Off-axis fiber optic slip ring

a fiber optic and slip ring technology, applied in the field of off-axis multi-channel fiber optic slip ring, can solve the problems of almost no way to handle and arrange so many fibers on the said rotatable members, optical loss is very obvious for multi-mode fibers, and it is almost impossible to use single-mode fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

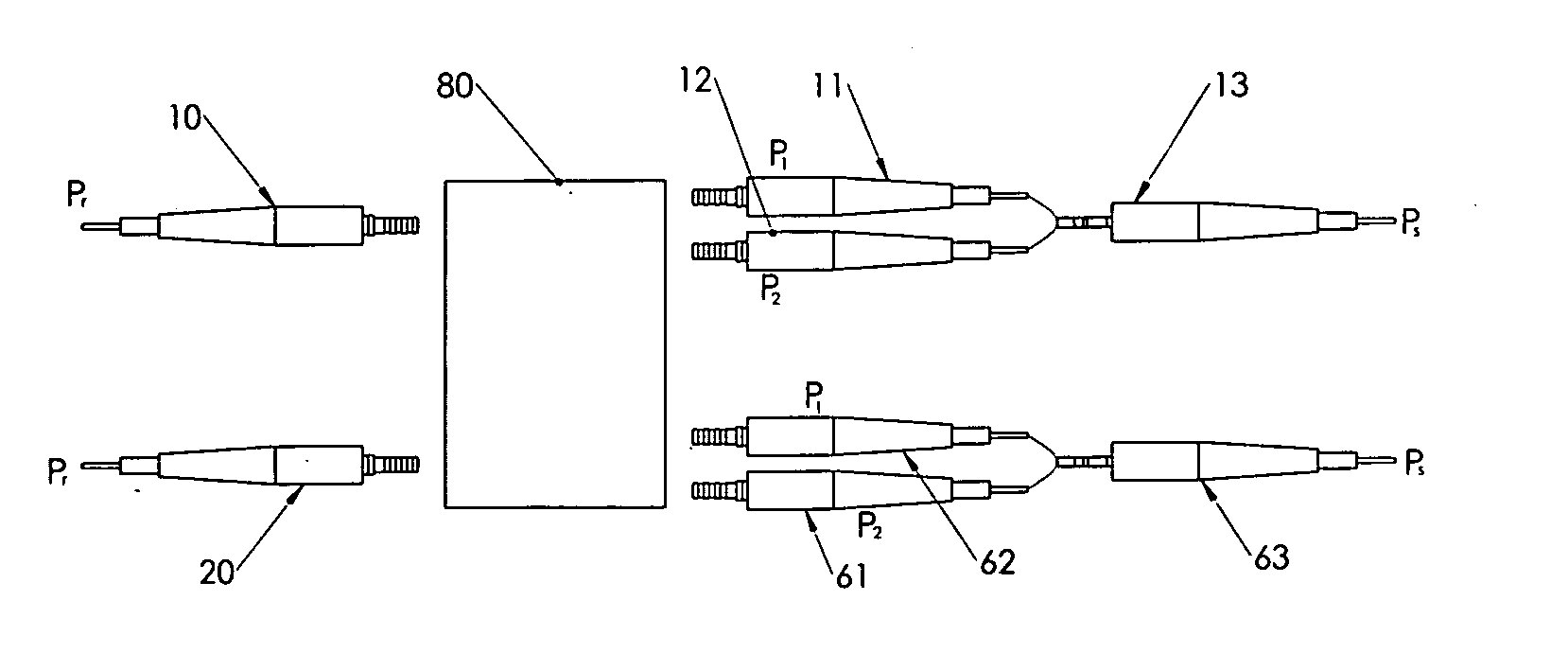

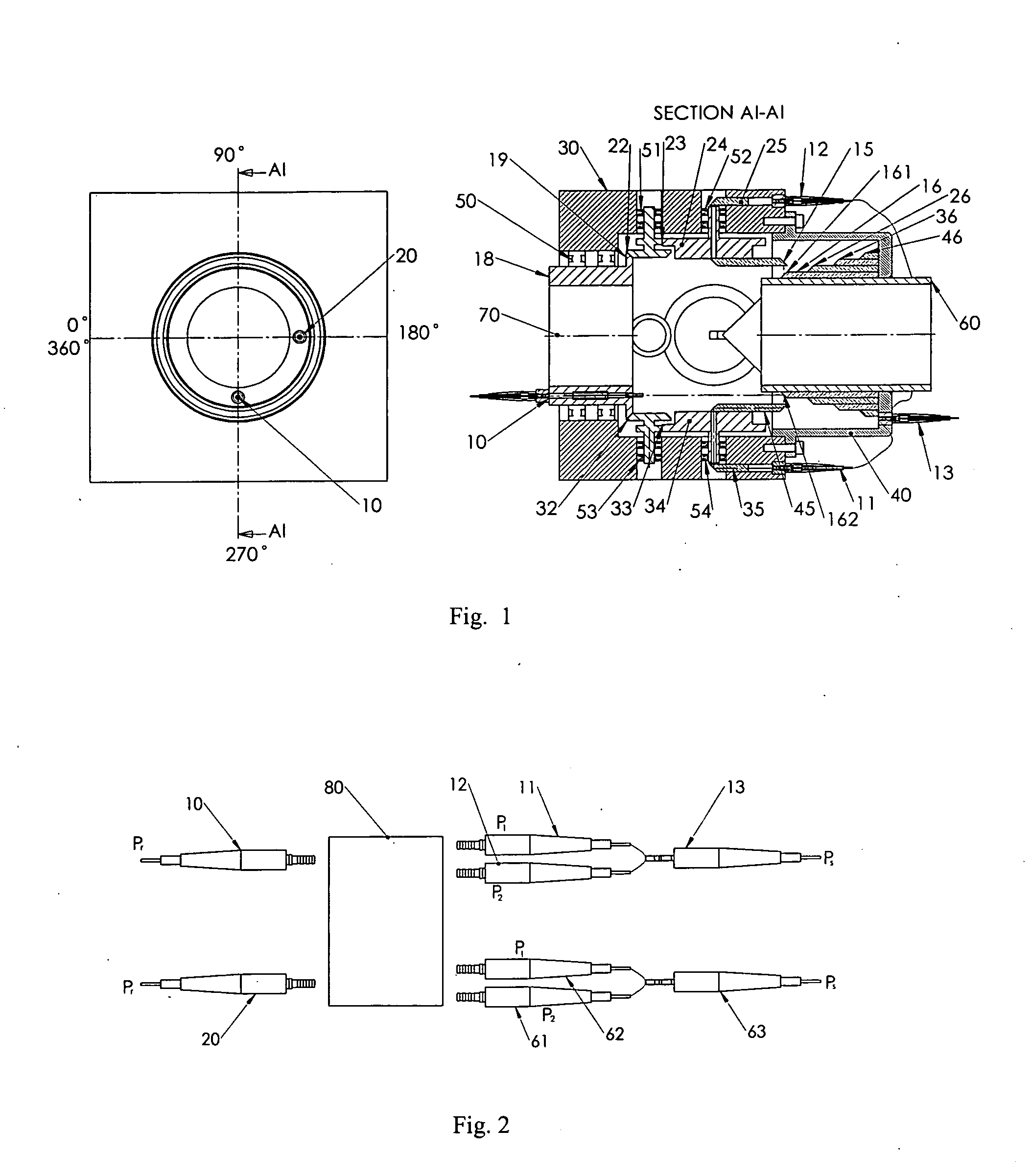

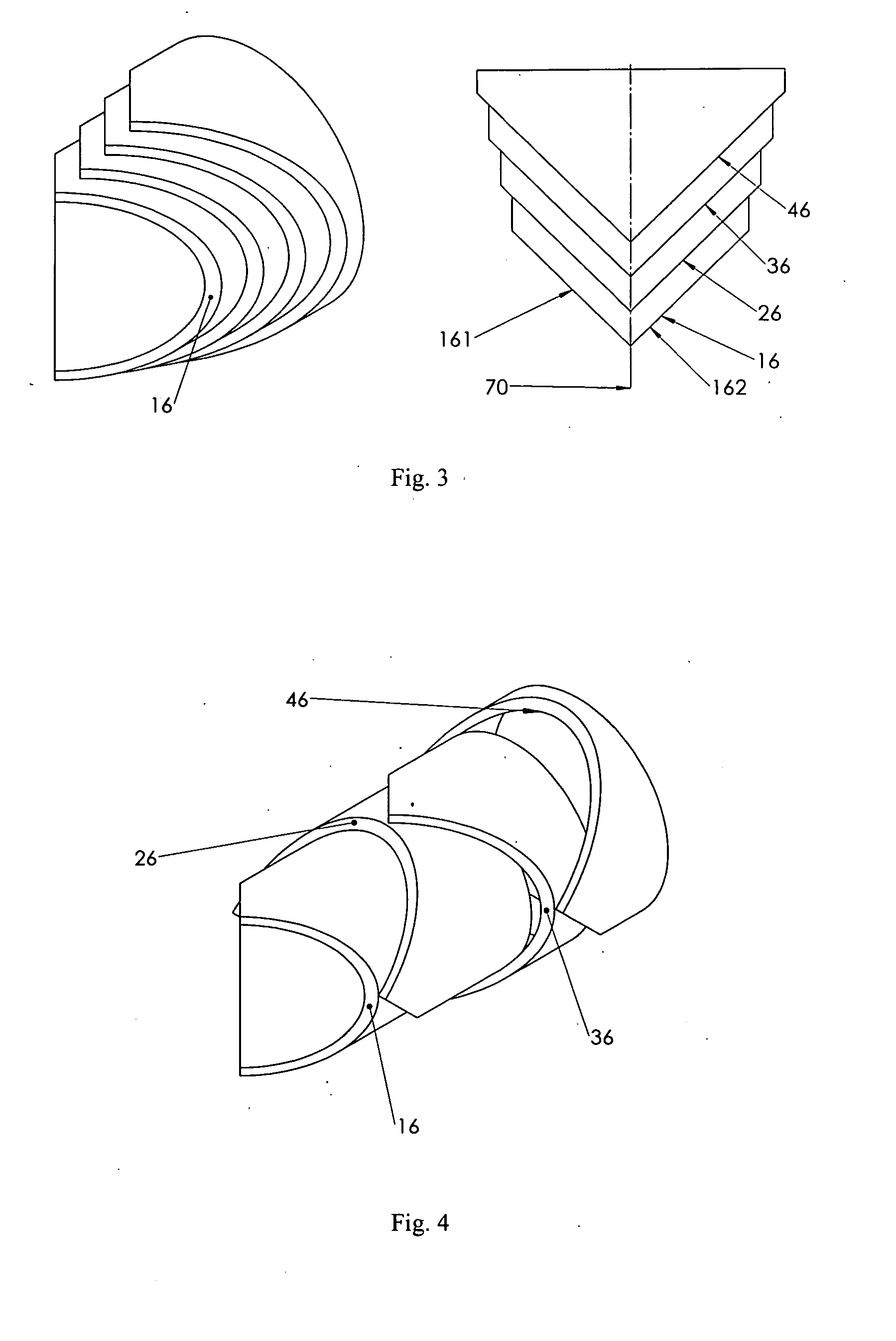

[0022]As shown in FIG. 1, a typical embodiment of a multi-channel off-axis optic slip ring in the present invention comprises rotor 18, stator 30, mirror array 16, 26, 36, 46, rhomboid prisms 15, 45, right angle prisms 25,35, gears 19,22, 23,24, collimators 10,20,11,12, and coupler 13. A pair of bearings 50 are mounted between rotor 18 and stator 30 to provide the main rotational interface. Other bearings 51, 52, 53, and 54 are used to rotationally support the gears 22, 23, 24; 32, 33, and 34 in the stator 30. Collimators 10, 20, and more (depends on how many channel would be built), are mounted on rotor 18 in circumferential direction at a different distances to the common rotational axis 70. The axis of the collimators 10, and 20 are parallel to the main rotational axis 70. The rotor 18 and the mirror holder 60 are hollow along the said common rotational axis so that a through bore is provided, leaving the central part of the interface totally free. That means all the optical sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com