Patents

Literature

3144 results about "Thermal shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

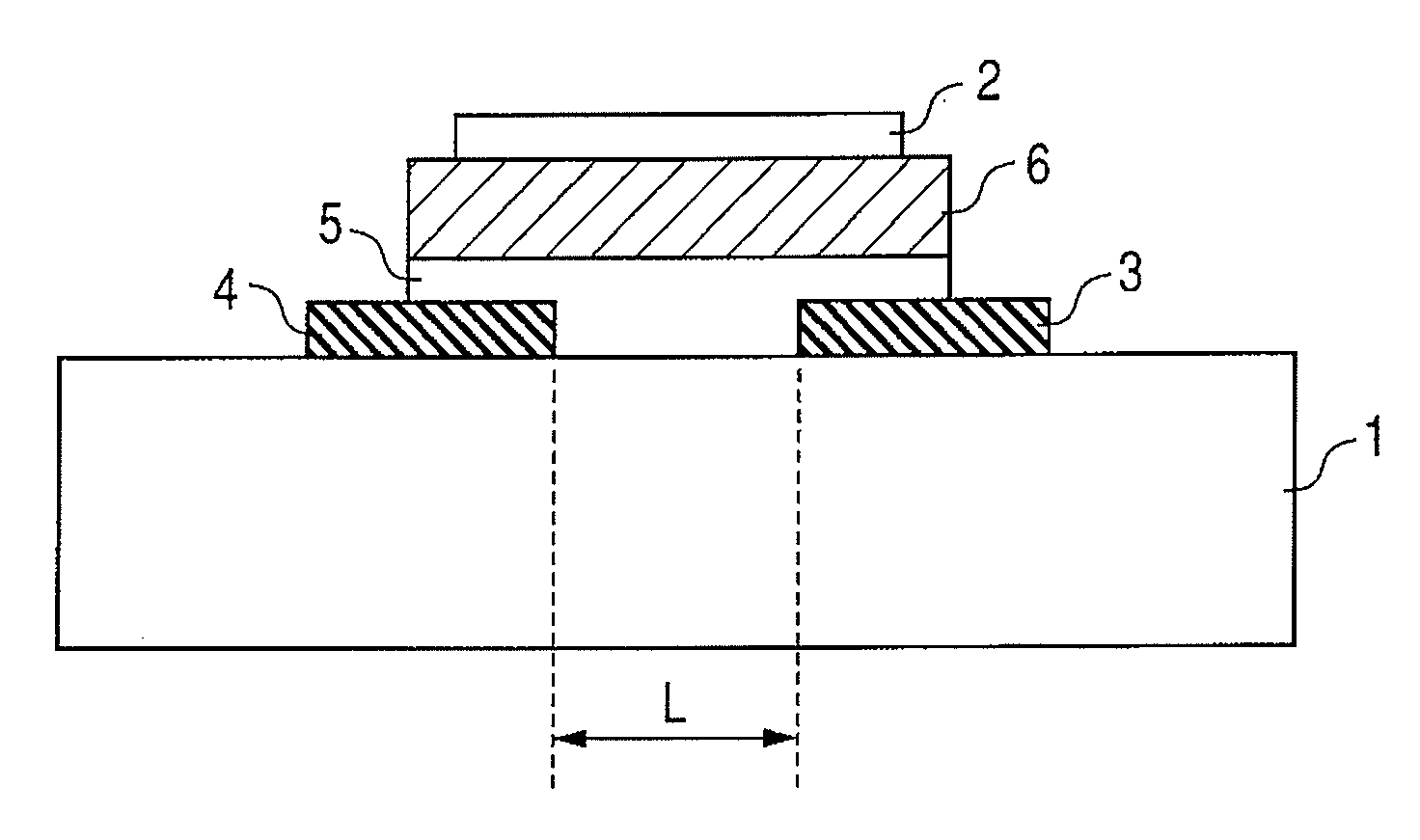

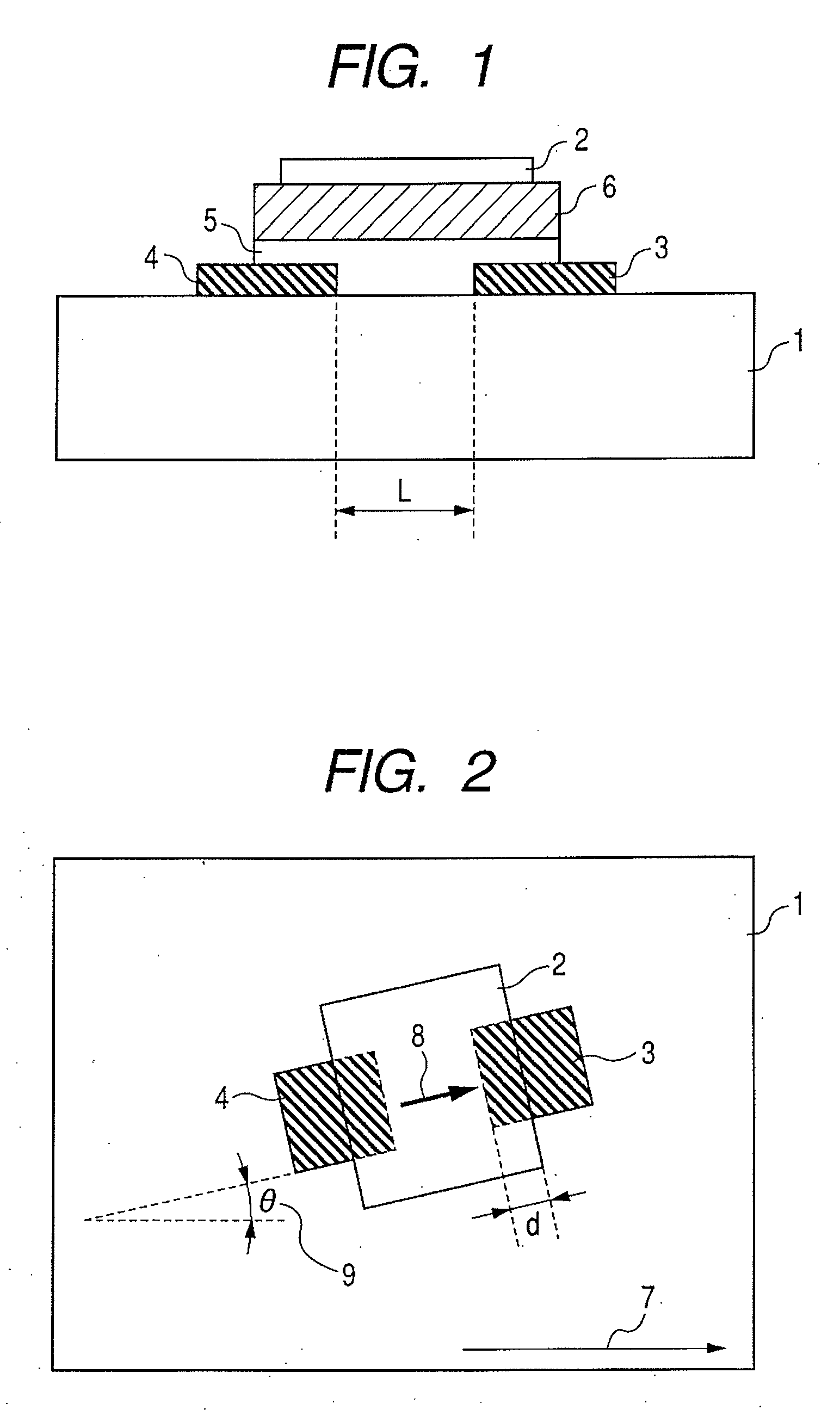

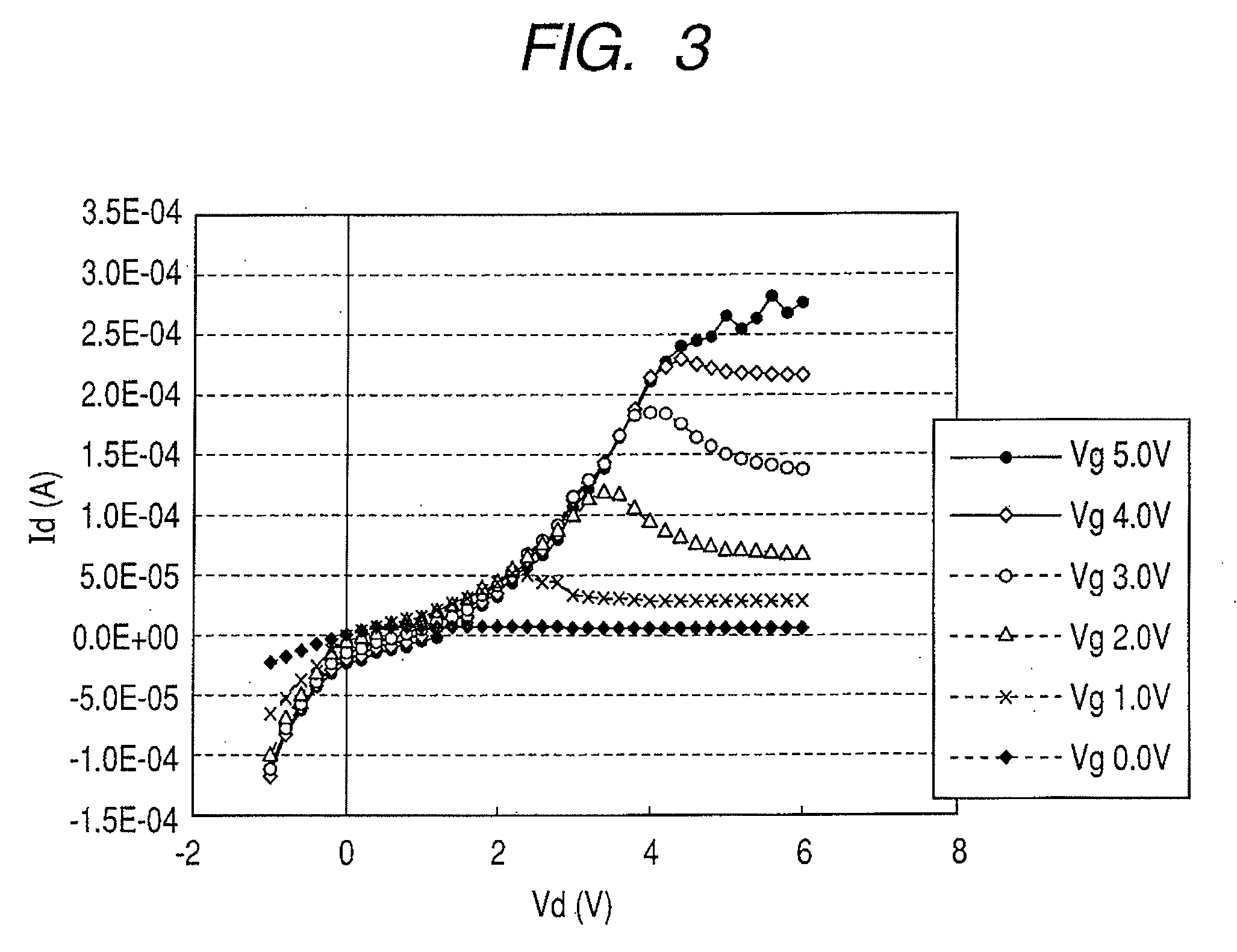

Semiconductor device

InactiveUS20090114910A1Uniform and high stabilityIncrease productionTransistorSolid-state devicesIn planeDevice material

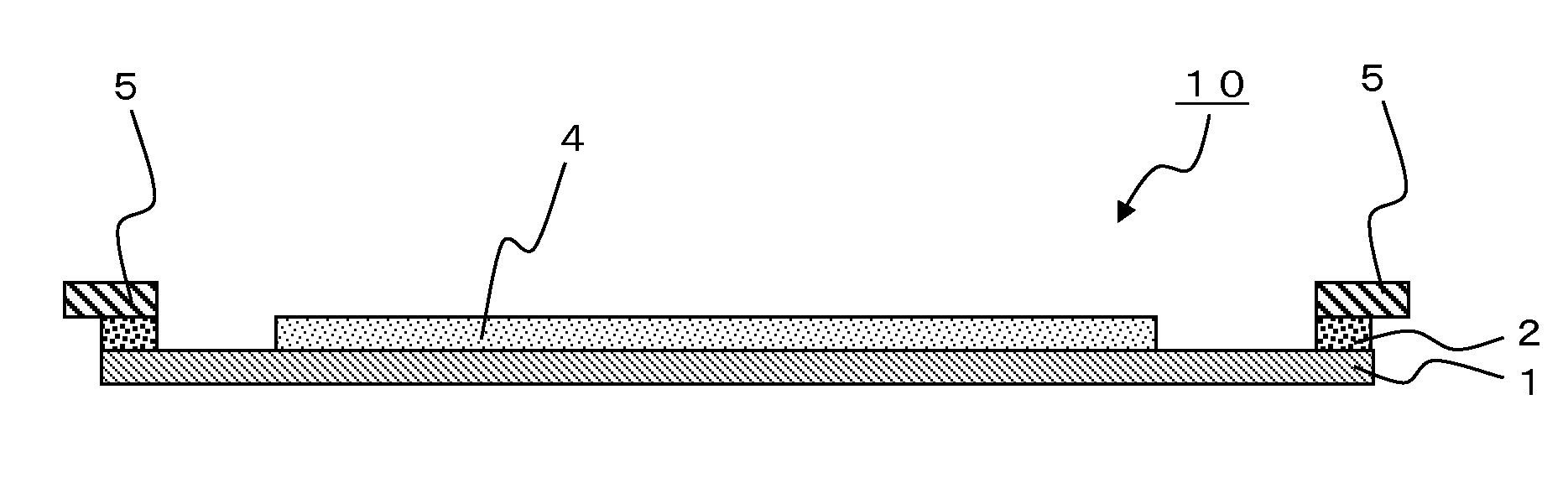

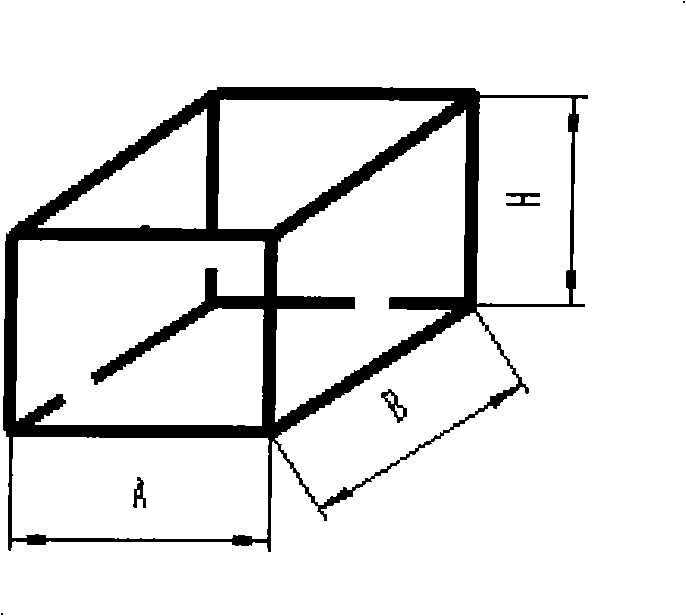

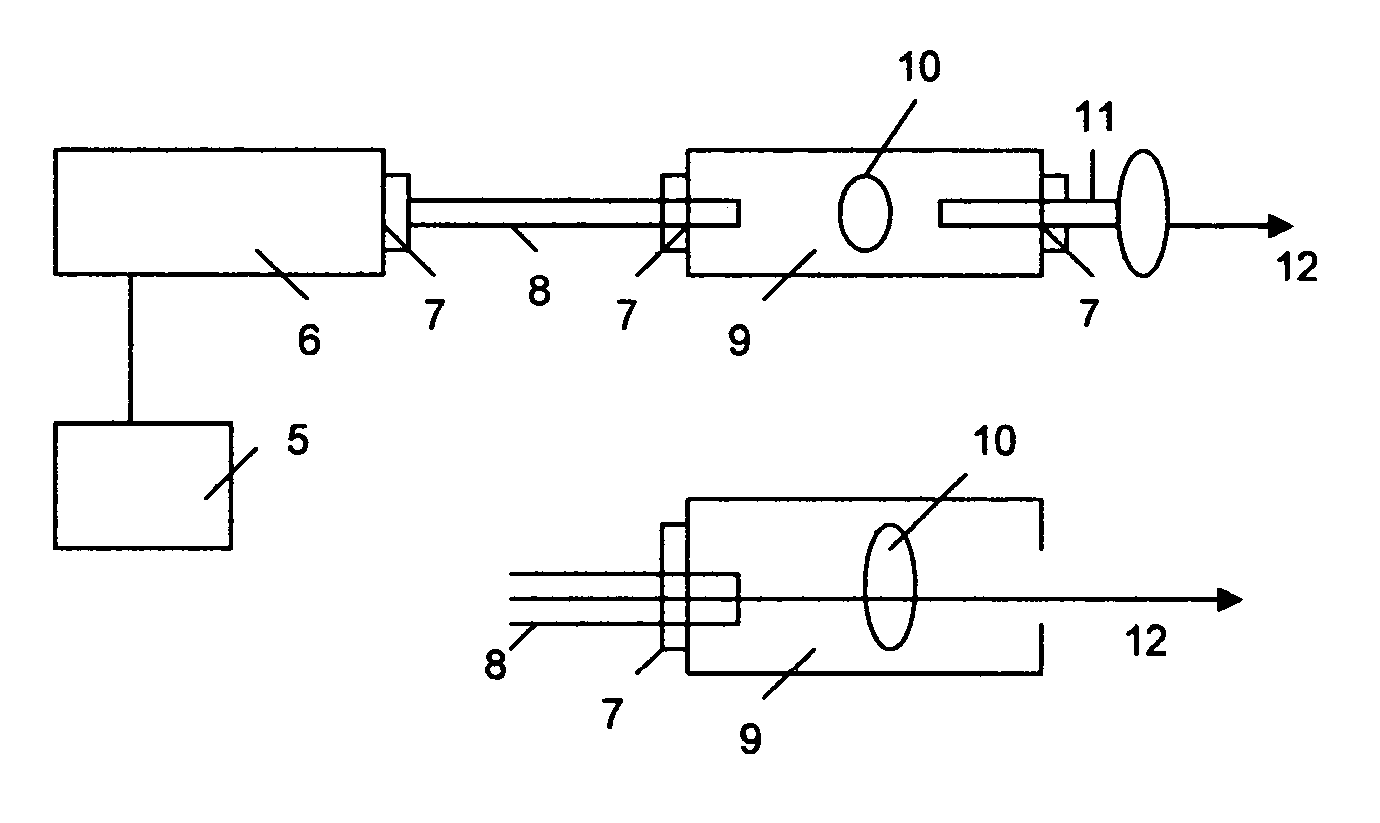

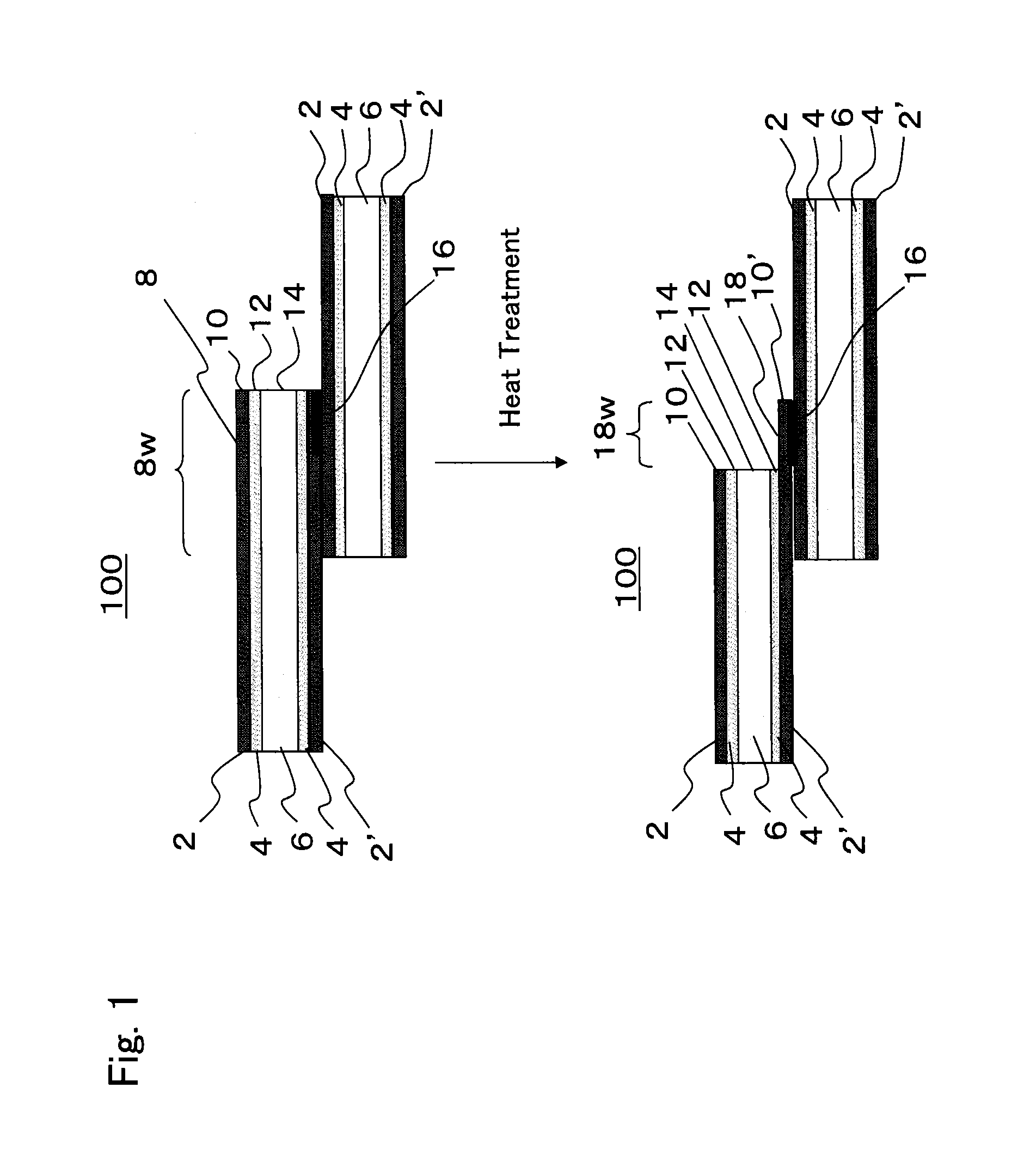

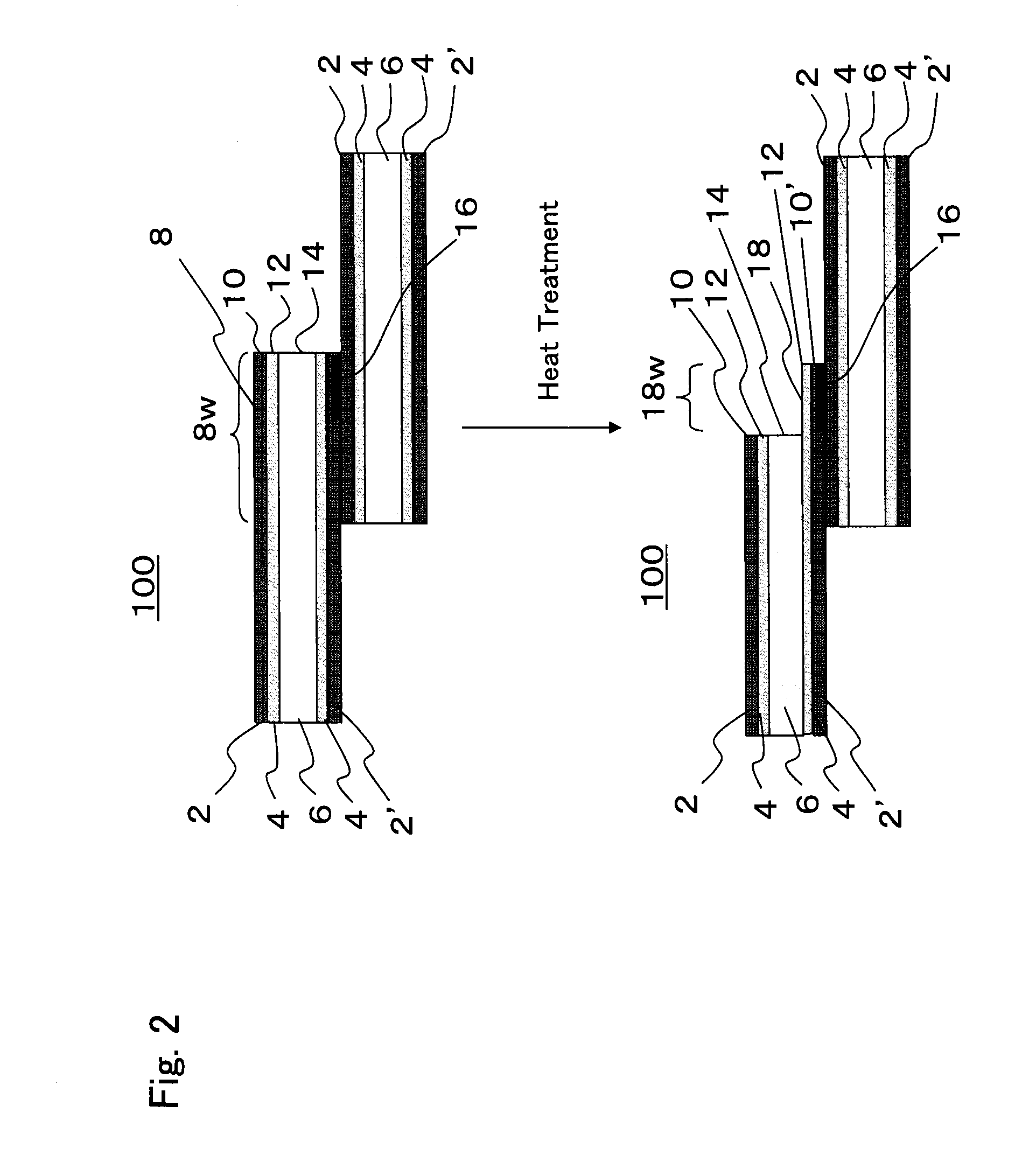

In the present invention, a thin film transistor is formed on a plastic film substrate (1) having anisotropy of thermal shrinkage rate or coefficient of thermal expansion in in-plane directions of the substrate. A channel is formed such thatthe direction (7) in which the thermal shrinkage rate or the coefficient of thermal expansion of the substrate is largest is nonparallel tothe direction (8) of a current flowing through the channel of the thin film transistor. Then, a thin film transistor having stable and uniform electrical characteristics, which is formed on the plastic film substrate, is provided.

Owner:CANON KK

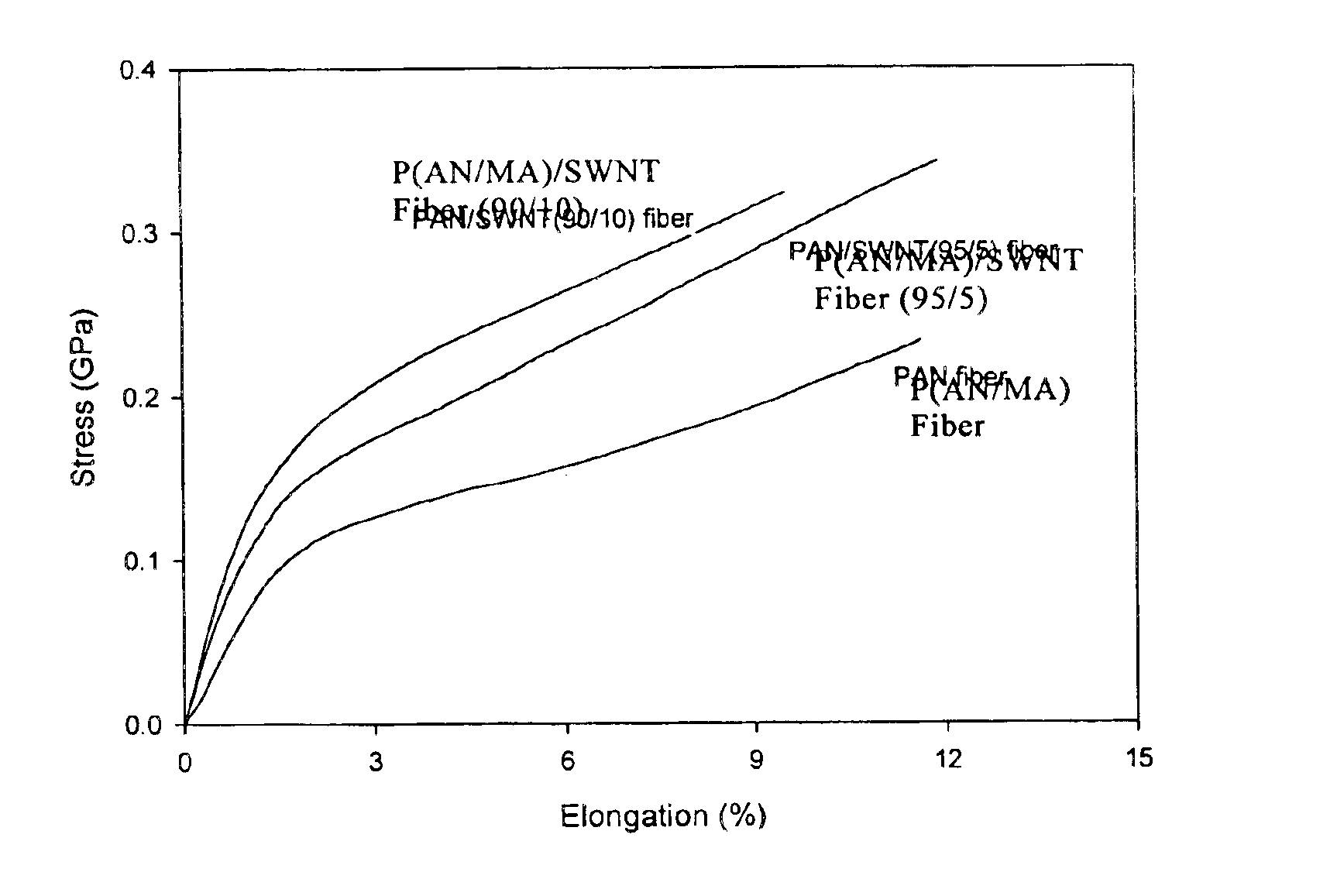

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

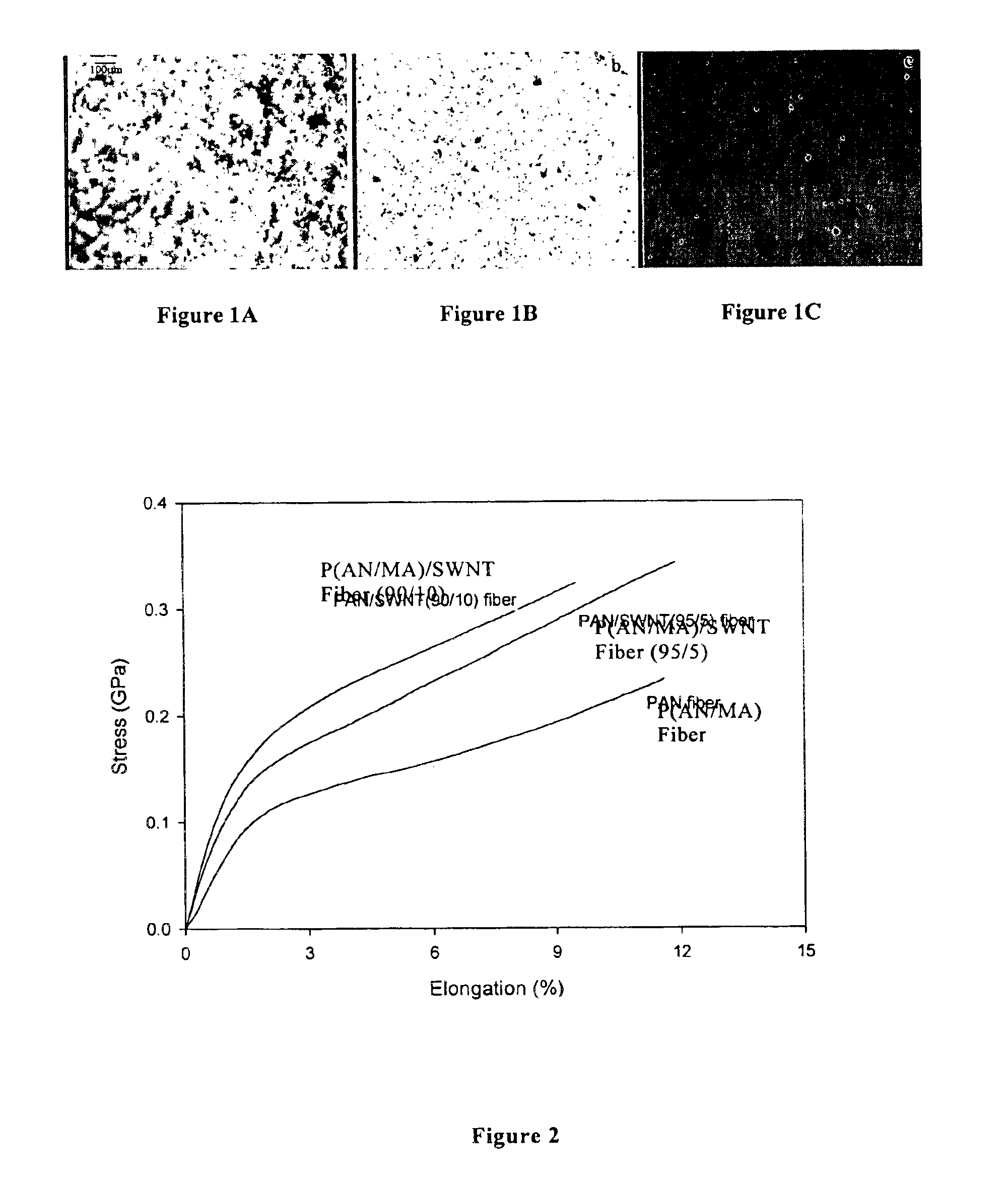

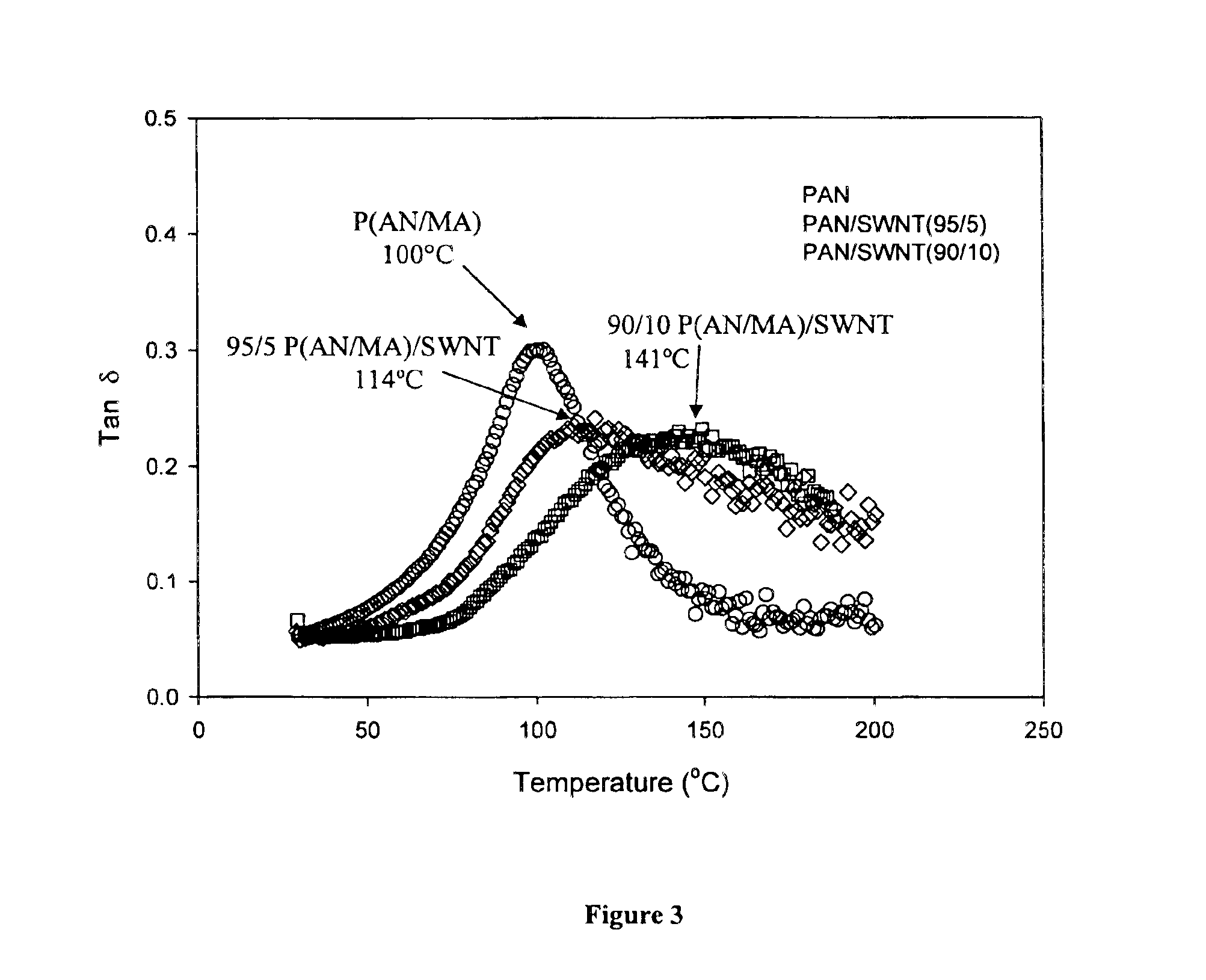

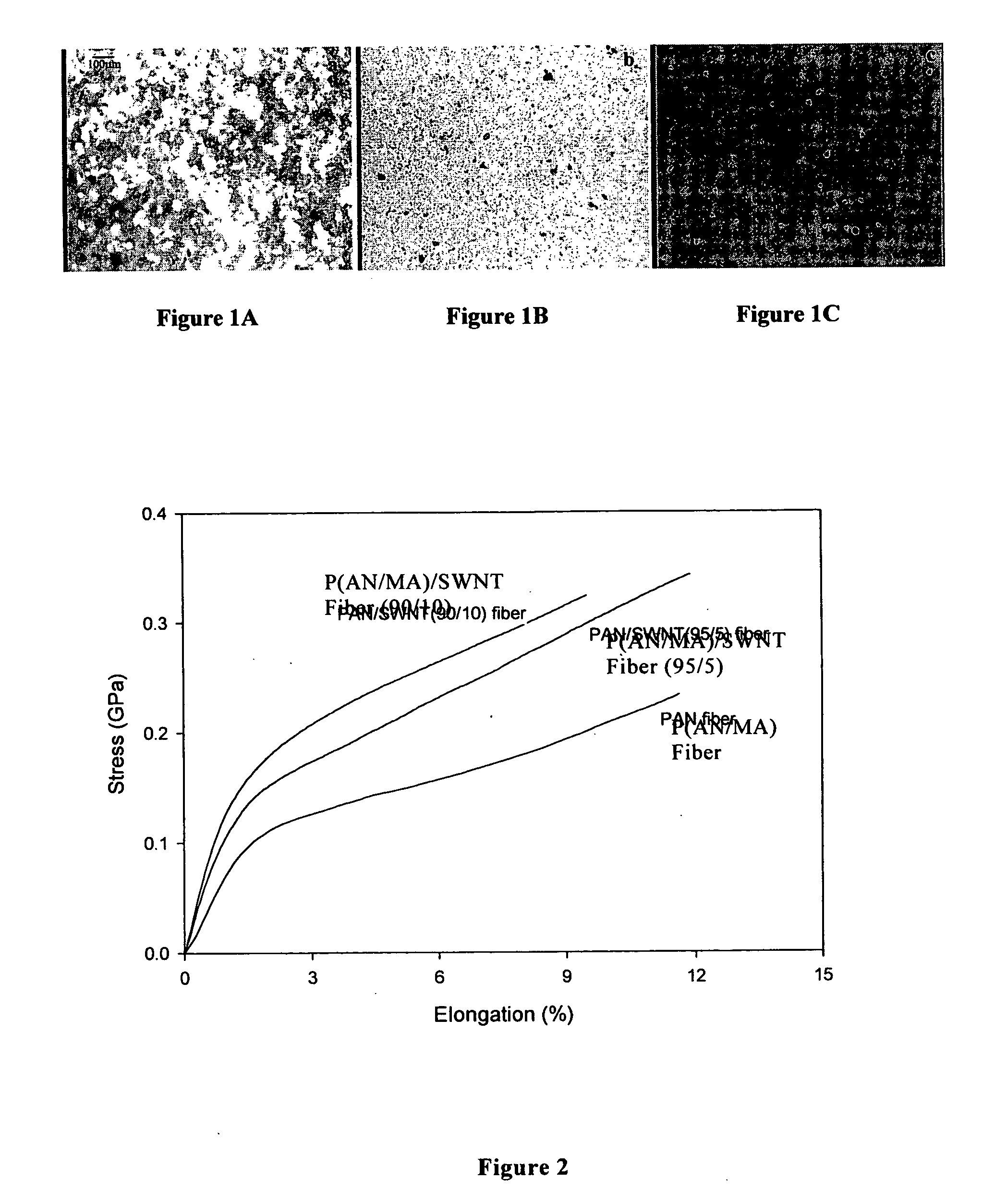

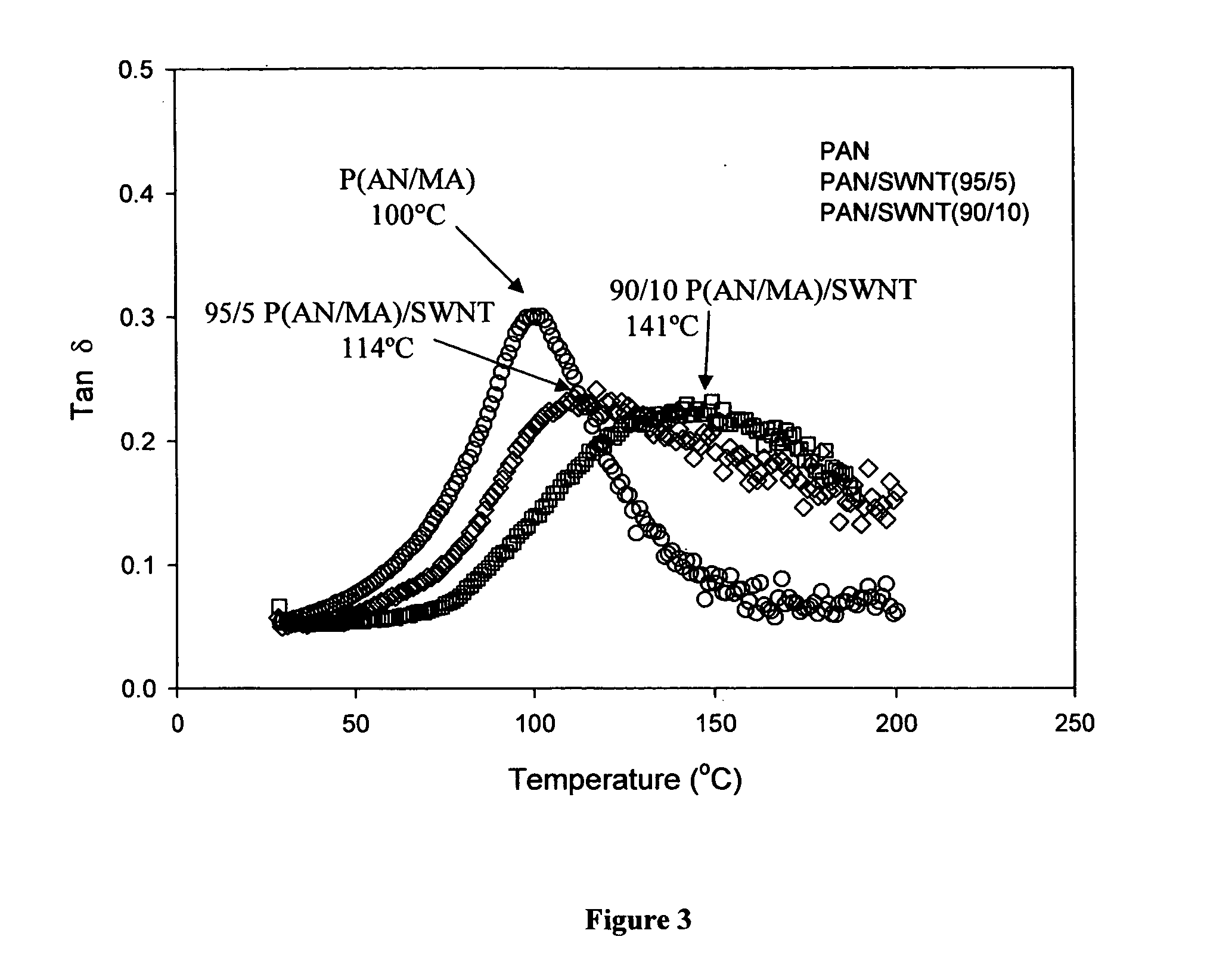

InactiveUS6852410B2Increased tensile modulusReduced thermal shrinkageMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

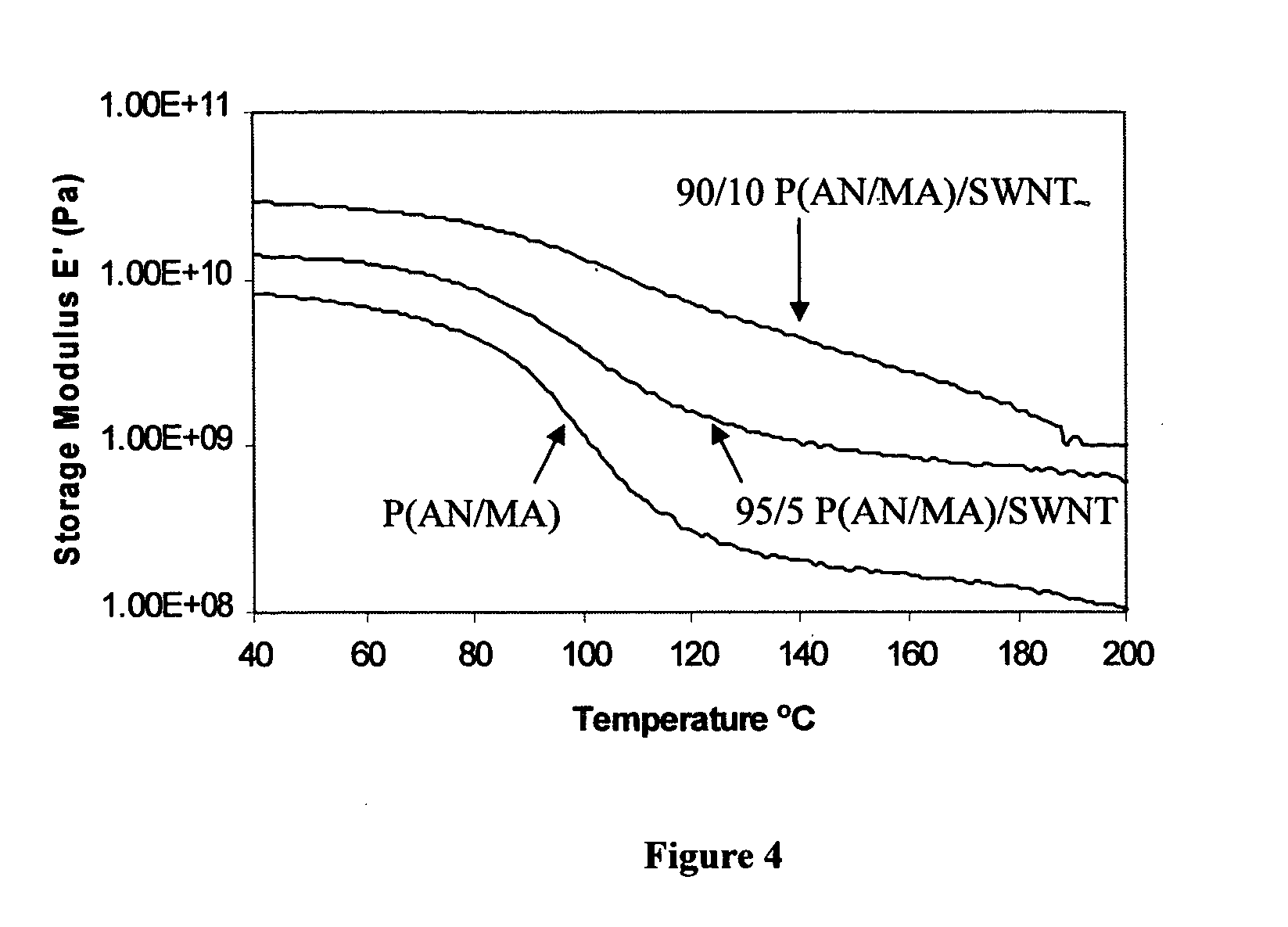

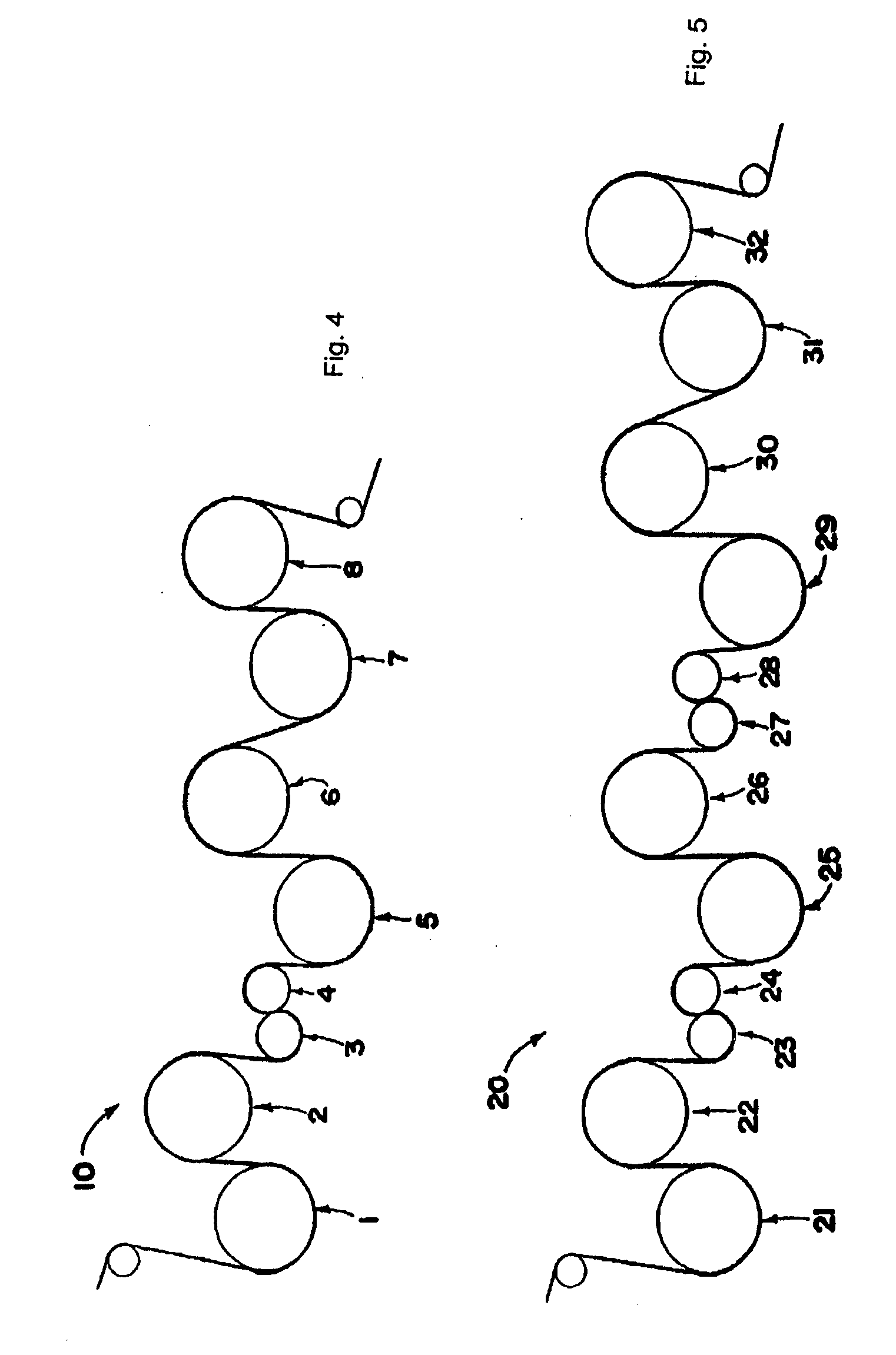

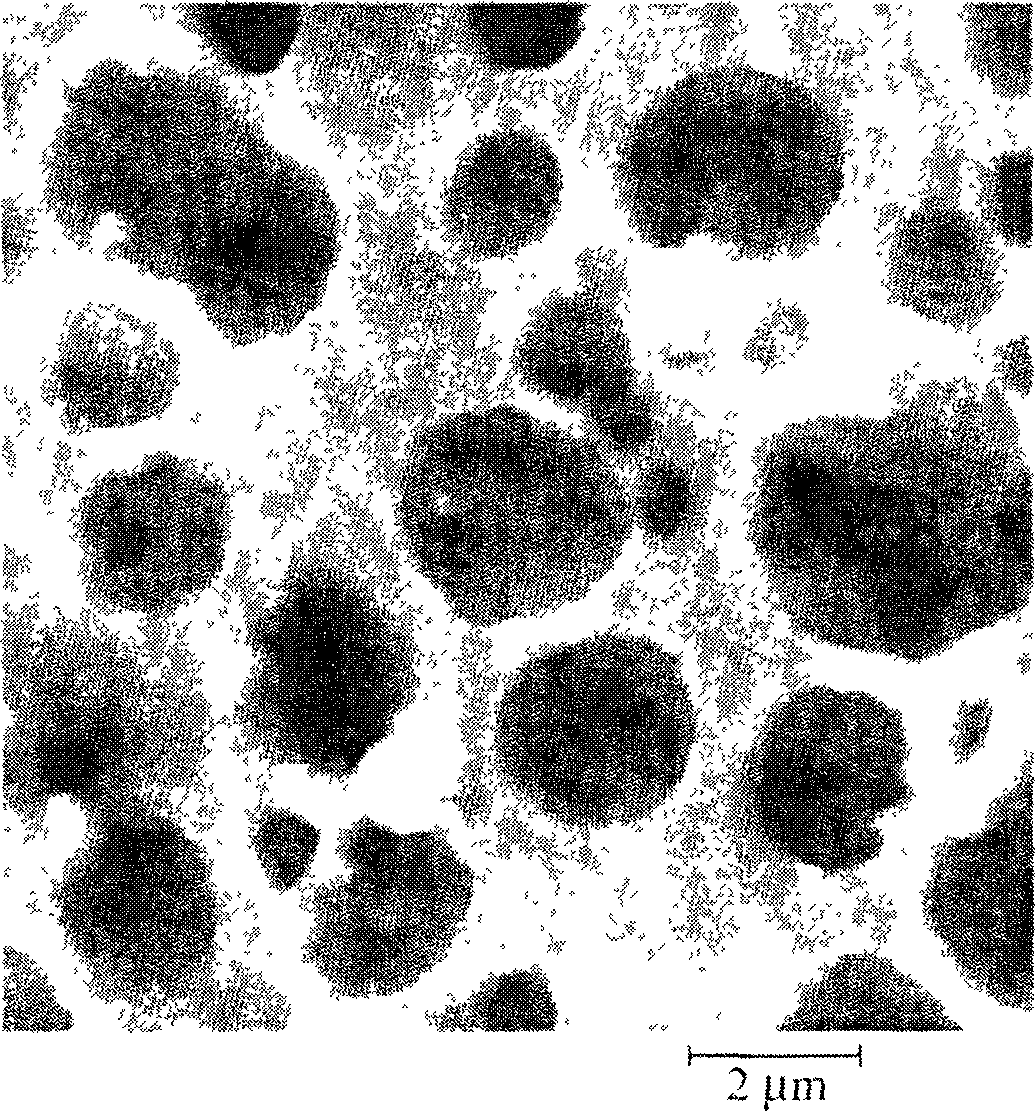

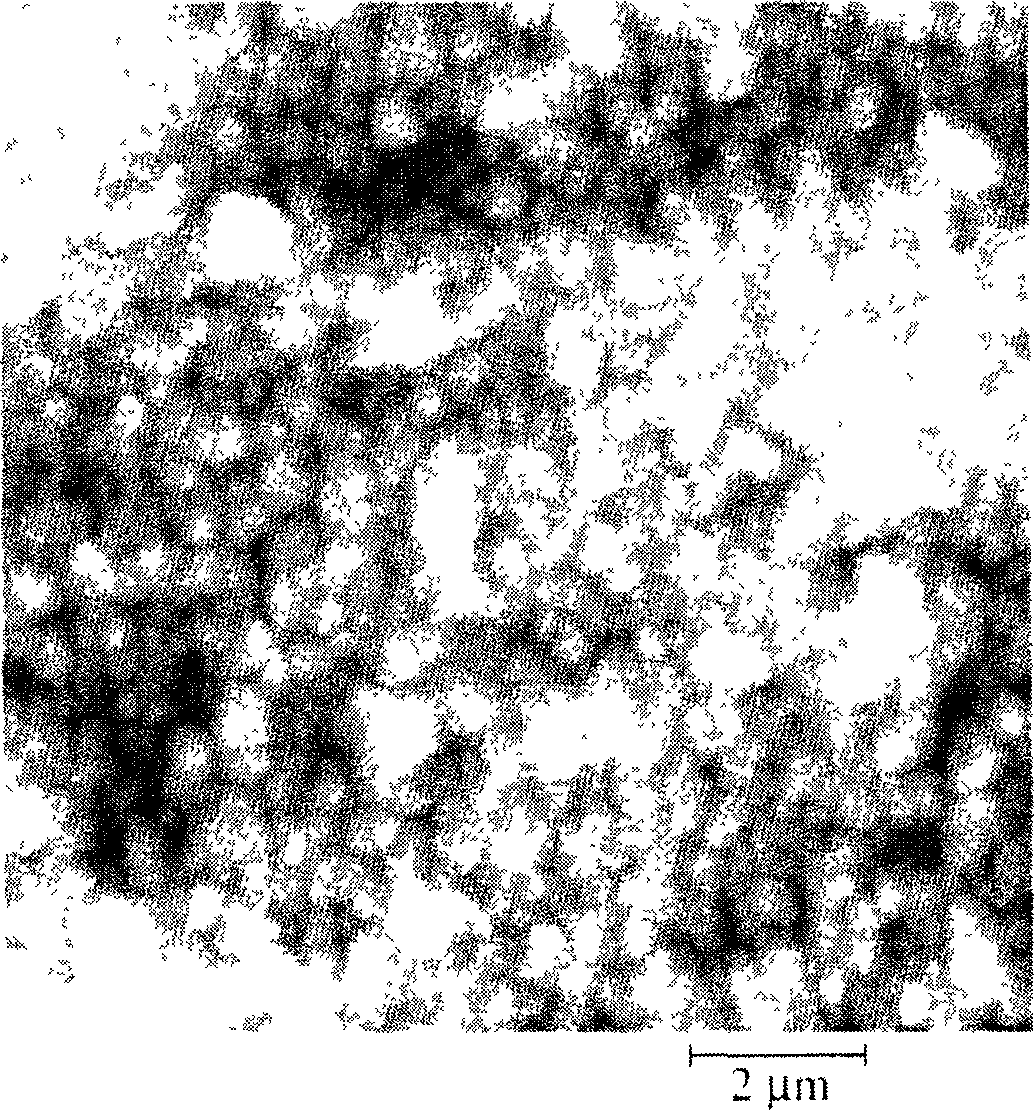

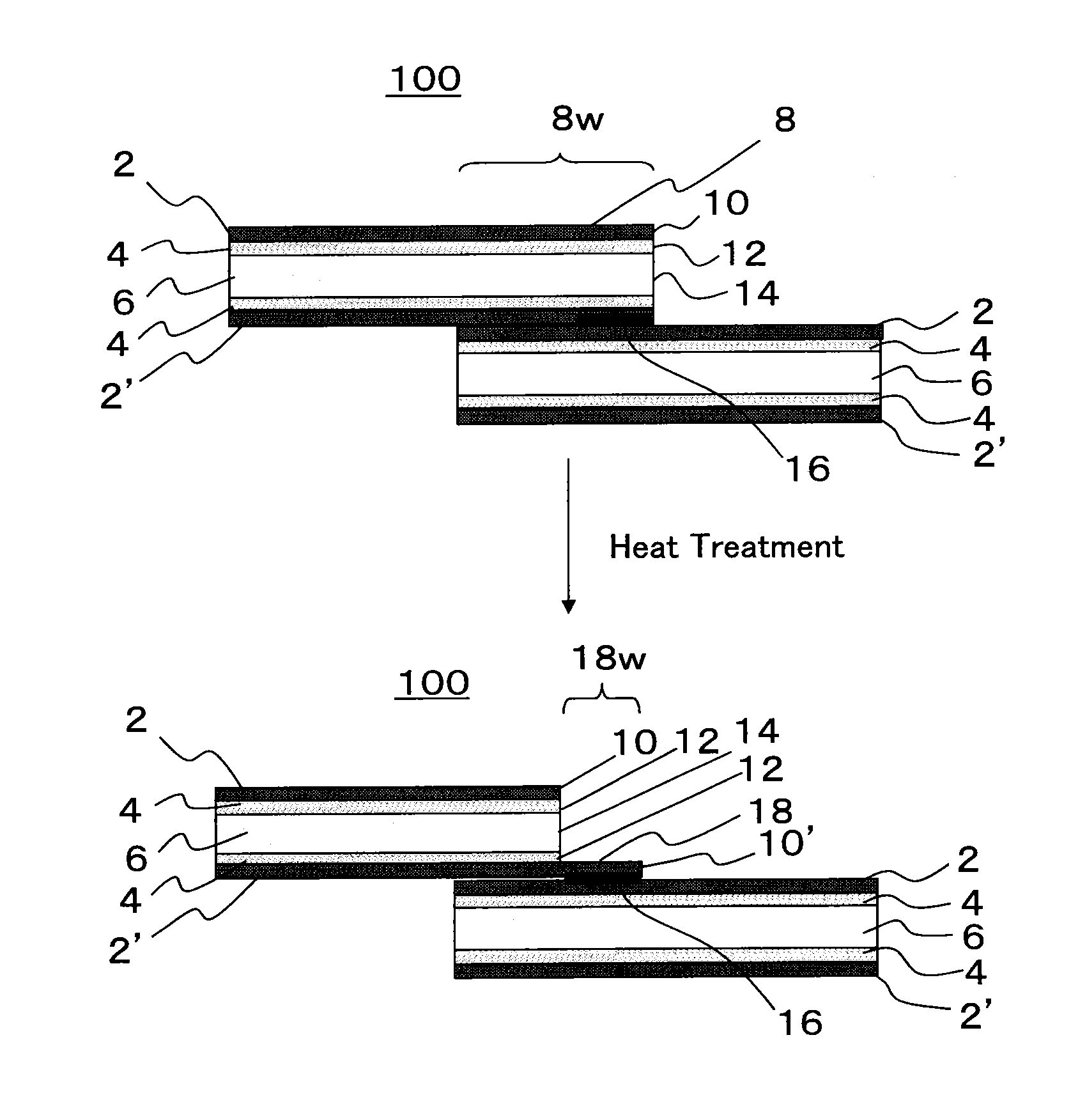

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

Macroscopic fiber comprising single-wall carbon nanotubes and acrylonitrile-based polymer and process for making the same

InactiveUS20050100501A1Good orientationIncrease modulusMaterial nanotechnologyElectroconductive/antistatic filament manufactureVitrificationPolymer science

The present invention relates to a high modulus macroscopic fiber comprising single-wall carbon nanotubes (SWNT) and an acrylonitrile-containing polymer. In one embodiment, the macroscopic fiber is a drawn fiber having a cross-sectional dimension of at least 1 micron. In another embodiment, the acrylonitrile polymer-SWNT composite fiber is made by dispersing SWNT in a solvent, such as dimethyl formamide or dimethyl acetamide, admixing an acrylonitrile-based polymer to form a generally optically homogeneous polyacrylonitrile polymer-SWNT dope, spinning the dope into a fiber, drawing and drying the fiber. Polyacrylonitrile / SWNT composite macroscopic fibers have substantially higher modulus and reduced shrinkage versus a polymer fiber without SWNT. A polyacrylonitrile / SWNT fiber containing 10 wt % SWNT showed over 100% increase in tensile modulus and significantly reduced thermal shrinkage compared to a control fiber without SWNT. With 10 wt % SWNT, the glass transition temperature of the polymer increased by more than 40° C.

Owner:GEORGIA TECH RES CORP

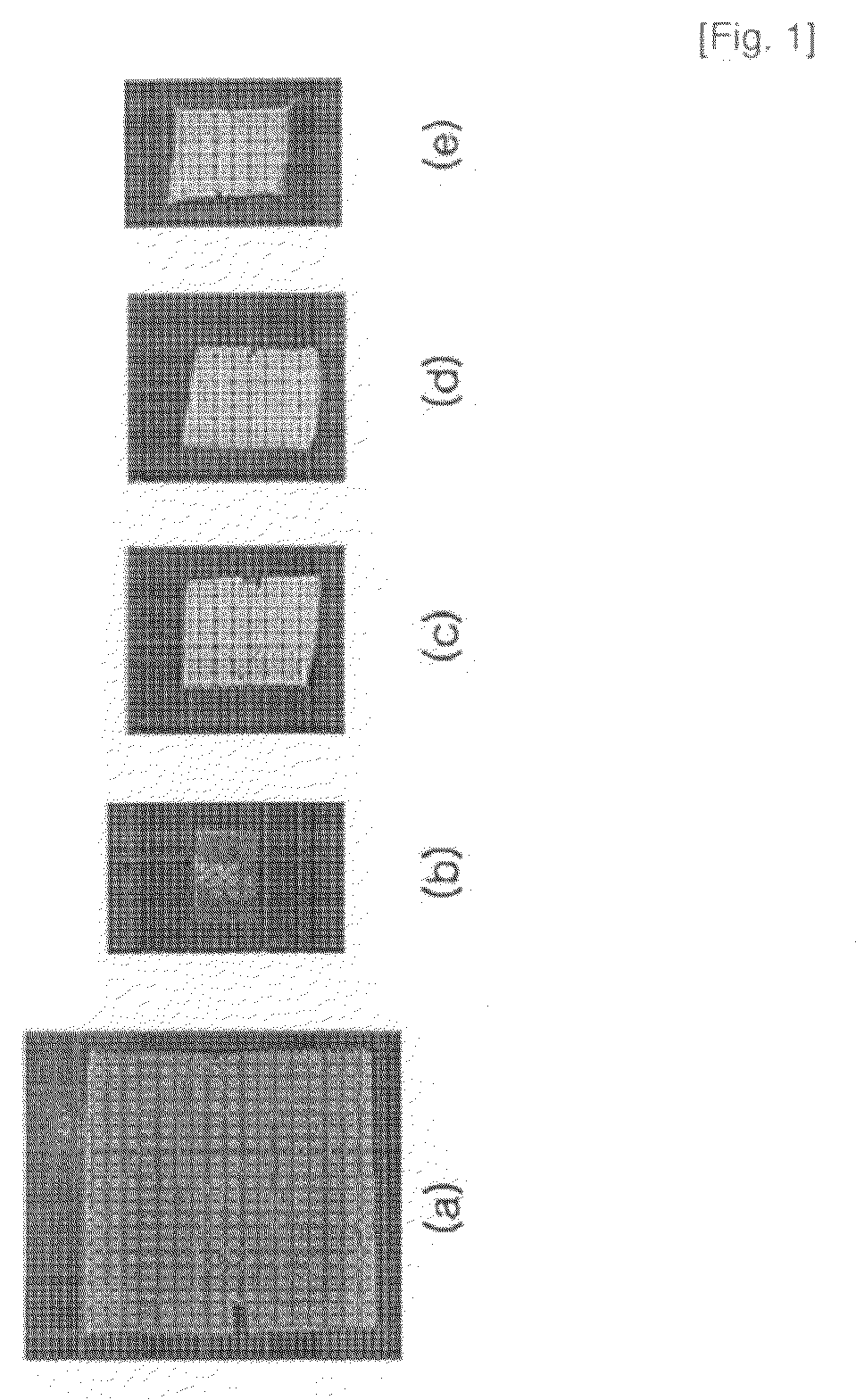

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveCN101542777AAvoid separationPrevent electrical short circuitSolid electrolytesLi-accumulatorsPorous substratePolyolefin

Owner:LG ENERGY SOLUTION LTD +1

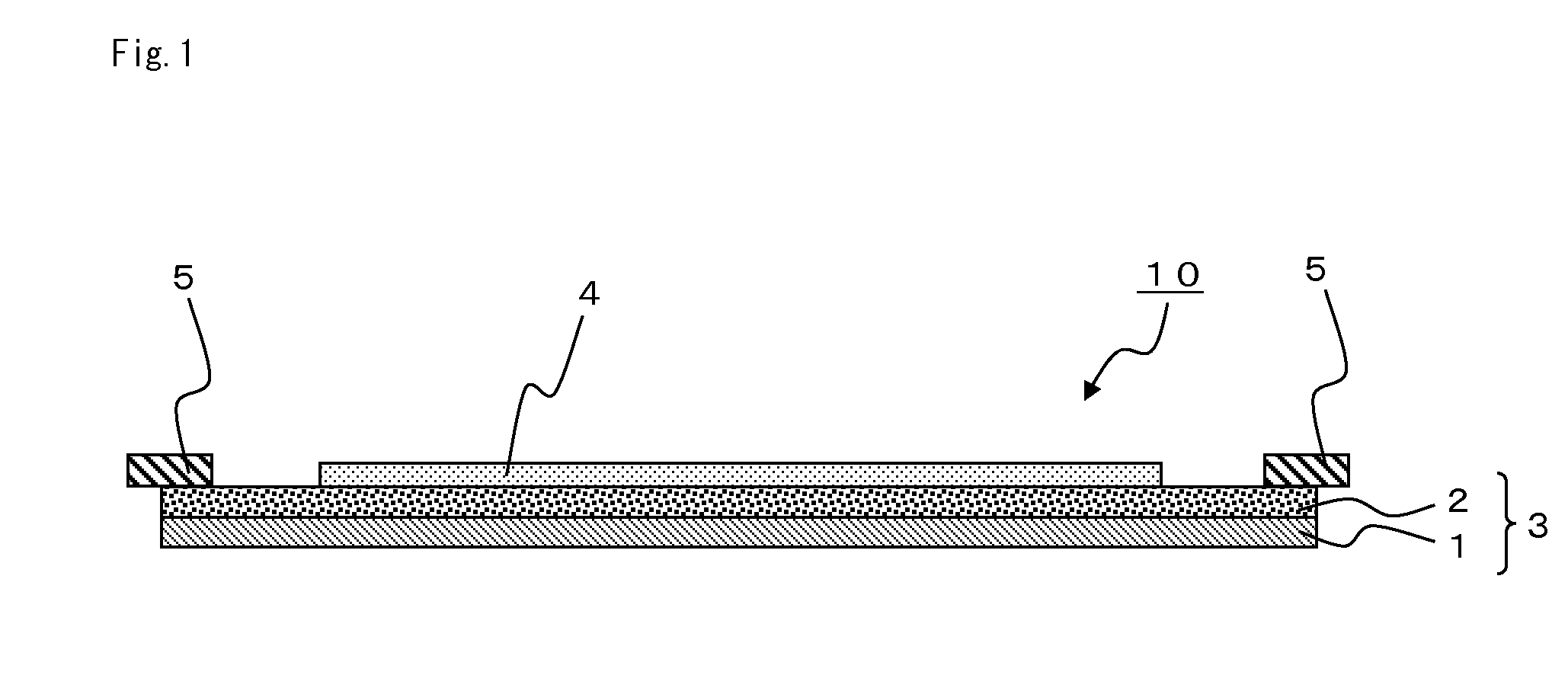

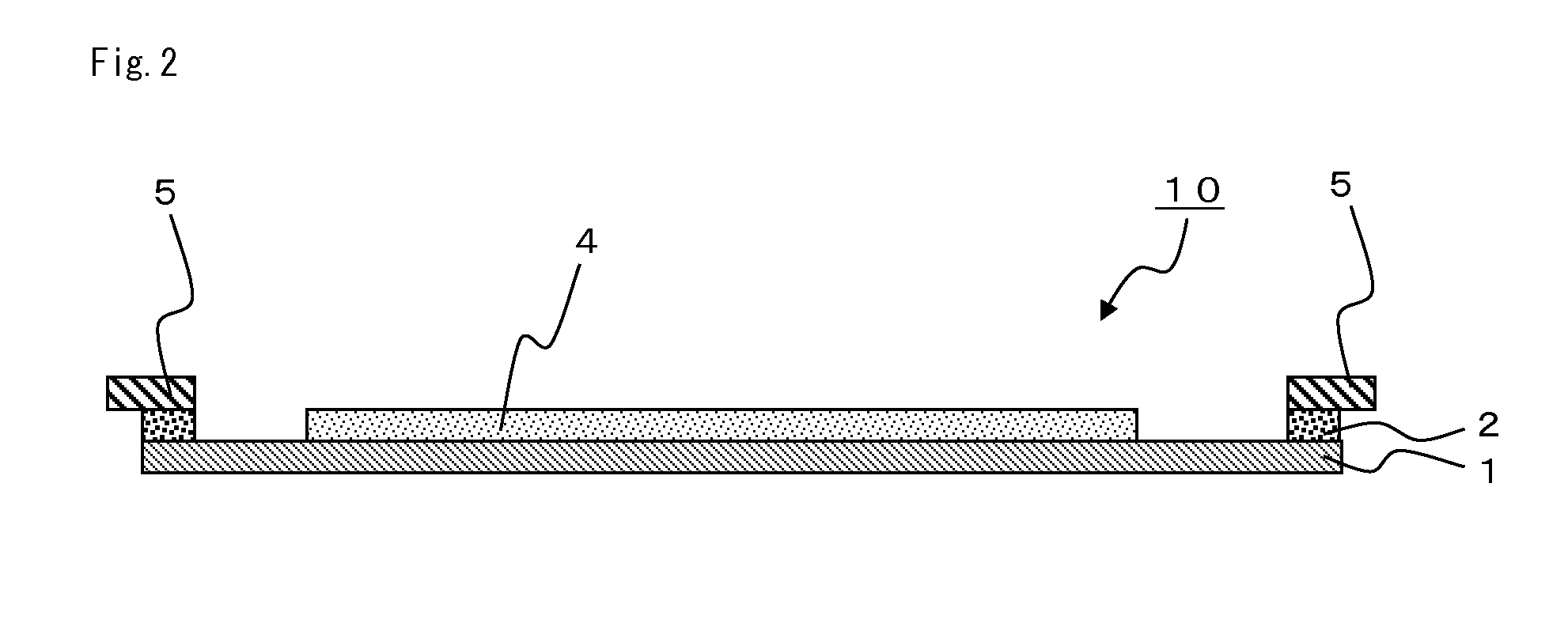

Dicing Sheet with Protective Film Forming Layer and Chip Fabrication Method

ActiveUS20140295646A1Improve printing accuracyWell formedLayered productsSemiconductor/solid-state device detailsTectorial membraneThermal contraction

A dicing sheet with a protective film forming layer has a substrate film, an adhesive layer, and a protective film forming layer, and at a minimum, the adhesive layer is formed in an area surrounding the protective film forming layer in a planar view, and the substrate film has the following characteristics (a)-(c): (a) the melting point either exceeds 130° C. or the film has no melting point; (b) the thermal contraction rate under conditions of heating at 130° C. for two hours is from −5 to +5%, and (c) the degree of elongation-to-break in the MD direction and the CD direction is at least 100%, and the stress at 25% is no more than 100 MPa.

Owner:LINTEC CORP

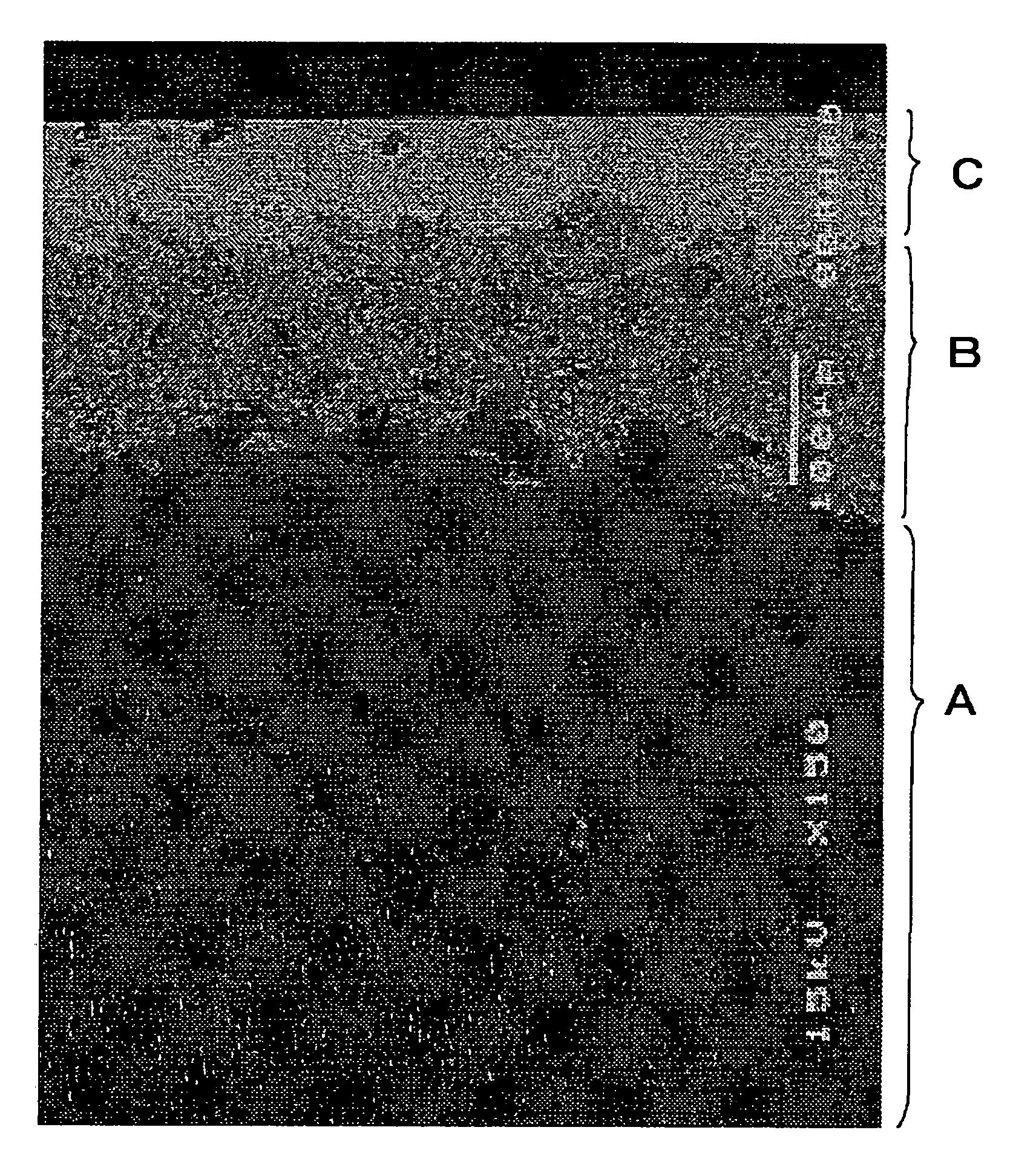

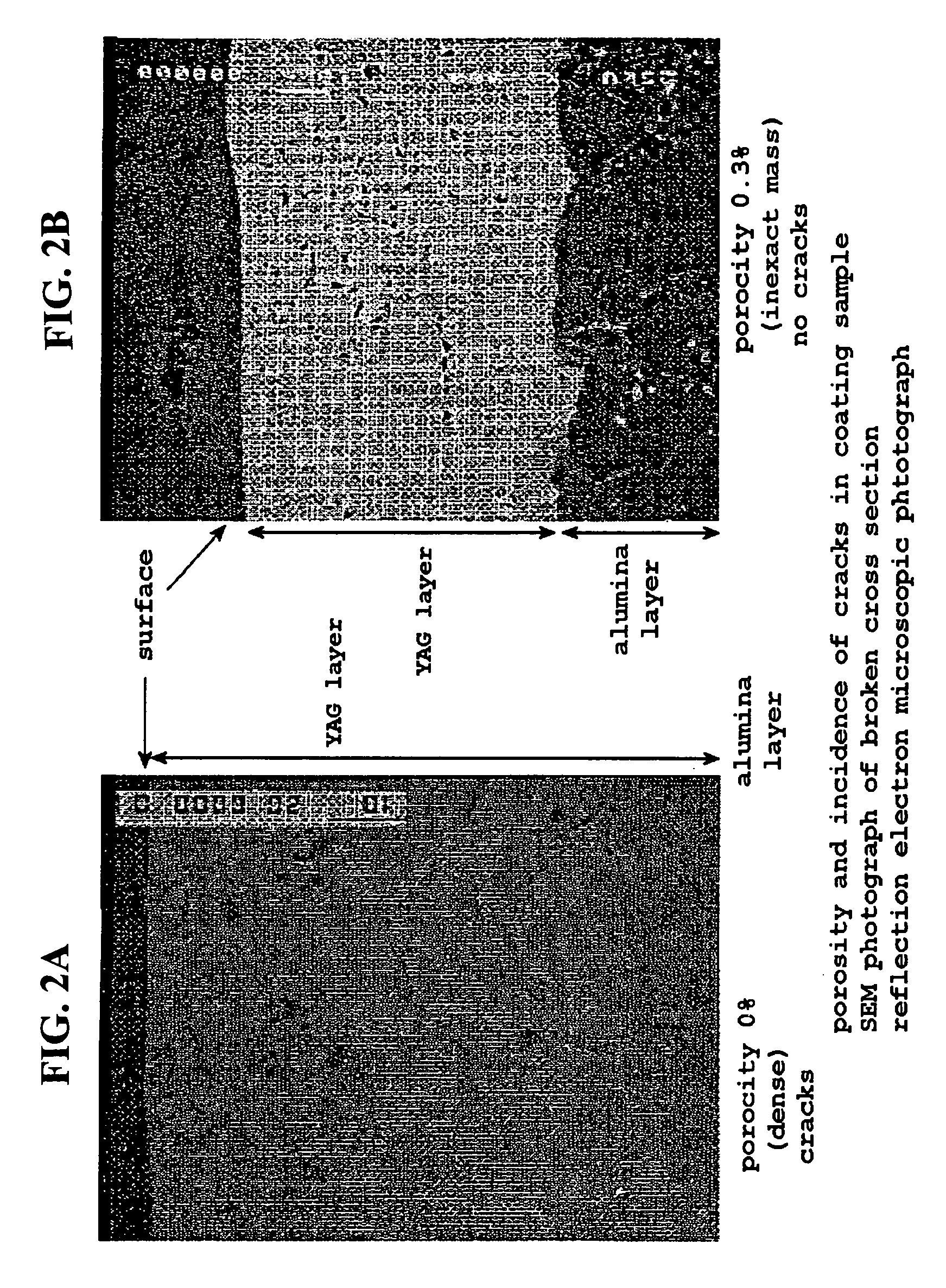

Plasma resistant member

InactiveUS20050227118A1Avoid crackingSufficiently durableElectric discharge tubesVacuum evaporation coatingPorosityHigh density

The present invention provides a plasma resistant member having a reinforced mechanical strength and being sufficiently durable to exposure to a low pressure high density plasma. At least the surface of the alumina based material is formed of an oxide or composite oxide layer of a group IIIA element via an intermediate layer. It is preferable in the construction of the plasma resistant member that the intermediate layer comprises 10 to 80% by weight of the oxide or composite oxide of the group IIIA element in the periodic table and 90 to 20% by weight of alumina. The intermediate layer may also comprise a course ceramic with a porosity of 0.2 to 5%. It is also desirable that at least one of the conditions such as a difference in the thermal shrinkage ratio at 1600 to 1900° C. of 3% or less is provided.

Owner:COVALENT MATERIALS CORP

Sea-island typed conjugate multi filament comprising dope dyeing component and a process of preparing for the same

InactiveUS6838172B2Improve shrinkageImprove fastnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterYarn

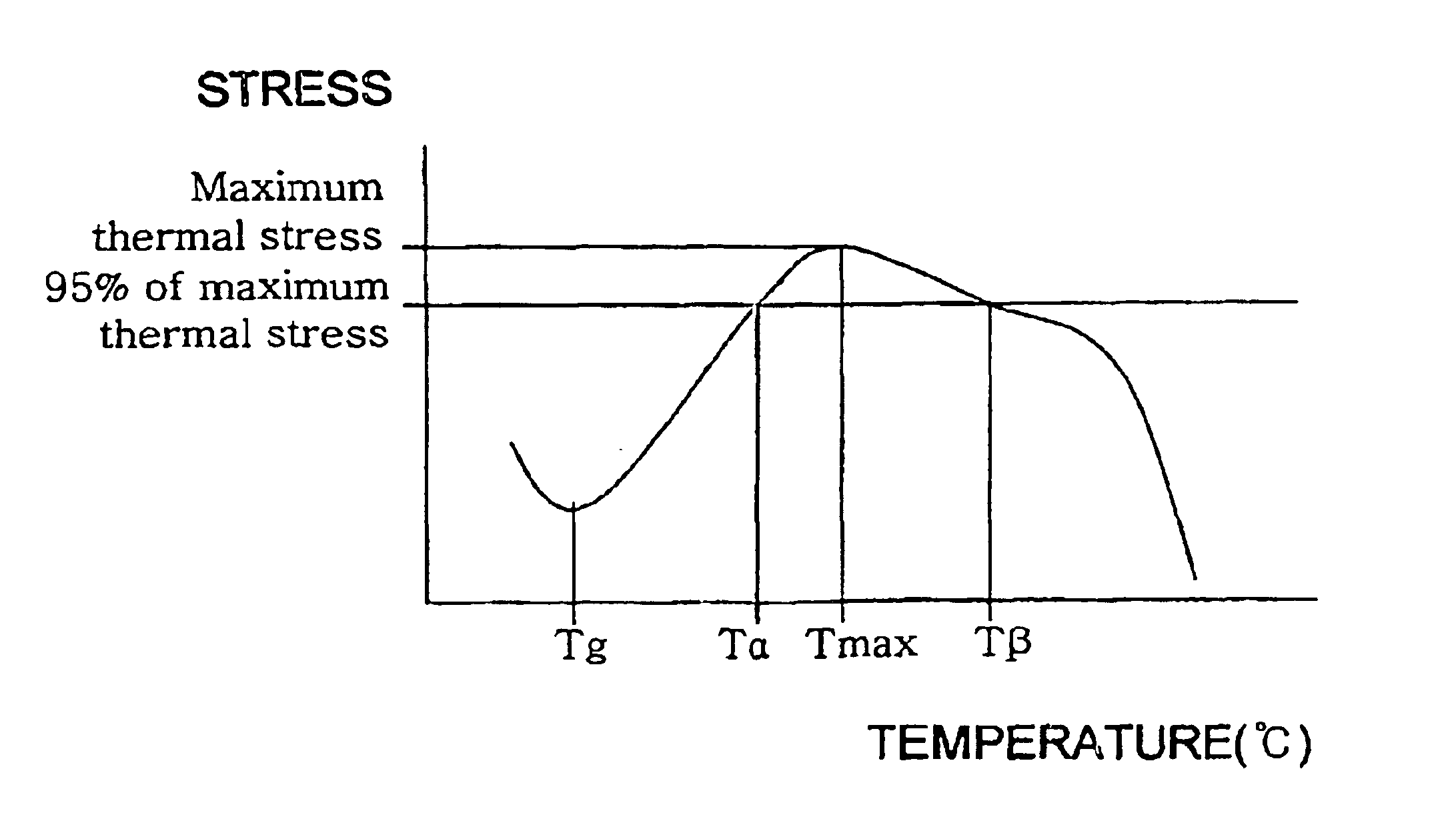

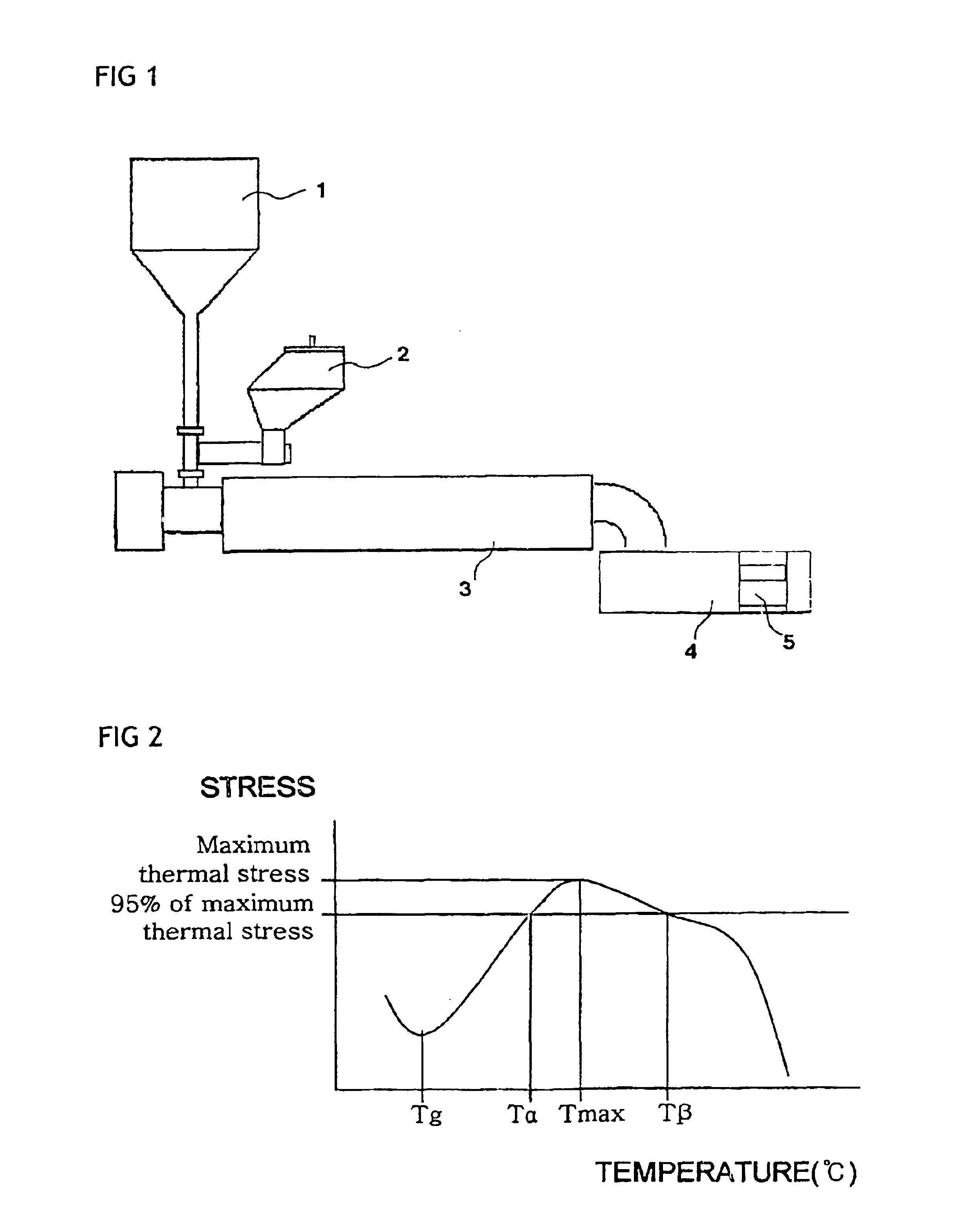

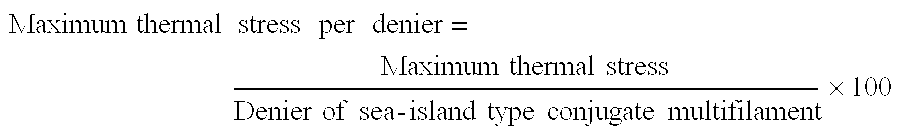

The present invention relates to a dope dyed sea-island type conjugate multifilament. In the dope dyed sea-island type conjugate multifilament, which comprises easy soluble polymer as a sea component and polyester as an island component, the island component contains a dope dyed component selected from the group consisting of carbon black, pigments and dyestuffs and the temperature range (Tα-Tβ) showing more than 95% of the maximum thermal stress of yarns is from 120° C. to 210° C. The dope dyed sea-island type conjugate multifilament of the present invention has an excellent thermal shrinkage property and excellent wash fastness and light fastness, and the dyeing process thereof can be omitted after producing a woven or knitted fabric because a dope dyed component is contained in the island component (ultra fine yarn). The dope dyed sea-island type conjugate multifilament of the present invention is useful as yarns for warp knit fabrics used in production of women's apparel.

Owner:KOLON IND INC

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

Polyester film

ActiveUS20070009750A1Poor producibilityHigh production costFlexible coversWrappersPolyesterIngested food

[Problems] The present invention provides a-polyester-film superior in heat resistance, chemical resistance, insulation property and thermal dimensional stability, and suitable for application to fields associated with boiling or retort treatment, which require tenacity, pinhole resistance, bending resistance, bag breakage resistance on dropping, impact resistance and the like, fields requiring thermoforming or vacuum forming, and various uses such as packaging bags for water-containing food, pharmaceutical products and the like. [Solving Means] The polyester film characteristically shows an initial elastic modulus in at least one direction of 2.5-10 GPa, an impact strength of 40-10000 J / mm, a thermal shrinkage in at least one direction at 150° C. of −0.5% to 6%, a haze of 0.001% to 7%, and an absolute value of the difference in the thermal shrinkage between the longitudinal direction and the transverse direction of not more than 1.1%.

Owner:TOYO TOYOBO CO LTD

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveUS20090111026A1Prevent extractionImprove electrochemical stabilitySolid electrolytesLi-accumulatorsPorous substratePolyolefin

An organic / inorganic composite separator includes (a) a polyolefin porous substrate having pores; and (b) a porous active layer containing a mixture of inorganic particles and a binder polymer, with which at least one surface of the polyolefin porous substrate is coated, wherein the porous active layer has a peeling force of 5 gf / cm or above, and a thermal shrinkage of the separator after being left alone at 150° C. for 1 hour is 50% or below in a machine direction (MD) or in a transverse direction (TD). This organic / inorganic composite separator solves the problem that inorganic particles in the porous active layer formed on the porous substrate are extracted during an assembly process of an electrochemical device, and also it may prevent an electric short circuit between cathode and anode even when the electrochemical device is overheated.

Owner:TORAY BATTERY SEPARATOR FILM +1

Miscible polyester blends and shrinkable films prepared therefrom

Disclosed are polyester blends useful for the preparation of heat-shrinkable films, and heat-shrinkable films prepared therefrom. The heat shrinkable film may be oriented in the machine direction to produce films with high machine-direction shrinkage but low transverse growth or shrinkage. The films are useful for roll-fed, shrink-on label applications. Also disclosed are heat-shrinkable roll-fed labels prepared from reactor-grade polyesters.

Owner:EASTMAN CHEM CO

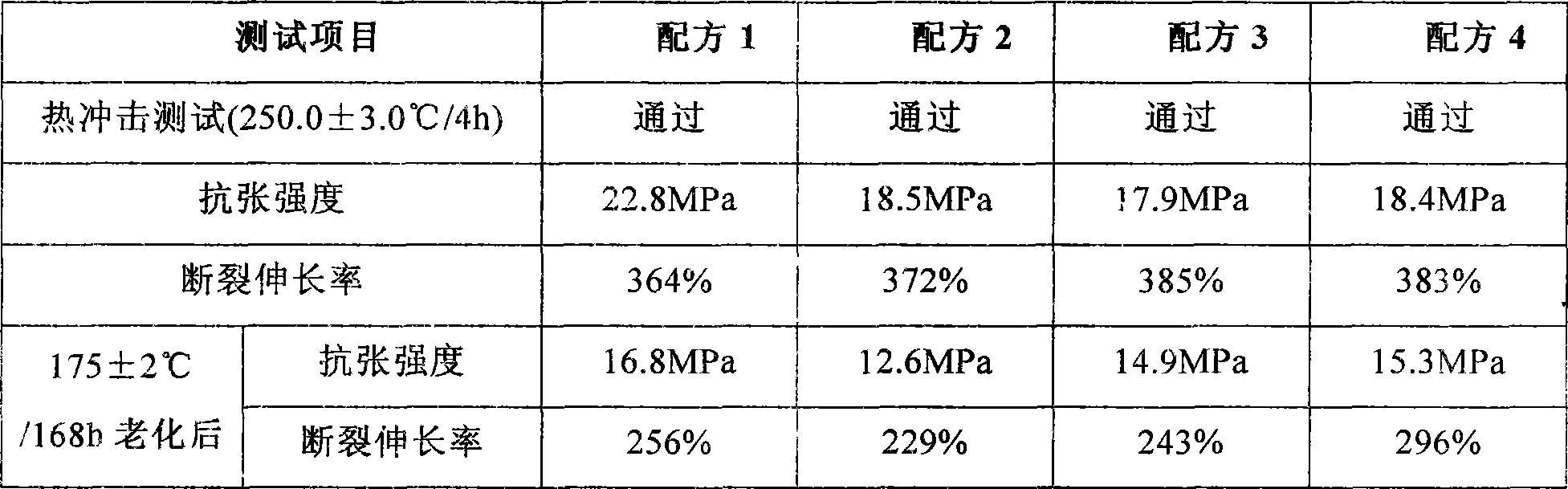

Radiation crosslinking flame-retardant polyolefin heat-shrinkable material and preparation method thereof

InactiveCN101386693AImprove insulation performanceEasy to preparePlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention relates to a radiation crosslinking flame-retardant polyolefin thermal shrinking material, which comprises the following substances in weight portion: 100 portions of polyolefin base material, 0 to 100 portions of composite flame retardant, 1 to 3 portions of lubricating agent, 0 to 5 portions of color master batch, 1 to 5 portions of composite antioxidant and 0 to 2 portions of titanium pigment. The radiation crosslinking flame-retardant polyolefin thermal shrinking material can pass a thermal shock test, can be used for manufacturing various thermal shrinking devices, has the advantages of environmental protection, excellent insulating property, simple preparation method, easily bought raw materials and low cost, and is suitable for industrialized production.

Owner:CHANGYUAN GRP +1

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Buffer substrate and use thereof

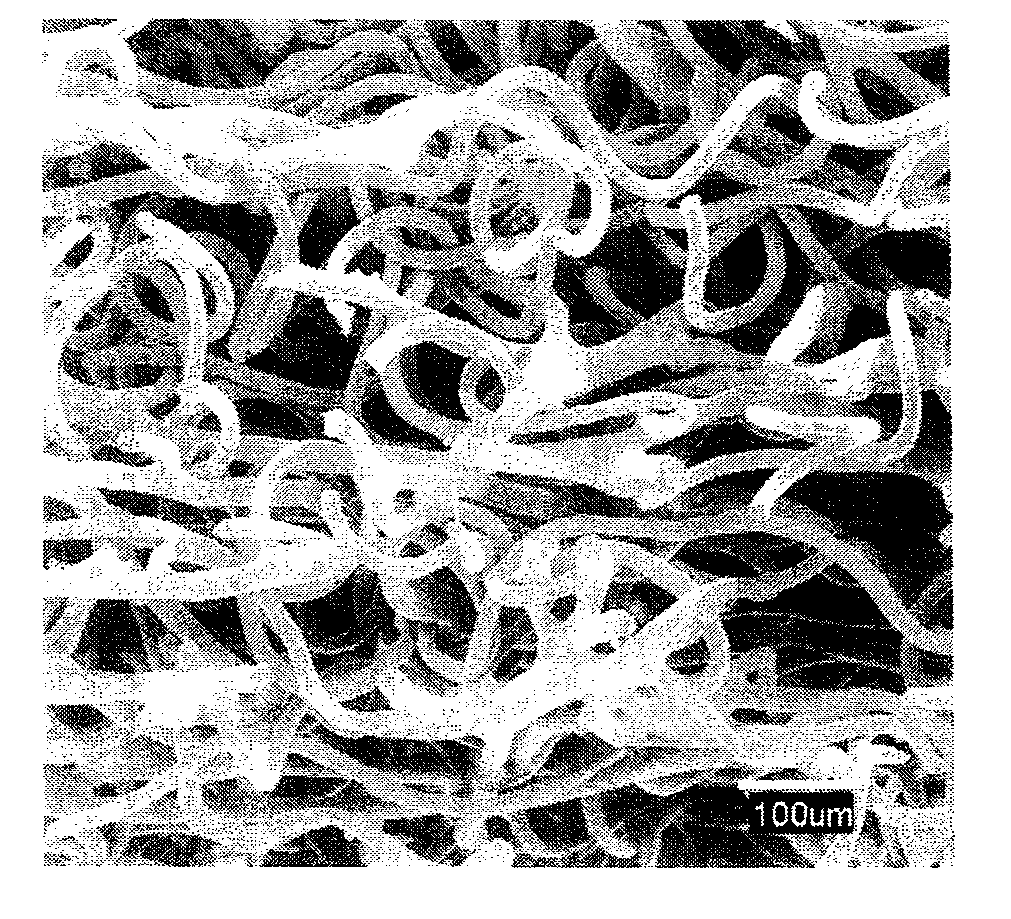

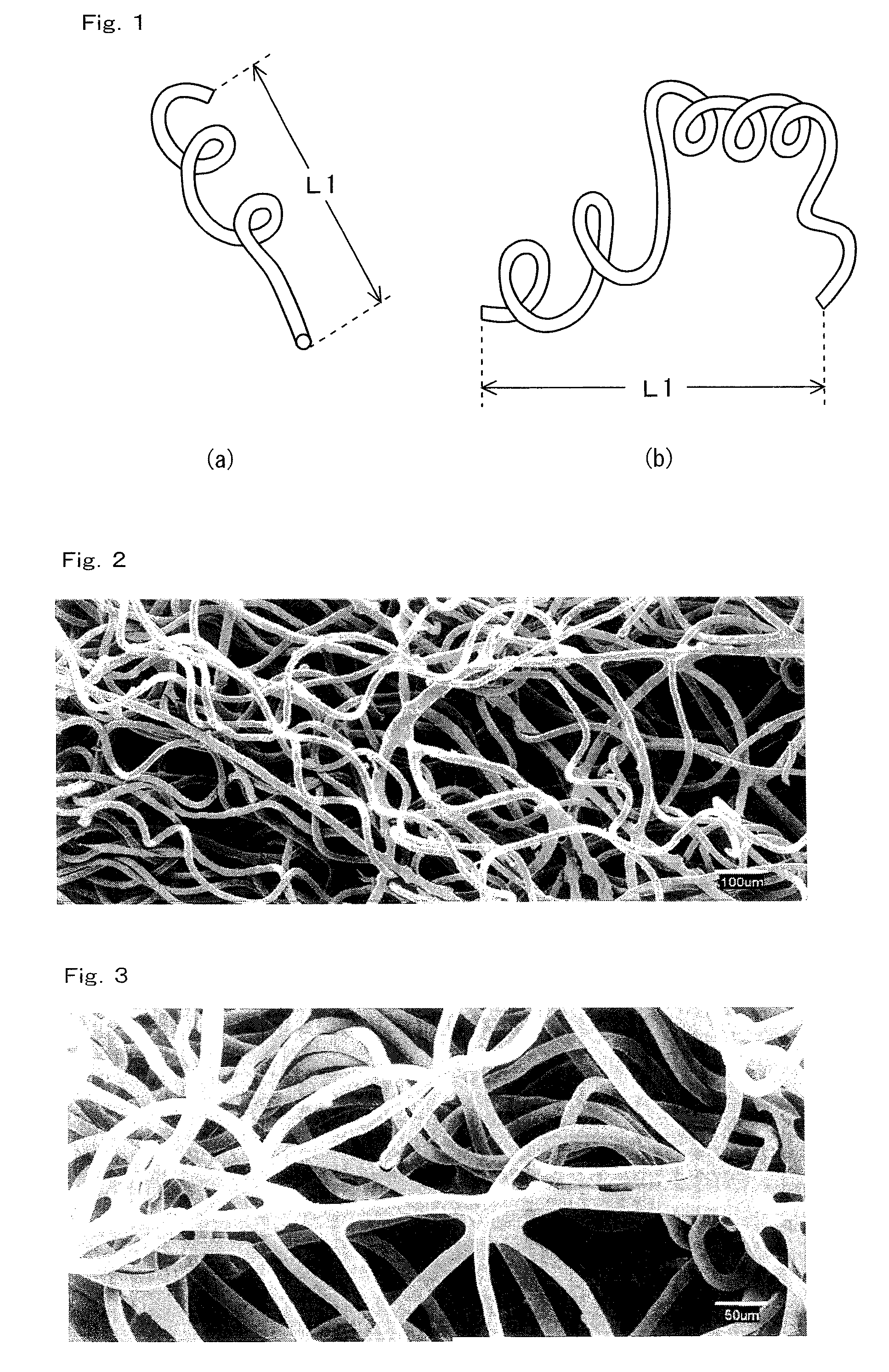

ActiveUS20100203788A1Improve breathabilityImprove buffering effectInsolesLaminationFiberPolymer science

In a nonwoven fiber assembly which comprises a fiber comprising a thermal adhesive fiber under moisture and in which the fiber are entangled with each other, the fibers are bonded at contacting points of the fibers by melting the thermal adhesive fiber under moisture to distribute the bonded points approximately uniformly, thereby obtaining a buffer substrate. The buffer substrate may further comprises a conjugated fiber comprising a plurality of resins which are different in thermal shrinkage and form a phase separation structure, and the conjugated fibers may have an approximately uniform crimps having an average curvature radius of 20 to 200 μm and are entangled with the fibers constituting the nonwoven fiber assembly. The buffer substrate can be obtained by a method comprising the steps of: forming a web from the fiber comprising the thermal adhesive fiber under moisture; and subjecting the obtained fiber web to a heat and moisture treatment with a high-temperature water vapor to melt the thermal adhesive fiber under moisture for bonding the fibers. The buffer substrate has a high air-permeability, an excellent cushion property and softness.

Owner:KURARAY CO LTD

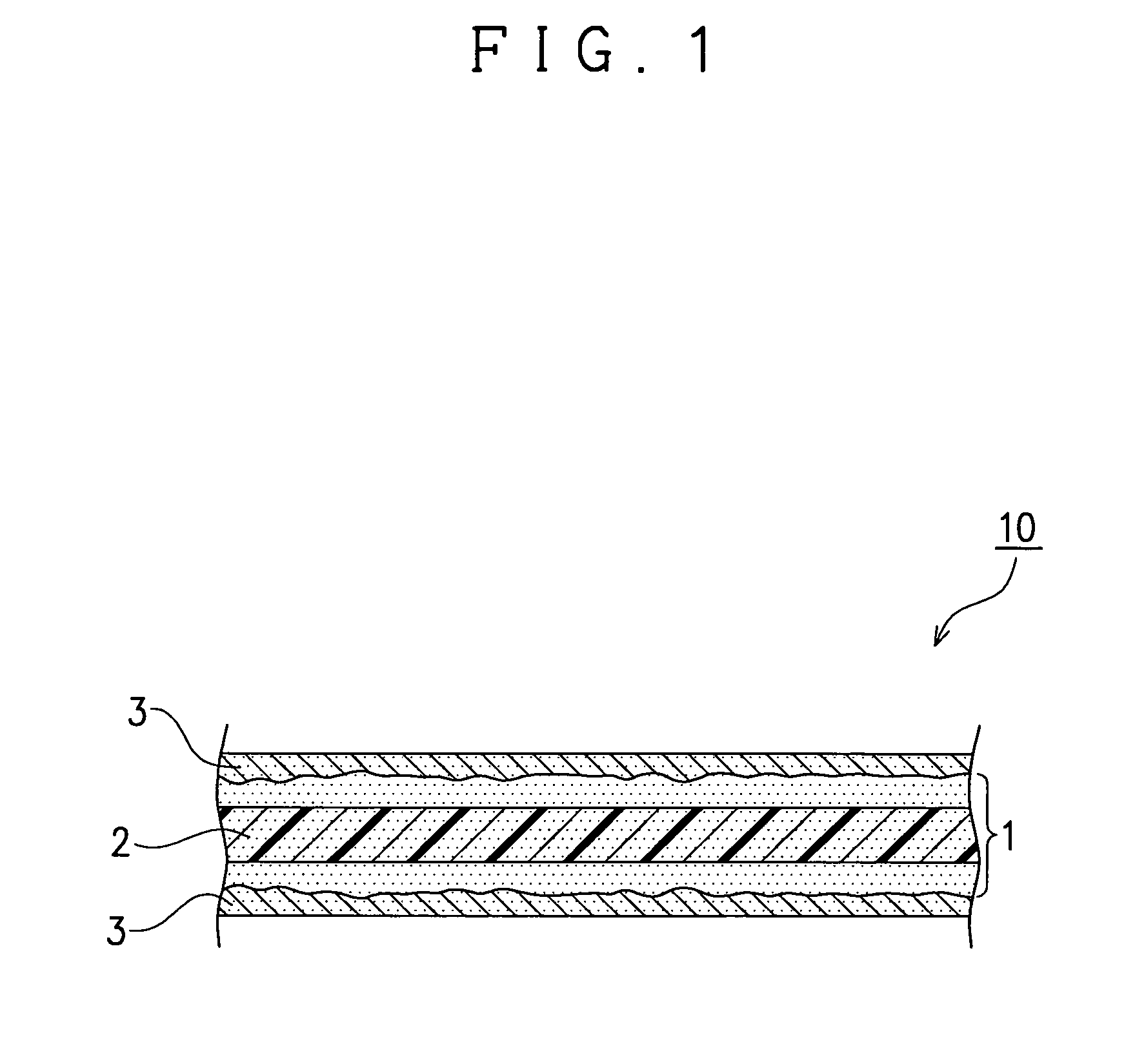

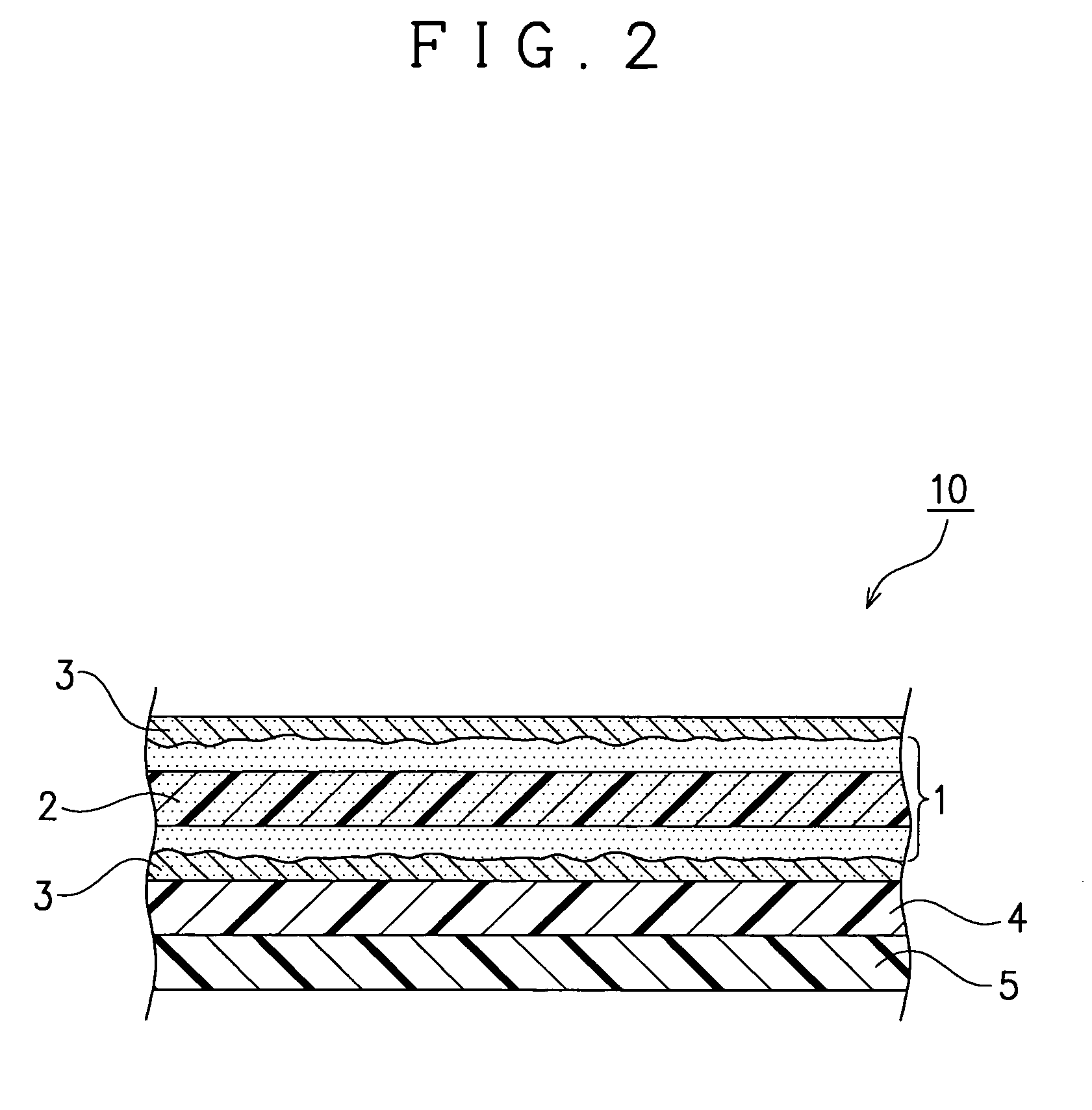

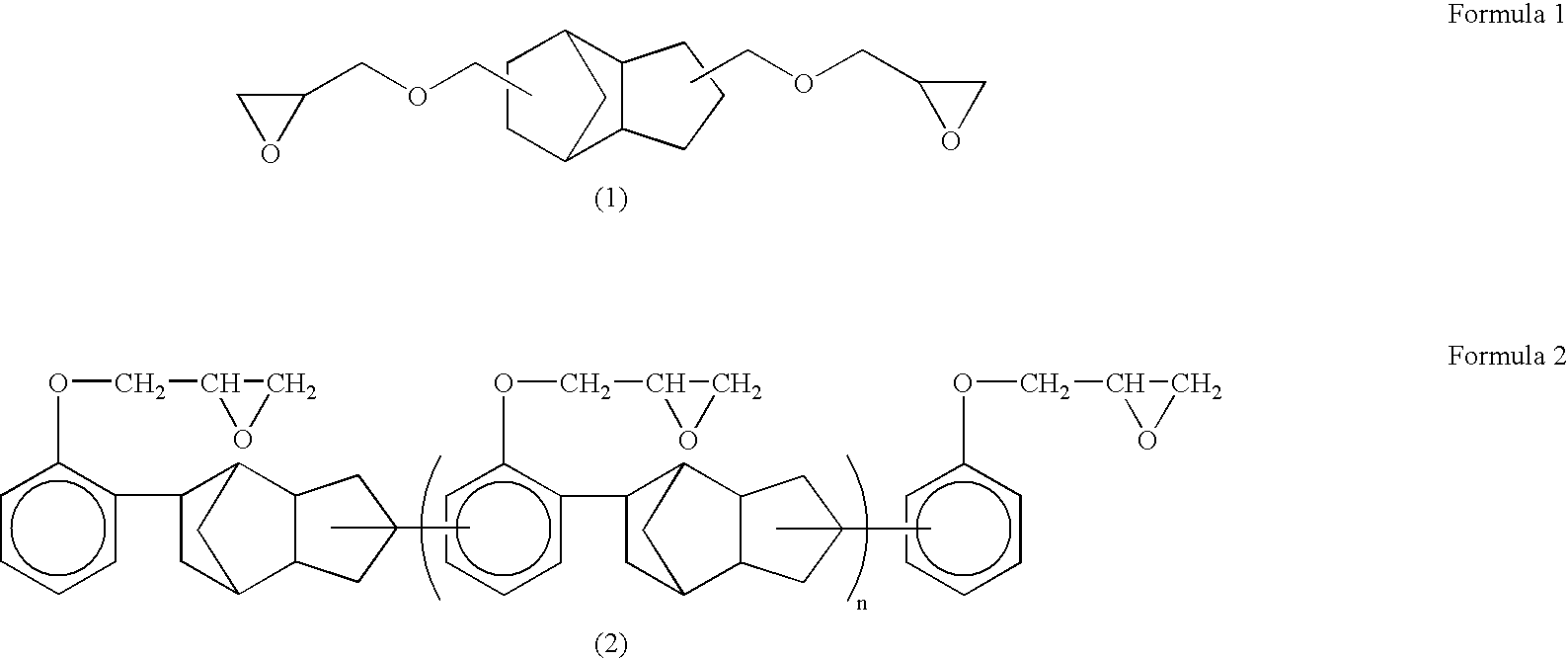

Resin sheet, liquid crystal cell substrate, liquid crystal display device, substrate for an electroluminescence display device, electroluminescence display device, and a substrate for a solar cell

InactiveUS20070042168A1Avoid misalignmentImprove impact resistanceLiquid crystal compositionsSolid-state devicesGlass fiberDisplay device

There is provided a resin sheet that achieves improvement in lightweight, low-profile and high impact characteristics, suppresses thermal shrinkage and expansion and is excellent in light transparency so as to prevent the display quality or the like of a display device from being deteriorated, as well as a substrate for a display device, a display device and a substrate for a solar cell, each having the aforesaid resin sheet. A resin sheet includes a cured resin layer containing a glass fiber cloth-like material and an overcoat layer laminated on the cured resin layer to have a surface roughness Rt of 200 nm or less, and is structured to have a haze value of 10% or lower.

Owner:NITTO DENKO CORP

Organic/inorganic composite separator having porous active coating layer and electrochemical device containing the same

ActiveUS7709152B2Prevent extractionImprove electrochemical stabilitySolid electrolytesNon-aqueous electrolyte accumulator electrodesPorous substratePolyolefin

An organic / inorganic composite separator includes (a) a polyolefin porous substrate having pores; and (b) a porous active layer containing a mixture of inorganic particles and a binder polymer, with which at least one surface of the polyolefin porous substrate is coated, wherein the porous active layer has a peeling force of 5 gf / cm or above, and a thermal shrinkage of the separator after being left alone at 150° C. for 1 hour is 50% or below in a machine direction (MD) or in a transverse direction (TD). This organic / inorganic composite separator solves the problem that inorganic particles in the porous active layer formed on the porous substrate are extracted during an assembly process of an electrochemical device, and also it may prevent an electric short circuit between cathode and anode even when the electrochemical device is overheated.

Owner:TORAY BATTERY SEPARATOR FILM +1

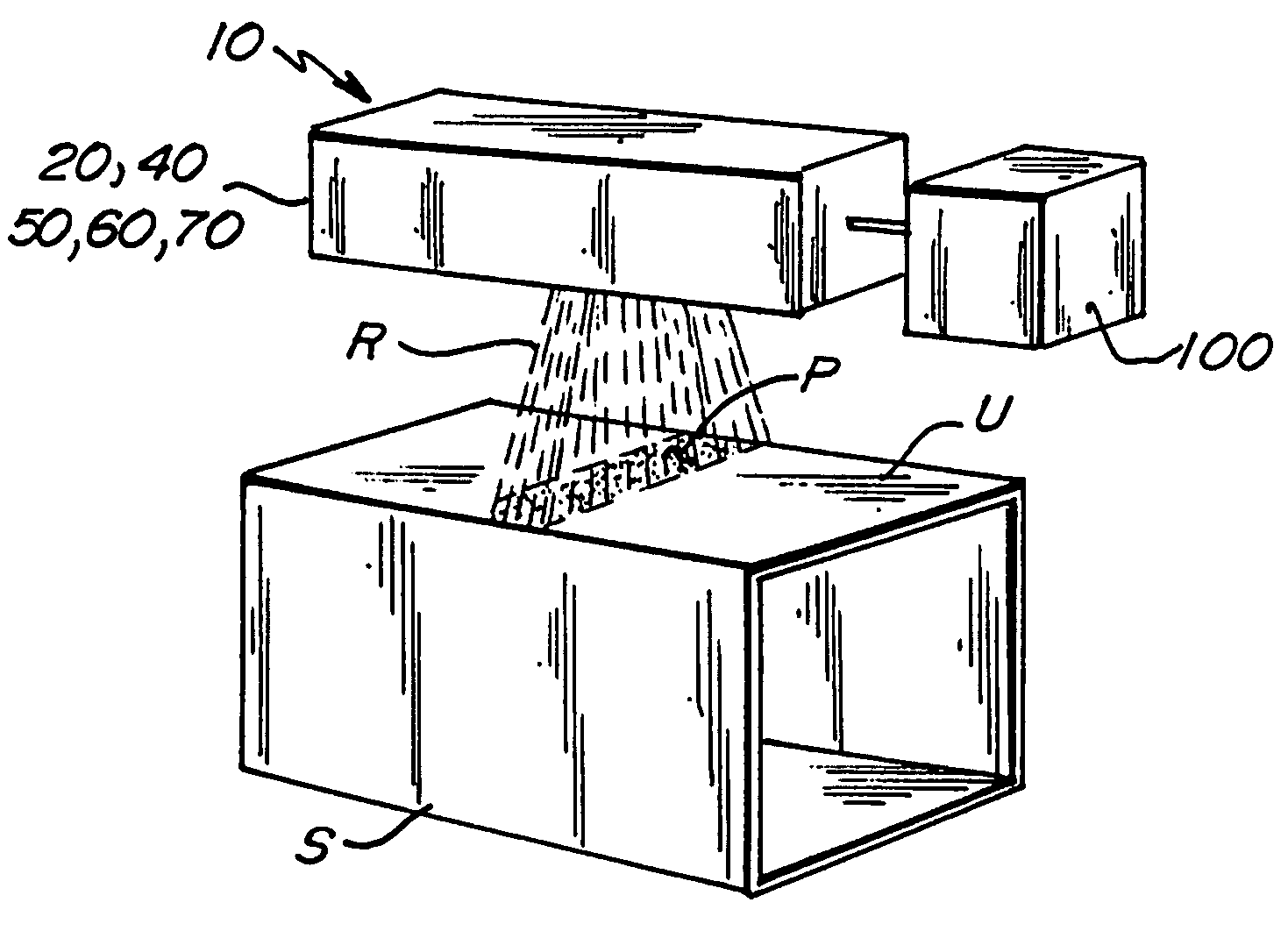

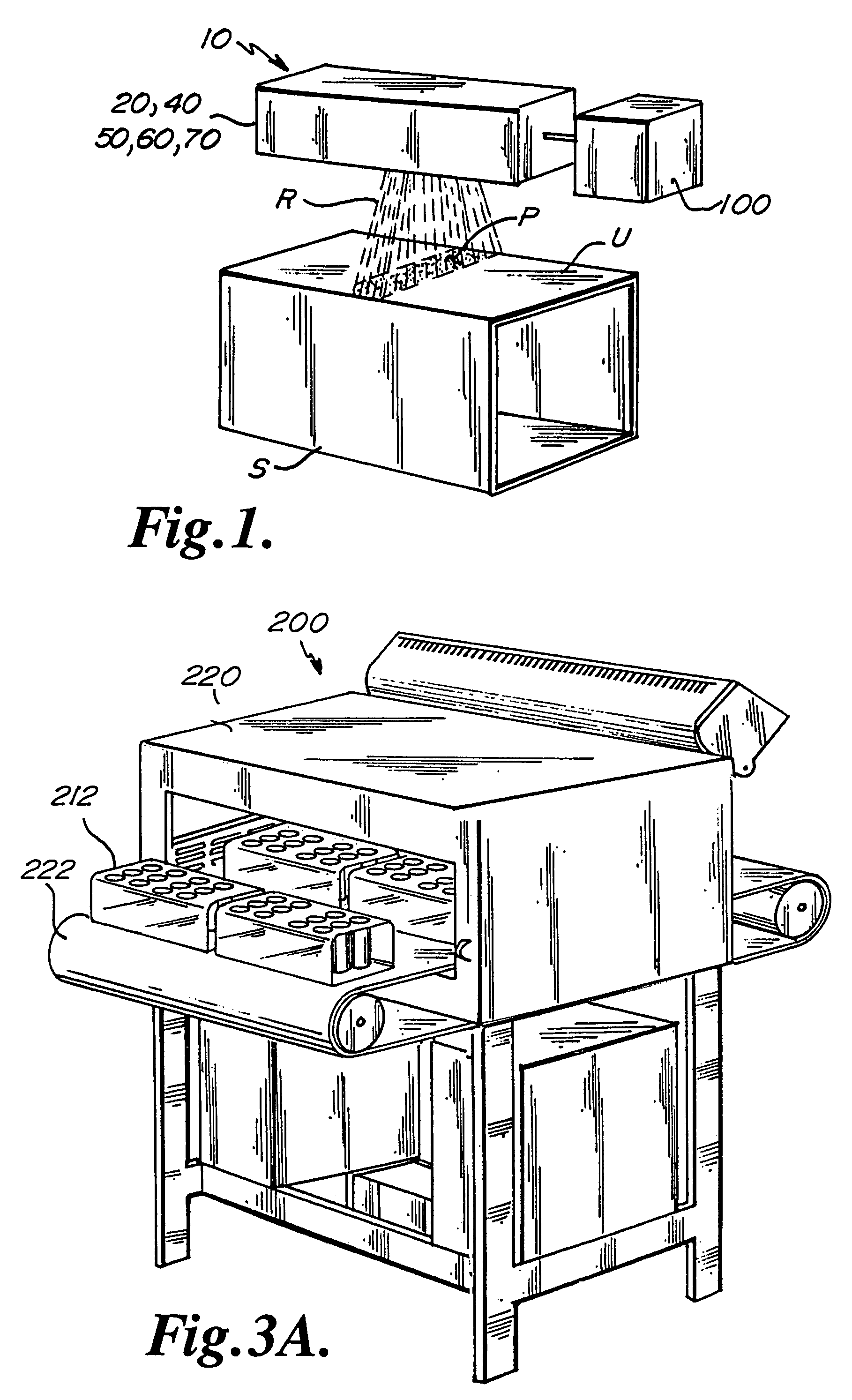

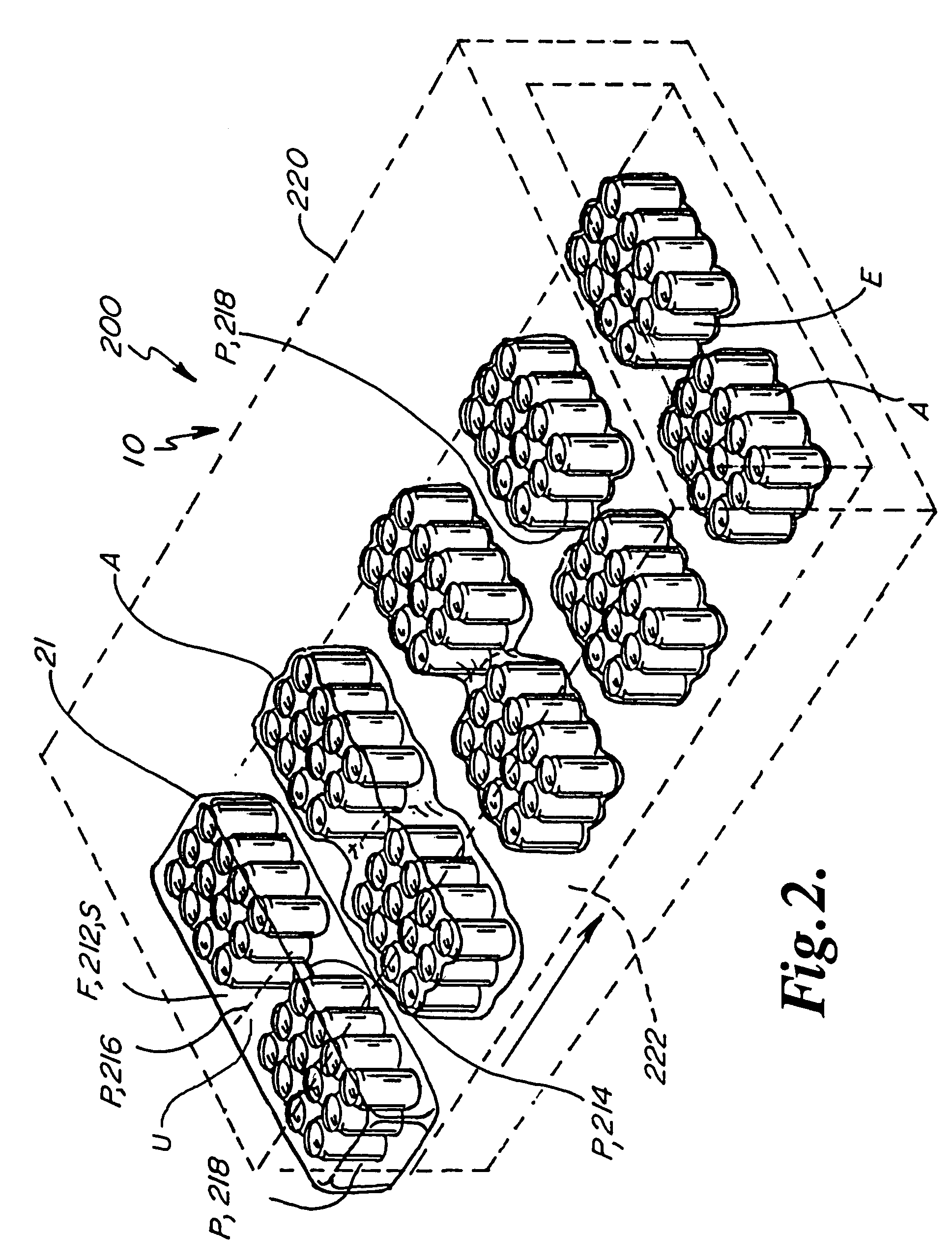

Apparatus and method for selective processing of materials with radiant energy

InactiveUS7823366B2Maximize contactReduce capacityWrappers shrinkageMechanical working/deformationControl systemDna testing

Apparatus selectively processes a substrate using radiant energy. The substrate can consist of any target material having a portion to be processed using the radiant energy and a larger portion to be unprocessed. The apparatus includes a source of radiant energy (preferably a quantum cascade laser) that has a customizable spectrum that can be configured to be specifically absorbed only by the portion to be processed, and a control system for targeting the radiant energy only at the portion to be processed. Specific examples of the use of the apparatus and method are in the technologies of heat-shrinking polyethylene film, fusing toner to paper in a laser printer, heating reaction vessels in DNA testing, and temperature profiling bottle pre-forms.

Owner:DOUGLAS MACHINE LIABILITY

Non-invasive method and system for the treatment of snoring and nasal obstruction

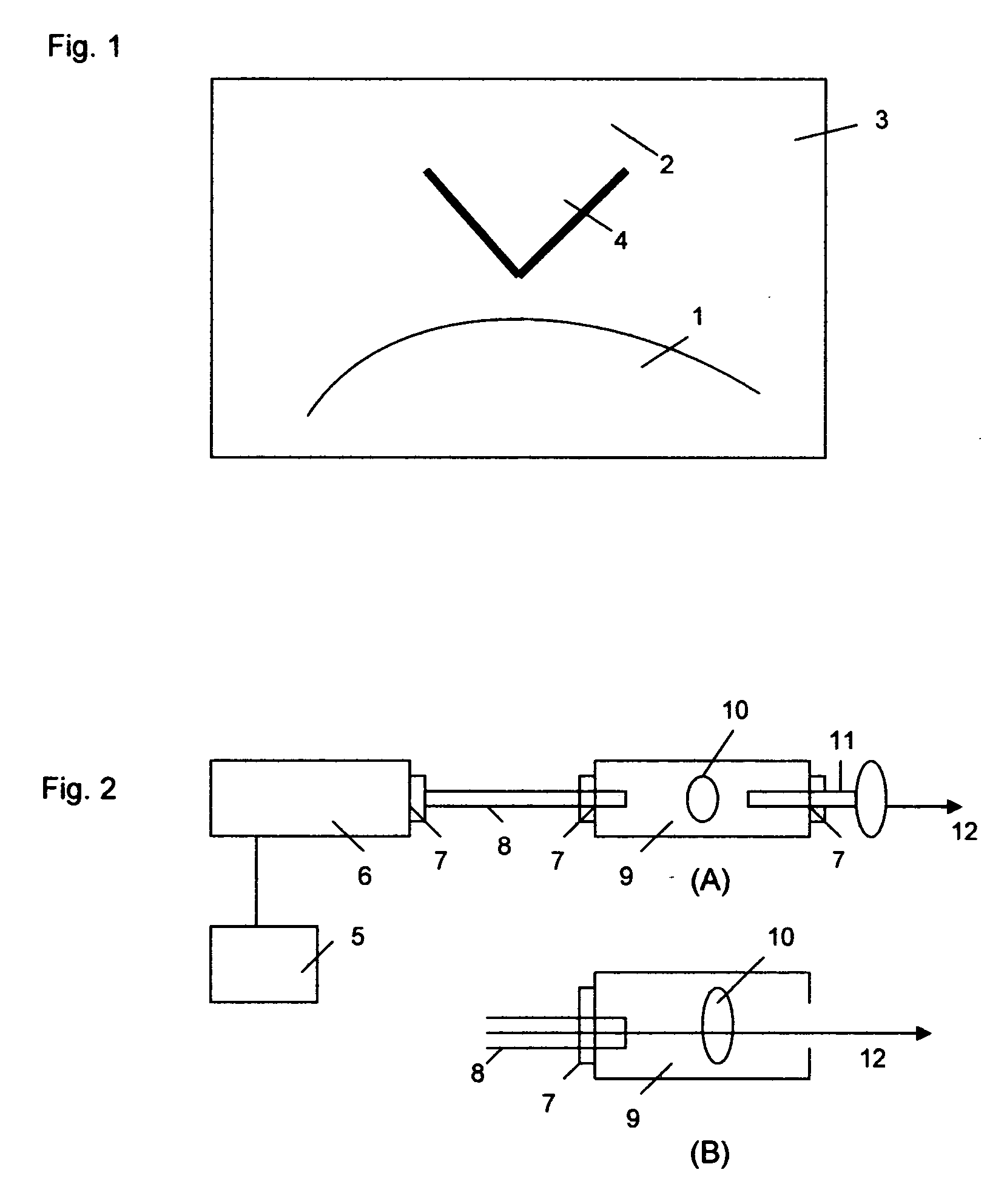

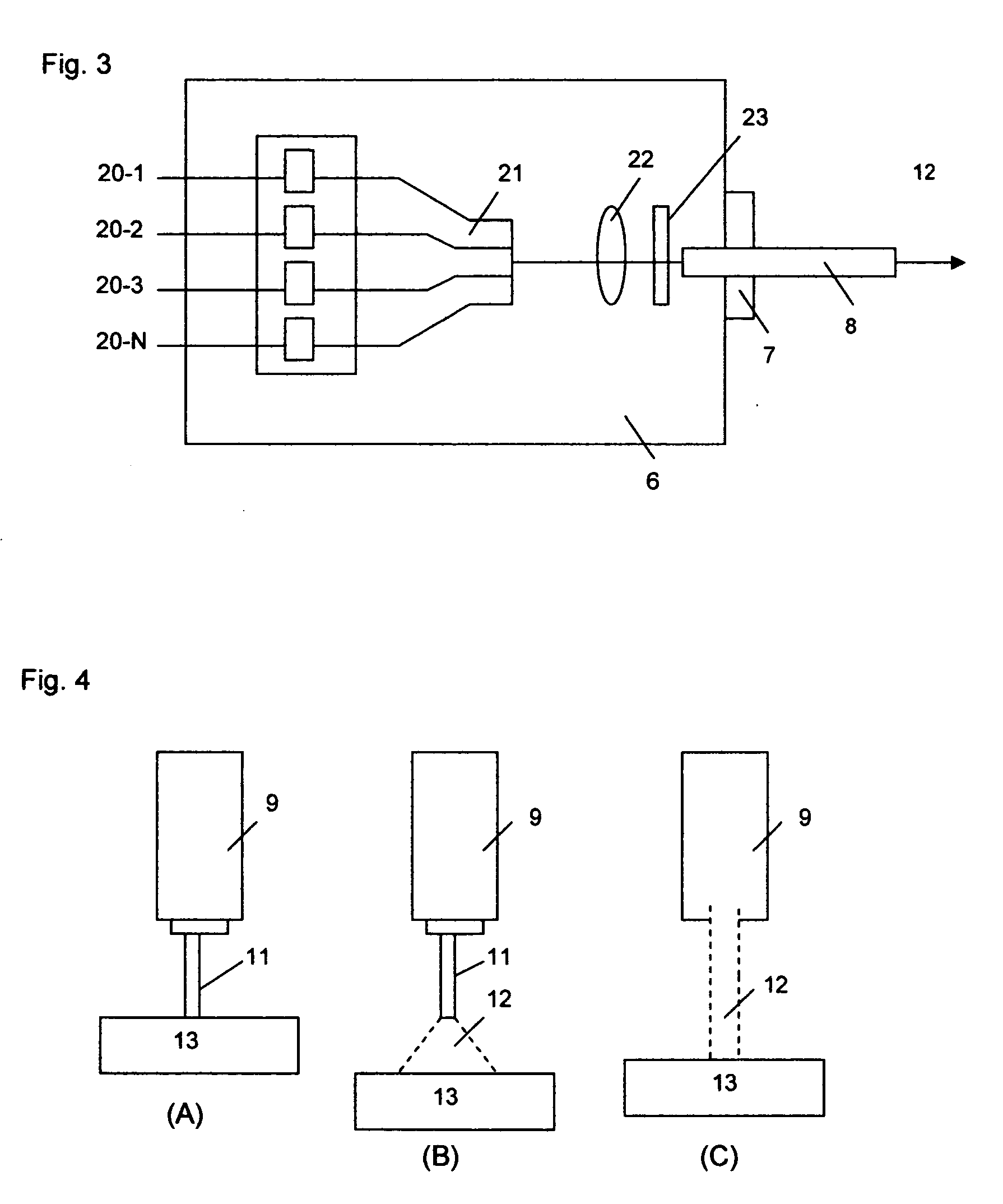

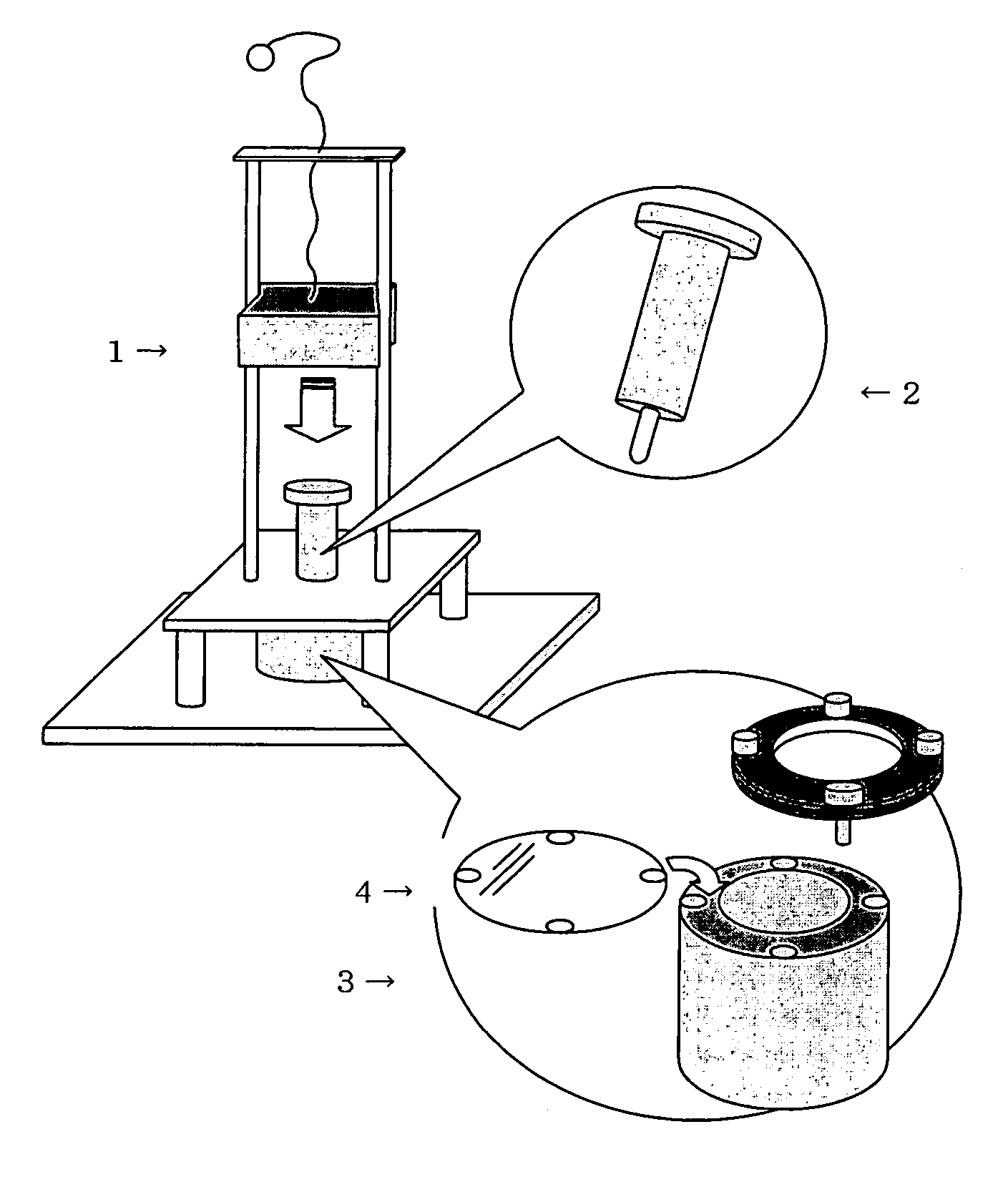

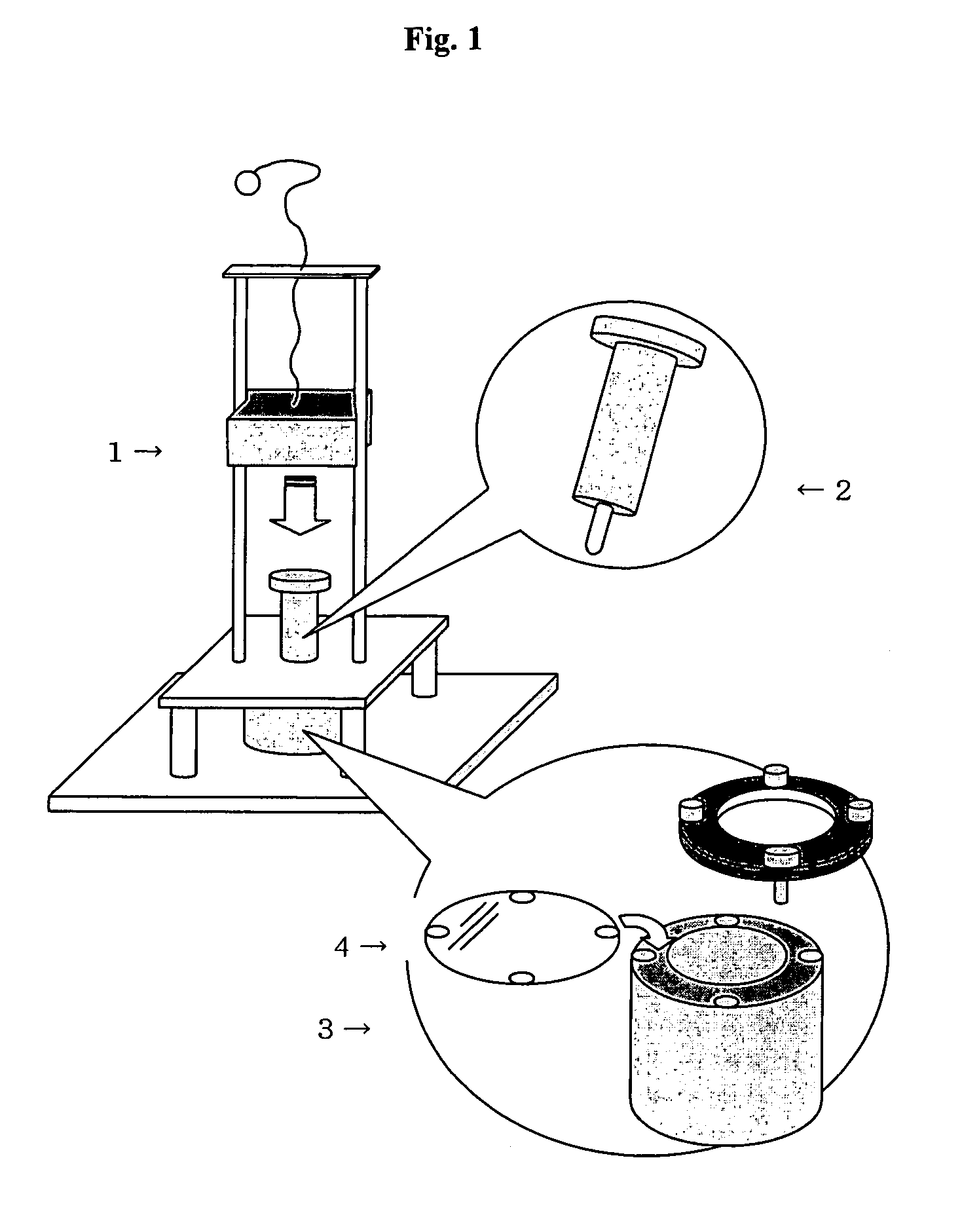

InactiveUS20060276861A1Efficient thermal shrinkage of treated areaSurgical instrument detailsLight therapyHigh power diode laserPalate muscle

Laser for thermal shrinkage of soft tissue of uvula, soft palate, nasal turbinate or tongue base for the treatment of snoring, nasal obstruction or sleep apnea are disclosed. The preferred laser includes infrared laser about 0.7 to 1.85 micron, pulse duration about 100 microsecond to 5 seconds, spot size of about 2 to 5 mm and power of about 2 to 20 W at the treated area. The laser energy is delivered to the treated area by an optical fiber and a hand piece to cause a localized temperature about 65 to 85 degree Celsius for sufficient shrinkage of the treated soft tissues. Optical fiber bundles to produce high-power diode laser output or multi-wavelength are also disclosed.

Owner:NEW VISION

Radiation cross-linked low-smoke halogen-free phosphor-free nanometer flame retardant thermal shrinkage material and method for preparing the same

ActiveCN1803907AImprove flame retardant performanceAvoid secondary disastersFireproof paintsCross-linkPhosphate

The disclosed radiation crosslinking low-fume non-halogen / phosphate nano flame-retardant heat-shrinkable material contains the ethene / vinyl-acetate copolymer, ethene / octene copolymer, polymer solvent, organosilicon polymer, composite antioxidant, nano Mg(OH)2 flame retardant, ultrafine Al(OH)3 Mg(OH)2 with activating-treated surface, lubricant, and lubricant; and can be manufactured by sitrring, extruding, drawing, air cooling, cutting grain, radiating, stretching and cooling form. The product has super flame-retardant effect and affects little to environment or human after abandonment. The preparation method is low cost and fit to industrial production.

Owner:广州凯恒科塑有限公司

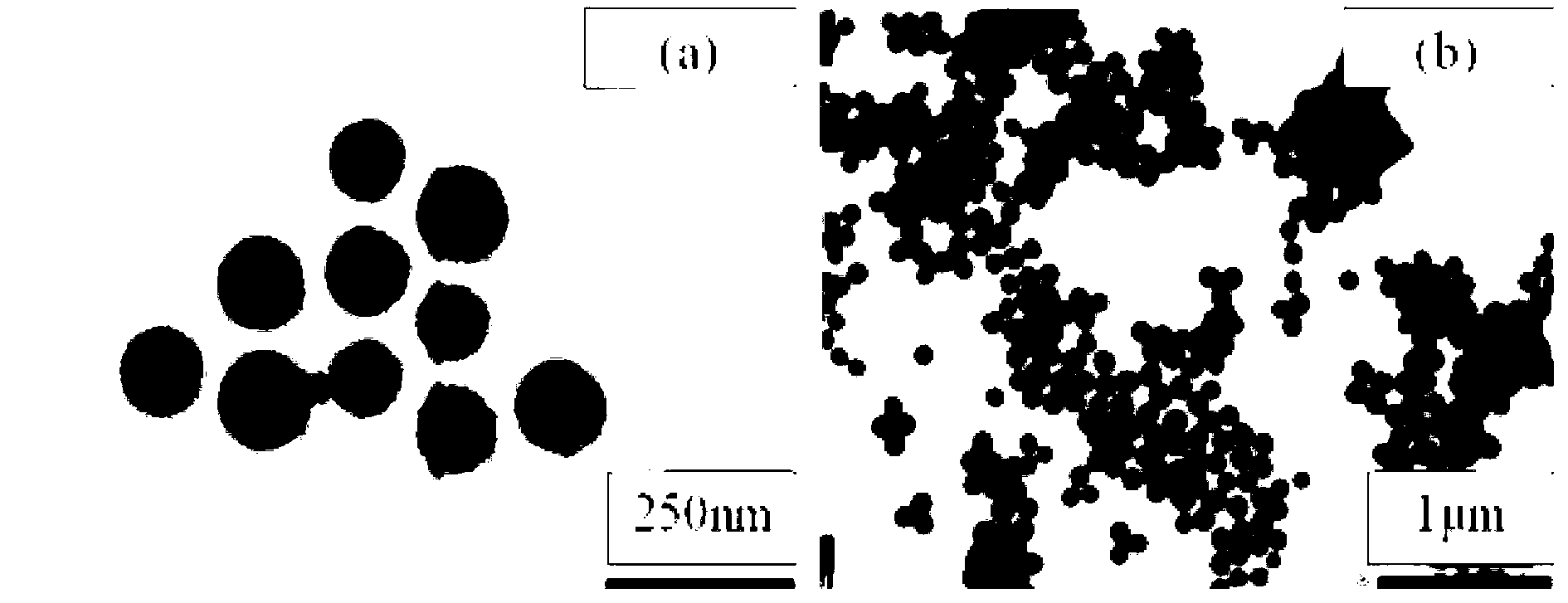

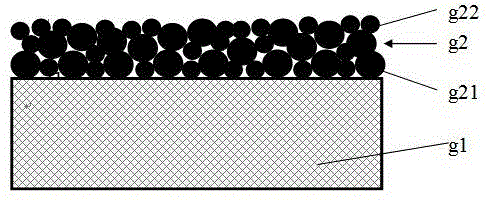

Inorganic/organic composite membrane, preparation method of inorganic/organic composite membrane and lithium ion secondary battery containing membrane

ActiveCN104064707AImprove thermal stabilityHigh strengthSecondary cellsCell component detailsPorous substrateInorganic particle

The invention discloses an inorganic / organic composite membrane which comprises a porous substrate and a porous insulating layer, wherein the porous insulating layer is attached to the porous substrate, and at least one surface of the porous substrate is coated with the porous insulating layer; the porous insulating layer comprises inorganic particles and a binding agent, wherein the inorganic particles are composed of n particles with different average particle diameters, n is large than or equal to 2, and the average particle diameters from the first type of inorganic particles to the nth type of inorganic particles are changed in a gradient manner. The invention further discloses a preparation method of the inorganic / organic composite membrane. The preparation method comprises the following steps: firstly, dissolving the binding agent into a solvent to form a polymer solution, then adding the inorganic particles, mixing to prepare the porous insulating layer, and then coating at least one surface of the porous substrate with the porous insulating layer. The invention further discloses a lithium ion secondary battery containing the membrane. The inorganic / organic composite membrane disclosed by the invention has the advantages of high stacking density, low thermal shrinkage rate, high puncture strength, simple preparation process and proper cost, and the lithium ion secondary battery containing the membrane has the advantages of good conservation rate of circulating volume and excellent safety performance and electrochemical performance.

Owner:东莞市魔方新能源科技有限公司

Heat shrink films and articles encapsulated therein

InactiveUS20090068486A1Synthetic resin layered productsDomestic containersPolymer scienceThin membrane

The present invention relates to a heat shrink film for encapsulating articles comprising a core layer having an upper surface and a lower surface, a first skin layer on the upper surface of the core layer, and a second skin layer underlying the lower surface of the core layer, wherein the core layer comprises a blend of (i) at least one polyterpene and (ii) a syndiotactic polypropylene or a cyclic olefin copolymer, wherein the ultimate shrinkage of the film is at least 25% at 135° C.

Owner:AVERY DENNISON CORP

Method of producing a weld-cut sealing/heat-shrinkable packaging film formed of a polyethylene terephthalate-based block copolymer polyester

A PET-based polyester packaging film capable of weld-cut sealing and heat-shrinkage refers to a film obtained by biaxially orienting a material prepared through block copolymerization of a PET / PETG / polyester elastomer with an epoxy resin and a catalyst. This film eliminates the most serious weak points in physical properties of conventional PET films, and is useful for packaging of books, bottlesets, food containers, etc., for general packaging, packaging of industrial materials, and the like, and is further useful in the field of packing and packaging of daily commodities, civil engineering and construction members, electric and electronic members, and automobile vehicle members, etc. Moreover, this film can be produced through effective use of the huge amount of recycled PET bottles and inexpensive PET for fiber as a prepolymer, and thus is also highly beneficial socially. Still further, even if incinerated after use, this film produces a combustion heat value lower than that of a polyethylene or polypropylene. Thus, this film barely damages incinerators or the like, and emits no toxic gases.

Owner:NAKAMOTO PAKKUSU

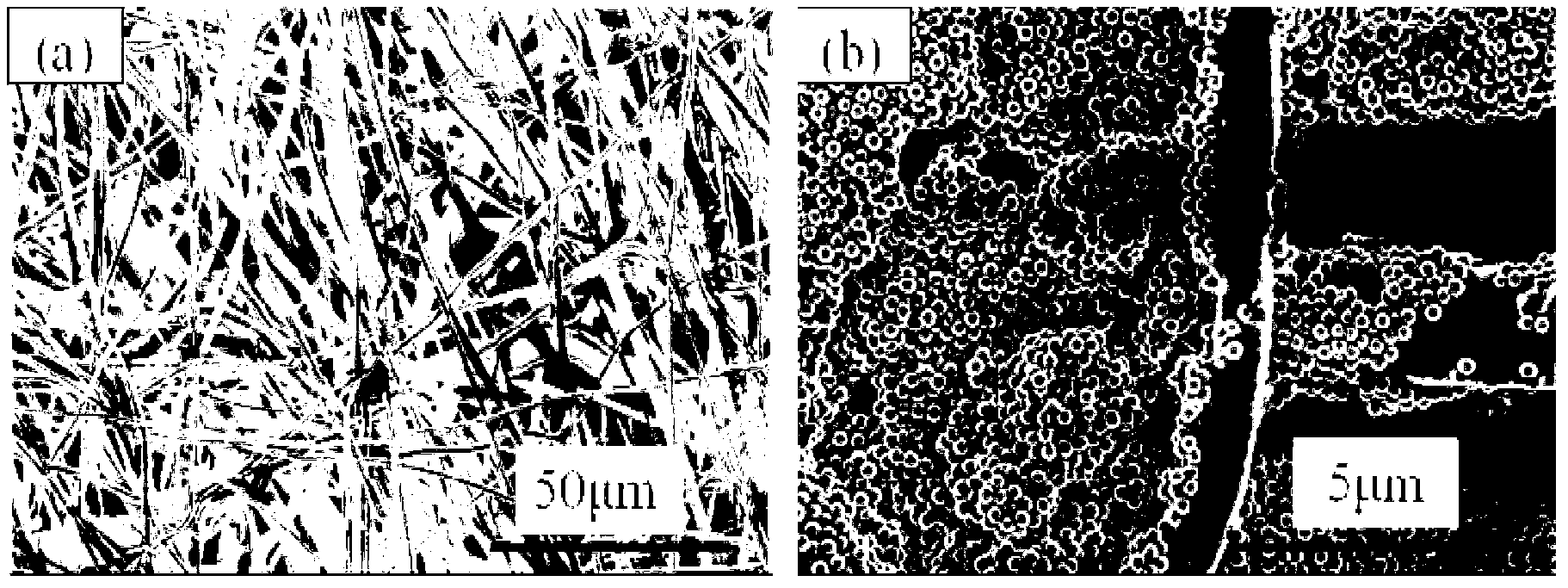

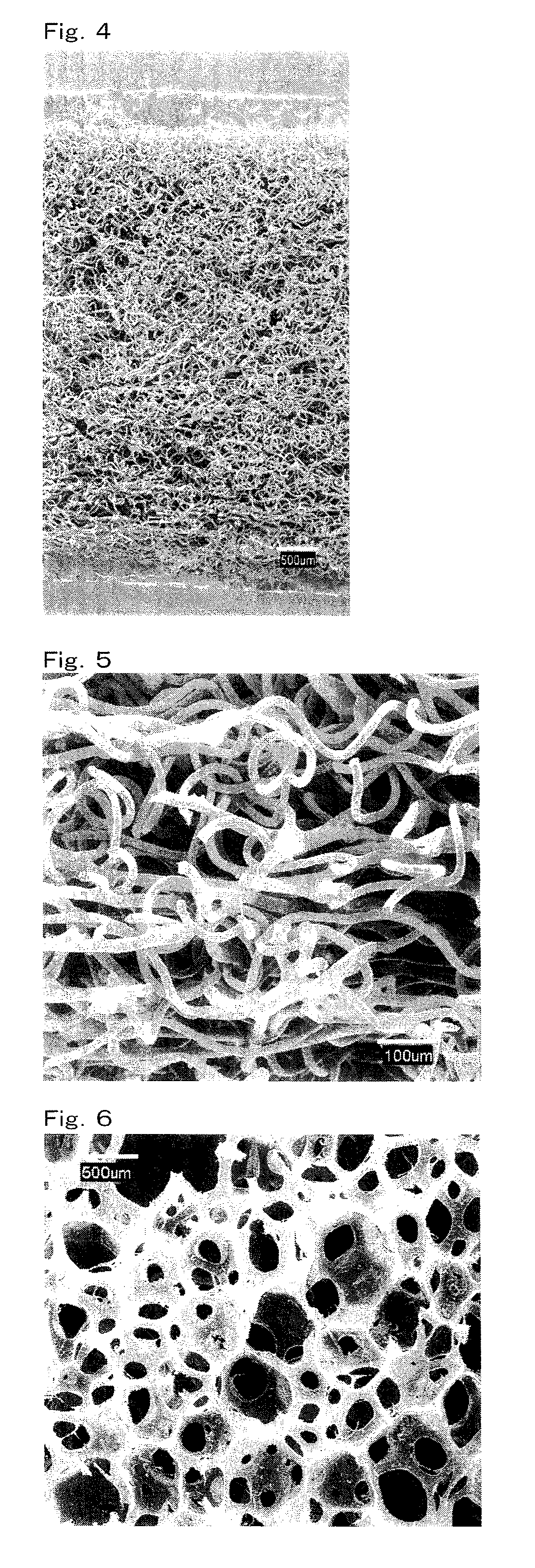

Composite microporous film, and production method and use thereof

ActiveCN1882436AGood adhesionHigh mechanical strengthSemi-permeable membranesFinal product manufactureDebyePolyolefin

Disclosed is a composite microporous film which is obtained by applying a liquid mixture containing (a) a fluororesin which can be gelated, (b) a good solvent therefor and (c) a poor solvent therefor having a dipole moment of not more than 1.8 Debye to at least one surface of a polyolefin microporous film and drying it, thereby forming a coating layer composed of a porous body of the fluororesin on the surface. The composite microporous film has columnar through holes in the coating layer, and has an excellent balance among permeability, adhesion to electrodes, mechanical strength, thermal shrinkage resistance, shutdown characteristics and meltdown characteristics.

Owner:TORAY IND INC

Low-smoke halide-free fireproof polyolefine material and its preparation method and application

A low-smoke and non-halogen poly-olefine material with radiant graft maleic anhydride vinyl-vinyl acetate multi-polymer as compatilizer is prepared by dissolving maleic anhydride 1-5 proportion into acetone, mixing with vinyl-vinyl acetate multi-polymer 100 proportion, volatilizing for acetone, granulating in double-screw extruder, and electronic-ray or gamma-ray radiating by electronic accelerator with 5-30KGy. The compatilizer graft rate is greater than or equal to 1%, it has better poly-olefine material performance, more white fire retardant and no need for anti-smoke agent. It can be used to make poly-olefine thermal shrinkage pipe with VW-1 vertical burning performance according to UL224 standard.

Owner:上海世龙科技有限公司

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

Laminated polyester film and laminated film

InactiveUS7022388B2Sufficient shock resistance and transparencyImprove adhesionWrappers shrinkageRecord information storagePolyesterRefractive index

There is provided a laminated polyester film which is improved in lubricity, transparency, dimensional stability, shock resistance and adhesion, and which comprises a polyester base film comprising polyester and to at least one direction, and a coating layer provided on at least one surface of the base film, wherein said coating layer contains polymer binder and inert particles, the refractive index of the inert particles being substantially same as that of the polymer binder, and wherein the laminated polyester film has a haze of 1.5% or less, a total light transmittance of 85% or more, 50% destructing energy per 100 μm film thickness of 0.3 J or more, and a thermal shrinkage at 230° C. for 30 minutes of 4% or less.

Owner:TEIJIN DUPONT FILMS JAPAN

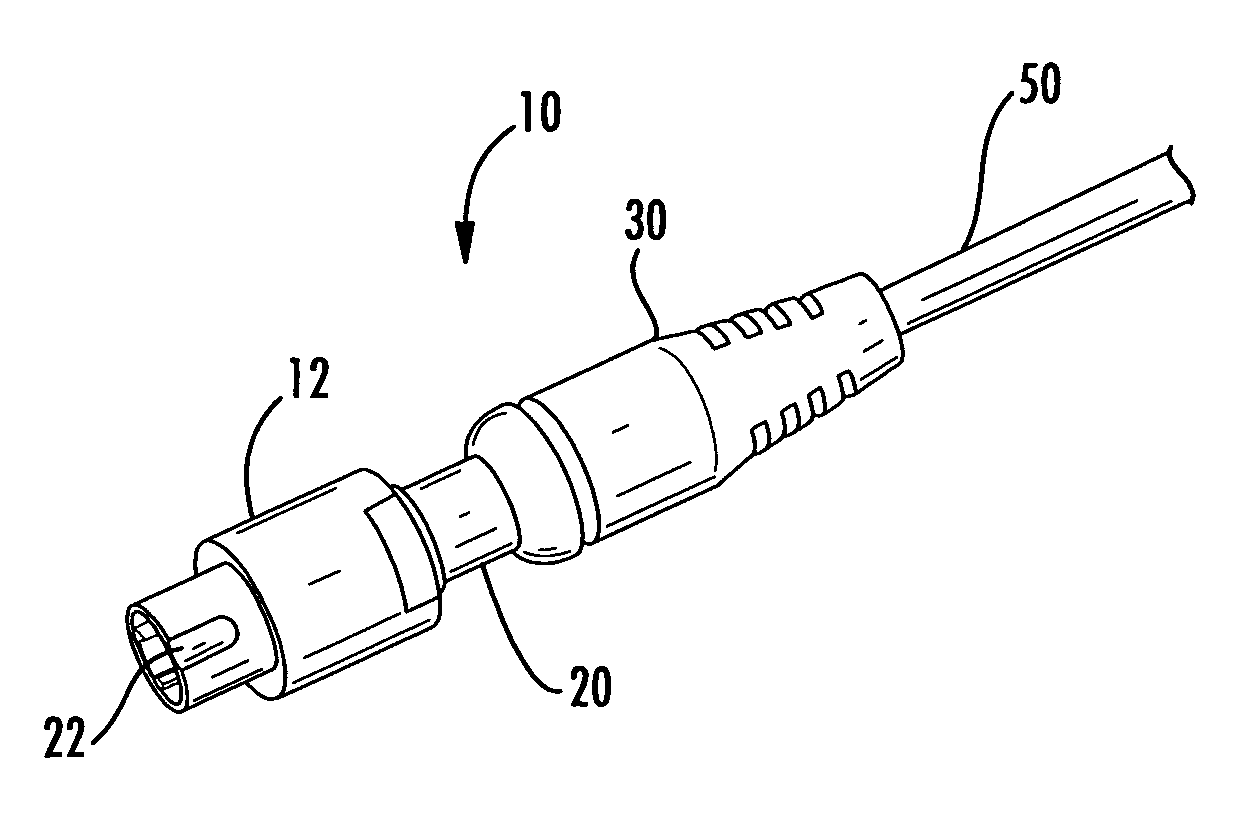

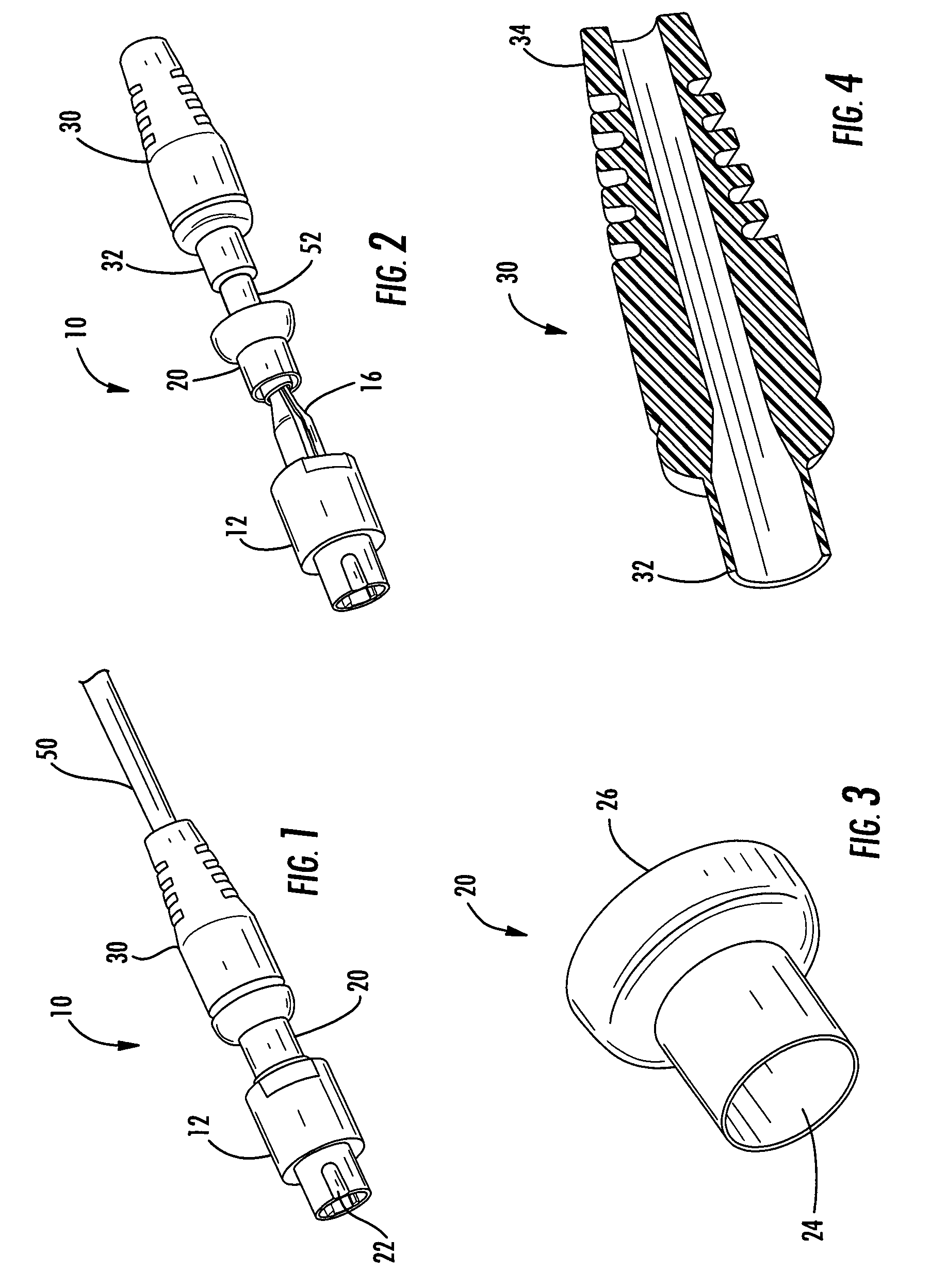

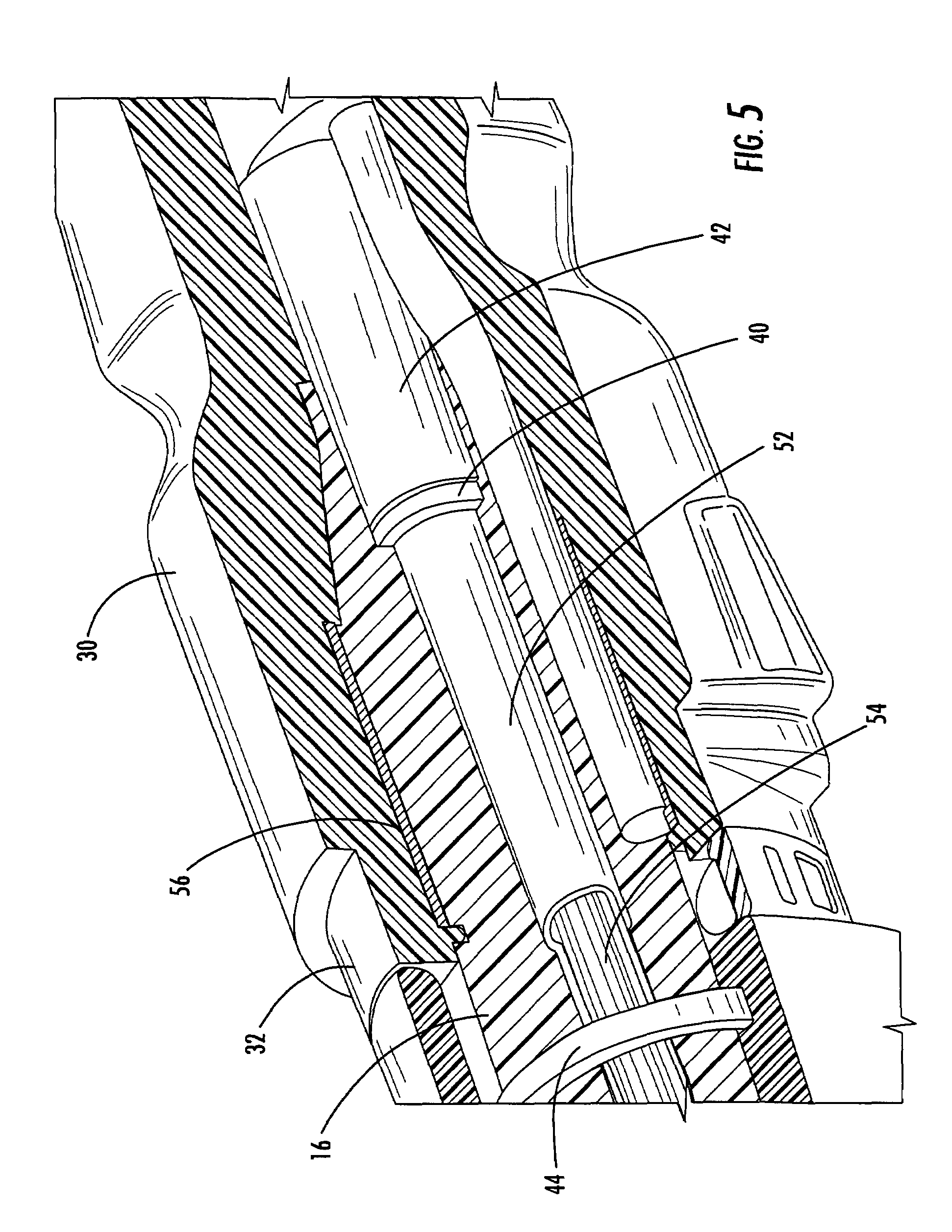

Fiber optic plug assembly with boot and crimp band

A fiber optic plug assembly of a fiber optic connector assembly is provided and generally includes a fiber optic plug mounted upon an end of a fiber optic cable; a pre-molded boot placed over the fiber optic plug and the fiber optic cable; and a crimp band mated over the pre-molded boot to secure the boot to the fiber optic cable; wherein the fiber optic plug assembly is operable to mate to a fiber optic receptacle. The plug assembly eliminates the need for an overmolded boot. Further, the present invention eliminates the need to perform a heat shrink between the buffer tube and crimp body through the internal O-ring. The plug assembly meets the standards of GR-3120-CORE while at the same time providing a simpler hardware package that can be assembled with ordinary connectorization tools.

Owner:CORNING OPTICAL COMM LLC

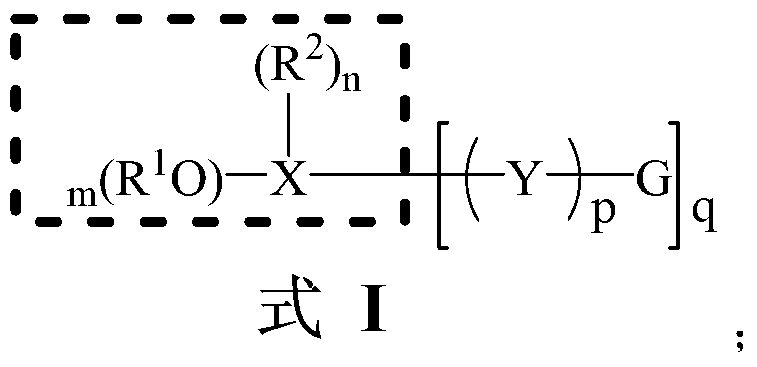

Block copolymer, composition thereof, and film made thereof

InactiveUS6841261B2Favorable spontaneous shrinkage resistanceLow temperature shrinkabilitySynthetic resin layered productsDomestic articlesDynamic viscoelasticityAromatic hydrocarbon

It is to provide a block copolymer and its copolymer composition which provides a heat shrinkable (multilayer) film with less spontaneous shrinkage while maintaining favorable low temperature shrinkability, and a heat shrinkable (multilayer) film containing the block copolymer. By using a block copolymer comprising a vinyl aromatic hydrocarbon and a conjugated diene characterized in that the relation of the loss tangent value obtained by dynamic viscoelasticity measurement with the temperature satisfies specific conditions, or a composition containing the copolymer composition as an essential component, a heat shrinkable (multilayer) film with less spontaneous shrinkability and less odor while maintaining favorable low temperature shrinkability can be obtained.

Owner:DENKA CO LTD

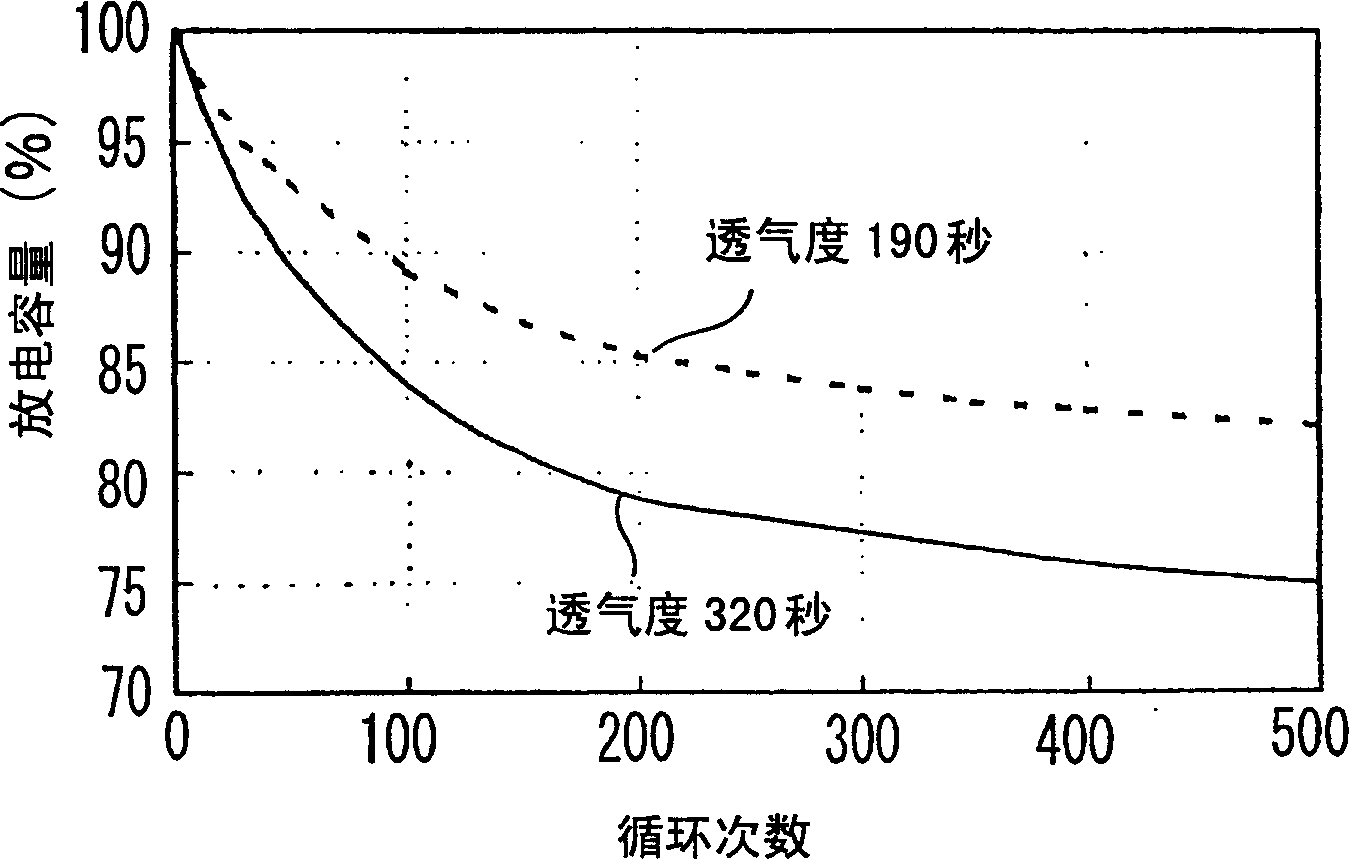

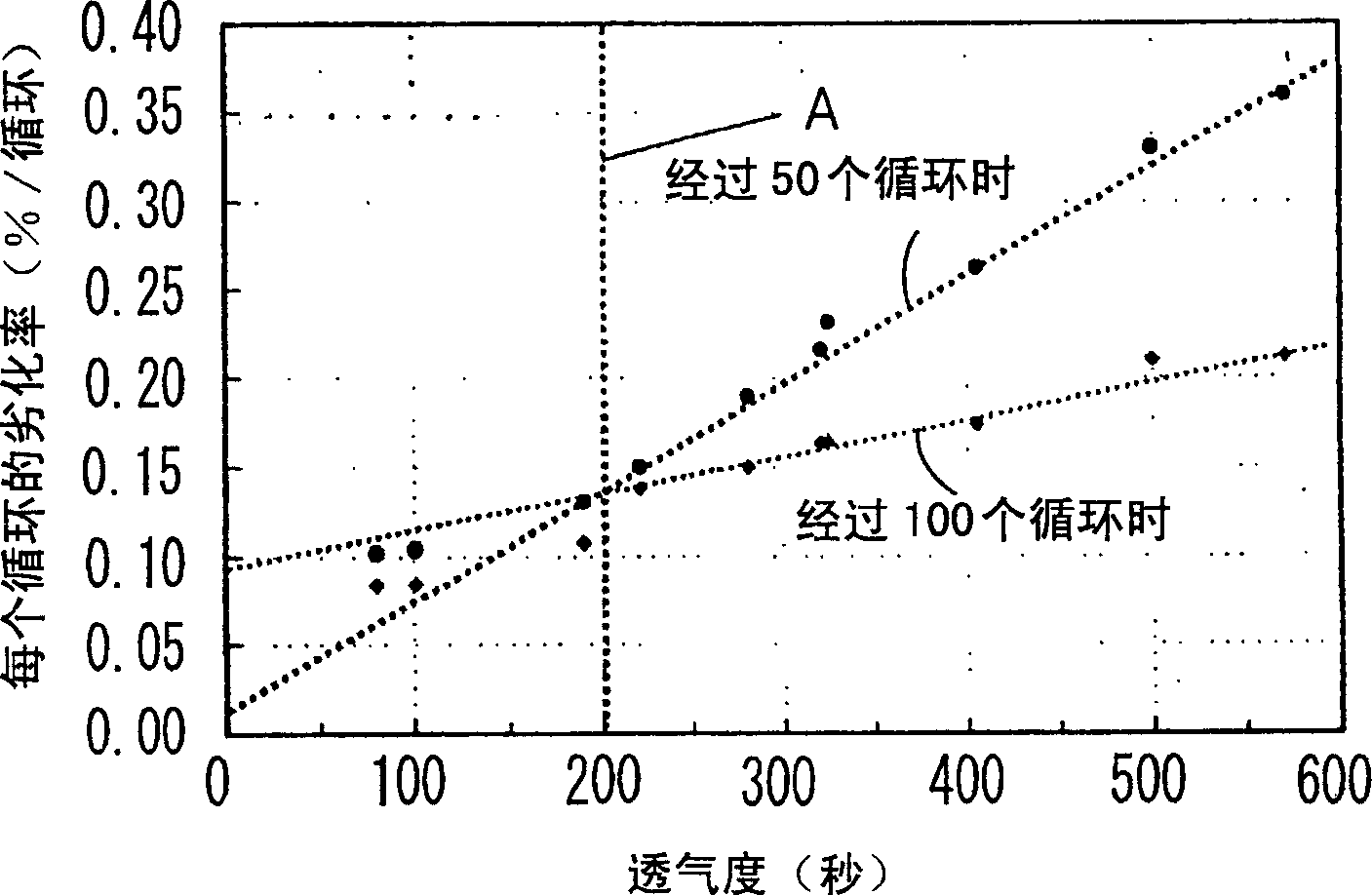

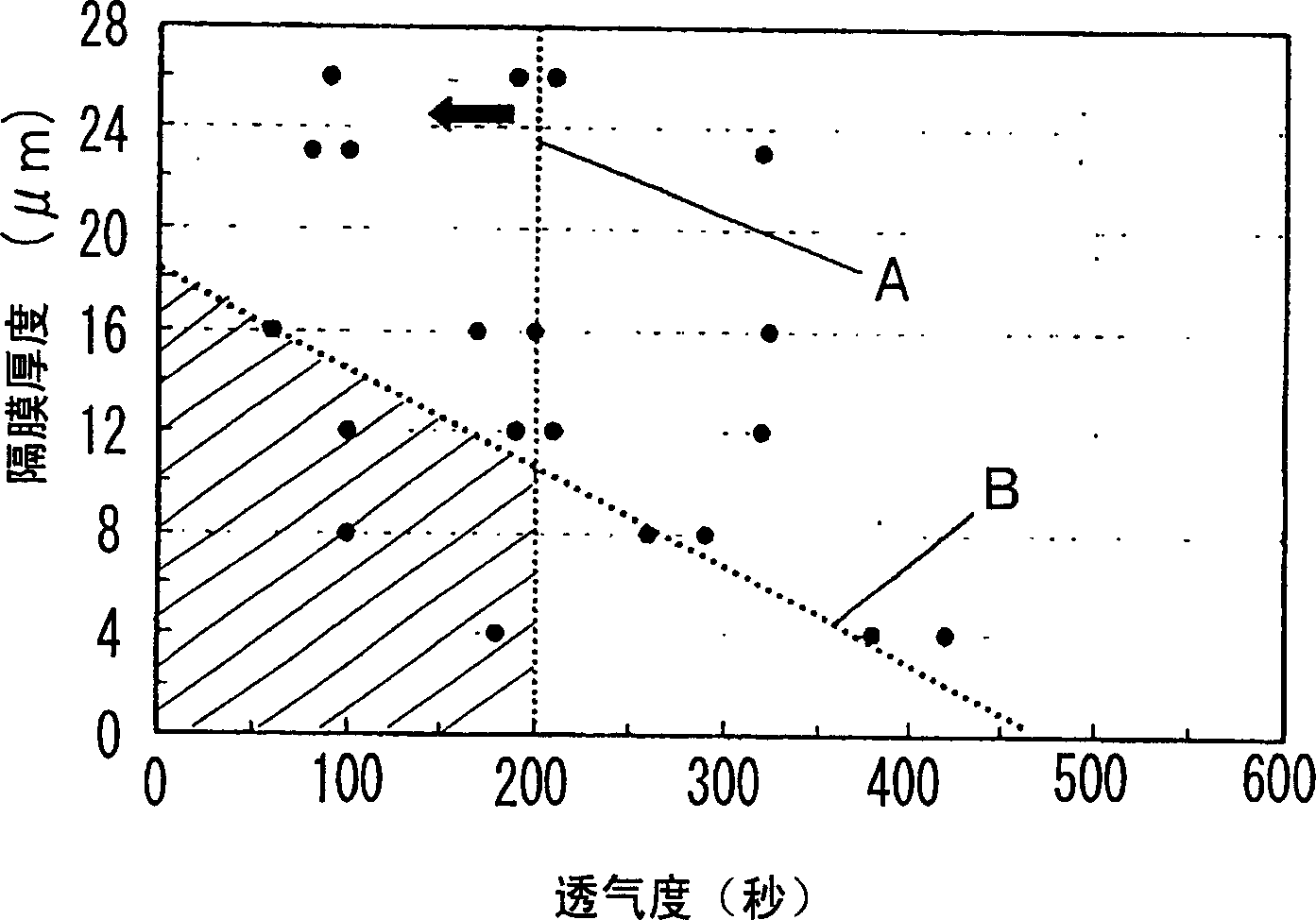

Separator for non-aqueous electrolyte battery and non-aqueous electrolyte battery

InactiveCN1725524ASmall thermal shrinkageImprove heat resistanceElectrode manufacturing processesCell seperators/membranes/diaphragms/spacersPolyolefinHeat resistance

The present invention provides a membrane that is used in non aqueous electrolyte batteries. And the present invention is characterized in that the membrane is formed by a micro-porous membrane that consists of a polyolefin layer and a heat-resistant layer, which overlap on each other. The heat-resistant layer is 1 Mu m to 4 Mu m thick and is formed by polyamide, polyimide, or polyamide imide, the melting point of which is above 180 DEG C. The air permeability of the membrane is less than 200 seconds. And the present invention can be used for preparing the membrane, which is used in non aqueous electrolyte batteries and has small thermal shrinkage, excellent heat resistance and excellent cycling characteristics, and also the non aqueous electrolyte batteries that adopt the membrane.

Owner:SANYO ELECTRIC CO LTD

Material used for halogen-free flame retardant heat shrinkable sheathing and cross-linking cable wire and preparation method thereof

The invention relates to a material used for a halogen-free, flame retardant and thermal shrinkage sleeve and crosslinked wires and cables as well as the preparation method, aiming to provide a material and the preparation preparation method for halogen-free, flame retardant and thermal shrinkage sleeve and crosslinked wires and cables in diversified colors. The preparation method comprises the following steps: first, evenly mixing the compound formed by polyolefin copolymer, silicon rubber, halogen-free ammonium polyphosphate composite fire retardant, lubricant, colorant color master batch and antioxidant in specific proportions through a high speed mixer, then extruding and granulating the compound by means of the mechanical blending, finally turning out the material for producing the halogen-free flame retardant and thermal shrinkage sleeve and crosslinked wires and cables.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com