Patents

Literature

52results about How to "Realize all-round grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

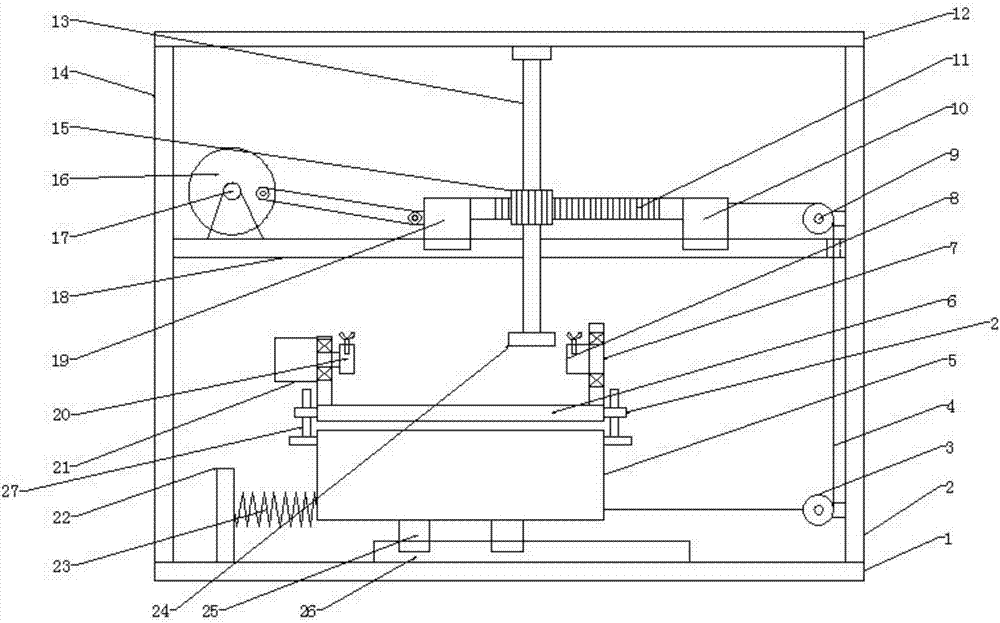

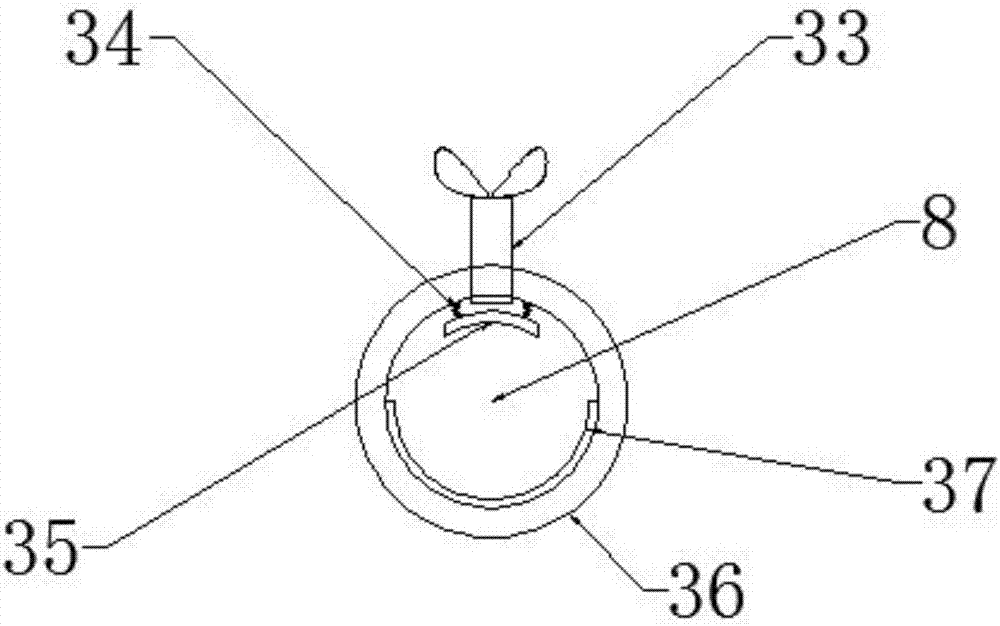

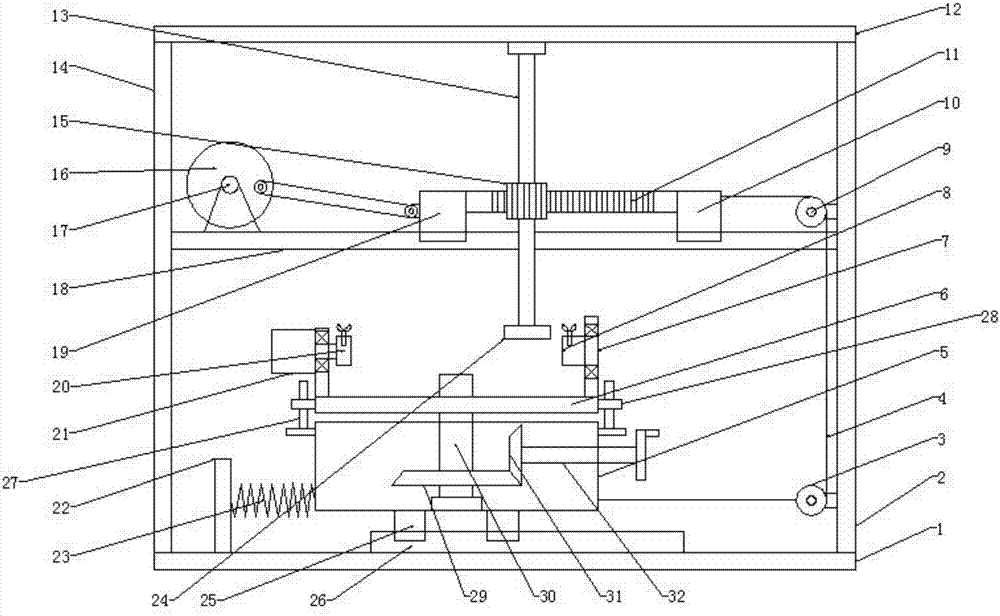

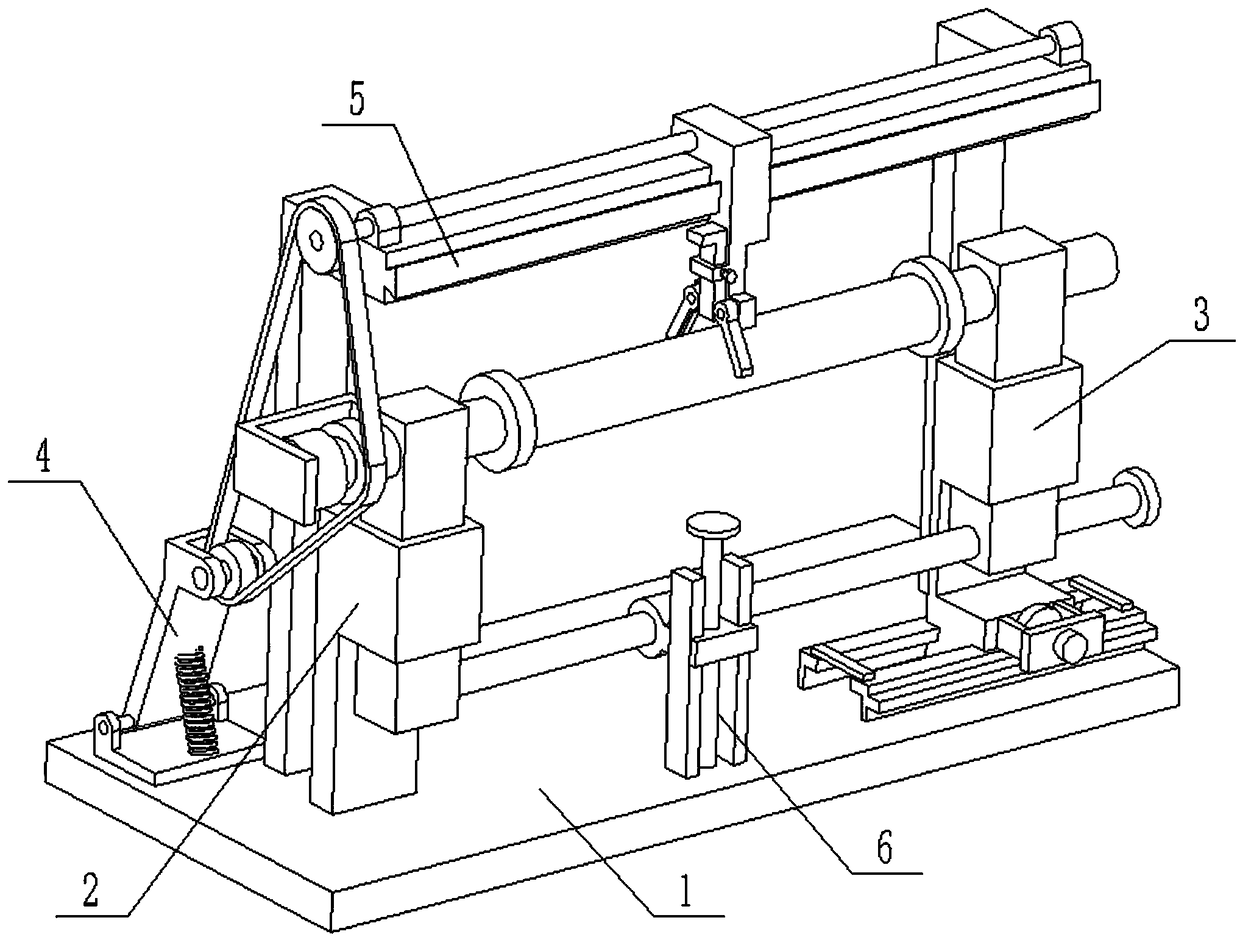

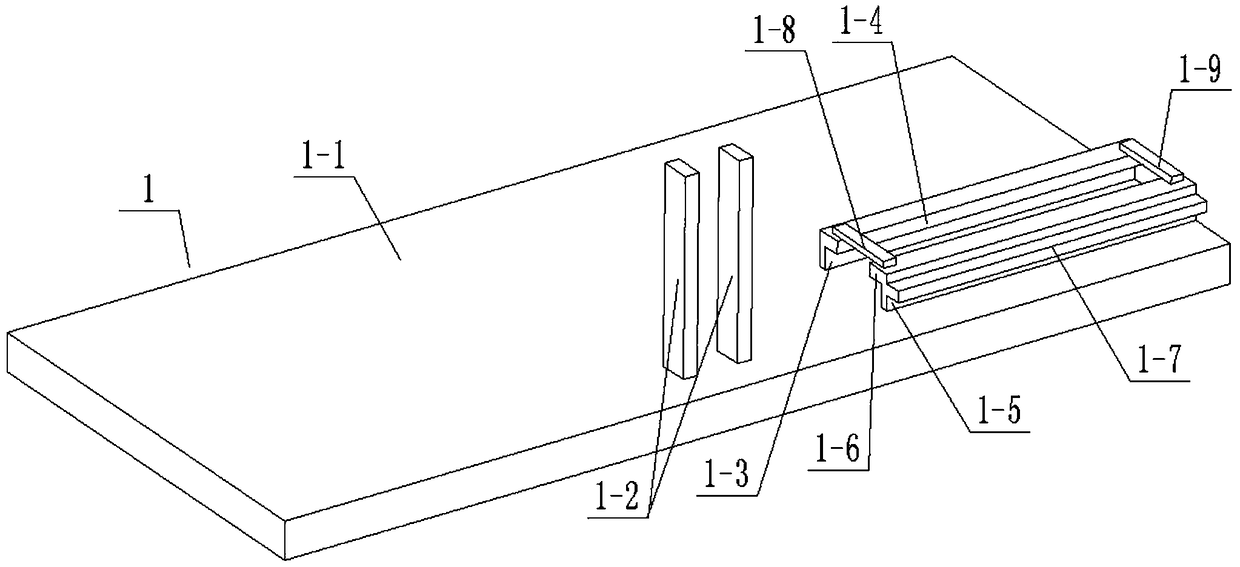

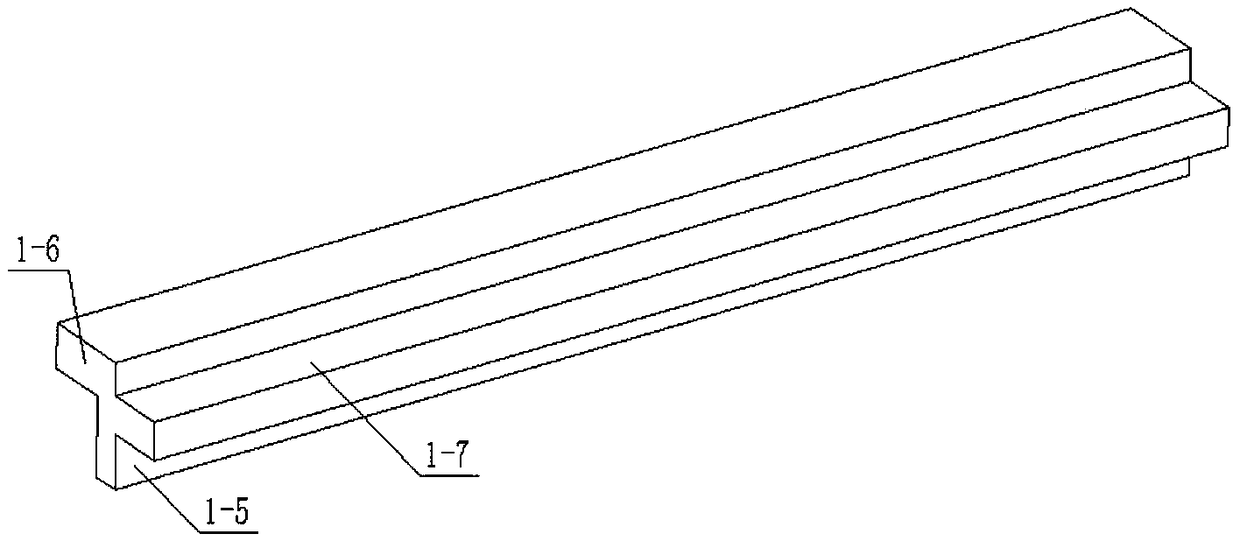

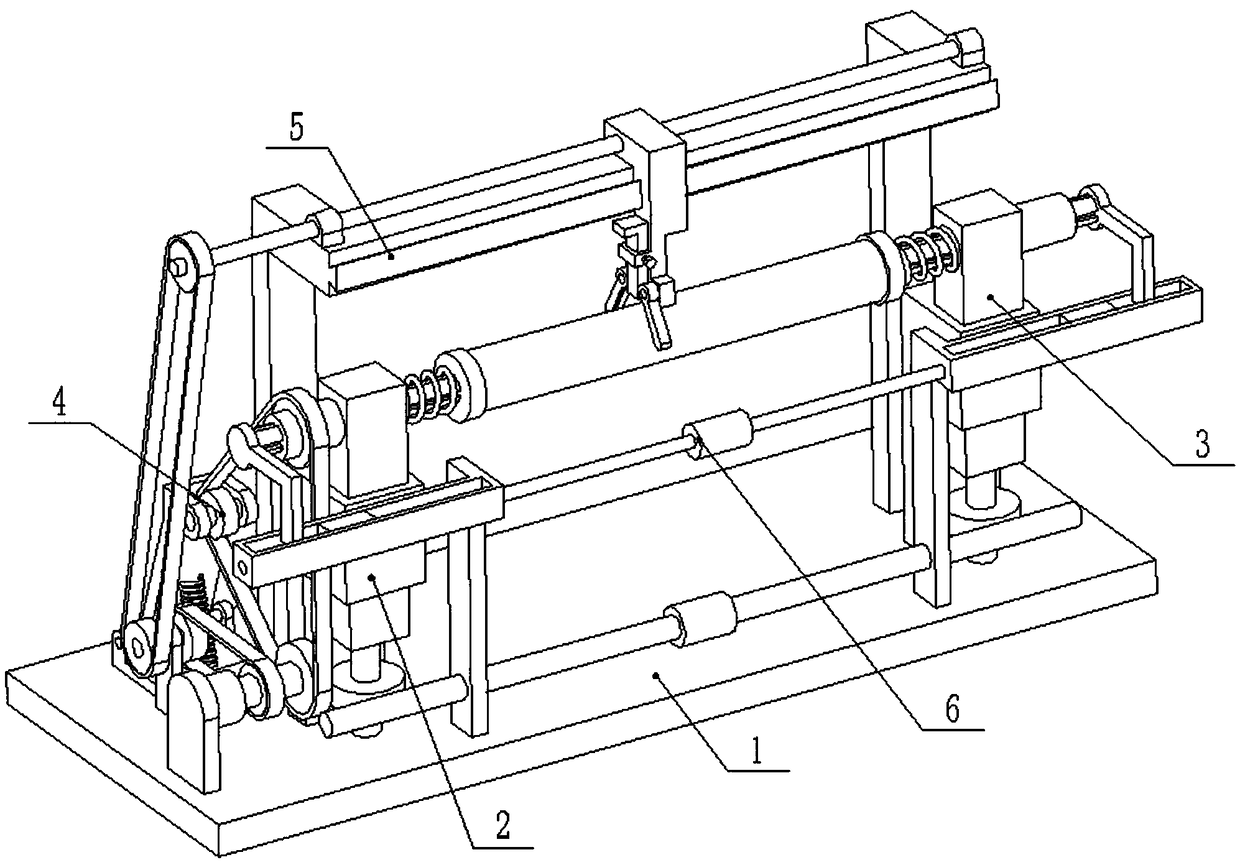

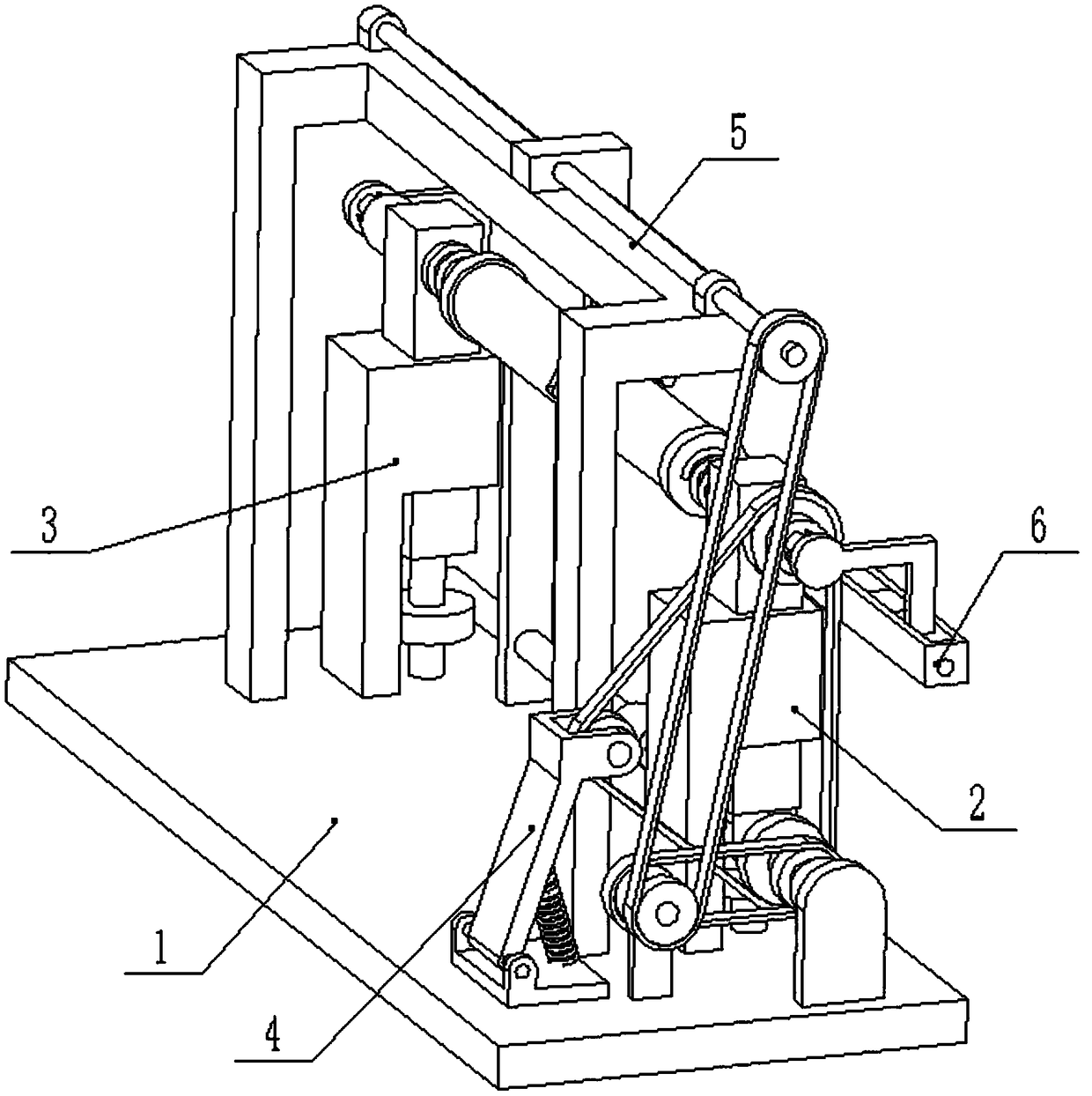

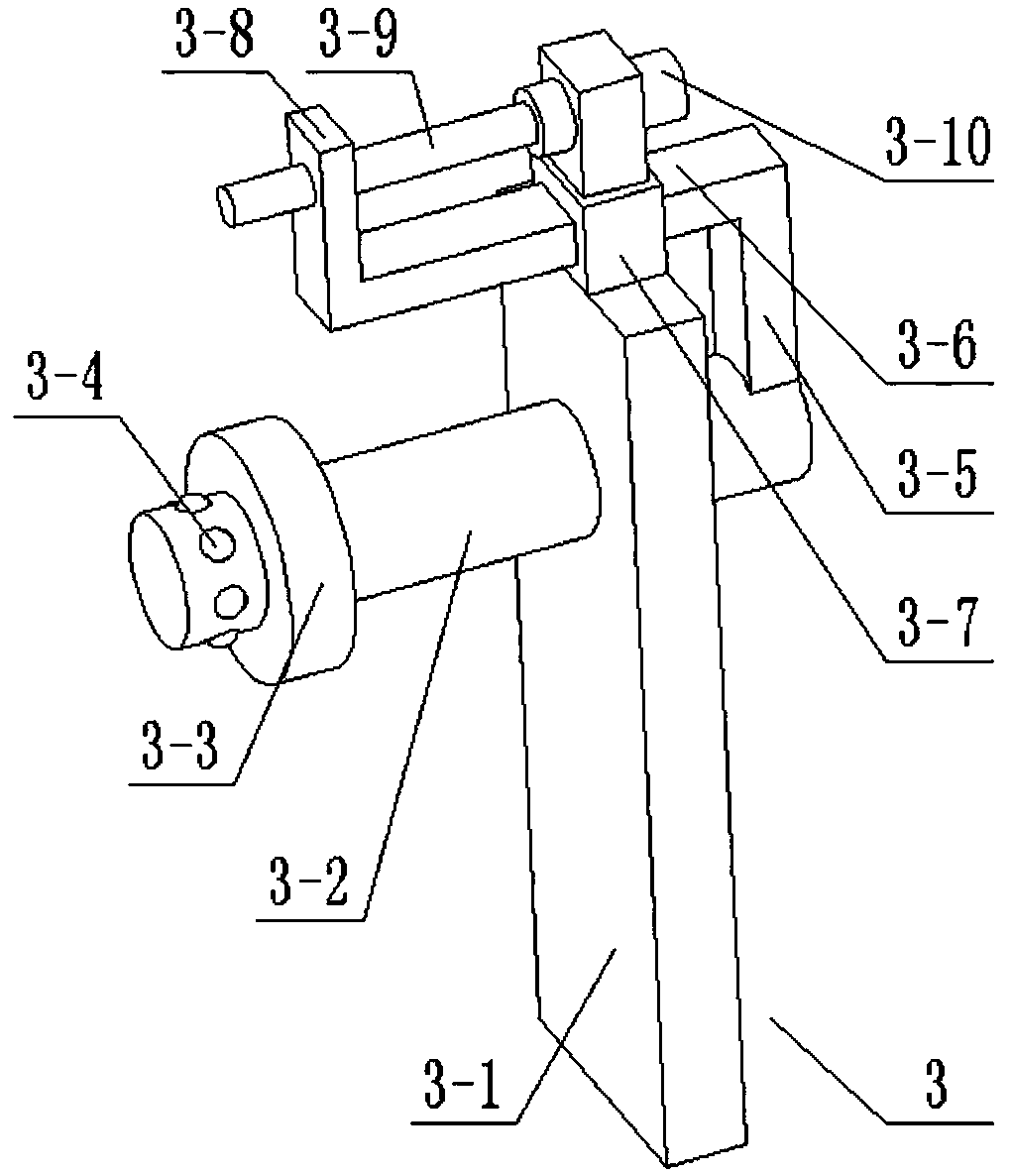

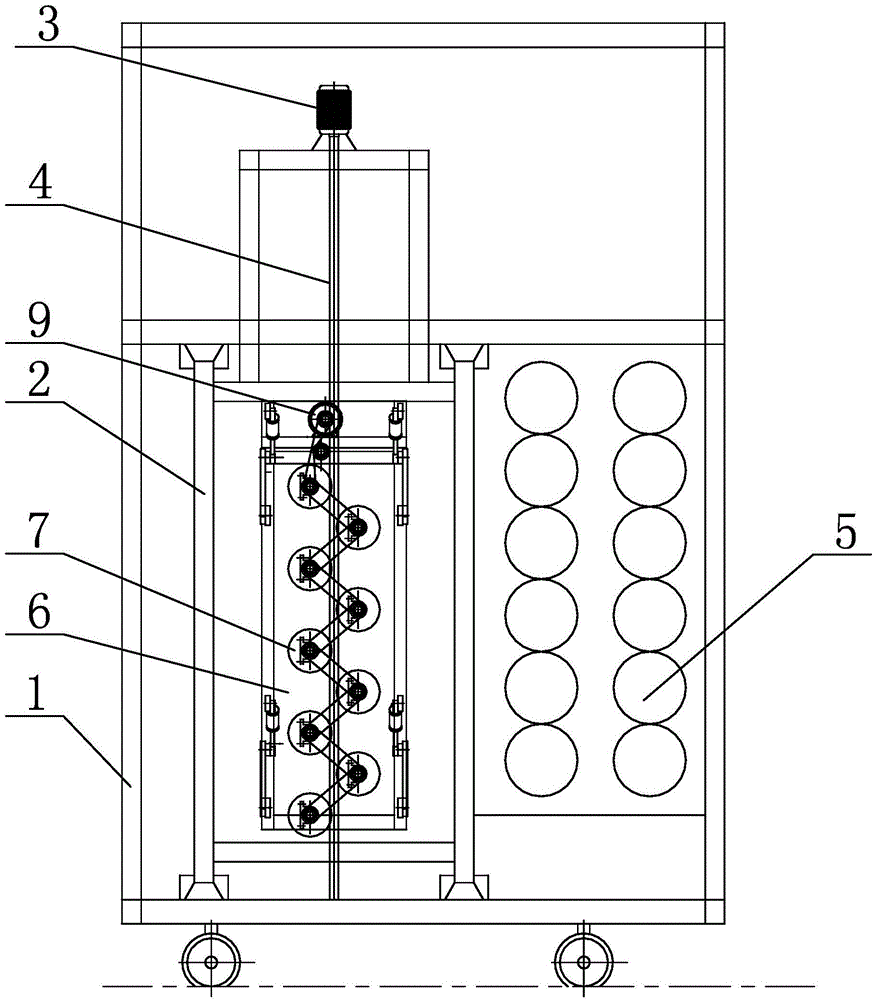

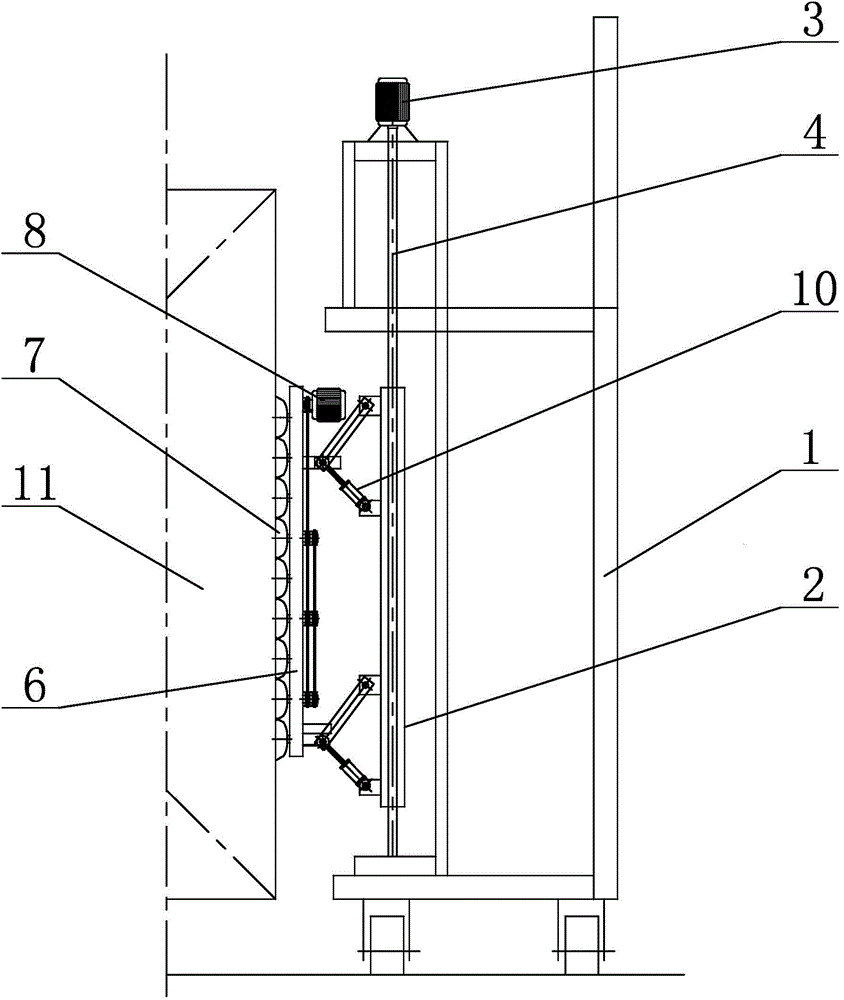

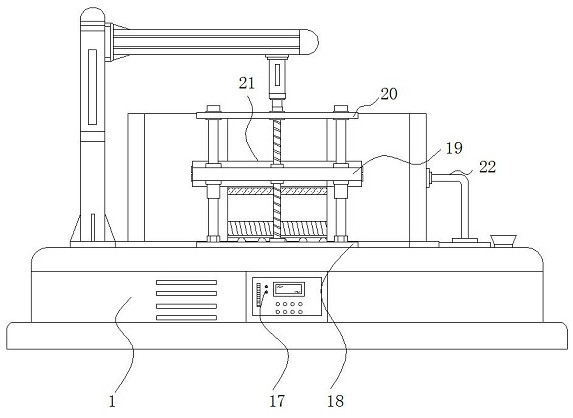

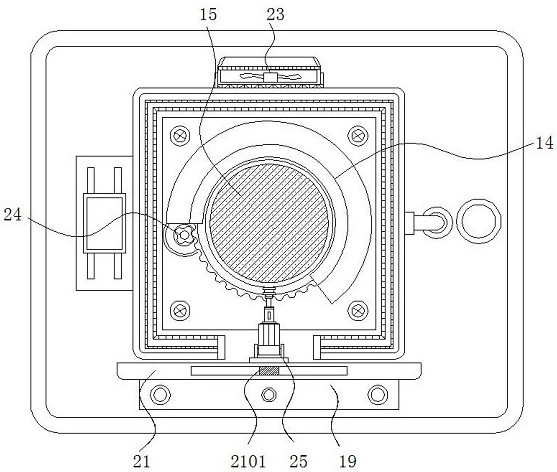

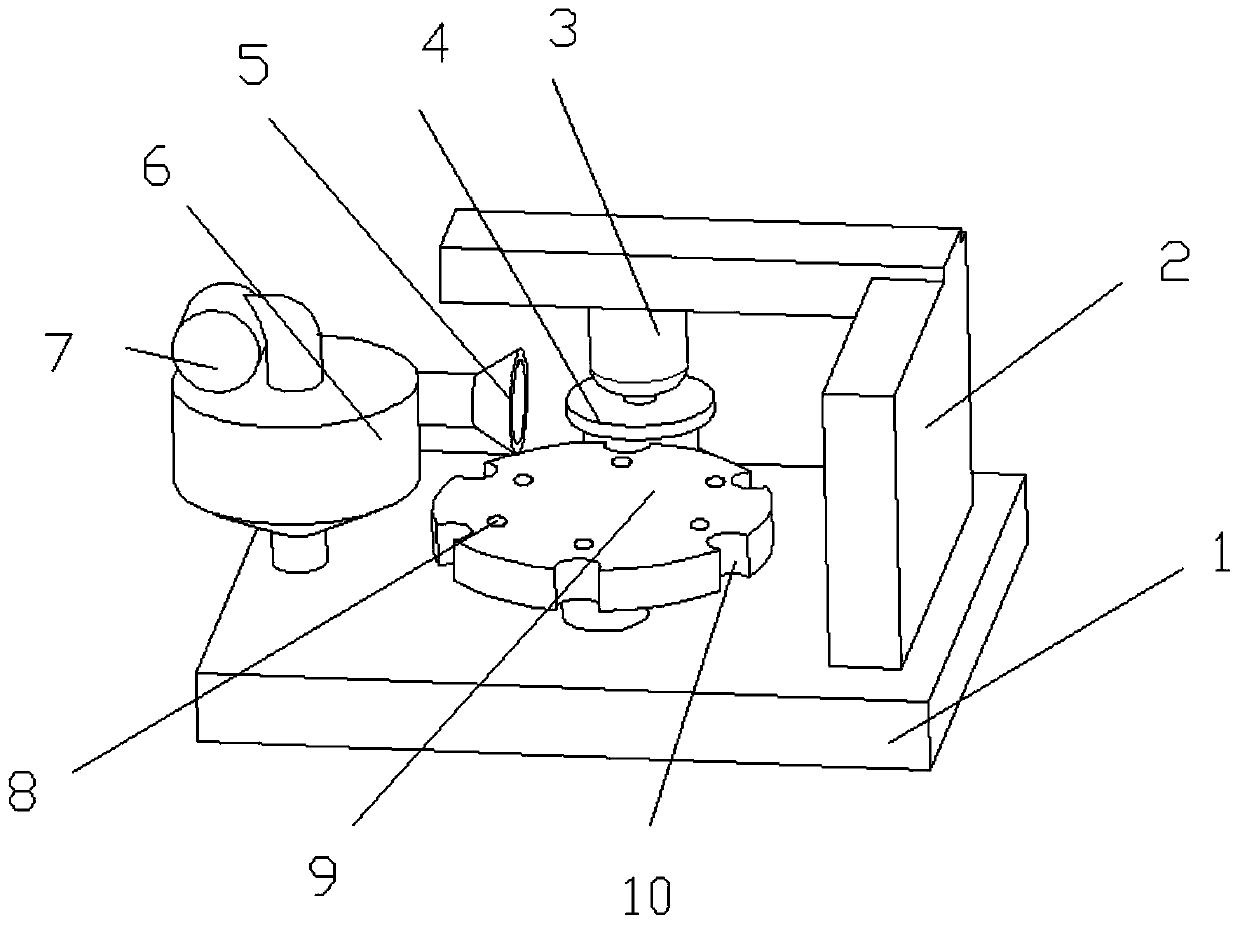

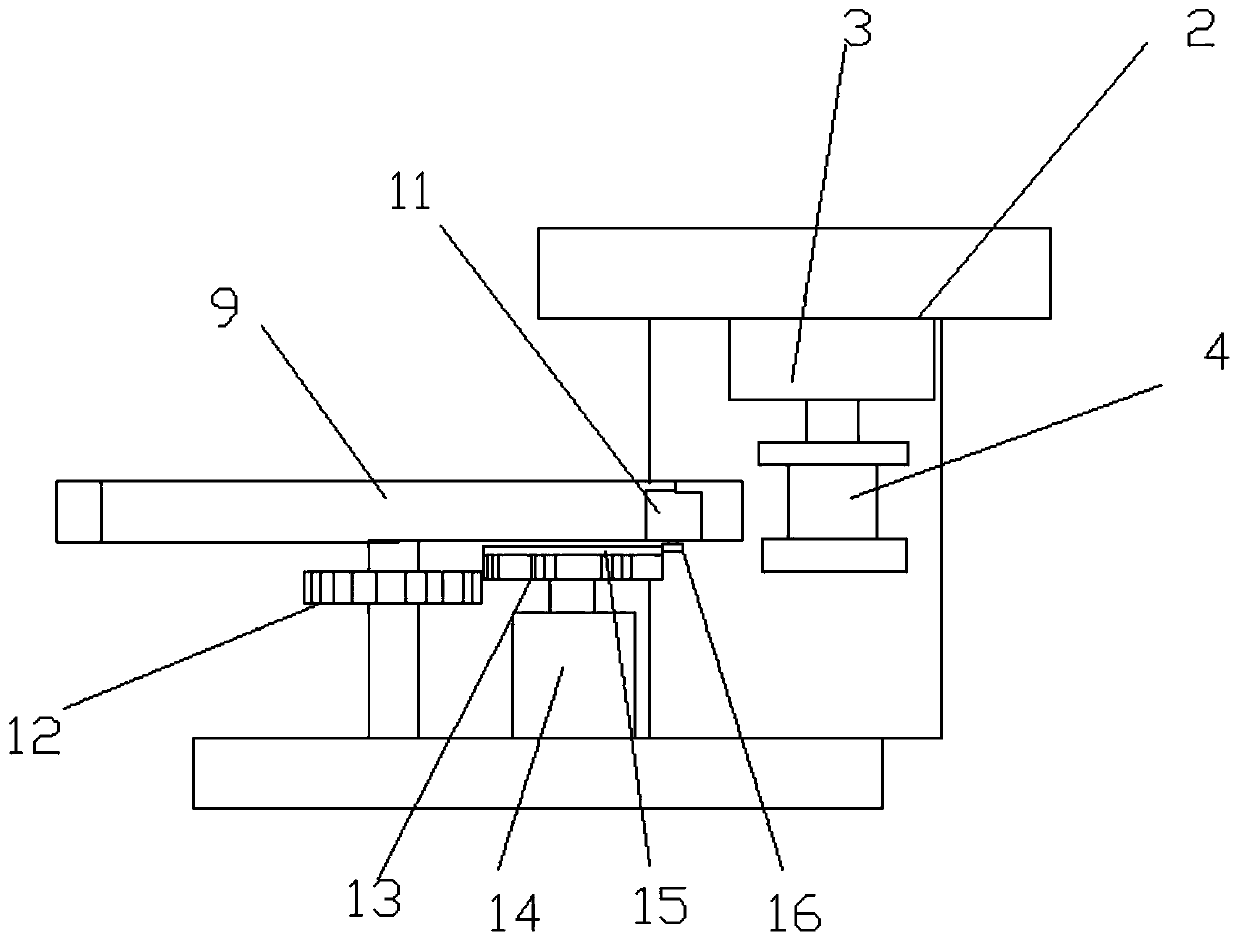

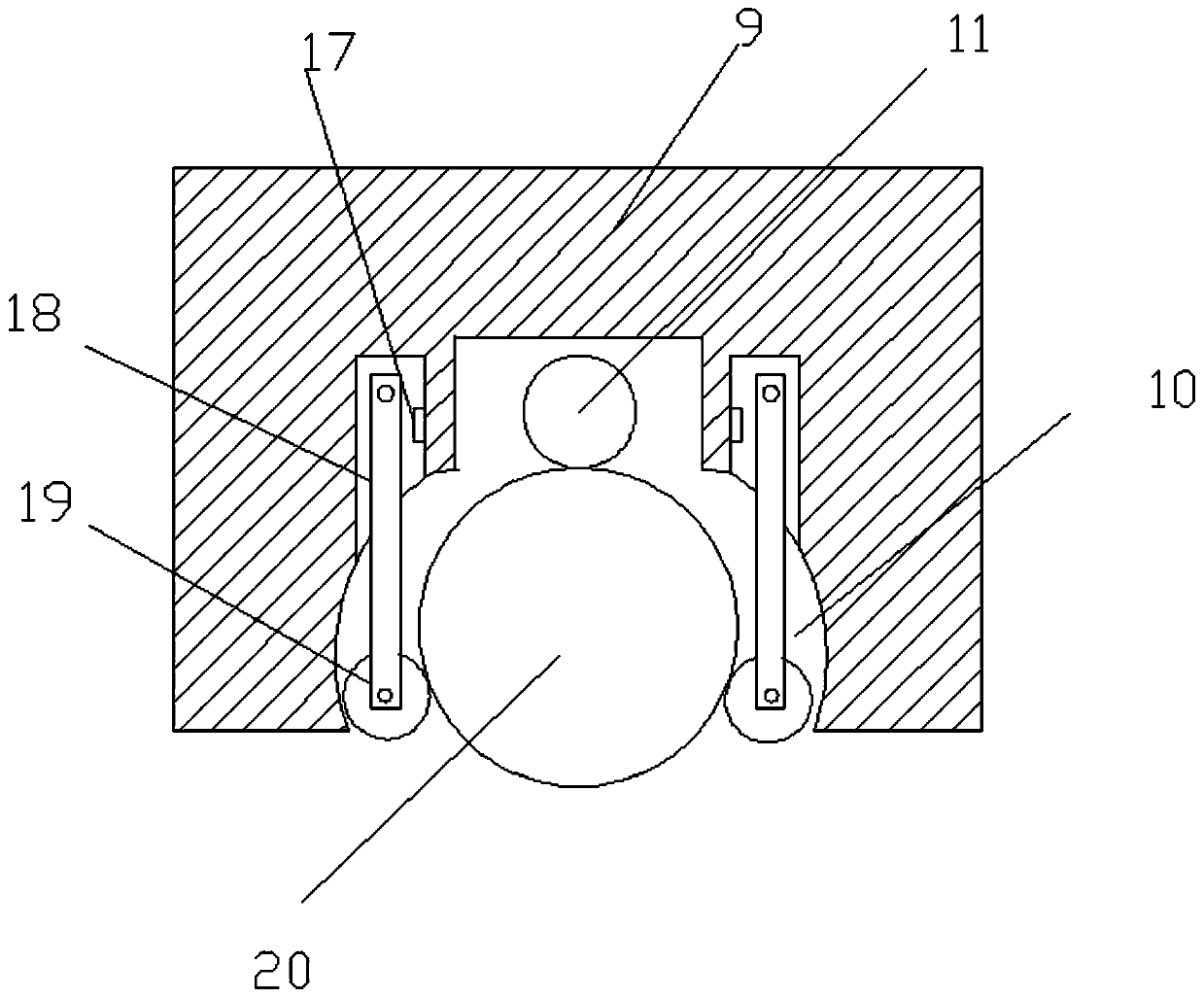

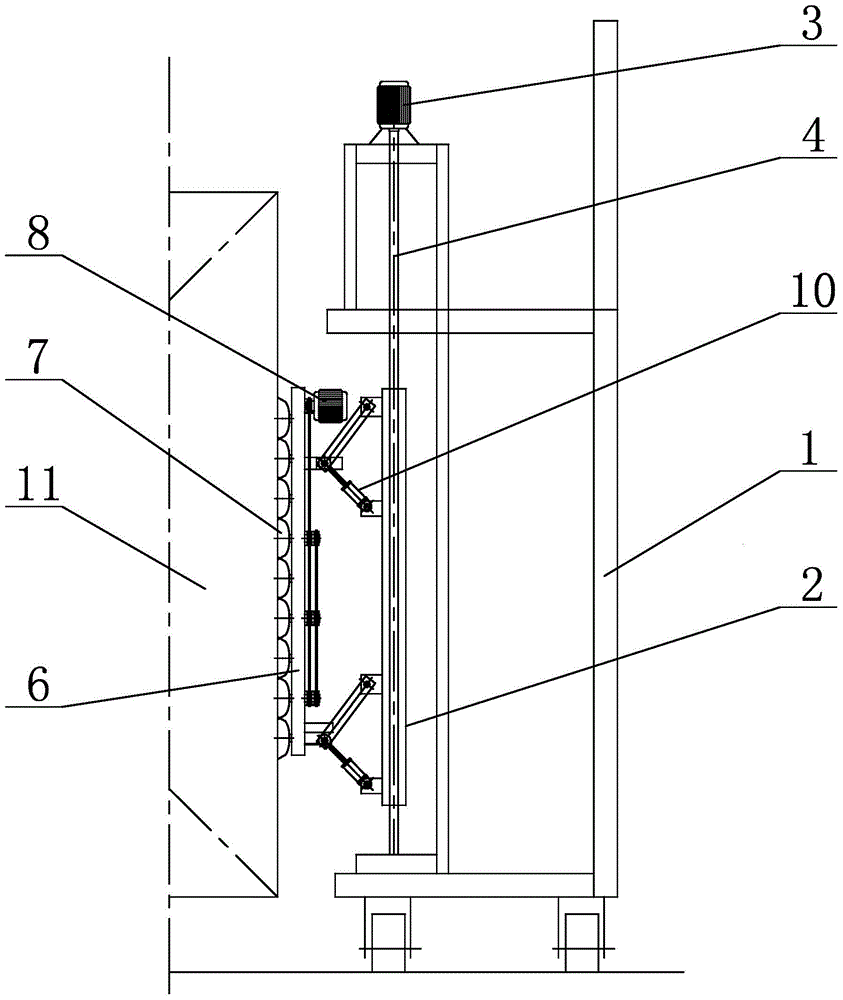

Efficient grinding and rust removing equipment for steel bars for building

InactiveCN107081666AImprove grinding efficiencyRealize all-round grindingGrinding carriagesGrinding drivesRebarPulley

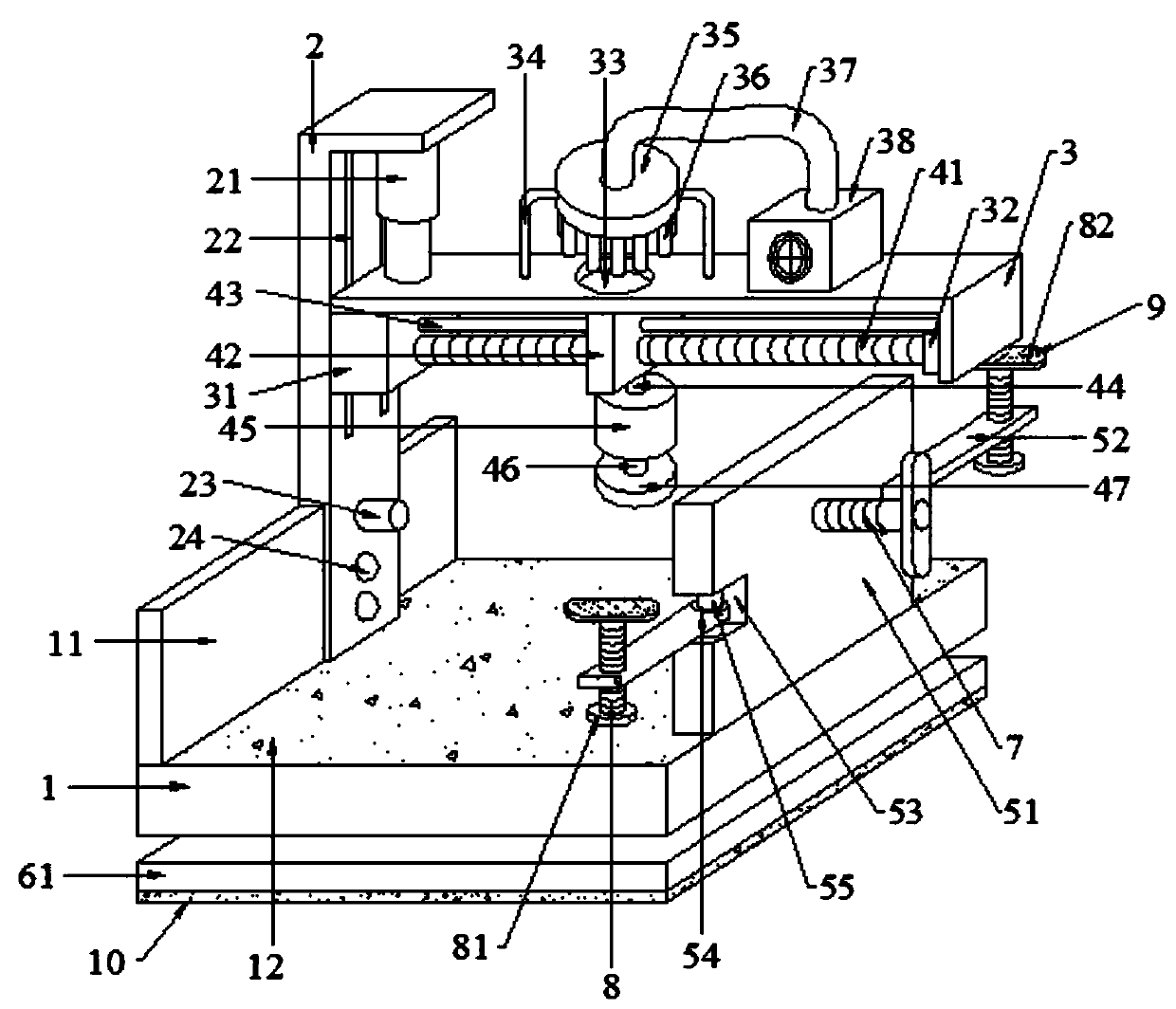

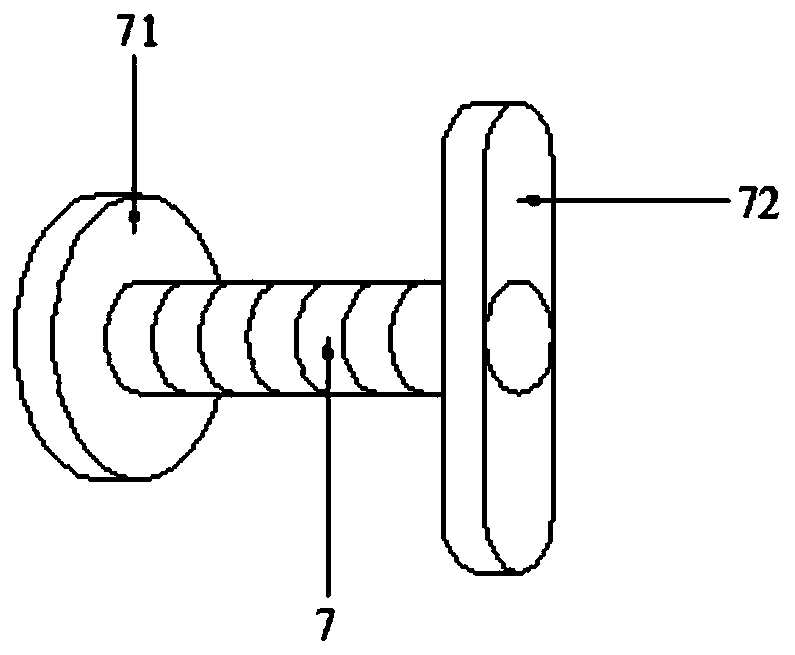

The invention discloses a high-efficiency grinding and derusting equipment for steel bars for construction, which comprises a bottom plate, a left side plate, a right side plate, a top plate, a slide rail, a first slider, a box body, a first spring, a workbench, a sleeve, a slide Rod, mounting plate, first motor, first clamping device, second clamping device, horizontal support plate, second motor, disc, connecting rod, second slider, rack, third slider, pull cord , the first fixed pulley, the second fixed pulley, racks, gears, rotating shafts, and grinding discs. The present invention is provided with a first clamping device and a second clamping device, which can fix steel bars of different diameters. The first motor, the second motor, the disc, the second slider, the rack, the gear, the third slider, the pull rope, the box body and the spring, through the cooperation of the above components, the steel bar can be polished in all directions, which further improves the grinding efficiency , with a first helical gear, a second helical gear and a threaded rod to adjust the distance between the workbench and the grinding disc to accommodate steel bars of different diameters.

Owner:长沙鼎成新材料科技有限公司

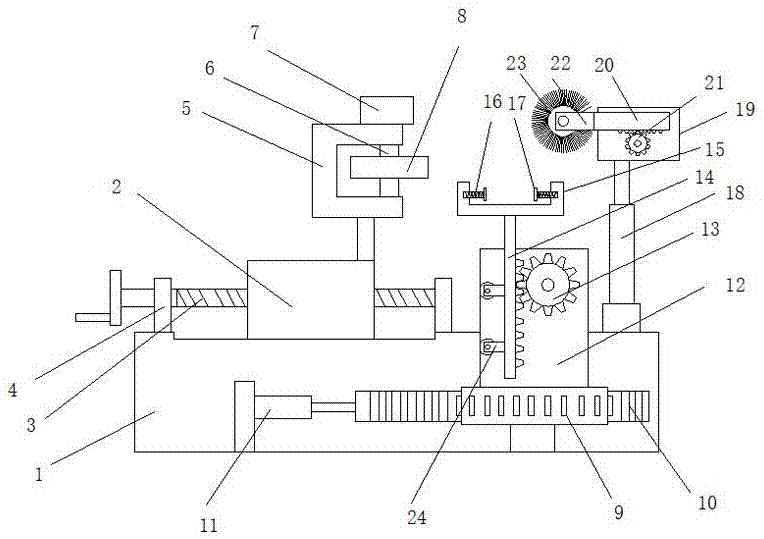

Automobile part continuous machining device

InactiveCN107225458AAchieve level adjustmentRealize up and down adjustmentEdge grinding machinesGrinding drivesArchitectural engineeringMachining

The invention discloses a continuous processing device for automobile parts, comprising a base, a chute is provided on the top of the base, a sliding block is slidably installed in the chute, and a horizontally arranged adjusting rod is threaded on the sliding block. Two fixing blocks are fixedly installed on the top of the base, the adjusting rod is rotatably connected with the fixing blocks, and the fixing blocks are sleeved on the adjusting rod, and the top of the sliding block is fixedly connected with a grinding frame, and the grinding frame is U-shaped In the structure, a vertically arranged rotating shaft is rotatably installed on the grinding frame, and a first motor is fixedly installed on the top of the grinding frame. The invention realizes all-round grinding of the parts, has high grinding accuracy, greatly improves the processing efficiency, ensures the quality of the parts processing, and also realizes the all-round deburring of the processed parts, and realizes the integration of grinding and deburring. , the cost of the device is saved, the processing efficiency is improved, the processing accuracy is also improved, and the quality of the parts processing is guaranteed.

Owner:合肥杰代机电科技有限公司

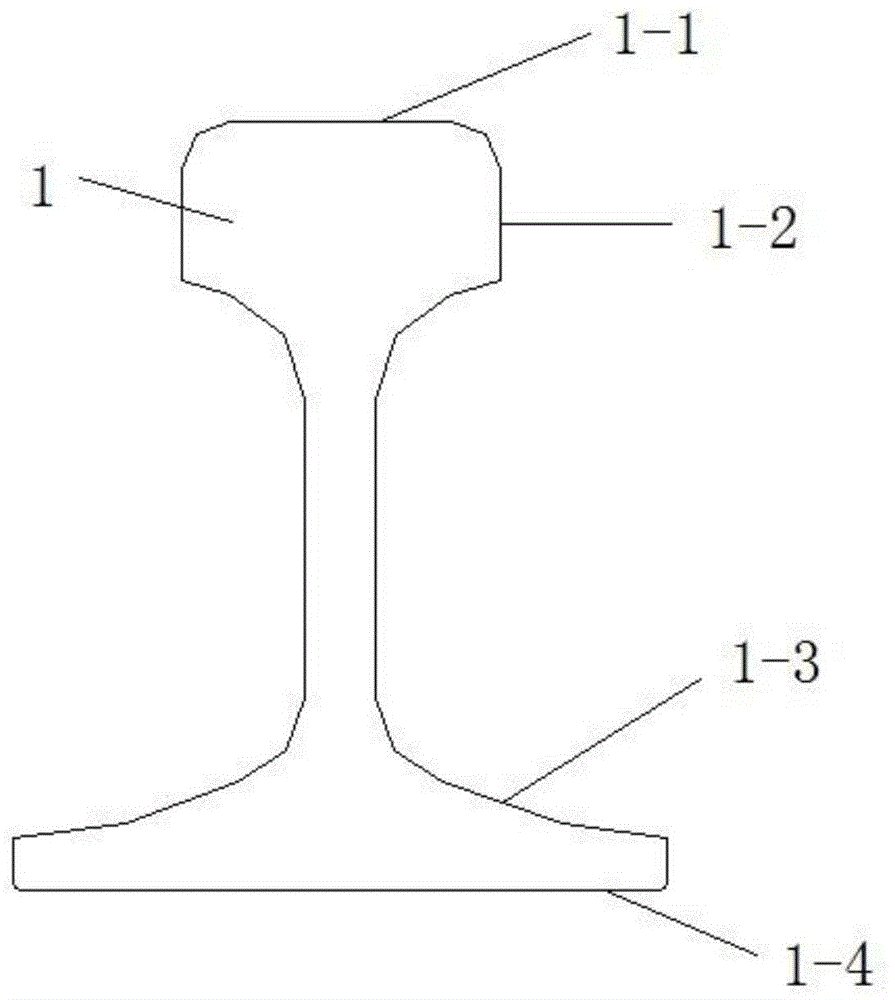

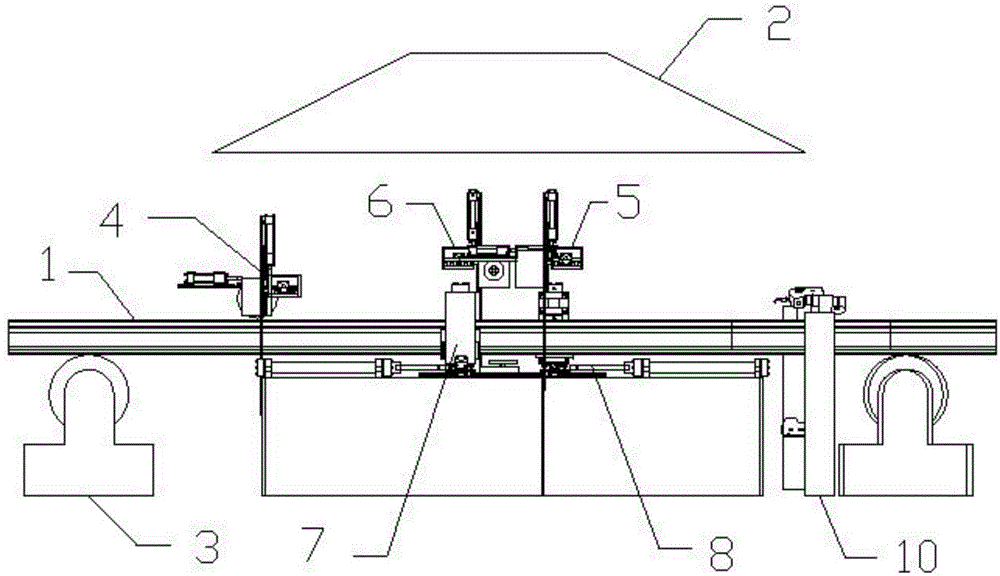

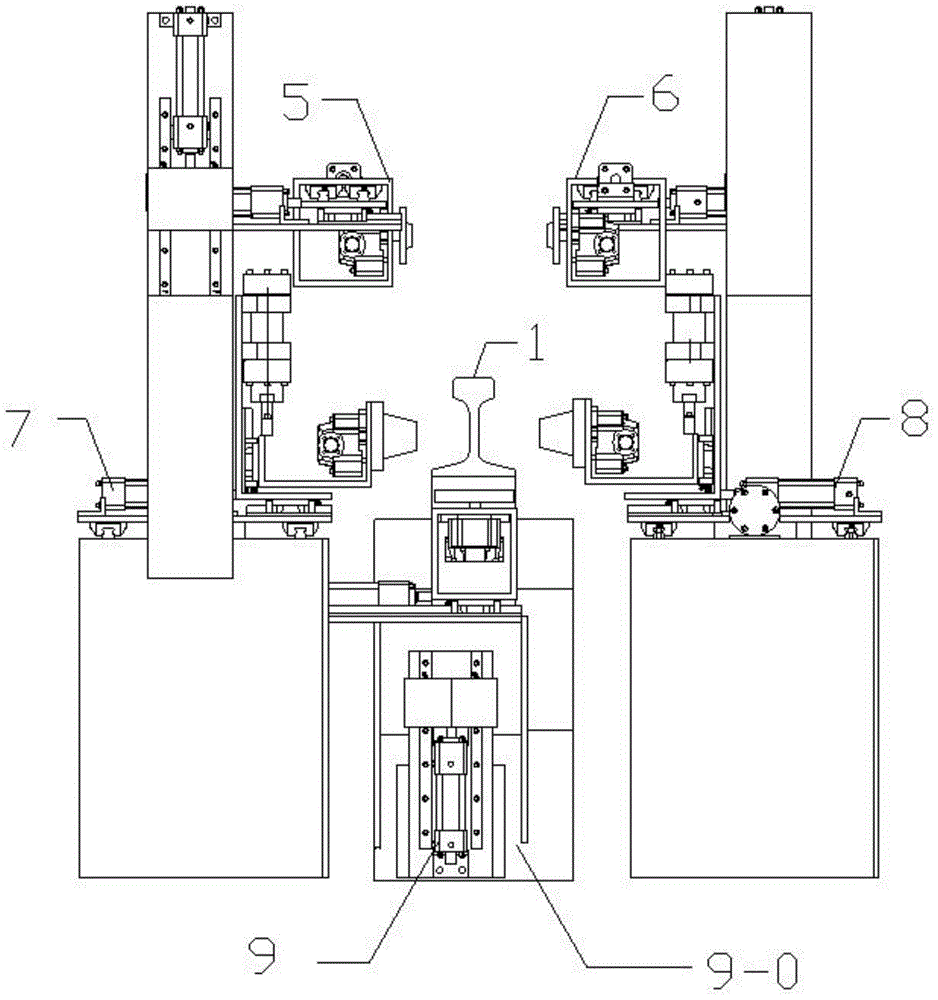

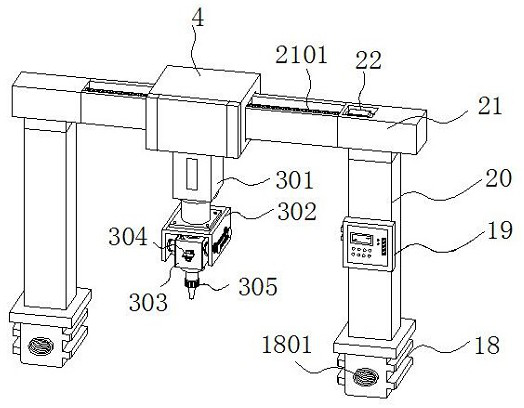

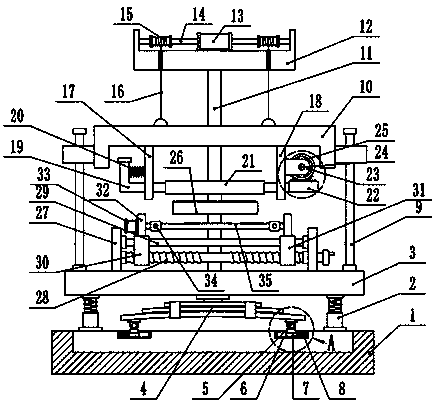

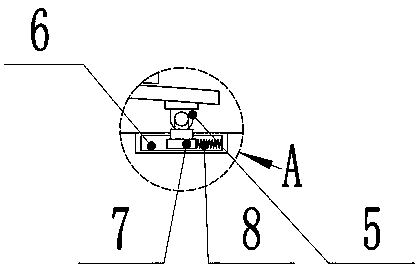

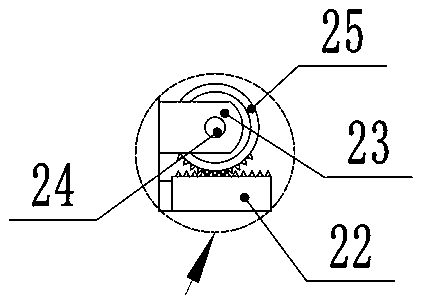

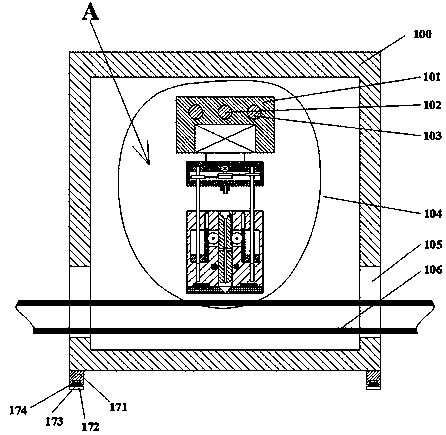

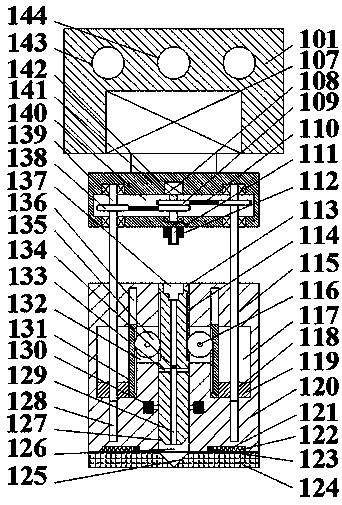

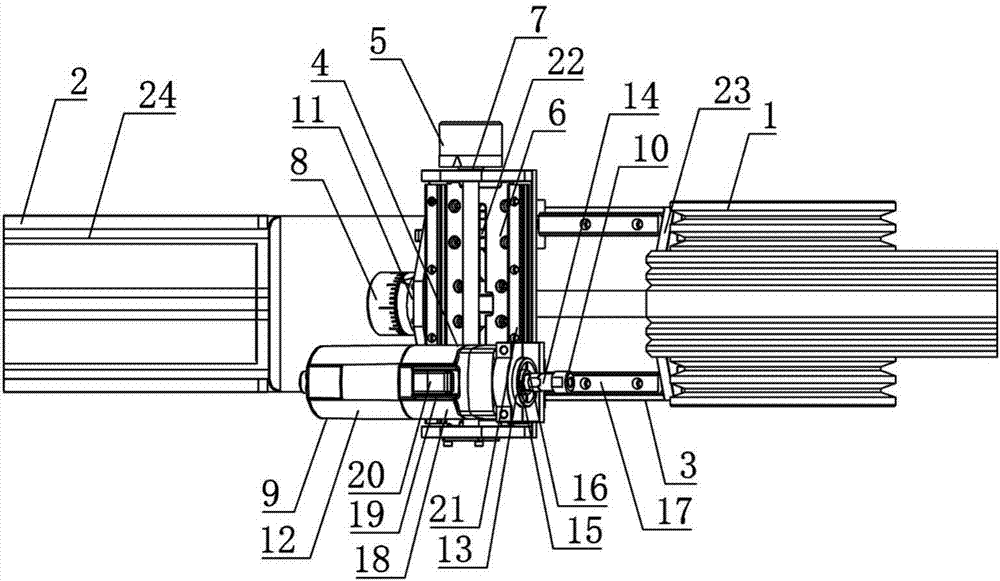

Steel rail grinding machine

InactiveCN104625930AImprove grinding speed and precisionKeep healthyGrinding feed controlGrinding machinesSurface grindingEngineering

The invention relates to a steel rail grinding machine which comprises a steel rail top surface grinding mechanism, a steel rail head side surface grinding mechanism, a steel rail triangular region grinding mechanism, a steel rail bottom grinding mechanism and a travelling line roller, wherein a steel rail is ground by the steel rail top surface grinding mechanism, the steel rail head grinding mechanism, the steel rail triangular region grinding mechanism and the steel rail bottom grinding mechanism in a process of sliding on the travelling line roller, wherein the steel rail bottom grinding mechanism comprises a center base, a base plate is fixedly connected onto the center base, a Z-direction oil cylinder and a Z-direction guide rail are arranged on the base plate, the Z-direction oil cylinder drives a Z-direction sliding base to reciprocate on the Z-direction guide rail; a Y-direction oil cylinder and a Y-direction guide rail are fixedly arranged on the top surface of the Z-direction sliding base, the Y-direction oil cylinder drives the Y-direction sliding base to reciprocate on the Y-direction guide rail; a hydraulic motor is vertically arranged inside the Y-direction sliding base, and an output shaft of the hydraulic motor is fixedly connected with a rail bottom grinding head.

Owner:戚恒

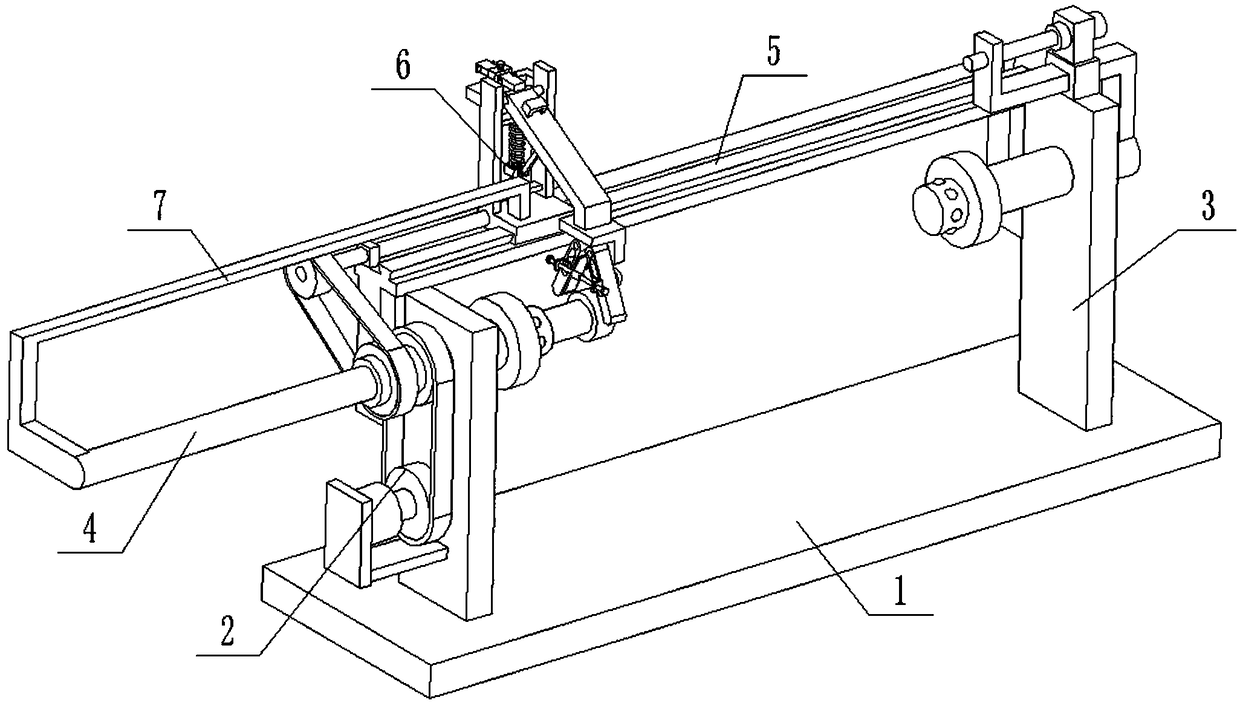

Grinding device of pipelines for building construction

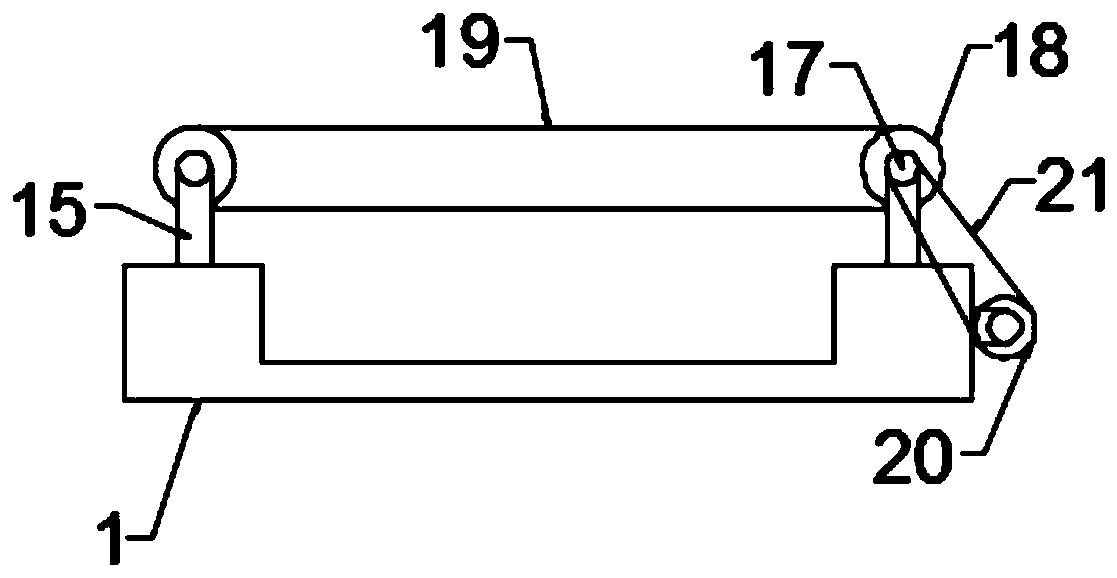

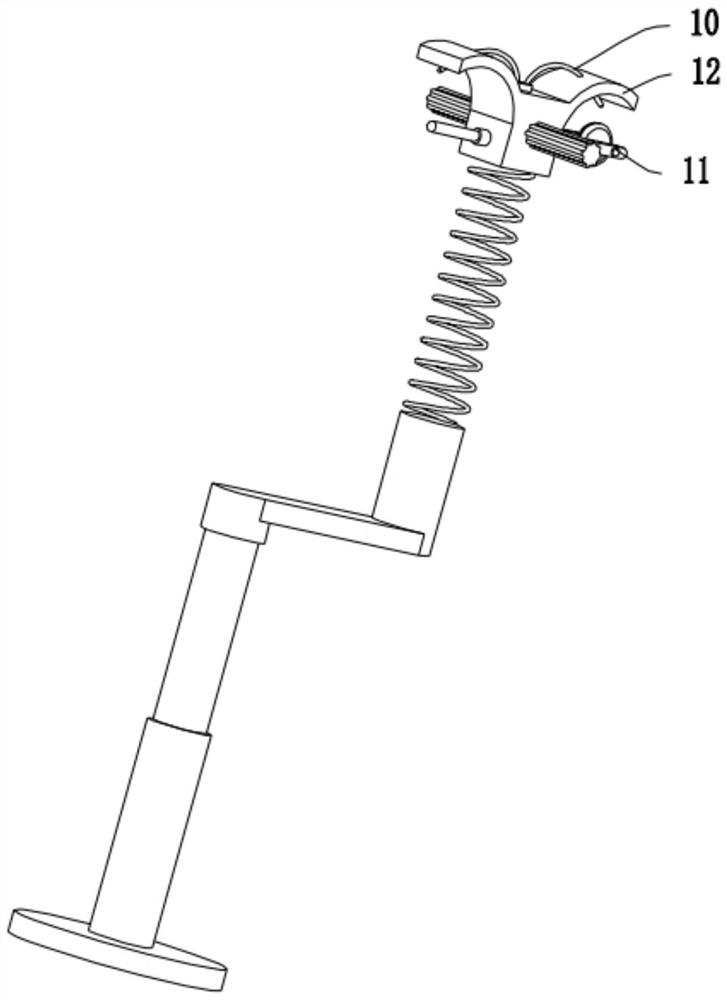

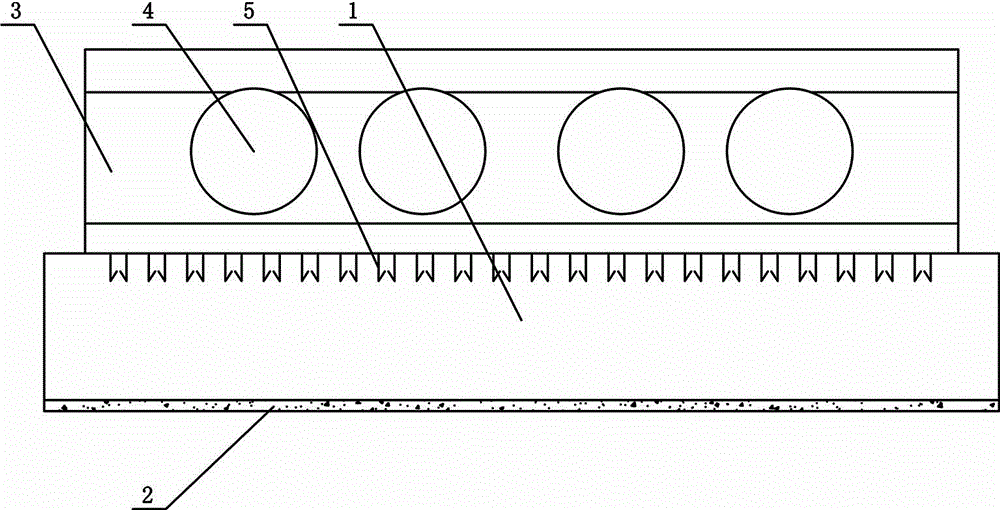

ActiveCN109129051AEasy flipRealize all-round grindingGrinding carriagesRevolution surface grinding machinesBaseboardReciprocating motion

The invention relates to the technical field of pipeline processing, in particular to a grinding device of pipelines for building construction. Two guide rods are fixedly connected to a baseboard. A first limiting board and a second limiting board are fixedly connected to one end of the baseboard. The inner side faces of the first limiting board and the second limiting board are both fixedly connected with a first convex edge and a second convex edge. One end of a left supporting board is fixedly connected to the baseboard, and the other end of the left supporting board is fixedly connected with a left sliding sleeve. The middle end of a left height adjustment seat is slidably connected into the left sliding sleeve. According to the grinding device of the pipelines for building construction, the pipelines can be driven to rotate in operation, and convenient turnover of the pipelines is achieved. All-round grinding of the pipelines is realized by reciprocating motion of a grinding board, the grinding efficiency and the grinding quality of the pipelines are improved, manual operation is reduced, and the working intensity of workers is reduced. The grinding device of the pipelines canbe suitable for grinding of the pipelines with different pipe diameters, and meanwhile the grinding speed can further be adjusted by adjusting the pressure between the pipelines and the grinding board.

Owner:江苏复华光电科技有限公司

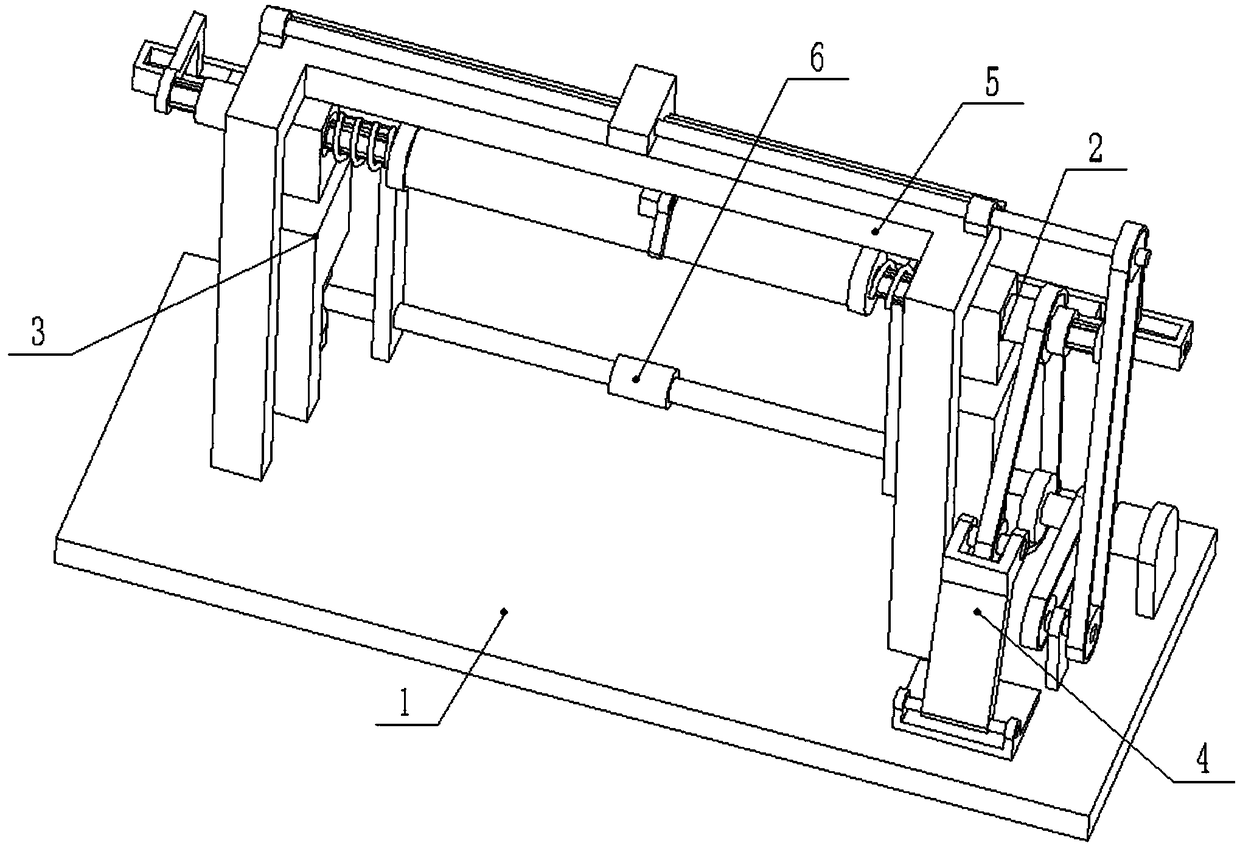

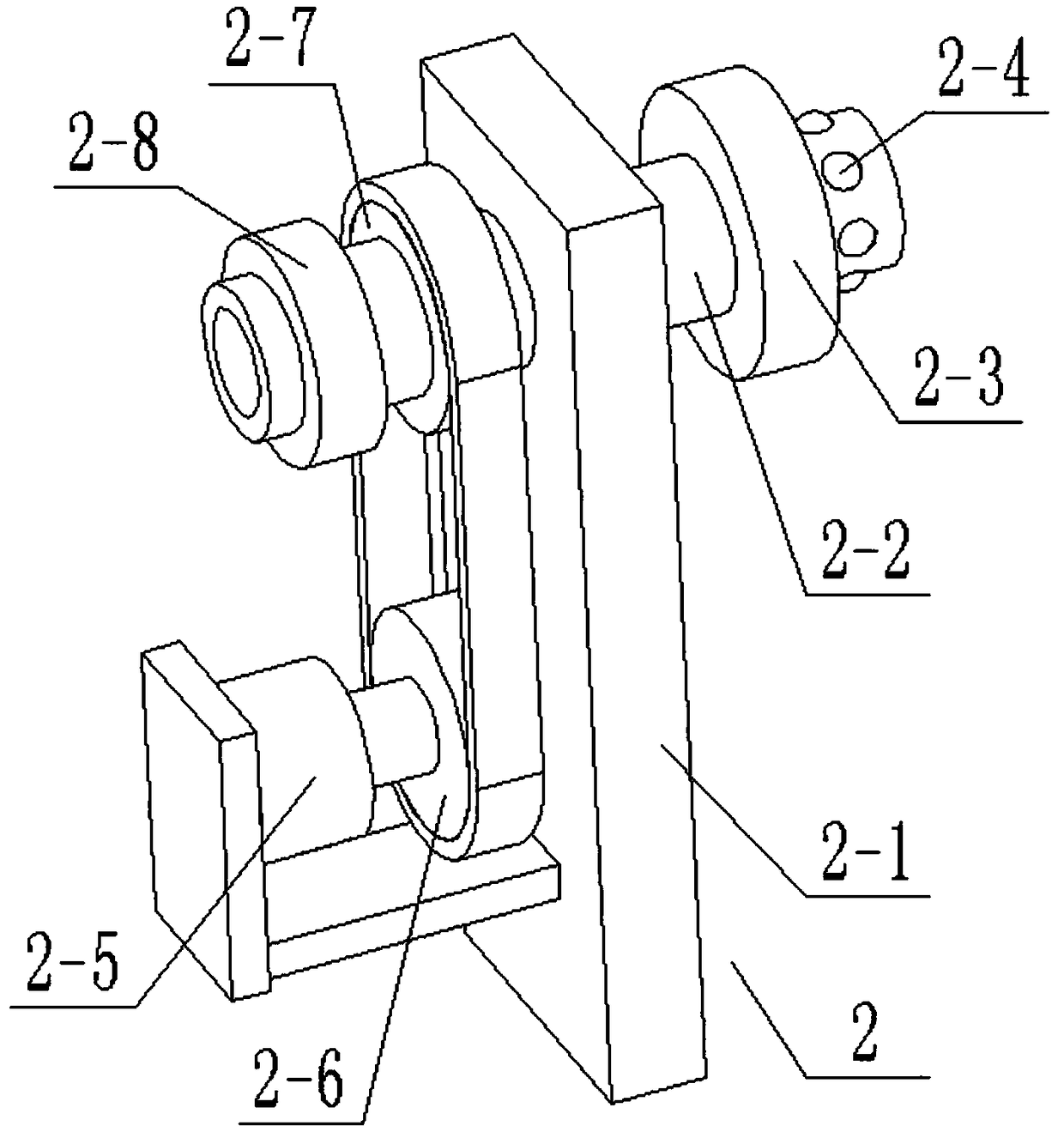

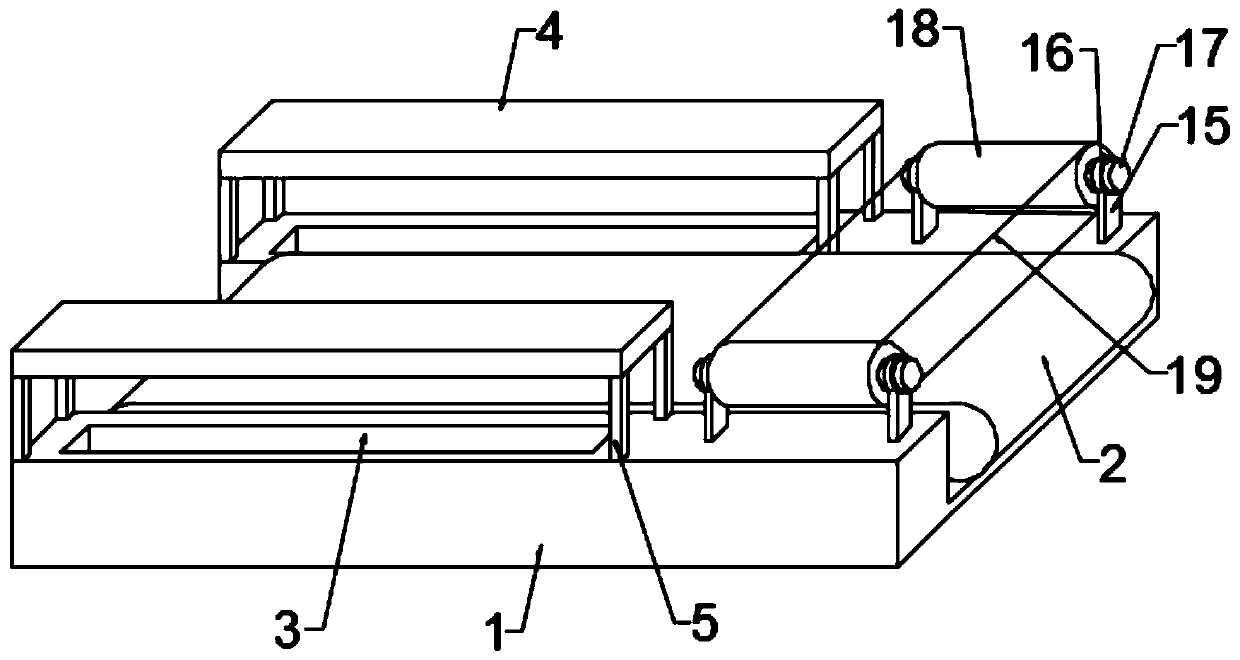

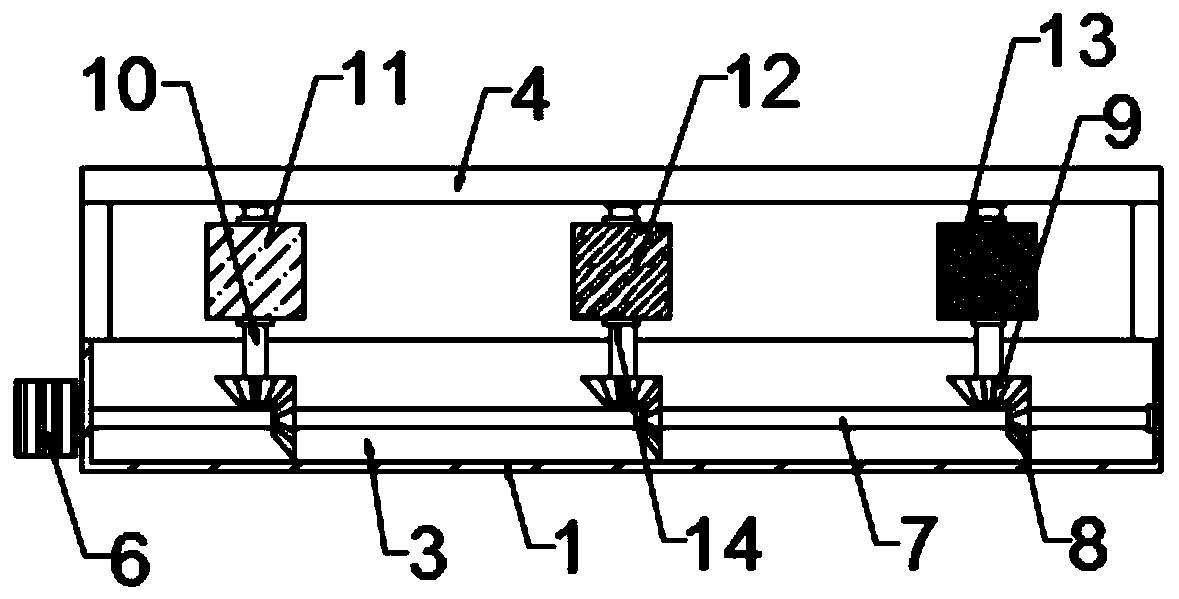

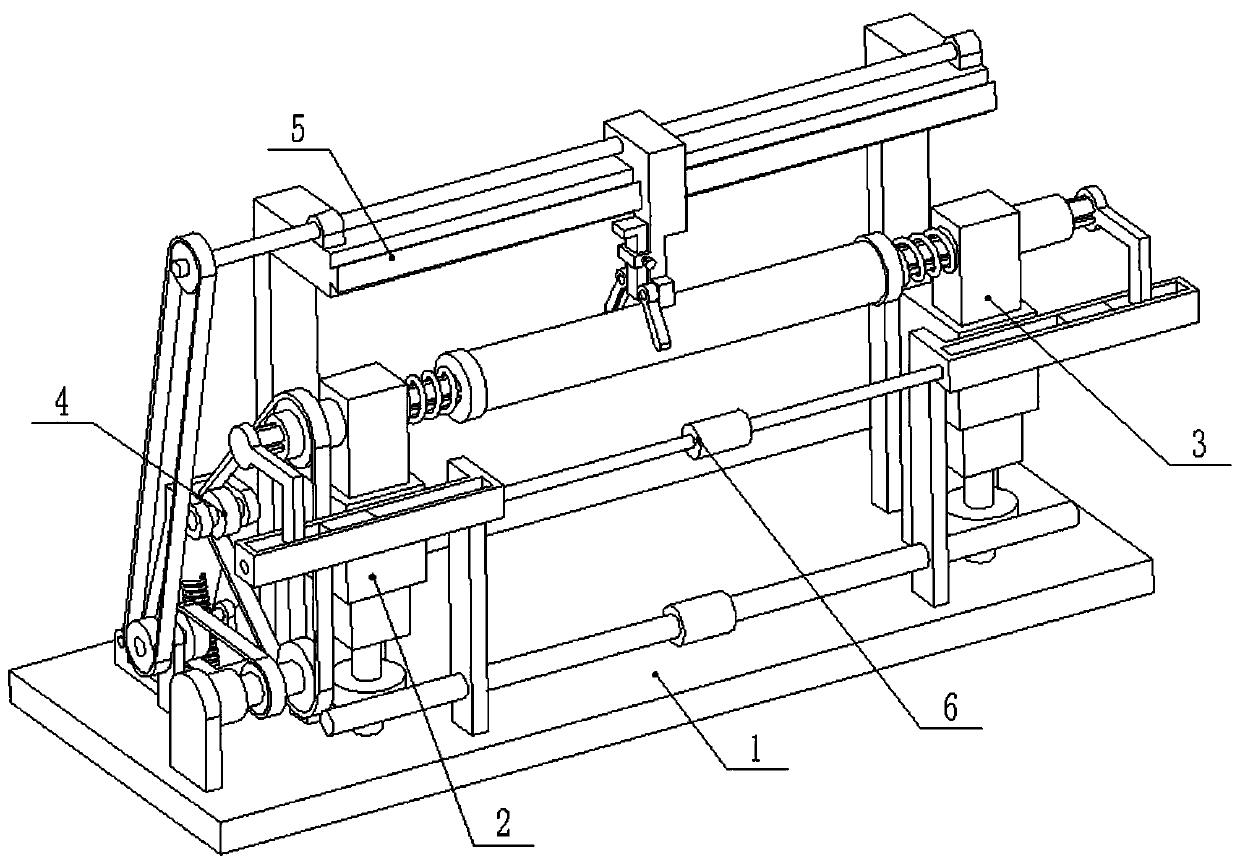

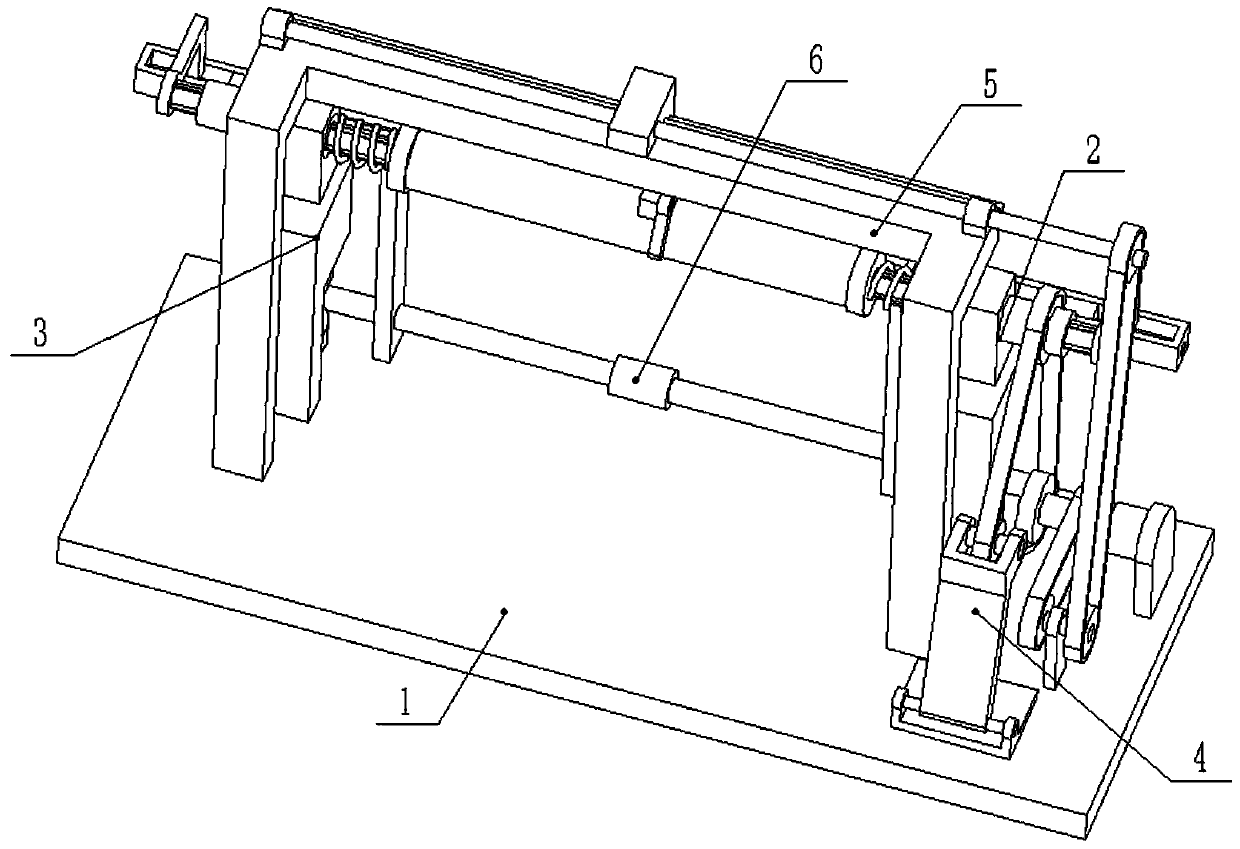

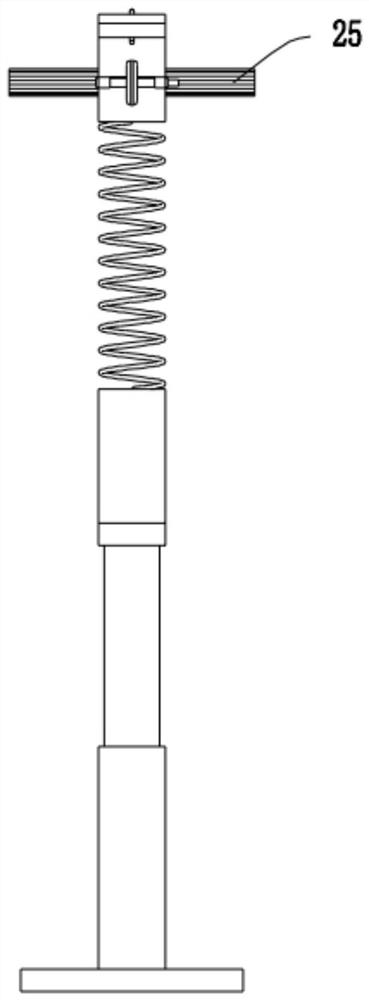

Pipeline grinding device for building construction

ActiveCN109048518AImprove grinding efficiencyImprove sanding qualityGrinding carriagesRevolution surface grinding machinesDrive shaftBuilding construction

The invention relates to the technical field of pipeline machining, in particular to a pipeline grinding device for building construction. The device comprises a motor, the motor is fixedly connectedto a bottom plate through an electric machine frame, one end of a driving shaft is connected to an output shaft of the motor through a coupler, and the other end of the driving shaft is fixedly connected with a driving belt wheel I, a driving belt wheel II is fixedly connected to the middle end of the driving shaft, the driving belt wheel II is in transmission connection with the driven belt wheelI through a belt, the driven belt wheel I and a driven belt wheel II are fixedly connected to the two ends of a driven shaft respectively, the middle end of the driven shaft is rotationally connectedto a shaft frame plate through a belt seat bearing. According to the pipeline grinding device, the pipeline can be driven to rotate during working, so that the pipeline can be conveniently turned over, all-directional polishing of the pipeline can be realized through reciprocating movement of a grinding plate, the grinding efficiency and the grinding quality of the pipeline are improved, the manual operation is reduced, the working intensity of workers is reduced; the device can be applied to the grinding of pipelines with different pipe diameters, and the grinding speed can be adjusted by adjusting the pressure between the pipeline and the grinding plate.

Owner:台州飞龙鞋业有限公司

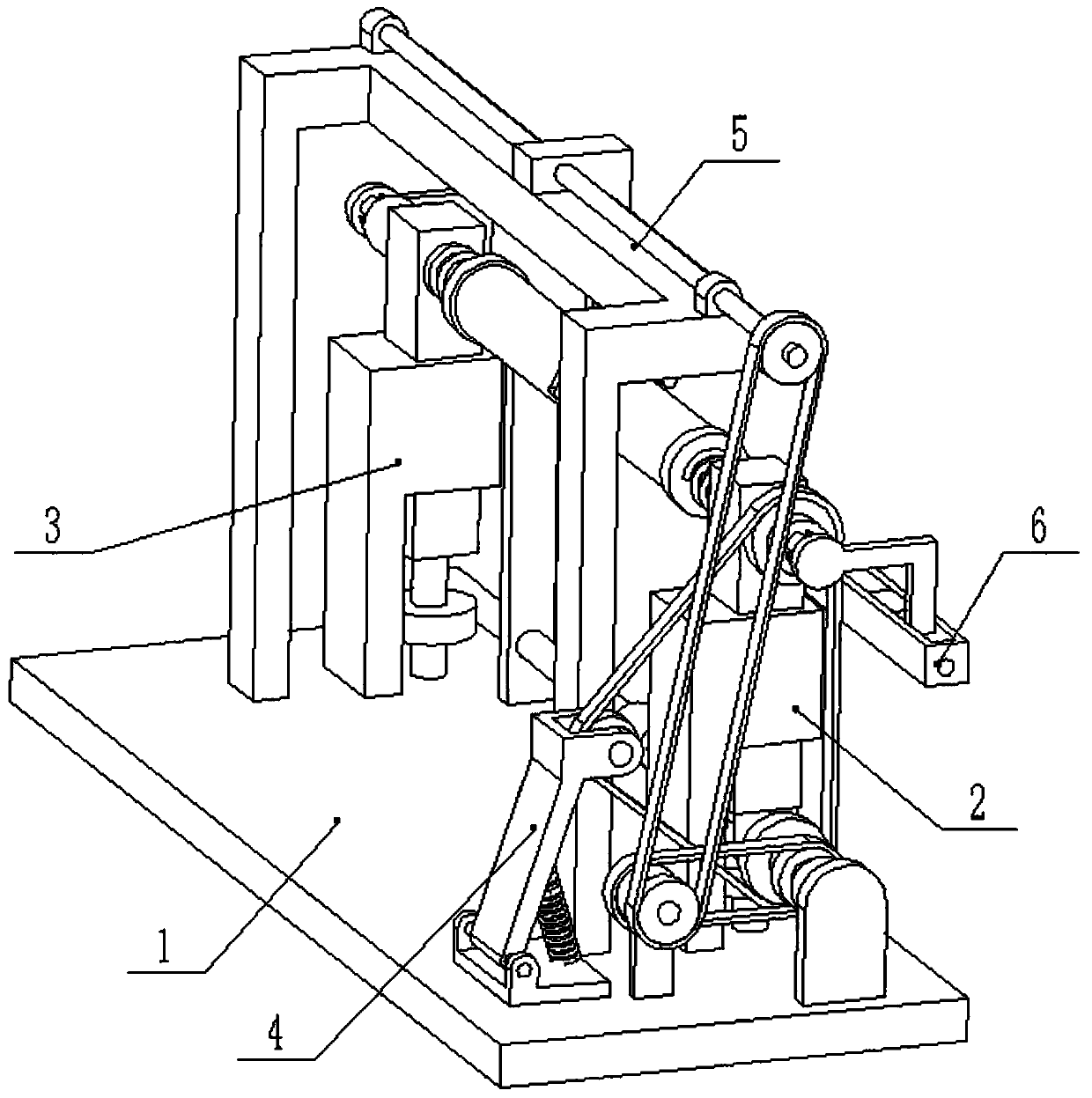

Pipeline grinding equipment for building

ActiveCN109015144AEasy flipRealize all-round grindingRevolution surface grinding machinesGrinding drivesReciprocating motionEngineering

The invention relates to the technical field of pipeline machining, in particular to pipeline grinding equipment for a building. A left supporting plate is fixedly connected to one end of a bottom plate. The middle end of a shaft sleeve is rotationally connected to the left supporting plate through a plummer block. A left top seat and a driving belt wheel are fixedly connected to the two ends of the shaft sleeve correspondingly. Multiple rubber protrusions I are evenly arranged on the shaft sleeve in a surrounding manner and are all located at the outer end of the left top seat. A driven beltwheel is fixedly connected to the shaft sleeve and located between the driving belt wheel and the left supporting plate. When the pipeline grinding equipment works, a pipeline can be driven to rotate,and convenient turnover of the pipeline is achieved; an inner surface grinding part and an outer surface grinding part do reciprocating motion to achieve omni-directional grinding of the pipeline, the grinding efficiency and grinding quality of the pipeline are improved, manual operation is reduced, and the work intensity of workers is reduced; and the pipeline grinding equipment can be suitablefor grinding of pipelines with different outer diameters, and meanwhile the grinding speed can be adjusted by adjusting the pressure between the pipeline and a grinding plate.

Owner:FUJIAN LIUJIAN GRP

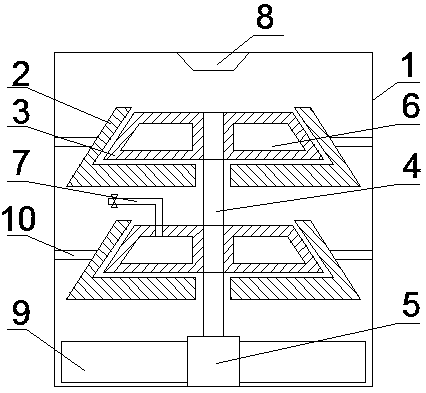

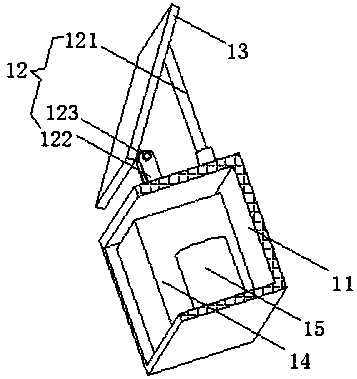

Dust collection type putty grinding device

ActiveCN104084858ARealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

Shell grinding equipment with dustproof structure for motor production

InactiveCN111805330AReduce occlusionAdjustable grinding angleEdge grinding machinesGrinding drivesGear wheelElectric machinery

The invention discloses shell grinding equipment with a dustproof structure for motor production. The shell grinding equipment includes a base, a dustproof cover, a turntable and a movable plate. A control panel is installed at the middle position of one end of the base, a water tank is formed in one side of the inner part of the base, a water pump is fixed inside the water tank, a water pipe is installed at the output end of the water pump, a bottom plate is installed at the middle position of the top of the base, a fluted disc is fixed to the top end of the bottom plate, and the turntable isinstalled at the top of the fluted disc. A rotating seat is installed at the top end, outside of the fluted disc, of the bottom plate, a transmission gear is installed at the end, away from the waterpump, of the top of the bottom plate, and a driving motor is installed in the base under the transmission gear. According to the shell grinding equipment with the dustproof structure for motor production, by arranging a pressure plate, pressing can be carried out under the action of a hydraulic lifting rod to compact a motor shell, and compared with a traditional clamping fixture, an upper-lowerclamping and fixing method can reduce the shielding on the outer wall of the motor shell.

Owner:东莞市奇趣机器人科技有限公司

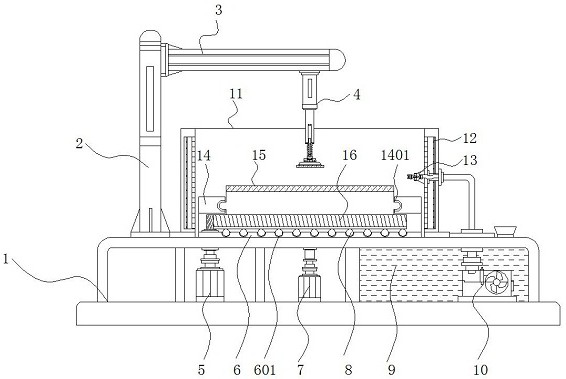

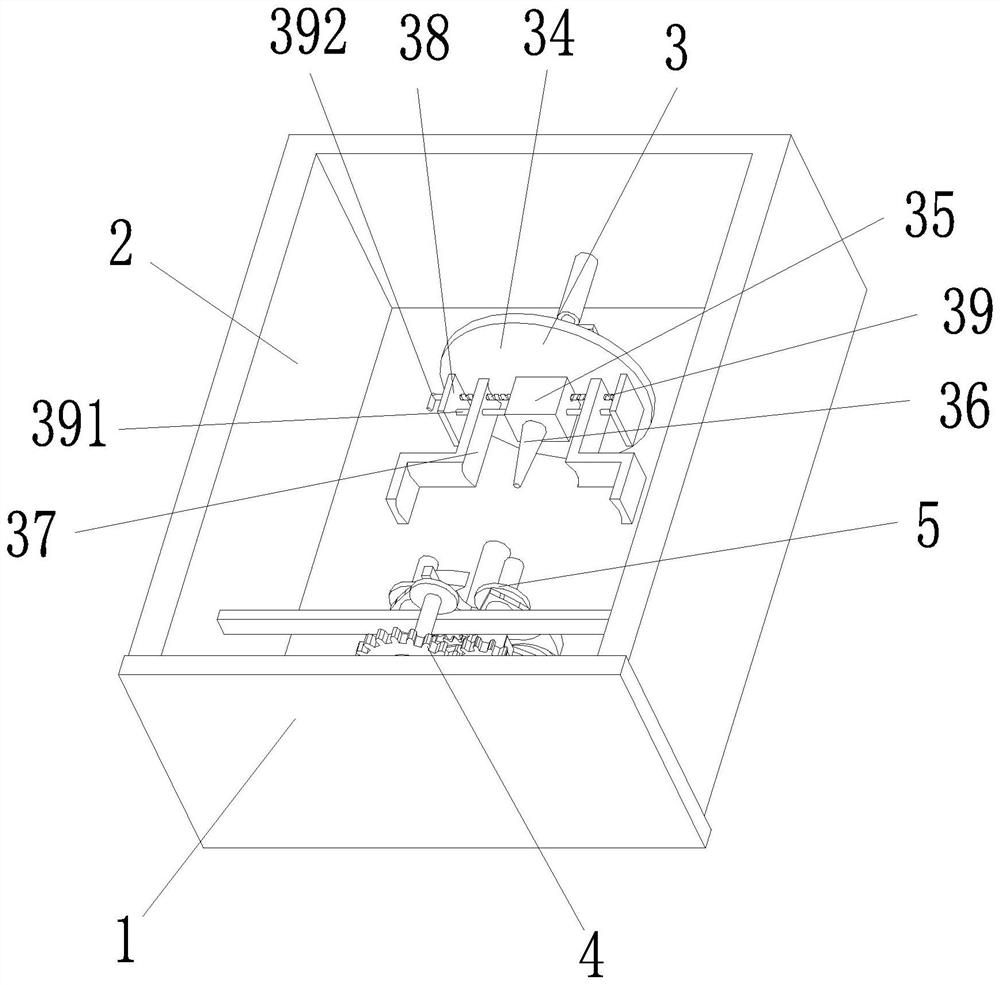

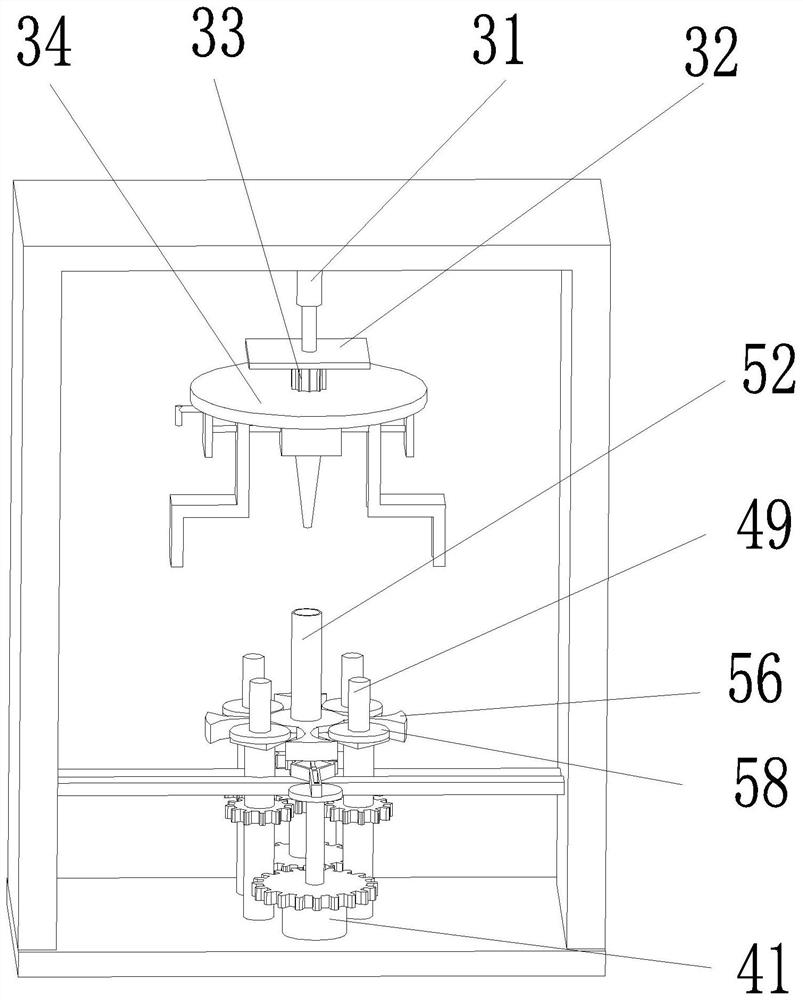

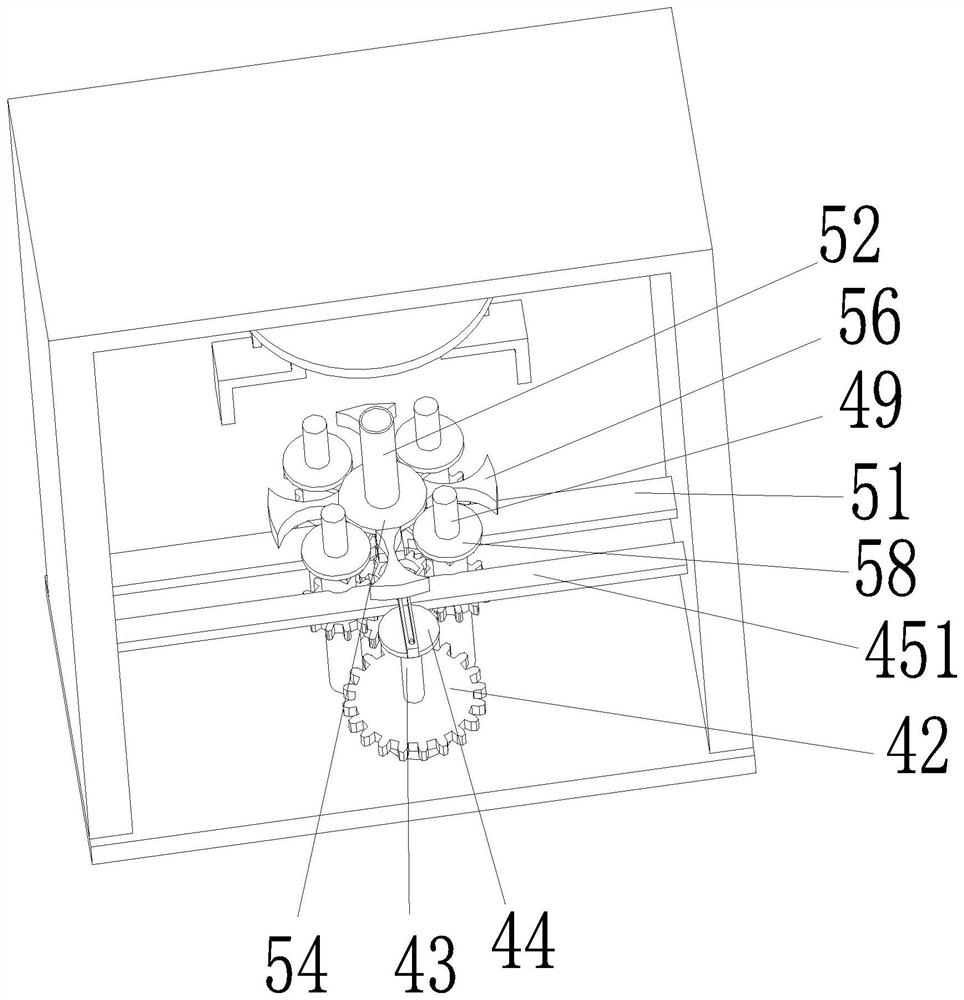

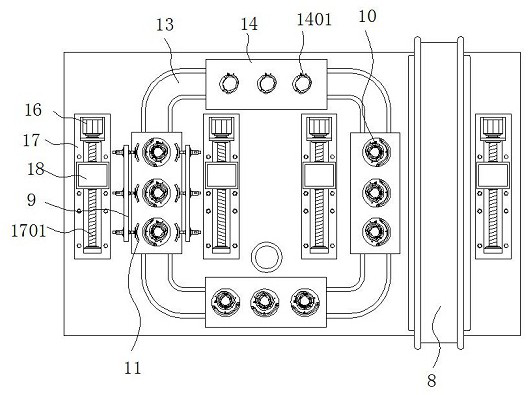

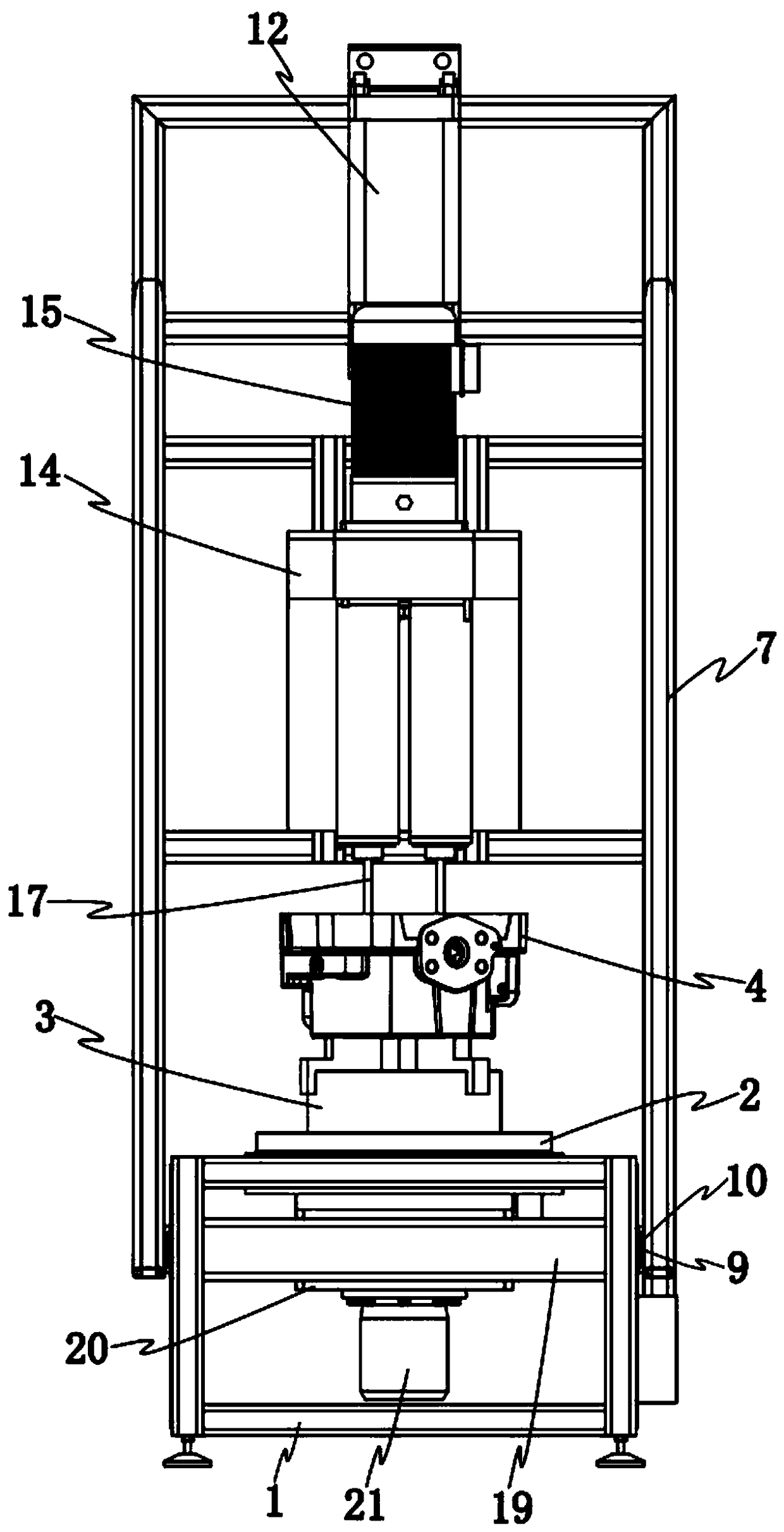

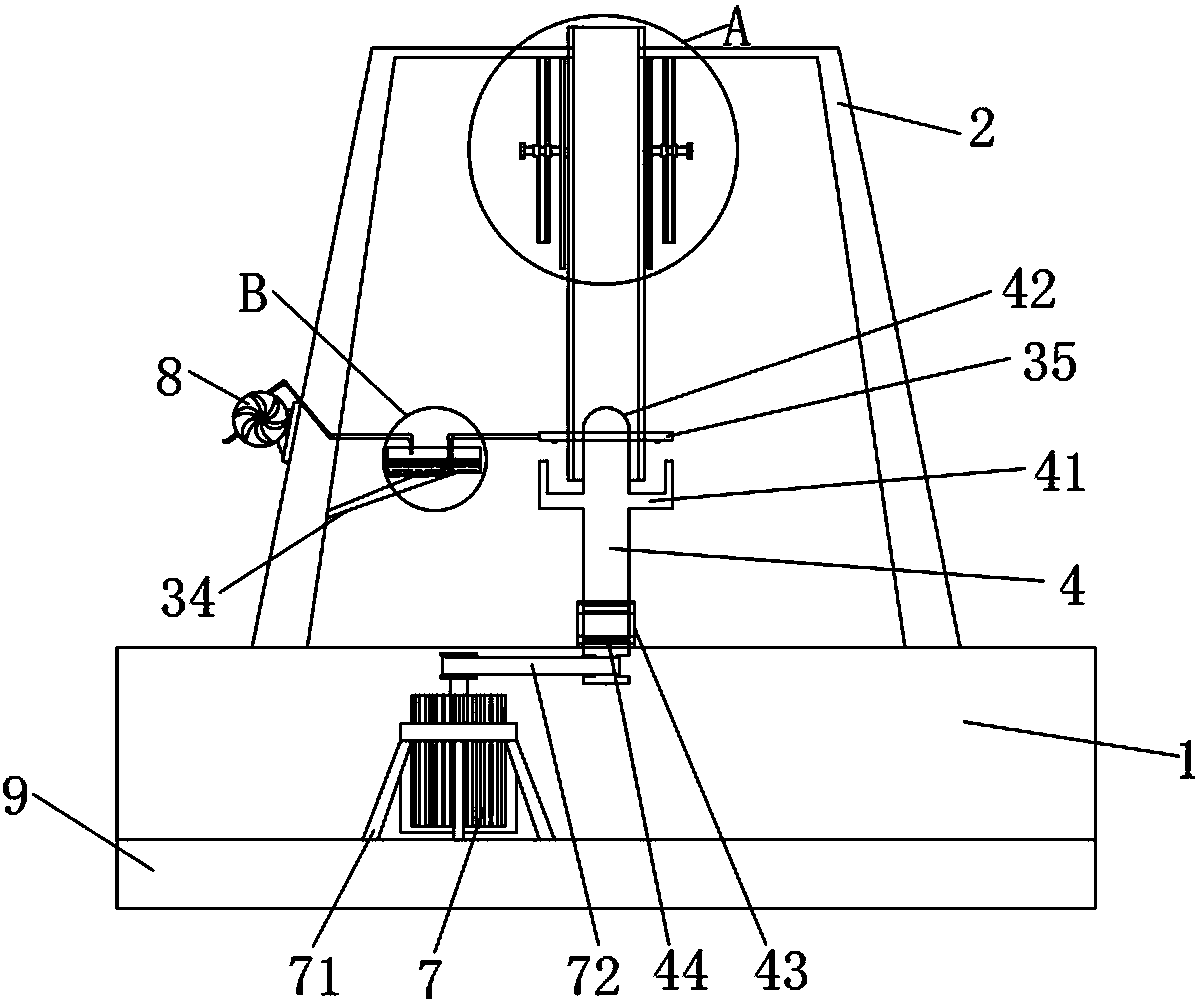

Metal connecting piece flange casting forming treatment system

InactiveCN112828693AAchieve grindingRealize all-round grindingRevolution surface grinding machinesGrinding drivesMachine toolIndustrial engineering

The invention relates to a metal connecting piece flange casting forming treatment system. The system comprises a bottom plate, a connecting frame, an upper end grinding device, a driving device and a lower end grinding device. The connecting frame is installed on the bottom plate, the connecting frame is of a U-shaped structure with a downward opening, the upper end grinding device is installed on the inner wall of the lower end of the connecting frame, the driving device is installed in the middle of the upper end of the bottom plate, the lower end grinding device is installed above the driving device, and the lower end grinding device is located under the upper end grinding device. According to the system, the problems that in common grinding for flanges, due to existence of flange holes, grinding of the lower end faces of the flanges is insufficient, due to existing common flange grinding machines, after the flanges are fixed through chucks, all end faces of the flanges are sequentially ground through a machine tool, and the grinding efficiency is reduced due to repeated operation can be solved.

Owner:吕帅旗

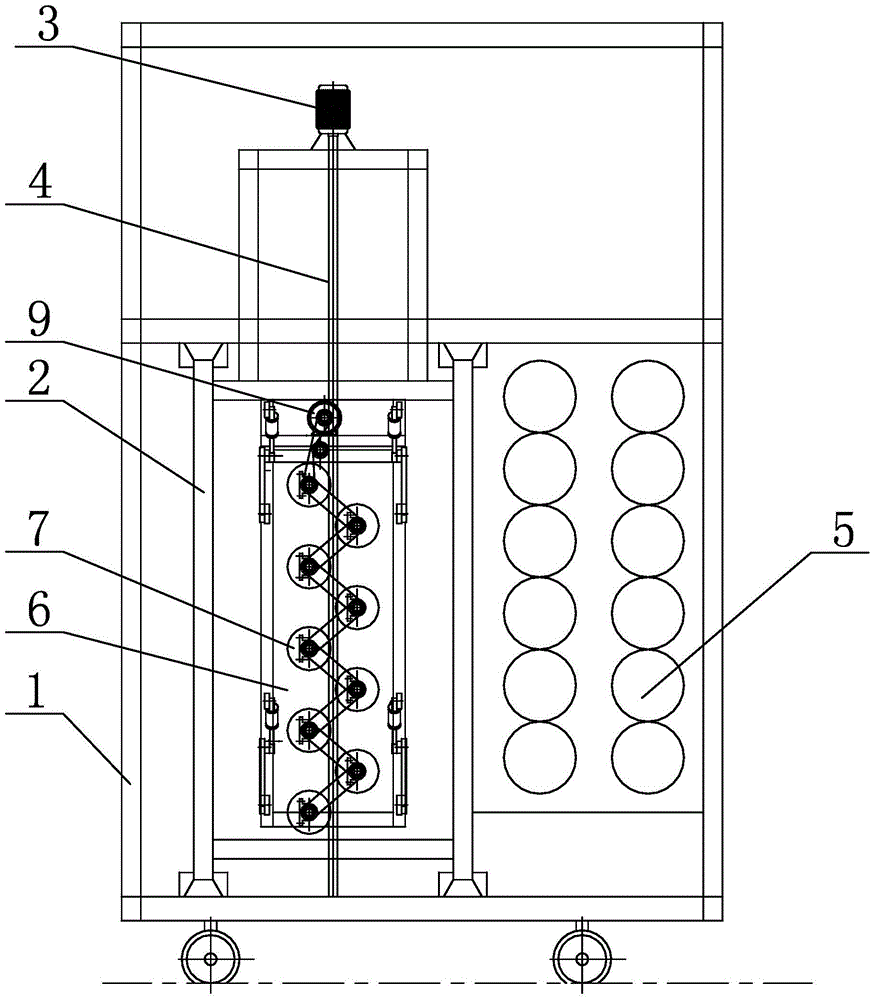

All-directional grinding device for cylindrical electronic components

ActiveCN110405579AAvoid cloggingAchieve continuous grindingGrinding drivesGrinding machinesRubber ringAir treatment

The invention relates to the field of electronic component production equipment, and particularly discloses an all-directional grinding device for cylindrical electronic components. The grinding device comprises a workbench, wherein the upper surface of the workbench is provided with a cyclone separator and a rotary fastening disk; a first motor is arranged on the workbench through a supporting frame, an output shaft of the first motor is connected with a grinding wheel, and the rotary fastening disk and a gear are coaxially and rotationally arranged on the workbench; a second motor is fixedlyarranged on the workbench, and an intermittent gear and a rubber ring are connected to the second motor; a plurality of clamping grooves are uniformly formed in the side wall of the rotary fasteningdisk, a rotating wheel is rotationally arranged on the inner side of each clamping groove, and a rubber wheel is connected to the rotating wheel; and a suction inlet is arranged at an air inlet end ofthe cyclone separator in a communicating mode, a collecting box is arranged at the bottom of the cyclone separator in a communicating mode, and an air pump is arranged at an air outlet end of the cyclone separator in a communicating mode. The all-directional grinding device for the cylindrical electronic components has the advantages of being simple in structure, convenient to operate, high in grinding efficiency, good in quality, high in air treatment quality, low in production cost and convenient to popularize and implement.

Owner:WUHAN KIND TECH DEV

Pipeline polishing equipment for outdoor buildings

InactiveCN108994706AEasy flipRealize all-round grindingGrinding carriagesGrinding machinesEngineeringUltimate tensile strength

The invention relates to the technical field of pipeline processing, in particular to pipeline polishing equipment for outdoor buildings. A left supporting plate is fixedly connected to one end of a bottom plate, the middle of a shaft sleeve is rotationally connected to the left supporting plate through a plummer block, a left top seat and a driving belt pulley are fixedly connected to the two ends of the shaft sleeve separately, a plurality of rubber protrusions I are evenly arranged on the shaft sleeve in a surrounding mode and located at the outer end of the left top seat, and a driven beltpulley is fixedly connected to the shaft sleeve and located between the driving belt pulley and the left supporting plate. When working, the pipeline polishing equipment for outdoor buildings can drive a pipeline to rotate so as to achieve convenient turning-over of the pipeline; and an inner surface polishing part and an outer surface polishing part do reciprocating movement to achieve all-dimensional polishing of the pipeline, so that the polishing efficiency and polishing quality of the pipeline are improved, manual operation is reduced, and the working strength of workers is reduced. Thepipeline polishing equipment for outdoor buildings can be applied to polish pipelines with different outer diameters, and meanwhile the polishing speed can be adjusted by adjusting the pressure between the pipeline and a polishing plate.

Owner:湖北勇胜建设工程有限公司

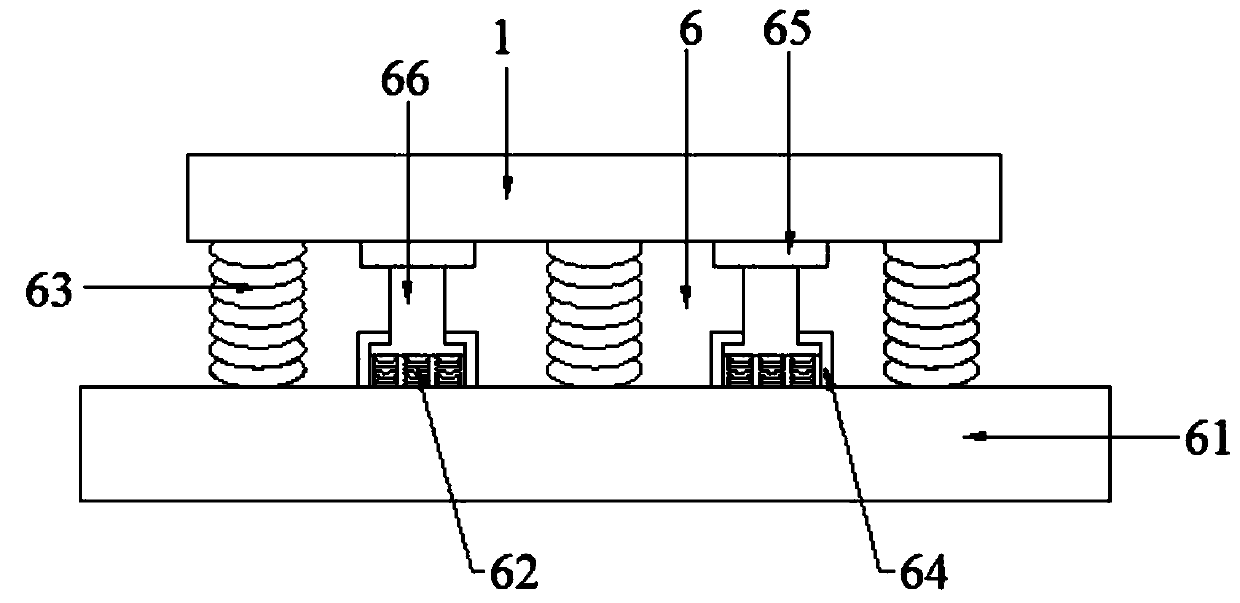

Machining equipment for fine polishing of lower bases of improved automotive shock absorbers

InactiveCN112171451AAvoid abnormal noiseNot easy to interfereGrinding drivesGrinding feed controlShock absorberManufacturing engineering

The invention discloses machining equipment for fine polishing of lower bases of improved automotive shock absorbers. The machining equipment specifically comprises a base, a first movable frame, a polishing mechanism, the lower bases of the shock absorbers, and a cyclic sliding rail, wherein the cyclic sliding rail is fixed to the middle of the top of the base, sliding blocks are uniformly arranged in the cyclic sliding rail, limiting bases are fixed to the top ends of the sliding blocks, and the lower bases of the shock absorbers are uniformly fixed to the tops of the limiting bases. According to the machining equipment for fine polishing of the lower bases of the improved automotive shock absorbers, a clamping plate and the polishing mechanism are arranged, and the edges of the lower bases of the shock absorbers can be embedded in clamping grooves of the clamping plates so that the lower bases can be clamped by the clamping plate more stably; and the polishing mechanism can polish spring grooves of the lower bases of the shock absorbers, so that the joints of lower spring seats and springs are smoother, the lower bases of the shock absorbers are not prone to interference with the springs, and abnormal sounds of the shock absorbers are avoided.

Owner:东莞市夯牛机电科技有限公司

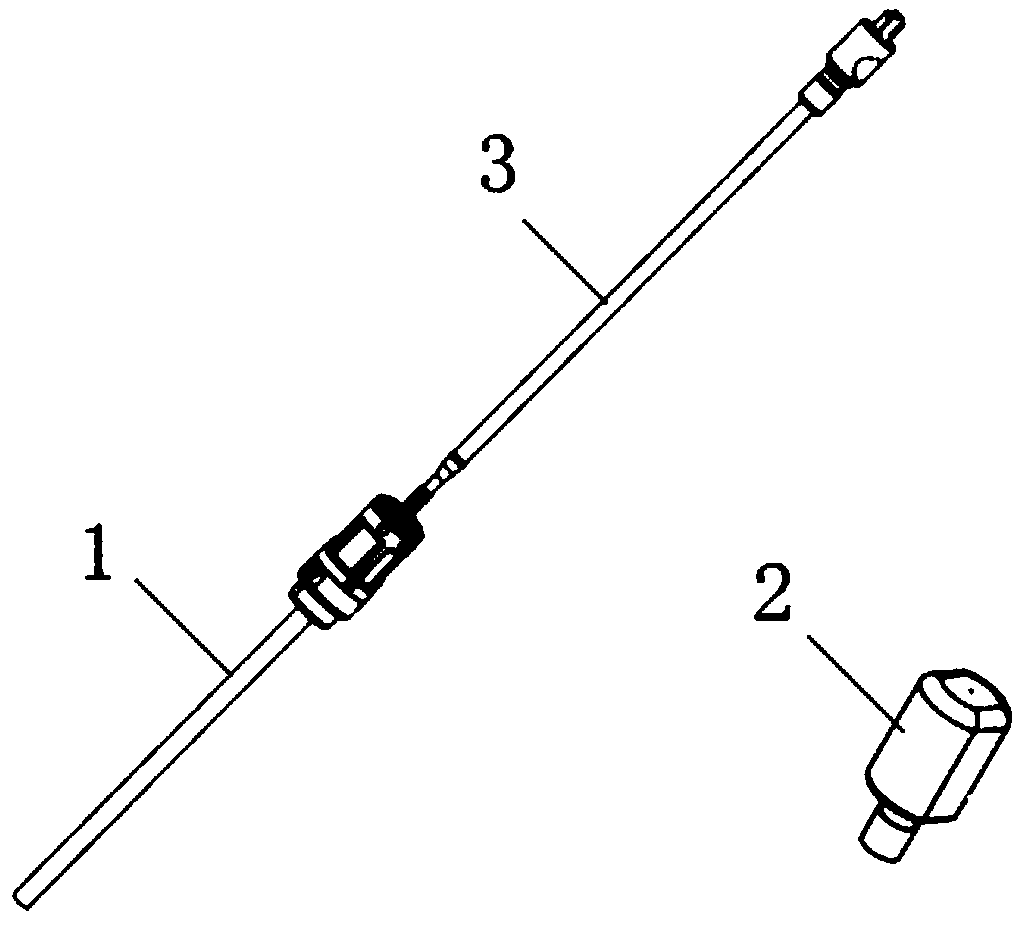

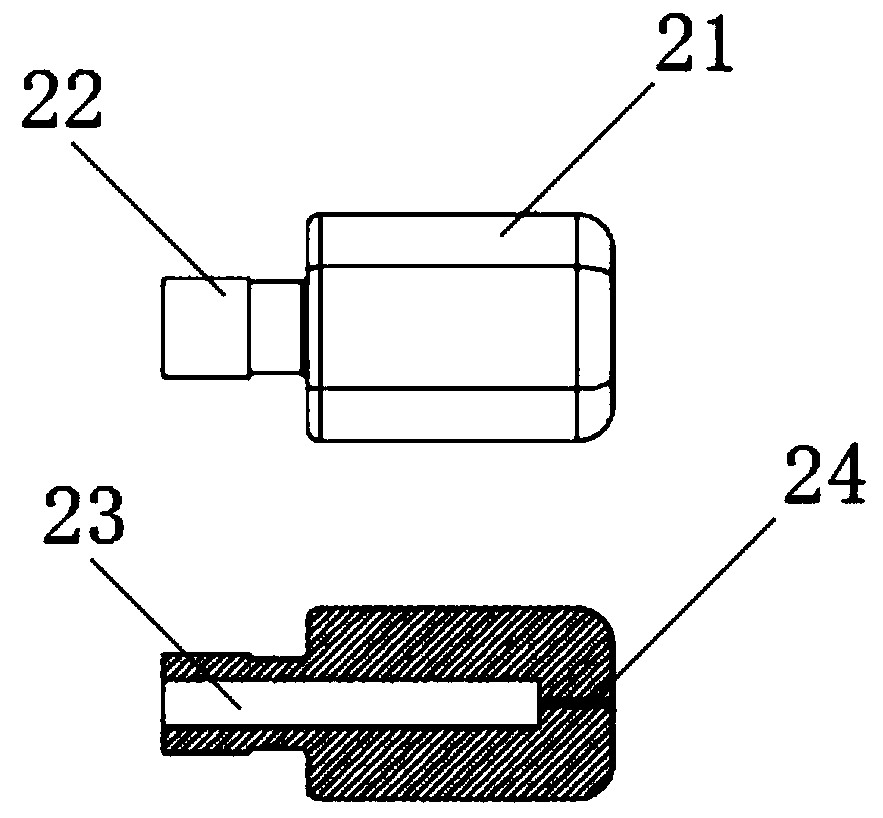

Medical planing grinding head

The invention provides a medical planing grinding head. The medical planing grinding head comprises a planing tool inner knife, a planing tool outer knife and a plug; the planing tool outer knife is provided with an assembly end and an outer knife tube, a center channel runs through the assembly end and the outer knife tube, the planing tool inner knife detachably penetrates into the center channel, and the plug is detachably connected to the assembly end to form seal at the end of the center channel. Compared with the prior art, the plug designed for the planing tool head can replace the inner knife to plug the outer knife tube when the inner knife is replaced in an operation, it is ensured that lavage fluid will not overflow from the outer knife tube, through small air-discharging holesdesigned in the plug, air in an operation region can be discharged, and it is avoided that since a lot of air bubbles are mixed into the lavage fluid, the visual field resolution of the operation region is decreased; with the open structure of the head of the outer knife, all-directional grinding is realized, and operation efficiency is improved.

Owner:上海利格泰医用设备有限公司

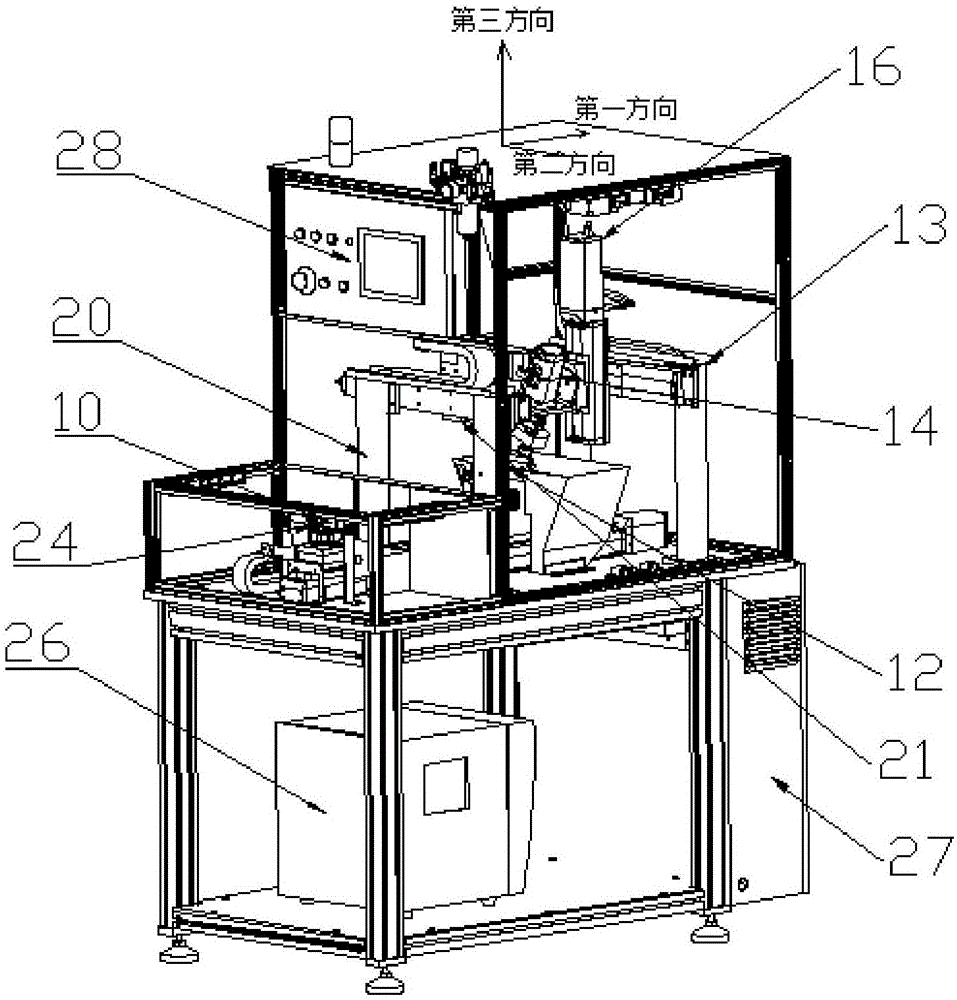

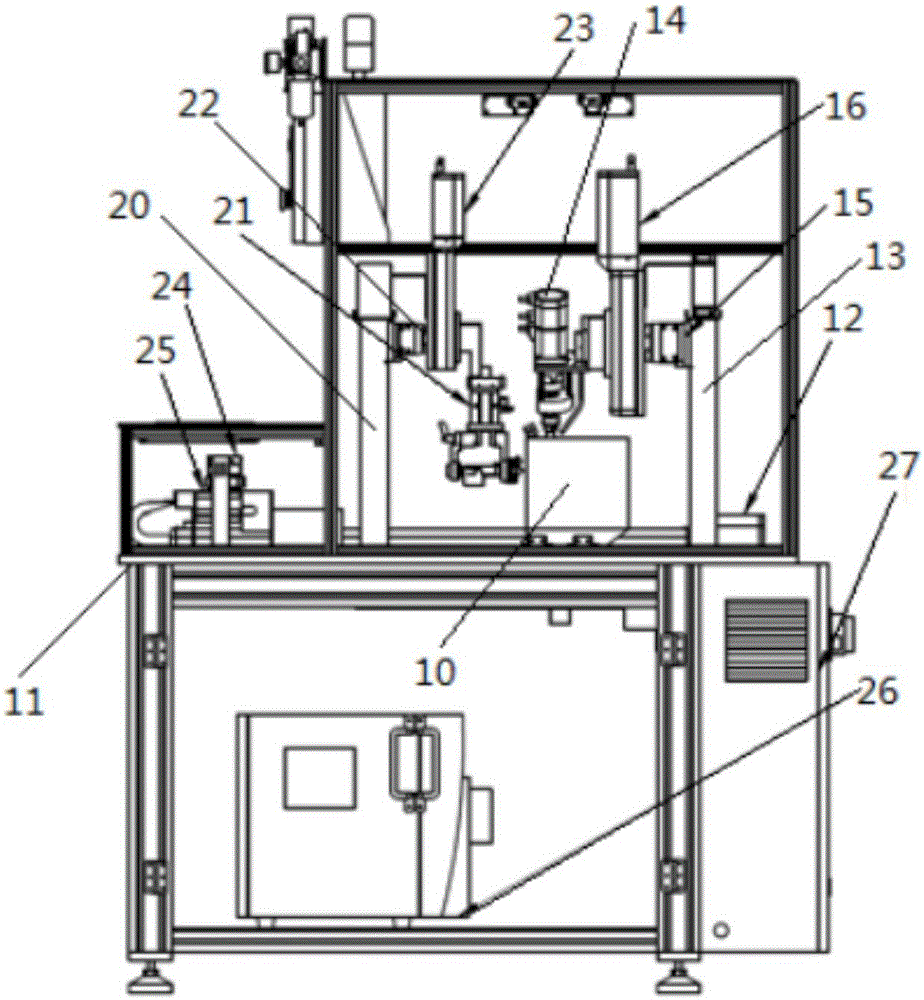

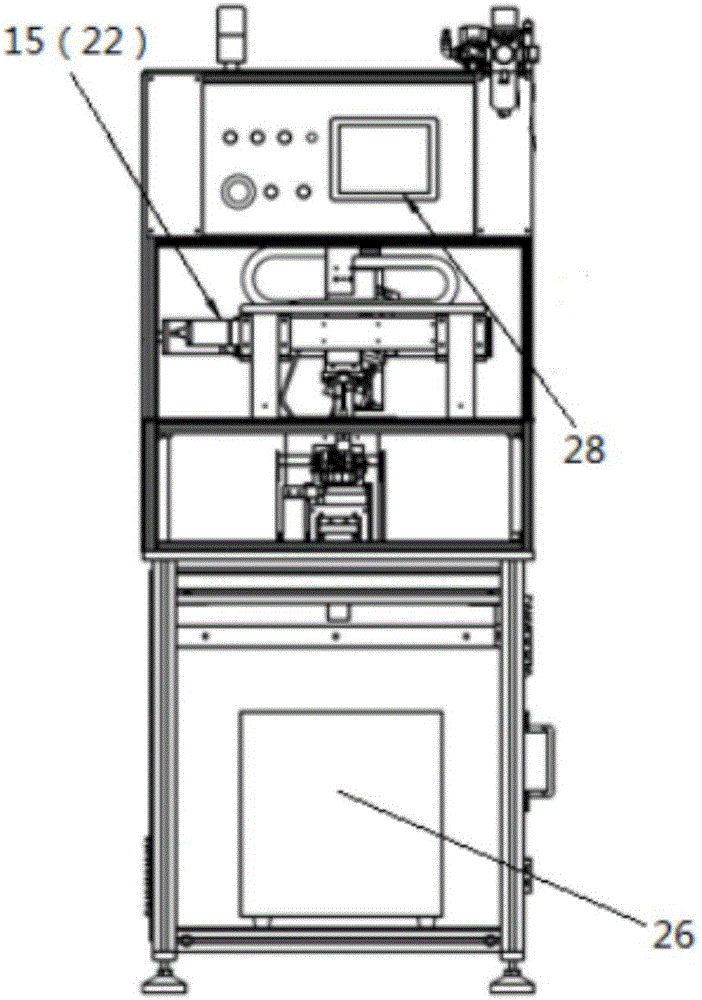

Deburring machine

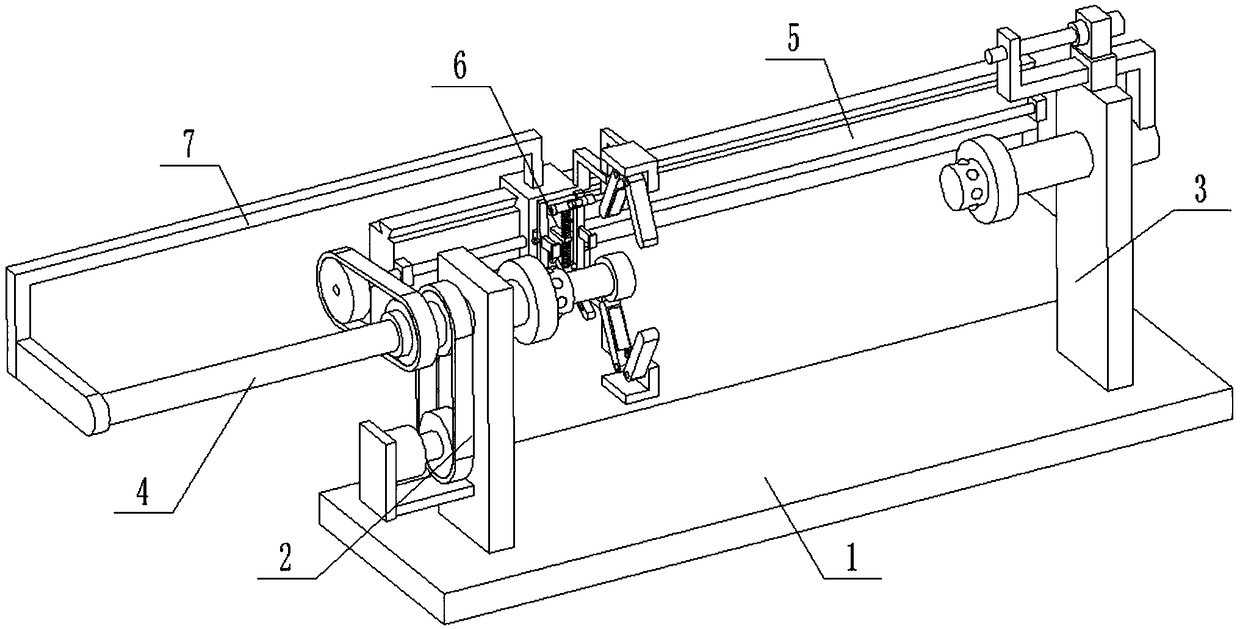

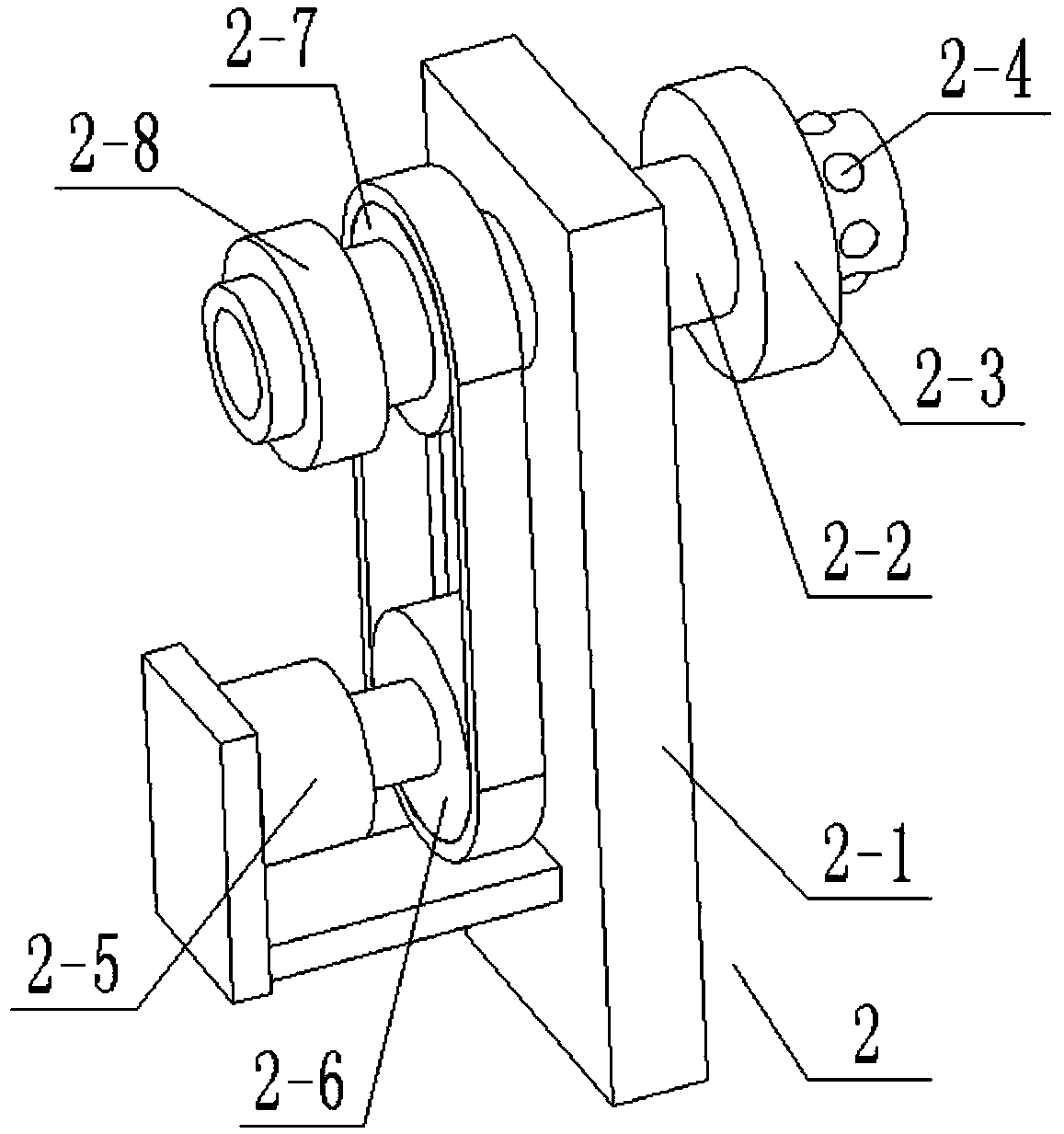

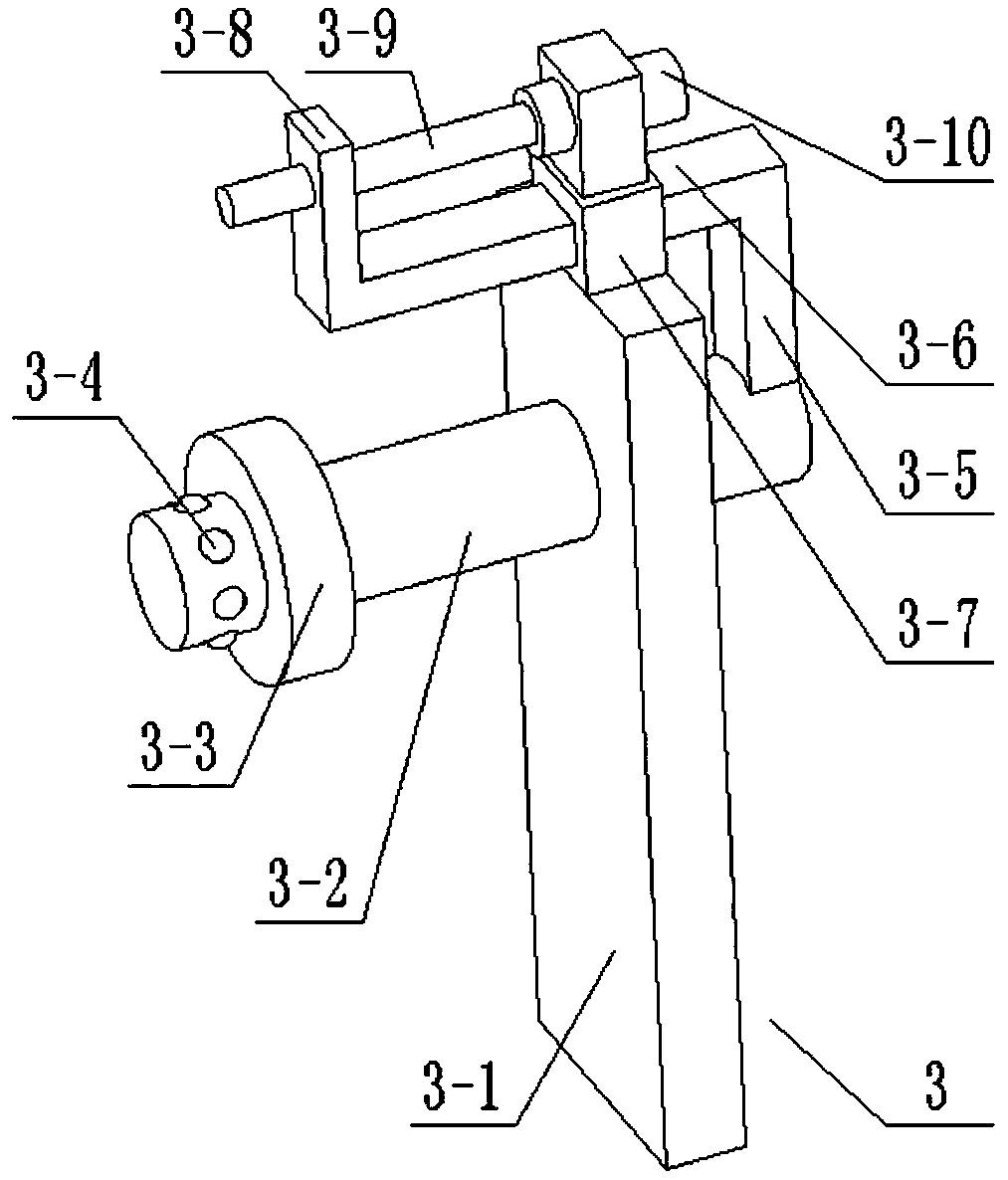

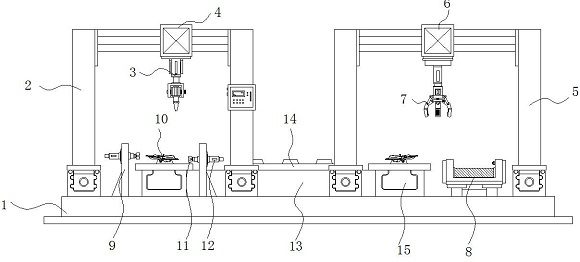

ActiveCN106695481ARealize all-round grindingImprove deburring efficiencyEdge grinding machinesGrinding carriagesDrive shaftEngineering

The invention discloses a deburring machine. The deburring machine comprises a machine frame, a first transmission shaft, a first support, a second transmission shaft and a third transmission shaft. The first transmission shaft is arranged on the machine frame and used for driving a workpiece to move in the first direction; the first support is disposed on the machine frame, and a grinding manipulator is disposed on the first support and used for grinding the workpiece; the second transmission shaft is arranged on the first support, connected with the third transmission shaft and used for driving the third transmission shaft to move in the second direction; the third transmission shaft is disposed on the second transmission shaft, connected with the grinding manipulator and used for driving the grinding manipulator to move in the third direction; the machine frame is further provided with a second support, the second support and the first support are arranged in a spaced mode, and a turnover manipulator is arranged on the second support and used for turning over workpieces. In this way, by means of the deburring machine disclosed by the invention, any position of the to-be-ground surfaces of the workpieces can be ground, the workpieces can be turned over, and omni-directional grinding of the workpieces is achieved.

Owner:SINPA INDAL AUTOMATION

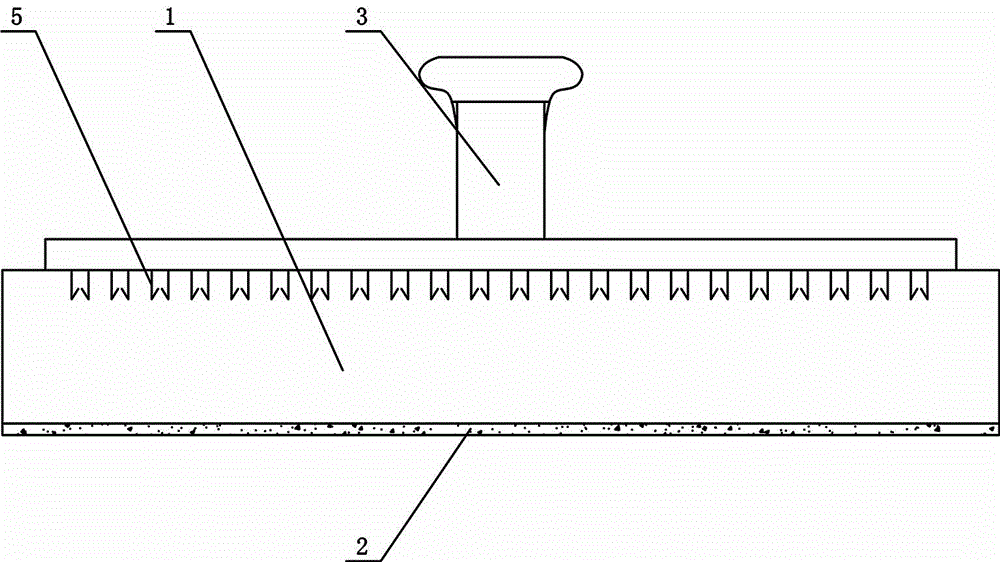

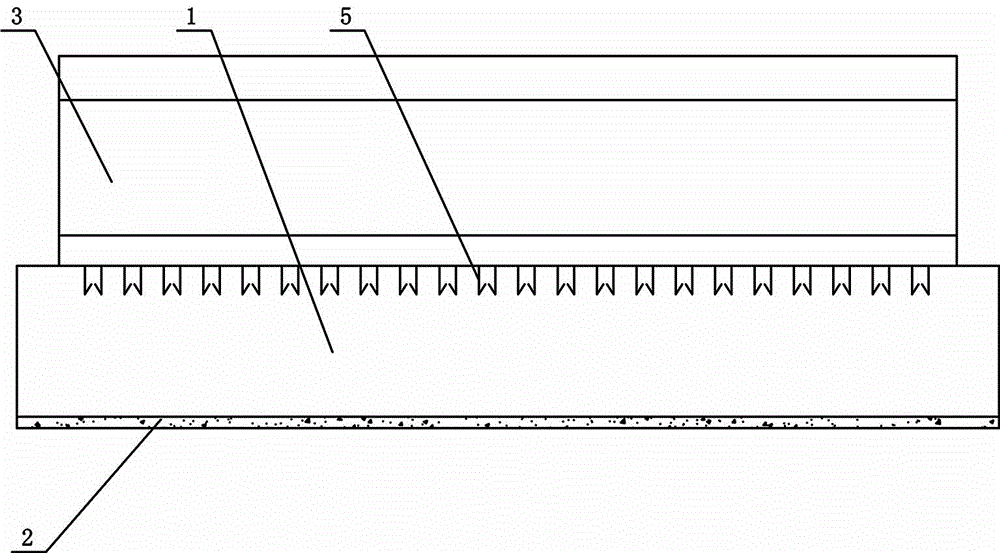

Efficient polishing device of building plates

InactiveCN109333197AWill not affect normal returnsRealize all-round grindingGrinding work supportsPlane surface grinding machinesEngineeringMachining

The invention discloses an efficient polishing device of building plates. The efficient polishing device comprises a body and a polishing device body, and further comprises bases which are fixed to the two sides of the body, and thus a machining groove is formed in the corresponding position, between the two bases, of the body; a feeding opening is formed in the base on one side, a pushing air cylinder is mounted in the machining groove, and a pushing plate is mounted at the output end of the pushing air cylinder; and the polishing device body is mounted on a cross beam which is located over the body, and a plurality of kidney-shaped receding grooves are formed in the body. The efficient polishing device has the beneficial effects that the innovation point is that through the joint effectof a blocking shaft and the pushing plate, not only can the plates be positioned, but also normal returning of the machined plates is not influenced, and meanwhile, through the design of two lead screw assemblies, the polishing device body can move in the X direction and the Y direction to polish the plates roundly.

Owner:刘景岳

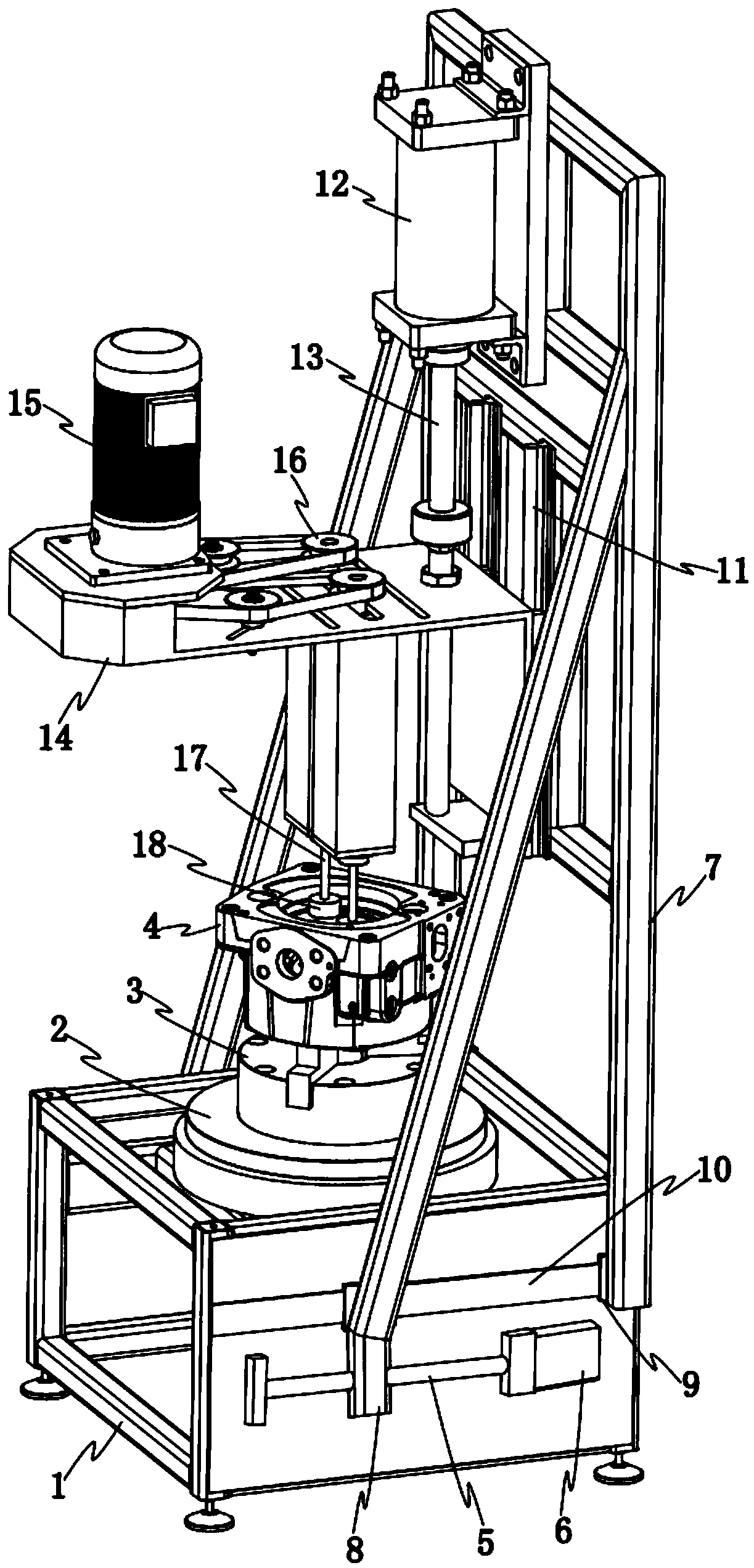

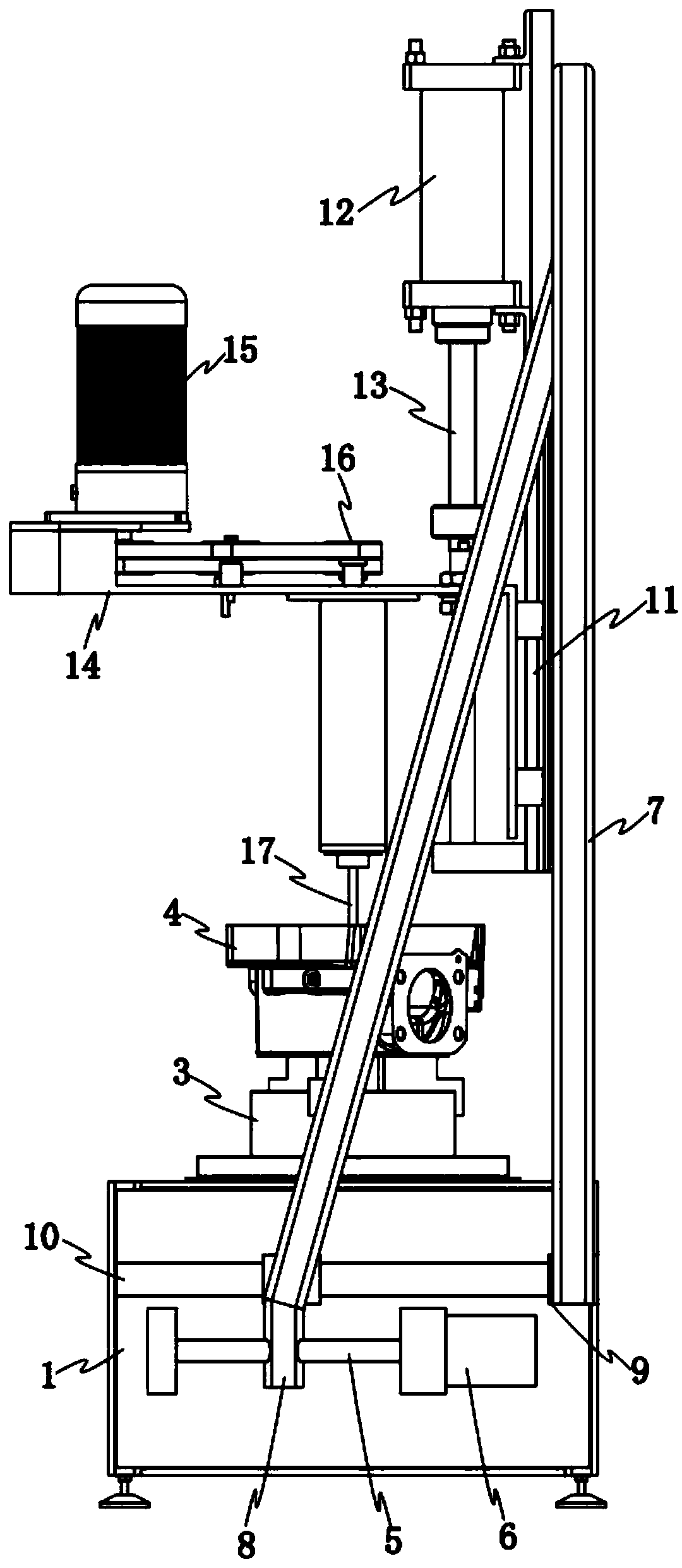

Grinding machine for inner wall of automobile air conditioner compressor cylinder body

PendingCN109176176AGuaranteed sanding consistencyImprove grinding efficiencyEdge grinding machinesRevolution surface grinding machinesCylinder blockEngineering

The invention relates to a grinding machine for an inner wall of an automobile air conditioner compressor cylinder body. The grinding machine comprises a bottom frame, a triangular frame body movablyconnected with the bottom frame. Horizontal sliding rails are arranged on the outer frame faces of two sides of the bottom frame. The foot end portions of two sides of the triangular frame body are connected with the horizontal sliding rails in a sliding-fit mode. Vertical sliding rails are fixed to the triangular frame body in a parallel mode. The vertical sliding rails are connected with the rear lateral face of a displacement plate seat in a sliding-fit mode. The displacement plate seat is provided with a grinding driving motor. A vertical rotating shaft is movably connected to the displacement plate seat in a penetrating mode. Driving wheels are fixedly arranged at the upper end of the vertical rotating shaft penetrating through and connecting with the displacement plate seat. A grinding wheel is fixed to the lower end of the vertical rotating shaft. The grinding machine has the function of up and down, front and rear, left and right adjusting, omnidirectional grinding of the interior of the compressor cylinder body is achieved, dead angle is not left, the traditional processing mode of manually assisted cylinder body grinding is avoided, uniformity of cylinder body grinding isguaranteed, grinding efficiency is improved, labor cost is reduced, and the grinding quality is ensured.

Owner:松阳县博美机械厂

Powder coating grinding device

InactiveCN108176454AQuality assuranceRealize all-round grindingCocoaGrain treatmentsRotational axisElectric machinery

The invention discloses a powder coating grinding device. The powder coating grinding device comprises a shell, a plurality of grinding bodies, grinding plates, a rotating shaft, a motor and a cold water supply unit; the multiple grinding bodies are longitudinally arranged in the shell and fixed to the shell through connecting pieces; the grinding bodies are circular truncated cone-shaped pieces and are each provided with a cavity in a circular truncated cone shape, and the bottom of each grinding body is provided with a discharge hole; the grinding plates are arranged in the cavities of the grinding bodies; the middles of the grinding plates are provided with assembly holes; the rotating shaft penetrates through the assembly holes and is fixedly connected with the grinding plates, and oneend of the rotating shaft is connected with the motor; annular cavities are formed in the grinding plates, the grinding plates are provided with water passing pipelines, and the water passing pipelines communicate with the cavities and are further connected with the cold water supply unit; and the upper portion of the shell is provided with a feed inlet which is located above the grinding plates.The powder coating grinding device improves the grinding quality and avoids adverse effects of the grinding temperature to powder coating.

Owner:高诗新材料股份有限公司

Dust collection putty grinding device

ActiveCN104084858BRealize all-round grindingAdjust the pressing forceGrinding carriagesGrinding bedsEngineeringMoving frame

The invention discloses a dust collection type putty grinding device which comprises a trolley capable of moving transversely. The trolley is provided with a vertical moving frame and a first driving mechanism driving the vertical moving frame to vertically move. A grinding assembly, a blowing mechanism and a dust collection cover are installed on the vertical moving frame, wherein the blowing mechanism is located on one side of the grinding assembly, and both the grinding assembly and the blowing mechanism are together covered with the dust collection cover. A dust removing device is connected to the rear portion of the dust collection cover through a dust collection air pipe. The grinding assembly comprises a supporting body installed on the vertical moving frame. The supporting body is provided with a plurality of rotatable grinding heads and a second driving mechanism, wherein the grinding heads are located on the front end face of the supporting body, and the second driving mechanism drives the grinding heads to rotate. According to the dust collection type putty grinding device, putty on the side of the trolley can be automatically ground, the grinding strength is adjustable, the ideal grinding effect can be achieved, and labor is greatly saved. In addition, when the dust collection type putty grinding device is used for putty grinding, almost no dust is discharged, no pollution is produced to the environment, and no negative effects are produced on the body health of workers.

Owner:安徽中车浦镇城轨交通运维科技有限公司

Surface grinding and rust-removing device for distance-adjustable type air duct motor rotary shaft

InactiveCN109434649AImprove versatilityImprove work efficiencyGrinding drivesGrinding machinesDual axisDrive motor

The invention discloses a surface grinding and rust-removing device for a distance-adjustable type air duct motor rotary shaft. The surface grinding and rust-removing device comprises a base, a supporting table, a dual-axis motor, a first drive motor, a rust-removing head and a second drive motor, wherein the output shafts at the two ends of the dual-axis motor are connected with connecting shaftsthrough shaft couplers; wire winding wheels are fixedly mounted on the connecting shafts; traction wires are wound on the wire winding wheels; the other ends of the traction wires are connected witha lifting plate; a movable frame is further welded on a limiting rod; and the lower side of the movable frame is welded with a rust-removing head. By changing the distance between the shaft couplers at the two sides, the rotary shaft is clamped by the shaft couplers, so that grinding on air duct motor rotary shafts of different lengths is met, universality of the device is greatly improved, and mould regulation is not required for the rotary shafts of different lengths, and therefore, working efficiency is greatly improved; and the rust-removing head moves left and right for performing grinding and rust-removing on the surface of the rotary shaft, and the second drive motor drives the rotary shaft to rotate, so that all-around grinding on the rotary shaft is realized, and rotary shaft grinding effect is greatly improved.

Owner:倪昌锋

Intelligent full-automatic spraying equipment

InactiveCN108722759ARealize all-round grindingSpray evenlyGrinding machinesSpray boothsMechanical engineering

The invention discloses intelligent full-automatic spraying equipment. The intelligent full-automatic spraying equipment comprises a machine body, and a first sliding cavity arranged in the machine body, wherein a sliding frame is arranged in the first sliding cavity through a sliding assembly in a manner of sliding frontward and backward; a first motor is fixedly arranged in the sliding frame; adriving shaft of the first motor extend downward and a rotary frame is fixedly mounted at the tail end of the bottom of the driving shaft; a first cavity is formed in the rotary frame; the first cavity is internally provided with a first rotary shaft, which extends up and down, in a rotatable manner; the tail end of the bottom of the first rotary shaft is rotatably arranged in a bottom wall of thefirst cavity. The equipment disclosed by the invention is simple in structure and convenient to operate; the equipment is driven by the same power source to switch polishing and rust removing, dust removing and spraying functions; a movement mechanism controlled by an upper computer is arranged in a processing process so that uniform spraying on workpieces is realized; all procedures are mutuallymatched and do not influence each other; the spraying efficiency and the spraying quality are improved and the practical performance of the device is improved.

Owner:QUZHOU YANHANG BUSINESS CONSULTING CO LTD

Integrated rust removing and preventing equipment for steel manufacturing

ActiveCN110666664AImprove grinding accuracyGuaranteed derusting effectGrinding drivesGrinding machinesPolishingMaterials science

The invention relates to the technical field of steel manufacturing and particularly discloses integrated rust removing and preventing equipment for steel manufacturing. The integrated rust removing and preventing equipment comprises a concave working platen and a transporting table, wherein the transporting table is positioned in a concave groove of the concave working platen; multiple stages ofpolishing and rust removing mechanisms are arranged at the front end of the concave working platen and are symmetrically mounted on the two sides of the transporting table; a rust preventing mechanismis arranged at the rear end of the concave working platen and stretches across the transporting table; a mounting plate is placed on the upper surface of the transporting table; and steel is rotatably mounted on the mounting plate. The concave working platen realizes automatic polishing and rust removal without manual polishing, improves the rust removing efficiency, saves the labor cost, combines rust removal with rust prevention, finishes the two processes of rust removal and rust prevention with one-time operation, reduces the carrying and transferring process, reduces application of different equipment and lowers the cost.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

Pipe grinding device for building construction

ActiveCN109048518BEasy flipRealize all-round grindingGrinding carriagesRevolution surface grinding machinesDrive shaftCoupling

The invention relates to the technical field of pipeline machining, in particular to a pipeline grinding device for building construction. The device comprises a motor, the motor is fixedly connectedto a bottom plate through an electric machine frame, one end of a driving shaft is connected to an output shaft of the motor through a coupler, and the other end of the driving shaft is fixedly connected with a driving belt wheel I, a driving belt wheel II is fixedly connected to the middle end of the driving shaft, the driving belt wheel II is in transmission connection with the driven belt wheelI through a belt, the driven belt wheel I and a driven belt wheel II are fixedly connected to the two ends of a driven shaft respectively, the middle end of the driven shaft is rotationally connectedto a shaft frame plate through a belt seat bearing. According to the pipeline grinding device, the pipeline can be driven to rotate during working, so that the pipeline can be conveniently turned over, all-directional polishing of the pipeline can be realized through reciprocating movement of a grinding plate, the grinding efficiency and the grinding quality of the pipeline are improved, the manual operation is reduced, the working intensity of workers is reduced; the device can be applied to the grinding of pipelines with different pipe diameters, and the grinding speed can be adjusted by adjusting the pressure between the pipeline and the grinding plate.

Owner:台州飞龙鞋业有限公司

Plastic shell edge odor removing and grinding device

InactiveCN109877671ARealize all-round grindingChange heightEdge grinding machinesGrinding carriagesEngineeringOmni directional

The invention discloses a plastic shell edge odor removing and grinding device. The plastic shell edge odor removing and grinding device comprises a motor box, a supporting frame and a bottom plate, wherein clamping devices are arranged on the two sides of a round hole of the supporting frame, a group of sliding groove plates are vertically fixed on each side of the clamping device, sleeves are movably connected between each group of sliding groove plates, pull rods are inserted into the sleeves, clamping plates are fixedly connected to the inner ends of the pull rods, an air blower pump is arranged on the outer side of the side frame of the supporting frame, the air blower pump is connected with a water tank through an air inlet pipe, a deodorant is arranged in the water tank, one side ofthe water tank is fixedly connected with a water outlet pipe, and the other end of the water tank is fixedly connected with a watering pipe. According to the device, grinding and odor removing functions can be separately adjusted, an inner grinding device and an outer grinding device arranged on a grinding rod can realize omni-directional grinding on the edge of a plastic pipe, the plastic pipe to be polished can be clamped through a clamping device, the height of the plastic pipe can be changed by sliding the pull rods up and down along sliding grooves so as to achieve grinding of differentstrength and at different positions.

Owner:湖南夏龙医疗器械制造股份有限公司

Stone sculpture grinding equipment and using method thereof

PendingCN112792689ARealize all-round grindingAchieve protectionUsing liquid separation agentPortable grinding machinesStone carvingDust control

The invention discloses stone sculpture grinding equipment. The equipment comprises a fixed base, a height adjusting part, a rotating connecting ring, a supporting rotating rod, a supporting column, a distance adjusting type telescopic spring, a water tank, a dust removal protection type gap grinding device and a dust removal protection type surface grinding device. The invention belongs to the technical field of stone sculpture grinding, and particularly relates to the stone sculpture grinding equipment and a use method thereof. A mode of combining multiple kinds of dust removal and grinding protection is adopted, the technical effect of all-directional stone sculpture grinding is achieved, and meanwhile the technical effects of safety protection on a grinder and dust removal are achieved. The problems that stone sculpture grinding equipment in the current market is poor in effect, complex in structure and inconvenient to maintain are effectively solved.

Owner:XIANGNAN UNIV

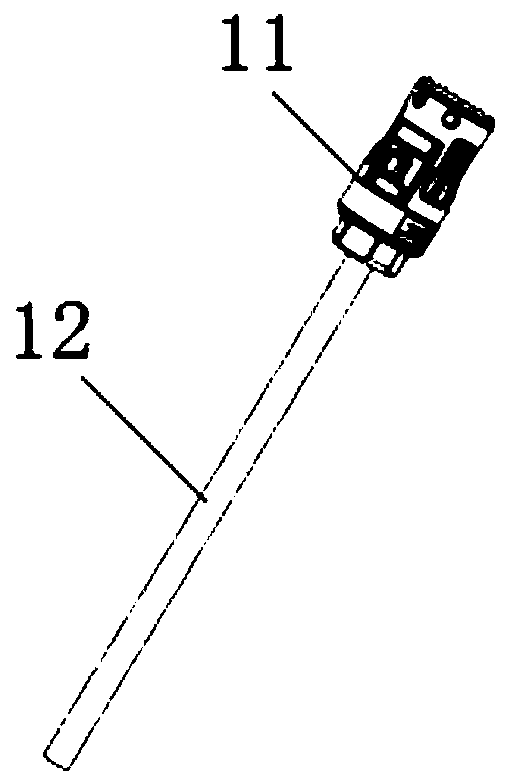

Plane grinding block tool

A plane grinding block tool is provided; the bottom end face of a sponge core is covered by a sand layer; the top end face of the sponge core is provided with a hand plate; the end face, making contact with the sponge core, of the hand plate is provided with barbs; the surface, vertical to the top end face of the sponge core, of the hand plate is provided with round holes allowing fingers to pass; the horizontal cross section of the core is in a round shape, rectangular shape, triangle shape or n-shape; the sand layer is bonded with the sponge core; the hand plate and the sponge core are connected through the barbs or bonded; the grinding blocks of different shapes can be formed according to different requirements and demands; the grinding block and the hand plate are combined to formed grinding blocks of various shapes according to different requirements and demands; by using the hand plate, a user cannot feel unconformable by contacting the sand layer with hands in a long time; the hand plate is provided with round holes, so the hand can easily grab the hand plate, and the grinding block is more convenient in operation.

Owner:湖北重泰研磨工具有限公司

Metal material machining device adopting renewable energy for power supply

InactiveCN109746805ASimple structureImprove efficiencyPhotovoltaic supportsGrinding carriagesElectric machineMetallic materials

The invention discloses a metal material machining device adopting renewable energy for power supply. The metal material machining device comprises a bottom plate. Sliding rails are arranged on the two sides of the upper end of the bottom plate. The upper end of each sliding rail is connected with a rail motor in a sliding manner, and the upper surfaces of the rail motors are fixedly connected with the bottom ends of the two sides of a support. An installation plate is arranged on the right side of the upper end of the support, and a quadrangle threaded hole in the upper end of the installation plate is connected with a threaded hole in the left side of a U-shaped plate in a threaded manner. An adjusting device is arranged at the upper ends of the U-shaped plate. The metal material machining device adopting the renewable energy for power supply is simple in structure and convenient to operate, renewable solar energy resources are adopted for power generation, great convenience is brought to use of users, in addition, all-directional polishing can be conducted on metal materials according to requirements, the metal materials are firmly fixed, material damage brought by deviation isavoided, the polishing quality is ensured, the working burden of personnel is reduced, resources are saved, and the use efficiency of the metal material machining device is improved.

Owner:梁廷洲

Polishing device for parts of all-terrain vehicle

InactiveCN111230610AReduce noiseProtect environmentLighting applicationsMechanical apparatusPhysicsPolishing

The invention relates to a polishing device for parts of an all-terrain vehicle. The polishing device comprises a base plate, an L-shaped supporting plate, an L-shaped movable plate, a servo motor, aclamping assembly and a damping assembly, wherein one side of the top end of the L-shaped movable plate is fixedly provided with a rotating box through screws, a threaded adjusting rod is connected with a movable block in a threaded penetrating manner, the other end of the threaded adjusting rod is movably clamped to a rotating base which is installed on the L-shaped movable plate through screws,and the other side of the upper surface of the base plate is provided with the clamping assembly. The polishing device has the advantages that a polishing wheel polishes the parts in all directions under the cooperation of a movable block and a hydraulic rod, clamping grooves and second threaded rods stabilize and fix tubular parts and plate parts respectively, first damping springs and second damping springs perform damping to reduce noise and protect the environment, a dust suction ring sucks polishing dust to protect the health of operators, LED lighting lamps and a wearproof pad provide convenience, and the whole polishing device is reasonable in design, realizes damping and noise reduction, ensures the health by sucking dust, and realizes all-directional polishing.

Owner:山东奥德斯工业股份有限公司

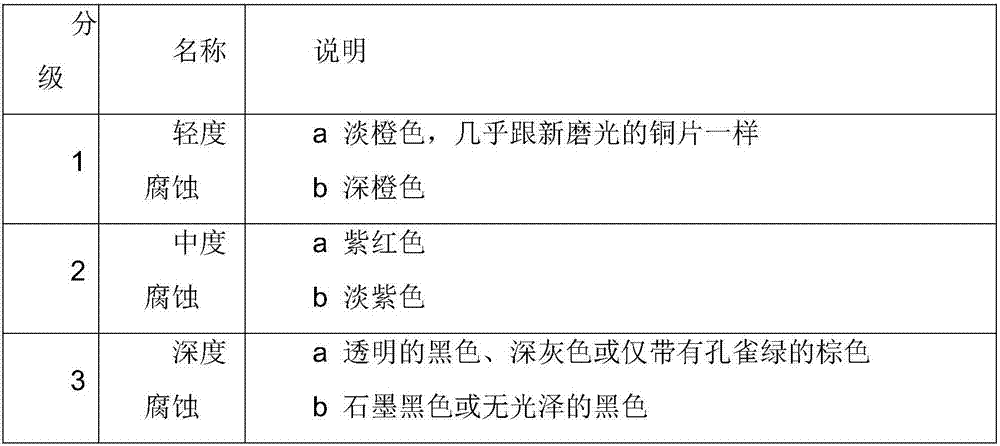

On-line petroleum product-caused copper sheet corrosion detection instrument and using method thereof

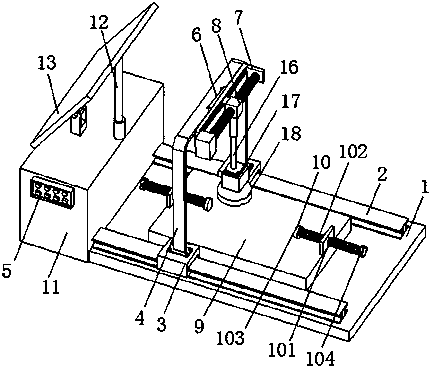

ActiveCN107121379ARealize all-round grindingRealize corrosion judgmentWeather/light/corrosion resistancePreparing sample for investigationPetroleum productCopper

The invention discloses an on-line petroleum product-caused copper sheet corrosion detection instrument, relates to a liquefied petroleum gas-caused copper sheet corrosion testing technology, and is used for solving the problem that in the conventional copper sheet corrosion testing technology, the error is higher than 3.5% when a corrosion standard color plate is used for determining the corrosion of a copper sheet sample. The on-line petroleum product-caused copper sheet corrosion detection instrument comprises a conveyer belt, a polishing structure and a turnover platform, wherein the polishing structure comprises a polishing sliding slot and a clamping fixture sliding along the polishing sliding slot up and down; the clamping fixture comprises a first motor, a clamping sliding frame, a first rotating shaft for controlling the clamping sliding frame to move, a second motor, a clamping head, a rotating block positioned on the end part of the clamping head, and a second rotating shaft for controlling the rotating block to move. Through a rotating mechanism and an overturning mechanism, 360-degree omnibearing polishing of a copper sheet is achieved, and the corrosion detection error is controlled to be lower than 3.5%. The invention further provides a using method of the on-line petroleum product-caused copper sheet corrosion detection instrument.

Owner:靖江市金舟船舶器材有限公司

Die-casting shell deburring machine and machining method thereof

ActiveCN113352173AImprove processing efficiencyIncrease flexibilityEdge grinding machinesGrinding drivesGrindingLamp shell

The invention discloses a die-casting shell deburring machine and a machining method thereof. The die-casting shell deburring machine comprises a machining table and a deburring mechanism arranged on the machining table, wherein a reversing assembly is arranged on the machining table; a limiting assembly is fixedly mounted at the top of a guide rail; a mounting bottom plate is arranged on the machining table; a first adjusting assembly is arranged on the mounting bottom plate; a second adjusting assembly is arranged on a lifting plate; and a third adjusting assembly is arranged on the mounting bottom plate. According to the die-casting shell deburring machine and the machining method thereof, through the arrangement of the deburring mechanism, automatic grinding of a lamp shell can be achieved; through the arrangement of the first adjusting assembly, the second adjusting assembly and the third adjusting assembly, the flexibility degree of the deburring machine can be improved, and multi-directional adjustment can be achieved according to needs; and through the arrangement of the reversing assembly, the lamp shell can be automatically transferred and rotated through the machine, the deburring machine can achieve all-directional grinding of burrs of the lamp shell, and the grinding efficiency is improved.

Owner:郑州纬达自动化科技有限公司

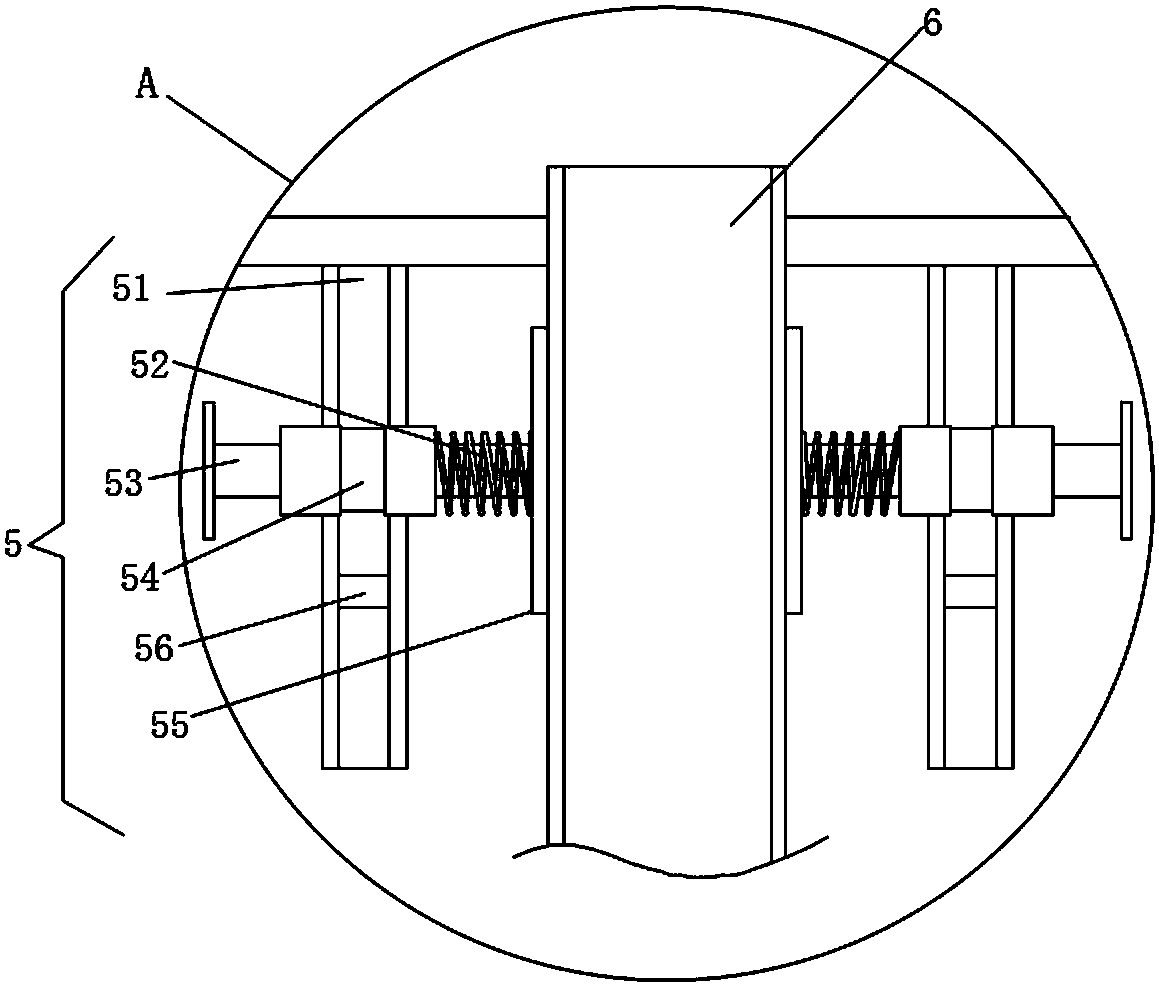

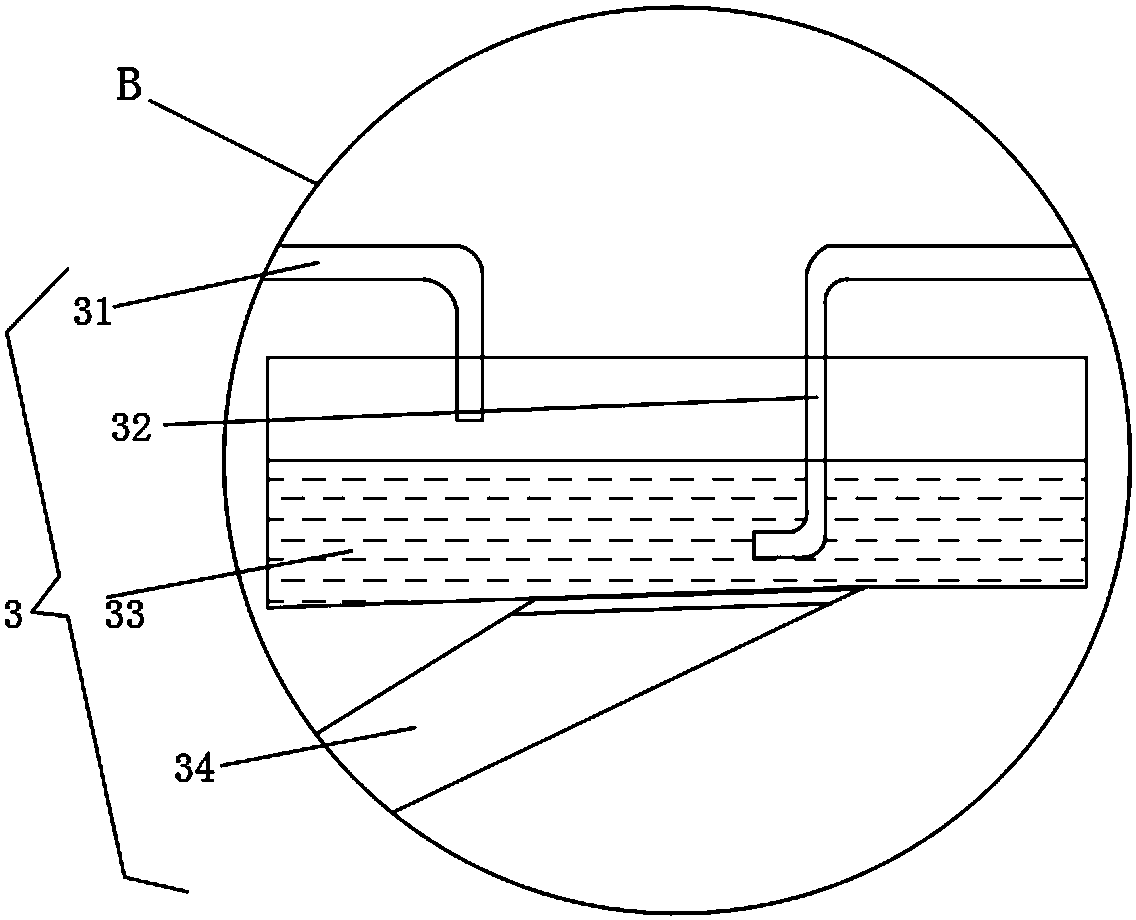

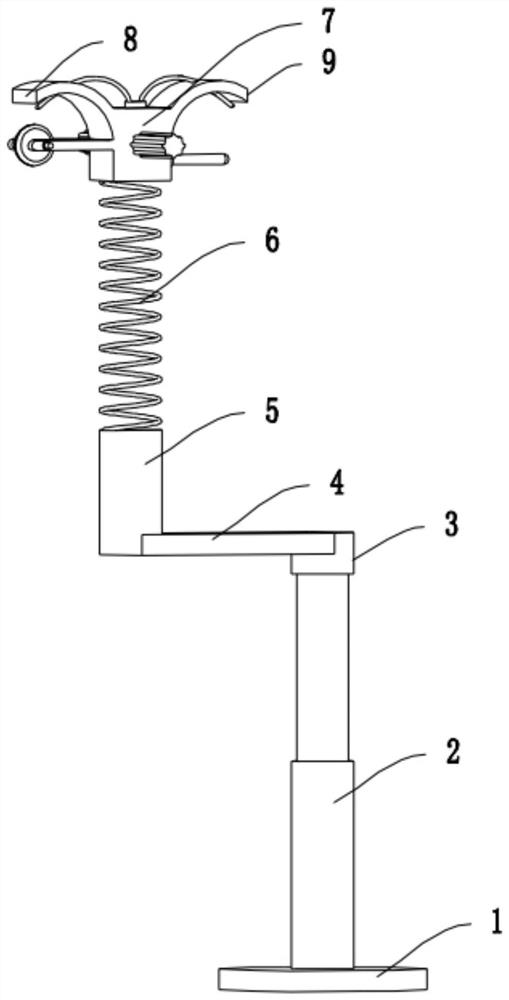

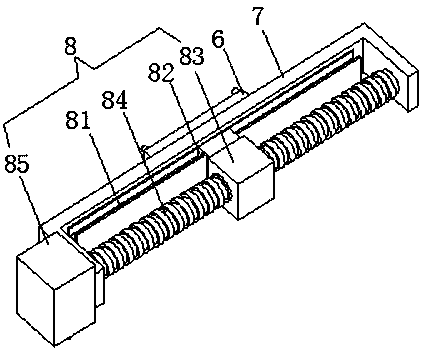

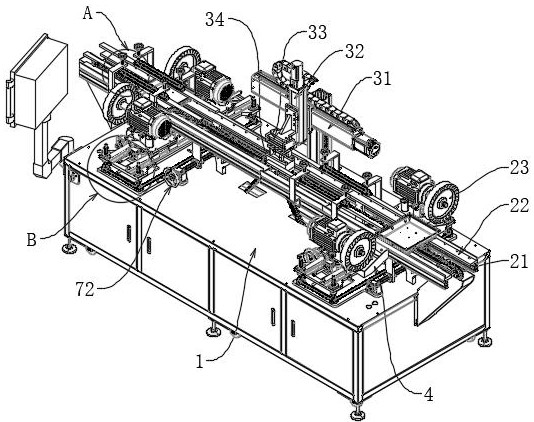

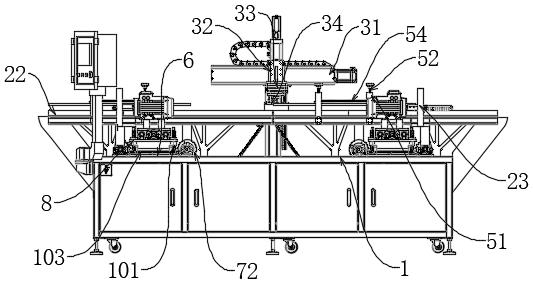

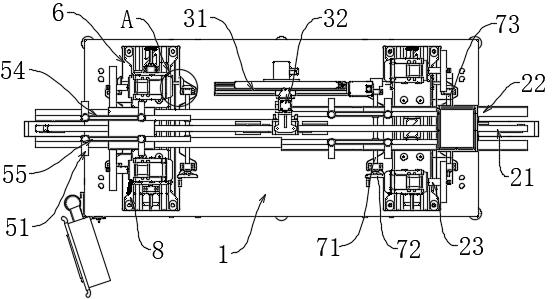

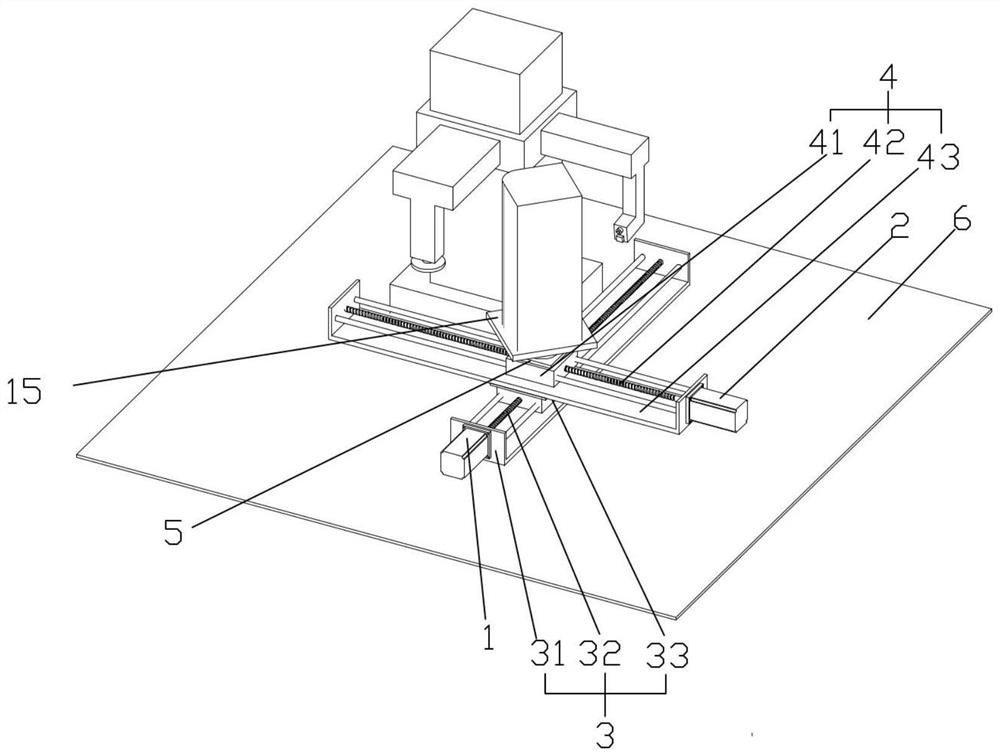

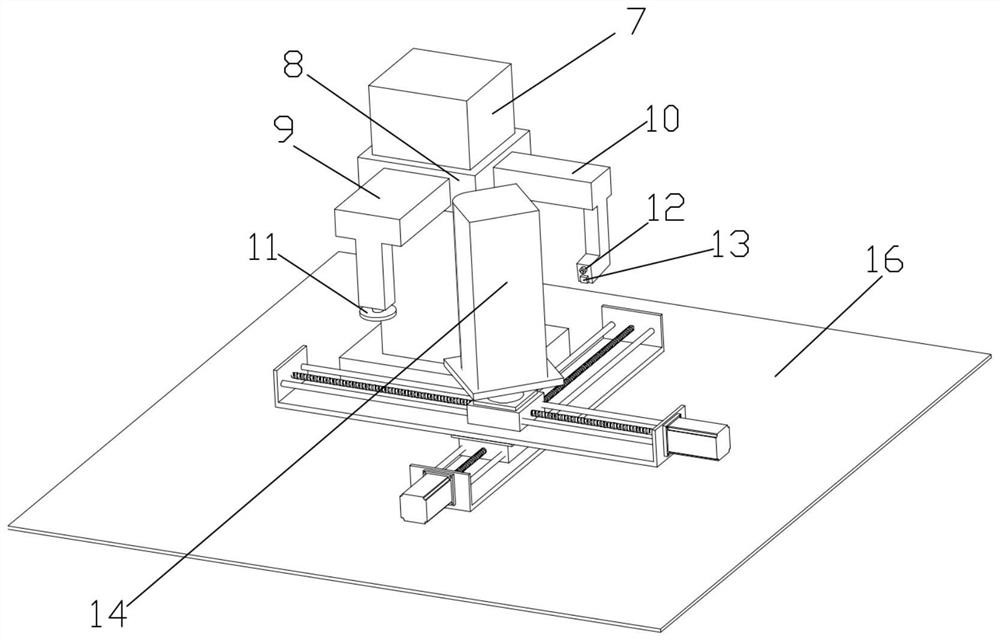

Arc edge polishing device and fence shape evaluation method

InactiveCN111761445AImprove accuracyHigh precisionEdge grinding machinesGrinding drivesElectric machineryEngineering

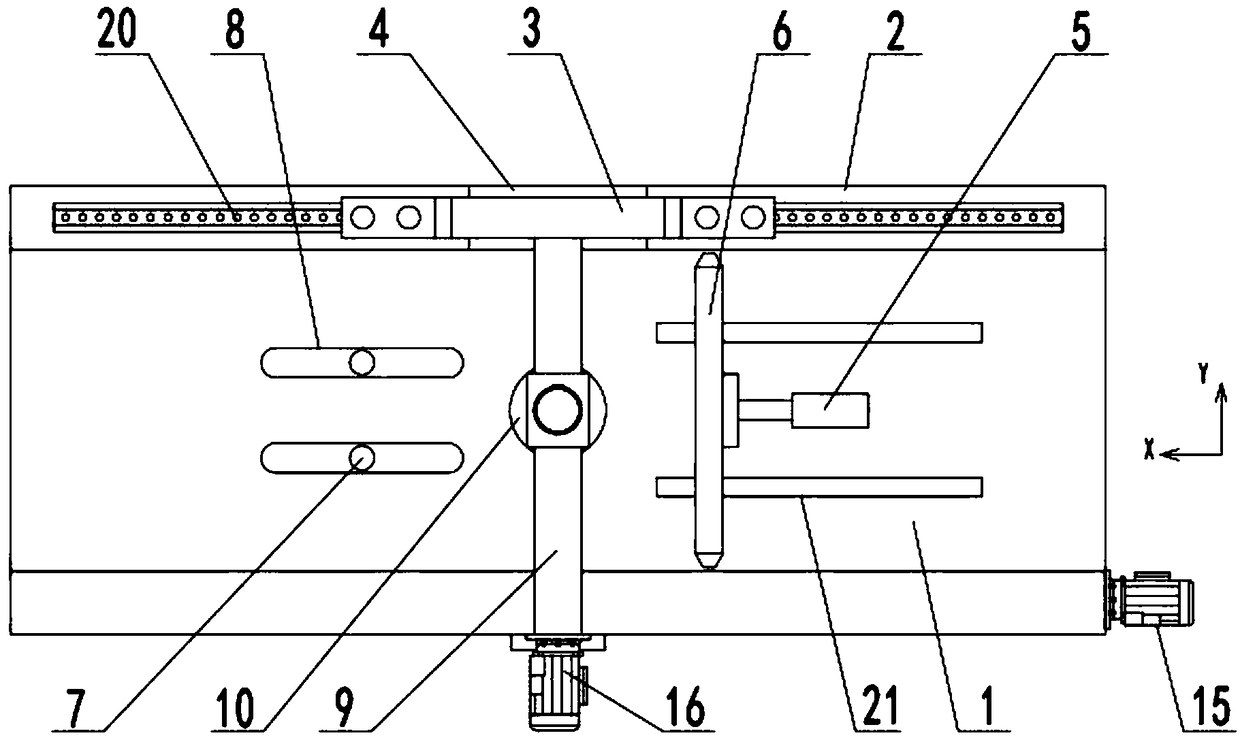

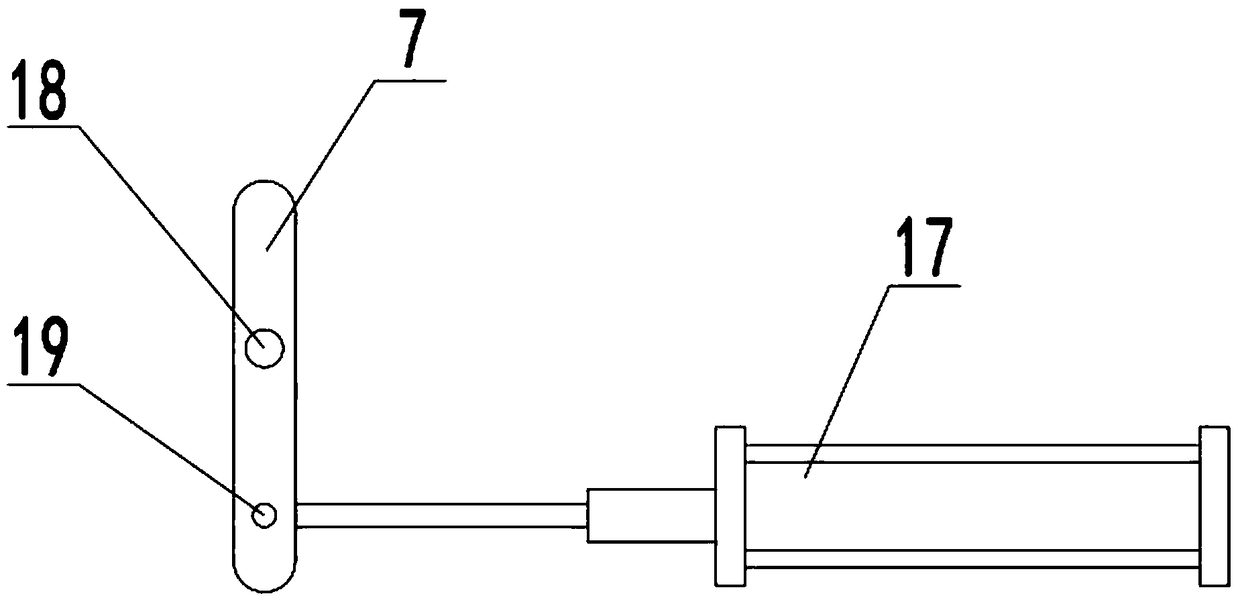

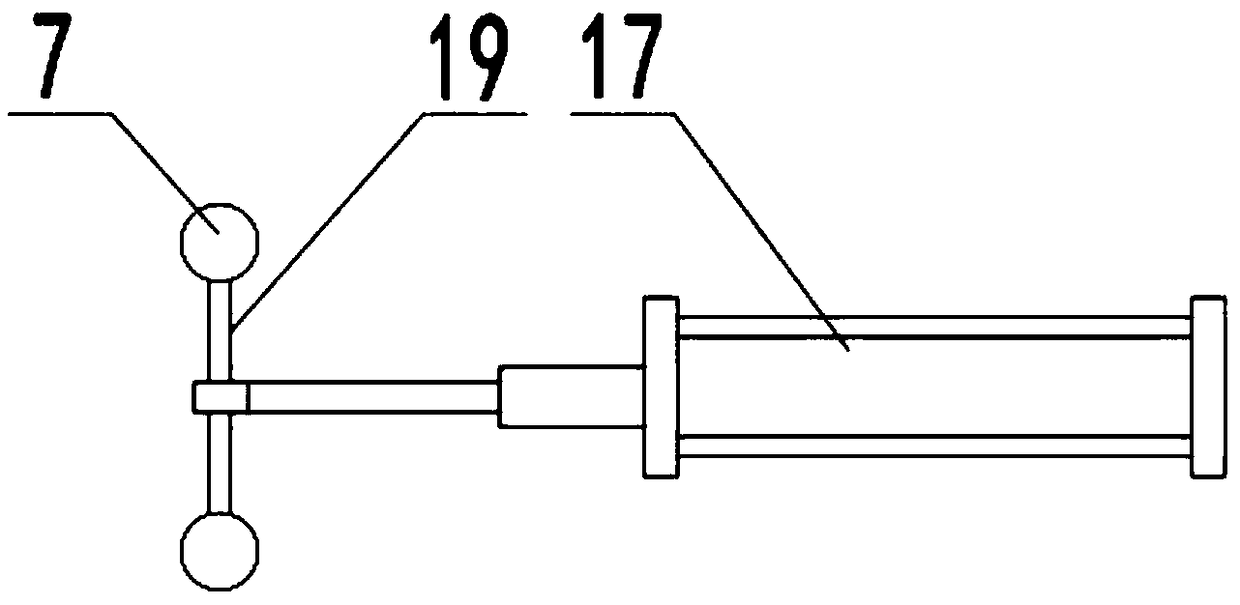

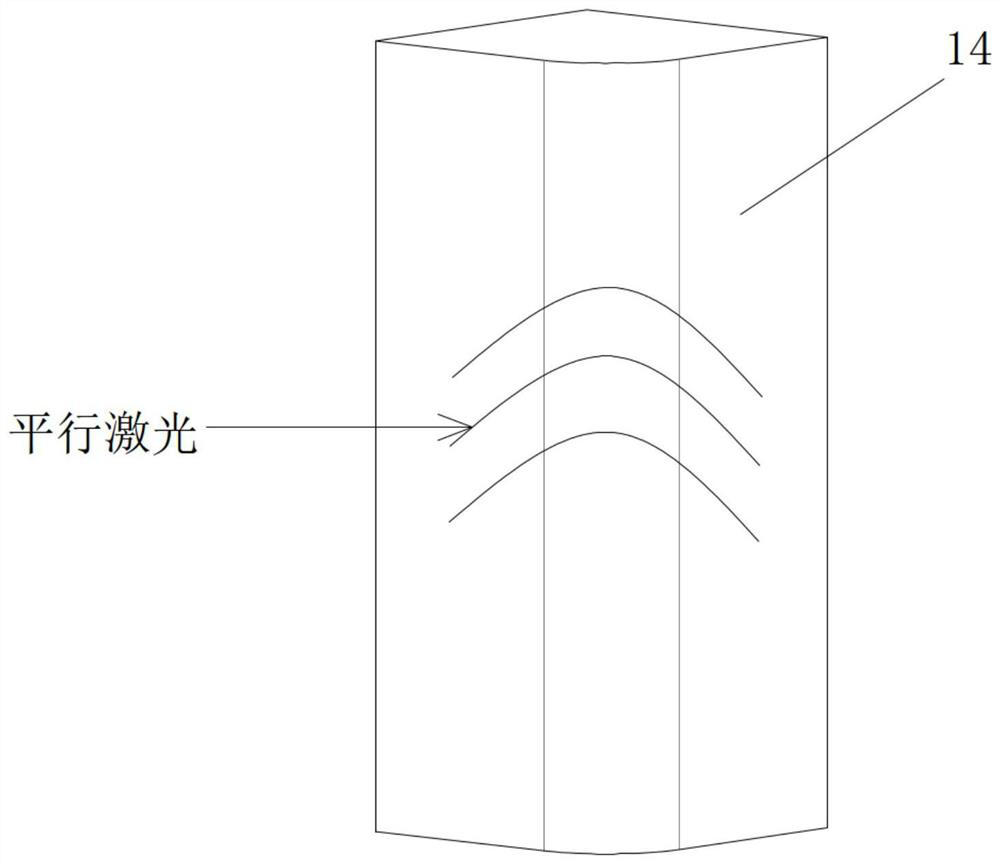

The invention relates to a part polishing technology, in particular to an arc edge polishing device and a fence shape evaluation method. A device conducting cyclic repeated automatic correcting and polishing and automatic detection and evaluating and then conducting correcting and polishing again is adopted, and therefore a new approach is provided for automatic part polishing. The arc edge polishing device comprises a worktable (6), an X-direction screw rod assembly (3) and a Y-direction screw rod assembly (4). The X-direction screw rod assembly (3) comprises an X-direction screw rod seat (31), an X-direction screw rod (32), an X-direction sliding seat (33) and an X-direction drive motor (1). The X-direction screw rod seat (31) is installed on the worktable (6), and a machine body of theX-direction drive motor (1) is installed on the X-direction screw rod seat (31). A rotating shaft of the X-direction drive motor (1) is linked with the X-direction screw rod (32), and the X-directionsliding seat (33) is in screw joint with the X-direction screw rod (32).

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com