System and method for grinding industrial robot on basis of visual information

An industrial robot and visual information technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, automatic grinding control devices, etc., can solve the problems of low efficiency, poor uniformity of workpiece processing, and large workload of manual grinding. , to achieve the effect of improving flexibility, ensuring uniformity and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

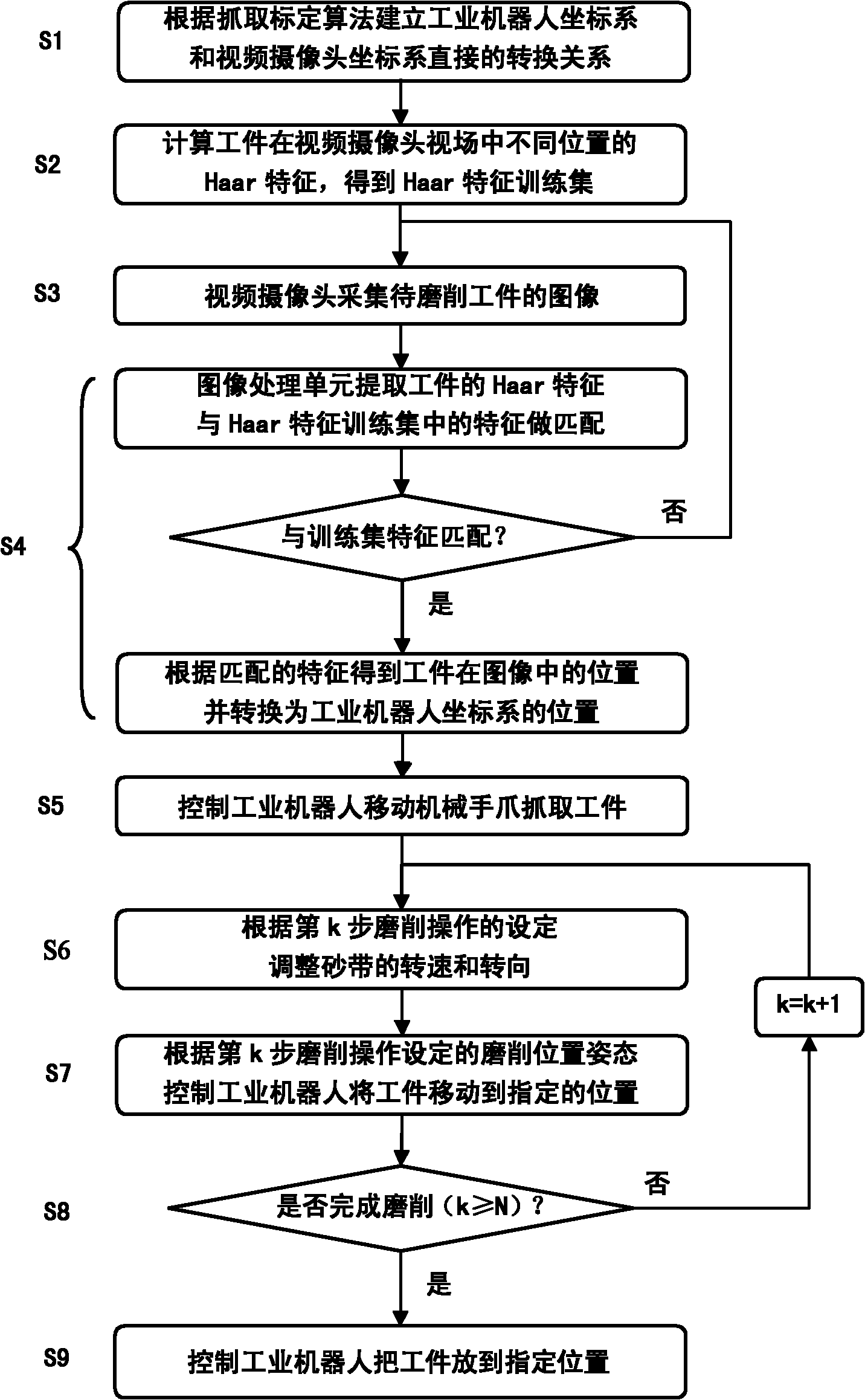

[0033] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

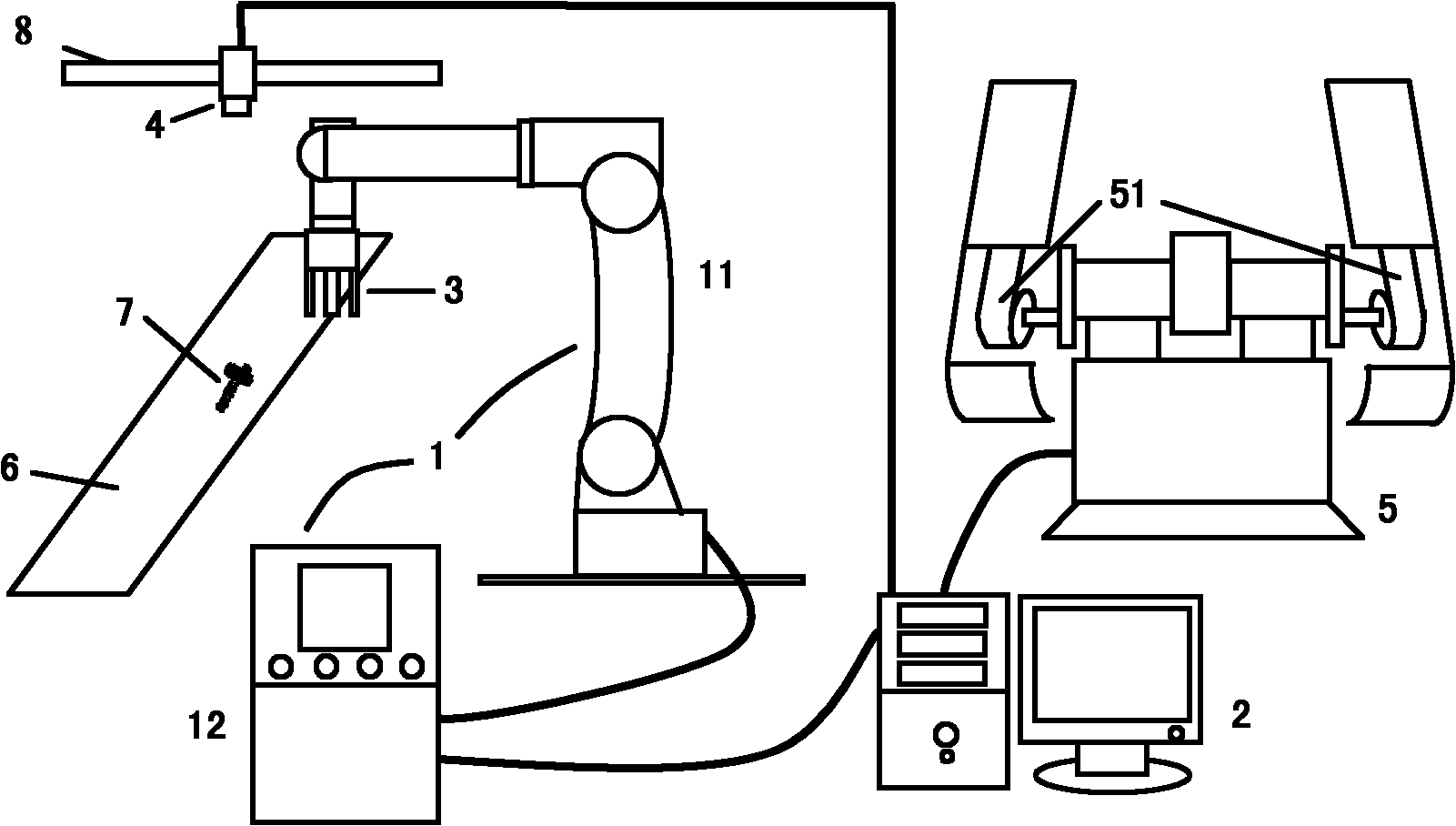

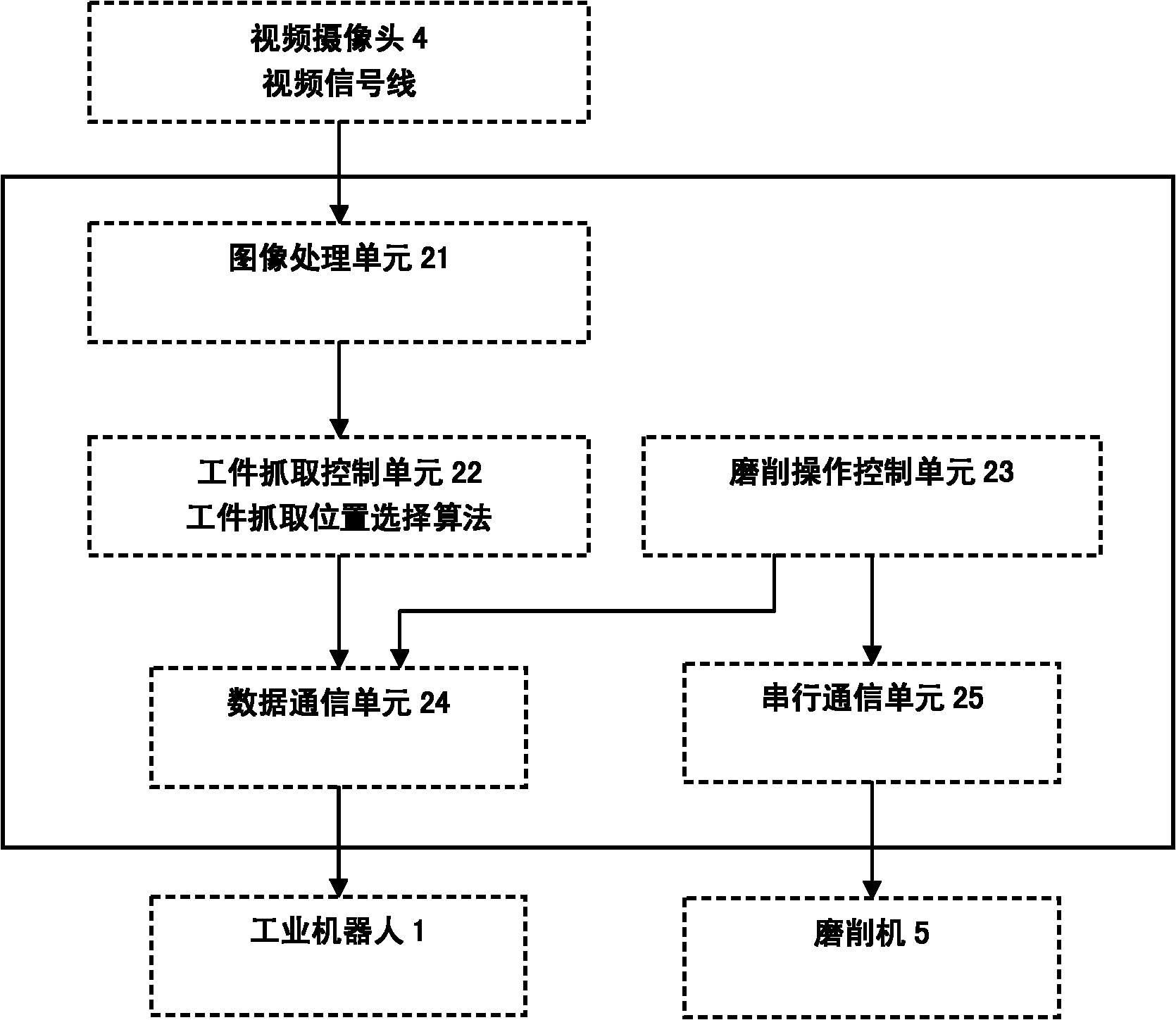

[0034] Such as figure 1 As shown, the industrial robot grinding system based on visual information includes an industrial robot 1, a computer 2, a manipulator 3, a video camera 4, and a grinding machine 5, and the computer 2 includes an image processing unit 21, a workpiece grasping control unit 22, Grinding operation control unit 23 , data communication unit 24 , serial communication unit 25 . A mechanical claw 3 is installed on the industrial robot 1 to grab the workpiece; a video camera 4 is fixed directly above the workbench for real-time acquisition of workpiece images on the workbench; the image processing unit 21 in the computer 2 passes the video The signal line is connected with the video camera 4; the computer 2 identifies and locates the workpiece, controls the manipulator claw 3 to grab the workpiece, controls the motion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com