Information writing film and sample storage body

A technology of information writing and thin film, applied in reproduction/marking methods, printing, instruments, etc., can solve the problems of poor wear resistance, thinning, and inability to develop white colors smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The information writing film 100 according to the first embodiment of the present invention will be described.

[0087] First, in the information writing film of the present invention, there can be various combinations of the color that the writing film layer expresses, the color that develops color, and the color that the reading auxiliary layer expresses.

[0088] Hereinafter, various combination examples will be described, but it is not limited to the following combinations, and it should be understood that various combinations as described above are possible.

[0089] The first configuration example is an example of a white laser marking information writing film pasted on the surface that can be used without selecting the surface color of the writing area of the object to be laser marked.

[0090] It should be noted that, in this first structural example, there is an example as a first combination example, that is, the color of the writing thin film layer is trans...

example 1

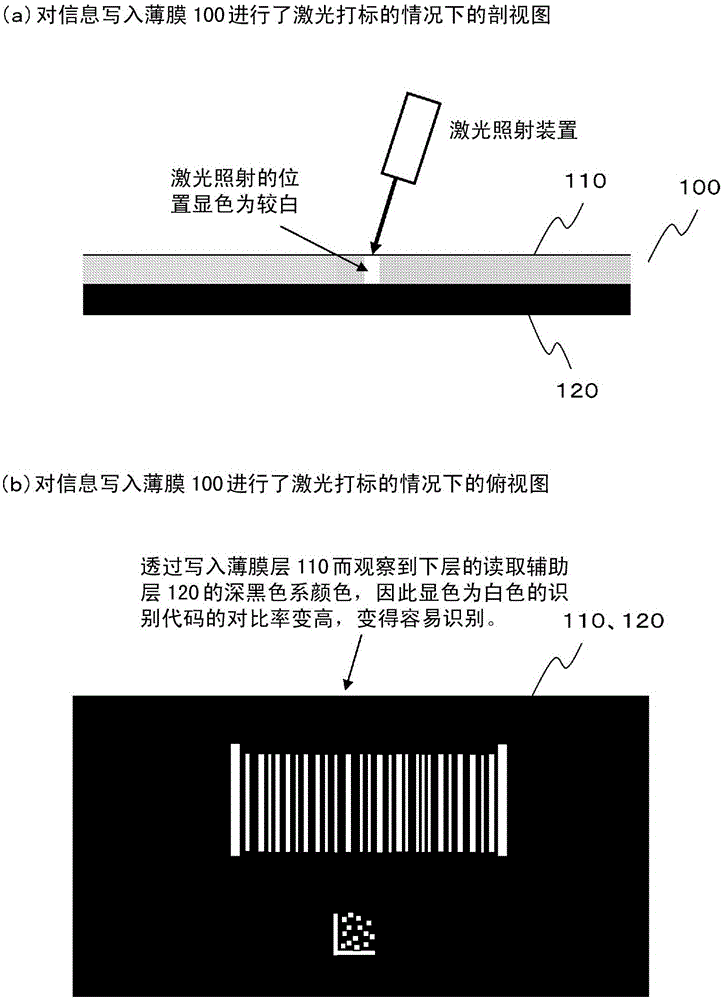

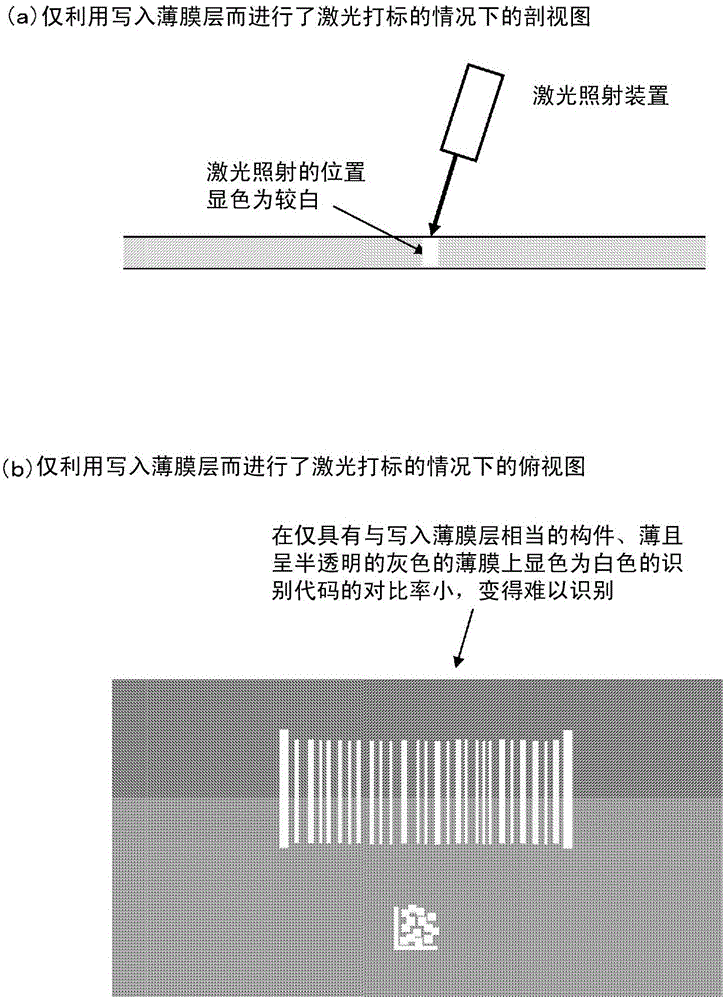

[0099] Example 1 is an example of an information writing film for white laser marking that can be used without selecting the surface color of the writing area of the object to be laser marked. The writing film layer The displayed color is translucent gray, the color development is white due to the foaming of the color-developing material by laser irradiation, and the reading auxiliary layer is black.

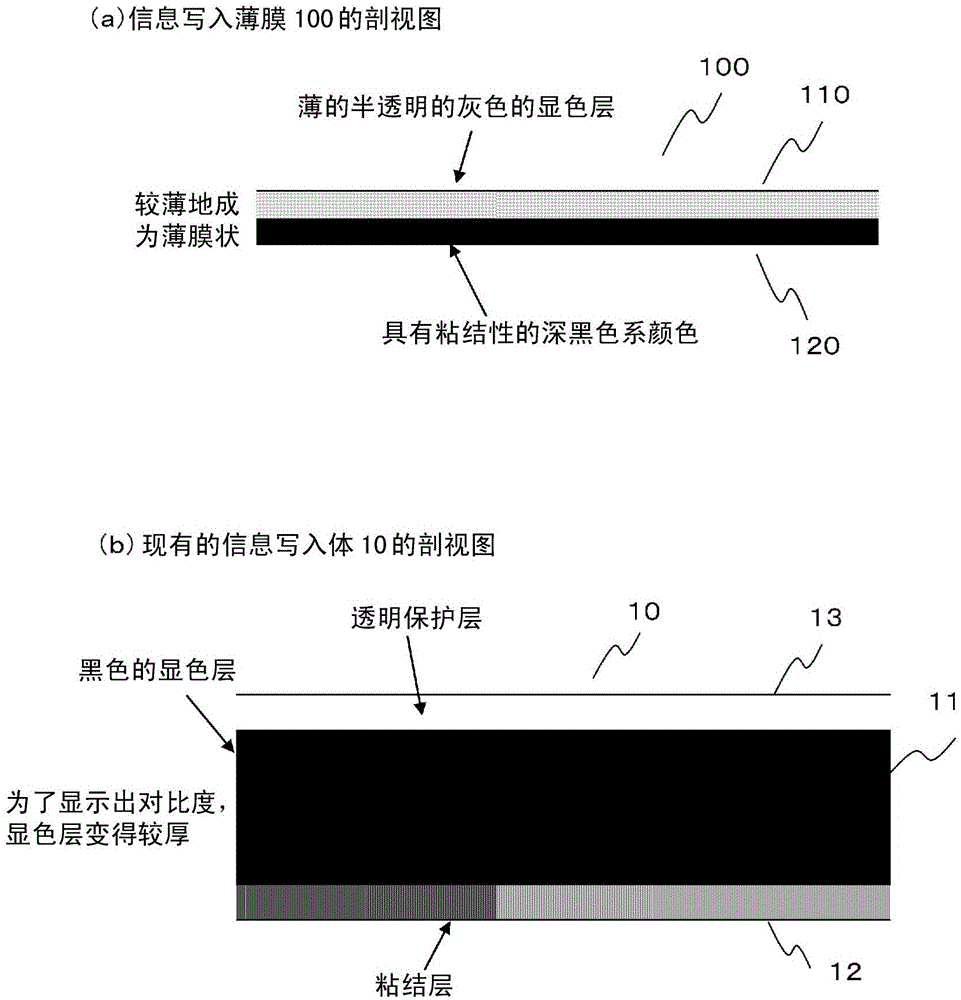

[0100] figure 1 (a) is a diagram schematically showing the structure of the first information writing film 100 of the present invention in Example 1. FIG. The cross section of the thin film is briefly shown.

[0101] Such as figure 1 As shown in (a), the first information writing film 100 has a two-layer structure including a writing film layer 110 and a reading auxiliary layer 120 .

[0102] The writing thin film layer 110 is formed into a film shape using a material obtained by kneading a transparent plastic material A with a black color-developing material B. Since it...

example 2

[0141] Example 2 is an example of a white laser marking information writing film pasted on the surface that can be used without selecting the surface color of the writing area of the object to be laser marked. The color of the writing film layer appears Transparent, the color is white when the color material is irradiated by laser light, and the reading auxiliary layer is black.

[0142] The structure of the information writing film 100 is as figure 1 identical Figure 4 That's it. Such as Figure 4 As shown in (a), a two-layer structure including a writing thin film layer 110 and a reading auxiliary layer 120 is adopted.

[0143] The writing thin film layer 110 is formed into a film shape using a material obtained by kneading a transparent plastic material A with a transparent color-developing material B. Since both the color-developing material B and the plastic material A are transparent, the writing film layer 110 that is thinly stretched and formed into a film becom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com