Technology for performing foundation pile quality detection and geology survey by adopting single tube longitudinal wave method

A technology of geological exploration and longitudinal wave, applied in the test of foundation structure, survey of foundation soil on site, foundation structure engineering, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

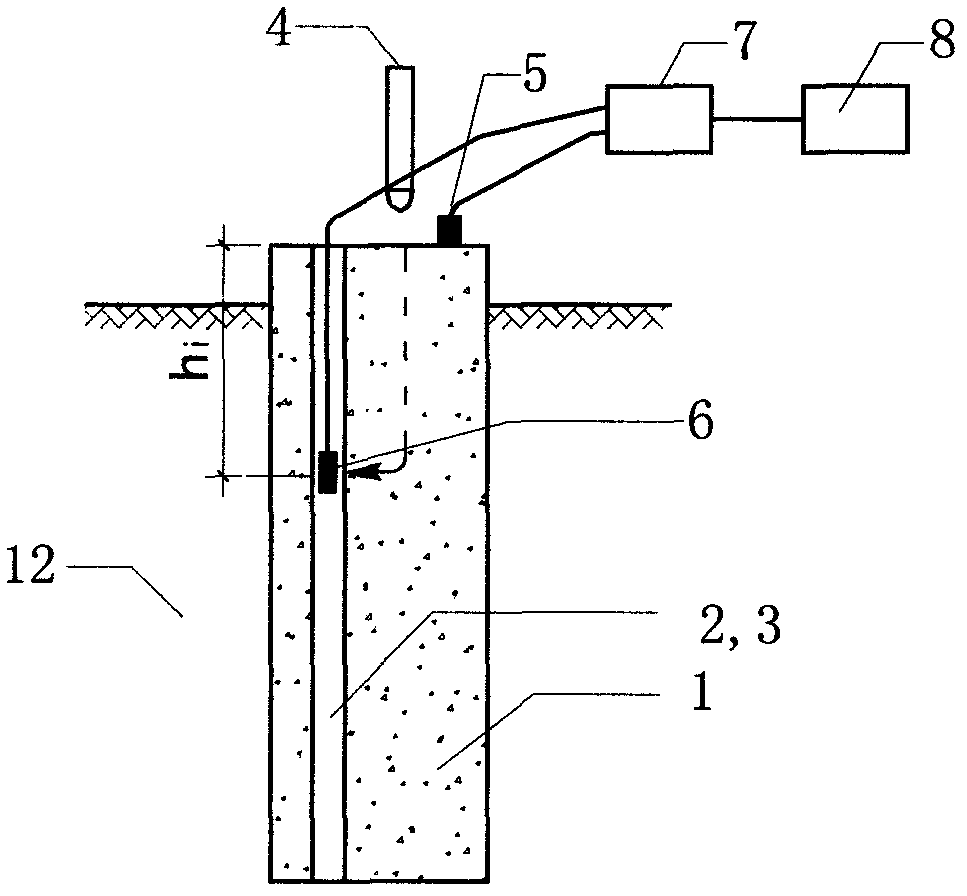

[0087] Testing the Construction Quality of Pile Body Concrete by Single Pile and Single Tube Longitudinal Wave Method

[0088] as attached figure 1 The single-pile and single-tube longitudinal wave method is used to detect the construction quality of the pile body concrete, and the acquisition instrument 8 uses a pile foundation dynamic tester, and the working principle diagram and connection of the single-tube longitudinal wave method signal processor 7 are as attached Figure 4 As shown, an iron hammer is used as the excitation hammer 4, and the acceleration sensor 5 is installed next to the excitation point on the top surface of the pile. 2 is the detection channel. as attached Figure 7 , attached Figure 8 And attached Figure 9 Shown are the wave travel diagrams of a pile measured at 22m, 25m and 29m respectively. The percussion synchronization signal superimposed on the signal of the wave travel diagram includes the downgoing wave and upgoing wave of the excitation ...

Embodiment 2

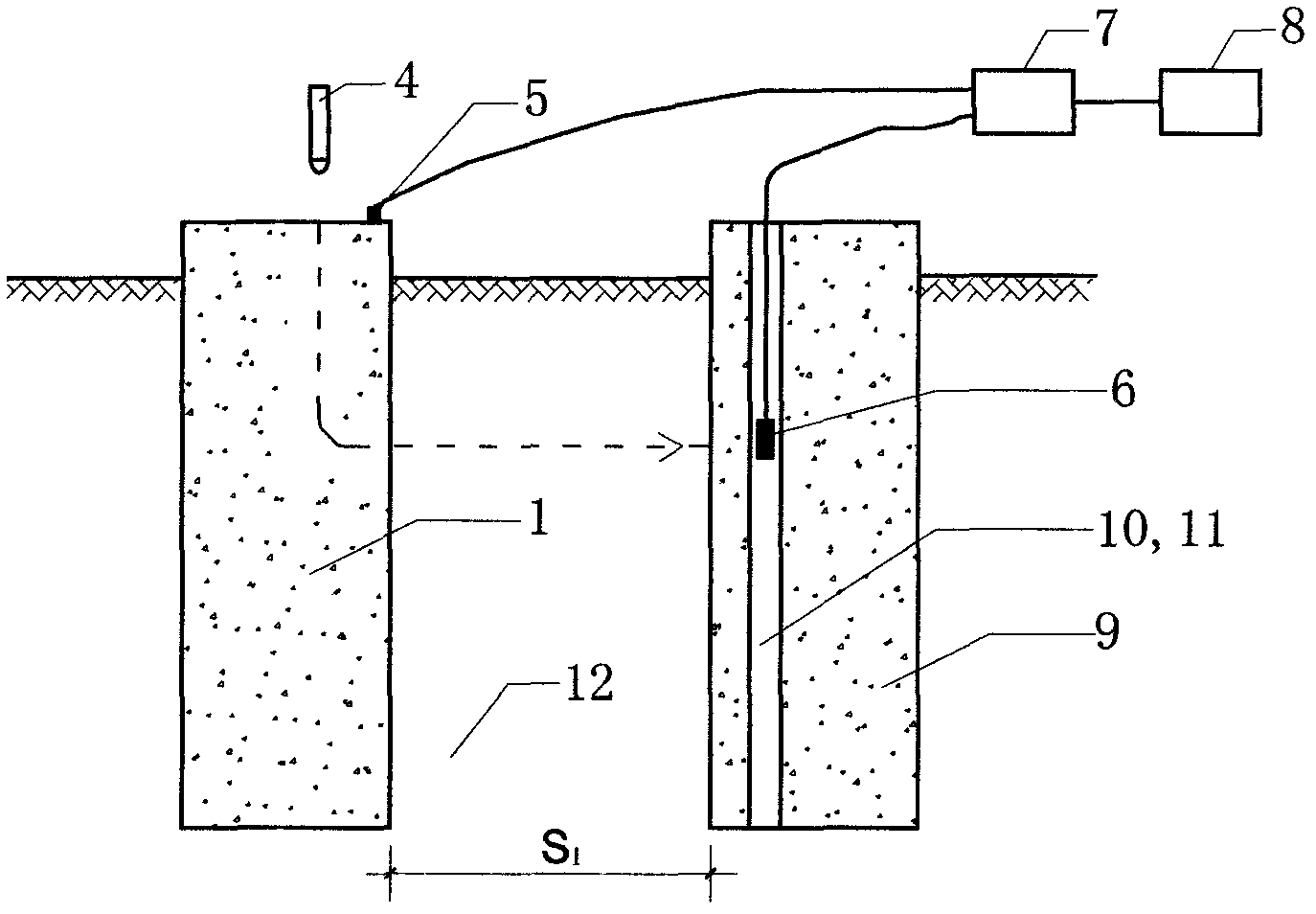

[0135] Using adjacent pile single tube longitudinal wave method to detect the construction quality of pile body concrete

[0136] A project is designed as a friction pile with a pile diameter of 1.8m and a pile length of 27m. figure 2 As shown, the acquisition instrument 8 uses an ultrasonic detector to detect the arrival time t of the longitudinal wave traveling down the pile body of the foundation pile 1 and propagating from the pile side geological soil layer 12 in the acoustic measuring tube 10 of the foundation pile 9 adjacent to 3.9m. i , the result is attached Figure 12 As shown, because the geology is relatively simple and the propagation time of the formation is relatively stable, the quality of pile concrete can be judged by the single pile and single pipe longitudinal wave method. From t i -h i It can be seen from the curve that there is no obvious convexity and accumulation phenomenon. It is considered that the concrete quality of the pile body is complete, and...

Embodiment 3

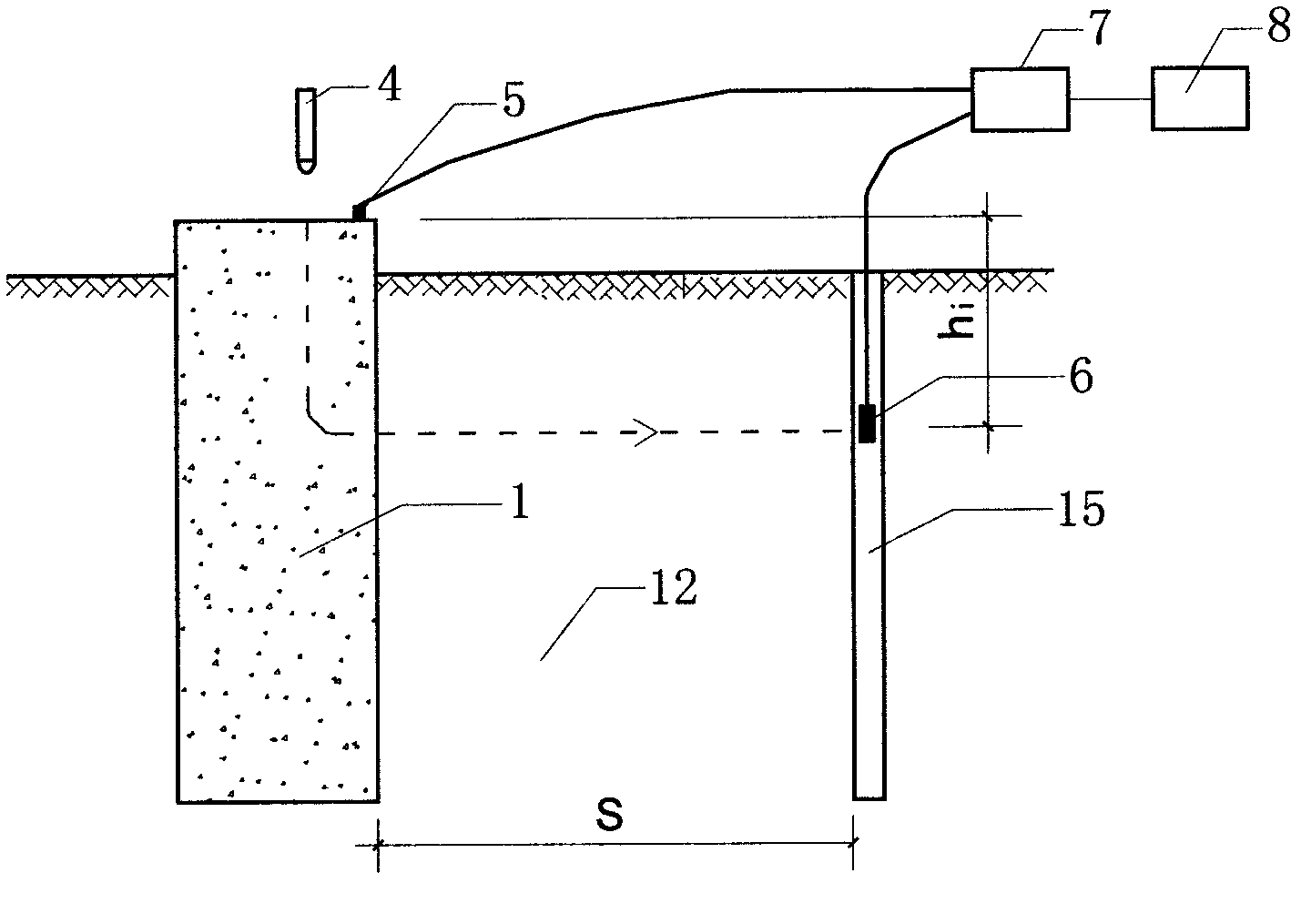

[0139] Using adjacent pile single pipe longitudinal wave method to detect the geology around the pile

[0140] as attached figure 2 As shown, the adjacent pile single-tube longitudinal wave method is used to detect the geological soil around the pile, in which the single-tube longitudinal wave method signal processor 7 and the acquisition instrument 8 constitute a combined seismograph, and the geophone uses RS-YH45III broadband and high-sensitivity ultrasonic waves Transducer, in this example, the acquisition instrument 8 utilizes an ultrasonic detector. Analogous to the cross-hole wave velocity test technology of geological exploration, the foundation pile 1 is used as the probe rod, and a heavy force rod is used on the top of the pile to impact the pile head, so that the pile body generates vibration waves that propagate downward and propagate to the periphery of the pile side, while The receiving hole needed for the test is directly adjacent to the acoustic pipe 10 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Pile length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com