Patents

Literature

848results about How to "Improve sanding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

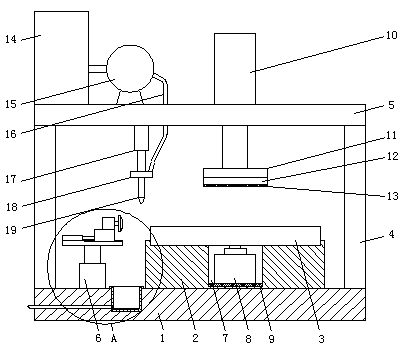

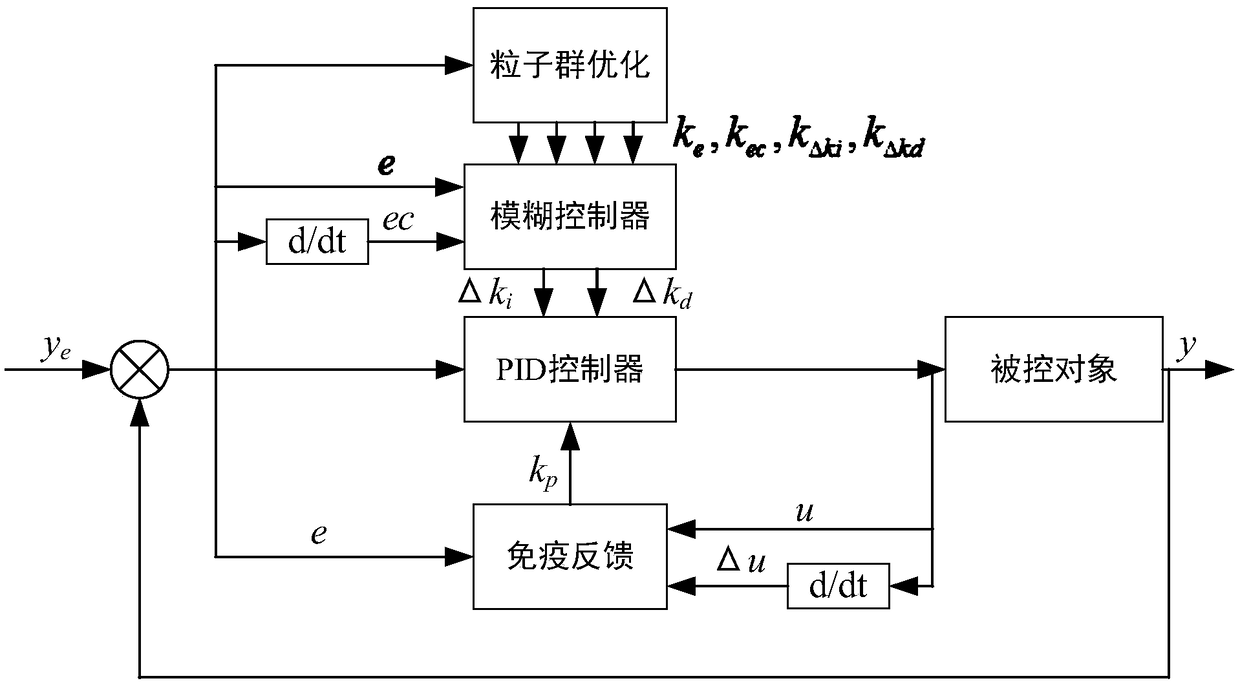

Constant pressure automatic grinding device and method based on fuzzy adaptive force control

InactiveCN104858782AReal-time control of grinding normal forceImprove versatilityGrinding feed controlSpeed/accelaration controlContact forceEngineering

The invention discloses a constant pressure automatic grinding method based on fuzzy adaptive force control. The grinding method comprises the following steps: detecting the contact force of a grinding head and a workpiece in a real-time manner to feed back force signals; changing an analog voltage value output by a controller according to a preset control algorithm, thereby controlling the output torque of an x-axis servomotor to control the contact force. The invention further provides a grinding device for realizing the grinding method. The grinding device comprises an industrial control main engine, a workbench, motion mechanisms, one-dimensional sensing equipment, a position sensor for acquiring the position coordinate of the workpiece, grinding equipment and workpiece clamping equipment. The grinding device can be used for detecting the normal grinding force in a grinding process based on an intelligent force control technology, and feeding back detection results; through the processing of the controller, driving signals are generated for continuous adjustment of the output torque of a driver, so that the normal grinding force can be controlled in a real-time manner and the constant pressure grinding can be realized.

Owner:SOUTH CHINA UNIV OF TECH

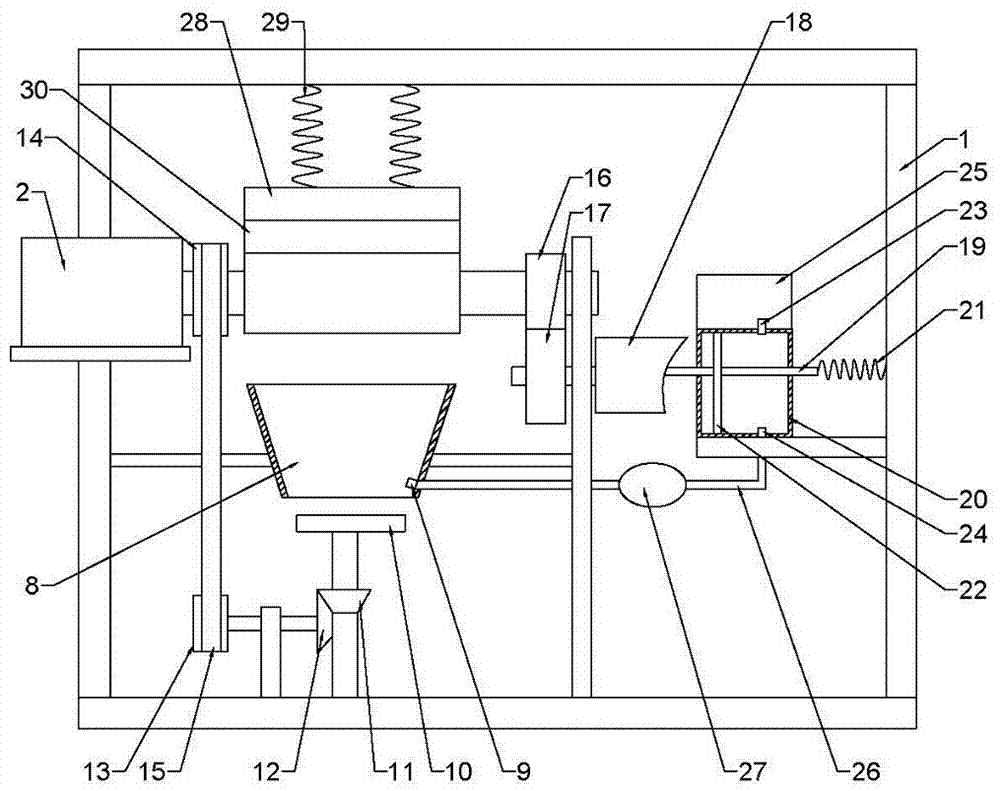

Building aluminum plate grinding device with cooling and dust removal function

InactiveCN107160246AImprove grinding efficiencyImprove sanding qualityPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftCooling effect

The invention discloses a building aluminum plate grinding device with the function of cooling and dust removal, which comprises a base and a top plate, a driving motor is connected to the right side of the lower end of the top plate, a driving shaft is connected to the lower end of the driving motor, and an upper driving belt is connected to the middle part of the upper end of the driving shaft The left end of the upper driving pulley is connected with the upper driven pulley through a belt, the upper end of the upper driven pulley is connected with a rotating cam at the coaxial position, the left end of the rotating cam is provided with a guide wheel, the left end of the guide wheel is connected with a guide rod, and the left end of the guide rod A wedge-shaped block is connected, the left end of the wedge-shaped block is in contact with a lifting wheel, the lower end of the lifting wheel is connected with a lifting shaft, the middle part of the lower end of the driving shaft is connected with a lower driving pulley, and the left end of the lower driving pulley is connected with a lower driven pulley through a belt. The middle part of the driven pulley is connected with a driven shaft. The invention realizes the synchronous rotation of the grinding wheel and the workbench, realizes the cooling effect on the grinding wheel, and takes away the aluminum dust produced during grinding.

Owner:苏锦忠

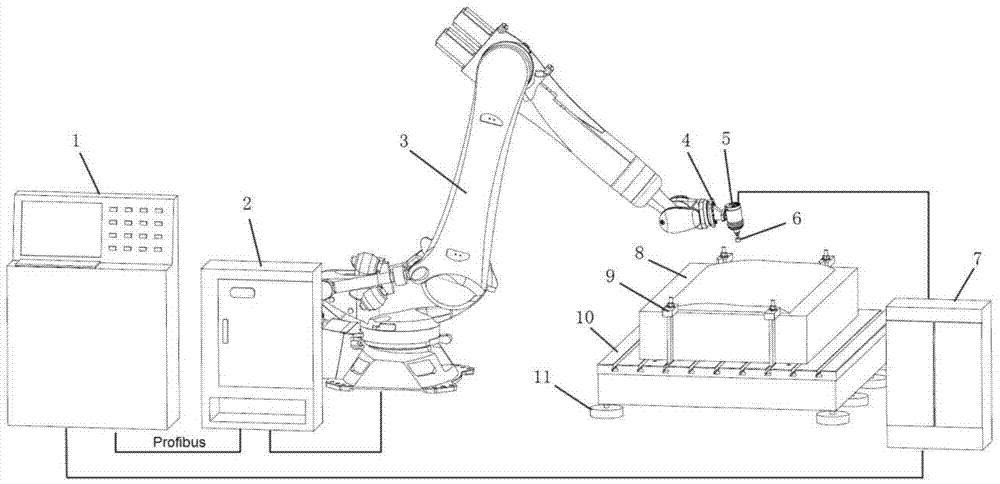

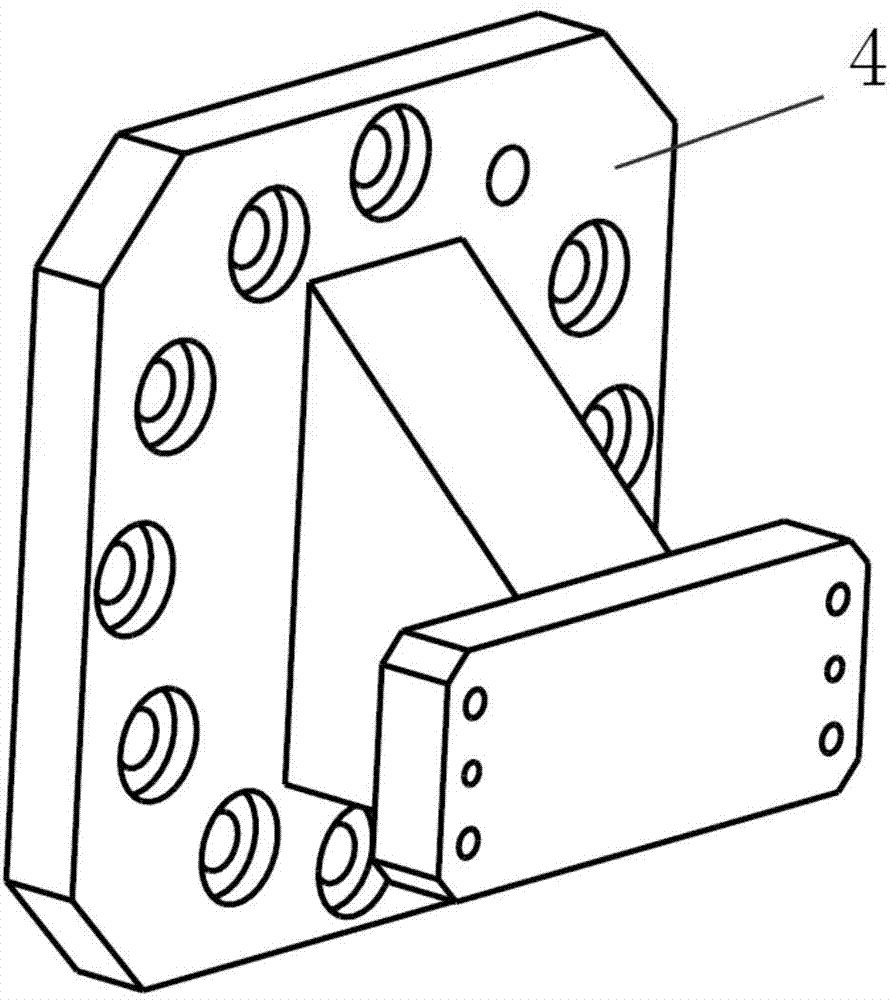

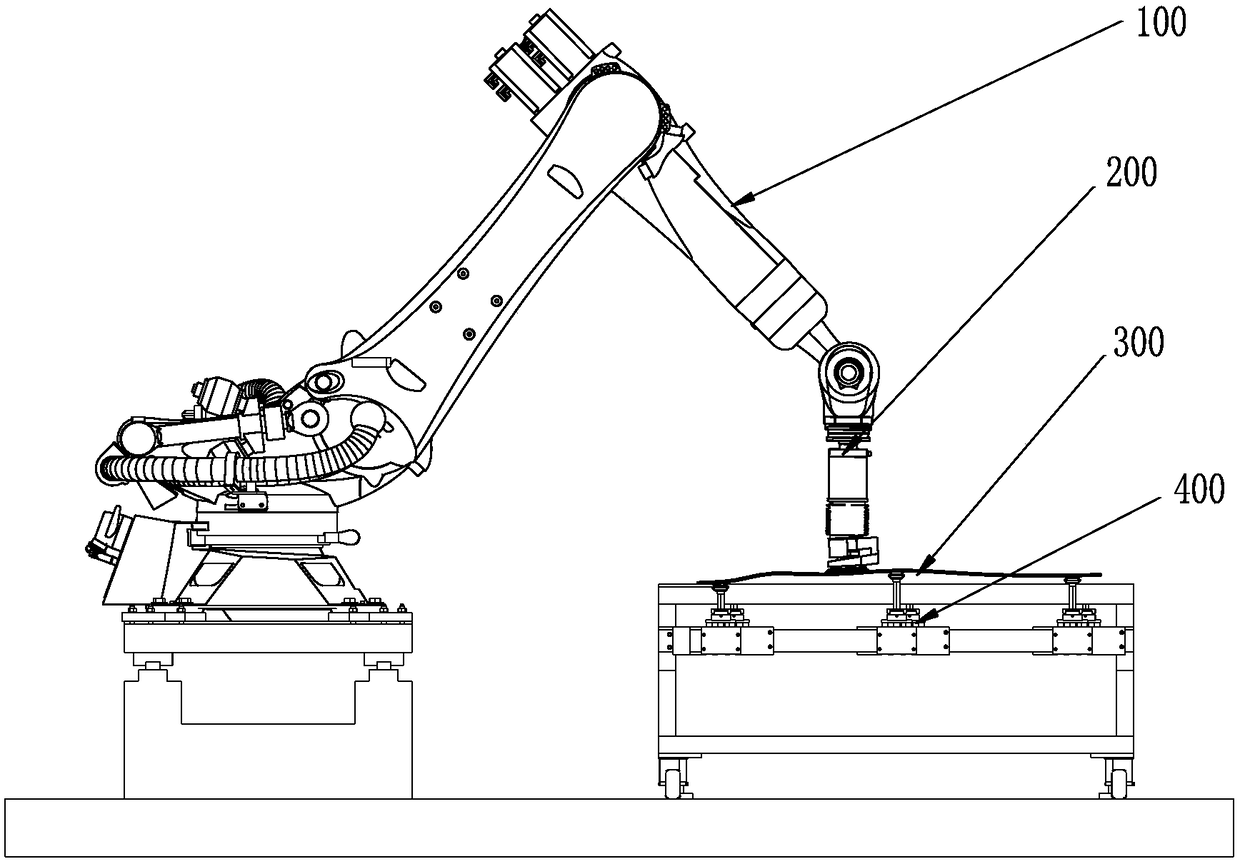

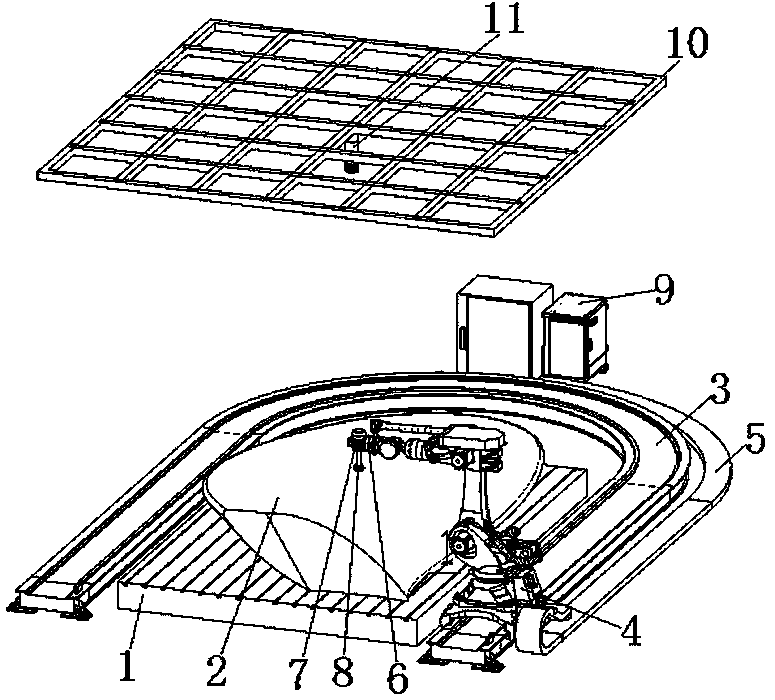

Free-form surface robot polishing system

ActiveCN103878666AWith soft force control functionKeep the pressure constantGrinding drivesGrinding machinesFree formMachined surface

The invention discloses a free-form surface robot polishing system. The system comprises a workbench, an industrial robot, a robot control cabinet, a polishing tool, a pneumatic main shaft, a connecting part, a pneumatic control cabinet and a system control cabinet. The system is high in automation degree, high in flexibility and particularly suitable for polishing a free-form surface. Specifically, the pneumatic main shaft fixed at the tail end of the industrial robot is used for clamping the polishing tool, the machined surface is tightly pressed by the polishing tool all the time by means of the pneumatic compliant force control function of the pneumatic main shaft, constant pressure is kept, the pose of the industrial robot is adjusted according to a planned route, the polishing pressure is in the normal direction of the machined surface, the polishing tool rotates at high speed through a pneumatic motor of the pneumatic main shaft, and then the industrial robot drives the polishing tool to polish a part according to the planned route.

Owner:中科君胜(深圳)智能数据科技发展有限公司

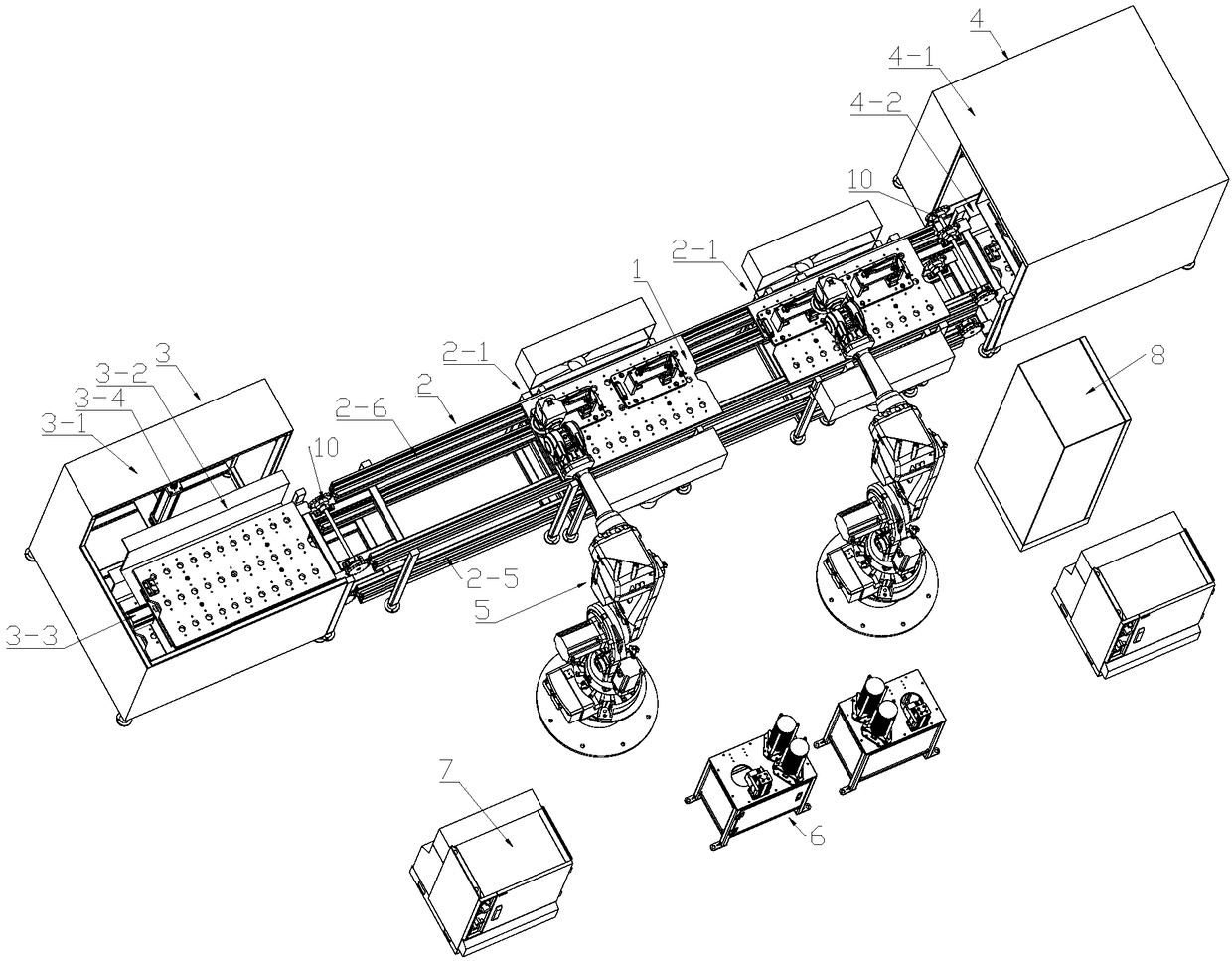

Robot parallel polishing system

ActiveCN103862340APressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

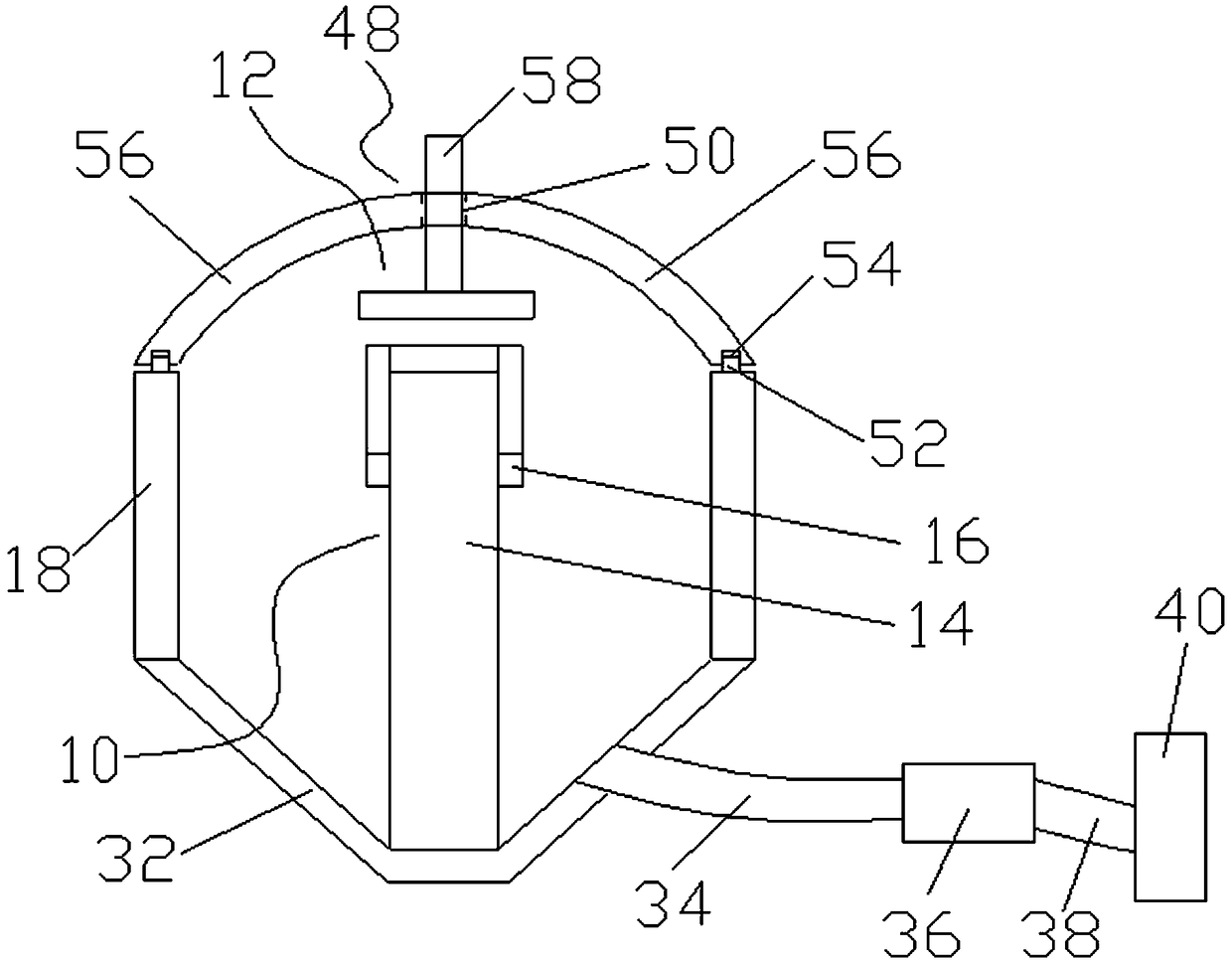

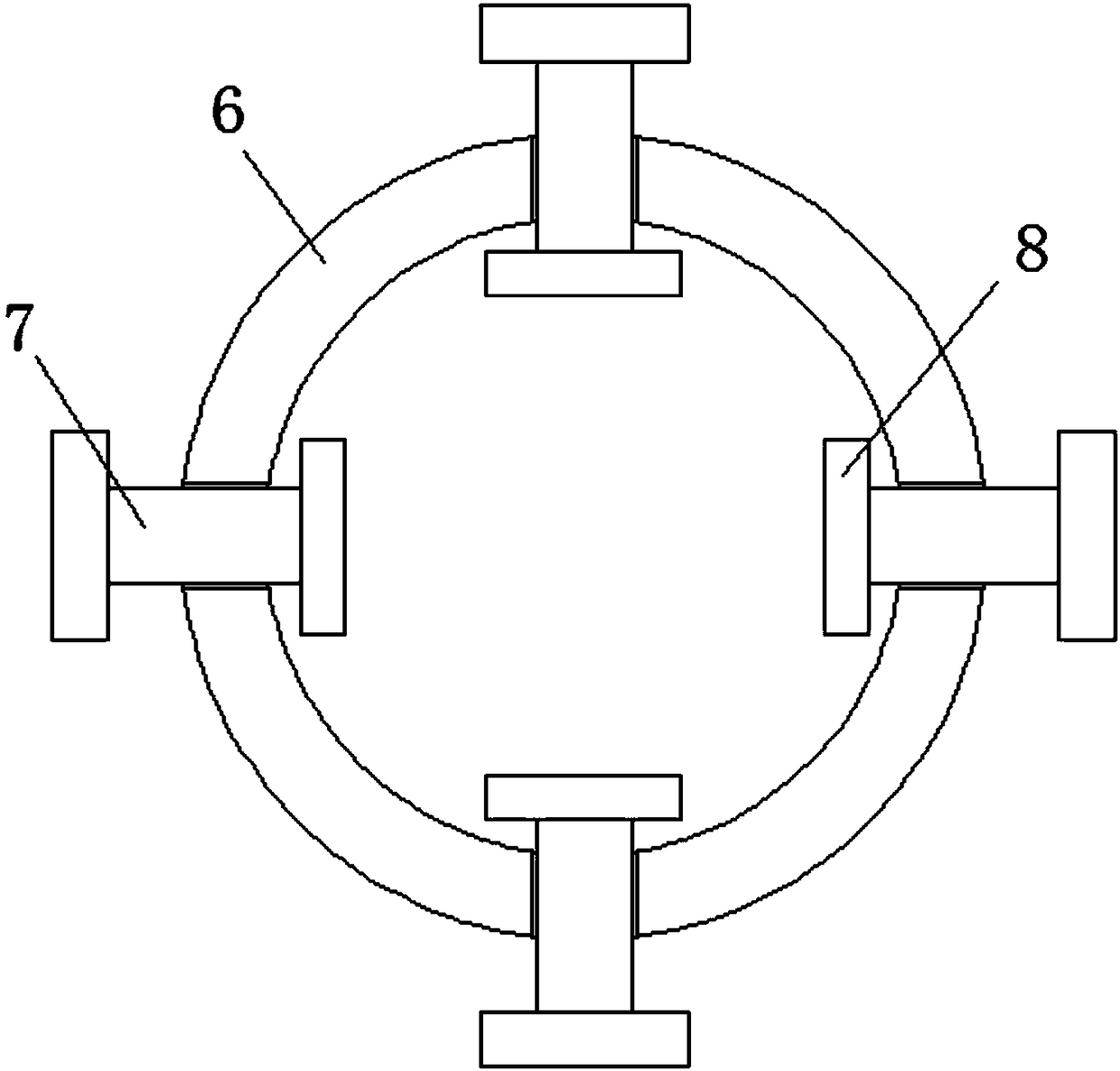

Grinding device for ring-shaped workpieces

ActiveCN109015138AAvoid flyingKeep healthyRevolution surface grinding machinesGrinding work supportsEngineeringElectromagnet

The invention relates to a grinding device for ring-shaped workpieces. The grinding device for the ring-shaped workpieces comprises a vertical frame, a clamping assembly and a grinding mechanism, wherein the vertical frame comprises a stand column and at least one stop block fixed to the stand column; a cylinder is arranged outside the stand column; the clamping assembly comprises three clamping parts arranged in the circumferential direction at equal intervals; each clamping part comprises a first circular arc plate, a second circular arc plate, a spring connected with the first circular arcplate and the second circular arc plate, and two iron rods connected with the first circular arc plate; each iron rod extends out of the cylinder; three electromagnets are arranged outside the cylinder, and each electromagnet corresponds to the two iron rods of the corresponding clamping part; the grinding mechanism is located above the stand column; a dust collection trough is fixed below the stand column and connected with a fan through a first air duct; and the fan is connected with a dust storage barrel through a second air duct. By means of the grinding device for the ring-shaped workpieces, the to-be-ground ring-shaped workpieces are tightly positioned, the grinding quality is good, and due to dual matching of the dust collection trough and a dust hood, dust flying is avoided.

Owner:SUZHOU SUTENG ELECTRONICS TECH

Polishing device for automobile parts

InactiveCN107322473AEasy to holdEasy to clamp and fixEdge grinding machinesGrinding work supportsLitterArchitectural engineering

The invention discloses a grinding device for auto parts, which comprises a working platform, a dust collection box, a waste box, a grinding wheel, a movable splint, a fixture seat and a fixed splint. The inner end of the fixed plate is fixedly provided with a slide plate, the movable splint is fixedly arranged on the surface of the right side wall of the slide plate, the right part of the fixture seat is fixedly installed with a fixed plate, the surface of the left side wall of the fixed plate is fixedly provided with a fixed splint, the inner cavity of the dust box A dust filter is arranged in the middle, and a fan is fixedly installed on the upper surface of the left part of the support base, and the air intake end of the fan communicates with the left inner cavity of the dust collection box. The invention is simple in structure, easy to use, has good clamping and fixing effect on the auto parts to be polished, improves the grinding quality of the auto parts, and can effectively collect and separate the dust and iron filings generated in the grinding process, improving the quality of the auto parts. The comfort of the processing environment.

Owner:叶巧敏

Automatic grinding device

The invention discloses an automatic grinding device. The automatic grinding device comprises a working table, a conveyor belt and at least one grinding mechanism, wherein the conveyor belt is arranged on the working table, and the grinding mechanism is arranged above the conveyor belt. The grinding mechanism comprises a driving wheel, a driven wheel, a grinding motor and an abrasive belt, wherein the driving wheel and the driven wheel are arranged on the two sides of the conveyor belt respectively, the grinding motor is connected with the driving wheel and supplies power to the driving wheel, and the abrasive belt winds the surface of the driving wheel and the surface of the driven wheel. The abrasive belt winds the driving wheel and the driven wheel and makes contact with grinded materials to form a grinding plane. The automatic grinding device is high in grinding efficiency, good in grinding effect, high in accuracy, and especially suitable for grinding different materials.

Owner:徐成炳

Automobile tire grinding and grooving integrated device

ActiveCN111702575AImprove efficiencyReduce the temperatureRevolution surface grinding machinesMetal working apparatusMechanical engineeringIntegrated devices

The invention provides an automobile tire grinding and grooving integrated device. The automobile tire grinding and grooving integrated device comprises a base, a rotary supporting component, a rotating shaft, and a supporting plate; the center of the top of the base is rotatably connected to the rotary supporting component; the rotary supporting component comprises the rotating shaft and the supporting plate; the top of the rotating shaft is fixedly connected with the supporting plate; the supporting plate is circular; the rotating shaft is rotatably connected to the center of the base; a mounting groove is formed in the upper end of the base and is positioned between the rotary supporting component and a supporting transmission device; a No. 1 driving device is mounted in the mounting groove; the No. 1 driving device is in transmission connection with the supporting transmission device; slots are formed in the position, positioned on the front side of the rotating device, at the upper end of the base and one side, close to the rotary supporting component, of the base; the slots are overlapped by rotating at 90 degrees; and the upper end of the rotary supporting component is horizontally clamped with a tire. The invention provides the automobile tire grinding and grooving integrated device, which solves the problems that the time and labor are wasted and the efficiency is lowwhen the tire is ground and grooves manually, the upper arc-shaped end surface and the lower arc-shaped end surface of the tire are ground unevenly by the existing mechanical grinding equipment.

Owner:庄慧明

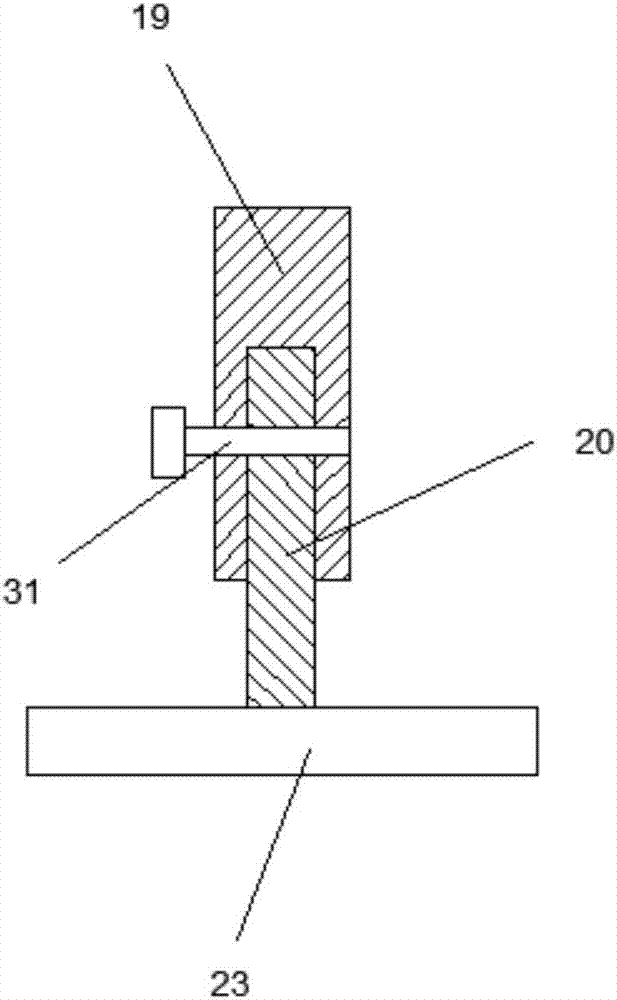

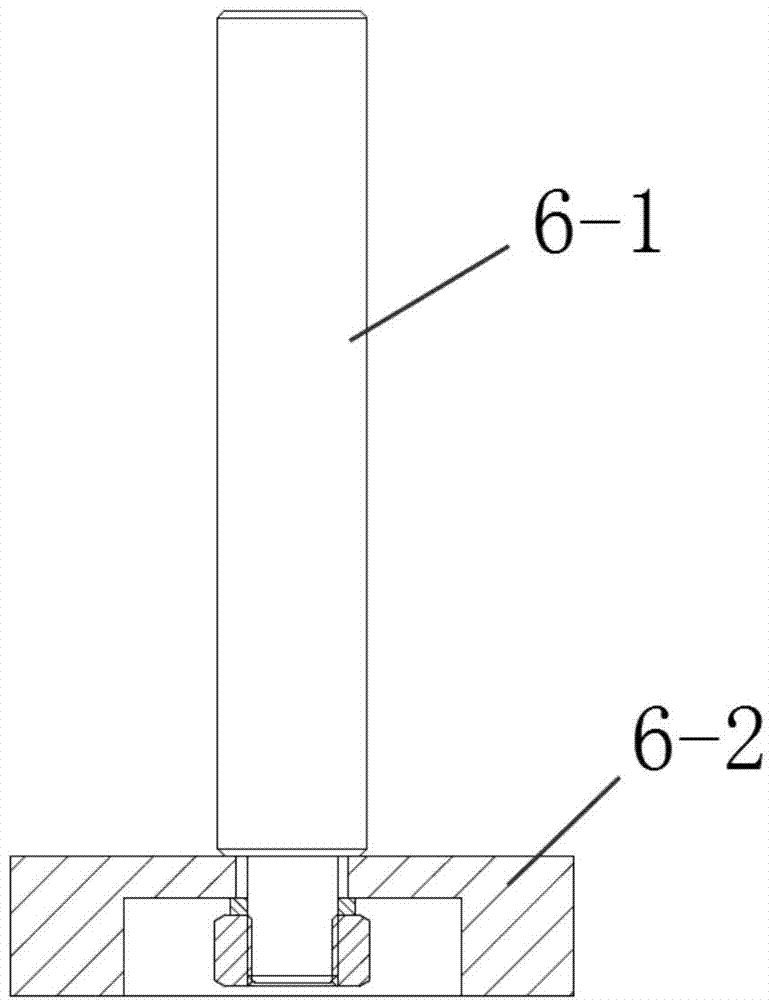

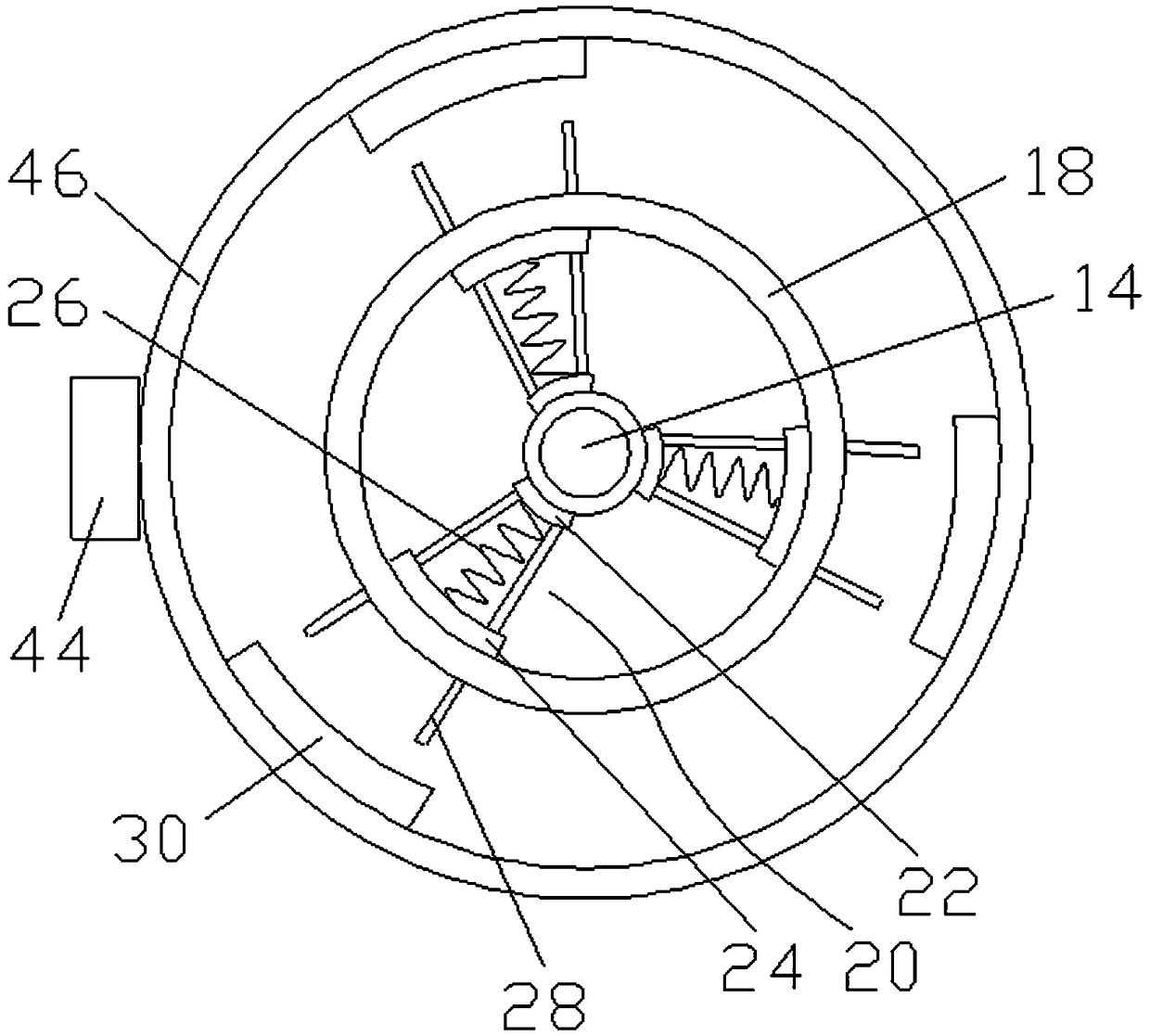

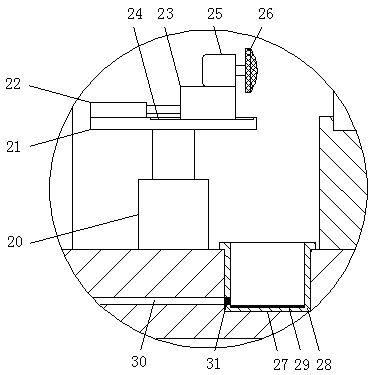

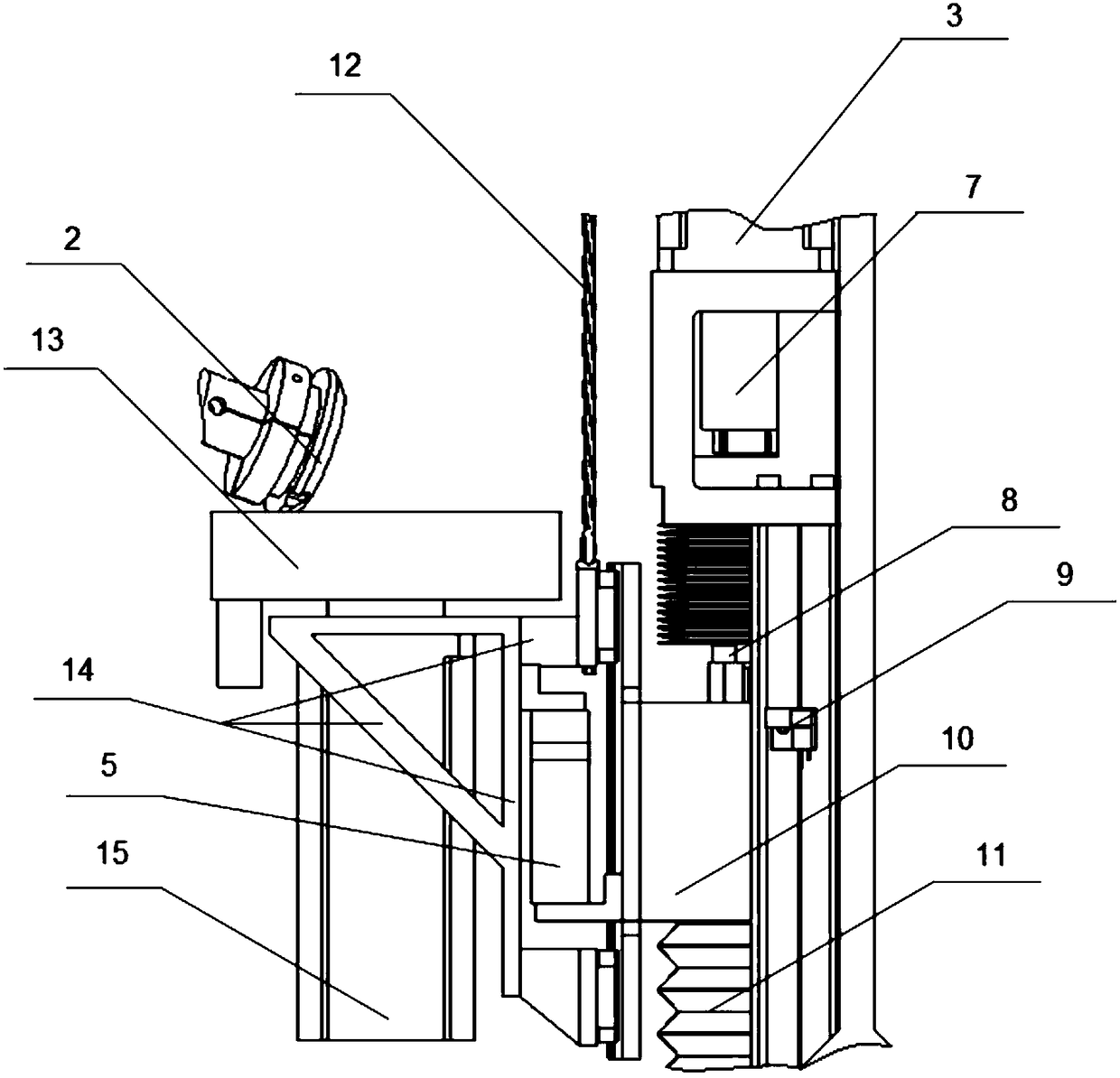

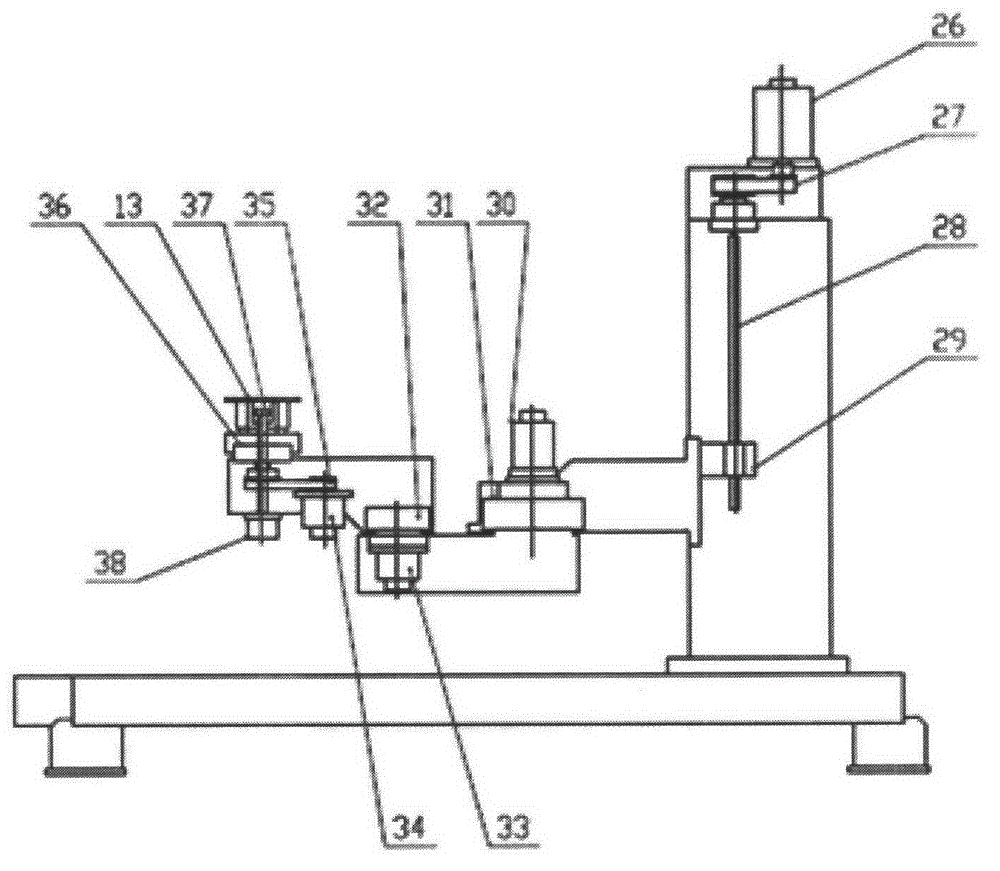

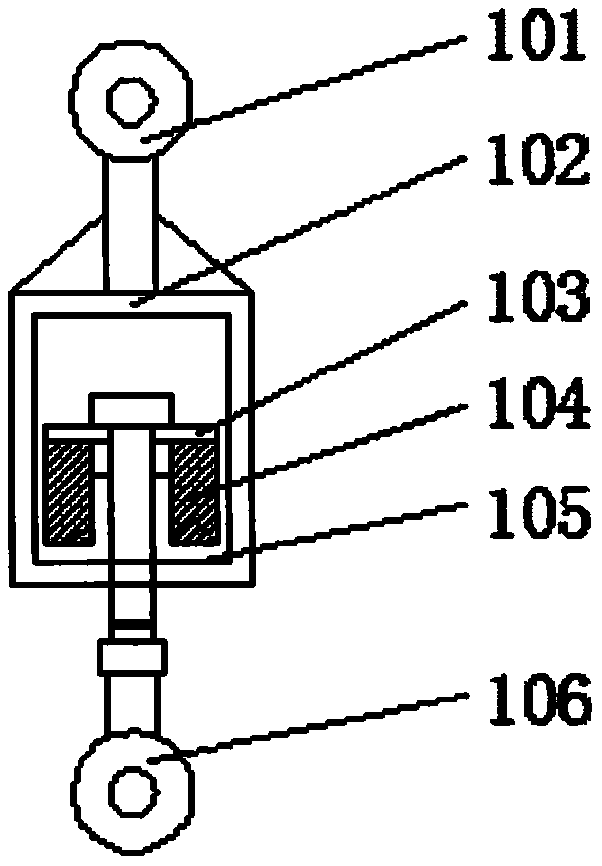

Constant force actuator for installing grinding head

PendingCN108908117AConstant grinding forceStable grinding accuracyGrinding wheel securing apparatusGrinding feed controlConstant forceControl system

The invention relates to a constant force actuator for installing a grinding head. The equipment comprises an actuator support seat, a dual-action low-friction air cylinder, an output end flange, a gap matching type linear bearing, a linear displacement sensor, an electric control system and a universal movable mechanism, wherein the dual-action low-friction air cylinder is arranged in the centerposition of the actuator support seat; a first electric proportional pressure regulating valve and a second electric proportional pressure regulating valve of the electric control system are arrangedat the output end of an air source main control valve in parallel; the output ends of the first electric proportional pressure regulating valve and the output end of the second electric proportional pressure regulating valve are respectively communicated with cavities formed in two sides of a piston of the dual-action low-friction air cylinder; the output end of the piston rod of the air cylinderis connected with an output end flange and can drives the output end flange to axially move; a clearance fit linear bearing is arranged at the outer side of the dual-action low-friction air cylinder;the output end flange and the actuator support seat are connected through the clearance fit linear bearing; the linear displacement sensor is arranged at the side surface of the dual-action low-friction air cylinder; the universal movable mechanism is connected with and arranged at the lower part of the output end flange.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

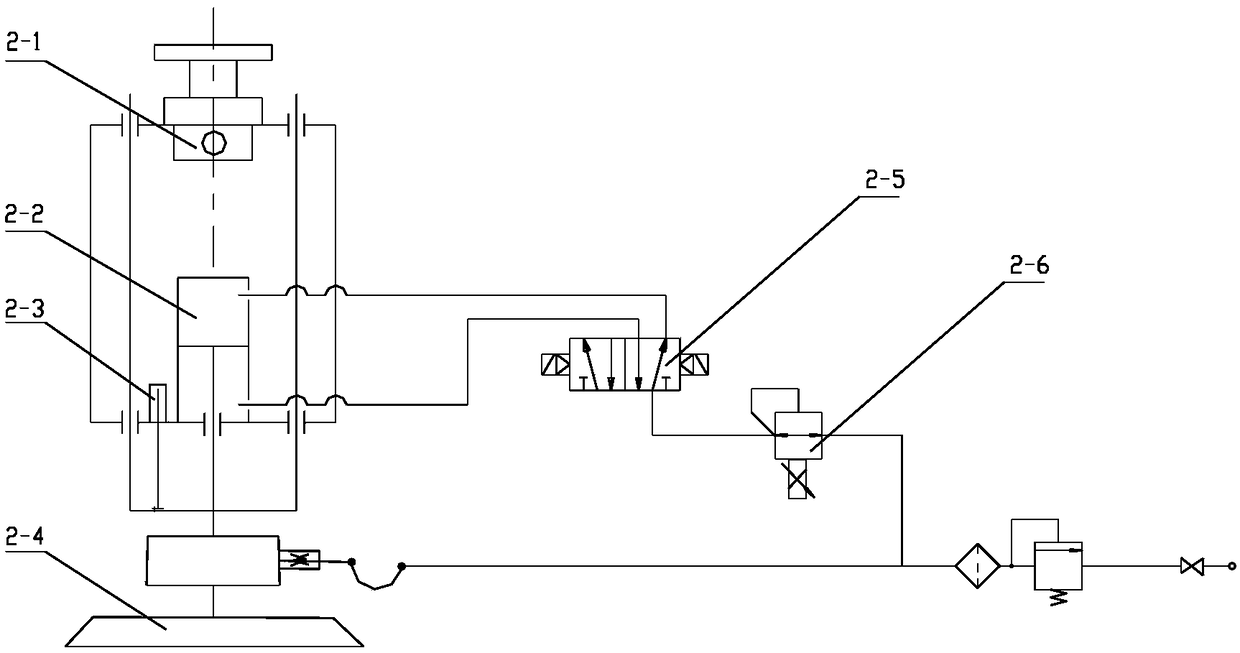

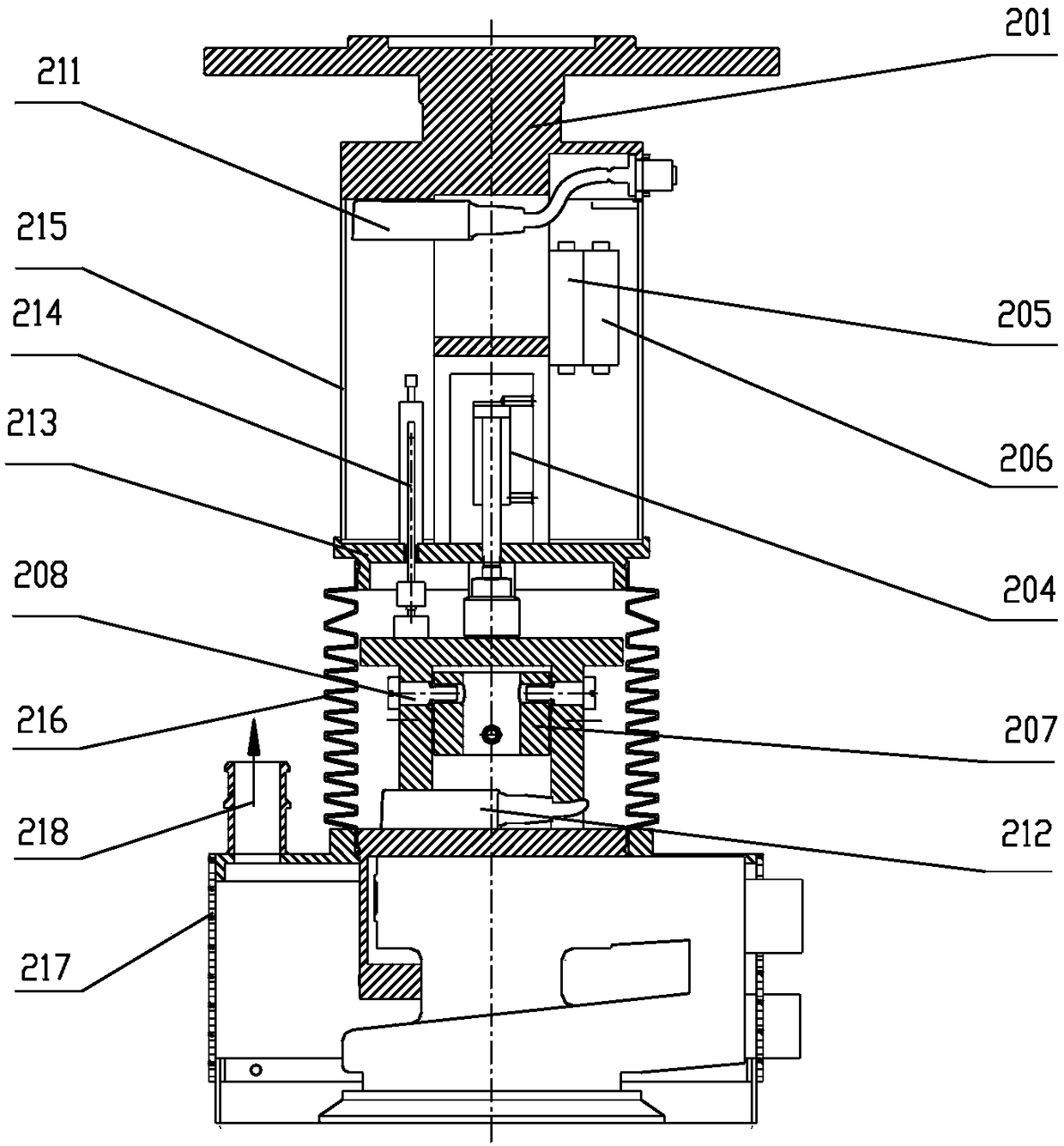

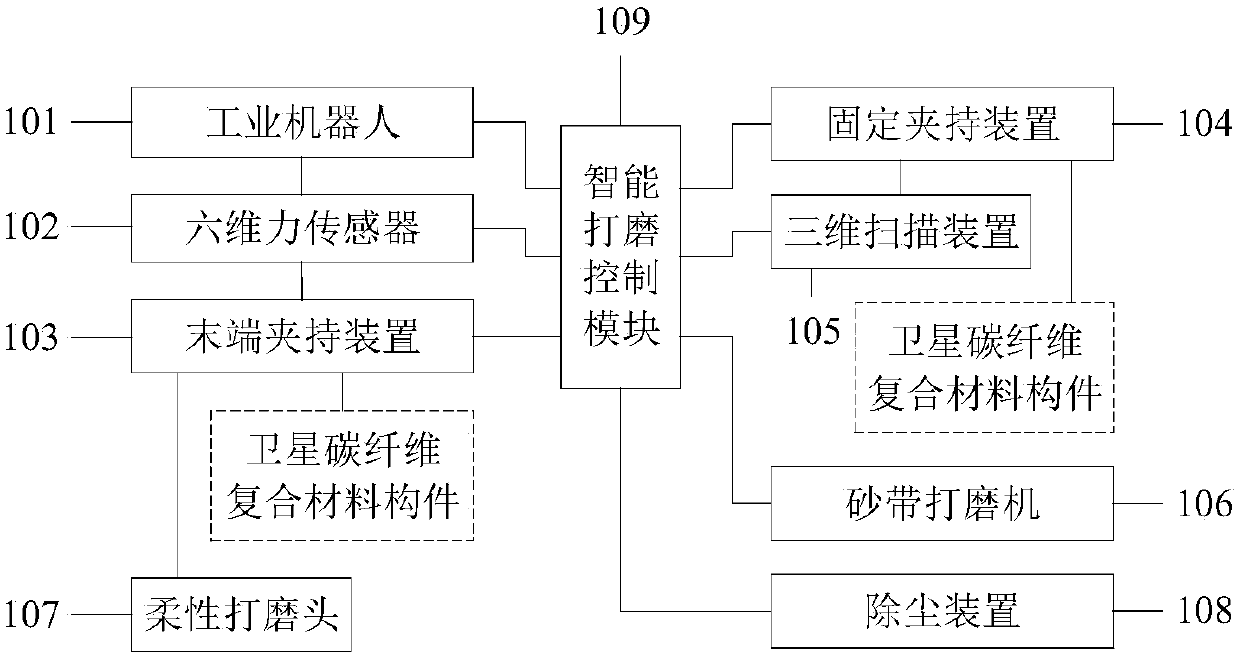

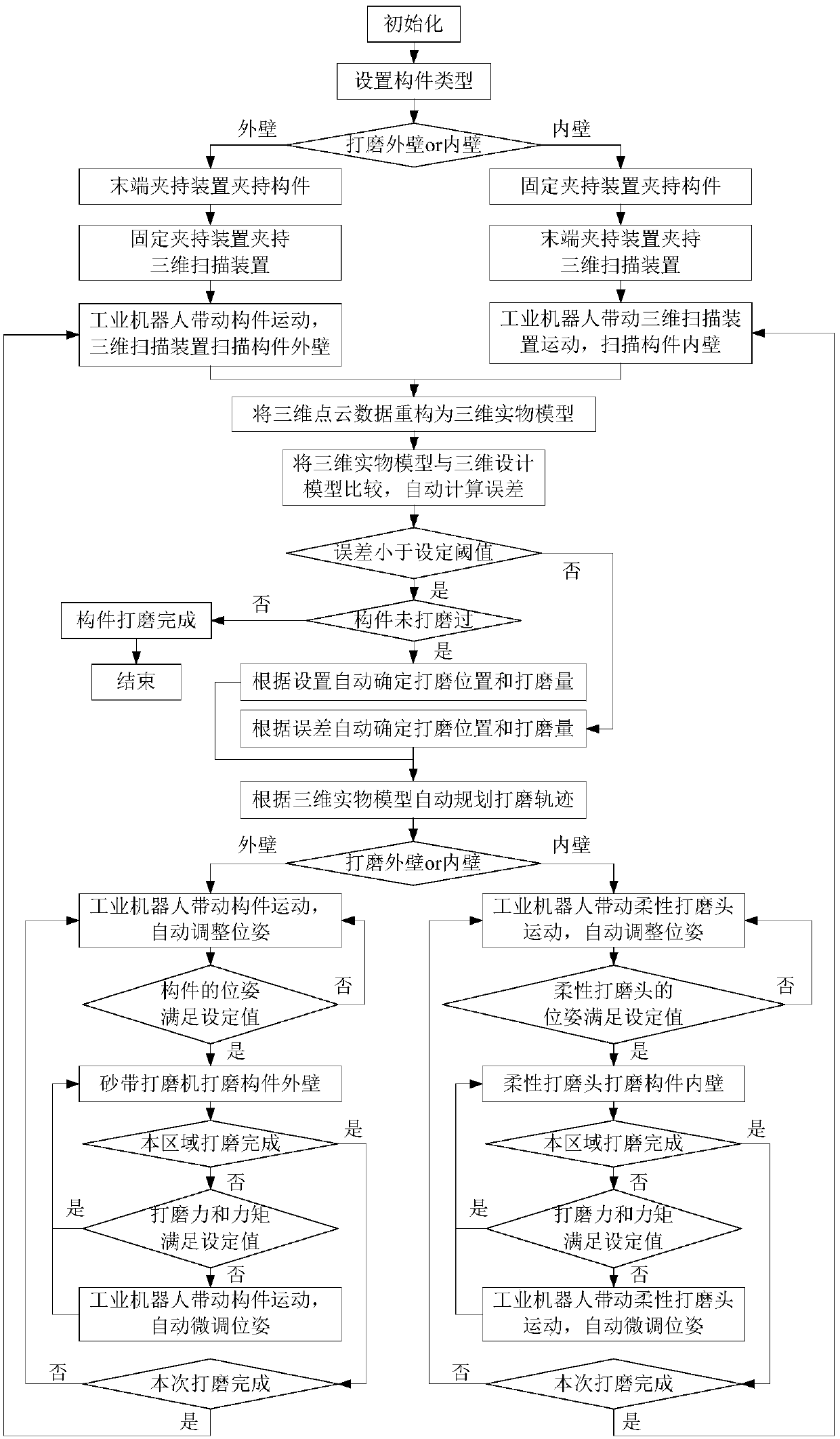

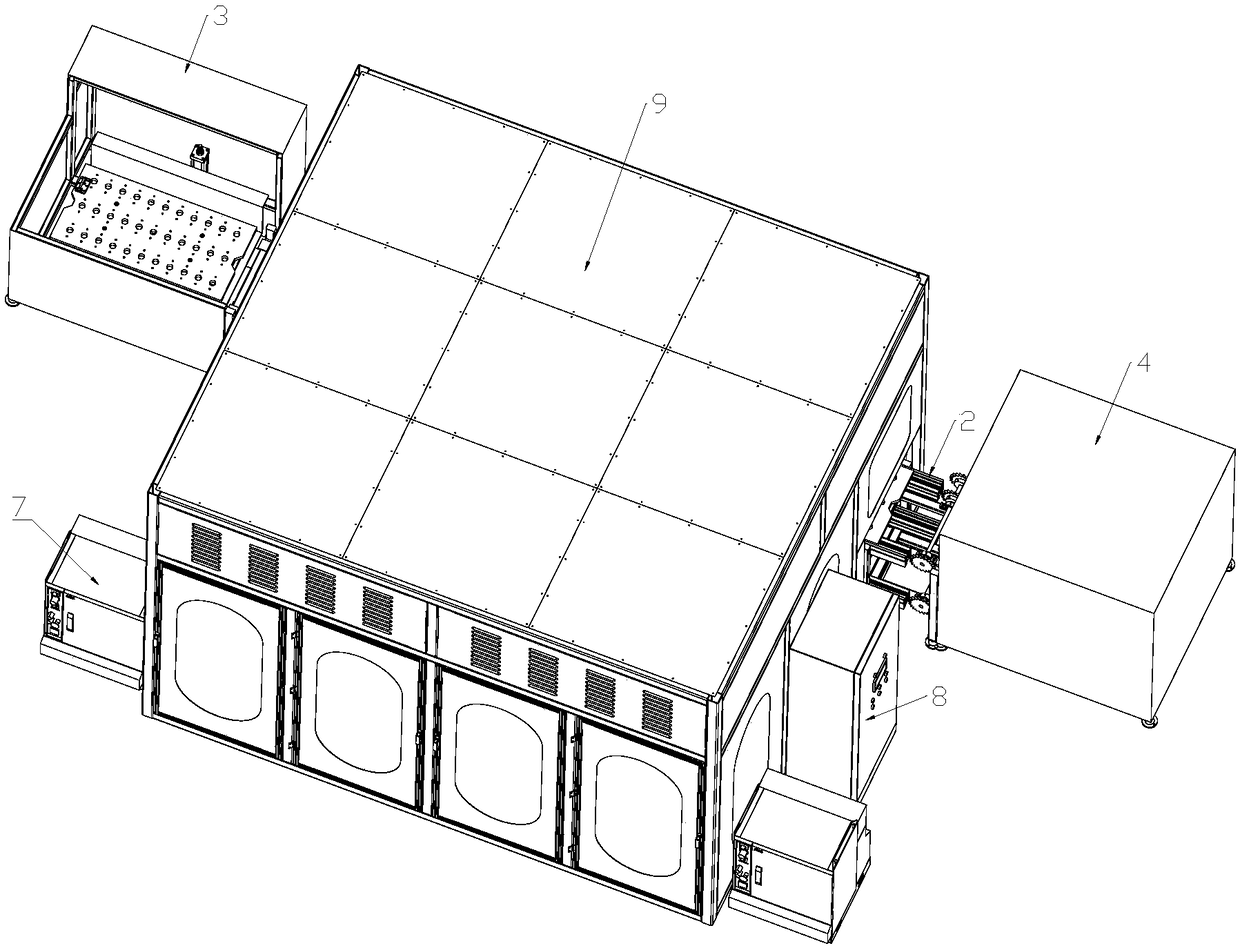

Intelligent grinding system and method as well as computer readable storage medium

ActiveCN109590815AImprove scalabilityImprove reliabilityBelt grinding machinesGrinding feed controlControl systemClosed loop

The invention provides an intelligent grinding system and method as well as a computer readable storage medium. The intelligent grinding system comprises an industrial robot, a six-dimensional force sensor, a tail end clamping device, a fixed clamping device, a three-dimensional scanning device, a sanding belt grinding machine, a flexible grinding head, a dust removal device and an intelligent grinding control system. According to the system, the method and the computer readable storage medium, the high-precision force-controlled grinding of a component is realized by utilizing the industrialrobot and the six-dimensional force sensor, the high-precision measurement of the component is realized by utilizing the three-dimensional scanning device, and the measurement-grinding process is automatically repeated in a closed-loop mode until the component precision meets a set value, the intelligent grinding of satellite carbon fiber composite material components with multiple varieties and single-piece small-batch can be completed, manual work is replaced, and the grinding quality and the grinding efficiency are improved.

Owner:SHANGHAI INST OF SATELLITE EQUIP

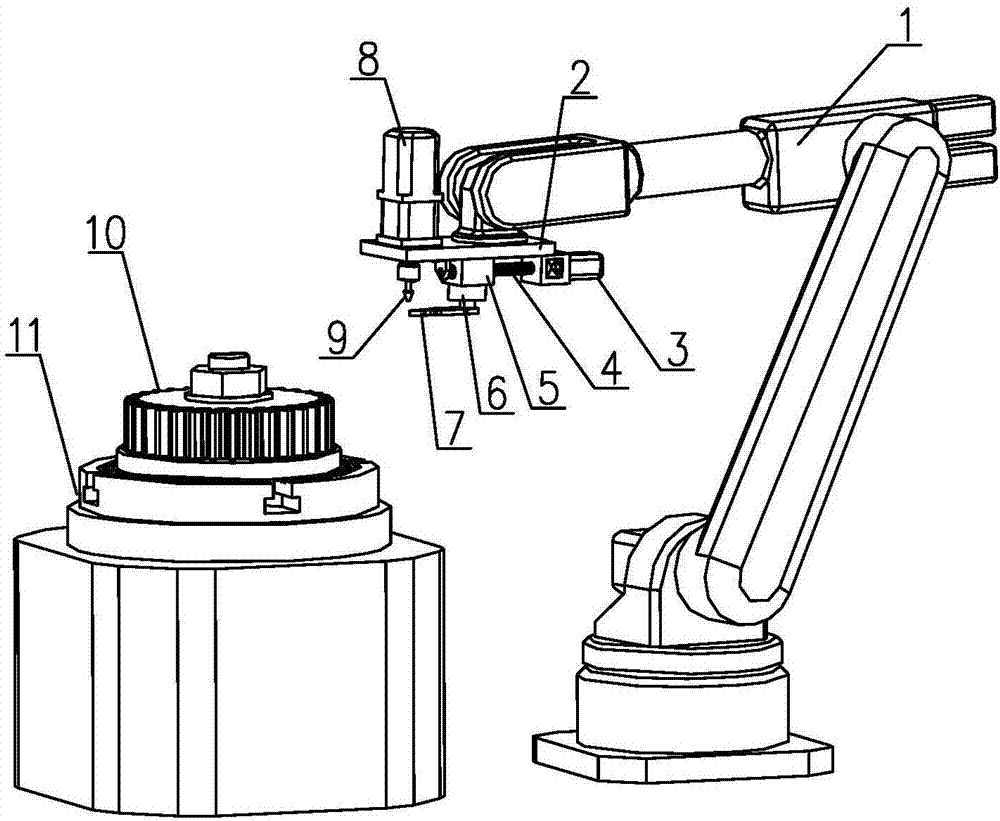

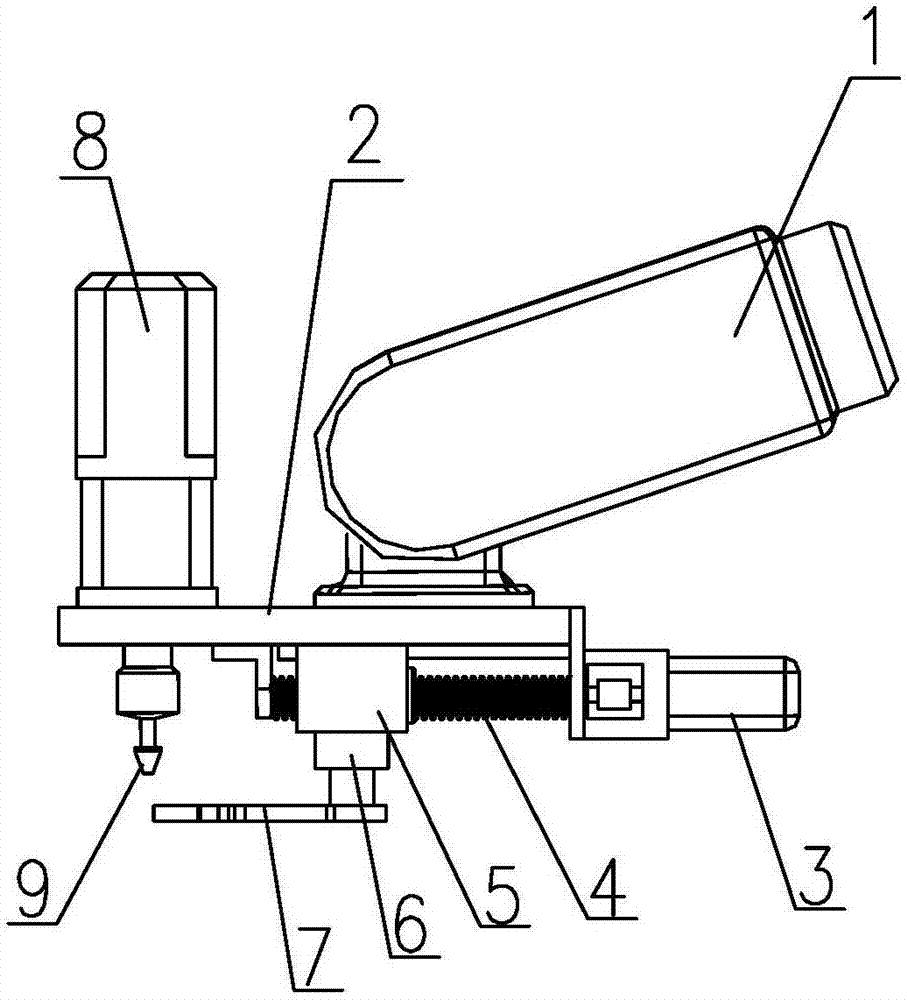

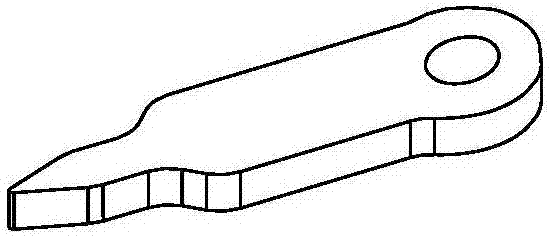

Mechanical hand for carrying out chamfering polishing on end face of gear and polishing method thereof

PendingCN107876904AControllable contact forceImprove machining accuracyManipulatorGear teethRobot handContact pressure

The invention provides a mechanical hand for carrying out chamfering polishing on the end face of a gear. A probe at the tail end of the mechanical hand and a polishing head are arranged to be an integrated linkage whole, a master controller enables the probe to make contact with the gear at the set contact pressure value, and the probe is arranged to be a sensor which monitors the contact pressure value in real time. The master controller adjusts the contact pressure value at the next moment. The displacement path of the probe is the polishing path of the polishing head. The invention furtherprovides a polishing method of the mechanical hand for carrying out chamfering polishing on the end face of the gear. The method comprises the steps that 1, the probe makes contact with the edge of the gear at the set contact pressure value; 2, when the gear is rotated, a force sensor feeds the real-time contact pressure value of the probe and the gear back to the master controller; 3, the position of the probe at the next moment is adjusted to enable the probe to be in tight fit with the gear, and copying description is carried out the gear contour; and 4, the polishing head and the probe are in integrated linkage, and the copied contour described by the probe is converted to be the polishing path of the polishing head. The contact force of the probe and the surface of the gear is controllable, the machining precision is high, and polishing quality is good.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lightweight anti-abrasion steel casting piece edge polishing device and edge polishing method thereof

InactiveCN110125753AAvoid damageStable jobEdge grinding machinesGrinding drivesMetallurgySteel casting

The invention discloses a lightweight anti-abrasion steel casting piece edge polishing device and an edge polishing method thereof. The lightweight anti-abrasion steel casting piece edge polishing device comprises a base; a workbench is fixedly arranged at the top end of the base and internally provided with a rotary device; the top end of the rotary device is provided with a rotary table, and therotary table is rotationally installed at the top end of the workbench; the left side and the right side of the top end of the base are provided with symmetrically-distributed supporting columns, thetop ends of the supporting columns are fixedly provided with a top plate, and the top plate is provided with a fixing device; the fixing device is arranged over the rotary table; the top end of the base is provided with a polishing device, a cooling device is arranged above the polishing device, and the cooling device is fixed to the top plate and located between the polishing device and the rotary table. The lightweight anti-abrasion steel casting piece edge polishing device can conveniently polish casting pieces, is high in polishing quality and good in polishing effect, and can conduct centralized processing on chippings generated during polishing, and cleaning is convenient.

Owner:昆山鑫启盛精密配件有限公司

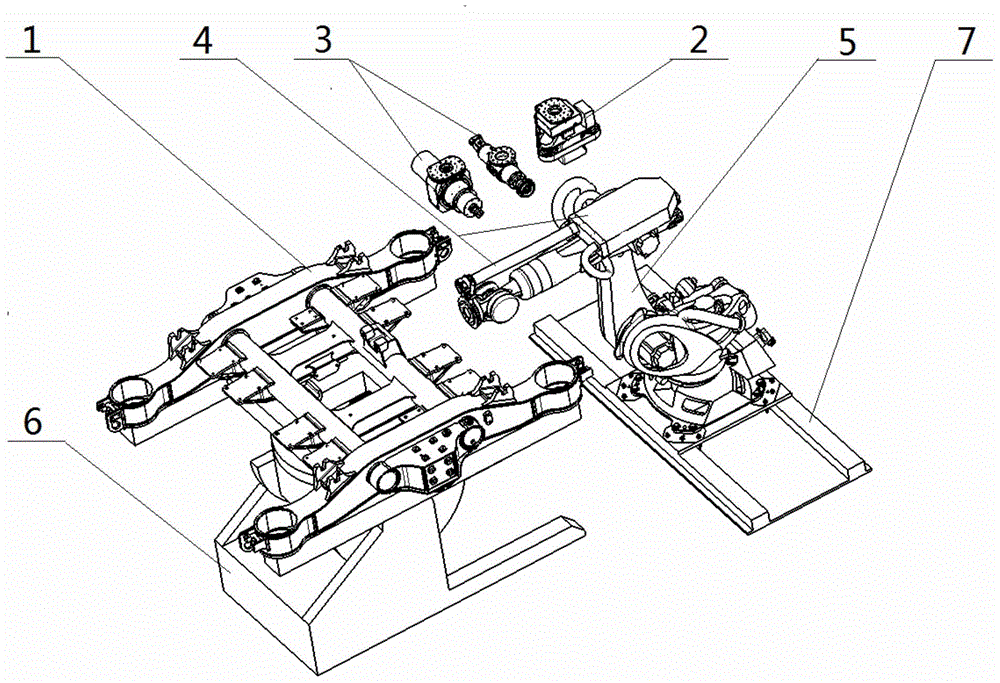

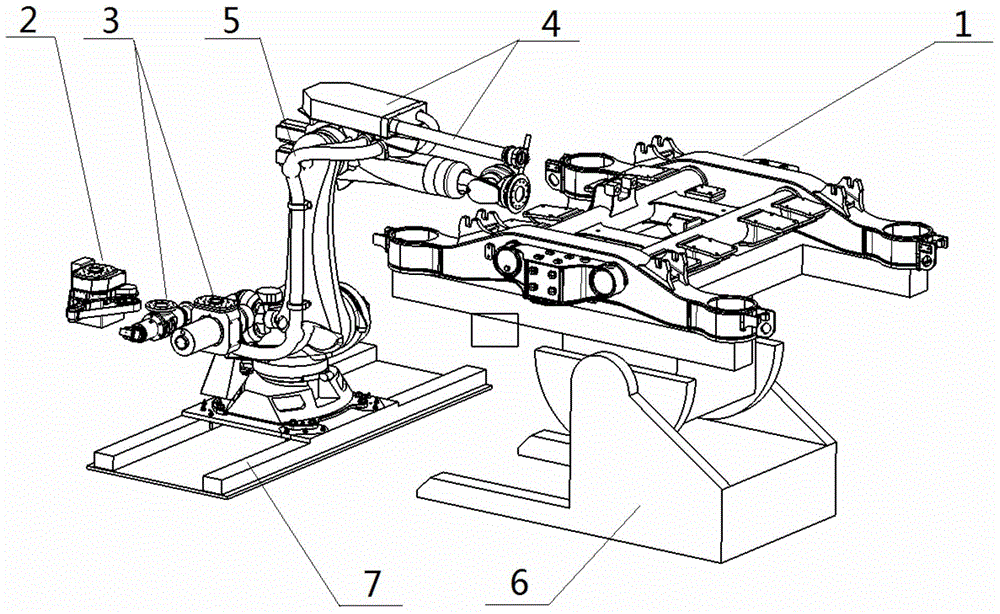

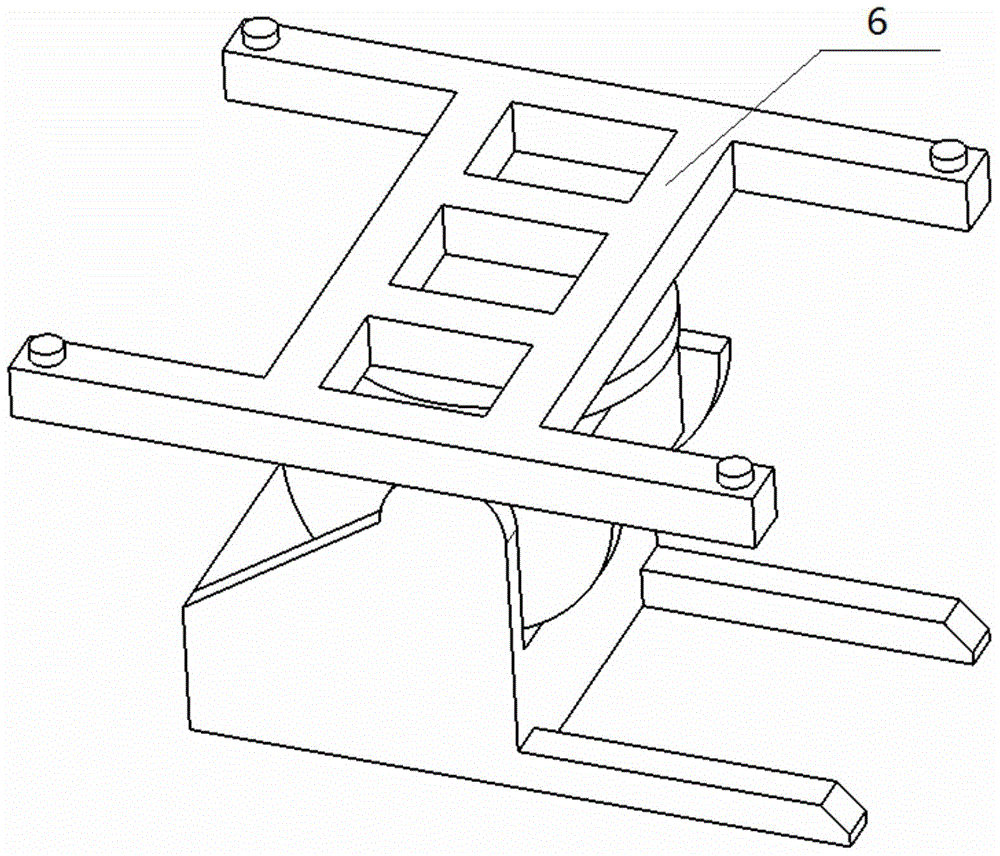

Polishing method and system

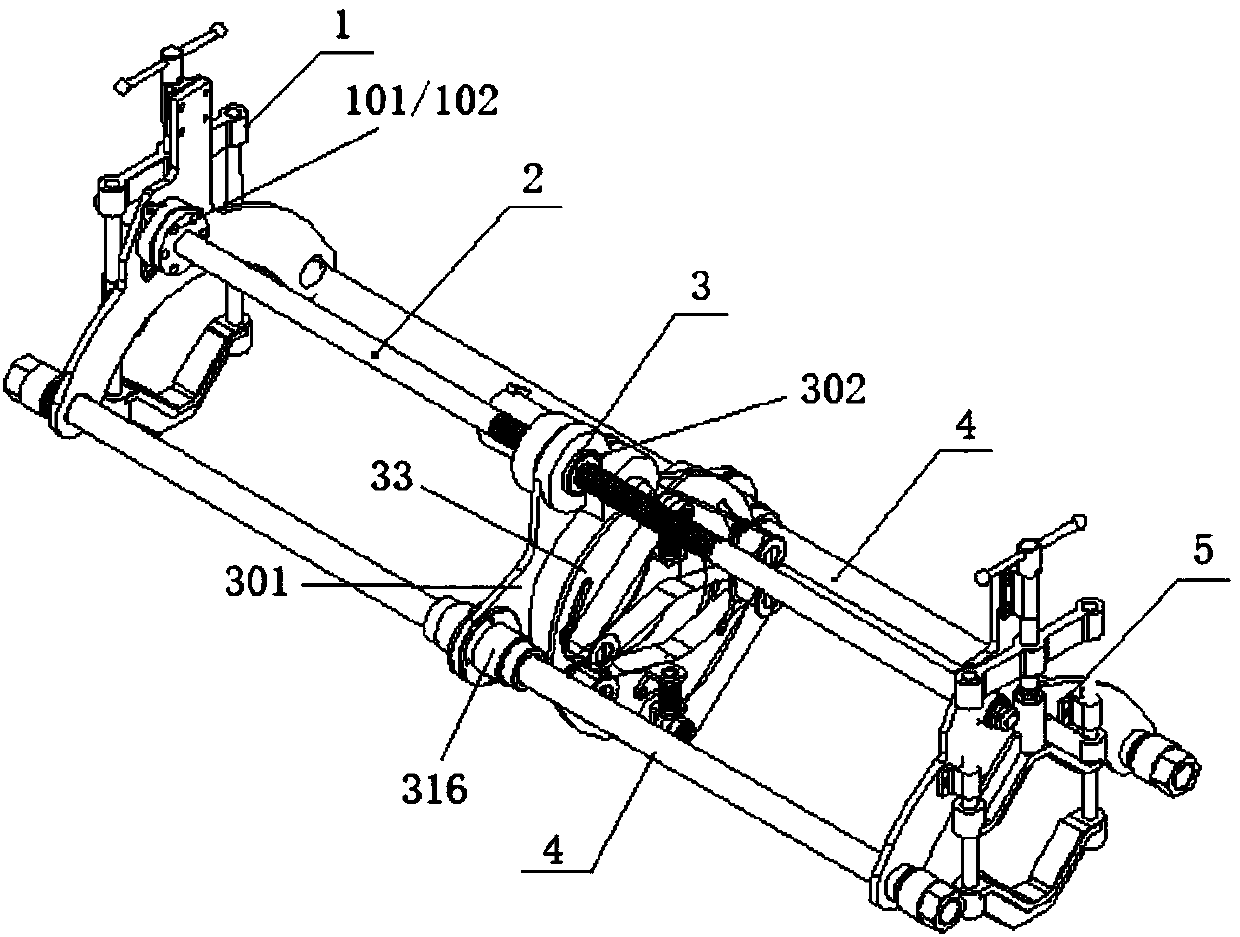

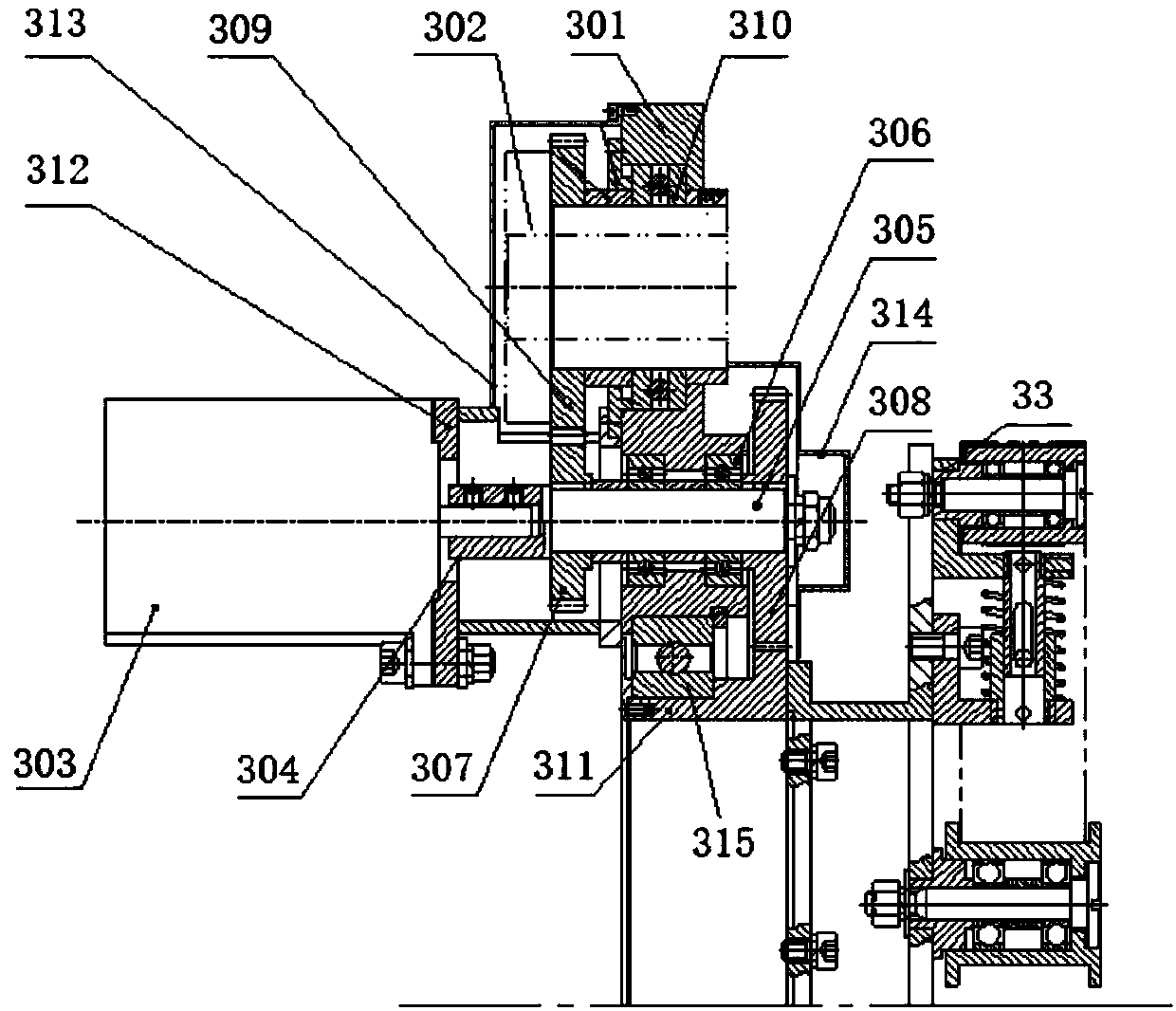

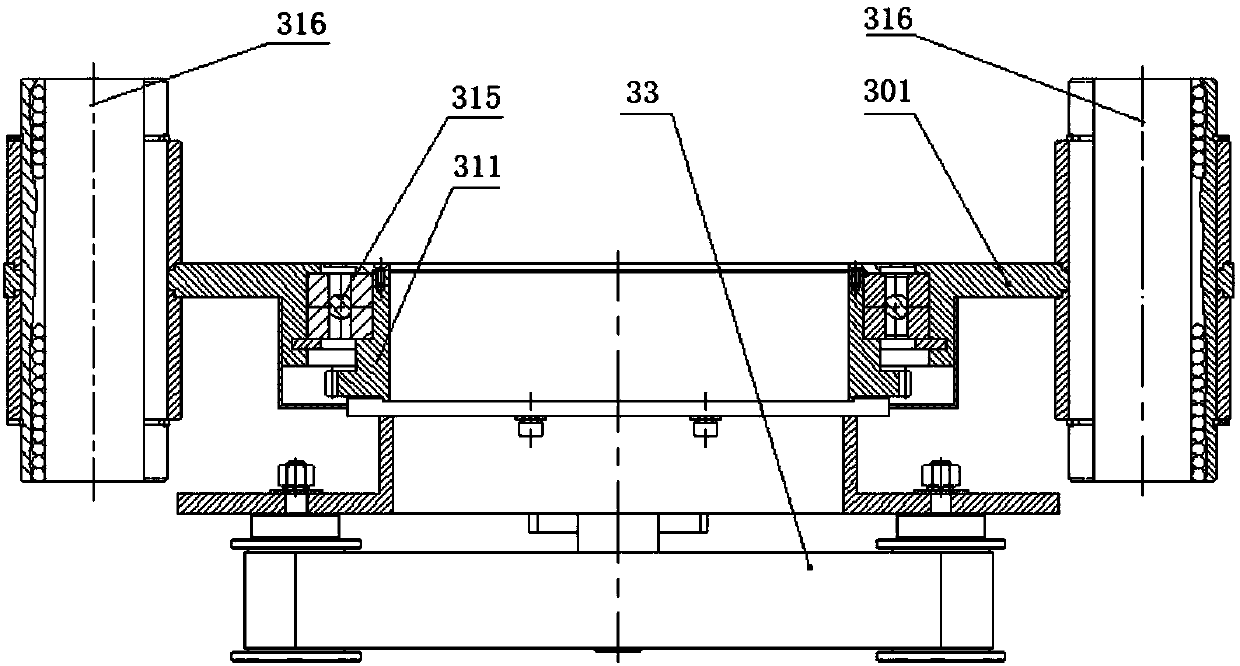

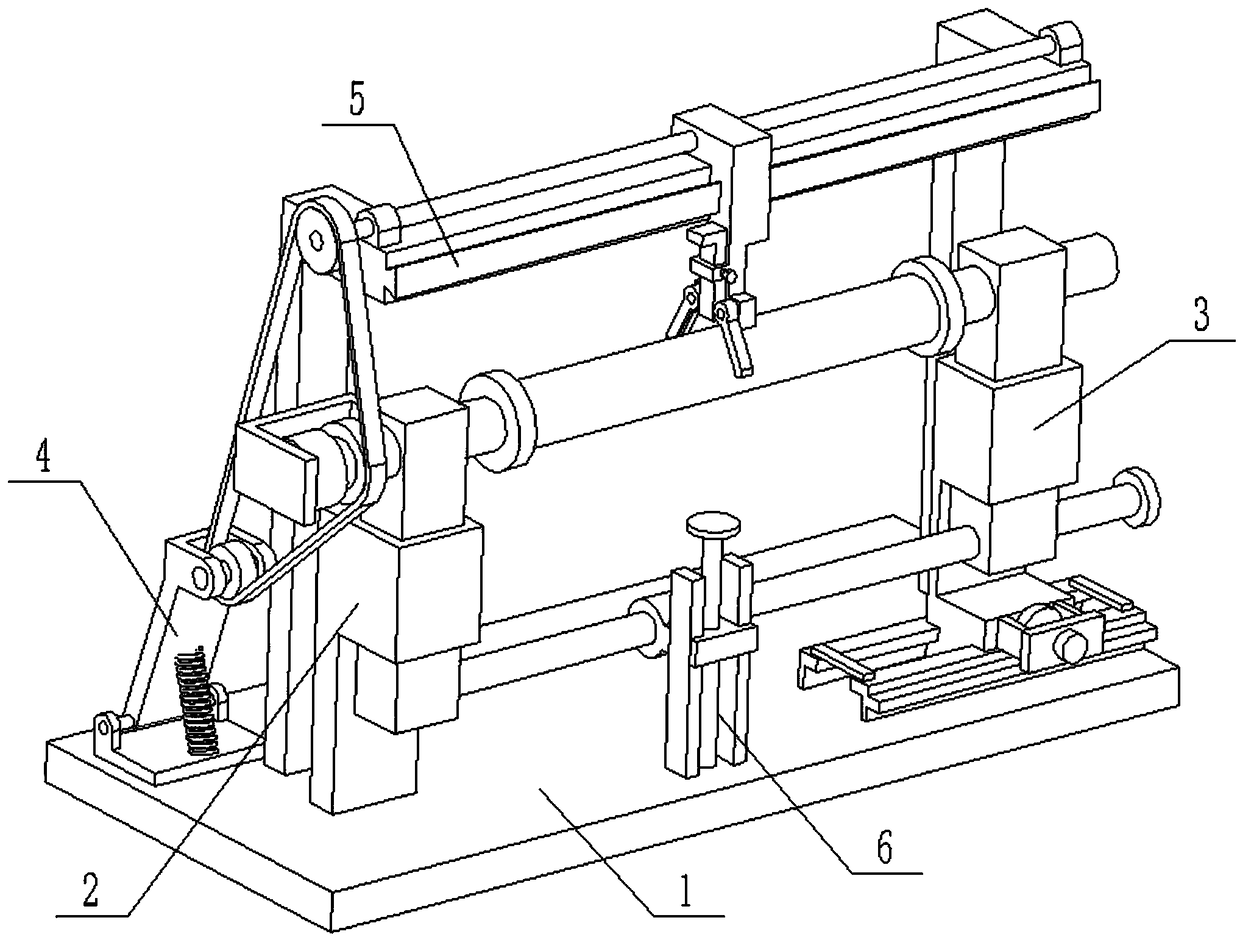

ActiveCN104440469AImprove work efficiencyImprove grinding accuracyGrinding carriagesPolishing machinesBogieAfter treatment

The invention relates to the technical field of after-treatment of the welding technology, in particular to a polishing method and system. A triangular sanding belt, a profiling polishing device and a buffing device are driven by a drive device to conduct polishing on a weld joint of a railway vehicle bogie which is located and clamped to a tool jig, and therefore a surface outline needed by design is obtained. According to the prior art, an automatic polishing technology and device are often used for polishing a non-metal structural component, a metal component, especially the railway vehicle bogie, is polished in the mode that workers hold manual polishing tools to complete polishing operation including profiling polishing, and the manual polishing mode has the defects that the work efficiency is low, and the polishing quality and the polishing precision are poor. Compared with the prior art, the polishing method and system improve the polishing quality and the polishing precision of the weld joint of the railway vehicle bogie and meanwhile improve the working efficiency.

Owner:CRRC QINGDAO SIFANG CO LTD

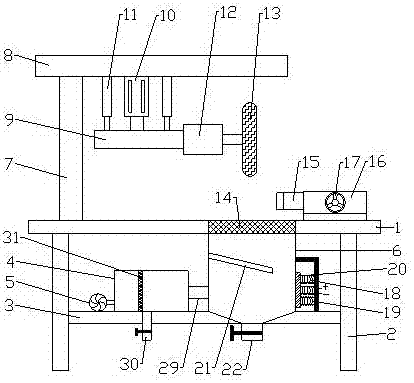

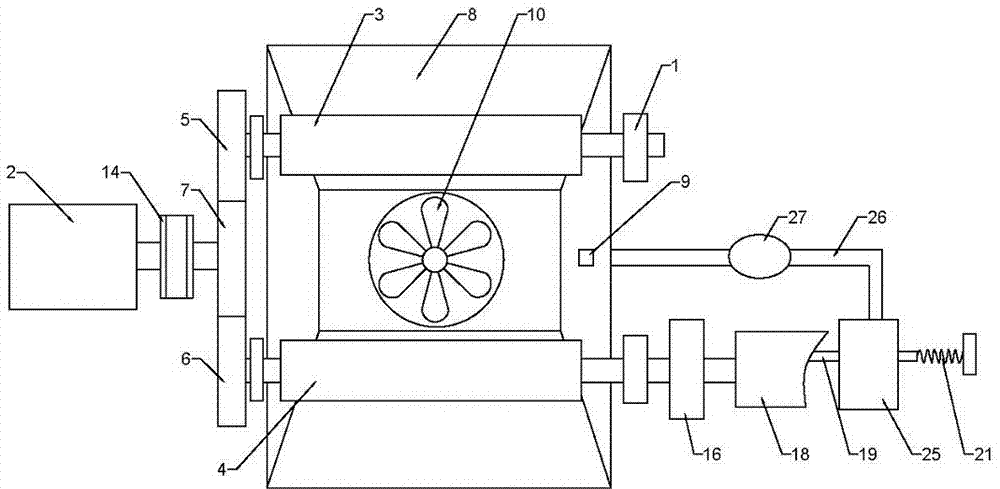

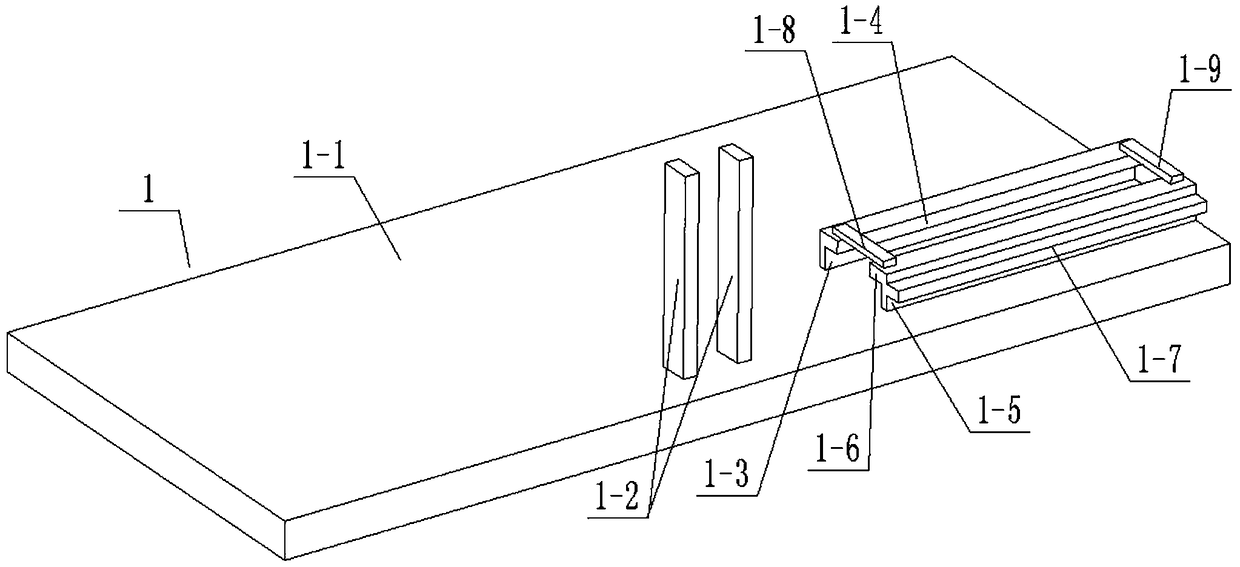

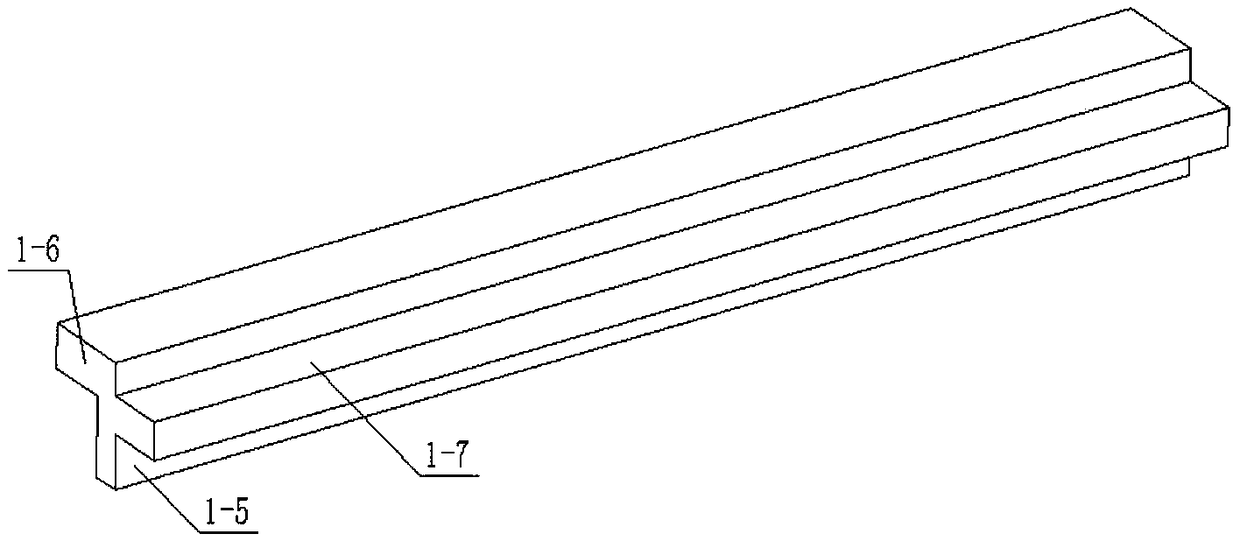

Fine polishing machine for planks

ActiveCN106938427AImprove sanding qualityHigh efficiency of fine grindingGrinding drivesGrinding machinesImpellerInlet valve

The invention relates to the field of polishing devices and discloses a fine polishing machine for planks. The fine polishing machine comprises a rack, a motor, a coarse polishing roller and a fine polishing roller. The coarse polishing roller is connected with a first gear, the fine polishing roller is connected with a second gear, and a third gear is engaged between the first gear and the second gear. A suction hood is arranged below the coarse polishing roller, a nozzle is arranged on the suction hood, an impeller is arranged on the bottom of the suction hood and connected with a first bevel gear, the first bevel gear is engaged with a second bevel gear, the second bevel gear is connected with a first belt wheel, and the motor is provided with a second belt wheel. The end portion of the fine polishing roller is fixedly connected with a cylindrical cam, the cylindrical cam abuts against a mandrel, the mandrel penetrates a polishing cylinder, springs are connected between the mandrel and the rack, a piston plate is fixedly connected to the mandrel, the piston cylinder is provided with a one-way liquid inlet valve and a one-way liquid outlet valve, the one-way liquid inlet valve communicates with a water tank, and the one-way liquid outlet valve communicates with the nozzle. Compared with the prior art, the fine polishing machine has the beneficial effects of being high in polishing efficiency, and the equipment cost is lower.

Owner:山东省博兴县兴博木业有限公司

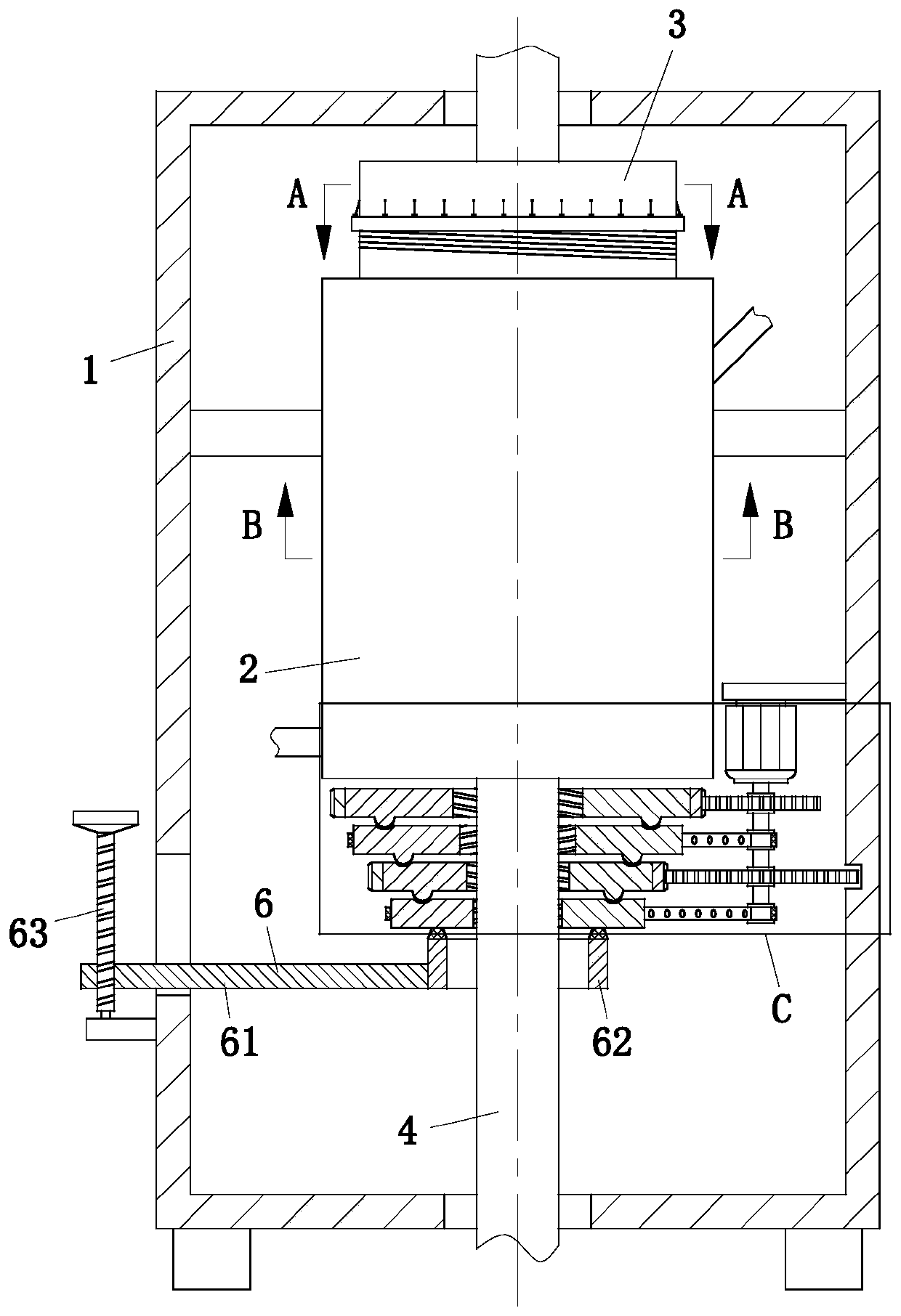

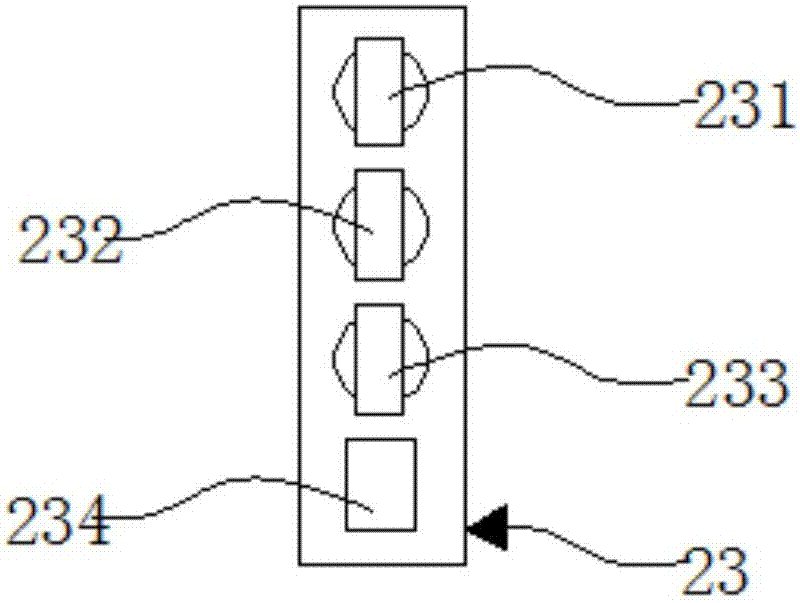

Polishing equipment suitable for steel pipes of different pipe diameters

ActiveCN109702634ASpeed up the flowImprove sanding qualityEdge grinding machinesPolishing machinesSteel tubeEngineering

The invention belongs to the technical field of steel pipe polishing equipment, and particularly relates to polishing equipment suitable for steel pipes of different pipe diameters. The polishing equipment comprises a rack, an outer cylinder, an inner cylinder and a pipe body, wherein the inner side of the rack is fixedly connected to the outer cylinder; through holes are formed in the top and bottom of the rack; the top end of the outer cylinder is fixedly connected to the inner cylinder; the outer cylinder is used for storing gravels; a polishing module is arranged at the bottom of the outercylinder and comprises a polishing ring No. 1, a polishing ring No. 2, a polishing ring No. 3, a polishing ring No. 4, a curved gear No. 1 and a curved gear No. 2; the polishing ring No. 1, the polishing ring No. 2, the polishing ring No. 3 and the polishing ring No. 4 are arranged from top to bottom in sequence; the inner diameters of a through hole No. 1, a through hole No. 2, a through hole No. 3 and a through hole No. 4 are decreased in sequence; and the through hole No. 1, the through hole No. 2, the through hole No. 3 and the through hole No. 4 are used cooperatively for the fine polishing of pipe bodies of different pipe diameters. The polishing equipment can effectively improve the polishing quality of the pipe body and reduces the clearing workload of the later period.

Owner:张家港市银坤泰金属制品有限公司

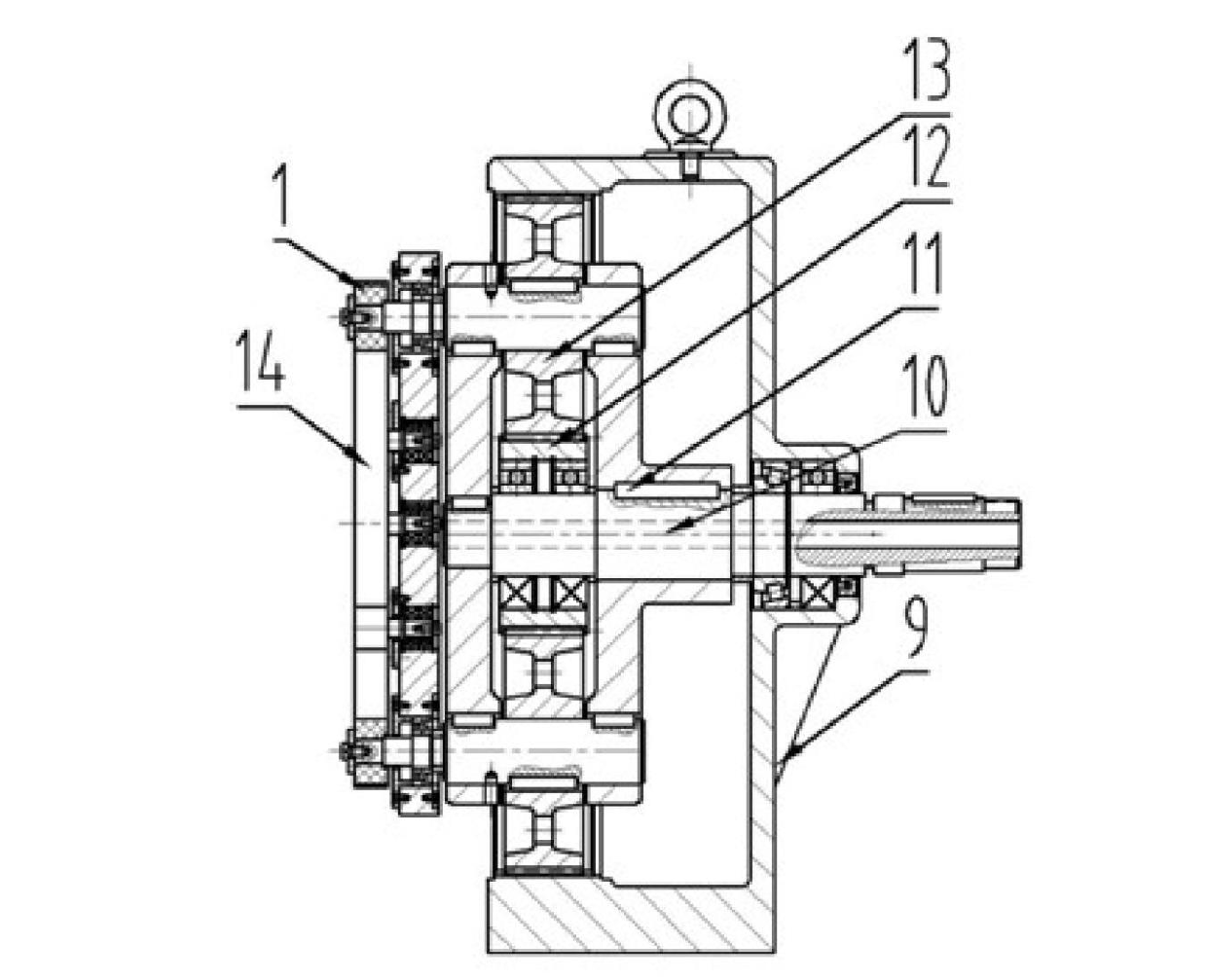

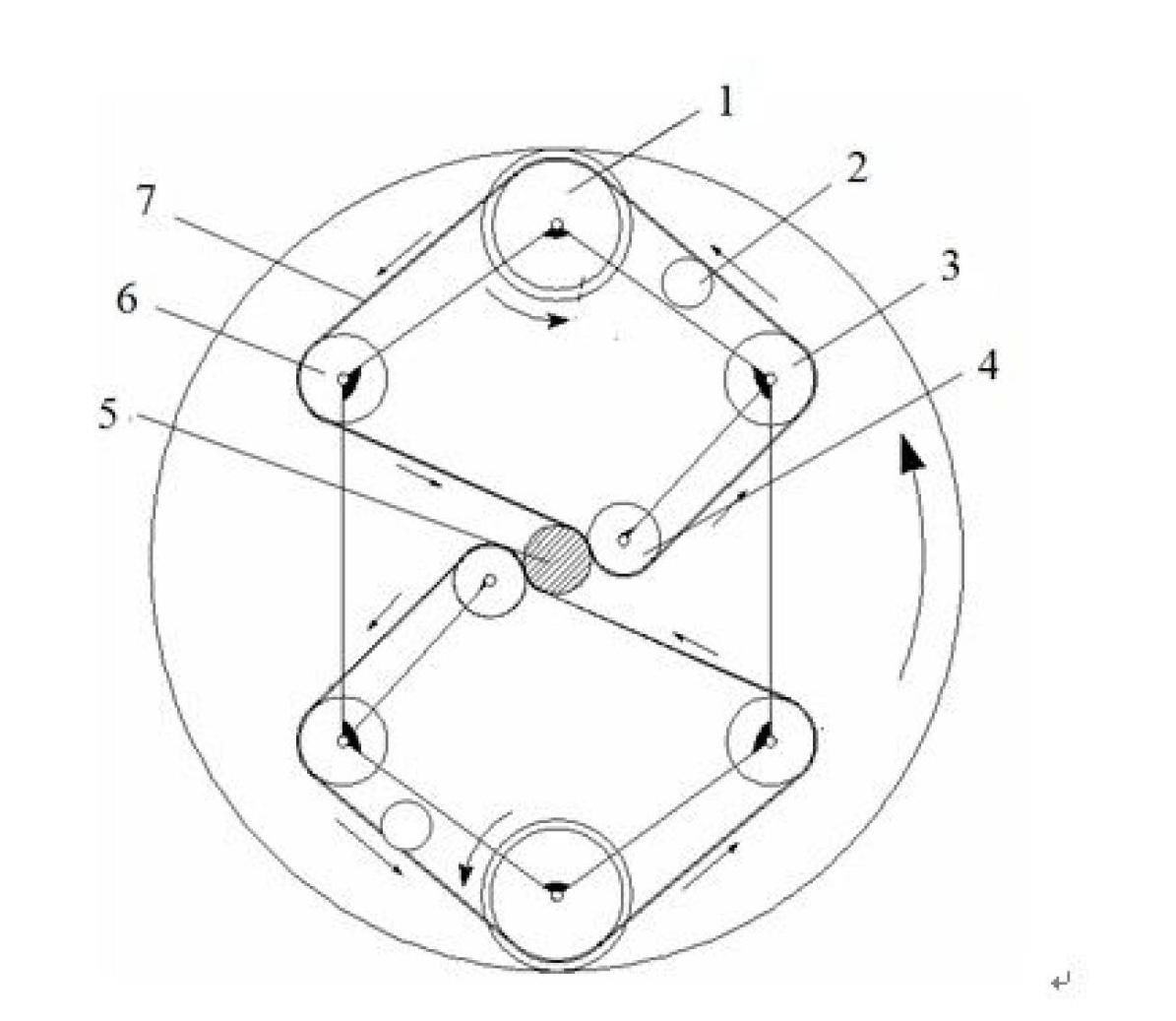

Abrasive belt wire polisher

The invention relates to an abrasive belt wire polisher, which is characterized by comprising a polishing mechanism driven by a motor, wherein the polishing mechanism comprises two abrasive belts which are symmetrically tensioned on two driving wheels; and the two driving wheels rotate under the drive of planet gears and rotate around wires to drive the abrasive belts to polish the wires at full angle. Double planet gear mechanisms are symmetrically arranged, and the abrasive belts are driven to polish the wires at full angle by the driving wheels, so that the wires are quickly and efficiently polished, polishing efficiency and polishing quality are improved, and polishing uniformity is ensured.

Owner:XIAN UNIV OF TECH

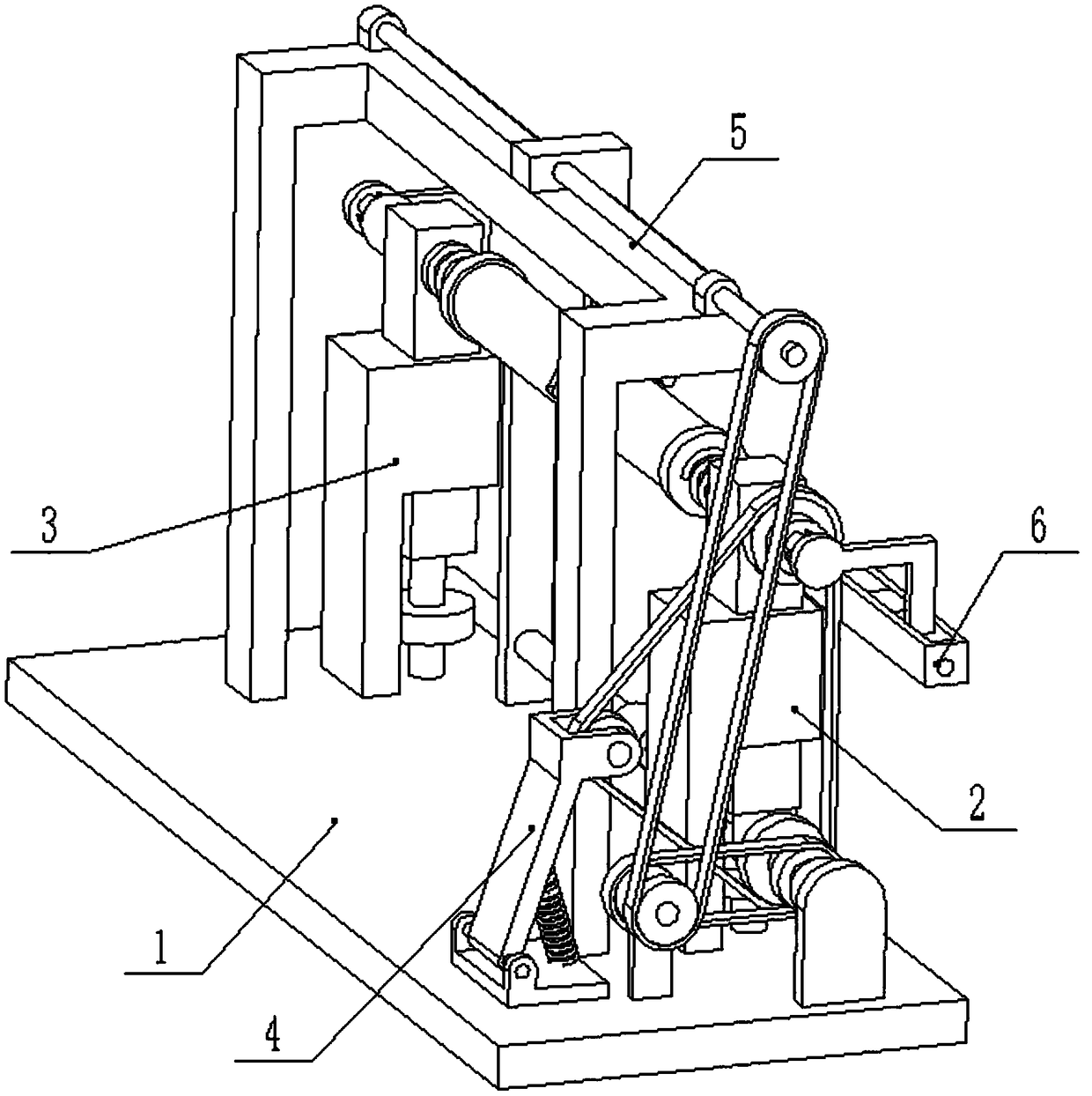

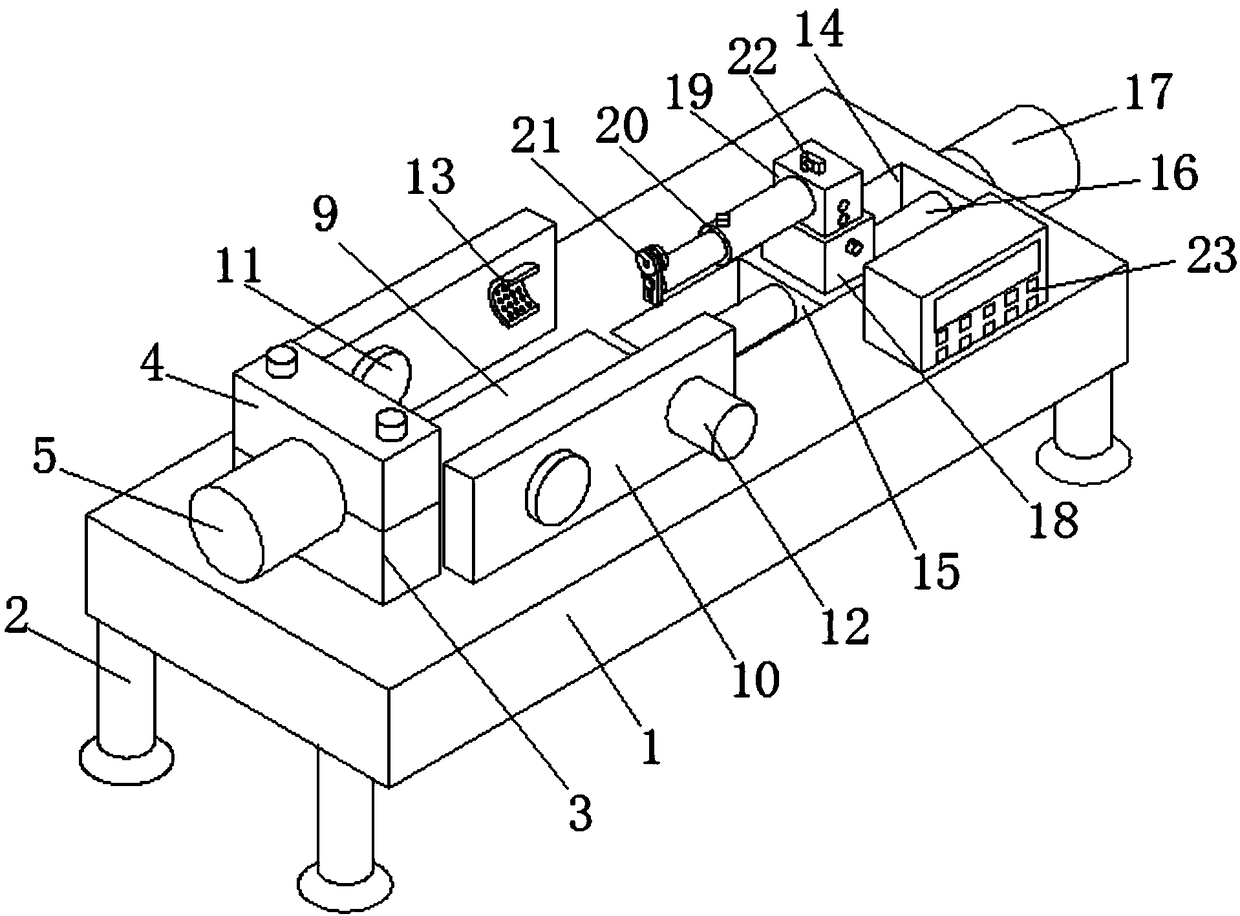

Automatic cable insulation layer polishing machine

PendingCN107745309AEasy to grind and polishQuick changeGrinding drivesBelt grinding machinesInsulation layerReciprocating motion

The invention discloses an automatic cable insulation layer polishing machine which comprises a first clamping device, a driving lead screw, a polishing device, reciprocating motion guide rods and a second clamping device; the first clamping device and the second clamping device clamp the two ends of a to-be-polished cable correspondingly; the driving lead screw and the reciprocating motion guiderods are mutually parallel and are fixedly connected between the first clamping device and the second clamping device; a polishing driving nut and polishing guide cylinders are arranged on the polishing device; the polishing driving nut is assembled with the driving lead screw; the polishing guide cylinders are assembled with the reciprocating motion guide rods; a polishing head carrying out rotary polishing around the outer wall of a cable insulation layer is arranged on the polishing device; and a motor driving the polishing driving nut and the polishing head to rotate is arranged on the polishing device. Rapid centering clamping on the cable and automatic reciprocating polishing on the cable insulation layer can be realized, the polishing efficiency and quality of the cable insulation layer are improved, safe operation of construction personnel is guaranteed, and the application scope of automatic polishing on the cable insulation layer is extended.

Owner:CHANGLAN CABLE ACCESSORIES

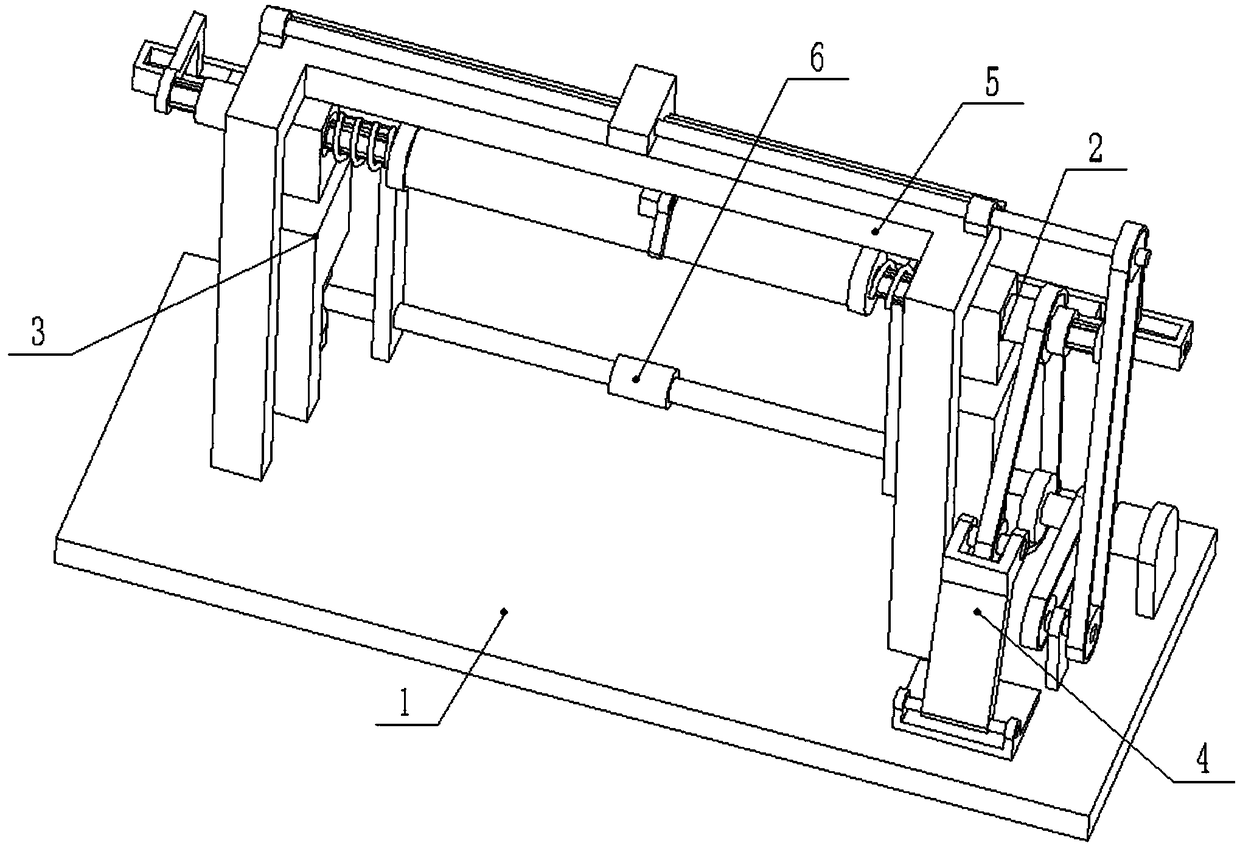

Grinding device of pipelines for building construction

ActiveCN109129051AEasy flipRealize all-round grindingGrinding carriagesRevolution surface grinding machinesBaseboardReciprocating motion

The invention relates to the technical field of pipeline processing, in particular to a grinding device of pipelines for building construction. Two guide rods are fixedly connected to a baseboard. A first limiting board and a second limiting board are fixedly connected to one end of the baseboard. The inner side faces of the first limiting board and the second limiting board are both fixedly connected with a first convex edge and a second convex edge. One end of a left supporting board is fixedly connected to the baseboard, and the other end of the left supporting board is fixedly connected with a left sliding sleeve. The middle end of a left height adjustment seat is slidably connected into the left sliding sleeve. According to the grinding device of the pipelines for building construction, the pipelines can be driven to rotate in operation, and convenient turnover of the pipelines is achieved. All-round grinding of the pipelines is realized by reciprocating motion of a grinding board, the grinding efficiency and the grinding quality of the pipelines are improved, manual operation is reduced, and the working intensity of workers is reduced. The grinding device of the pipelines canbe suitable for grinding of the pipelines with different pipe diameters, and meanwhile the grinding speed can further be adjusted by adjusting the pressure between the pipelines and the grinding board.

Owner:江苏复华光电科技有限公司

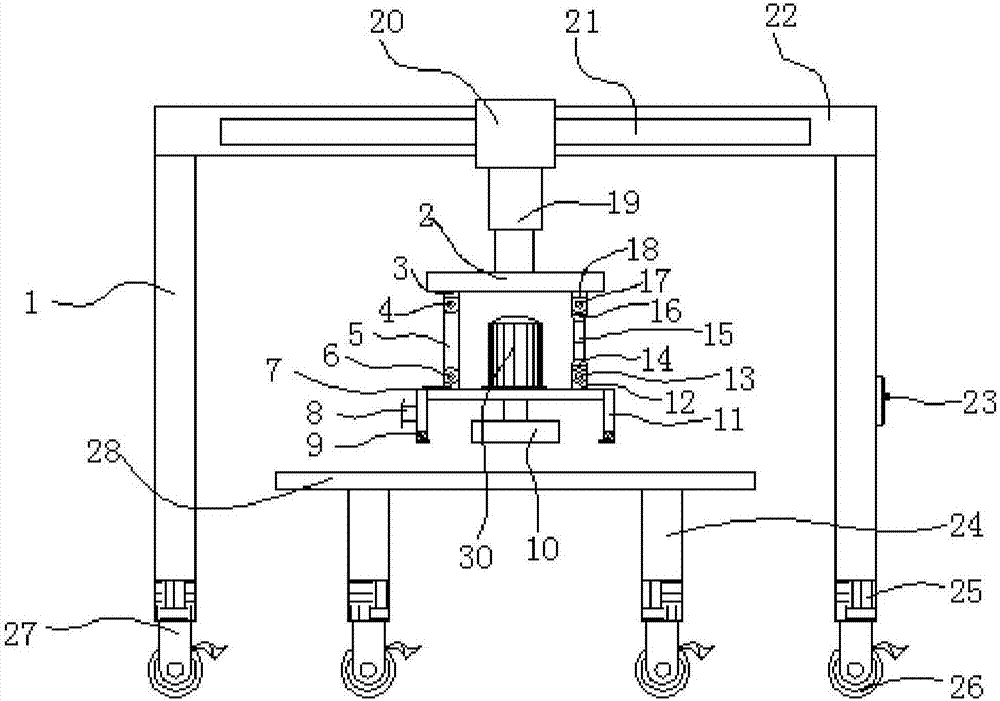

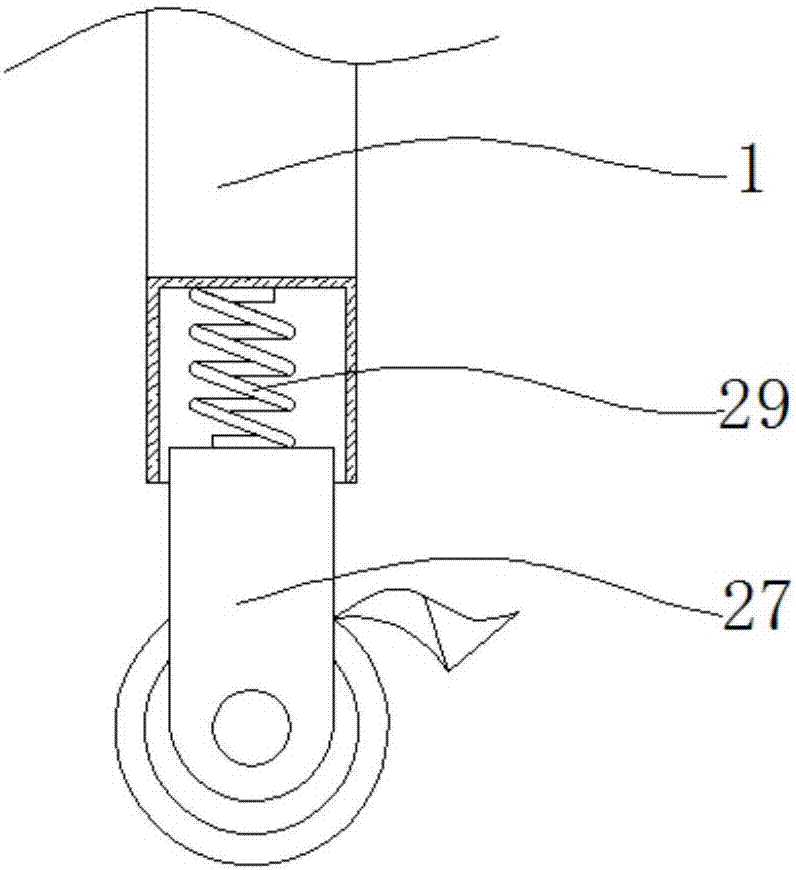

Medical sheet grinding machine

InactiveCN107009240AGuarantee stabilityIncreased service life and grinding qualityGrinding carriagesGrinding headsEngineeringMedical treatment

The invention discloses a medical sheet grinding machine, comprising a first support frame and a second support frame, the bottoms of the first support frame and the second support frame are fixedly connected with sleeves, and the inner cavity of the sleeve is The top of the movable leg is movably connected with a movable leg through a spring, the bottom of the movable leg is movably installed with a roller, the top of the second support frame is fixedly connected with a platform, and the lower end of the right side of the first support frame is fixedly installed with a controller. The present invention uses the first connecting rod, the first movable joint, the second connecting rod, the second movable joint and the third connecting rod and the fourth connecting rod, the third movable joint, the fifth connecting rod, the second electric telescopic rod, the The functions of the six connecting rods, the fourth movable joint and the seventh connecting rod can satisfy people's adjustment of the grinding angle of the grinding head, and solve the problem that the prior art is manual adjustment, and it is difficult for people to adjust the two legs to a consistent height , reducing platform stability issues.

Owner:浙江高派机器人科技有限公司

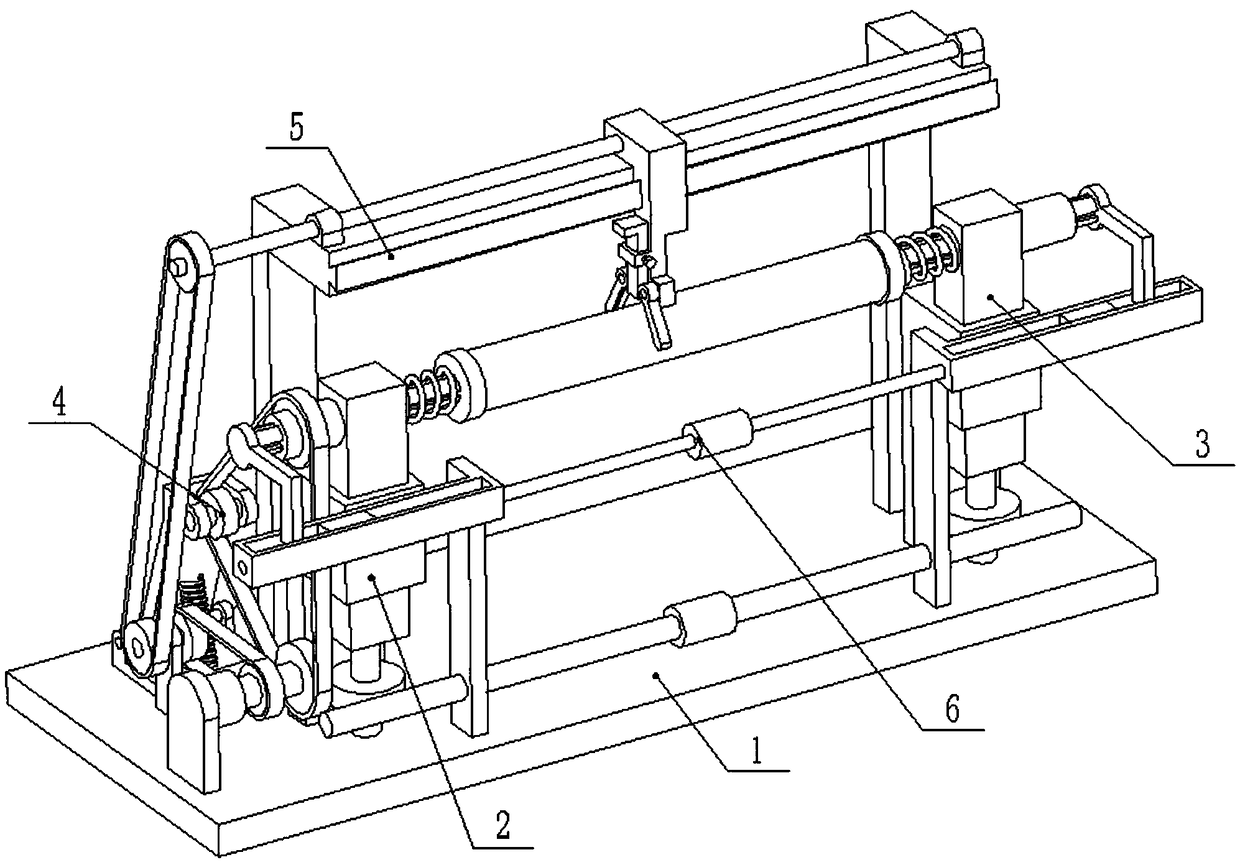

Pipeline grinding device for building construction

ActiveCN109048518AImprove grinding efficiencyImprove sanding qualityGrinding carriagesRevolution surface grinding machinesDrive shaftBuilding construction

The invention relates to the technical field of pipeline machining, in particular to a pipeline grinding device for building construction. The device comprises a motor, the motor is fixedly connectedto a bottom plate through an electric machine frame, one end of a driving shaft is connected to an output shaft of the motor through a coupler, and the other end of the driving shaft is fixedly connected with a driving belt wheel I, a driving belt wheel II is fixedly connected to the middle end of the driving shaft, the driving belt wheel II is in transmission connection with the driven belt wheelI through a belt, the driven belt wheel I and a driven belt wheel II are fixedly connected to the two ends of a driven shaft respectively, the middle end of the driven shaft is rotationally connectedto a shaft frame plate through a belt seat bearing. According to the pipeline grinding device, the pipeline can be driven to rotate during working, so that the pipeline can be conveniently turned over, all-directional polishing of the pipeline can be realized through reciprocating movement of a grinding plate, the grinding efficiency and the grinding quality of the pipeline are improved, the manual operation is reduced, the working intensity of workers is reduced; the device can be applied to the grinding of pipelines with different pipe diameters, and the grinding speed can be adjusted by adjusting the pressure between the pipeline and the grinding plate.

Owner:台州飞龙鞋业有限公司

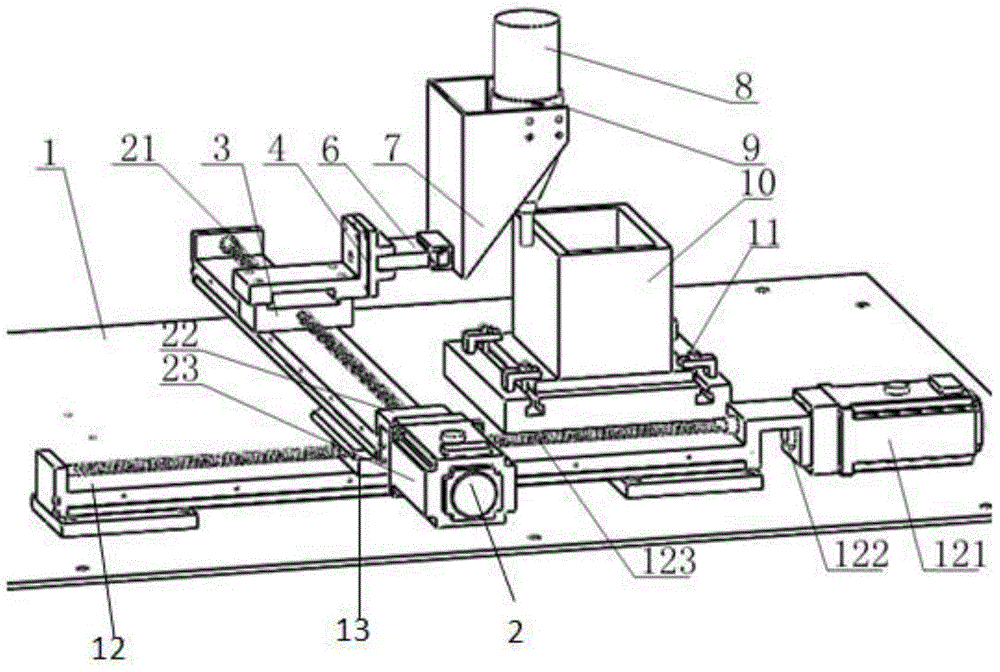

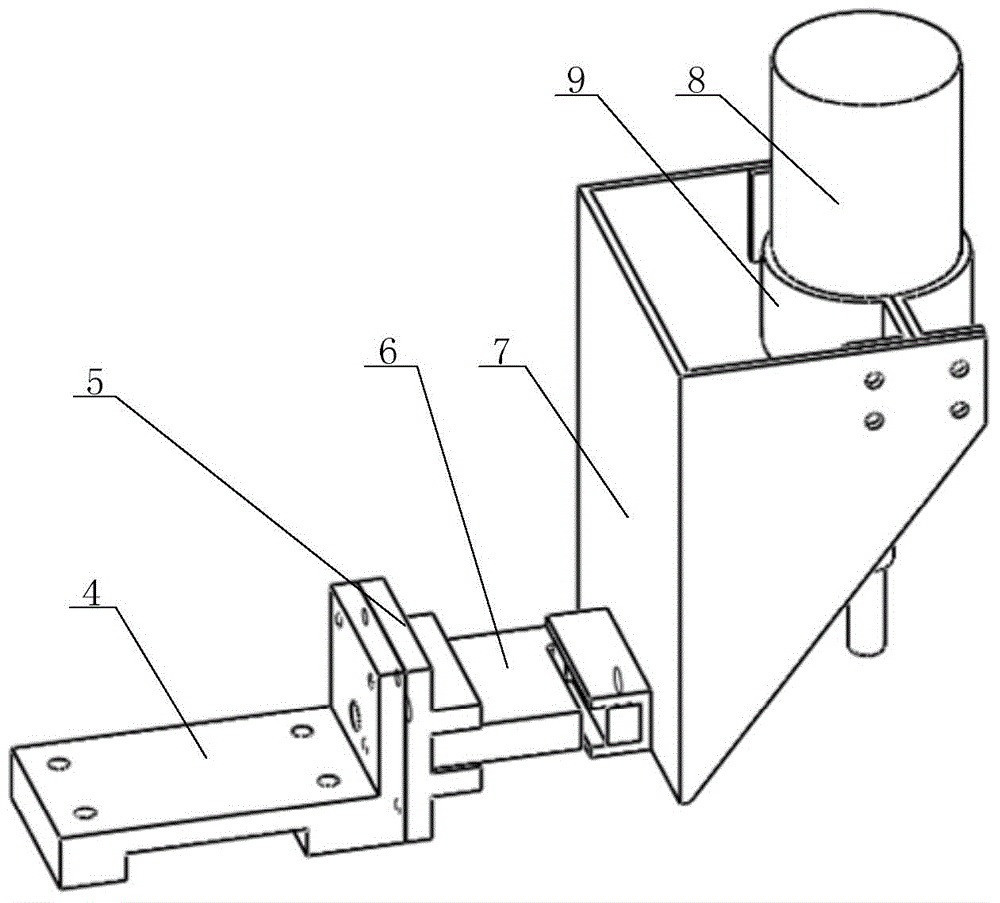

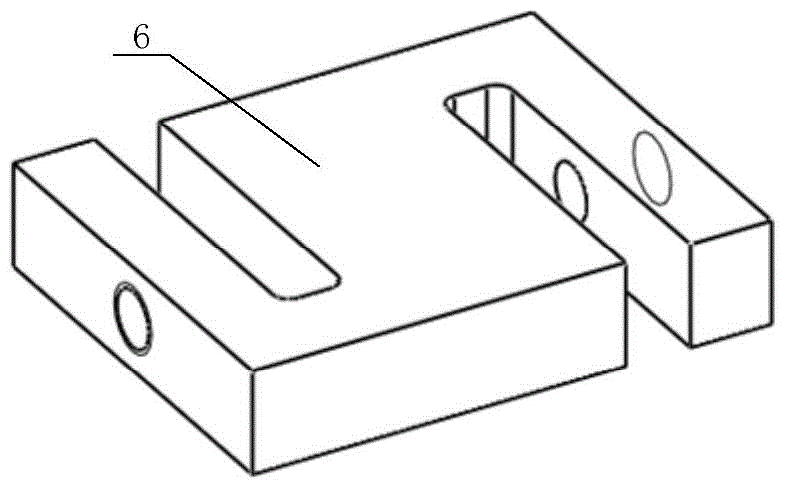

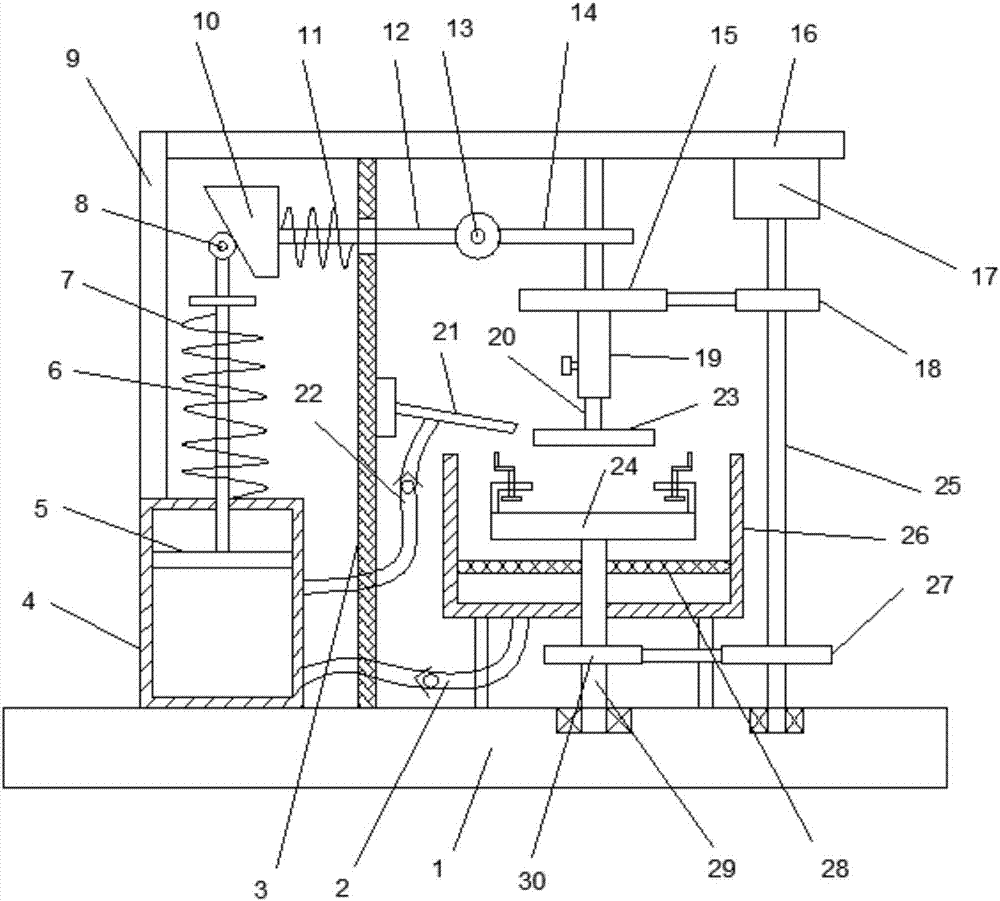

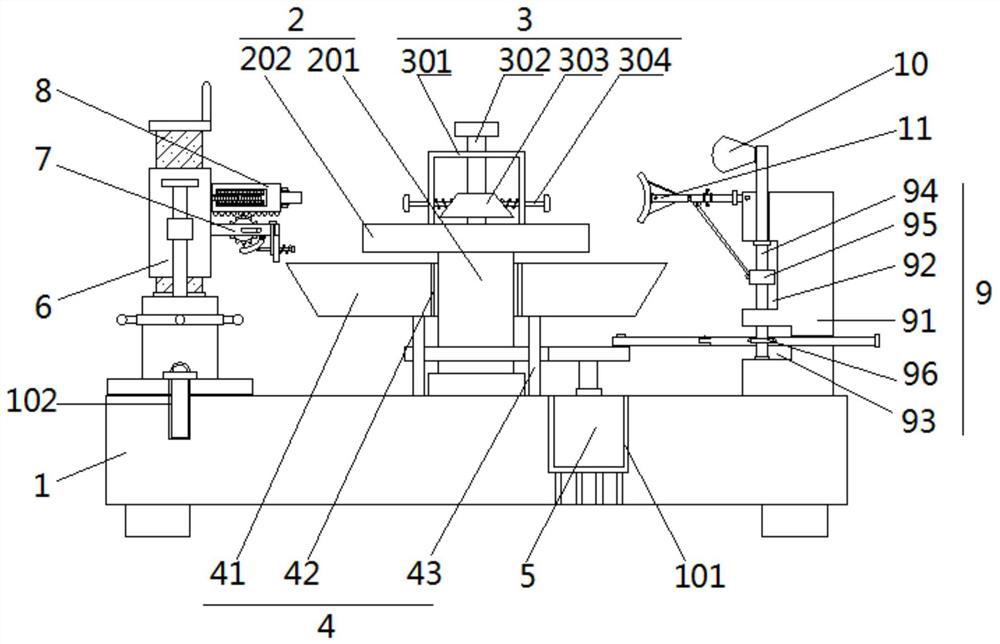

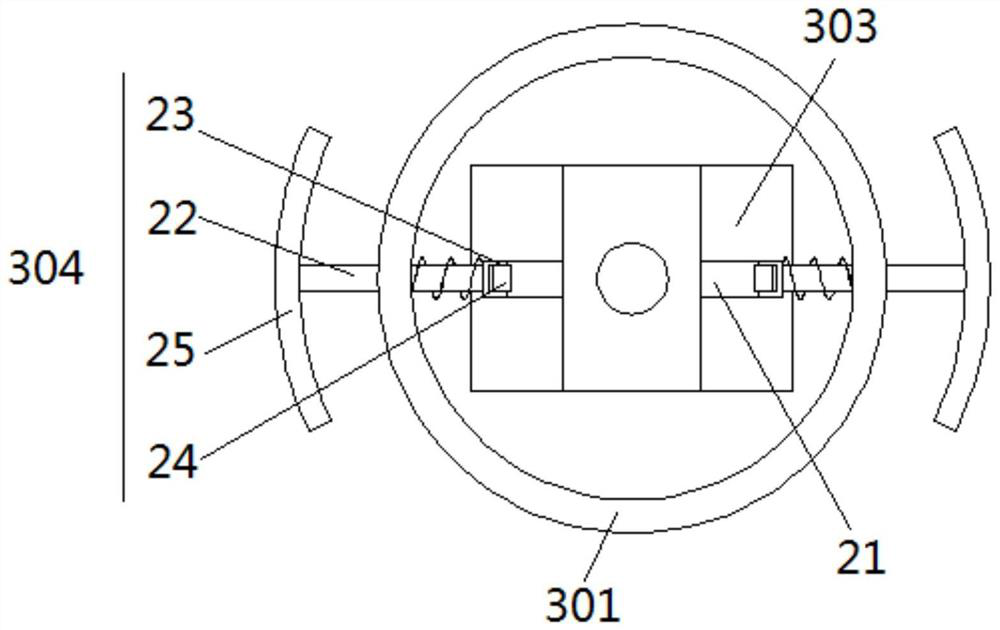

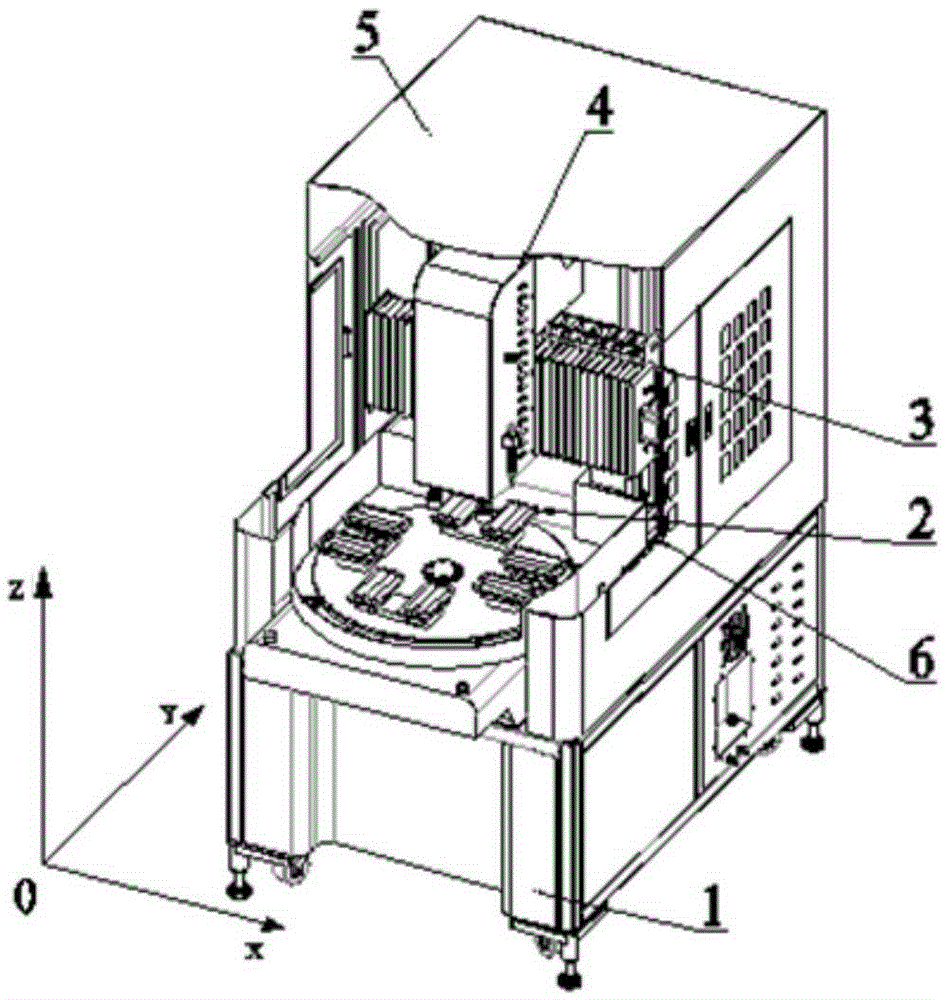

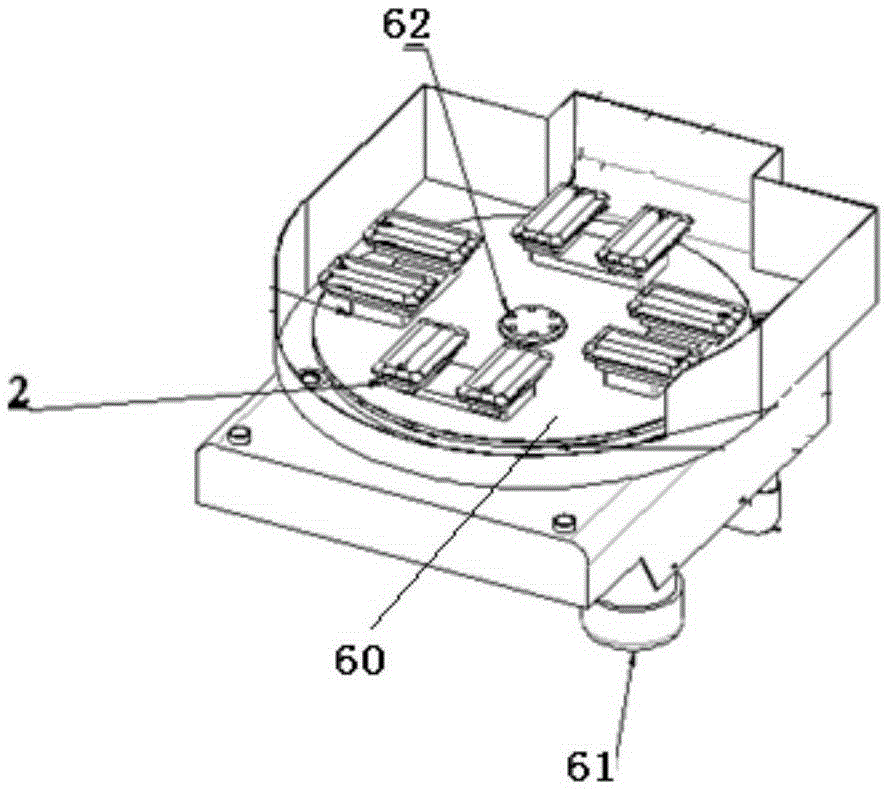

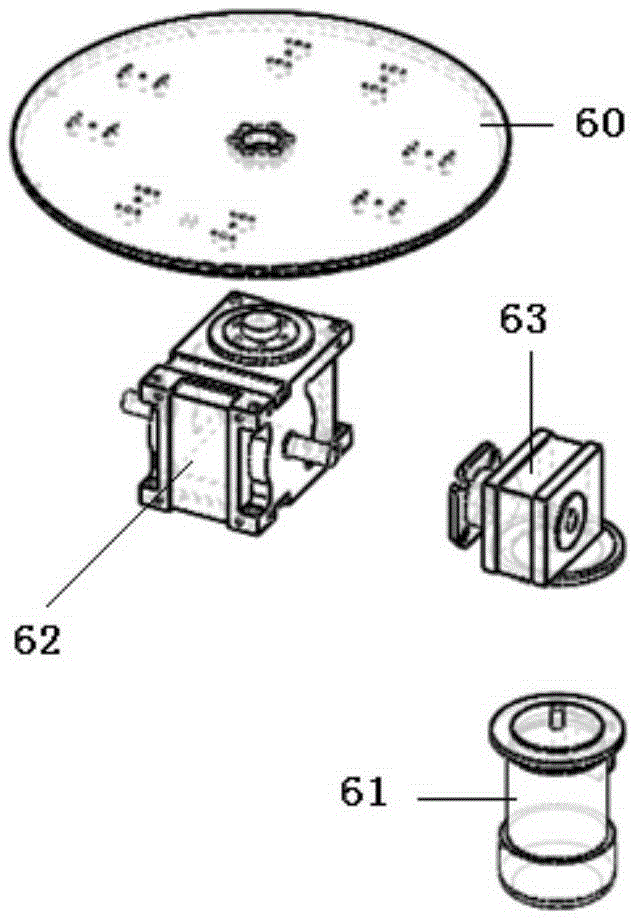

Disc grinder

A disc grinder comprises a jig assembly, a disc assembly, a grinding assembly and a three-axis carrying assembly. The jig assembly is mounted on the disc assembly, and the grinding assembly is mounted on the three-axis carrying assembly; the three-axis carrying assembly is used for carrying the grinding assembly to move in the vertical Z-axis direction, the horizontal X-axis direction and the horizontal Y-axis direction so as to achieve position adjustment of the grinding assembly, the X axis and the Y axis are perpendicular to each other; the disc assembly is used for driving the jig assembly to rotate for position transfer, and therefore a product fixed to the jig assembly is moved to the grinding position of the grinding assembly, and the grinding assembly is used for grinding the product fixed on the jig assembly. The disc grinder can improve the grinding efficiency, lower the cost and improve the product grinding quality.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Constant-force grinding device and grinding control method thereof

PendingCN109202688ASolve the problem of uncontrollable grinding forceGrinding force changes smoothlyLapping machinesGrinding feed controlData acquisitionControl variable

The invention discloses a constant-force grinding device. The device comprises a six-degree-of-freedom industrial robot, a floating grinder, a first-dimensional force sensor, a data acquiring device,a constant-force device and a controller. The invention also discloses a grinding control method on the basis of the abovementioned constant-force grinding device. The method comprises the following steps: grinding a workpiece to be grinded to grind based on a preset track; acquiring a grinding force simulating signal by the first-dimensional force sensor; calculating the grinding force error andthe error variation value based on the grinding force simulating signal and an expected value, and treating the grinding force error and the error variation value as input of a self-adaptive PID controller, wherein the output of the self-adaptive PID controller is the controlled variable of a servo motor; driving a linear movement die set to adjust in real time based on the controlled variable, and thus controlling the grinding force. With the adoption of the device, intelligent constant-force control is realized; the polishing and grinding production rate is increased; the product consistencyis ensured; the working conditions of workers are improved; and the cost is saved.

Owner:SOUTH CHINA UNIV OF TECH

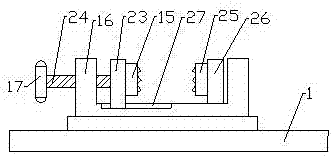

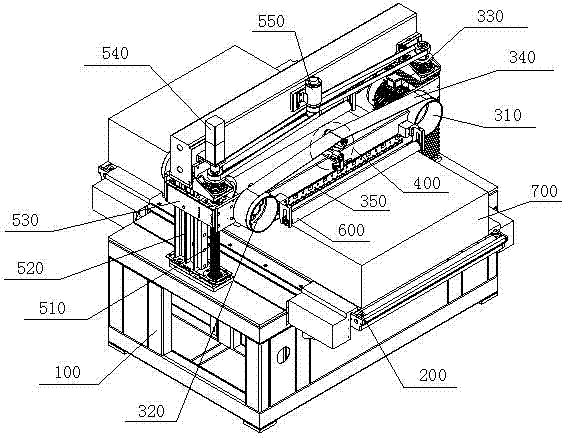

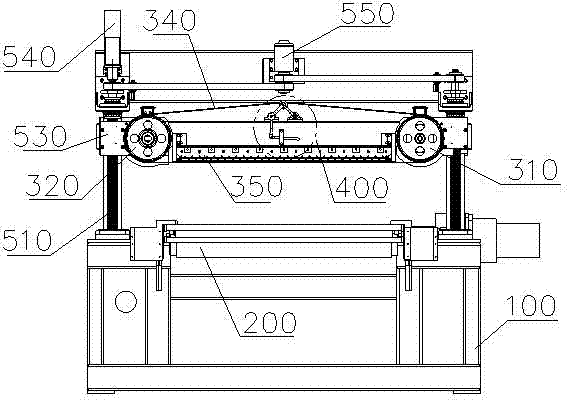

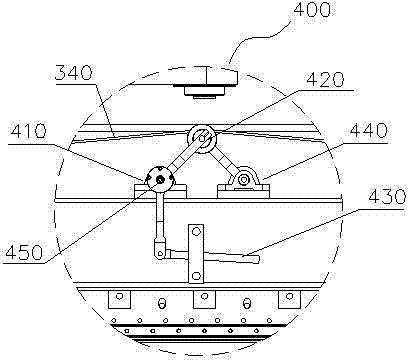

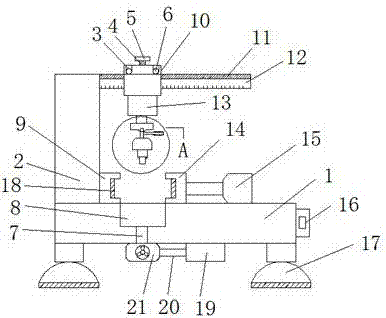

Numerical control polishing machine

InactiveCN104400583AImprove sanding qualityEnsure consistencyEdge grinding machinesGrinding drivesNumerical controlEngineering

The invention discloses a numerical control polishing machine. The numerical control polishing machine comprises a four-axis workpiece shifting device and a rotary polishing head, wherein the four-axis workpiece shifting device comprises a stand column, a Y-axis sliding seat, an X-axis rotary arm, a Z-axis rotary arm, an A-axis rotating work bench, a Y-axis driving assembly, an X-axis driving assembly, a Z-axis driving assembly and an A-axis driving assembly; and the rotary polishing head is provided with a main polishing mechanism, the main polishing mechanism comprises a main grinding wheel assembly, a main rotating arm and a main grinding wheel vertical / horizontal transforming assembly, the main grinding wheel assembly is mounted on the main rotating arm, and the main grinding wheel vertical / horizontal transforming assembly drives the main rotating arm to rotate, so that the rotary polishing head transforms at any angle in the vertical direction and the horizontal direction, and accordingly, a workpiece on the A-axis rotary work bench is polished in an omnibearing manner. The numerical control polishing machine can automatically polish a casting, effectively removes burrs and flashing of the casting and is efficient, environment-friendly, safe and simple and convenient to operate, the labor intensity is reduced, and the polishing quality is improved.

Owner:CHANGZHOU HIDEA MACHINERY

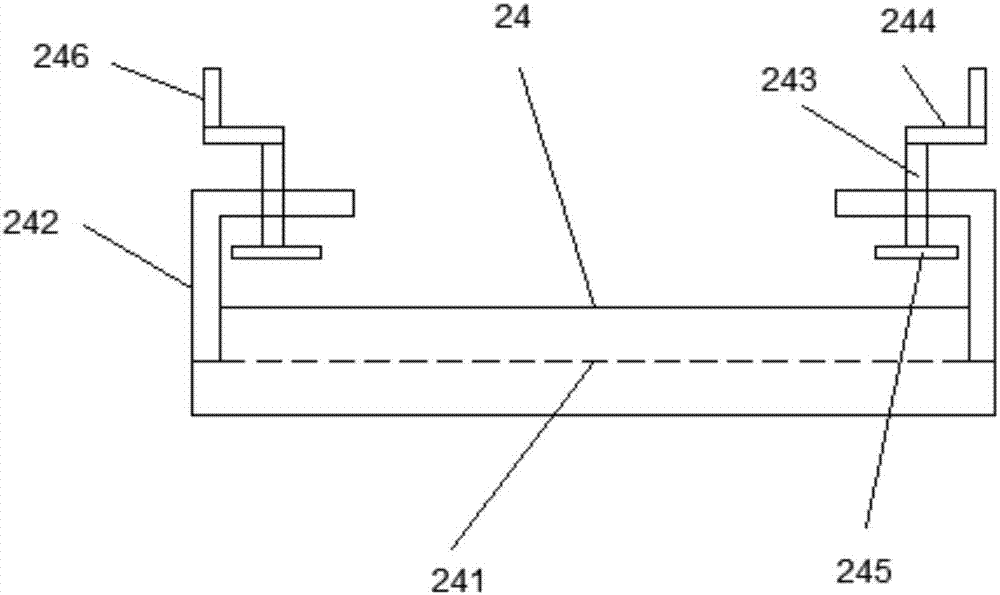

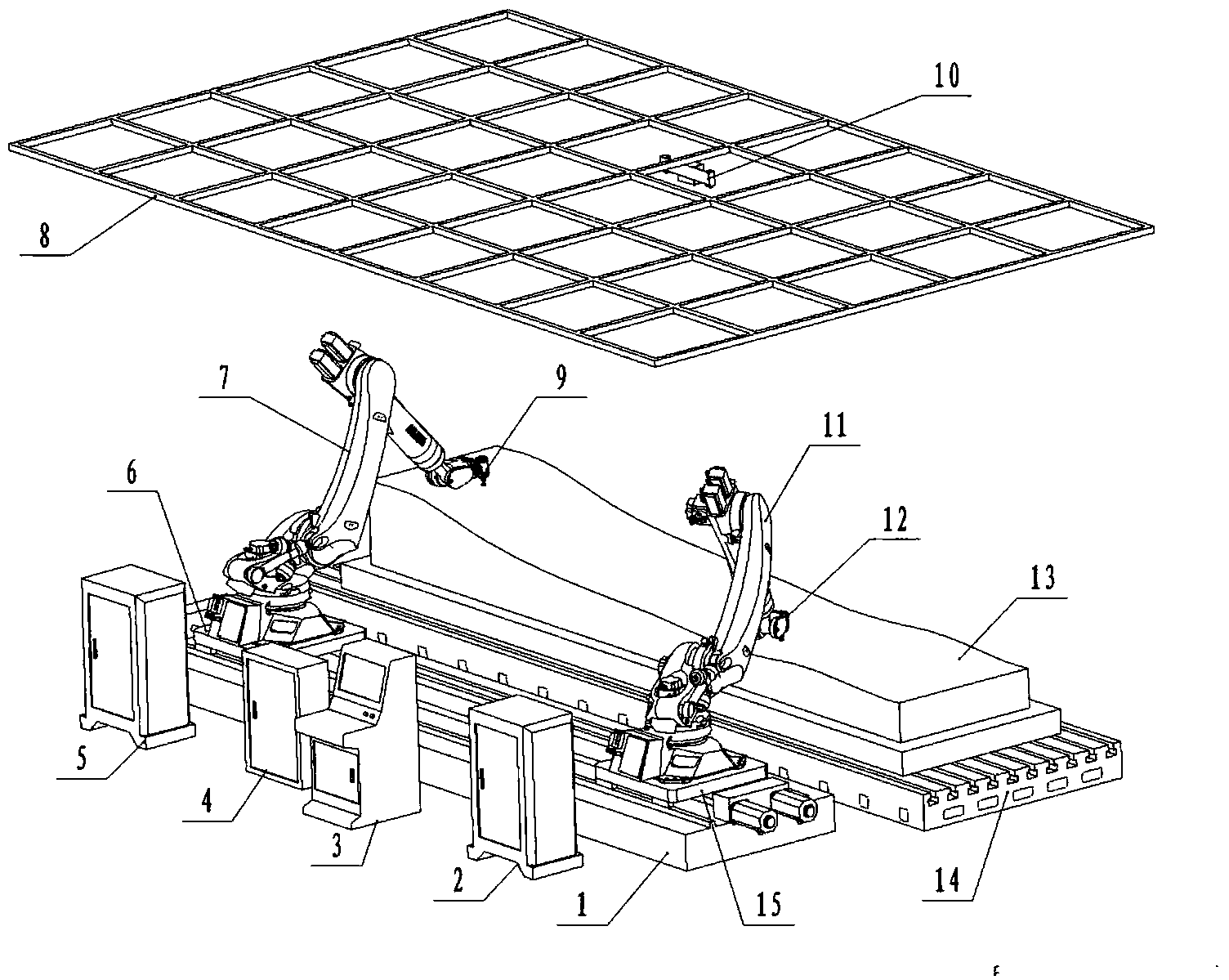

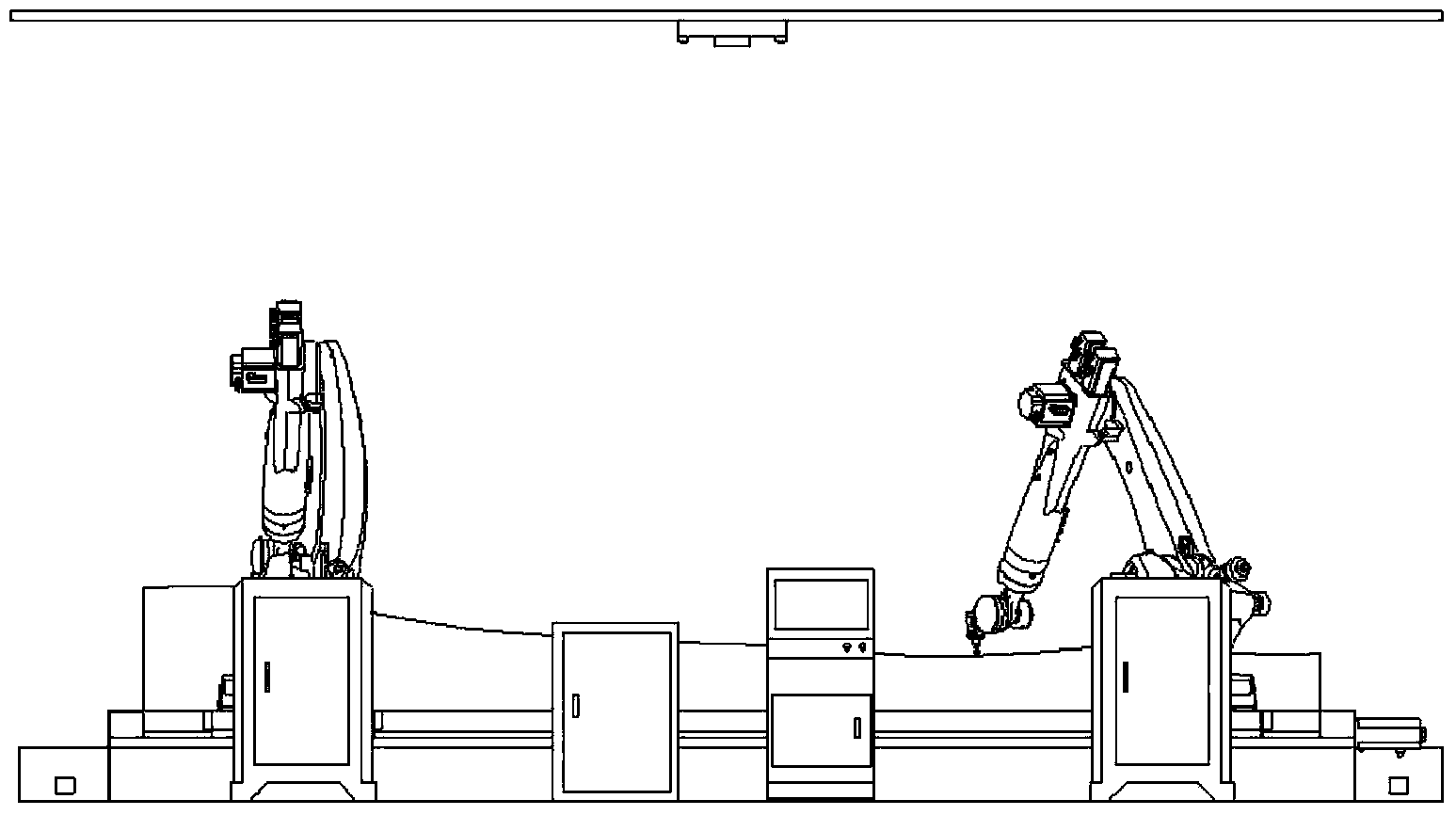

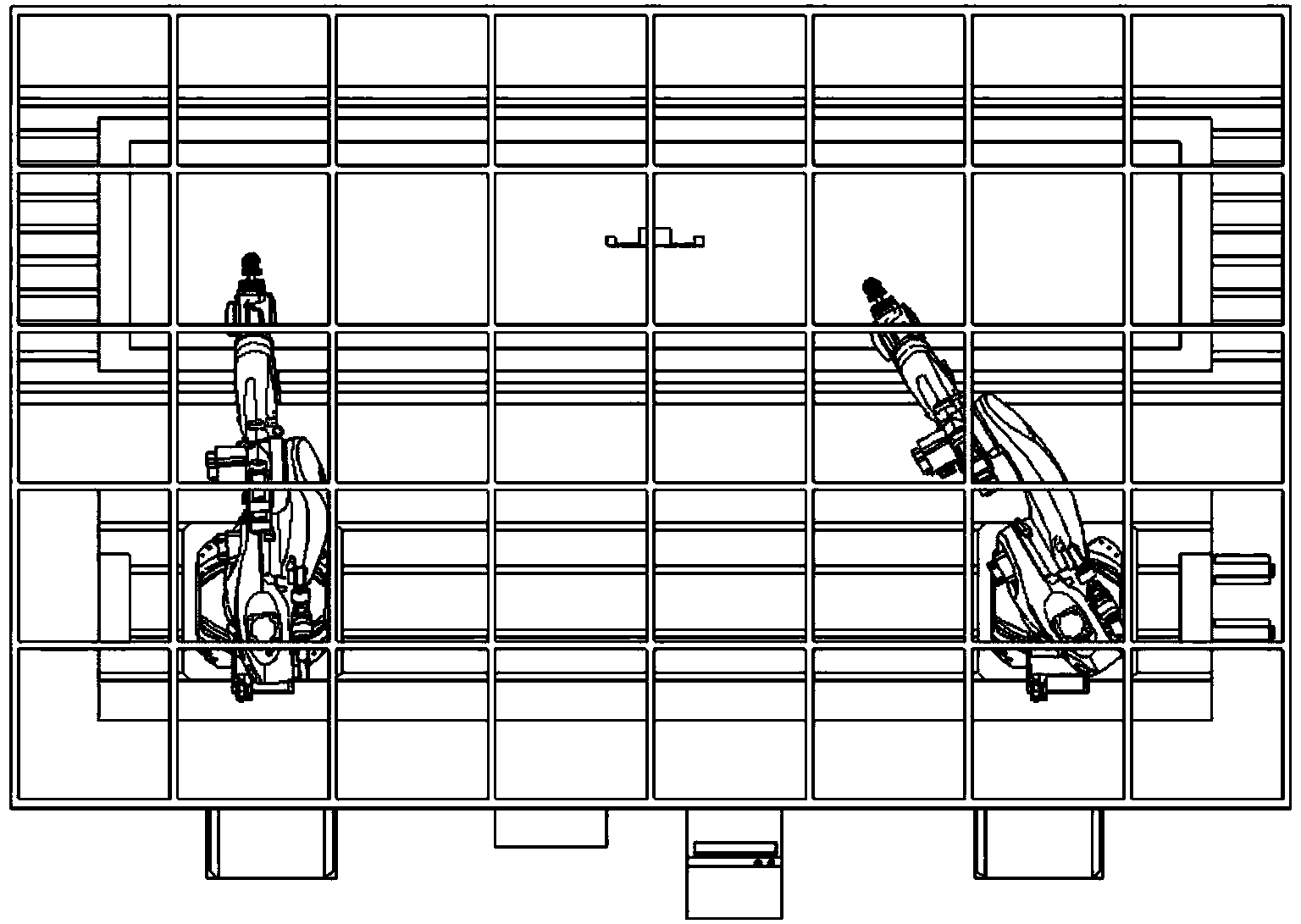

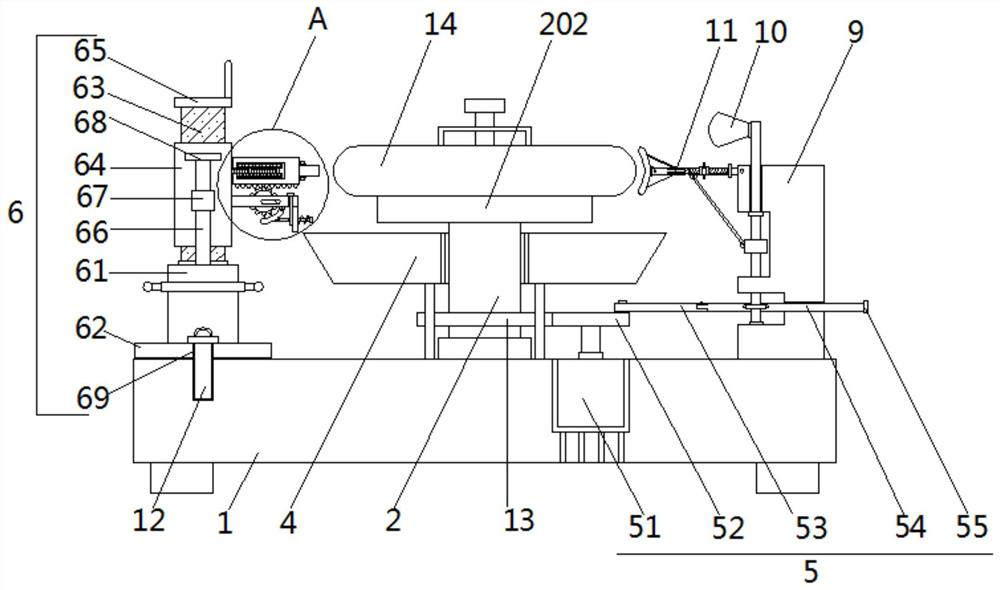

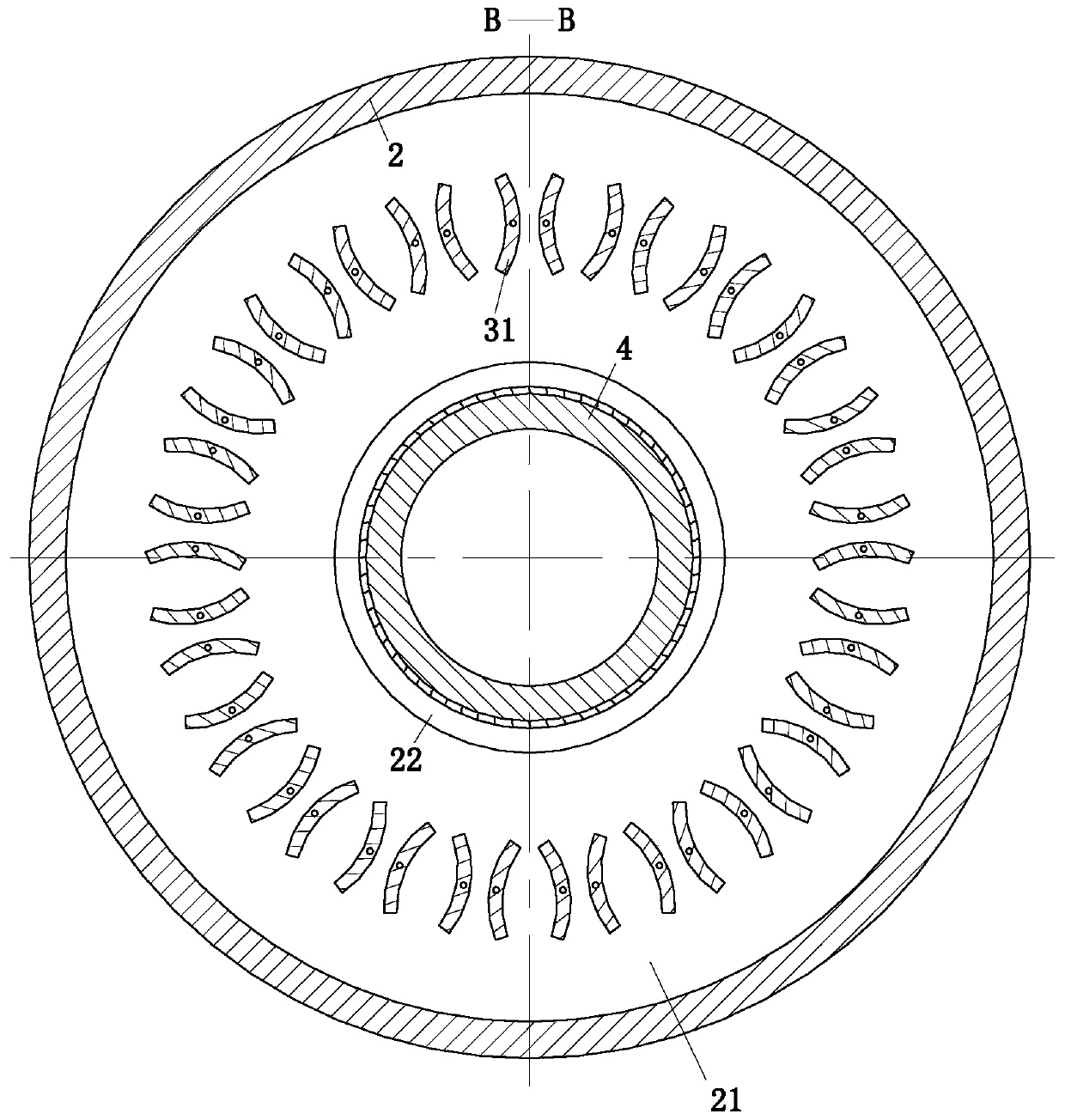

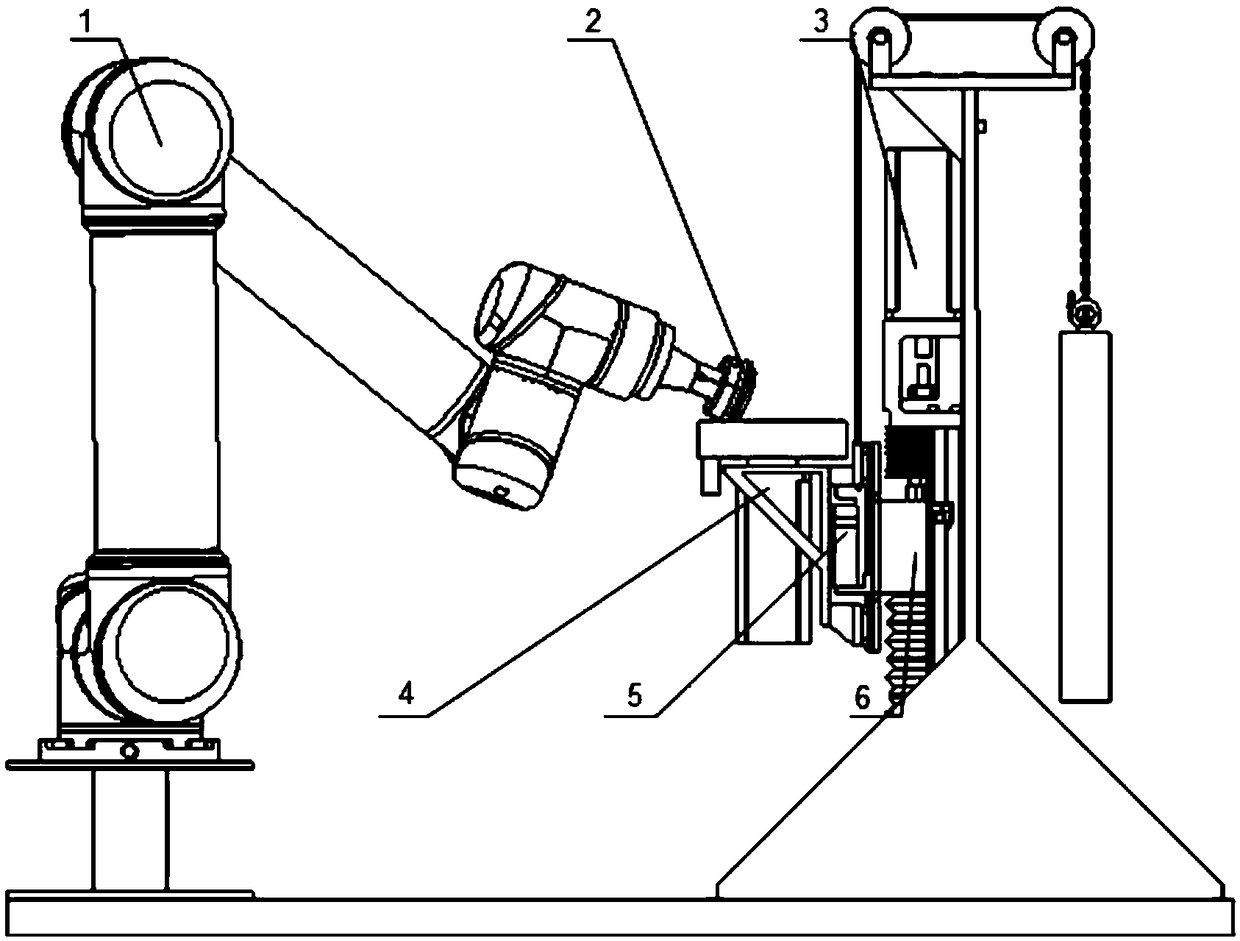

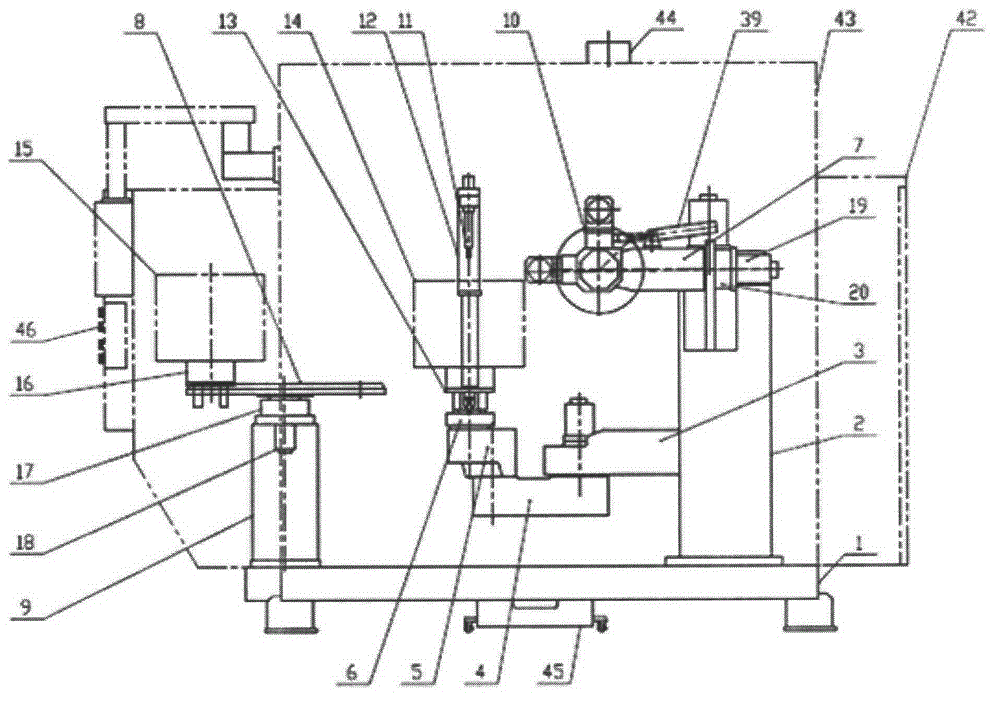

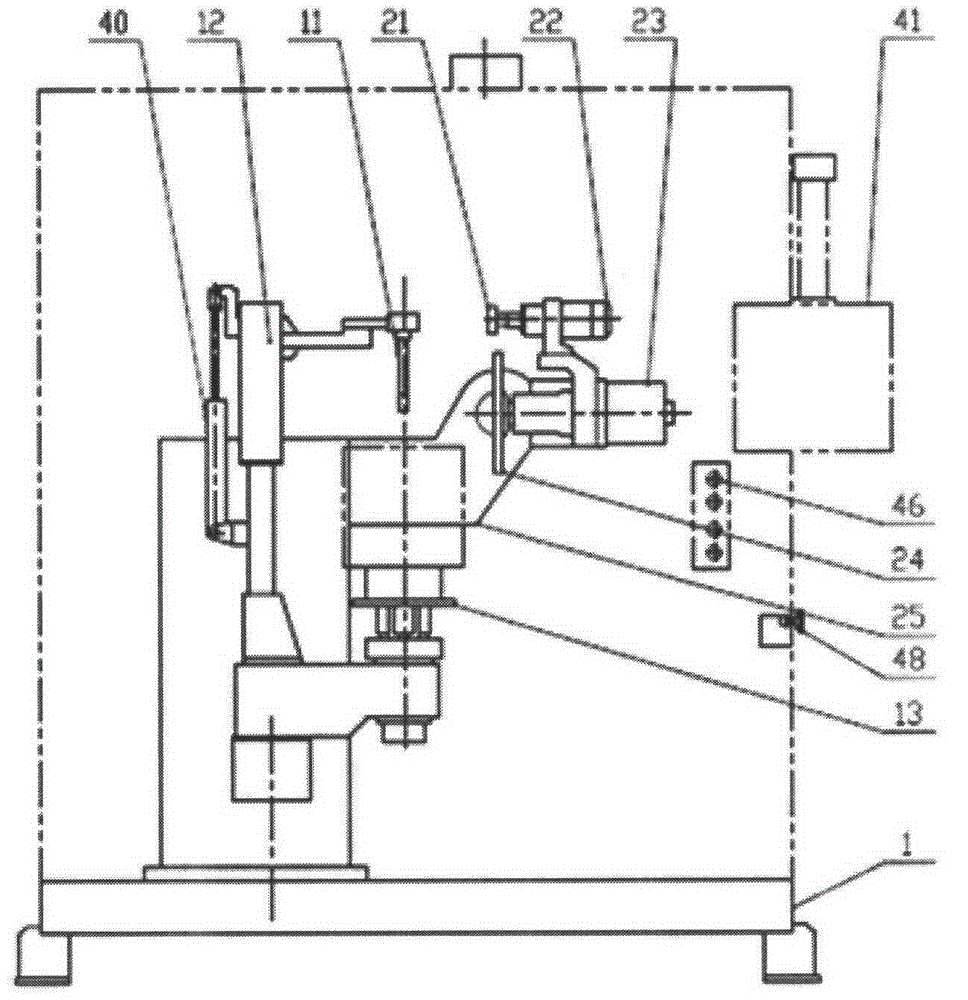

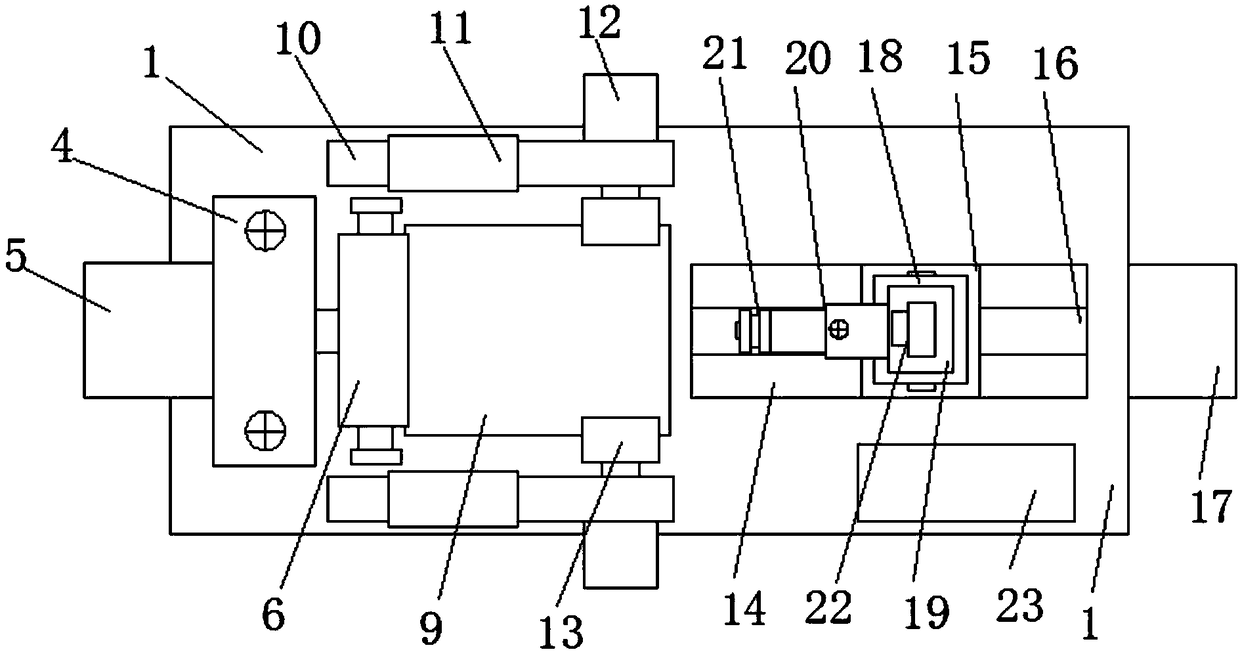

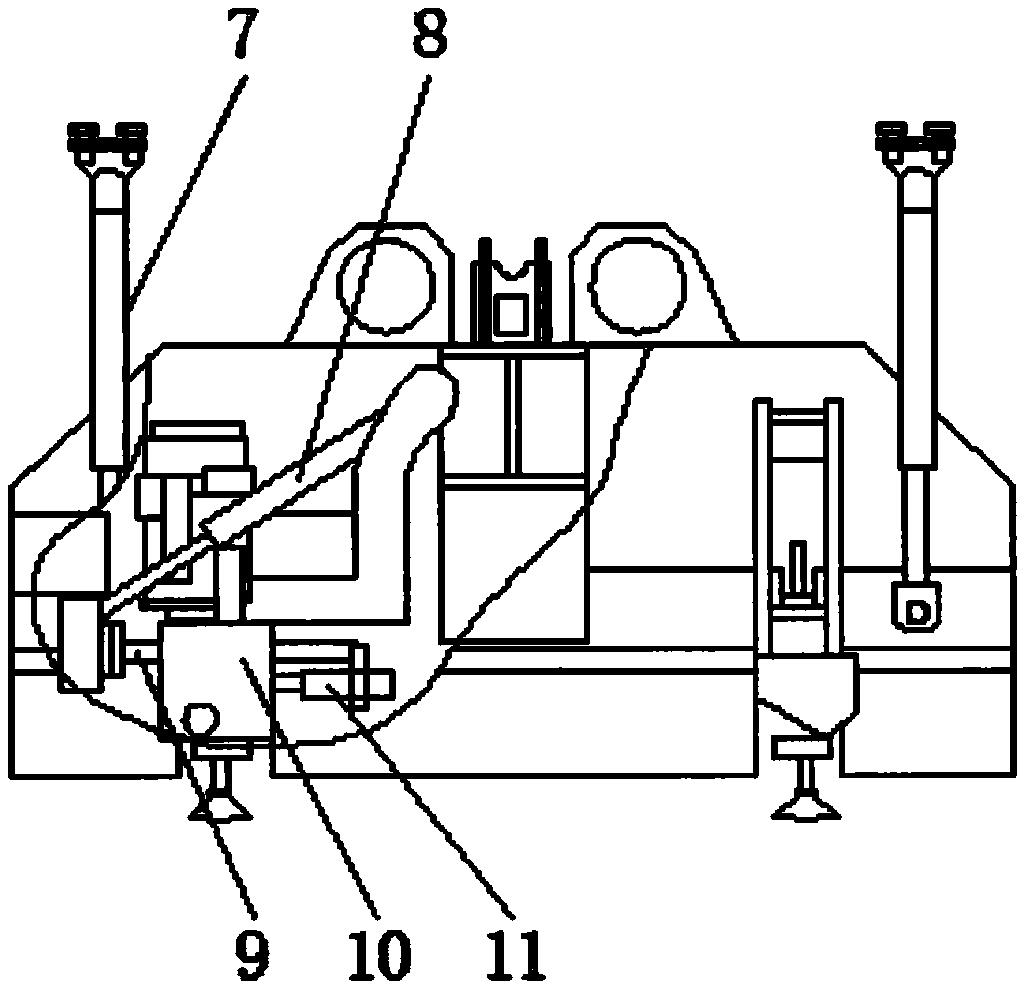

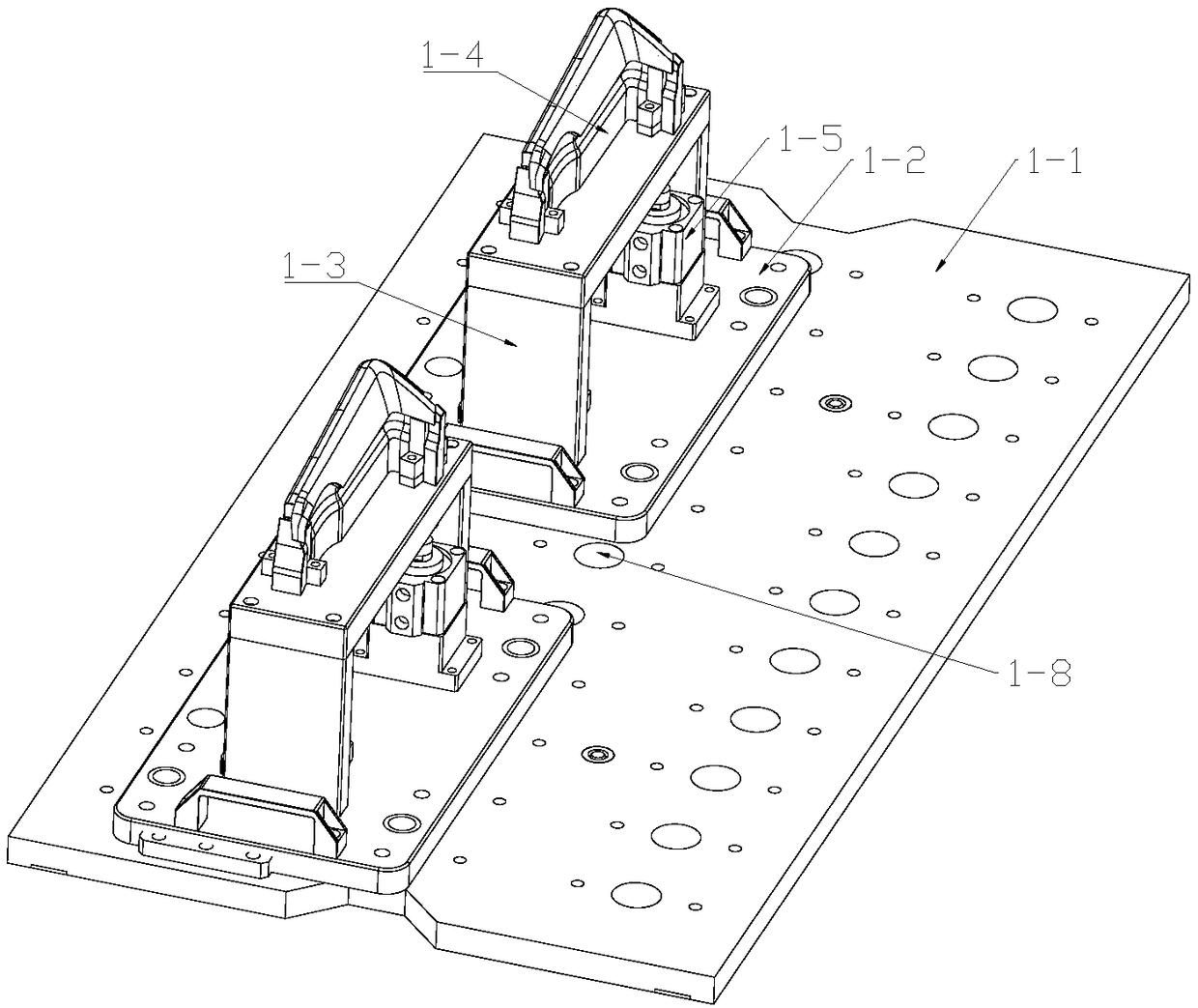

Automatic polishing system for water turbine blades

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

Steel pipe grinding device with waste recovery

ActiveCN108581778AEfficient recyclingRecycled steel pipe grinding is effectiveGrinding carriagesRevolution surface grinding machinesArchitectural engineeringWaste recovery

The invention discloses a steel pipe grinding device with waste recovery. The steel pipe grinding device comprises a base. A support plate with an opening is fixedly connected with an output shaft ofa variable frequency motor, and four pairs of adjusting bolts are connected with angles of the surface and the like of the support plate in a threaded mode. The top of the base is arranged on the leftside of a first clamping plate and is provided with a waste recovery groove. An electric cylinder body is fixedly arranged at the right end of the outside of a baffle, and an output shaft of the electric cylinder body penetrates through the baffle and is fixedly connected with a clamping block. A sliding groove is formed in the right side of the top of the base, the sliding groove is internally connected with a sliding block in a sliding mode, a stand column is arranged on the top of the sliding block, a telescopic rod is welded at the top end of the left side of the stand column, and a grinding device is fixedly arranged on the top portion of the telescopic rod through fastening bolts. The steel pipe grinding device is simple and reasonable in structural design, convenient to operate, disassembly and assembly, and easy to adjust; the inner wall and the outer wall of a steel pipe are effectively grinded; the waste recovery can be realized; safety and stability are achieved; the application scope is wide; and promotion and popularization are beneficial.

Owner:山东中正钢管制造有限公司

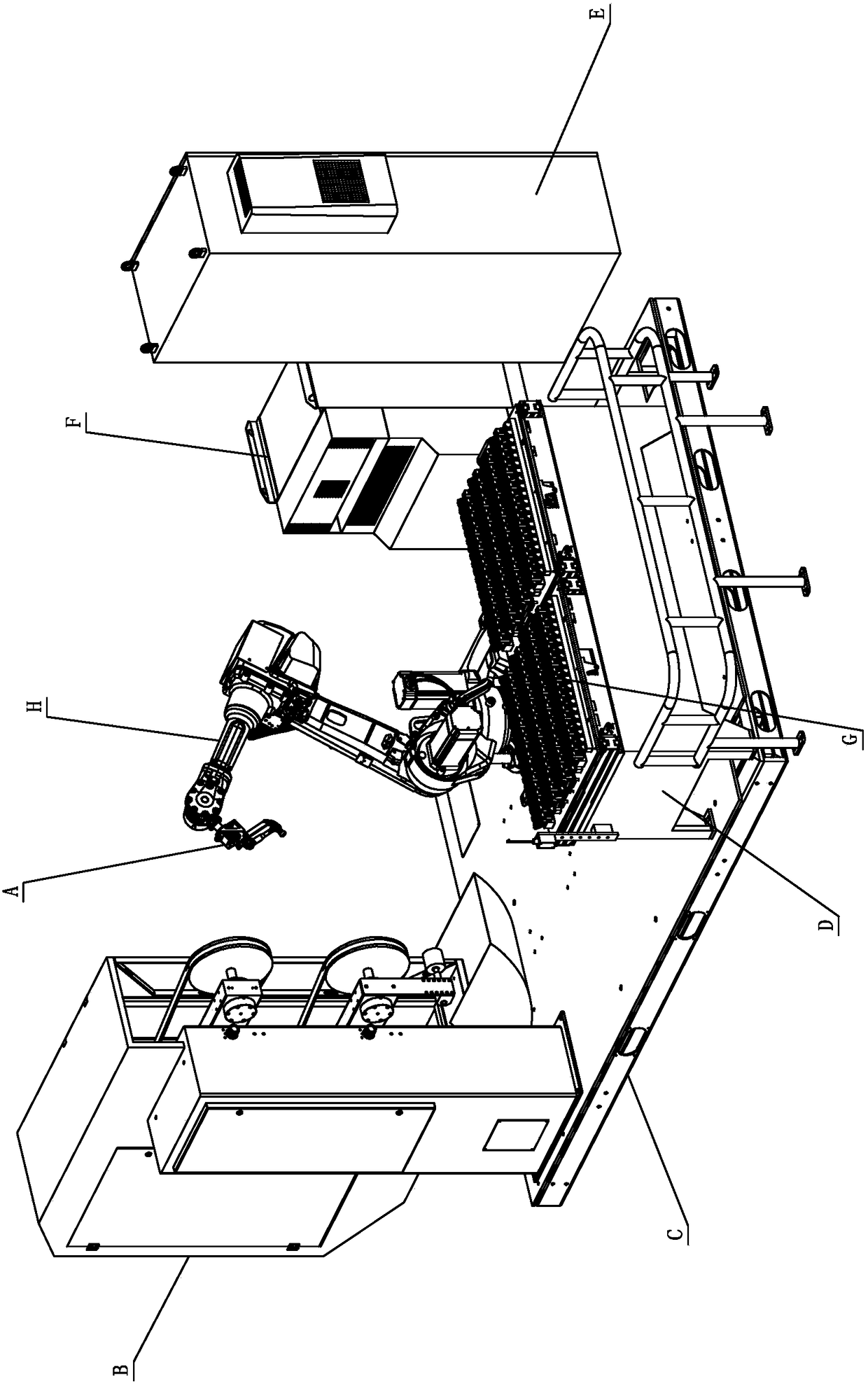

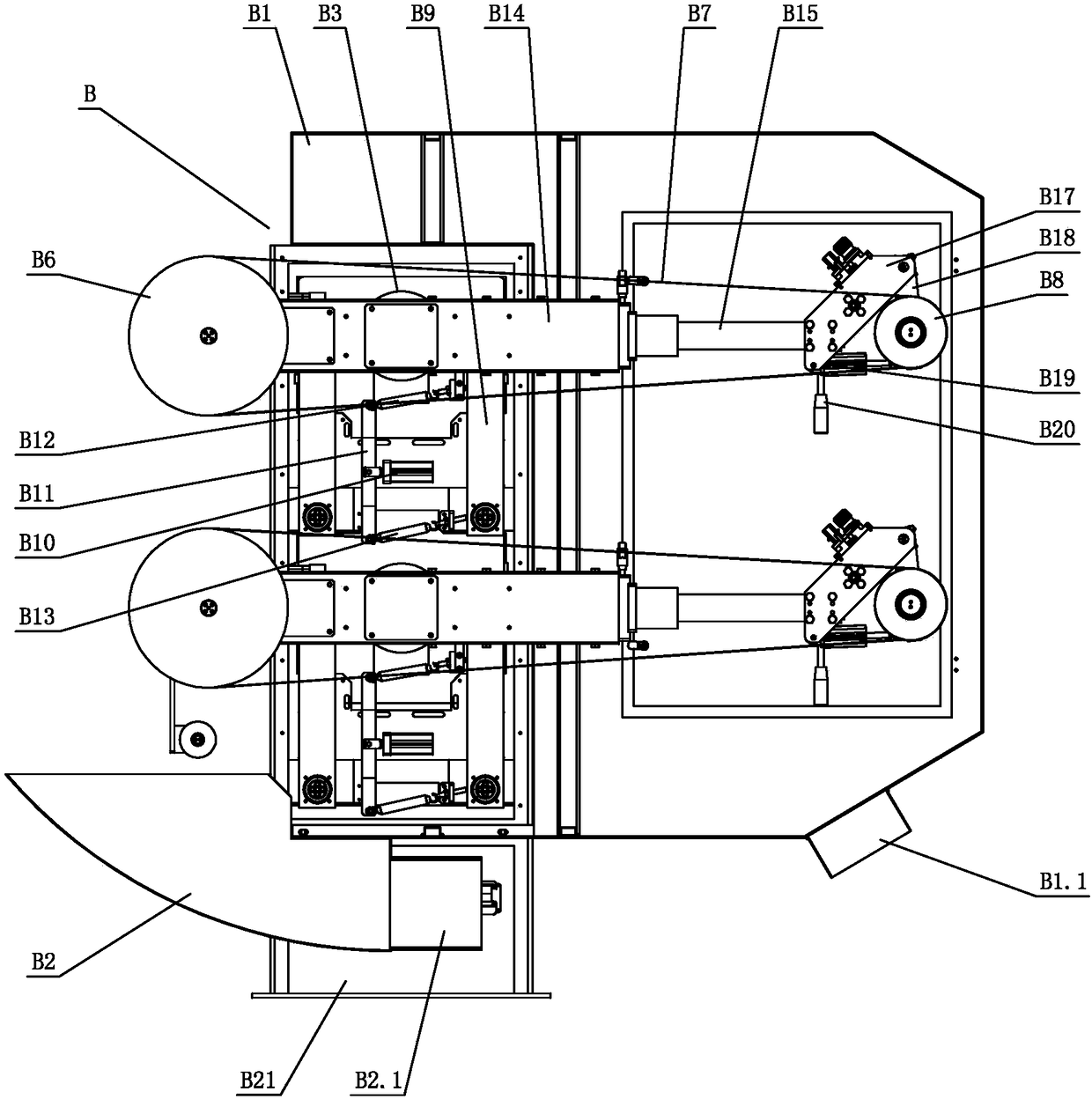

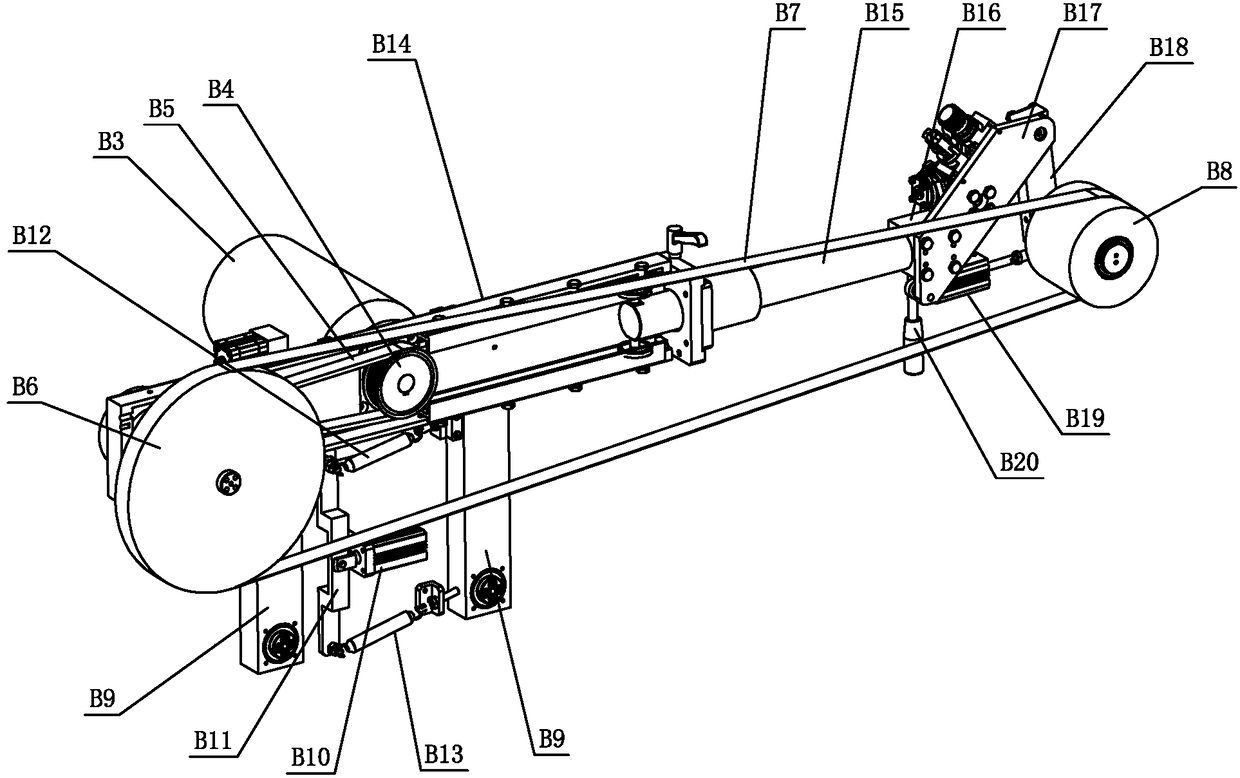

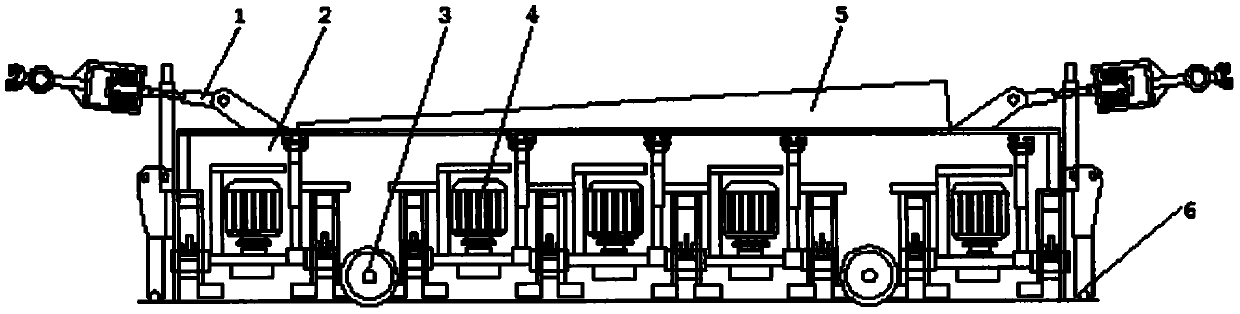

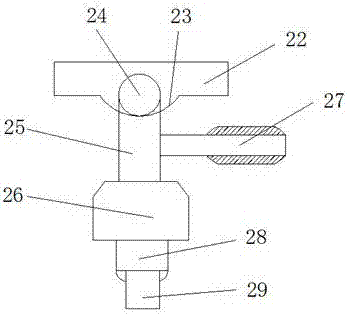

Double-station belt sanding system for sanding hammer heads

PendingCN108340249AShorten the timeEasy to operateBelt grinding machinesGrinding feedersEngineeringAutomation

A double-station belt sanding system for sanding hammer heads comprises a belt sanding mechanism, a feeding and discharging mechanism, a conveying robot and a control mechanism. The belt sanding mechanism, the feeding and discharging mechanism and the conveying robot are electrically connected with the control mechanism. The belt sanding mechanism comprises two or more belt sanding assemblies which are movably arranged overall relative to a sanding support. A force control device is arranged between the belt sanding assemblies and the sanding support. The feeding and discharging mechanism comprises a feeding and discharging worktable. Two or more feeding and discharging pushing devices are arranged on the feeding and discharging worktable. Each feeding and discharging pushing device is provided with a detachable storage plate in a matched mode and drives the storage plate to reciprocate. A plurality of hammer head workpieces are arranged on the storage plates. The double-station belt sanding system for sanding hammer heads has the characteristics of being high in automation degree, high in sanding efficiency, good in sanding quality, convenient to operate, low in labor intensity, low in labor cost, reliable in performance, good in sanding consistency, high in work stability and high in safety coefficient, and effectively improving production efficiency.

Owner:GUANGDONG LXD ROBOTICS CO LTD

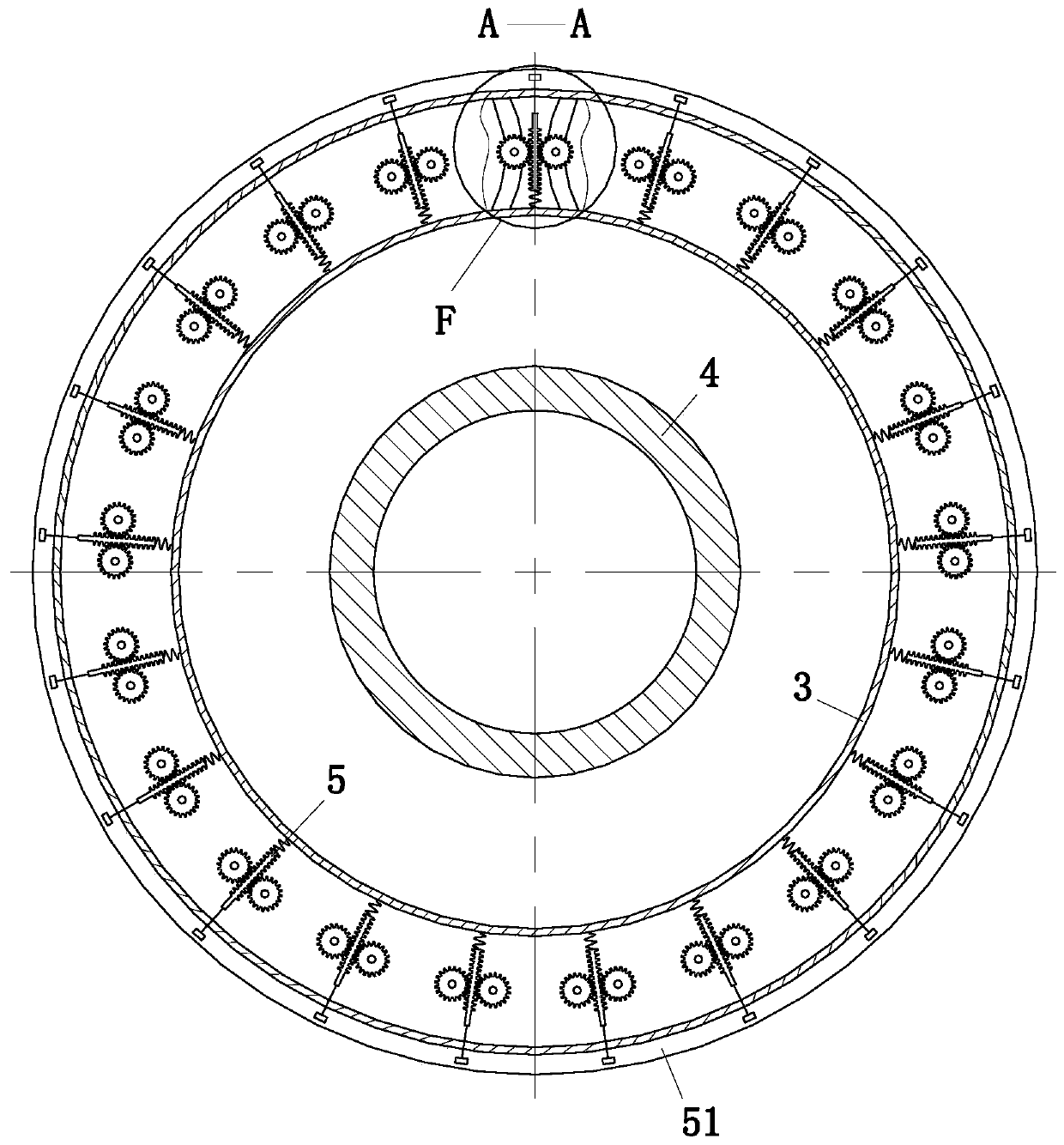

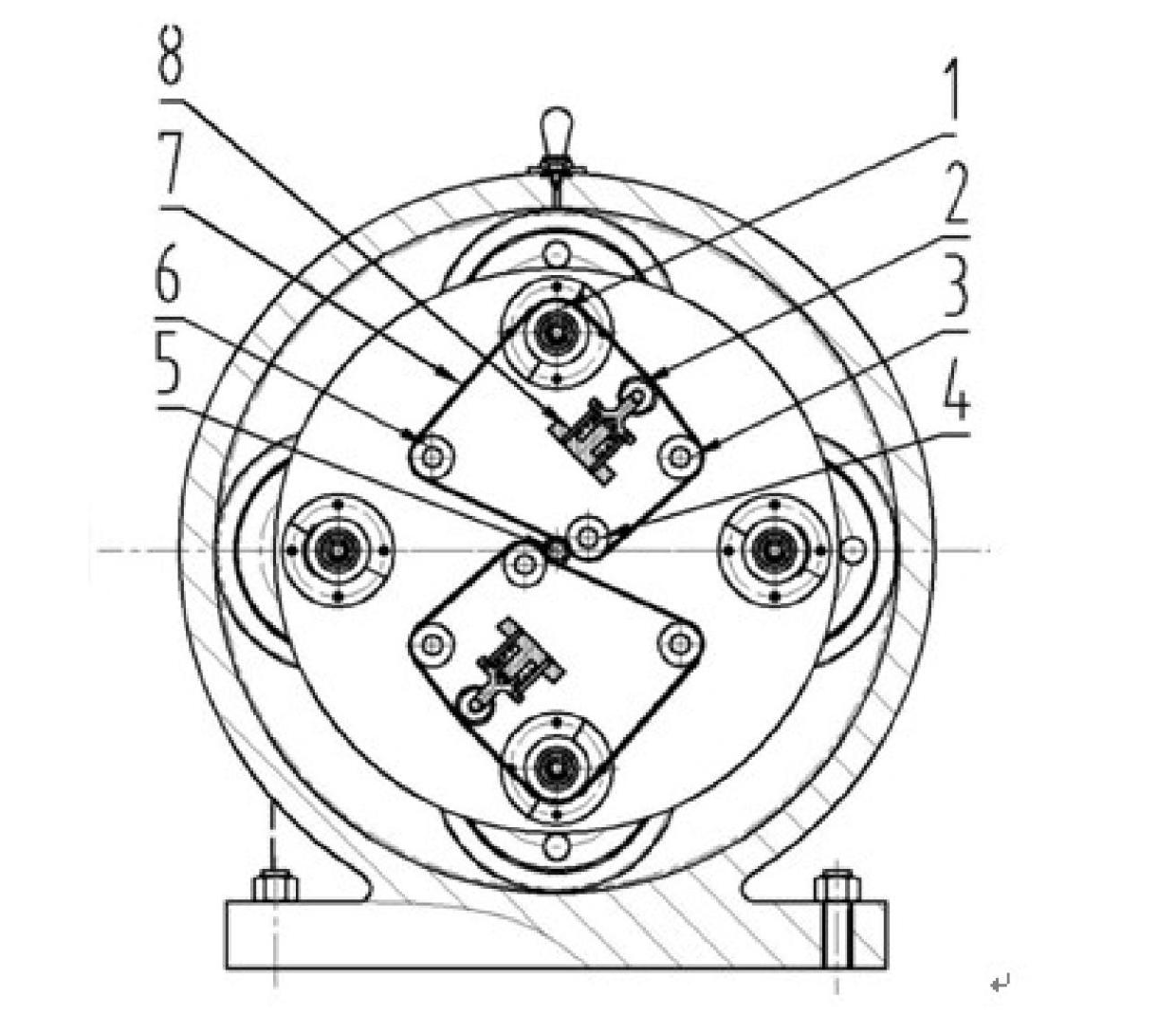

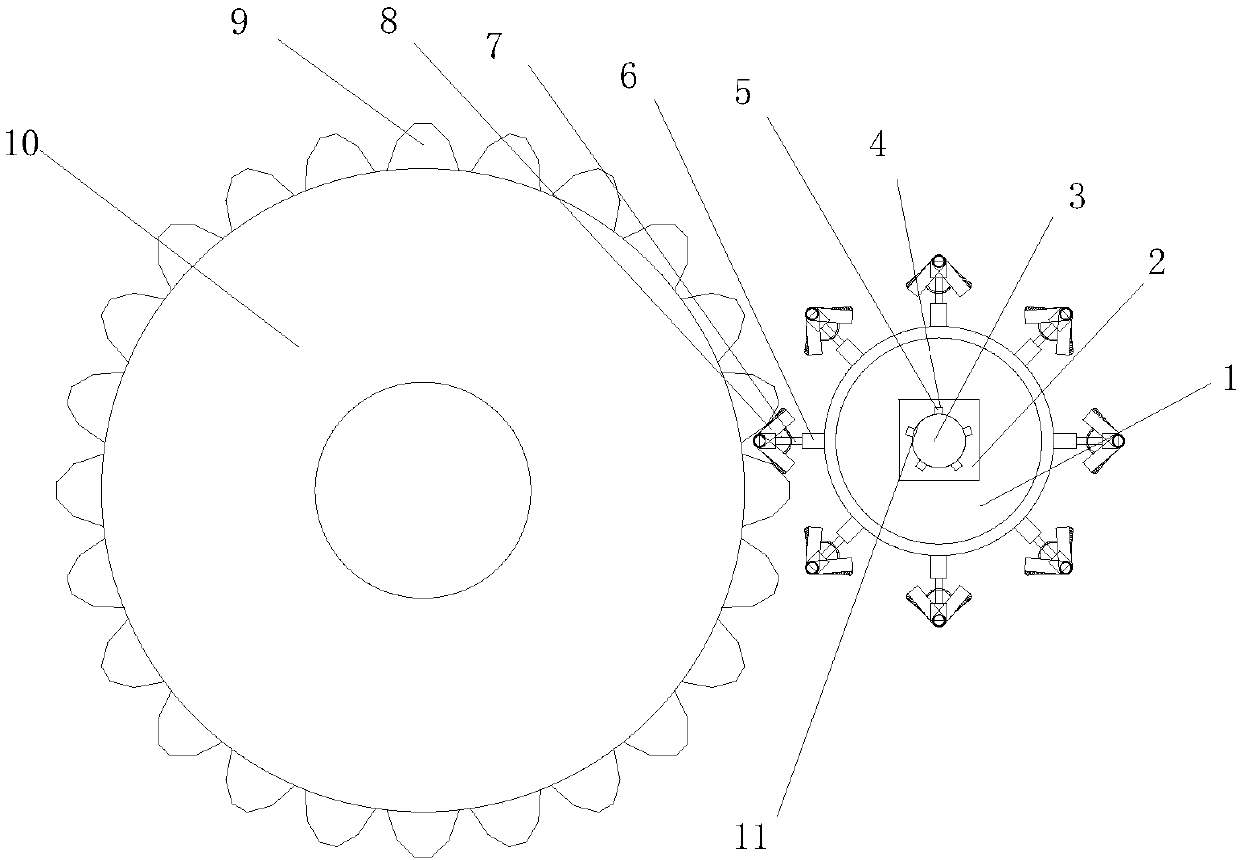

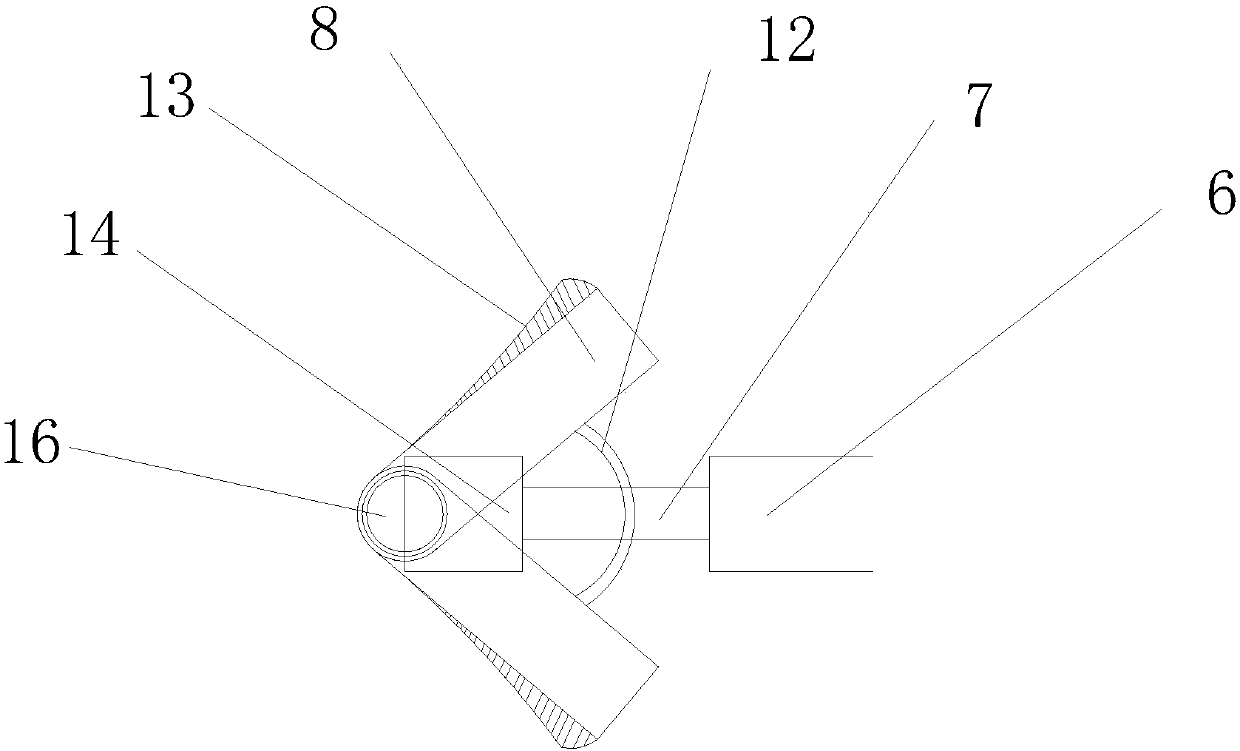

Gear tooth surface grinding mechanism

PendingCN107695459AImprove grinding efficiencyReduce manual operationsGear teethGear wheelElectric machinery

The invention aims at providing a gear tooth surface grinding mechanism. The gear tooth surface grinding mechanism comprises a gear. The gear is provided with uniform gear teeth. One side of the gearis provided with a grinding device used for accurately grinding the surfaces of the gear teeth. The grinding device comprises multiple sets of grinding heads and a rotary disk. The multiple sets of grinding heads are uniformly arranged on the periphery of the rotary disk. Connecting blocks of the grinding heads are connected with driving motors through rotary rods. The grinding heads make contactwith the side faces of the gear teeth. A connecting hole in the center of the rotary disk is connected with a connecting rod of a rotating motor. Automatic cycle all-in-one grinding is achieved. The grinding efficiency is improved. The manual operating difficulty is lowered. Meanwhile, by adopting the angle-adjustable grinding heads, the gear tooth surface grinding mechanism can effectively adaptto the gear tooth space according to the size of the gear tooth space, promote grinding blades to conduct deep grinding, improve the grinding quality and lower the grinding cost.

Owner:六安市金龙齿轮有限公司

Rail grinding trolley

PendingCN109750566AEasy to panTraversing for easy panningRailway track constructionVehicle frameDerailment

The invention discloses a rail grinding trolley. The rail grinding trolley comprises a frame, a grinding unit and derailment protection devices, wherein traction rods are separately arranged on the upper two sides of the frame, walking wheels are fixed to the lower part of the frame, the grinding unit is arranged in the frame, a dust collection channel is arranged on the upper part of the frame, the derailment protection devices are fixed to the left side and right side of the frame, lifting devices are arranged on the two sides of the inner part of the frame, deflection electric cylinders arearranged below the lifting devices, guide rods are arranged on the lower parts of the deflection electric cylinders, guide seats are arranged on the outer sides of the guide rods, and electric cylinders are fixed to one side of the guide seats. The rail grinding trolley is provided with a transverse moving structure capable of moving horizontally conveniently, and the guide seats can move on theguide rods under the driving action of the electric cylinders, so that the transverse moving of the grinding unit is realized, obstacles on both sides of a rail are conveniently avoided during grinding, and the operation range is expanded.

Owner:长沙瀚鹏电子技术有限公司

Valve polishing device

InactiveCN107953199AEasy clampingAvoid displacementGrinding machinesGrinding work supportsFixed frameEngineering

The invention discloses a valve polishing device. The valve polishing device comprises a base, a vertical column and a crossbeam. The vertical column is fixedly connected to the upper end of the base,and one side of the vertical column is fixedly connected with the crossbeam. The upper end of the base is fixedly connected with a first clamp, and a second clamp is arranged on one side of the firstclamp; the second clamp is slidably connected with the base; one side of the second clamp is fixedly connected with a second air cylinder; a collecting groove is formed in the surface of the base; adust collector is fixedly connected to the lower end of the base; a fixing frame is slidably connected to the outer side of the crossbeam; and the top of the fixing frame is rotatably connected with pulleys through connecting rods. According to the valve polishing device, the first clamp and the second clamp are arranged, the second clamp is fixedly connected with the second air cylinder, the second air cylinder pushes the second clamp to move, thus the distance between the first clamp and the second clamp can be effectively adjusted, and a valve can be well clamped, so that the valve is prevented from moving when being polished.

Owner:XINCHANG LIYONGDA REFRIGERATION MACHINERY

Automatic polishing device and polishing system thereof

InactiveCN108436708AHealth hazardImprove grinding efficiencyGrinding machinesAutomatic grinding controlControl systemProgrammable logic controller

The invention relates to an automatic polishing device and a polishing system thereof. The automatic polishing device comprises a workpiece positioning mechanism, a conveying line, a feed mechanism, adischarge mechanism, a polishing mechanism, a sandpaper replacing mechanism, a manipulator control cabinet, an electric control cabinet and a dust cover. The automatic polishing device has the functions of positioning, polishing and sandpaper replacement, and a manipulator and a polishing head group are controlled by a PLC (Programmable Logic Controller) control system, so that automatic polishing can be completed even in the conditions of large workpiece error ratio and large workpiece deformation, the polishing efficiency and the product polishing quality are increased, and manual polishingis replaced, so that human health cannot be harmed by dust.

Owner:NINGBO HUIZHIHENGDONG AUTOMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com