Patents

Literature

159results about How to "Improve deburring efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

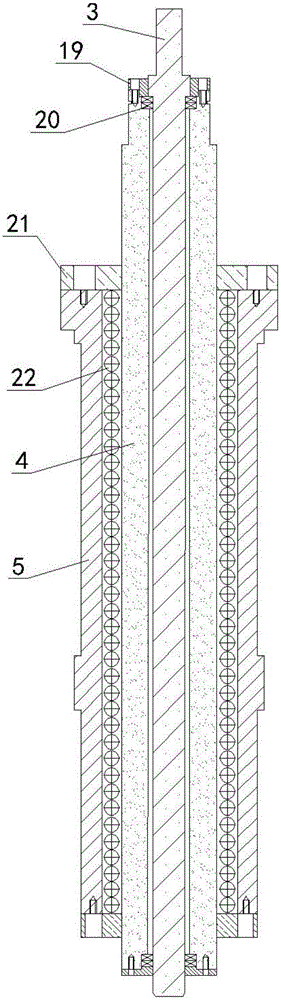

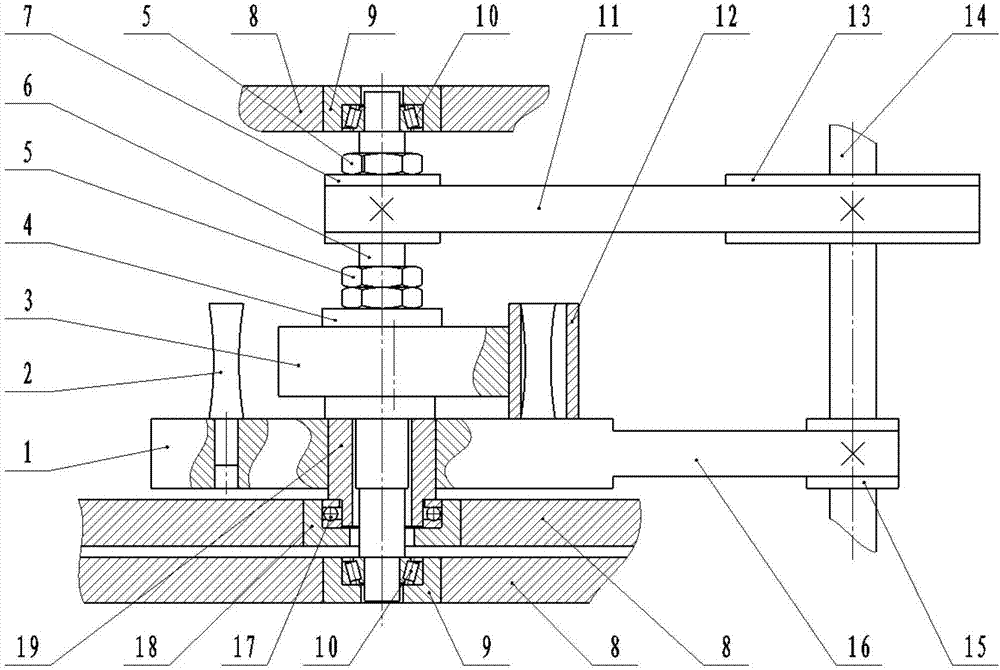

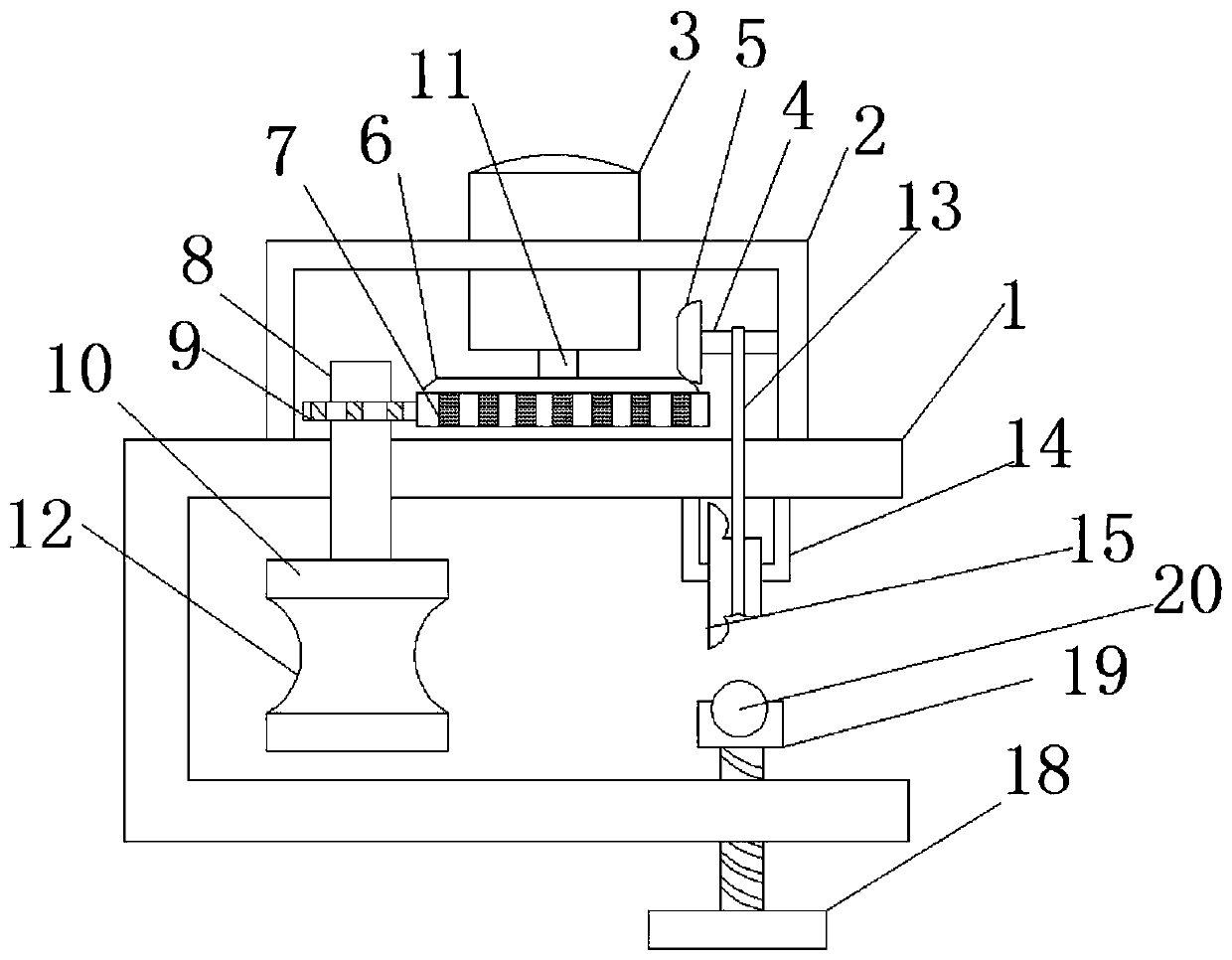

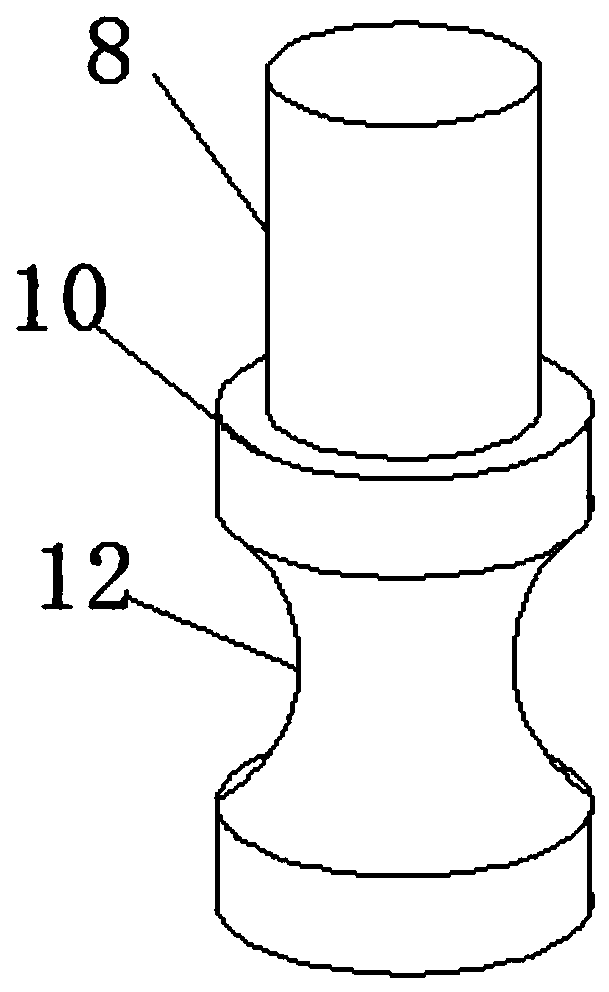

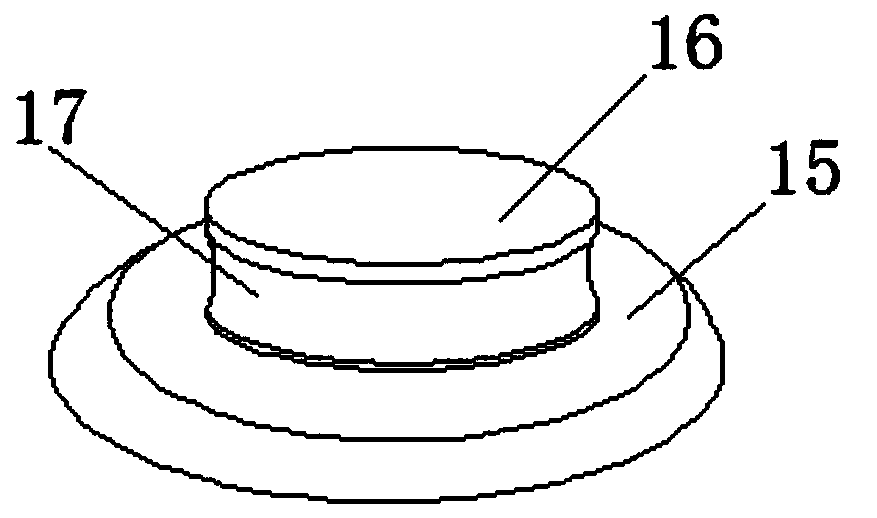

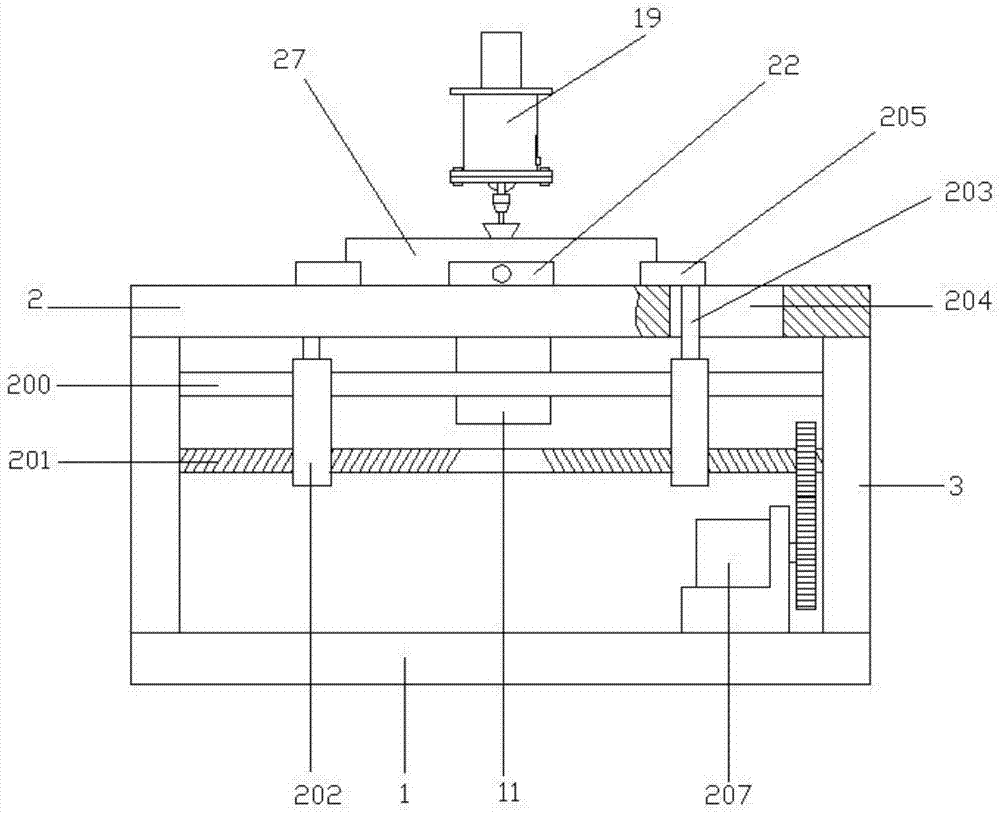

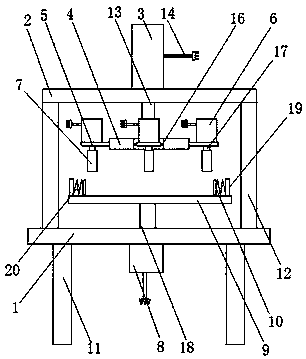

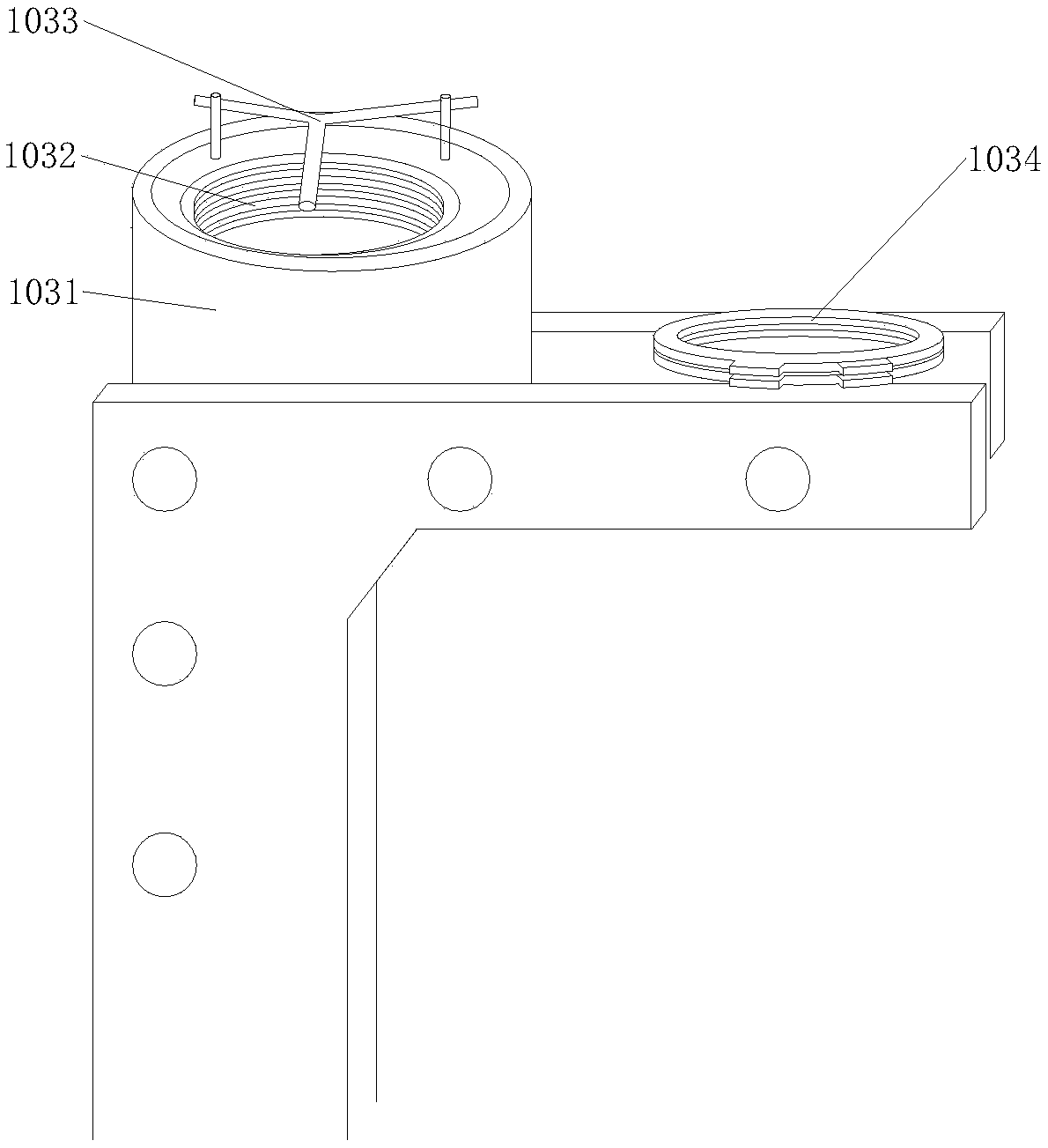

Special equipment for deburring of hub valve hole

ActiveCN103624183AQuality improvementImprove deburring efficiencyVehicle componentsMechanical engineering

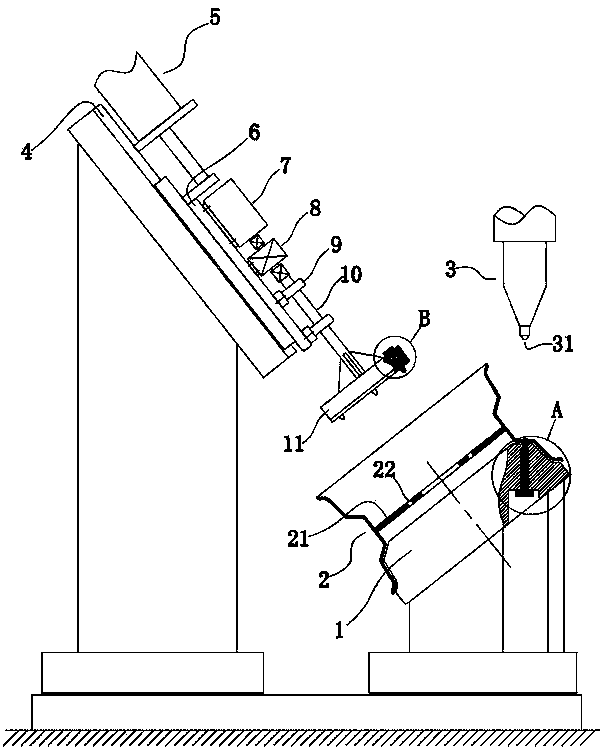

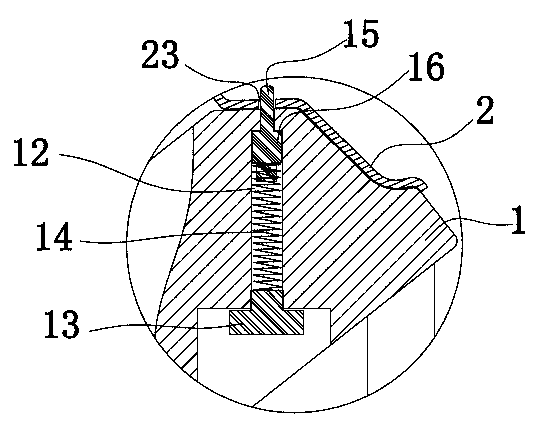

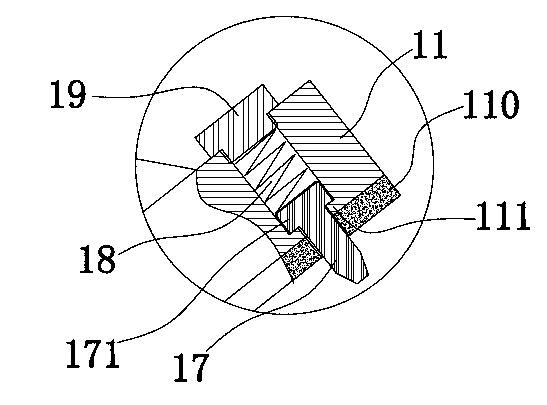

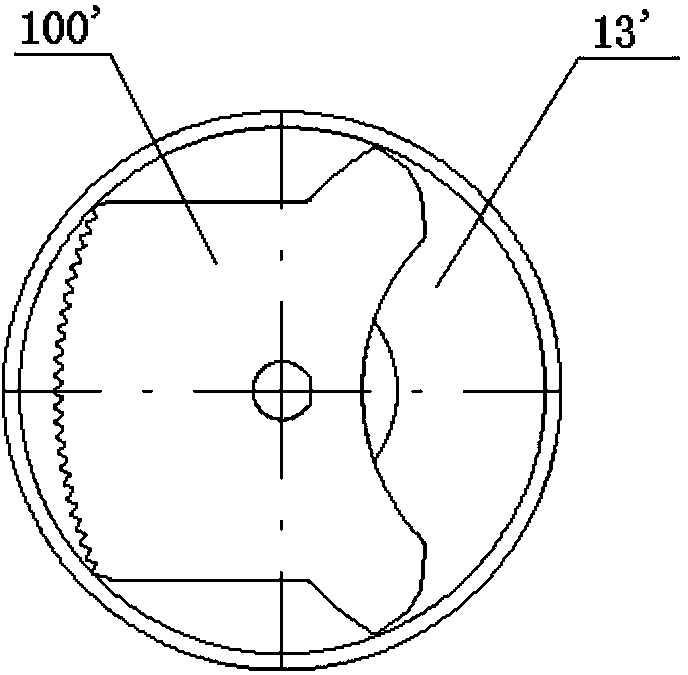

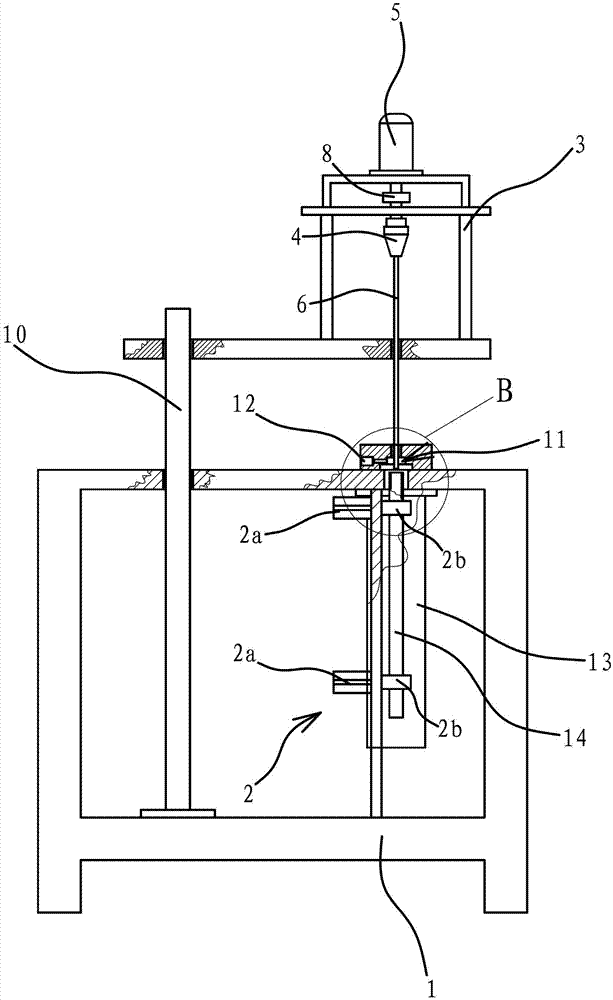

The invention discloses special equipment for deburring of a hub valve hole. The special equipment can effectively improve deburring efficiency, reduce labor intensity and guarantee stable deburring quality. The special equipment comprises a machine table, an annular lower die table and a punch, wherein the annular lower die table is arranged on the machine table and matched with the inner peripheral face of a hub, and the punch is located above the annular lower die table. The outer peripheral face of the annular flow die table is provided with a vertical hole corresponding to the hub valve hole, and the included angle between the center line of the vertical hole and the center line of the annular lower die table is the same as that between the axis of the hub and the center line of the valve hole. An alignment ejector pin capable of moving upward and downward and a first reset spring located below the alignment ejector pin and used for ejecting the alignment ejector pin are disposed in the vertical hole. The punch is located over the alignment ejector pin.

Owner:ZHEJIANG JINGU CO LTD

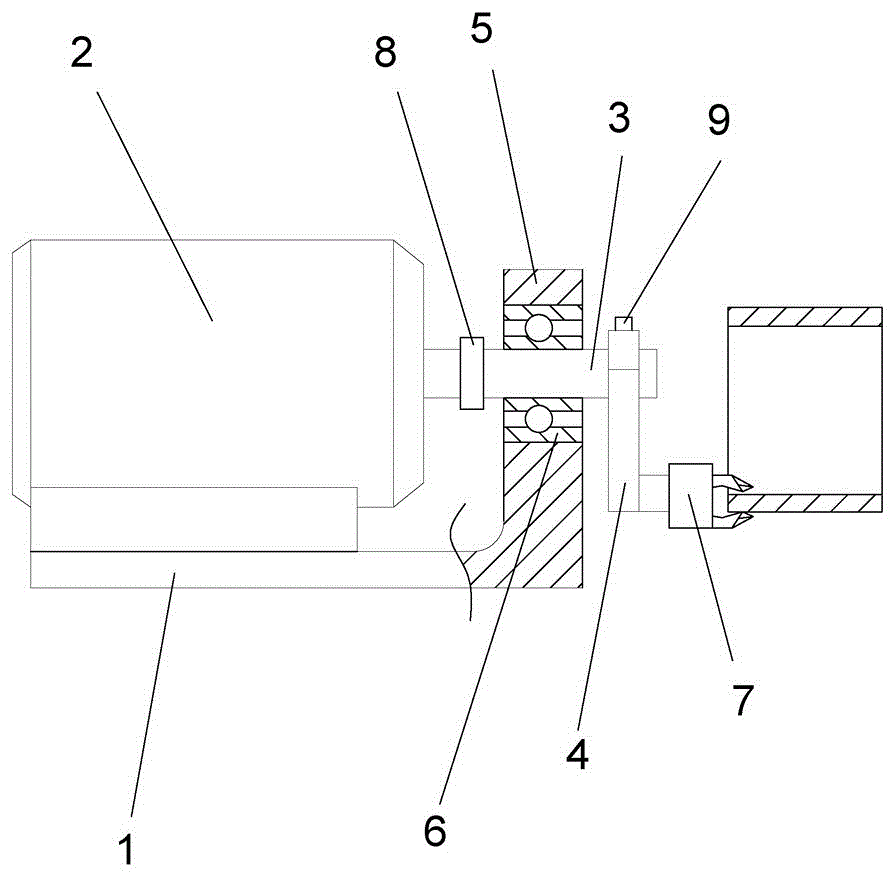

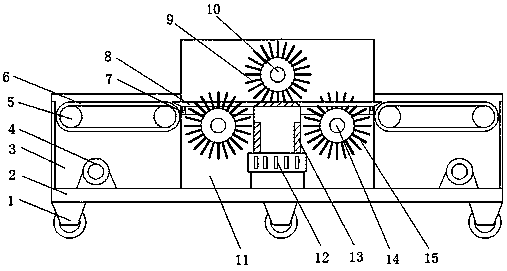

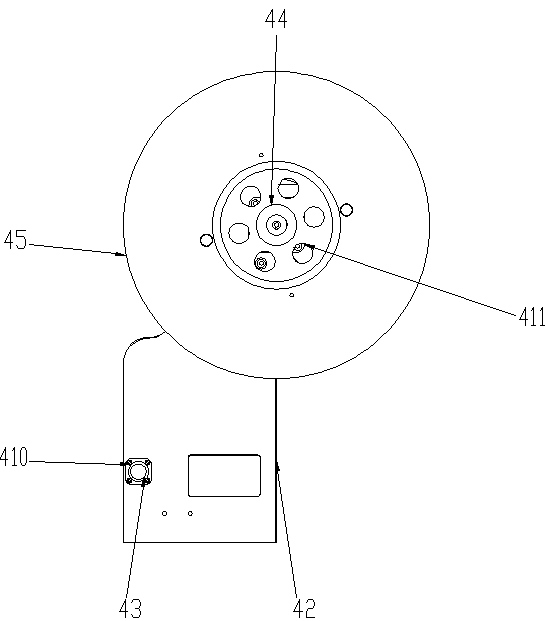

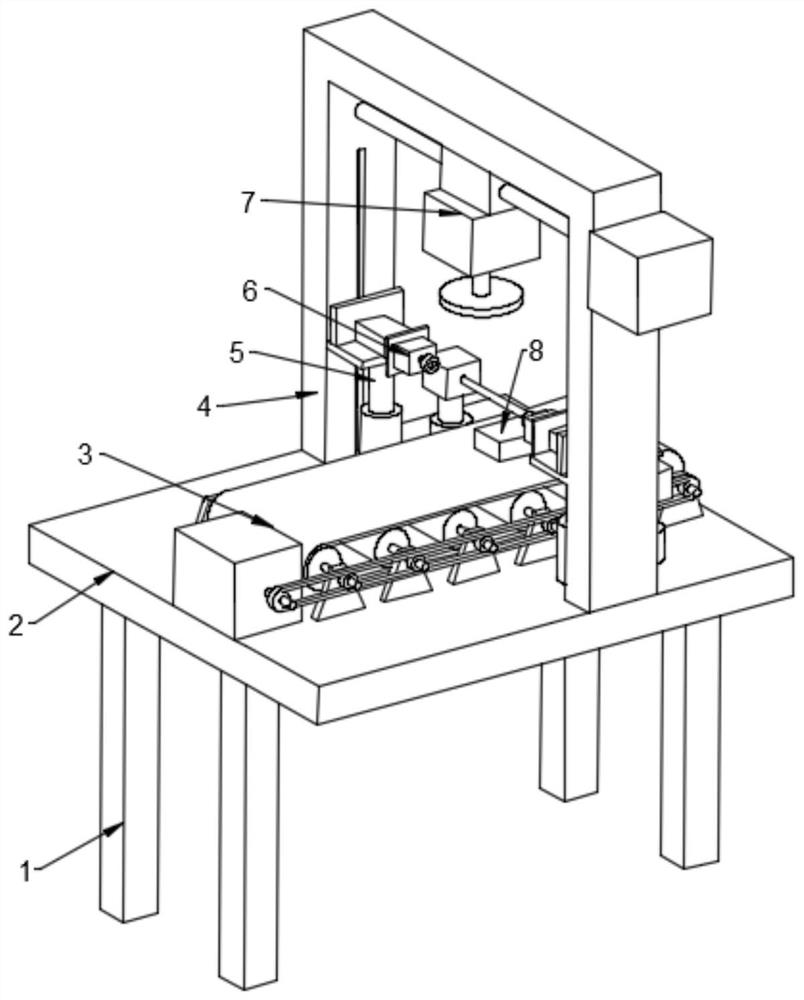

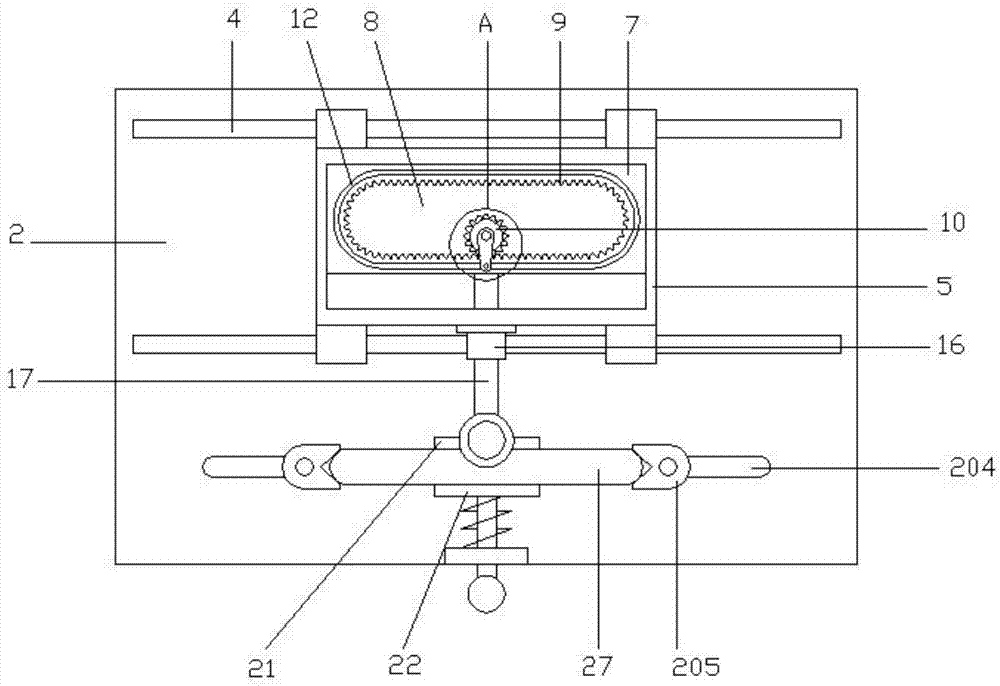

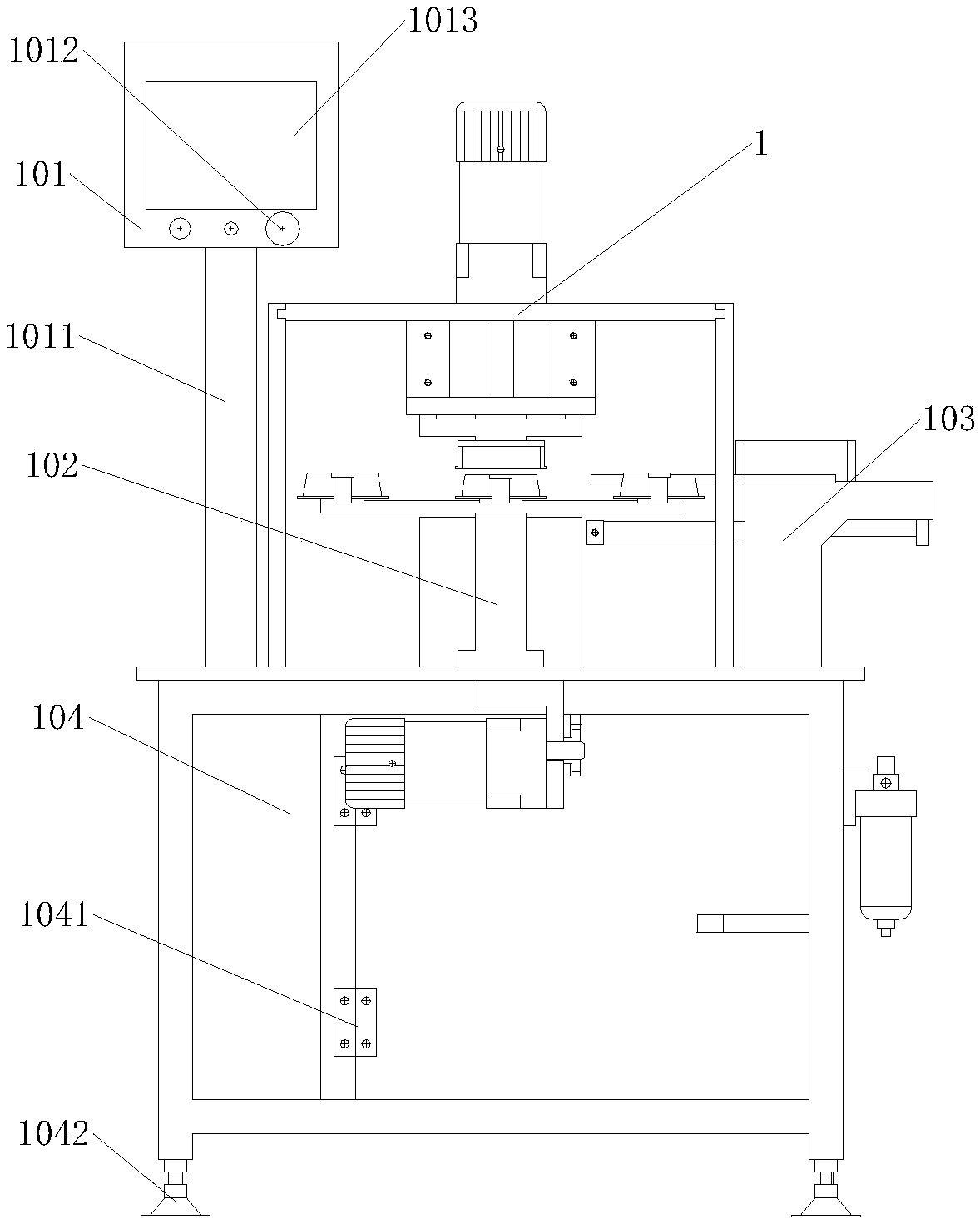

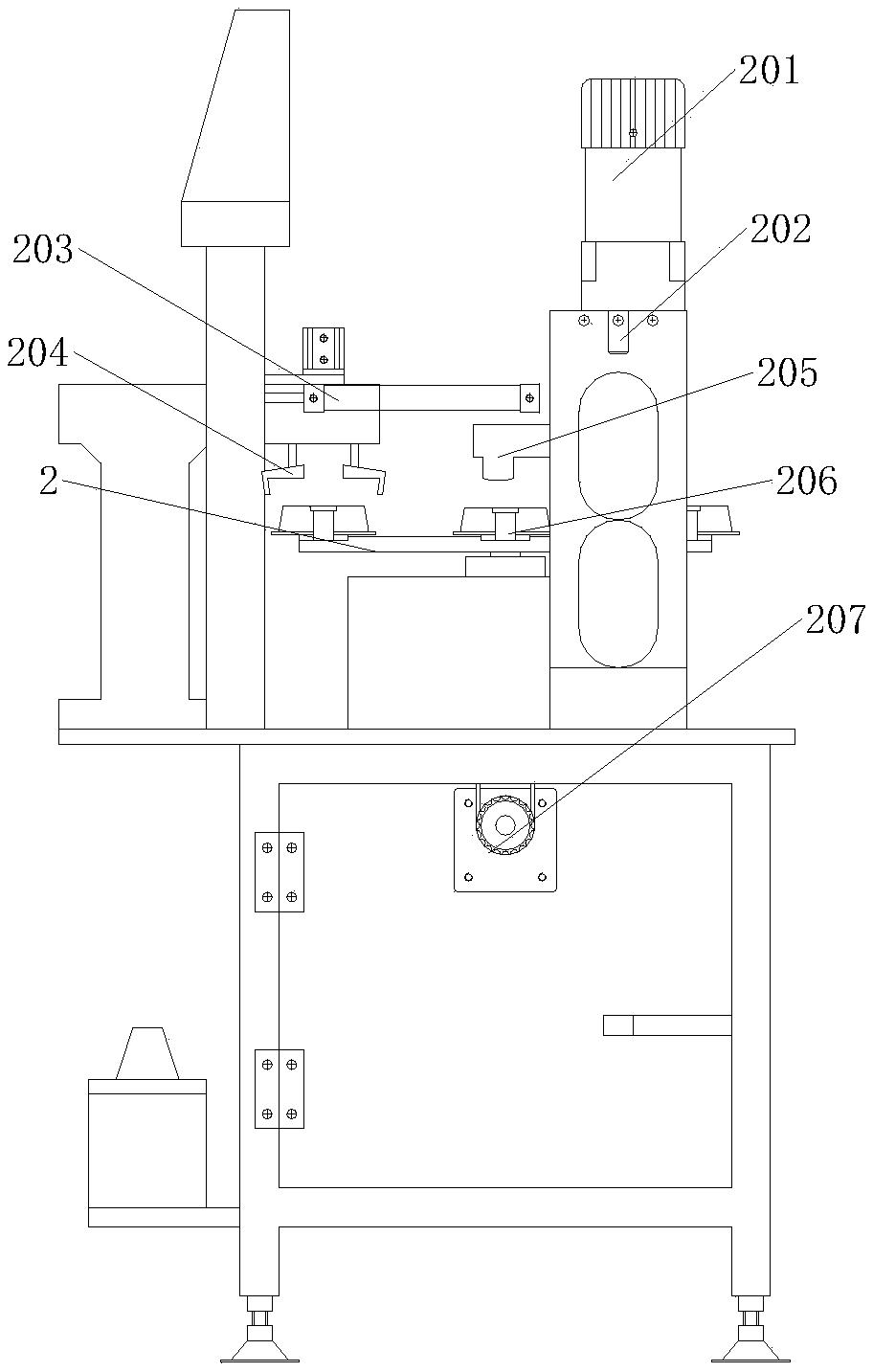

Deburring machine

ActiveCN104339236AQuick contactImprove deburring efficiencyEdge grinding machinesGrinding drivesSpeed reductionElectric machine

The invention discloses a deburring machine. The deburring machine comprises a loading station, a plane abrasion station and a teeth sweeping station, wherein the three stations are respectively and correspondingly provided with a loading mechanism, a plane abrasion mechanism and a teeth sweeping mechanism. The deburring machine also comprises a station shifting mechanism for transferring workpieces from the previous station to the next station; the plane abrasion mechanism comprises a first motor, a speed reduction transmission mechanism connected with the first motor, a grinding wheel, a revolution adapting piece and a rotation driving piece, wherein the revolution adapting piece is connected with an output shaft of the speed reduction transmission mechanism; the rotation driving piece and the revolution adapting piece rotate relative to each other; the rotation driving piece is eccentric to the output shaft of the speed reduction transmission mechanism; the grinding wheel is concentrically connected with an output shaft of the rotation driving piece. By adopting the structure, the grinding wheel simultaneously does revolution motion and rotation motion in the operating process, and the motion track forms an envelope line track, thus, the workpieces are conveyed to the lower part of the grinding wheel by virtue of the clamping mechanism, and the operating surface of the grinding wheel can be quickly in contact with the end surfaces of the workpieces, therefore the deburring efficiency is greatly improved.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

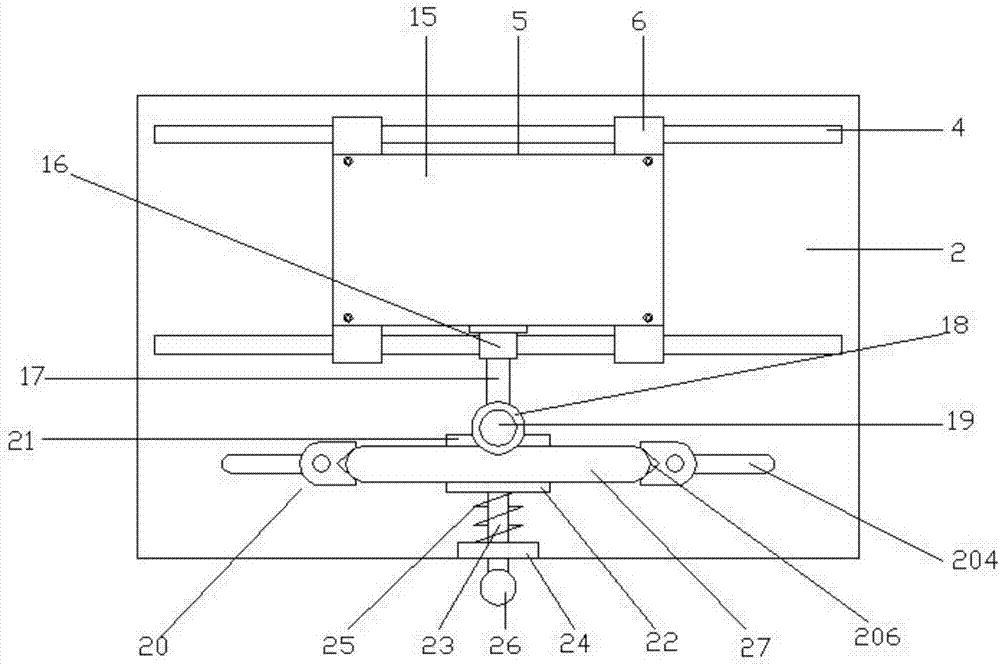

Efficient wood board deburring equipment for building construction

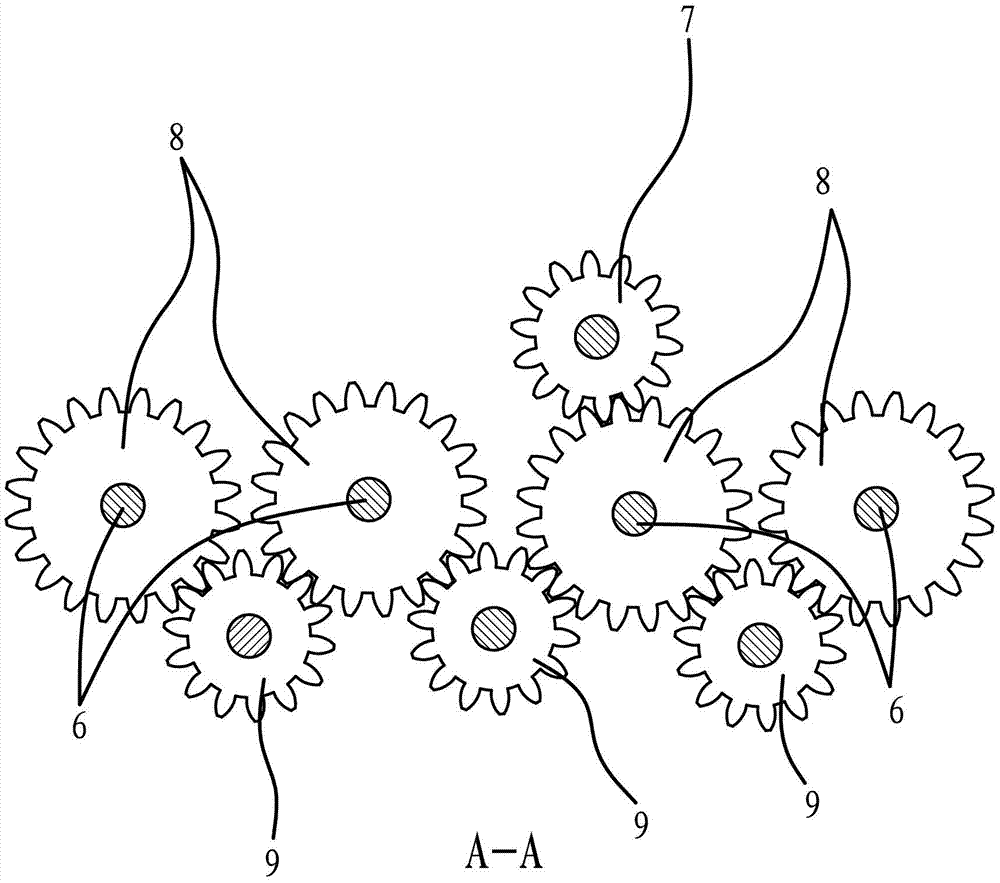

InactiveCN112355778AImprove deburring efficiencySpeed up the construction processEdge grinding machinesGrinding drivesGear driveGear wheel

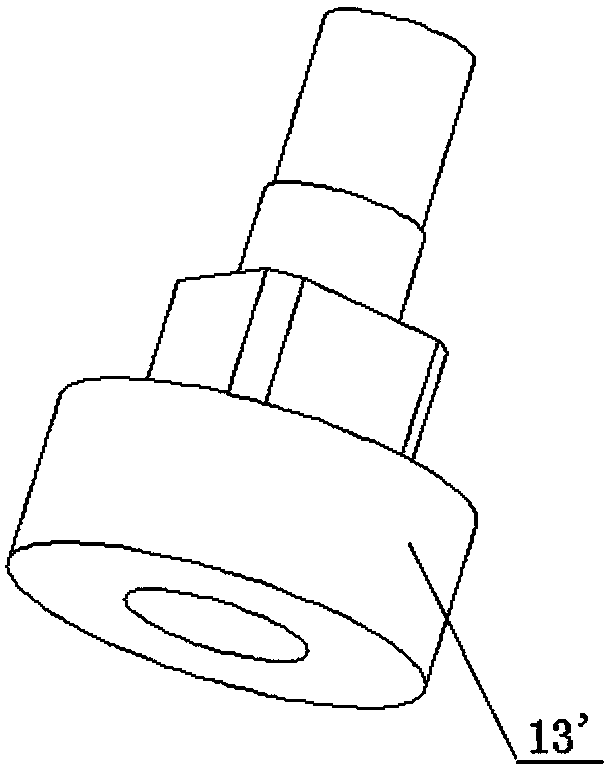

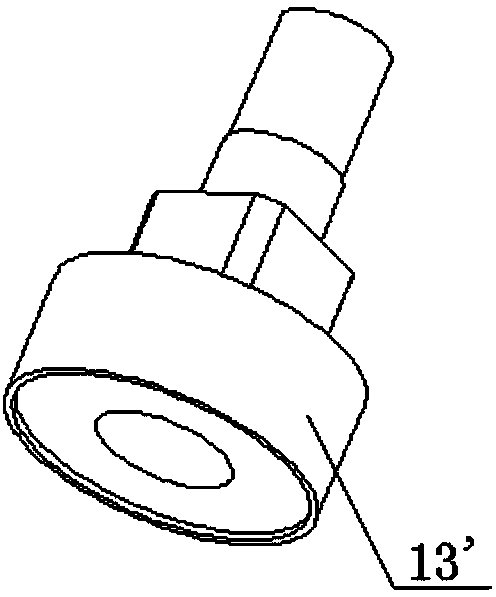

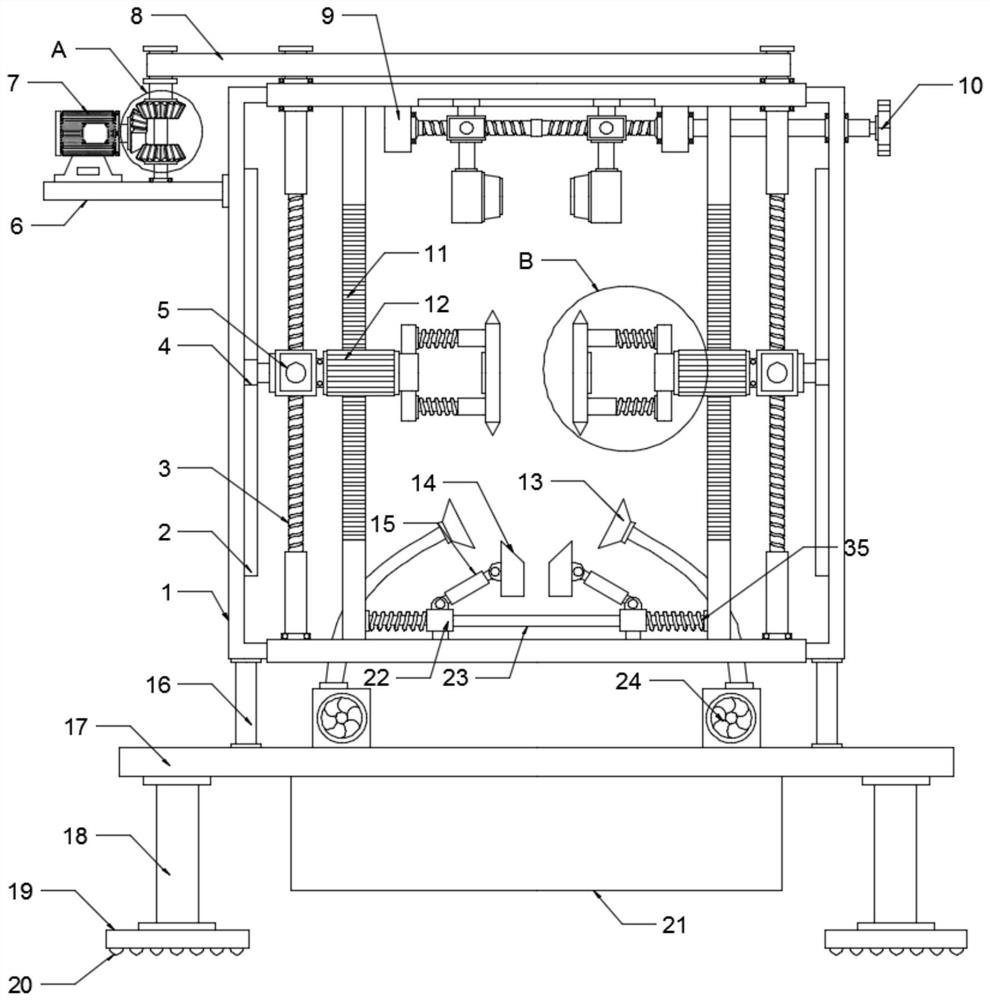

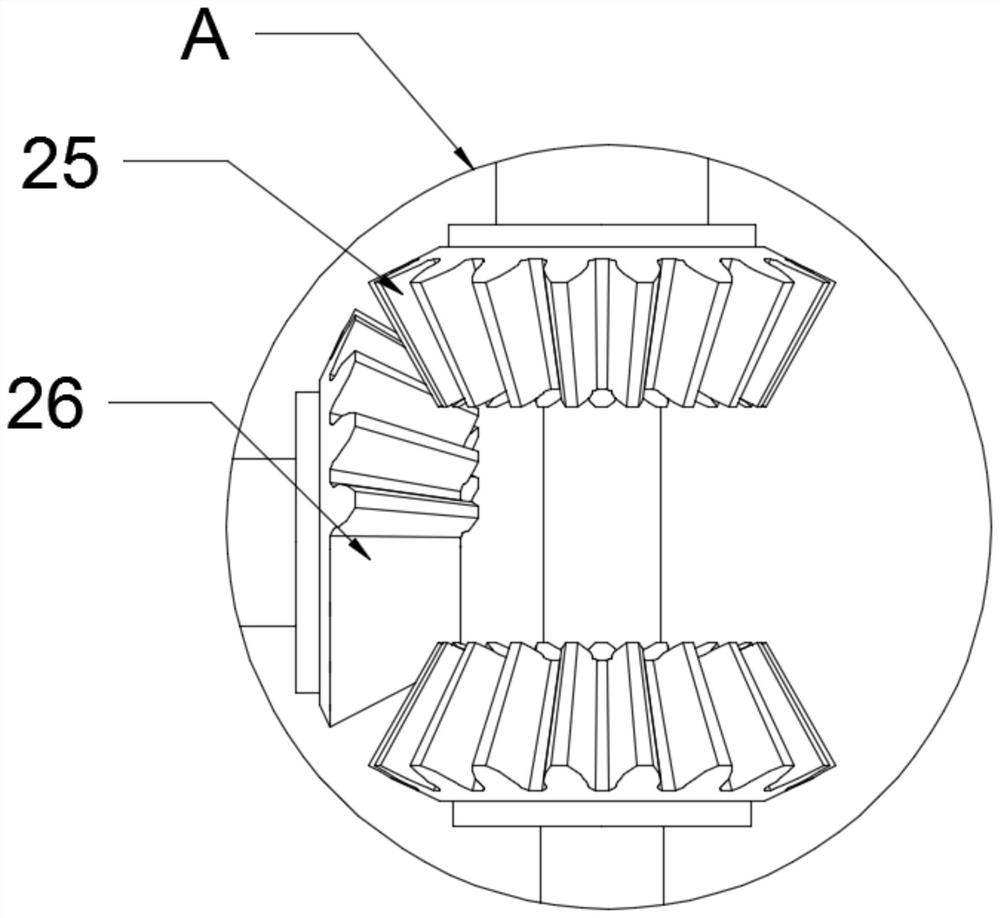

The invention discloses efficient wood board deburring equipment for building construction, and relates to the technical field of building construction equipment. The efficient wood board deburring equipment comprises a treatment box and a supporting base, supporting seats are symmetrically arranged on the left side and the right side of the upper portion in the treatment box, a screw rod is arranged between the supporting seats and rotationally connected with the supporting seats, nuts are symmetrically arranged on the left side and the right side of the surface of the screw rod, clamps are fixedly connected to positions below the nuts, lead screws are symmetrically arranged on the left side and the right side in the treatment box, lead screw nuts are arranged on the surfaces of the leadscrews, and rack plates are arranged on one sides of the lead screw nuts. Wood boards are clamped and fixed in the clamps, the lead screw nuts drive gears to move up and down on the surfaces of the rack plates in the vertical direction, the rack plates mesh with the gears to drive the gears to rotate, the gears drive a grinding wheel to rotate on the surfaces of the wood boards, the grinding wheelcarries out deburring treatment on the wood boards, a dust suction machine sucks chippings generated in the grinding process into a material collecting groove through a dust suction port, unified collection treatment is carried out, the deburring efficiency is effectively improved through double-face grinding of the wood boards, and the construction process is accelerated.

Owner:刘先贵

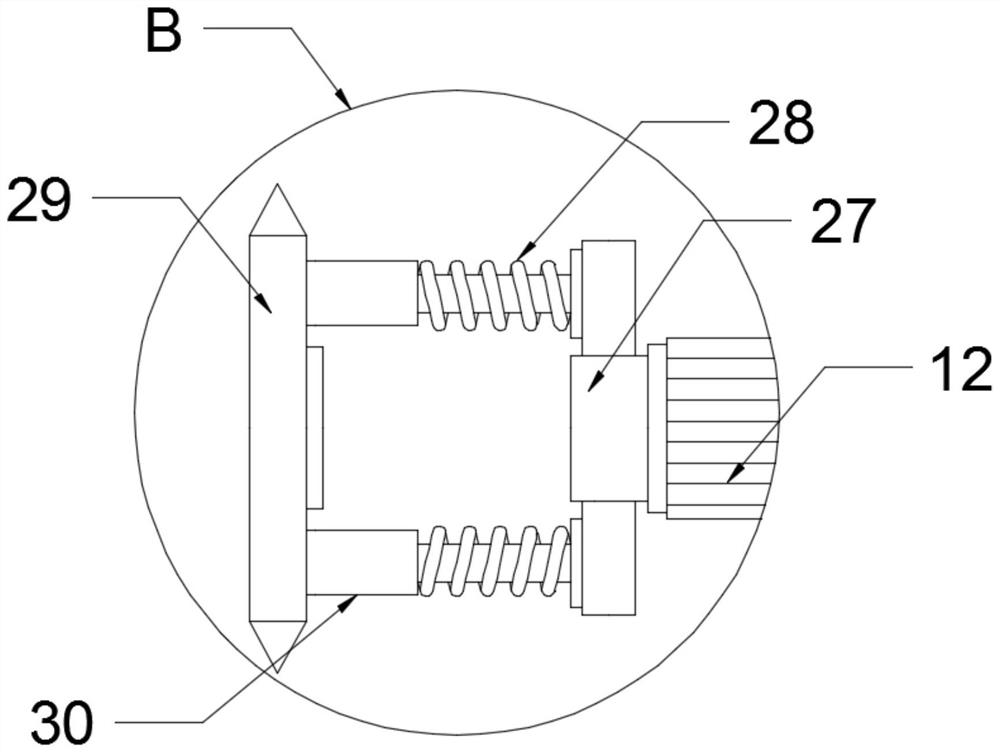

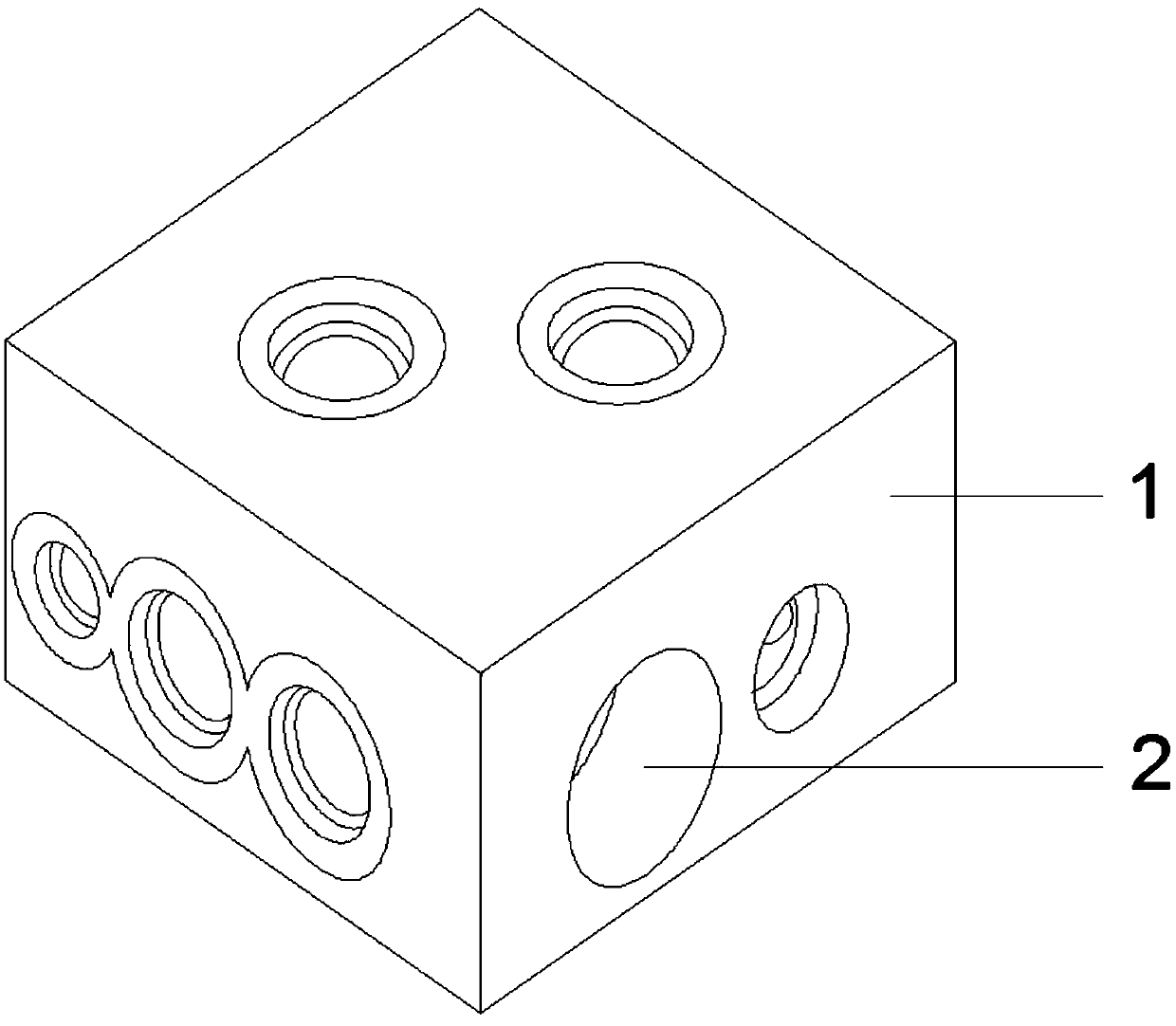

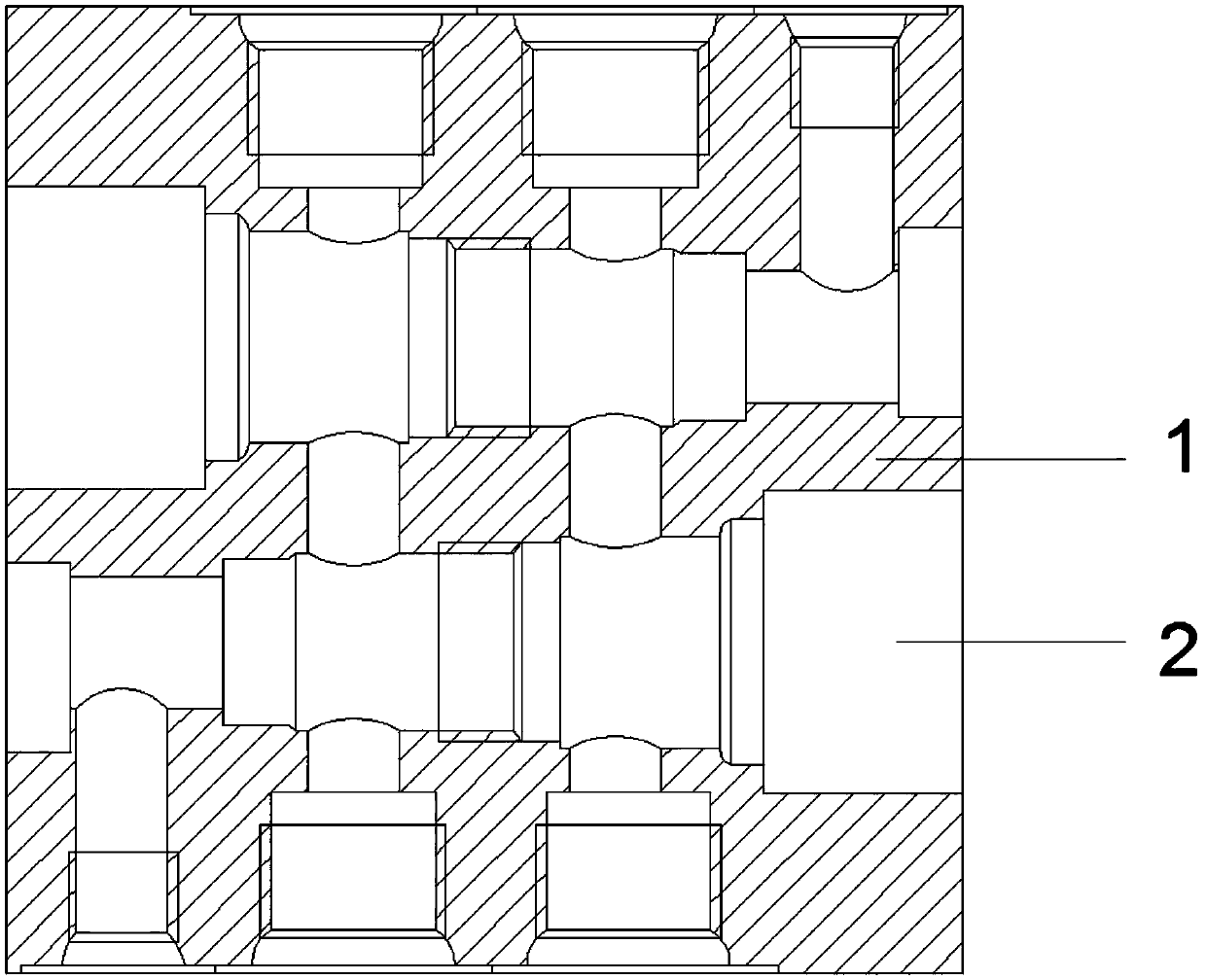

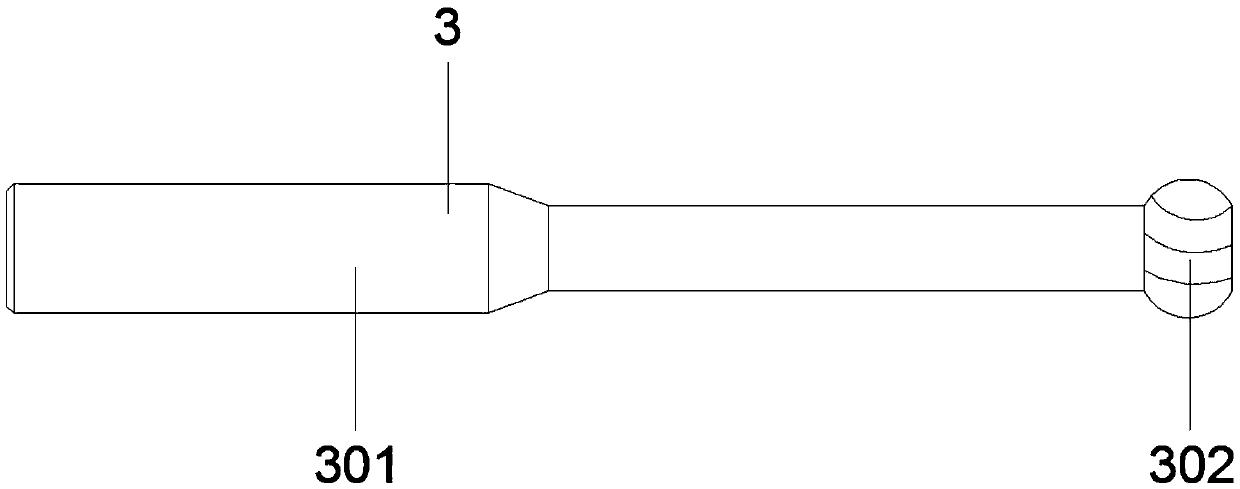

Hydraulic pump valve body processing technology

The invention provides a hydraulic pump valve body processing technology which comprises the following processing steps: step 1, adopting square tool steel; step 2, performing sawing, and interceptingthe tool steel which is 3-5 MM larger than a labeling length according to the labeling length required in a drawing; and step 3, performing profile rough milling. A hole is processed by a compound tool, so that the processing time is effectively shortened; and burrs are removed by combining machine tool processing with manual operation, so that the burr removal efficiency is high, and the manualburr removal cost is reduced; and therefore, problems and defects in the prior art are effectively solved.

Owner:苏州莱易精密机电有限公司

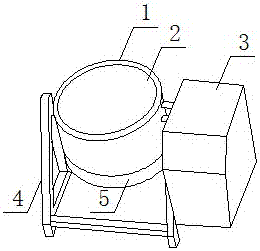

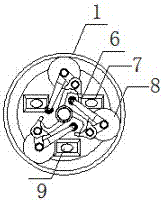

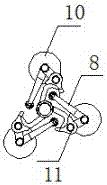

Surface deburring device for manufacturing bearing steel balls

ActiveCN110355680APlay the role of guide limitImprove grinding efficiencyEdge grinding machinesGrinding carriagesSteel ballEngineering

The invention relates to the field of bearing steel ball processing, in particular to a surface deburring device for manufacturing bearing steel balls. The surface deburring device comprises a base and further comprises a grinding mechanism, a rocking mechanism and a horizontal swinging mechanism; the horizontal swinging mechanism comprises a rotating plate capable of doing positive and negative reciprocated motion in the horizontal state, and the rotating plate is horizontally arranged above the base; the rocking mechanism includes two connecting vertical plates, and the two connecting vertical plates are symmetric and are arranged at the top of the rotating plate in a spaced manner; and the grinding mechanism includes a grinding pot, the two ends of the grinding pot are movably arrangedbetween the two connecting vertical plates through a rotating shaft, the inside of the grinding pot is provided with a discharging assembly, and the top of the grinding tank is provided with a liquidinlet pipe and a feeding pipe. The surface deburring device can comprehensively conduct deburring on the steel balls in a large batch, and therefore the deburring efficiency is improved.

Owner:宁波奉化精瑞钢球有限公司

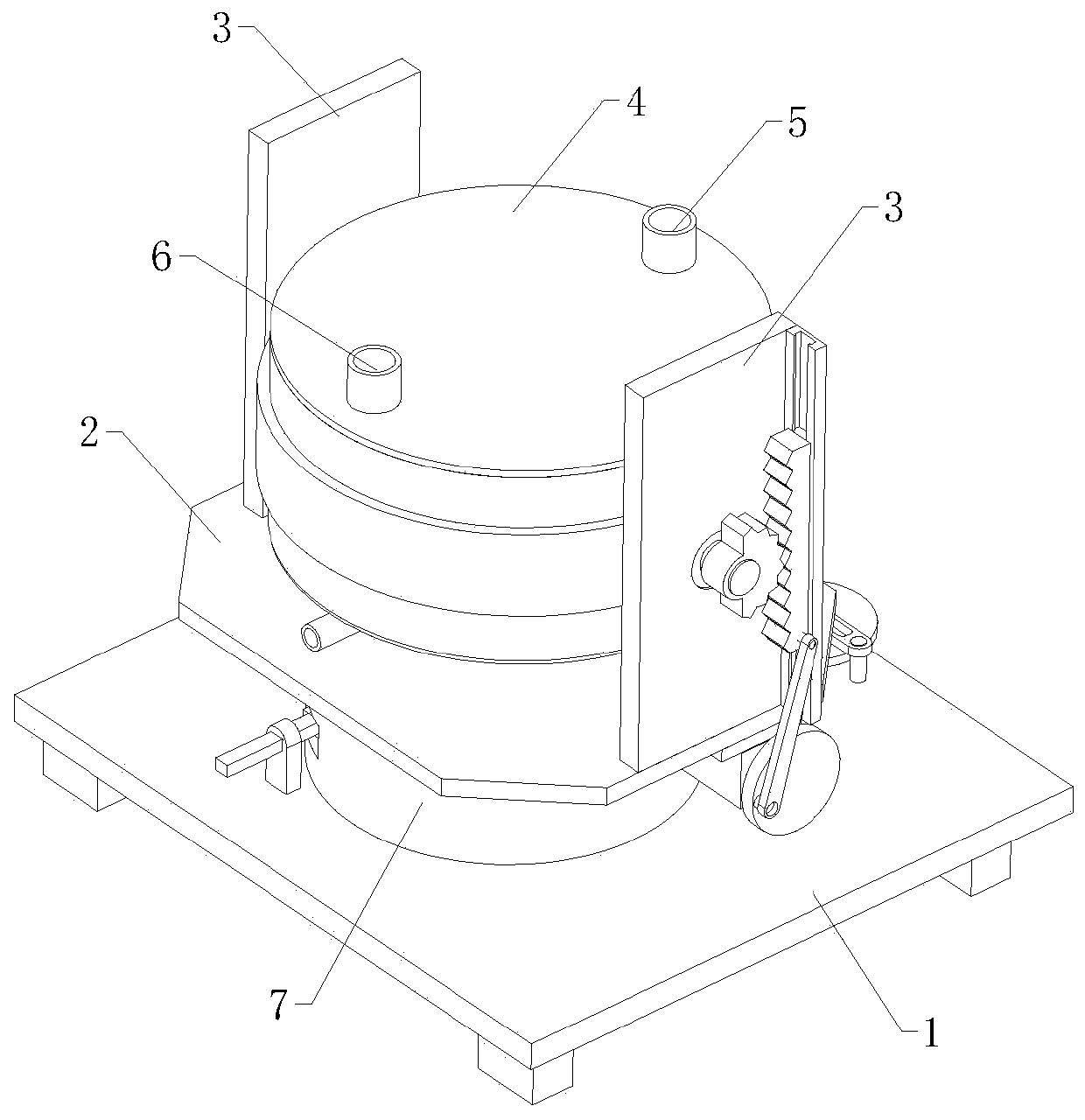

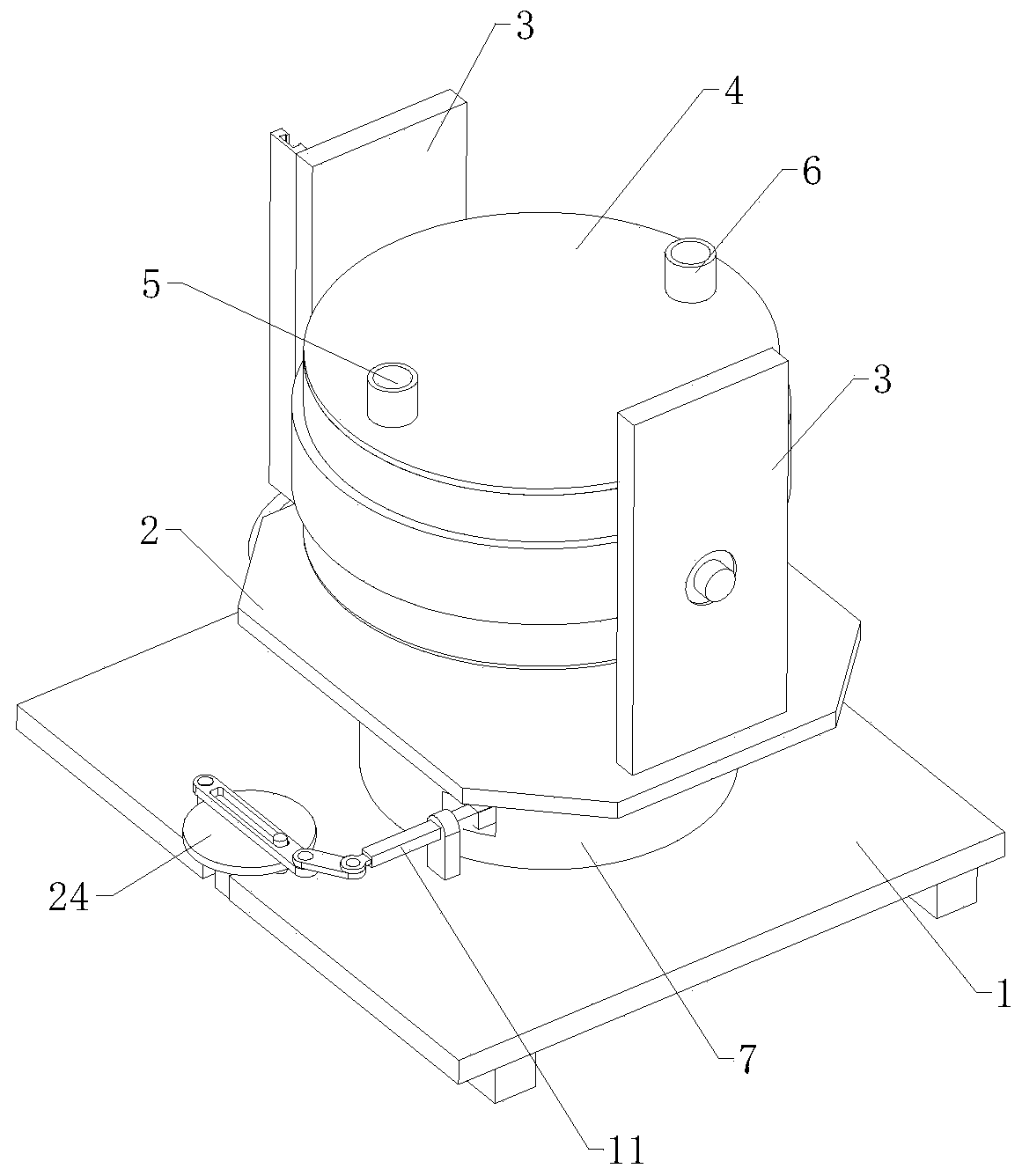

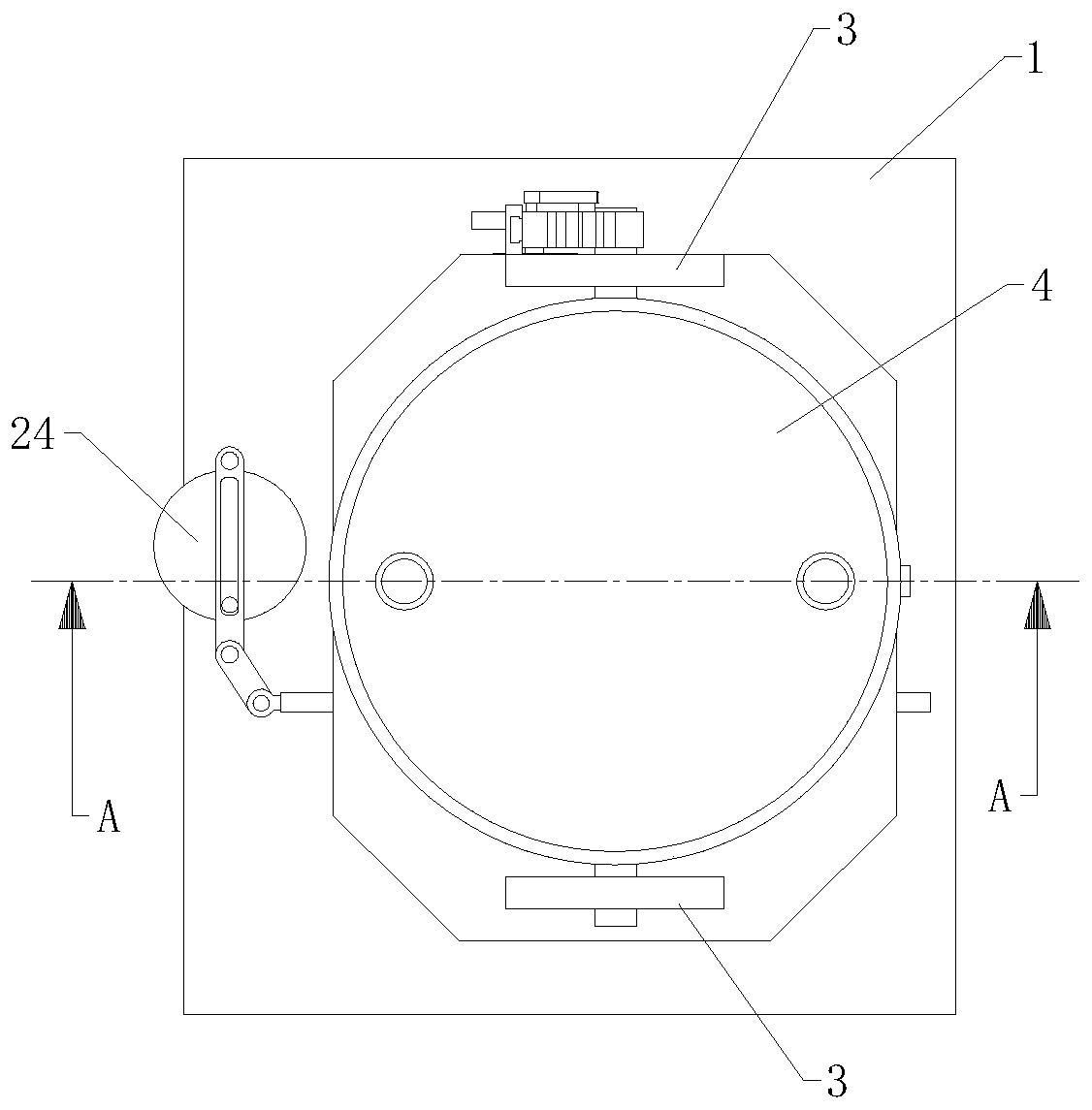

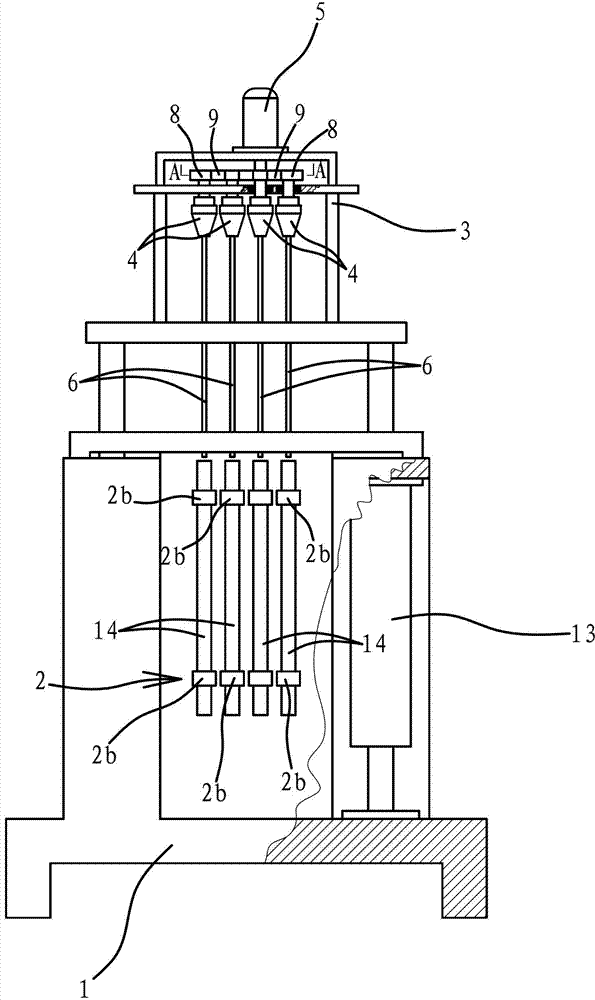

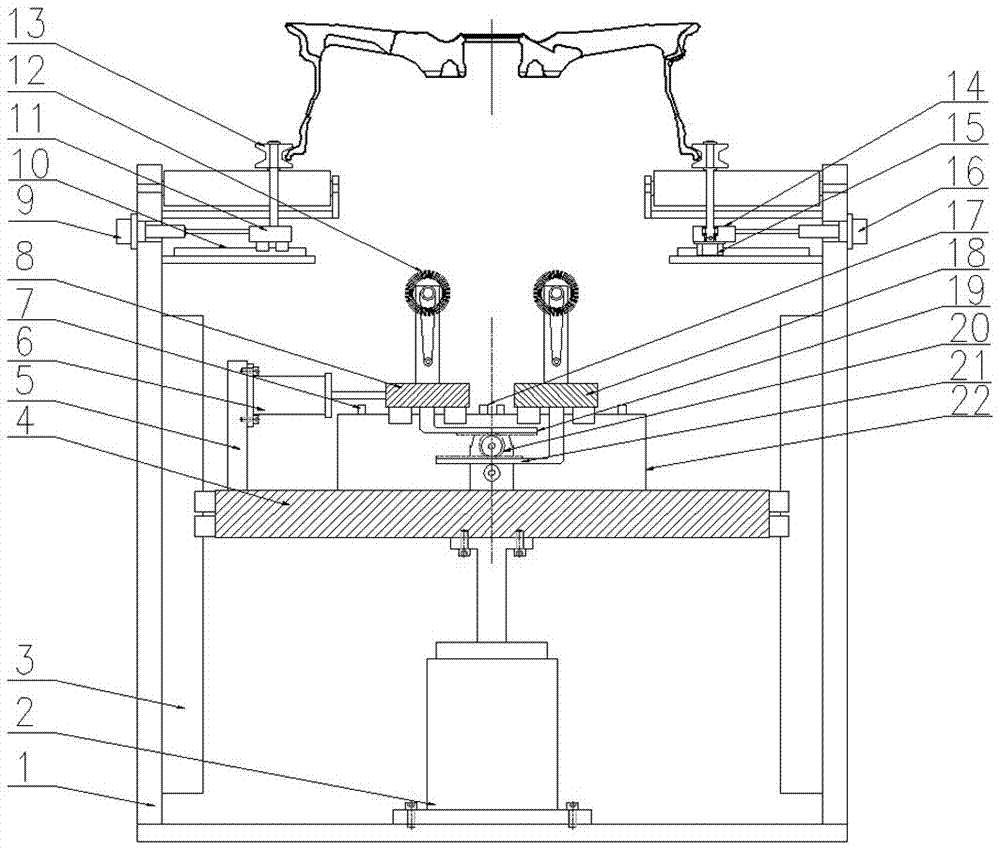

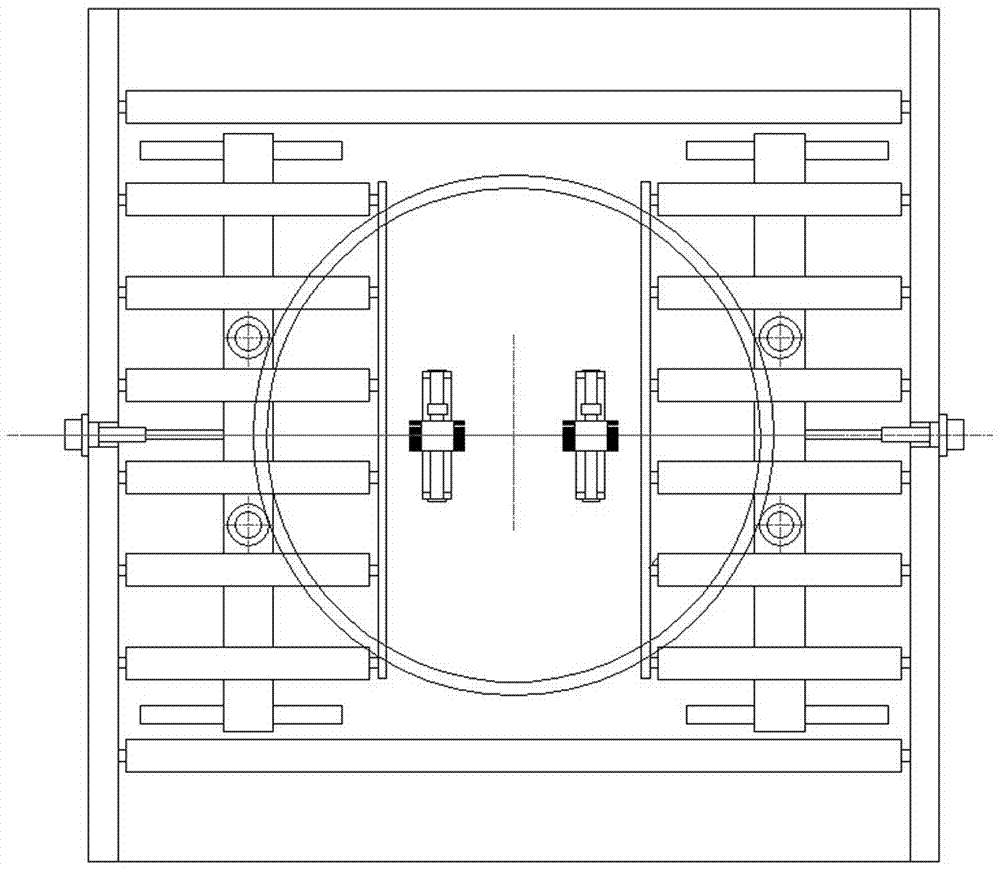

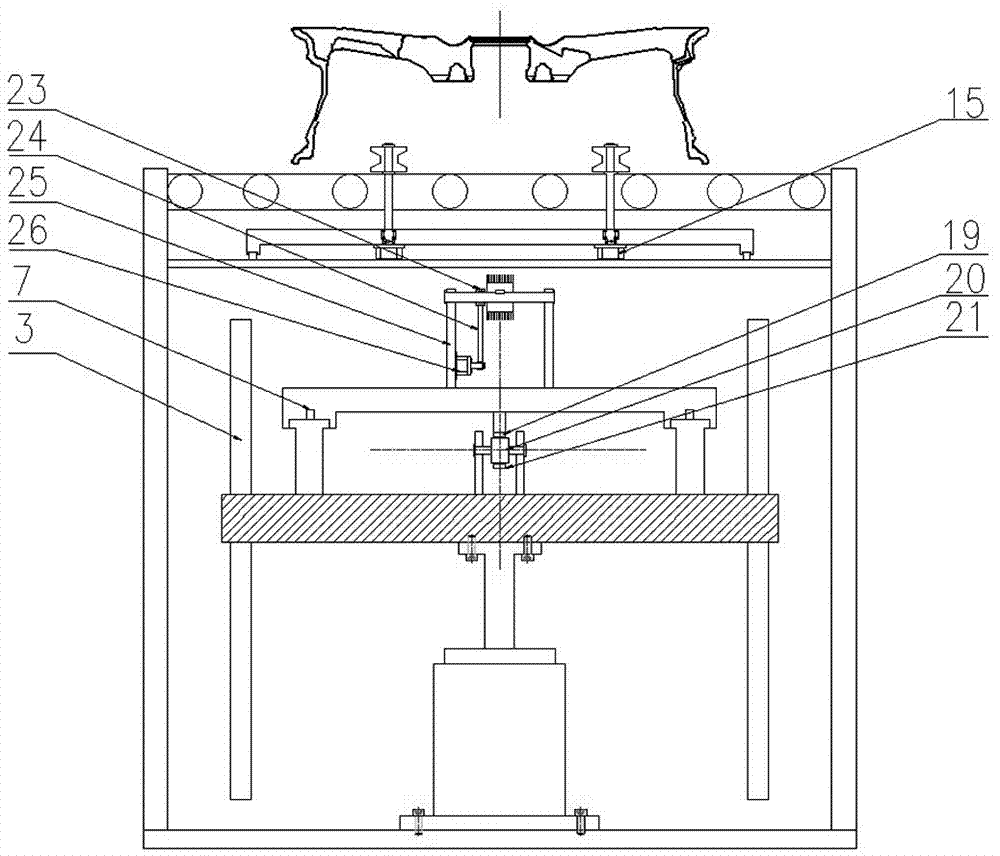

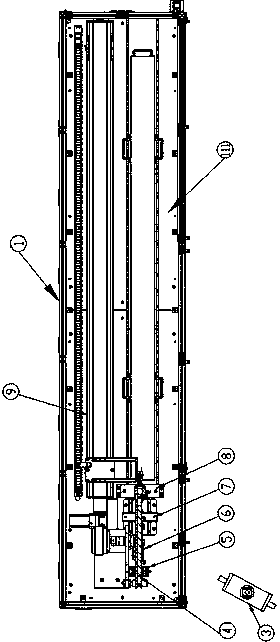

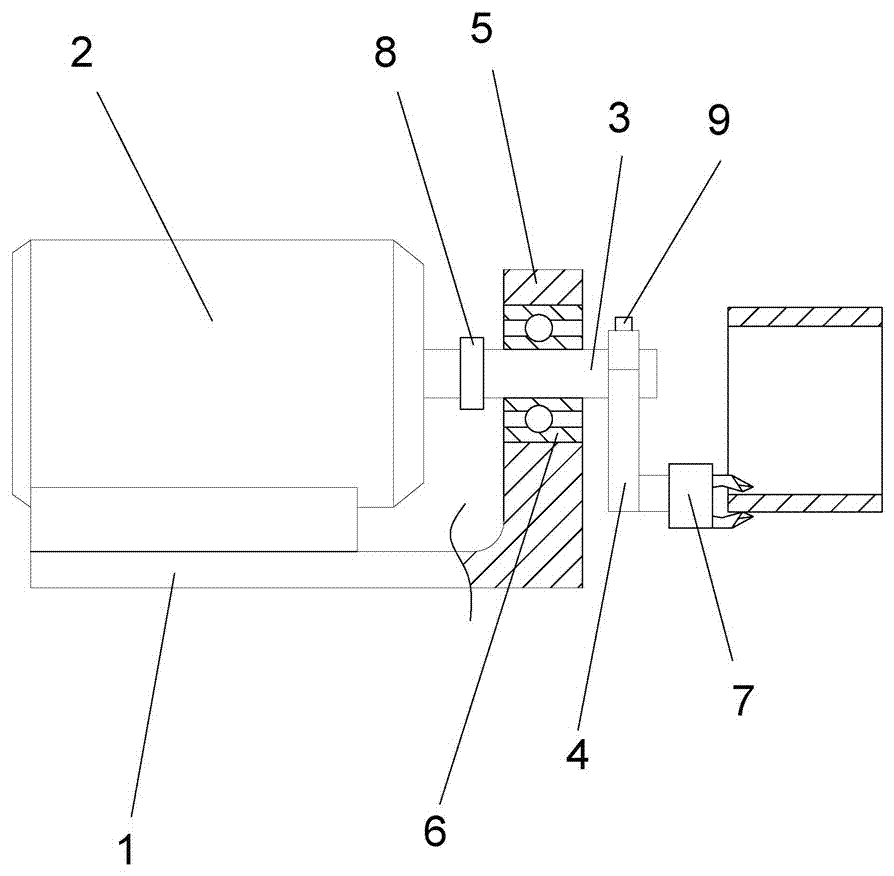

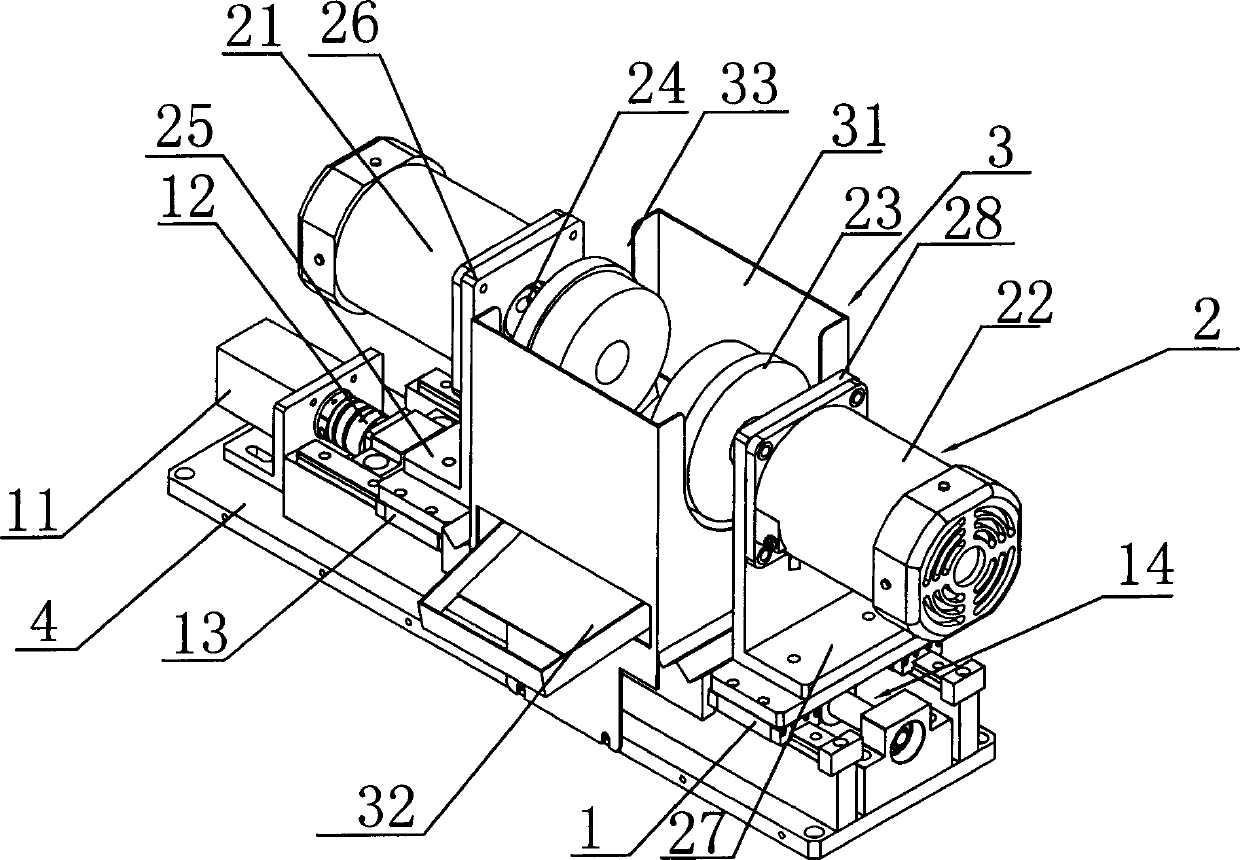

Rocker shaft bore-deburring machine

ActiveCN103028781AEasy to operateImprove efficiencyFeeding apparatusReaming devicesElectric machineryMechanical equipment

The invention provides a rocker shaft bore-deburring machine, which belongs to the technical field of mechanical equipment. The invention solves the problems of the conventional deburring method, i.e. low deburring efficiency and high cost. The rocker shaft bore-deburring machine comprises a base, clamping mechanisms which can clamp rocker shafts are arranged on the base, a tool holder is also arranged on the base, tool chucks and a motor capable of driving the tool chucks to rotate are axially and fixedly connected with the tool holder, one end of each tool chuck is fixedly connected with a tool, the tools are aligned with the bores of the rocker shafts when the rocker shafts are clamped by the clamping mechanism, the motor is connected with the other ends of the tool chucks in a transmission way, and a driving mechanism which can drive the tool holder to move to cause the tools to reciprocate in a manner relative to the rocker shafts is also arranged on the base. The rocker shaft bore-deburring machine has the advantages of high machining efficiency, high stability and the like.

Owner:ZHEJIANG QIANGNENG MOTIVITY

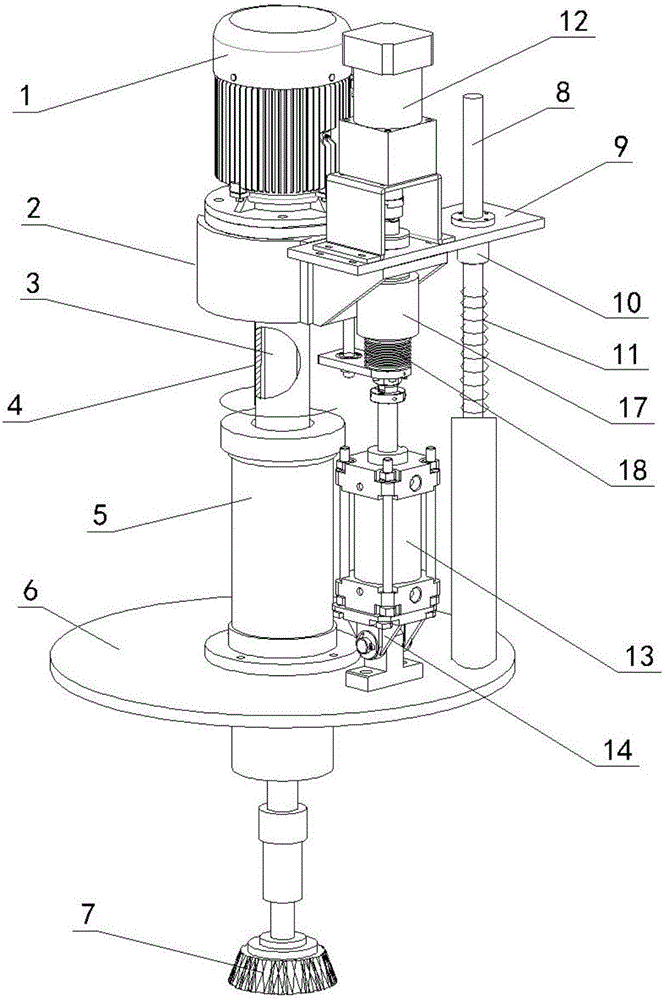

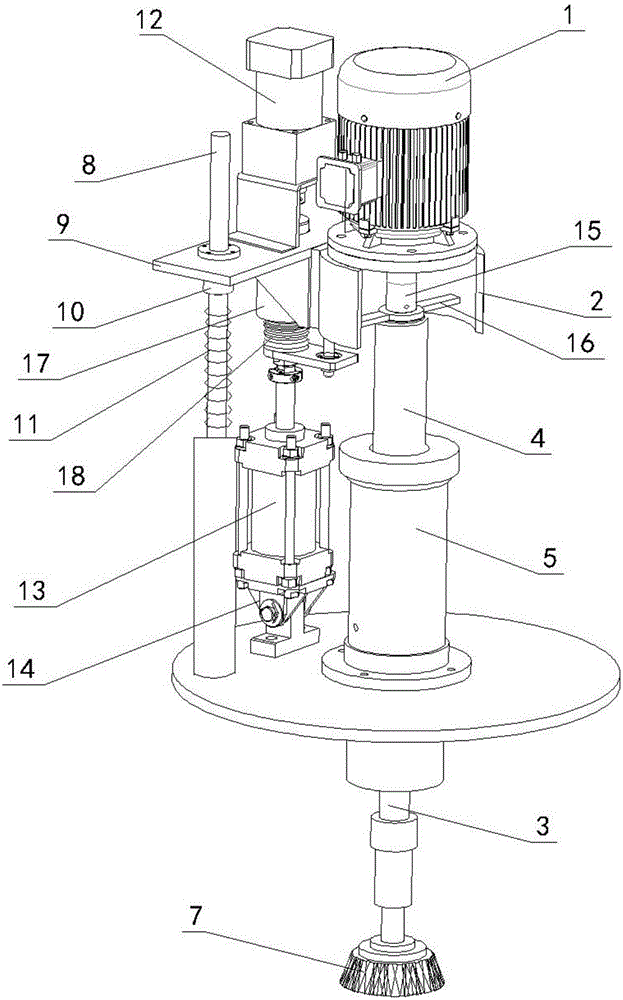

Automatic deburring device capable of realizing compensation

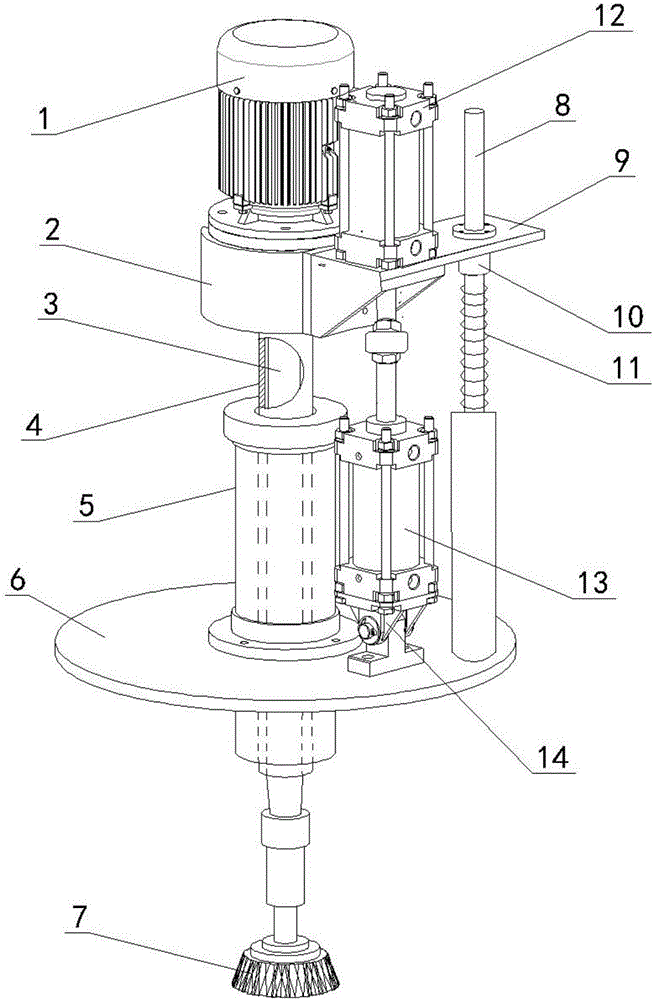

ActiveCN106695485ARealize automatic deburring functionGuaranteed smoothnessEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses an automatic deburring device capable of realizing compensation. The automatic deburring device capable of realizing compensation is characterized in that the output shaft of a motor is vertically downward; a rotating shaft fixedly connected with the output shaft of the motor penetrates through a fixed guide base; a hairbrush which rotates along with the rotating shaft is mounted at the shaft end of the bottom of the rotating shaft; the fixed guide base is mounted on a horizontal base plate; a hollow guide shaft fixedly connected with a motor mounting base is arranged between the rotating shaft and the fixed guide base; the rotating shaft can rotate in the hollow guide shaft; the hollow guide shaft can move up and down along the fixed guide base; a lifting guide base is horizontally arranged on the motor mounting base in an overhanging manner; a lifting cylinder is mounted on the lifting guide base; a compensation cylinder is mounted on the base plate; the lifting cylinder and the compensation cylinder in the coaxial position are fixedly connected, and the ends of a piston rod of the lifting cylinder and the ends of a piston rod of the compensation cylinder are opposite; the motor is driven by the lifting cylinder to vertically rise and fall; and the wearing capacity of the hairbrush is compensated by the compensation cylinder. The automatic deburring device capable of realizing compensation disclosed by the invention is used for performing deburring treatment on the surface of a workpiece, has a compensation function, and can prolong the service life of the hairbrush.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

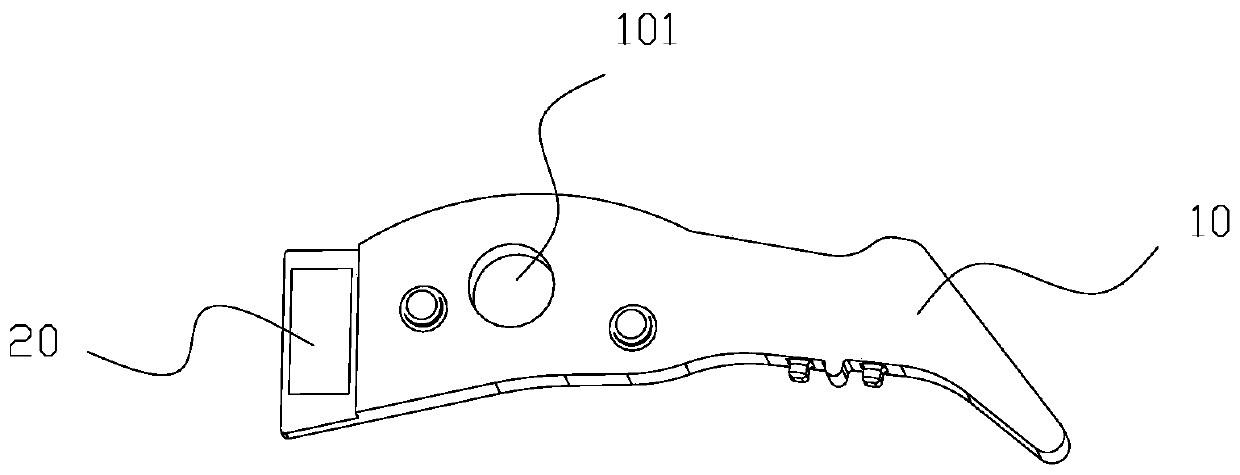

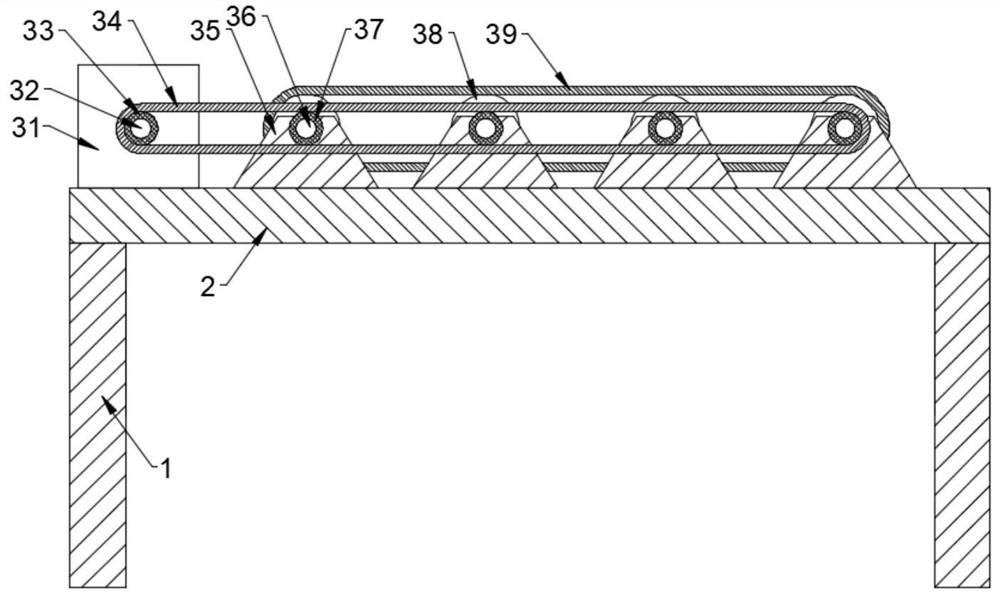

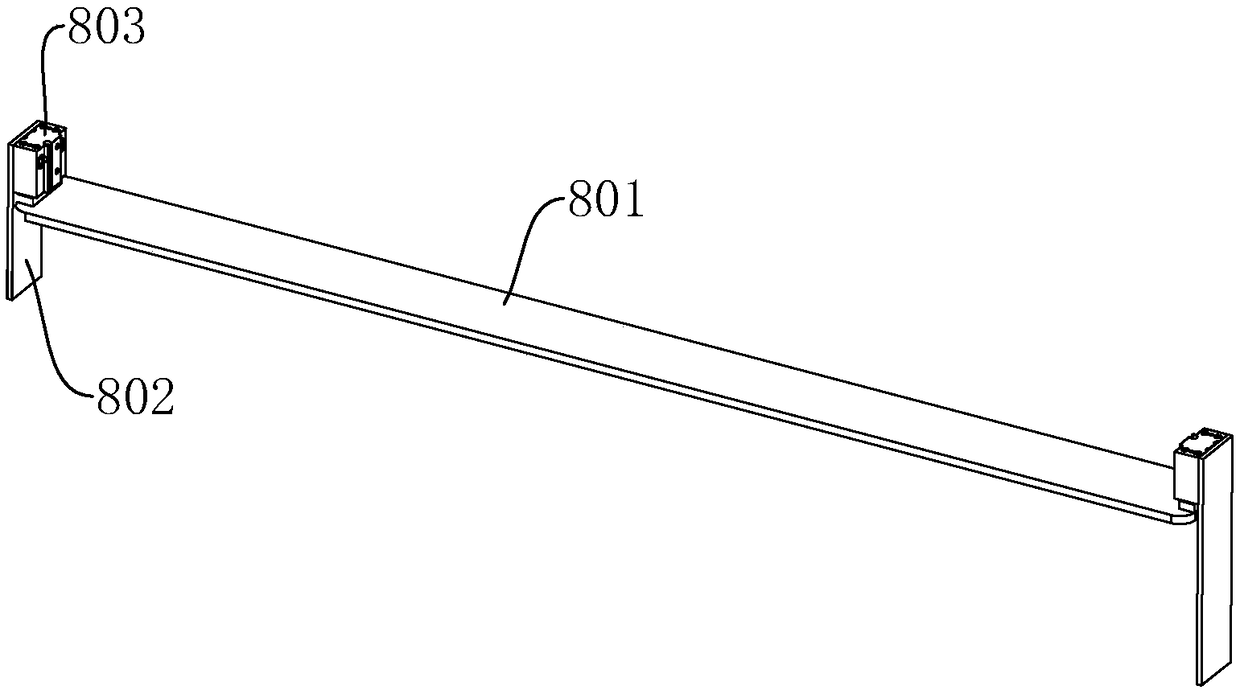

Contact synchronous belt conveying device of circuit breaker assembling equipment and method

InactiveCN111360311AEasy to fixSave spaceShearing machinesCleaning using toolsDrive shaftElectric machinery

The present invention relates to the technical field of circuit breaker production, and discloses a contact synchronous belt conveying device of circuit breaker assembling equipment and a method. Thecontact synchronous belt conveying device of the circuit breaker assembling equipment comprises a synchronous belt support, a synchronous belt motor, a synchronous belt driving shaft and a synchronousbelt driven shaft. The contact synchronous belt conveying device of the circuit breaker assembling equipment and the method have the advantages of improving the conveying efficiency of the synchronous belt, saving equipment space and improving the overall processing efficiency.

Owner:丁水珍

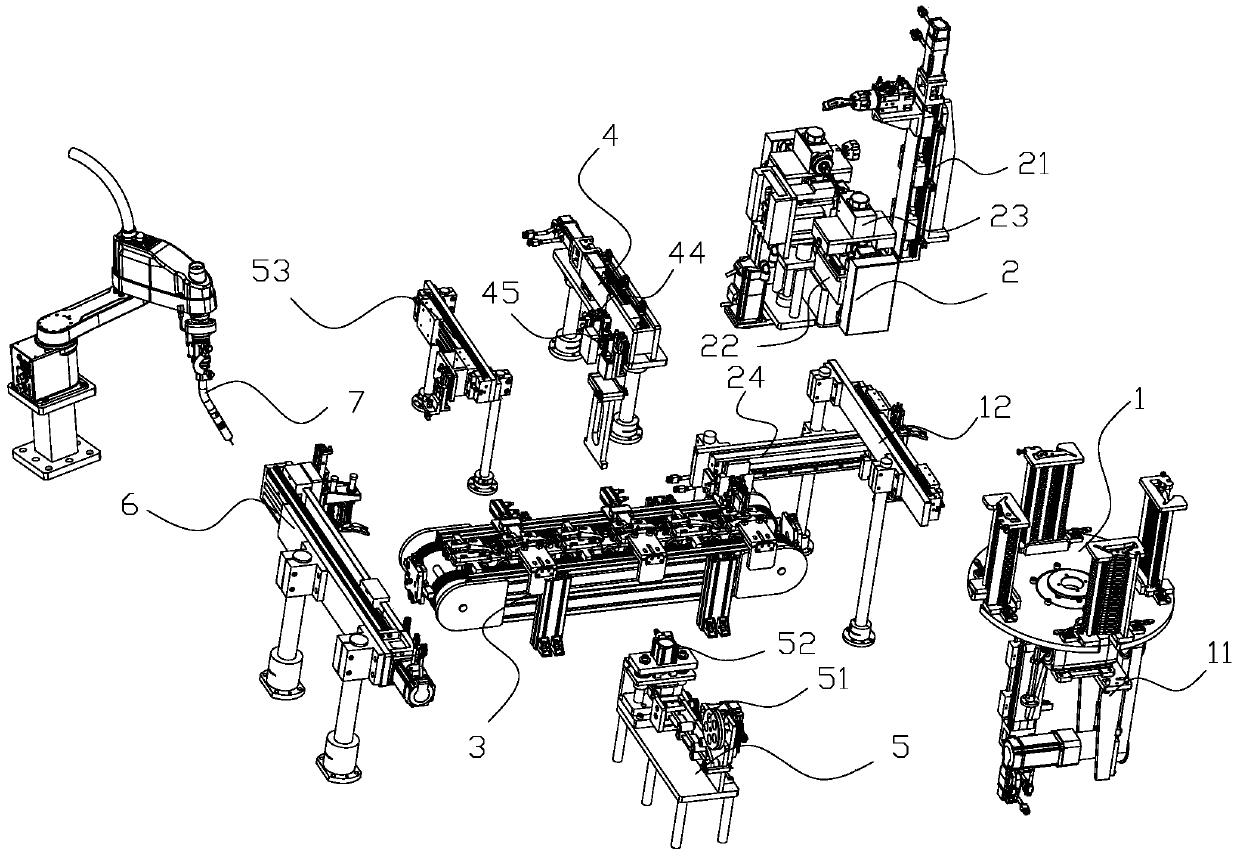

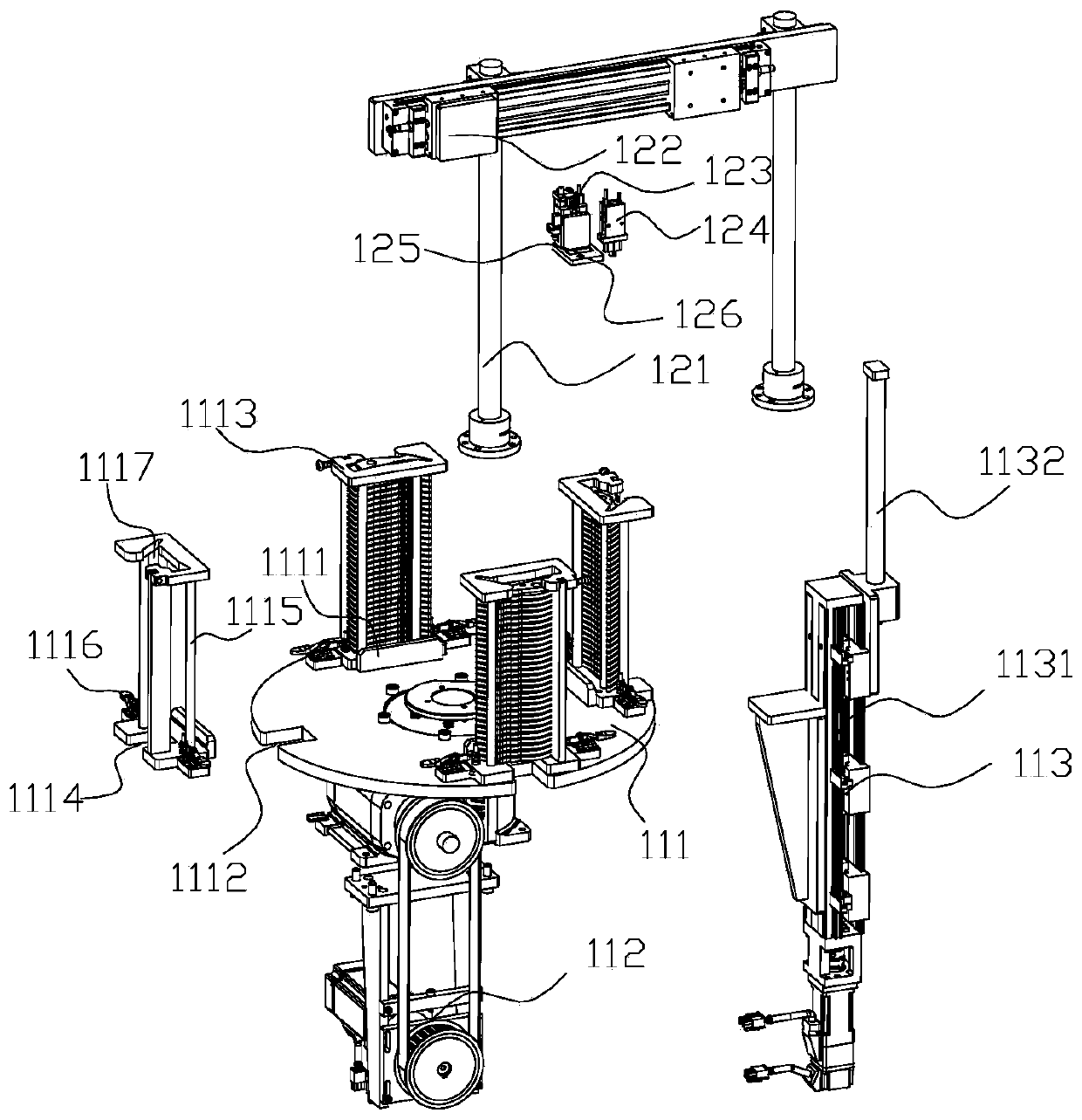

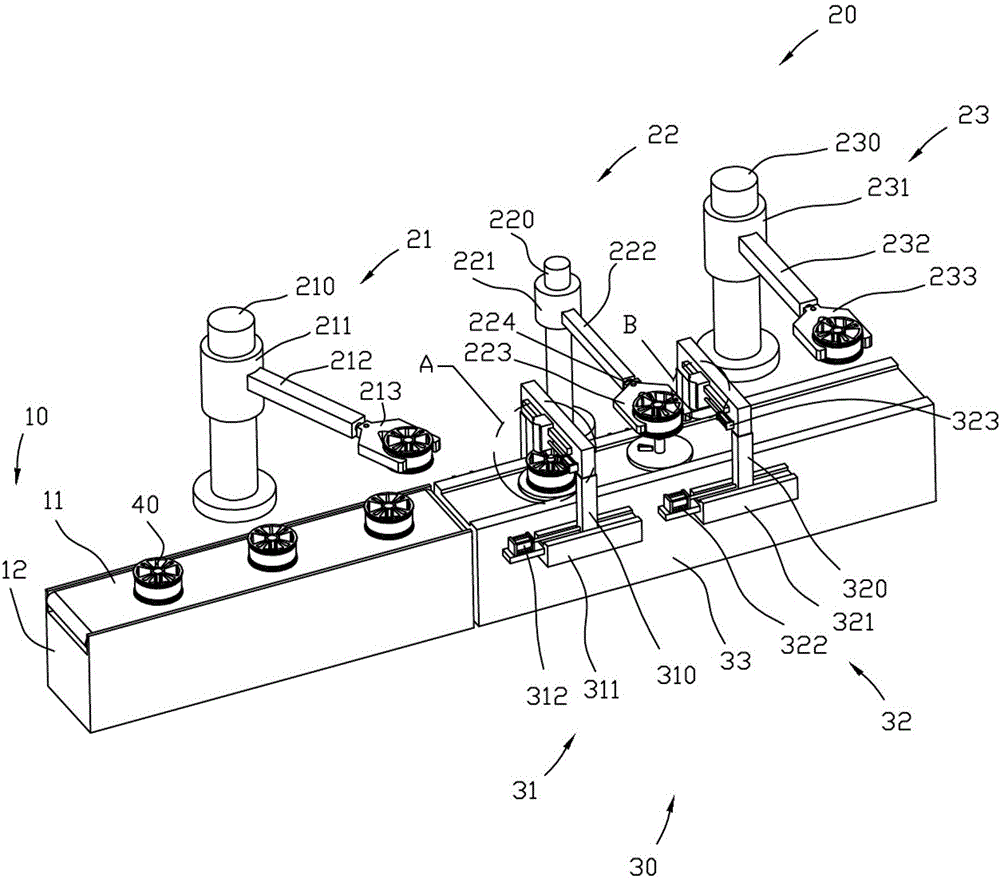

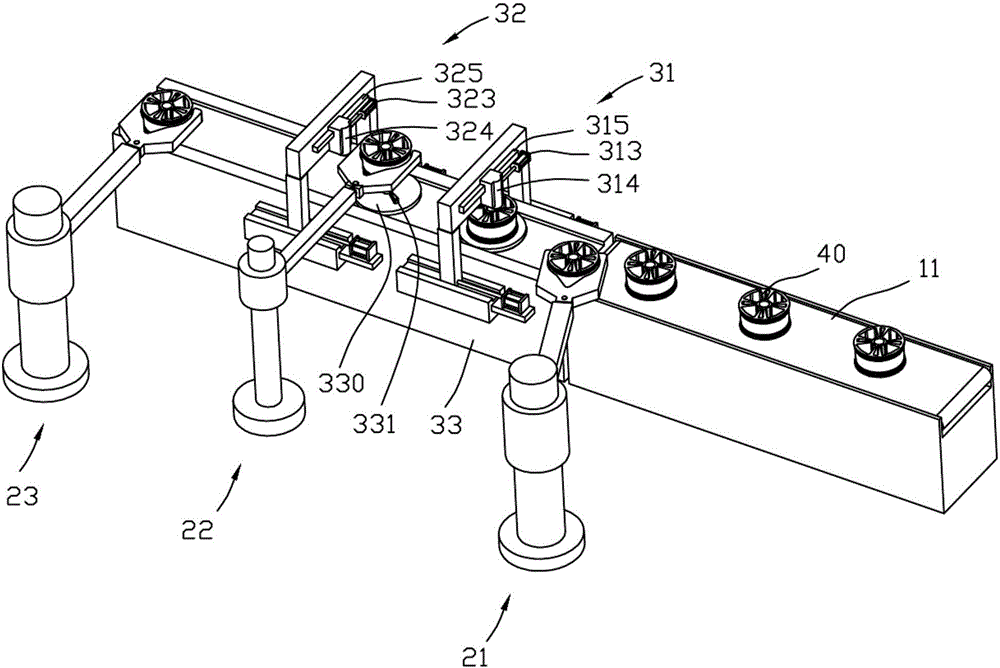

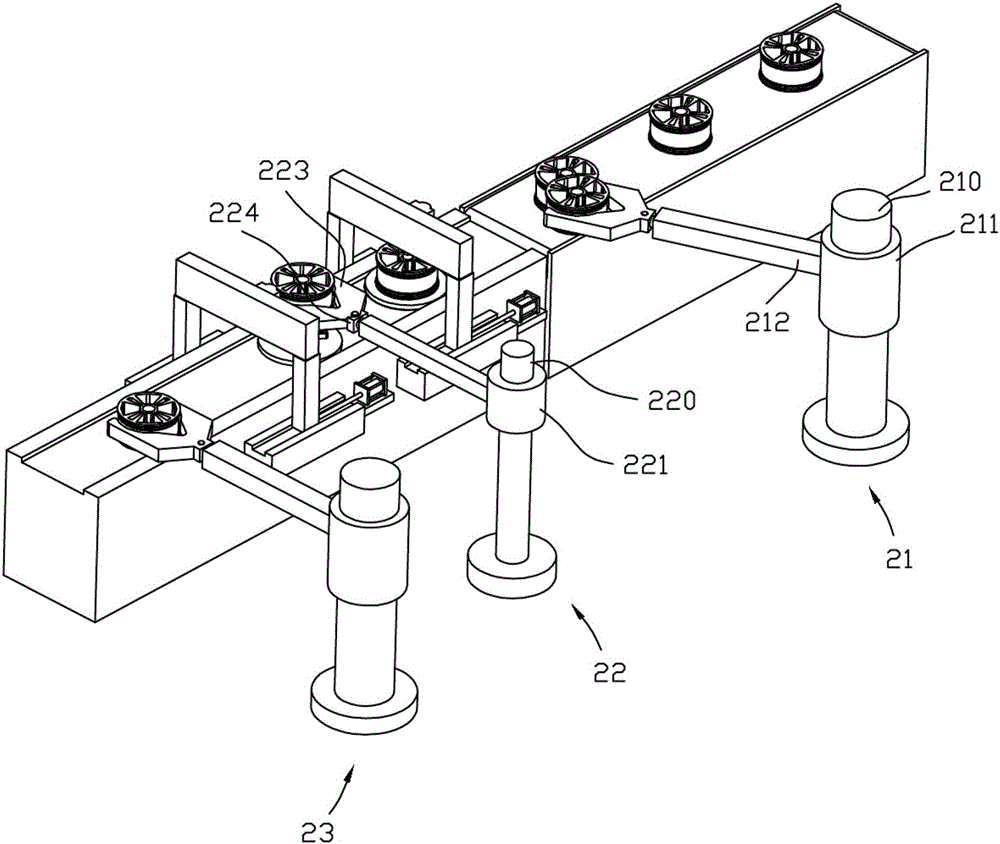

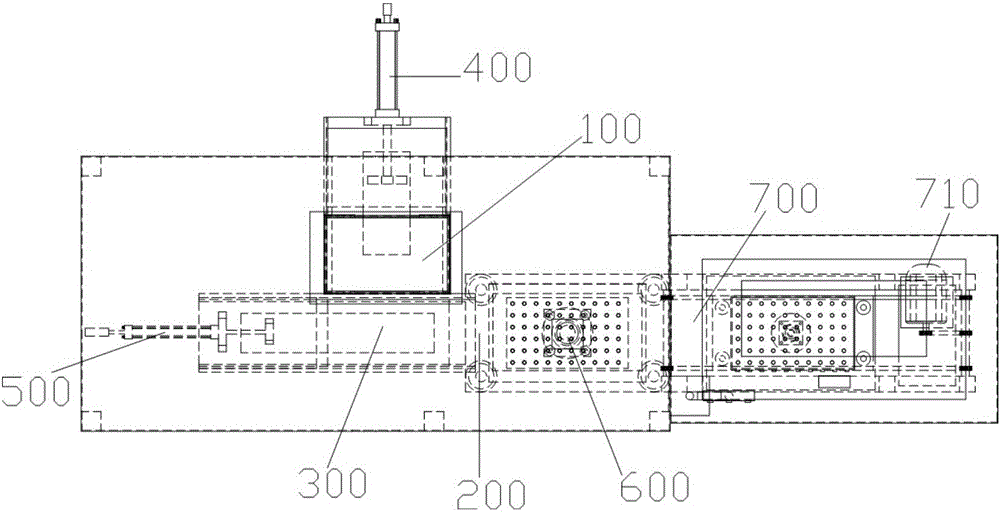

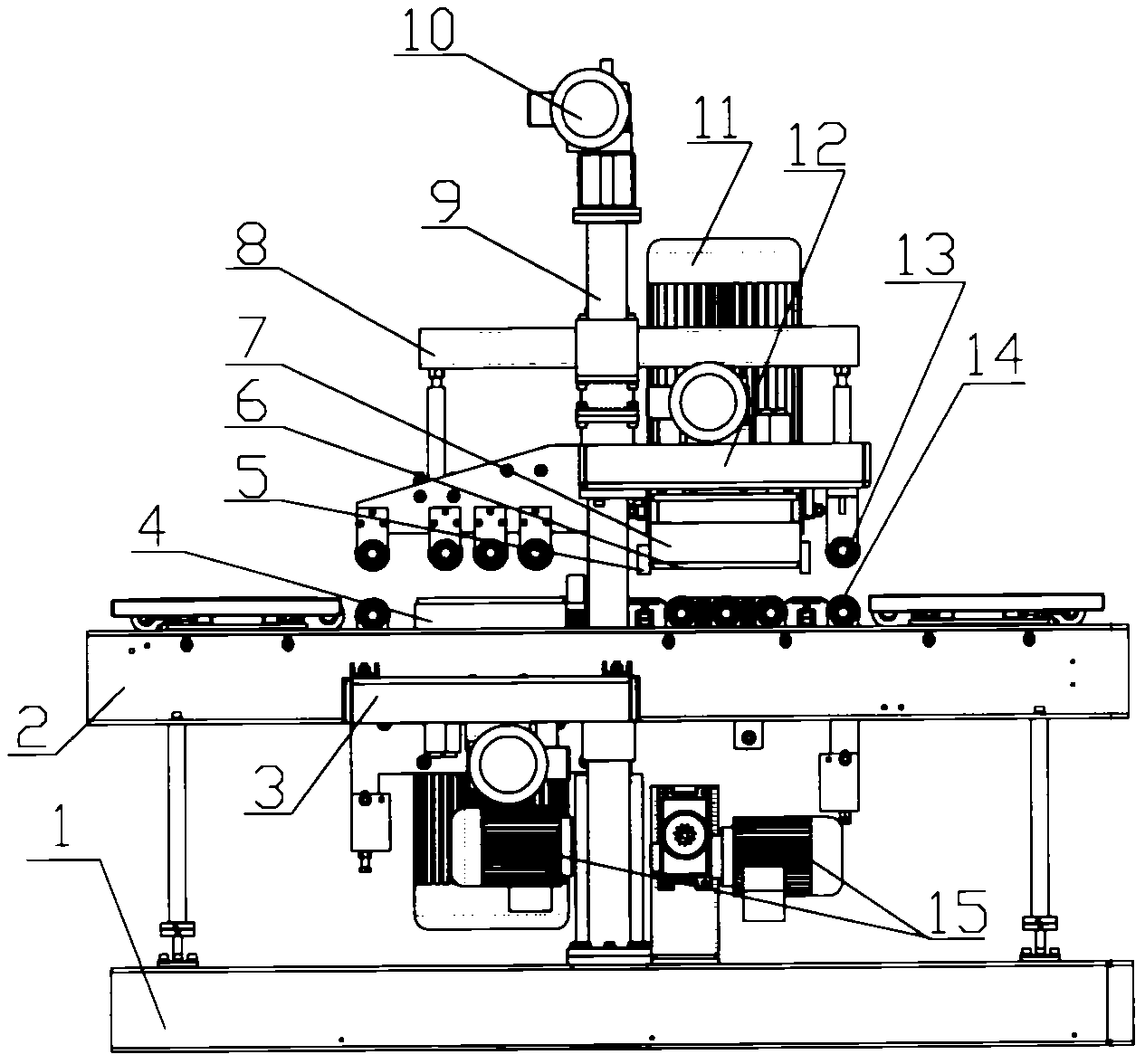

Vehicle hub aftertreatment equipment

ActiveCN106217163AEasy to polishImprove deburring efficiencyEdge grinding machinesGrinding feedersEngineeringManipulator

The invention discloses vehicle hub aftertreatment equipment. The vehicle hub aftertreatment equipment comprises a conveying module, a manipulator module and a polishing module; the conveying module includes a conveying belt and a conveying base; the conveying belt is positioned above the conveying base; the manipulator module includes a first manipulator, a second manipulator and a third manipulator, wherein the second manipulator is provided with an overturning module; the polishing module includes a polishing platform, a upstream polishing module and a downstream polishing module; the upstream polishing module and the downstream polishing module respectively include first polishers and second polishers; and first polishing tools and second polishing tools are respectively mounted below the first polishers and the second polishers, and can move in the horizontal direction. The vehicle hub aftertreatment equipment optimizes the problem of traditional hub burr removing equipment incapable of polishing two end surfaces, adds an overturning function of the second manipulator for preferably polishing two surfaces of hubs, and is high in burr removing efficiency.

Owner:湖南省品源机械制造有限公司

Deburring device applied to automobile exhaust pipes

The invention discloses a deburring device applied to automobile exhaust pipes. The deburring device comprises an installation frame, a motor, an output shaft, a driving gear, an inner gear, a rotary gear and a shaping cutter, wherein the motor is arranged on the installation frame, the output shaft is connected with the motor, the driving gear is arranged on the output shaft, the inner gear is fixed to the installation frame and shares the same axis with the driving gear, the rotary gear is meshed with outer teeth of the driving gear and inner teeth of the inner gear, and the shaping cutter is coaxially connected with the rotary gear, can shape pipe openings of the exhaust pipes and can perform deburring on outer walls and inner walls of the exhaust pipes at the same time. The deburring device disclosed by the invention can shape the pipe openings of the exhaust pipes and perform deburring on the outer walls and the inner walls of the exhaust pipes at the same time, so that the pipe openings are round and neat, used time is small, and deburring efficiency is high.

Owner:浙江新诚汽车部件有限公司

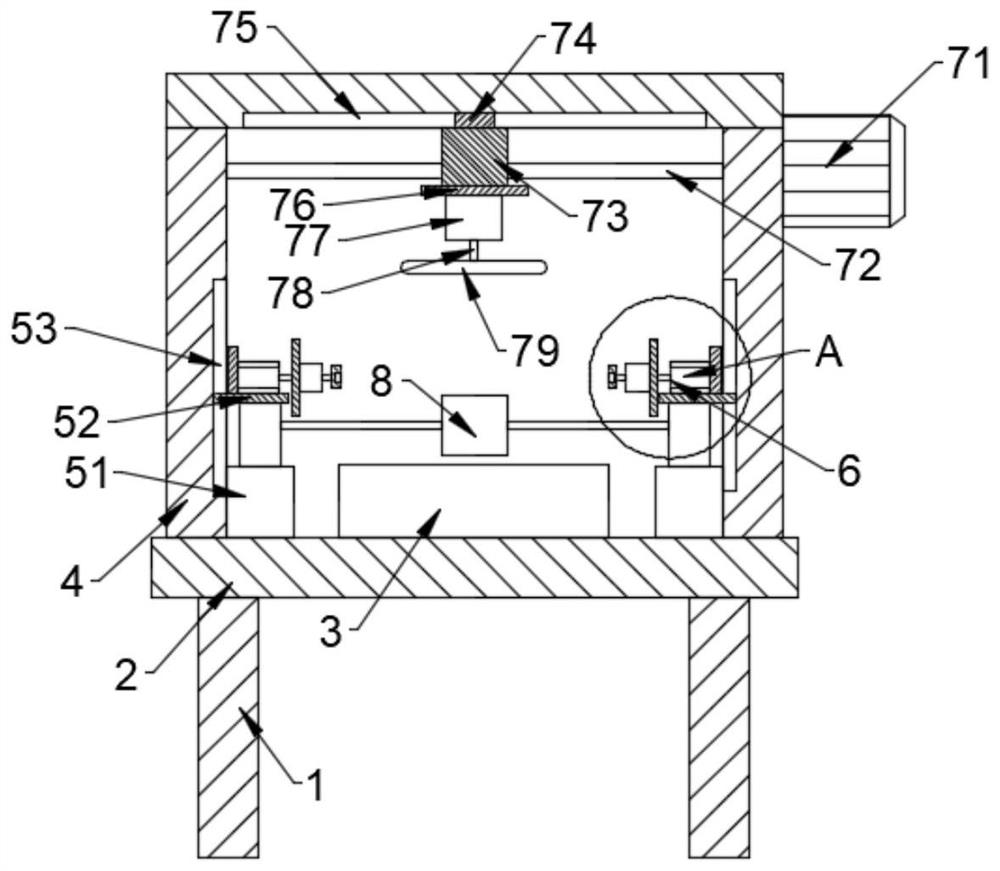

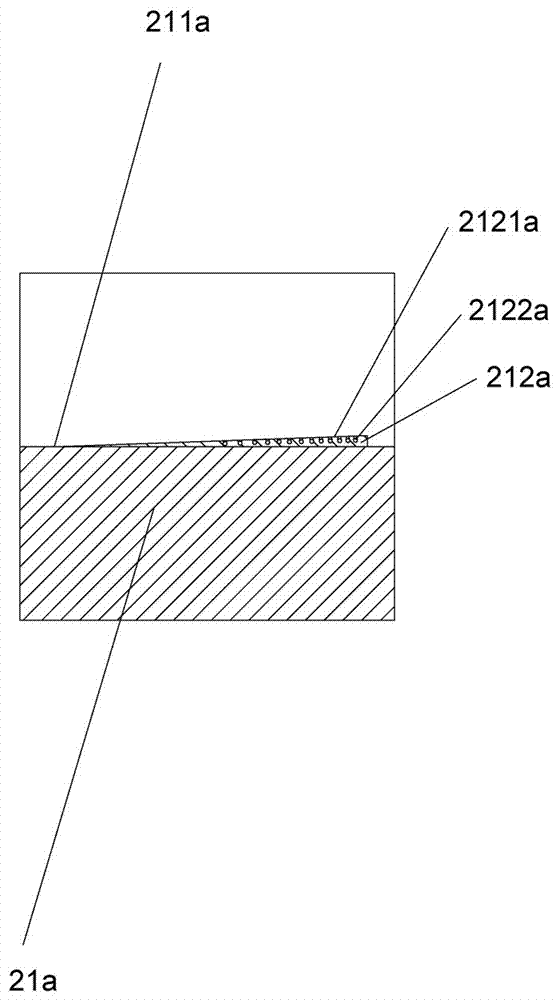

Automatic polypropylene (PP) board punching machine and PP board processing method

ActiveCN106078899AImprove processing efficiencyImprove deburring efficiencyMetal working apparatusPunchingEngineering

The invention discloses an automatic polypropylene (PP) board punching machine and a PP board processing method. The automatic PP board punching machine comprises a machine frame, a semi-finished product storage cabin, a base plate, a semi-finished PP board supporting platform, a longitudinal air cylinder, a transverse air cylinder, a punching assembly, a conveying belt and a deburring assembly, wherein the semi-finished product storage cabin, the base plate and the semi-finished PP board supporting platform are arranged on the machine frame; the longitudinal air cylinder is arranged on the machine frame and used for pushing a to-be-punched semi-finished PP board on the bottommost layer of the semi-finished product storage cabin onto the semi-finished PP board supporting platform; the transverse air cylinder is arranged on the machine frame, perpendicular to the longitudinal air cylinder and used for pushing the to-be-punched semi-finished PP board on the semi-finished PP board supporting platform onto the base plate; the punching assembly is arranged over the base plate; the conveying belt is arranged on the side, close to the base plate, of the machine frame; and the deburring assembly is arranged under a specific processing position of the conveying belt. According to the automatic PP board punching machine, burrs in all through holes in the PP board are removed through hot melting of the deburring assembly, manual removal of the burrs on by one is not needed, the deburring efficiency is improved, and the PP board processing efficiency is improved.

Owner:深圳市赛柏敦自动化设备有限公司

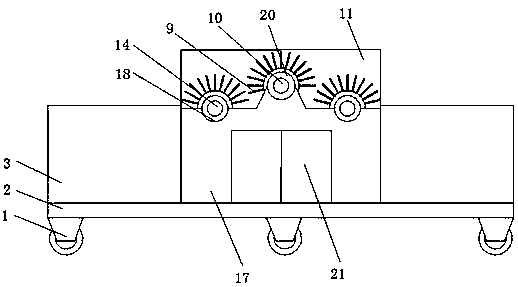

Deburring device having waste material collection function and applied to production of bamboo summer sleeping mat

InactiveCN108789017AEasy to useImprove efficiencyEdge grinding machinesGrinding wheel securing apparatusEngineeringFiber

The invention discloses a deburring device having a waste material collection function and applied to production of a bamboo summer sleeping mat. The deburring device comprises a pedestal; the two sides of the top of the pedestal are each connected with a box body through a bolt; between the inner walls of the two sides of the two box bodies are each connected with a conveying roller through a bearing; the same conveying belt is connected between the two conveying rollers which are positioned inside the same box body in a sleeving manner; the middle part of one end of the top of the pedestal is connected with a supporting plate through a bolt; and the top of one side of the supporting plate is connected with a first rotating shaft through a bearing. According to the deburring device disclosed by the invention, a triangular structure is formed among a first deburring roller brush and two second deburring roller brushes; the burrs at the double surfaces of the bamboo summer sleeping matcan be removed at a time simultaneously; the deburring device is simple and convenient to use, needs not to be brushed manually, remarkably improves the deburring efficiency in the production of the bamboo sleeping mat, has the waste material collection function, prevents removed burrs and burr fibers from escaping in air and protects the working environment of a worker.

Owner:安吉登冠竹木开发有限公司

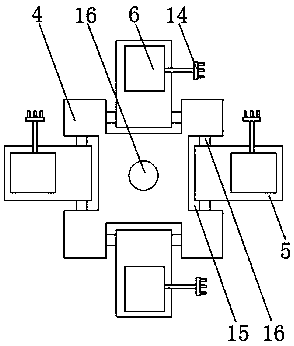

Wheel flange brush burr device

InactiveCN107297655AImprove deburring effectImprove deburring efficiencyEdge grinding machinesPolishing machinesTransmission beltElectric machine

A wheel flange brush burr device is composed of clamp roller motors, a right clamp cylinder, an inner stroke switch, a right feed slide, an upper rack, a gear, a lower rack, a feeding guide rail, a belt pulley, a transmission belt, a rotating-shaft support, a servo motor and the like. After materials are supplied, a left clamp cylinder and the right clamp cylinder move synchronously to have a wheel clamped; the clamp roller motors are started to drive the wheel to rotate; a lifting cylinder is started to pull a lifting platform to move upwards, meanwhile, a feeding cylinder is started to drive a left feed slide and the right feed slide to move back and forth, and the servo motor is started to drive a burr brush to move circularly and reversely; the lifting cylinder stops moving when the burr brush contacts the flange surface, the burr brush starts to brush burrs, the lifting cylinder contracts after the burrs are brushed, a lifting platform moves downwards to be reset, the wheel is released from the clamp roller motors, the wheel is transfer to the next process through a roller bed, another wheel with burrs to be brushed is received, and so on.

Owner:CITIC DICASTAL

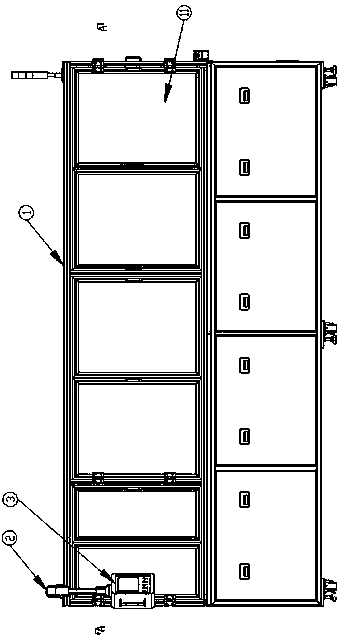

Full-automatic efficient cutting machine for bus bar

PendingCN108274241APrevent slippingAvoid offsetOther manufacturing equipments/toolsEngineeringMechanical engineering

A full-automatic efficient cutting machine for a bus bar is characterized in that the full-automatic efficient cutting machine comprises a square cutting machine shell; a controller support is arranged on the top of the cutting machine shell; one end of the controller support is fixed to the top of the cutting machine shell, and a controller is fixed to the bottom of the other end of the controller support and is a PLC; and an operation room is arranged on the upper portion of the cutting machine shell, and a discharging assembly, a deburring mechanism, a straightening mechanism, a compressionfeeding mechanism, a cutting mechanism and a traction mechanism are sequentially arranged on a bottom plate of the operation room from left to right. Using of manual work is avoided, labor force is liberated, the time and labor are saved in operation, and the requirement of enterprises for large-scale mechanical production is met conveniently.

Owner:苏州市中辰昊科技有限公司

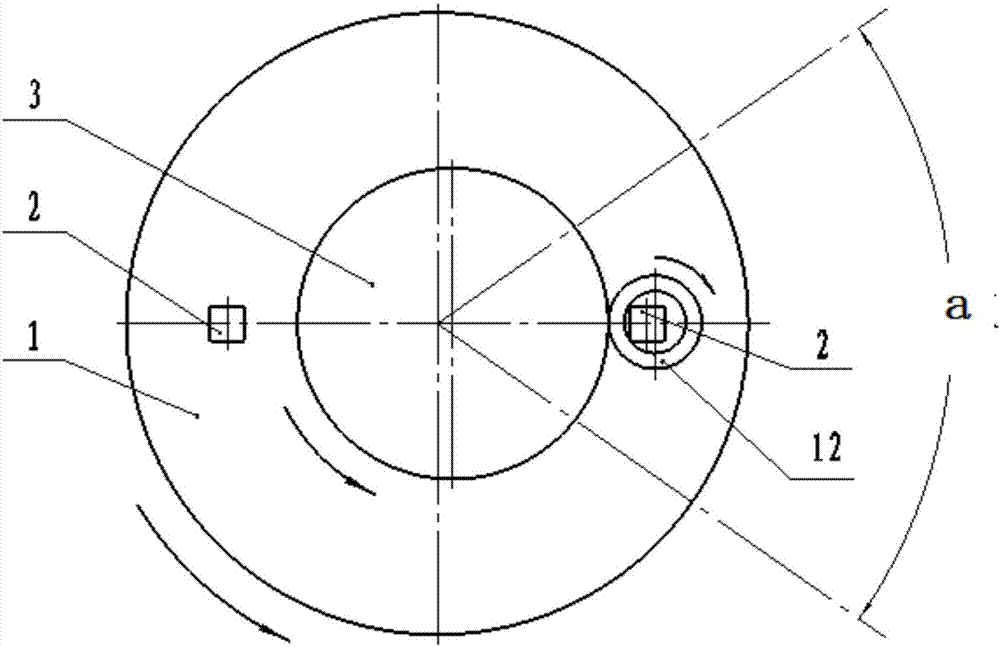

Circular pipe-shaped workpiece inner hole orifice deburring machine

The invention discloses a circular pipe-shaped workpiece inner hole orifice deburring machine which comprises a rack, wherein a hollow short shaft is fixedly mounted on the rack; the hollow short shaft is fixedly connected with a circular working table having the functions of a belt pulley; a stepped long shaft is mounted in the inner hole gap of the hollow short shaft; an eccentric driving wheel and a first belt pulley are mounted on the stepped long shaft; two deburring scraping knives are mounted on the circular working table having the functions of the belt pulley in the diameter direction; the first belt pulley is connected with a second belt pulley through a first driving belt; the circular working table having the functions of the belt pulley is connected with a third belt pulley through a second driving belt; a motor drive power input shaft is mounted on the second belt pulley and the third belt pulley; the motor drive power input shaft is connected with a motor. The circular pipe-shaped workpiece inner hole orifice deburring machine has the benefits that the structure is simple, the cost is low, the operation is convenient, burrs can be efficiently removed without causing any damage to the hole wall, and meanwhile the inner hole orifice chamfering can also be realized through simple adjustment.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

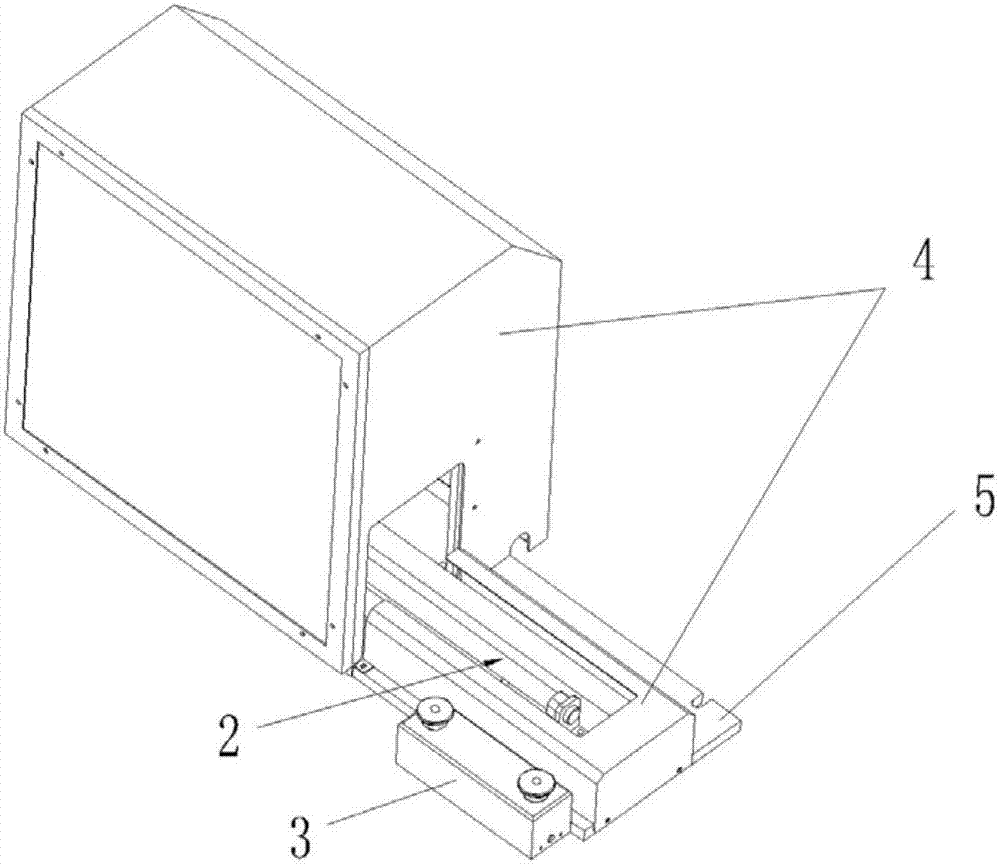

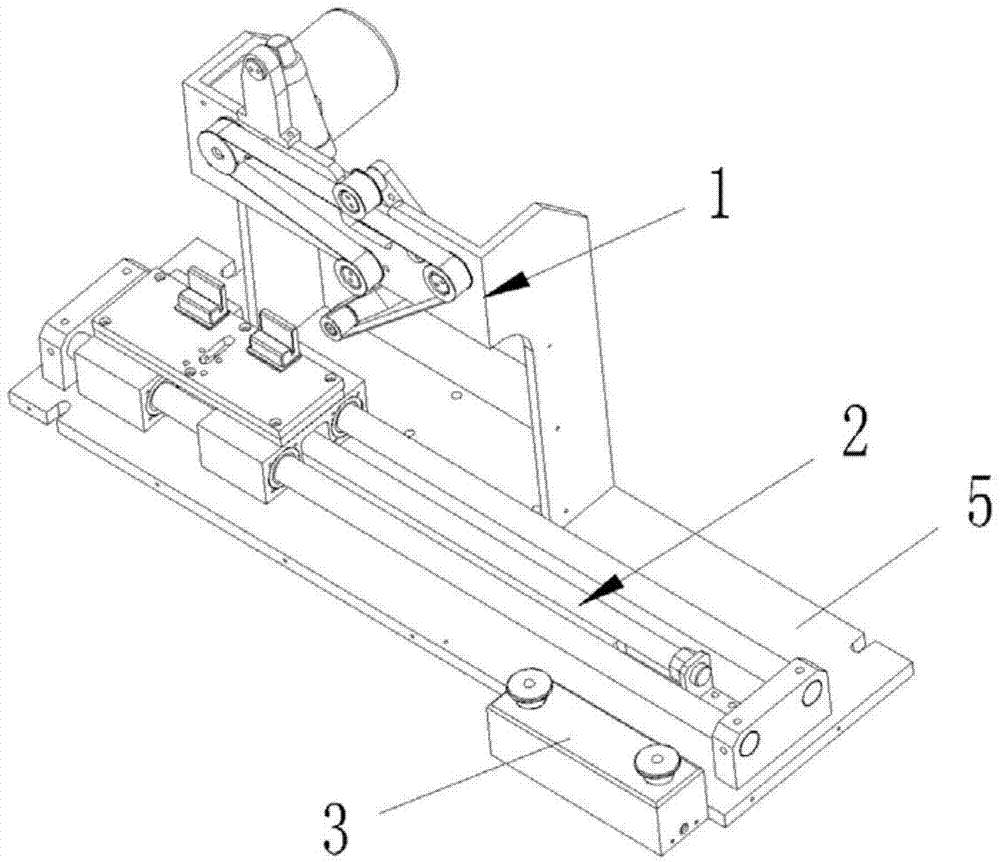

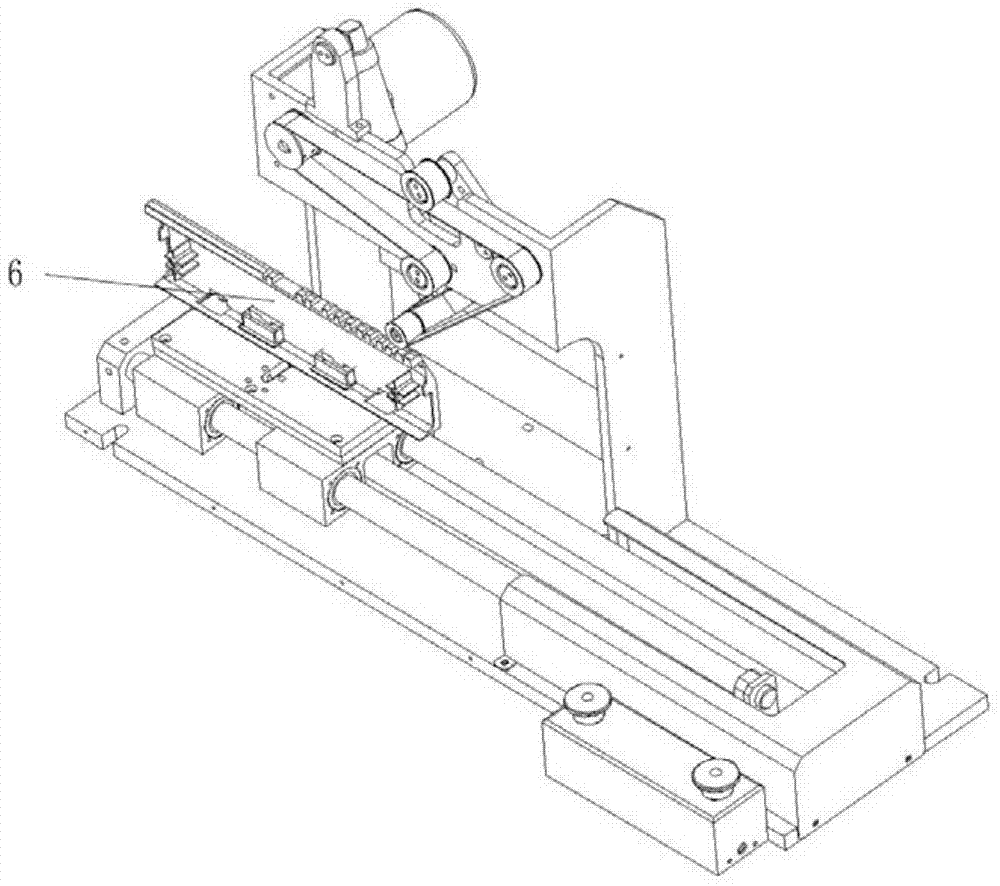

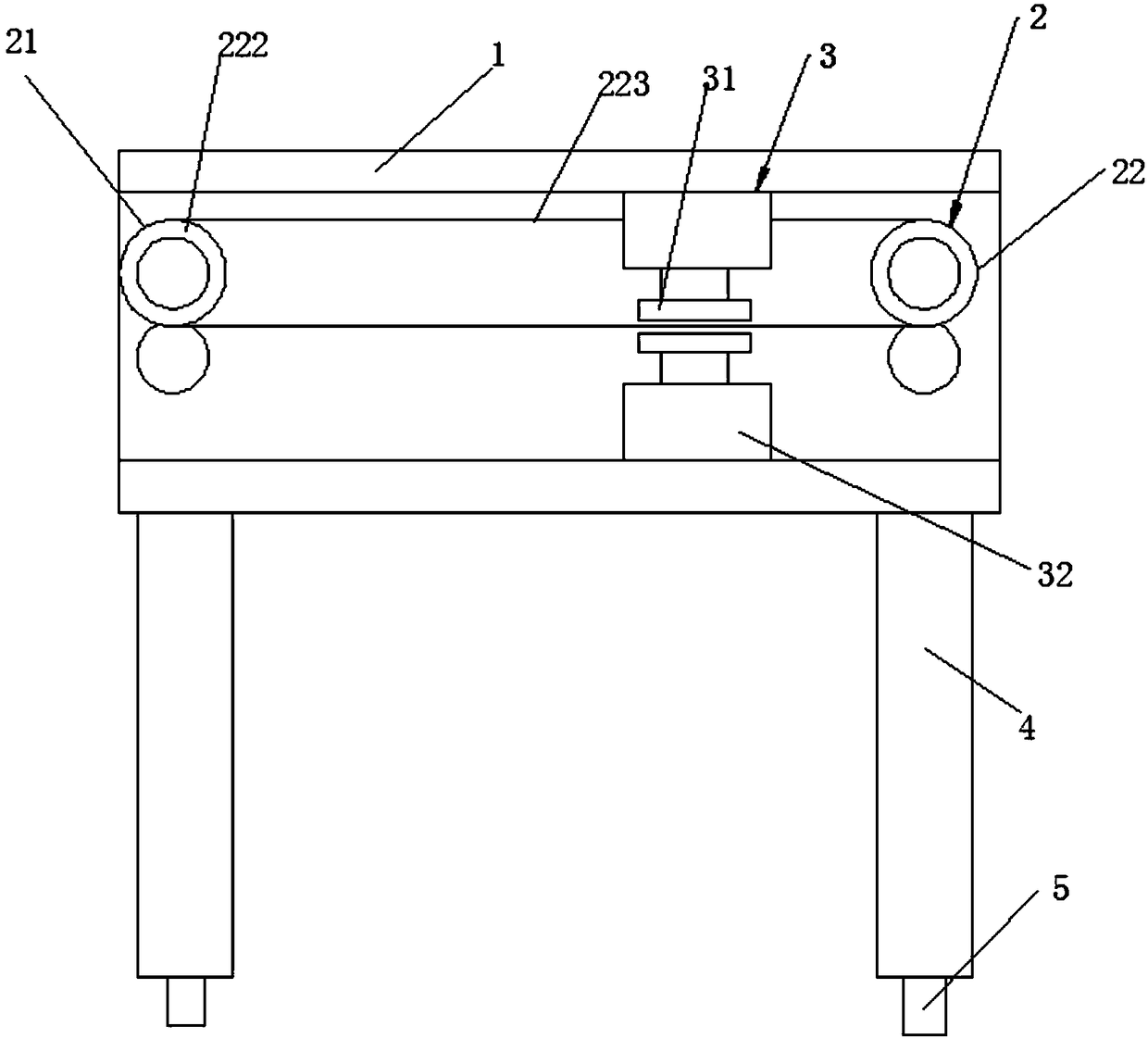

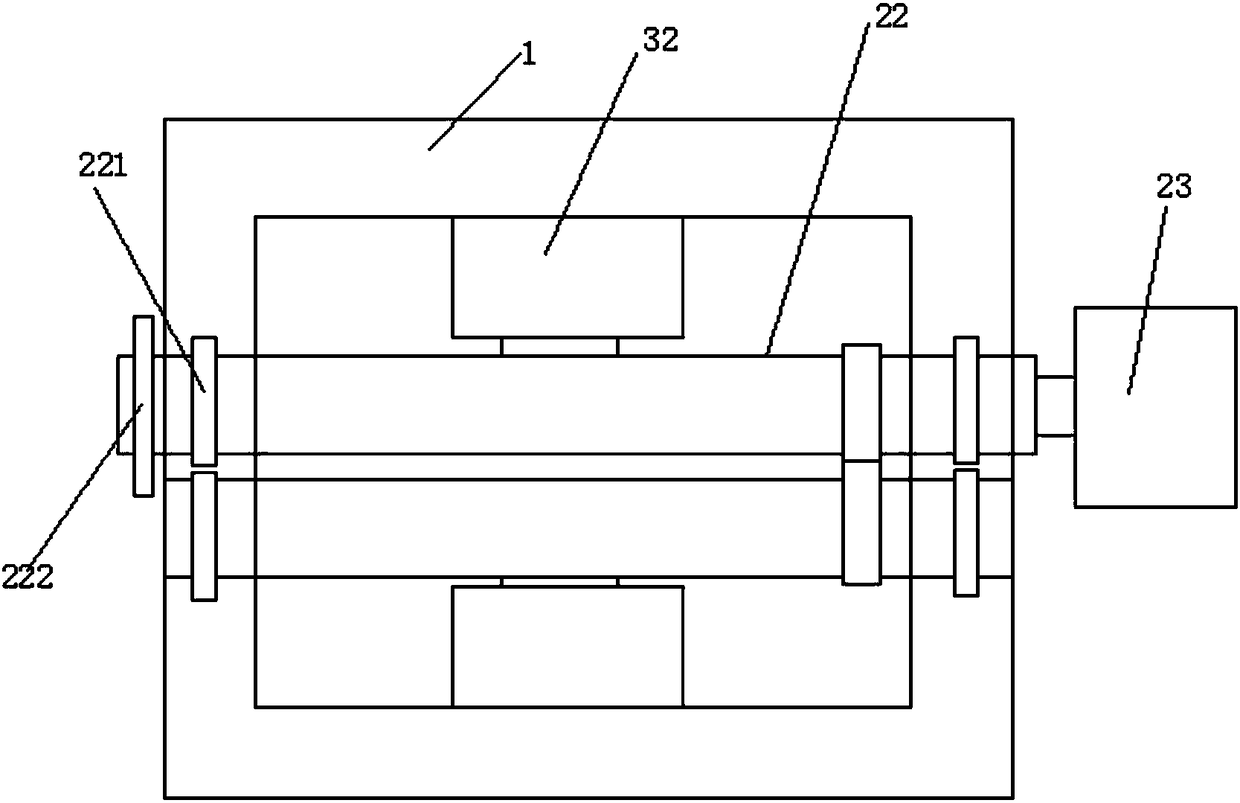

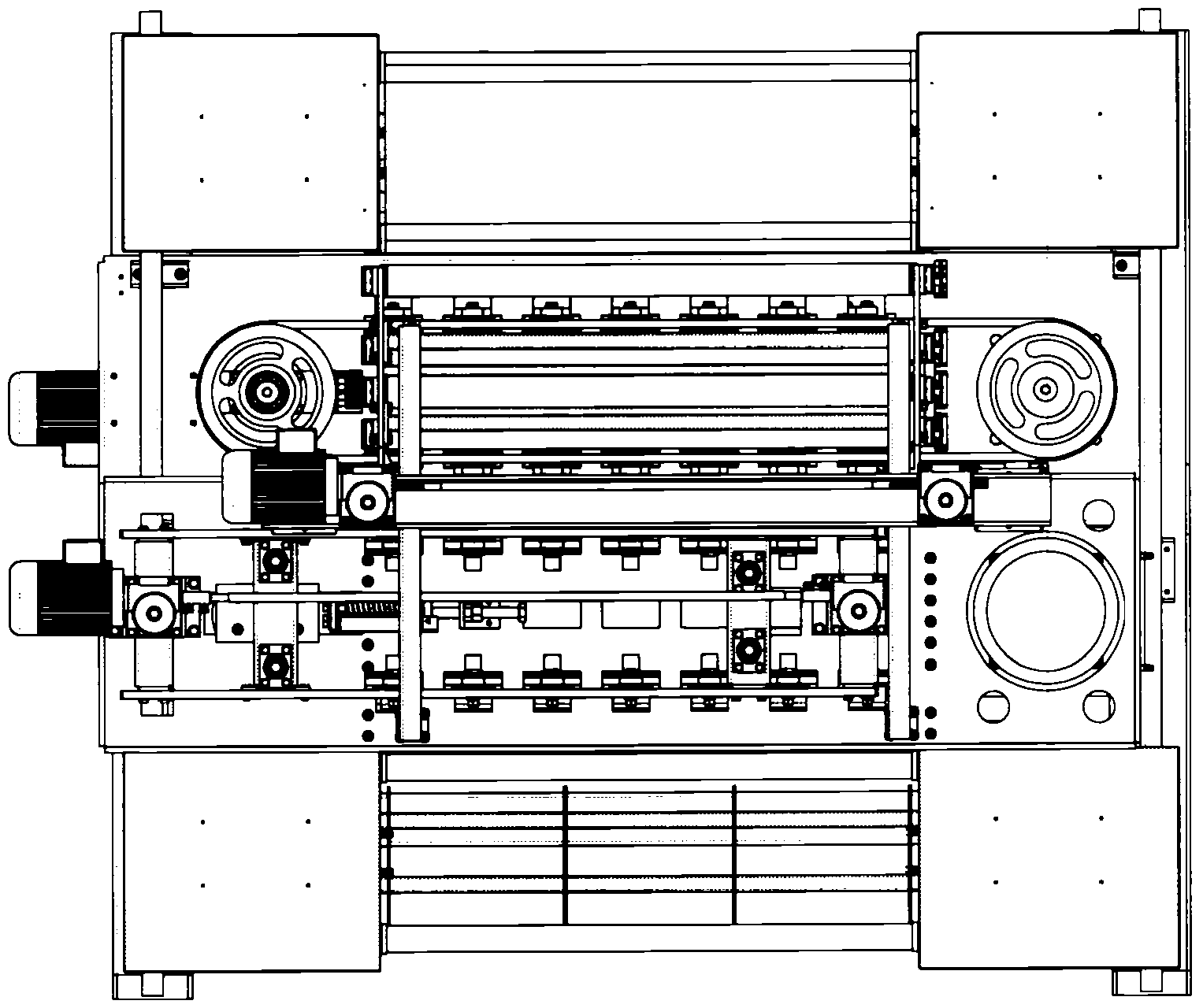

Deburring machine

InactiveCN103786084ASave human effortImprove deburring efficiencyBelt grinding machinesGrinding work supportsMechanical equipmentEnergy consumption

The invention relates to the technical field of mechanical equipment, in particular to a deburring machine. The deburring machine comprises a mounting table, a controller, a workpiece horizontally-moving device and a workpiece grinding device. The workpiece horizontally-moving device and the workpiece grinding device are respectively arranged on the mounting table, the workpiece grinding device is arranged on one side of the workpiece horizontally-moving device, the controller is fixedly connected with the mounting table, and the workpiece horizontally-moving device and the workpiece grinding device are electrically connected with the controller respectively. With the deburring machine, manpower is saved, and the deburring efficiency is high; in the deburring process, workpieces cannot be damaged, the precision requirement and the using requirement of parts cannot be affected either, the appearance of the workpieces is good after the workpieces are processed, and the defective percentage is low; besides, the deburring machine is simple in structure, small in size, low in production cost and energy consumption, easy to operate and wide in application range, and the deburring machine can be popularized and applied on a large scale easily.

Owner:DONGGUAN JUNLI AUTOMATION TECH

Metal pipe section deburring device for electromechanical machining

InactiveCN112207691AImprove deburring efficiencyImprove efficiencyEdge grinding machinesGrinding carriagesEngineeringMirror image

The invention relates to the technical field of electromechanical machining, in particular to a metal pipe section deburring device for electromechanical machining. The metal pipe section deburring device comprises a workbench, a conveying device is arranged on the workbench, grinding frames are arranged at the positions, located on the two sides of the conveying device, of the workbench, grindingdevices are arranged on the upper portions of the grinding frames, two lifting devices which are distributed in a mirror image mode are arranged below the grinding frames, clamping rotating devices are arranged on the lifting devices, and a blocking device is further arranged on the upper side of the conveying device. The metal pipe section deburring device has the advantages that a metal pipe isdriven by the conveying device to move and is blocked by the blocking device, then the clamping rotating devices clamp the metal pipe, the lifting devices drive the metal pipe to ascend, the clampingrotating devices drive the metal pipe to rotate, and meanwhile, the grinding devices at the top carry out comprehensive grinding on the metal pipe, after grinding, the lifting devices drive the metalpipe to descend, and meanwhile, the blocking device ascends, the ground metal pipe is released, the deburring operation can be carried out on the metal pipe very quickly, and the deburring efficiencyis improved.

Owner:SUZHOU WABOTE INTELLIGENT TECH CO LTD

Pipe cutting machine with deburring function

ActiveCN106964984AImprove continuityShort timeOther manufacturing equipments/toolsVehicle componentsEngineeringExhaust pipe

The invention discloses a pipe cutting machine with a deburring function. The pipe cutting machine comprises a rack, an exhaust pipe clamping device arranged on the rack and a cutting mechanism which is arranged on the rack, located above the exhaust pipe clamping device and has the function of being close to or away from an exhaust pipe. The exhaust pipe clamping device comprises a first clamping seat and a second clamping seat capable of being close to or away from the first clamping seat and furthermore comprises a deburring device arranged on the rack, a first detection mechanism, a first drive mechanism, a second detection mechanism and a pair of second drive mechanisms, wherein the first detection mechanism is arranged on the rack and is used for detecting whether the cutting mechanism cuts off the exhaust pipe or not, the first drive mechanism is used for driving the second clamping seat to be away from or close to the first clamping seat, the second detection mechanism is used for detecting whether the second clamping seat is moved in place or not, and the second drive mechanisms are used for driving the deburring device to be close to or away from the first clamping seat and the second clamping seat correspondingly. After pipe cutting is completed, the deburring action is performed immediately, continuity is good, the process of unloading on the pipe cutting machine and the process of loading on a deburring machine are omitted, time consumption is short, and production efficiency is high.

Owner:浙江新诚汽车部件有限公司

Plate deburring equipment

InactiveCN110883639AAvoid offsetIncrease frictionEdge grinding machinesGrinding drivesGear wheelPneumatic motor

The invention discloses plate deburring equipment comprising a U-shaped groove. The top end of the U-shaped groove is fixedly connected with a power cabin with the top end fixedly connected with a pneumatic motor, and the output end of the pneumatic motor is fixedly connected with a rotating column; the bottom end of the rotating column is fixedly connected with a first bevel gear with the bottomend fixedly connected with first gears, and one side of the power cabin is rotatably connected with a rotating rod through a rotating shaft; the top end of the rotating rod is fixedly connected with asecond bevel gear, and the first bevel gear is engaged with the second bevel gear; the part, in the power cabin, of the top end of the U-shaped groove is rotatably connected with the rotating rod through the rotating shaft, and the top end of the rotating rod is fixedly connected with a second gear; and the first gears are engaged with the second gear, and the bottom end of the rotating rod is fixedly connected with a grinding column. Compared with an existing device, the plate deburring equipment has the advantages that the equipment is moved along the edge of a plate while the gears are driven by the pneumatic motor to engage mutually and the equipment is driven to grind the plate; and the deburring efficiency of the equipment is improved.

Owner:湖北乔木森家具有限公司

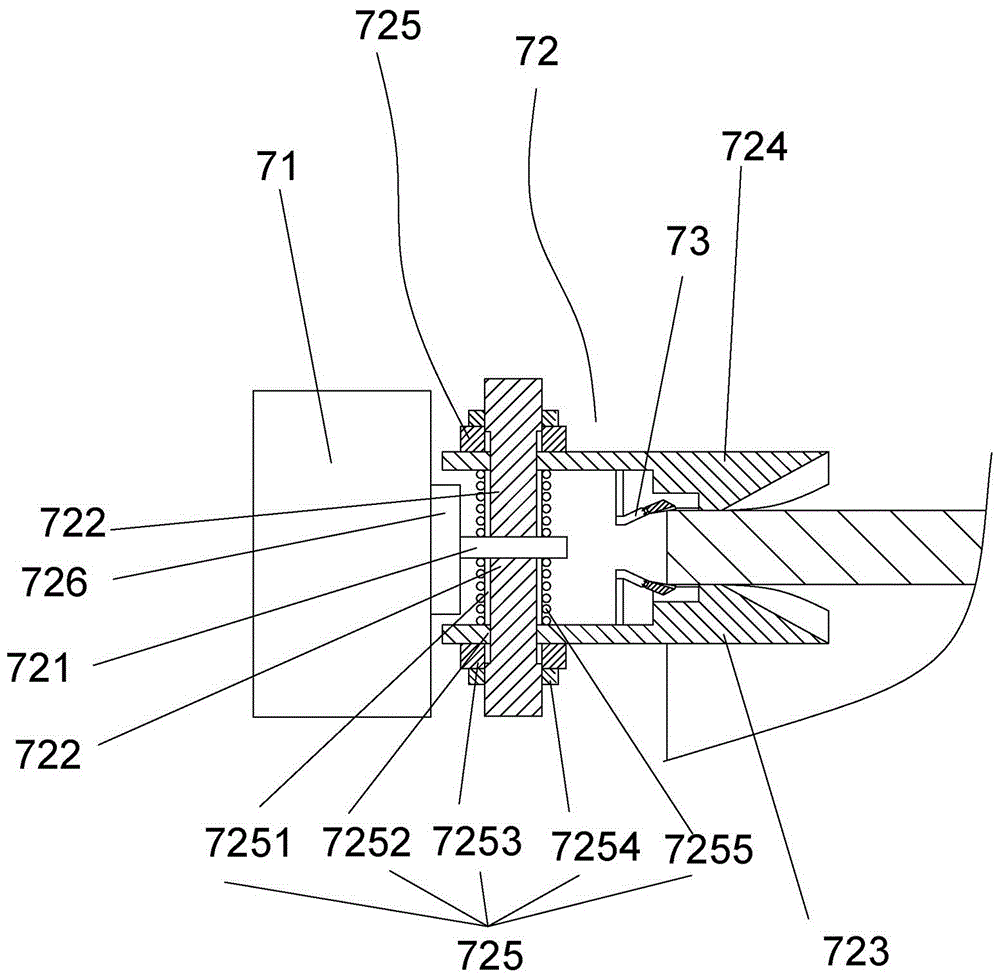

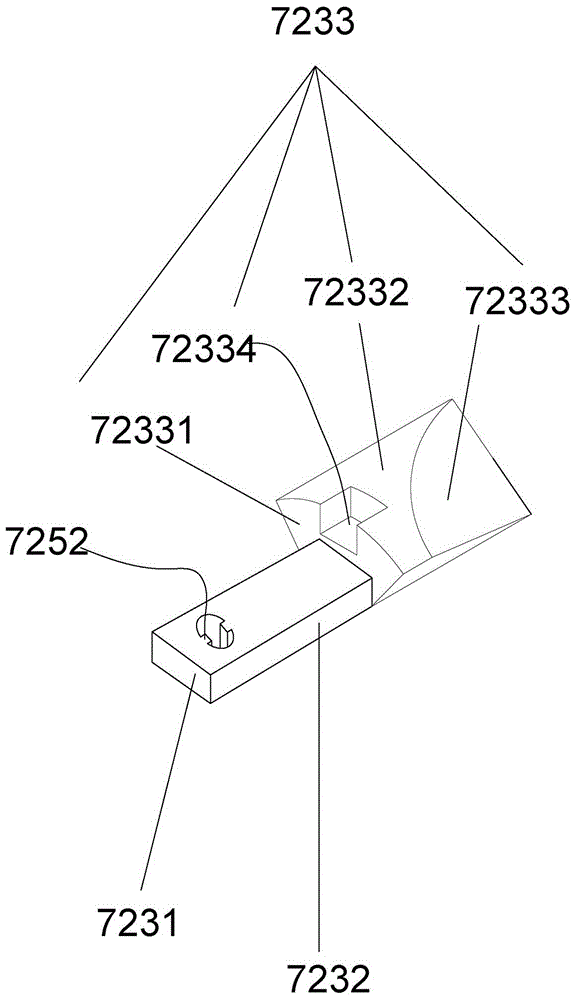

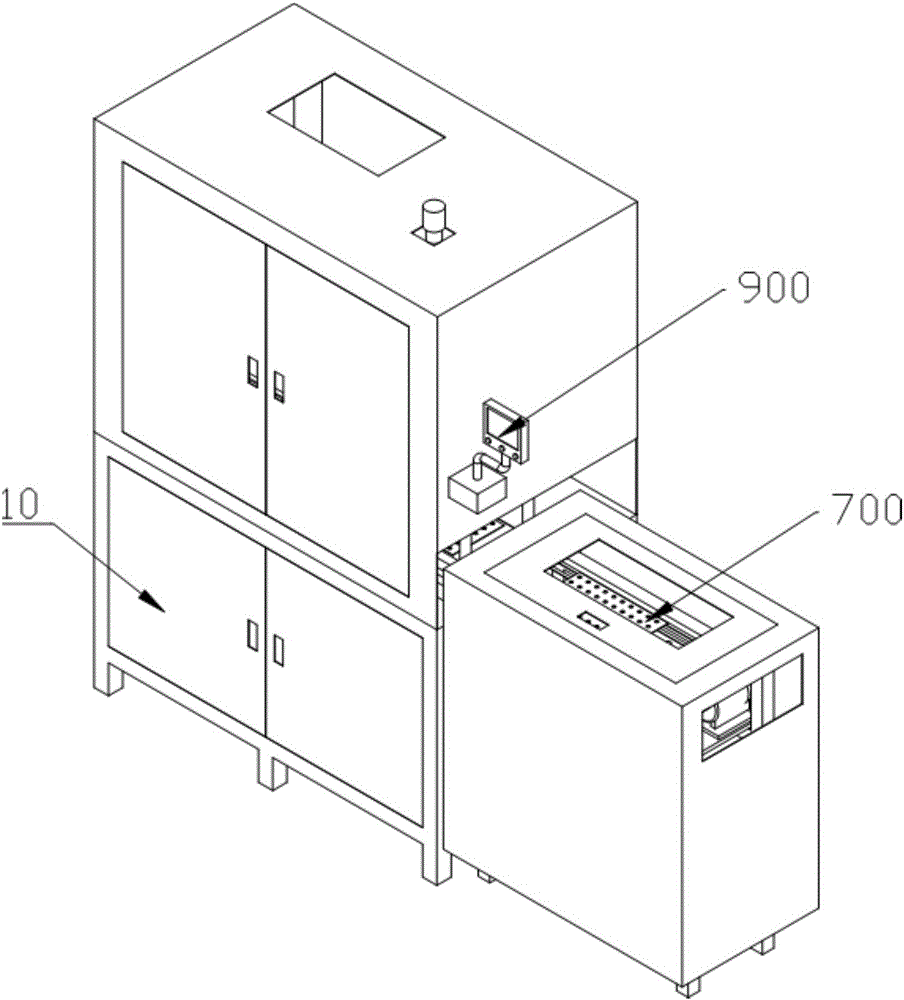

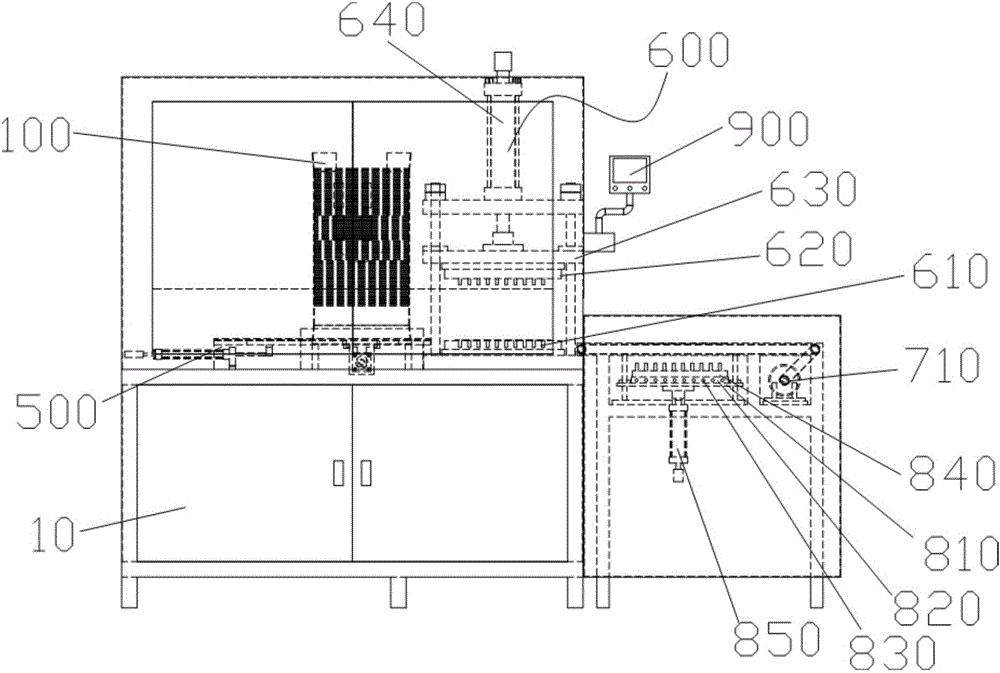

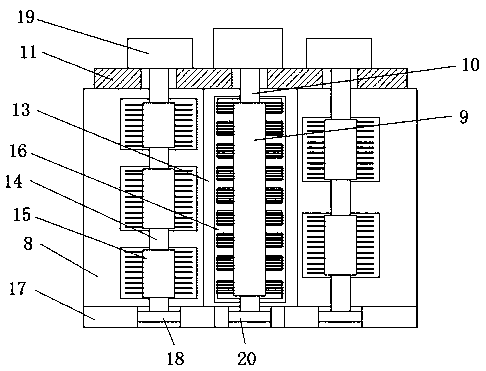

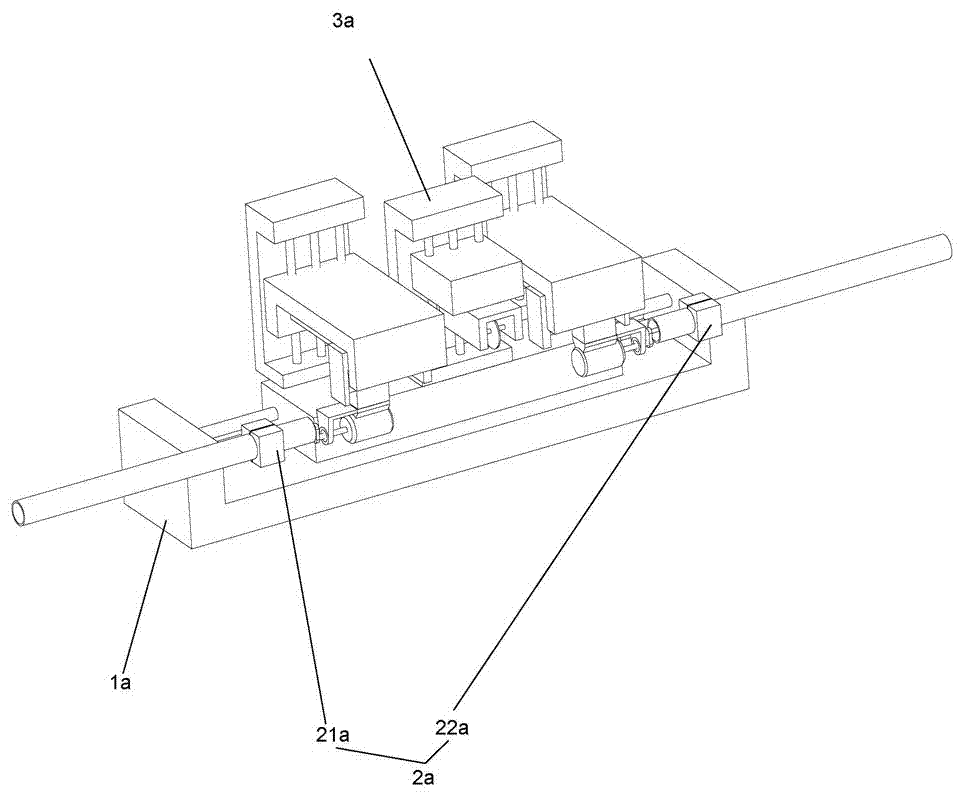

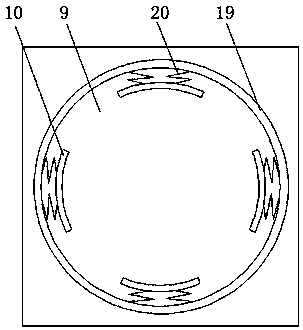

Automatic deburring mechanism for magnetic shoe automatic deburring system

InactiveCN104209835ANo manual operationReduce labor costsEdge grinding machinesBall screwEngineering

The invention relates to a magnetic shoe treatment mechanism, in particular to an automatic deburring mechanism for a magnetic shoe automatic deburring system. The automatic deburring mechanism for the magnetic shoe automatic deburring system comprises a support and a deburring device arranged on the support, wherein a servo driving device is arranged on the support, the servo driving device comprises a servo motor, forward and reverse ball screws, a forward guide rail sliding block and a reverse guide rail sliding block, the deburring device comprises two symmetrically arranged deburring motors and special disc hairbrushes which are connected onto rotating shafts of the deburring motors, and the two deburring motors are respectively and fixedly arranged on the forward guide rail sliding block and the reverse guide rail sliding block. The automatic deburring mechanism for the magnetic shoe automatic deburring system has the advantages that, by adopting the forward and reverse ball screws and the forward and reverse guide rail sliding blocks to drive the two deburring motors to drive the special disc hairbrushes to conduct deburring to a magnetic shoe, full-automatic operation is realized, no person is needed for operation and the labor cost is reduced; by adopting the special disc hairbrushes, the deburring effect is good, the energy is saved and the environment is protected.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD +1

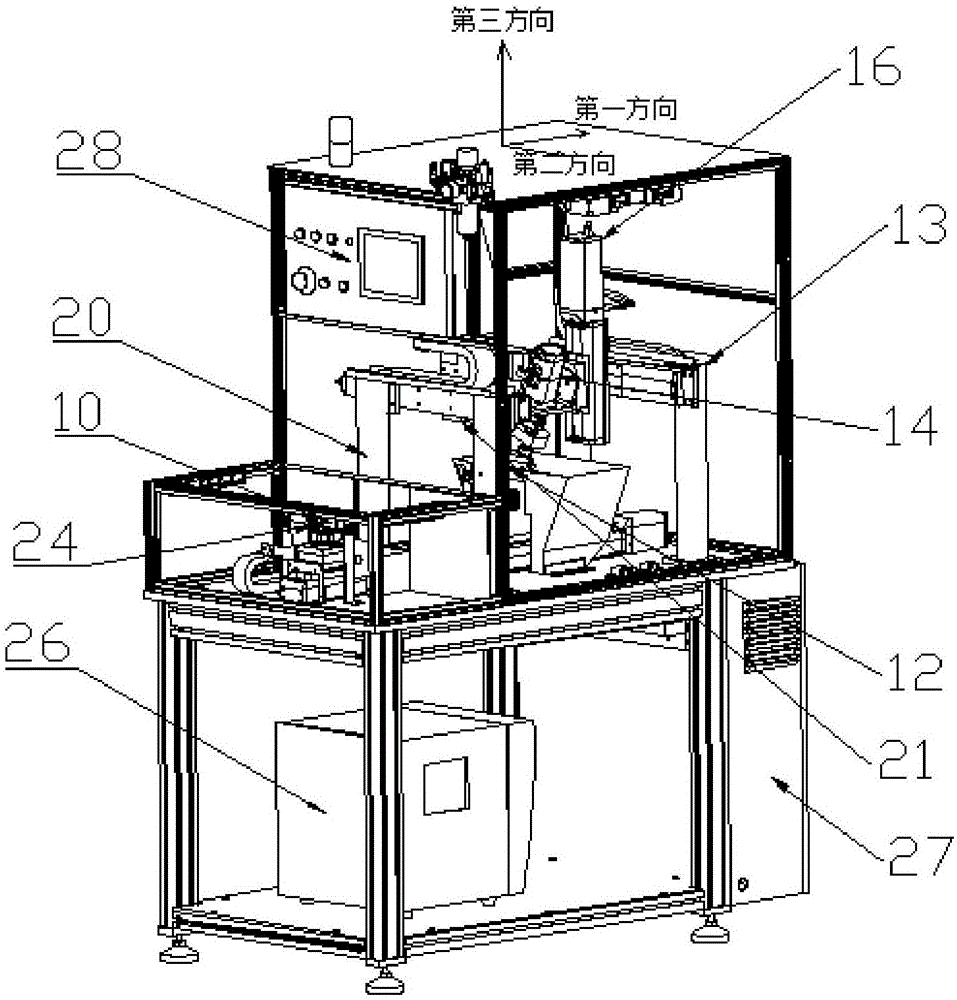

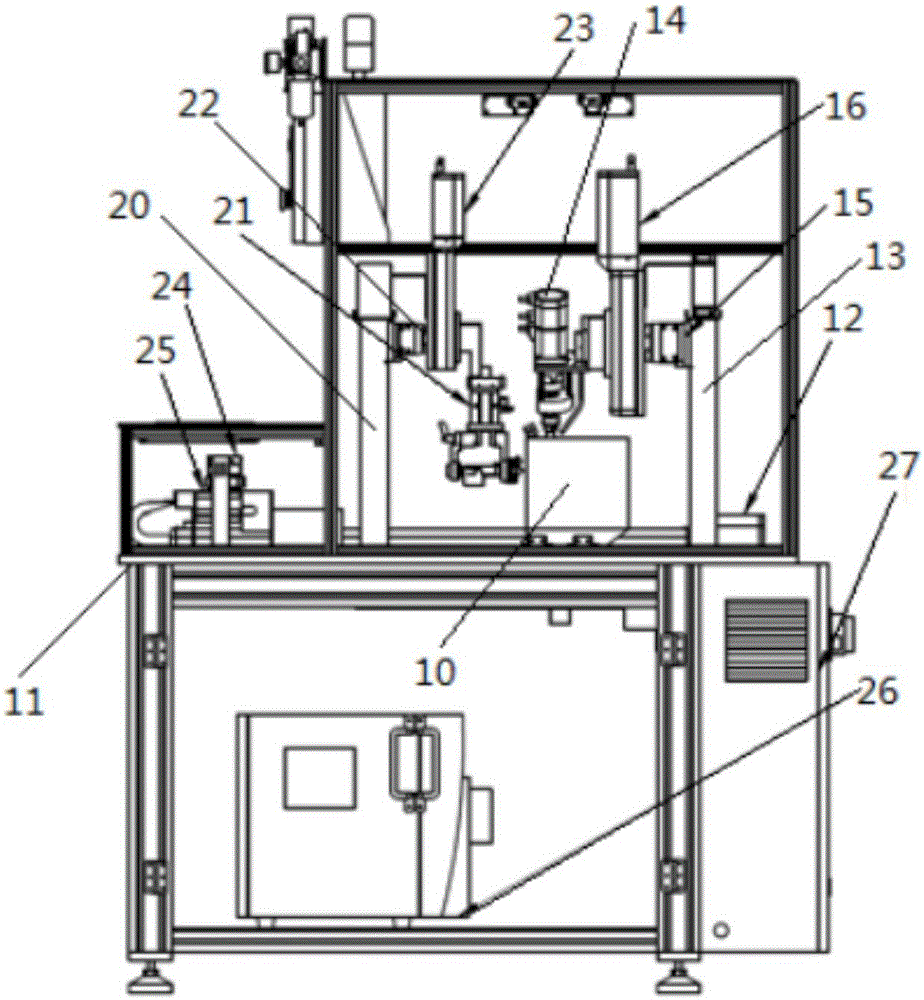

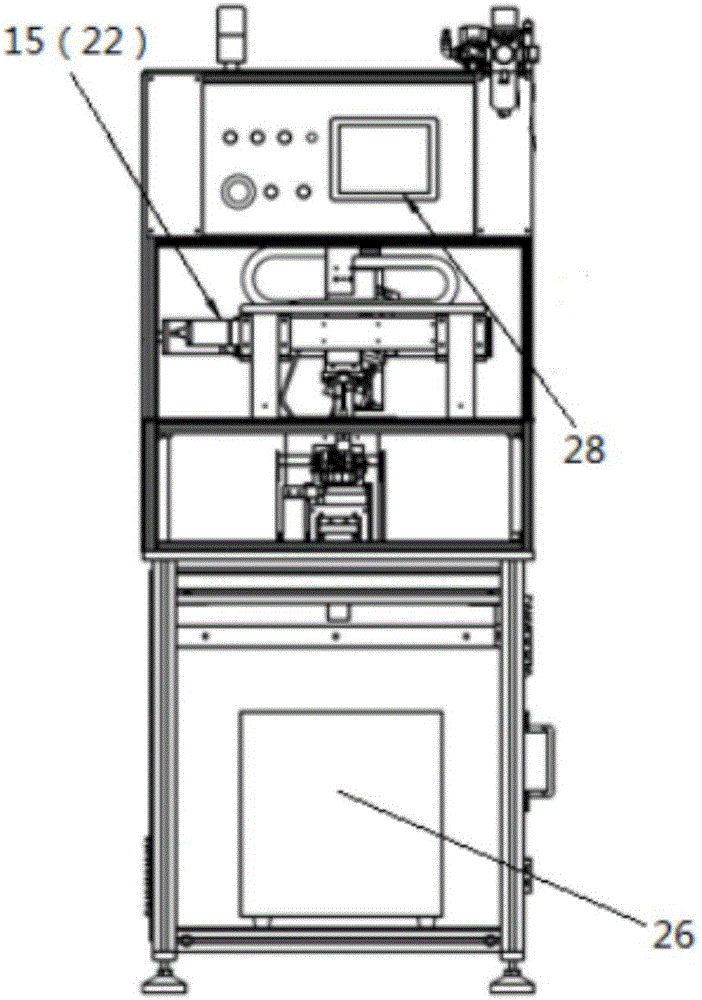

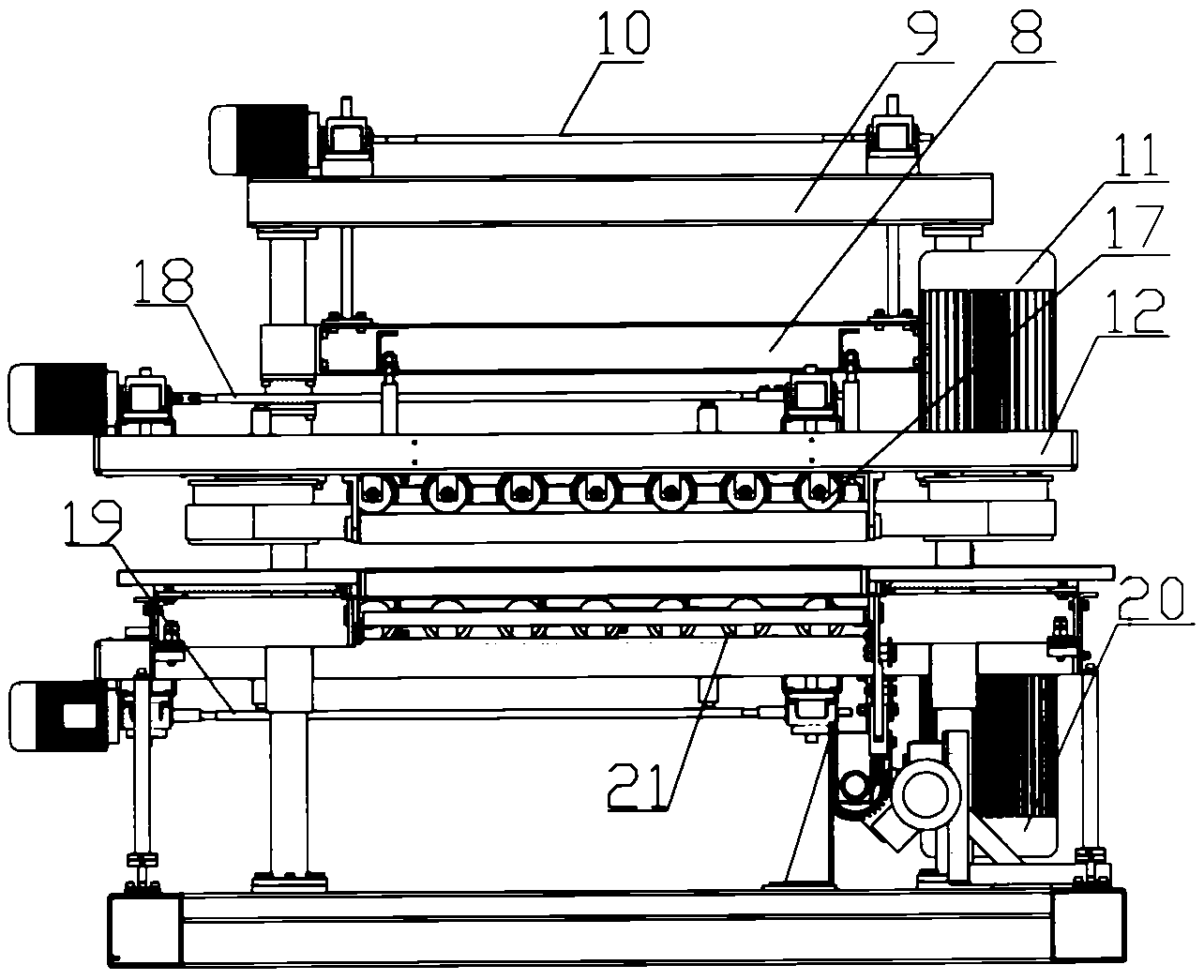

Deburring machine

ActiveCN106695481ARealize all-round grindingImprove deburring efficiencyEdge grinding machinesGrinding carriagesDrive shaftEngineering

The invention discloses a deburring machine. The deburring machine comprises a machine frame, a first transmission shaft, a first support, a second transmission shaft and a third transmission shaft. The first transmission shaft is arranged on the machine frame and used for driving a workpiece to move in the first direction; the first support is disposed on the machine frame, and a grinding manipulator is disposed on the first support and used for grinding the workpiece; the second transmission shaft is arranged on the first support, connected with the third transmission shaft and used for driving the third transmission shaft to move in the second direction; the third transmission shaft is disposed on the second transmission shaft, connected with the grinding manipulator and used for driving the grinding manipulator to move in the third direction; the machine frame is further provided with a second support, the second support and the first support are arranged in a spaced mode, and a turnover manipulator is arranged on the second support and used for turning over workpieces. In this way, by means of the deburring machine disclosed by the invention, any position of the to-be-ground surfaces of the workpieces can be ground, the workpieces can be turned over, and omni-directional grinding of the workpieces is achieved.

Owner:SINPA INDAL AUTOMATION

Deburring device special for cabinet handle

PendingCN107471031AImprove deburring efficiencyEasy to operateEdge grinding machinesGrinding carriagesEngineeringSlide plate

The invention relates to the technical field of machining and discloses a chamfering device special for a cabinet handle. The chamfering device comprises a base and a base plate, wherein two parallel sliding rails are arranged on the top surface of the base plate, a rectangular frame is arranged between the two sliding rails, the side face of the rectangular frame is in sliding connection with the sliding rails through a sliding block, and a sliding plate is arranged in the rectangular frame and is perpendicular to the rectangular frame in sliding direction. A kidney-shaped hole is formed in the sliding plate, the inner wall of the kidney-shaped hole is provided with a gear ring, a gear extending into the kidney-shaped hole and meshed with the gear ring is arranged on the top surface of the base plate, and a driving motor connected with the gear is arranged at the bottom of the base plate. A sliding sleeve is arranged on one side of the rectangular frame, a sliding rod is arranged in the sliding sleeve, the inner end of the sliding rod is fixedly connected with the side face of the sliding plate, the outer end of the sliding rod extends to form a connecting ring, an electric grinding mechanism is arranged on the upper side face of the connecting ring, and a handle positioning mechanism is also arranged on the base plate. The chamfering device has the advantages of being convenient to operate and good in stability and making the cabinet handle deburring efficiency high.

Owner:毛啸宇

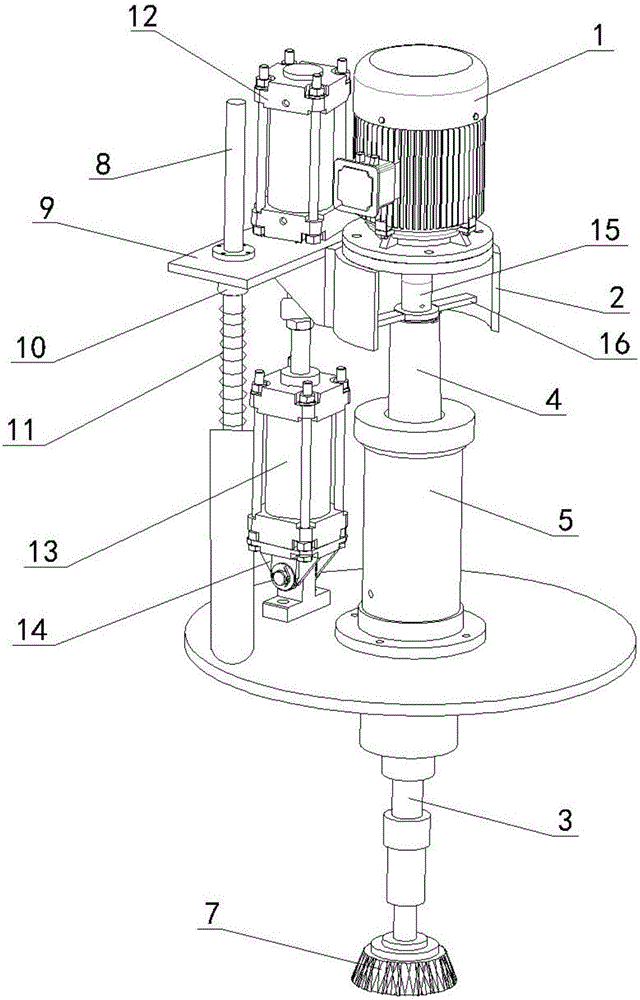

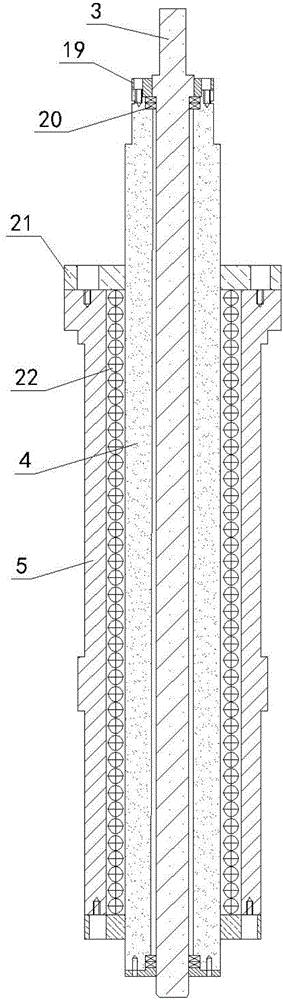

Automatic deburring device capable of realizing accurate compensation

ActiveCN106625093ARealize automatic deburring functionGuaranteed deburring effectEdge grinding machinesGrinding drivesMechanical engineeringPiston rod

The invention discloses an automatic deburring device capable of realizing accurate compensation. The automatic deburring device is characterized in that an output shaft of a motor is vertically downward, a rotary shaft fixedly connected with the output shaft of the motor penetrates through a fixed guide seat, a brush rotating with the rotary shaft is installed at the bottom shaft end of the rotary shaft, and the fixed guide seat is installed on a horizontal base plate; a hollow guide shaft fixedly connected with a motor installation seat is arranged between the rotary shaft and the fixed guide seat, the rotary shaft is capable of rotating in the hollow guide shaft, and the hollow guide shaft is capable of moving up and down along the fixed guide seat; and a lifting guide seat is arranged on the motor installation seat in a manner of horizontally overhanging, a compensation motor is installed on the lifting guide seat, a lifting cylinder is installed on the base plate, thread fit is formed between an output shaft of the compensation motor and a piston rod of the lifting cylinder, and the wear amount of the brush is compensated through the driving of the compensation motor. The automatic deburring device disclosed by the invention is used for carrying out deburring treatment on the surface of a workpiece, and capable of realizing accurate compensation and prolonging the service life of the brush.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

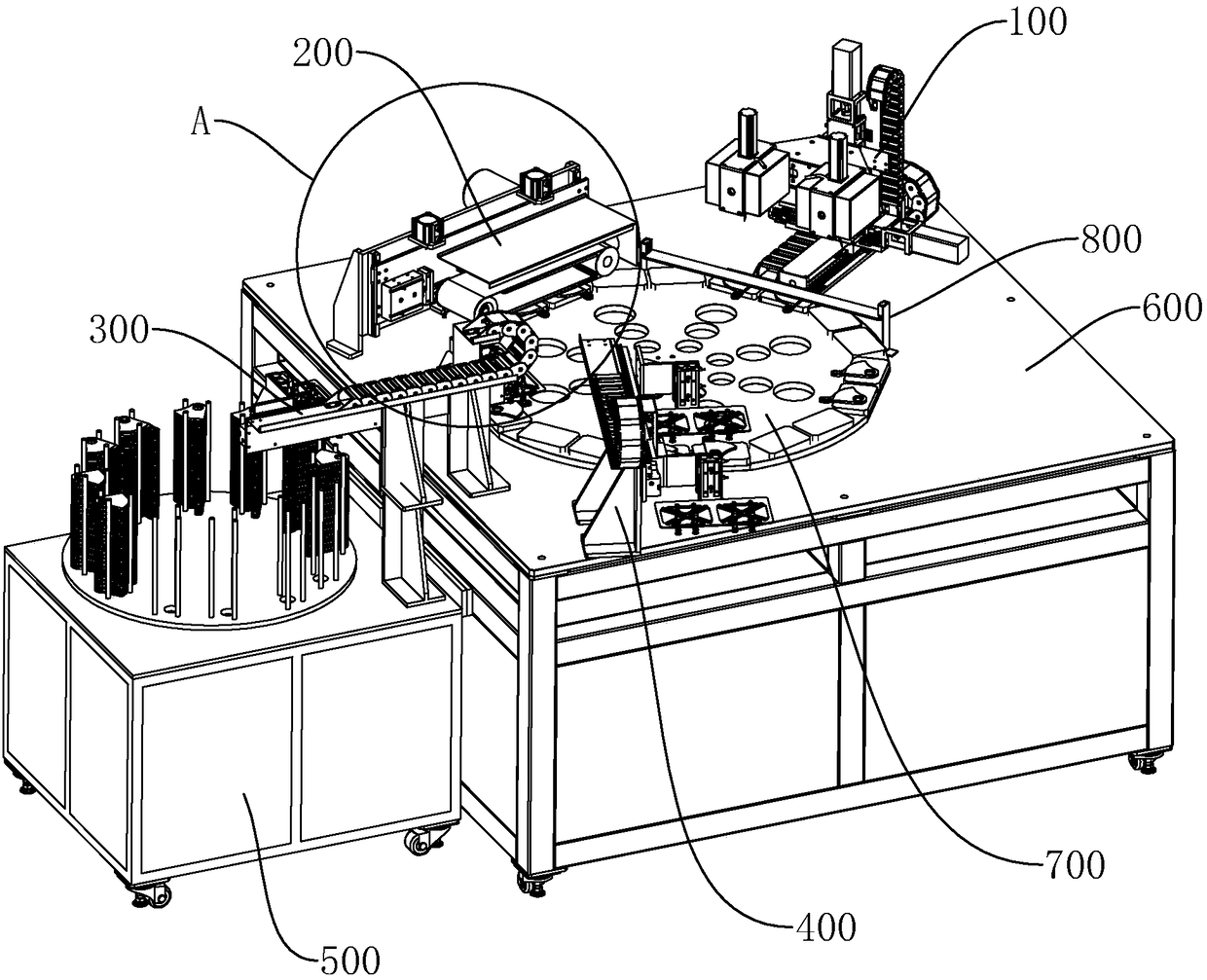

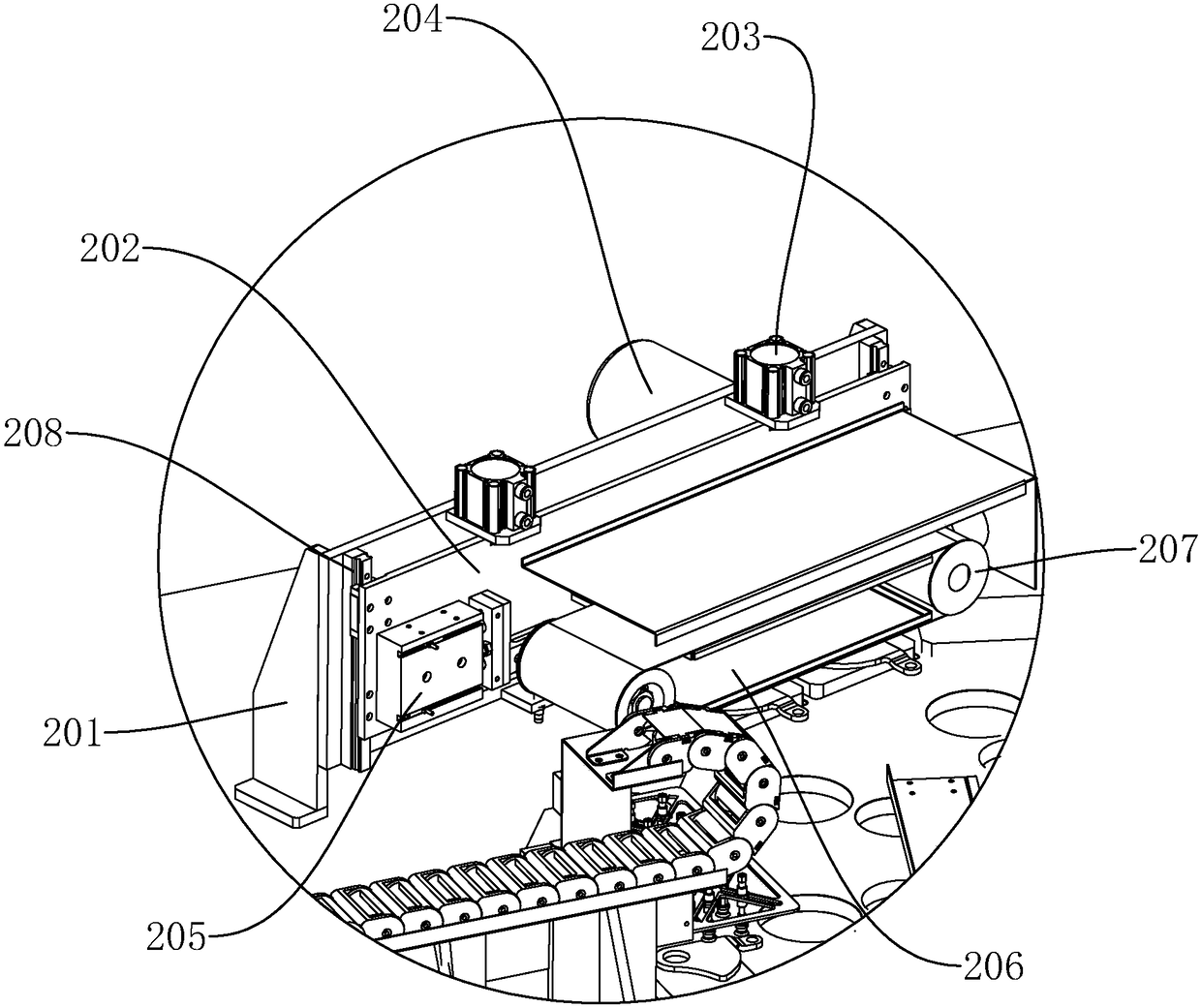

Deburring device

PendingCN108274327ARealize the deburring processReduce labor costsEdge grinding machinesGrinding feedersEngineeringSurface grinding

The invention discloses a deburring device. The deburring device solves the problem that existing deburring operation is low in efficiency. The deburring device comprises a machine table, a rotating disc, a feeding mechanism, a plane grinding mechanism, a side surface grinding mechanism, a discharging mechanism and a storage mechanism; the rotating disc is arranged on the machine table in a rotating mode; a feeding station, a plane grinding station, a side surface grinding station and a discharging station which are distributed along the edge of the rotating disc are arranged on the machine table; the feeding mechanism is arranged on the machine table and corresponds to the feeding station; the plane grinding mechanism is arranged on the machine table and corresponds to the plane grindingstation; the side surface grinding mechanism is arranged on the machine table and corresponds to the side surface grinding station; the discharging mechanism is arranged on the machine table and corresponds to the discharging station; and the storage mechanism corresponds to the feeding mechanism and supplies materials to the feeding mechanism. According to the deburring device, in the deburring process of products, manual participation is not needed, and therefore the labor cost can be saved, and the deburring efficiency of the products can be improved.

Owner:嘉兴和新精冲科技有限公司

Bamboo mat deburring device

InactiveCN108527063AImprove deburring efficiencyEdge grinding machinesGrinding feedersDrive motorEngineering

The invention provides a bamboo mat deburring device comprising a box body, a bamboo mat conveying device and deburring device bodies. The deburring device bodies comprise electric cylinders and deburring grinding blocks, the deburring device bodies are separately arranged on the upper and lower side walls of the interior of the box body, bases of the electric cylinders are fixedly connected withthe inside of the box body, and the deburring grinding blocks are fixedly disposed at the output ends of the electric cylinders. The two deburring grinding blocks are disposed opposite to each other,the bamboo mat conveying device comprises a driving roller group I and a driving roller group II, the driving roller group I is disposed at the feeding end of the box body, the driving roller group IIis disposed at the discharging end of the box body, and one end of any driving roller of the driving roller groups is connected with a driving motor; and the two deburring grinding blocks simultaneously perform deburring on both sides of the bamboo mat, and the efficiency of deburring is improved.

Owner:杨欣

Deburring equipment for inner hole orifice of tubular workpiece

InactiveCN108838789AImprove deburring efficiencyQuality improvementEdge grinding machinesGrinding carriagesDrive shaftPiston rod

The invention discloses deburring equipment for an inner hole orifice of a tubular workpiece. The deburring equipment comprises an operating table, a top plate, an air cylinder, a fixing plate, regulating plates, grinding motors, grinding shafts, a motor II, a bearing plate and a fastening plate. The deburring equipment is characterized in that the operating floor is arranged on a bracket; the topplate is arranged on stand plates; the air cylinder is arranged on the top plate; the fixing plate is arranged on a piston rod; the regulating plates are arranged in connecting grooves through connecting shafts; the grinding motors are arranged on the regulating plates; the grinding shafts are arranged on transmission shafts I; and the motor II is arranged on the operating table. The multiple regulating plates are arranged on the fixing plate of the piston rod of the air cylinder, the grinding motors are arranged on the regulating plates, the grinding shafts are arranged on the transmission shafts I of the grinding motors, and the inner hole orifice of the tubular workpiece on the bearing plate can be subjected to deburring through the grinding shafts, so that the deburring efficiency ofthe tubular workpiece is improved.

Owner:芜湖瑞德机械科技有限公司

One-circle and double-grinding chamfer deburring machine and deburring method thereof

ActiveCN102366919BAchieve resilienceAchieve separationEdge grinding machinesBelt grinding machinesMotor driveEngineering

The present invention relates to a one-circle two-chamfer deburring machine and a deburring method comprising the following steps after starting up: (1) The upper wheelhead motor drives the upper grinding belt to rotate horizontally (2) the lower wheelhead motor drives the lower grinding belt to rotate horizontally and (3) when a deburred workpiece goes through a passage formed by the active feeding roller row and the upper grinding belt, an upper abrasive block elastically contacts surface of the workpiece and, under the drive of the upper wheelhead motor and the upper active drum, polishes and deburrs the front side of the workpiece twice; the lower abrasive block elastically contacts the surface of the workpiece and, under the drive of the lower wheelhead motor and the lower active drum, polishes and deburrs the back side of the workpiece twice.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

Cylindrical grinding device used for removing burrs of parting surfaces of castings

PendingCN106965052ANo distractionAvoid sanding effectsEdge grinding machinesGrinding/polishing safety devicesEngineeringCylindrical grinding

The invention discloses a cylindrical grinding device used for removing burrs of the parting surfaces of castings. The cylindrical grinding device comprises a case, a top cover, a control box, a support, a collecting box, fixing grooves, pushing plates, a grinding device, suction disks, grinding disks, suction nozzles, first telescopic rods, first rotating wheels, second rotating wheels, second telescopic rods and transmission rods. The cylindrical grinding device has the beneficial effect that by fixing the case on the support, the device is more stable in use; by arranging the multiple grinding disks inside the grinding device, the device is higher in burr removing efficiency, and the grinding disks can be adjusted in height through the second telescopic rods so as to be capable of grinding the parting surfaces of the castings with different heights; and the suction nozzles are arranged on one sides of the grinding disks and move along with the grinding disks through the first telescopic rods and the first rotating wheels, so that the falling burrs of grinding disks grinding can be sucked immediately by the suction nozzles, and accordingly the situation that grinding is affected by the falling burrs is avoided. The device has the characteristics that the burr removing efficiency is high, and the falling burr interference does not exist in the grinding process.

Owner:鹰普罗斯叶轮(宜兴)有限公司

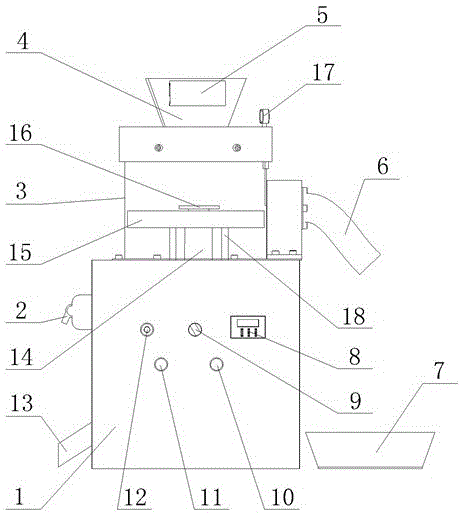

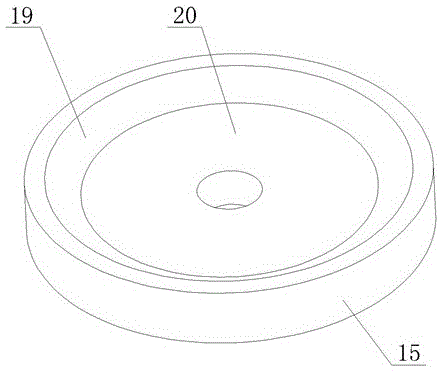

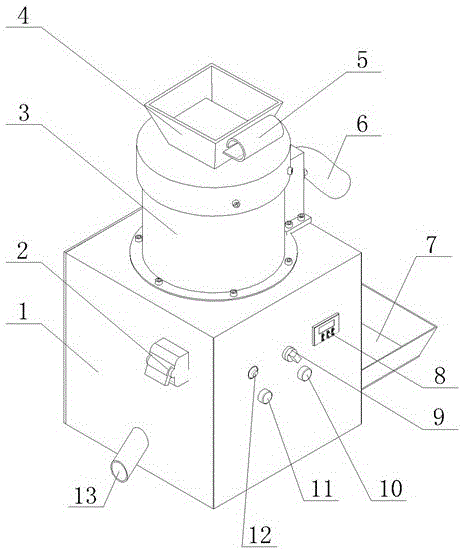

Small super-hard material grinding wheel segment deburring machine

InactiveCN105058185AImprove deburring efficiencyImprove work efficiencyEdge grinding machinesGrinding drivesEngineeringGrinding wheel

The invention discloses a small super-hard material grinding wheel segment deburring machine, and belongs to the technical field of deburring machines. The small super-hard material grinding wheel segment deburring machine comprises a base, wherein an outer cover is fixed to the top of the base; a plurality of openings are formed between the inside of the base and the outer cover; a feeding hopper is arranged at the top of the outer cover; a feeding valve is installed at the lower end of the feeding hopper; a discharging pipe is arranged on the lateral surface of the outer cover; a discharging valve is installed in the position where the discharging pipe and the outer cover are communicated; a vertical rotary shaft is rotationally connected with the top of the base. A work grinding wheel is installed at the top end of the vertical rotary shaft and located in the outer cover. The space defined by the upper portion of the work grinding wheel and the outer cover is a work area. The lower end of the vertical rotary shaft is in drive connection with a motor. The work grinding wheel is designed into a disc shape, so that the deburring efficiency is improved. The small super-hard material grinding wheel segment deburring machine is compact in structure, low in manufacturing cost and high in work efficiency. Only four minutes are needed to removing burrs of 100 grinding wheel segments, and the work time is largely shortened.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Intelligent clutch edge-hair-free treatment device

PendingCN108857670AAvoid wear and tearExtended service lifeEdge grinding machinesGrinding drivesImpellerGrind

The invention discloses an intelligent clutch edge-hair-free treatment device, and belongs to the field of clutch piece processing. According to the technical scheme, the intelligent clutch edge-hair-free treatment device is characterized by including a device main body, a selecting mounting platform, and a diamond grinding head; the selecting mounting platform is fixedly mounted on the outer wallof the device main body, a burr removing seat grind is movably mounted on the upper wall of the selecting mounting platform, and an automatic rotating bottom disc is movably mounted above the burr removing seat grind; and the diamond grinding head is fixedly mounted above the burr removing seat grind. According to the intelligent clutch edge-hair-free treatment device, an impeller is adopted, a clutch piece can be made to rotate at the high speed, the primary burr removing is conducted, the clutch piece is thrown above the diamond grinding head, and once grinding for multiple pieces is achieved; the automatic rotating bottom disc is arranged below the diamond grinding head, and the diamond grinding head can be made to rotate automatically, so that the effect of efficient burr removing isachieved; and an intelligent speed setting valve is arranged, the function of intelligent speed adjustment is achieved, and the chips can be processed by arranging a dust sucking hose.

Owner:绍兴上虞恒发摩配厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com