Micro-scale line electrode electrolysis machining method and micro-vibration line electrode system

A wire electrode and micro-scale technology, applied in the direction of electric processing equipment, electrochemical processing equipment, electrode manufacturing, etc., can solve the problems of unsustainable processing and short circuit, so as to improve processing accuracy and processing efficiency, avoid short circuit phenomenon, electrolysis The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

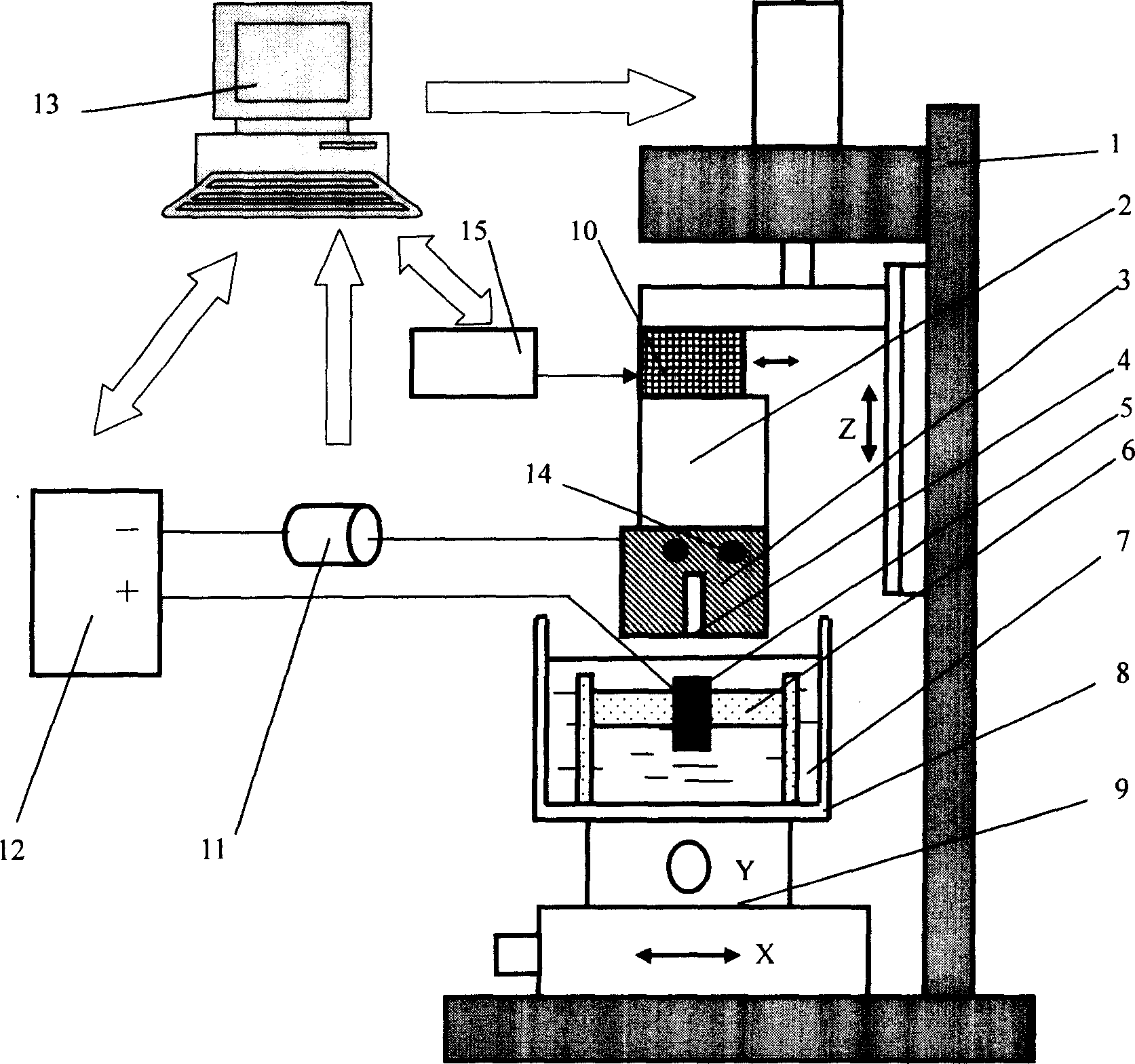

[0020] according to figure 1 As shown, the microscale wire electrode electrolytic machining device of the present invention consists of the following parts:

[0021] (1), including machine tool body 1, Z-axis 2, piezoelectric ceramics 10, XY two-dimensional CNC workbench 9, computer 13, voltage amplifier 15, etc., which can realize three-degree-of-freedom movement;

[0022] (2), by the electrolyte tank 8 installed on the XY numerical control workbench 9', and the workpiece fixture 6 and the workpiece 5 fixed in the electrolyte tank. The electrolyte 7 is filled with the electrolyte tank 8 to immerse the workpiece;

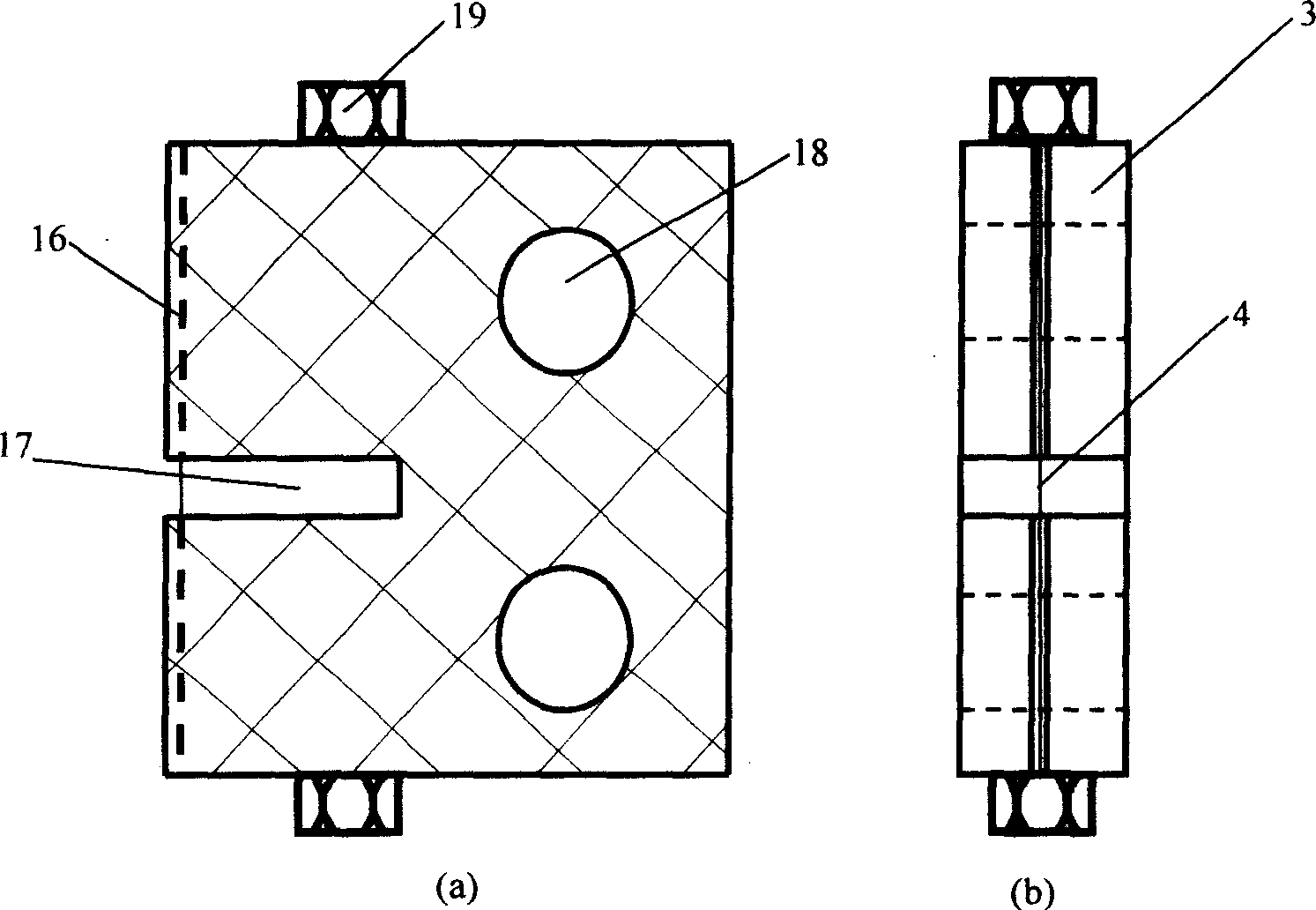

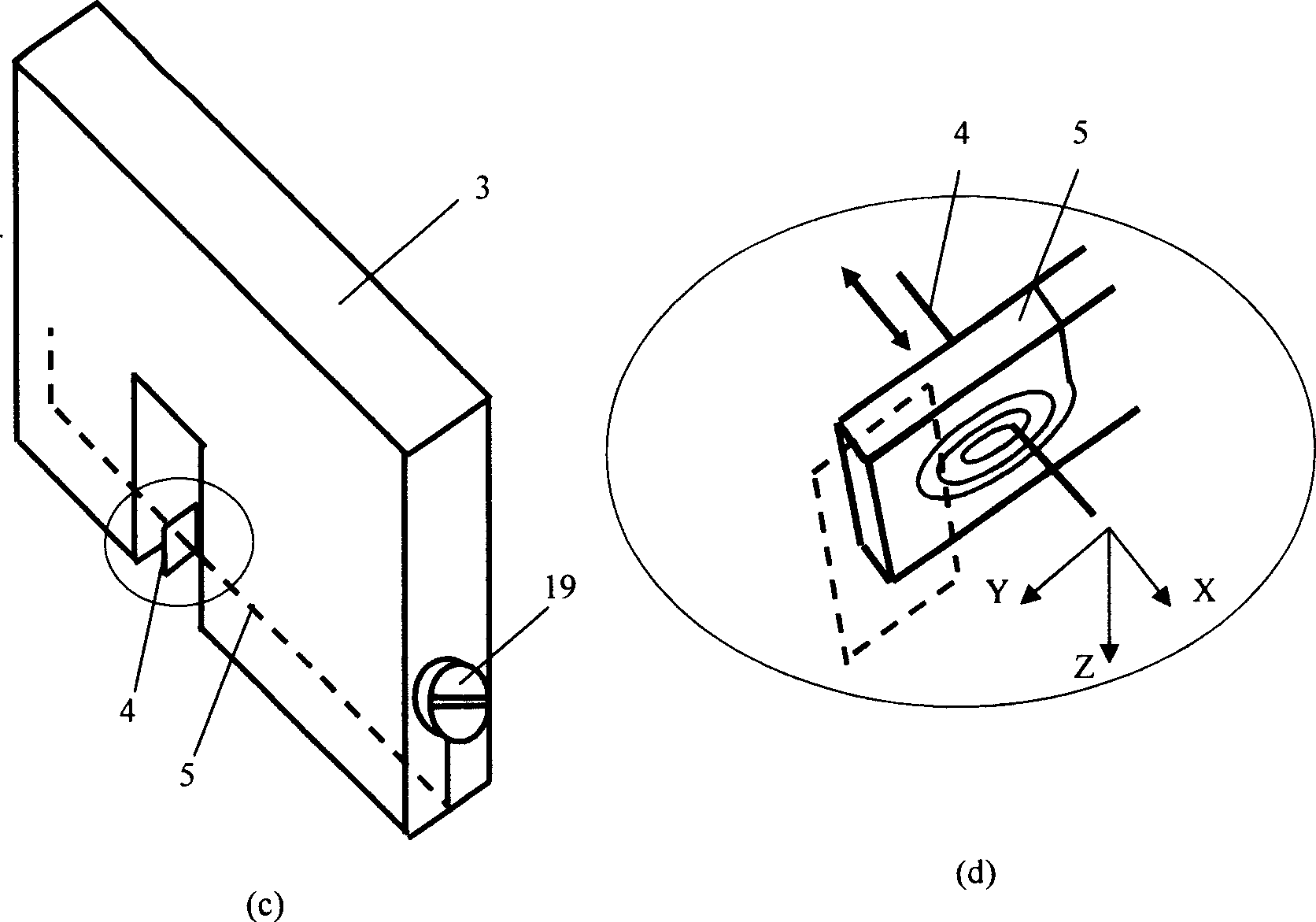

[0023] (3) The wire electrode 4 wound in a wire electrode frame structure 3 is fixed by two upper and lower conductive screws 19 at both ends, and the wire electrode 4 is maintained at a certain tension. Use two screws 14 to connect the wire electrode frame structure 3 to the Z-axis 2 of the machine tool through the positioning holes 18 thereon;

[0024] (4), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com