Patents

Literature

1933 results about "Single tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Discharge lamp

InactiveUS20100259152A1Irradiation of becomes intensiveImprove reliabilityIncadescent screens/filtersSolid cathode detailsCapacitanceGas-discharge lamp

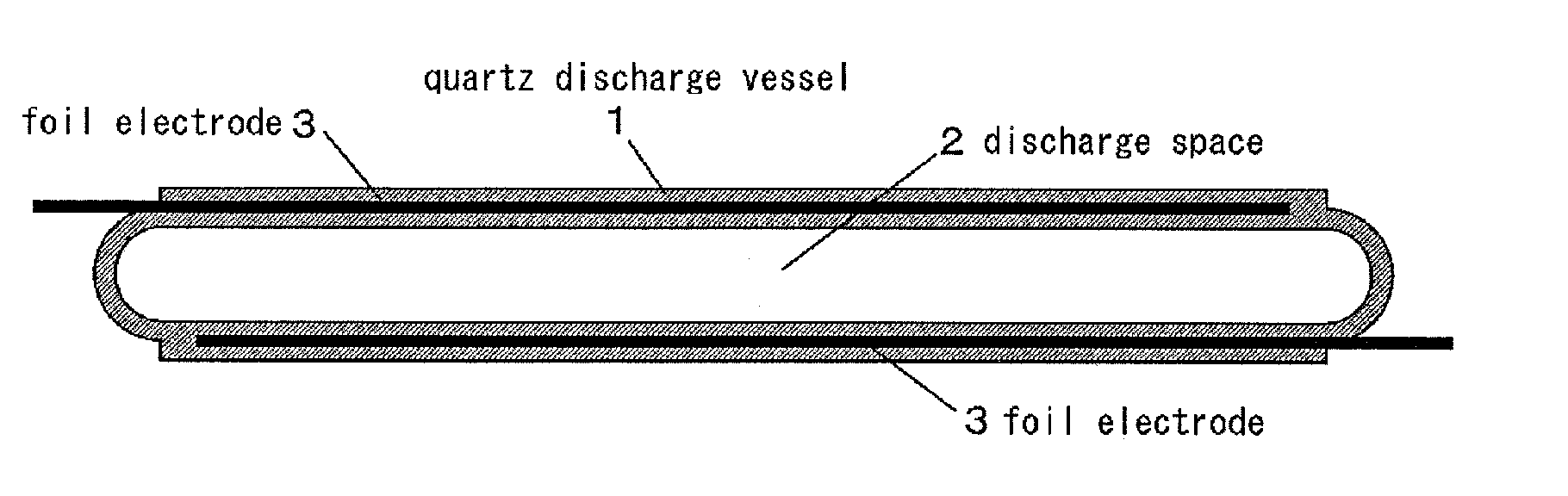

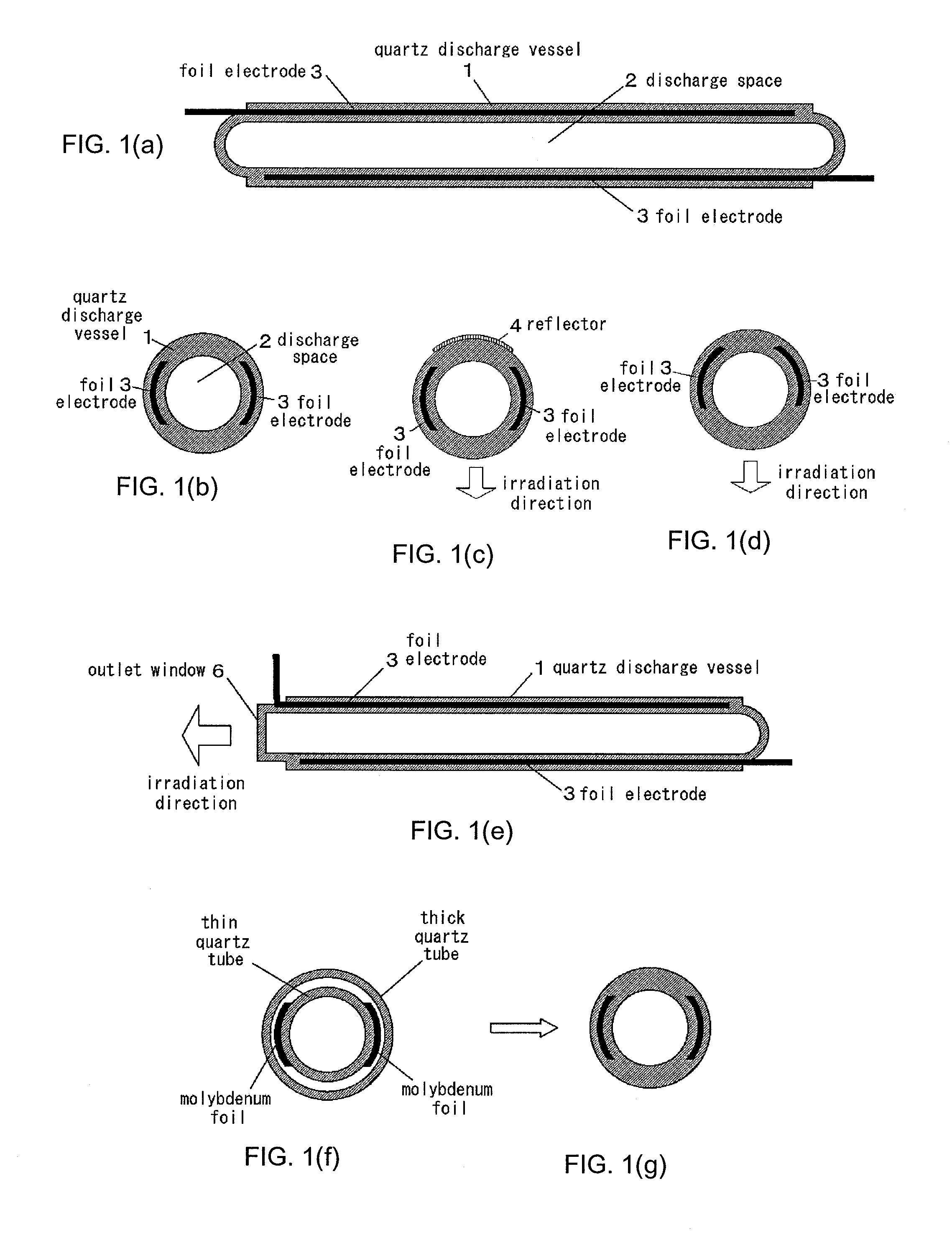

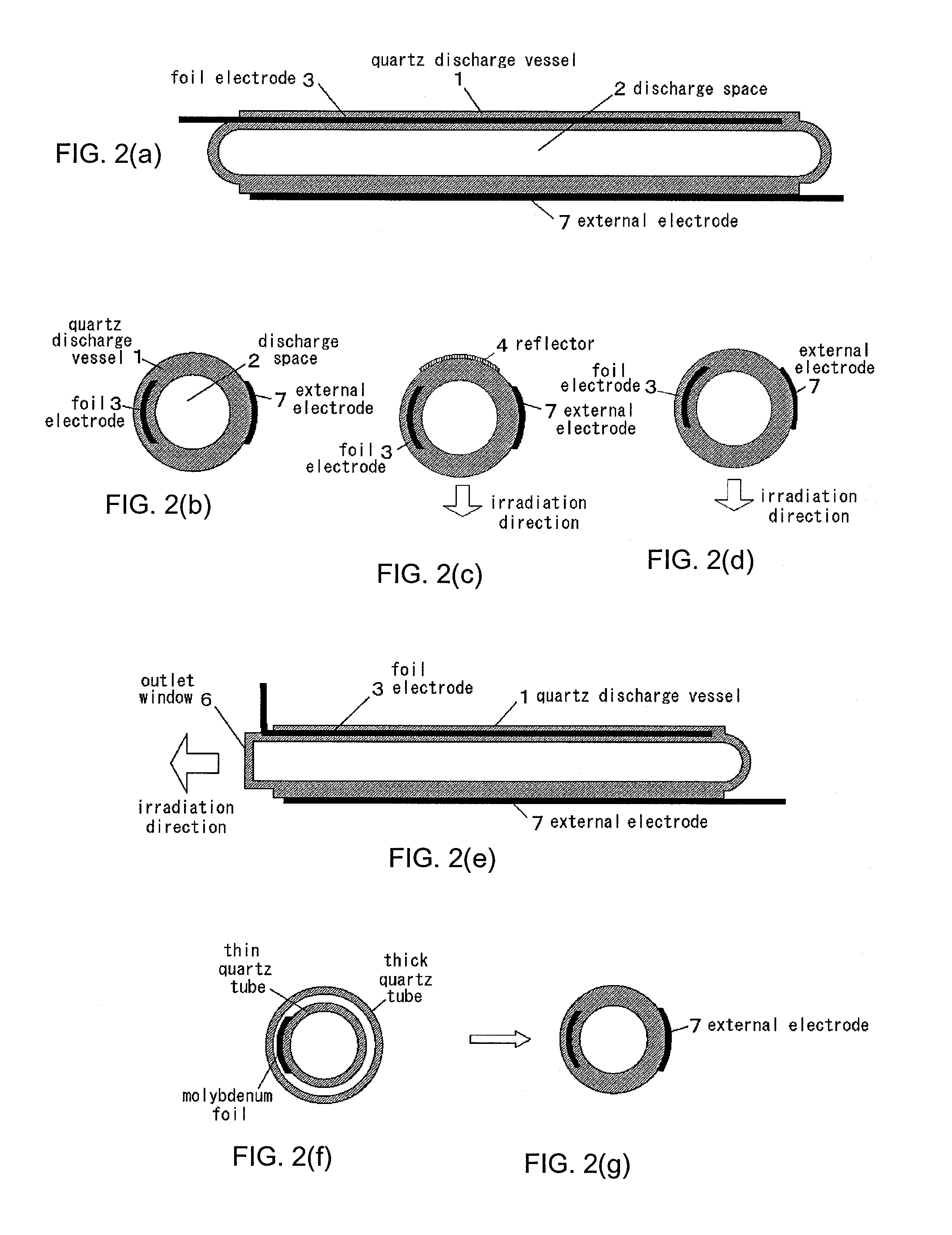

The object of this invention is to prevent surface discharge even when a high voltage is applied in a dielectric-barrier discharge lamp or a capacitively coupled high frequency discharge lamp with no electrodes in a discharge space. Ribbon foil electrodes 3 are embedded in the wall of a quartz discharge vessel 1. The discharge vessel 1 is disposed such that the foil electrodes 3 face each other on both sides of the axis of the quartz discharge vessel 1. It may be disposed such that the foil electrodes 3 have a truncated V-shaped cross-section. The single tube quartz discharge vessel 1 is filled with discharge gas to form excimer molecules by dielectric barrier discharge or capacitively coupled high-frequency discharge.

Owner:ORC MFG

PCR method

InactiveUS7101663B2Permit useReduce errorsMicrobiological testing/measurementRecombinant DNA-technologySentinel lymph nodeCarcinoembryonic antigen

A method for balancing multiplexed PCR methods is provided. In the method, two or more sequential temporal PCR stages are used to effectively separate two or more PCR reactions in a single tube as an alternative to primer limiting to modulate the relative rate of production of a first amplicon by a first primer set and a second amplicon by a second primer set during the first and second amplification stages. Also provided are rapid RT-PCR methods that find particular use in intraoperative diagnoses and prognoses, for instance in diagnosing malignant esophageal adenocarcenoma by determining expression levels of carcinoembryonic antigen (CEA) in sentinel lymph nodes.

Owner:UNIVERSITY OF PITTSBURGH

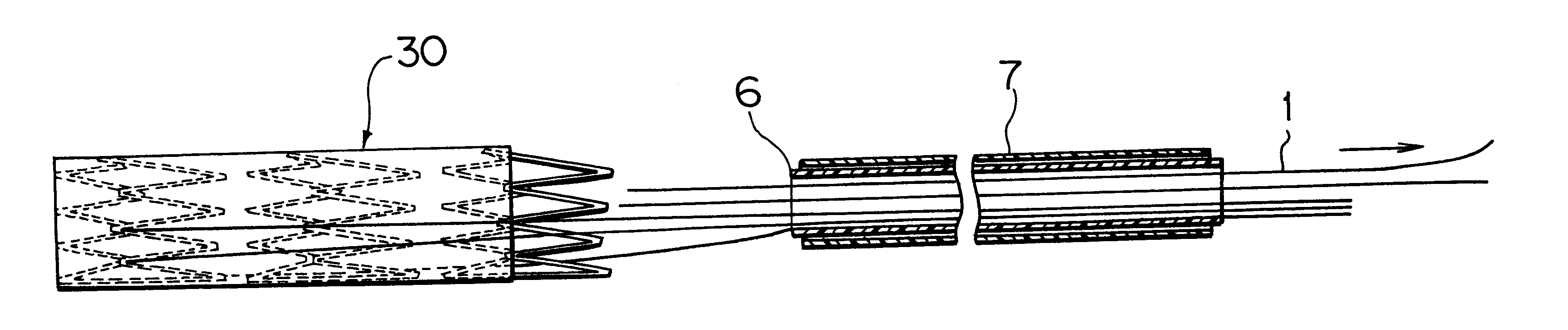

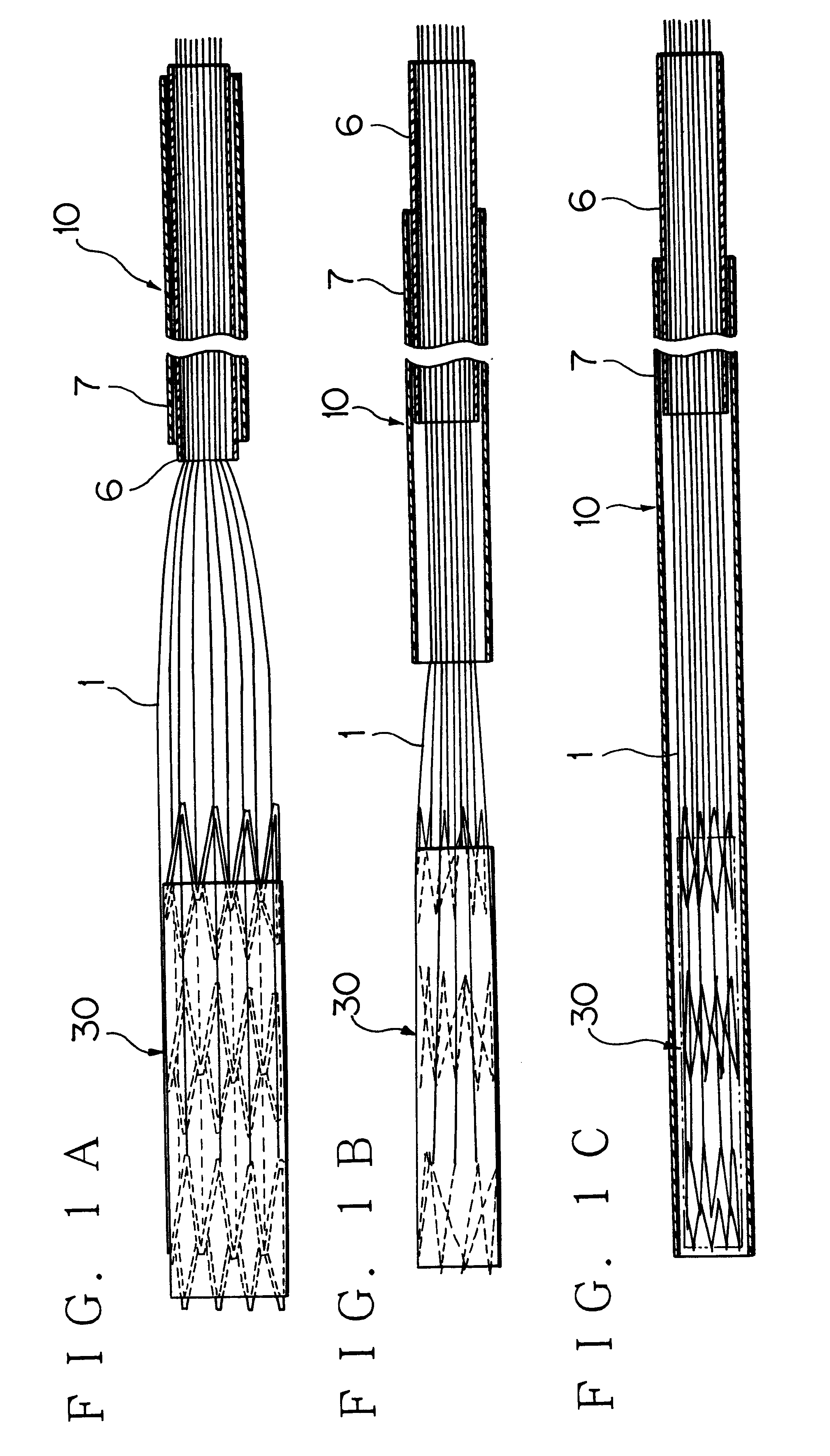

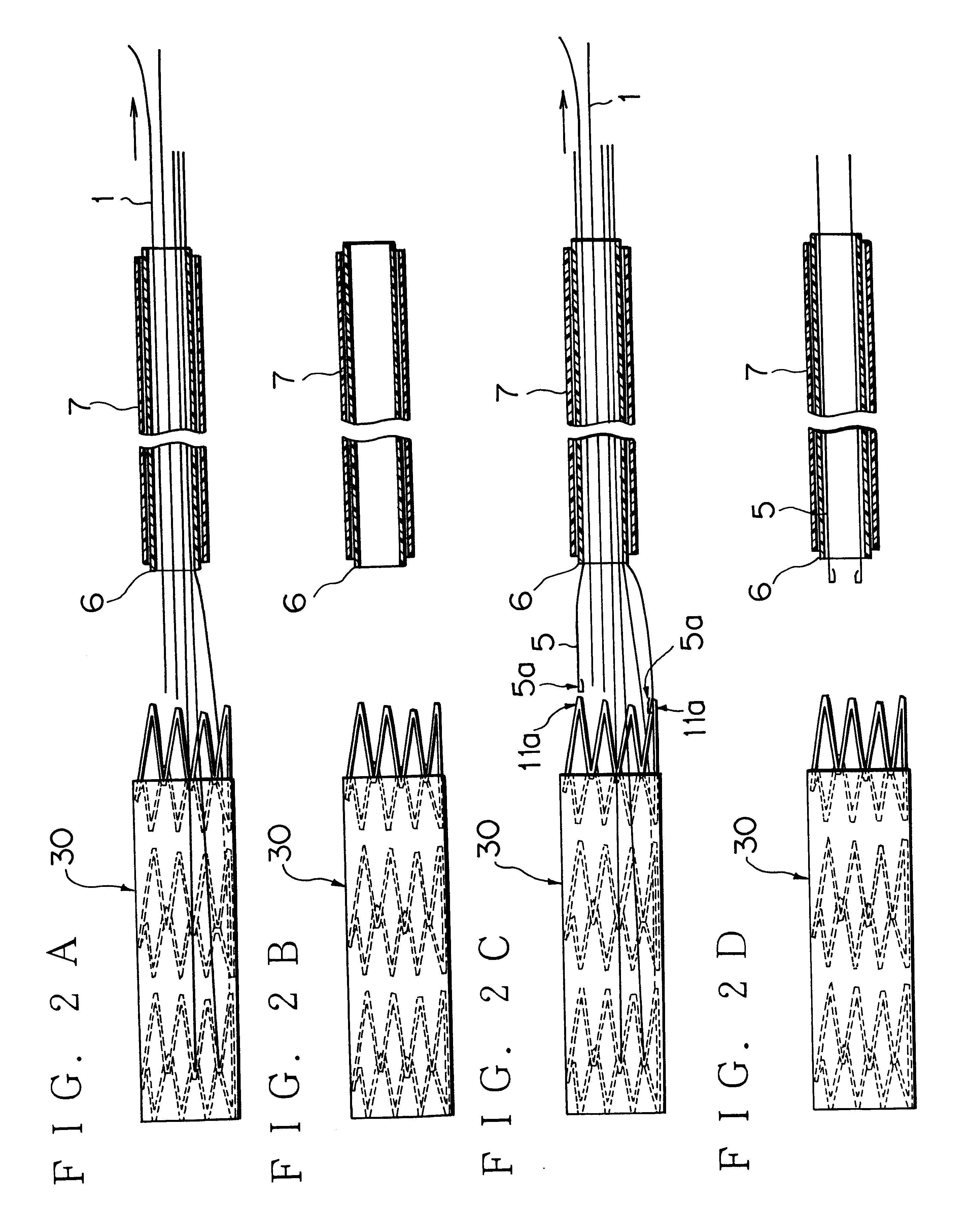

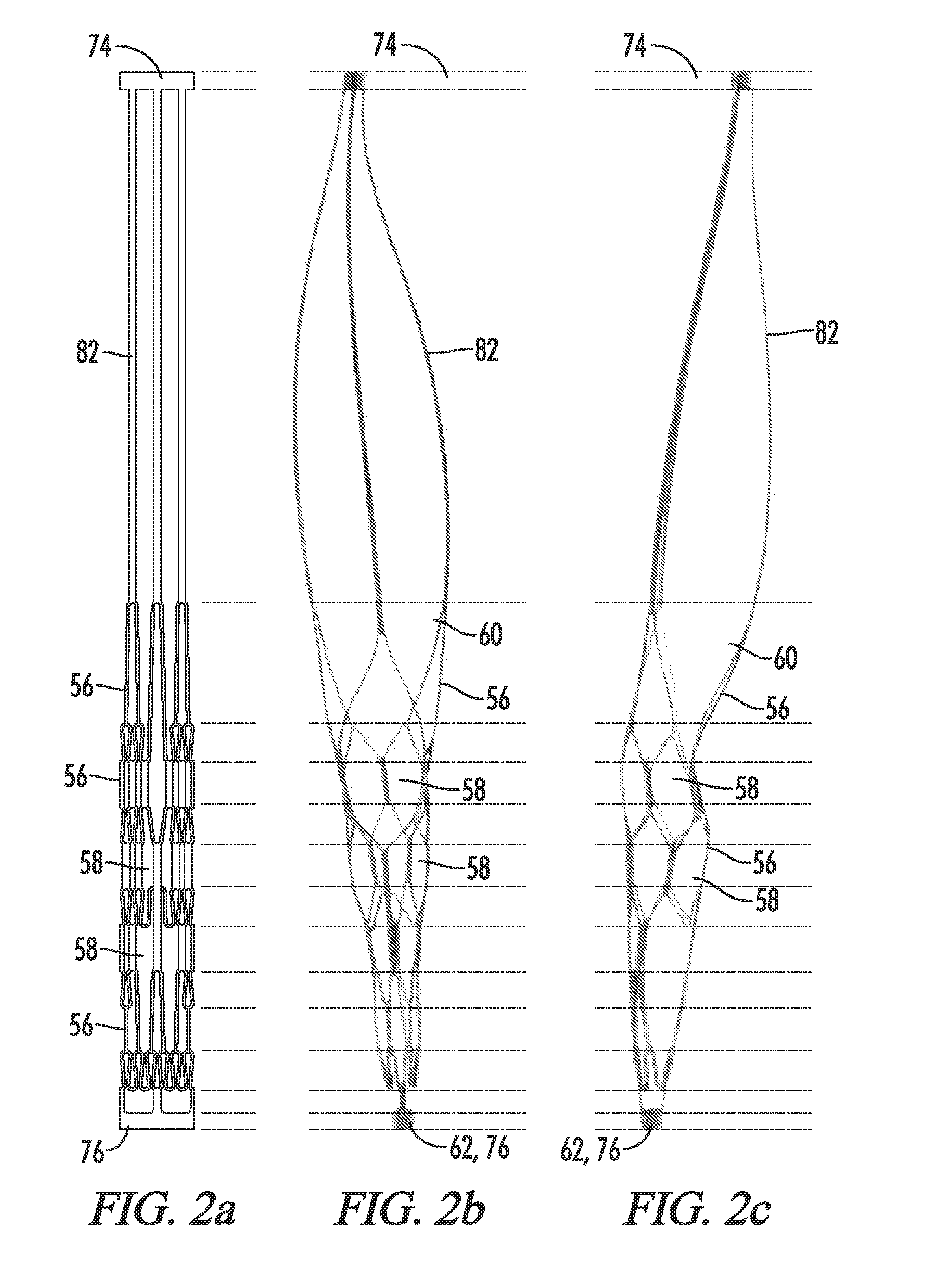

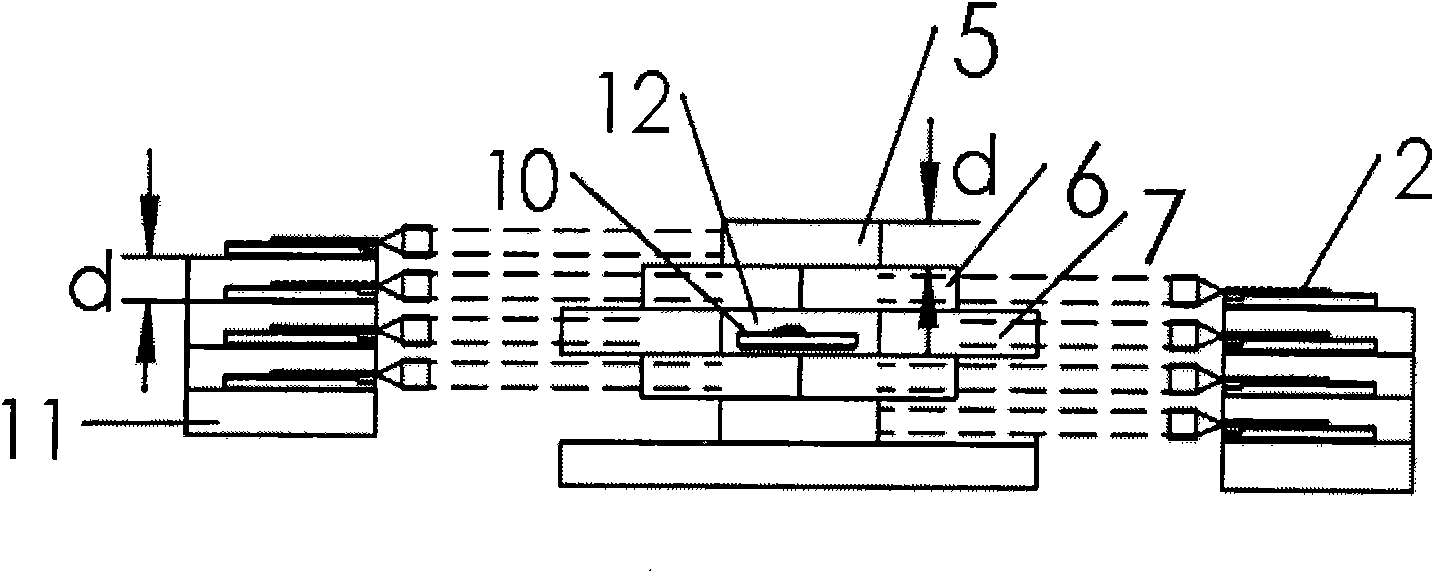

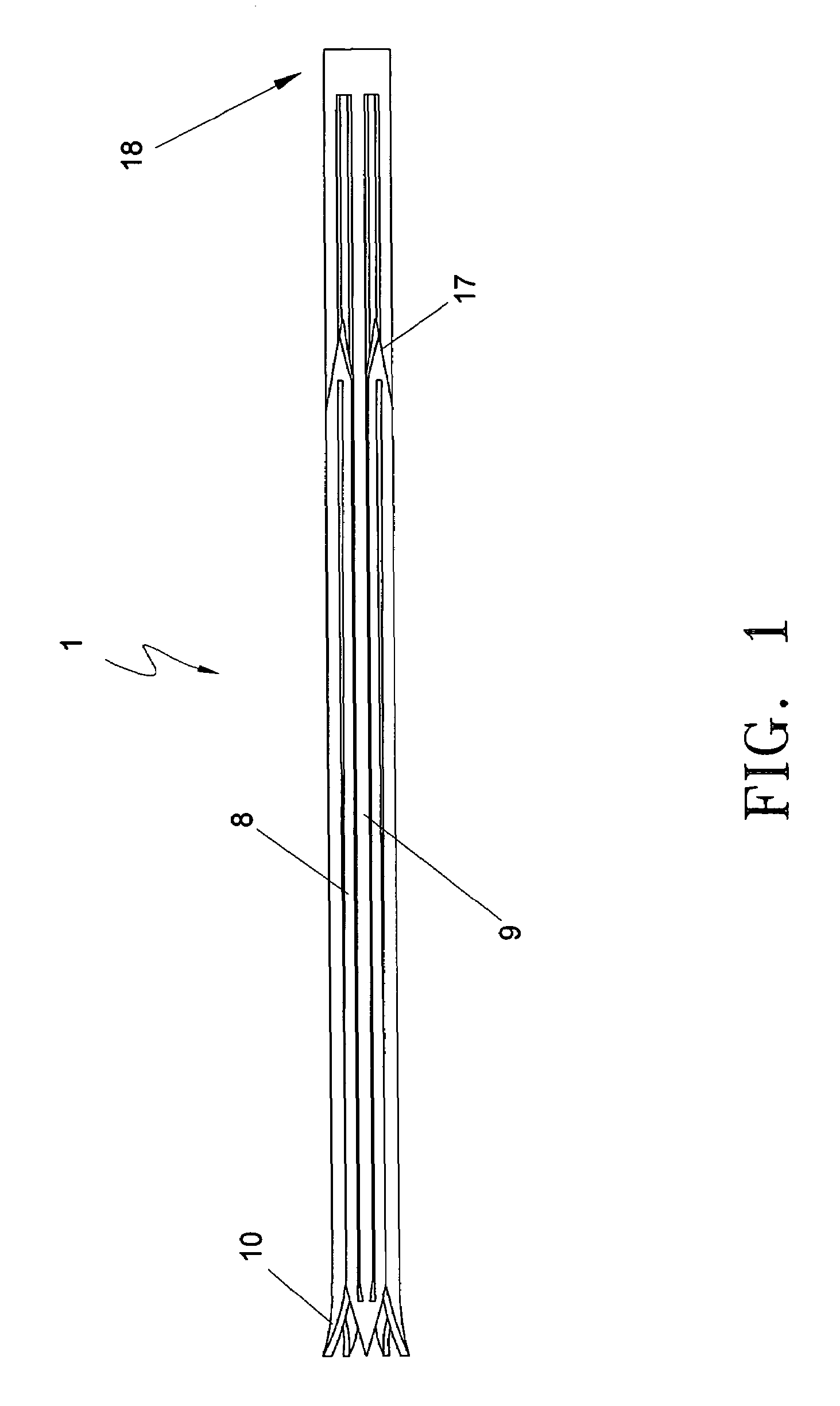

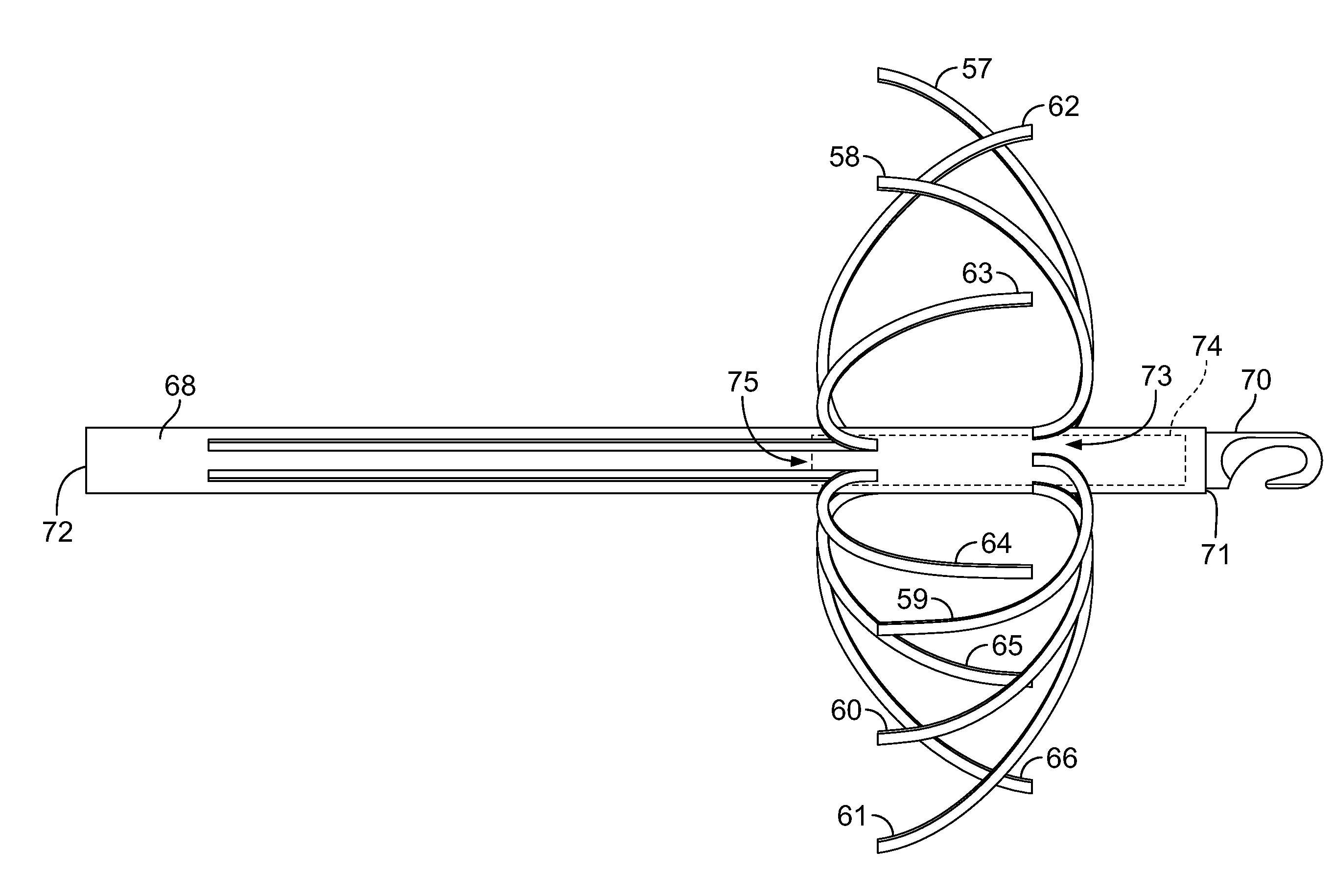

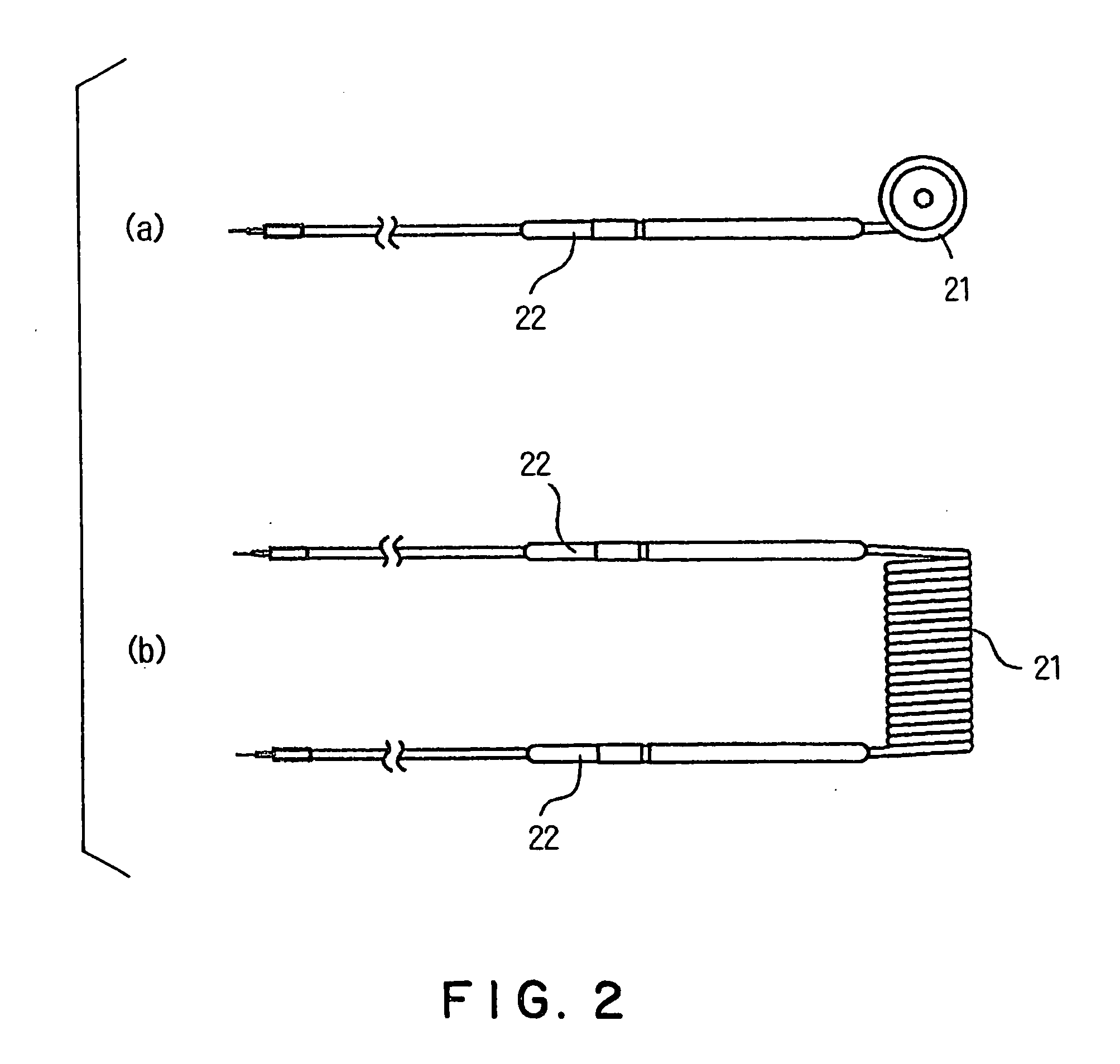

Stent (or stent graft) locating device

A stent locating device that includes leading wires, a pushing rod for holding the leading wires, and a sheath for loading the pushing rod. The pushing rod includes inner and outer tubes. The inner tube is used as a guiding wire channel. An annular portion between the inner and outer tubes is used as a leading wire channel. The pushing rod may be a single tube having a hollow portion that is used as a guiding wire channel and a plurality of leading wire channels arranged in the body thereof at regular intervals circumferentially. The pushing rod may have a plurality of leading wires, crossing leading wires, or a combination of leading wires and auxiliary leading wires which are distributed at regular intervals circumferentially and are derived from the tip of a leading wire channel(s).

Owner:ISHIMARU SHIN

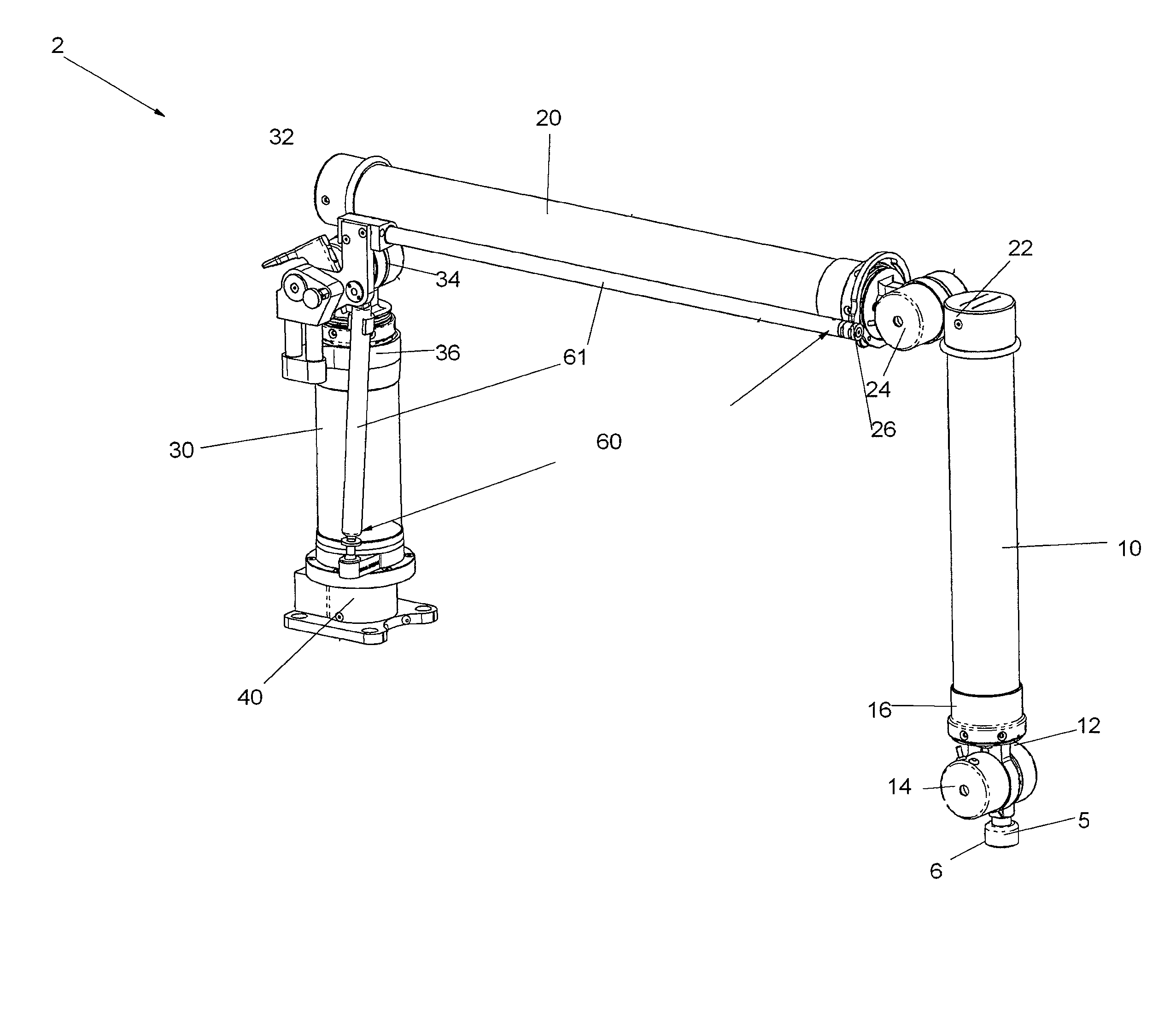

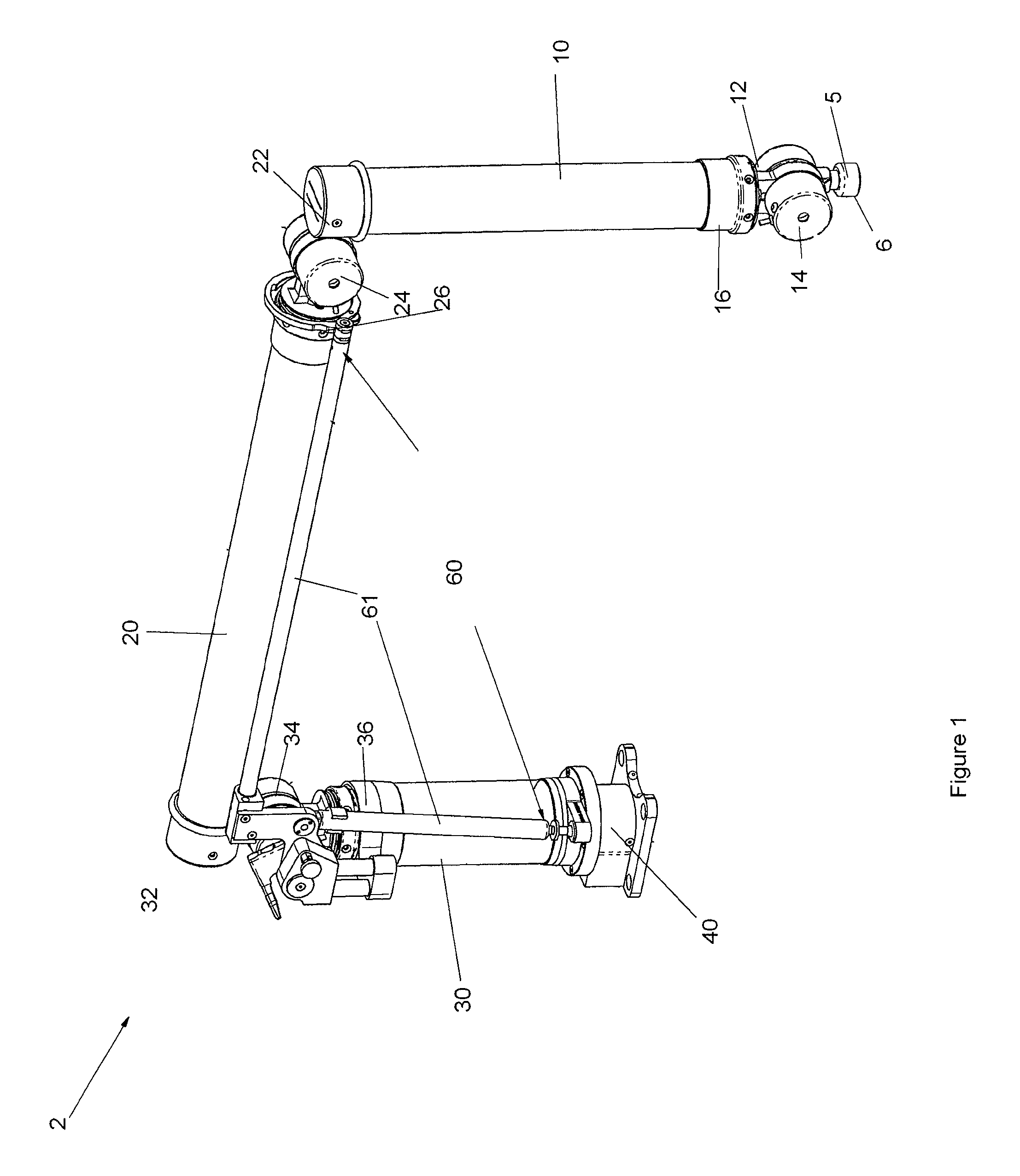

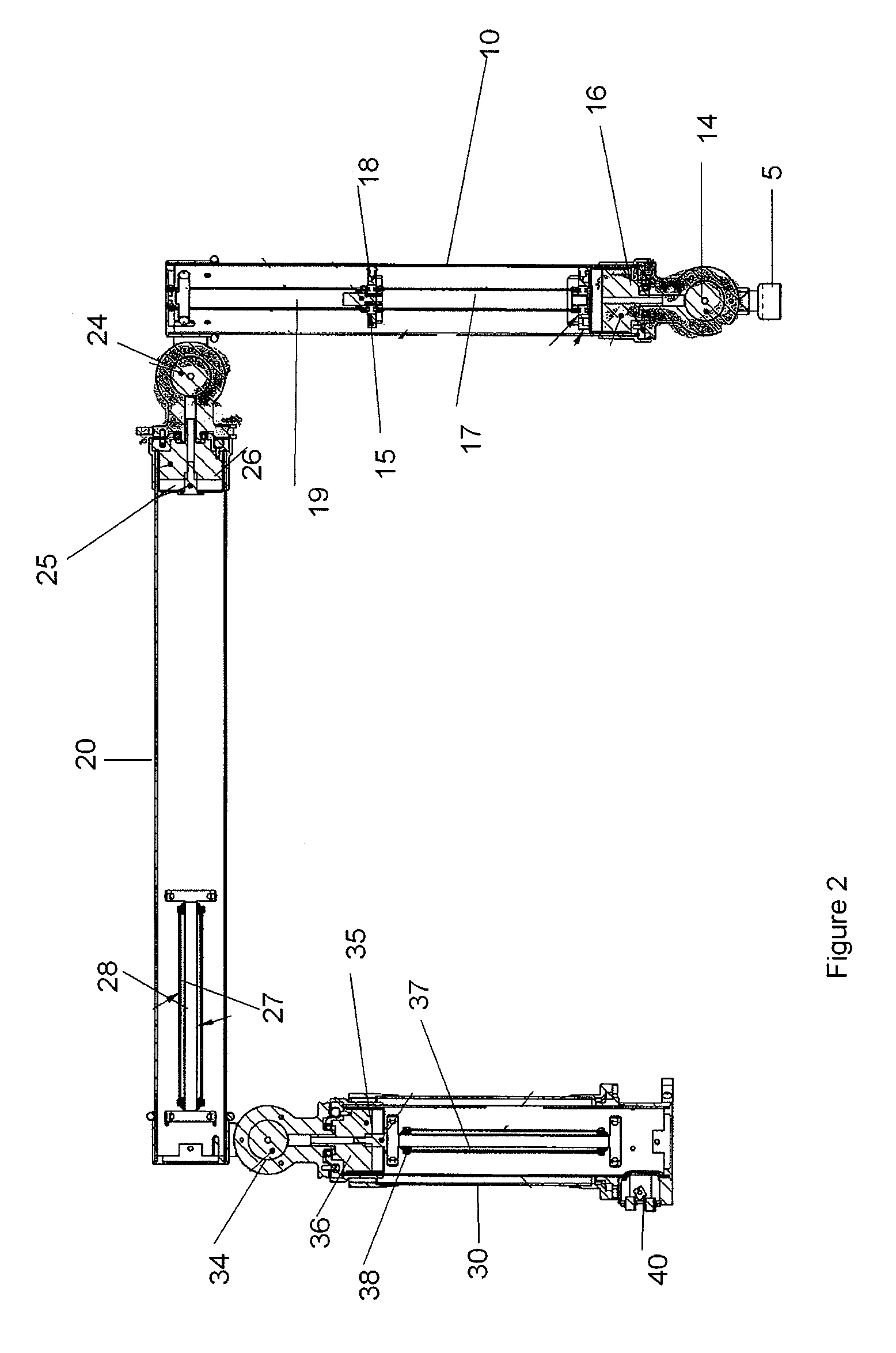

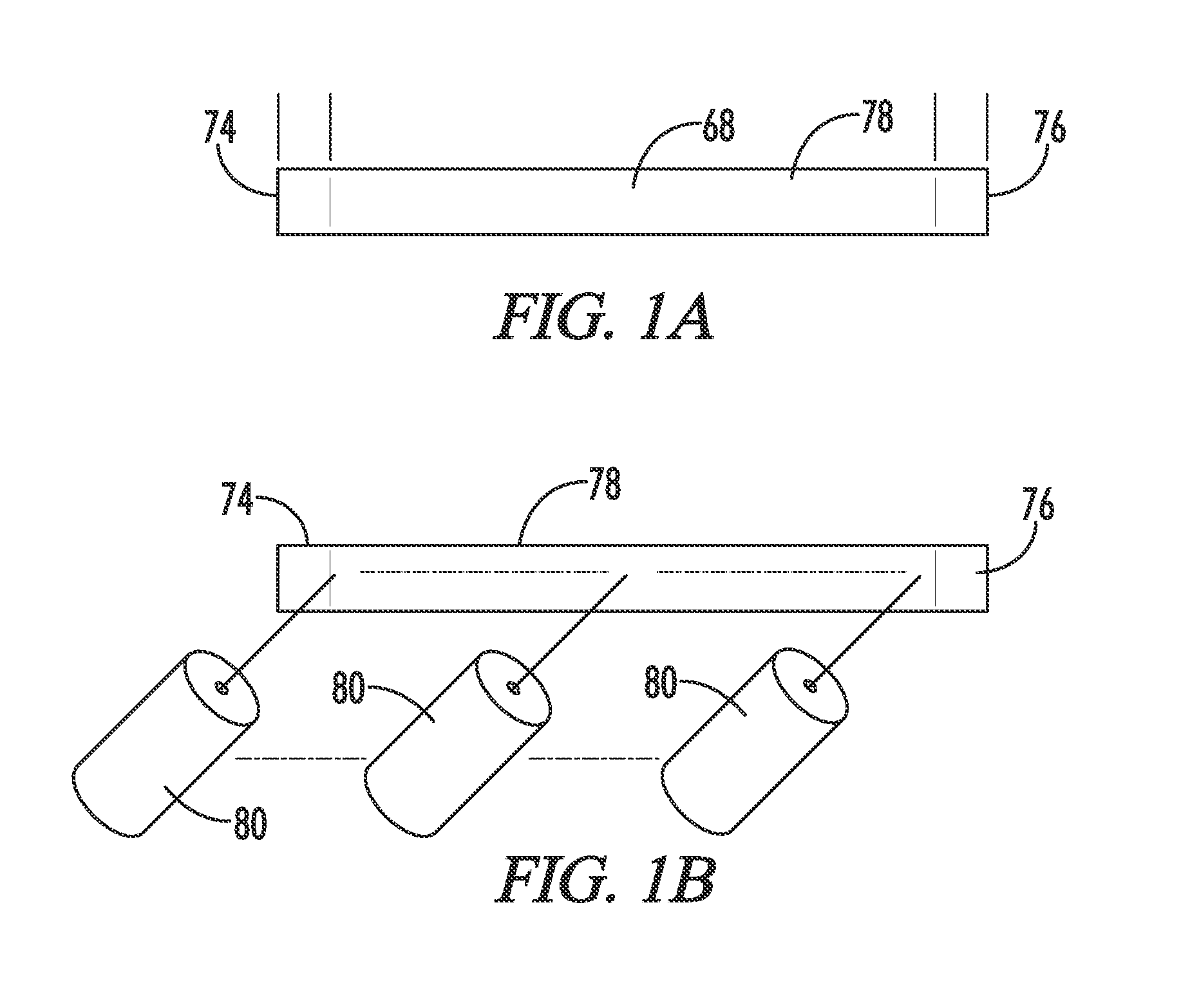

Coordinate measurement machine

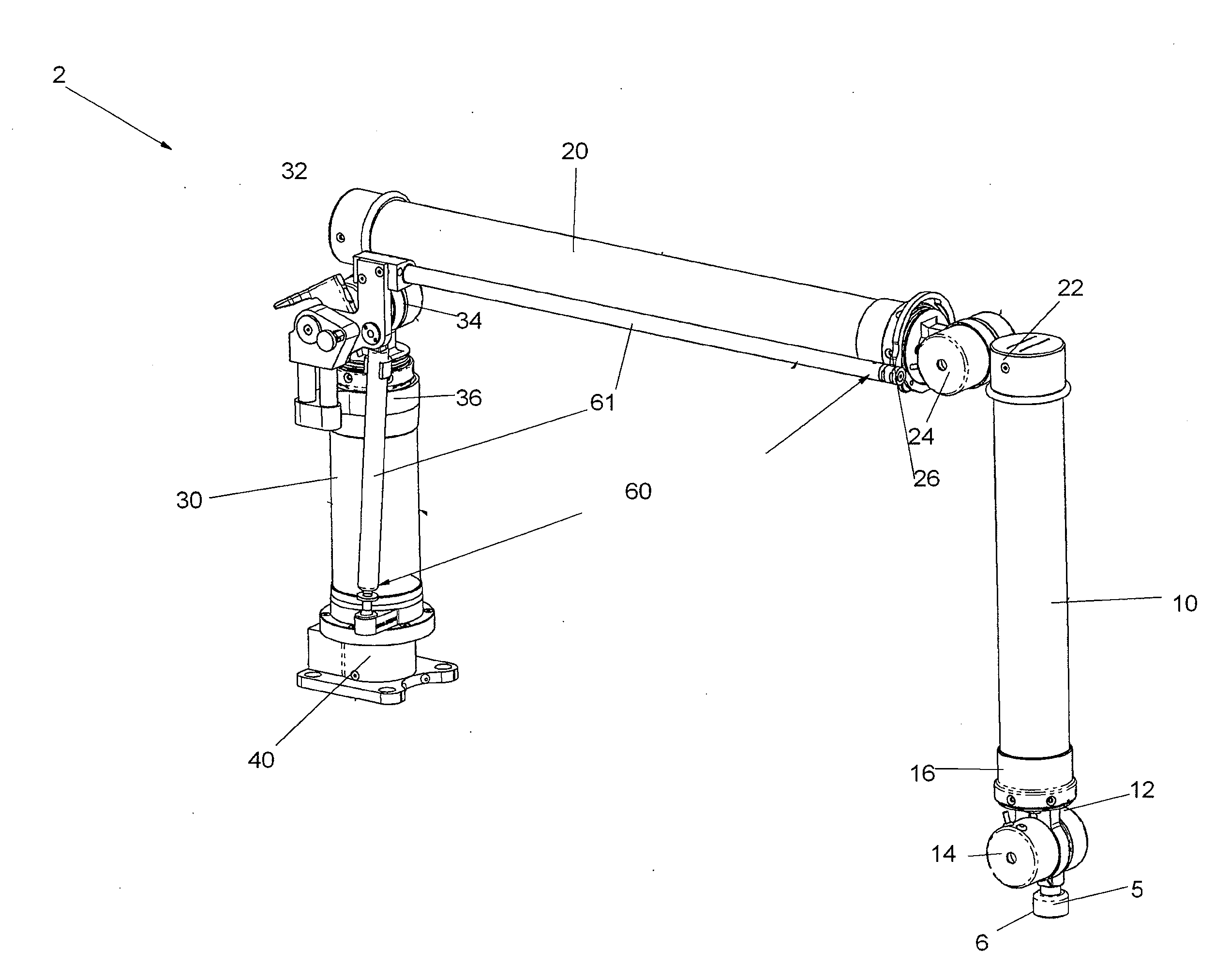

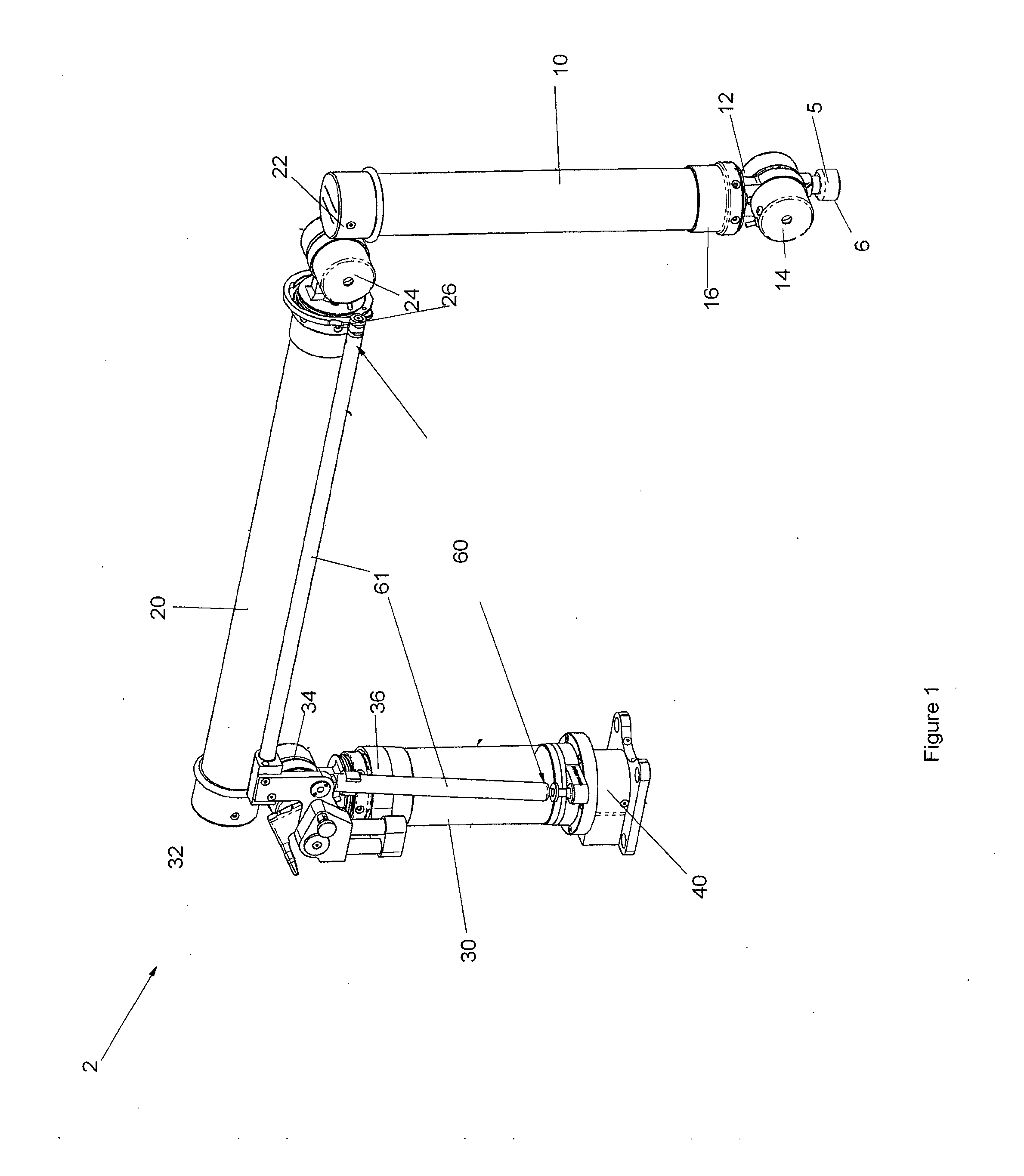

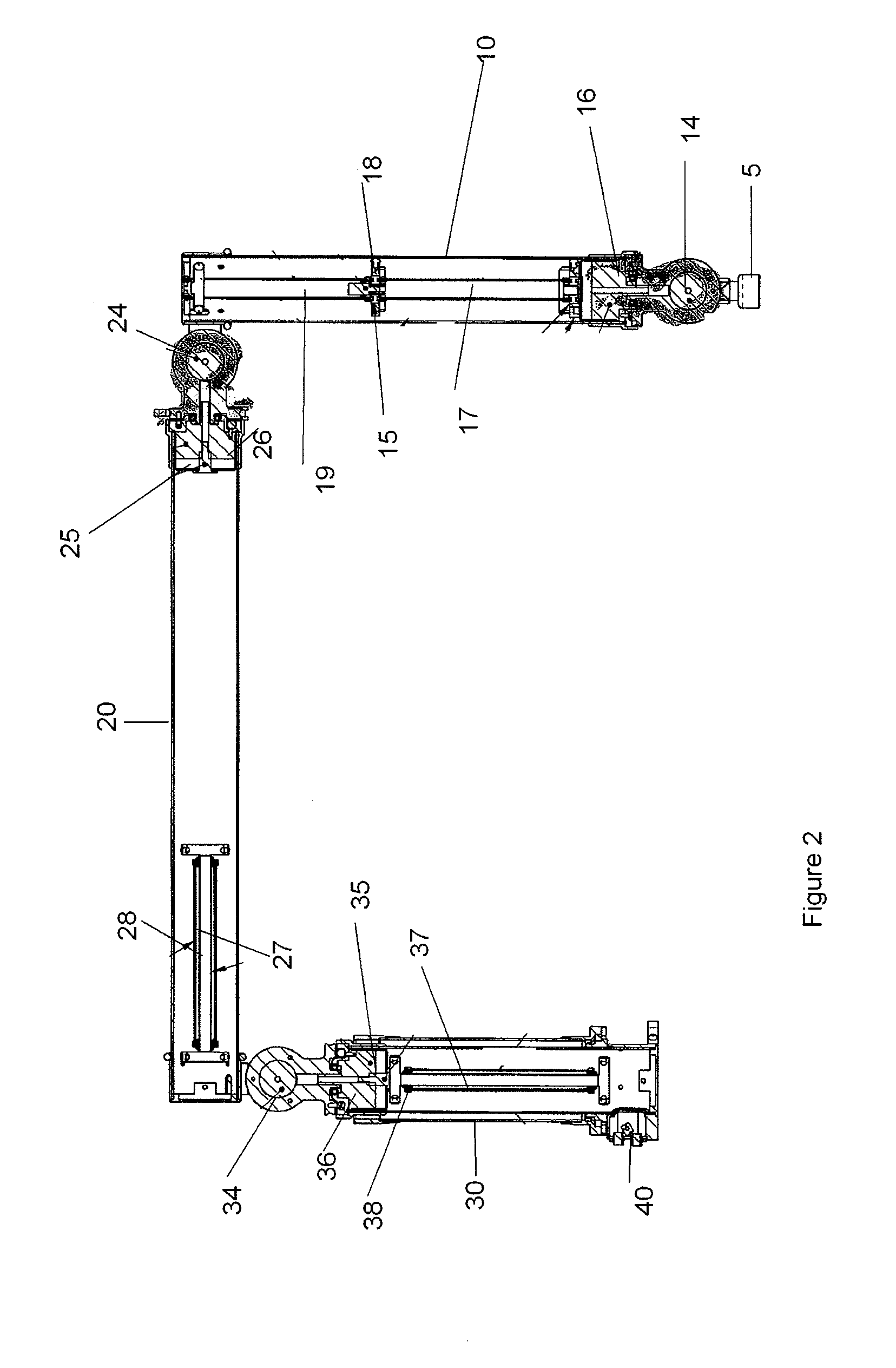

A portable coordinate measurement machine having three articulating arm transfer members can provide accurate measurements. The transfer members can be single tube assemblies. The transfer members can each be rotatably joined by relatively short articulating joint assemblies allowing relative rotation of adjacent transfer members about two degrees of freedom. Encoders can be used to measure the relative rotation about each of the degrees of freedom, and signals from the encoders can be digitized by processor boards positioned within the transfer members. Processor boards can be placed in tandem in the transfer members, and one or more of the processor boards can be mounted on a rotatable assembly. Slip rings can electrically couple all of the processor boards to allow for infinite rotatability of the articulating arm.

Owner:HEXAGON TECH CENT GMBH

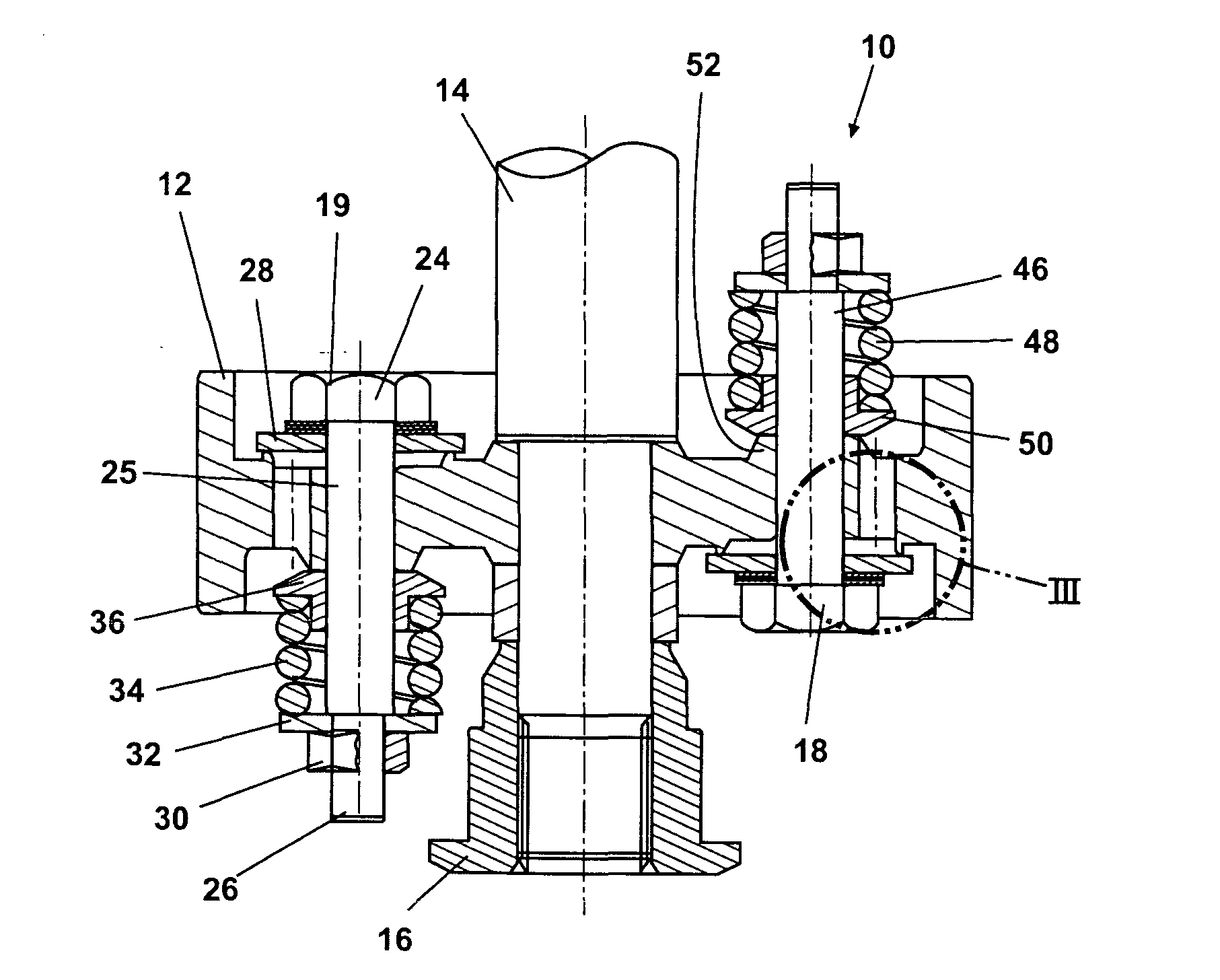

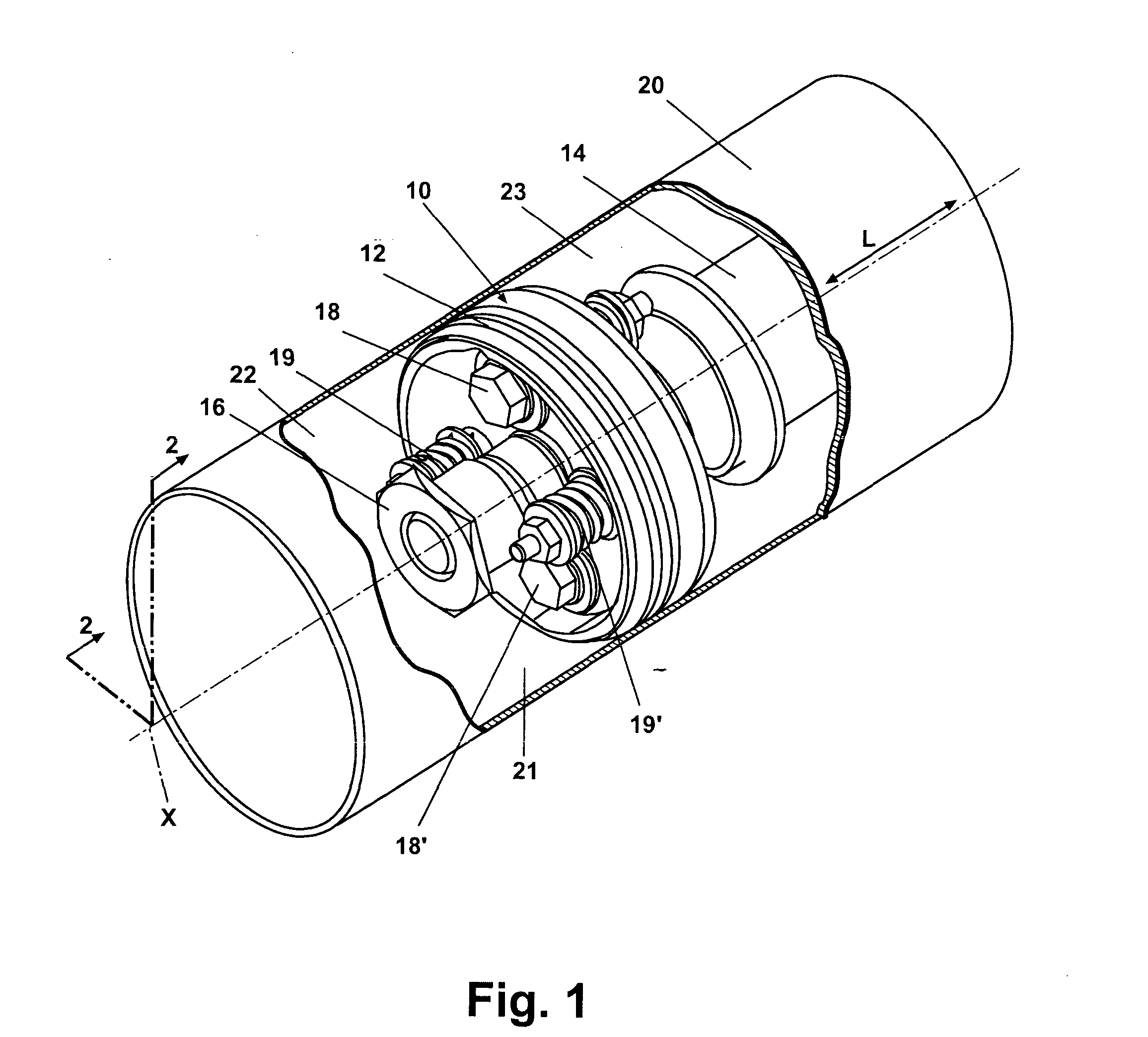

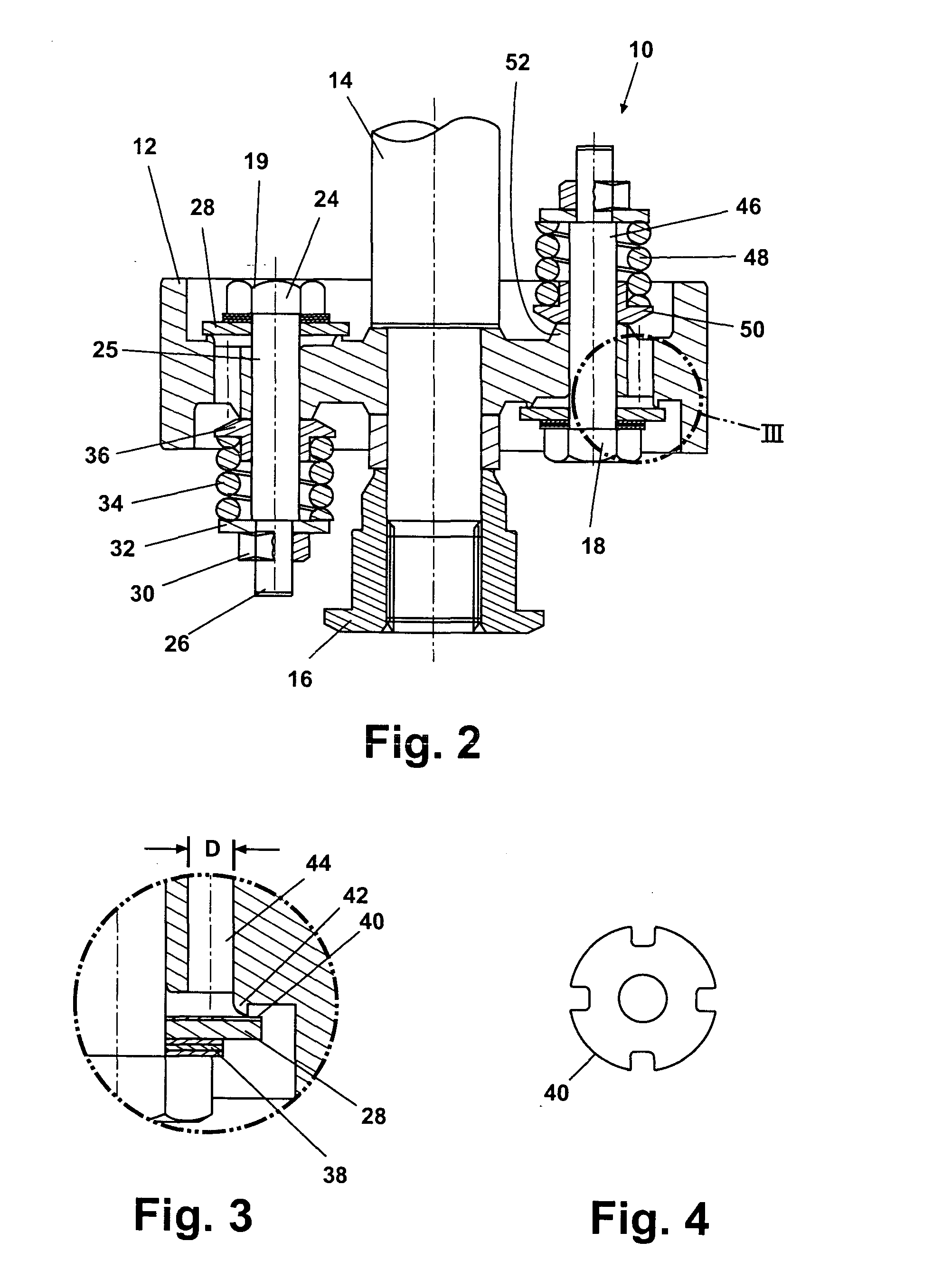

Coordinate measurement machine

ActiveUS20090083985A1Mechanical measuring arrangementsDegrees of freedomCoordinate-measuring machine

A portable coordinate measurement machine having three articulating arm transfer members can provide accurate measurements. The transfer members can be single tube assemblies. The transfer members can each be rotatably joined by relatively short articulating joint assemblies allowing relative rotation of adjacent transfer members about two degrees of freedom. Encoders can be used to measure the relative rotation about each of the degrees of freedom, and signals from the encoders can be digitized by processor boards positioned within the transfer members. Processor boards can be placed in tandem in the transfer members, and one or more of the processor boards can be mounted on a rotatable assembly. Slip rings can electrically couple all of the processor boards to allow for infinite rotatability of the articulating arm.

Owner:HEXAGON TECH CENT GMBH

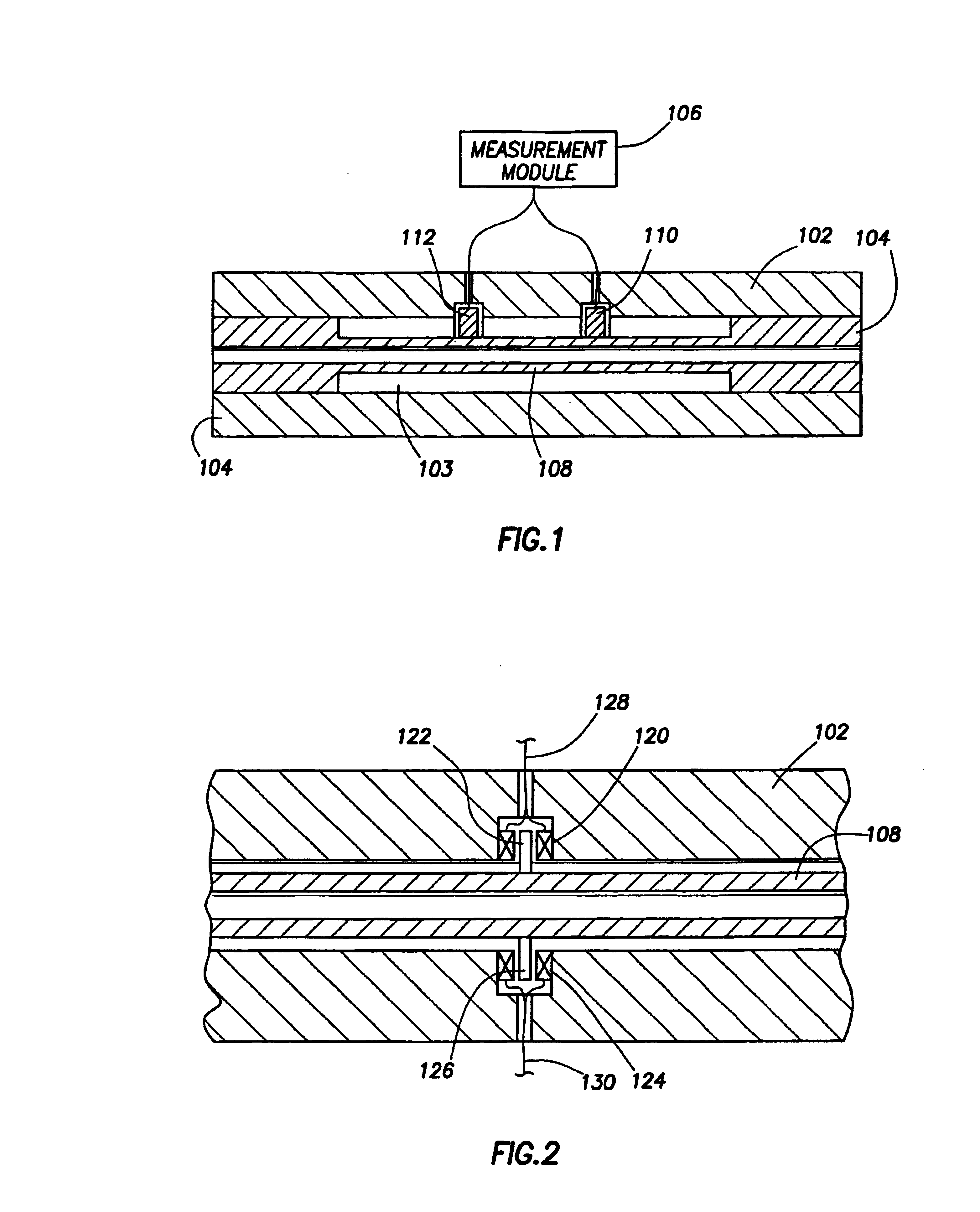

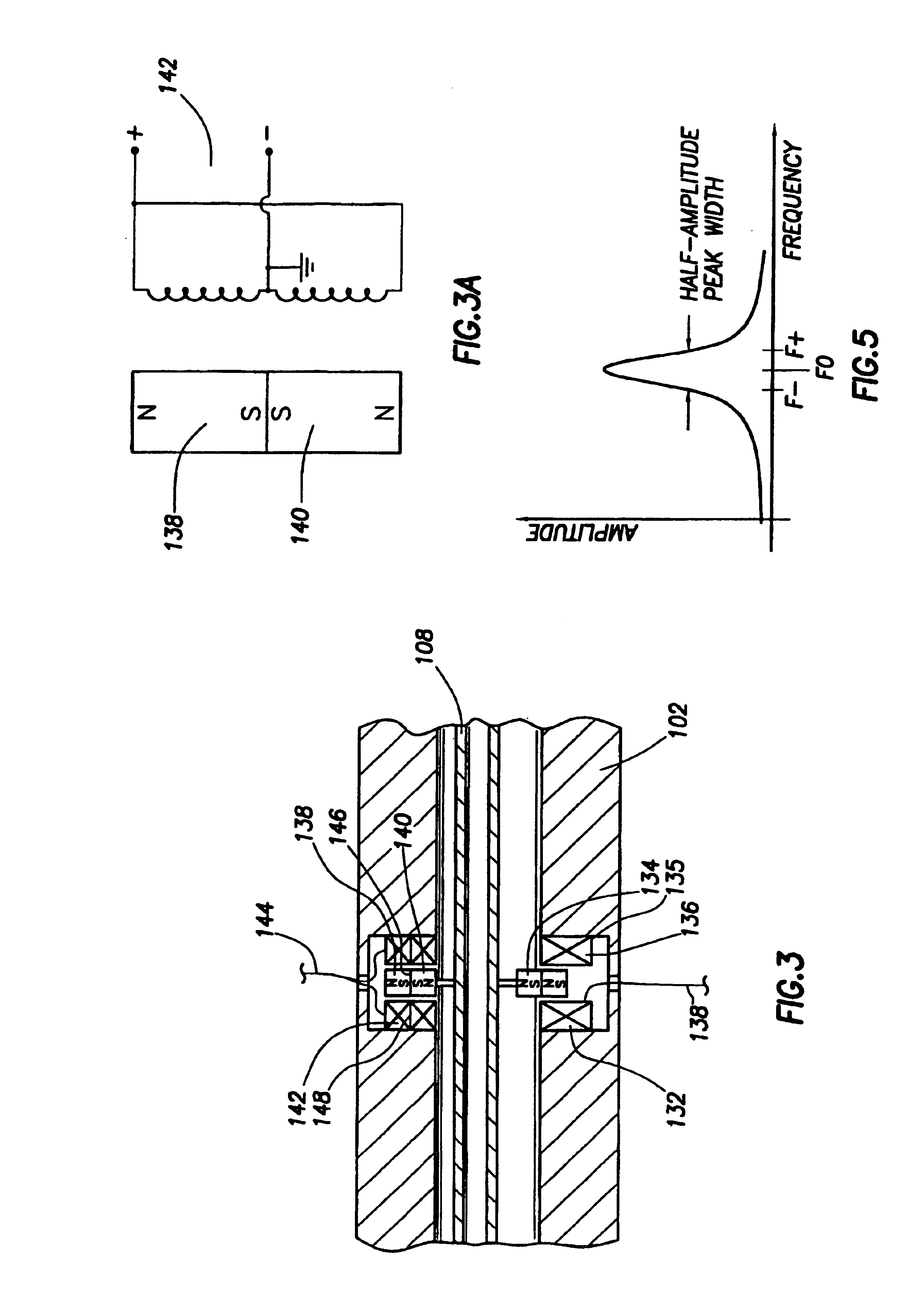

Single tube densitometer

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

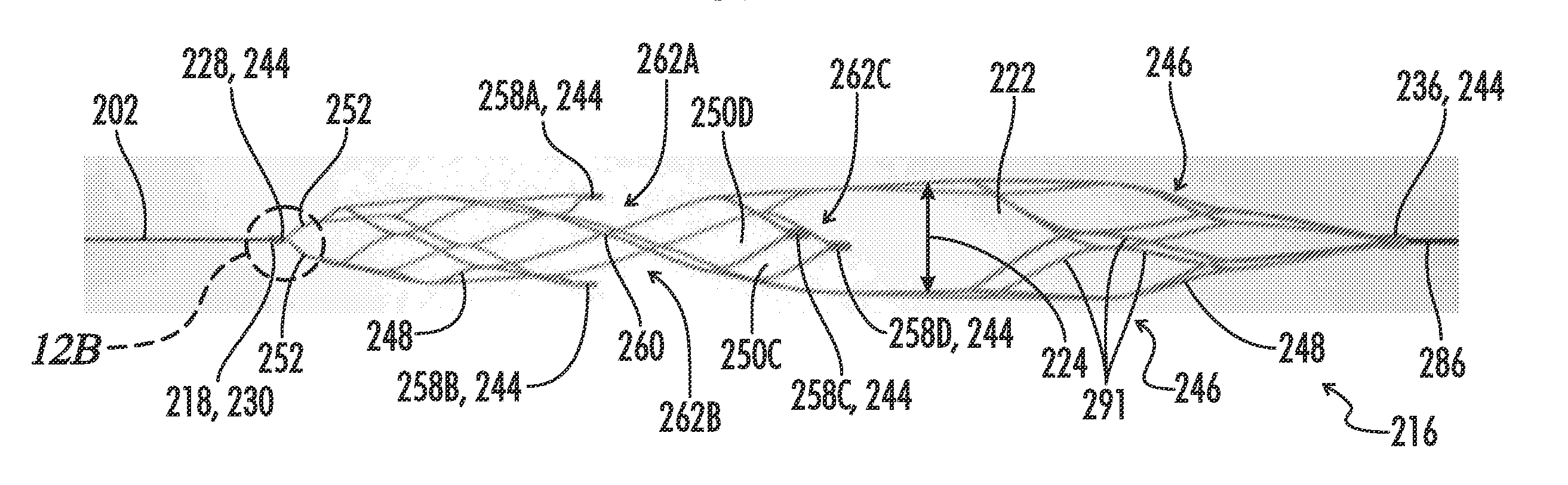

Clot Retrieval System

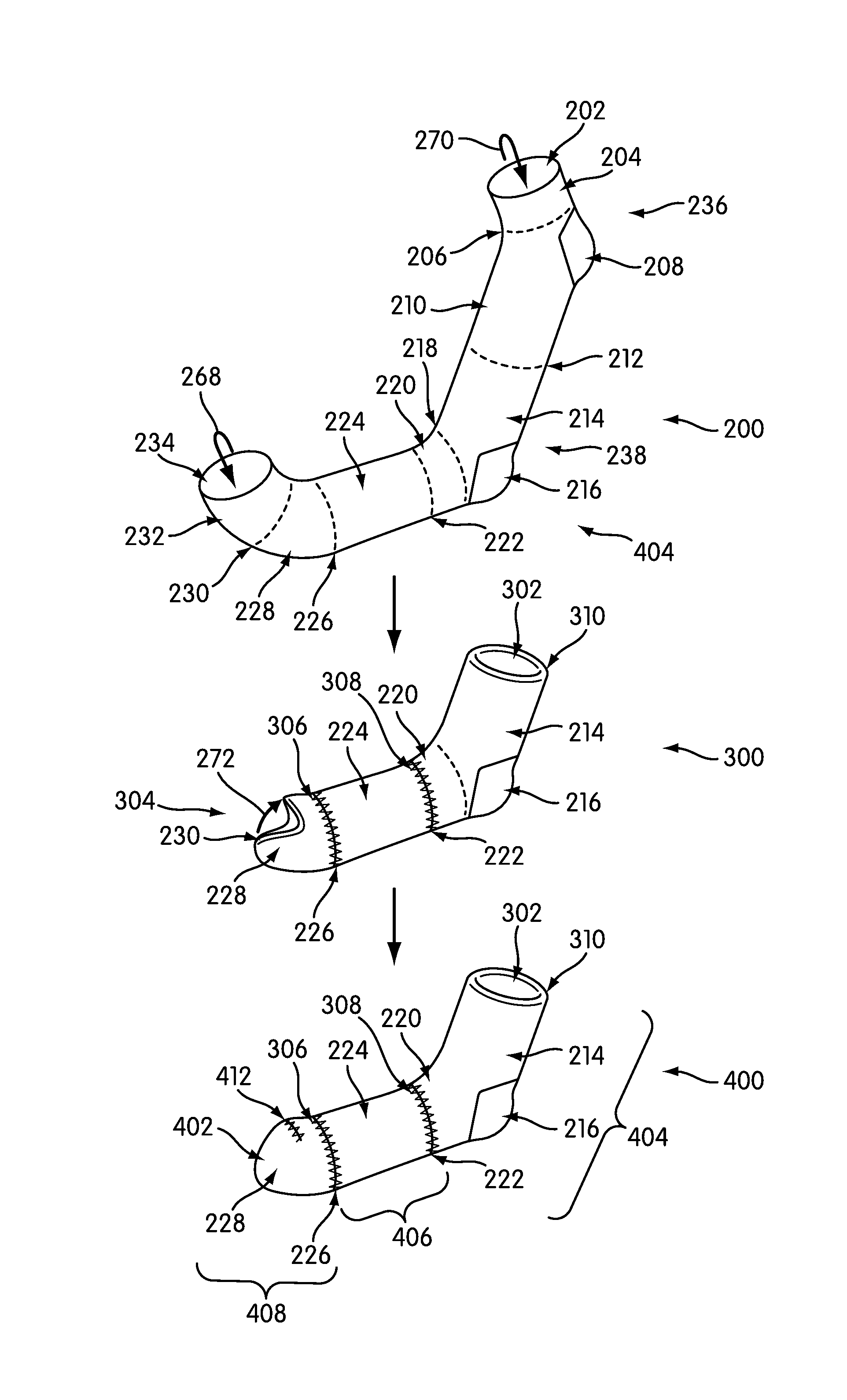

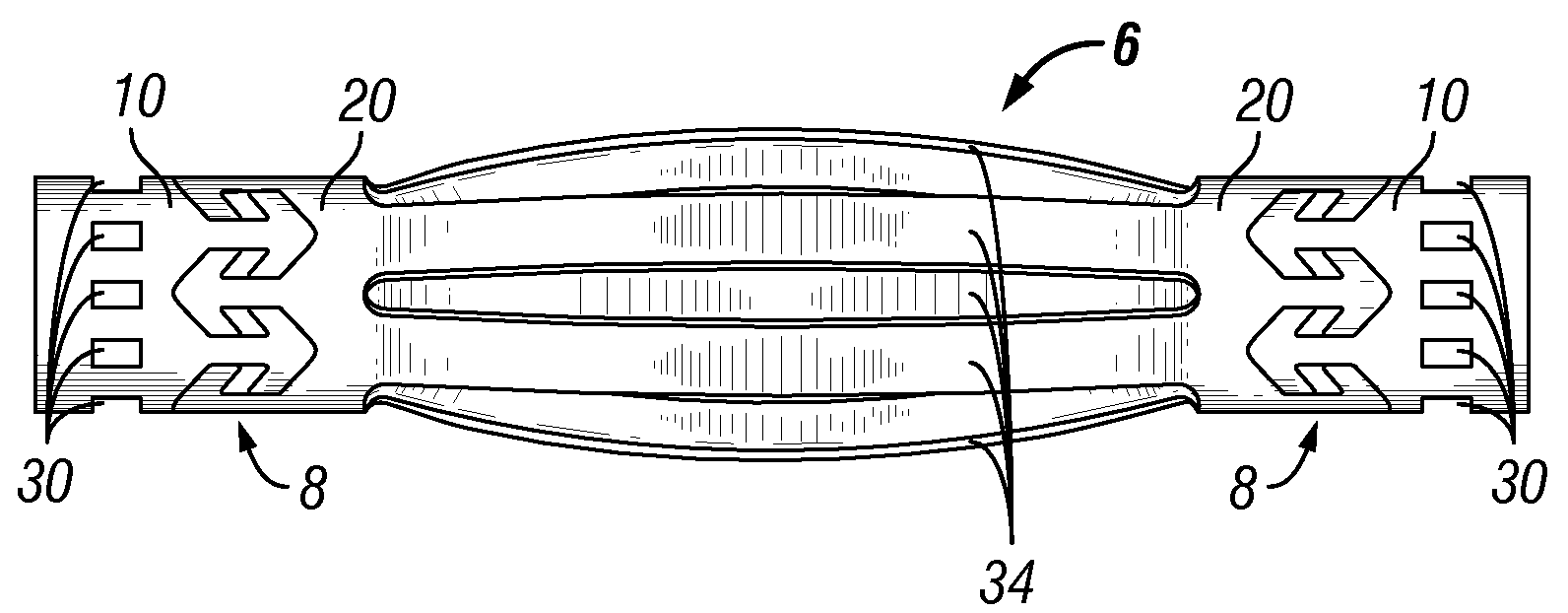

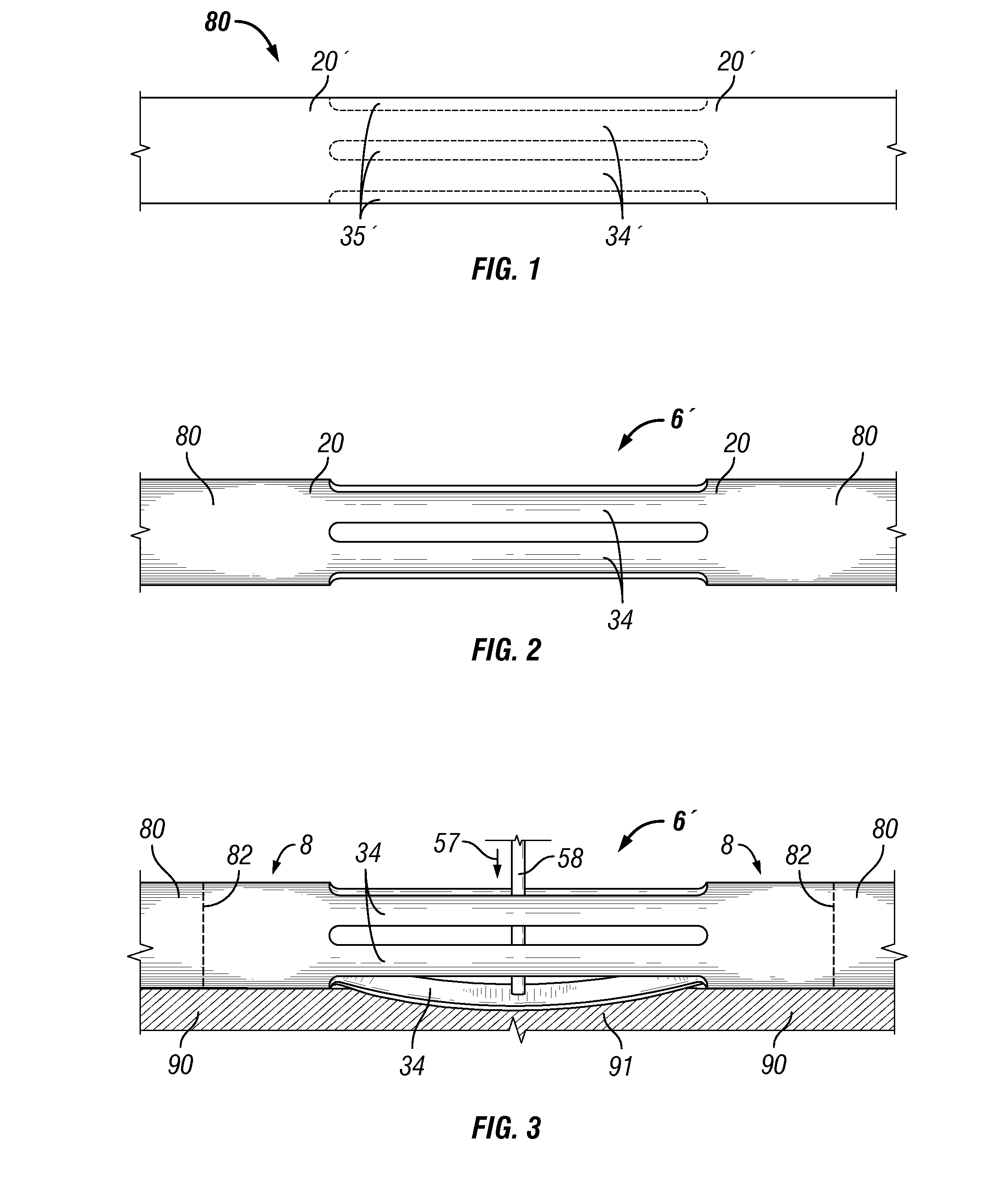

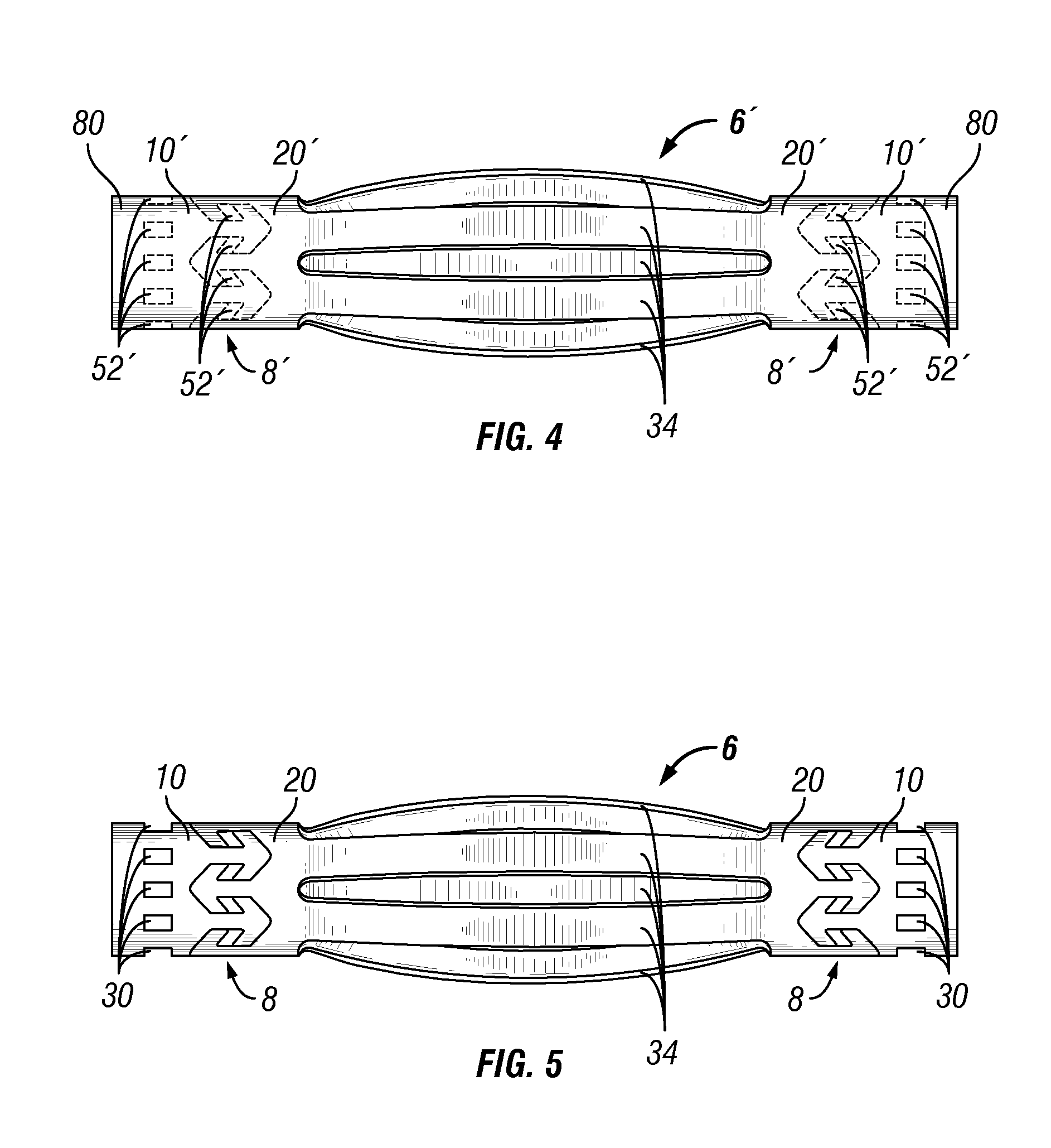

ActiveUS20150320431A1Easy and cheap to reliably manufactureIncrease heightSurgeryDilatorsBiomedical engineeringBlood vessel

A platform of devices for removing obstructions and other objects within a blood vessel or other interior lumen of an animal is provided. The system may be deployed in the lumen from a catheter(s) and the system includes a proximal hub, and a distal basket comprised of a plurality of cells. A number of different baskets designs are disclosed. Methods of manufacturing such baskets out of a single tube of a memory metal without the need for any welding or soldering, and methods of use are also disclosed.

Owner:LEGACY VENTURES

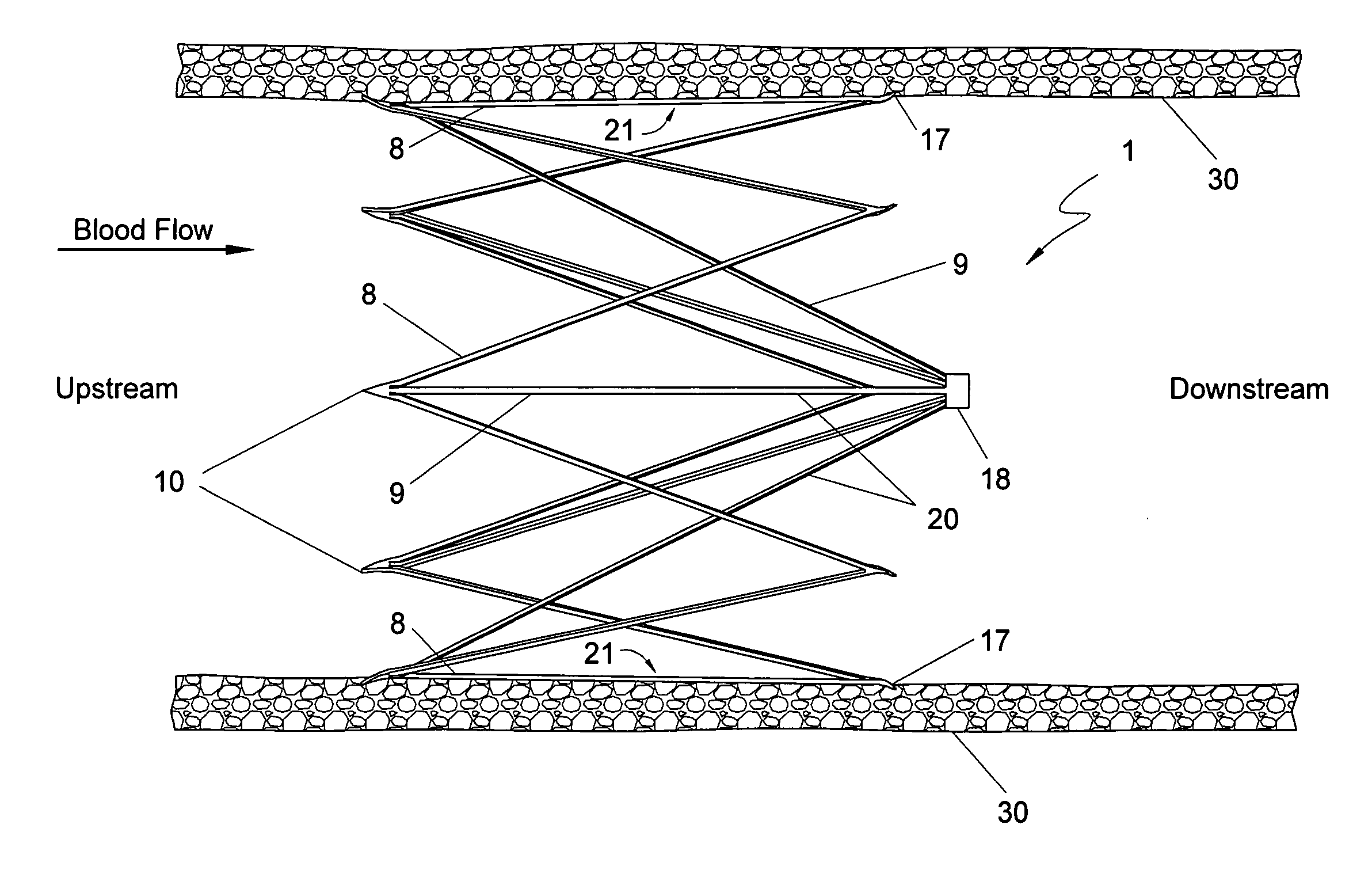

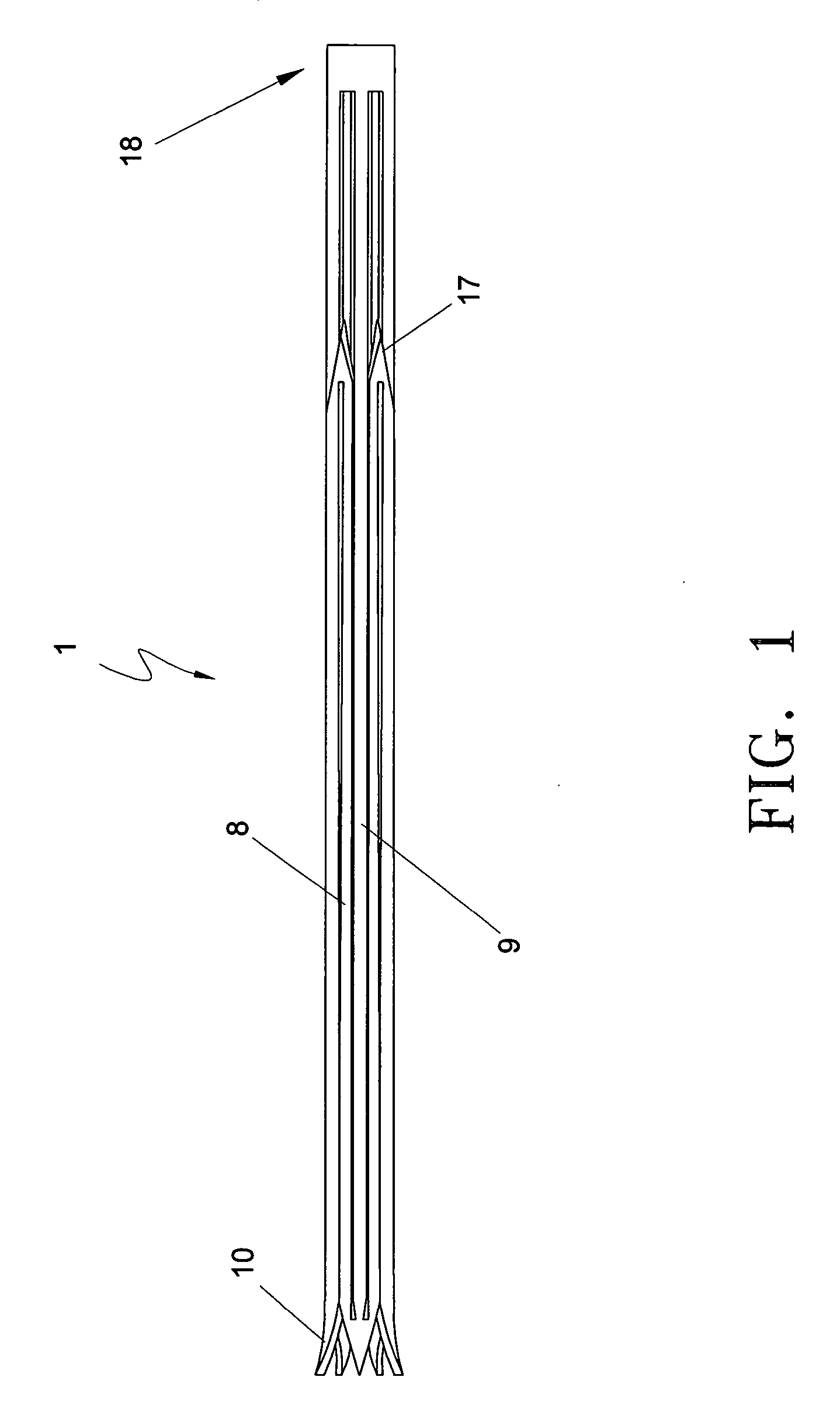

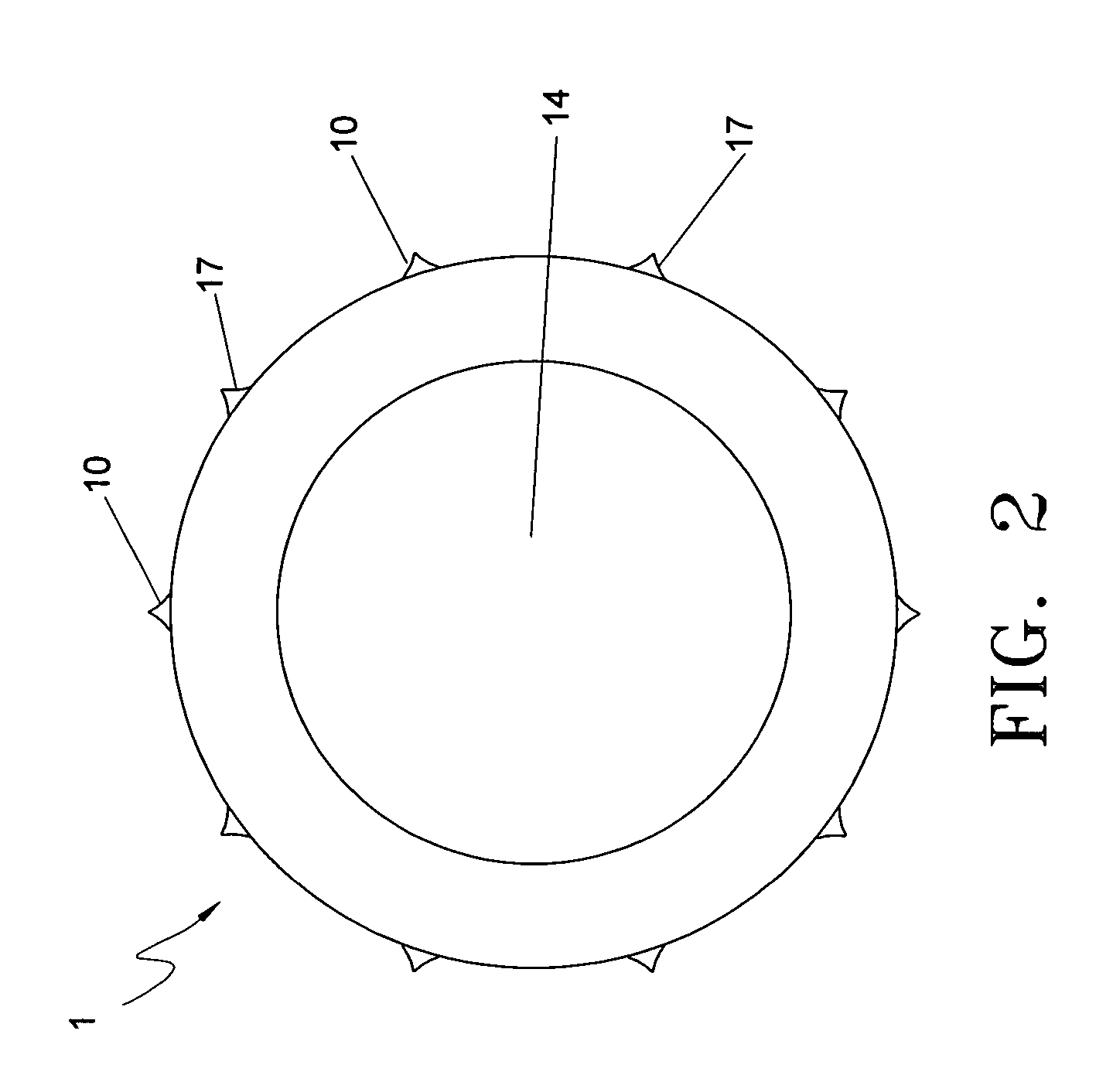

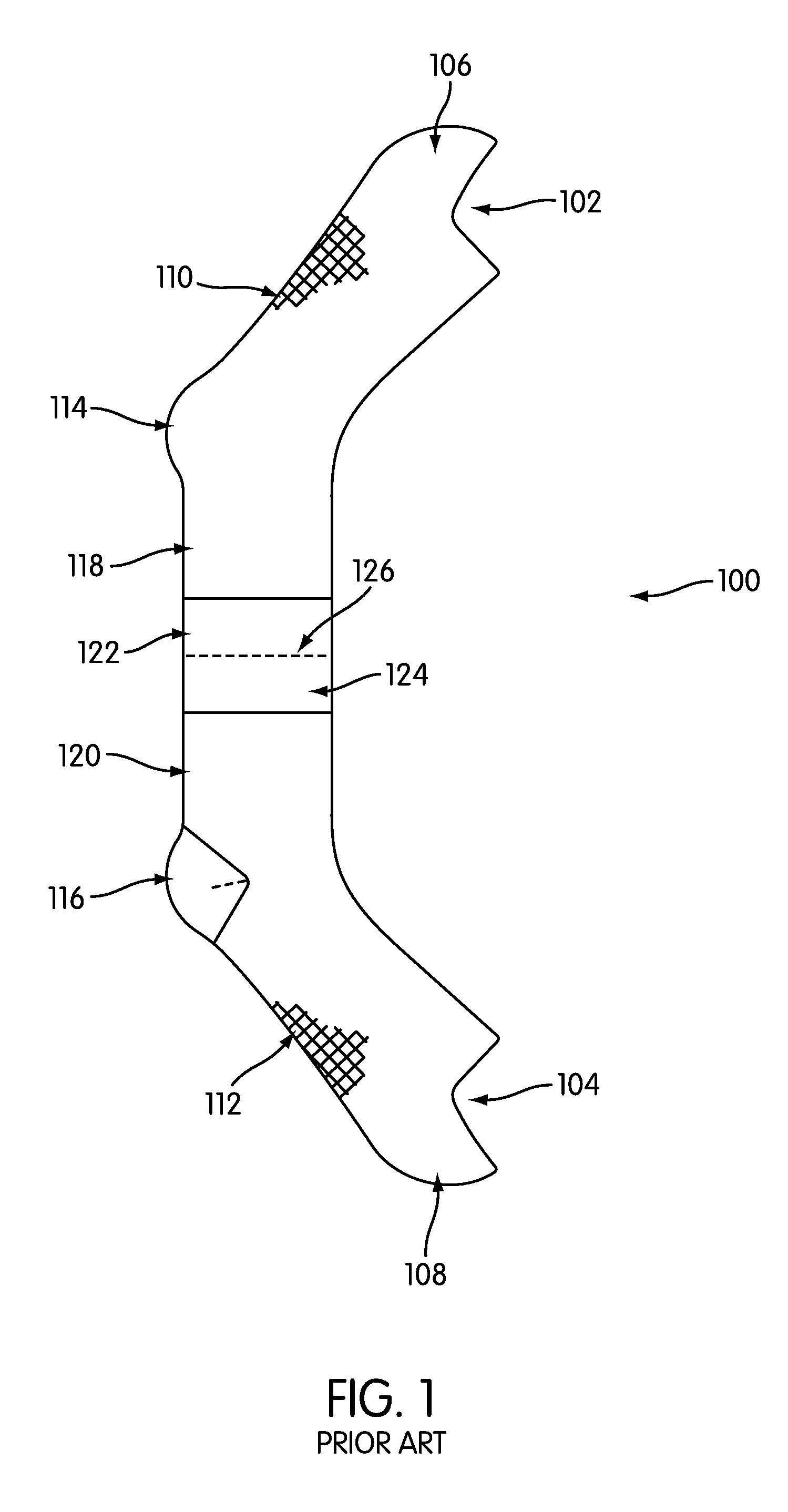

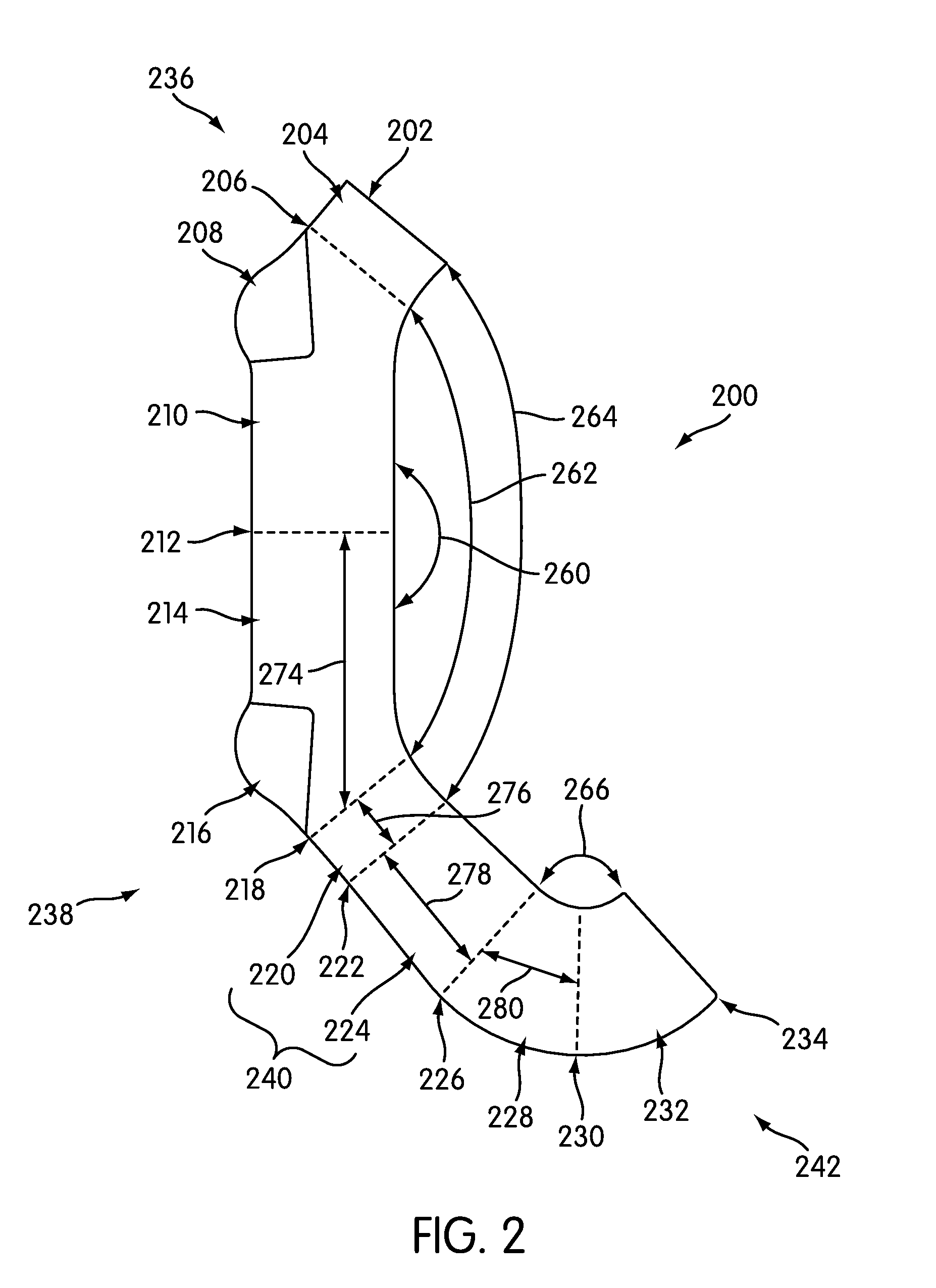

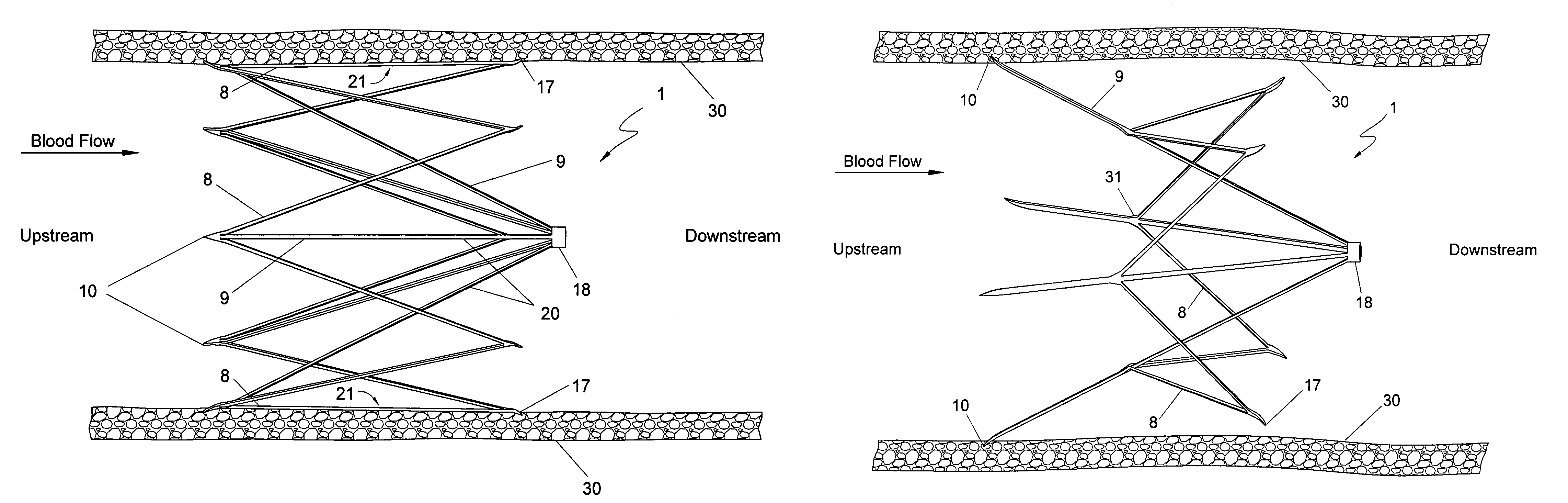

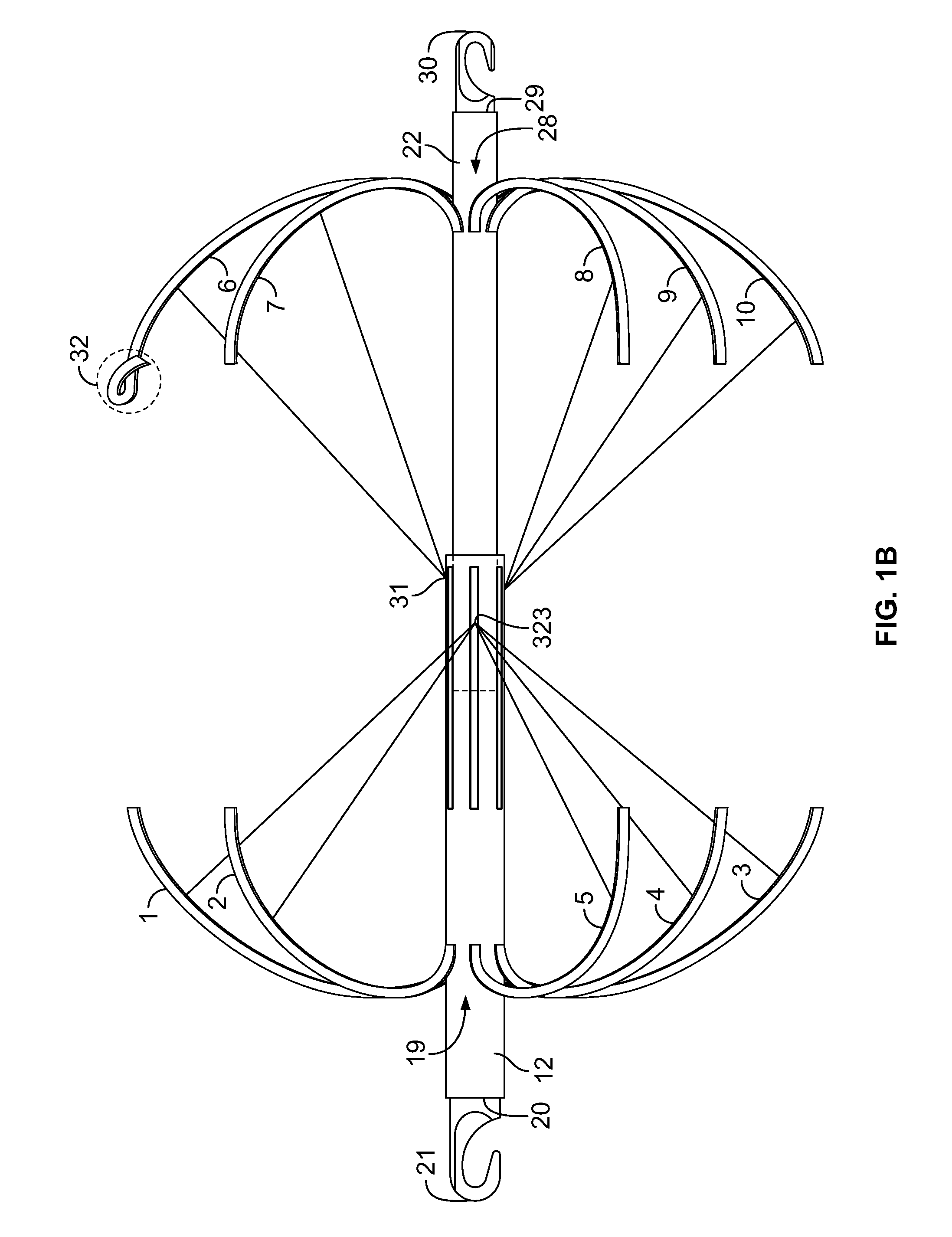

Blood clot filter

InactiveUS20050288703A1Be at easeImproves Structural IntegritySurgeryDilatorsEngineeringStructural integrity

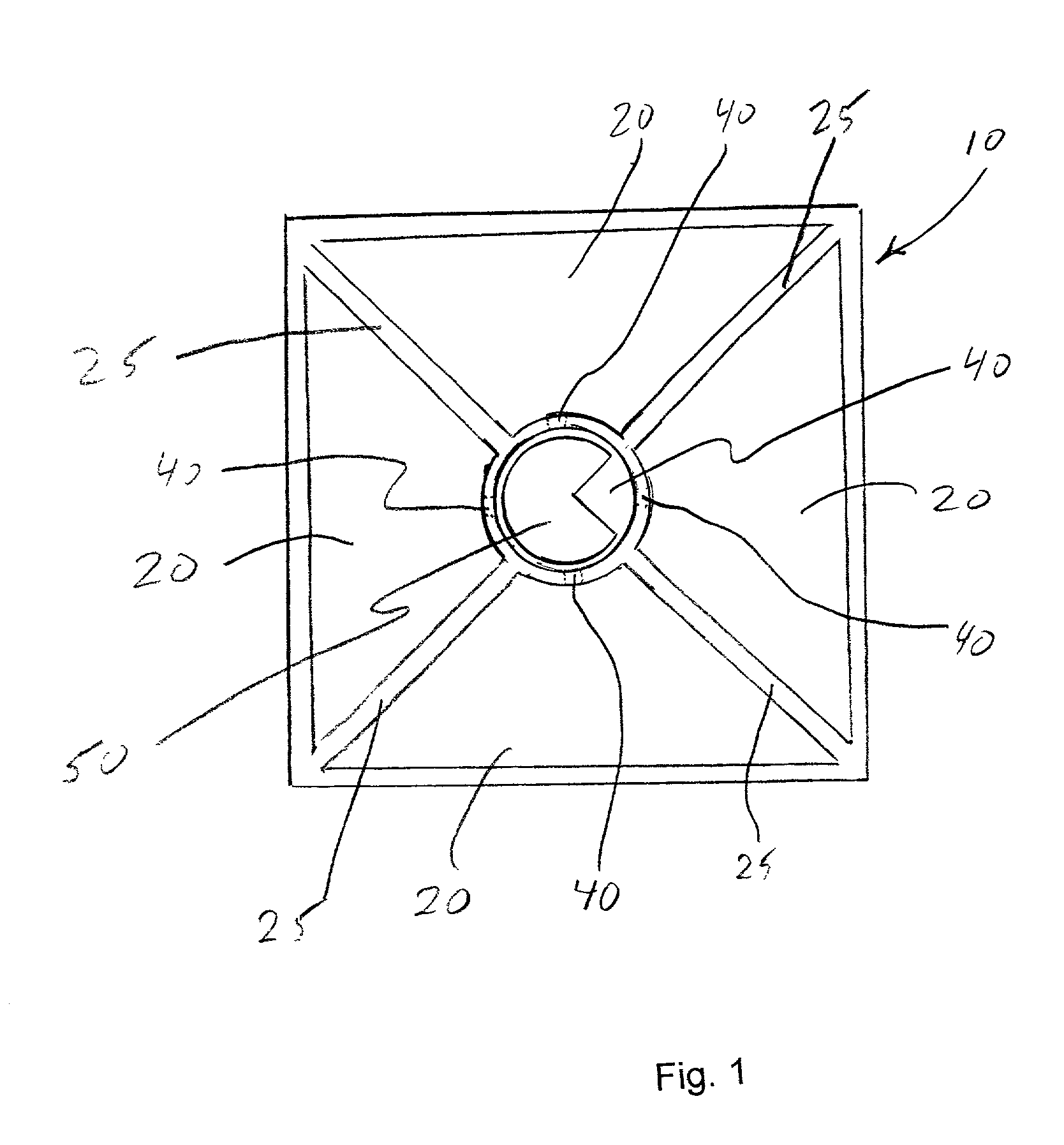

A compact blood clot filter having an alignment section that overlaps with a filter section in an axial direction is formed from a single tube without any welding points to provide high structural integrity, low profile and low manufacturing cost. The filter section has filter struts that extend radially and longitudinally from a hub. The alignment section has alignment struts in which the downstream end of each alignment strut forms a junction with the downstream end of an adjacent alignment strut while the upstream end of each alignment strut forms a junction with the upstream end of an adjacent alignment strut and with one of the filter struts to ensure symmetrical deployment of the filter struts and provide stable centering of the filter section.

Owner:ANGIODYNAMICS INC

Sock with Zones of Varying Layers

ActiveUS20120266362A1Ornamental textile articlesInsolesTwo layerElectrical and Electronics engineering

A sock with zones of varying numbers of layers is formed as a single tube on a circular knitting machine. At least one end of the tube is doubled back over a portion of the remainder of the tube to form a double layer first zone. The sock further includes a single layer zone adjacent to the double layer first zone, where no such folding occurs. Optionally, a second end of the tube may also be folded to create a third zone having two layers of material.

Owner:NIKE INC

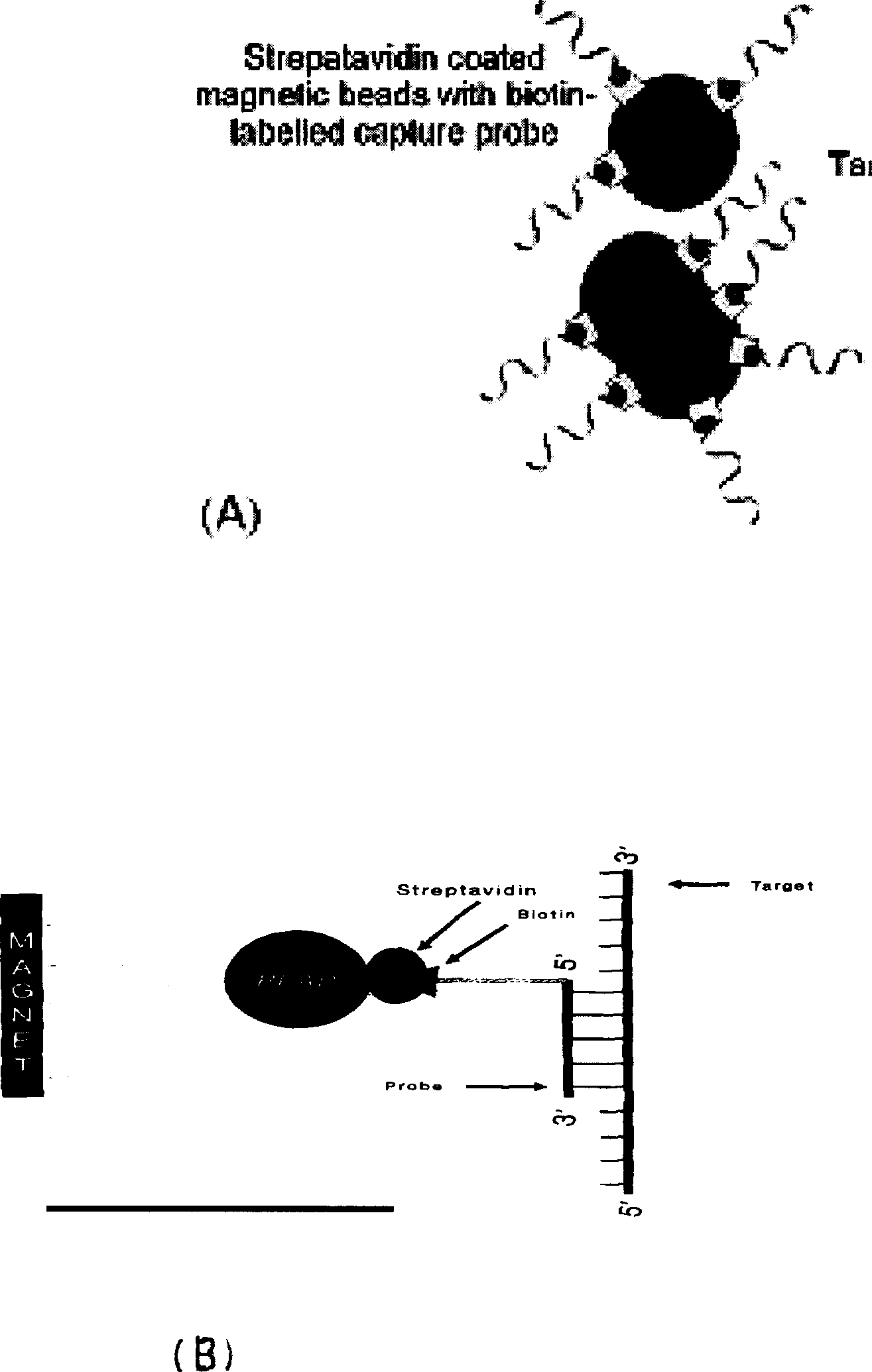

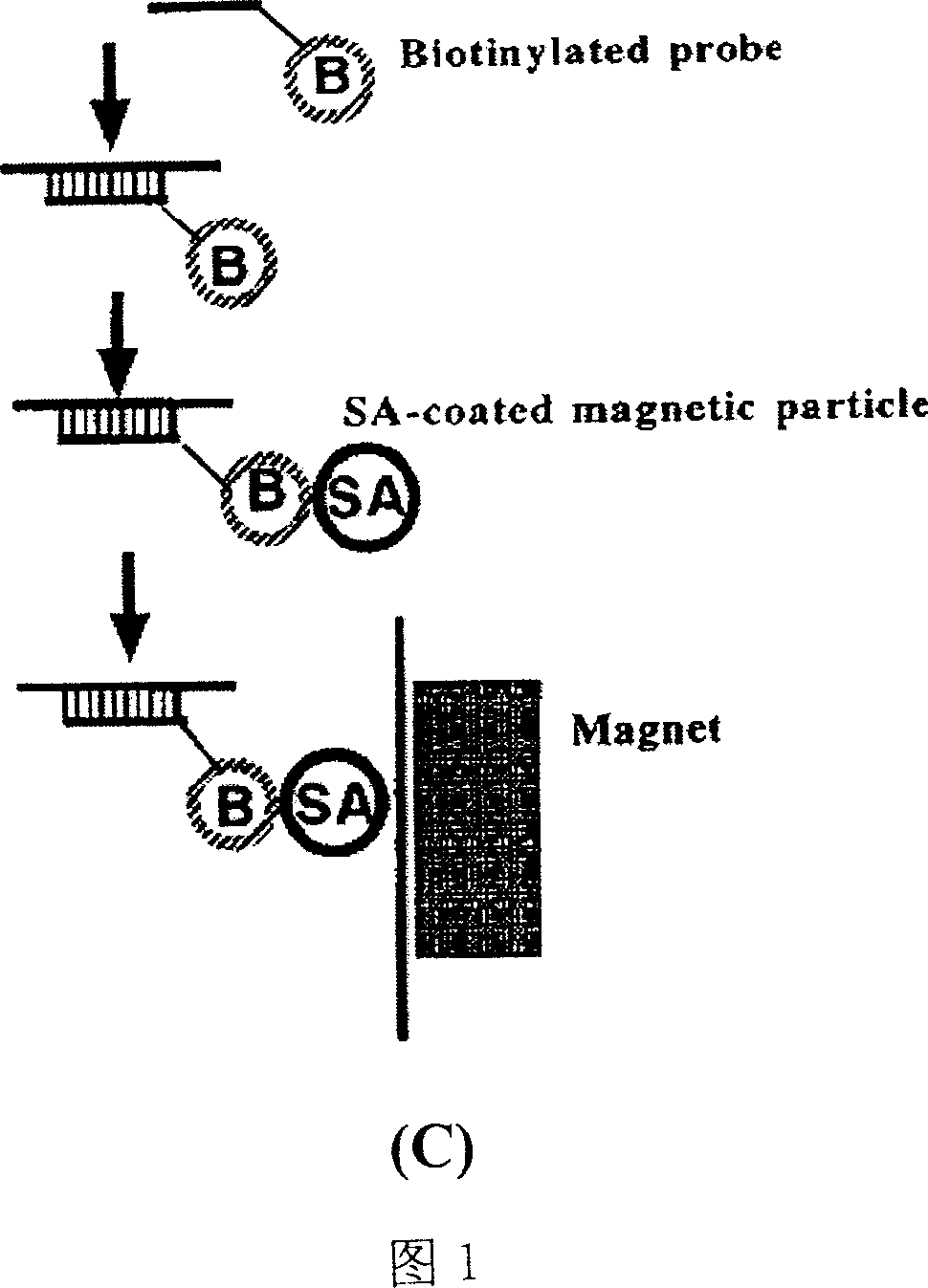

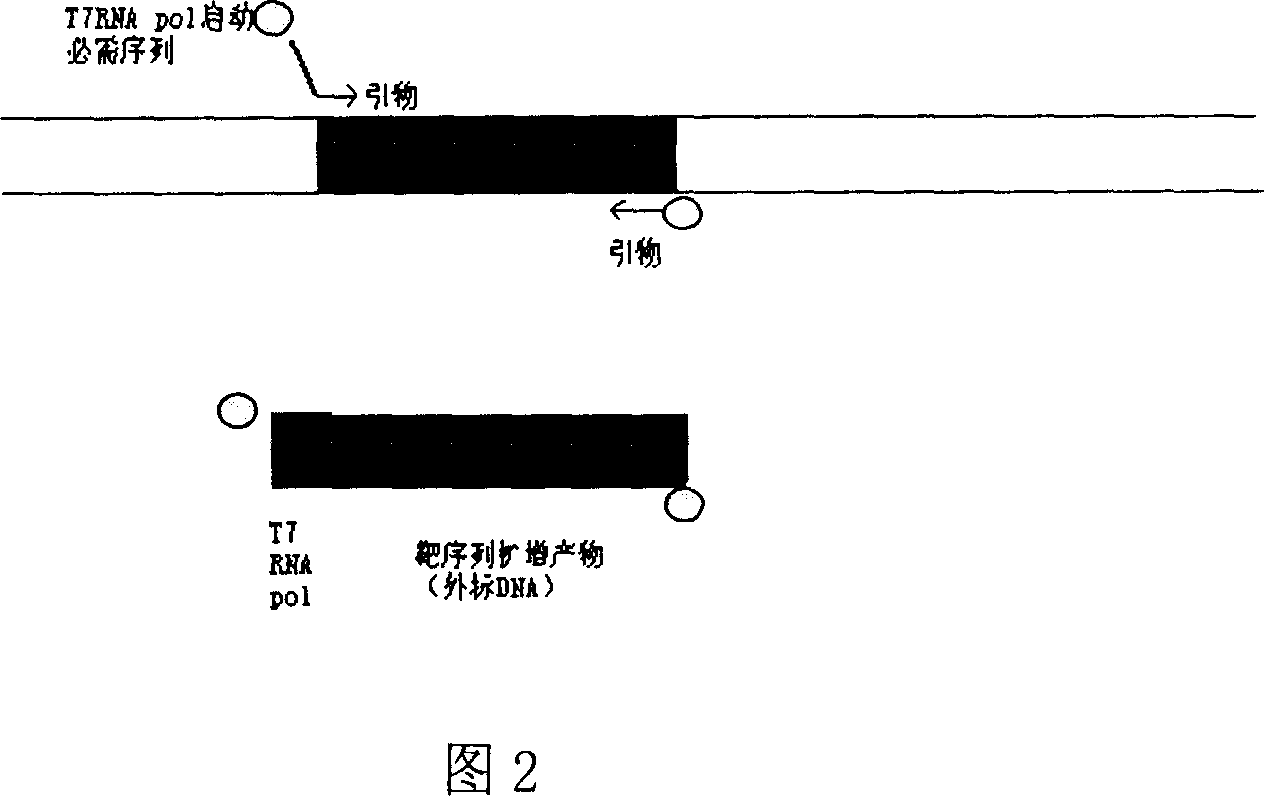

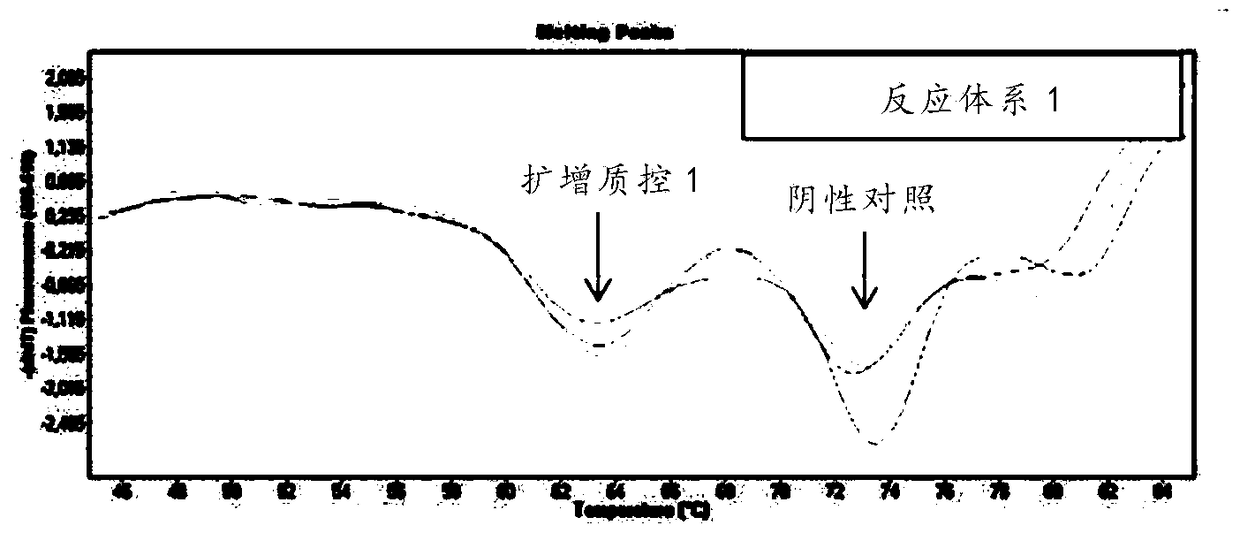

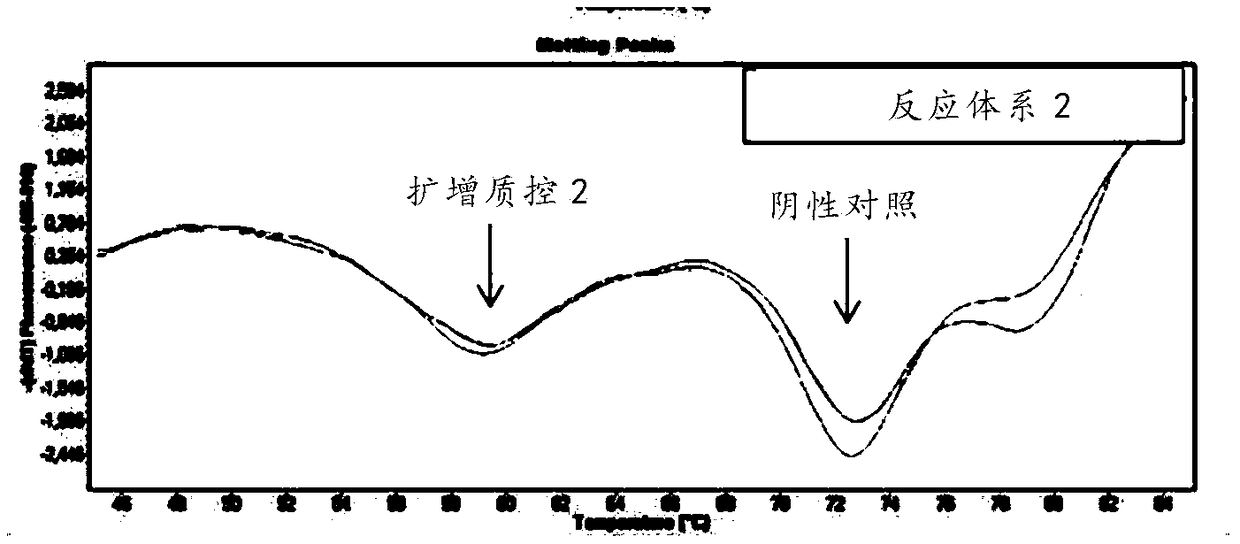

Method for inspecting hepatitis and AIDS virus nucleic acid by synchronous amplification and its reagent kit

ActiveCN1940087AHigh degree of automationHigh sensitivityMicrobiological testing/measurementMagnetic beadFluorescence

A method for inspecting hepatitis and AIDS nucleic acid by synchronized amplification and its reagent knit are disclosed. The process is carried out by taking magnetic ball as automatic medium, specific synchronized capturing HBV, CHV and HIV nucleic acid, accelerating biotin primer construction and purification by RNA external label and internal label, real-time synchronized inspecting and T-PCR amplifying based on Tagman probe. The reagent knit consists of dis-inhibitor, cracking liquid, magnetic ball suspension, washing liquor, internal check, RT-PCR reactive liquor, enzyme mixture, fluorescent mixture, positive check and negative check. It's accurate and automatic, has single-tube operation, closed inspection AND synchronized extraction, and it has better sensitivity and specific performance and can be used for large-scale blood screening and large-capacity clinical inspection.

Owner:SHANGHAI KEHUA BIO ENG

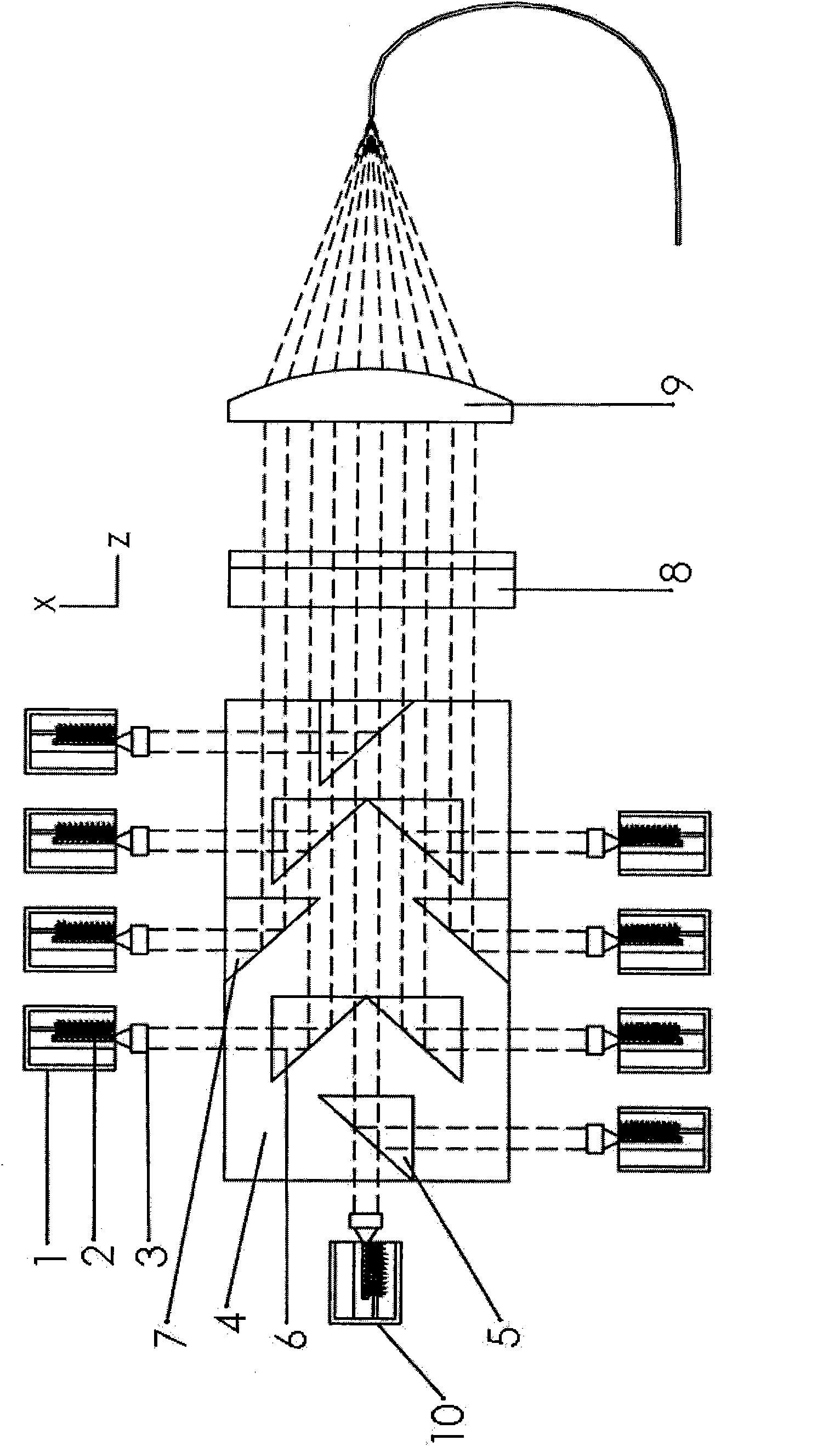

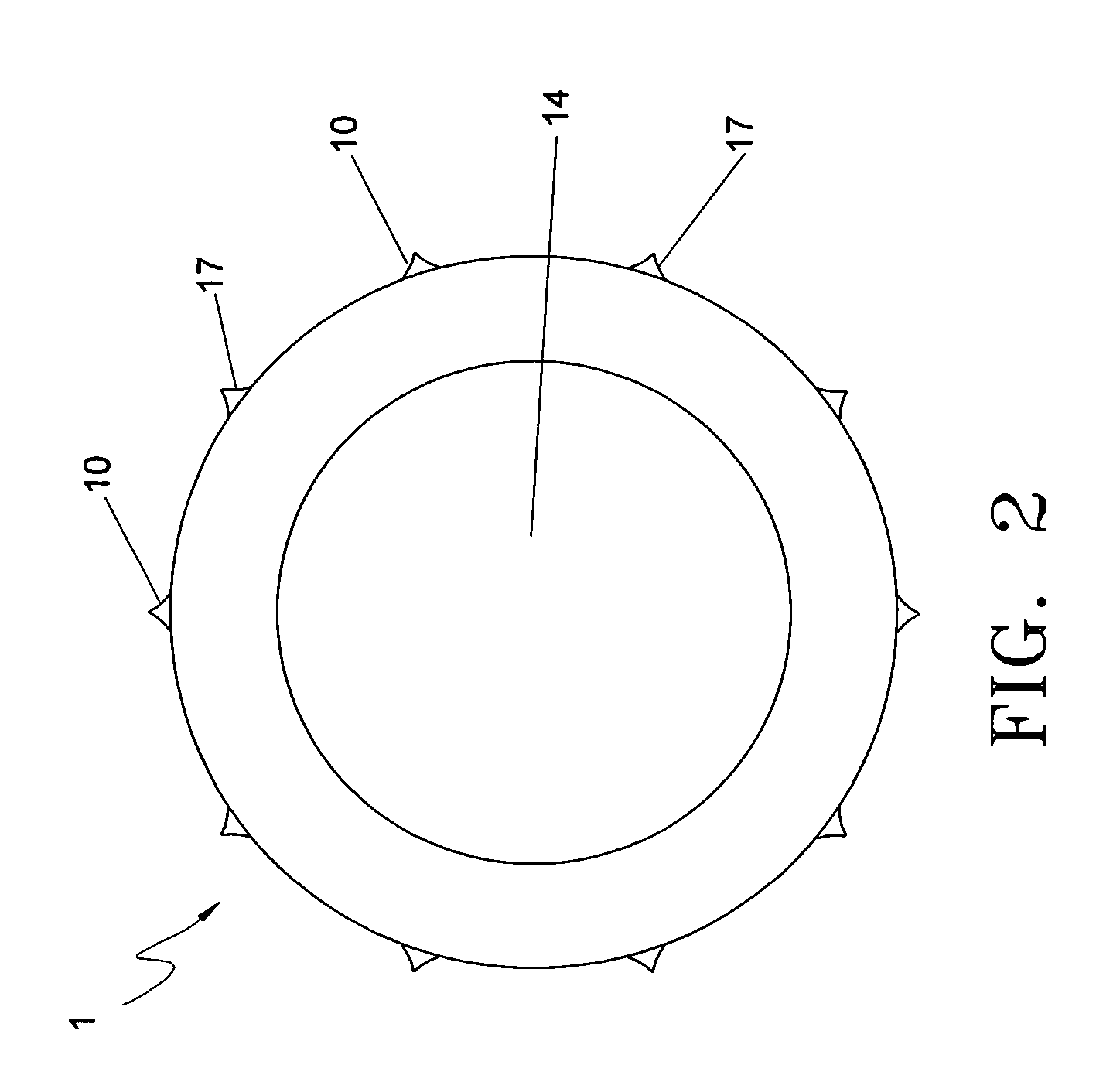

Fiber coupling module of high-power semiconductor laser

InactiveCN101833150ASolve the lack of spaceAdequate cooling spaceCoupling light guidesLight beamPrism

The invention relates to a fiber coupling module of a high-power semiconductor laser, which comprises a plurality of single-tube semiconductor lasers with the same wavelength in the same polarization state, beam collimation lenses, a glass flat plate, reflecting prisms and a focusing device, wherein expect one path of the single-tube semiconductor lasers, the other single-tube semiconductor lasers are all parallel to an axis x and arrayed in a ladder shape; the beam collimation lenses are arranged in front of each single-tube semiconductor laser, and the light emitted by each single-tube laser passes through a beam collimation lens and then passes through a reflecting prism; each reflecting prism keeps consistent with a single-tube laser corresponding to the reflecting prism on the horizontal height; the light emitted by the plurality of single-tube lasers is transmitted to the focusing device through reflecting; and beams emitted by the single-tube lasers arranged in the direction of an axis z is directly transmitted to the focusing device through gaps among the plurality of the reflecting prisms and then combined with other beams to focus together and then enter a fiber. In the invention, the distances of the welding positions of each single-tube laser become longer, and the high-power semiconductor laser fiber coupling module has easy welding, convenient debugging, good heat radiating effect and high coupling efficiency.

Owner:吉林省长光瑞思激光技术有限公司

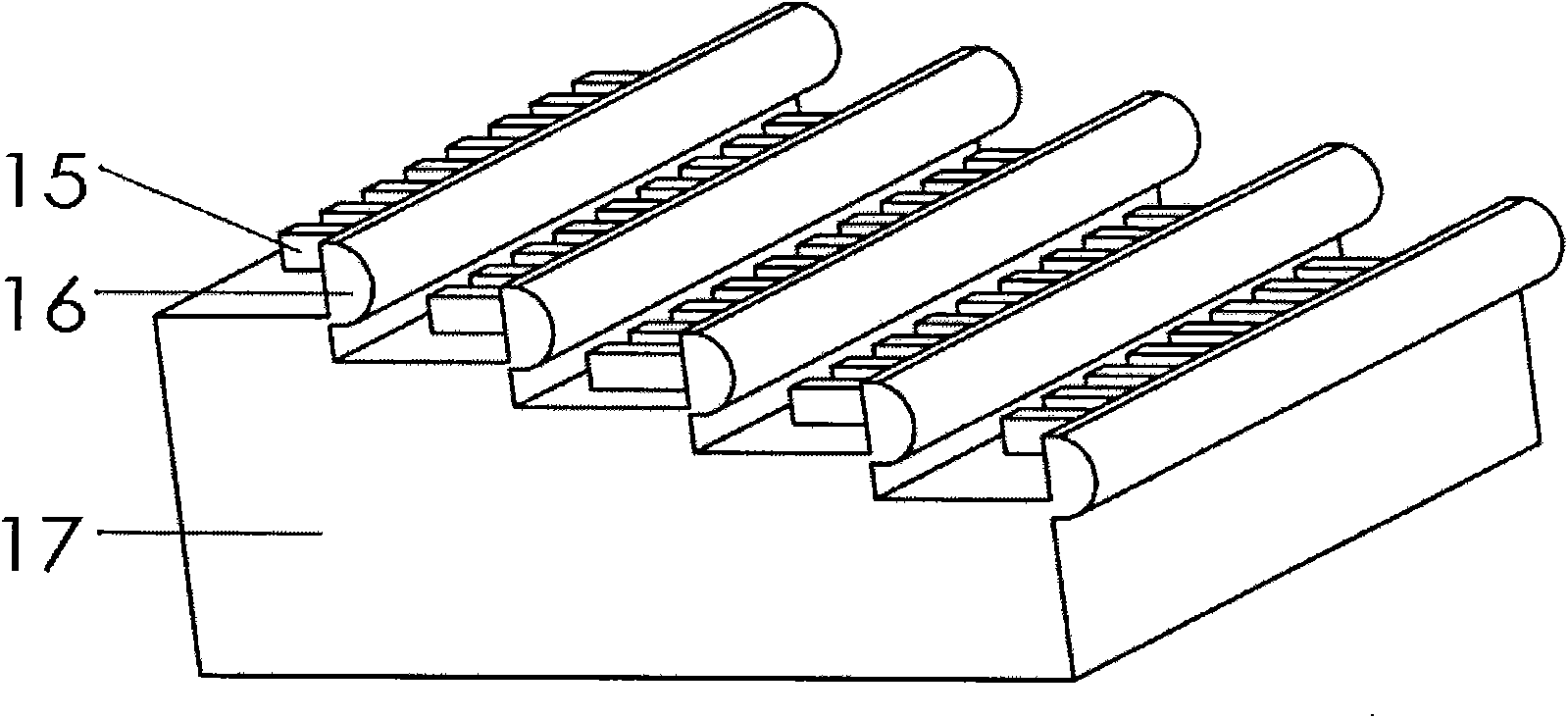

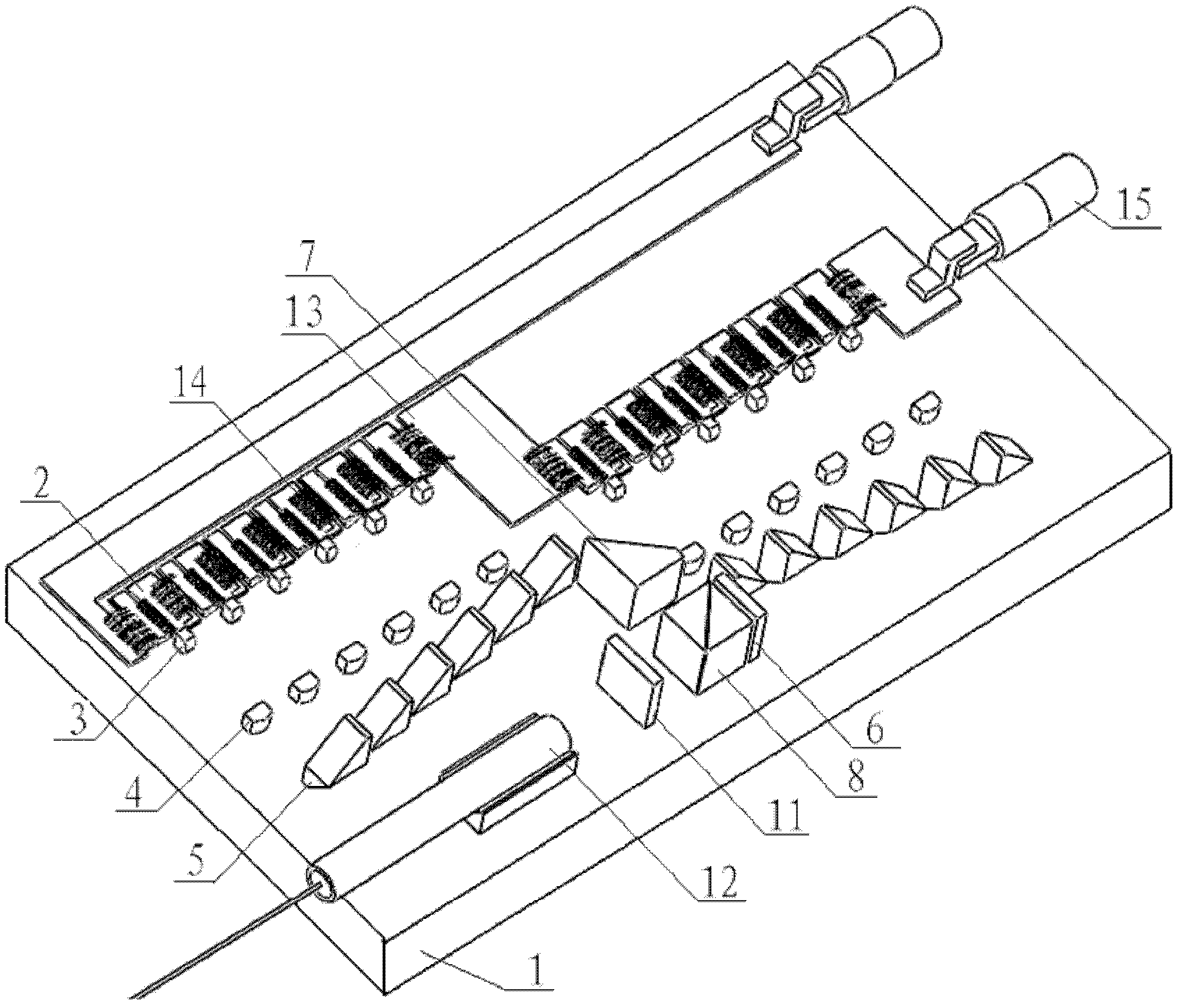

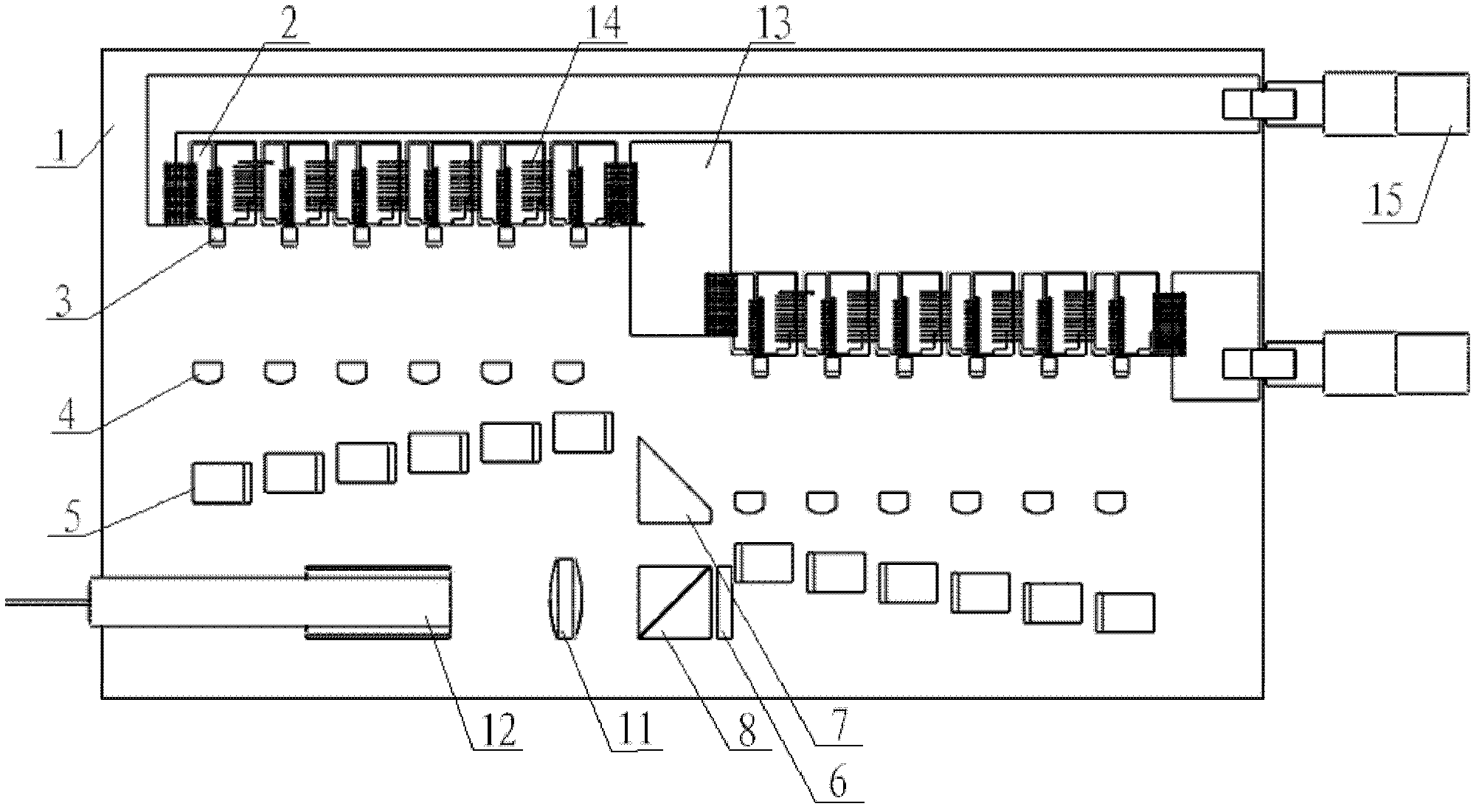

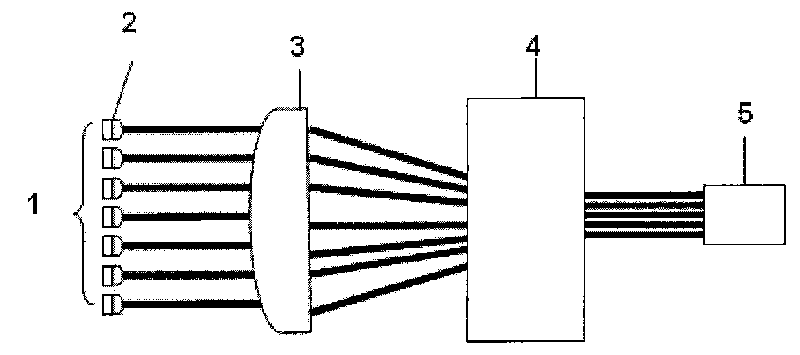

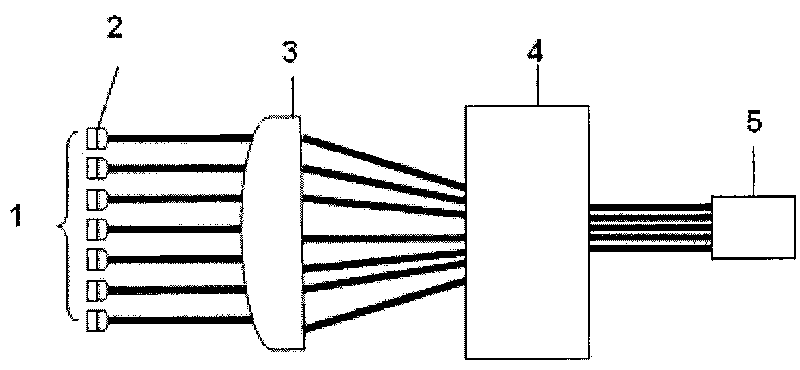

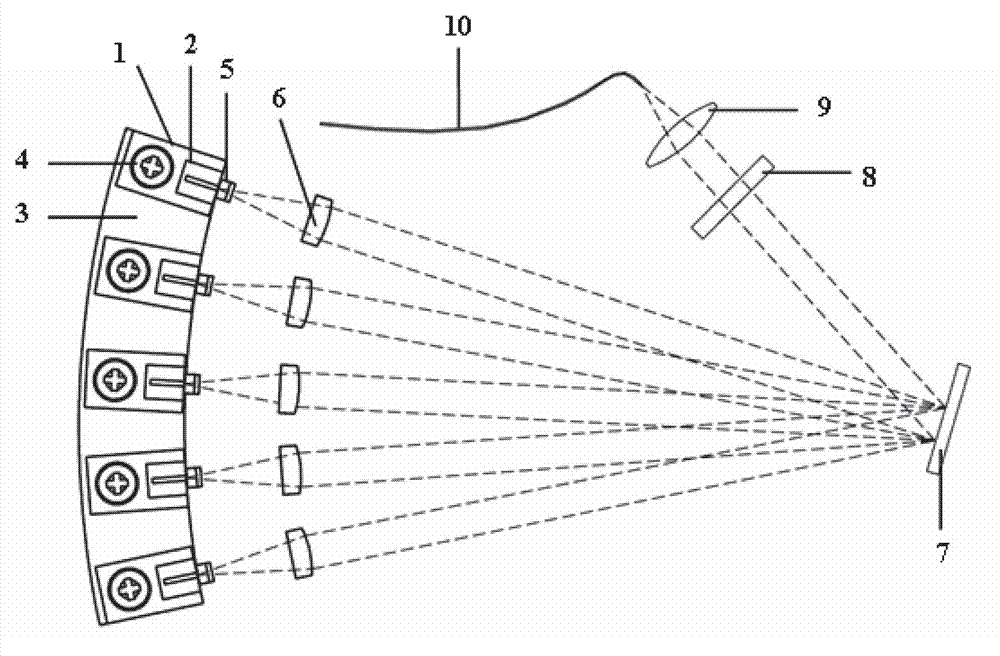

Optical fiber coupling module of platform-type turning and reflecting single-tube semiconductor laser

InactiveCN102401949ASmall light-emitting area widthImprove cooling effectSemiconductor laser arrangementsLaser arrangementsComputer moduleLight beam

The invention provides an optical fiber coupling module of a platform-type turning and reflecting single-tube semiconductor laser and belongs to the technical field of laser; the optical fiber coupling module comprises a bearing platform (1), a plurality of groups of single-tube semiconductor lasers (2), a plurality of fast axis collimators (3), a plurality of slow axis collimators (4), a plurality of turning and reflecting prisms (5), an ordinary reflecting prism (7), a beam-combining prism (8), and fast / slow axis focusing lens combinations (9) and (10) and an optical fiber coupling head (12); each group of the single-tube semiconductor lasers comprises a plurality of the single-tube semiconductor lasers; each single-tube semiconductor laser corresponds to one fast axis collimator, one slow axis collimator and one turning and reflecting prism; all the optical devices are laid on the bearing platform without steps and pedestals; the light-emitting positions of the single-tube semiconductor lasers are located at the same height; the light beams emitted by the single-tube semiconductor lasers are subjected to the collimation, turning and reflection, beam-combination and focusing processes through the optical devices and finally are coupled to the optical fiber coupling head.

Owner:BEIJING UNIV OF TECH

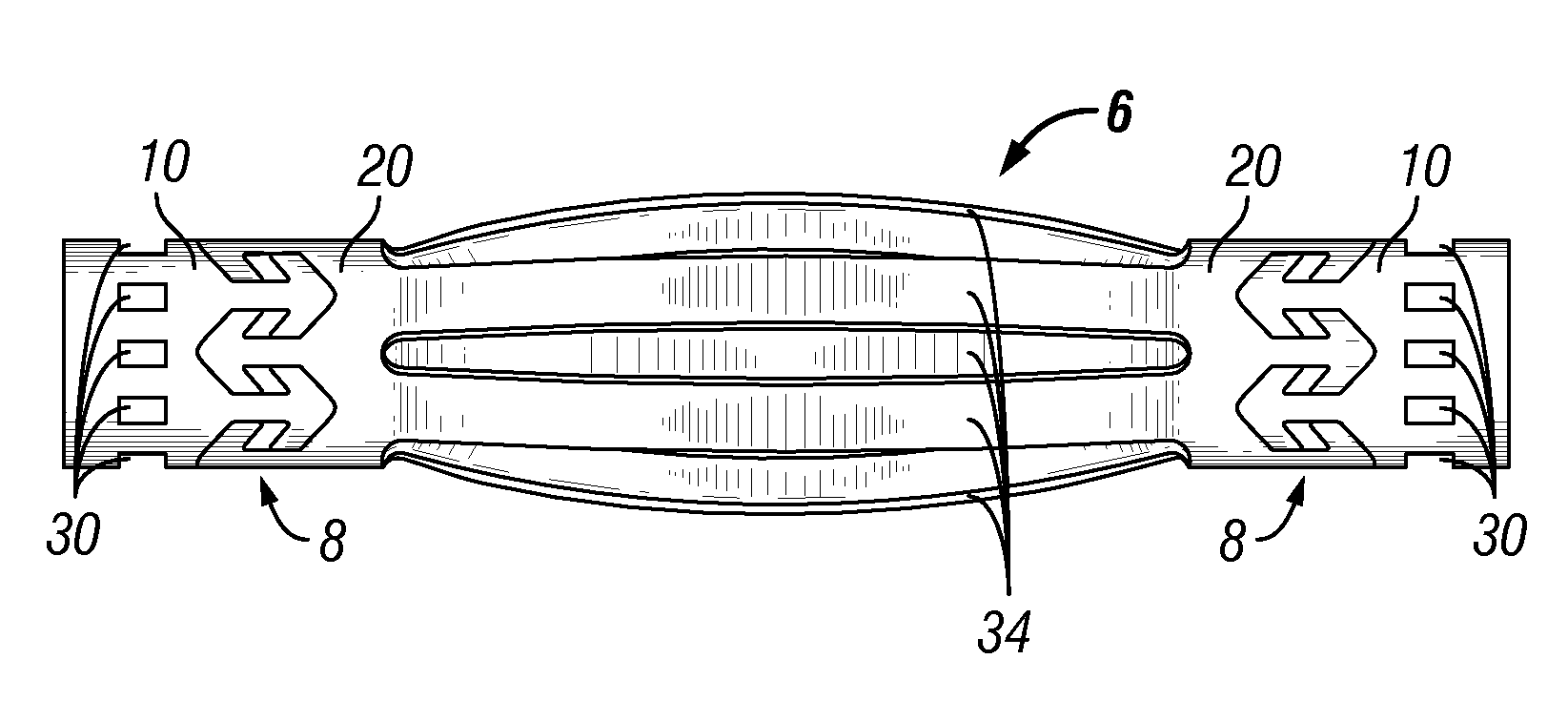

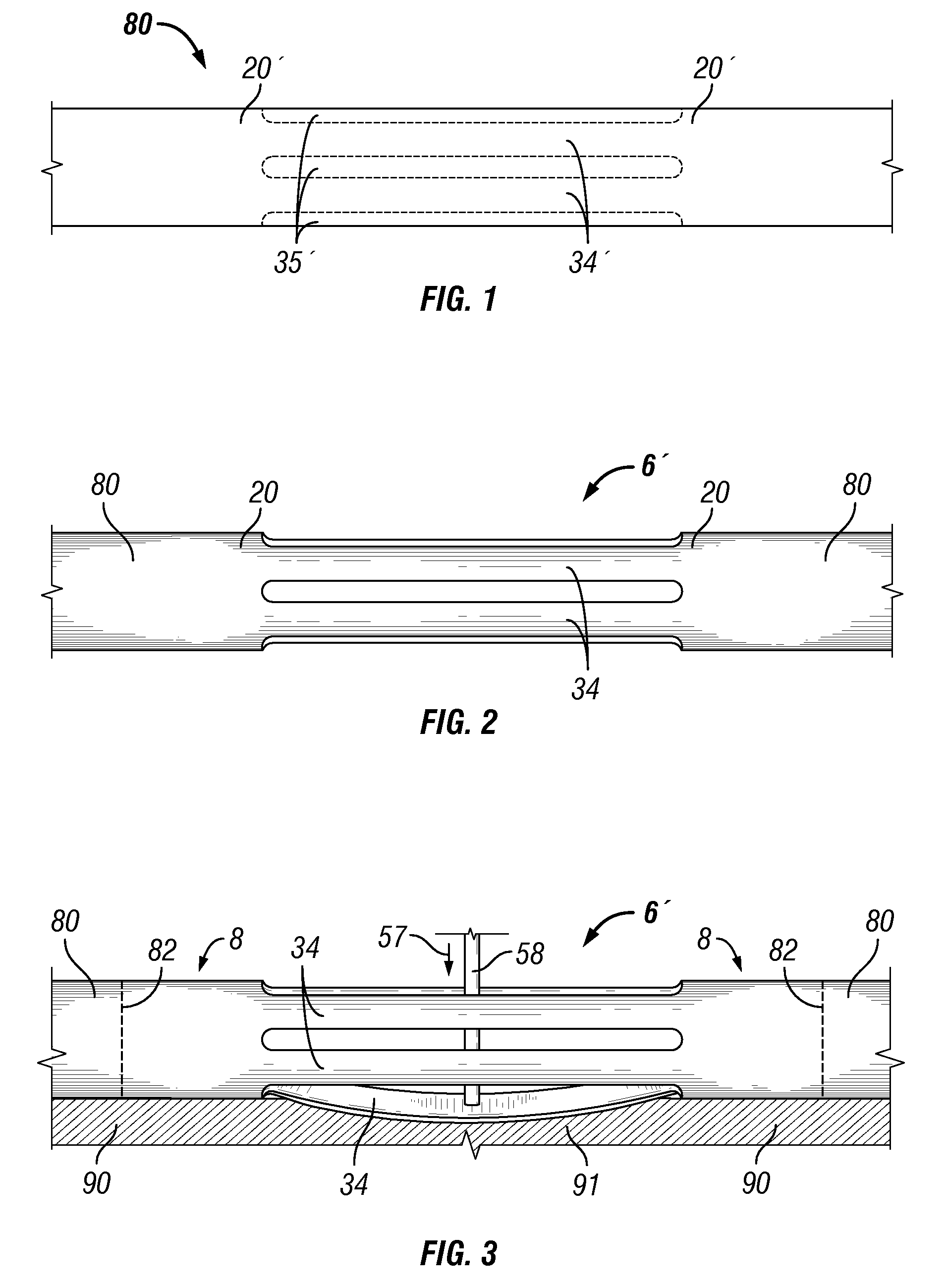

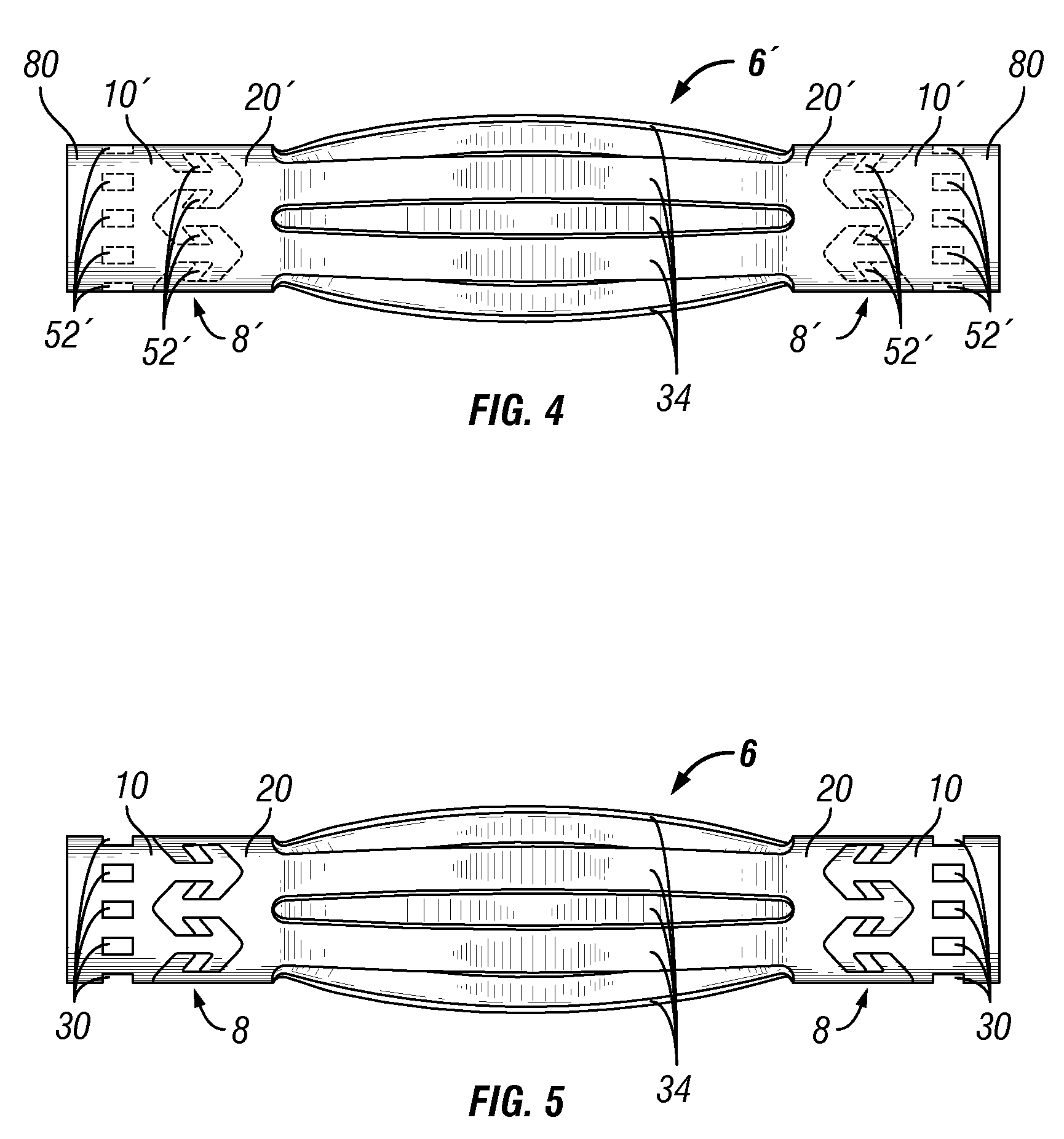

Low Clearance Centralizer and Method of Making Centralizer

ActiveUS20080283237A1Efficient preparationDrilling rodsFluid removalShaft collarMechanical engineering

A bow-spring centralizer includes a center assembly having a plurality of bow springs and a pair of generally tubular moving collars secured one to each end of each bow spring, the center assembly formed intermediate a pair of generally tubular stop collars. Each moving collar / stop collar combination forms an interlocking and axially extendable collar. The centralizer is formed from a single tube. The tube is cut using a laser according to a cut pattern that creates interlocked stop collar / moving collar combinations that are rotatably locked but axially movable one relative to the other. Each of the interlocked stop collars and moving collars includes a plurality of circumferentially spaced heads, each head integrally formed on one of a plurality of circumferentially spaced extensions protruding from the stop collar or moving collar. The heads may have a variety of projected shapes, such as a rectangular, arrow or a teardrop shaped. Each head is axially slidably captured within one of a plurality of chambers on the other tubular member (stop collar or moving collar) to which the first member is coupled. The extensions of each interlocked tubular member define the outer walls of the chamber in which a head of the opposing tubular member is slidably captured.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Blood clot filter

InactiveUS7722635B2Be at easeImproves Structural IntegritySurgeryDilatorsEngineeringStructural integrity

A compact blood clot filter having an alignment section that overlaps with a filter section in an axial direction is formed from a single tube without any welding points to provide high structural integrity, low profile and low manufacturing cost. The filter section has filter struts that extend radially and longitudinally from a hub. The alignment section has alignment struts in which the downstream end of each alignment strut forms a junction with the downstream end of an adjacent alignment strut while the upstream end of each alignment strut forms a junction with the upstream end of an adjacent alignment strut and with one of the filter struts to ensure symmetrical deployment of the filter struts and provide stable centering of the filter section.

Owner:ANGIODYNAMICS INC

Multi-single pipe light beam coupling type high-power semiconductor laser

InactiveCN101707326AAvoid pitfalls that reduce overall efficiencyEasy to processSemiconductor laser arrangementsLaser output parameters controlHigh power lasersCoupling

The invention relates to a high-power semiconductor laser, in particular to a multi-single pipe light beam coupling type high-power semiconductor laser. A plurality of single pipe semiconductor lasers, the emitting ends of which are provided with fast axis collimation cylindrical lenses, are arranged in parallel in the same direction; a cylindrical lens, a slow axis collimation lens perpendicular to a normal line of the cylindrical lens, and an optical fiber for receiving a focused light beam are sequentially arranged along the optical path transmission direction of the single pipe semiconductor lasers; the cylindrical lens further compresses the light beam fast axis of each single pipe semiconductor laser, and the slow axis collimation lens collimates the slow axis and focuses light beams; and finally, the light beams are output after focused and coupled into the optical fiber. The laser has simple structure and easy processing of elements, overcomes the defects existing in the prior art for manufacturing the high-power laser and is easy to realize higher power and luminance output.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

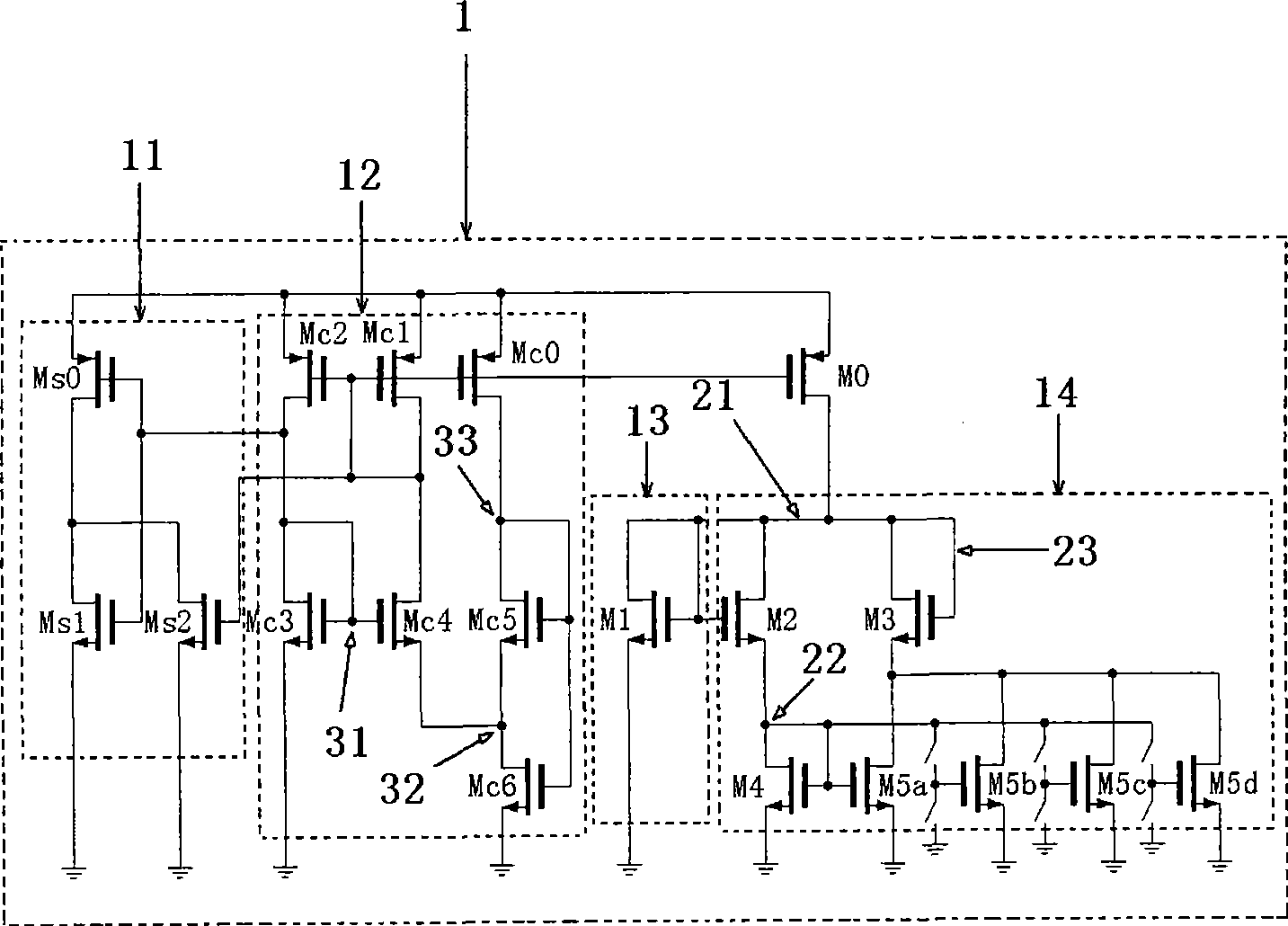

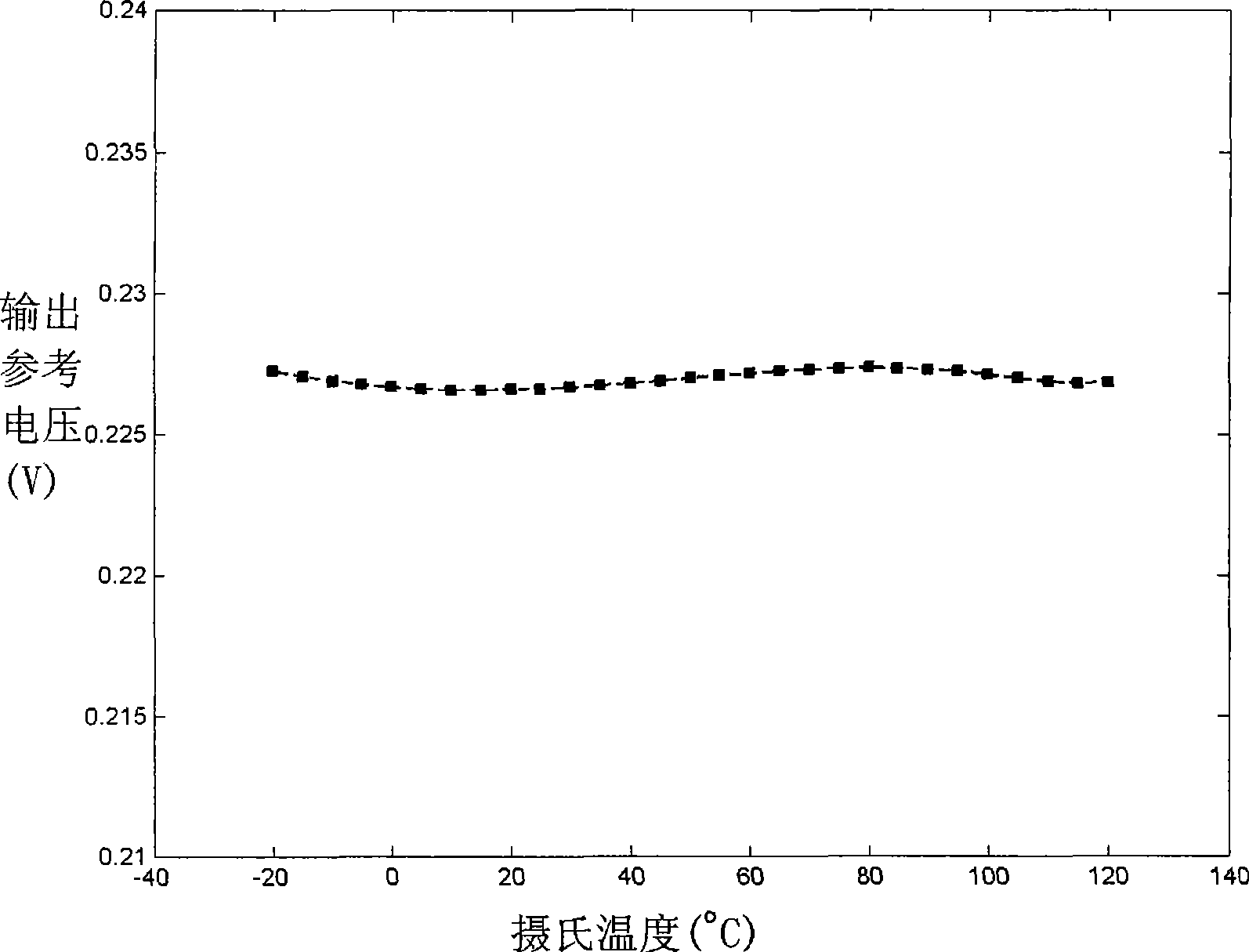

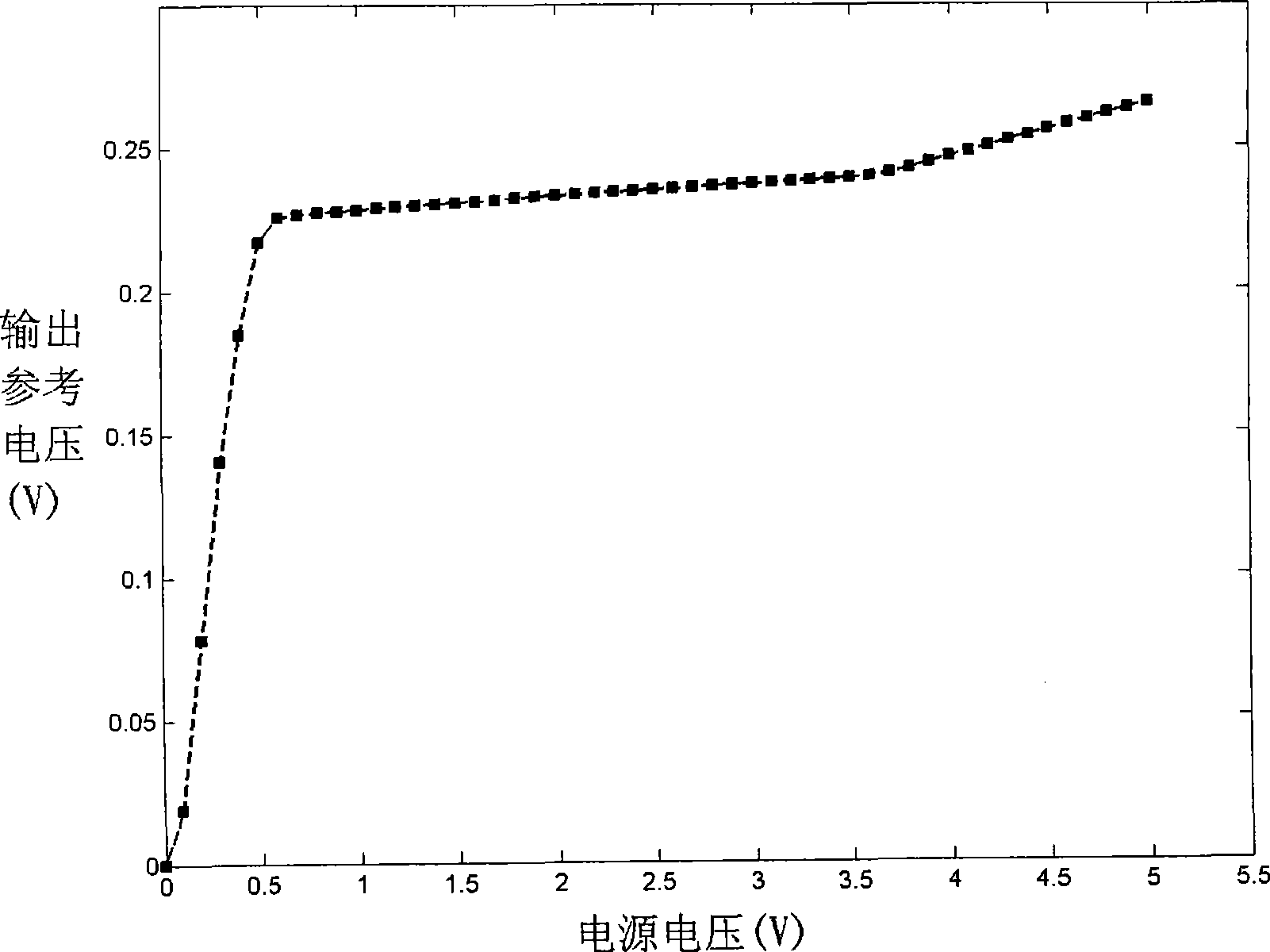

Low-voltage low-power consumption CMOS voltage reference circuit

ActiveCN101470459AReduce power supply voltageReduce voltageElectric variable regulationCapacitanceLow voltage

The invention discloses a low-voltage low-power-consumption CMOS voltage reference circuit, which is used for generating a voltage reference. The CMOS voltage reference circuit comprises a starting circuit 11, a self-bias current source 12, a voltage generator 13 with negative temperature coefficient, a voltage reference regulator 14 and a single-tube current mirror MOS transistor M0. The CMOS voltage reference circuit adopts an MOS transistor operating at a sub-threshold area to generate a voltage with negative temperature coefficient, utilizes a sleeve and a folded structure of the MOS transistor operating at the sub-threshold area to substitute a resistance for amplifying a voltage with positive temperature coefficient, thereby offsetting the voltage with positive temperature coefficient by the voltage with negative temperature coefficient, and generating a temperature-independent voltage reference. The CMOS voltage reference circuit eliminates the use of passive devices and an operation amplifier, wherein the passive devices relate to a resistance, a capacitor and the like, thereby greatly reducing the component number of the circuit and the static operating current, and reducing the power consumption and the area of the circuit.

Owner:SOI MICRO CO LTD

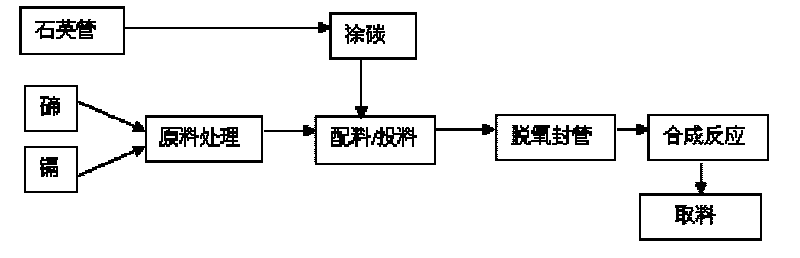

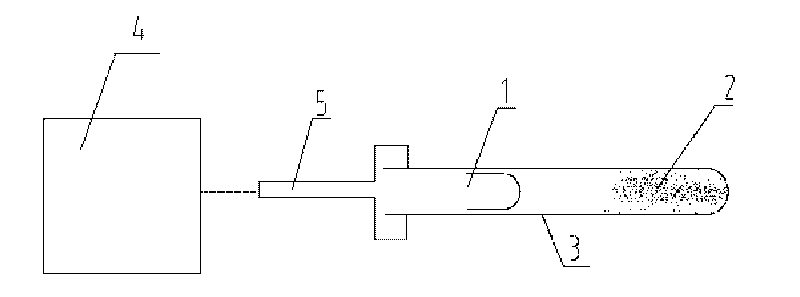

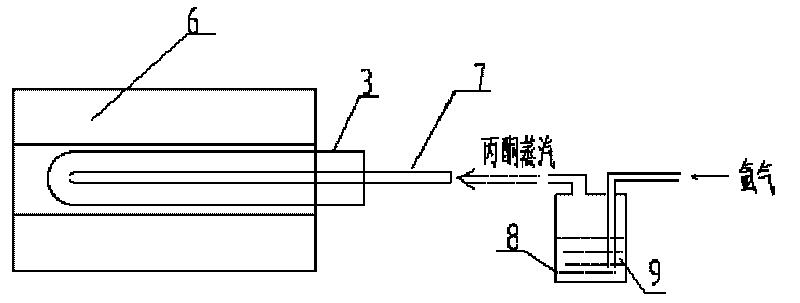

Method for preparing high-purity cadmium telluride

ActiveCN101734630AAvoid direct contactEvenly meltedBinary selenium/tellurium compoundsMolten stateMass ratio

The invention discloses a method for preparing high-purity cadmium telluride. The reaction process is carried out in a closed quartz tube with melting point above cadmium and tellurium and after carbon coating treatment, wherein the mass ratio of a 5N cadmium material to a 5N tellurium material is 1: 1.1-1.15. The method comprises the following steps: dividing the weighed tellurium material into N parts according to the charging times N, dividing the weighed cadmium material into N-1 parts, alternately adding each part of tellurium material and each part of cadmium material into the quartz tube and adding the tellurium material into the quartz tube firstly and lastly, removing oxygen after charging, sintering and sealing the tube by using a sealed bulb, and slowly performing high-temperature and high-pressure synthetic reaction. The method has the advantages that the contact area of the raw materials is larger in a molten state, the reaction speed is more sufficient compared with the solid raw material, the micro-sized crushing treatment for the raw materials is avoided, the shape requirement of the raw materials is relaxed, the preparation cost is greatly reduced, the purity of the raw material is ensured, the method is suitable for large-scale production, the synthetic conversion rate of the cadmium telluride can reach 98 to 99.5 percent, and the single-tube yield of 800 to 1,000 grams can be ensured by using the quartz tube with the inside diameter of 32 millimeters under the premise of safety.

Owner:中国东方电气集团有限公司

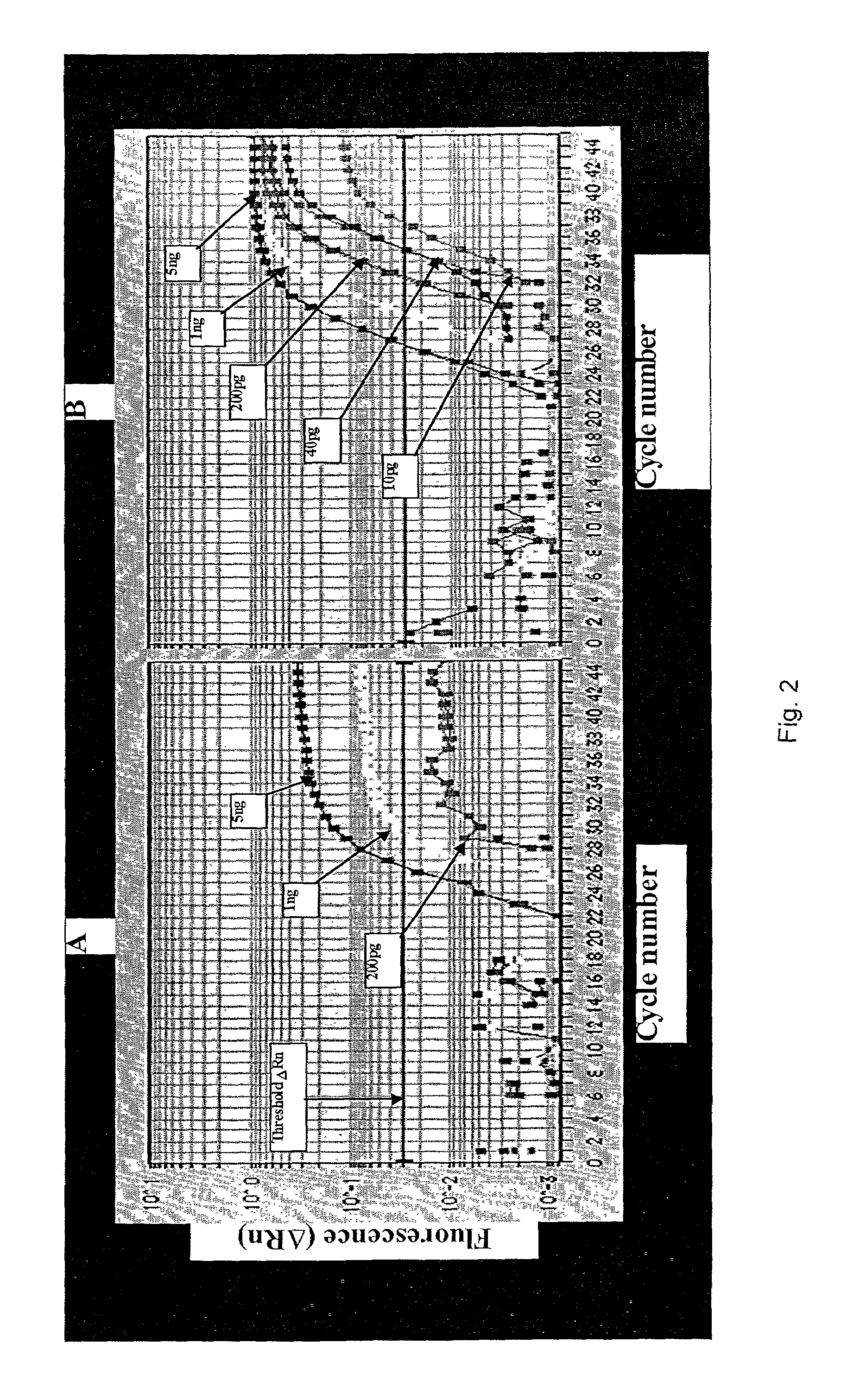

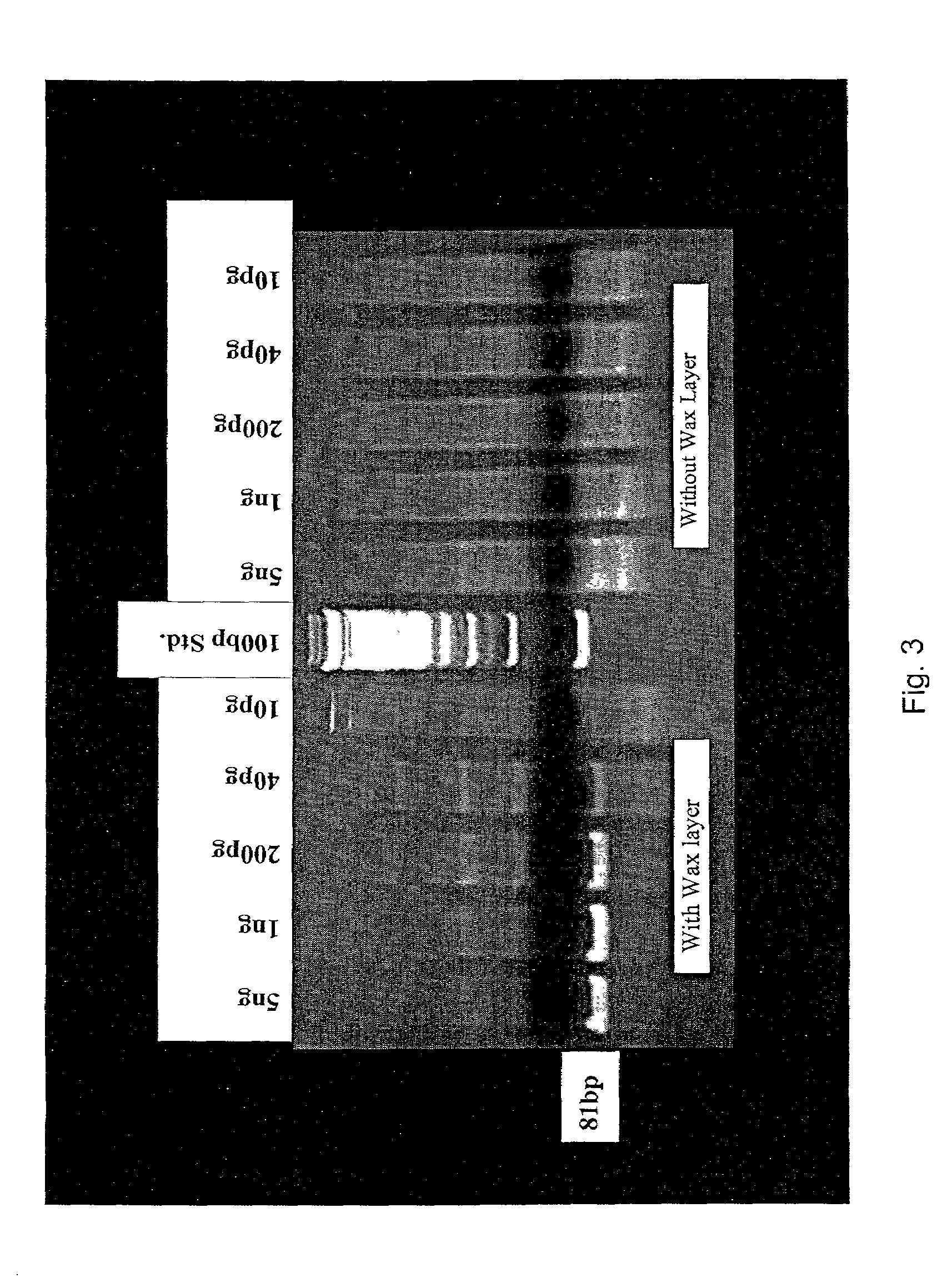

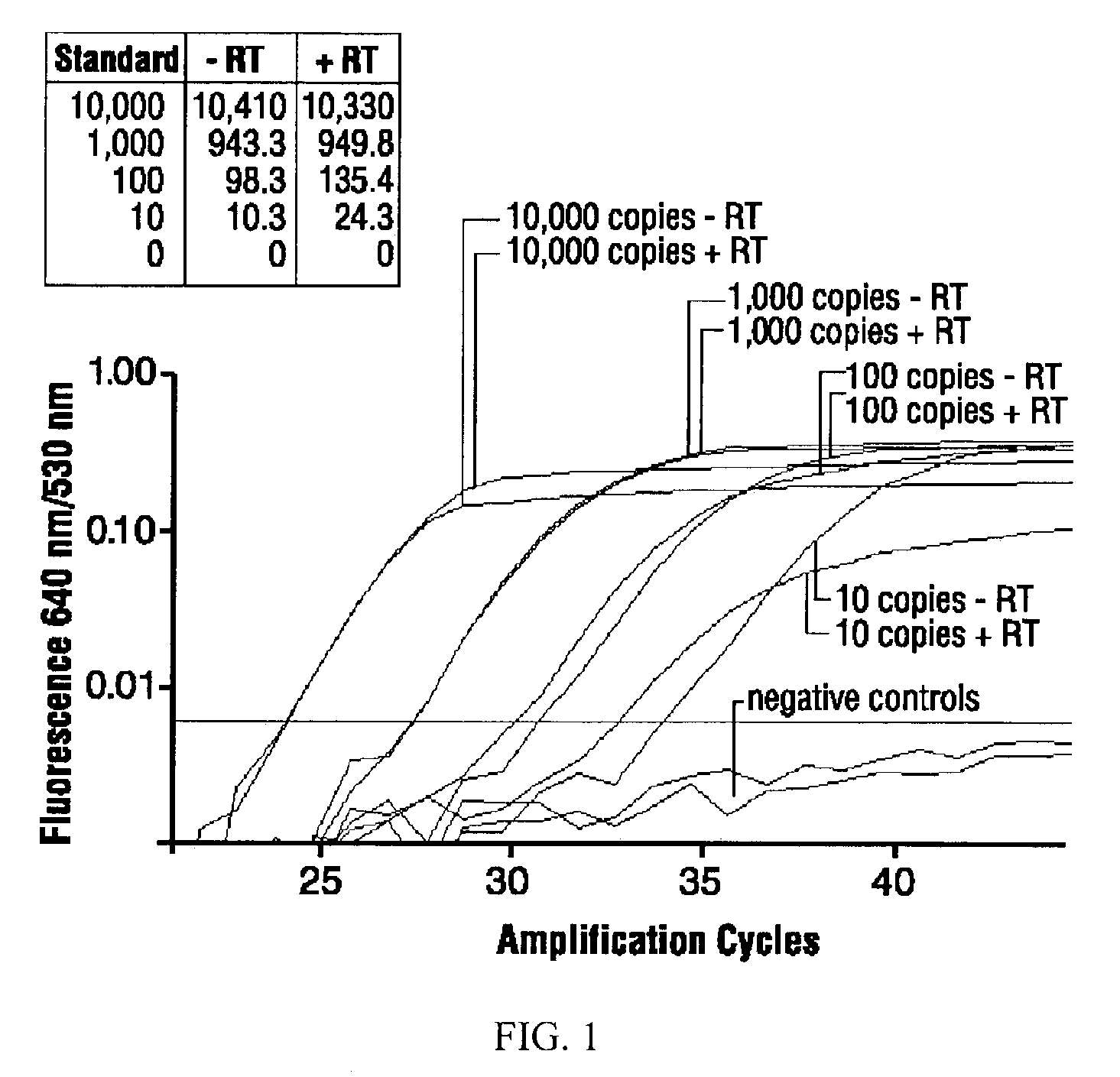

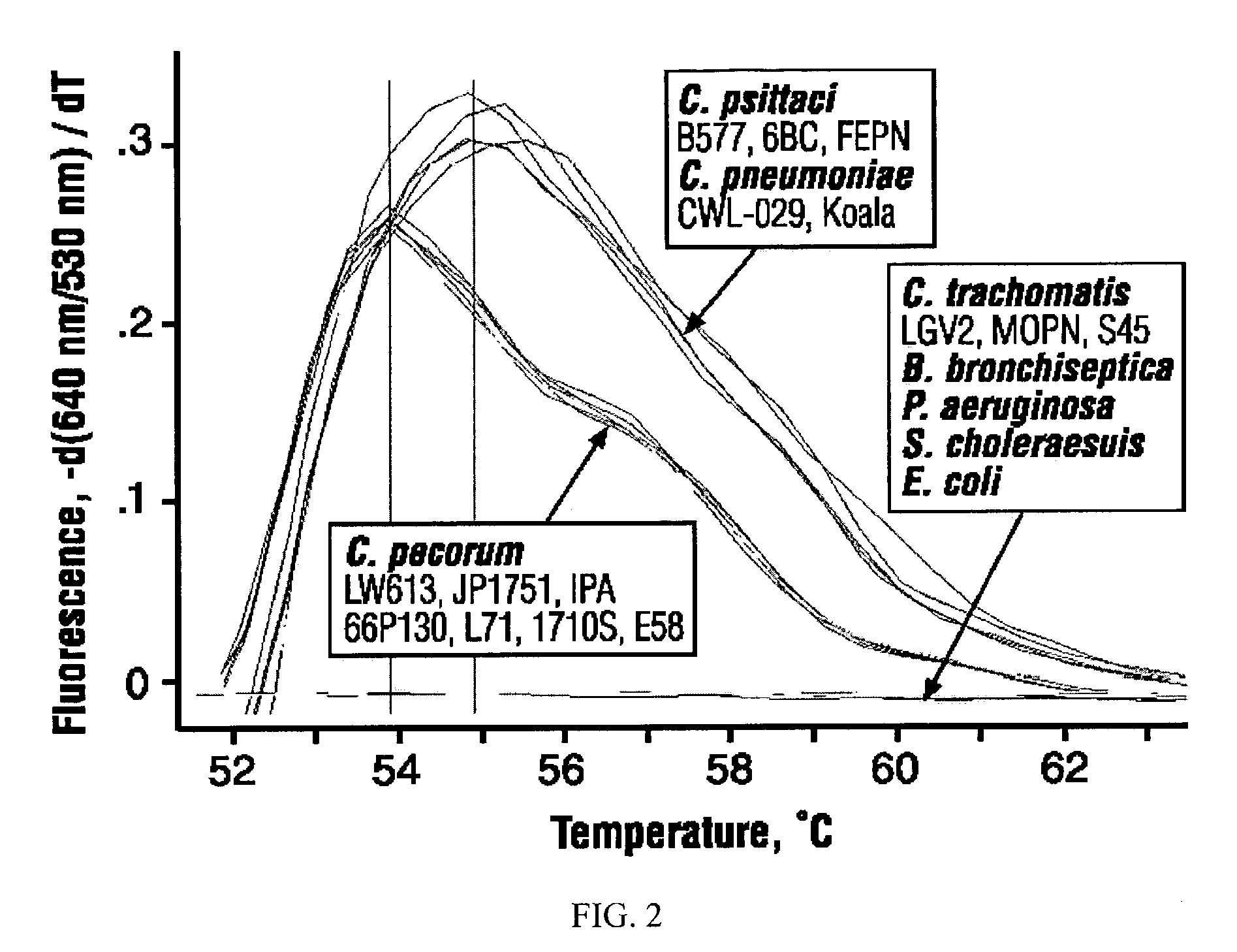

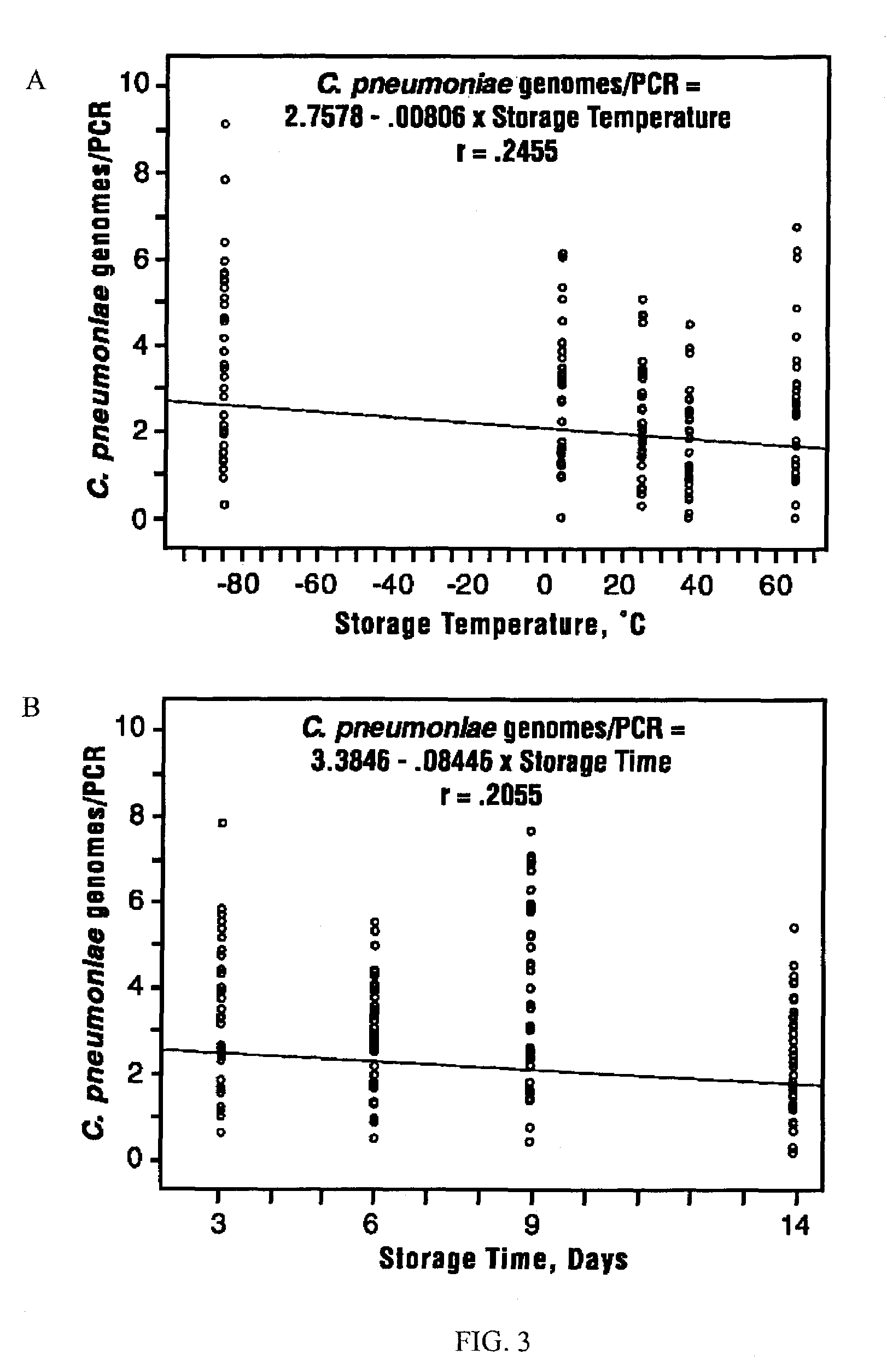

High-sensitivity real-time polymerase chain reaction for detection of nucleic acids

InactiveUS7252937B2Easy extractionImprove stabilitySugar derivativesMicrobiological testing/measurementClinical settingsHybridization probe

The invention features methods that are capable of detecting single target molecules in a sample input volume of, e.g., 5 μl, and of quantifying organismal, e.g., chiamydial, DNA. Desirably, these methods employ a single tube format coupled with fluorescent detection of amplicons. This approach facilitates the application of quantitative PCR (qPCR) to microbiological diagnosis in clinical settings. The invention also features primers and probes for the detection of Chlamydia. The use of specific hybridization probes with qPCR amplification provides the ability for identification of individual species or strains of microorganisms.

Owner:AUBURN UNIV

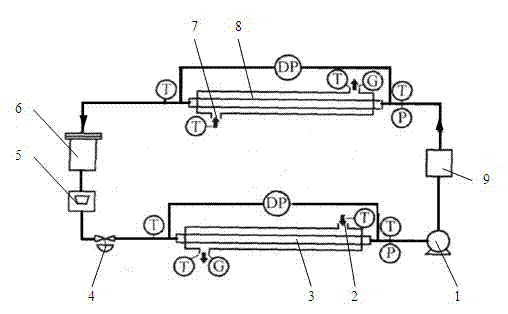

Method and device for predicting node temperature of shell and tube heat exchanger

InactiveCN102261968AEasy to installIncrease flexibilityTemperature measurement of flowing materialsShell and tube heat exchangerEngineering

The invention belongs to the technical field of heat transfer and discloses a method and a device for predicting the node temperature of a shell and tube heat exchanger. The invention relates to a single-tube heat exchange tube testing device; based on the device, the heat transfer characteristics of a single heat exchange tube can be acquired; and the node temperature of tube pass and shell passfluid of the shell and tube heat exchanger can be determined by matching the method for predicting the node temperature of the shell and tube heat exchanger. The method mainly comprises the followingsteps of: determining the length of a tested heat exchange tube section according to a space between baffles in the heat exchanger, determining a cylinder section number needed by constructing a shell pass cylinder, processing a heat exchange tube sealing plate, welding a tube flange, and assembling a testing device; determining testing parameters according to tube pass and shell pass inlet / outlet temperatures of the heat exchanger, testing the heat transfer performance of the heat exchange tube section, and establishing a mapping relationship between single tube inlet / outlet temperatures andupstream and downstream fluid temperatures outside the tube; and starting a computer program, inputting design data of the heat exchanger, executing an analysis command, and outputting a temperature value of each node inside the heat exchanger after the analysis is ended.

Owner:NANJING UNIV OF TECH

Shock absorber staged valving system

InactiveUS20050056507A1Dampen an automobile vehicle ride deflectionSpringsShock absorbersPistonValve opening

A shock absorber piston assembly includes a shock absorber piston having a first face and an opposed second face. A plurality of fluid passages extend between the first face and the second face. A plurality of valves attach to the piston, including: at least two rebound valves, each connectable to one of the fluid passages, and at least two compression valves, each connectable to one of the fluid passages. Each of the valves actuates at one of a plurality of valve opening pressures individually adjustable for each valve. The shock absorber piston assembly can be used in either a monotube or a dual tube shock absorber.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

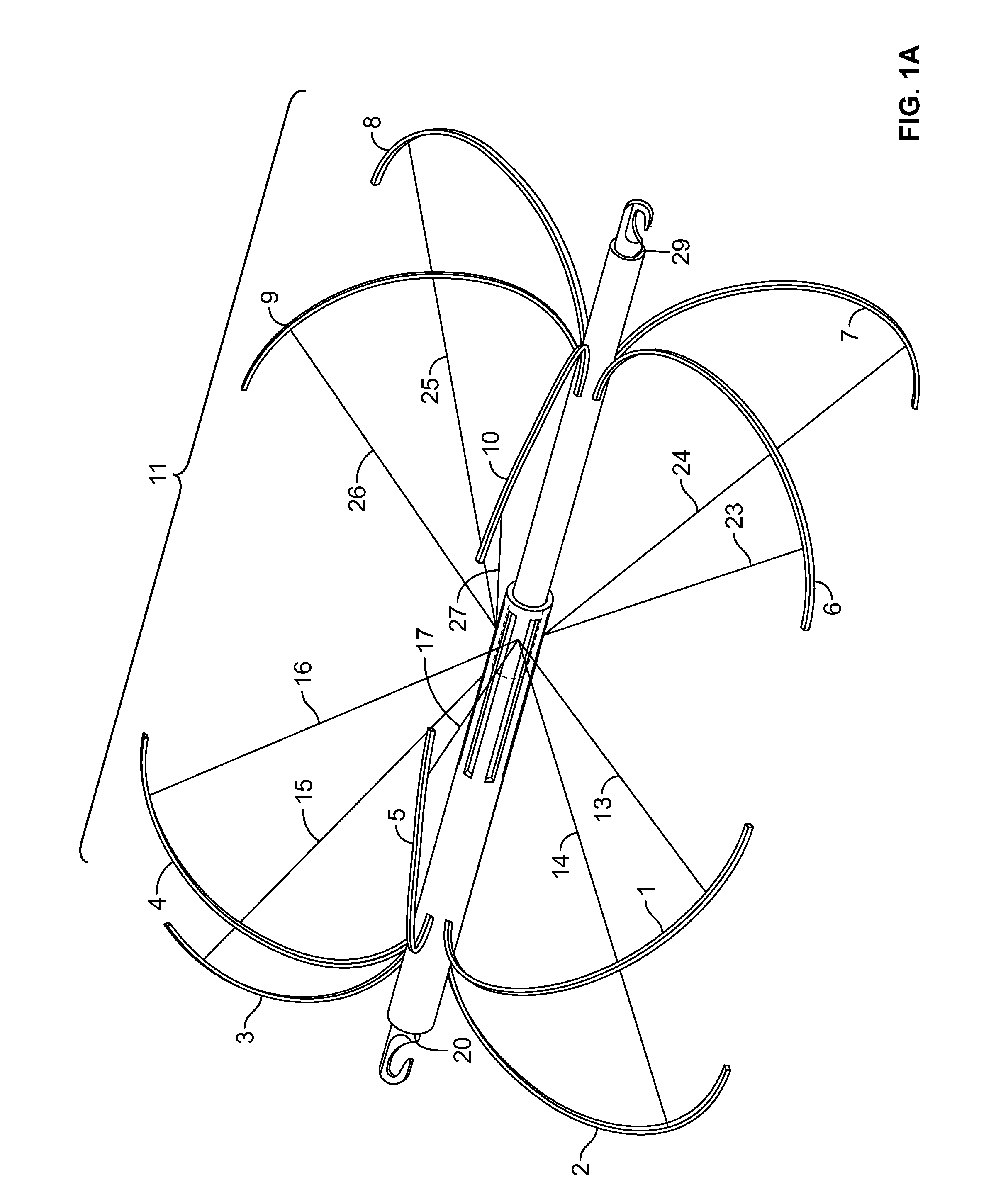

Percutaneous Retrievable Vascular Filter

Retrievable vena cava filters for the temporary or permanent prevention of Pulmonary embolism (PE) are disclosed. A filter in accordance with the present invention has a tube-within-tube structure with overlapping semi-spheres. The semi-spheres comprise a plurality of expandable legs. The first tube may have a plurality of slots allowing for deployment of a first or second sets of expandable legs on the second tube. The free end of each leg in the first set of expandable legs may be oriented in a direction the same as or opposite to the free end of each leg in the second set. The filter may also be formed from a single tube. In certain embodiments, the filter of the present invention can be retrieved from either end.

Owner:MERIT MEDICAL SYST INC

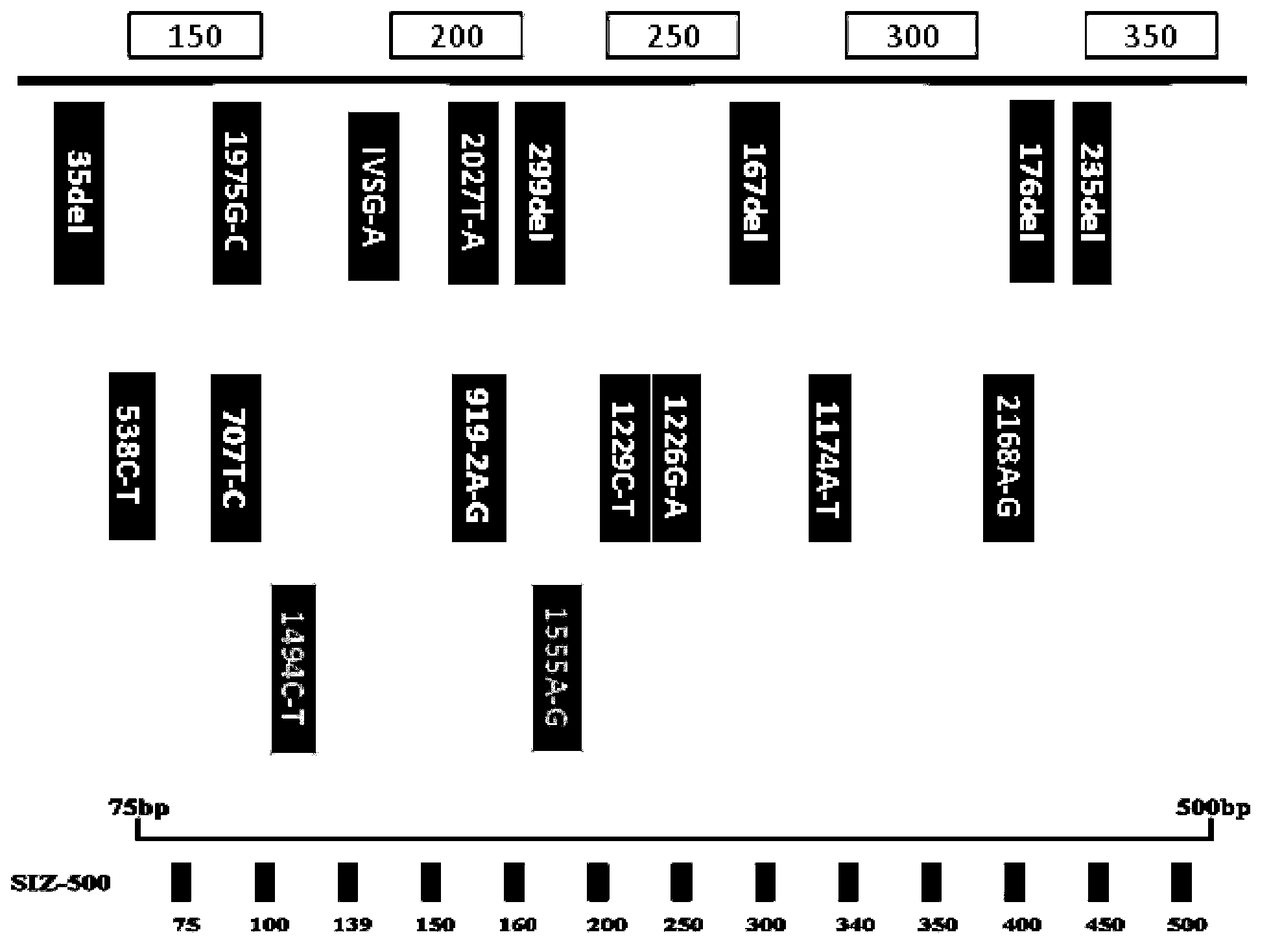

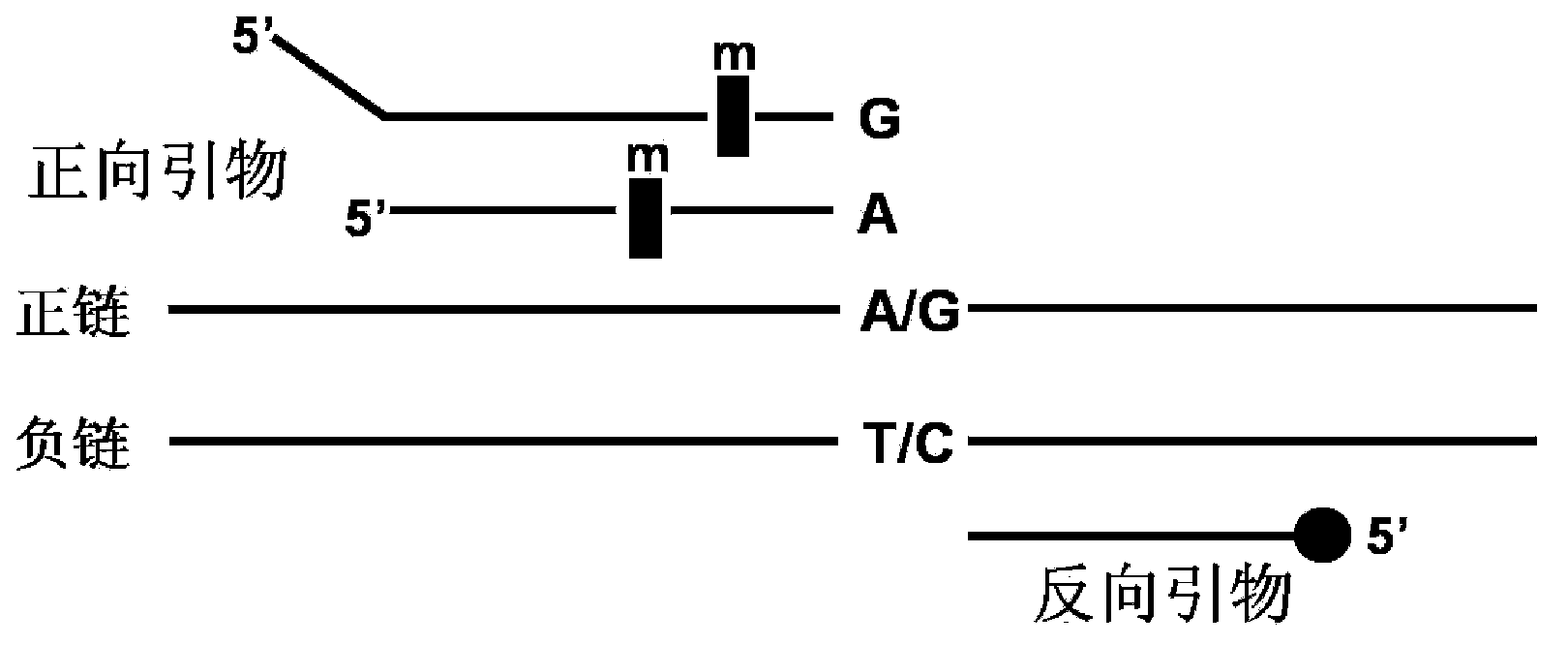

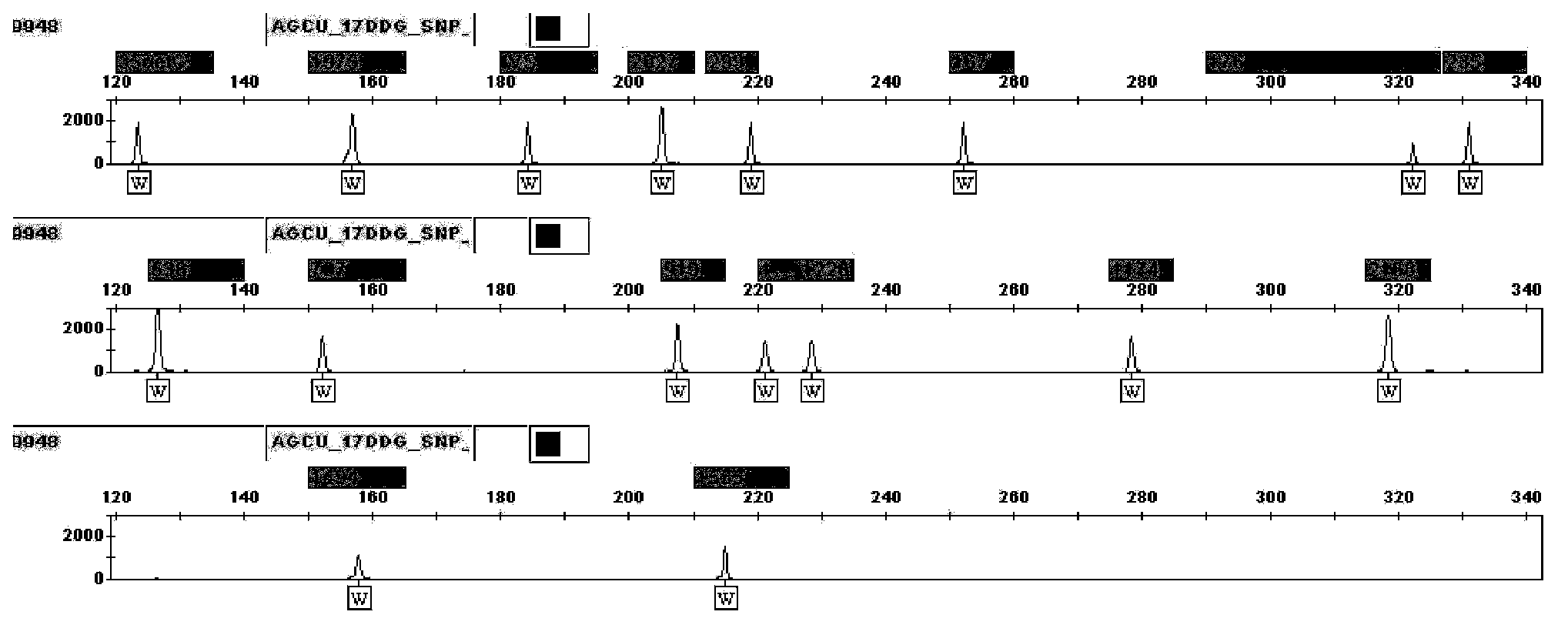

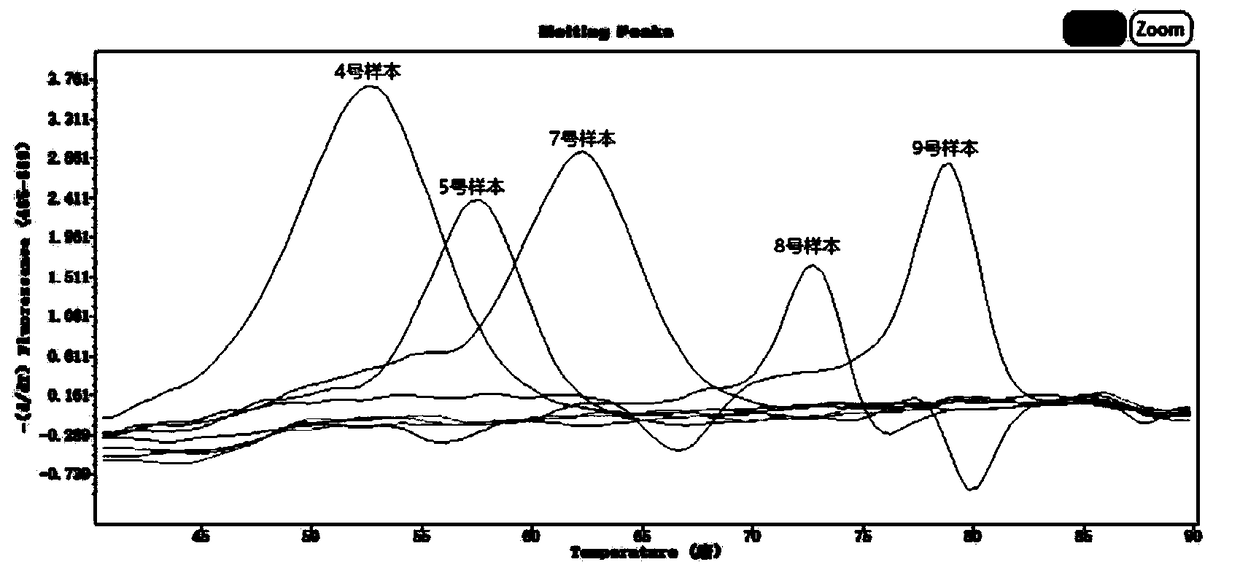

Gene detection kit for hereditary hearing loss

ActiveCN103352080AWide range of usesImprove detection success rateMicrobiological testing/measurementHybrid typeVirulent characteristics

The invention discloses a fluorescence detection kit capable of detecting 17 non-syndromic hereditary hearing loss susceptibility genes. The kit adopts 17 pairs of specific primers to conduct genetic typing on the hearing loss susceptibility genes, and 17 hotspot mutations in four most common Chinese hearing loss related genes can be detected at the same time in a single tube within 3 hours. The kit comprises primer combinations of 17 polymorphic sites of hereditary hearing loss on a GJB2 (CX26) gene, an SLC26A4 (PDS) gene, a GJB3 gene and a 12SrRNA (MTRNR1) gene, can be used for accurately judging the wild type, the pure mutant type or the hybrid type of the 17 sites, and achieves diagnosis and screening of the hearing loss genes. The kit provided by the invention can be applied to rapidly and efficiently detecting the hearing loss genes and is a rapid, convenient, economical and efficient screening kit for hearing loss virulence genes.

Owner:AGCU SCIENTECH +1

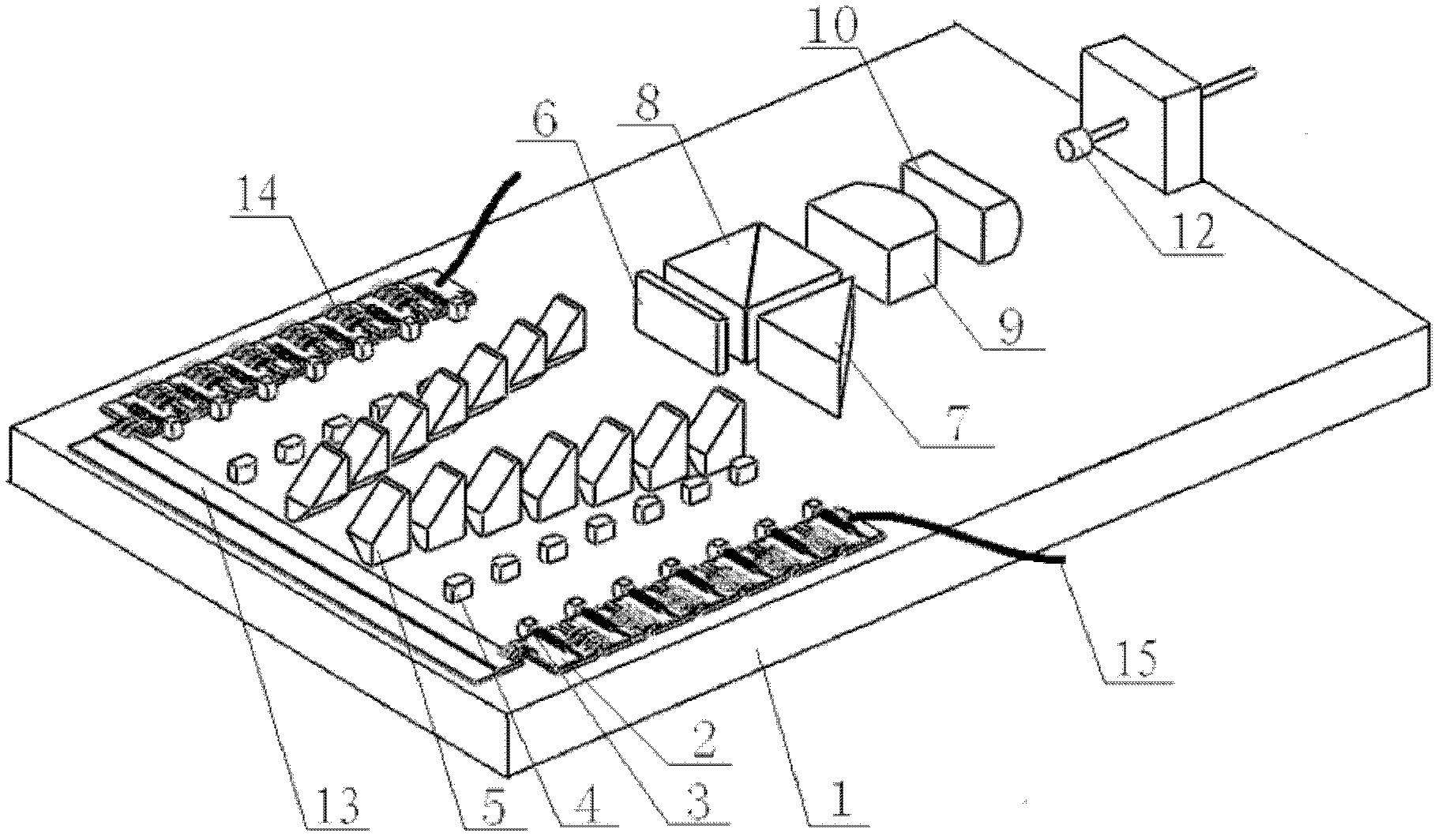

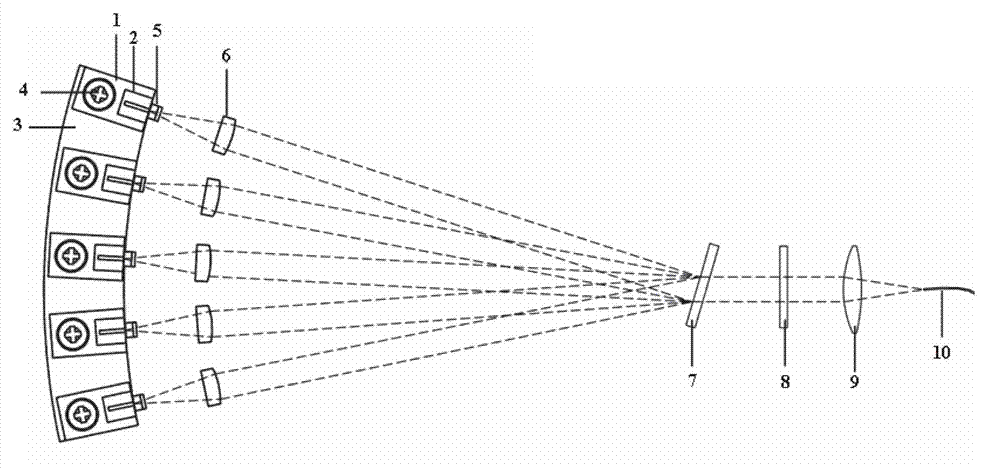

External-cavity-beam-combination semiconductor laser fiber coupling module

InactiveCN102931585AFine core diameterIncrease powerSemiconductor laser arrangementsLaser arrangementsResonant cavityLight beam

The invention relates to an external-cavity-beam-combination semiconductor laser fiber coupling module. The external-cavity-beam-combination semiconductor laser fiber coupling module comprises a plurality of single-tube semiconductor lasers of the same wavelength; each single-tube semiconductor laser is fixed on an arc-shaped heat sink; and multiple light beams emitted by the single-tube semiconductor lasers enter a diffraction grating through different inclination angles, light spots are overlapped on the diffraction grating, the external-cavity feedback and wavelength locking of the light beams emitted by all the single-tube semiconductor lasers are realized in a resonant cavity formed by rear cavity faces of the lasers and an external cavity mirror under the light splitting function of the diffraction grating and the feedback action of the external cavity mirror, the multiple light beams are combined into one light beam by the diffraction grating so as to realize external-cavity beam combination, and finally the light beam is coupled into a multimode fiber through a focusing mirror. According to the external-cavity-beam-combination semiconductor laser fiber coupling module, the light beams emitted by the single-tube semiconductor lasers are combined and output in beam quality of a single laser, so that the fiber coupling module has the advantages of small core diameter, high power and high-beam-quality laser output.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

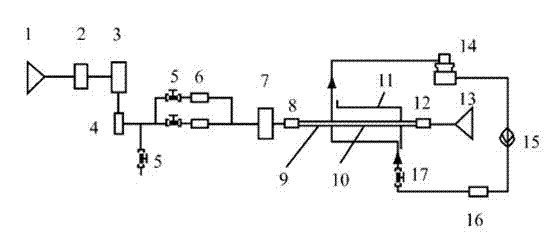

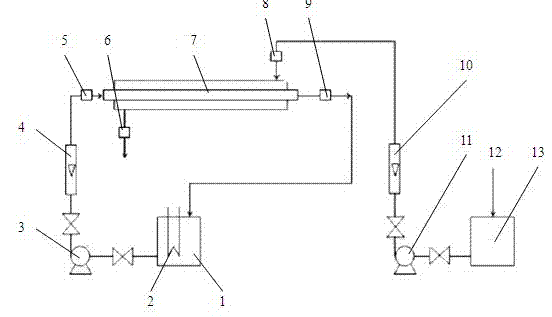

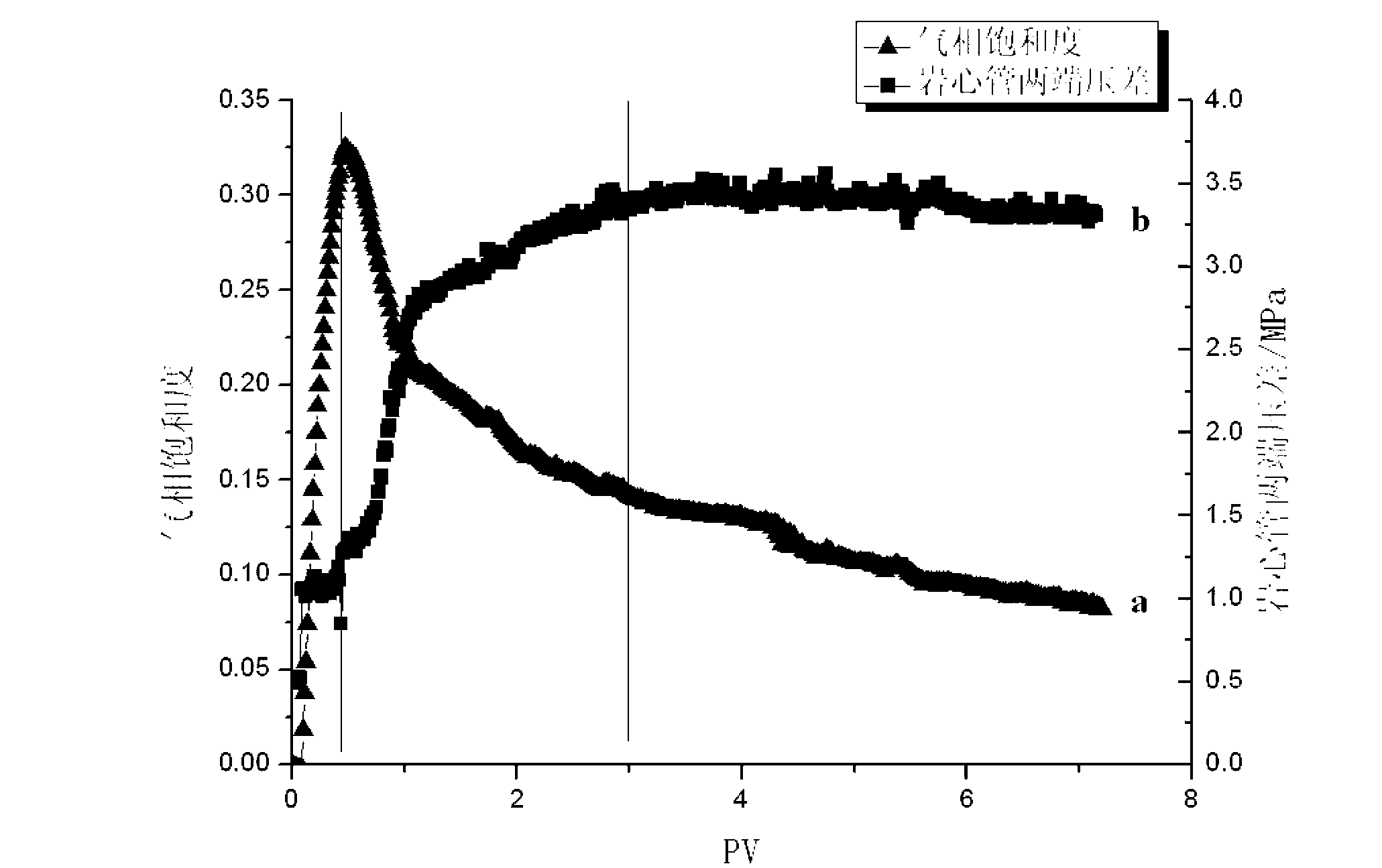

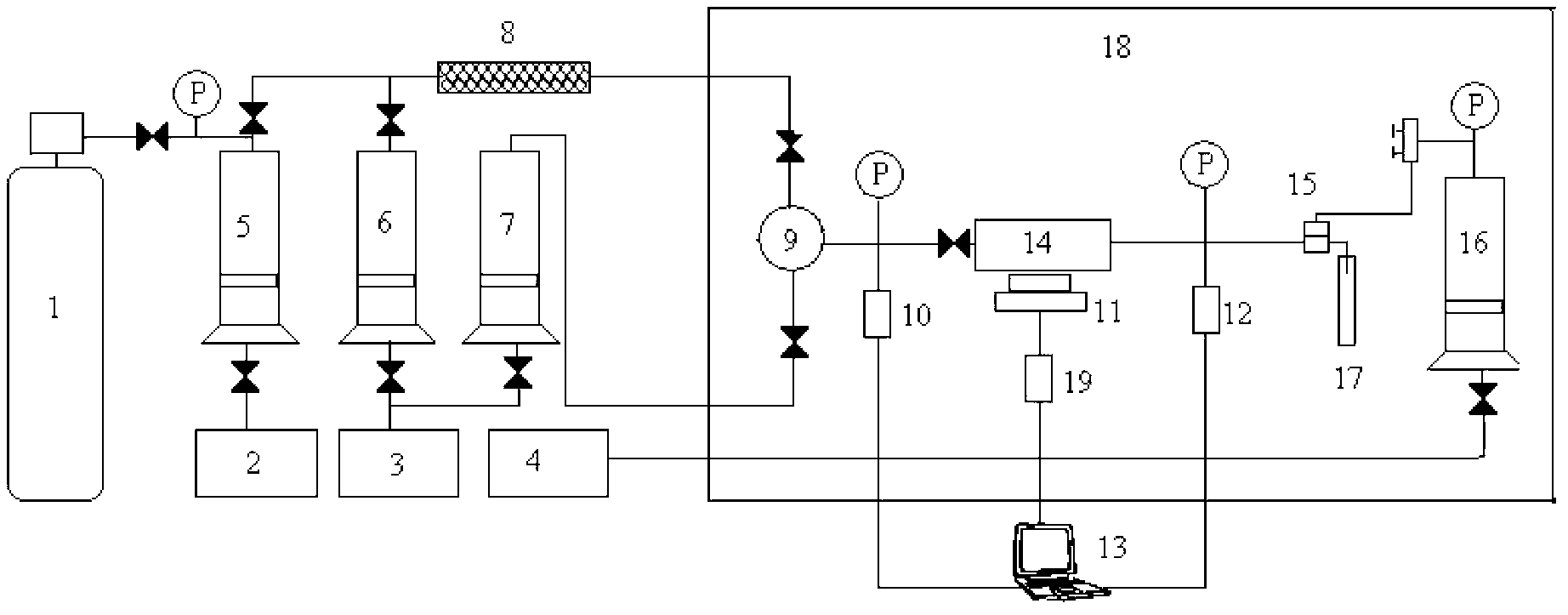

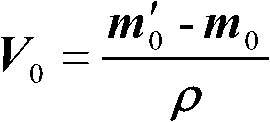

Apparatus and method for measuring gas phase saturation degree of single tube core during foam flooding process

ActiveCN102980828AReal-time measurement of gas phase saturationWeighing by absorbing componentGas cylinderGas phase

The present invention relates to an apparatus for measuring a gas phase saturation degree of single tube core during a foam flooding process. The apparatus mainly comprises a foam generation device, a middle container for holding formation water, a constant temperature oven , a core tube and a data acquisition system, wherein the foam generation device part mainly for mainly producing foam for core flooding mainly comprises a gas cylinder, middle containers, a constant flow pump, a foam generator and other equipment, the core tube, a pressure gauge, a scale, a back pressure valve and an output fluid collection device are arranged inside the constant temperature oven, an injected fluid is injected into the core in the constant temperature oven, a quality of the core tube is measured, and the data acquisition system mainly for data acquisition mainly comprises a computer, a pressure sensor, a weight weighing sensor and other equipment. According to the present invention, changes of the qualities of the sing tube core at different time points are converted into different gas phase saturation degrees in the tube core, and the fluid injection amount and changes of pressure on both ends of the single tube core are combined so as to analyze reservation conditions of the foam in the single tube core at different injection amounts.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

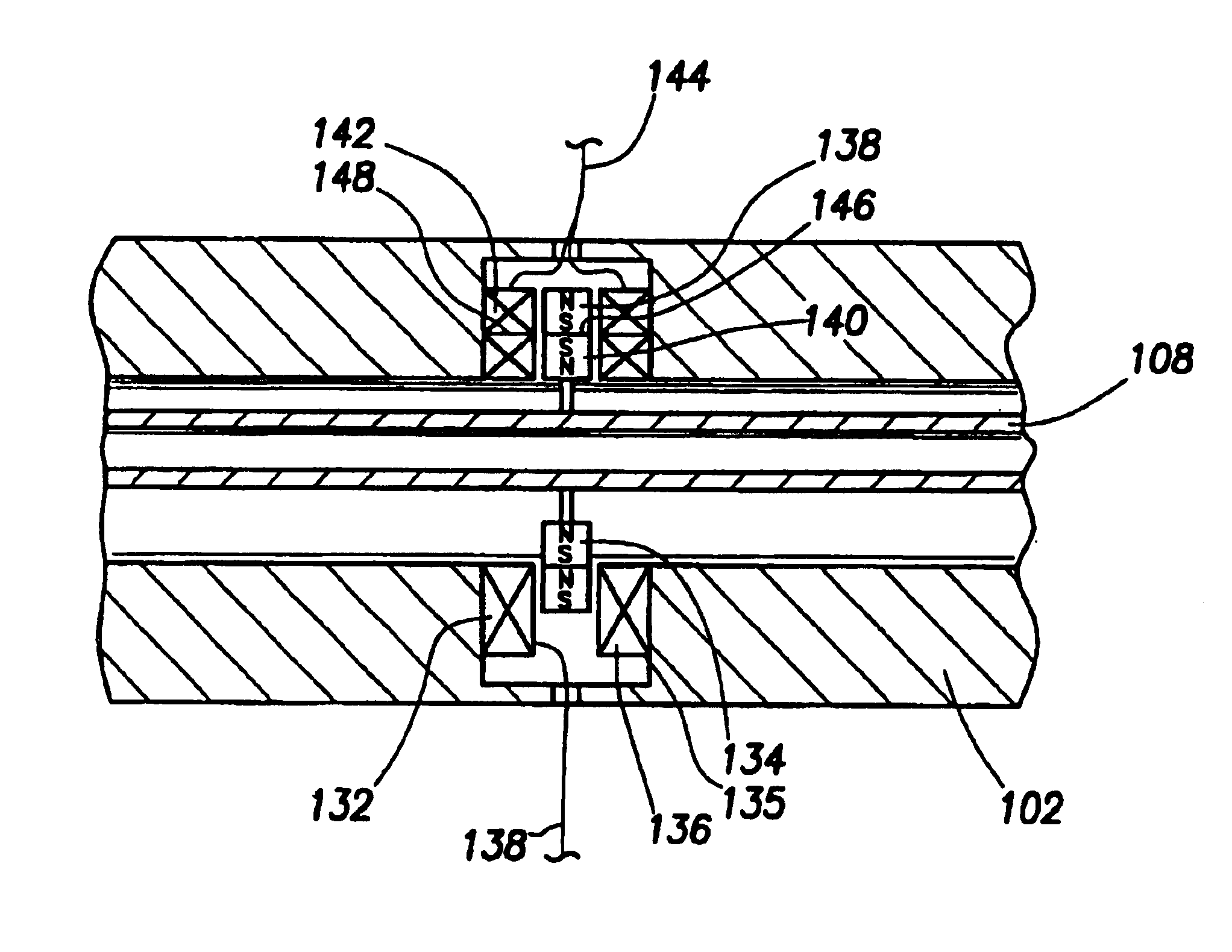

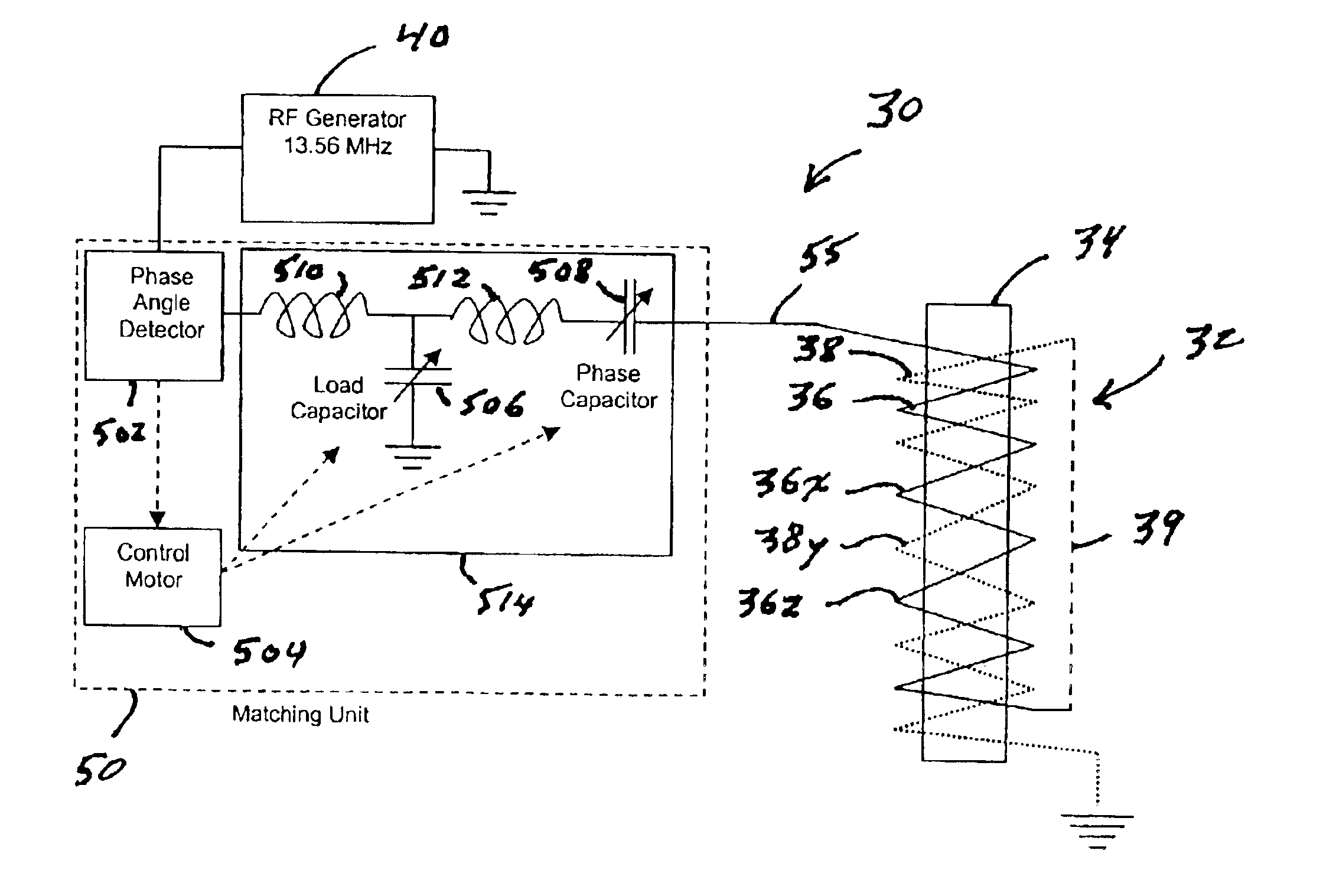

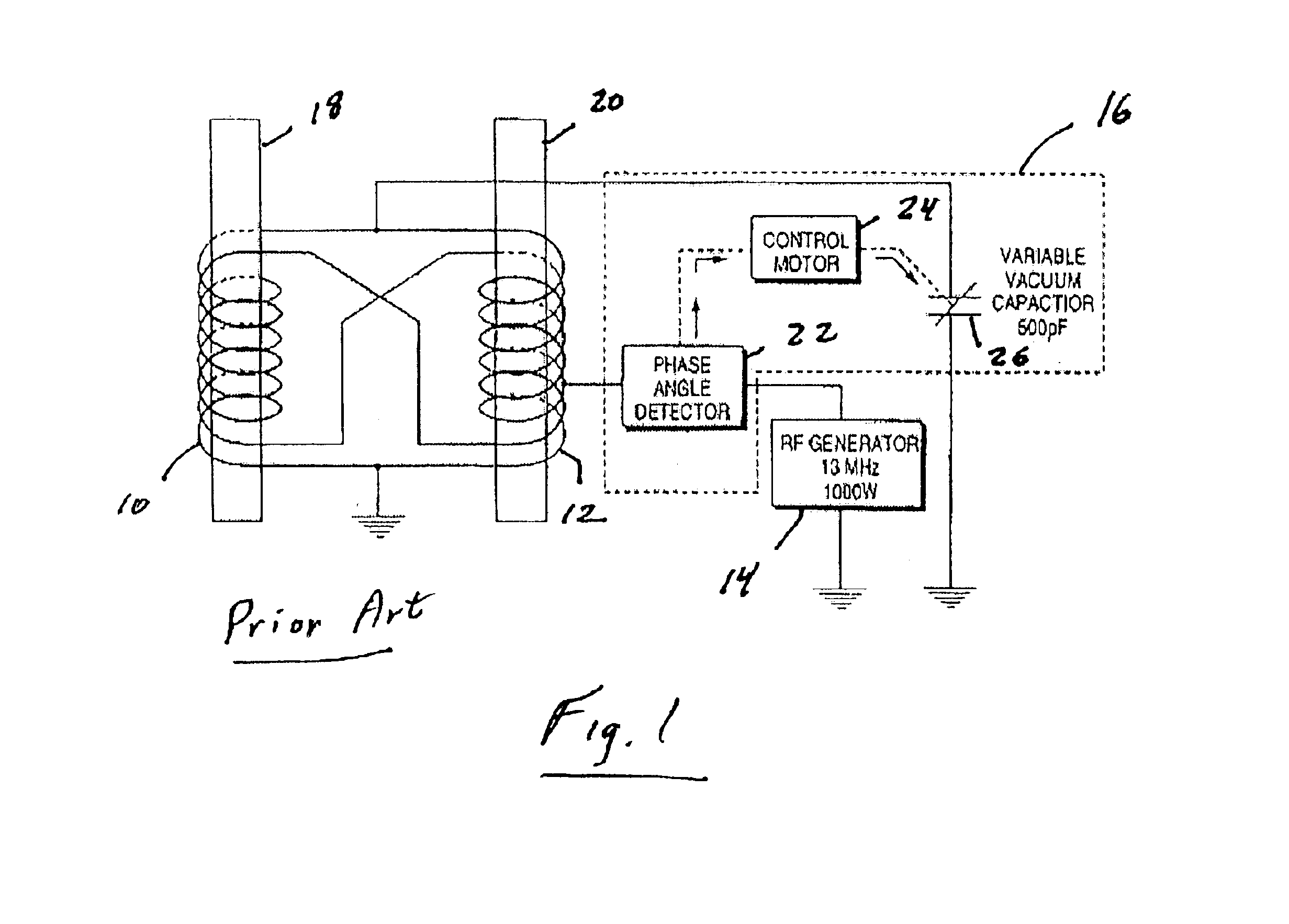

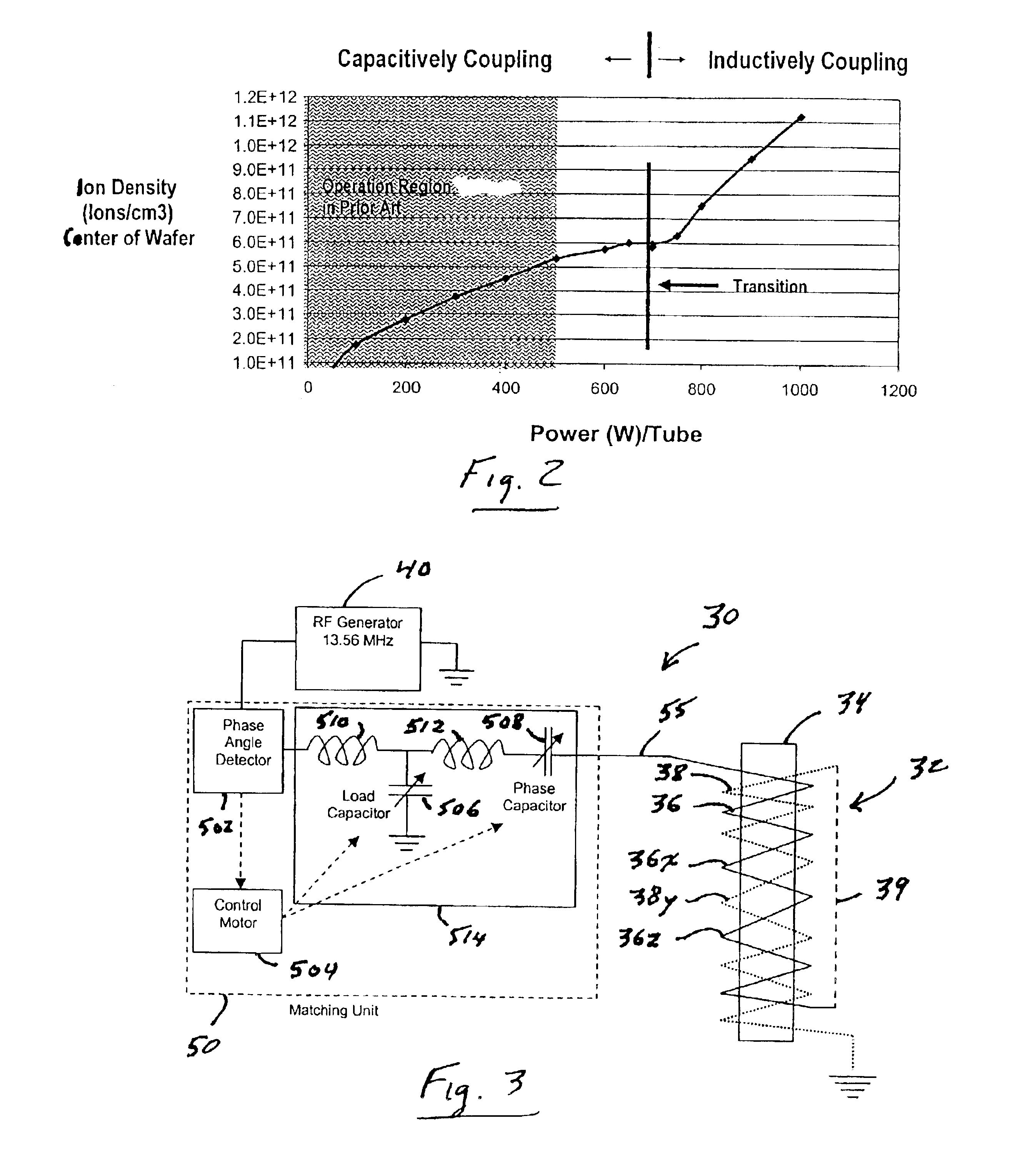

Single-tube interlaced inductively coupling plasma source

InactiveUS6855225B1Electric discharge tubesElectric arc lampsImpedance matchingInductively coupled plasma

A plasma source for use in, for example, semiconductor processing contains a radio-frequency generator, an impedance matching network, and a coil that encloses a tube. The coil is bifilar, i.e., the turns of one are interlaced with the turns of a second winding. The matching network supplies only a single coil in the plasma source, unlike conventional arrangements wherein a single matching network supplies multiple coils in the plasma source.

Owner:NOVELLUS SYSTEMS

Respiratory pathogen multi-detection reagent kit

InactiveCN109355437AHigh detection sensitivityHigh sensitivityMicrobiological testing/measurementMicroorganism based processesCoronavirus 229EFluorescence

The invention discloses a respiratory pathogen multi-detection reagent kit. The respiratory pathogen multi-detection reagent kit has the advantages that the respiratory pathogen multi-detection reagent kit is based on multi-PCR (polymerase chain reaction) technologies, detection results can be determined by the aid of fluorescence resonance energy transfer via the melting temperature ranges, the respiratory pathogen multi-detection reagent kit can be used for qualitatively simultaneously detecting 16 types of respiratory pathogens, the 16 types of respiratory pathogens include 12 types of RNA(ribonucleic acid) viruses (influenza A viruses, influenza B viruses, H1N1 influenza A viruses, type A and type B respiratory syncytial viruses, type -1 / -2 / -3 parainfluenza viruses, type OC43 coronaviruses, type 229E coronaviruses, rhinoviruses and human metapneumovirus), 2 types of DNA (deoxyribonucleic acid) viruses (adenoviruses and bocavirus) and 2 types of bacteria (mycoplasma pneumoniae andbordetella pertussis), the respiratory pathogen multi-detection reagent kit is high in detection sensitivity, and the sensitivity even can reach 1 copy / reaction; the multi-detection reagent kit is good in specificity, and negative results of pathogens which have identical sampling sites and similar pathogenic mechanisms and are not in the detection range of the respiratory pathogen multi-detectionreagent kit can be obtained; the respiratory pathogen multi-detection reagent kit is short in operation time and easy to operate and can be used for quickly detecting the 16 types of respiratory pathogens in a single tube of a reaction system, the results are clear and are easy to interpret, and the like.

Owner:上海捷诺生物科技股份有限公司

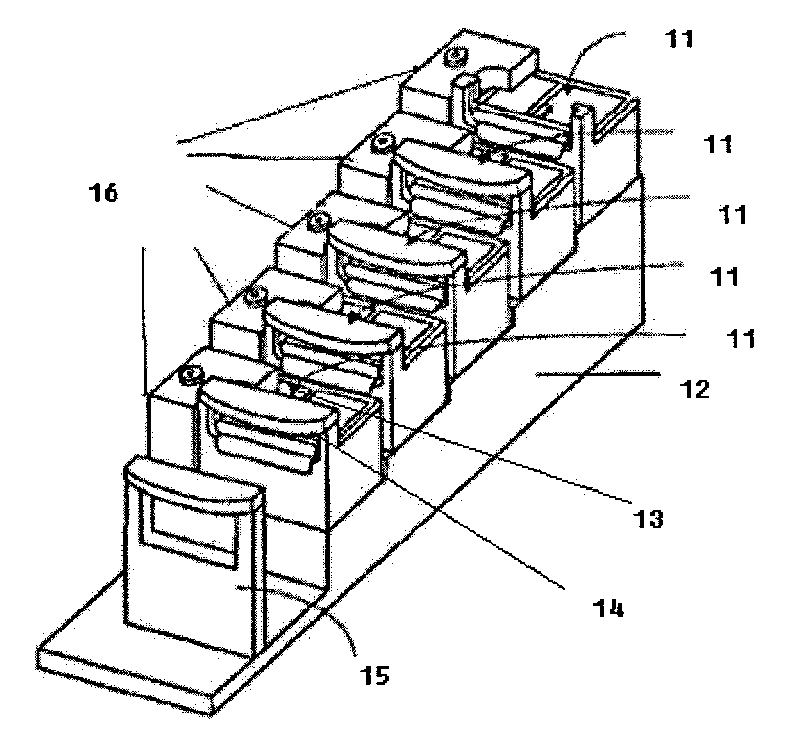

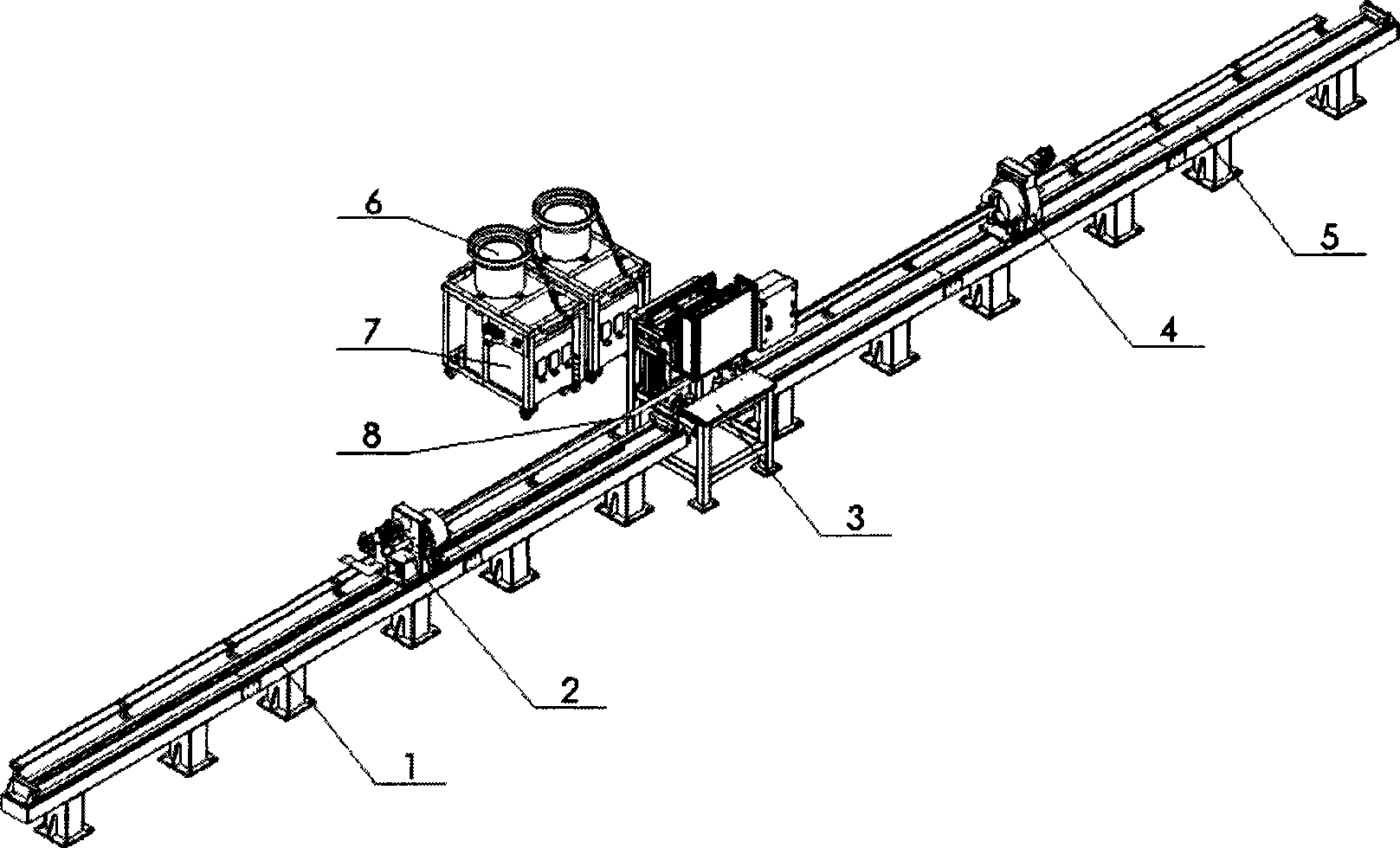

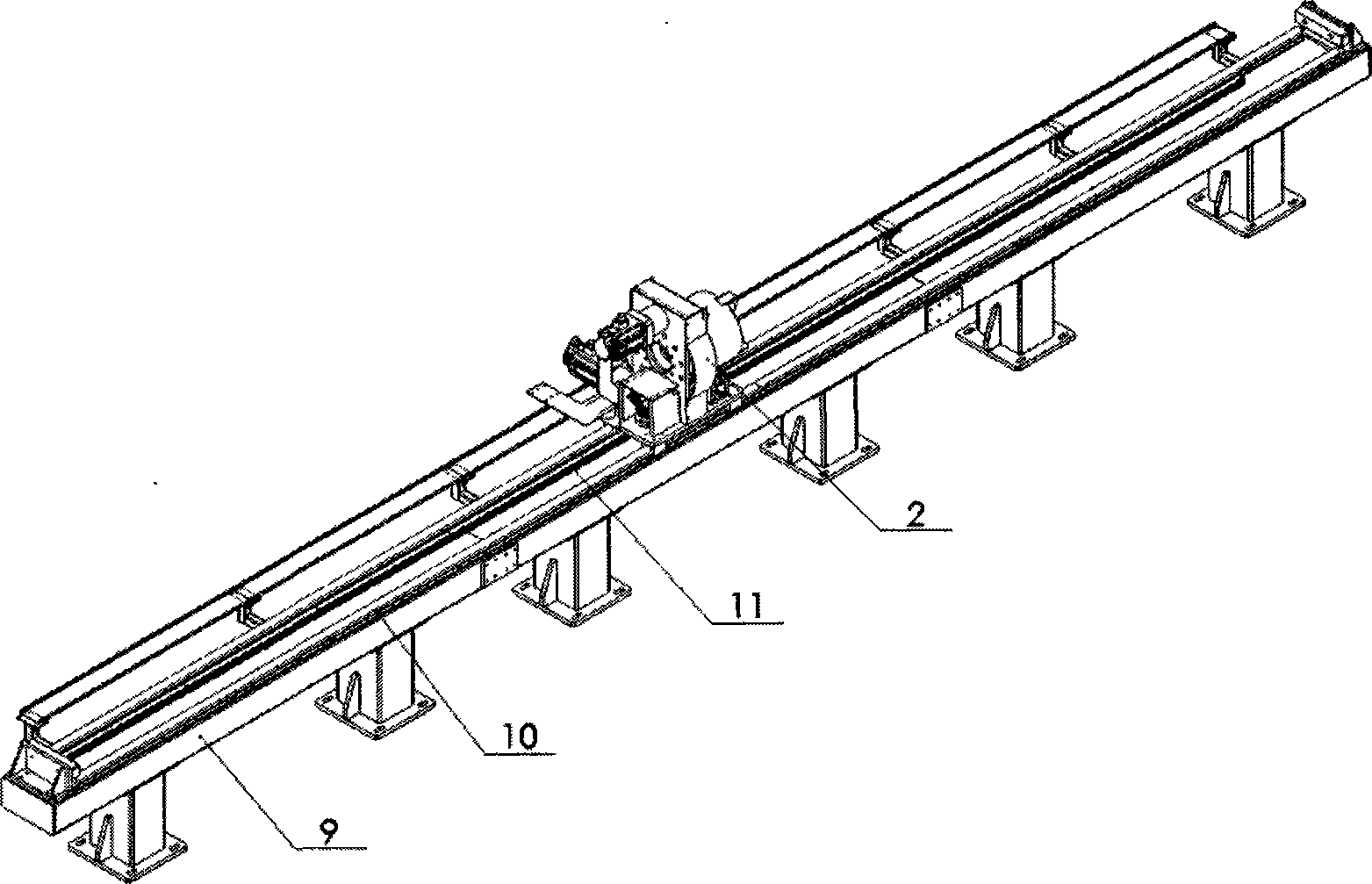

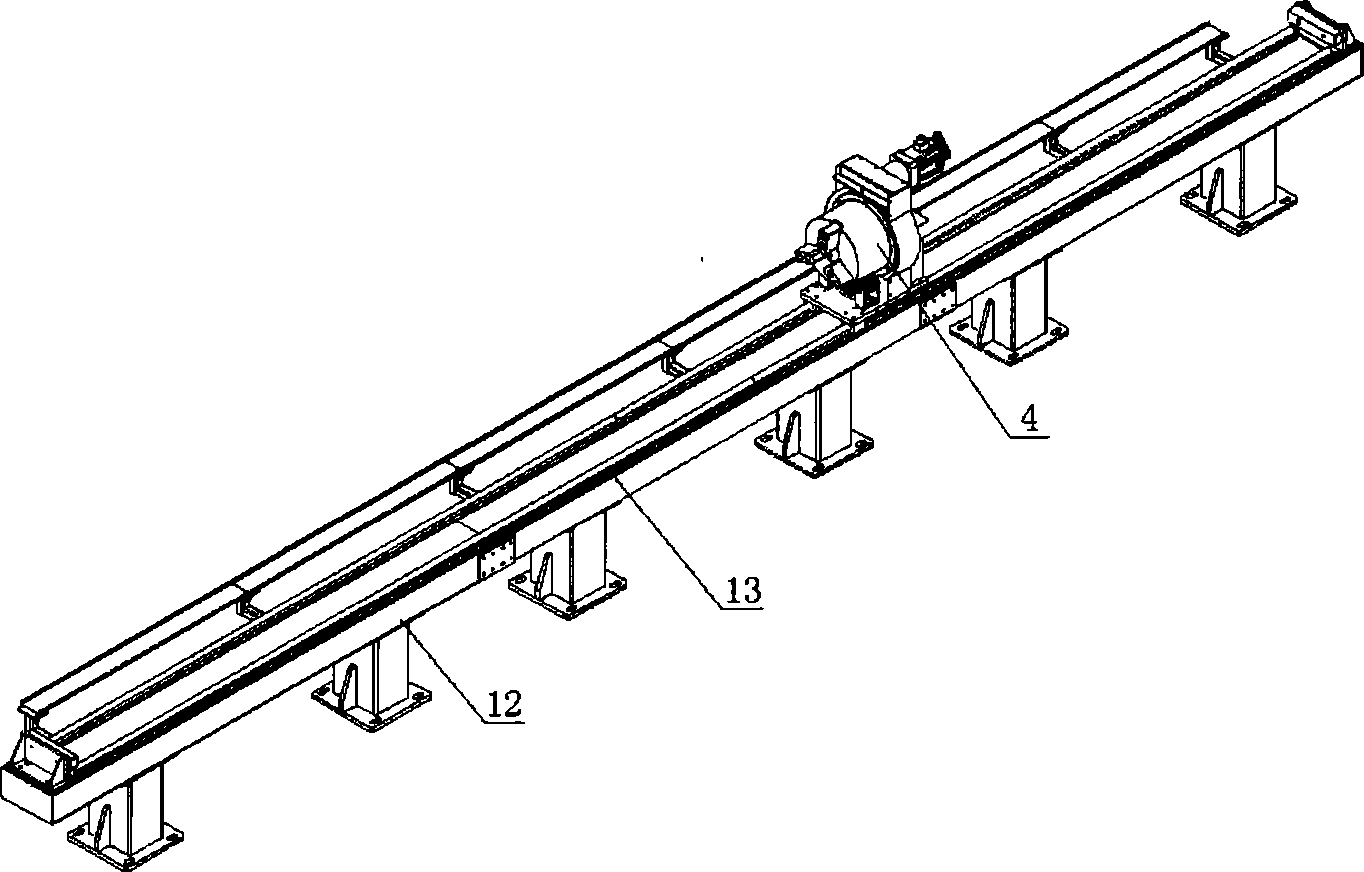

Full-automatic single-tube pin welding device

ActiveCN101422844AFully automatedReduce torsional deformationWelding accessoriesStud weldingEngineering

The invention relates to a full-automatic single tube and pin welding machine which belongs to the technical field of welding, and the welding machine comprises a machine bed at a driving end, a machine bed at a driven end, a driving feeding mechanism, a welding operation machine, a driven feeding mechanism, an automatic charging mechanism and a welding host. The driving feeding mechanism and the driven feeding mechanism realize the horizontal feeding of a welded steel pipe along the longitudinal direction of the welding machine and the radial rotary feeding motion of the steel pipe, the welding operation machine is provided with a pneumatic welding fixture and two automatic stud welding guns, the pneumatic welding fixture realizes the holding and positioning of the steel pipe according to production tact in the welding process, and the horizontal distance between the two stud welding guns and the vertical distance between the automatic stud welding guns and the welded steel pipe are adjustable. The automatic charging mechanism realizes the automatic pin charging process. The welding machine has simple structure, the feeding motion of two degrees of freedom can be realized by a servo motor, the positioning precision is high, the clamping action of the welding fixture and the charging process are pneumatically controlled, and the operation is convenient. The welding machine can complete pin welding operation automatically or manually.

Owner:EUROCRANE

Low clearance centralizer and method of making centralizer

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

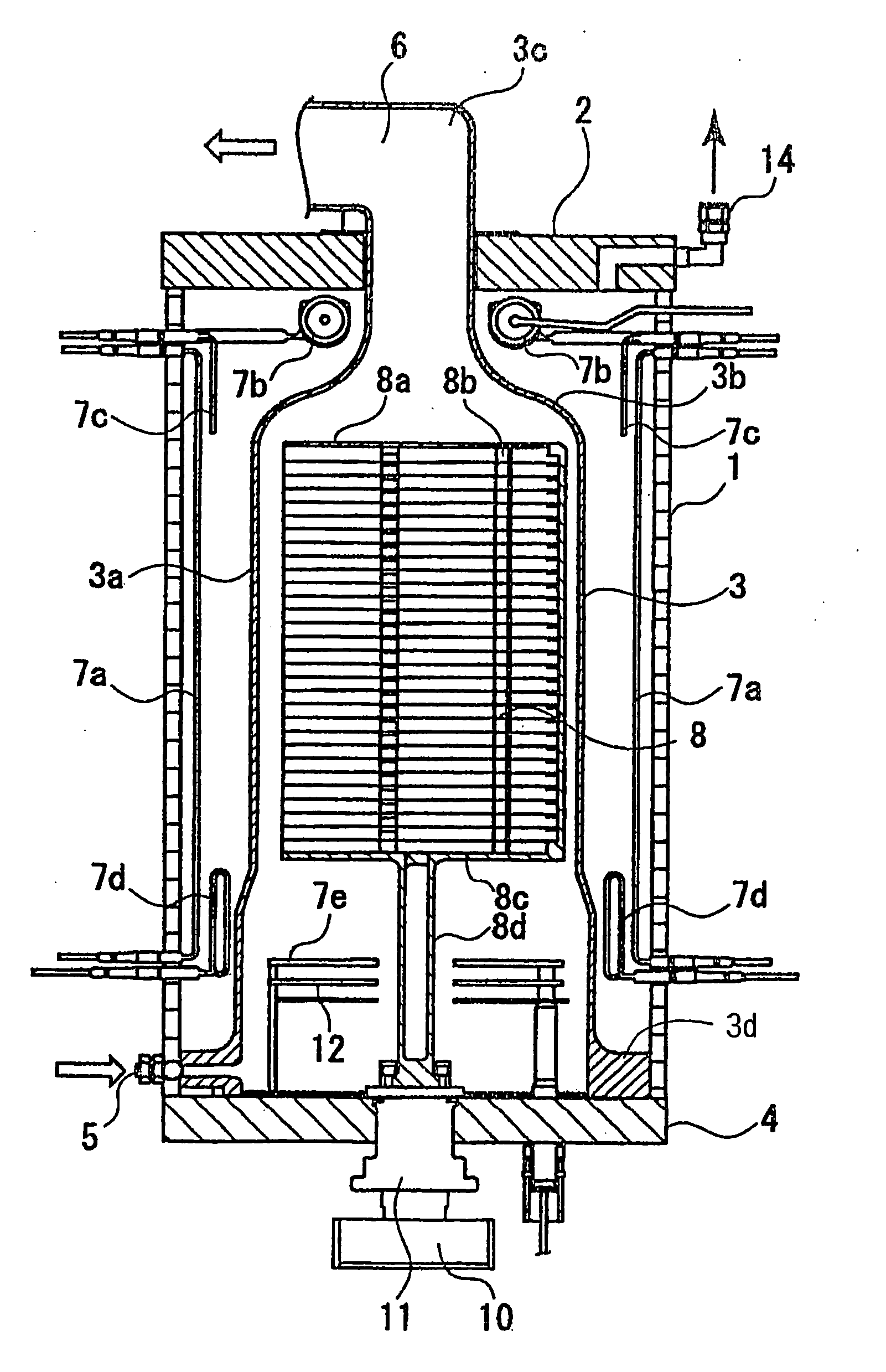

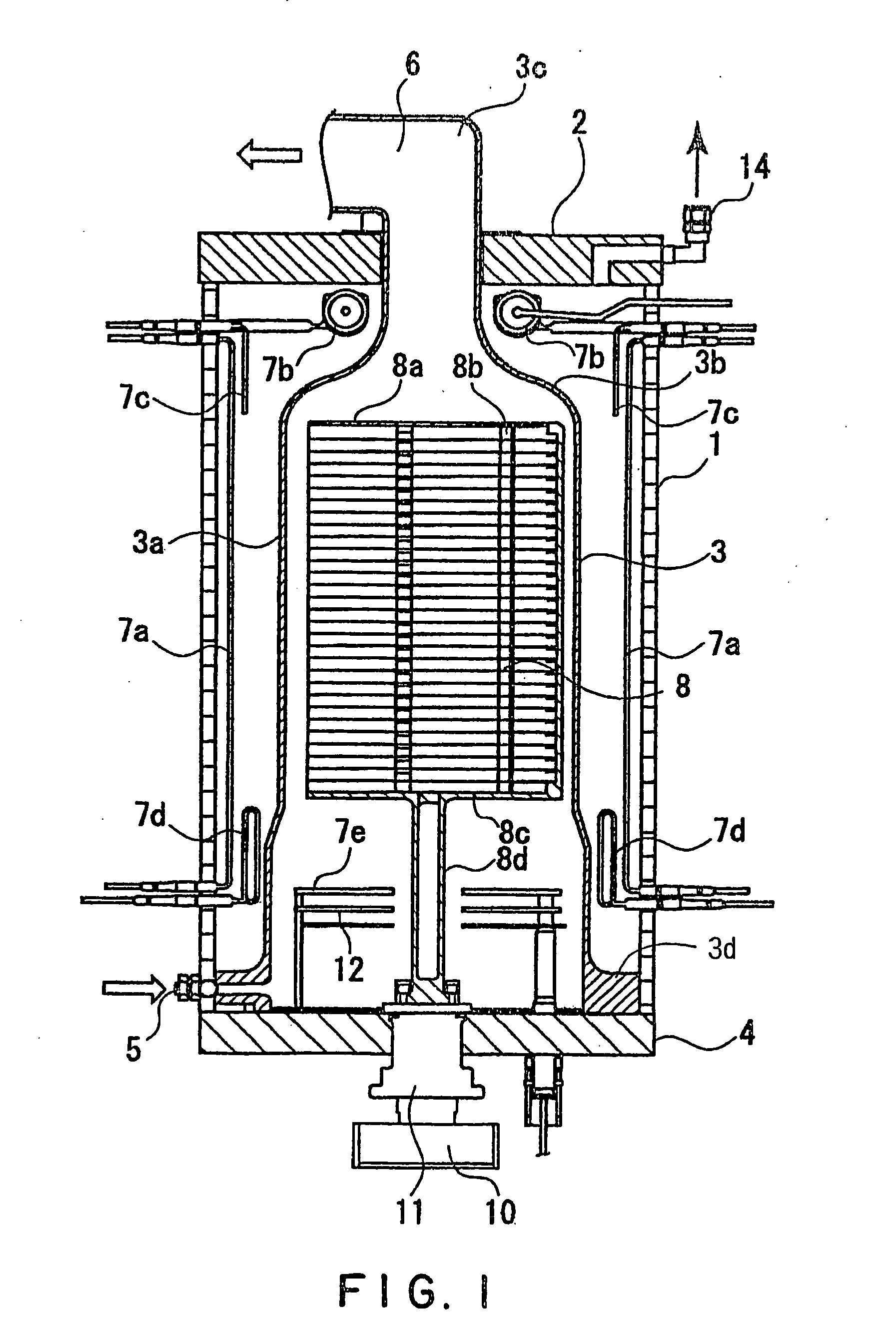

Heat treatment apparatus

ActiveUS20060021582A1Inhibition effectHeating fastMuffle furnacesSemiconductor/solid-state device manufacturingProcess supportEngineering

The present invention is a thermal processing unit including: a heating-furnace body whose upper end has an opening; a reaction tube consisting of a single tube contained in the heating-furnace body; a gas-discharging-unit connecting portion formed at an upper portion of the reaction tube, the gas-discharging-unit connecting portion having a narrow diameter; a substrate-to-be-processed supporting member for supporting a substrate to be processed, contained in the heating-furnace body; and a heating unit for heating the substrate to be processed supported by the substrate-to-be-processed supporting member. The heating unit has: a first heating portion arranged around the reaction tube, a second heating portion arranged around the gas-discharging-unit connecting portion, a third heating portion arranged around an upper portion of the reaction tube, a fourth heating portion arranged around a lower portion of the reaction tube, and a fifth heating portion arranged under the substrate-to-be-processed supporting member.

Owner:TOKYO ELECTRON LTD

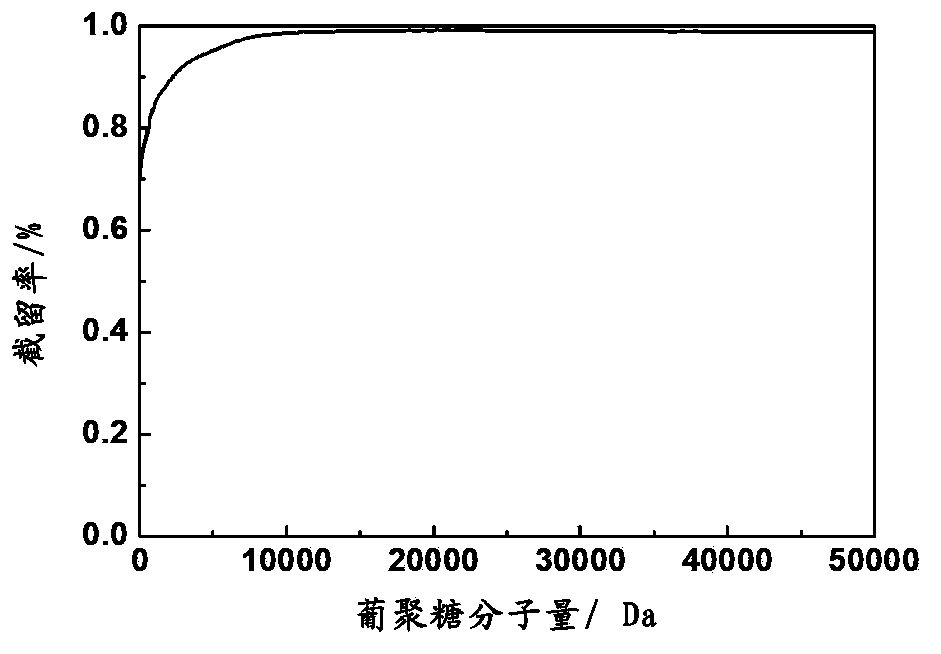

Method for preparation of ceramic nanofiltration membrane by improved sol-gel technique

The invention relates to a method for preparation of a ceramic nanofiltration membrane by an improved sol-gel technique. The method includes: adding nano-particles with certain particle size into sol to prepare a film coating solution, conducting film coating on a porous supporting body by the prepared film coating solution, airing and drying a wet film, and then carrying out direct calcinations, thus obtaining the nanofiltration membrane. In the invention, the nano-particles with a size of 3-50nm are employed to modify the supporting body surface macropore defect, and also can achieve the purpose of toughening gel and increasing its strength, thus effectively avoiding the problem of film cracking during drying. On a sheet, single tube or multi-channel supporting body with a pore diameter of 50-200nm, the ceramic membrane that is intact, crack-free, defect-free and has a pore diameter of 1-10nm can be prepared. The ceramic nanofiltration membrane prepared by the method has the advantages of narrow pore diameter distribution, simple process and good repeatability, and is suitable for large scale ceramic nanofiltration membrane production.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com