Patents

Literature

204results about How to "Reduce runout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

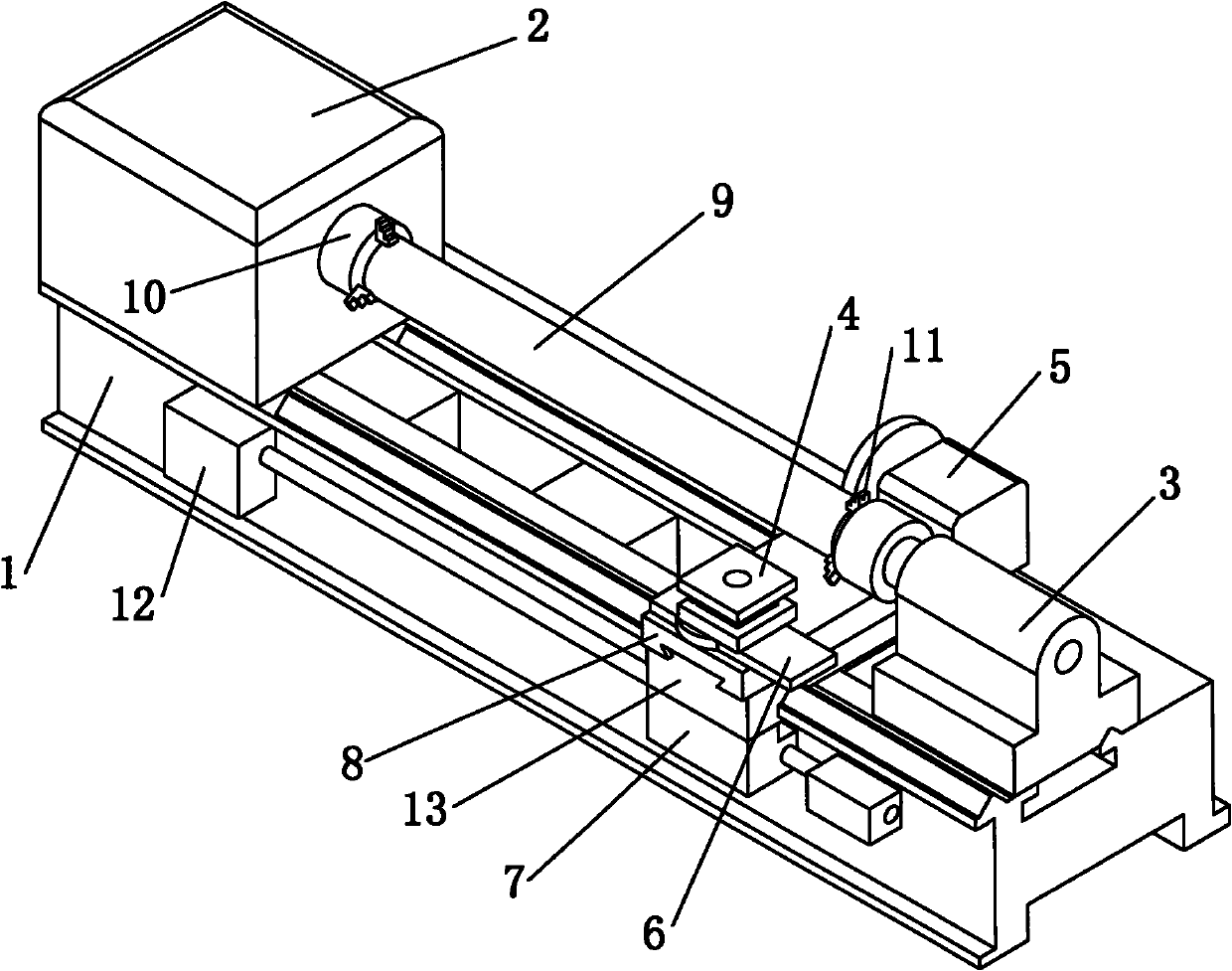

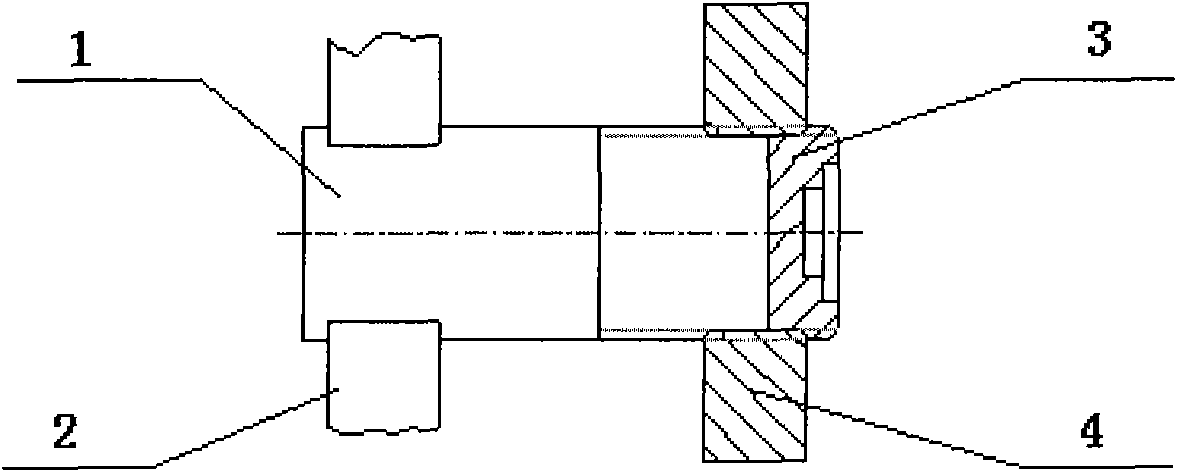

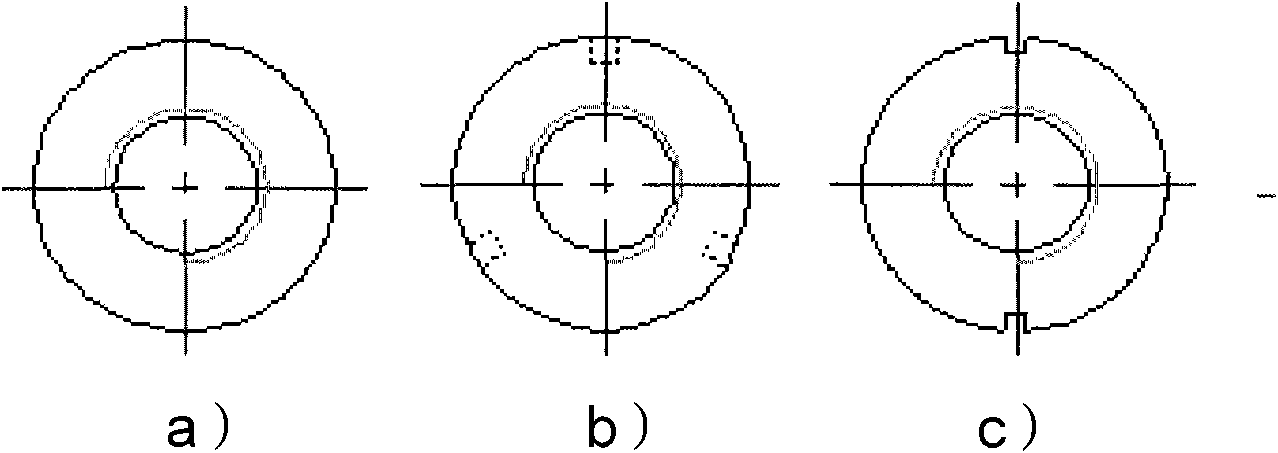

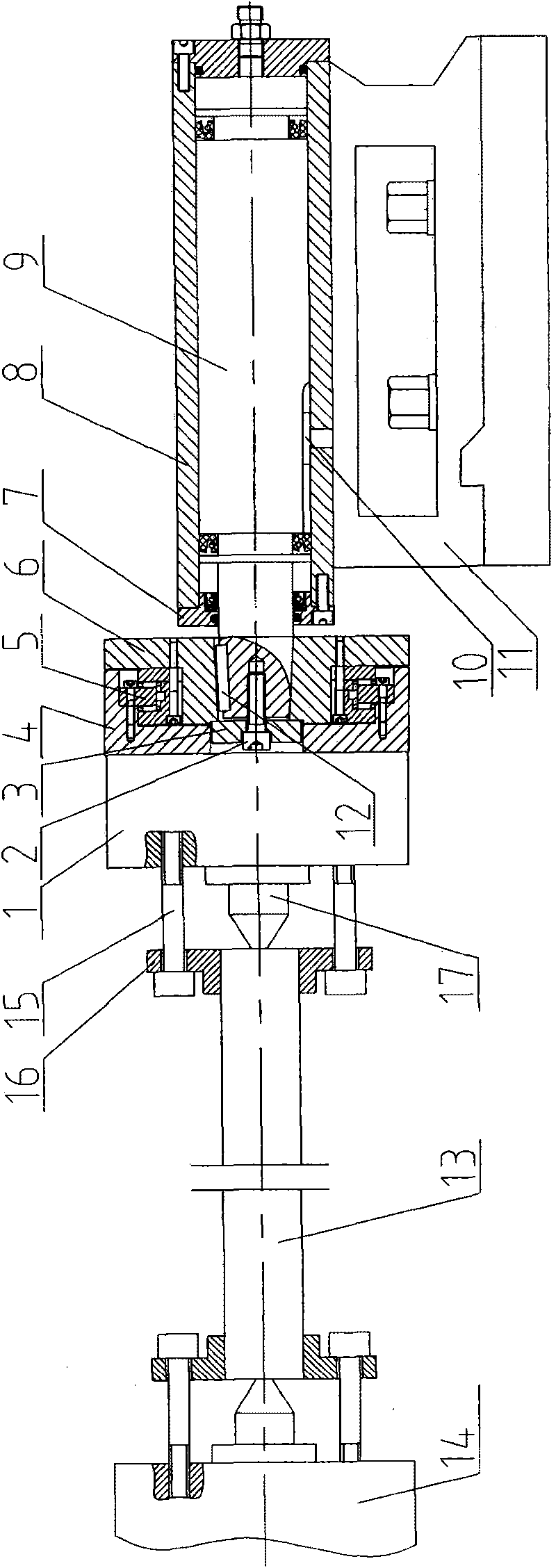

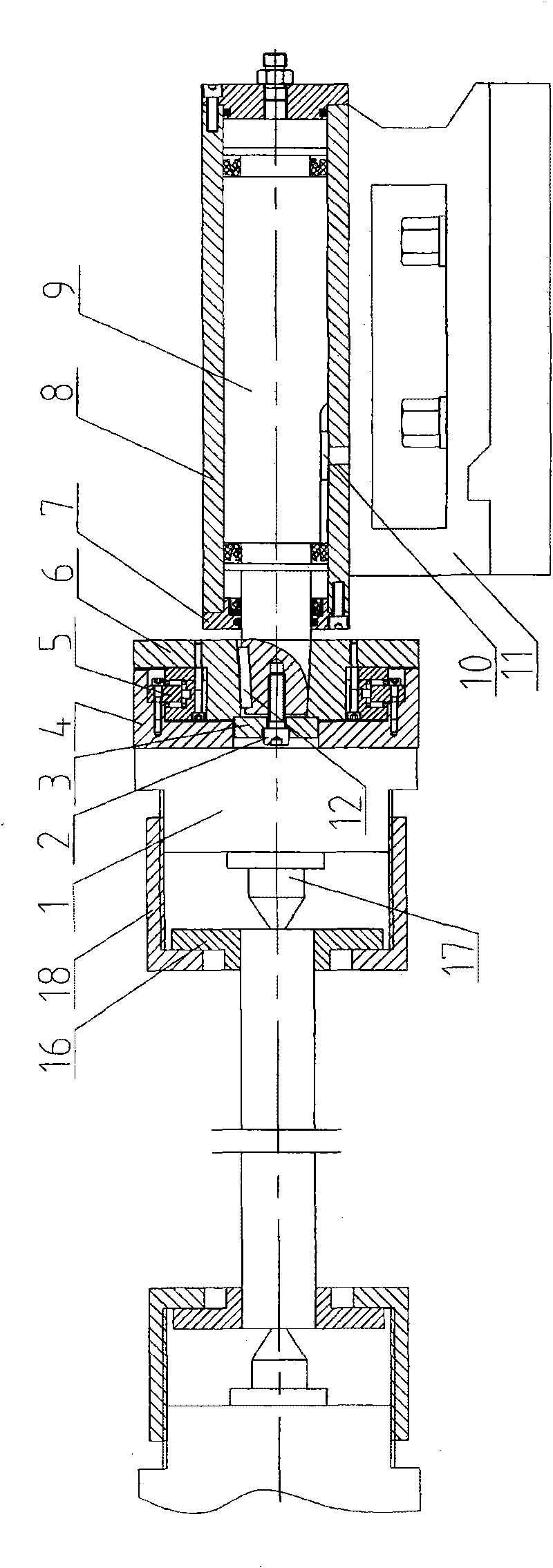

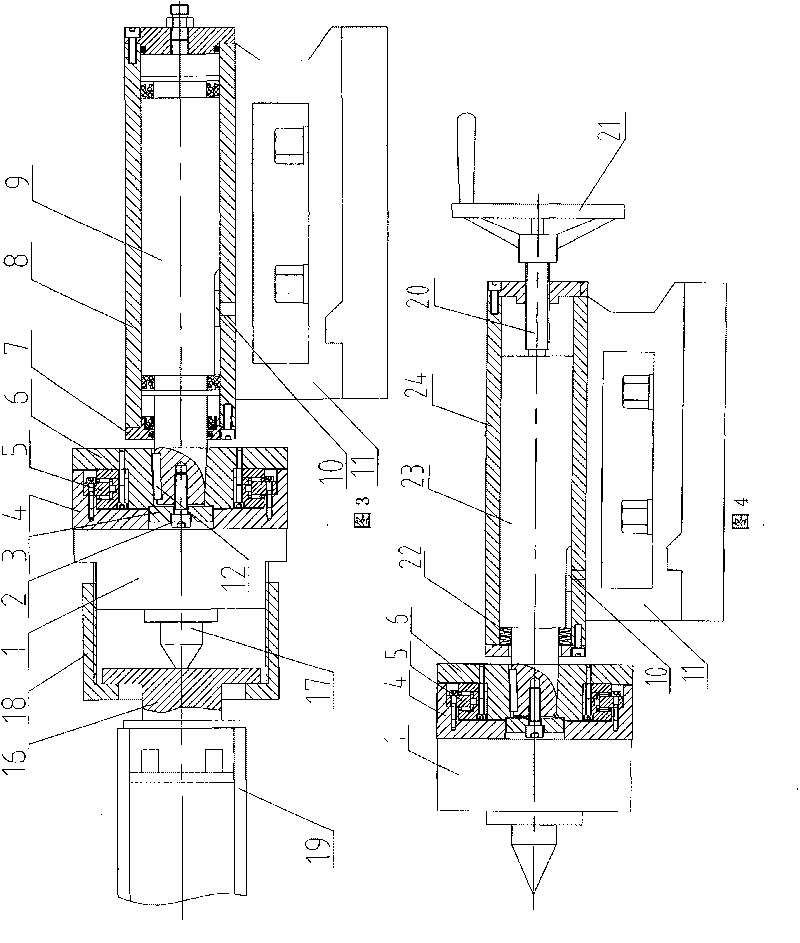

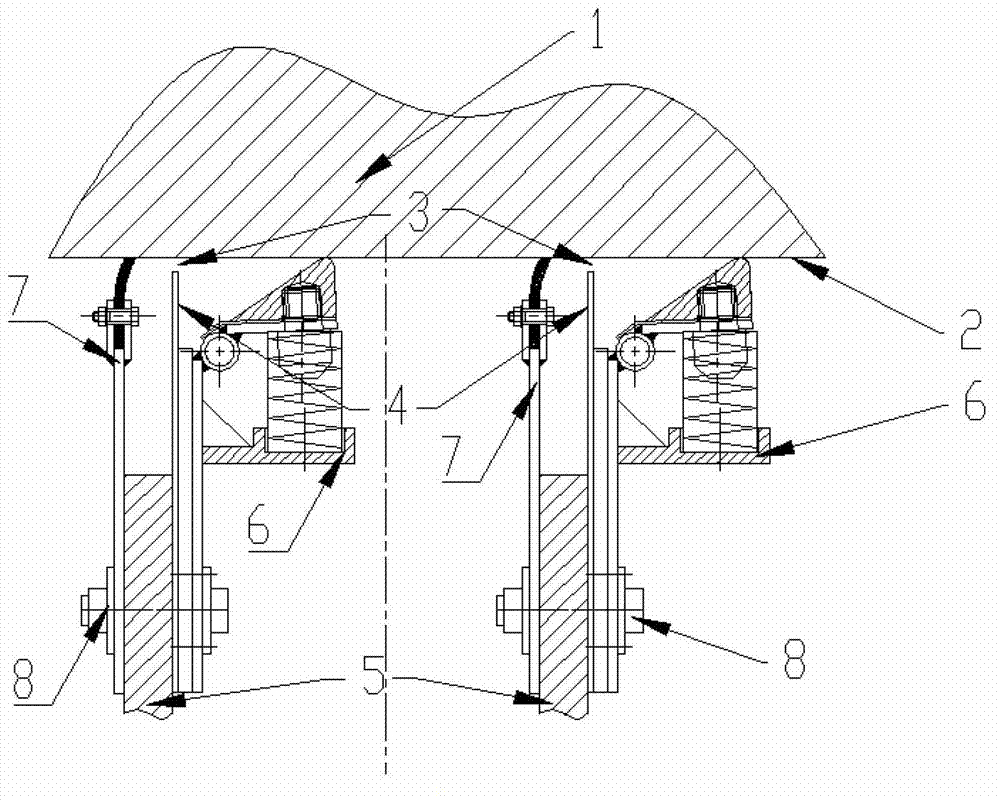

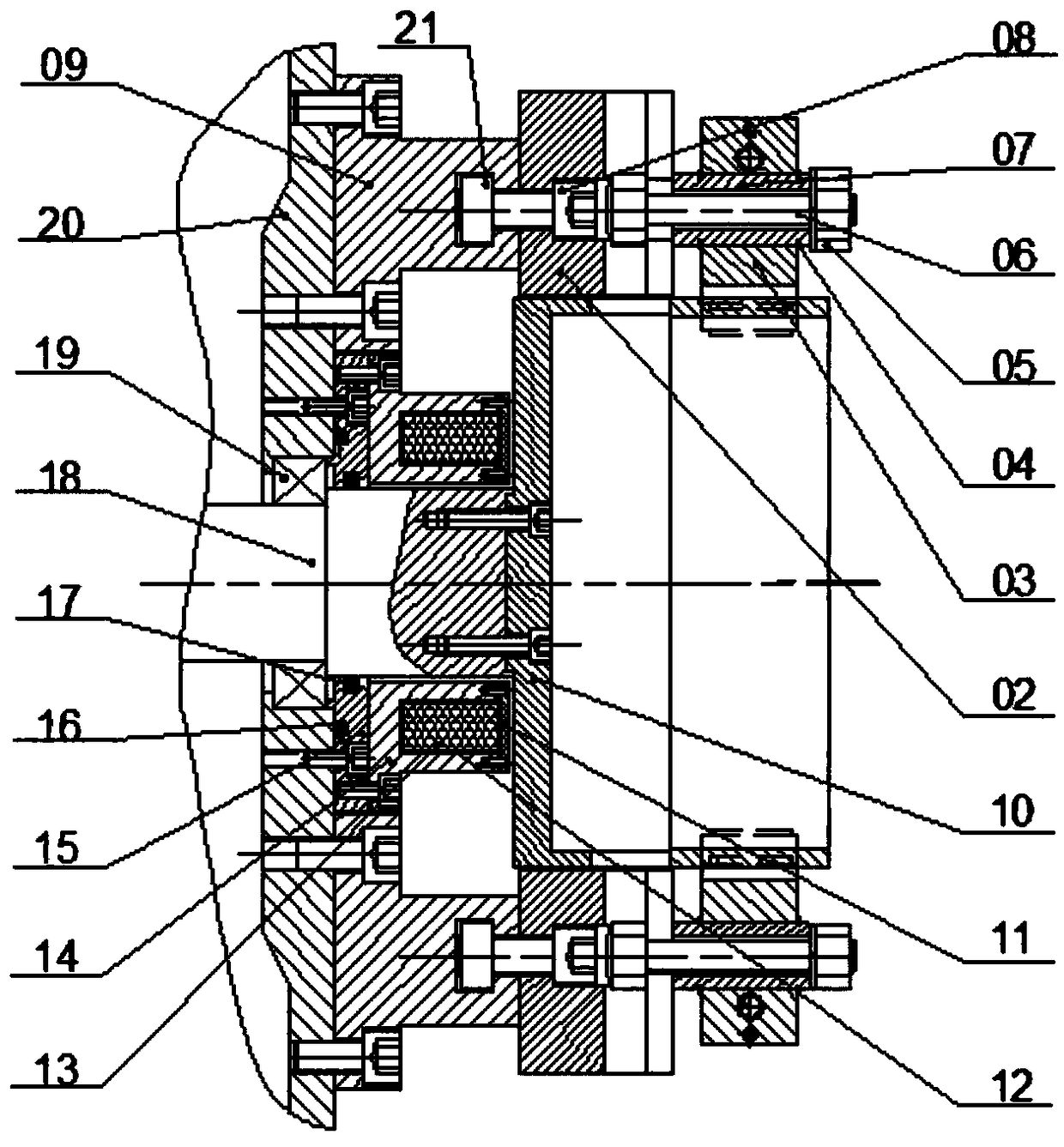

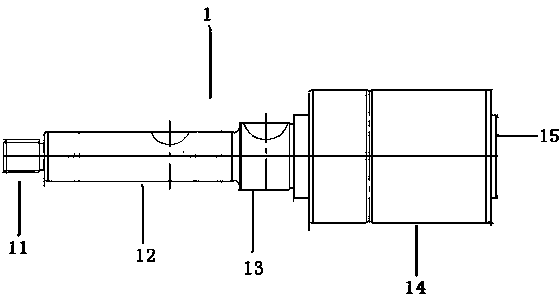

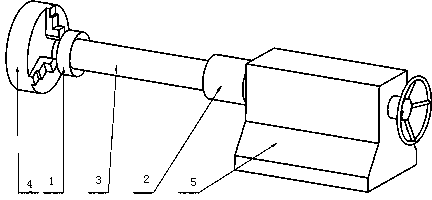

Machine tool for grinding composite workpiece under tensioning state

InactiveCN102000980AImprove rigidityReduce runoutTailstocks/centresOther manufacturing equipments/toolsPosition toleranceMachine tool

The invention provides a machine tool for grinding a composite workpiece under the tensioning state. The machine tool comprises a machine tool, a grinding device and a tailstock tensioning device, wherein the grinding device is arranged at one end of a carriage opposite to a knife rest in the machine tool and is connected with a feeding mechanism on the carriage; and the tailstock tensioning device is arranged on the rear of a machine tool body. The machine tool can finish turning and grinding axial workpieces, and can effectively reduce radial runout, circular degree and other form and position tolerances of the workpiece and improve the machining accuracy by adopting a clamping mode under the tensioning state.

Owner:赵显华

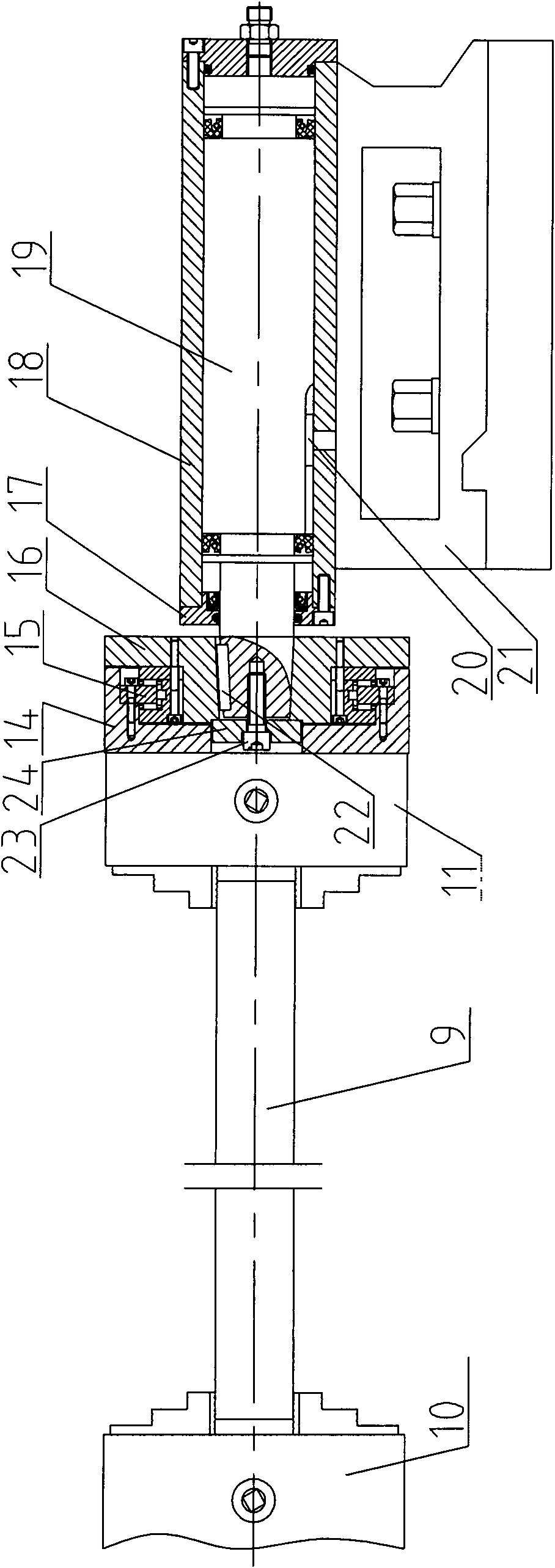

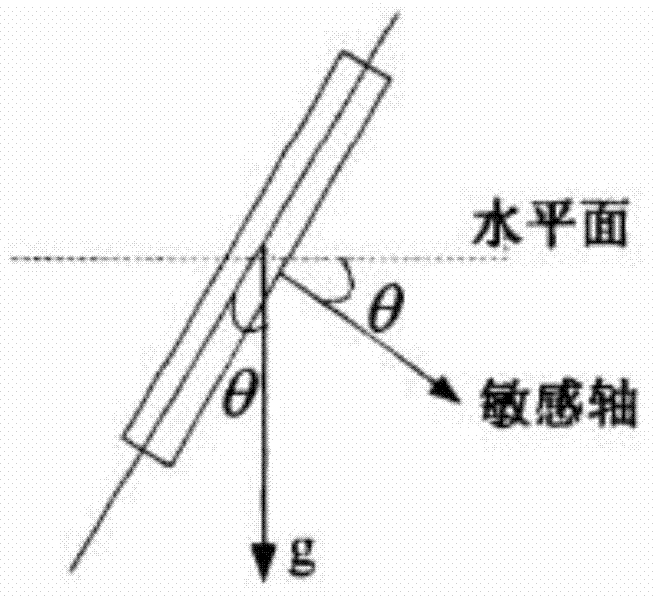

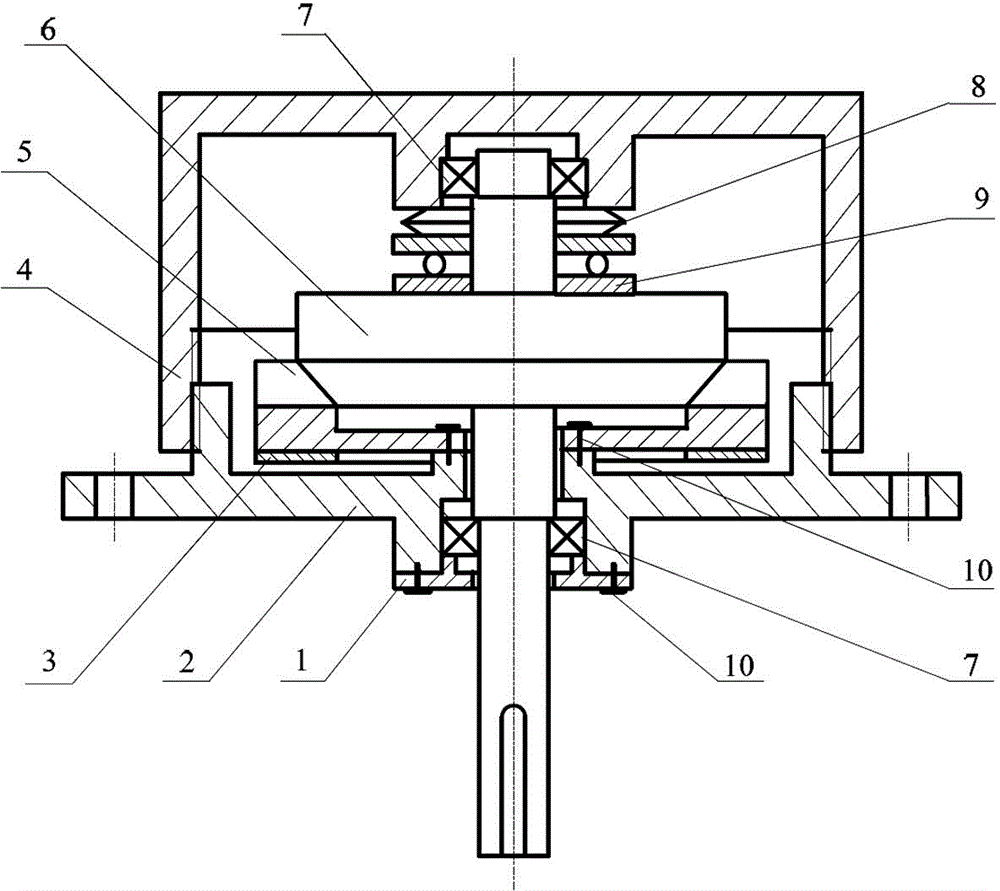

Calibrating device and calibrating method for borehole clinometer

The invention relates to an angle calibrating device and belongs to the detection field. The calibrating device for a borehole clinometer is characterized by comprising an angle encoder, a sample clamp and a corner drive mechanism, wherein the angle encoder is used as a main calibrating device, the sample clamp is used for fixedly installing the borehole clinometer to be detected, the angle encoder is horizontally arranged and connected with the sample clamp through a bearing rotating shaft base, the two sides of the bearing rotating shaft base are respectively provided with one bearing, the first bearing of one side of the bearing rotating shaft base is connected with the angle encoder, the second bearing of the other side of the bearing rotating shaft base is connected with the sample clamp, the angle encoder and the sample clamp rotate with the same rotating shaft and the same angle, and the corner drive mechanism is used for driving the angle encoder to rotate. According to the angle calibrating device, a cohesion type synchronous main shaft is adopted for connection, the coaxial precision is greatly improved, the stability and the reliability of the device are improved, value loss of output angle displacement transmitting from the corner drive mechanism to the bearing rotating shaft base is basically avoided, the calibration sensitivity is improved greatly, the configuration cost of the device is lowered, and the cost performance is greatly improved.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

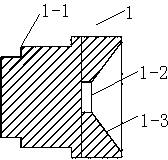

Turning positioning fixture for thin-wall rotational parts and clamping method

ActiveCN101972943AReduce distortionNot easy to damagePositioning apparatusMetal-working holdersEngineeringAxial force

The invention relates to a turning positioning fixture for thin-wall rotational parts and a clamping method. The fixture comprises a cylindrical positioning body and threaded rings, wherein an external thread is lathed on the external surface of the positioning end; the threaded rings are circular rings with internal diameter the same as the external diameter of the positioning body; the internal surfaces of the threaded rings are provided with internal threads matched with the external thread on the positioning body; and during positioning, one end of the positioning body is clamped on a machine tool and the positioning end is closely contacted with the part, and the positioning body is closely matched with the part through the external thread on the external surface and the internal threads on the threaded rings. In the embodiment, the clamp force on the part is mainly axial force, thus overcoming the negative effect that radial force leads to workpiece deformation during traditional machining; and the positioning body is clamped and lathed at the site, and during positioning and clamping, firstly the positioning body is ensured to be fit with the end face of the part and the end face runout of the part is ensured to be identical with that of the spindle of the machine tool, thus ensuring the flatness and the parallelism of the part. The fixture can carry out automatic alignment and positioning while screwing the threaded rings, is convenient to operate and reduces artificial operation errors.

Owner:BEIJING RES INST OF TELEMETRY

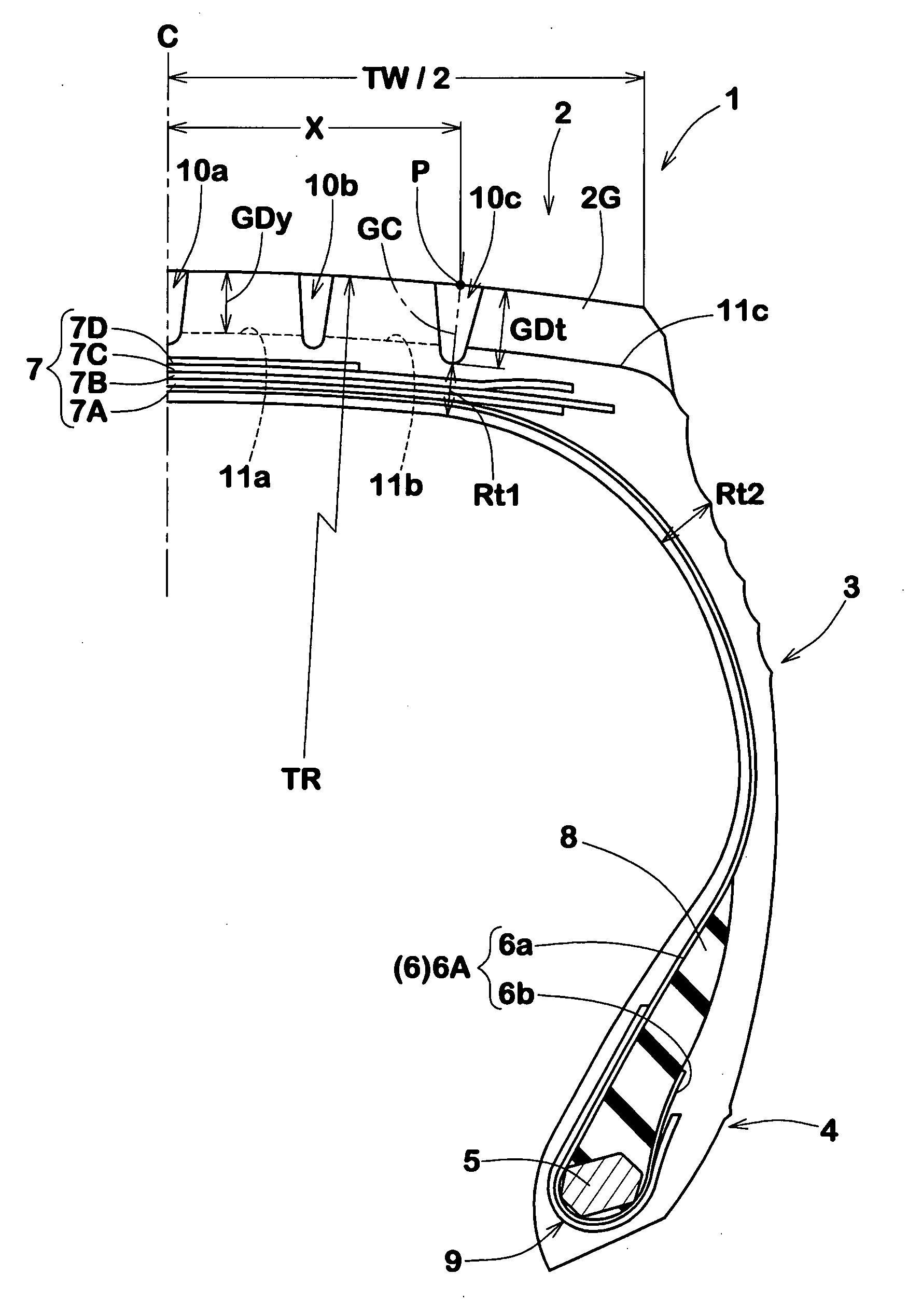

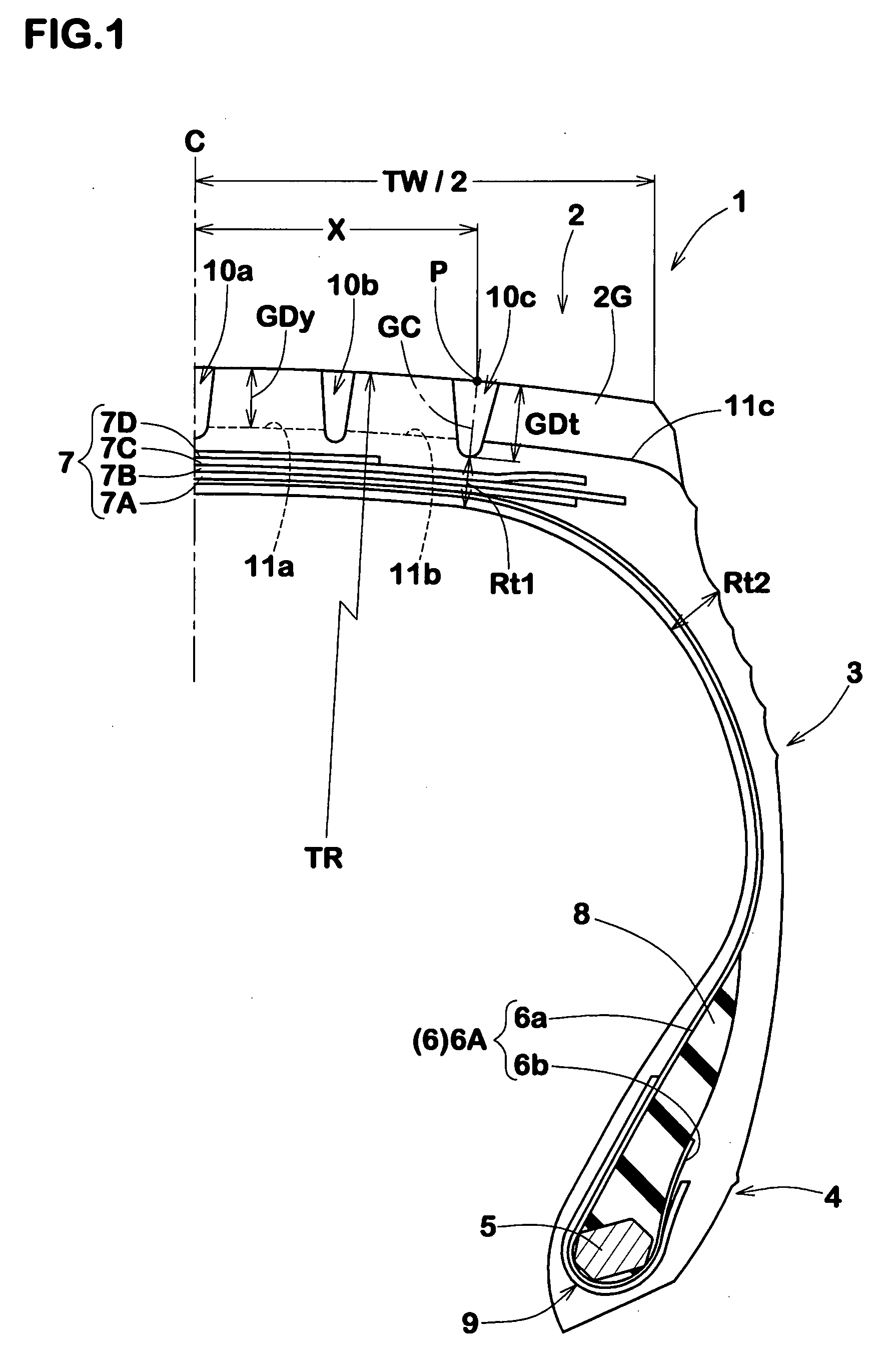

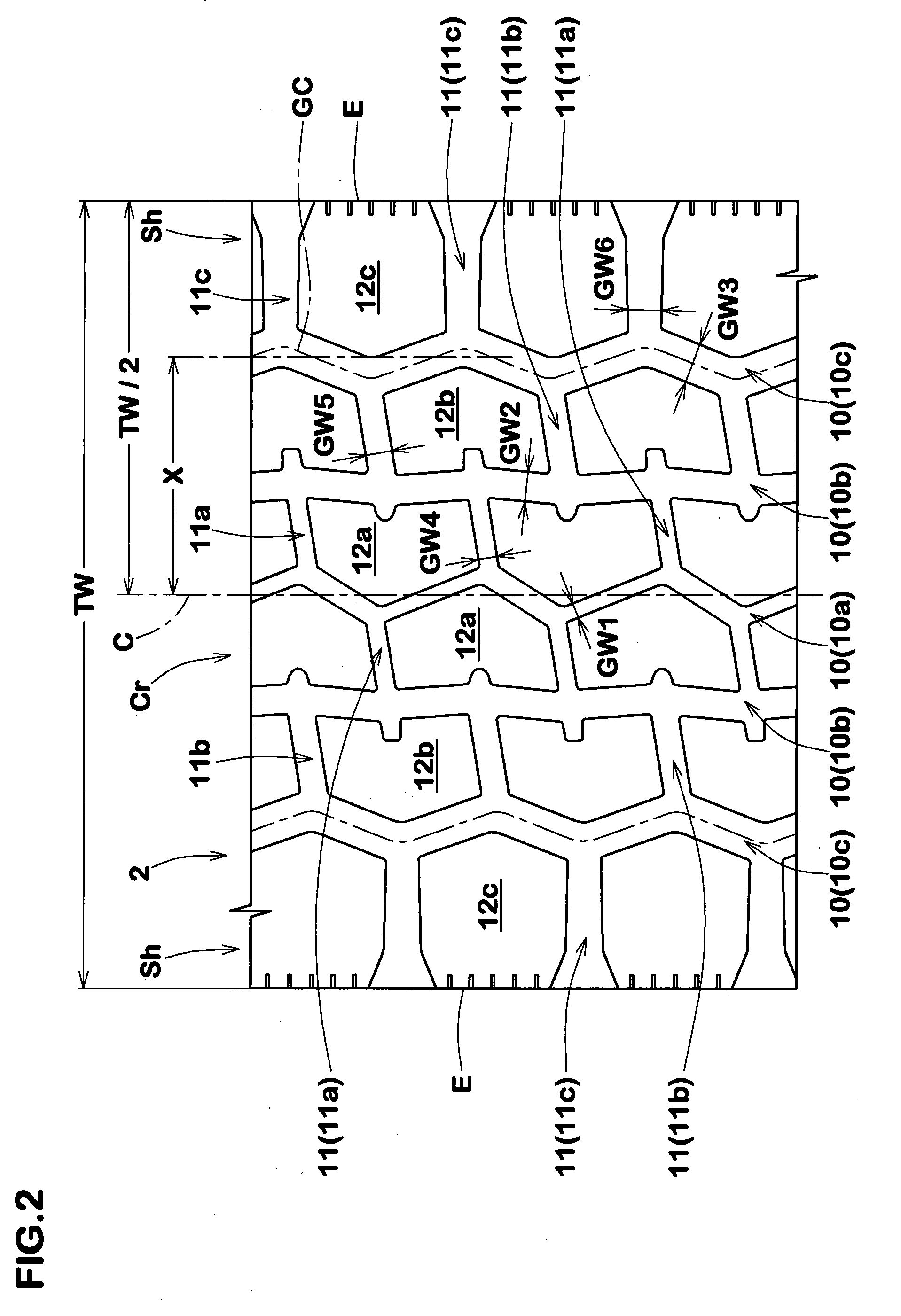

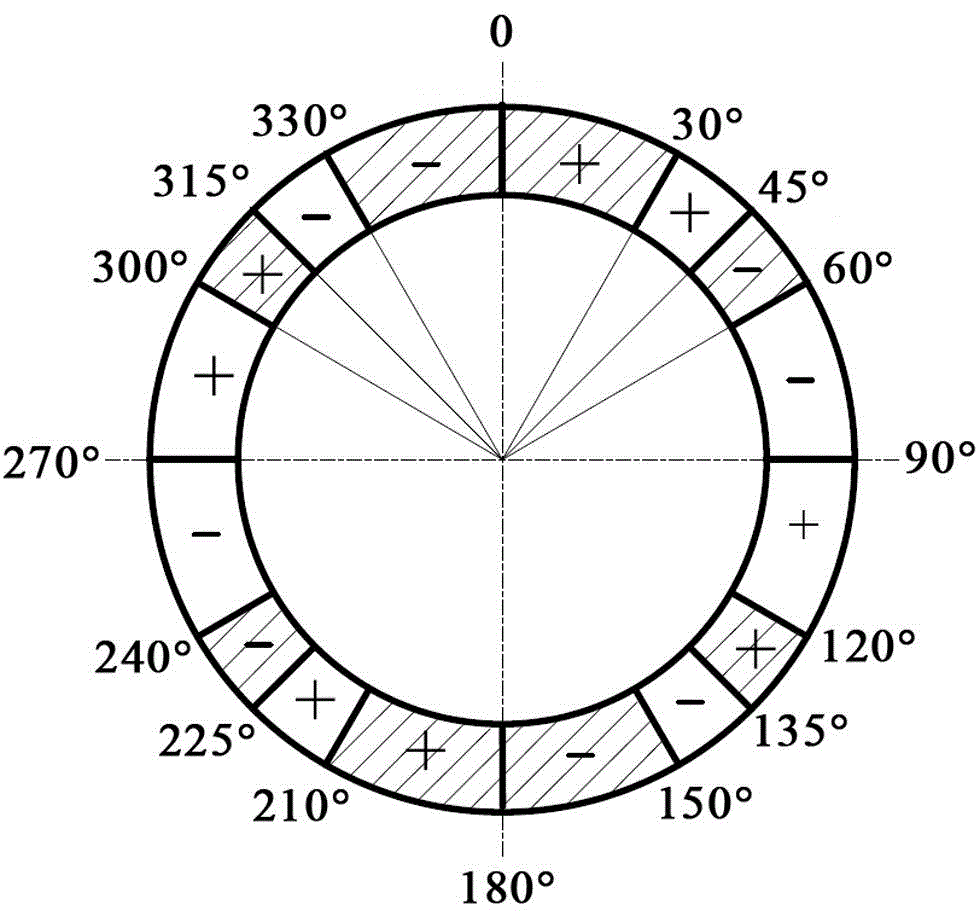

Heavy duty tire

InactiveUS20080047643A1Reducing radial run-outUneven tread wearPneumatic tyre reinforcementsTyre tread bands/patternsHeavy dutyMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

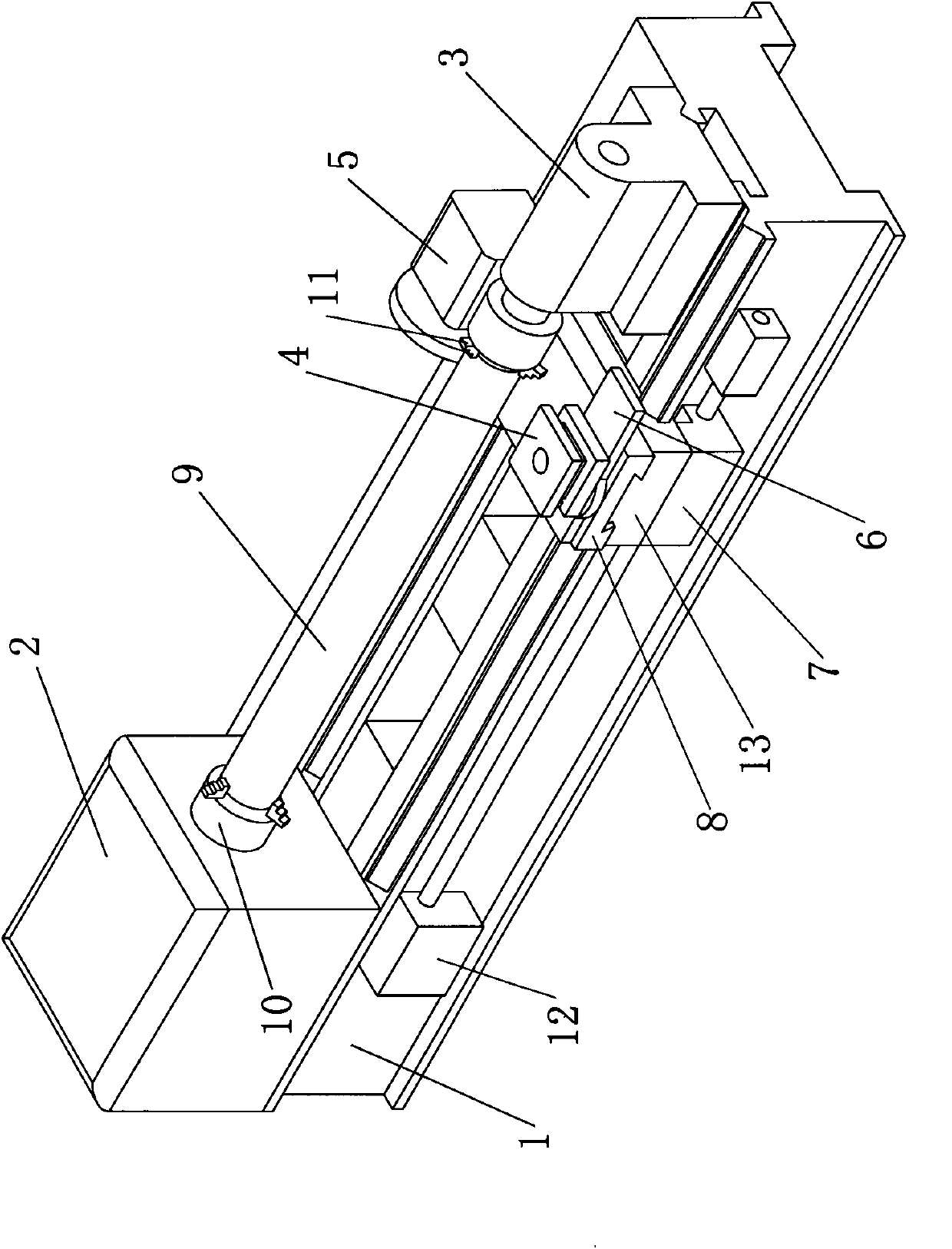

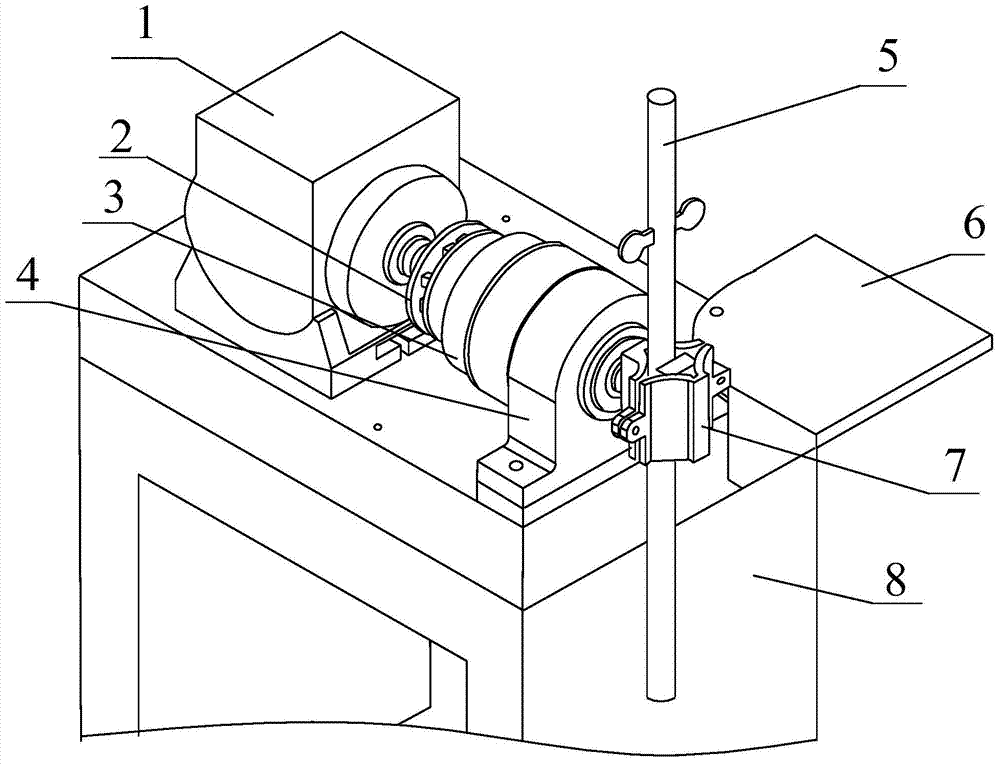

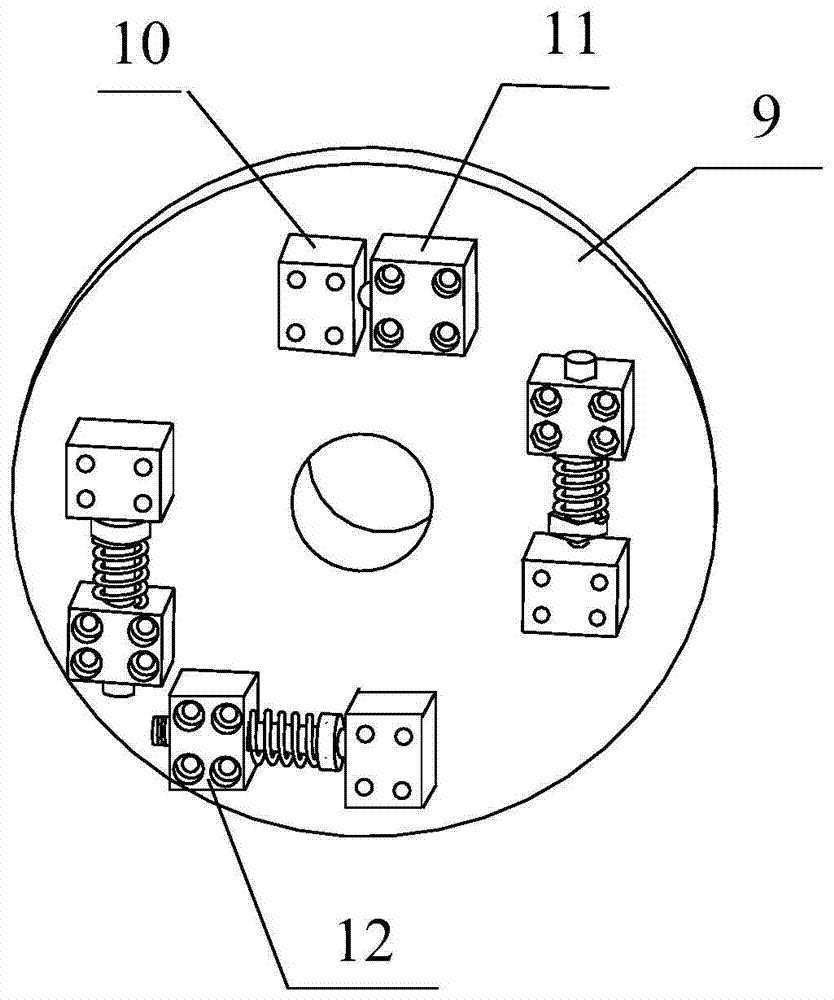

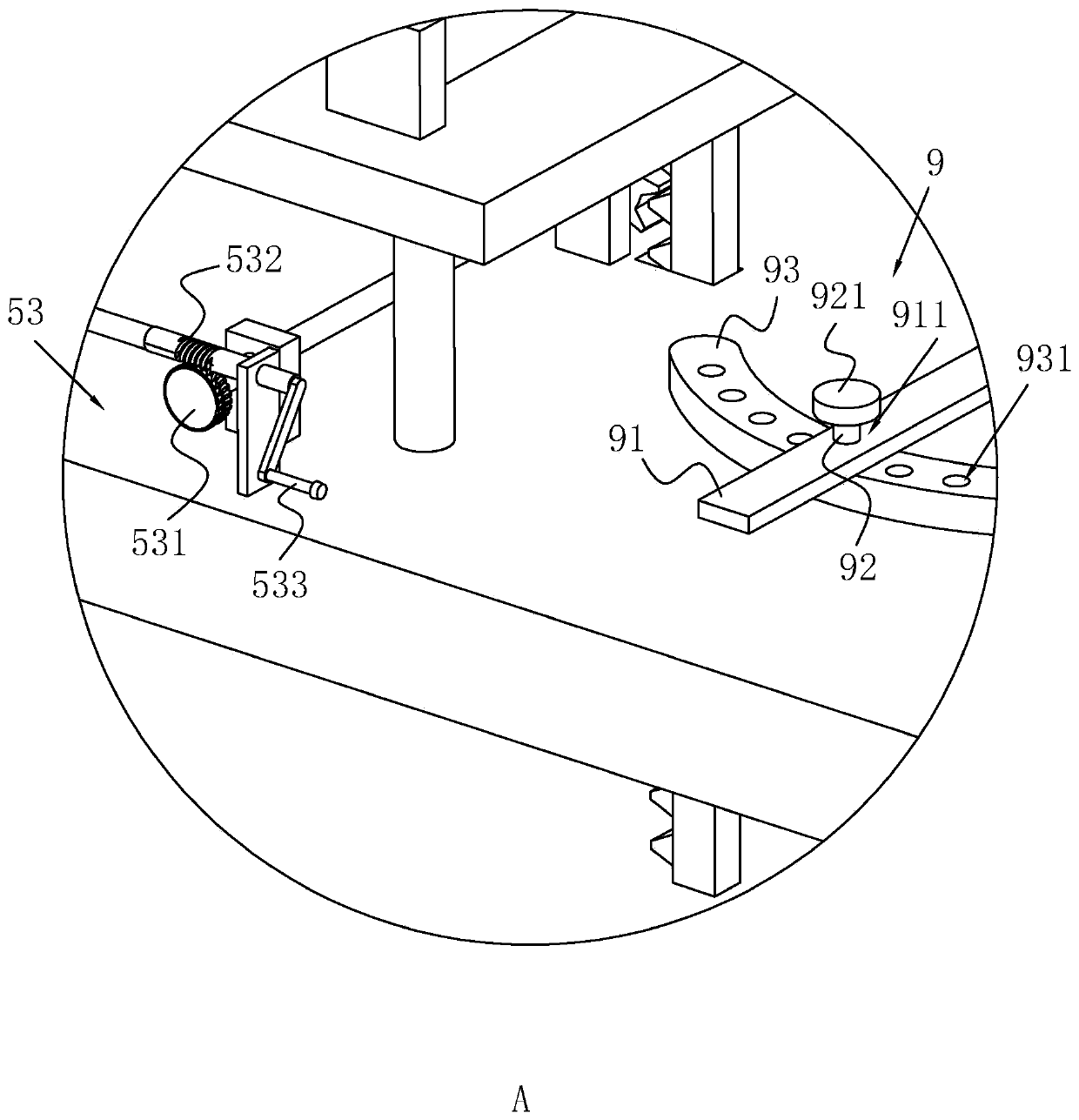

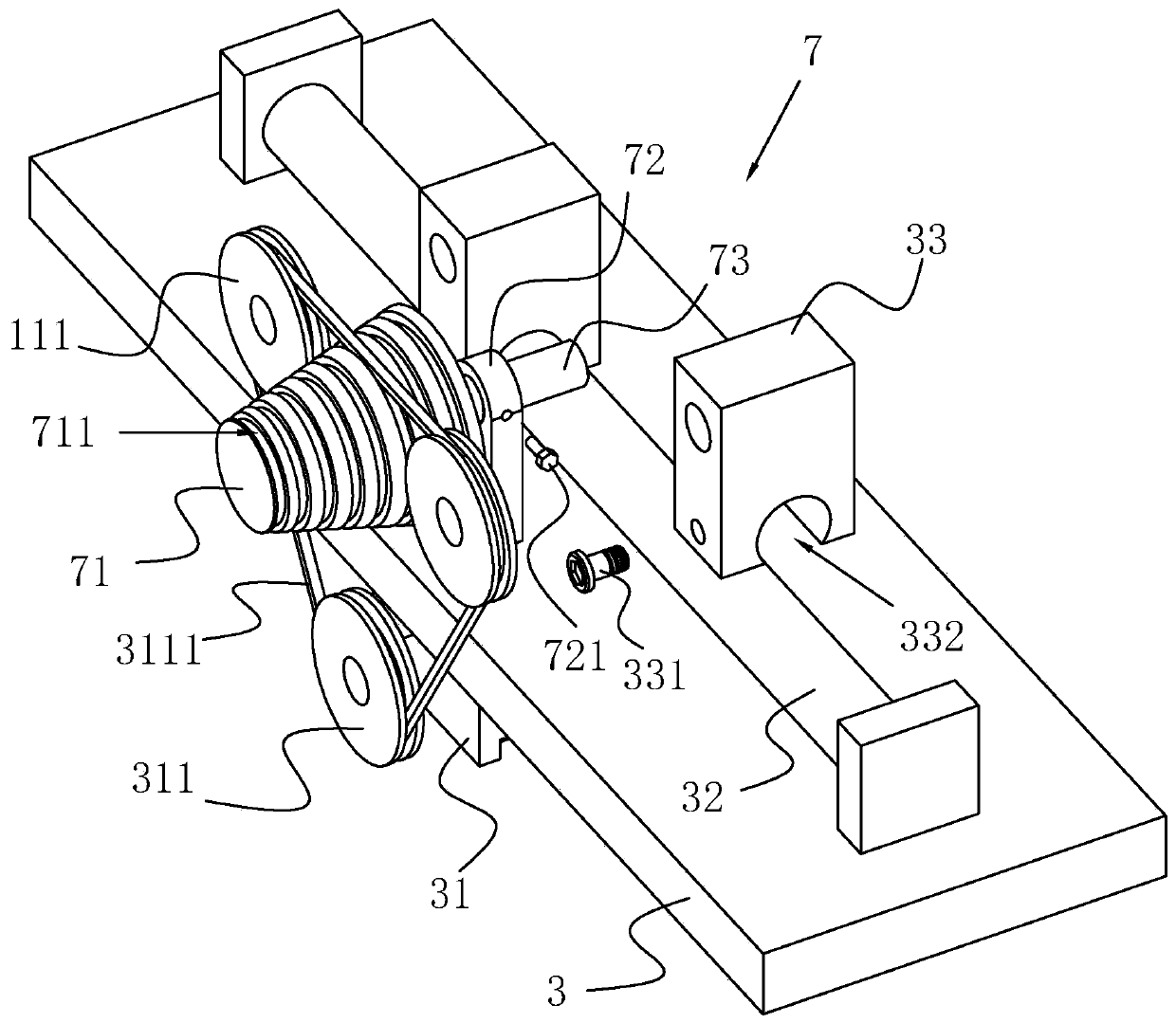

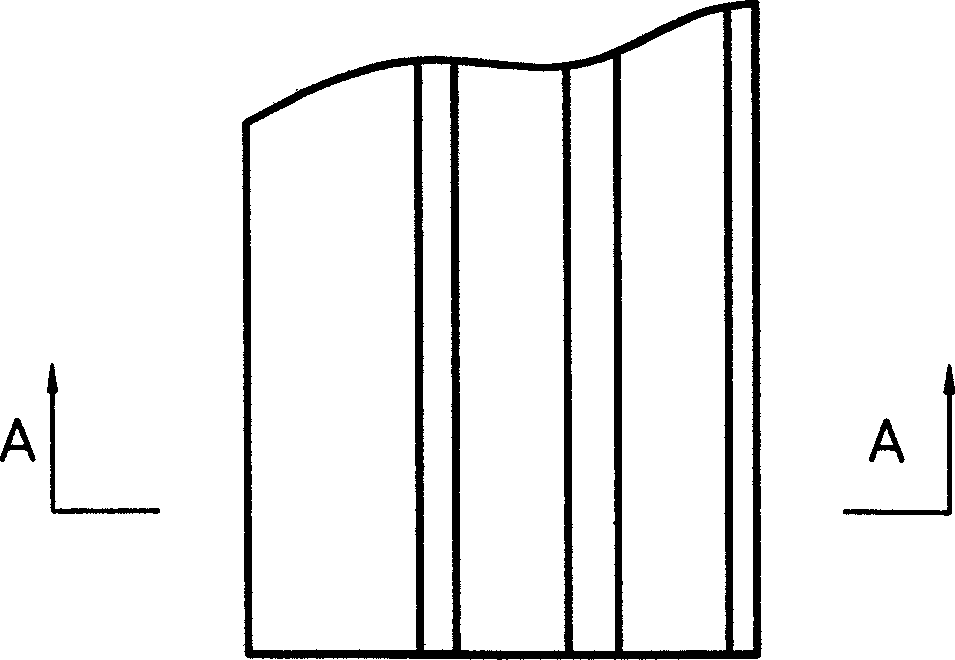

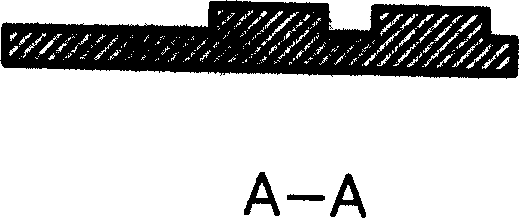

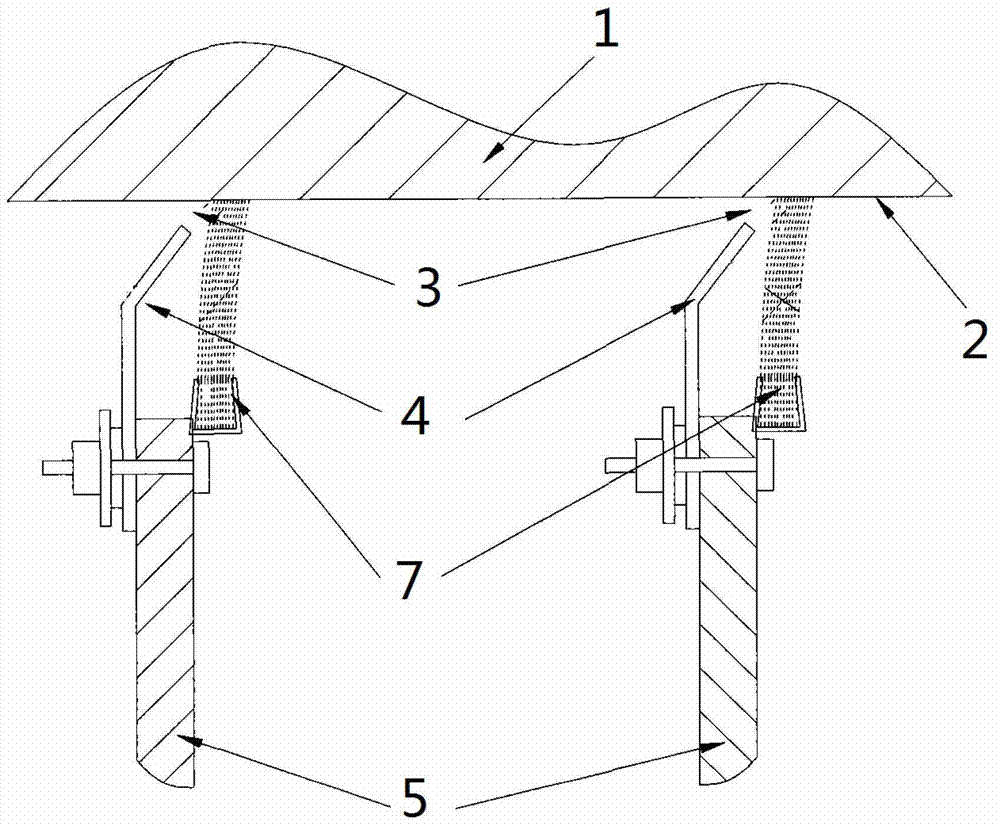

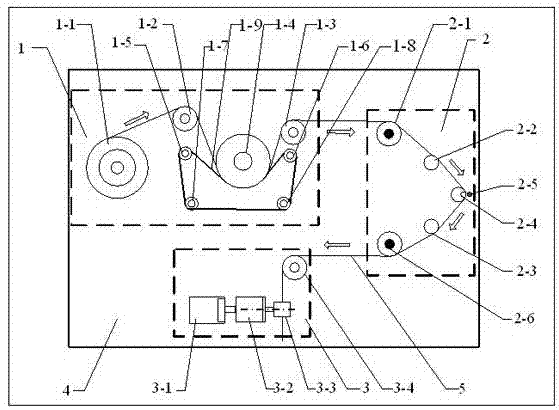

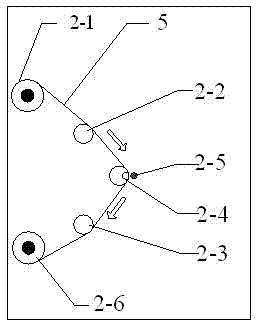

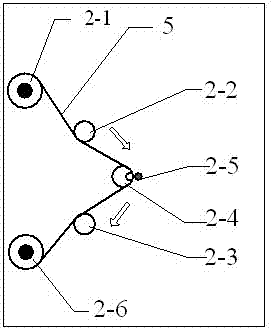

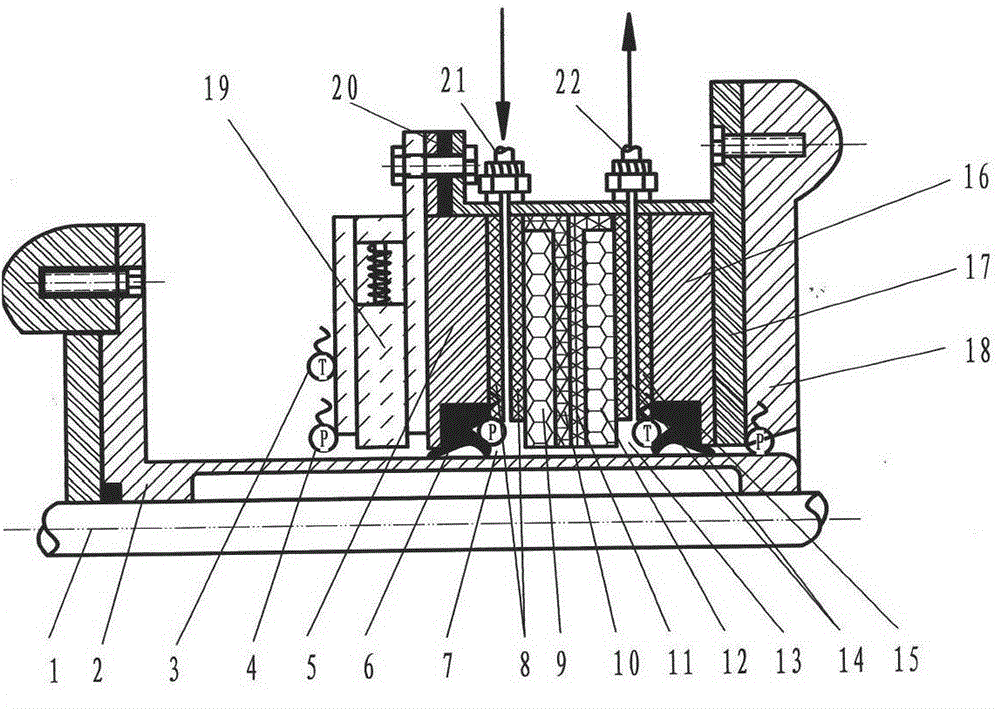

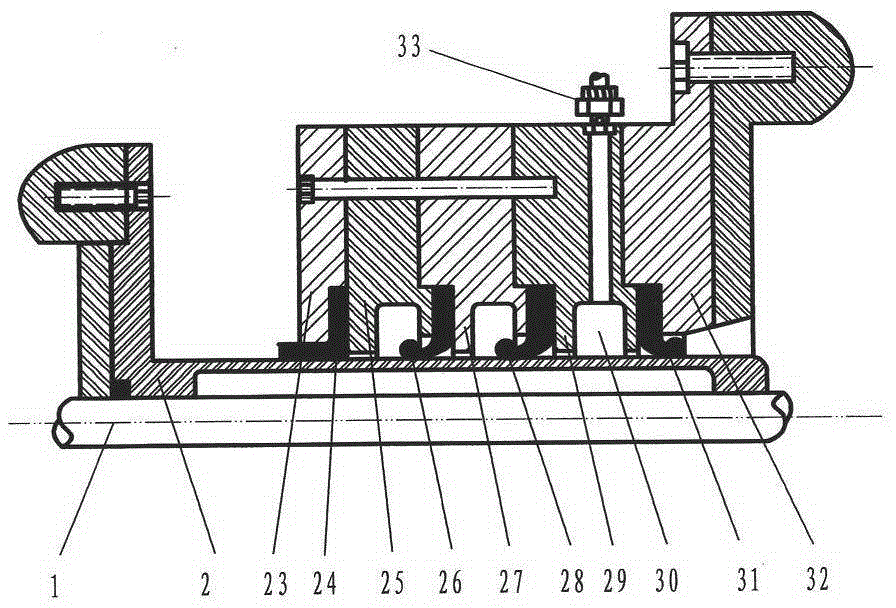

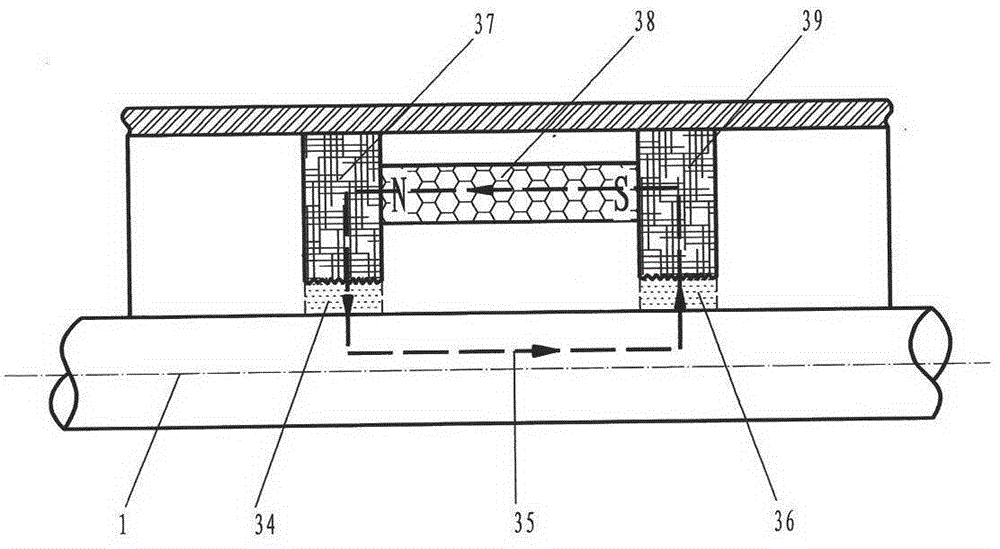

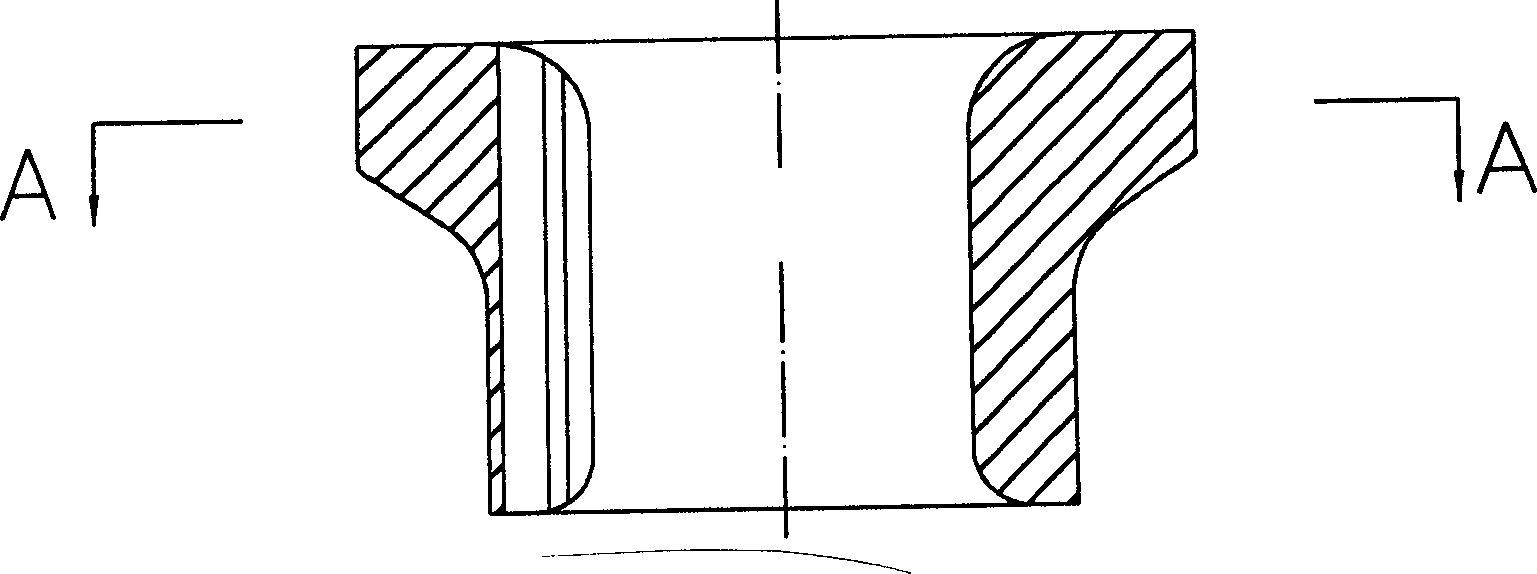

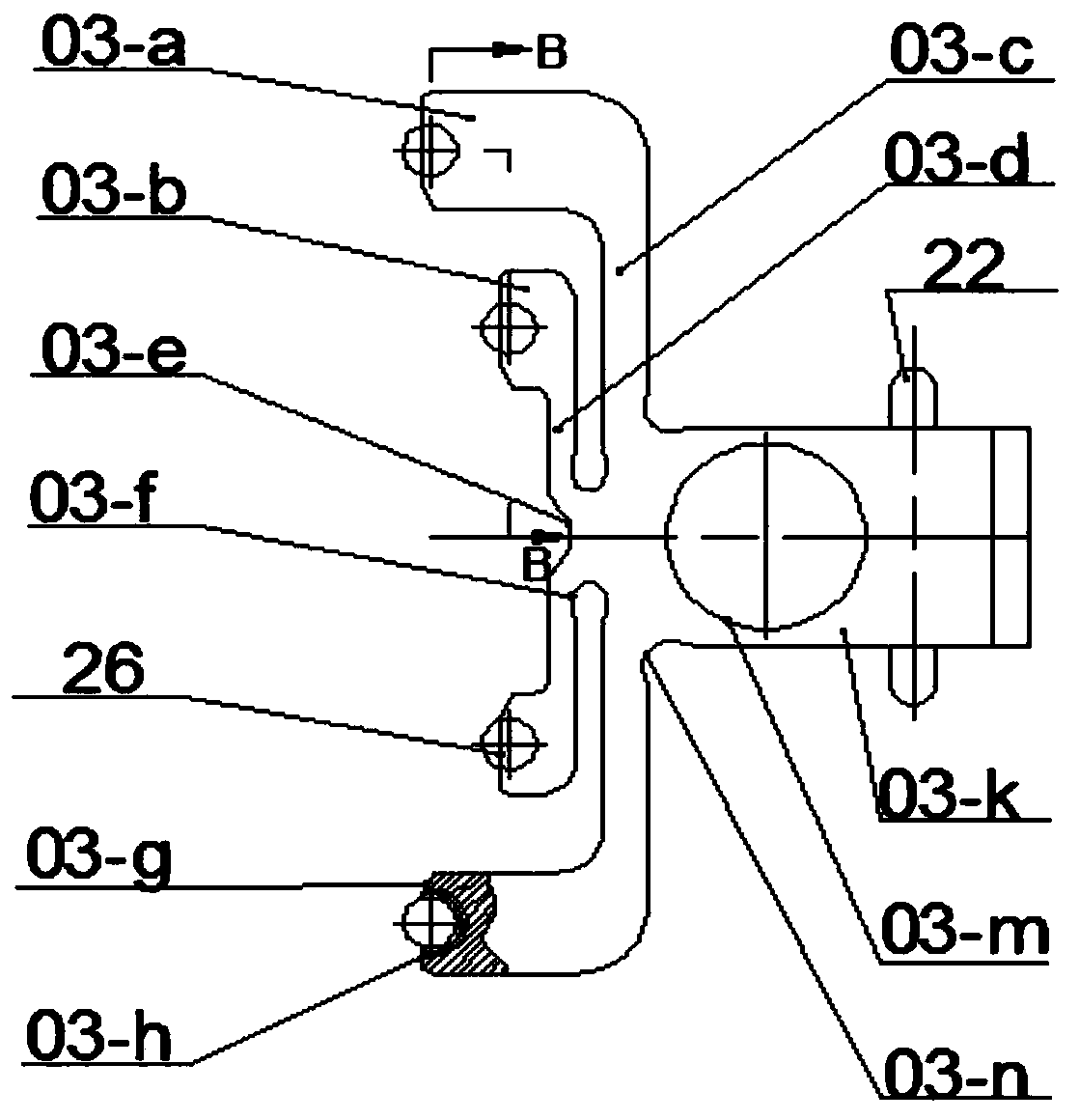

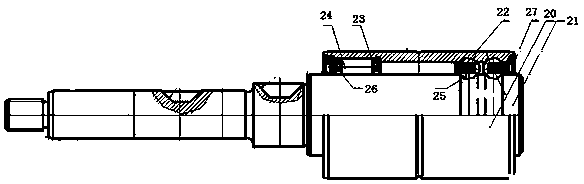

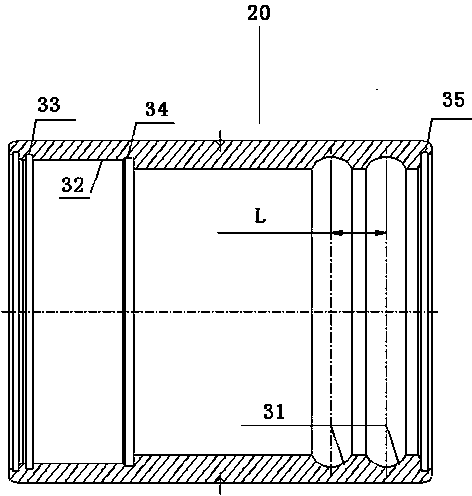

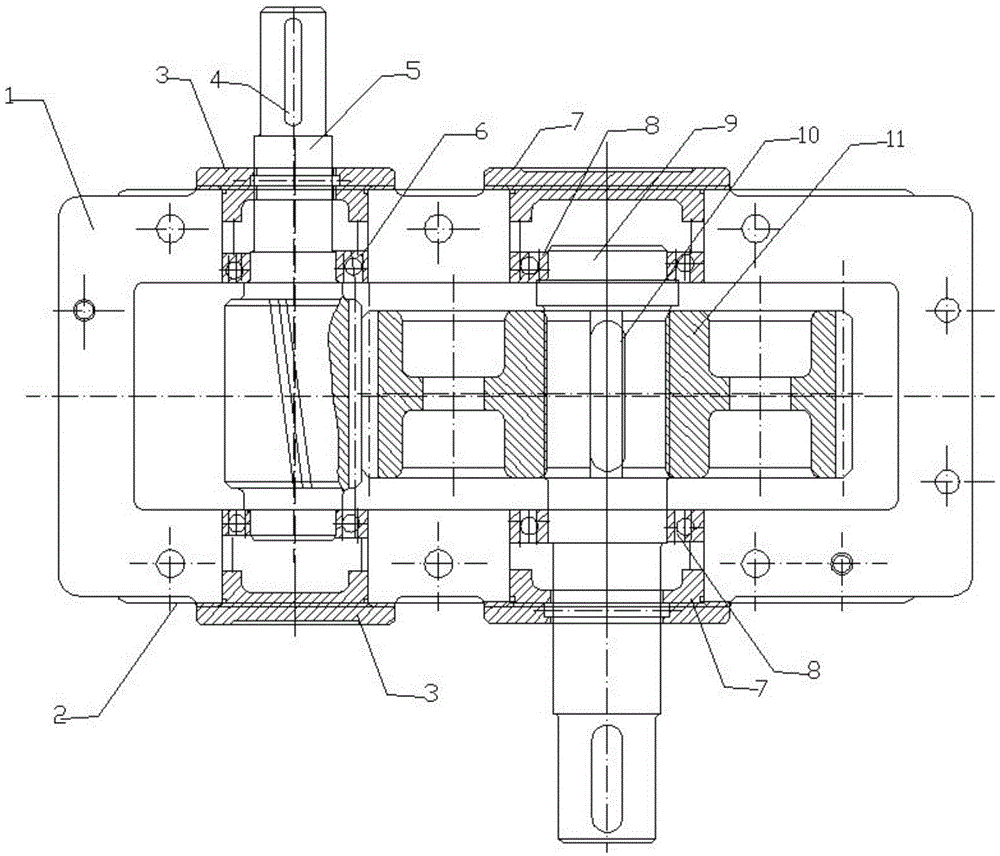

Technique and device for processing shaft type and pipe type workpieces in tightened state

InactiveCN101733655AImprove rigidityReduce runoutAutomatic conveying/guiding stockPositioning apparatusProcessing accuracyPull force

The invention provides a technique and a device for processing shaft type and pipe type workpieces in a tightened state. In the technique, the two ends of a workpiece are positioned by propping a central hole by a tip; then one end of the workpiece at a machine tool spindle end is pulled or a technical head of the workpiece at the machine tool spindle end is pulled; the tip at a back end and the other end of the workpiece or the technical head at the other end are pulled backwards under the same pulling force so as to ensure that the workpiece is in the tightened state; and therefore, the workpiece is not only positioned through the tip, but also is in the tightened state to perform outer circle processing. The device comprises a floating chuck arranged at the front end of a machine tool spindle and a tightening device arranged on the tail part of a machine tool, wherein the tightening device is also provided with the floating chuck; and the back end of the tightening device is provided with a hydraulic cylinder for a pull rod of the floating chuck. The technique and the device can ensure that the same positioning datum is adopted during multi-station processing and process the workpiece in the tightened state, so the processing rigidity of the workpiece is enhanced, the workpiece tends to elongate in the axial direction and the processing accuracy can be effectively improved.

Owner:赵显华

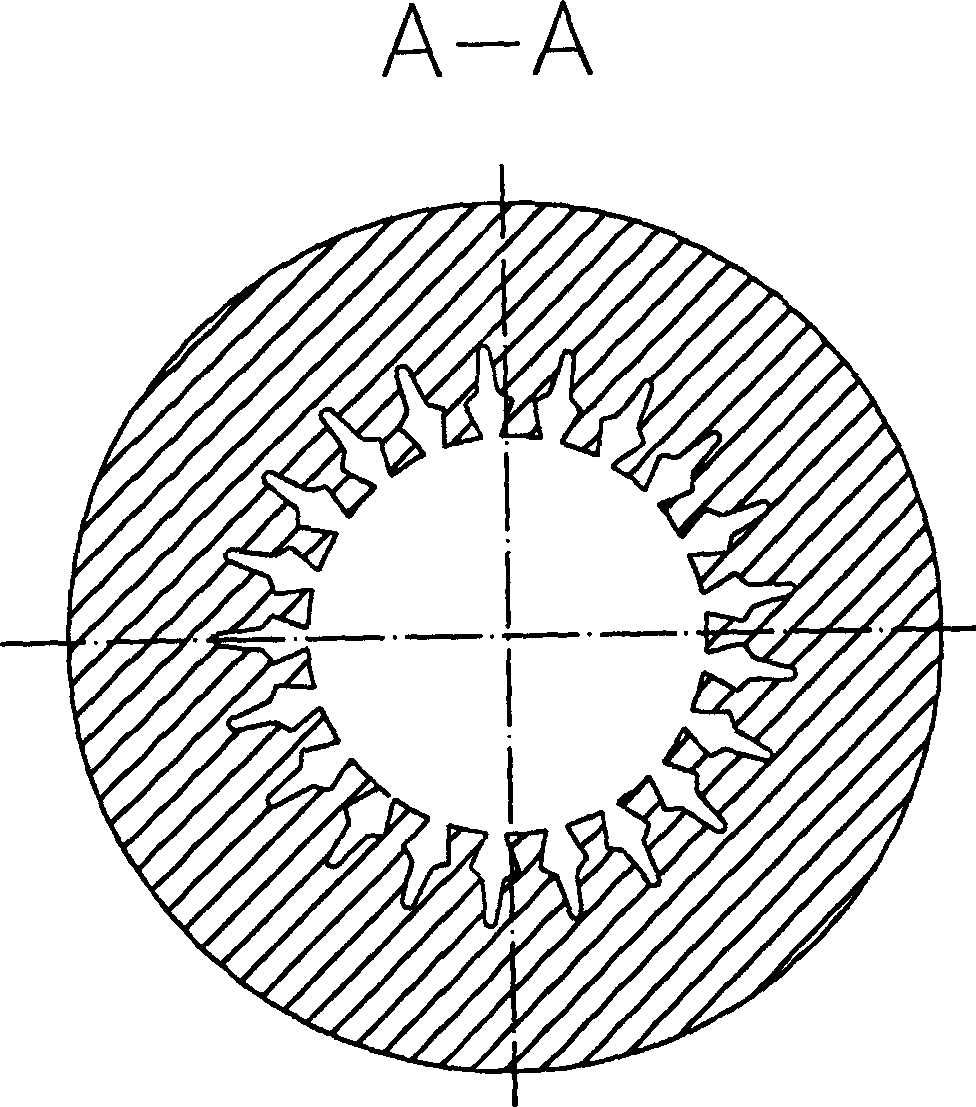

Standing-wave type ultrasonic motor of two driving frequency

InactiveCN104377988AEasy to driveImprove controlPiezoelectric/electrostriction/magnetostriction machinesElectricityElectric machine

The invention provides a standing-wave type ultrasonic motor of two driving frequency, which comprises a base, a preloaded shell, a stator, a piezoelectric ceramic piece, a rotor, a thrust bearing and a disc spring. The stator is arranged on the base; a shifting gear used for shifting the rotor is disposed on the upper surface of the stator; the rotor passes through a central axial hole of the stator and matches with the inner side of the shifting gear of the stator; an upper and lower shaft of the rotor are respectively connected with the preloaded shell and the base; the thrust bearing and the disc spring are disposed on the upper share of the rotor; the piezoelectric ceramic piece of a circular ring sheet structure is adhered at the lower surface of the stator; a polarization partition disposed on the piezoelectric ceramic piece is capable of respectively stimulating the stator to produce two different bending vibration modes under the driving of input voltage with two different frequency. Driving frequency of the ultrasonic motor is changed to allow the motor to externally output two different torques and speeds, and thus, using range of the motor is enlarged, driving and control ability of micro electromechanical products are improved.

Owner:HEBEI UNIVERSITY

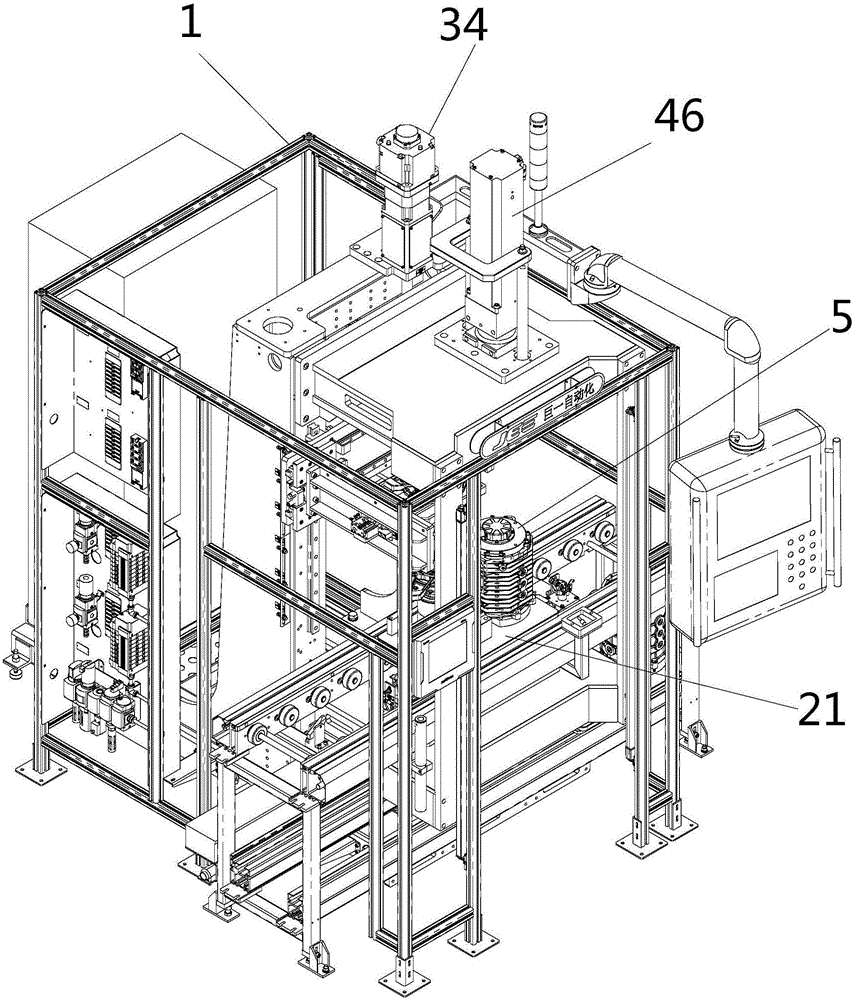

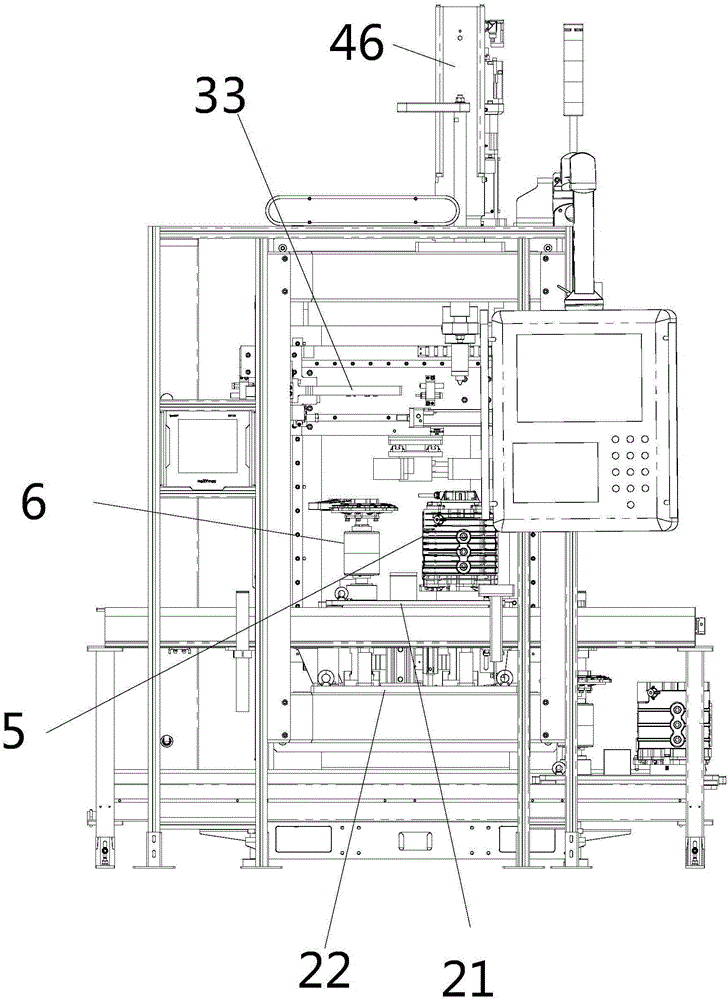

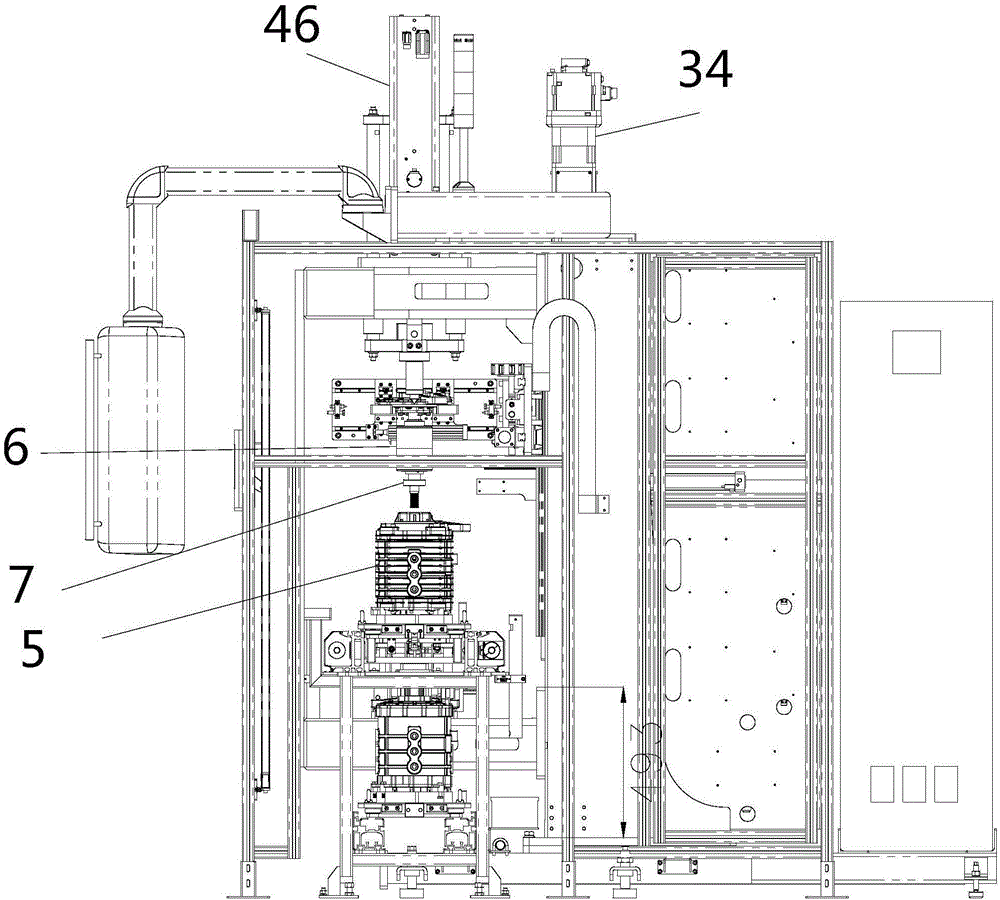

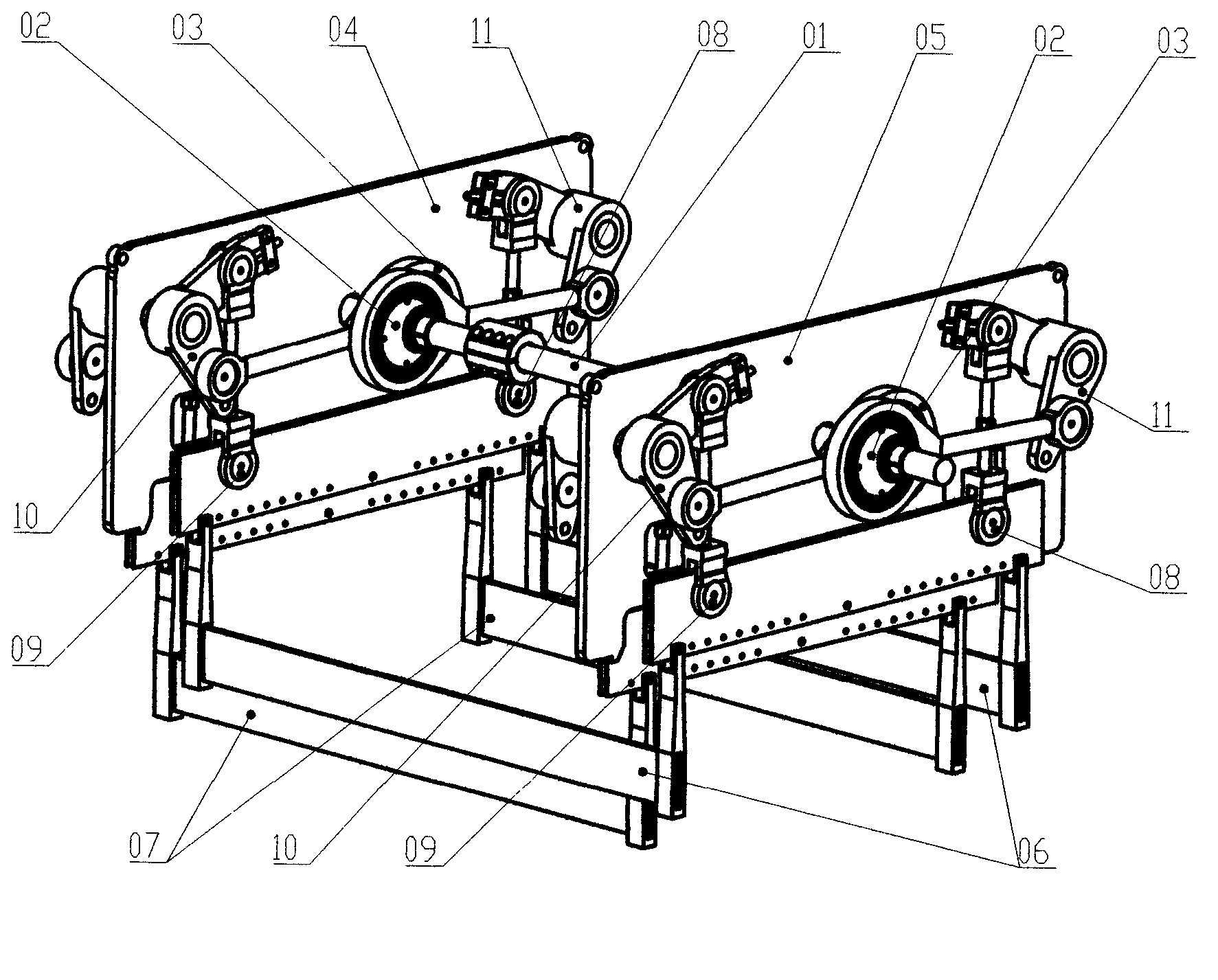

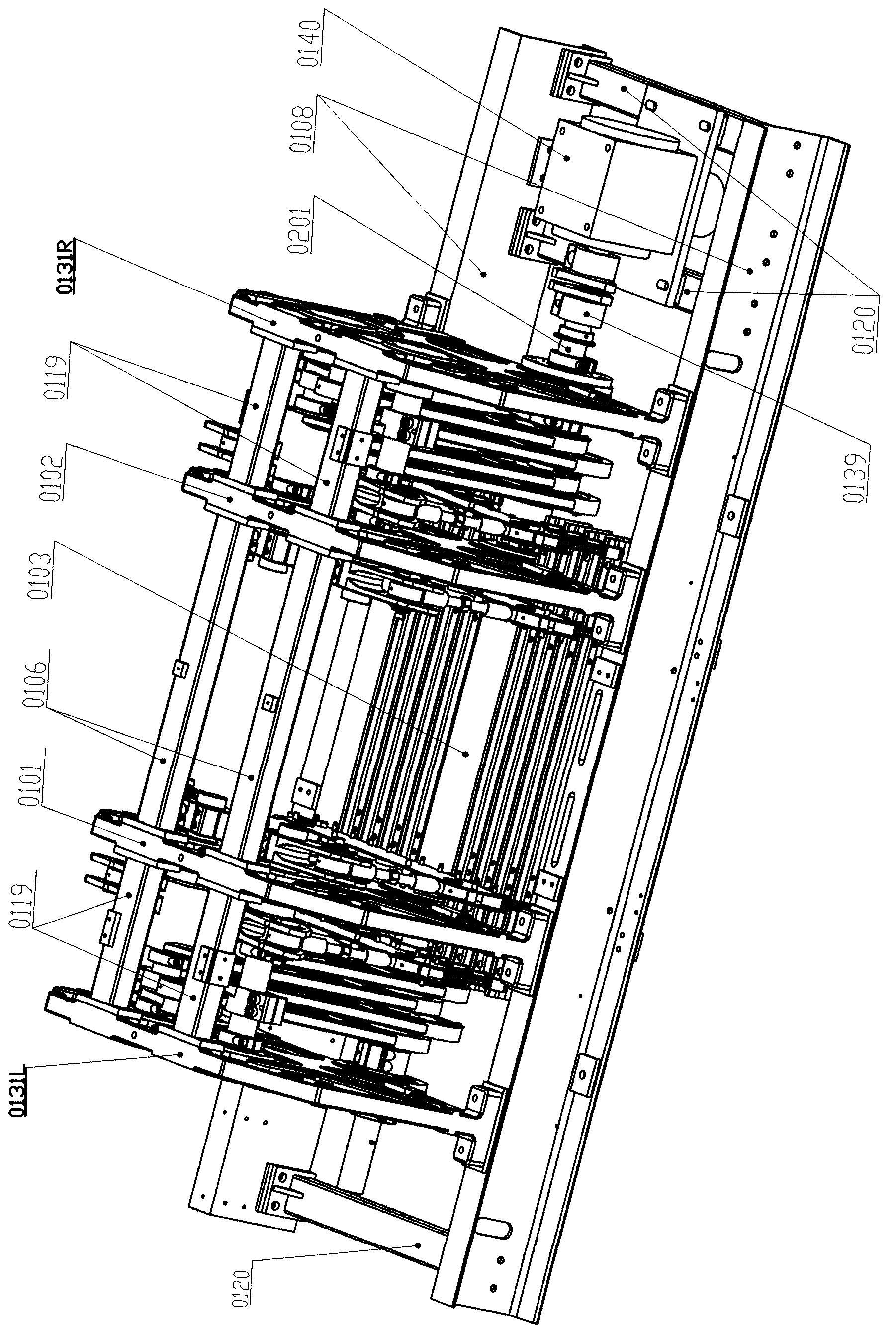

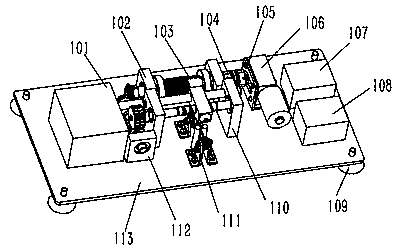

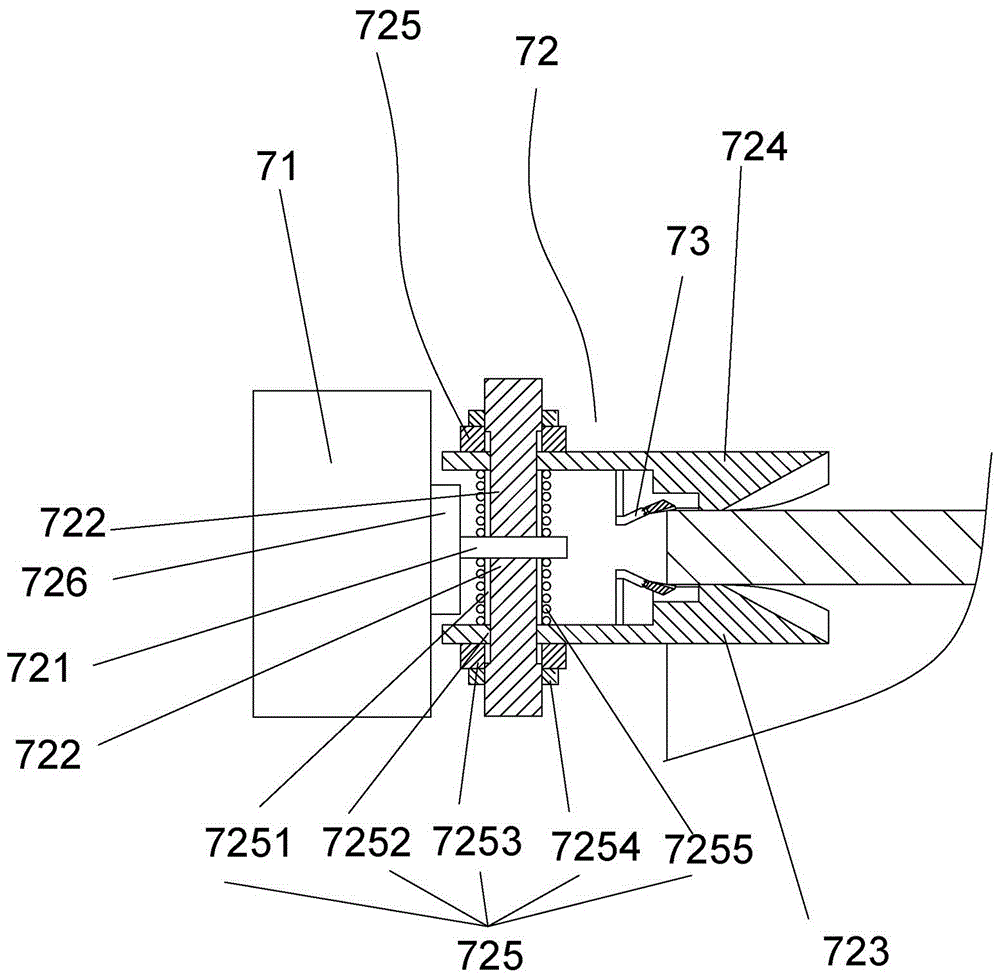

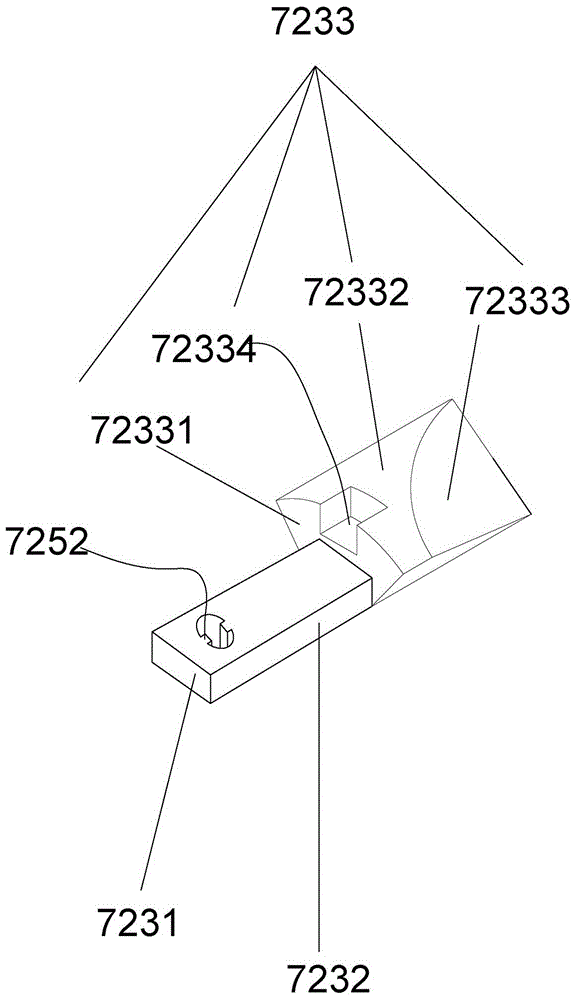

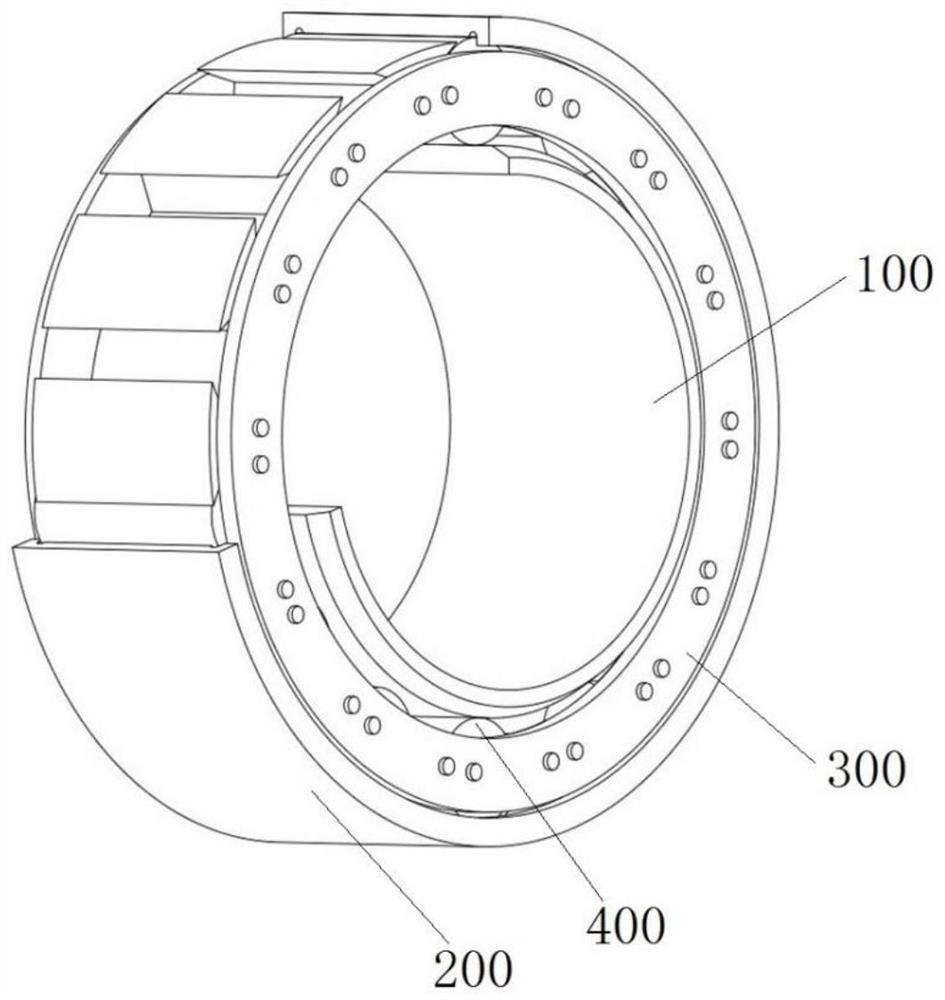

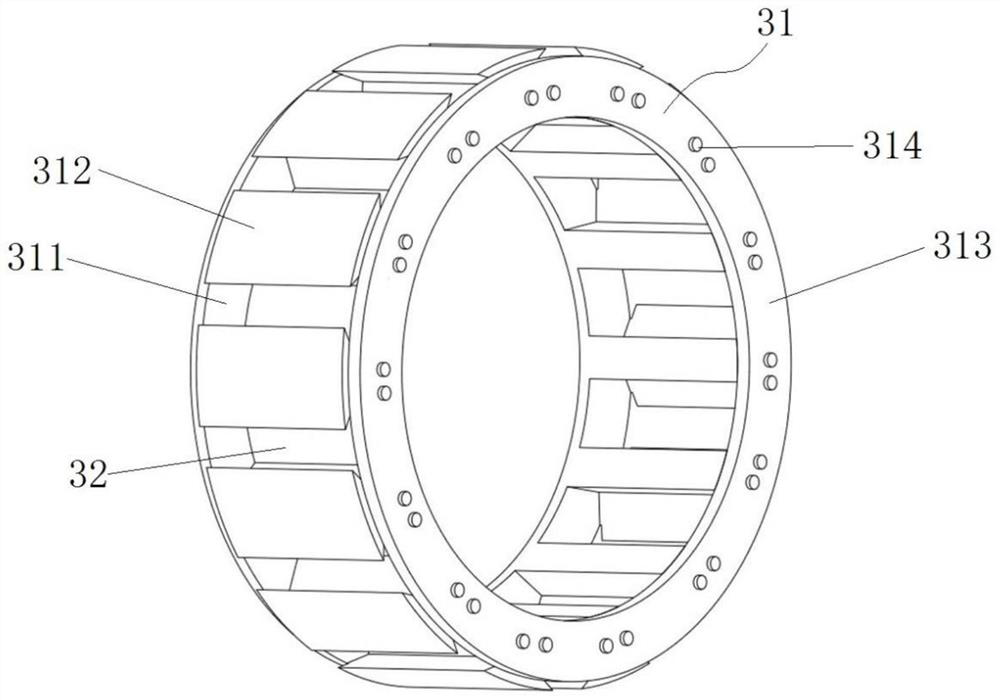

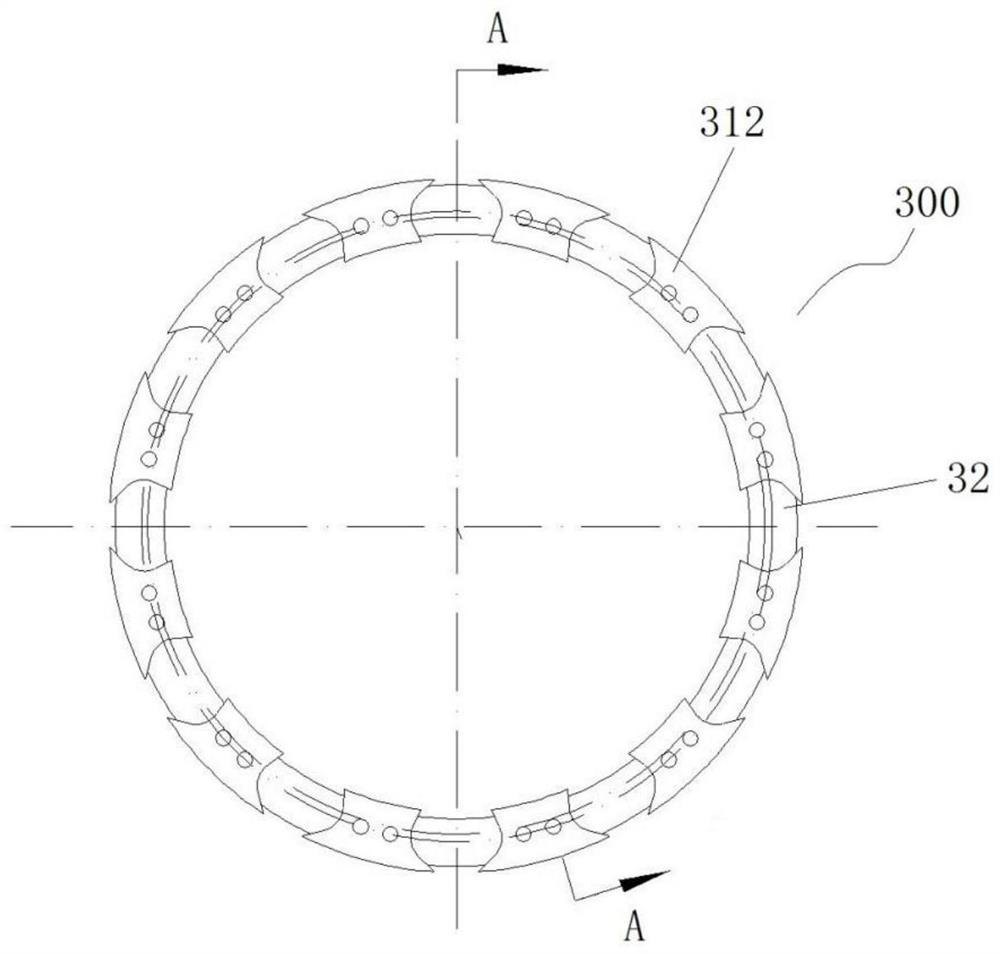

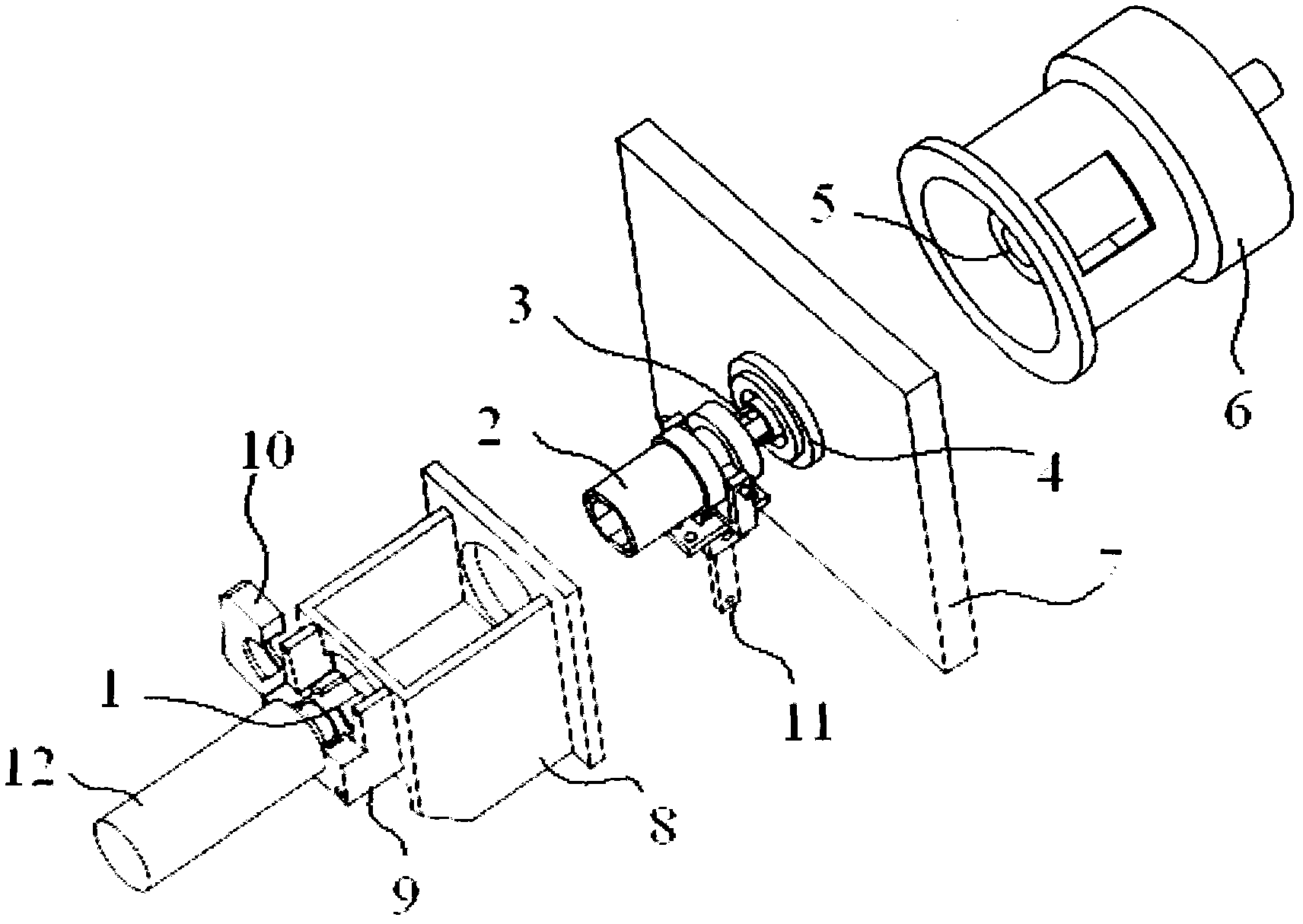

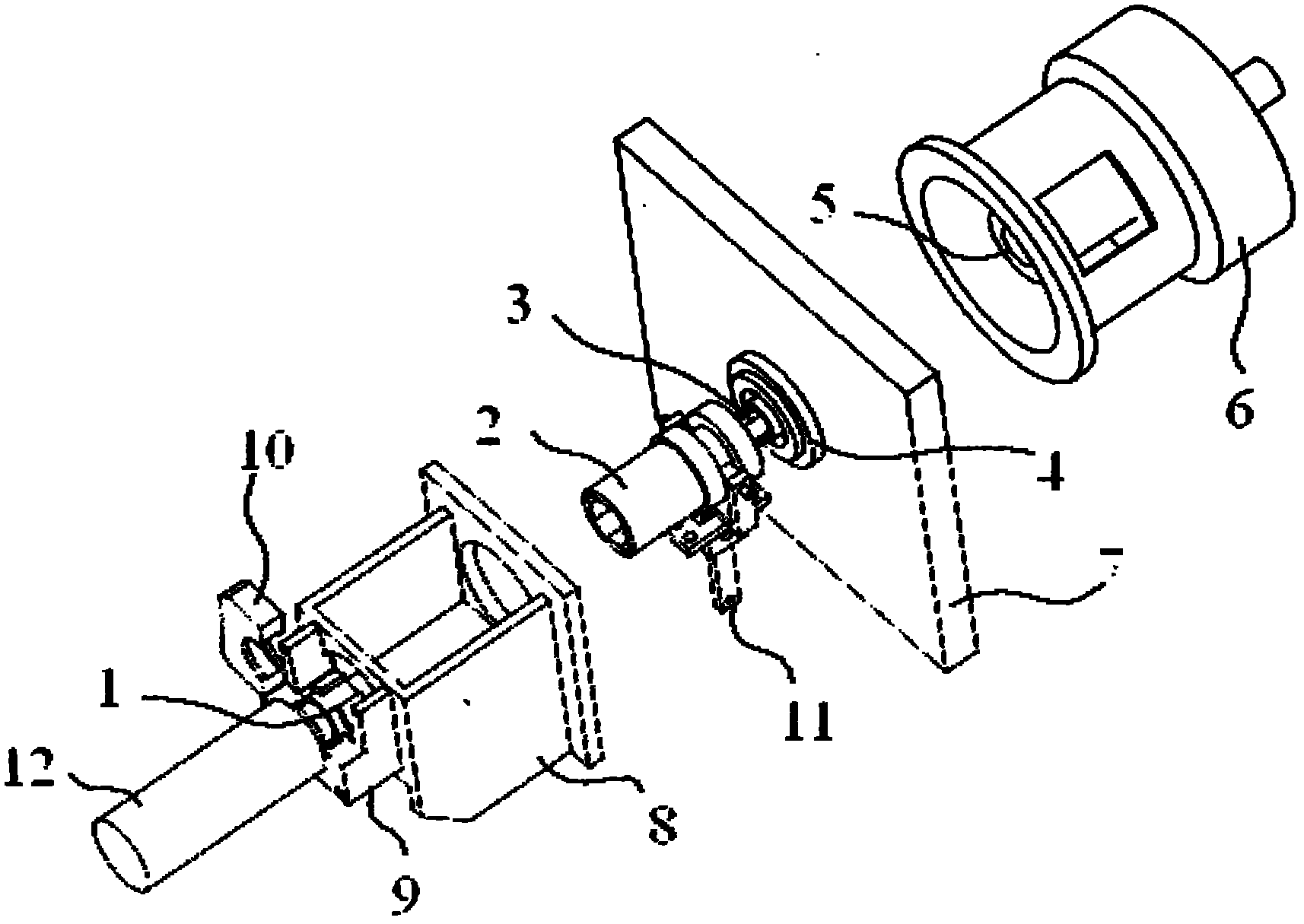

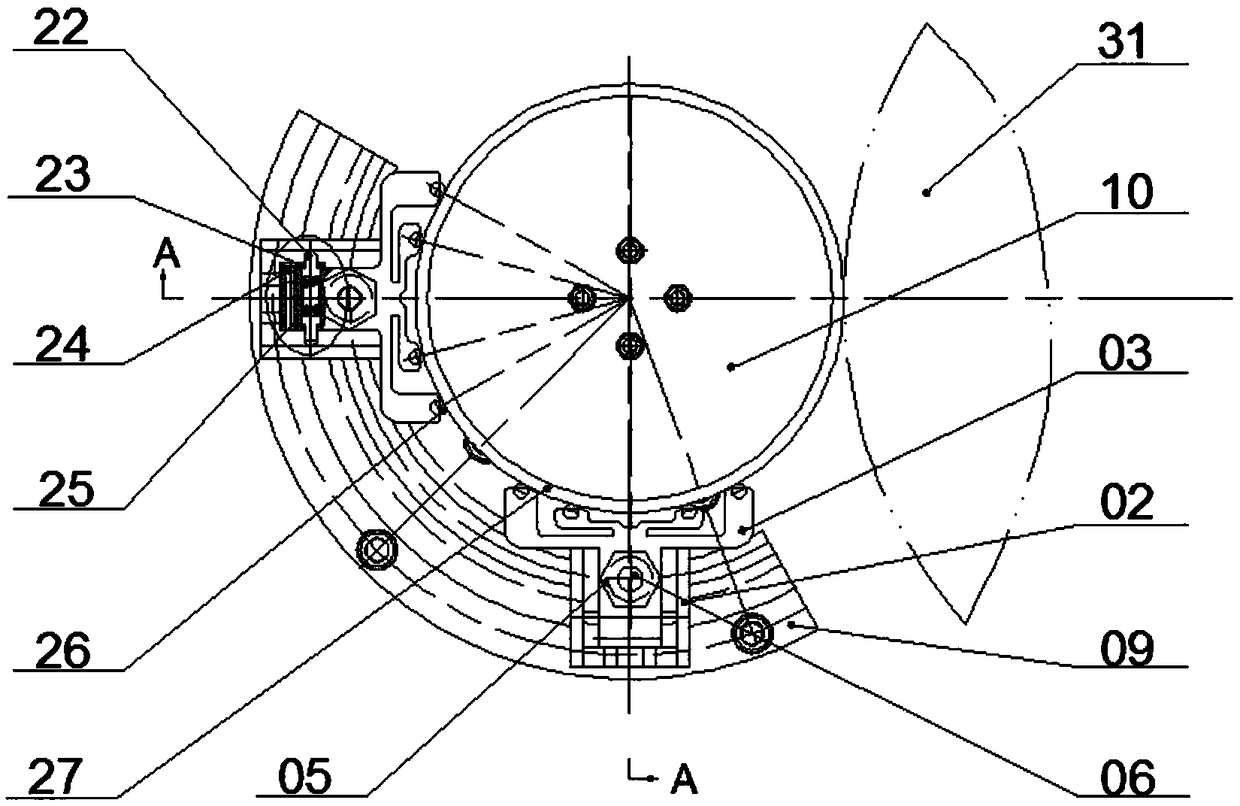

Stator and rotor assembling equipment in new energy motor assembly

The invention discloses stator and rotor assembling equipment in the new energy motor assembly. The stator and rotor assembling equipment comprises a machine body, wherein a double-layer lifting positioning mechanism, a rotor clamping displacement mechanism, a stator tight holding mechanism and a press mounting mechanism are arranged on the machine body; wherein the double-layer lifting positioning mechanism comprises a movable tray and a fixed bottom plate in vertical arrangement; a rotor installing position and a stator installing position are arranged in parallel on the movable tray; the rotor lamping displacement mechanism comprises a vertical sliding installing seat, a transverse sliding installing seat and a holding claw assembly; the press mounting mechanism comprises a press head and an upper center; the upper center is vertically arranged in a cavity of the center of the press head; the upper part of the upper center is provided with an annular position limiting lug boss; the upper end of the upper center is provided with a spring in a sleeving way. The stator and rotor assembling equipment has the advantages that the upper end and the lower end of the rotor are simultaneously jacked by the upper center and the lower center to do synchronous descending along with the press head through being driven by an electric cylinder until the assembly is in place; the stator and rotor assembly concentricity is ensured; the influence of the magnetic force between the stator and the rotor on the assembly is overcome.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Ring-disk electrode

InactiveCN1789996AGuaranteed coaxialityReduce runoutMaterial electrochemical variablesCurrent noiseDiffusion

The invention discloses a ring-disk electrode body in the electrochemical analysis measuring electrode domain, which is characterized by the following: setting the ring and disk electrode at the axle and two bottoms at the same plane with macromolecular material insulating ring and adhesion layer between them; embedding the ring electrode in the end part of ring union body; connecting the ring union body with the screw of ring guide rod with guide matching face; contacting the disk electrode roof and the probe in the hole of disk guide rob bottom stickly; setting the ring and disk guide rod at the same axle with insulation sleeve and compacting by nut; setting the protection lid and sealing ring on the bottom of electrode body. The invention is applied to detect the diffusion coefficient and electrochemical parameter with large insulation resistance between ring and disk and small contact resistance in the signal guide system, which reduces the current noise and utility lifetime.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

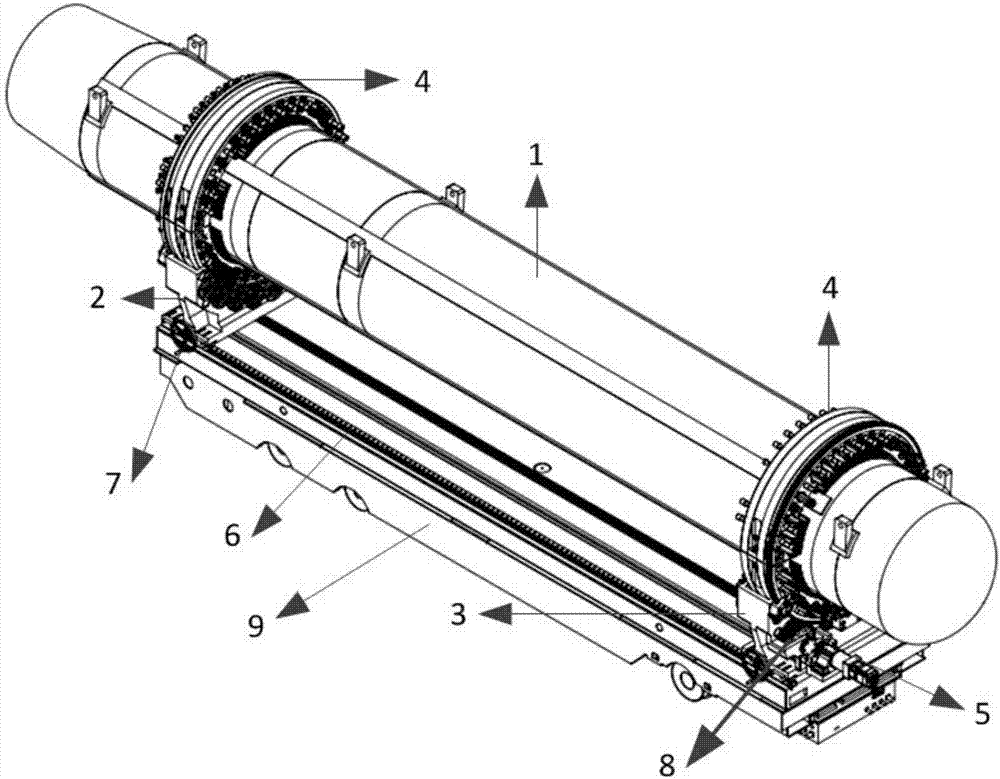

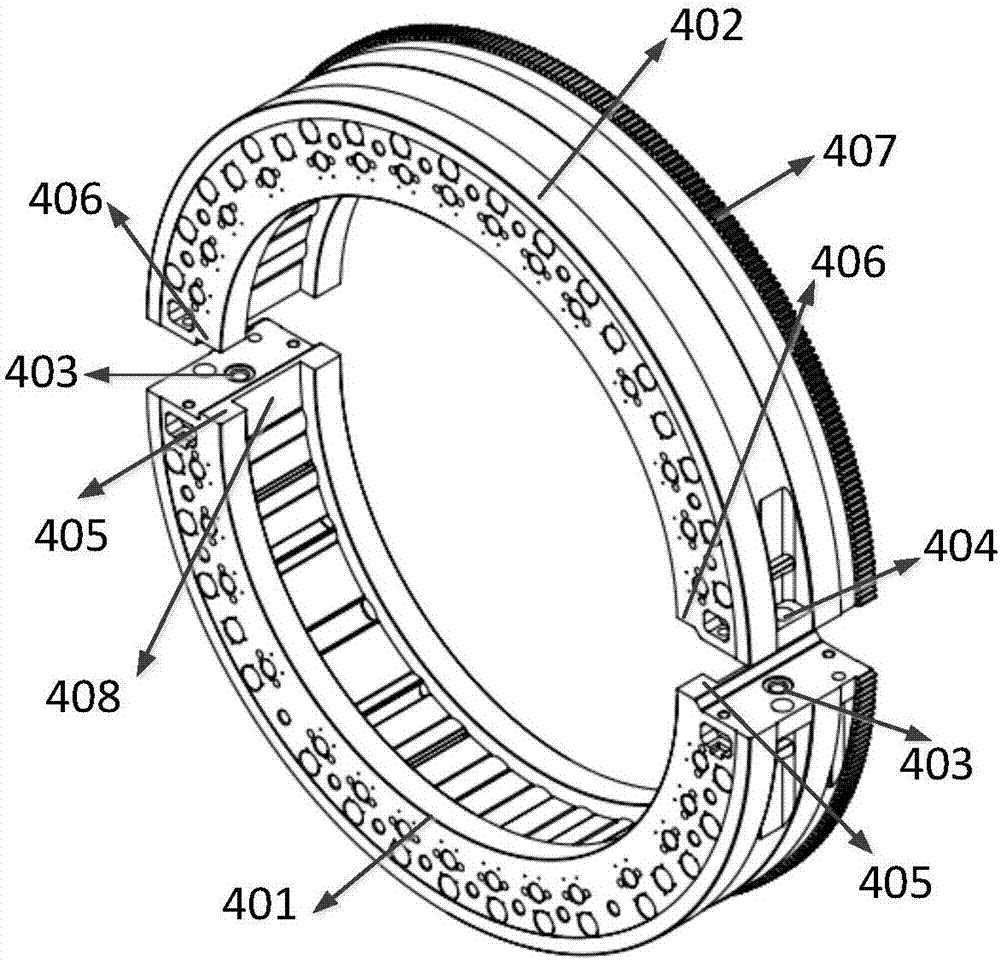

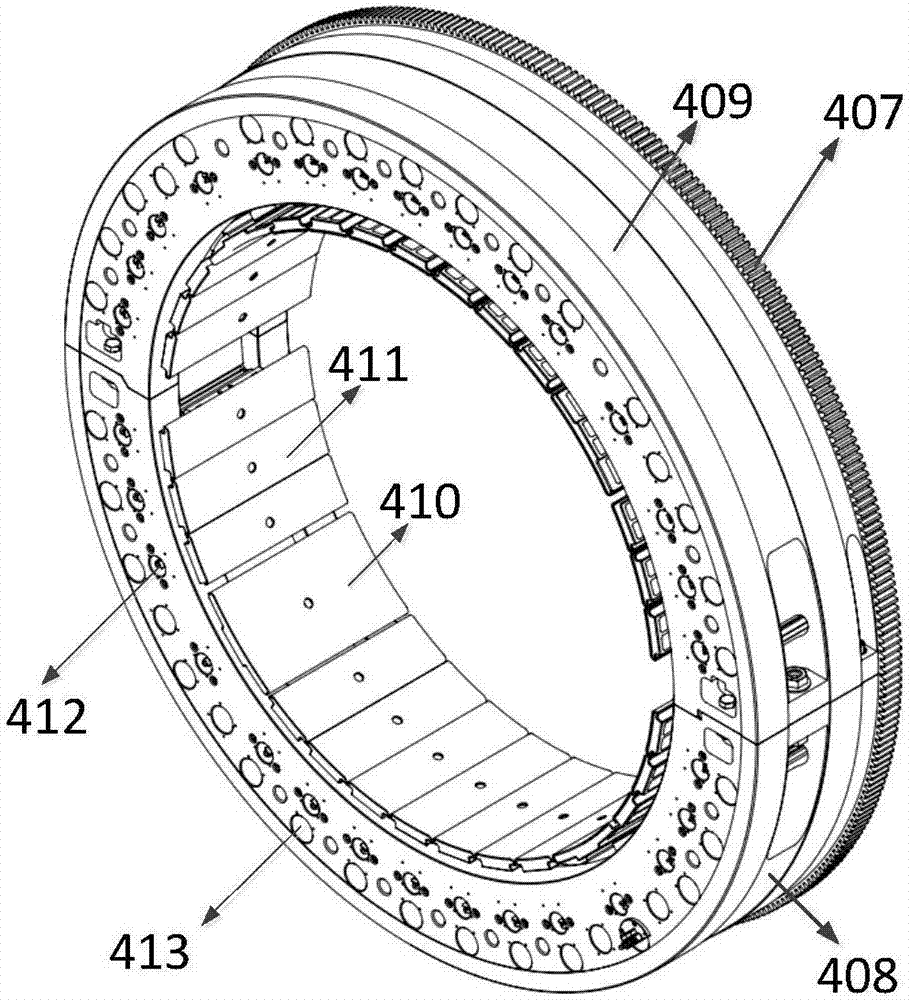

Clamping system and clamping method for large similar cylindrical workpieces

PendingCN107283191AAvoid collision and friction damageEasy and accurate clampingWork holdersPositioning apparatusPhysicsEngineering

The invention provides a clamping system for large similar cylindrical workpieces. The clamping system comprises at least two workpiece clamping devices; the workpiece clamping devices comprise first fixture bodies with semicircular structures and second fixture bodies; the first fixture bodies and the second fixture bodies are relatively connected to form a complete ring structure; and along the outer edge of the ring structure, transmission teeth engaged with external gears are arranged on the edges of the same side surfaces of the first fixture bodies and the second fixture bodies. The clamping system further comprises a bearing platform, and support bases arranged on the bearing platform in parallel; and a rotary driving device is arranged on one support base, and comprises a rotary driving mechanism and a driving gear connected with an output shaft end of the rotary driving mechanism. The invention further provides a clamping method for the large similar cylindrical workpieces. The clamping system has the advantages of safety, reliability, convenience in operation and high adaptability.

Owner:重庆真测科技股份有限公司 +1

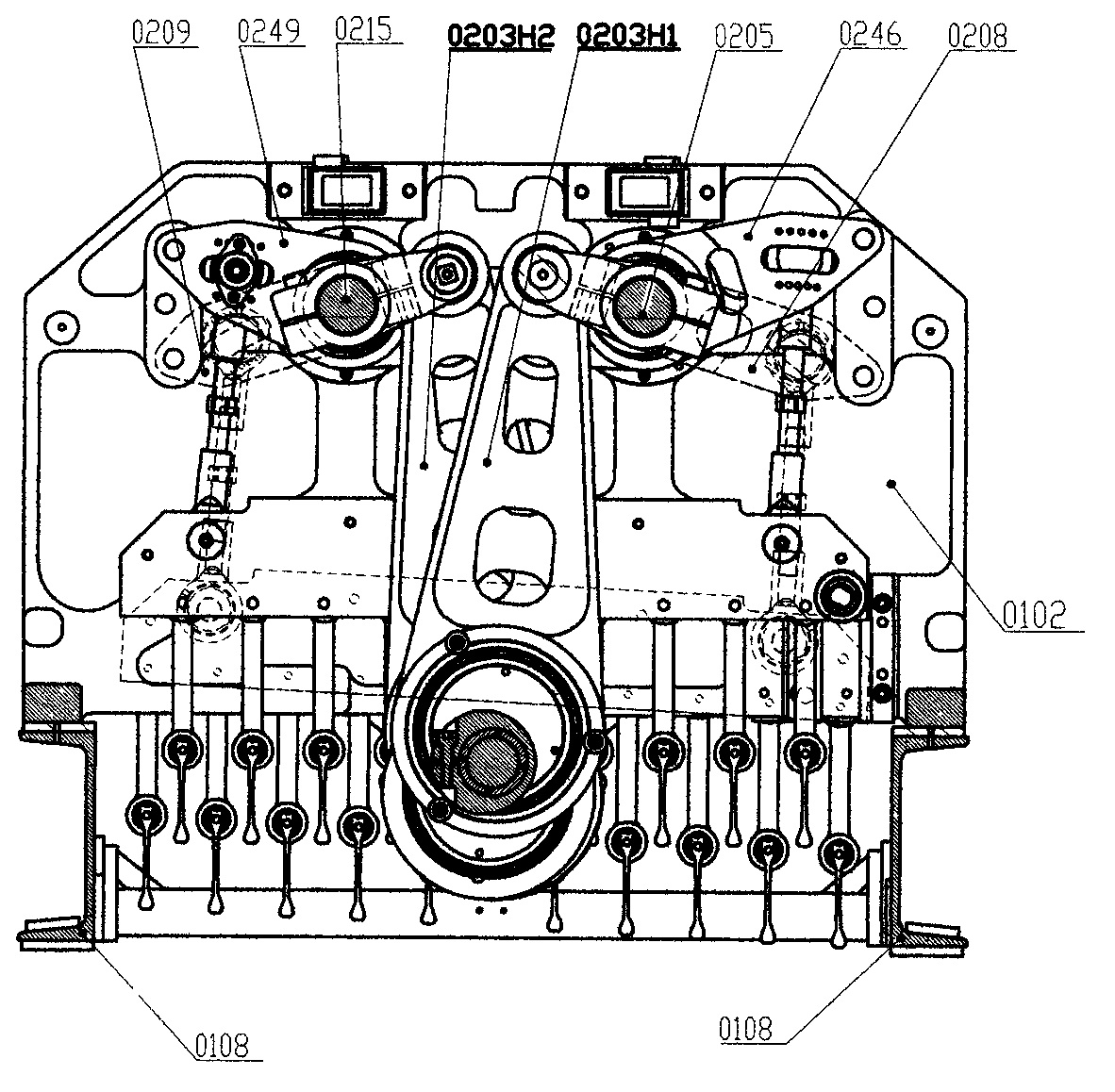

High-speed jacquard shedding device and jacquard machine provided with same

The invention discloses a high-speed jacquard shedding device, belonging to the technical field of shedding of a jacquard machine. An inner jacquard knife mechanism and an outer jacquard knife mechanism alternately move up and down by transmission of motion between each of swing mechanisms and a main transmission shaft; the main transmission shaft is synchronously equipped with four sets of eccentric wheel and connecting rod mechanisms for driving the swing mechanisms; each set of eccentric wheel and connecting rod mechanisms comprise an equal-eccentricity symmetrical connected eccentric wheel and two connecting rods; the swing mechanisms with swing arm shafts are arranged above the same lateral ends of the inner jacquard knife mechanism and the outer jacquard knife mechanism; the swing arm shafts are formed by extending in parallel along a left main wall plate and a right main wall plate; the swing arm shafts are equipped with fixed swing arms connected with ends in the same directions of an inner jacquard knife frame and an outer jacquard knife frame through lifting rods, movable swing arms, and connecting rod swing arms for driving the swing arm shafts at the two ends of the main wall plates; and the connecting rod swing arms and the movable swing arms of the swing mechanisms are connected with one connecting rod and another connecting rod in one corresponding set of eccentric wheel and connecting rod mechanism respectively. Due to the adoption of the scheme, the inner jacquard knife mechanism and the outer jacquard knife mechanism are high in motion synchronization precision and clear for shedding. The invention further provides a jacquard machine provided with such device.

Owner:SHAOXING JIABAO TEXTILE MACHINERY TECH

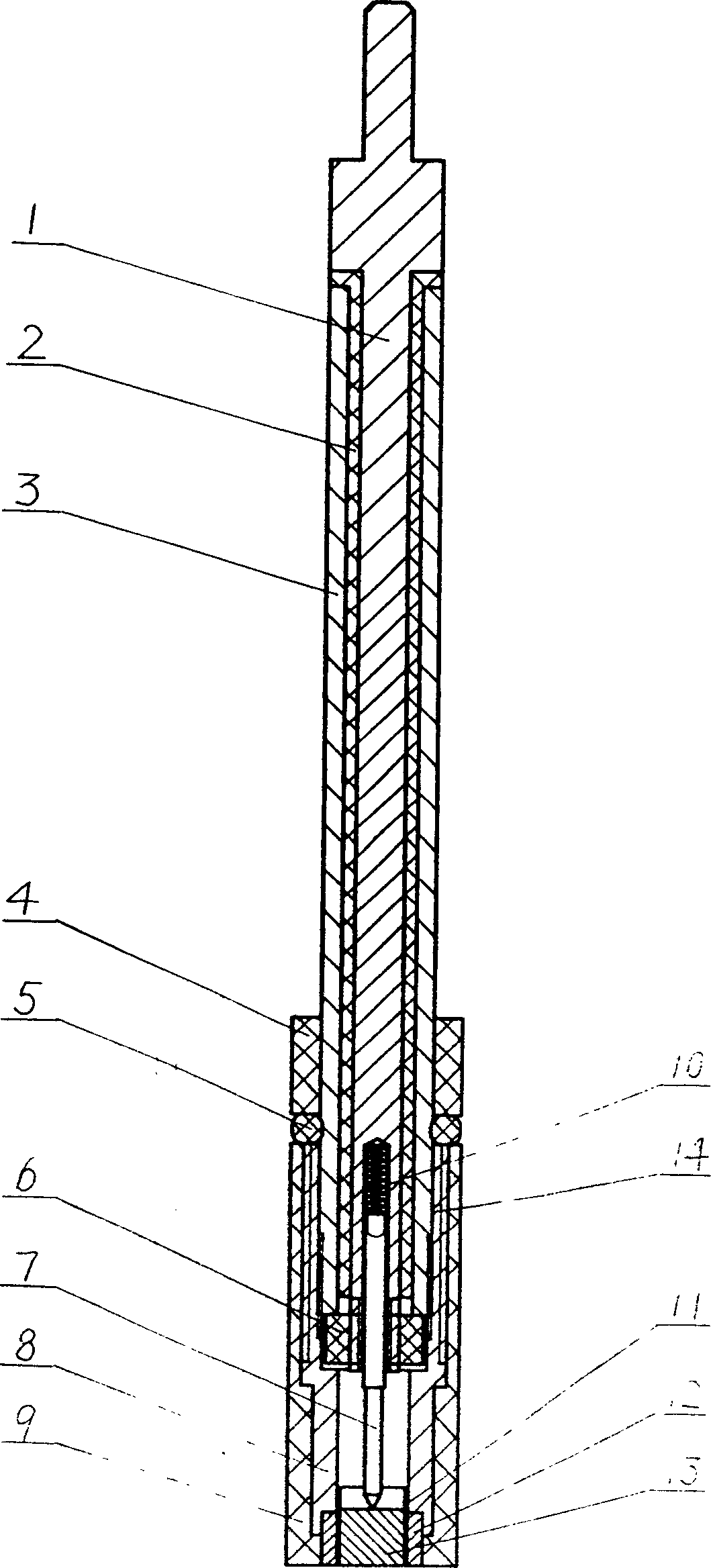

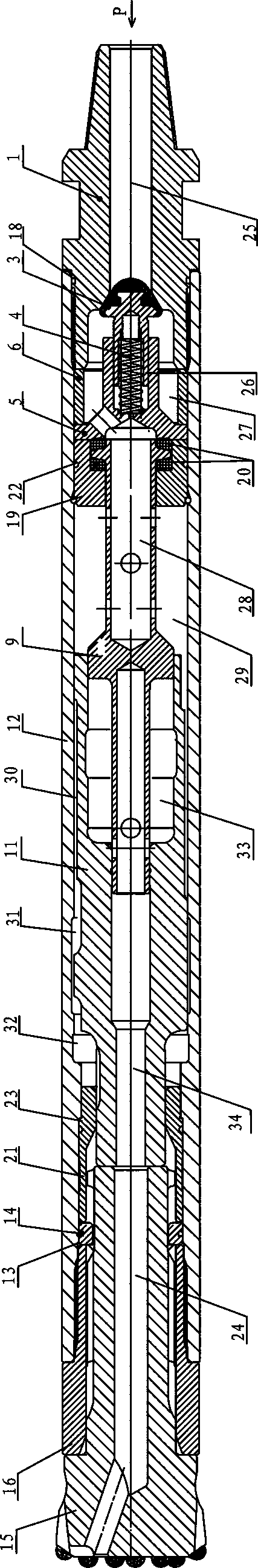

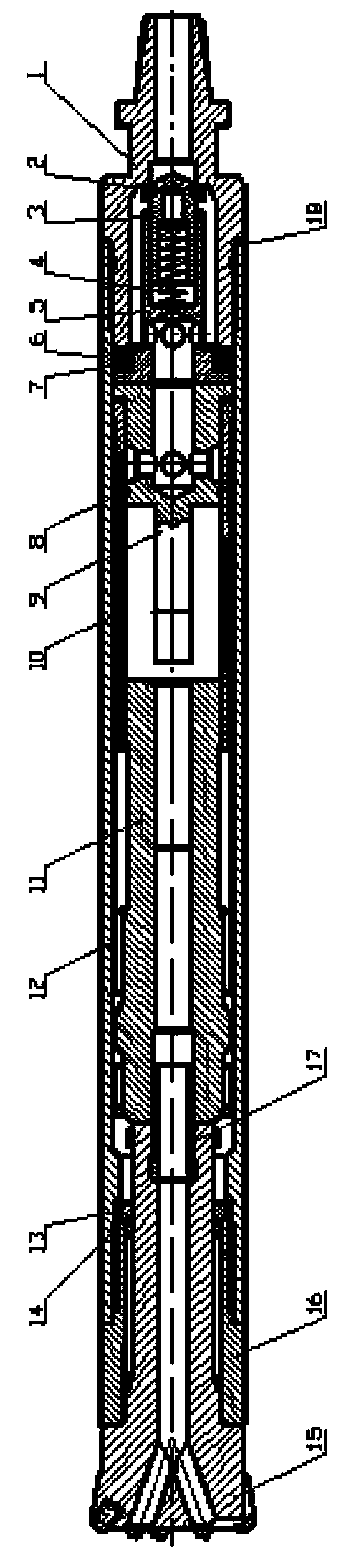

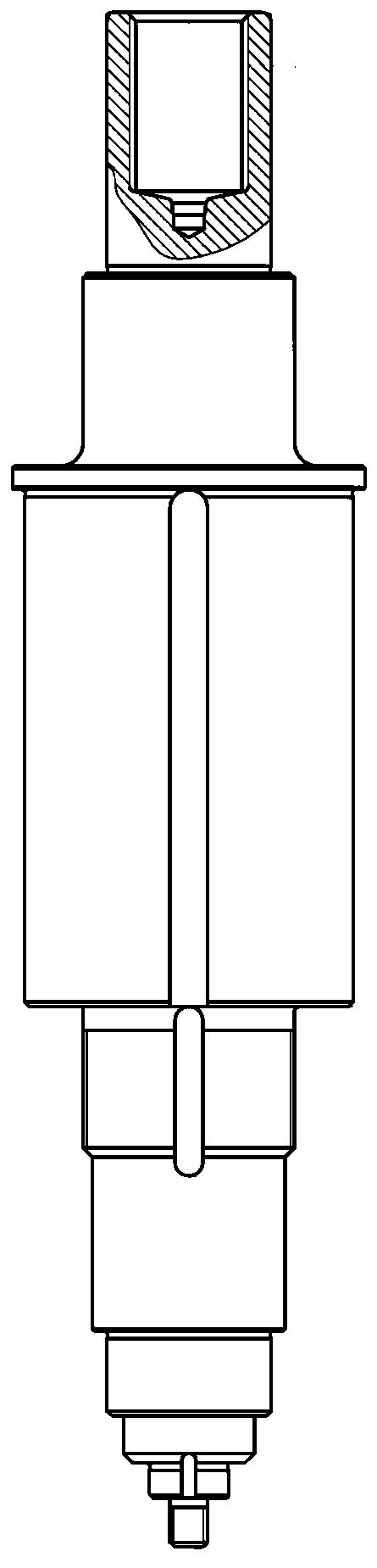

Efficient down-hole hammer

InactiveCN103375131AReliable connectionGuaranteed stability and efficiencyBorehole drivesPistonDrill bit

An efficient down-hole hammer comprises a back joint, a check valve, an air distribution rod, a piston, a cylinder, a clamping ring, a drill head and a front joint. The check valve is a one-way valve and comprises a valve seat, a spring and a steel washer. The slotted piston is provide with a hole, a positioning sleeve is arranged at the back end of a valve end cover, and the air distribution rod, a positive vibration-proof rubber ring and a negative vibration-proof rubber ring are clamped in the positioning sleeve together. The efficient down-hole hammer is not provided with an inner cylinder structure, the air distribution mode is greatly innovated, a vibration-proof fine tuning device arranged between the back joint and the air distribution rod can effectively absorb counterforce of piston motion, the air distribution rod can be subjected to automatic fine tuning so as to keep the assembling verticality, the adaptive drill head is not provided with a tail pipe, and therefore high pressure air leakage is reduced, work efficiency is improved and production cost is reduced. In addition, the piston has a reliable service life.

Owner:YICHANG WUHUAN ROCK DRILLING TOOLS

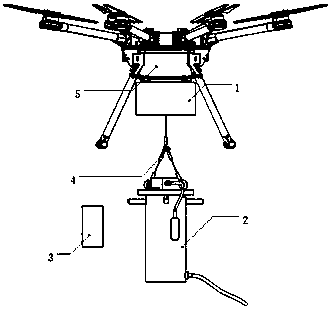

Automatic fixed-depth water taking device and control method thereof

ActiveCN110333100AWind evenlyReduce runoutTransmission systemsWithdrawing sample devicesComputer moduleEngineering

The invention relates to an automatic fixed-depth water taking device and a control method thereof. The device comprises a mounted winch and a fixed-depth water sampler, wherein a storage battery, a winding drum shaft assembly, a steel wire rope, a coupler, a worm shaft assembly, a motor assembly, a mounted winch control module, a reciprocating lead screw rope arranging assembly, a pulley assemblyand a winch mounting bottom plate are arranged in the mounted winch. The lifting of the water sampler can be realized, and rope arranging and guiding structures are added, so that in a running process, the steel wire rope is stable in winding, small in jumping, difficult in bad phenomena of rope pressing, rope jumping, rope disordering, rope separation and the like, and reliable in structure. Thewater sampler comprises a water sampling bottle, an upper cover plate, a lower cover plate, an underwater control box, a waterproof connector, a pressure transmitter and an electromagnetic chuck. Thedevice can communicate with the winch and a remote controller to realize automatic and accurate fixed-depth water taking, and is convenient to operate. According to the device, existing two depth control methods are combined, and wireless signals are utilized, so that the control automation level is high, the structure is relatively economical, and the control function is stable.

Owner:JINLING INST OF TECH

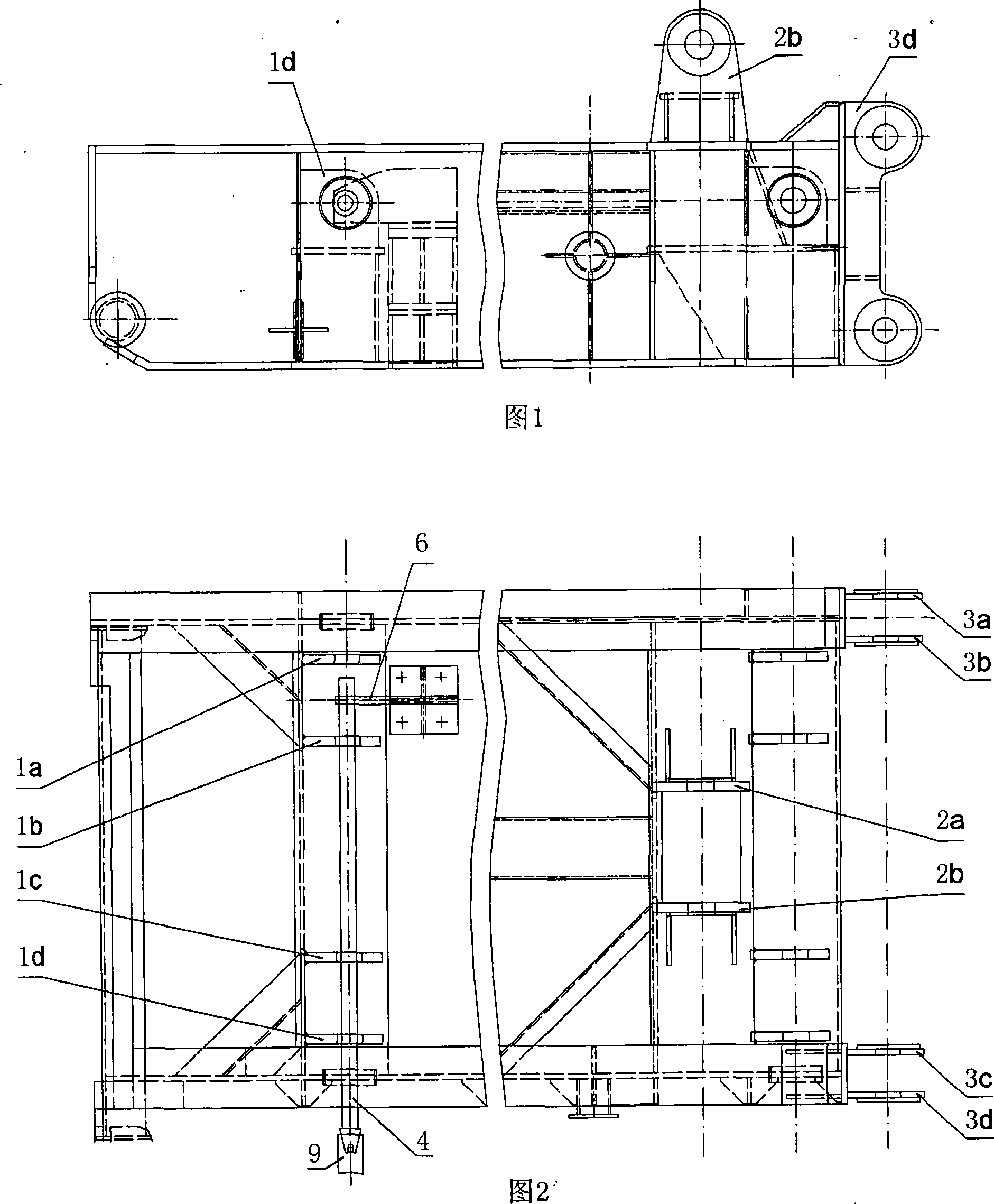

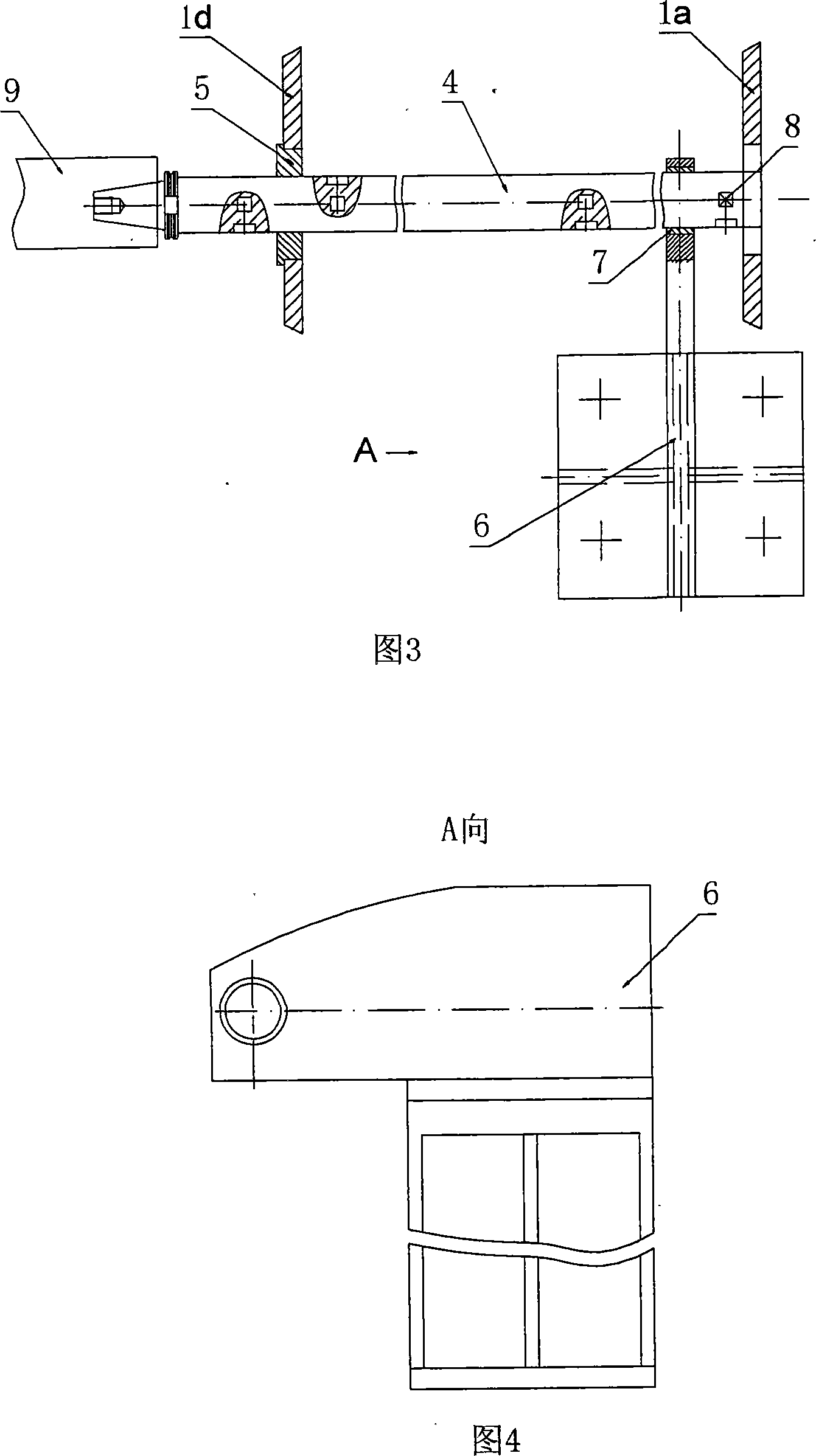

Coaxial large strided distance ear base hole boring auxiliary device and boring process method

InactiveCN101195175AGuaranteed coaxialityReduce runoutBoring/drilling machinesEngineeringMachine tool

The invention relates to an auxiliary device for borings of coaxial large span length ear base holes and a method for manufacturing the borings. The auxiliary device comprises an extending knife bar, a transitional supporting sleeve and a support, wherein the transitional supporting sleeve is inserted in an ear base hole which is manufactured through a common short knife bar and near a constructional element of the end surface of a machine tool main axle, a support supporting sleeve is inserted in a round hole on the support, and the extending knife bar is passed respectively through the transitional supporting sleeve and the support supporting sleeve and supported in auxiliary by the transitional supporting sleeve and the support supporting sleeve. The method for manufacturing the borings adopts the auxiliary device to manufacture the coaxial long center ear base holes on a large scale boring and milling machine. The coaxiality of coaxial ear base holes and center distance and the depth of parallelism between central lines of different axis ear base holes can be guaranteed, a derrick and a drill floor are connected on a basal seat after adopting the method to manufacture the borings of coaxial long center ear-seat holes on large scale structural elements as a driller, which has high assembly preciseness, little cooperating gap, and is stable while in use, installing working amount can be decreased greatly, and installing working efficiency can be increased.

Owner:RG PETRO MACHINERY GROUP

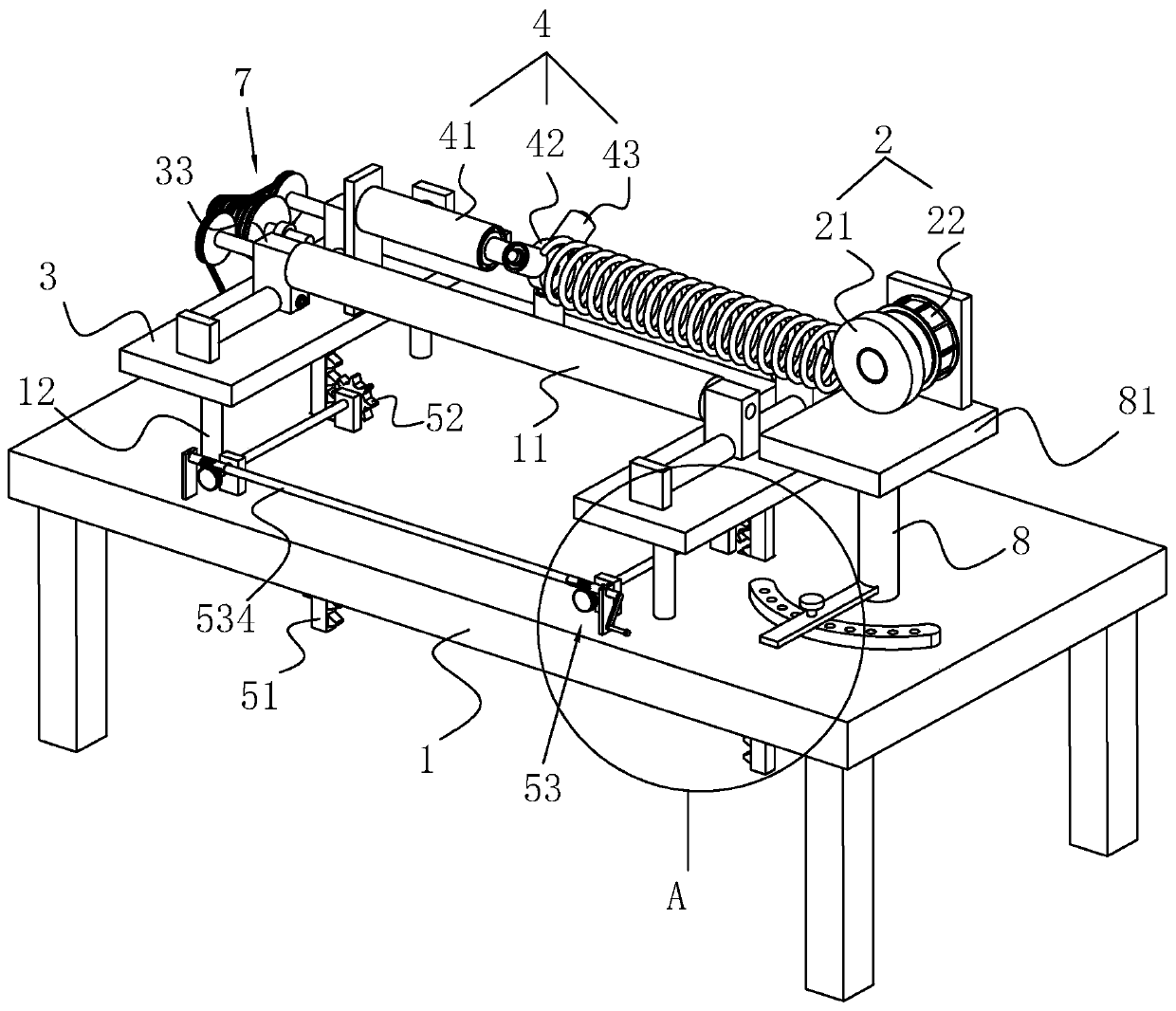

Spring end face grinding device and grinding method thereof

InactiveCN111037389ALower the altitudeImprove grinding performanceGrinding carriagesGrinding drivesElectric machineryEngineering

The invention relates to a spring end face grinding device and a grinding method thereof, and belongs to the technical field of spring grinding. The spring end face grinding device comprises a bottomplate, wherein a grinding assembly used for grinding a spring is arranged on the bottom plate, and the grinding assembly comprises a grinding wheel and a rotating motor; a mounting plate is arranged on the bottom plate, an abutting assembly used for abutting against one end, away from the grinding assembly, of the spring is arranged on the mounting plate, two rotating rollers are horizontally arranged on the mounting plate, and a driving source for driving the rotating rollers to rotate is arranged on the mounting plate; and a lifting assembly used for driving the mounting plate to ascend anddescend is arranged on the bottom plate. When a larger spring is polished, the mounting plate is driven to move downwards through the lifting assembly to reduce the height of the spring, and then theabutting assembly abuts against the spring; and the height of the spring is adjusted, so that the grinding position of the spring and the center of the grinding wheel are on the same horizontal line,the grinding effect of the grinding wheel on the spring is improved, radial jumping of the spring in the grinding process is reduced, and the grinding quality is effectively improved.

Owner:CHENGDU CHENHUI SPRING MFG

Copper roll type method of making commutators

InactiveCN1558475AEvenly distributed between slicesReduce labor intensityCommutators manufactureCopper coilEngineering

The invention discloses a copper coil type manufacturing method of a commutator, comprising in turn the following steps: wire rolling, drawing, annealing, punching out, pressing, solidifying, reaming, lathing an outer periphery, channeling, sanding, and polishing etc, wherein the pressing step makes an annealed wire be pressed into an annular commutator segment assembly. The invention eliminates the original fussy sheet arranging step so that the produced commutator provides an good article roundness, which makes the dynamic unbalance of the commutator be minimized.

Owner:ZHEJIANG GREATWALL COMMUTATOR

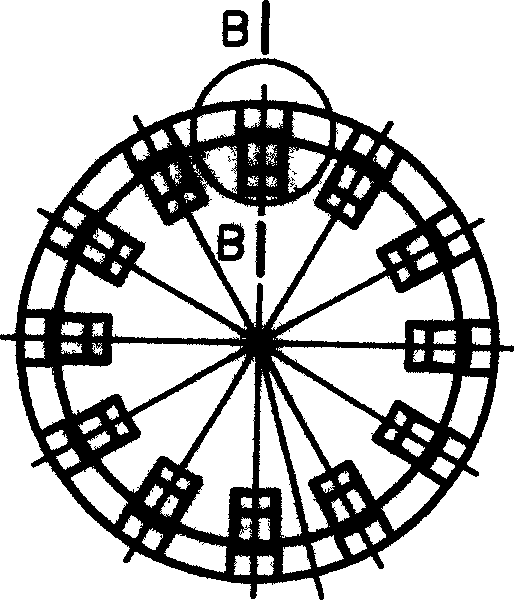

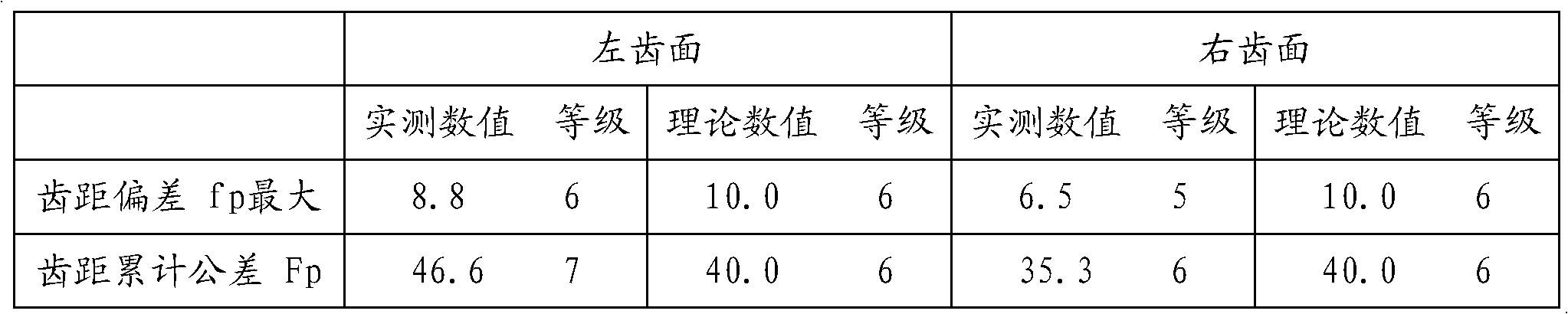

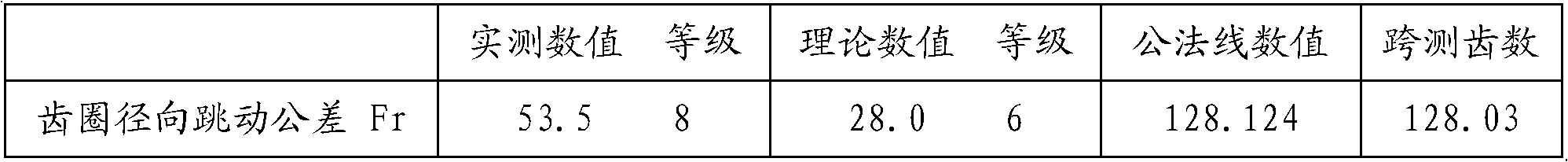

Gear grinding processing method

InactiveCN102126053AReduce runoutOvercoming the phenomenon of individual out-of-tolerance valuesGear teethGear grindingDesign standard

The invention discloses a gear grinding processing method, which comprises the following step of dividing teeth of the gear to be subjected to grinding processing into at least two continuous groups sequentially along the circumferential direction; then dividing the teeth in each group into at least two continuous subgroups sequentially; and in the grinding process, firstly grinding first subgroups in all the groups sequentially, then grinding second subgroups in all the groups sequentially, grinding all the subgroups sequentially in the manner, and repeating the operations until all teeth are ground to achieve the design standard. The gear grinding processing, which is provided by the invention, is scientific and reasonable, is beneficial to overcoming of various defects in the prior artand achieves the effect of reducing the circular runout of the gear and the circular pitch deviation.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

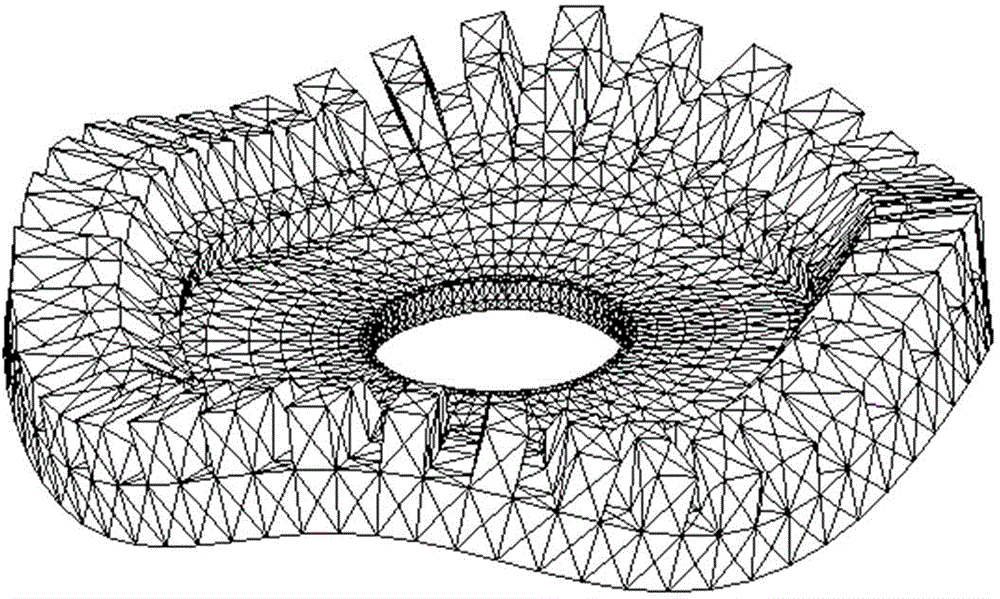

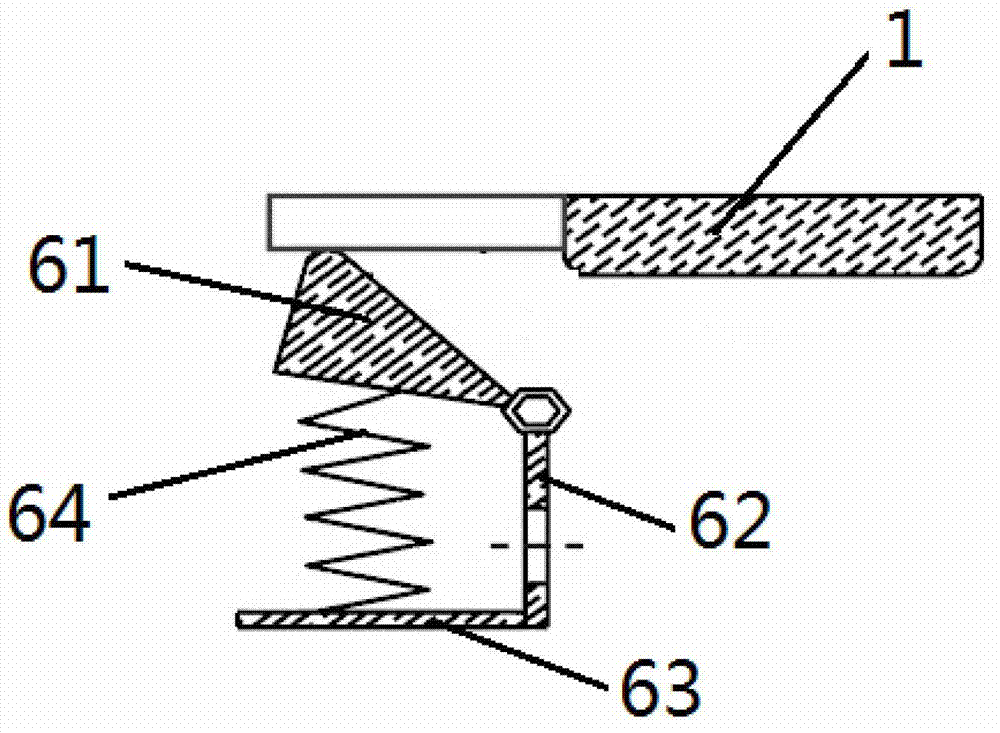

Flexible sealing structure of rotary air pre-heater

ActiveCN102901118AGuarantees a stable sealGood sealing effectEngine sealsCombustion processEngineeringMechanical engineering

The invention discloses a flexible sealing structure of a rotary air pre-heater. The flexible sealing structure is a contact type sealing device and comprises a sealing sliding block, a regulation supporting seat and a supporting fixing plate; the sealing sliding block is rotatablely connected with the supporting fixing plate; the supporting fixing plate is relatively arranged on a radial baffle plate of the air pre-heater fixedly; the regulation supporting seat is fixedly connected with the supporting fixing plate; a compression spring is arranged between the regulation supporting seat and the sealing sliding block; the sealing sliding block is in contact with a fan-shaped plate or an axial arc-shaped plate of the air pre-heater; a reset regulation device is arranged between the sealing sliding block and the regulation supporting seat; two ends of the reset regulation device are respectively connected with the sealing sliding block and the regulation supporting seat; and the reset regulation device is used for regulating the maximal resilience modulus of the compression spring positioned between the sealing sliding block and the regulation supporting seat. By using the flexible sealing structure, through regulating the reset regulation device, the regulation of sealing acting force between a moving component and a stationary component in the air pre-heater is realized; the wear of a sealing surface is decreased; and the service life of a quick-wear part is prolonged.

Owner:南京通用电气装备有限公司

Deburring device applied to automobile exhaust pipes

The invention discloses a deburring device applied to automobile exhaust pipes. The deburring device comprises an installation frame, a motor, an output shaft, a driving gear, an inner gear, a rotary gear and a shaping cutter, wherein the motor is arranged on the installation frame, the output shaft is connected with the motor, the driving gear is arranged on the output shaft, the inner gear is fixed to the installation frame and shares the same axis with the driving gear, the rotary gear is meshed with outer teeth of the driving gear and inner teeth of the inner gear, and the shaping cutter is coaxially connected with the rotary gear, can shape pipe openings of the exhaust pipes and can perform deburring on outer walls and inner walls of the exhaust pipes at the same time. The deburring device disclosed by the invention can shape the pipe openings of the exhaust pipes and perform deburring on the outer walls and the inner walls of the exhaust pipes at the same time, so that the pipe openings are round and neat, used time is small, and deburring efficiency is high.

Owner:浙江新诚汽车部件有限公司

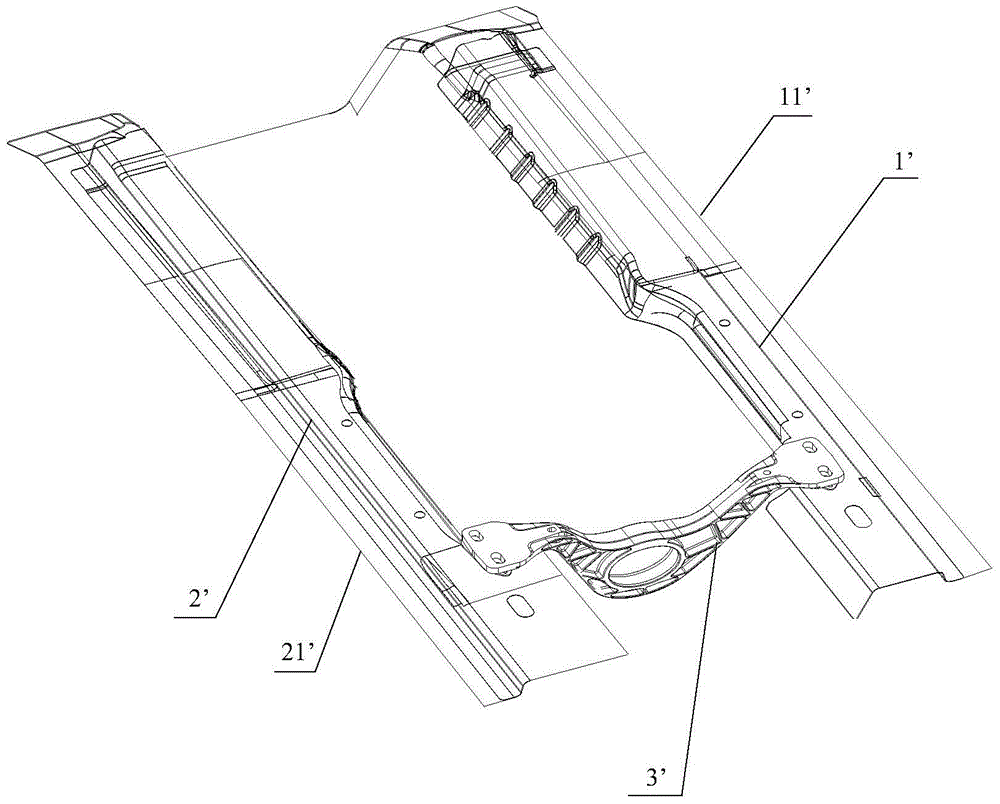

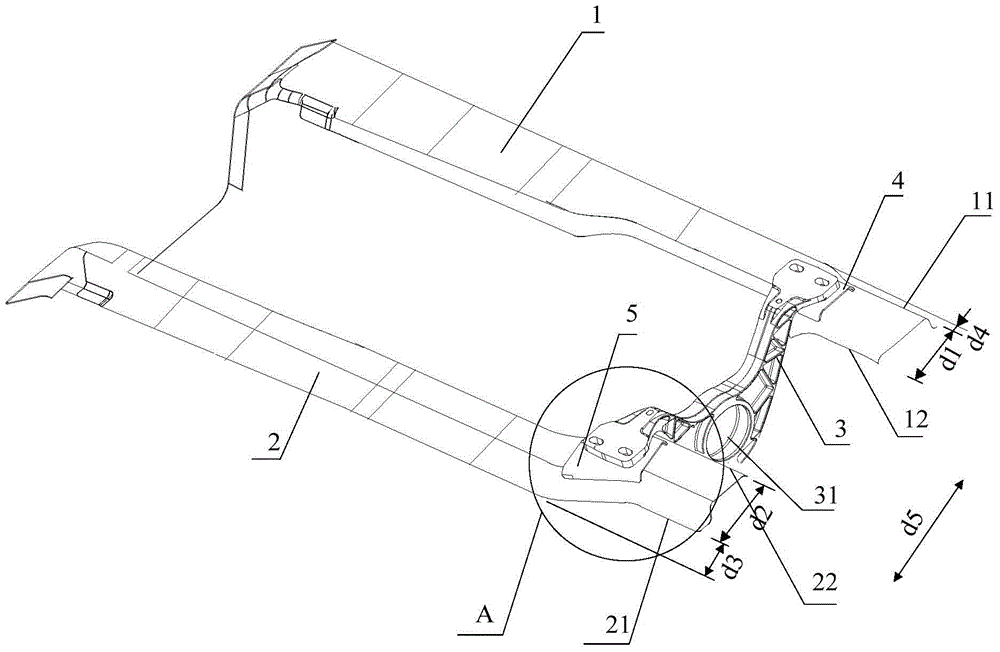

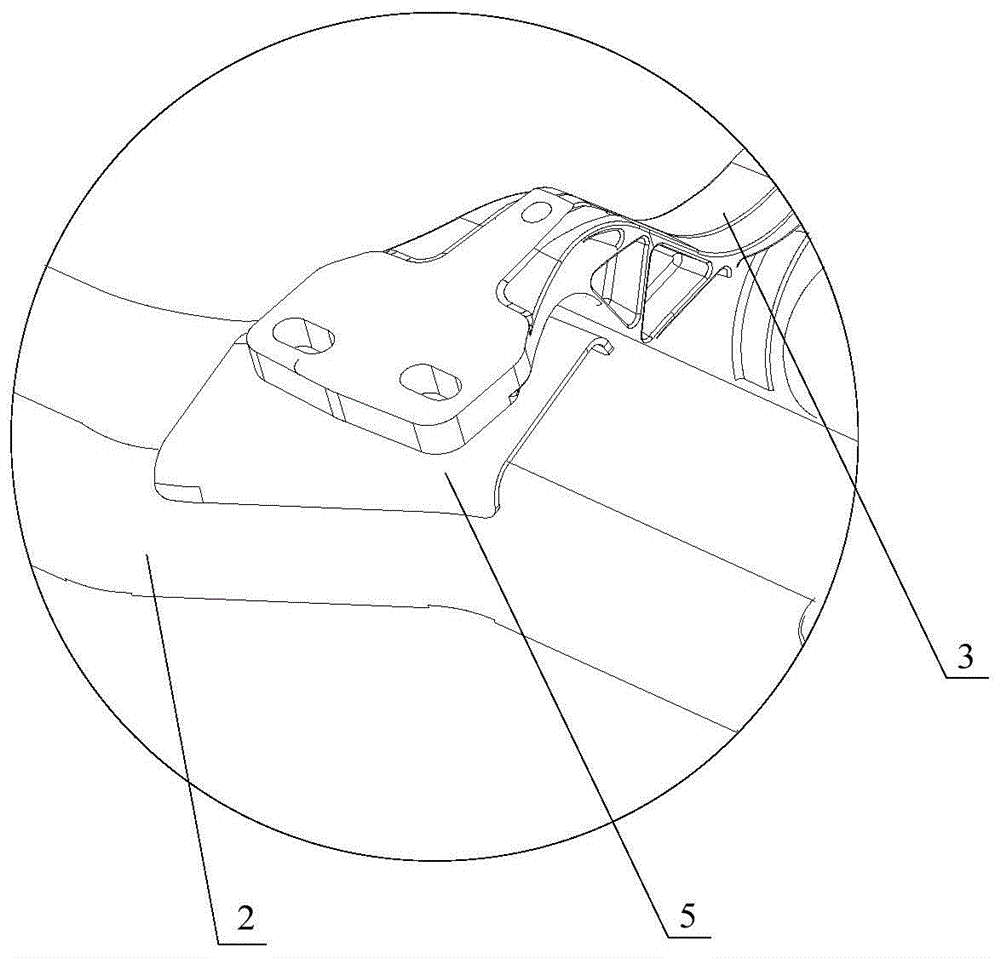

Transmission shaft installation structure and vehicle having transmission shaft installation structure

InactiveCN104828141AHigh vibration frequencyIncrease stiffnessUnderstructuresControl devicesSteering wheelDrive shaft

The invention provides a transmission shaft installation structure and a vehicle having the transmission shaft installation structure. The transmission shaft installation structure comprises a first longitudinal beam, a second longitudinal beam and a transmission shaft installation bracket of which the two ends are connected to the first longitudinal beam and the second longitudinal beam, and a middle passage is arranged between the first longitudinal beam and the second longitudinal beam. The transmission shaft installation structure is characterized in that the outer wall of the position, connected with the transmission shaft installation bracket, of first longitudinal beam is bent towards the middle passage. As the outer wall, positioned on the right of the transmission shaft installation bracket, of first longitudinal beam is sunken towards the middle passage, compared with the prior art, the width of the first longitudinal beam which is positioned on the right of the transmission shaft installation bracket is decreased, thus the stiffness of the installation position, on the first longitudinal beam, of the transmission shaft installation bracket is greatly improved, the vibration frequency and stiffness of the transmission shaft installation bracket are further improved, the vibration, transmitted to a vehicle body, of a transmission shaft is reduced, the vibration of the vehicle body directly transmitted to passengers through seats, a steering wheel and a floor board is reduced, and therefore the riding comfort is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Multi-station cold heading method of automobile wheel cup nut, and mold thereof

The invention relates to a multi-station cold heading method of an automobile wheel cup nut, and a mold thereof. The multi-station cold heading method of the automobile wheel cup nut comprises six stations: pre-shaping, shaping, finishing, forming a flange, compositely extruding and finishing forming. A preform sequentially passes through the six stations, namely, pre-shaping, shaping, finishing,forming a flange, compositely extruding and finishing forming so as to be processed by one machine; in order to solve the problem that a molding part is easy to crack due to shear cracks since the preform is made of low-carbon steel so as to be easy to tear, the method provided by the invention adopts a six-step forming method; according to the method provided by the invention, the product dimension accuracy is improved, the product quality is high, the material utilization ratio is high, and the forming efficiency is high.

Owner:DONGFENG MOTOR FASTENER CO LTD

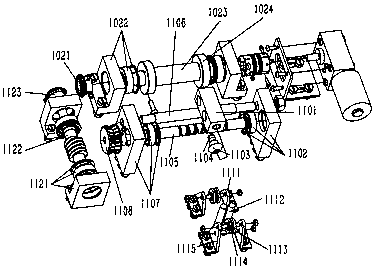

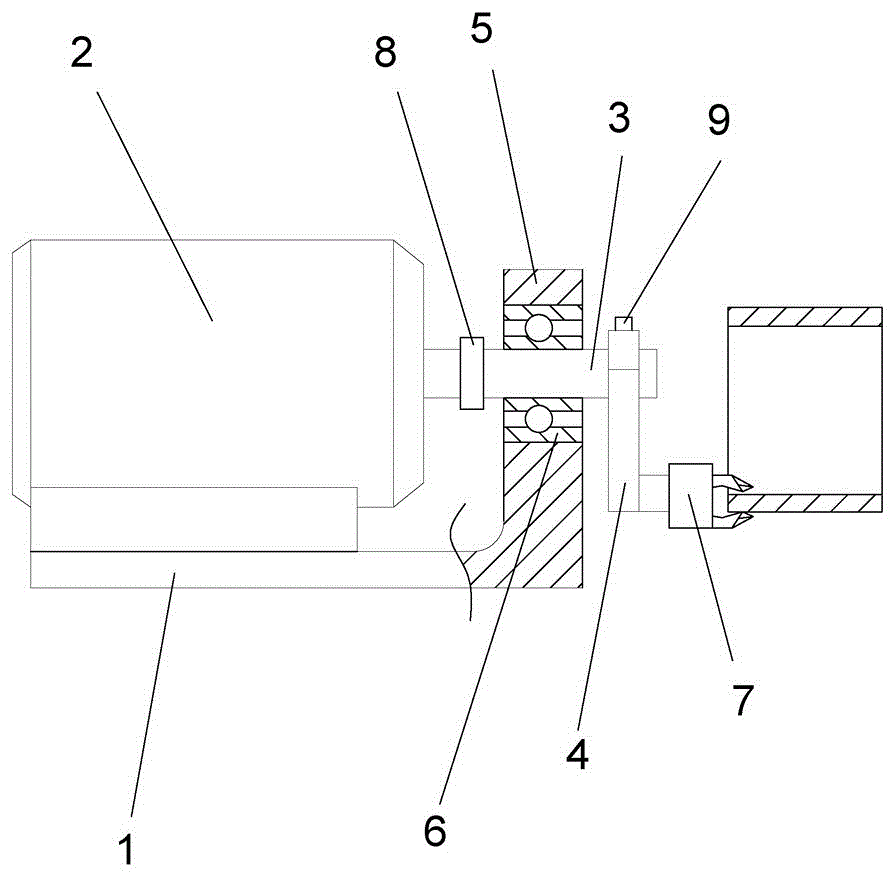

WEDG device for on-line electrode manufacturing in micro electric spark machining

ActiveCN103659525AReduce runoutSmooth runningGrinding machinesElectrical-based auxillary apparatusCopper wireEngineering

The invention discloses a WEDG device for on-line electrode manufacturing in micro electric spark machining and relates to the technical field of on-line tool electrode manufacturing in micro electric spark machining. The WEDG device aims to solve the problems that in an existing WEDG machining method, when the dimension of an electrode to be manufactured is very small, the requirements for the tension, operation speed and stability of a wire electrode are very high, the surface quality and precision of the micro electrode are affected and the dimension uniformity of the micro electrode is also affected by repeated machining. A wire electrode is conveyed out by a wire conveying mechanism of the WEDG device and conveyed into a wire collection mechanism after being machined by a machining discharging mechanism. The WEDG device is an on-line electrode manufacturing device which has the advantages that wire conveying is stable, the run-out of the wire electrode is very small at the discharging wheel position and wire conveying speed is low; the design of initiative wire supply through a stepping motor is adopted in a wire conveying module, copper wires are supplied at a constant speed, and constant tension is supplied to the copper wires in the manner that a hysteretic braking pressing wheel is pressed by a belt.

Owner:HARBIN INST OF TECH

Preparation method for drive motor shaft of new energy automobile

The invention relates to a preparation method for a drive motor shaft of a new energy automobile. The preparation method includes the steps of round steel blanking, stress relieving, surface sand blasting, phosphating, saponification treatment, cold extruding outer shaping, internal spline manufacturing, machining, heat treatment and the like. According to the preparation method for the drive motor shaft of the new energy automobile, cold extrusion is adopted to replace traditional gear shaping molding process, and prior hot forging process of blanks is omitted, so that the strength of products and the tooth profile accuracy are effectively improved; and the preparation method for the drive motor shaft of the new energy automobile has the advantages of reasonable process, raw material saving, cost saving, simple operation, stable work, high production efficiency, high product qualification rate, and good molding quality.

Owner:浙江浙研冷挤压有限公司

Cylindrical roller bearing and retainer thereof

InactiveCN111765171ACurbing the Centrifugal TrendReduce slippageRoller bearingsBearing componentsEngineeringMechanical engineering

The invention relates to a cylindrical roller bearing and a retainer thereof. The retainer comprises an annular body. Multiple pocket holes distributed in the circumferential direction are formed in the annular body, the rotating direction of the retainer is defined from back to front, and the pocket holes comprise rear side walls and front side walls. The rear side walls are V-shaped side walls,and the rear side walls comprise rear side wall inner inclined surfaces and rear side wall outer inclined surfaces which are sequentially arranged in the radial direction of the retainer from inside to outside. The rear side wall inner inclined surfaces are inclined backwards from inside to outside, the rear side wall outer inclined surfaces are inclined forwards from inside to outside, and the rear side wall inner and outer inclined surfaces are arranged in a V-shaped crossed manner in order to position a roller. The roller is positioned at an ideal radial position through the V-shaped side walls, the centrifugal motion trend of the roller is restrained, large contact force is still kept between the roller and an inner ring, the slip degree of the roller is reduced, and the slip conditionof the roller is effectively improved. The retainer can be radially positioned by the roller through the V-shaped side walls, the vortex motion radius of the retainer is reduced, and the motion stability of the retainer is improved.

Owner:HENAN UNIV OF SCI & TECH

Intelligent sealing device for ship tail shaft numerical control magnetic fluid

The invention discloses an intelligent sealing device for ship tail shaft numerical control magnetic fluid. According to the main structure of the intelligent sealing device, a stuffing box is arranged at the sealed part of a tail shaft, one end of the box is provided with a gland, and the other end of the box is connected with a sternpost through a flange. Two layers of PTFE ring box sleeves are arranged in the middle of the box in parallel, and nx twelve radial hedging magnetic sector permanent magnets are embedded in each layer of box sleeve. Magnetic fluid circulating cavities are formed between the box sleeves in which the magnets are embedded and a shaft tube. The two sides of each permanent magnet box sleeve are each provided with a stainless steel circular ring and provided with eight magnetic fluid injecting or discharging holes, wherein the outer sides of the two stainless steel circular rings are each provided with a stainless steel clamping ring. An AH type metal framework teflon sealing ring is clamped on a tail shaft tube. An MCU is arranged, a magnetic fluid input pump and an electromagnetic overflow valve are controlled according to the pressure and temperature sensor information, the pressure in the magnetic fluid circulating cavities and the pressure at the draft of a warship and a submarine can be randomly the same, sealing, lubricating and cooling functions are achieved on the tail shaft tube through circulation of pressurized cold and hot magnetic fluid, and an electromagnetic sealing brake is arranged for strengthening static sealing of the tail shaft tube during downtime.

Owner:宝嘉智能科技(南通)有限公司

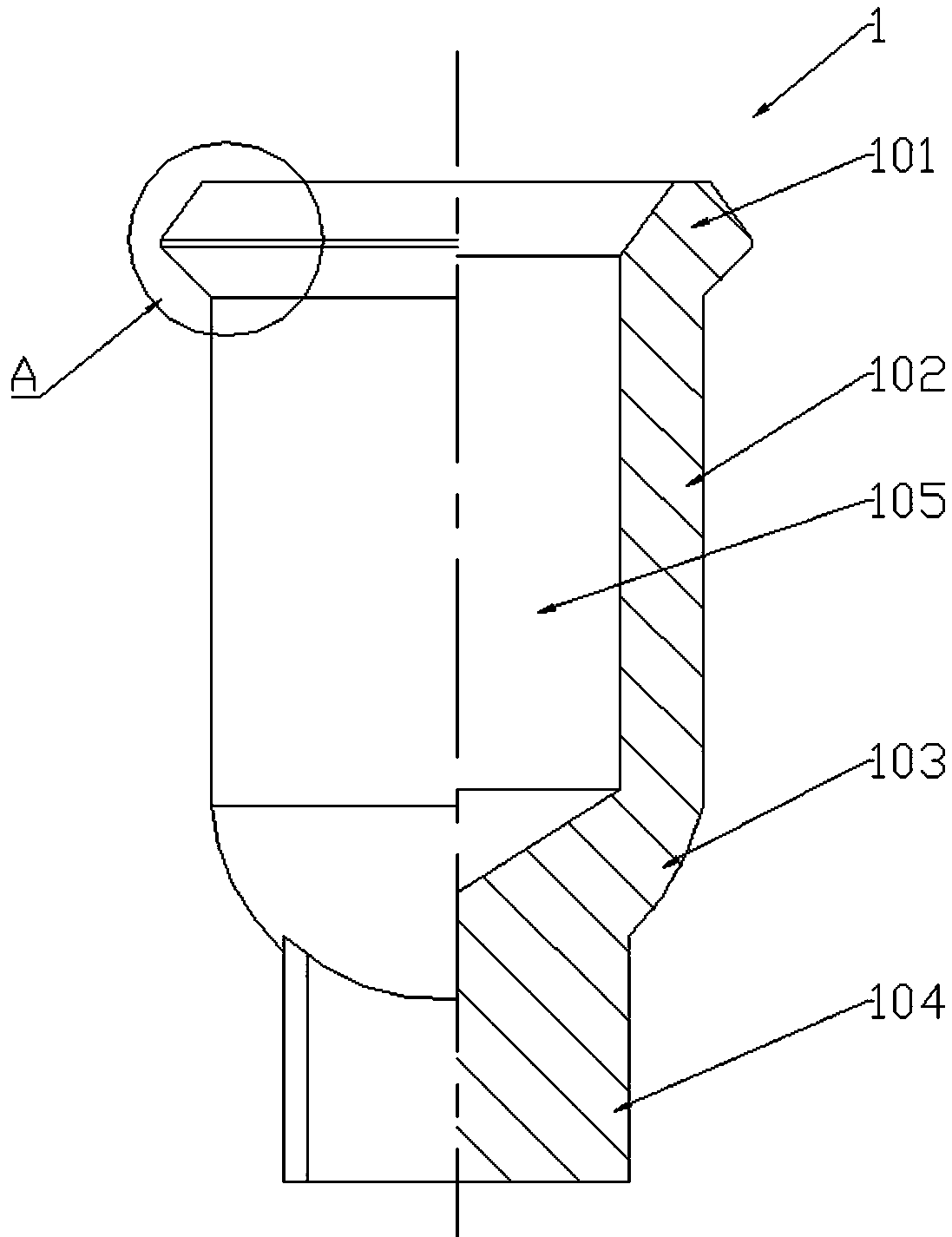

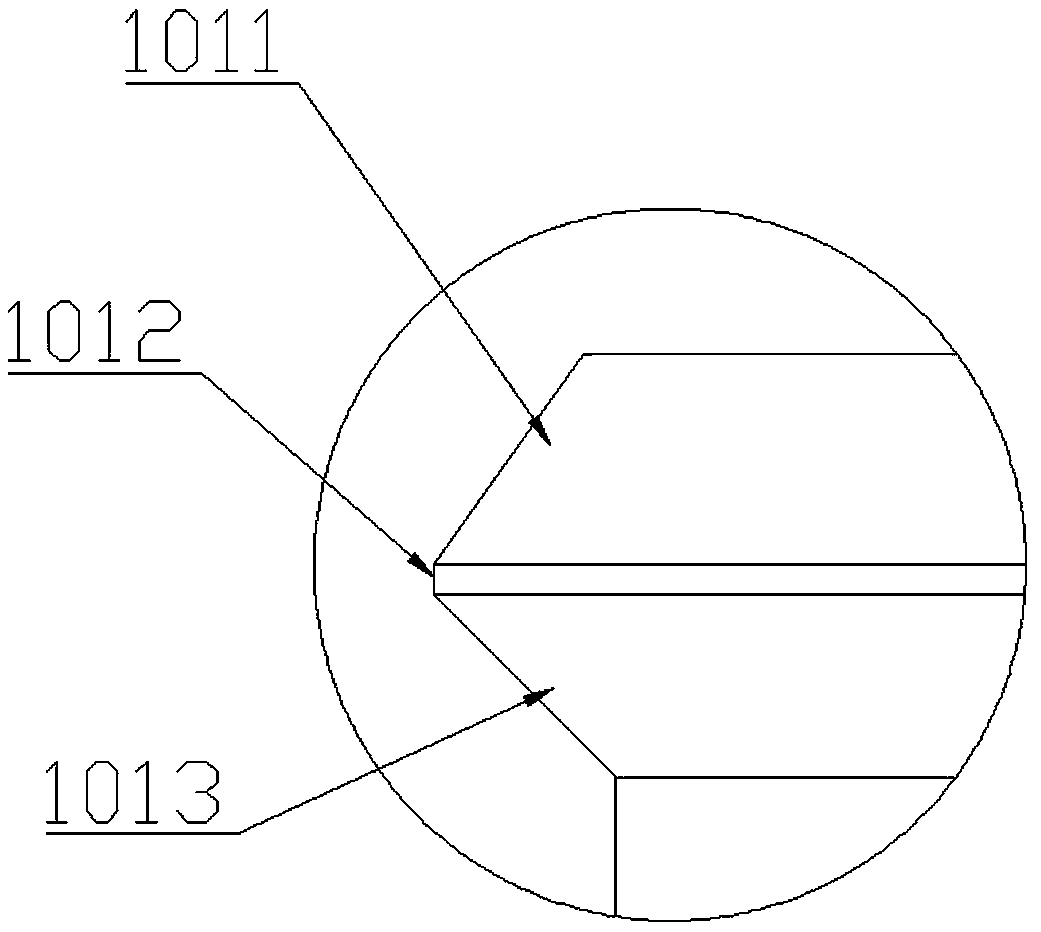

Air expansion shaft driving device

InactiveCN102009865AReduce runoutImprove the winding effectCoupling-brake combinationArticle deliveryCouplingAgricultural engineering

The invention discloses an air expansion shaft driving device. The air expansion shaft driving device comprises an air expansion shaft spline which is fixed at the end part of the air expansion shaft, wherein the air expansion shaft spline is in contact connection with a clutch spline through a shifting fork; the clutch spline is connected to a spline shaft; the spline shaft is connected with a shaft coupler through a bearing pedestal; the shaft coupler is arranged in a magnetic powder clutch brake; and the magnetic powder clutch brake provides driving. A bearing is directly arranged on an air expansion shaft, so the air expansion shaft driving device greatly reduces the radial runout during the operation of the air expansion shaft and greatly improves the rolling performance of a splitting machine.

Owner:苏州高新区禾云设备设计事务所

Elastic rolling floating support for centerless grinding of outer circle of annular part

PendingCN108655845ASmall elastic deformationAddress bearing marks and even superficial burnsRevolution surface grinding machinesRolling resistanceMagnetic poles

The invention discloses an elastic rolling floating support for centerless grinding of an outer circle of an annular part. The elastic rolling floating support comprises elastic supporting bodies, supporting sleeves, compressed springs, transition blocks and a supporting seat; the elastic supporting bodies press the supporting sleeves through T-shaped bolts to be connected to the transition blocks, the transition blocks are connected and fixed on the supporting seat of a machine tool shell, one end of each elastic supporting body is provided with a plurality of pairs of supporting heads, alloyballs are correspondingly arranged at the end parts of the supporting heads, and the other ends of the elastic supporting bodies are fixed on the supporting seat; and a coil shell is arranged on theinner side of the supporting seat, a coil is arranged in the coil shell, a sealing body is arranged outside the coil, a magnetic pole is arranged on the outer side of the coil shell, and the magneticpole is fixed on a workpiece shaft. According to the elastic rolling floating support, non-supporting mark grinding is achieved through rolling friction between supporting points and the surface of the workpiece, and follow-up treating matters caused by support marks and even burn are greatly reduced, the influence of the elastic deformation of the workpiece on the grinding efficiency and the quality is reduced, the stress of the elastic supporting points tends to be consistent, and all the points are always in effective supporting states.

Owner:ANHUI SYNCHRONOUS AUTOMATION TECH

Integral shaft-connect type fan clutch bearing

The invention discloses an integral shaft-connect type fan clutch bearing. The bearing adopts a row of rollers and double-row steel balls, the double-row steel balls adopt an angular contact structure in a geometric form, the bearing comprises a bearing outer ring, a mandrel, a steel ball holder, a roller holder and a seal ring, wherein channels and a raceway are machined on the bearing outer ring and used for bearing the rolling elements and guiding the rotation of rolling elements, the rolling elements comprise the steel balls and the cylindrical rollers, the mandrel is inserted into the bearing outer ring in the axial direction, inner channels are machined on the outer diameter of the mandrel and used for bearing the steel balls and guiding the rotation of the steel balls, an inner raceway is further machined on the outer diameter of the mandrel and used for bearing the cylindrical rollers, the steel ball holder is arranged between the bearing outer ring and the mandrel and makes the steel balls distributed in the channels at equal intervals, the roller holder adopts a design of a cylinder-shaped structure and a spring collar structure, a spring collar is assembled on the bearing outer ring in a matched mode to prevent the cylindrical rollers from springing out in the axial direction, and the sealing ring is installed in a seal groove formed in the end of the bearing outer ring in a pressed mode and remains still with the bearing outer ring.

Owner:长沙优力电驱动系统有限公司

Novel decelerator

InactiveCN104653710AReduce runoutReasonable structureToothed gearingsGearing detailsGear wheelDrive shaft

Disclosed is a novel decelerator. The novel decelerator comprises a housing, wherein two small shaft bearings are respectively arranged at two ends of a small shaft, and support the small shaft on the housing, two large shaft bearings are respectively arranged at two ends of a large shaft, and support the large shaft on the housing, key grooves are formed in stretching ends of the small shaft and the large shaft, the small shaft and the large shaft are positioned by being connected with an external motor and a work mechanism through small keys and large keys, the two ends of the small shaft and the two ends of the large shaft are sealed through small shaft covers, large shaft covers and seal rings, a gear is arranged in the middle of the small shaft and meshed with a large deceleration gear, a motor is installed at the stretching end of the small shaft, and the stretching end of the large shaft is used as an output shaft. The work mechanism is installed on the novel decelerator, and therefore radial jumping of a transmission shaft portion in a deceleration box and a transmission wheel supported by the transmission shaft portion can be effectively reduced, and furthermore the novel decelerator has the advantage of being reasonable in structure.

Owner:XIAN DAYU PHOTOELECTRIC TECH

Turning clamp and turning method of polycrystalline rod material

InactiveCN103434037AStable clampingReduce runoutWorking accessoriesFine working devicesEngineeringMachine tool

The invention relates to a turning clamp and turning method of a polycrystalline rod material. A left end fixing disk is a cylinder, one end of the left end fixing disk is a step shape, a blind hole is formed in the bottom end of the interior of a hole in the other end of the left end fixing disk, the upper end of the interior of the hole in the other end of the left end fixing disk is an inner conical surface, a right end fixing disk is a cylinder, one end of the right end fixing disk is a plane, and the other end of the right end fixing disk is a round protruding surface. The turning method of the polycrystalline rod material comprises the steps that a three-jaw chuck at the left end of a lathe is used for fixedly clamping the left end fixing disk with the inner conical surface, the left end fixing disk is used for fixing one side, with a conical surface, of the polycrystalline rod material in the process of machining, the end face of the other side of the polycrystalline rod material bonds with the right end fixing disk, a center of a tailstock of the lathe is used for carrying out centering abutting operation, a hard alloy tool is tightly clamped, after tool setting is accomplished, turning of the polycrystalline rod material is carried out according to preferable technological parameters which include that the cutting speed is 94m / min, the longitudinal feed ratio is 0.2, the amount of feed is 2mm and the angle of feed is 80 degrees, meanwhile, a dust removal and cooling device is started, and inspection is carried out according to the requirement for machining accuracy after turning is accomplished. The turning clamp and turning method of the polycrystalline rod material are stable in clamping, low in radial runout and high in safety, and improve machining efficiency and the product percent of pass.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com