Method for preparation of ceramic nanofiltration membrane by improved sol-gel technique

A technology of ceramic nanofiltration membrane and gel method, which is applied in the field of preparation of ceramic nanofiltration membrane, can solve the problems of increasing equipment investment cost and production cost, being unsuitable for preparation of ceramic nanofiltration membrane, etc. Loss modulus, reduction of internal seepage, effect of hindering stress propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] When the average particle size of the sol is 8nm and the titanium content is 1mol L -1 TiO with an average particle size of 21nm was added to the acidic sol 2 Nanoparticles get a stable coating solution, TiO 2 The particle content is 0.5g / L. Use the prepared coating solution on a porous sheet support (surface structure is 100nm Al 2 o 3 Ceramic film) was coated by spin coating method, dried in an oven at 40°C, heated at 1°C / min, and calcined at 400°C for 4 hours to obtain a titanium dioxide ceramic film with a pore diameter of 7 nm and a porosity of 40%. . figure 1 It is the surface electron micrograph of the film after the calcining of Example 1; figure 2 It is a cross-sectional electron microscope image of the calcined film in Example 1; it can be seen from the figure that the film layer prepared by this method is uniform without cracks, and there is almost no infiltration phenomenon during film coating.

Embodiment 2

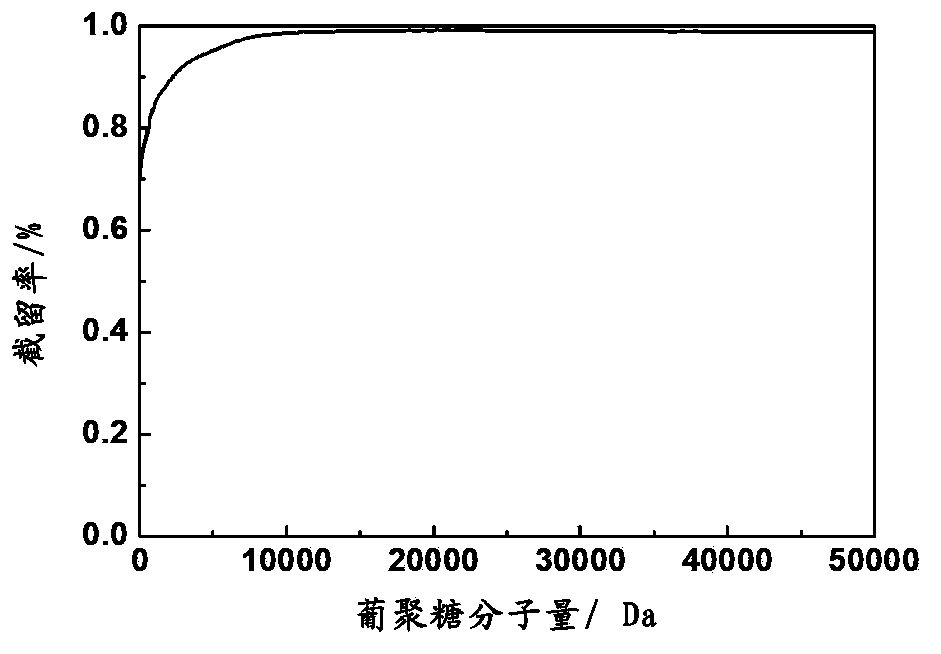

[0028] When the average particle size of the sol is 2nm and the titanium content is 1mol L -1 TiO with an average particle size of 25nm was added to the alkaline sol 2 Nanoparticles get a stable coating solution, TiO 2 The particle content was 0.2 g / L. Use the prepared coating solution on a porous sheet support (surface structure is 100nm Al 2 o 3 Ceramic membrane) was coated by dip coating, dried in an oven at 70°C, heated at 1°C / min, and calcined at 300°C for 3 hours to obtain a ceramic membrane with a pore size of 8nm. Then, when the titanium content is 0.2mol·L -1 Add 10nm TiO to titanium sol 2 Nanoparticles (0.05g / L) obtained a stable coating solution and repeated coating drying and sintering to obtain a titanium dioxide nanofiltration membrane with a pore size of 2.1nm and a porosity of 50%. Figure 3A It is the cut-off curve of the ceramic membrane to dextran after calcined in Example 2; it can be seen from the figure that the dextran molecular weight cut-off of t...

Embodiment 3

[0030] The average particle size of the sol is 3nm, and the titanium content is 1.5mol L -1 Add TiO with an average particle size of 5nm in the acidic sol 2 Nanoparticles get a stable coating solution, TiO 2 The particle content was 0.2 g / L. Using the prepared coating solution on the tubular ZrO 2The ultrafiltration membrane (pore size is 50nm, single tube 10cm long) is coated with dip coating method, dried in a constant temperature and humidity box at 65°C and 70%RH, and heated at 2°C / min, at 600°C Calcined at ℃ for 3 hours to obtain a titanium dioxide ceramic membrane with a pore diameter of 4.5 nm and a porosity of 45%. Figure 4 It is the relationship diagram of the storage modulus and temperature before and after adding particles of the gel material, Figure 5 It is the relationship diagram of loss modulus and temperature before and after adding particles of the gel material. It can be seen from the figure that after doping particles, the storage modulus and loss mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com