High-speed jacquard shedding device and jacquard machine provided with same

A jacquard opening and high-speed technology, which is applied in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of unfavorable weaving jump, low weaving efficiency, and large vibration of the whole machine, so as to effectively control the warp yarn breakage rate and improve weaving efficiency , Weaving opening clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

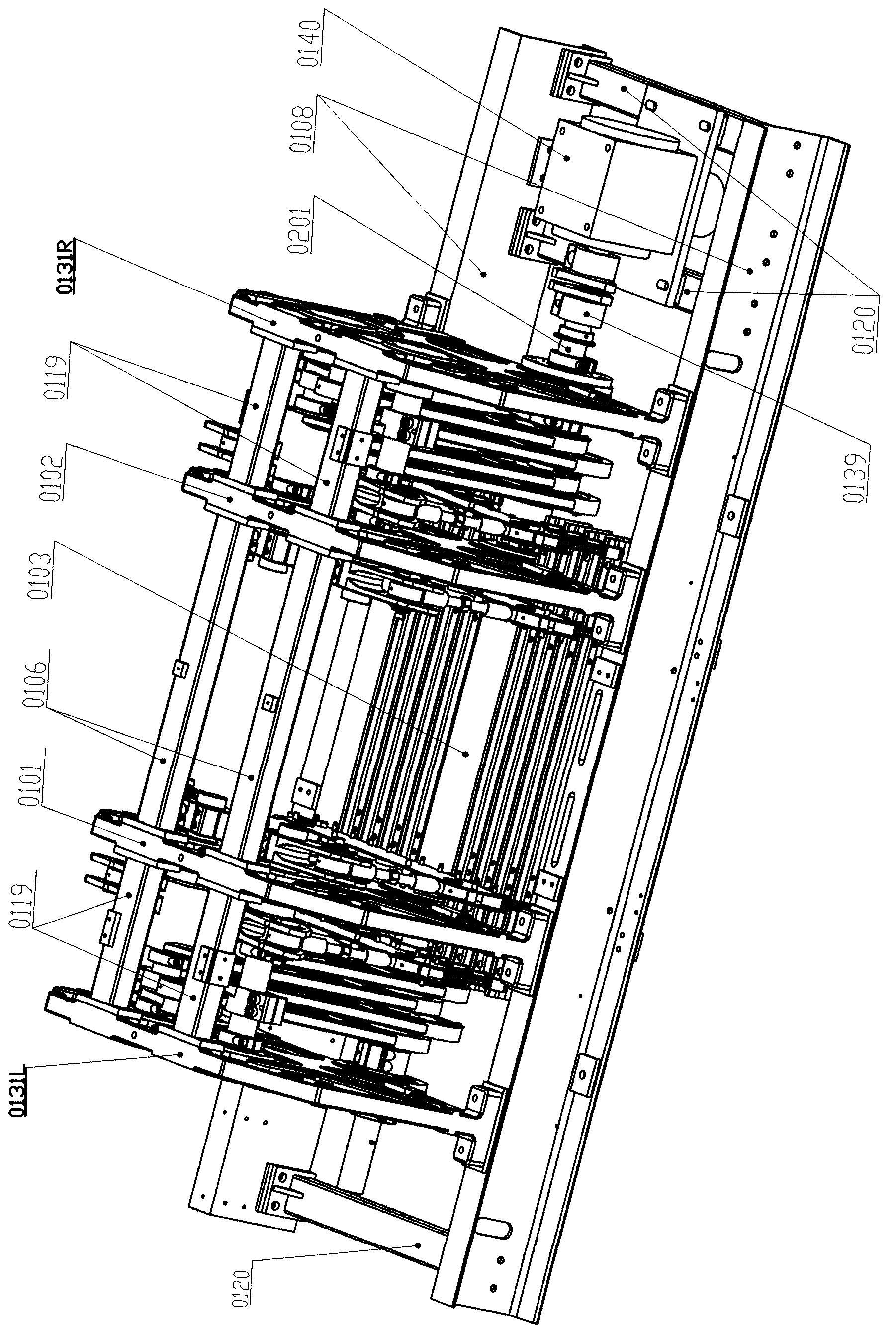

[0043] Such as figure 2 As shown, the jacquard machine of the present invention is configured, and its frame consists of a bottom frame, a left main wall panel 0101, a right main wall panel 0102, a left auxiliary wall panel 0131L, a right auxiliary wall panel 0131R, a tubular brace 0103, two supports It consists of long supports 0106 and four short supports 0119, in which, the entire bottom frame is connected by two bottom beams 108 and three cross braces 0120, the bottom beam 108 is made of large cross-section channel steel, and the left side of the bottom frame is installed sequentially A left auxiliary wall panel 0131L, a left main wall panel 0101, a right main wall panel 0102 and a right auxiliary wall panel 0131R are installed symmetrically on the right side of the bottom frame, between the left main wall panel 0101 and the upper part of the right main wall panel 0102 It is connected and fastened by two long supports 0106, and connected and fastened by two short supports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com