Carbon brush structure of collecting ring

A collector ring and carbon brush technology, applied in the field of collector rings, can solve problems such as current instability, discharge, and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

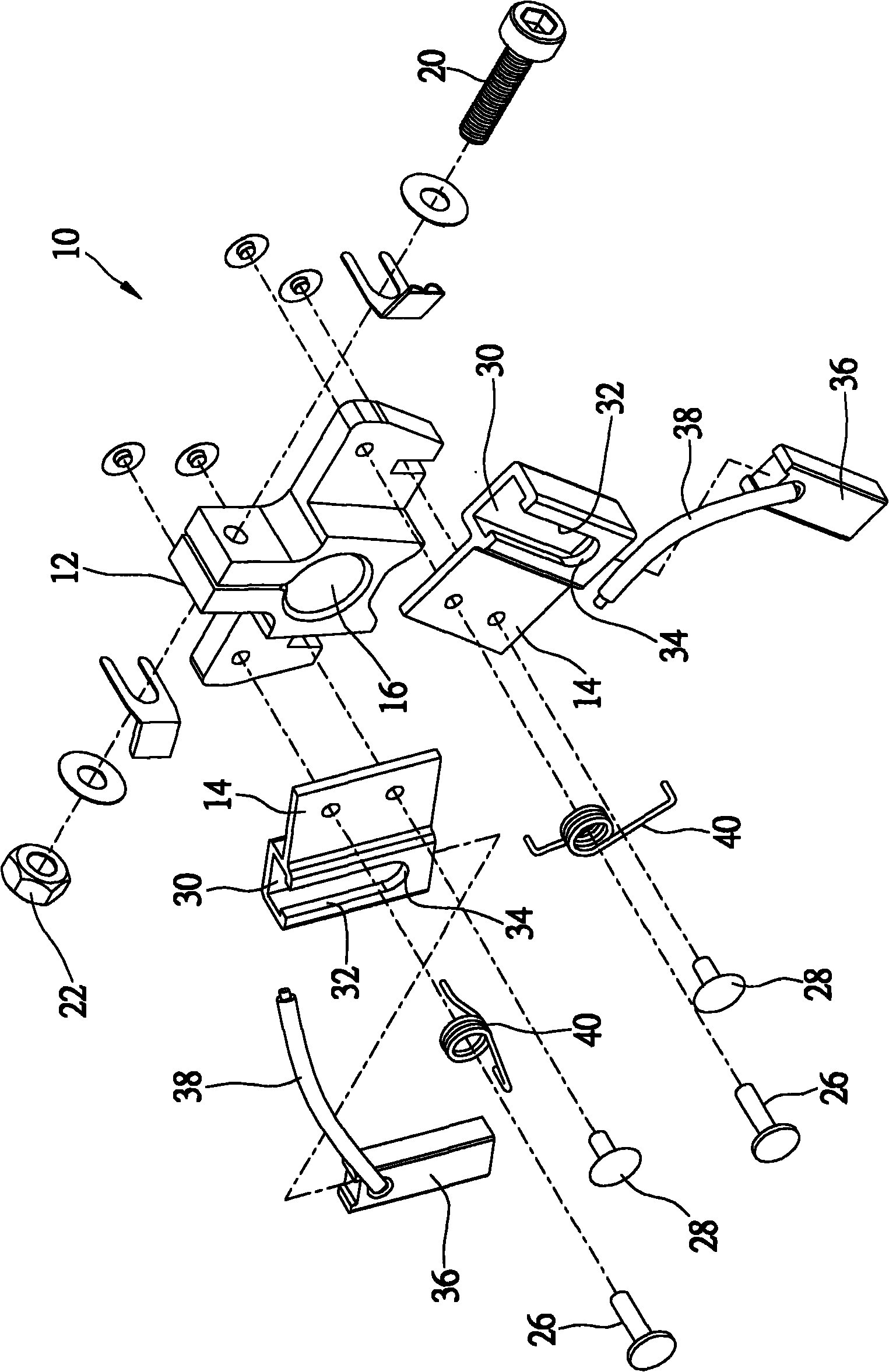

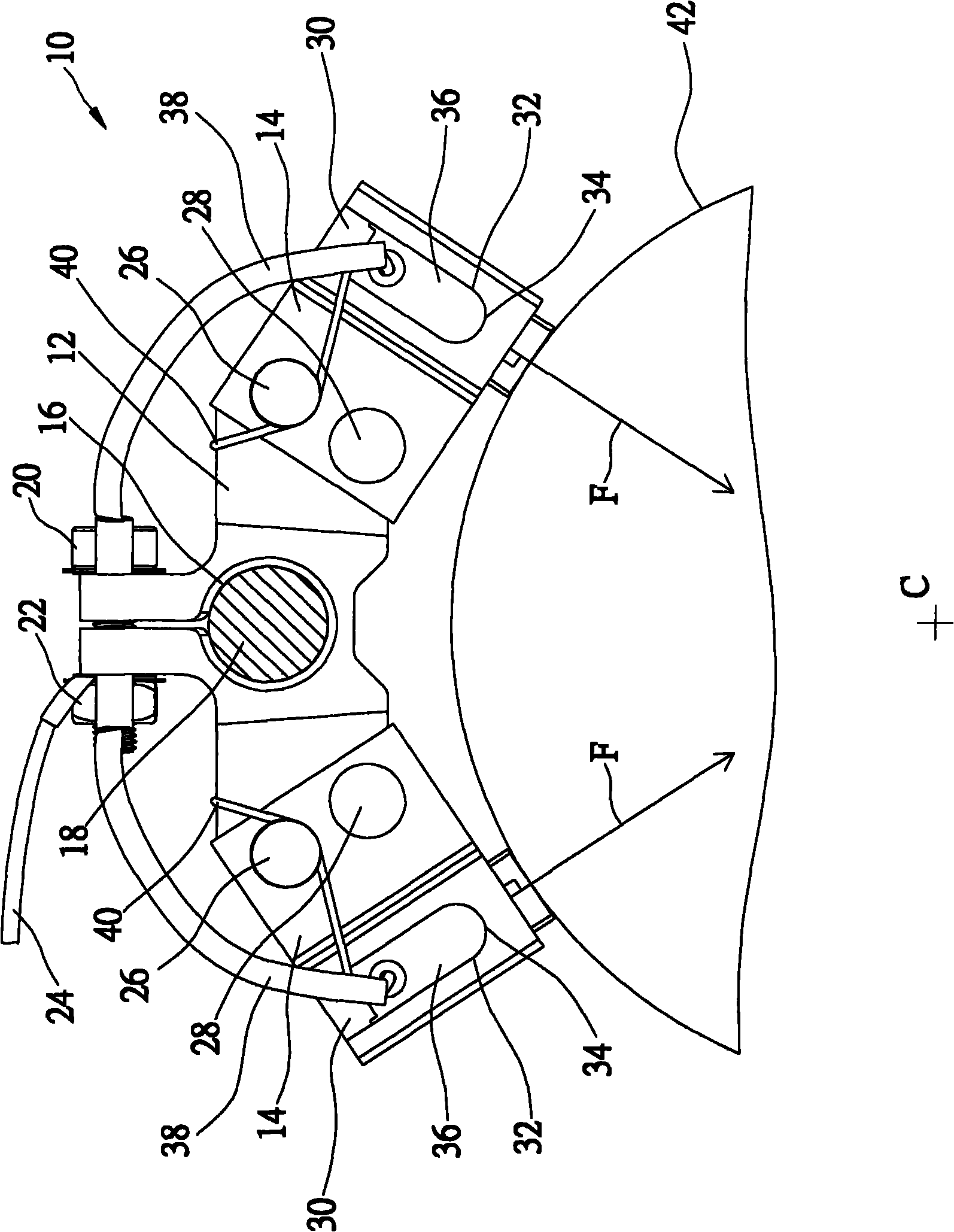

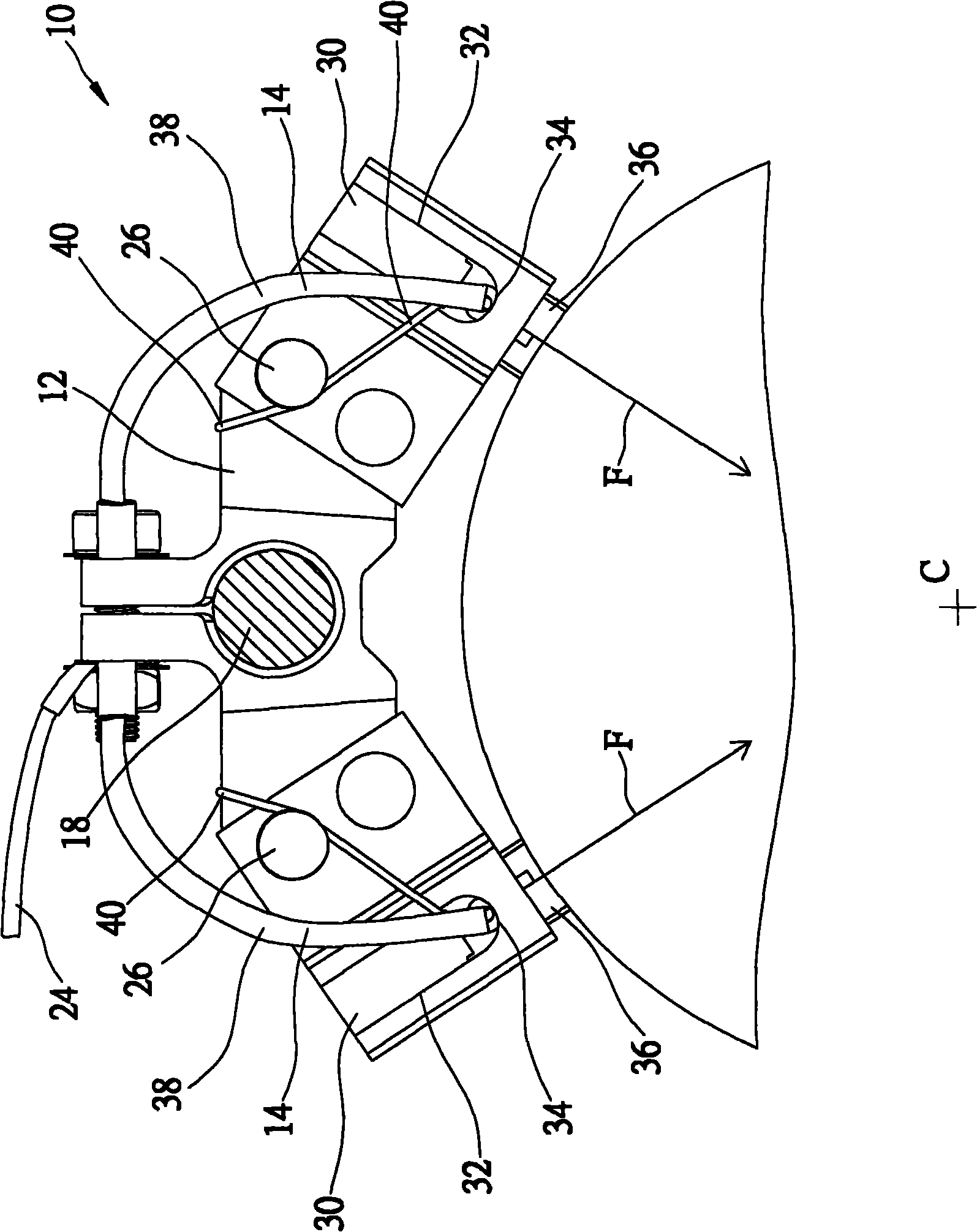

[0030] see figure 1 and figure 2 As shown, the carbon brush structure of the slip ring provided by a preferred embodiment of the present invention is mainly composed of a base 10 , two carbon brushes 36 and two biasing members.

[0031] The base 10 has a base 12 and two brackets 14 . The base 12 has a shaft hole 16 for passing through a rod 18 , and a bolt 20 and a nut 22 are used to fix the base 12 to a predetermined position of the slip ring. The bolt 20 and nut 22 hold a wire 24 for connection to an external circuit (not shown). The two brackets 14 are fixed on two sides of the base 12 by two rivets 26 and 28 respectively, and are skewed at a predetermined angle. Each bracket 14 has a guide rail 30 at its outer end. In this embodiment, the guide rail 30 is a rectangular pipe with open ends, and a guide groove 32 is defined on the side wall of the pipe 30 . The guide groove 32 starts from the outer end of the pipe 30 and extends inward about 3 / 4 of the length of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com