Patents

Literature

114results about How to "High contrast ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

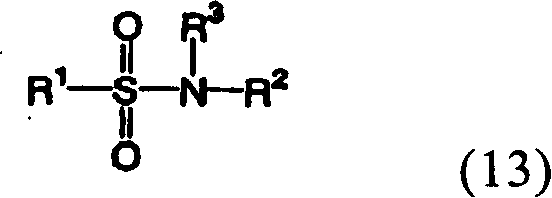

Application Year

Inventor

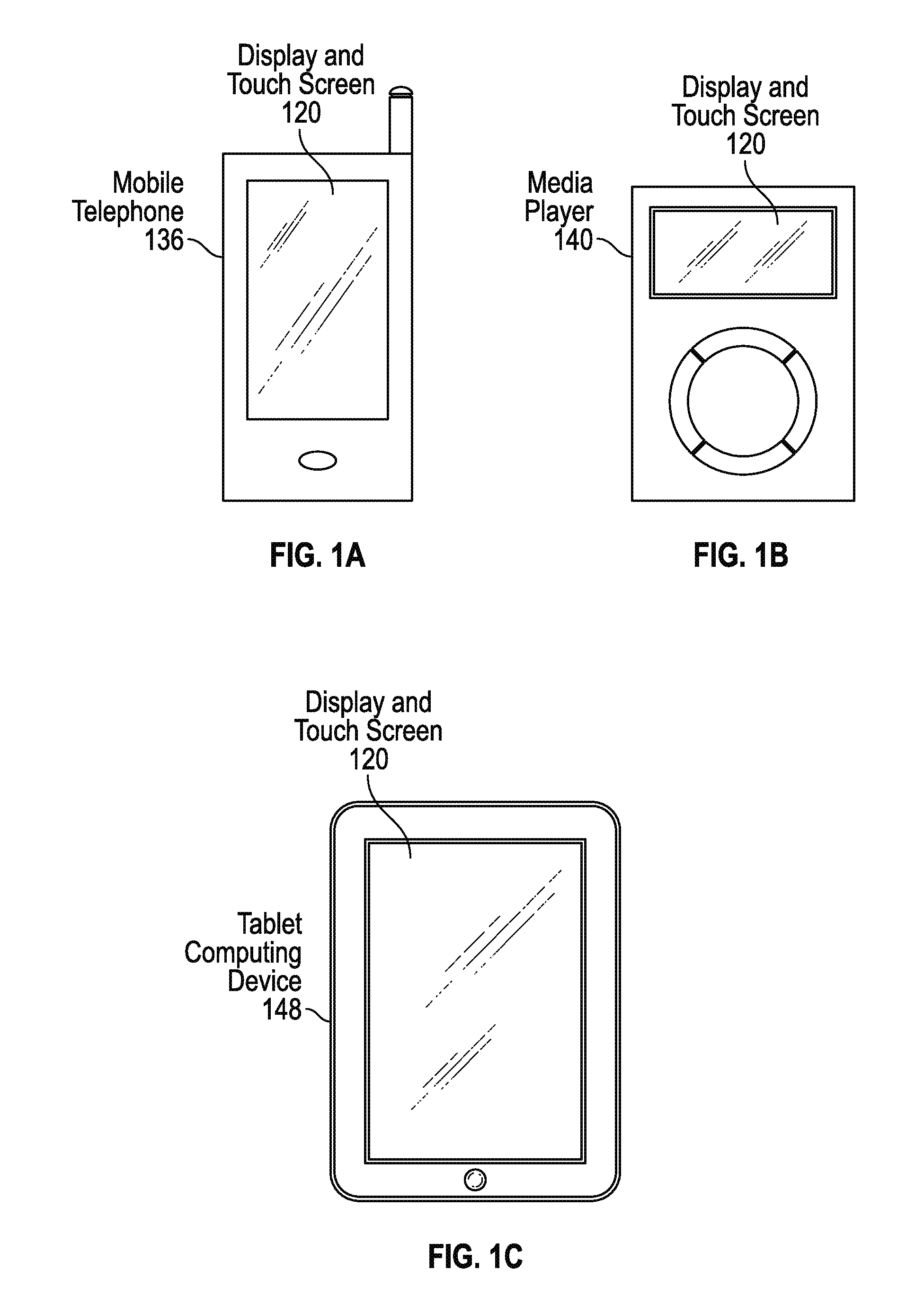

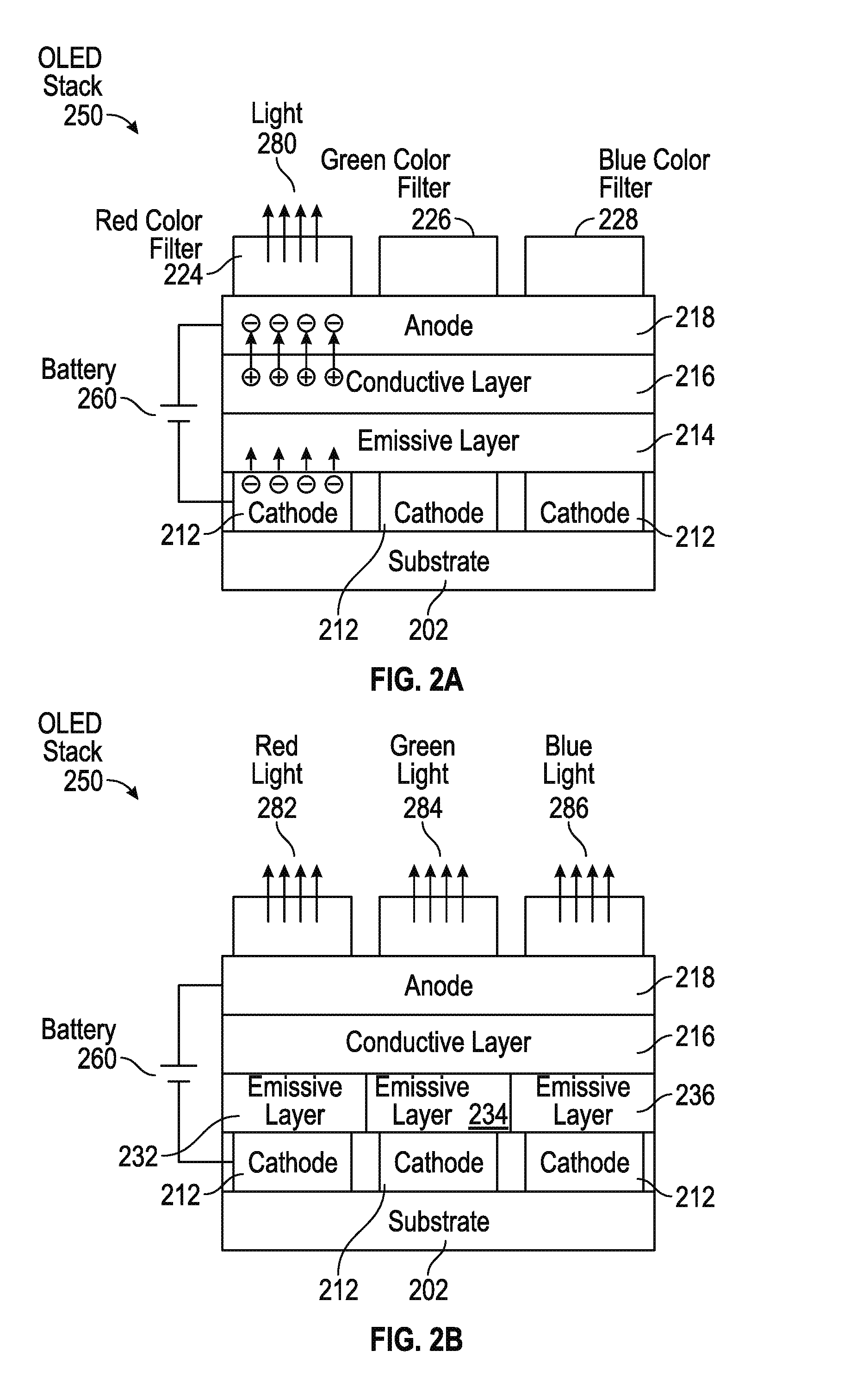

Integrated silicon-oled display and touch sensor panel

ActiveUS20150331508A1Wide viewing angleHigh contrast ratioSolid-state devicesDiodeElectrostatic dischargeFingerprint detection

An integrated Silicon-OLED display and touch sensor panel is disclosed. The integrated Silicon-OLED display and touch sensor panel can include a Silicon substrate, an array of transistors, one or more metallization layers, one or more vias, an OLED stack, color filters, touch sensors, and additional components and circuitry. Additional components and circuitry can include an electrostatic discharge device, a light shielding, a switching matrix, one or more photodiodes, a near-infrared detector and near-infrared color filters. The integrated Silicon-OLED display and touch sensor panel can be further configured for near-field imaging, optically-assisted touch, and fingerprint detection. In some examples, a plurality of touch sensors and / or display pixels can be grouped into clusters, and the clusters can be coupled to a switching matrix for dynamic change of touch and / or display granularity.

Owner:APPLE INC

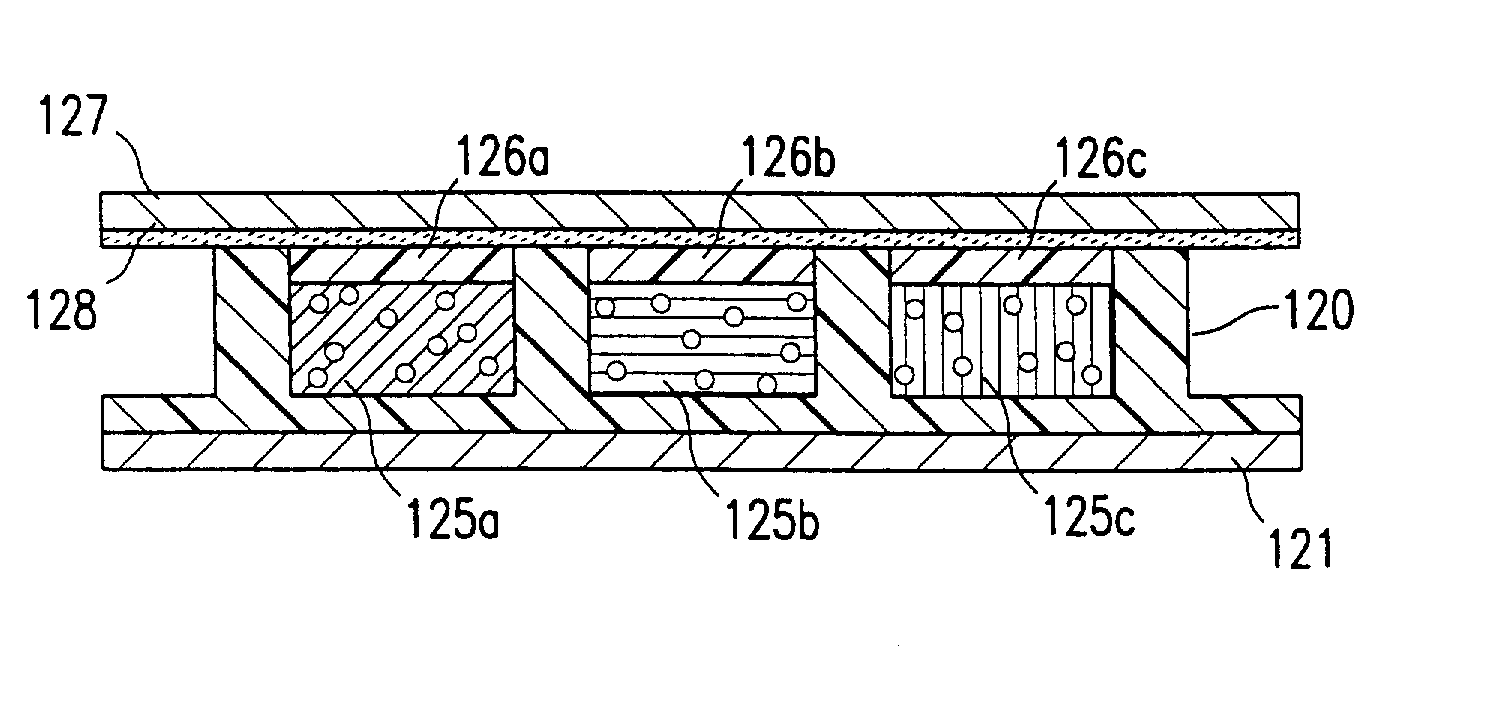

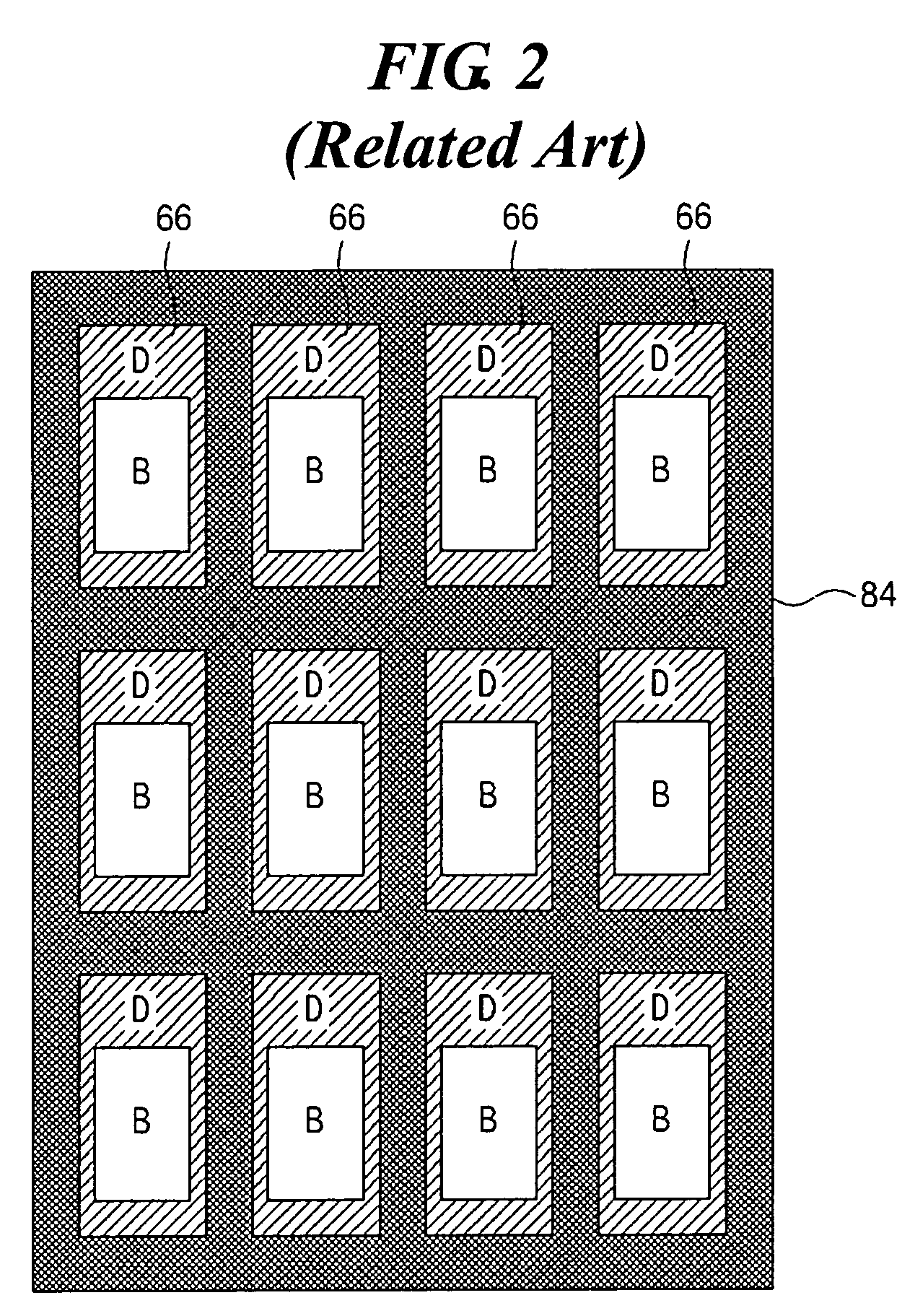

Process for roll-to-roll manufacture of a display by synchronized photolithographic exposure on a substrate web

InactiveUS20020182544A1High aspect ratioWell-defined shapePhoto-taking processesPhotomechanical apparatusDisplay deviceRefractive index

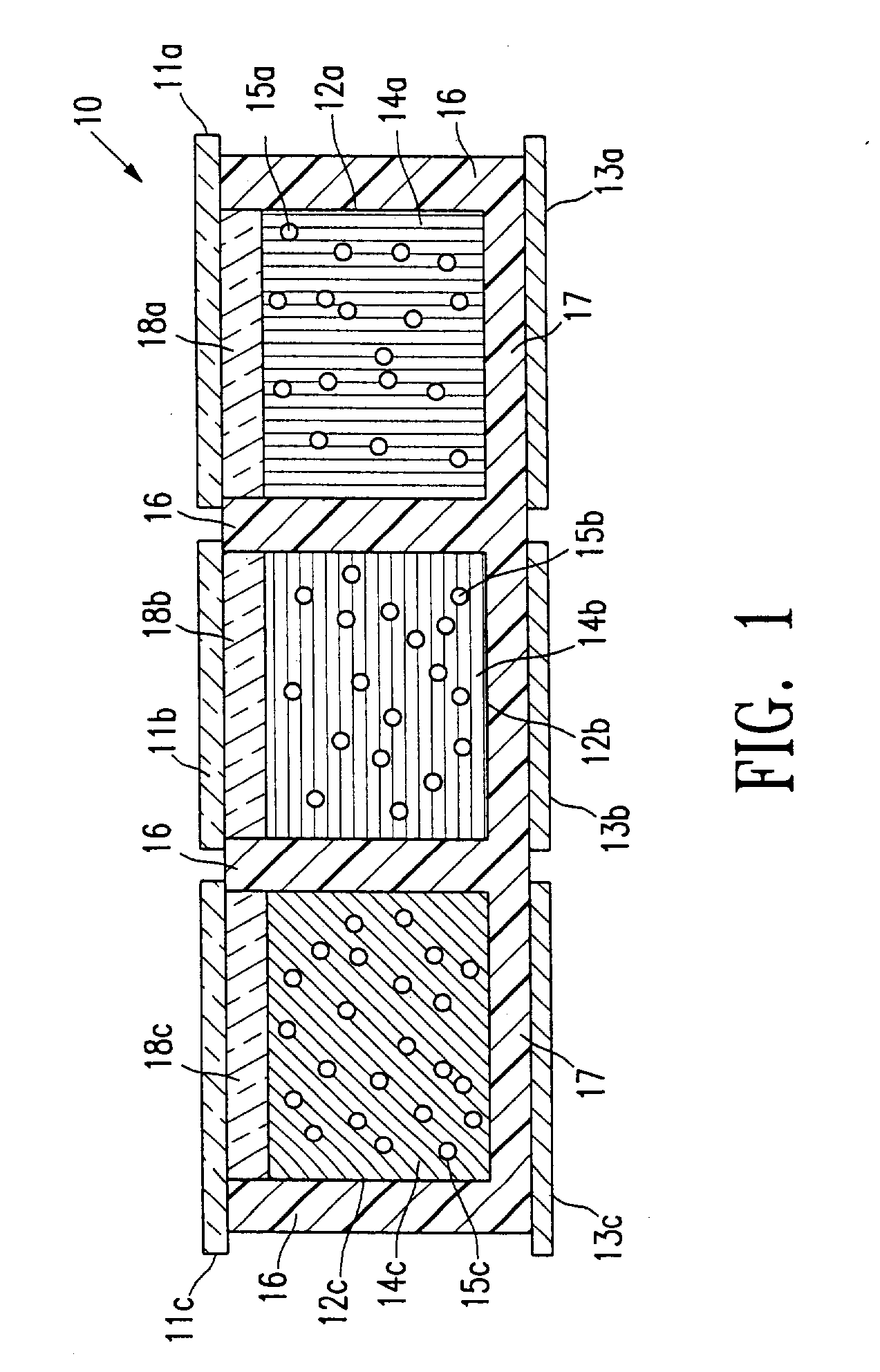

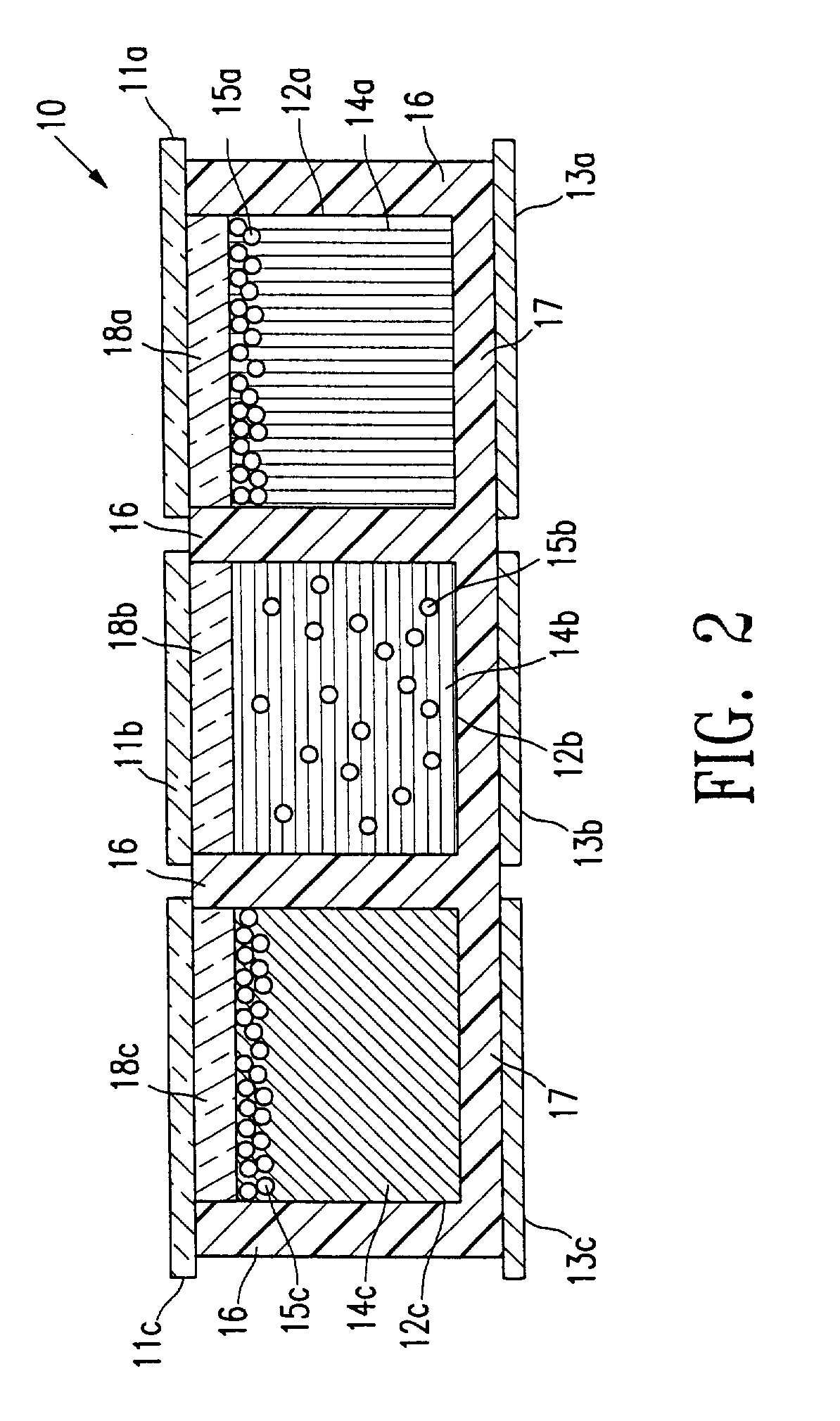

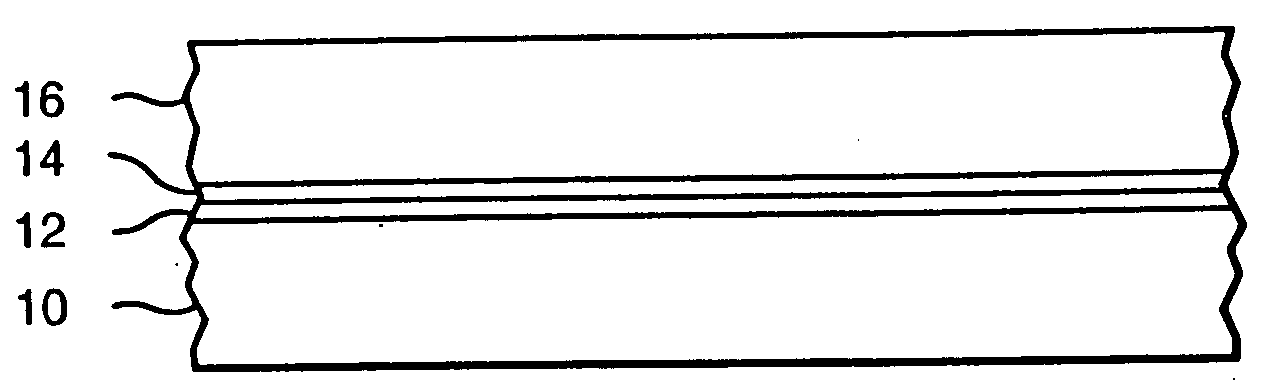

<heading lvl="0">Abstract of Disclosure< / heading> This invention relates to an electrophoretic display or a liquid crystal display and novel processes for its manufacture. The electrophoretic display (EPD) of the present invention comprises microcups of well-defined shape, size and aspect ratio and the microcups are filled with charged pigment particles dispersed in an optically contrasting dielectric solvent. The liquid crystal display (LCD) of this invention comprises well-defined microcups filled with at least a liquid crystal composition having its ordinary refractive index matched to that of the isotropic cup material. A novel roll-to-roll process and apparatus of the invention permits the display manufacture to be carried out continuously by a synchronized photo-lithographic process. The synchronized roll-to-roll process and apparatus permits a pre-patterned photomask, formed as a continuous loop, to be rolled in a synchronized motion in close parallel alignment to a web which has been pre-coated with a radiation sensitive material, so as to maintain image alignment during exposure to a radiation source. The radiation sensitive material may be a radiation curable material, in which the exposed and cured portions form the microcup structure. In an additional process step, the radiation sensitive material may be a positively working photoresist which temporarily seals the microcups. Exposure of a selected subset of the microcups via the photomask image permits selective re-opening, filling and sealing of the microcup subset. Repetition with additional colors permits the continuous assembly of a multicolor EPD or LCD display.

Owner:E INK CALIFORNIA

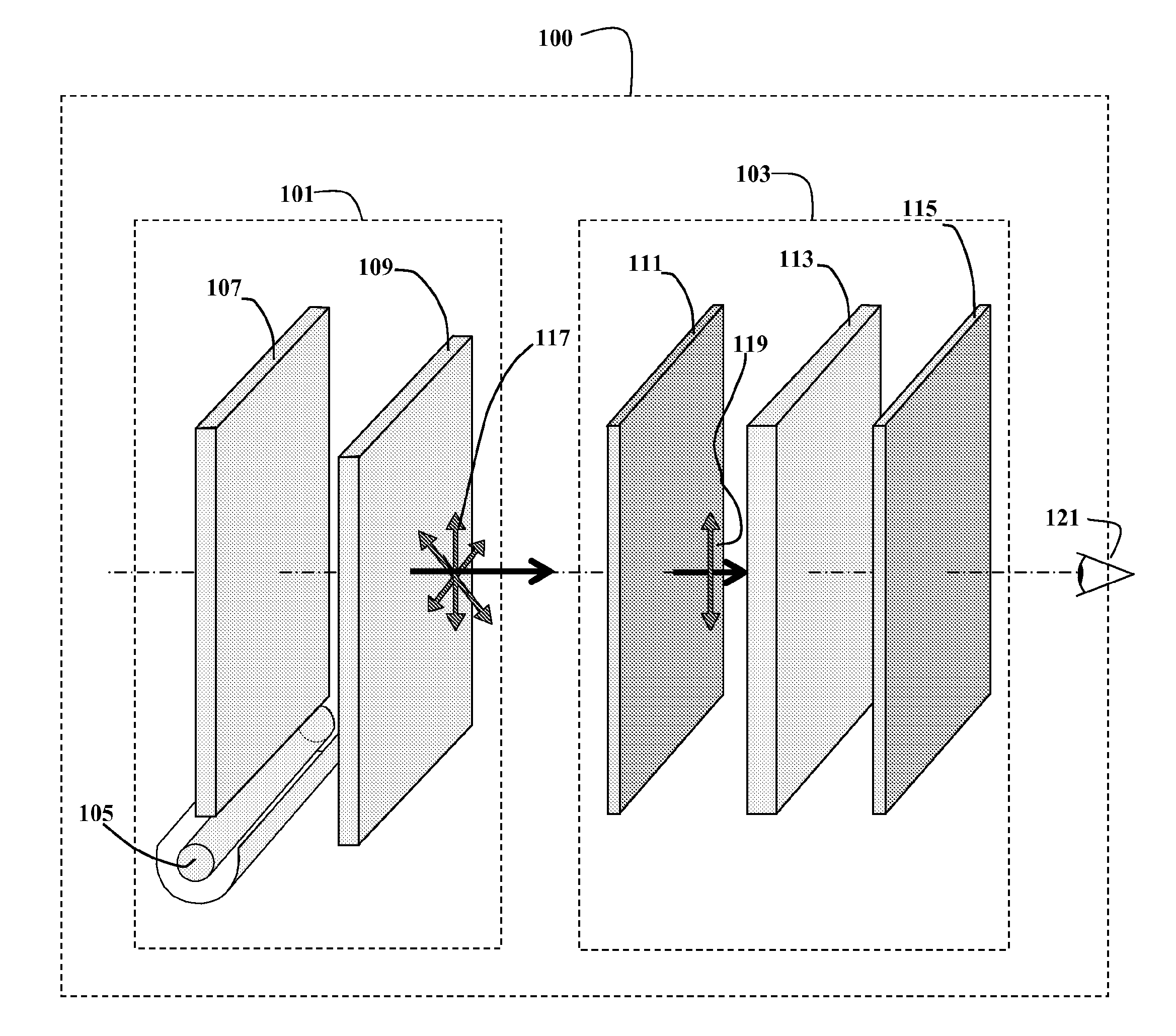

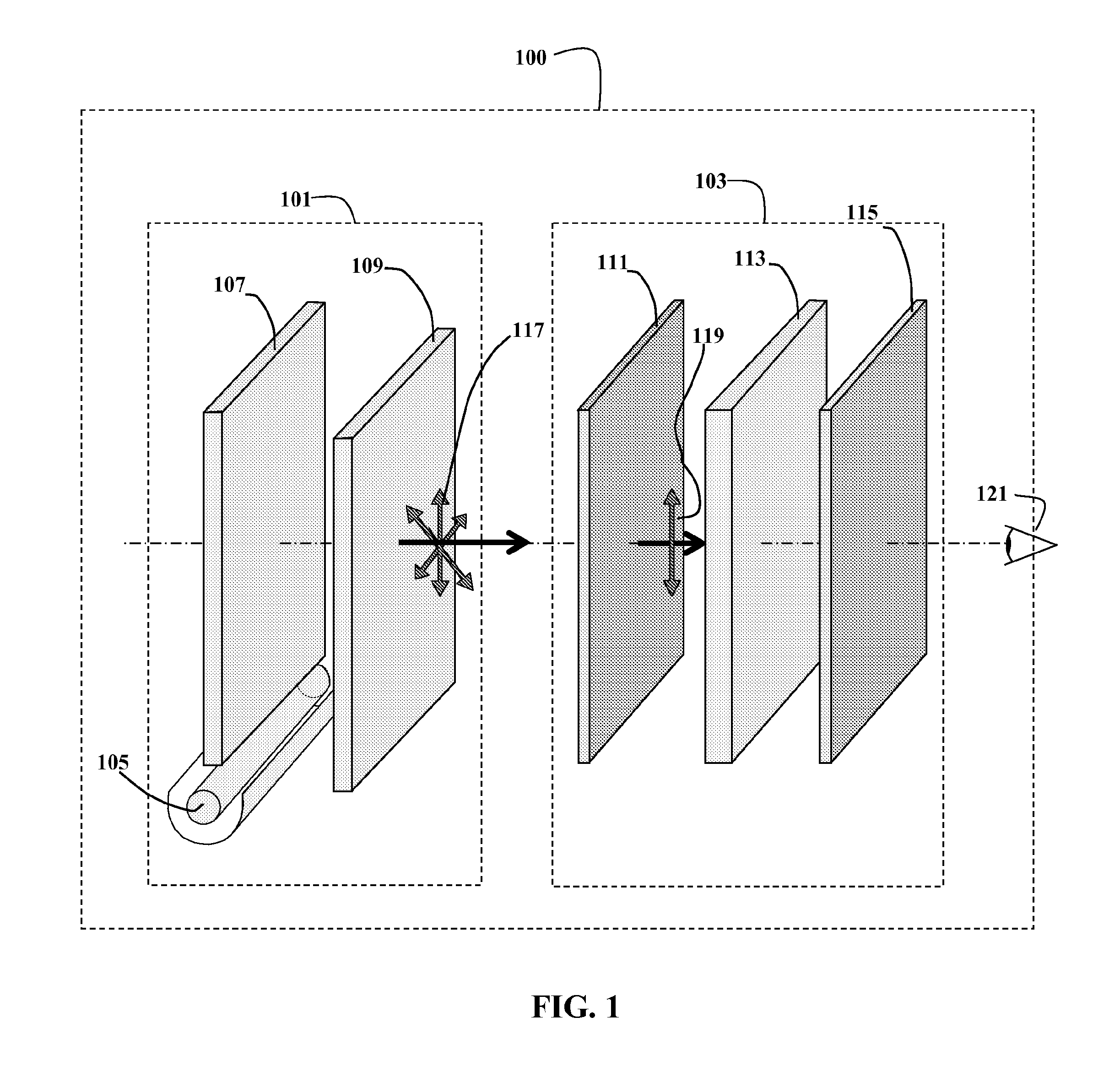

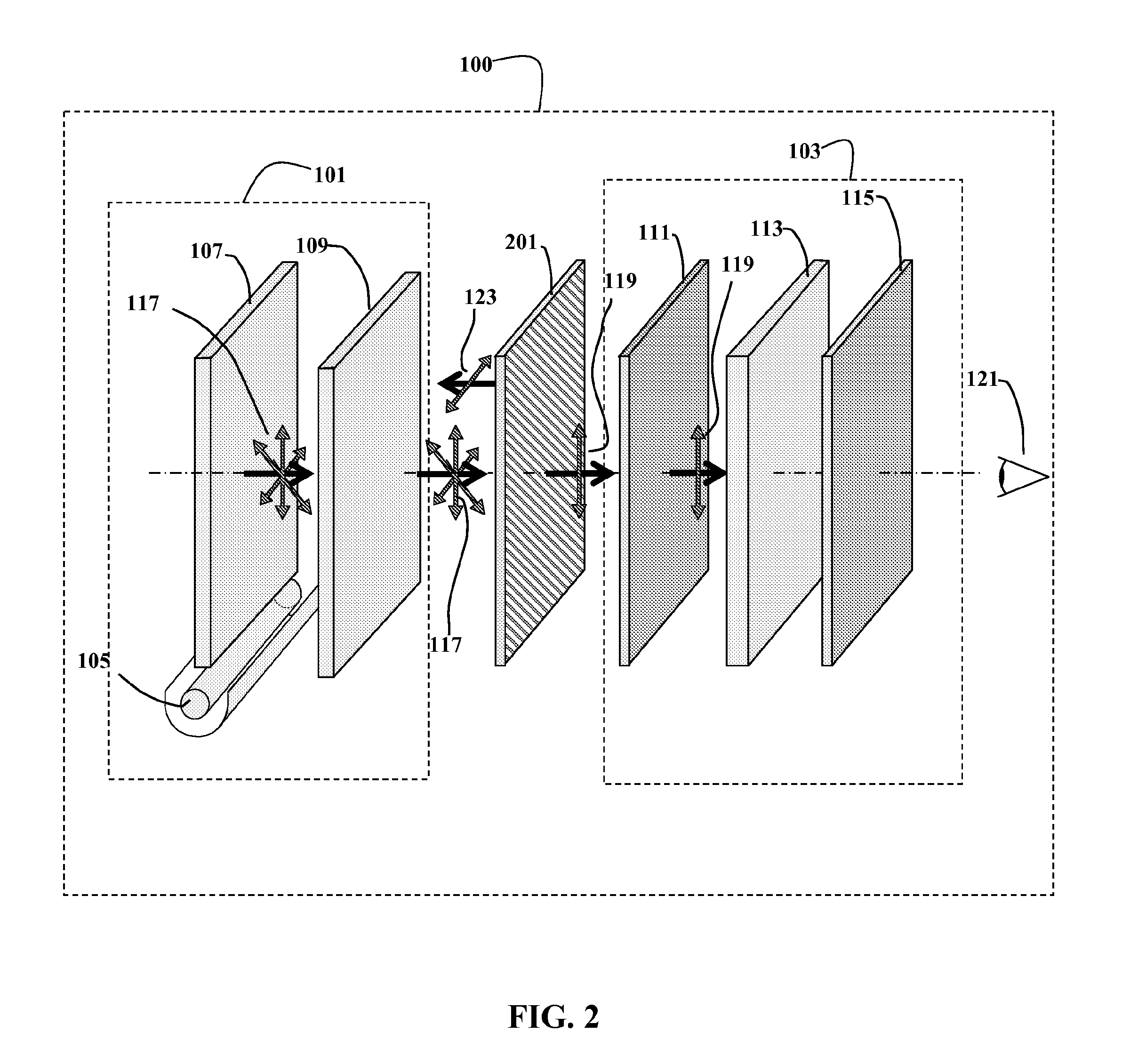

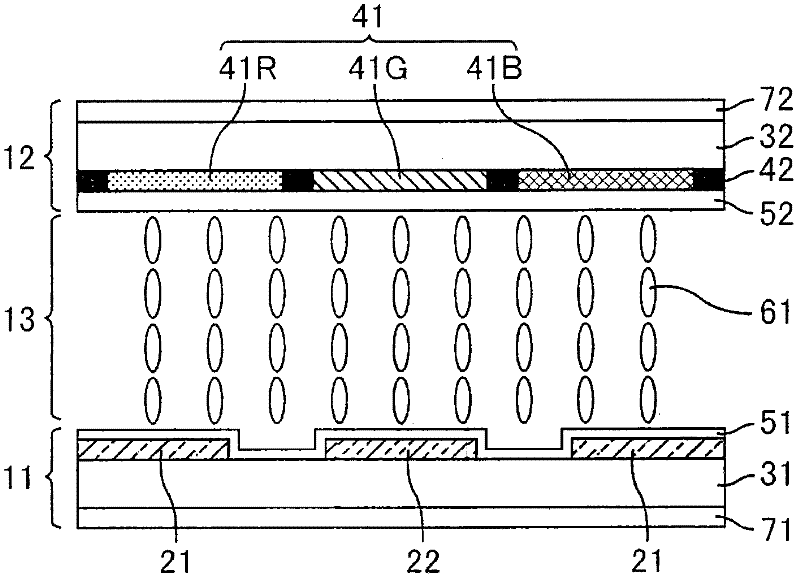

Microelectrical mechanical structure (MEMS) optical modulator and optical display system

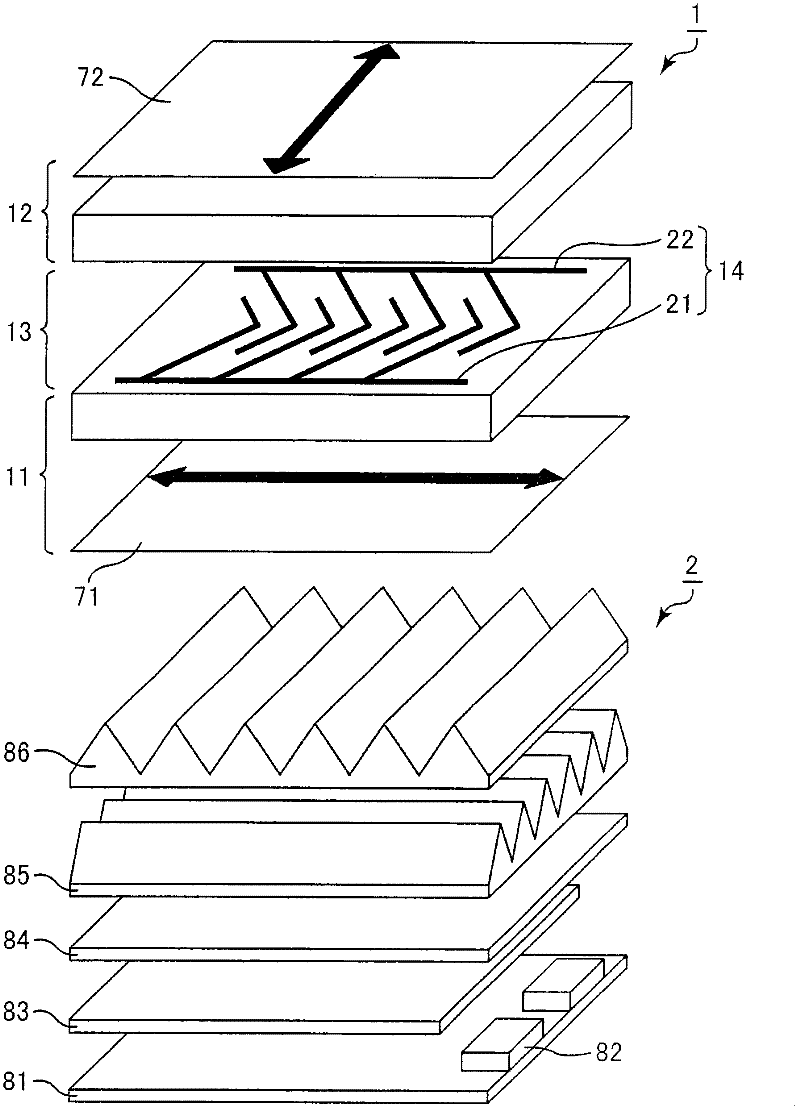

InactiveUS20050002086A1Eliminating light attenuation of lightEliminating expenseTelevision system detailsColor television detailsPlanar substrateActuator

A MEMS optical display system includes an illumination source for providing illumination light, a collimating lens for receiving the illumination light and forming from it collimated illumination light, and a converging microlens array having an array of lenslets that converge the collimated illumination light. The converging microlens array directs the illumination light to a microelectrical mechanical system (MEMS) optical modulator. The MEMS optical modulator includes, for example, a planar substrate through which multiple pixel apertures extend and multiple MEMS actuators that support and selectively position MEMS shutters over the apertures. A MEMS actuator and MEMS shutter, together with a corresponding aperture, correspond to pixel. The light from the converging microlens array is focused through the apertures and is selectively modulated according to the positioning of the MEMS shutters by the MEMS actuators, thereby to impart image information on the illumination light. The light is then passed to a diffused transmissive display screen by a projection microlens array.

Owner:MICROSOFT TECH LICENSING LLC

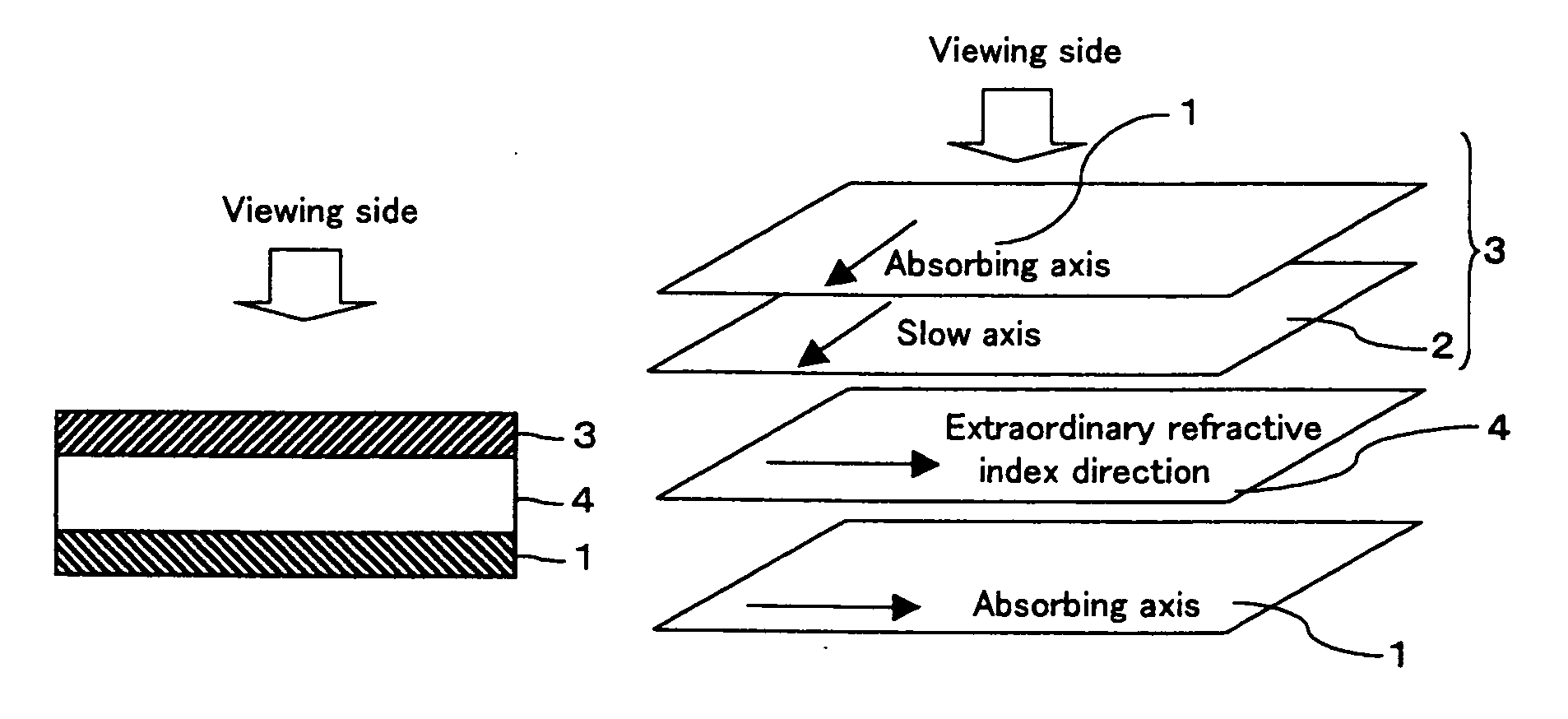

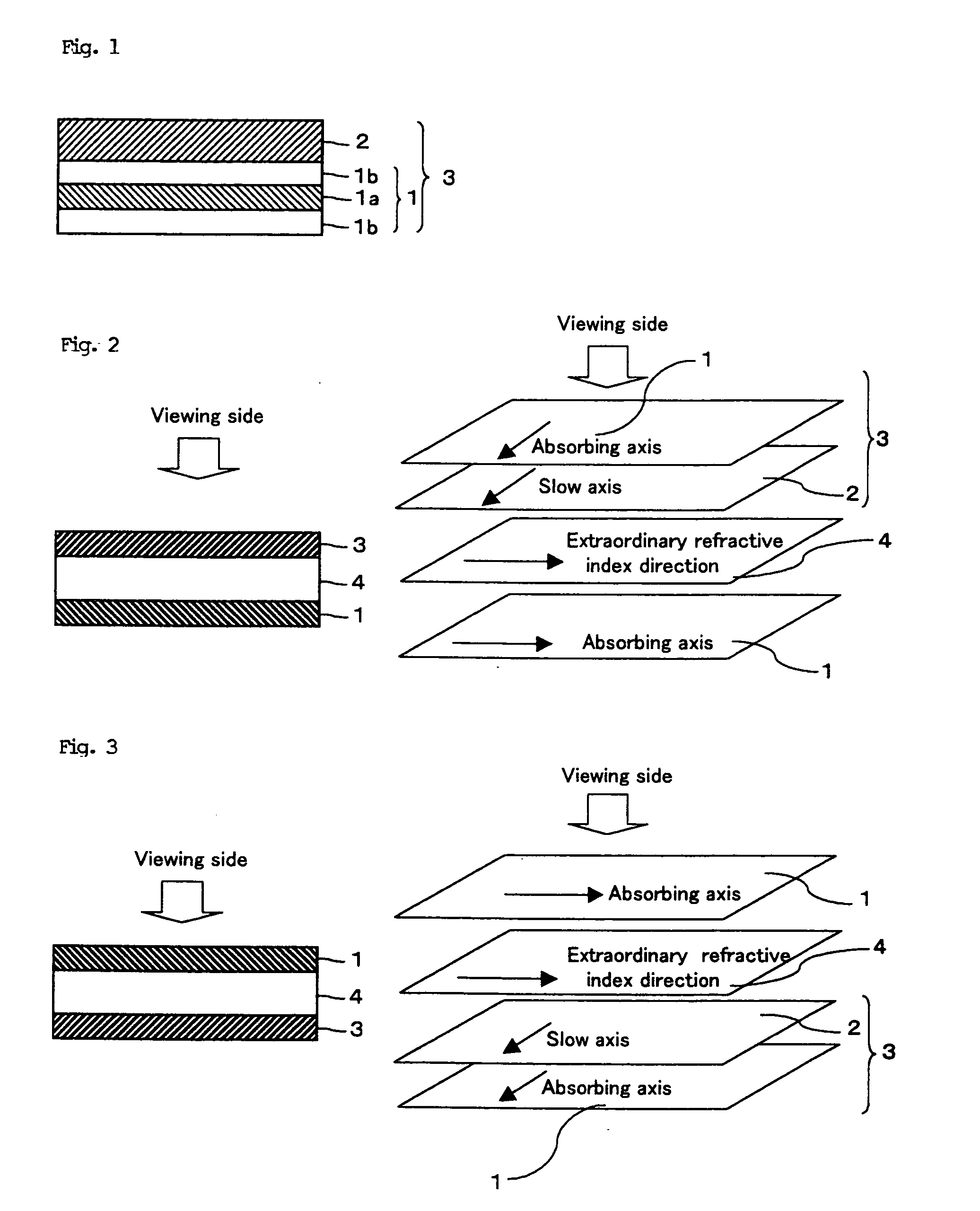

Optical film and display system

InactiveUS20040032547A1Small variationStable valuePolarising elementsNon-linear opticsIn planeLiquid-crystal display

An optical film in which a polarizing plate and a retardation film are laminated so that an absorbing axis of the polarizing plate and a slow axis of the retardation film may be perpendicular or may be parallel to each other, wherein a value Nz represented by Nz=(nx1-nz1) / (nx1-ny1) satisfies a range of 0.4 through 0.6, and an in-plane retardation Re1=(nx1-ny1)xd1 is 200 through 350 nm, where, a direction of the retardation film in which an in-plane refractive index within the film surface concerned gives a maximum is defined as X-axis, a direction perpendicular to X axis is defined as Y-axis, a thickness direction of the film is defined as Z-axis, refractive indexes in axial direction are defined as nx1, ny1, nz1, respectively, and a thickness of the film is defined as d1 (nm), may realize an easily viewable display with high contrast ratio in a wide range when applied to a display system, preferably used for a liquid crystal display operating in IPS mode.

Owner:NITTO DENKO CORP

NanoEmbossed shapes and fabrication methods of wire grid polarizers

InactiveUS20100134719A1High contrast ratioHigh transmissionVacuum evaporation coatingSputtering coatingLiquid-crystal displayWire grid

A wire grid polarizer may be formed by embossing a substrate surface with a mold having a plurality of grooves to form raised ridges; and depositing a metal line profile onto the ridges through one or more baffles oriented at an oblique angle to the normal of the substrate. The metal line profile is characterized by a cross-sectional width that tapers such that the metal line profile is wider proximate a vertex of the ridges than proximate a base of the ridges. A wire grid polarizer may comprise a substrate with a plurality of raised ridges and a plurality of metal lines on the raised ridges. The metal lines are characterized by cross-sectional metal line profiles having triangular shapes with a tip down configuration. Such a wire grid polarizer may be used in a liquid crystal display.

Owner:AGOURA TECH

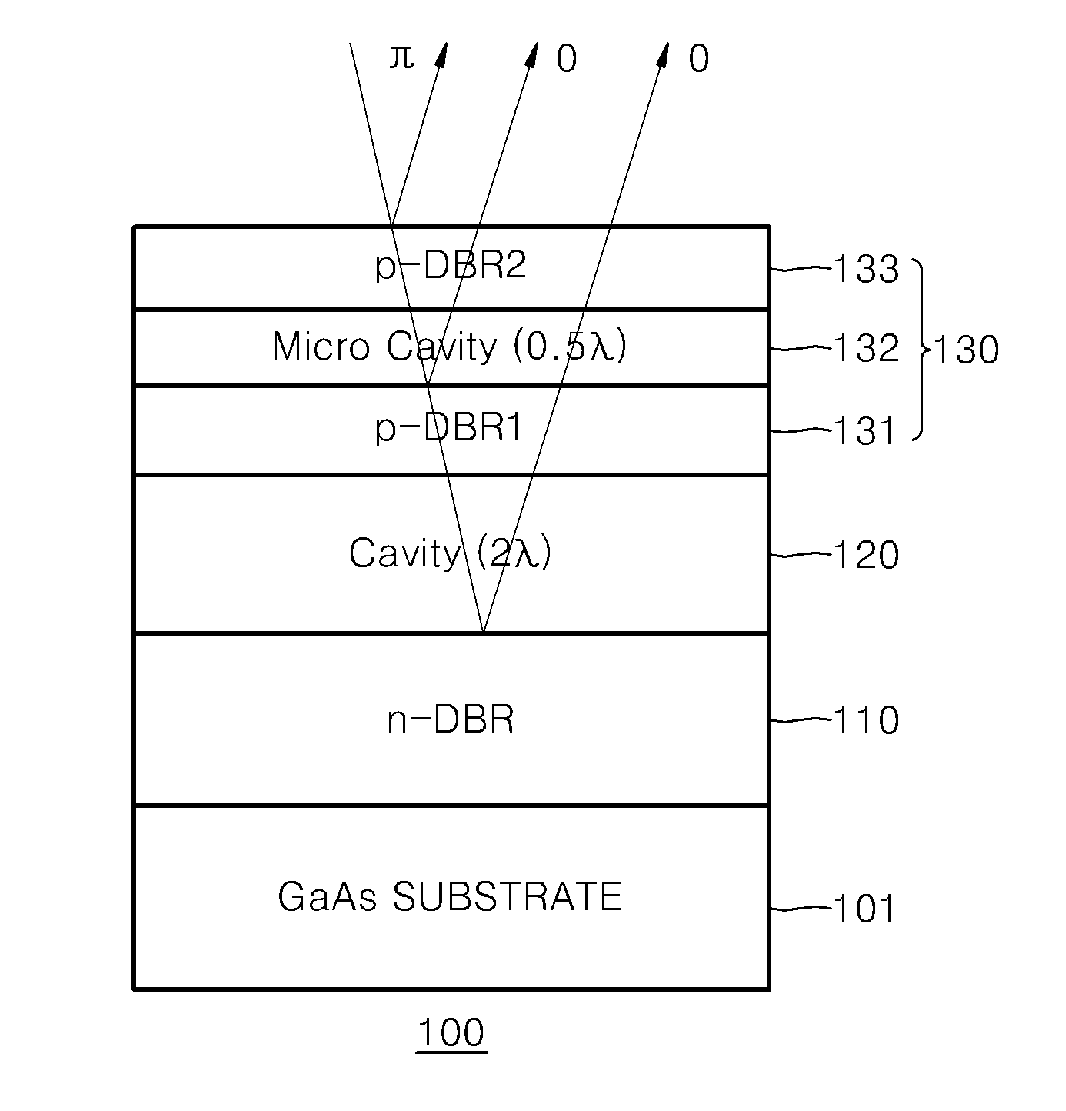

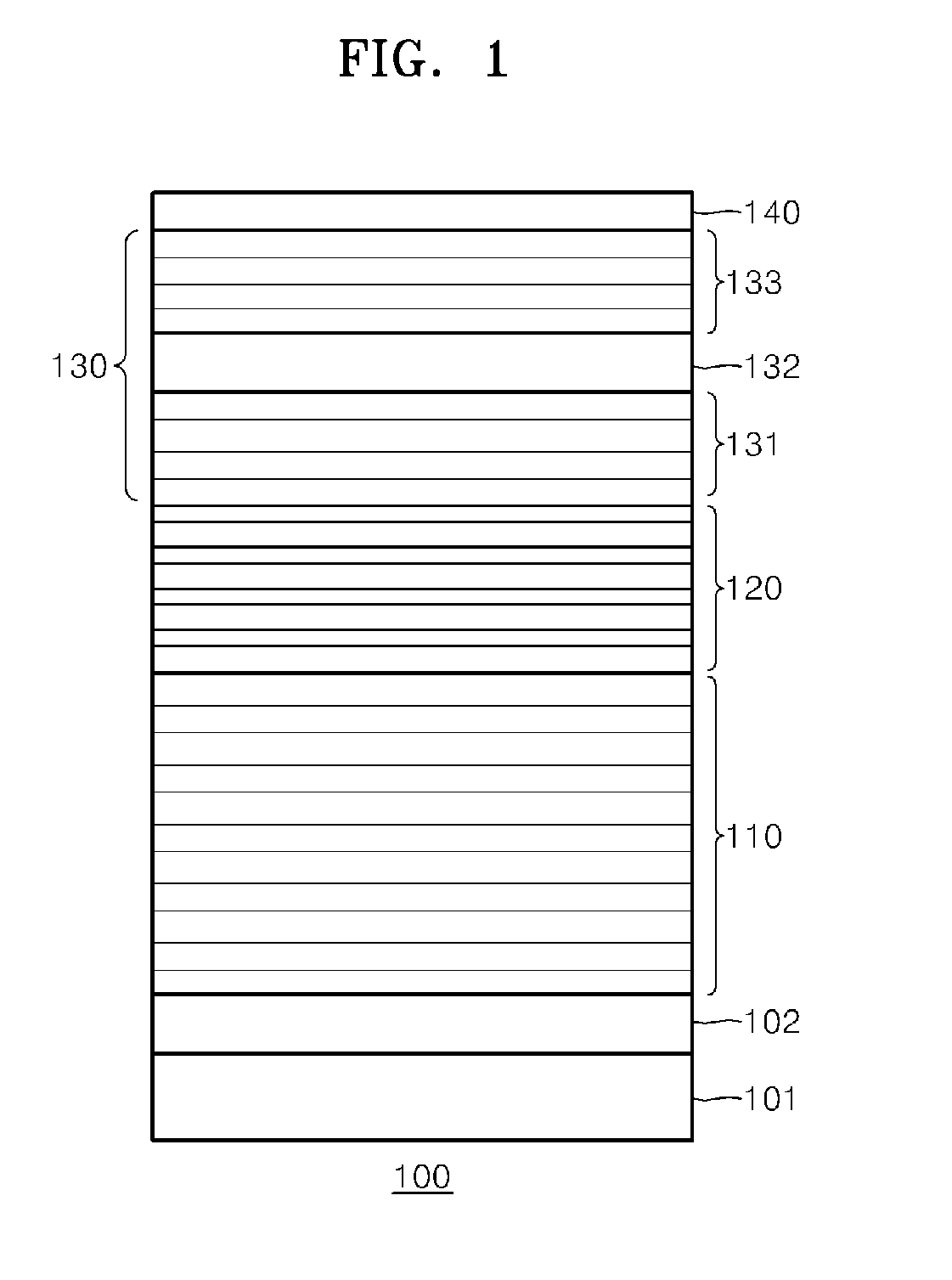

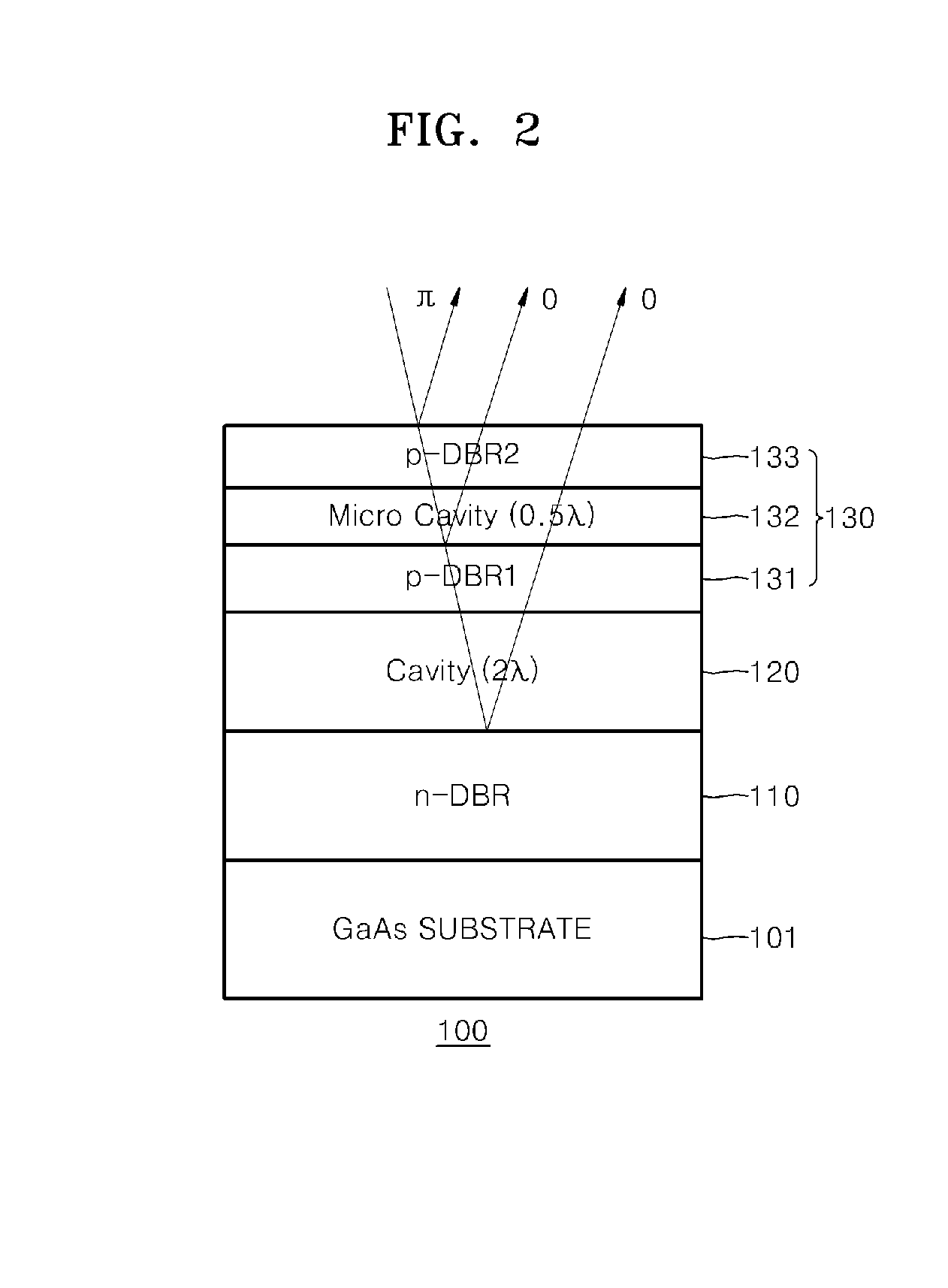

Optical modulator using multiple fabry-perot resonant modes and apparatus for capturing 3D image including the optical modulator

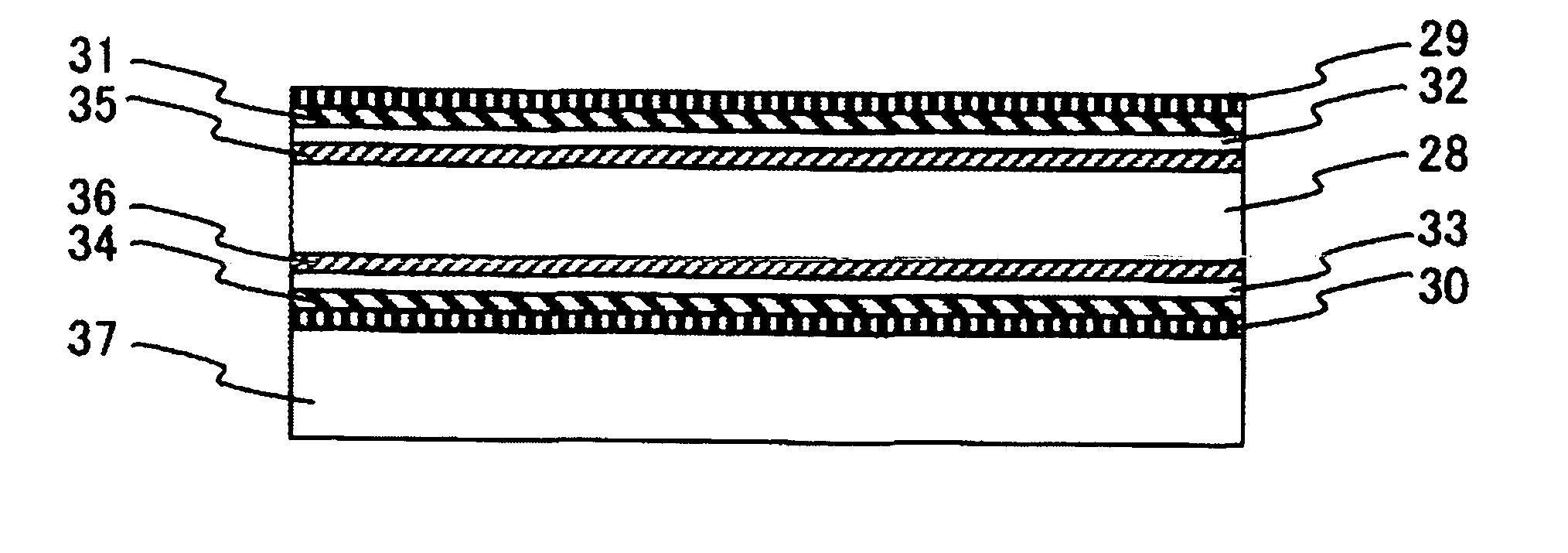

InactiveUS20120162380A1High contrast ratioWide bandwidthNanoopticsUsing optical meansHigh contrastMultiple quantum

An optical modulator that performs wide bandwidth optical modulation by using multiple Fabry-Perot resonant modes, and an apparatus for capturing a three-dimensional image including the optical modulator are provided. The optical modulator may include: a substrate; a first contact layer disposed on the substrate; a bottom distributed Bragg reflective (DBR) layer disposed on the first contact layer; an active layer disposed on the bottom DBR layer and includes a multiple quantum well layer; a top DBR layer disposed on the active layer; a cavity layer disposed in the top DBR layer; and a second contact layer disposed on the top DBR layer. Since the optical modulator achieves both a high contrast ratio and a wide bandwidth by using two or more Fabry-Perot resonant modes, the optical modulator may show a stable performance even when a resonant wavelength is changed during manufacture or due to an external environment such as temperature.

Owner:SAMSUNG ELECTRONICS CO LTD +1

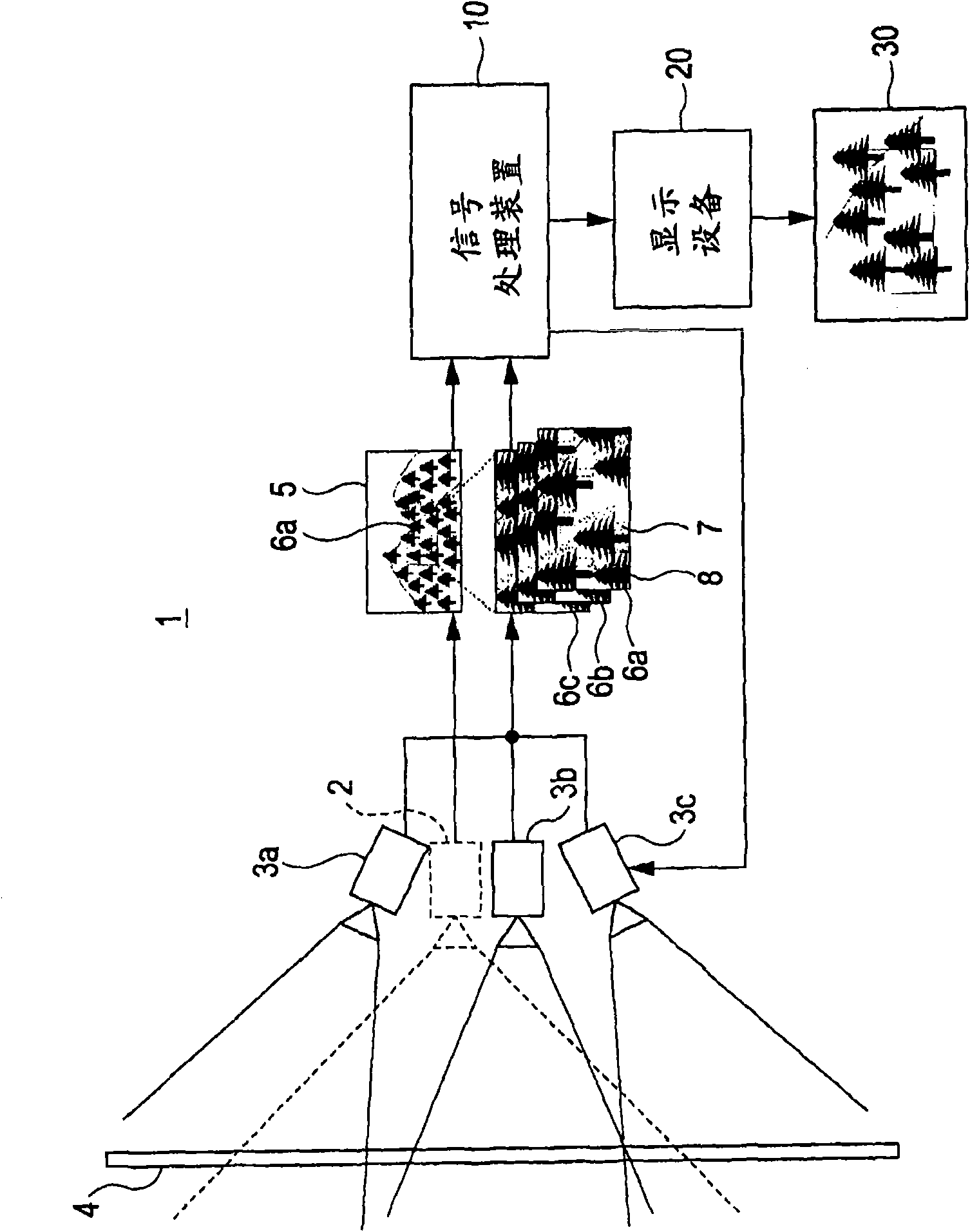

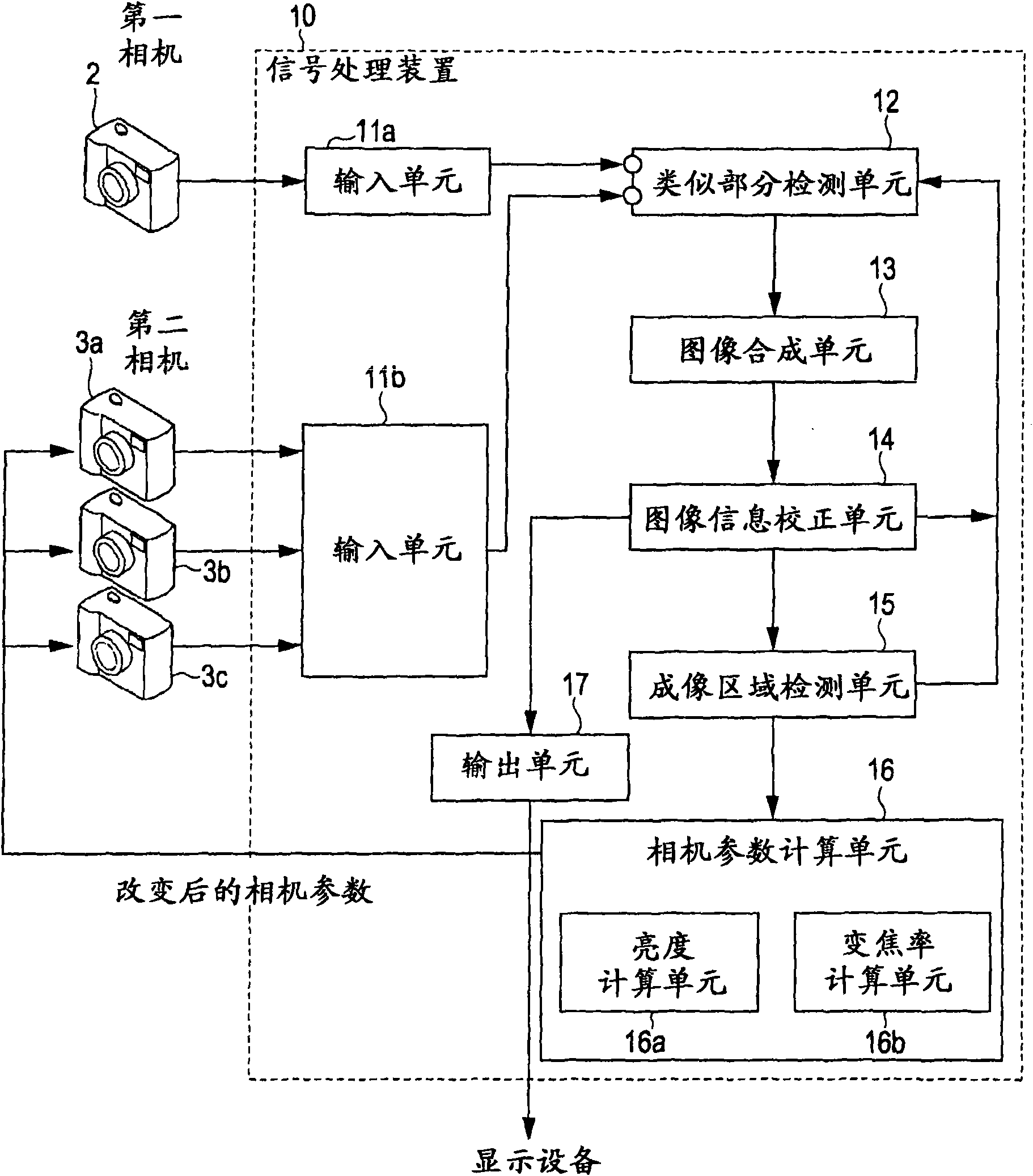

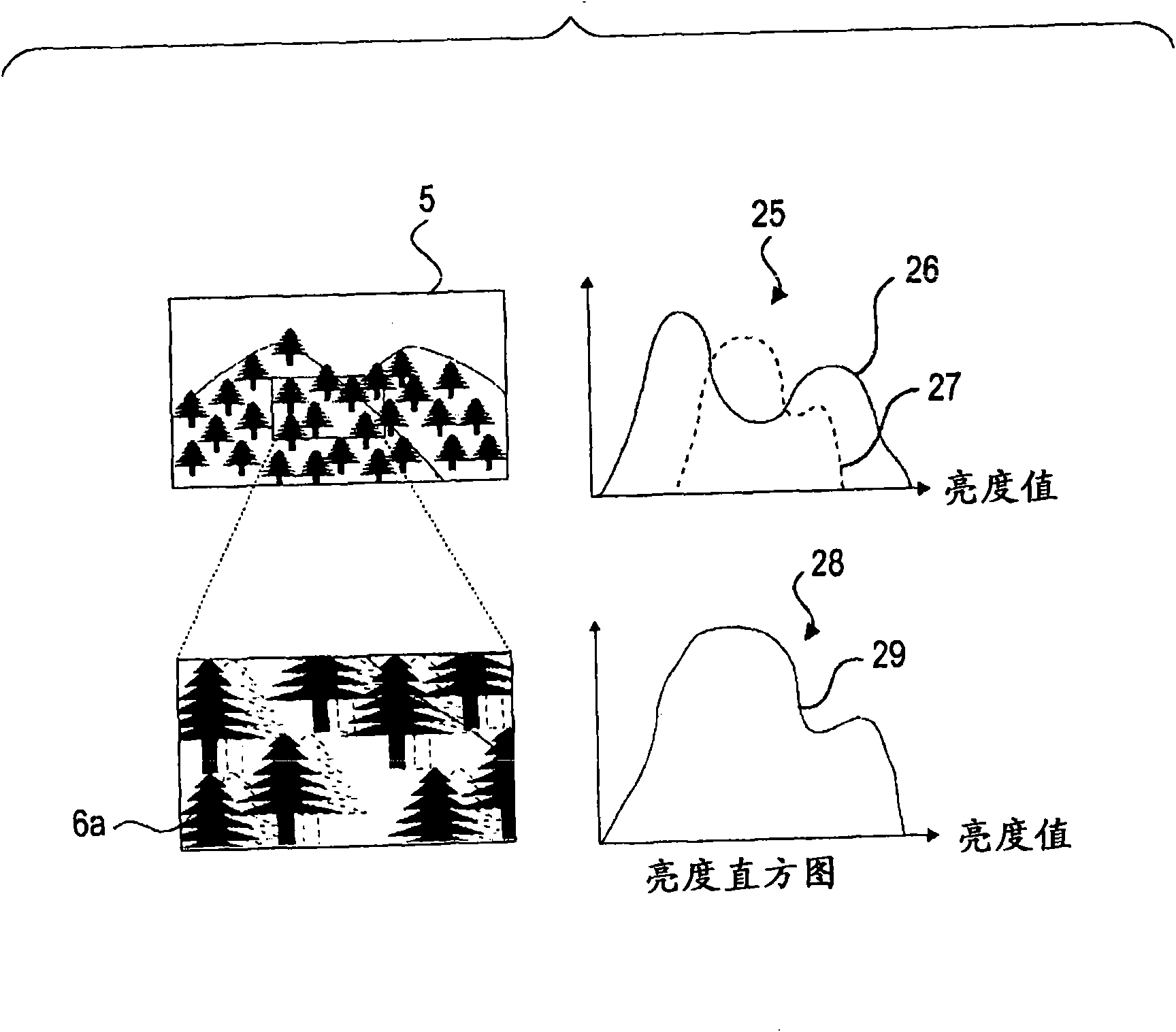

Signal processing apparatus, signal processing method, program and recording medium

InactiveCN101616260AHigh contrast ratioHigh resolutionTelevision system detailsGeometric image transformationPattern recognitionSignal processing

The invention discloses a signal processing apparatus, a signal processing method, a program and a recording medium. The signal processing apparatus includes: an input unit receiving a first image generated by a first camera and higher-resolution second images generated by a plurality of second cameras; a similar portion detecting unit detecting a similar portion between part of a subject included in the first image and a subject included in each of the second images; an image synthesizing unit pasting the second images at positions corresponding to the detected similar portions within the first image to generate a synthesized image; an imaging area detecting unit detecting an area, for which image information is insufficient in the first image and is difficult to complement by the second cameras, as a non-imageable area from the synthesized image; and a camera parameter calculation unit changing a camera parameter for controlling the second camera that captures the second image by which the image information insufficient in the first image is complemented.

Owner:SONY GRP CORP

Liquid crystal display

ActiveUS20060221280A1High contrast ratioWide view angle rangeNon-linear opticsHigh contrastVertical alignment

A liquid crystal display of a vertical alignment (VA) mode using a circular polarization plate is provided which can reduce light leak as observed along an oblique direction and achieve a high contrast ratio. The VA mode uses a liquid crystal layer of vertical alignment in an initial alignment state. A film having generally isotropic optical characteristics in an omnidirection is used as a protective film, on a liquid crystal cell side, of first and second polarization plates disposed outside the liquid crystal cell, and first and fourth retardation films have an Nz coefficient smaller than 1.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

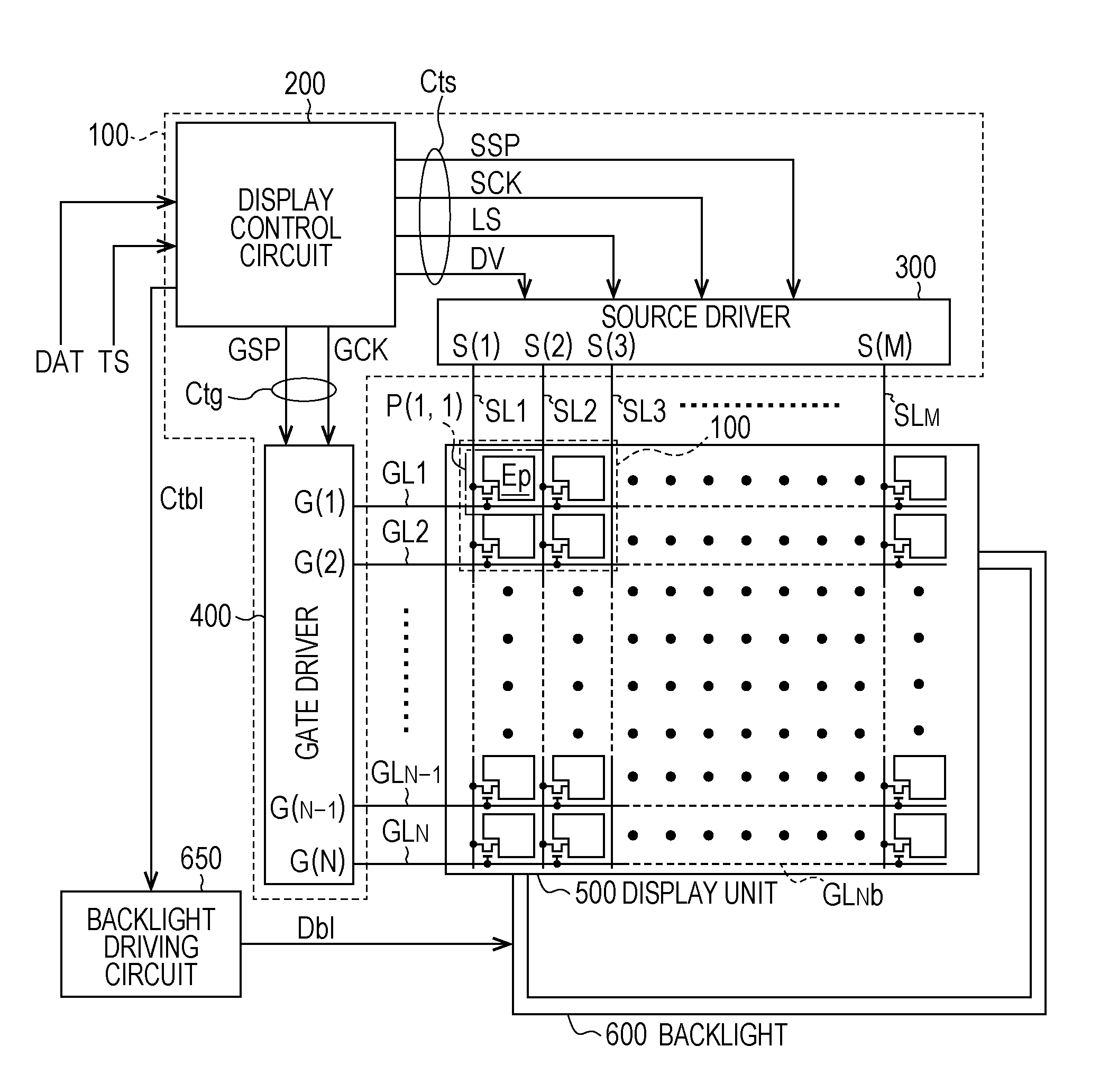

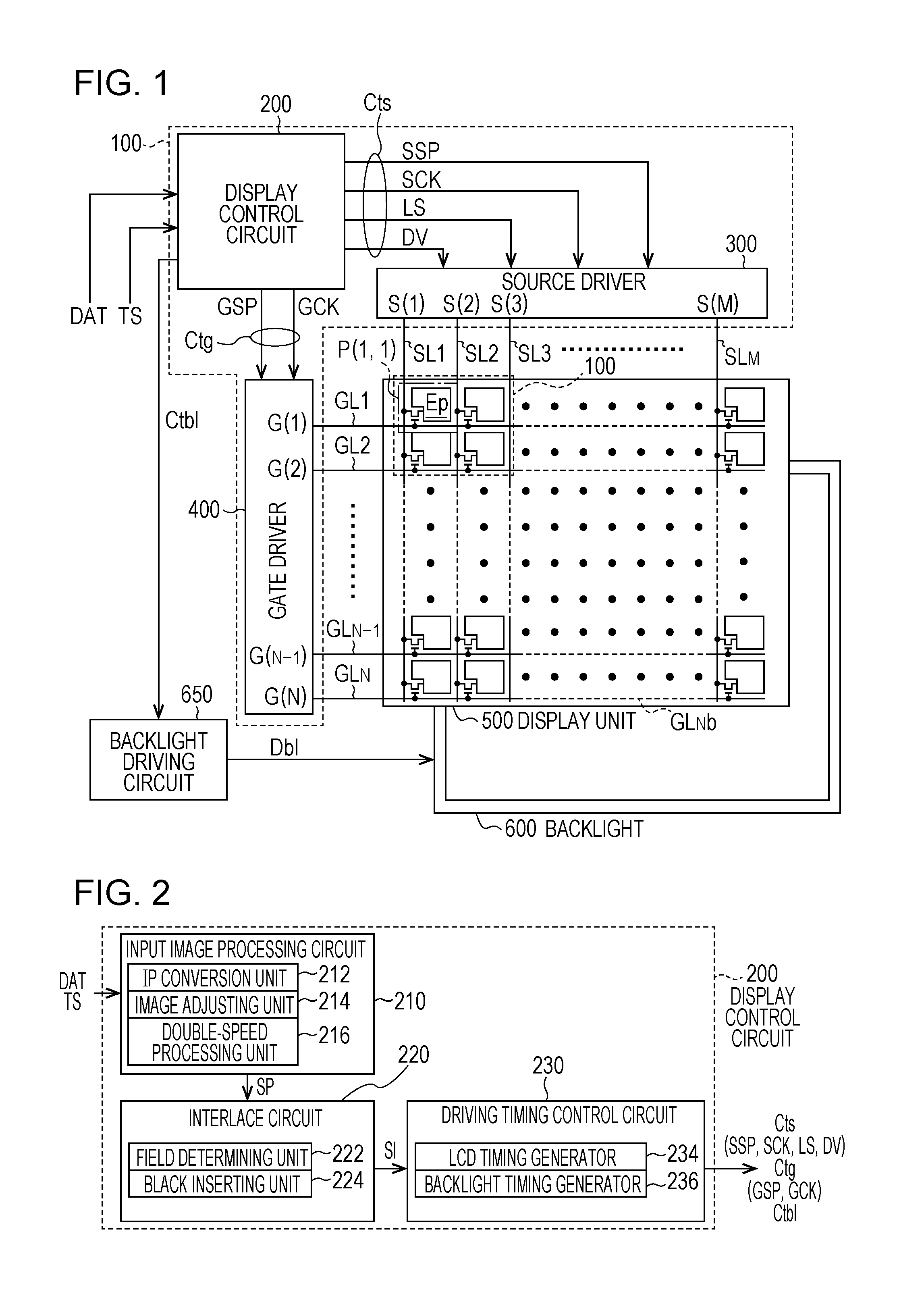

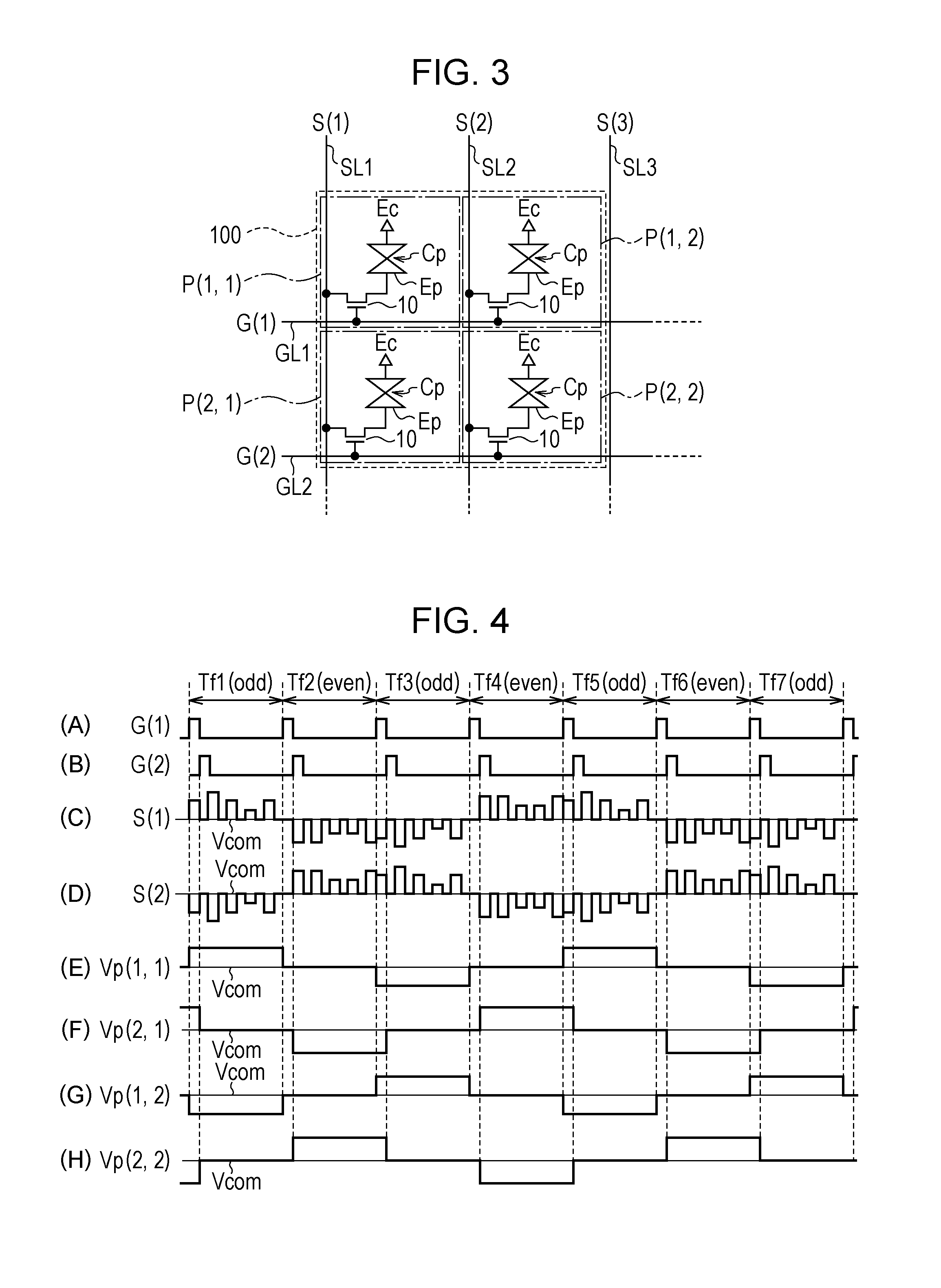

Display device, driving method thereof, and display driving circuit

InactiveUS20130271436A1Suppress flickerResolution does not deteriorateCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayProgressive scan

A display control circuit of a liquid crystal display device generates a double-speed progressive image signal by changing an input image signal based on interlaced scanning into a progressive scanning mode, and also by doubling the frame frequency. With the double-speed progressive image signal, a pixel value equivalent to an odd-numbered scanning line in an odd-numbered frame remains unchanged, a pixel value equivalent to an even-numbered scanning line is replaced with a black pixel value, a pixel value equivalent to an even-numbered scanning line in an even-numbered frame remains unchanged, and a pixel value equivalent to an odd-numbered scanning line is replaced with a black pixel value. An image that the double-speed interlace image signal represents is displayed on a liquid crystal panel.

Owner:SHARP KK

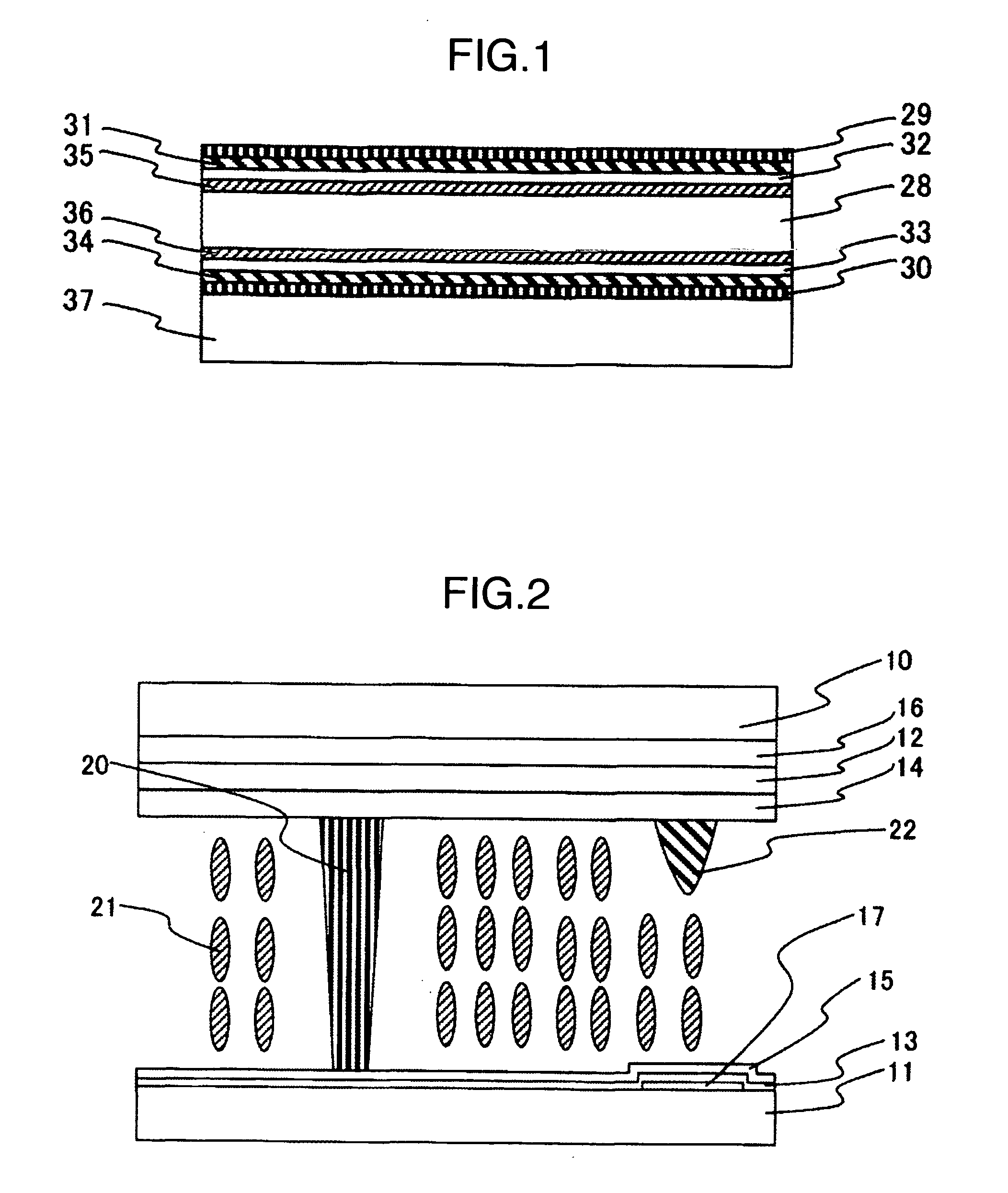

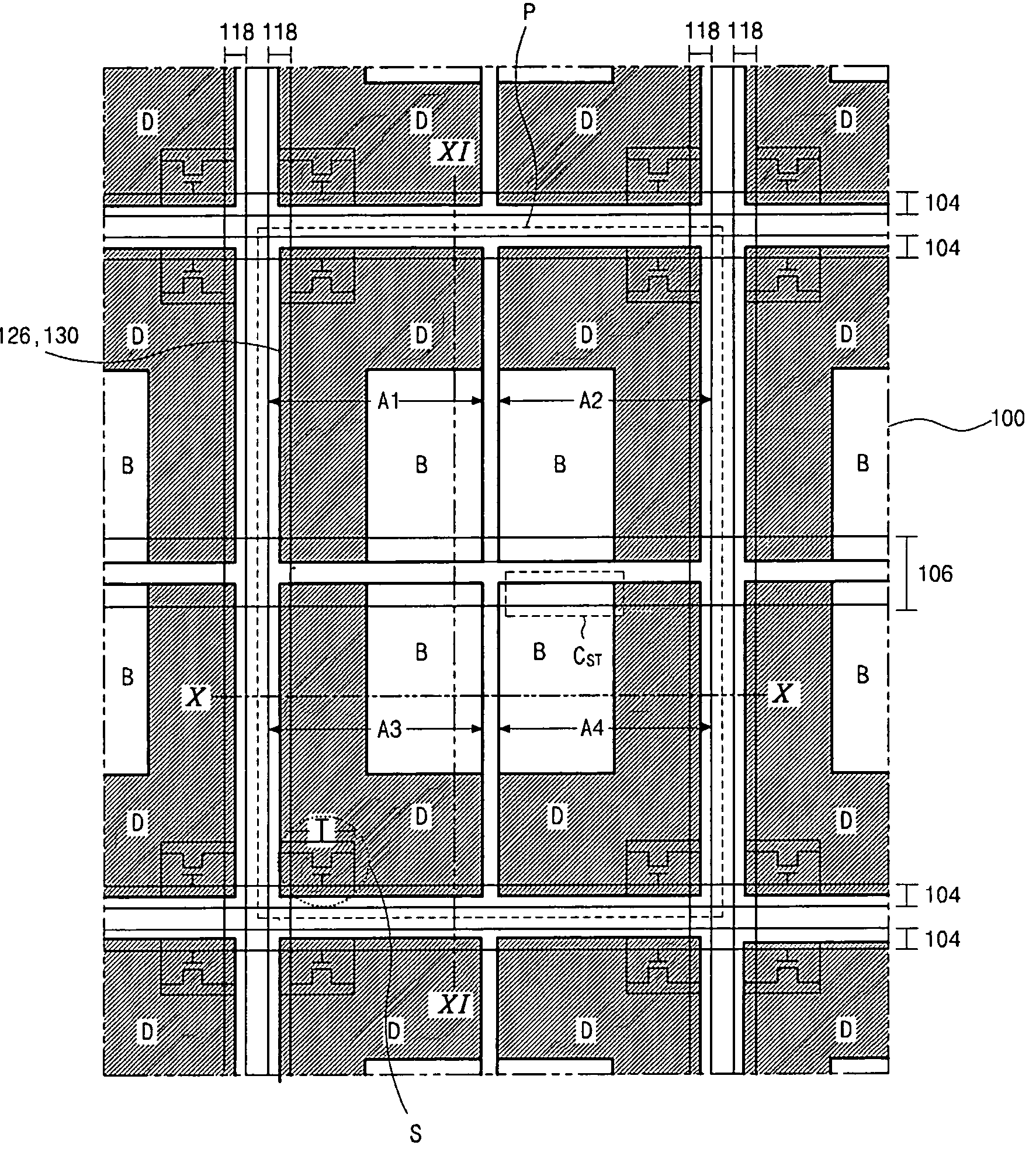

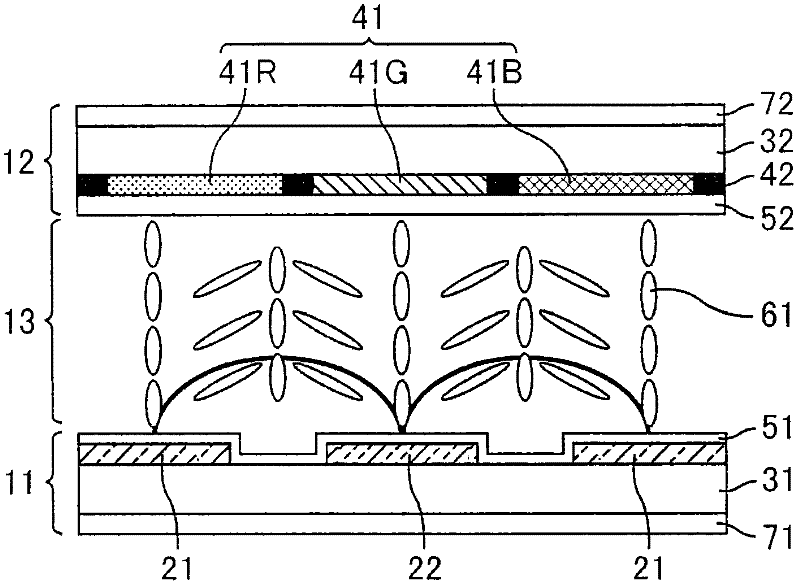

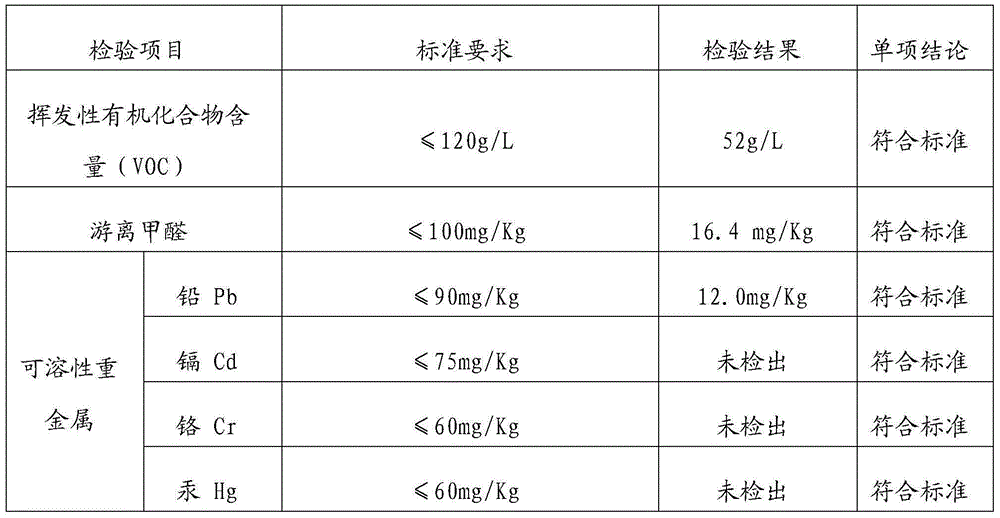

Transflective liquid crystal display and method of fabricating the same

ActiveUS20050018114A1Increase brightnessHigh contrast ratioSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayEngineering

A transflective liquid crystal display includes gate and data lines perpendicular to each other and defining a plurality of unit pixels. Each unit pixel includes a plurality of sub-pixel regions, which each have a transmissive portions and a reflective portion. The transmissive portions are gathered together within each unit pixel at corners of the sub-pixel regions opposing corners in which thin film transistors near the crossings of the gate and data lines are disposed. A passivation layer covering the thin film transistors and the gate and data lines has an opening that corresponds to the transmissive portions in the unit pixel. A reflector is formed over the passivation layer in each sub-pixel region and corresponds in position to the reflective portion. A pixel electrode in each sub-pixel region contacts the thin film transistor through a contact hole in the passivation layer.

Owner:LG DISPLAY CO LTD

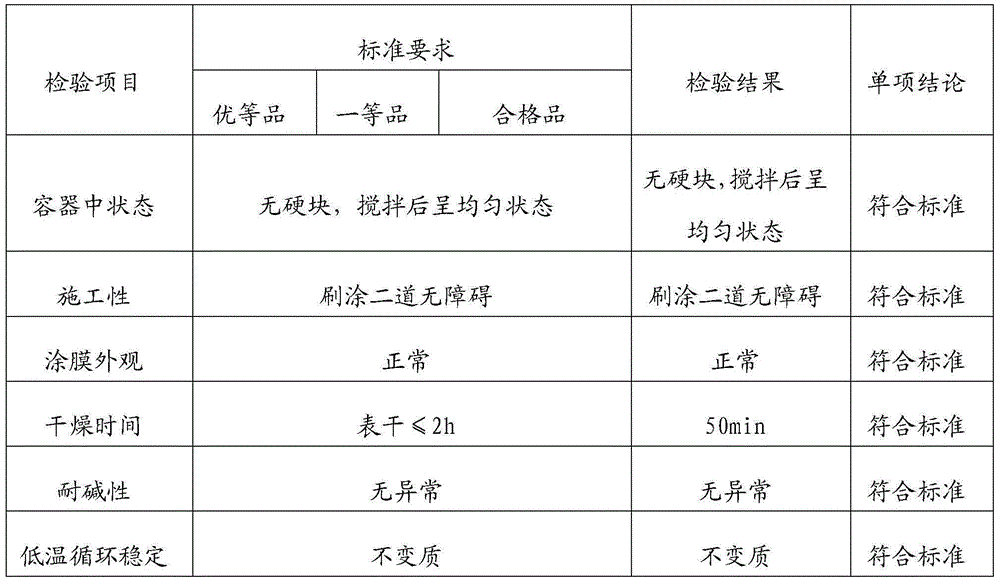

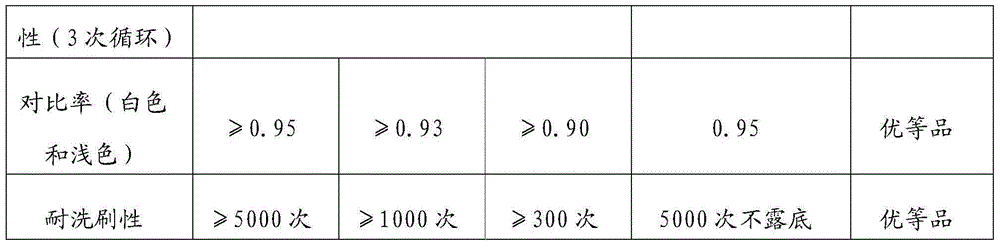

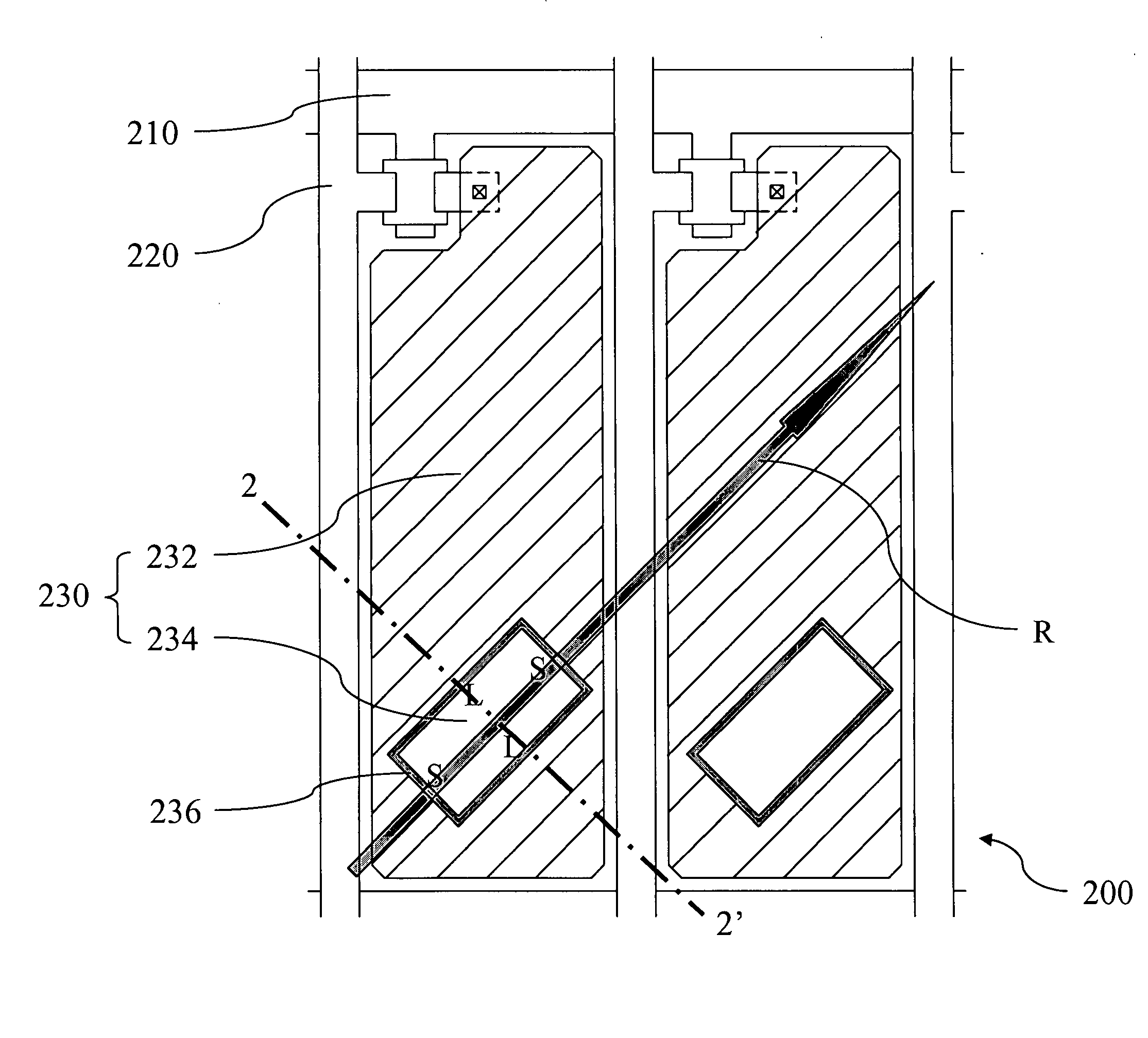

Graphene-modified building coating material

ActiveCN103740158AImprove adhesionHigh contrast ratioPolyurea/polyurethane coatingsFiberCarbon fibers

The present invention discloses a graphene-modified building coating material, which comprises a solvent, a commonly used additive and a main film forming substance, and further comprises graphene for modification, wherein the amount of the added graphene is 0.001-20% of the weight of the building coating material, the building coating material can further be added with the auxiliary additive, and the amount of the added auxiliary additive is 0-8% of the weight of the building coating material. According to the present invention, graphene is added to the existing building coating material so as to modify the water resistance mechanical strength of the building coating material and increase adhesion of the building coating material and the substrate, the contrast ratio and the scrubbing resistance; the bamboo carbon fibers are added to the building coating material so as to provide effects of bacterial inhibition, antibacterial and anti-ultraviolet light, such that the building coating material has the characteristic of green environmental protection; and the bone glue is added to the building coating material so as to improve bonding property and increase adhesion.

Owner:NINGBO MORSH TECH

Environment-friendly anticorrosive and antibacterial inner wall negative ion paint

InactiveCN107936660AGood antibacterial and antifungal effectHigh contrast ratioAntifouling/underwater paintsPaints with biocidesEmulsionDeodorant

The invention provides an environment-friendly anti-corrosion and anti-bacterial interior wall anion coating, which is composed of the following components in parts by weight: 200-250 parts of synthetic resin emulsion, 50-150 parts of anion powder, 15-30 parts of anti-corrosion and anti-bacterial agent, filler 220-280 parts, 3-6 parts of defoamer, 5-9 parts of dispersant, 6-10 parts of film-forming aid, 6-10 parts of thickener, 10-18 parts of leveling agent, 200-250 parts of pigment , 250-300 parts of water. The object of the present invention is to provide an environment-friendly anti-corrosion and anti-bacterial interior with good and long-lasting antibacterial and anti-mildew effects, good performance, non-toxic and harmless to the human body, green environmental protection, good safety, containing negative ions, and capable of inhibiting bacteria and deodorizing. Negative ion paint for walls.

Owner:清远市思彤新材料科技有限公司

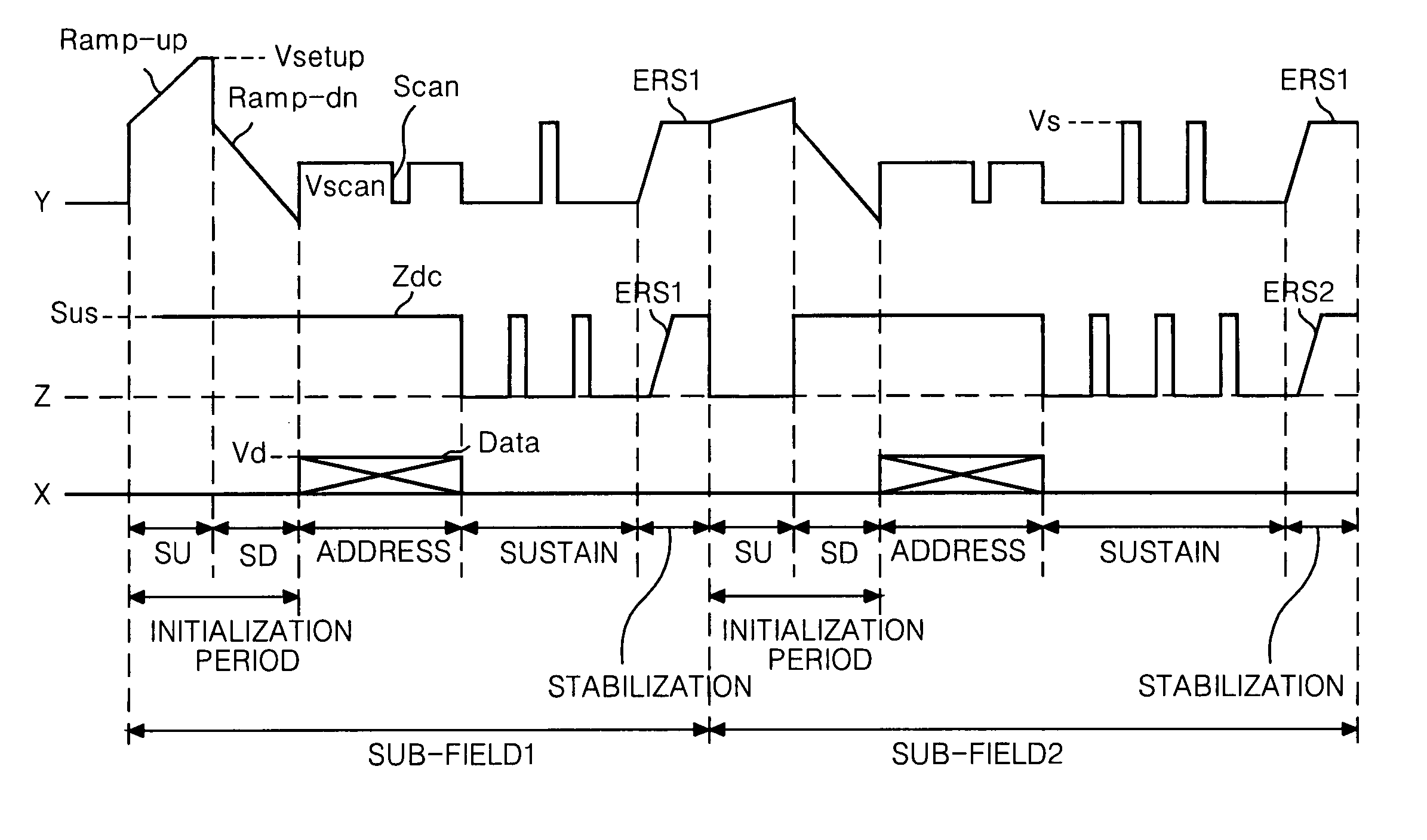

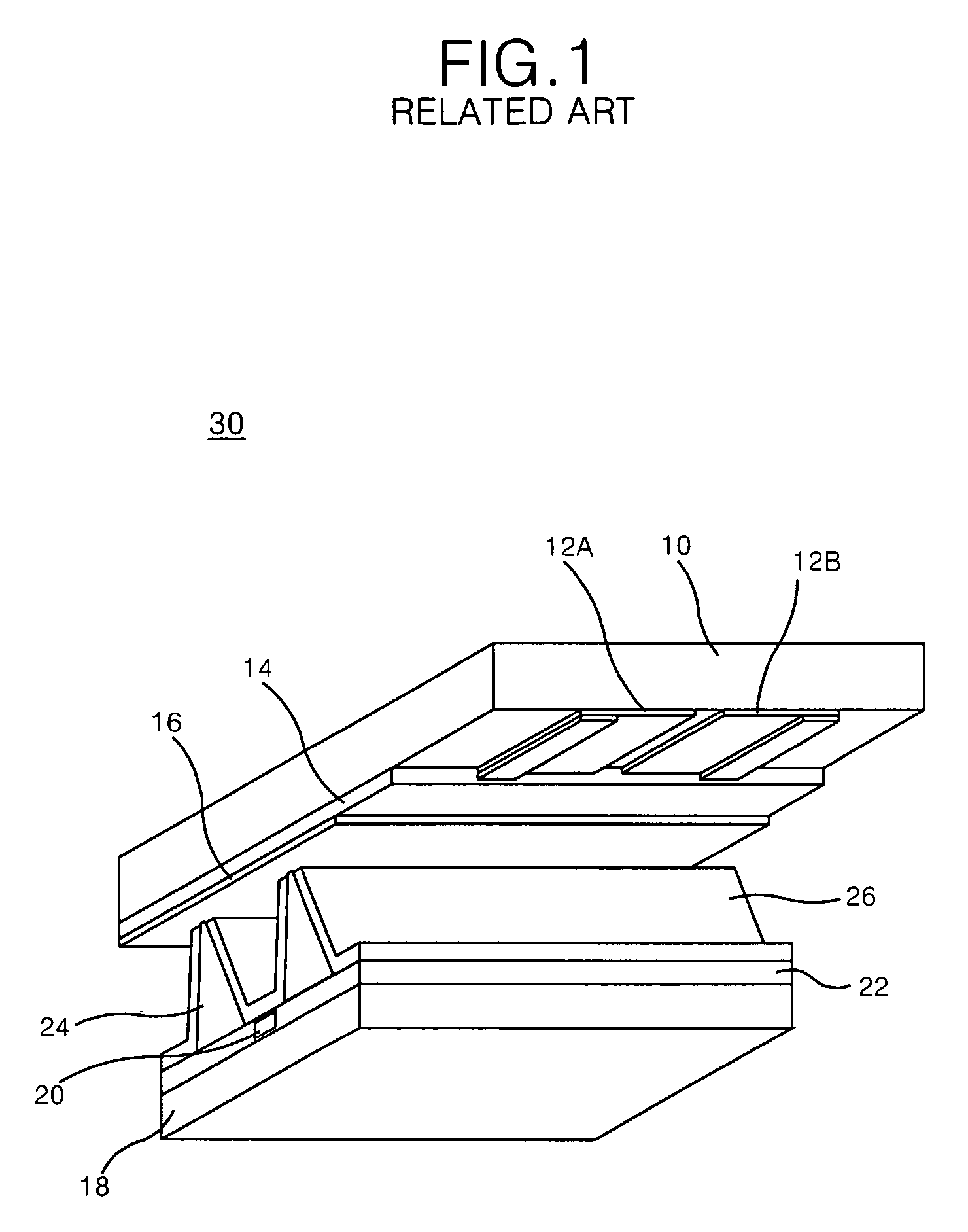

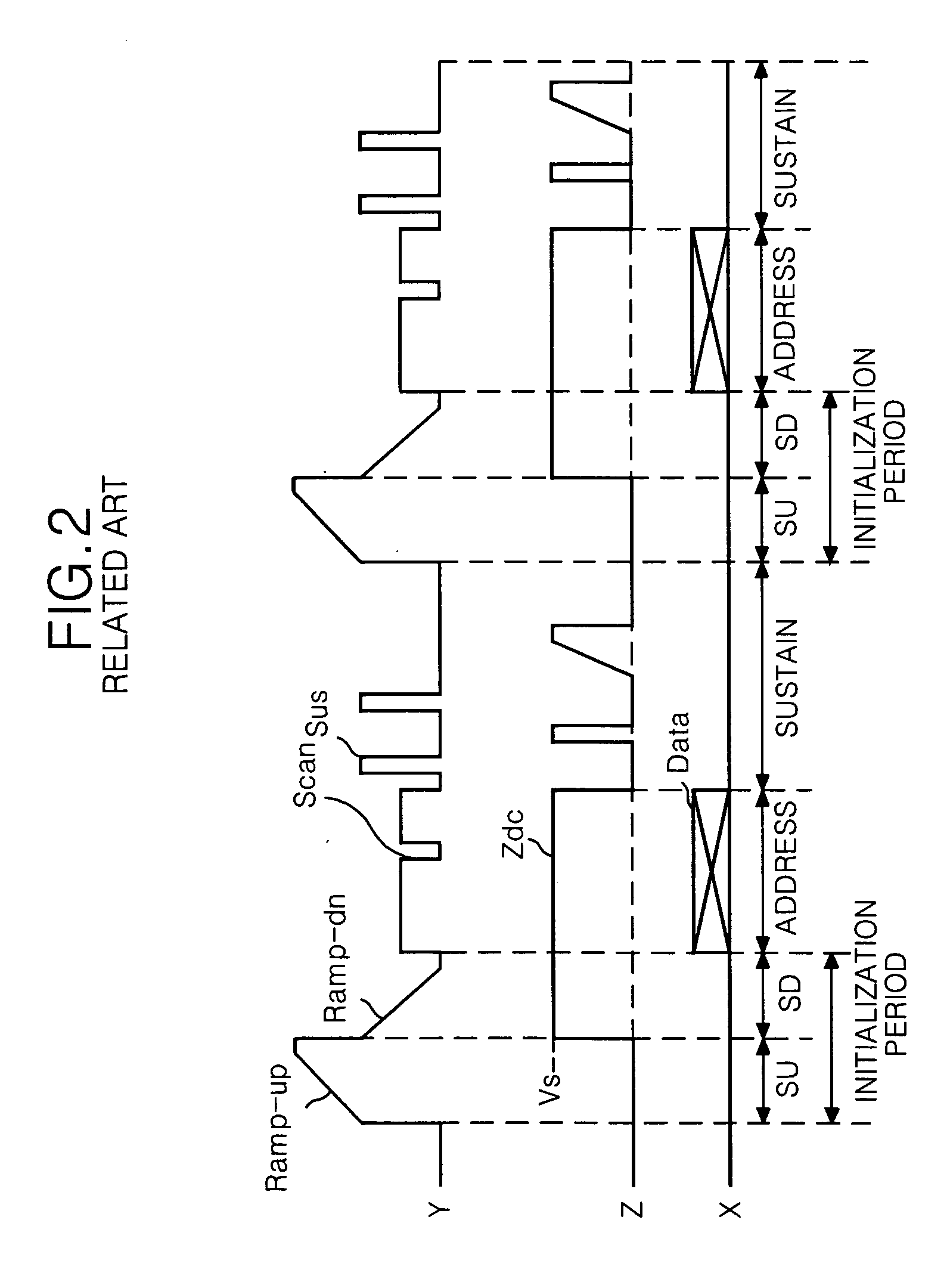

Method of driving plasma display panel

InactiveUS20060164342A1High contrast ratioIncrease contrastCathode-ray tube indicatorsInput/output processes for data processingVoltagePlasma display

The present invention relates to a method of driving plasma display panel. A method of driving a plasma display device driven by dividing a plurality of scan electrode lines into the m (m is a integer more than 2) number of groups, according to the present invention includes: applying p (p is a natural number more than 1) number of first reset pulse having a first voltage to the scan electrode lines included in more than one group among m number of groups during a specific frame; and simultaneously applying q (q is a natural number more than 1) number of second reset pulse having a second voltage different from the first voltage to the second electrode line included in the rest groups except for more than one group during the specific frame.

Owner:LG ELECTRONICS INC

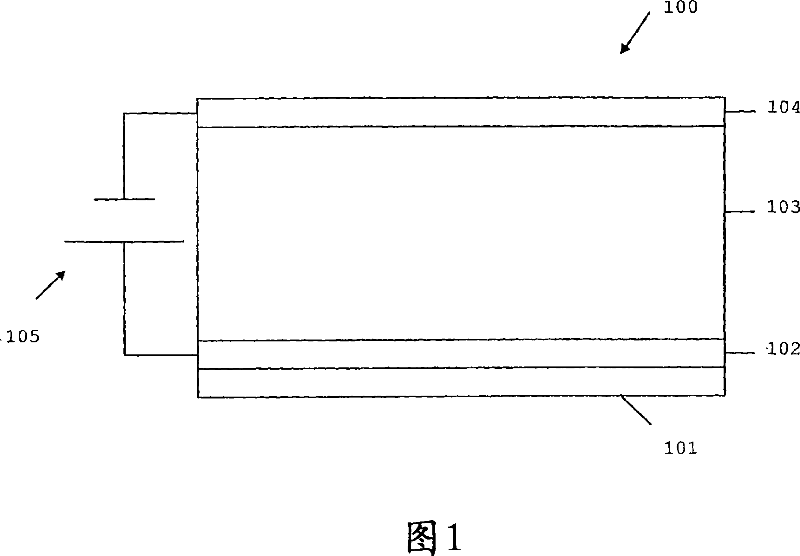

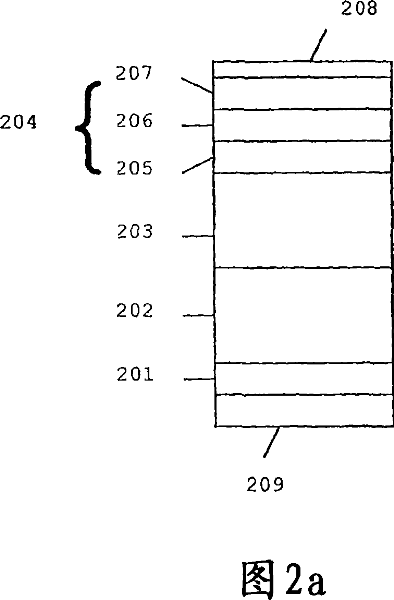

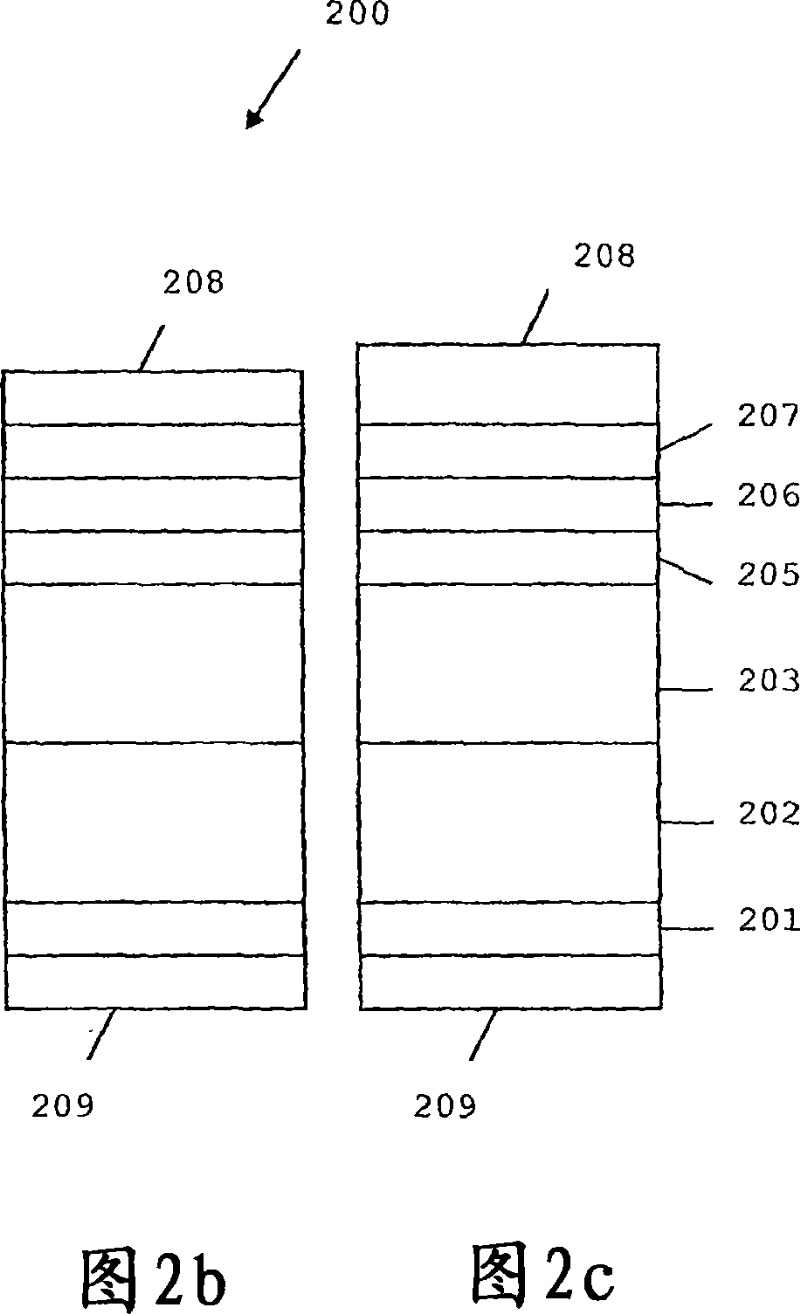

Organic light emitting devices comprising dielectric capping layers

ActiveCN101044642AImprove light outputReduce reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceOptoelectronics

The present invention is directed to an organic light emitting device comprising a multilayer structure with a first electrode, a second electrode, at least one layer of organic material, arranged between said first electrode and said second electrode, and a dielectric capping layer, arranged on said second electrode opposite to said first electrode, wherein said capping layer comprises an outer surface, opposite to said second electrode, for emission of light generated in said at least one layer of organic material. The capping layer has the effect that a reflectance of external light is reduced whereas outcoupling of the light generated in the at least one layer of organic material through said capping layer is increased.

Owner:IBM CORP

Environment friendly coating

InactiveCN101397431ALow free formaldehyde contentHigh contrast ratioCoatingsAlkylphenolResidual monomer

The invention relates to interior wall paint, in particular to an environment-friendly paint which can be widely applied to the decoration of indoor walls, ceilings, plasterboards and the like, does not contain APEO (alkylphenol polyethenoxy ether), is scentless and has low free formaldehyde. The paint is prepared by mainly adopting the technology as follows: first, a dispersant, a wetting agent, a foam suppressor, a thickening agent and a mildew-proof algaecide are added into water sequentially under low speed; titanium pigment, a pH regulator, coarse whiting, calcined kaolin or washed kaolin, french chalk and a mildew-proof agent are added sequentially under medium speed; high-speed dispersion or sanding are carried out until the fineness of less than 50 Mum; and finally, a polystyrene-acrylic copolymer, a polyacrylic copolymer or a vinyl acetate copolymer-acrylic copolymer, a film-forming accessory agent, an antifreezing agent, a preservative, the foam suppressor, a rheology agent and H2O are added sequentially under low speed. The paint dose not contain APEO, thus having no effect on the reproductive system of human and animal; the paint has low odor, and no odor basically, reduces the harm of the residual monomer to human body, and has extremely good physical performances, thus being capable of meeting the requirements on indoor decoration.

Owner:SKSHU PAINT

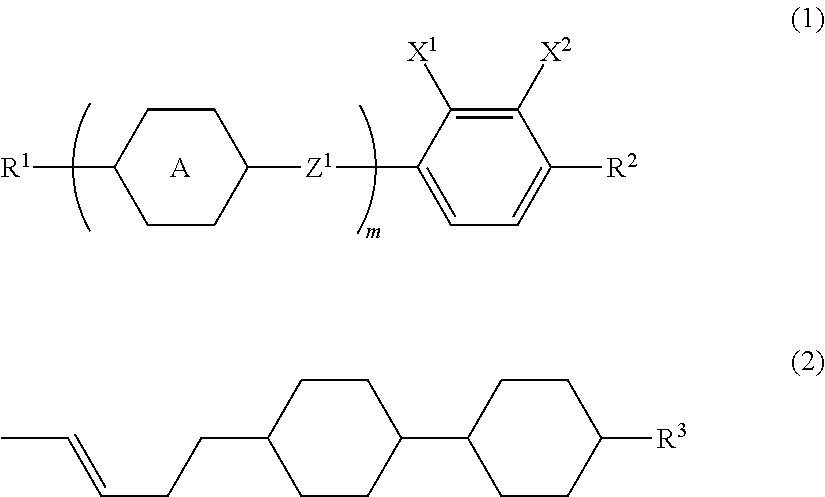

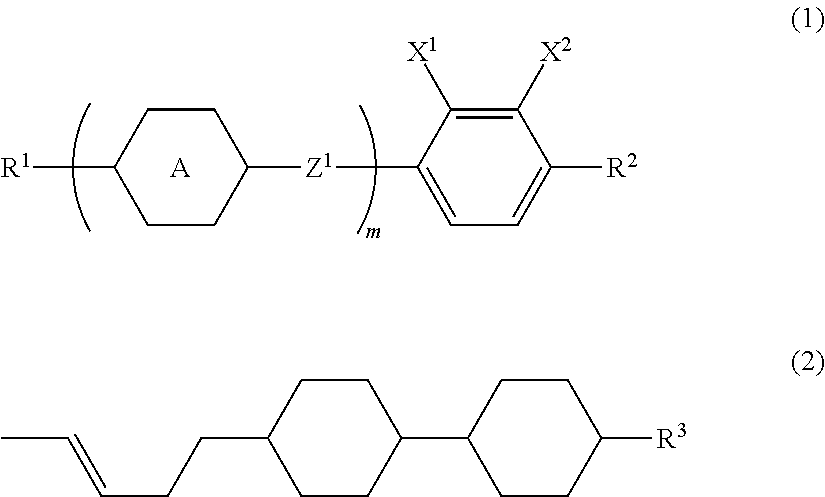

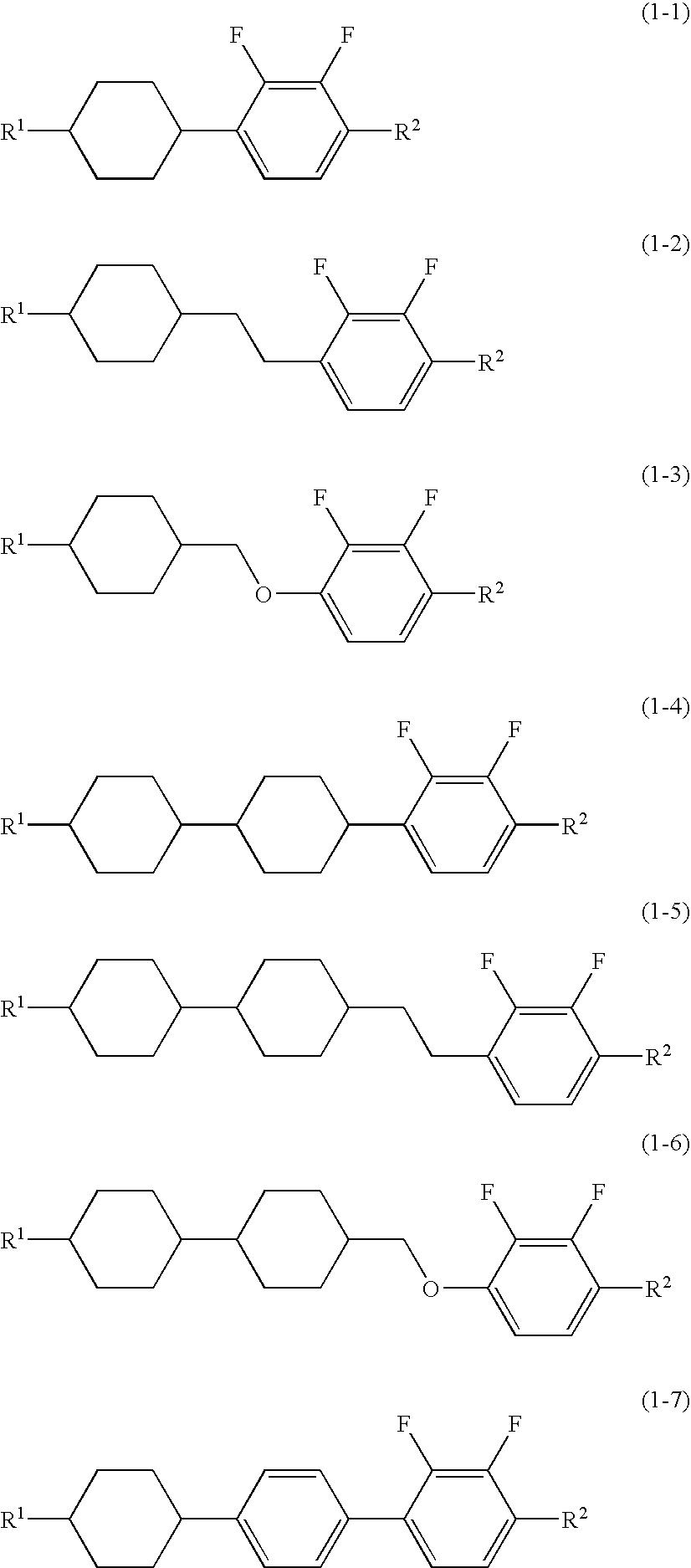

Liquid Crystal Composition and Liquid Crystal Display Device

ActiveUS20110001918A1Large specific resistanceHigh voltage hold ratioLiquid crystal compositionsThin material handlingHigh contrastDielectric anisotropy

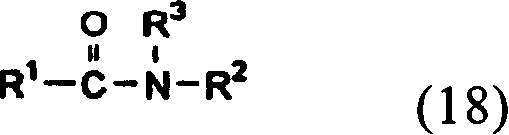

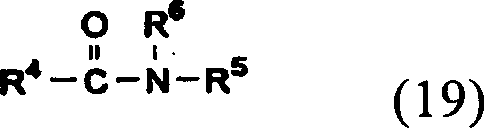

The subject is to provide a liquid crystal composition that satisfies at least one characteristic among characteristics such as a high maximum temperature of a nematic phase, a low minimum temperature of a nematic phase, a low viscosity, a suitable optical anisotropy, a negatively large dielectric anisotropy, a large specific resistance, a high stability to ultraviolet light and a high stability to heat, or that is suitably balanced regarding two or more characteristics. The subject is to provide an AM device that has a short response time, a high voltage holding ratio, a high contrast ratio, a long service life and so forth.The invention provides a liquid crystal composition having a negative dielectric anisotropy that contains a specific compound having a negatively large dielectric anisotropy as a first component, and a specific two-ring compound having a low viscosity as a second component, and provides a liquid crystal display device containing the composition.

Owner:JNC PETROCHEM +1

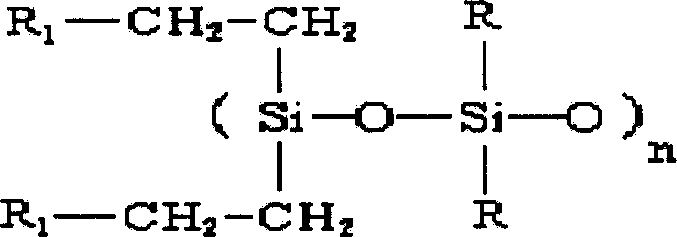

High performance silicon emulsion and its preparation

This invention relates to high performance of silicon emulsion and its production. It is prepared from octaalkyl cyclotetrasiloxane and octavinyl cyclotetrasiloxane mixed monomer, and acrylic acid monomer acted with catalyst, initiator, emusifier and pH regulator. Its process includes polymerizing seed emulsion, polymerizing nucleic emulsion, and polymerizing nucleic shell silicon emulsion. It has uniformly sized particles and is stable quality and production. Coatings with it are waterproof, weatherproof, washing resistant and stain-resistant.

Owner:上海建研建材科技有限公司

One coat paint prepared by organic and inorganic compound emulsion and preparation method thereof

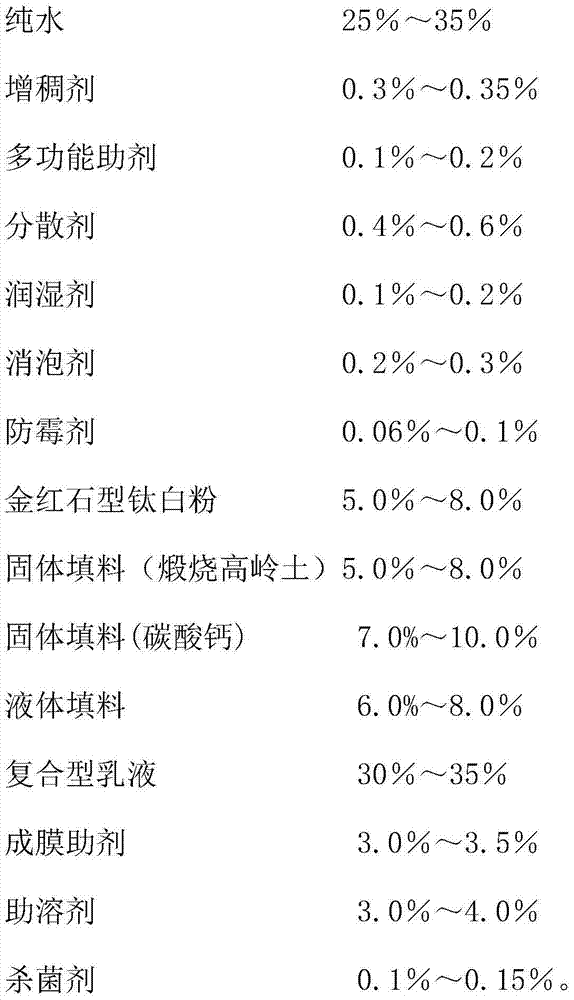

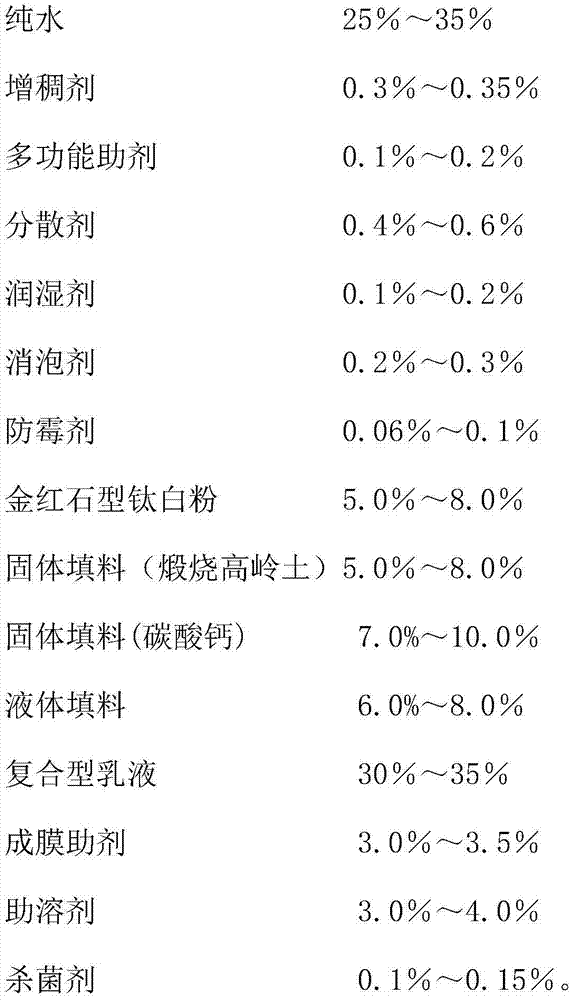

The invention discloses a one coat paint prepared by an organic and inorganic compound emulsion and a preparation method thereof. The one coat paint is used for sealing and decorating an exterior wall. The one coat paint comprises the following components: pure water, a thickener, multifunctional additives, a dispersant, a wetting agent, a defoaming agent, a mildew-proof agent, rutile type titanium dioxide, a filler, a liquid filler, the compound emulsion, film-forming additives, a cosolvent and a fungicide. The one coat paint disclosed by the invention has the performances of a primer paint, namely excellent alkali burnout resistance and salting-out resistance; furthermore, all the performances are in line with the requirements of primer paint first-grade products for the exterior wall of buildings. The one coat paint further has the performances of a finish paint of the exterior wall: a paint film has excellent contrast ratio, scrub resistance, weatherability and stain resistance, and all the performances are in line with the requirements of high-grade products of latex paint for the exterior walls of the buildings.

Owner:NIPPON PAINT YASHILI

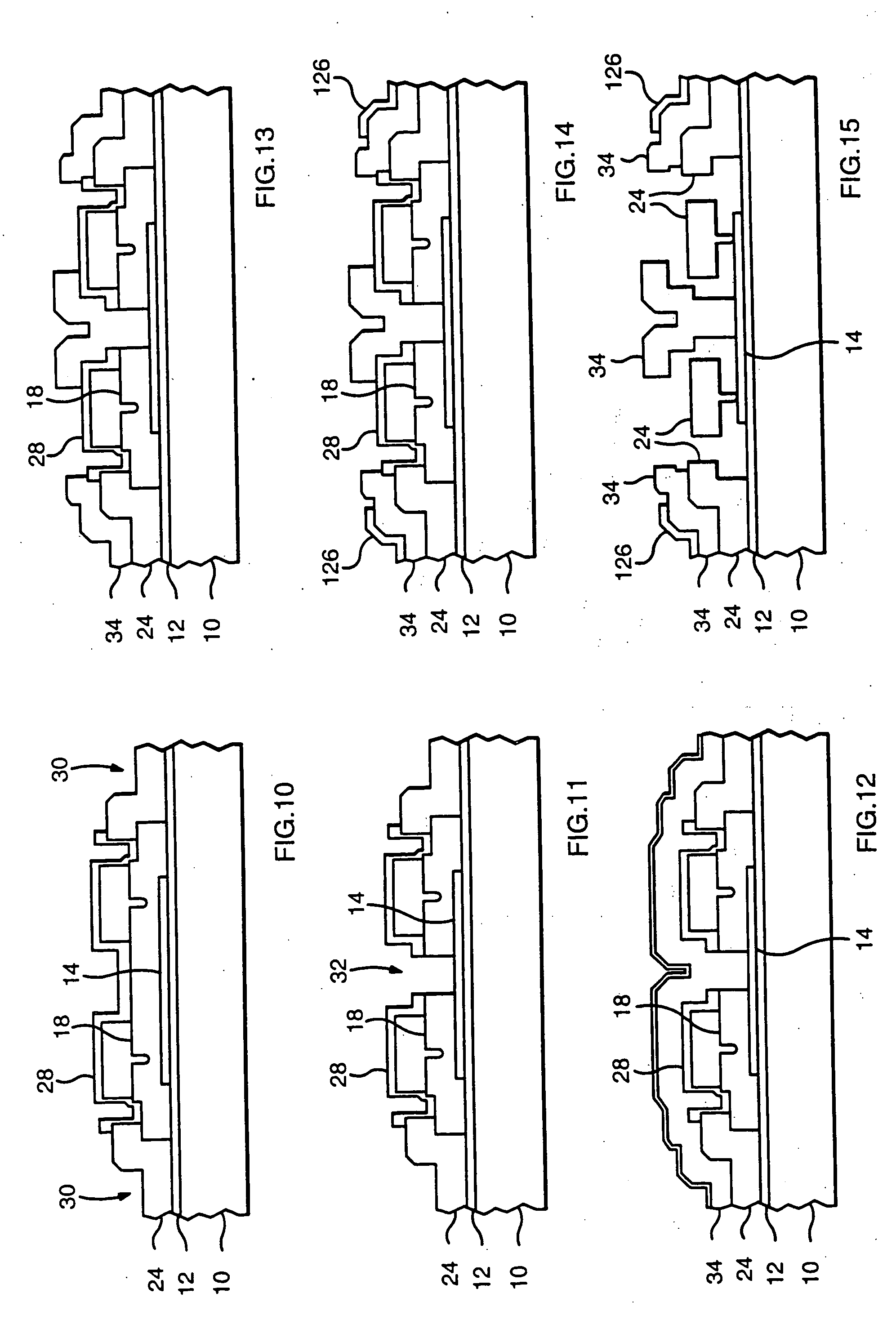

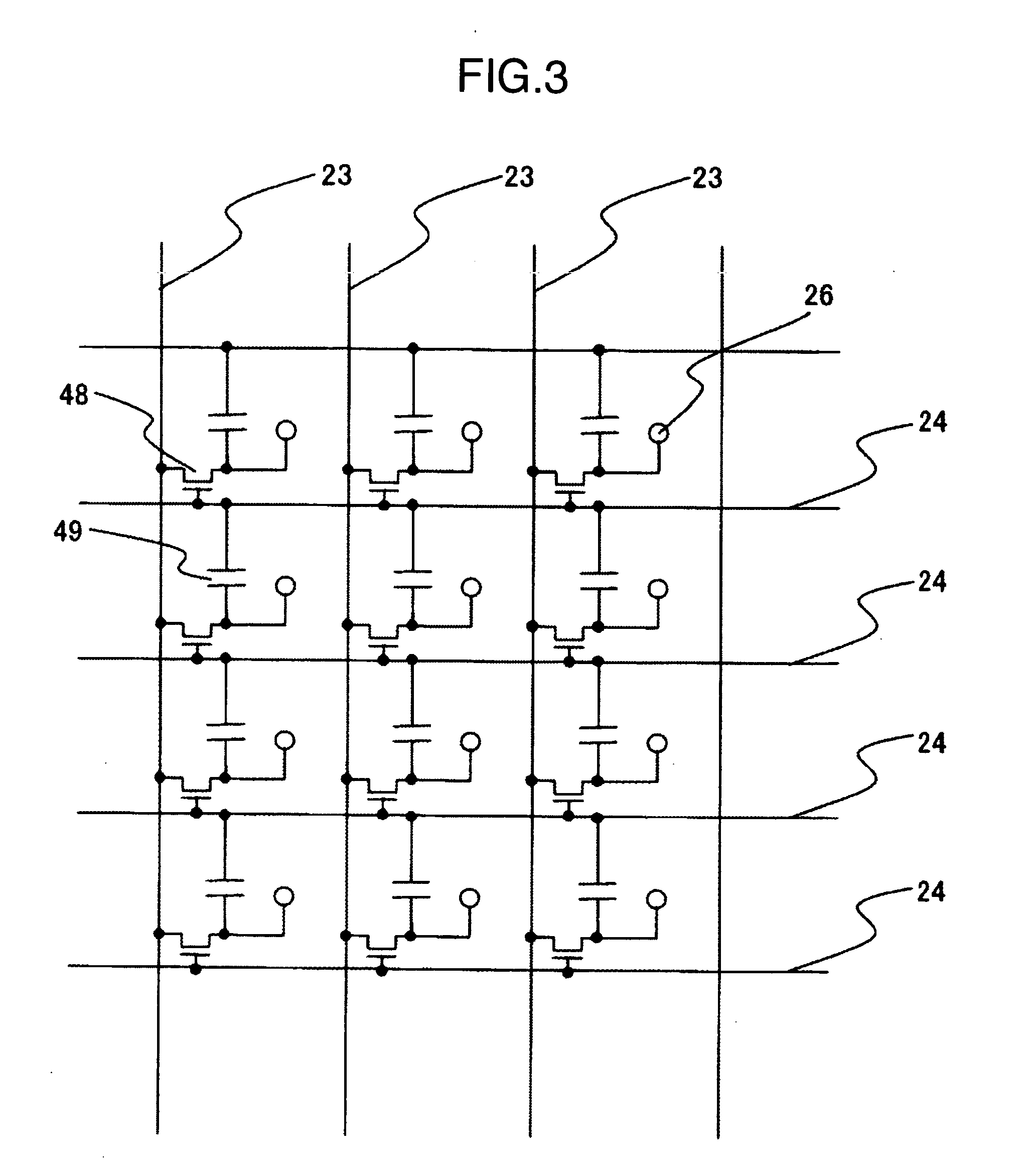

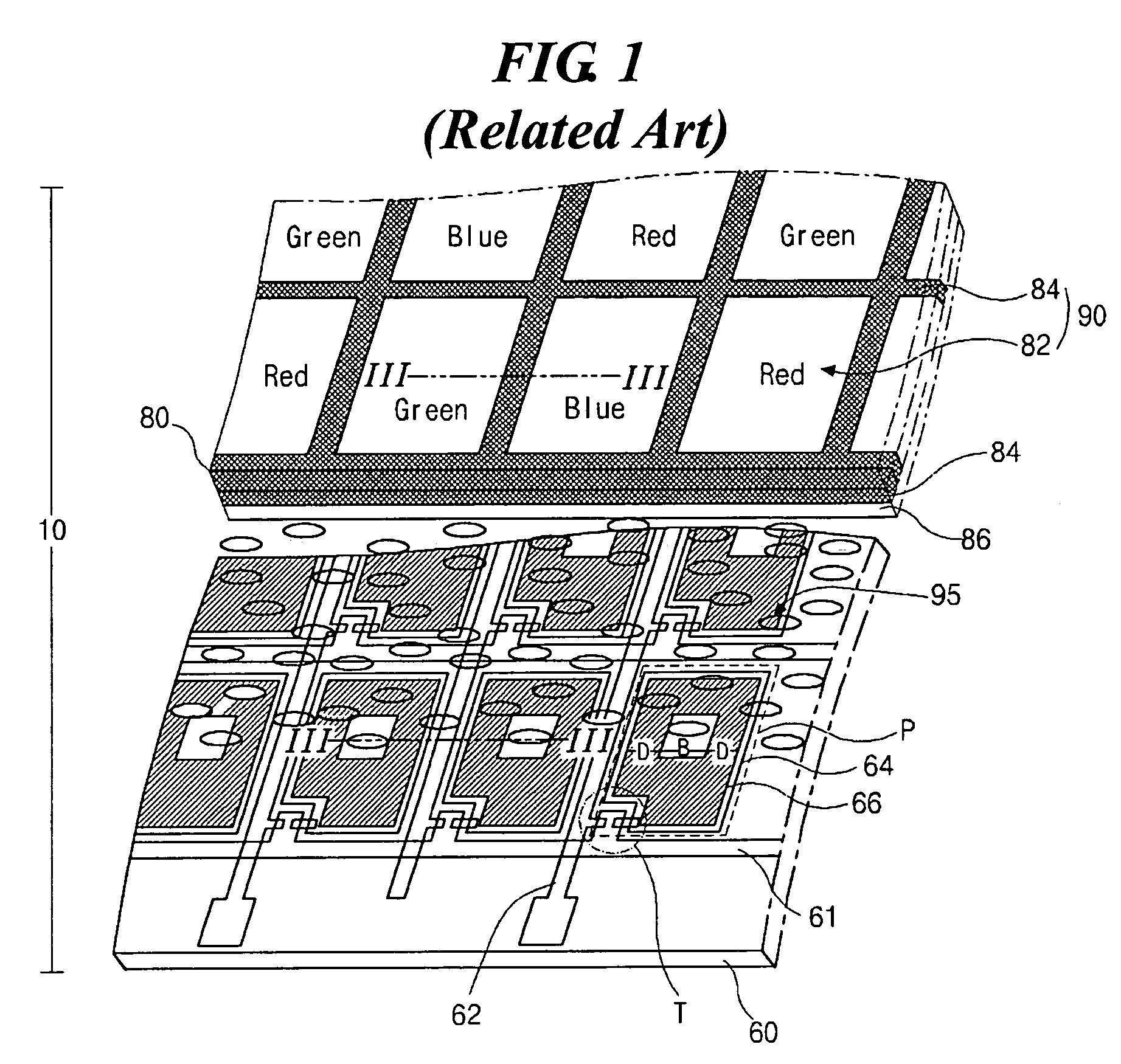

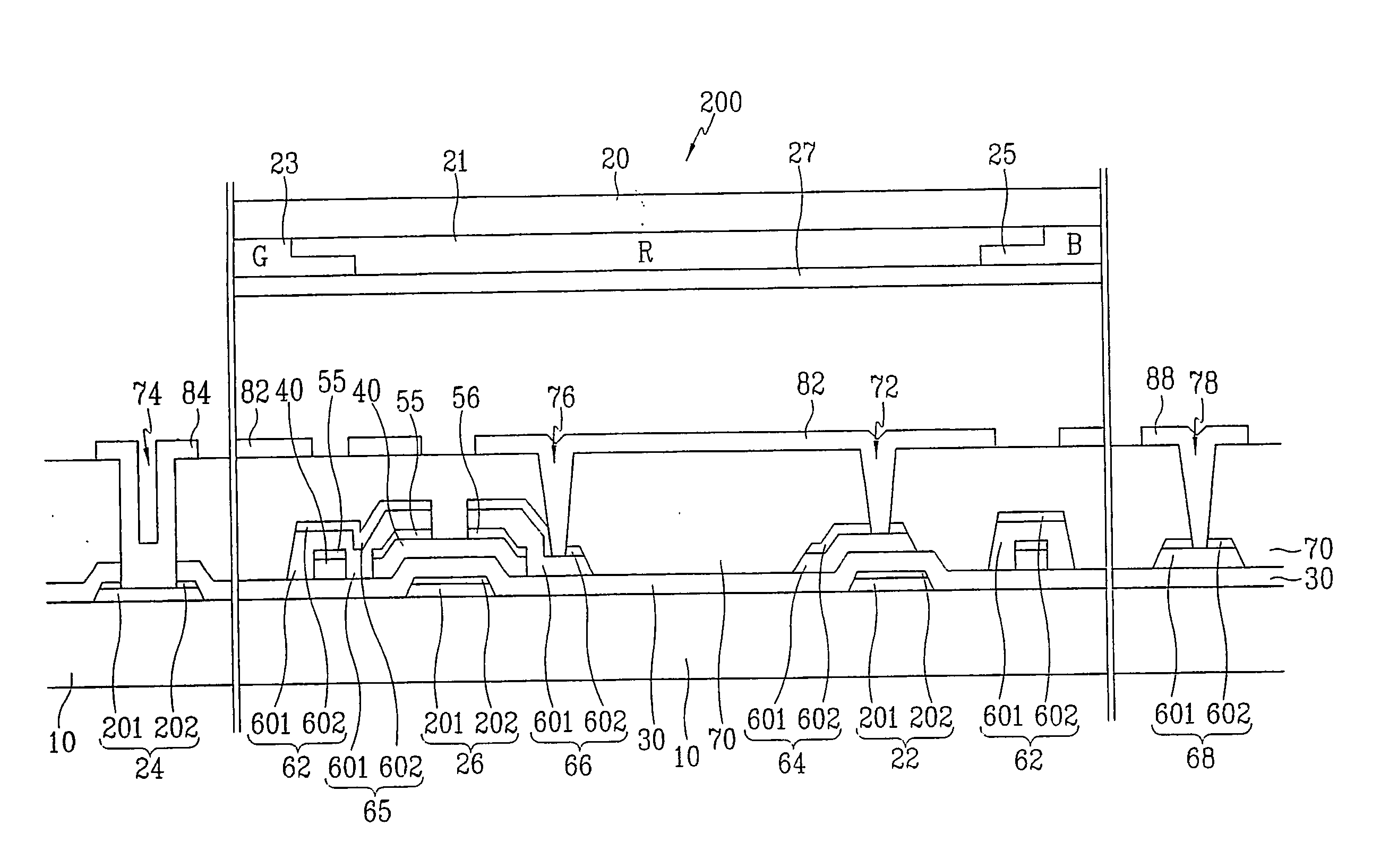

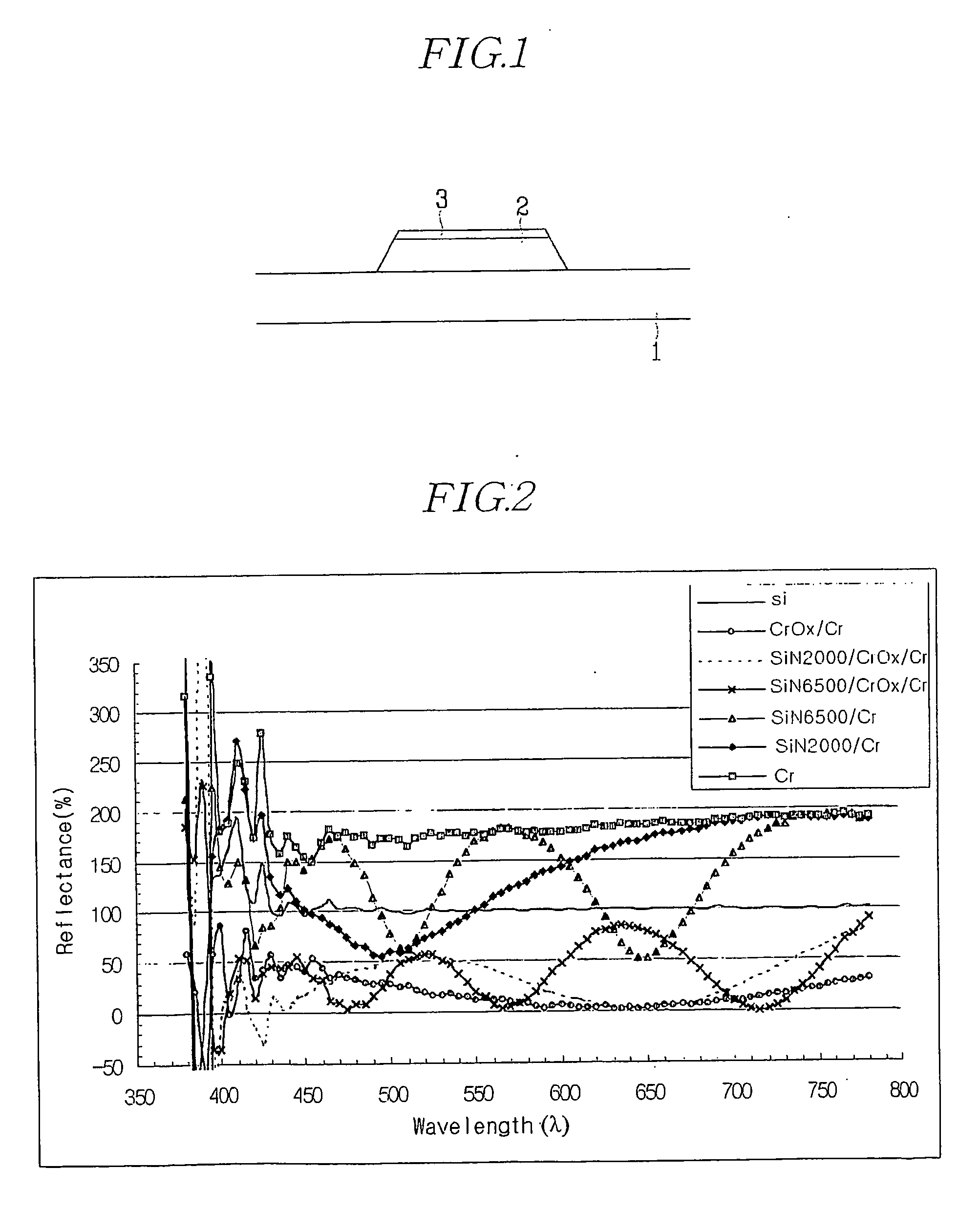

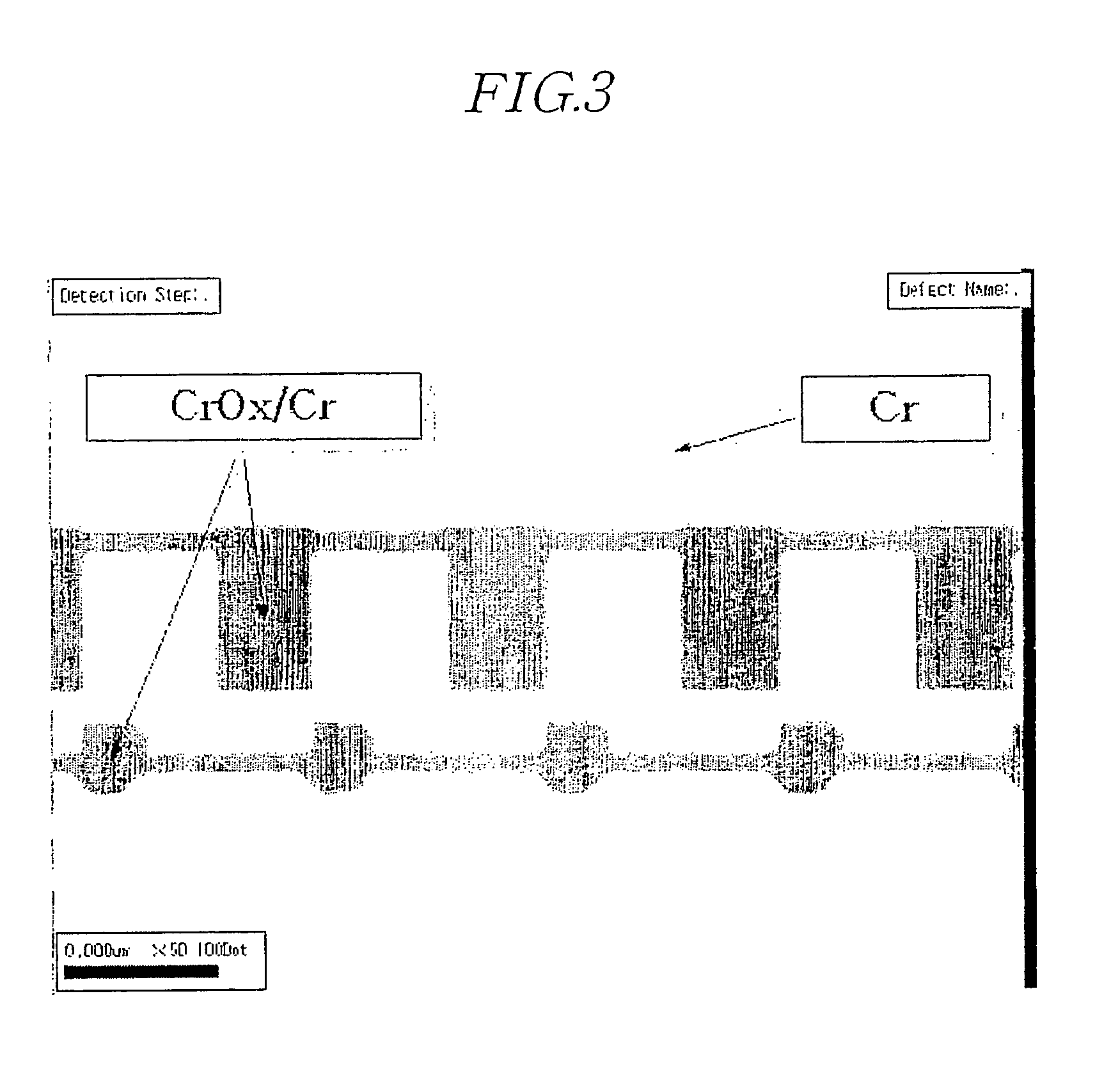

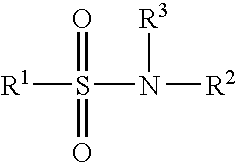

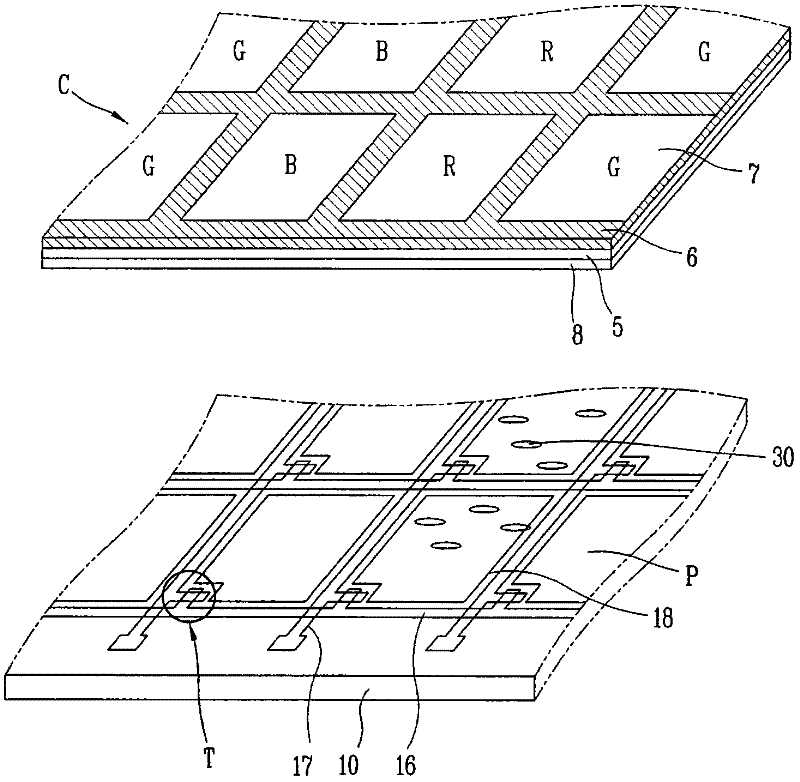

Wire for a display device, a method for manufacturing the same, a thin film transistor array panel including the wire, and a method for manufacturing the same

InactiveUS20050173732A1Prevent reduction of aperture ratioHigh contrast ratioTransistorSemiconductor/solid-state device detailsHigh contrastOhmic contact

First, a Cr film and a CrOx film are deposited and patterned using an etchant including 8-12% Ce(NH4)2(NO3)6, 10-20% NH3 and remaining ultra pure water to form a gate wire including a plurality of gate lines, a plurality of gate electrodes and a plurality of gate pads. Next, a gate insulating film, a semiconductor layer and an ohmic contact layer are formed in sequence. A Cr film and CrOx film are deposited in sequence and patterned using an etchant including 8-12% Ce(N114)2(NO3)6, 10-20% NH3 and remaining ultra pure water to form a data wire including a plurality of data lines, a plurality of source electrodes, a plurality of drain electrodes and a plurality of data pads. A passivation layer is deposited and pattered to form a plurality of contact holes respectively exposing the drain electrodes, the gate pads and the data pads. A transparent conductive material or a reflective conductive material is deposited and patterned to form a plurality of pixel electrodes, a plurality of subsidiary gate pads and a plurality of subsidiary data pads electrically connected to the drain electrodes, the gate pads and the data pads, respectively. The gate lines and the data lines with low reflectance are used as a light-blocking film for blocking the light leakage between the pixel areas, and do not increase the black brightness. Accordingly, a separate black matrix need not be provided on the color filter panel, thereby securing both aperture ration of the pixel and high contrast ratio.

Owner:SAMSUNG DISPLAY CO LTD

Optical Compensation Polarizing Plate, Image Display Unit and Liquid Crystal Display Unit

ActiveUS20070292635A1Easy to viewIncrease contrastLiquid crystal compositionsPolarising elementsTectorial membraneIn plane

All optical compensation polarizing plate comprising: a first transparent protective film; a polarizer; a second transparent protective film; and an optical compensation layer in this order, wherein at least one of the first and second transparent protective films is a cellulose acylate film having a retardation value in plane Re (nm) and a retardation value in film thickness direction Rth (nm) which fulfill the following formulae (I) and (II), and Nz and Re1 defined by the following formulae (III) and (IV), of the optical compensation layer fulfill the following formulae (V) and (VI): (I) |Re|≦10, (II) |Rth|≦25, (III) Nz=(nx1−nz1) / (nx1−ny1), (IV) Re1=(nx1−ny1)×d1, (V) 0.4≦Nz≦0.6 (VI) 100≦Re1≦350, wherein Re1 is a retardation value in plane (nm) at a wavelength of 590 nm; Nz is an Nz factor at a wavelength of 590 nm; nx1 is a refractive index along a slow axis in a film plane; ny1 is a refractive index along a direction perpendicular to the slow axis in a film plane; nz1 is a refractive index along a thickness direction of the film; and d1 is a thickness of the film (nm).

Owner:FUJIFILM CORP

Optical compensating polarizing plate, image display device and liquid crystal display device

ActiveCN1957273AHigh contrast ratioLittle deterioration in optical performancePolarising elementsNon-linear opticsCelluloseIn plane

An optical compensation polarizing plate comprising: a first transparent protective film; a polarizer; a second transparent protective film; and an optical compensation layer in this order, wherein at least one of the first and second transparent protective films is a cellulose acylate film having a retardation value in plane Re (nm) and a retardation value in film thickness direction Rth (nm) which fulfill the following formulae (I) and (II), and Nz and Re1 defined by the following formulae (III) and (IV), of the optical compensation layer fulfill the following formulae (V) and (VI): (I) |Re|<=10, (II) |Rth|<=25, (III) NZ=(nx1-nz1) / (nx1-ny1), (IV) Re1=(nx1-ny1) x d1, (V) 0.4<=Nz<=0.6 (VI) 100<=Re1<=350, wherein RE1 is a retardation value in plane (nm) at a wavelength of 590 nm; Nz is an Nz factor at a wavelength of 590 nm; nx1 is a refractive index along a slow axis in a film plane; ny1 is a refractive index along a direction perpendicular to the slow axis in a film plane; nz1 is a refractive index along a thickness direction of the film; and d1 is a thickness of the film (nm).

Owner:FUJIFILM CORP

Liquid crystal display device

ActiveCN102282504AHigh contrast ratioImprove viewing angle characteristicsNon-linear opticsDielectric anisotropyLight beam

Disclosed is a liquid crystal display device of which viewing angle characteristics are improved without reducing the transmittance. Specifically disclosed is a liquid crystal display device which comprises a liquid crystal display panel including a liquid crystal layer and a pair of substrates that hold the liquid crystal layer therebetween and a backlight unit disposed at the rear side of the liquid crystal display panel. One of the pair of substrates is provided with a pair of comb-shaped electrodes of which comb teeth alternately engage with each other with a gap interposed therebetween. The liquid crystal layer includes liquid crystal molecules with positive dielectric anisotropy, and the liquid crystal molecules are oriented perpendicular to a surface of the one of the substrates while voltage is not applied. A difference between the proportion of the liquid crystal molecules oriented at angles of 20 DEG to 60 DEG and -60 DEG to -20 DEG with respect to the surface of the one of the substrates to the entire liquid crystal molecules included in the liquid crystal layer while white is displayed and the proportion of light beams entering the surface of the one of the substrates at angles of 20 DEG to 60 DEG and -60 DEG to -20 DEG to the entire light beams emitted from the backlight unit and entering the liquid crystal display panel is less than 20%.

Owner:SHARP KK

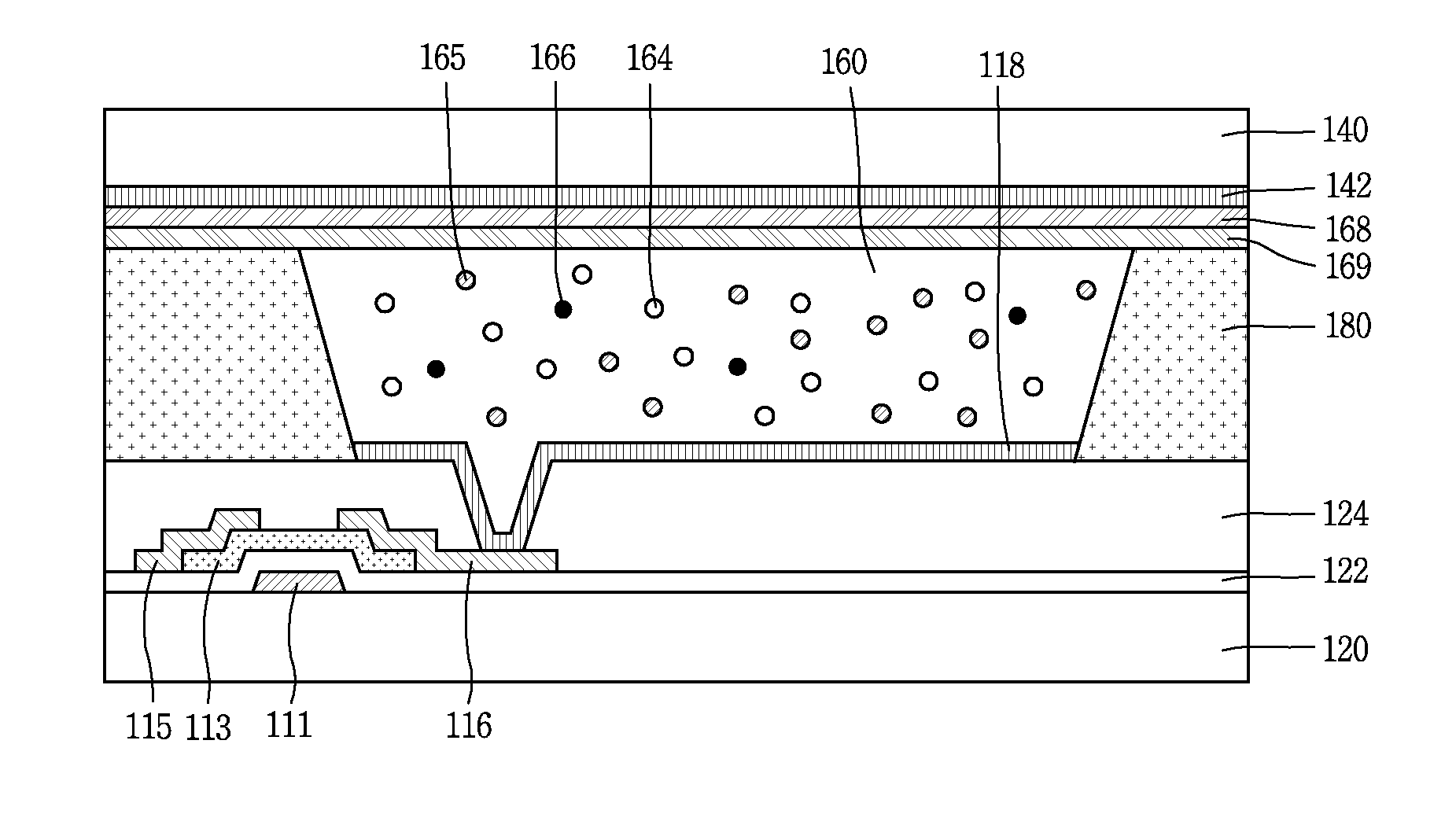

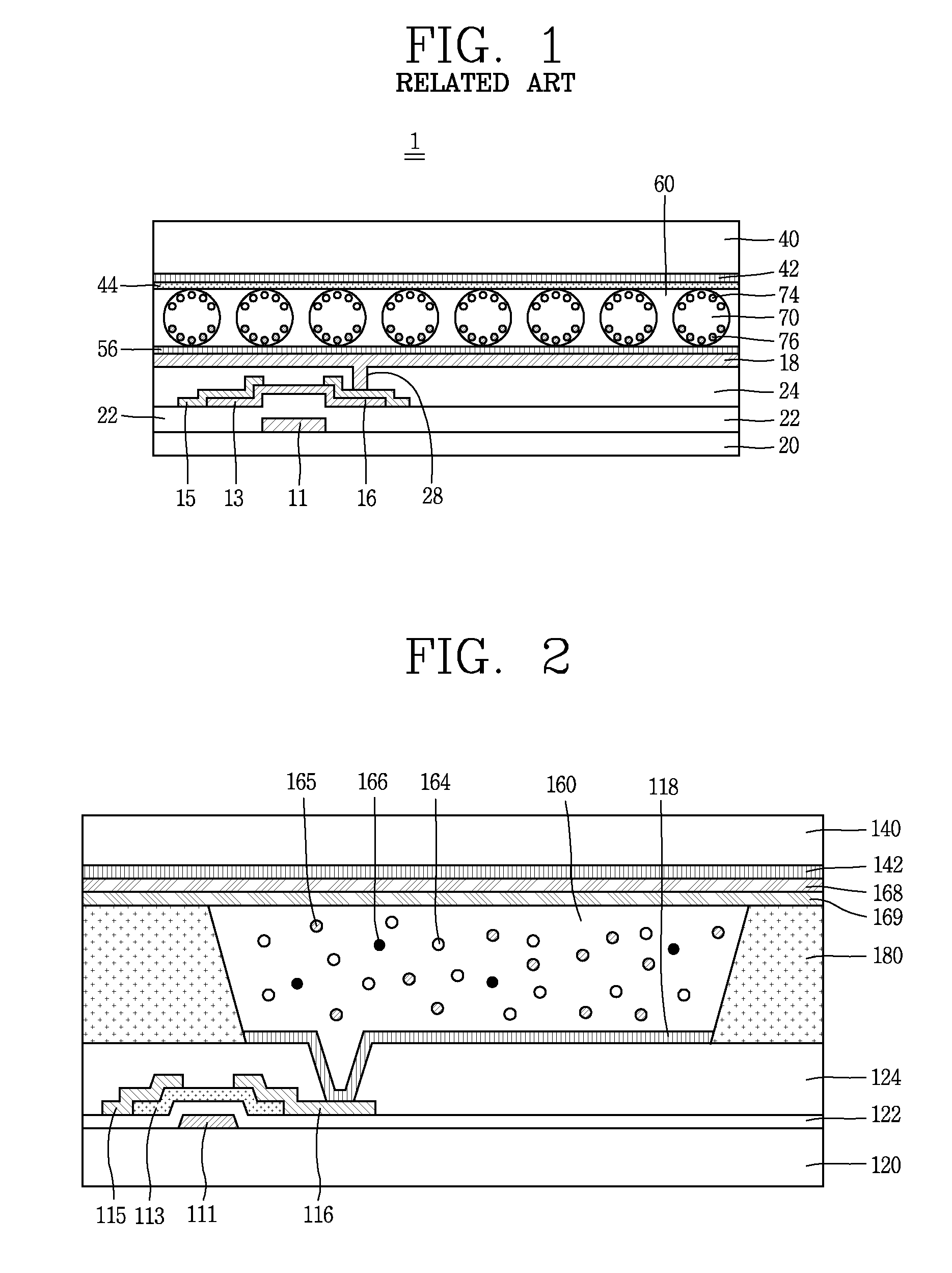

Electrophoretic display device and method of fabricating the same

ActiveUS20120013968A1High brightness ratioHigh contrast ratioSemiconductor/solid-state device manufacturingNon-linear opticsElectrophoresisDisplay device

Disclosed is an electrophoretic display (EPD) device capable of implementing colors with high brightness. Each sub-pixel implement colors with driving color particles, white particles and black particles, and the EPD device has an enhanced contrast ratio due to black particles.

Owner:E INK CORPORATION

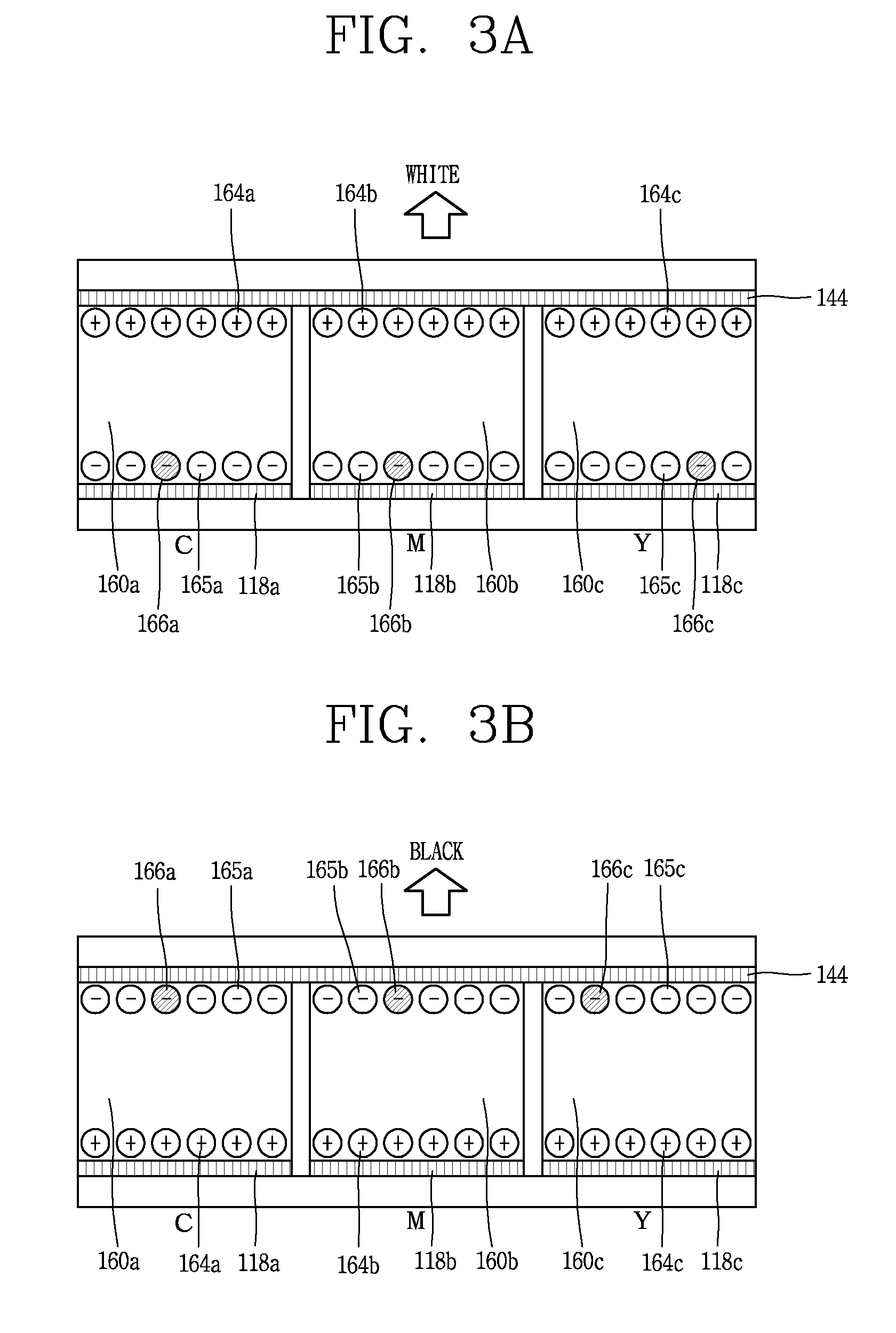

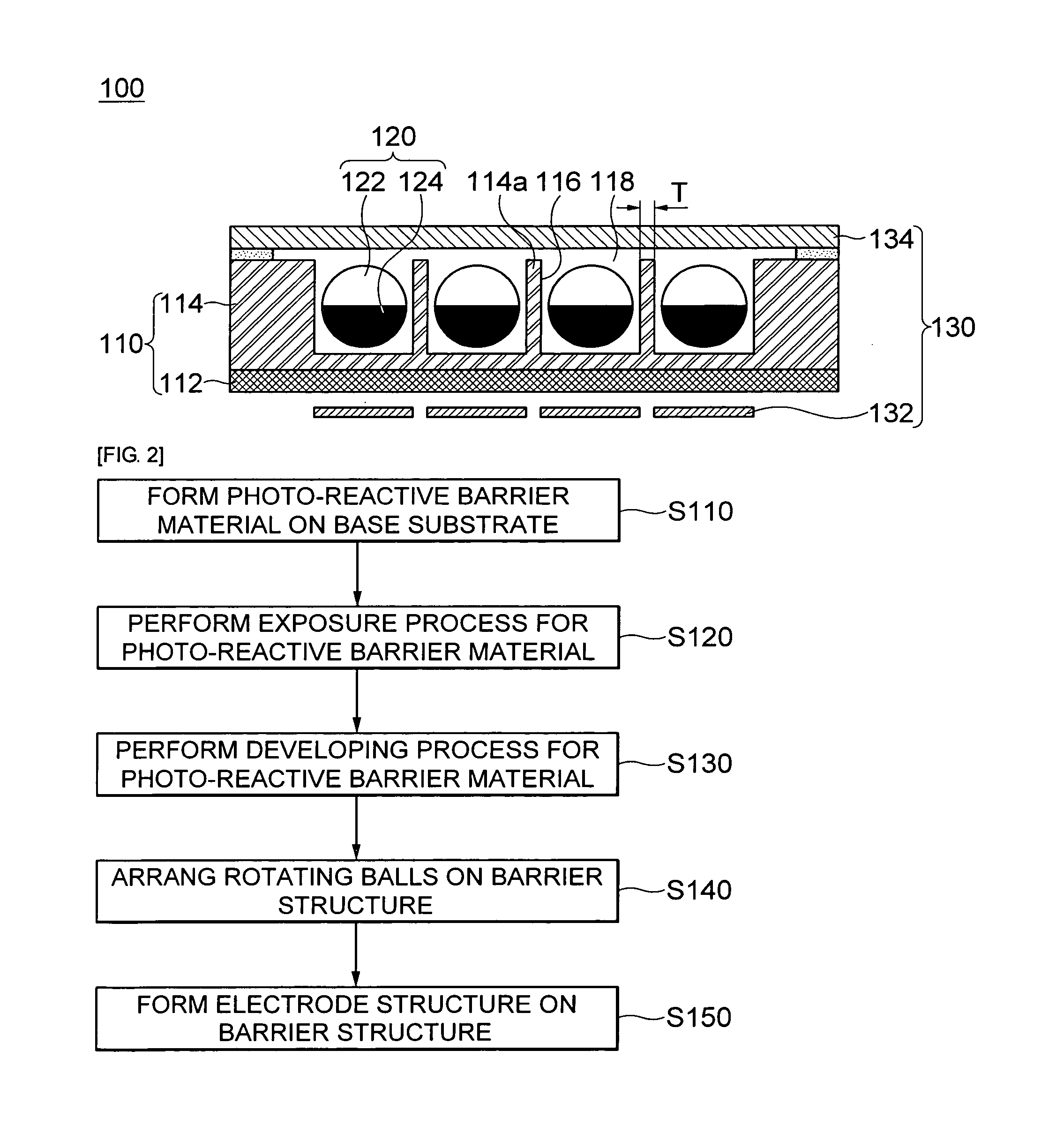

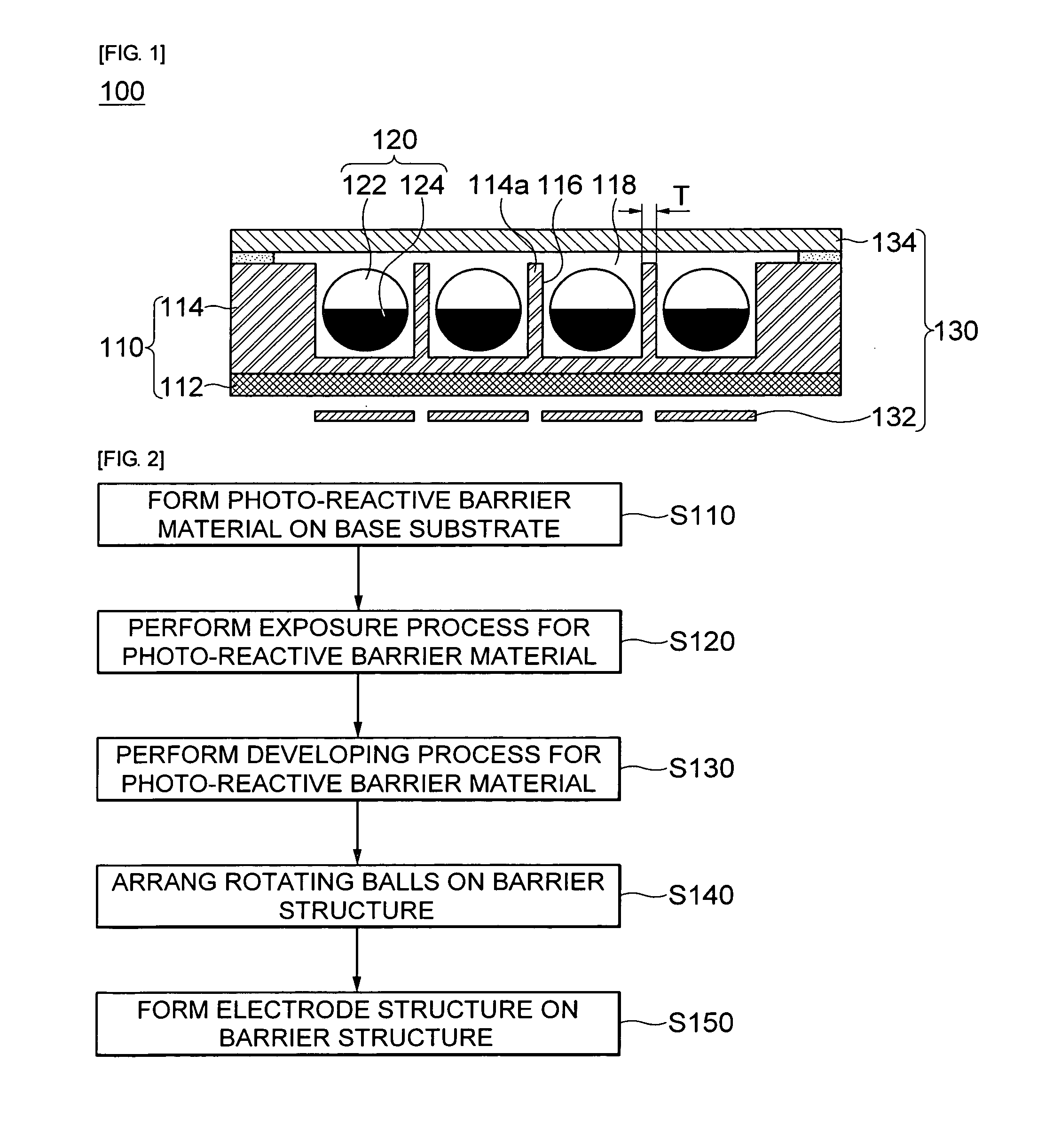

Color electronic paper display device and method for manufacturing the same

InactiveUS20110298786A1Improve color clarityHigh contrast ratioCathode-ray tube indicatorsNon-linear opticsDisplay deviceEngineering

The present invention provides a color electronic paper display device including: rotating balls; a barrier structure for partitioning the rotating balls; and an electrode structure which is provided in the barrier structure and applies voltages to the rotating balls, wherein the barrier structure is made of a photo-reactive barrier material including insulating resin, hardener, and a photo-sensitive material.

Owner:THE HONG KONG UNIV OF SCI & TECH +1

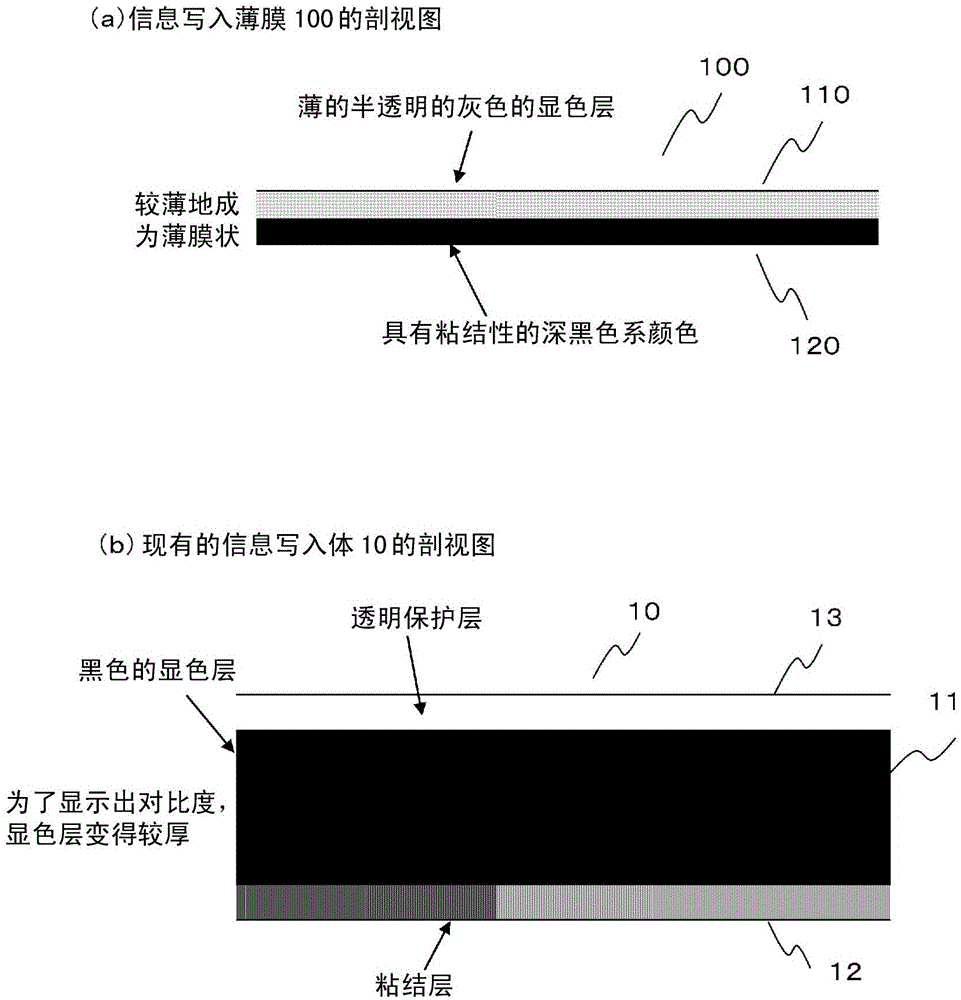

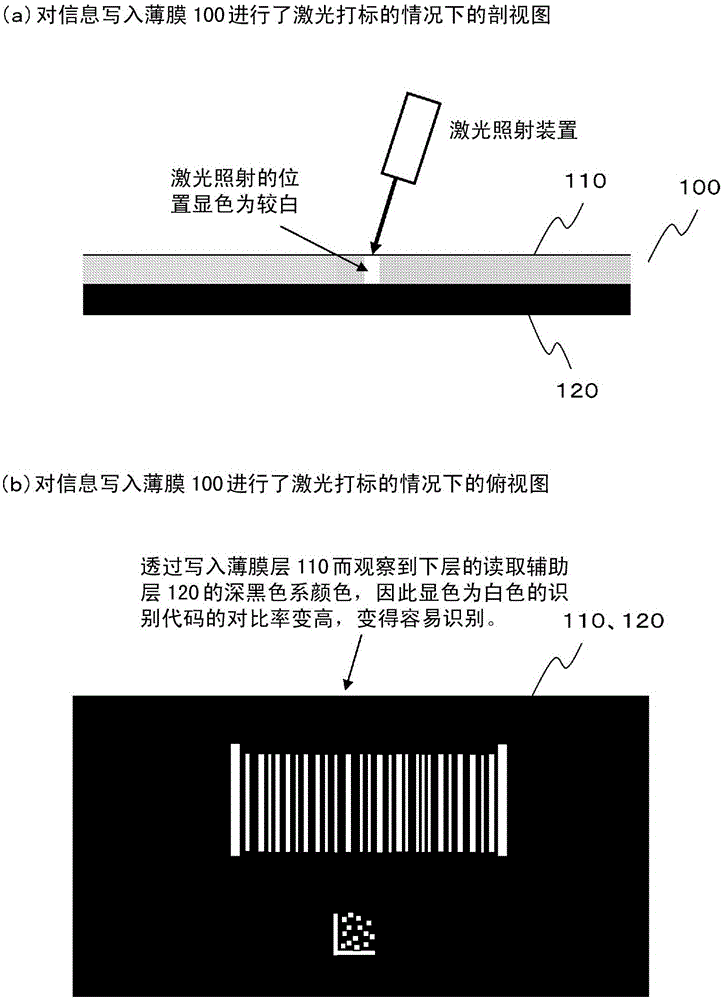

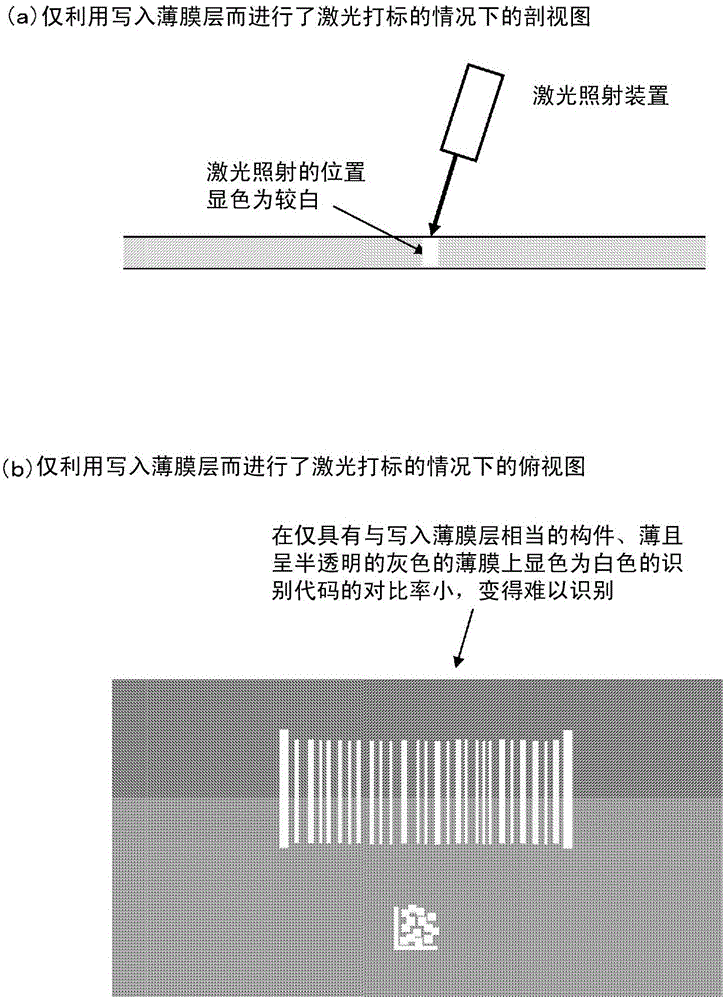

Information writing film and sample storage body

InactiveCN105121173AGood chemical resistanceImprove wear resistanceStampsLaboratory glasswaresLength waveLaser beams

To provide an information writable film that is chemical and abrasion resistance, and is suitable for high contrast white laser marking. The information writable film comprises a writable film layer 110 and a reading assistance layer 120. The writable film layer 110 is formed into a film shape by thinly stretching a material, which material is mixed a color former composition for coloring white when receiving the particular wavelength laser beam by changing its physical and chemical characteristic and a transparent plastic composition. The reading assistance layer 120 is installed for enhancing the contrast ratio. The writable film layer 110 is provided with laser coloring properties and chemical and abrasion resistance. During writing, an identification code is written by laser by coloring the color former in the writable film layer 110. During reading, the contrast ratio is enhanced by superimposing the color of the reading assistance layer 120.

Owner:角田 新一郎 +1

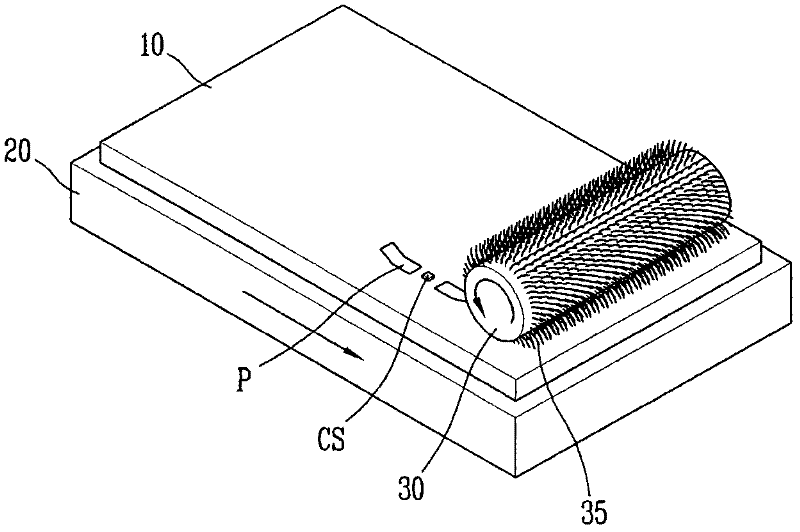

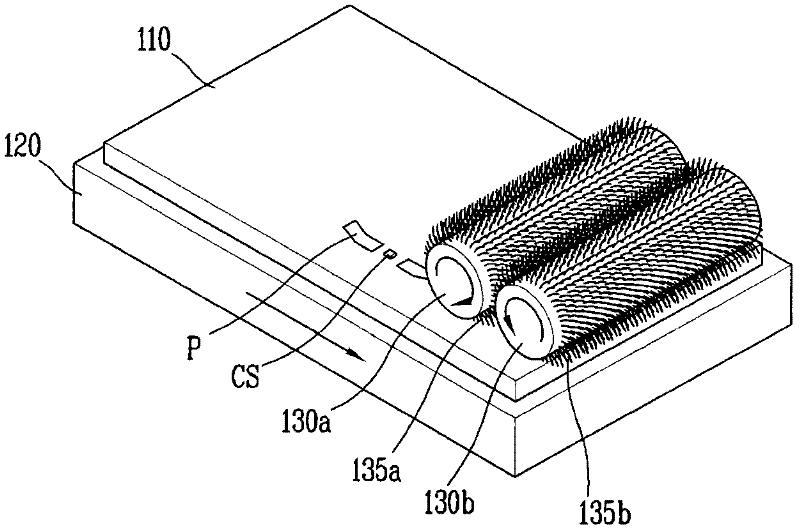

Rubbing method and method of fabricating liquid crystal display device using the same

InactiveCN102452037AReduced black brightnessHigh contrast ratioLapping machinesNon-linear opticsLiquid-crystal displayEngineering

A rubbing method and a method of fabricating a liquid crystal display (LCD) device using the same are discussed. The rubbing method is capable of decreasing disclination and rubbing tails resulting from a pattern of a high stair-step such as a column spacer. The rubbing method includes loading a substrate having an alignment layer formed thereon on a stage; performing a primary rubbing process on the alignment layer, by rotating a first rubbing roll on which a first rubbing cloth is rolled, in an opposite direction to a forming direction of a desired pretilt angle; and performing a secondary rubbing process on the primarily-rubbed alignment layer, by rotating a second rubbing roll on which a second rubbing cloth is rolled, in the forming direction of the desired pretilt angle.

Owner:LG DISPLAY CO LTD

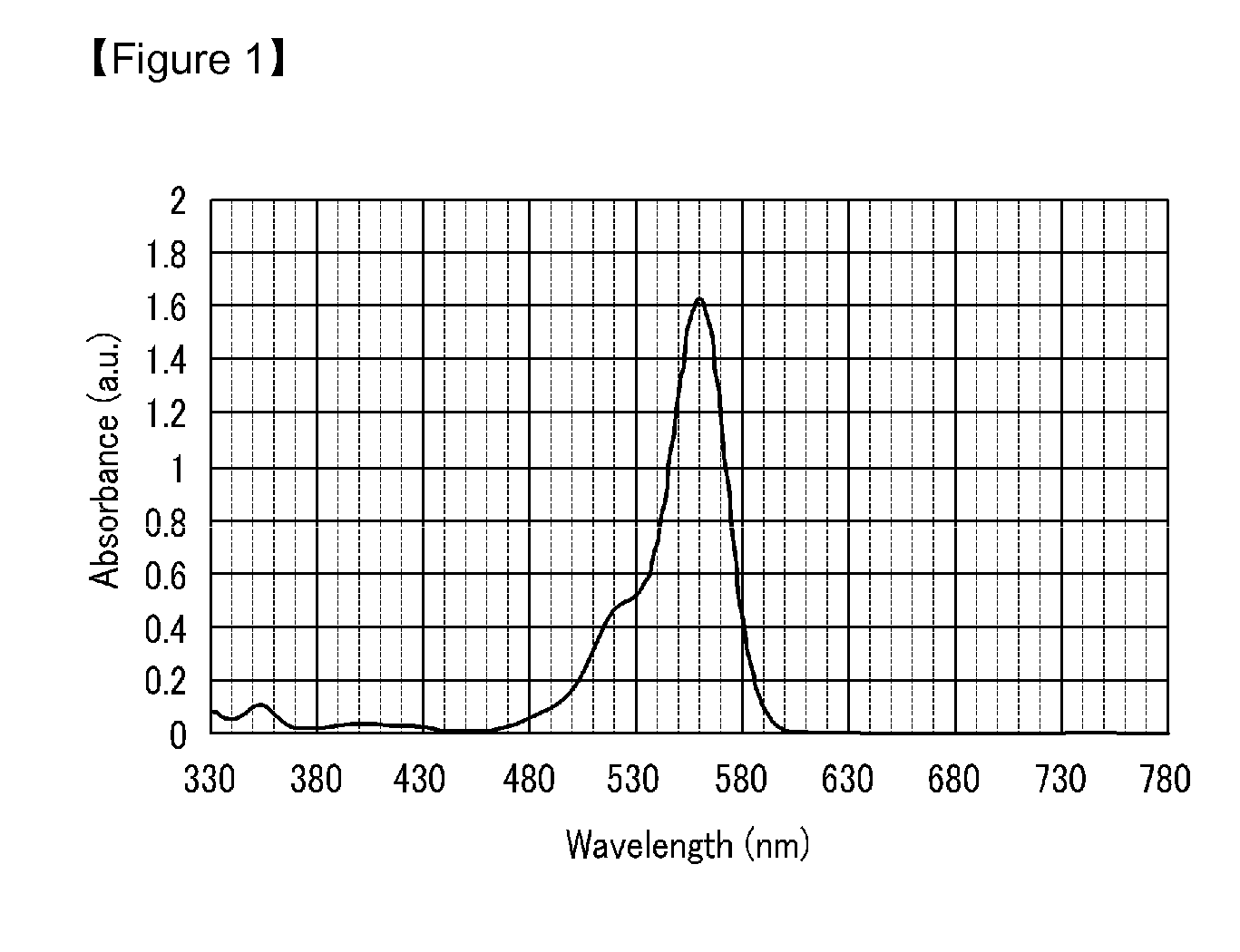

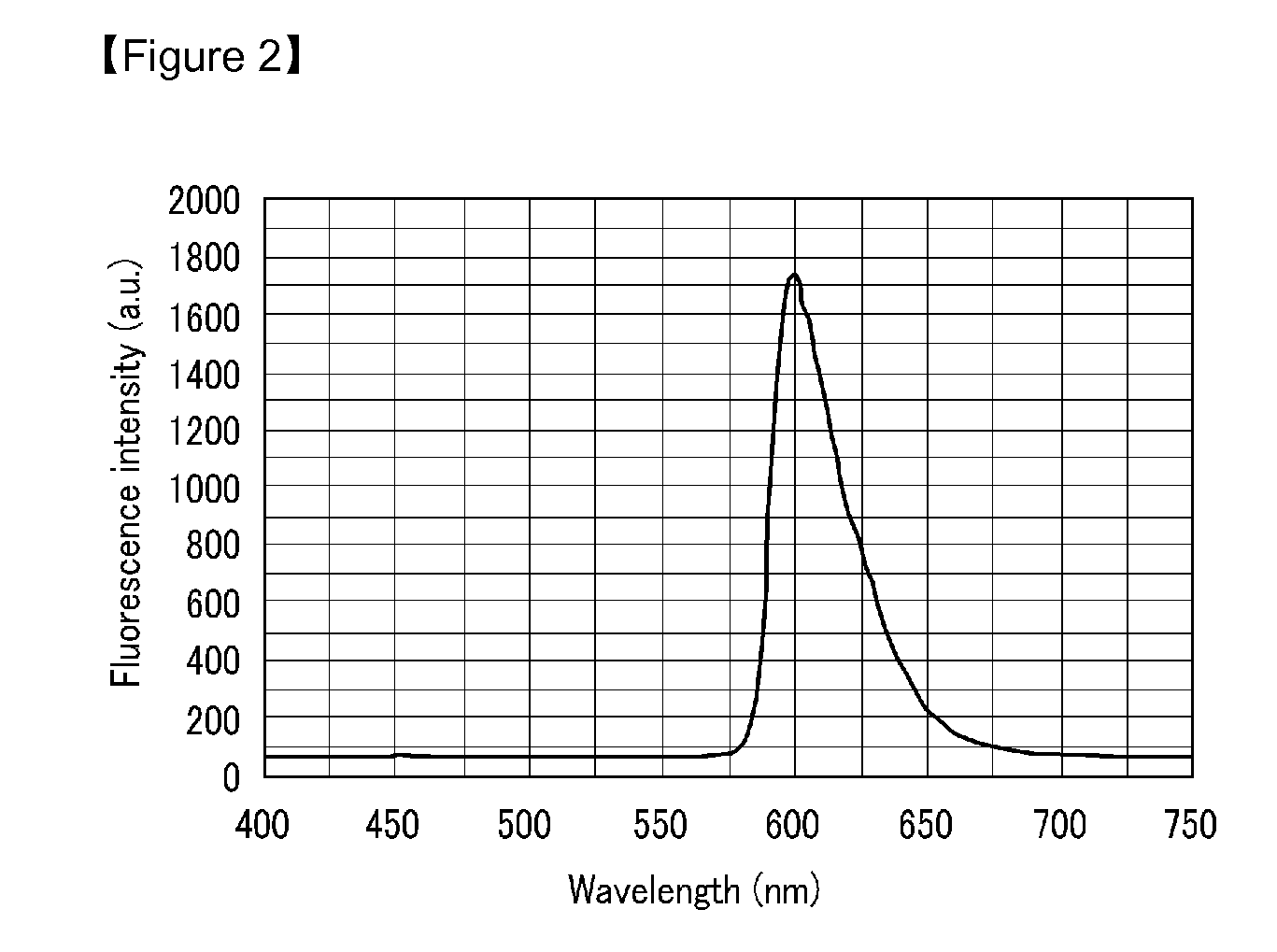

Photosensitive Resin Composition and Color Filter Using the Same

InactiveUS20140319421A1High contrast ratioHigh luminance ratioOptical filtersPhotomechanical apparatusFluorescenceLength wave

Disclosed are a photosensitive resin composition including a composite dye that includes a red fluorescent dye re-emitting light at a 400 to 800 nm fluorescent wavelength; and a metal complex dye including at least one metal ion selected from Mg, Ni, Co, Zn, Cr, Pt, and Pd, and a color filter using the same.

Owner:CHEIL IND INC

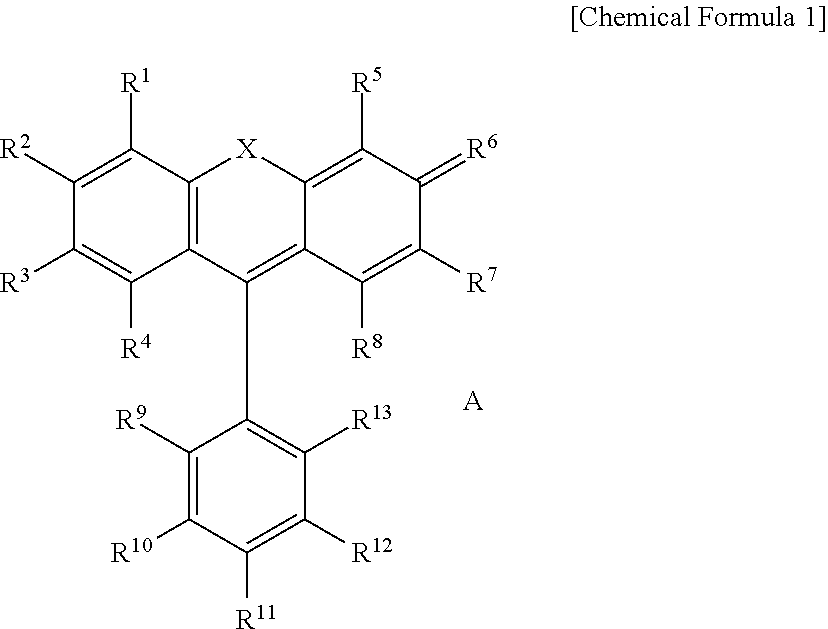

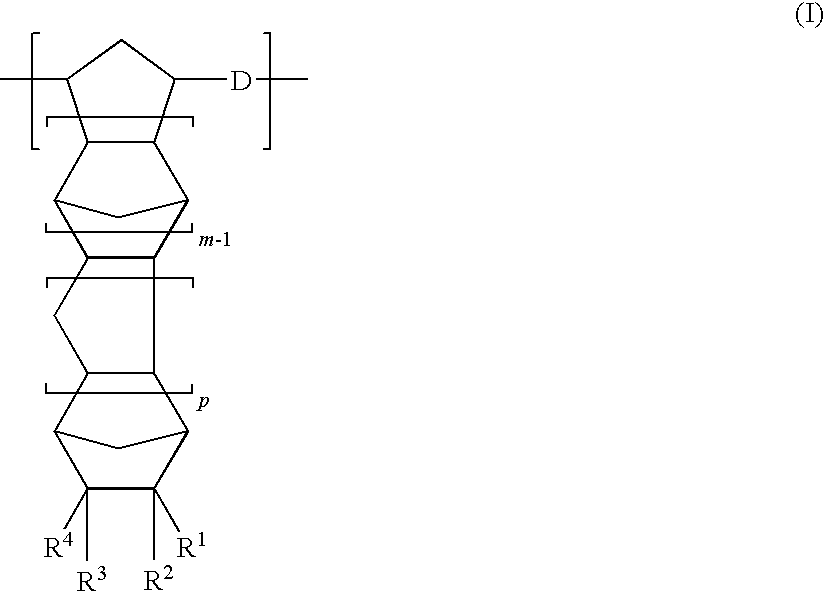

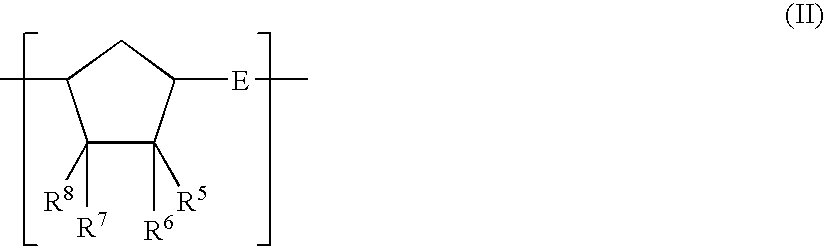

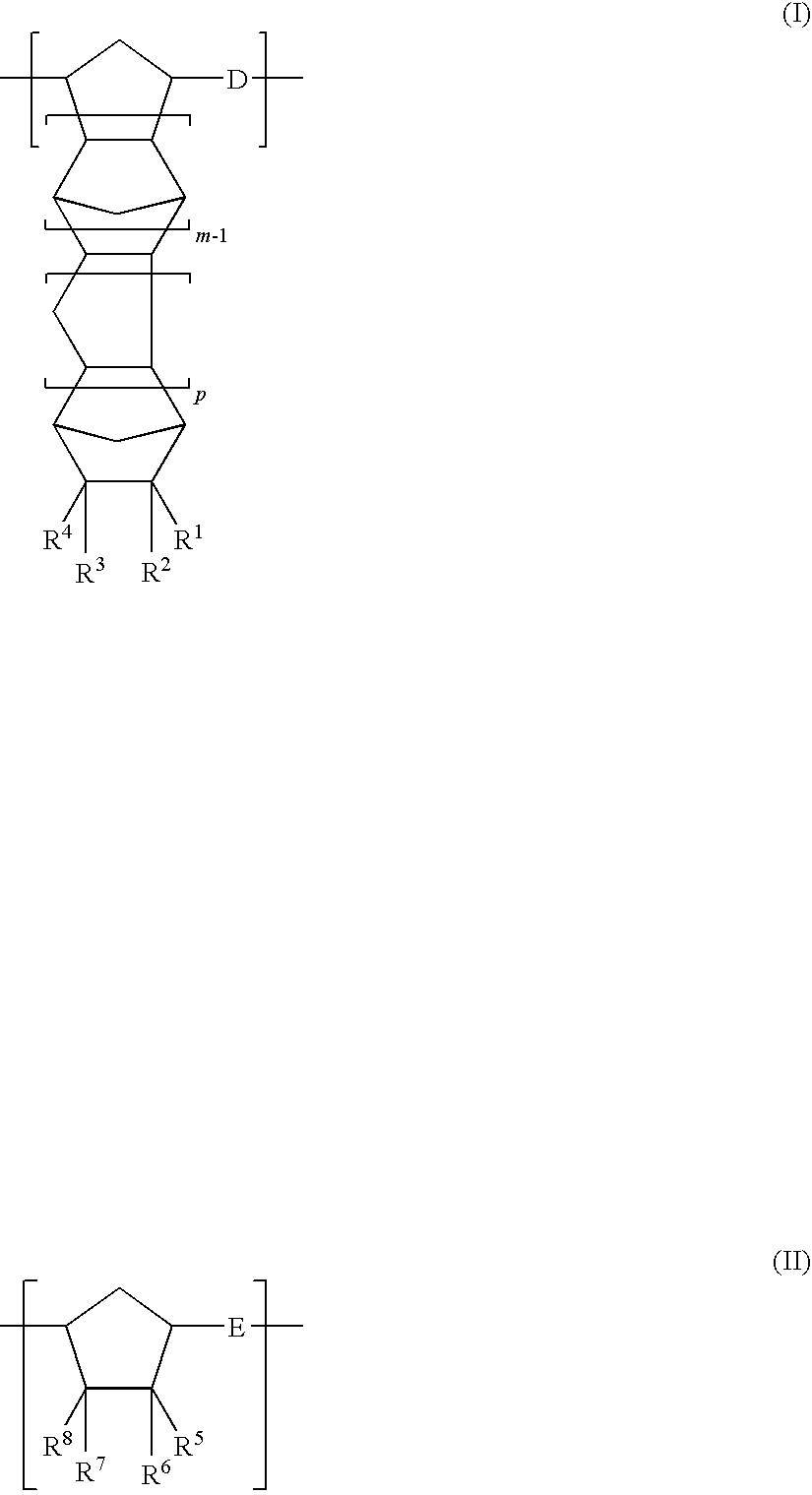

Optical film, polarizing plate, and liquid crystal display device

InactiveUS20090191362A1Good view angle compensation effectHigh contrast ratioLiquid crystal compositionsSynthetic resin layered productsHigh contrastChemistry

An optical film has a film a formed of a cyclic olefin resin, and a homeotropically orientated optical anisotropic layer b disposed on the film a. This optical film preferably satisfies the below listed formulae (1) to (3).−600nm≦Rth≦200nm (1)0nm≦R≦600nm (2)NZ≦1 (3)(In formulae (1) to (3), Rth indicates the retardation in the thickness direction of the optical film at a wavelength of 550 nm; R indicates the in-plane retardation of the optical film at a wavelength of 550 nm; and NZ indicates (nx−nz) / (nx−ny)).When the optical film is used in an ISP mode liquid crystal display device, light leakage and color fading (discoloration) during black display are prevented stably for a long term, and a good viewing angle compensation effect is obtained (i.e., high contrast ratio at all angles).

Owner:JSR CORPORATIOON

Interior wall antibacterial and mildew-resistant functional coating

ActiveCN105017892AGood antibacterial and antifungal effectNo smellAntifouling/underwater paintsPaints with biocidesCelluloseEnvironmental resistance

The invention discloses an interior wall antibacterial and mildew-resistant functional coating which contains the following ingredients, by weight, 18-40 parts of antibacterial powder, 10-20 parts of a mildew preventive, 10-20 parts of a preservative, 1.2-3.6 parts of hydroxyethyl cellulose, 100-500 parts of deionized water, 0.2-0.8 part of a water treatment agent, 0.5-1.5 parts of a pH regulator, 2.8-5 parts of a wetting agent, 3.6-10 parts of a dispersant, 448-668 parts of a colouring agent, 1-2 parts of an antifoaming agent, 70-230 parts of a modifier, 6-9.4 parts of a filling material, 110-277 parts of an emulsion, 12.8-22 parts of a film forming agent, 12-60 parts of an antifreezing agent, 30-90 parts of a thickening agent, 60-200 parts of Huizhu and 1-10 parts of superfine cellulose. The interior wall antibacterial and mildew-resistant functional coating has excellent antibacterial effect and long antibacterial and mildew-resistant time and can be used to remarkably improve indoor environment and raise air quality. In addition, the coating is harmless to human body, has no peculiar smell, has good mechanical property and decoration property, and is a highly-efficient environmental-production functional interior wall coating.

Owner:魏淑贞

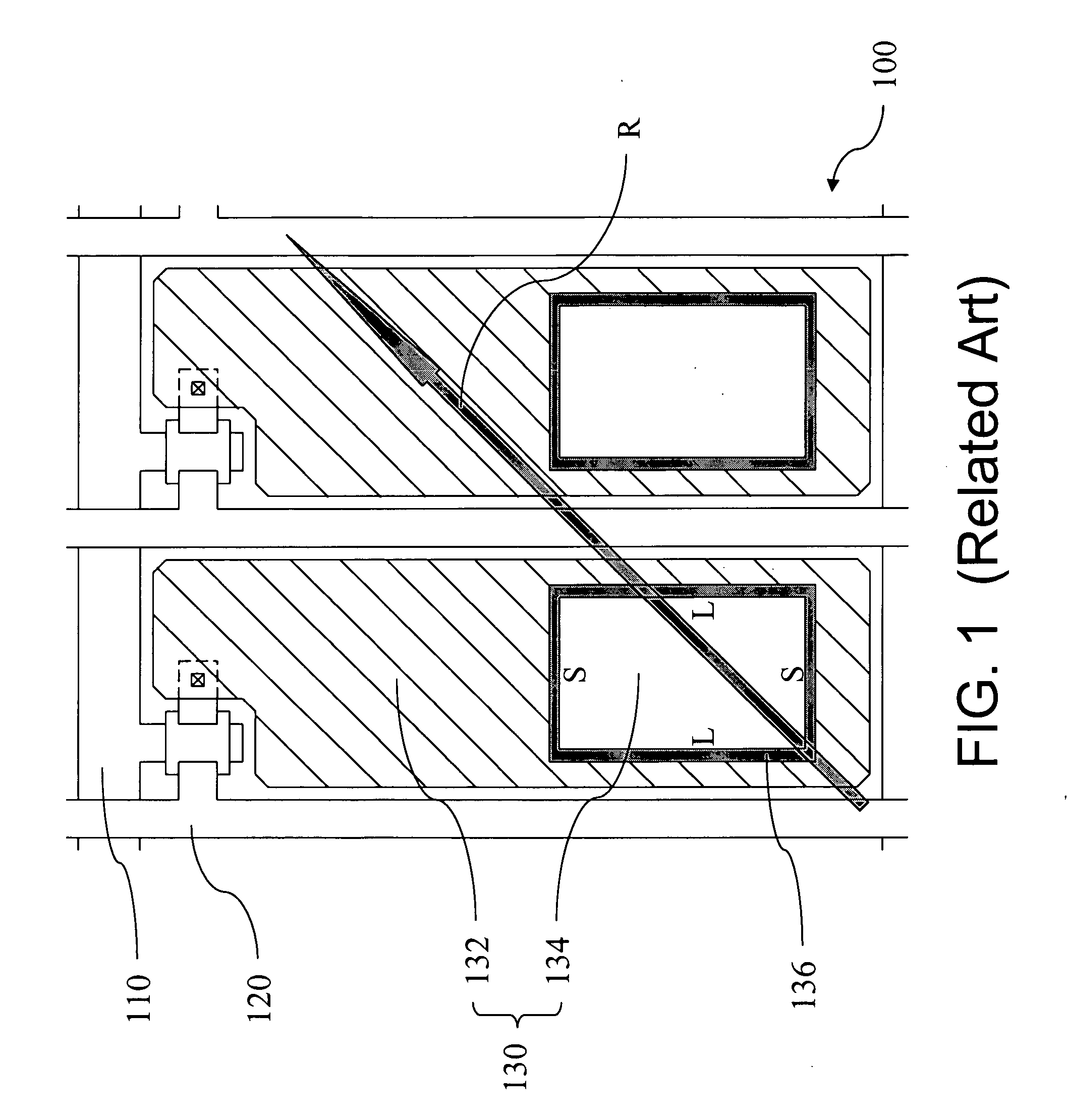

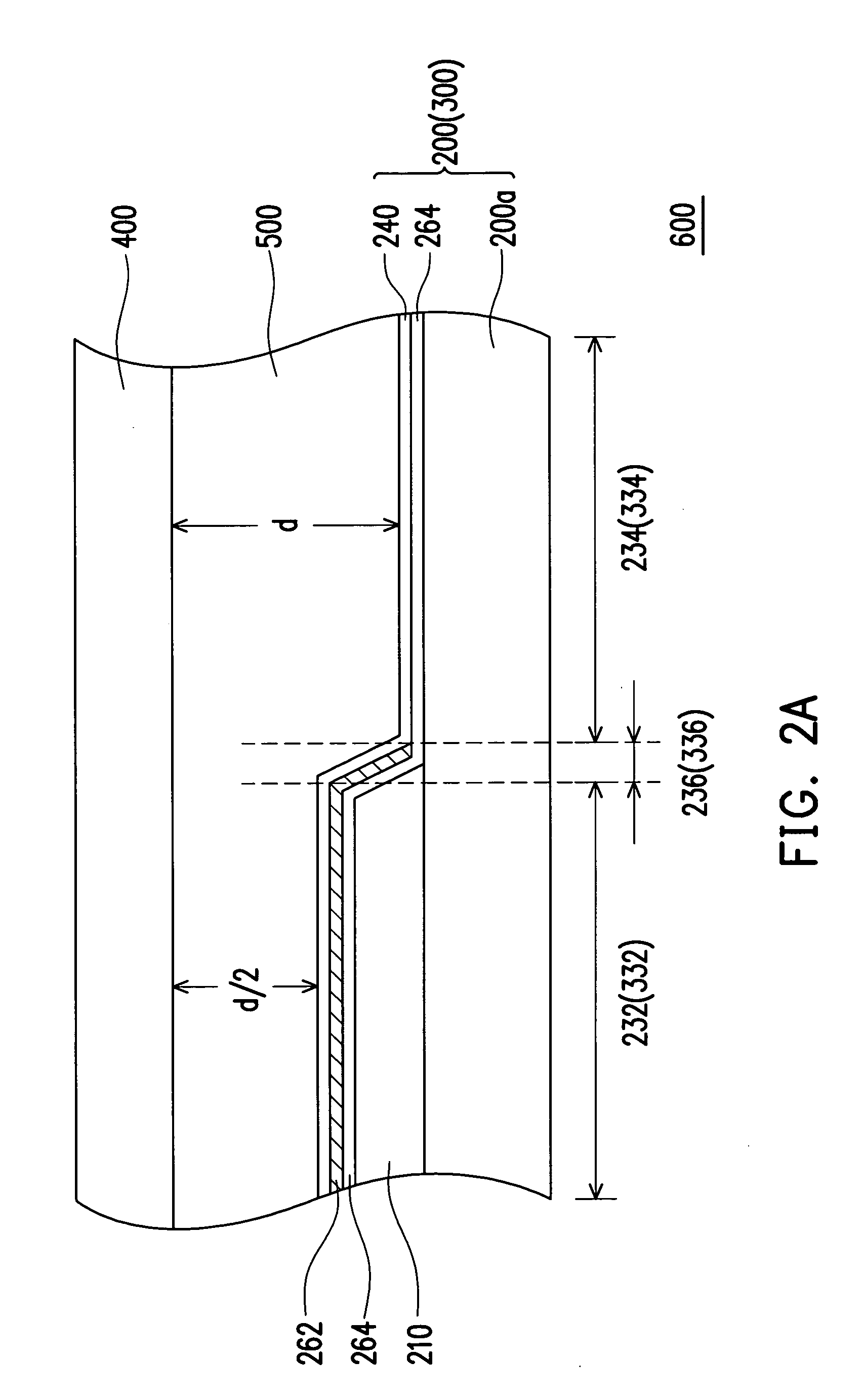

Thin film transistor array and transflective liquid crystal display panel

InactiveUS20070165169A1High contrast ratioNon-linear opticsLiquid-crystal displayTransflective liquid-crystal display

An array substrate including a substrate, multiple pixels arranged in an array on the substrate, and an alignment film disposed on the pixels is provided. The pixel includes a reflective region, a transmissive region, and a transition region formed between the reflective region and the transmissive region, wherein an included angle between at least one side of the transition region and a rubbing direction of the alignment film is smaller than or equal to 30 degree. In addition, a transflective LCD including the array substrate as described above and a fabricating method of an array substrate is further provided.

Owner:INNOLUX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com