Patents

Literature

211results about How to "Realize automatic grinding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

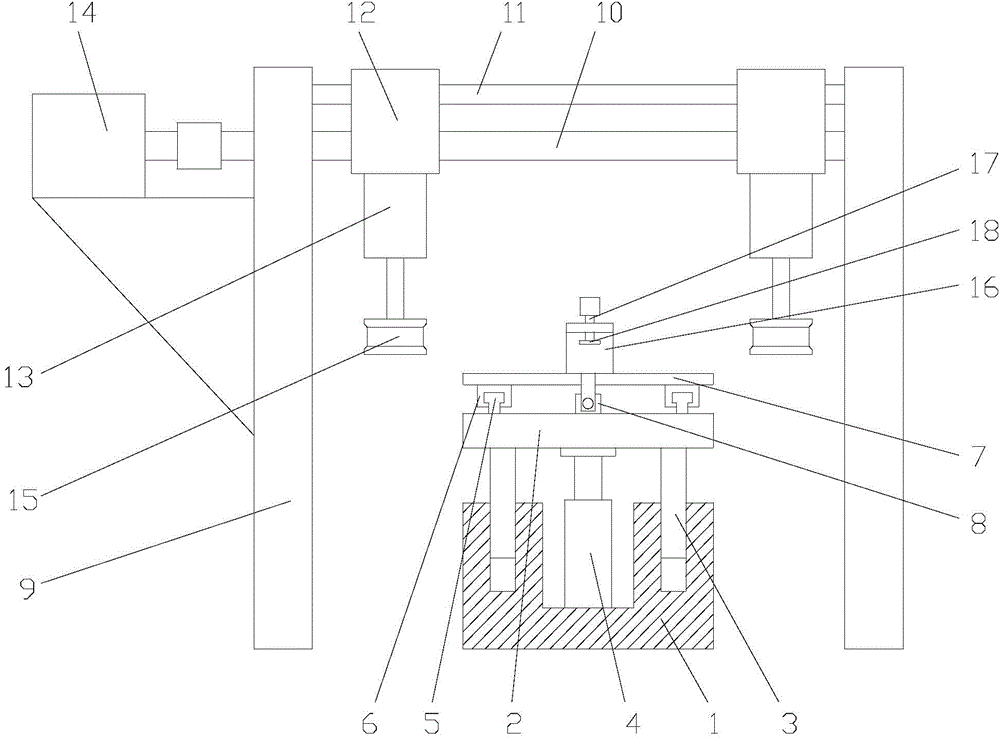

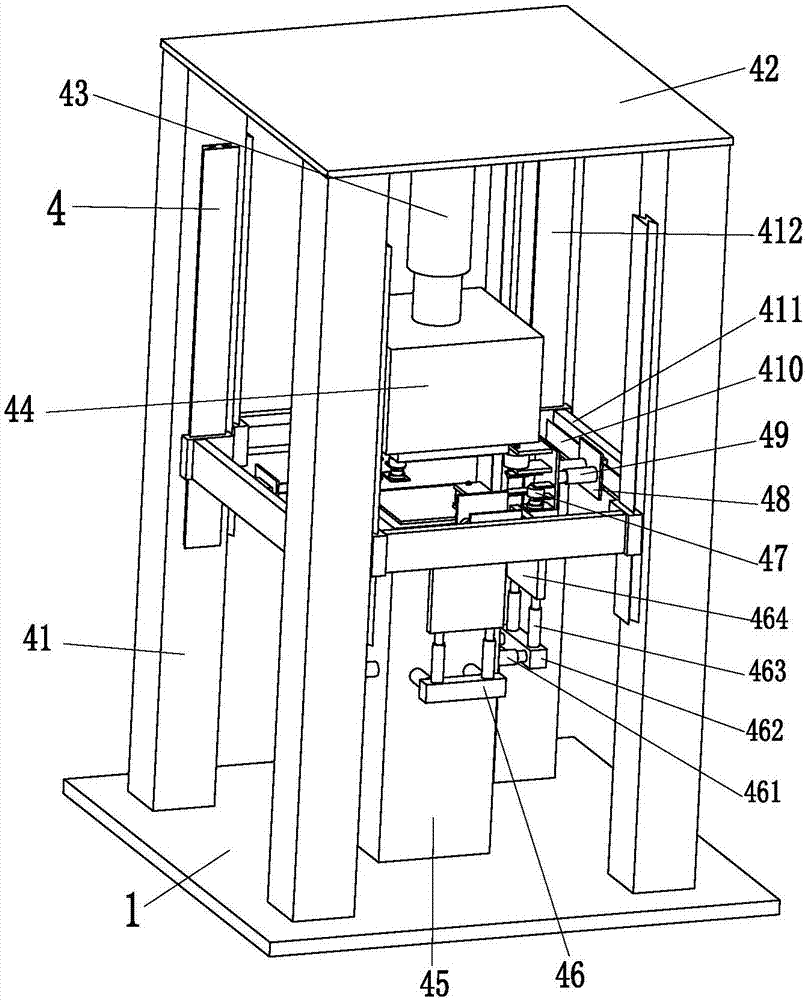

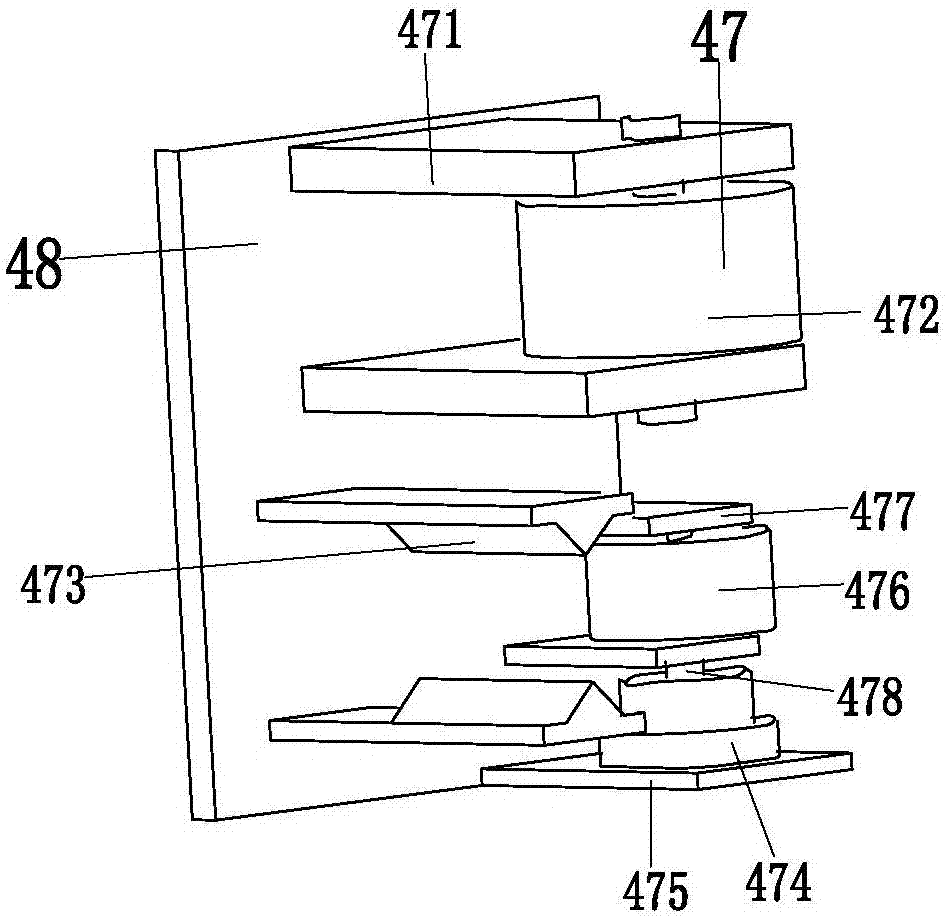

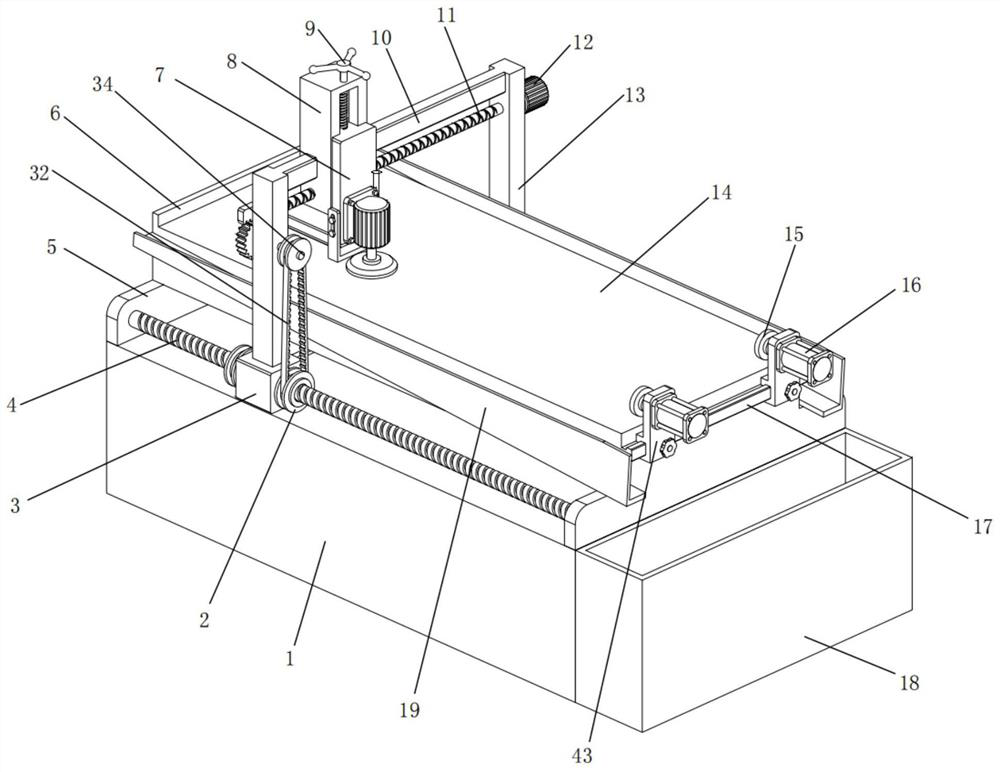

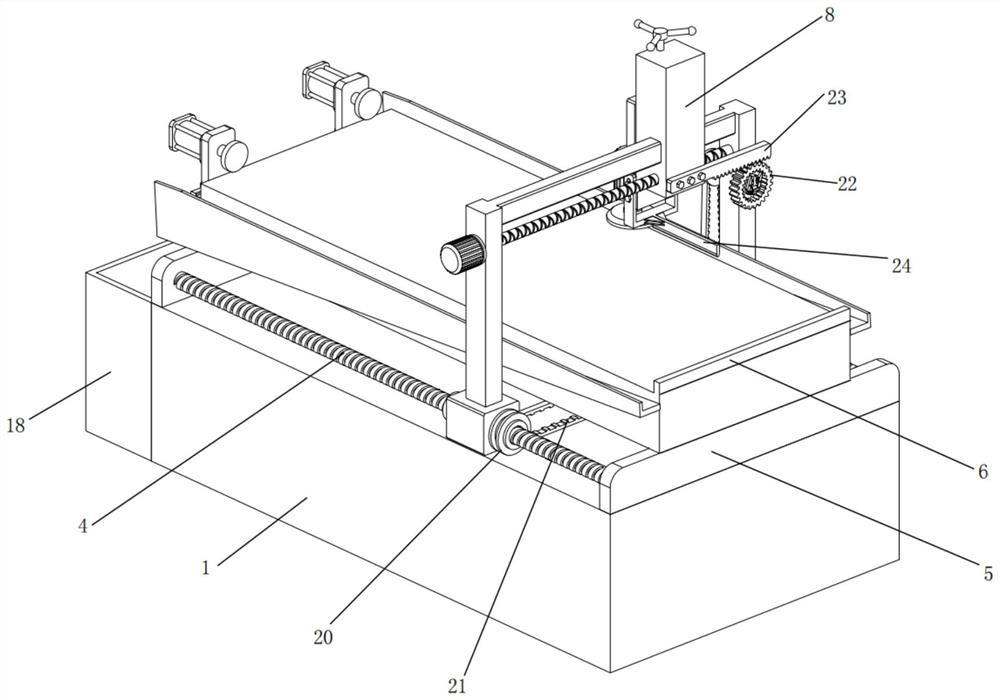

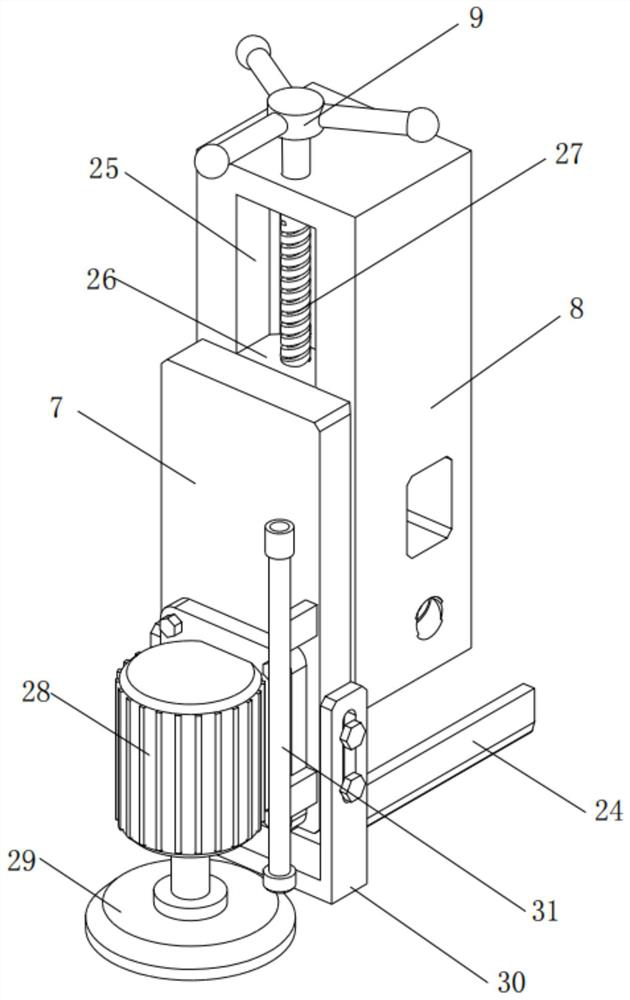

Automatic glass grinding machine

InactiveCN104385076ARealize automatic grinding processImprove grinding efficiencyEdge grinding machinesGrinding drivesGrinding wheelScrew thread

The invention discloses an automatic glass grinding machine. The automatic glass grinding machine comprises a base, a lifting worktable, a guide rail, a carrying plate, a pressing device and a feed cylinder, as well as a vertical frame, a lead screw arranged on the vertical frame by use of a bearing, a guide rod fixed on the vertical frame and parallel to the lead screw, a connecting block in threaded fit with the lead screw, a grinding motor arranged on the connecting block, and a lead screw driving motor arranged on the vertical frame, wherein the connecting block is in slide fit with the guide rod; the rotor shaft of the grinding motor is arranged vertically; a grinding wheel is arranged on the end portion of the rotor shaft of the grinding motor. The automatic glass grinding machine is capable of realizing automatic grinding on different glass plates by automatically adjusting the up-and-down height positions of the carrying plate by use of a lifting cylinder, automatically realizing the longitudinal feed of the glass plates by use of the feed cylinder and realizing transverse feed of the grinding motor by use of the lead screw driving motor, and further is high in grinding working efficiency and low in labor intensity.

Owner:重庆天和玻璃有限公司

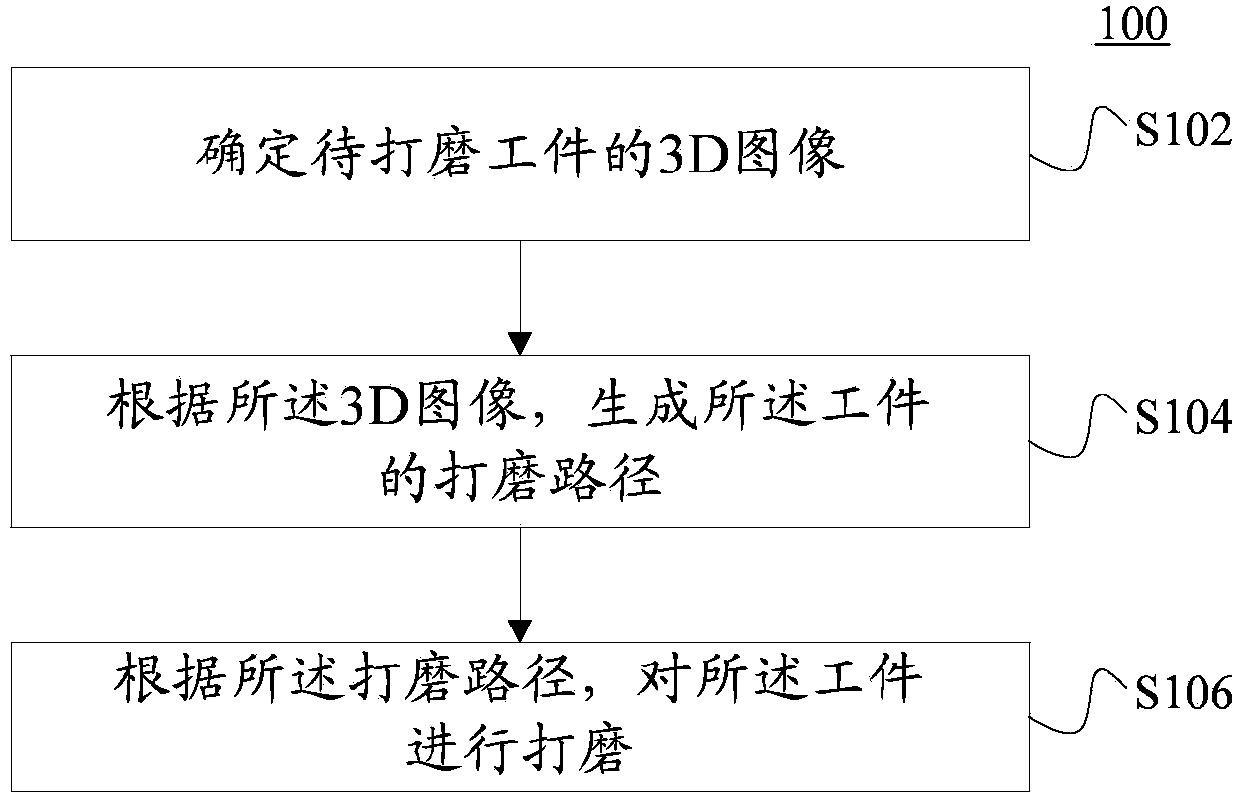

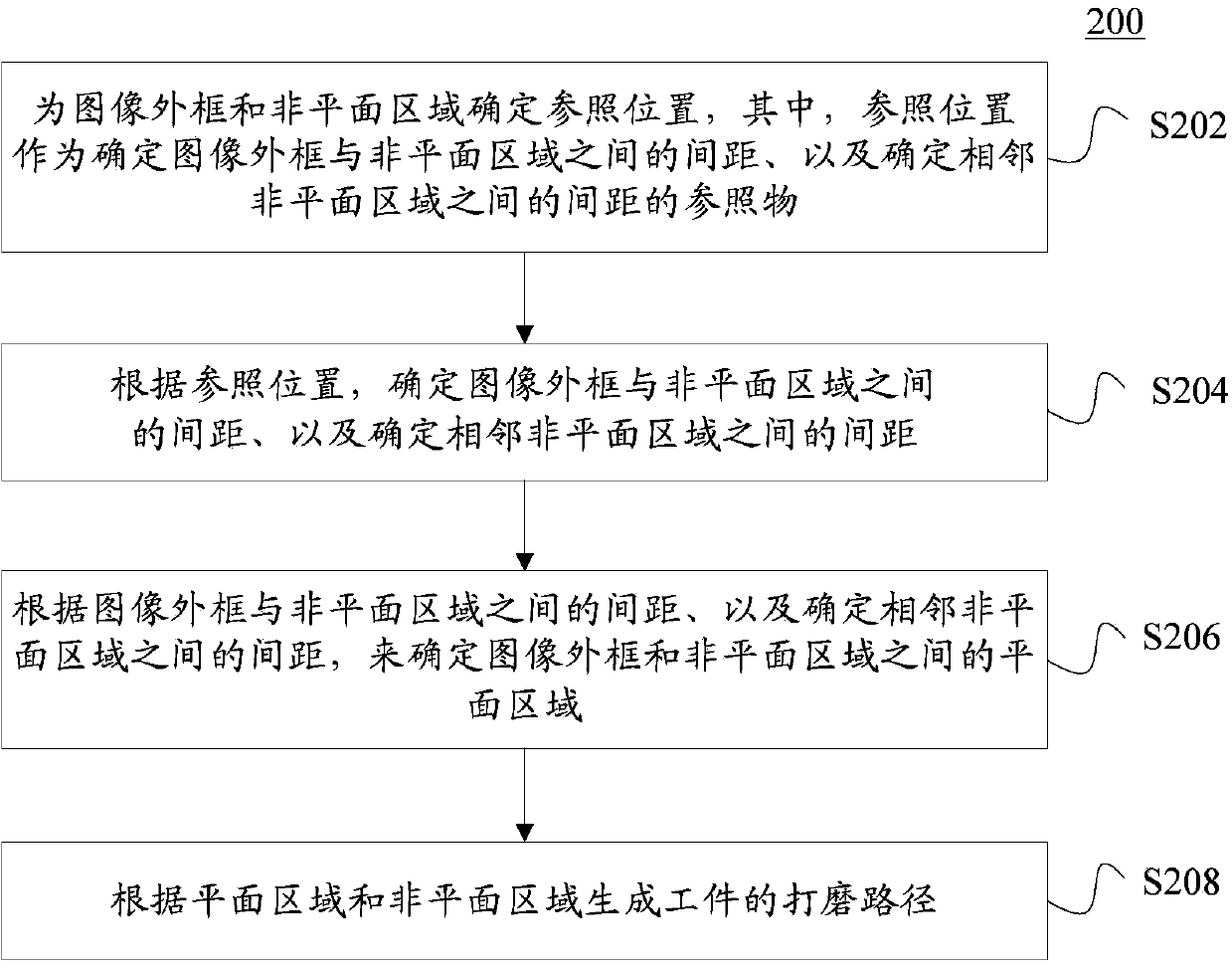

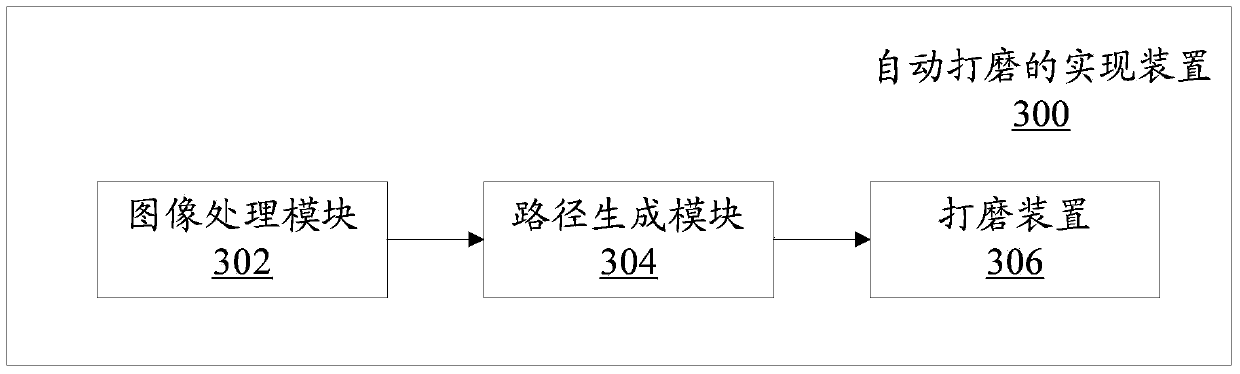

Automatic polishing method and device

InactiveCN103995934ARealize automatic grinding processIncrease productivitySpecial data processing applications3d imageWorking environment

The invention provides an automatic polishing method which comprises the steps of determining a 3D image of a workpiece to be polished, generating the polishing path of the workpiece according to the 3D image, and polishing the workpiece according to the polishing path. According to the method, automatic polishing is achieved on the irregular workpiece by means of the polishing path generated according to the 3D image, production efficiency is improved, human intervention is not needed during polishing, and as a result, the whole polishing process can be conducted in a totally sealed space, labor is liberated, and the working environment is improved.

Owner:智慧工匠(北京)科技有限公司

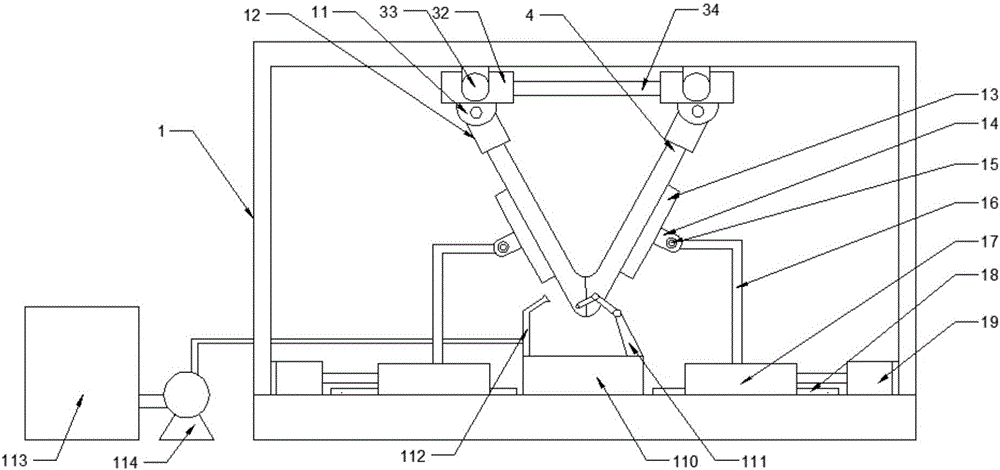

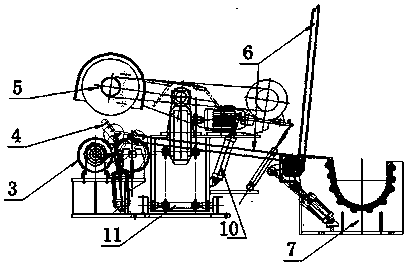

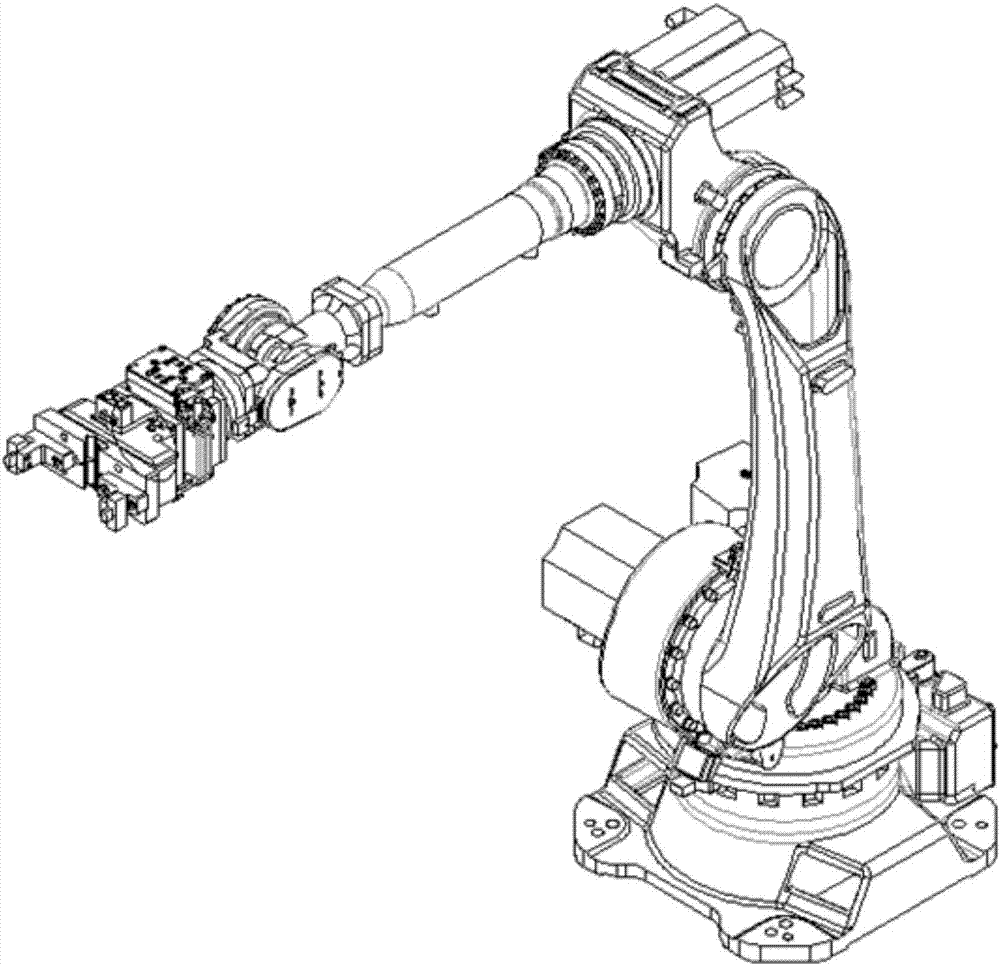

Automatic grinding device and method thereof

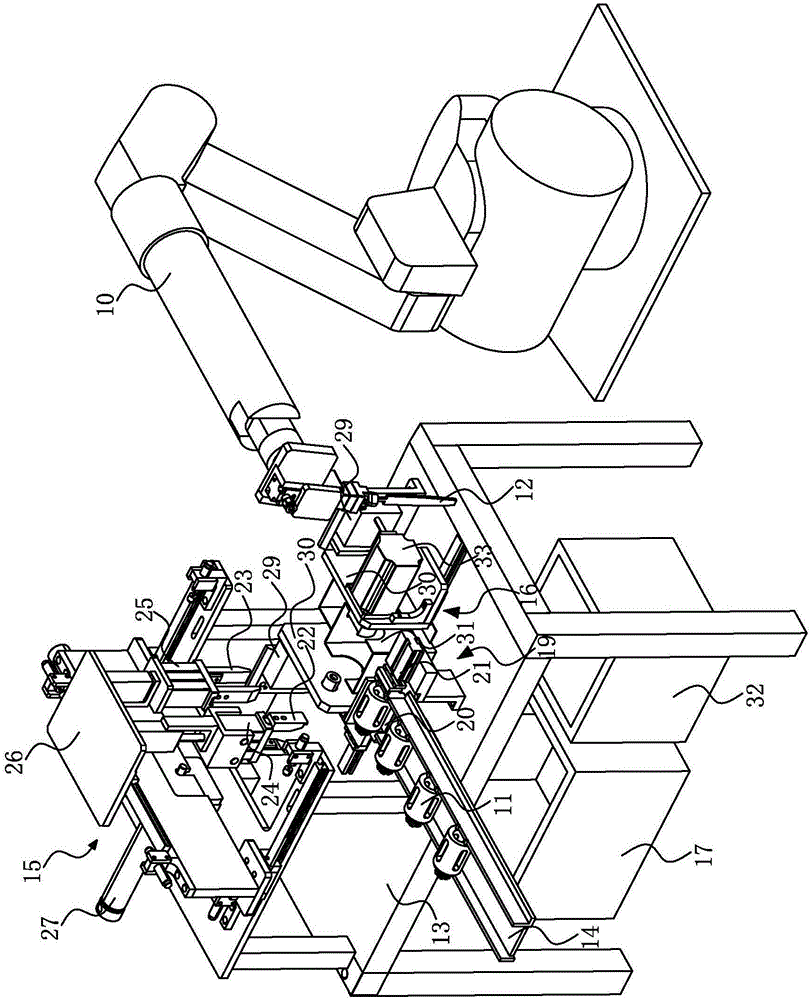

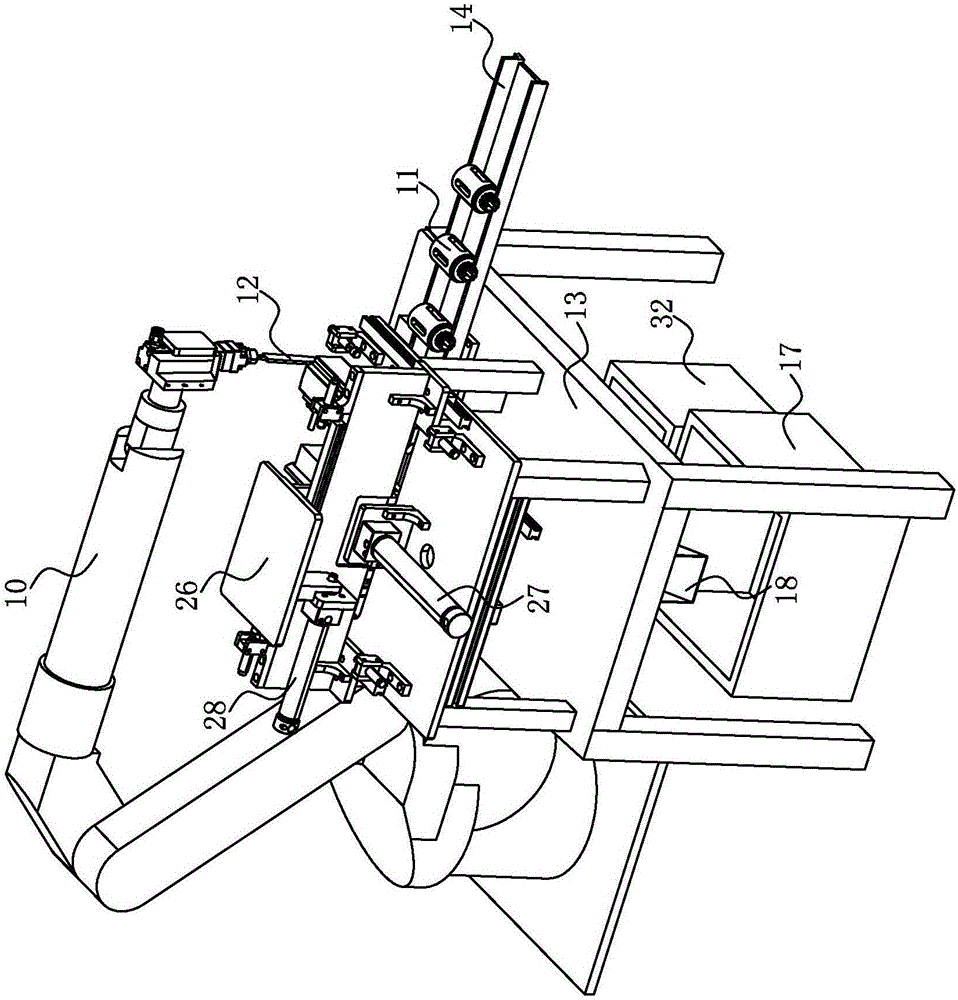

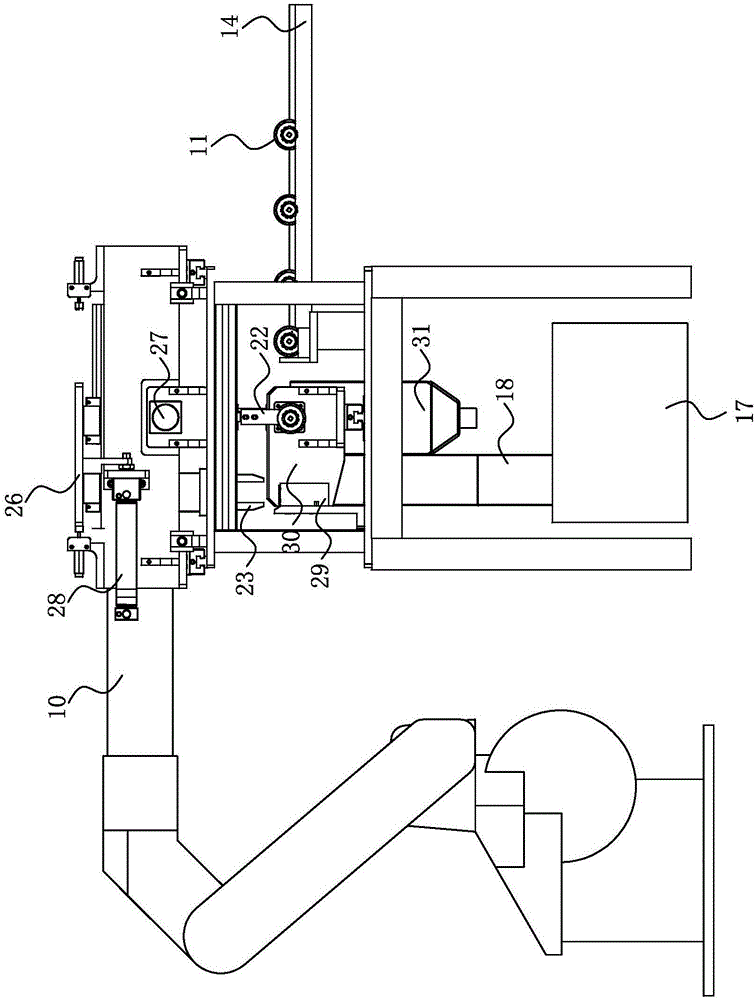

ActiveCN106346337ARealize automatic grinding processImprove work efficiencyGrinding machinesGrinding feedersRobotic armMechanical engineering

The invention provides an automatic grinding device and method thereof. The automatic grinding device comprises grinding tools which is clipped on the end of the mechanical arm, a staging with the sequential establishment of the feeding station, a grinding station and a receiving station, a material trough which is arranged on the feeding station with a plurality of grinding work pieces placed side by side inside, a clamping structure which clamp the work pieces moving from the feeding station to the grinding station and moving from the grinding station to the receiving station, a fastening structure which is arranged on the grinding station and clamp the work pieces for grinding, a control unit which control the action of the mechanical arm, the clamping structure and the fastening structure. The automatic grinding device and method thereof has the advantages of grinding work pieces automatically and improving the work efficiency. Grinding with the automatic grinding device and burnishing each work piece with the same strength and angle is conducted, thereby solving the problems of low efficiency of manual grinding and differences in the surface of the work pieces while grinding caused by grinding with the existing technology.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

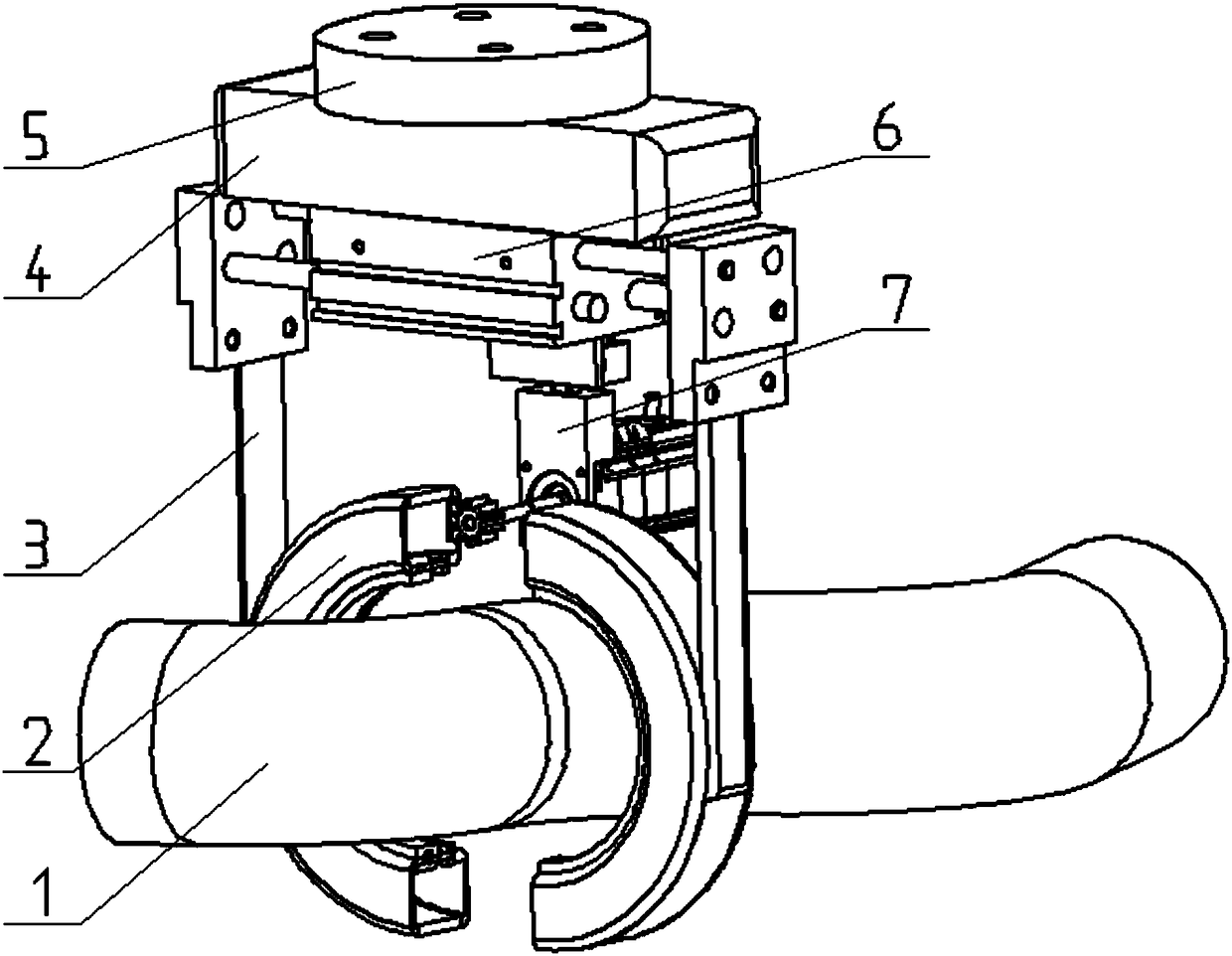

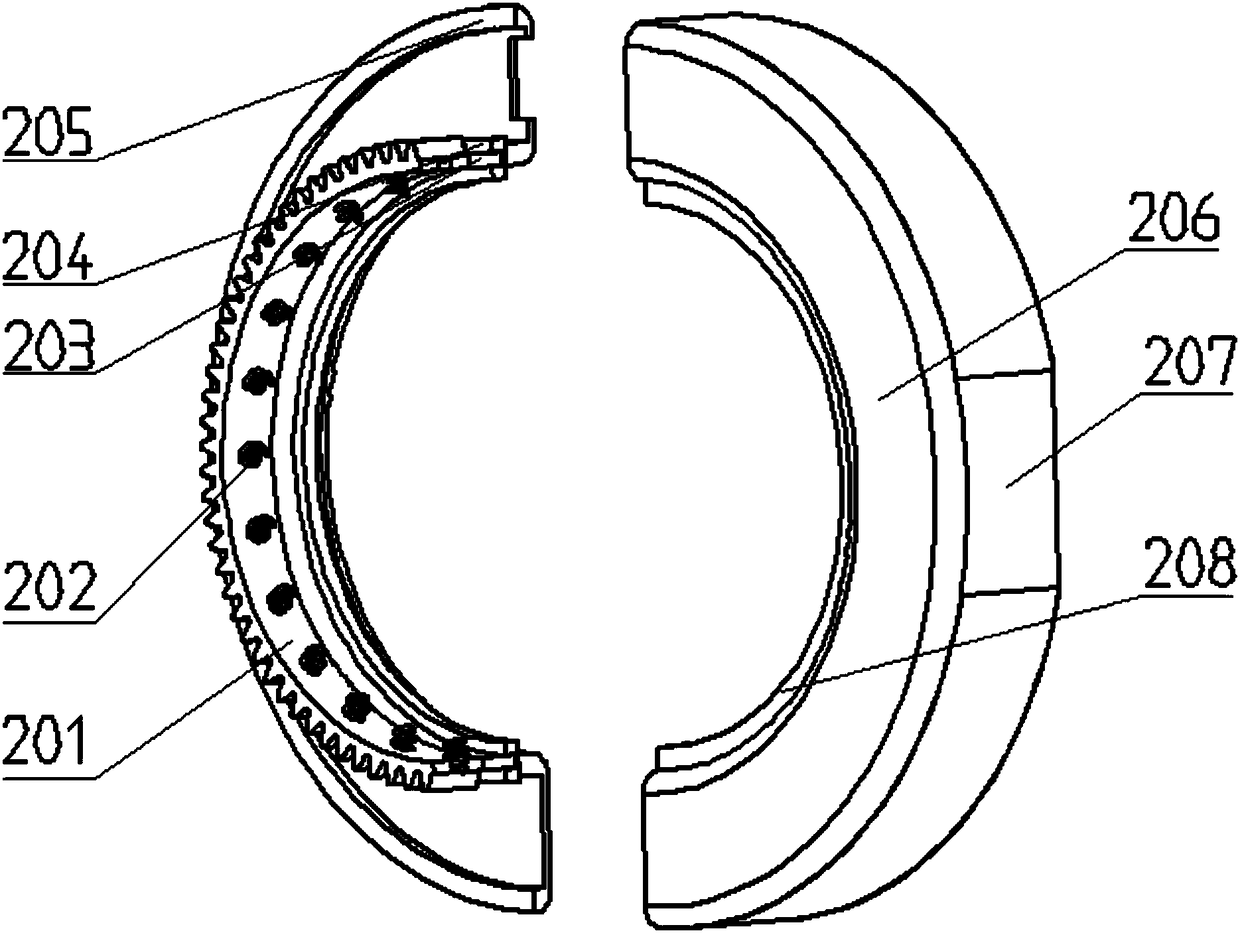

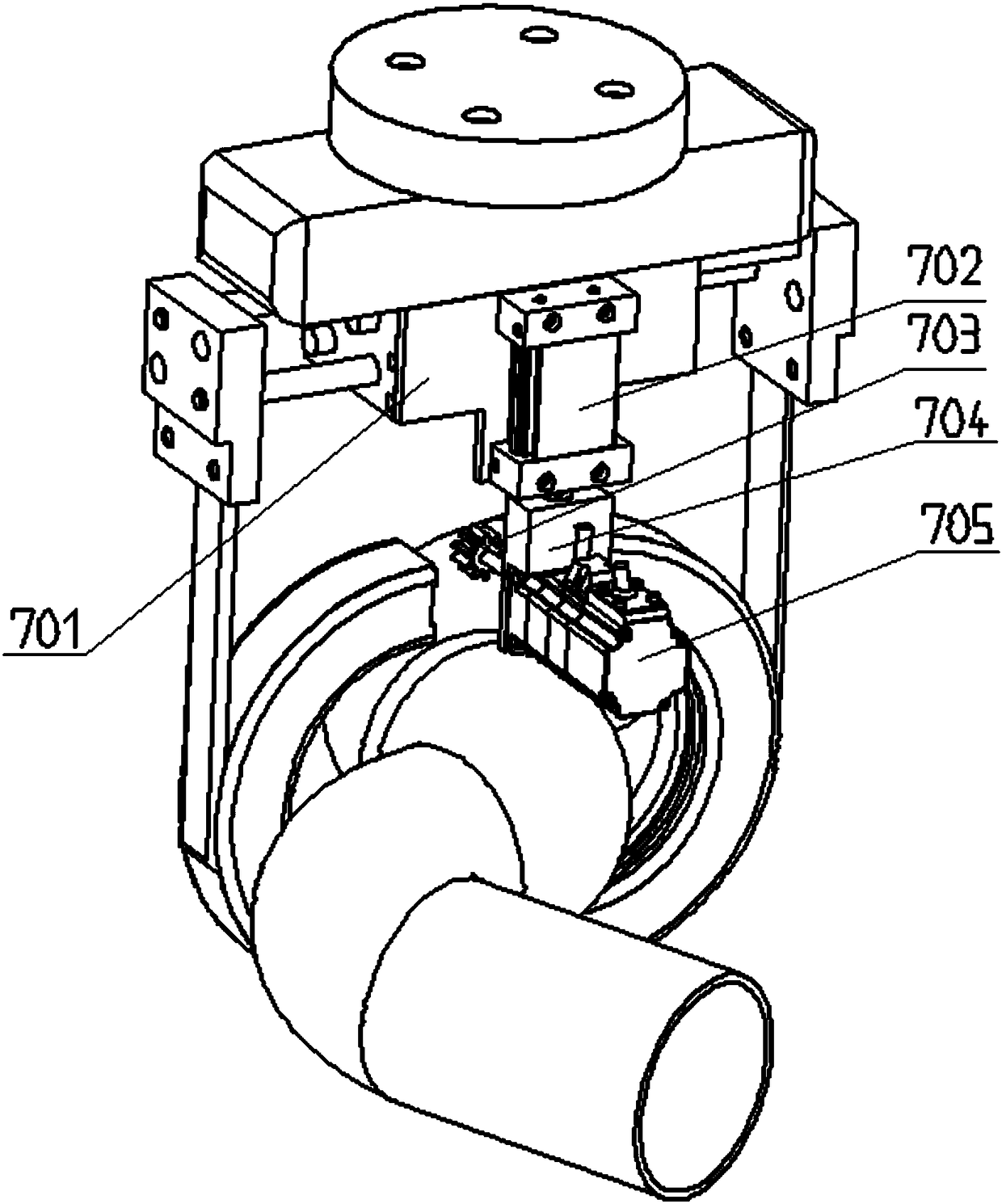

Circular pipe weld joint automatic grinding device

InactiveCN108214247ARealize automatic grinding processAchieve regulationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a circular pipe weld joint automatic grinding device and belongs to the field of grinding automatic equipment. The device is composed of a circular pipe, a grinding unit, supporting arms, a controller, a mounting flange, a wide gas claw and driving unit. The mounting flange is fixed to the controller. The wide gas claw is mounted under the controller. One side of a cylindermounting plate on the driving unit is mounted on the back side of the controller, and a thin cylinder is mounted on the other side of the cylinder mounting plate. A servo motor is connected with thethin cylinder through a motor fixing seat. A gear is mounted on a spindle of the servo motor. The supporting arms are mounted on paws on the two sides of the wide gas claw. Side covers in the grindingunit are connected with the supporting arms correspondingly. A front cover and a rear cover are mounted on the front and rear sides of the side covers correspondingly. A sliding guide rail is mountedon the rear cover. A semicircular gear ring is mounted on the sliding guide rail through a sliding block. Springs are mounted on the inner side of the semicircular gear ring, and a grinding materialis fixed through the springs. The circular pipe is fixed and all positions of a weld joint are exposed. Through the grinding device, the circular pipe splicing weld joint can be ground automatically.

Owner:SHANDONG SICHUANG ROBOT TECH CO LTD

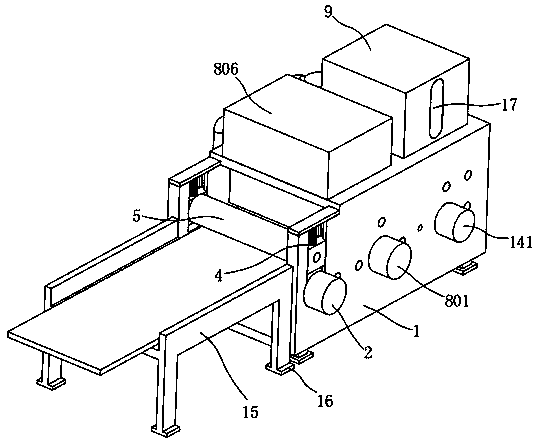

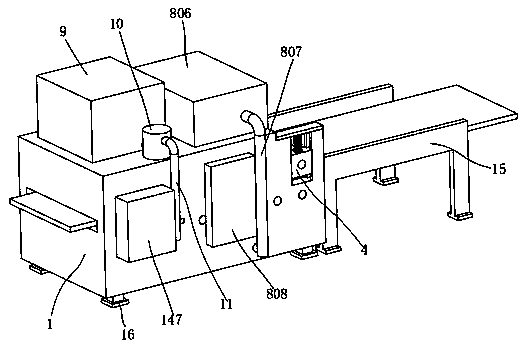

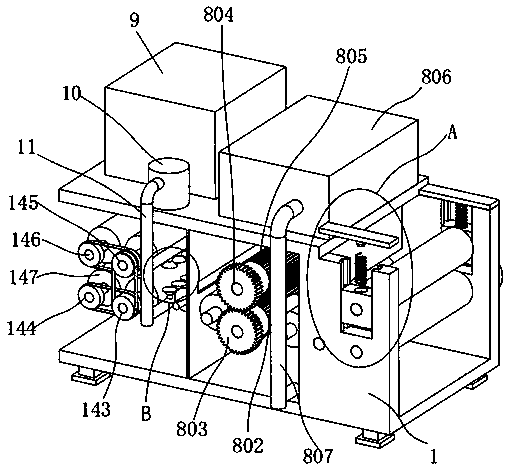

Double-layer gluing equipment for plastic floor substrate

InactiveCN110624776AAvoid pollutionImprove solidLiquid surface applicatorsGrinding drivesEngineeringNozzle

The invention discloses double-layer gluing equipment for a plastic floor substrate. The double-layer gluing equipment comprises a box body, wherein a first motor is fixed on the side wall of the front side of the box body; an output shaft of the first motor is fixed with an active material conveying roller; a clamping mechanism is arranged above the active material conveying roller; a driven material conveying roller is rotationally connected to the clamping mechanism; a guide material conveying roller is rotationally connected to the middle of the box body; two clapboards are fixed in the middle of the box body; a grinding mechanism is arranged between the two clapboards; and a glue storage box is fixed at the upper end of the box body; the glue storage box communicates with a glue pump,the output end of the glue pump communicates with a first glue conveying pipe, the lower end of the first glue conveying pipe communicates with two second glue conveying pipes, the upper and lower opposite ends of the two second glue conveying pipes communicate with atomizing nozzles, and the rear ends of the atomizing nozzles are provided with glue flattening mechanisms. According to the double-layer gluing equipment, the automatic polishing, dust suction, double-side gluing and glue flattening of the substrate can be realized on one device, the working efficiency is high, the equipment costis low, and the gluing quality is good.

Owner:ANJI TIAN ZE PLASTIC CO LTD

Automatic chamfering device

PendingCN107297653ARealize automatic feeding processRealize automatic grinding processEdge grinding machinesGrinding carriagesStructural engineeringMachine

The invention discloses an automatic chamfering device, which comprises a machine base, a feeding mechanism, a conveying mechanism, two lead rails, multiple vertical rods, multiple first cross rods, second cross rods, and two chamfering mechanisms; the conveying mechanism comprises a belt conveyer; two lead rails are symmetrically arranged along the central line of a conveying belt of the belt type conveyer; any one lead rail comprises a vertical plate perpendicular to the conveying belt and a cross plate in parallel to the conveying belt, wherein the bottom part of the cross plate is fixedly connected with the upper part of the vertical plate; multiple vertical rods are perpendicular to the conveying belt, and the lower end of any one vertical rod is fixedly connected to one end of the cross plate closing to the edge of the conveying belt; multiple first cross rods are in parallel to the conveying belt, and corresponding to the vertical rods one by one; one end of any one first cross rod closing to the central line of the conveying belt is fixedly connected with the upper ends of the vertical rods; the second cross rods are hinged with the other ends of the first cross rods. The automatic chamfering device has the advantages of good chamfering quality, high efficiency, compact and small equipment, and others.

Owner:京磁材料科技股份有限公司

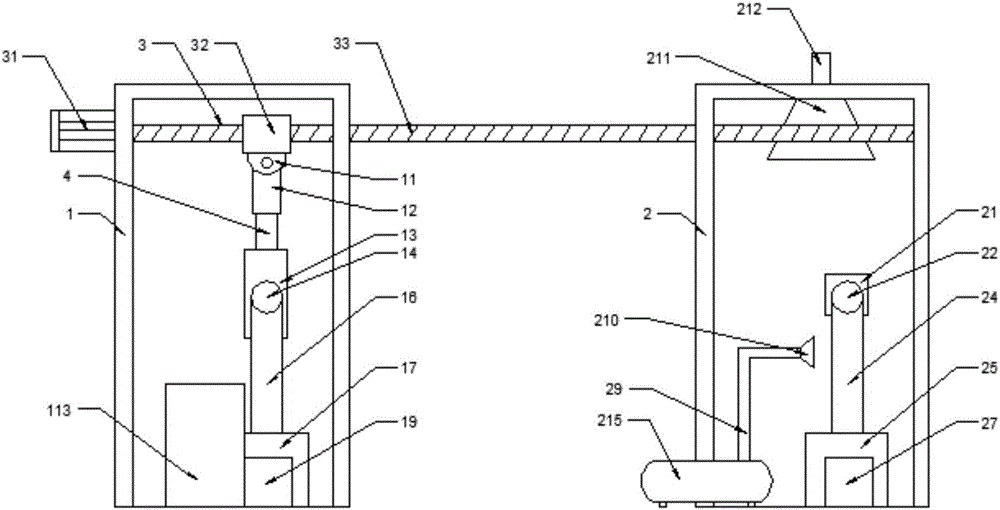

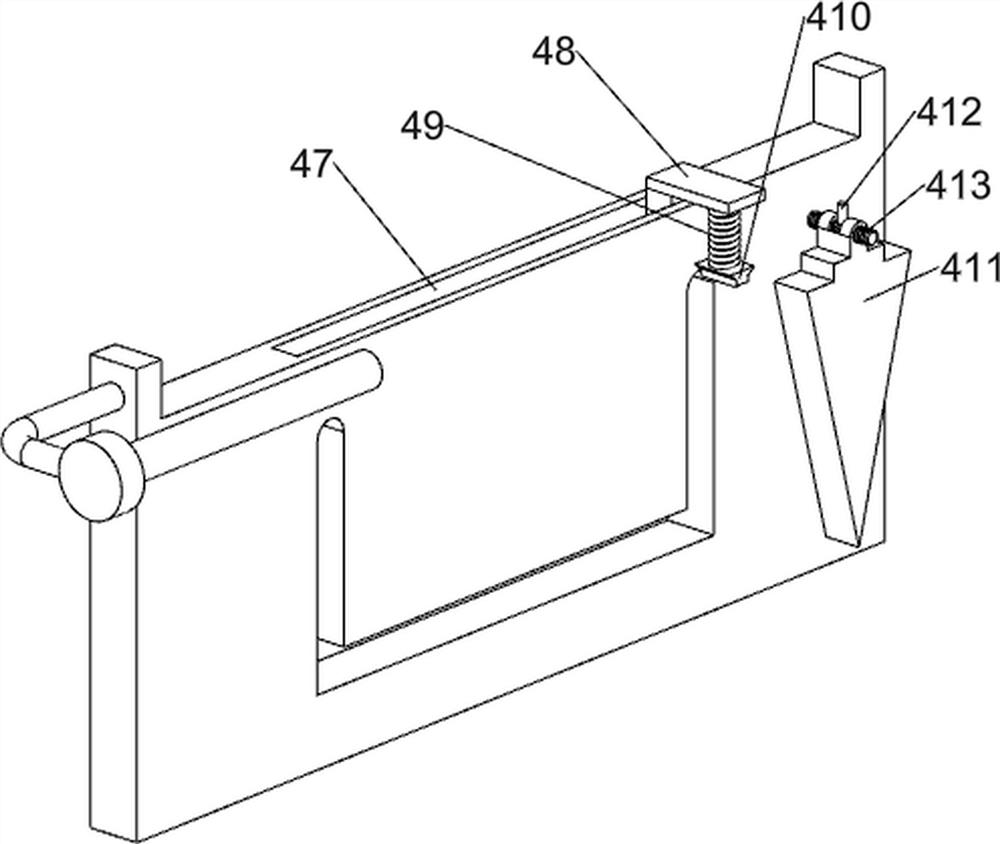

Welding and polishing device for machining bicycle frame

InactiveCN106002259AGuaranteed aestheticsGuaranteed cleanlinessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining system

The invention provides a welding and grinding device for processing a bicycle frame, comprising: a welding mechanism and a grinding mechanism, and the frame of the welding mechanism and the frame of the grinding mechanism are respectively fixed at symmetrical positions on both sides of the upper part. There are lead screws, each screw is provided with a screw nut, and a connecting rod is connected between the two screw nuts, the lower surface of the screw nuts is respectively fixed with a fine-tuning shaft, and the fine-tuning shaft is rotatably connected with a pneumatic card. claw. The vehicle frame processing system described in the present invention has a simple structure and a reasonable design, and can accurately fix two metal pipes into a V shape, thereby improving the accuracy and efficiency of welding. It is also equipped with a cooling system, which improves the welding quality and ensures The quality of the bicycle frame is improved; the automatic grinding of the solder joints of the bicycle frame is realized, the grinding efficiency is improved, the aesthetics of the frame is guaranteed, and the labor intensity is reduced.

Owner:天津维尔纳复合材料有限公司

Casting part grinding device capable of lowering temperature

ActiveCN105108618AAchieve heatingExtended service lifeGrinding machinesGrinding/polishing safety devicesEngineeringWater spray

The invention relates to a casting part grinding device capable of lowering the temperature. The device comprises a grinding box body and a support frame, and the grinding box body is arranged at the upper end of the support frame; a heating device and a grinding roller set are arranged in the grinding box body, and the heating device is located in front of the grinding roller set; a material inlet and a material outlet are formed in two side walls of the grinding box body respectively; a first conveying belt and a second conveying belt are arranged at the two sides of the grinding box body respectively, the end, close to the grinding box body, of the first conveying belt passes through the material inlet, extends into the grinding box body and gets close to the heating device, the end, close to the grinding box body, of the second conveying belt passes through the material outlet, extends into the grinding box body and gets close to the grinding roller set, and the horizontal position of the second conveying belt is lower than that of the first conveying belt; a water spray device is arranged over the position, corresponding to the second conveying belt, of the inner side of the grinding box body, and a waste water collector is arranged under the position, corresponding to the second conveying belt, of the inner side of the grinding box body. By means of the device, a casting part can be heated and ground automatically, the grinding efficiency is high, the temperature can be lowered, dust can be removed, and the service life is long.

Owner:TANGSHAN HONGLI HARDWARE TOOLS

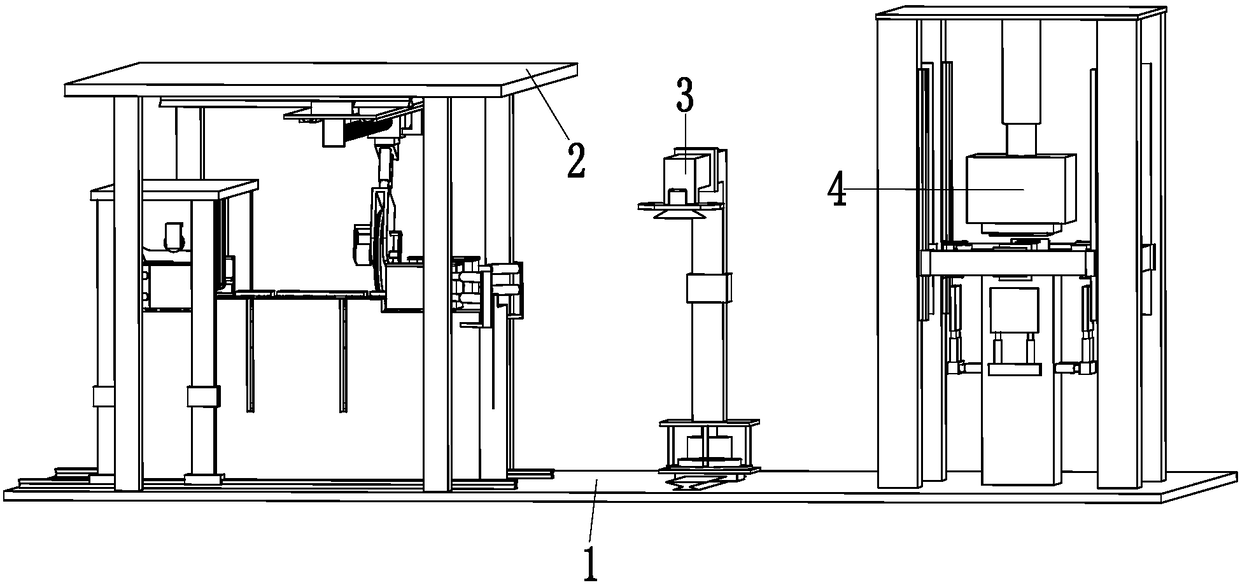

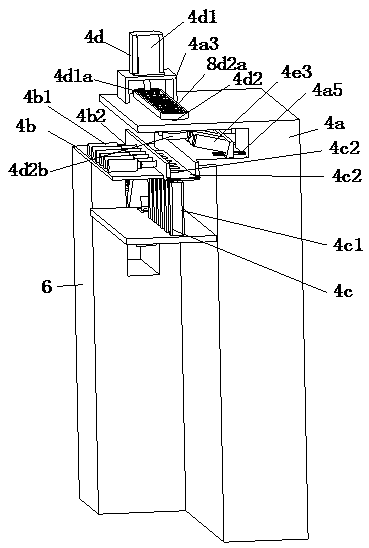

Grinding equipment and grinding method

ActiveCN105666280AAchieve grindingImplement servo controlSpherical surface grinding machinesGrinding feed controlControl systemEngineering

The invention discloses grinding equipment and a grinding method. The grinding equipment and the grinding method aim at solving the problems that at present, manpower is mainly adopted to grind a pot billet, consequently, operation efficiency is low, the requirement of an existing grinding device for the position of the pot billet is low, and certain limitation exists. The grinding equipment comprises a grinding mechanism and a control system; and the grinding mechanism comprises a grinding support, a first supporting rod, a second supporting rod, a first telescopic arm, a second telescopic arm, a third supporting rod, a grinding wheel and a grinding wheel driving device. One end of the first supporting rod is movably connected with the grinding support, and the first supporting rod can rotate relative to the grinding support; and the other end of the first supporting rod is movably connected with the second supporting rod. According to the grinding equipment, the automatic grinding requirement for workpieces with different sizes can be met, the extremely-high adaption is achieved, the grinding quality is good, efficiency is high, the production period is short, the cost is low, the good application prospect is achieved, and the equipment is worth applying and popularizing in a large-scale manner.

Owner:SICHUAN FUDE ROBOT

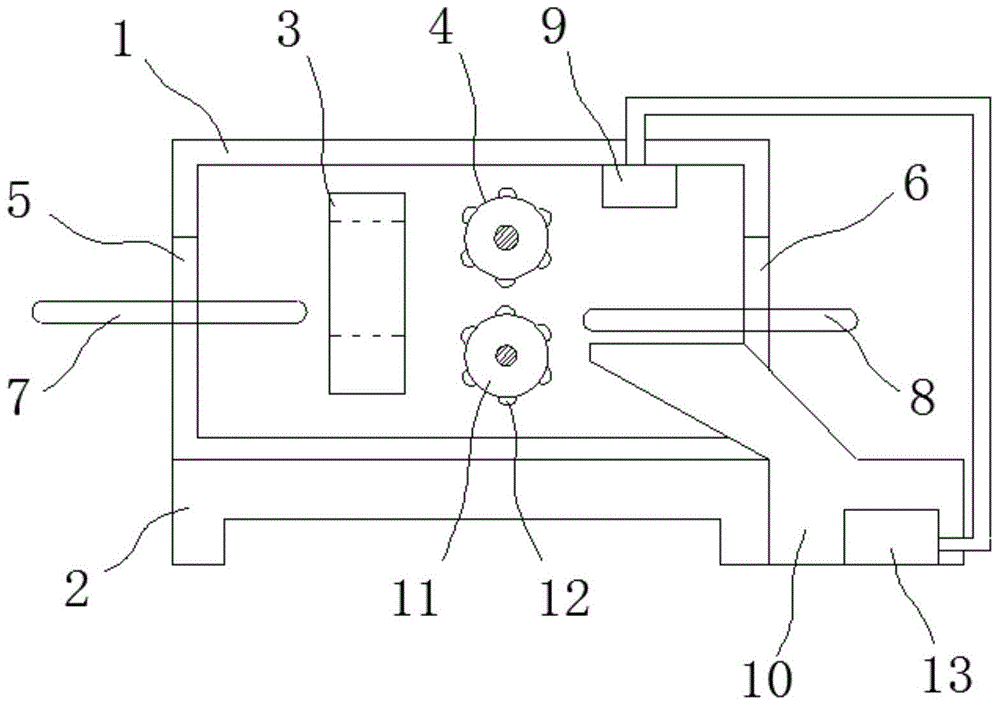

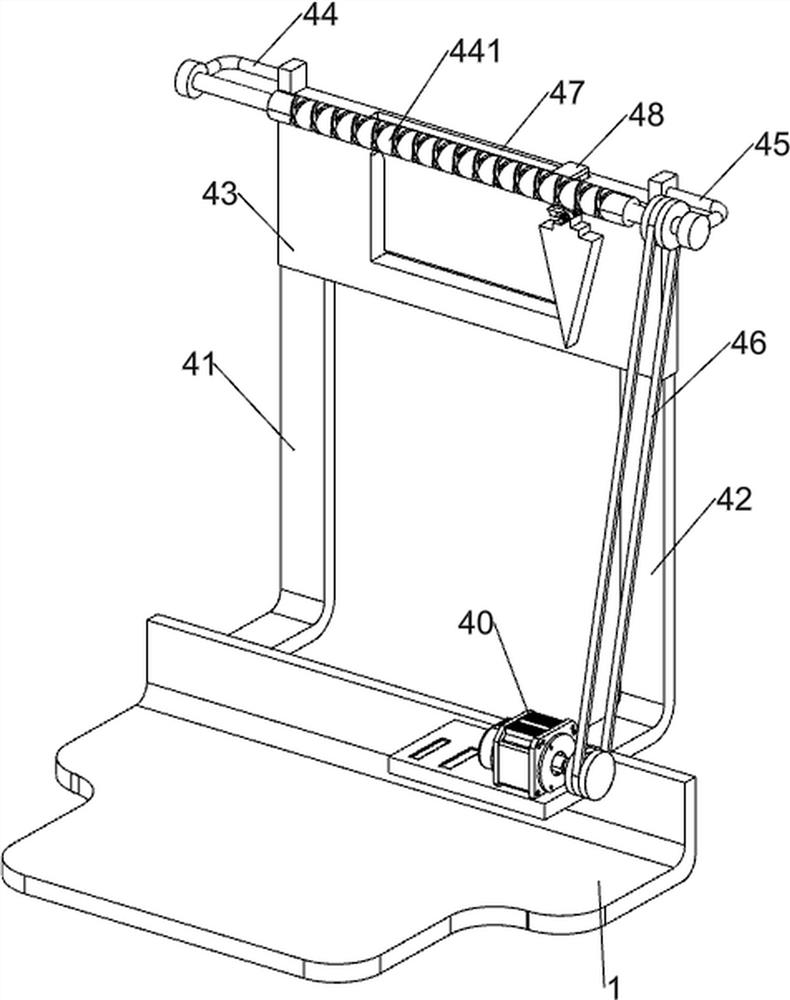

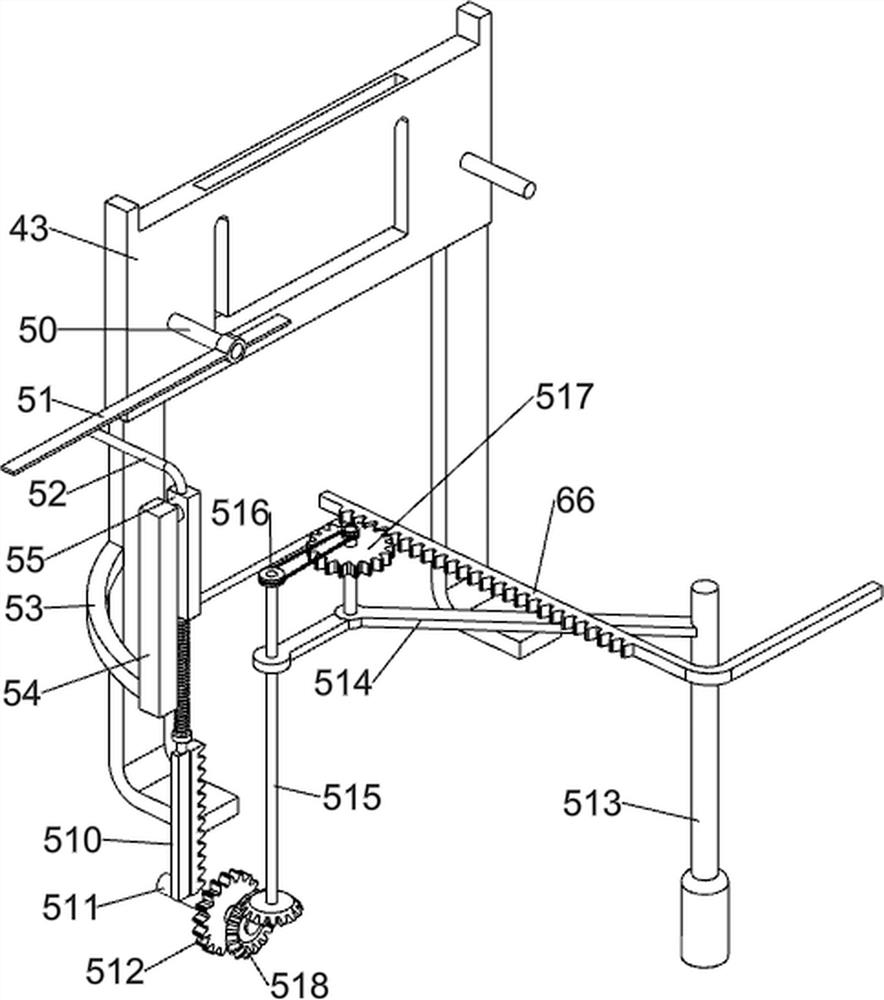

Polycrystalline silicon solar panel maker capable of cutting and polishing of battery piece

InactiveCN108231630ASupport fixed and stableThe phenomenon of sliding will not appearFinal product manufactureSemiconductor/solid-state device manufacturingPolycrystalline siliconElectrical and Electronics engineering

The present invention relates to a polycrystalline silicon solar panel maker capable of cutting and polishing of a .battery piece. The maker comprises a support base plate, a cutting device, a carrying device and a polishing device. The left end of the support base plate is provided with the cutting device, the polishing device is installed at the right end of the support base plate, the carryingdevice is located between the cutting device and the polishing device, and the carrying device is connected with the support base plate. The problems can be solved that the location has deviation whenthe battery piece is cut, the support is instable and the whole battery piece cannot be supported when the battery piece is cut, the phenomenon of sliding of the battery generates when the battery piece is cut, the cut battery piece is carried by manual operation, the cut battery piece needs to perform polish by manual operation, and the polishing effect is poor the current production process ofthe polycrystalline silicon battery piece; and functions of stable support and fixing of the polycrystalline silicon battery piece, the positioning cutting of the battery piece and automatic polishingof the cut battery piece can be achieved.

Owner:范满香

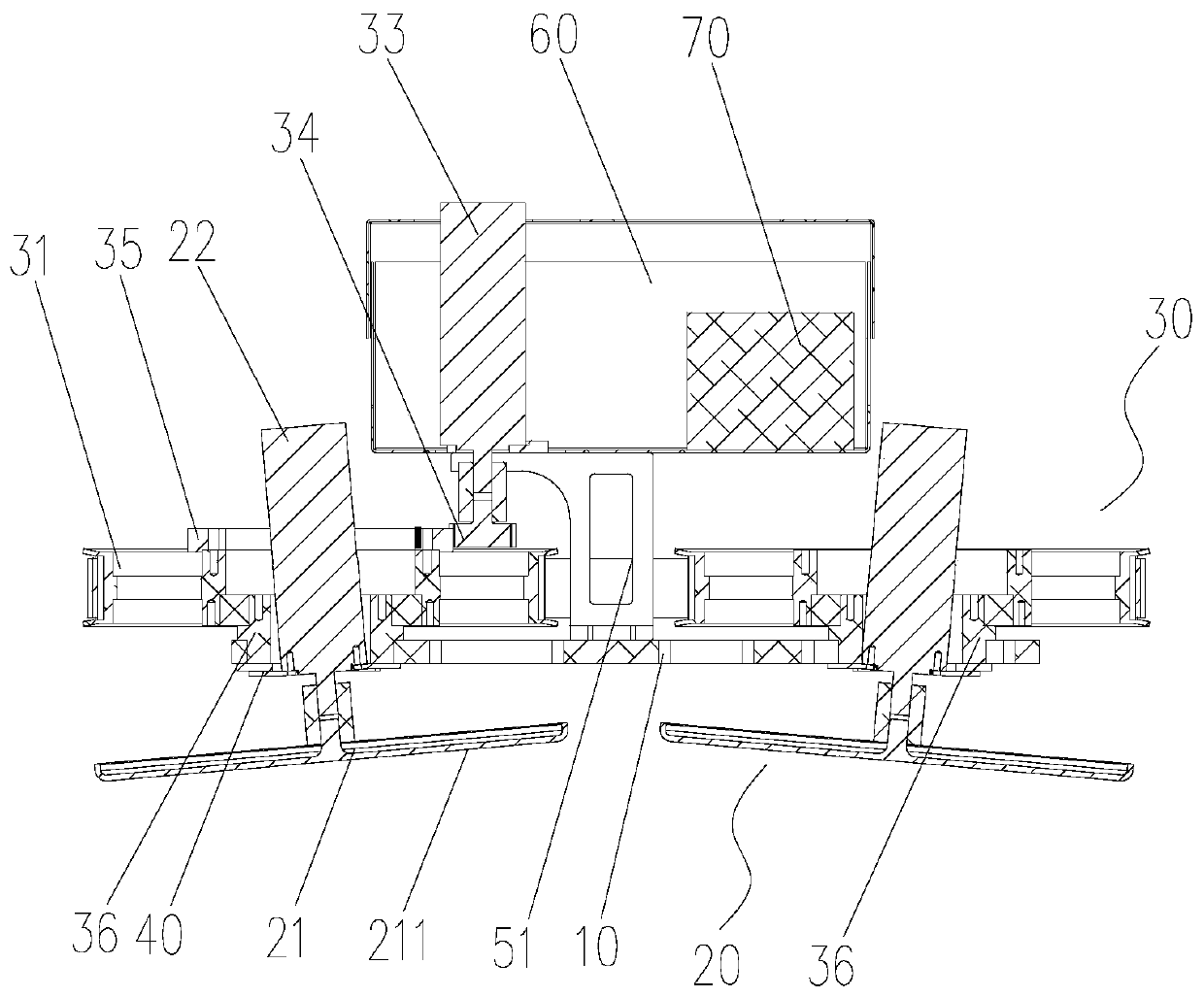

Concrete corner trowelling device

ActiveCN110695788ARealize automatic grinding processImprove efficiencyGrinding feed controlBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a concrete corner trowelling device. The concrete corner trowelling device comprises a mounting bottom plate, at least two trowelling mechanisms and a guide mechanism, wherein the trowelling mechanisms are mounted on the mounting bottom plate, the polishing surfaces of the trowelling mechanisms are obliquely arranged on the horizontal plane, when the trowelling mechanisms rotate, the outer peripheries of the polishing surfaces contact the concrete ground, so that the concrete corner trowelling device moves on the concrete ground, the polishing surfaces carry out polishing treatment on the concrete ground, and the guide mechanism is arranged on the mounting bottom plate and / or the trowelling mechanisms, the orthographic projection of at least a part of the guiding mechanism on the concrete ground exceeds the orthographic projection of the mounting bottom plate and the trowelling mechanisms on the concrete ground, so that the guide mechanism is prior to the mounting bottom plate and the trowelling mechanisms to contact an obstacle, and steering of the concrete corner trowelling device is achieved. The device solves the problems of low efficiency and poor precision caused by manual grinding of the corner area of the concrete ground in the prior art.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Grinding device for grinding wooden chesses

InactiveCN107825259ARealize automatic grinding processImprove work efficiencyGrinding carriagesGrinding machinesWork in processMaterial transfer

The invention relates to the field of mechanical production equipment, in particular to a grinding device for grinding wooden chess, including a vibrating plate, a raw material conveying mechanism, a first grinding mechanism, a second grinding mechanism, a turning mechanism, a semi-finished product conveying mechanism and a third grinding mechanism , the raw material conveying mechanism, the second grinding mechanism, the semi-finished product conveying mechanism and the third grinding mechanism are sequentially arranged on the side of the vibrating plate, the raw material conveying mechanism is provided with a positioning mechanism, and the first grinding mechanism is located beside the raw material conveying mechanism On the side, the discharge end of the vibrating plate is provided with a feeding track, and the discharge end of the feeding track is located above the raw material conveying mechanism. The turning mechanism includes a first positioning component and a turning component, and the positioning component is fixed on the semi-finished product conveying mechanism. The turning assembly is fixed on the second grinding mechanism. The invention realizes the automatic grinding of wood chess raw materials and improves the working efficiency of grinding.

Owner:叶倩倩

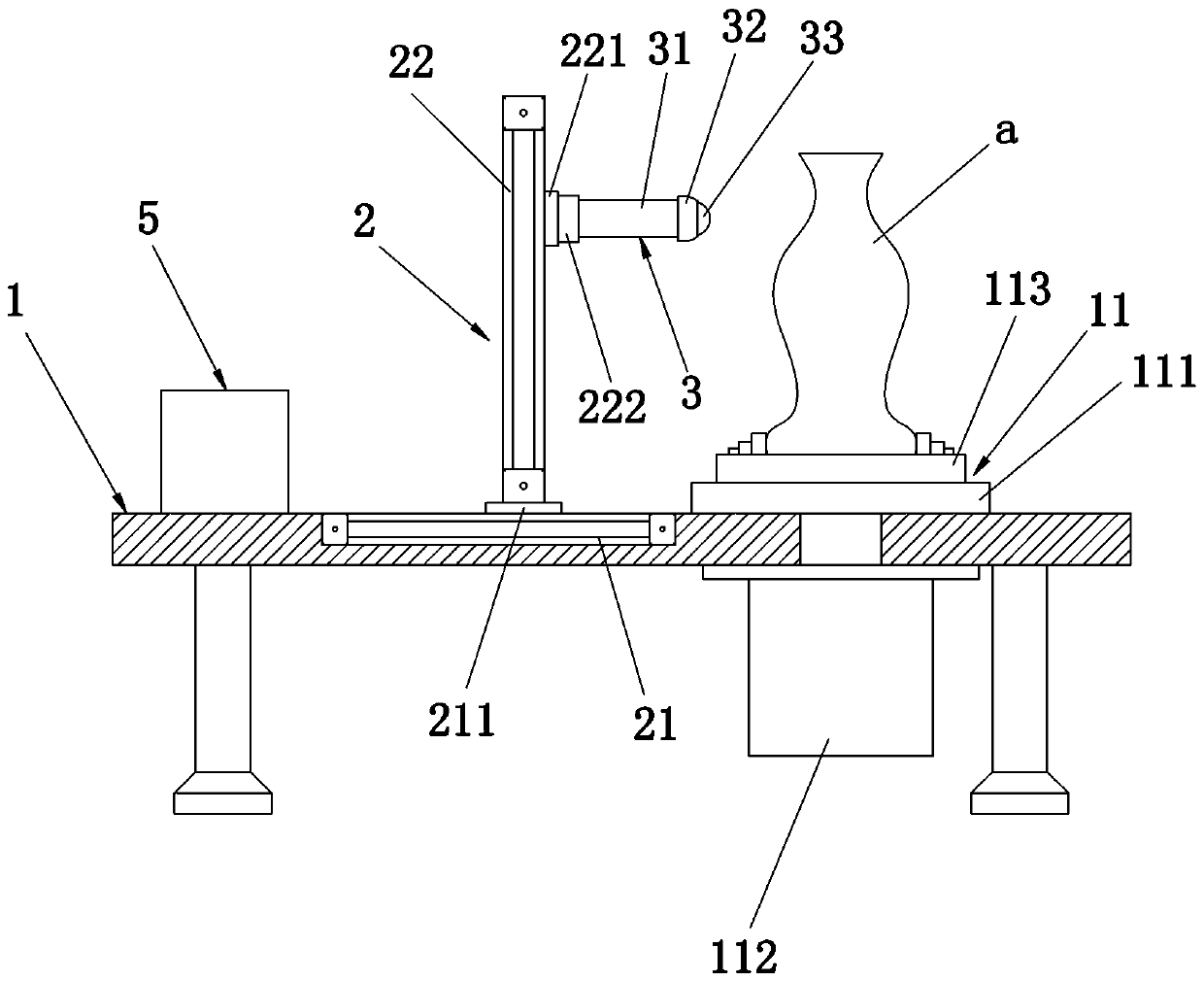

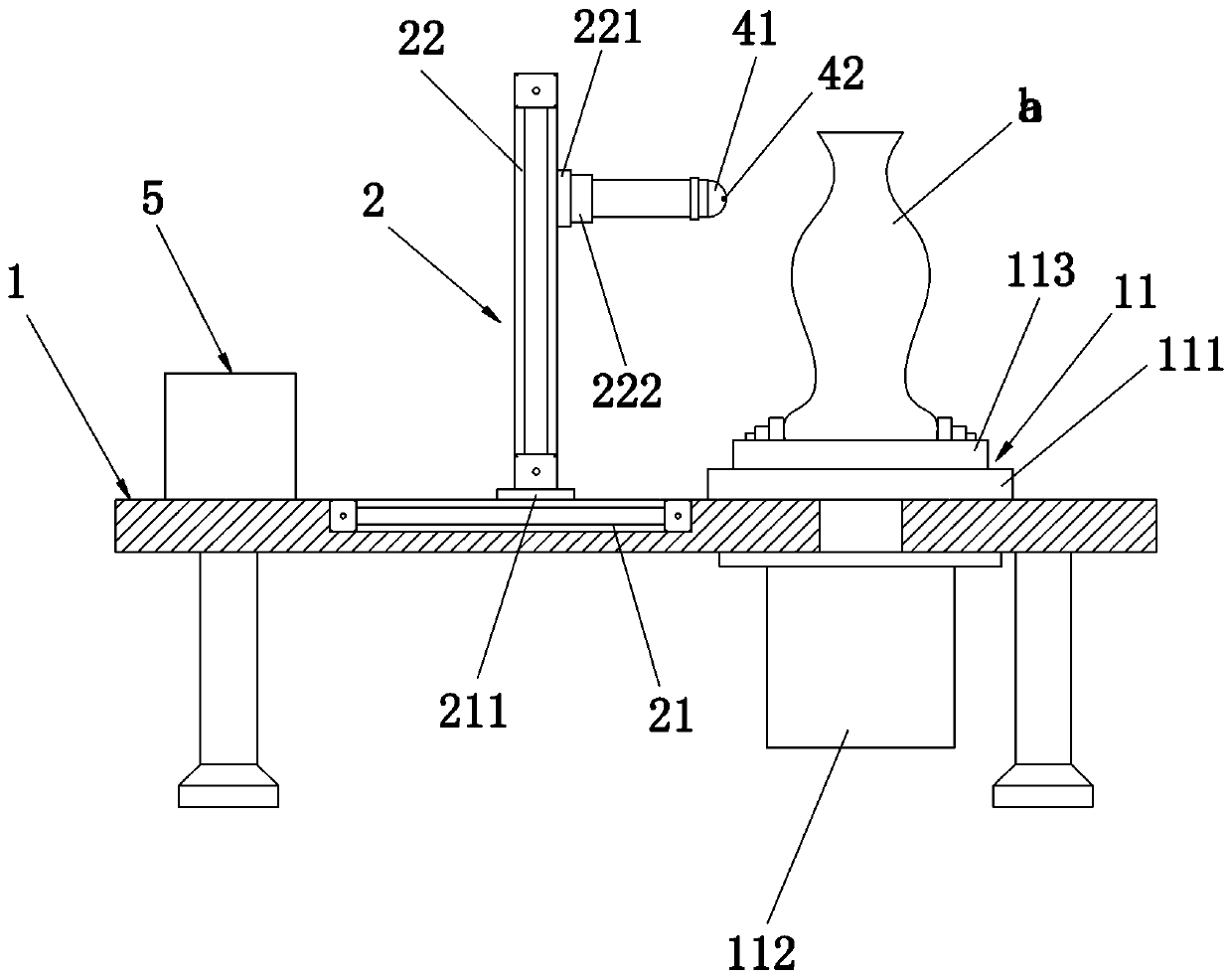

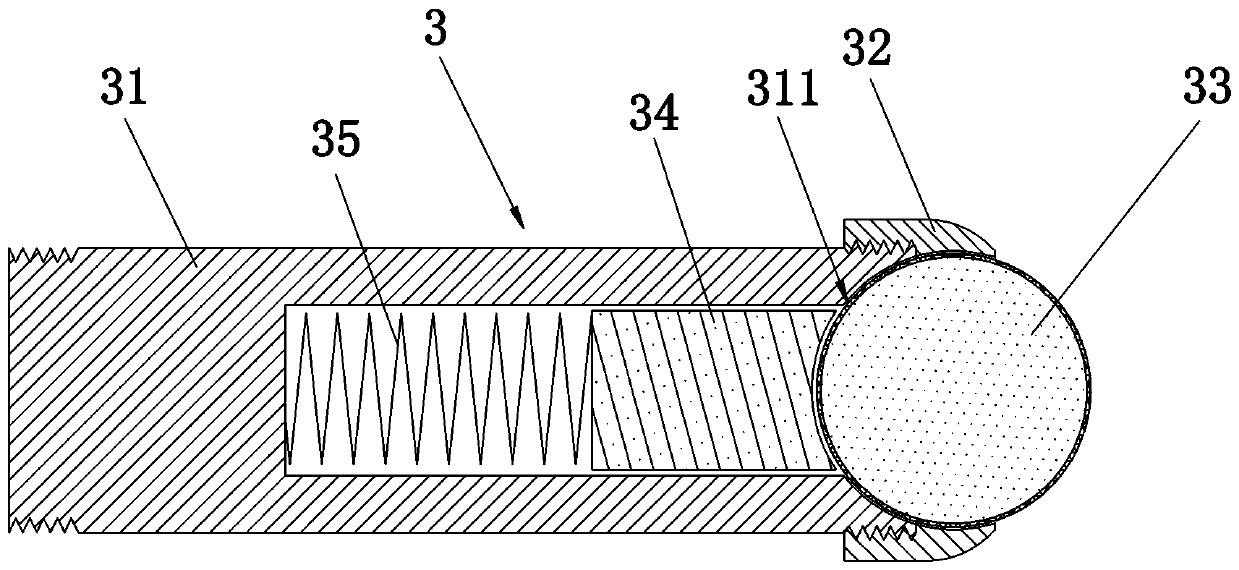

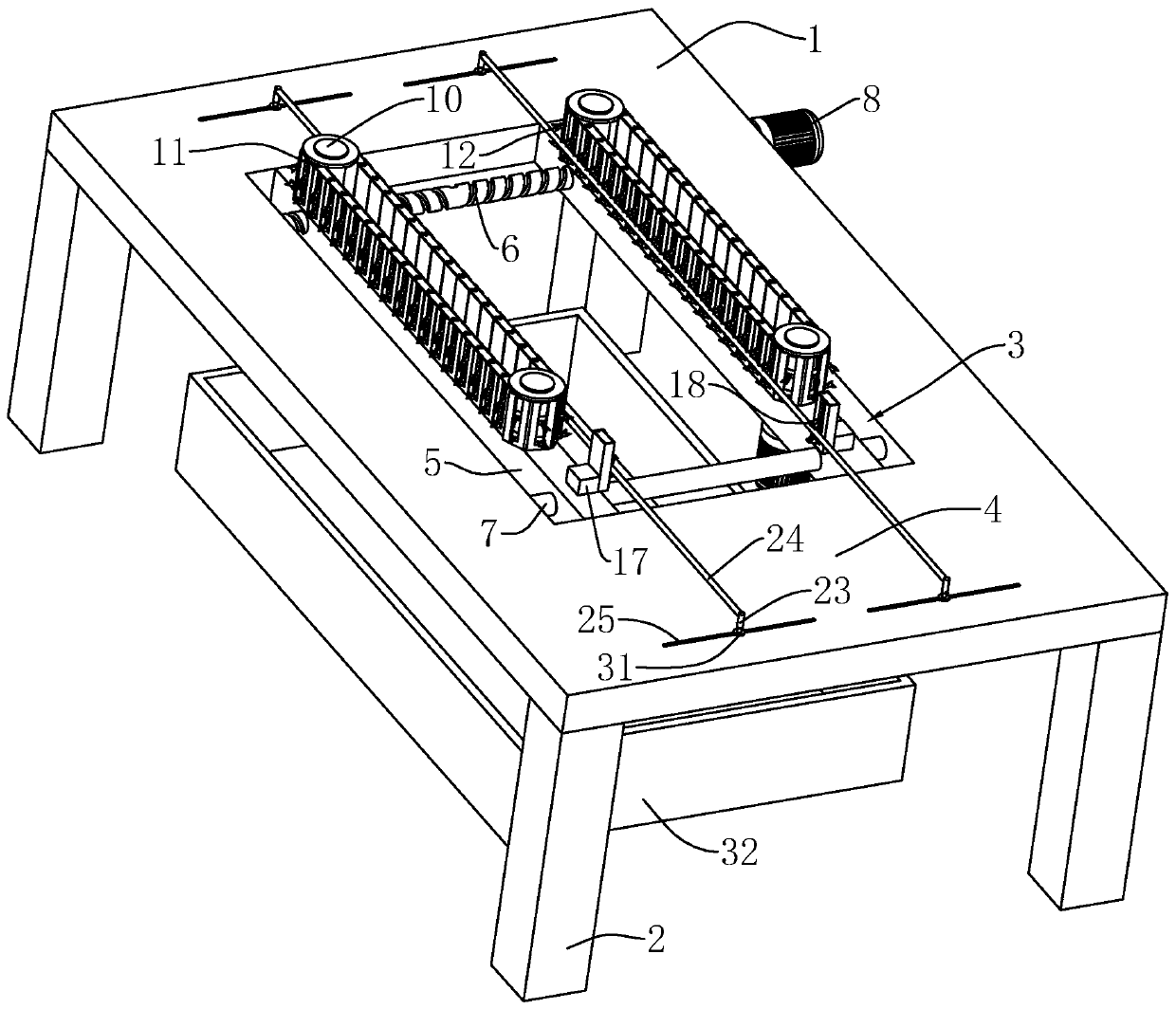

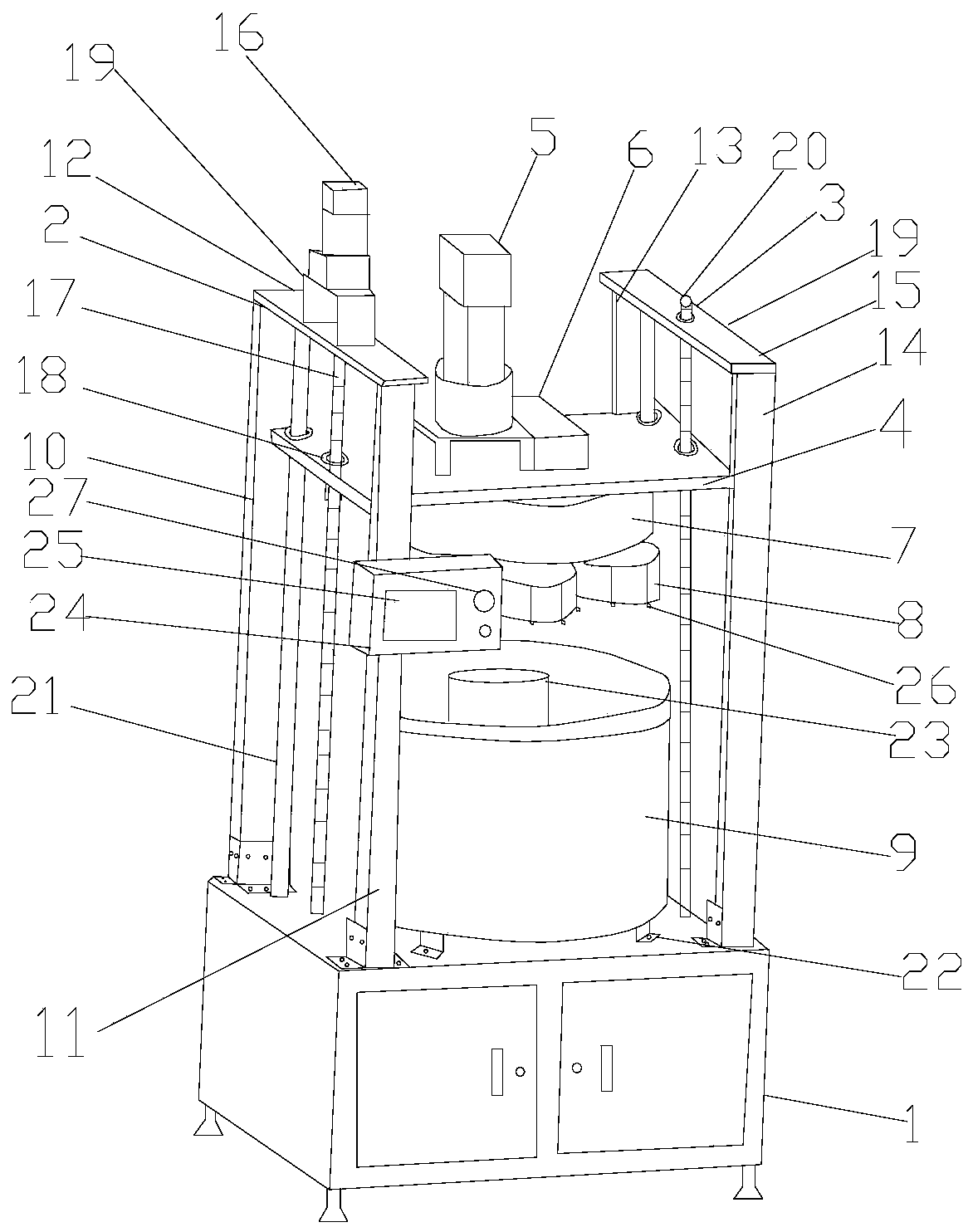

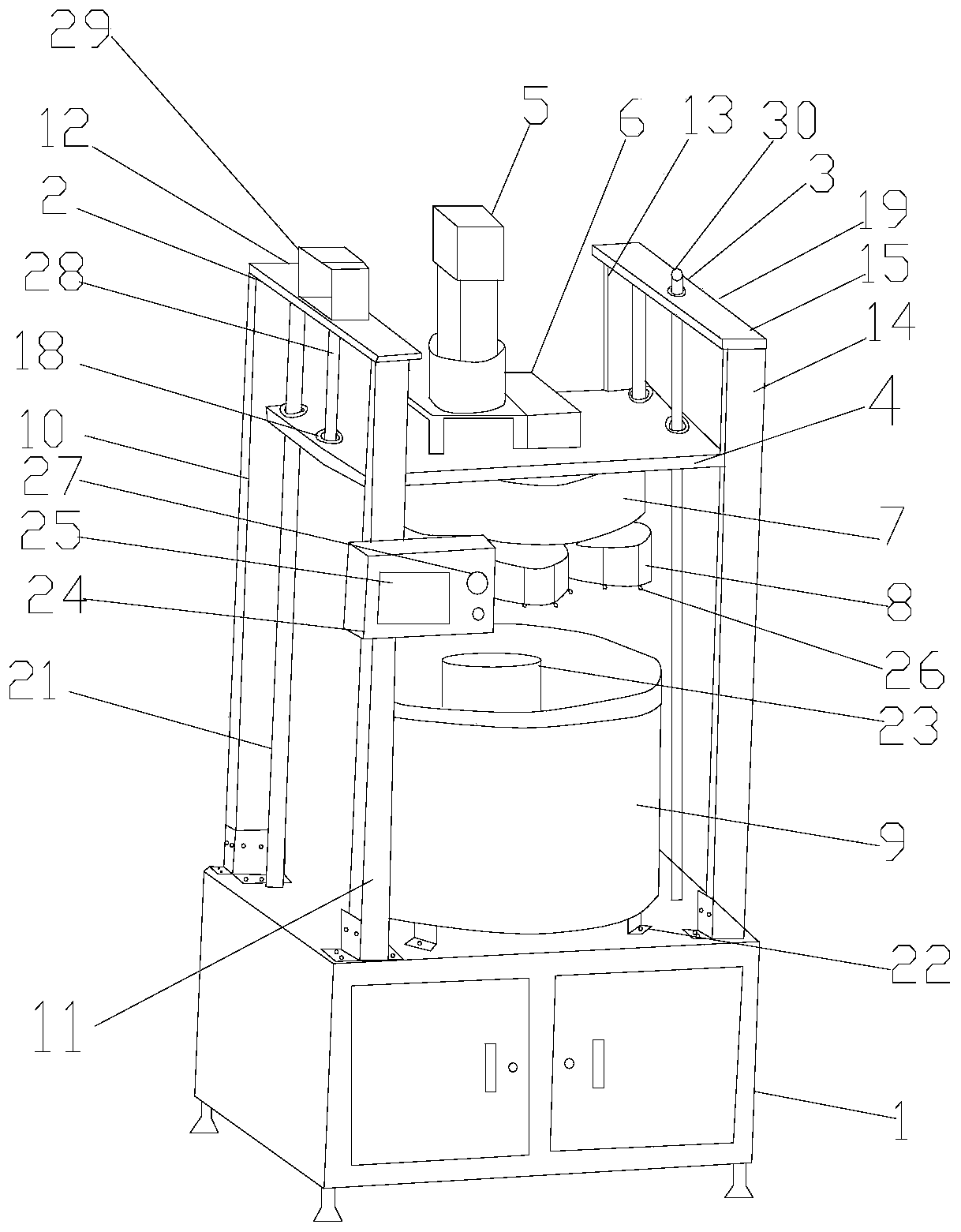

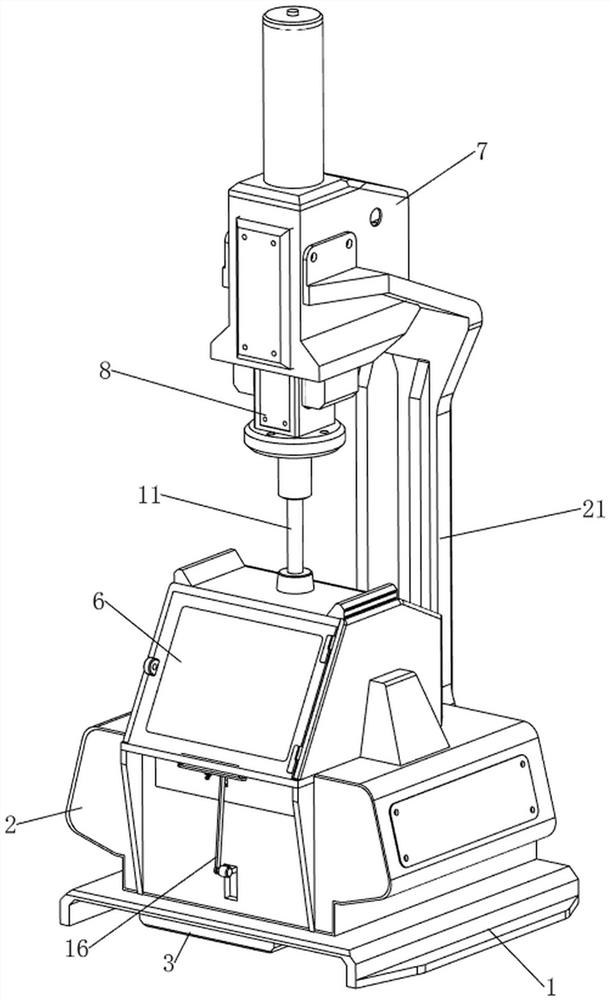

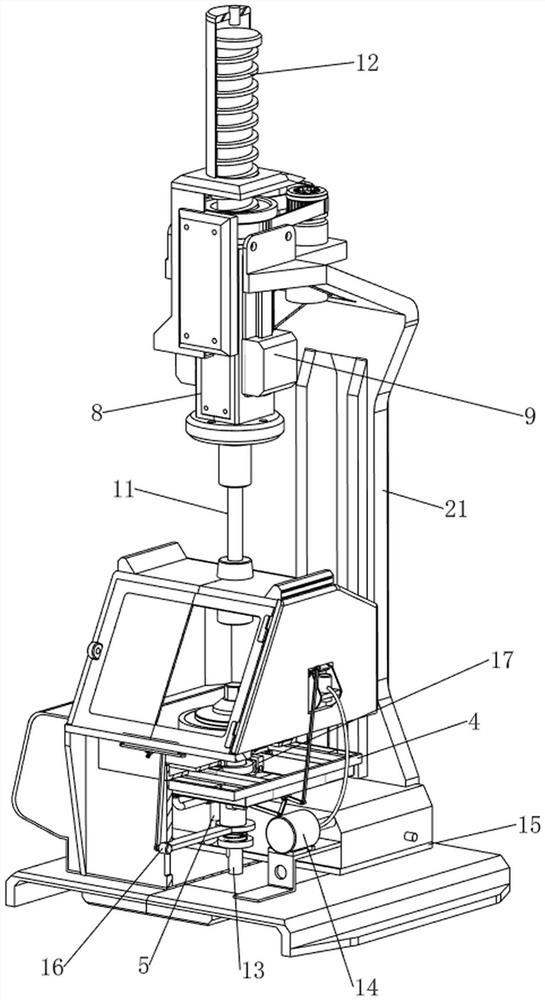

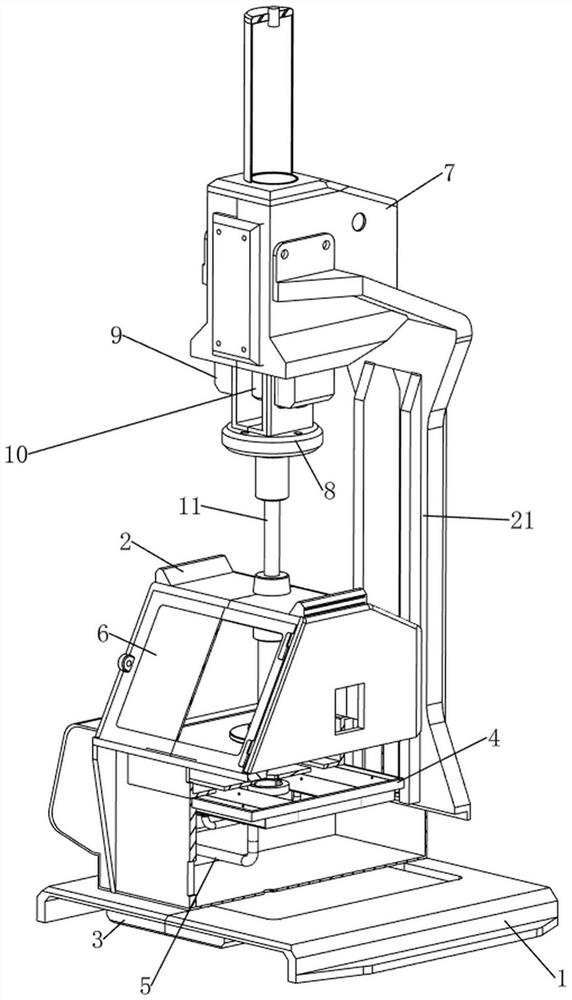

Ceramic blank automatic polishing machine

ActiveCN110860971ARealize automatic grinding processImprove sanding effectGrinding carriagesCeramic shaping apparatusPolishingWorkbench

The invention discloses a ceramic blank automatic polishing machine, and relates to the field of ceramic production equipment. The ceramic blank automatic polishing machine comprises a workbench, a sandbag polishing head and a driving device; the workbench is rotatably provided with a fixing seat where a ceramic blank can be placed; the sandbag polishing head is arranged on the upper portion of the workbench and driven to move up and down on the outer surface of the ceramic blank under action of the driving device, and polishing of the ceramic blank can be achieved. The ceramic blank automaticpolishing machine can achieve automatic polishing of the ceramic blank, the polishing effect and the polishing efficiency of the ceramic blank are improved advantageously, and the problems that the traditional ceramic polishing procedure relies on the manpower mode, the production efficiency is low, and the product quality is variable are solved. In addition, it is a large breakthrough to adopt the sandbag polishing head to polish the ceramic blank, the shape of the sandbag polishing head can be automatically changed along with changing of the outline of the ceramic blank in the polishing process, thus, unnecessary abrasion to the ceramic blank can be avoided, and in addition, precision polishing of the ceramic blank can be achieved.

Owner:FUJIAN JIAMEI GRP

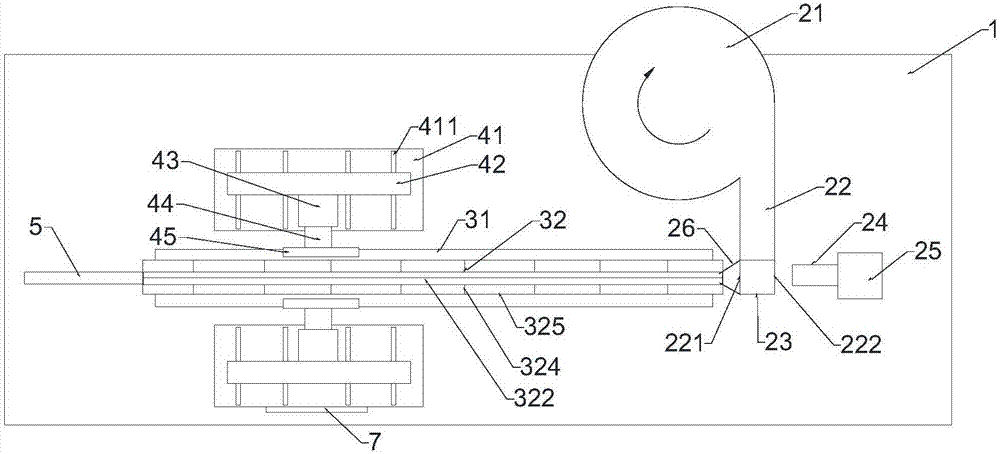

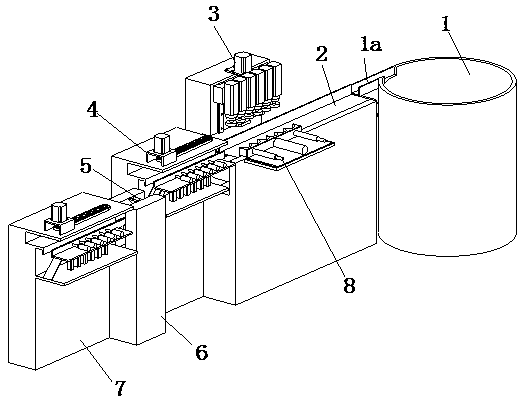

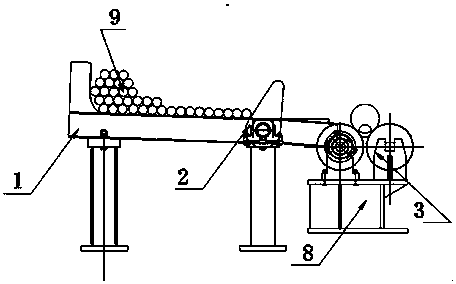

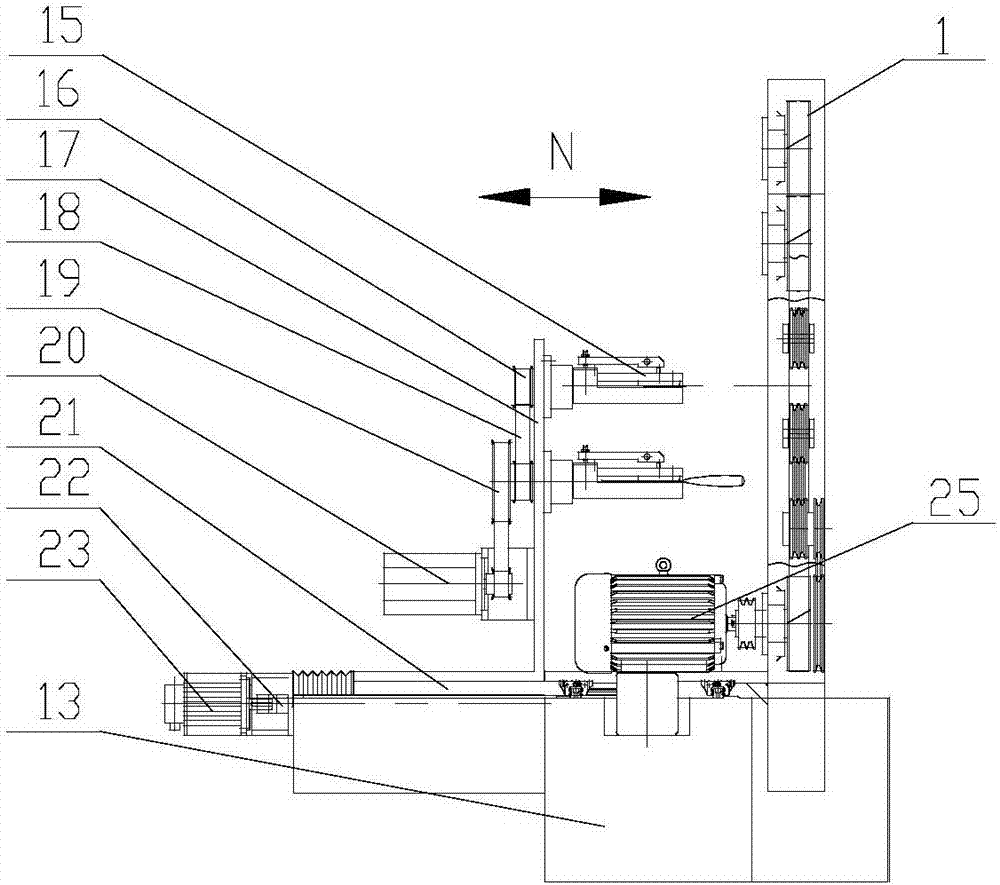

Automatic bar surface spiral grinding device

PendingCN108262655AControl rotation speedImprove grinding efficiencyRevolution surface grinding machinesEngineeringUltimate tensile strength

The invention relates to an automatic bar surface spiral grinding device, and belongs to the technical field of metallurgical industry special steel enterprise bar surface coping equipment. Accordingto the technical scheme, a feeding rack (1), a baffle (2), a coupled wheel roller bed (3), a grinding head (5), a transition plate (6) and a collection tank (7) are included; the feeding rack (1) is arranged on one side of the coupled wheel roller bed (3), and the collection tank (7) is arranged on the other side of the coupled wheel roller bed (3); the feeding rack (1) is obliquely arranged towards one side of the coupled wheel roller bed (3); the feeding rack (1) is provided with the baffle (2), the transition plate (6) is arranged between the coupled wheel roller bed (3) and the collectiontank (7), the transition plate (6) and the collection tank (7) are rotationally connected, and the grinding head (5) is arranged above the coupled wheel roller bed (3). The automatic bar surface spiral grinding device has the beneficial effects that the surfaces of bars different in specification and screw pitch can be automatically ground, the bar grinding efficiency and appearance quality are improved, and the labor intensity of workers is relieved.

Owner:SHIJIAZHUANG IRON & STEEL

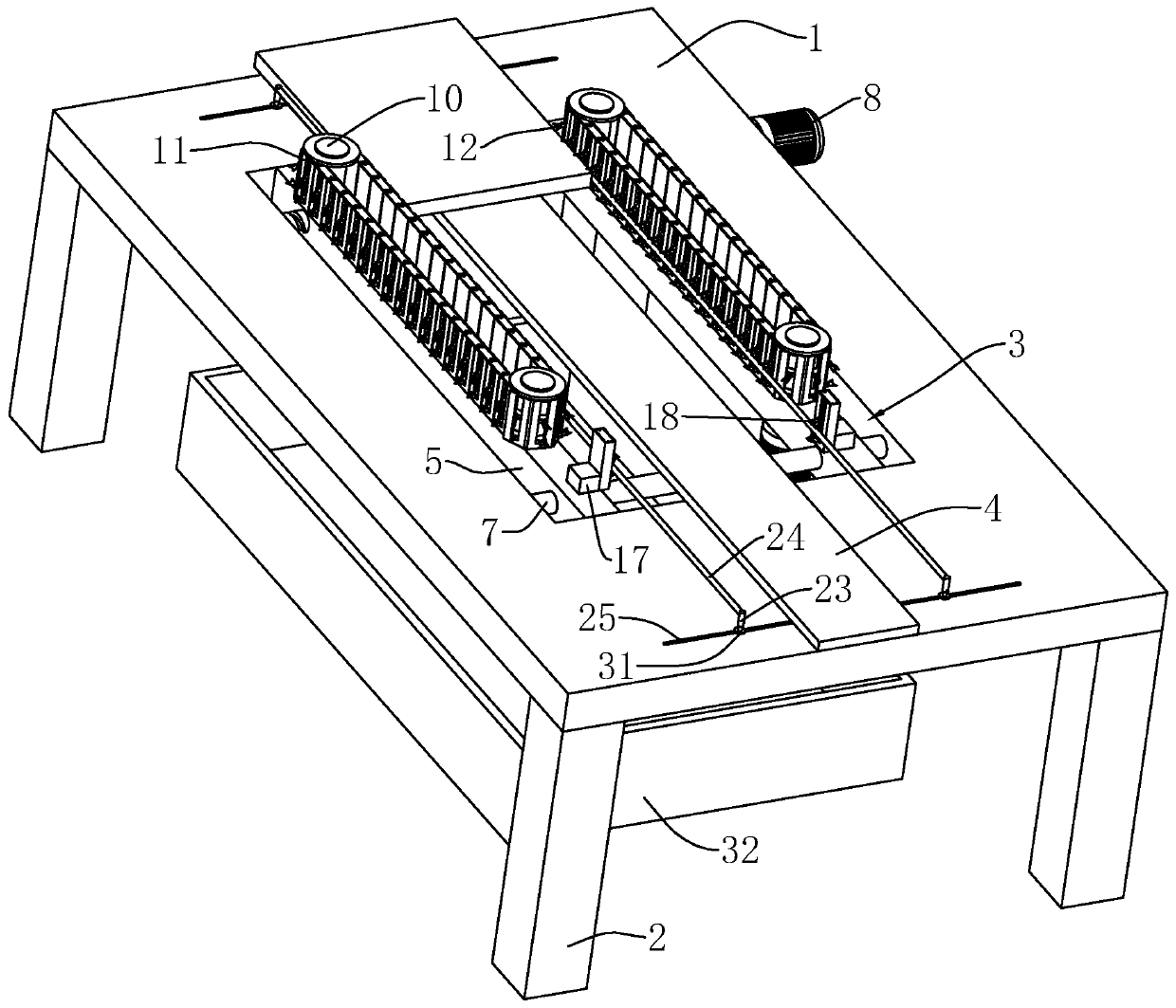

Board corner polishing machine

ActiveCN110774090ARealize automatic grinding processEdge grinding machinesProfiling/shaping machinesElectric machineryPolishing

The invention relates to a board corner polishing machine. The board corner polishing machine comprises a working bracket; the working bracket comprises a working panel, support legs, and an accommodating tank formed in the working panel in a penetrating mode; a conveying plate arranged on the upper side of the accommodating tank is arranged on the working panel; two cutting frames are arranged onthe working bracket; each cutting frame is fixedly connected with a rotating motor; two rotating rollers are mounted on the cutting frames; conveying chain plates sleeve the two rotating rollers; therotating motors drive the rotating rollers to rotate; the rotating rollers drive the conveying chain plates to rotate; the rotating rollers are arranged on the upper sides of the cutting frames, andpenetrate out from the accommodating tank of the working panel; and cutters for cutting the edges of boards are arranged on the conveying chain plates. The board corner polishing machine achieves an automatic polishing effect of no need of polishing edge lines of the boards by operators through hand holding of polishing pieces.

Owner:北京五木家具有限公司

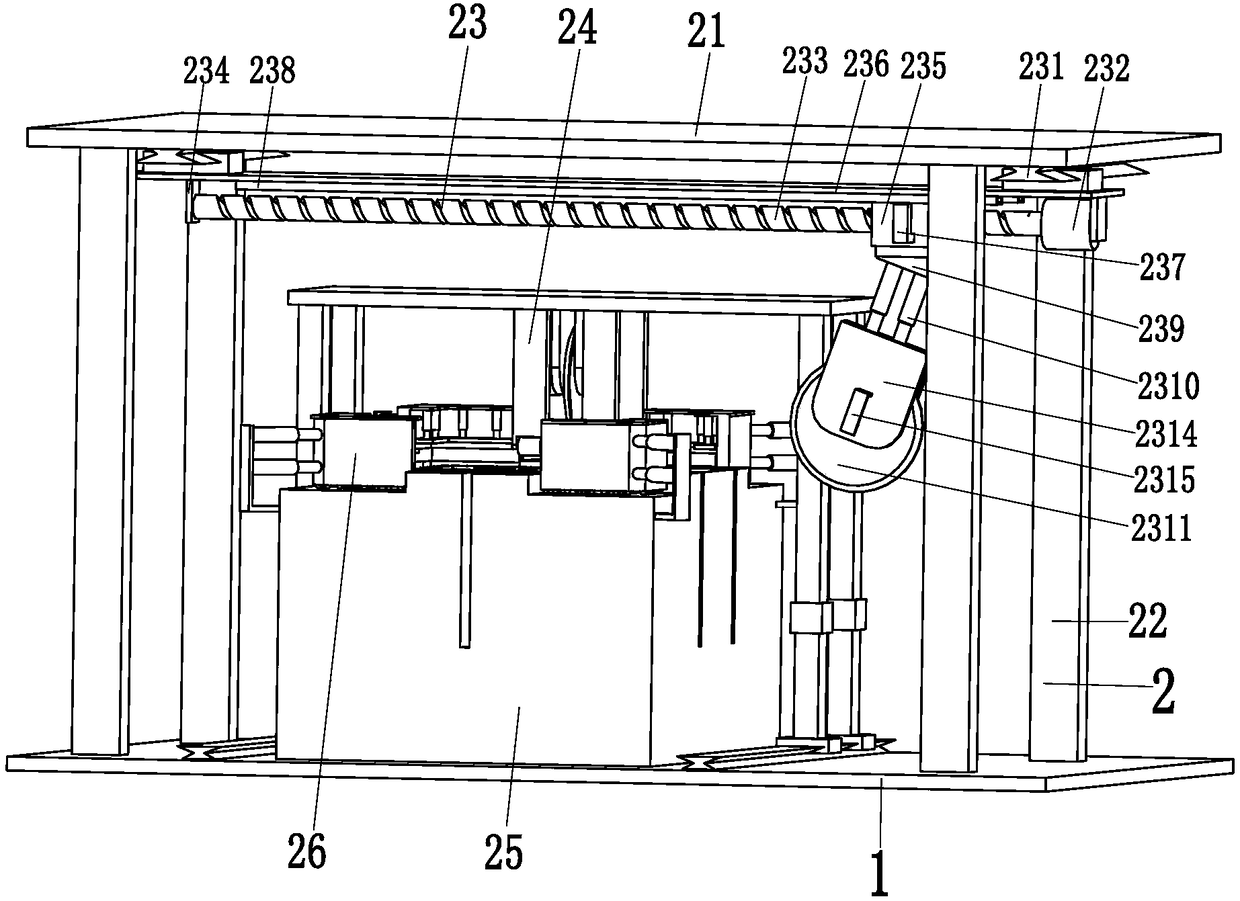

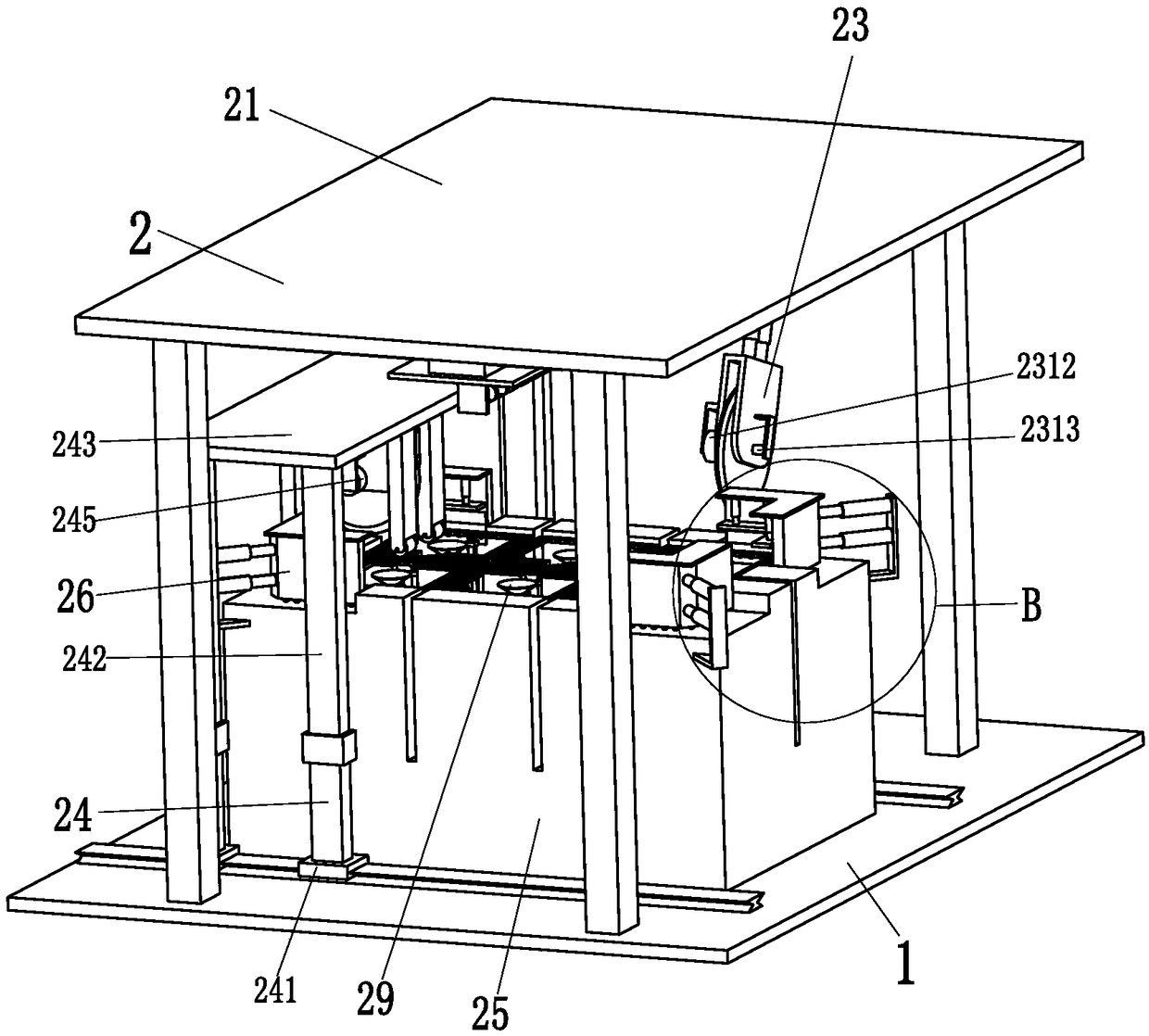

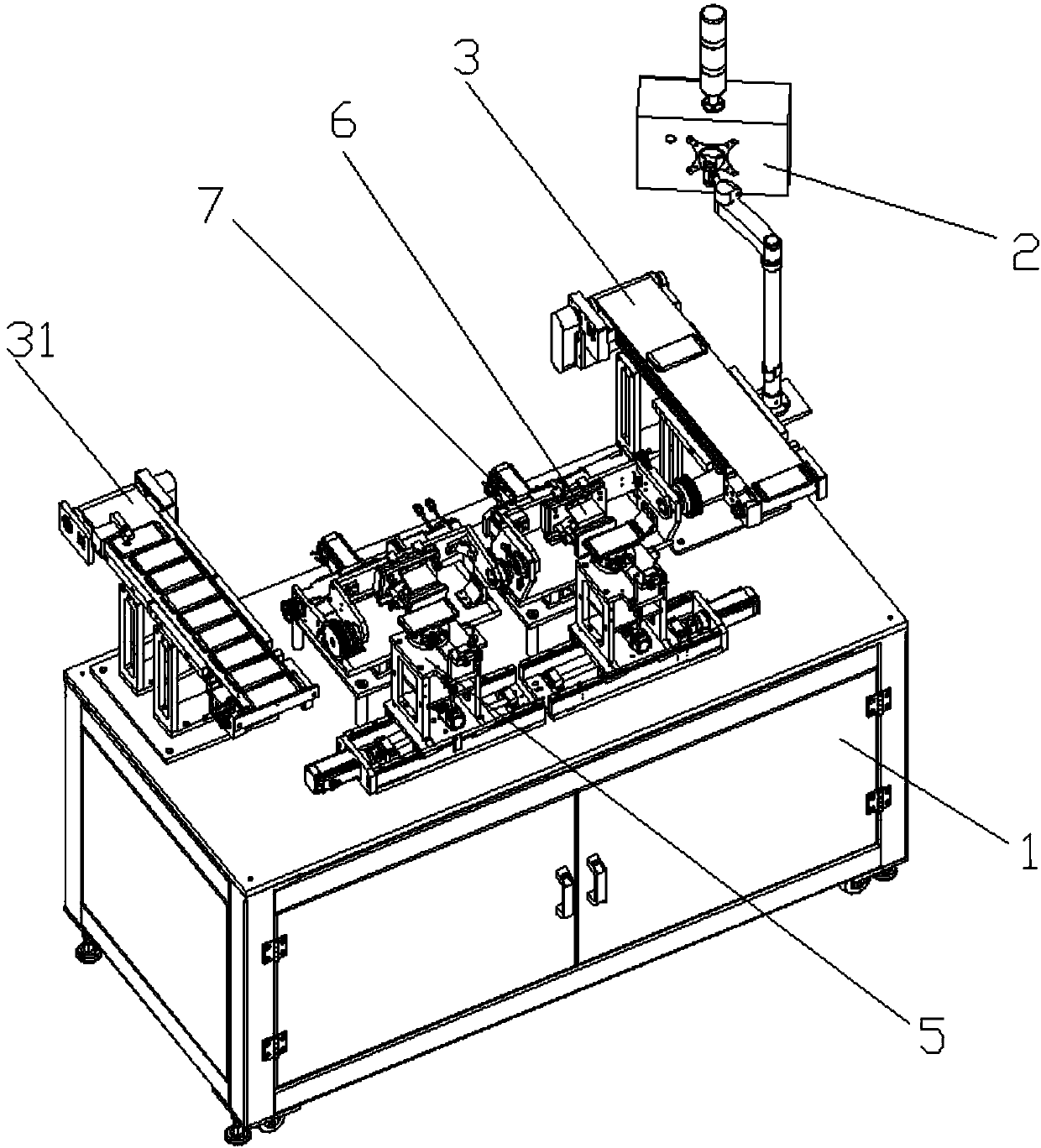

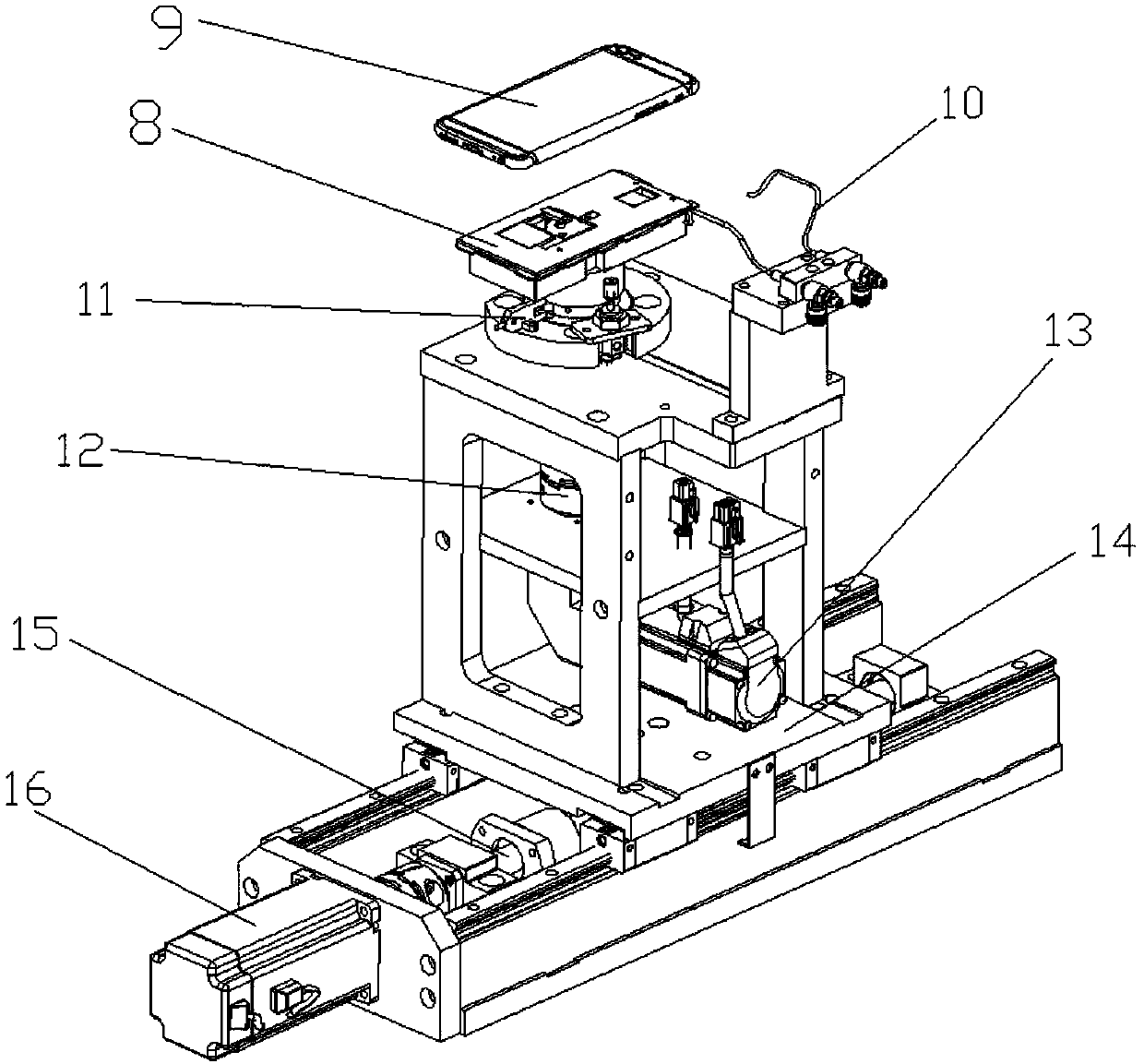

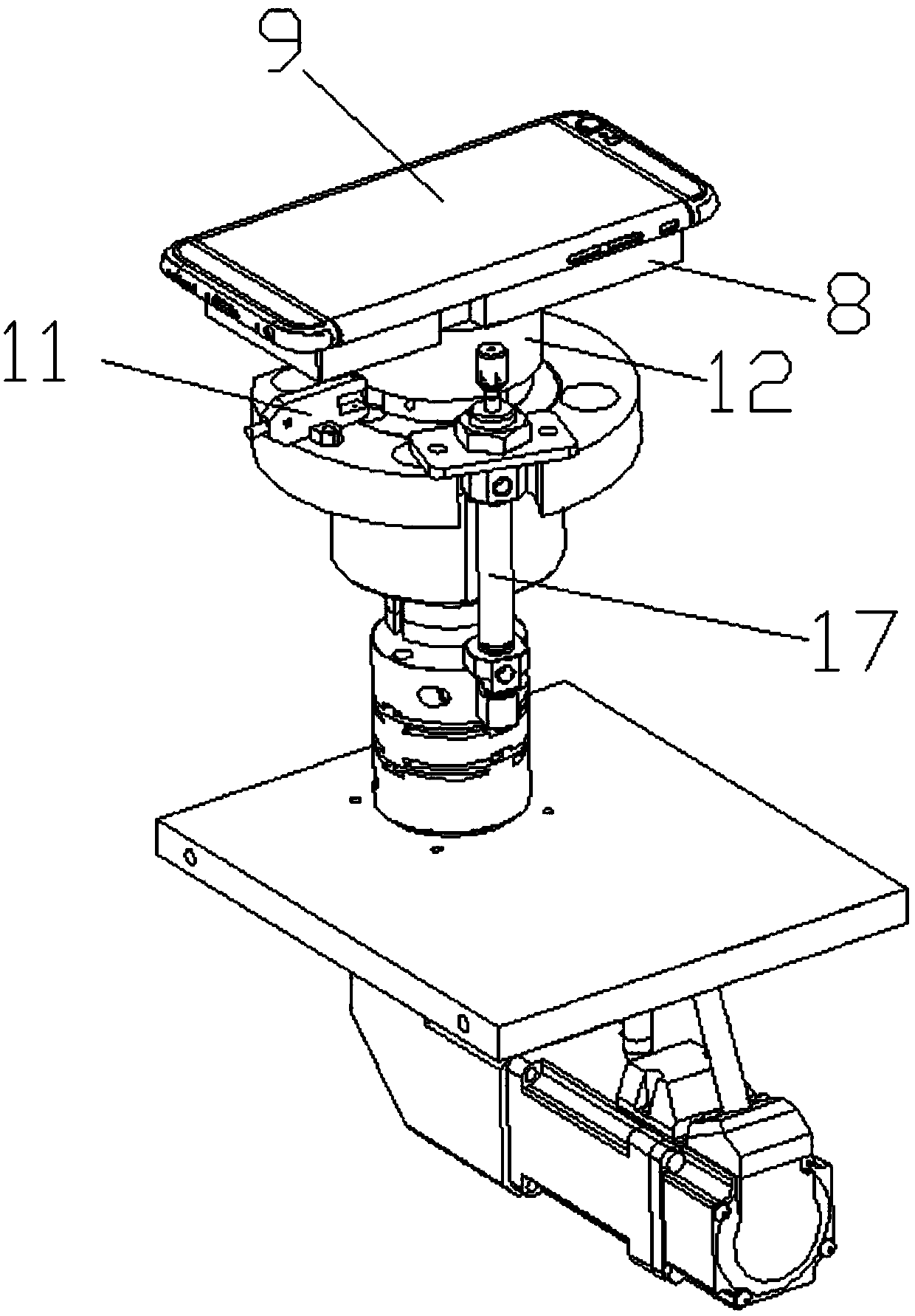

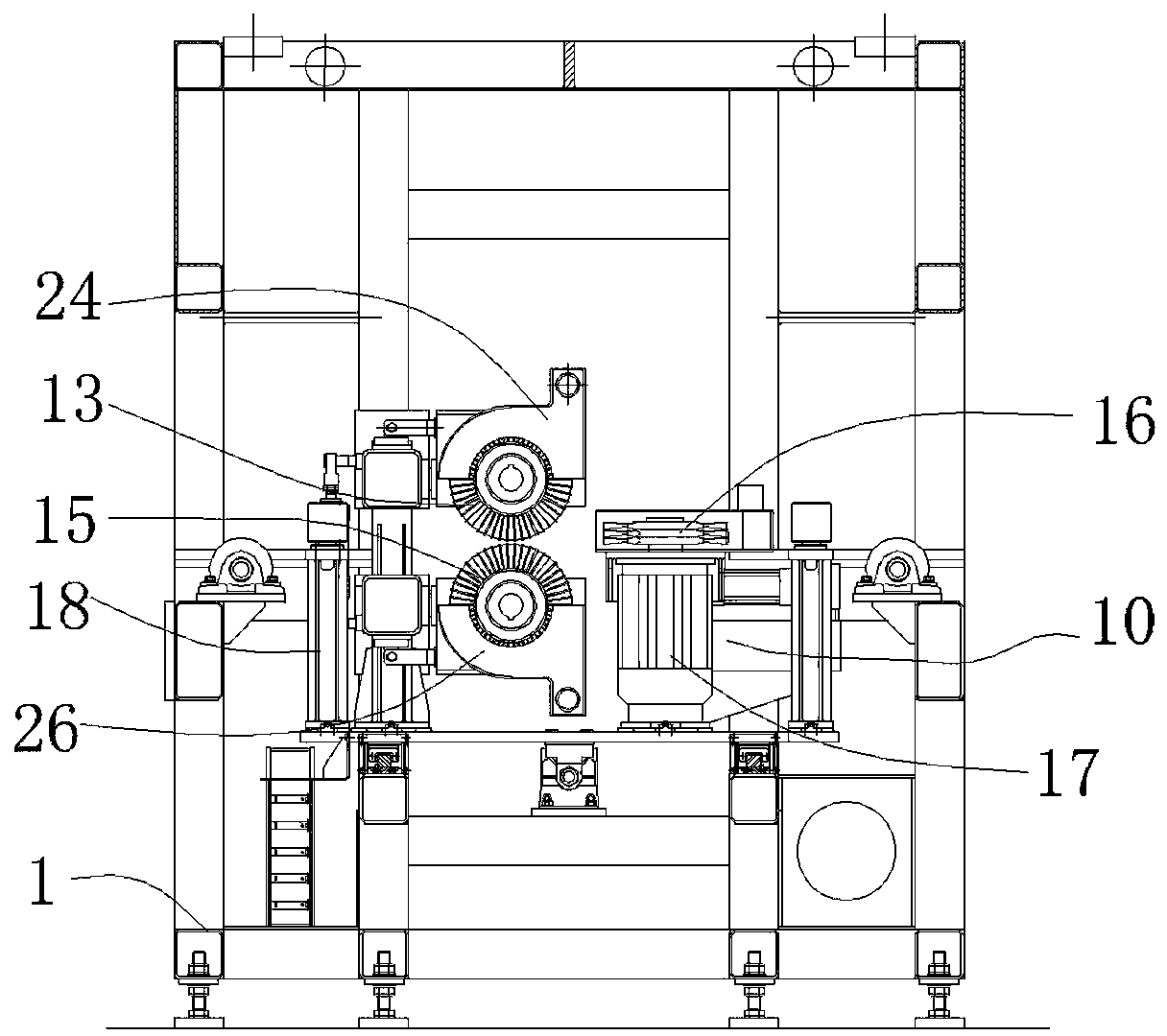

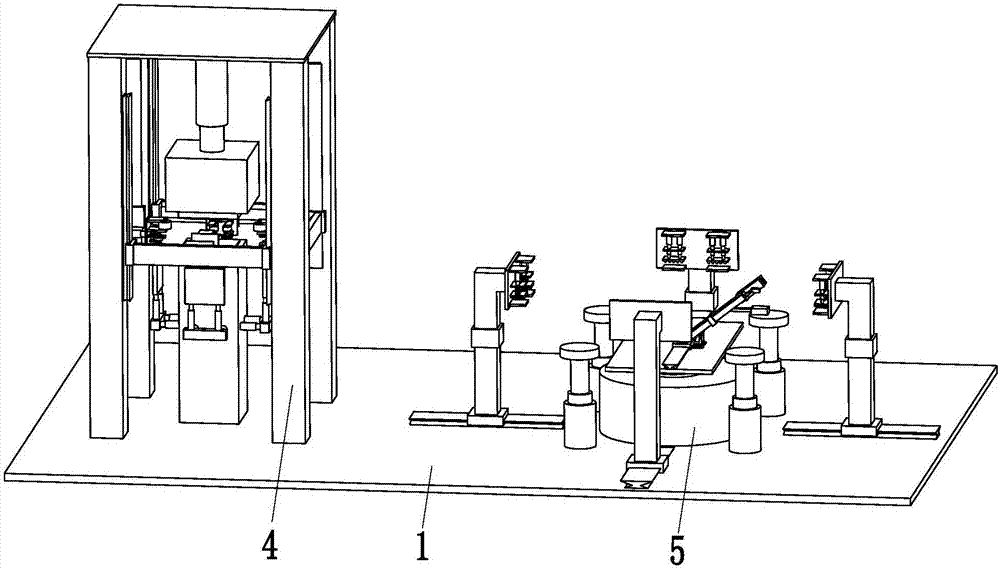

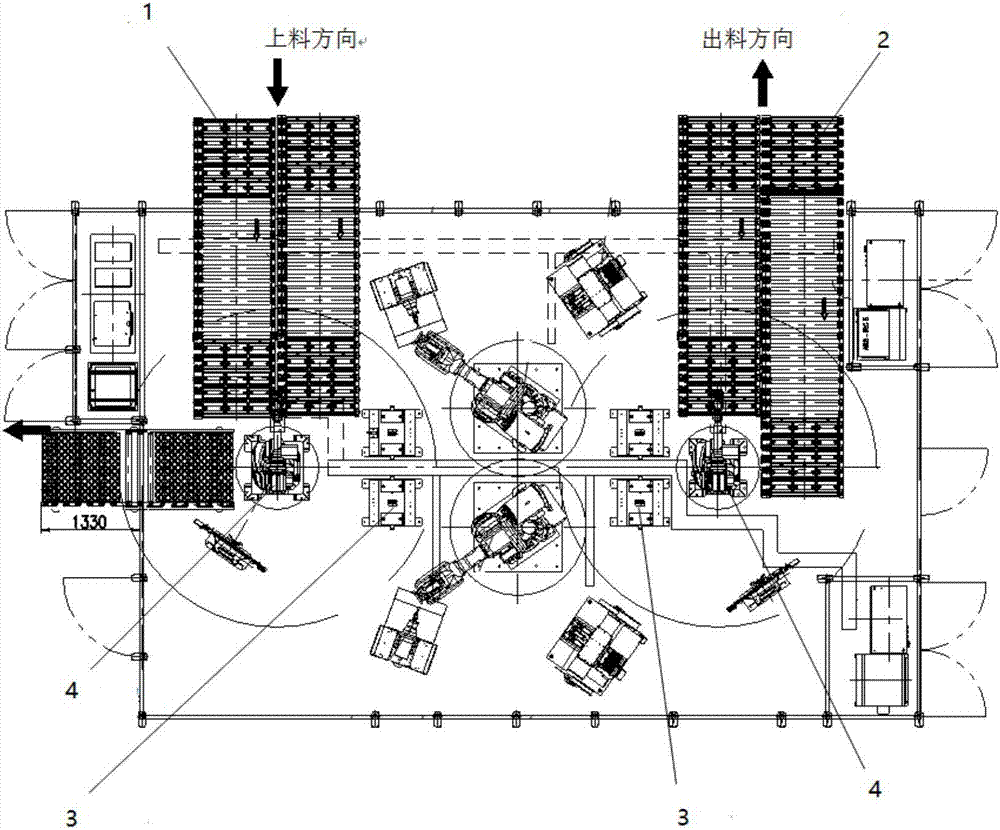

Multi-axis polishing machine of back cover of smart phone

InactiveCN107695826AImprove processing efficiencyReduce labor costsEdge grinding machinesGrinding carriagesEngineeringLaser sensor

The invention discloses a multi-axis polishing machine of a back cover of a smart phone. The multi-axis polishing machine of the back cover of the smart phone comprises a machine cabinet. The two endsof the machine cabinet are provided with a feeding conveyer belt and a discharging conveyer belt correspondingly. Clamp devices are arranged between the feeding conveyer belt and the discharging conveyer belt. Automatic polishing devices are correspondingly arranged in front of the clamp device. Each automatic polishing device comprises a longitudinal lead screw mechanism fixed to the tabletop ofthe machine cabinet, wherein the longitudinal lead screw mechanism is provided with a U-shaped sliding frame, a swinging frame is provided with a U-shaped rotating frame, the front face of the U-shaped rotating frame is provided with a polisher, the back face of the polisher is meshed with a gear through a rack, the gear is connected with a rack motor, the rack motor is fixed to the back face ofthe U-shaped rotating frame, an end shaft of one end of the U-shaped rotating frame is connected with a rotating motor through a belt transmission mechanism, an end shaft of the other end of the U-shaped rotating frame is provided with a baffle, and the rotating motor is arranged on the U-shaped sliding frame, and the end face of the U-shaped sliding frame is provided with a laser sensor used forsensing the position of the baffle. The multi-axis polishing machine of the back cover of the smart phone can achieve automatic polishing of the arc line edge of the back cover of the smart phone, ishigh in polishing efficiency and achieves flexible control.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

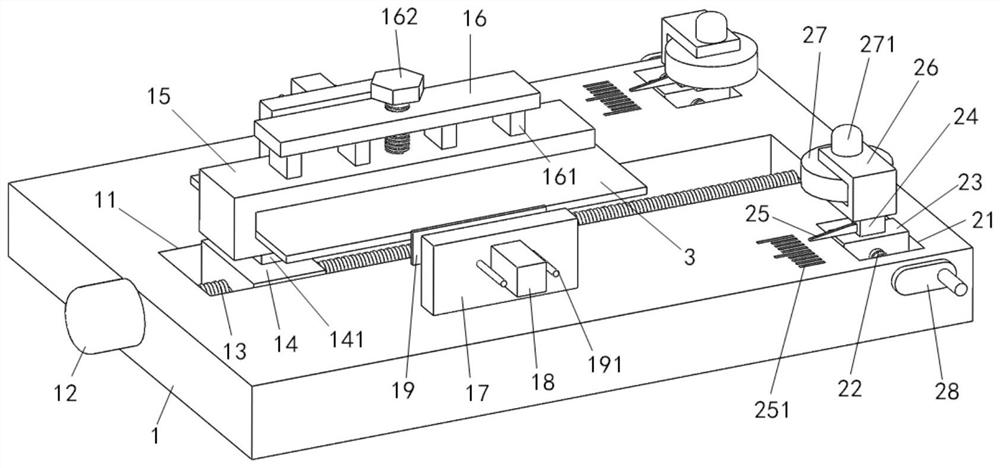

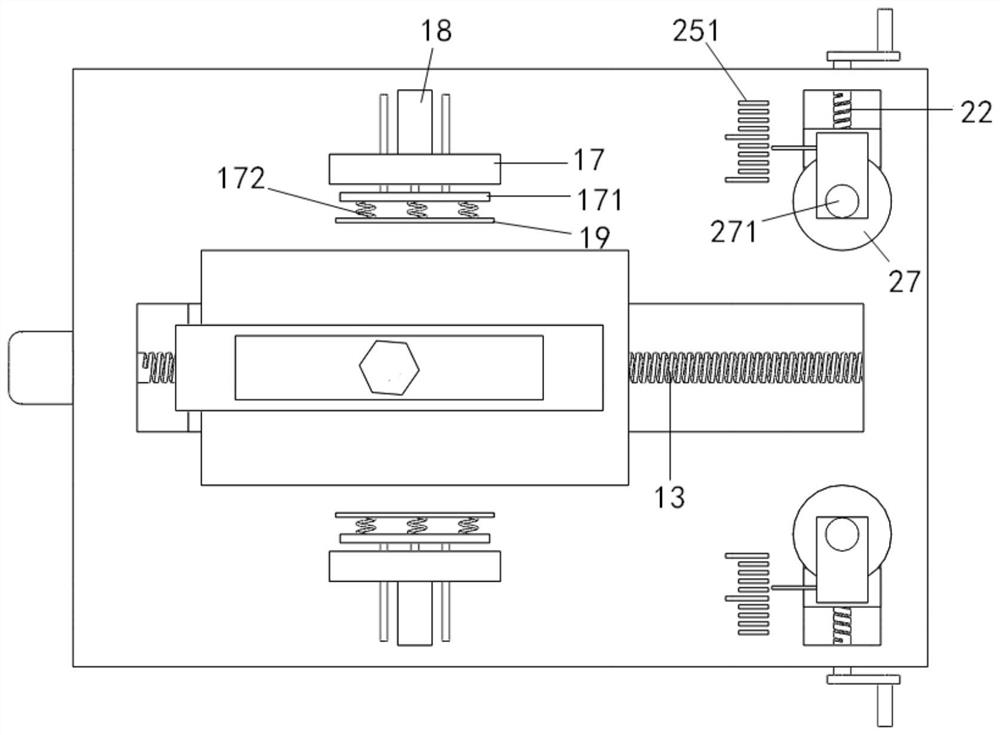

Double-faced grinding device for stainless steel plate edge burrs

InactiveCN111975525AGuaranteed widthHigh degree of automationEdge grinding machinesGrinding work supportsStructural engineeringSS - Stainless steel

The invention discloses a double-faced grinding device for stainless steel plate edge burrs. The double-faced grinding device comprises a base. A transverse moving groove is formed in the center of the top face of the base, and a moving block is arranged in the moving groove in a sliding manner. A connecting block arranged on the top face of the moving block is provided with a clamping bracket, wherein the clamping bracket extends forwards. A pair of locating plates is located at the positions, at the two sides of the clamping bracket, of the top face of the base. A pair of grinding wheels isarranged at the two sides of the rear portion of the top face of the base. The double-faced grinding device has the beneficial effects that a stainless steel plate obtained after cutting can be located and clamped; stainless steel plates can move forwards and backwards; the pair of grinding wheels is arranged at the two sides of each stainless steel plate, and edges of the stainless steel plates can be ground automatically; in addition, the two grinding wheels can be adjusted in the left-right direction, the double-faced grinding device can be adapted to the stainless steel plates of differentspecifications, and the width of each ground stainless steel plate can be guaranteed; and the double-faced grinding device is high in automation degree and good in effect.

Owner:汪祖平

Sanding and grinding equipment for steel basin

PendingCN112428038AAchieve placementAchieve grindingRevolution surface grinding machinesGrinding drivesEngineeringMaterials science

The invention relates to grinding equipment, in particular to sanding and grinding equipment for a steel basin. The sanding and grinding equipment for the steel basin can blow away chippings generatedin the grinding process, can achieve automatic discharging and is easy to operate. The sanding and grinding device for the steel basin comprises a bottom plate a grinding mechanism, a rotating mechanism is arranged on the bottom plate; and the grinding mechanism is placed on the rotating mechanism. The steel basin is placed through the rotating mechanism, and then the steel basin is ground through cooperation of the grinding mechanism; through cooperation of a moving mechanism and the grinding mechanism, the steel basin is automatically ground, and therefore manual grinding is not needed; andthrough cooperation of the grinding mechanism and a pushing mechanism, when a handle makes contact with a rotating plate, a pressing rod drives a rotating disc to move downwards, and therefore peoplecan conveniently take up the ground steel basin.

Owner:刘家鑫

Watchcase grinding equipment and application thereof

InactiveCN111571417ATurn fasterRealize automatic grinding processEdge grinding machinesPolishing machinesEngineeringGrinding

The invention provides watchcase grinding equipment and application thereof. The watchcase grinding equipment comprises a grinder support, a supporting device mounted on the upper portion of the grinder support, a grinding device, a first drive device and a containing device located below the grinding device and used for containing grinding materials, wherein the supporting device and the first drive device are mounted on the supporting device. A clamping device used for clamping a watchcase is mounted on the grinding device. The grinding device is driven by the first drive device to rotate, and therefore the grinding device drives the watchcase to rotate. The supporting device comprises a supporting plate. The watchcase grinding equipment further comprises a second drive device mounted onthe supporting device. The second drive device drives the supporting plate to ascend and descend, and therefore the watchcase is driven to ascend and descend to descend into the containing groove, and the watchcase is in contact with grinding materials; and mutual friction between the watchcase and the grinding materials is achieved while the watchcase rotates, automatic grinding is achieved, andgrinding efficiency is improved. The watchcase grinding equipment is used for grinding of various kinds of metal watchcases.

Owner:苏州椿桔五金制品有限公司

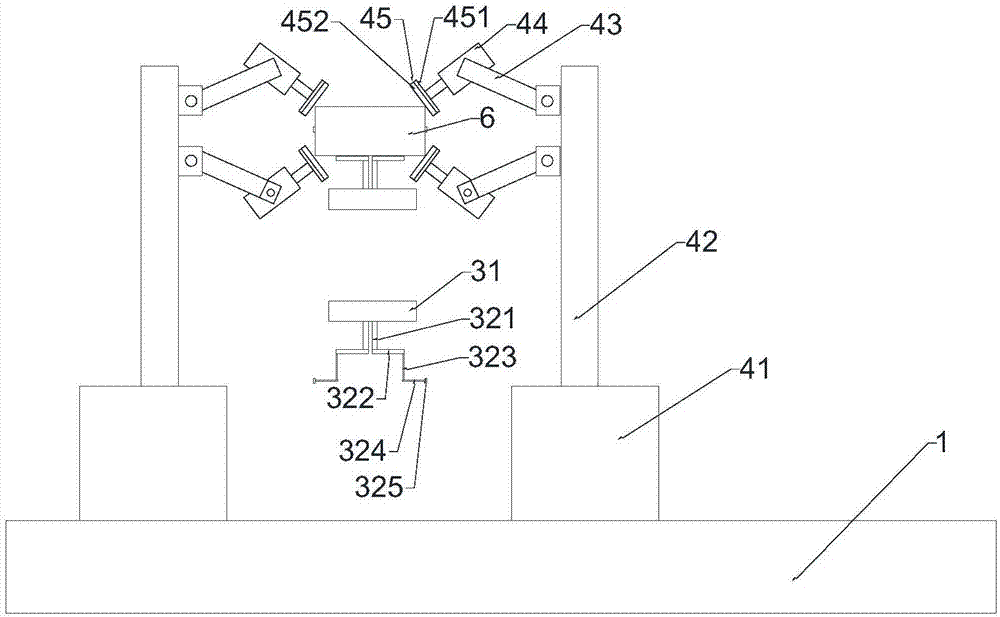

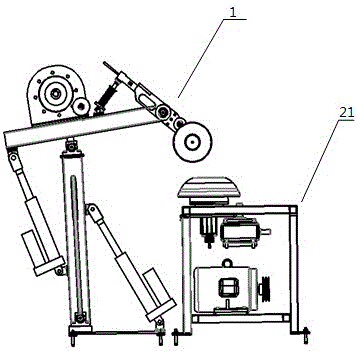

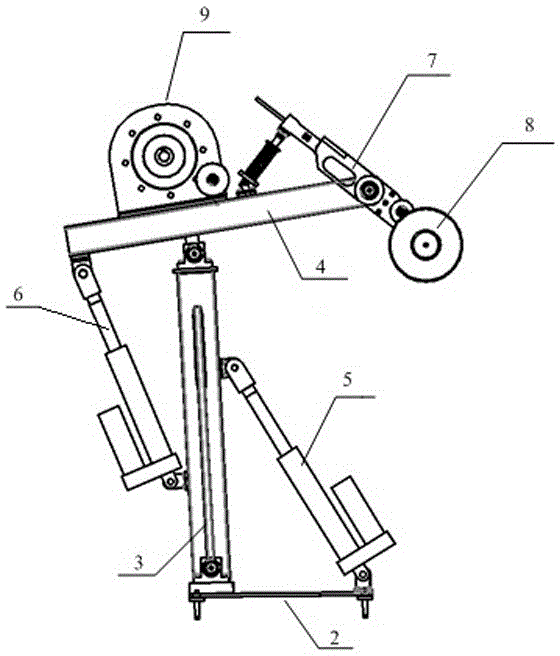

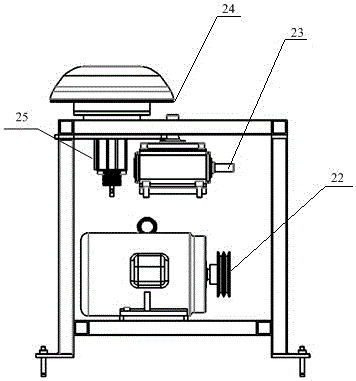

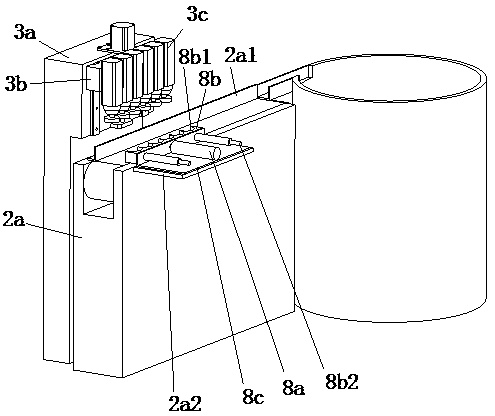

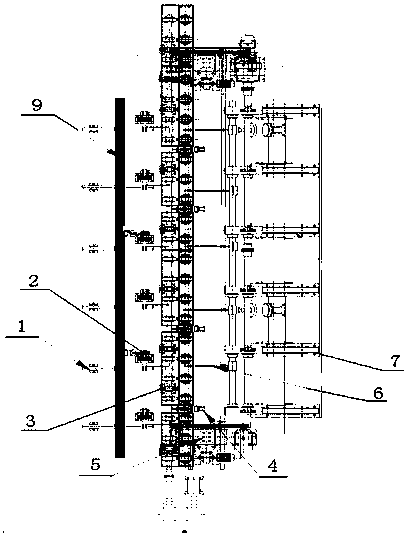

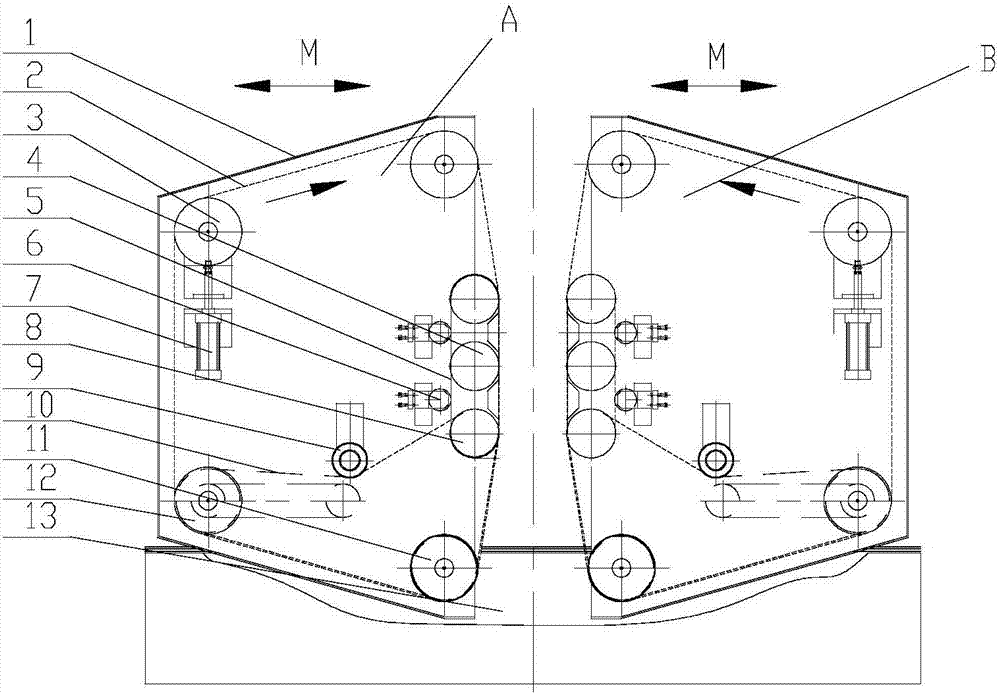

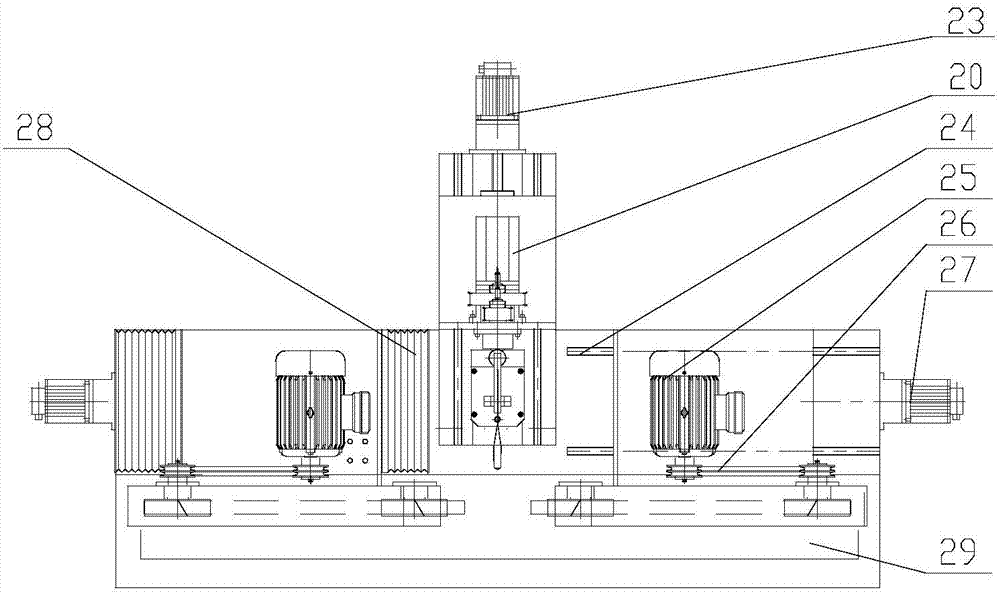

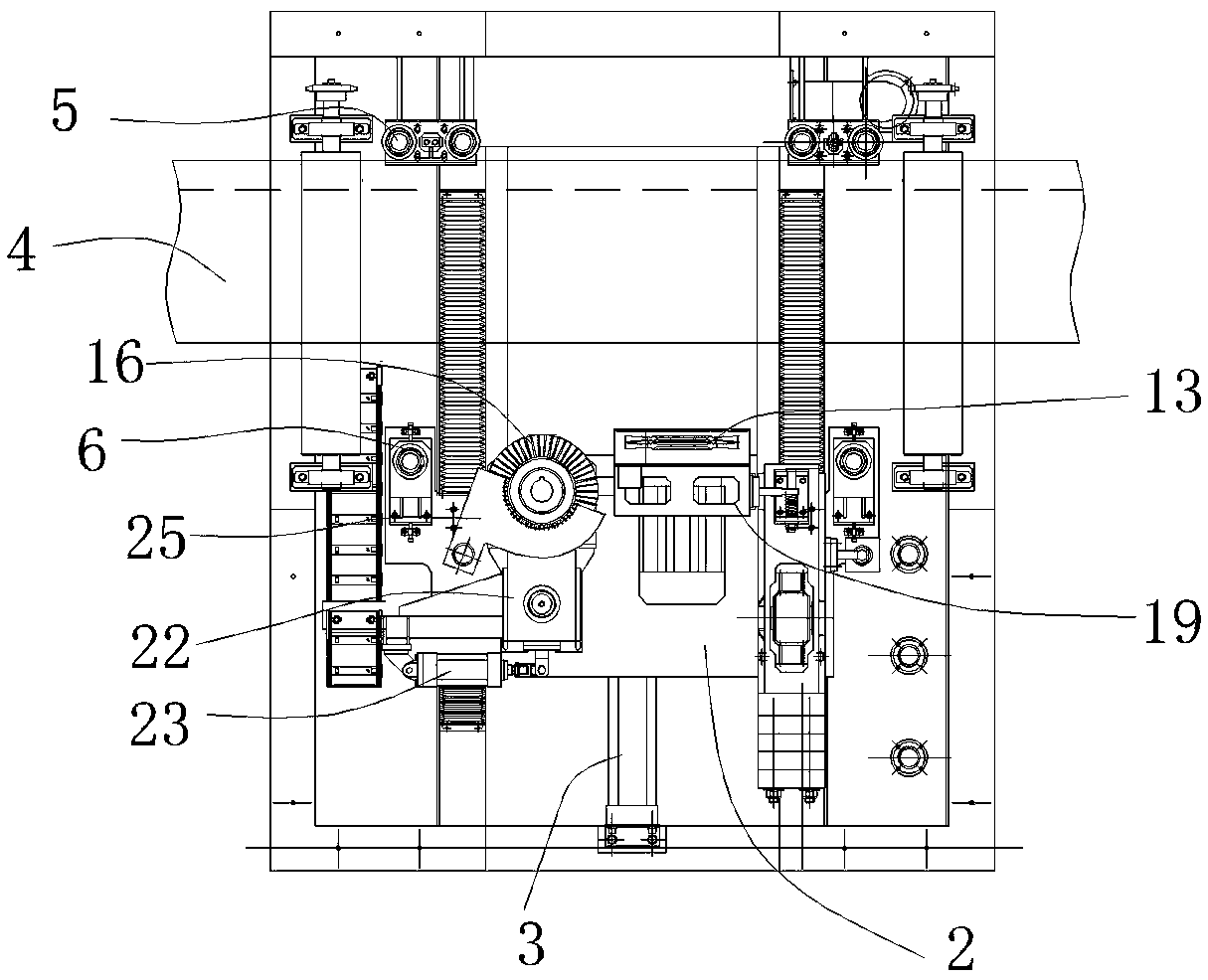

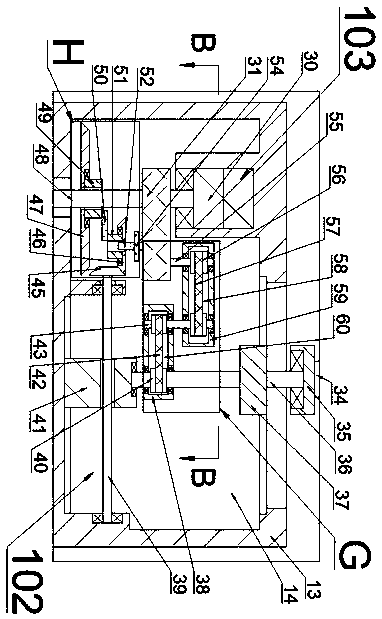

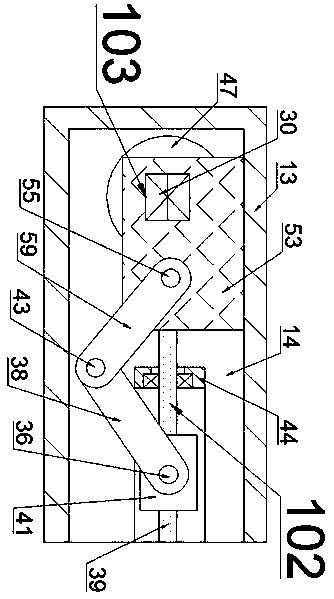

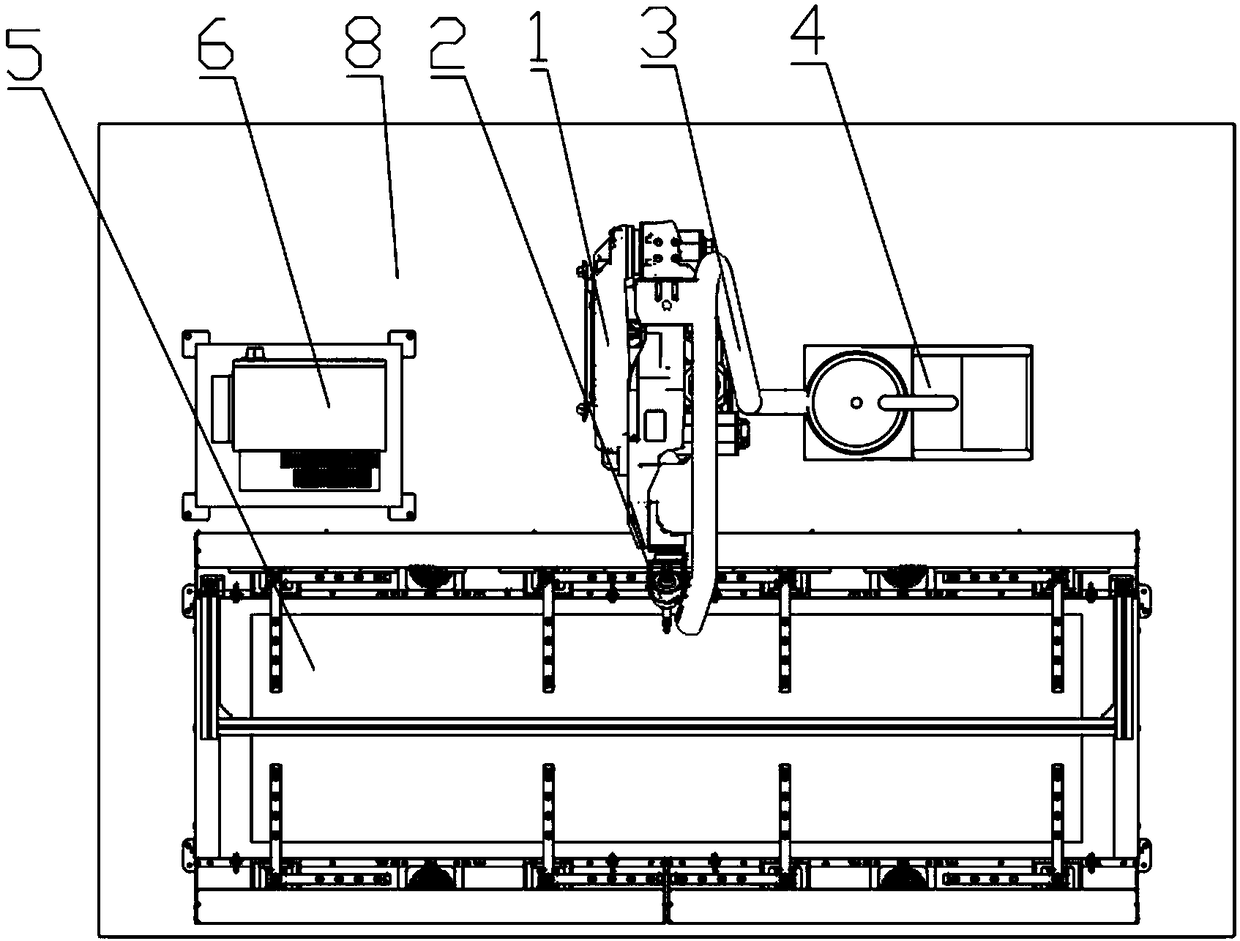

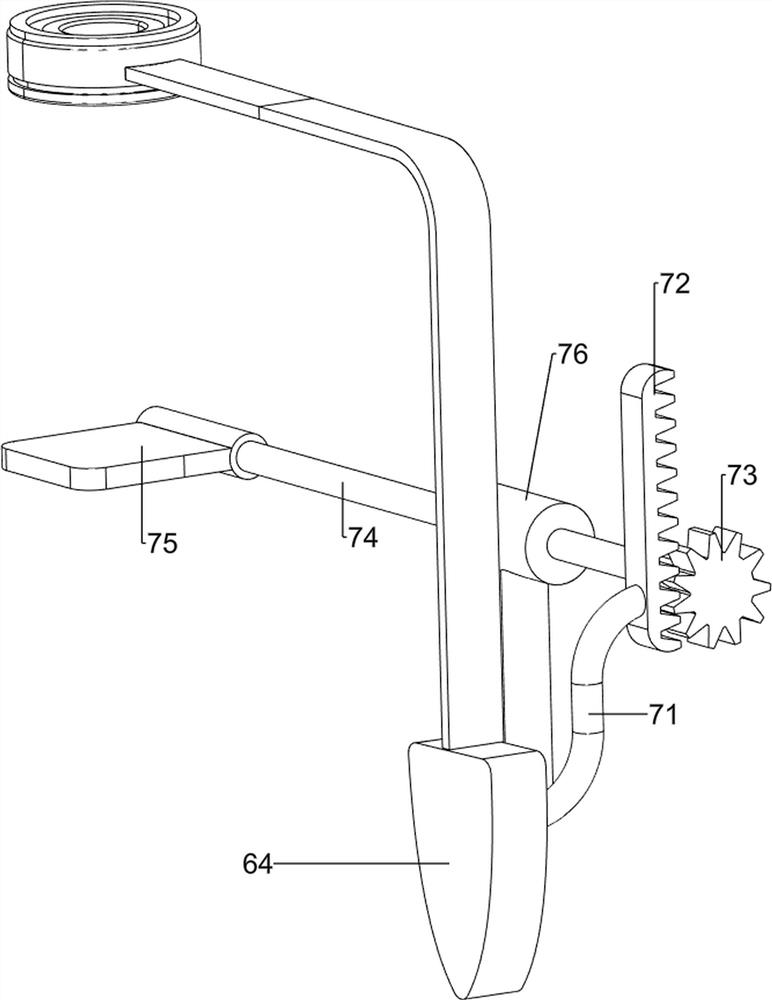

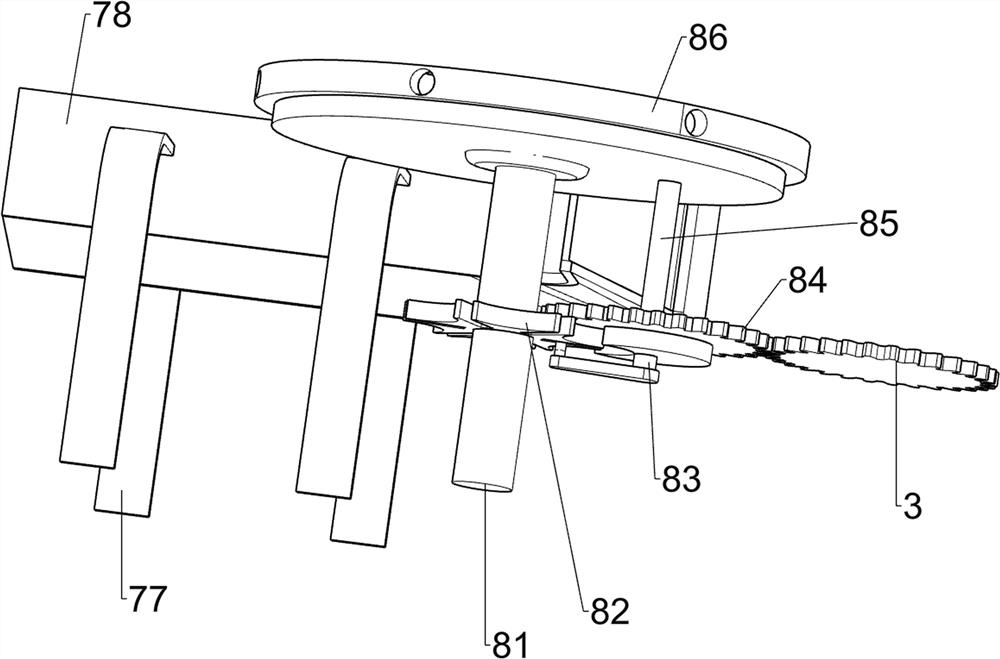

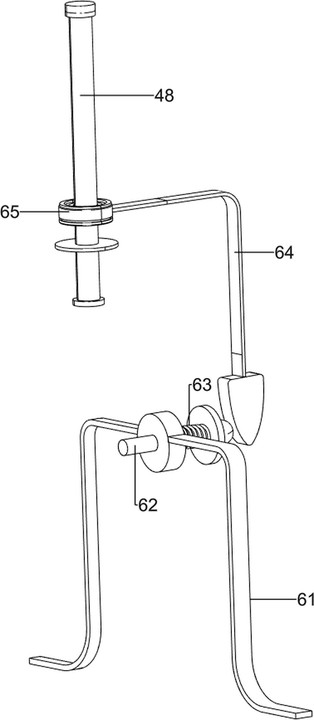

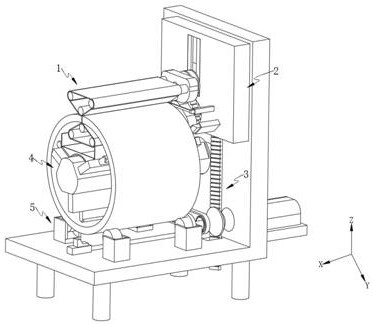

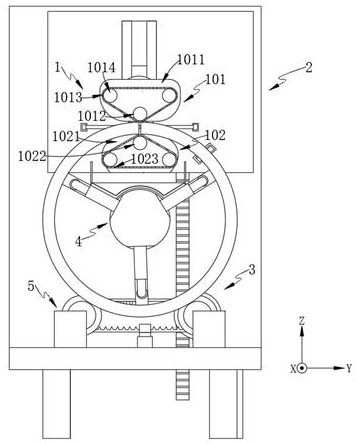

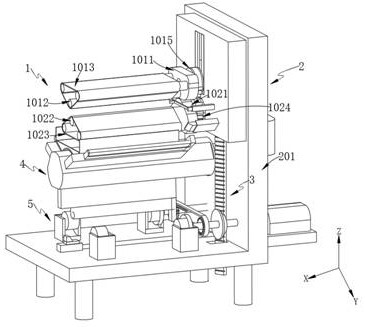

Counter-position placement abrasive belt grinding robot

InactiveCN106863078ARealize automatic grinding processReduce labor intensityBelt grinding machinesGrinding work supportsEngineeringBelt grinding

The invention relates to abrasive belt grinding equipment, in particular to a counter-position placement abrasive belt grinding robot. The counter-position placement abrasive belt grinding robot comprises a machine body, a left grinding unit, a right grinding unit, a left grinding unit feeding mechanism, a right grinding unit feeding mechanism and a workpiece feeding unit, wherein the left grinding unit, the right grinding unit, the left grinding unit feeding mechanism, the right grinding unit feeding mechanism and the workpiece feeding unit are arranged on the machine body; the left grinding unit and the right grinding unit are connected with the left grinding unit feeding mechanism and the right grinding unit feeding mechanism correspondingly; a workpiece located between the left grinding unit and the right grinding unit is ground through driving of the left grinding unit feeding mechanism and the right grinding unit feeding mechanism; and the workpiece feeding unit is arranged on one side of the left grinding unit and the right grinding unit and used for feeding a workpiece to be ground to the position between the left grinding unit and the right grinding unit. The counter-position placement abrasive belt grinding robot can greatly lower the labor intensity of enterprise workers, improve the production efficiency of enterprises and reduce cost for production enterprises.

Owner:杨晓东

Grinding machine for grinding edges of metal workpieces

PendingCN109465703ARealize automatic grinding processImprove efficiencyEdge grinding machinesGrinding carriagesEngineeringMoving frame

A grinding machine for grinding edges of metal workpieces comprises a machine base, a first limiting mechanism arranged on the machine base, a moving frame slidably arranged on the machine base, a second limiting mechanism corresponding to the first limiting mechanism, and a grinding mechanism arranged on the moving frame, wherein the moving frame is connected with a moving drive mechanism for driving the moving frame to move; the moving drive mechanism is used for driving the moving frame to move away from or close to the first limiting mechanism; the second limiting mechanism is arranged onthe moving frame, and the metal workpieces are limited between the first limiting mechanism and the second limiting mechanism after movement of the moving frame; and the grinding mechanism is used forgrinding the edges of the metal workrpieces. With the grinding machine for grinding the edges of the metal workpieces, automatic grinding on the edges of the metal workpieces can be achieved, the efficiency is improved, and labor is saved.

Owner:NINGBO JINFENG WELDING & CUTTING MACHINERY MFR

Polysilicon cell plate production line for producing solar cell panels

InactiveCN108010993ARealize automatic grinding processImprove grinding effectFinal product manufacturePhotovoltaic energy generationProduction lineFrame based

The invention relates to a polysilicon cell plate production line for producing solar cell panels. The production line comprises a supporting base plate, a polishing device and a frame mounting device. The left end of the supporting base plate is provided with the polishing device. The frame mounting device is mounted on the right end of the supporting base plate. The frame mounting device comprises a frame base column, a frame motor, a frame chute, four frame slide rods, a frame connecting wrench, four frame clamping mechanisms, two frame telescoping columns, a glue applying branched chain, ascraping and wiping branched chain, a frame electric slide block, a frame angle push rod, an angle connecting wrench and four frame supporting push rods. The polysilicon cell plate production line settles problems of requirement for manual polishing of the cell plate after cutting, low polishing effect, requirement for manual frame mounting of the cell plate, mounting error in mounting the frame,artificial glue application action of the cell plate and the frame and the like in production of existing polysilicon cell plate.

Owner:吴秋敏

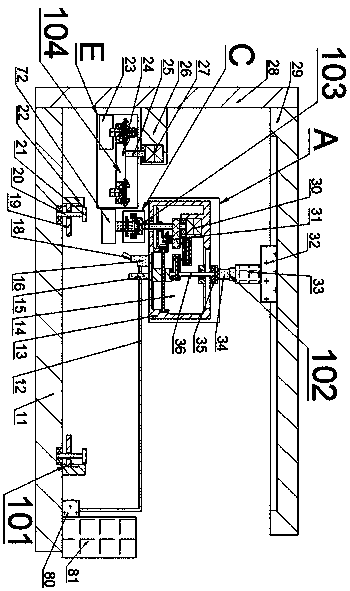

Building aluminum formwork working face machining device and method

ActiveCN114043338ARealize automatic grinding processReduce labor intensityEdge grinding machinesGrinding carriagesReciprocating motionPolishing

The invention discloses a building aluminum formwork working face machining device and method. The device comprises a workbench, mounting plates are fixedly connected to the two sides of the upper end face of the workbench, a first threaded rod is rotationally connected between the two ends of the two mounting plates, a polishing table is fixedly connected between the middle positions of the upper ends of the two mounting plates, and a flange is arranged on one side of the upper end face of the polishing table. By means of an arranged scraping plate and a U-shaped frame, chippings generated by polishing and sprayed cooling liquid can be scraped away in the using process, the scraping plate moves along with reciprocating motion of a moving block in the using process, the chippings and the cooling liquid on the working face of an aluminum formwork can be pushed and scraped into discharging groove plates on the two sides of the polishing table together in the moving process and then flow into a collecting box through the inclined bottom faces of the discharging groove plates, the chippings and the cooling liquid are filtered through a filtering plate in the collecting box, and then the surface of the aluminum formwork can be kept in a clean state.

Owner:湖南鑫政铝业科技有限公司

Liquid crystal display screen scratch grinding treatment device

ActiveCN111098205ARealize automatic grinding processRealize the grinding processGrinding drivesGrinding machinesLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display screen scratch grinding treatment device. The liquid crystal display screen scratch grinding treatment device comprises a grinding table; a screen clamping device is arranged on the end surface of the upper side of the grinding table; the screen clamping device is used for clamping and fixing a display screen; the grinding table is fixedly connectedto a supporting frame positioned on the left side of the screen clamping device; the end surface of the right side of the supporting frame is fixedly connected to a sliding rail positioned on the upper side of the screen clamping device; a scratch removing device is arranged on the sliding rail; a grinding device used for grinding a screen scratch is arranged in the scratch removing device; a cutter changing device is arranged on the end surface of the left side of a motor seat; and the cutter changing device is used for replacing a grinding cutter of the grinding device so that the screen can be subjected to rough grinding, fine grinding and polishing treatment by using the grinding device. The liquid crystal display screen scratch grinding treatment device can realize automatic grindingtreatment on a display scratch, and is good in treatment effect.

Owner:安徽盛诺科技集团股份有限公司

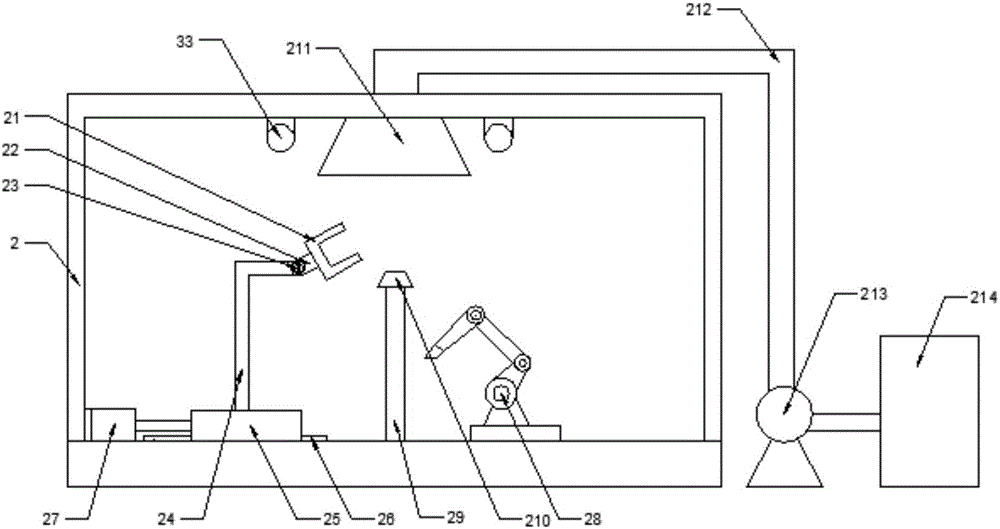

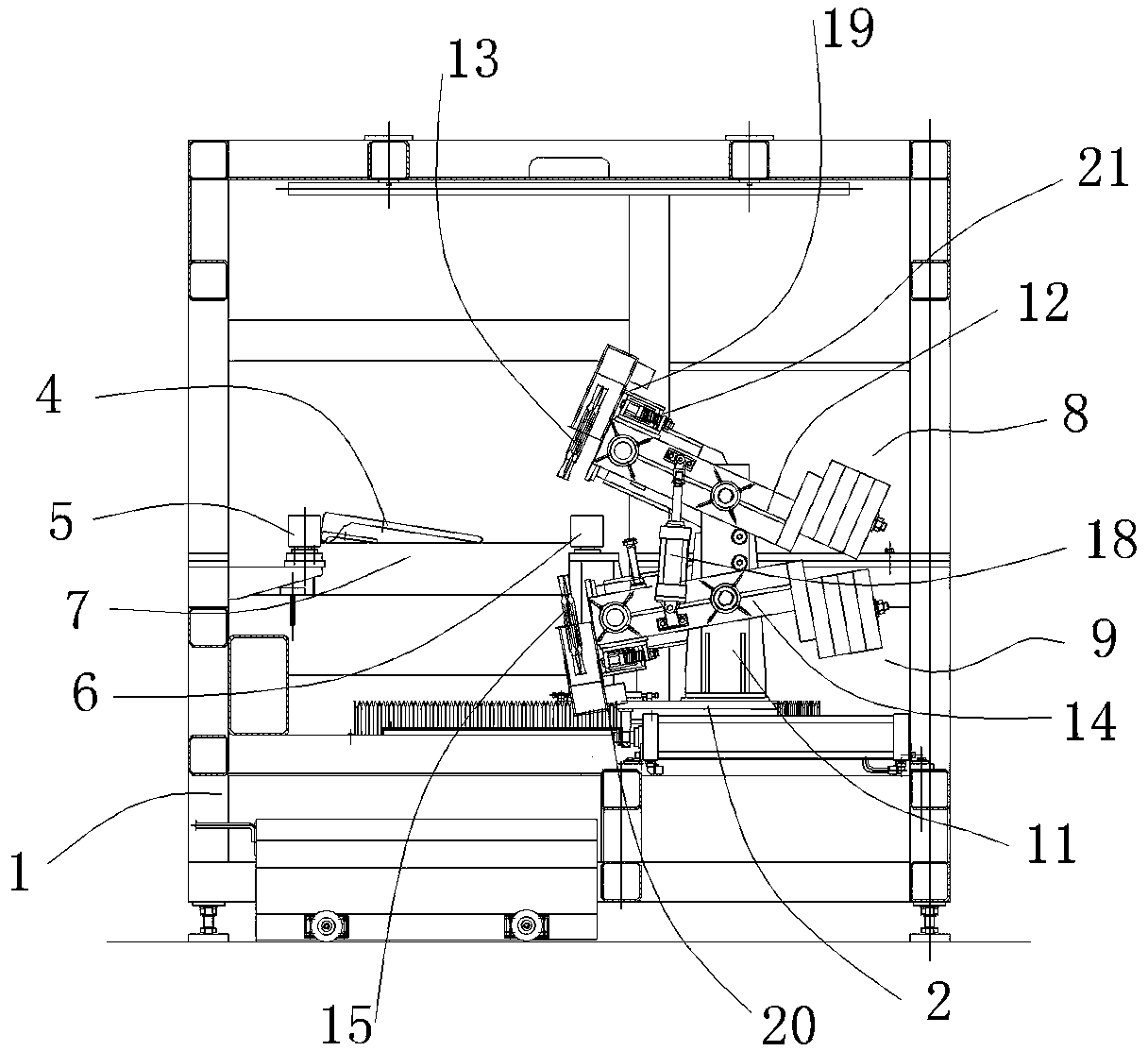

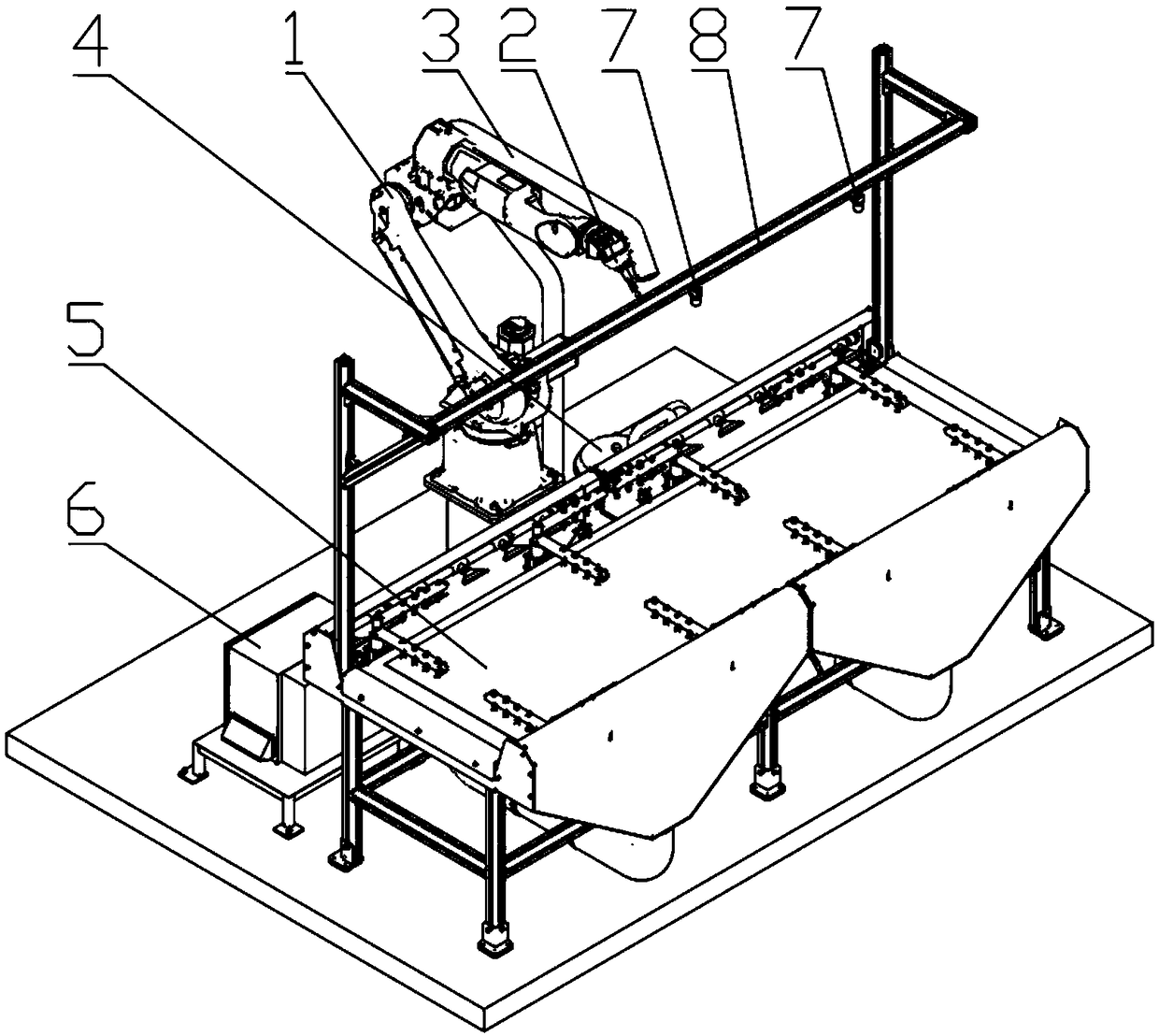

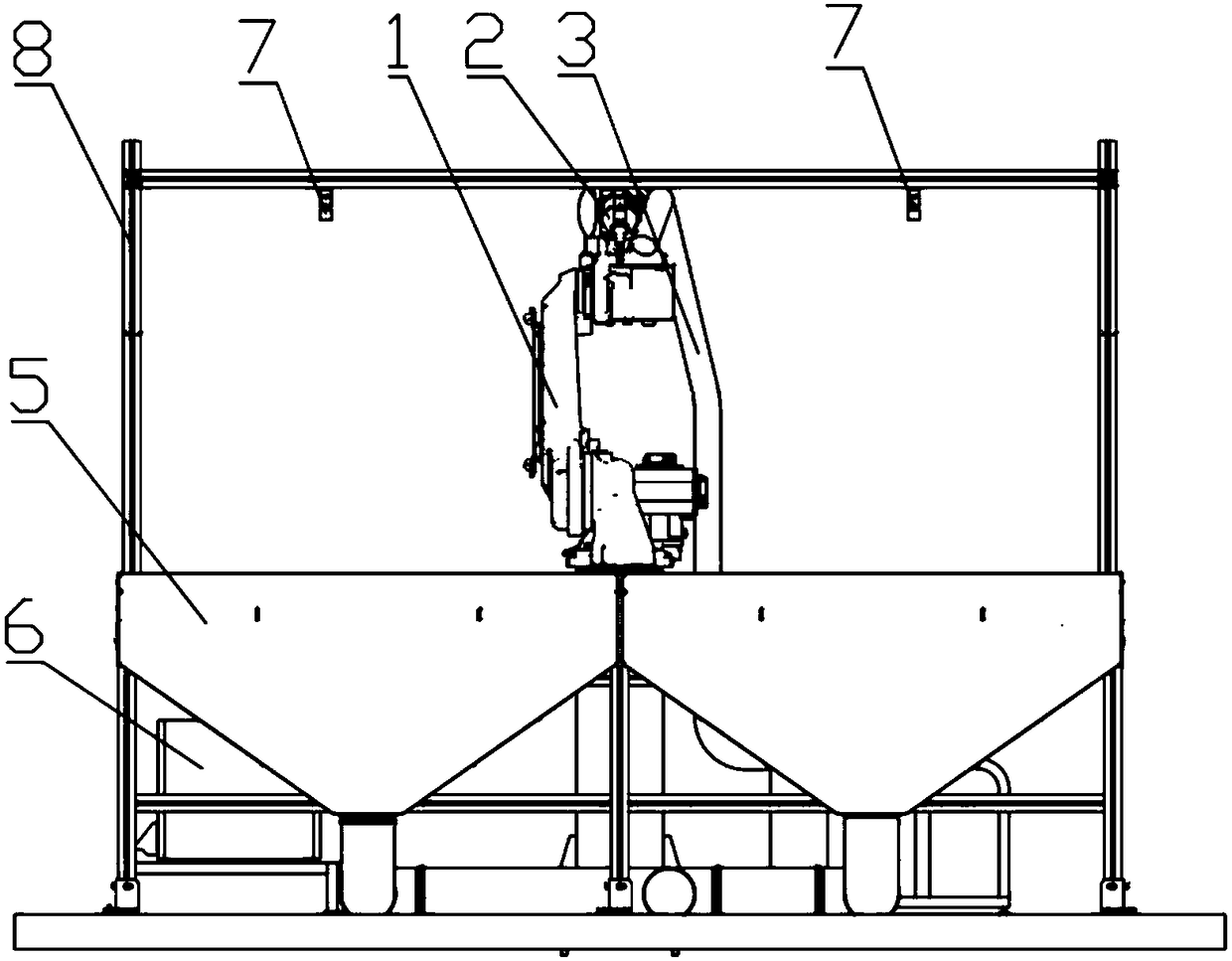

Wood veneer flaw visual identification and automatic polishing workstation

PendingCN109079652AEnsure consistencyRealize automatic grinding processGrinding feed controlGrinding feedersWood veneerEngineering

The invention discloses a wood veneer flaw visual identification and automatic polishing workstation. The wood veneer flaw visual identification and automatic polishing workstation comprises a controlcabinet, a frame and a mechanical hand arranged at one side of the frame, wherein a polishing table is fixedly arranged at the middle part of the frame in a horizontal direction; dust removal protective shields are fixedly arranged on the frame of the front side and rear side of the polishing table; a clamping device and a blowing device are also arranged at the front side and rear side of the polishing table; multiple vision cameras are arranged at the upper part of the polishing table; a floating polishing head is arranged at the tail end of the mechanical hand; and the mechanical hand, theclamping device, the blowing device and the vision cameras are electrically connected to the control cabinet. The wood veneer flaw visual identification and automatic polishing workstation has the beneficial effects that the vision cameras are used for precisely identifying veneer flaws, and the control cabinet controls the motion of the mechanical hand so as to precisely polish a flaw position;the full-automatic operation in the whole polishing process is realized, and thus, the polishing efficiency is improved; and the polishing pressure is effectively controlled through procedures, and thus, the consistency of polishing quality is ensured.

Owner:YANTAI WALU ROBOT AUTOMATION CO LTD

Cylindrical iron rod grinding equipment

PendingCN112388486ARealize automatic feedingRealize automatic grinding processRevolution surface grinding machinesGrinding drivesGear wheelElectric machinery

The invention relates to grinding equipment, in particular to cylindrical iron rod grinding equipment. The cylindrical iron rod grinding equipment can achieve automatic feeding, automatic grinding anduniform grinding of iron rods. The cylindrical iron rod grinding equipment comprises a bottom plate, a motor arranged on one side of the top of the bottom plate, a first circular gear arranged on anoutput shaft of the motor, a rotating mechanism arranged on one side of the top of the bottom plate and located on one side of the motor, a lifting mechanism arranged at the top of the rotating mechanism, and an intermittent feeding mechanism arranged on the side, away from the rotating mechanism, of the top of the bottom plate. Through cooperation of the rotating mechanism, the lifting mechanismand the intermittent feeding mechanism, automatic feeding and automatic grinding of the iron rods can be achieved, the peripheries of the iron rods can be ground in an all-around mode, and the workingefficiency of people is improved.

Owner:李统

Pipe fitting weld joint polishing equipment

InactiveCN114161277AAutomatic detection of weld seam positionWide range of grindingGrinding carriagesBelt grinding machinesPipe fittingPolishing

The invention provides pipe fitting weld joint polishing equipment which is characterized by comprising polishing assemblies distributed at the inner end and the outer end of a polishing piece; the detection unit is arranged at the fixed end of the polishing assembly; the fixing unit is arranged at the side part of the detection unit; after the position of the welding seam is found by the detection unit in the rotating process of the grinding piece, the position of the grinding piece is locked through the fixing unit; the arc length between the first prediction assembly and the second prediction assembly is set to be equal to the effective length of the rack, and it is ensured that when the reverse wedge-shaped plate is inserted into the welding seam, the first grinding roller and the second grinding roller just make the upper end face and the lower end face of a grinding piece make contact; therefore, the welding seam position of the grinding piece can be automatically detected.

Owner:HUZHOU TEACHERS COLLEGE +1

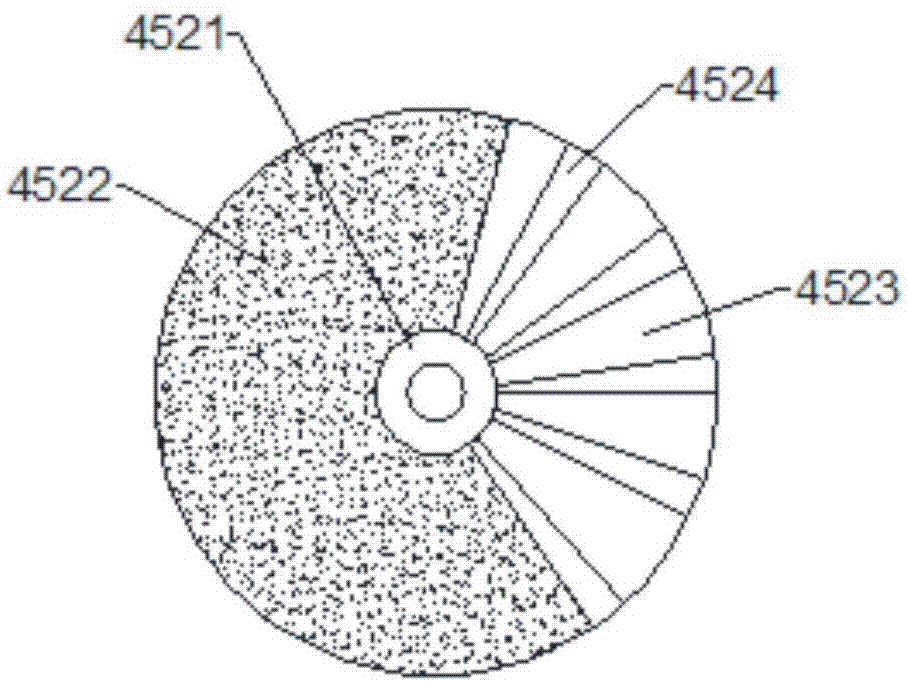

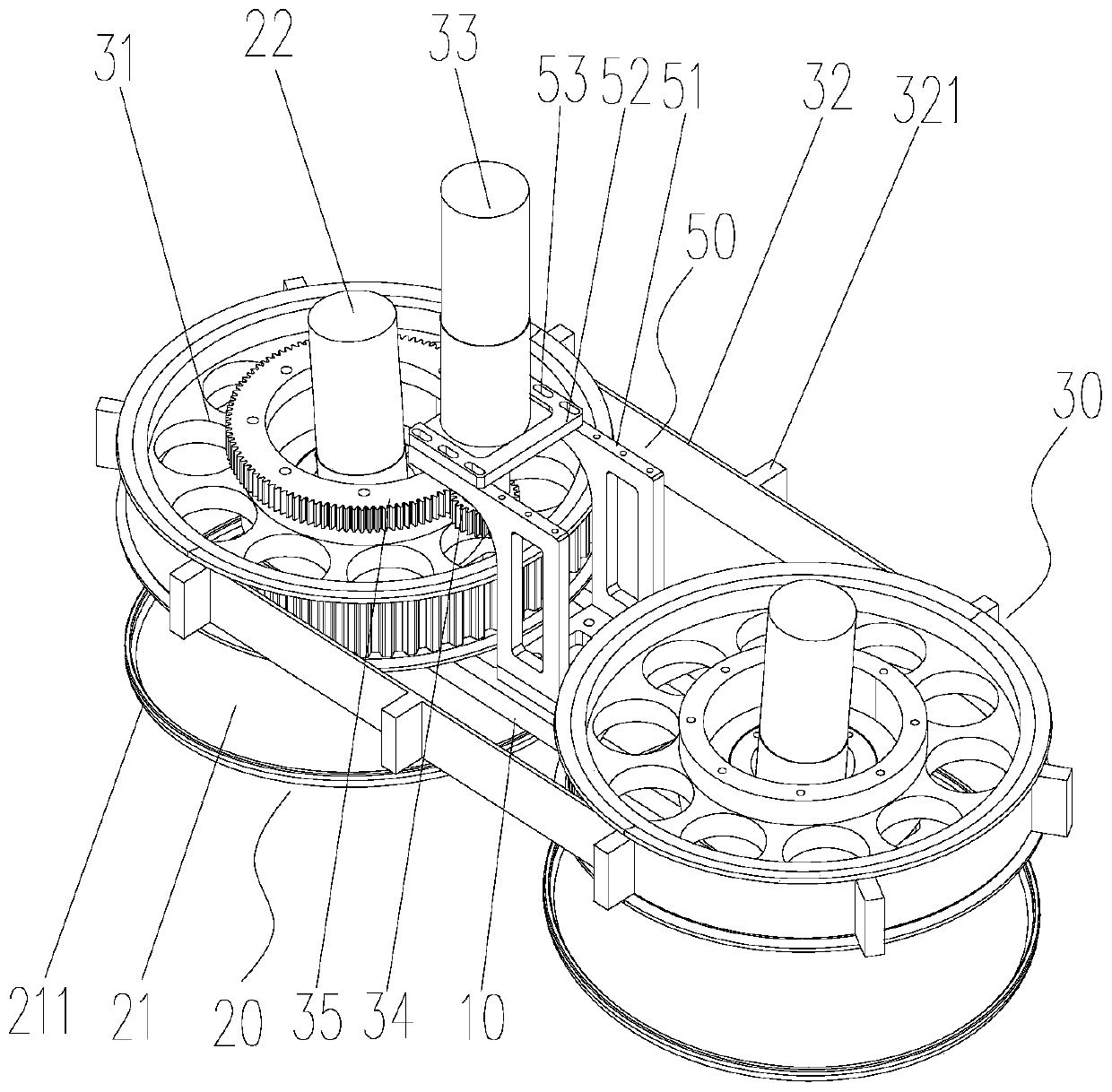

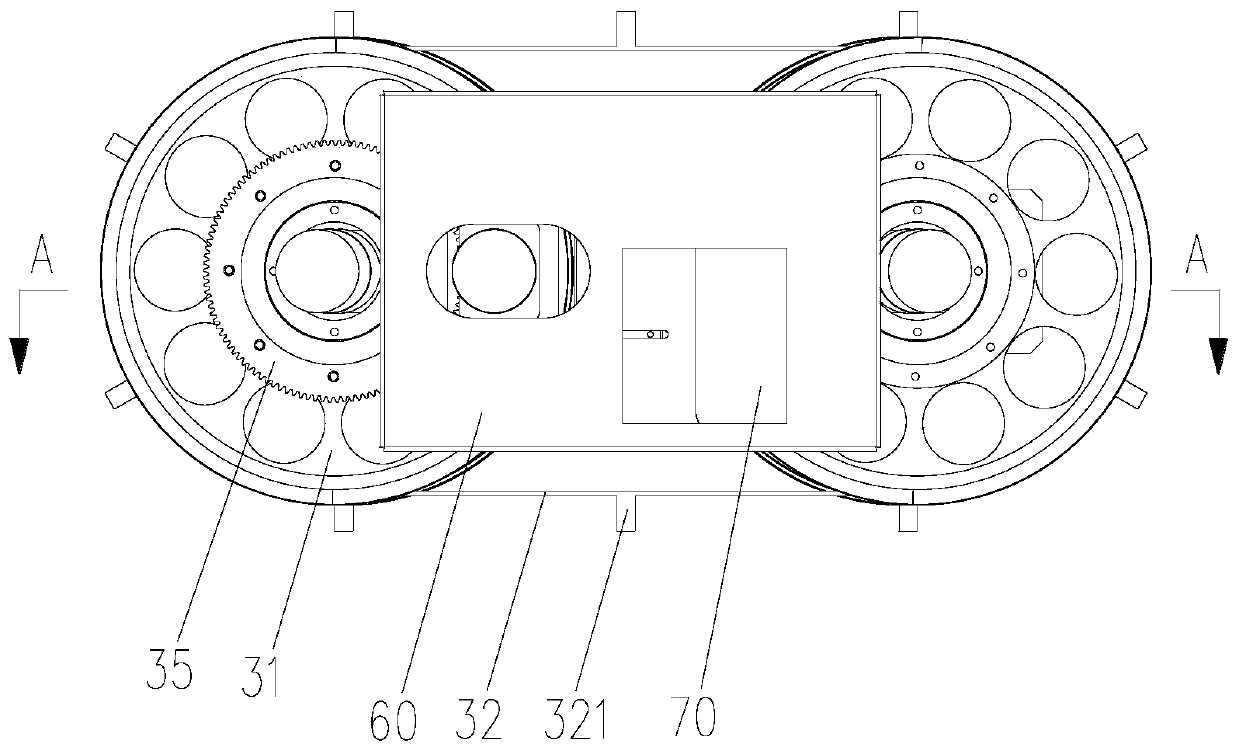

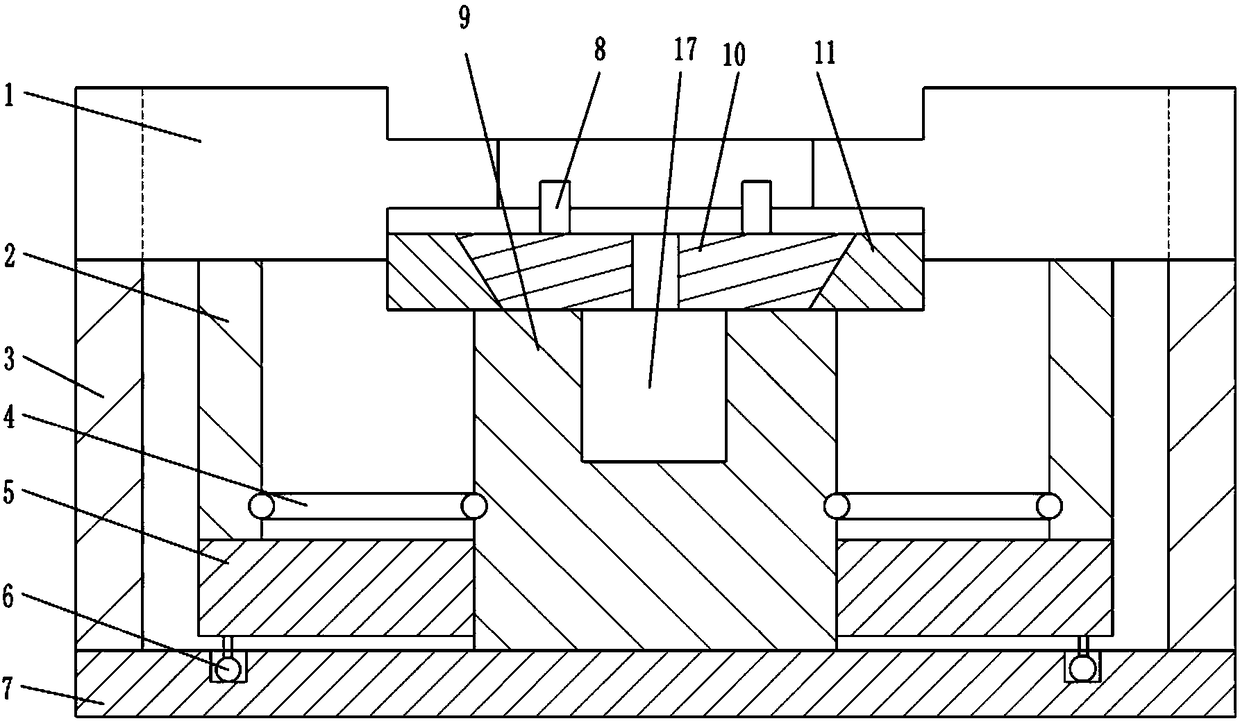

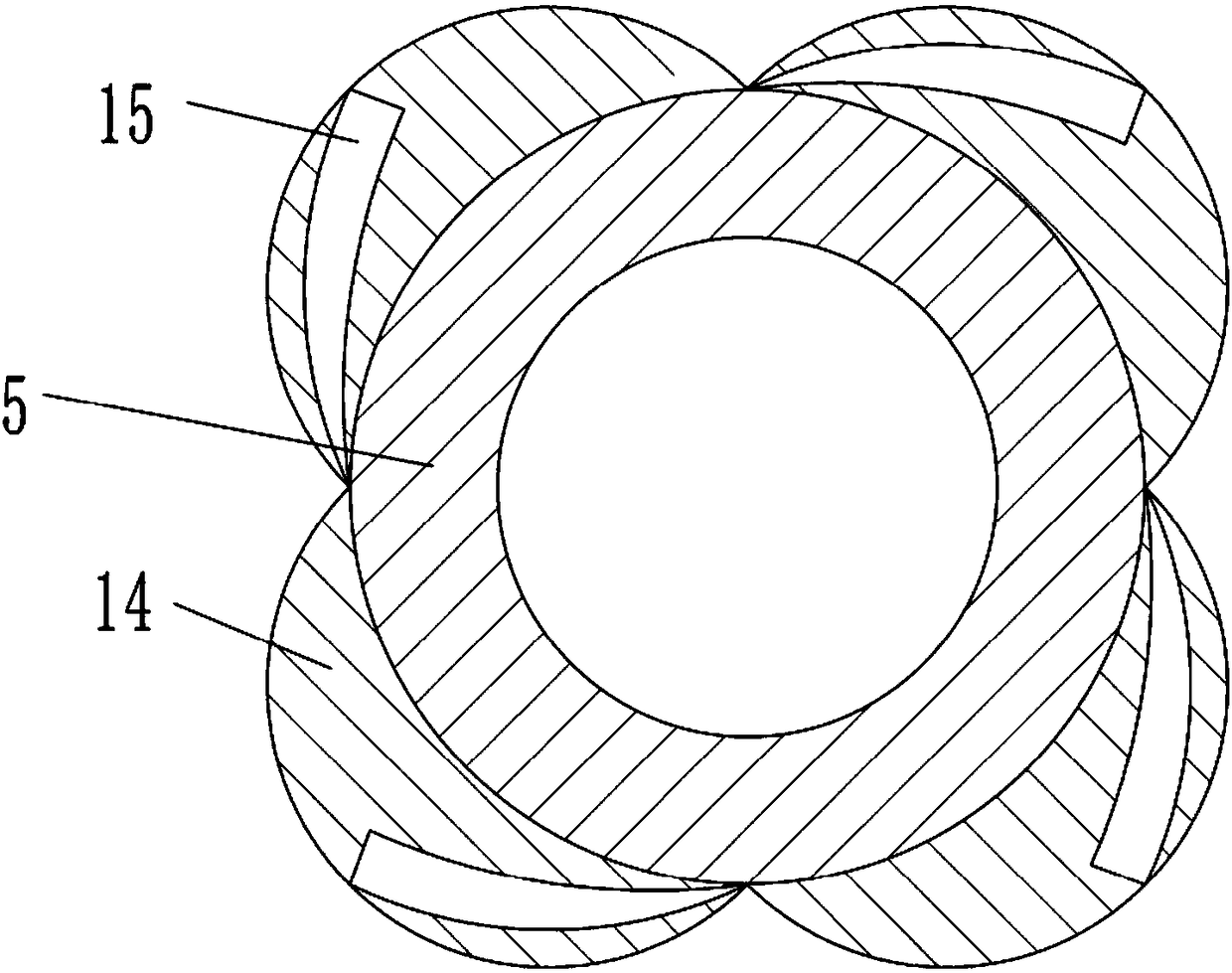

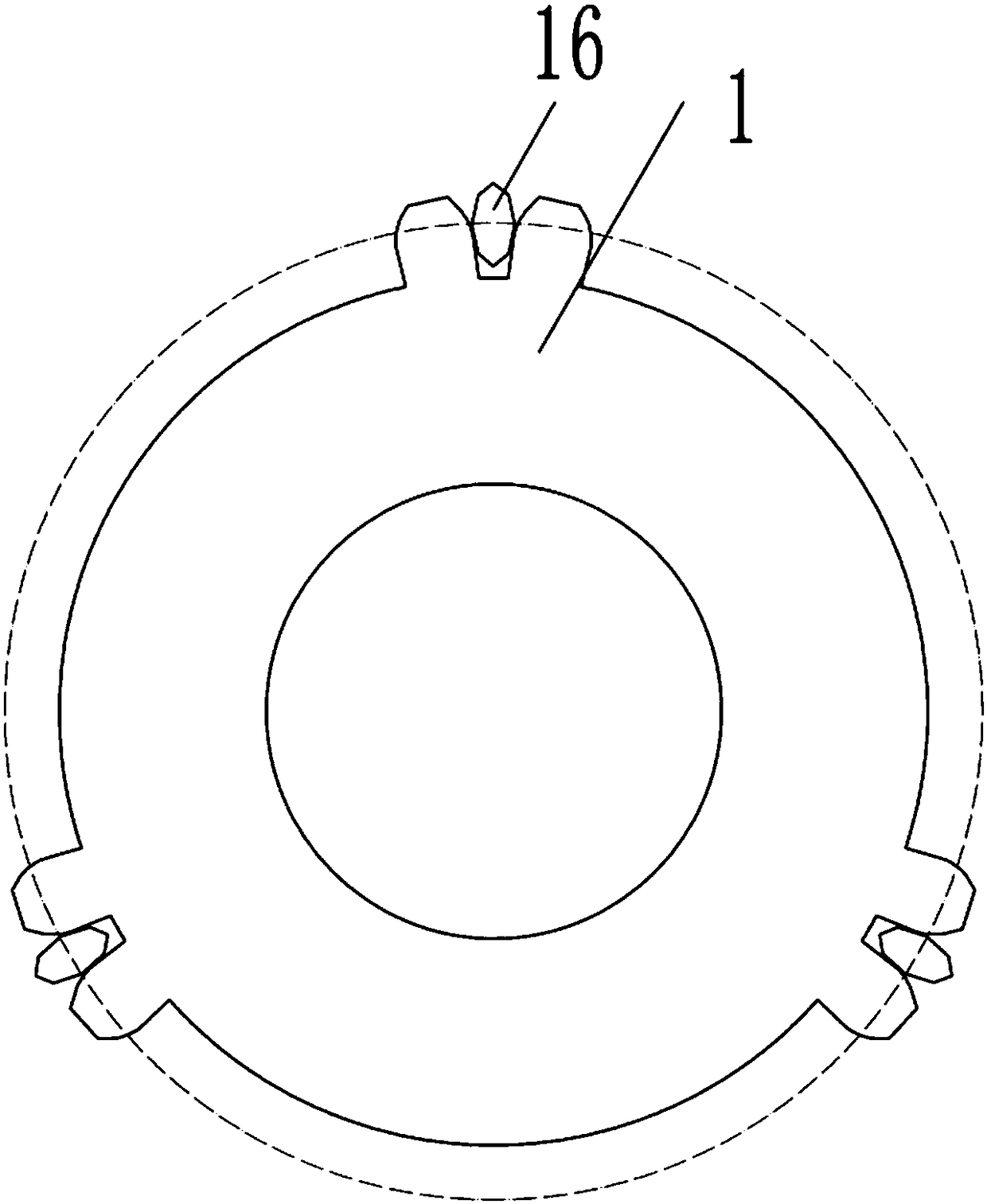

Fixing device for grinding inner hole of gear

ActiveCN108188927ARealize automatic lockingQuality improvementRevolution surface grinding machinesGrinding work supportsCircular discGear wheel

The invention belongs to the technical field of gear machining equipment, and particularly discloses a fixing device for grinding an inner hole of a gear. The fixing device comprises a round base, andeccentric locking cams are evenly distributed in the circumferential direction of the base. An annular round disc and a supporting column are arranged on the base, the annular round disc is rotatablyconnected to the base, arc-shaped sliding grooves are formed in the annular round disc, movable rods are slidably connected to the interiors of the arc-shaped sliding grooves, telescopic rods are connected to the lower portions of the movable rods, and the telescopic rods are fixedly connected to the supporting column. A motor is arranged in the supporting column, an output shaft of the motor islocated on the upper end face of the supporting column, four fan-shaped fixing blocks are slidably connected to the upper end face of the supporting column, and the inner rings of the fan-shaped fixing blocks are in wedge shapes. A gear disc with a planetary gear structure internally arranged are arranged on the fan-shaped fixing blocks in an erected mode, and positioning blocks are arranged on planetary gears. The side face of the gear disc is a wedge-shaped face capable of being matched with the inner rings of the wedge-shaped blocks of the fan-shaped fixing blocks. According to the scheme,the fixing device can achieve fixing of the gear when the inner hole of the gear is ground.

Owner:CHONGQING SHUNHUAI MACHINERY MFG CO LTD

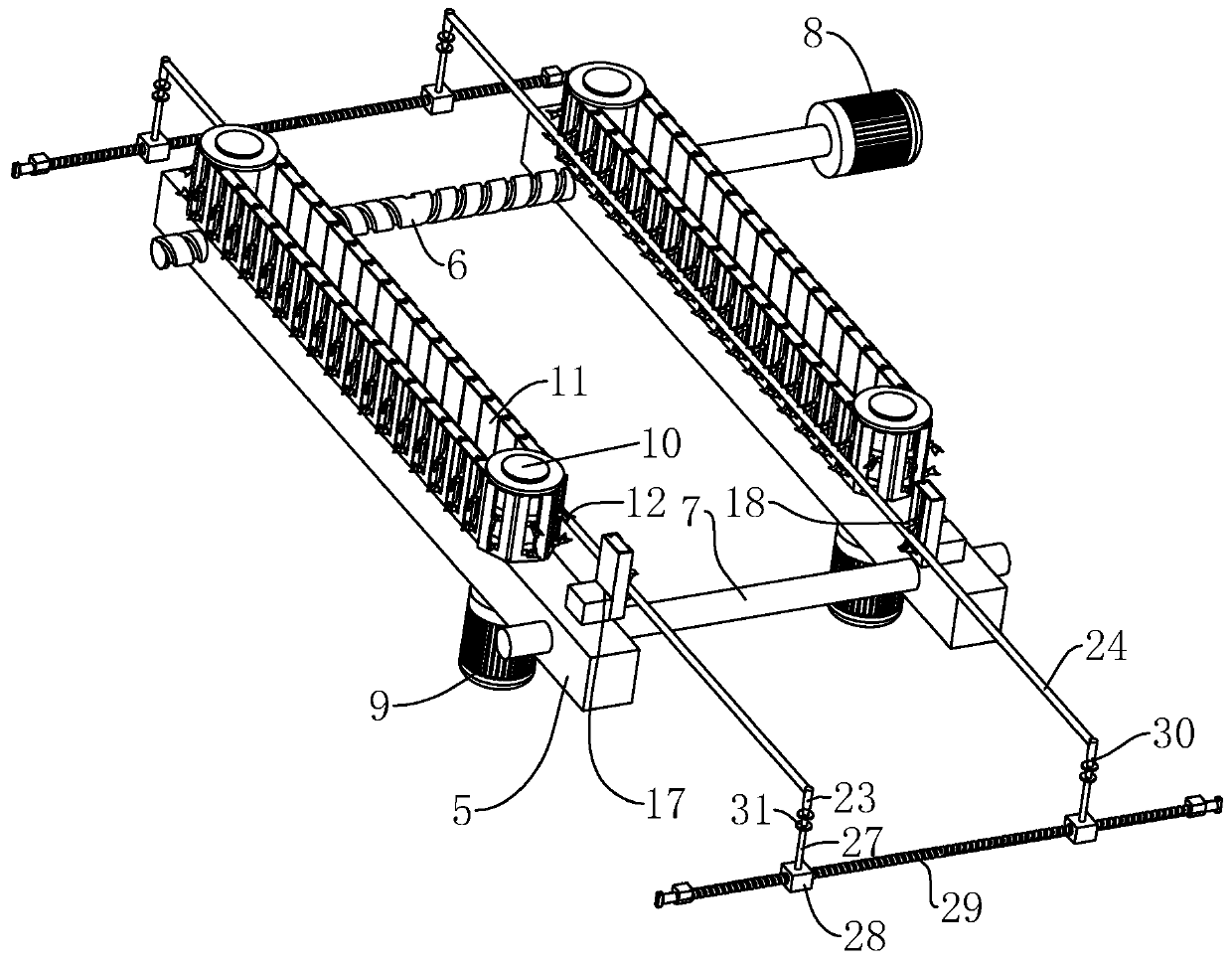

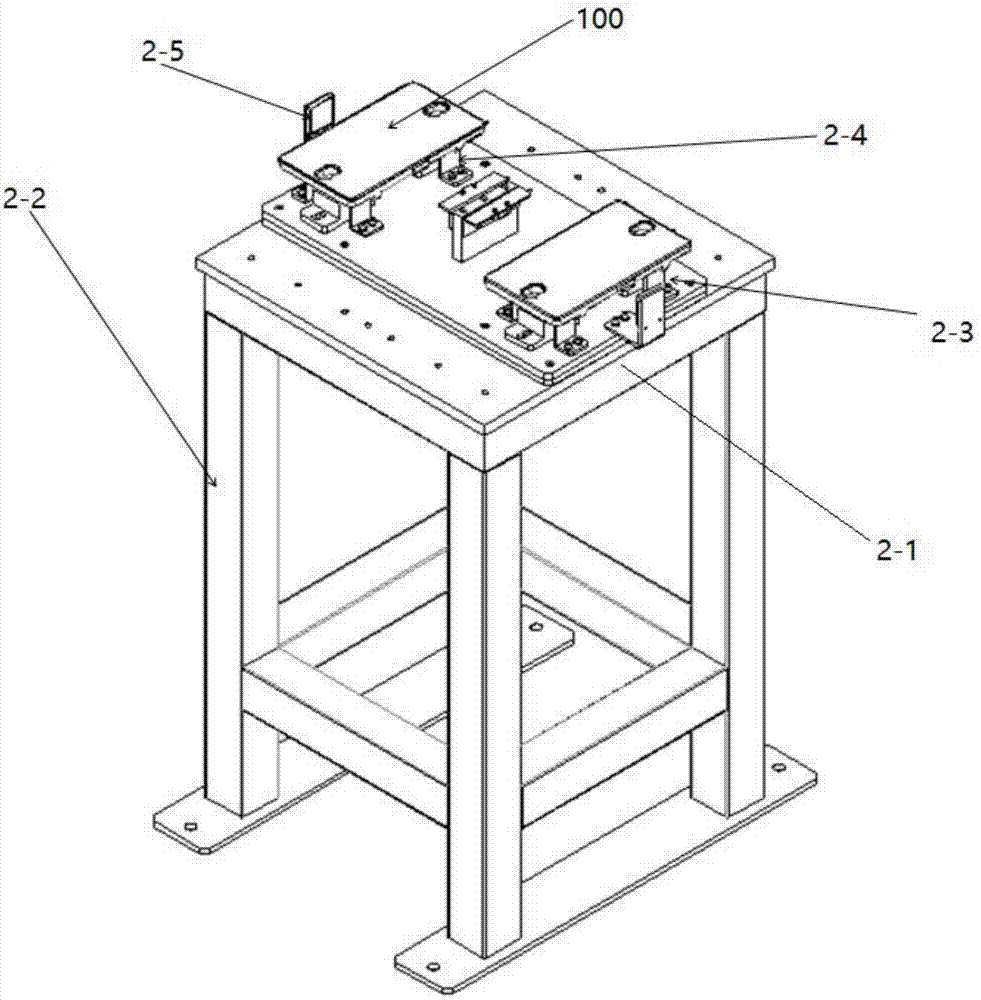

Transmission group for polishing production line

PendingCN106926120ARealize automatic grinding processImprove sanding qualityEdge grinding machinesGrinding feed controlProduction lineQuality level

The invention discloses a transmission group for a polishing production line. The transmission group comprises a feeding roller bed used for conveying to-be-machined workpieces, a discharging roller bed used for conveying machined workpieces, and positioning tool tables arranged on the above feeding roller bed and the above discharging roller bed correspondingly. Each above positioning tool table comprises a worktable, a support, a positioning block, guide plates and photoelectric opposite-transmitting switches, wherein the above worktable is supported by the above support; the above positioning block is fixed to the surface of the worktable; the above positioning block is fixedly provided with the above guide plates so as to position a workpiece; and the above positioning block is provided with the above photoelectric opposite-transmitting switches so as to detect whether the workpiece exists or not. The transmission group for the polishing production line has the beneficial effects that automatic recognition and automatic polishing on products are achieved, the polishing quality of the products is greatly improved, and the quality level of the products is improved.

Owner:ANHUI CHAOHU CASTING FACTORY +1

Preliminary outer surface layer grinding treatment equipment for lens processing

InactiveCN114102341ARealize automatic grinding processGrinding carriagesOptical surface grinding machinesTwo temperatureEngineering

The invention relates to outer surface layer grinding treatment equipment, in particular to preliminary outer surface layer grinding treatment equipment for lens processing. The technical problem to be solved is to provide the preliminary outer surface layer grinding treatment equipment for lens processing, which can realize constant temperature of cleaning water. According to the technical scheme, the preliminary outer surface layer grinding treatment equipment for lens machining comprises a base, a first shell, a cover plate, a first support, a second shell and the like, the first shell is arranged in the middle of the top of the base, strip-shaped grooves are formed in the front side and the rear side in the first shell, and the cover plate is slidably connected to the upper side of the front portion of the first shell; a first support is arranged on the rear side of the top of the base. Through the detection effect of the temperature sensor on the water temperature, the water temperature can be kept between two temperature values, and the constant temperature effect on water can be achieved.

Owner:江西超联光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com