Deburring device applied to automobile exhaust pipes

An automobile exhaust and deburring technology, which is applied in the field of automobile exhaust pipes, can solve the problems of large removal at the pipe opening, unremoved, weak welding, etc., to achieve the effect of improving efficiency, improving effect, and ensuring the effect of deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

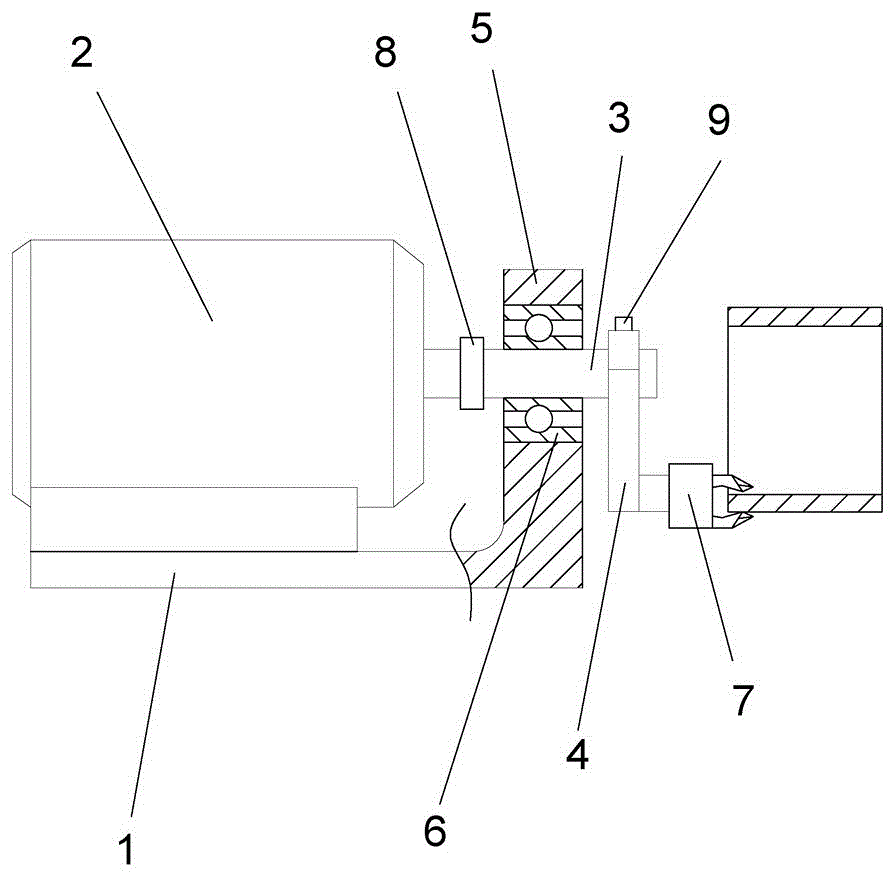

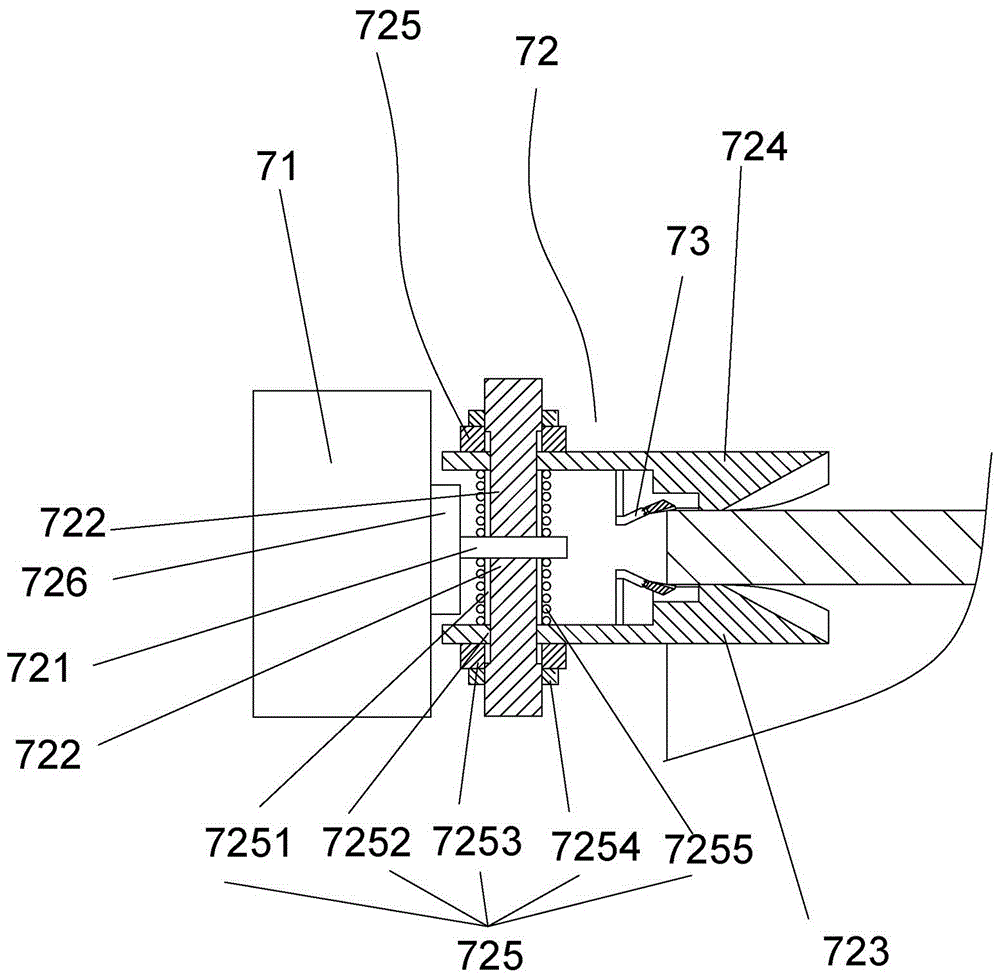

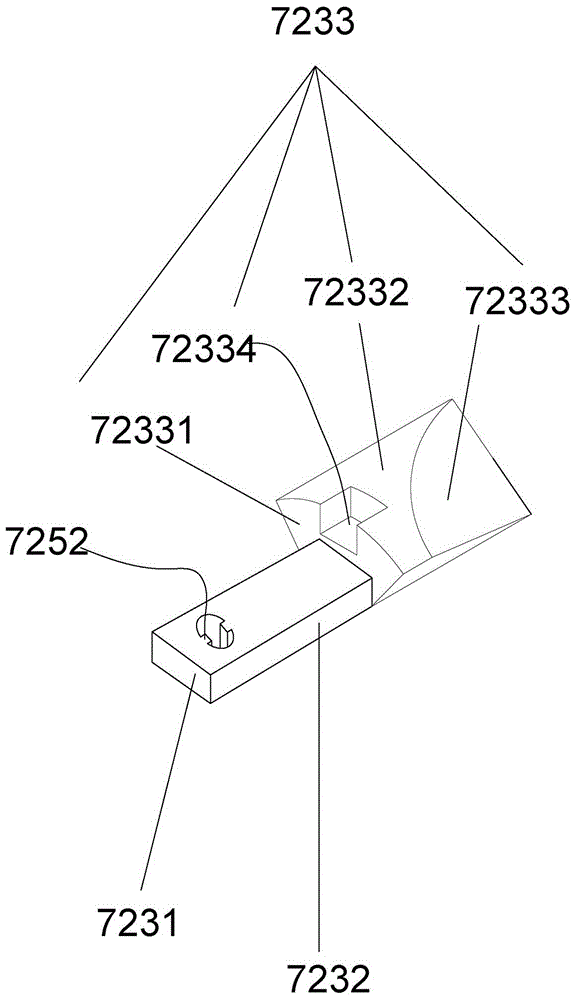

[0029] Embodiment 1: as Figure 1-5 Shown, a kind of deburring device for automobile exhaust pipe is characterized in that it comprises a mounting frame 1, a motor 2 arranged on the mounting frame 1, an output shaft 3 connected with the motor 2, and the The rotating handle 4 connected to the output shaft 3, and the deburring tool 7 connected to the rotating handle 4, which can shape the nozzle of the exhaust pipe and simultaneously deburr the outer wall and the inner wall of the exhaust pipe, the mounting frame 1 A fixed block 5 is also arranged on the top, and a bearing 6 is arranged on the output shaft 3, and the bearing 6 is located between the motor 2 and the rotating handle 4, and the bearing 6 is fixed in the fixed block 5. in the bearing mounting hole. During installation, the output shaft 3 is connected with the motor shaft through the coupling 8. This deburring device no longer adopts the method of directly using the tool to deburr in the prior art, but performs the ...

Embodiment 2

[0037] Embodiment 2: In order to improve the shaping effect, the mouth of the exhaust pipe can be properly heated to increase the deformability at the mouth of the pipe. Preferably, the device also includes a heating device, and the heating device can adopt a heat gun or an electric heating device. Heating wire. Therefore, the heating device can indirectly improve the deburring efficiency.

[0038] All the other are with embodiment 1.

Embodiment 3

[0039] Embodiment 3: A weight block 9 is fixedly arranged at the end of the rotating handle 4 away from the deburring tool 7 . The weight block 9 makes the center of mass of the turning handle 4 approach the center of rotation as much as possible, and the turning handle 4 rotates more stably. Correspondingly, the deburring cutter 7 is just more stable, and the deburring effect is just better. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com