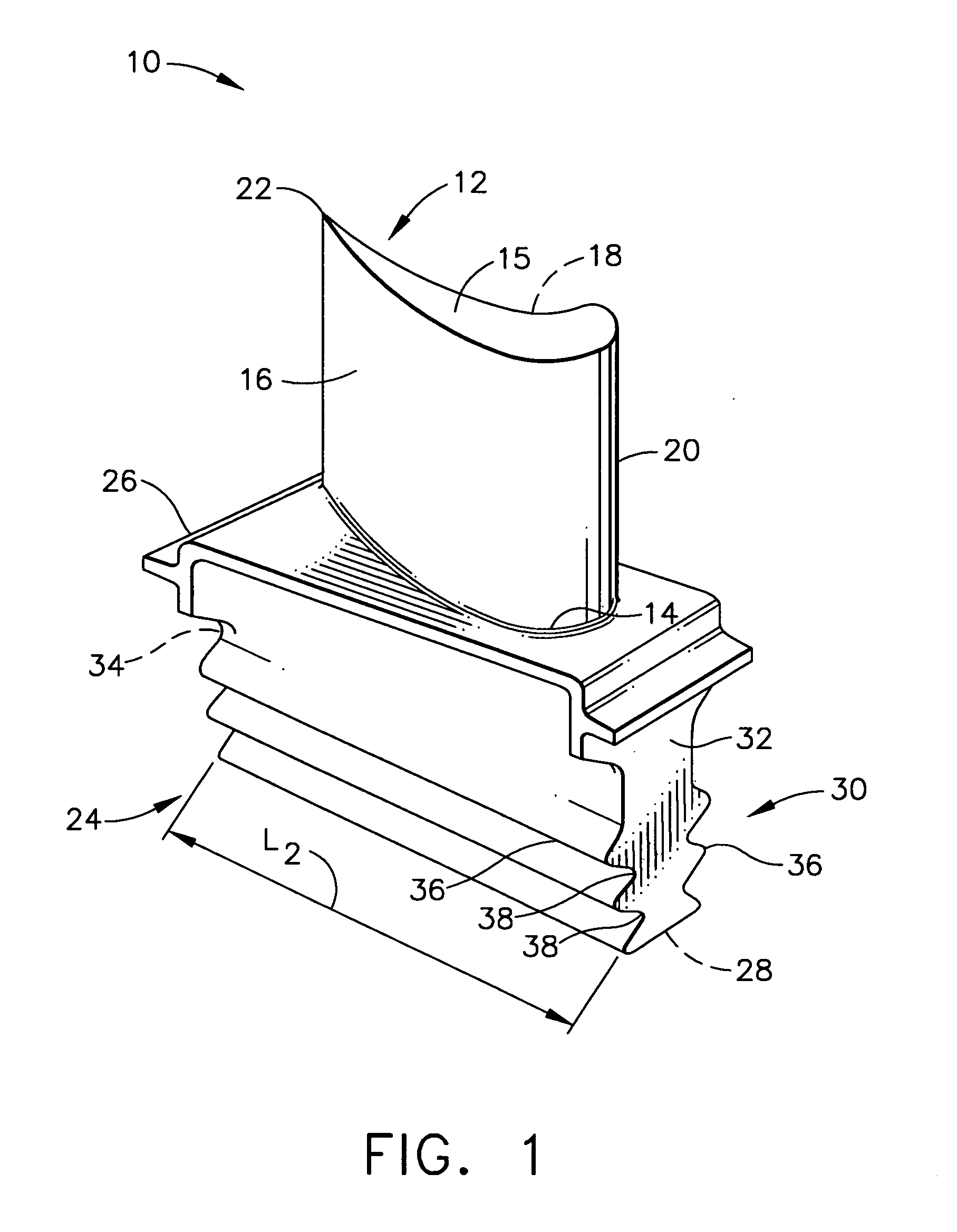

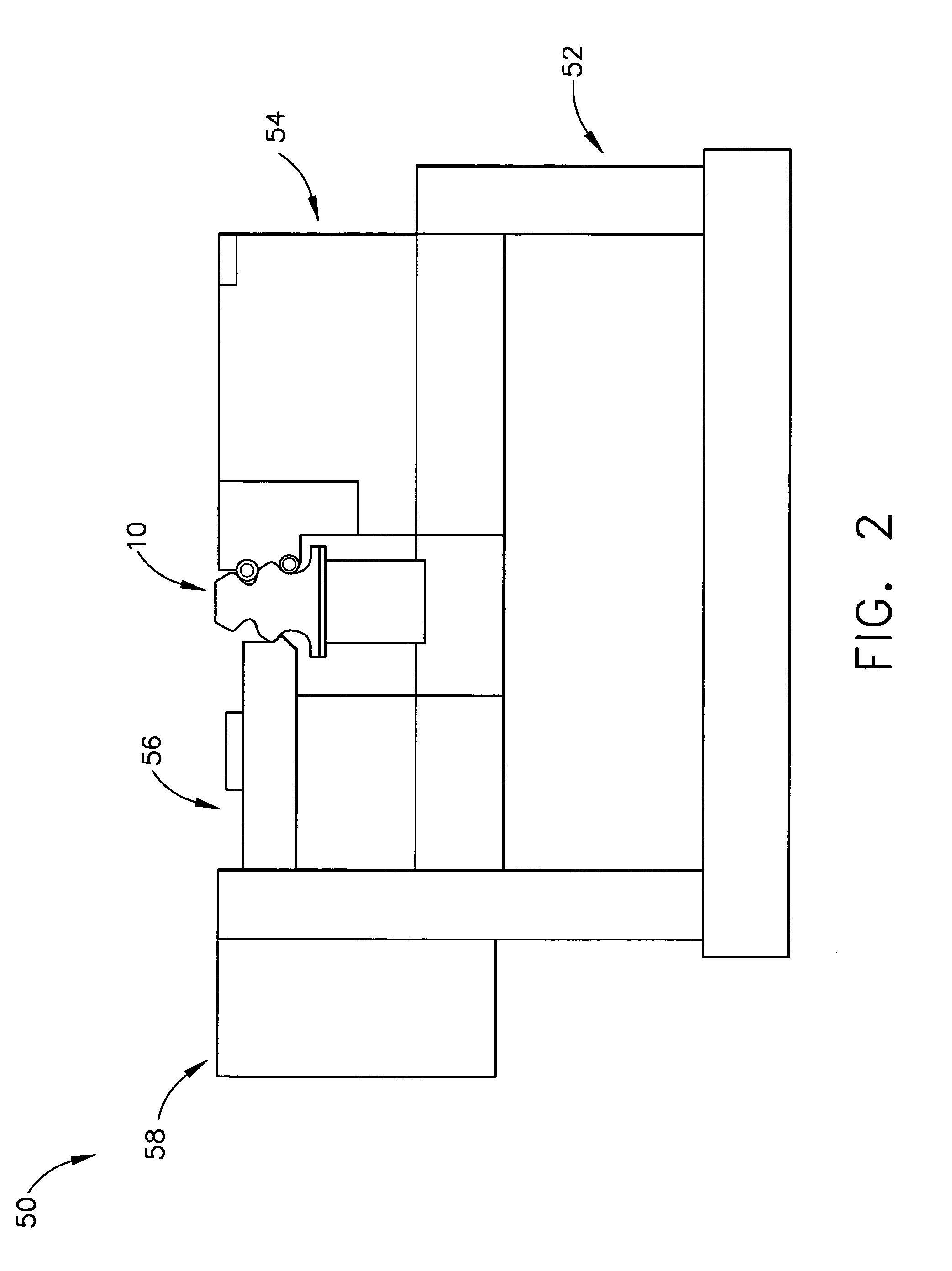

Method and apparatus for rebuilding gas turbine engines

A method for repairing a turbine blade for a gas turbine engine is provided. The method includes securing the blade into a clamping fixture, obtaining a zero reference from a gauging surface on the clamping fixture, coupling the clamping fixture to a grinding machine, and grinding the blade based on the zero reference.

Owner:GENERAL ELECTRIC CO

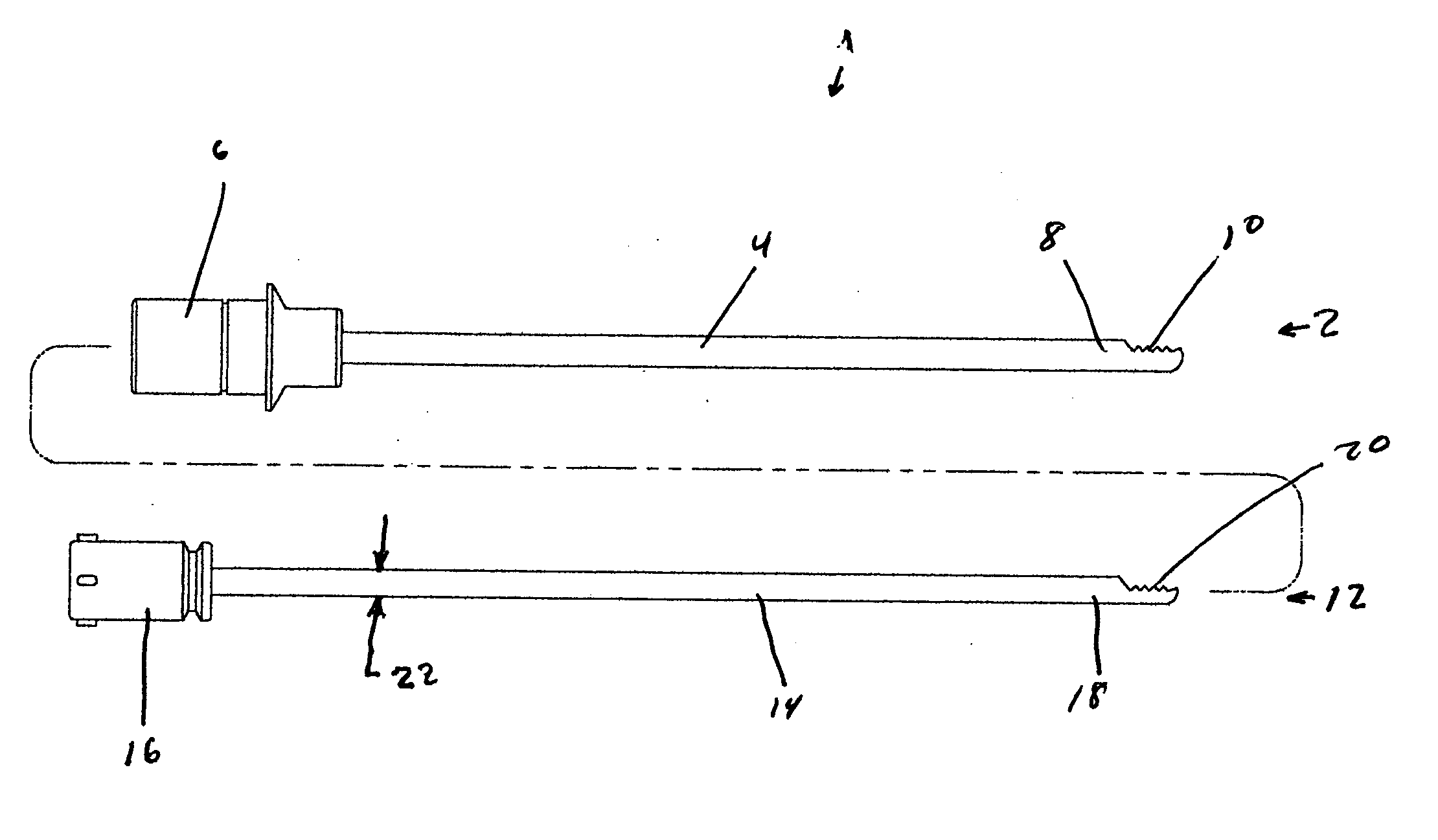

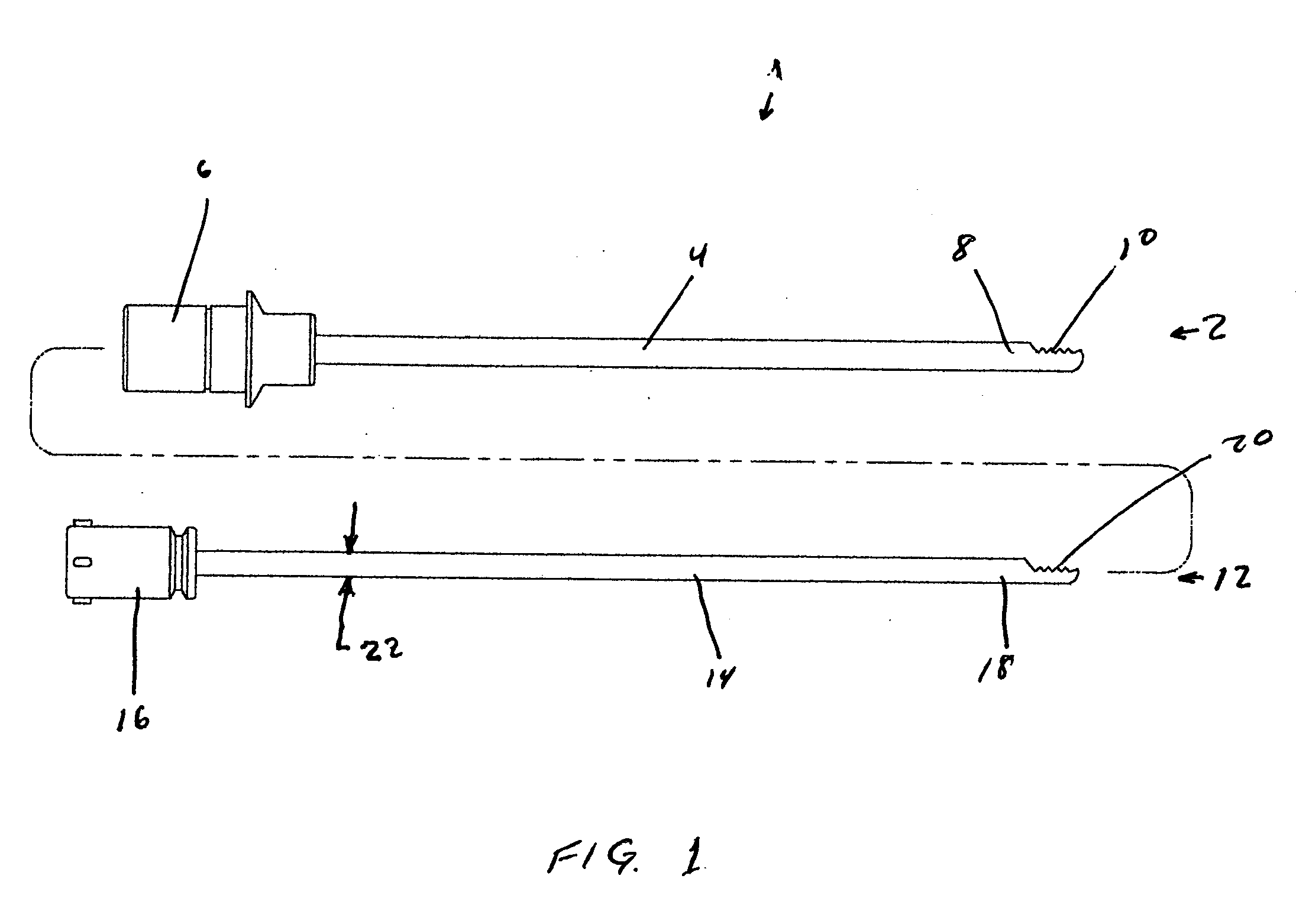

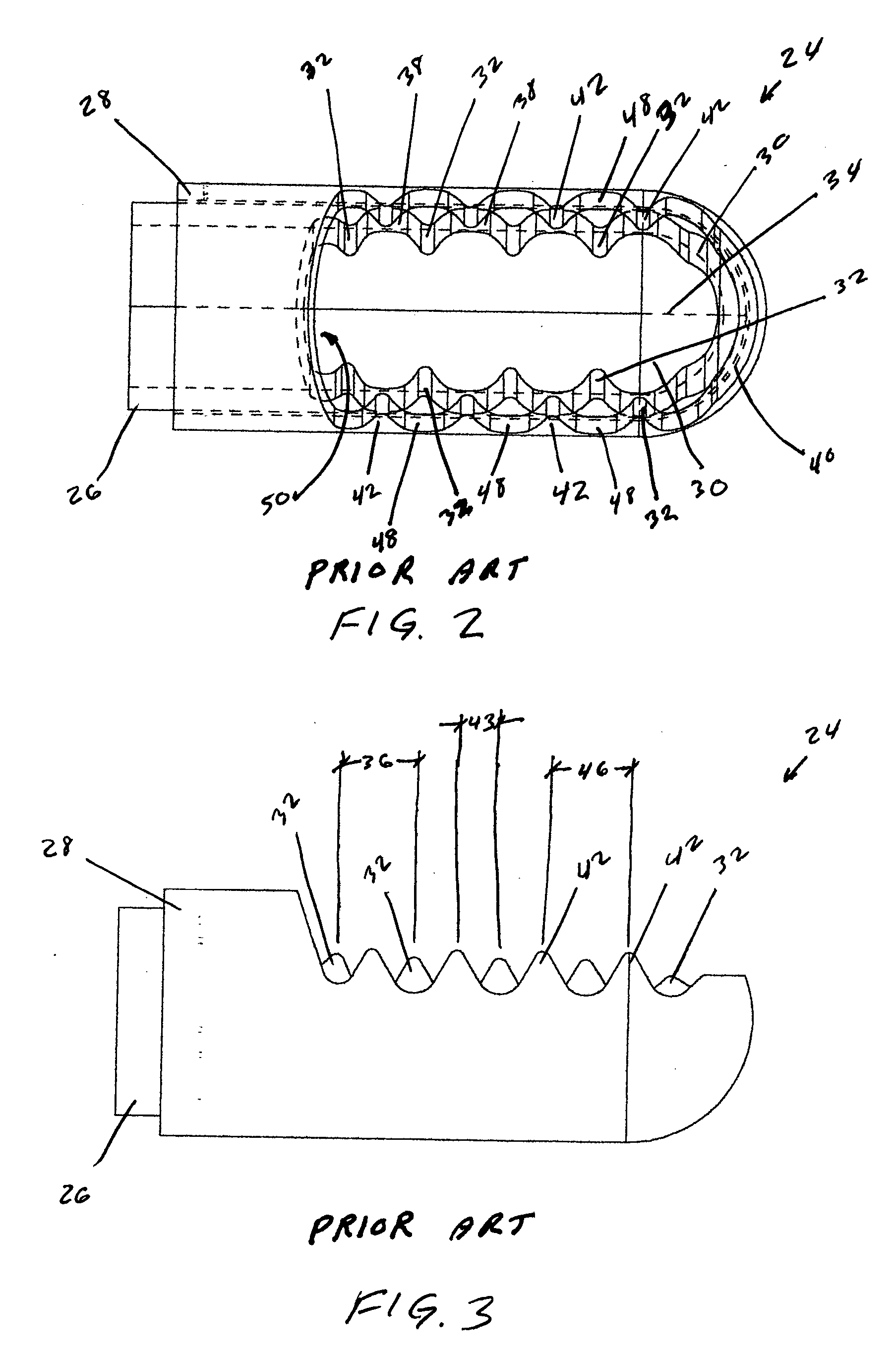

Asymmetric shaver and methods for making same

InactiveUS20050065538A1Improve resection efficiencyImprove efficiencyCannulasSawing tools dressing arrangementsCnc grindingEngineering

A surgical shaver blade is provided with a stationary elongated outer tube, having a cutting window at its distal tip and a rotatable elongated inner tube having a cutting window at its distal tip. Each cutting window is not symmetrical about any line in a sectional view through the window normal to the tube axis. In a preferred embodiment the cutting edges of each window have a plurality of teeth, the teeth of one lateral cutting edge being offset axially from the teeth of the other lateral edge so that the teeth of one edge align axially with the valleys between teeth on the opposite edge. When the shaver is used in oscillate mode, the teeth of one direction of rotation align with tissue that was between teeth during the previous opposite direction rotation thereby enhancing the ability of the teeth to penetrate the tissue and prevent its ejection from the cutting window as the cutting edges approach. In another embodiment the outer window is asymmetric without teeth and the inner window is asymmetric with teeth. In yet another embodiment only the inner cutting edges are asymmetric. The cutting edges are formed in a single grinding operation or multiple grinding operations using a multi-axis CNC grinding machine, or electrochemically.

Owner:ASYMMETRICS

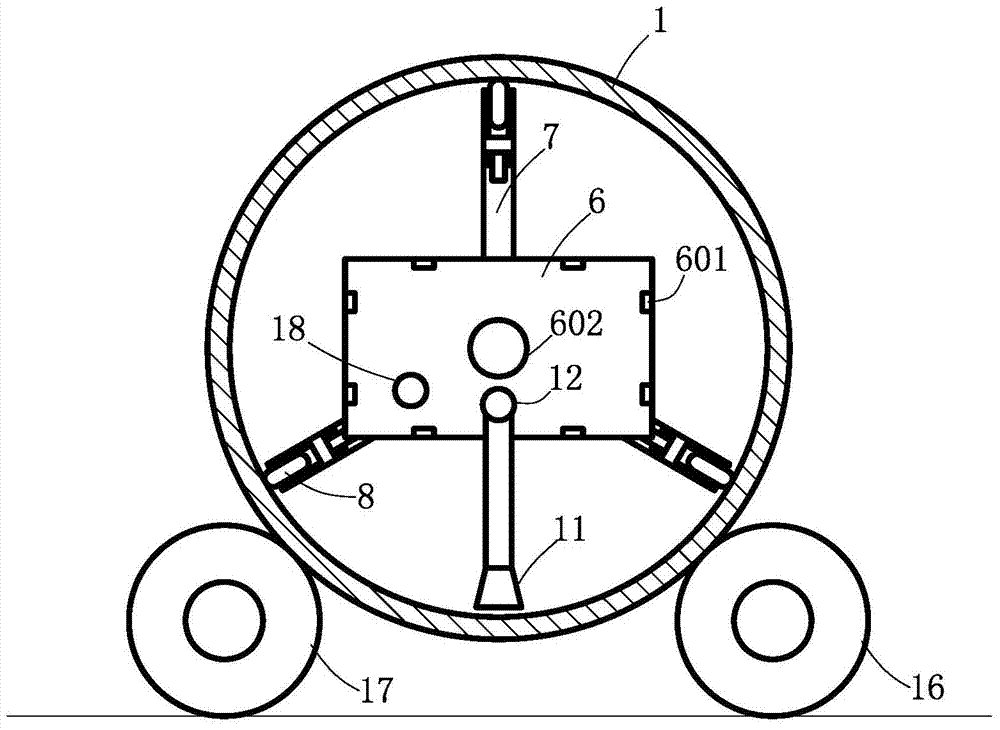

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

Entrainment air flow control and filtration devices

ActiveUS20090311951A1High energyImprove performanceCombination devicesAuxillary pretreatmentFiltrationAir treatment

Devices and systems are provided, that entrain ambient air within a primary stream of pressurised air, for use in a variety of applications including aircraft, buildings and other stationary structures. The ambient air is drawn through an air treatment such a filter before entrainment within the primary stream. The combined streams are then delivered to a ventilation system, an air curtain or other suitable recipient of treated, thermally conditioned air. The systems include air curtain systems and ventilation systems for aircraft and other vehicles.

Owner:VEFT AEROSPACE TECH

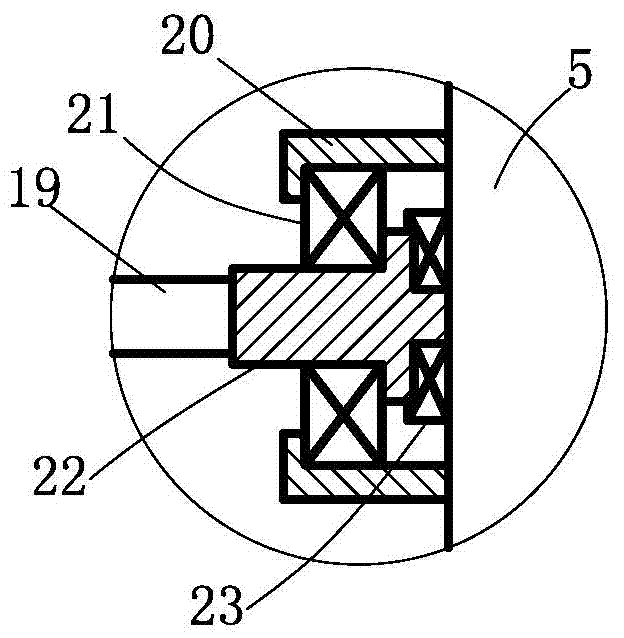

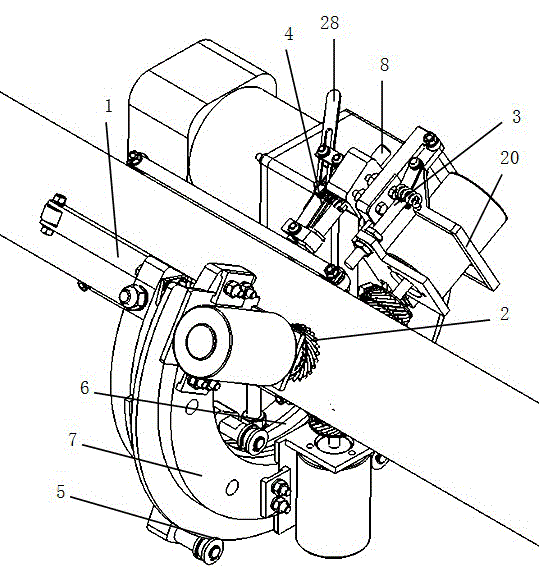

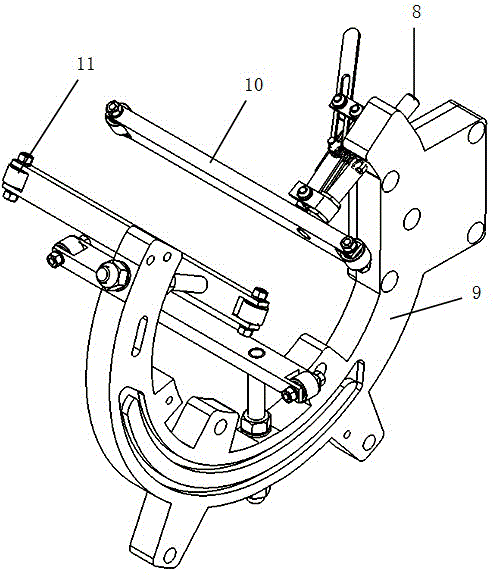

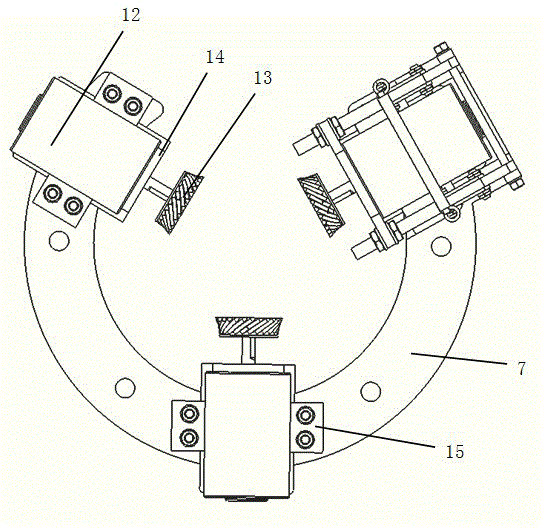

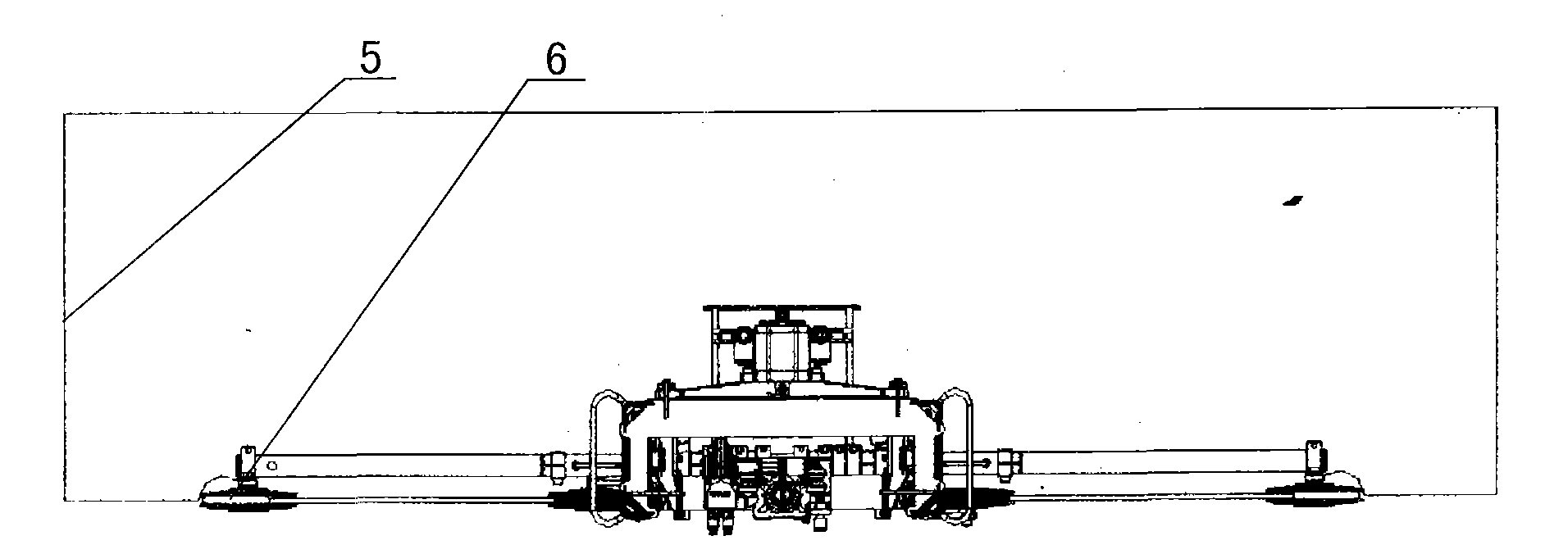

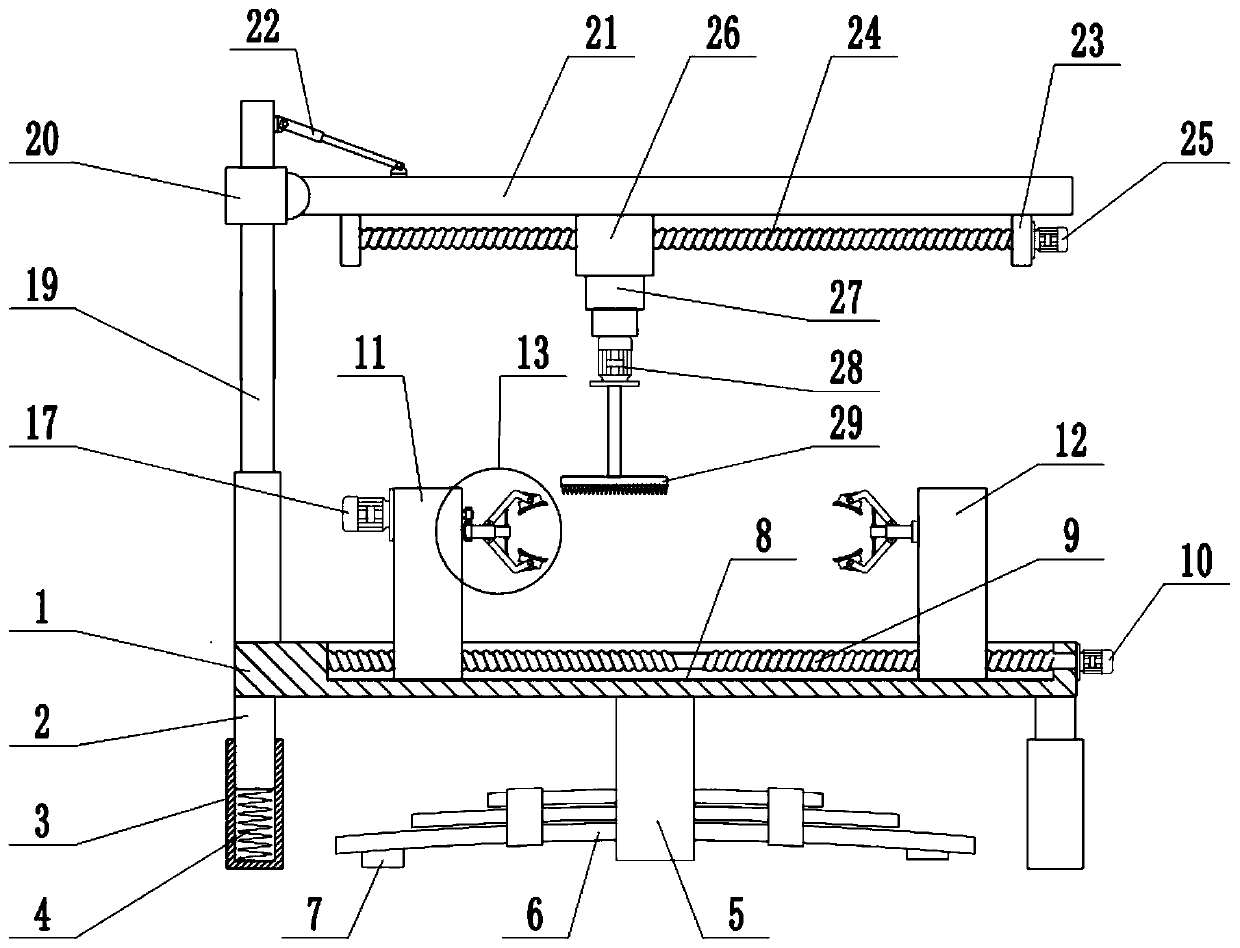

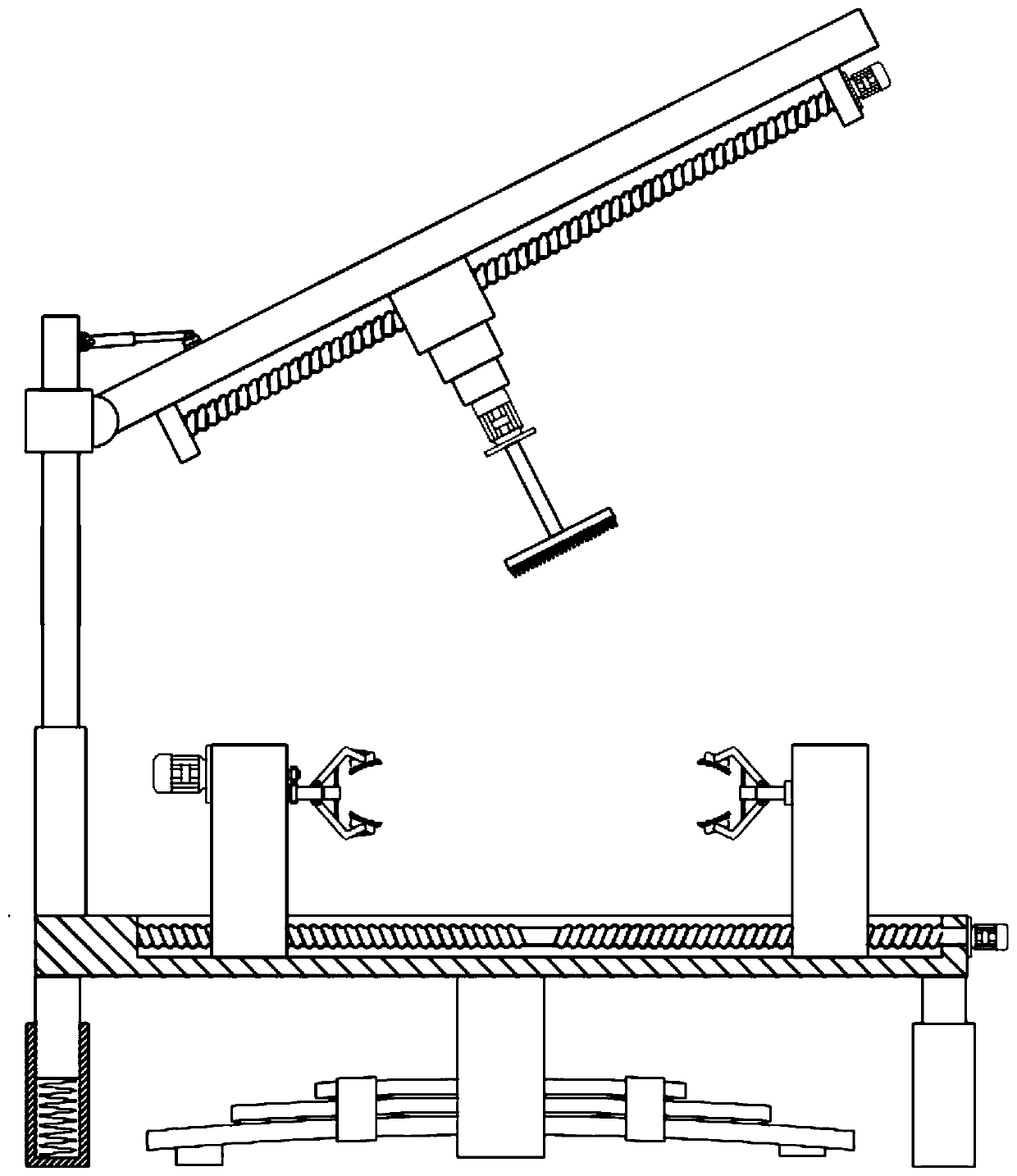

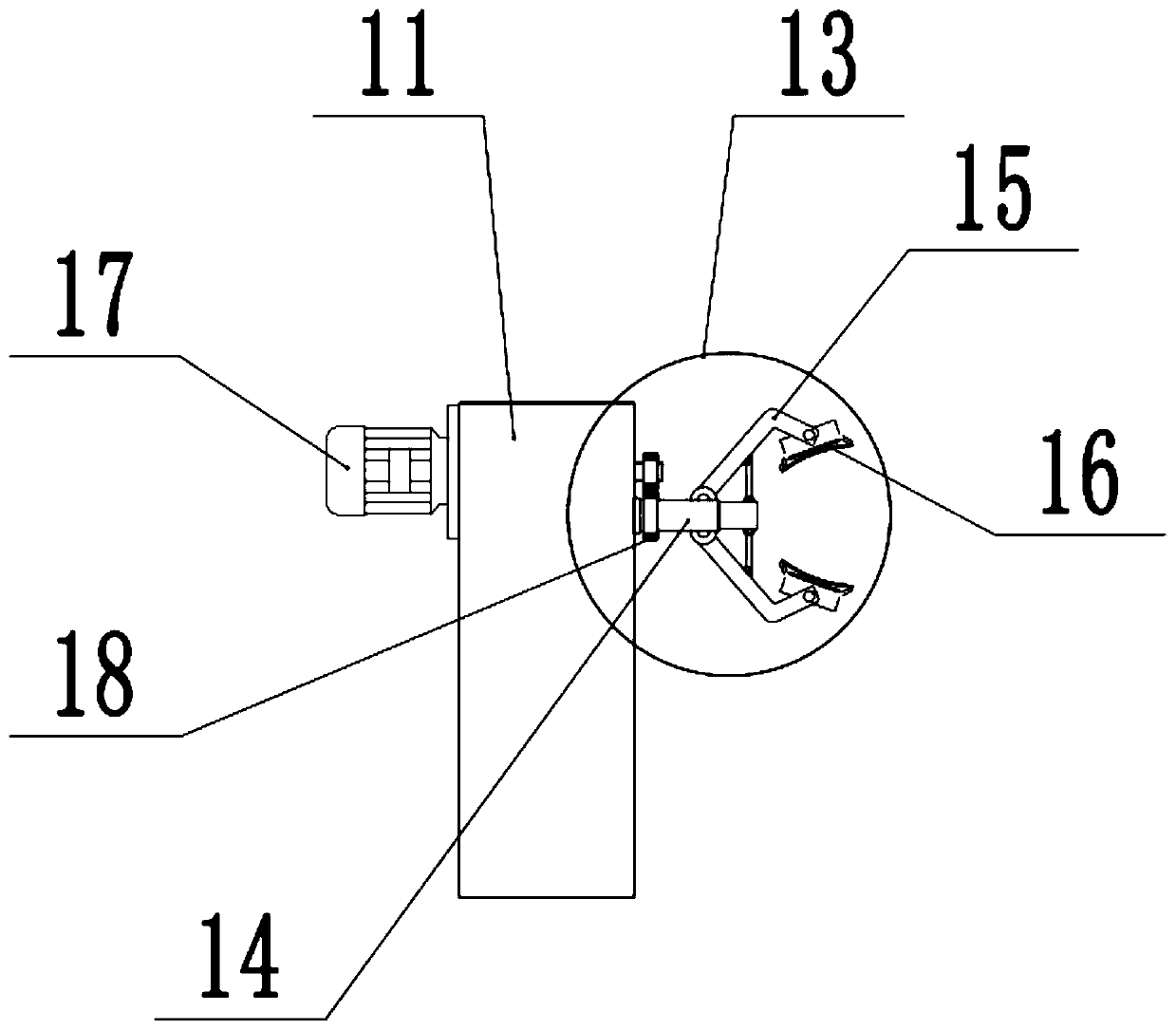

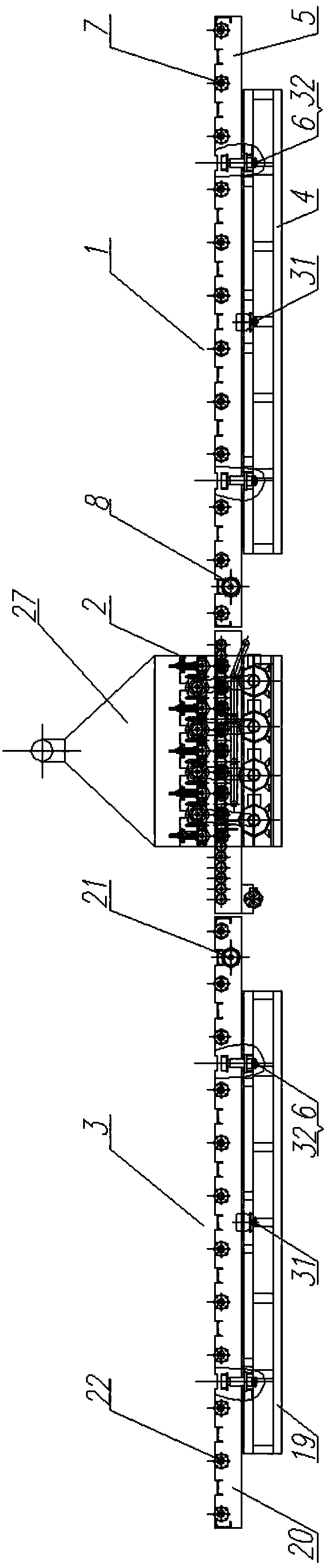

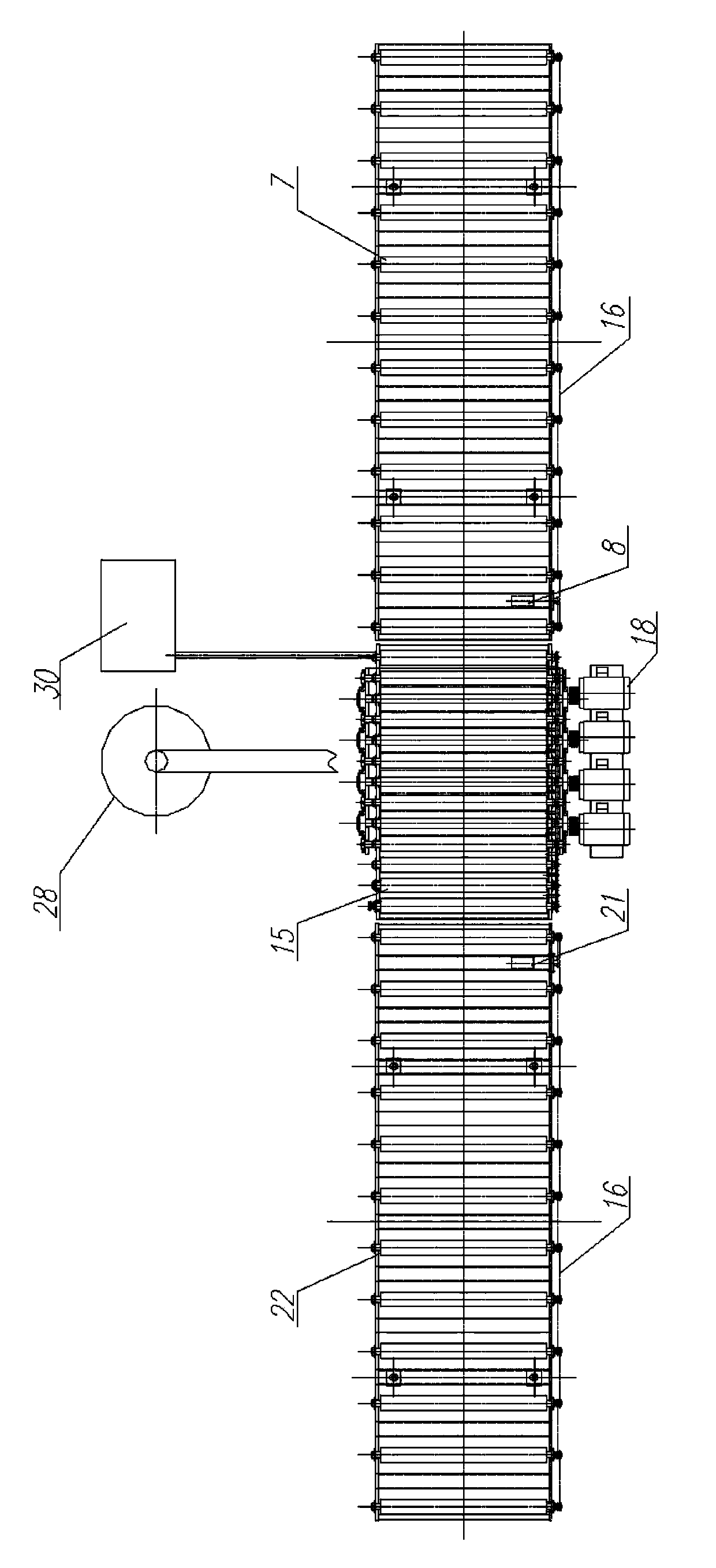

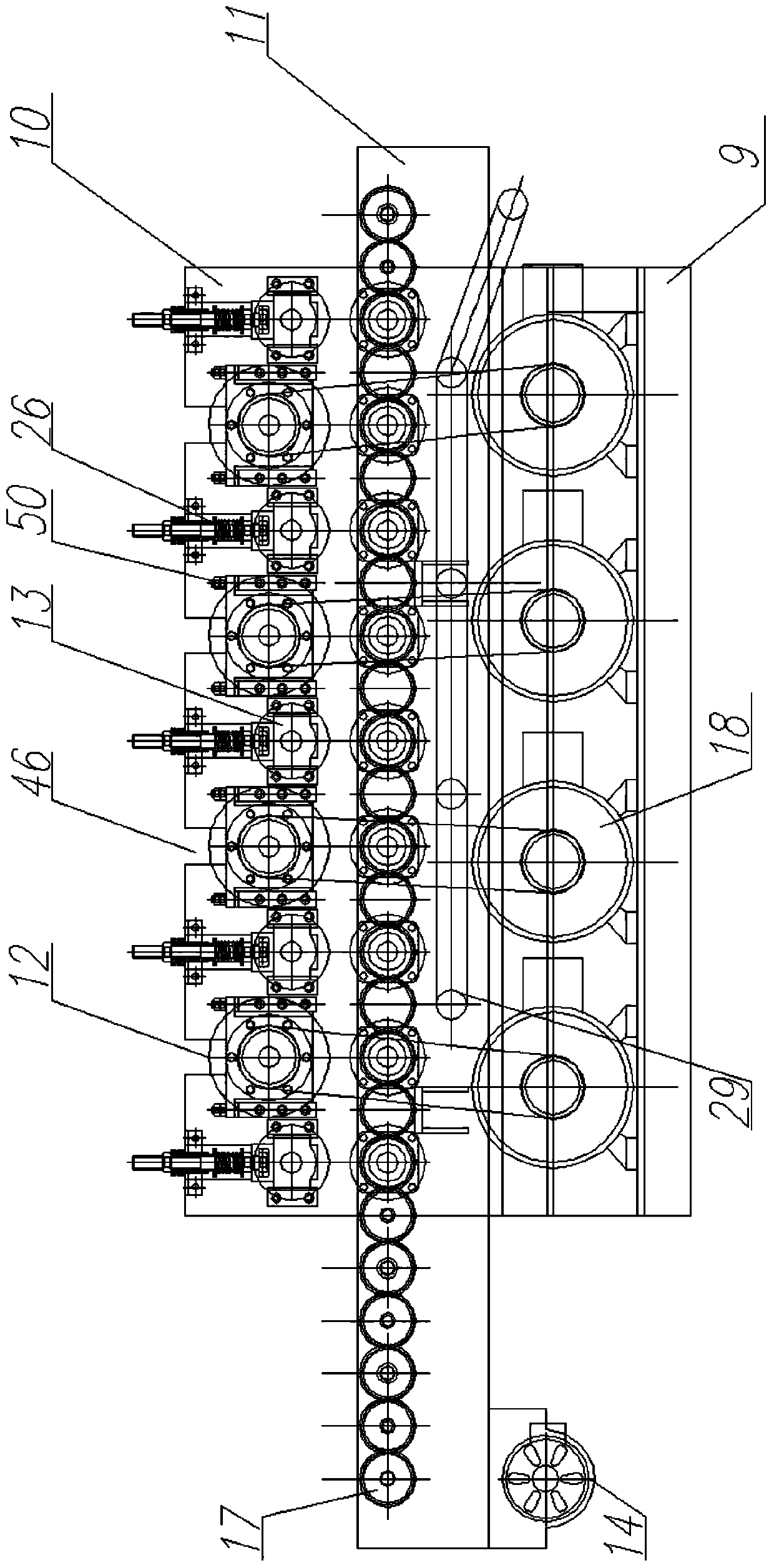

Derusting and polishing device for outer surface of steel pipe

The invention discloses a derusting and polishing device for the outer surface of a steel pipe. The device comprises a rack part (1), a polishing part (2), a polisher locking mechanism (3), a rack locking mechanism (4), a guide rail part (5) and a reciprocating mechanism (6); a high-speed motor drives a steel wire brush to rotate for polishing and derusting the outer surface of the steel pipe, and the reciprocating mechanism (6) drives the polishing part (2) to rotate around a shaft of the steel pipe in a reciprocating manner to achieve the purposes of derusting and polishing the outer surface of the whole circumference of the cylindrical steel pipe; the device is suitable for steel pipes with different diameters due to the adjustable structure; the device is convenient and quick to mount and dismount due to the arrangement of the polisher locking mechanism (3) and the rack locking mechanism (4). The device can be applied to derusting and polishing of the outer surfaces of cylindrical metal guard railings and suspended metal pipelines in public places.

Owner:GUANGDONG UNIV OF TECH

Ruthenium-barrier polishing slurry

InactiveUS20080148649A1Reduce removal rateOther chemical processesSemiconductor/solid-state device manufacturingDielectricEthylene oxide

The polishing slurry is useful for removing ruthenium layers from patterned semiconductor substrates in the presence of at least one nonferrous interconnect metal and a dielectric. The polishing slurry includes 0.001 to 10 weight percent periodic acid or salt, at least 0.0001 weight percent inhibitor for reducing removal rate of the nonferrous interconnect metals, 0.00001 to 5 weight percent organic additive for reducing dielectric removal rate, the organic additive being selected from at least one of water soluble polymers and surfactants, the organic additive containing an ethylene oxide group or an amide group, 0.1 to 50 weight percent abrasive and balance water; and the slurry having a pH of greater than 8 to 12.

Owner:LIU ZHENDONG

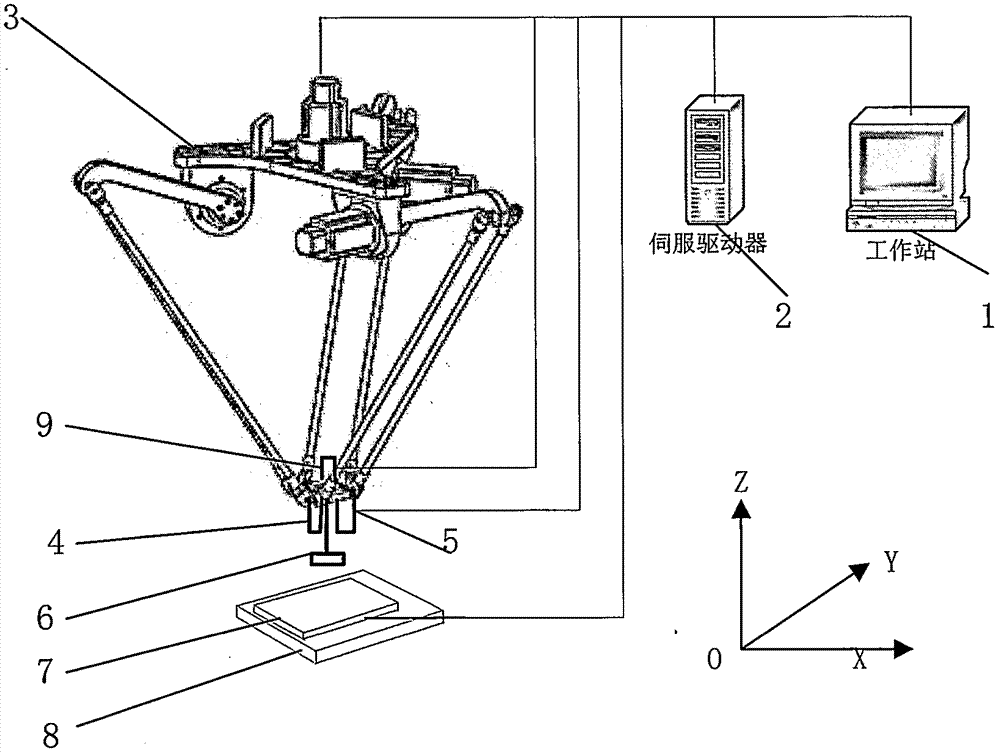

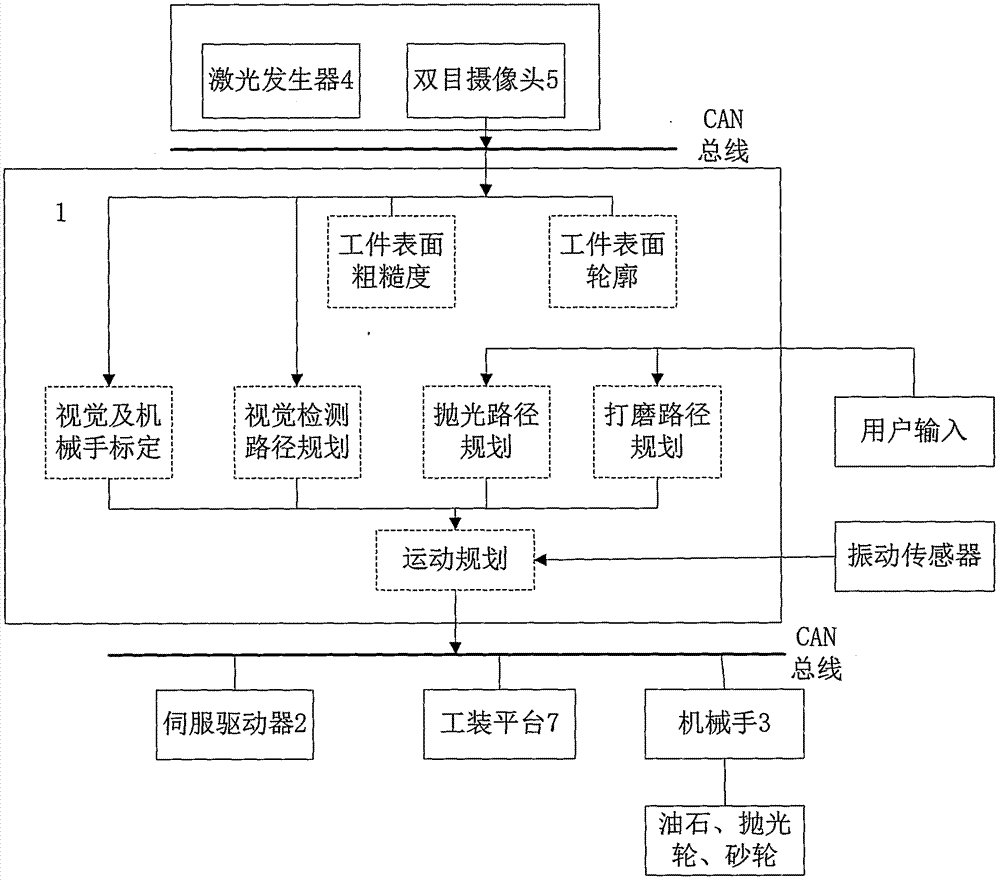

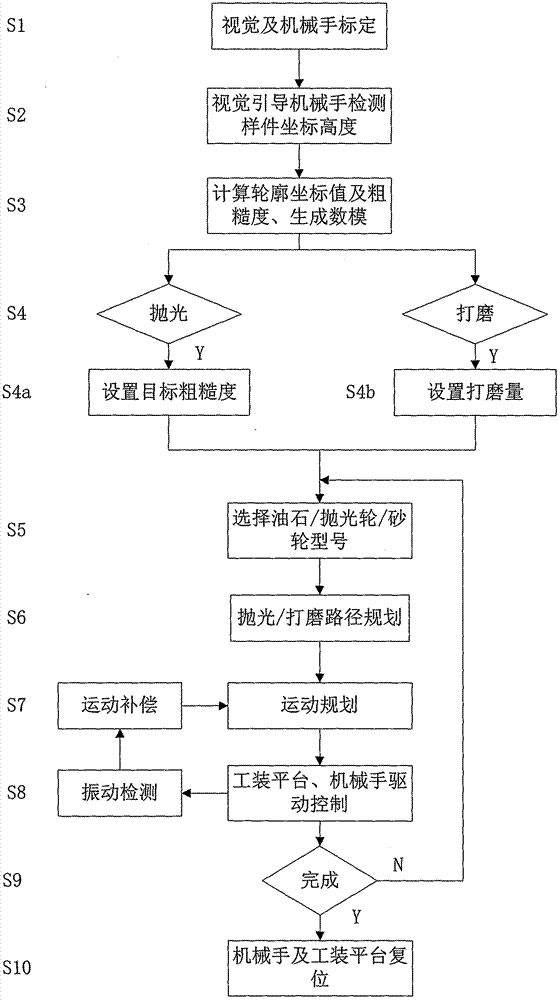

Complex curved face grinding and polishing system and method

InactiveCN107052950AFlexible setting methodHigh speedProgramme-controlled manipulatorGrinding feed controlThree degrees of freedomEngineering

The invention relates to a complex curved face grinding and polishing system and method. The system comprises a three-degree-of-freedom manipulator, a visual detection device, a vibrating sensor and a three-degree-of-freedom tool platform. An installation clamp is arranged at the tail end of the manipulator and can install an oilstone, a polishing wheel and a grinding wheel. The visual detection device comprises a laser generating device and a binocular camera, is installed on the manipulator, and detects the outline and roughness of a workpiece. During working, the workpiece is installed on the three-degree-of-freedom tool platform. The visual detection device guides the manipulator to scan the outline of the workpiece, a three-dimensional outline data model is generated, and the roughness is analyzed. Polishing or grinding setting can be conducted on a work station. During grinding, setting can be conducted in three modes that a referential three-dimensional data model is compared with an actually measured workpiece three-dimensional data model, modification is conducted on the actually measured three-dimensional data model with a drawing tool, and grinding data are directly set on the actually measured three-dimensional data model.

Owner:上海莫亭机器人科技有限公司

Fluid dispense tips

InactiveUS6981664B1Further-reduced surface tensionIncreased dispensing precision capabilityLiquid surface applicatorsClosuresDecreased pressureBiomedical engineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. The tip may optionally be formed with a Luer™-style fitting on the body, such that the tip is compatible with pumps that utilize such a fitting.

Owner:DL TECH

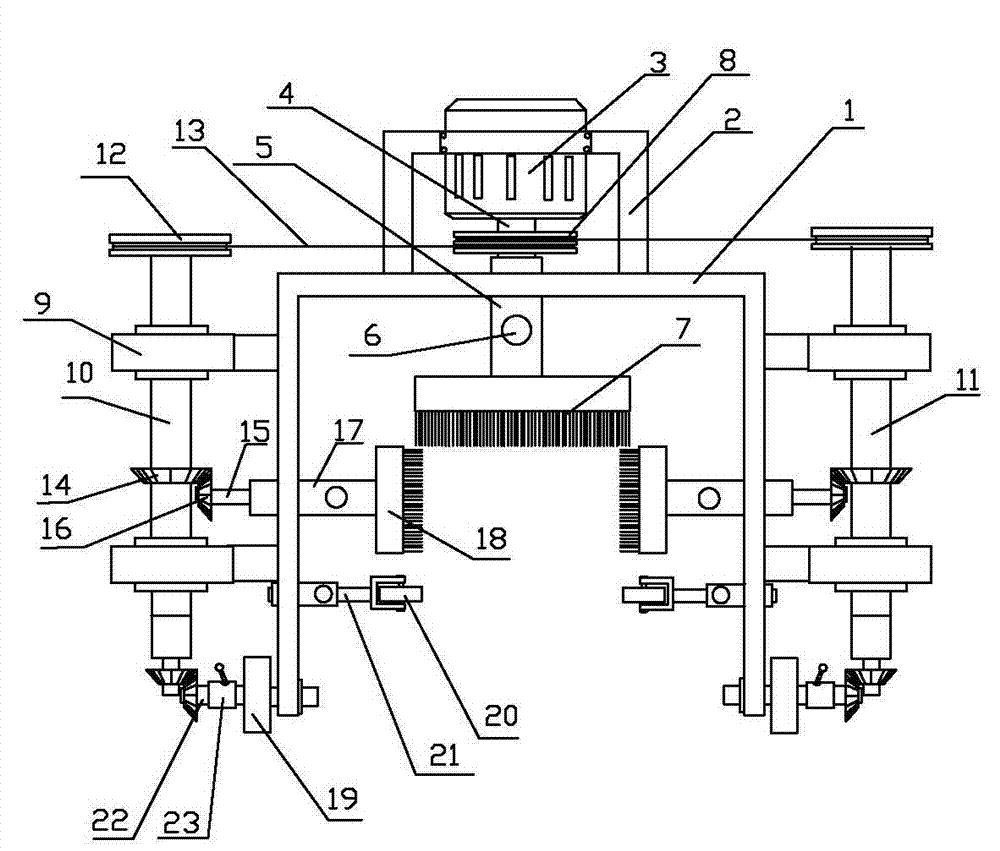

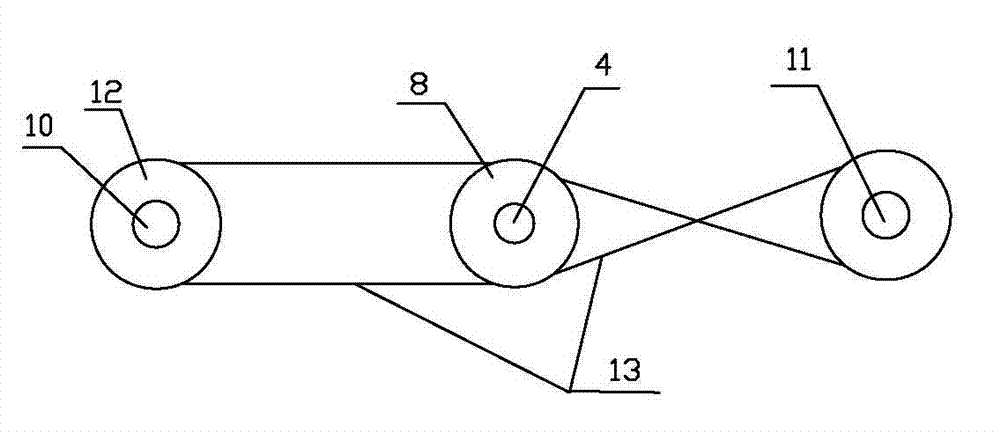

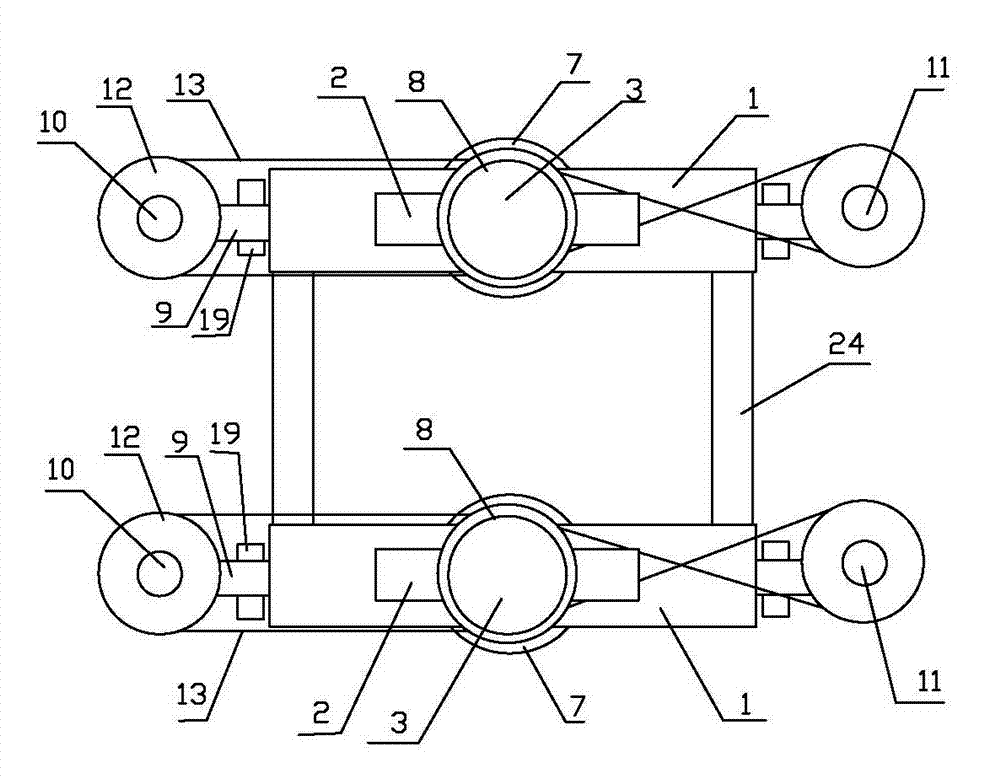

Square tube multiple face synchronous derusting machine

The invention discloses a square tube multiple face synchronous derusting machine. The derusting machine comprises an inverted-U-shaped rack and is characterized in that an upper motor is fixed to the middle of the upper wall of the inverted-U-shaped rack, and an upper horizontal rotating wire brush is fixed to the lower end of a shaft sleeve of a motor spindle, a fixed belt wheel at the upper end of the spindle is connected with driven shafts outside the left wall and the right wall of the inverted-U-shaped rack for transmission, and the middle of the driven shaft on the left and the middle of the driven shaft on the right are respectively meshed with a shaft end bevel gear of a transverse rotating shaft for transmission through a bevel gear; each transverse rotating shaft is provided with a transverse shaft sleeve connected with the transverse rotating shaft in a matched mode through a spline, and an upper perpendicular face rotating wire brush is fixed to the inner end of each transverse shaft sleeve; idler wheels are arranged at the bottom end of the inverted-U-shaped rack; synchronous rotation of the horizontal rotating wire brush and the perpendicular face rotating wire brushes is achieved through one motor, and thus the upper surface and the two side faces of a square tube can be polished and derusted synchronously. Thus, dust on the surface of the square tube can be cleared away fast with the derusting machine, energy is saved, labor efficiency can be improved, and the using effect of the square tube is improved.

Owner:南通通州东大机械有限公司

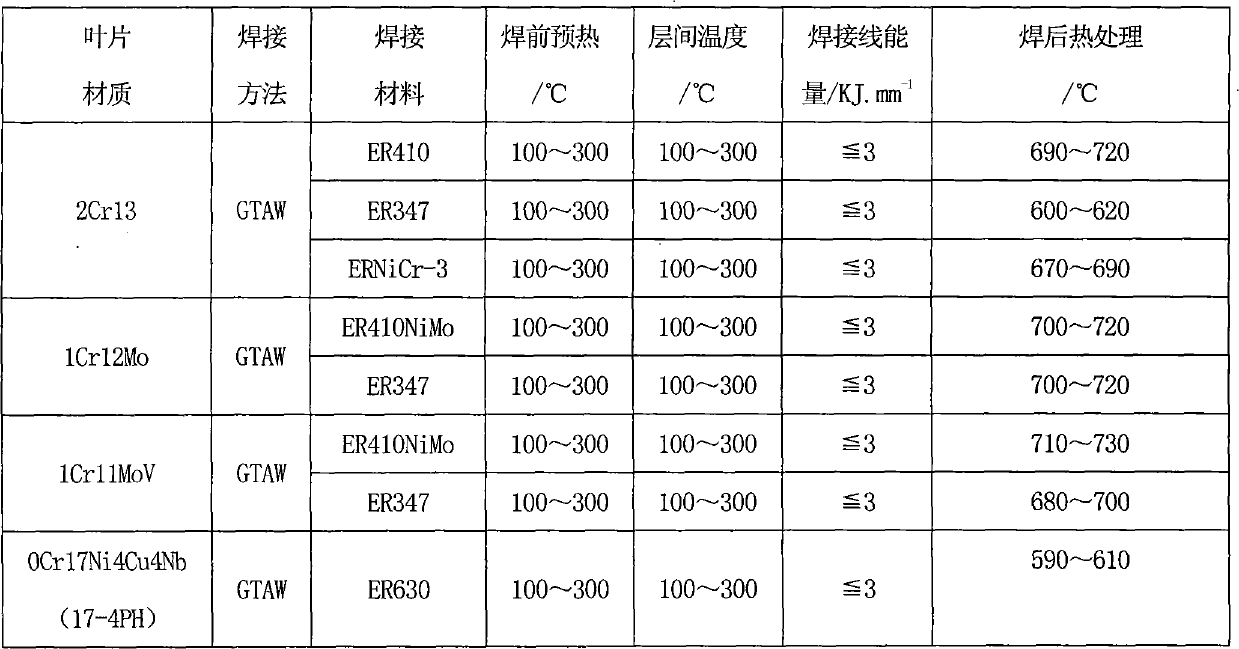

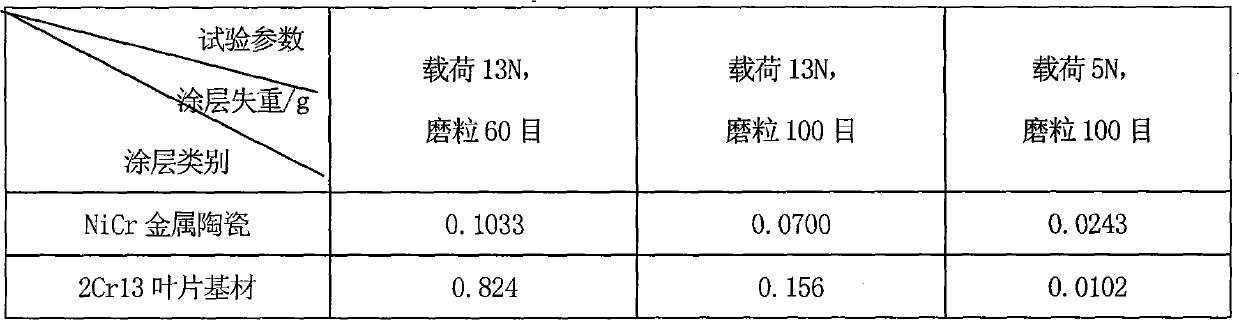

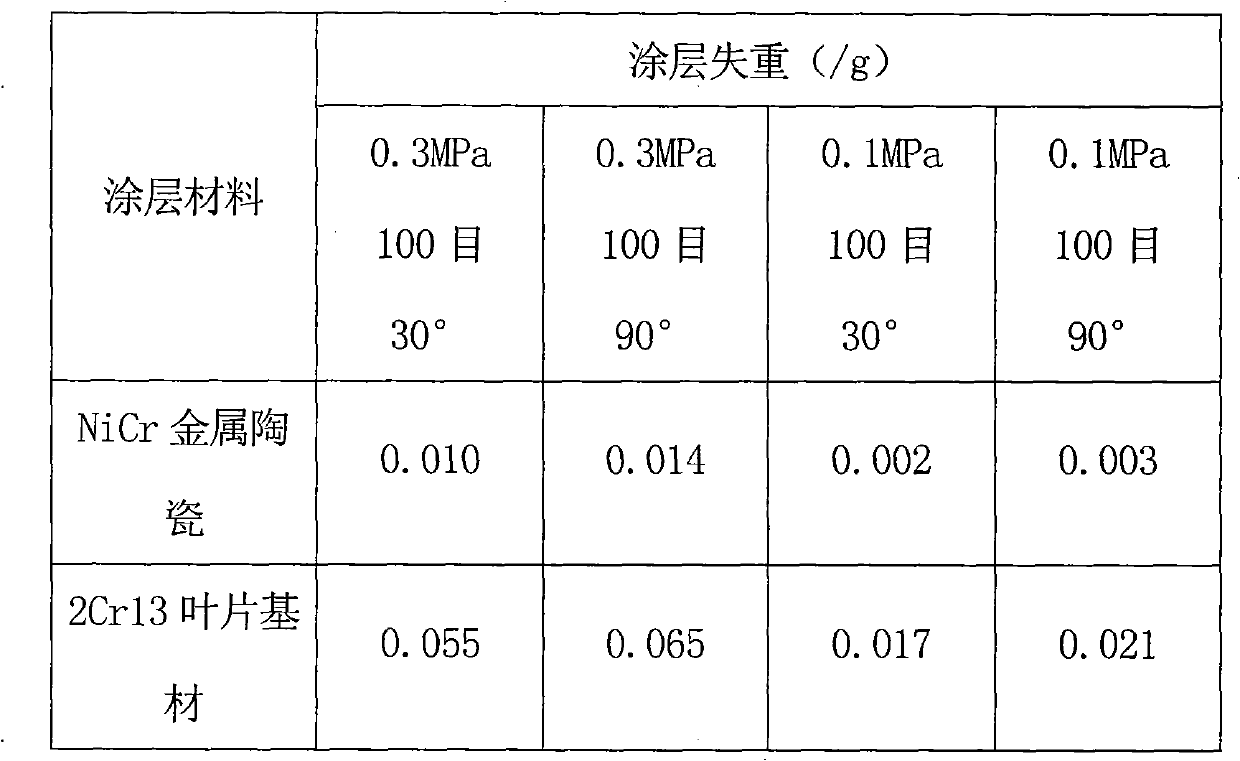

Process for repairing water erosion damage of flow passage component of steam turbine and protecting flow passage component of steam turbine

ActiveCN101767261AExtended service lifeNo change in vibration characteristicsMolten spray coatingPolishing machinesPower stationEconomic benefits

The invention discloses a process for repairing water erosion damage of a flow passage component of a steam turbine and protecting the flow passage component of the steam turbine. In the process, molded lines of the flow passage component of the steam turbine are repaired by adopting copy overlaying of manual argon tungsten arc welding aiming at the phenomenon of the water erosion damage existing in the flow passage component of the steam turbine. A water erosion resistant coating is prepared by supersonic speed flame spraying so as to achieve the purposes of repairing the molded lines of the flow passage component of the steam turbine and protecting the molded lines at large area on line and prolonging the service life of the flow passage component of the steam turbine. Through the process of the invention, the flow passage component of the steam turbine can be repaired and protected at large area on line in a short time without changing vibration characteristic, steam-driven characteristic and strength characteristic of the flow passage component of the steam turbine, so that the process has the advantages of high on-site operability, small deformation of the repaired workpiece, remarkable improvement on water erosion resistance and the like, can solve the common problem of water erosion in the flow passage component of the power station steam turbine in service on site, improves the running safety and efficiency of units and increases economic benefit of a power plant.

Owner:XIAN THERMAL POWER RES INST CO LTD

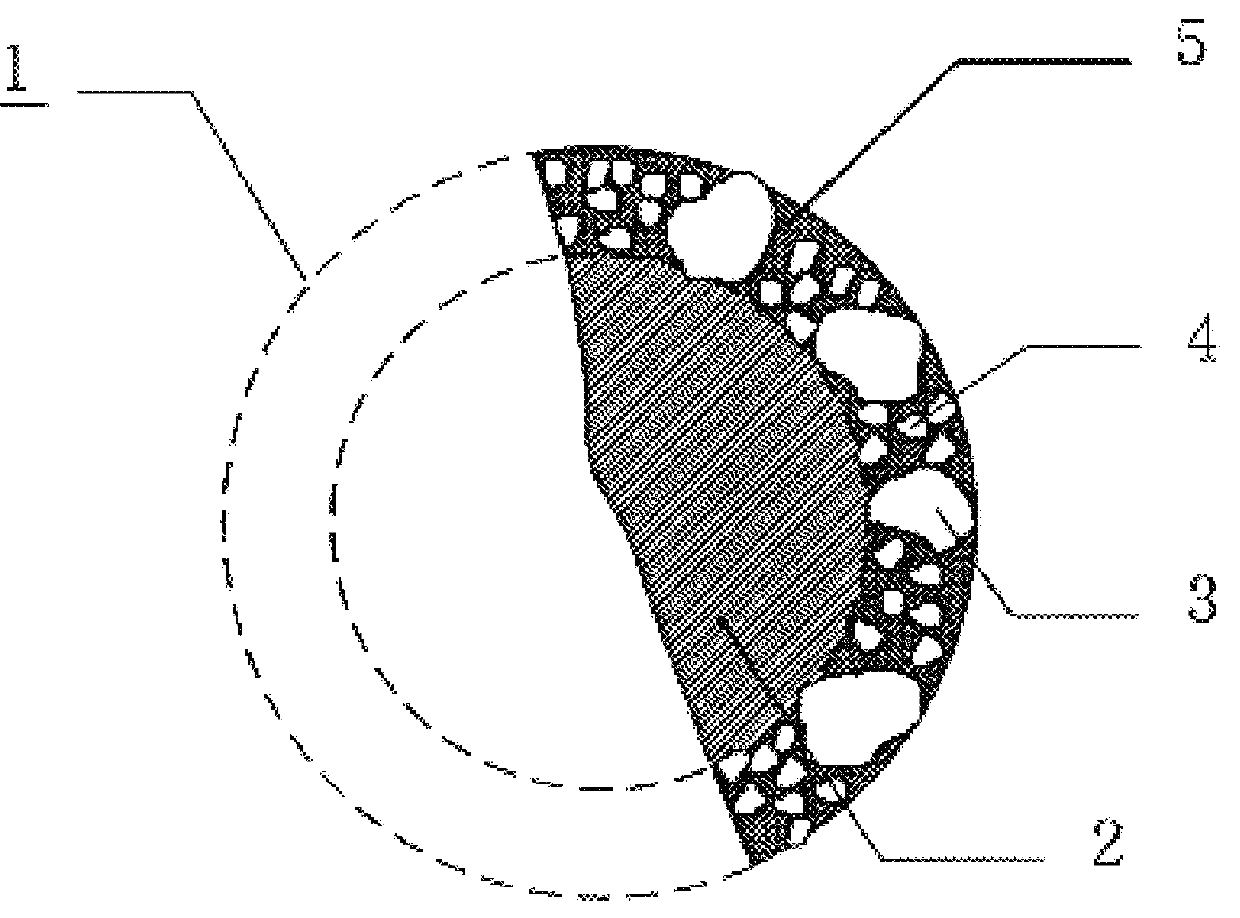

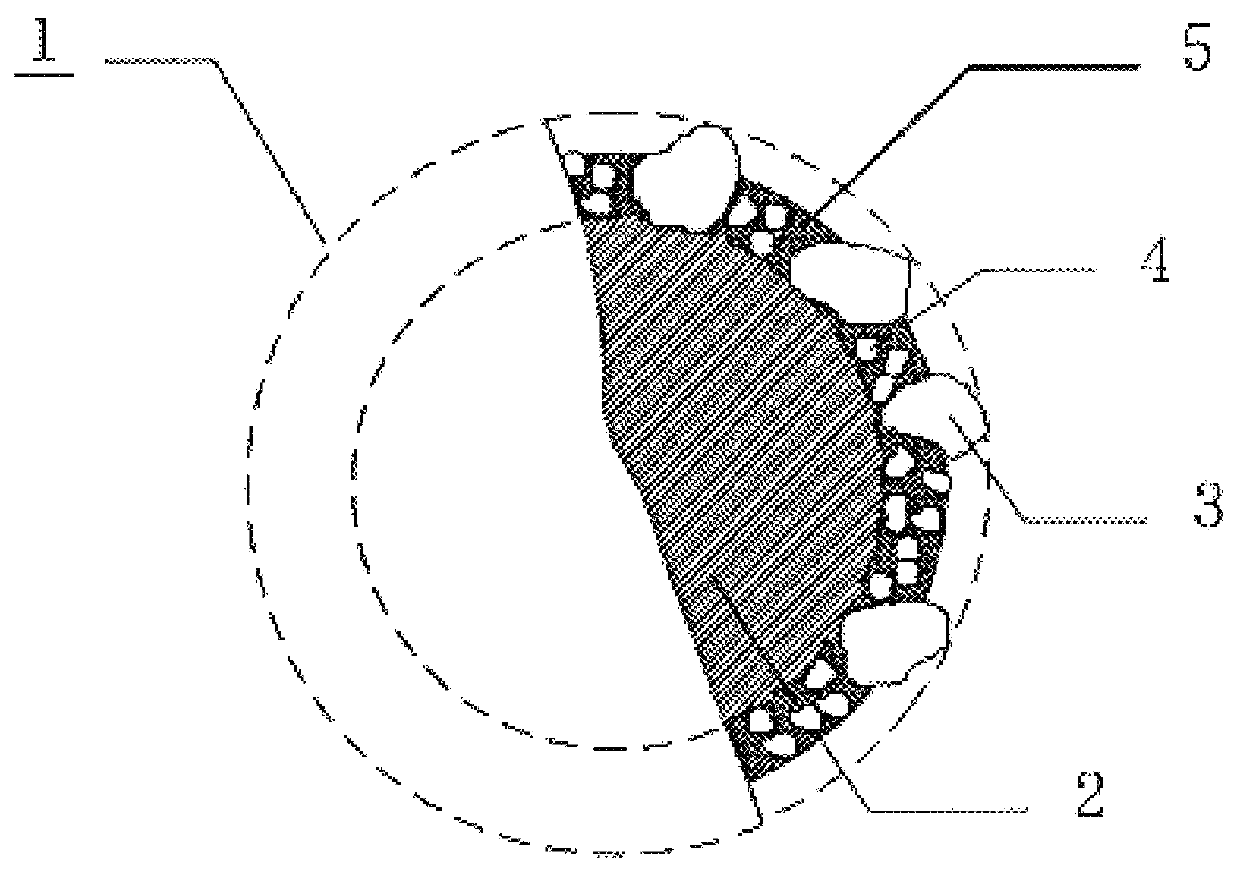

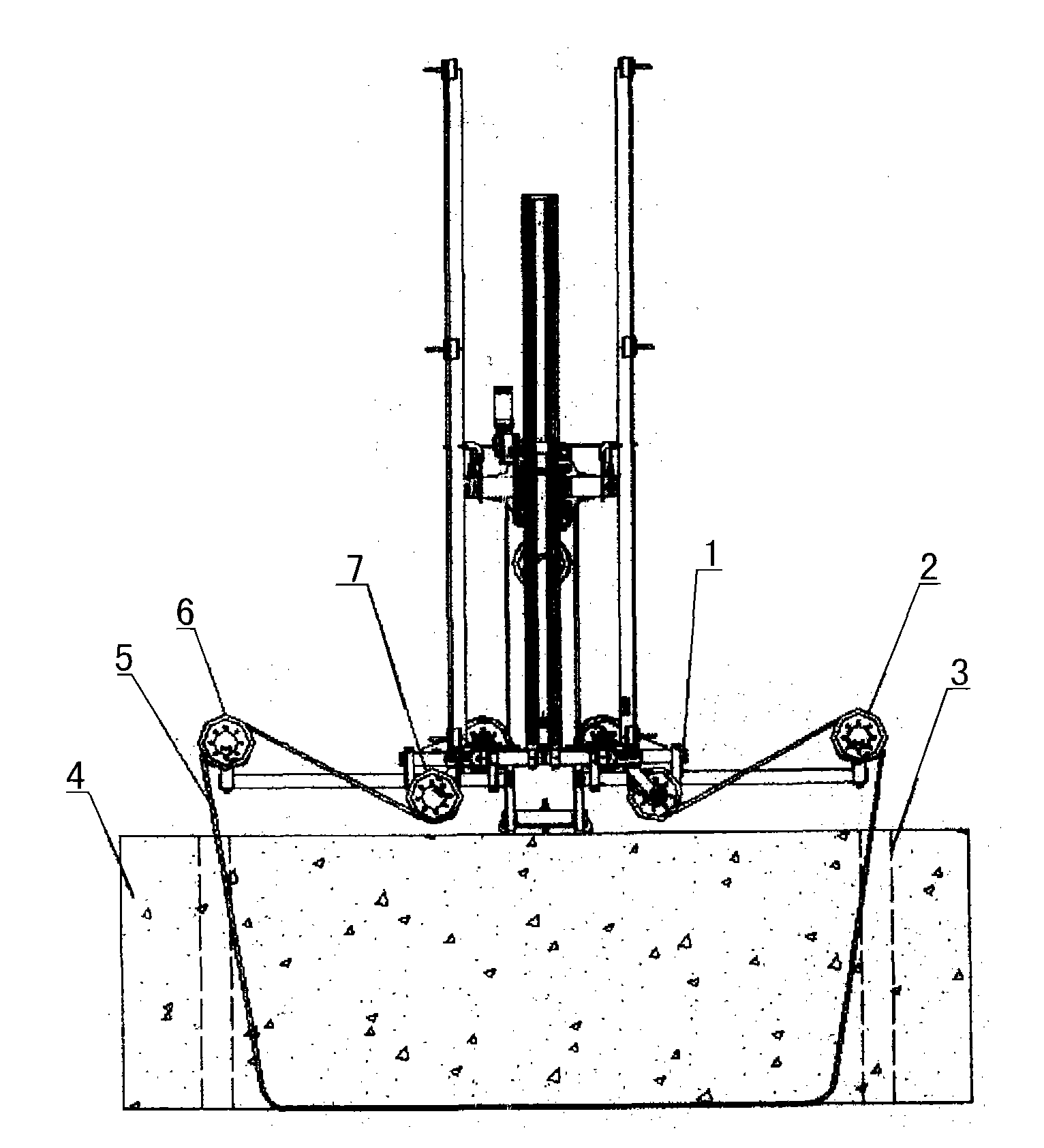

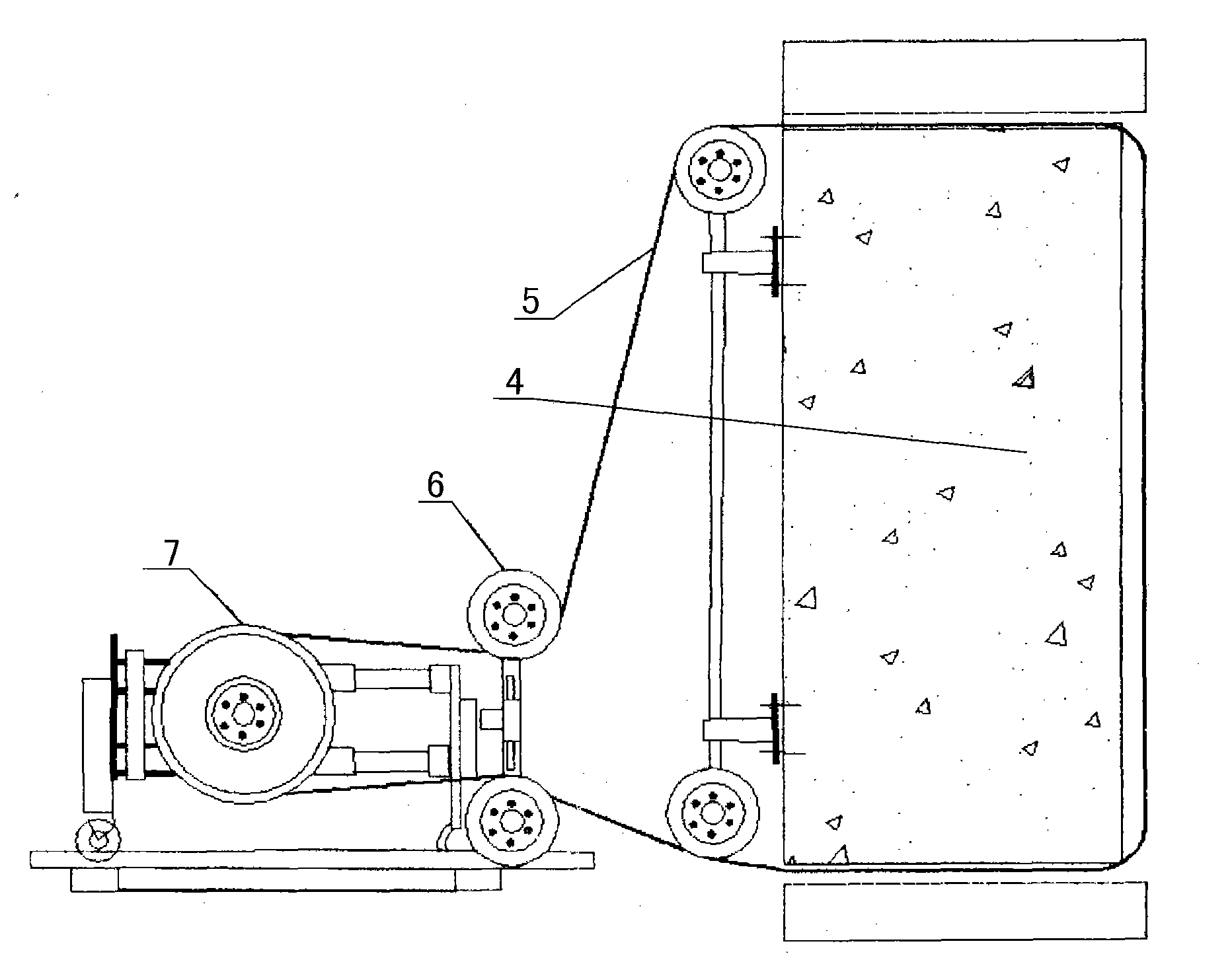

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Methods, Wires, and Apparatus for Slicing Hard Materials

Methods, wires, and apparatus for use in cutting (e.g., slicing) hard, brittle materials is provided. The wire can be a super-abrasive wire that includes a wire core and super-abrasive particles bonded to the wire core via a metal bonding layer. This wire, or another type of wire, can be used to slice workpieces useful for producing wafers. The workpieces can be aligned within a holder to produce wafers using the device and methods presently provided. The holder rotates about its central axis, which translates to workpieces moving in orbit around this axis. A single abrasive wire, or multiple turns of wire stretched tightly between wire guides, is then contacted with the rotating holder to slice the workpieces.

Owner:UNIVERSITY OF SOUTH CAROLINA

Wire saw for cutting hard and fragile materials and manufacturing method thereof

InactiveCN101564828AReduce sheddingImprove bindingAbrasion apparatusGrinding machinesCopper platingUV curing

The invention relates to a wire saw for cutting hard and fragile materials and a manufacturing method thereof. The wire saw is fixed with an grinding material on a core wire through a bonding agent and is characterized in that the bonding agent consists of an inner layer UV resin bonding agent and an outer layer heat reactive resin bonding agent; and the grinding material is evenly and continuously distributed in a monolayer mode around the core wire, partial grinding material is embedded in the UV resin bonding agent, other partial grinding material is exposed outside the heat reactive resin bonding agent to form an exit lip, and the rest part is enwrapped by the outer layer heat reactive resin. The grinding material adopts a diamond or CBN adopting surface metal plating; and the core wire adopts a copperized music wire. The manufacturing method is performed continuously and quickly according to the following steps: under the traction of a driving device, setting out the core wire continuously through a wire plate, surface preparation, cleaning, drying, coating with the inner layer UV resin bonding agent, grinding material cementation, UV curing, coating with the outer layer heat reactive resin bonding agent, thermocuring and drawing in a cable to form a plate. The wire saw and the method solve the problem of driving aspects before cured resin is completely cured, and can effectively solve the problem that the grinding material in the prior art is easy to agglomerate.

Owner:NANJING NORMAL UNIVERSITY

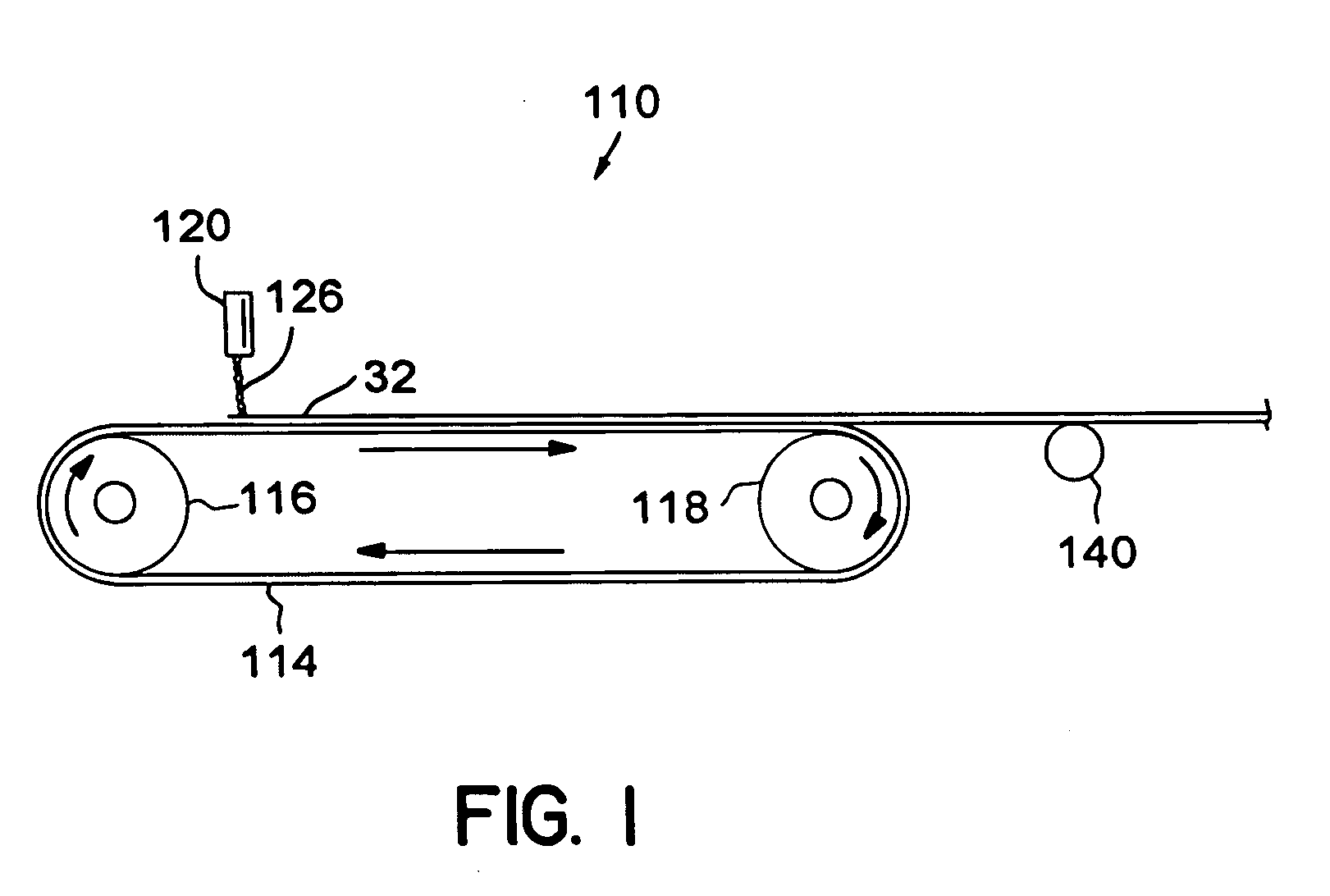

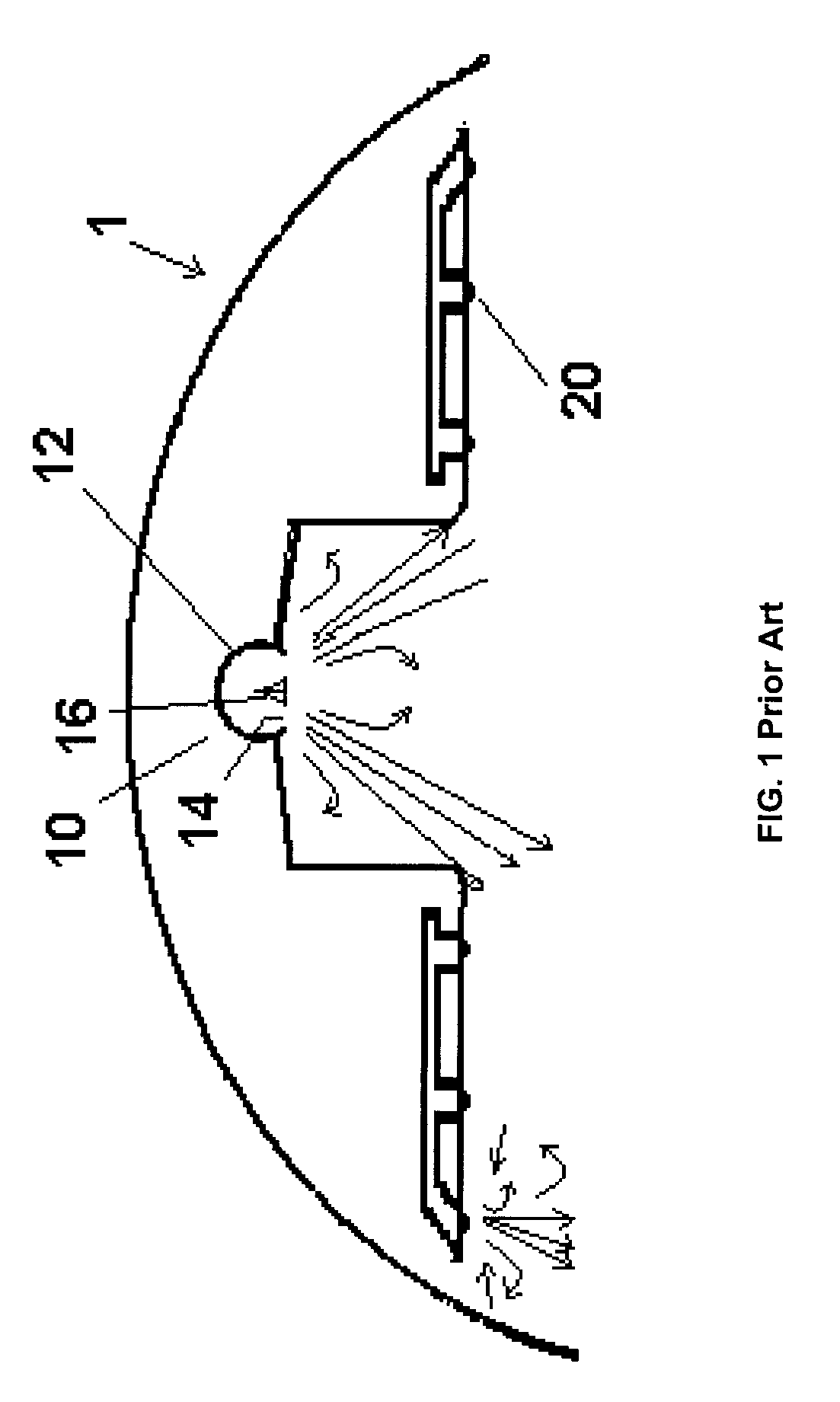

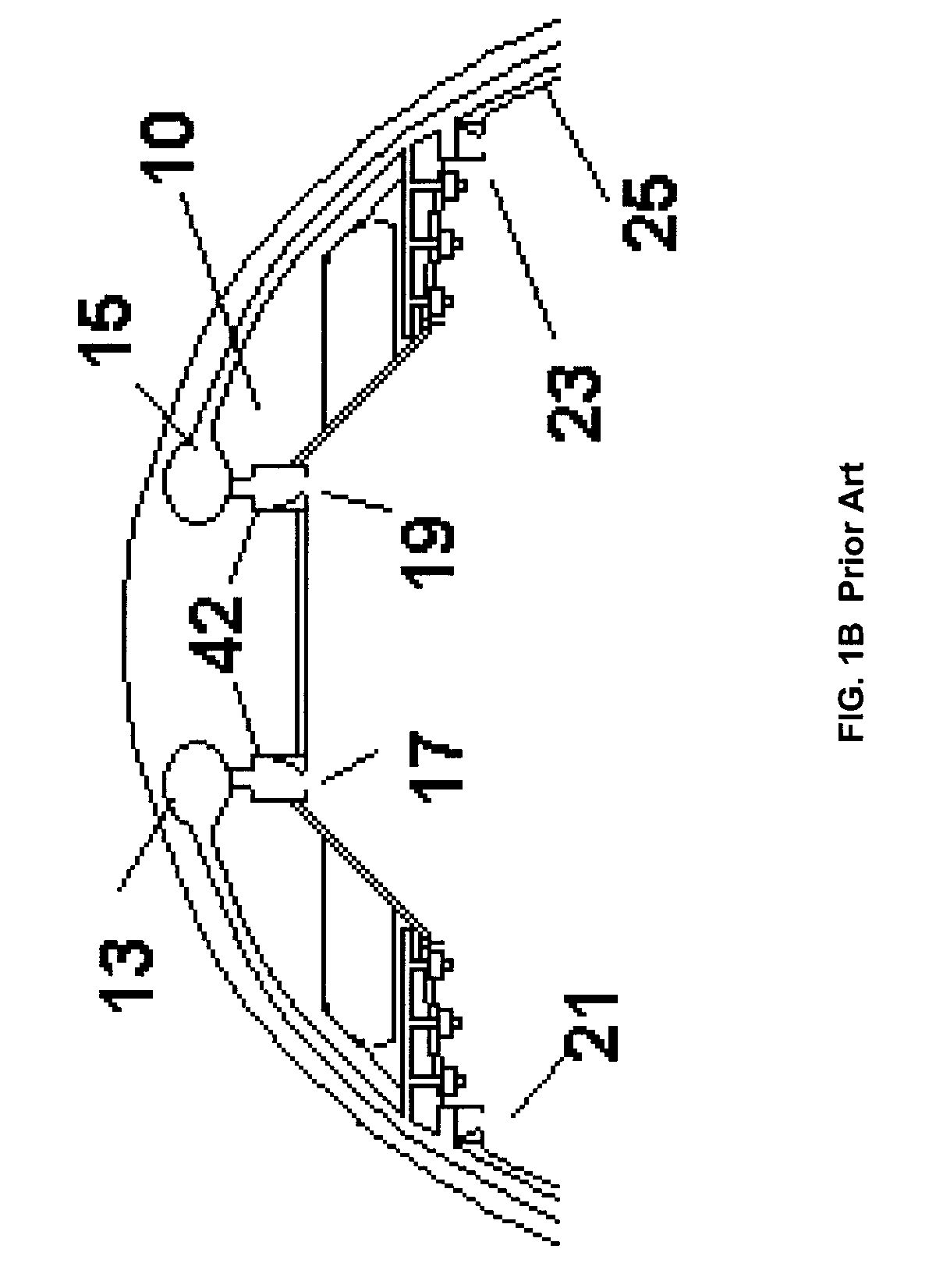

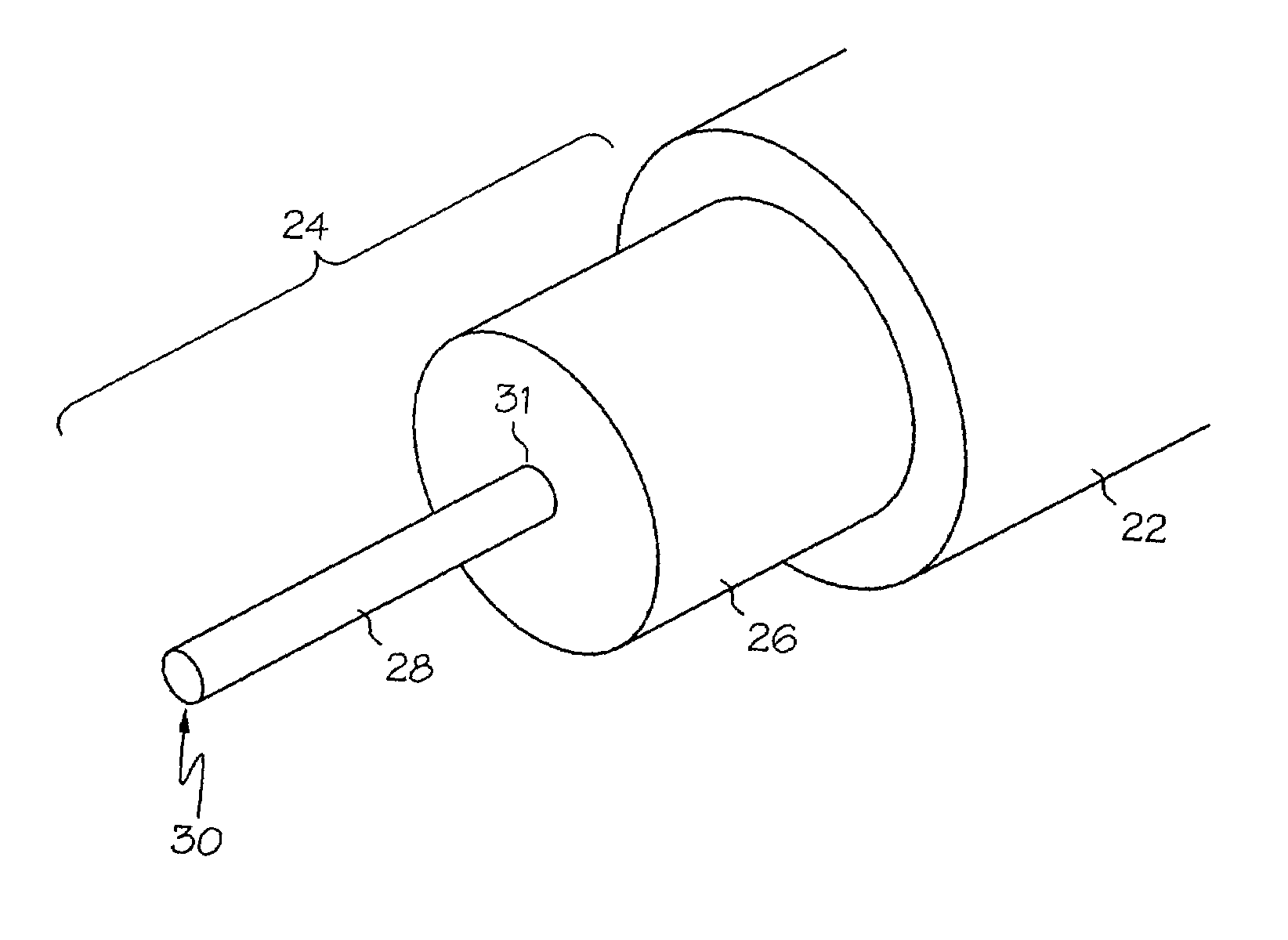

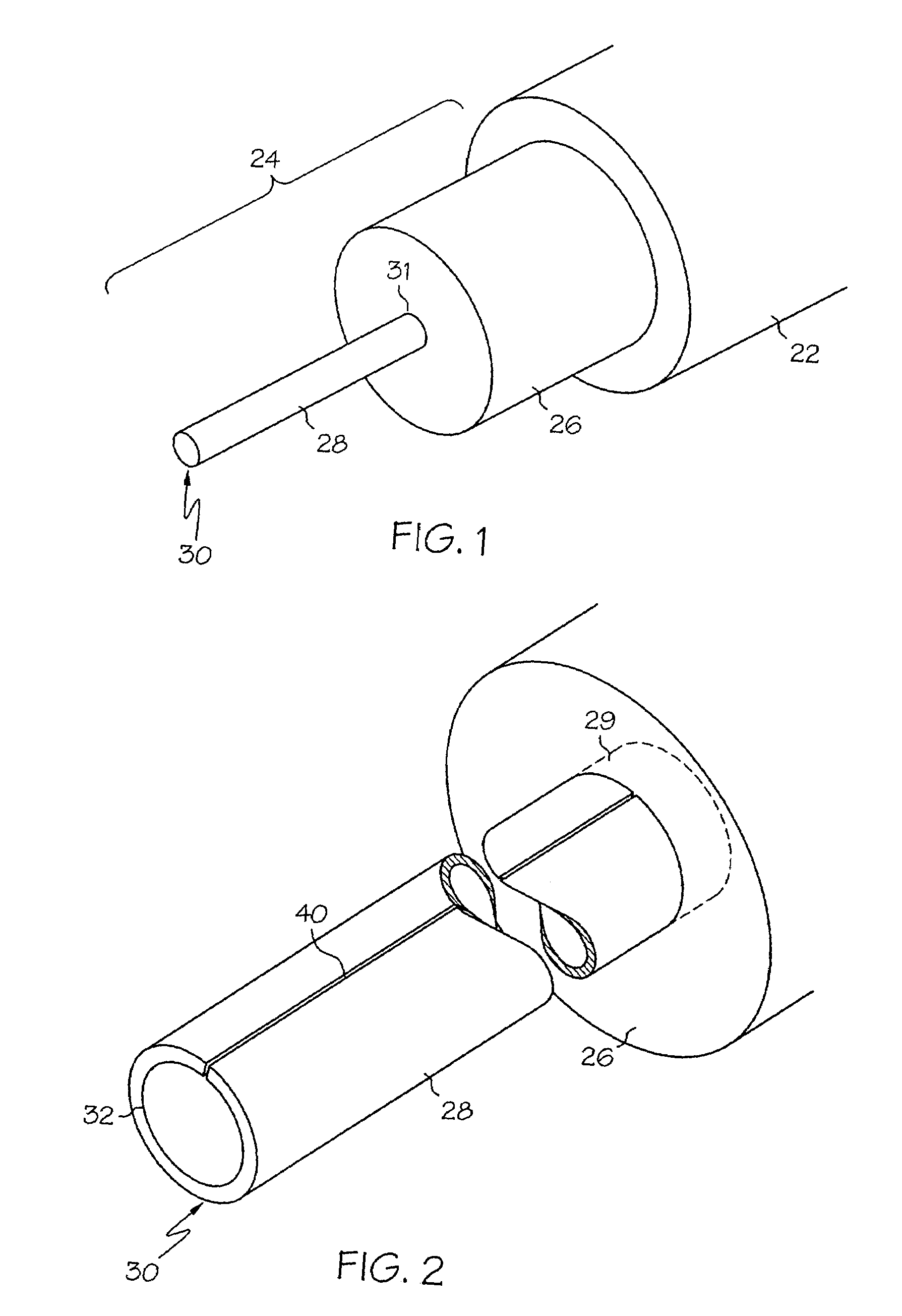

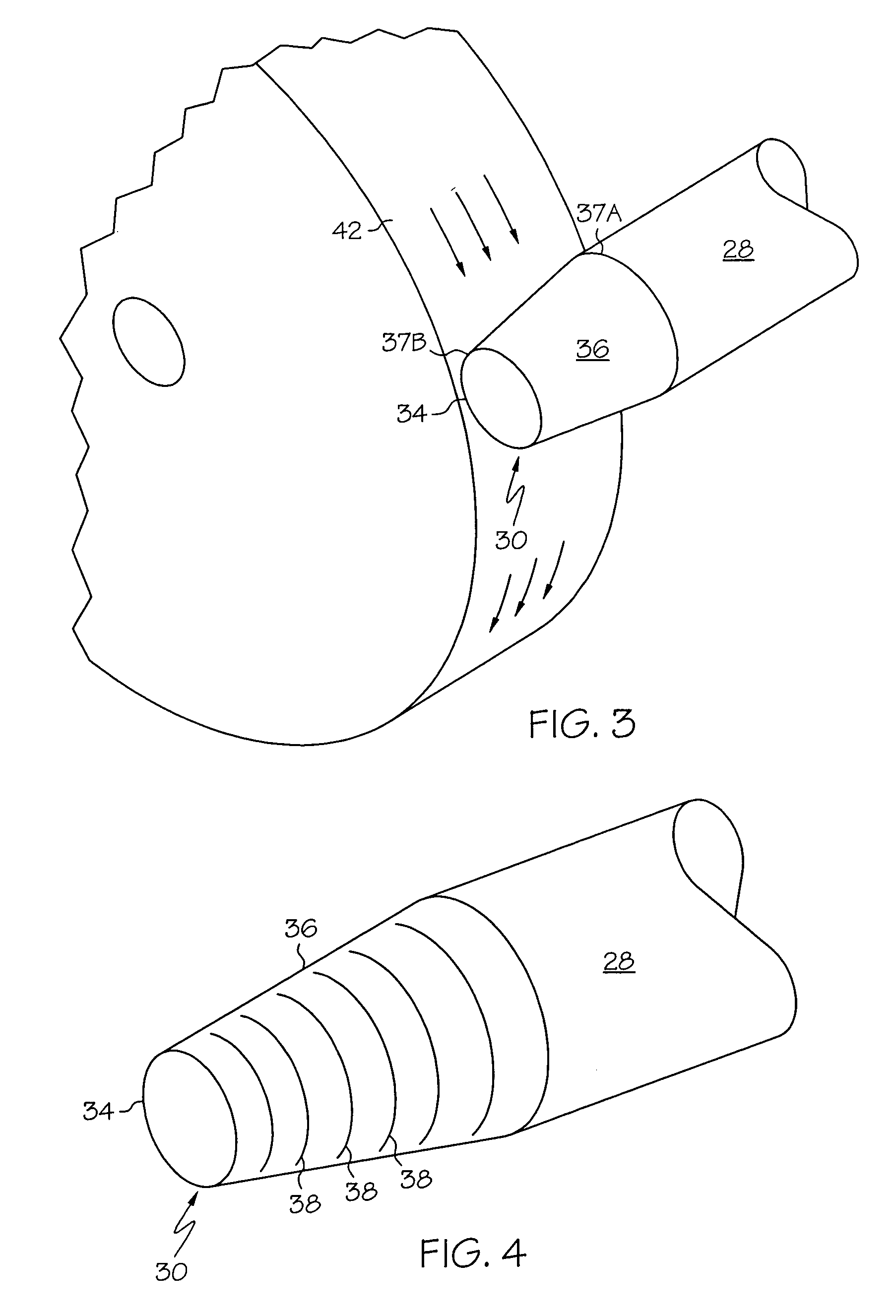

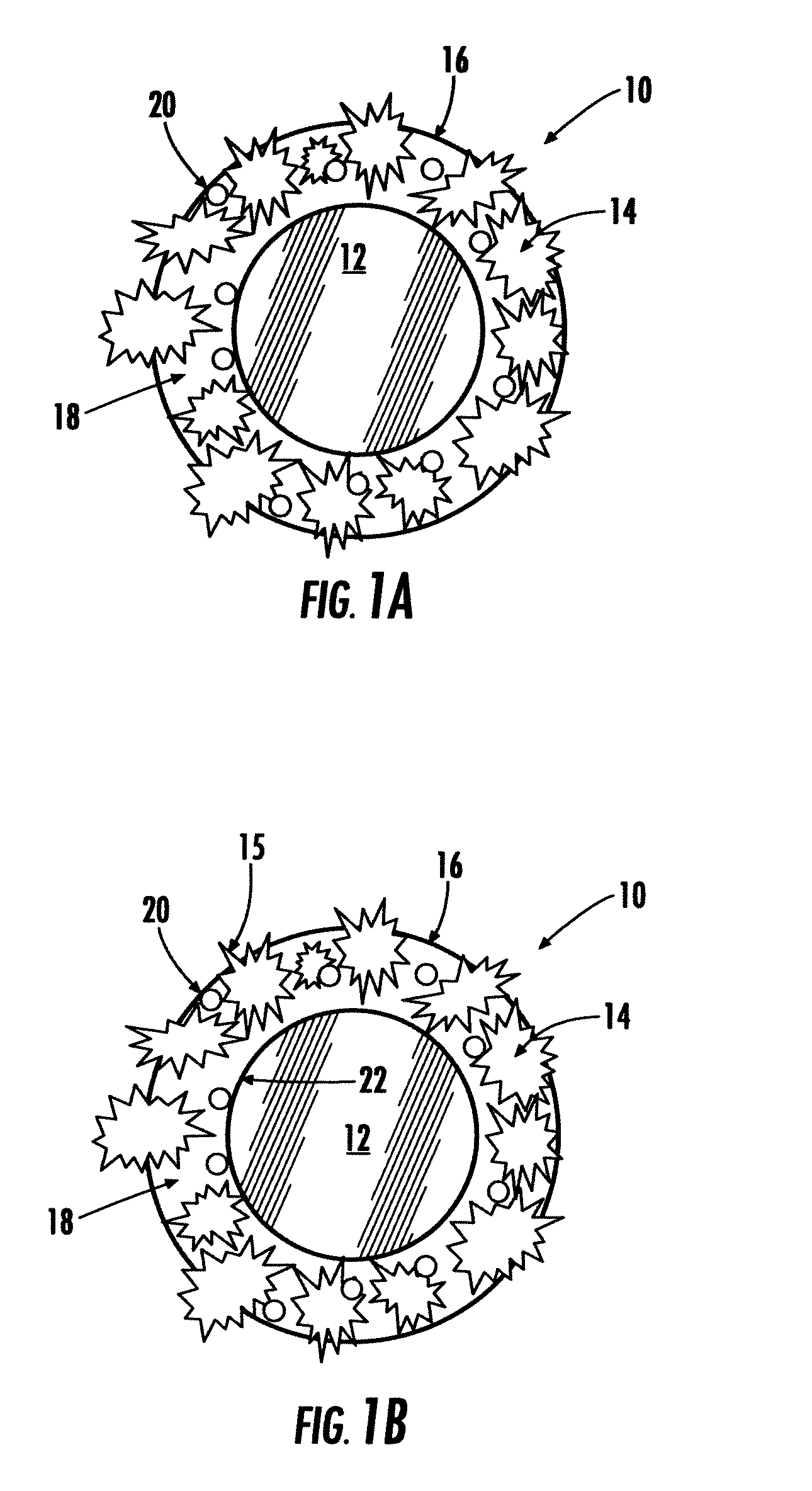

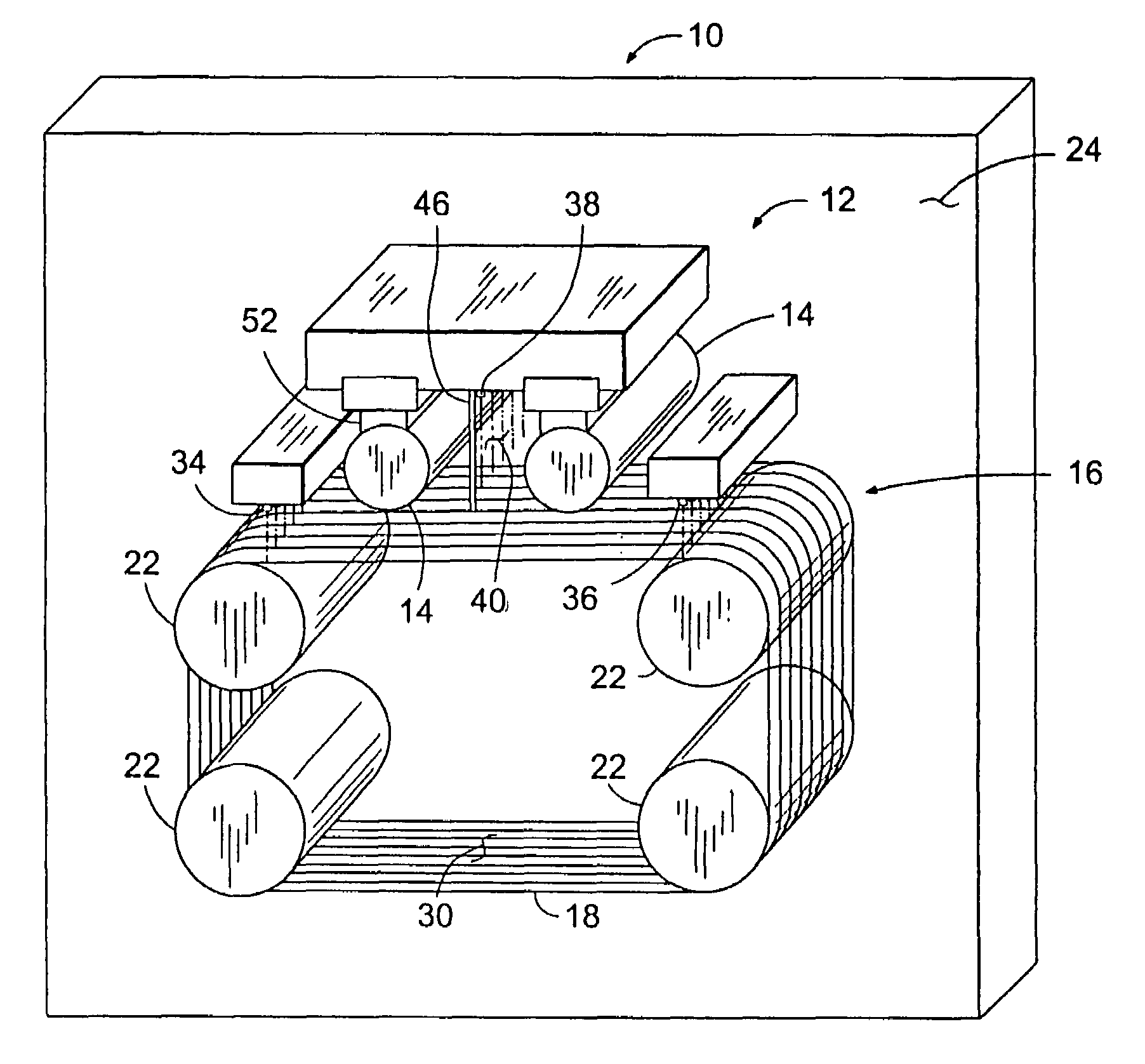

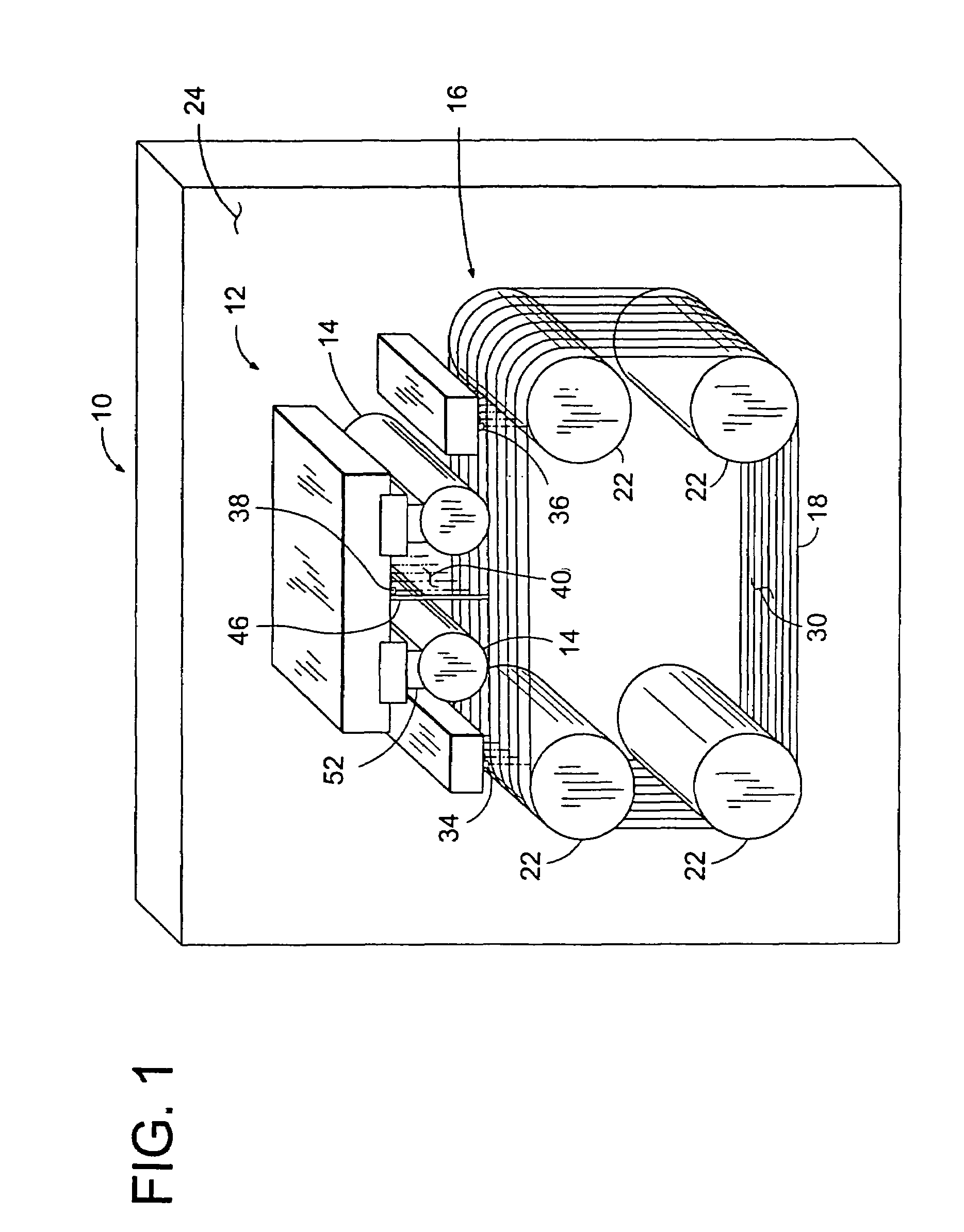

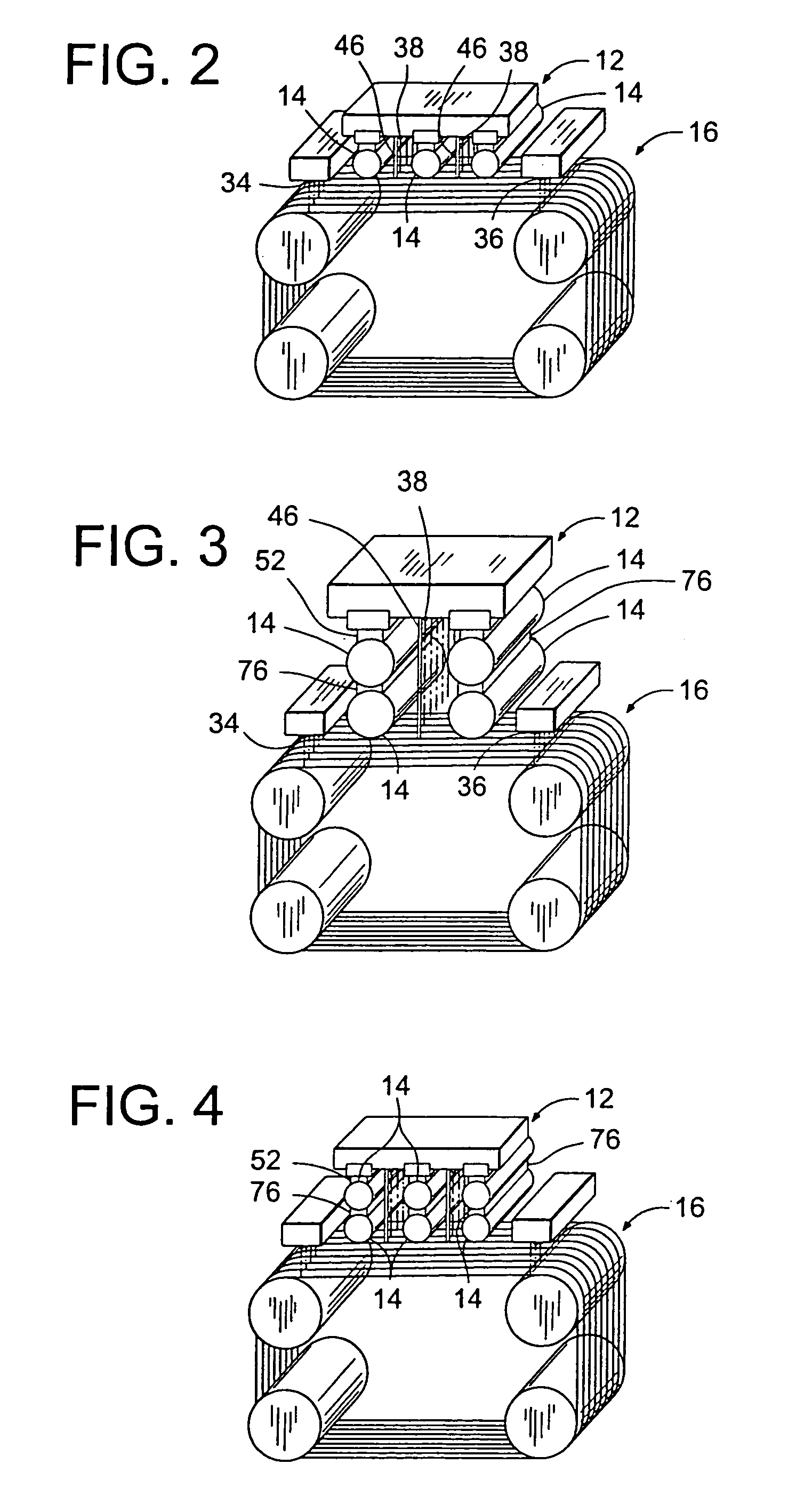

Wire saw and process for slicing multiple semiconductor ingots

InactiveUS6941940B1Improve throughputQuality improvementMetal sawing devicesSemiconductor/solid-state device manufacturingIngotSingle crystal

A wire saw (10) for simultaneously slicing multiple, generally cylindrical monocrystalline ingots (14) into wafers. The wire saw includes a cutting head (16), an ingot support (12), and multiple generally parallel lengths of cutting wire (18) defining a cutting web (30). A slurry delivery system includes nozzles (34, 36, and 38) positioned for dispensing slurry along the wire web generally at lateral sides of each ingot. A process for simultaneously slicing at least two generally cylindrical semiconductor ingots into wafers includes mounting at least two ingots to a common ingot support, moving the ingot support relative to the cutting web so that the two ingots simultaneously press against the cutting web at cutting regions, and dispensing a liquid slurry to at least three locations on the wire web including two outermost sides of the cutting regions and a location between each pair of ingots.

Owner:GLOBALWAFERS CO LTD

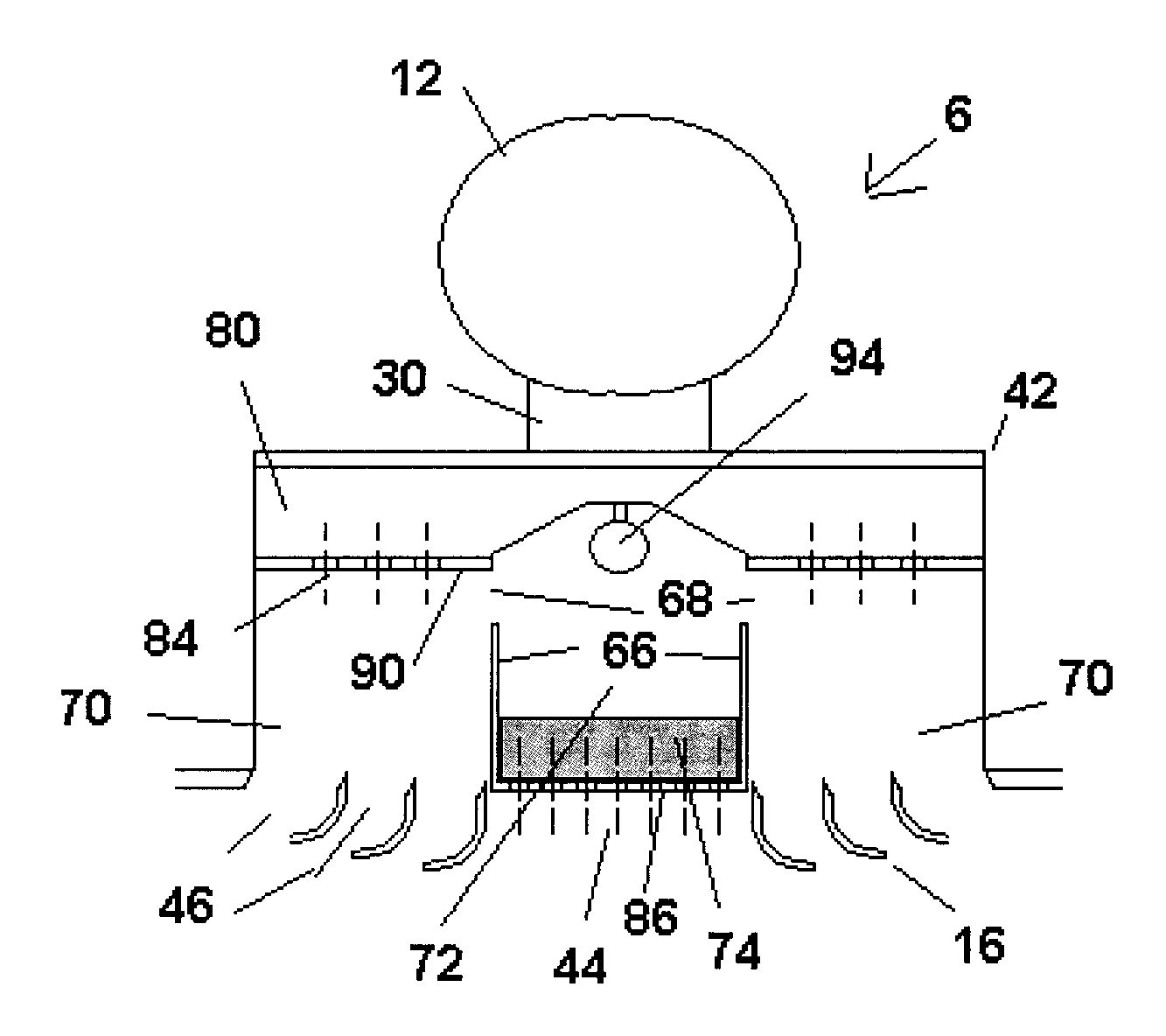

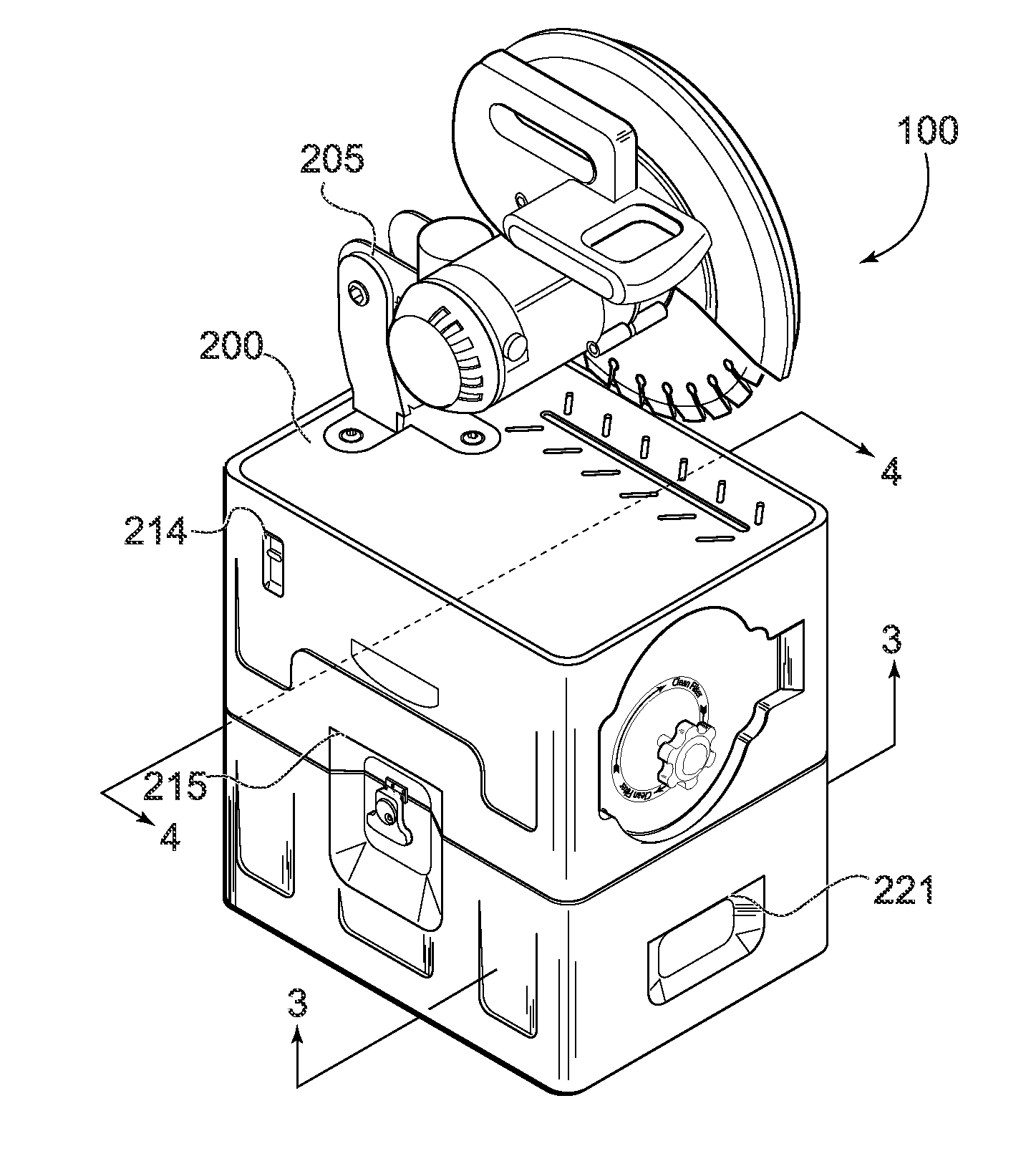

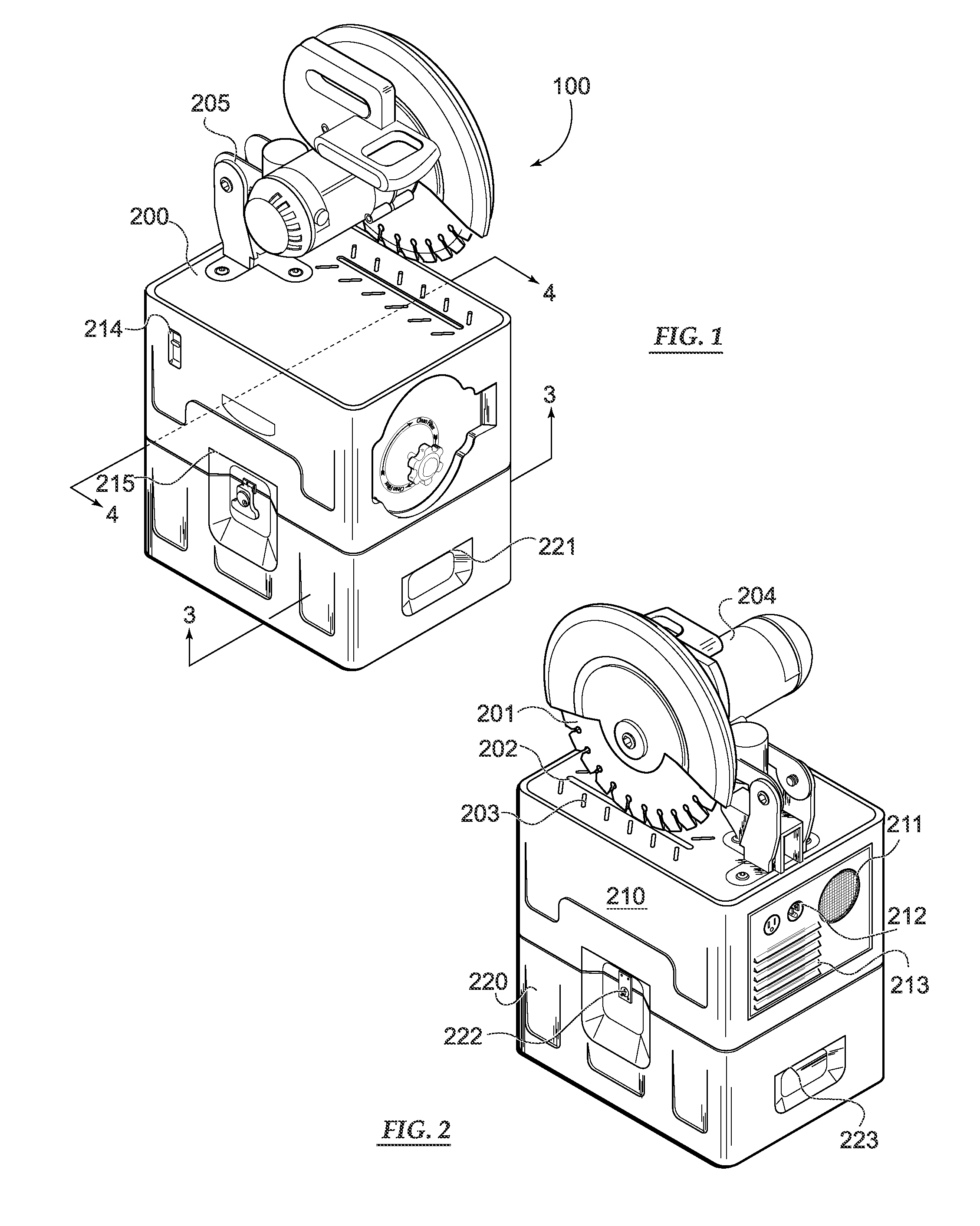

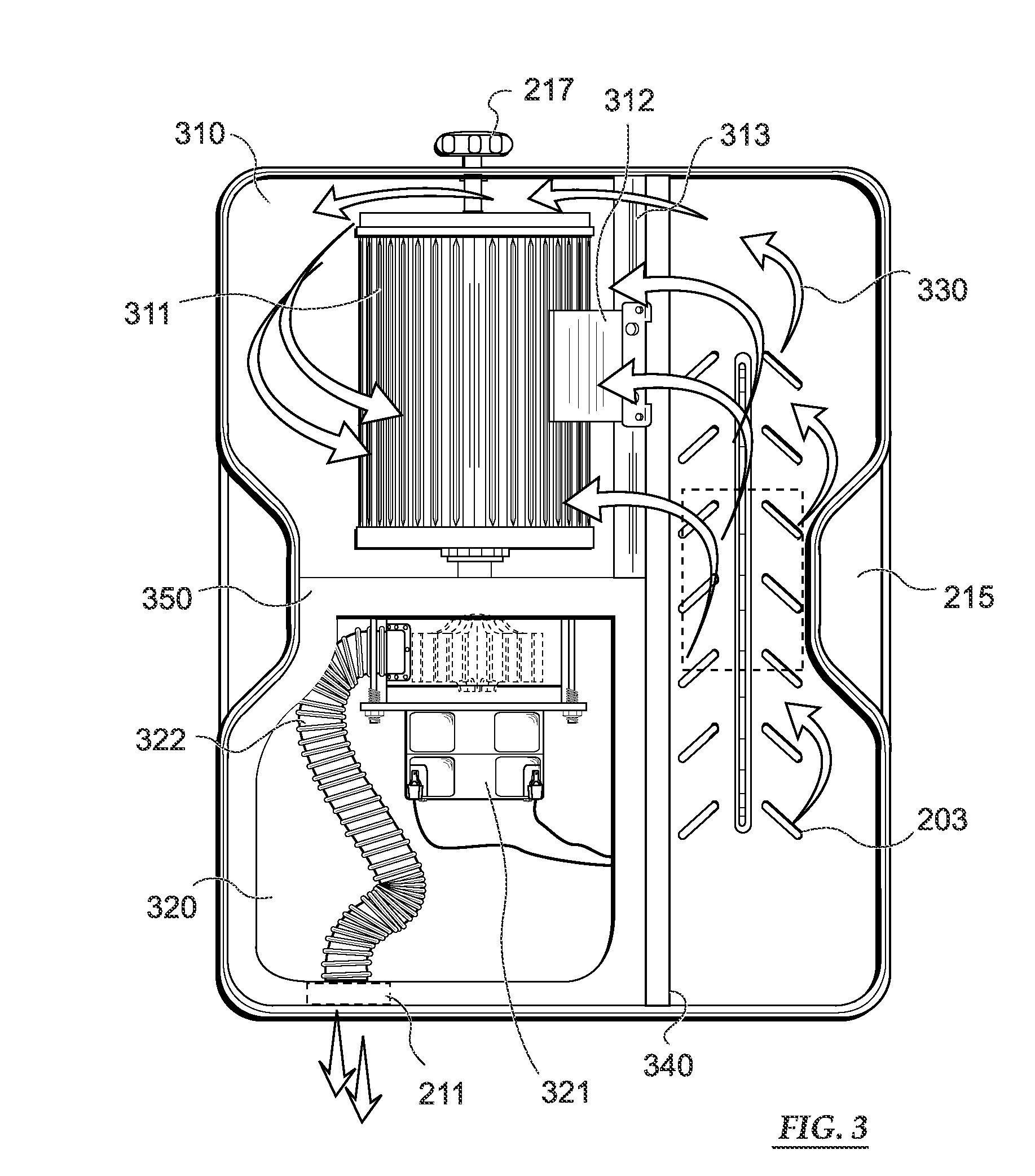

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

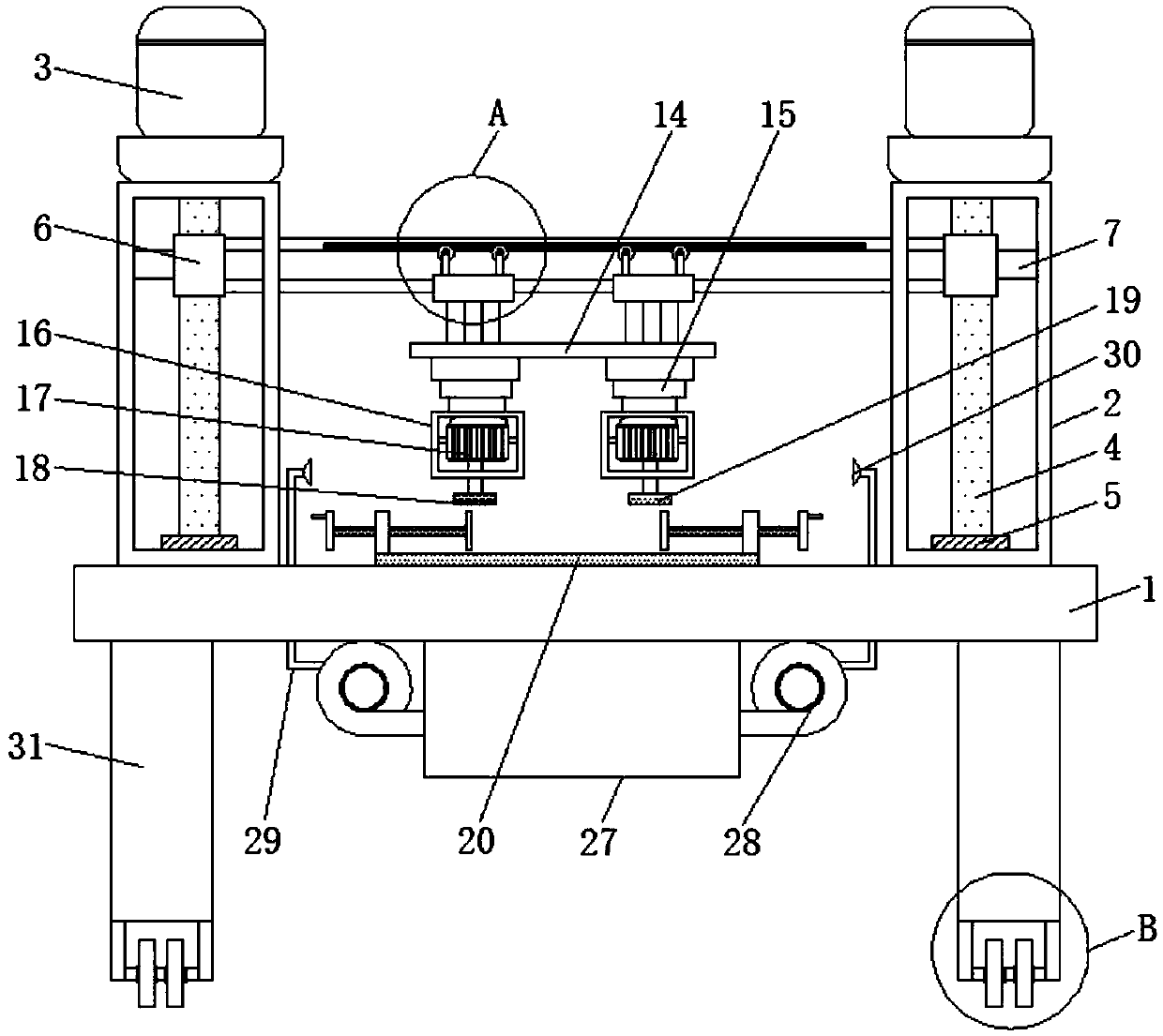

Polishing device for bearing machining

InactiveCN107695881AQuality improvementEasy to adjustGrinding carriagesGrinding machinesEngineeringMachining

The invention provides a grinding device for bearing processing, which relates to the technical field of bearing processing. The grinding device for bearing processing includes a processing table, a lifting box is fixedly installed on both sides of the top of the processing table, a lifting motor is fixedly installed on the top of the lifting box, and a screw rod is movably connected to the output end of the lifting motor. The grinding device for bearing processing is equipped with a processing table, a lifting box, a lifting motor, a screw, a bearing body, a telescopic block, a slider, a guide rod, a slip ring, a wheel shaft, a pulley, a wheel groove, a bracket, a horizontal plate, and a hydraulic telescopic rod. And the grinding motor, after the lifting motor is started, the grinding device including the grinding motor can be driven to move up and down on the top of the processing table through the rotation of the driving screw, and the grinding motor can be driven on the top of the processing table by sliding on the guide rod through the slip ring Moving left and right, in summary, the bearing processing and grinding device achieves the effect of easy adjustment, which is convenient for people to operate, saves time and effort, and is conducive to grinding out bearings with better quality.

Owner:郑艳峰

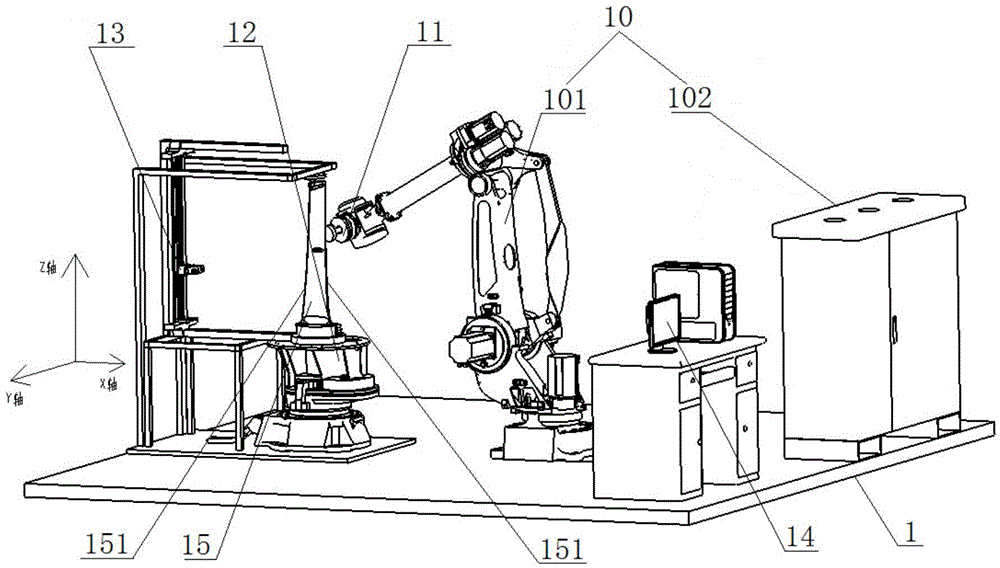

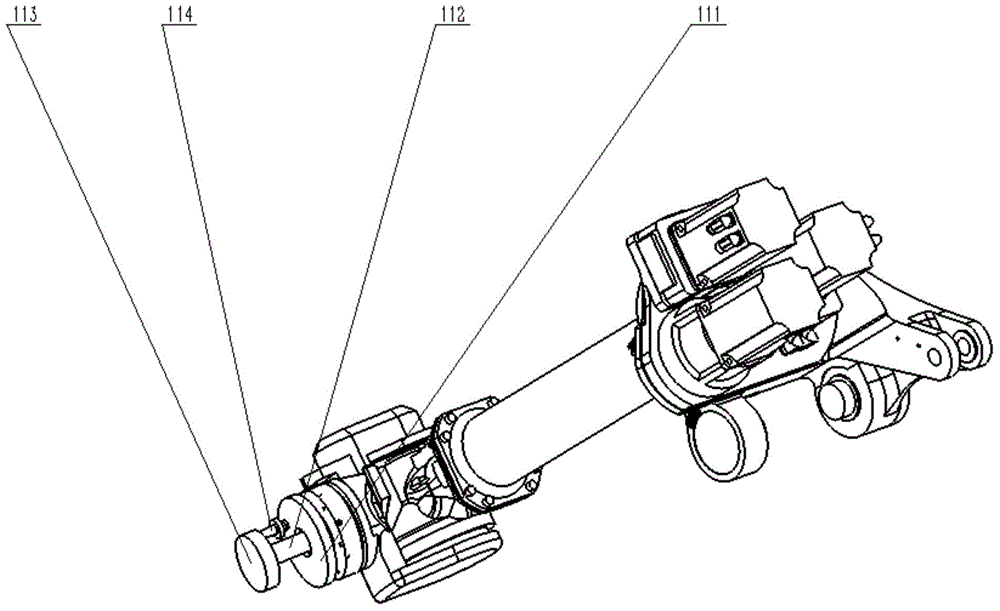

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

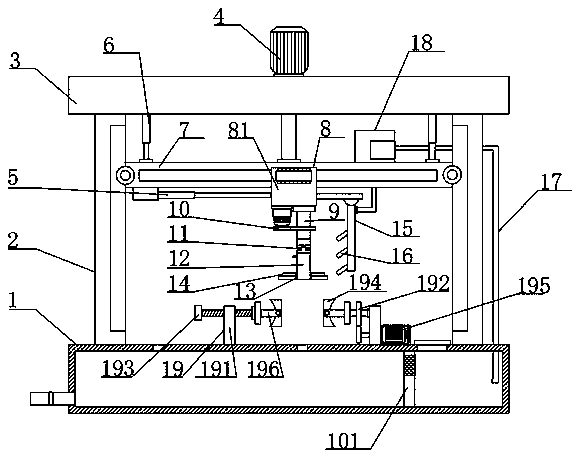

Automatic grinding machine for industrial machinery and grinding method

InactiveCN108789087AIncrease flexibilityImprove stabilityGrinding carriagesGrinding drivesHydraulic cylinderCoupling

The invention discloses an automatic grinding machine for industrial machinery and a grinding method. The automatic grinding machine comprises a base box body, wherein left and right sides of the topof the base box body are symmetrically equipped with stand columns; a top plate is arranged on the tops of the two groups of the stand columns; the outer wall of a bearing rod is movably equipped witha slide assembly; the bottom of the slide assembly is sequentially equipped with a grinding motor and a rotary rod from left to right; the bottom of the rotary rod is equipped with a universal shaftcoupler; the top of the base box body is equipped with a fixed clamp; and the right side of the top of the base bottom box is spliced with a water conveying hose I. The grinding machine for industrialmachinery is high in flexibility and is good in stability; a hydraulic cylinder drives the bearing rod to lift through a pushing rod, so that a grinding disc in grinding can lift; and an electric telescopic pole extends and shortens to drive the slide assembly to move left and right, so that the grinding disc in grinding can move left and right, and therefore, the automatic grinding machine has relatively high flexibility, and improves grinding working efficiency.

Owner:CHENGDU PUJIANG KEXIAN TECH

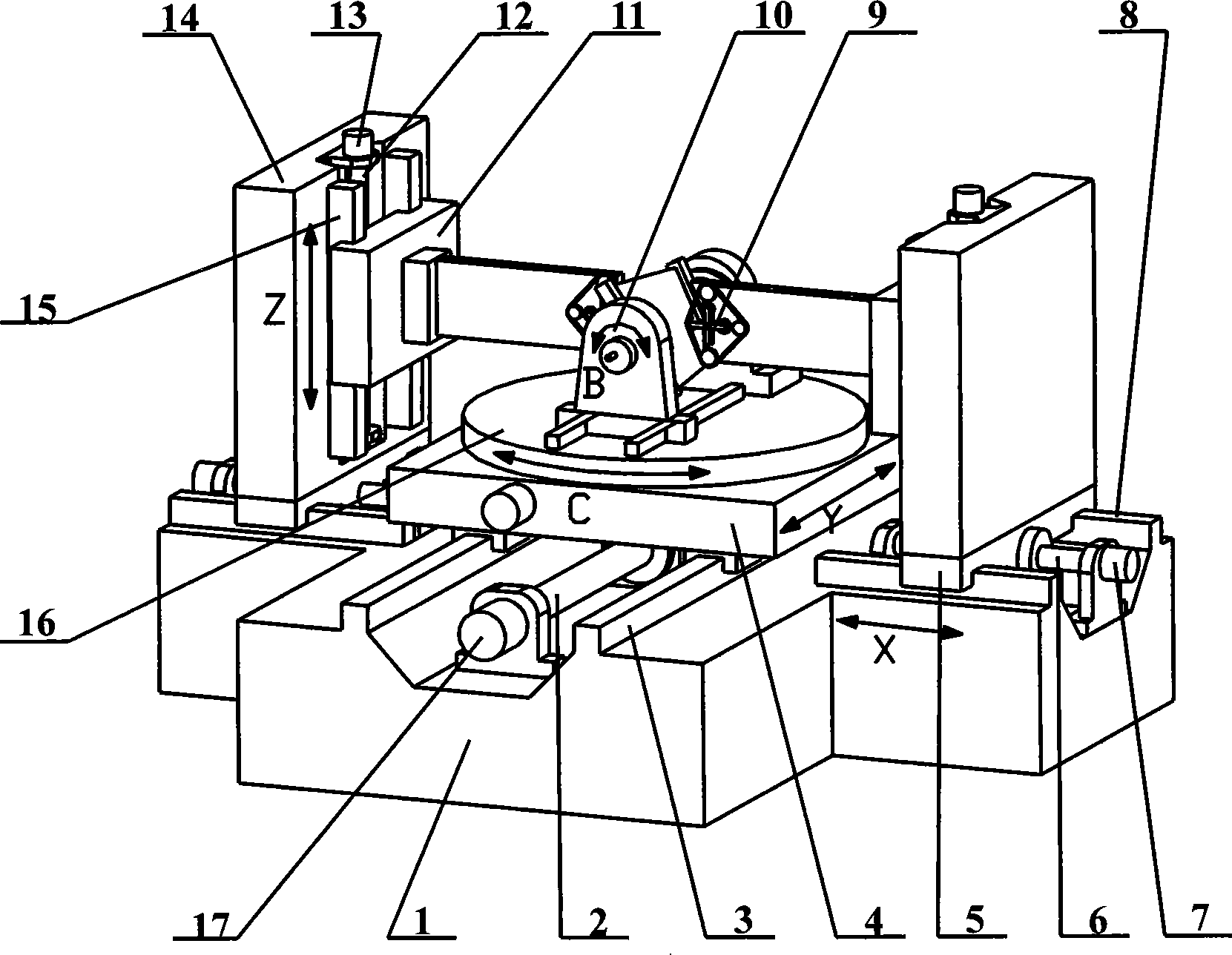

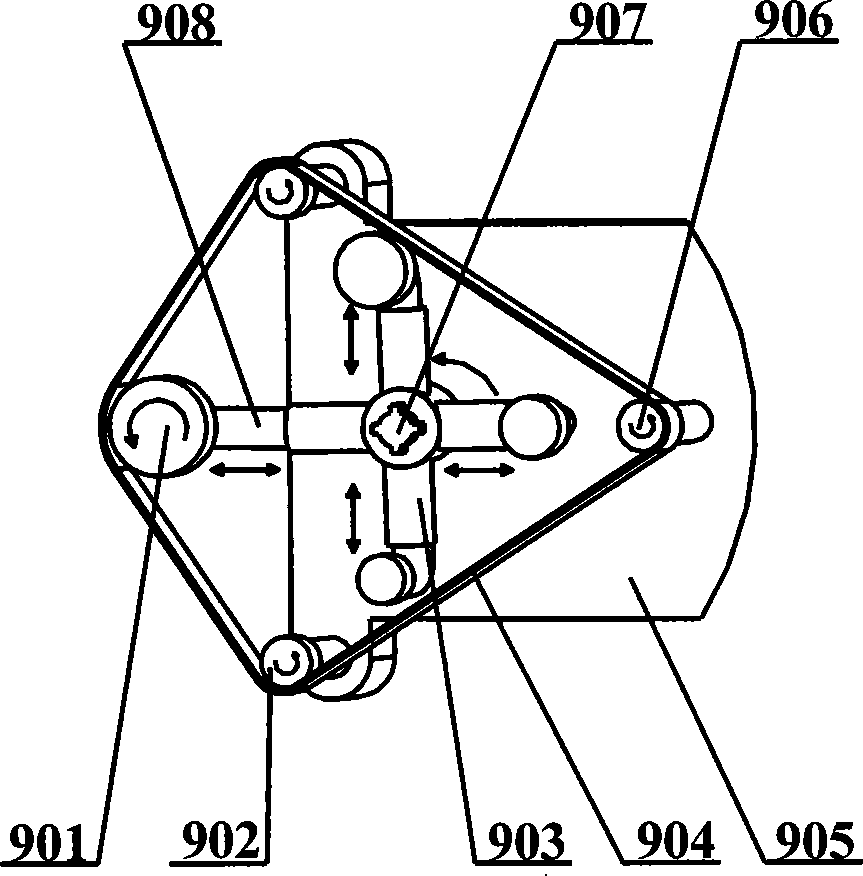

Two-sided synchronous high-efficiency milling and casting machine tool for impeller vane

InactiveCN101244531APrevent processing deformationImprove grinding and polishing efficiencyGrinding machinesImpellerEngineering

The invention relates to a grinding and polishing machine tool of synchronous double-faced blade with a high efficiency, belonging to the mechanical manufacturing field. A moving mechanism in Y direction and two moving mechanism in X direction are fixed on the bed, two moving mechanism in X direction are coaxial and are distributed in symmetrically horizontally vertical to the moving mechanism in Y direction; two grinding and polishing tool system of sand belt variable gear trains are respectively connected with two moving mechanism in Z direction; the two moving mechanism in Z direction are respectively connected with two upright columns; the two upright columns are respectively connected with the two moving mechanism in X direction; a reversing jig is arranged on the rotary worktable, and the reversing jig can achieve the clamping of the blade and the rotation of the blade around the central shaft B of the reversing jig; the rotary worktable is connected with the moving mechanism in Y direction, and the rotary worktable provides the rotation around the central shaft C. The grinding and polishing machine tool of synchronous double-faced blade with a high efficiency has the advantages that the faces of the blade at double sides has synchronous grinding and polishing, not only the efficiency of grinding and polishing is improved obviously, but also because force is exposed on double sides of the blade during grinding and polishing process, the process deformation of the blade is effectively avoided.

Owner:JILIN UNIV

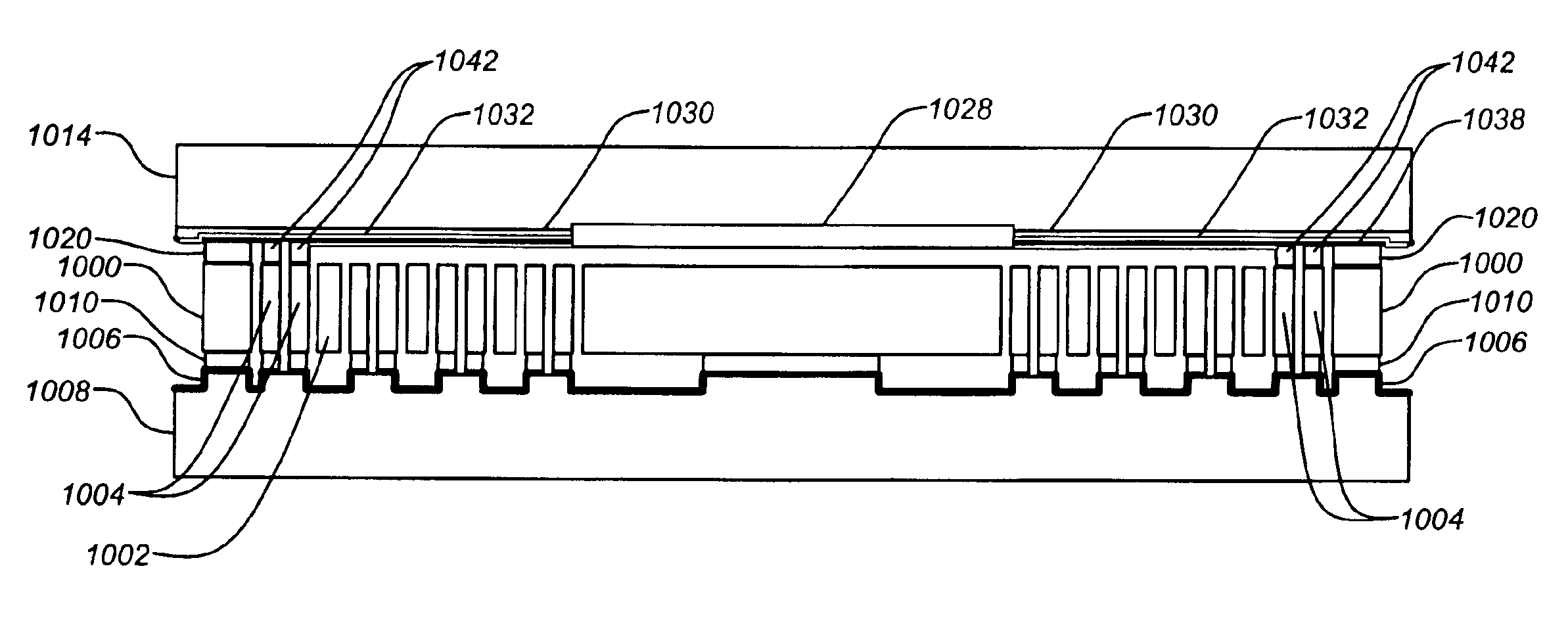

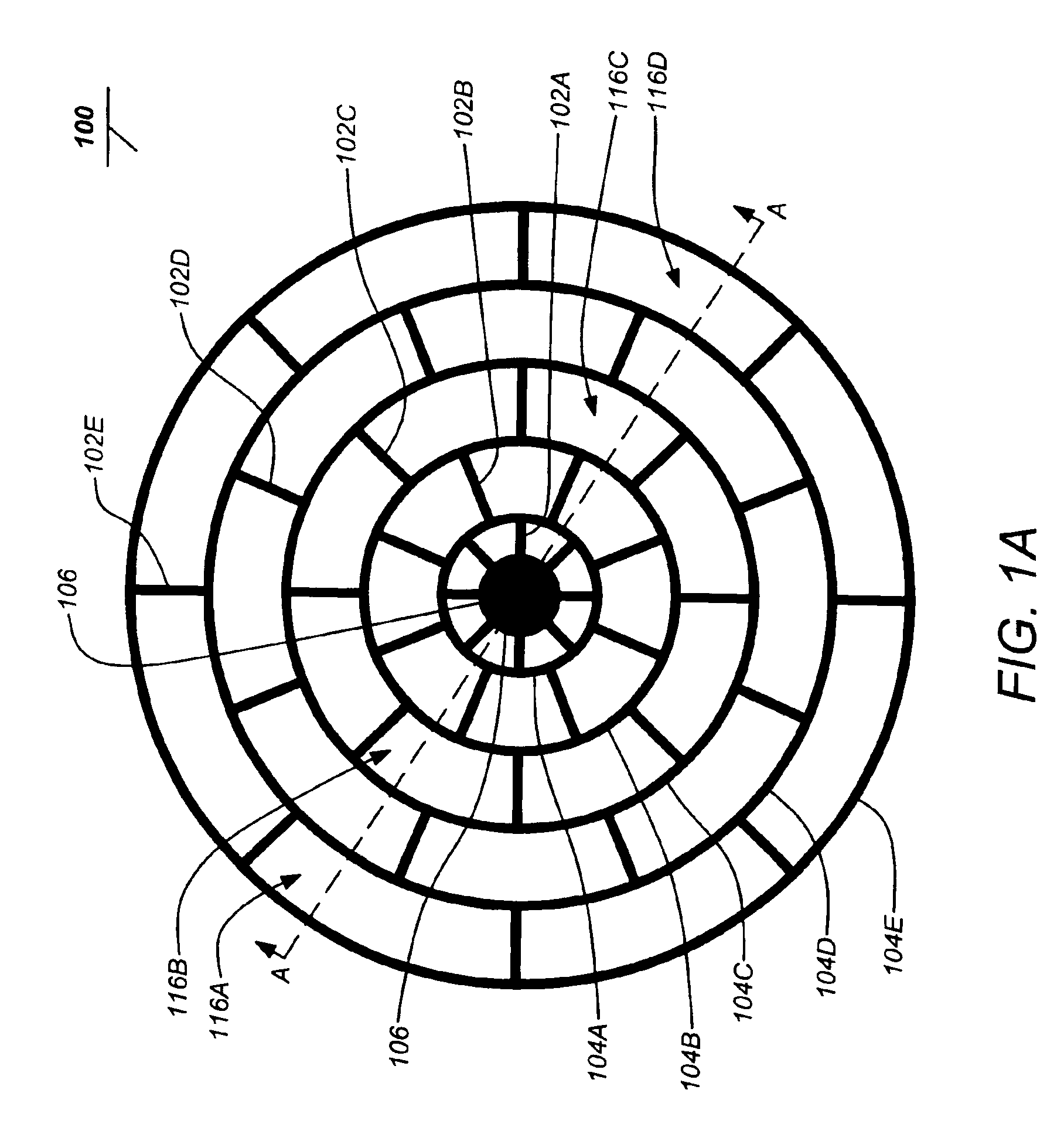

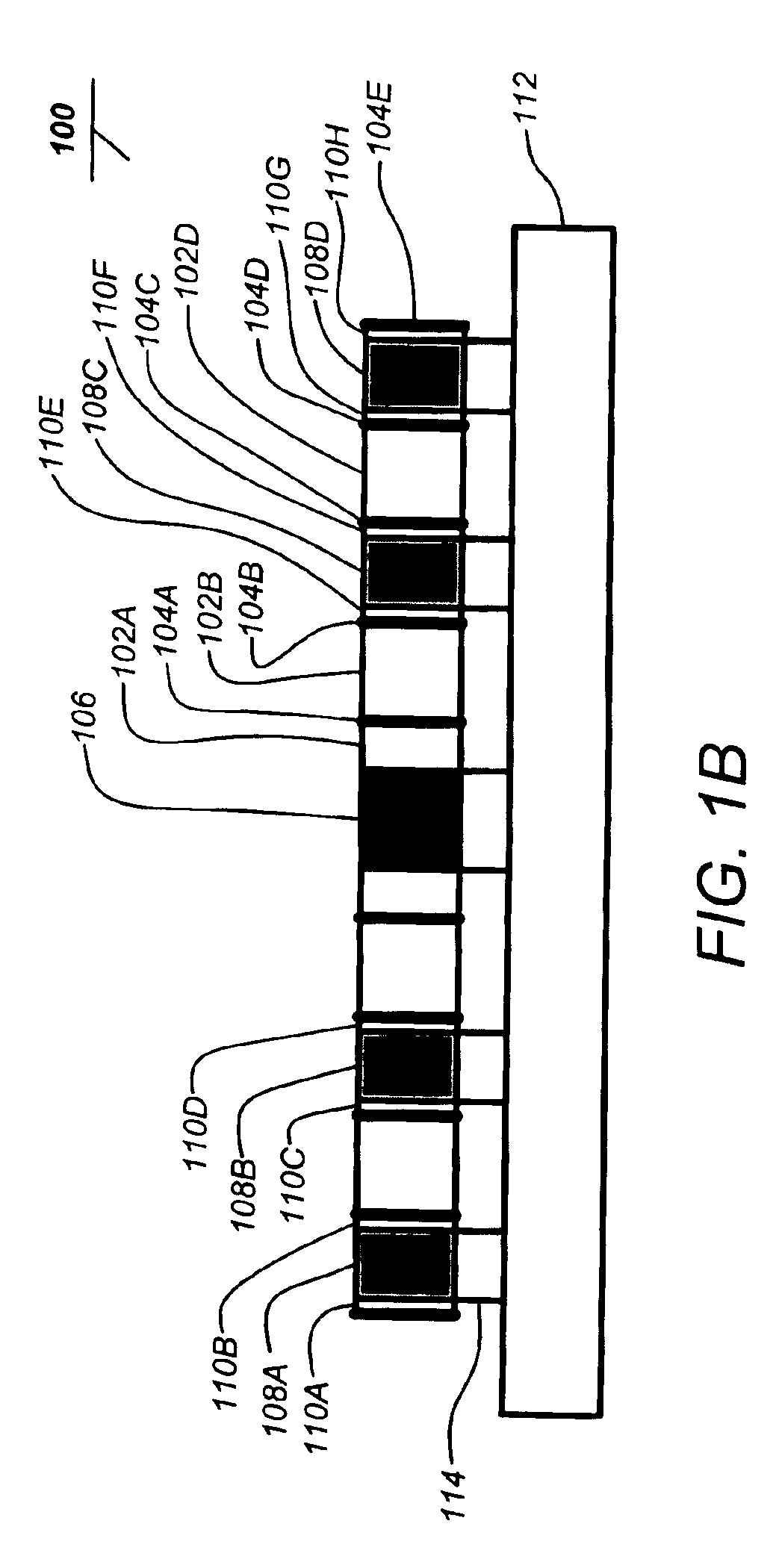

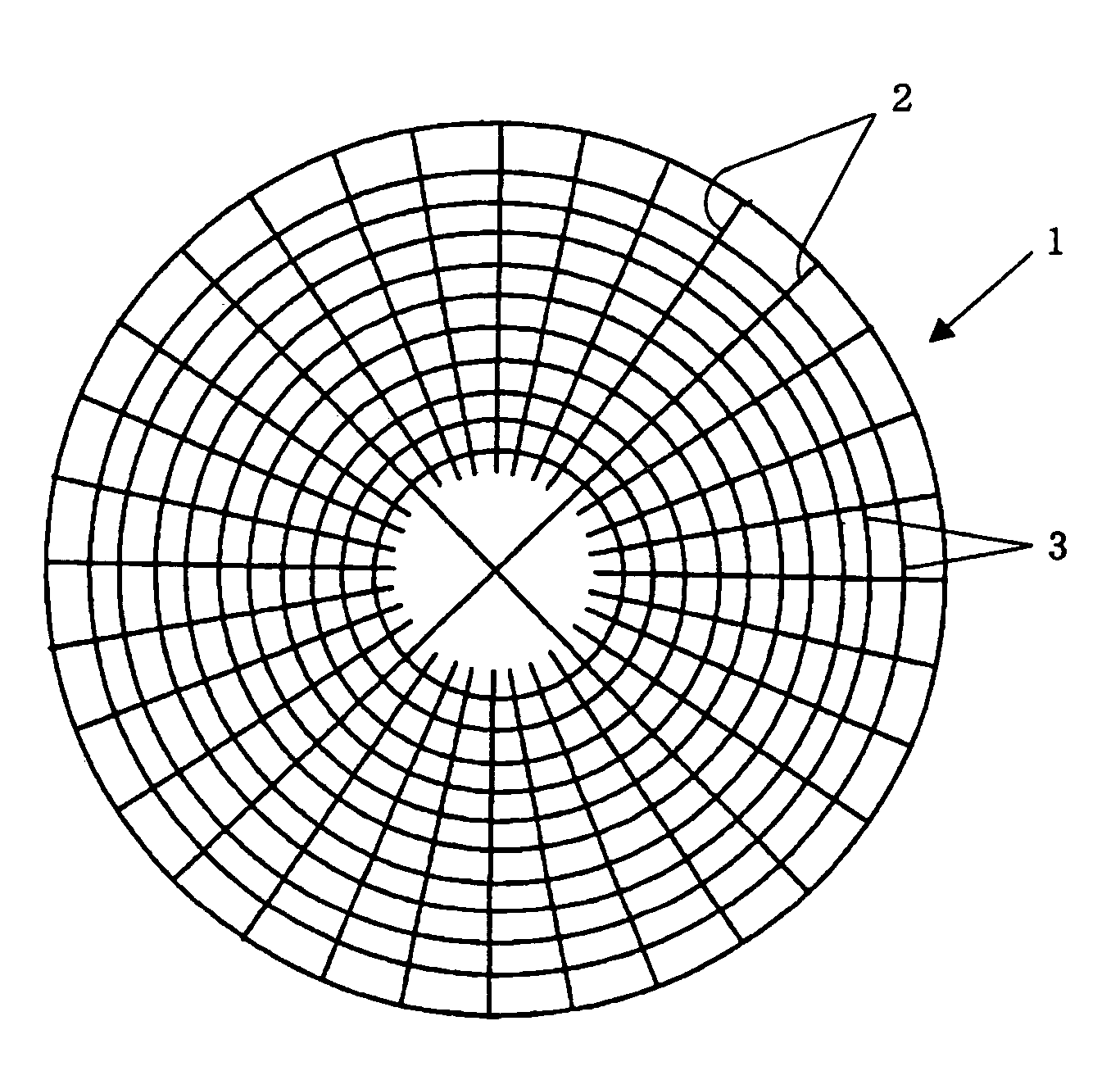

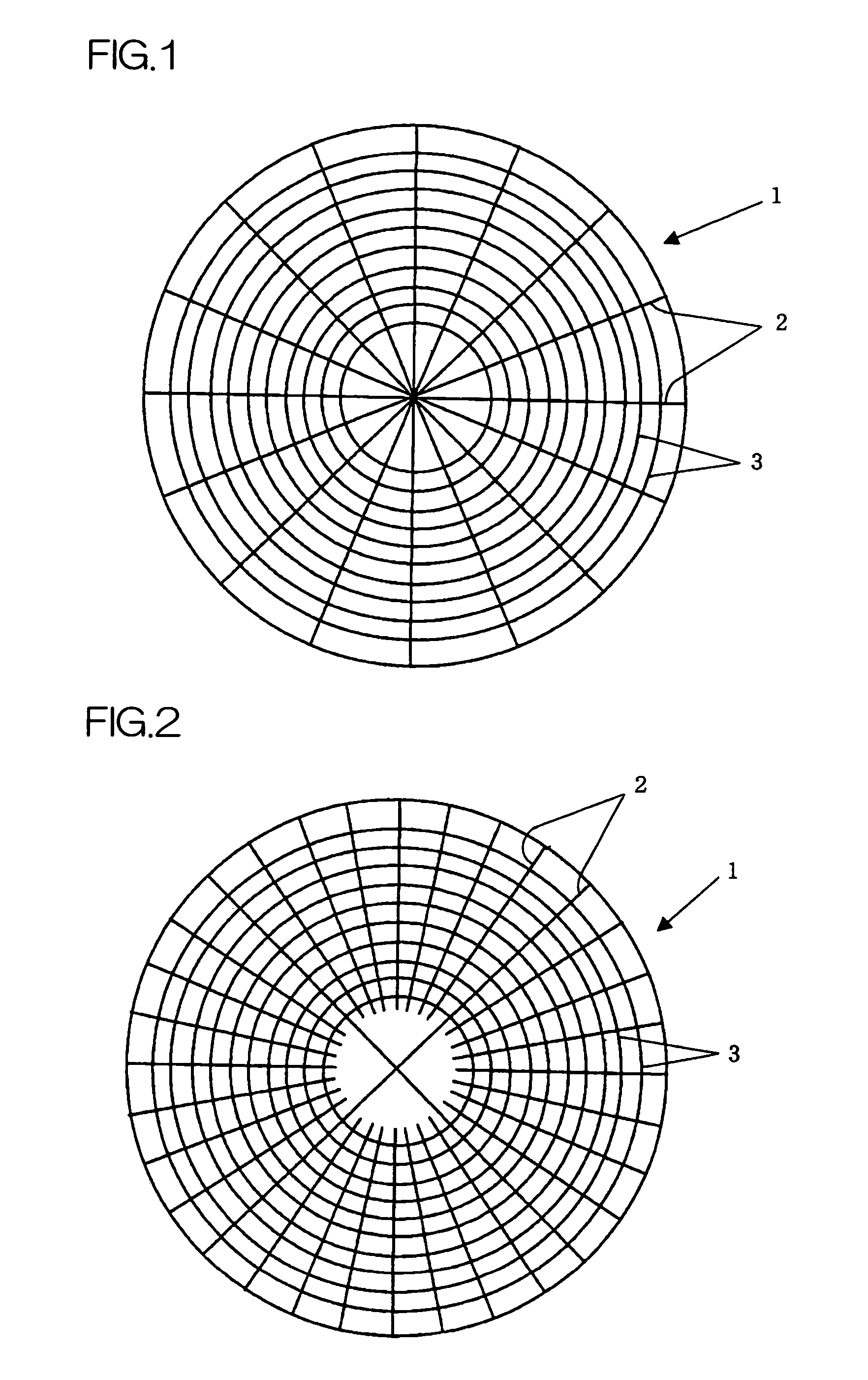

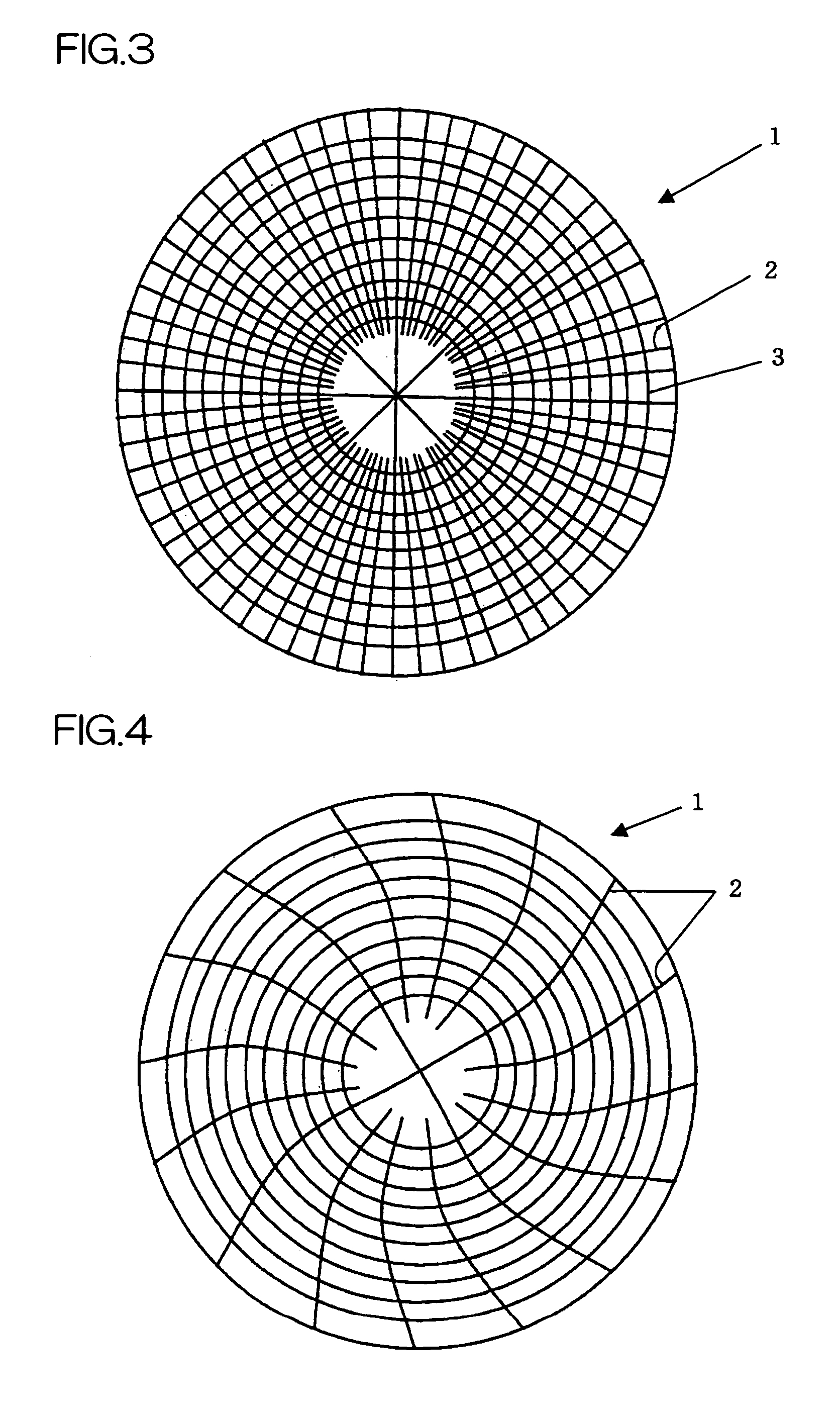

Method of manufacturing chemical mechanical polishing pad

ActiveUS7329174B2InhibitionIncrease ratingsFlexible-parts wheelsGrinding devicesRound tableMilling cutter

The present invention relates to a method of manufacturing a chemical mechanical polishing pad which provides a chemical mechanical polishing pad which fully suppresses the occurrence of a scratch on the polished surface and has an excellent polishing rate.The method comprising either one of a group of steps (A) and a group of steps (B), the group of steps (A) including(A1) the step of preparing a composition for forming a chemical mechanical polishing pad;(A2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form;(A3) the step of mounting the pad-like form on the round table of a cutting machine having at least a milling unit equipped with a milling cutter, a drive unit capable of angle indexing and positioning and a round table journaled by the drive unit;(A4) the step of forming the second group of grooves with the milling cutter; and(A5) the step of forming the first group of grooves, and the group of steps (B) including(B1) the step of preparing a composition for forming a chemical mechanical polishing pad;(B2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form having the second group of grooves by using a metal mold having projections corresponding to the shapes of the second group of grooves; and(B3) the step of forming the first group of grooves.

Owner:JSR CORPORATIOON

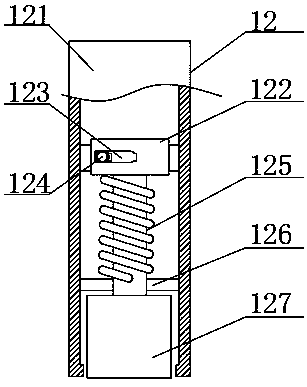

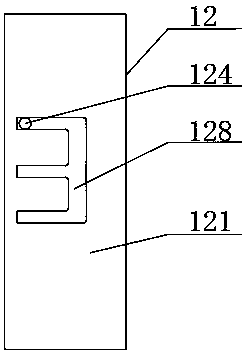

Overturning grinding rust removal device for metal plate

InactiveCN110142678AFast clamping speedEasy to remove rustGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to the field of metal processing equipment, and more specifically relates to an overturning grinding rust removal device for a metal plate. The overturning grinding rust removaldevice for the metal plate comprises a workbench, a left clamping block, a right clamping block and a rust removal brush plate, wherein a slide groove is formed in the upper surface of the workbench;a bidirectional screw rod is installed in the slide groove; the left clamping block and the right clamping block sleeve the bidirectional screw rod; a second telescoping mechanism is fixedly connectedto the upper surface of the workbench; a lifting block sleeves a stretching end of the second telescoping mechanism; an installation plate is hinged to the sidewall of the lifting block; a displacement screw rod is arranged below the installation plate; a movable block sleeves the middle part of the displacement screw rod; a fourth telescoping mechanism is fixedly connected to the lower surface of the movable block; and a rust removal motor is fixedly connected to the lower end of the fourth telescoping mechanism. The metal plate is clamped by virtue of the clamping plate to keep fixed, and high clamping speed is achieved; in a rust removal process, the rust removal brush plate moves to left and right, so that a rust removal range is expanded; and through arrangement for a rotary motor, rust removal can be conveniently carried out on the front surface and the back surface of the metal plate.

Owner:蒋艳红

Metal sheet surface scale grinding and removing machine

InactiveCN104175197AImprove work efficiencyReduce labor intensityGrinding machinesGrinding/polishing safety devicesElectric machineryEngineering

Disclosed is a metal sheet surface scale grinding and removing machine which is formed by connection of a feed device, a grinding device and a discharge device. The feed device is provided with a feed frame, and feed rolls which are driven by a feed motor and arranged in parallel are arranged on the feed frame. The grinding device is provided with a grinding base, supporting wallboards fixed on the grinding base and a supporting frame mounted above the grinding base through a lifting device. Grinding rolls are fixedly mounted between the two supporting wallboards, upper pressure rolls are elastically mounted between the two supporting wallboards, and supporting rolls which are driven by a conveying motor and arranged in parallel are mounted on the supporting frame. The grinding rolls are driven through grinding motors fixed on the grinding base. A discharge frame is arranged on the discharge device, and discharge rolls driven through a discharge motor and arranged in parallel are arranged on the discharge frame. The grinding rolls in stepped arrangement are adopted to grind the surfaces of sheets gradually, scale removal efficiency is high, and the surfaces of the sheets with the scales removed are high in flatness and uniform in smooth finish.

Owner:张坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com