Patents

Literature

6600results about How to "Avoid short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

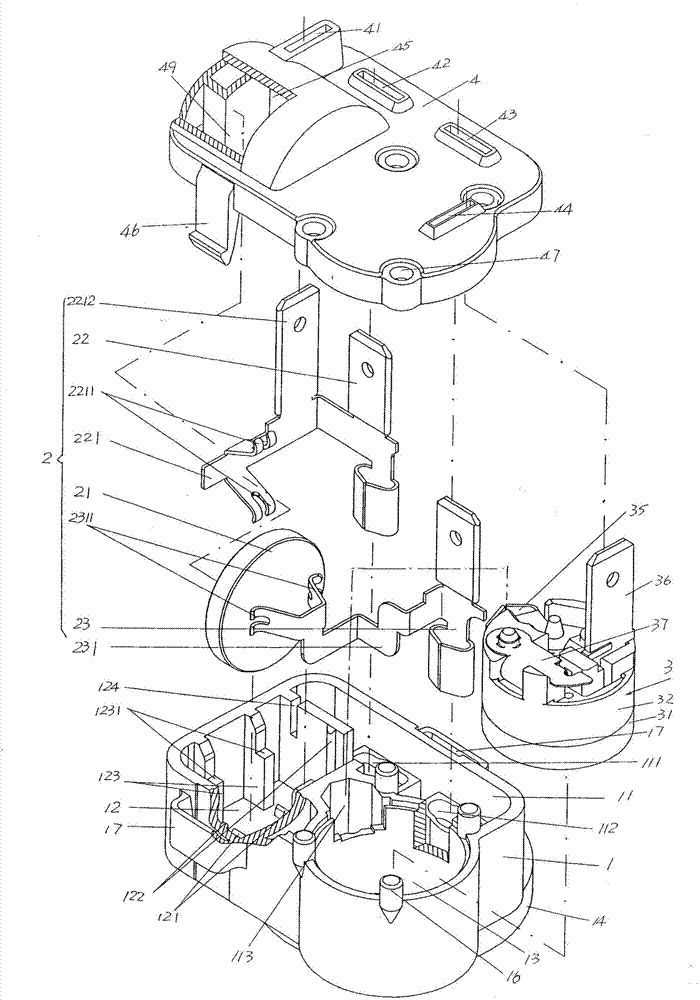

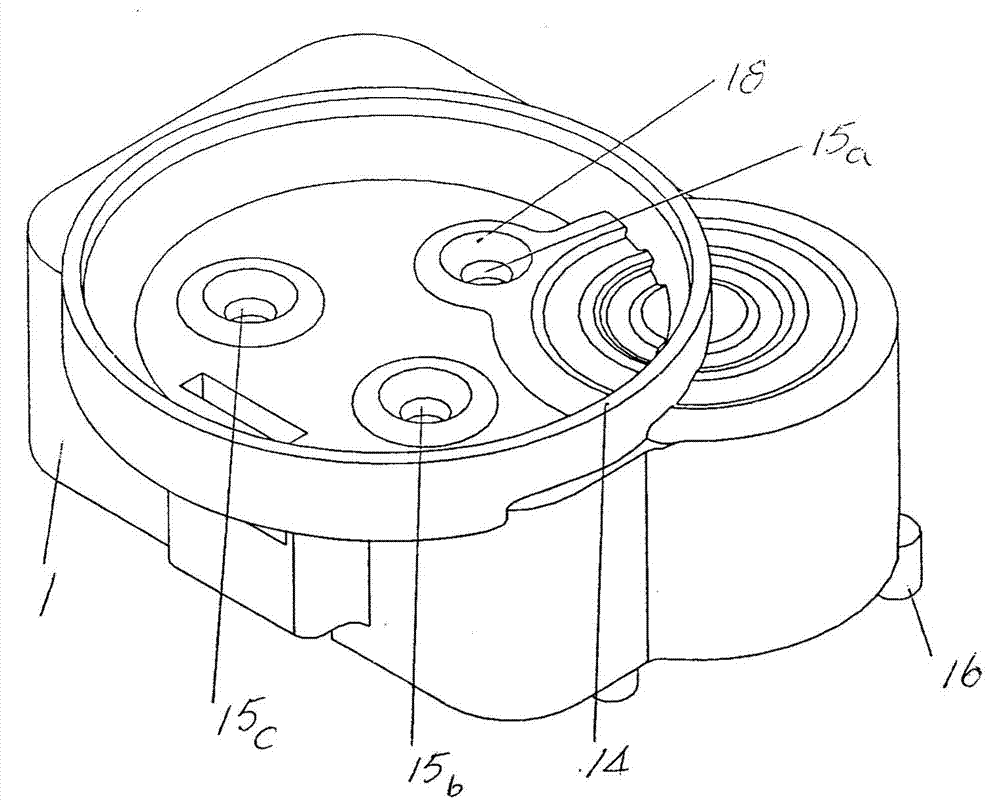

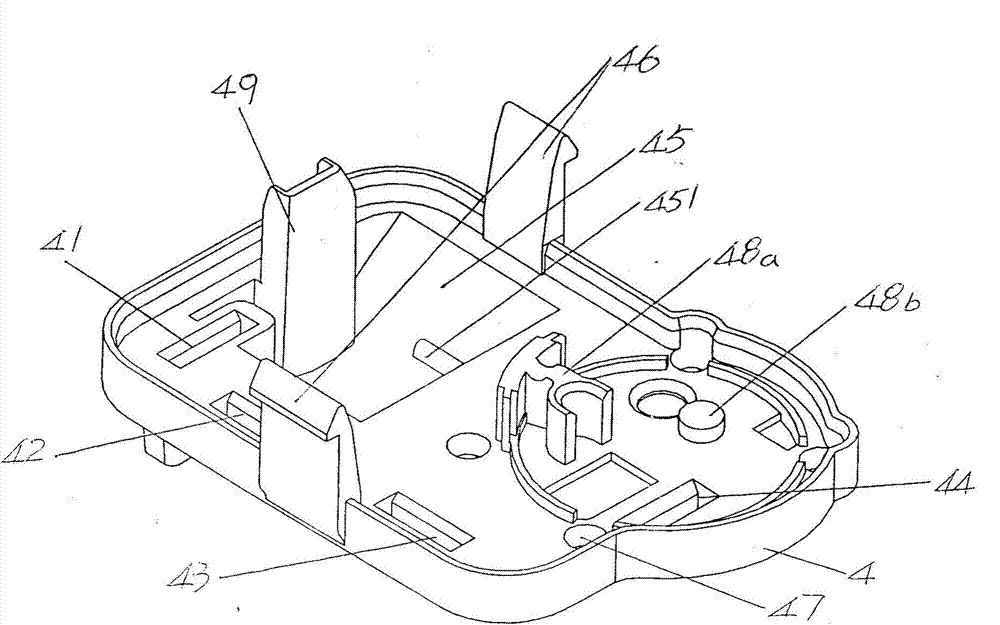

Power-dissipation-free and energy-saving type start protector of single phase AC motor

InactiveCN104734570AReduce volumeSmall footprintSingle-phase induction motor startersEmergency protective circuit arrangementsRefrigeration compressorEngineering

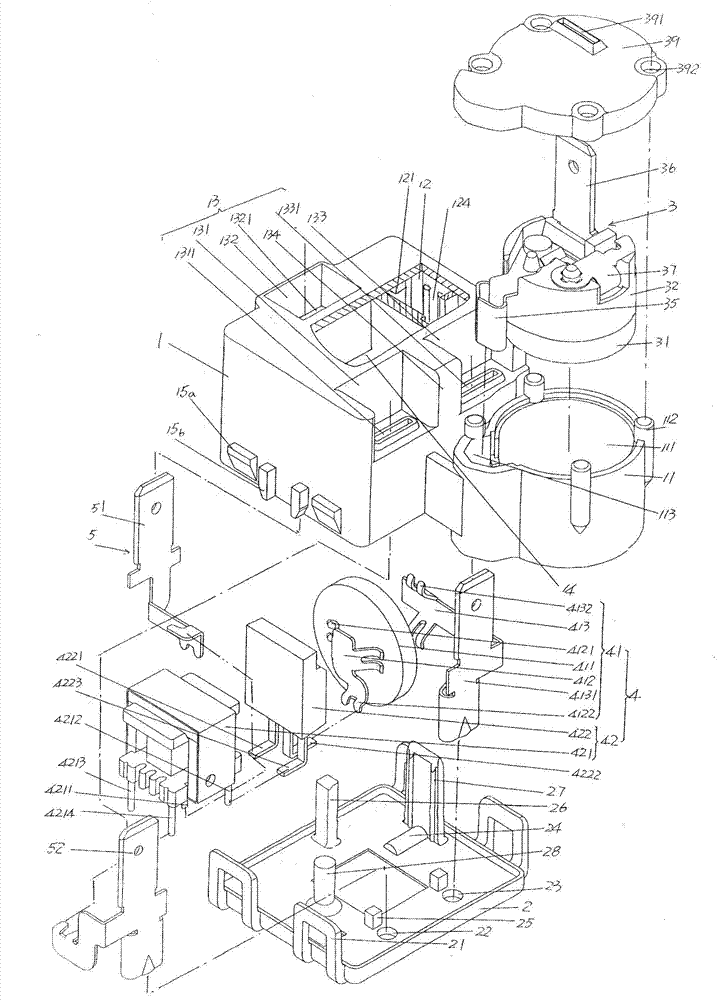

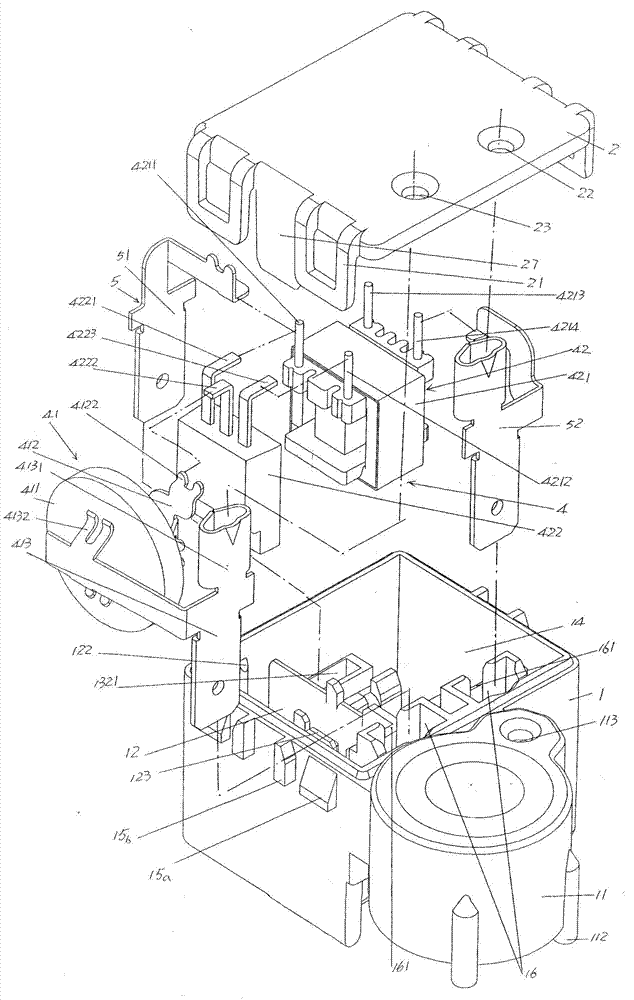

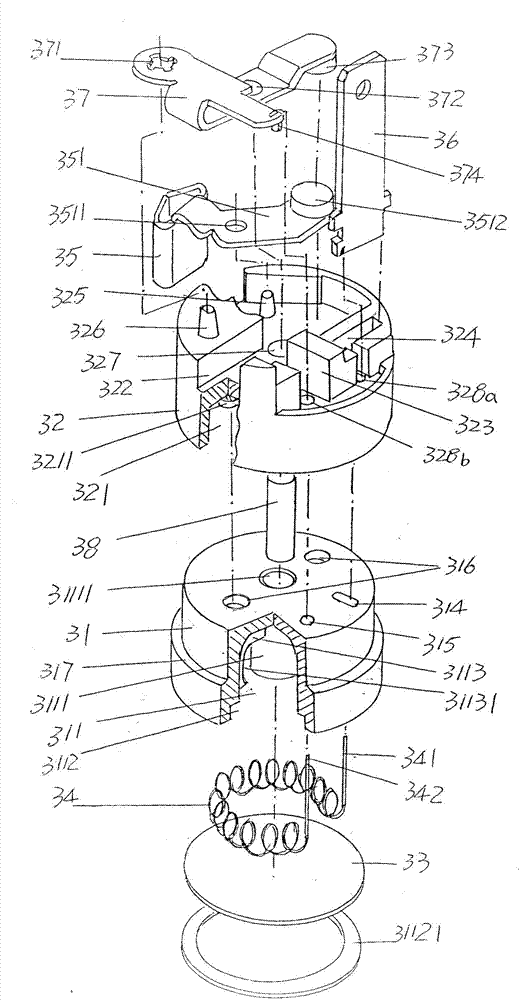

The invention provides a power-dissipation-free and energy-saving type start protector of a single phase AC motor and belongs to the technical field of refrigeration compressors. The power-dissipation-free and energy-saving type start protector comprises a shell, a shell cover, an overload protector, a power-dissipation-free starter and an external terminal mechanism. The shell is provided with an overload protector seat, a power-dissipation-free starter accommodation cavity, an external terminal mechanism cavity and a start controller accommodation cavity. The shell cover is provided with a first three-terminal jack and a second three-terminal jack. The overload protector is arranged in an overload protector accommodation cavity. The power-dissipation-free starter comprises a power-dissipation-free starter body and a start controller. The external terminal mechanism is matched with the external terminal mechanism cavity. The start protector is characterized in that the external terminal mechanism cavity comprises a first insertion cavity, a second insertion cavity and a third insertion cavity, the second insertion cavity is formed in the left side of the shell, and the bottom wall of the second insertion cavity is provided with a second shell insertion groove; the first insertion cavity and the third insertion cavity are formed in the right side of the shell, a first shell insertion groove is formed in the bottom wall of the first insertion cavity, and a third shell insertion groove is formed in the bottom wall of the third insertion cavity; the external terminal mechanism comprises a first insertion piece and a second insertion piece, the first insertion piece is matched with the second shell insertion groove in an inserted mode, and the second insertion piece is matched with the first shell insertion groove in an inserted mode.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

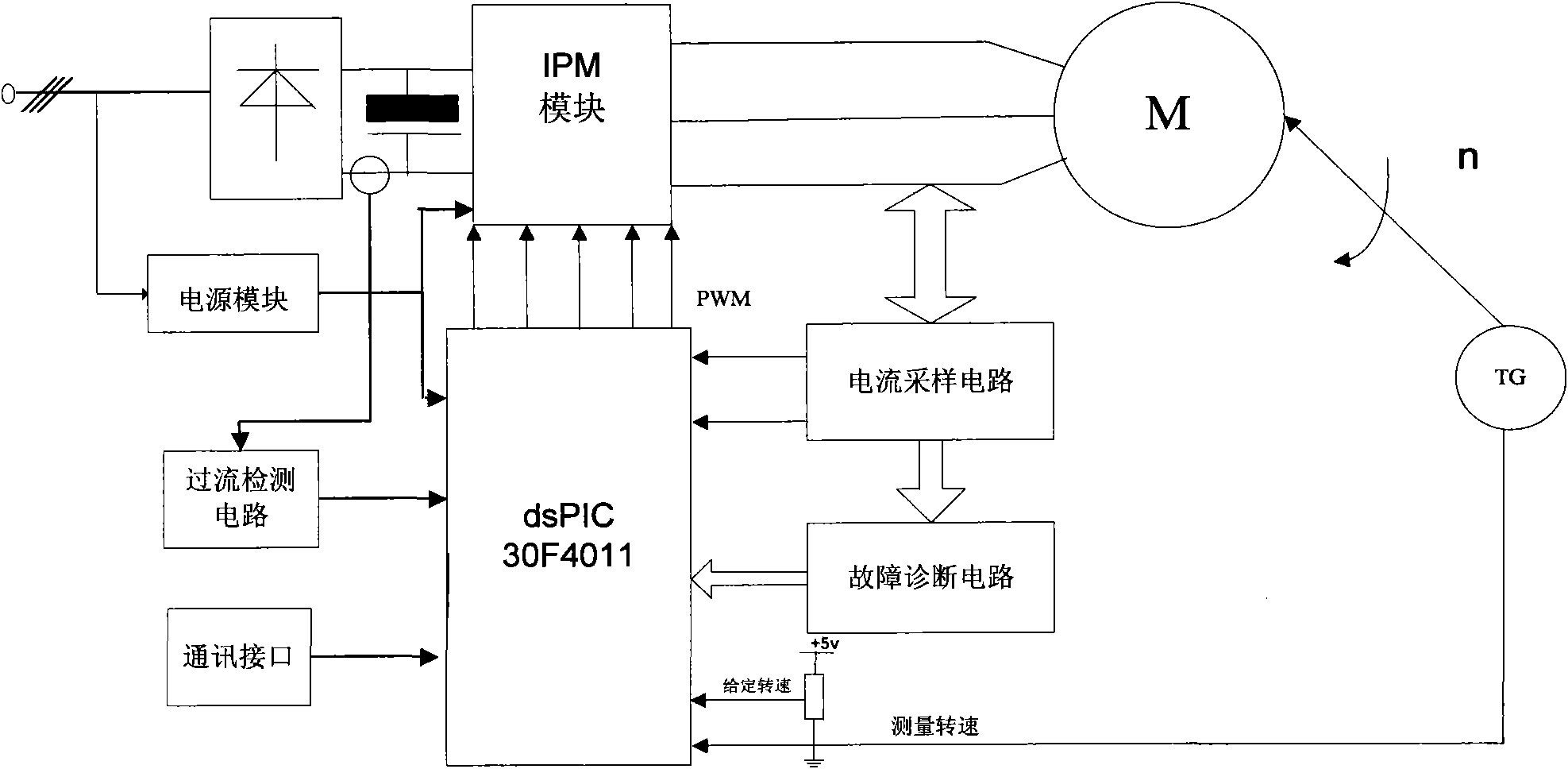

Singlechip-based induction motor variable frequency speed regulation control system

InactiveCN101977016AEfficient and rapid detectionDetect enoughAC motor controlEmergency protective circuit arrangementsMicrocontrollerEngineering

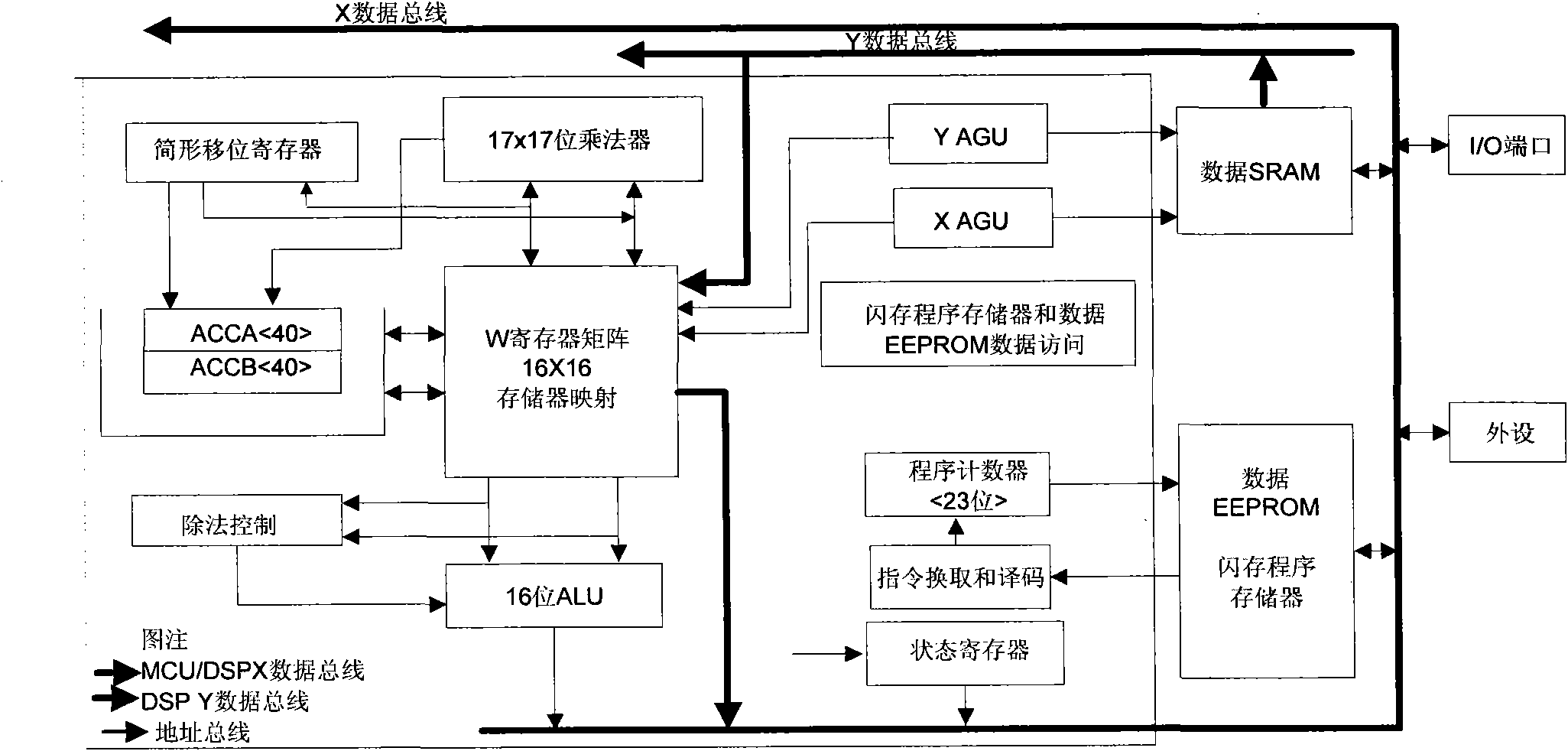

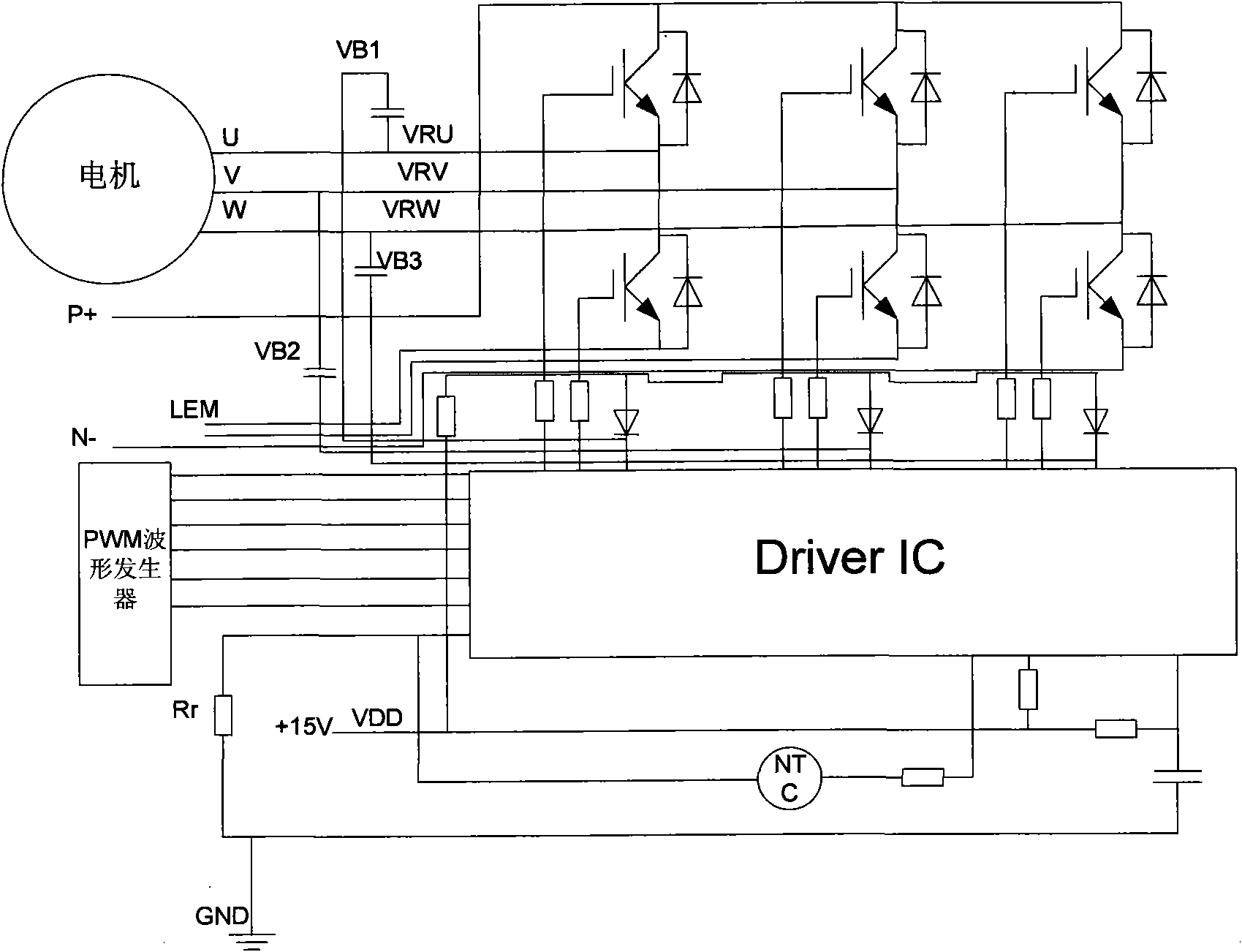

The invention discloses a singlechip-based induction motor variable frequency speed regulation control system. The system comprises a main circuit, an auxiliary power circuit, an inverter circuit, a control part, an over-current protection circuit, a rotation speed detection circuit and other peripheral circuits. A 16-bit high-performance signal controller dsPIC30F4011 which is produced by the Microchip Company is used as a control core by the system to perform speed regulation based on vector control motor excitation. A digital signal controller dsPIC30F4011 of the America Microchip Technology Company is used as a chip special for motor control, a digital signal processor (DSP) inner core is embedded, and the chip has quick data processing capacity and is provided with abundant input and output equipment and interface circuits; an intelligent power module (IPM) IRAMSIOUP 60A of the IR Company is an inverter switching device, so that the variable frequency speed regulation control system of an asynchronous motor is constructed; and the system has the characteristics that the system is simple to drive and easy to realize.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

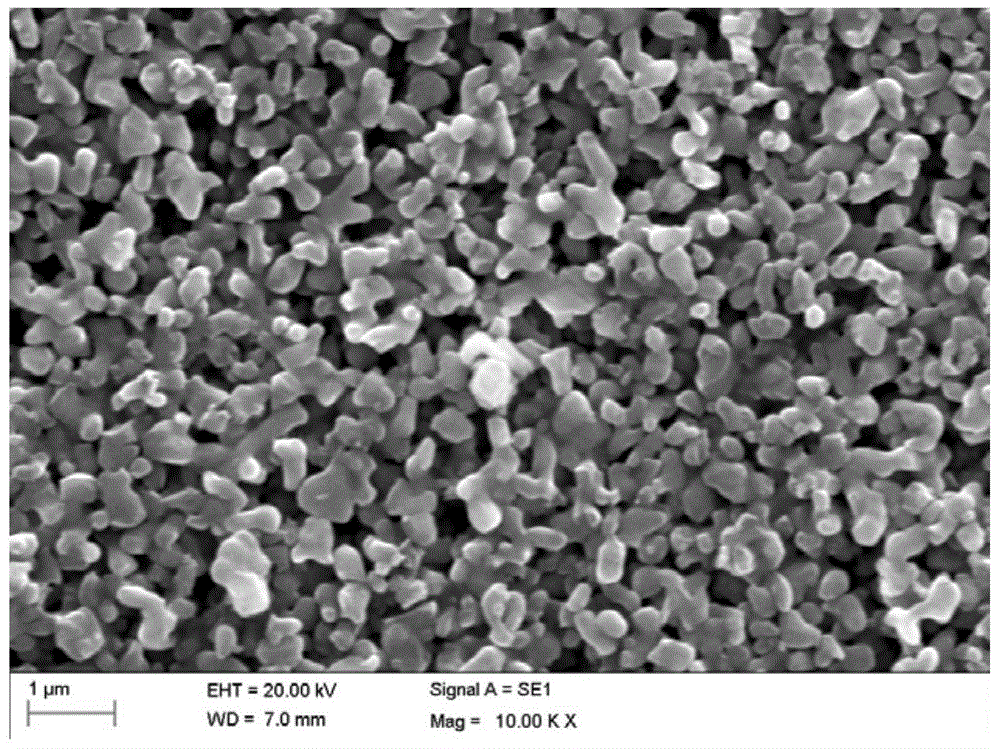

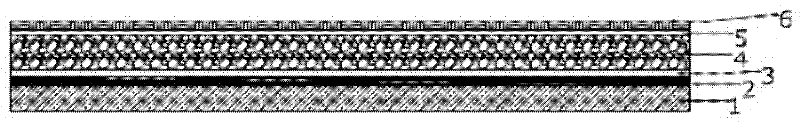

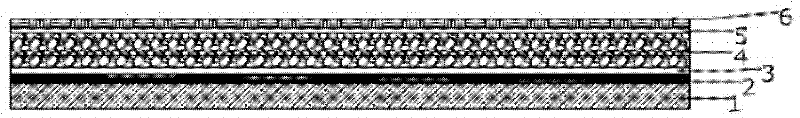

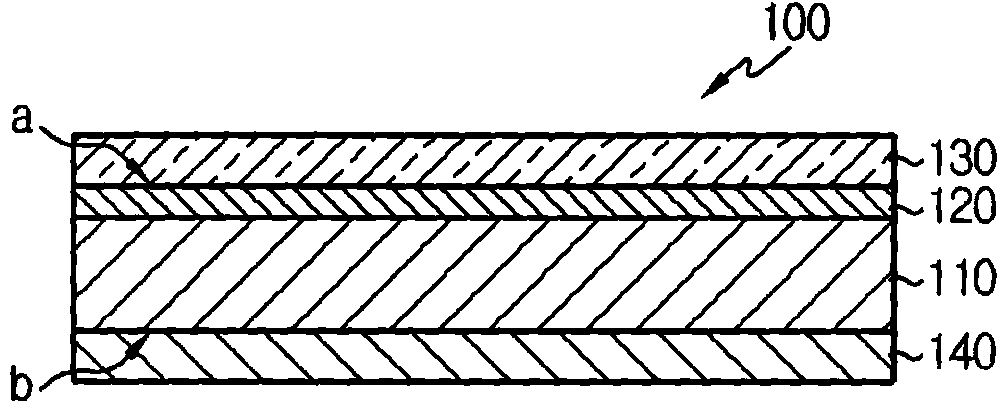

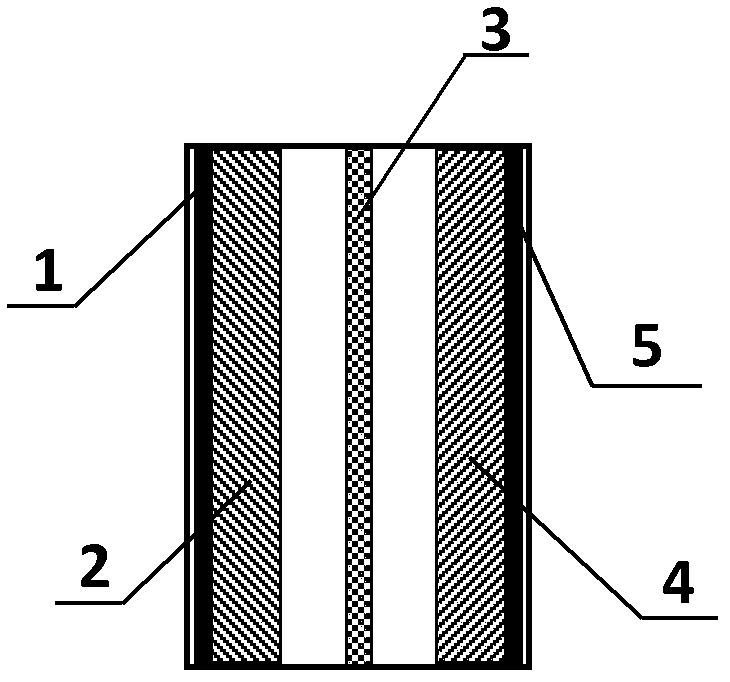

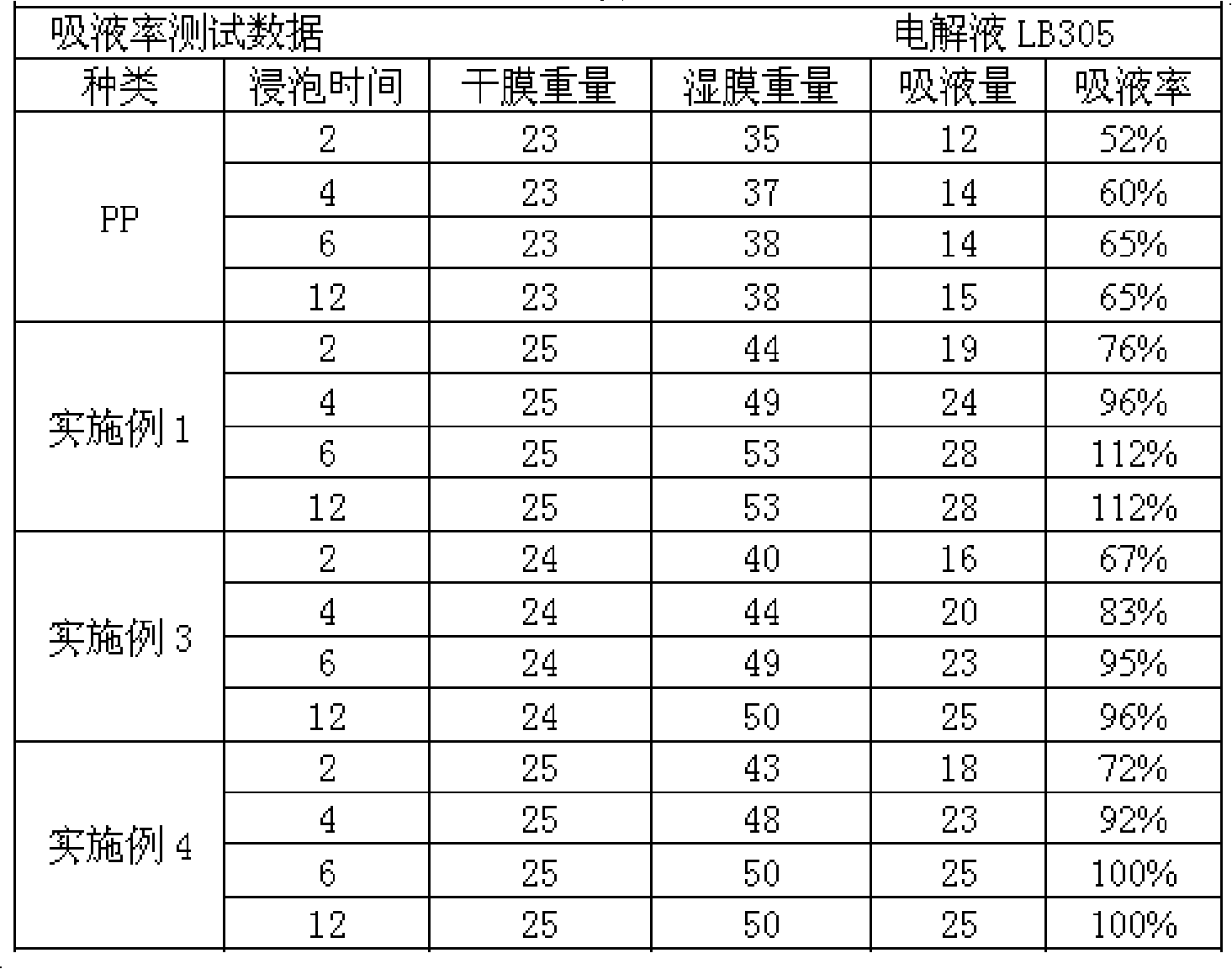

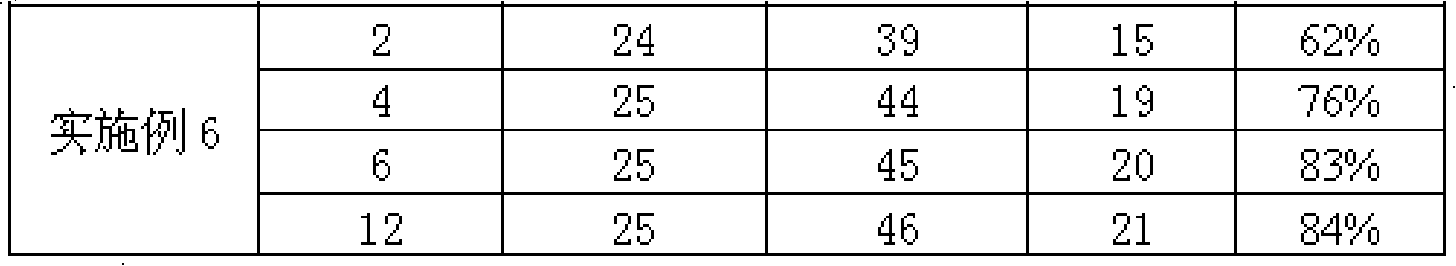

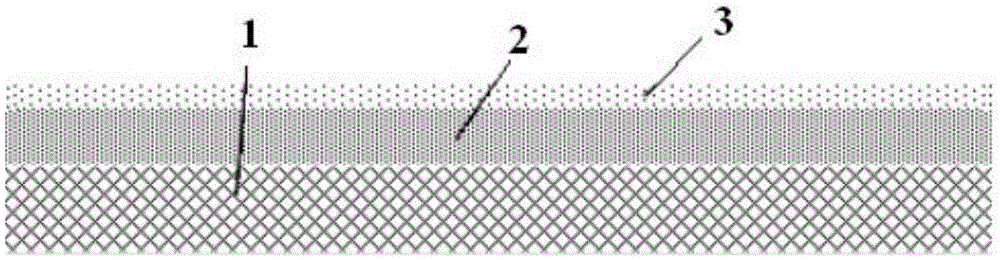

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

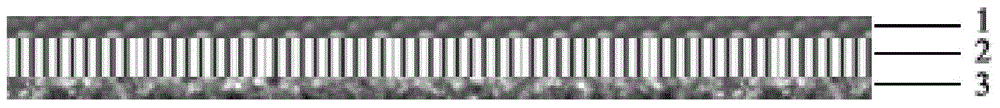

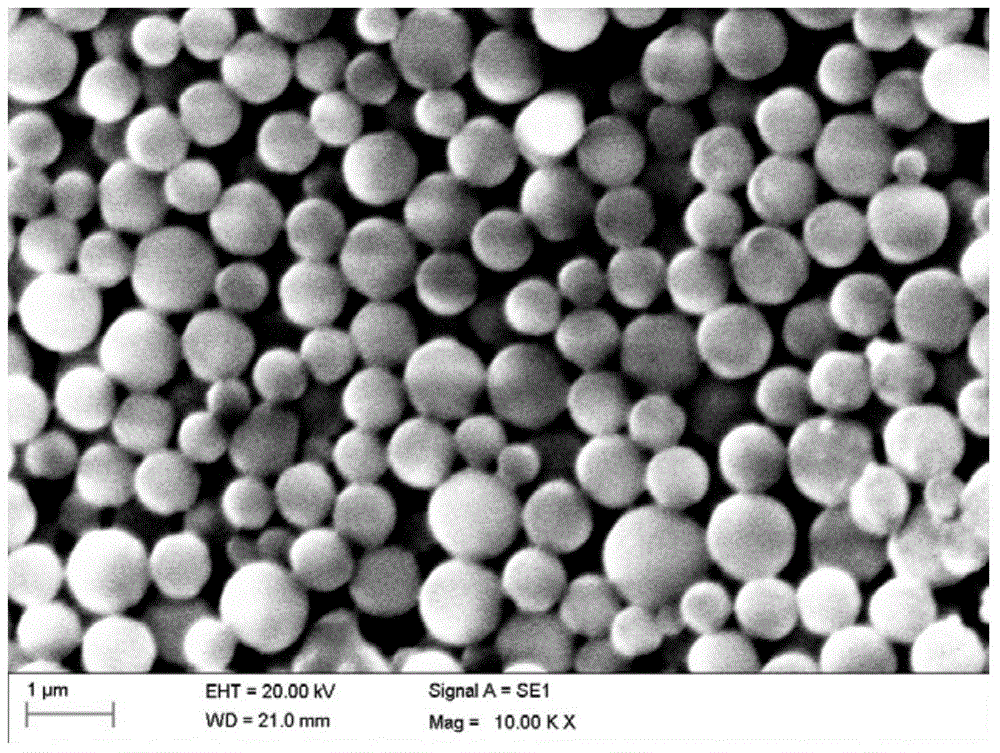

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

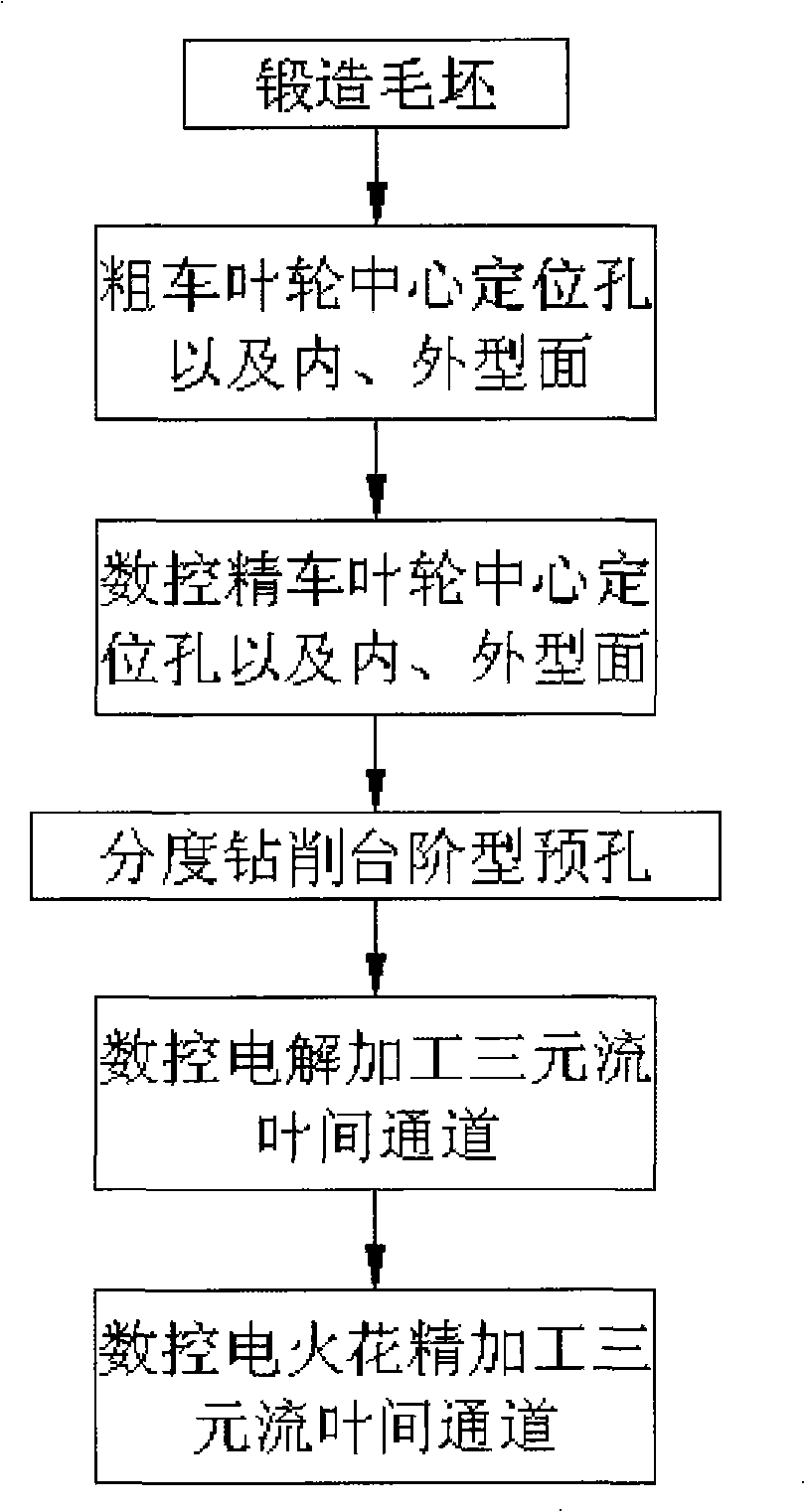

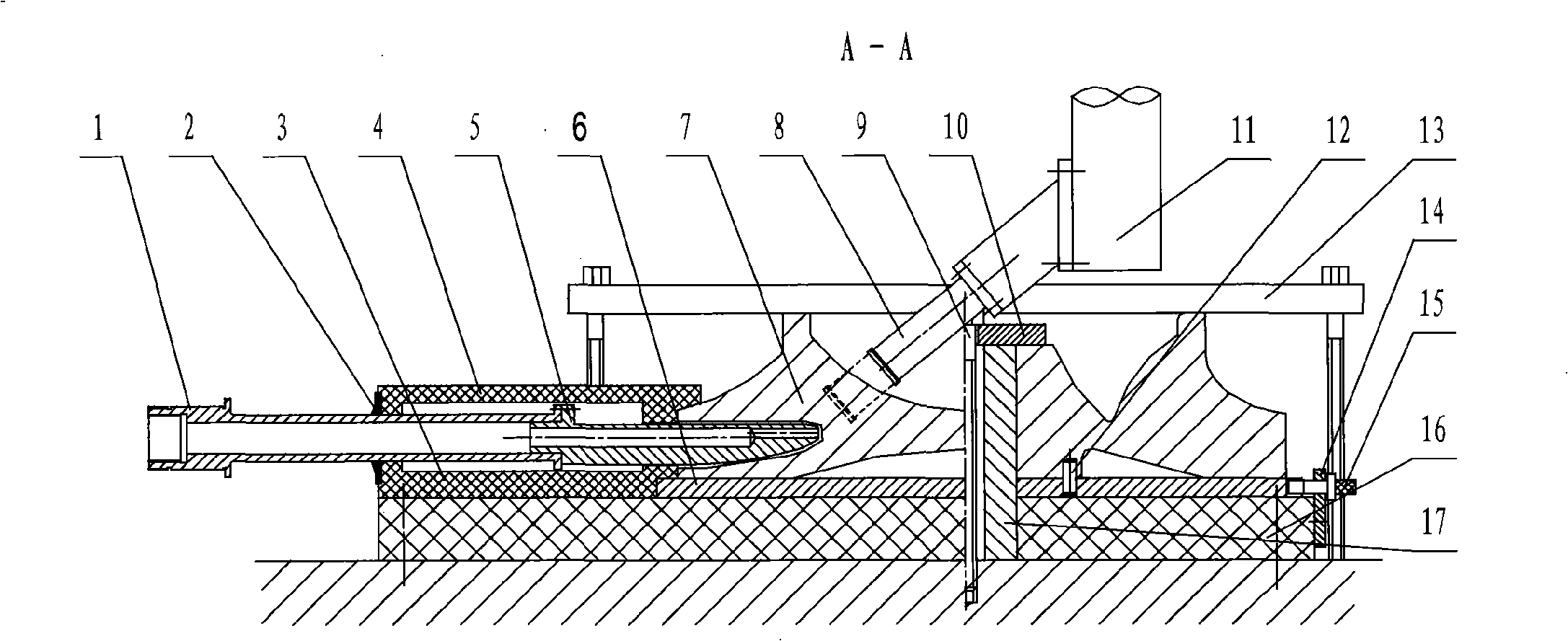

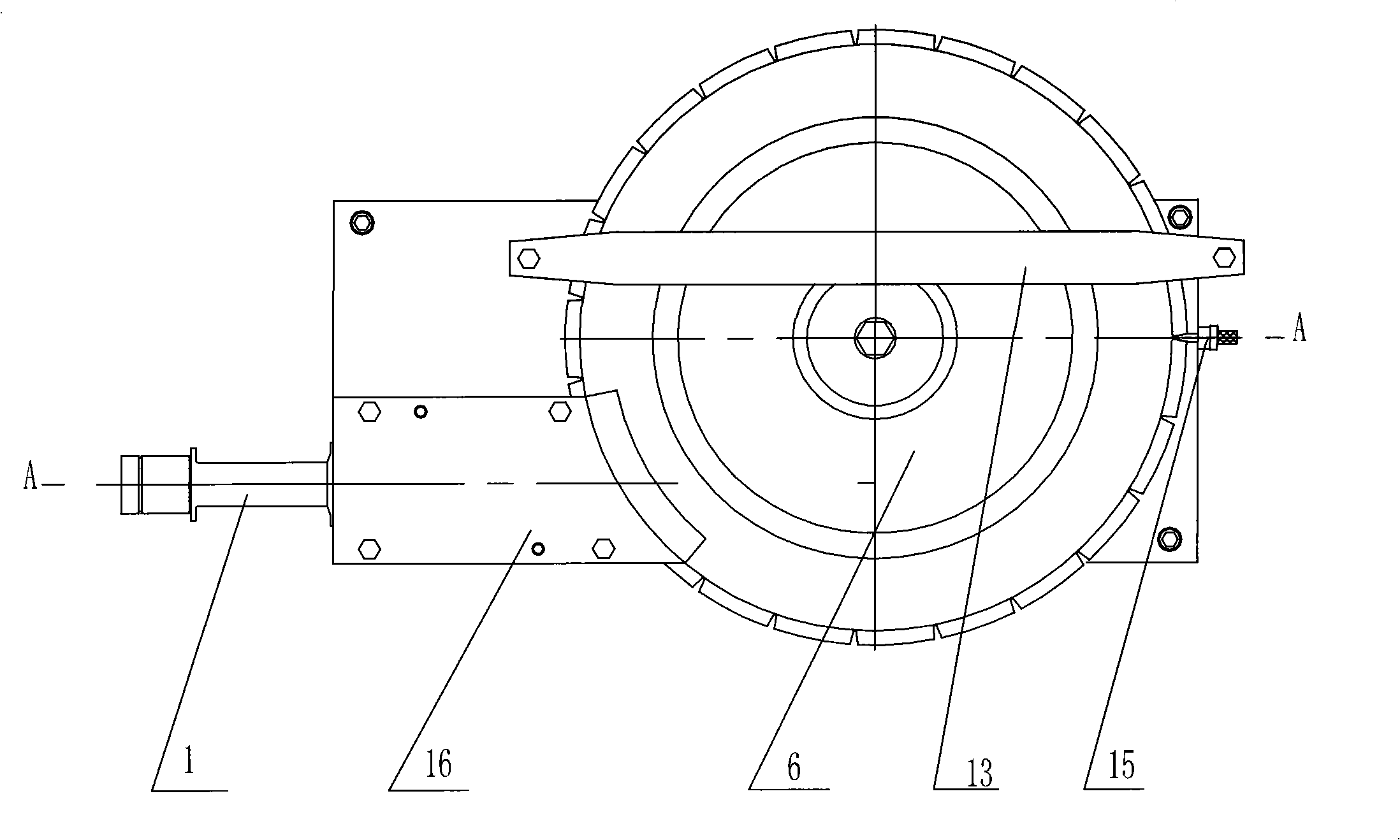

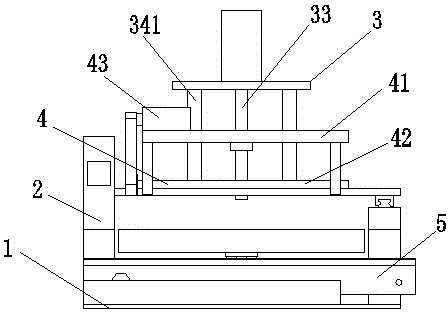

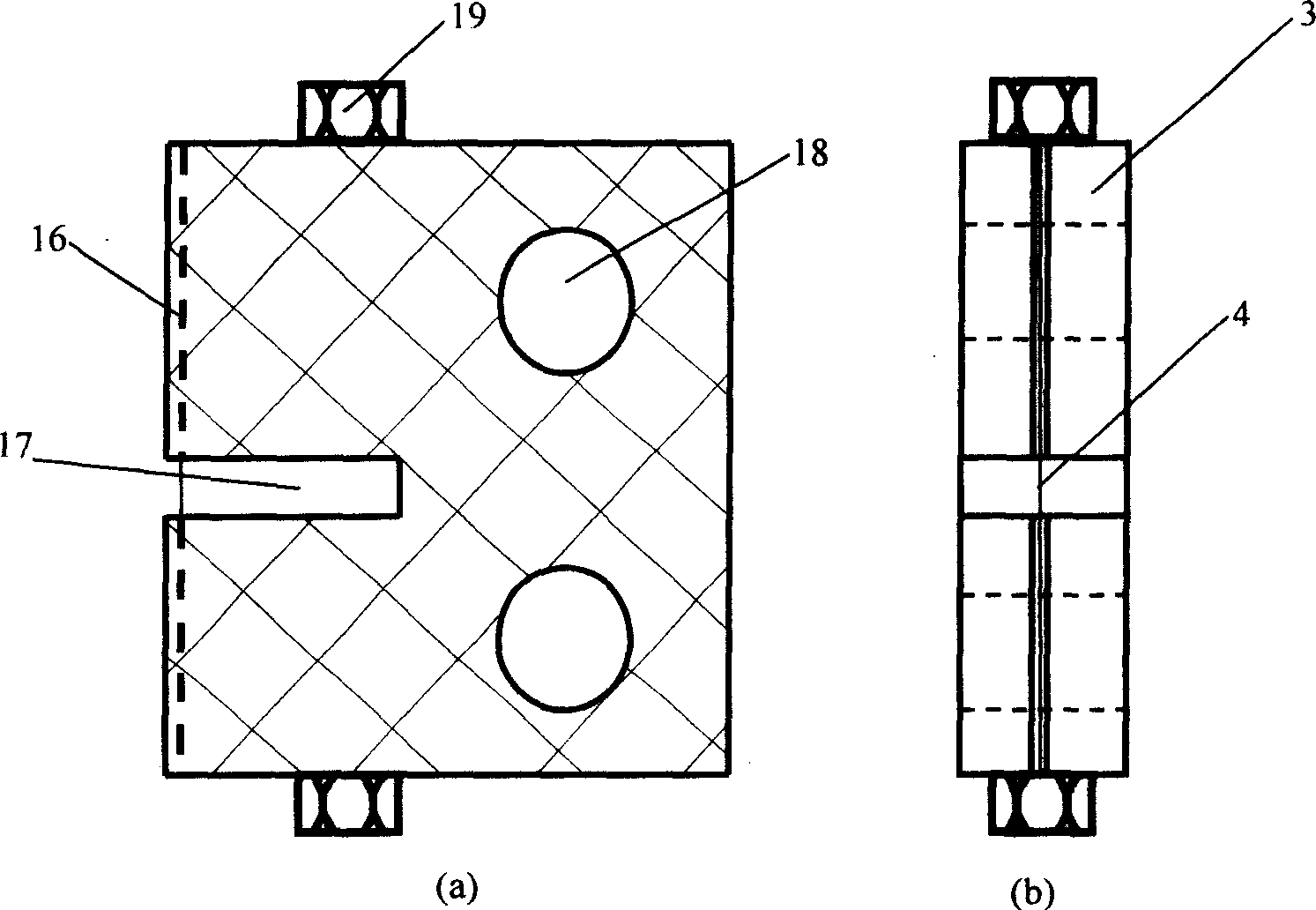

Method for manufacturing three-dimensional flow enclosed-type impeller inter-impeller passage and special clamp thereof

InactiveCN101524805AImprove efficiencyAvoid the phenomenon that is prone to blind spots in processingImpellerEngineering

The invention relates to a method for manufacturing a three-dimensional flow enclosed-type impeller inter-impeller passage and a special clamp thereof. A specially designed and manufactured molding or quasi-molding tool cathode is used for numerical control electrolytic processing to remove most remainder, then a specially designed and manufactured molding or quasi-molding tool electrode is used for numerical control electric spark precision processing to achieve the design requirement, thereby the three-dimensional flow enclosed-type impeller inter-impeller passage that can not be processed resulting from interference of numerical control milling cutter and undercutting can be manufactured, besides, the method has the technical and economical characteristics of high precision and efficiency, and low cost compared with the prior three manufacturing methods of integral casting, divided processing rewelding and numerical control milling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

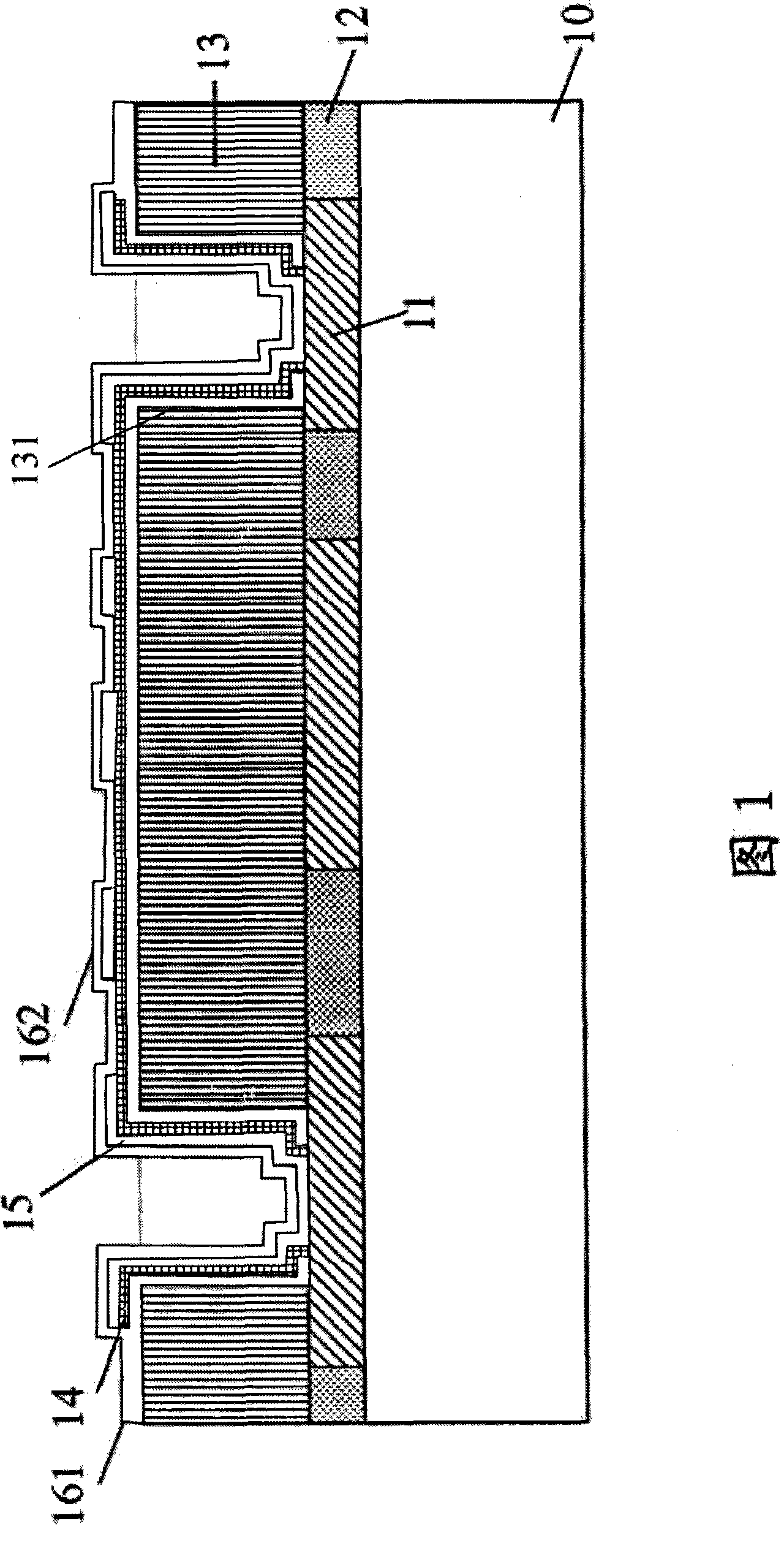

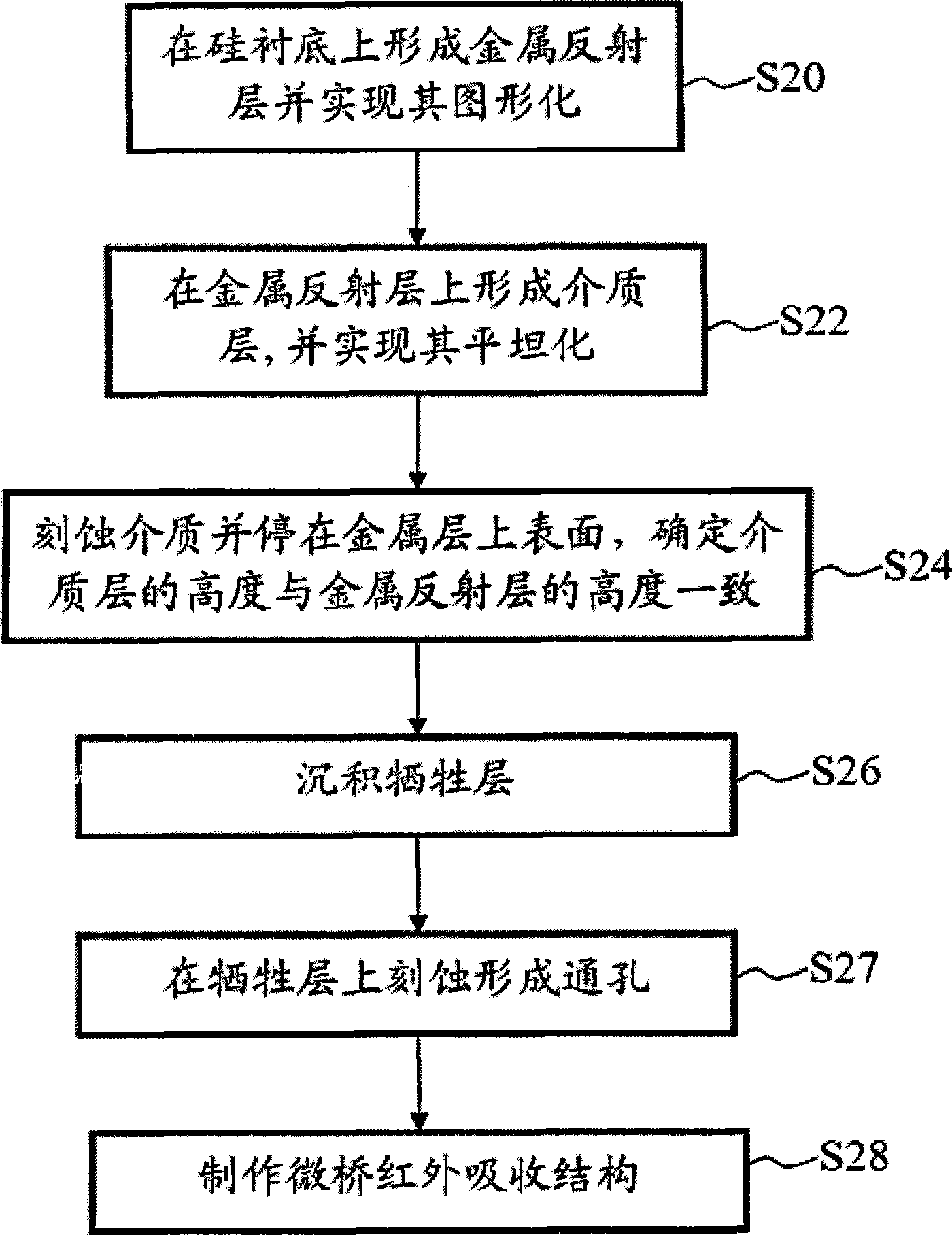

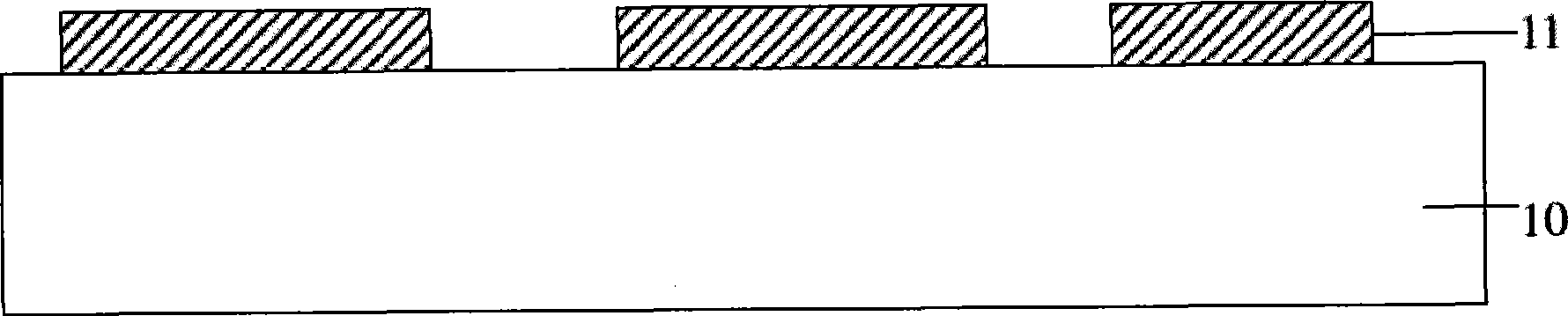

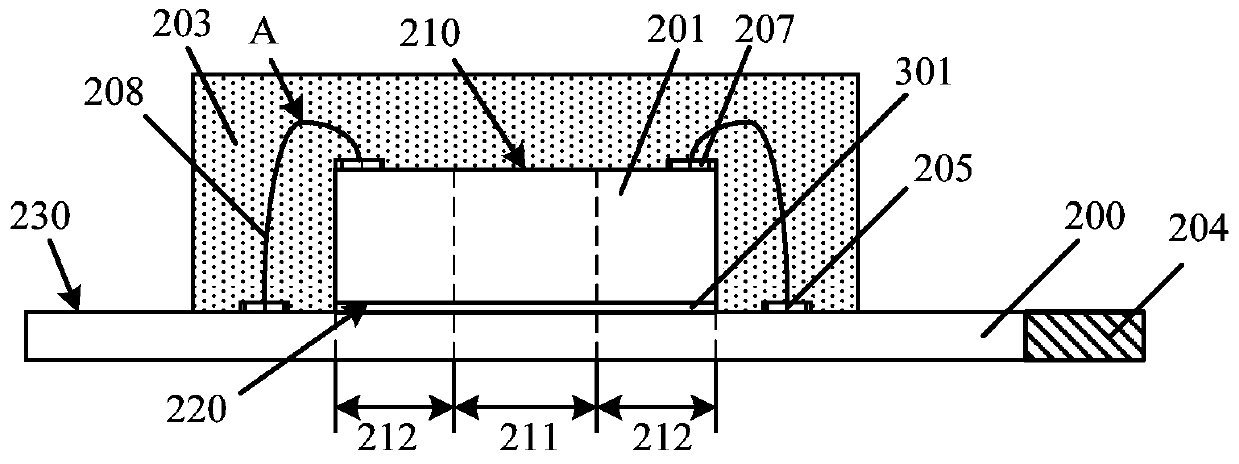

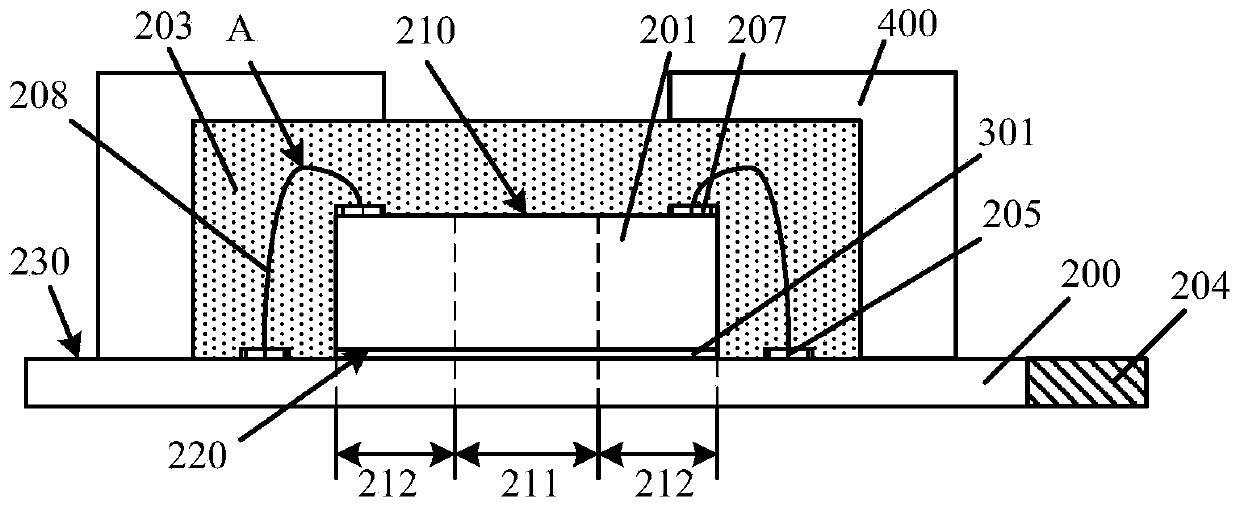

Infrared receiver and manufacturing method thereof

ActiveCN101445215AAvoid short circuitSolve the process surface planarization problemTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMetallic electrodeInfrared detector

The invention provides an infrared receiver and a manufacturing method thereof. A metallic reflecting layer, a dielectric layer, a sacrifice layer, a sensitive material detecting layer and a metallic electrode are precipitated on a silicon bulk of the infrared receiver in sequence. The metallic reflecting layer is provided with a metallic reflection pattern. The height of the dielectric layer and the height of the metallic reflecting layer are the same. The invention also provides the manufacturing method of the infrared receiver, comprising the following steps: the metallic reflecting layer is formed on the silicon bulk and patterning is carried out on the metallic reflecting layer; the dielectric layer is formed on the metallic reflecting layer and planarization is carried out on the dielectric layer; medium is etched and reserved on the surface of a metallic layer, and the height of the dielectric layer and the height of the metallic reflecting layer are confirmed to be the same; the sacrifice layer is precipitated; and a microbridge infrared absorption structure is fabricated.

Owner:ZHEJIANG DALI TECH +1

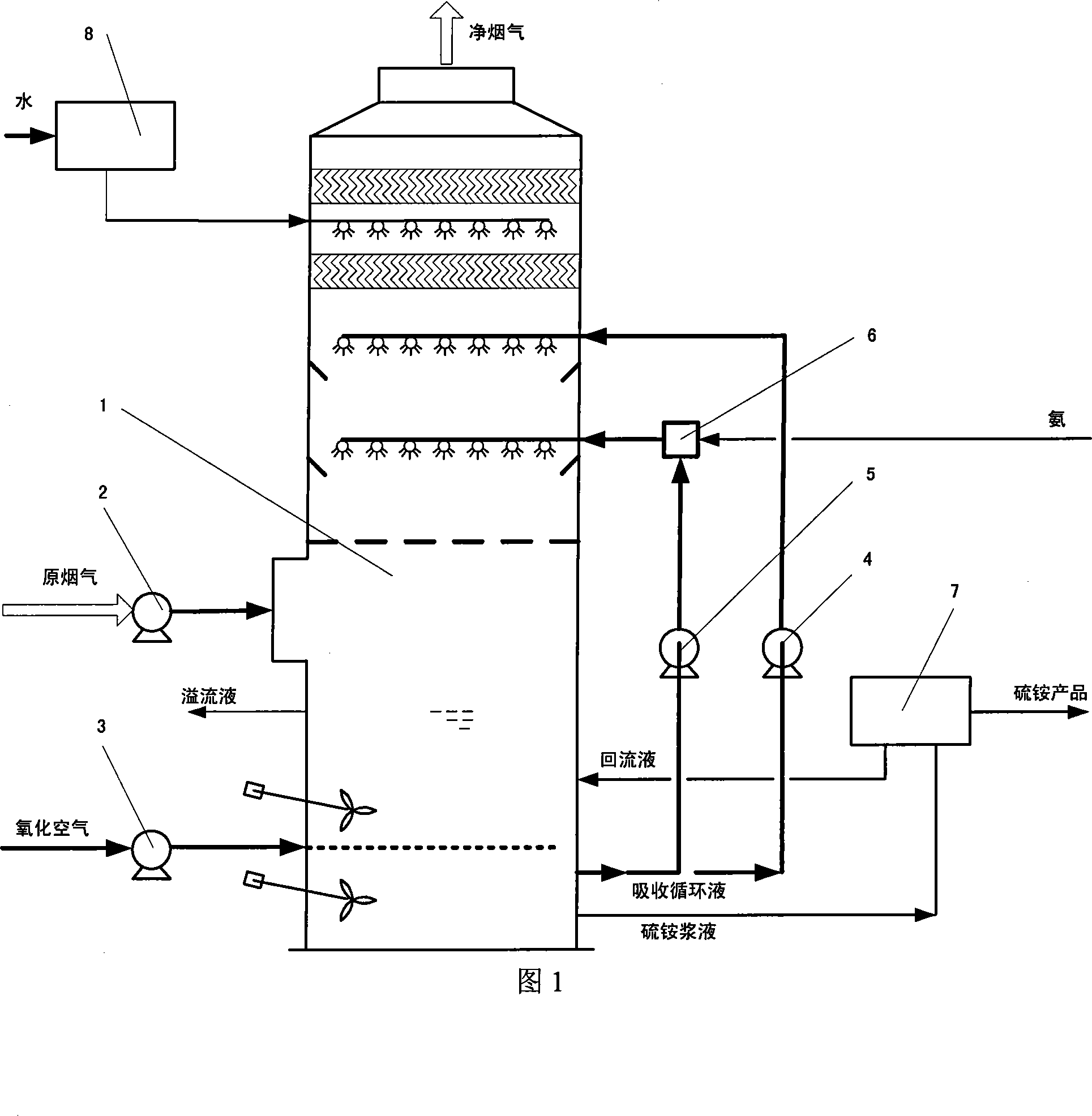

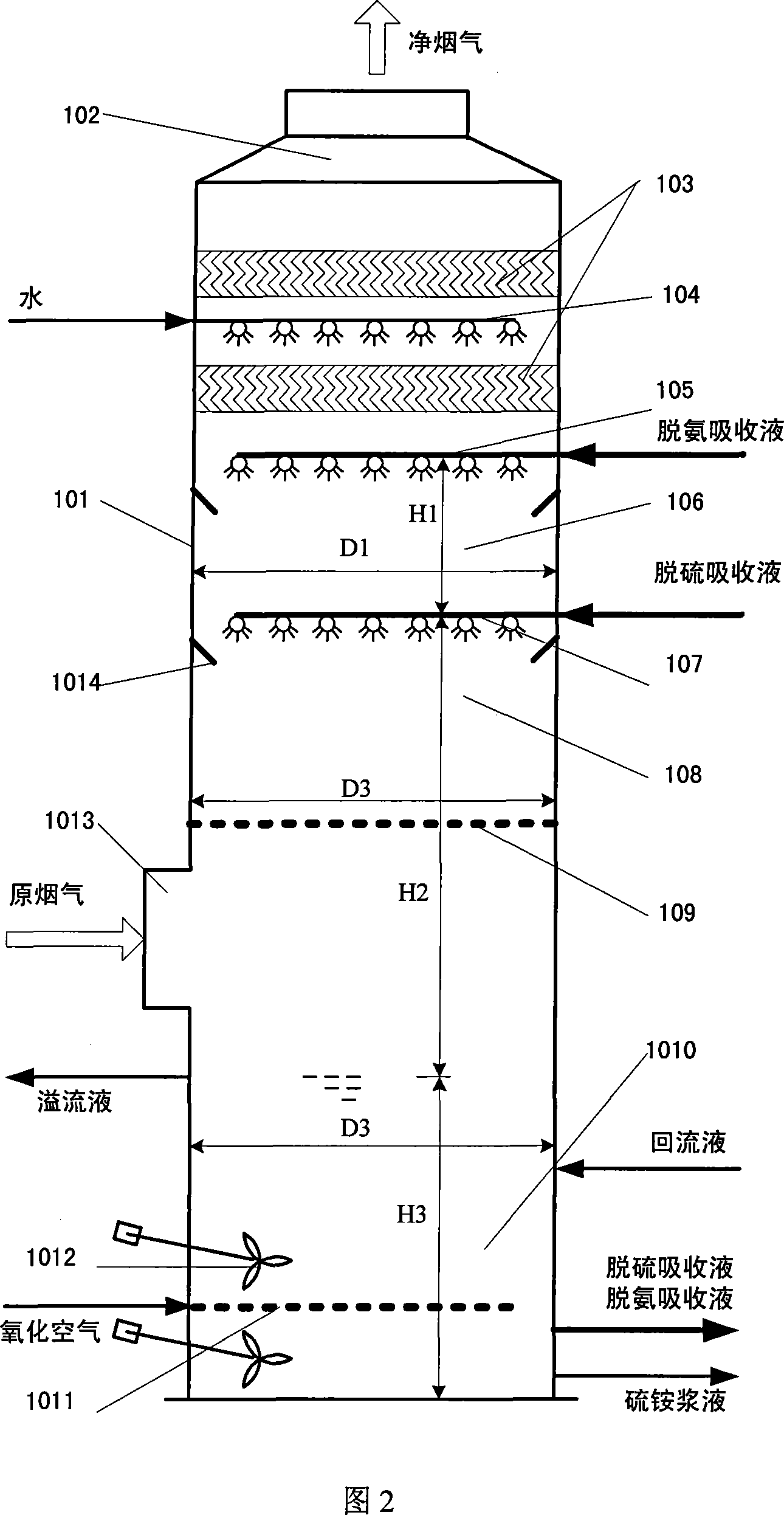

Method and device for reclaiming sulfur dioxide from countercurrent flue gas

InactiveCN101085410AAvoid short circuitImprove efficiencyDispersed particle separationSulfur compoundsSulfur dioxideFlue gas

The invention relates to the new SO2 absorption device with three function areas, namely deamination zone, desulfuration zone and oxidization zone. It has purification air exhaust at the top of the SO2 absorption device, top of the inside of the tower composed of water and liquid separator of the flush water distributor, deamination circulation absorbing distributor connected to its inlet under the air and liquid separation component, under the deamination zone set with desulfuration circulation absorbing outlet connected liquid absorbing distributor, under which set the desulfuration zone, with absorbent liquid overflow outlet on the tower, and oxidization crystallization zone under the overflow outlet. It is low in investment, small in energy consumption, strong in gas treatment ability, high in efficiency, applicable for mass mode industrial application.

Owner:娄爱娟

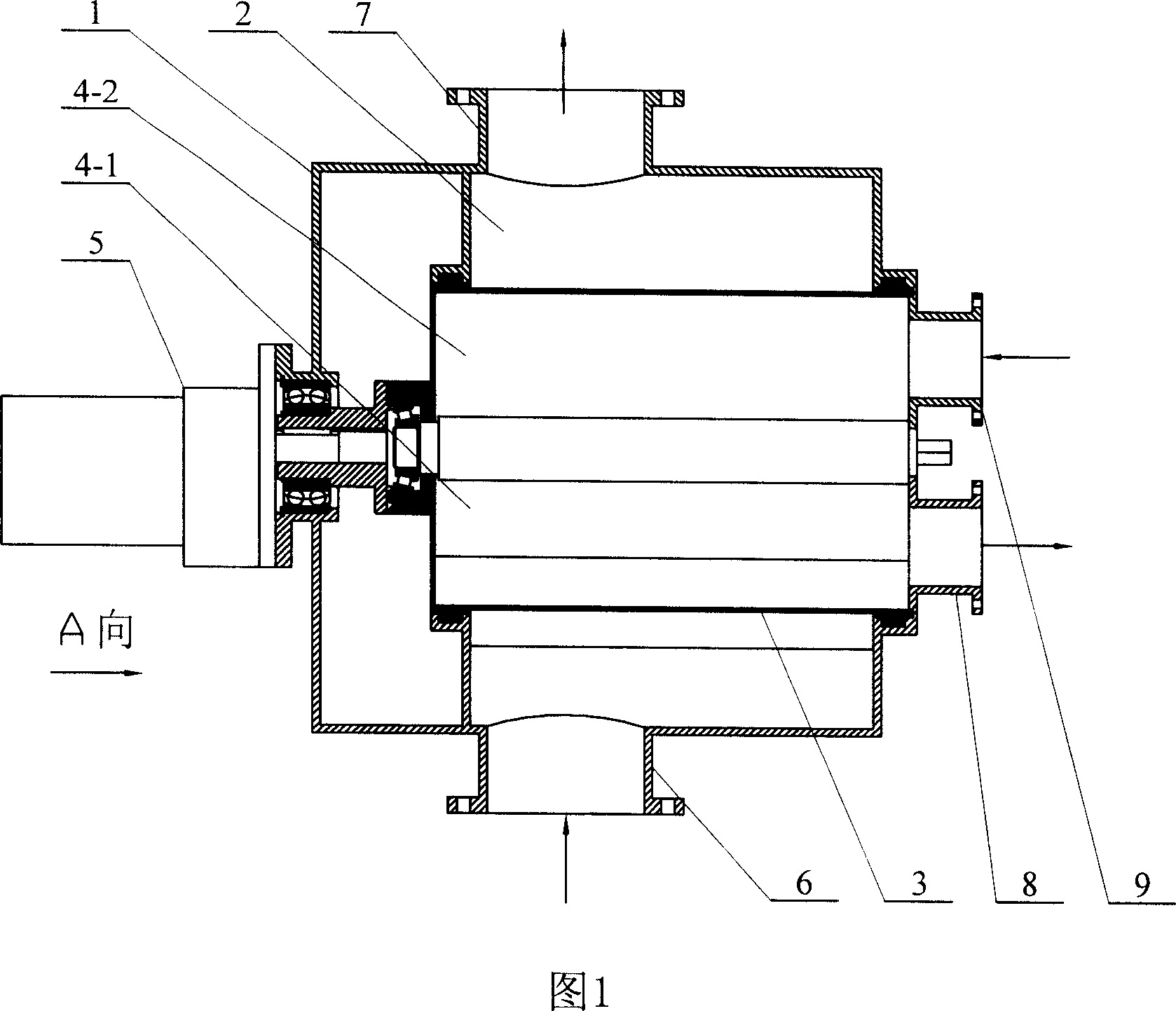

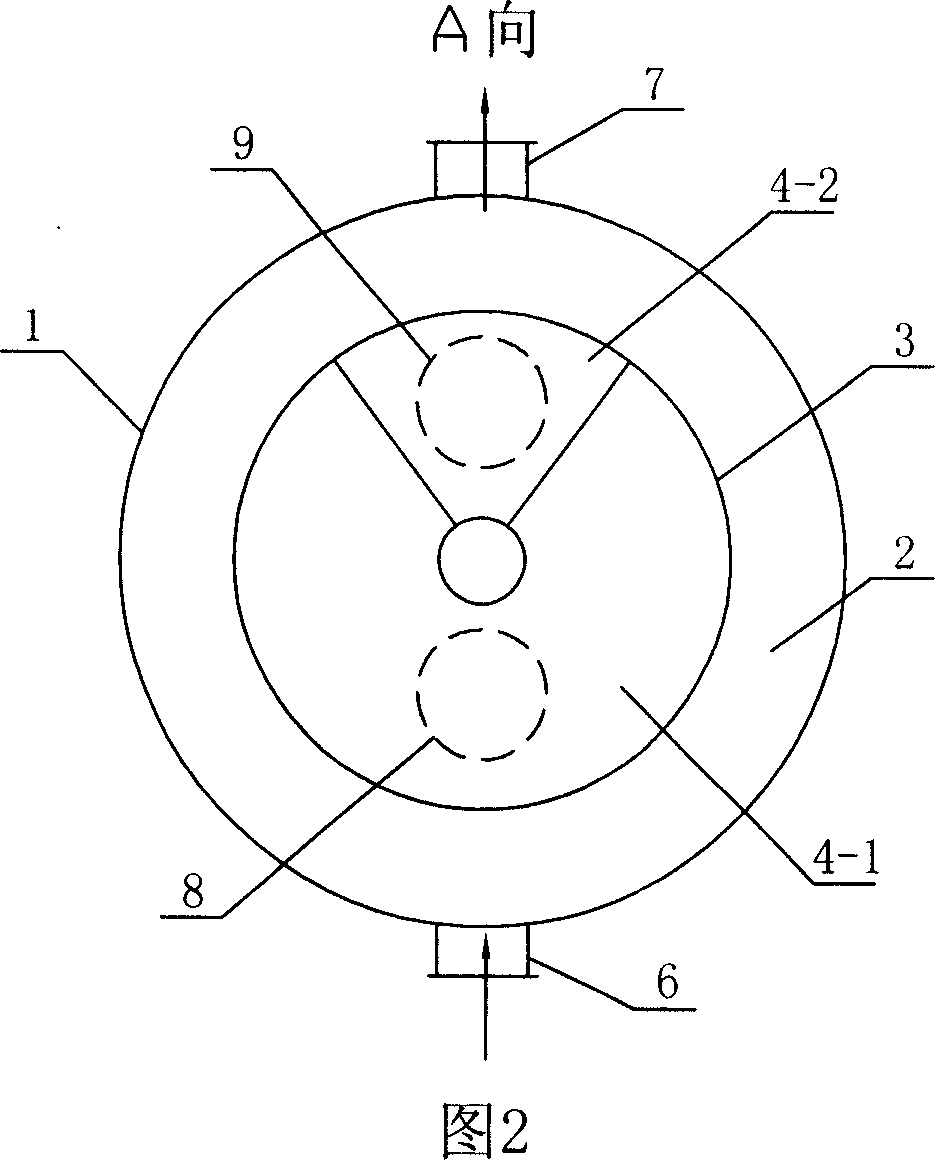

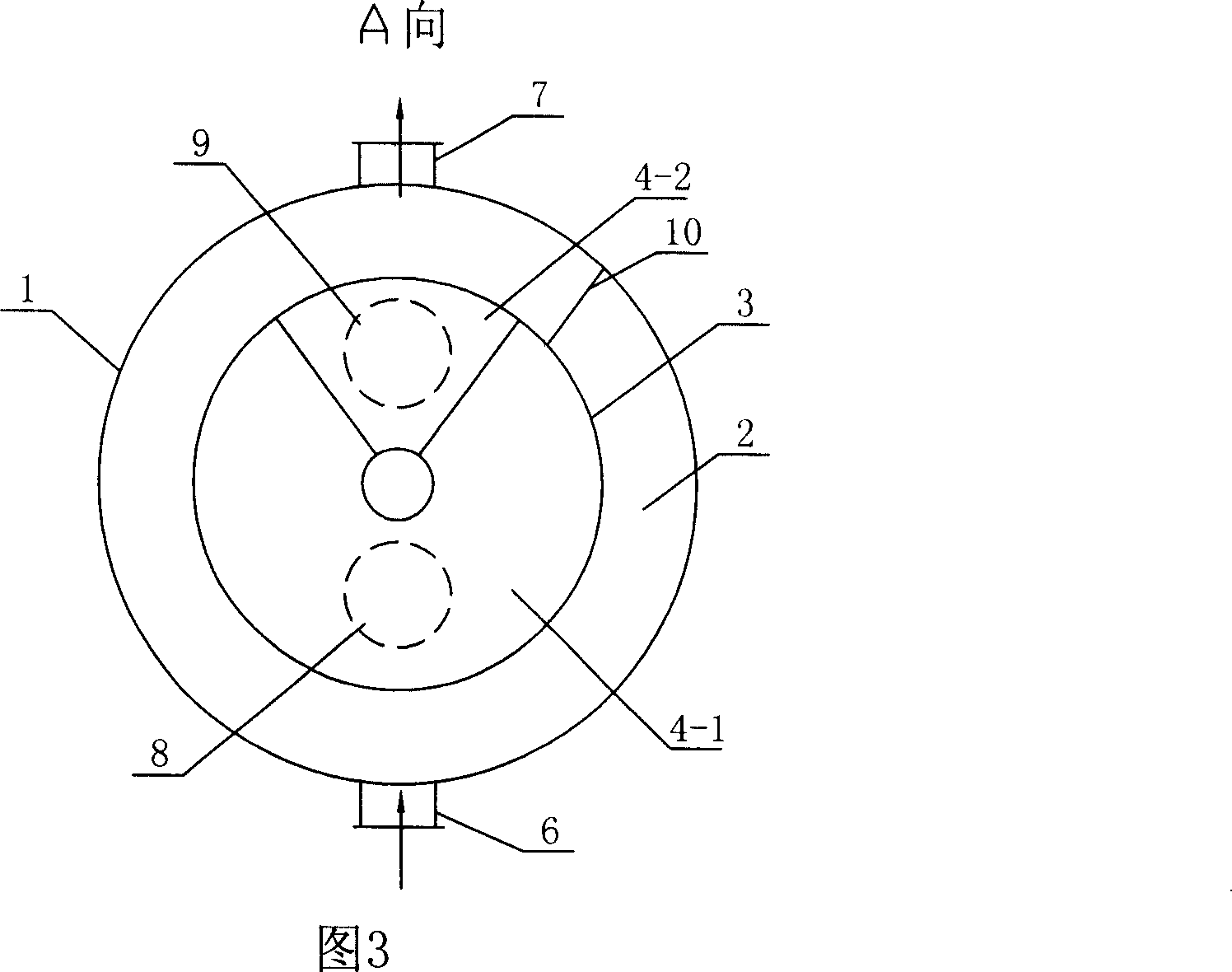

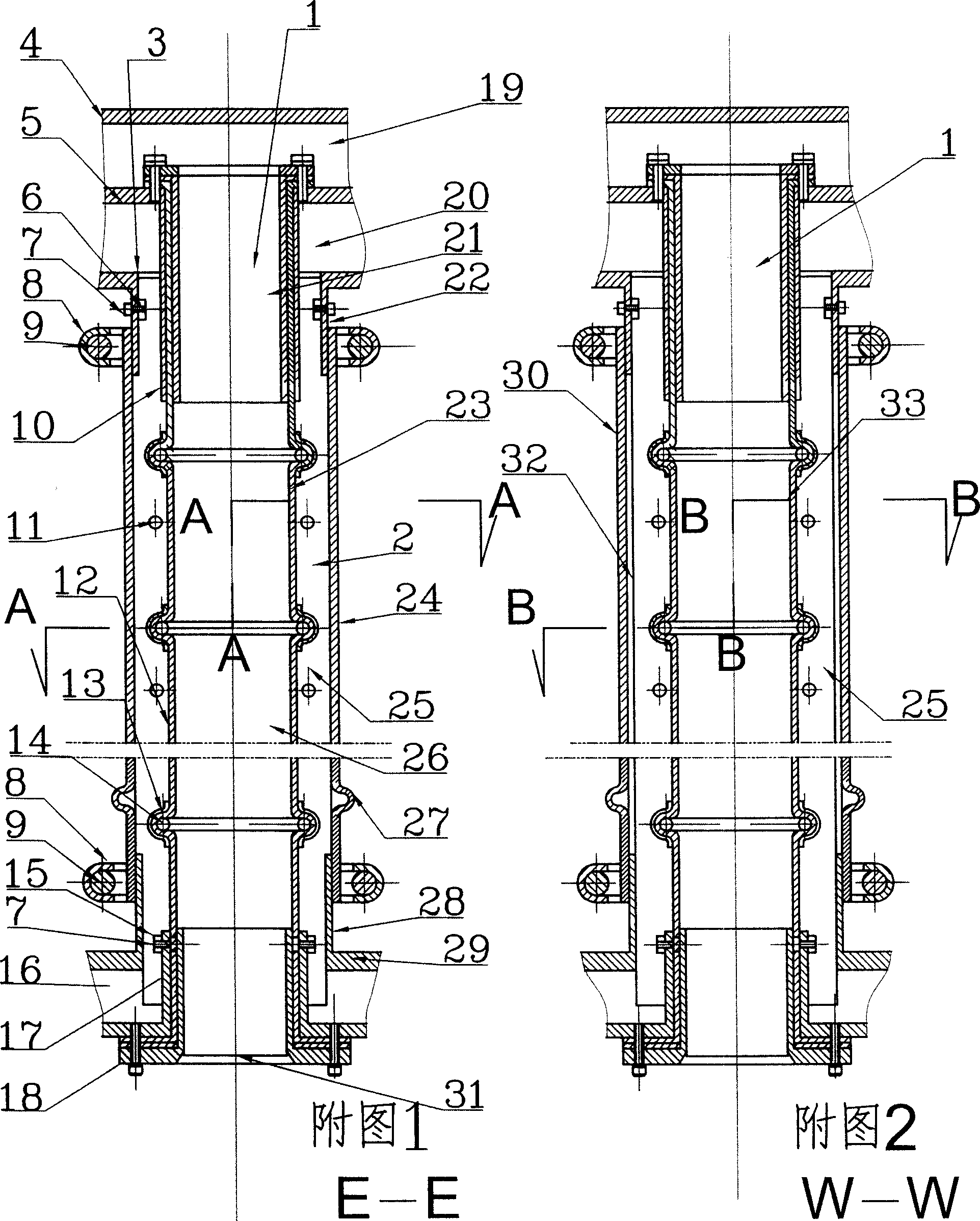

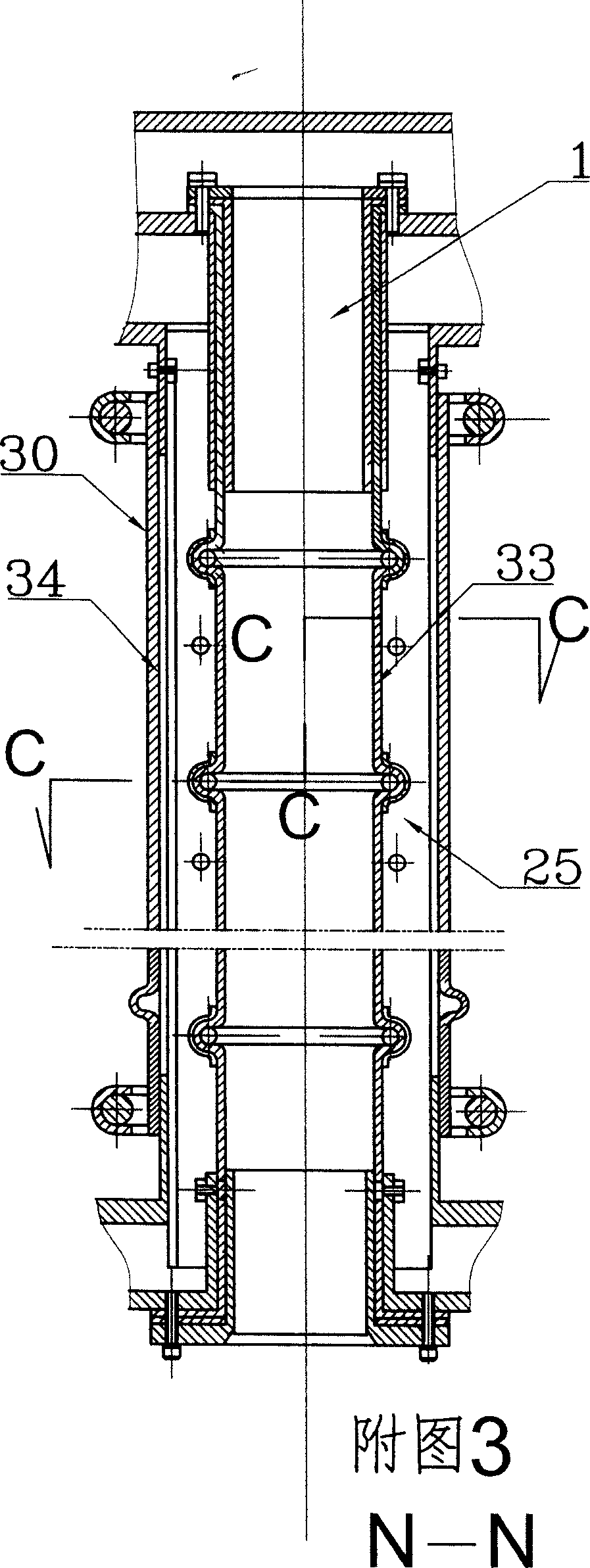

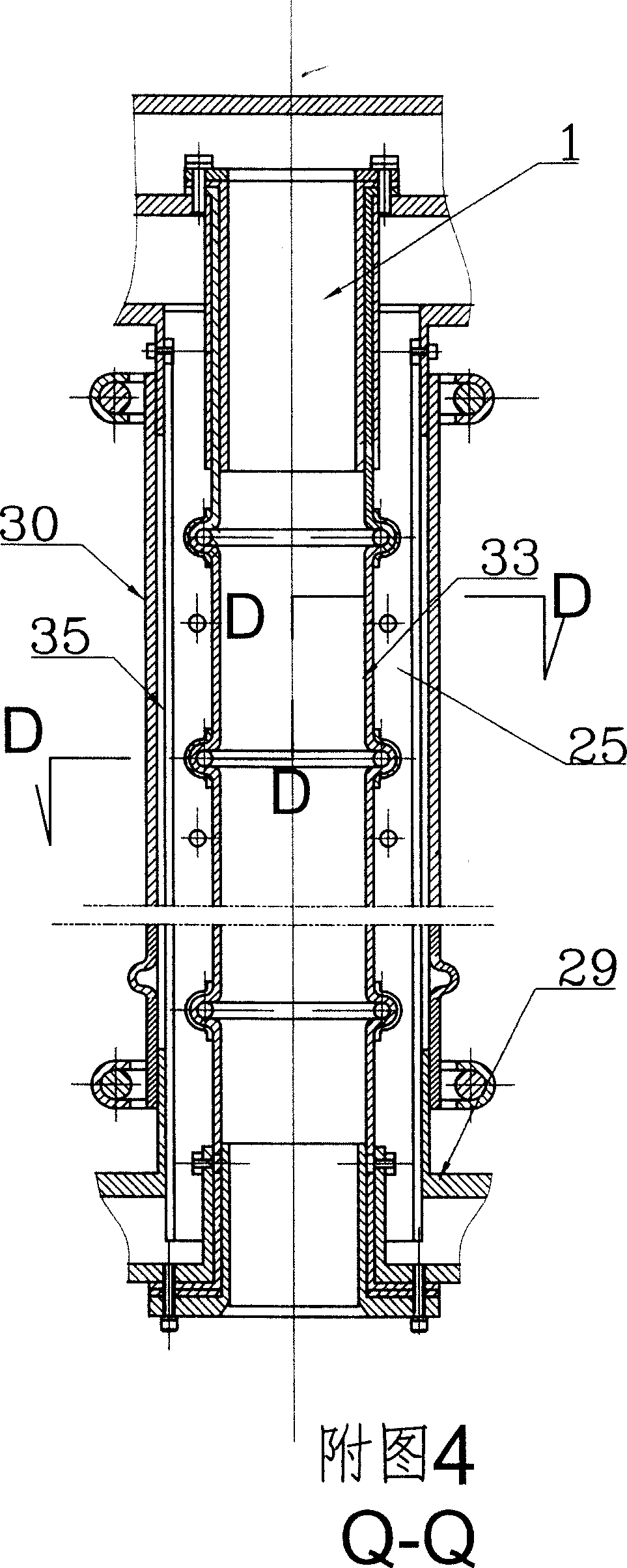

Block-free balanced-pressure clog-proof device for sewage and surface water source heat pump and system therefor

InactiveCN1920447APlay the role of auxiliary cleaning filter surfaceSolve processing problemsHeat pumpsArtificial water canalsWater sourceEngineering

The invention relates to a non-resistance pressure balance anti-resistance device of heat pump of ground water, and relative system, wherein the outer frame (1) of anti-resistance device has external water inlet (6) and external water outlet (7); the rotation filter cylinder (3) is inside the outer frame (1); the rotation filter cylinder (3) is divided into internal water inlet area (4-1) and internal water outlet area (4-2); the internal water inlet area (4-1) is connected to the internal water inlet area outlet (8) and the internal water outlet area (4-2) is connected to the internal water outlet area inlet (9). The invention has stable water pressure and stable flux, with small size and low cost.

Owner:BEIJING RUIBAOLI THERMAL TECH CO LTD

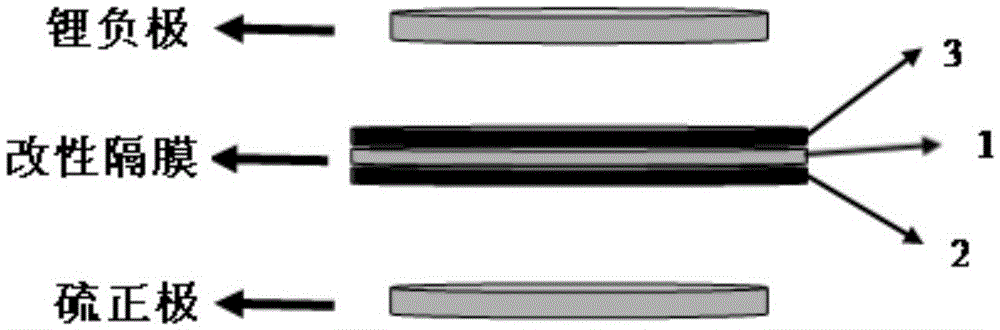

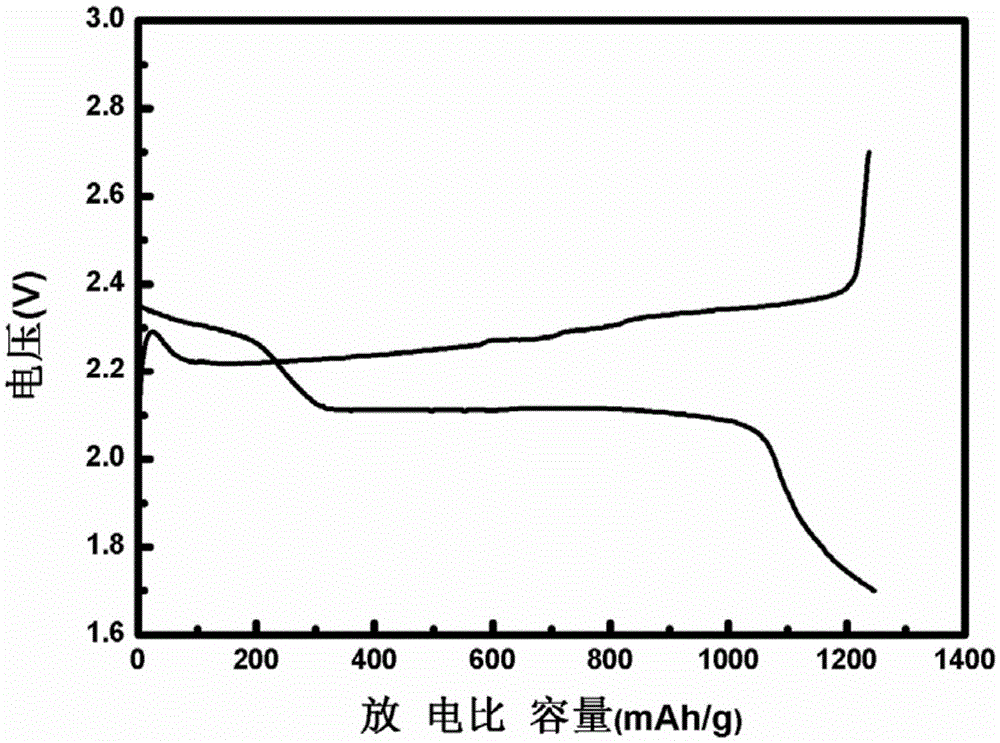

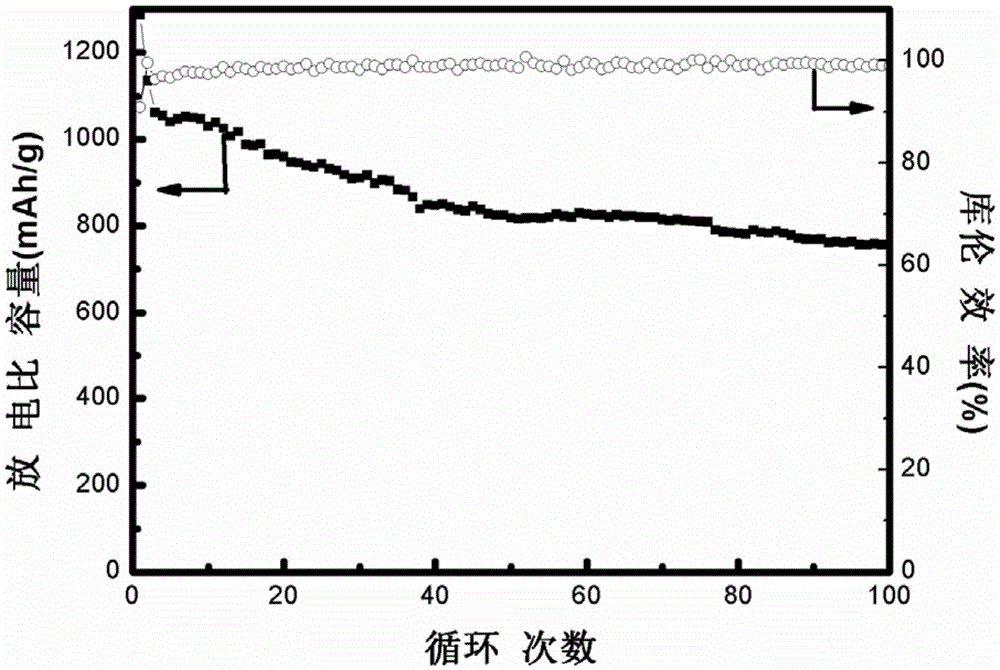

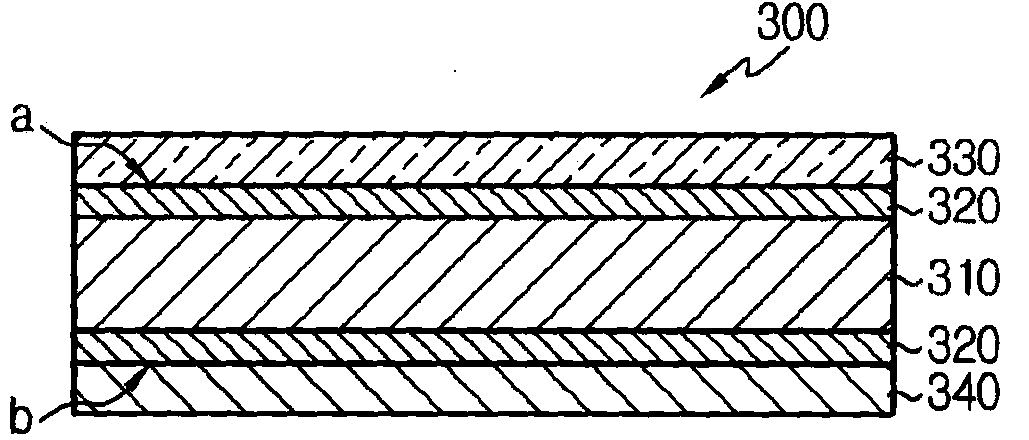

Modified diaphragm and preparation method and application therefor

InactiveCN105679983AImprove ionic conductivityLarge specific surface areaCell seperators/membranes/diaphragms/spacersLi-accumulatorsCyclic processPorous carbon

The invention discloses a modified diaphragm. The modified diaphragm comprises a diaphragm substrate, and an electronic conductive coating layer and an inorganic hard coating layer positioned on the two surfaces of the diaphragm substrate respectively, wherein the electronic conductive coating layer is a mixed coating layer with graphene and a porous carbon material; and the inorganic hard coating layer is a nitrogen-carbon material coating layer, a nitrogen-silicon material coating layer, a carbon-boron material coating layer or a silicon-carbon material coating layer. The preparation method comprises the steps of uniformly coating the two surfaces of the diaphragm substrate with the electronic conductive coating layer and the inorganic hard coating layer respectively, and drying the two surfaces respectively obtain the modified diaphragm. The modified diaphragm has high diffusion and absorption capacity for an organic electrolyte, high ionic conductivity, and an obvious adsorption and blocking effect on poly-sulfur-lithium; in addition, the modified diaphragm can further restrain a shuttle effect, prevent battery short-circuit, effectively restrain the growth of negative electrode metal lithium dendrites in a cyclic process, prevent from punching the diaphragm, and protect the lithium negative electrode, so that the problem that the diaphragm is punched after dendrites formation is solved, and the safety performance of the battery is improved.

Owner:CENT SOUTH UNIV

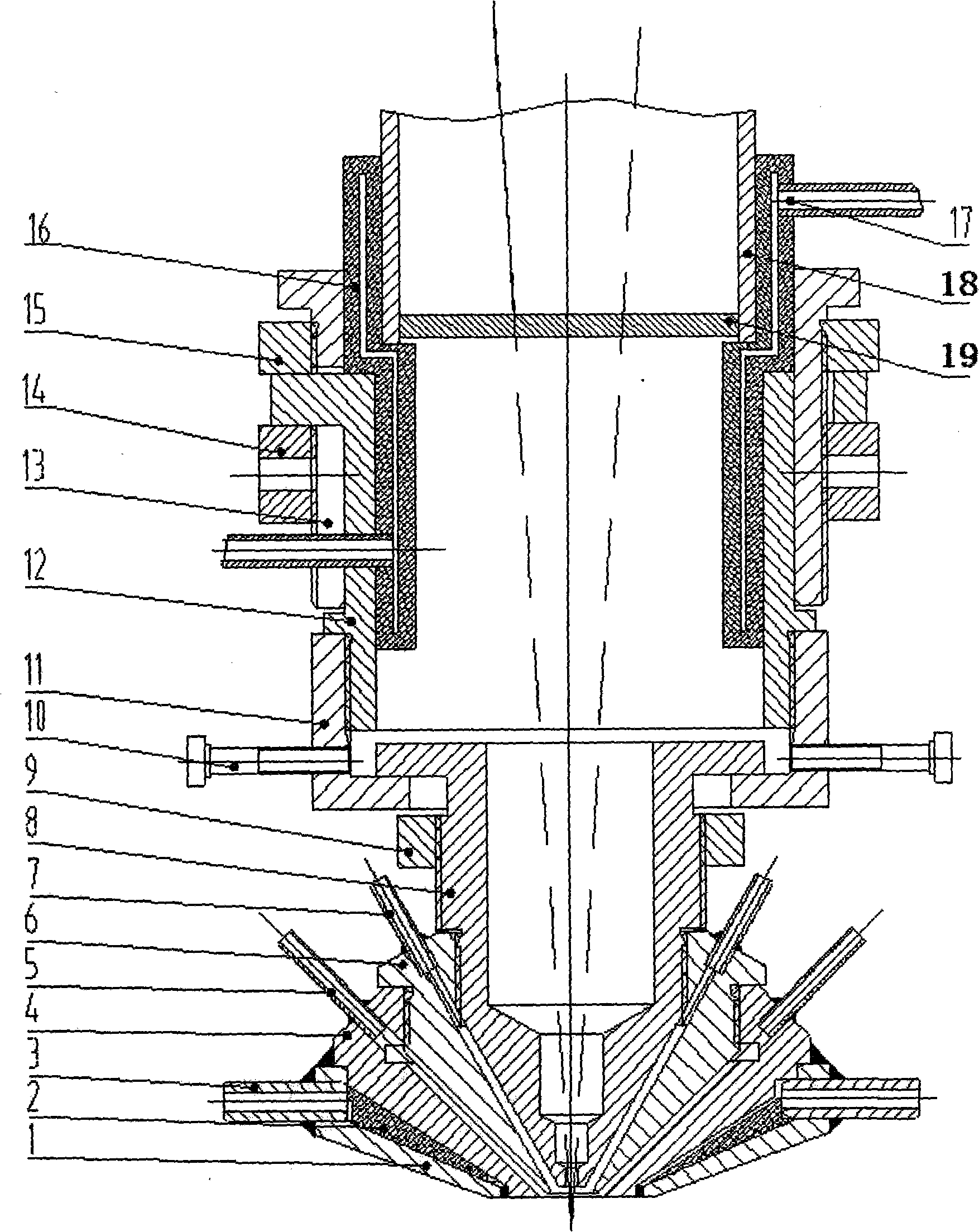

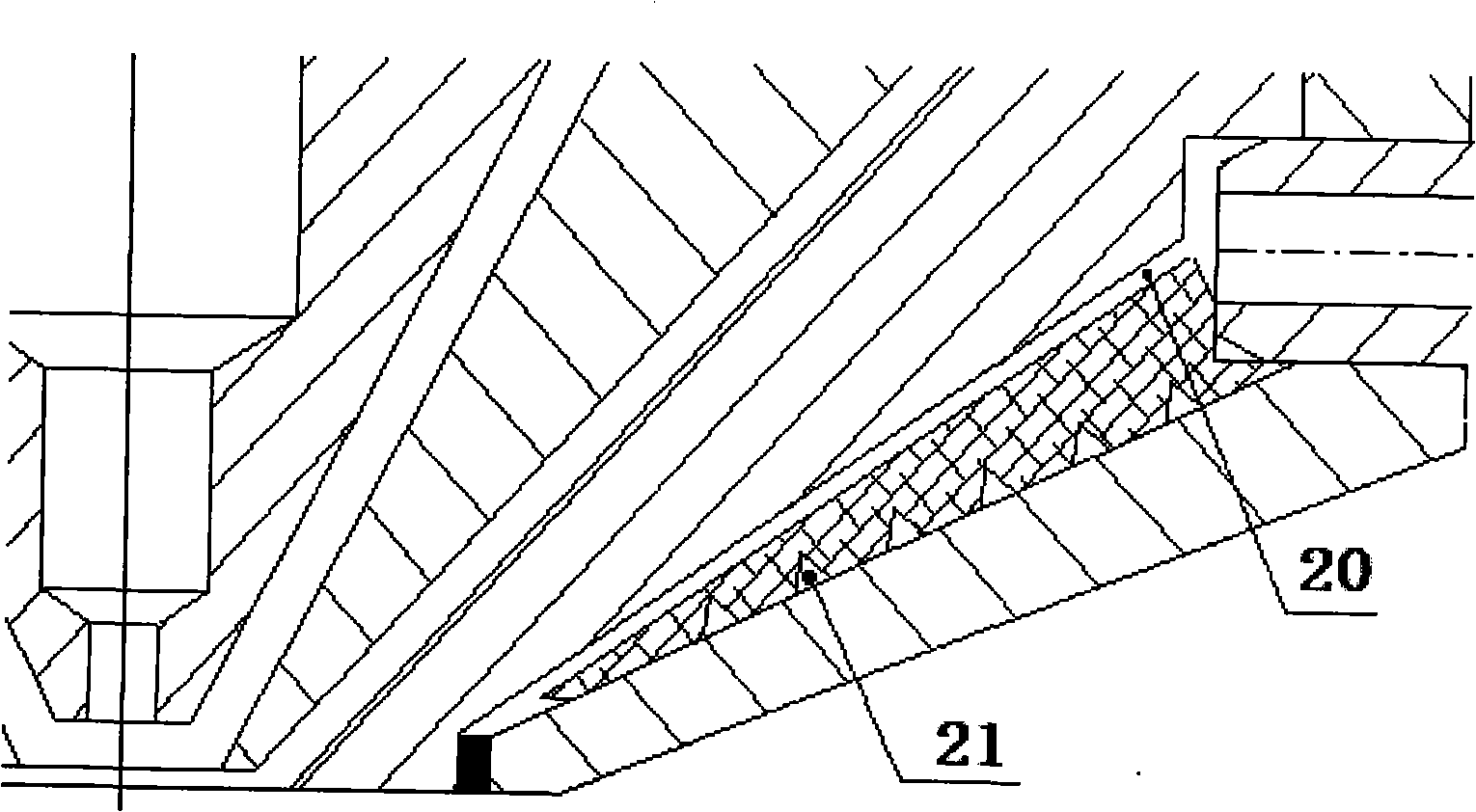

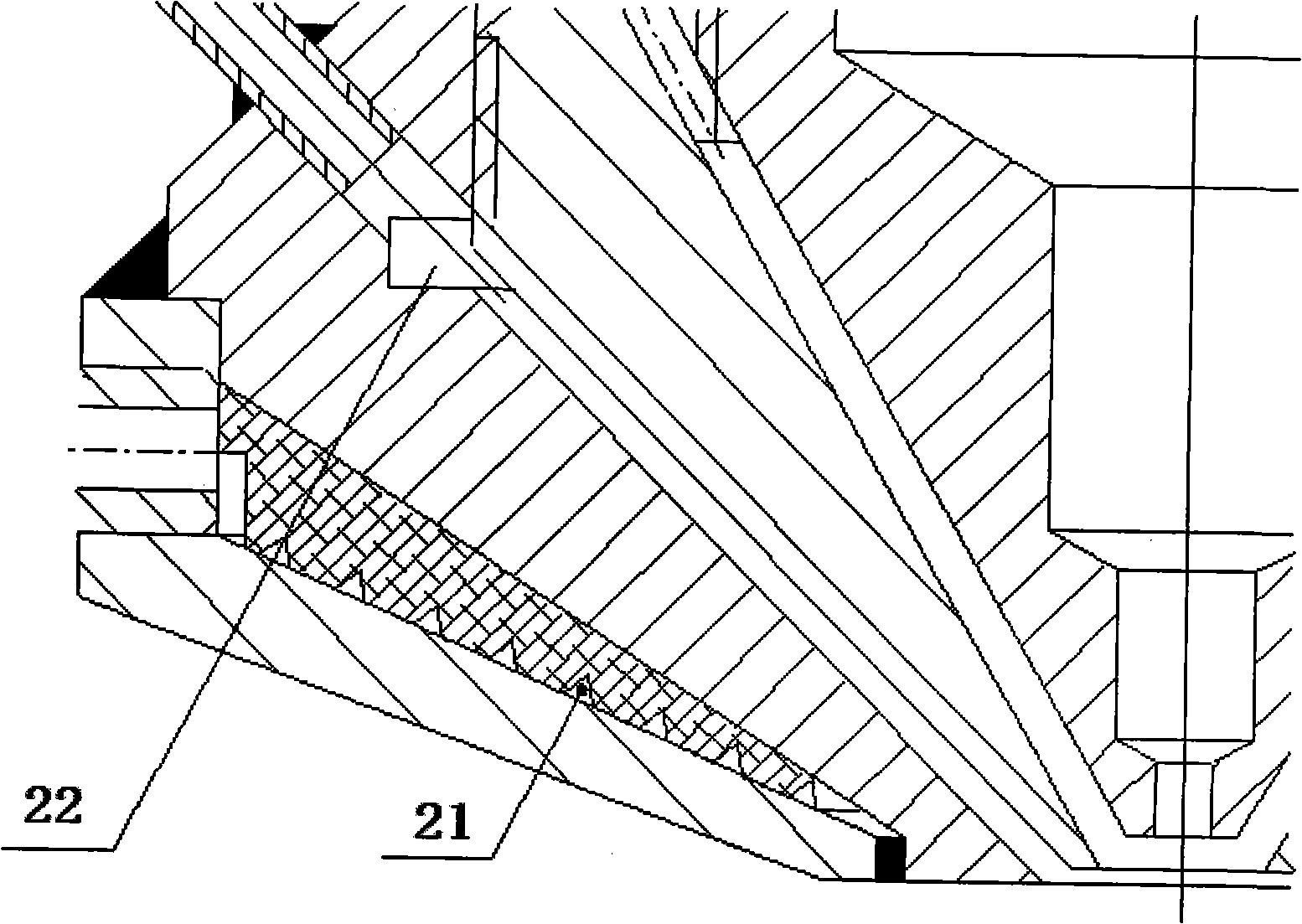

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

High-capacity metal lithium powder composite cathode and preparation method thereof, and multi-layer composite electrode

InactiveCN102201565AHigher quality than capacityQuality improvementNon-aqueous electrolyte accumulator electrodesAdhesiveTin

The invention discloses a high-capacity metal lithium powder composite cathode and a preparation method thereof and a multi-layer composite electrode. The high-capacity metal lithium powder composite cathode comprises the following components in part by weight: 1 to 80 parts of metal lithium powder, 10 to 90 parts of cathode powder, 1 to 10 parts of conductive agent, 1 to 4.5 parts of adhesive and 0 to 0.5 part of surfactant. By compounding the metal lithium powder with materials such as graphite, soft carbon, hard carbon, tin and oxides thereof, silicon and oxides thereof and the like, mass ratio capacity and volume ratio capacity of a cathode material are improved, using amount of active substances is reduced, and the battery specific capacity is improved; the specific capacity of the cathode can be adjusted by adjusting the rate of metal lithium to the graphite; short circuit in a battery caused by piercing of a diaphragm through metal dendritic crystal growth can be effectively prevented through the separation of an insulating protective layer, so that the safety performance of the battery is improved; and the metal lithium powder is counteracted with irreversible capacity loss of the cathode, and primary Kulun efficiencies of the graphite, the hard carbon, the soft carbon, the tin, the silicon and other cathode materials are improved.

Owner:EC POWER LLC

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

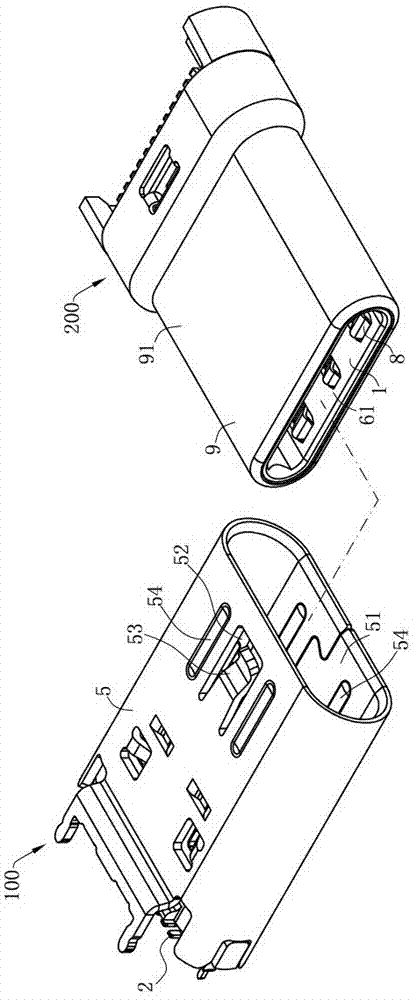

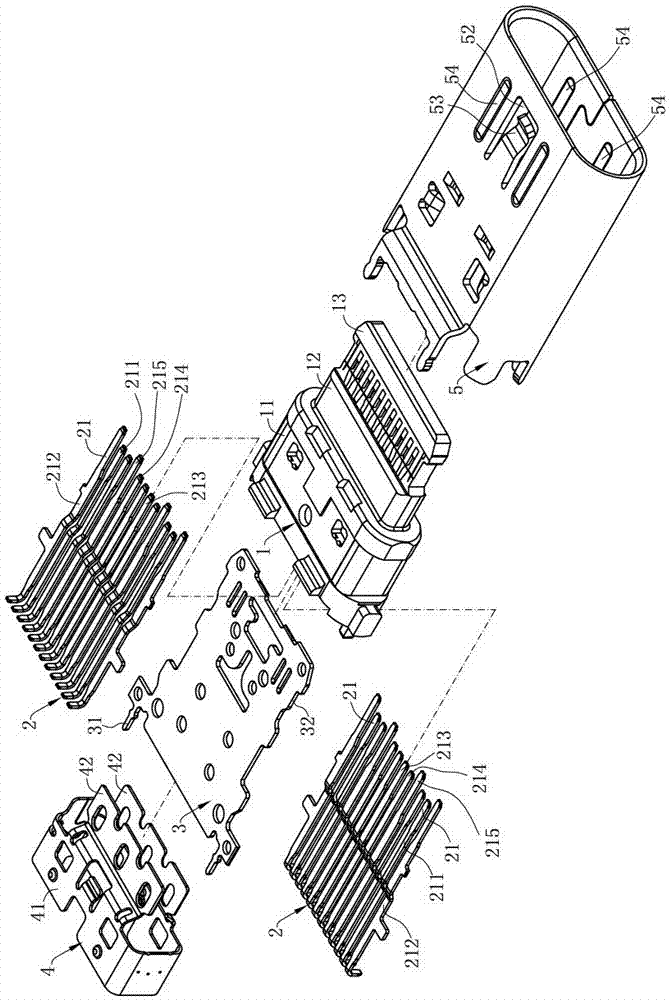

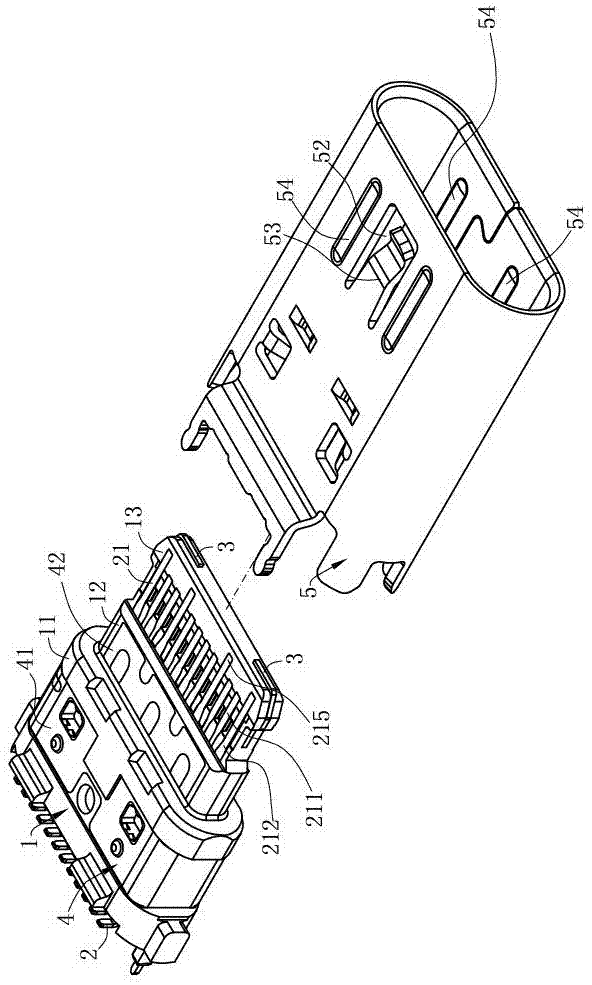

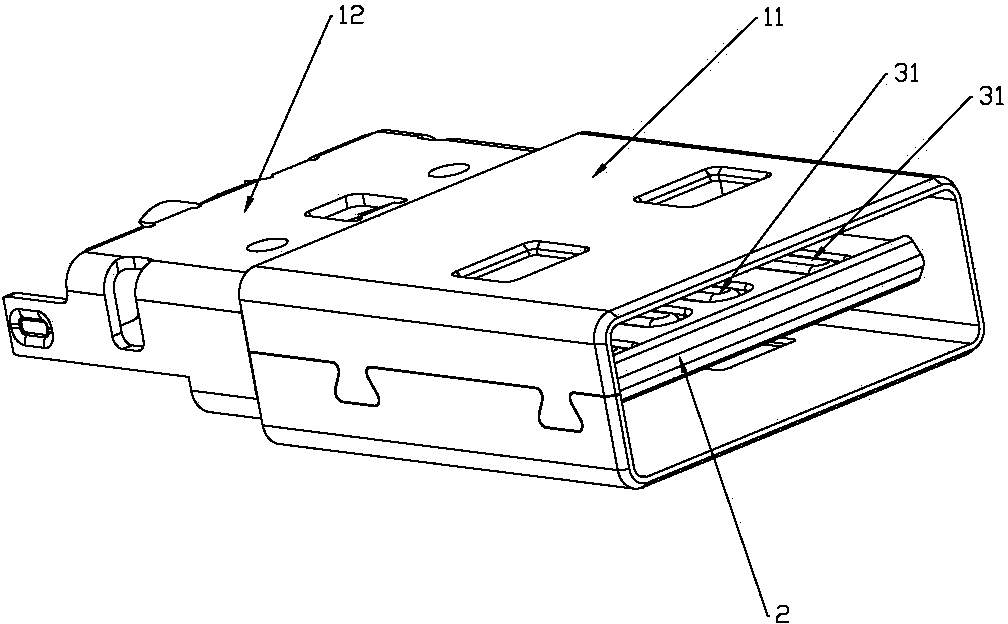

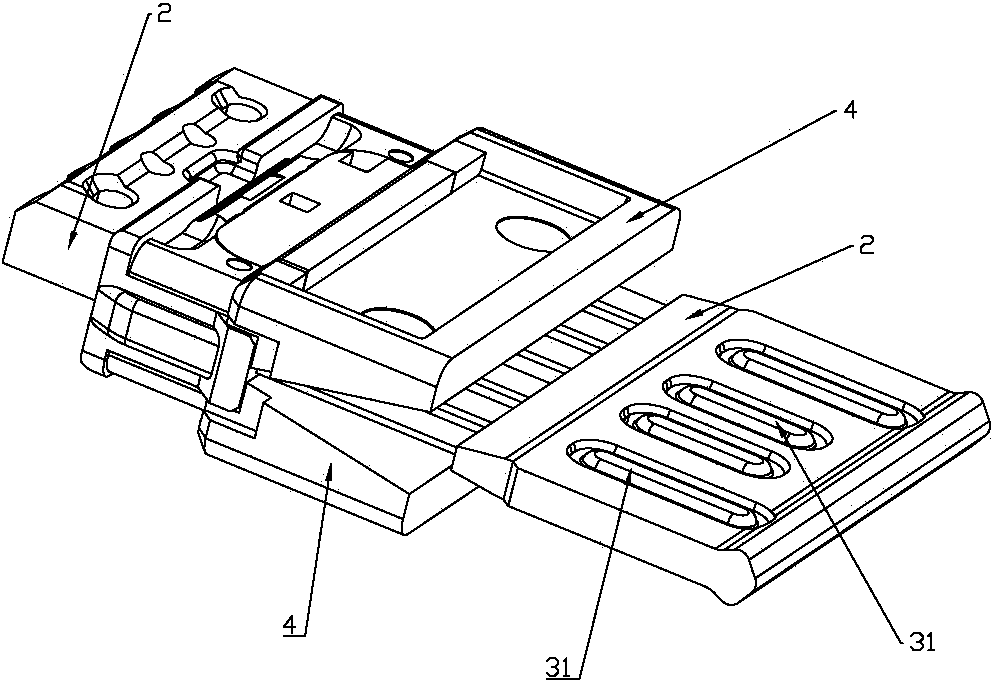

Electrical connector combination

ActiveCN107104329AAvoid short circuitReliable electrical connectionCoupling contact membersTwo-part coupling devicesEngineeringElectrical connector

The invention discloses an electrical connector combination. The electrical connector combination comprises an electrical connector and an abutting connector, wherein the electrical connector comprises a base and a tongue plate, the tongue plate forwards extends from the base, a first signal terminal is fixedly arranged on the base and is exposed on a surface of the tongue plate, an insertion space is formed between a metal shell and the tongue plate, the abutting connector comprises a plastic seat, a second signal terminal is fixedly arranged on the plastic seat and extends and enters an abutting space, a grounding elastic sheet is fixedly arranged on a wall part and is in contact with a shielding shell, the electrical connector and the abutting connector are provided with a first abutting state and a second abutting state when the electrical connector and the abutting connector are abutted along an abutting direction, in the first abutting state, the shielding shell partially enters the insertion space and communicates with the metal shell, a gap is formed between the grounding elastic sheet and the first signal terminal, and the second signal terminal is not in contact with the first signal terminal, and in the second abutting state, the tongue plate is inserted into the abutting space, the shielding shell communicates with the metal shell, and the second signal terminal is in contact with the first signal terminal.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

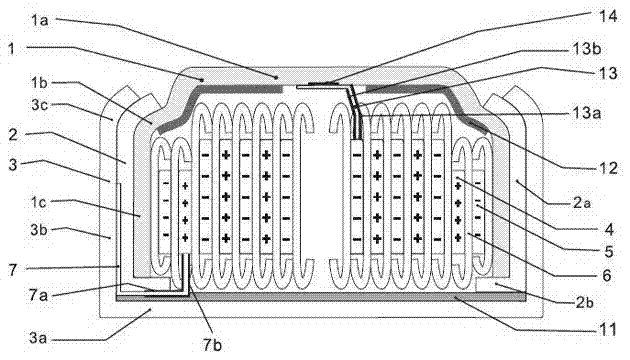

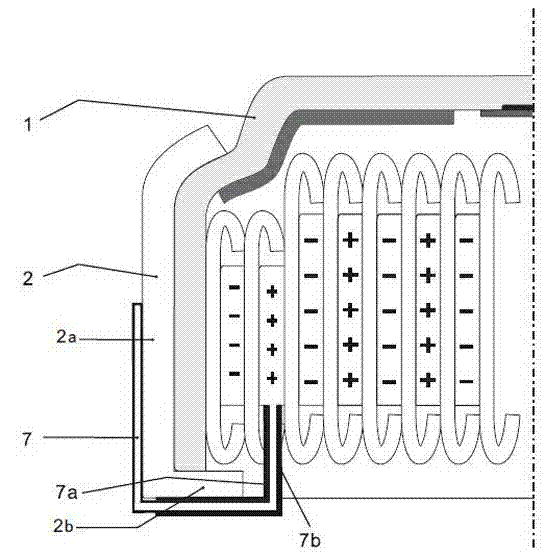

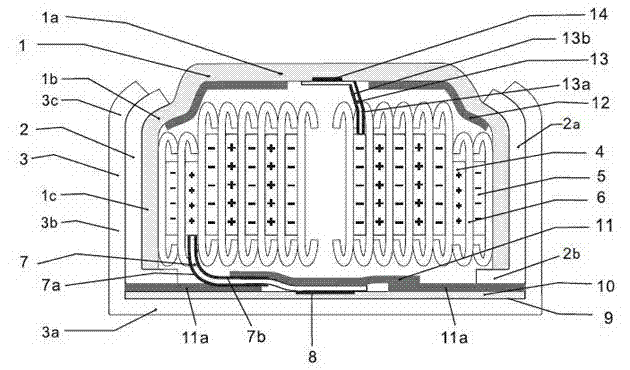

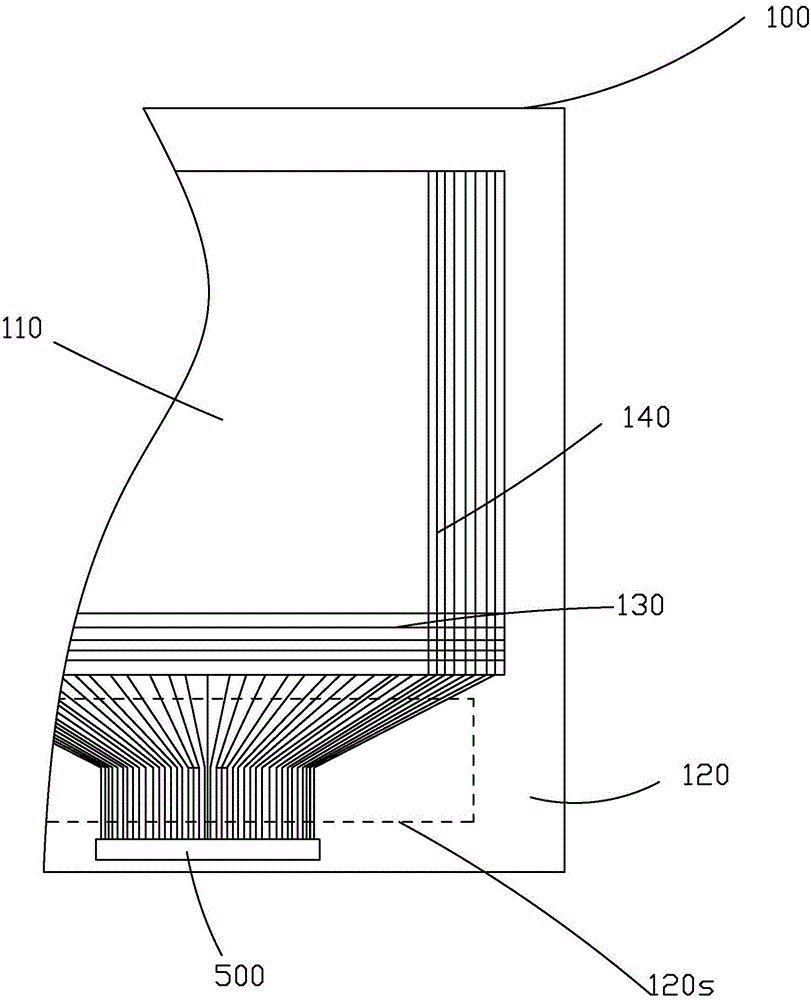

Rechargeable lithium ion button cell battery

ActiveCN104332647AAvoid short circuitImprove reliabilityFinal product manufactureCylindrical casing cells/batteryElectrical batteryButton battery

A rechargeable lithium ion button cell battery having a sealed housing comprises an inner casing and an outer casing , both casings have at least one flat area as top or bottom of the battery, and a round or oval sidewall vertically formed to the flat area. An insulation gasket is positioned between said sidewalls, and the outer casing opening is mechanically crimped to complete the seal of the battery. Inside the sealed housing the anode and cathode electrodes are spiral wound with separator to be a round or oval roll. Said roll axis is vertical to the said flat areas of the casings. The two electrodes are tapered in width to fully utilize the inner space. The electrodes comprise current collectors of metal foils coated with lithium-intercalating active materials, leaving small area of uncoated metal foils as conductor tabs for connecting the electrodes to the casings. The tabs could be welded or by tight contacting to the casings, in several options. Insulation washers or tapes are applied to the naked metal surfaces of the electrodes or casings inside of the housing to prevent short circuit and enable the battery to have longer cycle life.

Owner:ZHUHAI ZHI LI BATTERY

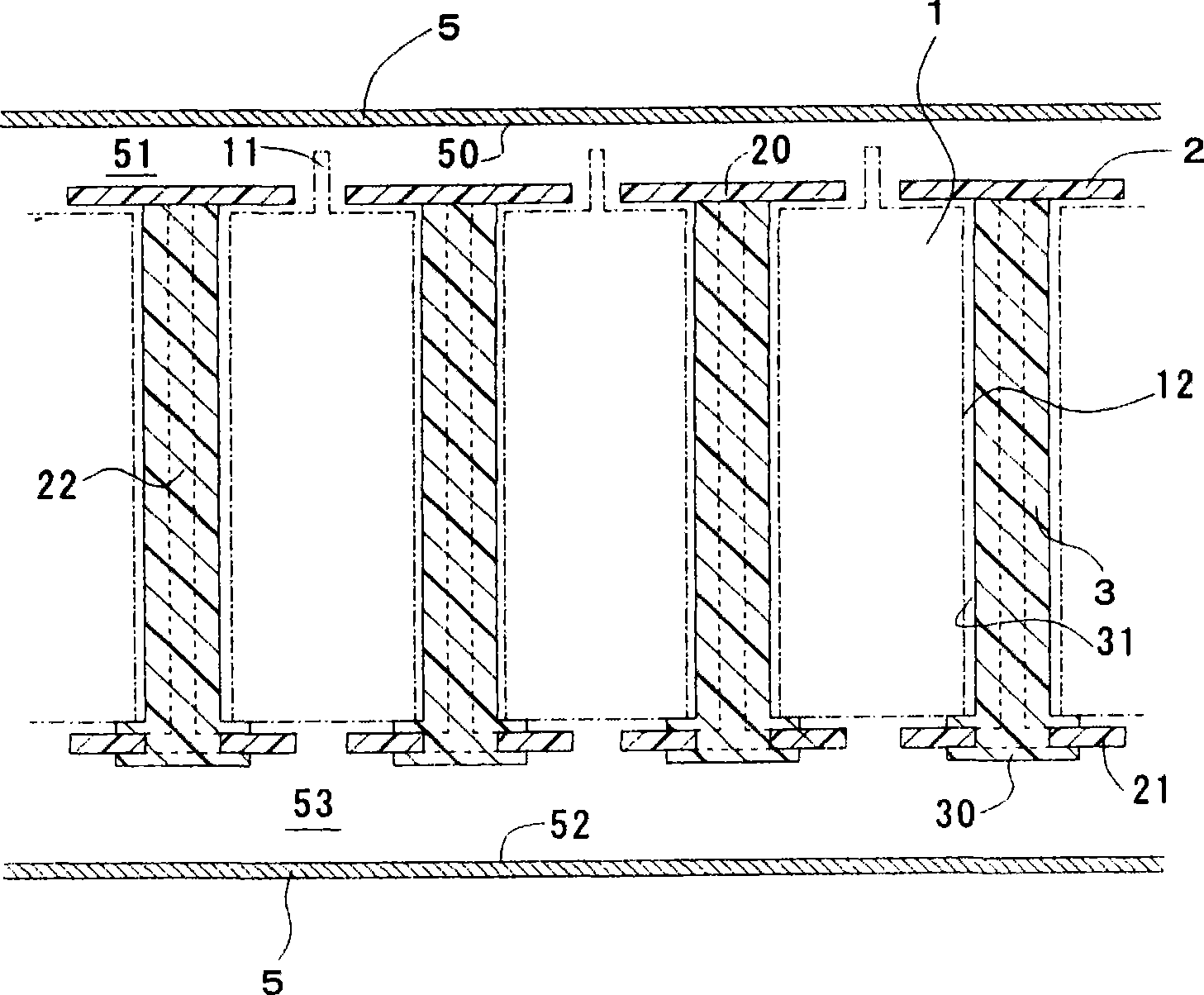

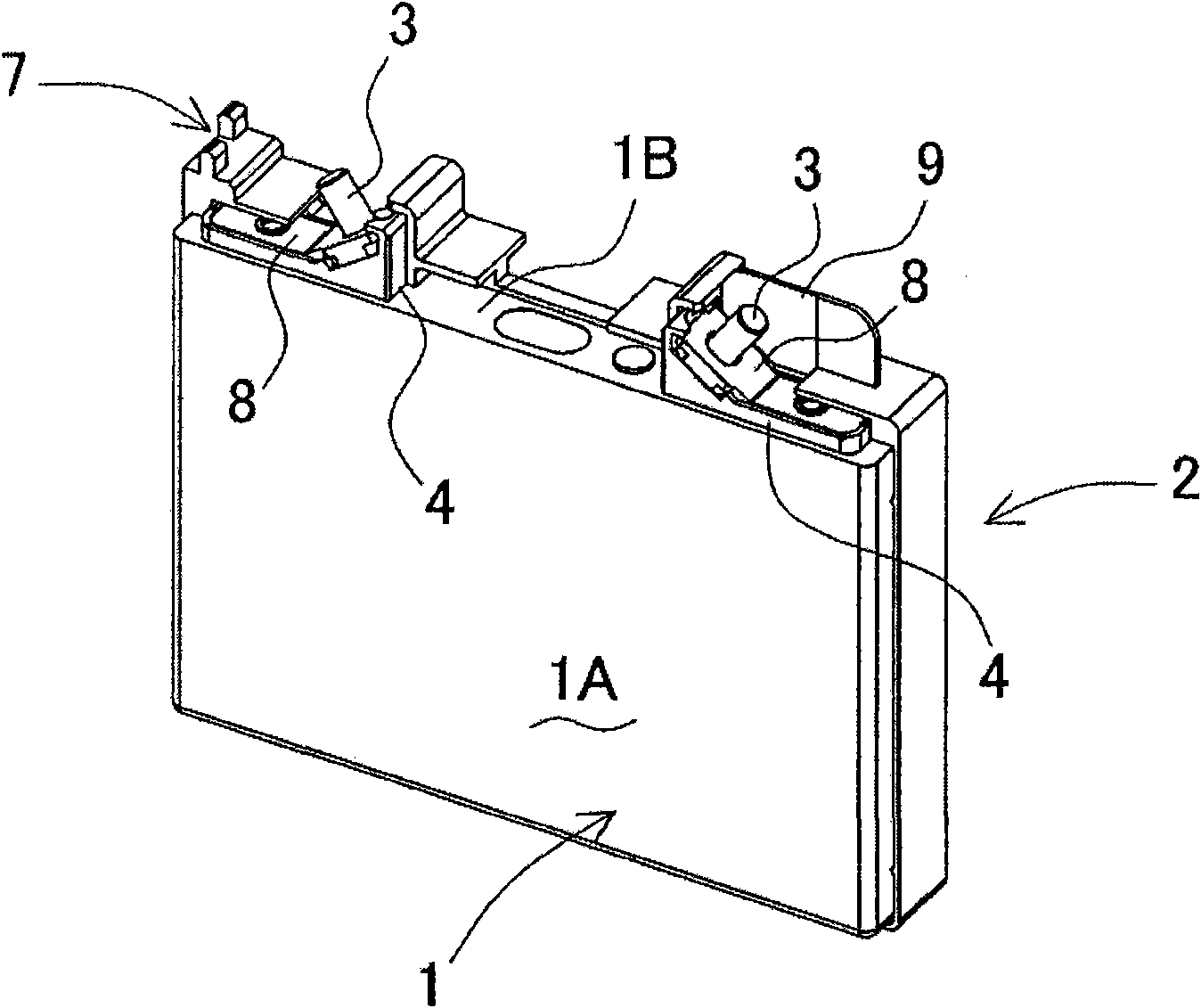

Battery assembly

ActiveCN101378141ASave car spaceAvoid short circuitCell temperature controlCell component detailsSoft materialsMechanical engineering

A battery assembly includes single-battery cells, and thermally-conductive members. The thermally-conductive members are formed of a soft material as a plated configuration. The soft material exhibits thermal conductivity and electric insulatability. The single-battery cells, and the thermally-conductive members are adhered to each other, and are disposed one after another alternately in a row, thereby interposing the thermally-conducive members between the single-cell batteries. The thermally-conductive members include a radiation surface respectively from which heat that the single-battery cells produce radiates. The single-battery cells are cooled indirectly by cooling the radiation surfaces of the thermally-conductive members.

Owner:TOYODA GOSEI CO LTD

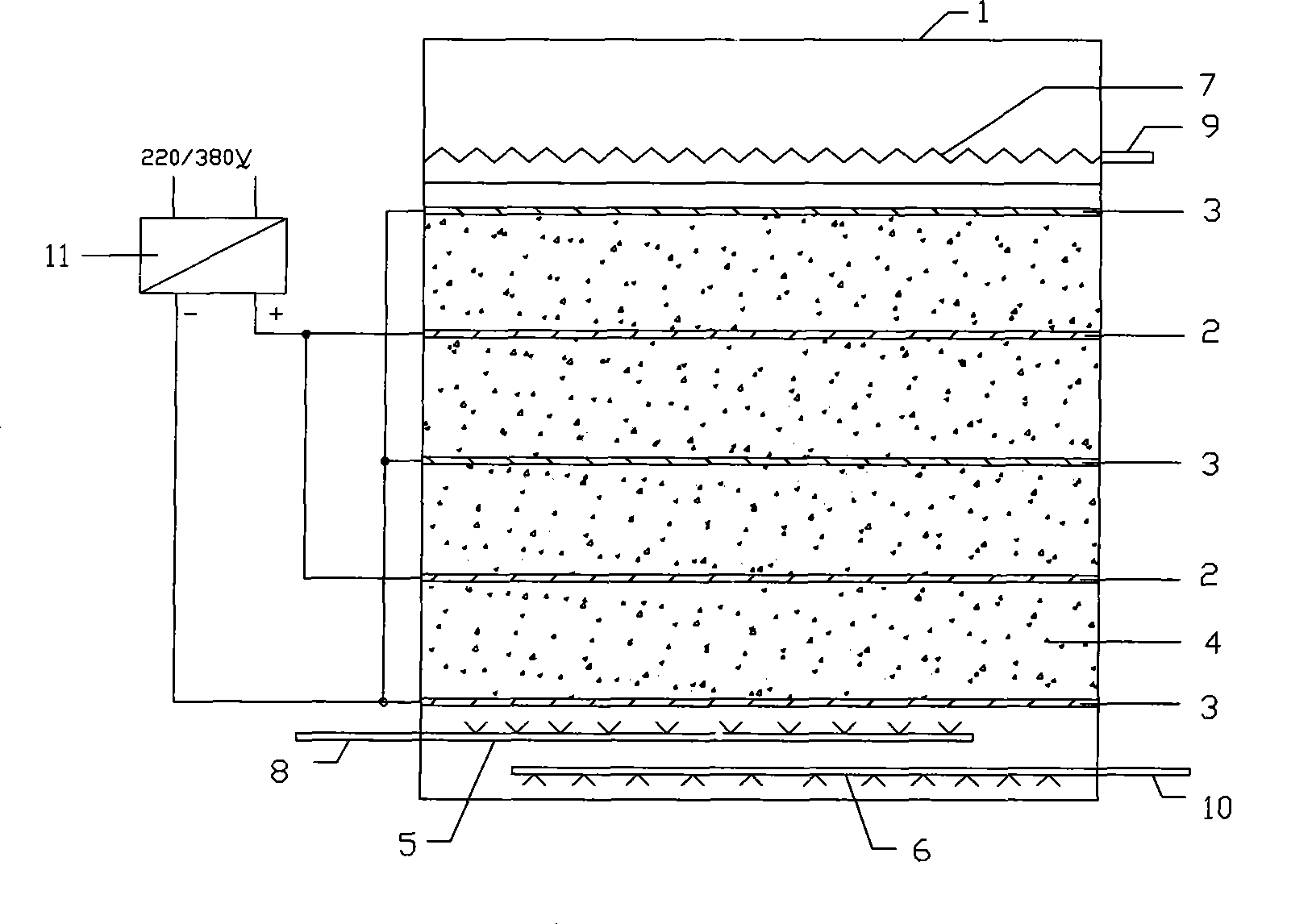

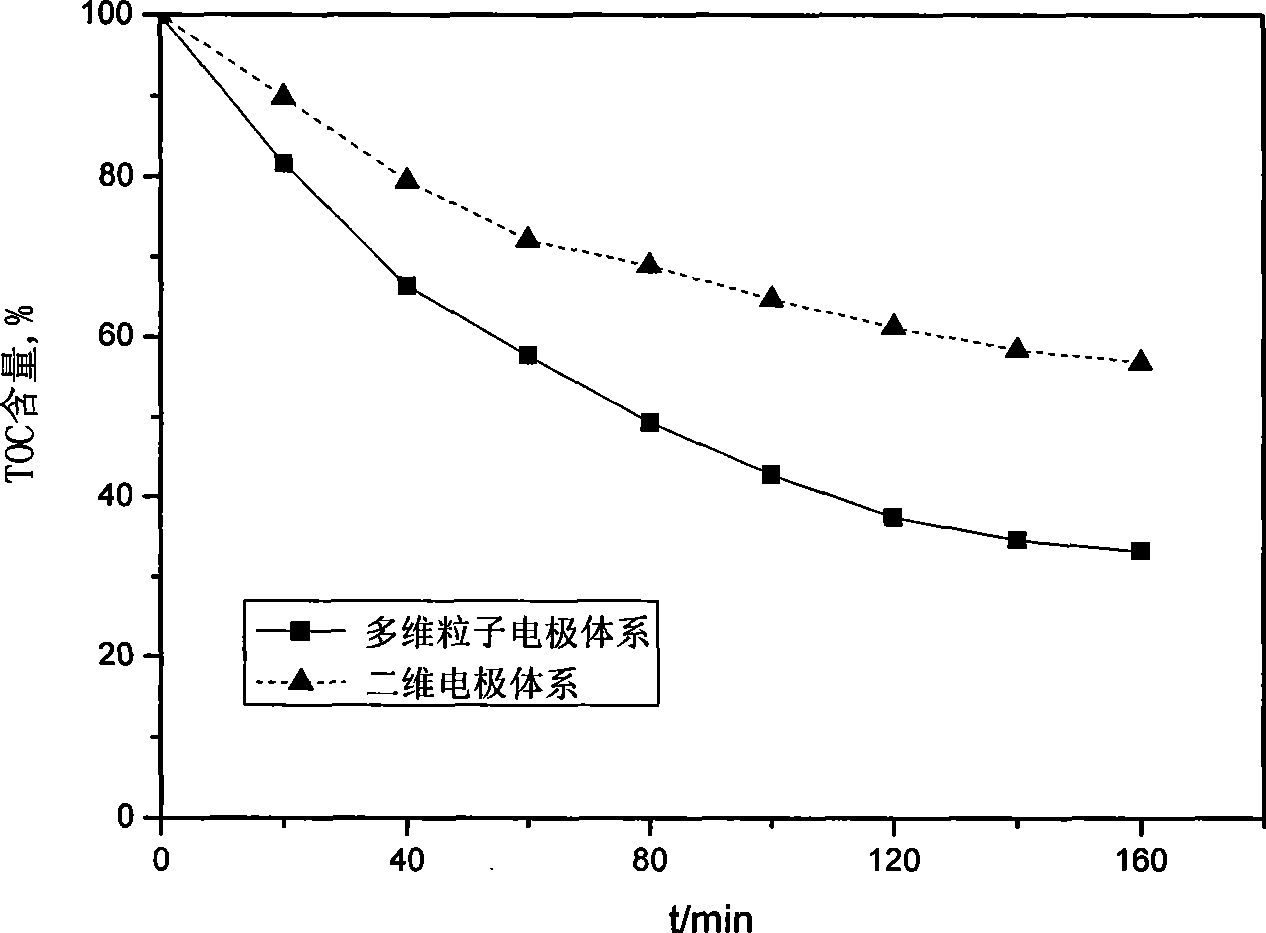

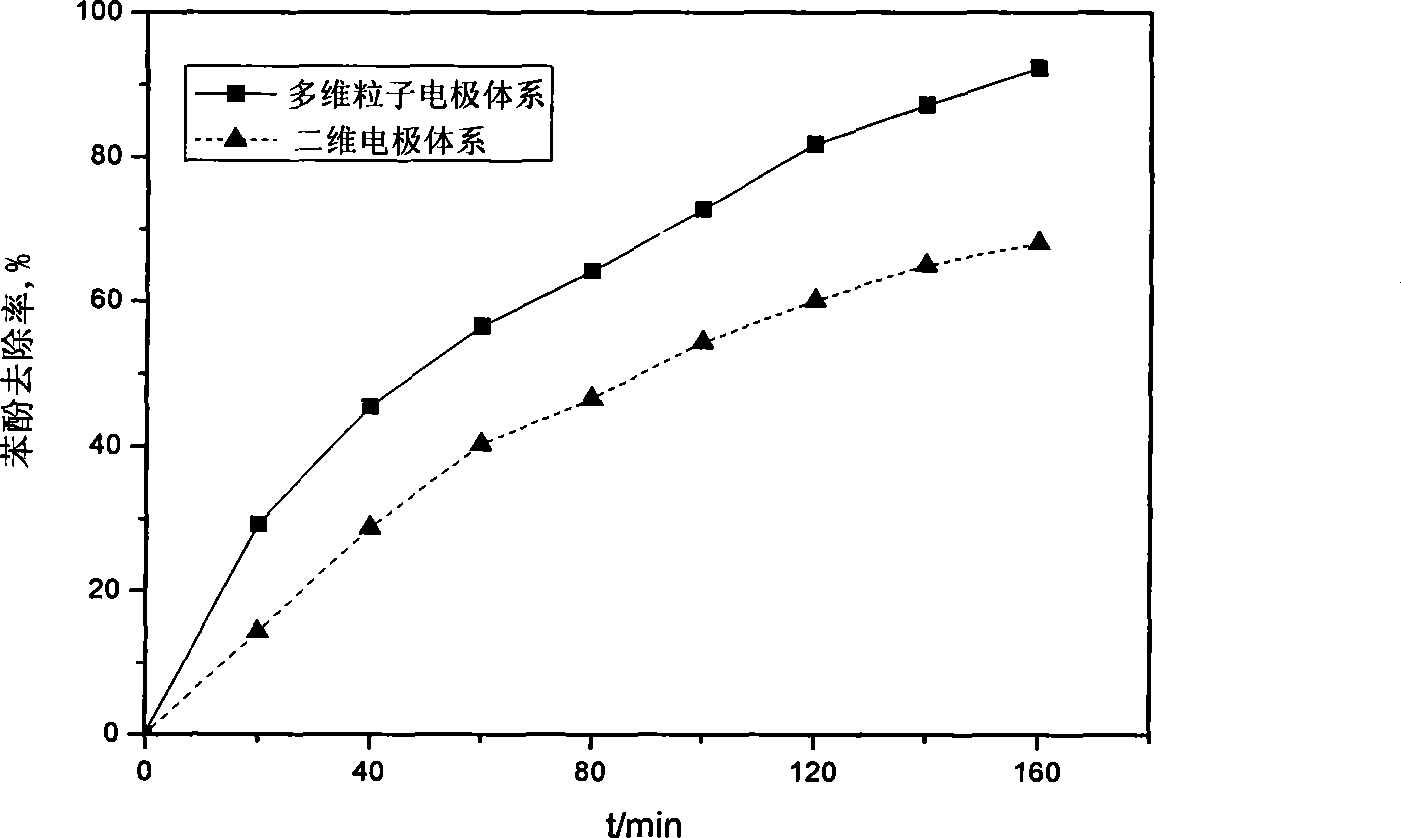

Wastewater treatment device of horizontal polar plate multi-electrodes electrocatalysis reactor

ActiveCN101423266AGuaranteed to alternateAvoid short circuitWater/sewage treatment by electrochemical methodsElectricityWater flow

Horizontal polar plate multi-dimensional electrode electrocatalysis reactor wastewater treatment equipment comprises a shell, a cathode plate and an anode plate which are relatively parallel, a particle electrode filled between the cathode plate and the anode plate, a water distributor, a water inlet pipe, an aerator, an air inlet pipe, an effluent weir trough, a water outlet pipe and a power supply; the cathode plate and the anode plate are respectively connected with the cathode and the anode of the power supply; a plurality of through holes are distributed on the cathode plate and the anode plate which are horizontally positioned in the shell of the equipment; the water distributor, the water inlet pipe, the aerator and the air inlet pipe are positioned at the lower part of the shell of the equipment; and the effluent weir trough and the water outlet pipe are arranged at the upper part of the shell of the equipment. After being evenly distributed by the water distributor, the wastewater flows across a reactor from bottom to top; the horizontal polar plate structure design not only avoids the short circuit of water flow and improves the mass transfer effect, but also ensures that the wastewater can alternatively flow across the cathode plate and the anode plate and the oxidation reaction of the anode plate and the reduction reaction of the cathode plate coexist in a system, and causes different organic pollutants in wastewater which can be degraded by the oxidation reaction and the reduction reaction to be degraded and treated.

Owner:南京赛佳环保实业有限公司

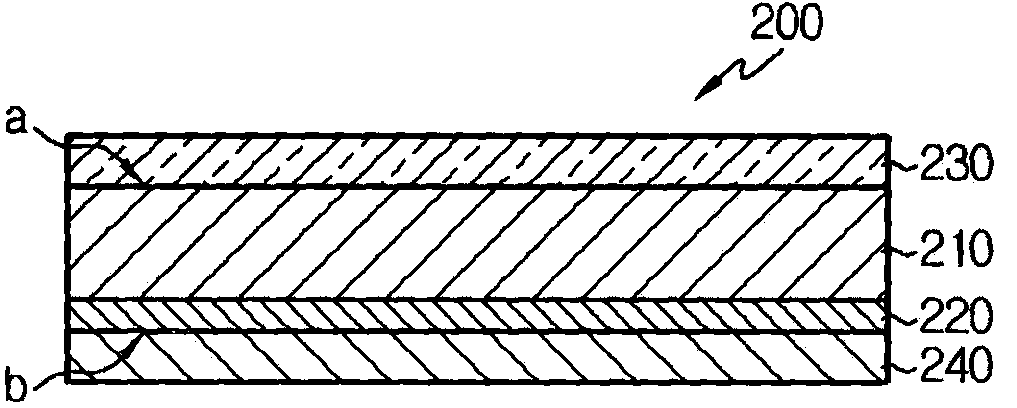

Separator, manufacturing method thereof, and electrochemical device employing same

ActiveCN103493253APrevent infiltrationReduce transfer rateFinal product manufactureCell electrodesPorous substratePorous coating

Disclosed is a separator in which a porous coating layer is formed of a mixture of inorganic material particles and a binder polymer on the surface of a porous substrate.

Owner:LG ENERGY SOLUTION LTD +1

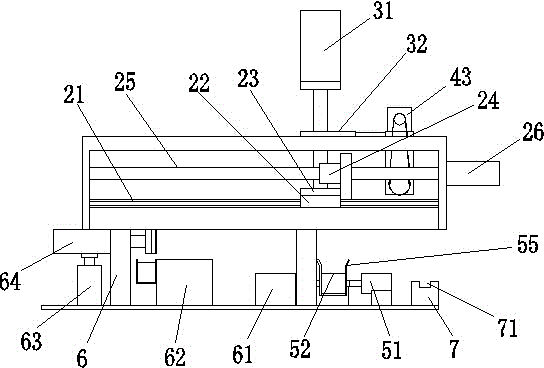

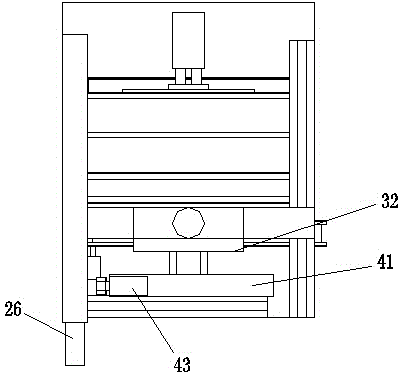

Automatic soldering tin machine for terminal pin of transformer

InactiveCN104923875ASimple structureReasonable designPrinted circuitsMetal working apparatusElectric machineTransformer

The invention discloses an automatic soldering tin machine for a terminal pin of a transformer. The automatic soldering tin machine for the terminal pin of the transformer comprises a machine frame, a transverse movement device, a lifting device, a clamping device, a soldering tin device and a feeding device. The transverse movement device comprises guide rails, a sliding block is arranged on the guide rails, the sliding block is connected with a transverse movement plate, the transverse movement plate is connected with a sliding sleeve, the sliding sleeve is connected with a transverse movement screw, and one end of the transverse movement screw is connected with a transverse movement motor. The lifting device comprises a lifting motor, the lifting motor is installed on a lifting frame, and the lifting frame is connected with the transverse movement plate through a guide rod; the output end of the lifting motor is connected with a lifting lead screw, and a lifting plate is arranged on the lifting lead screw. The clamping device comprises a support connected with the lifting plate, a transmission motor is arranged on the support, the output end of the transmission motor is in transmission connection with a clamping part through a belt, and the clamping part is hinged to the lower portion of the support. The soldering tin device comprises a scaling powder groove and a molten tin bath. The automatic soldering tin machine for the terminal pin of the transformer has the advantages of being simple in structure, reasonable in design, high in automation degree and stable in operation; in addition, the working efficiency is high, discharging is order, and the terminal pin of the transformer can be welded edge by edge.

Owner:江西耀润磁电科技有限公司

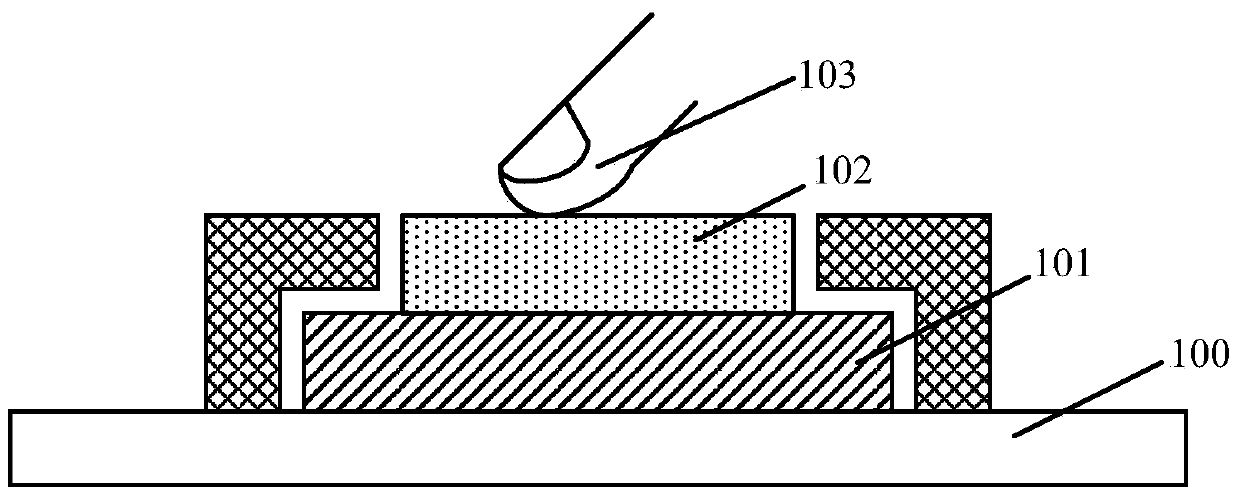

Packaging structure and packaging method for fingerprint recognition chip

InactiveCN104051367AReduce manufacturing costPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringFingerprint

The invention discloses a packaging structure and a packaging method for a fingerprint recognition chip. The packaging structure comprises a substrate, a sensing chip, a plurality of wires and a plastic package layer. The substrate is provided with a first surface, and the first surface of the substrate is provided with a first welding pad layer. The sensing chip is located on the first surface of the substrate and provided with a first surface and a second surface, the second surface of the sensing chip is located on the first surface of the substrate, the first surface of the sensing chip is provided with a sensing area and a peripheral area, and the surface of the portion, in the peripheral area, of the sensing chip is provided with a second welding pad layer. The two ends of the wires are electrically connected with the first welding pad layer and the second welding pad layer respectively, the wires have top points with the maximum distance to the surface of the substrate, and a first distance is reserved between the top points and the first surface of the sensing chip. The plastic package layer is located on the surface of the substrate and the surface of the sensing chip and surrounds the wires and the sensing chip, and a second distance is reserved between the surface of the plastic package layer and the first surface of the sensing chip and is larger than the first distance. According to the packaging structure, the requirement for the sensitivity of the sensing chip is lowered, and application is wider.

Owner:CHINA WAFER LEVEL CSP

Lead free solder paste and application thereof

ActiveCN101232967ADamage causedAvoid short circuitPrinted circuit assemblingWelding/cutting media/materialsDicarboxylic acidCarboxylic acid

A solder paste composed of solder alloy powder and flux, the volume expansion rate of which is 0.5% or less when the solder alloy is melted, and the flux contains bisphenol A type epoxy resin and a hardening agent selected from carboxylic anhydrides and dicarboxylic acids agent, the solder paste can be used for high temperature solder applications. In terms of mass%, the solder alloy has the following alloy composition: 70-98 mass% of Bi; 0-0.5% of Ag, Cu, Sb, In, Zn, Ni, Cr, Fe, Mo, P, Ge and One or more elements selected from Ga; the balance is composed of Sn.

Owner:SENJU METAL IND CO LTD +1

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

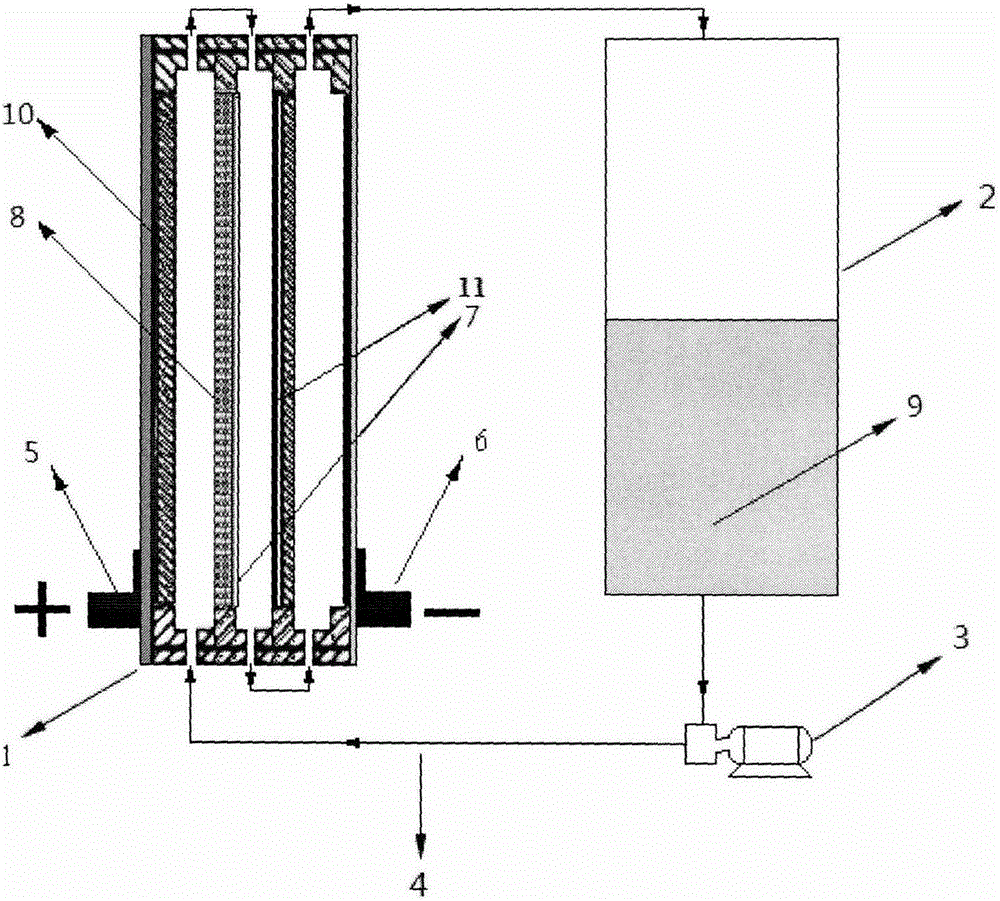

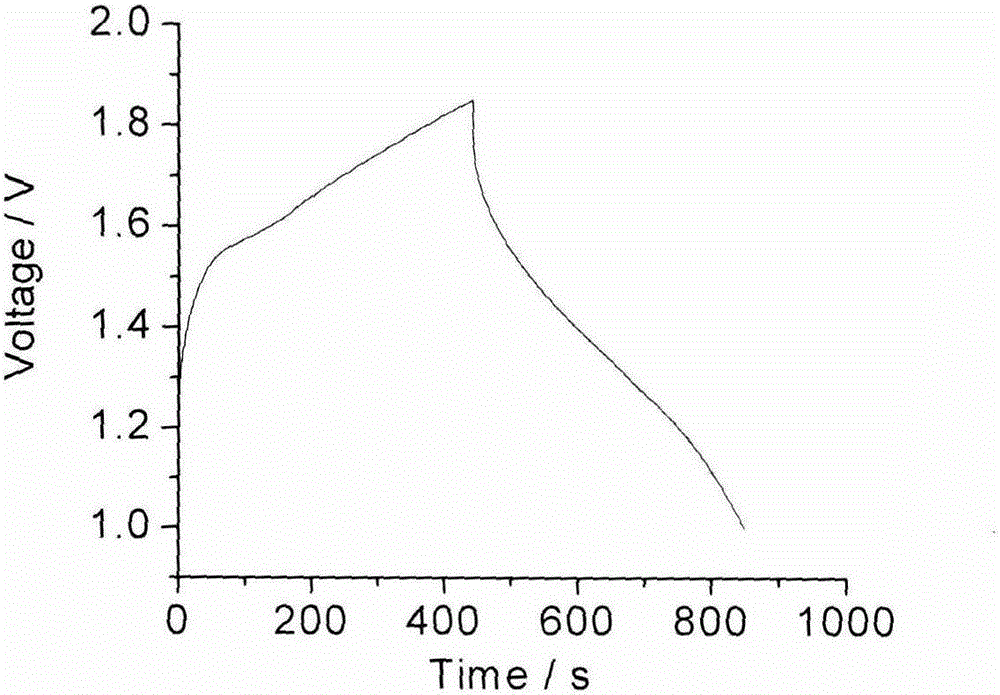

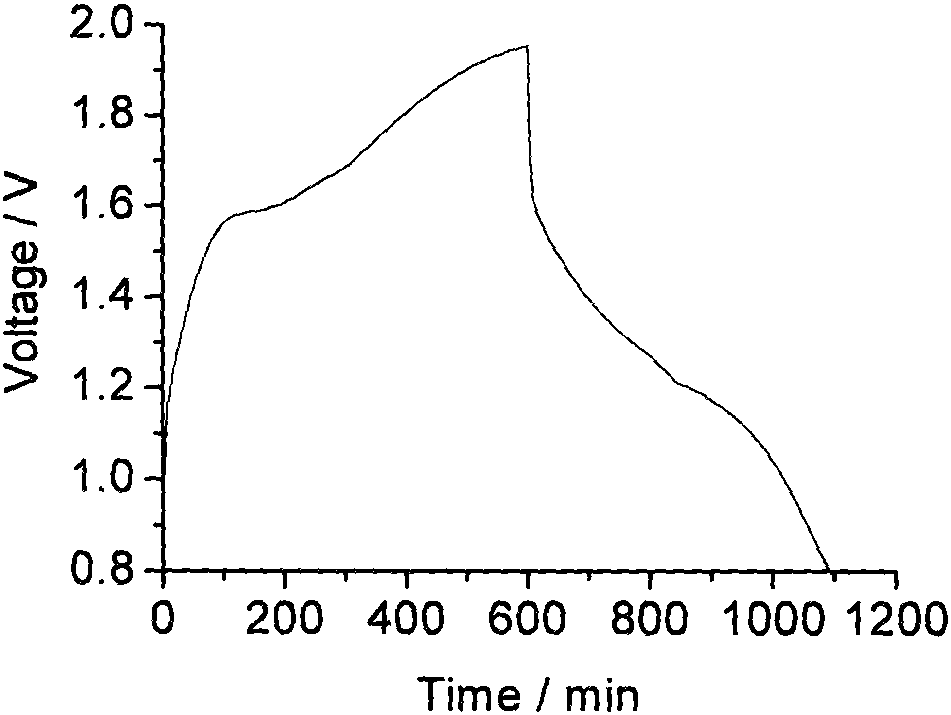

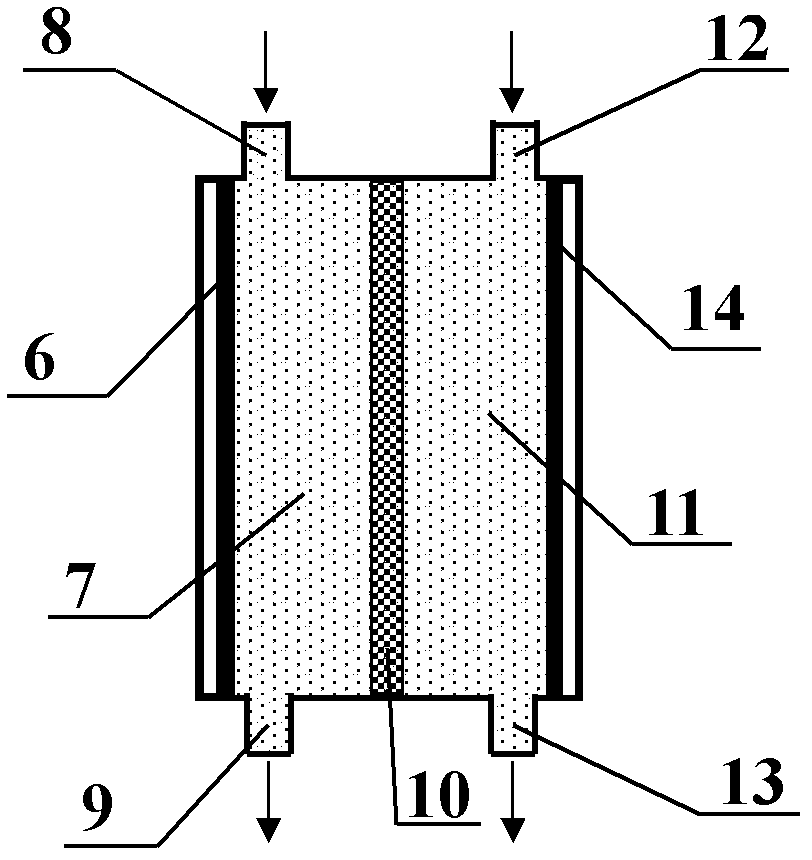

Water-based zinc-manganese single flow battery

ActiveCN105336971AIncrease the speed of mass transferEliminate deformationRegenerative fuel cellsWater basedManganese oxide

The invention relates to a water-based zinc-manganese single flow battery; a positive electrode active material is an oxide of manganese, a metal composite oxide, a metal oxide or a carbon material, a negative electrode is a zinc electrode, an electrolyte solution is a nearly neutral aqueous solution containing a zinc salt and a manganese salt, positive electrode active ions and negative electrode active ions can coexist in one electrolyte solution, and an ion exchange membrane is not required for separating the positive electrode and the negative electrode; in processes of charging and discharging, the electrolyte solution constantly flows between an electrolyte solution storage tank and an electric pile through a pipeline under pushing of a liquid pump. During charging, zinc ions are deposited onto a negative electrode current collector from the electrolyte solution, the zinc ions and manganese ions are co-embedded into the positive electrode active substance at the same time, and the manganese ions are subjected to oxidation deposition; during discharging, the negative electrode deposited zinc is dissolved into the electrolyte solution, and the positive electrode manganese oxide is partially reduced and dissolved and is extricated to the electrolyte solution with the zinc ions simultaneously. The battery has the outstanding characteristics of simple manufacture, relatively high specific energy and specific power, low cost, long cycle life, environmental friendly and the like, and is widely applied in electric power, transportation, electronics and other fields.

Owner:NO 63971 TROOPS PLA

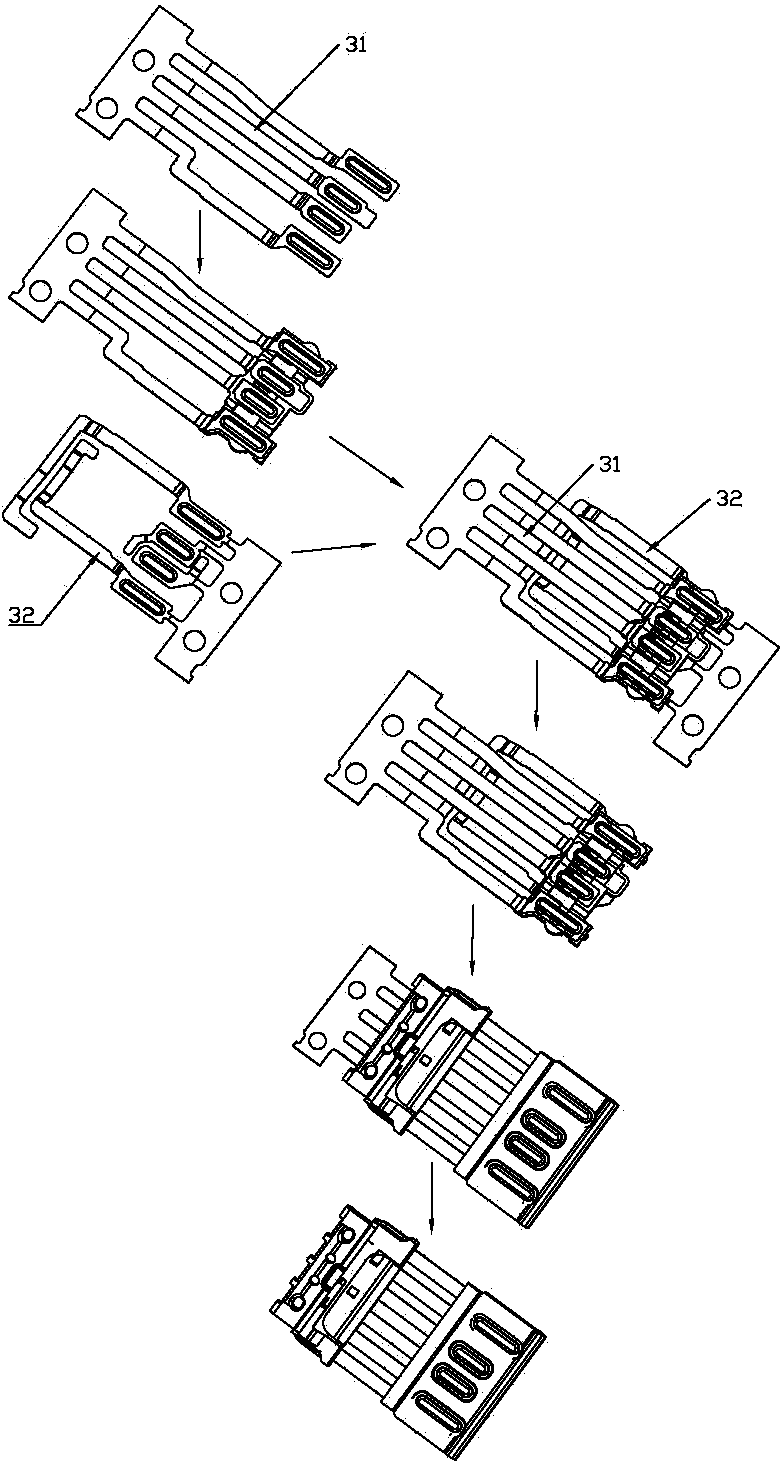

Manufacturing method of USB connector with double-face inserting function

ActiveCN103762479AReduce generationAvoid damageContact member manufacturingContact member assembly/disassemblyLaser processingEngineering

The invention relates to the technical field of connectors, in particular to a manufacturing method of a USB connector with a double-face inserting function. The method includes the following steps that firstly, first injection molding of an upper terminal is carried out; secondly, a lower terminal and the upper terminal subjected to first inject molding are subjected to laser processing together; thirdly, a conducting terminal subjected to laser processing is subjected to second injection molding. The upper terminal and the lower terminal are processed in a twice injection molding mode, the short-circuit phenomenon possibly happening in the first injection molding process is avoided, and the possibility of generating defective products is effectively reduced. The USB connector manufactured according to the method can be freely inserted into equipment without considering the positive direction and reverse direction, can be easily recognized by the equipment and is very convenient to use and effectively prevents connectors from being damaged in the insertion process.

Owner:盐城市悦之泽汽车零部件有限公司

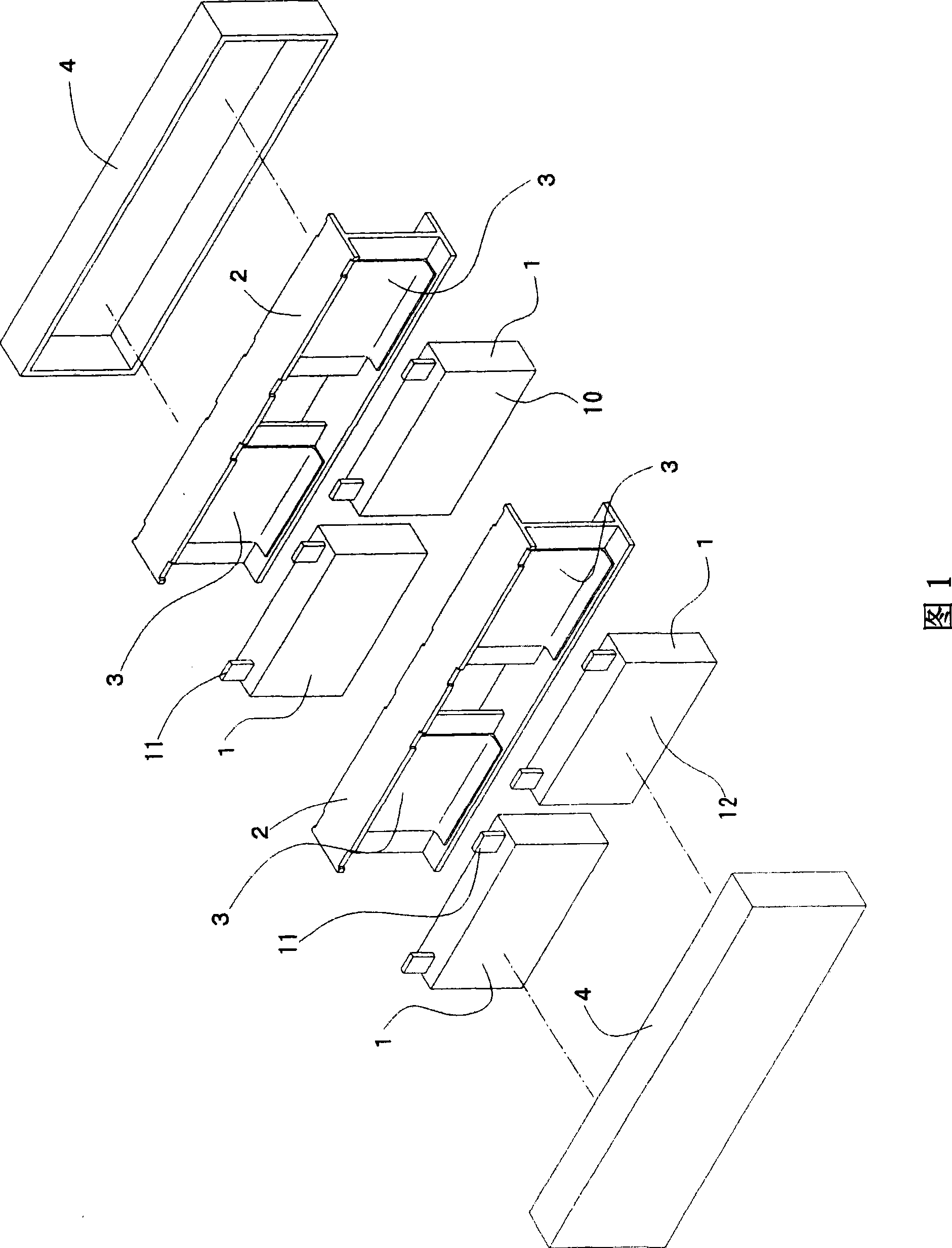

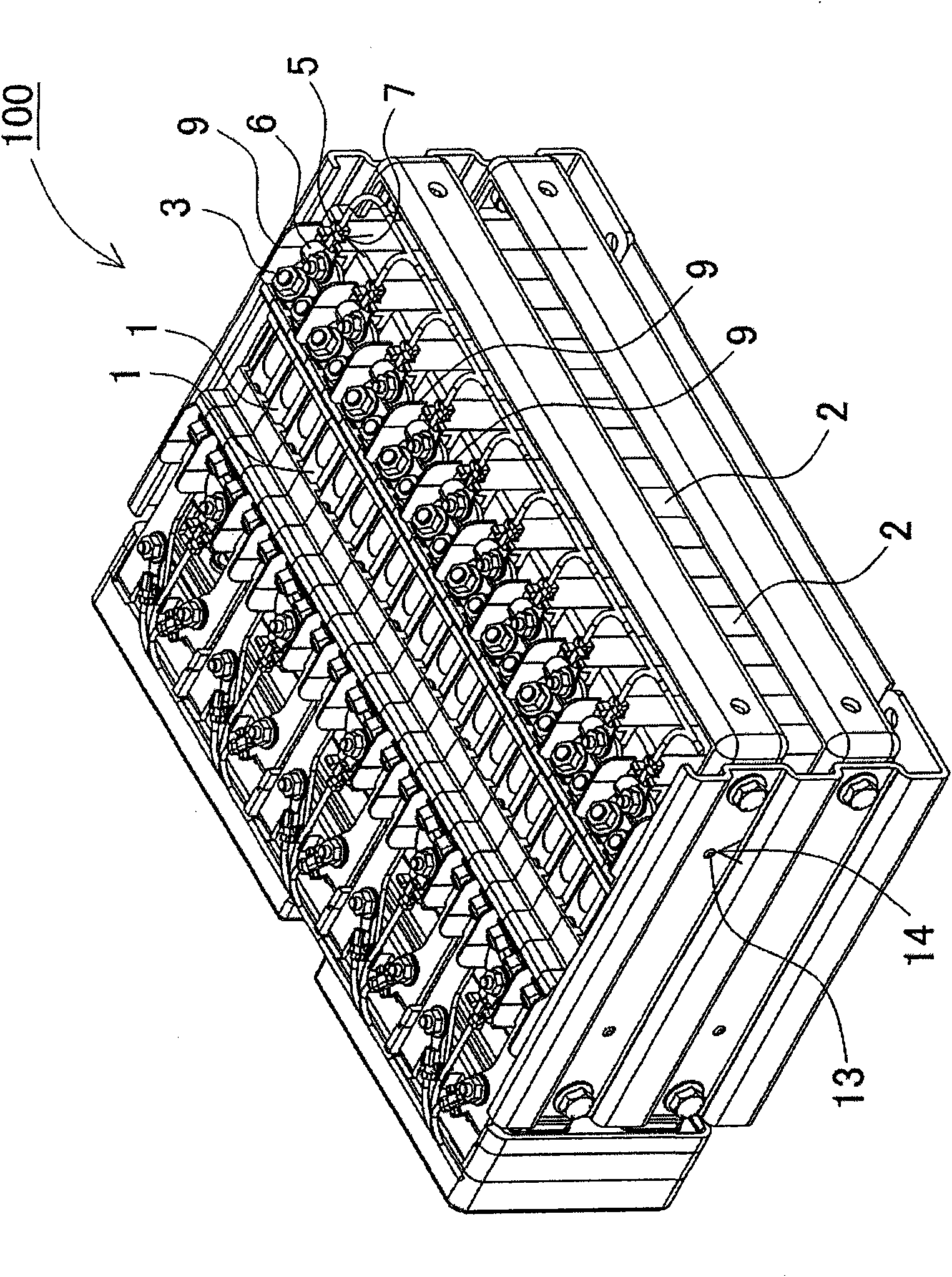

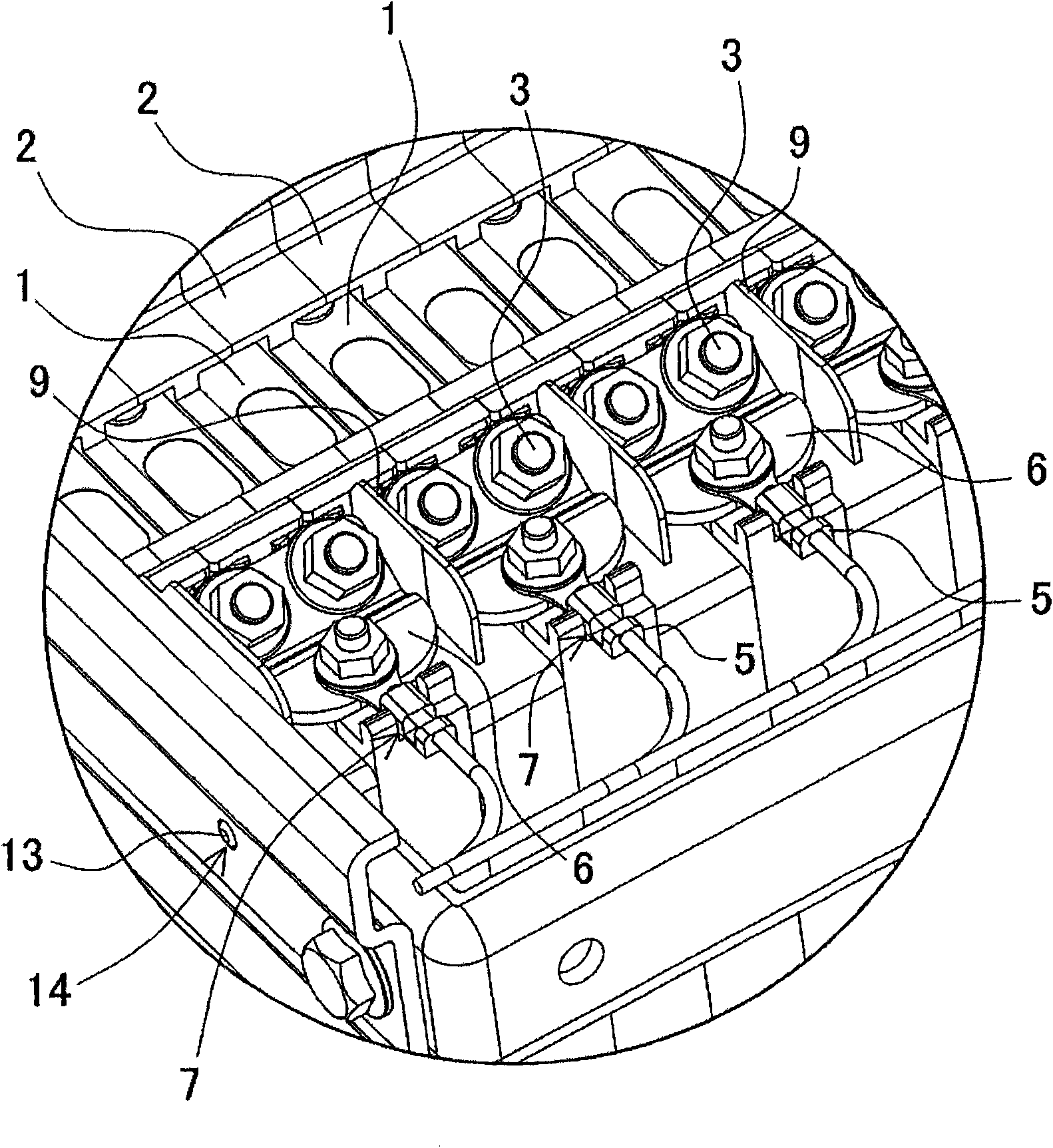

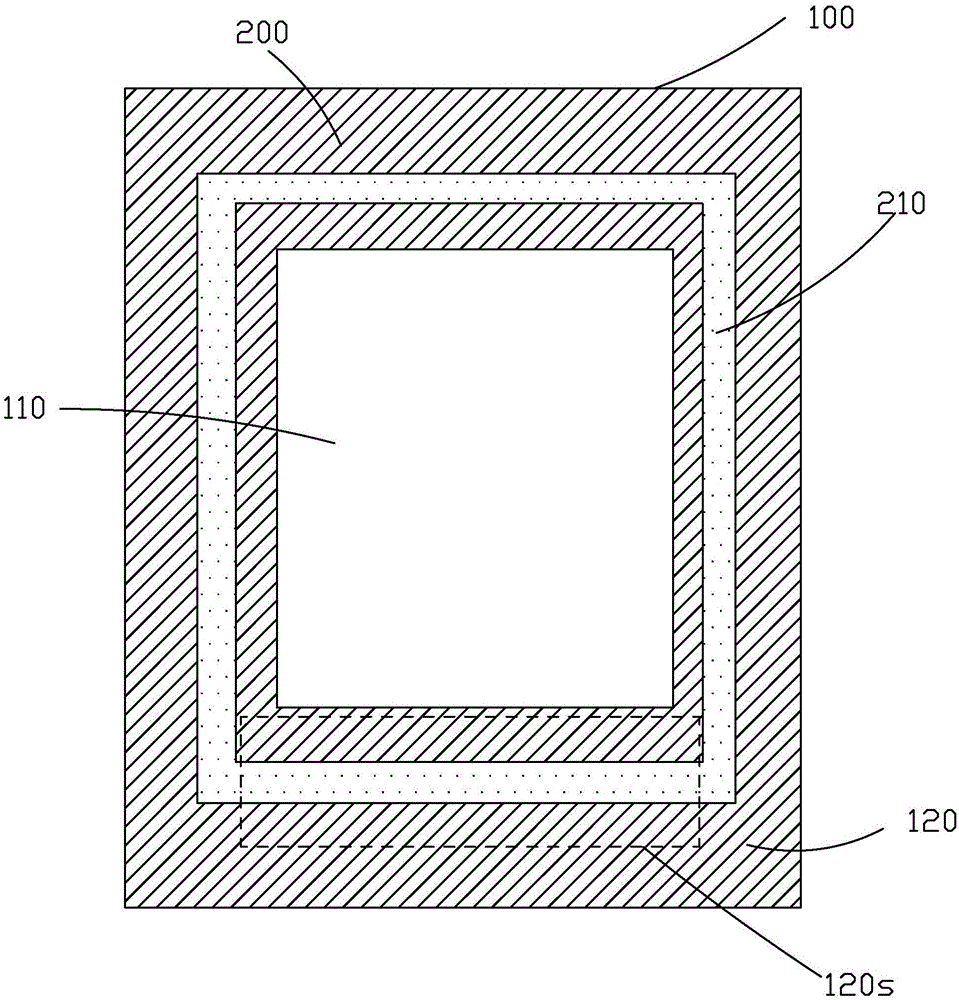

Battery array and battery array separator

ActiveCN101789517APrevent rotationPrevent protrudingSecondary cellsCell component detailsElectricityBattery cell

The invention provides a battery array and battery array separator, the battery array can firmly connect a connecting terminal with the battery cell without damaging the member and prevent the common rotation of the electrodes with a simple structure in the connection of the connection terminal such as a bus bar and the like. The battery array is provided with a plurality of rectangular battery cells (1) having electrode terminals (3), separators (2) inserted between adjacent rectangular battery cells to insulate those rectangular battery cells, and connecting terminals to electrically connect adjacent electrode terminals of rectangular battery cells stacked with intervening separators. Connecting terminals are attached to electrode terminals by a threaded fastening system, and separators are provided with rotation prevention walls that contact connecting terminals and prevent connecting terminal rotation during threaded fastener tightening. Consequently, connecting terminal rotation during fastening is prevented, and deformation of a connecting terminal or battery cell is prevented.

Owner:SANYO ELECTRIC CO LTD

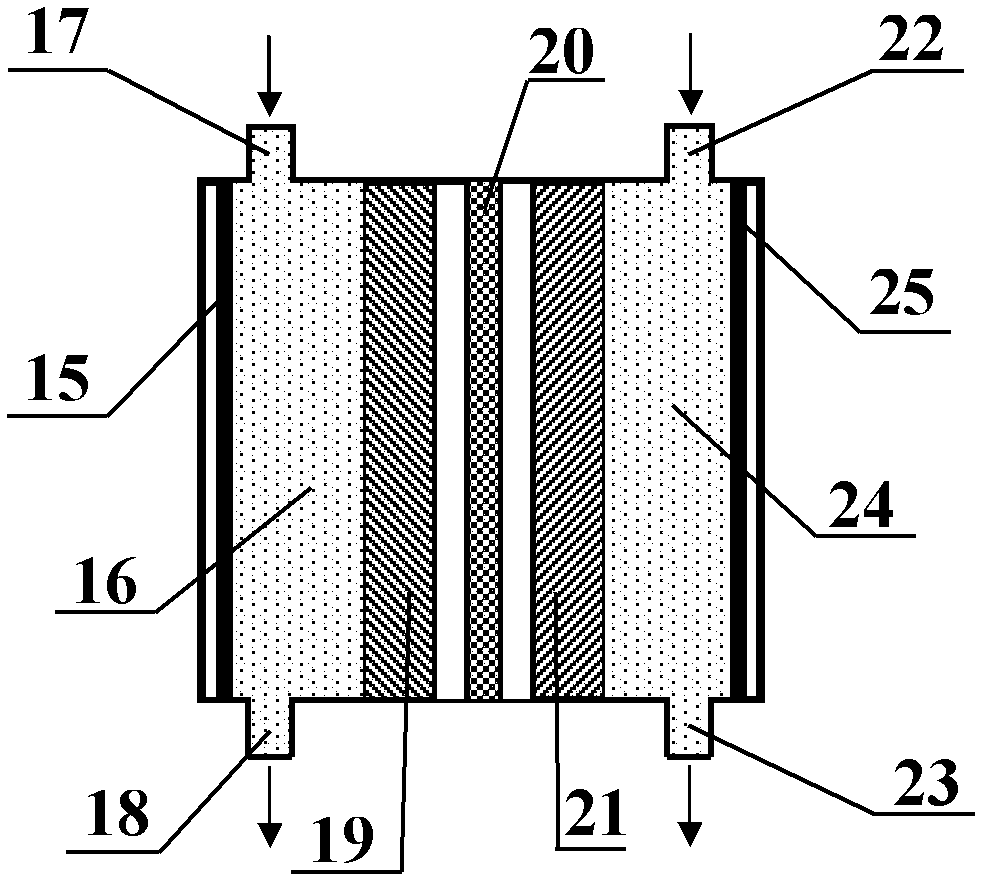

Lithium ion liquid flow battery

ActiveCN103187551APrevent internal short circuitImprove cycle life and safety performanceRegenerative fuel cellsCell component detailsElectrical batteryChemical energy

The invention discloses a lithium ion liquid flow battery, belonging to a chemical energy storage battery technology field. A fixed electrode layer is arranged between an electrode reaction chamber and a diaphragm of the lithium ion liquid flow battery of the invention, thereby avoiding the direct contact between the diaphragm and a flowing electrode suspension liquid, effectively avoiding internal short circuit of the battery, and raising safety performance and work efficiency of the battery.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

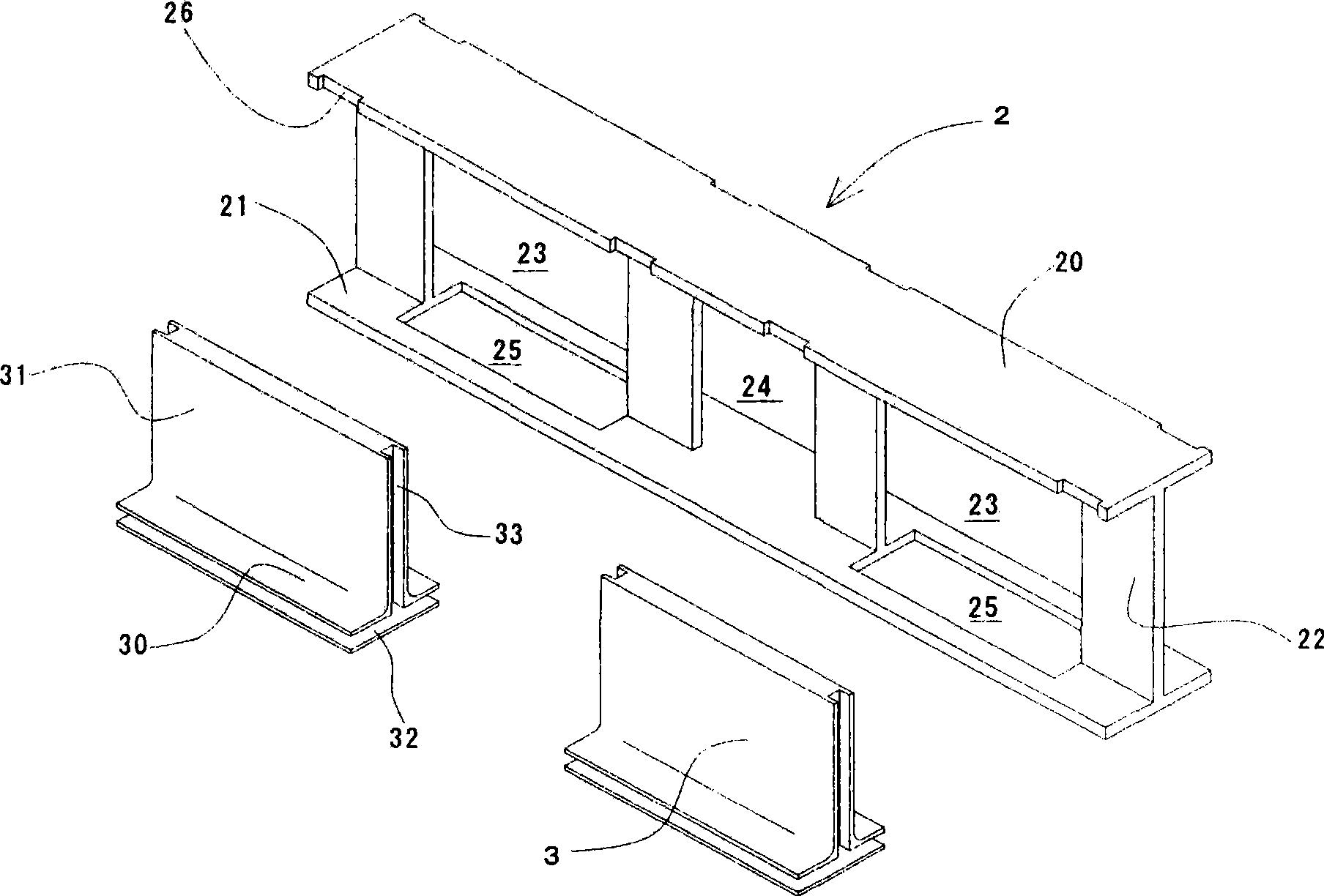

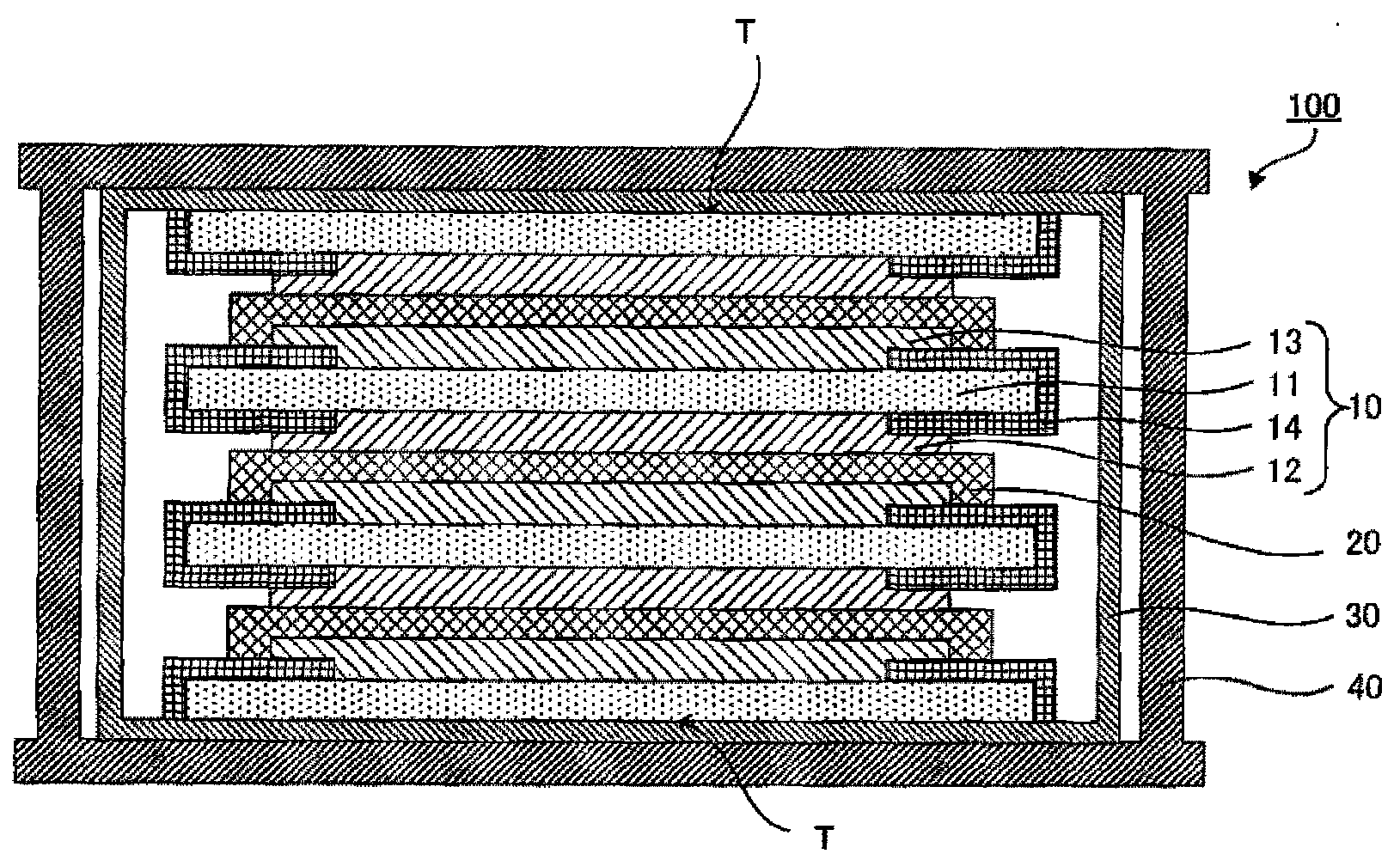

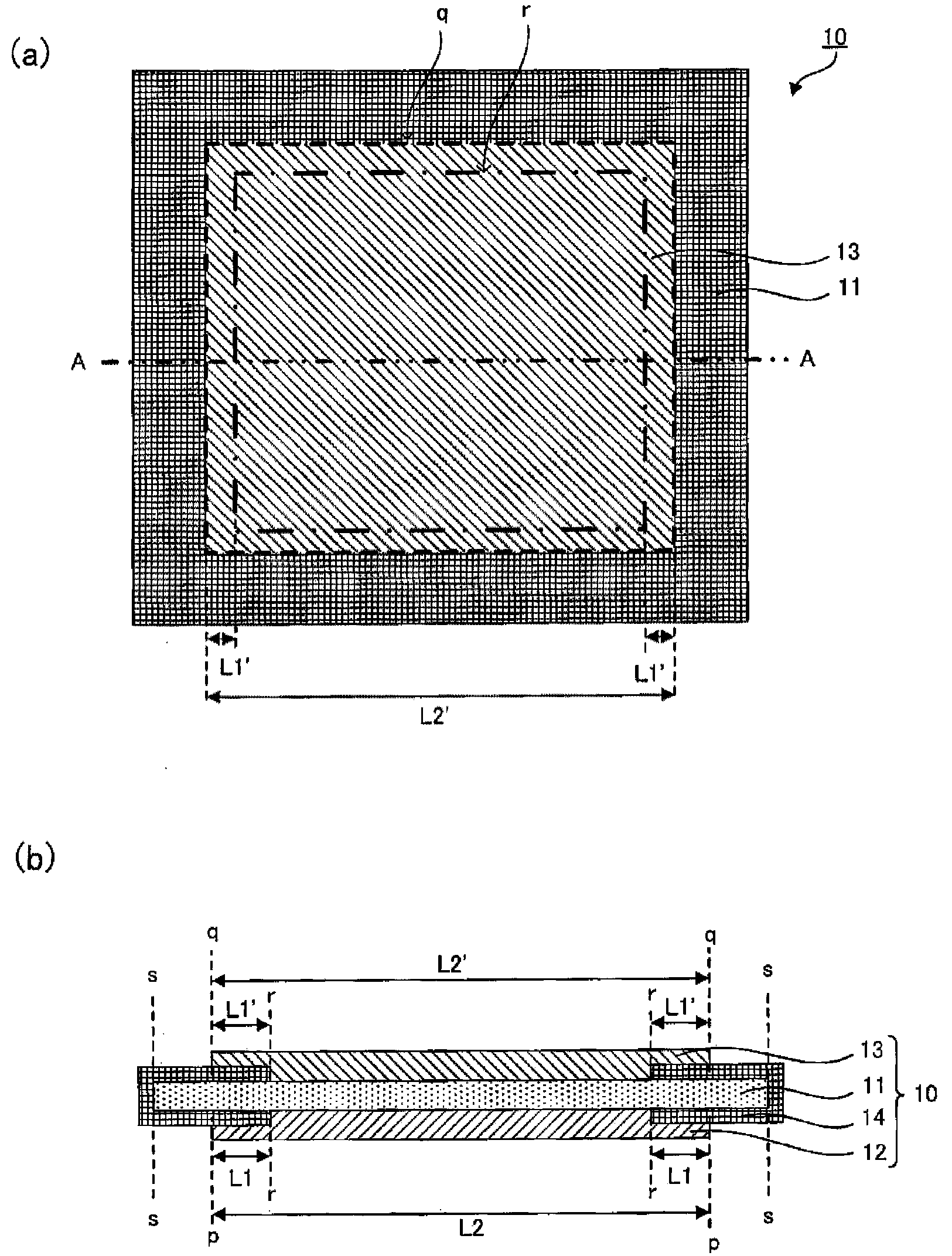

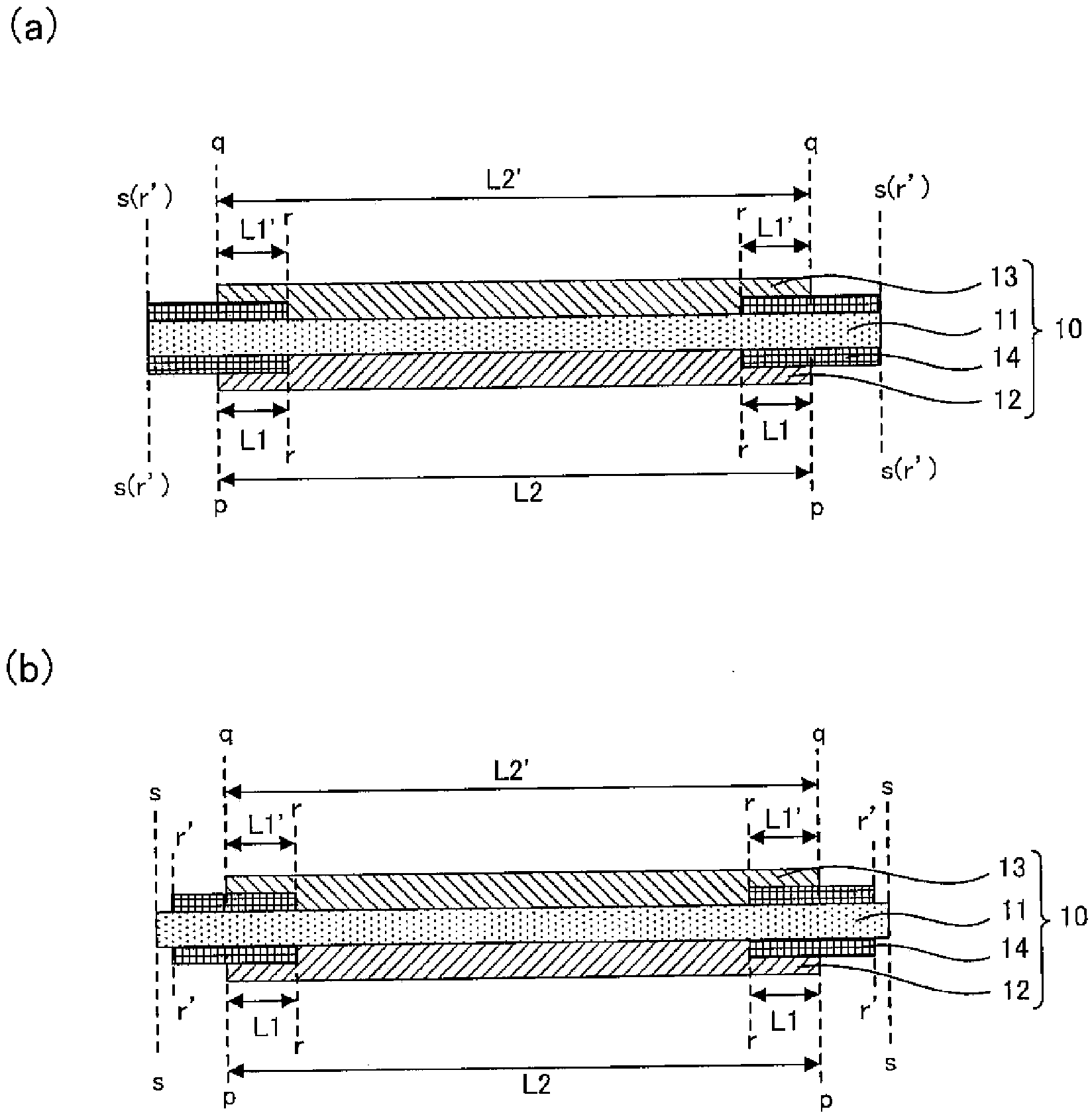

Bipolar all-solid-state battery

ActiveCN103548196AAvoid breakingAvoid short circuitLarge-sized flat cells/batteriesFinal product manufactureAll solid stateEngineering

The present invention addresses the problem of providing: a bipolar all-solid-state battery wherein breakage of a collector of a bipolar electrode is prevented, thereby suitably preventing the occurrence of a short circuit; and a method for manufacturing the bipolar all-solid-state battery. The present invention solves the above-described problem by providing a bipolar all-solid-state battery which comprises: a bipolar electrode that comprises a collector and an electrode active material layer which is composed of a positive electrode active material layer that is formed on one surface of the collector and contains a positive electrode active material and a negative electrode active material layer that is formed on the other surface of the collector and contains a negative electrode active material; and a solid electrolyte layer that contains a solid electrolyte, in said bipolar all-solid-state battery, a plurality of the bipolar electrodes being laminated with the solid electrolyte layer interposed between each two of the bipolar electrodes. The bipolar all-solid-state battery is characterized in that the electrode active material layer is formed inside the end portions of the collector and a reinforcing layer, which is formed on the surface of the collector, is arranged between each end portion of the electrode active material layer and the surface of the collector.

Owner:TOYOTA JIDOSHA KK

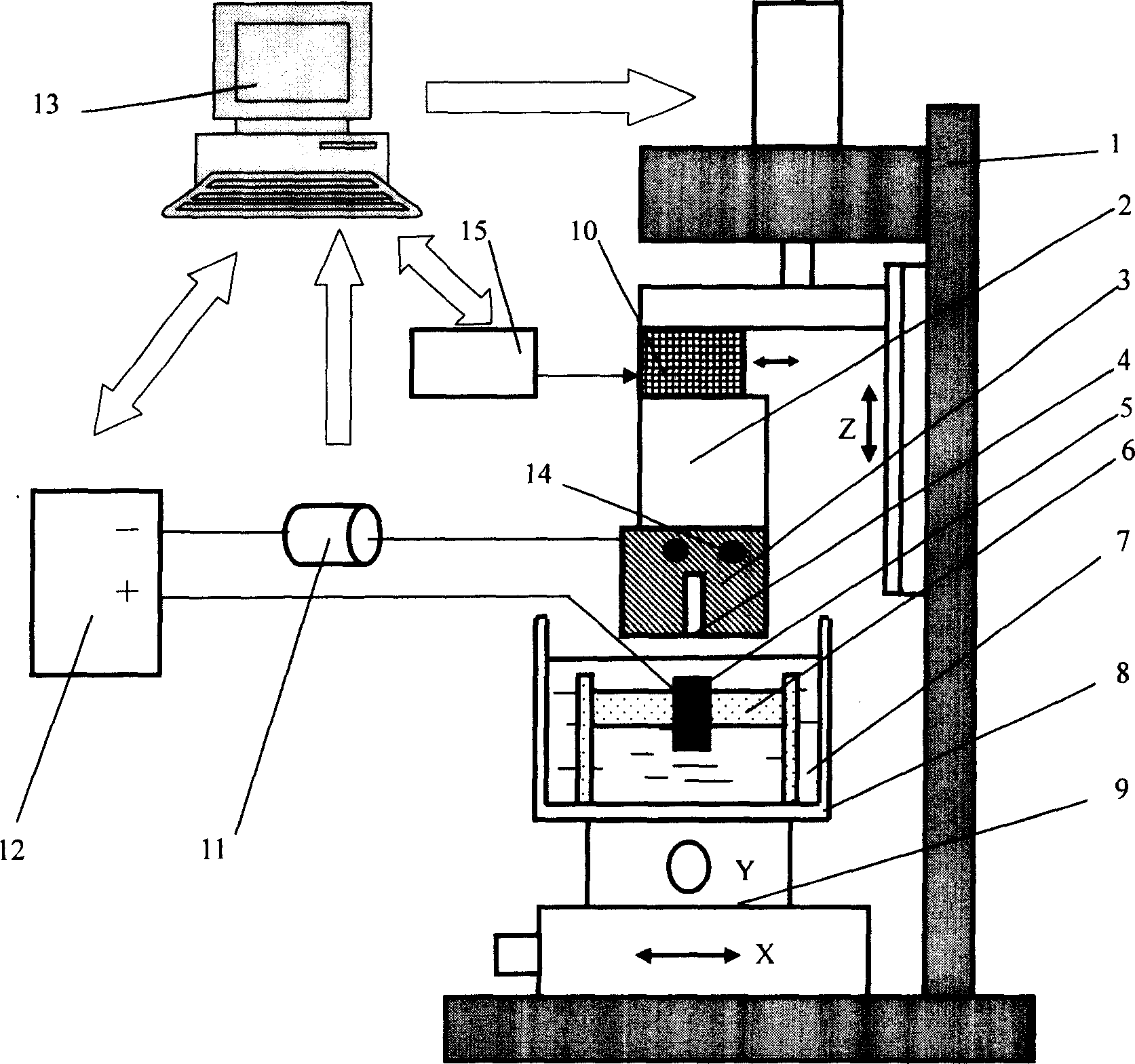

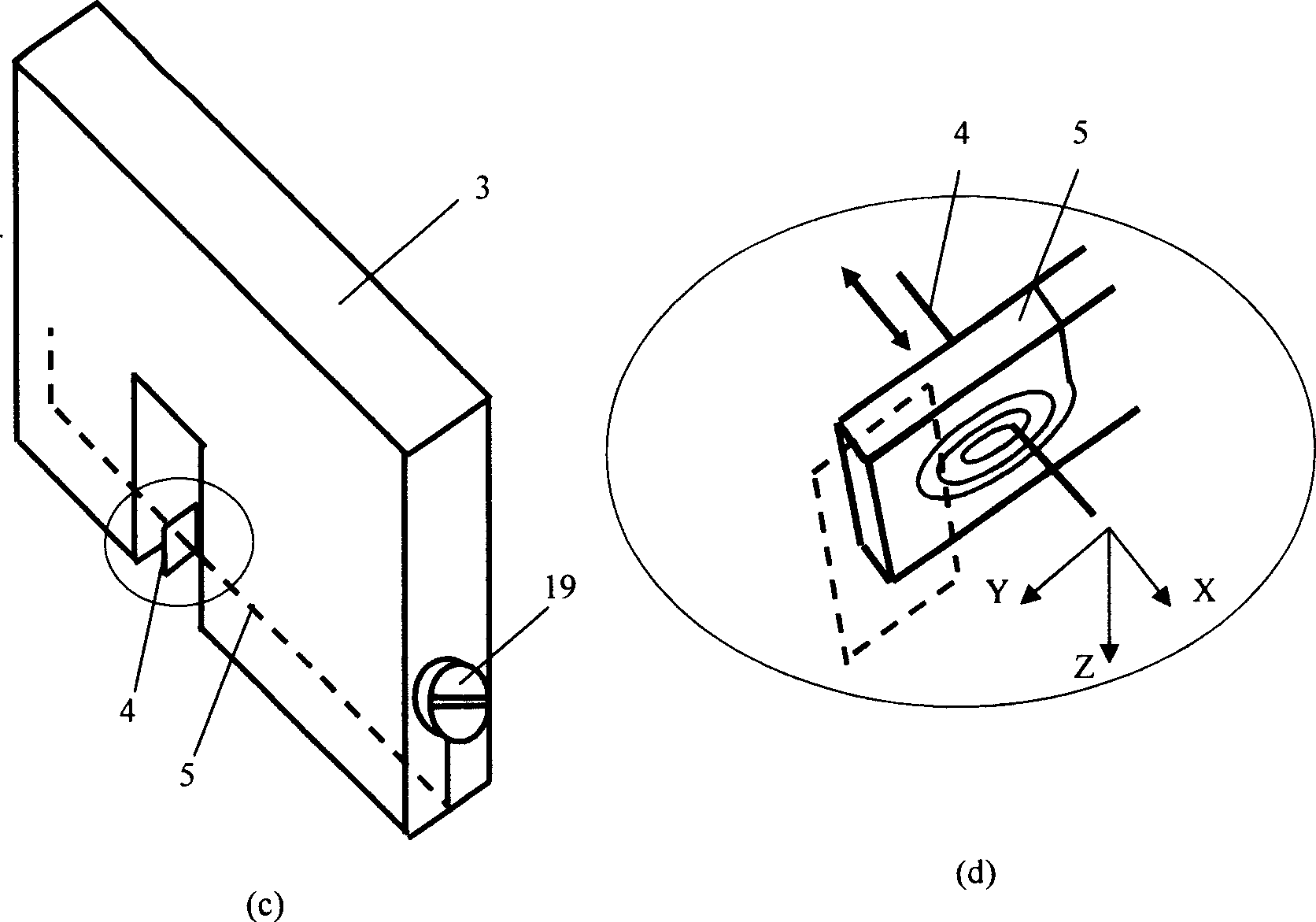

Micro-scale line electrode electrolysis machining method and micro-vibration line electrode system

InactiveCN1850411AEasy to excludeAvoid short circuitMechanical vibrations separationElectrical-based machining electrodesNumerical controlElectrolysis

The present invention relates to a microdimesion wire electrode electrolytic machining method. It is characterized by that in the course of electrolytically microcutting metal material by using wire electrode it utilizes a microvibration device to make the wire electrode produce microvibration perpendicular to its feeding direction, so that it is favourable for discharging electrolytic product from machining gap so as to prevent the short circuit from producing and greatly raise electrolytic quality. Said microvibration wire electrode system is mounted on the Z-axis of numerical control machine tool and is formed from wire electrode frame, microdimension wire electrode mounted on the wire electrode frame and microvibation device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

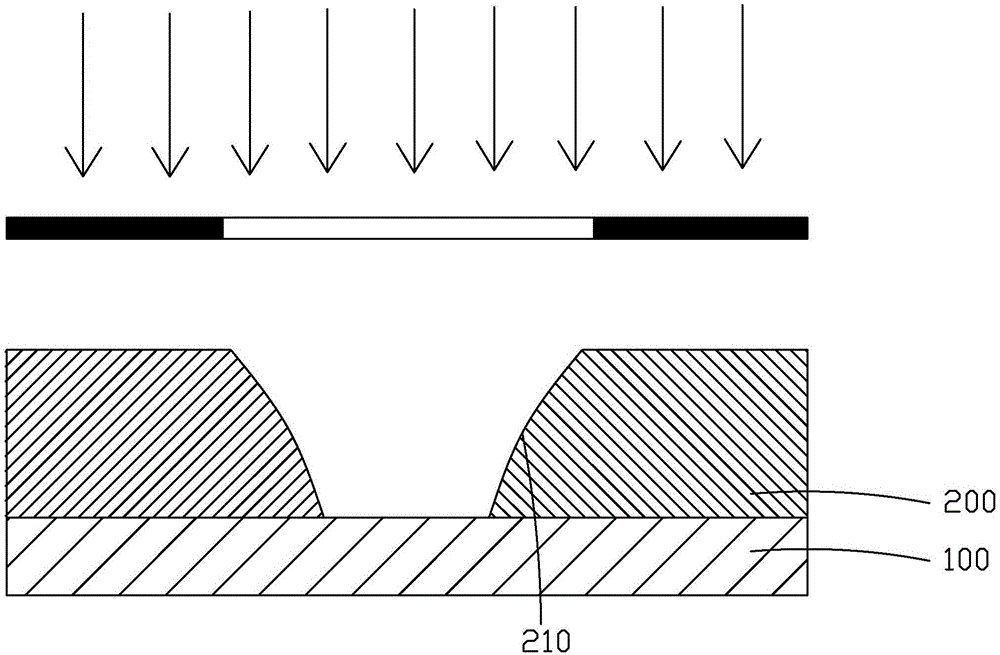

Manufacturing method of TFT (Thin Film Transistor) substrate structure

ActiveCN105068373AGuaranteed opening rateImprove display qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusAdhesion forceLiquid-crystal display

The invention provides a manufacturing method of a TFT (Thin Film Transistor) substrate structure. According to the manufacturing method of the TFT substrate structure, via holes and a groove are formed in a planarization layer through single exposure by utilizing a halftone photomask, and half-exposure is realized through half-light-transmitting patterns on the halftone photomask; the groove with smaller depth is formed in the planarization layer of a fan-out area, so that the slope of the groove in the planarization layer of the fan-out area is decreased, the phenomenon of residue of a transparent conductive layer at corners of the groove caused by non-thorough photoresist exposure at the corners of the groove during photoresist exposure developing is avoided, and the phenomenon of short circuit between metal lines of the fan-out area is further avoided; meanwhile, the aperture ratio of an effective display area is not influenced, and the display quality of a liquid crystal display panel is greatly improved; moreover, by widening the groove in the planarization layer of the fan-out area, the phenomenon of reduction of an adhesion force of a frame sealing adhesive caused by decrease of the slope of the groove and reduction of the depth of the groove is avoided, and the adhesion property of the frame sealing adhesive in the liquid crystal display panel is further protected from being influenced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Energy-saving type single-phase alternating current machine starting protector

InactiveCN104734569AReduce power consumptionIncrease power consumptionSingle-phase induction motor startersEmergency protective circuit arrangementsRefrigeration compressorElectrical resistance and conductance

The invention discloses an energy-saving type single-phase alternating current machine starting protector, and belongs to the technical field of refrigerating compressor. The energy-saving type single-phase alternating current machine starting protector comprises a shell, a single-phase alternating current machine starter, a single-phase alternating current machine protector and a shell cover; a positive temperature coefficient thermistor cavity and a single-phase alternating current machine protector cavity are formed in a shell cavity; the single-phase alternating current machine starter comprises a positive temperature coefficient thermistor, a first pin and a second pin; the single-phase alternating current machine protector is arranged in the single-phase alternating current machine protector cavity; the shell cover is matched with the shell. The energy-saving type single-phase alternating current machine starting protector is characterized in that a plug-in piece is extended from a reed of the first pin, and a plug-in-piece hole, a first pin hole, a second pin hole and a protector pin hole are formed in the shell; a pair of bottom-wall top embossments are formed in the cavity bottom wall of the positive temperature coefficient thermistor cavity, side-wall top embossments are formed in the side cavity walls and the rear cavity wall, the lower portion of the positive temperature coefficient thermistor is supported by the pair of bottom-wall top embossments, the front side of the positive temperature coefficient thermistor is contacted with the front cavity wall top embossments, and the rear side of the positive temperature coefficient thermistor is contacted with the rear cavity wall top embossments. The energy-saving type single-phase alternating current machine starting protector has the advantages that the energy-saving effect is good, the size is small, and the weight is light; the installation is convenient; a mold structure is simplified; electric short-circuit is prevented; the assembling efficiency is high.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

Microporous polymer isolating film for Li-ion battery and method for producing the same

ActiveCN101212036AIncrease surface areaHigh porositySolid electrolytesFinal product manufactureHydrophilic monomerPolymer science

The invention relates to a diaphragm used for power maintaining device as a lithium ion secondary battery and a preparation method thereof, which belongs to a field of manufacturing battery and capacitor. The diaphragm of the invention takes water as reaction medium; polymers colloid and emulsion are obtained through polymerization reaction generated by polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer with an initiator in water solution; by adopting tape-casting and coating process, the polymers colloid and emulsion are coated on a plastic baseband; the diaphragm is obtained through stripping after drying. The diaphragm has good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability; and the prepared lithium ion battery is characterized by good cycle stability and long service life.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

Non-woven fabric based multi-layer composite diaphragm for lithium ion battery and preparation method of multi-layer composite diaphragm

ActiveCN105470435AImprove high temperature closed cell performanceHigh tensile strengthCell component detailsEmulsionInorganic particle

The invention discloses a non-woven fabric based multi-layer composite diaphragm for a lithium ion battery and a preparation method of the multi-layer composite diaphragm. The non-woven fabric based multi-layer composite diaphragm comprises a non-woven fabric base material, an intermediate thermoplastic material coating and an outer-layer ceramic coating. The preparation method comprises the following steps of (1) mixing and uniformly stirring thermoplastic material particles, a binding agent and a solvent to form a mixed emulsion 1, and mixing and uniformly stirring inorganic particles, the binding agent and the solvent to form a mixed emulsion 2; and (2) uniformly applying the mixed emulsion 1 on one surface of the non-woven fabric base material, drying the mixed emulsion 1 to form the thermoplastic material coating, applying the mixed emulsion 2 on the thermoplastic material coating, drying the mixed emulsion 2 to form a ceramic coating, and rolling the ceramic coating to prepare a three-layer composite diaphragm. The three-layer composite diaphragm prepared according to the method has high-temperature obturator performance, favorable liquid absorption capability and mechanical property.

Owner:TIANNENG SAFT ENERGY JOINT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com