Patents

Literature

1467results about How to "Easy to exclude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing modified epoxy resin

ActiveUS20070027233A1Reduce removalEasy to excludeFilm/foil adhesivesCircuit susbtrate materialsSolubilityPolymer chemistry

This invention provides a process for producing an epoxy resin composition having core / shell rubber particles (rubber-like polymer particles) dispersed in an epoxy resin, wherein an epoxy resin composition excellent in the dispersed state of rubber-like polymer particles in an epoxy resin with a reduced amount of contaminants is produced easily and efficiently. The epoxy resin composition having rubber-like polymer particles dispersed well in an epoxy resin with less contaminant is obtained by bringing an aqueous latex of rubber-like polymer particles (B) into contact with an organic medium (C) showing partial solubility in water, then bringing an organic medium (D) having lower partial solubility in water than that of the organic medium (C) into contact therewith to separate water substantially, to remove the rubber-like polymer particles as a dispersion (F) having the polymer particles dispersed in the organic medium, and mixing it with an epoxy resin (A), followed by distilling volatile components away.

Owner:KANEKA CORP

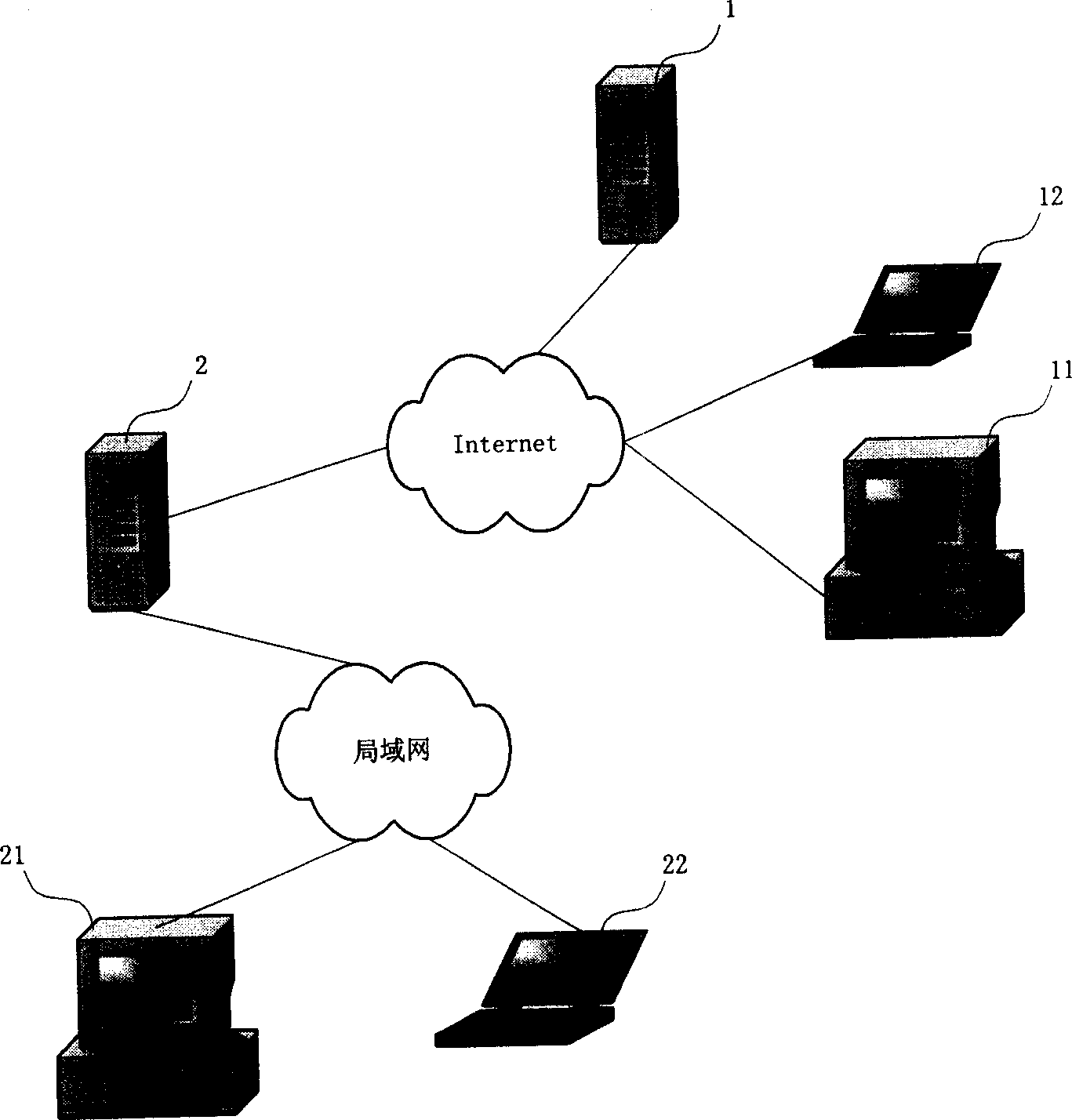

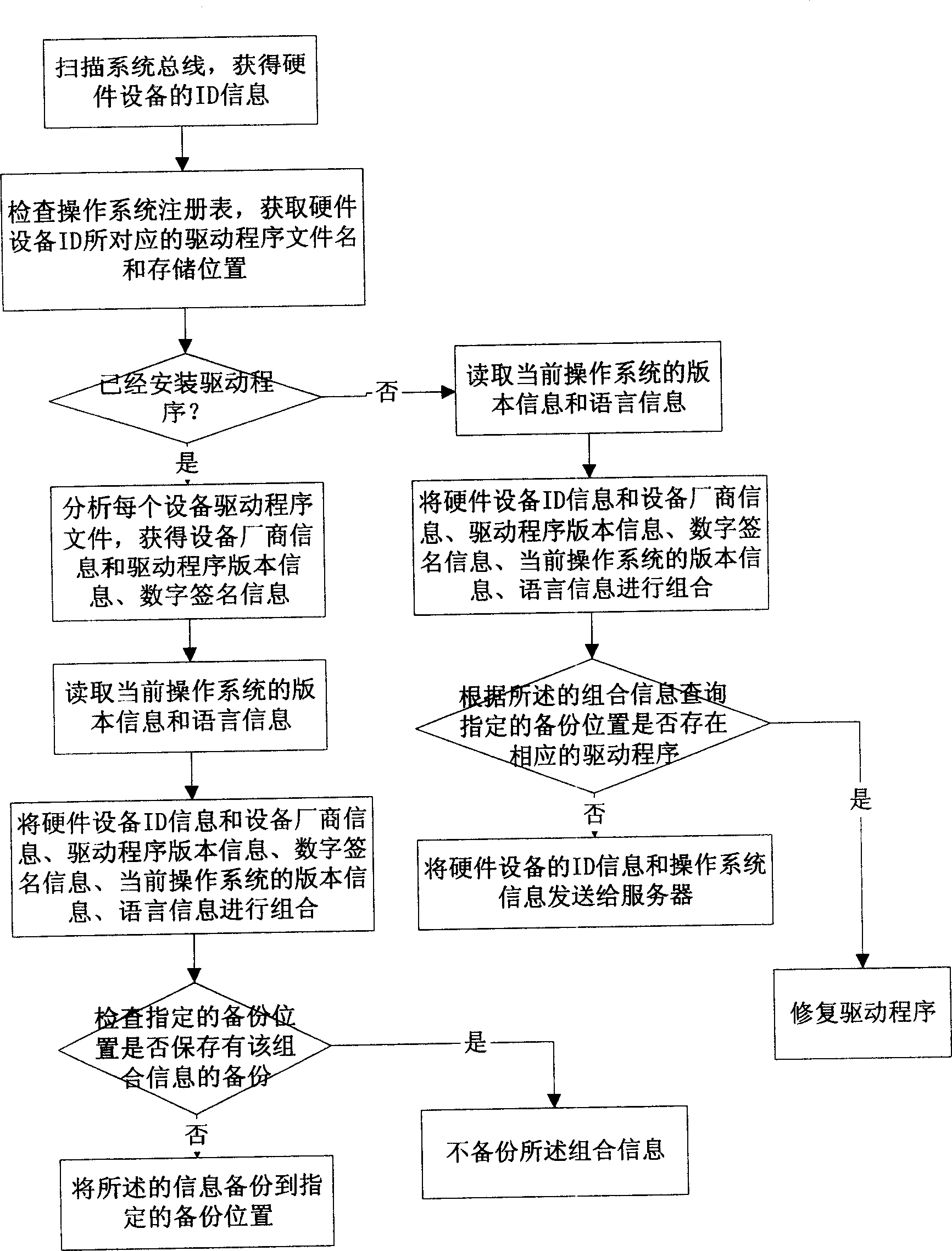

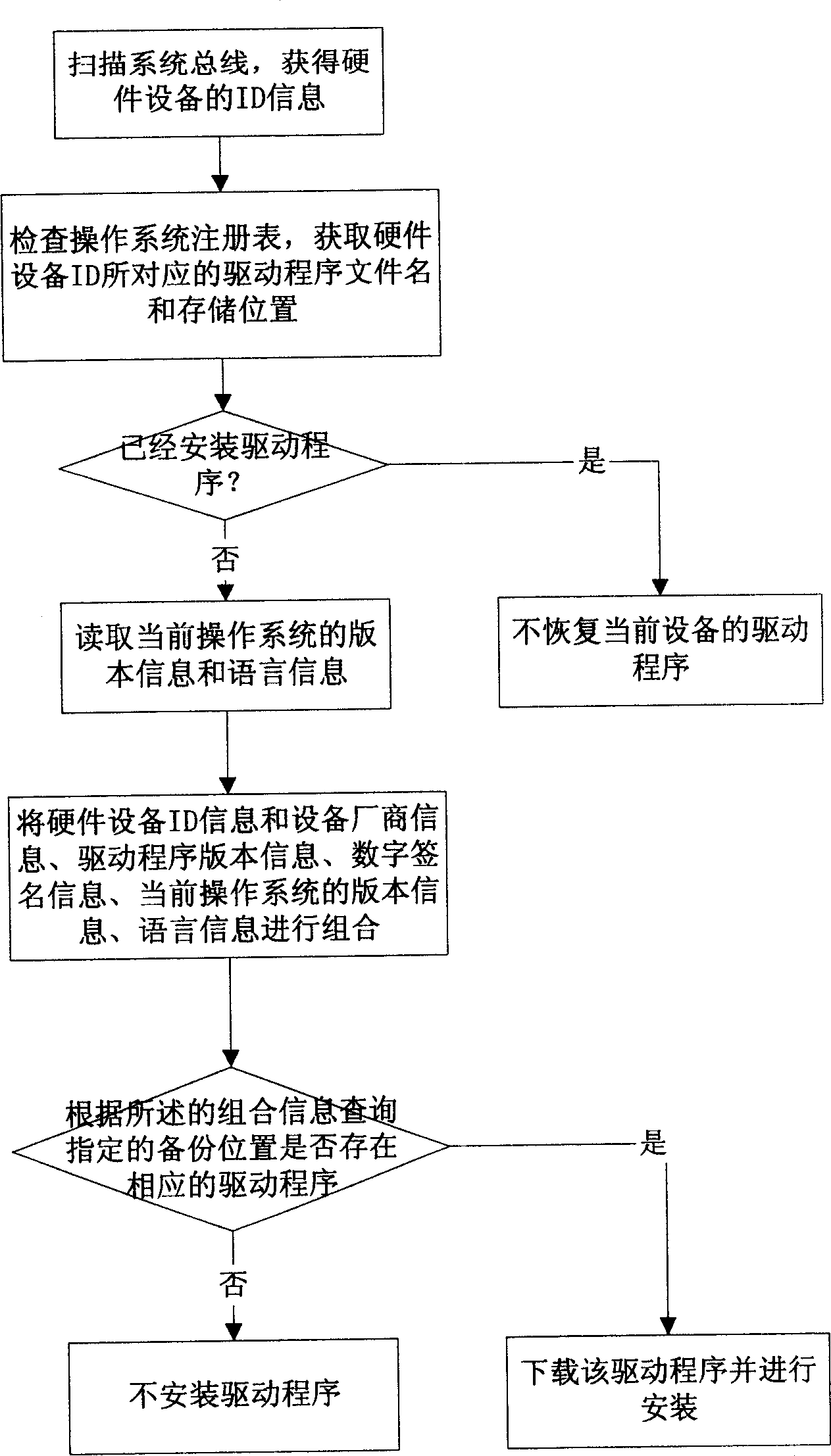

Automatic detesting method for computer system hardware device

The present invention discloses automatic detecting method of computer system hardware devices. The deputy module in computer system is used in detecting computer system hardware devices in computer system and maintaining and managing the hardware devices and the drive program. The detection includes real-time detecting hardware devices and diagnosing the abnormality; issuing hardware device fault report in designated format; and automatically installing, repairing or updating the drive programs of the hardware devices. The present invention realizes the automatic management and maintenance of the hardware devices and the drive programs to reduce back-up cost, raise service efficiency and update the drive programs.

Owner:南通英可达信息技术有限公司

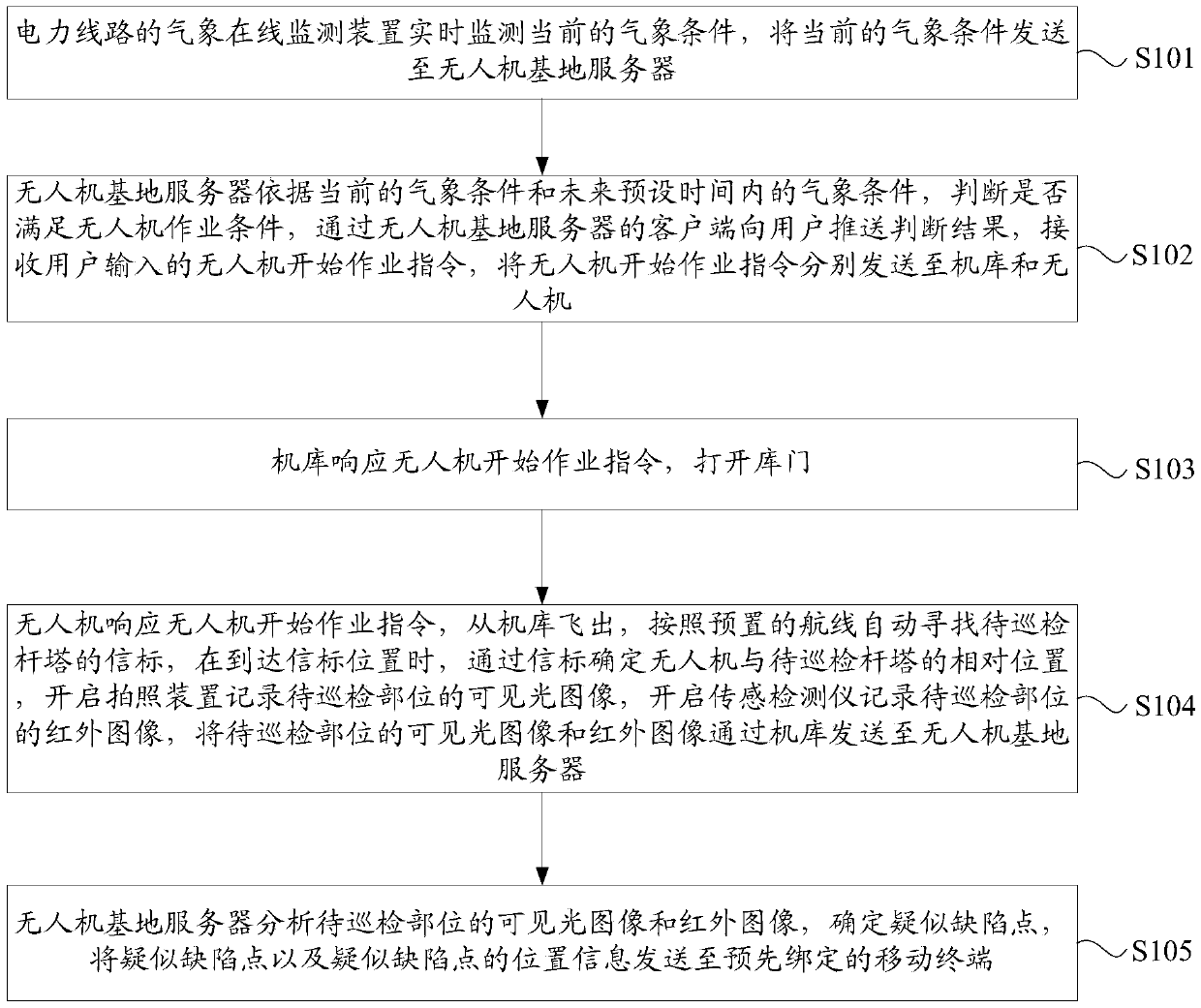

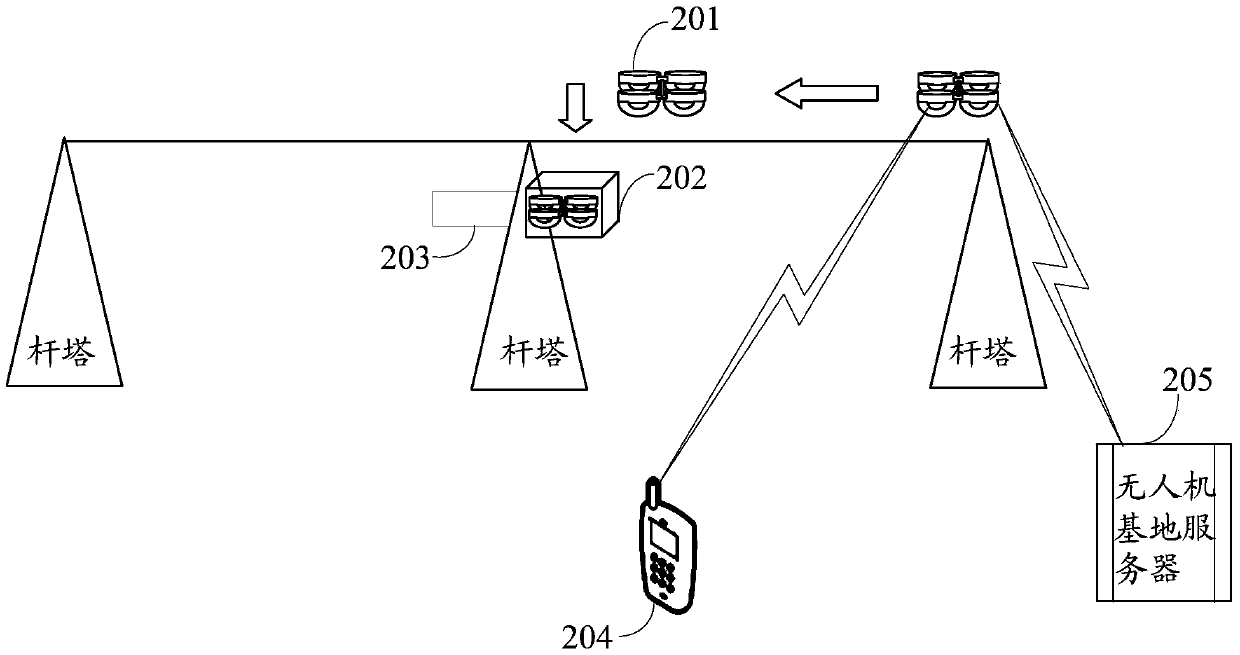

Control method and system for intelligent unmanned aerial vehicle patrol for power line

ActiveCN105511495AEasy to excludeEasy and safe maintenanceOptically investigating flaws/contaminationProgramme control in sequence/logic controllersReal-time computingInfrared image

The invention discloses a control method and system for intelligent unmanned aerial vehicle patrol for a power line. The method includes the steps that after receiving an instruction, input by a user, of starting unmanned aerial vehicle operation, an unmanned aerial vehicle base server transmits the instruction of starting unmanned aerial vehicle operation to a hangar and an unmanned aerial vehicle; the hangar responds to the instruction of starting unmanned aerial vehicle operation, and a hangar door is opened; the unmanned aerial vehicle responds to the instruction of starting unmanned aerial vehicle operation, flies out of the hangar, determines the position of the unmanned aerial vehicle relative to a tower to be patrolled through a beacon and transmits shot visible images and infrared images of the portion to be patrolled to the unmanned aerial vehicle base server through the hangar; the unmanned aerial vehicle base server analyzes the visible images and infrared images of the portion to be patrolled to determine suspected defect points and transmits the suspected defect points and position information of the suspected defect points to a mobile terminal bound in advance. According to the technical scheme, the power line in a region poor in natural condition can be patrolled normally, and safety maintenance can be conducted on the power line better.

Owner:STATE GRID CORP OF CHINA +1

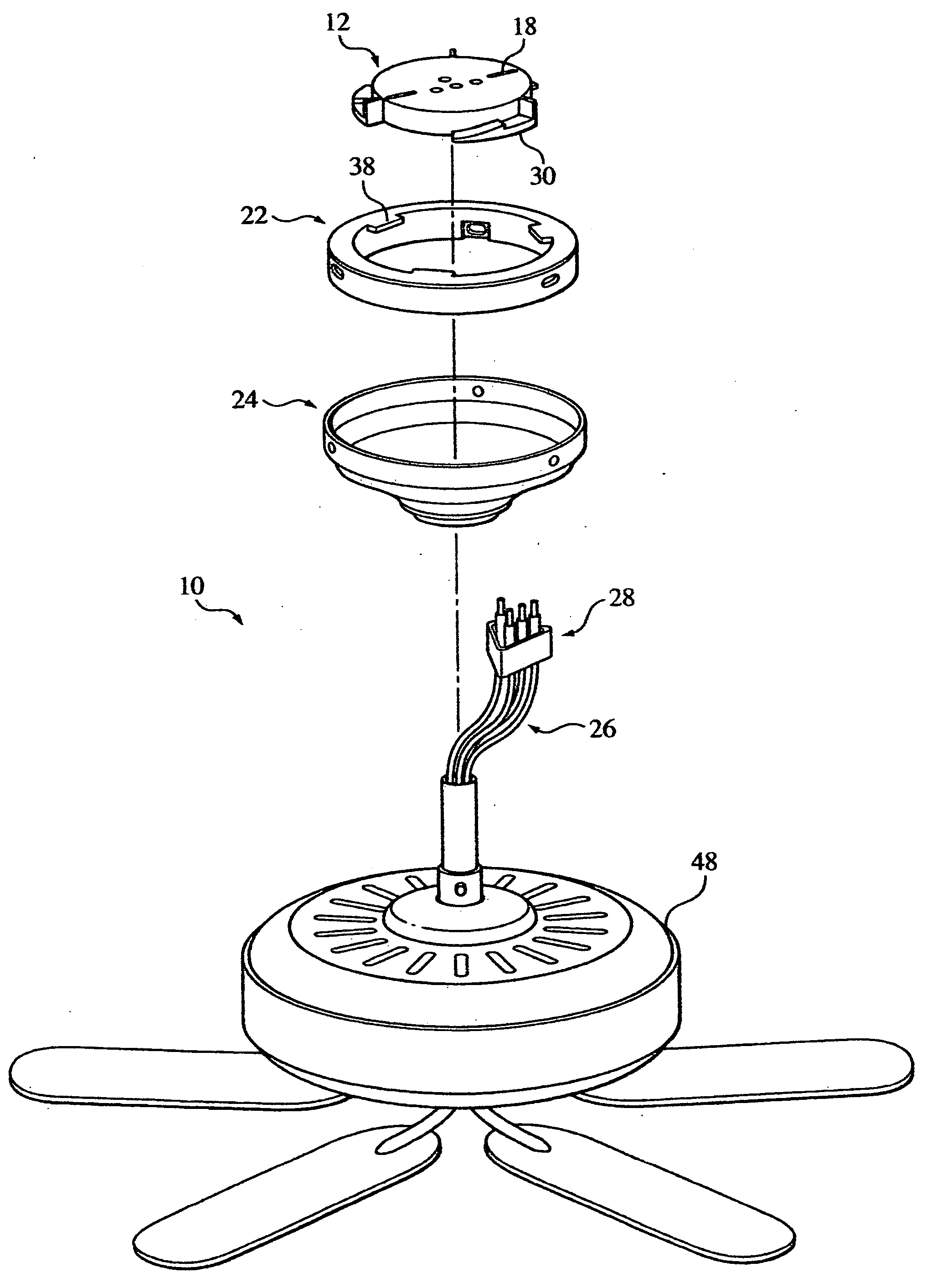

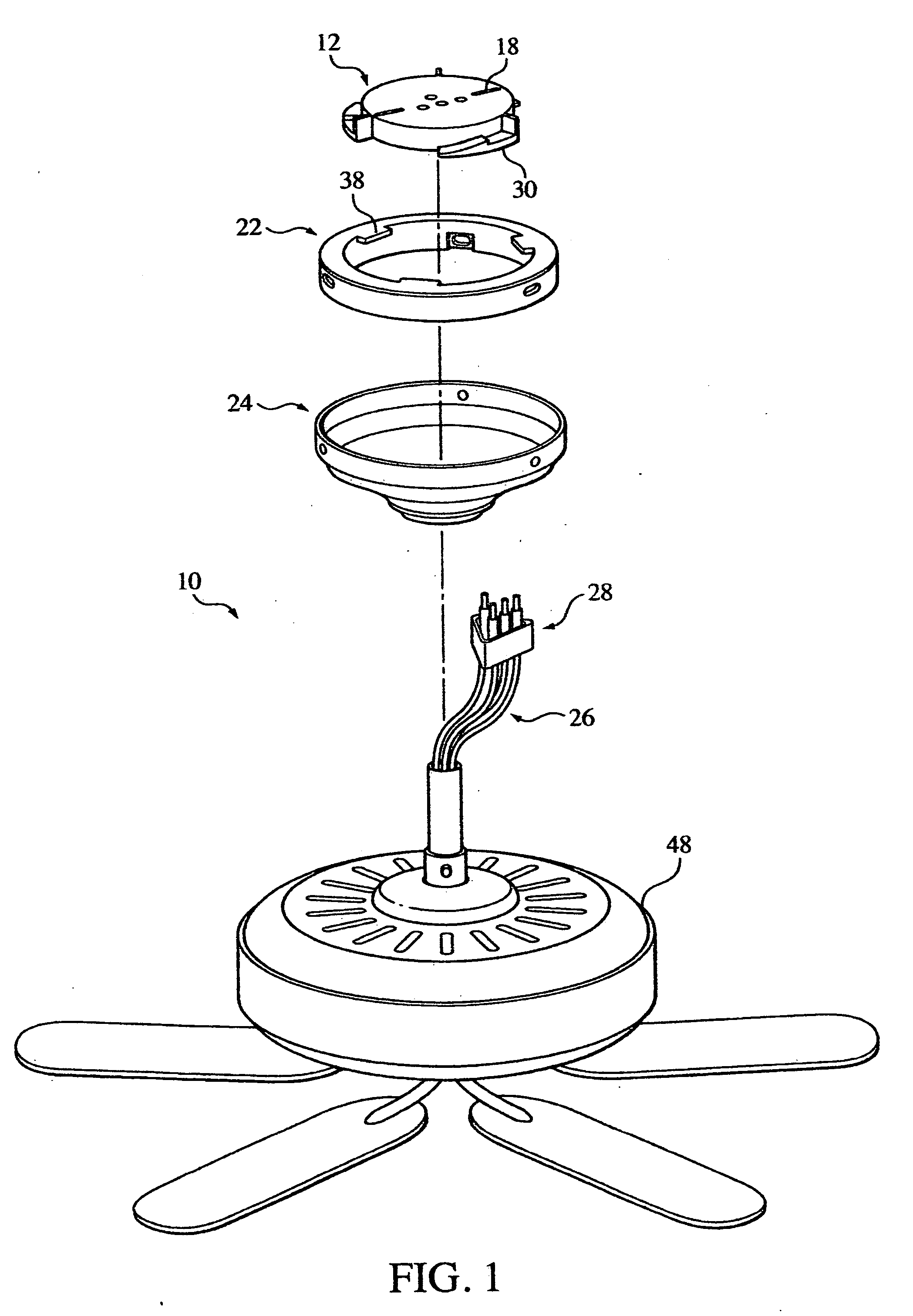

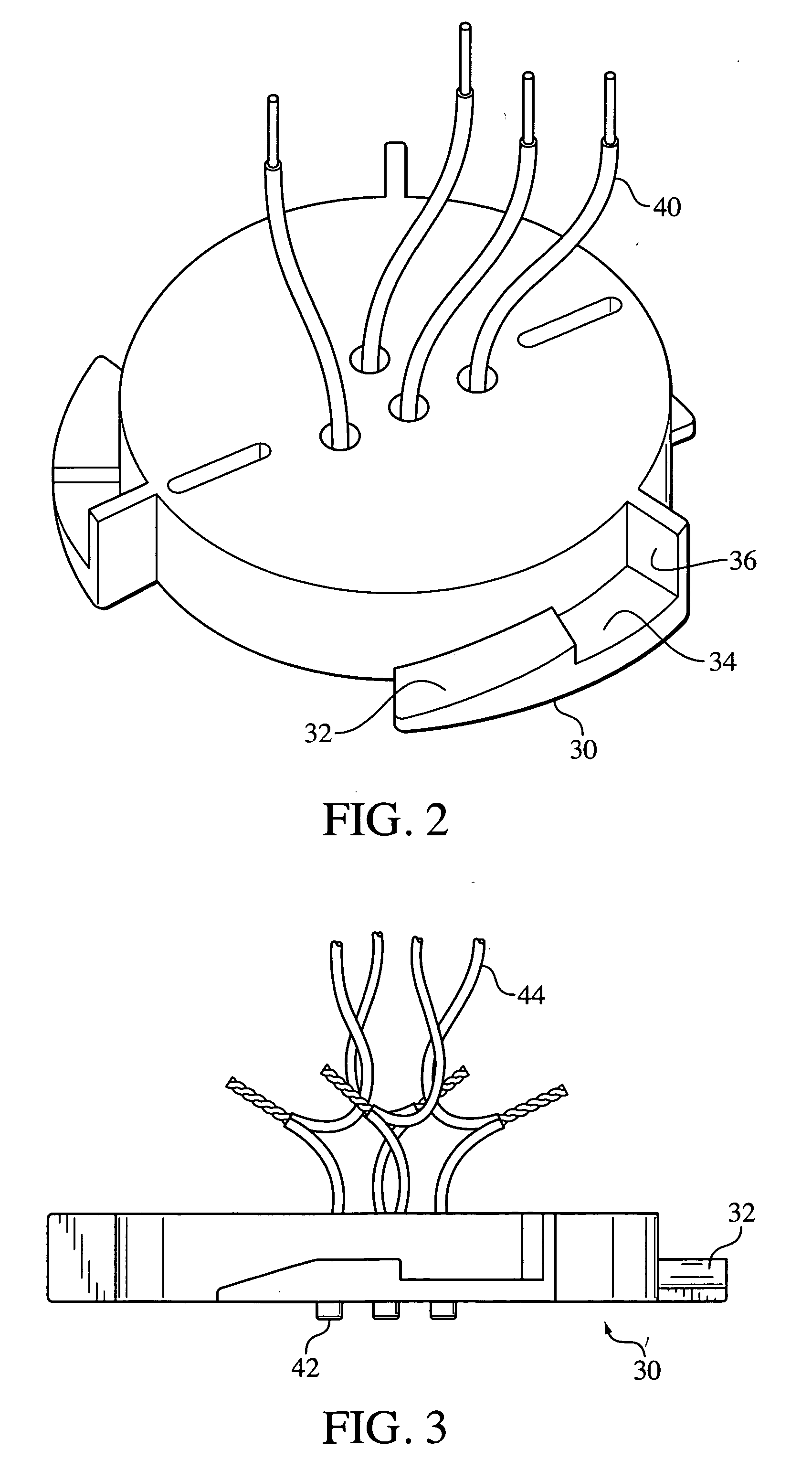

Ceiling fan

InactiveUS20100329885A1Easily and conveniently attachableEasily and conveniently to and removablePump componentsFiling appliancesCeiling fanEngineering

A ceiling fan comprising bracket components which are easily and conveniently attachable in a suitable position by one person thru simple operation and adjustment of mechanical parts. Attachment components are removably secured to a ceiling plate connected to a house circuit in an initial room then capable of easy removal therefrom and attachable to a ceiling plate installed in another room. A fan circuit is connectable to a house circuit by simple plug members and fan unit is quickly positionable into a secure position by position against and rotation of cooperable components with ceiling plate.

Owner:CRINER JERRY D +1

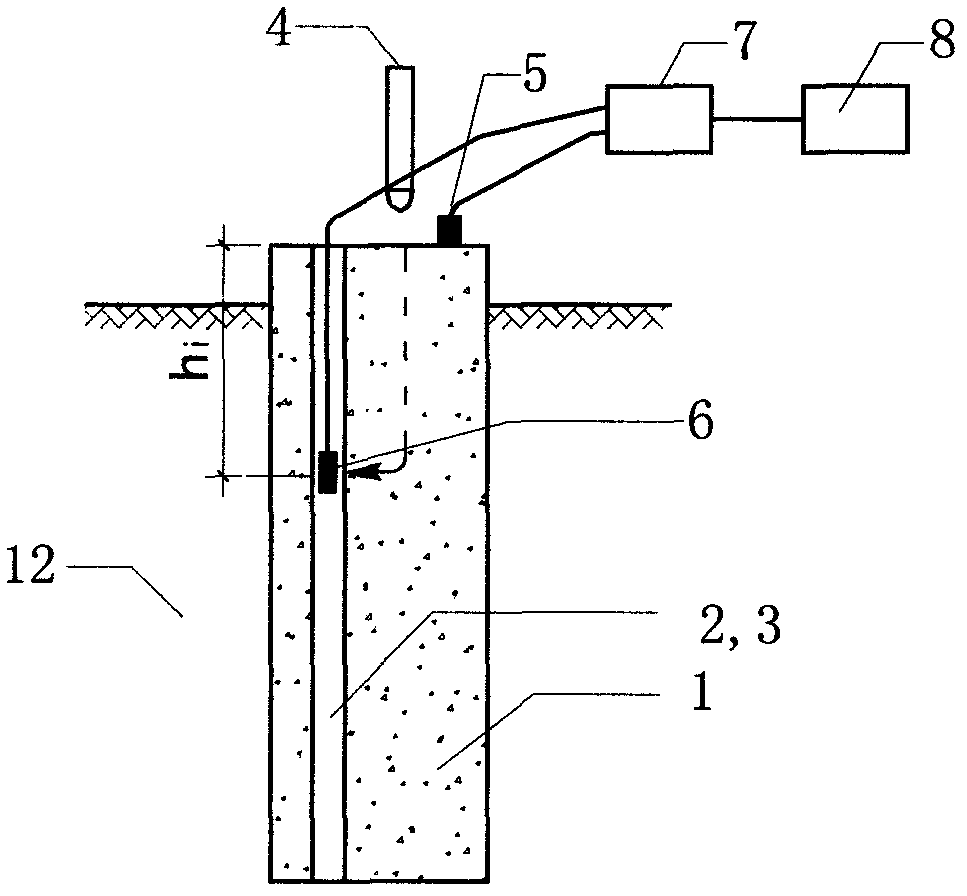

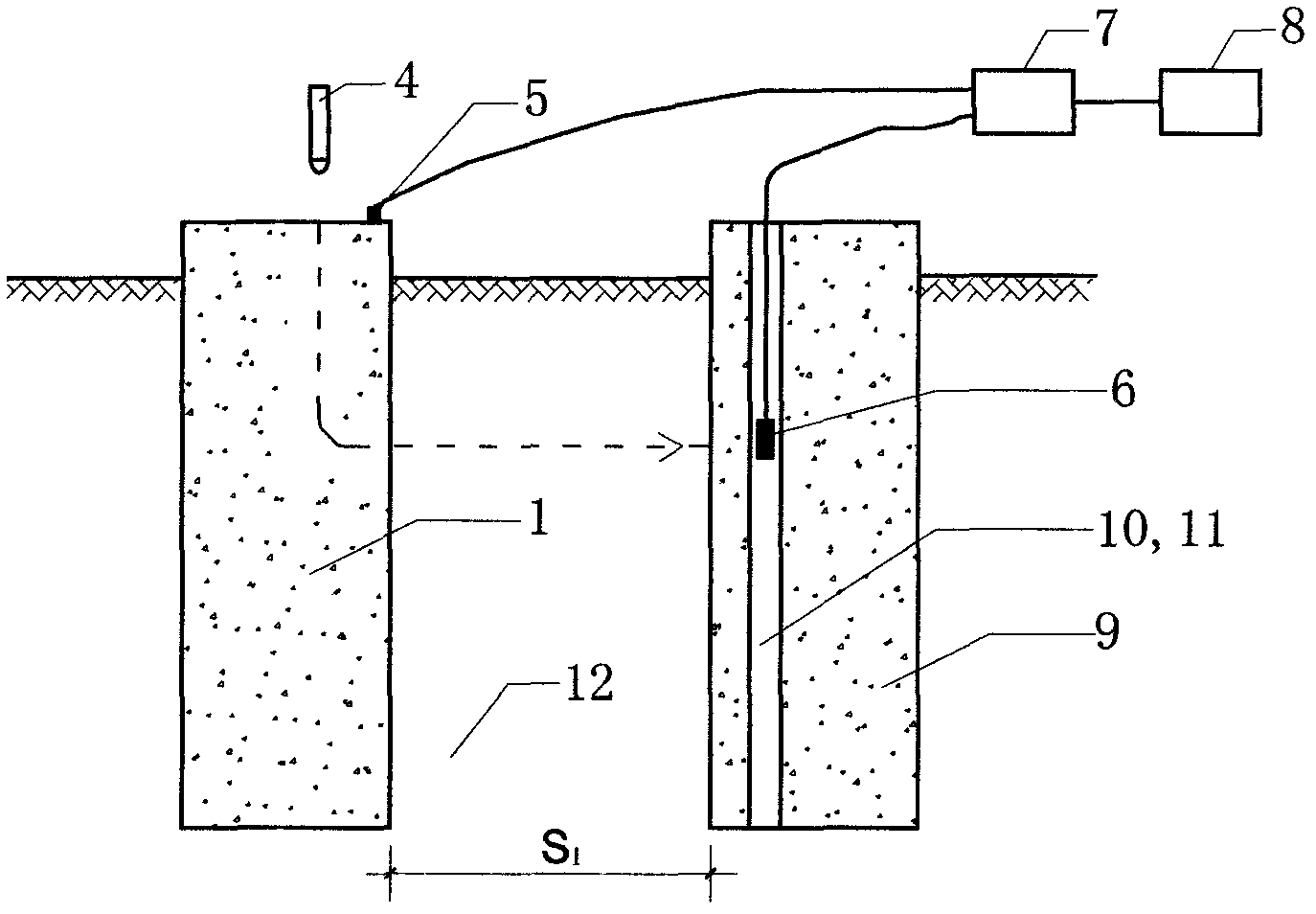

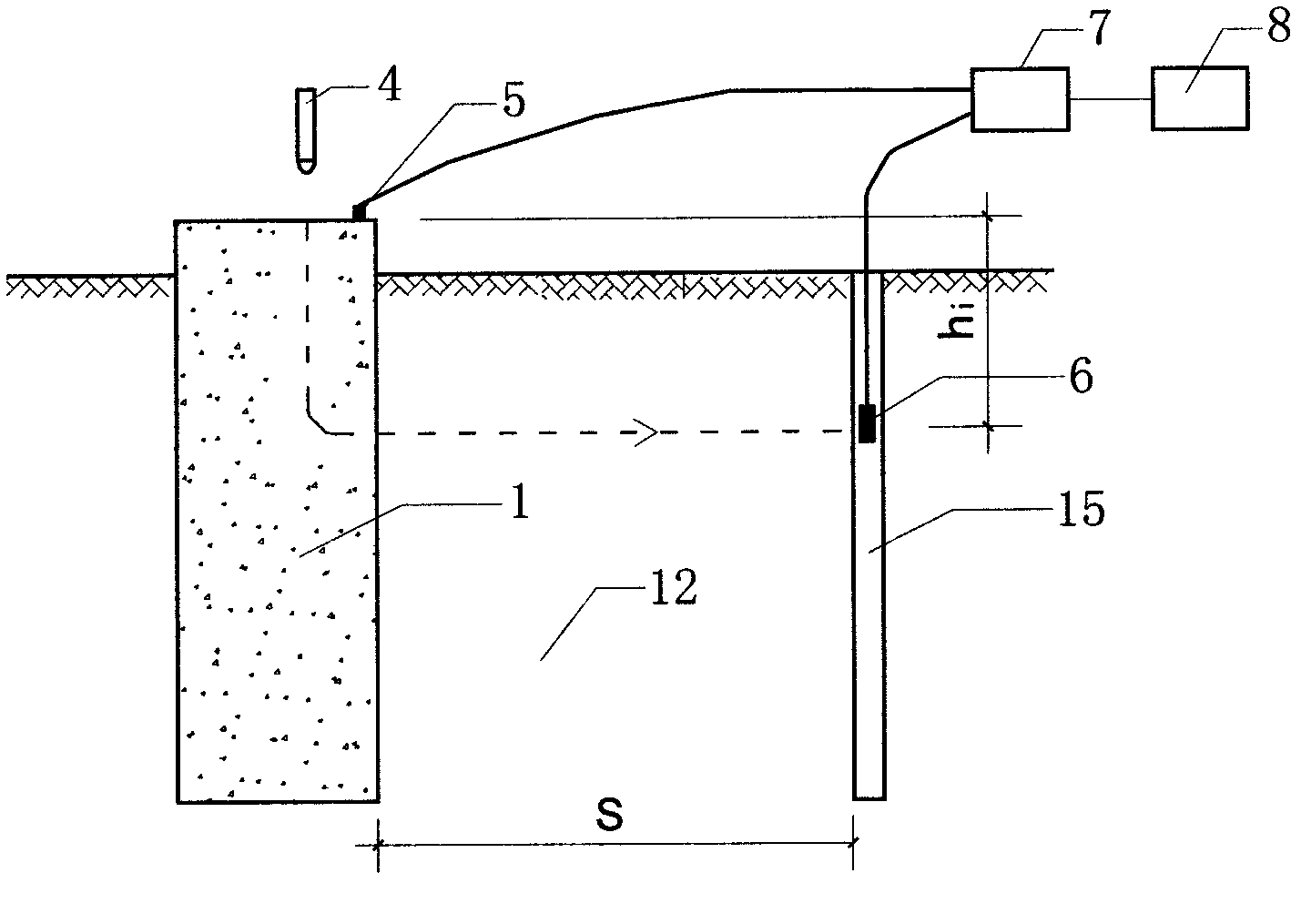

Technology for performing foundation pile quality detection and geology survey by adopting single tube longitudinal wave method

InactiveCN103255785AAchieve non-destructive quality inspectionImprove accuracyFoundation testingIn situ soil foundationCombined testTesting equipment

The invention relates to a technology for performing foundation pile quality detection and geology survey by adopting a single tube longitudinal wave method. The technology is relevant to comprehensive testing of the actual using effect of a foundation pile and is characterized in that longitudinal wave transmitting downwards along a pile body is generated by knocking the top surface of the foundation pile, the longitudinal wave velocity and pile length of the foundation pile can be accurately measured by detecting the time difference of arrival of the longitudinal wave in a sounding pipe, and the quality of pile body concrete can be judged; actual measurement on the time difference of arrival of the longitudinal wave which is transmitted from the pile side soil along the knocked pile body can be conducted in adjacent pipelines or geological bore holes, and the length of the foundation pile, the pile body quality and the chambering degree can be measured; and the wave length of a geological soil layer can be measured, the condition of the geological soil layer around the pile can be judged, and the rock-inlet condition of the foundation pile can be analyzed. By means of the technology for performing foundation pile quality detection and geology survey by adopting the single tube longitudinal wave method, a signal processor can be configured externally or inserted in on the basis of the existing low-strain ultrasonic detection devices and the like, the technology can achieve foundation pile quality nondestructive testing and geology survey, is an economic and ready-made pile foundation nondestructive testing auxiliary validation method and can remarkably improve accuracy and service level of pile foundation quality decision.

Owner:陈彦平

Automatic lip gloss image enhancement method based on color space

ActiveCN103914699AEasy transitionEasy to excludeImage enhancementCharacter and pattern recognitionState of artPattern recognition

The invention relates to an automatic lip gloss image enhancement method based on the color space. The method comprises the following steps that 1, face identification and five sense organ locating are carried out on an image, and a lip contour area is determined; 2, fuzzy processing is carried out on the lip contour area, and a lip contour fuzzy graph is generated; 3, according to a probability graph of the color space, the probability that each pixel in the lip contour area is the lip is calculated, a lip probability graph is generated and is combined with the lip contour fuzzy graph generated in the step 2, and then a final probability graph is obtained by calculation; 4, according to the final probability graph and the lip gloss color selected by a filter, each pixel in the lip contour area is automatically coated with lip gloss, and finally a result graph after being automatically coated with the lip gloss is obtained. Compared with a lip gloss processing method in the prior art, the method has the advantages of being easier to implement, higher in speed, better in identification precision and more applicable to mobile intelligent equipment.

Owner:MEITU

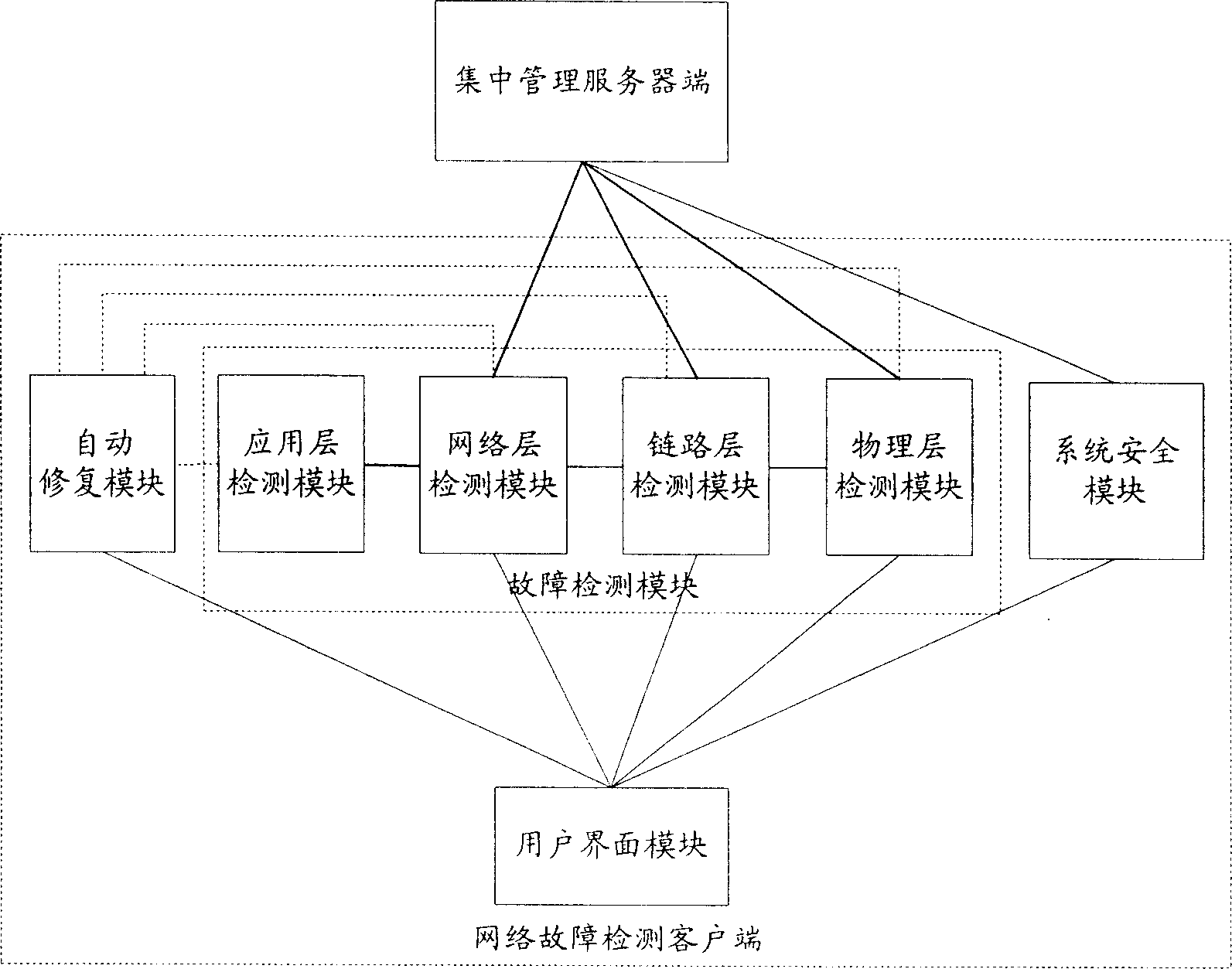

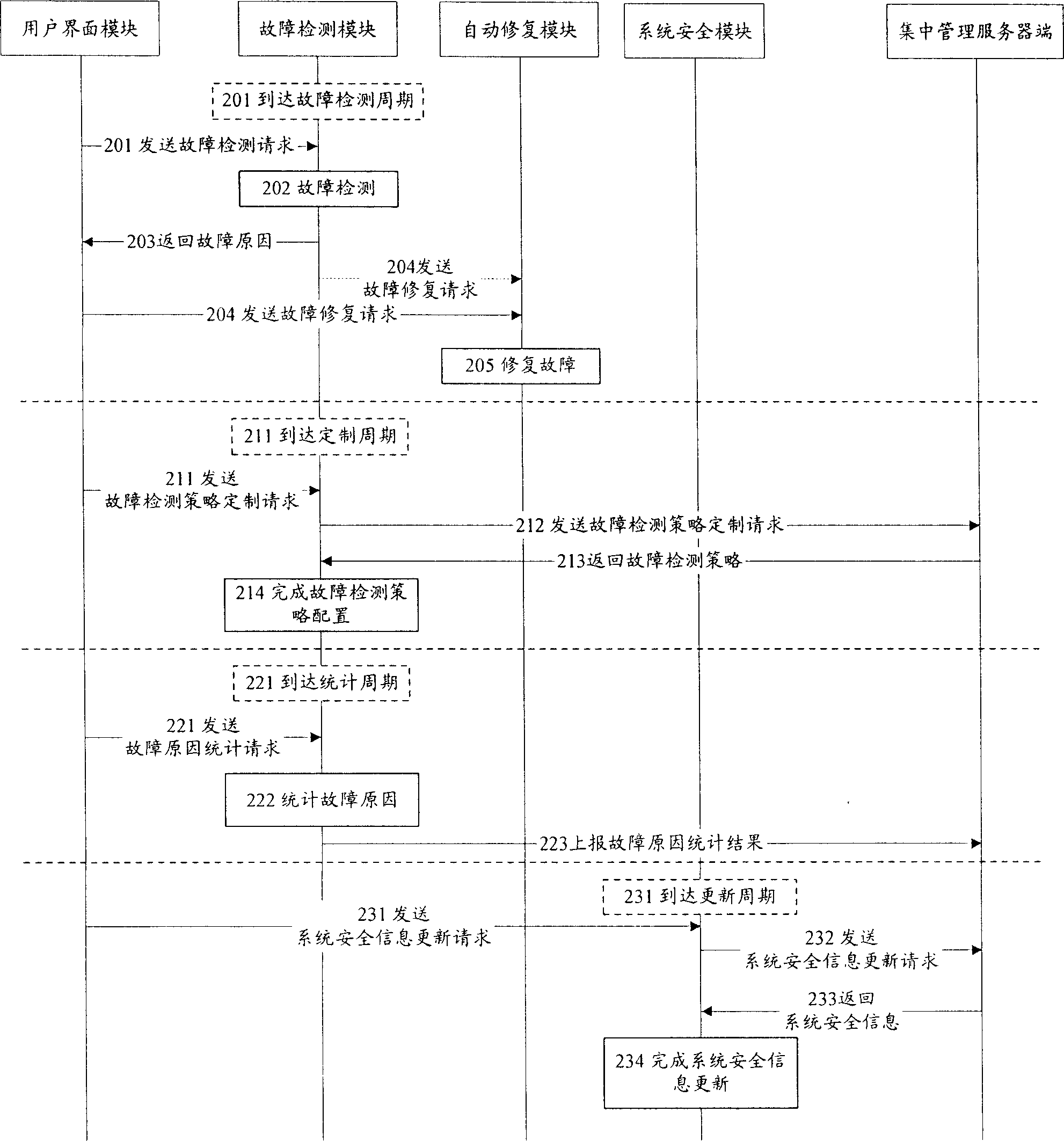

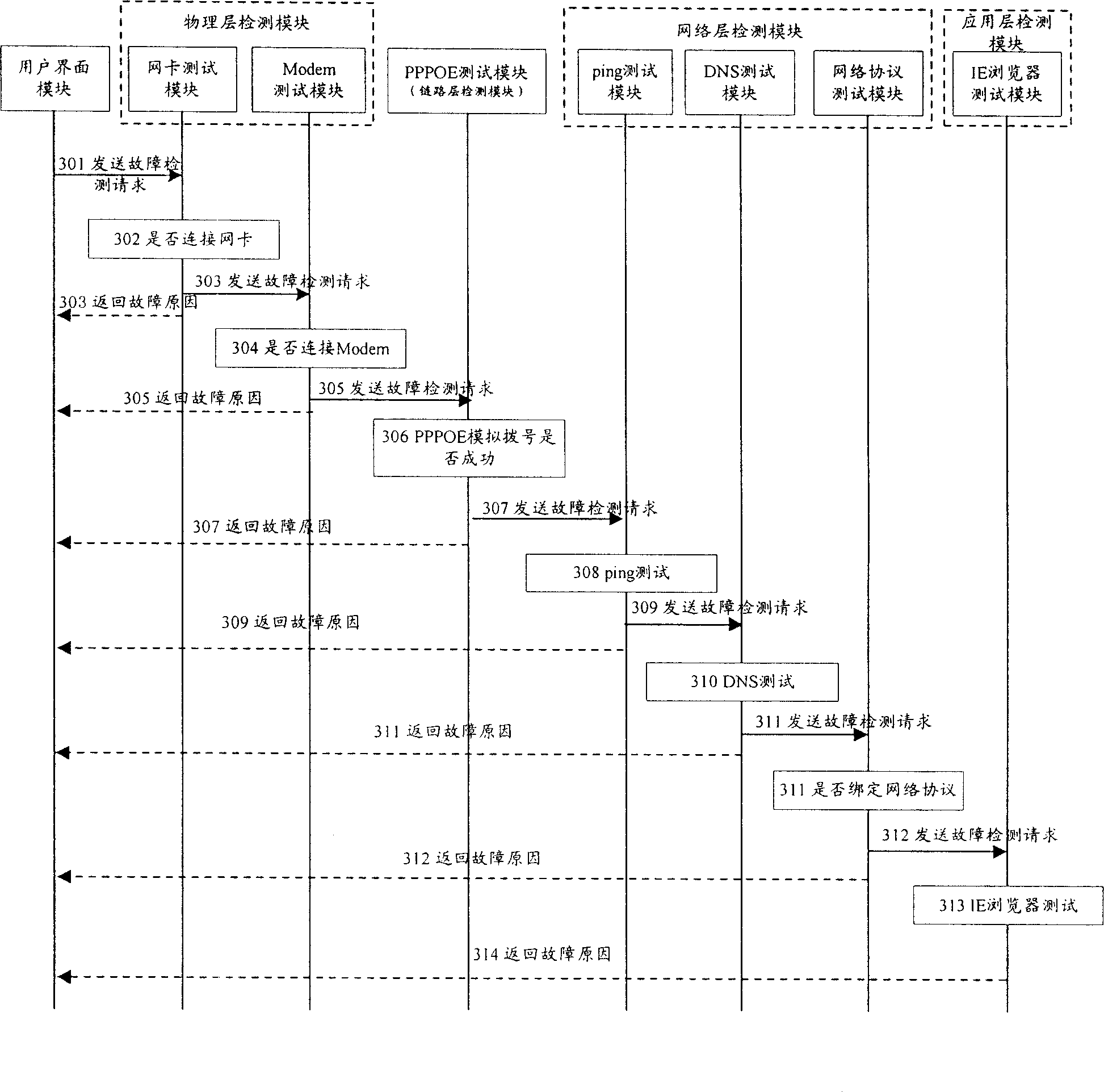

System and method for detecting faults in network

InactiveCN1917454AFlexible customization of fault detection strategiesReduce fault reporting rateData switching networksNetwork connectionFailure causes

The system comprises a network failure detecting client-side mounted on a PC. The network failure detecting client-side comprises: a failure detecting module for testing the network connection of PC when receiving a failure detecting request, and for returning the failure cause to the user's interface module when detecting a failure; and a user's interface module for receiving the failure cause from the failure detecting module and returning it to the PC.

Owner:HUAWEI TECH CO LTD

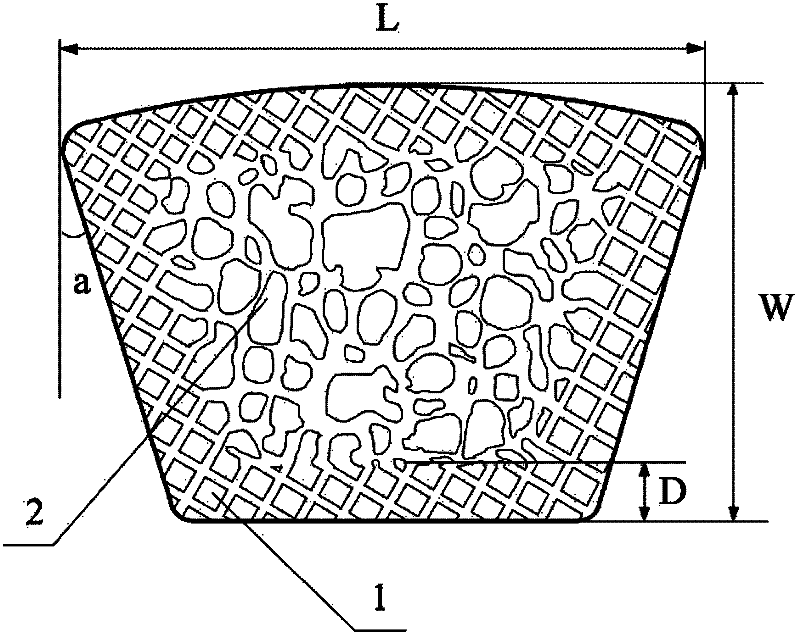

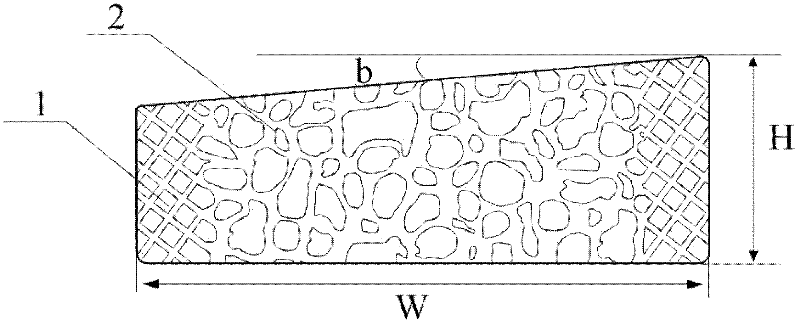

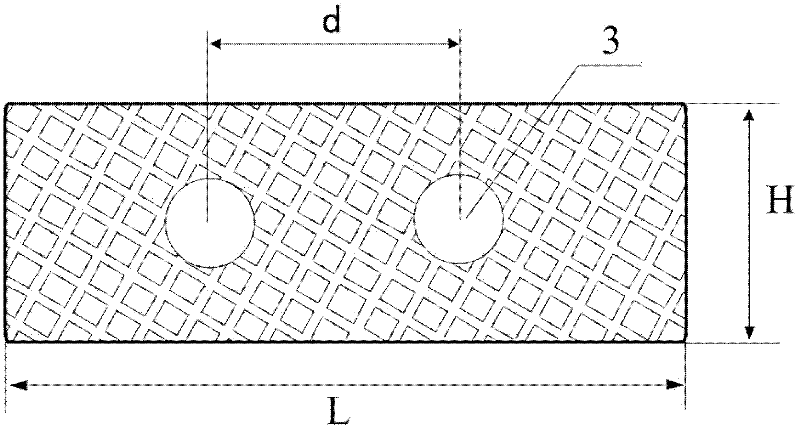

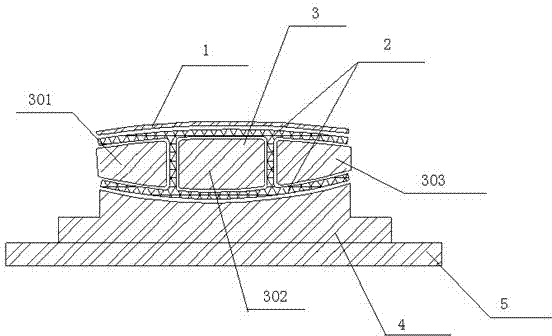

A bioactive porous titanium alloy human cervical intervertebral fusion device and its preparation method

ActiveCN102293693AEven by forceSolve the interface binding problemInternal osteosythesisMedical devicesMetallurgyDrug biological activity

The invention provides a porous titanium alloy human cervical interbody fusion cage with bioactivity and a preparation method thereof. The method comprises the following steps: firstly, inputting model data into electron beam melting equipment according to a design requirement to prepare a porous titanium alloy human cervical interbody fusion cage; secondly, preparing gelatin microspheres; and immersing gelatin microsphere dry powder in an rhBMP-2 solution for gelatin coating modification, preparing a gelatin solution A in double distilled water, immersing the porous titanium alloy human cervical interbody fusion cage in the gelatin solution A, mixing the rhBMP-2 gelatin microspheres and absolute ethanol to obtain suspension B, and immersing the gelatin-coating-modified porous titanium alloy human cervical interbody fusion cage in the suspension B to prepare the porous titanium alloy human cervical interbody fusion cage internally containing an rhBMP-2 sustained-release system. The cervical interbody fusion cage prepared with the method has modulus of elasticity close to that of natural bone tissues, and the porous structure and the bioactivity factor sustained-release system inside the cervical interbody fusion cage can induce growth of new bone tissues, so that the binding problem of bone-material interfaces is solved. Therefore, the cervical interbody fusion cage has bettermechanical compatibility and bone integration capability than those of a compact material.

Owner:维度(西安)生物医疗科技有限公司

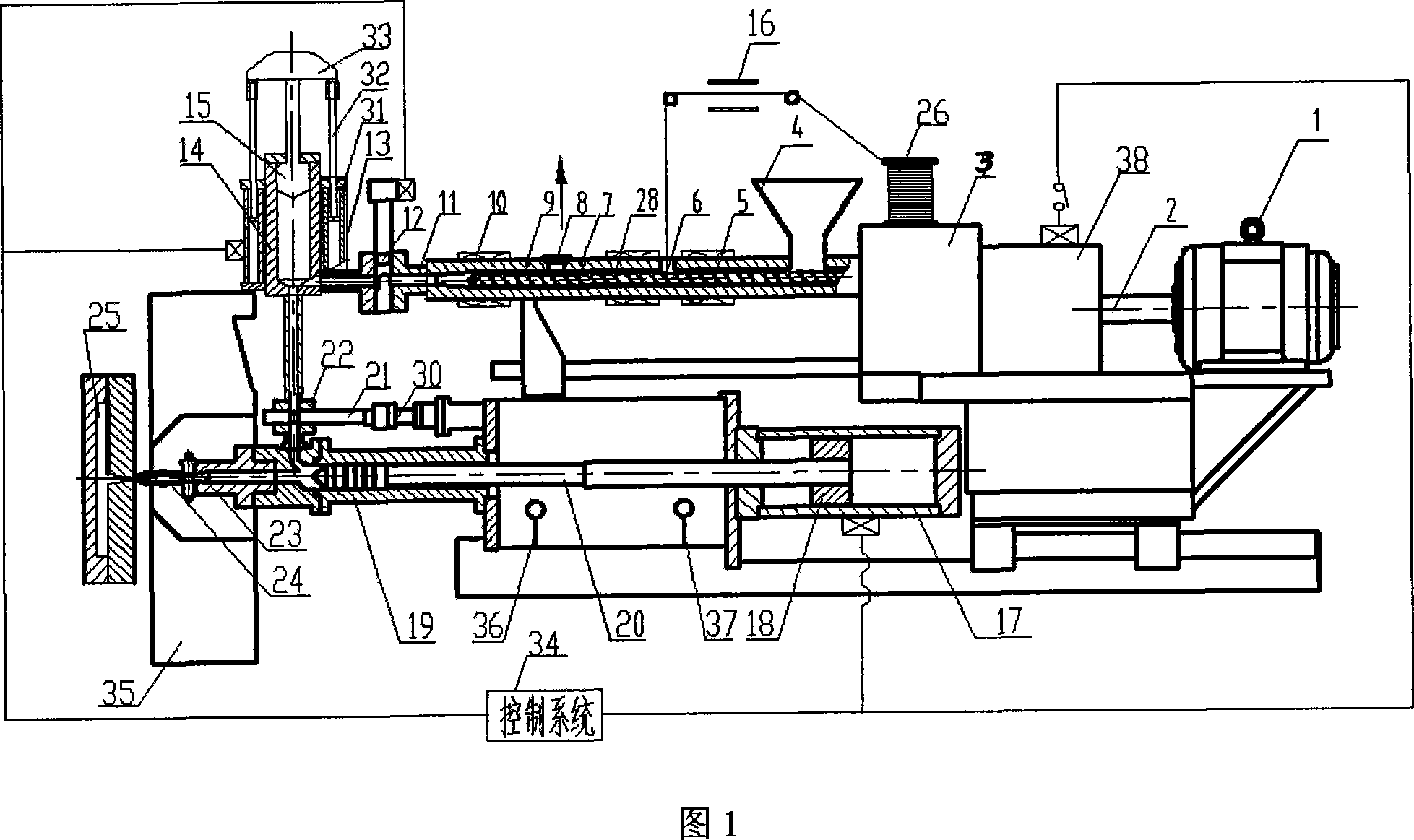

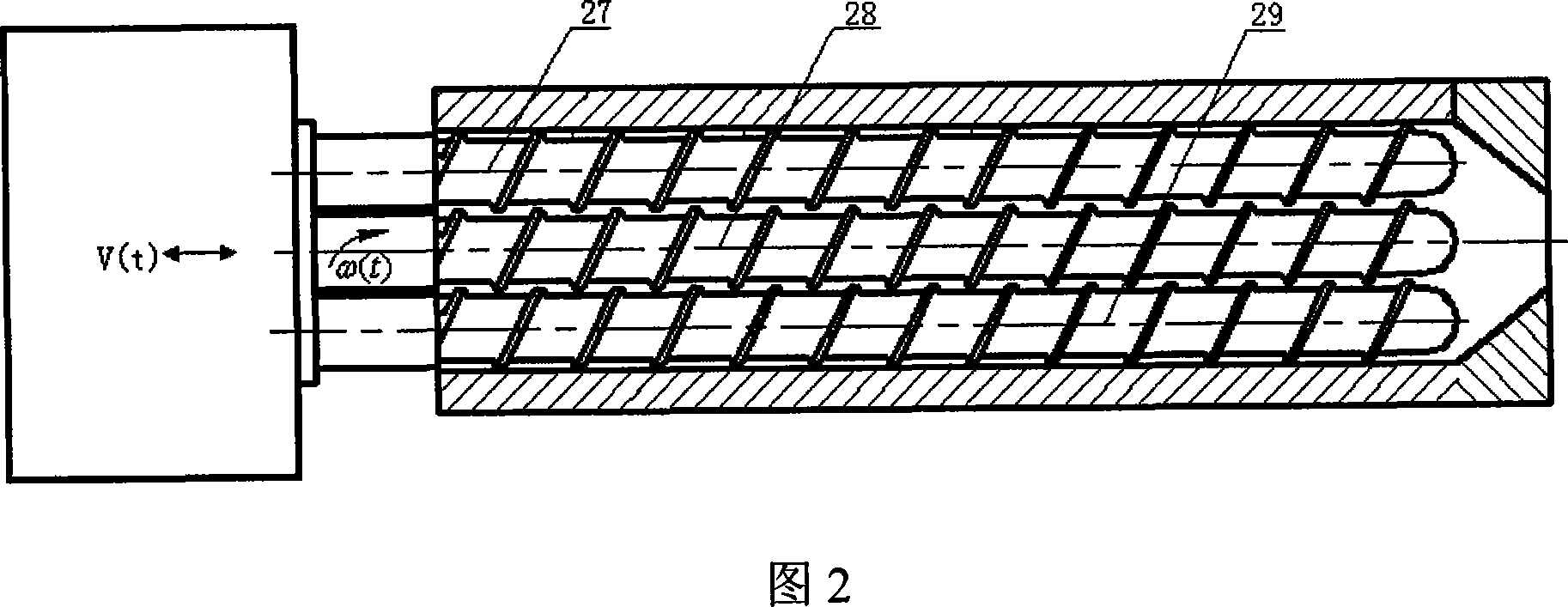

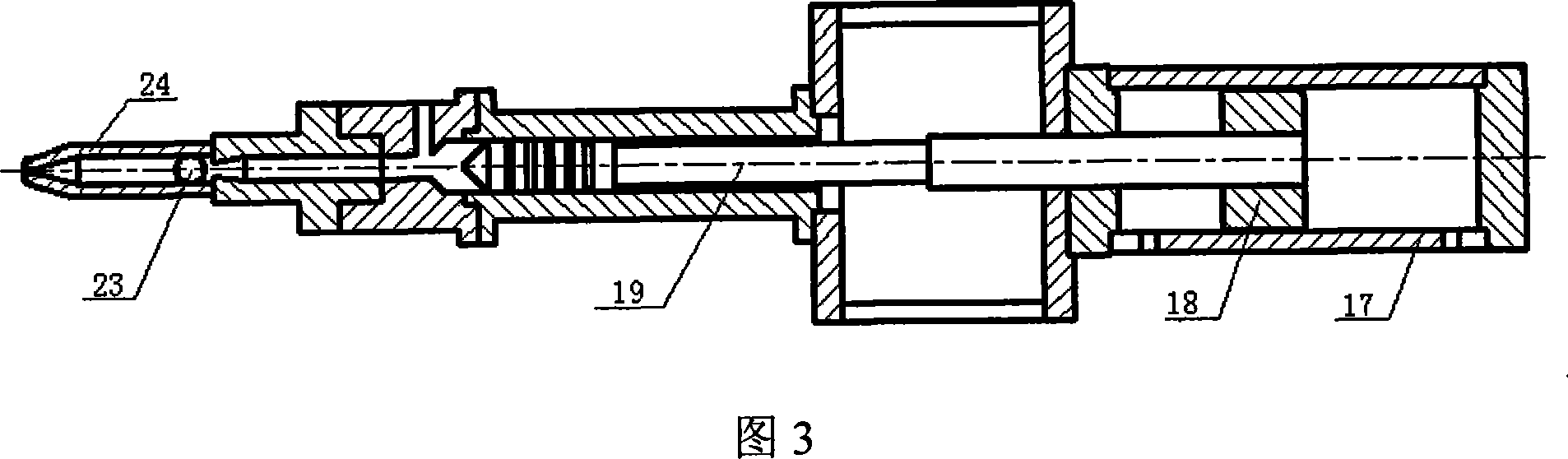

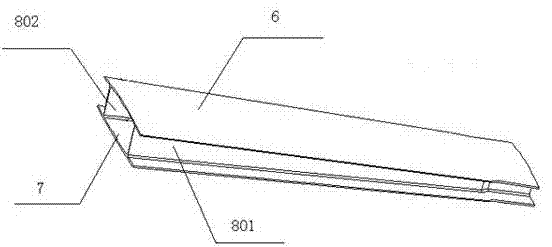

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

Manufacture method of box-shaped structural main beam made from composite material

The invention relates to a manufacture method of a box-shaped structural main beam made from a composite material. The method comprises the following steps of: A, manufacturing a male mold, a female mold and an assistant tooling balance press plate; B, paving and gluing a prepreg of the composite material on the male mold, and vacuumizing and previously compacting under the normal temperature; C, laying the previously-compacted composite material on the female mold; D, combining the assistant tooling balance press plate, the male mold and the female mold from top to bottom, and packaging in a vacuum bag; E, putting the vacuum bag into a hot-press tank for vacuumizing and checking the air impermeability; and F, rising and keeping the temperature of the hot-press tank, keeping the pressure and rising the temperature after the tank is pressured, keeping the pressure and the temperature, cooling, releasing the pressure, and removing the male mold, the female mold, the assistant tooling balance press plate and a substrate to finally obtain the box-shaped structural main beam made from the composite material. According to the manufacture method, each molded surface region of the prepreg of the composite material can be pressured within a resin gel time, and the loosing of parts caused by the small pressure can be avoided.

Owner:JIANGXI HONGDU AVIATION IND GRP

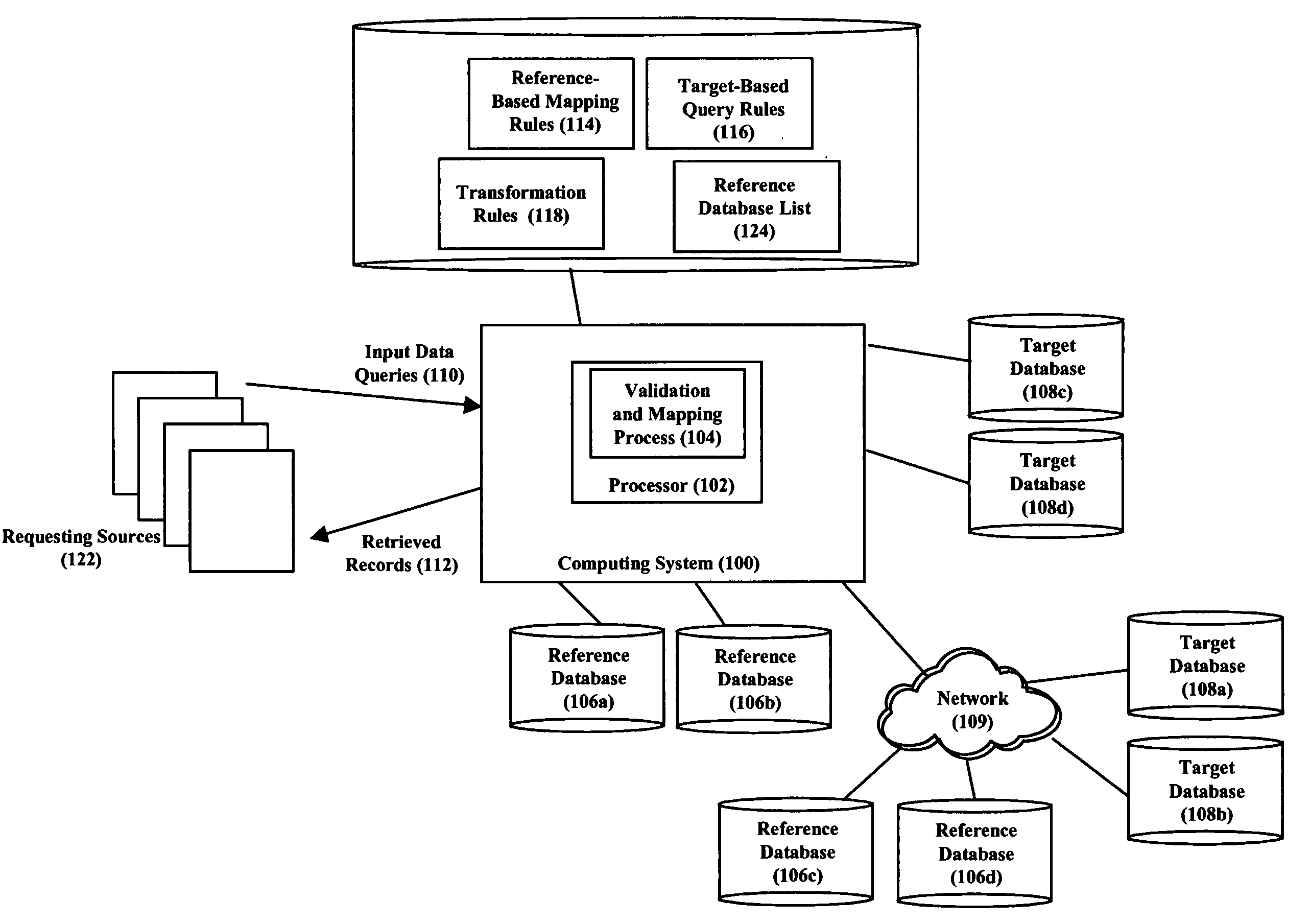

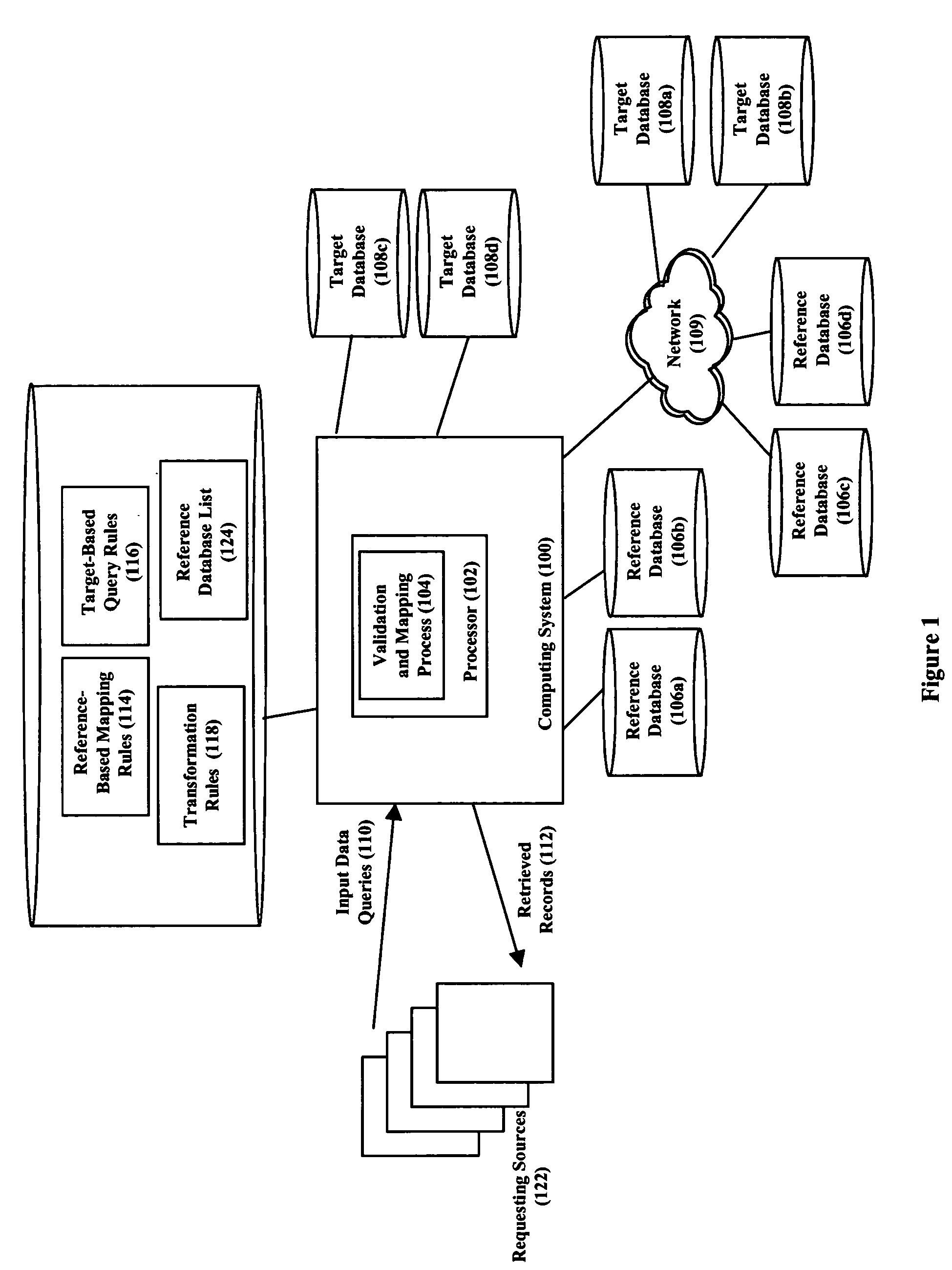

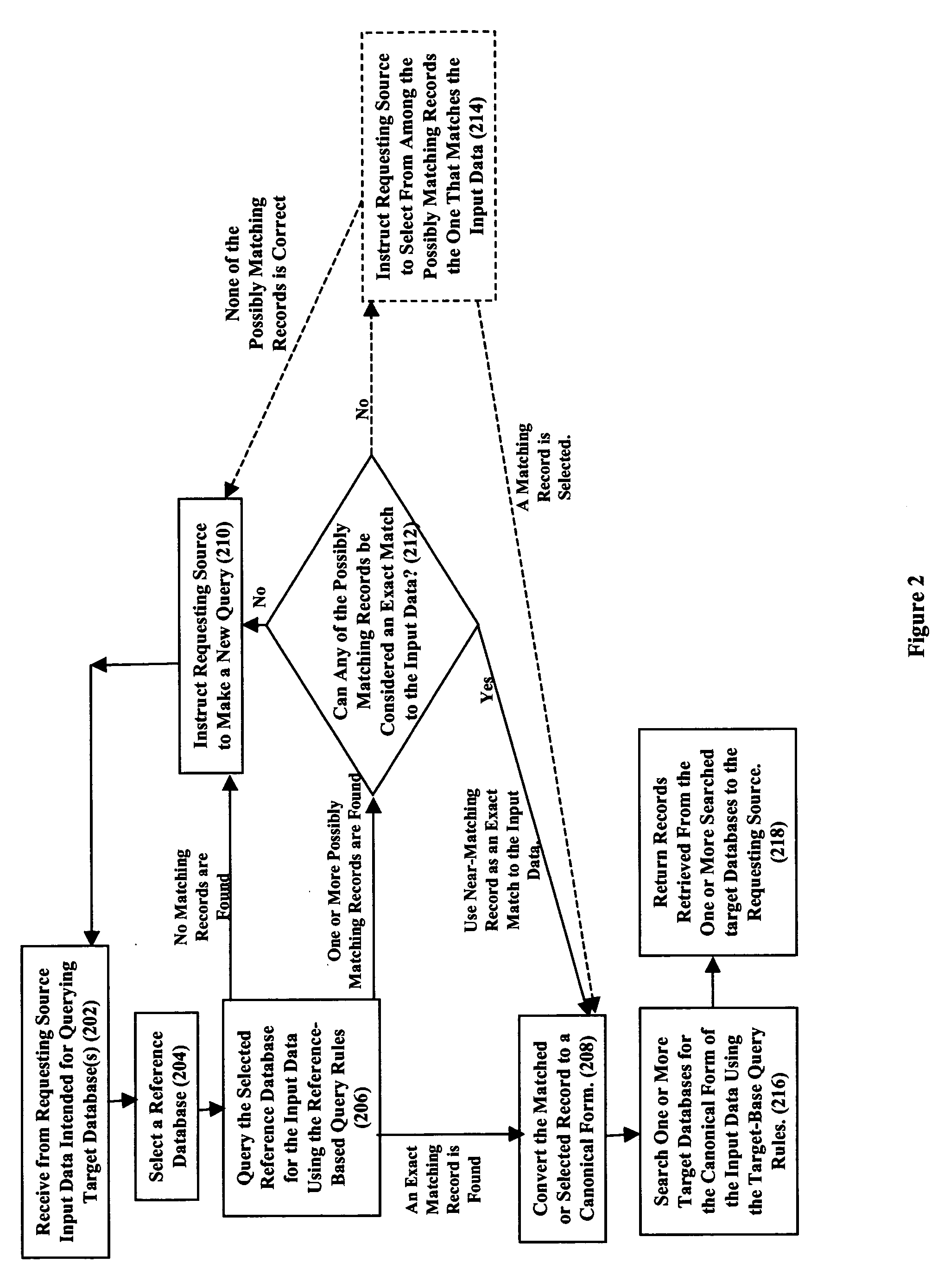

Two-stage data validation and mapping for database access

ActiveUS20050240569A1Reduce the numberReduce complexityDigital data information retrievalDigital data processing detailsData validationExact match

Input data queries directed at a plurality of target databases and originating from any of a plurality of sources are first converted to validated canonical forms, which are then used to query the target databases. Specifically, upon receiving an input data query, a relatively accurate reference database is selected based on the type of the input data. This reference is then queried for the input data with the intent of finding an exact matching record or a near-matching record that can be considered an exact match and thereby validating the input data. Otherwise, the requesting source is instructed to provide a new query. Once having a validated record, it is converted to a canonical form, which is then used to query the target databases intended to be searched. In a further embodiment, multiple reference databases are queried to determine a canonical form of the data or to determine multiple canonical forms of the data.

Owner:NYTELL SOFTWARE LLC

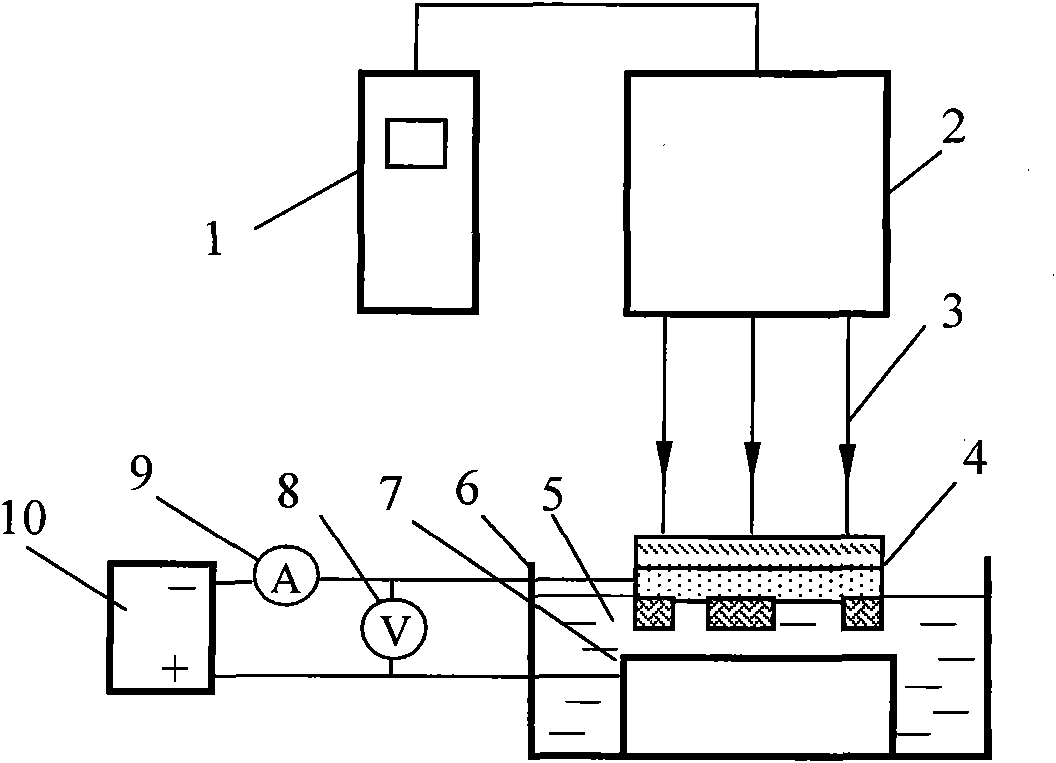

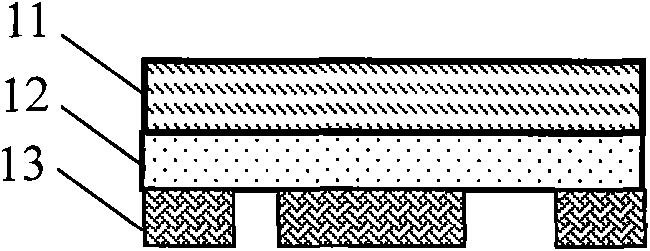

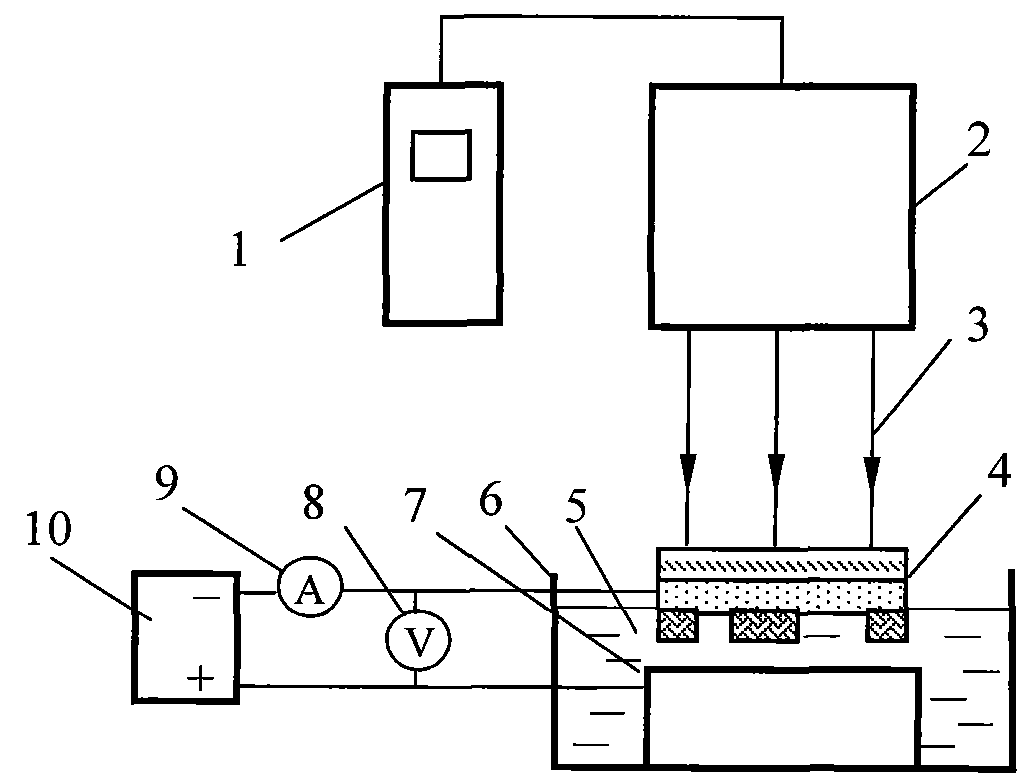

Method and device for realizing photoelectrochemical micro-etch processing of masked electrode

The invention provides a method and a device for realizing the photoelectrochemical micro-etch processing of a masked electrode, and relates to the micro processing field in the manufacturing technology. A masked electrode used by the invention comprises a glass substrate, an indium tin oxide (ITO) layer and a photoresist mask layer, wherein the conductive light-permeable ITO layer is used as a tool electrode for electrochemical processing and can be permeated by a laser beam, and the photoresist mask layer can limit the action zones of the laser beam and the electrochemical electrode to achieve the double effects of a beam mask and an electric field mask. When the laser beam permeates the masked electrode, a mask pattern is imaged on the surface of a workpiece, the force effect of a shock wave generated by the irradiation of the laser between the workpiece and the electrolyte enables the passivation layer to be removed by the generation of stress corrosion. Meanwhile, the workpiece material at the laser-irradiated part is removed by etching under the action of the photoelectrochemical reaction. The invention can effectively enhance the processing efficiency, the micro processing degree and the processing precision of the complex pattern, and is applicable to the micro processing of the conductive metal material.

Owner:JIANGSU UNIV

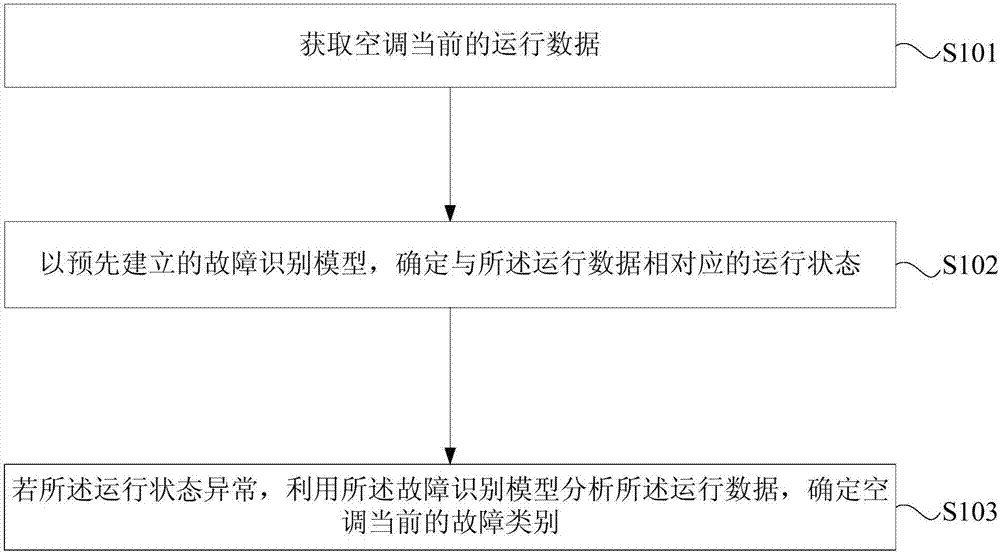

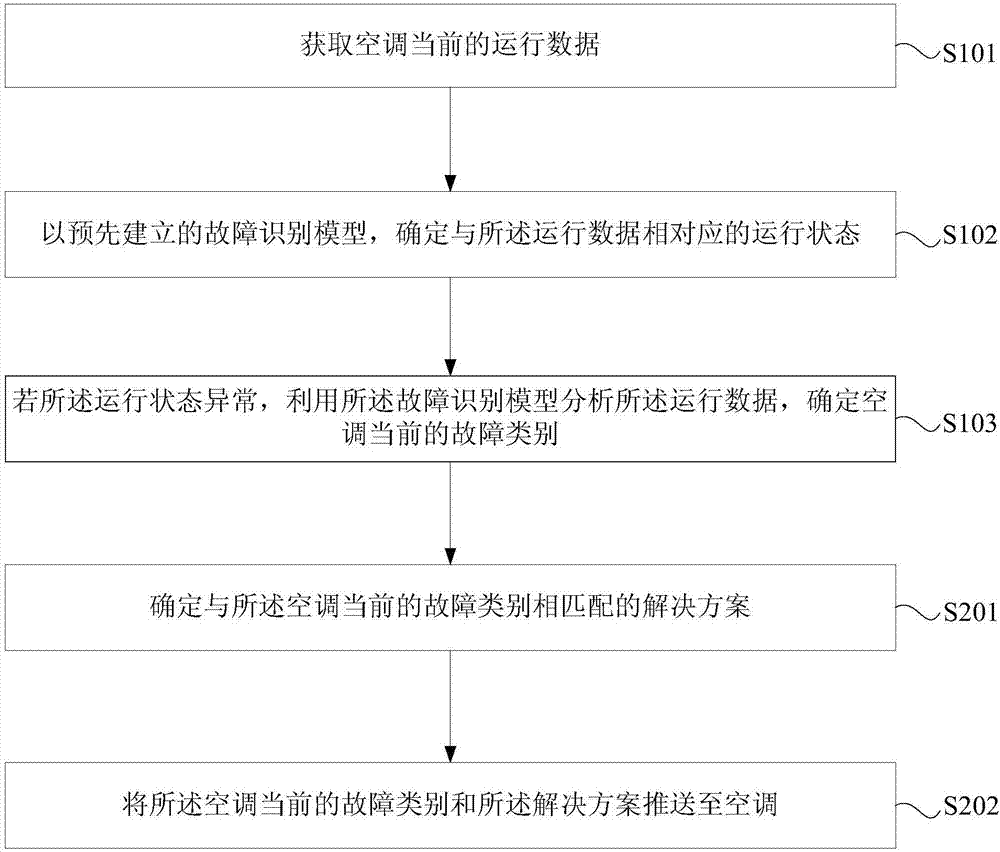

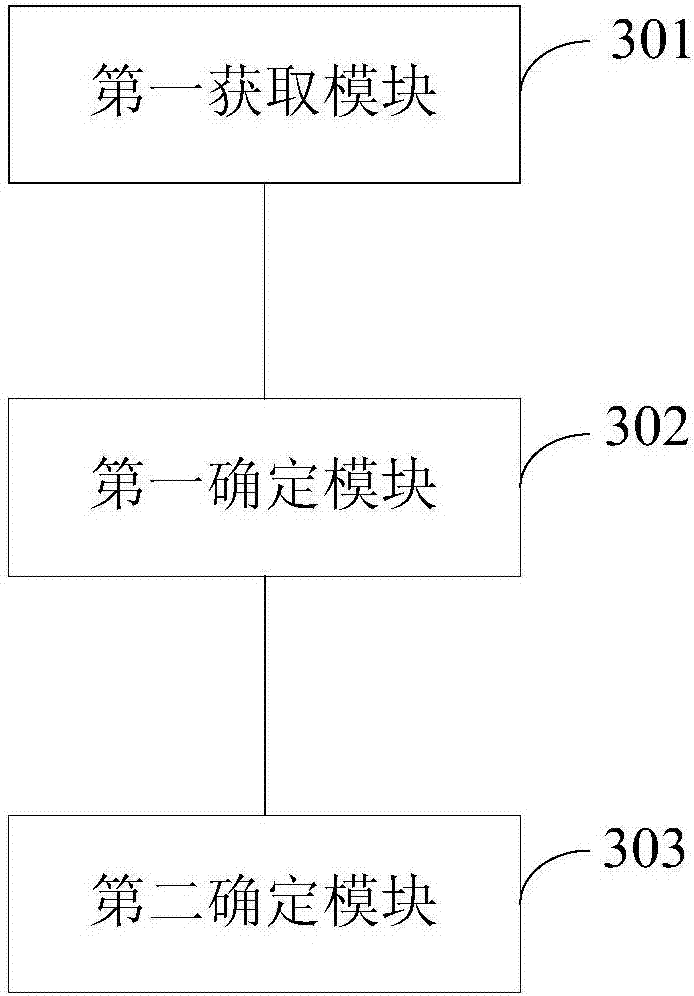

Air conditioner fault identification method, device and system

ActiveCN107990485AImprove experienceReal-time fault identificationMechanical apparatusSpace heating and ventilation safety systemsReliability engineering

The invention discloses an air conditioner fault identification method, device and system. The air conditioner fault identification method comprises the steps that the current operation data of an airconditioner are obtained; the operation state corresponding to the operation data is determined according to a pre-established fault identification model; if the operation state is abnormal, the operation data are analyzed through the fault identification model, and the current fault type of the air conditioner is determined. By the adoption of the air conditioner fault identification method, device and system, the fault of an air conditioner product can be found in time, so that the fault can be conveniently cleared in time, and the user experience can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

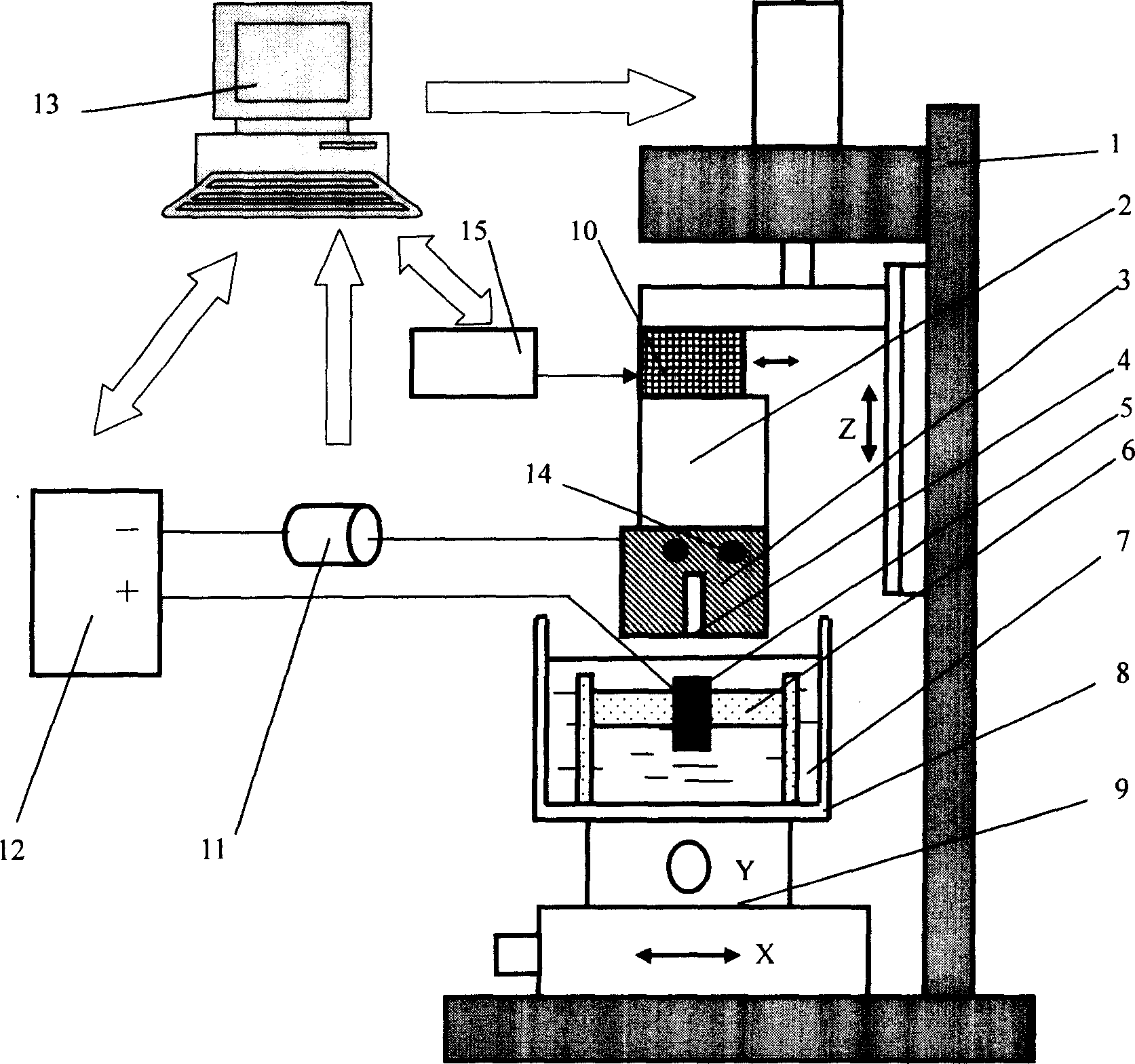

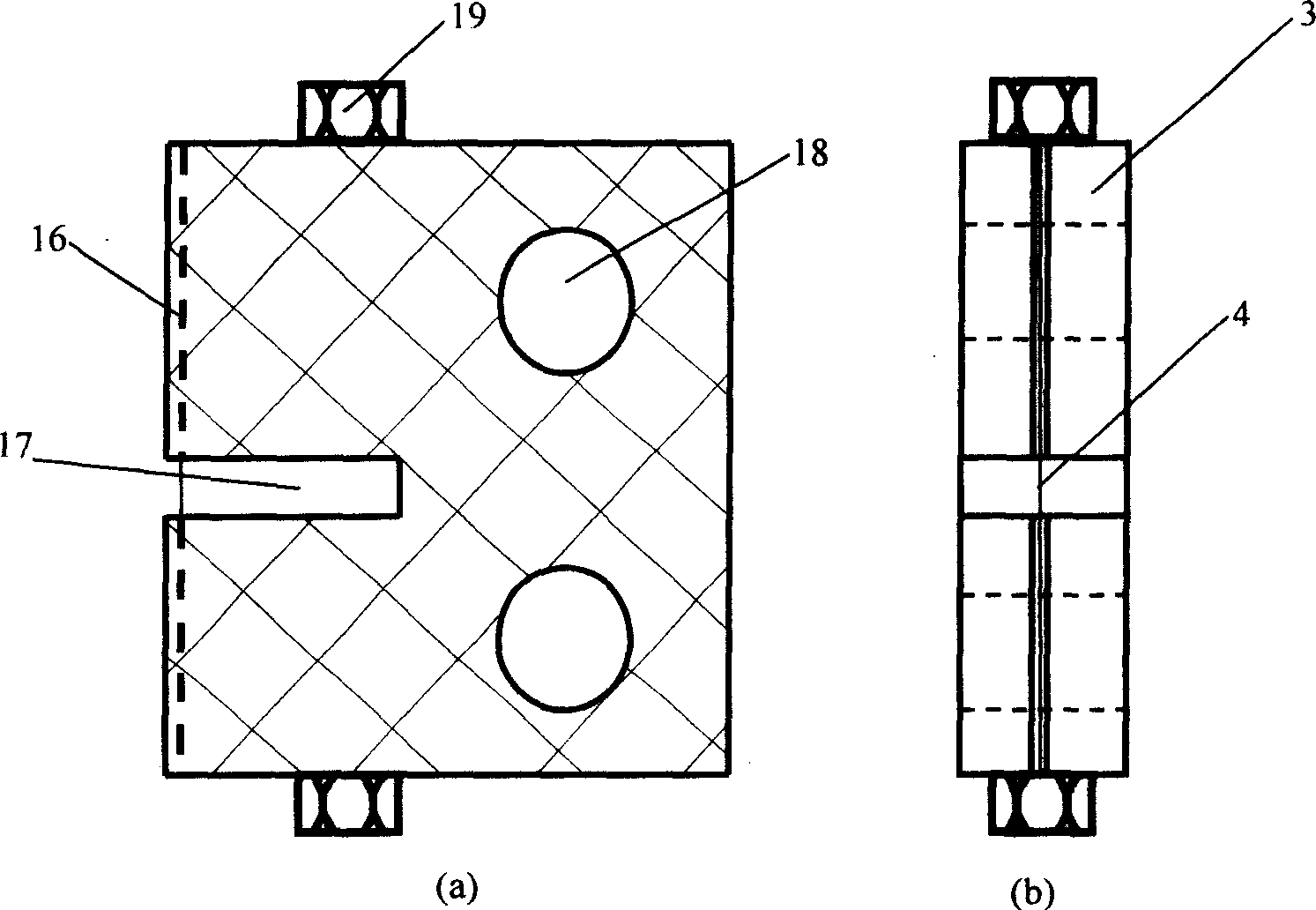

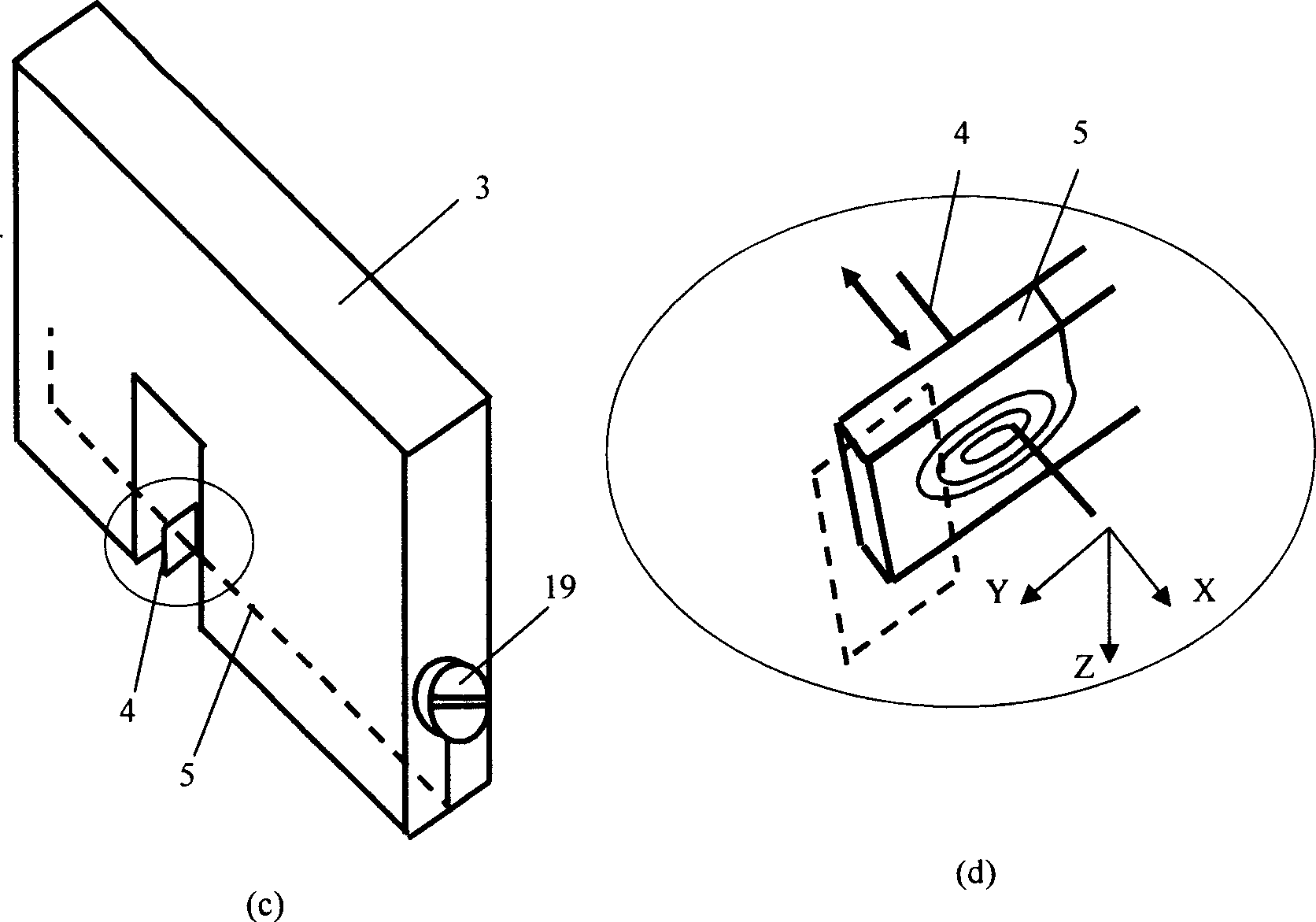

Micro-scale line electrode electrolysis machining method and micro-vibration line electrode system

InactiveCN1850411AEasy to excludeAvoid short circuitMechanical vibrations separationElectrical-based machining electrodesNumerical controlElectrolysis

The present invention relates to a microdimesion wire electrode electrolytic machining method. It is characterized by that in the course of electrolytically microcutting metal material by using wire electrode it utilizes a microvibration device to make the wire electrode produce microvibration perpendicular to its feeding direction, so that it is favourable for discharging electrolytic product from machining gap so as to prevent the short circuit from producing and greatly raise electrolytic quality. Said microvibration wire electrode system is mounted on the Z-axis of numerical control machine tool and is formed from wire electrode frame, microdimension wire electrode mounted on the wire electrode frame and microvibation device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Air bubble detection method for air tightness test

ActiveCN105389814AEasy to excludeImprove accuracyDetection of fluid at leakage pointImage enhancementMethod comparisonLeakage rate

The invention relates to an air bubble detection method for an air tightness test. The method comprises the following steps: a camera carries out shooting; inter-frame difference method comparison is carried out on an image; clustering analysis is carried out on coordinate points of a frame difference pixel; a frame difference image NewDiffImg is obtained; analysis in a centroid distance variance method is carried out; radius and roundness error values are compared; the leakage rate is obtained and the like. Compared with the prior art, the method has the following beneficial effects that a computer vision technology is used for detecting air bubbles in a pressure container air tightness test, the camera is directly used for acquiring the image, the operation is simple, the cost is greatly reduced in comparison with the fact that an expensive device such as a fiber probe and an electron probe acquires physical parameters, impurities whose shapes are similar to air bubbles can be well eliminated, the image is shot from the water surface of a detection pool, the air leakage position can be positioned, and accuracy of the detection result can be improved.

Owner:ZHEJIANG UNIV OF TECH

Porous pole piece and preparation method thereof and lithium ion battery

InactiveCN105633350AHigh porosityIncrease fluid retentionSecondary cellsNon-aqueous electrolyte accumulator electrodesPower performanceLithium electrode

The invention is suitable for the field of lithium ion batteries, and provides a preparation method of a porous pole piece. The preparation method comprises the following steps: mixing a pore forming material and slurry to obtain a mixture, and coating a pole piece with the mixture; and baking the pole piece at 100 to 150 DEG C to obtain a porous pole piece, wherein the porosity of the pole piece is 35 to 45 percent. The invention also provides a lithium ion battery containing the porous pole piece. The porous pole piece has higher porosity and further has higher liquid preserving capacity. The lithium ion battery containing the pole piece has higher multiplying power performance and higher cycling performance. Meanwhile, the formed pores are convenient for discharging gases, so that the service life of the battery is prolonged. According to the porous pole piece and the preparation method thereof and the lithium ion battery containing the porous pole piece, the preparation method is simple, the operation is simple and convenient, and the industrialized production can be realized.

Owner:OPTIMUM BATTERY CO LTD

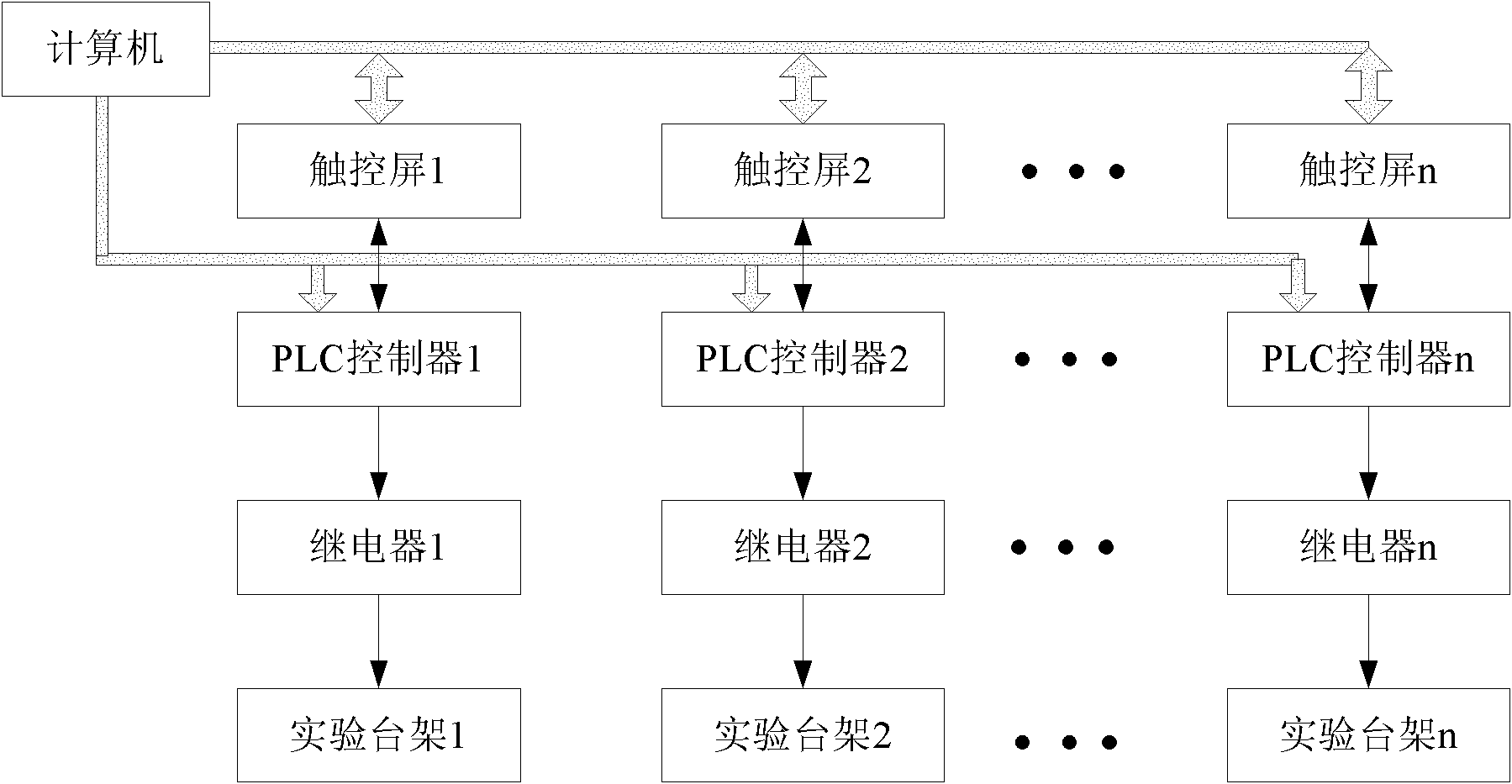

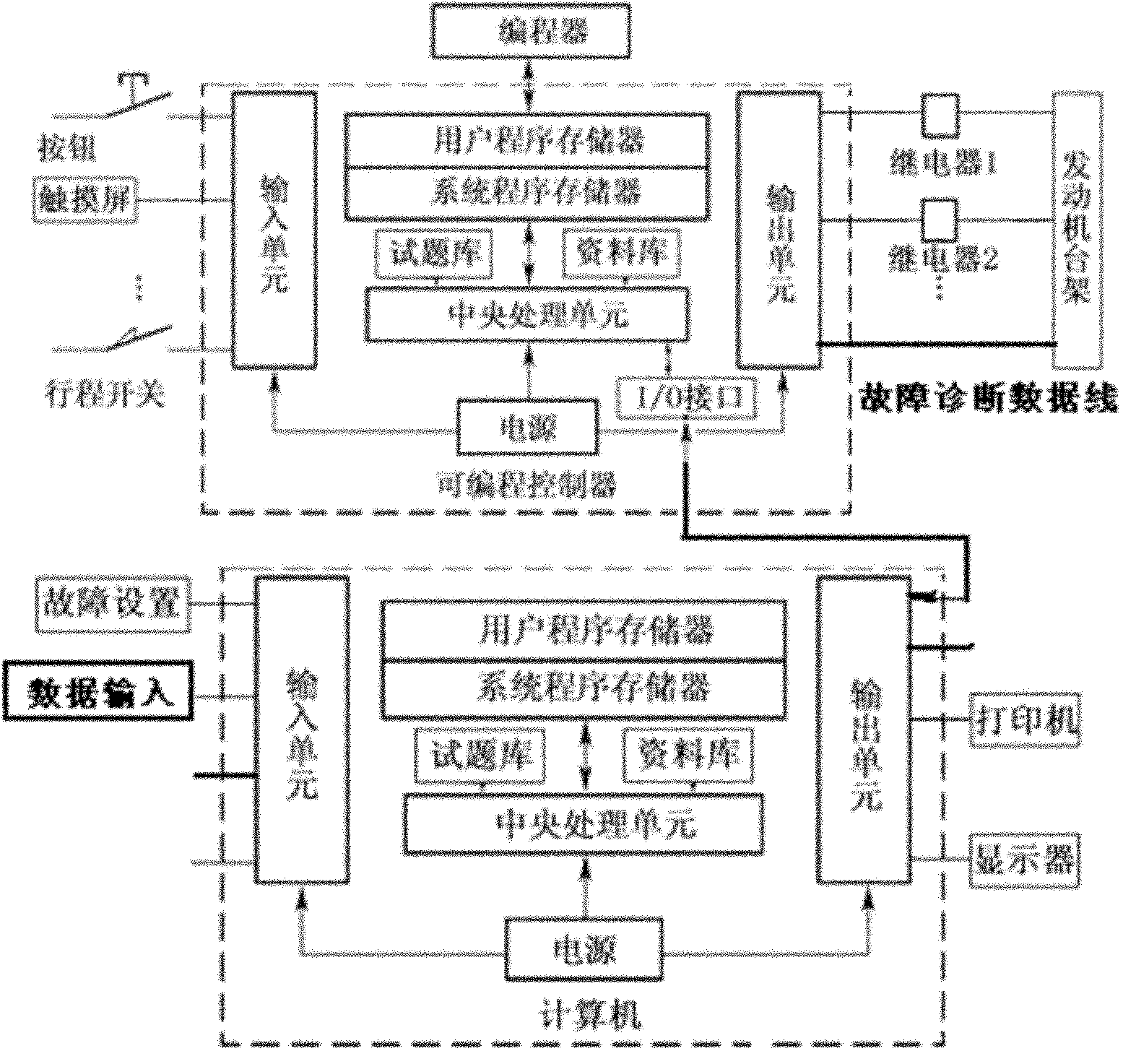

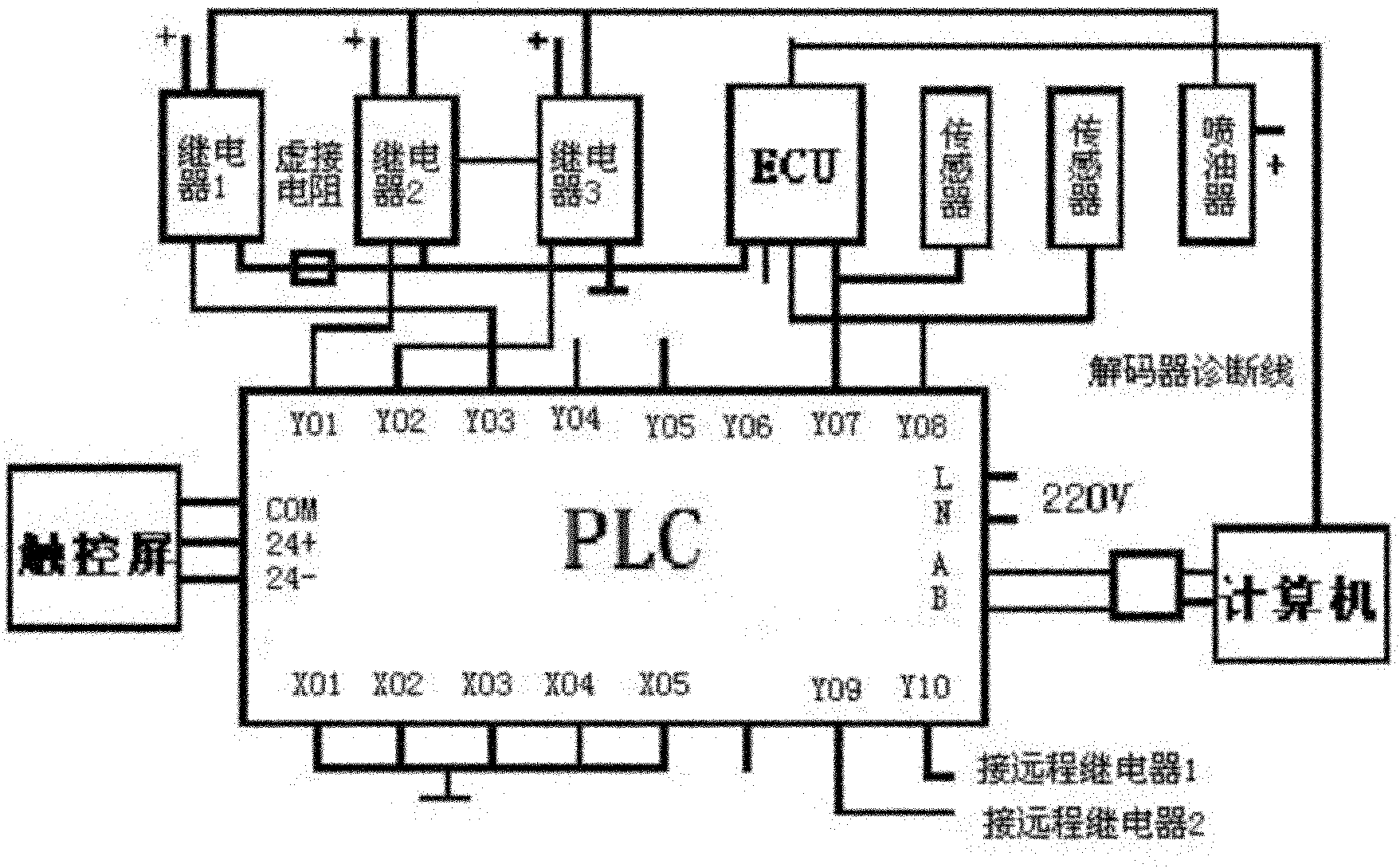

Vehicle failure intelligent setting, practical training and check-out system and realization method thereof

InactiveCN102117564AQuality improvementImprove efficiencyCosmonautic condition simulationsElectrical appliancesProgrammable logic controllerTest question

The invention discloses a vehicle failure intelligent setting, practical training and check-out system and a realization method thereof. The system comprises a test bench, a relay, a PLC (Programmable Logic Controller) and a touch screen, wherein the test bench is connected with the PLC through the relay; the system has a standalone edition mode and a network edition mode according to that whether the system is connected to the network or not; in the standalone edition, the PLC is directly connected with the touch screen; in the network edition, the system also comprises a computer which is connected with the touch screen and the PLC respectively, and the PLC is connected with the touch screen. The method is that a teacher can retrieve the test questions in an item pool through the touch screen or the computer and conduct failure setting on a vehicle on the test bench through the PLC and the relay; and a student can read the technical information in a data bank through the touch screen for conducting fault diagnosis and reporting the result to the PLC or the computer. The system and realization method can conduct intelligent failure setting, technical information storage and automatic scoring statistics, and improve practical training and check-out quality and efficiency.

Owner:广州市铭珠电控设备科技有限公司

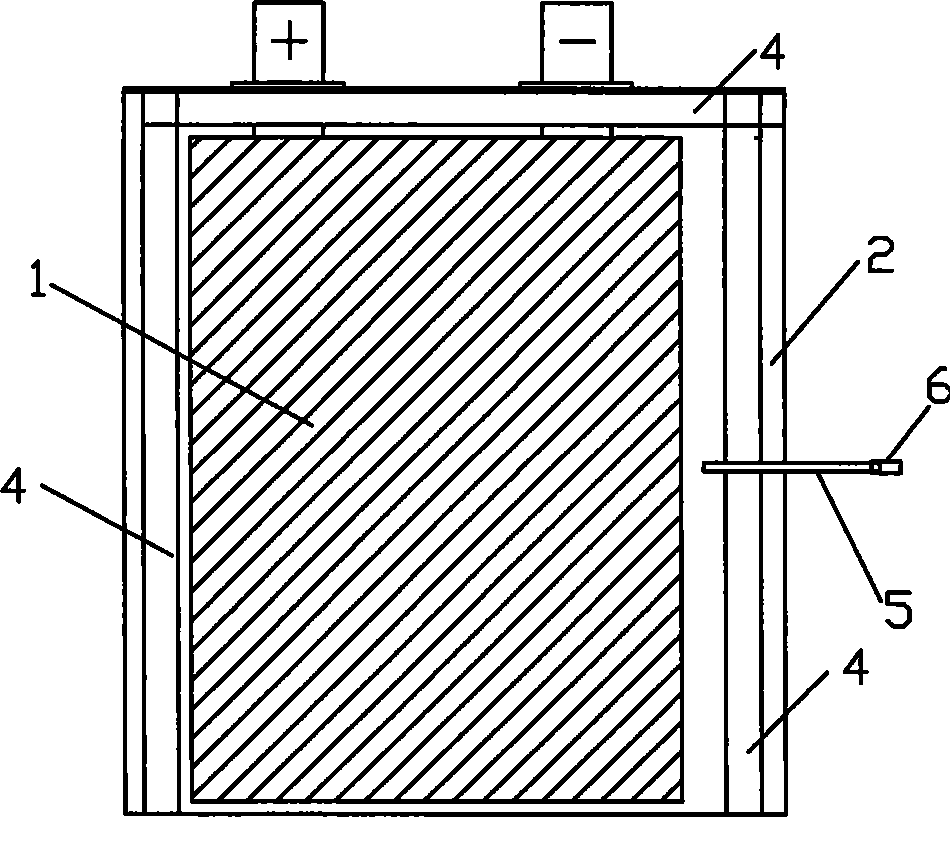

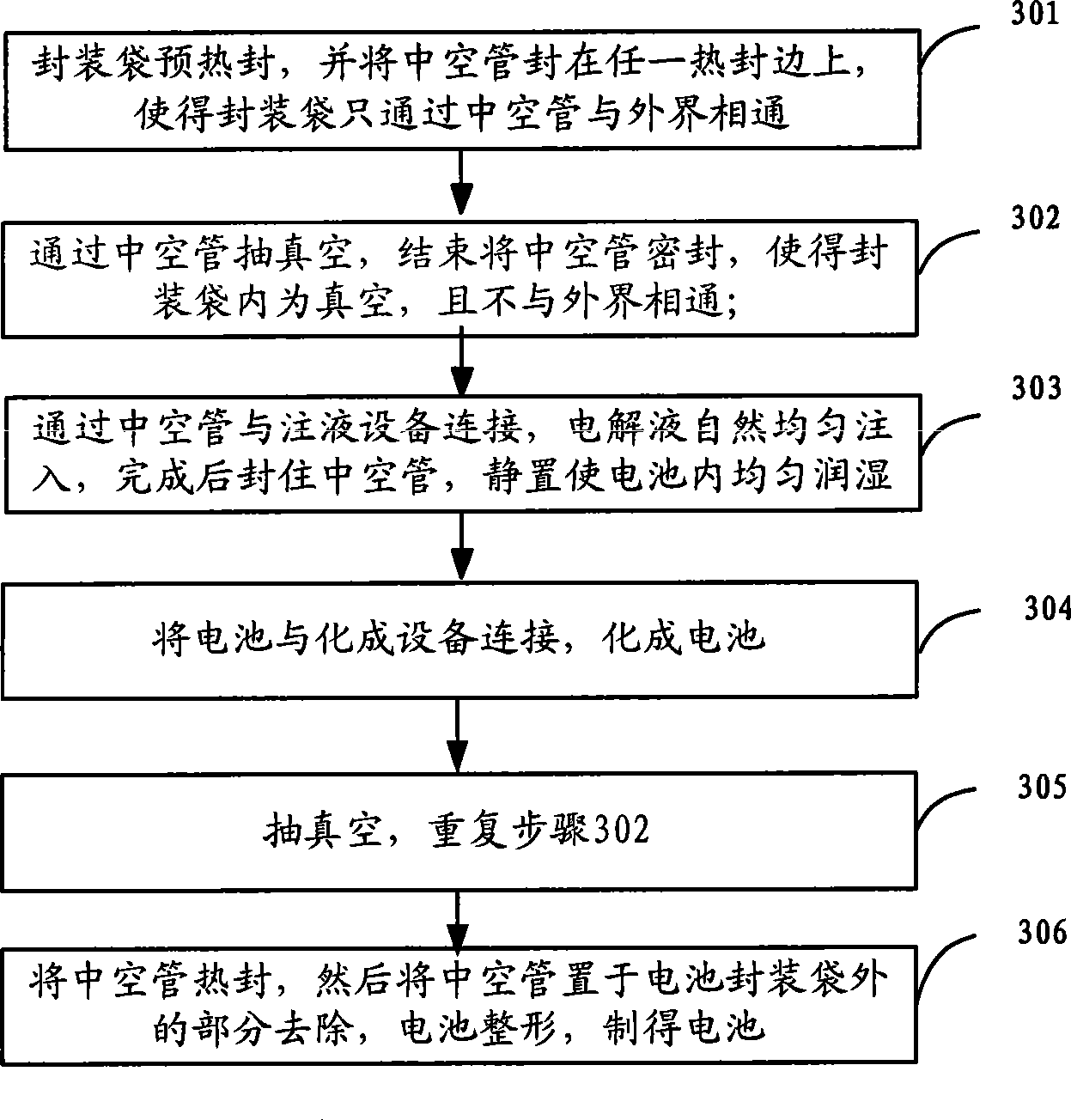

Method for manufacturing lithium ion battery

InactiveCN101533927AImprove performanceAchieve vacuum exhaustFinal product manufactureJackets/cases materialsEngineeringLithium-ion battery

The invention relates to a method for manufacturing lithium ion battery, which includes steps of packaging at least one hollow pipe on a package bag of a battery, and vacuumizing the battery through the hollow pipe. The invention also provides a package bag for the lithium ion battery, wherein the hollow pipe is arranged at side edge of the package bag for vacuumizing in battery manufacturing process. The invention can be used to manufacture flexible package lithium ion battery with different sizes, shapes and capacities, has simple process and production equipment, and is favorable to improve battery performance.

Owner:林道勇 +1

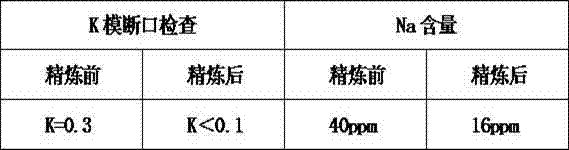

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

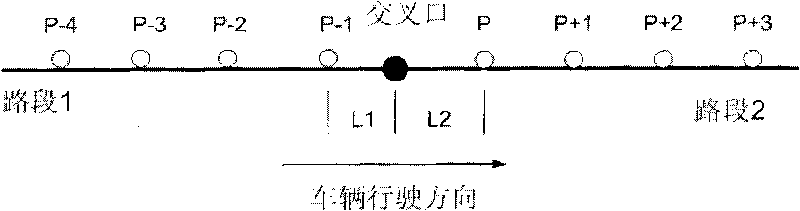

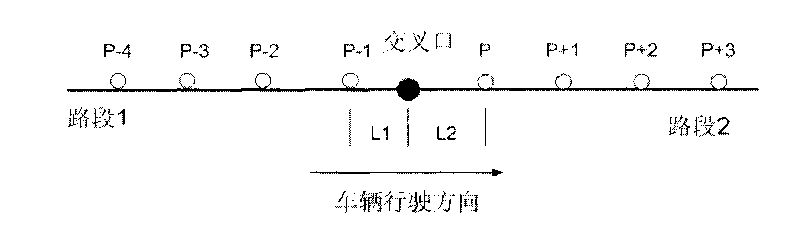

Road-section average travel time measuring method suitable for low-frequency sampling

InactiveCN101739823AEfficient measurementEffective average travel timeDetection of traffic movementActive measurementLow frequency

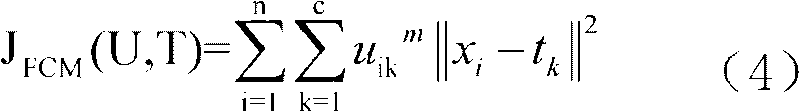

The invention relates to a road-section average travel time measuring method suitable for low-frequency sampling, which comprises the following steps: (1) sampling taxi GPS data at low frequency to obtain the estimated time of each vehicle at the crossroads; (2) according to the geographical position information at each crossroad and the estimated time of each vehicle at the crossroads, obtaining the vehicle travel time of a certain road section as a sample *i; and (3) calculating the average travel time according to the following reference formula (8), wherein in the clustering center, tf stands for quick type, tm stands for medium type, and tl stands for slow type. The road-section average travel time measuring method suitable for low-frequency sampling can effectively measure the average travel time of the road section and meet the requirements for traffic real-time performance and accuracy.

Owner:ZHEJIANG UNIV OF TECH

Metal 3d printer

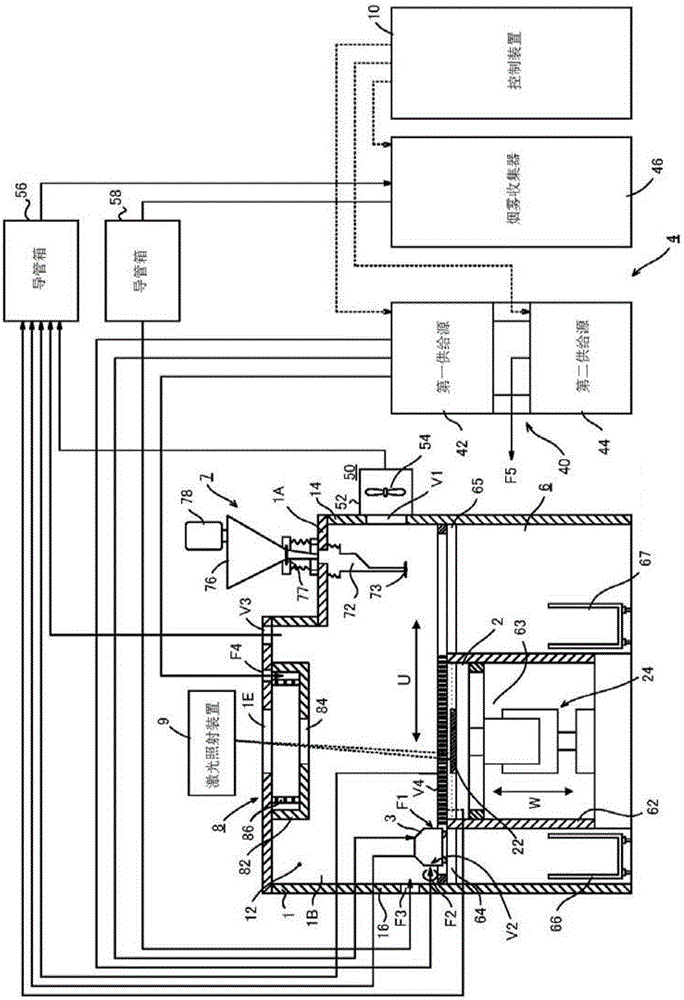

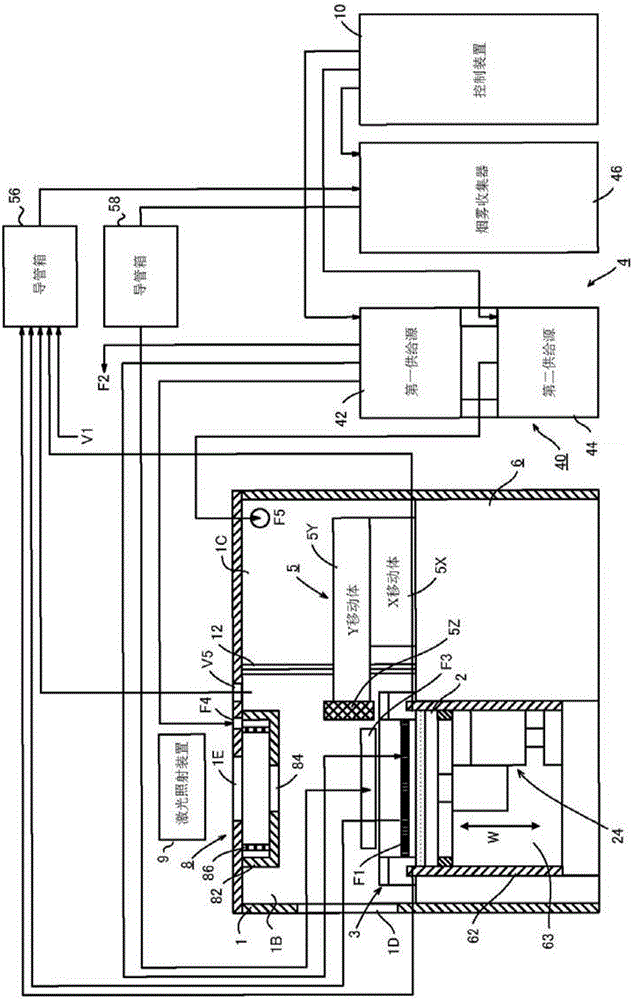

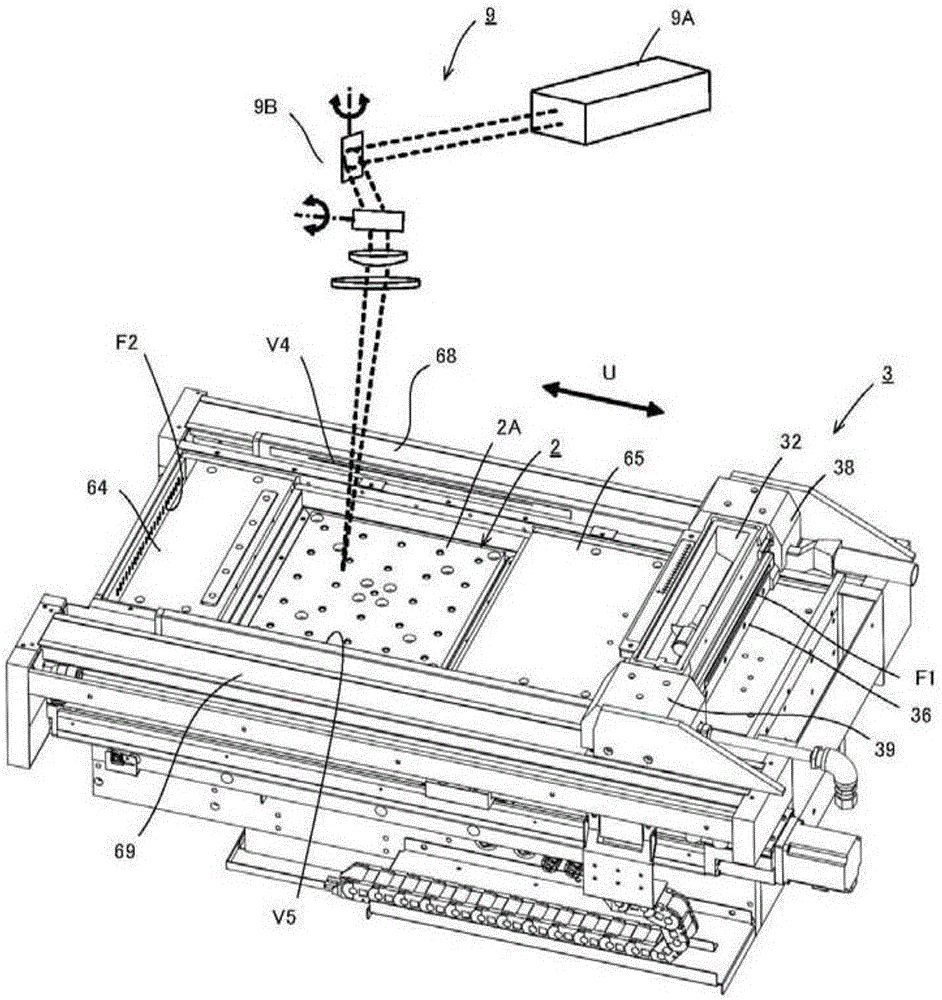

ActiveCN106346003AEasy to excludeEasy dischargeAdditive manufacturing apparatusIncreasing energy efficiency3d printerIrradiation

A metal 3D printer includes: a housing (1) forming a molding chamber (1B); a recoater head (3) reciprocating in the direction of a horizontal U axis in the molding chamber to form a powder layer of a metal; a laser irradiation device (9) irradiating an irradiation region in the powder layer with a laser beam to form a sintered layer; and an inert gas supply device (4). The inert gas supply device includes: a first suction port (V1) disposed on one (14) of the side walls facing each other in the direction of the U axis, which is far away from the irradiation region; a first blowout port (F1) disposed on a side of the recoater head to face the first suction port; and a second blowout port (F2) disposed to face the first suction port across the irradiation region.

Owner:SODICK CO LTD

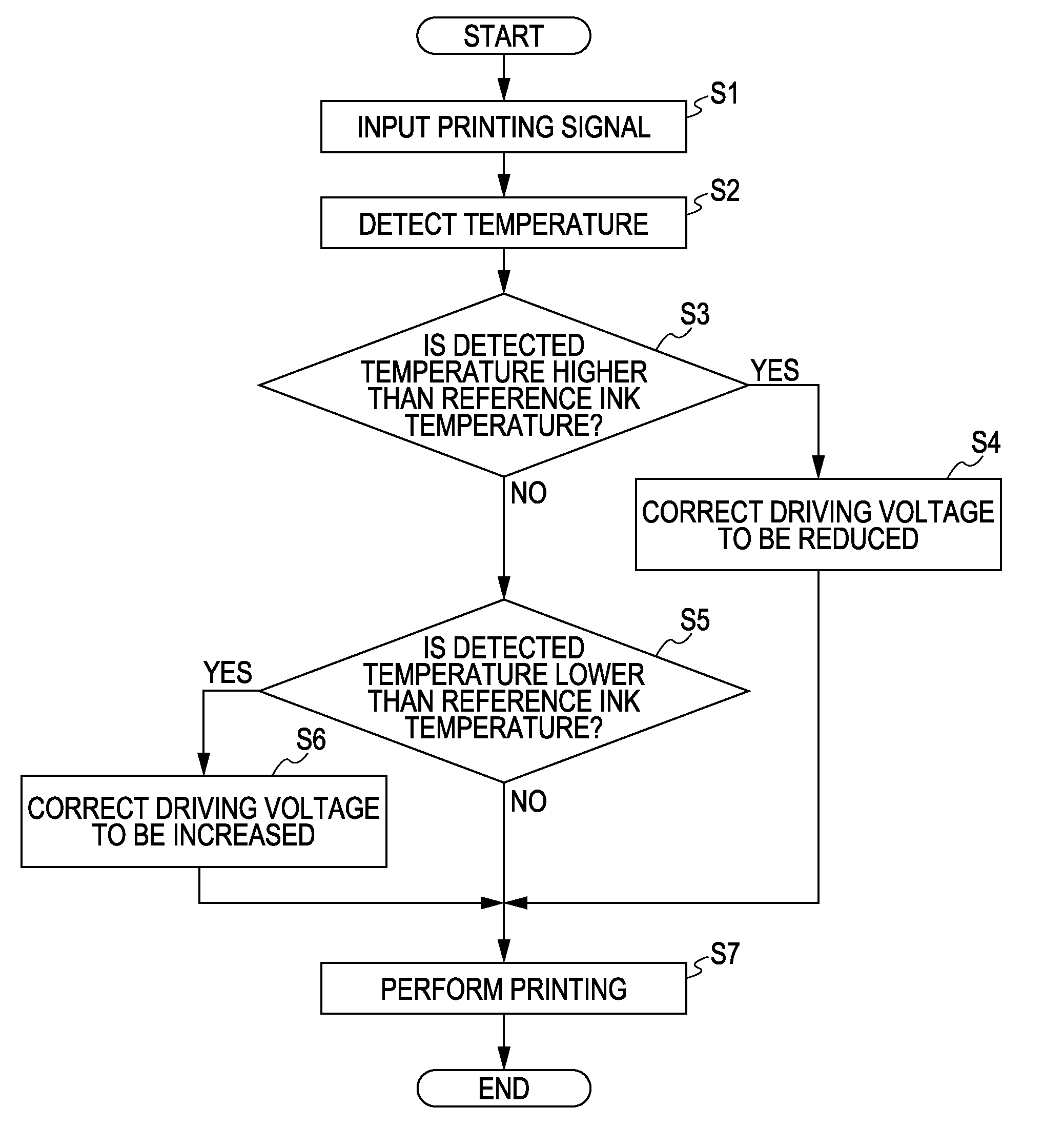

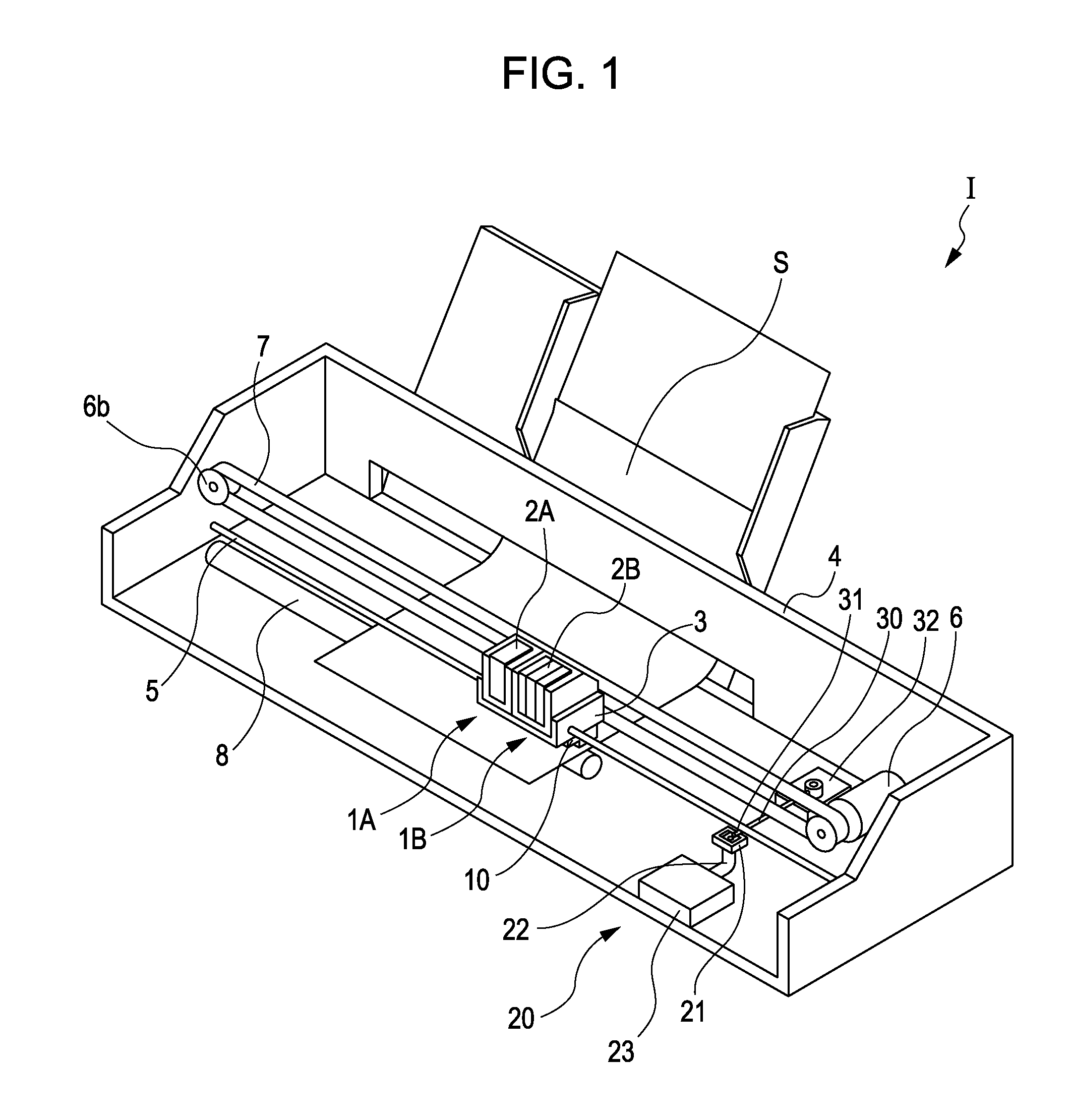

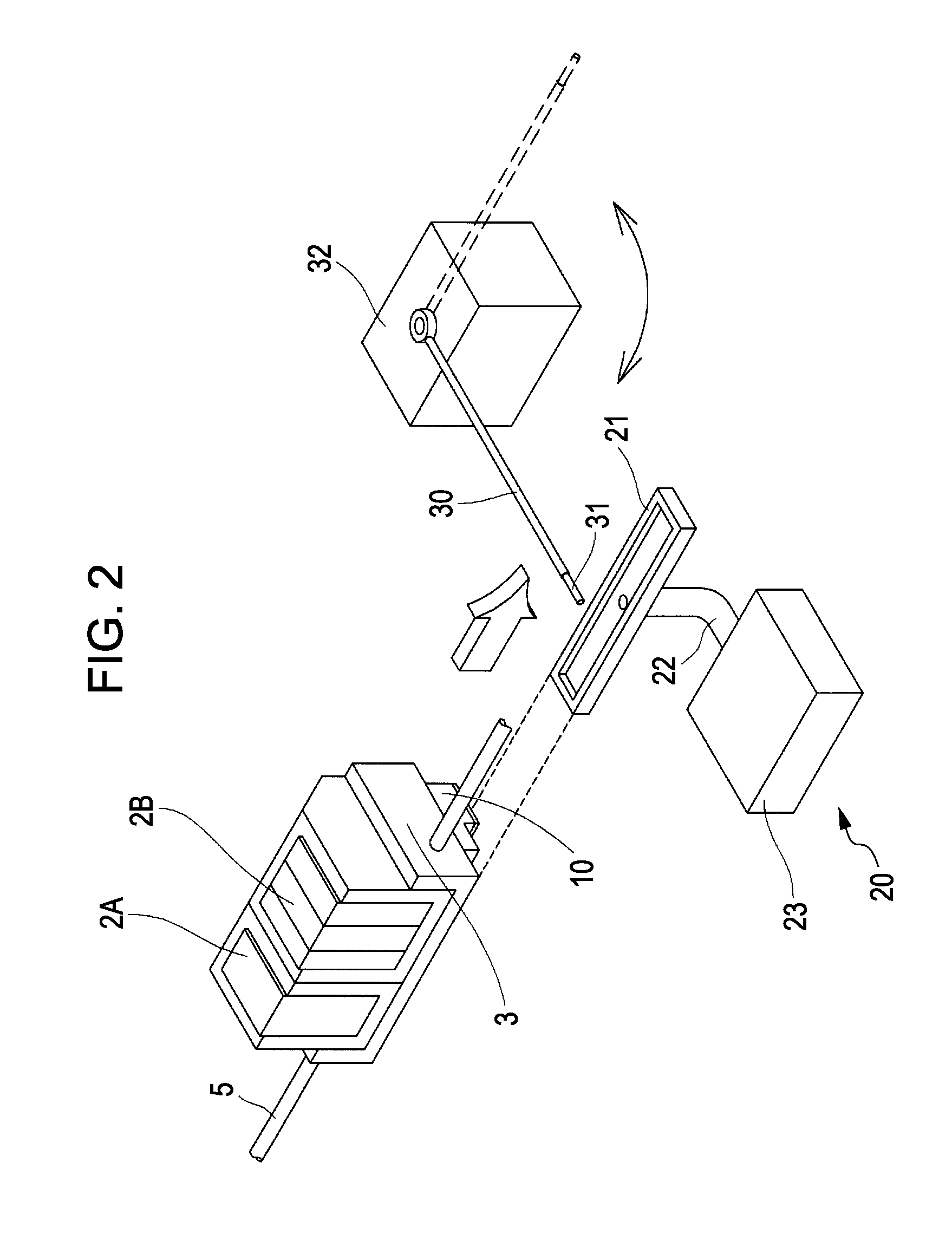

Liquid ejecting apparatus and control method

InactiveUS20120007906A1Small sizeSuppressing in costOther printing apparatusLiquid jetPressure generation

A liquid ejecting apparatus includes: a liquid ejecting head that includes nozzle openings through which liquid is ejected and pressure generation units that cause changes in pressure of the liquid inside pressure generation chambers communicating with the nozzle openings; a control unit that supplies a driving signal for causing the liquid ejecting head to eject the liquid, to the pressure generation units, and controls ejection of the liquid by the liquid ejecting head; and a temperature detection unit that detects a temperature of a contact portion with which the liquid ejected by the liquid ejecting head comes in contact, wherein the control unit corrects the driving signal on the basis of the temperature information detected by the temperature detection unit.

Owner:SEIKO EPSON CORP

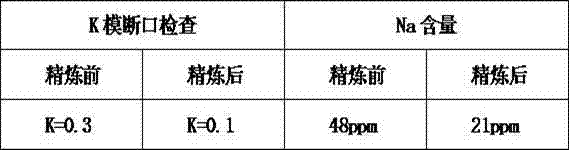

Flux for aluminum and aluminum alloy melt refining and preparation method of flux

The invention discloses flux for aluminum and aluminum alloy melt refining. The flux consists of the following components in percentage by mass: 5-40% of Na3AlF6 and K3AlF6, 20-50% of MgCl2 and / or AlF3, 10-40% of KCl, 3-8% of K2TiF6 and 0.1-3% of graphite powder, and the flux is prepared by virtue of a hybrid melting method. Na3AlF6 and K3AlF6 in the flux have effects of adsorbing and dissolving impurities of aluminum oxide, and Na3AlF6 and K3AlF6 can be matched for use to achieve relatively good effects. The flux is prepared by adopting a hybrid melting method, so that the water in the components can be completely removed, and the flux is uniform in component and stable in quality.

Owner:SHANDONG NANSHAN ALUMINUM

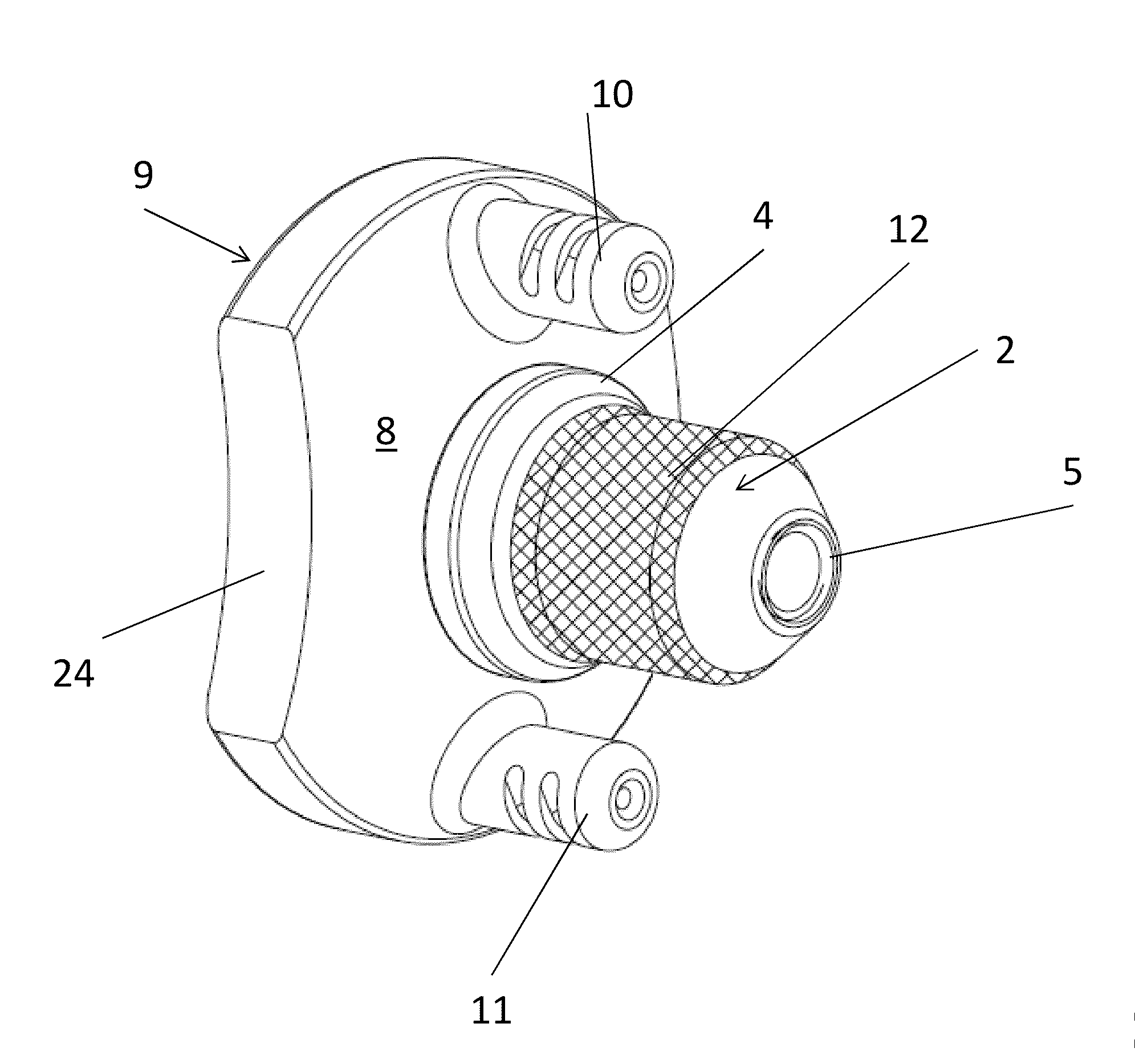

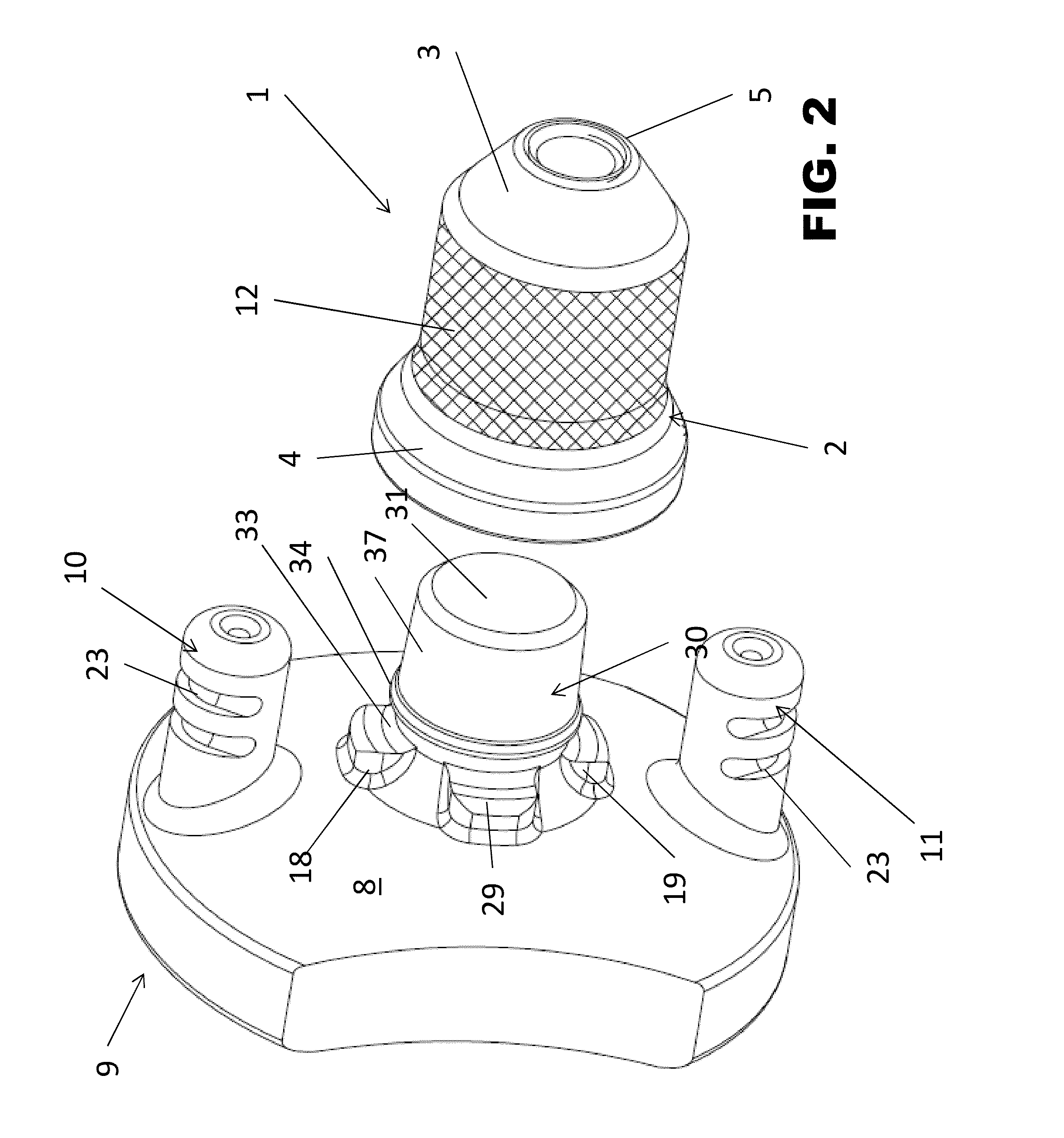

Glenoid Anchor for a Shoulder Joint Prosthesis

InactiveUS20160270922A1Easy to disassembleEasy to excludeJoint implantsShoulder jointsShoulder BladesShoulder joint prosthesis

The present invention relates to an improved glenoid anchor for a shoulder joint prosthesis, in particular a convertible prosthesis, of the type intended to be fixed to the glenoid cavity of the shoulder blade and comprising:a pin with an internally hollow and essentially thimble-like conical sleeve, which has a tapered distal end and an open proximal end;an annular recess formed inside the cavity of the pin in the vicinity of said open proximal end, for receiving by means of snap-engagement an edge of a lug of a prosthesis component;at least one pair of oppositely arranged anti-rotation notches in the proximity of said annular groove for receiving by means of snap fit oppositely arranged teeth of the same lug intended to be snap-engaged together with said pin.

Owner:LIMA CORPORATE SPA

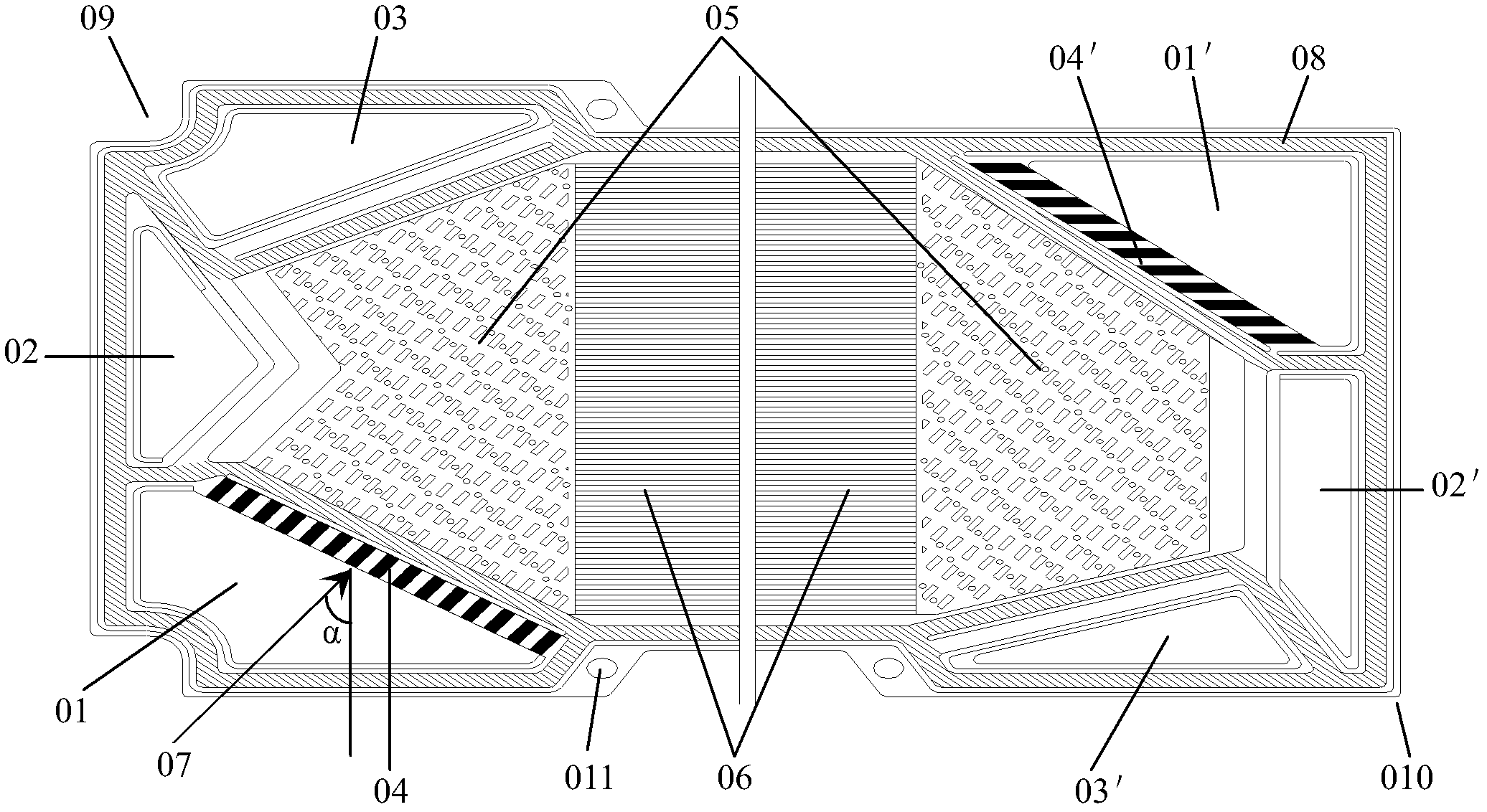

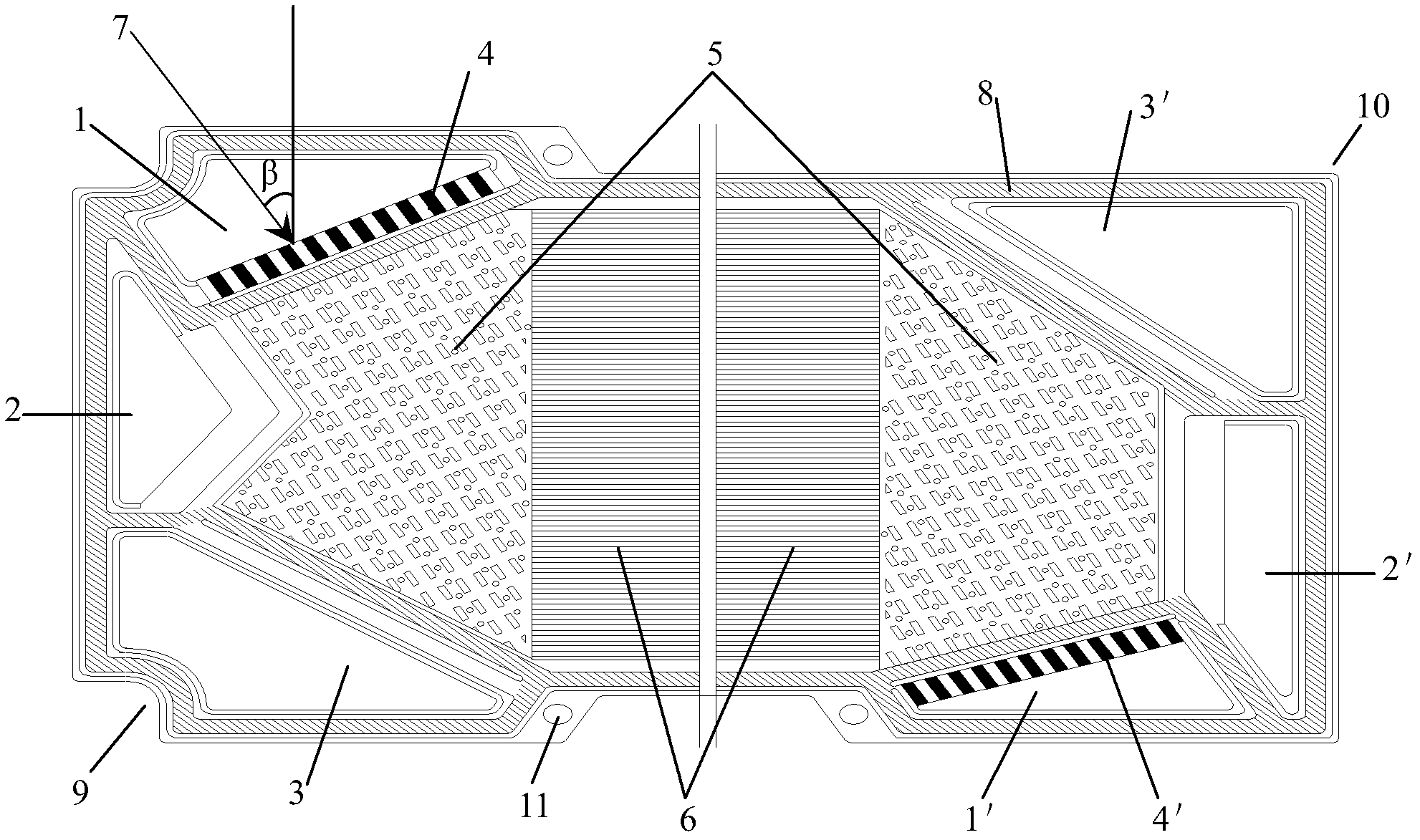

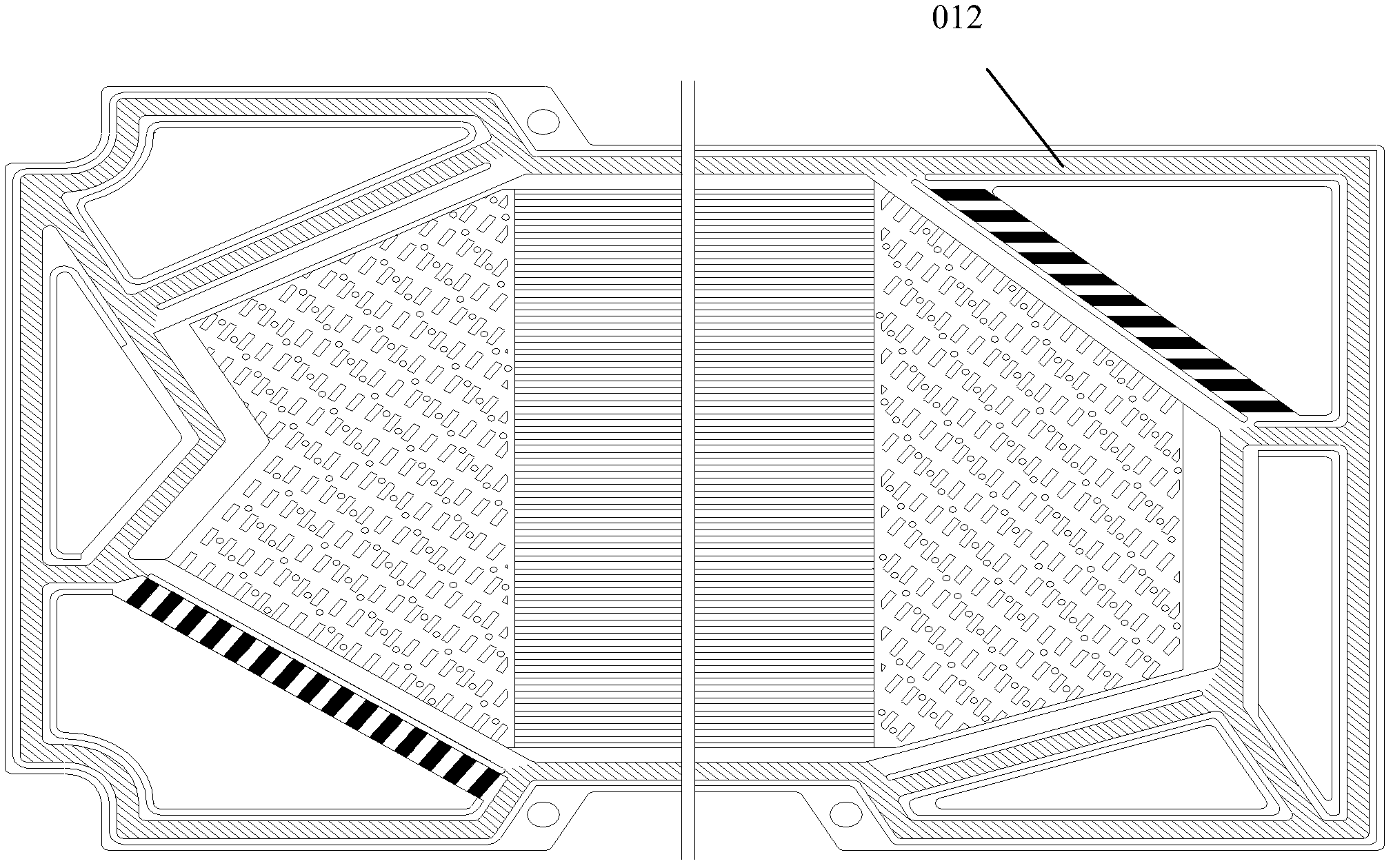

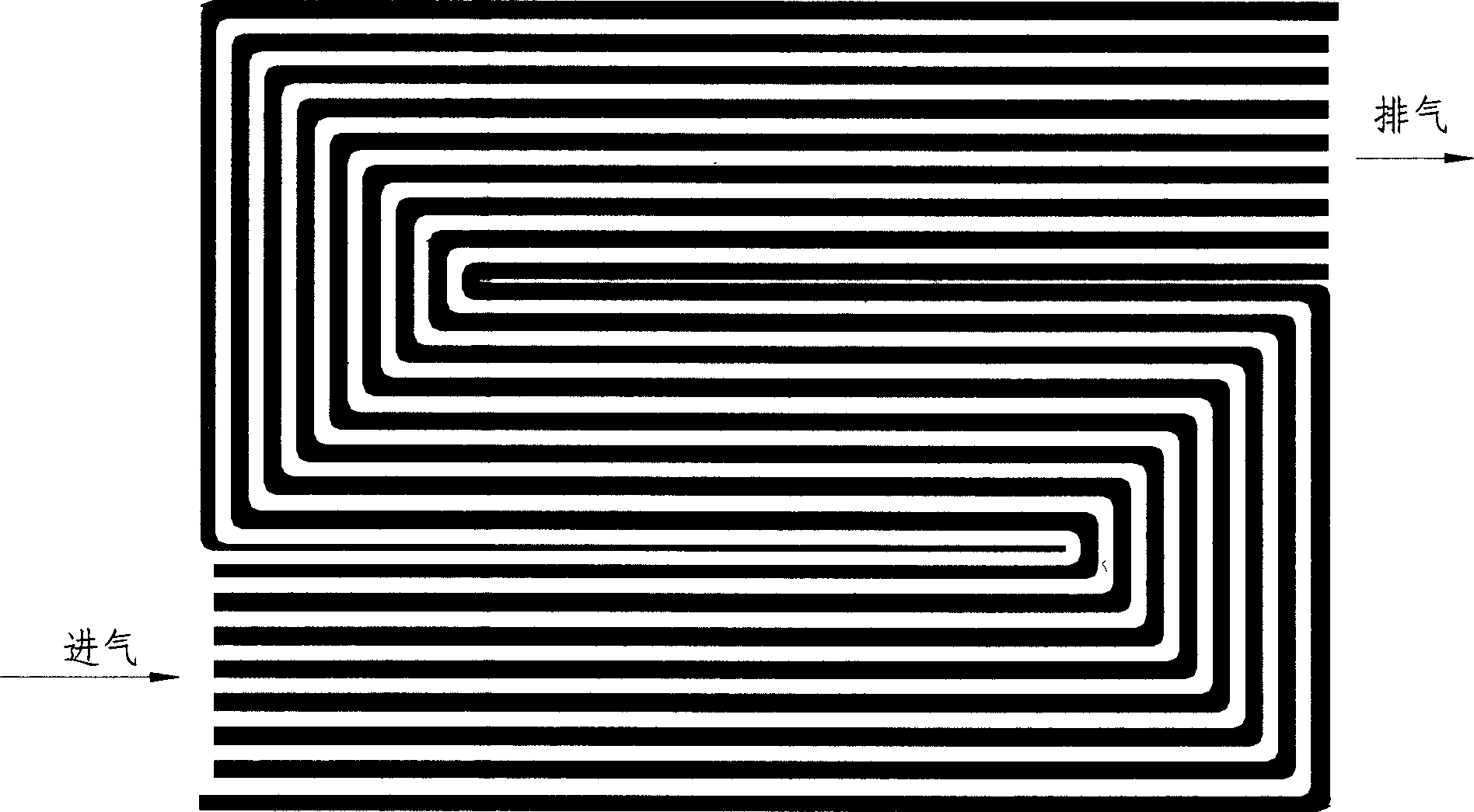

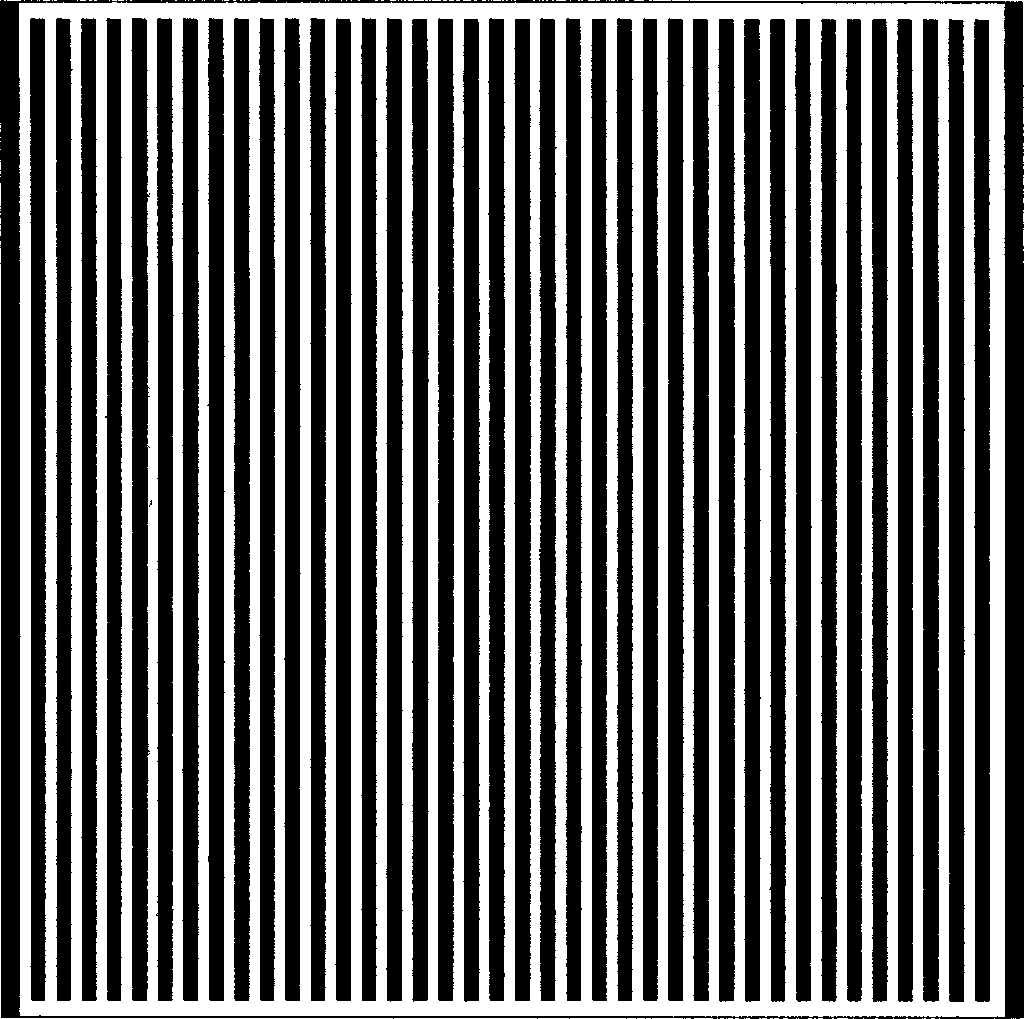

PEMFC (proton exchange membrane fuel cell) metal bipolar plate conducive to improving fluid distribution

ActiveCN102306805AIncrease the differential pressureReduce resistanceCell electrodesProton exchange membrane fuel cellSupport point

The invention provides a PEMFC (proton exchange membrane fuel cell) metal bipolar plate conducive to improving fluid distribution. The PEMFC metal bipolar plate comprises a cathode monopolar plate and an anode monopolar plate in corresponding connection, wherein three-cavity public pipelines are arranged on the two sides of the cathode and anode monopolar plates, and a direct current field flow channel, a distribution flow channel and an inlet / outlet flow channel are arranged in the middle;; the direct current field flow channel is formed by bulges and grooves in parallel; the distribution flow channel is formed by channelization islands distributed regularly and reversely-convex support points; the inlet side and outlet side of the cathode and anode monopolar plates are asymmetrical; andthe inlet area of an air cavity public pipeline is 0.1-0.5 time greater than the outlet area. The metal bipolar plate has the advantages that: the distribution flow channel improves the distribution conditions of reaction gas and cryogen, and thus can improve the galvanic pile performance and optimize the galvanic pile water management capacity; the inlets and outlets of three cavities are asymmetrical, thereby saving space to the greatest degree; an assembled galvanic pile is suitable for the operations of horizontally, laterally and vertically placing the galvanic pile; and the outer positioning in battery pile assembly can avoid torsion and deformation of the battery pile, thereby improving the flatness of the battery pile.

Owner:SUNRISE POWER CO LTD +1

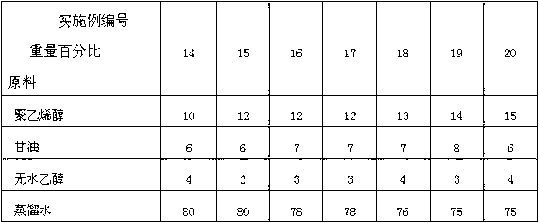

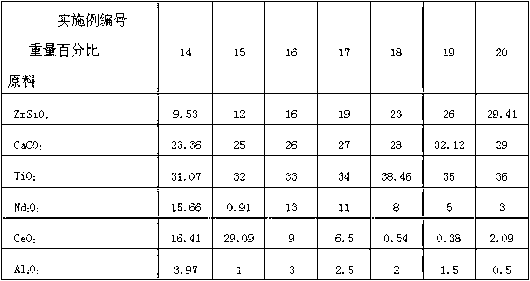

Method for preparing radioactive waste solidified body

InactiveCN102930915AImprove performanceEasy to excludeRadioactive decontaminationHigh densityPolyvinyl alcohol

The invention discloses a method for preparing a radioactive waste solidified body. The method is characterized by comprising the following steps of: finely grinding a raw material which comprises 9.53 to 29.41 weight percent of ZrSiO4, 23.36 to 32.12 weight percent of CaCO3, 31.07 to 38.46 weight percent of TiO2, 0 to 15.66 weight percent of Nd2O3, 0 to 29.09 weight percent of CeO2 and 0 to 3.97 weight percent of Al2O3; drying the raw material; and adding polyvinyl alcohol sol, granulating, screening, molding, discharging the sol, performing vacuum hot-pressing sintering, and thus obtaining the radioactive waste solidified body. By adoption of the method, the raw material is low in cost, a high-purity and high-density perovskite acorite and titanite combined mineral solidified body is prepared at low temperature by using a simple and practical hot-pressing sintering technology, and foundation is laid for engineering application to artificial rock solidification treatment of high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

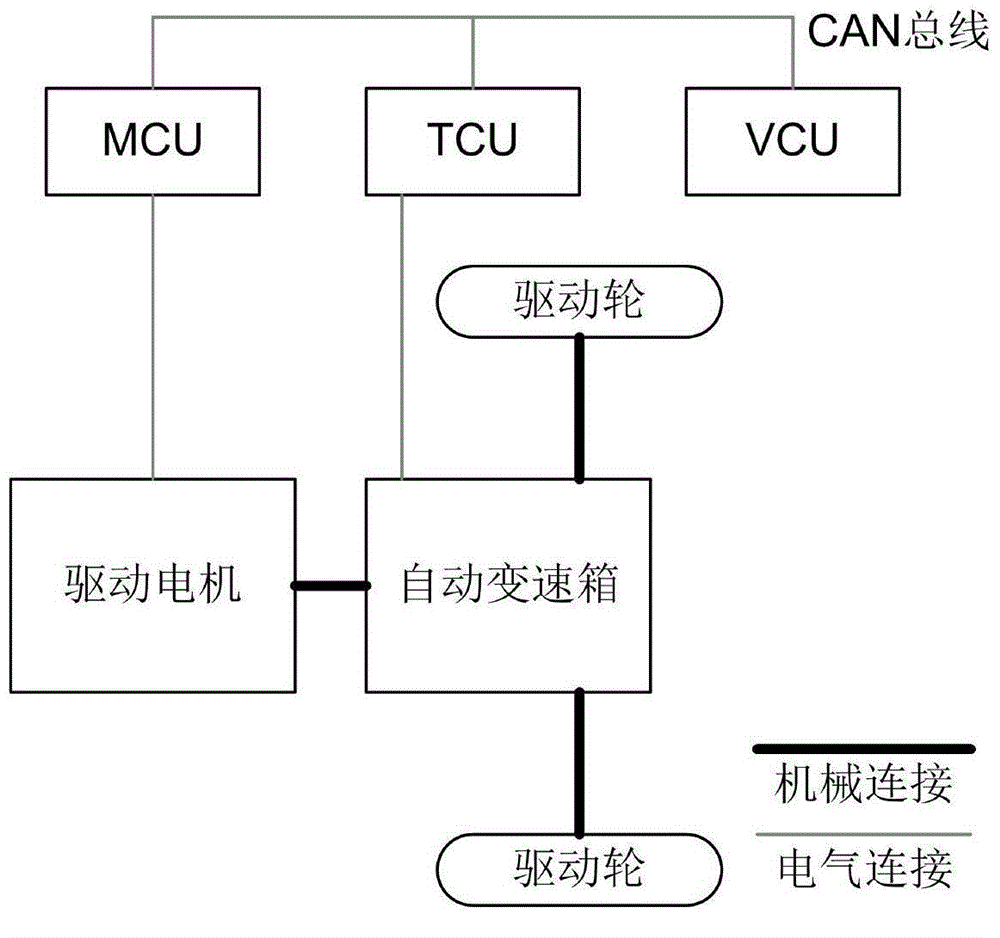

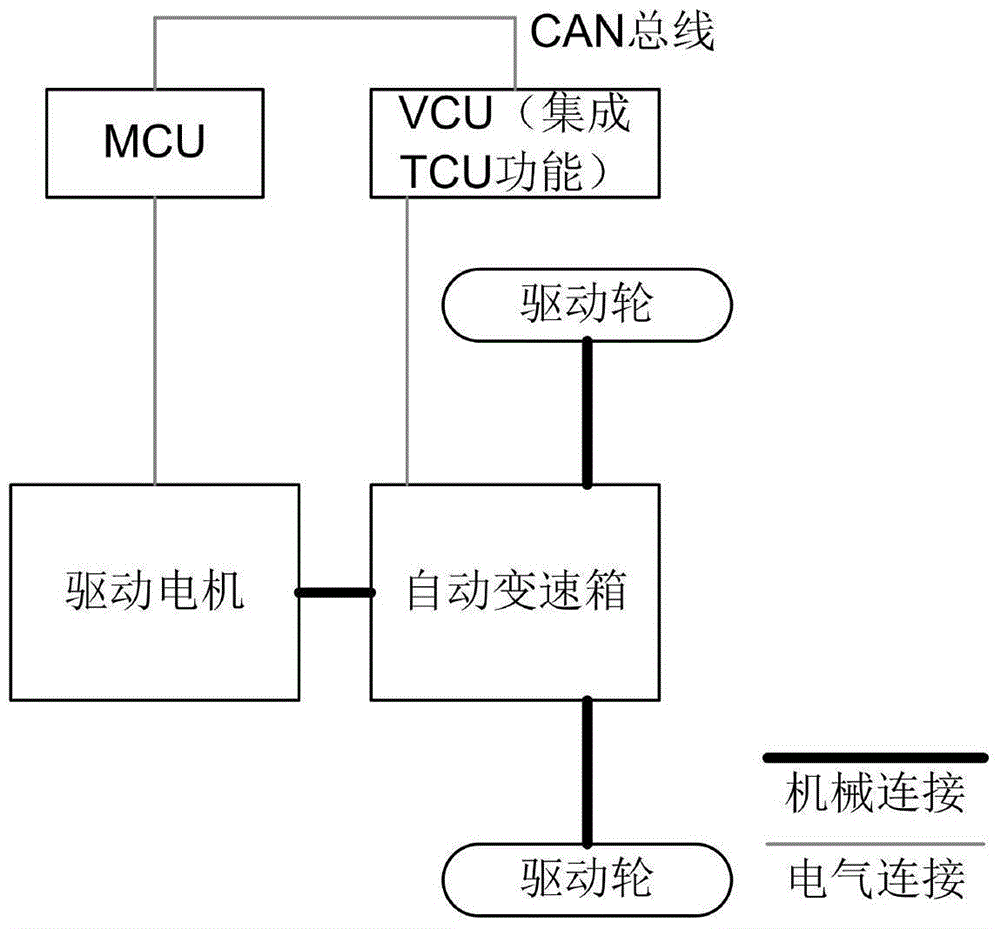

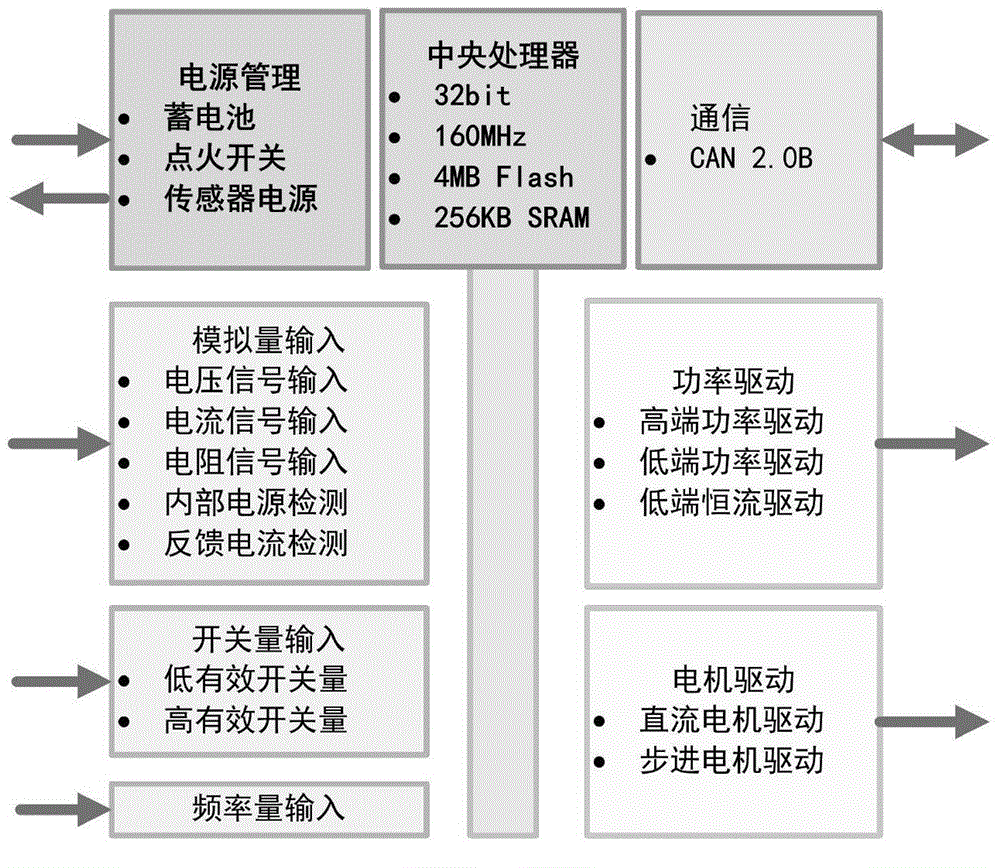

New-energy entire car controller integrated with transmission case control function

InactiveCN104802790ASmooth startReduce in quantitySpeed controllerElectric energy managementMotor driveNew energy

The invention provides a new-energy entire car controller integrated with a transmission case control function. The controller is integrated with the transmission case control function, i.e., an original entire car control function and a transmission case control function are integrated in the entire car controller, so that a special TCU (transmission control unit) is not needed any more; analog input, on-off input and frequency input are connected with respective sensors; a power-driven part and a motor-driven part are connected with respective actuators; the components are connected together with an internal bus on a controller circuit board by virtue of internal connecting wires so as to form a complete controller hardware circuit. New-energy entire car controller software integrated with the transmission case control function is realized by virtue of an entire car control algorithm and a transmission case control algorithm. The new-energy entire car controller can be used for shortening the development cycle, lowering the development cost, reducing automobile parts such as a controller, an auxiliary connector and wire harnesses and lowering the purchase costs of the parts.

Owner:BEIJING JIUZHOU HUAHAI TECH

Manufacturing technology of isometric aluminium nickel cobalt titanium permanent magnet alloy

A process for preparing the permanent-magnet AlNiCo alloy with equiaxed crystals includes such steps as proportionally mixing Al, Ni, Co, Cu, Ti, NbFe (1: 1), Fe, Si, FeS and SmCo, charging the mixture in furnace, preparing casting mould, vacuumizing, electric heating, filling Ar gas, casting, annealing, two-stage preheating, solution treating, magnetic field controlled cooling and three-stage tempering.

Owner:宁波盛事达磁业有限公司

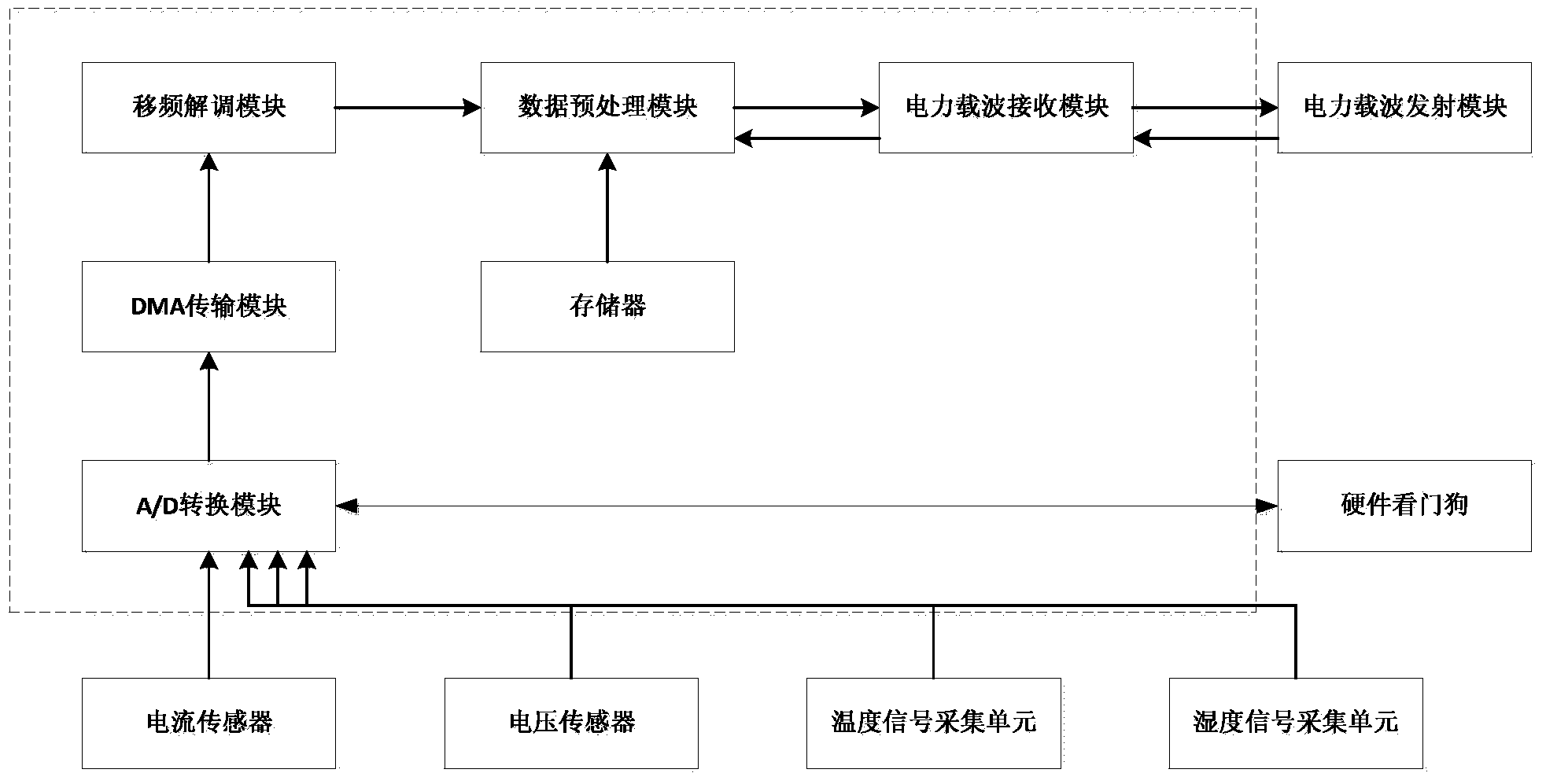

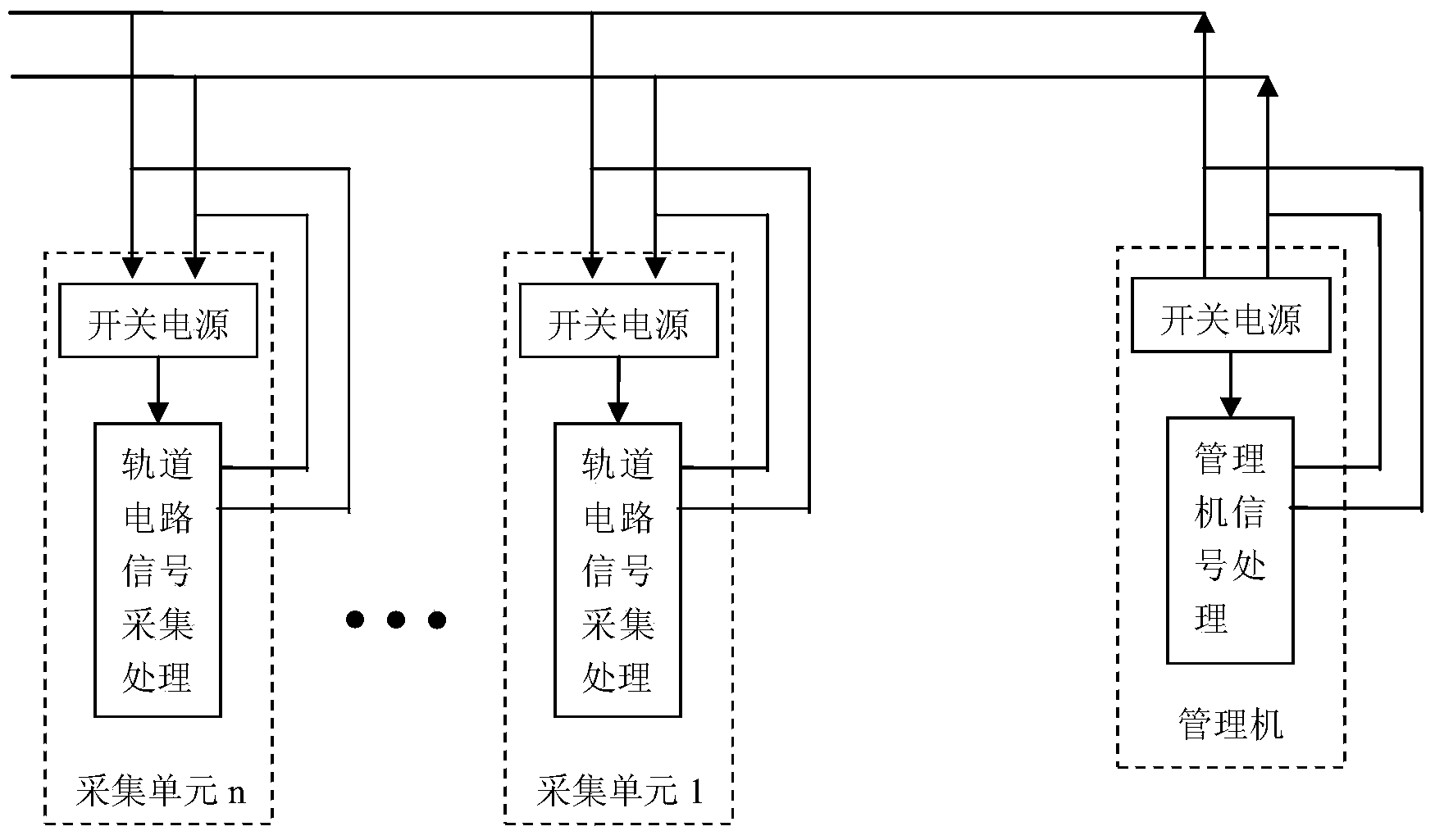

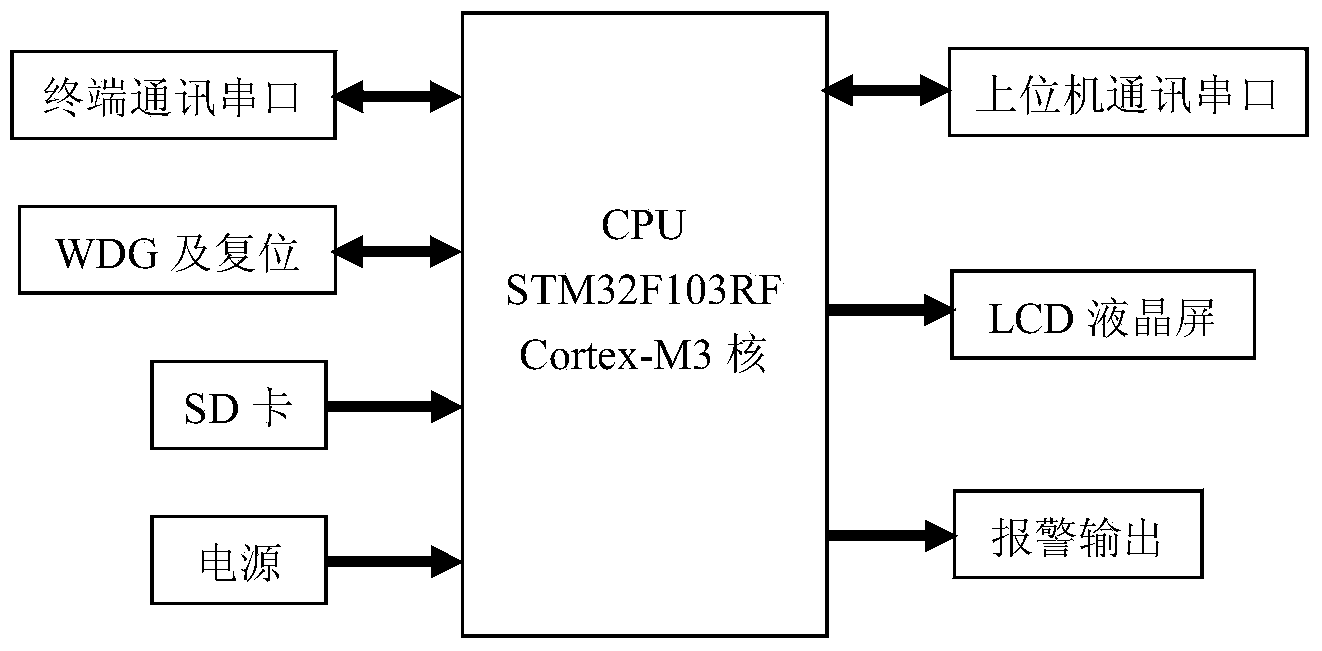

Outdoor track circuit integrated monitoring system and method

The invention discloses a track circuit signal collecting system, which comprises a track circuit signal collecting unit, an A / D (analog to digital) conversion module, a DMA (direct memory access) transmission module, a frequency shift demodulation module, a memory, a data transmission module and a data processing module, wherein data address inquiry signal work partitions in circuit work state detection signals are respectively detected out through the data processing module, so whether the states of the work partitions have faults or not is judged. A detection system provided by the invention can be used for monitoring whether railway signals and railway equipment are normal or not in real time. Through collecting data such as current in cables and steel-clad copper wires on a railway, rail surface and cable voltage, and temperature and humidity of railway equipment, the operation state of each partition of the railway can be mastered at any time, the work state of each partition is qualitatively analyzed, and the possibly generated faults can be eliminated in advance. When the faults occur, the faults can be positioned in specific intervals and equipment according to monitoring signals, and great convenience is brought for fault elimination.

Owner:宁波思高信通科技有限公司

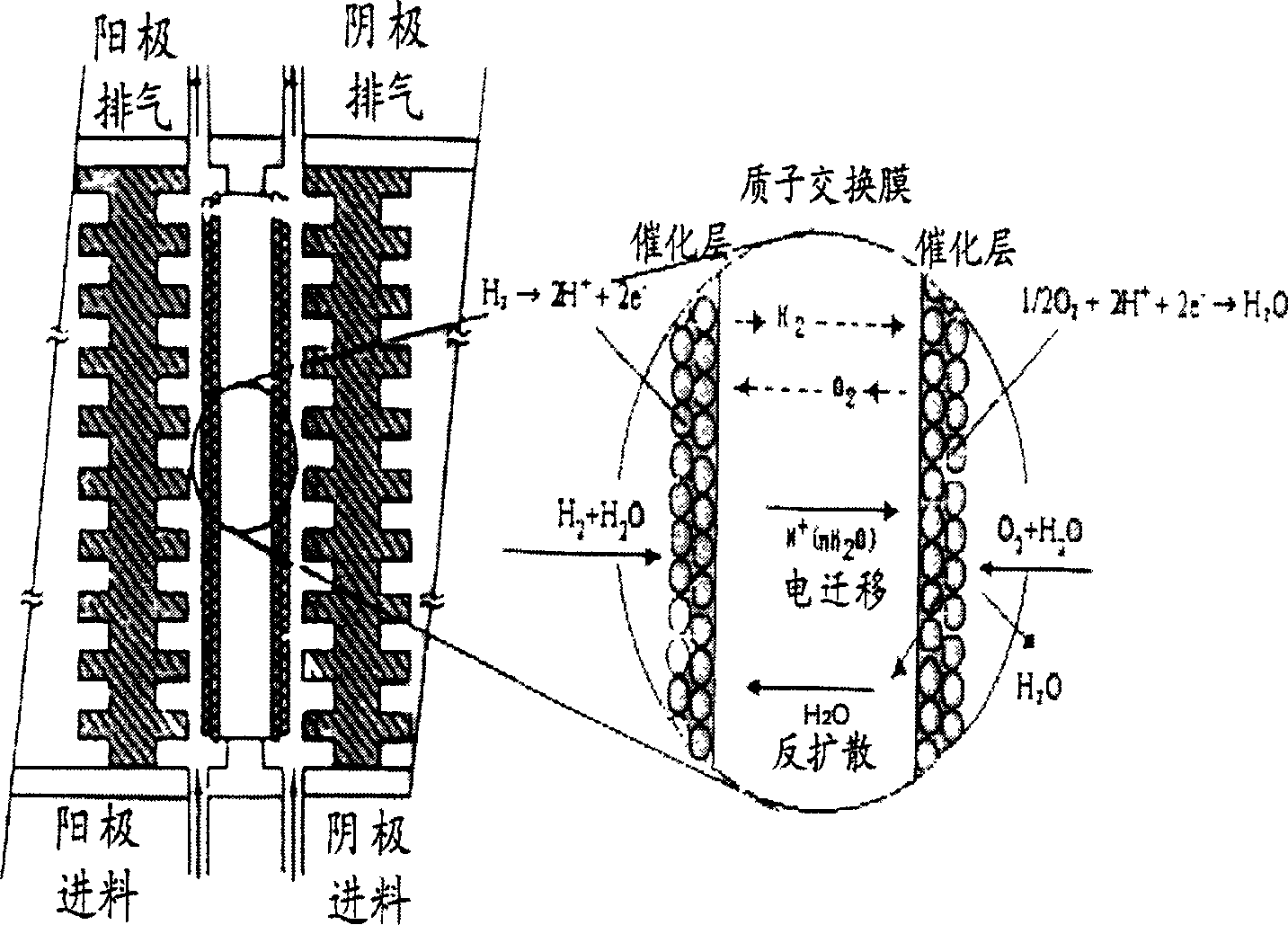

Proton exchange film fuel cell flow field structure

ActiveCN1622377AEasy to excludePromote accumulationCell electrodesSolid electrolyte fuel cellsProtonEngineering

The present invention relates to proton exchange membrane fuel cell. The flow field structure of proton exchange membrane fuel cell consists of netted flow field and deflecting stripes. The deflecting stripes are set inside the netted flow field and parallel to one group of sealing side walls, and have width equal to the height of the netted flow field. Each of the deflecting stripes has one end connected perpendicularly to the side wall and the other end constituting the gas channel. The gas channel has width not smaller than that of the gas inlet. The present invention has the advantages of high pole area utilization, being favorable to the exhaust of water produced in the electrochemical reaction and the elimination of inertial component, no dead arean of gas flow, and stable operation of the cell under low pressure and normal pressure.

Owner:SUNRISE POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com