Inorganic/organic composite membrane, preparation method of inorganic/organic composite membrane and lithium ion secondary battery containing membrane

An inorganic composite and separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of small compactness, small surface roughness, insufficient bulk density of the separator, poor heat resistance of the separator, etc., to improve safety and stability. , The effect of preventing fire accidents and reducing the resistance of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation methods of the positive electrode sheet, the negative electrode sheet and the lithium ion secondary battery are the same as those of Comparative Example 1.

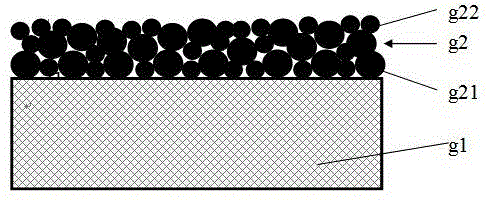

[0052] Such as figure 1 As shown, the porous substrate g1 of the organic / inorganic composite diaphragm is coated with a layer of porous insulation g2, and the inorganic particles in the porous insulation layer g2 include two different particle sizes of the first type of inorganic particles g21 and the second type of inorganic particles g22 , The binder adheres to the surface of the inorganic particles after mixing with the inorganic particles, which is not shown in the figure.

[0053] Preparation of diaphragm:

[0054] (1) Preparation of porous insulating layer g2

[0055] Add 15wt% polyacrylate emulsion (40% in the aqueous solution) to deionized water, stir for 1h, and then add 40% of the first Al 2 O 3 Particles (average particle size of 0.3μm, particle size distribution of 0.05~2.0μm) and 45wt% of the ...

Embodiment 2

[0059] The preparation methods of the positive electrode sheet, the negative electrode sheet and the lithium ion secondary battery are the same as those of Comparative Example 1.

[0060] Preparation of diaphragm:

[0061] (1) Preparation of porous insulating layer g2

[0062] Add 15wt% polyacrylate emulsion (40% in aqueous solution) to deionized water, stir for 1h, and then add 25% of the first Al 2 O 3 Inorganic particles (the average particle size is 0.3μm, and the particle size distribution range is 0.08~2μm), 30% of the second type Al 2 O 3 Inorganic particles (average particle size of 0.6μm, particle size distribution range of 0.1~3.0μm) and 30wt% of the third type Al 2 O 3 The particles (average particle size of 1.0μm, particle size distribution range of 0.1~4.5μm) were stirred for 2h and then ground in a ball mill for 1h to prepare a slurry with a solid content of 40%.

[0063] (2) Coating a porous insulating layer g2 on the surface of the porous substrate g1

[0064] Take a pol...

Embodiment 3

[0066] (1) Preparation of porous insulating layer g2

[0067] Add 3wt% of polyvinylidene fluoride to N-methylpyrrolidone and stir at 45℃ for 1h, then add 40% of the first TiO 2 Particles (the average particle size is 0.25μm, the particle size distribution range is 0.08~1.8μm), 30% of the second type TiO 2 Particles (average particle size of 0.7μm, particle size distribution range of 0.1~3.5μm) and 27wt% third type TiO 2 The particles (the average particle size is 1.2μm, the particle size distribution range is 0.1~5μm) are stirred for 2h and then ground in a ball mill for 1h to prepare a slurry with a solid content of 65%.

[0068] (2) Coating a porous insulating layer g2 on the surface of the porous substrate g1

[0069] Take a polypropylene microporous film with a thickness of 12μm as the porous substrate g1, and then use gravure coating to uniformly cover the prepared slurry on one surface of the porous substrate g1 with a coating thickness of 2μm, and then divide the pole pieces in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com