Patents

Literature

4232 results about "Slip ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting power or signals. It can improve mechanical performance, simplify system operation and eliminate damage-prone wires dangling from movable joints.

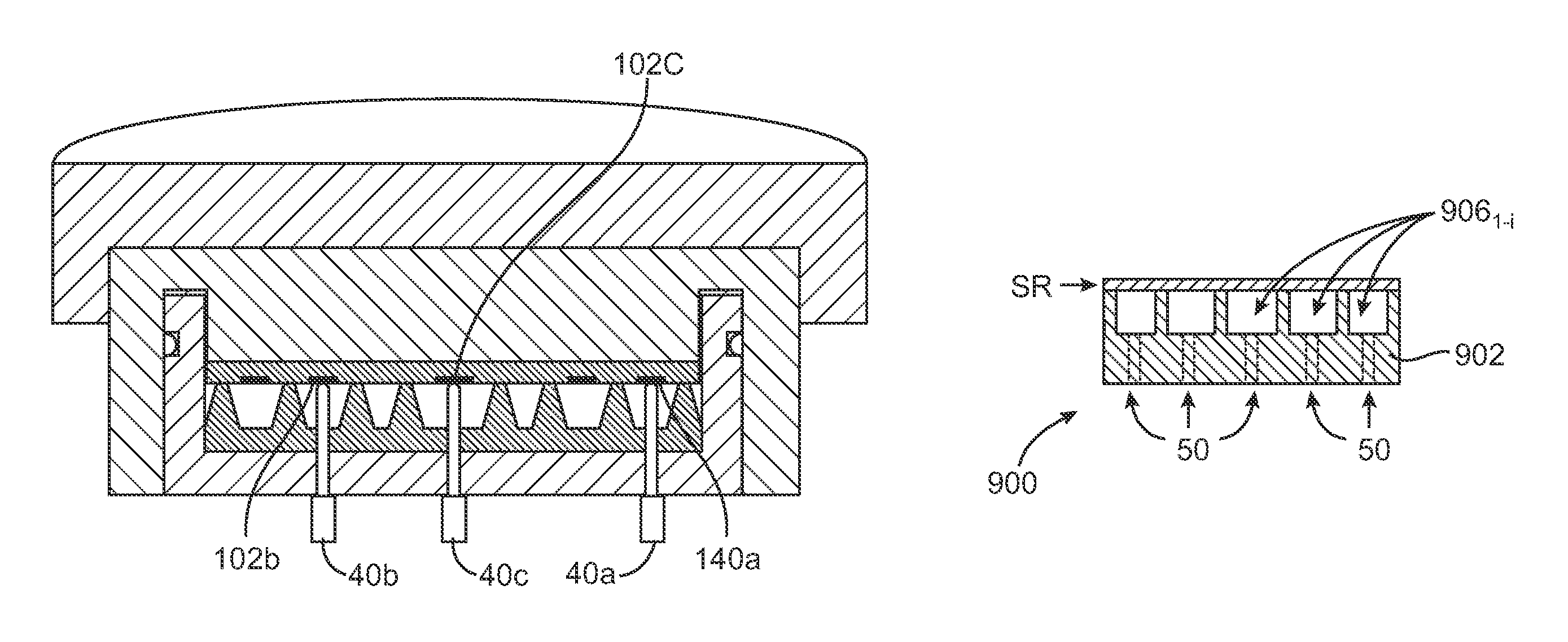

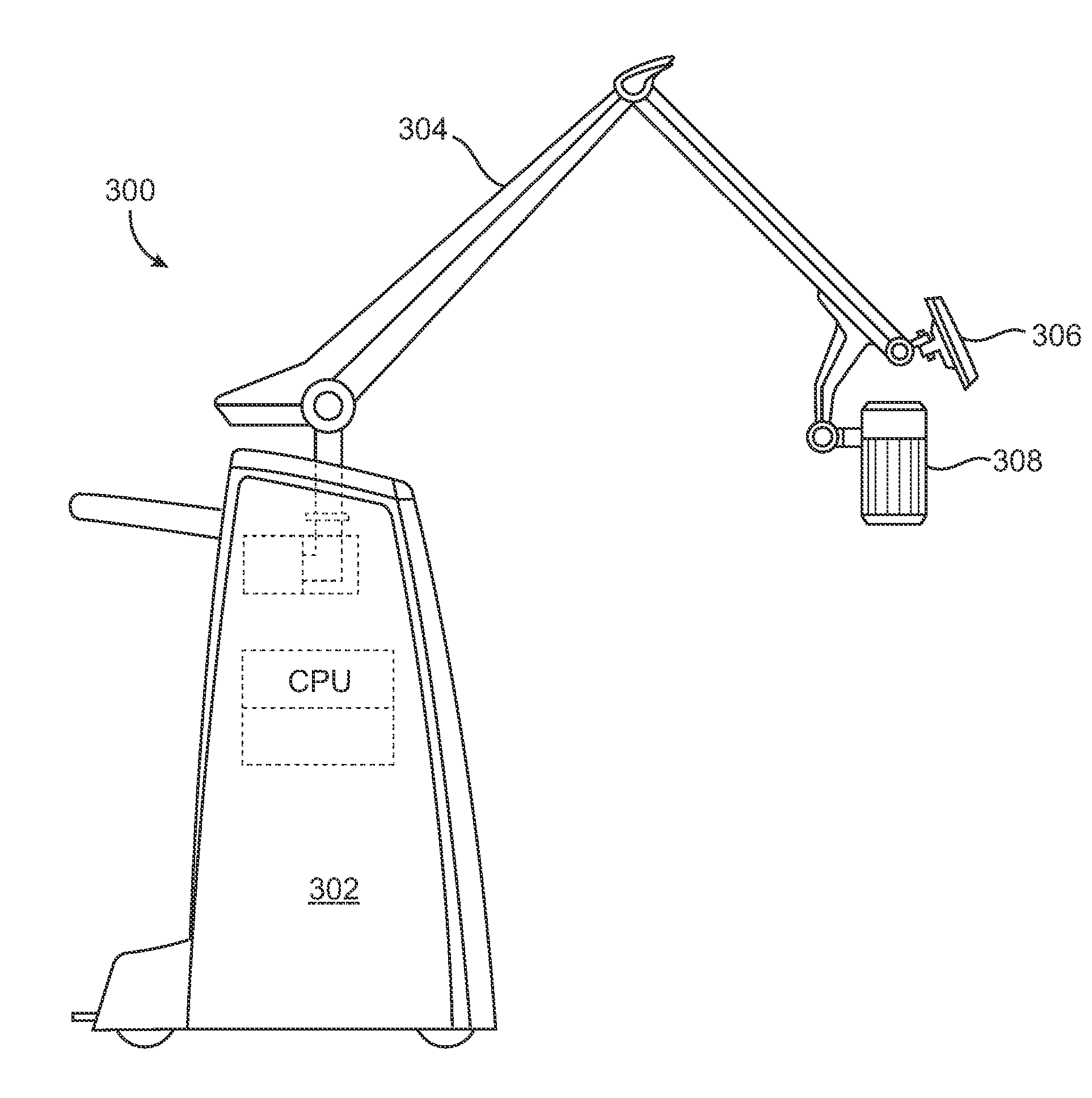

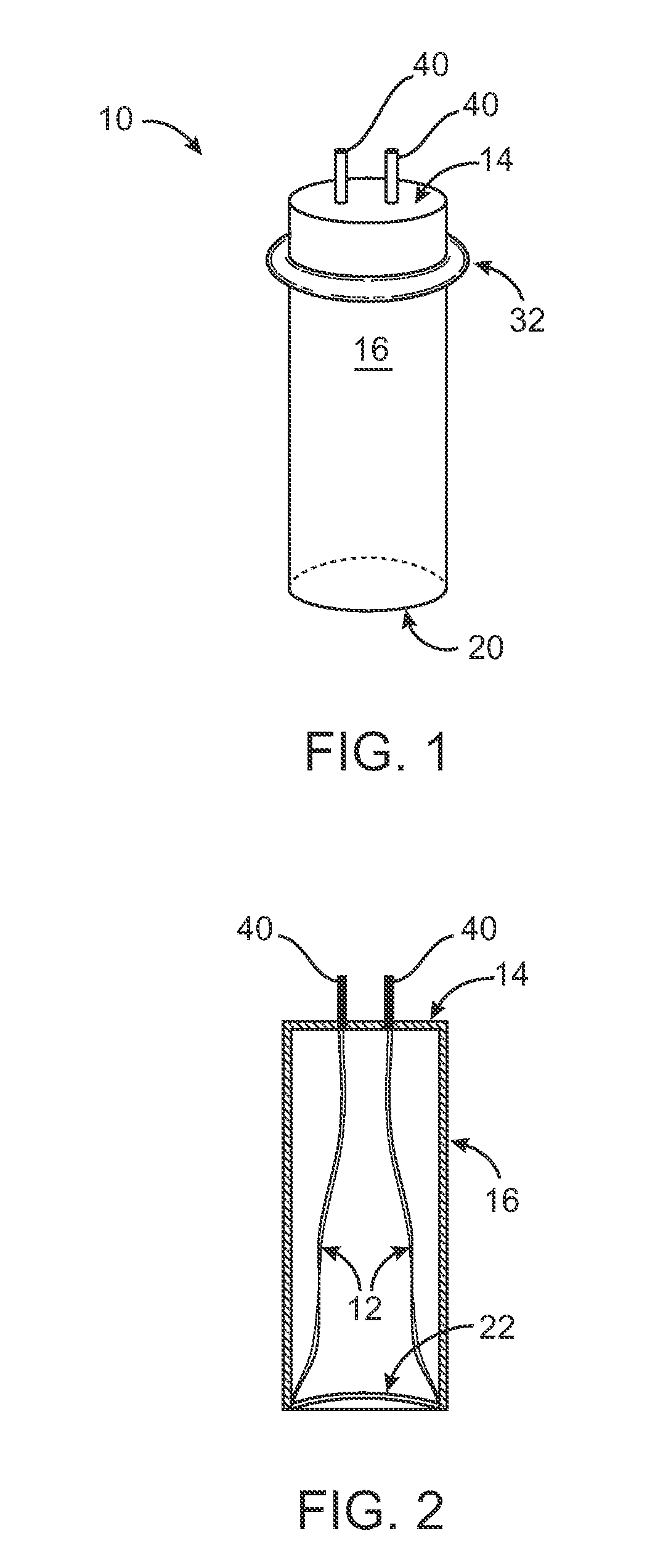

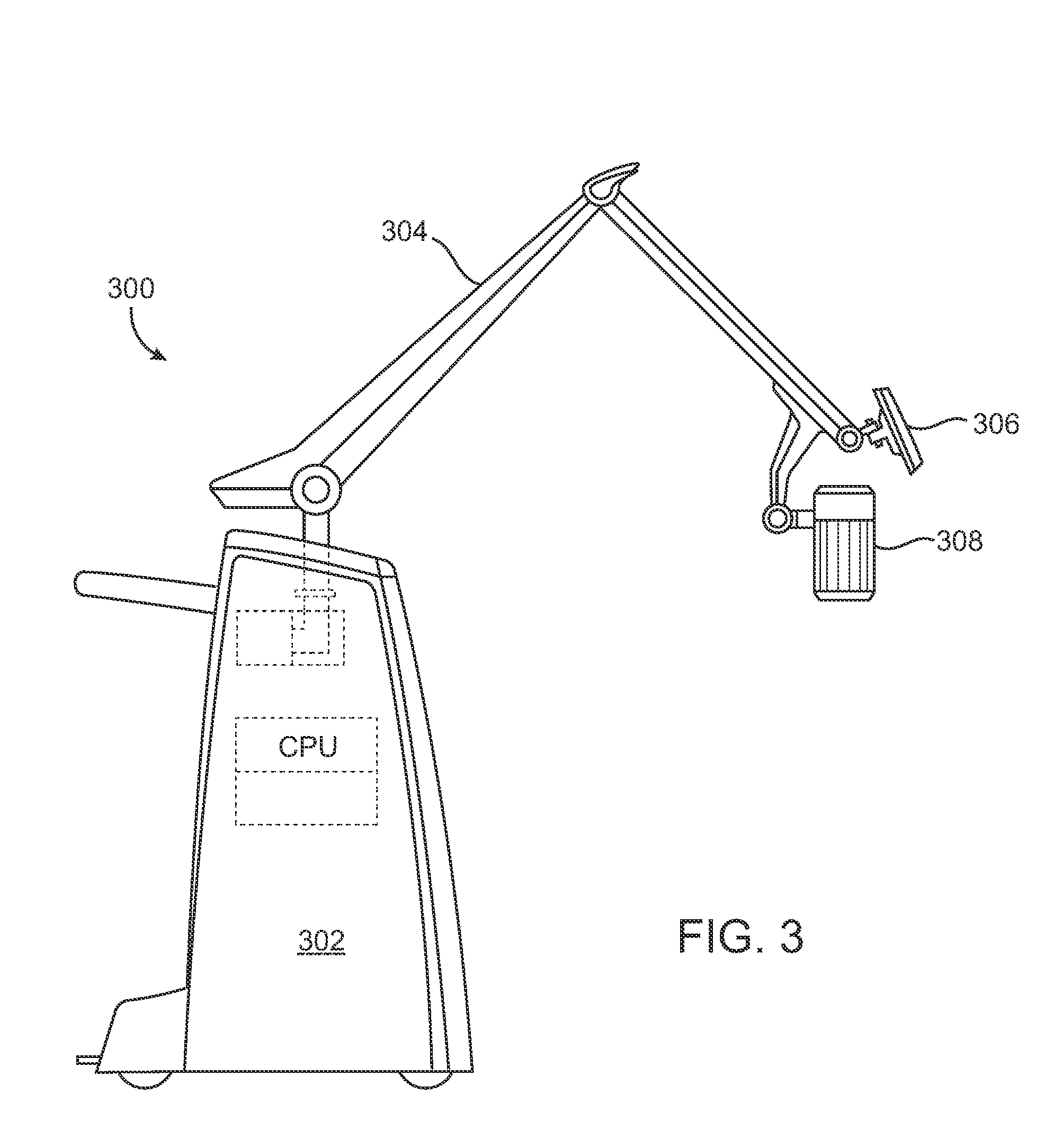

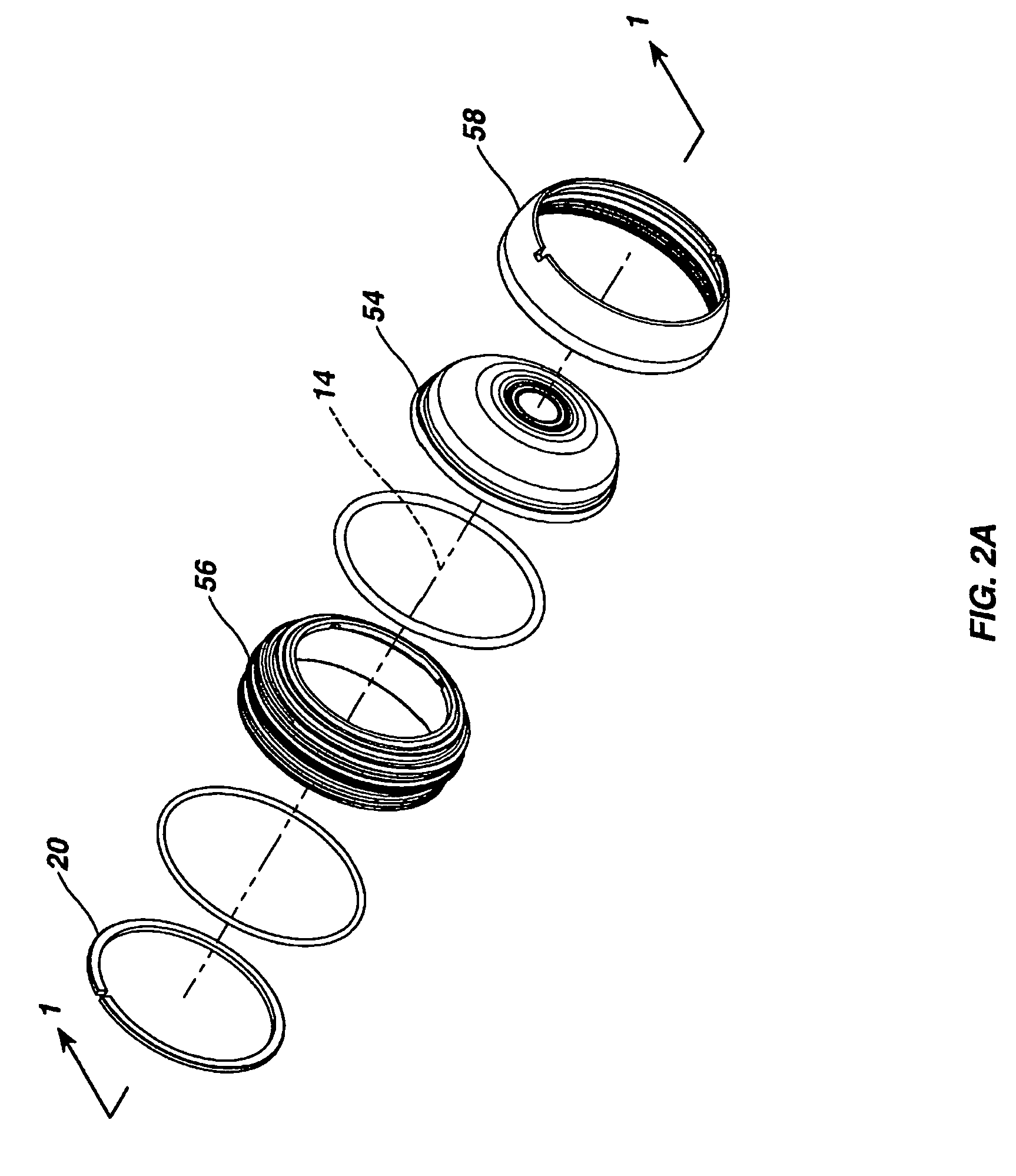

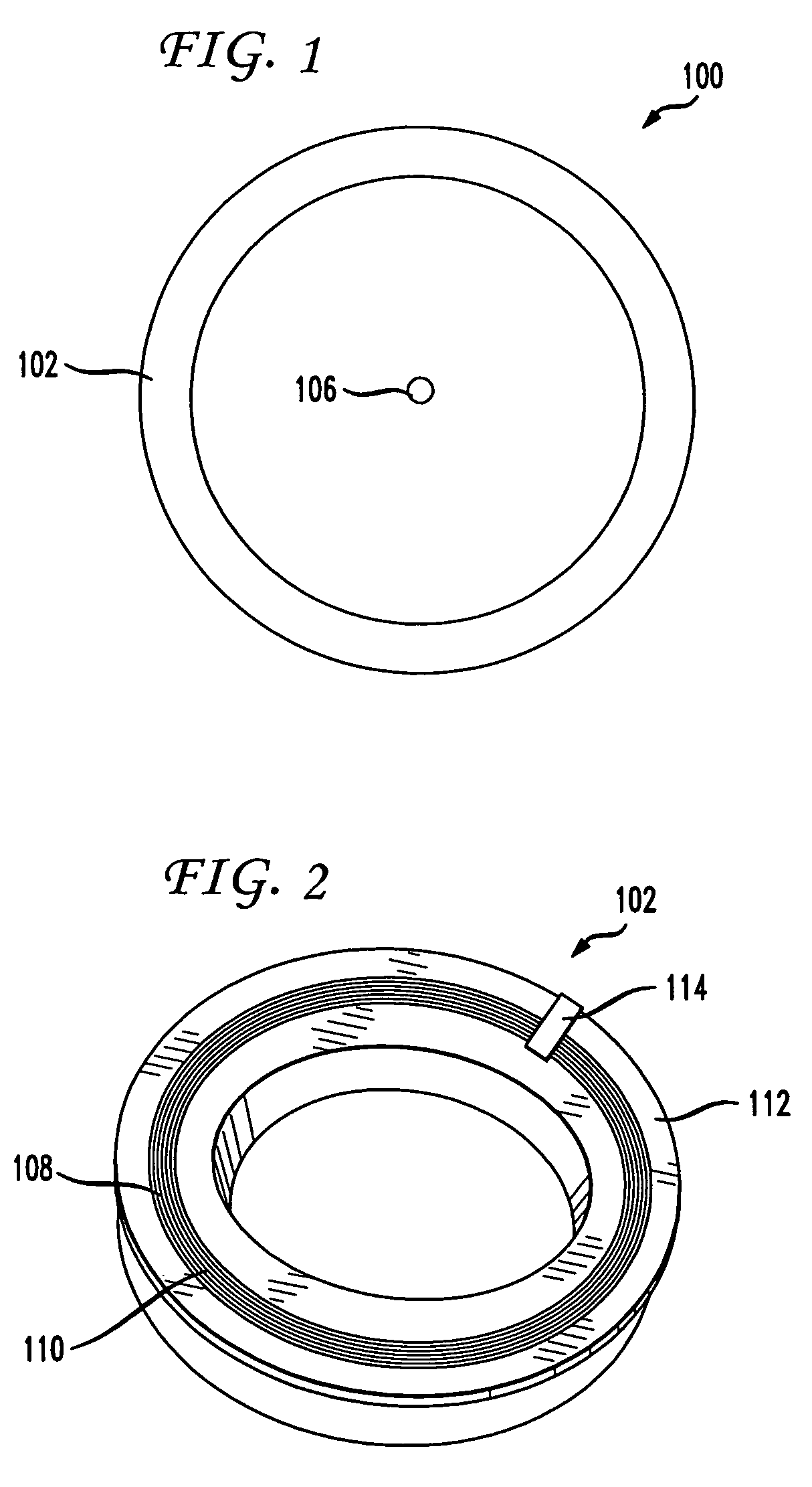

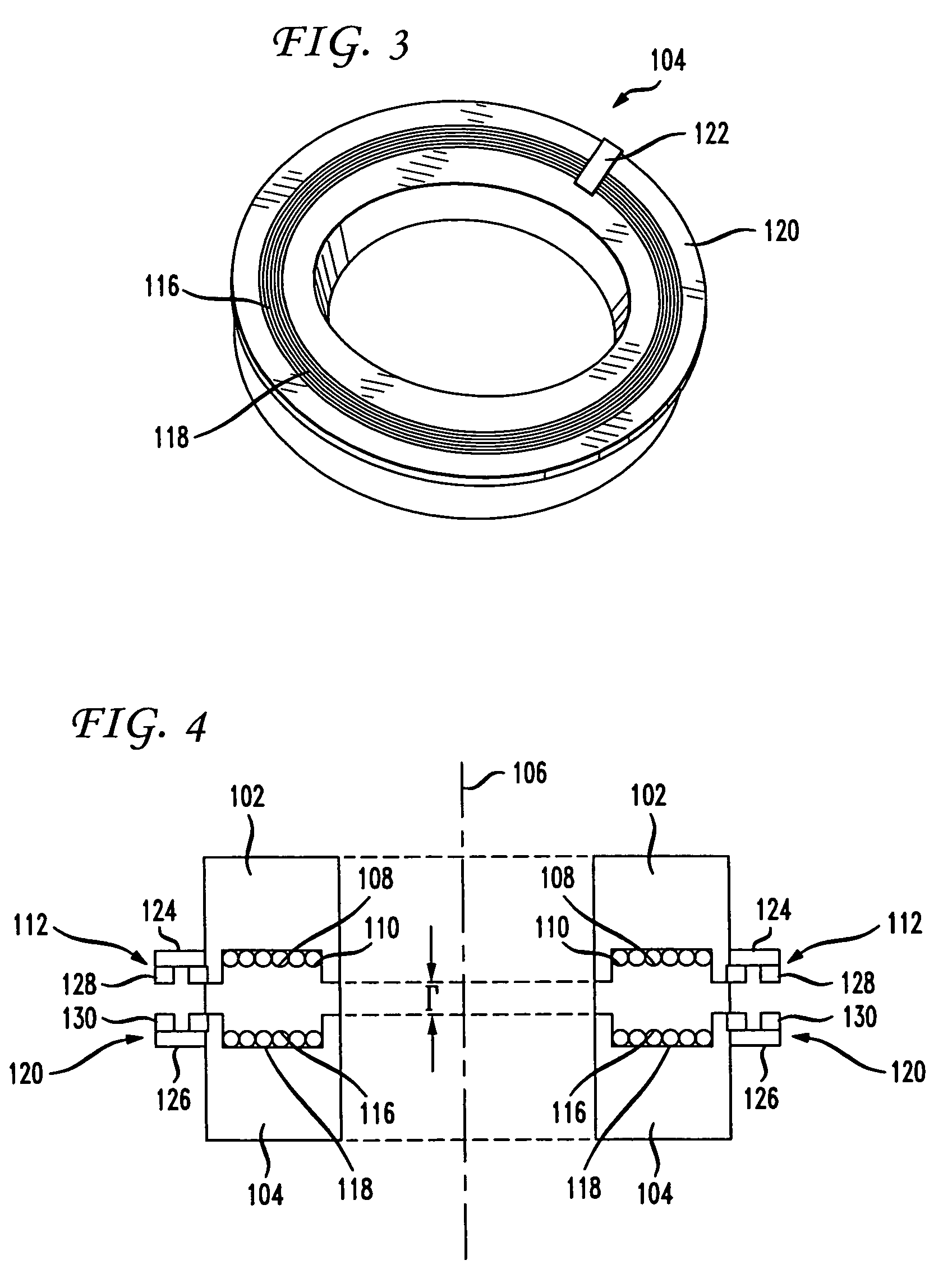

Slip ring spacer and method for its use

ActiveUS8142200B2Easy extractionEasy to insertUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorTransducer

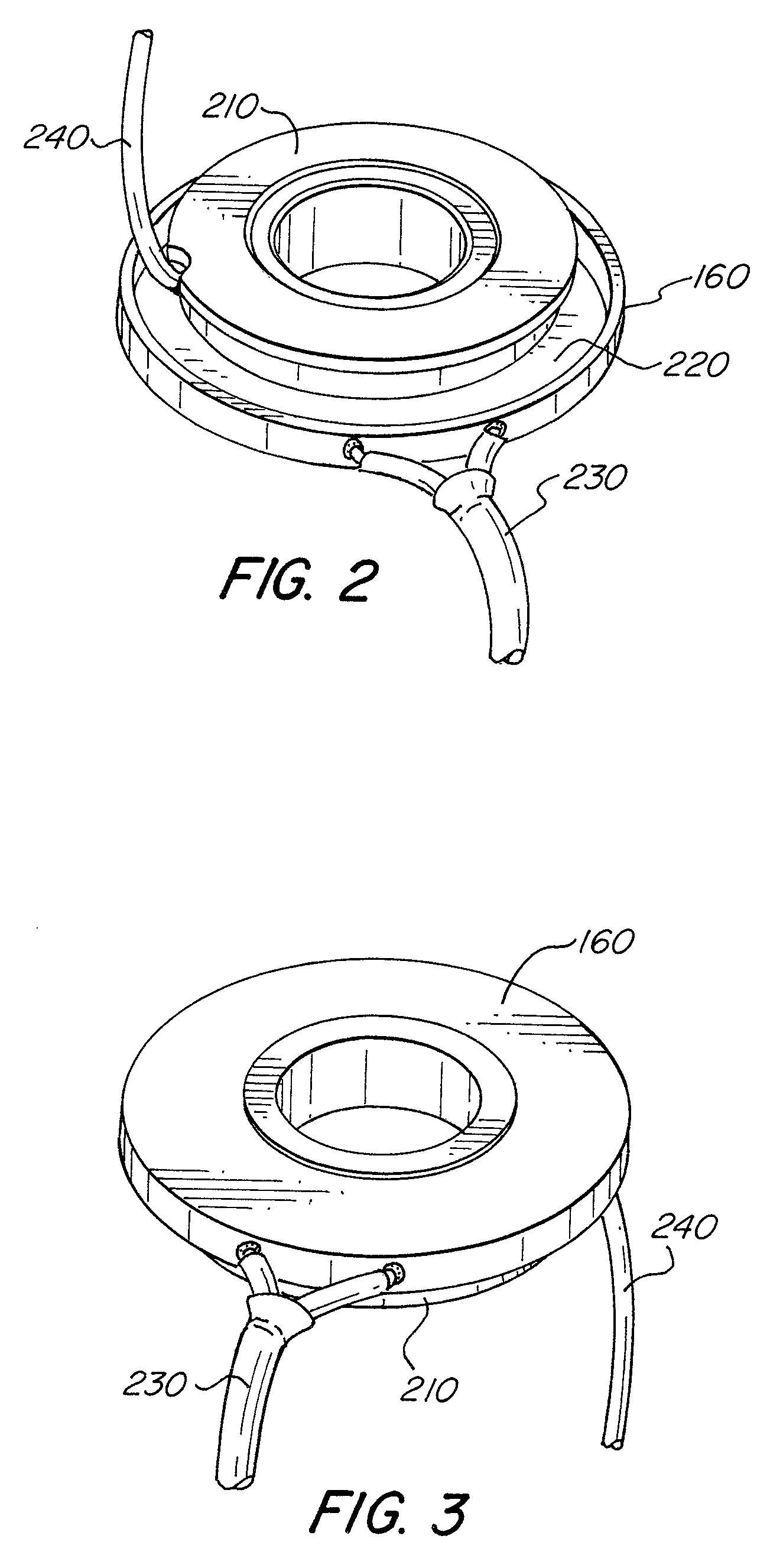

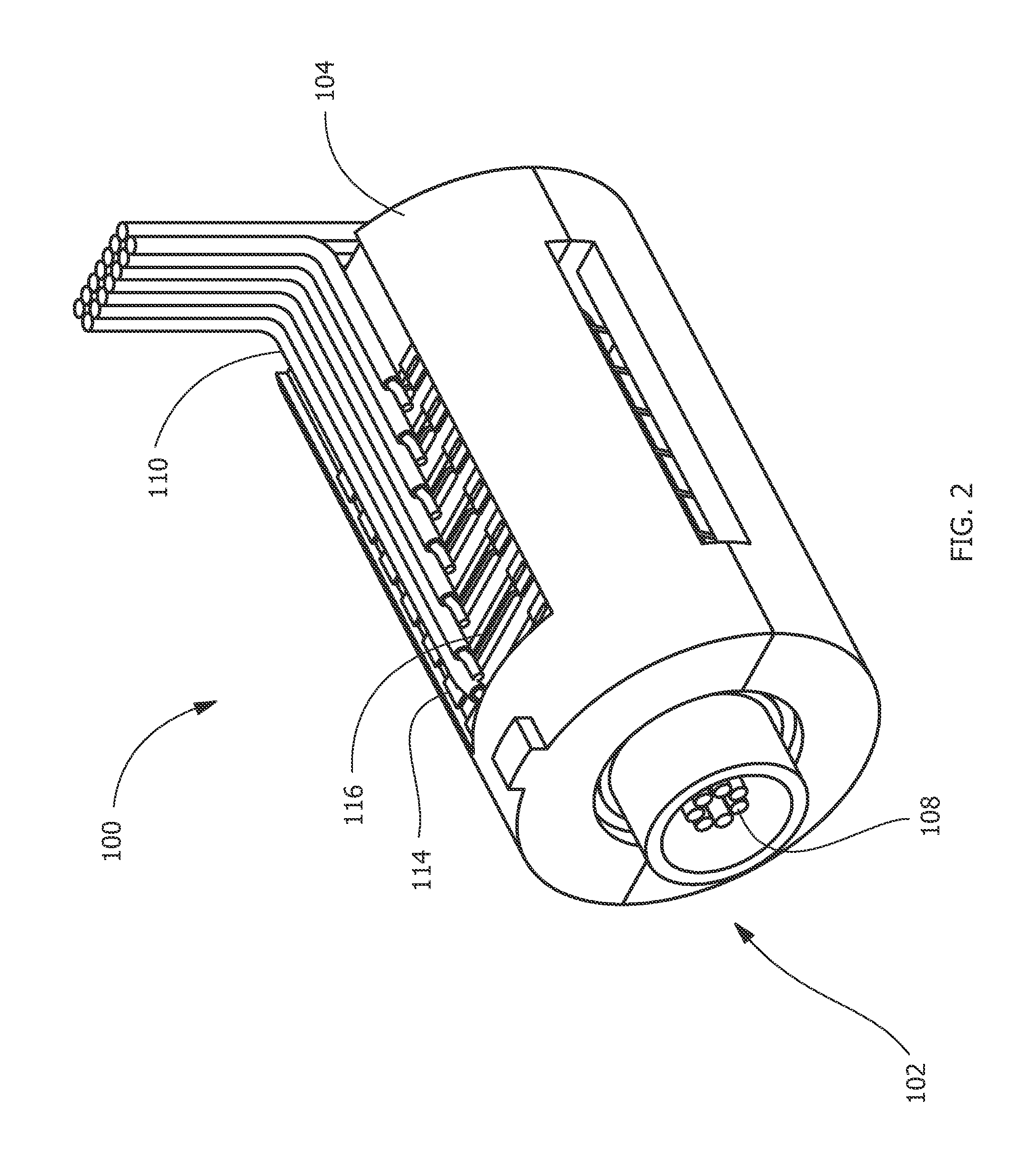

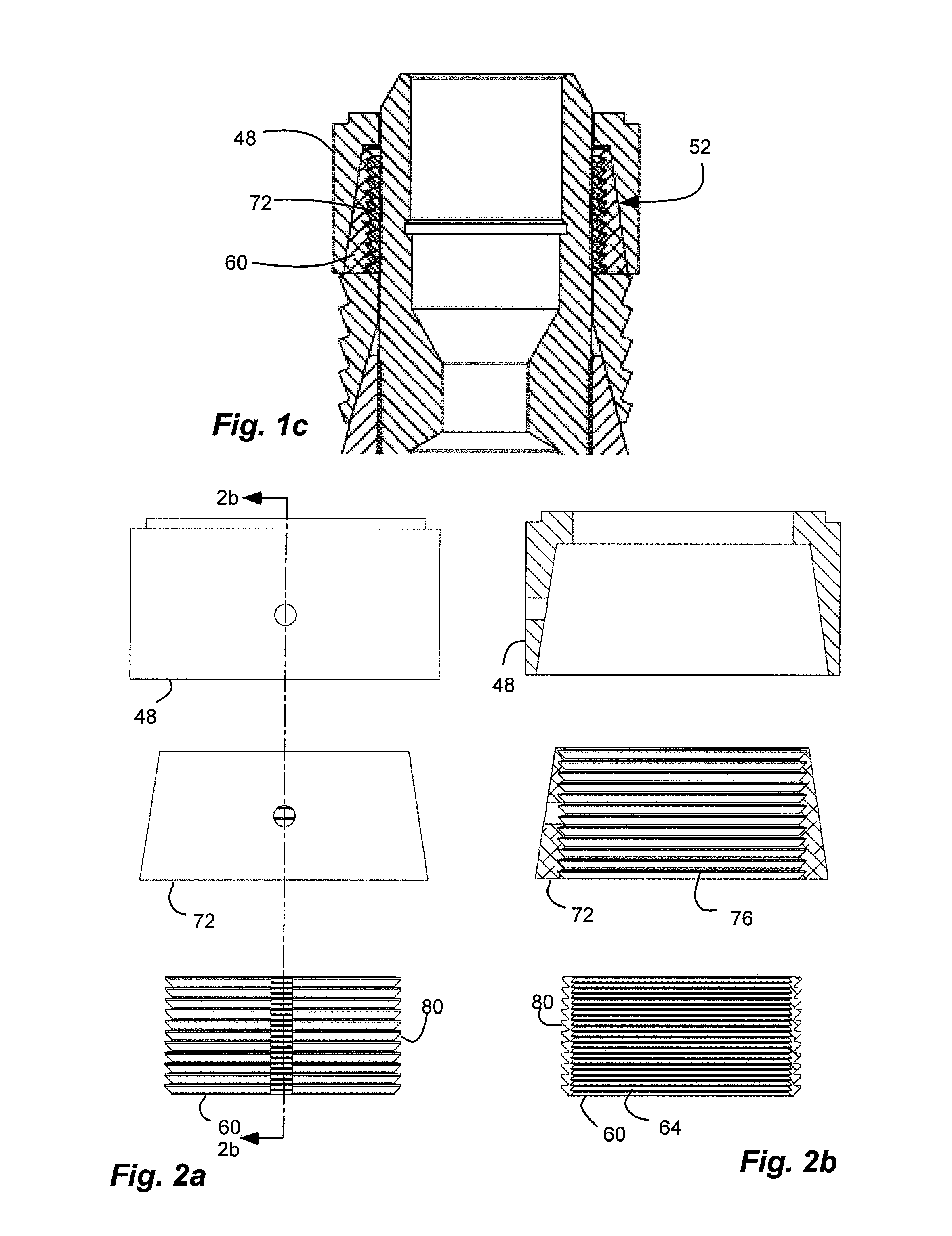

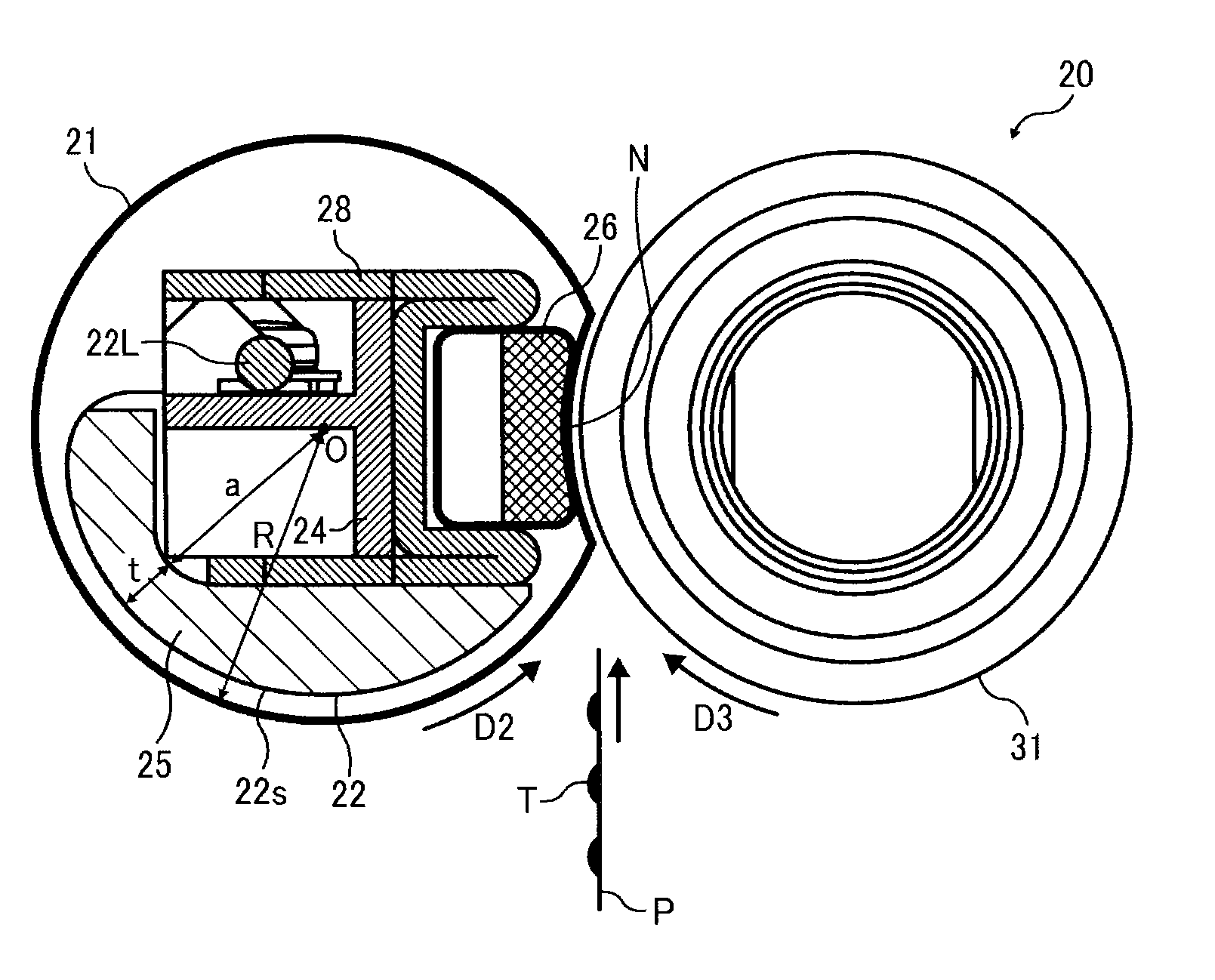

An interchangeable transducer for use with an ultrasound medical system having a keyless adaptor and capable of operating in a wet environment. The interchangeable transducer has an adaptor for engaging a medical system, an ultrasound transducer and additional electronics to provide a self-contained insert for easy replacement and usage in a variety of medical applications. A slip ring spacer is also disclosed, the slip ring spacer for use with a pancake slip ring having a base and flange configuration to form one or more channels around each contact ring of the pancake slip ring. The channels provide fluid isolation around each connector to help reduce electronic cross talk and contact corrosion between the connector pads of the slip ring while the slip ring is immersed in a wet environment.

Owner:SOLTA MEDICAL

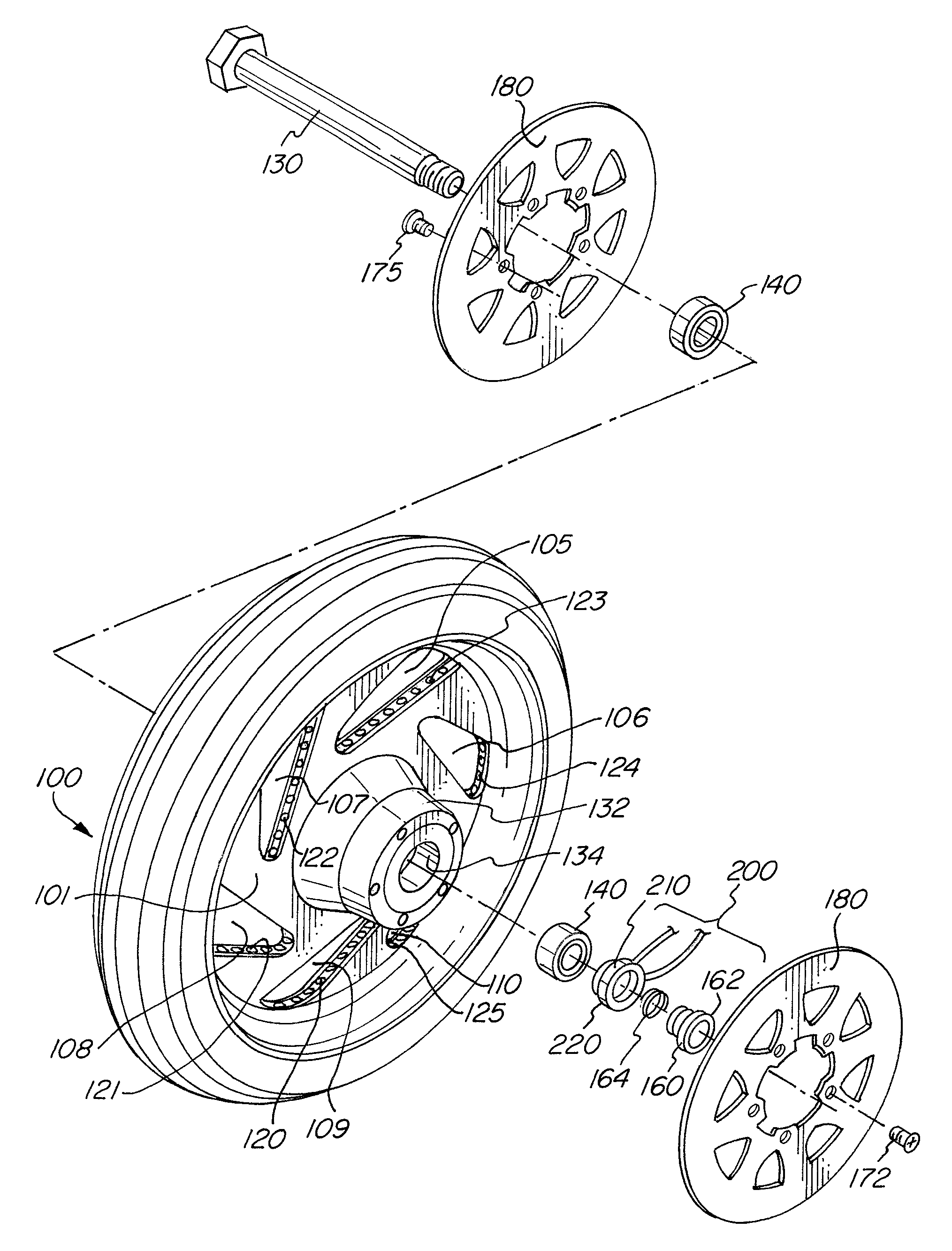

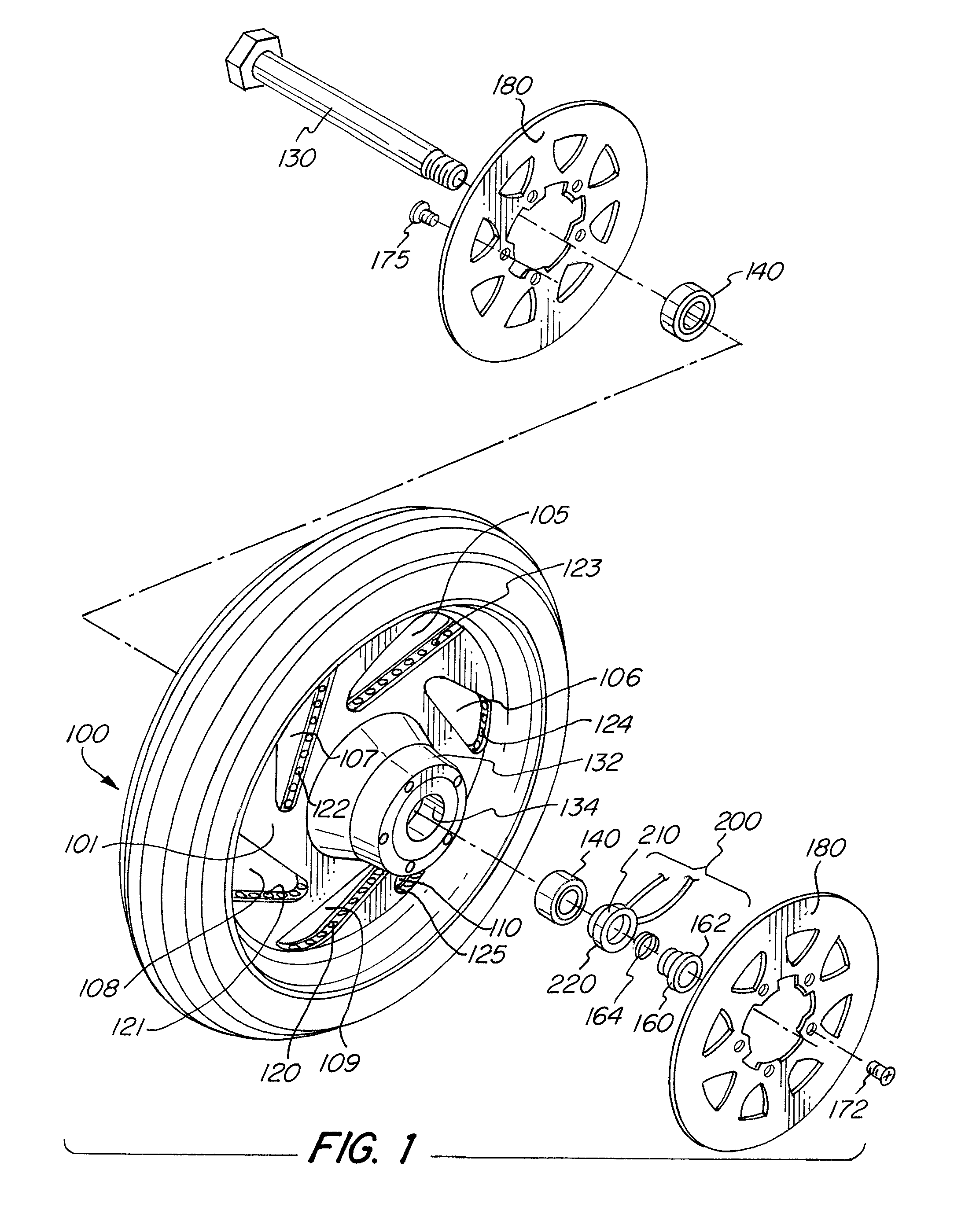

Illuminated vehicle wheel with bearing seal slip ring assembly

InactiveUS8322901B2Luminance providedEasy to replaceRotary current collectorLighting support devicesLight-emitting diodeElectrical element

Owner:MICHELOTTI WILLIAM M

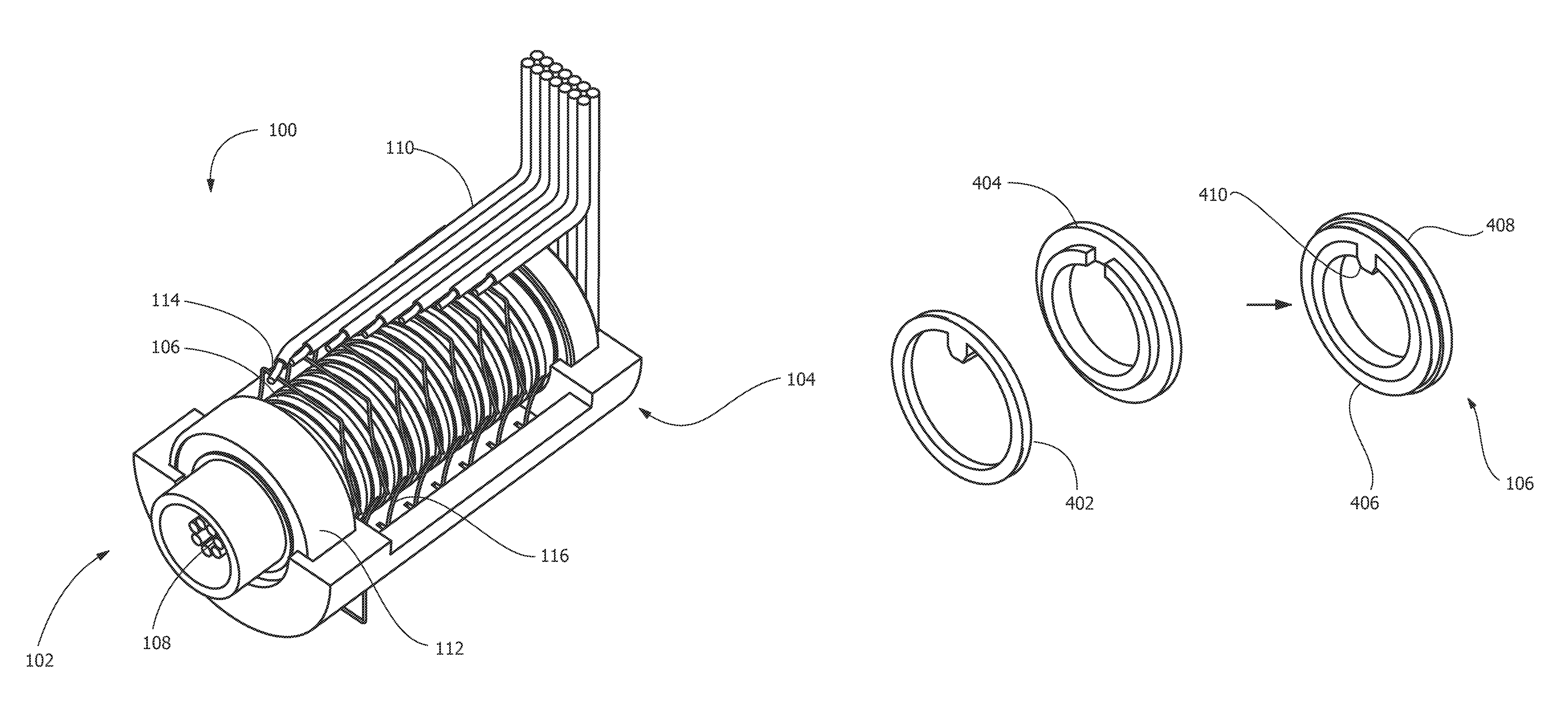

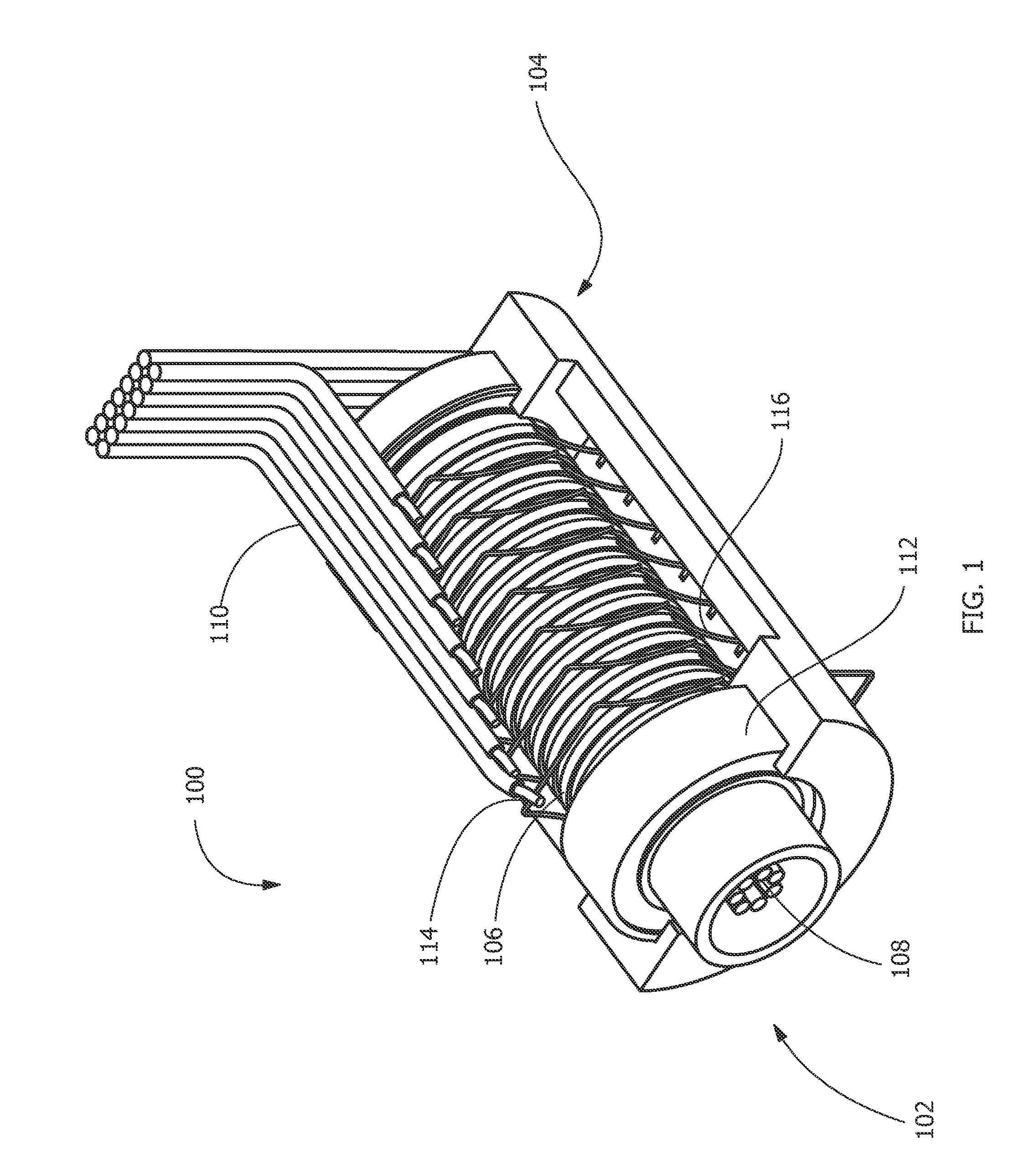

Method of fabricating a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

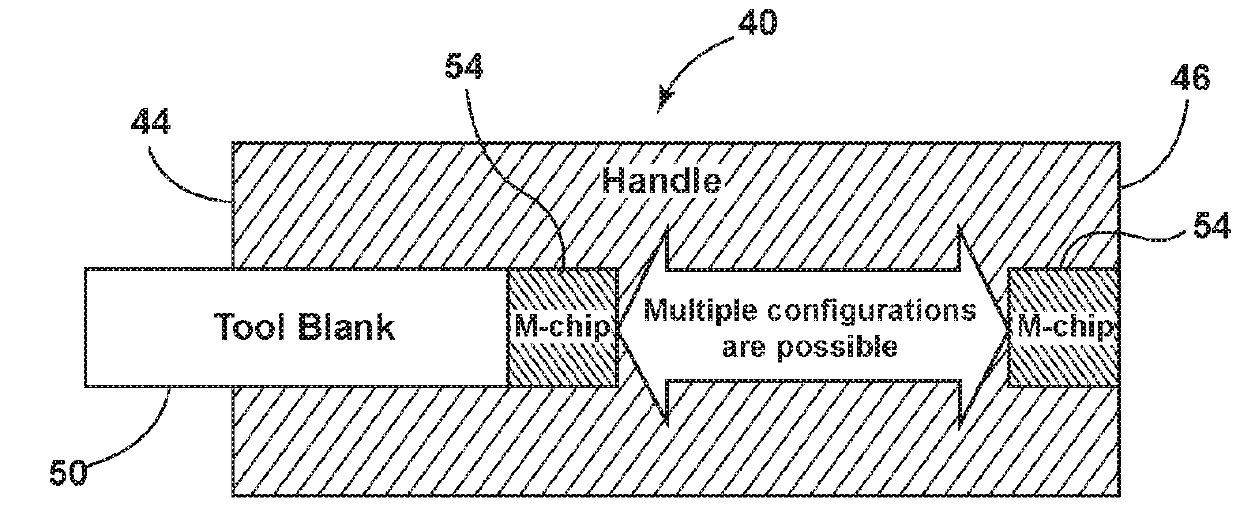

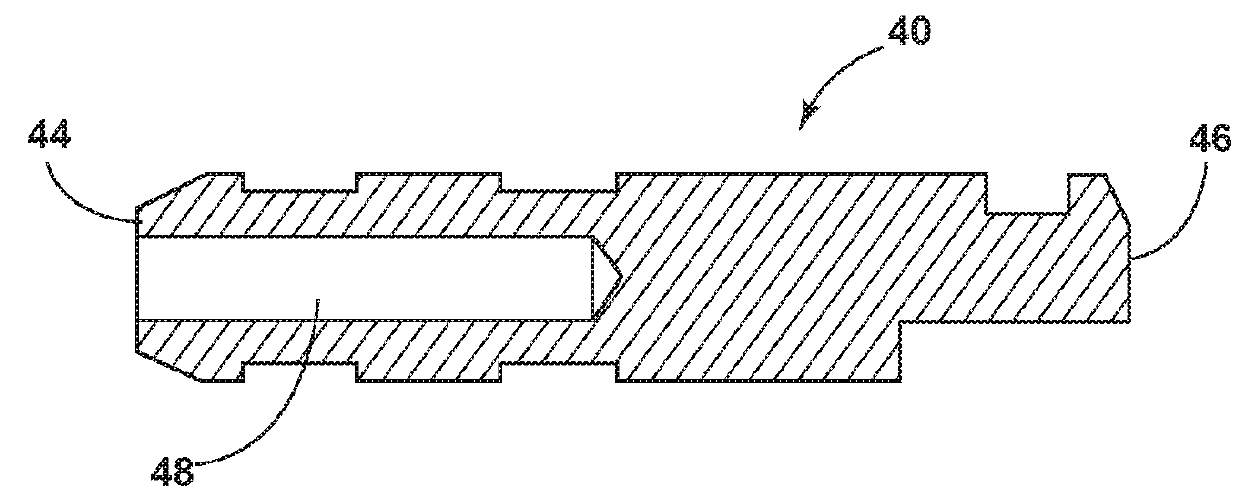

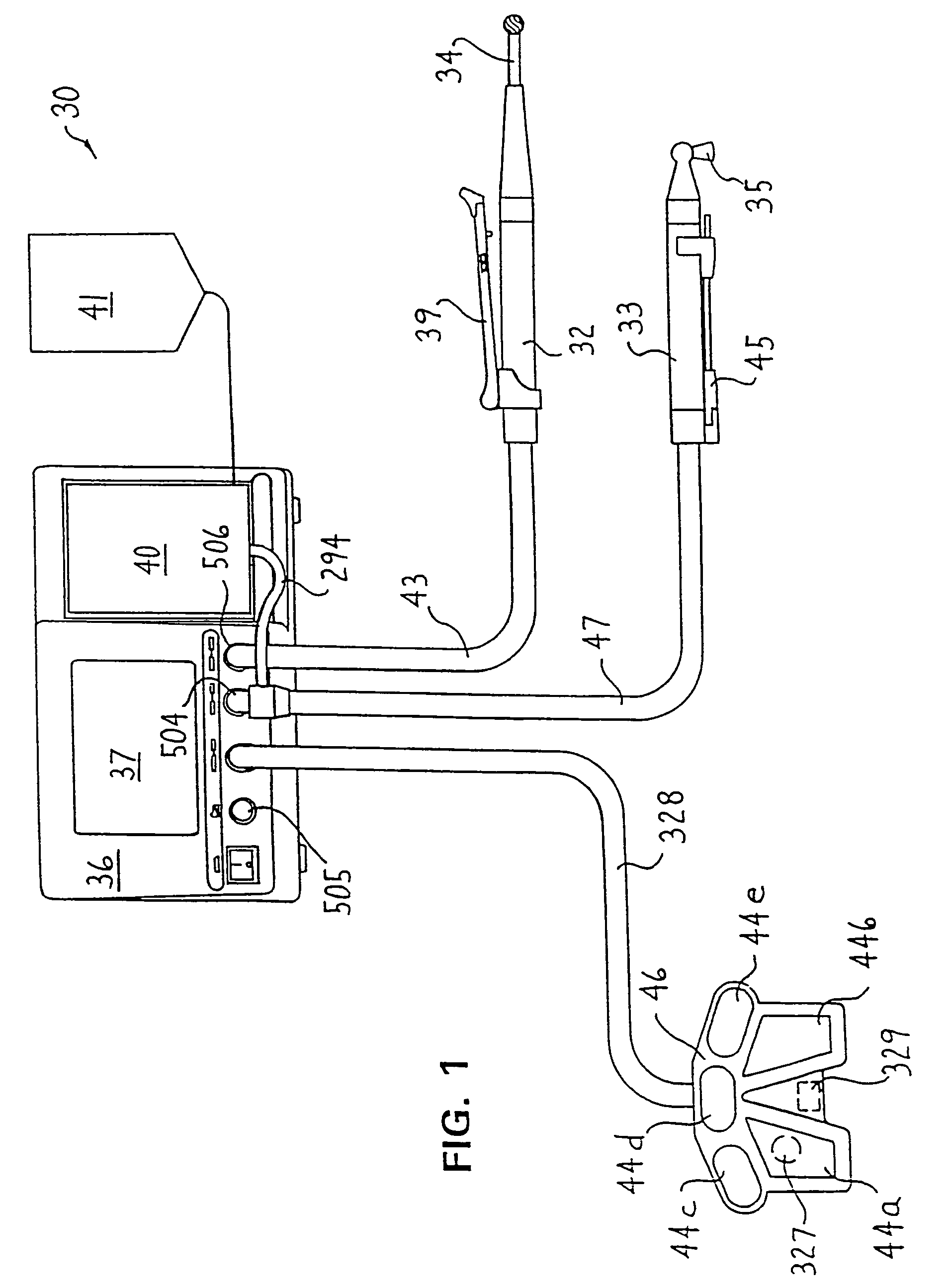

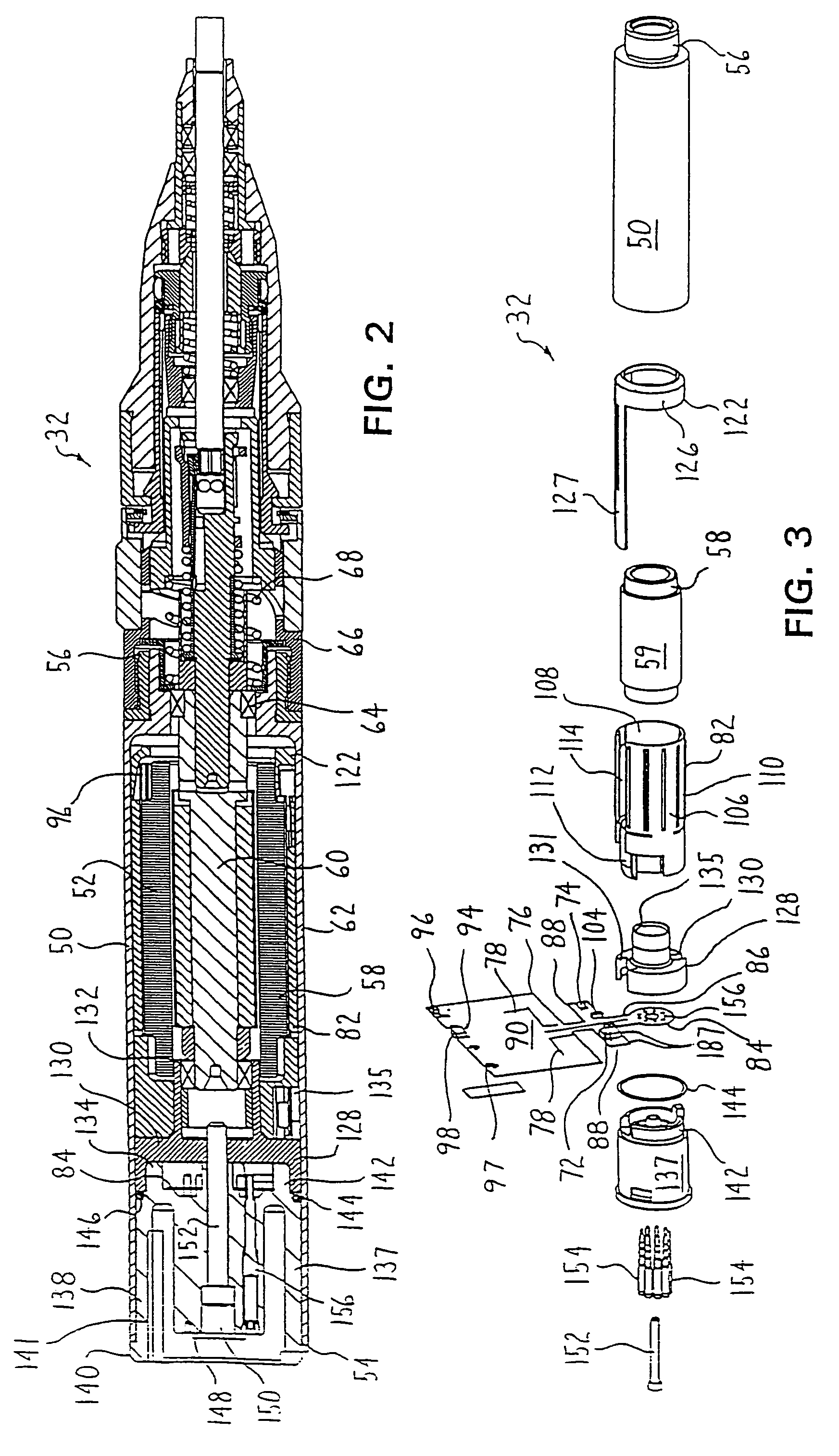

Electronic tool recognition system for dental devices

A tool for use with an electronic tool recognition system includes a tool blank with a distal tip configured for performing a procedure and a proximal handle encasing, fixedly, a proximal end of the tool blank. A tool-identifying apparatus including a mechanical resonator is embedded in a proximal end of the tool blank to provide a tool identifier. A conductive wire in electrical contact with the resonator provides the identifier to a processor. In another arrangement, conductive brushes in contact with slip rings provide the identifier to a processor. In another arrangement, a dental tool handle includes an insulating portion defining a recess in a proximal end of the handle configured to receive either a sensor or an information-managing chip.

Owner:THE KERR

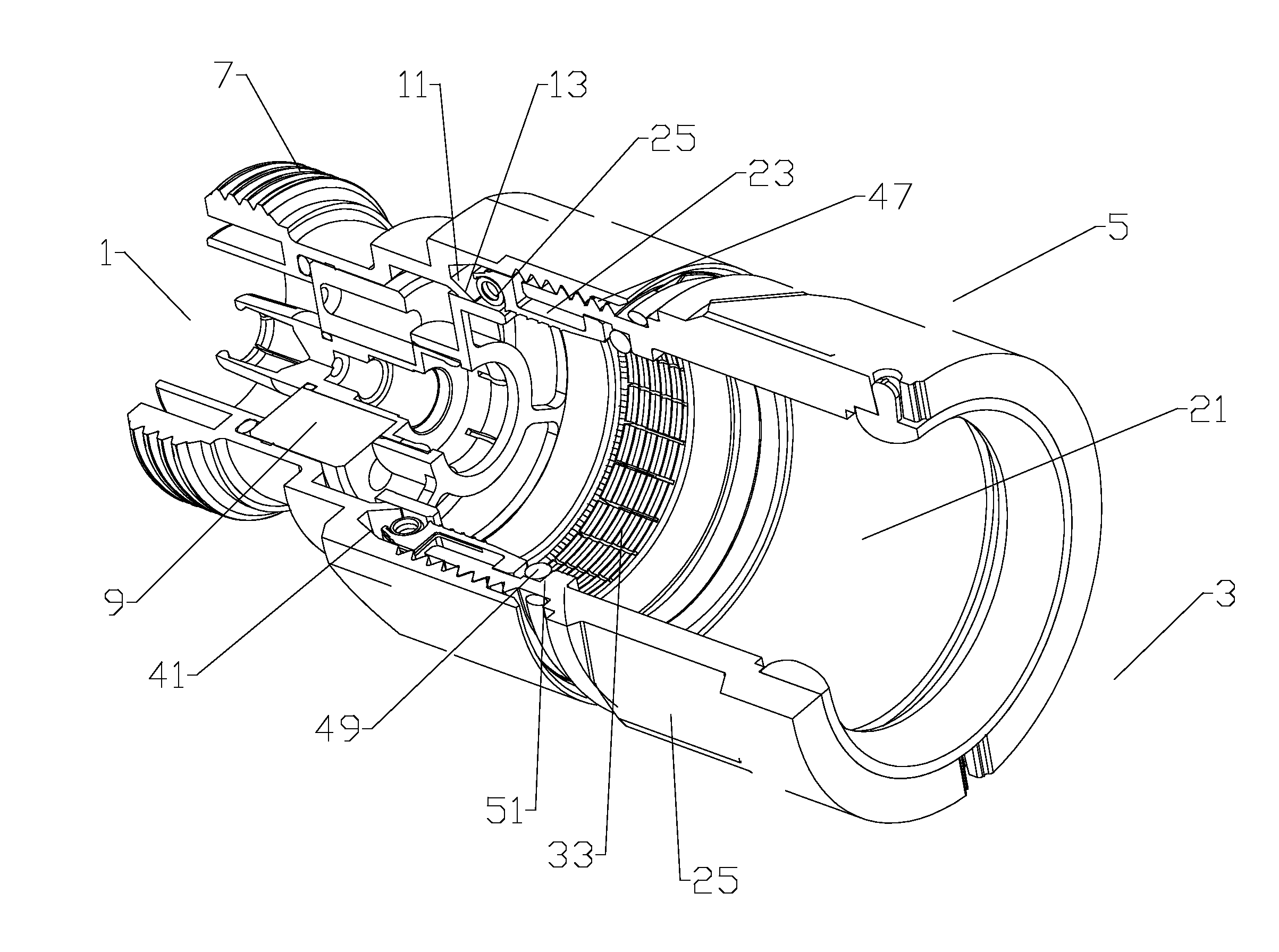

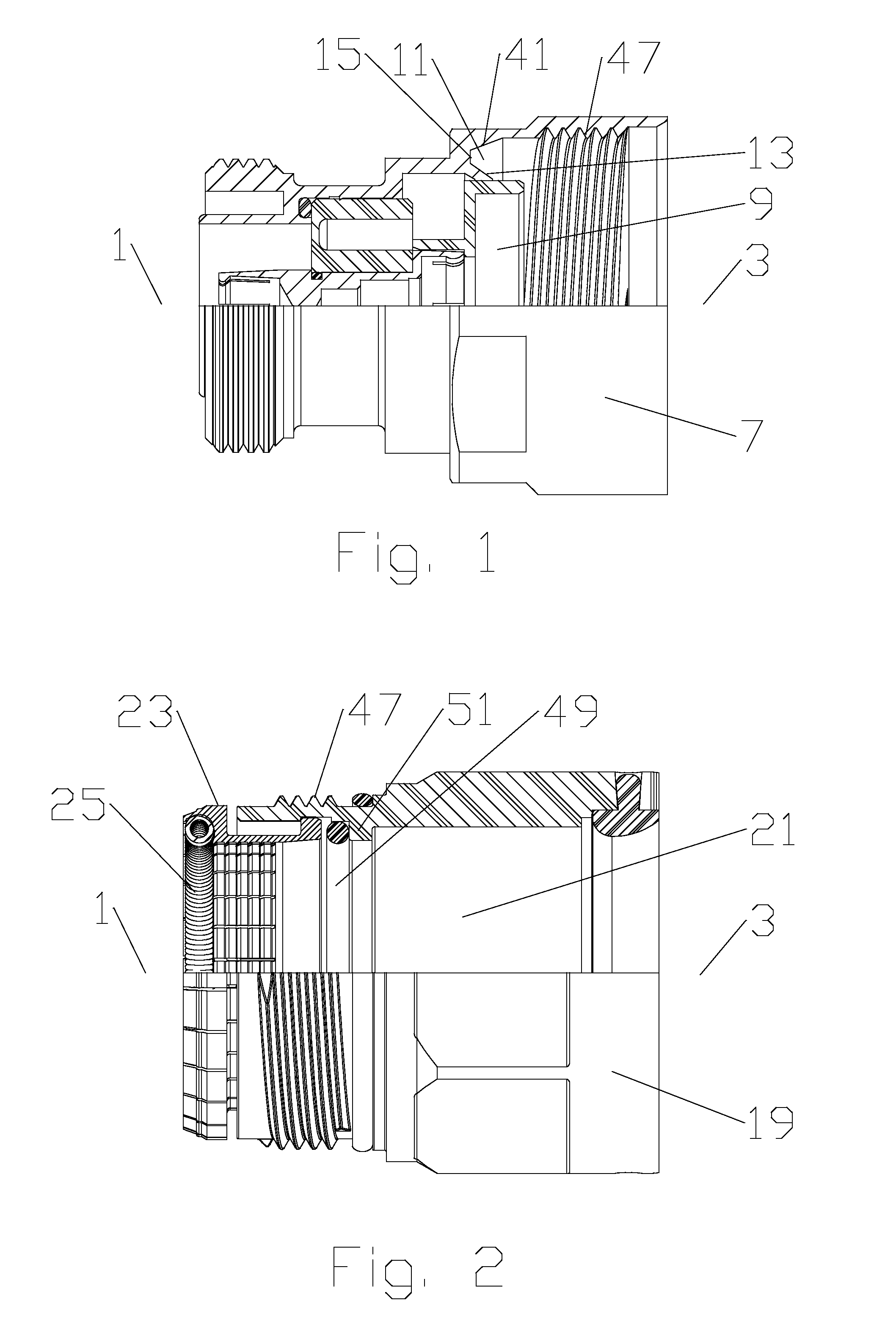

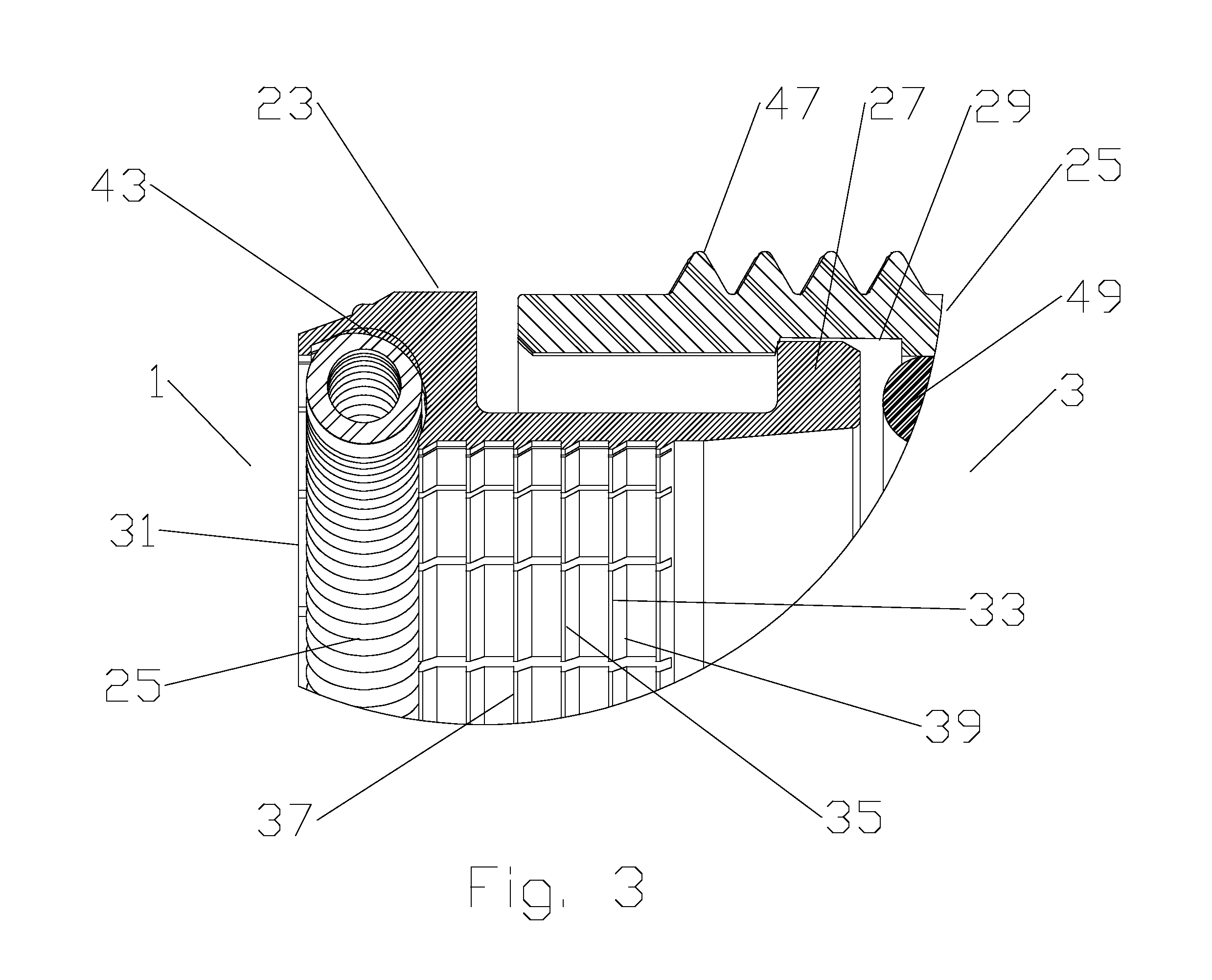

Clamp and Grip Coaxial Connector

ActiveUS20120064764A1Simple structureReduce the overall diameterElectrically conductive connectionsTwo pole connectionsLeading edgeElectrical conductor

A coaxial connector with a connector body is provided with a connector body bore. An annular coupling groove is provided in the connector body bore open to a cable end of the connector body. A clamp sidewall of the coupling grove is angled inward from a bottom of the coupling groove. A slip ring seated within the coupling body bore is provided with a grip surface. An annular compression body is positioned between the slip ring and the clamp sidewall. The connector body and the coupling body are coupled together via threads. The slip ring is dimensioned for axial advance of the coupling body along the threads to exert a compression force against the compression body to clamp a leading edge of the outer conductor between the compression body and the clamp sidewall.

Owner:COMMSCOPE TECH LLC

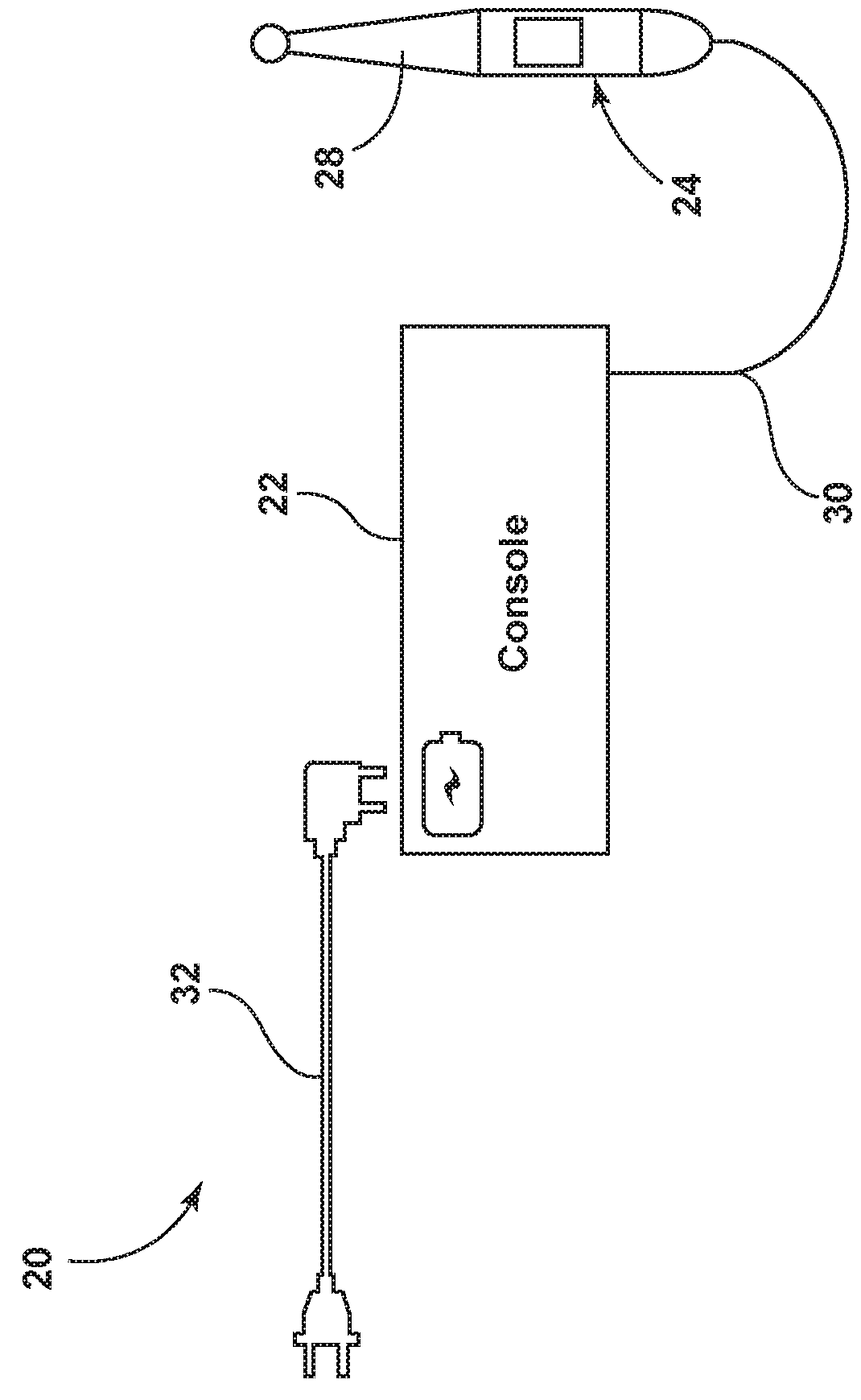

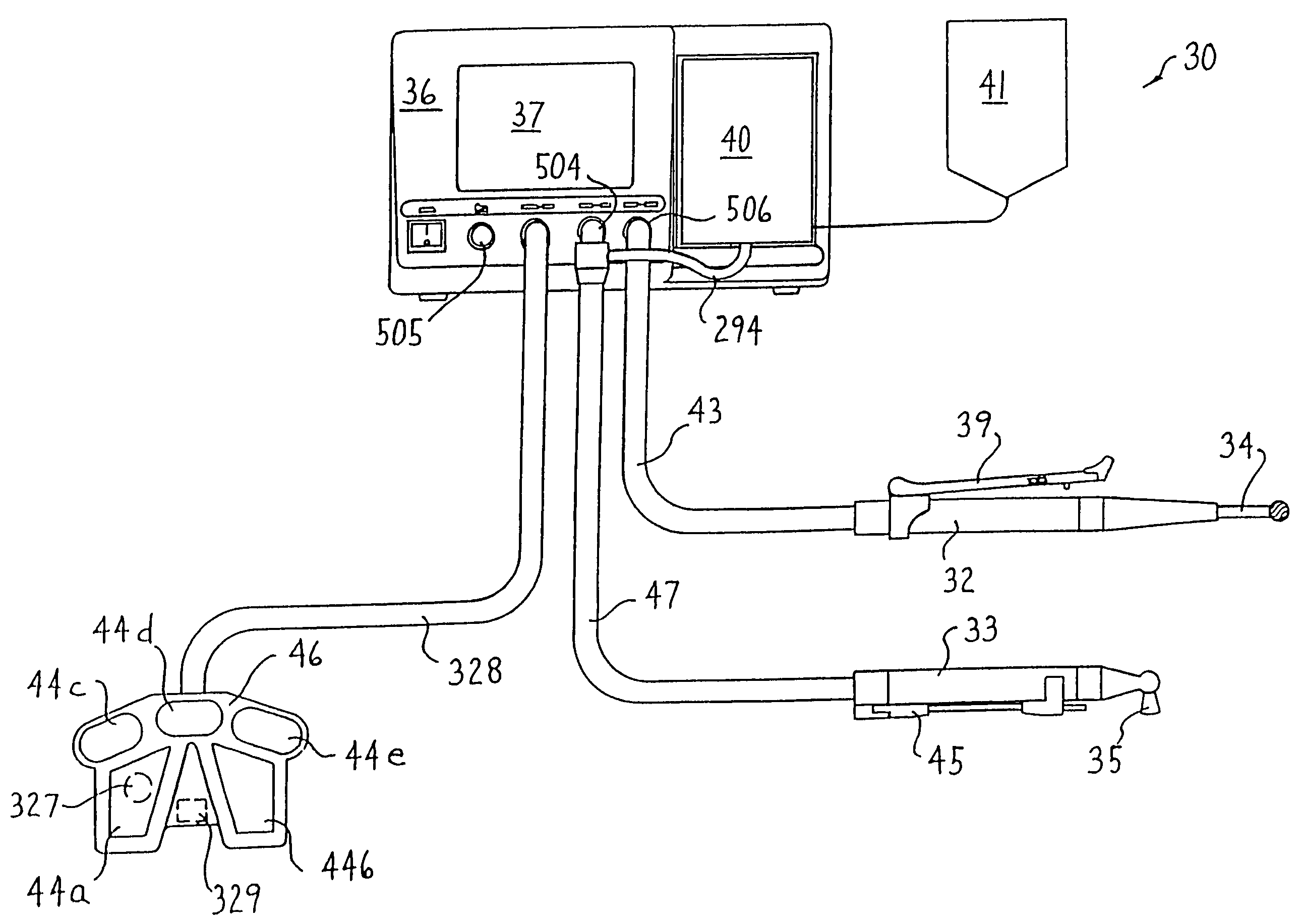

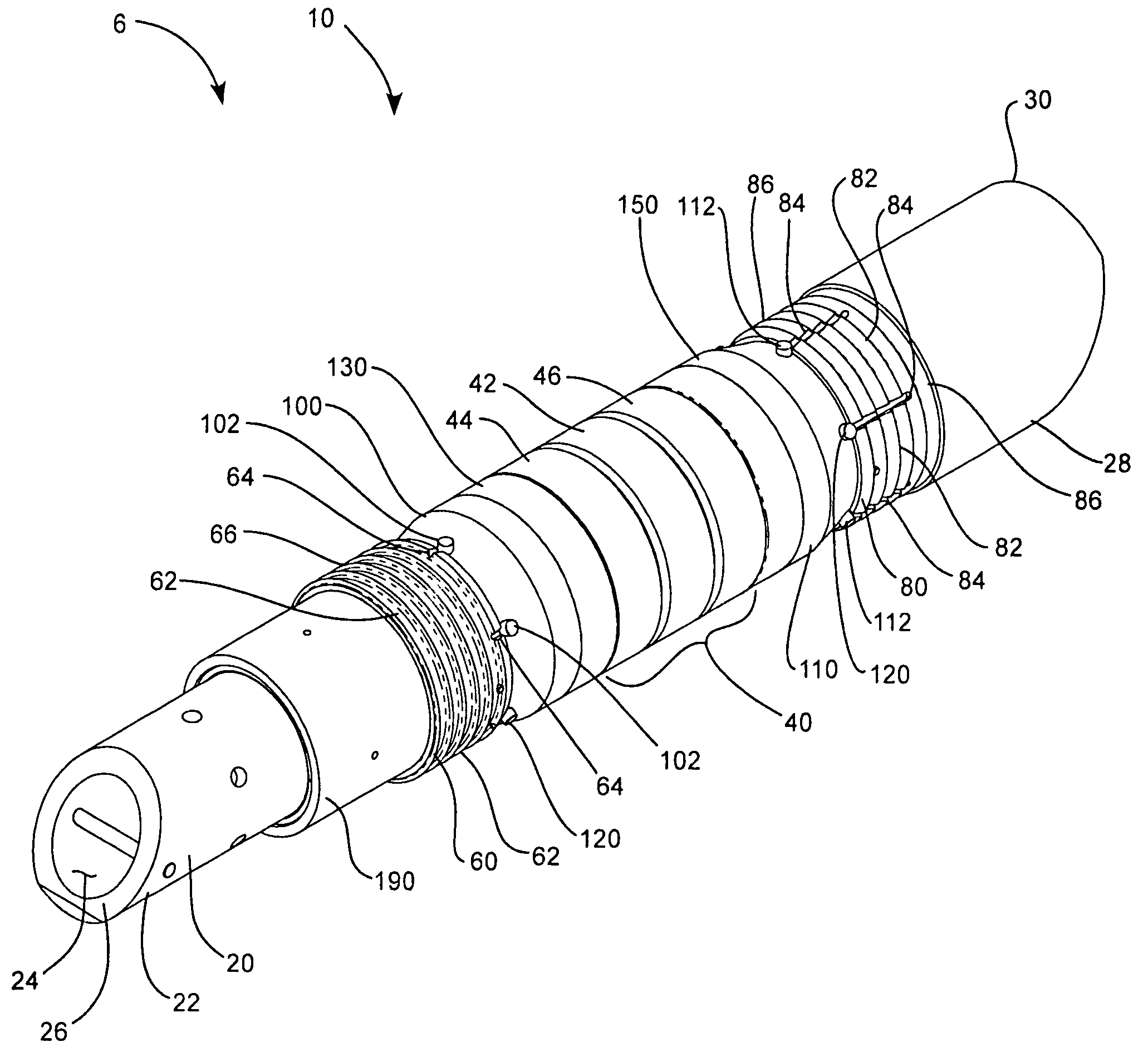

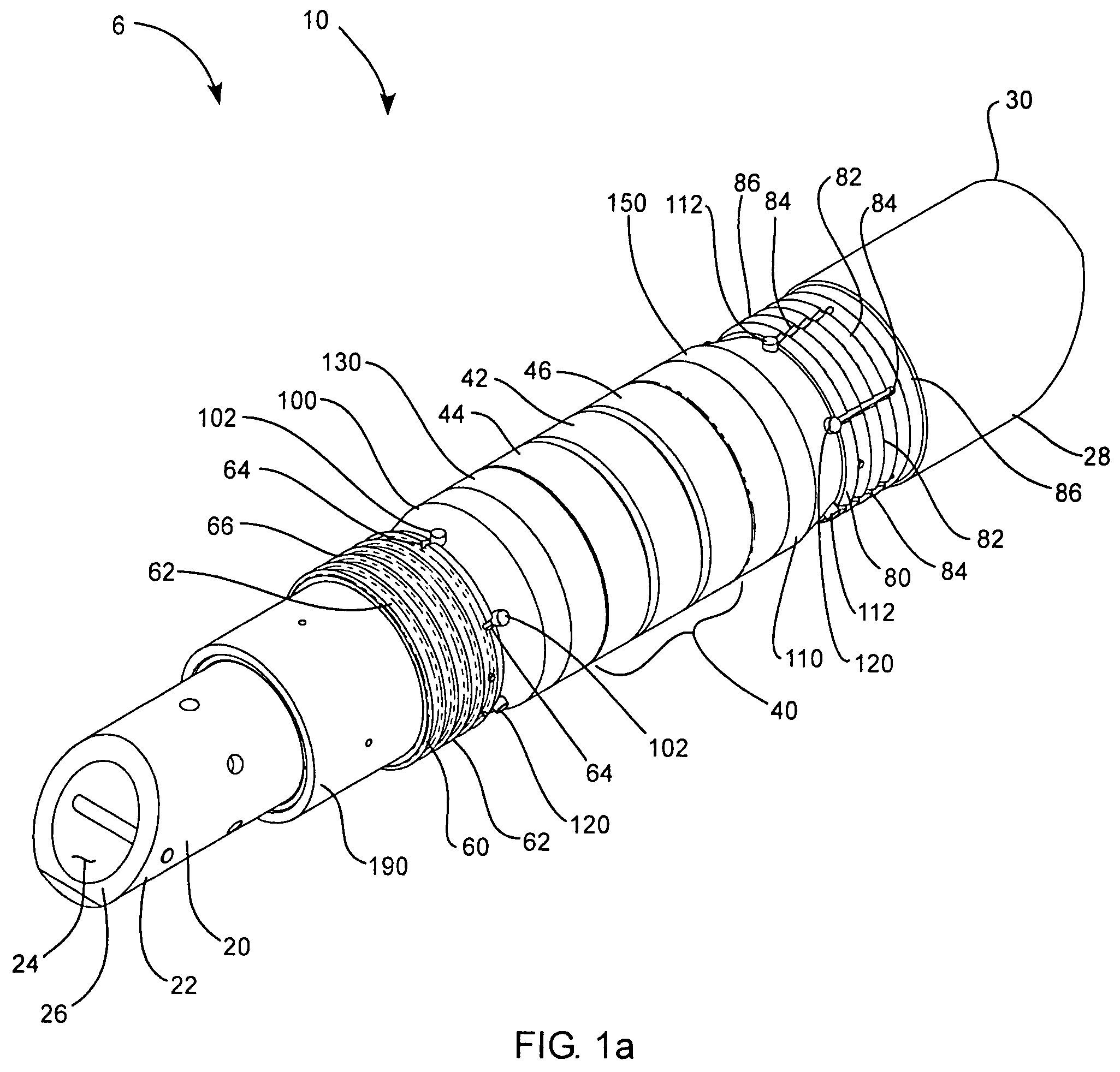

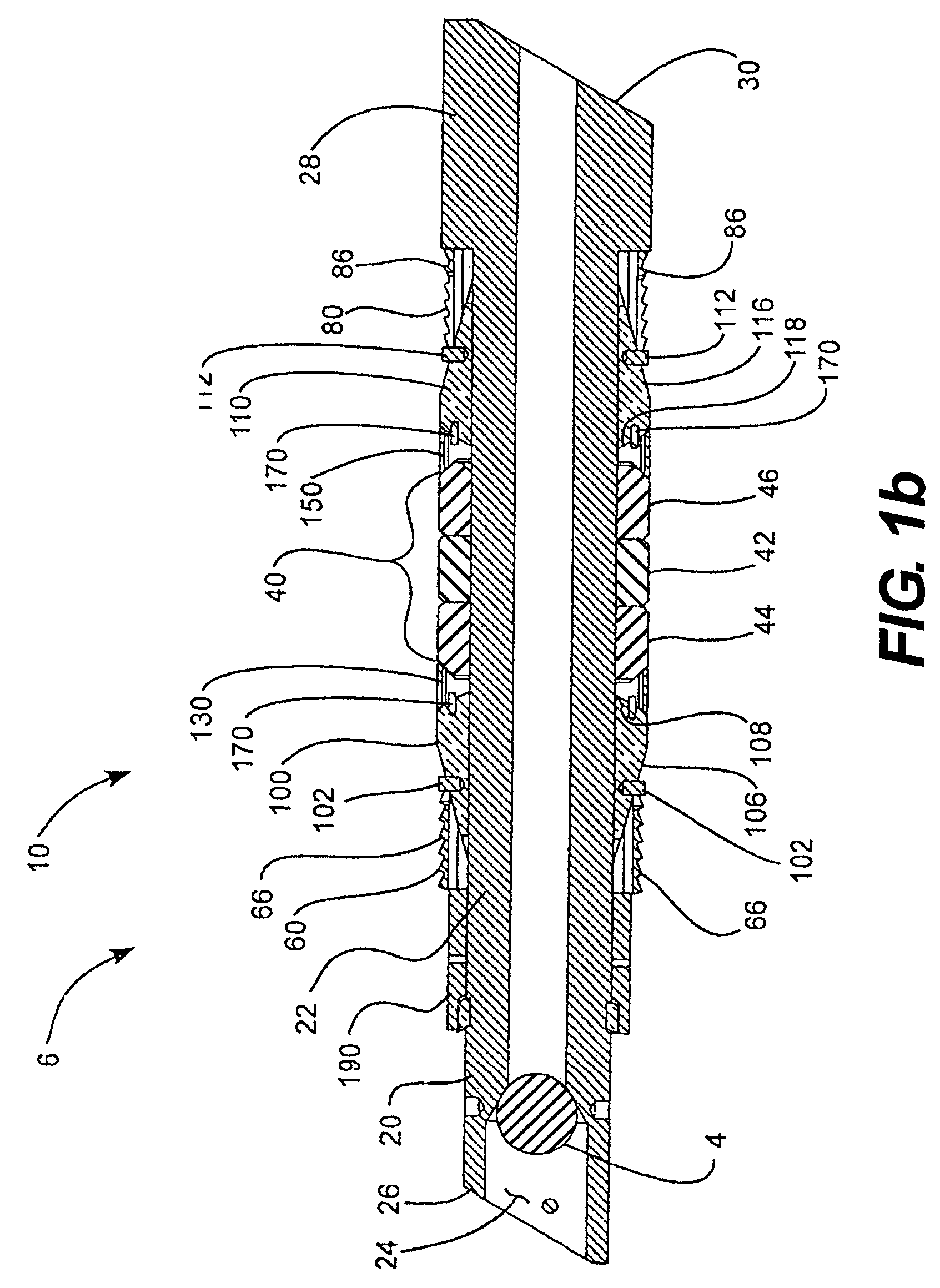

Surgical tool system including plural powered handpieces and a console to which the handpieces are simultaneously attached, the console able to energize each handpiece based on data stored in a memory integral with each handpiece

A surgical tool system (30) with a powered surgical handpiece (32). A removable handswitch (39) is attached to the handpiece. The handswitch includes a slip ring (192) that removably holds the handswitch to the handpiece. A lever arm (212) is pivotally attached to the slip ring. A magnet (190) is fitted in the lever arm. The angle of the lever arm is set by the surgeon to indicate the on / off state and operating speed of the handpiece. Internal to the handpiece is a sensor (94) that generates a signal based on the relative proximity of the magnet. The sensor signal is thus employed as the control signal for regulating the operation of the handpiece. Thus a surgeon can selectively use the handpiece with or without the mounted control switch.

Owner:STRYKER CORP

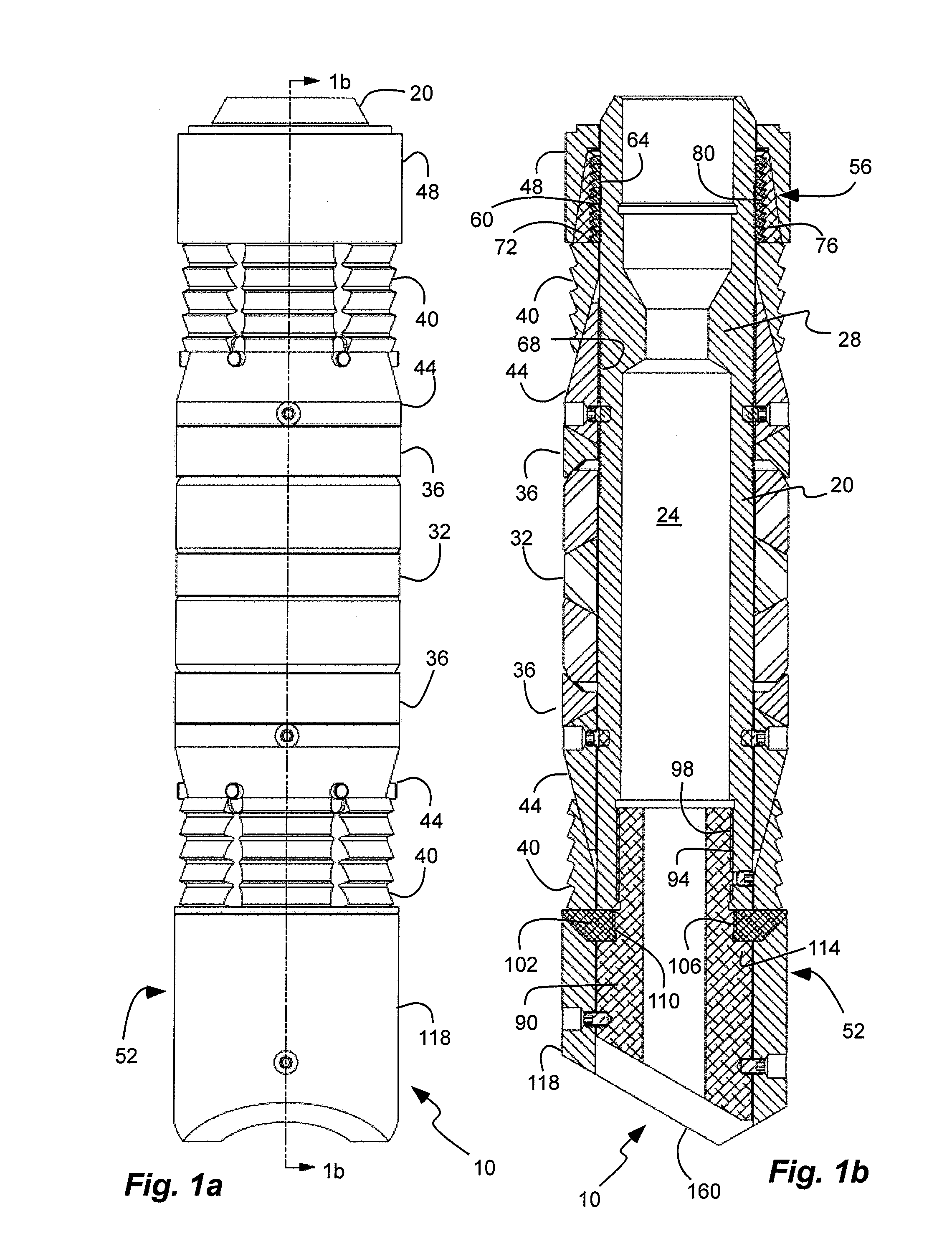

Means for creating field configurable bridge, fracture or soluble insert plugs

InactiveUS8267177B1Improves drill out performanceFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

A plug for a pipe in an oil or gas well includes a packer, a slip ring and a cone disposable on a mandrel and pressed between an upper push sleeve and a lower anvil on the mandrel. The plug can be field configurable with a frac plug kit, a bridge plug kit and a soluble insert plug kit. A pair of concentric locking rings is disposed between the push sleeve and the mandrel with an outer annular cone with an outer conical shape tapered upwardly and inwardly.

Owner:BEAR CLAW TECH LLC

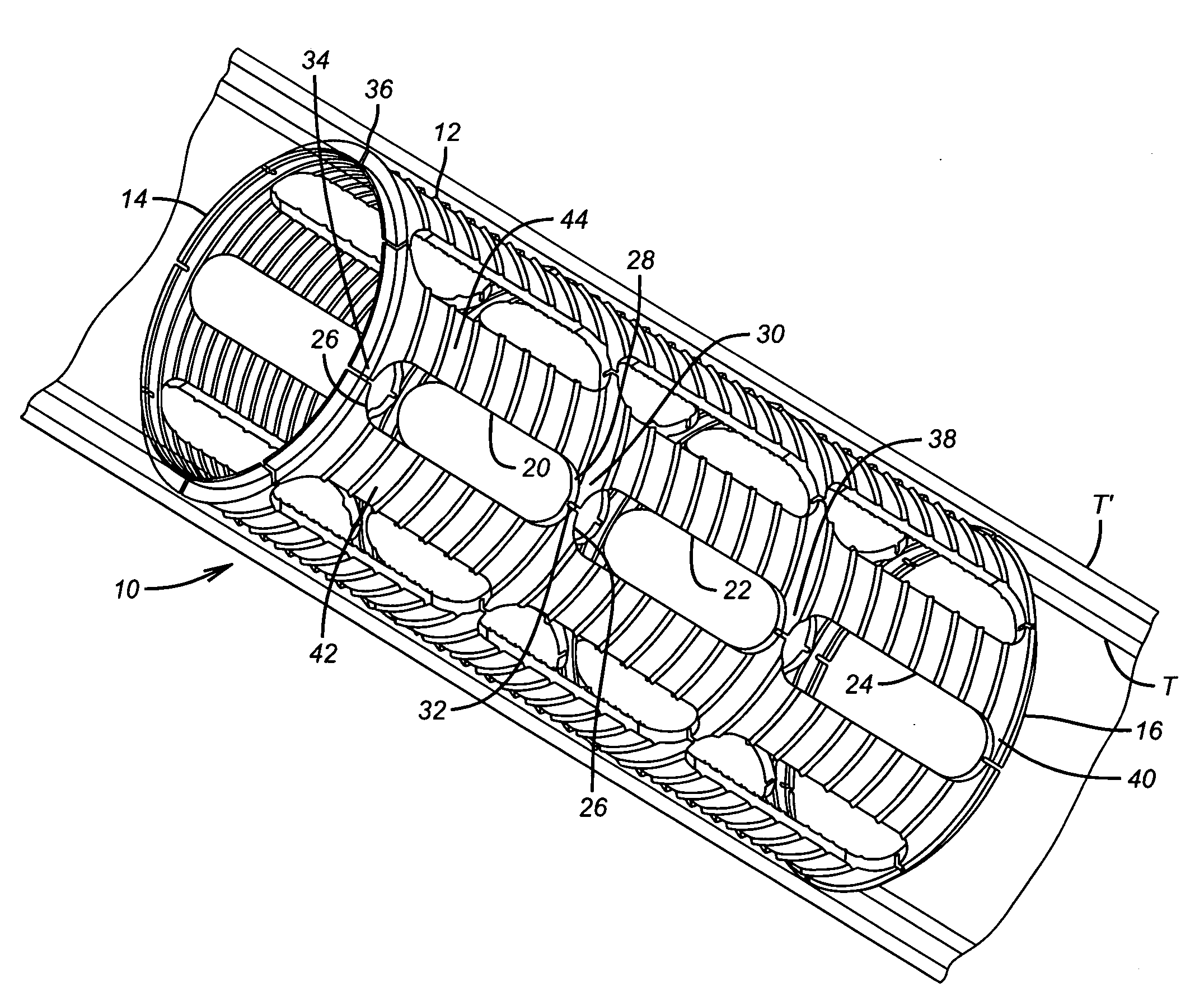

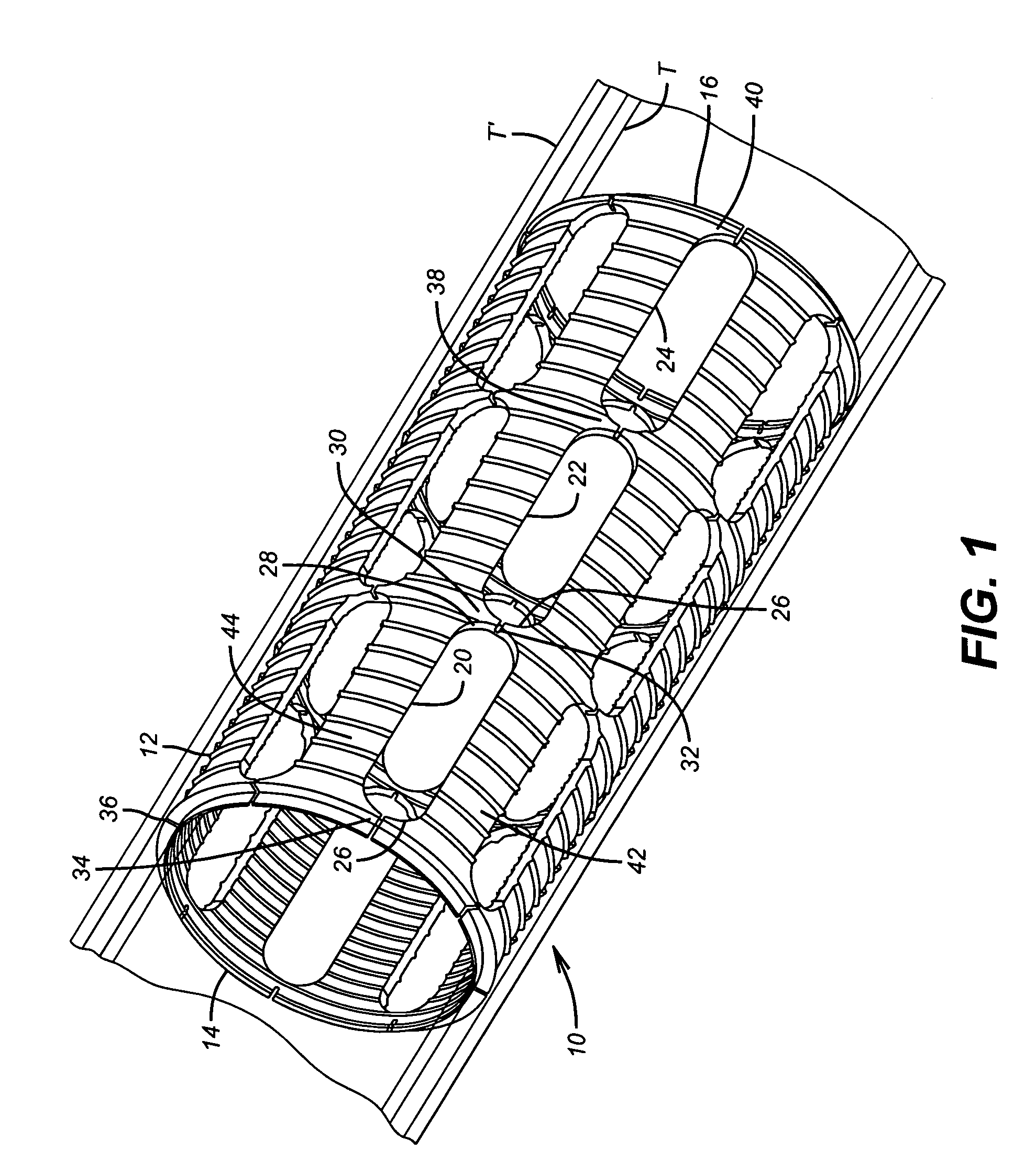

Drillable down hole tool

InactiveUS7735549B1Reduce longitudinal extrusionReduce uneven fracturingFluid removalSealing/packingLongitudinal fractureAxial load

A down hole flow control device used in a well bore includes a central mandrel and a packer ring disposed thereon. The packer ring is compressible along a longitudinal axis of the central mandrel to form a seal between the central mandrel and the well bore. Upper and lower slip rings are disposed on the central mandrel and include a plurality of slip segments joined together by fracture regions to form the slip rings. The fracture regions are configured to facilitate longitudinal fractures to break the slip rings into the plurality of slip segments that secure the down hole flow control device in the well bore. The upper and lower slip rings have different fracture regions from one another to induce sequential fracturing with respect to the upper and lower slip rings when an axial load is applied to both the upper slip ring and the lower slip ring.

Owner:BEAR CLAW TECH LLC

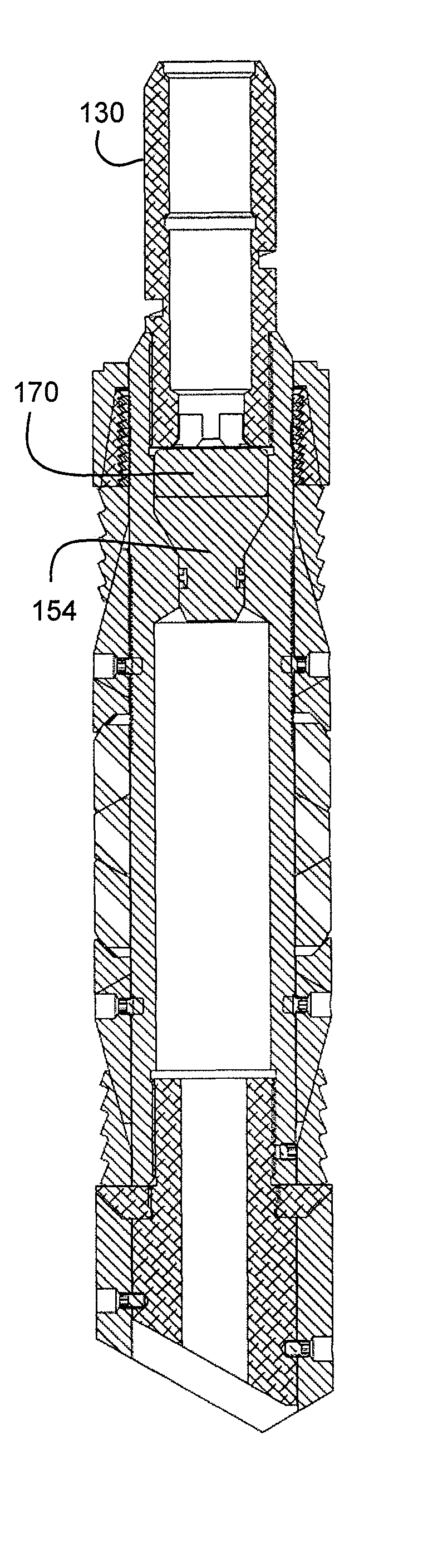

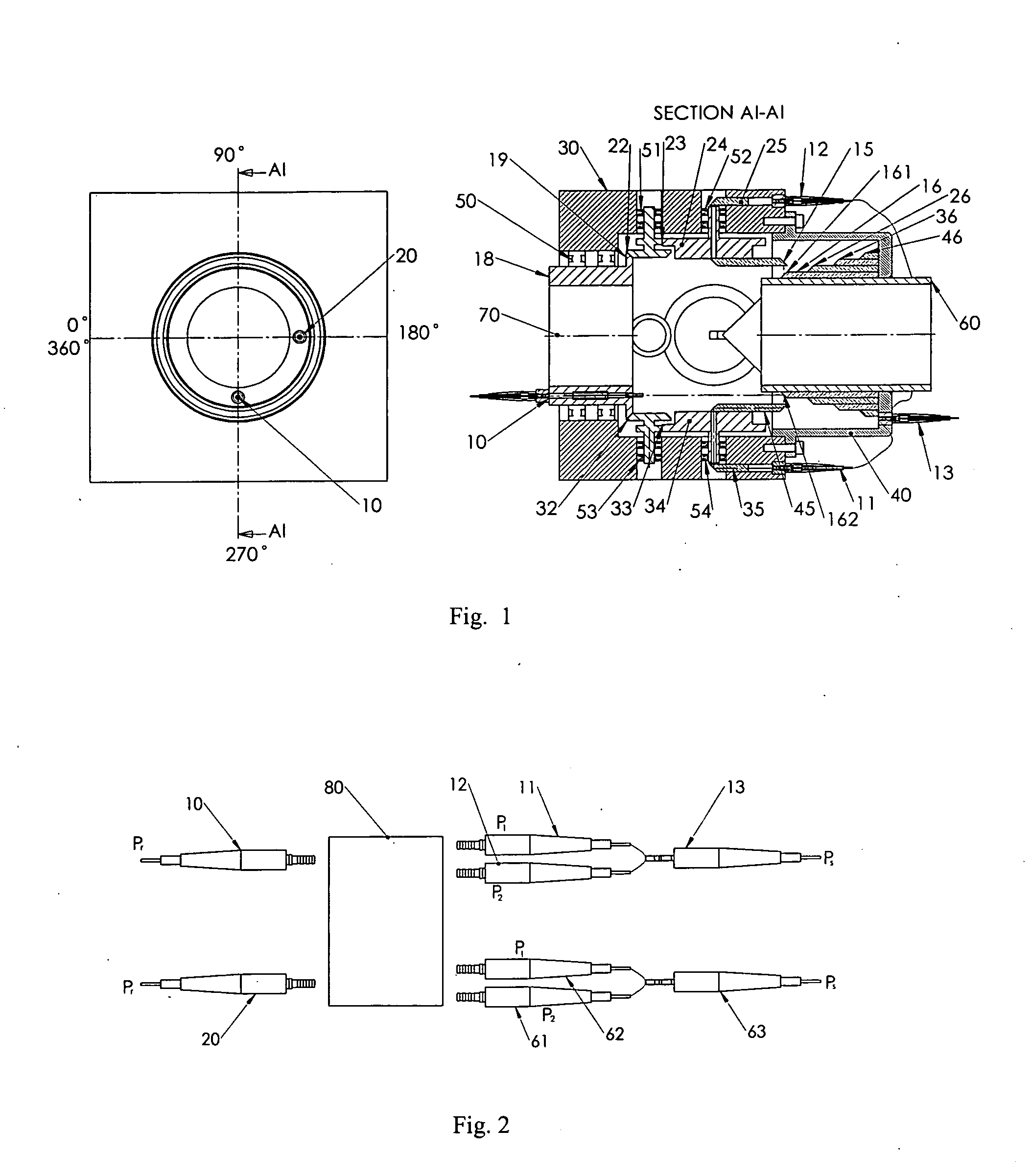

Interchangeable high intensity focused ultrasound transducer

InactiveUS20080243035A1Easy extractionEasy to insertUltrasound therapySurgerySonificationUltrasonic sensor

An interchangeable transducer for use with an ultrasound medical system having a keyless adaptor and capable of operating in a wet environment. The interchangeable transducer has an adaptor for engaging a medical system, an ultrasound transducer and additional electronics to provide a self-contained insert for easy replacement and usage in a variety of medical applications. A slip ring spacer is also disclosed, the slip ring spacer for use with a pancake slip ring having a base and flange configuration to form one or more channels around each contact ring of the pancake slip ring. The channels provide fluid isolation around each connector to help reduce electronic cross talk and contact corrosion between the connector pads of the slip ring while the slip ring is immersed in a wet environment.

Owner:LIPOSONIX

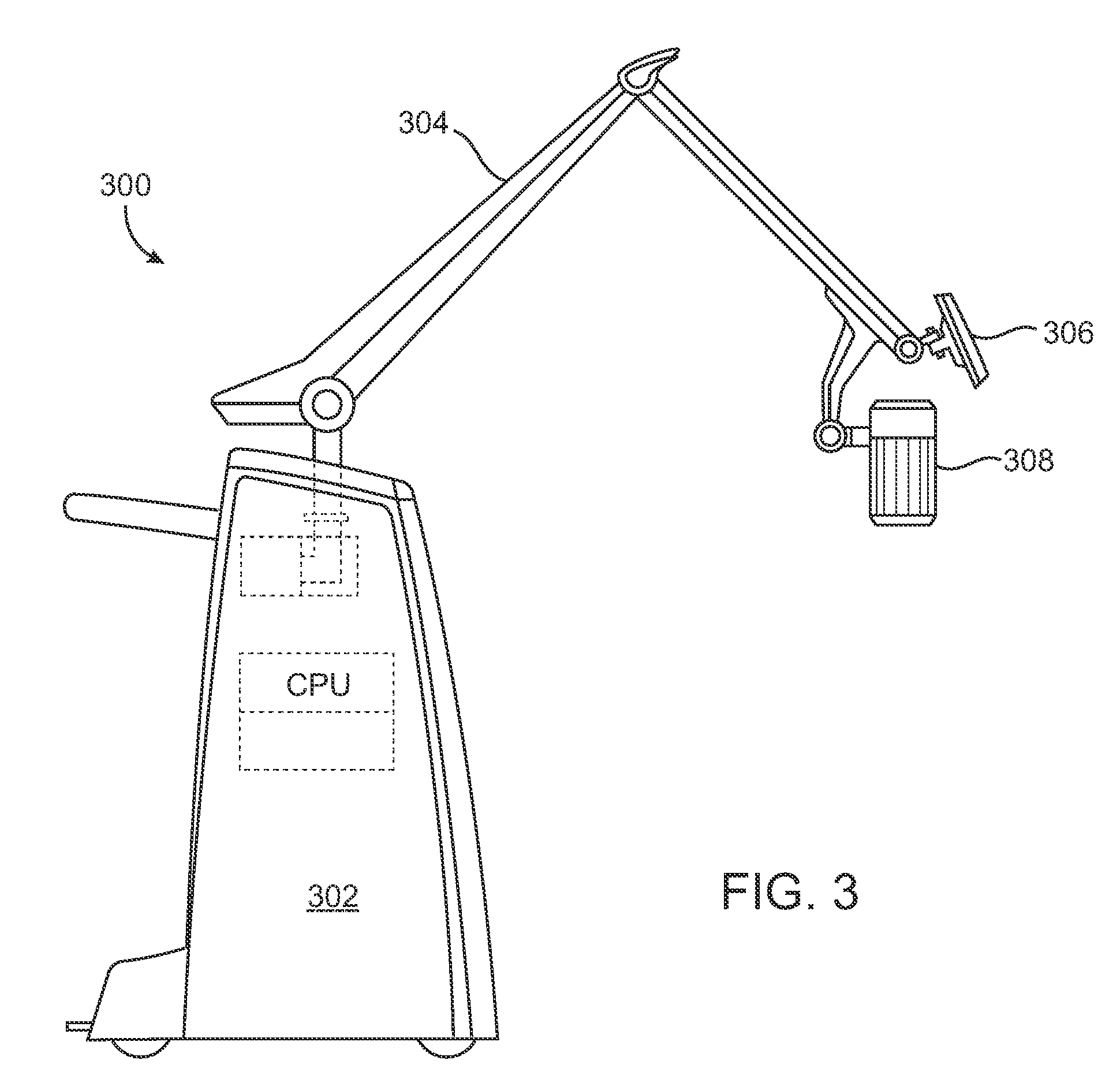

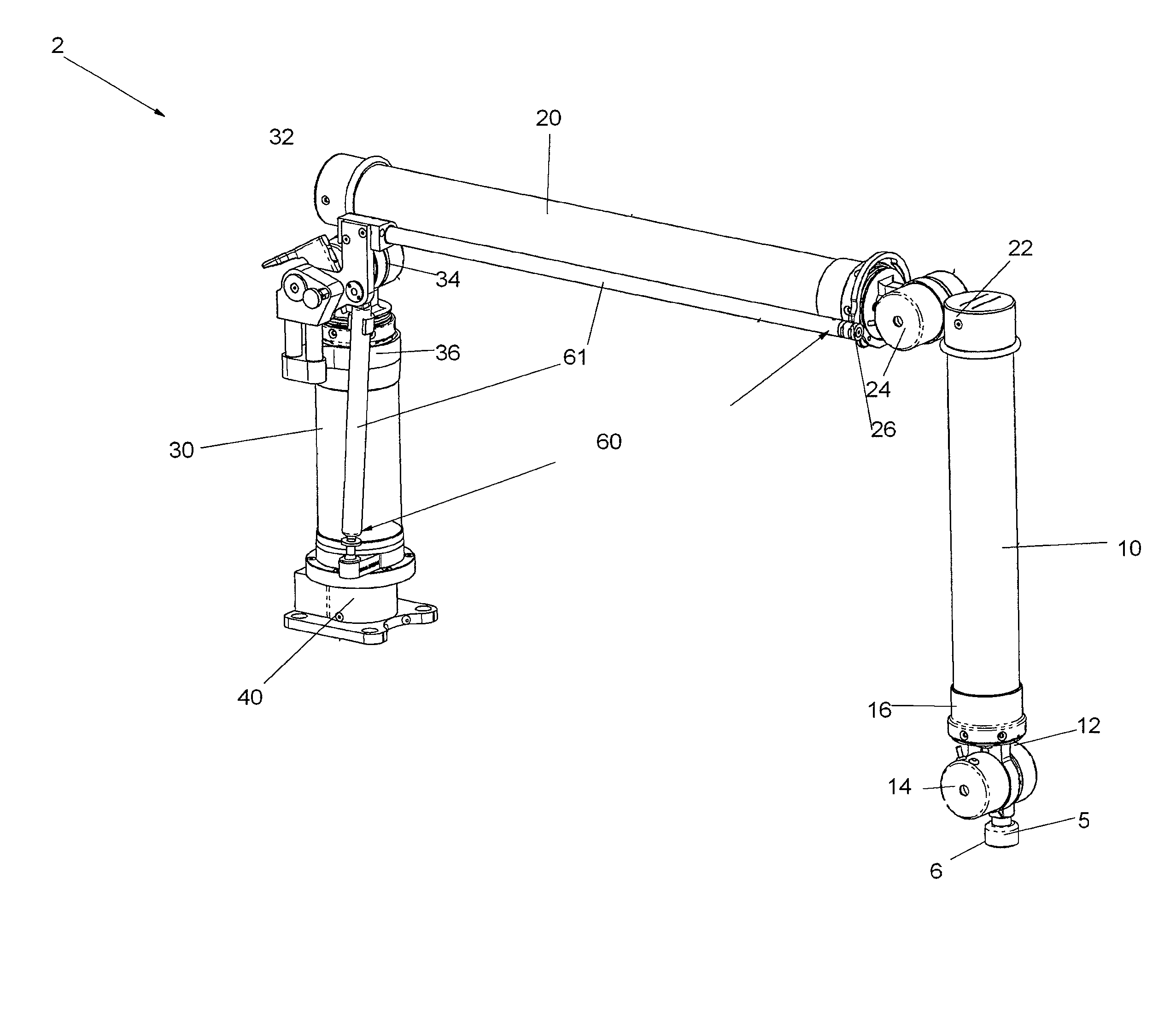

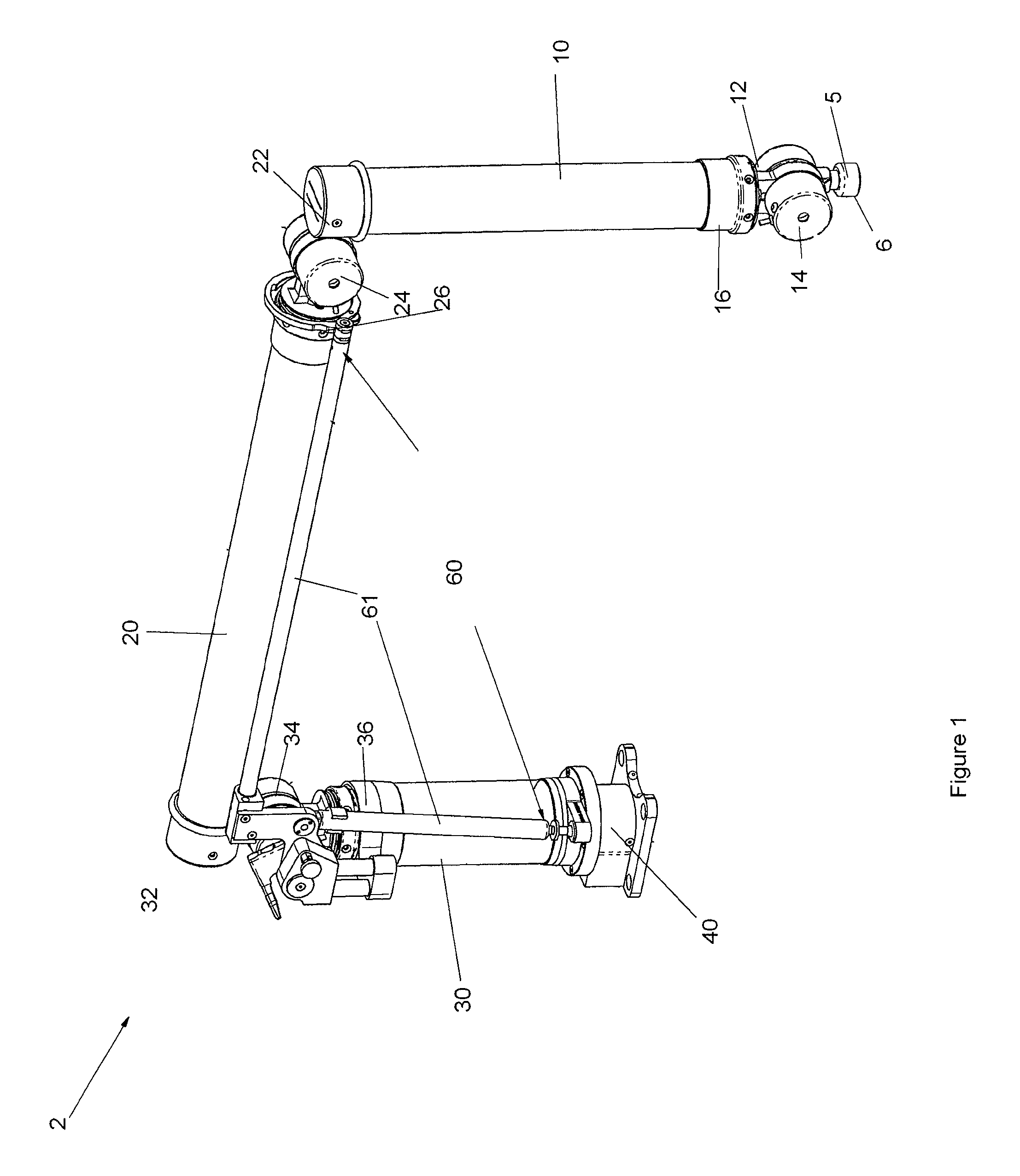

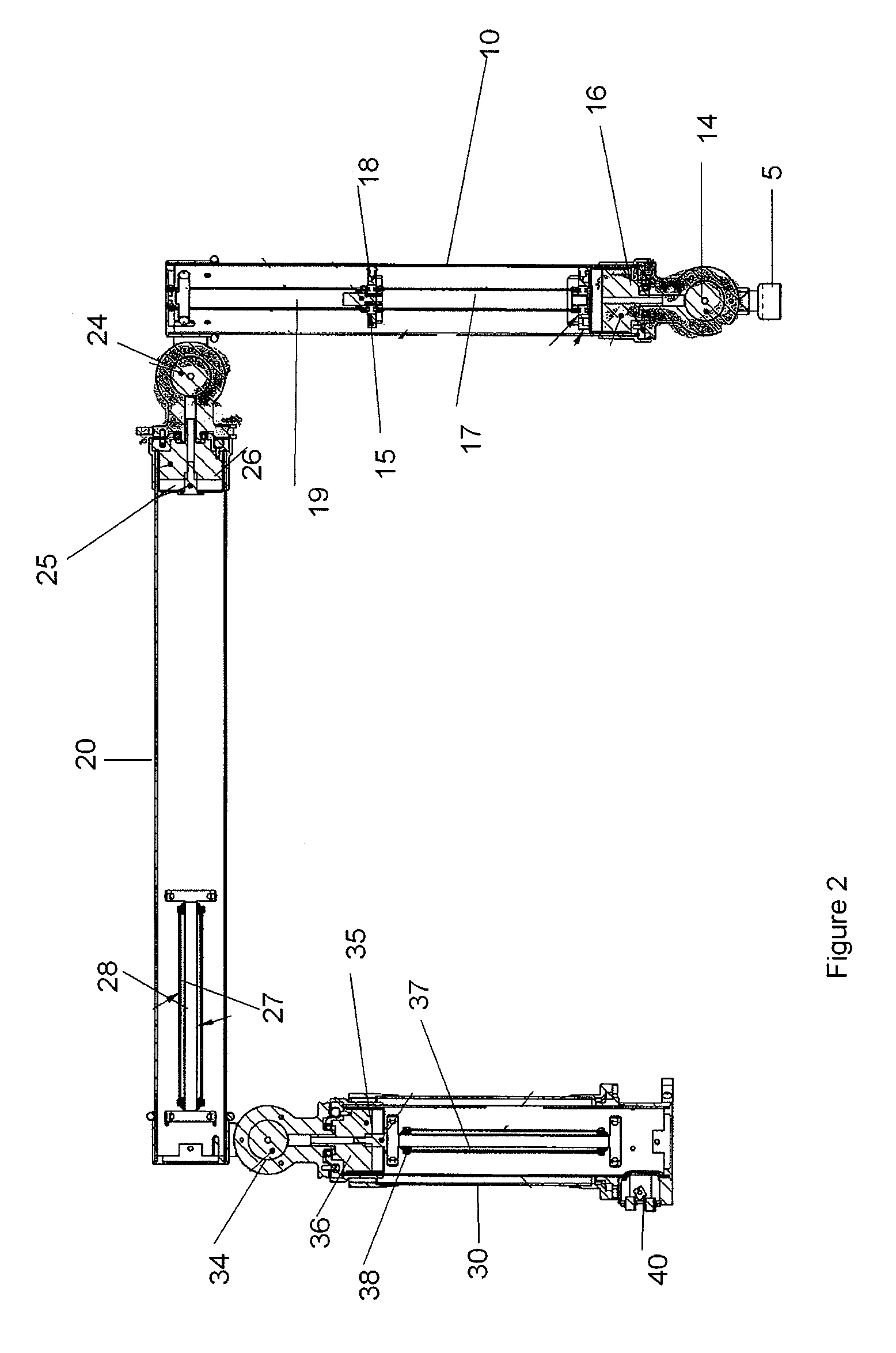

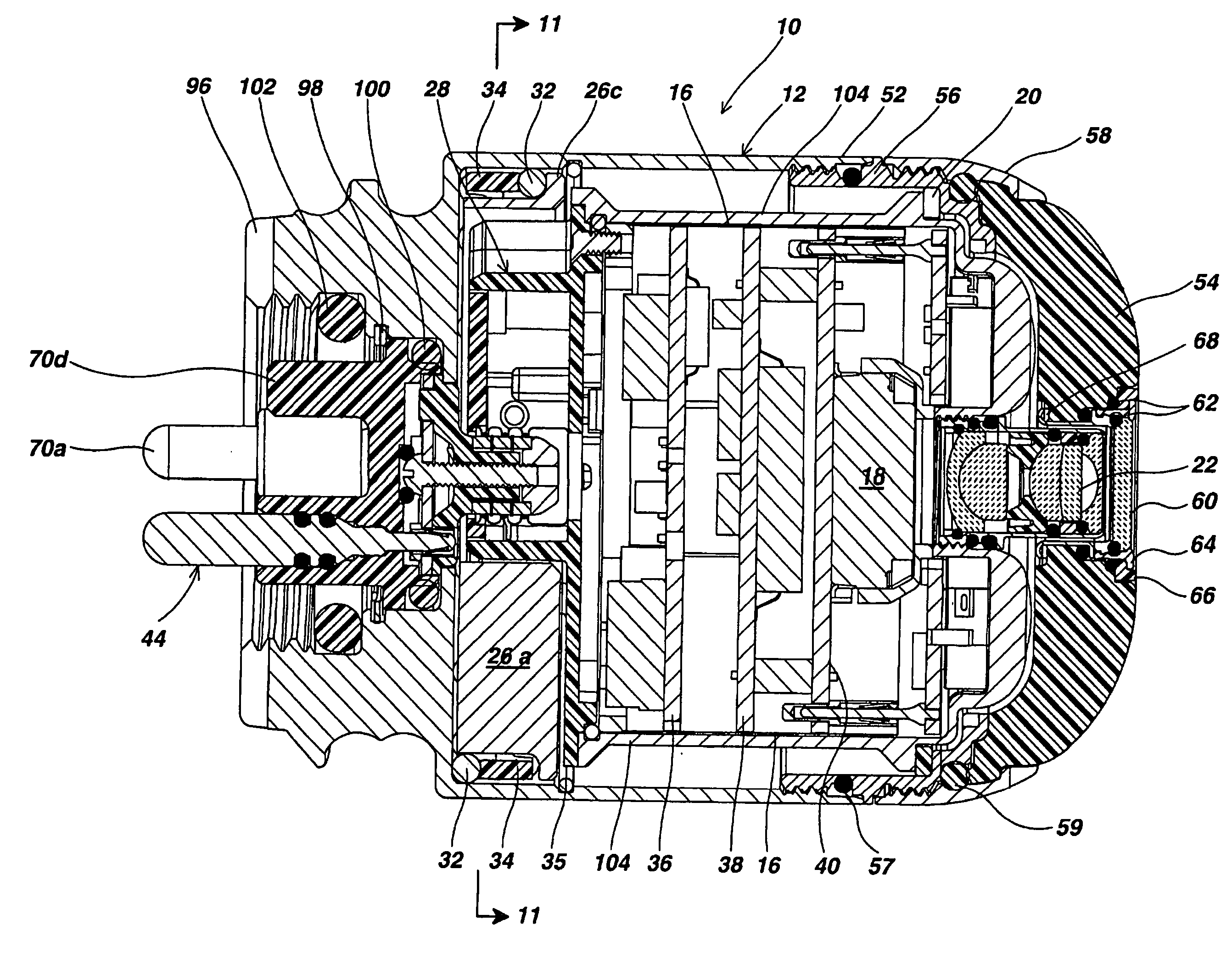

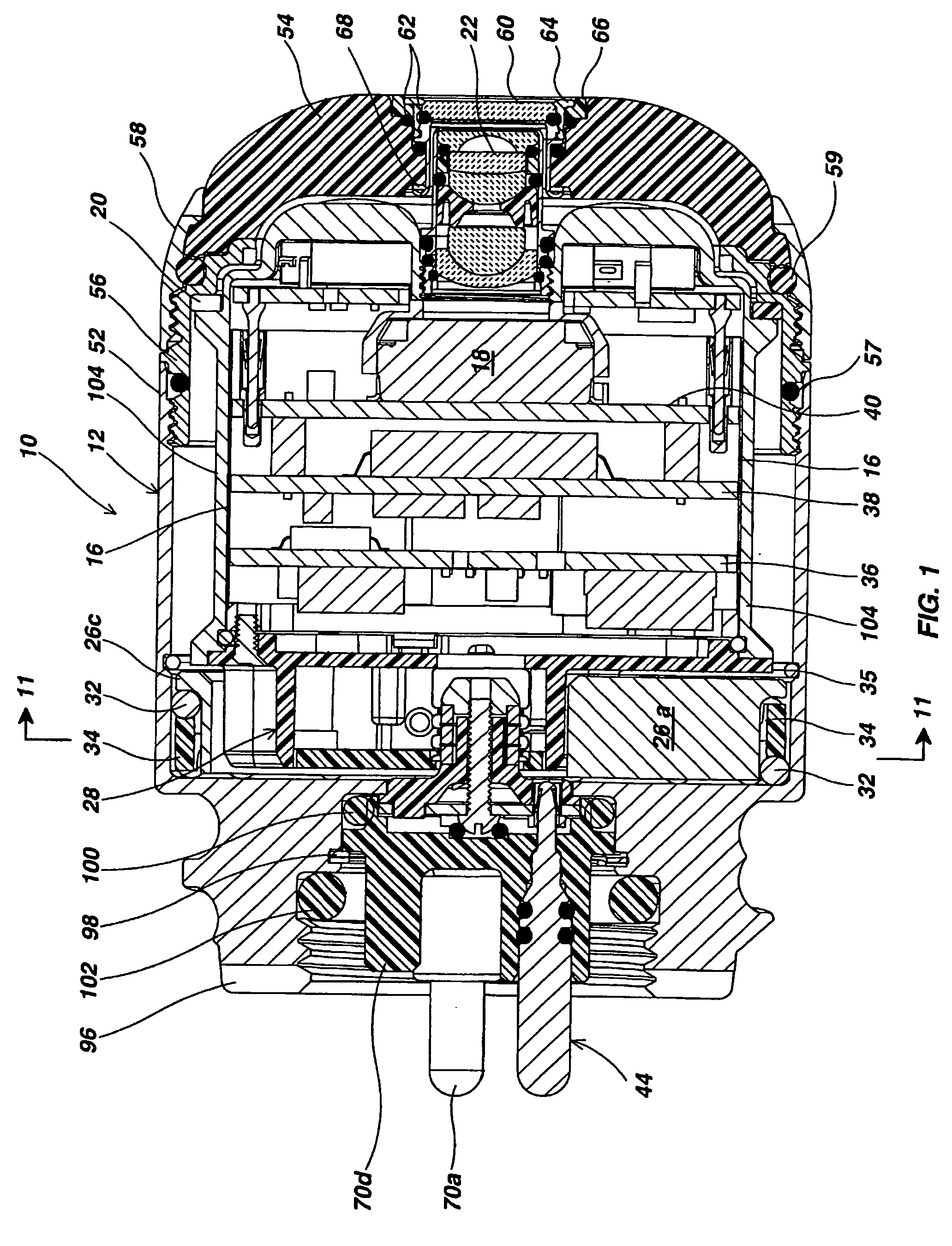

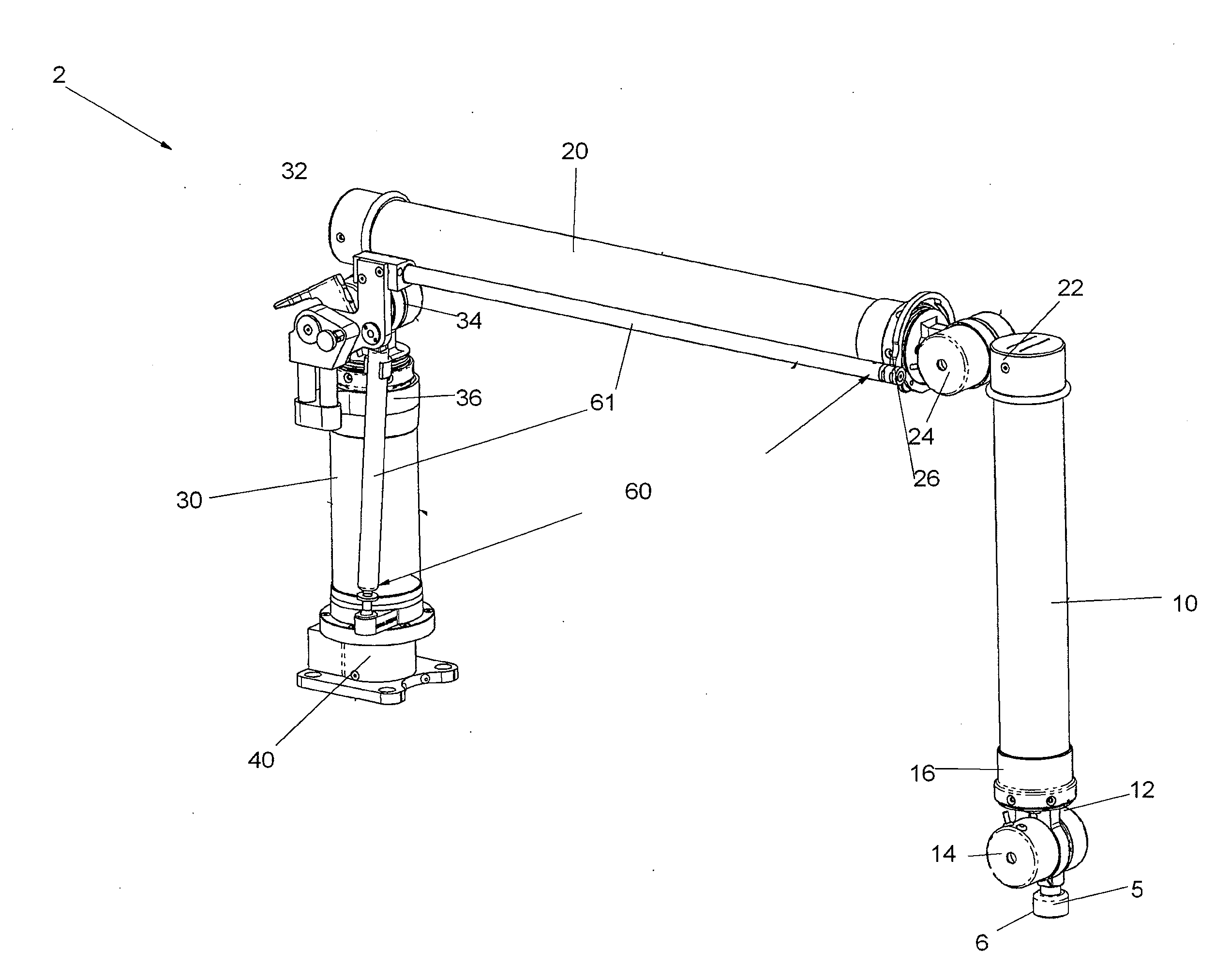

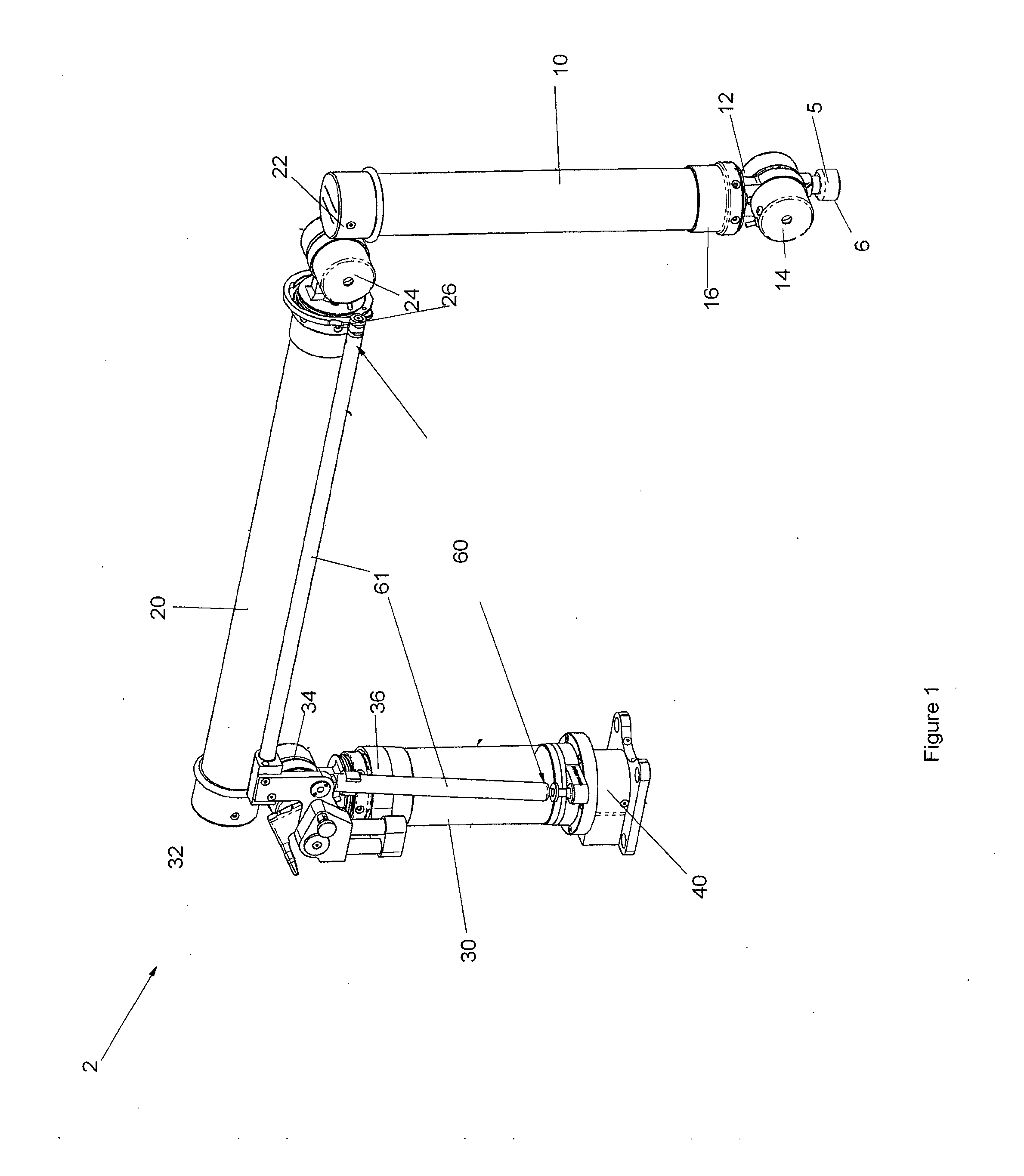

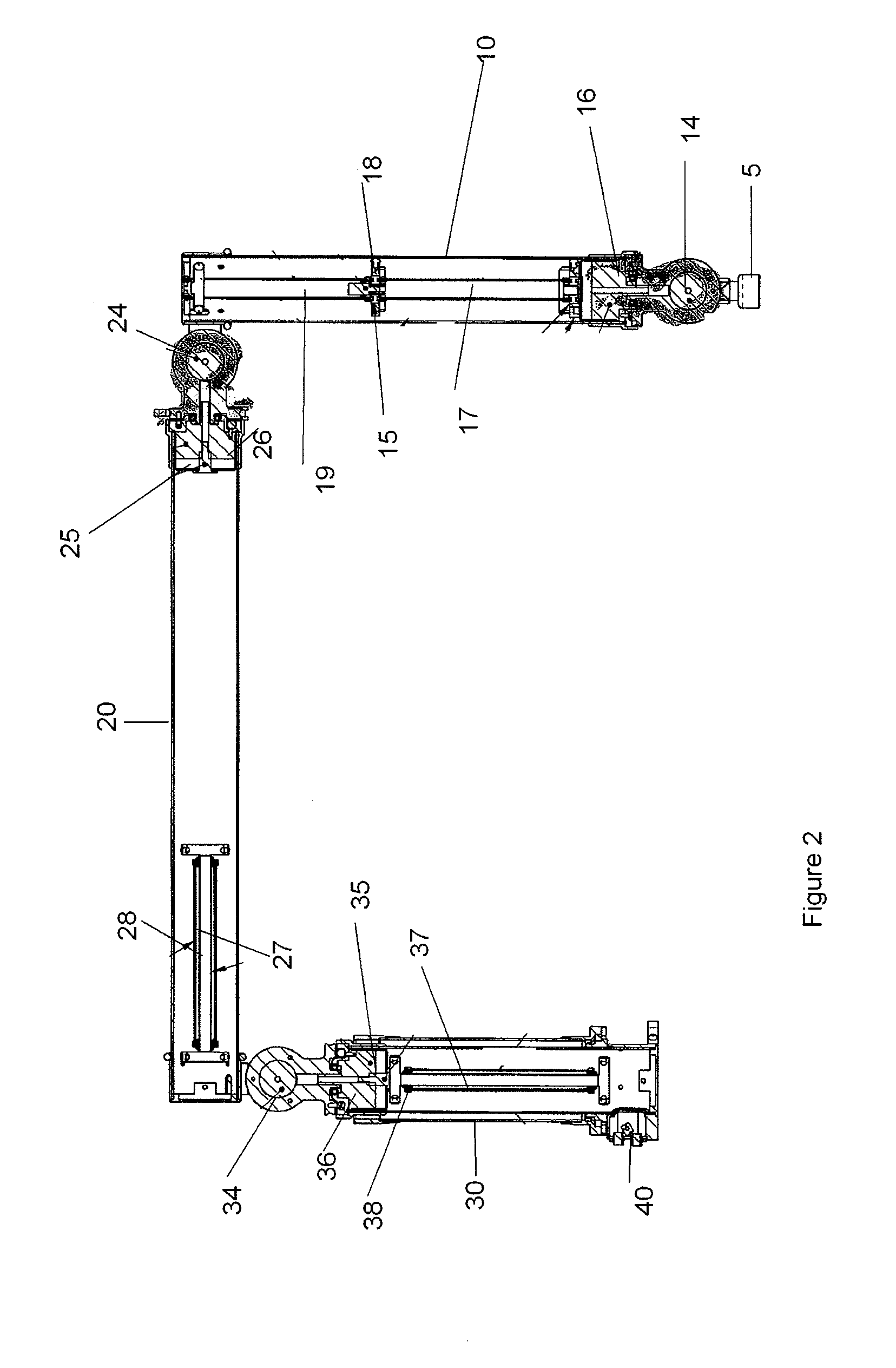

Coordinate measurement machine

A portable coordinate measurement machine having three articulating arm transfer members can provide accurate measurements. The transfer members can be single tube assemblies. The transfer members can each be rotatably joined by relatively short articulating joint assemblies allowing relative rotation of adjacent transfer members about two degrees of freedom. Encoders can be used to measure the relative rotation about each of the degrees of freedom, and signals from the encoders can be digitized by processor boards positioned within the transfer members. Processor boards can be placed in tandem in the transfer members, and one or more of the processor boards can be mounted on a rotatable assembly. Slip rings can electrically couple all of the processor boards to allow for infinite rotatability of the articulating arm.

Owner:HEXAGON TECH CENT GMBH

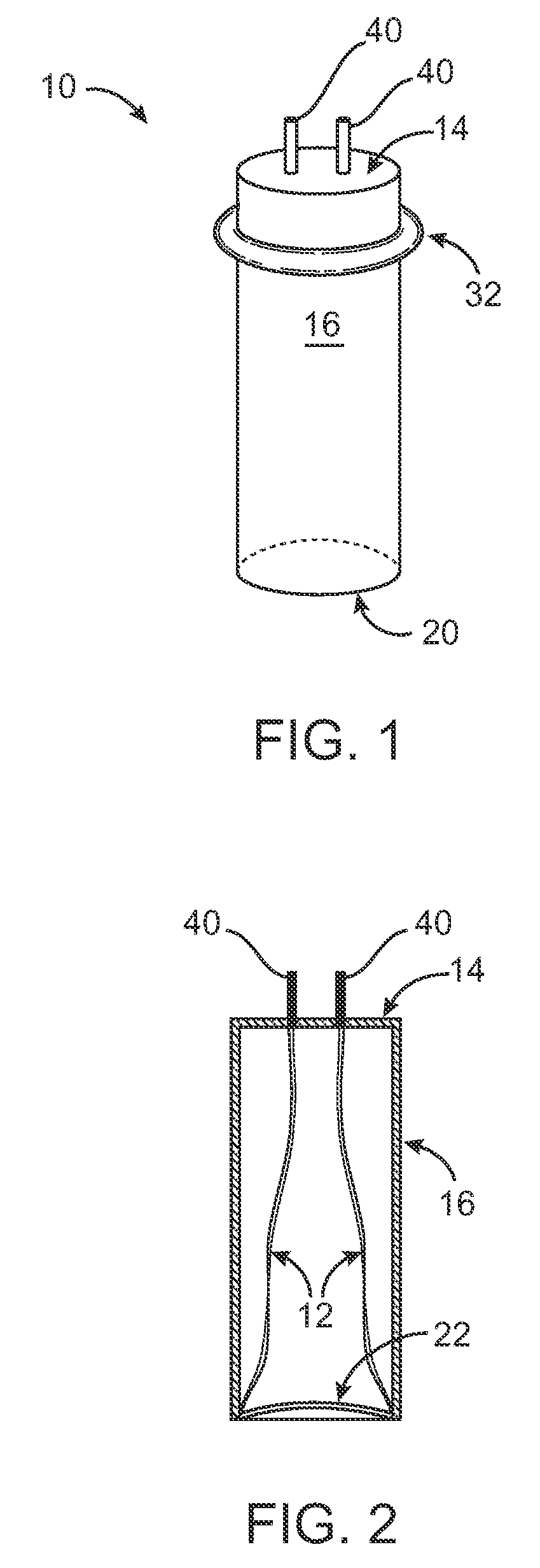

Self-leveling camera head

ActiveUS20050275725A1Television system detailsMaterial analysis by optical meansFree rotationEngineering

A self-leveling camera head includes an eccentric leveling weight assembly that is supported inside an outer housing for free rotation about an axis. The leveling weight assembly can be removably coupled to a separate camera module assembly supported inside the outer housing for rotation about the axis so that its images will be “upright”, i.e. earth normal. A slip ring assembly includes a fixedly mounted connector assembly that removably mates with a contact assembly mounted to the camera module assembly. In an alternative embodiment the camera module assembly does not rotate within the outer housing. Instead a processing circuit processes a video output from a high resolution image sensing device in the camera module assembly, generates a sub-sampled region and rotates it into a predetermined orientation for display. The output of an orientation sensor in the camera head may be processed to achieve the predetermined desired orientation of the video that is stored or displayed.

Owner:SEEK TECH

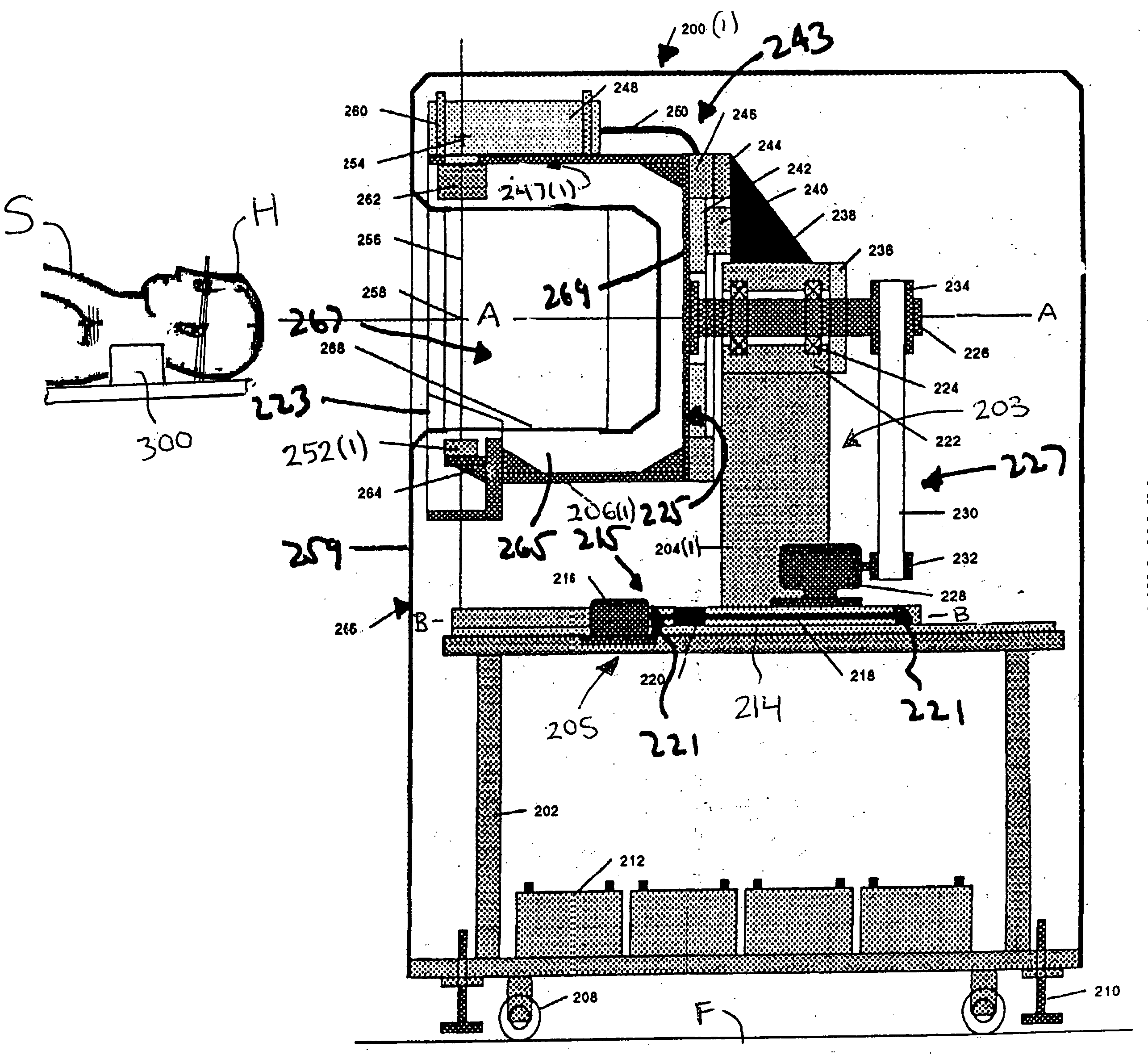

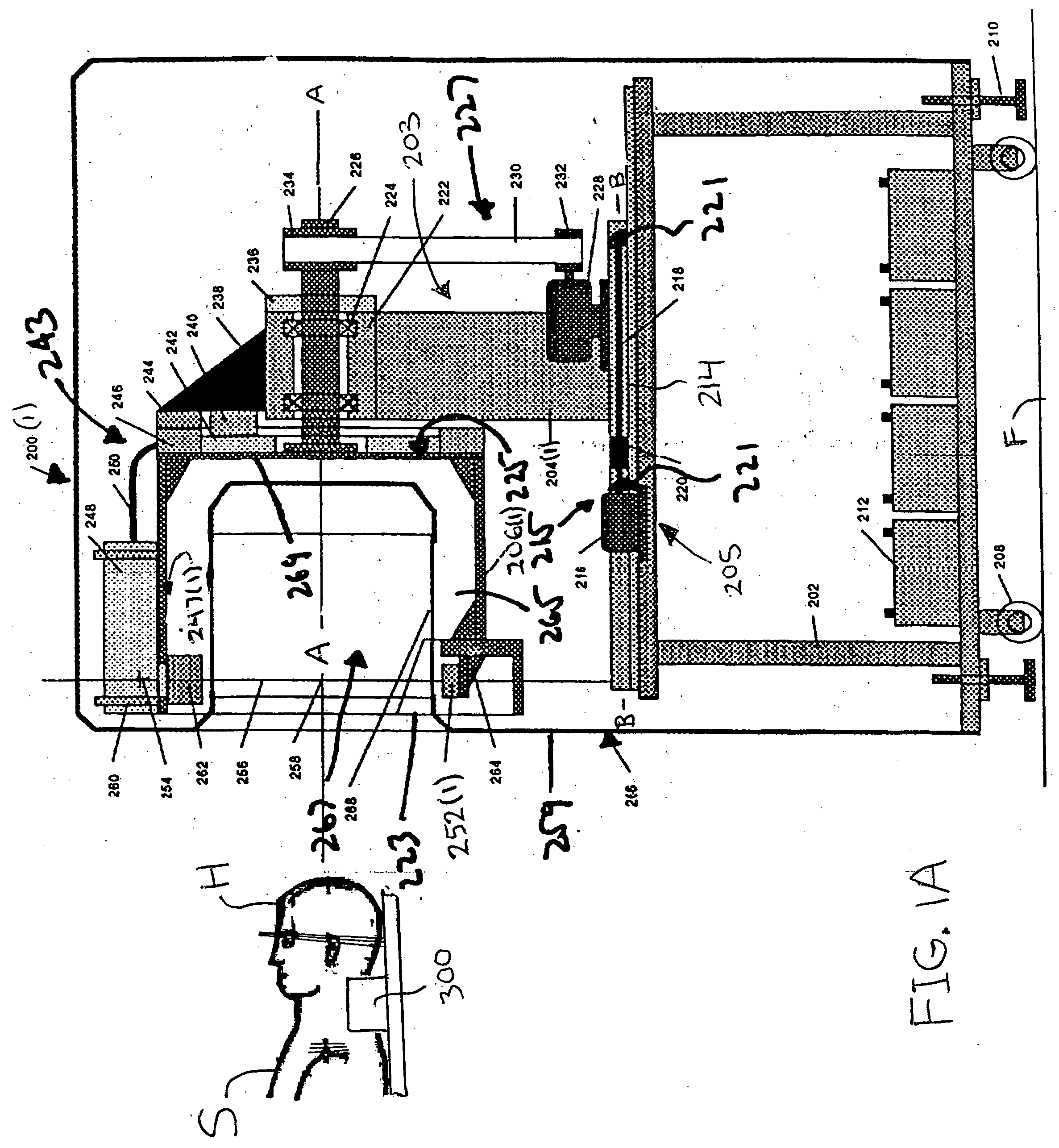

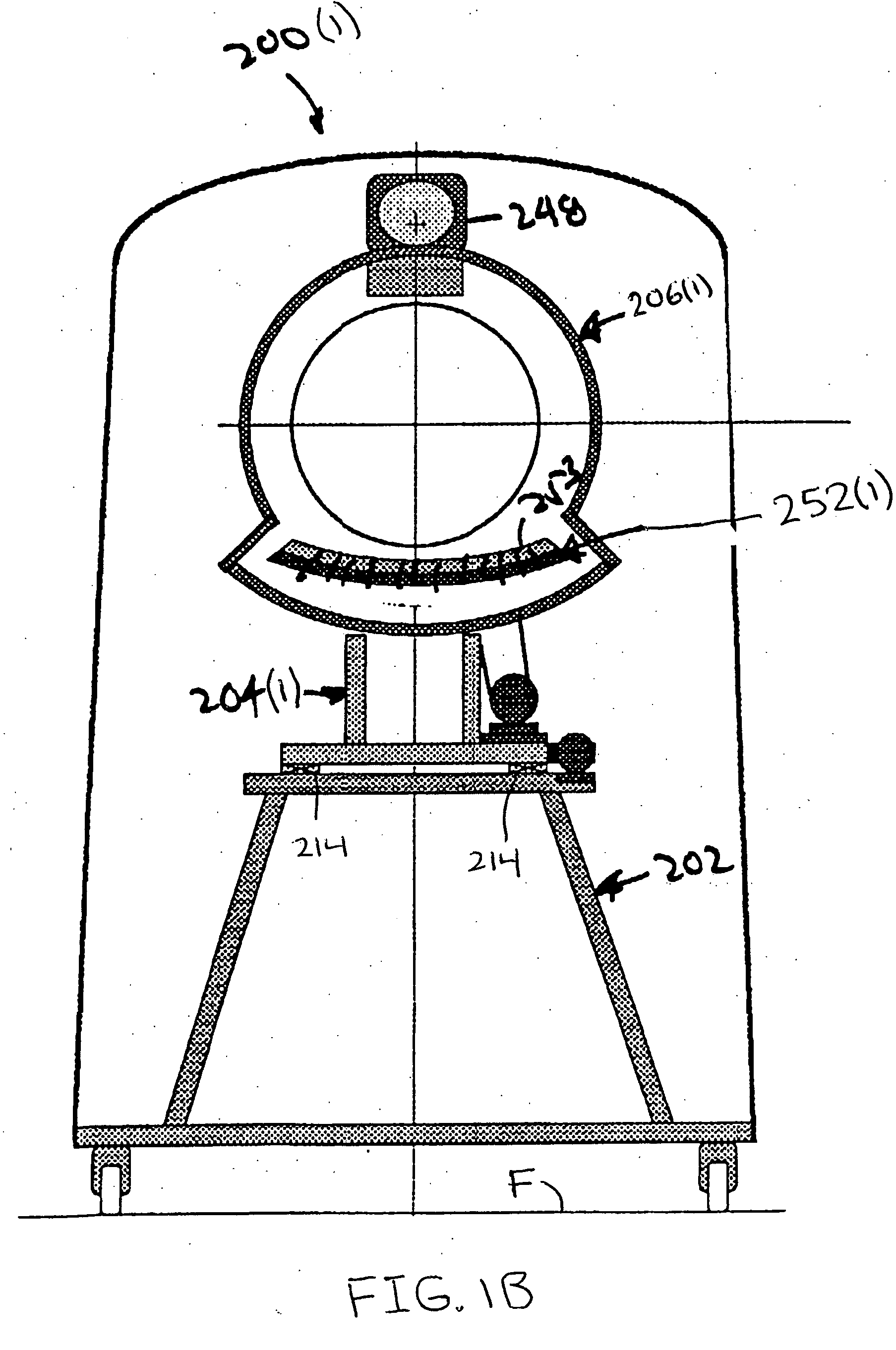

Portable computed tomography scanner and methods thereof

InactiveUS20050135560A1Less riskAddressing slow performanceRadiation diagnosis data transmissionX-ray apparatusX-rayEngineering

A computed tomography scanner includes a base system and a rotor system. The rotor system has an axle that is rotationally mounted to the base system. At least one x-ray source is mounted to the rotor system. A power interface system at least partially disposed about the axle couples power to the x-ray source. The power interface may include a slip ring assembly or a cable assembly that winds and unwinds about the axle as the rotor system rotates.

Owner:BRAIN SAVING TECH

Coordinate measurement machine

ActiveUS20090083985A1Mechanical measuring arrangementsDegrees of freedomCoordinate-measuring machine

A portable coordinate measurement machine having three articulating arm transfer members can provide accurate measurements. The transfer members can be single tube assemblies. The transfer members can each be rotatably joined by relatively short articulating joint assemblies allowing relative rotation of adjacent transfer members about two degrees of freedom. Encoders can be used to measure the relative rotation about each of the degrees of freedom, and signals from the encoders can be digitized by processor boards positioned within the transfer members. Processor boards can be placed in tandem in the transfer members, and one or more of the processor boards can be mounted on a rotatable assembly. Slip rings can electrically couple all of the processor boards to allow for infinite rotatability of the articulating arm.

Owner:HEXAGON TECH CENT GMBH

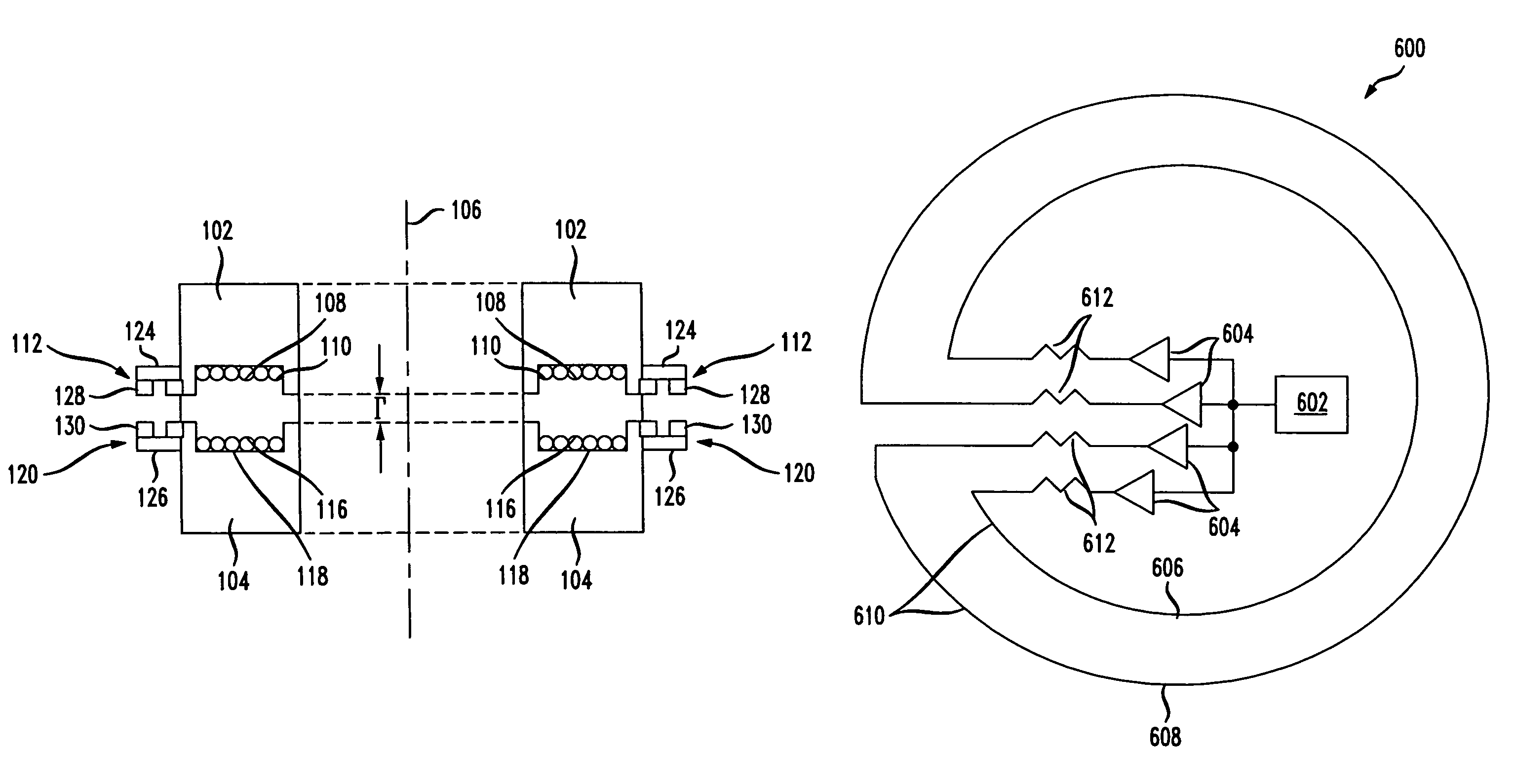

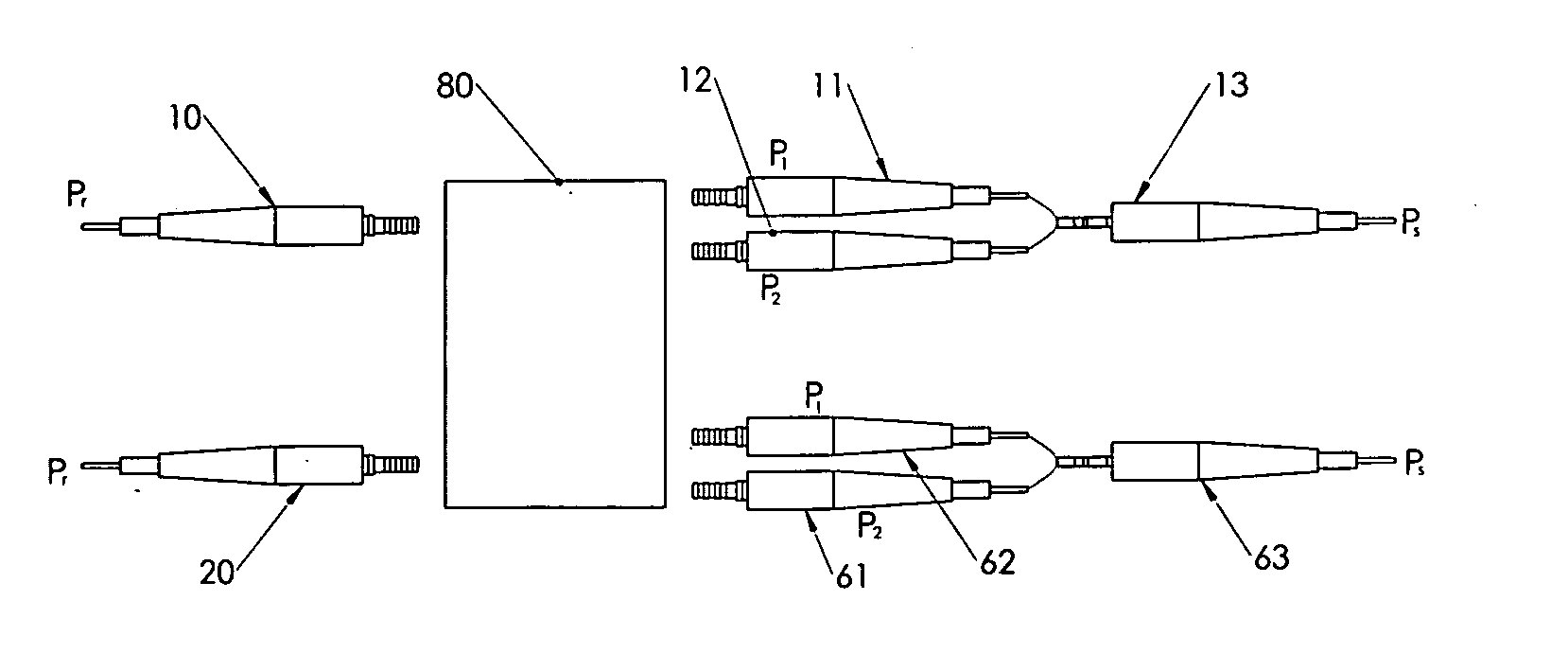

Transmission lines applied to contact free slip rings

A non-contacting rotary interface has a first core with a first pair of balanced transmission lines coupled to the first core and a second core moveable in relation to the first core with a second pair of balanced transmission lines coupled to the second core and configured to receive signals from the first pair of balanced transmission lines. The first pair of balanced transmission lines has a first transmit wire coupled to a first transceiver at a first end of the first transmit wire, a second transceiver coupled to the first transmit wire at a second end of the first transmit wire, a second transmit wire coupled to a third transceiver at a first end of the second transmit wire, and a fourth transceiver coupled to the second transmit wire at a second end of the second transmit wire. The balanced transmission lines may be electrical traces on a circuit board.

Owner:VOXIS

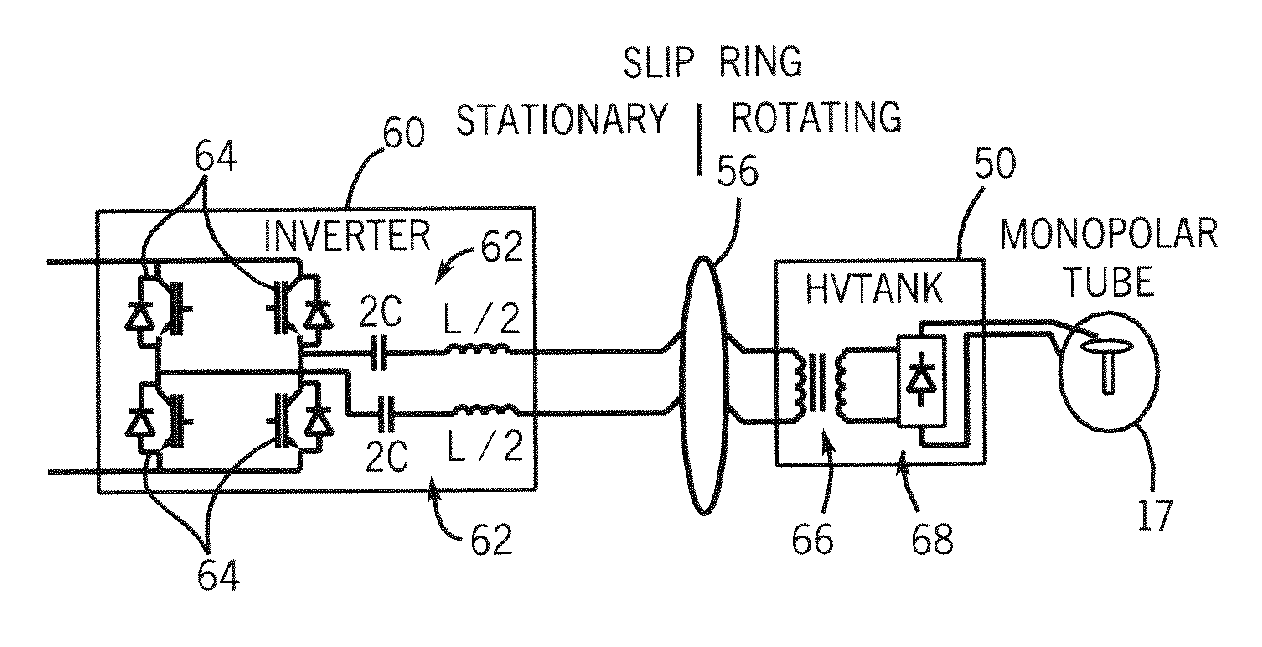

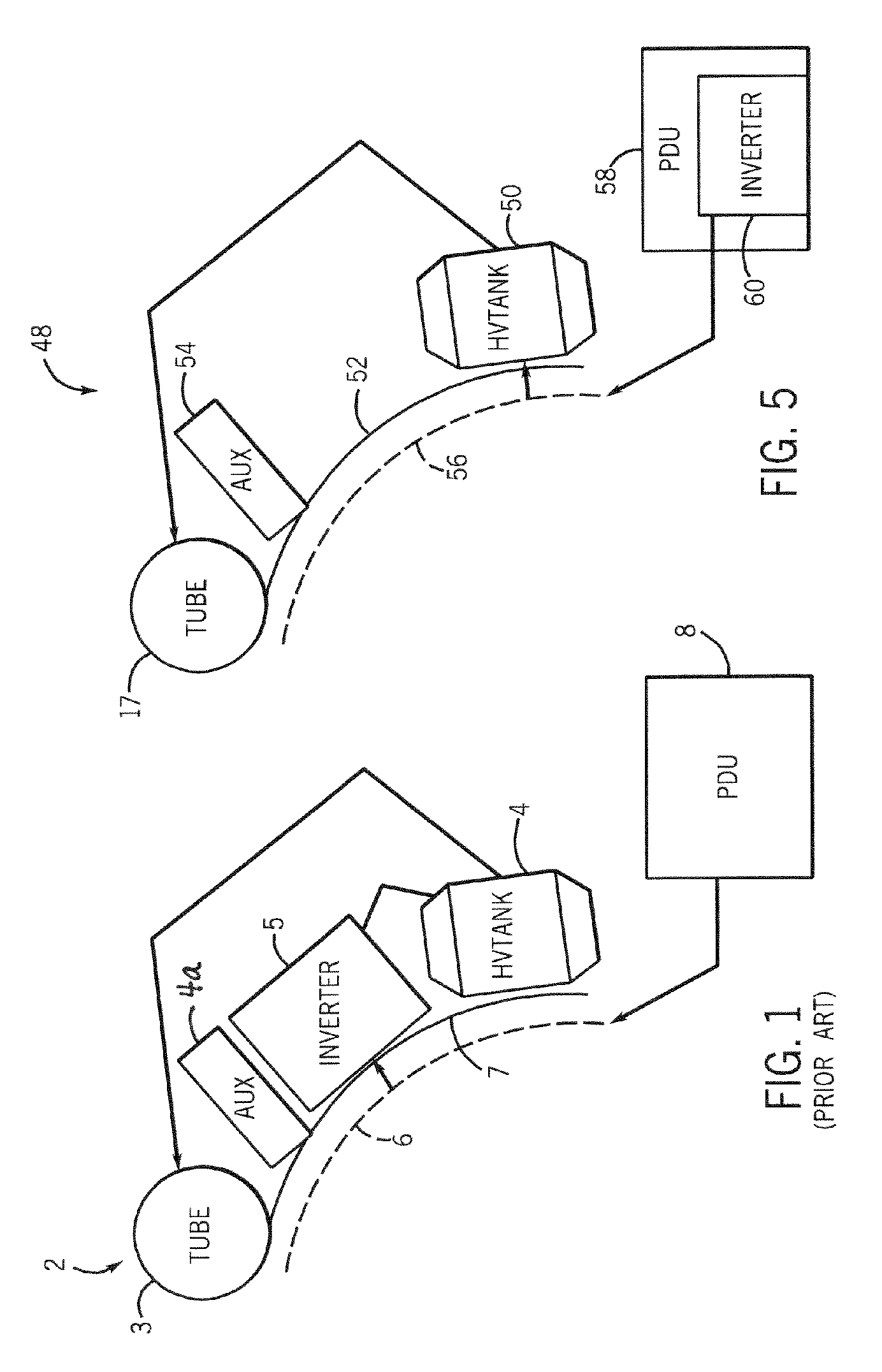

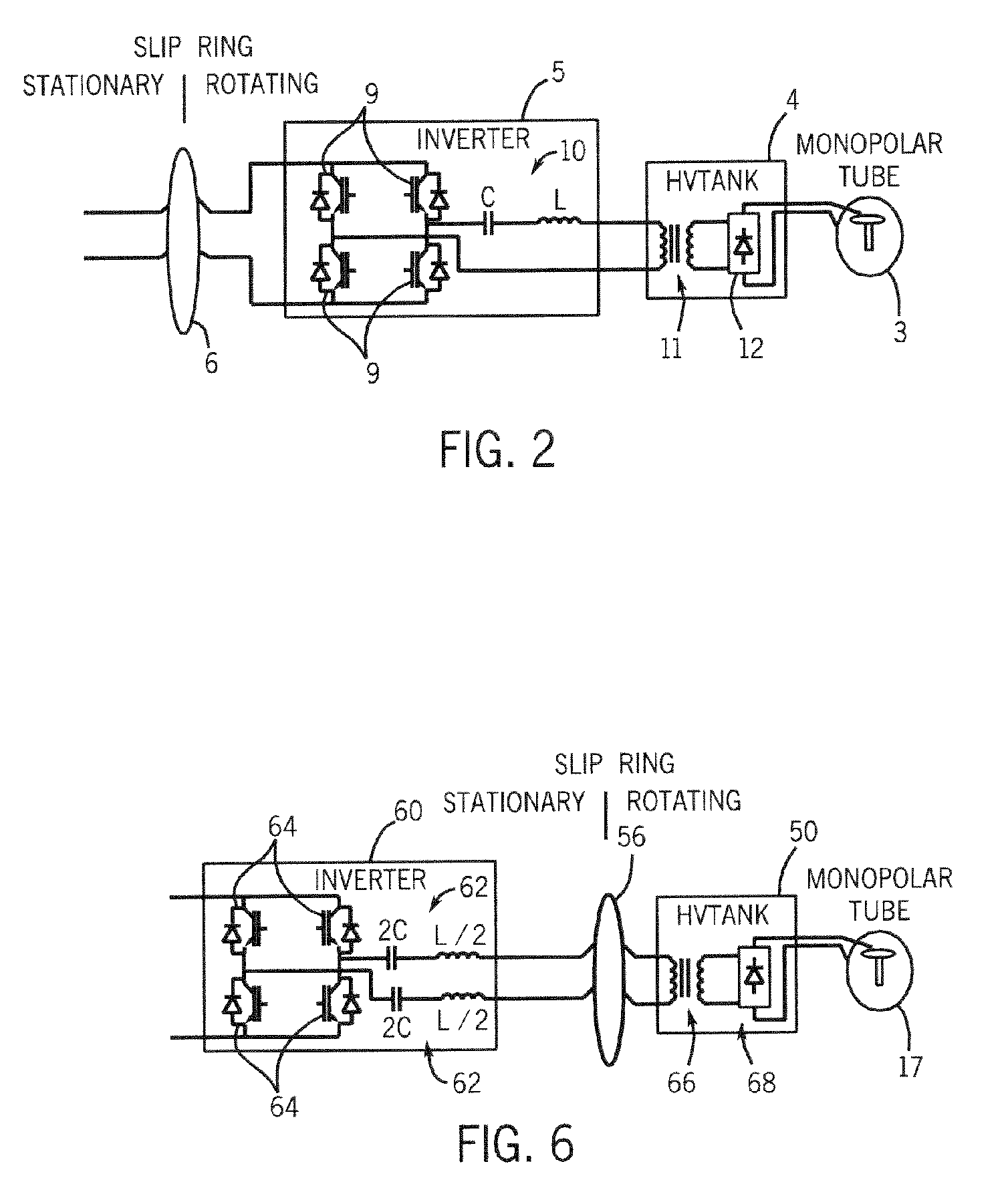

X-ray generator and slip ring for a CT system

InactiveUS6975698B2Radiation diagnosis data transmissionMaterial analysis using wave/particle radiationTransformerFuel tank

The present invention is directed to an apparatus for supplying power to a rotatable x-ray tube for generation of an x-ray beam for acquisition of CT data. The apparatus includes a slip ring to transfer power from a stationary inverter to a rotatable HV tank. The HV tank conditions the transferred power and creates a voltage potential across the x-ray tube for x-ray generation. The inverter has a single or pair of series resonant circuits connected either directly to the slip ring or indirectly through a transformer to limit frequency content and reduce common-mode component of the voltage and current waveforms carried by the slip ring as well as reduce power losses.

Owner:GENERAL ELECTRIC CO

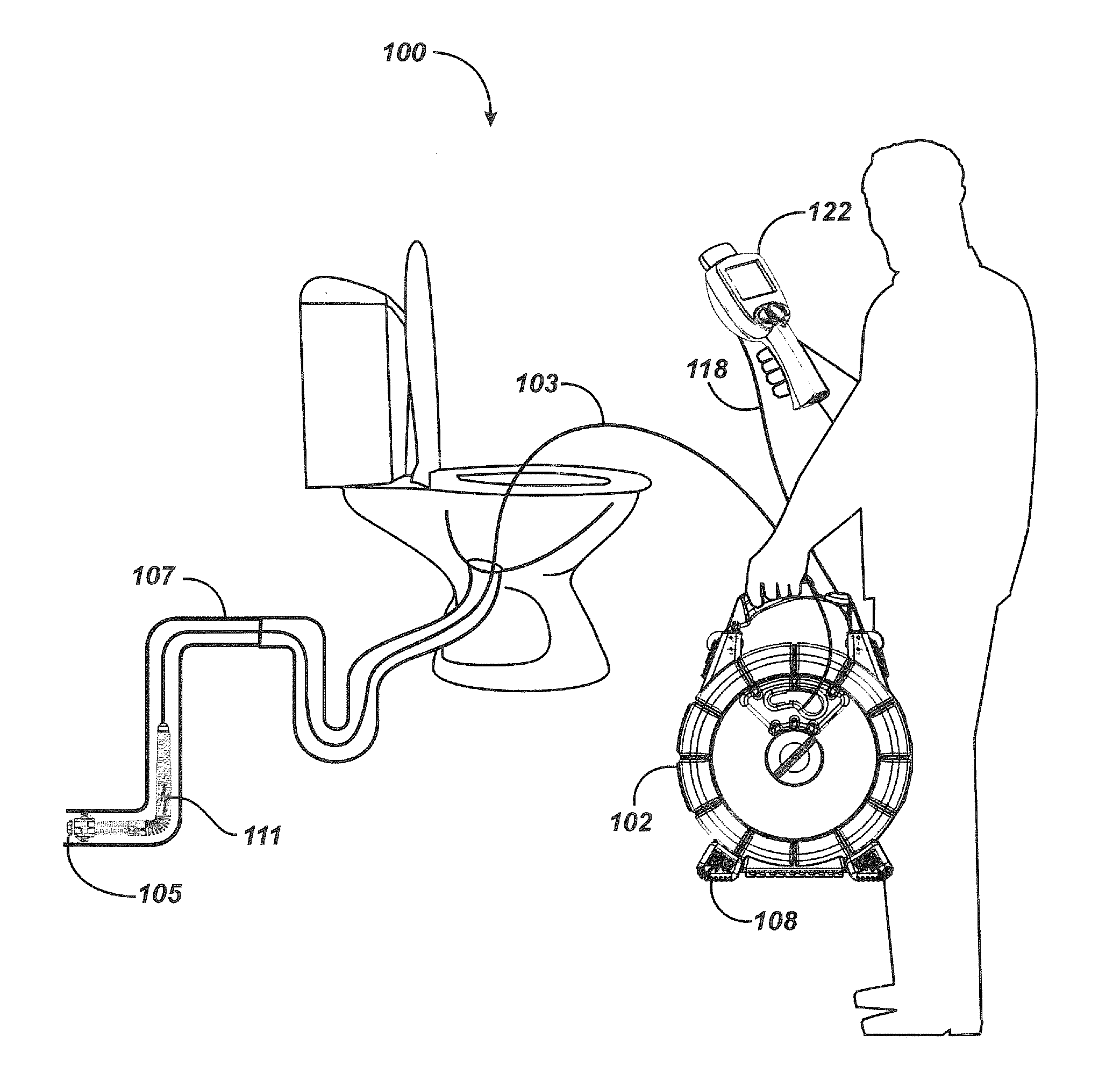

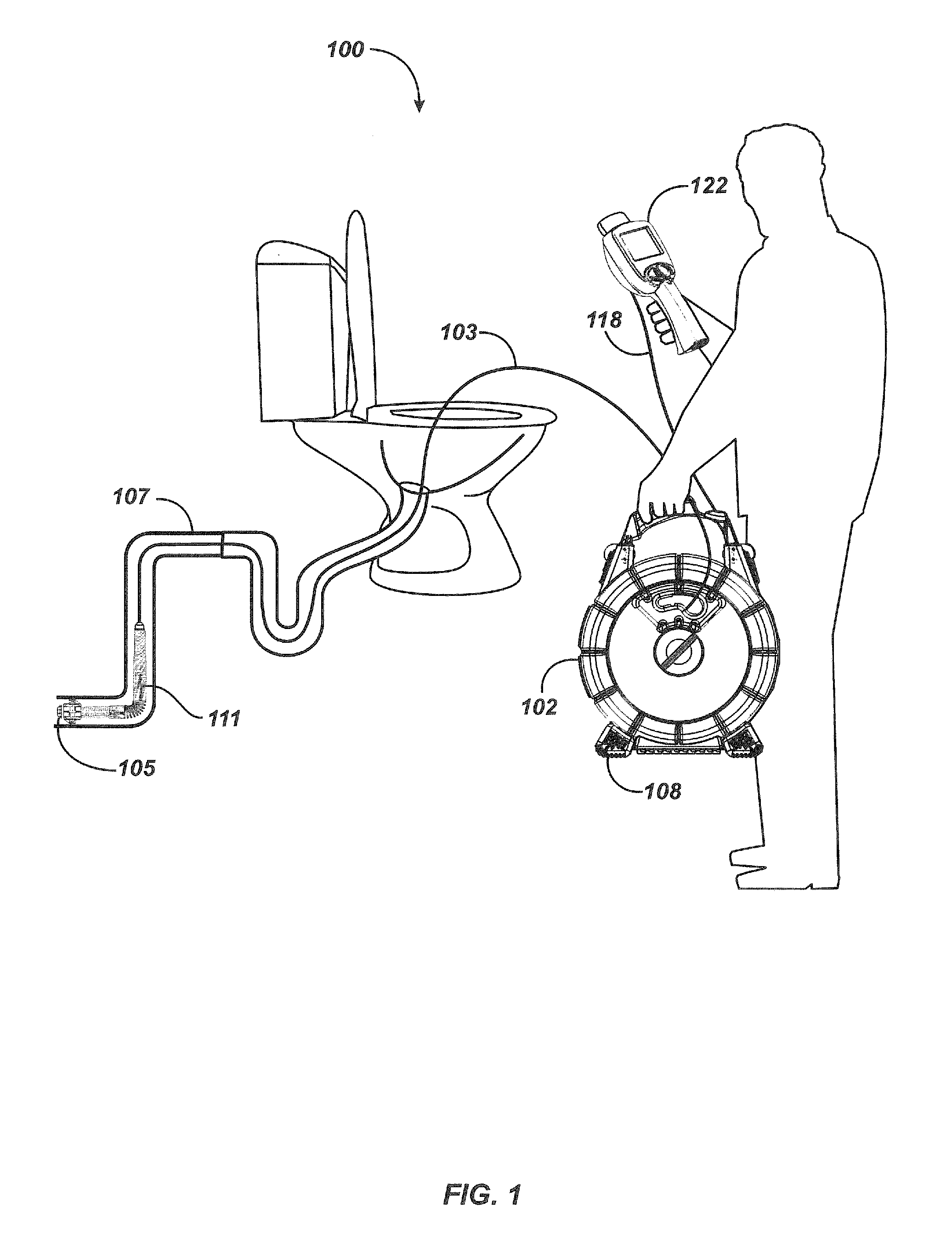

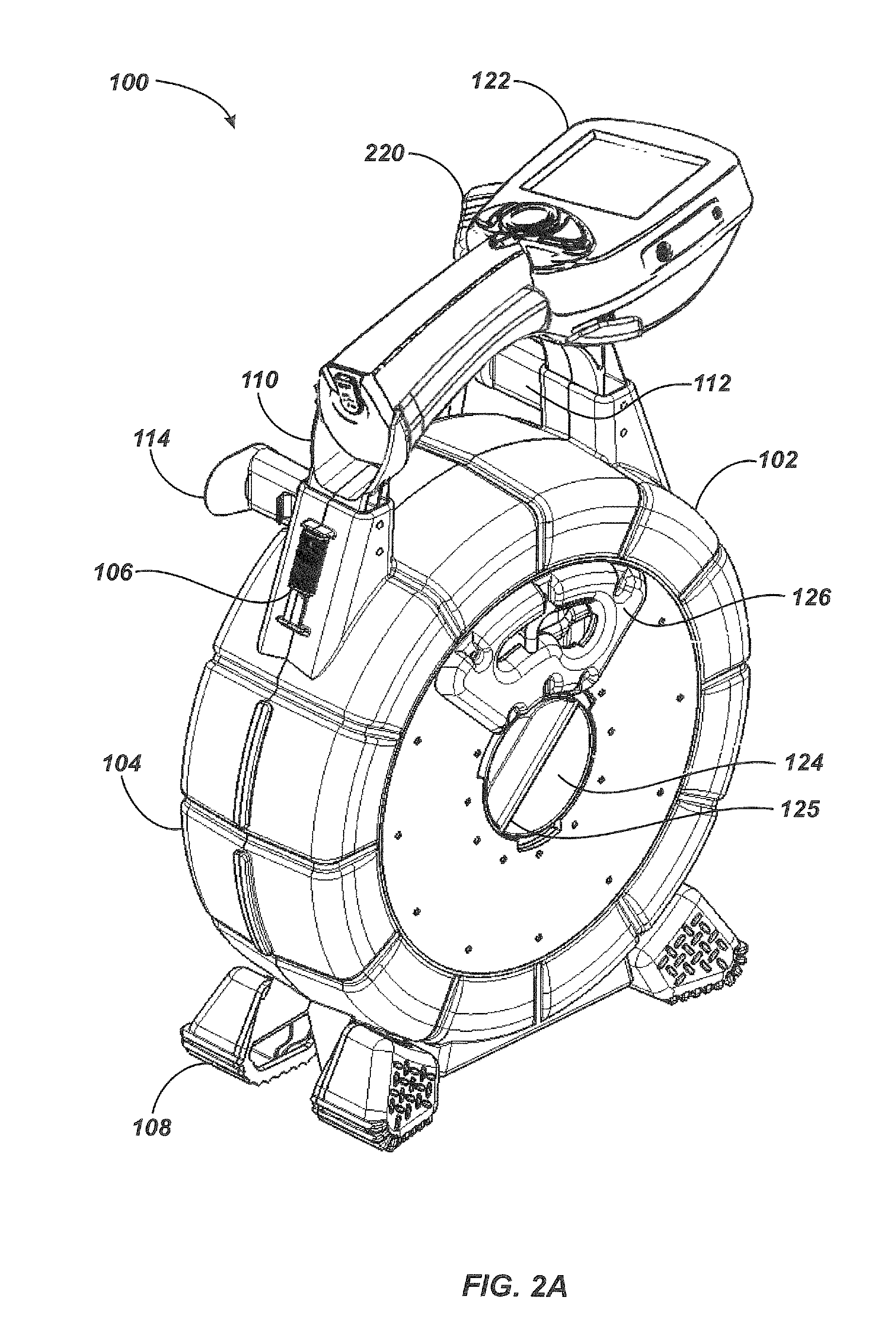

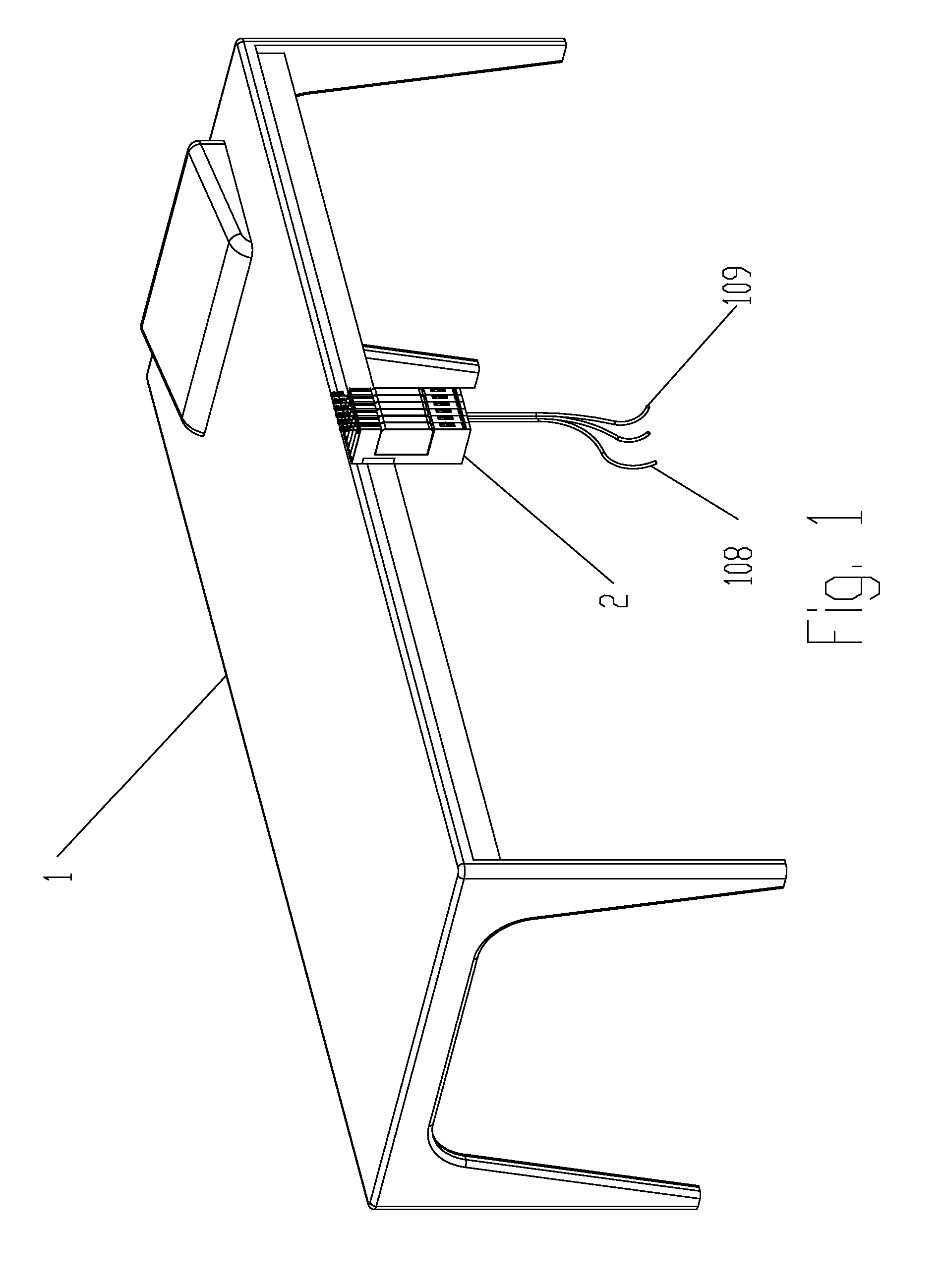

Pipe Inspection System with Replaceable Cable Storage Drum

ActiveUS20100208056A1Measurement apparatus componentsColor television detailsElectrical conductorDisplay device

A pipe inspection system includes a cable storage drum and a housing configured to removably receive and rotatably support the cable storage drum. A push-cable with a plurality of conductors is stored in the cable storage drum. A camera head is connected to a distal end of the push-cable. A slip-ring assembly has first and second mating portions that when mated provide conductive paths between the plurality of conductors at a proximal end of the push-capable and a display device. The first portion of the slip-ring assembly is mounted on the housing and the second portion of the slip-ring assembly is mounted on the removable cable storage drum. The system connection cable joining the inspection system with a display unit is removable and may be replaced with cables compatible with various alternate image display systems.

Owner:SEESCAN

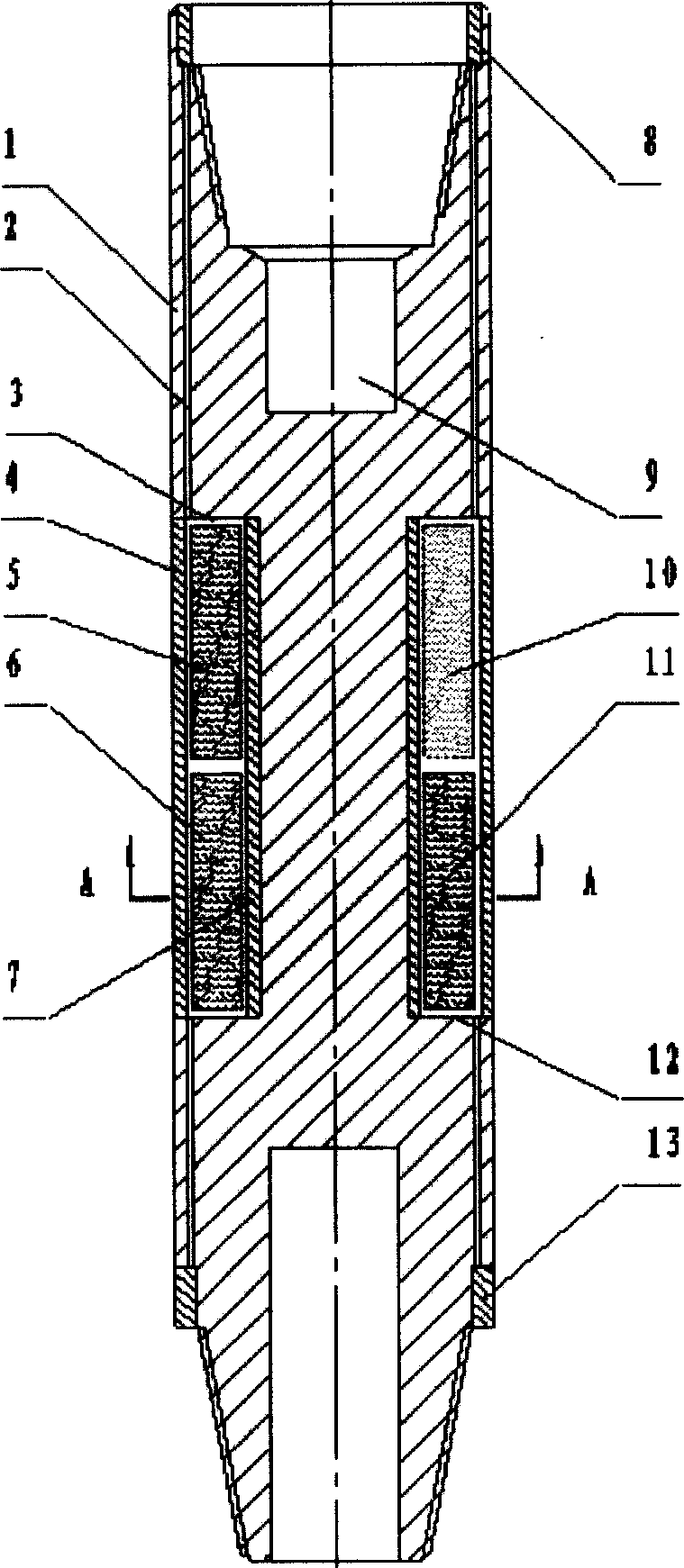

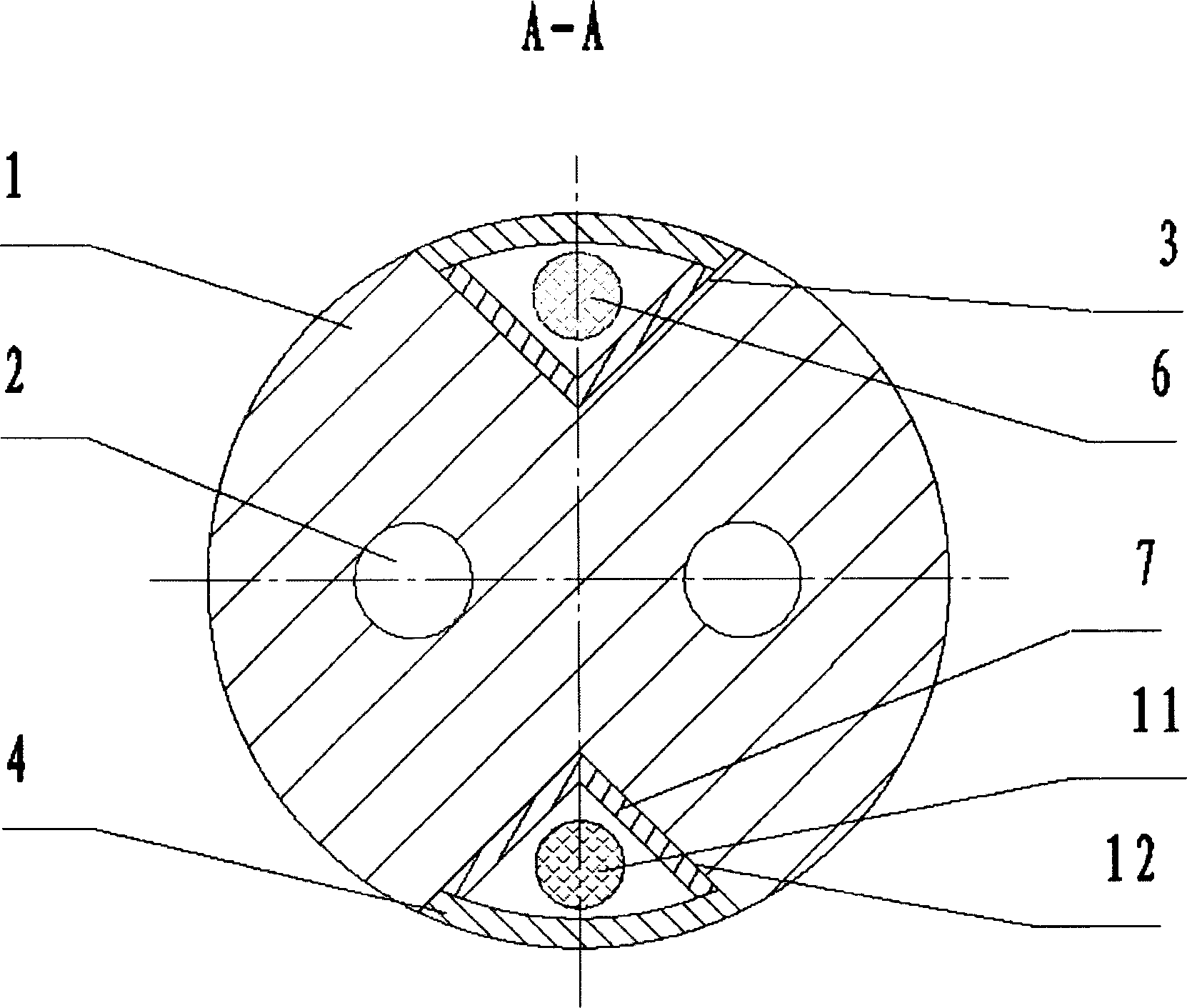

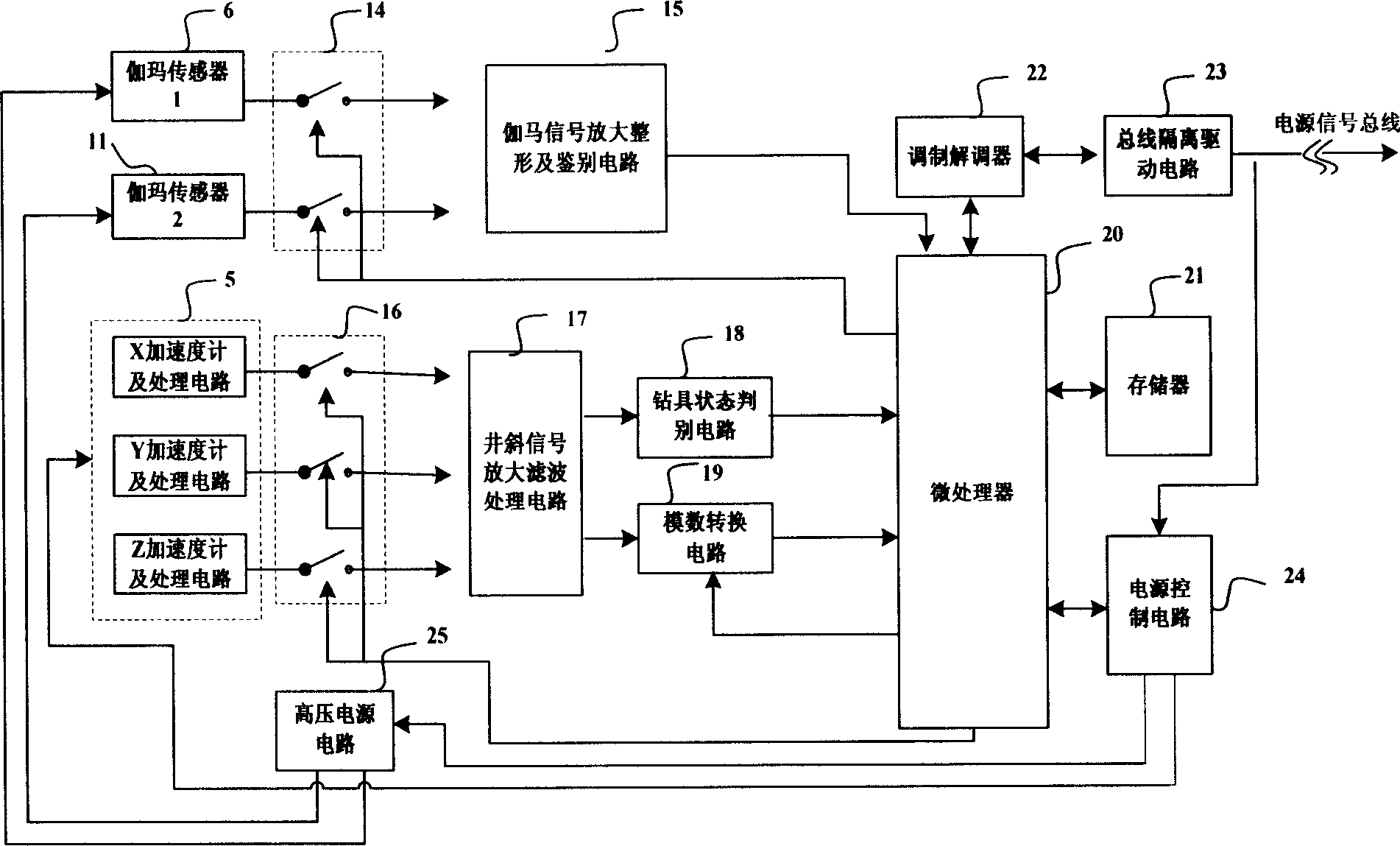

Well deflection and position gamma measuring nistrument during drilling

ActiveCN1676874AControl walkAchieve geosteeringSurveyNuclear radiation detectionLithologySignal processing circuits

The invention is direction and position drill-following survey apparatus comprising a drill collar, two V slots, metal shielding layer, tow gamma sensor, three-axis acceleration sensor, signal processing circuit module, high pressure sealing cover board, boring liquor conducting channel, upper slip ring connector, lower slip ring connector, wire hole. The invention integrated gamma survey and directional survey in just a short section which enables the drill not only survey the rock properties real-timely, but also tell the upper and lower rock characteristics when boring well., so to effectively find out the upper cover layer of the storage layer and seize the best timing entering the oil storage layer. Moreover, meanwhile assorting the upper and lower rock properties, the direction and drill status also can be obtained without any delay, which, facilitating adjusting the well boring track according to the geographic data and manage the drill travels a best track underground among the oil storage. The invention is suitable for geological guiding in fossil engineering.

Owner:中石化石油工程技术服务有限公司 +3

Expandable slip ring

An expandable slip ring is used to secure attachment of an expanded tubular to a surrounding tubular. It features elongated generally axially oriented openings separated by narrow segments. As a swage is advanced within a tubular that has the slip ring outside it the narrow segments or tabs expand and can break but the ring is still held to its shape as the expansion progresses due to the integrity of other tabs that can subsequently break as the swage advances within the tubular that is surrounded by the slip ring. The integrity of the slip ring is enhanced for storage and run in while the expansion characteristics are more uniform as the ring retains some structural integrity during much of the expansion process.

Owner:BAKER HUGHES INC

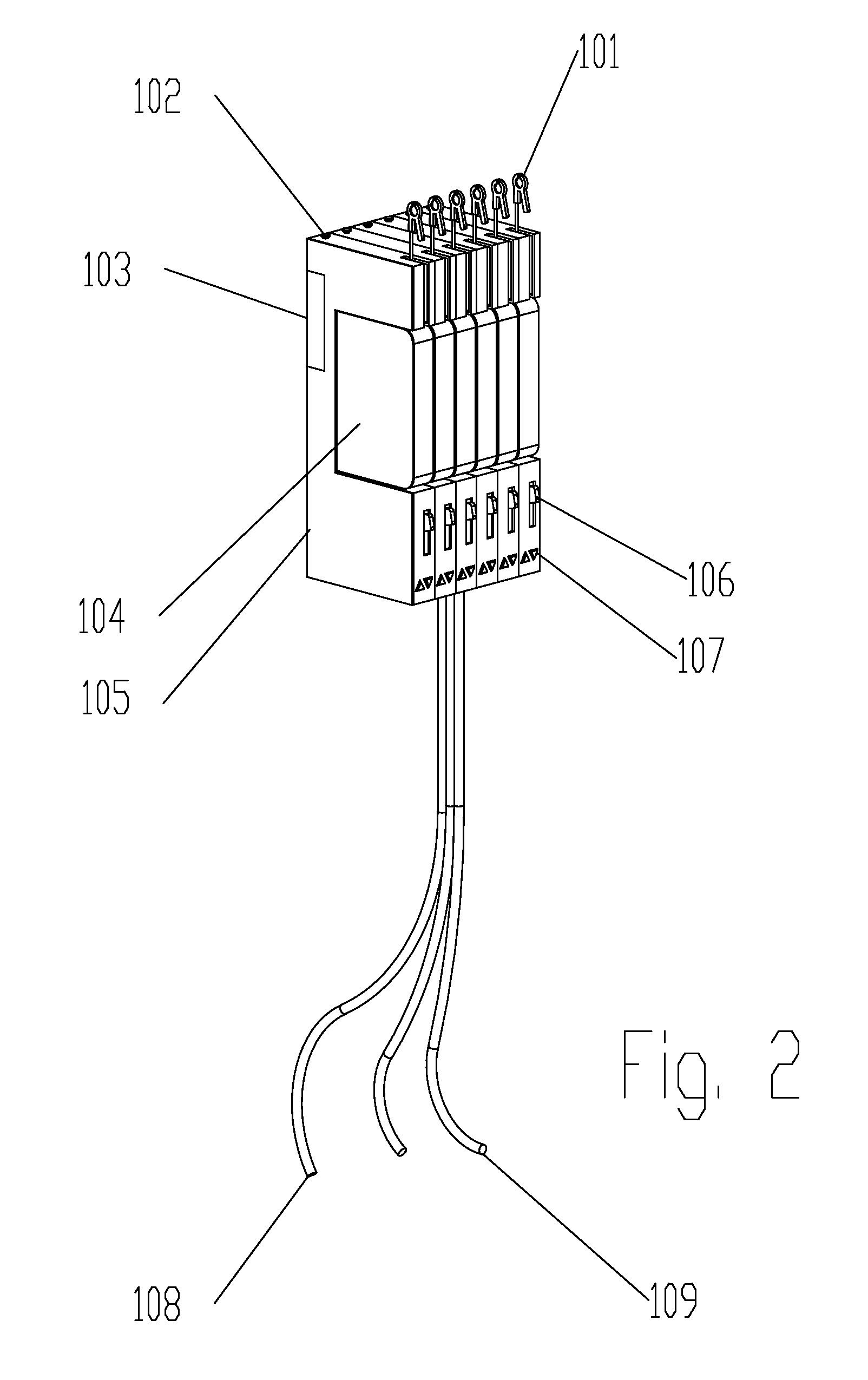

ECG cable management system

A scalable cable management system comprises an electronics module with a microcontroller; a plurality of drive modules and a releasably engaged cable cartridge for each drive module. Each cable cartridge houses a lead wire cable spool with an electrical slip ring connected to the wire. Stationary electrical contacts pickup signals from the slip ring for use by the electronics module. A device such as an electric or spring-driven motor, with a gear train and an optional clutch, controllably rotate the cable spool. A cleaning assembly cleans portions of the lead wire as it is extended or retracted. The microcontroller receives strain signals representative of tension on a lead wire from cable strain gauge. The electronics module may also include a defibrillator protection sub-system, a crossbar transfer switch, an instrumentation amplifier and a communications unit. Test terminals are also provided for assessing integrity of each lead wire.

Owner:I Q INNOVATIONS

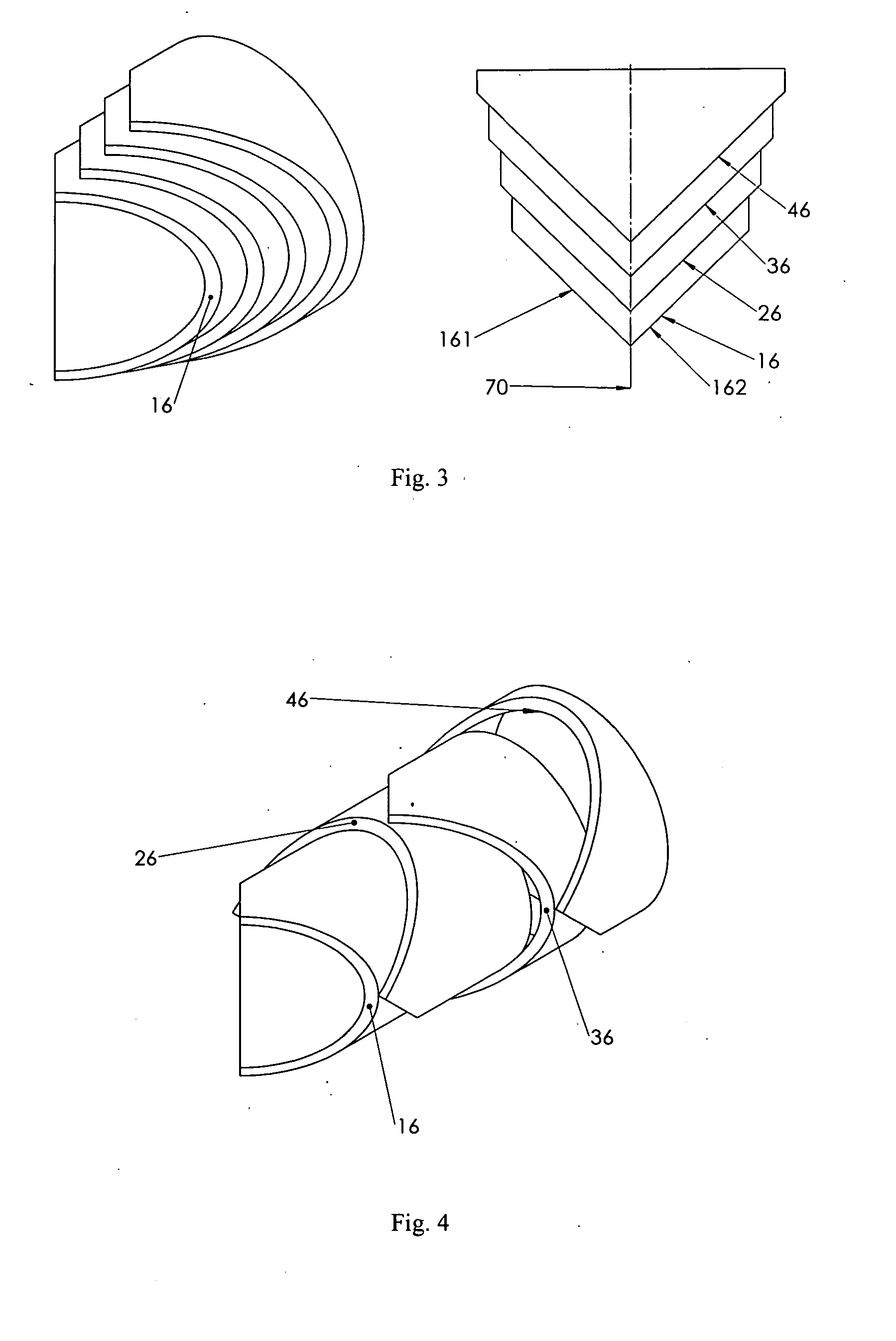

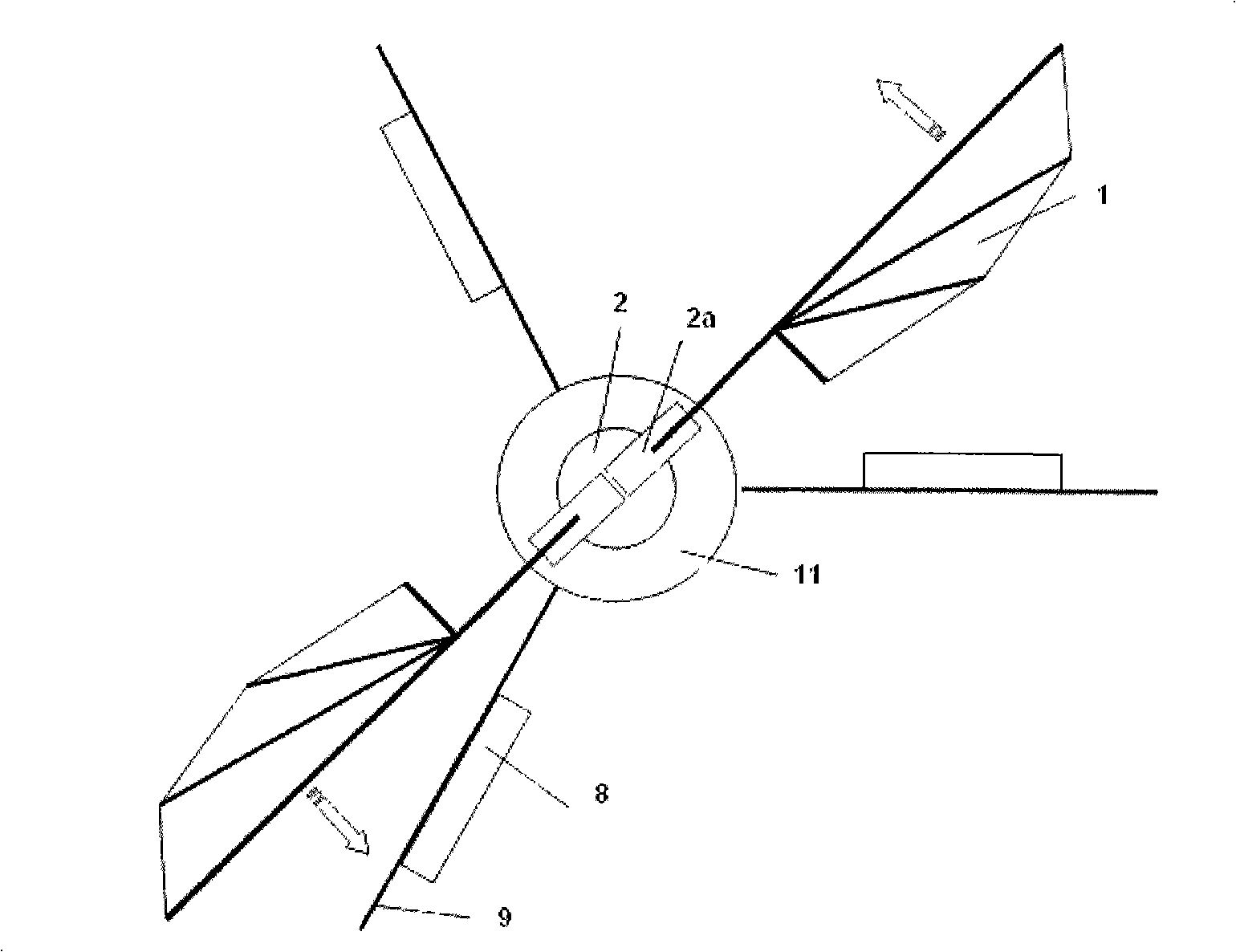

Off-axis fiber optic slip ring

ActiveUS20100226607A1Increase the number ofCoupling light guidesPrismElectrical and Electronics engineering

A multi-channel off-axis optic slip ring system is disclosed. The invention eliminates the huge number of fiber bundles and photodiodes in most published patents. A couple of conventional optical components such as mirrors and prisms are used to transmit optical signals with high quality and low optic losses. The optical signal pick-up is realized through a pair of prisms mounted on gear transmission systems. It is a true passive, bi-directional rotational optical transmission device which could be used for both multi-mode and single mode fibers without the limitation to the through bore diameters.

Owner:PRINCETEL

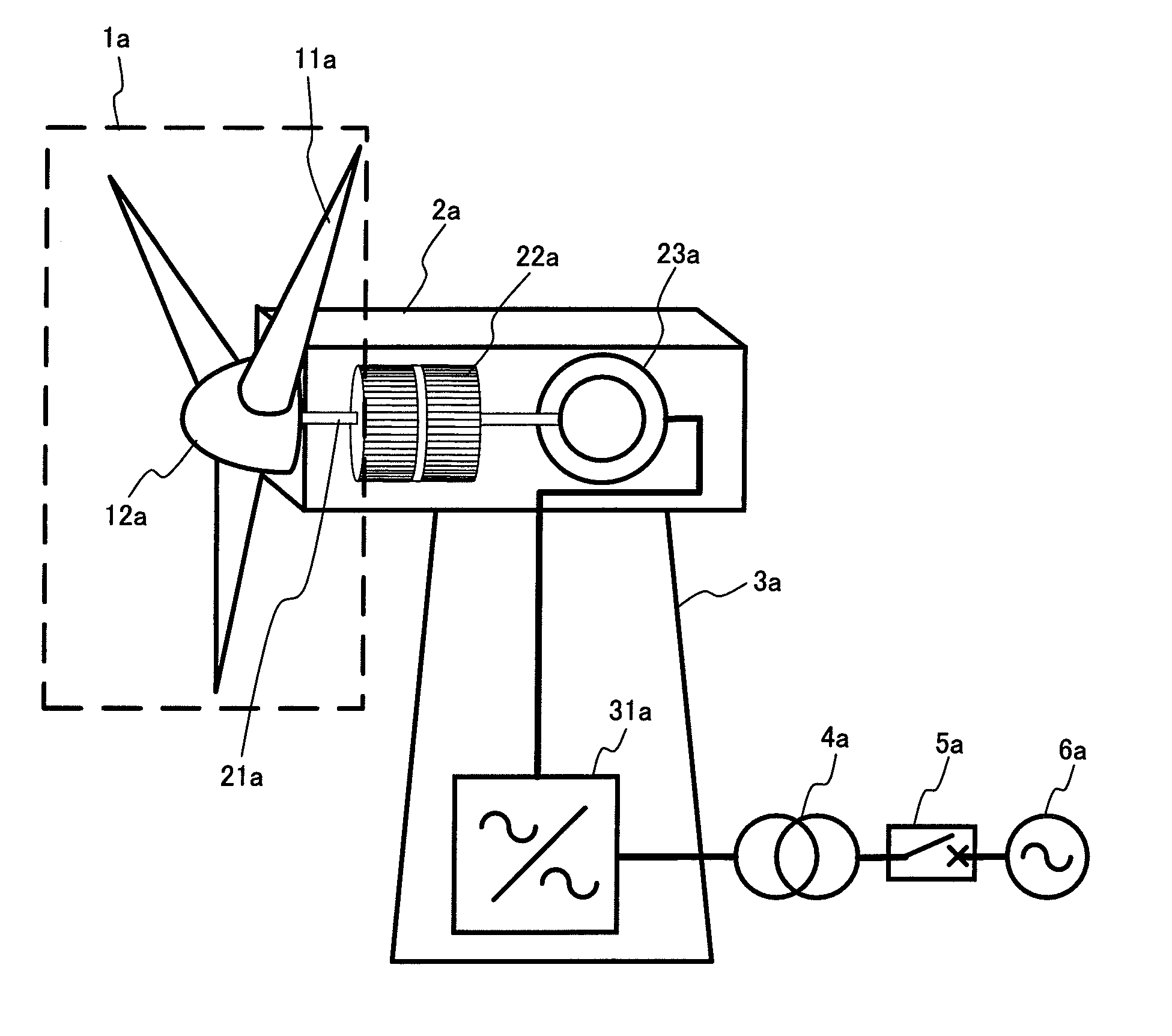

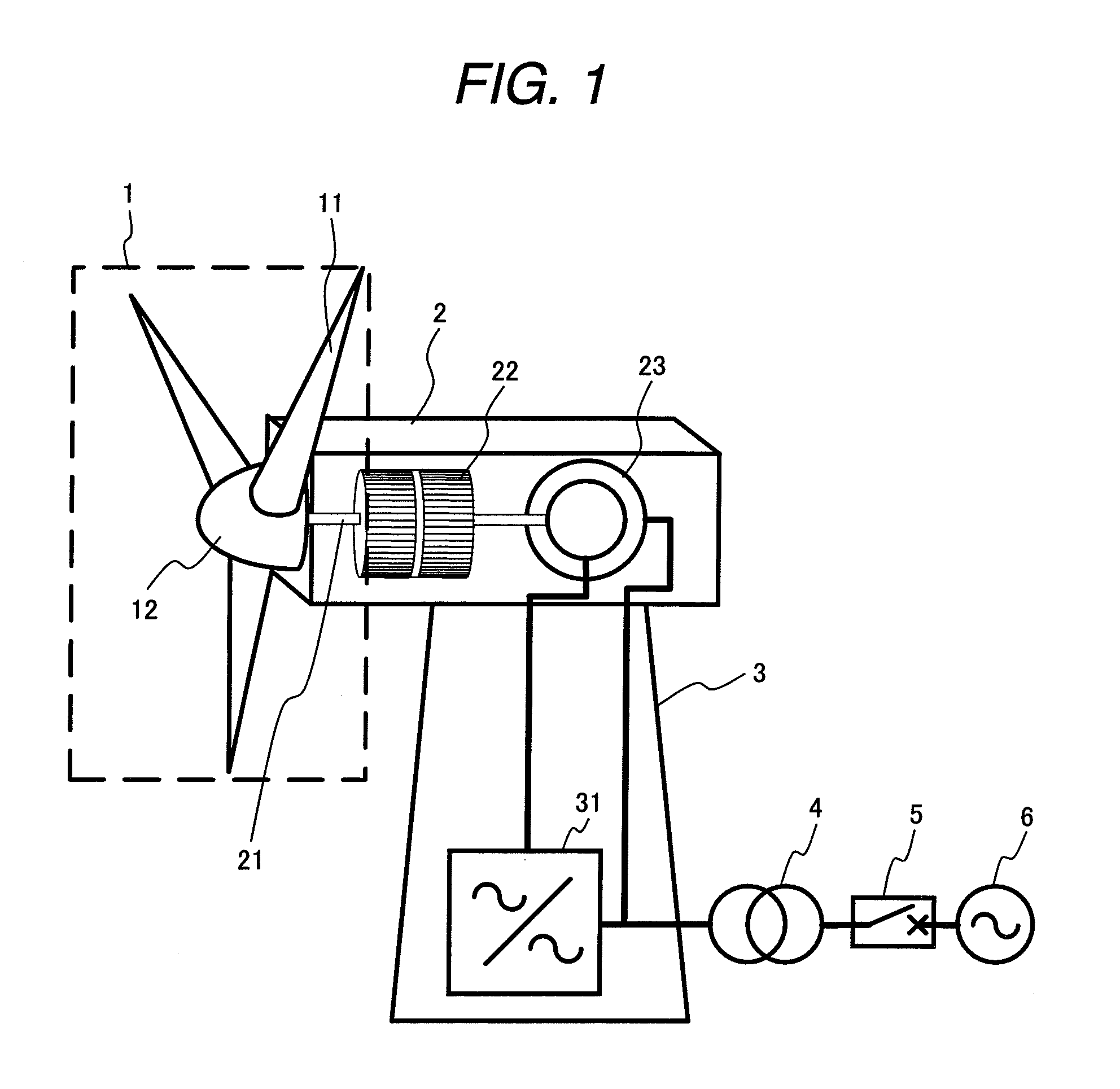

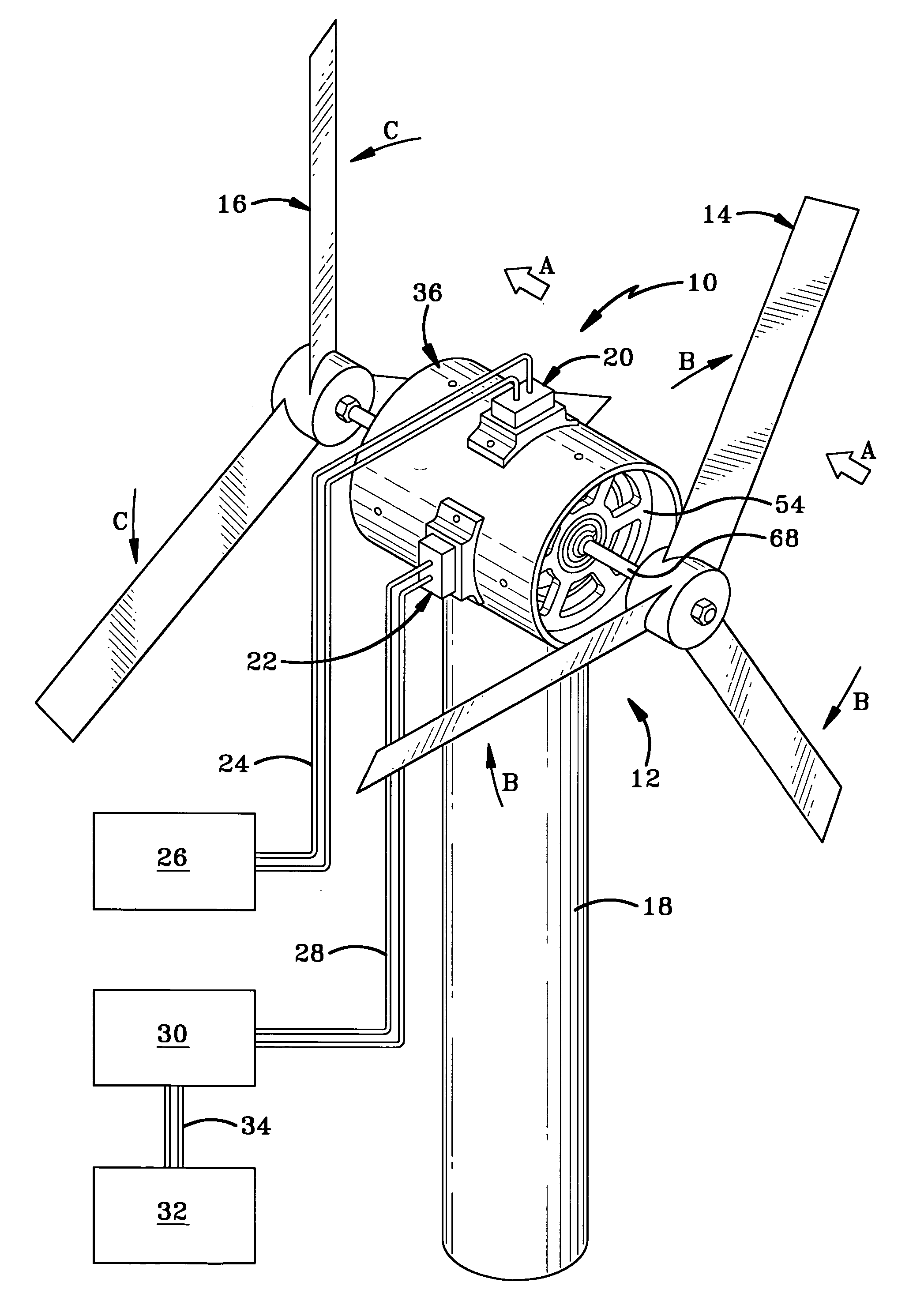

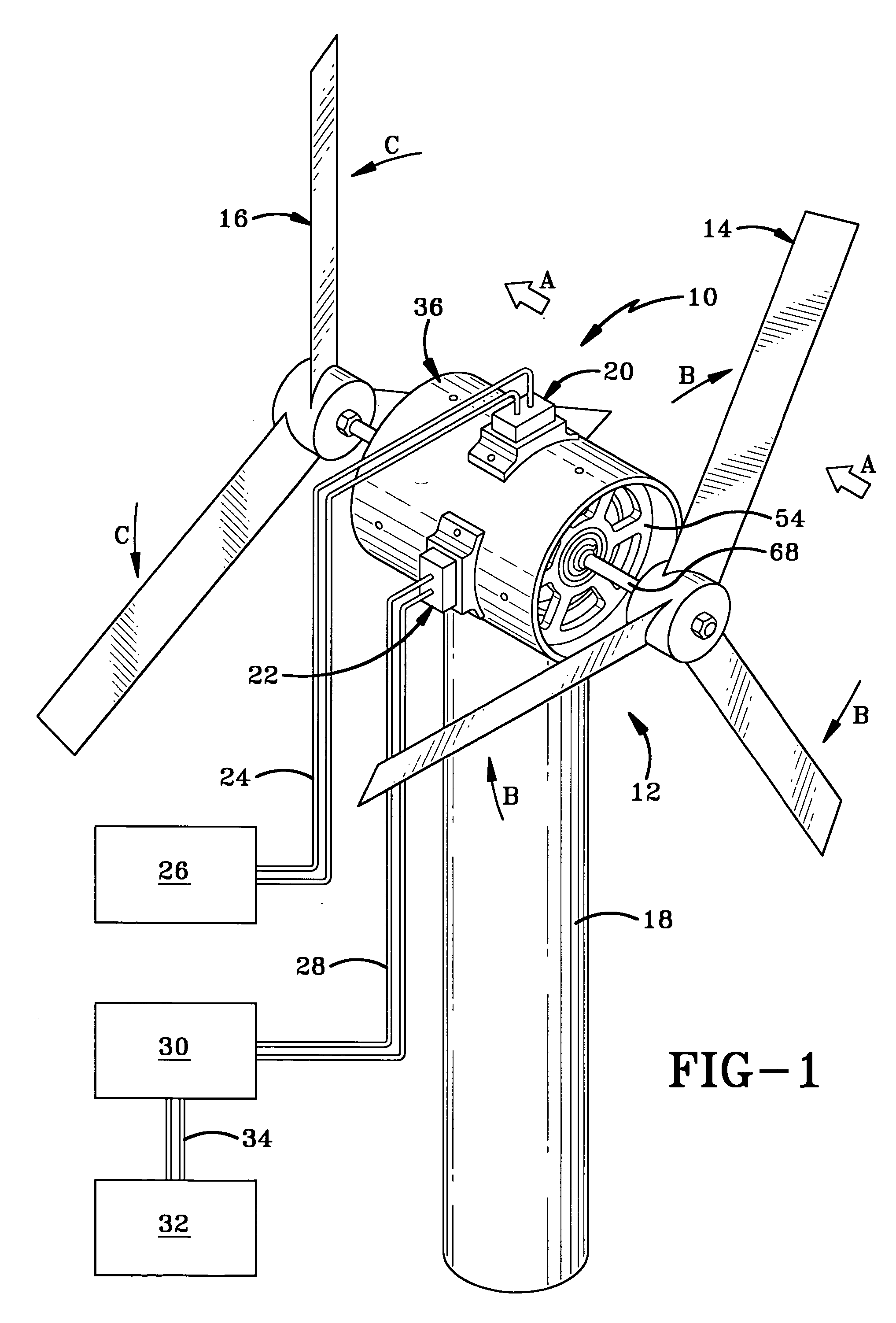

Wind turbine and operating method thereof

InactiveUS20080069692A1Prevent speedingControl moreRotational speed controlLevel controlClassical mechanicsControl theory

A pitch controller, uninterruptible power supply, and rotational speed detector are disposed in the rotor in a wind turbine. When a slip ring failure or wire breakage occurs, the pitch controller internally creates a pitch angle command so as to control the pitch angle.

Owner:HITACHI LTD

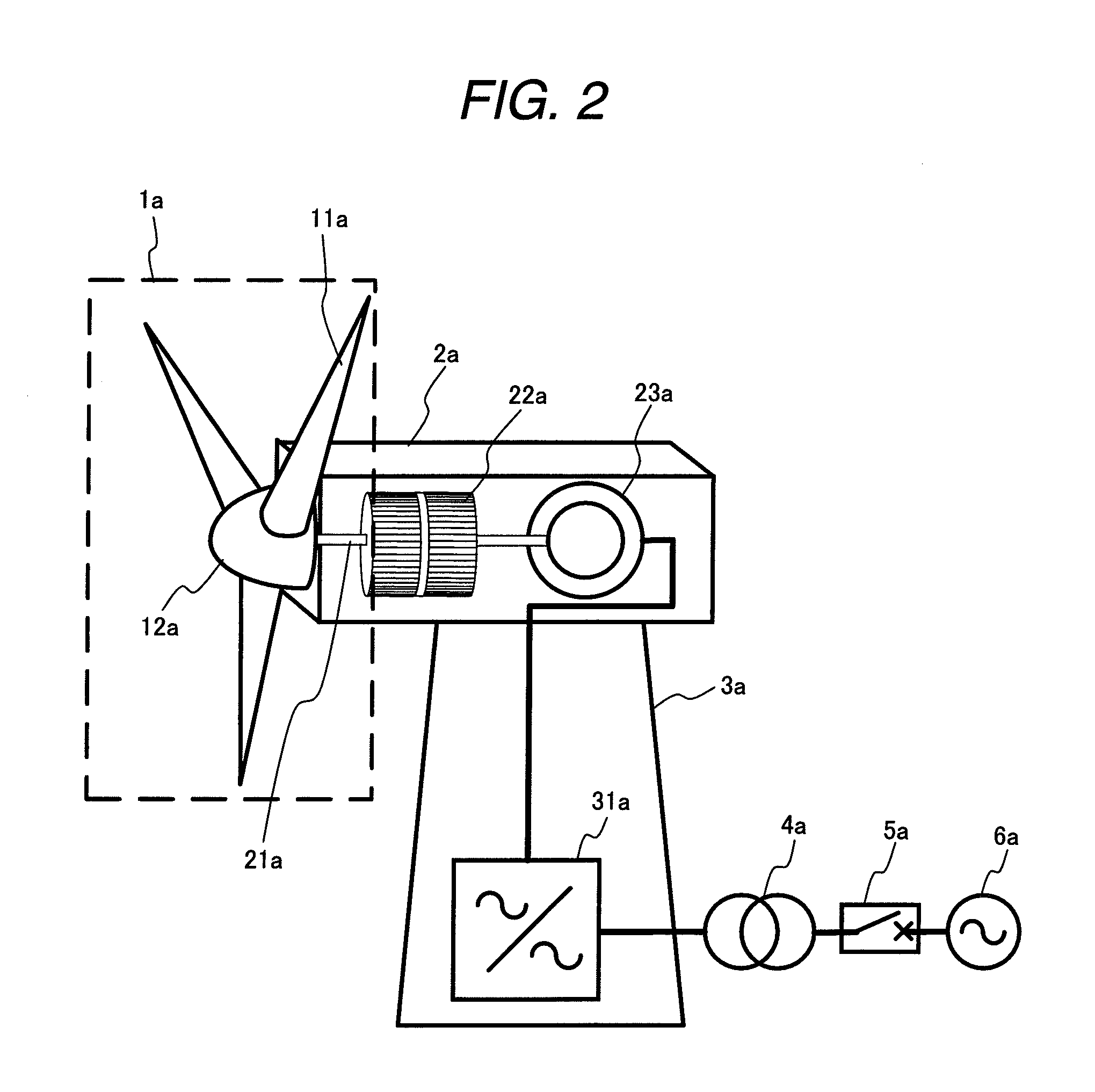

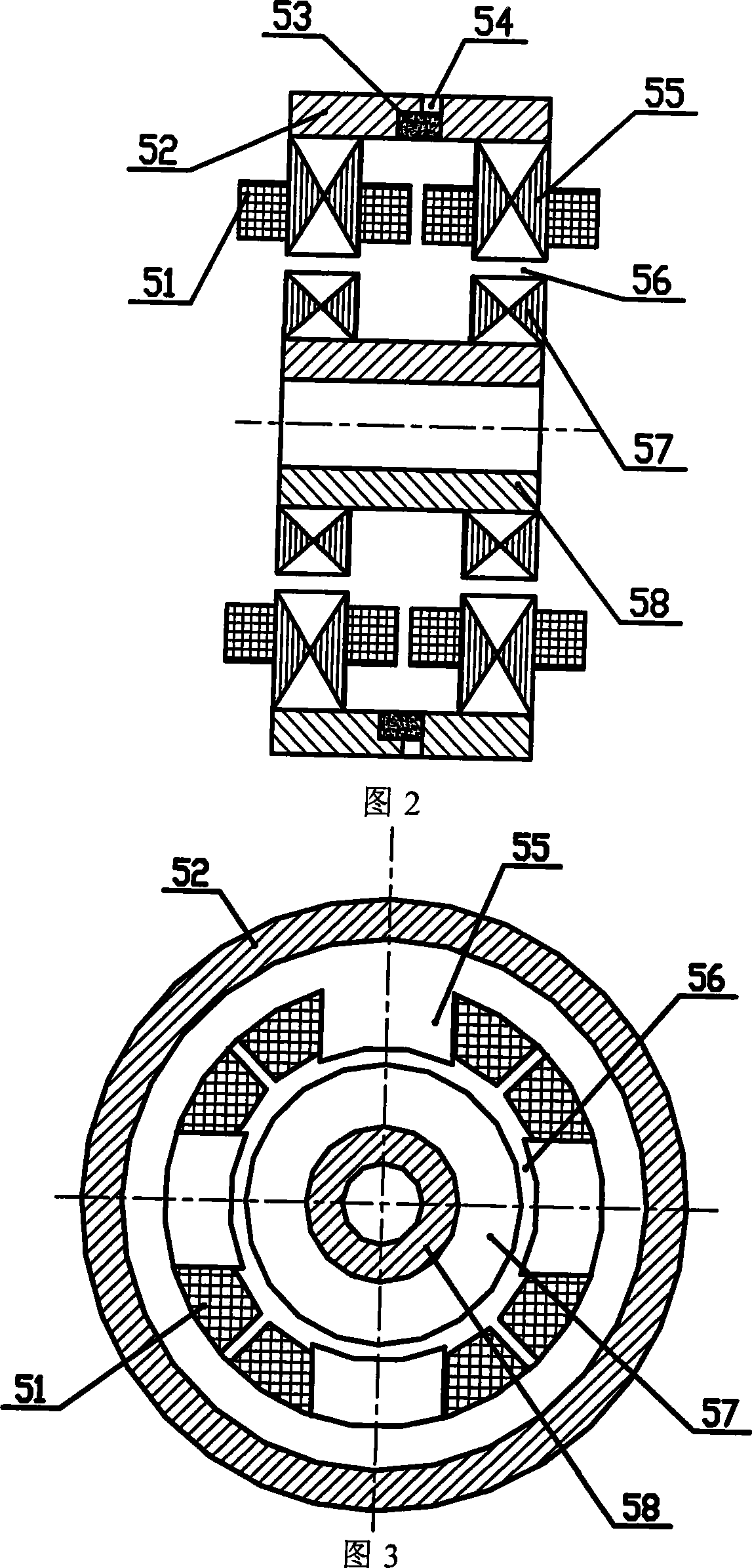

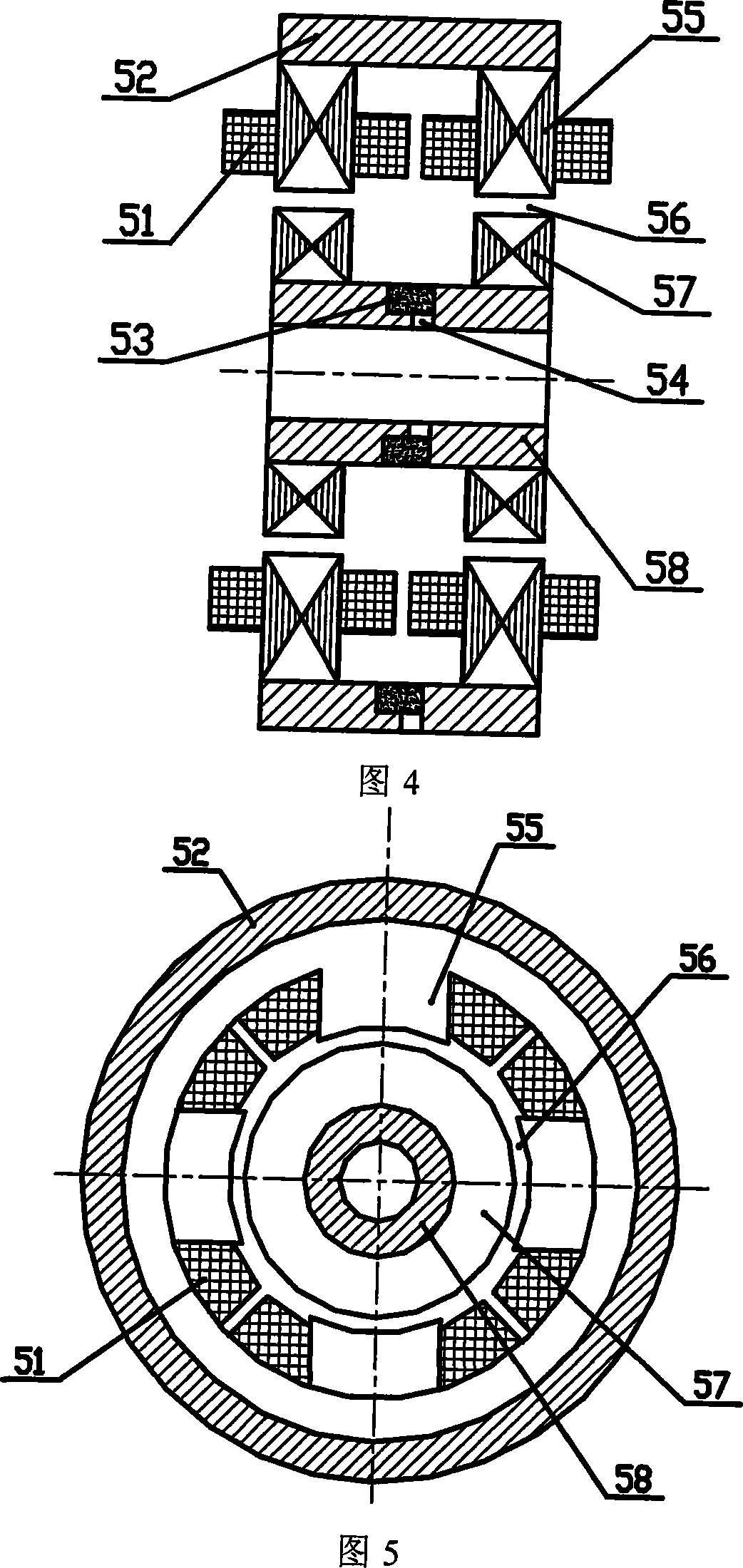

Double-frame magnetic suspension control moment gyro

InactiveCN101219714AReduce volumeReduce weightSpacecraft guiding apparatusAxial displacementMagnetic bearing

The invention relates to a magnetic suspension controlled moment gyro with double frames, essentially consisting of a flywheel, an inner frame system and an outer frame system. The flywheel is arranged in the middle of the magnetic suspension controlled moment gyro with the double frames and essentially comprises a rotary shaft, a radial mixed magnetic bearing, an axial magnetic bearing, a radial displacement sensor, an axial displacement sensor, a high-speed motor and a gyro room; the inner frame system and the outer frame system essentially comprise the frames, a mechanical bearing, a moment motor, a reducer, an angle position sensor, a conductive slip ring a control system; the inner frame system is connected with a shaft hole on one end of the gyro room through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the gyro room; the outer frame system is connected with a shaft hole on one end of the inner frame through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the inner frame. The invention reduces noise, size and weight of the system through the mixed magnetic bearing, and eliminates bearing friction, and thus prolongs life span and promotes control accuracy of the controlled moment gyro.

Owner:BEIHANG UNIV

Counter rotating generator

A counter rotating generator has an outer housing including a cylindrical sidewall defining a pair of openings and a pair of circular mounting plates connected to the outer housing adjacent respective opposed ends thereof. A first shaft and an armature mounted thereon are rotatably mounted on one mounting plate. A second shaft and a field magnet mounted thereon via an inner housing is rotatably mounted on the other mounting plate in a direction opposite the armature. Slip rings are mounted on and encircle the inner housing. A pair of brush assemblies are mounted on the outer housing and extend respectively through the openings in sidewall thereof with brushes contacting the slip rings between and adjacent the inner housing and the outer housing sidewall. The large-diameter slip rings more quickly dissipate heat caused by frictional engagement of the brushes and slip rings, thus allowing the generator to operate at higher rates of revolution and higher temperatures.

Owner:FLORES PAUL JR

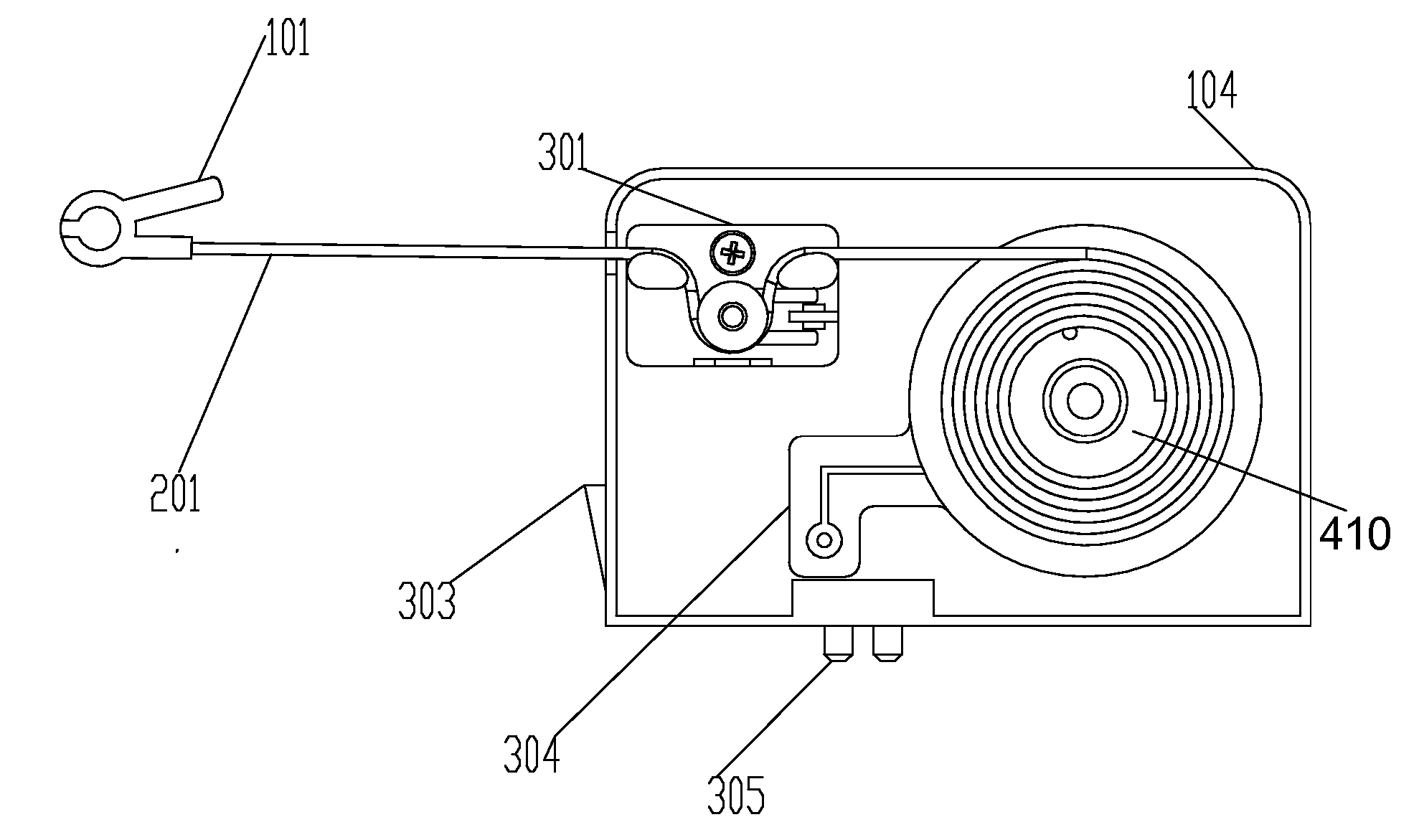

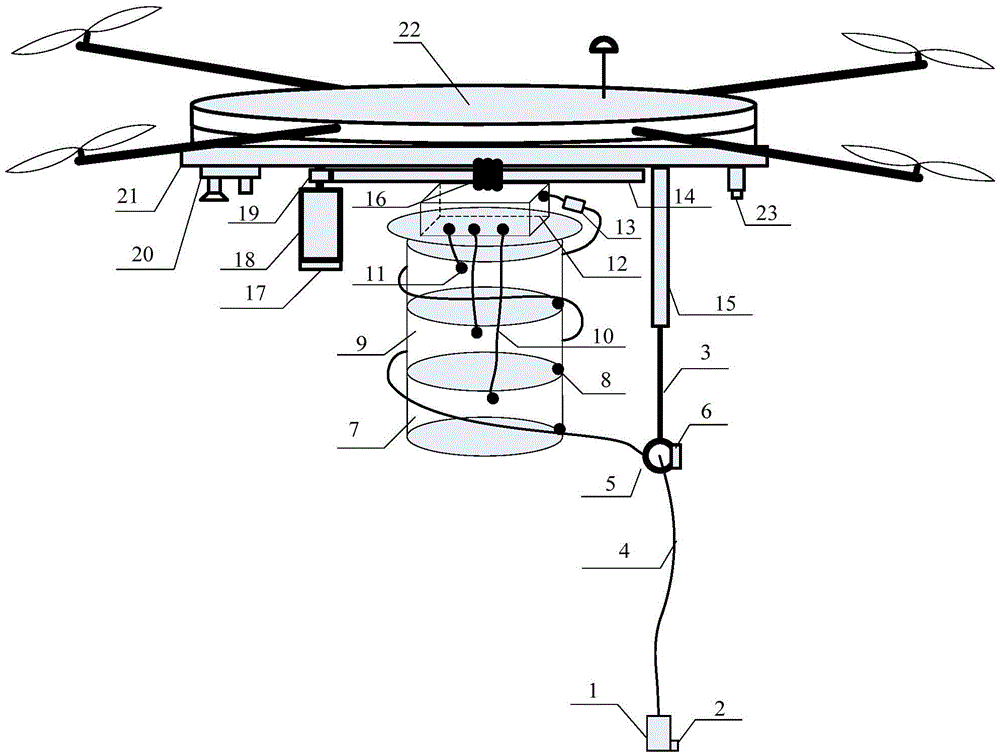

Automatic sampler of water quality sampling UAV (Unmanned Aerial Vehicle)

ActiveCN105571904AReduce weightImprove performanceWithdrawing sample devicesUncrewed vehicleWater quality

The invention discloses an automatic sampler of a water quality sampling UAV (Unmanned Aerial Vehicle). The automatic sampler comprises a main body support, a fixed height sensor, a water sample collecting device, a lifting device, a sample dividing device, a sample storage device and a control circuit board, wherein the water sample collecting device comprises a submersible pump, a pressure and liquid level sensor, a flexible water pipe and a flow sensor and is capable of completing fixed-depth sampling; the lifting device comprises a servo motor, a magnetic encoder, a reduction gear, a slip ring, a bearing, a proximity switch, a telescopic rod and a ceramic eye component and is capable of realizing retracing and releasing functions of the water sample collecting device; the sample storage device is formed by three layers of detachable plastic bottles. According to the automatic sampler disclosed by the invention, the weight of the automatic sampler can be effectively reduced, and the performance of the whole water quality sampling UAV is increased; meanwhile, the fixed-depth sampling is realized through the lifting device and the pressure and liquid level sensor which is additionally arranged in a sampling opening, the water quality collecting device can be retracted during a flying process of the water quality sampling UAV, and the safety during the flying process of the water quality sampling UAV is increased.

Owner:WUHAN BOGAN SPACE TECH CO LTD

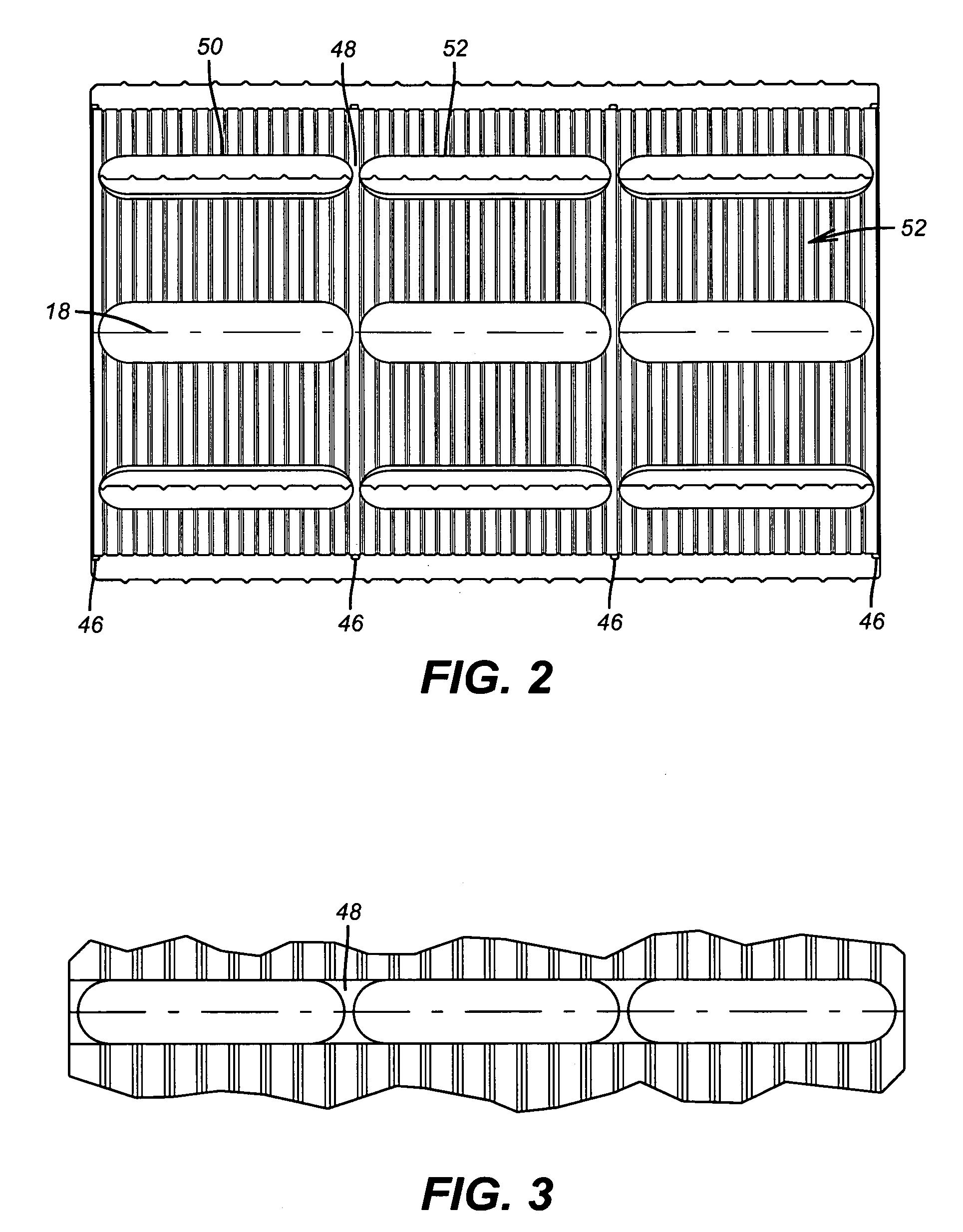

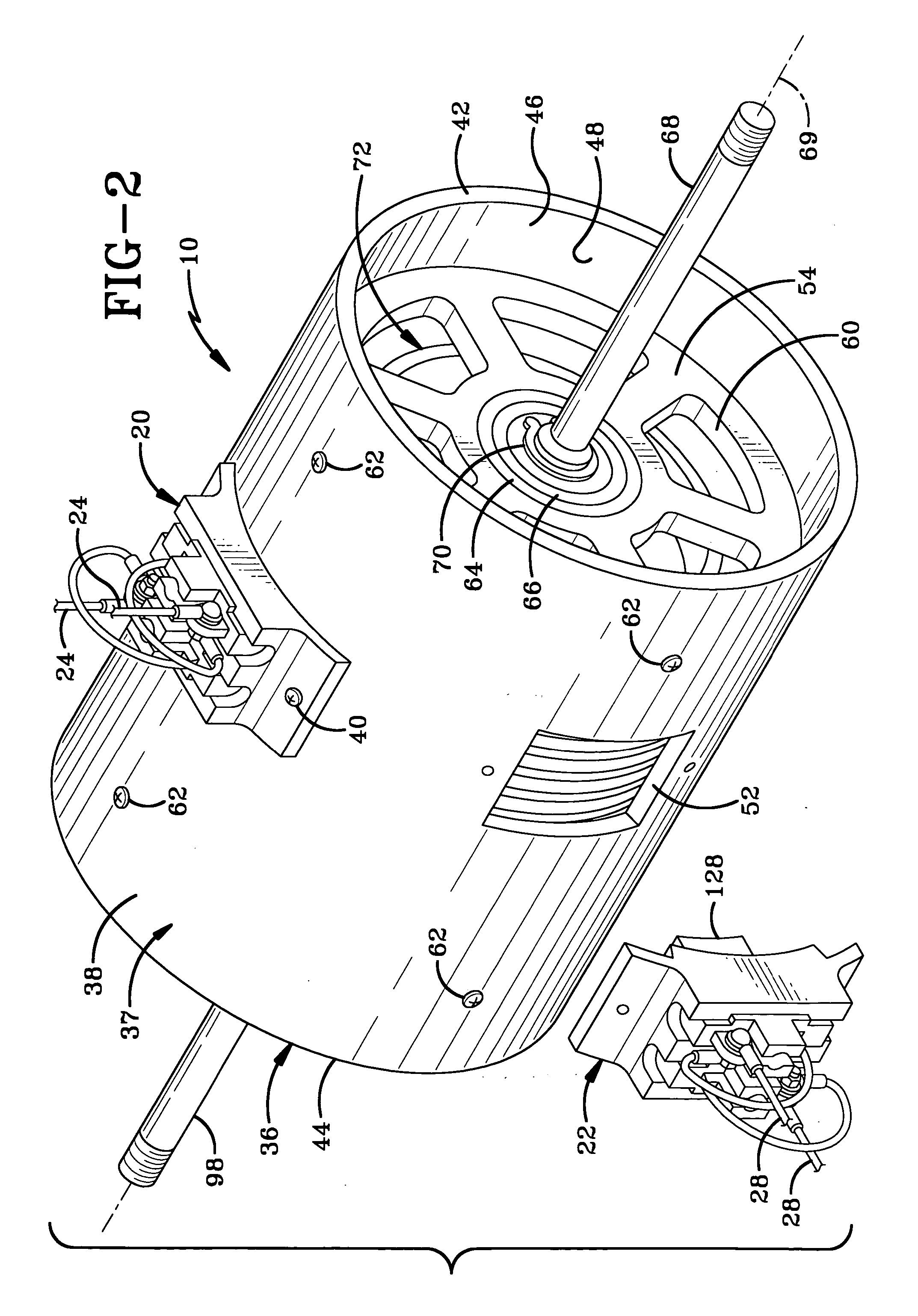

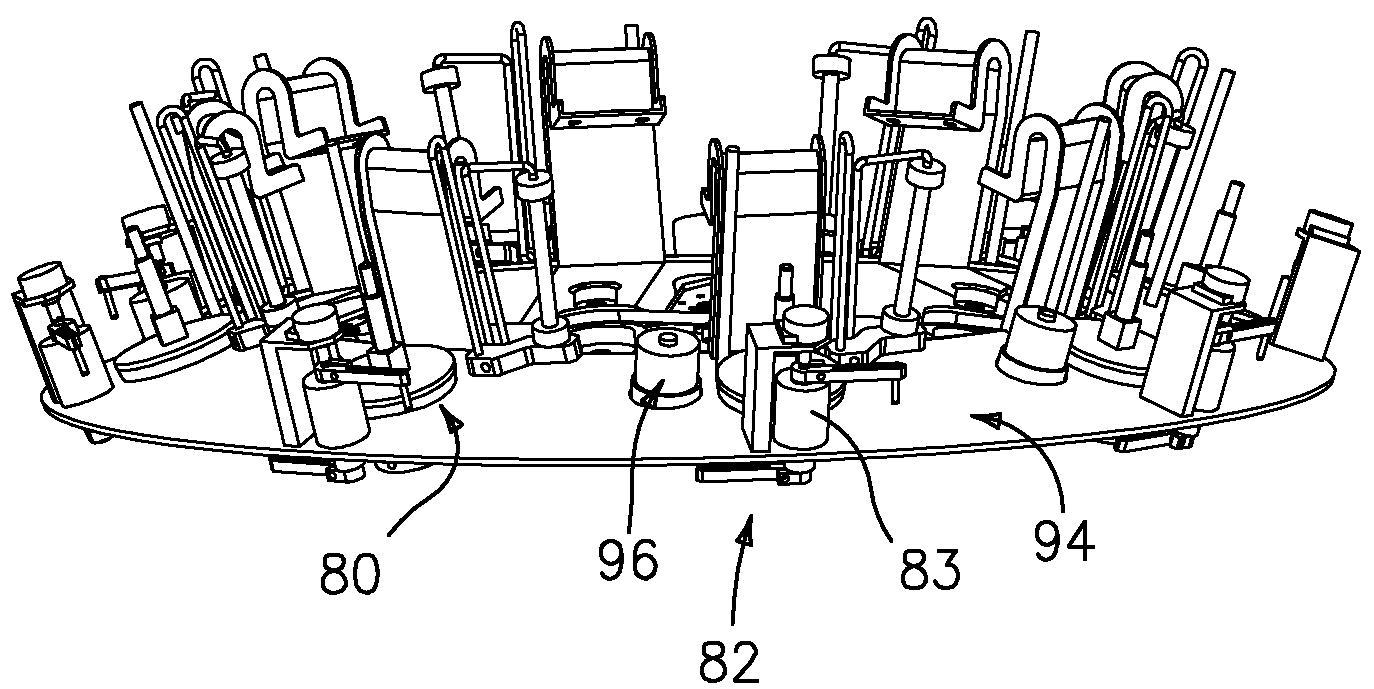

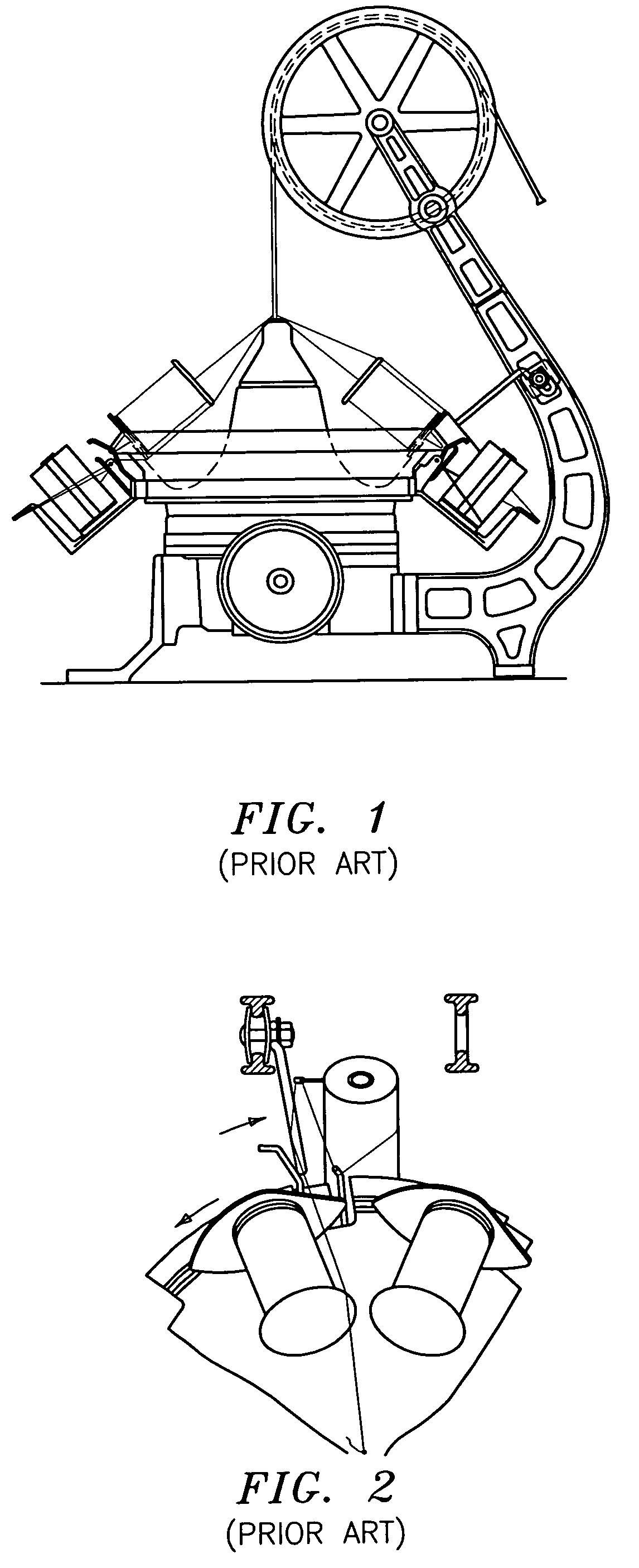

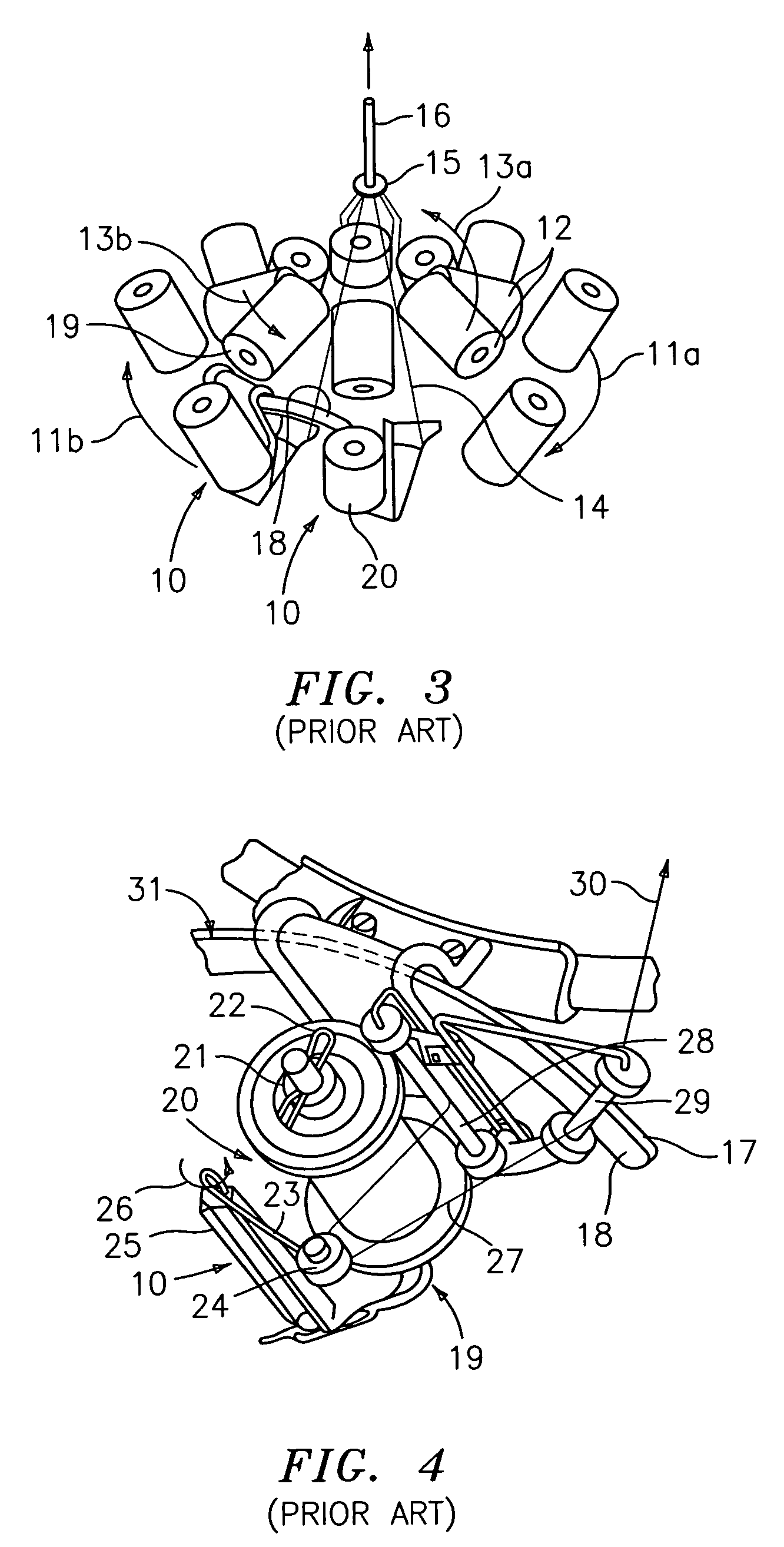

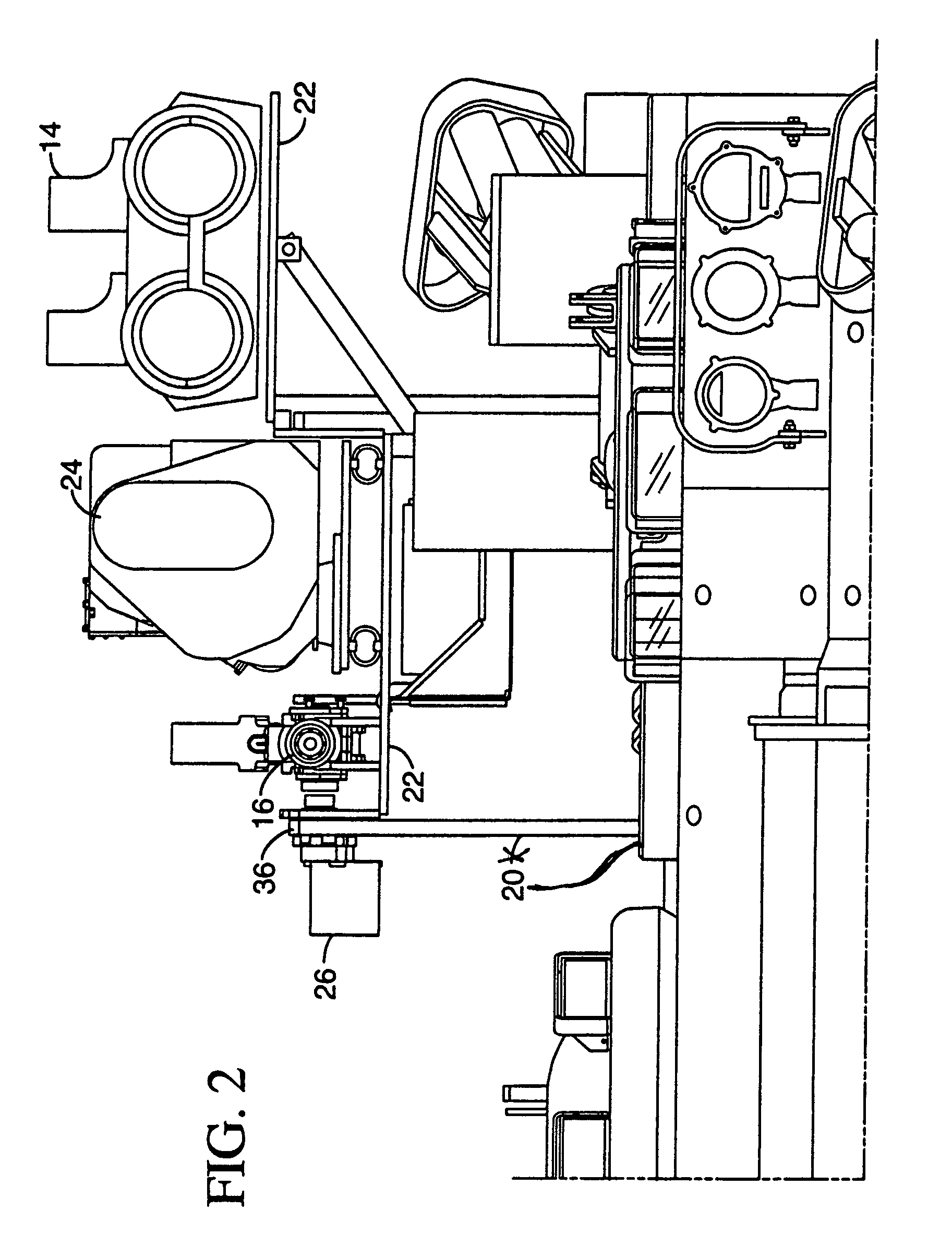

Powered lower bobbin feed system for deflector type rotary braiding machines

A Powered Lower Bobbin Feed (“PLBF”) system is disclosed for improving the operation of deflector type rotary braiding machines, such as the Wardwell Rapid Braider. The PLBF eliminates or reduces the impulsive tension spikes set up by the deflection and feed process in current rotary braiding machines by uniquely controlling the lower bobbin filament feed. These tension spikes result from: the rapid rotational acceleration and deceleration required of the lower bobbin as a result of the feed process; the lever arm tension control and bobbin ratchet mechanism; and the shape of the filament deflector surface. Such failure limits the operating speed of rotary braiding machines, the minimum size of filament that can be braided effectively, or the ability to maintain the quality of the braid produced. By eliminating or reducing these spikes, the PLBF therefore can increase the working speed of circular braiding machines and improve the uniformity of braided filaments generated by such machines at a given speed. In the preferred embodiment, the PLBF comprises: a slip ring designed to provide power to the lower bobbins; a variable speed powered lower bobbin concept; a feedback control system for the bobbins to assure bobbin feed matches braid consumption; and an improved, more contoured, deflector surface to minimize feed tension spikes. The new contour can be created: by retrofitting existing deflectors with a spline; or, by making new deflectors that incorporate the overall contour of a retrofitted deflector.

Owner:STOLBERGER

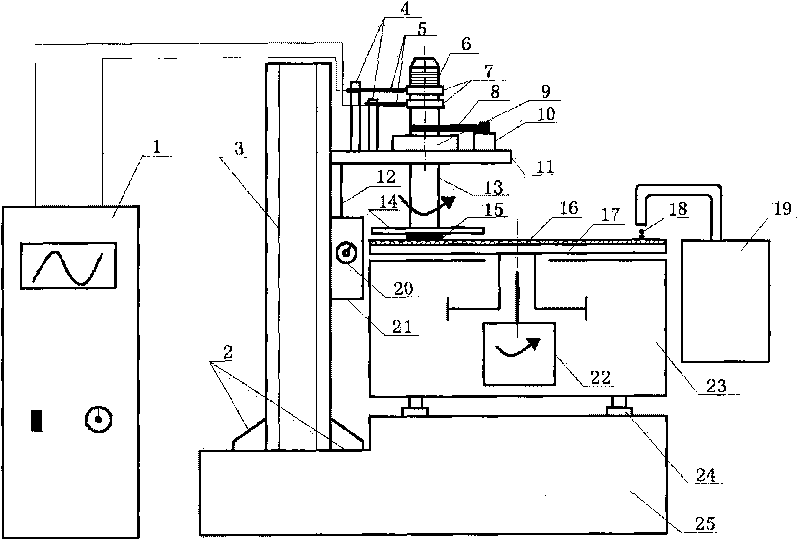

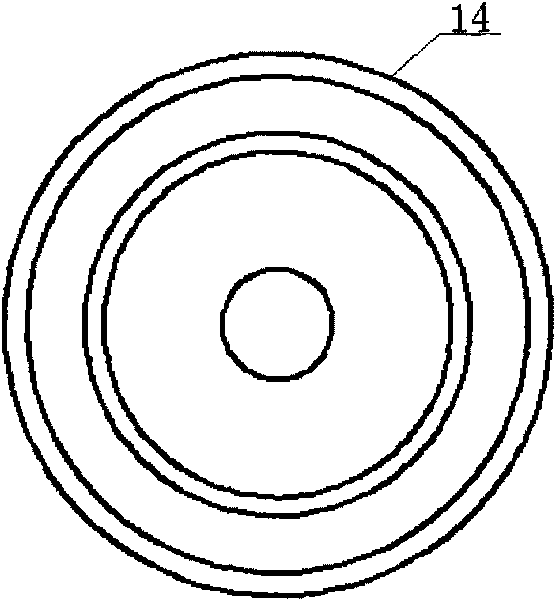

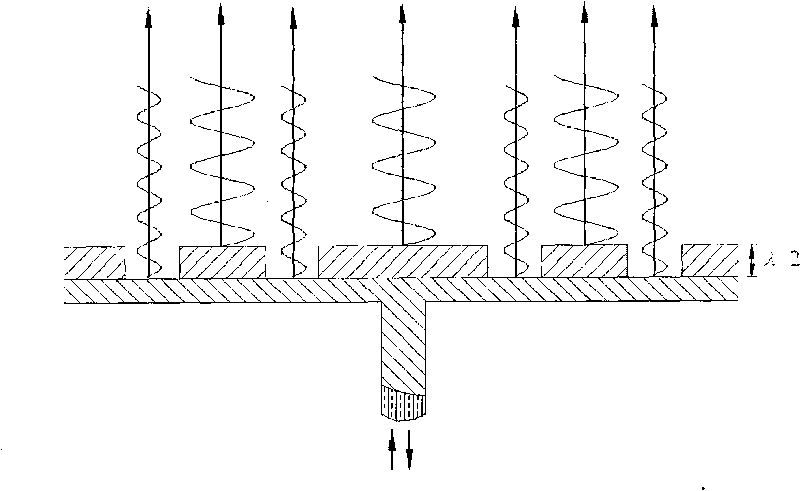

Device and method for polishing sapphire substrate material by ultrasound assisted chemical machinery

InactiveCN101716745AReduce polishing costsShorten polishing timeLapping machinesFine working devicesUltrasonic assistedTransformer

The invention discloses a device and a method for polishing a sapphire substrate material by ultrasound assisted chemical machinery, which belong to the technical field of polishing of sapphire substrate materials. An ultrasound power supply is connected to a positive terminal and a negative terminal of an ultrasonic transducer through a conducting wire, a carbon brush and a copper slip ring; the ultrasonic transducer converts an electrical signal into a mechanical vibration signal; and ultrasonic vibration is transmitted to a polishing head and a sapphire substrate arranged on the polishing head through an amplitude transformer. Compared with the traditional chemical mechanical polishing process, the method has the advantages that: due to the adoption of a composite action structure of ultrasonic vibration and chemical machinery, the method reduces the polishing cost and the polishing time of the sapphire substrate, improves surface topography precision of the sapphire substrate, meets the performance requirement of serving as the substrate material, and improves the polishing efficiency and the polishing quality; the polishing efficiency is improved by over one time; and the surface roughness of the polished sapphire is less than angstrom level. The ultrasonic assisted chemical mechanical polishing process is characterized by simple operation, convenience and practicability.

Owner:TSINGHUA UNIV

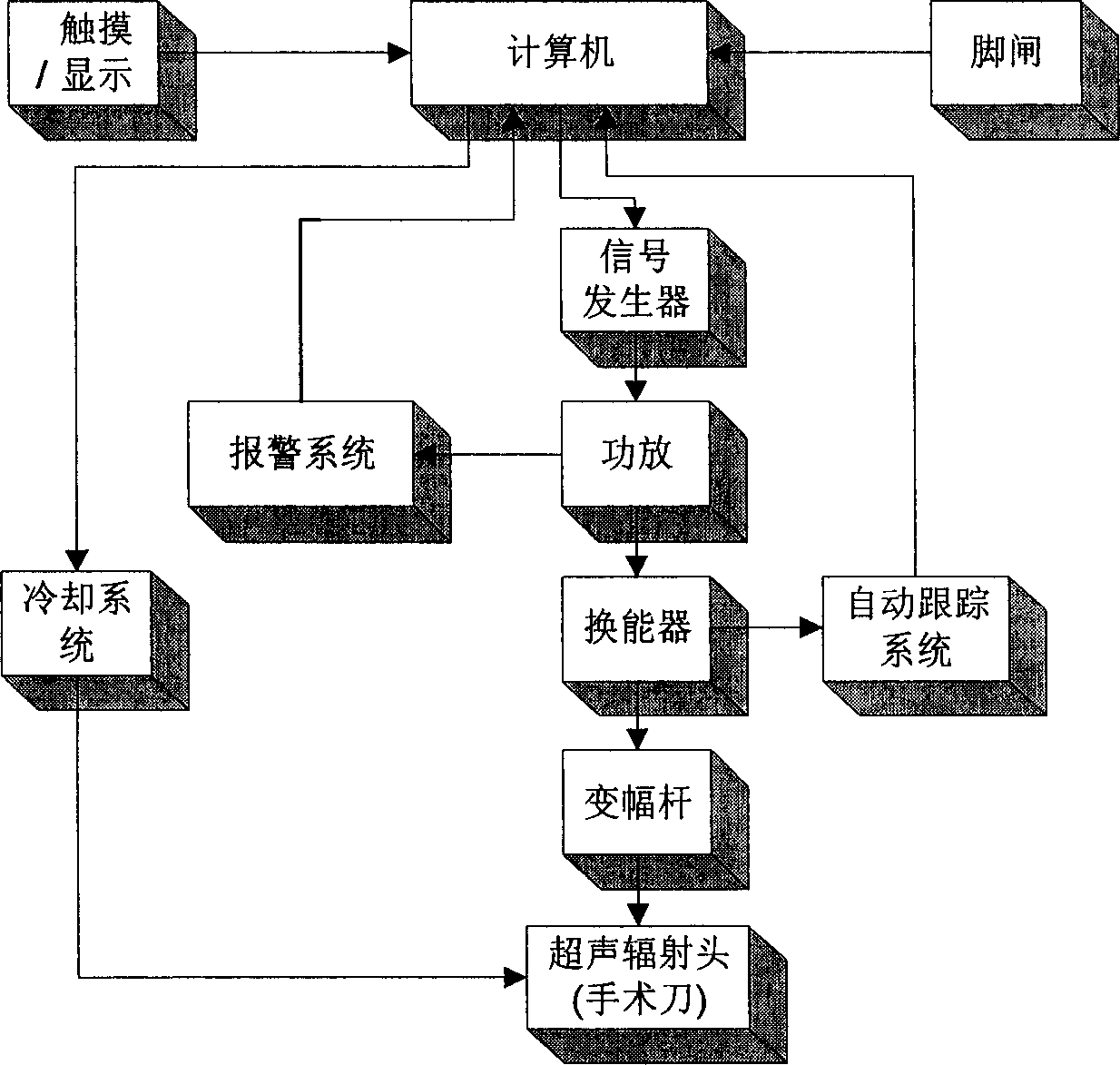

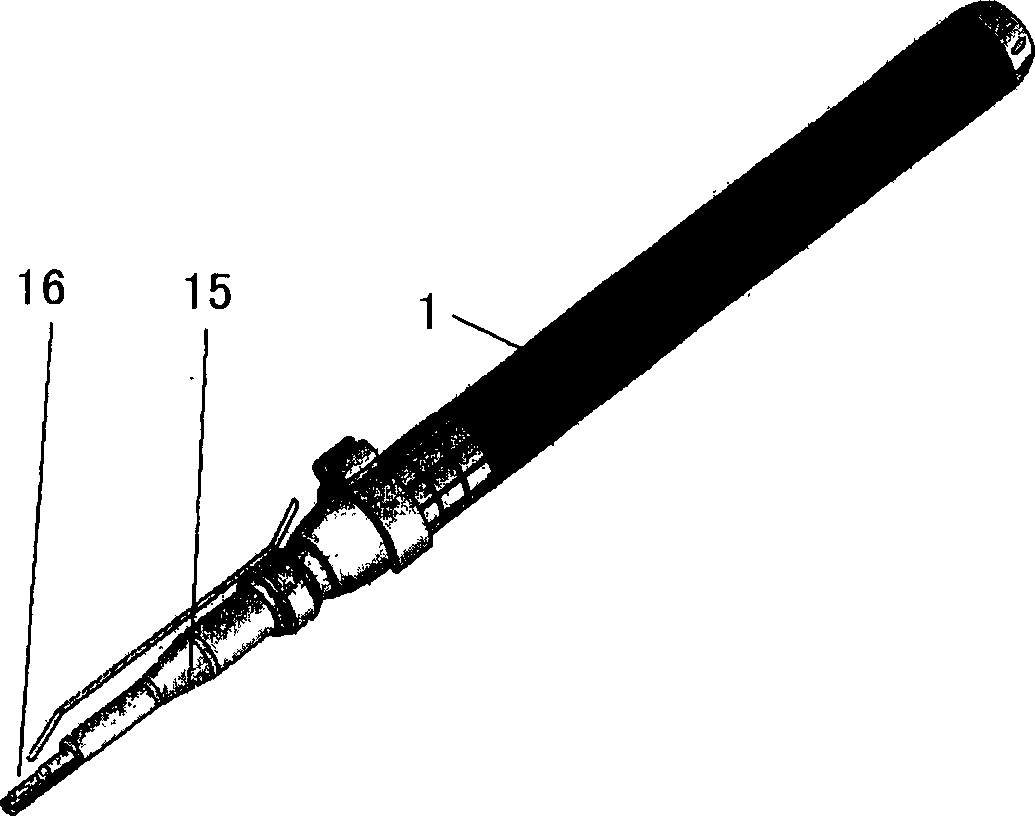

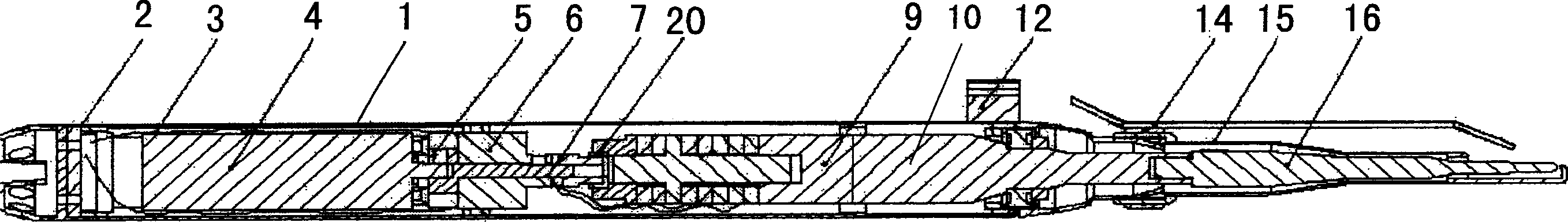

Compound vibrated ultrasonic bone surgery apparatus

ActiveCN1732861AImprove operational safetyImprove operating precisionEndoscopic cutting instrumentsStress concentrationEngineering

A compound vibrating supersonic bone surgery instrument, including handle, operating knife and main machine, and inside the shell of the handle includes: transfer the signal emitted by supersonic signal generator to supersonic mechanical waves of energy converter, deliver the supersonic mechanical waves emitted by energy converter after amplitude magnification to amplitude changing pole of surgery knife to make the surgery knife vibrate longitudinally at supersonic frequency; install in the back end of the handle, and the energy converter and amplitude changing pole are rotated or swayed by driving motor; install on the clutch between the said driving motor and energy converter to deliver the supersonic signal emitted by supersonic signal generator to electric slip-ring of energy converter; cross the center bore of electric slip-ring and deliver the rotating and swaying movement of driving motor to the clutch of energy converter. The invention installs driving motor at the base of the energy converter, accomplishing compound supersonic vibration; accomplishing cold cutting; avoiding the broken of surgery knives as a result of the concentration of stress.

Owner:北京速迈医疗科技有限公司

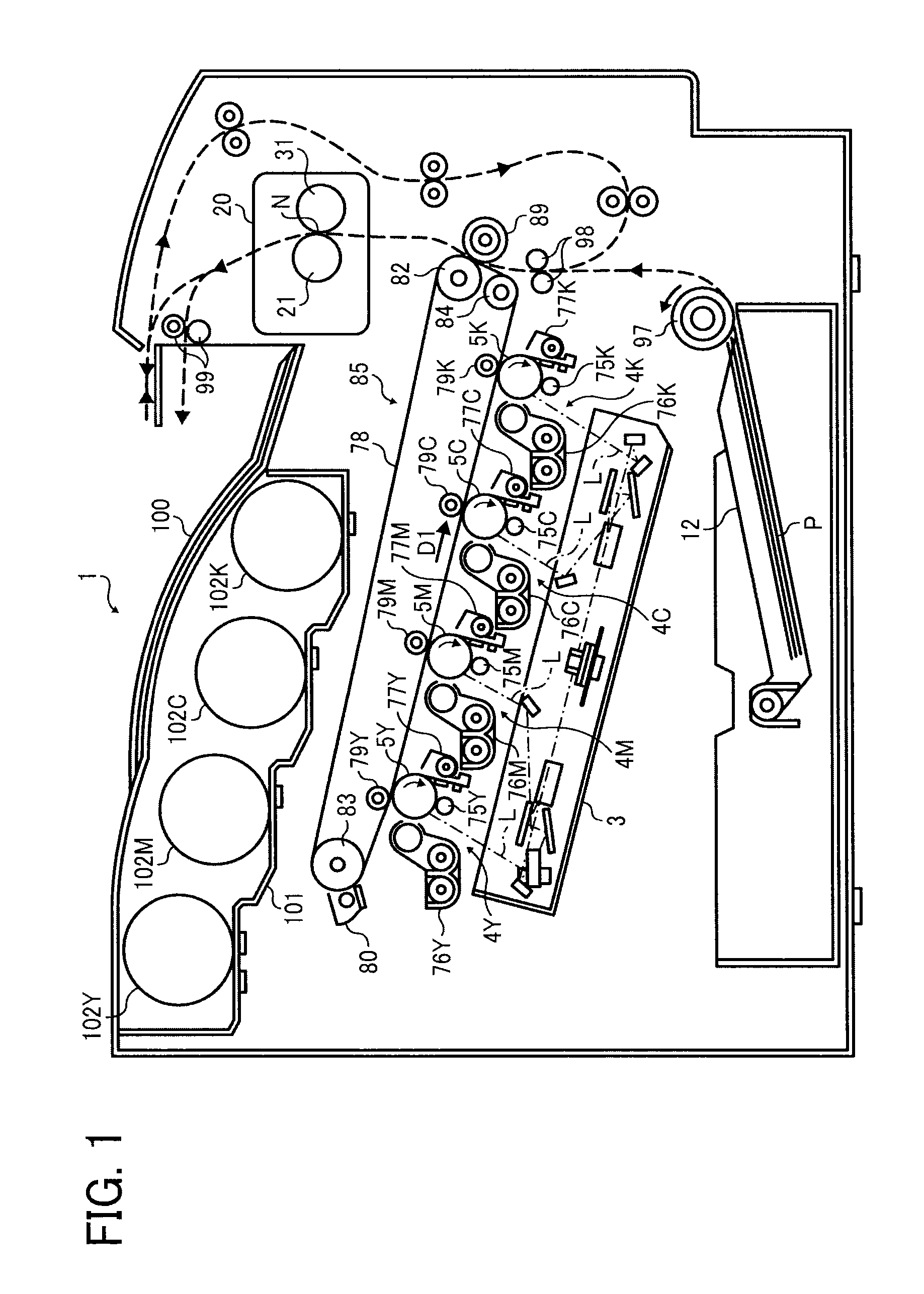

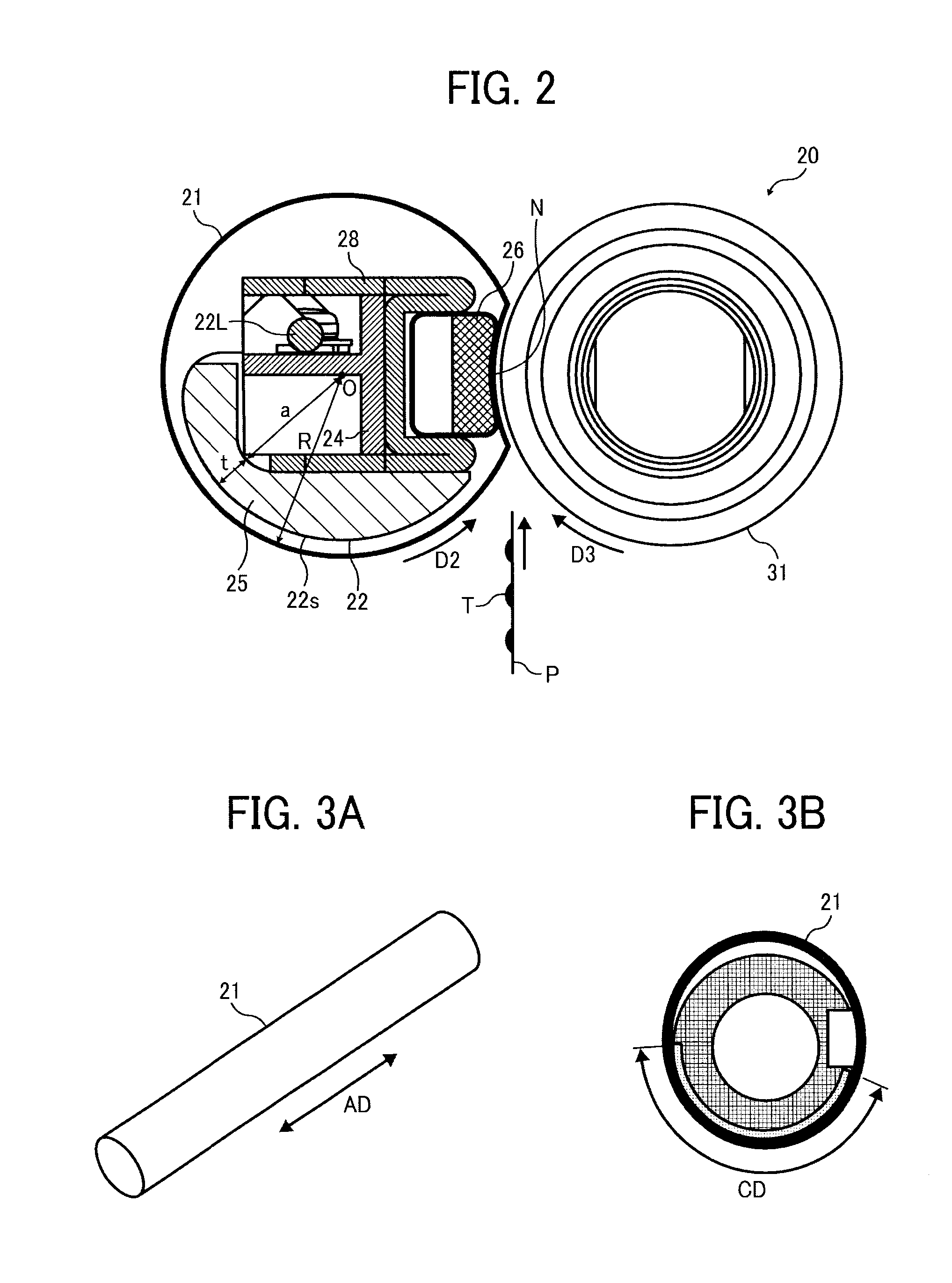

Belt device with mechanism capable of minimizing increase of rotation torque of endless belt and fixing device and image forming apparatus incorporating same

A belt device includes a flange assembly including a tube inserted into a loop formed by an endless belt at each lateral end of the endless belt in an axial direction thereof and a slip ring slidably contacting a groove mounted on the tube. An inner diameter ID 51 of the slip ring through a rotation axis of the slip ring is smaller than a minimum outer diameter OD50a of the tube through the rotation axis of the slip ring. The minimum outer diameter OD50a is smaller than a maximum outer diameter OD21 of a track of the endless belt rotating in a predetermined direction of rotation through the rotation axis of the slip ring. The maximum outer diameter OD21 is smaller than an outer diameter OD51 of the slip ring through the rotation axis of the slip ring.

Owner:RICOH KK

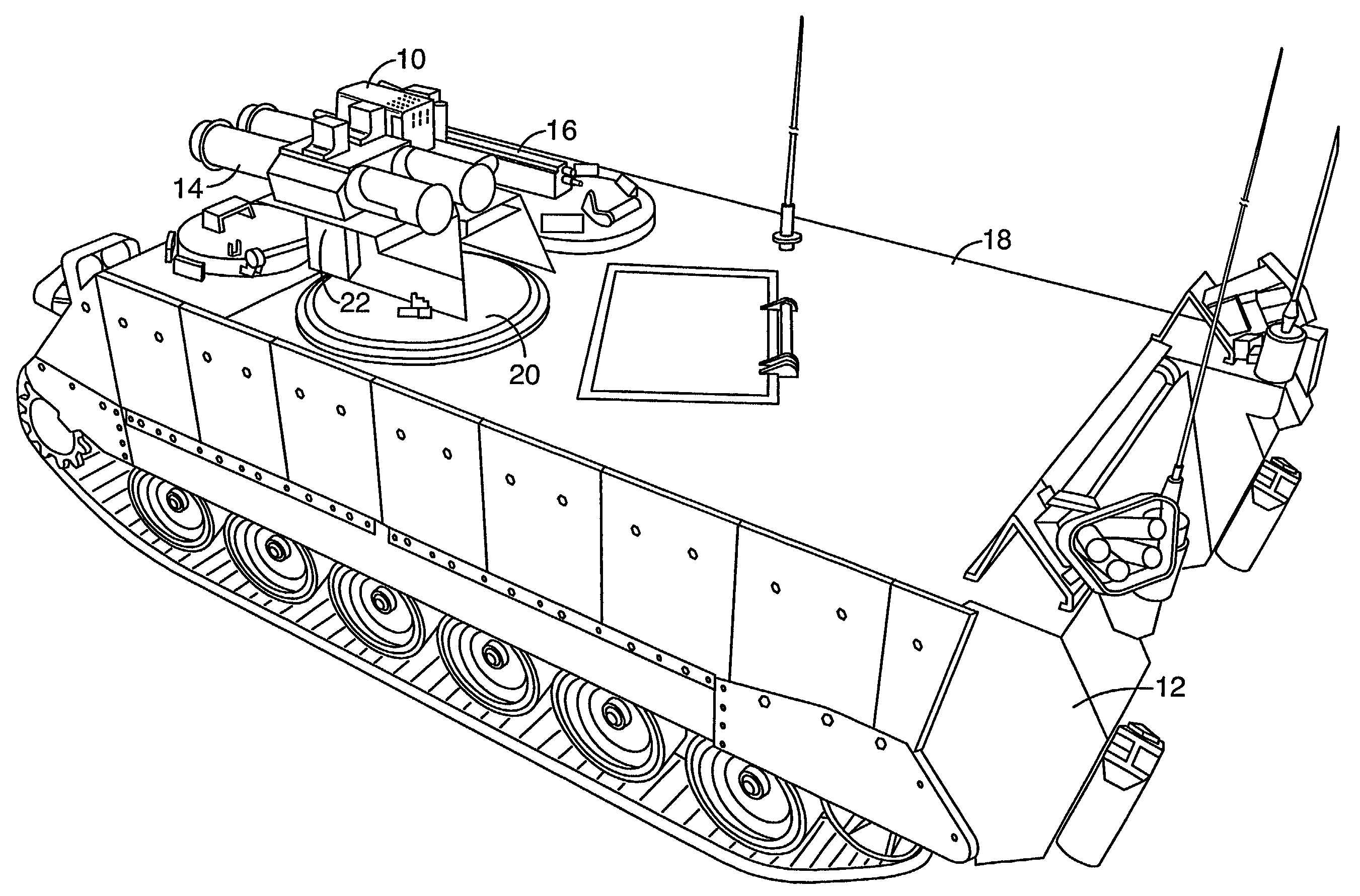

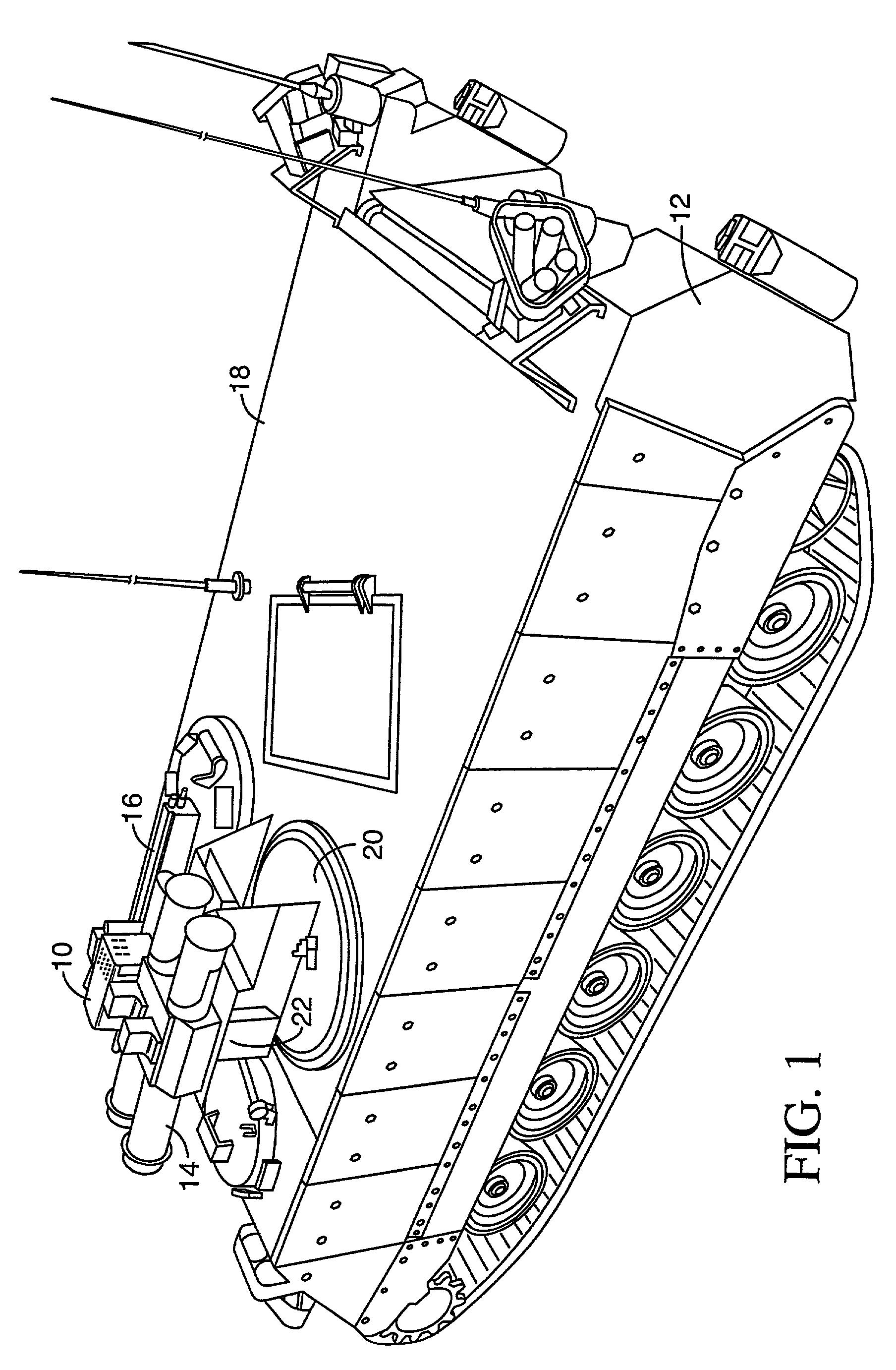

Anti-tank guided missile weapon

An anti-tank guided missile (ATGM) weapon system with an overhead mounted, electrically driven, remote controlled weapon station that supports a tube-launched optically-tracked wire-guided (TOW) missile launcher and a machine gun, typically the caliber .50 M2, on a single traversing and elevating platform. Above-deck assemblies include the TOW and gun cradle, a dual pod missile launcher, the Improved Target Acquisition System (ITAS), target acquisition subsystem (TAS), elevation and traverse motors and gear transmissions and drive electronics, and an ammunition case. Below-deck assemblies include the ATGM weapon system control handles, biocular display, control panel, ITAS fire control system (FCS), ITAS battery power source (BPS), slip-ring, and gunner's seat. Electrical cables connecting the two assemblies penetrate the vehicle deck directly below the weapon System.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

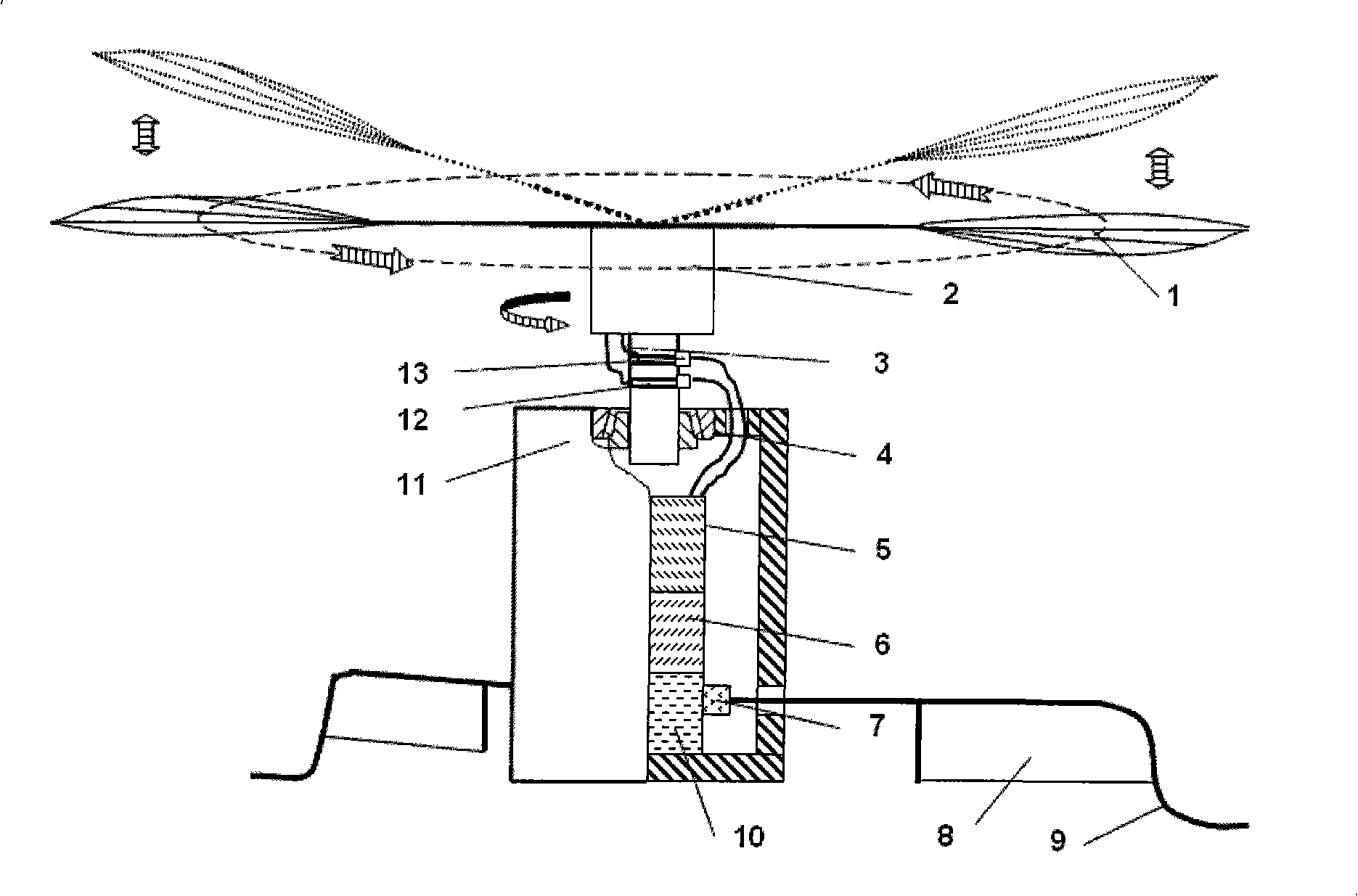

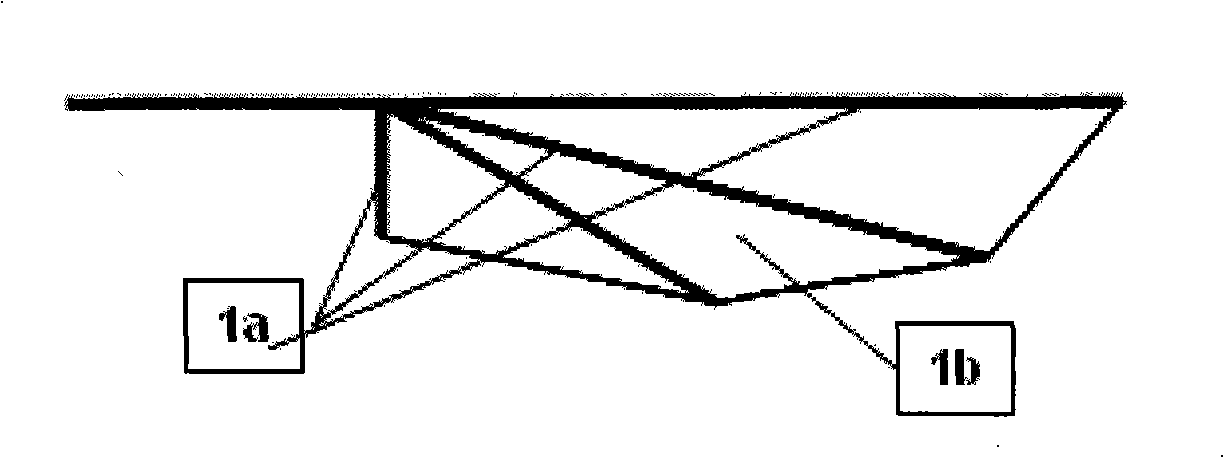

Flapping rotor wing design method and microminiature flapping rotor wing designed according to the method

InactiveCN101492093AAchieve vertical takeoff and landingHover in the airOrnithoptersFlapping wingRotary wing

The invention provides a method for driving flapping wings to rotate by thrust produced by the flap of the flapping wings instead of driving by an electric motor, and the method combines with flapping wing and rotary wing technology. An aircraft designed by the method of the invention comprises the flapping wings, an electromagnetic driving mechanism, a connecting shaft, a roller bearing, a power supply, useful load, an electric steering engine, control surfaces, an undercarriage, a controller, an aircraft shell, a slip ring and an electric brush, wherein the electromagnetic driving mechanism drives a pair of flapping wings to flap up and down. The aircraft shell is connected with a rotary connecting shaft through the roller bearing, three control surfaces are evenly distributed at the lower part of the aircraft shell, and simultaneously the control surfaces have the function of the undercarriage of the aircraft. The flapping rotary wings of the invention have high pneumatic efficiency and can satisfy the mission and requirements of vertical takeoff and landing and hovering stopping of the aircraft. Simultaneously, the rotation of the flapping wings of the aircraft is a self-driven rotation, and the rotation is not offset by a torsion resisting mechanism which is added additionally. The aircraft has the advantages of simple design structure, light weight and high flight efficiency and is suitable for miniaturization aircraft design requirements.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com