Circular pipe-shaped workpiece inner hole orifice deburring machine

A deburring machine, circular technology, applied in the field of non-ferrous metal material processing equipment, can solve the problems of easily damaged workpiece inner hole, low efficiency, large workload, etc., and achieve the effect of saving labor cost, convenient use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

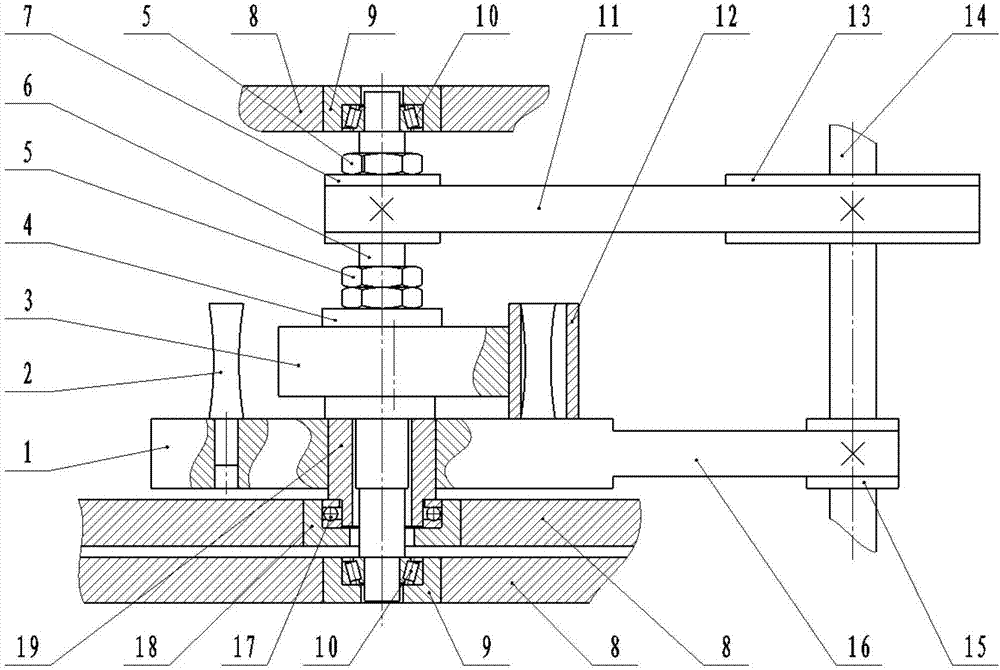

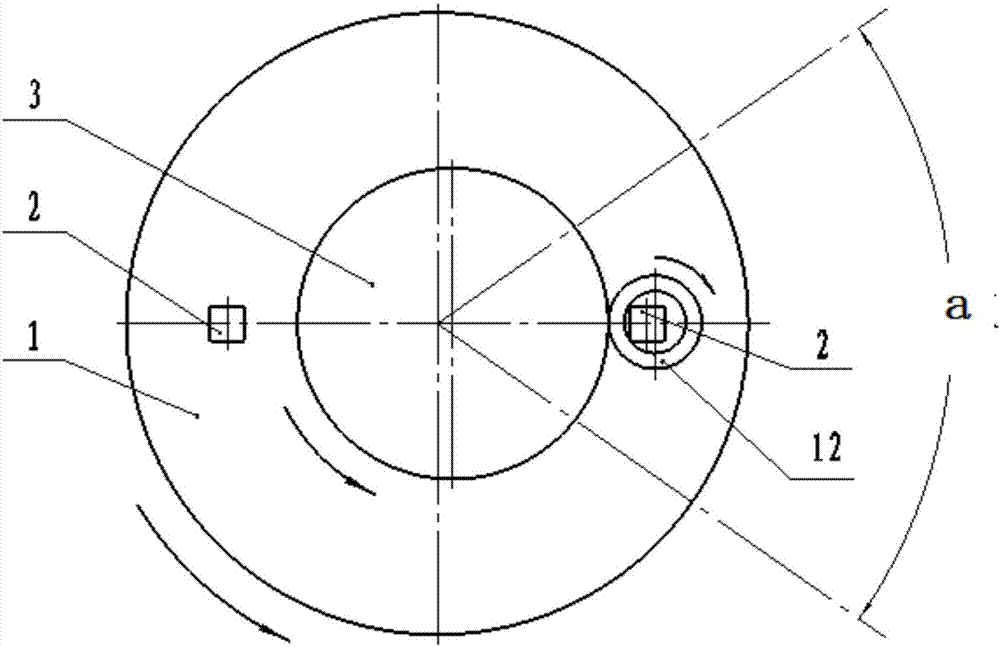

[0013] A deburring machine for the inner hole orifice of a circular tubular workpiece of this embodiment, such as figure 1 As shown, it includes a frame 8. A bearing mount 18 is fixedly mounted on the frame 8, and a thrust ball bearing 17 is mounted on the bearing mount 18; the thrust ball bearing 17 and the hollow short shaft 19 A shaft journal with a step at the lower end is fixedly connected; the upper end of the hollow stub shaft 19 is fixedly connected to a circular worktable 1 with a pulley function; the circular worktable 1 with a pulley function can be together with the hollow stub shaft 19 Rotation; The hollow short shaft 19 has a step long shaft 6 installed in the gap between the inner holes to ensure that the step long shaft 6 and the hollow short shaft 19 are concentric, while the outer diameter of the step long shaft 6 and the inner hole of the hollow short shaft 19 are kept constant The gap can be freely rotated between each other; and the upper and lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com