Patents

Literature

8215results about How to "Improve grinding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

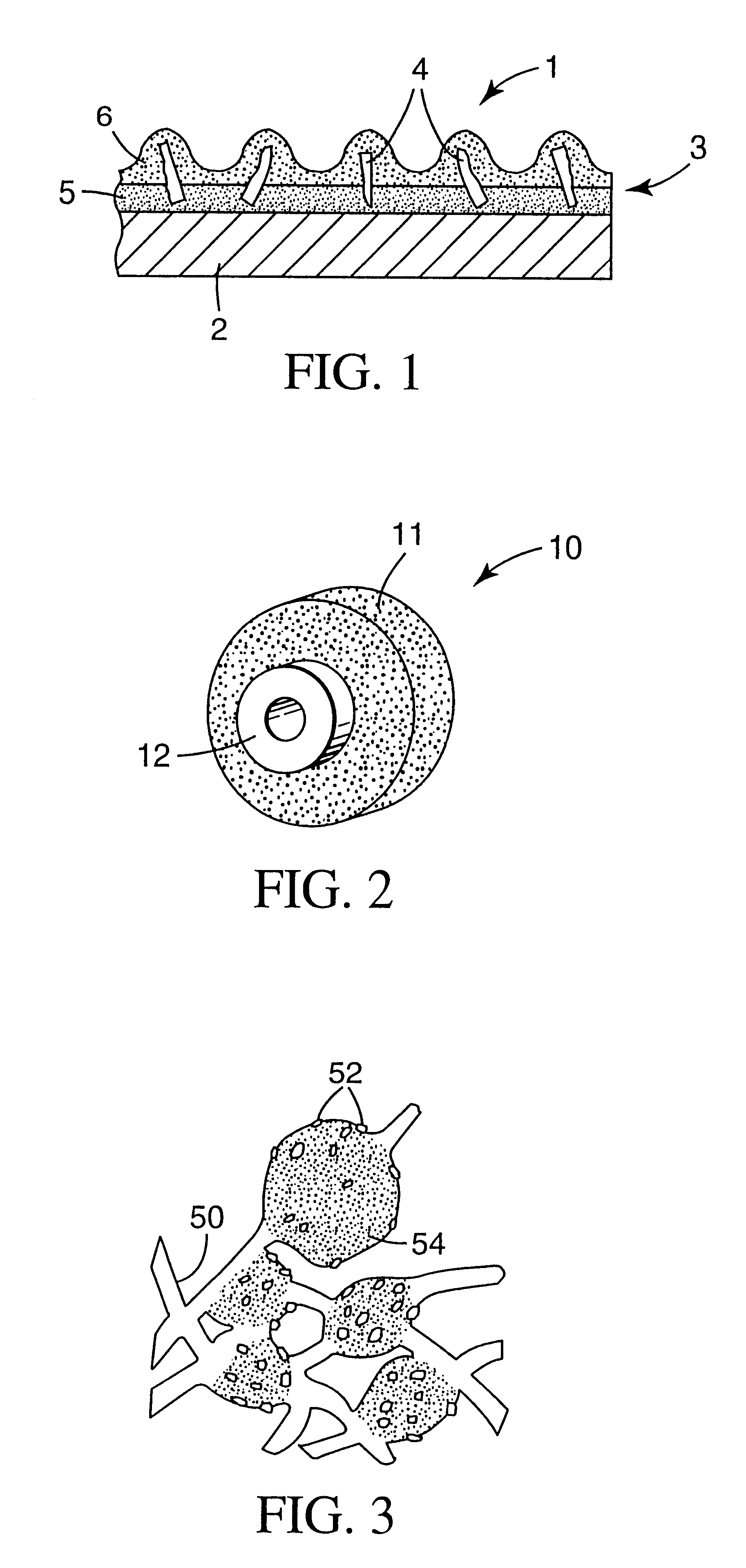

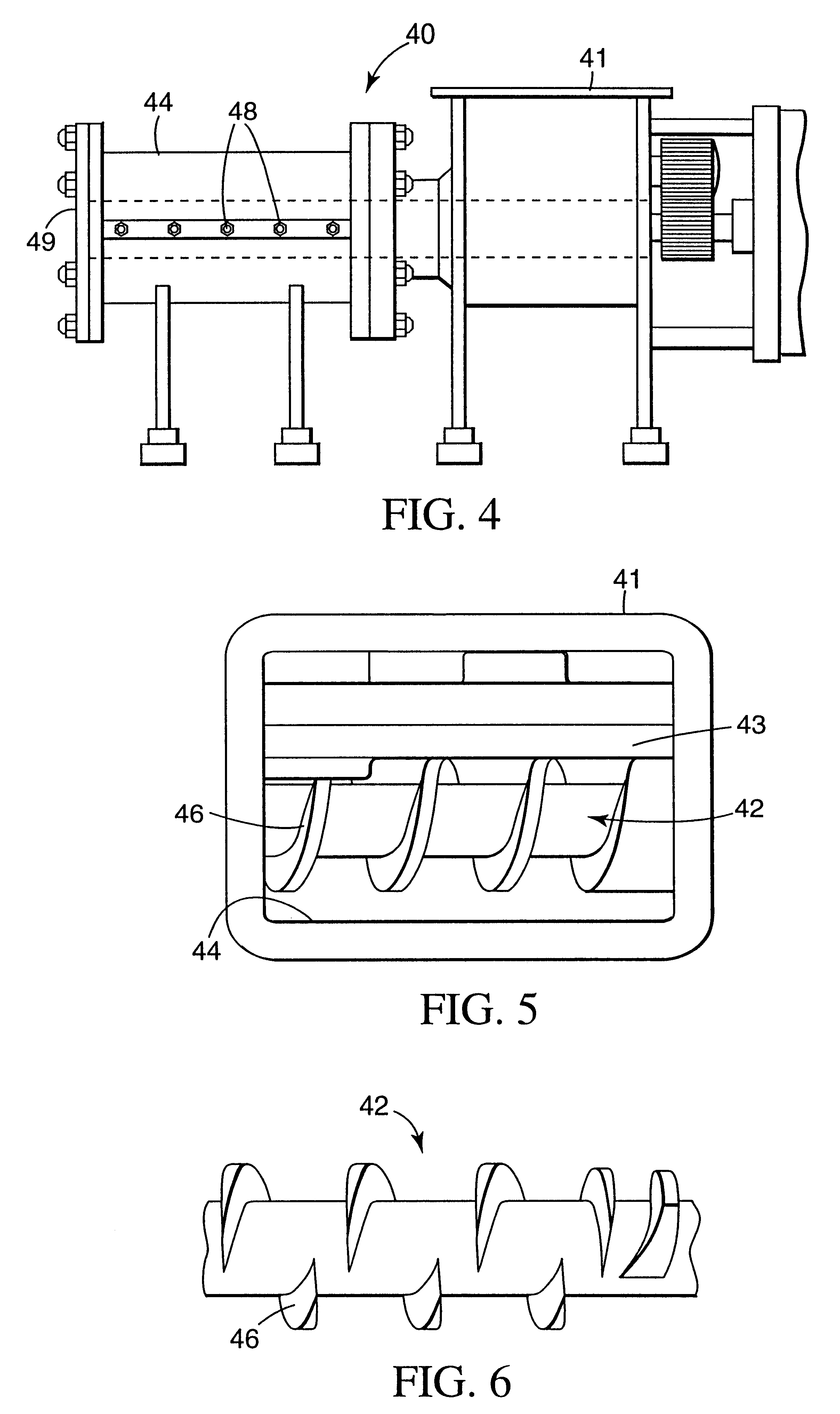

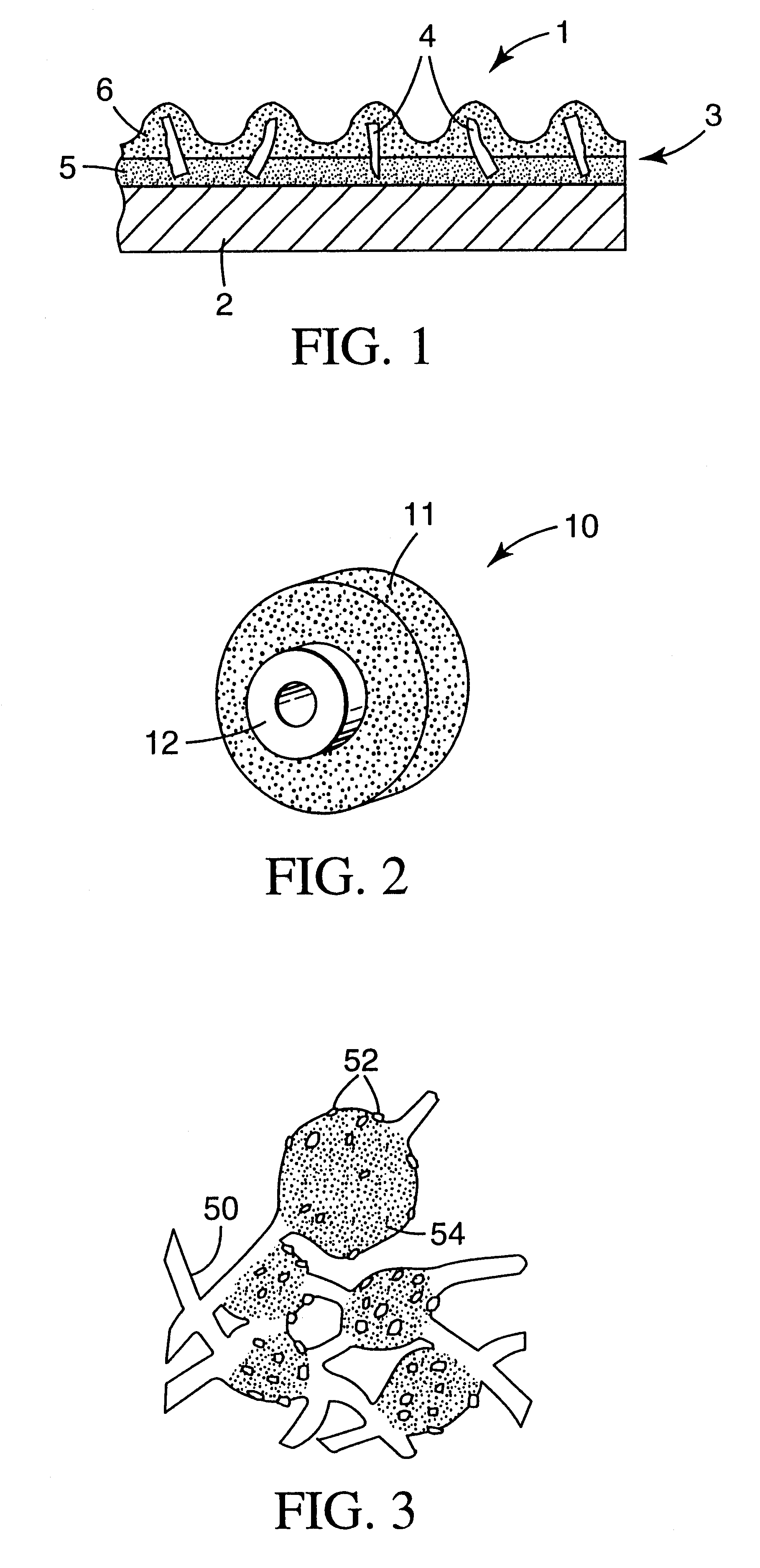

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

Abrasive grain, abrasive articles, and methods of making and using the same

InactiveUS6287353B1Easy accessImprove grinding efficiencyPigmenting treatmentOther chemical processesComposite materialCeramic materials

Owner:3M INNOVATIVE PROPERTIES CO

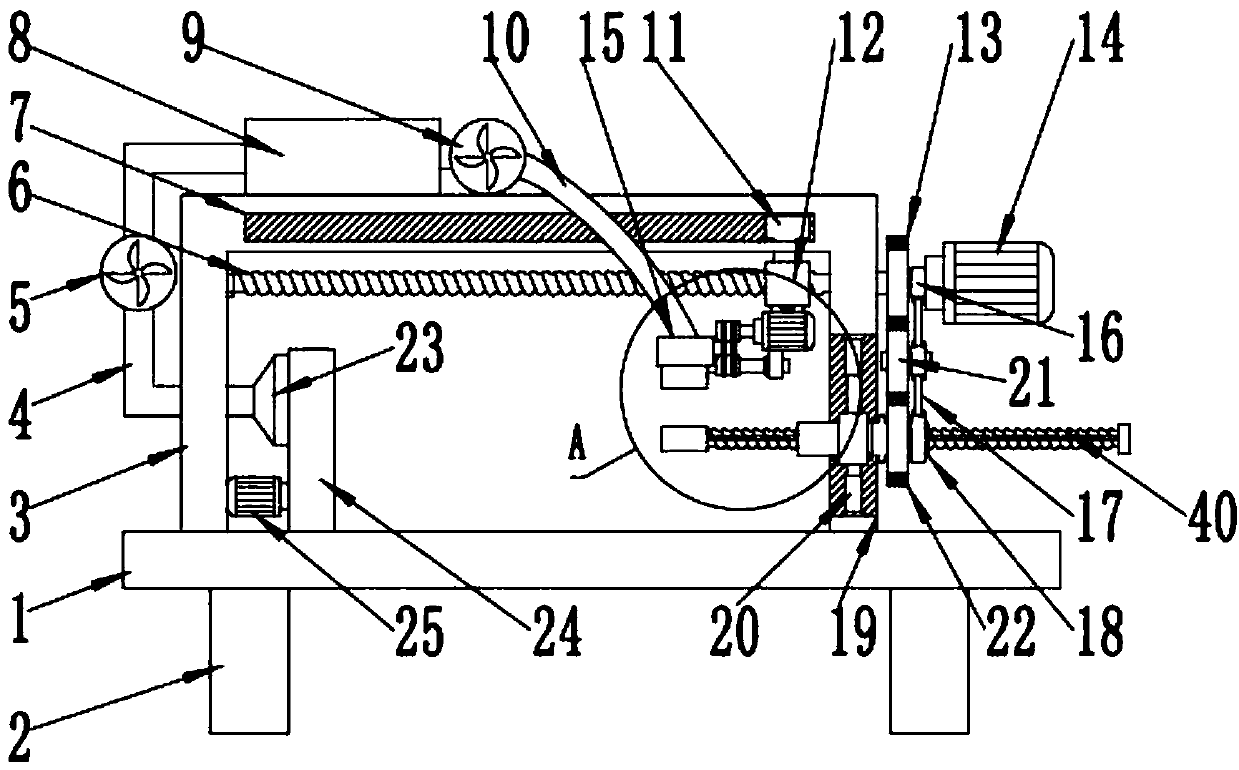

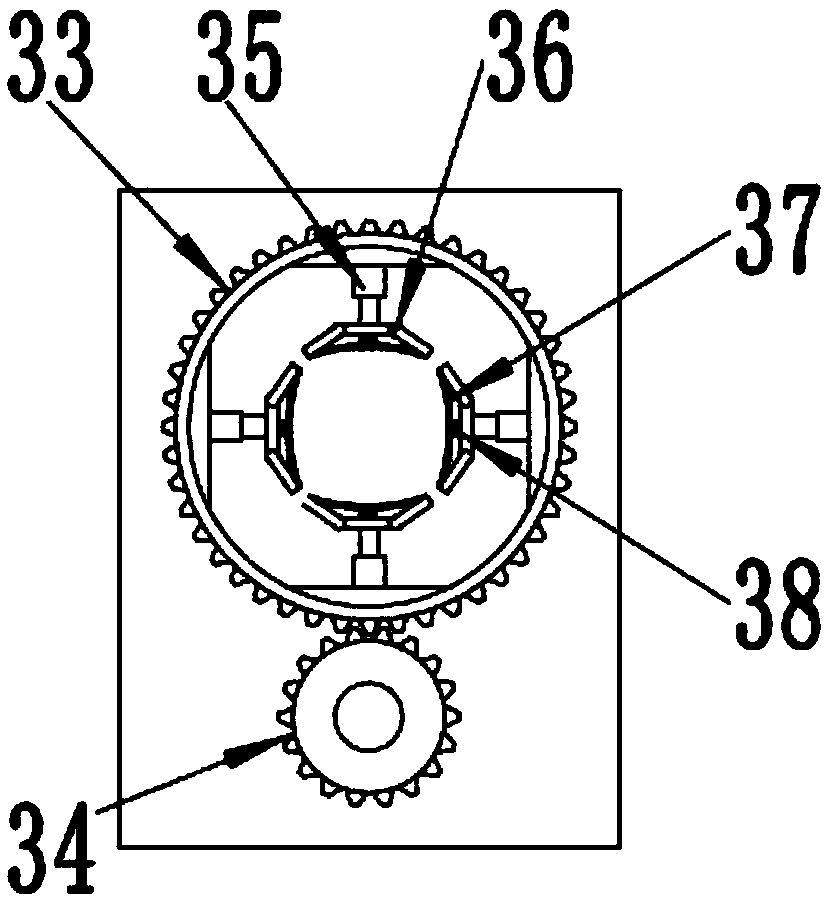

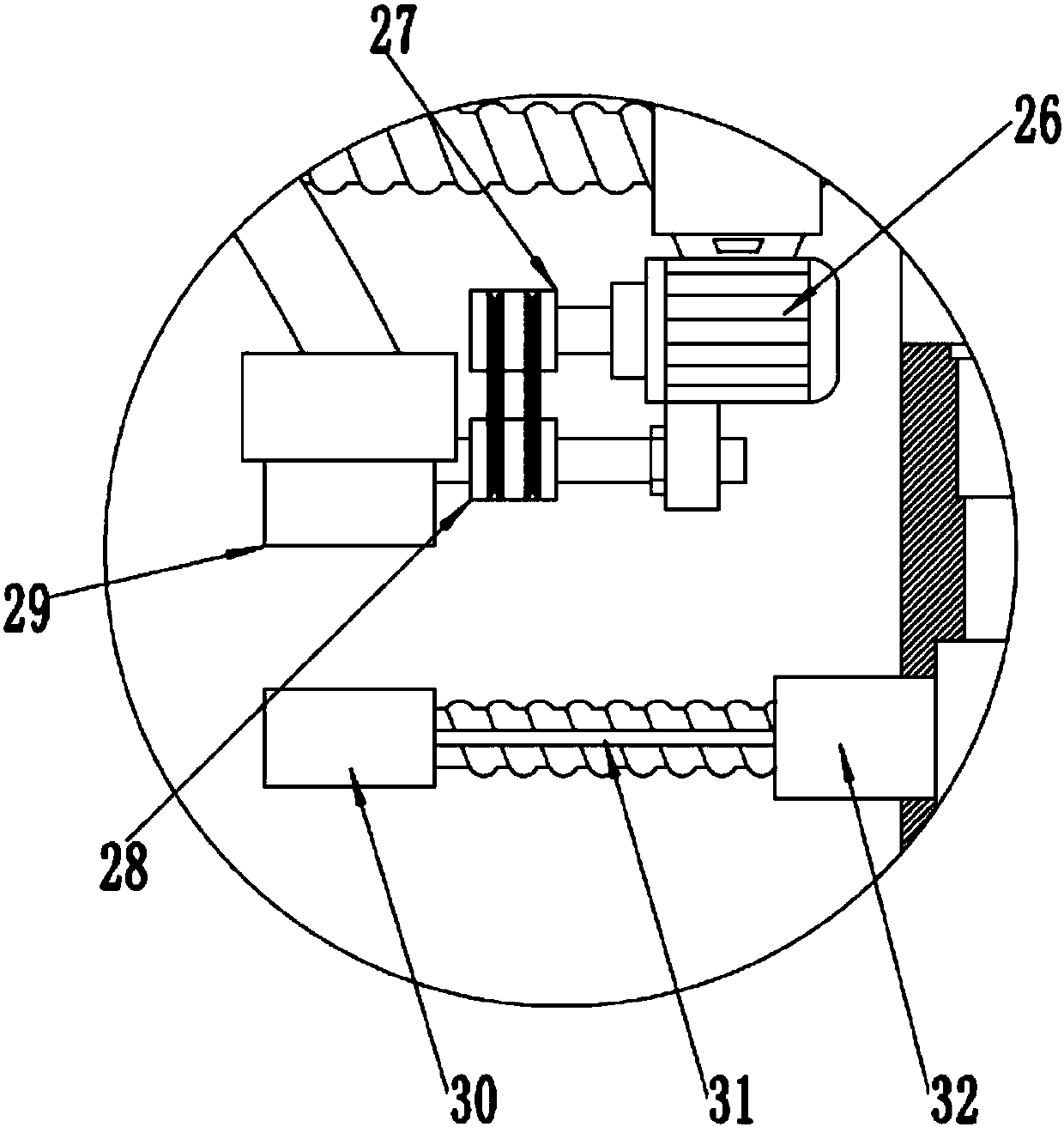

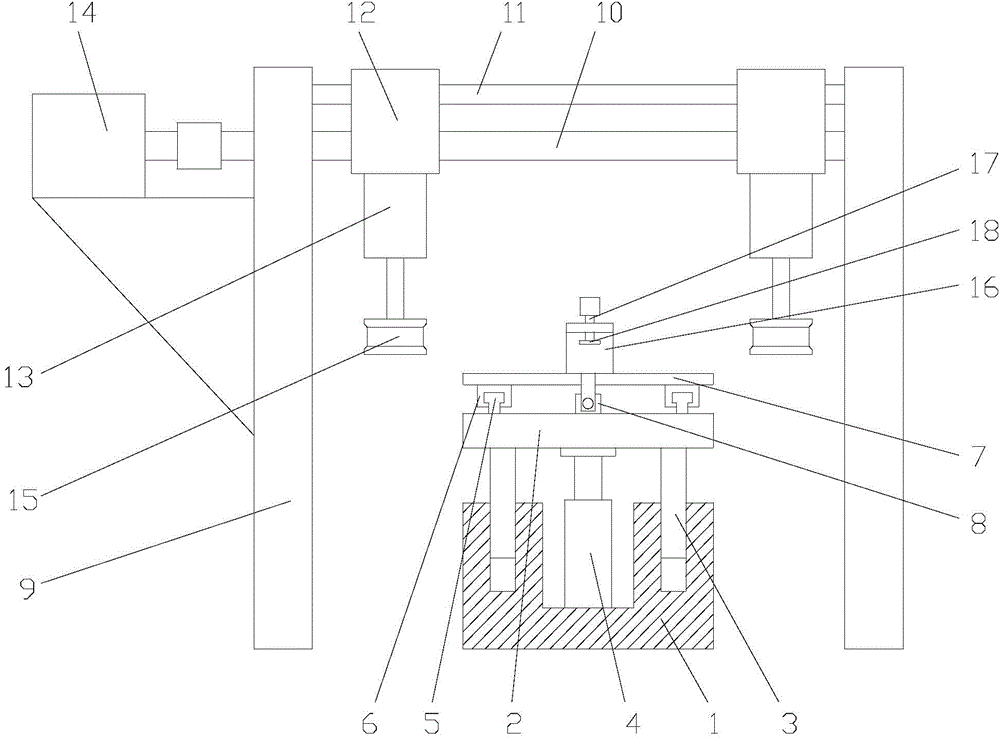

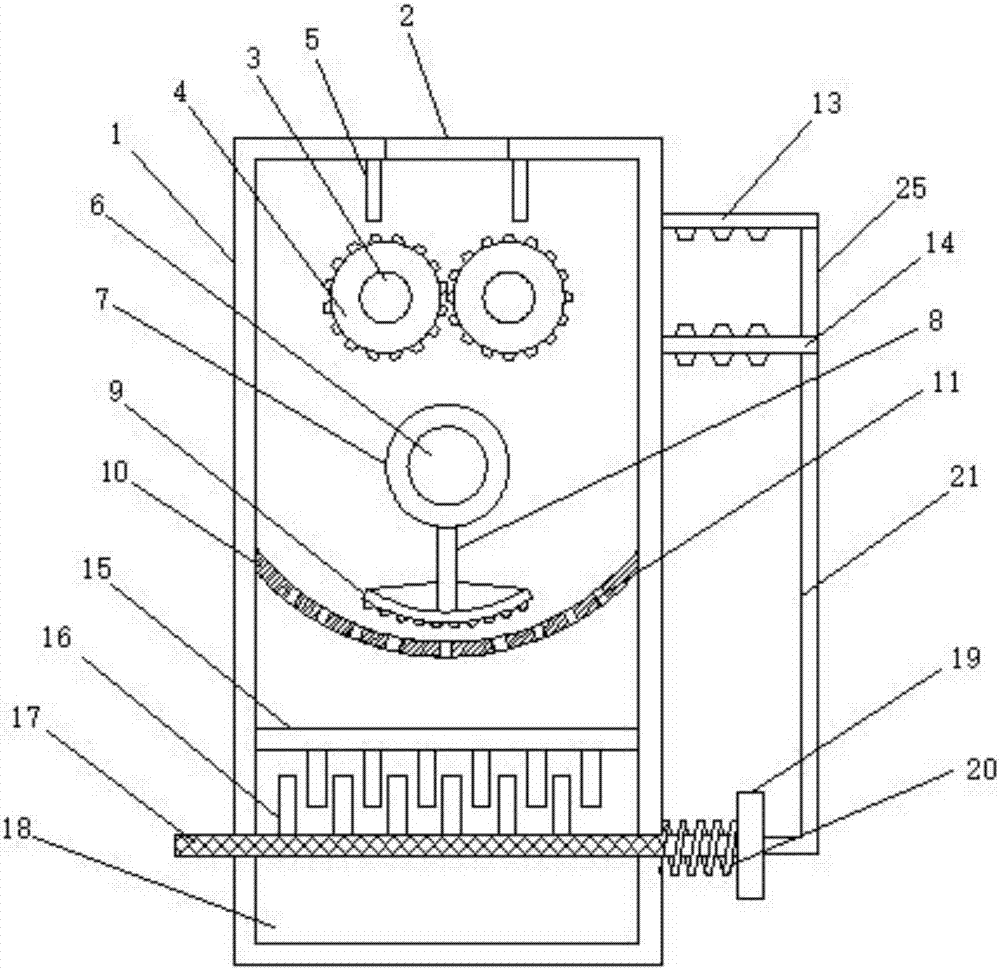

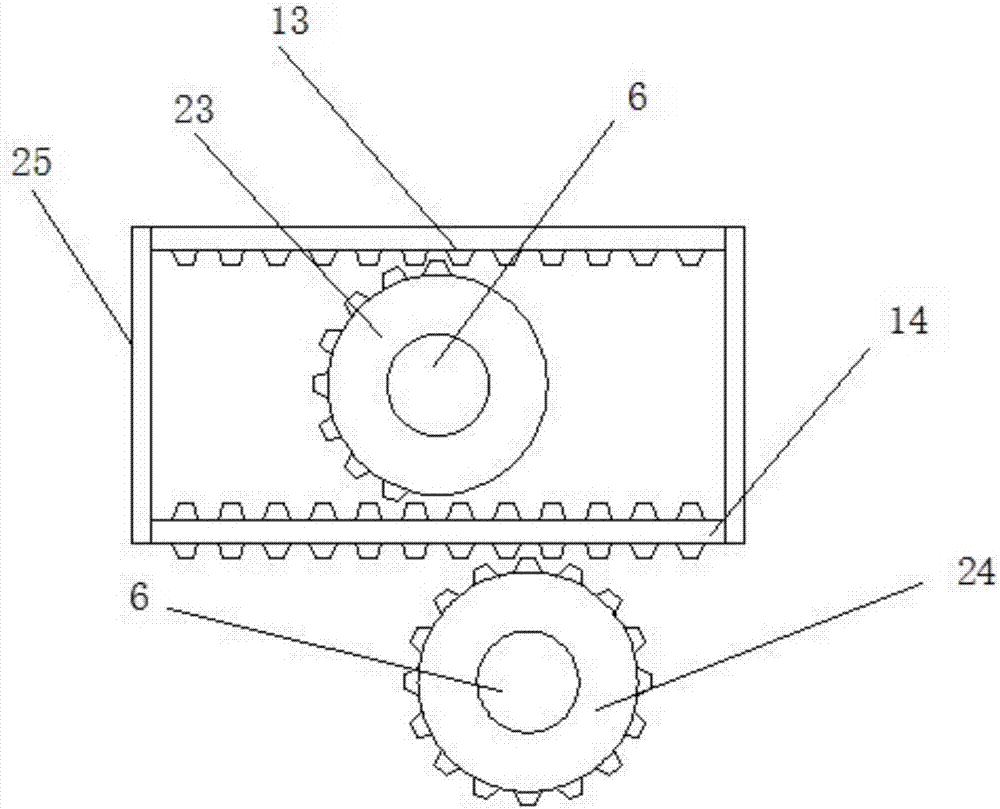

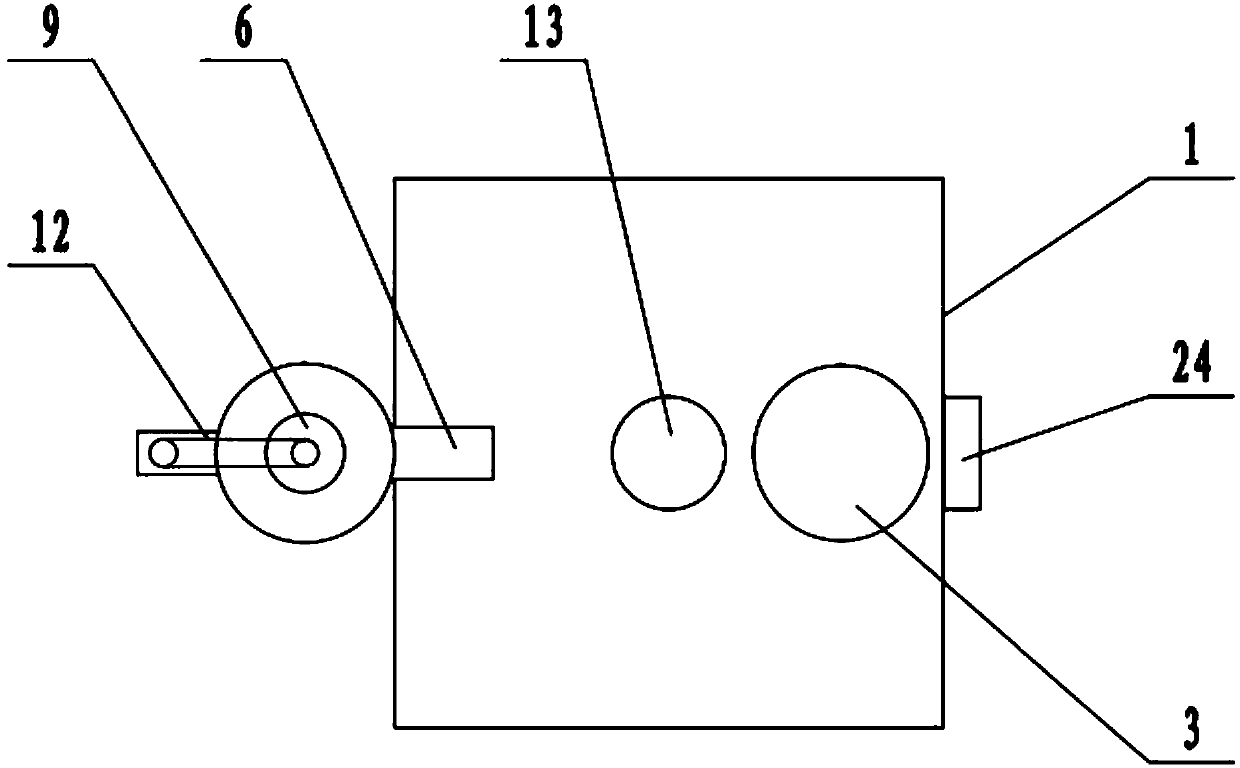

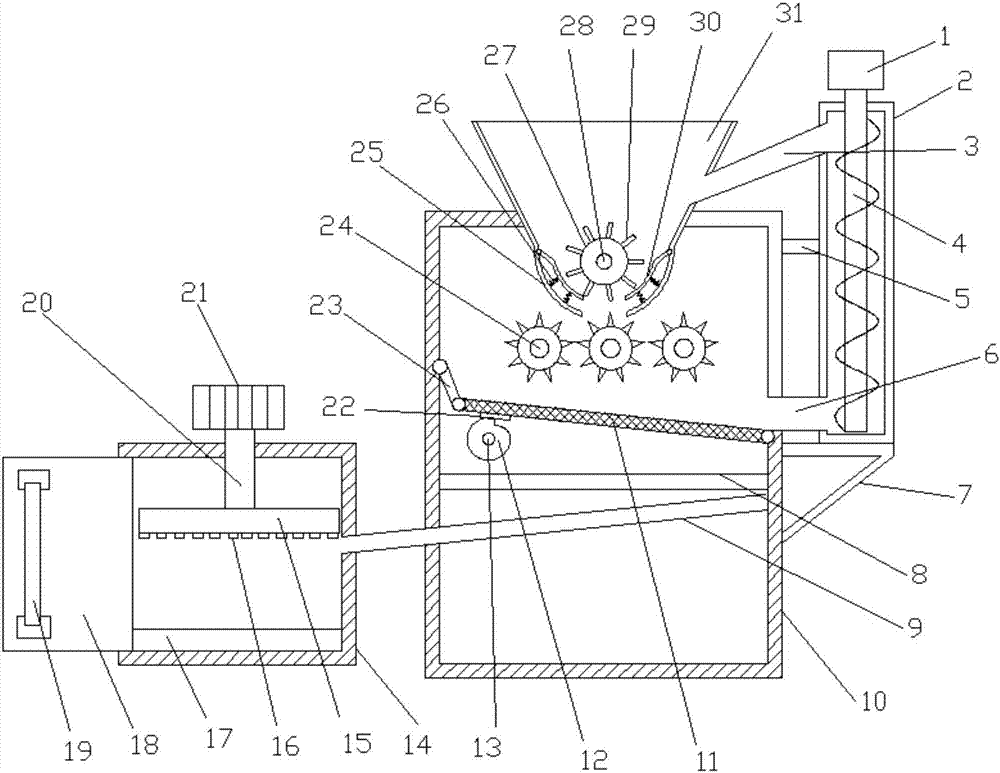

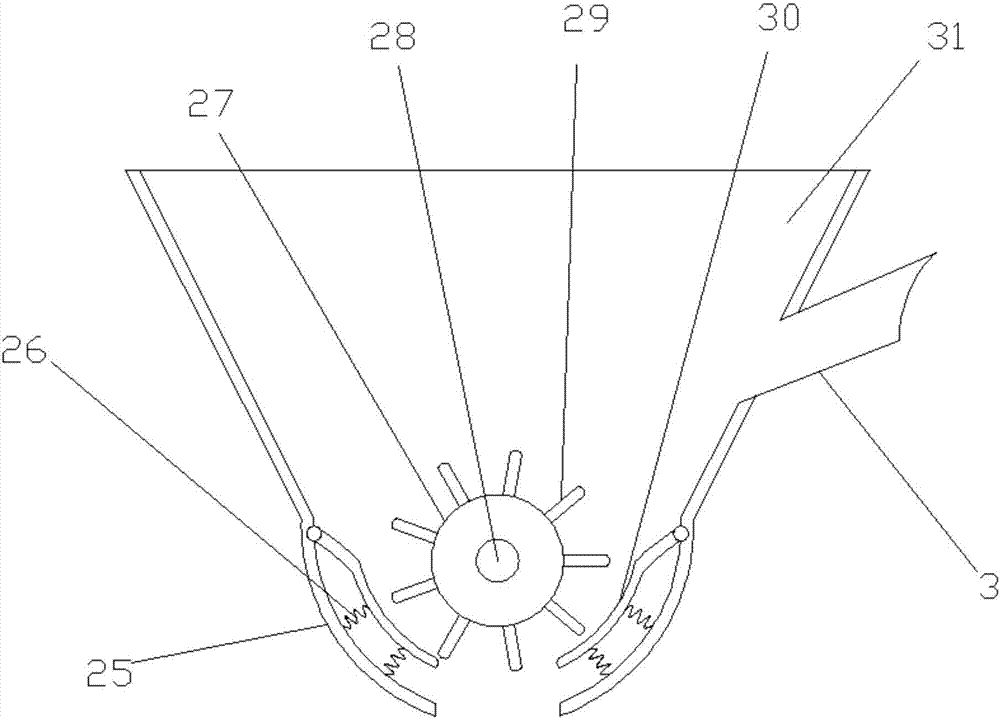

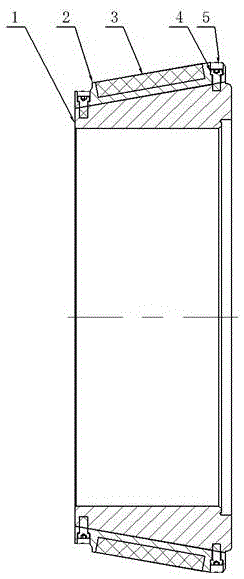

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

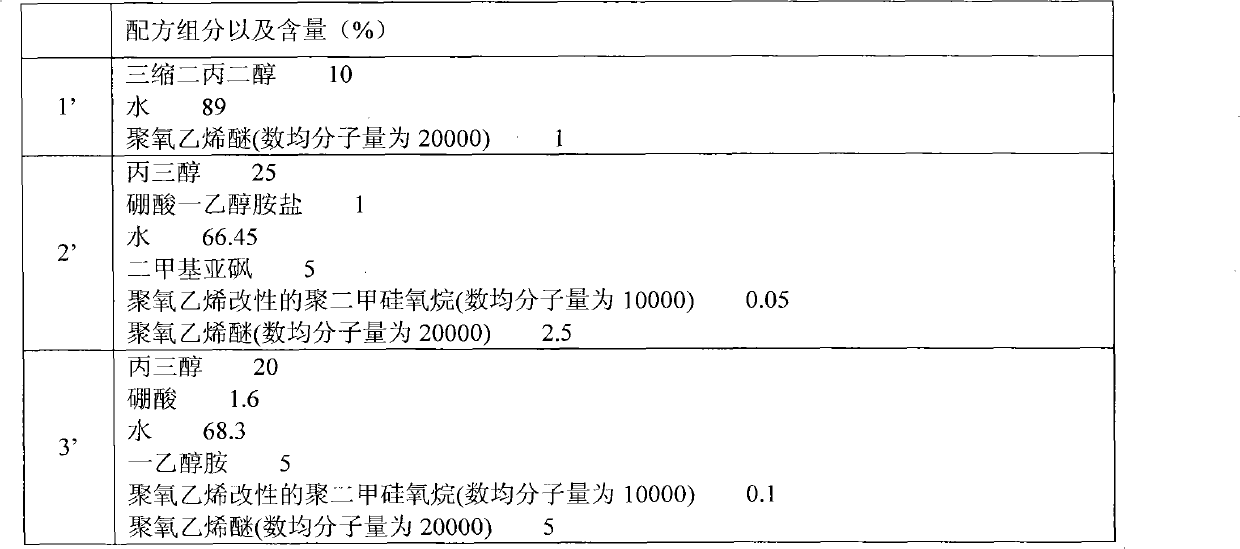

Water diamond lapping liquid and its preparation method and use

InactiveCN101186804AEnvironmentally friendlyAccelerated corrosionPolishing machinesOther chemical processesAlloySuspending Agents

The invention provides aqueous diamond polishing liquid, process for preparation and purpose. The main components are diadust, dispersion stabilizer, suspending agent, pH modifying agent, antiseptic agent, organic solvent and deionized water. The preparing technique of the invention is that organic solvent, diadust, prior prepared suspending agent, deionized water and dispersion stabilizer are mixed, then the mixture is stirred or supersonically dispersed uniformly, finally pH modifying agent and antiseptic agent are added, and the preparation is accomplished after shaking up. The lapping liquid can be widely used in grinding and polishing in various departments and areas of optical instruments, glasses, ceramics, rigid alloy, diamonds, artificial lens, optical fiber, LED display, integrated circuit, semiconductor, hard disk and the like. The lapping liquid can be kept in uniform and stable state, generates no precipitation, delamination or invalidation.

Owner:BEIJING GRISH HITECH

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

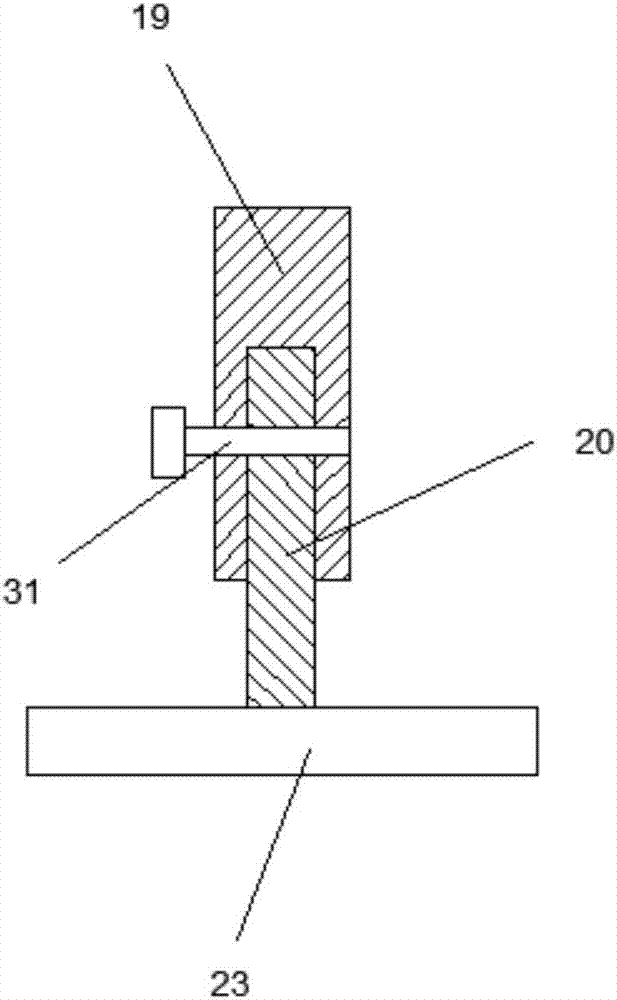

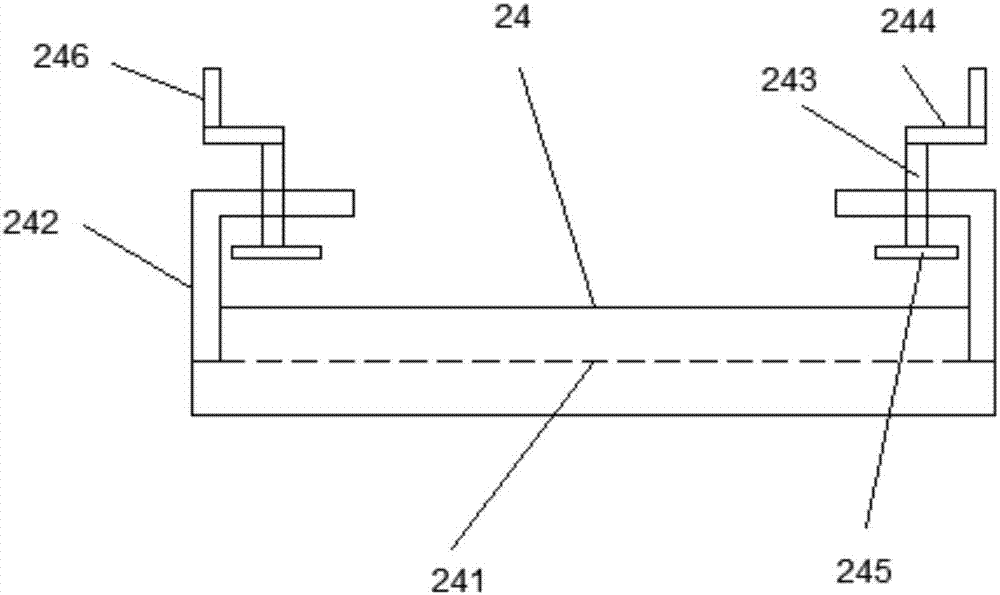

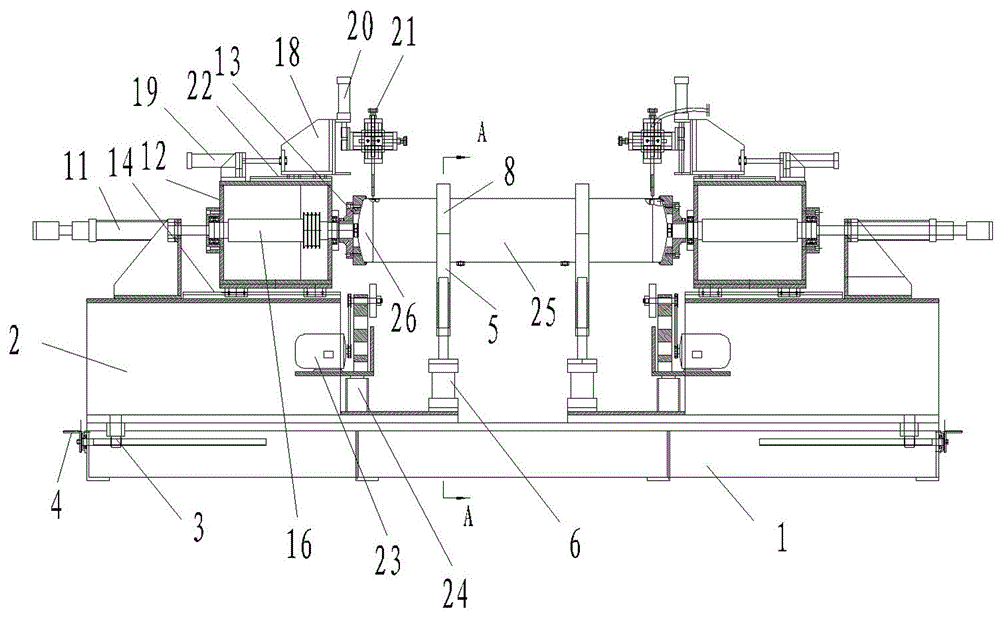

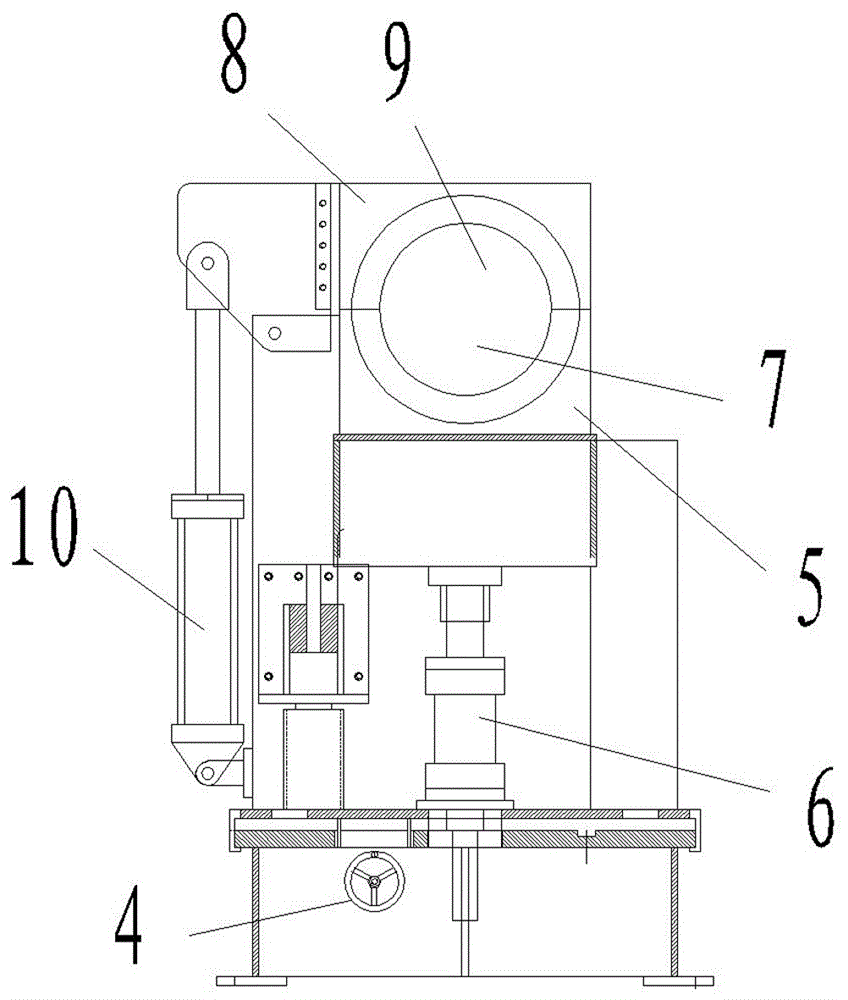

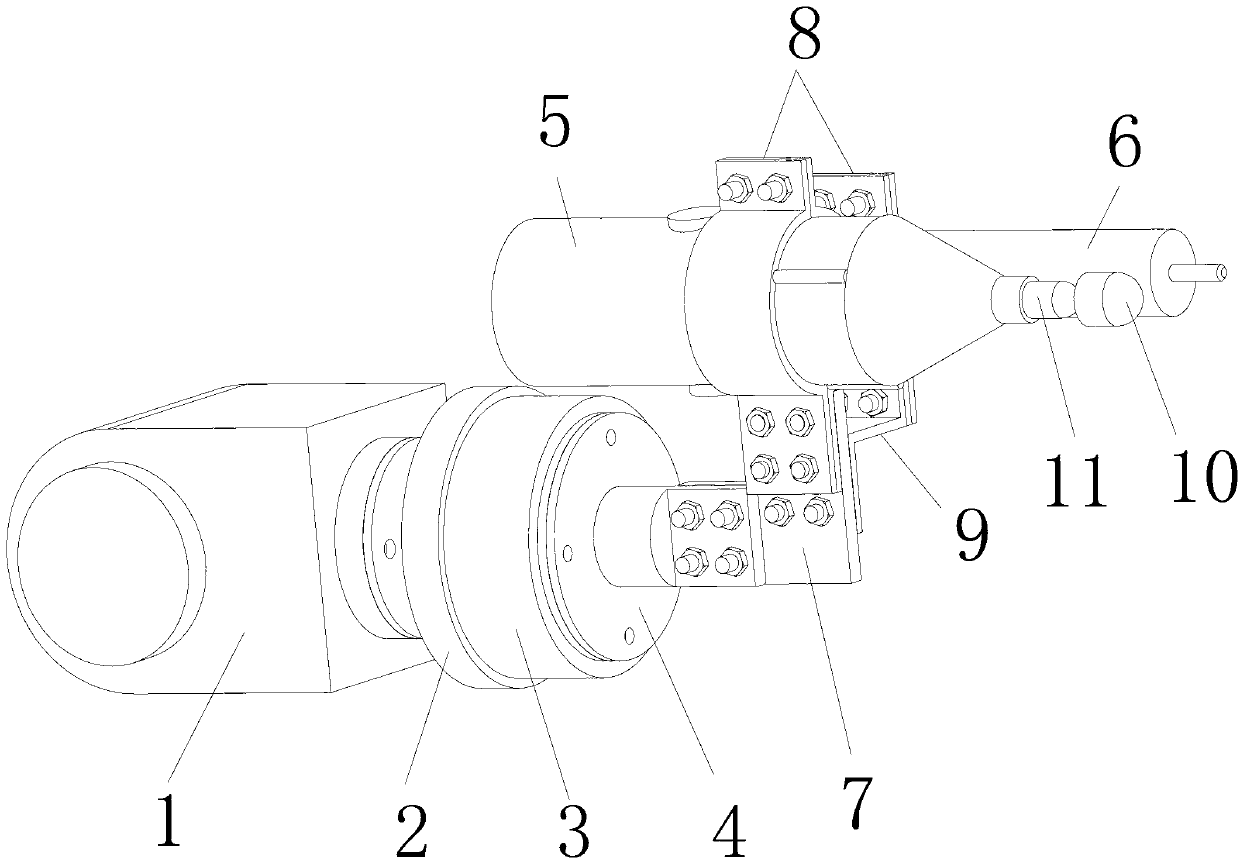

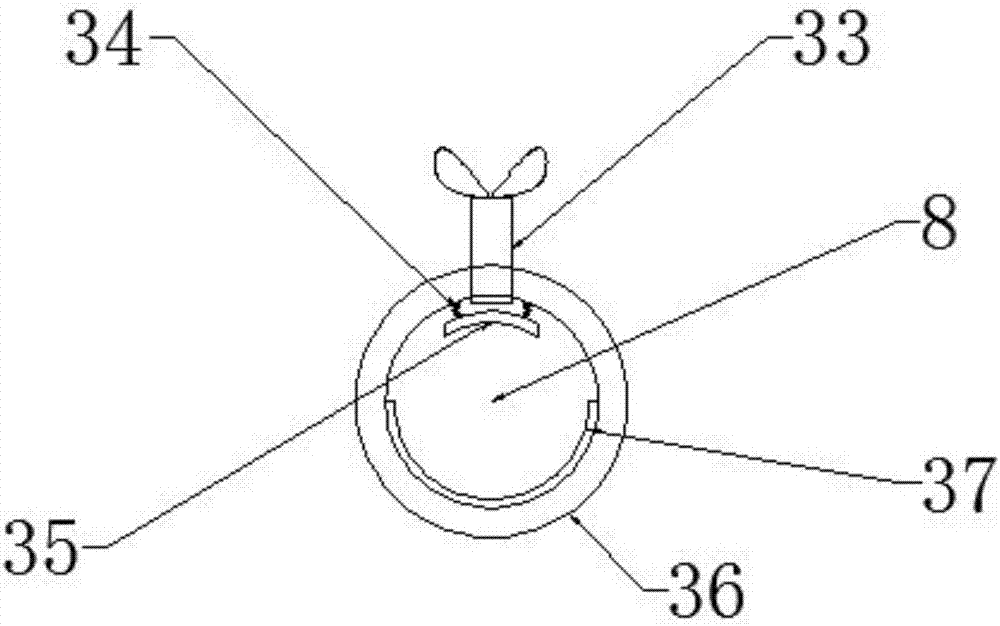

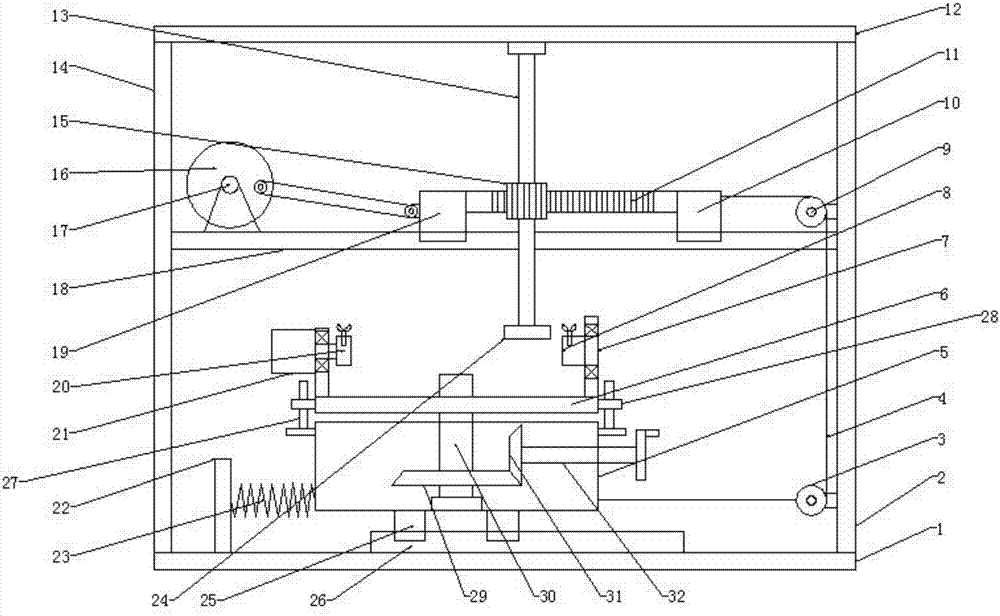

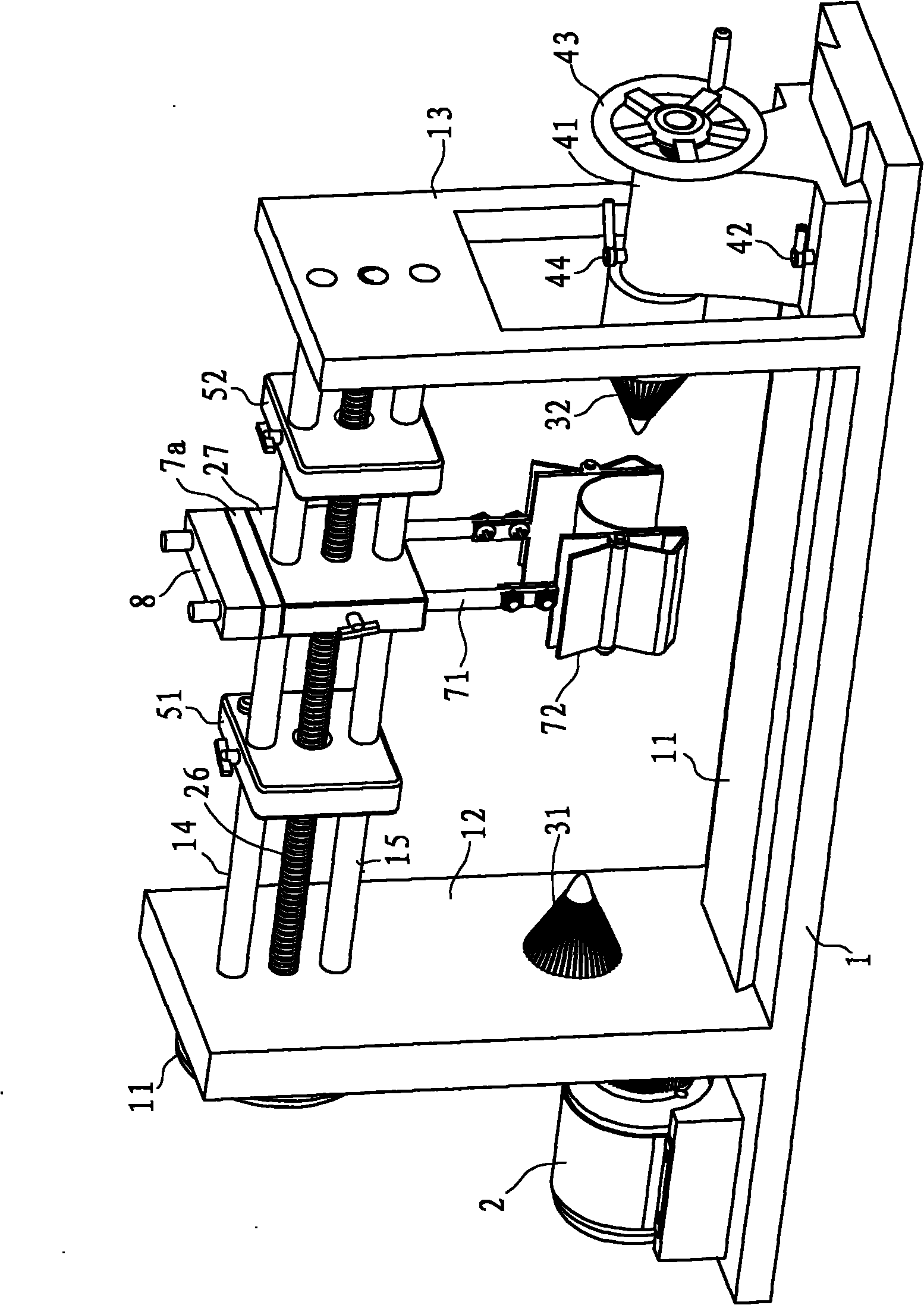

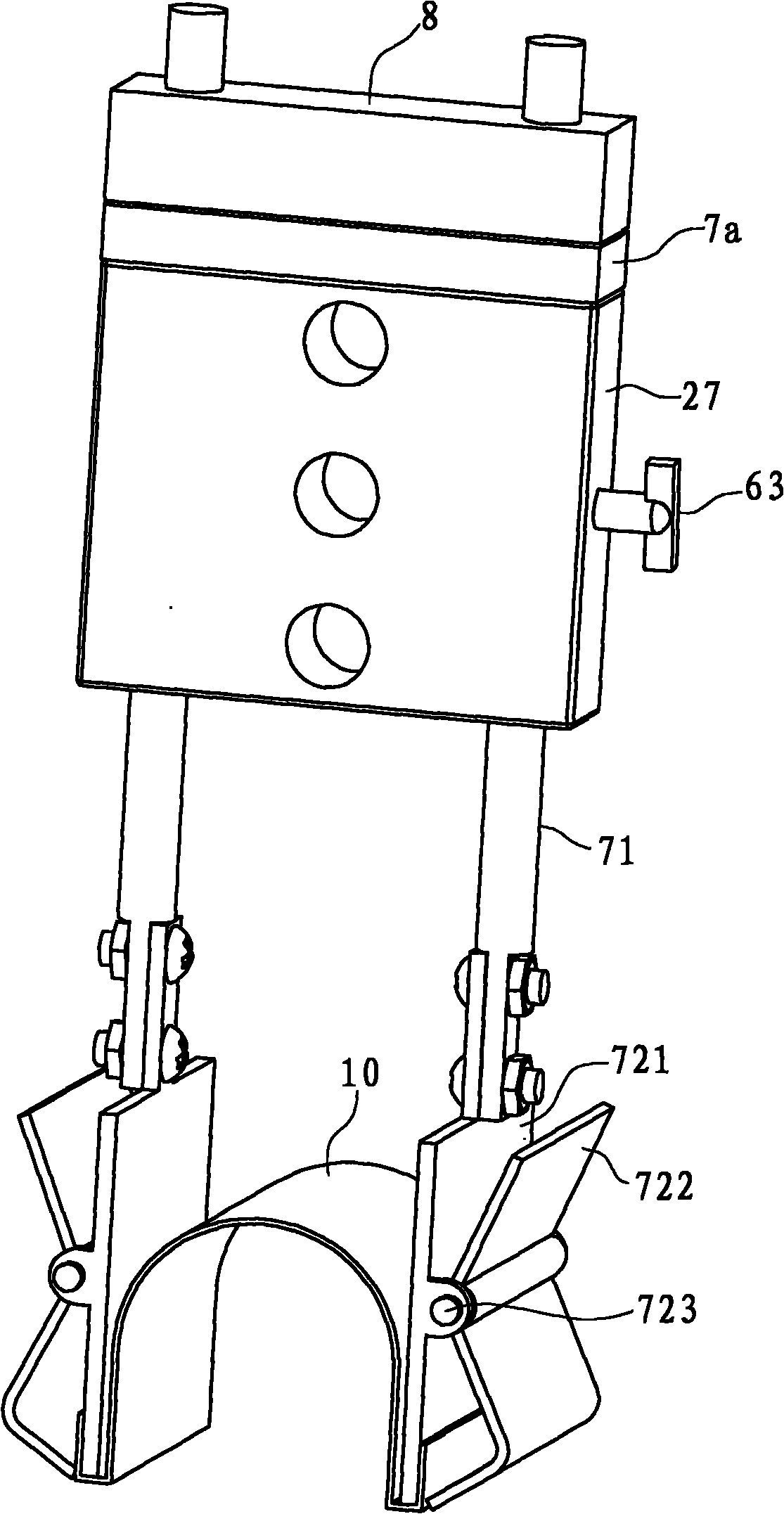

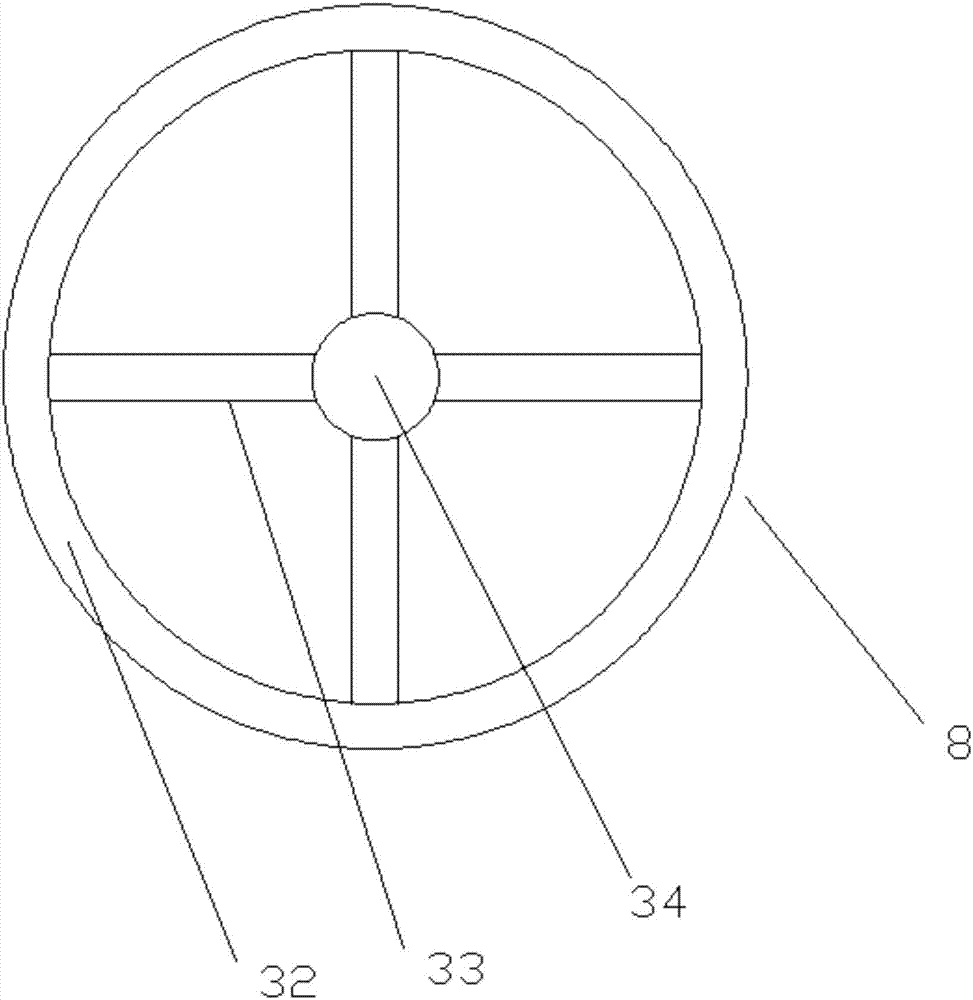

Automatic girth welding device for air cylinder for automobile

InactiveCN106736084AImprove welding efficiencyImprove grinding efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsThrough transmissionPiston rod

The invention discloses an automatic girth welding device for an air cylinder for an automobile. The automatic girth welding device comprises a base, wherein two symmetric machine seats on the base, an air cylinder bracket located between the two machine seats, and clamping mechanisms separately arranged on the two machine seats, wherein each clamping mechanism comprises a clamping cylinder, a mobile box seat and an air cylinder end cover clamp; piston rods of the clamping cylinders are connected with the outer sides of the mobile box seats; the air cylinder end cover clamps are arranged on the inner sides of the mobile box seats; the mobile box seats are further provided with servo motors; the servo motors are connected with rotating shafts arranged along the axial direction of the air cylinder through transmission devices; the rotating shafts are connected with the air cylinder end cover clamps; a cylinder body of the air cylinder is arranged on the air cylinder bracket; the clamping cylinders push the air cylinder end cover clamps to move towards the direction of the cylinder body of the air cylinder, so that air cylinder end covers are clamped with the cylinder body of the air cylinder; the servo motors are started to enable the air cylinder end cover clamps to drive the whole air cylinder to rotate and be subjected to welding; after the air cylinder rotates a circle, girth welding is completed; and furthermore, the automatic girth welding device is high in efficiency and high in quality.

Owner:BENGBU TONGDA AUTO PARTS

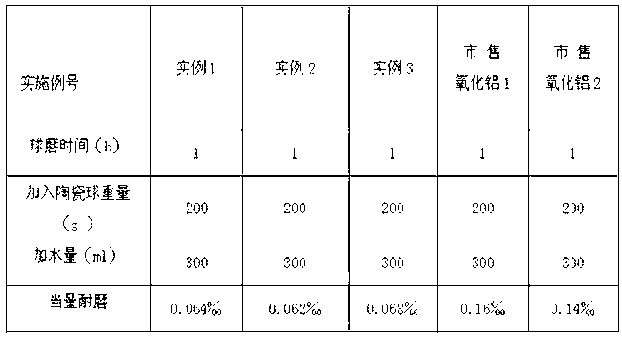

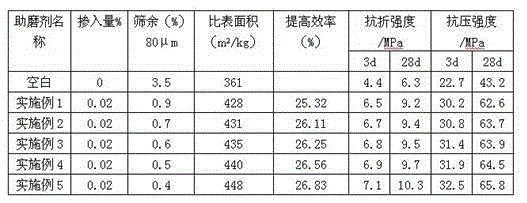

Ultra-wear-resistant alumina ceramic ball and preparation method thereof

The invention provides an ultra-wear-resistant alumina ceramic ball. The ultra-wear-resistant alumina ceramic ball comprises the following chemical components: 90-95% by weight of Al2O3, 5-8% by weight of SiO2, 0.3-0.5% by weight of CaO, 0.5-0.9% by weight of MgO, 1-2% by weight of ZrO and 0.1-0.5% by weight of La2O3 / Y2O3, wherein the equivalent wear loss is less than 72 per mil. A provided preparation method comprises the following process steps of: adopting alumina powder and other mineral raw materials for burdening, refining mud, drying, calcining, synthesizing, ball-milling, granulating, forming and firing to obtain a product. According to the invention, the wear resistance of the product can achieve the standard of the alumina ceramic ball; and furthermore, the ultra-wear-resistant alumina ceramic ball has the advantages of lower cost of the raw materials, better grinding performance and high performance-price ratio of the product, is more suitable for being applied in production, and can reduce the production cost of an enterprise and improve the production efficiency of the enterprise.

Owner:JINGDEZHEN BETTERWEAR NEW MATERIALS

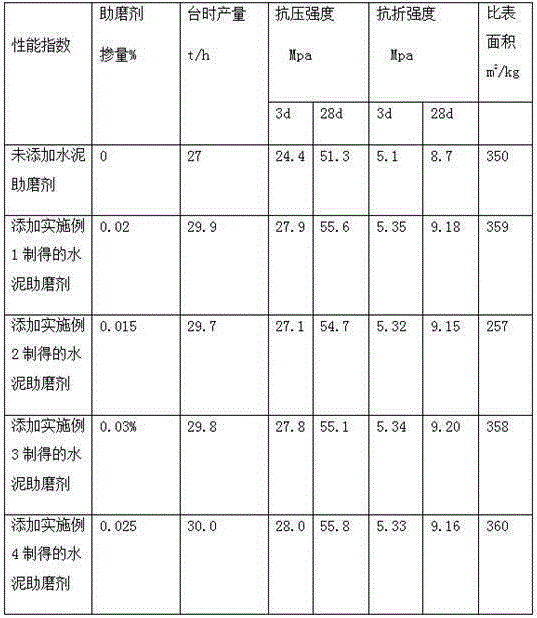

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

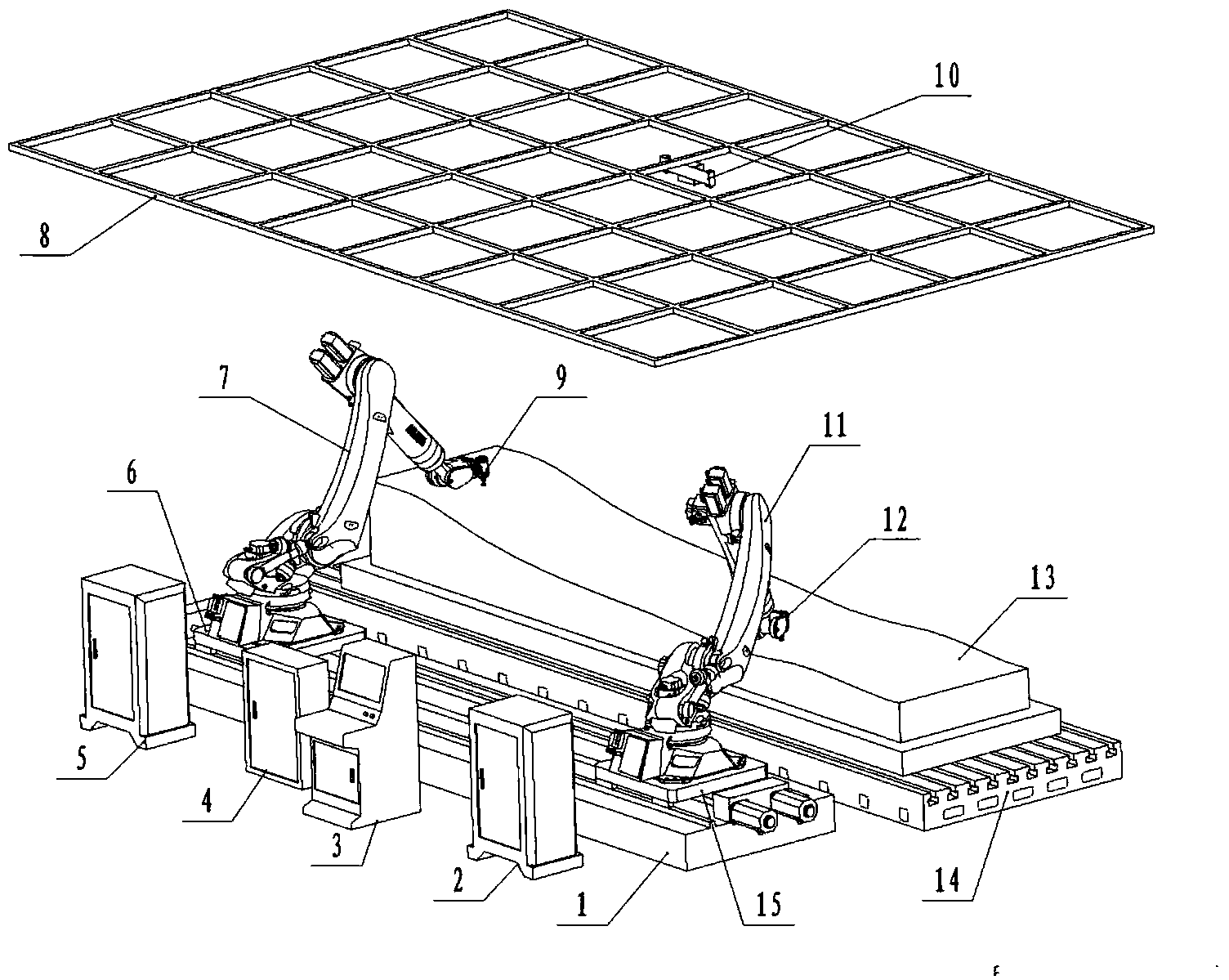

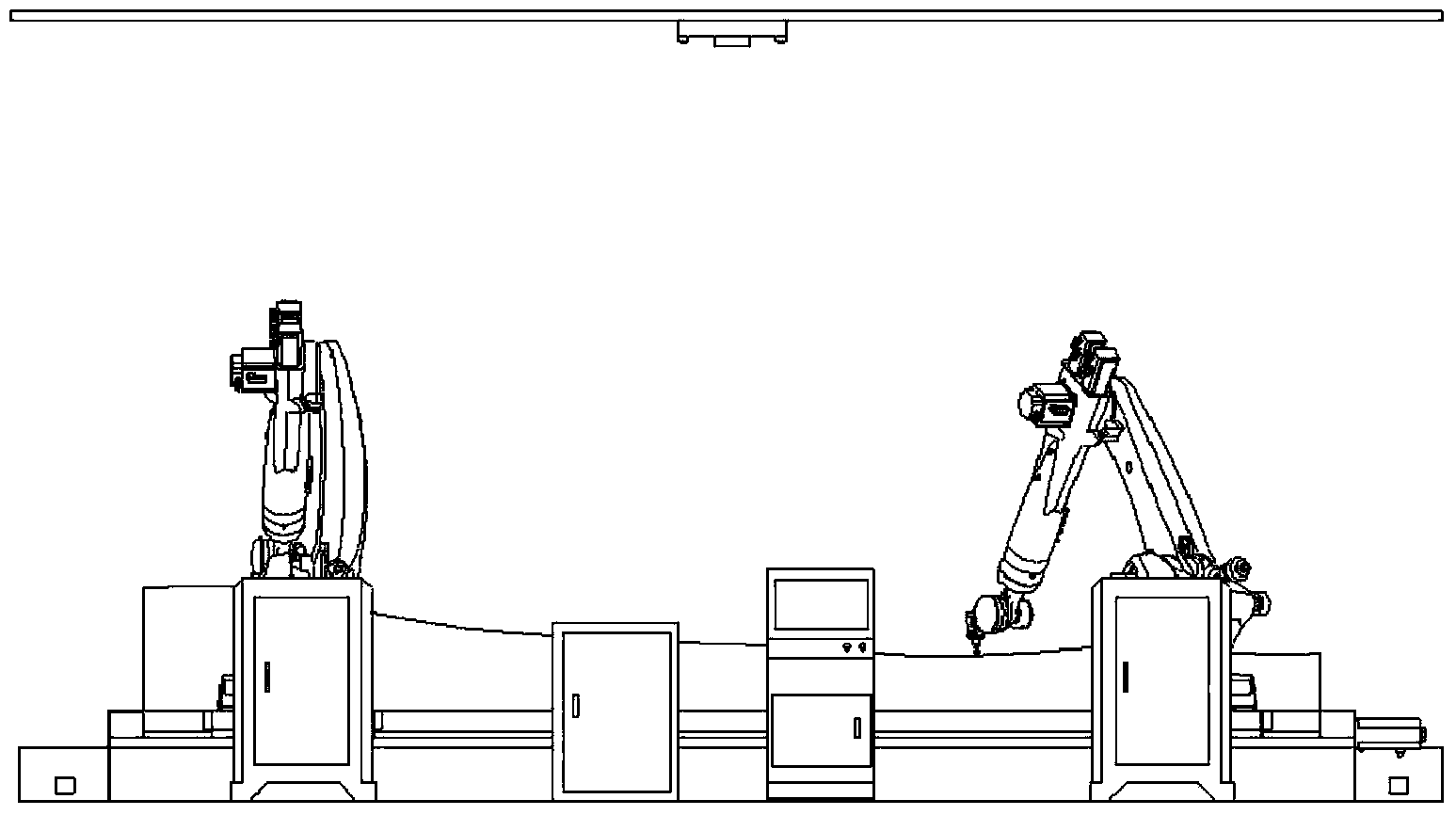

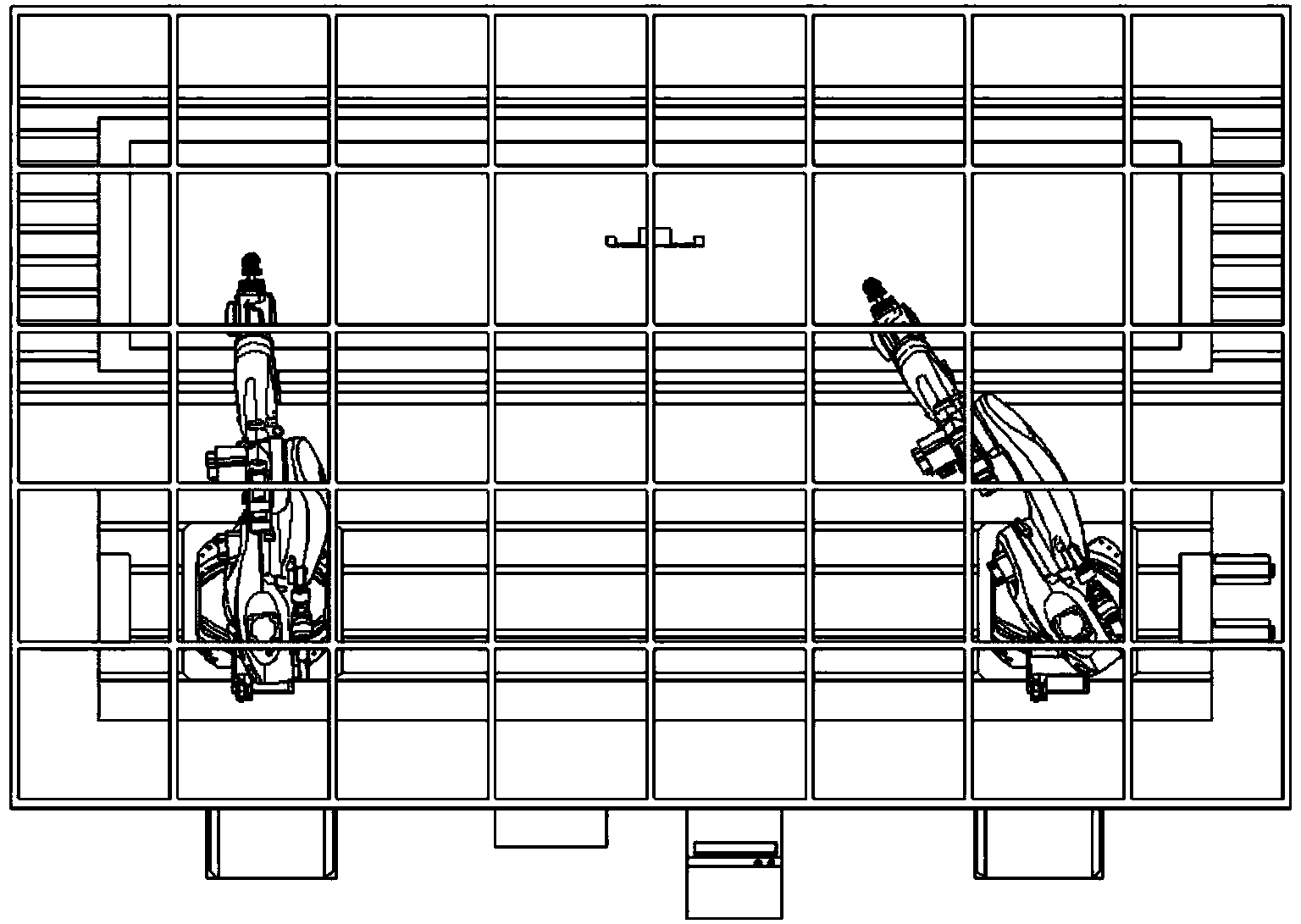

Robot parallel polishing system

ActiveCN103862340APressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

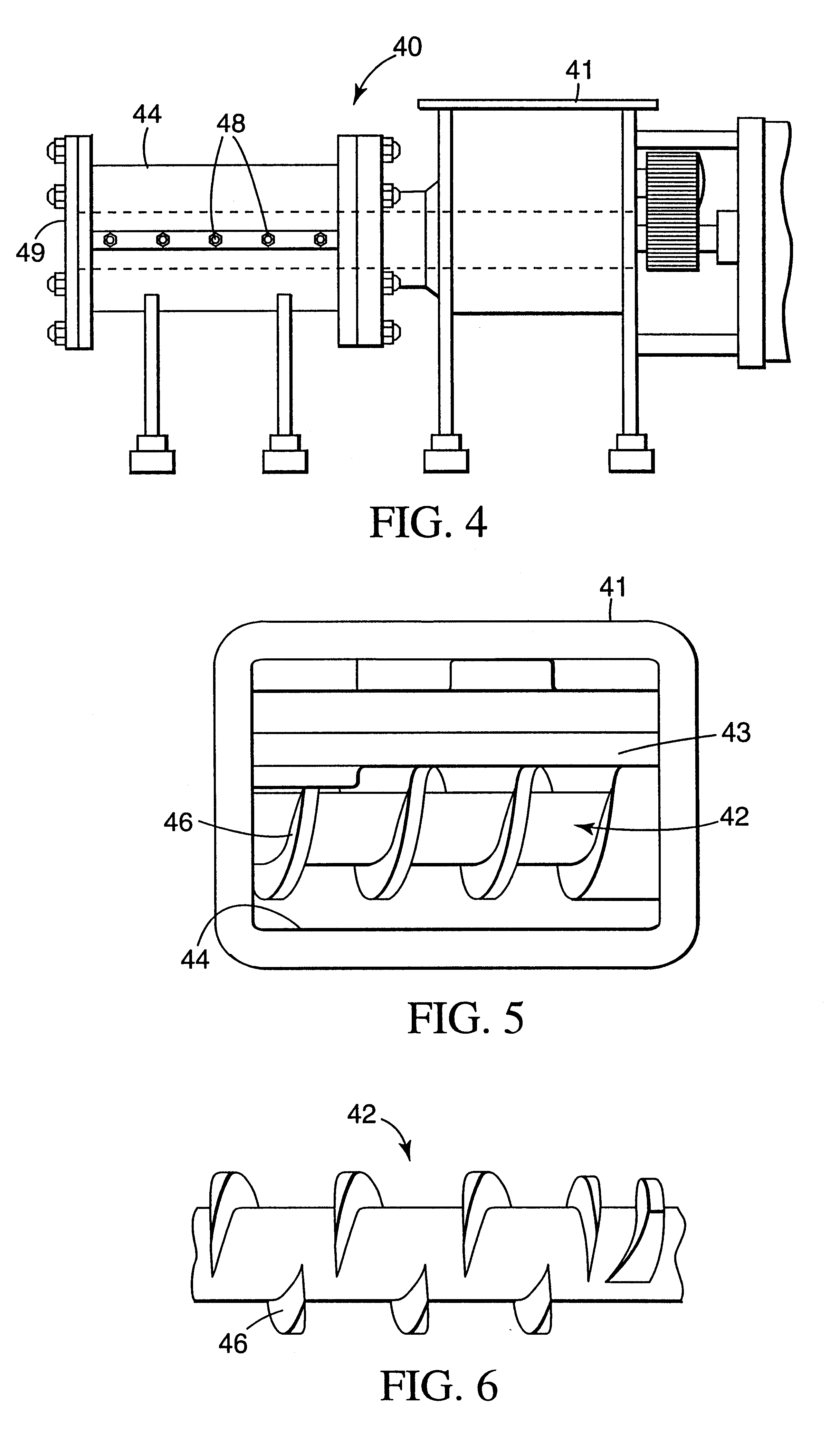

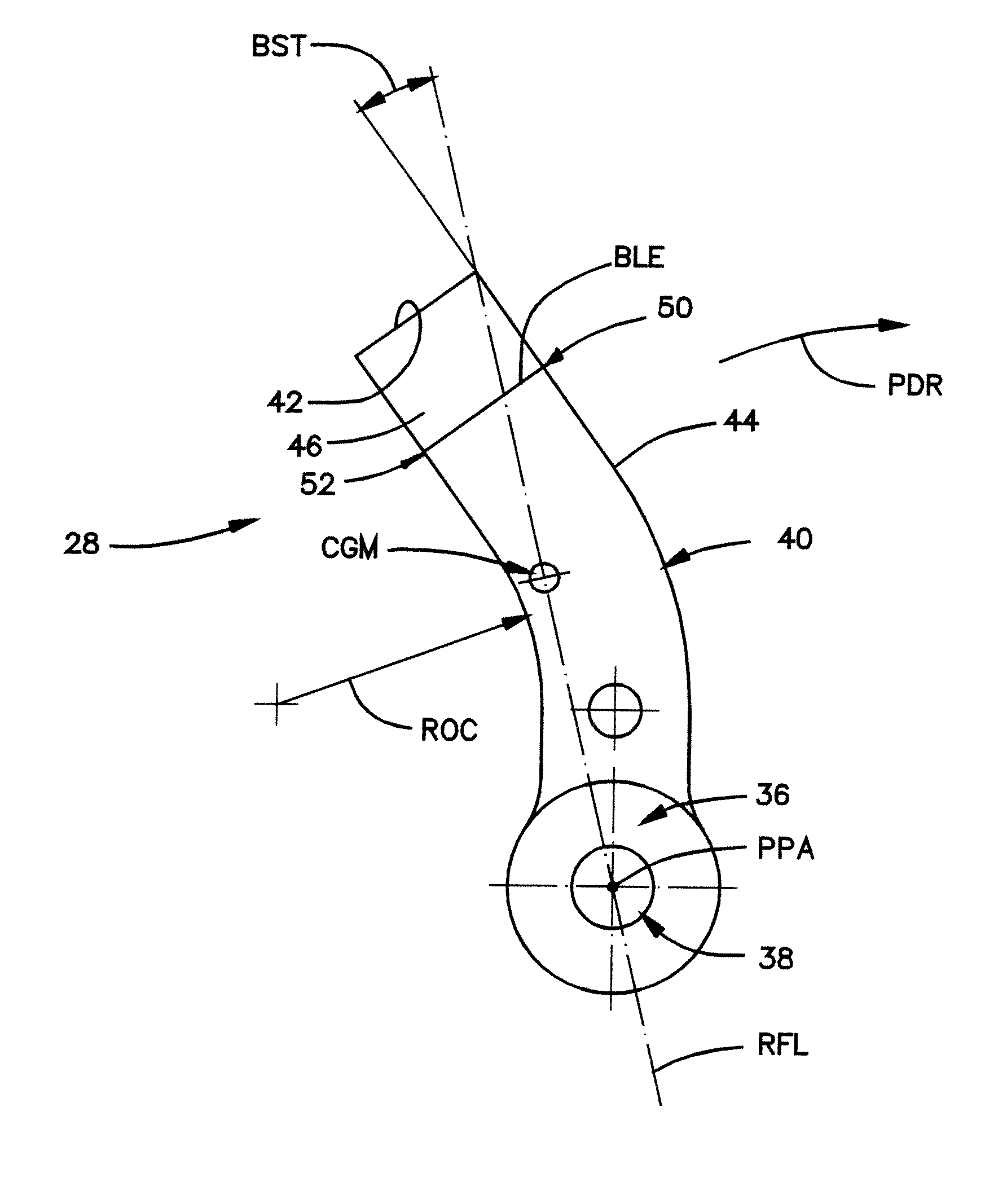

Hammer for a material size reduction machine

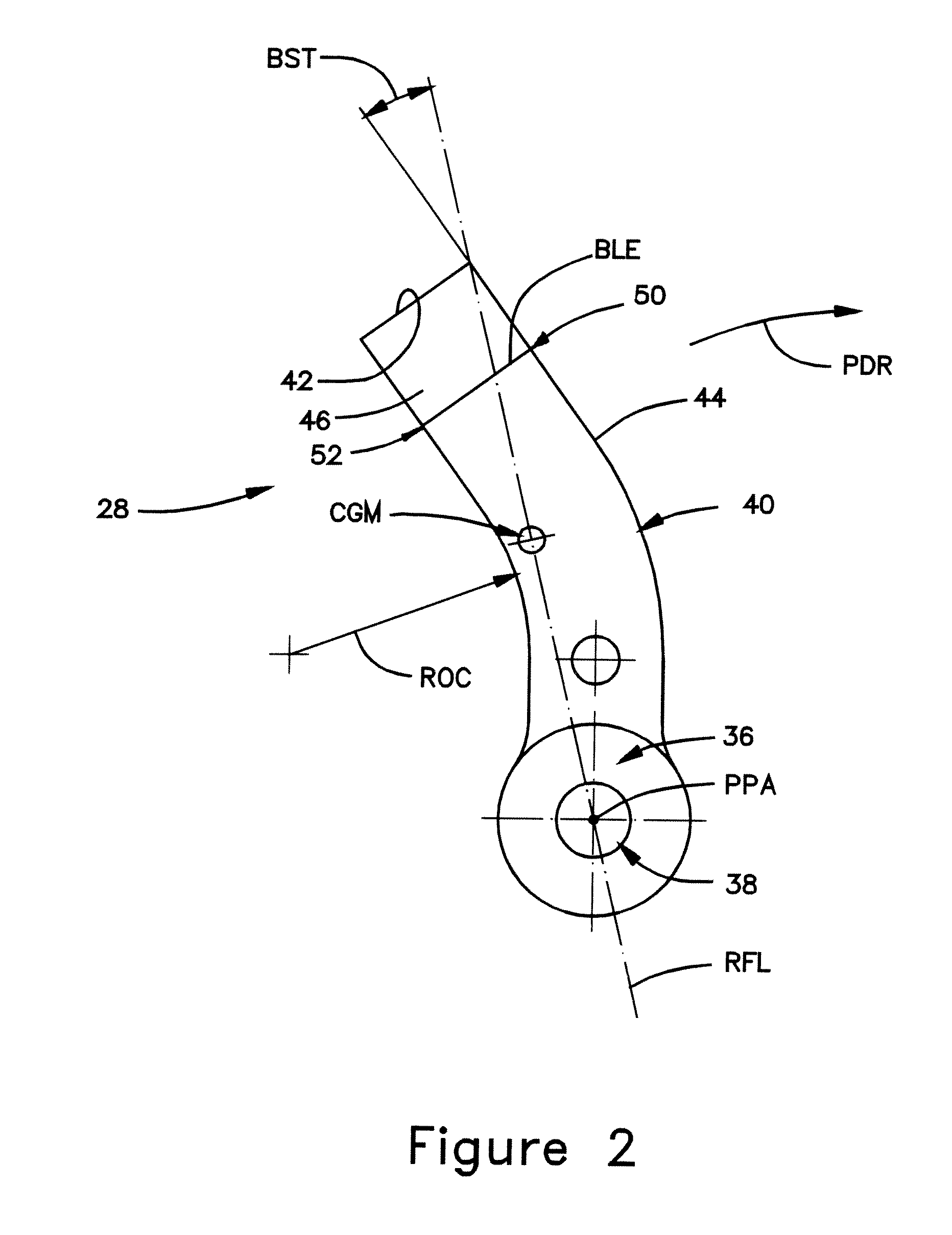

InactiveUS7325761B2Favorable impact wear characteristicImprove grinding efficiencyGrain treatmentsMechanical engineeringSize reduction

A hammer 28 is provided for a material size-reducing machine of the type including a rotor on which the hammer is individually pivotally mounted. The hammer 28 includes a mounting end 36 having a throughbore for receiving a pivot pin therethrough in connection with the pivot mounting of the hammer on the rotor, an extending portion 40 with the center of mass CGM located therein. The extending portion has a non-linear body portion 44 and a linear body portion 46 with the linear body portion 46 being inclined in a direction opposite to the rotation direction at an angle between 5 to 45 degrees as measured relative to a line RFL extending through the center of the pivot pin and the center of mass CGM of the hammer.

Owner:ARVOS RAYMOND BARTLETT SNOW LLC

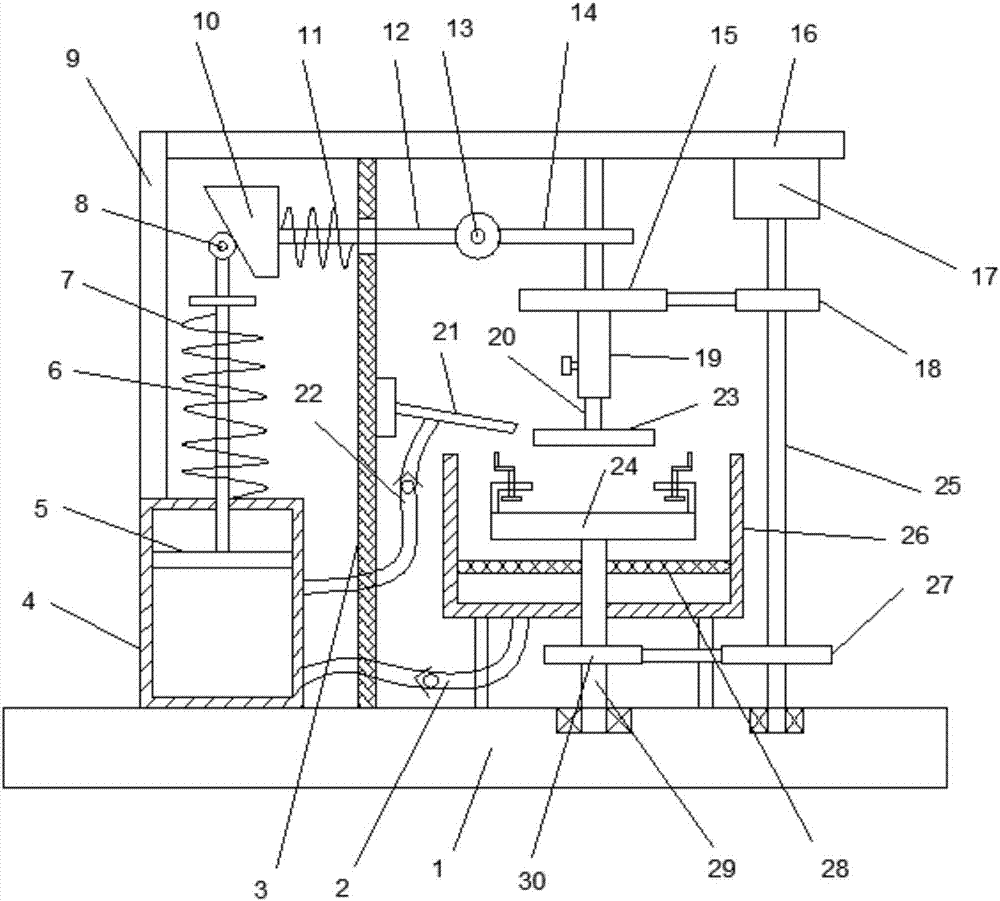

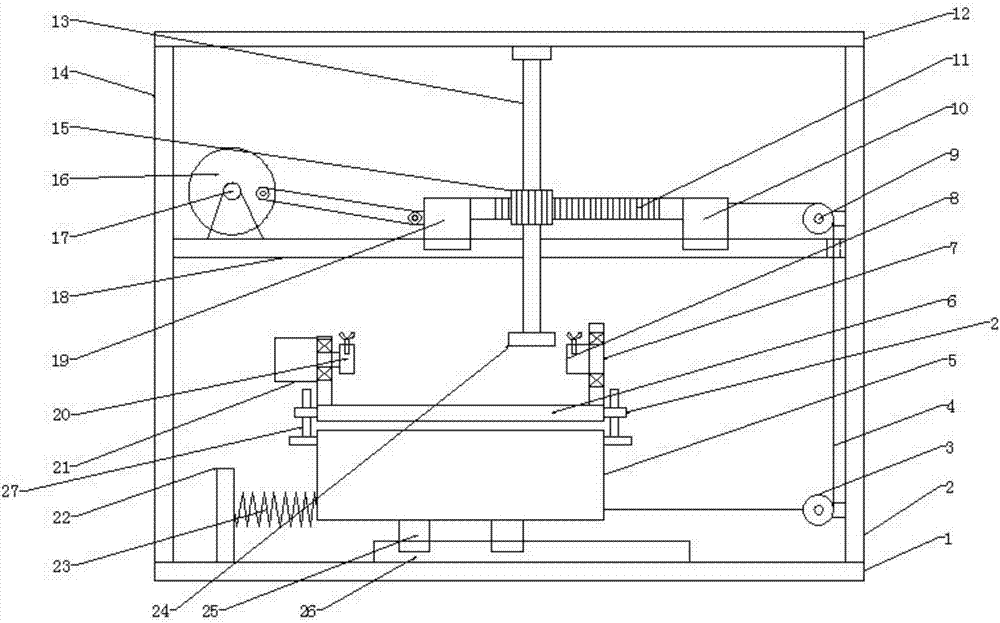

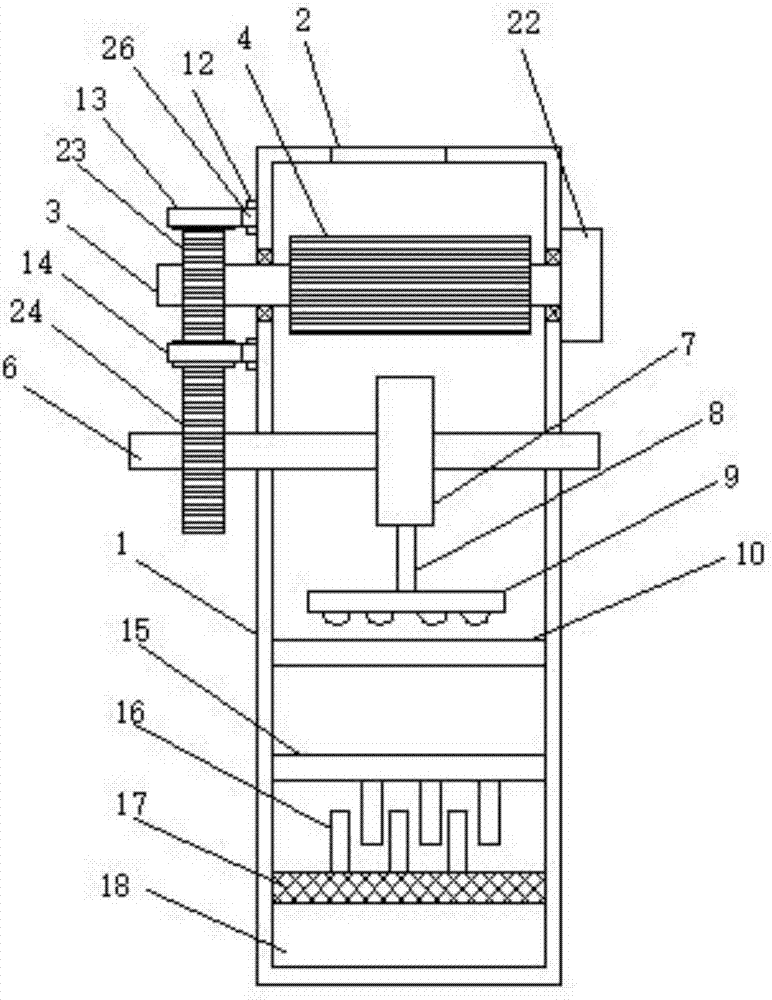

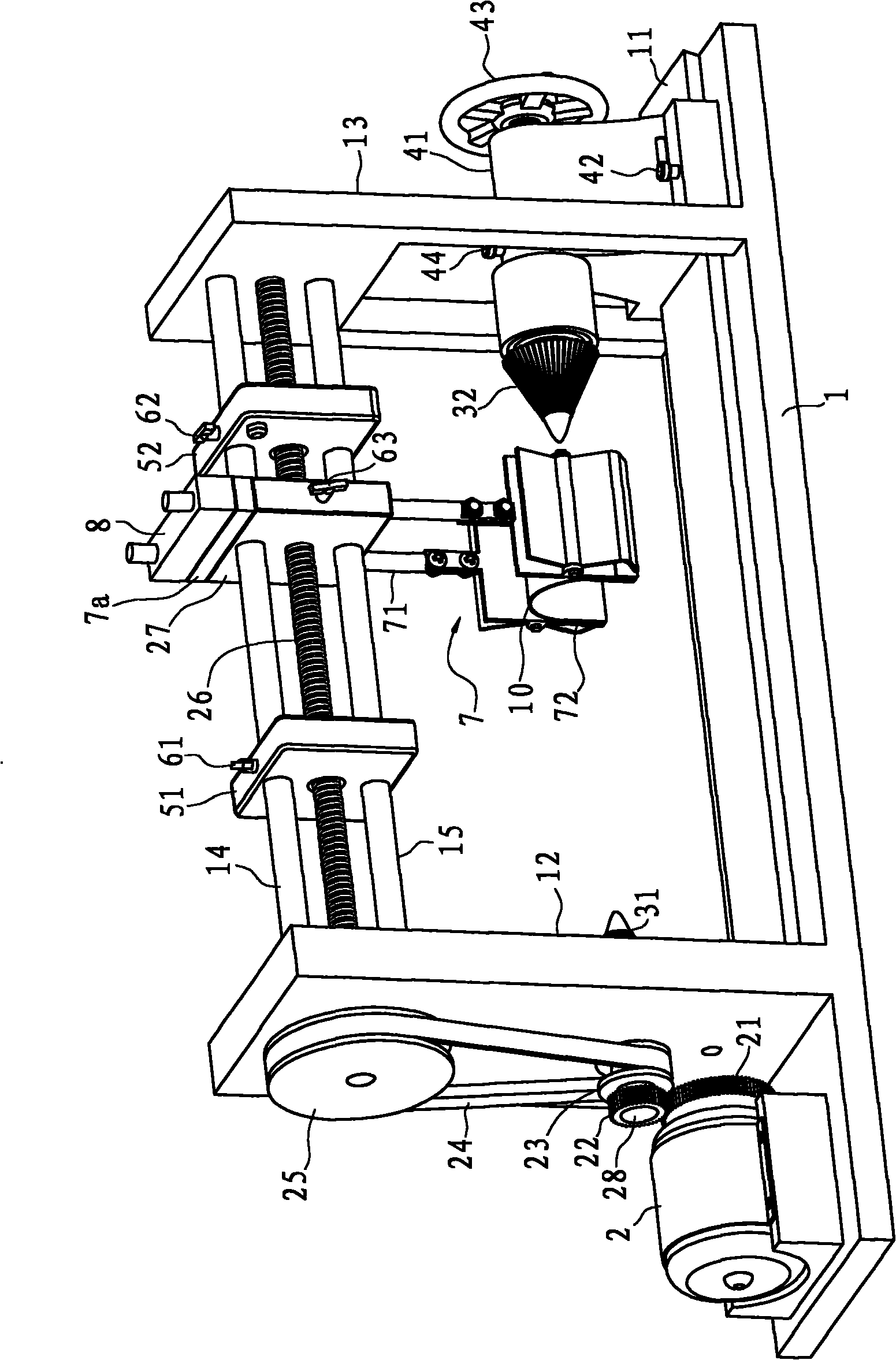

Automatic glass grinding machine

InactiveCN104385076ARealize automatic grinding processImprove grinding efficiencyEdge grinding machinesGrinding drivesGrinding wheelScrew thread

The invention discloses an automatic glass grinding machine. The automatic glass grinding machine comprises a base, a lifting worktable, a guide rail, a carrying plate, a pressing device and a feed cylinder, as well as a vertical frame, a lead screw arranged on the vertical frame by use of a bearing, a guide rod fixed on the vertical frame and parallel to the lead screw, a connecting block in threaded fit with the lead screw, a grinding motor arranged on the connecting block, and a lead screw driving motor arranged on the vertical frame, wherein the connecting block is in slide fit with the guide rod; the rotor shaft of the grinding motor is arranged vertically; a grinding wheel is arranged on the end portion of the rotor shaft of the grinding motor. The automatic glass grinding machine is capable of realizing automatic grinding on different glass plates by automatically adjusting the up-and-down height positions of the carrying plate by use of a lifting cylinder, automatically realizing the longitudinal feed of the glass plates by use of the feed cylinder and realizing transverse feed of the grinding motor by use of the lead screw driving motor, and further is high in grinding working efficiency and low in labor intensity.

Owner:重庆天和玻璃有限公司

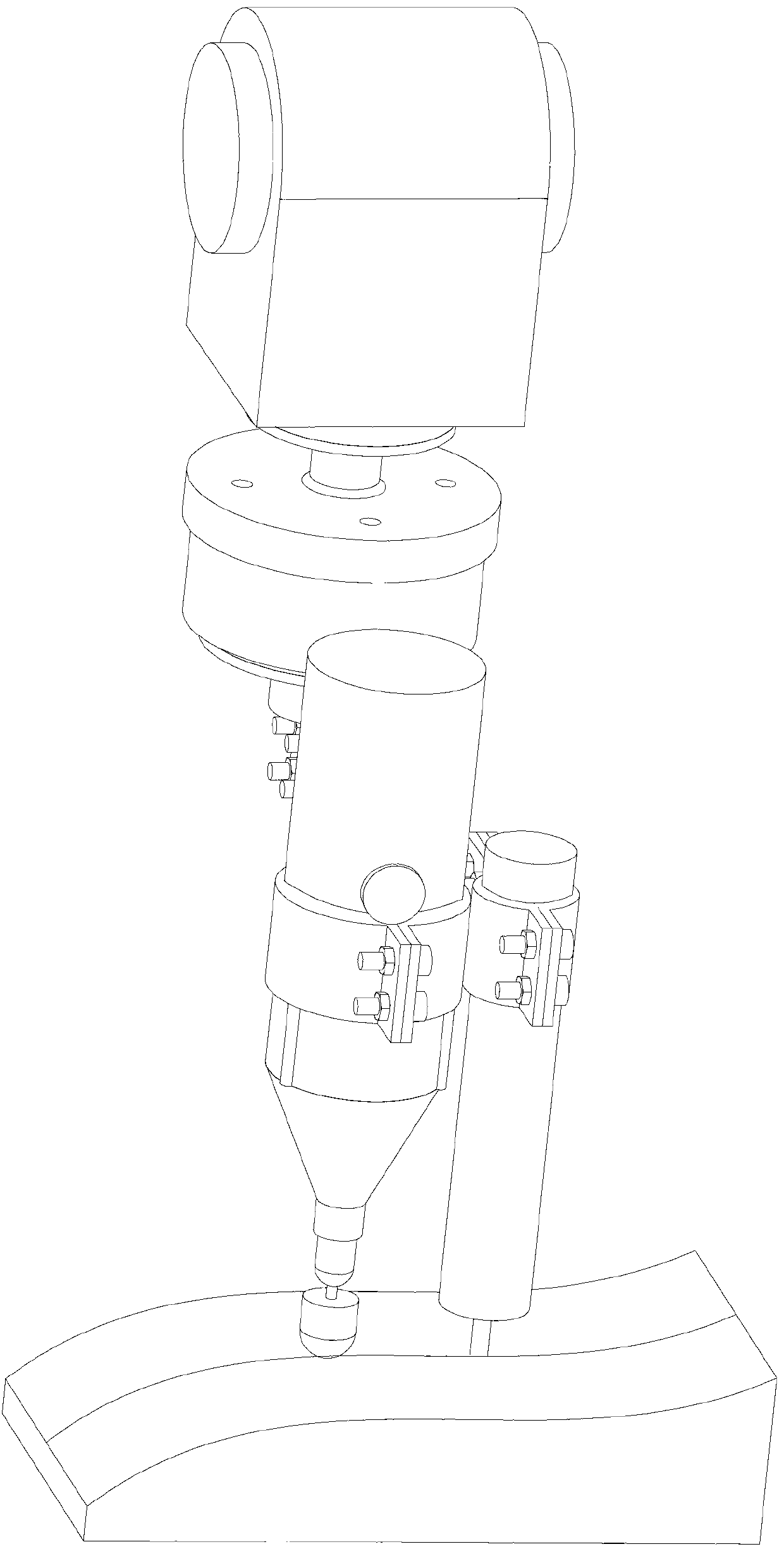

Robot polishing device and polishing method thereof

InactiveCN103009218ADetect force informationSuitable grinding forceGrinding feed controlGrinding machinesSurface plateForce sensor

The invention discloses a robot polishing device, which comprises a robot, a sensor permanent seat, a force sensor, a fixed base, an electric polisher and a displacement sensor, wherein the electric polisher and the displacement sensor are installed on the fixed base; the fixed base is fixedly arranged on the panel of the force sensor; the force sensor is fixedly arranged on the sensor permanent seat; and the sensor permanent seat is fixedly arranged on the tail end of the robot. The invention also discloses a polishing method of the robot polishing device. The robot polishing device disclosed by the invention has the advantages of simple structure, easiness in control and strong generality and can be used for polishing complex curved surfaces, the production efficiency is improved, the cost is lowered, and the processing quality is improved.

Owner:SOUTH CHINA UNIV OF TECH

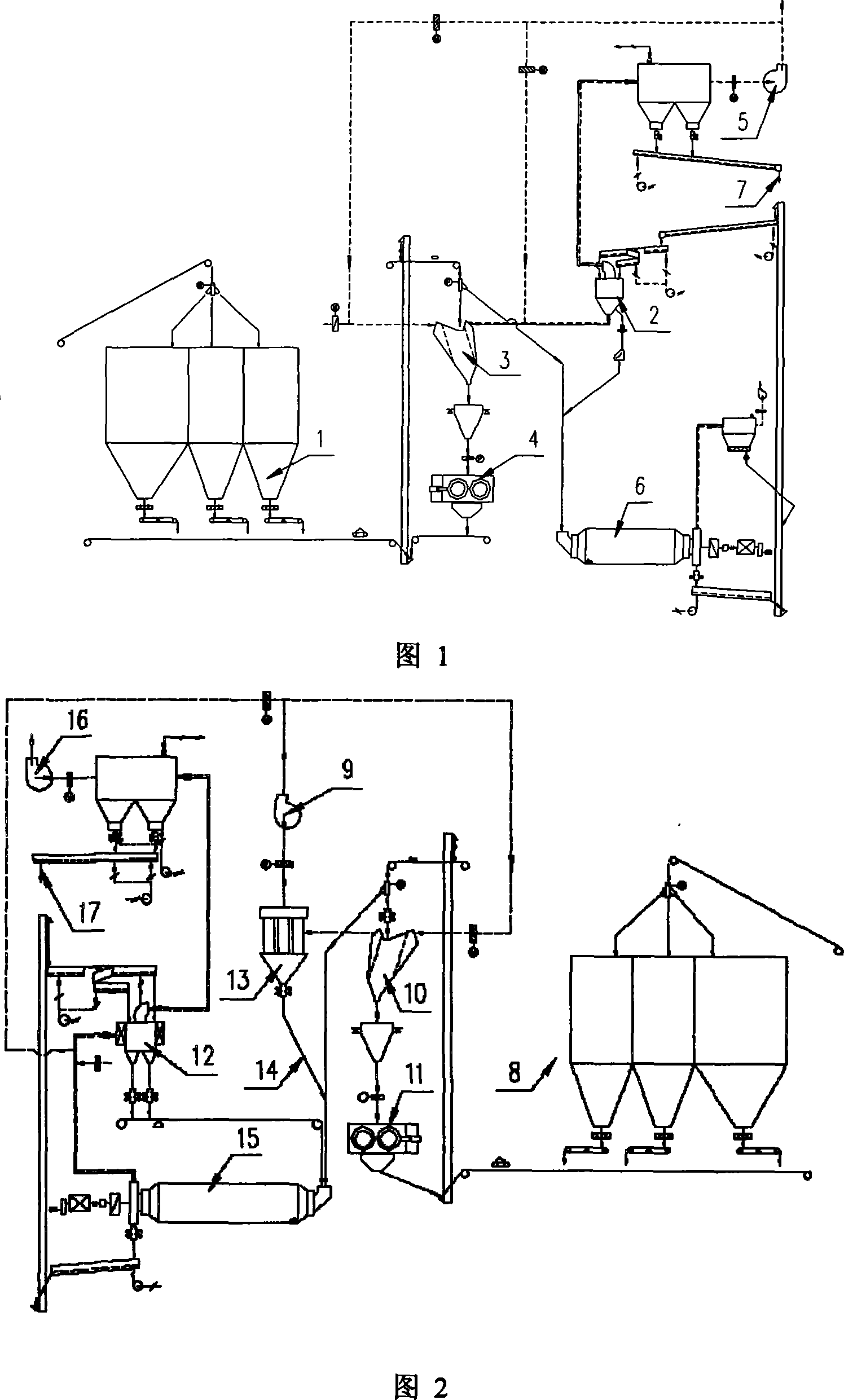

Roller press combination grinding device

ActiveCN101134175AEliminate wear and tearAdapt to the requirements of different statesGrain treatmentsMetallic materialsOperation mode

The present invention relates to one kind of combined rolling press grinding apparatus, and belongs to the field of inorganic non-metal material grinding technology. The combined rolling press grinding apparatus includes one dispensing mechanism, one lifting and conveying mechanism, one rolling press, one ball mill, one powder concentrator, one dust collector and one fan. The present invention has the advantages of low milling loss, simple structure, several operation mode, high grinding efficiency, low power consumption, etc.

Owner:天津椿本输送机械有限公司 +1

Efficient grinding and rust removing equipment for steel bars for building

InactiveCN107081666AImprove grinding efficiencyRealize all-round grindingGrinding carriagesGrinding drivesRebarPulley

The invention discloses a high-efficiency grinding and derusting equipment for steel bars for construction, which comprises a bottom plate, a left side plate, a right side plate, a top plate, a slide rail, a first slider, a box body, a first spring, a workbench, a sleeve, a slide Rod, mounting plate, first motor, first clamping device, second clamping device, horizontal support plate, second motor, disc, connecting rod, second slider, rack, third slider, pull cord , the first fixed pulley, the second fixed pulley, racks, gears, rotating shafts, and grinding discs. The present invention is provided with a first clamping device and a second clamping device, which can fix steel bars of different diameters. The first motor, the second motor, the disc, the second slider, the rack, the gear, the third slider, the pull rope, the box body and the spring, through the cooperation of the above components, the steel bar can be polished in all directions, which further improves the grinding efficiency , with a first helical gear, a second helical gear and a threaded rod to adjust the distance between the workbench and the grinding disc to accommodate steel bars of different diameters.

Owner:长沙鼎成新材料科技有限公司

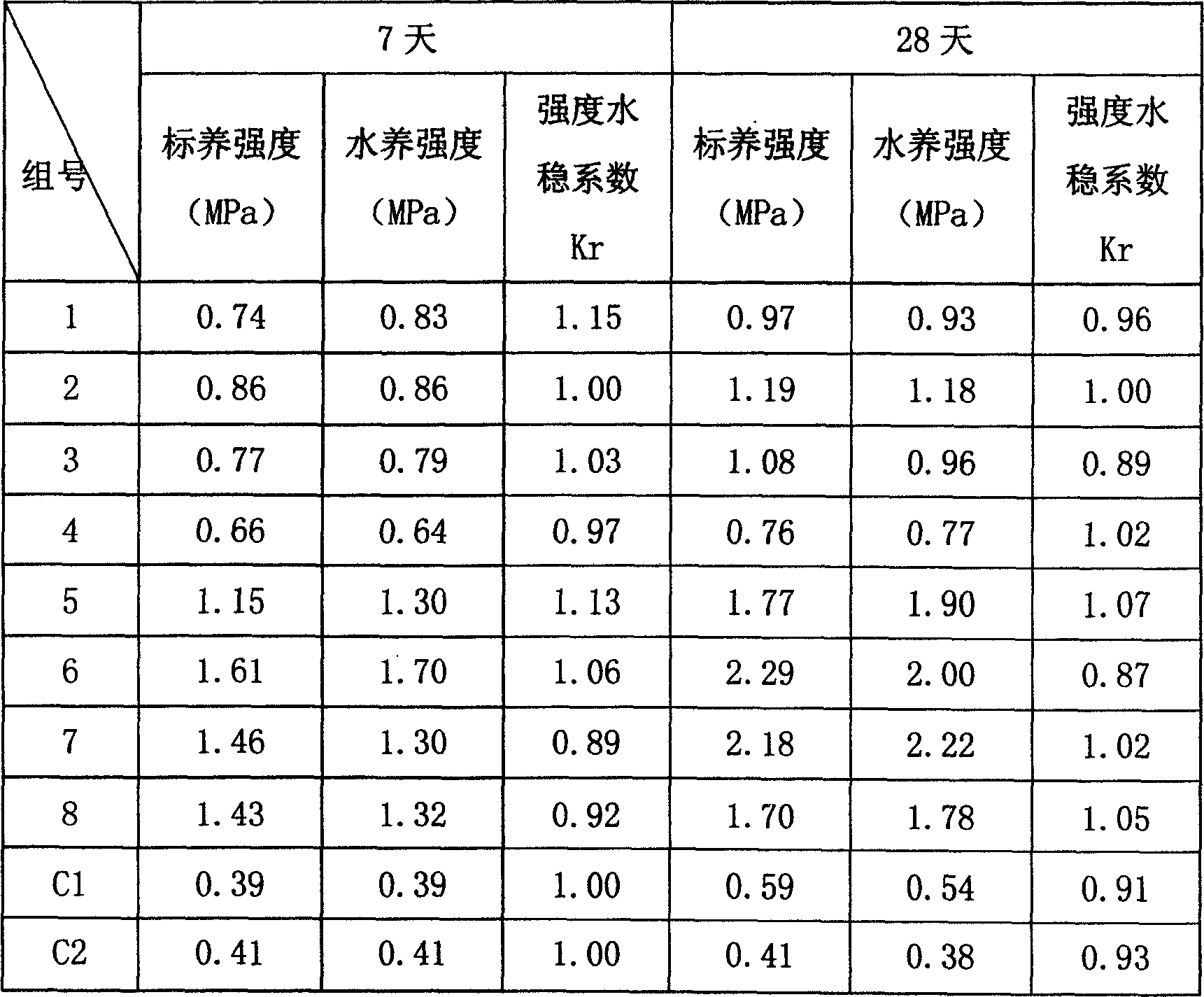

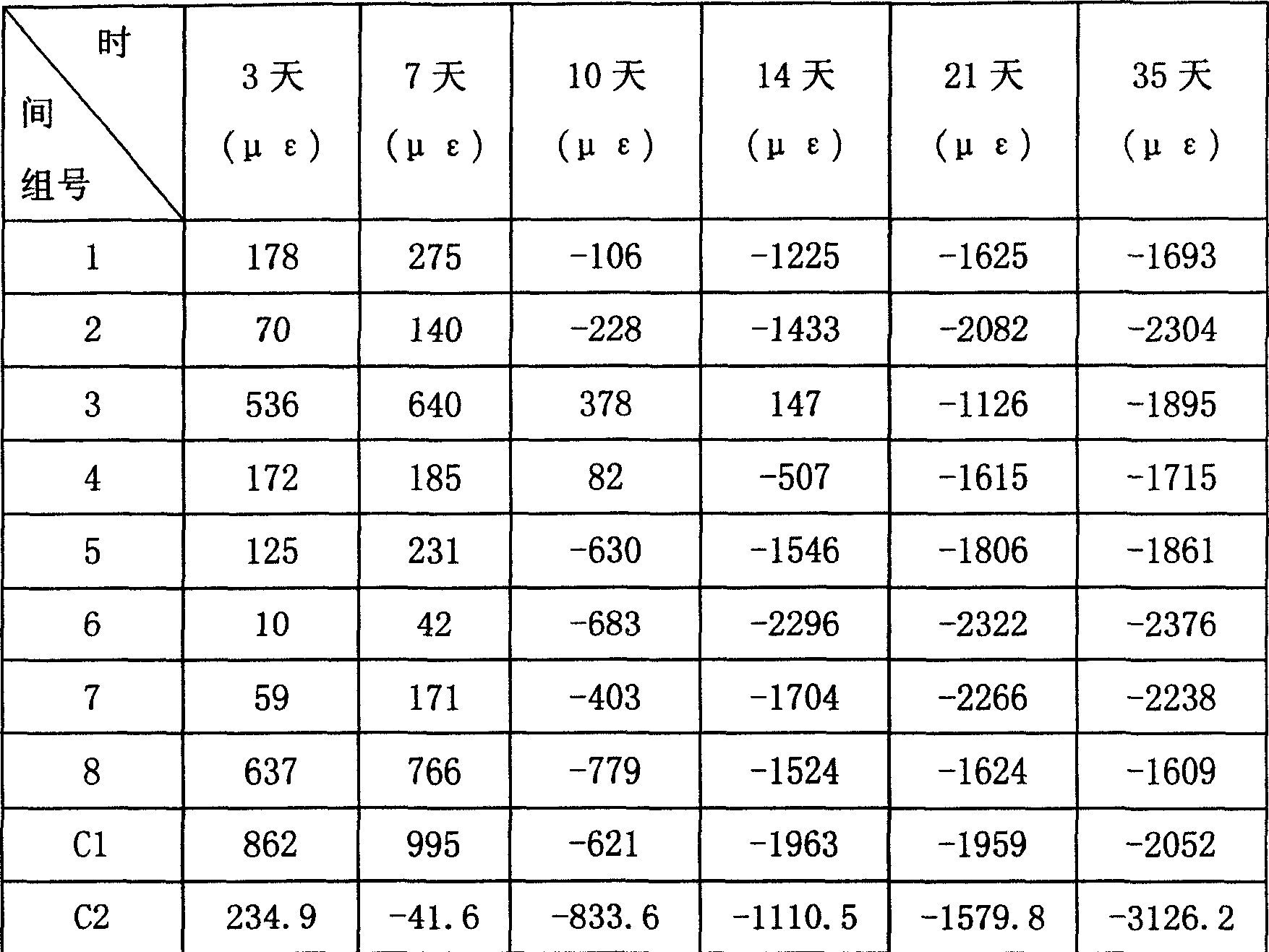

Soil solidifying agent

The soil curing agent as one kind of engineering material for curing and stabilizing various kinds of soil is especially suitable for curing silt and other kinds of low viscosity soil. The soil curing agent has main cement material comprising ore powder, flyash and water, as well as proper amount of alkali exciting component, expanding component and surfactant, and is prepared through mixing the materials and grinding to Blaine fineness of 3000-5000 sq m / kg. Specifically, it consists of mineral admixture 40-60 wt%, cement 15-25 wt%, alkali exciting component 5-15 wt%, expanding component 15-25 wt% and surfactant 0.01-0.1 wt%.

Owner:SOUTHEAST UNIV

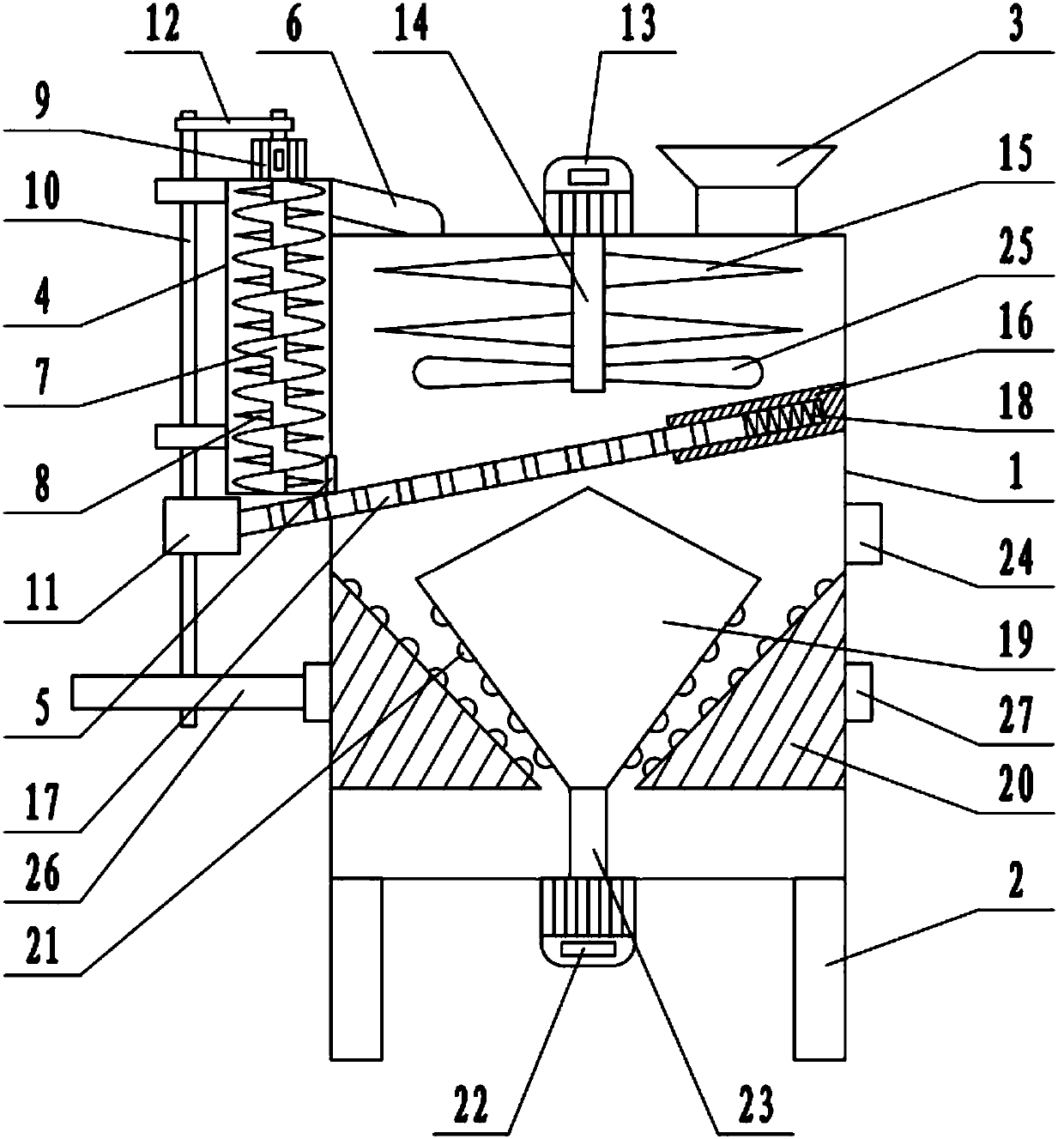

Sandstone smashing and grinding device for building engineering

The invention discloses a sandstone crushing and grinding device for construction engineering, which comprises a box body and a feeding port, the feeding port is arranged on the top wall of the box body, and two first horizontal shafts are arranged inside the box body , the inside of the box is also provided with a second horizontal shaft whose axis is parallel to the axis of the first horizontal shaft, one end of one of the first horizontal shafts is provided with a semi-circular gear, and an upper rack is arranged above the semi-circular gear, and the semi-circular gear A double-sided rack is arranged under the gear, a rotating gear is arranged at one end of the second horizontal axis, a swing rod is arranged on the rotating sleeve, a swing grinding disc is arranged at the lower end of the swing rod, and a side and the inner wall of the box are arranged under the swing grinding disc. connected to the fixed grinding disc, and the bottom of the box is also provided with a screen plate and a plurality of cross bars. The invention has the advantages of simple structure, high crushing efficiency, good crushing effect on sand and stone crushed three times, and can screen sand and stone grains at the same time, and has strong practicability.

Owner:宋衡星

Self-circulation Chinese herbal medicine crushing and grinding integration device

InactiveCN107790244ACrushed fullyImprove crushing effectGrain treatmentsReciprocating motionElectric machinery

The invention discloses a self-circulation Chinese herbal medicine crushing and grinding integration device. The self-circulation Chinese herbal medicine crushing and grinding integration device comprises a shell, support legs, a feed port, a crushing motor, a crushing shaft, a crushing blade, a conical grinding hammer and a grinding motor; the left side wall of the shell is fixedly connected witha circulating cylinder; a screw rod is arranged in the circulating cylinder; the upper surface of the circulating cylinder is fixedly connected with a double-shaft motor; the upper surface of the shell is fixedly connected with the crushing motor; a shaft extension end of the crushing motor is fixedly connected with the crushing shaft; a screen plate is arranged below the crushing shaft; a grinding table is arranged below the screen plate; the conical grinding hammer is arranged in the grinding table; traditional Chinese medicines are crushed by using the crushing blade, and are stirred by using stirring blades during crushing, so that the traditional Chinese medicines are crushed more sufficiently; the crushed traditional Chinese medicines fall onto the screen plate, and the screen plateperforms a left-right reciprocating motion to improve the efficiency of the traditional Chinese medicine passing through the screen plate; and the conical grinding hammer and the grinding table are matched to crush the traditional Chinese medicines, and are opposite in rotating direction to improve the grinding efficiency.

Owner:李欢欢

Cement grinding aid and preparation method thereof

The invention relates to a cement grinding aid, in particular to a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from, by weight, 13-18 parts of polymeric polylol, 8-12 parts of tri-isopropanolamine, 12-15 parts of polyol ether, 15-20 parts of ethanediol, 25-30 parts of triethanolamine, 15-18 parts of molasses, 13-15 parts of lignin, 0.03-0.06 part of sodium chloride, 0.5-1 part of silane coupling agents and 40-45 parts of water. By means of the obtained cement grinding aid, in the cement production process, the phenomena of clinker fine particle aggregation and ball pasting can be effectively improved, mobility of clinker particles is enhanced, thereby the pulverization effect of grinding media in a grinding machine for materials is enhanced, grinding efficiency can be improved by 15-20%, the cement machine-hour yield is increased, electricity consumption is greatly lowered, production cost is lowered, in addition, strength of cement at different ages can be remarkably improved, and flowability of the cement is improved.

Owner:内蒙古同佳技术发展有限公司

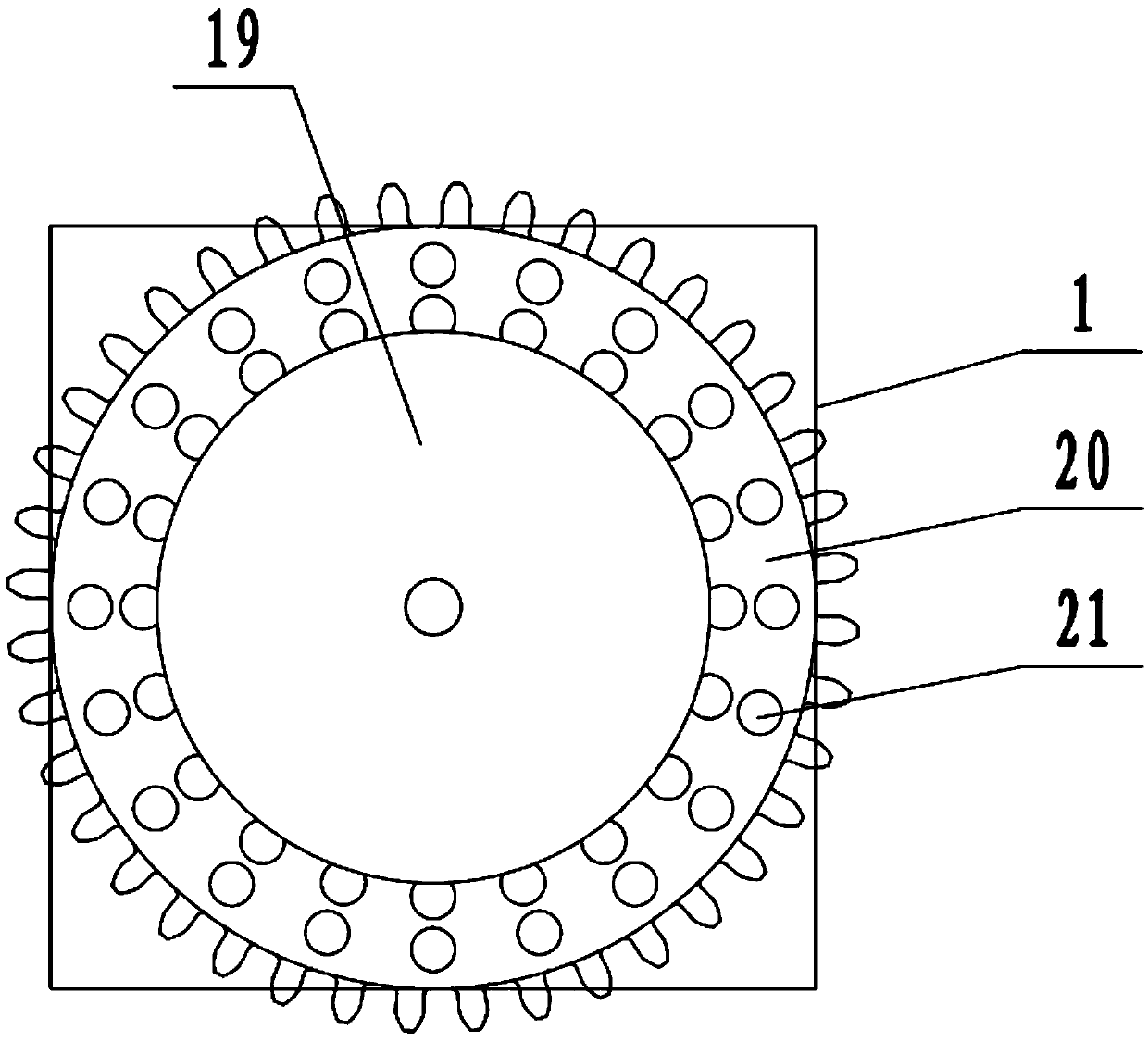

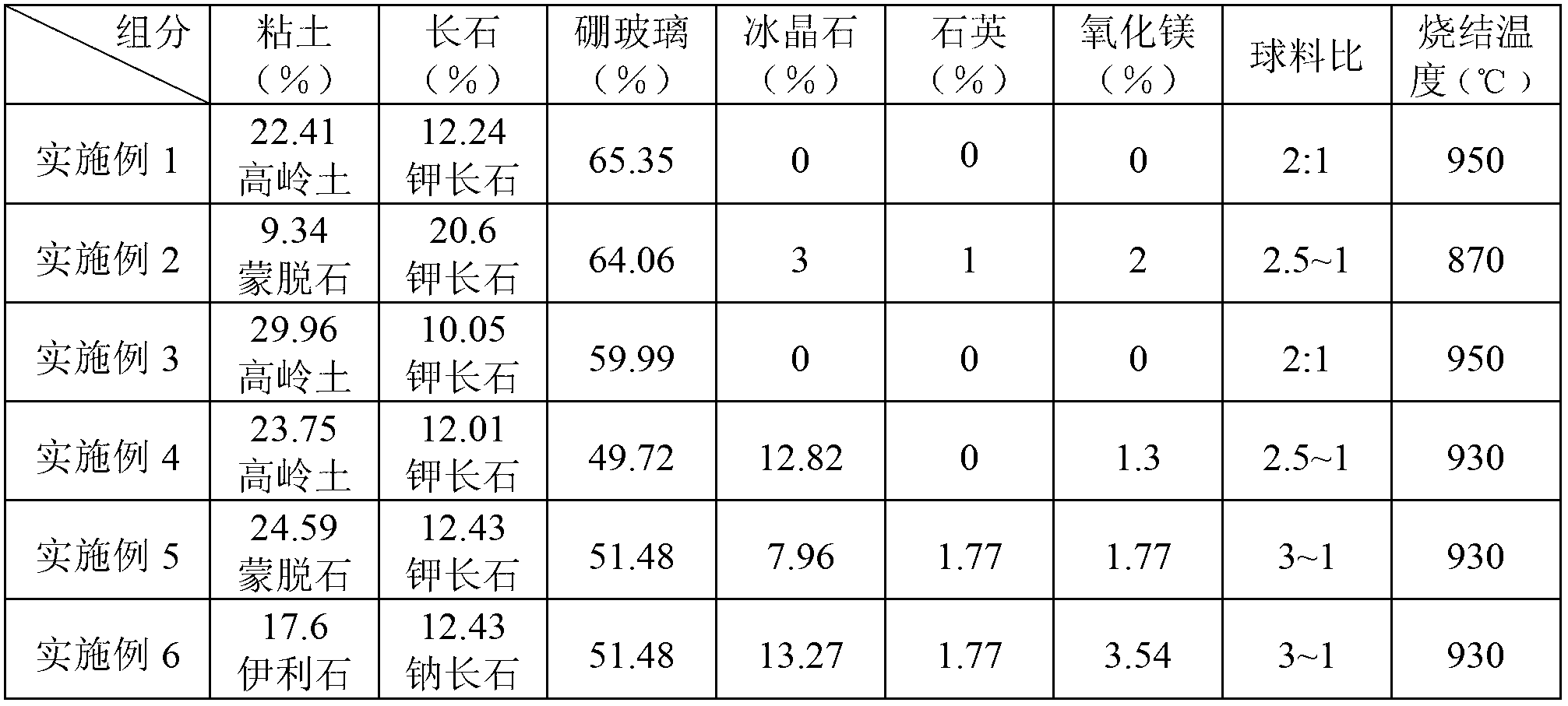

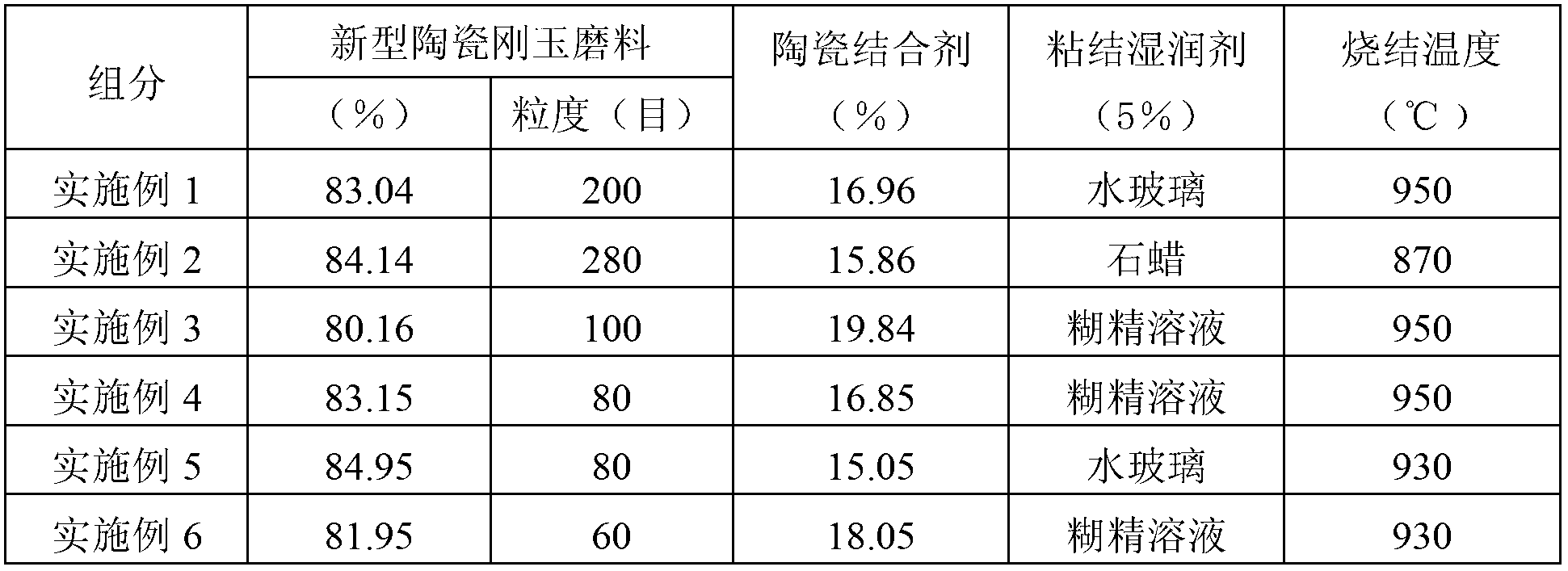

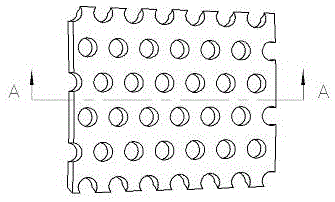

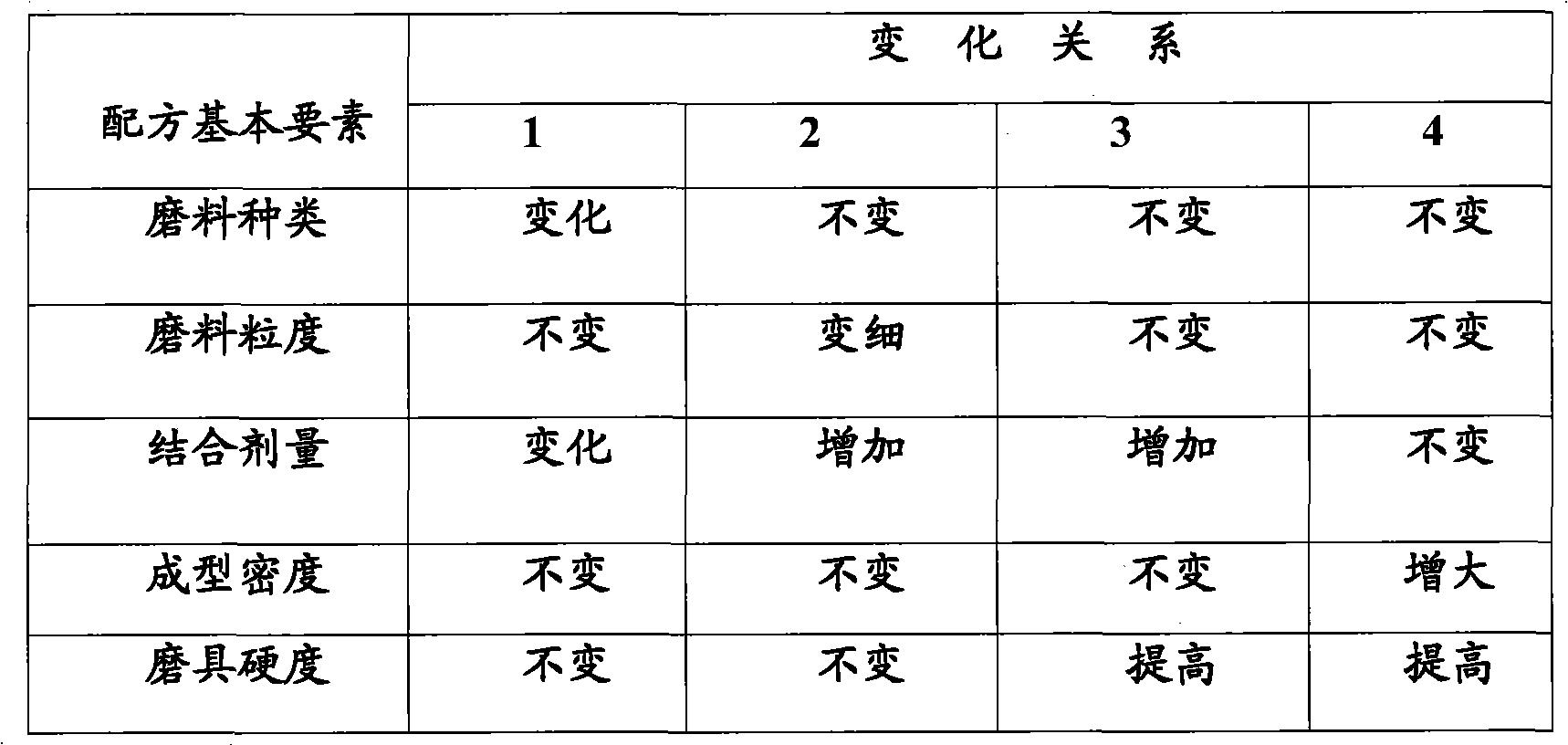

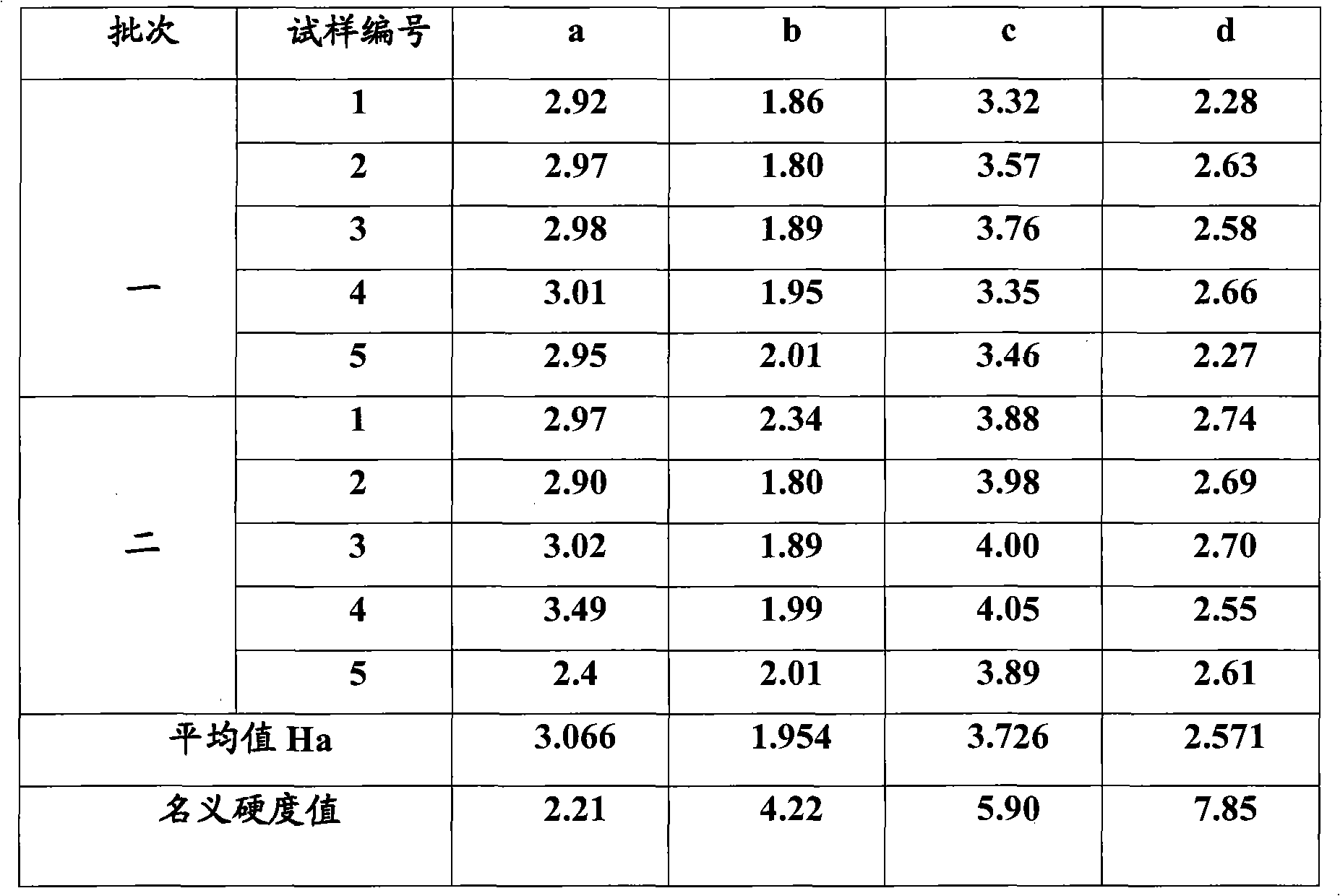

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

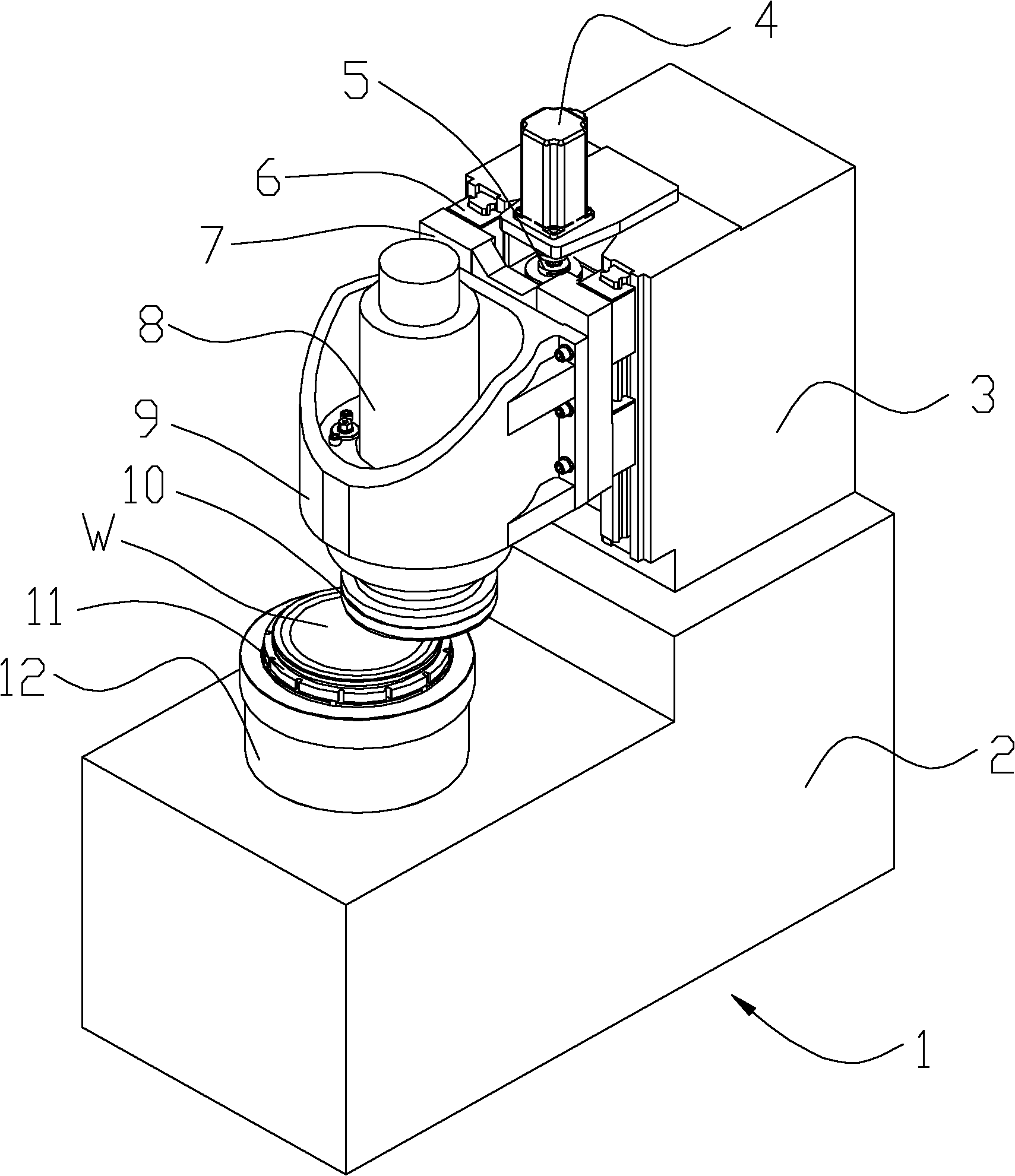

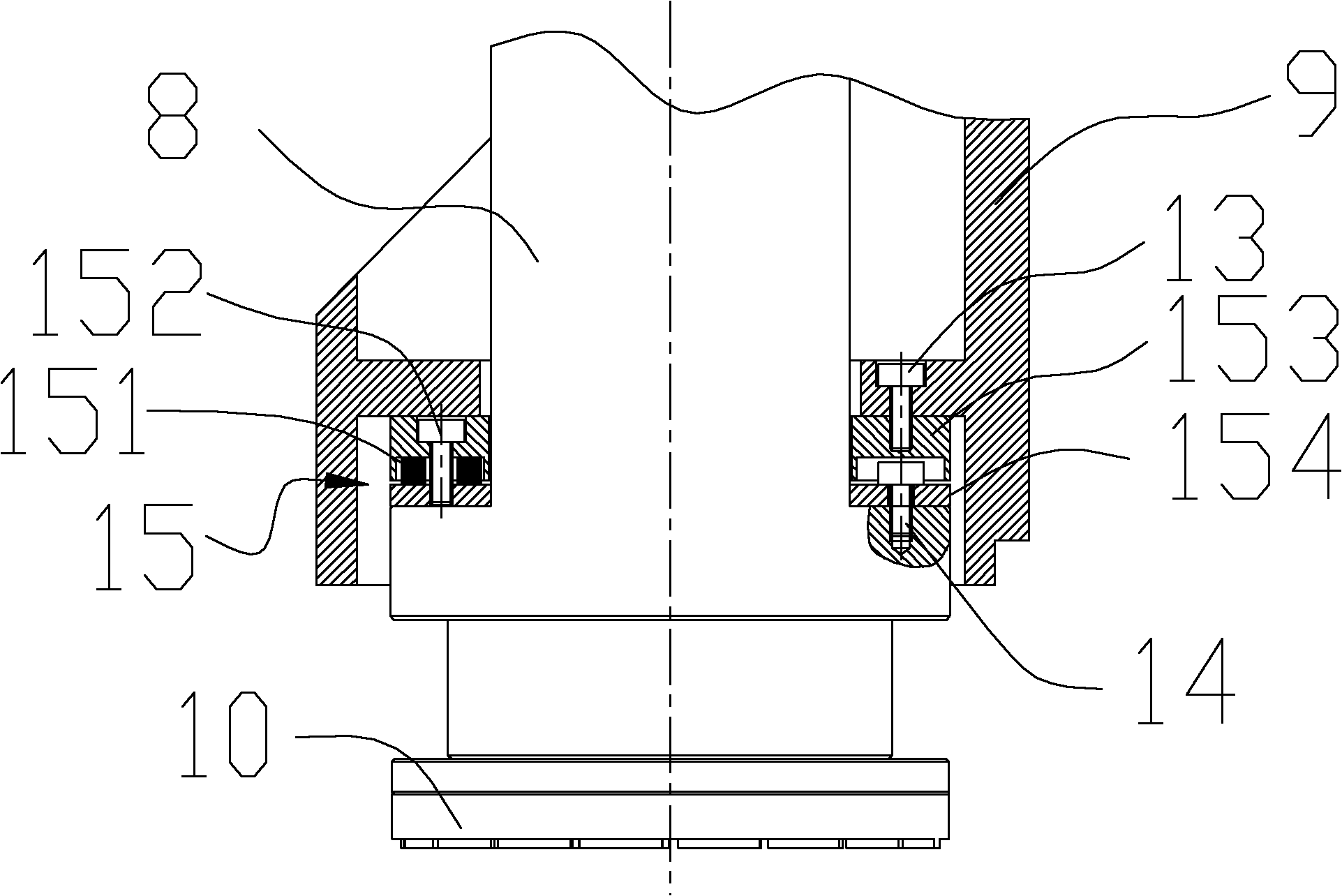

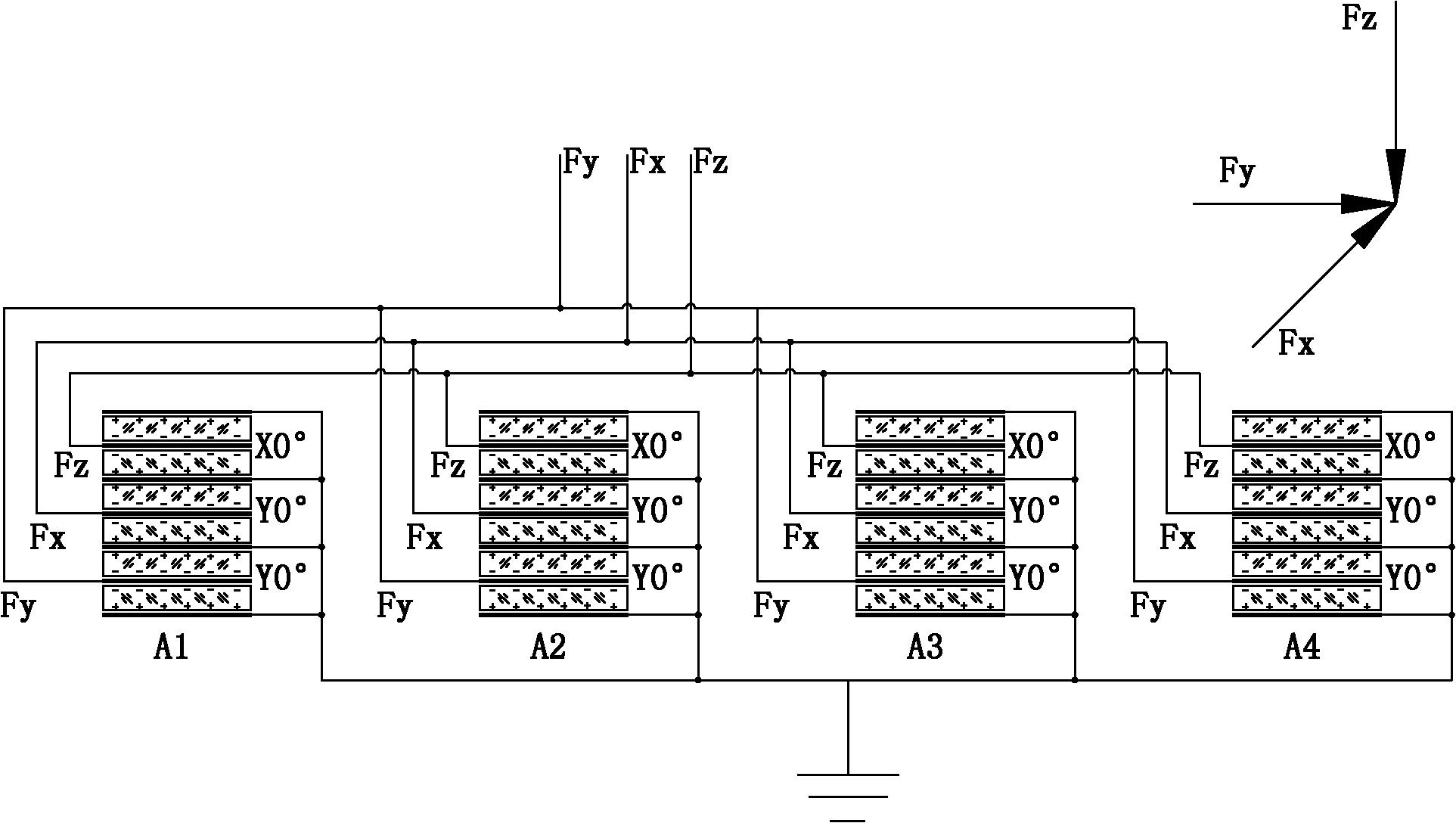

Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

ActiveCN102009387AImprove machining accuracyImprove processing qualityGrinding feed controlMeasurement deviceTangential force

The invention belongs to the ultraprecision machining field of the hard and brittle semiconductor crystalline materials and relates to a grinding force on-line measurement device used in the grinding process of the semiconductor wafer and a force-controlling grinding method. The invention discloses a semiconductor wafer grinding force on-line measurement device which is used as the feedback element of a grinding force adaptive control system. The grinding force measurement device adopts the piezoelectric measuring principle and contains a sensor part and a data processing unit, wherein the sensor part is used for the on-line measurement of the radial force Fr, the tangential force Ft and the axial force Fz; and the data processing unit is used to collect and analyze the grinding force data and perform feedback control to the feed speed and feed amount of the grinding wheel, thus the aim of on-line measurement can be achieved. The invention has the following advantages: the grinding force on-line measurement device has simple structure, and the modifications to the original equipment are less; the grinding force on-line measurement links are fewer, the response speed is fast, and the precision is high; and the grinding efficiency of the semiconductor wafer can be increased and the thickness of the damaged layer is reduced.

Owner:宁波知行半导体有限公司

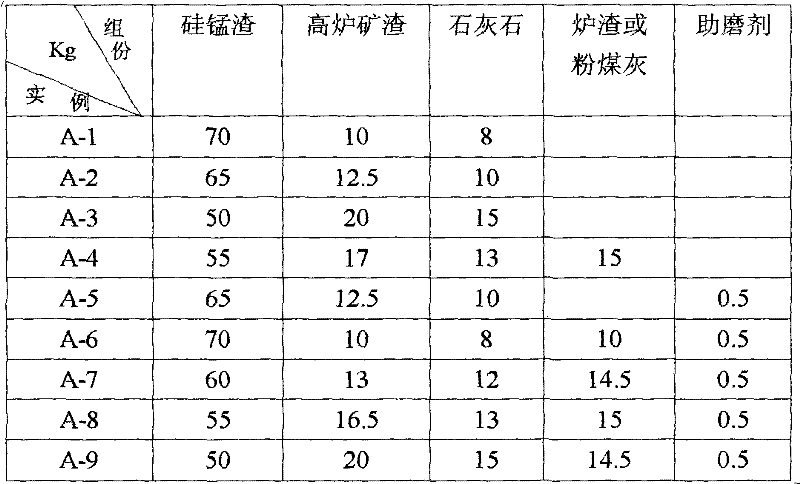

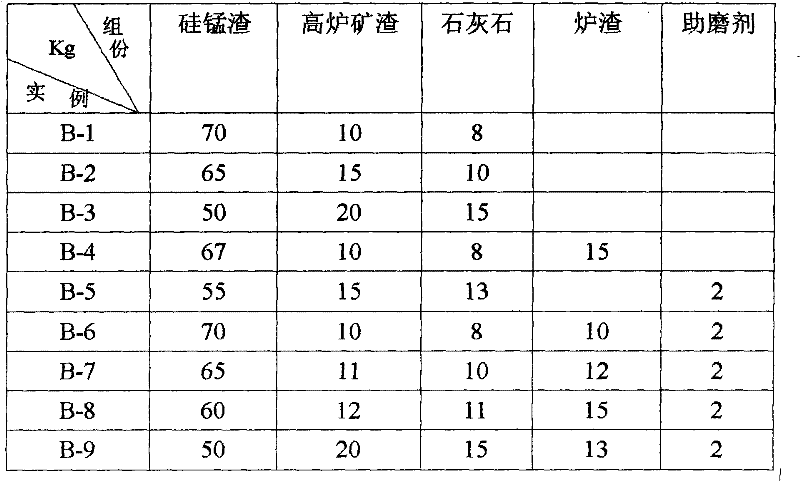

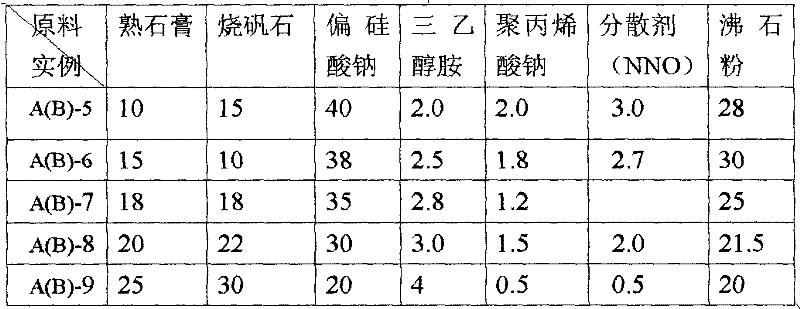

Composite admixture for cement or high-performance concrete and preparation method thereof

InactiveCN102180612ASave resourcesGood social benefitsSolid waste managementIndustrial wasteHigh performance concrete

A composite admixture for cement or high-performance concrete and a preparation method thereof. The admixture comprises silicon manganese slag, slag, limestone, furnace slag or fly ash, and grinding aids, and the mass ratios are: 50-70 of silicon-manganese slag, 10-20 of slag, 8-15 of limestone, 10-15 of furnace slag or fly ash, and 0.5 or 2 of grinding aids. The preparation method comprises: adding the raw materials according to the ratios into a ball mill, grinding till the grinding fineness meets that the Blaine specific surface area is not less than 400 m2 / kg or 450 m2 / kg so as to obtain the silicon manganese slag-based composite admixture for cement or high-performance concrete. The preparation of the admixture can use a large amount of industrial waste residues - silicon manganese slag discharged from the production of silicomanganese alloy, and the admixture is prepared with a proper amount of slag, limestone, furnace slag or fly ash, and a small amount of grinding aids, which has remarkable economic effect, and outstanding social benefits and environmental benefits.

Owner:葫芦岛市辽西混凝土外加剂有限公司

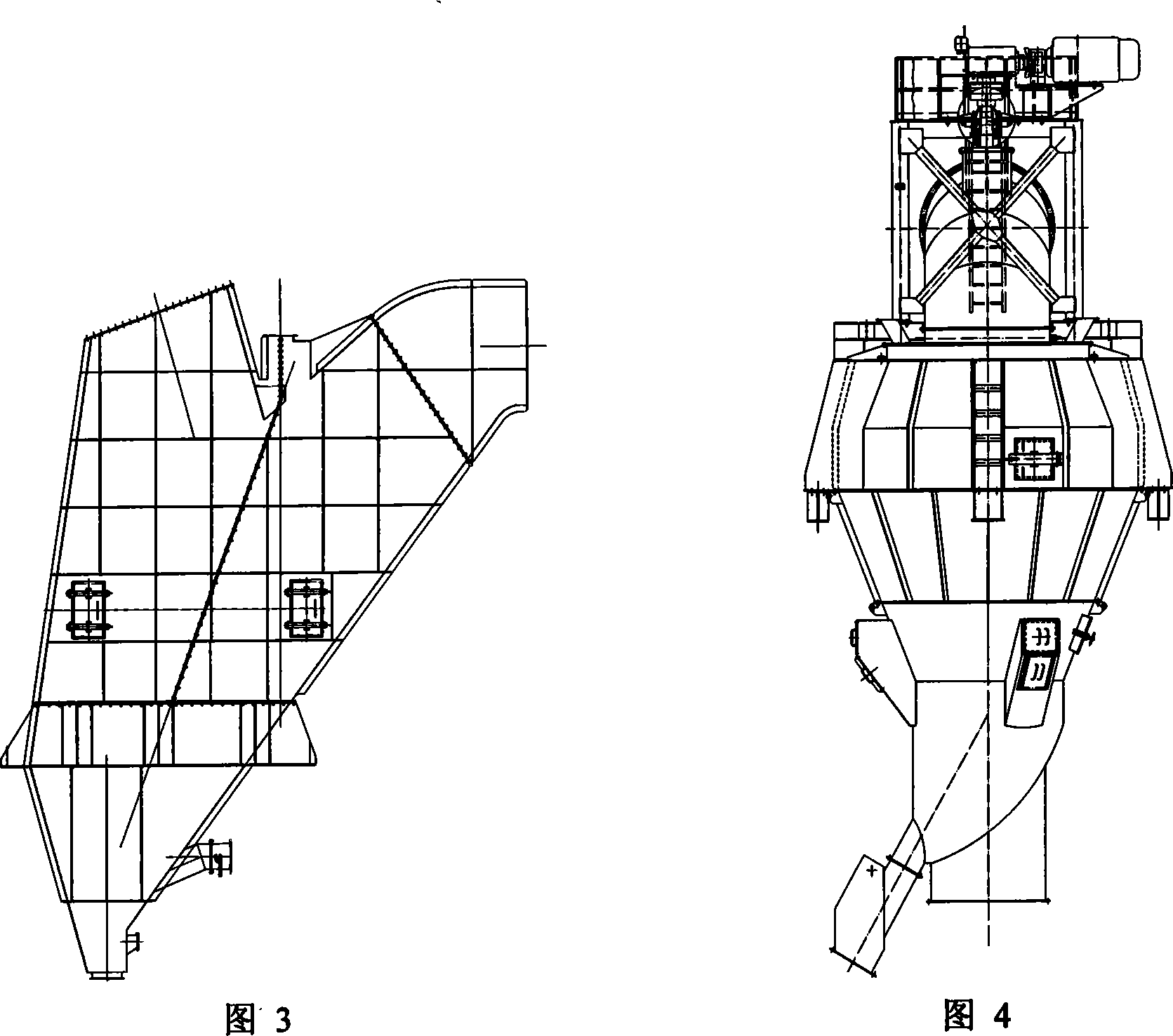

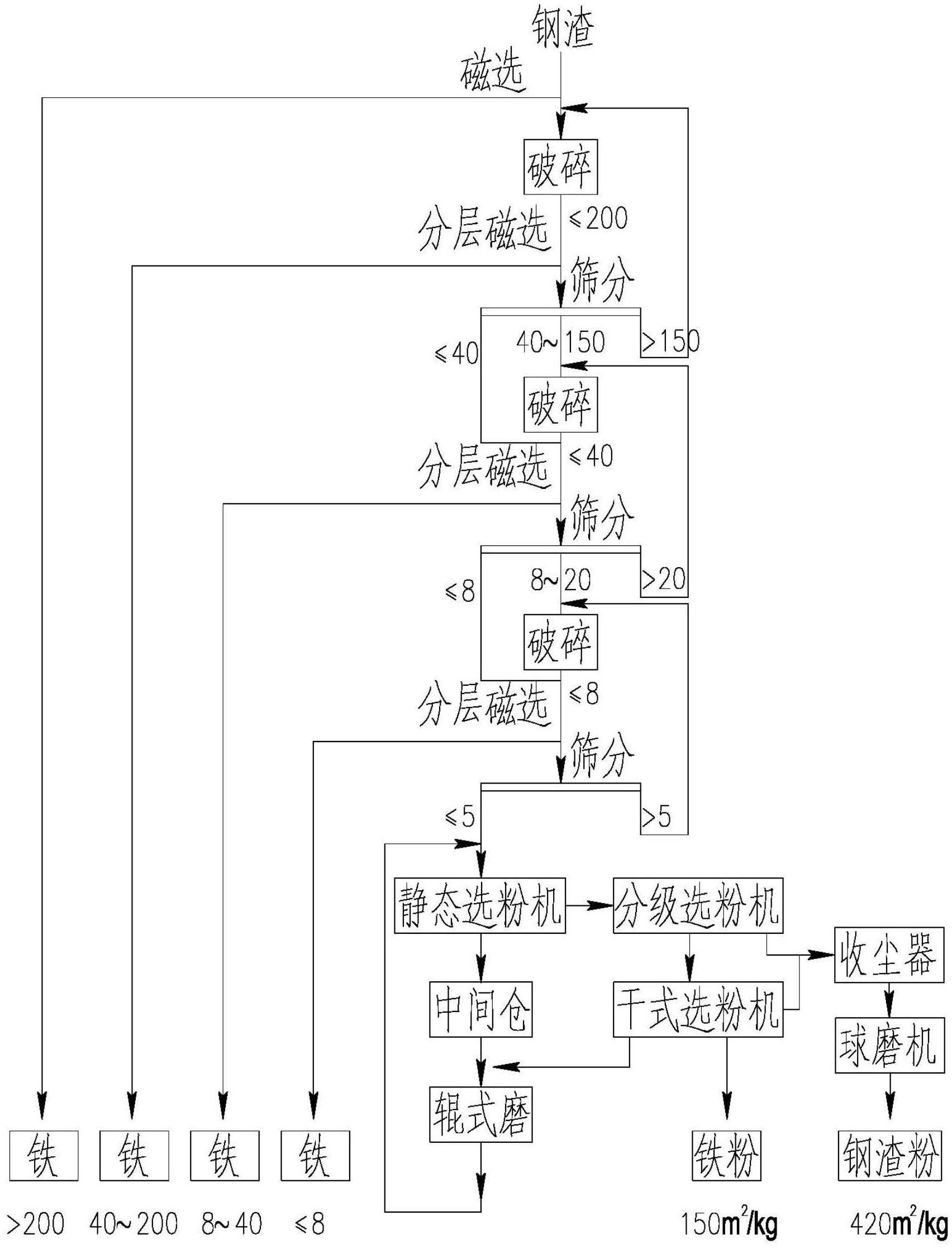

Method for efficiently recovering and reselecting steel slag

ActiveCN102688880AEffectively electedIncrease cycle loadSolid waste disposalRecycling and recovery technologiesEcological environmentSlag

The invention discloses a method for efficiently recovering and reselecting steel slag, comprising the following steps of: A, smashing and magnetically selecting: selecting iron in steel slag in a stock dump by a lifting electromagnet, directly charging the steel slag into a smasher to be smashed, and magnetically selecting the smashed steel slag by a rubber belt conveyor and a permanent magnetic iron remover in a layering way; B, smashing and magnetically selecting again: magnetically selecting the treated steel slag by the rubber belt conveyor of a head wheel belt permanent magnetic tumbling cylinder and the permanent magnetic iron remover in a layering way; C, extruding and smashing the steel slag into fine powder by a roller type grinding circulating system; D, selecting the iron powder with refine grain diameter by a dry type powder selector; and E, grinding the fine powder steel slag which is separated by the roller type grinding circulating system and a steel slag selecting and recovering system by a ball grinder system. The method is simple and easy, and convenient to operate, so that when the iron is selected, the steel slag low-heat concrete which accords with the national standard requirement can be produced by the steel slag. The production cost and the energy consumption can be reduced, the land occupancy can be reduced, the ecological environment can be protected, and the good economic benefit, social benefit and environmental benefit can be obtained.

Owner:武汉市天沭科技发展有限公司

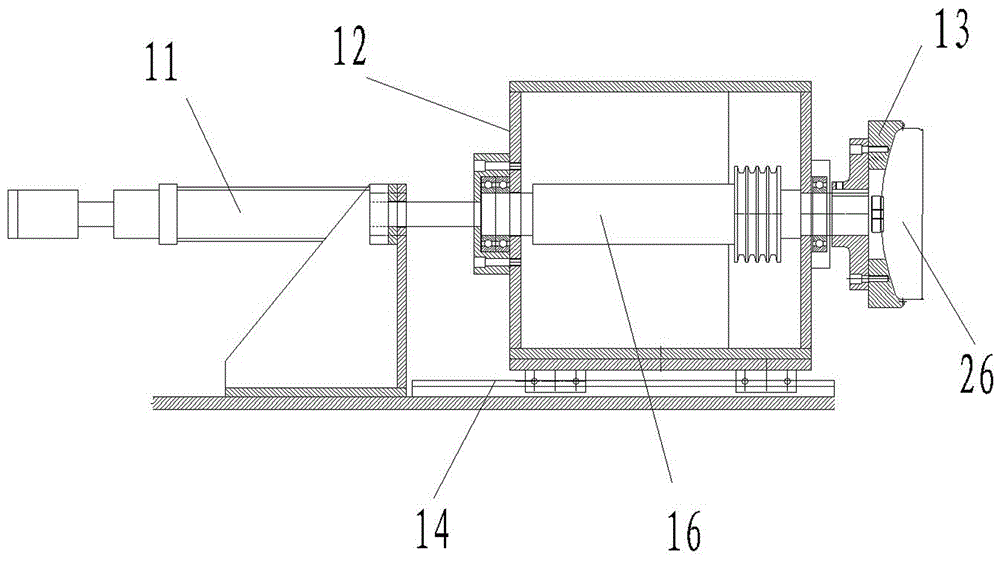

Grinding device of pipes used for curved surface anti-buckling tests of adhesive tapes

InactiveCN102152208AImprove grinding efficiencyGood uniformityPortable grinding machinesEngineeringDrive wheel

The invention provides a grinding device of pipes used for the curved surface anti-buckling tests of adhesive tapes. The grinding device comprises a base, a motor, a rotating shaft, a dead head, a tip, a screw and a slider. A first upright plate and a second upright plate are arranged on the upper end surface of the base at interval, a driving gear is arranged on an output shaft of the motor, therotating shaft can be arranged on the lower end part of the first upright plate in a rotating manner, the outer end of the rotating shaft is provided with a driving wheel and an input gear which simultaneously rotates with the driving wheel, the input gear is in meshing transmission with the driving gear, the inner end of the rotating shaft is provided with a first clamp component, the dead head is arranged on one side of the second upright plate, and the screw is in transmission connection with the driving gear through a speed reduction mechanism; the slider is sheathed on the screw, and thebottom end of the slider is provided with a clamp. Compared with the prior art, the grinding device has the advantages that as manual grinding is replaced by mechanical grinding, the grinding efficiency is greatly improved; as personal factors are eliminated, the uniformity of ground pipes used for tests is good, and the data accuracy and reliability of the anti-buckling tests of adhesive tapes can be ensured.

Owner:NINGBO SOKEN CHEM

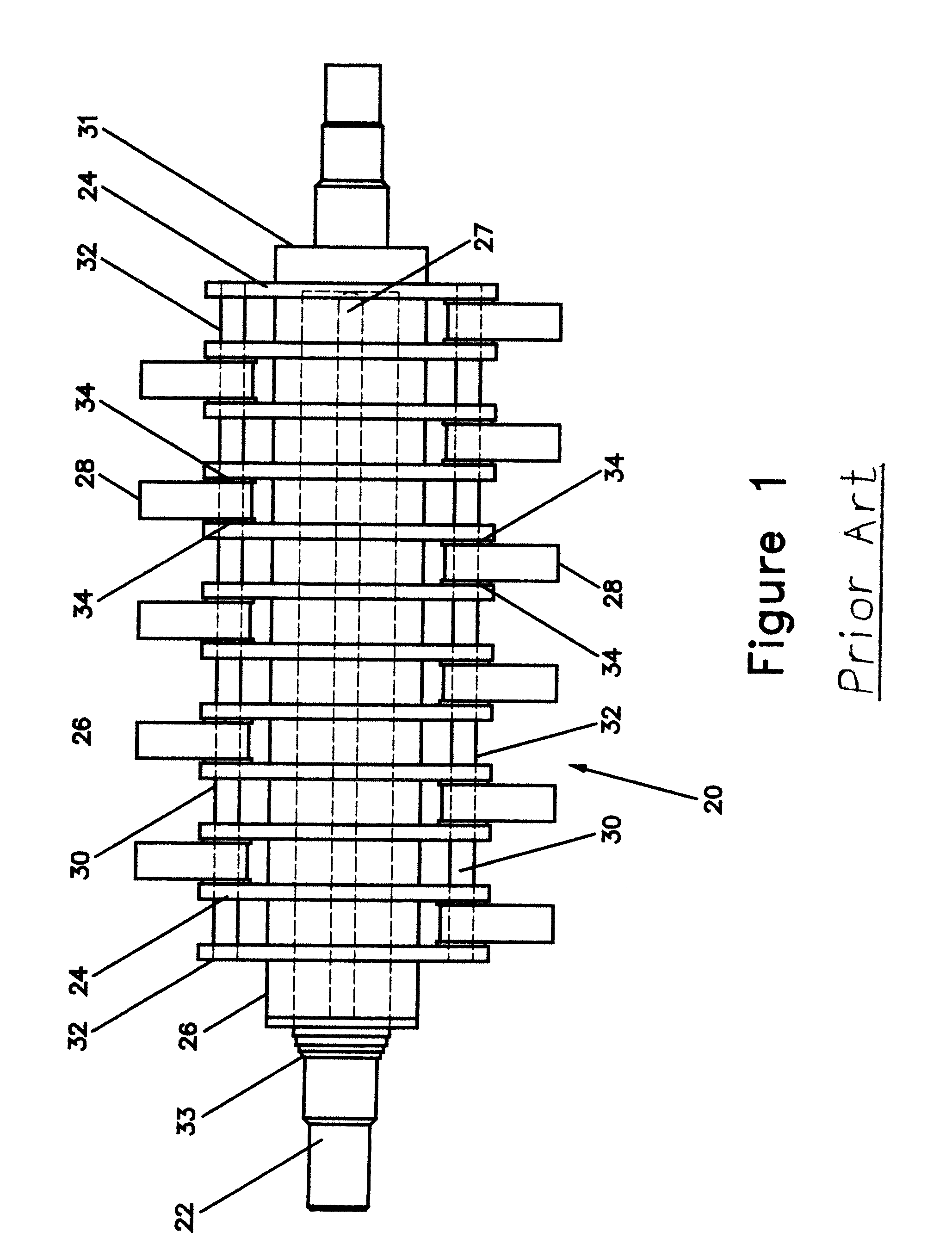

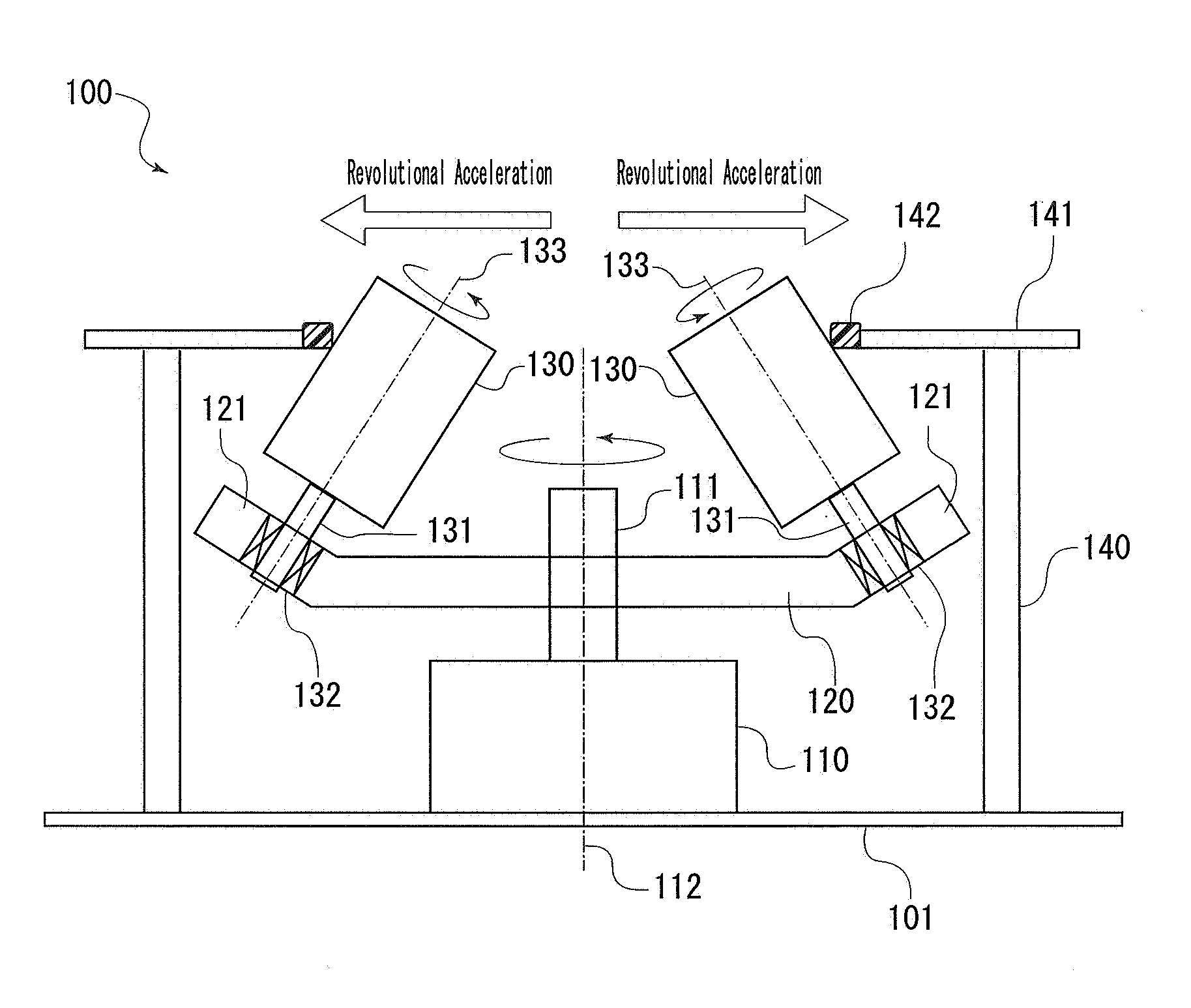

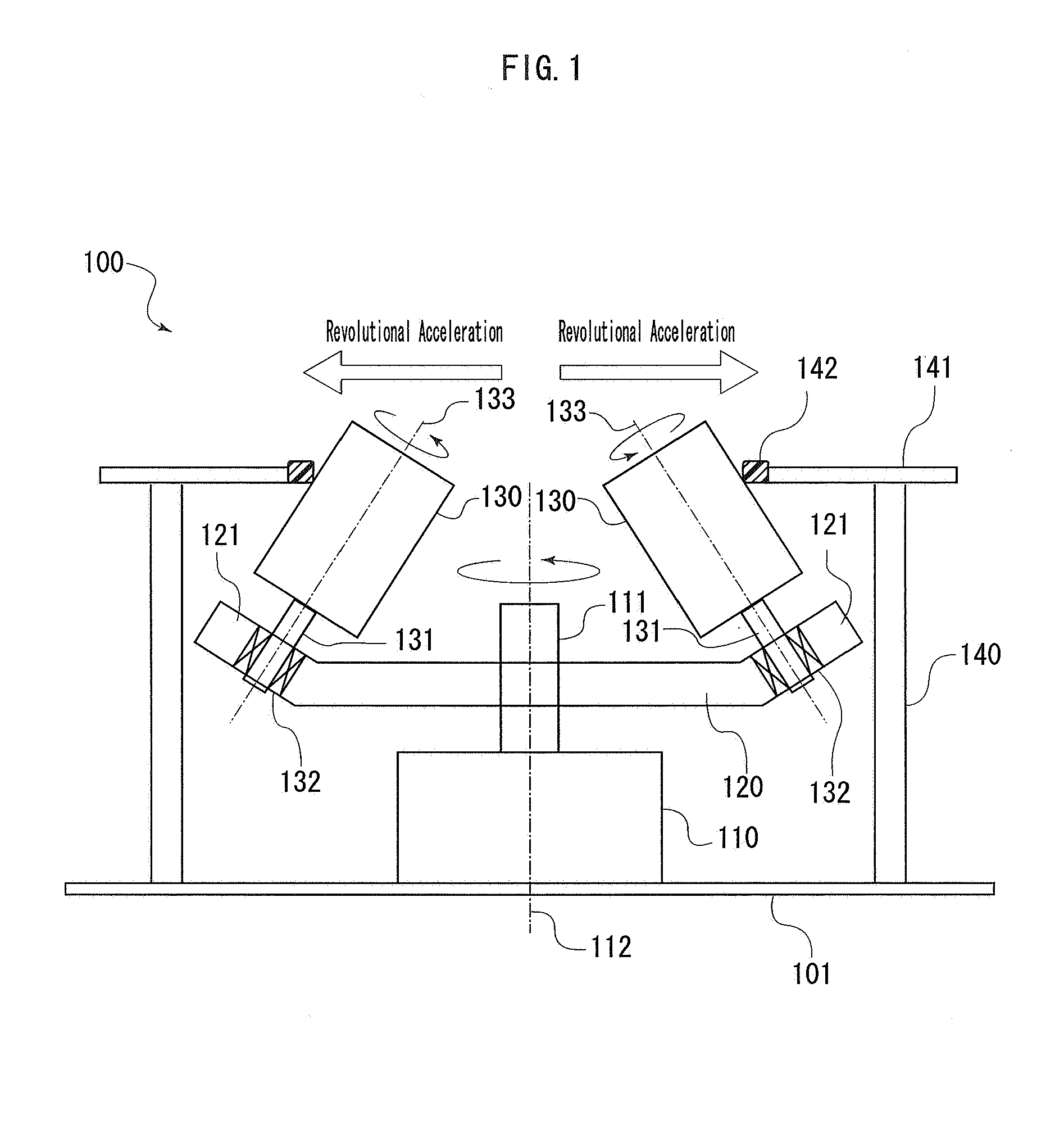

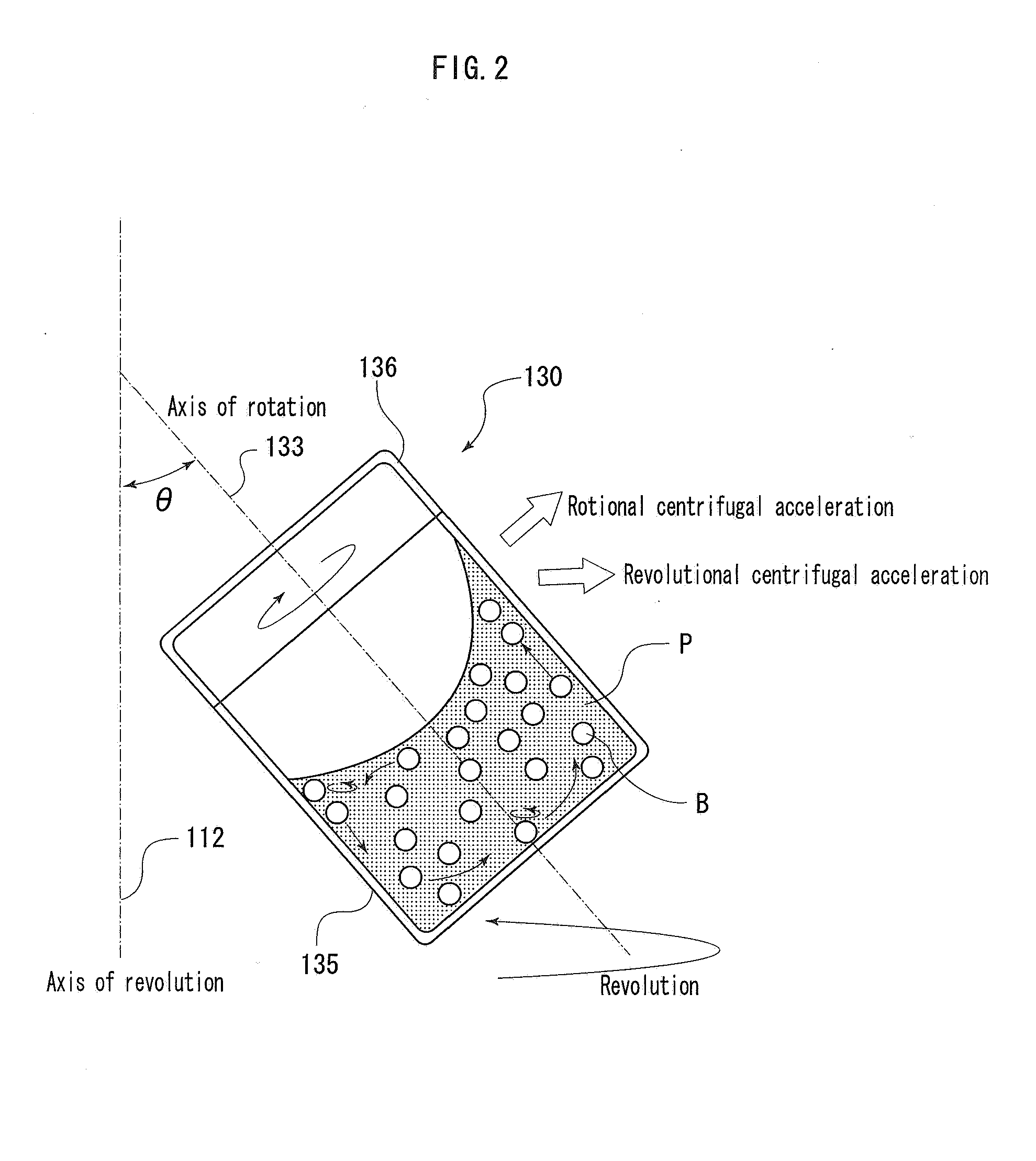

Planetary ball mill

A planetary ball mill includes: a revolution turning arm turned about a revolution shaft rotated by a driving force; mill pots each supported on the revolution turning arm so as to be rotated about a rotation shaft inclined from the vertical direction toward the side of the revolution shaft; and an outer circumferential pot receiver which is disposed fixedly on the upper side of the revolution turning arm along the whole part of a circumference around the revolution shaft and with which the outer peripheral surfaces of the mill pots revolving attendantly on the turning of the revolution turning arm make contact, whereby the mill pots are put into rotation.

Owner:NAGAO SYST INC

Efficient bone smashing and grinding device for food processing

InactiveCN107413498ASpeed up the fallPrevent overflowSievingScreeningMechanical engineeringFood processing

The invention discloses an efficient bone smashing and grinding device for food processing. The efficient bone smashing and grinding device comprises a smashing box and a grinding box. The smashing box is provided with a material control device, a circulation feeding device, a smashing device, a screen cloth, a screen cloth vibrating mechanism, an iron removing plate and a discharging plate. The material control device comprises a discharging hopper. The discharging hopper is arranged at the upper end of the smashing box. An arc-shaped volute is arranged at the bottom end of the discharging hopper. The bottom end of the volute is provided with an opening and further communicates with the smashing box. A material distributing rotary table is sleeved with the volute. The material distributing rotary table is arranged on a material distributing rotating shaft in the middle of the volute in a sleeving mode. The two ends of the material distributing rotating shaft are arranged on bearings on the corresponding side walls of the volute in a sleeved mode separately. A plurality of material distributing plates are evenly and symmetrically arranged on the material distributing rotary table. According to the efficient bone smashing and grinding device for food processing, feeding is stable, the sealing property is good, circulation smashing is achieved, grinding can be facilitated, working efficiency is high, the screen cloth and the screen cloth vibrating mechanism are ingeniously arranged and thus screening efficiency is high.

Owner:汪云霞

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

Manufacturing method of detachable ceramic alloy composite grinding roller

The invention discloses a manufacturing method of a detachable ceramic alloy composite grinding roller. The manufacturing method comprises the following steps: firstly, uniformly mixing ceramic particles and low-melting-point alloy powder by binders so as to obtain a mixture; stuffing the mixture in a mold cavity, and forming the mixture into a biscuit; putting the biscuit together with a mold into a drying cabinet, and drying and sintering the biscuit to obtain a ceramic precast part; and taking out the sintered ceramic precast part, fixing the taken ceramic precast part on the surface of a roller skin liner casting mold cavity, casting abrasion-proof alloying metal liquid to obtain a roller skin liner of which the surface presents metallurgical bond by the ceramic precast part and an abrasion-proof alloy material, and finally fixing the roller skin liner on the surface of a roller core. According to the manufacturing method of the detachable ceramic alloy composite grinding roller disclosed by the invention, the roller skin liner is small in size and light in weight, the casting quality and the heat treatment technology are easy to control, and the qualified rate of finished products is high; the surface of the roller skin liner is composited by the high abrasion-proof ceramic precast part and an abrasion-proof alloy, so that the surface of the roller skin liner has double abrasion-proof properties and the toughness of the metal materials; the end surface of the roller skin liner is fixed by bolts, so that the roller skin liner can be detached on the site, and a new roller skin liner is replaced.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

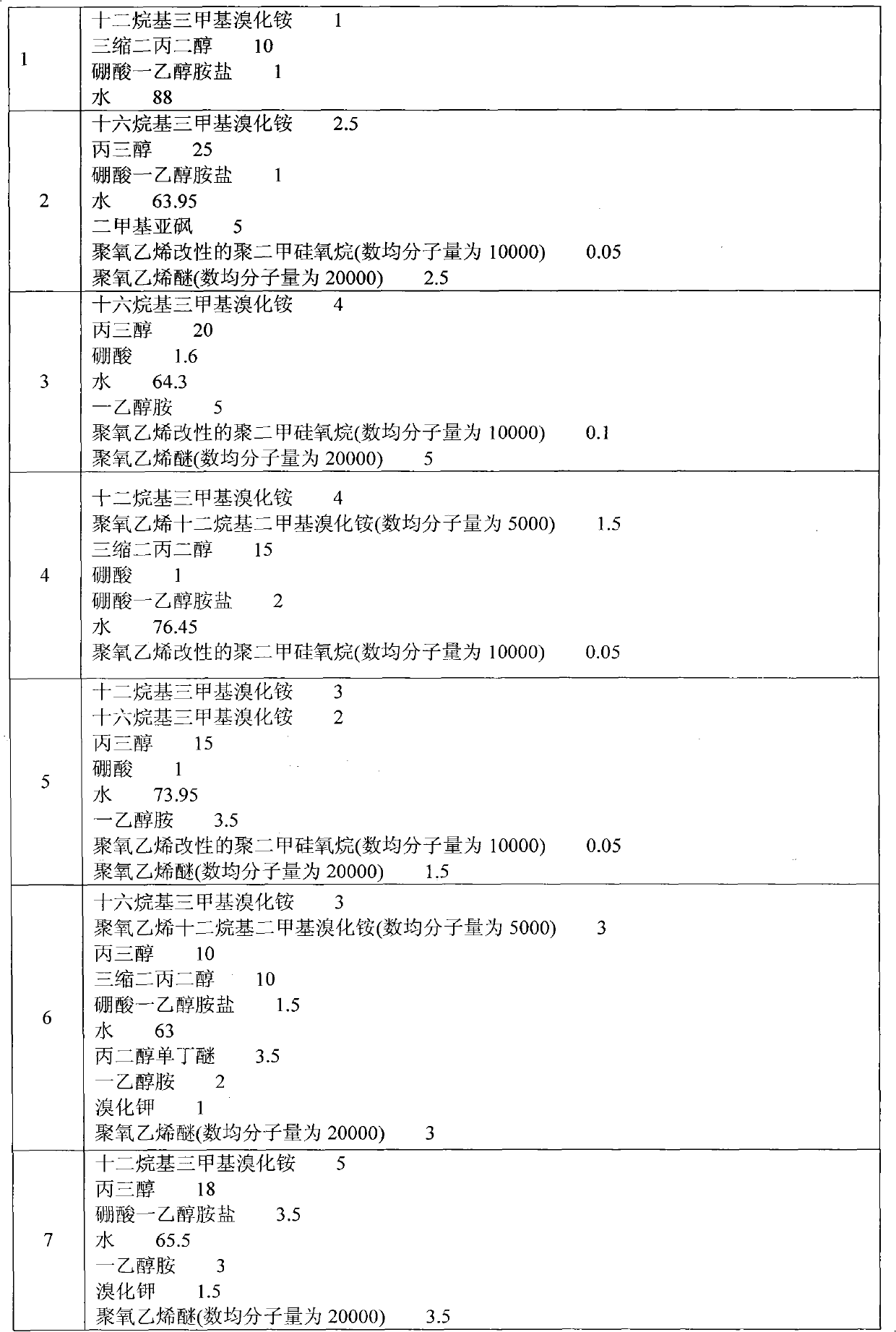

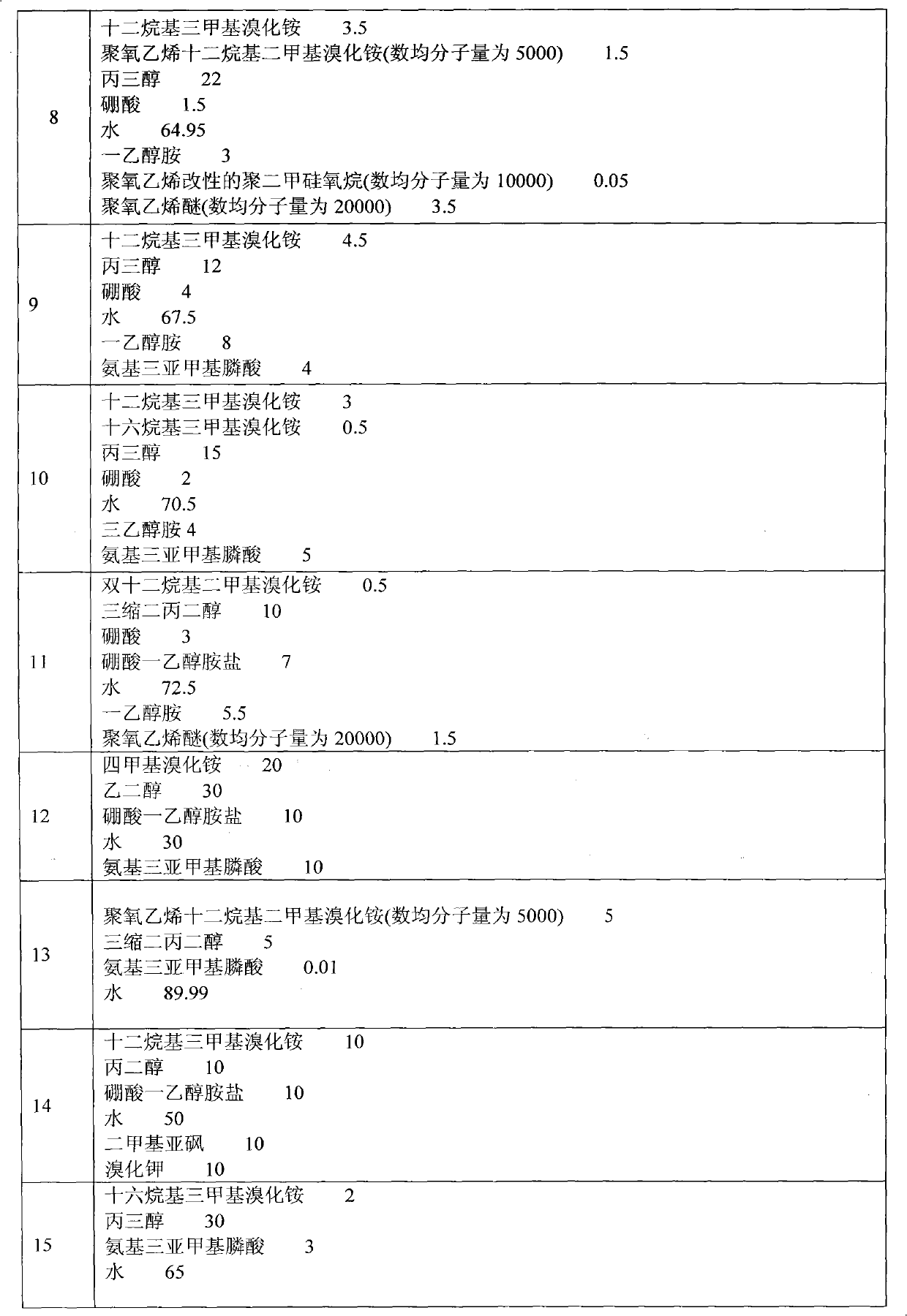

Water-based glass grinding fluid

InactiveCN102559354AImprove cooling effectImprove the lubrication effectLubricant compositionAlcoholActive agent

The invention discloses a water-based glass grinding fluid which comprises a brominated alkyl quaternary ammonium salt surfactant, organic alcohol, a corrosion inhibitor and water. The water-based glass grinding fluid has excellent properties of cooling, lubricating, washing, corrosion preventing and the like, and has a better chemical dressing function on a diamond grinding tool; and according to the water-based glass grinding fluid, the grinding precision can be remarkably improved, the service life of the grinding tool is prolonged, and the greasy blockage of the grinding tool is effectively prevented. The water-based glass grinding fluid has good glass grinding efficiency, excellent chemical stability and low cost, has no harm to the health, does not pollute the environment, is convenient for use, and can be widely applied to the grinding and cleaning processes of various kinds of glass.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

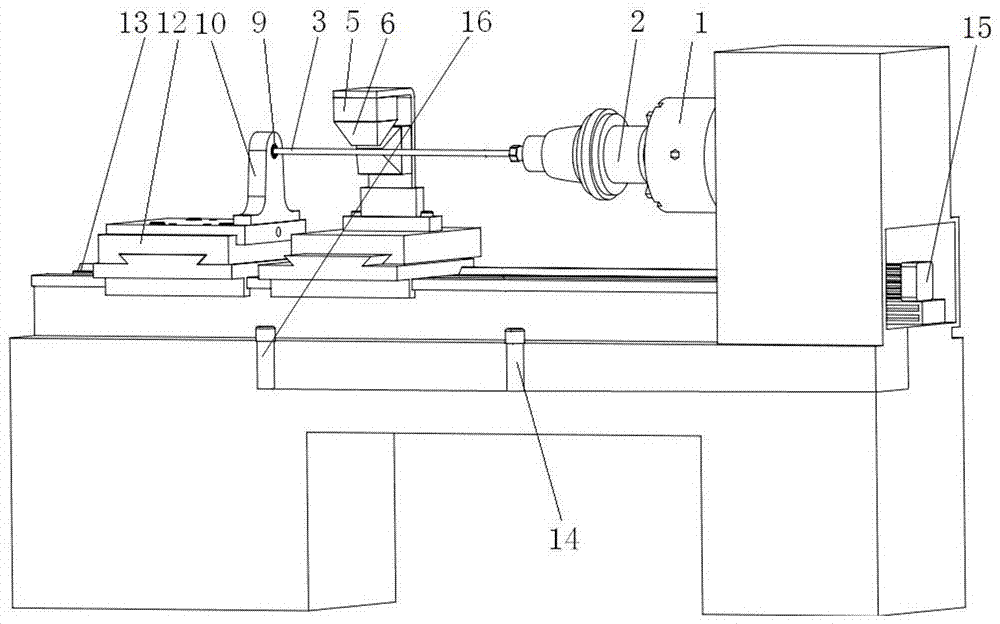

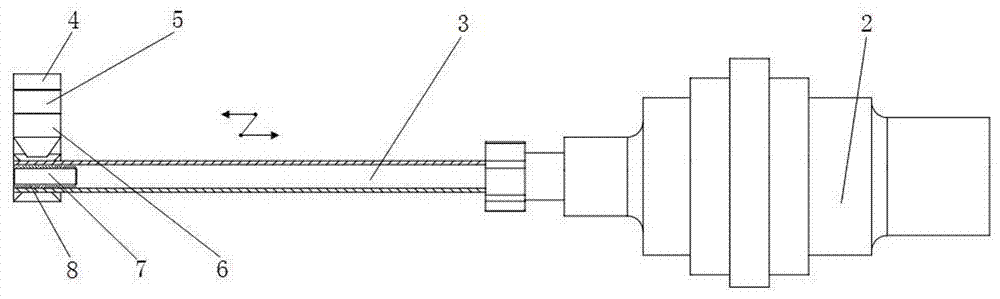

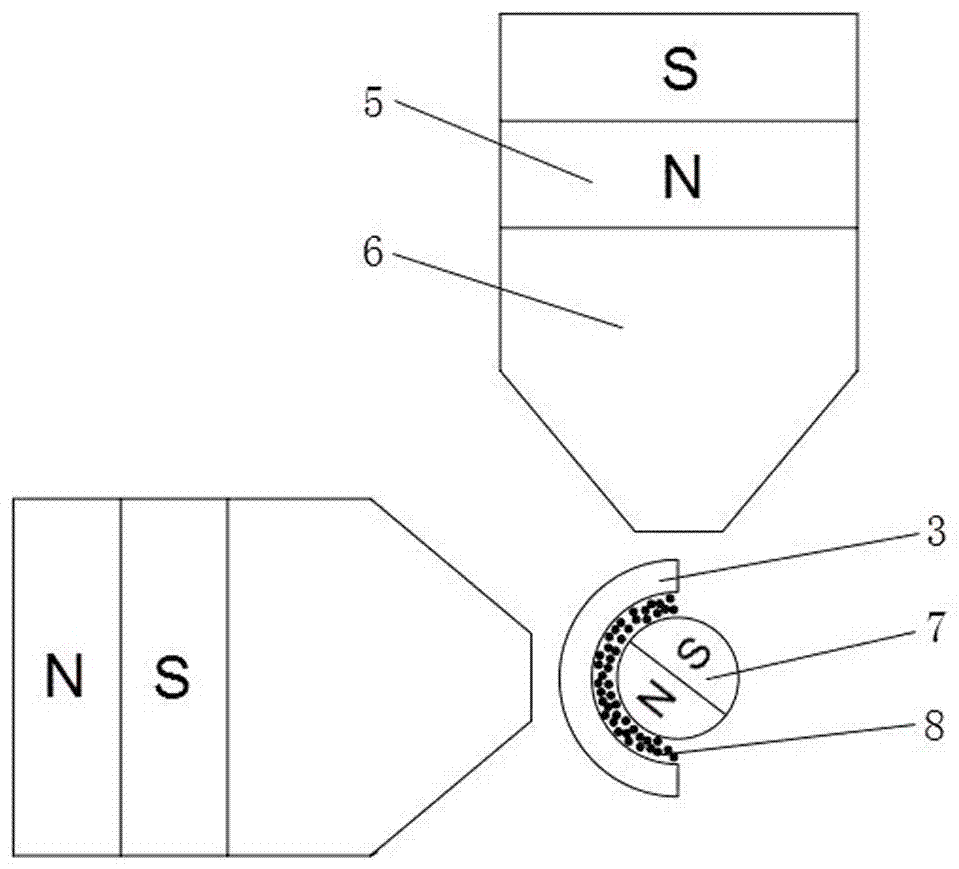

Inner surface polishing device of large-length-diameter-ratio slender pipe and method thereof

InactiveCN106938410AIncrease magnetic inductionIncrease grinding pressureGrinding work supportsMaterial removalDiameter ratio

The invention belongs to the technical field of magnetic grinding, and in particular, relates to an inner surface polishing device of a large-length-diameter-ratio slender pipe and a method thereof. The polishing device is characterized by comprising a machine tool body, a moving mechanism arranged on the machine tool body, a workpiece clamping mechanism arranged on the machine tool body and a grinding mechanism arranged on the machine tool body; the grinding mechanism includes an ultrasonic generator and a magnetic grinding device; and the magnetic grinding device includes an external grinding device and an internal grinding device. The polishing device adds ultrasonic vibration into the traditional magnetic grinding process, so that magnetic grinding particles generate a high-frequency impact effect on the inner surface of the slender pipe; an auxiliary magnetic pole is added in an inner cavity of the slender pipe for forming a magnetic loop with an external magnetic pole, so that the magnetic induction strength of unit space is improved, and the grinding pressure is also increased; and the material removing quantity is 1.5 times of that in traditional magnetic grinding.

Owner:UNIV OF SCI & TECH LIAONING

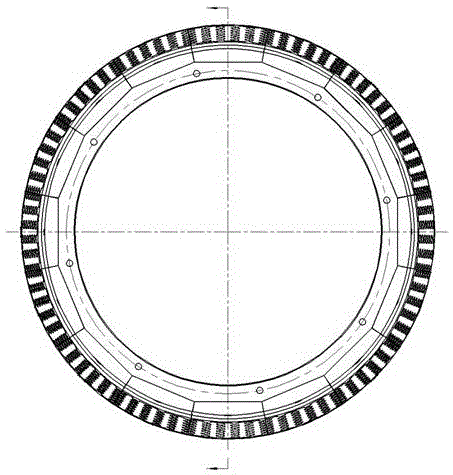

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com