Patents

Literature

609results about How to "Reduce jumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

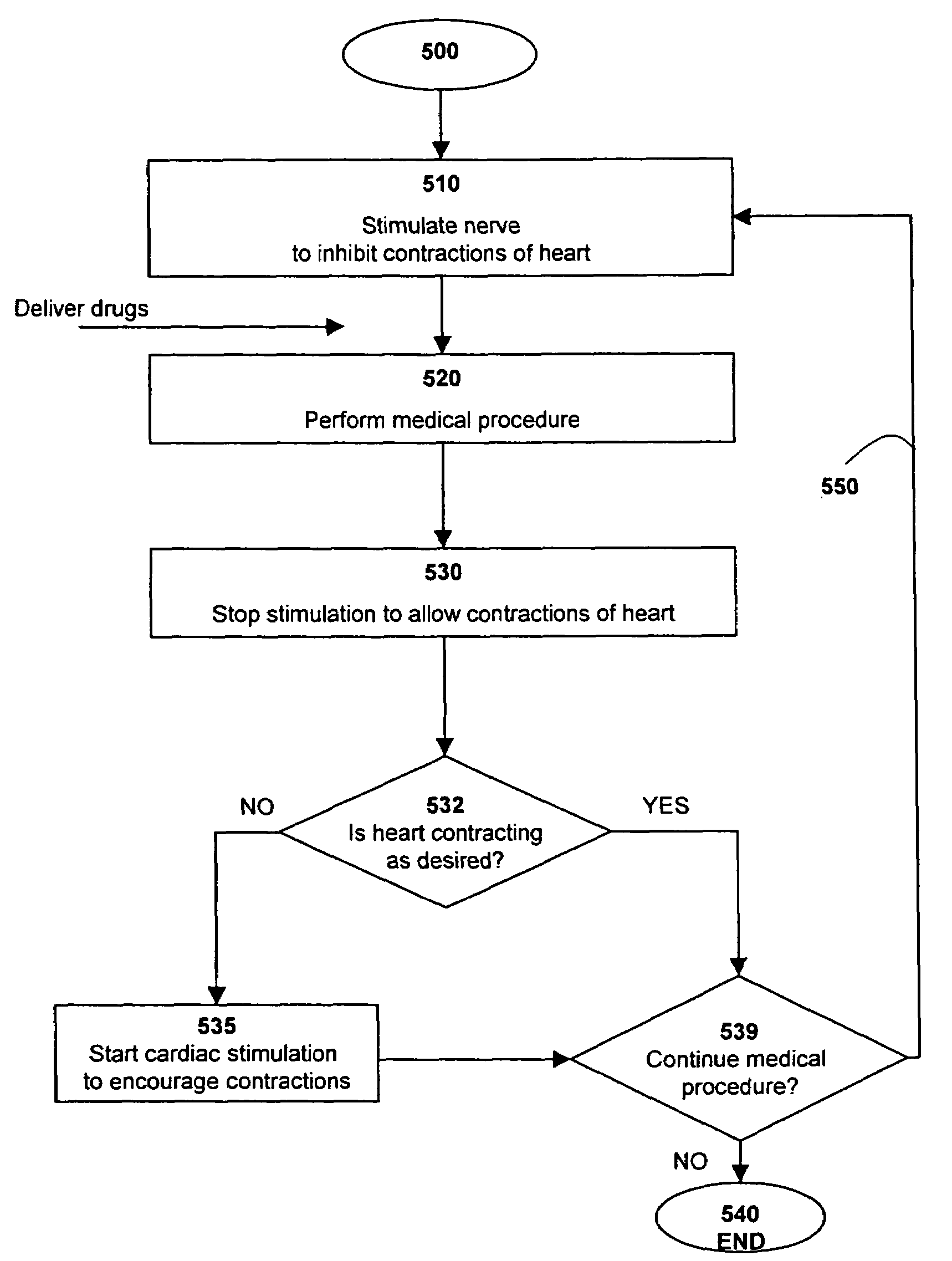

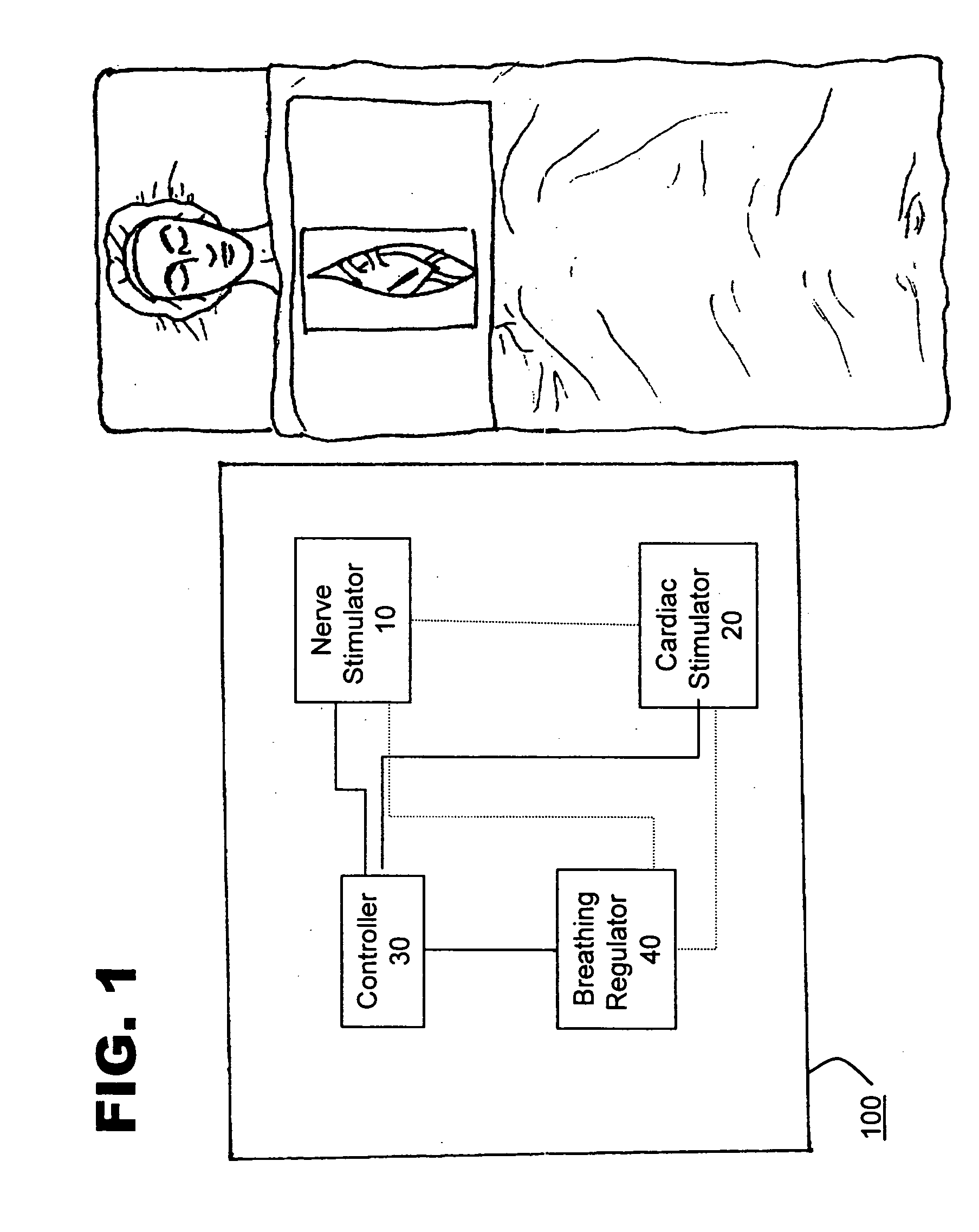

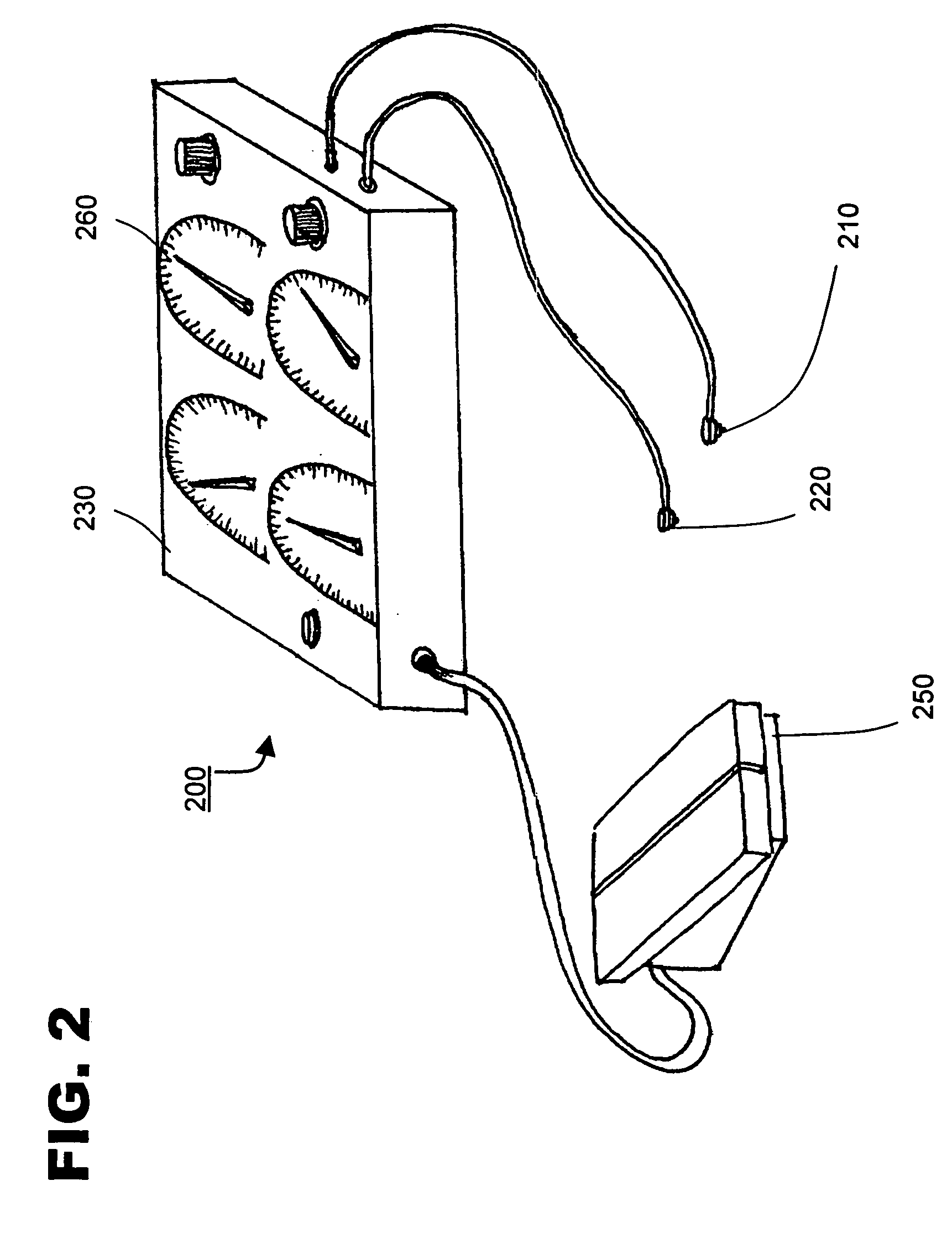

Method and system for nerve stimulation prior to and during a medical procedure

InactiveUS7184829B2Prevent beatingStimulate beatingTransvascular endocardial electrodesHeart defibrillatorsSacral nerve stimulationNerve stimulation

A method of performing a medical procedure, such as surgery, is provided. A nerve is stimulated in order to adjust the beating of the heart to a first condition, such as a stopped or slowed condition. The medical procedure is performed on the heart or another organ. The stimulation of the nerve is stopped in order to adjust the beating of the heart to a second condition, such as a beating condition. The heart itself may also be stimulated to a beating condition, such as by pacing. The stimulation of the nerve may be continued in order to allow the medical procedure to be continued. Systems and devices for performing the medical procedure are also provided.

Owner:MEDTRONIC INC

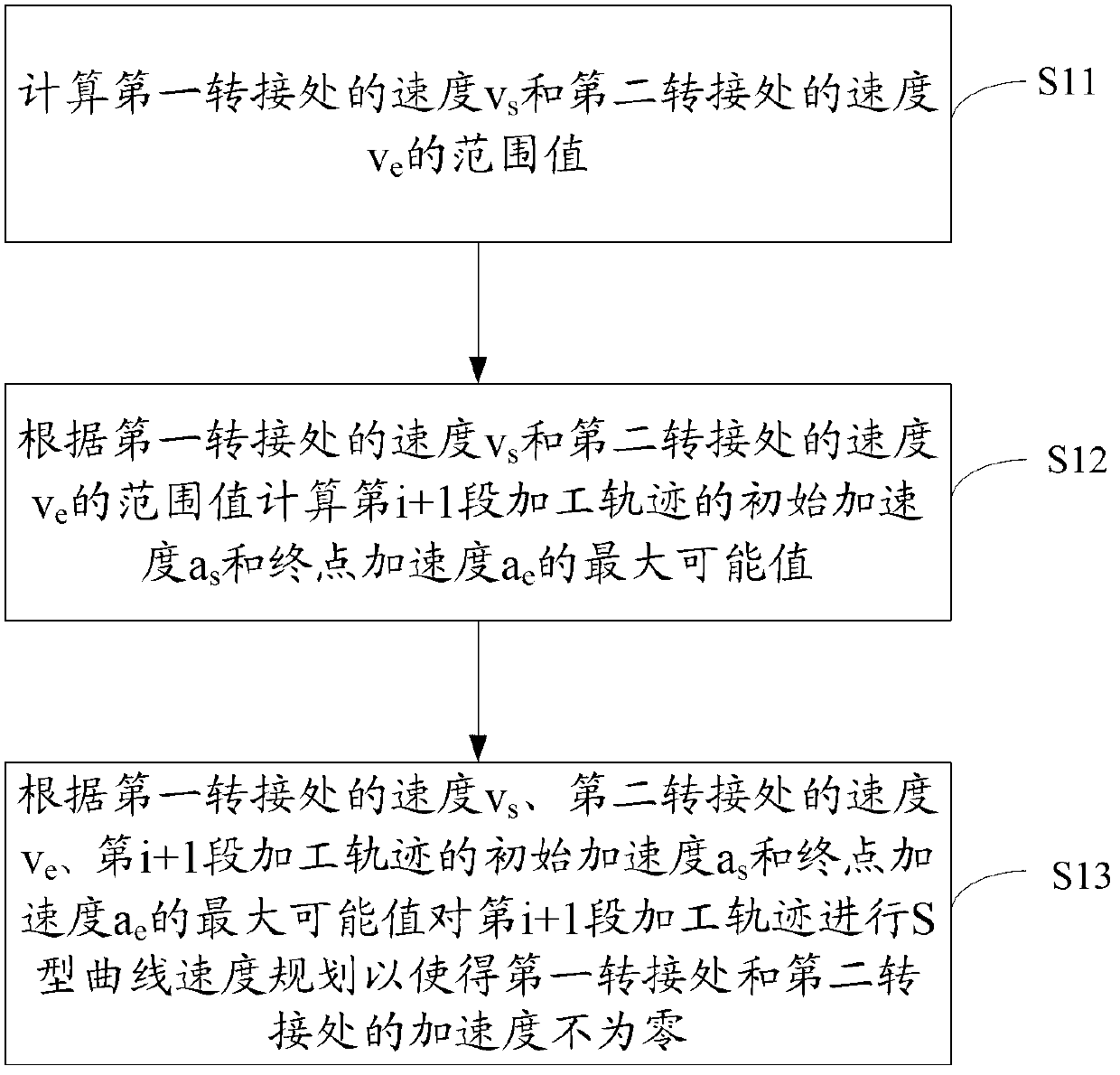

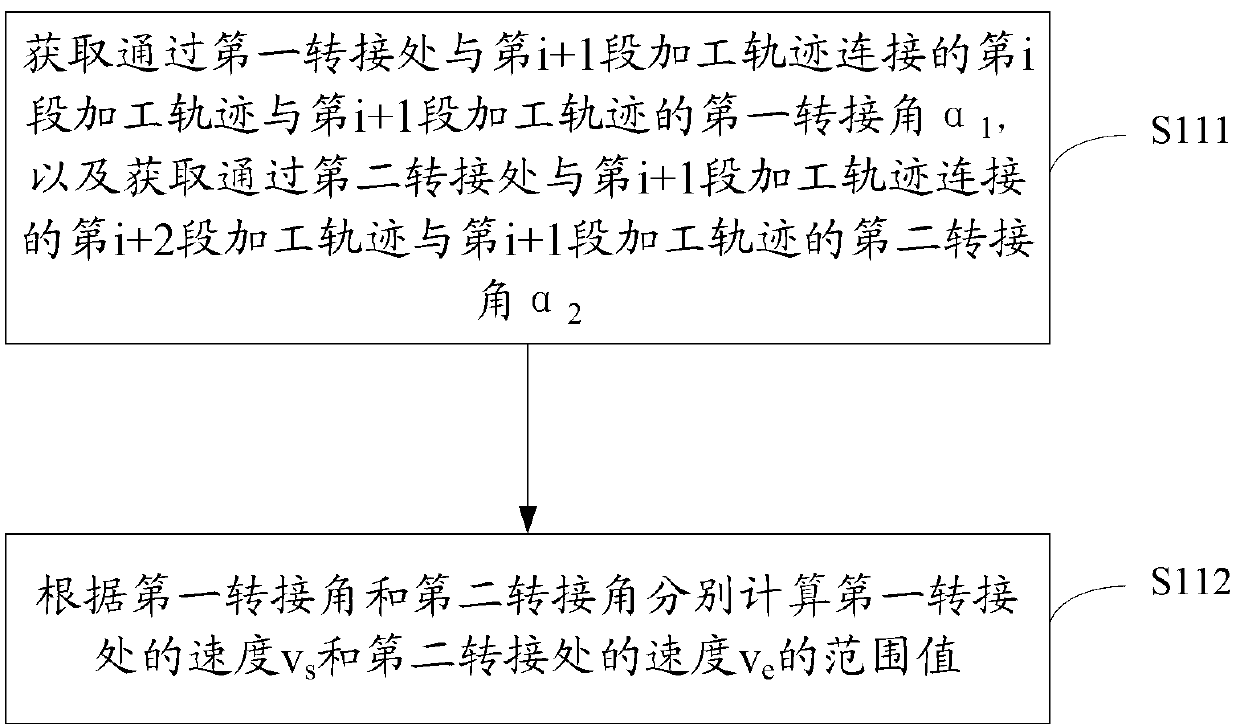

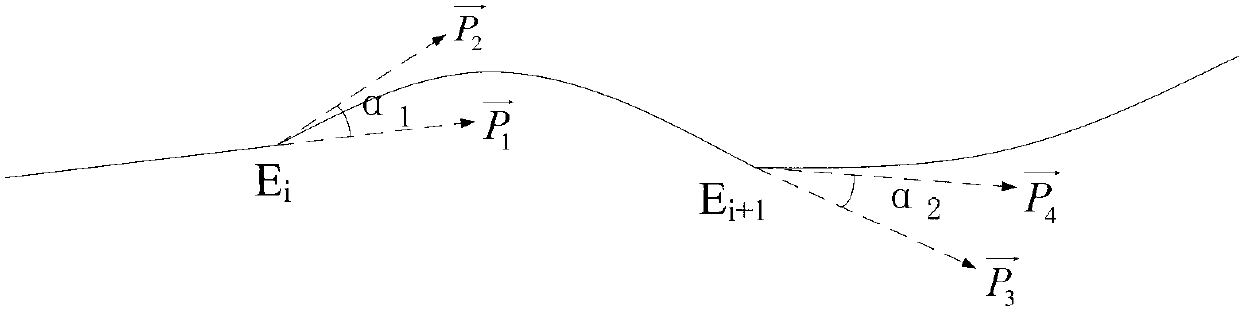

Acceleration and deceleration controlling method based on S-shaped curve and equipment using the same and numerically-controlled machine tool

The invention discloses an acceleration and deceleration controlling method based on an S-shaped curve. An S-shaped curve is applied to speed planning of an i+1 section of a processing track, wherein the i+1 section of the processing track is arranged between a first transfer position and a second transfer position, and accelerations of the first transfer position and the second transfer position are controlled not to be zero. The invention further discloses a controlling device of acceleration and deceleration based on the S-shaped curve and the numerically-controlled machine tool. Due to the fact that the acceleration and deceleration method based on the S-shaped curve and the equipment using the acceleration and deceleration controlling method based on the S-shaped curve of a numerically-controlled system control the accelerations of the first transfer position and the second transfer position not to be zero, processing efficiency can be effectively improved, and impact to the machine tool during the processing process is reduced.

Owner:BEIJING A&E TECH

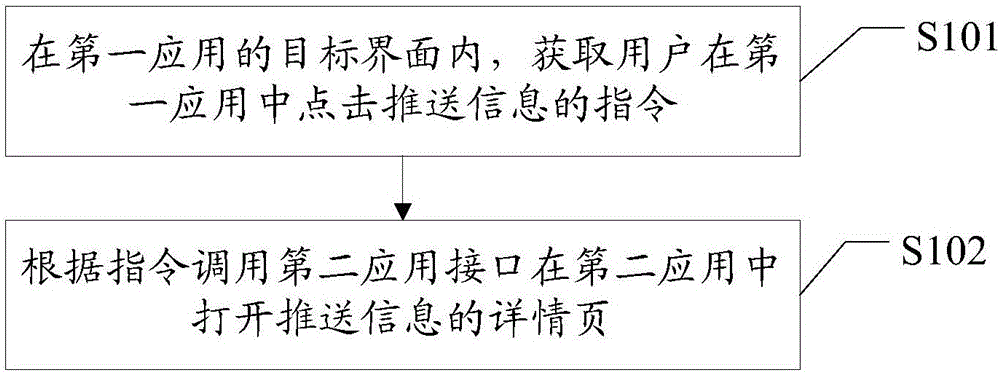

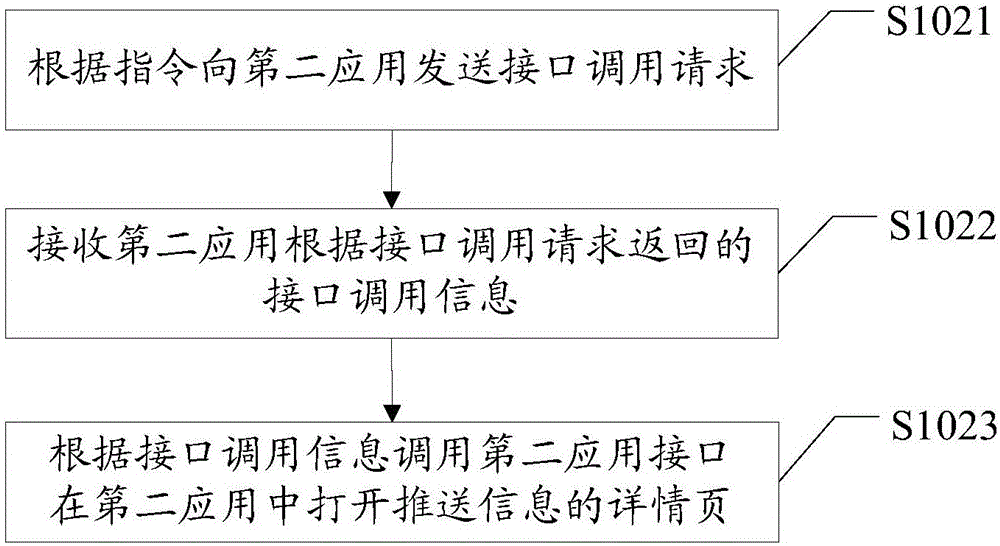

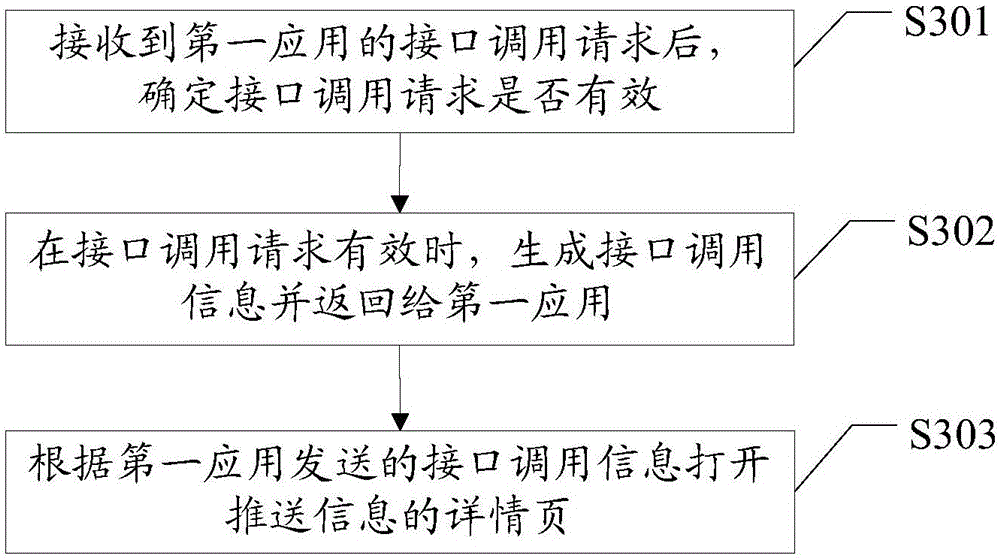

Information interaction method and device

ActiveCN106651522AImprove experienceReduce jumpingPayment architectureBuying/selling/leasing transactionsThird partyPayment

The invention discloses an information interaction method and device, and belongs to the technical field of electronic commerce. The information interaction method comprises the steps of: in a target interface of a first application, acquiring an instruction representing that a user clicks on push information in the first application, wherein the push information is push information of a third-party application or website in the first application; and according to the instruction, calling a second application interface to open a detail page of the push information in a second application, wherein the second application is a payment application. The second application is the payment application, when the user clicks on the push information in the first application, by directly opening the detail page of the push information in the payment application, the user can directly carry out commodity payment in the payment application, so that jumps in different applications are reduced, an operation path is shortened, and user experience and return on investment are promoted.

Owner:TENCENT TECH (SHENZHEN) CO LTD

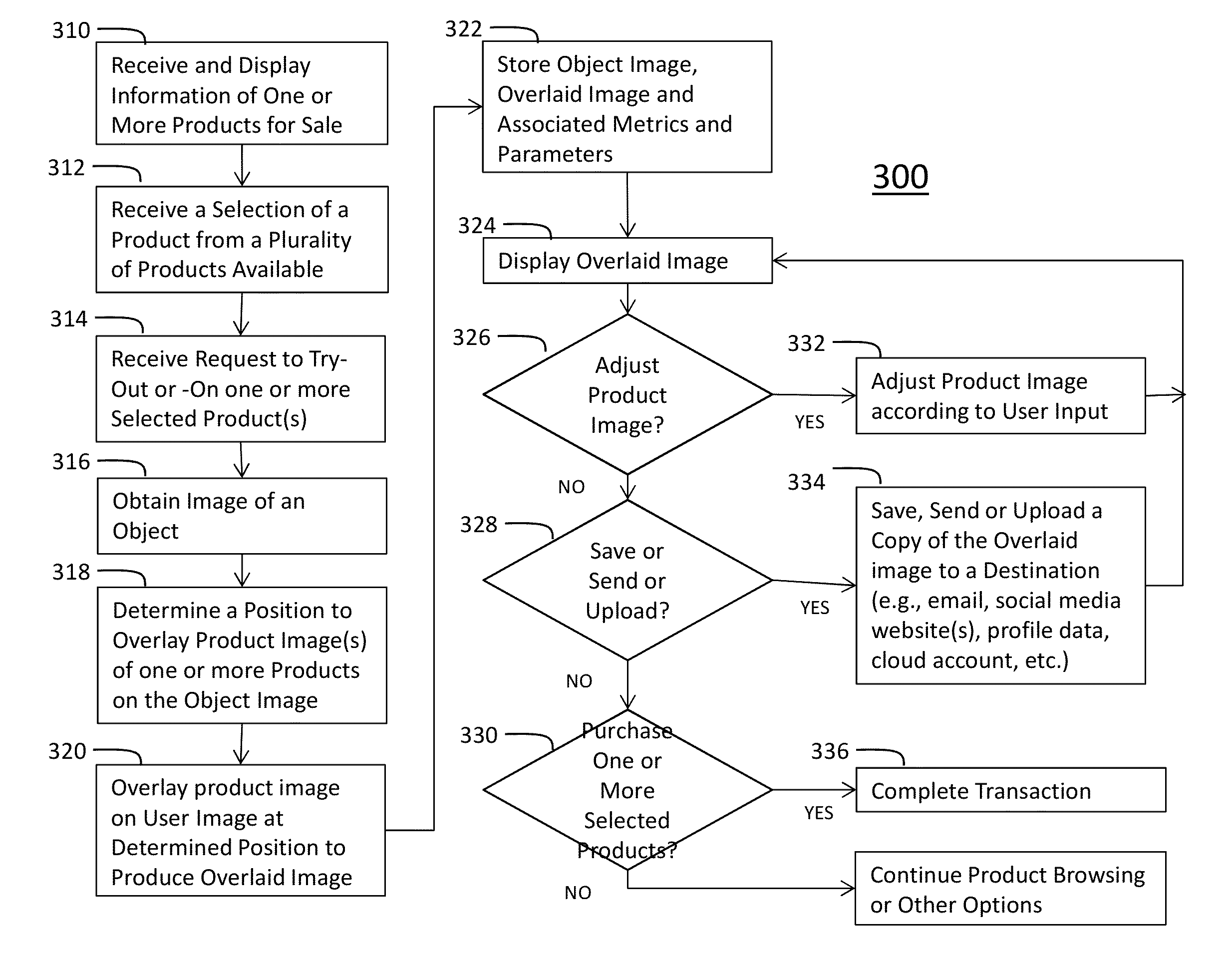

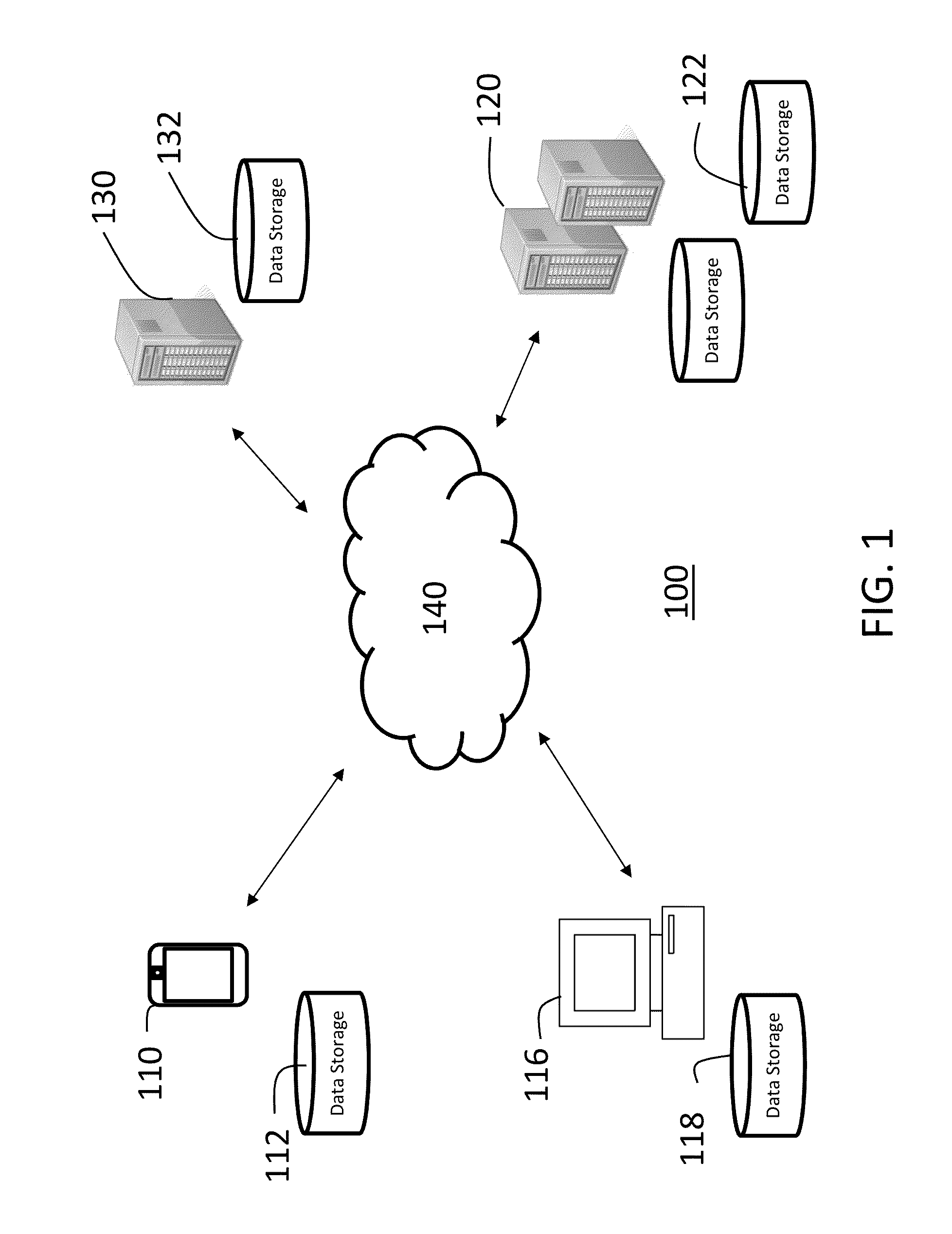

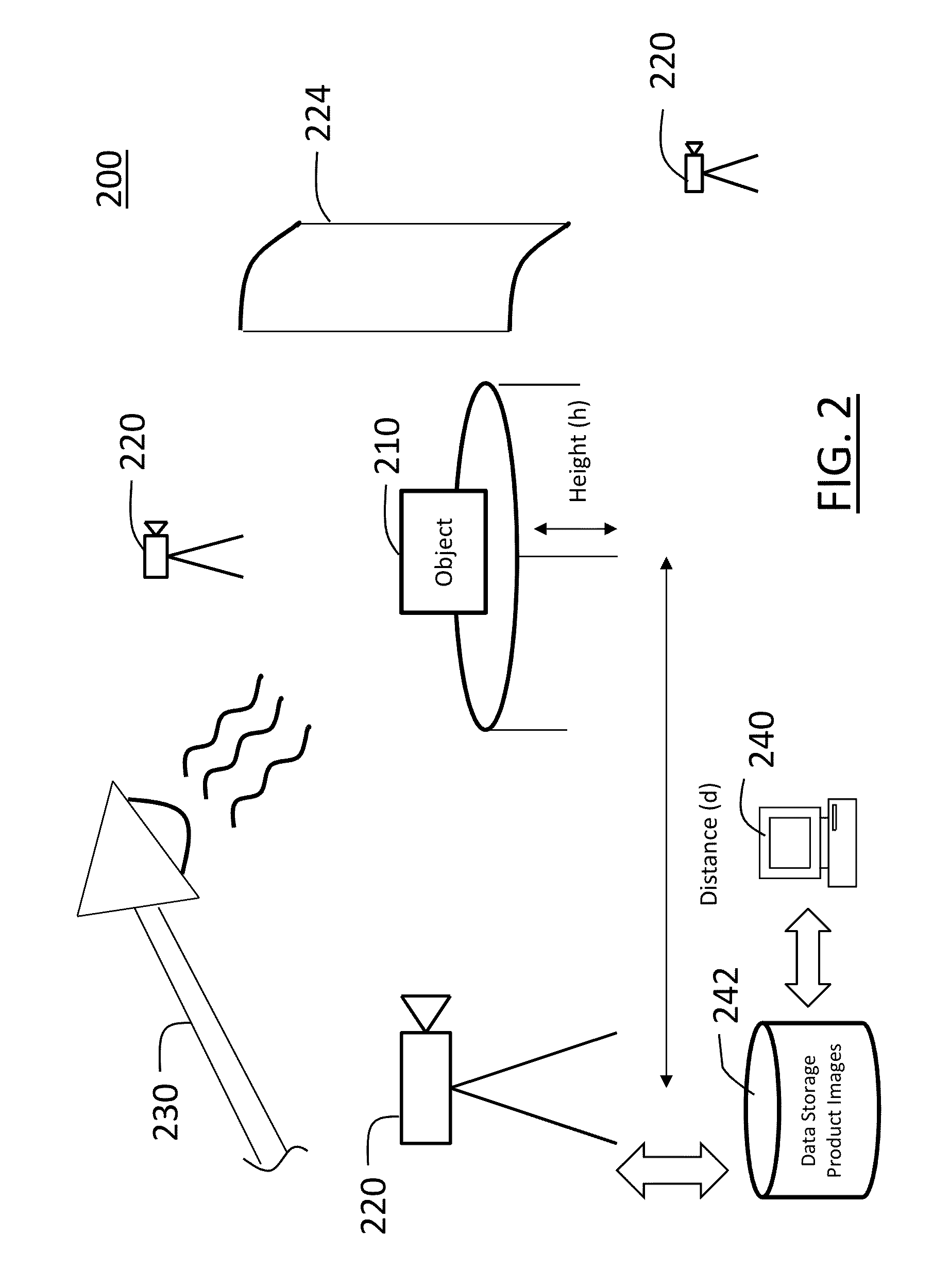

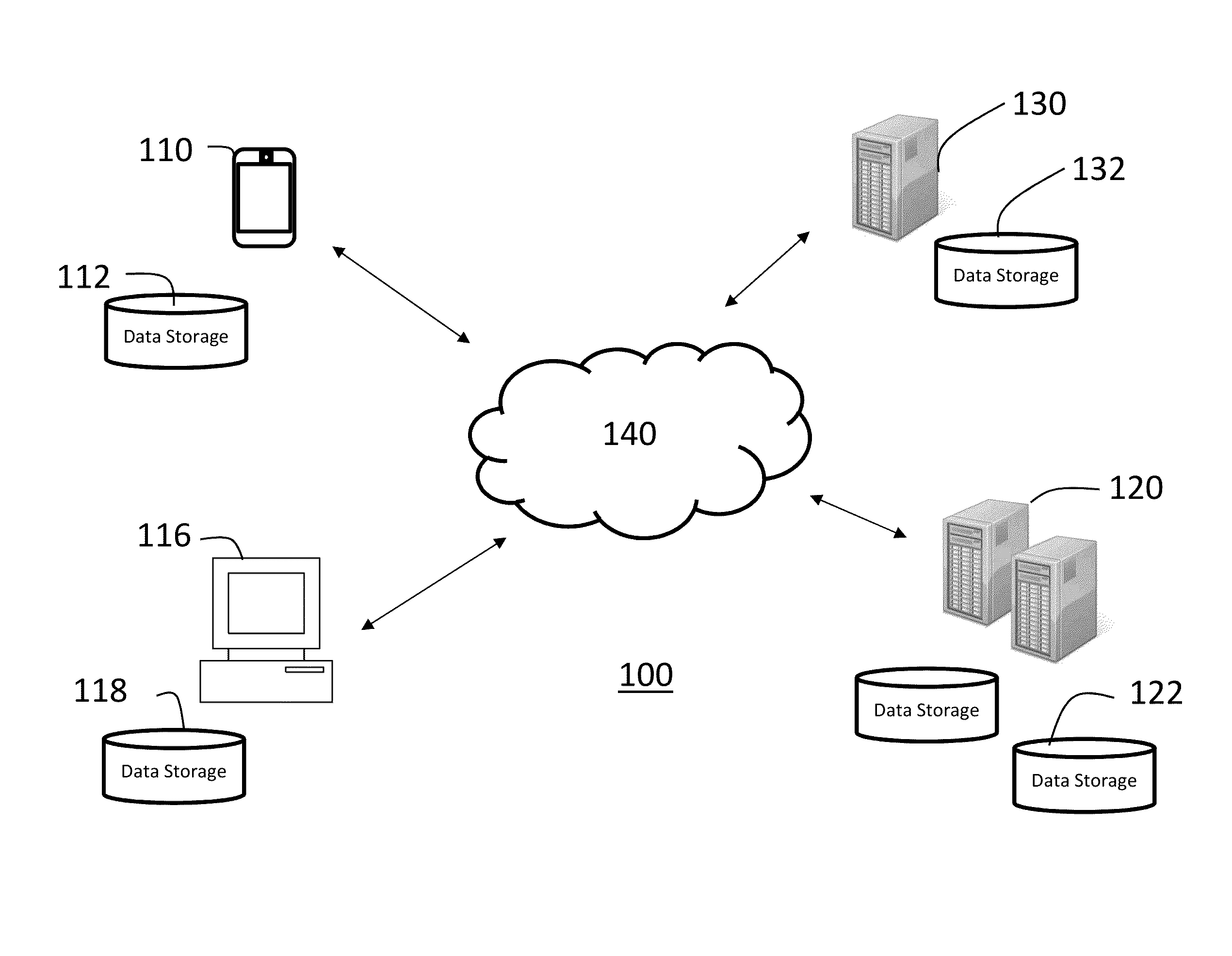

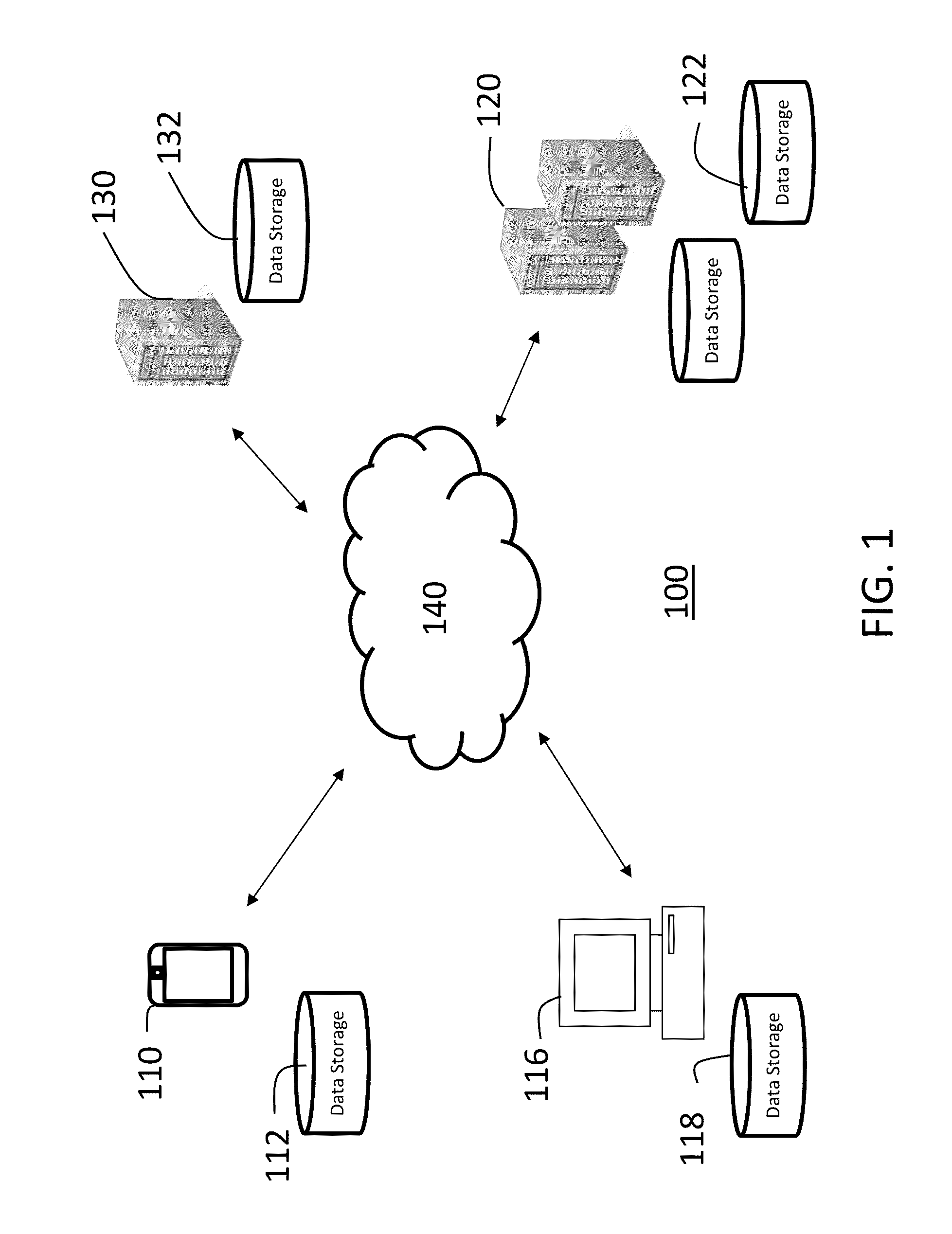

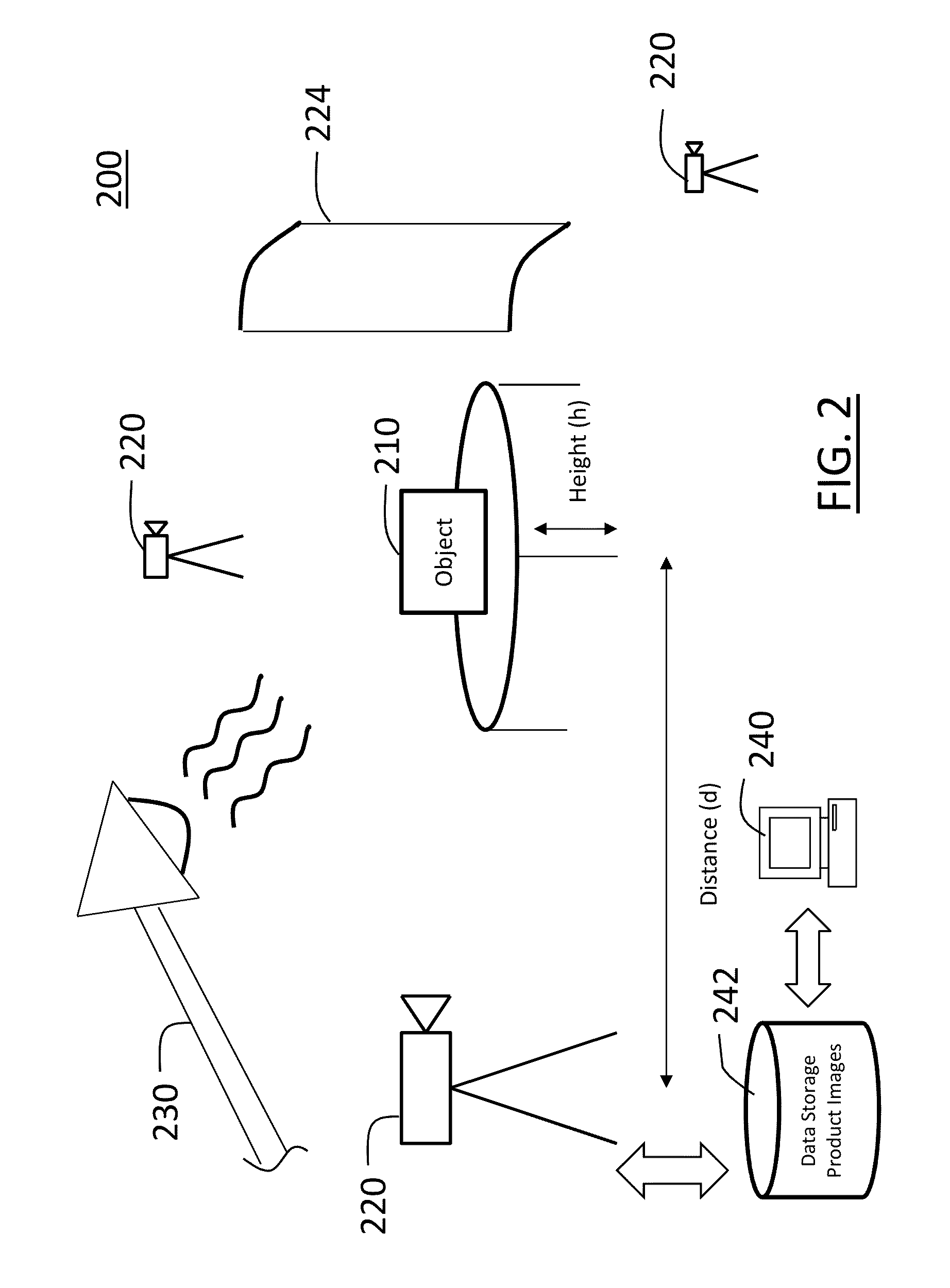

Method and system for trying out a product in relation to a real world environment

ActiveUS20140279242A1Reduce jumpingCathode-ray tube indicatorsBuying/selling/leasing transactionsProduct imageComputer program

A method, system and computer program are provided to allow one or more users to try out one or more products. The method, system and computer program involve providing information on one or more products offered for sale under restricted conditions of time or quantity, obtaining a real image of an object, determining one or more features from the object image, determining a position to overlay a first product image on the object image based on the determined one or more features, overlaying the first product image on the object image based on the determined position to provide an overlaid image, and displaying the overlaid image. The first product image is an image of a product from the one or more products

Owner:GILT GRP LP

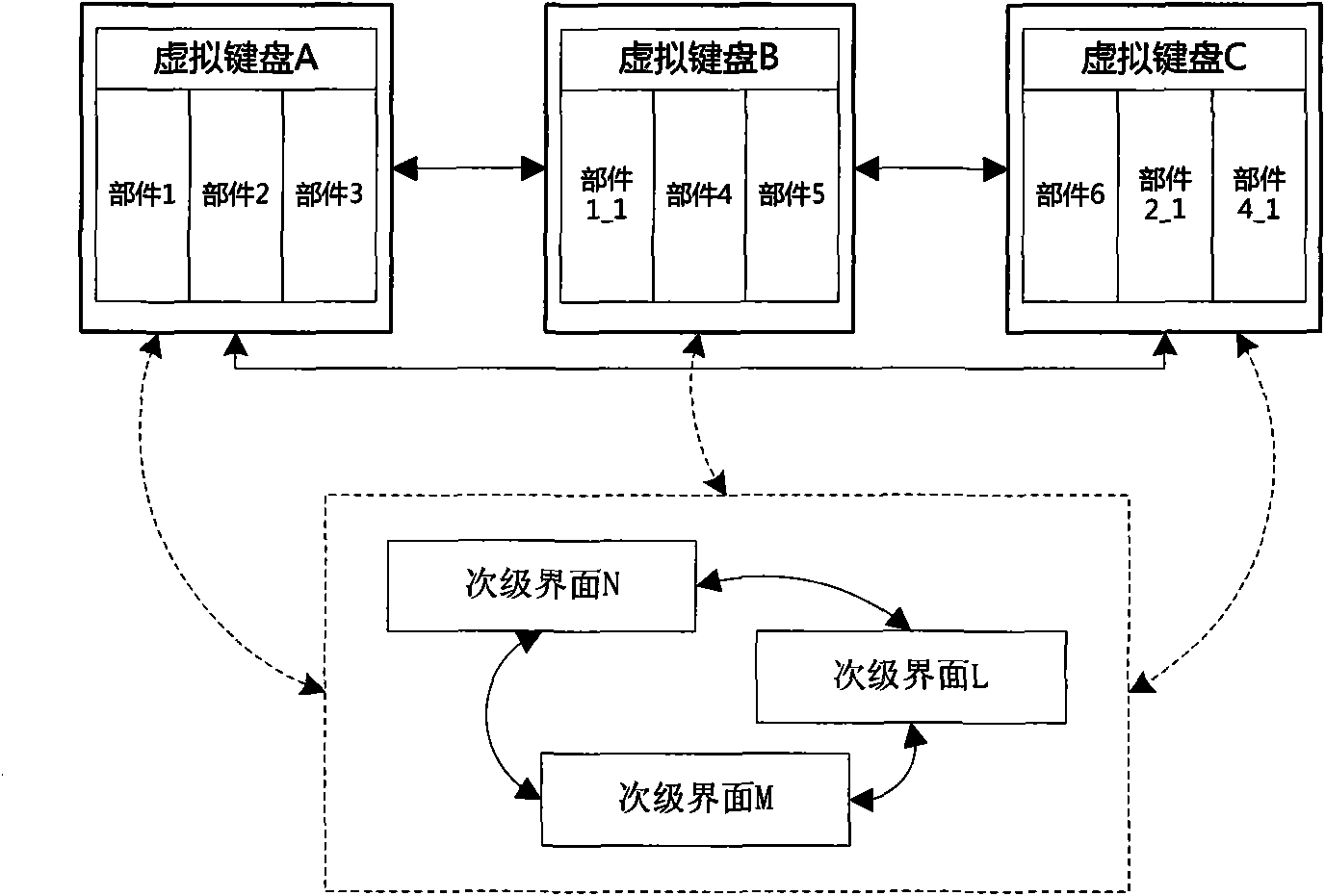

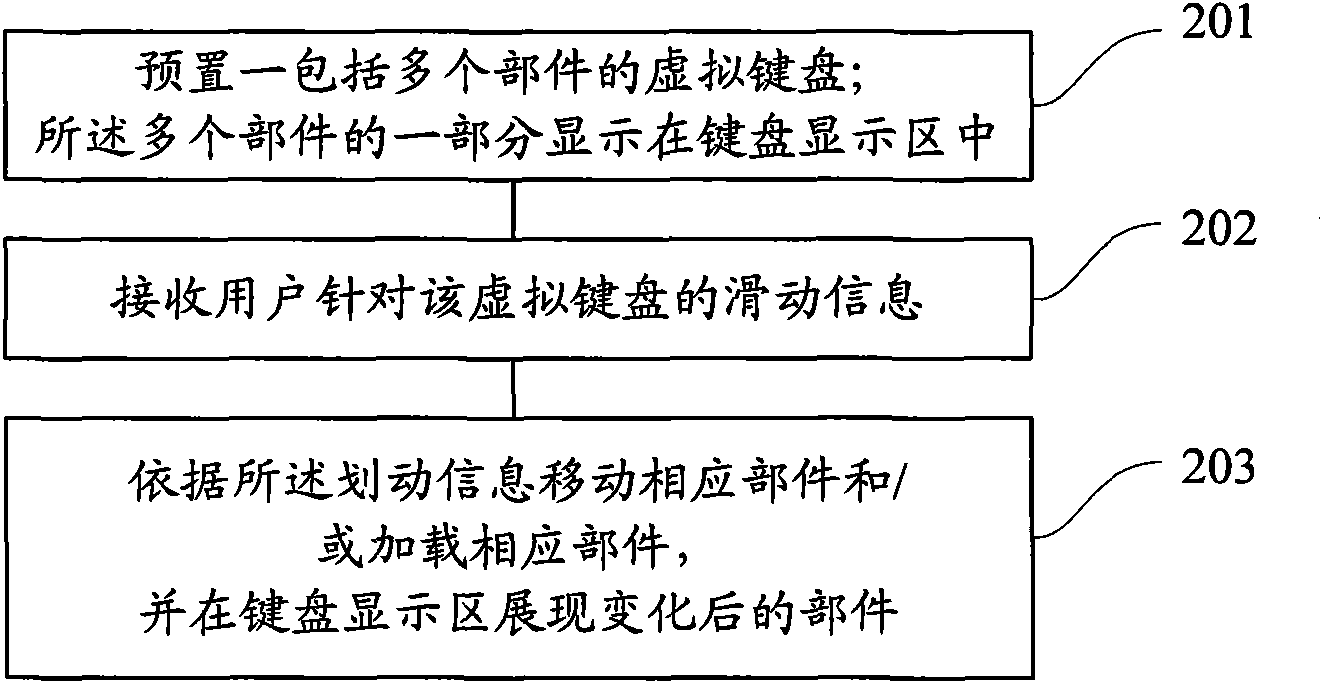

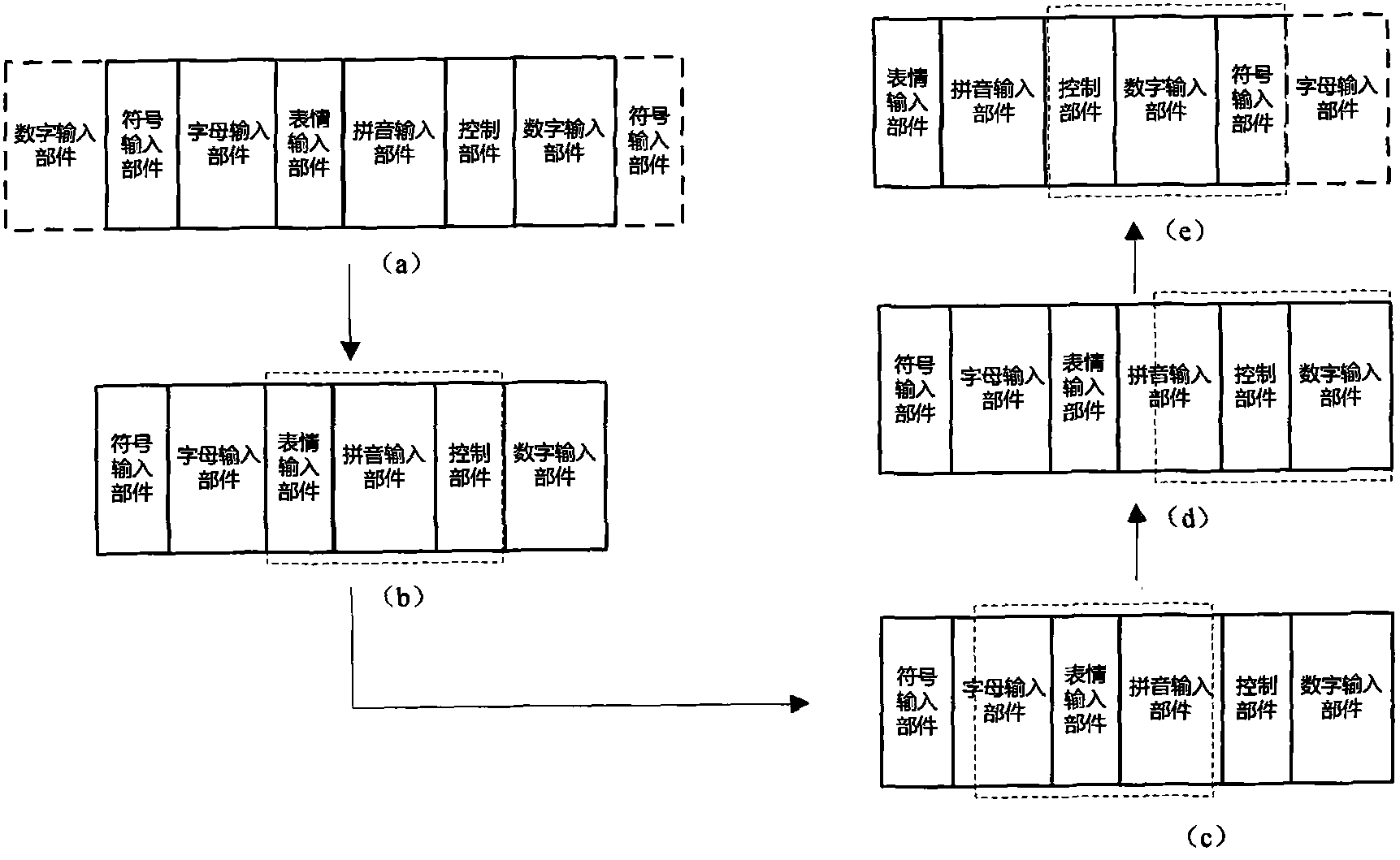

Method for displaying virtual keyboard, virtual keyboard and touch screen terminal

ActiveCN102314296AImprove efficiencyAvoid frequent openingInput/output processes for data processingTouchscreenInput function

The invention provides a method for displaying a virtual keyboard, the virtual keyboard and a touch screen terminal. The method comprises the following steps of: receiving sliding information of a user for the virtual keyboard, wherein the virtual keyboard comprises a plurality of parts, and a part of the plurality of parts are displayed in a keyboard display area of a screen; and moving and / or loading the corresponding part in the virtual keyboard according to the sliding information, and displaying the changed part in the keyboard display area of the screen. The application of a panoramic keyboard is provided, unlimited sliding of the user can be accepted, keyboards with different input functions are prevented from being frequently opened and closed by the user in the input process, the problem of interruption when the user switches the keyboards can be solved, the using efficiency of various keyboards is improved, and using smoothness and continuity are improved.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

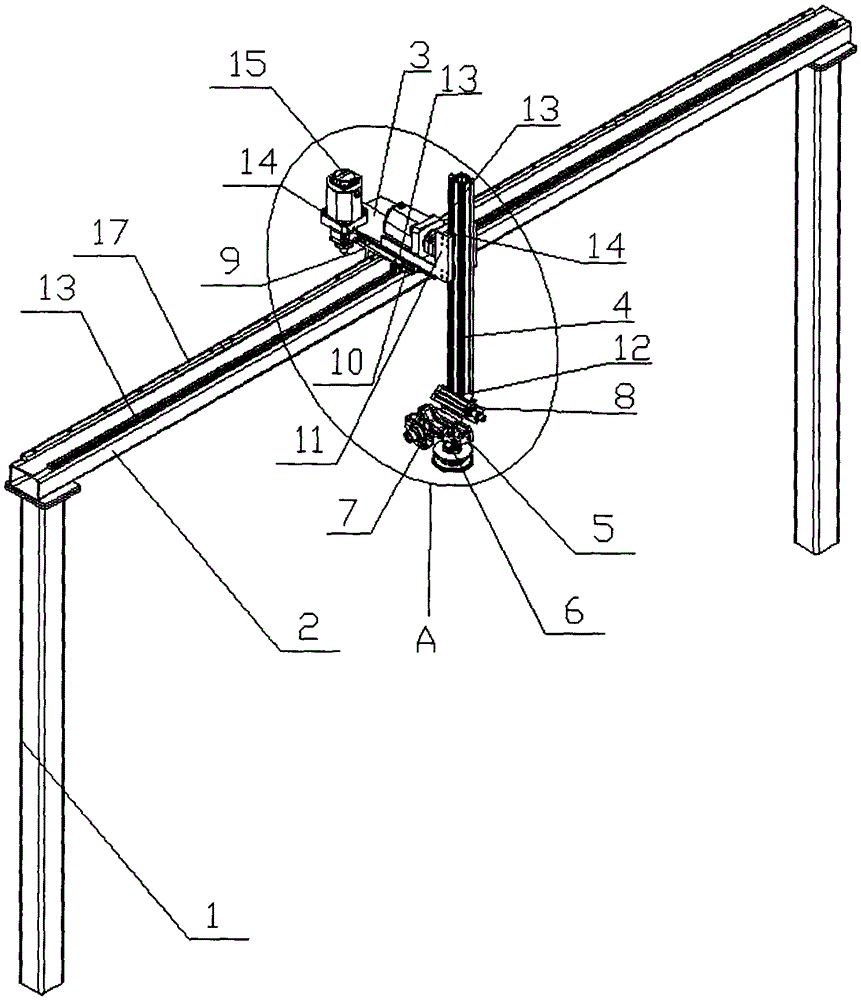

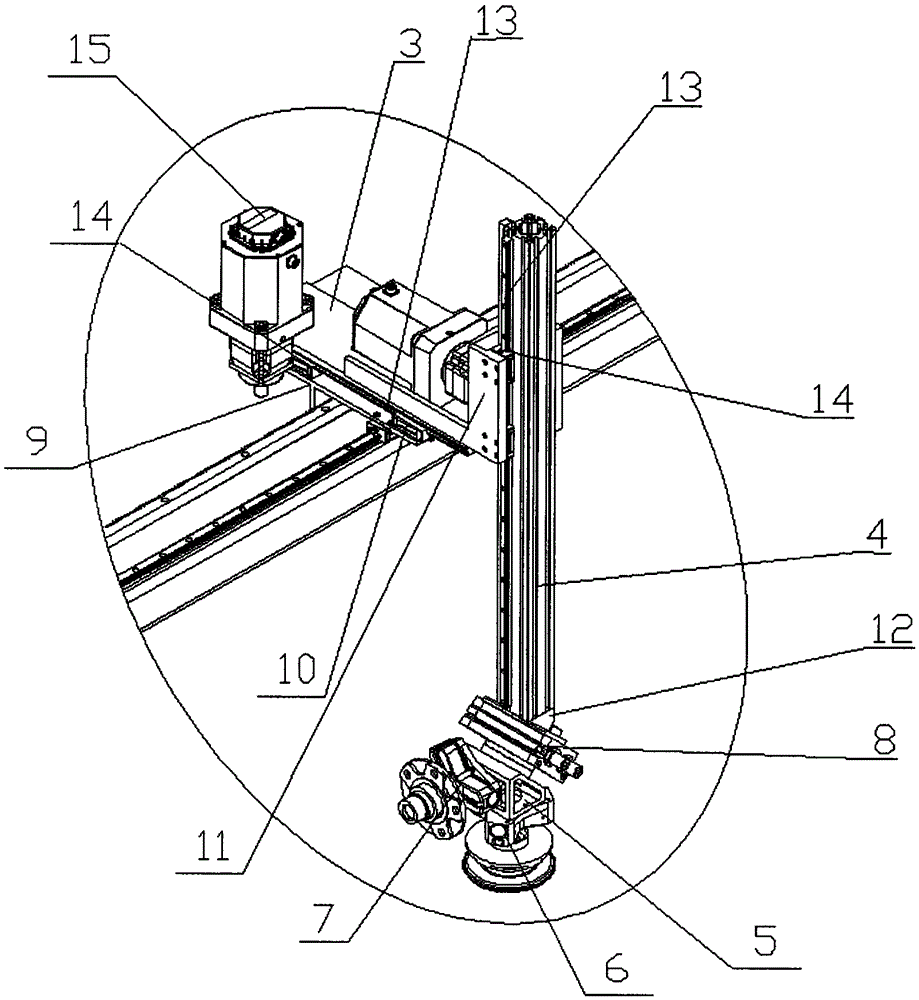

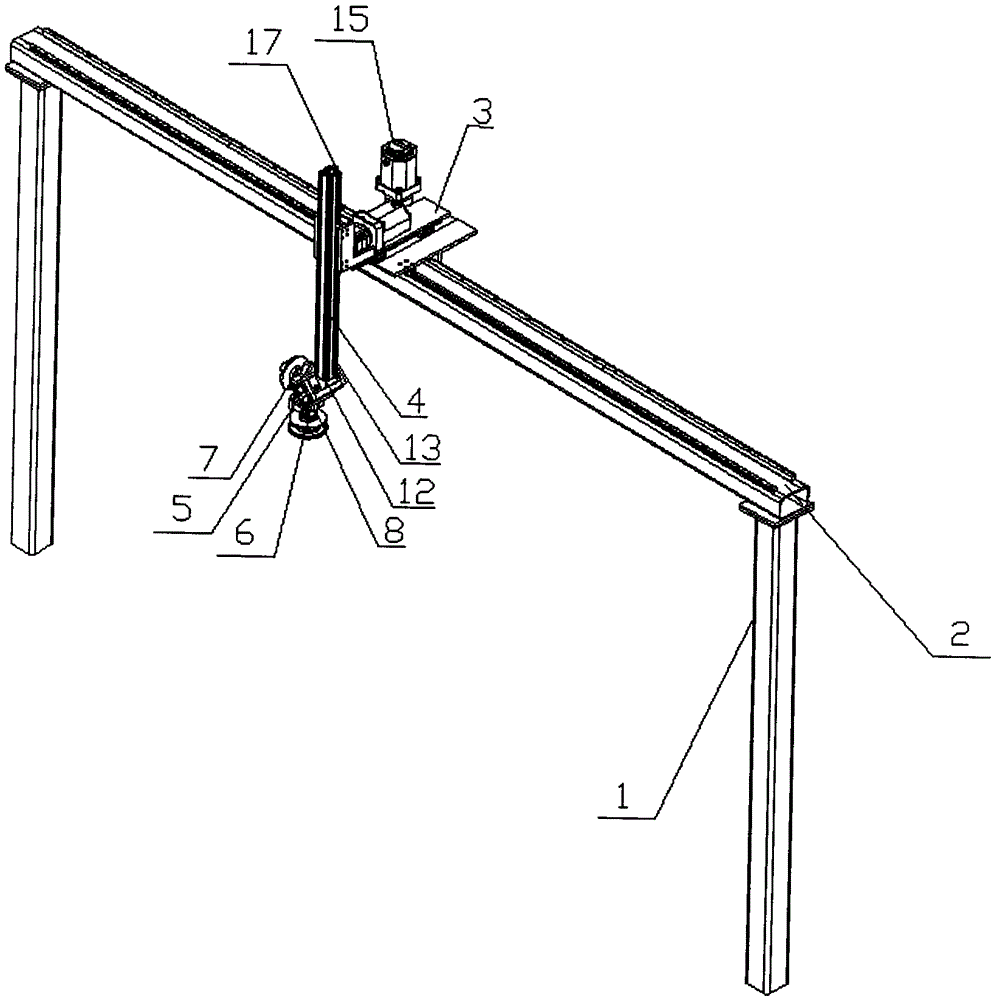

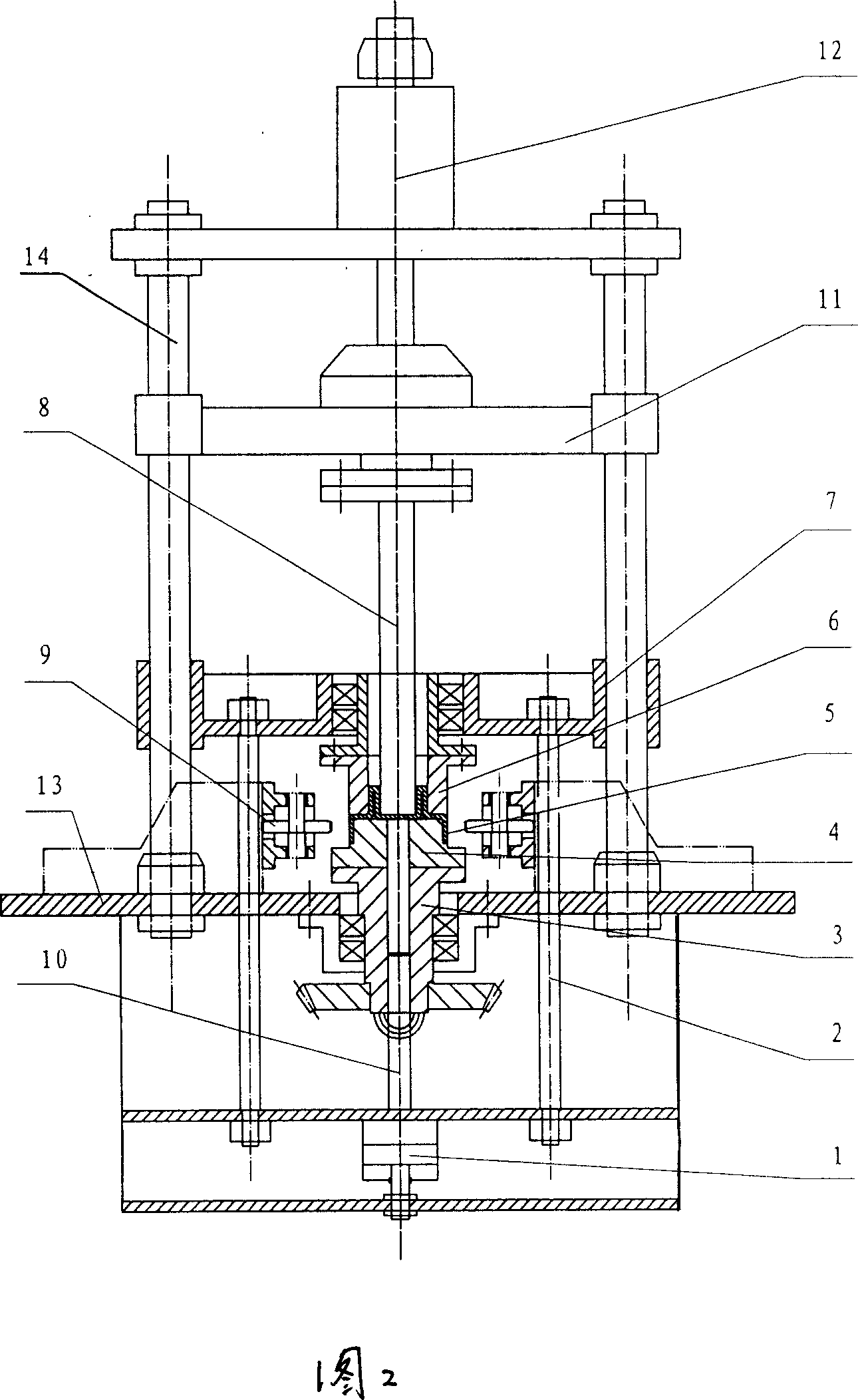

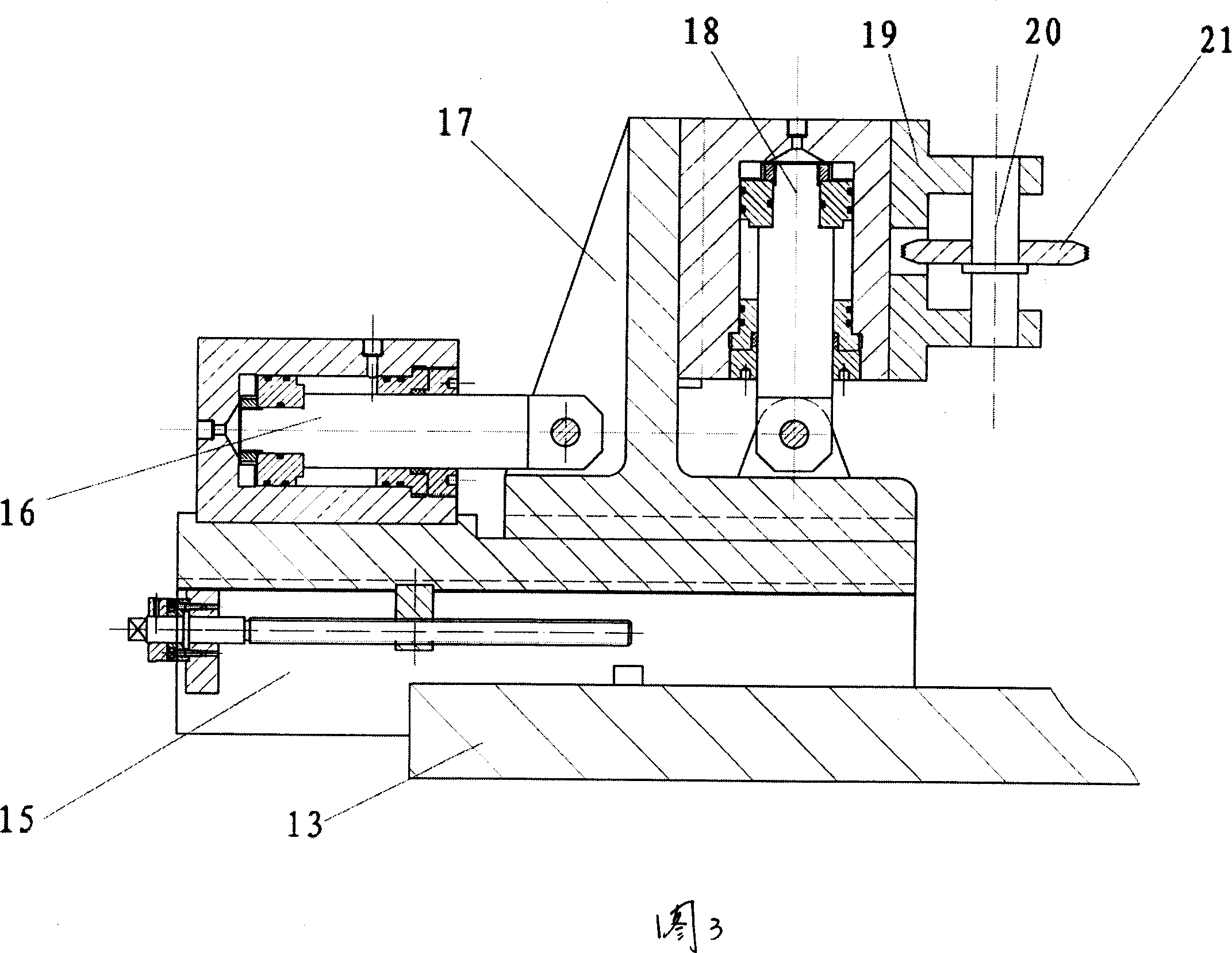

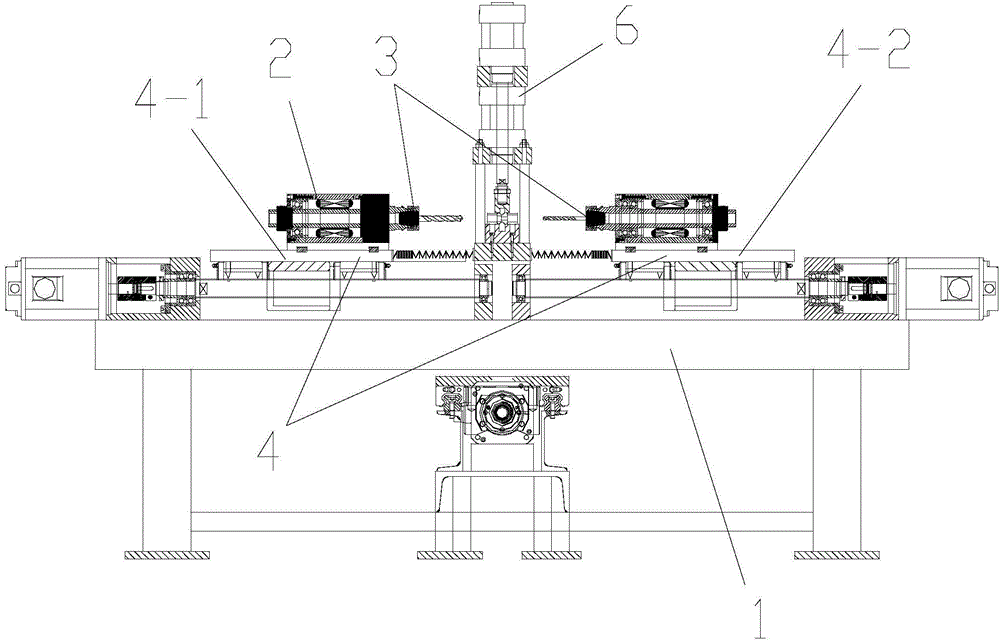

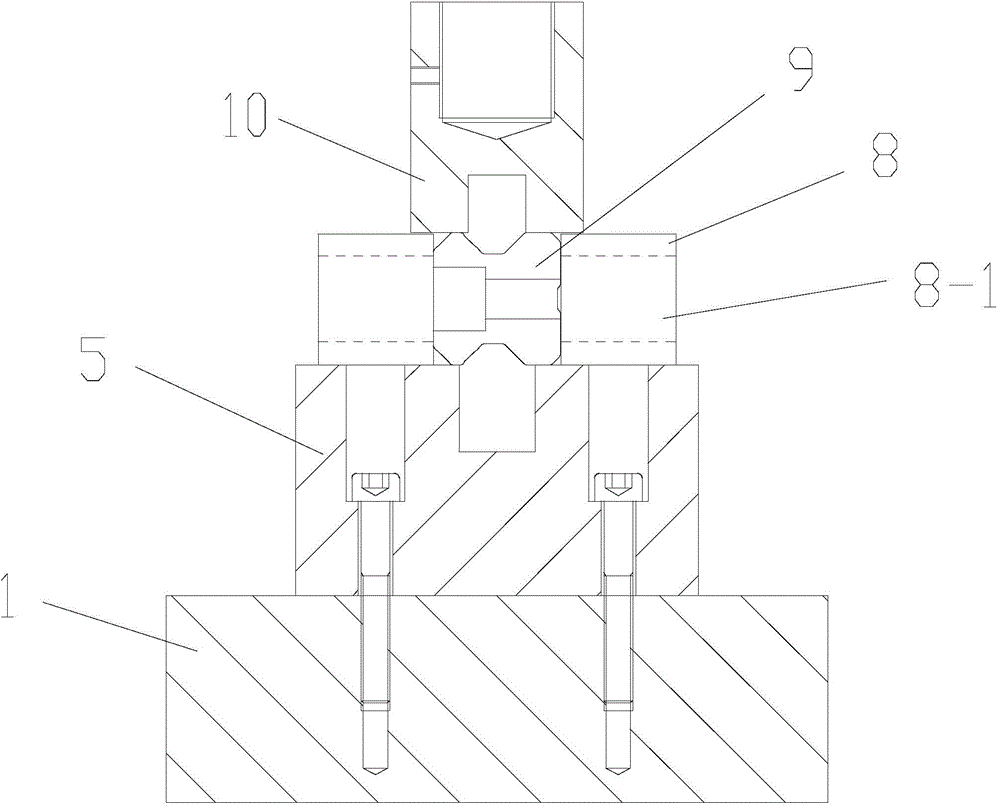

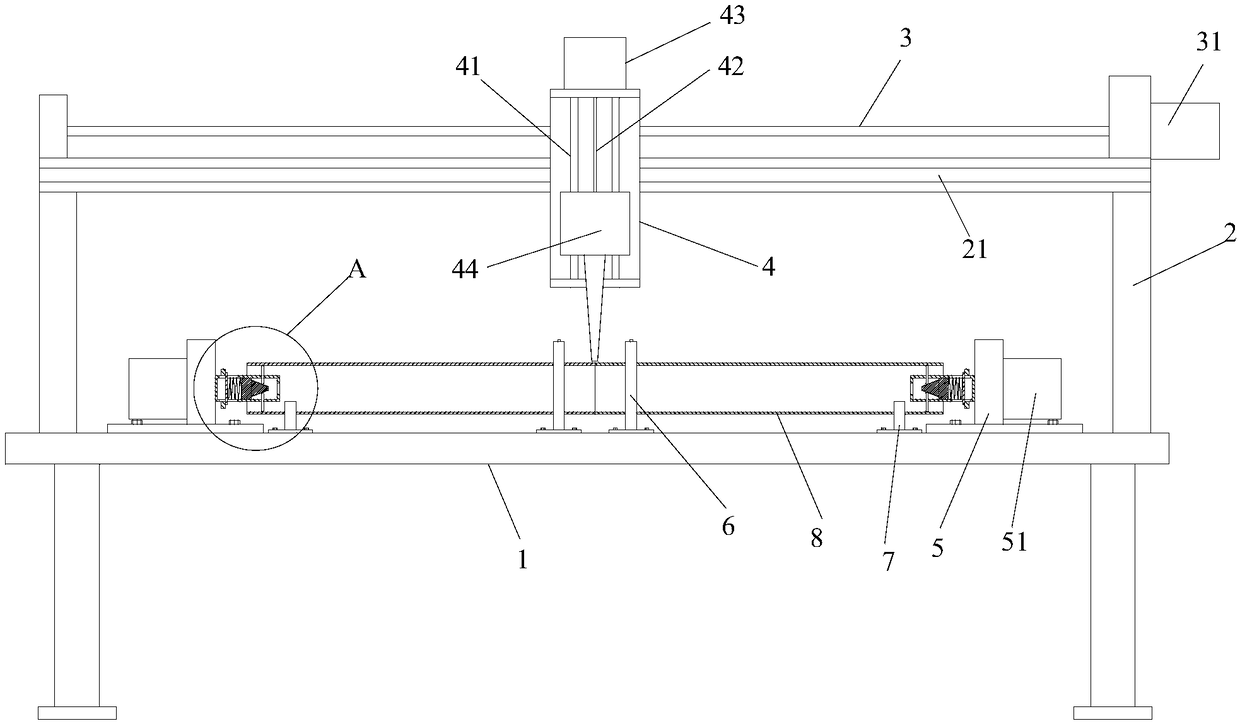

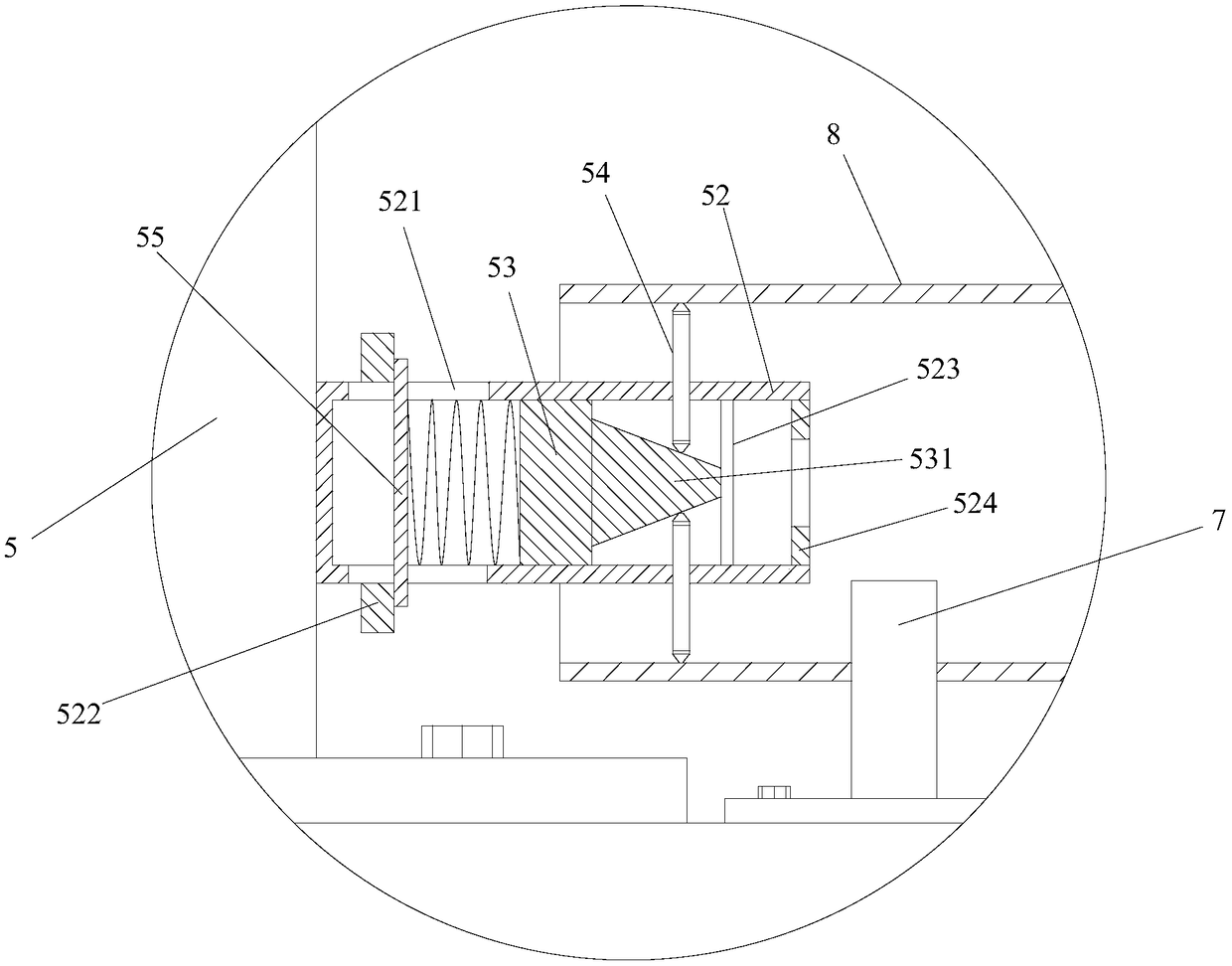

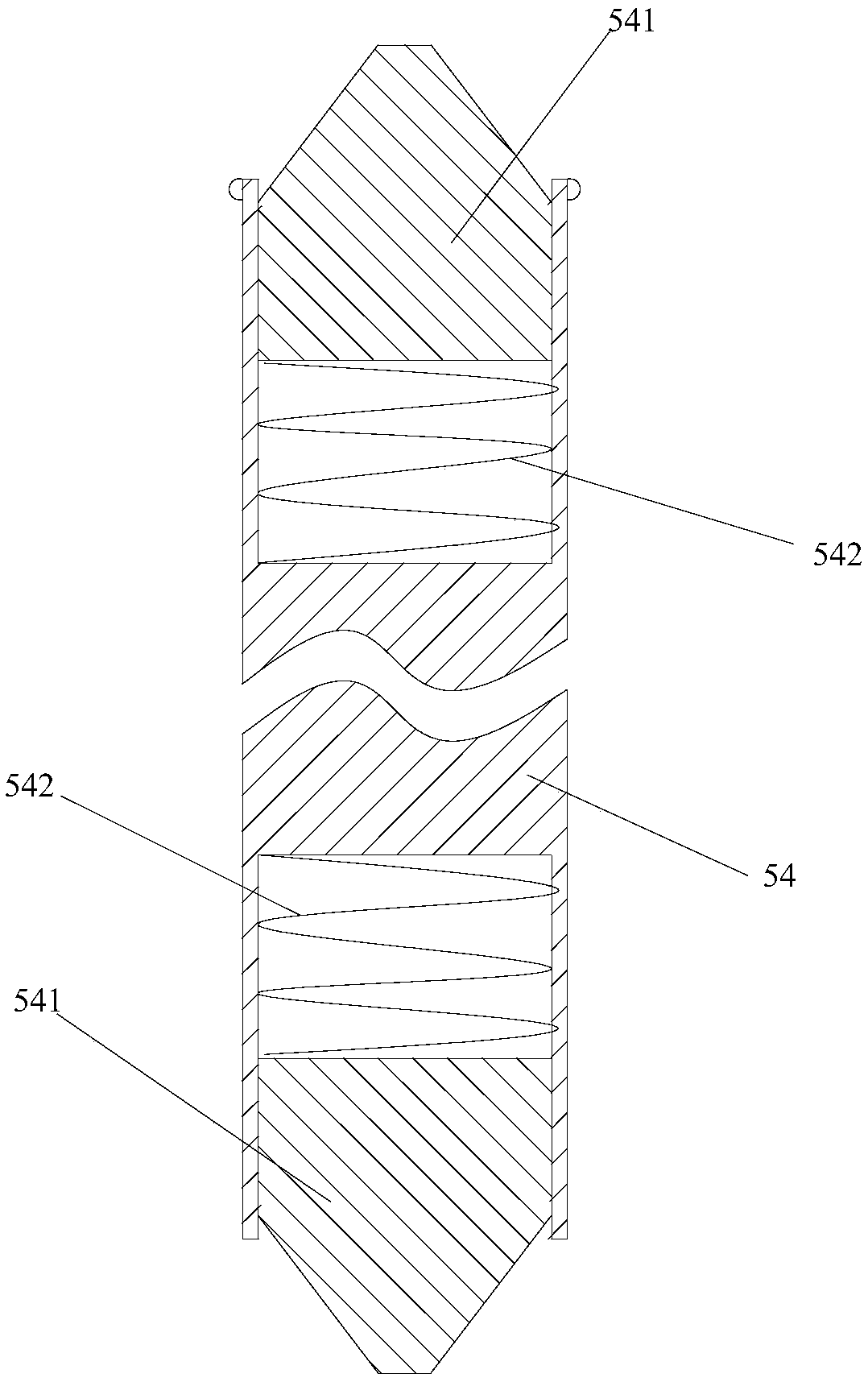

High-speed truss manipulator

InactiveCN105522573ASmall footprintHigh guiding precisionProgramme-controlled manipulatorVibration amplitudeEngineering

The invention discloses a high-speed truss manipulator. A first sliding block is arranged on an X-direction track on a supporting frame in a sliding mode; a Y-direction track is arranged on a second sliding block fixed to the first sliding block in a linearly reciprocated sliding mode; a Z-direction track is arranged on a third sliding block fixed to the Y-direction track in a longitudinally and linearly reciprocated sliding mode; a mechanical clamping jaw installation support is rotationally positioned at the lower end of the Z-direction track; an included angle of 135 degrees is formed between the axial direction of a rotary shaft of the mechanical clamping jaw installation support and the Z direction; first and second mechanical clamping jaws are symmetrically distributed on the two sides of the rotary shaft of the mechanical clamping jaw installation support; an included angle of 90 degrees is formed between the axial directions of the first and second mechanical clamping jaws; first, second and third drive devices are used for driving the first sliding block, the Y-direction track and the Z-direction track to move respectively; a rotary drive device is used for driving the mechanical clamping jaw installation support to rotate. The manipulator can operate stably at high speed, the vibration amplitude is small after movement is finished, the speed is high as two manipulators operate alternately, and the occupied space is small.

Owner:SUZHOU KAILINJIE ROBOT CO LTD

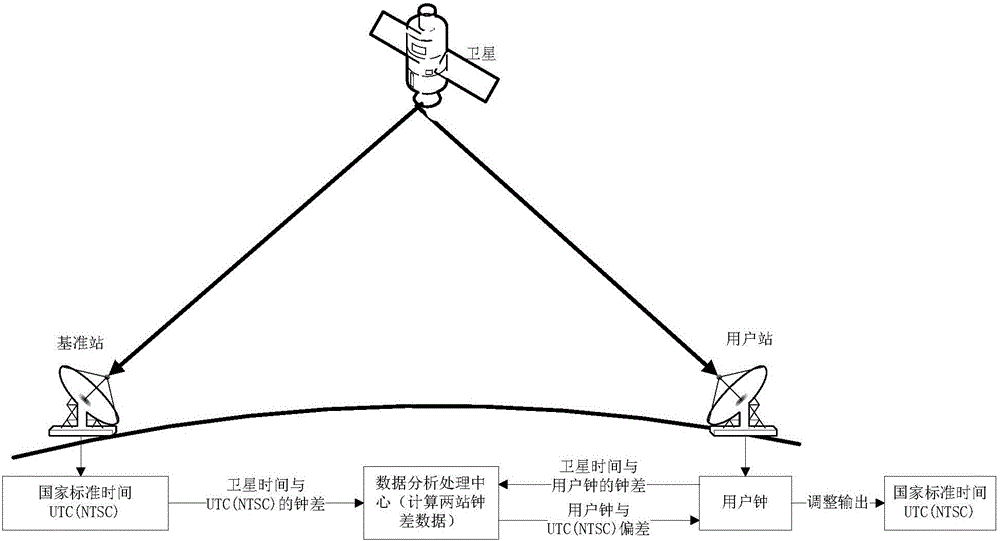

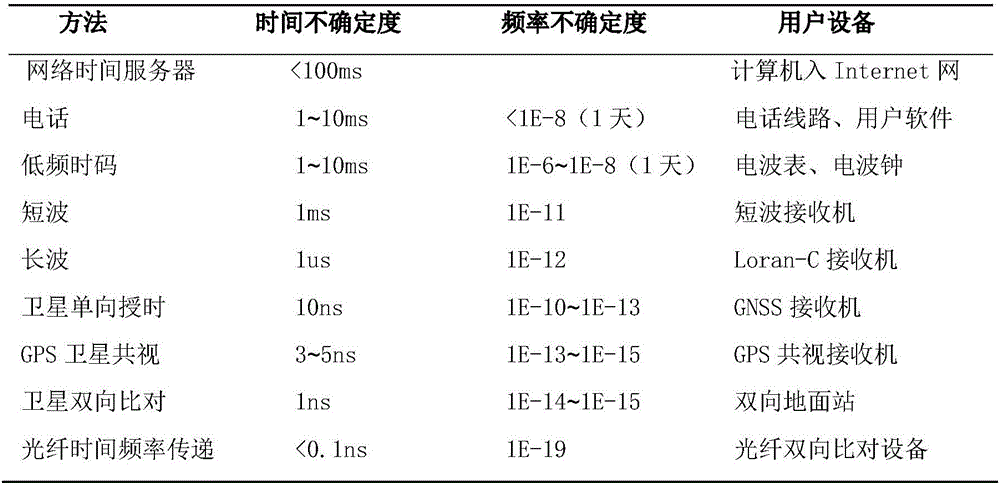

National standard time remote recurrence method

InactiveCN105867108AIncrease the number of observationsHigh precisionRadio-controlled time-piecesNational standardLeast squares

The invention provides a method for long-distance reappearance of the national standard time. First, calculate the star station clock difference between the reference station and each visible satellite and each user station and each visible satellite, and calculate the star station clock difference. According to the final fitting result, each user station will make a corresponding difference with the star station clock error of the visible satellite common to the reference station, and each user station will respectively remove the gross error The mean value of the difference data is taken as the time difference between the reference time of each user station and the national standard time of the base station; the time difference value is returned to each user station correspondingly, thereby controlling the output of the local atomic clock to synchronize it with the national standard time. The invention can make up for the lack of 1-5ns real-time timing precision in the current timing system, and provide real-time and continuous real-time timing with 2ns precision.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

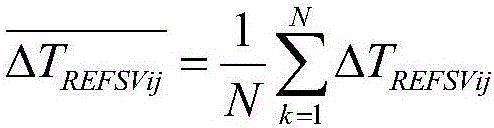

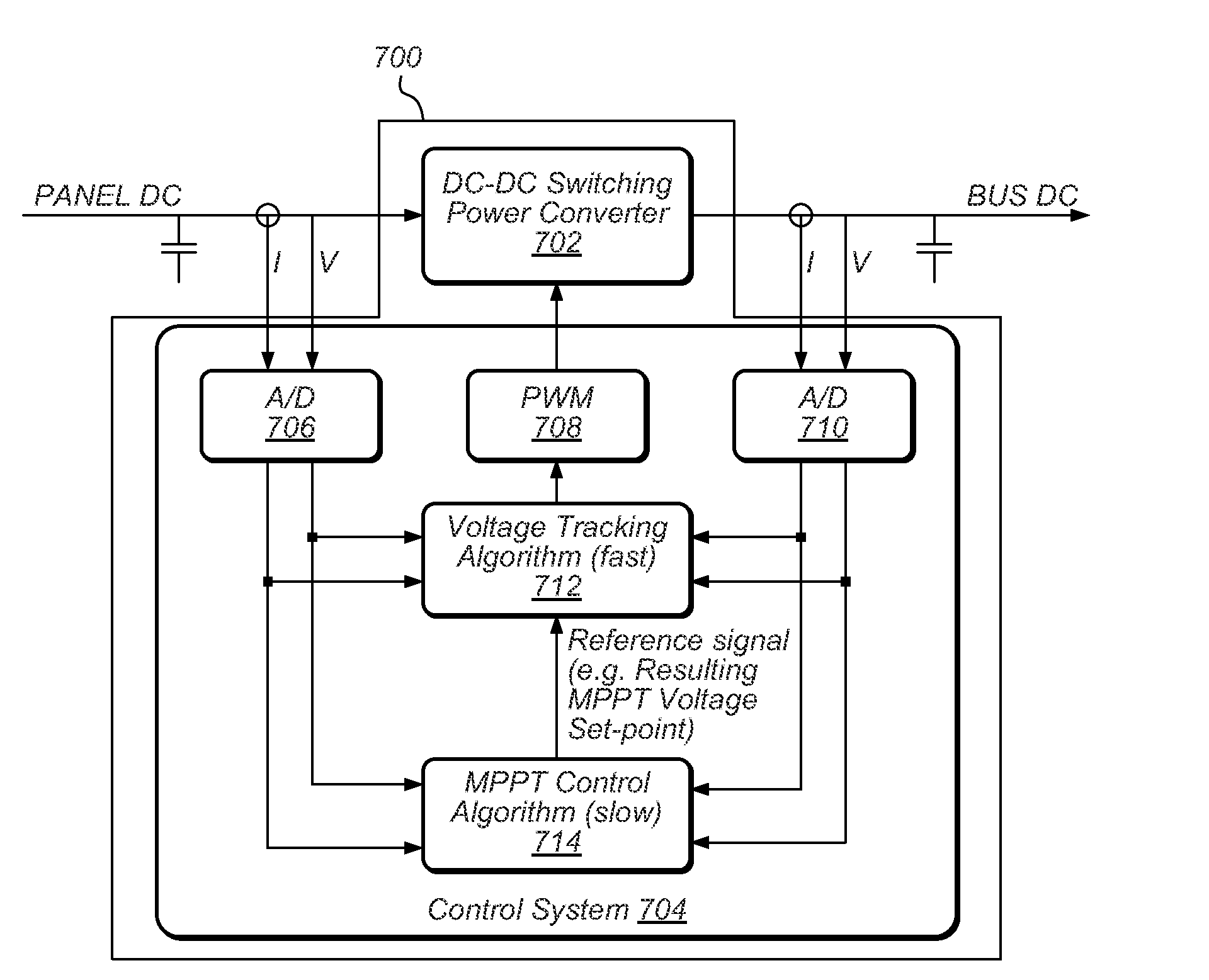

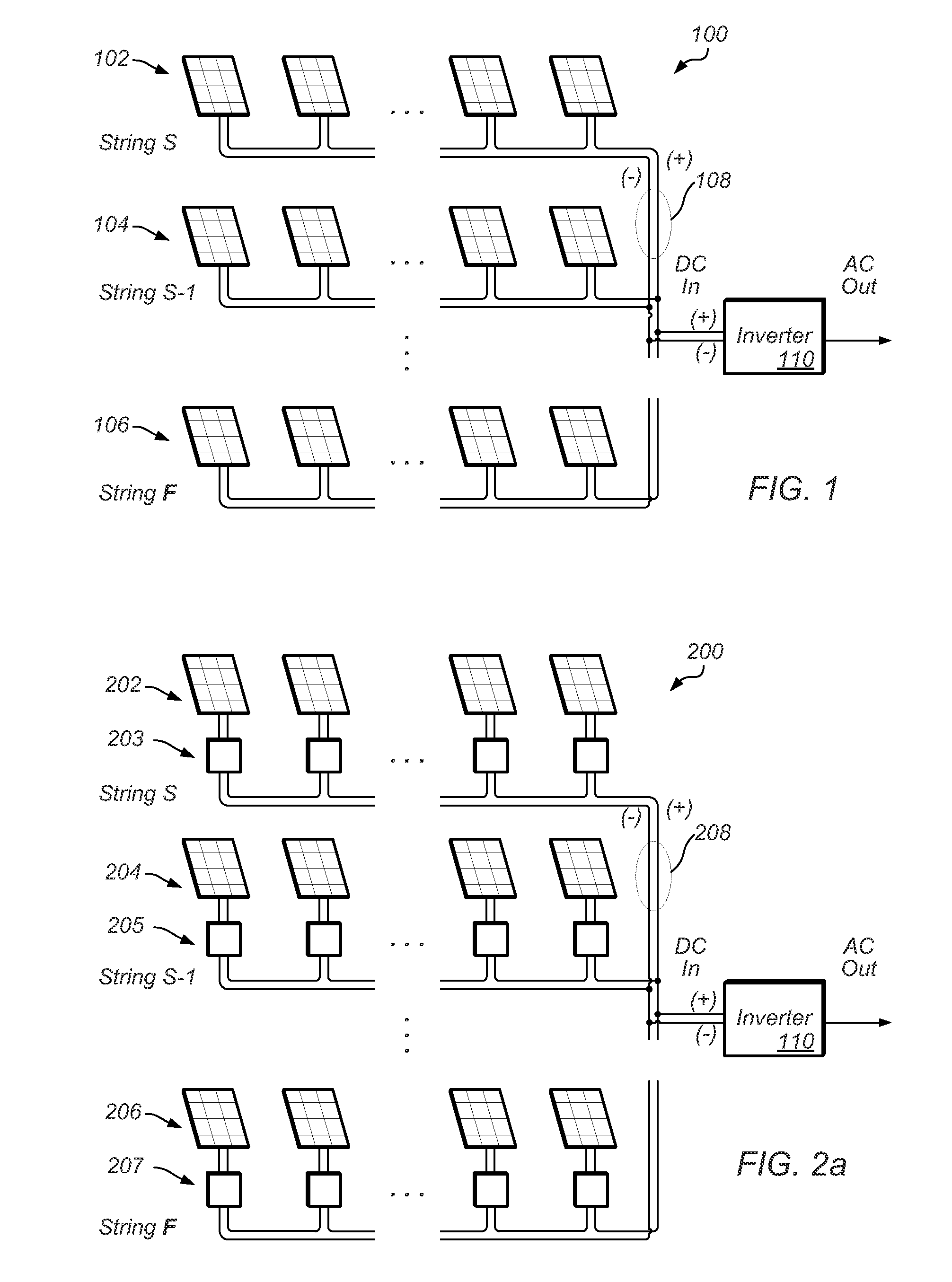

Dynamic Frequency and Pulse-Width Modulation of Dual-Mode Switching Power Controllers in Photovoltaic Arrays

ActiveUS20120206118A1Reduce switching frequencyImprove efficiencyPower supply linesSingle network parallel feeding arrangementsDual modeTransverter

A converter unit configured to couple to a photovoltaic panel may include a controller that monitors: an output voltage and output current obtained from the photovoltaic panel by a switching power core within the converter unit, and an output voltage and output current produced by the switching power core. The controller may calculate a desired duty-cycle value based on the monitored values, and implement a mapping algorithm that translates the duty-cycle value to a pulse-width value and a modulus value. The pulse-width value and the modulus value may be used to simultaneously respectively modulate the pulse-width and pulse-period of a pulse-width modulated (PWM) signal, while maintaining an appropriate linear final duty-cycle ratio between the pulse-width and the pulse-period of the PWM signal. The PWM signal may be provided to the switching power core to control the switching of the switching power core.

Owner:BLUED ACQUISITION CORP

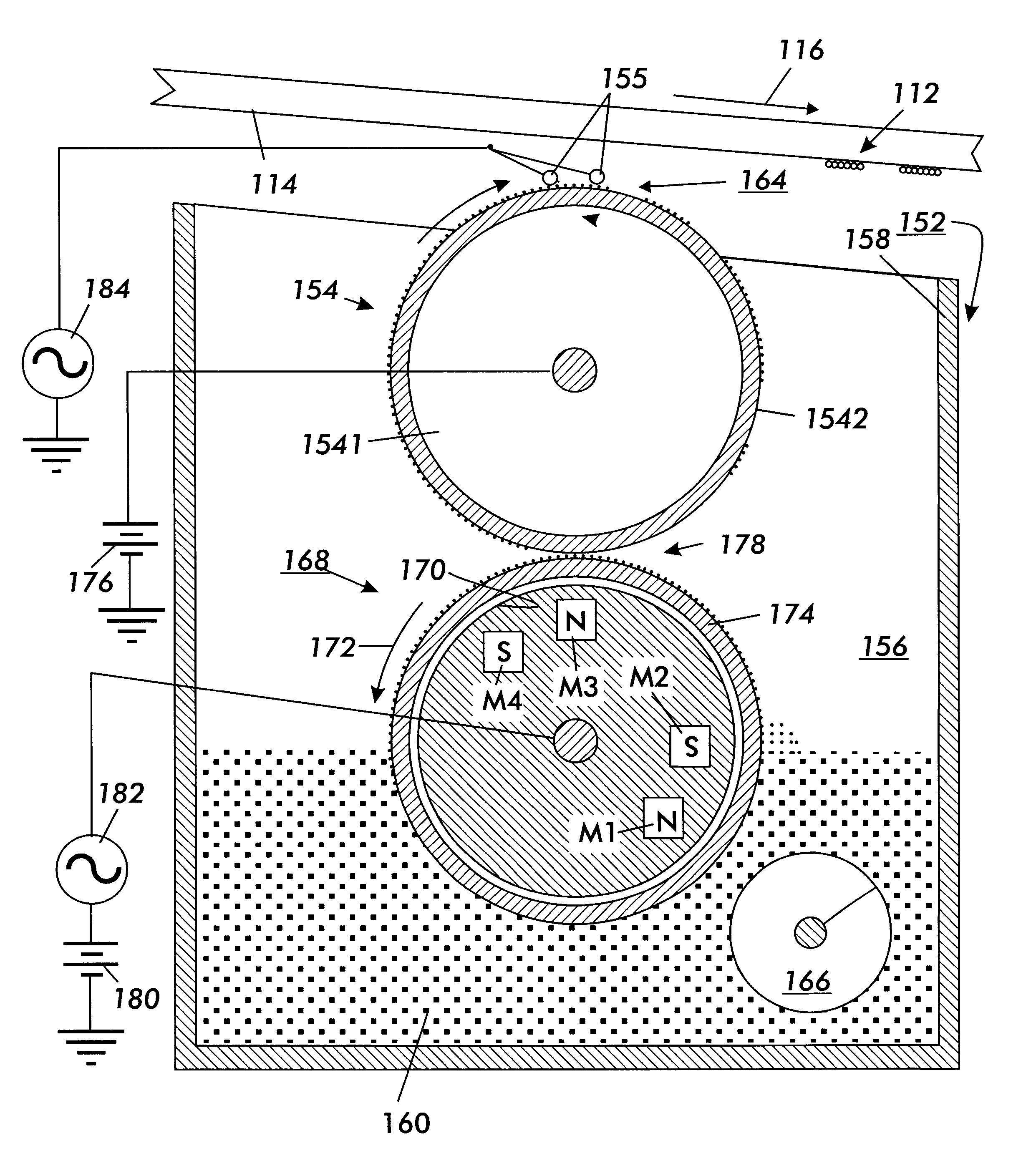

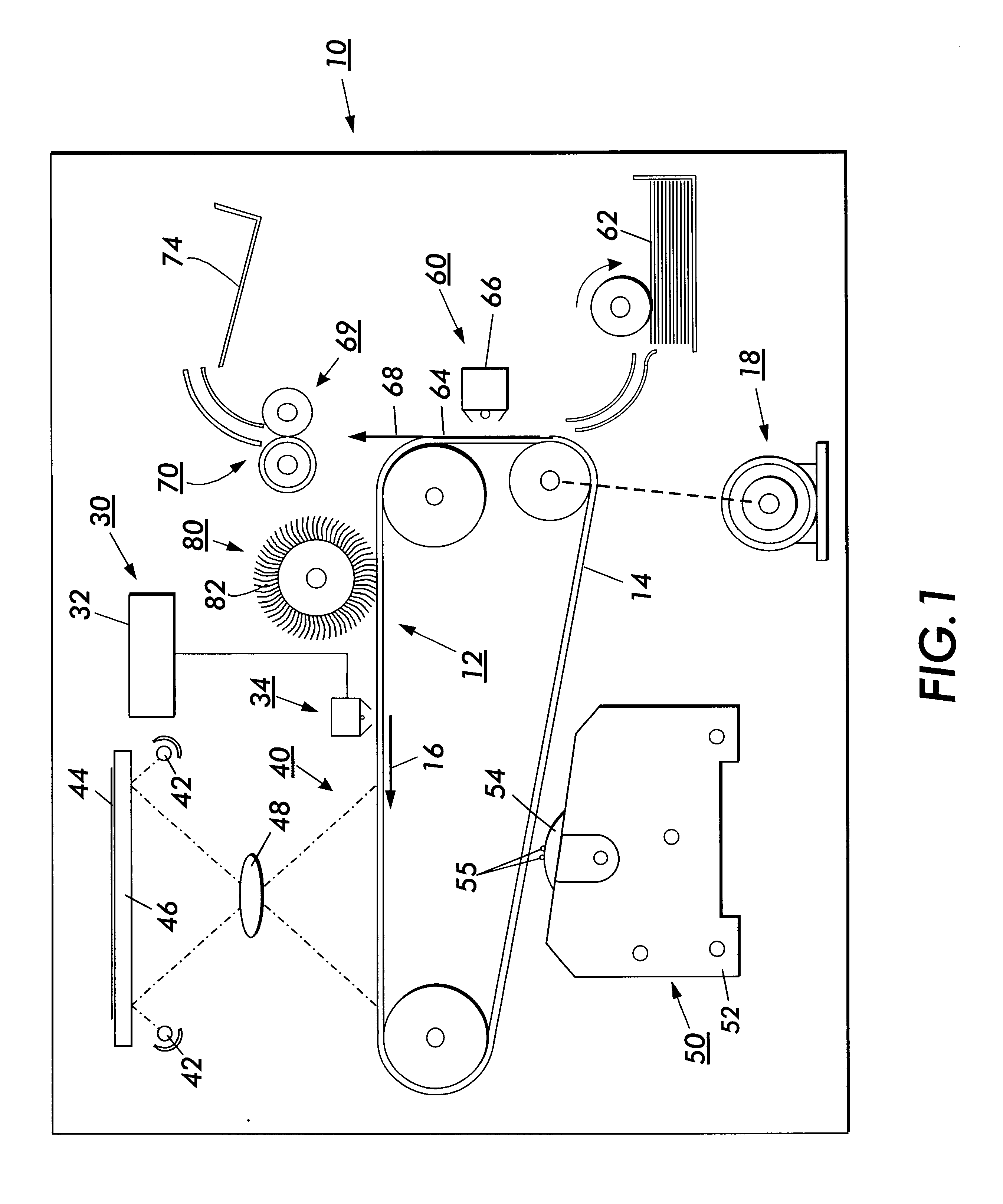

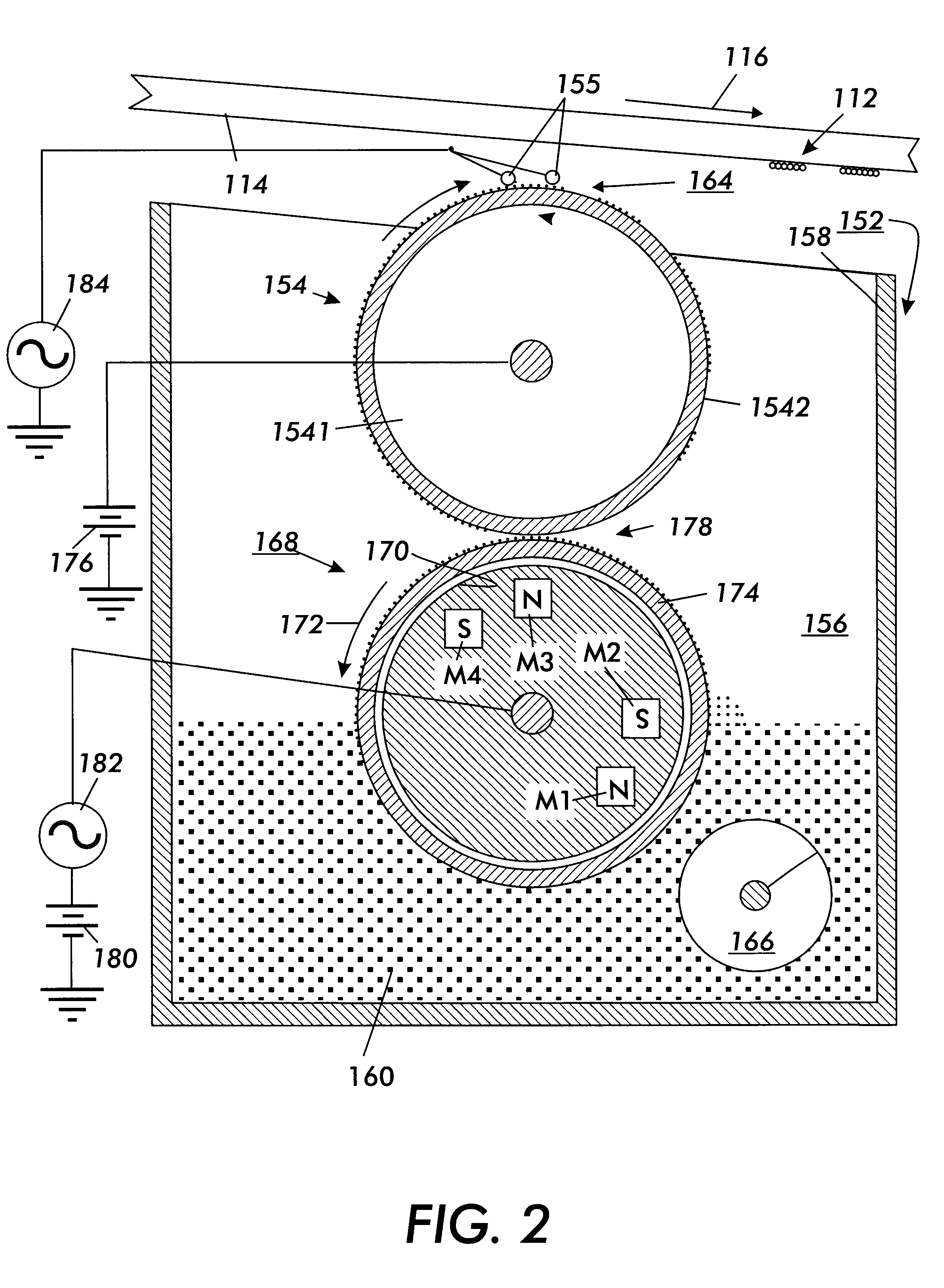

Donor rolls and methods of making donor rolls

InactiveUS6327452B1Finish evenlyControlled electrical propertyLiquid surface applicatorsAgricultural rollersMetallurgyCeramic coating

A roller includes a core and a ceramic coating formed over the core. The roller has a composite runout of less than 20 mum and a total indicator reading runout of less than 7 mum. The ceramic coating has a smooth finish and has controlled electric properties. This roller can be used as a donor roller for transporting toner to a photoconductive member so as to achieve high-quality image development.

Owner:XEROX CORP

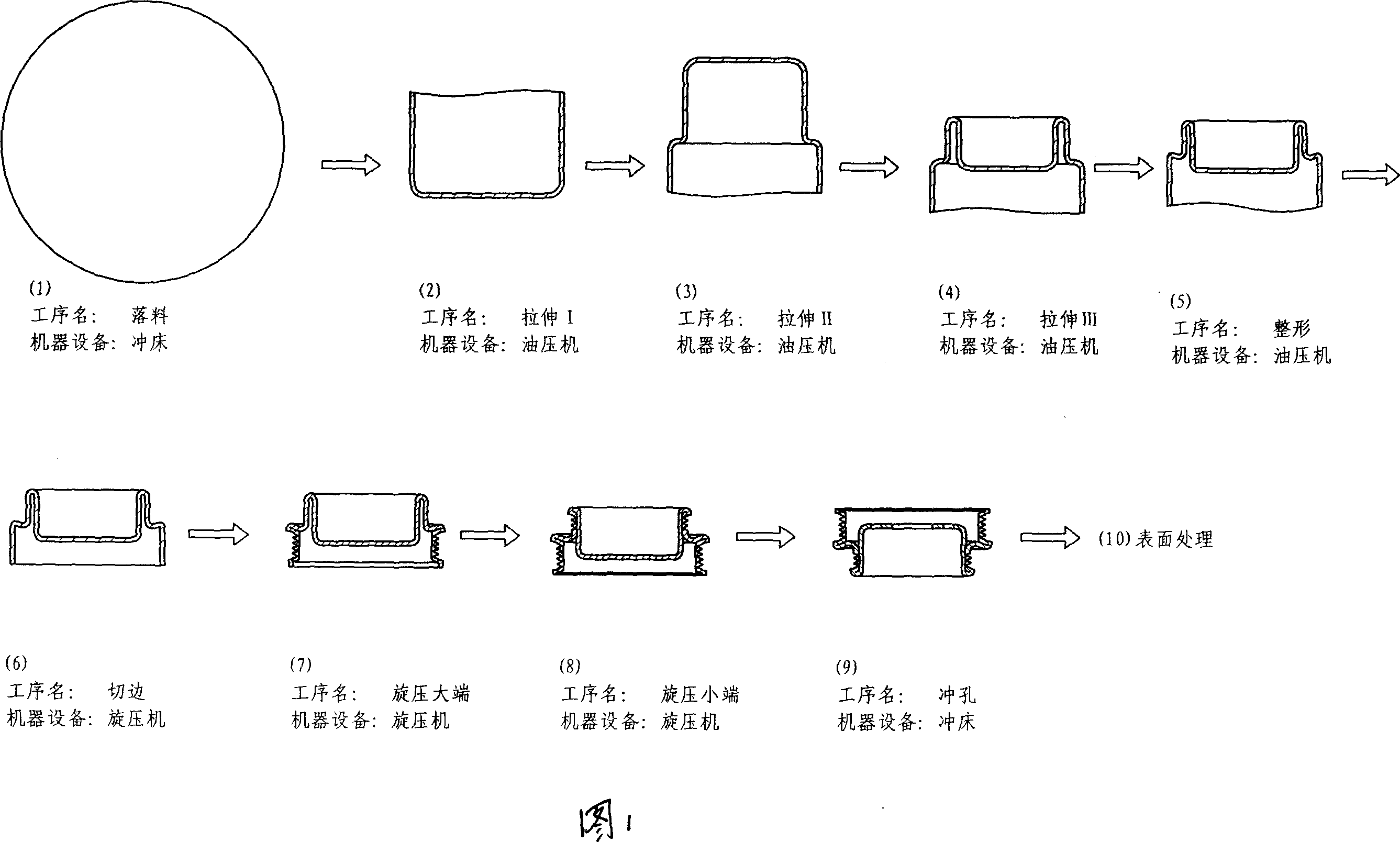

Two-stage coaxle multi-wedge type pulley and processing technology and equipment

InactiveCN1975208AHigh fastnessReduce jumpingPortable liftingGearing elementsPunchingWork in process

The inventive belt pulley comprises bull and pony wheels integral formed by spinning of flat cold-rolled sheets. The process of manufacturing the belt pulley consists in: blanking; multistretching; shaping; spinning; punching and surfacing. The blanking is stretched into the semi-finished products for the two-stage coaxial multi-wedge pulley on the oil press by the multistretching and the times of multistretching can depend on the product conditions. The shaped and edged semi-finished pulley once-through complete the following process: spinning the big end and then spinning the small end by the spinning process.

Owner:温州市南亚机械配件有限公司

Efficient polishing device used for metal casting machining and polishing method of efficient polishing device

InactiveCN110125754AReduce the impactAvoid influenceEdge grinding machinesGrinding drivesSlide plateEngineering

The invention discloses an efficient polishing device used for metal casting machining and a polishing method of the efficient polishing device. The efficient polishing device comprises a machine body. An installation cavity is formed in the bottom end of the machine body. A rotation motor is installed in the installation cavity. The output end of the rotation motor is fixedly connected with a work table. The work table is installed at the bottom end in the machine body in a rotating manner. Clamping devices which are symmetrically distributed are arranged on the left side and the right side of the top end of the work table. A lead screw, a stop piece and a slippage motor are sequentially arranged at the top end in the machine body from left to right. The left end of the lead screw is connected with the side wall in the machine body in a rotating manner, and the right end of the lead screw penetrates through the stop piece and is connected to the output end of the slippage motor. A slide block is installed on the lead screw. A slide plate is fixedly arranged at the bottom end of the slide block. A lifting cylinder is installed at the bottom end of the slide plate. By means of the efficient polishing device and the polishing method, castings can be conveniently polished, chippings can be collected during polishing, processing is facilitated, influences of vibration on the polishing effect during polishing are reduced, and the product quality is improved.

Owner:昆山鑫启盛精密配件有限公司

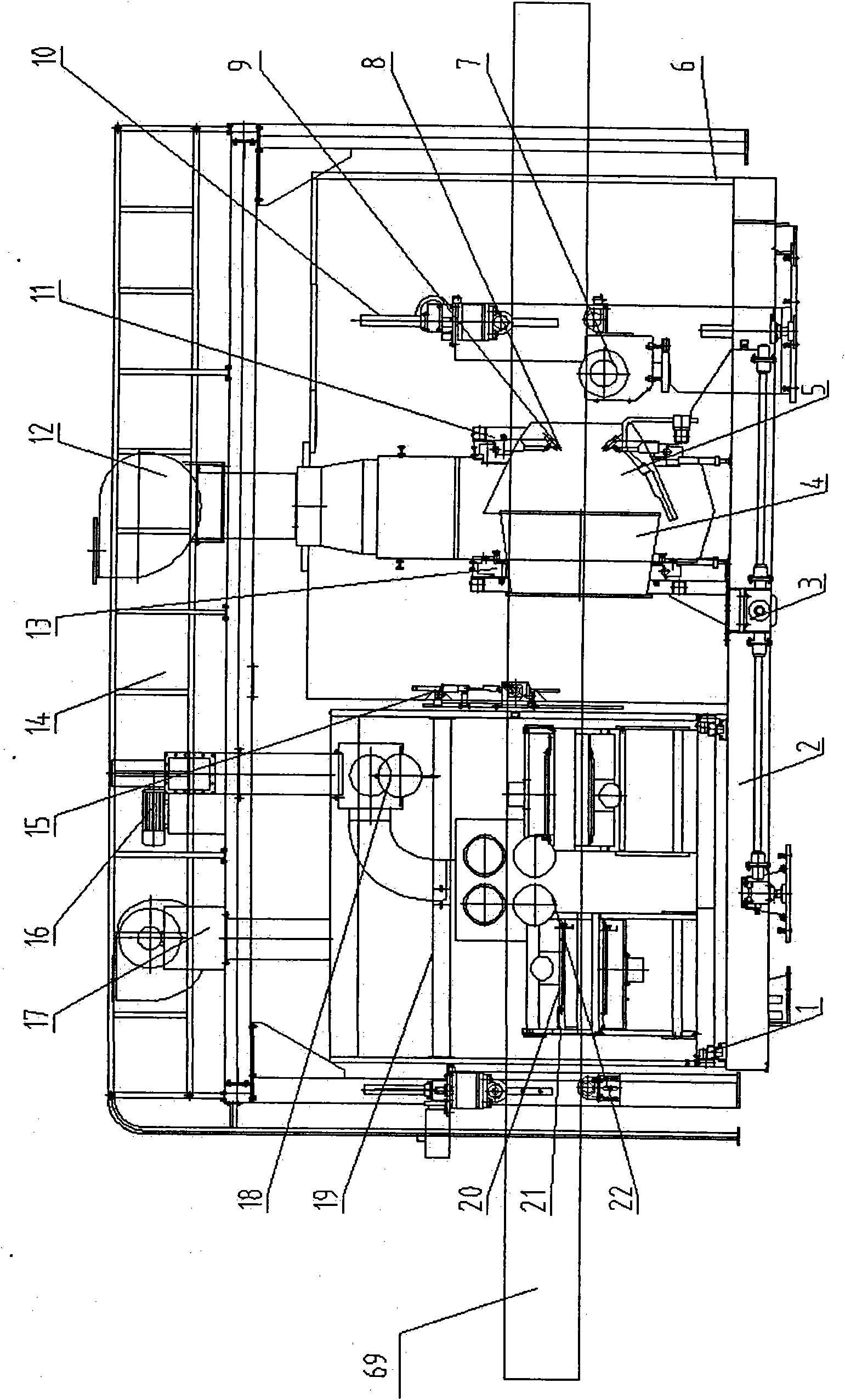

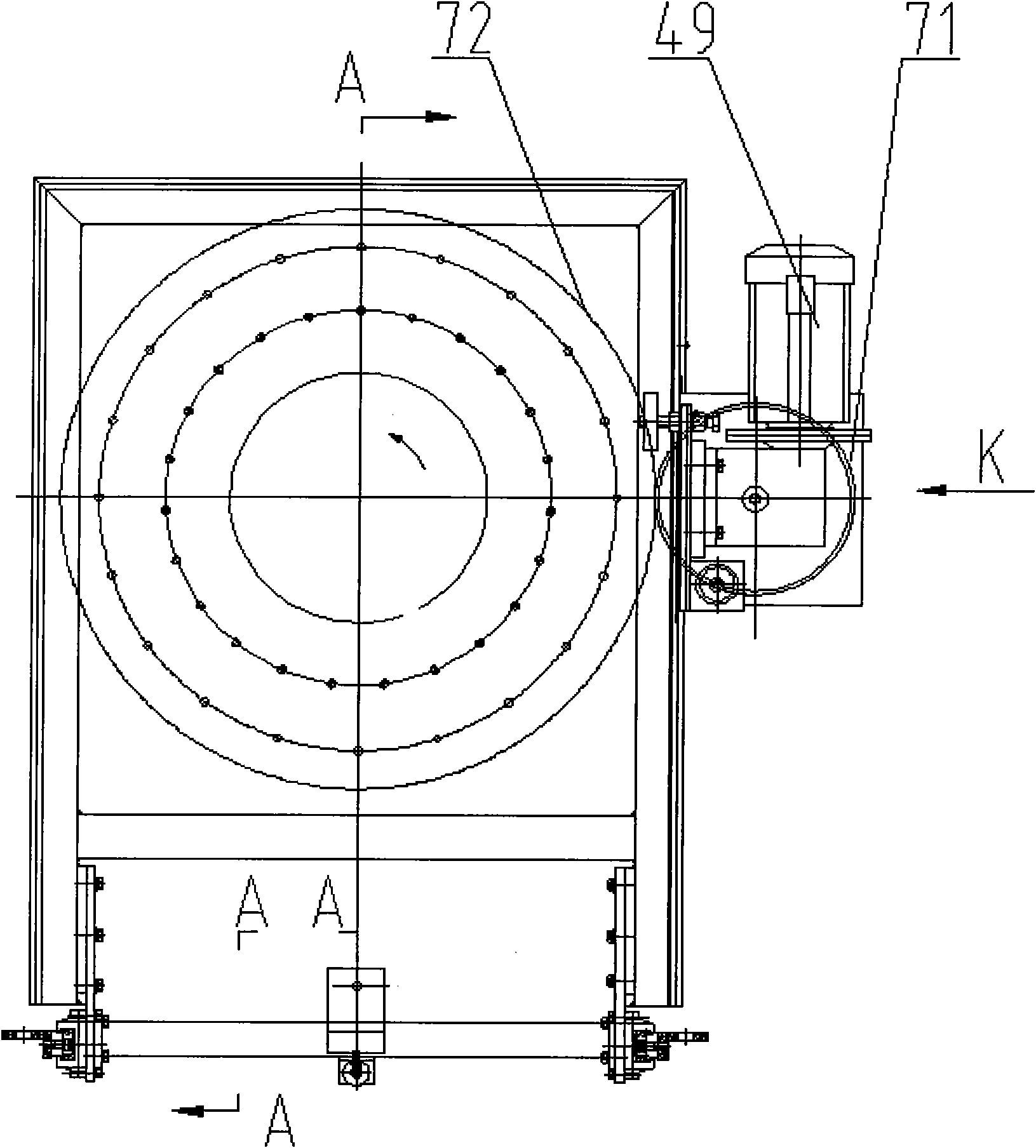

Antirust spraying device on outer surface of steel pipe

ActiveCN101927222ATo achieve overlapping functionsFast curingSpraying apparatusPretreated surfacesUV curingMetallic materials

The invention discloses an antirust spraying device on an outer surface of a steel pipe. The device comprises a lifting mechanism, two sets of UV curing mechanisms with the same structure, a UV paint spraying mechanism, a pressing roller mechanism, a cooling mechanism and a recovery mechanism. A lifting frame drives the spraying device to move up and down, and when the spraying device sprays steel pipes with different diameters, a centre line of the spraying device coincides with those of the steel pipes. The UV curing mechanisms make the UV paint on the surface of the steel pipe rapidly cured without a special drying furnace device, and the space is saved. The UV paint spraying mechanism effectively controls the thickness of the UV paint film, and the pressing roller mechanism reduces the steel pipe jump in the movement and reduces the influence of the steel pipe jump on the paint film uniformity. In the spraying process, coatings in a front spraying roller and a rear spraying roller are driven upwards by a fan, are filtered by a filter screen and are returned to a coating barrel by a recovery roller through a recovery oil passage. Therefore, the recovery rate of the coatings is improved. The antirust spraying device can be used for spraying steel pipes, sections, rods, wheel hubs and other metal materials.

Owner:HANGZHOU ZHEJIANG UNIV JINGYI ELECTROMECHANICAL TECH ENG

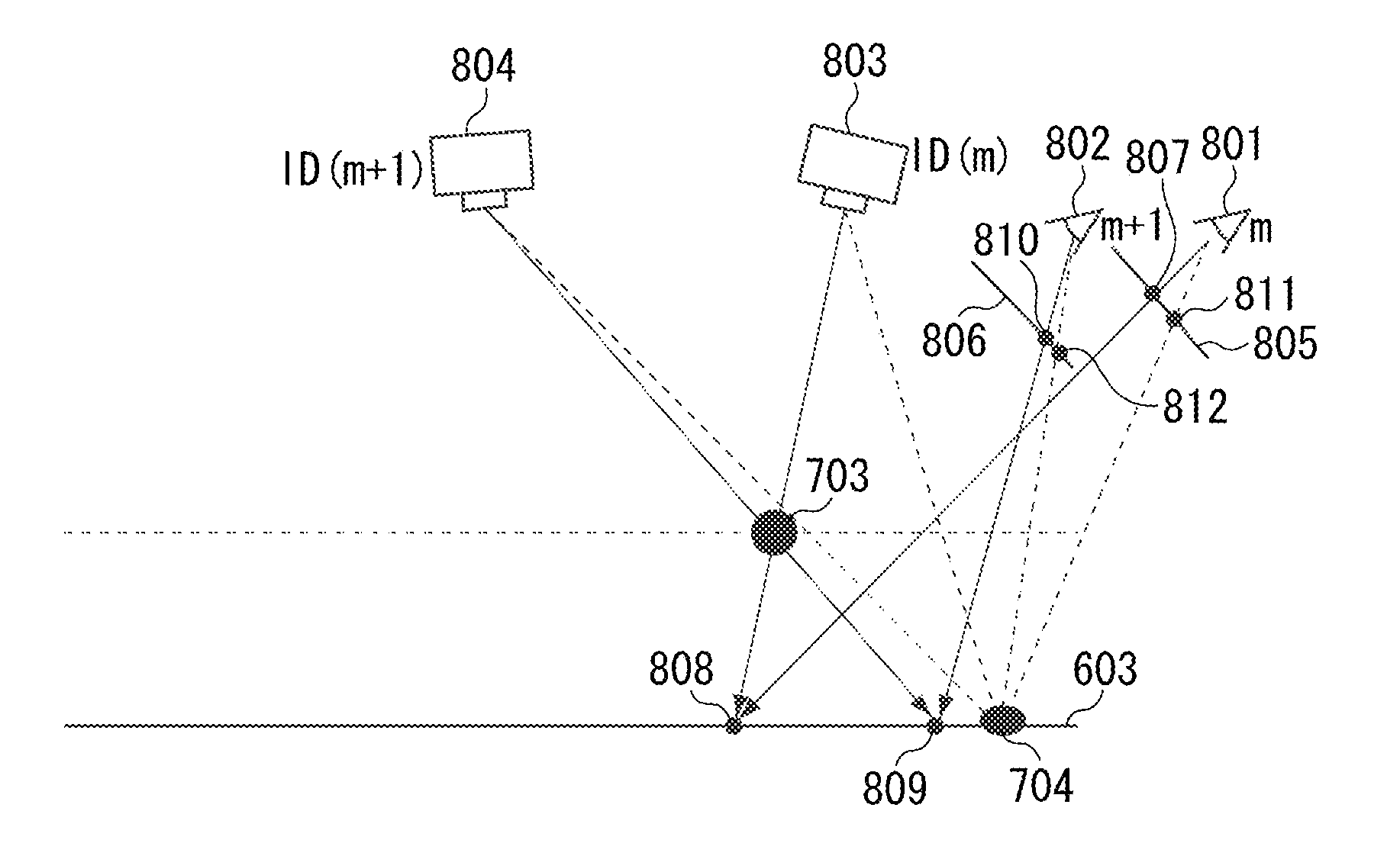

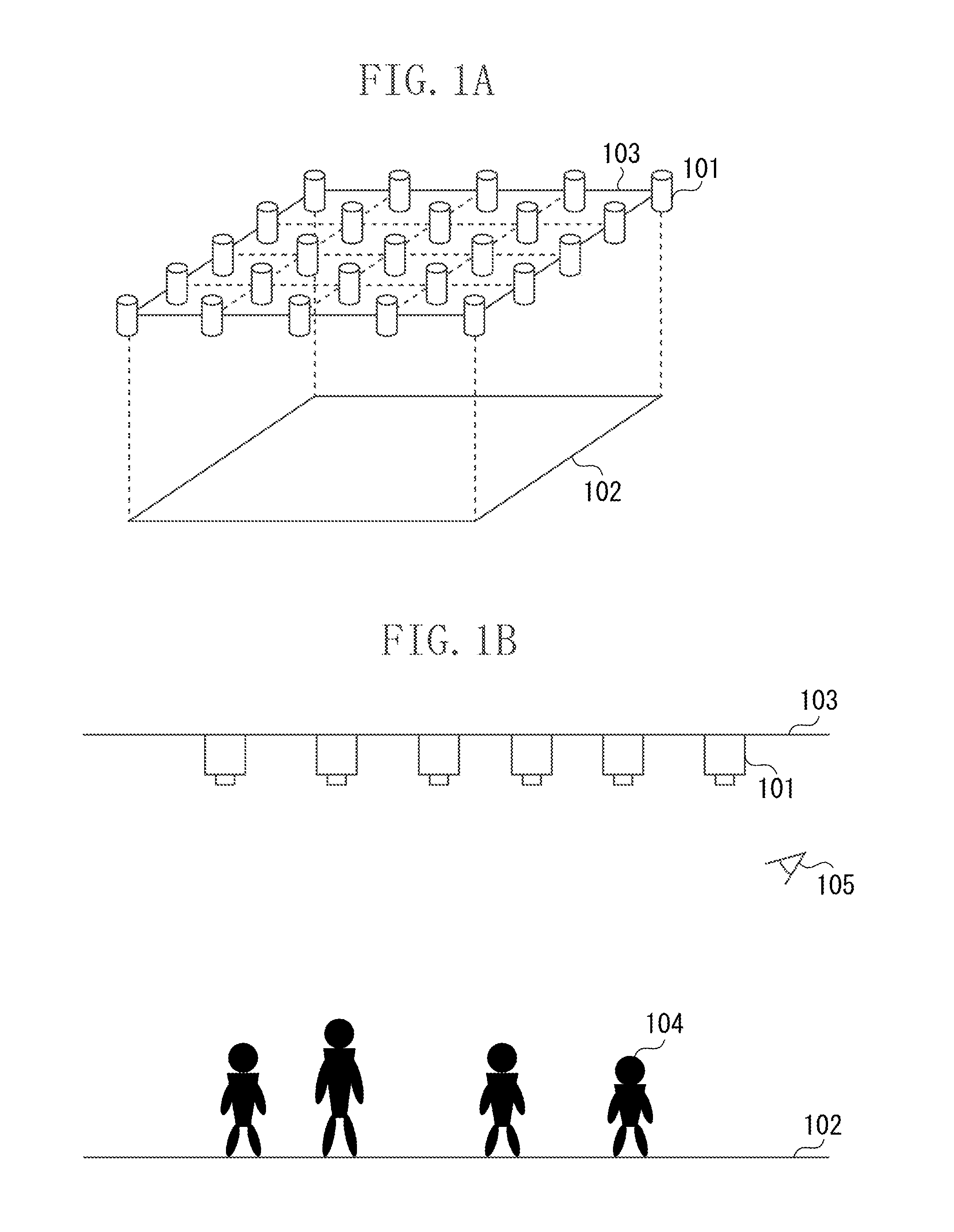

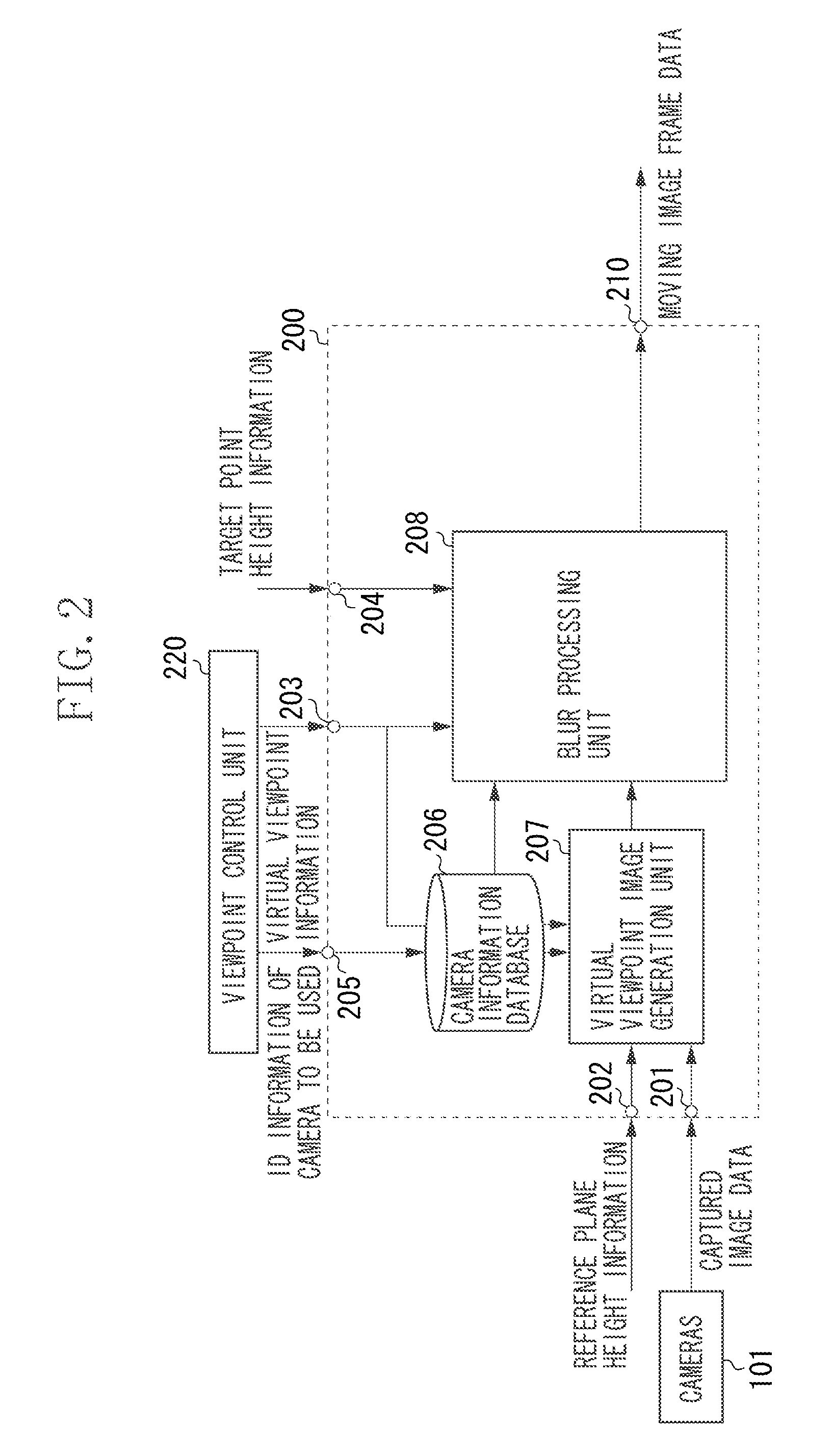

Image processing apparatus and image processing method

InactiveUS20110254973A1Reduce jumpingTelevision system detailsColor television detailsImaging processingViewpoints

An image processing apparatus includes an acquisition unit configured to acquire a captured image selected according to specified viewpoint information from a plurality of captured images captured by a plurality of imaging units at different viewpoint positions, a generation unit configured to generate an image according to the specified viewpoint information using the viewpoint information of the selected captured image and the specified viewpoint information from the selected captured image, and a blurring processing unit configured to execute blurring processing on the generated image, wherein, when an imaging unit corresponding to a captured image for a target frame is different from an imaging unit corresponding to a captured image for a frame adjacent to the target frame, the blurring processing unit executes blurring processing on the generated image corresponding to the target frame.

Owner:CANON KK

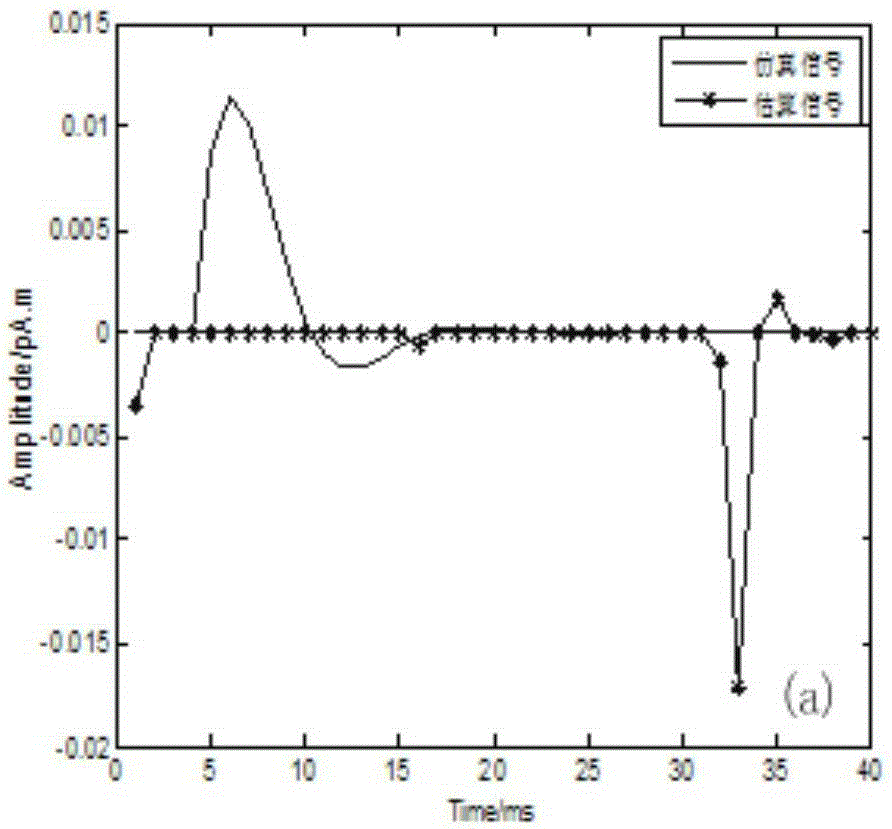

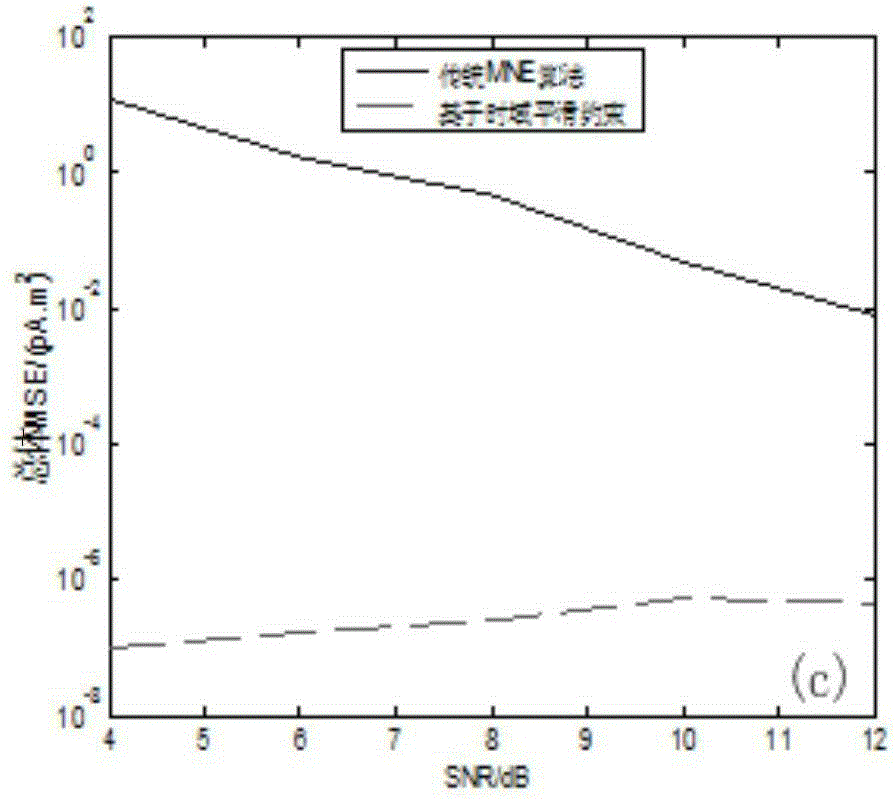

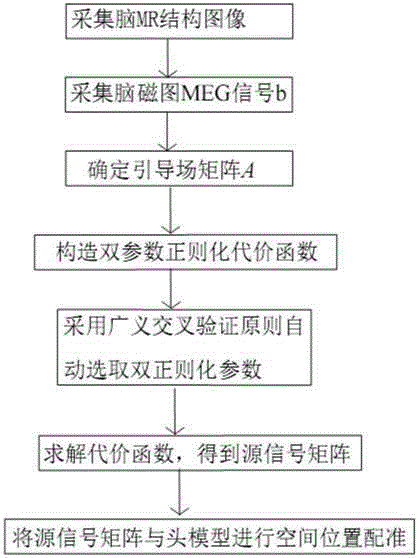

Brain magnetic source intensity positioning method

ActiveCN105147288ARealize automatic positioningFaster and more precise positioningDiagnostic recording/measuringSensorsSpecific gravityMean square

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

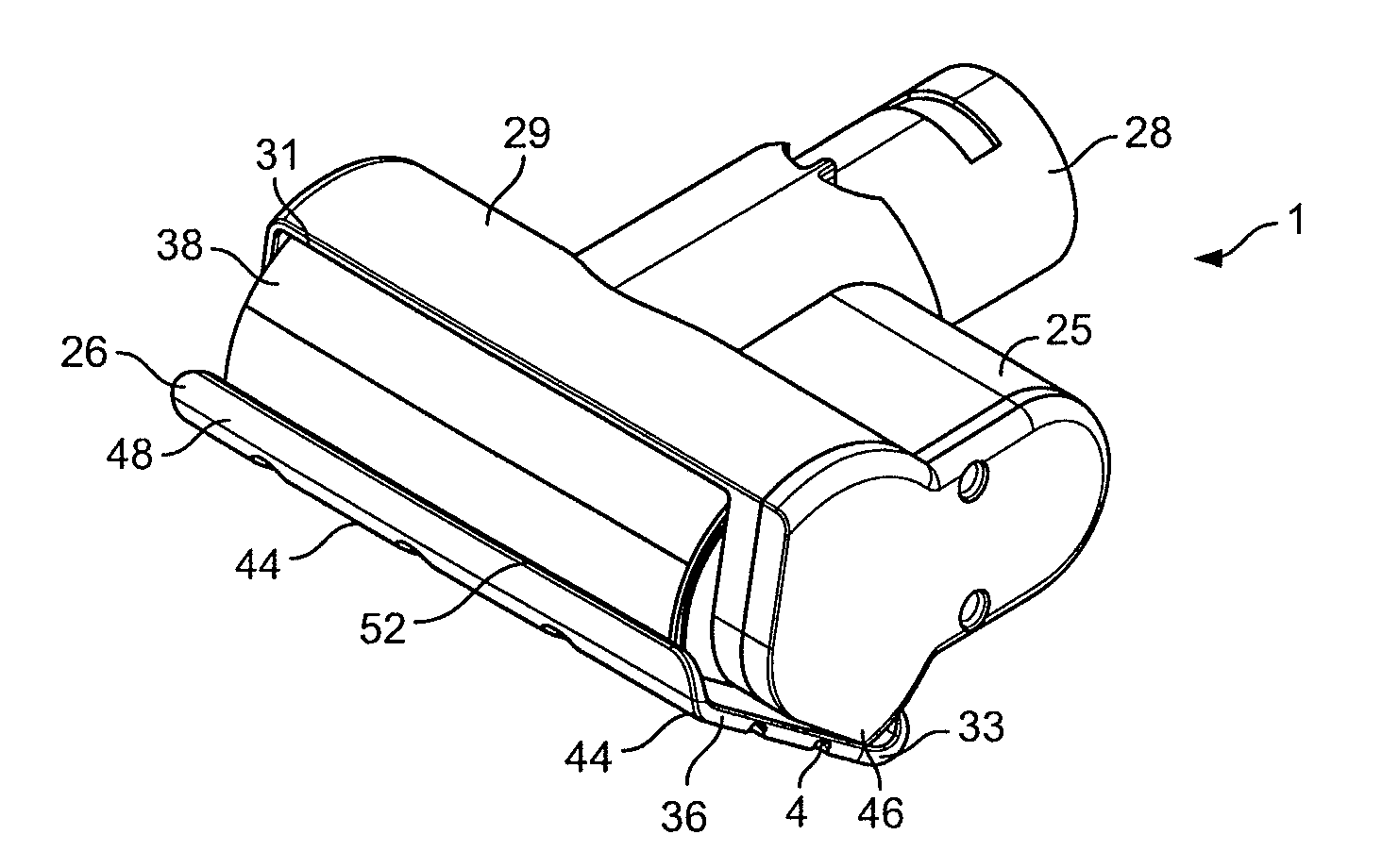

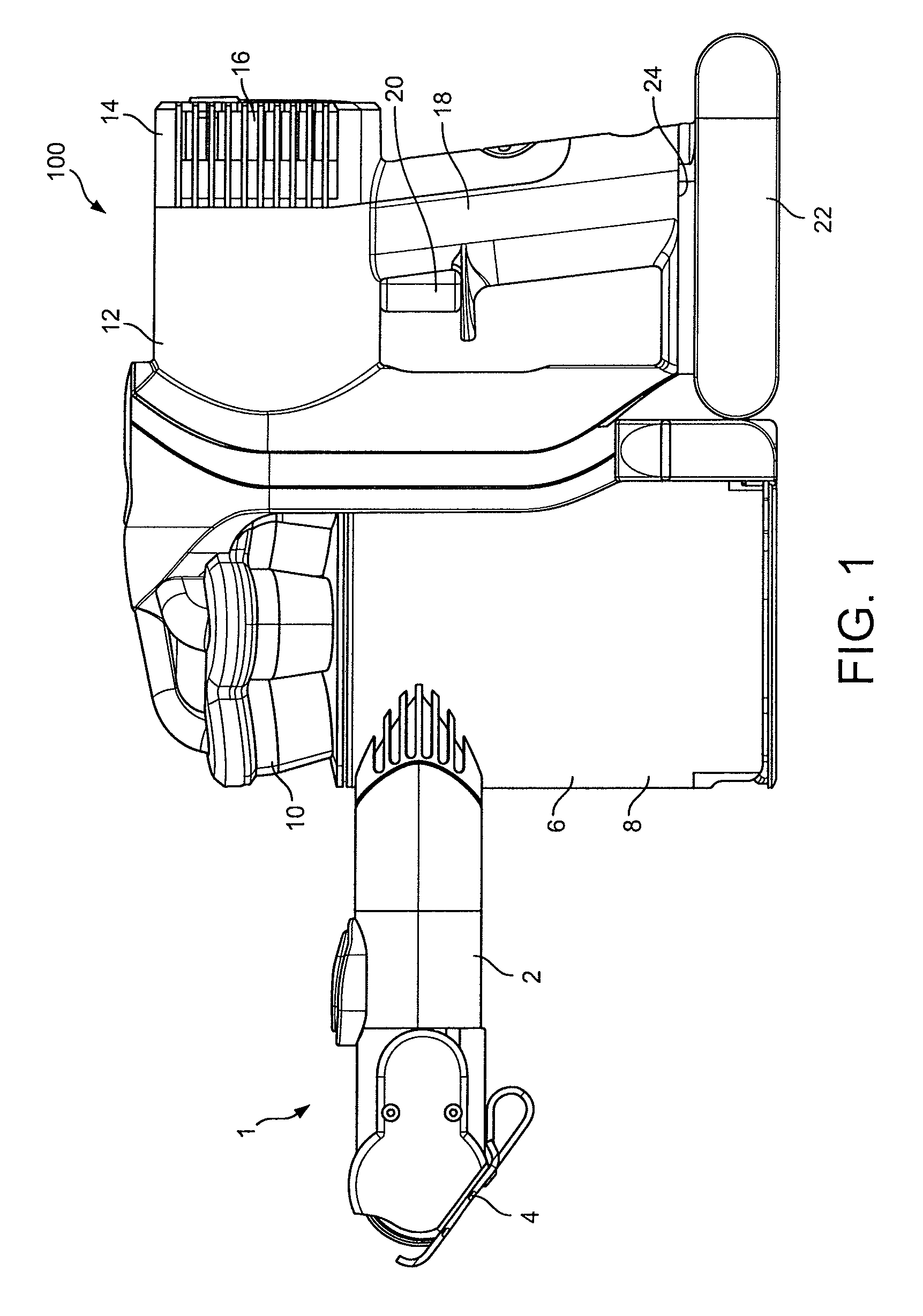

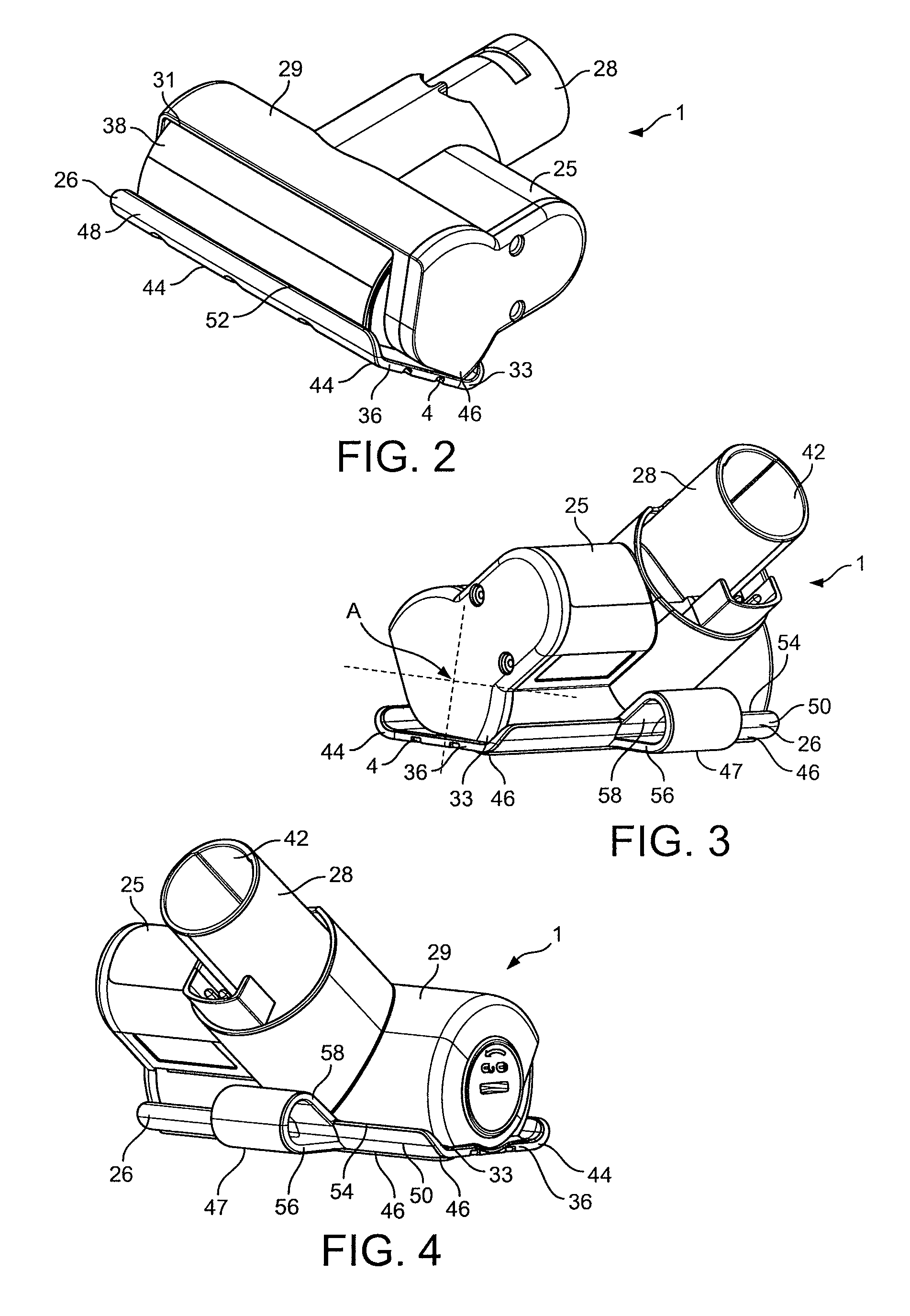

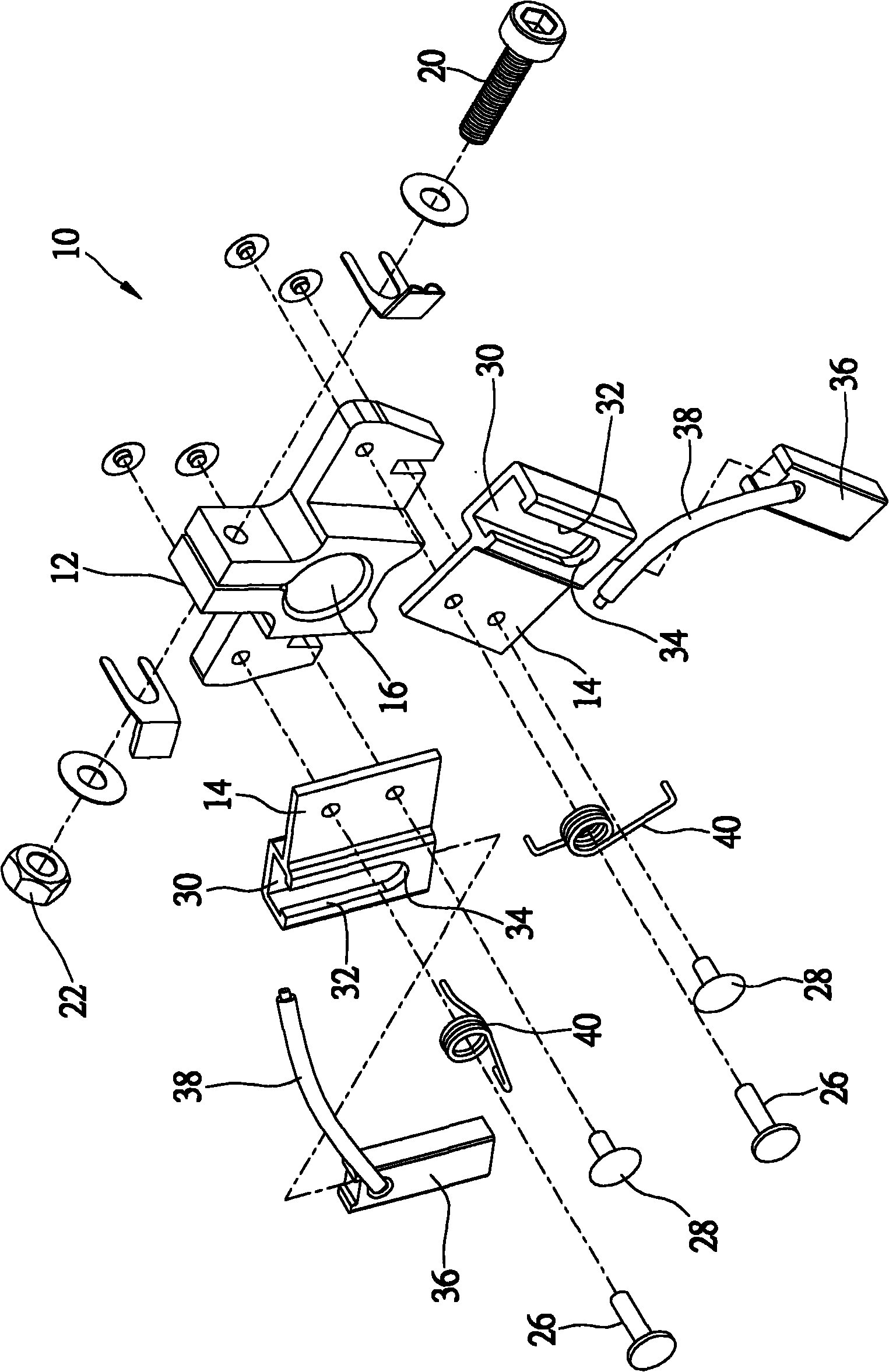

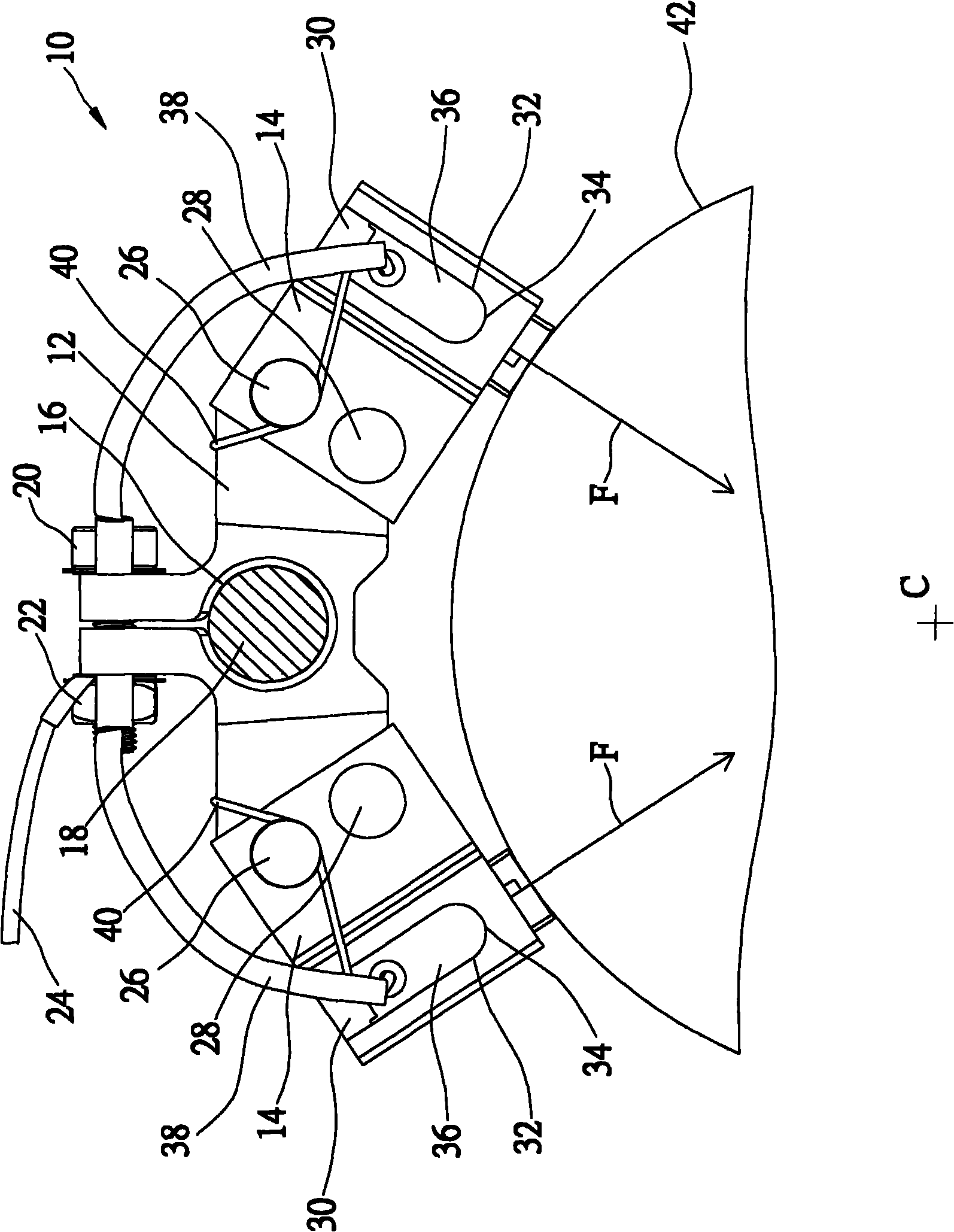

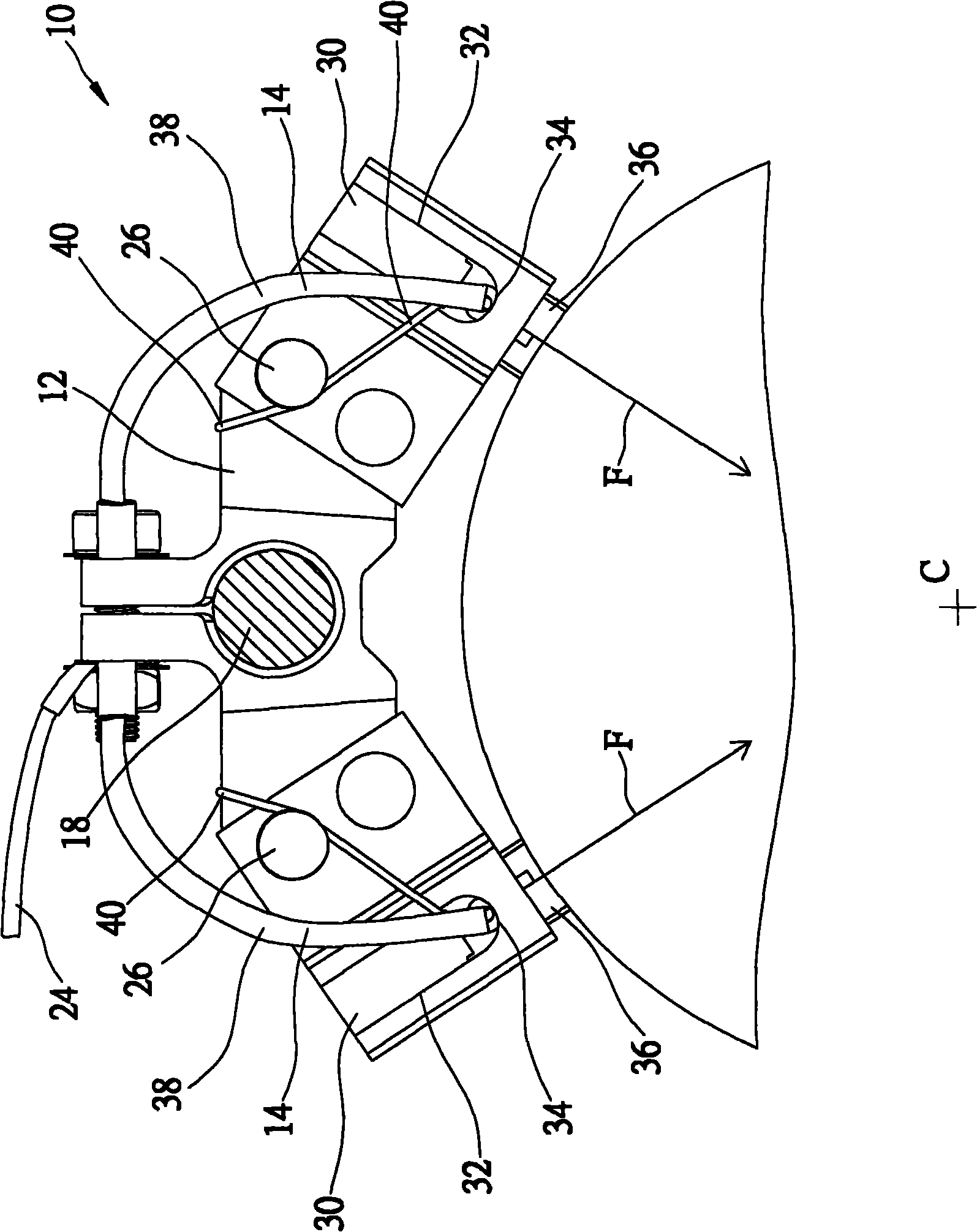

Floor tool

ActiveUS8214967B2Increase distanceReduce jumpingCarpet cleanersFloor cleanersEngineeringMechanical engineering

Owner:DYSON TECH LTD

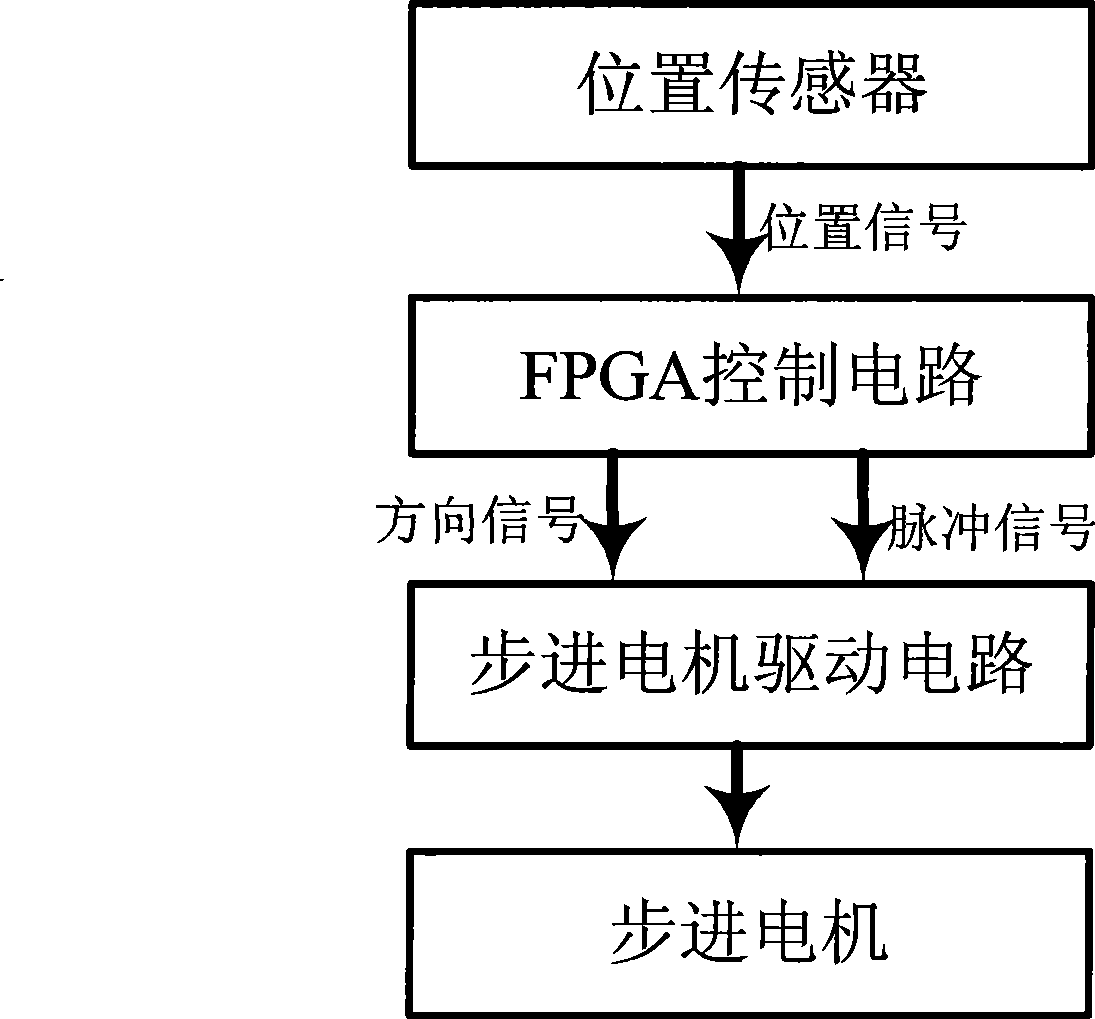

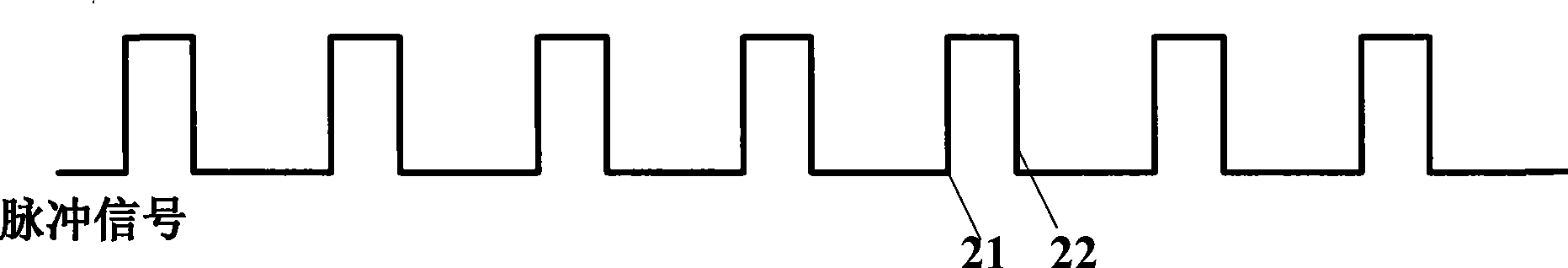

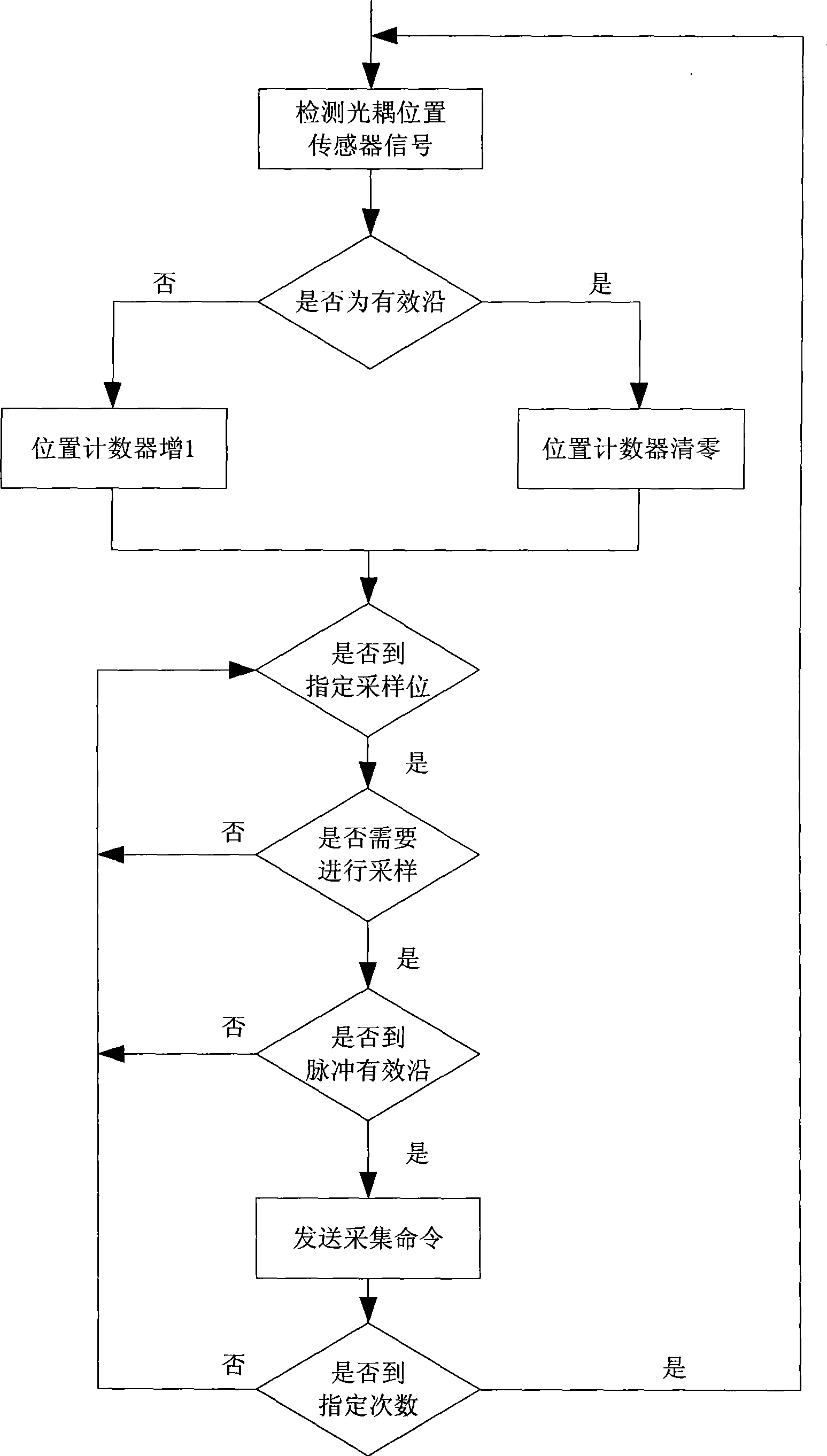

Dynamic data collection system and accurately positioning method for collection position

ActiveCN101425772APrecise positioningIncrease working frequencyDynamo-electric converter controlControl using feedbackAutomatic controlCollection system

The invention discloses a dynamic data acquiring system and a method for precisely positioning an acquiring position thereof. The dynamic data acquiring system comprises an FPGA controller, a step motor, a driving circuit of the step motor, and a position sensor. An FPGA controlling circuit sends direction and pulse signals to the driving circuit of the step motor and maintains a position counter. The driving circuit of the step motor receives driving pulses and direction signals and drives the step motor to move. In the moving process of the step motor, when the FPGA detects that the position sensor has the effective jump, the FPGA resets the position counter, and the position counter counts the sent pulses; after a sent pulse number reaches the set position pulse number of acquiring points and the effective condition of the pulses is detected, the data acquiring operation is carried out. The invention has the advantages of accurate positioning of the acquiring points, high real-time performance, automatic control, simplicity, reliability and lower cost.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

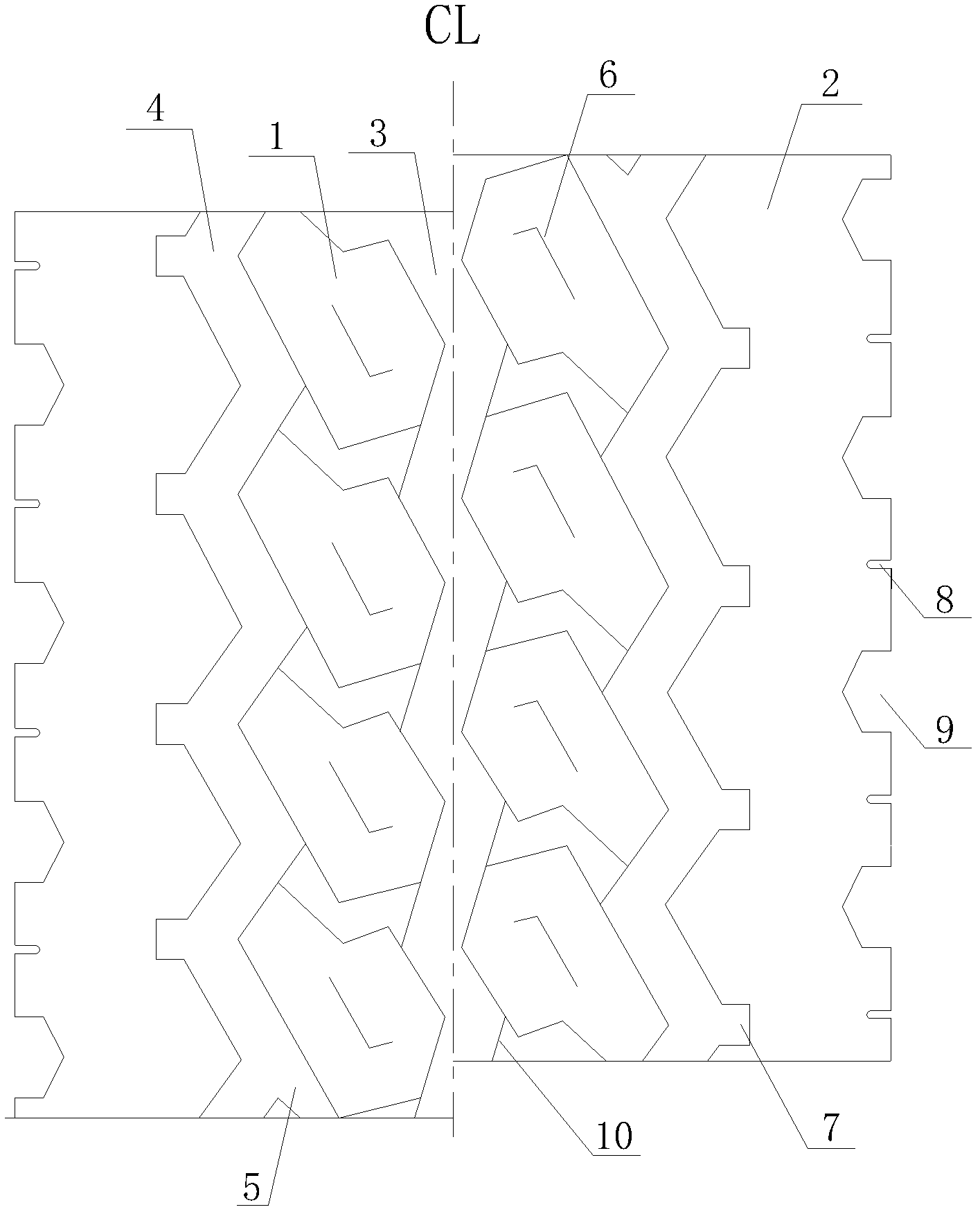

Tire tread of cargo truck

InactiveCN103158444ASufficient braking forceImprove maneuverabilityTyre tread bands/patternsWave shapePoint symmetry

The invention relates to a truck tire, in particular to a tire tread pattern structure of a truck tire. A tire tread of a cargo truck comprises a central longitudinal circumferential pattern groove which is arranged at the position of a longitudinal center line of the tire tread and enables the tire tread to be evenly divided into two symmetrical parts in a left-right mode. Side part pattern blocks and tire shoulder pattern blocks are sequentially arranged on two sides of the central longitudinal circumferential pattern groove form interior to exterior. The side part pattern blocks and the tire shoulder pattern blocks are separated by an auxiliary longitudinal circumferential pattern groove. Each two adjacent side part pattern blocks along the circumferential direction are separated by an auxiliary pattern groove. The central longitudinal circumferential pattern groove and the auxiliary longitudinal circumferential pattern groove are respectively in a wave shape. Two ends of each auxiliary pattern groove are respectively communicated with the central longitudinal circumferential pattern groove and the auxiliary longitudinal circumferential pattern groove. The side part pattern blocks on two sides of the central longitudinal circumferential pattern groove are in point symmetry and arranged in a vertically staggered mode. The tire shoulder pattern blocks are integral pattern blocks. According to the tire tread of the cargo truck, mixed patterns are adopted. The tire tread of the cargo truck has sufficient braking force and good operational properties, and is attractive.

Owner:QINGDAO YELLOWSEA RUBBER

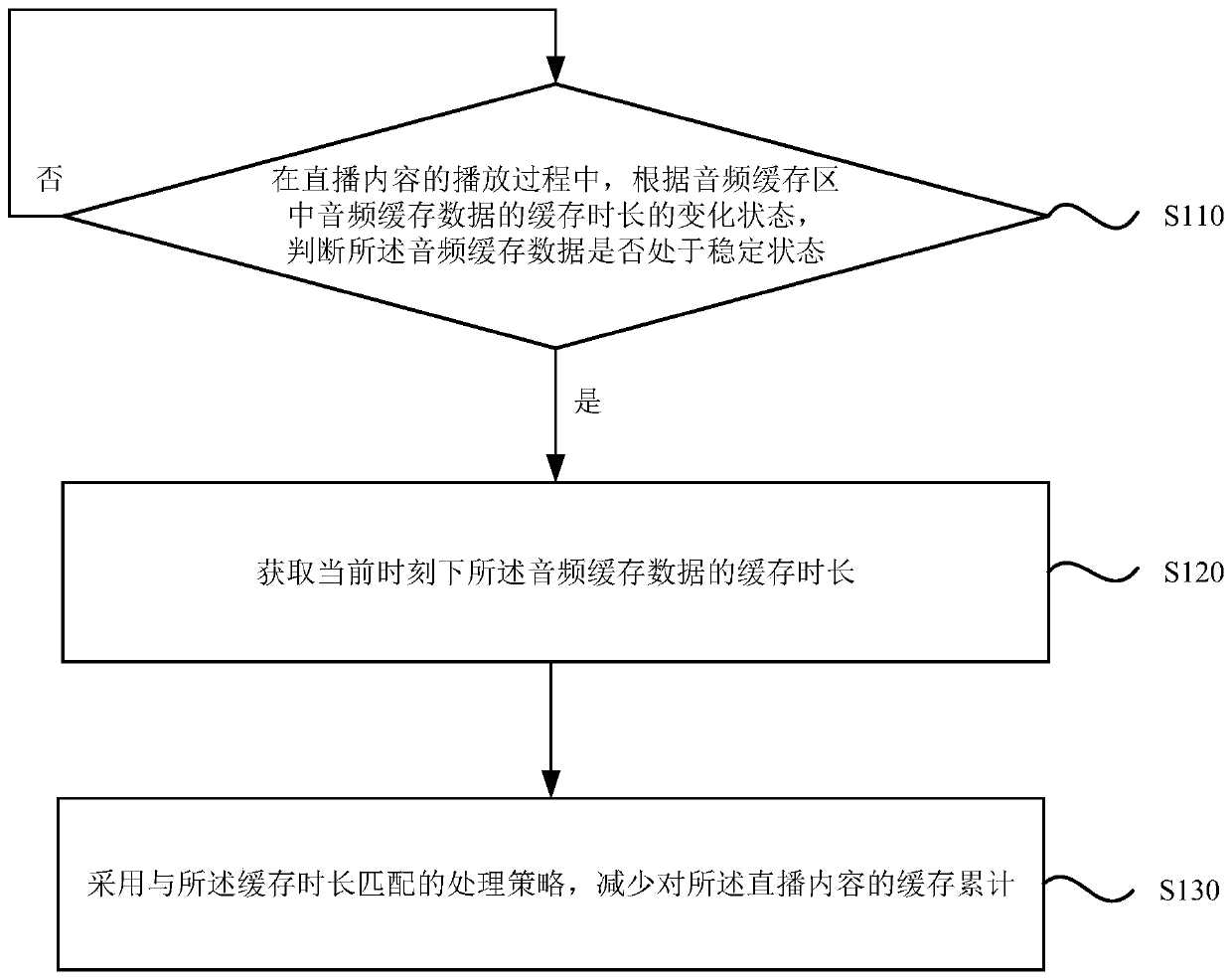

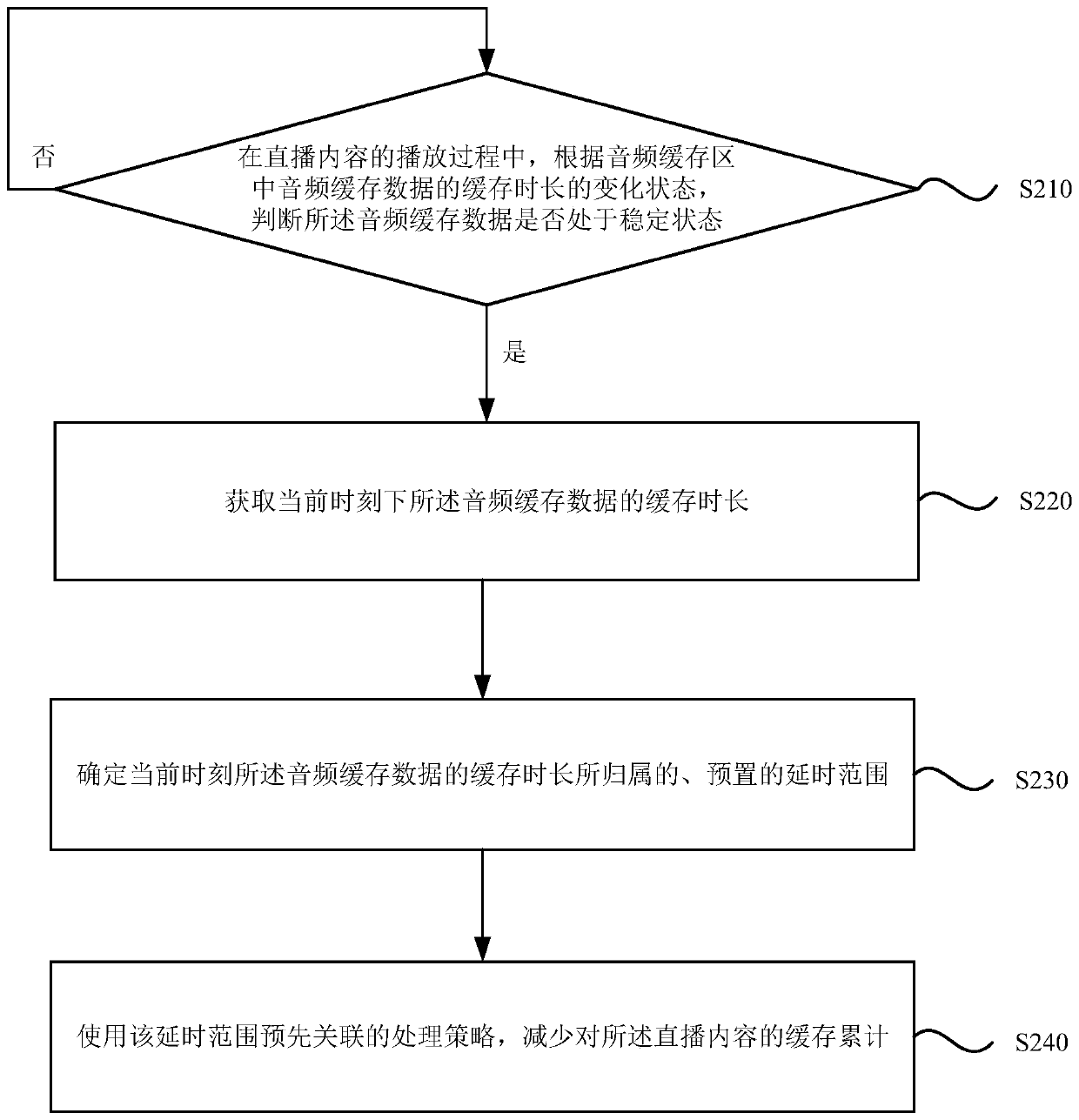

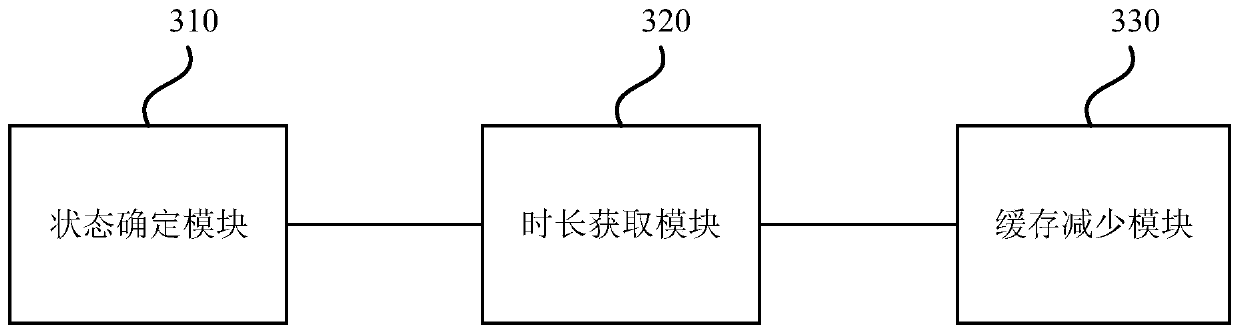

Live streaming cache processing method and device, equipment and storage medium

ActiveCN110248204ASmooth playbackReduce cache accumulationSelective content distributionStable stateParallel computing

The embodiment of the invention discloses a live streaming cache processing method and device, equipment and a storage medium. The method comprises the following steps: judging whether audio cache data is in a stable state or not according to the change state of the cache duration of the audio cache data in an audio cache region in the playing process of live streaming contents; wherein the live broadcast content comprises the audio cache data; if yes, obtaining the caching duration of the audio caching data at the current moment; and reducing the cache accumulation of the live streaming content by adopting a processing strategy matched with the cache duration, so as to reduce the situations of multiple content jumps and multiple-speed start and stop occurring when the cache accumulation of the live streaming content is played, thereby enabling the live streaming content to be played smoothly.

Owner:GUANGZHOU HUYA TECH CO LTD

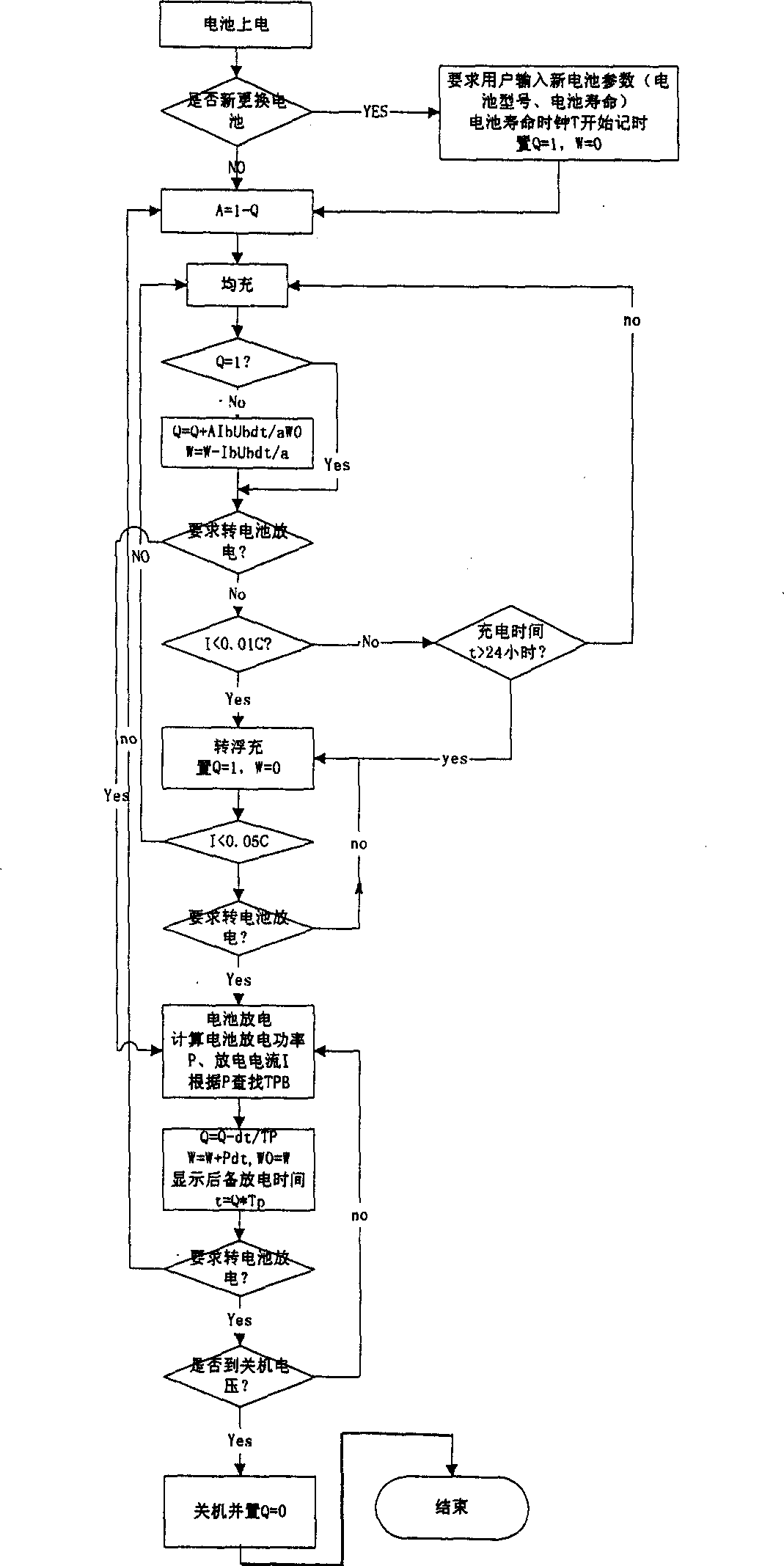

Calculation method of back-up period of battery in UPS

InactiveCN1349106AReduce jumpingHigh precisionBatteries circuit arrangementsElectrical testingElectricityConstant power

The invention discloses a method for calculating back up time of UPS. The reference of back up time is based on time of discharge in constant power. Since the characteristic of rectified load of UPS,the calculated back up time does not preset big jump, with jumping between different discharge curves under constant current being reduced and accuracy being increased in calculating the back up time, except the change, add or substract of load happens. The invention gives a good solution for calculating charge rate and back up time especially in underfill.

Owner:EMERSON NETWORK POWER CO LTD

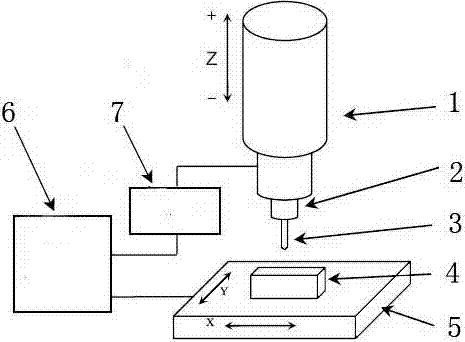

Novel method for on-line positioning of superfine milling cutter and workpiece

InactiveCN103170878AImprove detection accuracyAchieving Detection AccuracyMeasurement/indication equipmentsProgrammable logic controllerMilling cutter

The invention discloses a novel method for on-line positioning of a superfine milling cutter and a workpiece, and belongs to the field of superfine manufacturing. The novel method for on-line positioning of the superfine milling cutter and the workpiece is characterized in that the superfine milling cutter is clamped in a cutter tool chuck of a high-speed main shaft; a closed-loop circuit is built between the main shaft and the workpiece. A specially designed sensor is used for detecting sudden changing voltage of the closed-loop circuit in a feed process of a cutter tool. A voltage comparator is used for converting measured values into digital signals and sending to a programmable logic controller (PLC) of a tool. The PLC records coordinates of the cutter tool and contact points of the workpiece and sets a starting point of a processing position. The detection method can prevent influences over cutter tool positioning caused by tool bouncing, thermal expansion of the main shaft and other errors. The detection method is capable of achieving an on-line positioning accuracy at a submicron level. Meantime, the detection method has the advantages of being simple in needed equipment, low in cost and convenient to carry out.

Owner:SUZHOU UNIV OF SCI & TECH

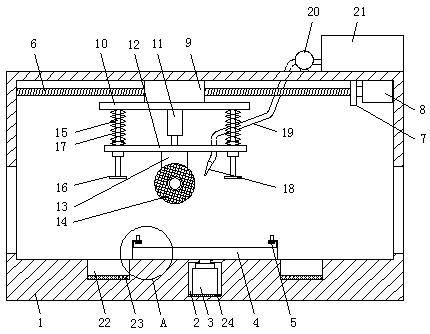

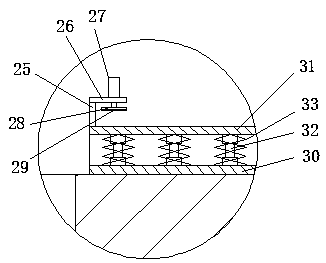

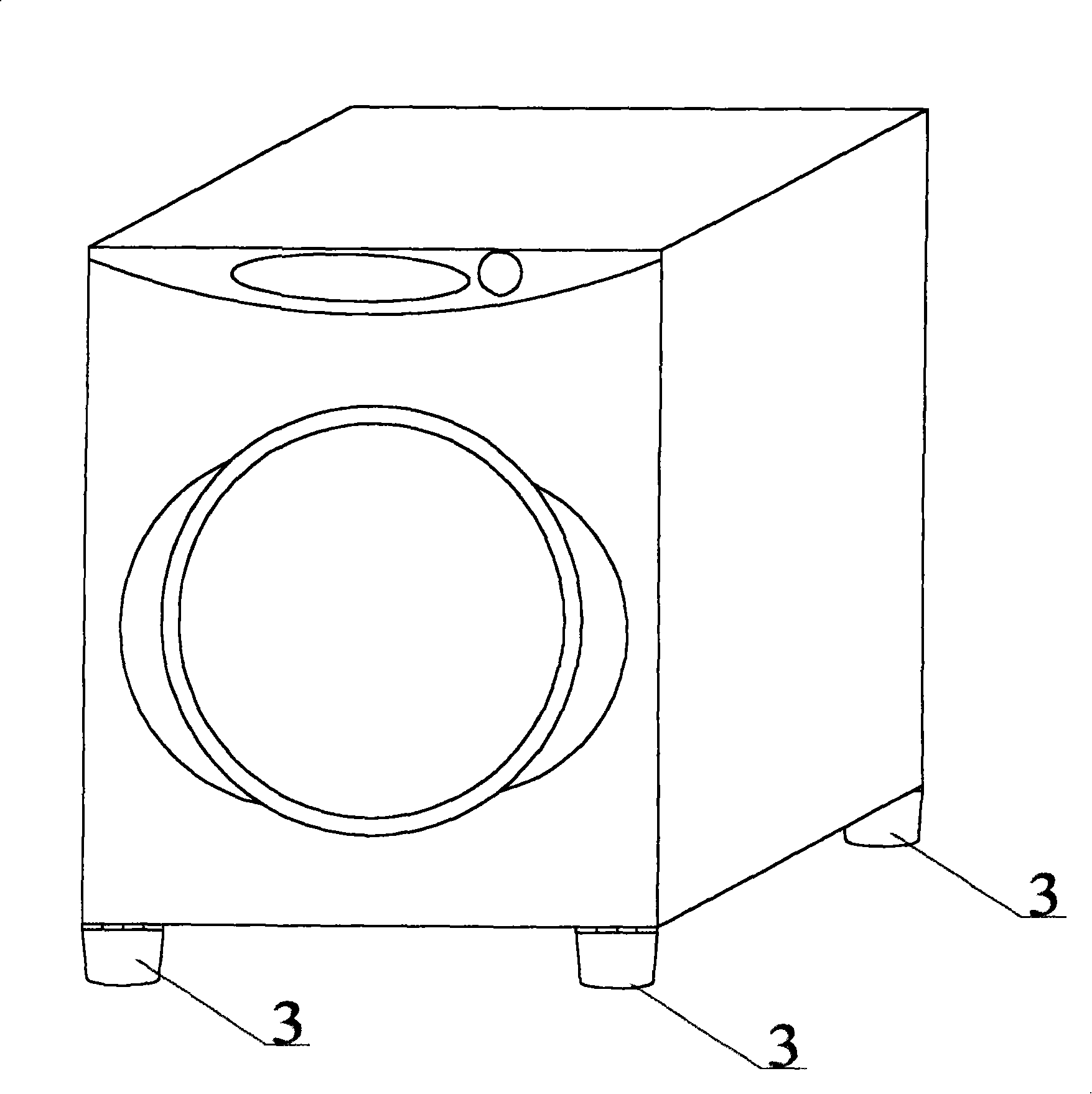

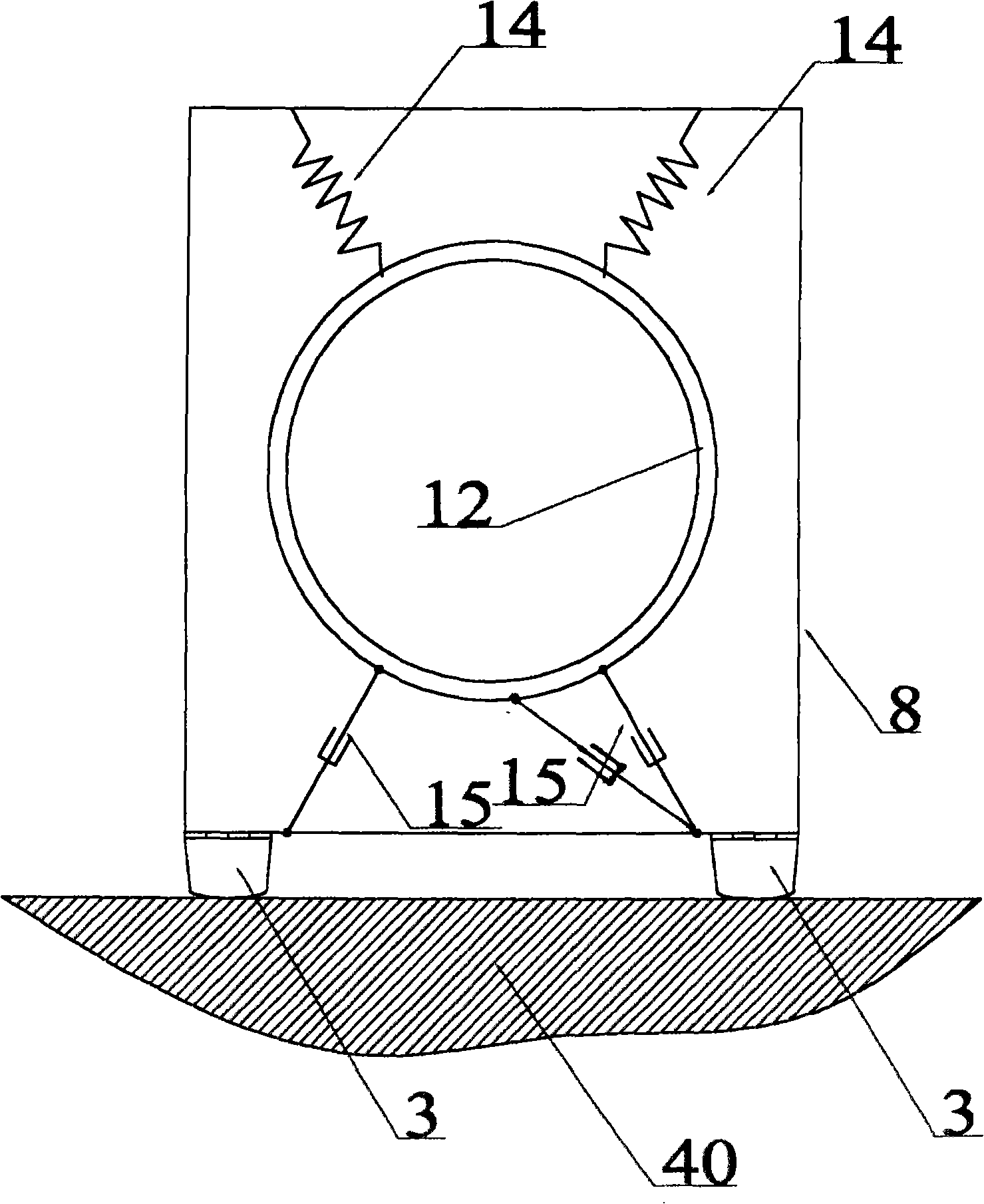

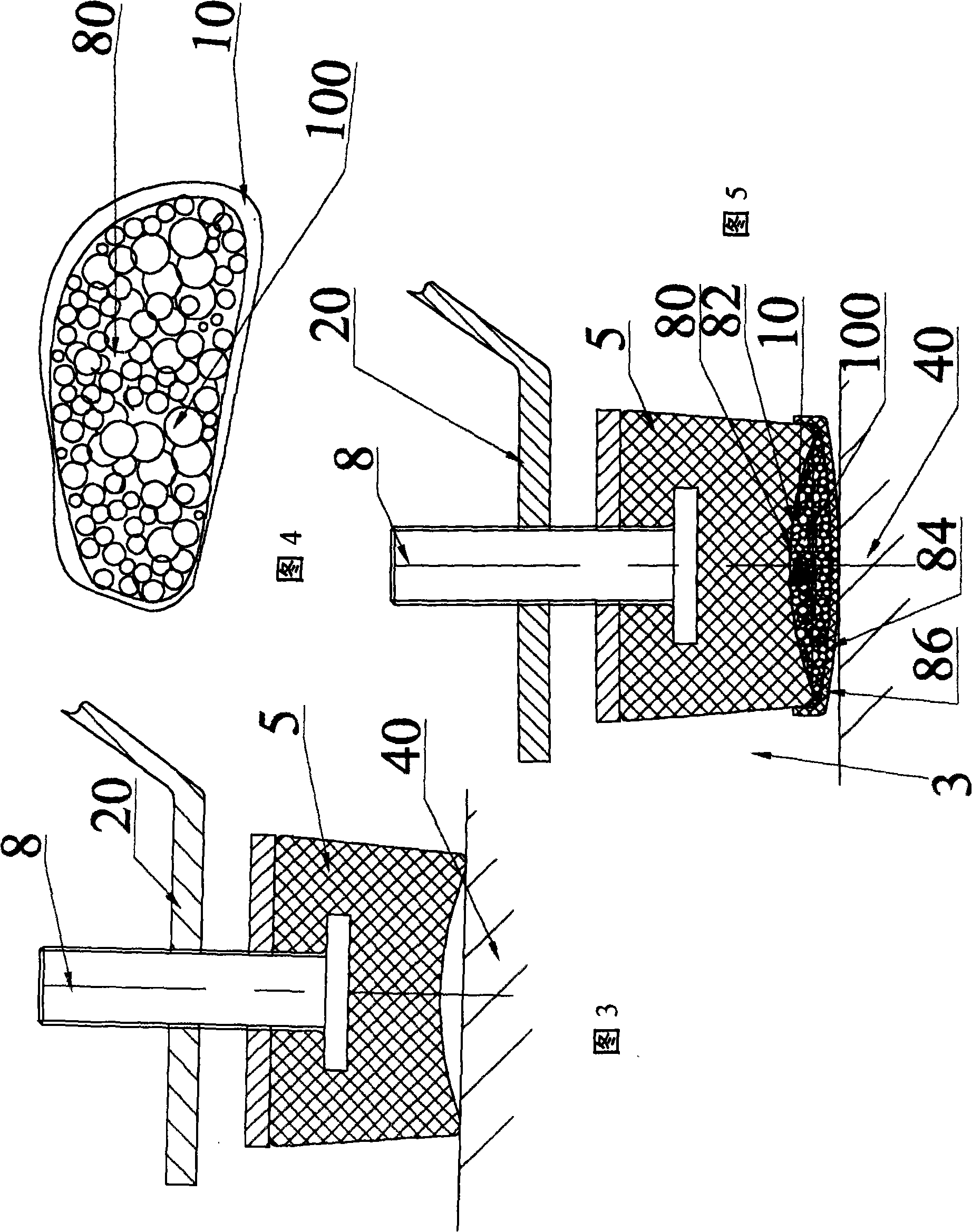

Barrel roll laundry machine wide band elastic granule damper

InactiveCN101302703AReduce jumpingReduce wanderingOther washing machinesTextiles and paperElastic vibrationBroadband

The invention relates to a broadband elastic particle damper of a rolling laundry machine, the elastic particle damper 3 is formed by combining an elastic vibration isolator 5 with a particle damper 10; the elastic particle damper 3 can be positioned between a case 8 of the rolling laundry machine and a supporting ground 40, or between an oscillating damper 15 and the case 8 of the rolling laundry machine or a tumbling cylinder 12, or can be simultaneously positioned between the case 8 of the rolling laundry machine and the supporting ground 40 as well as between the oscillating damper 15 and the case 8 of the rolling laundry machine or the tumbling cylinder 12; the particle damper 10 comprises a sealed cavity 80 and particles 100 that are padded in the cavity, and is mainly used for providing frictional damping for a vibrating system in a broadband range and inhibiting formants by utilizing the mutual frictional action between the particles.

Owner:吕崇耀

Method and system for trying out a product in relation to a real world environment

ActiveUS9418378B2Reduce jumpingBuying/selling/leasing transactionsMobile application execution environmentsComputer scienceProduct image

A method, system and computer program are provided to allow one or more users to try out one or more products. The method, system and computer program involve providing information on one or more products offered for sale under restricted conditions of time or quantity, obtaining a real image of an object, determining one or more features from the object image, determining a position to overlay a first product image on the object image based on the determined one or more features, overlaying the first product image on the object image based on the determined position to provide an overlaid image, and displaying the overlaid image. The first product image is an image of a product from the one or more products.

Owner:GILT GRP LP

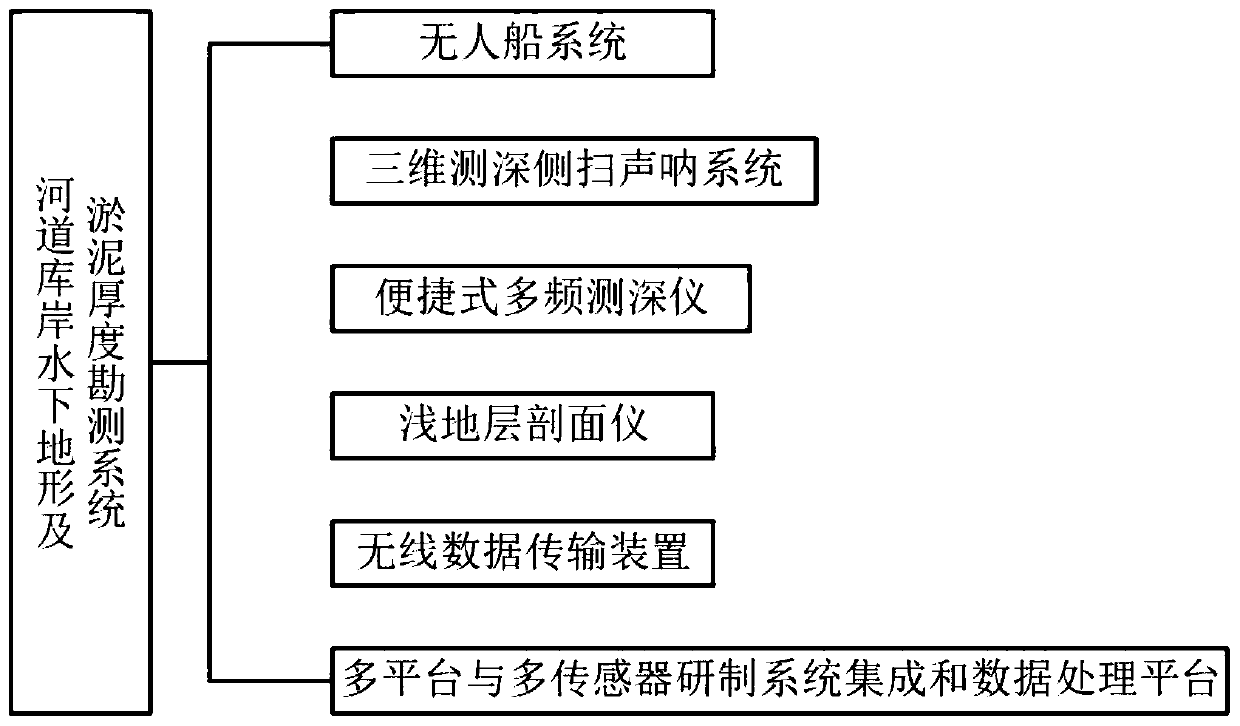

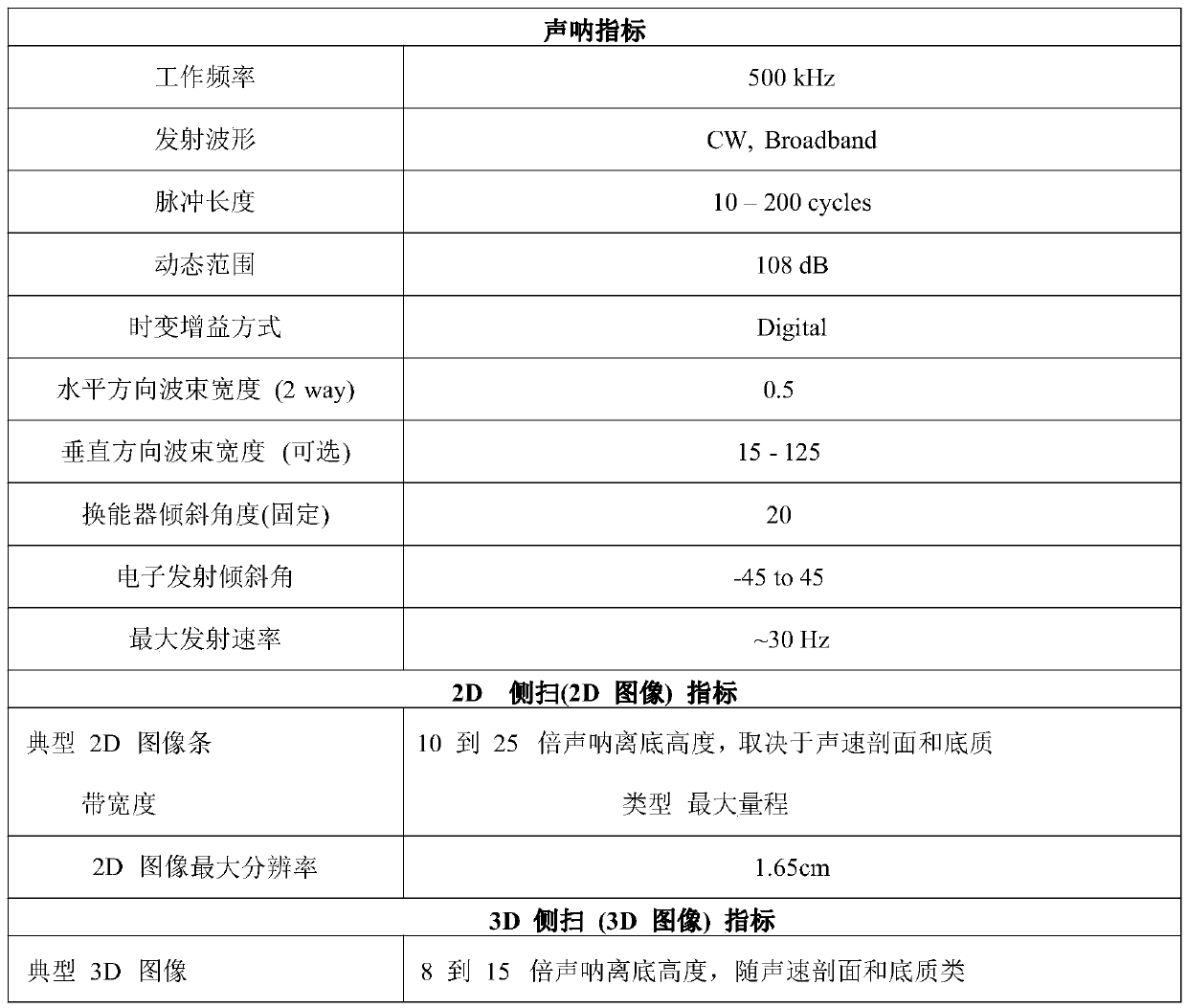

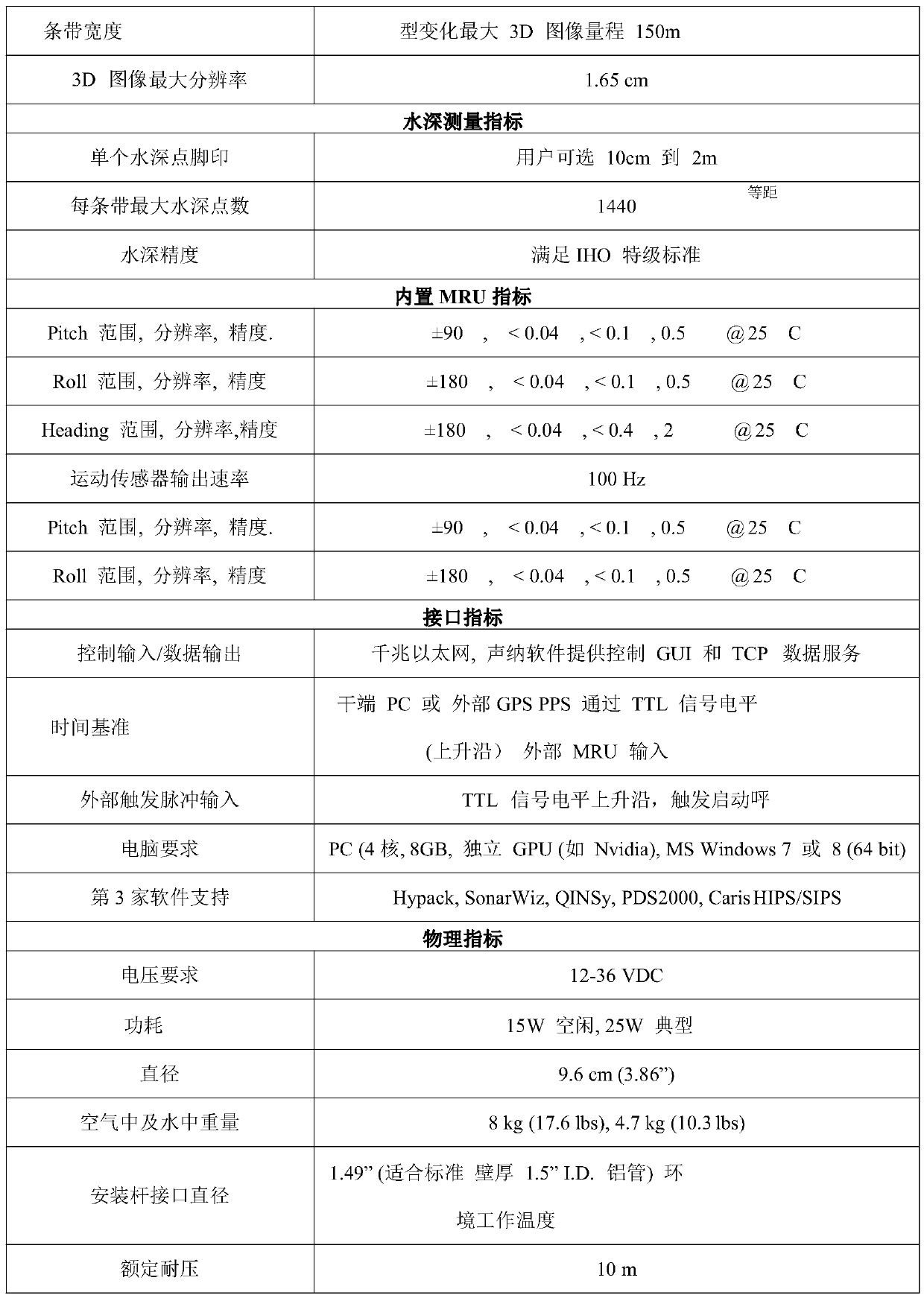

Underwater topography and sludge thickness survey system for riverway reservoir bank

ActiveCN111580113AEasy to detectIncrease widthWater resource assessmentAcoustic wave reradiationTerrainMultiple sensor

The invention relates to a riverway reservoir bank underwater terrain and sludge thickness survey system. The system comprises an unmanned ship system, a three-dimensional sounding side-scan sonar system, a portable multi-frequency depth finder, a shallow stratum profiler, a ground profile instrument, a wireless data transmission device and a multi-platform and multi-sensor development system integration and data processing platform. The three-dimensional sounding side-scan sonar system is used for simultaneously obtaining a 2D sonar image, a high-resolution 3D side-scan image and strip sounding data in one-time measurement navigation; the portable multi-frequency depth finder is used for pipeline route investigation and sedimentation condition investigation; the shallow stratum profiler can measure water depth data and shallow profile data, and profile display is carried out on a water bottom stratum; the wireless data transmission device is suitable for carrier-grade point-to-point network application; and the multi-platform and multi-sensor development system integration and data processing platform is used for realizing transmission communication of real-time data and constructing an underwater topographic survey network of the heterogeneous unmanned ship.

Owner:YELLOW RIVER ENG CONSULTING

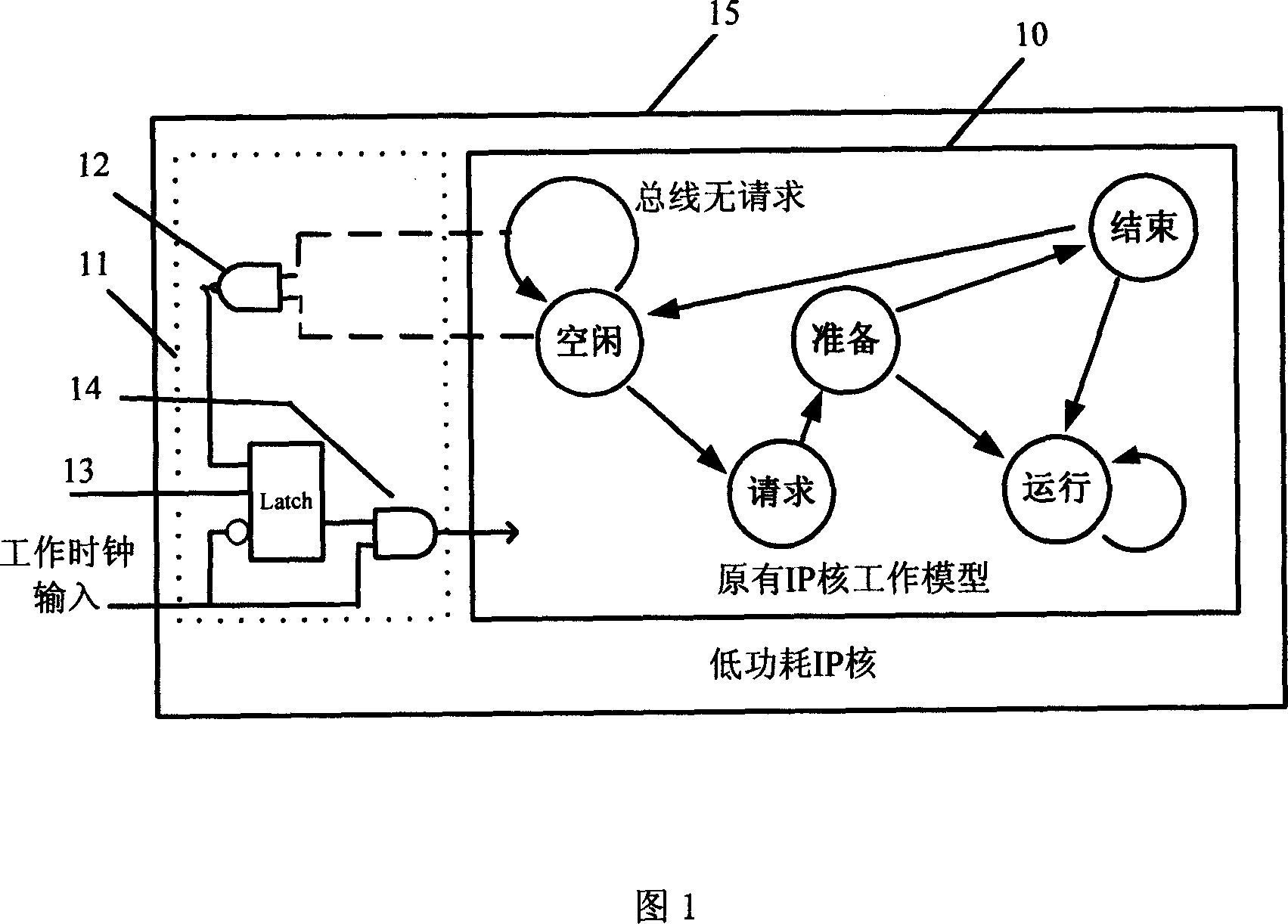

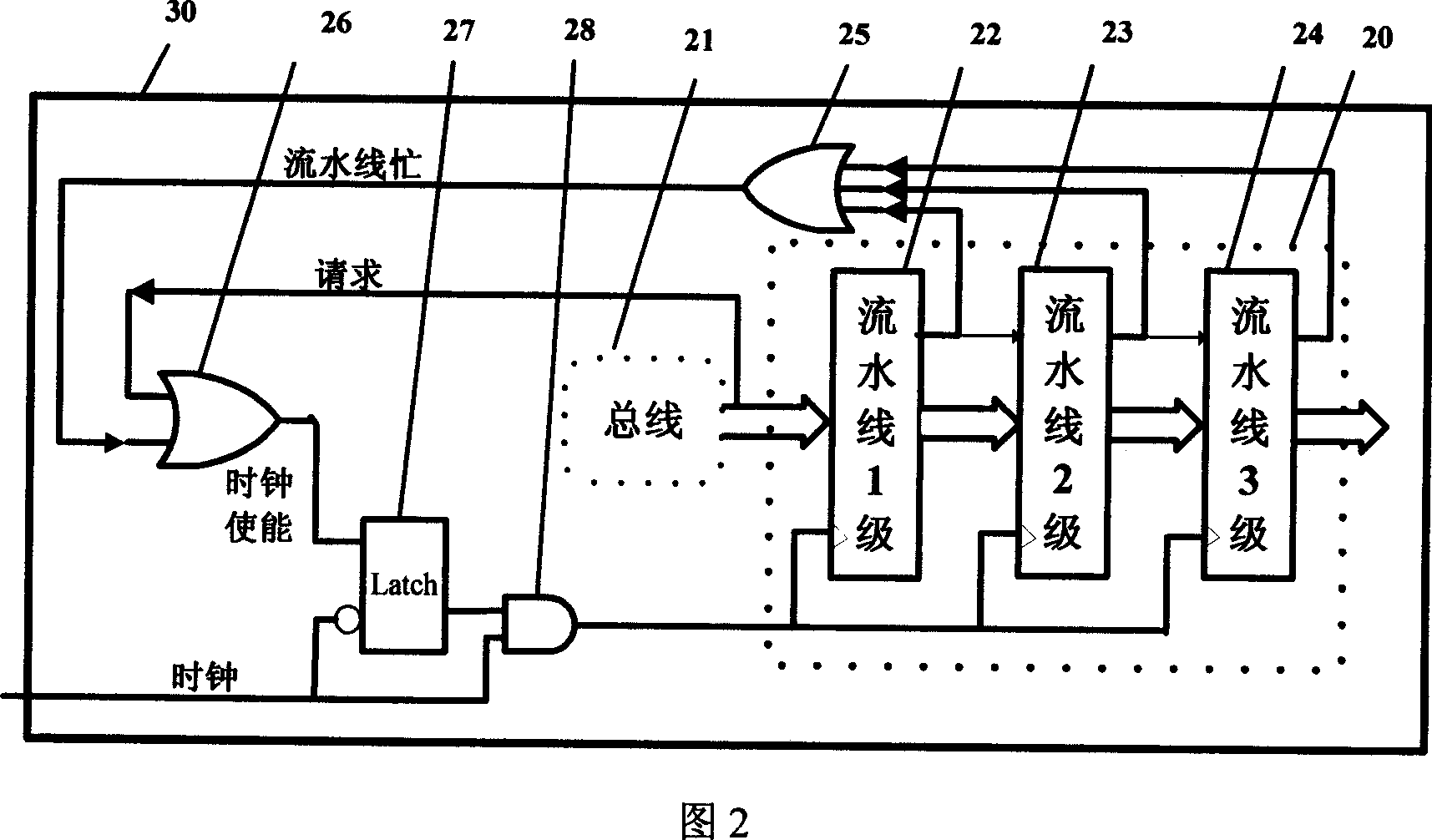

Power consumption reduction method for intellectual core and functional module for chip system

ActiveCN101078950AReduce jumpReduce dynamic power consumptionPower supply for data processingDynamic power dissipationLogic circuitry

The invention discloses a power decreasing method of various intellective property core and functional module in SoC, which comprises the following steps: a) dividing all states of original functional module to two specie-' free' state and ' working' state; b) providing a logic circuit; connecting to the original functional module; constructing new low power functional module; finishing the logic function with the logic circuit; keeping clock close if without request for the original functional module; opening the clock if with the request for the original functional module; entering the original functional module into the ' working' state; closing the clock till the original functional module in ' free' state without bus request. This invention decreases dynamic state and leaking power consumption of IP core and auto-switches power source of the IP core at the same time.

Owner:INST OF COMPUTING TECHNOLOGY - CHINESE ACAD OF SCI

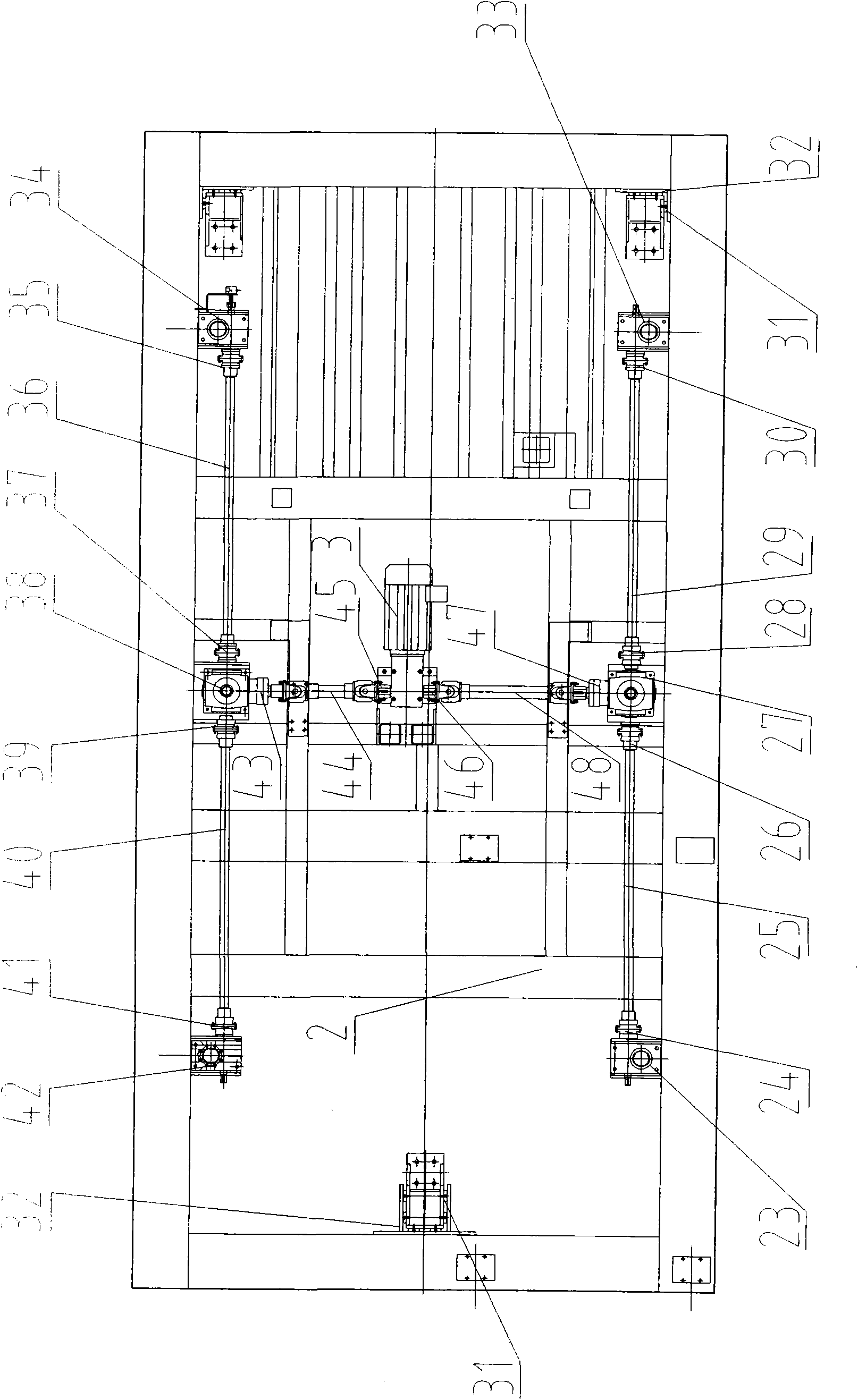

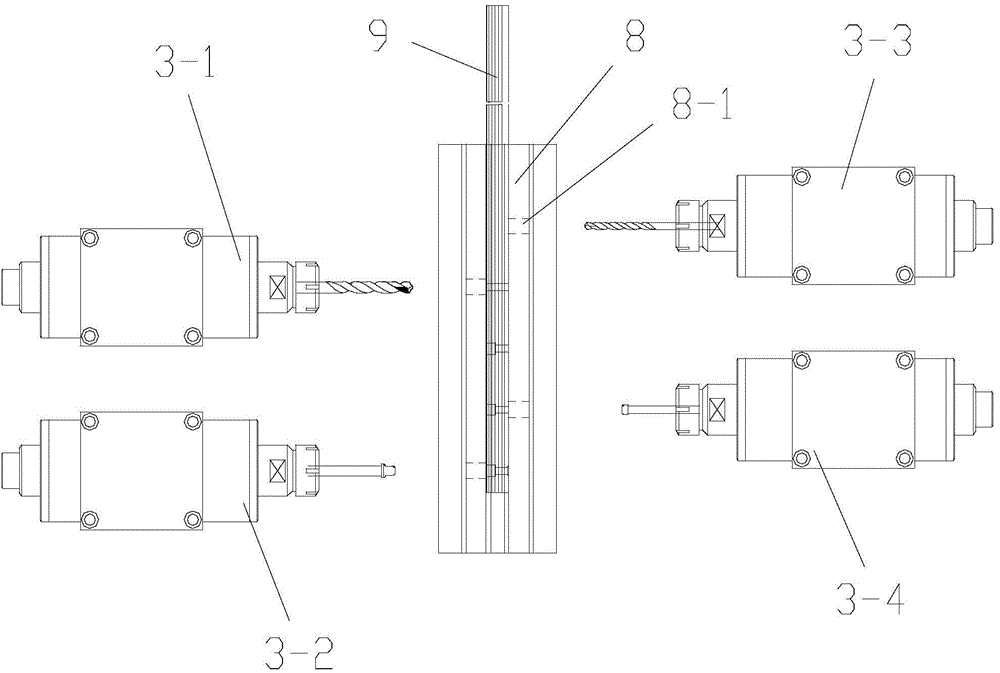

Guide rail machining device

ActiveCN104924080AImprove rigidityHigh strengthOther manufacturing equipments/toolsSynchronous motorMotor drive

A guide rail machining device comprises a working table. A drilling tool main shaft driven by a DC synchronous motor is arranged on the working table, arranged on a transverse guide rail and connected with a lead screw and nut mechanism driven by a motor. A supporting table for supporting a workpiece and a pressing cylinder for fixing the workpiece are installed on the working table. A pull rod for pulling the workpiece is arranged at the front end of the working table. By means of the structure, the guide rail is moved through the pull rod and fixed through the pressing cylinder, the drilling tool main shaft is only moved transversely without being moved longitudinally, and therefore the hopping of the drilling tool main shaft is reduced, and the machining quality of the guide rail is improved. The lead screw and nut mechanism driven by the motor mainly comprises a motor, a lead screw and a nut pair, wherein the motor drives the lead screw to rotate and drives the nut pair to move as well.

Owner:LISHUI UNIV

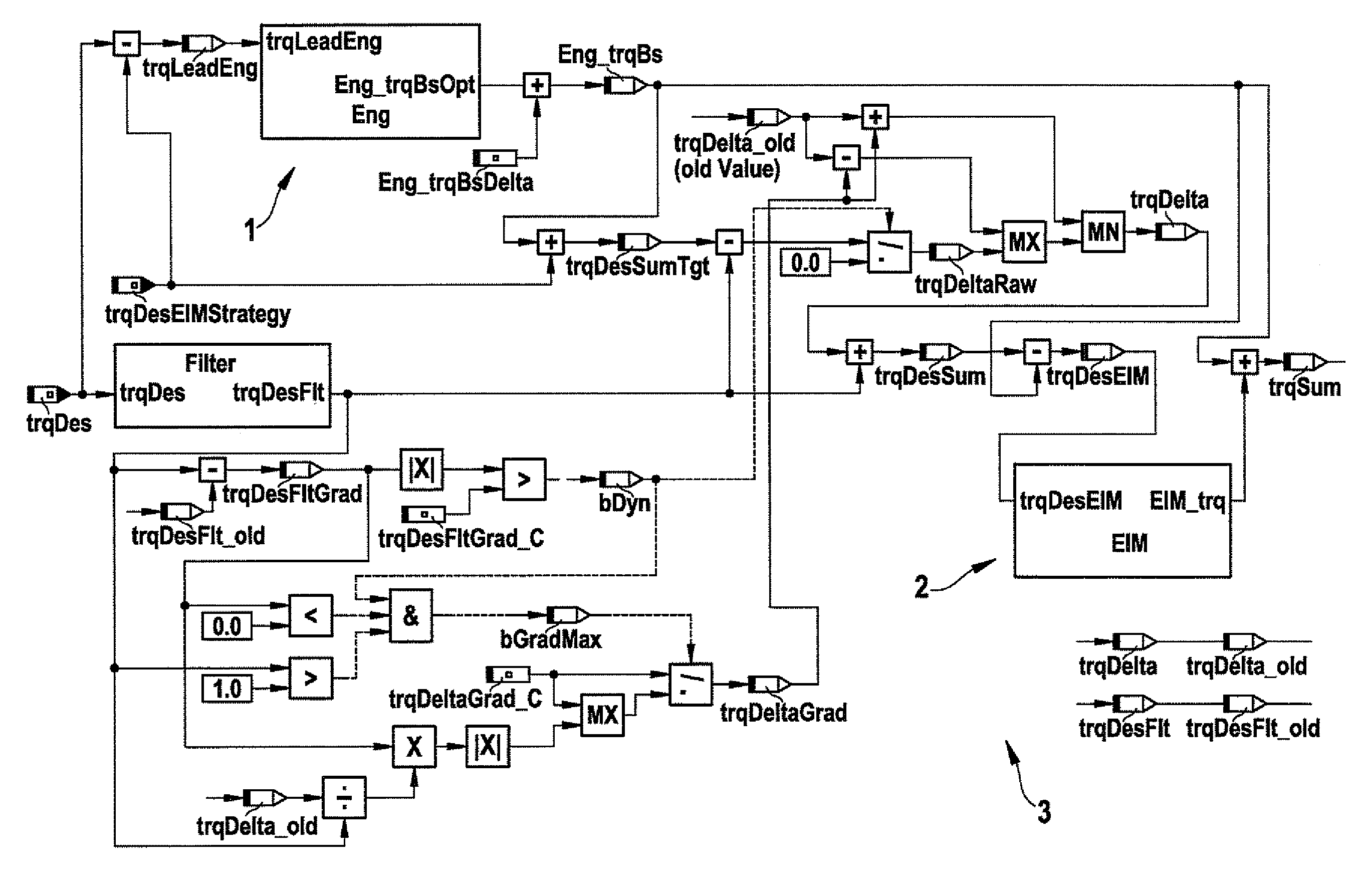

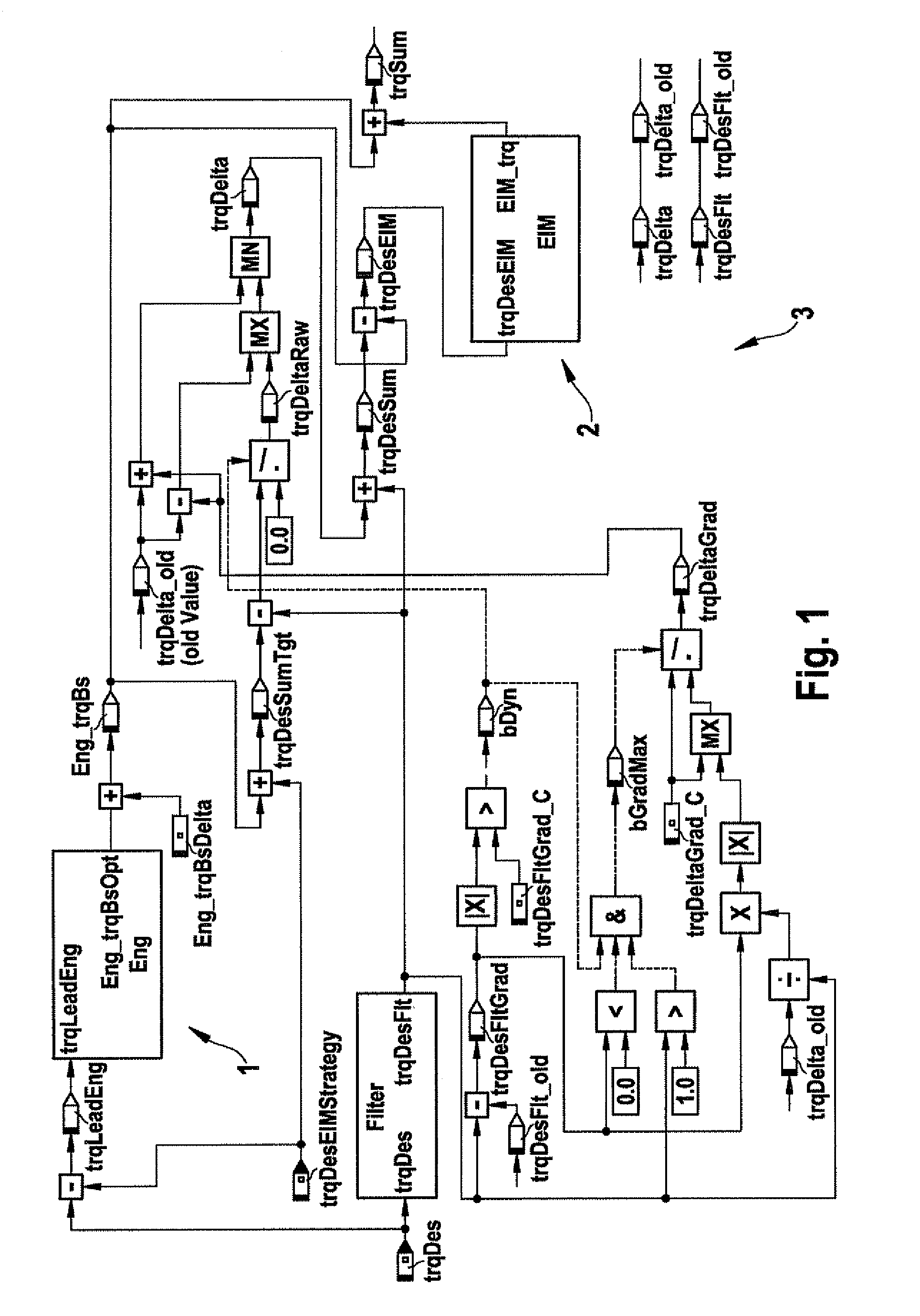

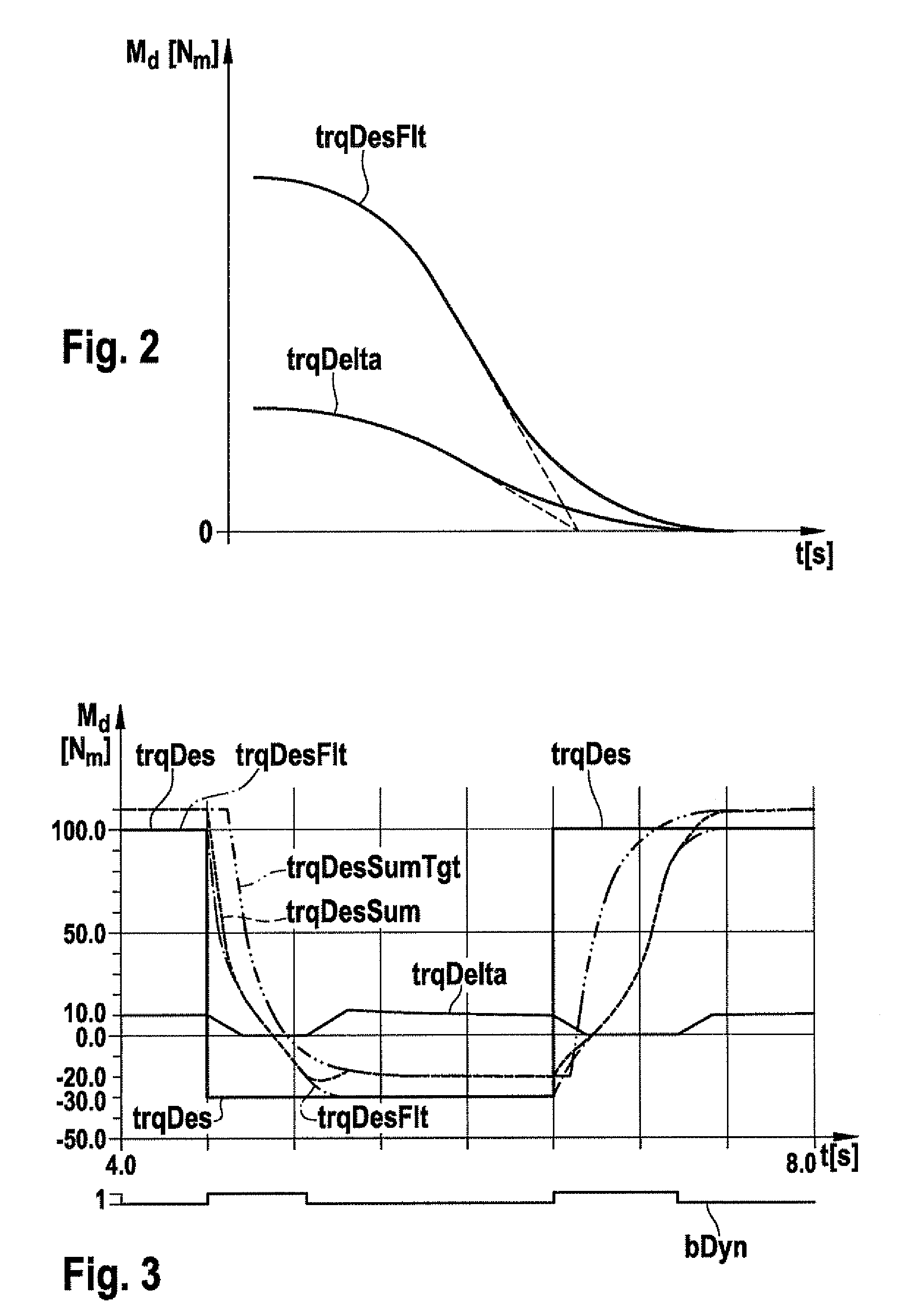

Method for operating a drive device, in particular a hybrid drive device

InactiveUS20100299009A1Sudden torque peaks on the drive trainComfort of the occupants of the vehicle is increasedInternal combustion piston enginesDigital data processing detailsMobile vehicleElectric machine

A method for operating a drive device, in particular a hybrid drive device, of a vehicle, in particular a motor vehicle, having at least one internal combustion engine and at least one electrical machine as drive units, which are mechanically coupled to one another, as a function of a torque demand, in particular a filtered torque demand, in a normal operation, an ideal target torque for the particular drive unit being defined for each of the drive units and, in a dynamic operation, a target torque being defined for each of the drive units which together meet the torque demand.

Owner:ROBERT BOSCH GMBH

Automatic welding device for machining

ActiveCN108907599AAvoid pullingAvoider squeezeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses an automatic welding device for machining. The automatic welding device for machining comprises a workbench, a cross beam and a moving column. The moving column is provided with a welding head capable of moving. The two sides of the welding head are each provided with a first limiting unit, a second limiting unit and an adjusting seat. Each first limiting unit is close to the welding head, and each second limiting unit is close to the adjusting seat. According to the automatic welding device for machining, the first limiting units are utilized to approach to the position of a weld seam to conduct locating, so that bounce of a steel tube circular seam caused by the cylindricity error due to the self-lengths of steel tubes is lowered and transferred to the ends far away from the circular seam of the steel tubes; and meanwhile, through ejector rods on the adjusting seats, flexible transition between bounce of the steel tubes and the axis of rotating shafts is achieved when circular seam welding is conducted, since the connection strength brought by spot welding locating can be stronger than flexible fixation exerted by the ejector rods on the steel tubes, the end, far away from the circular seam, of each steel tube can bounce, and then the weld seam is prevented from being pulled or squeezed.

Owner:HUILIAN XINXIANG ELECTRONICS TECH CO LTD

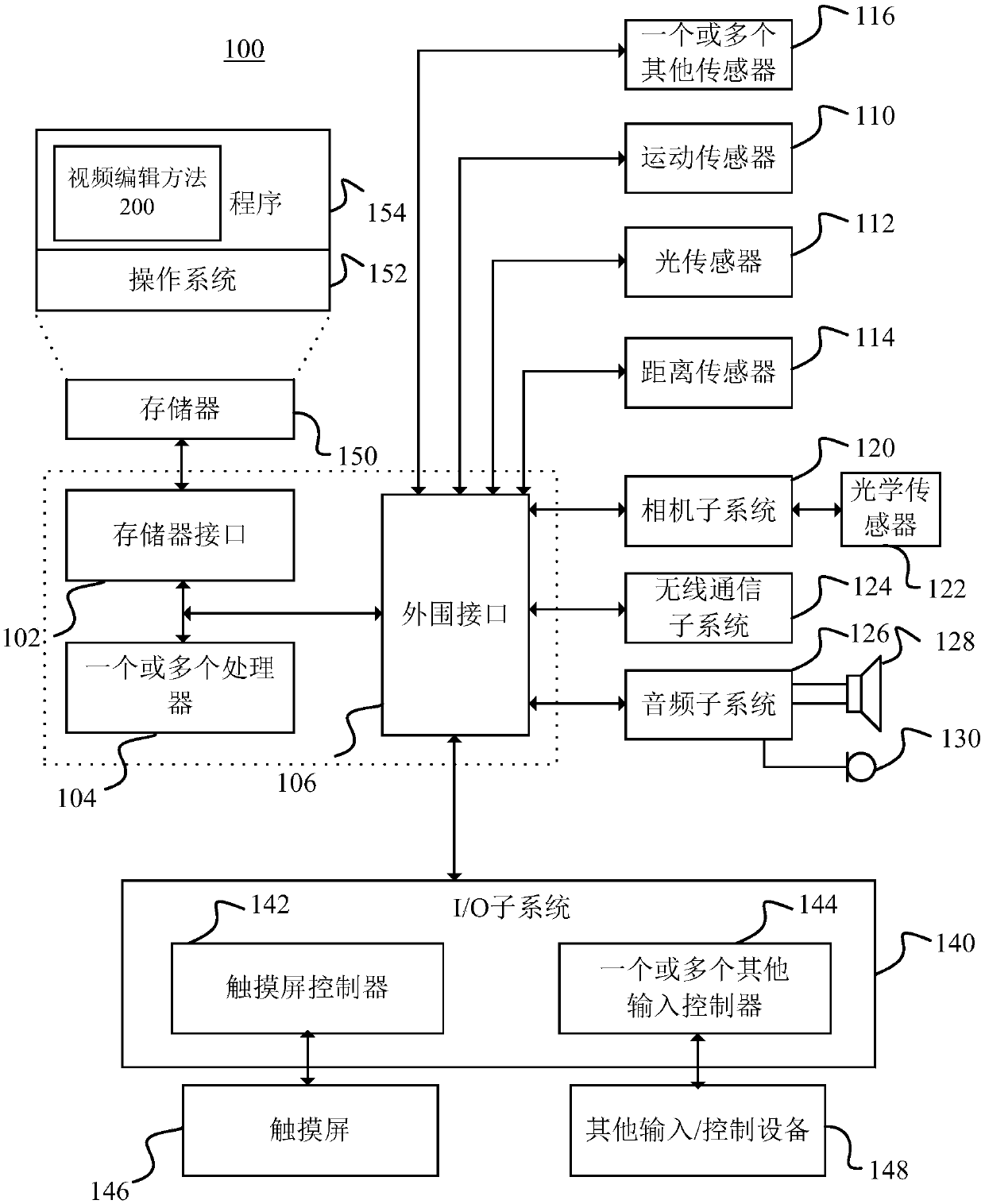

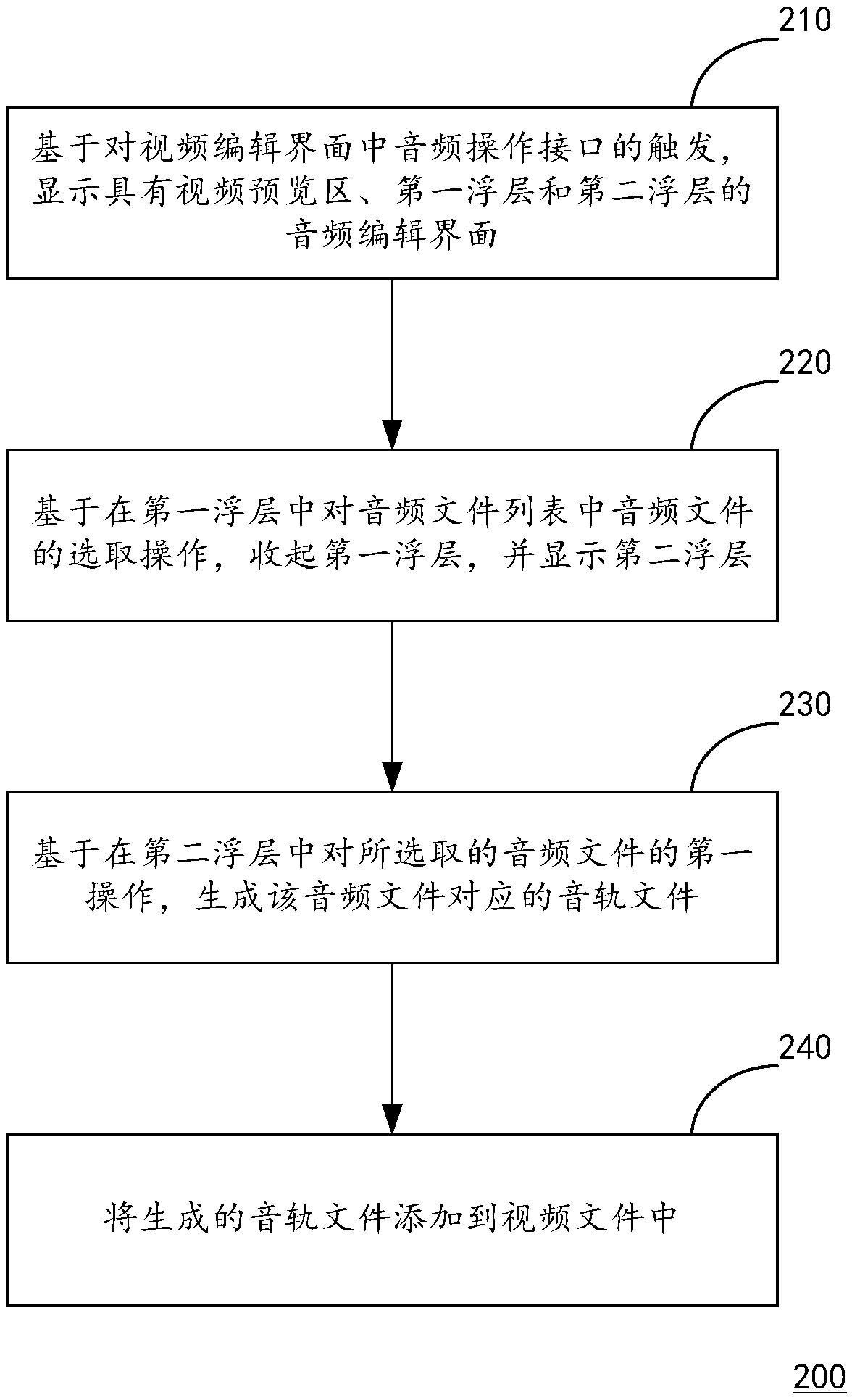

Video editing method and device and mobile terminal

ActiveCN110971957AEasy to viewMeet new needsTelevision system detailsColor television detailsComputer hardwareEngineering

The invention discloses a video editing method and device and a mobile terminal. The method comprises the steps that based on triggering of an audio operation interface in a video editing interface, an audio editing interface is displayed, wherein the audio editing interface comprises a video preview area, a first floating layer used for displaying an audio file list and a second floating layer used for audio editing; on the basis of selection operation on audio files in the audio file list in the first floating layer, the first floating layer is packed up, and a second floating layer is displayed; an audio track file corresponding to the audio file is generated based on first operation on the selected audio file in the second floating layer; and the generated audio track file is added into the video file. According to the invention, the music and the video are cut in real time in a one-to-one comparison manner, so that a user can check a mapping relationship between the music and thevideo conveniently.

Owner:ALIBABA GRP HLDG LTD

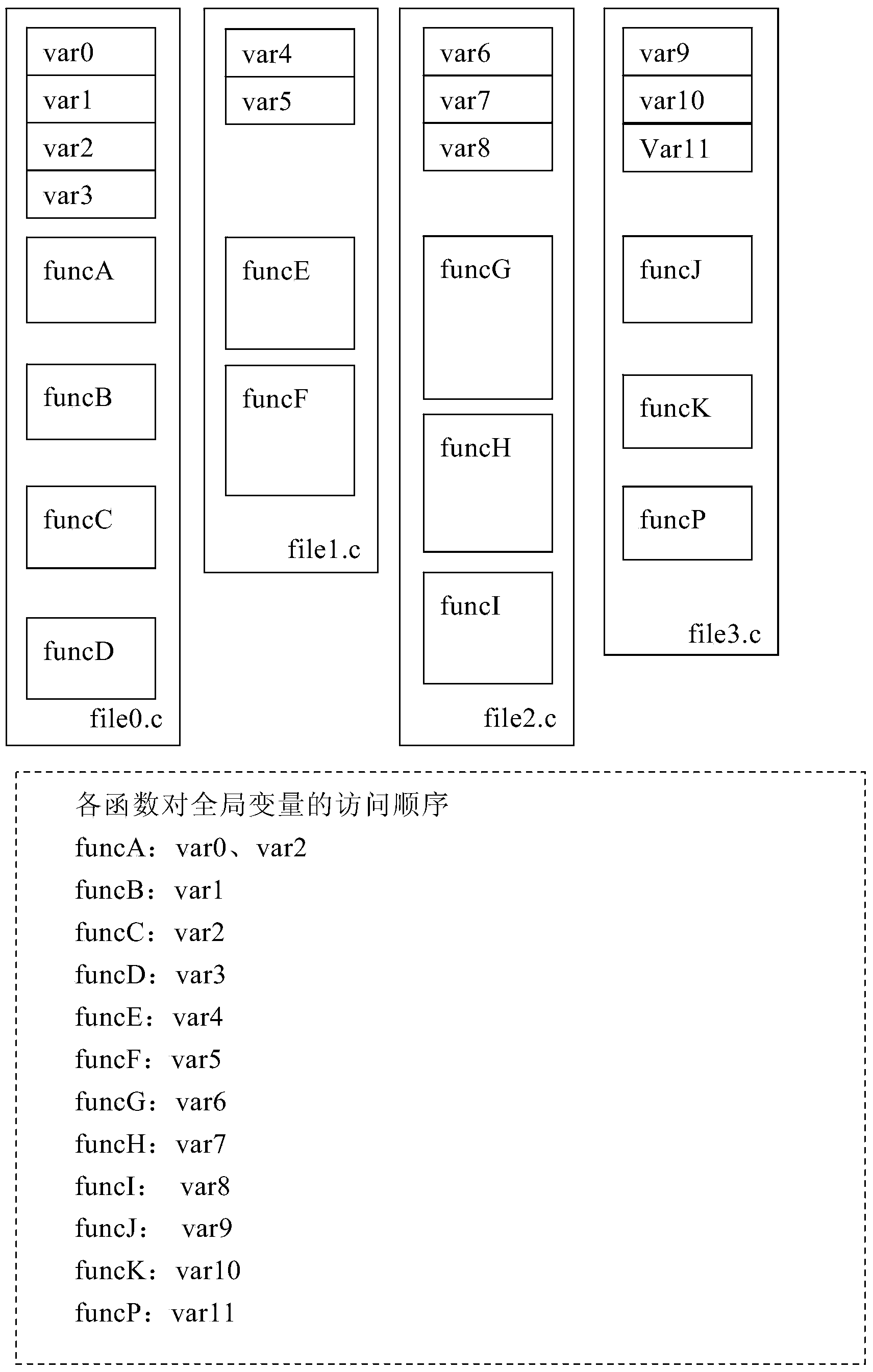

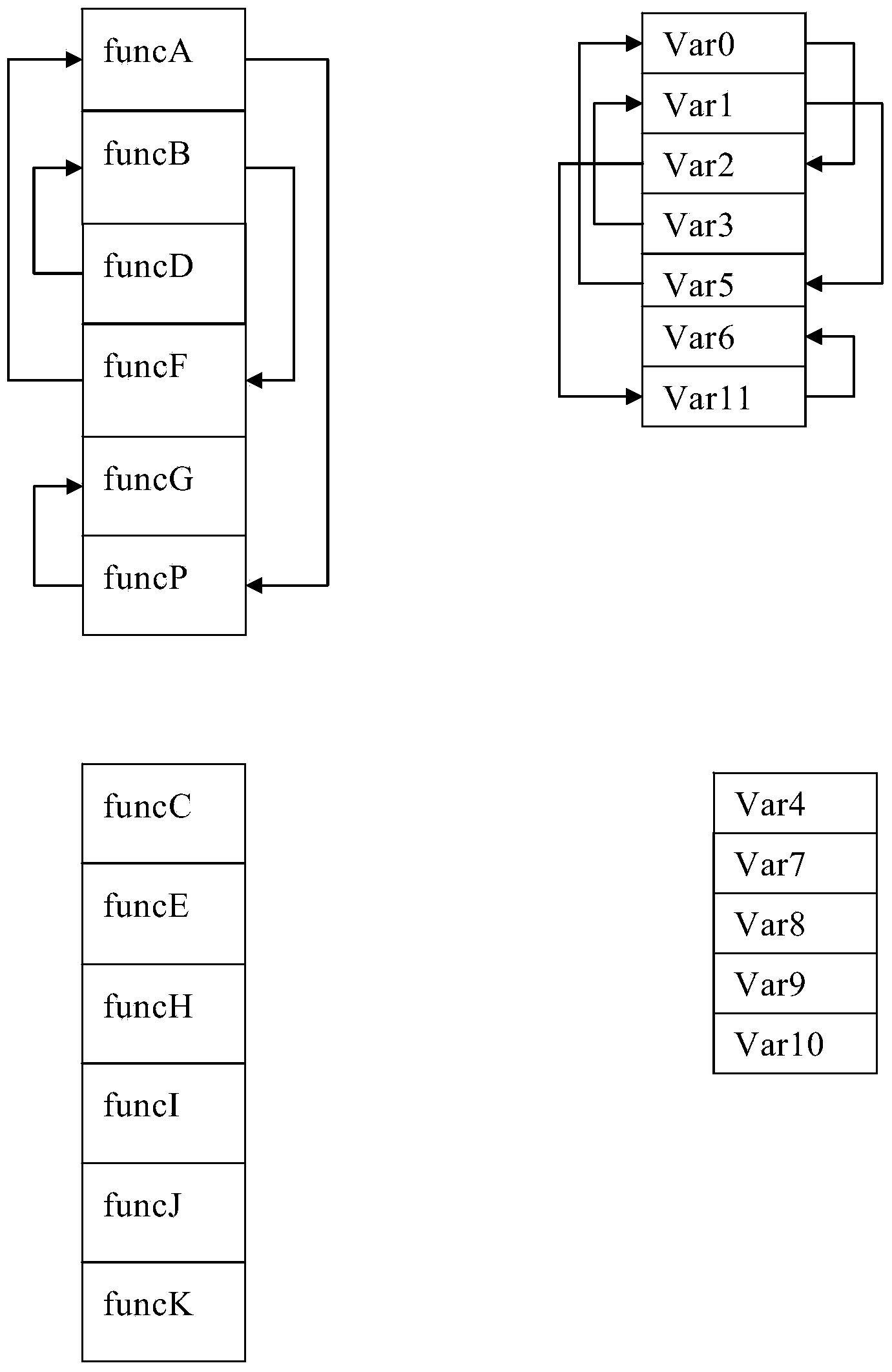

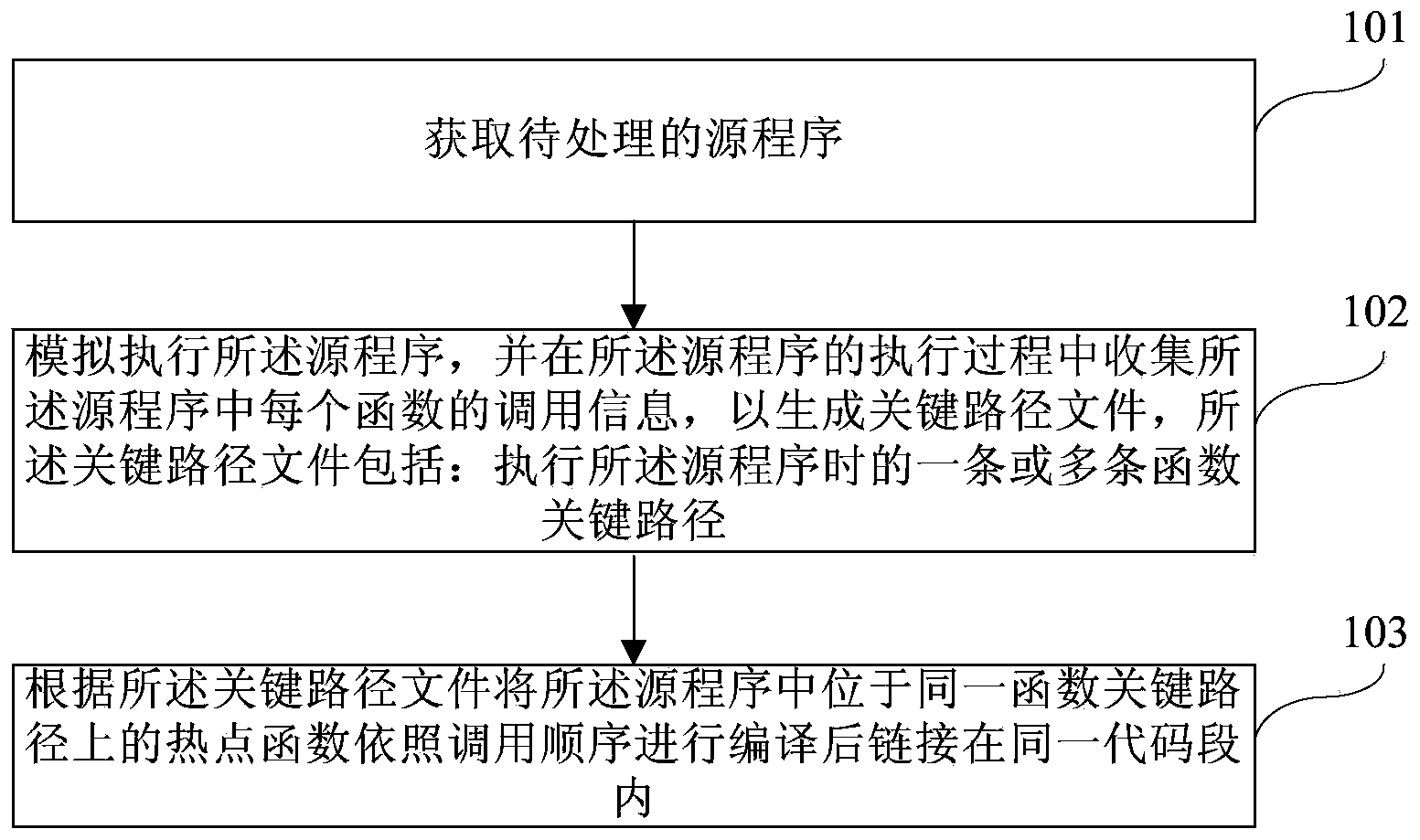

Method, device and system for converging hotspot functions and variables in computer programs

ActiveCN103713933AReduce jumpingReduce instruction jumpsSoftware simulation/interpretation/emulationMemory systemsProgramming language

The embodiment of the invention discloses a method, device and system for converging hotspot functions and variables in computer programs. The method for converging the hotspot functions in the computer programs includes the steps that source programs to be processed are acquired; the source programs are simulated and executed, calling information of each function in the source programs is collected when the source programs are executed to generate a critical path file, wherein the critical path file comprises one or more function critical paths when the source programs are executed; according to the critical path file, the hotspot functions, located in the same function critical path, in the source programs are compiled in the calling sequence and then linked into a same code segment, wherein the function critical paths are used for describing one or more hotspot functions and the calling sequence among the hotspot functions when the source programs are executed. According to the method, device and system, Cache Miss of instructions and Cache Miss of data can be effectively reduced.

Owner:济南闲什科技发展有限公司

Carbon brush structure of collecting ring

The invention discloses a carbon brush structure of a collecting ring. The carbon brush structure comprises a base, two carbon brushes and two bias voltage pieces, wherein the base is provided with two guide rails; the two carbon brushes are arranged on the guide rails of the base respectively and can move along the guide rails; the two bias voltage pieces act on the two carbon brushes respectively, drive the two carbon brushes to move towards a conducting ring of the collecting ring and keep the two carbon brushes in contact with the conducting ring. The two guide rails pass through the circle center of the conducting ring, so that the carbon brushes are prevented from jumping and are worn uniformly.

Owner:TAIWAN LONG HAWN ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com