Patents

Literature

483results about How to "High separation precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

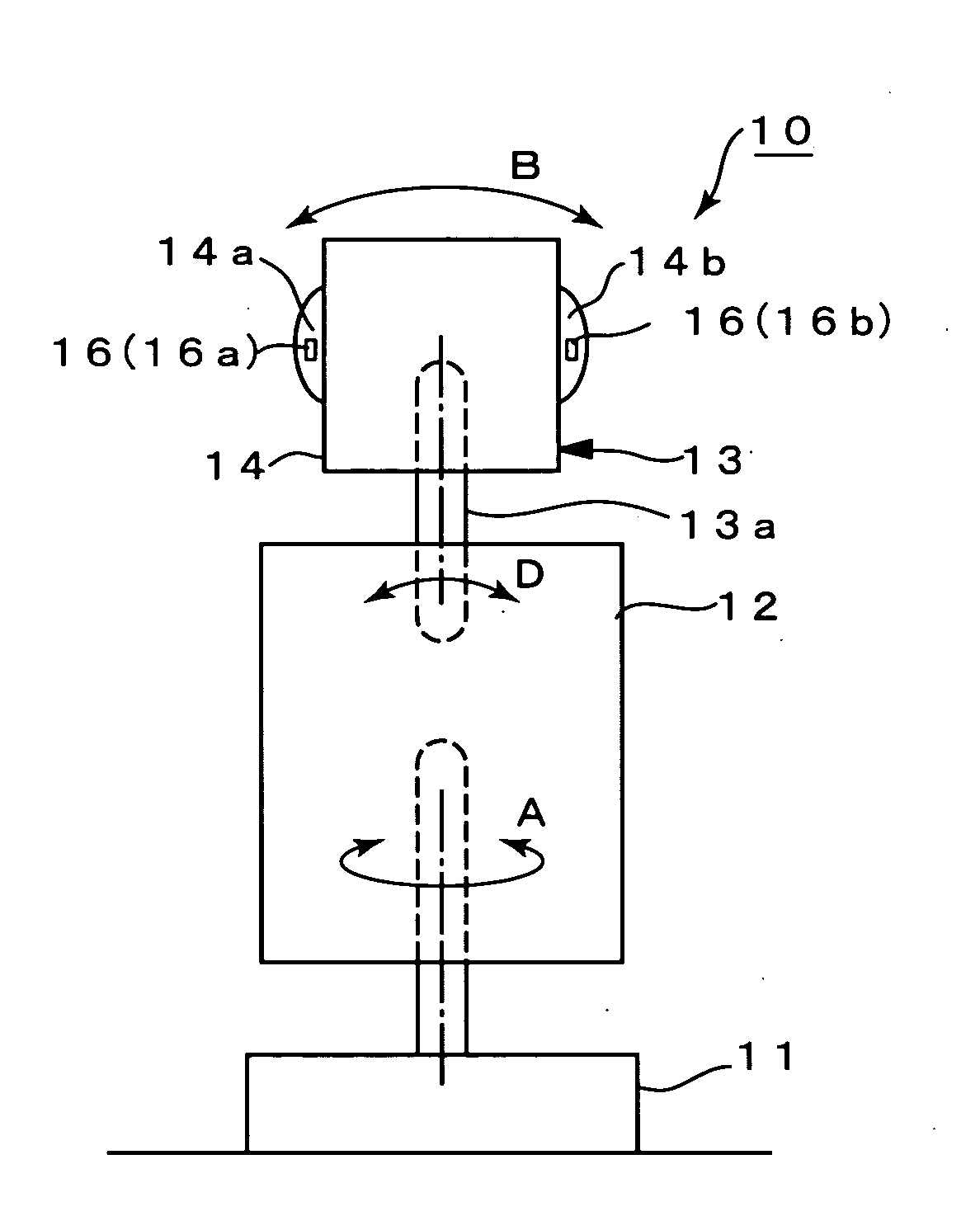

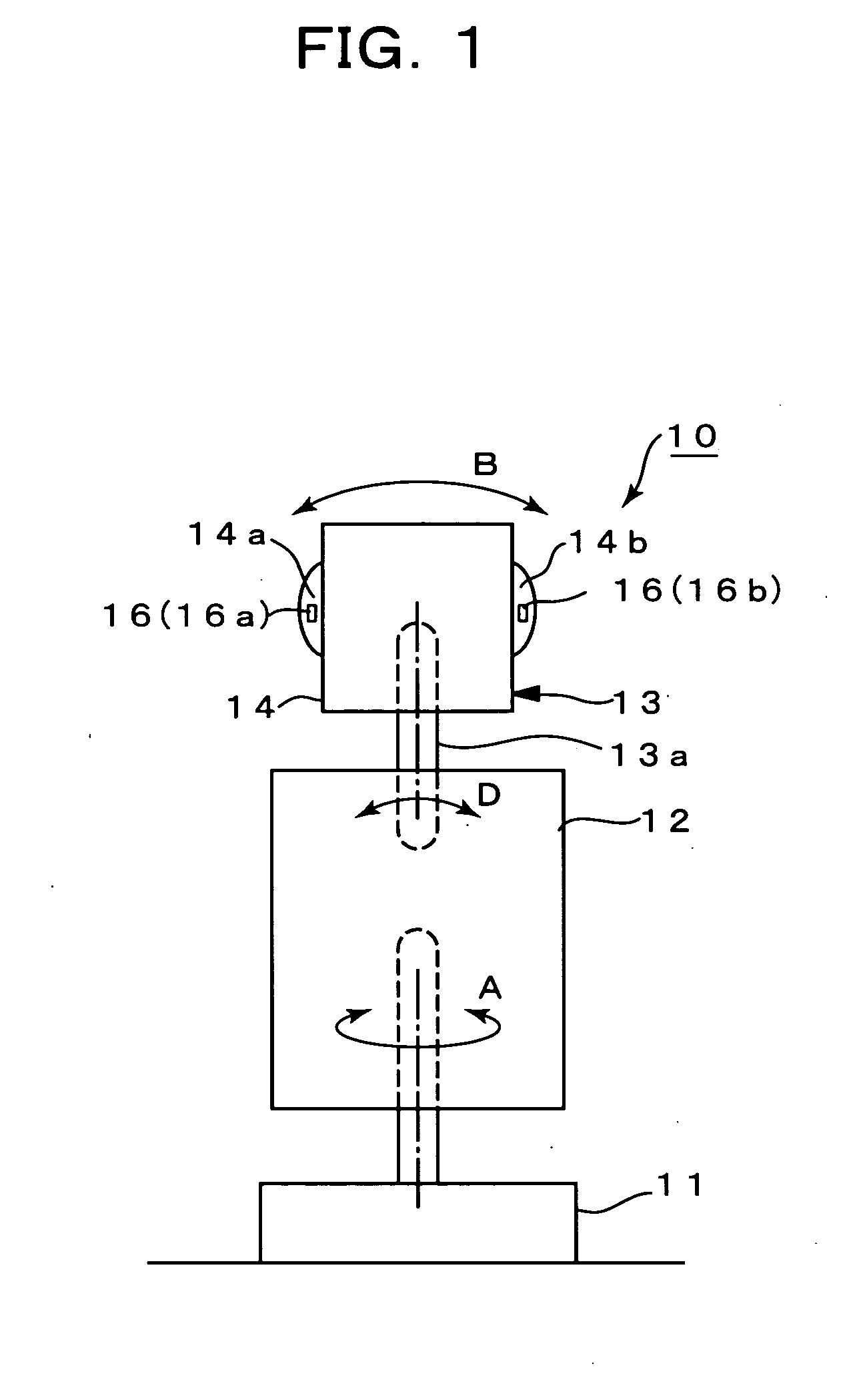

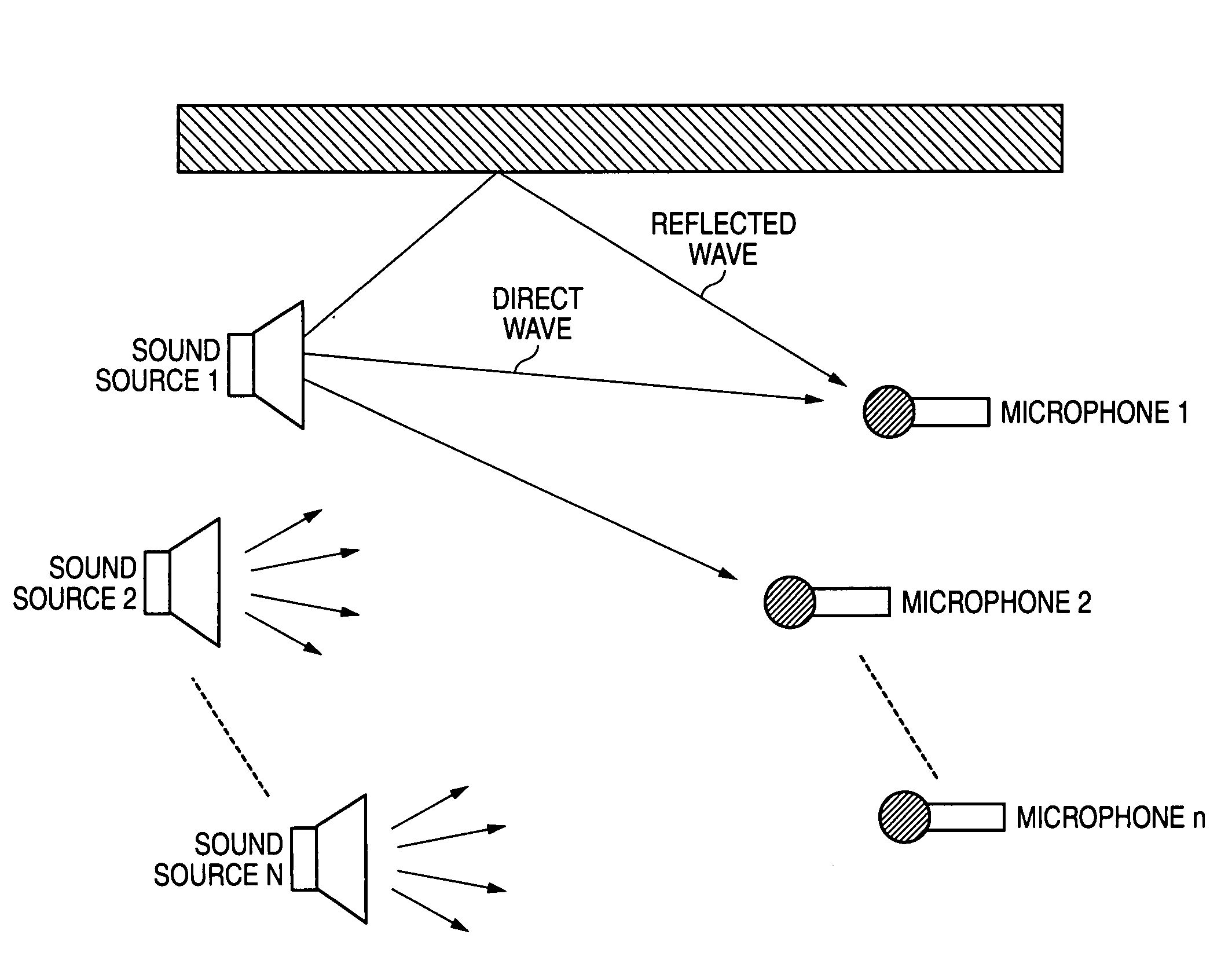

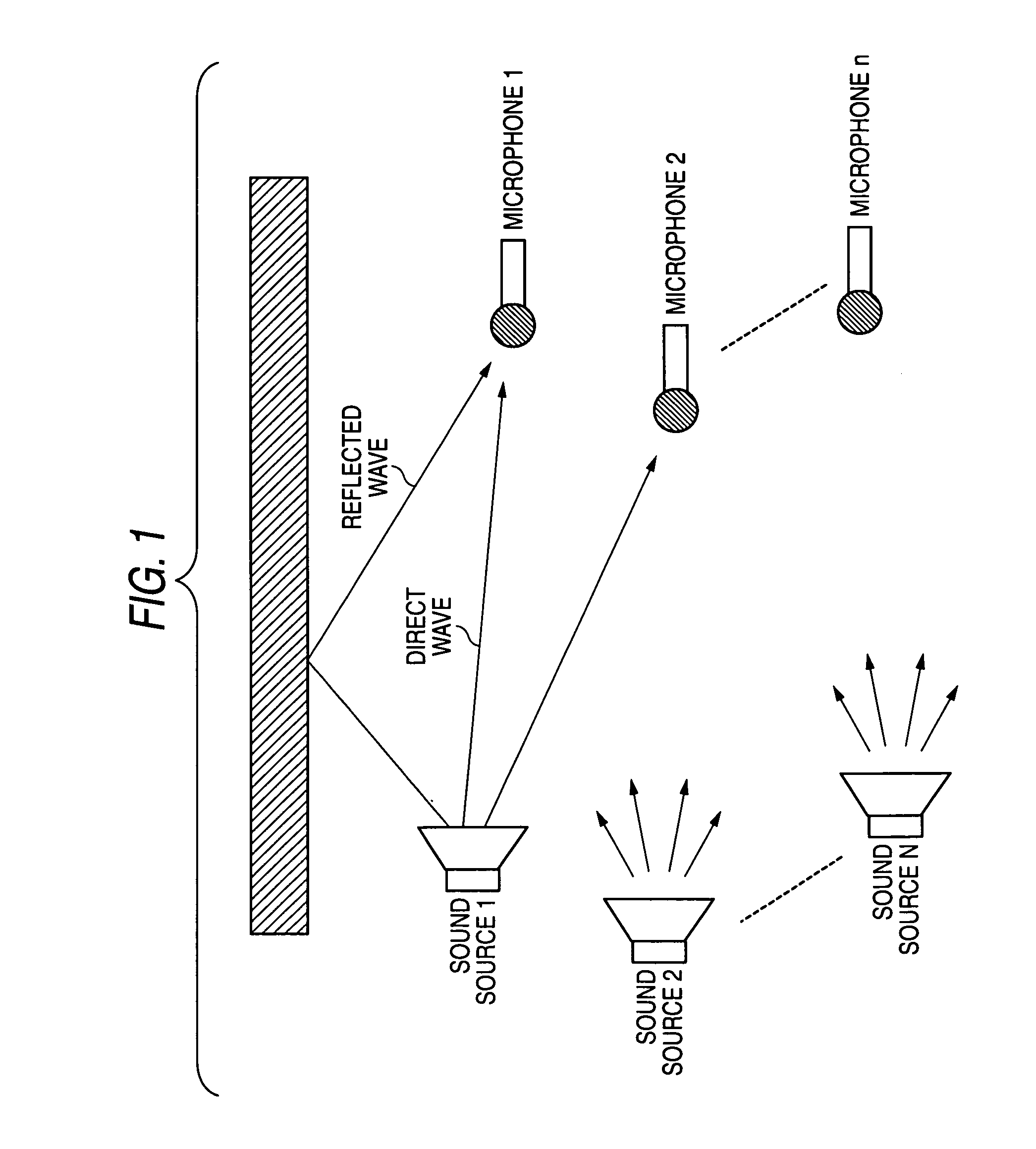

Robotics visual and auditory system

InactiveUS20090030552A1Accurate collectionAccurately localizeProgramme controlComputer controlSound source separationPhase difference

It is a robotics visual and auditory system provided with an auditory module (20), a face module (30), a stereo module (37), a motor control module (40), and an association module (50) to control these respective modules. The auditory module (20) collects sub-bands having interaural phase difference (IPD) or interaural intensity difference (IID) within a predetermined range by an active direction pass filter (23a) having a pass range which, according to auditory characteristics, becomes minimum in the frontal direction, and larger as the angle becomes wider to the left and right, based on an accurate sound source directional information from the association module (50), and conducts sound source separation by restructuring a wave shape of a sound source, conducts speech recognition of separated sound signals from respective sound sources using a plurality of acoustic models (27d), integrates speech recognition results from each acoustic model by a selector, and judges the most reliable speech recognition result among the speech recognition results.

Owner:JAPAN SCI & TECH CORP

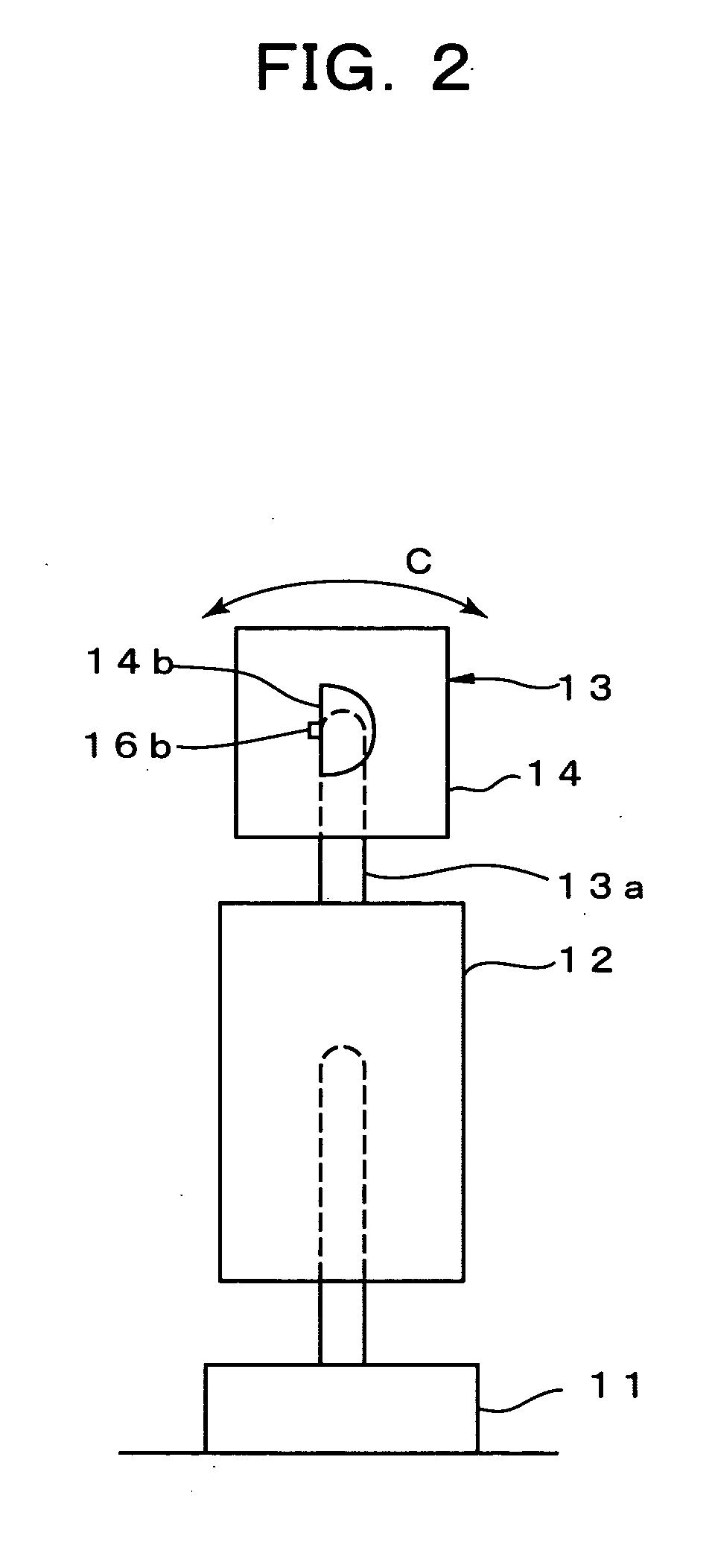

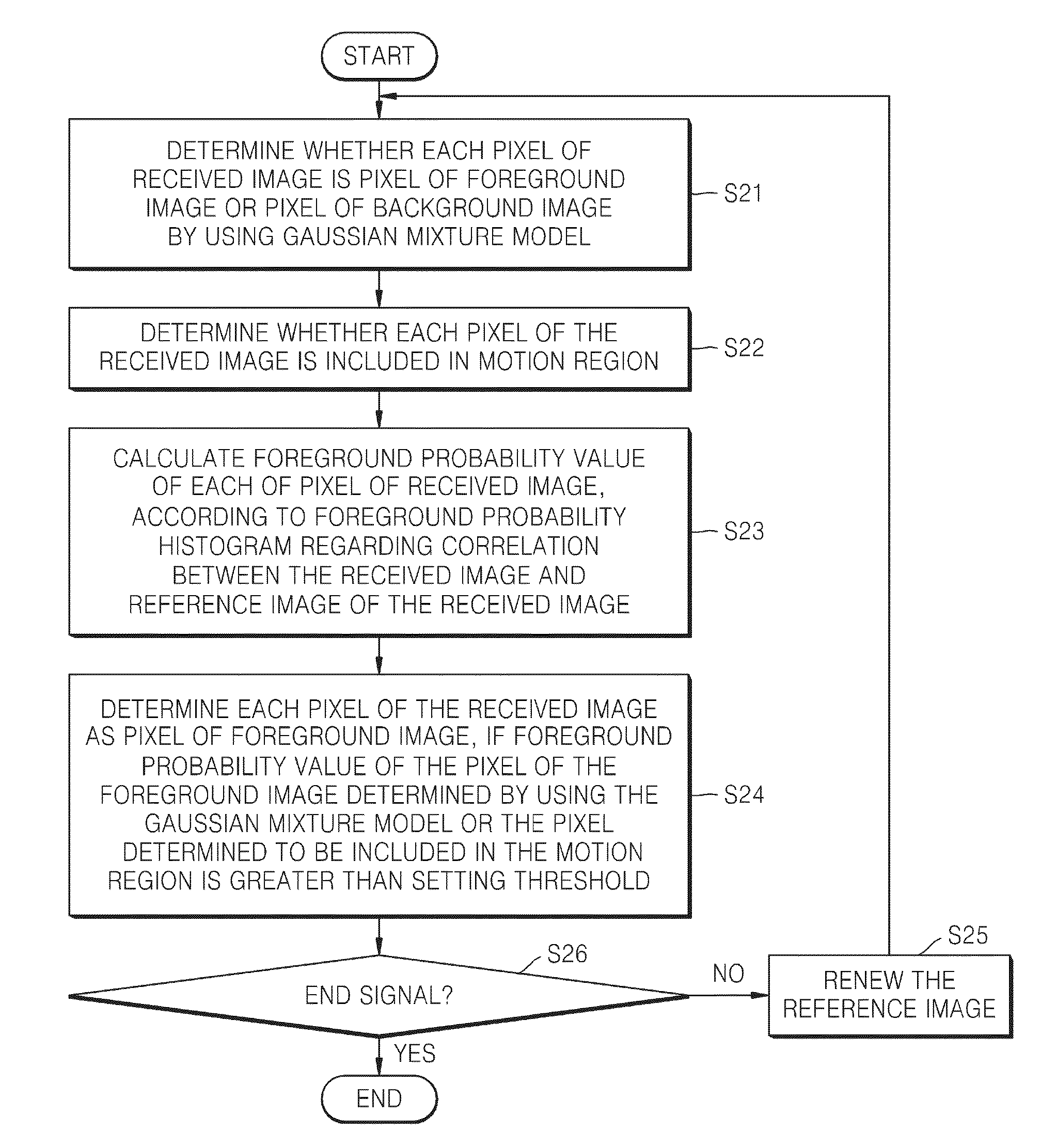

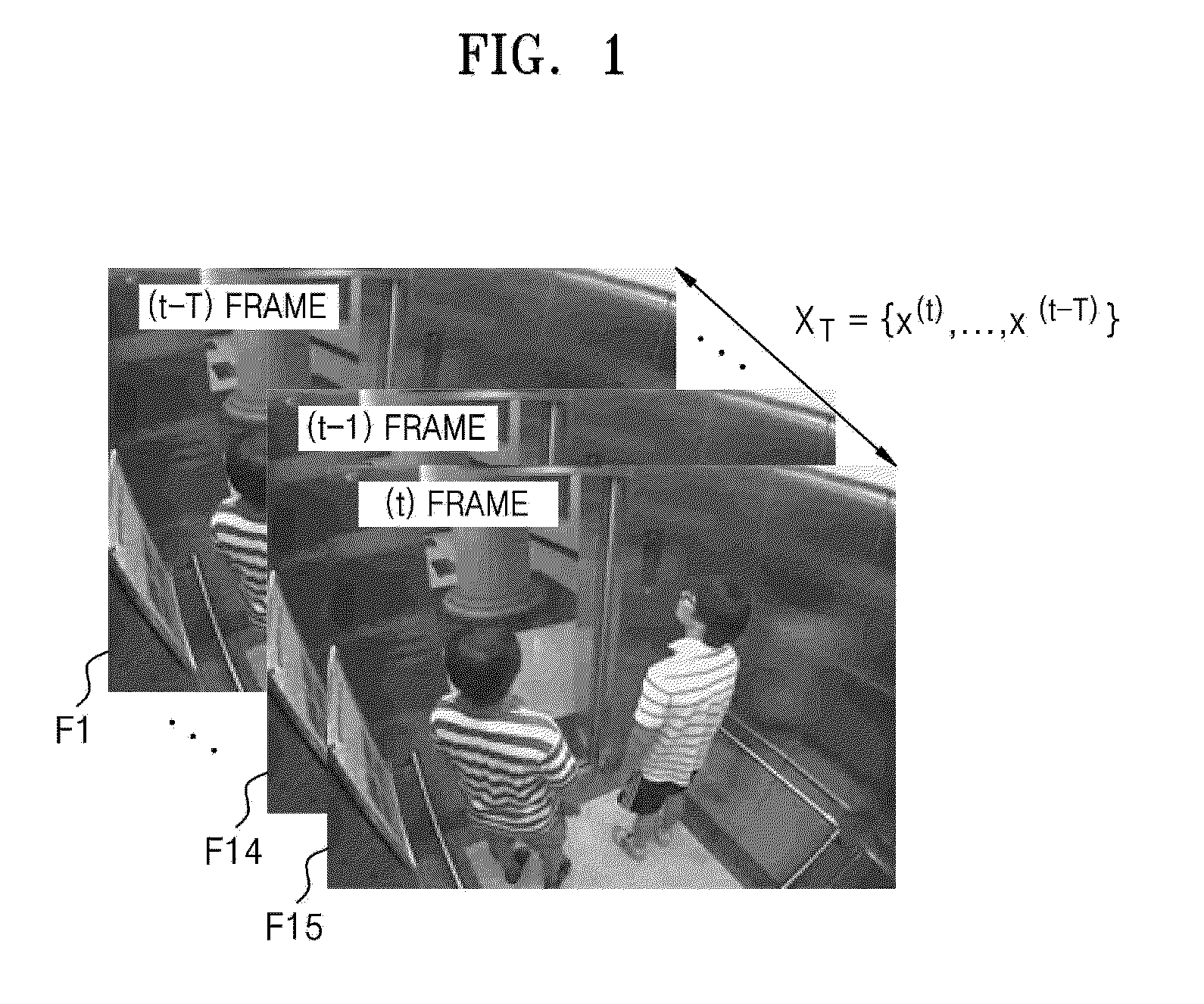

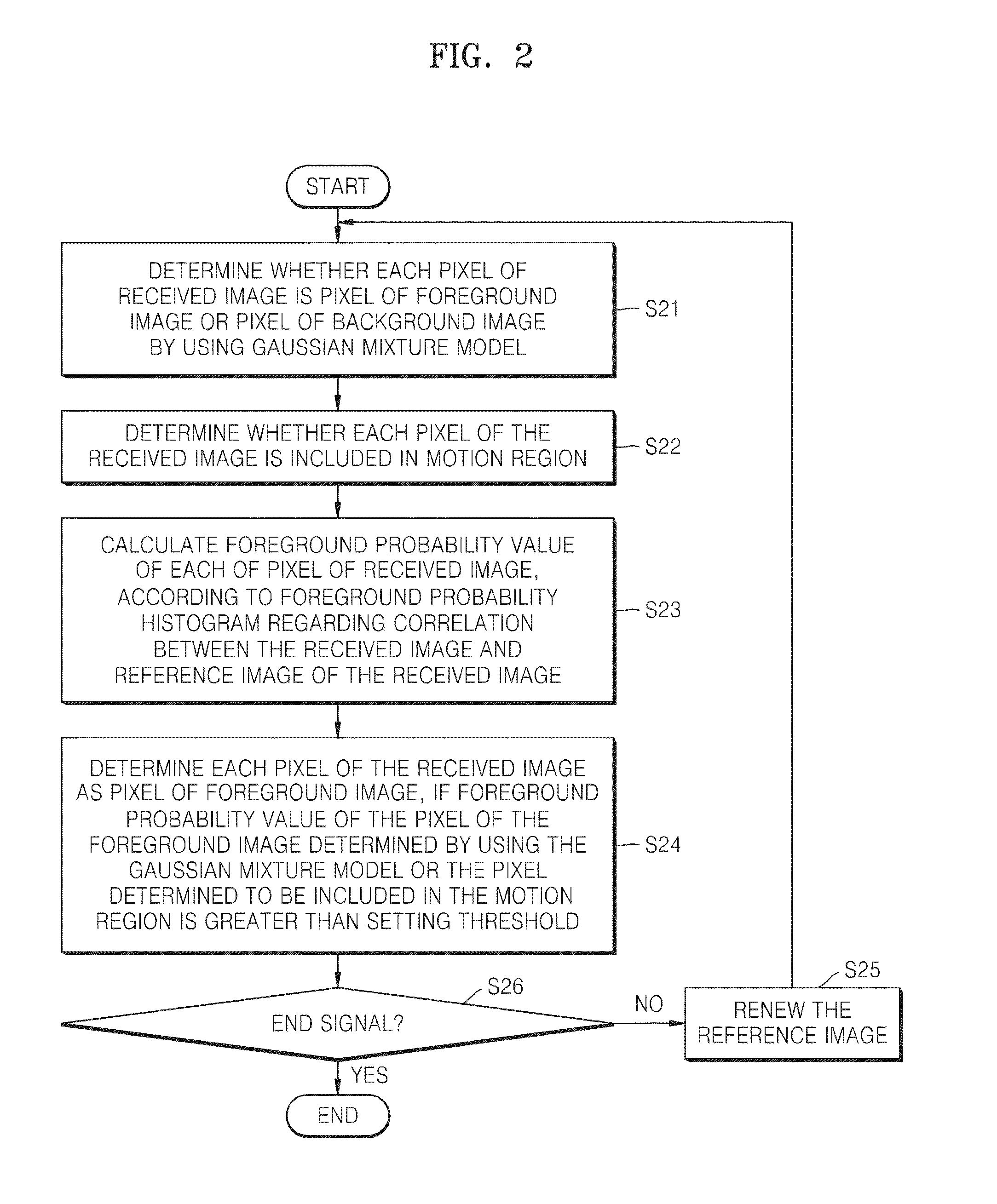

Image processing method

ActiveUS20130243322A1High separation precisionImage enhancementImage analysisImaging processingBackground image

An image processing method of separating an input image into a foreground image and a background image, the method including determining a pixel of the input image as a pixel of the foreground image if a foreground probability value of the pixel of the foreground image determined by using the Gaussian mixture model or the pixel determined to be included in a motion region is greater than a setting threshold.

Owner:HANWHA VISION CO LTD +1

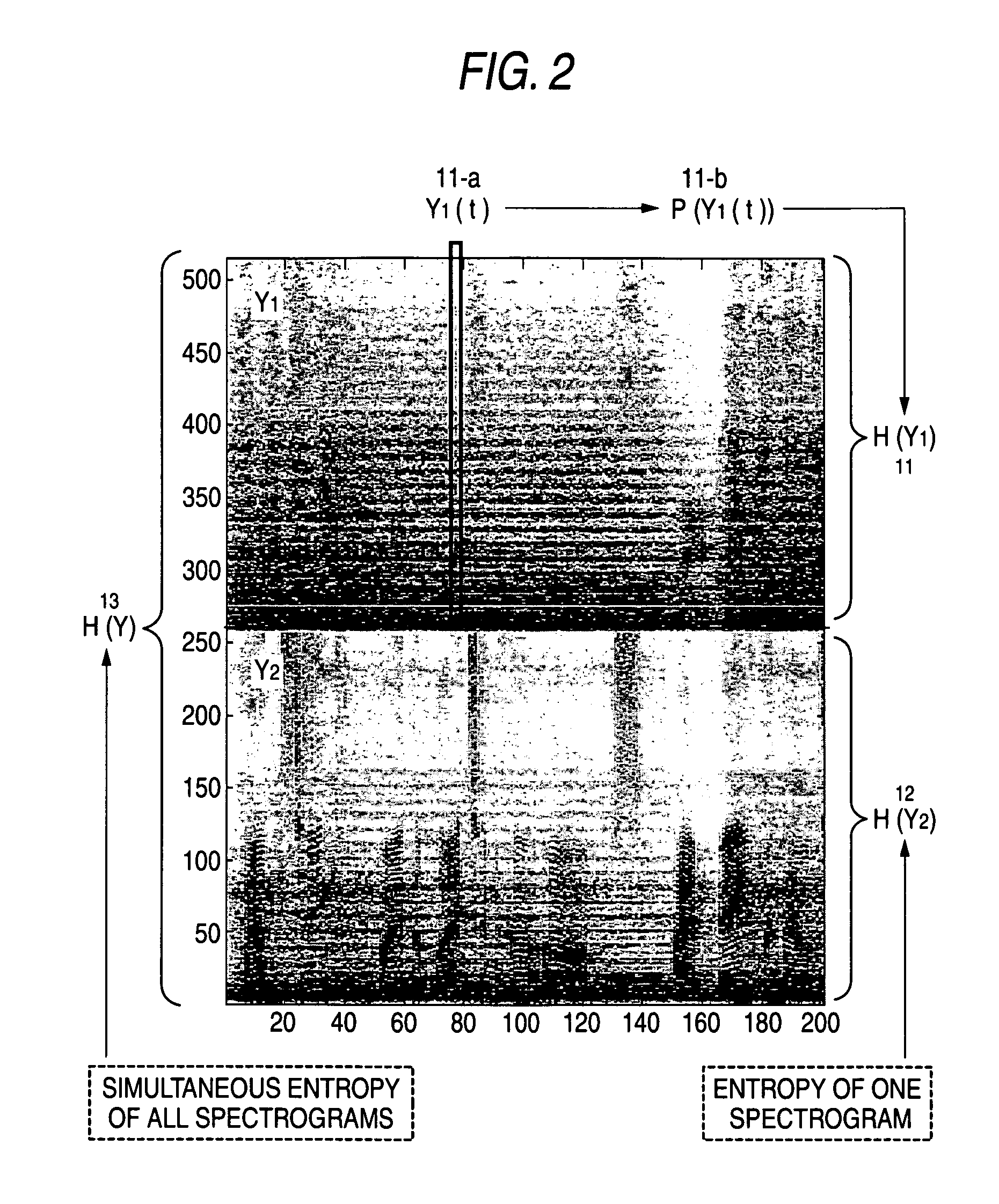

Signal separating device, signal separating method, and computer program

InactiveUS20080228470A1Improves independenceMinimize informationSpeech analysisDigital computer detailsConvolutionEngineering

A signal separating device that is inputted with signals formed by mixing plural signals and separates the signals into individual signals includes a signal converting unit that converts input signals into signals in the time-frequency domain and generates observation spectrograms and a signal separating unit that generates separated results from the observation spectrograms generated by the signal converting unit. The signal separating unit interprets the observation spectrograms as observation signals subjected to convolutive mixtures in the time-frequency domain and generates separated results by executing processing for solving convolutive mixtures in the time-frequency domain.

Owner:SONY CORP

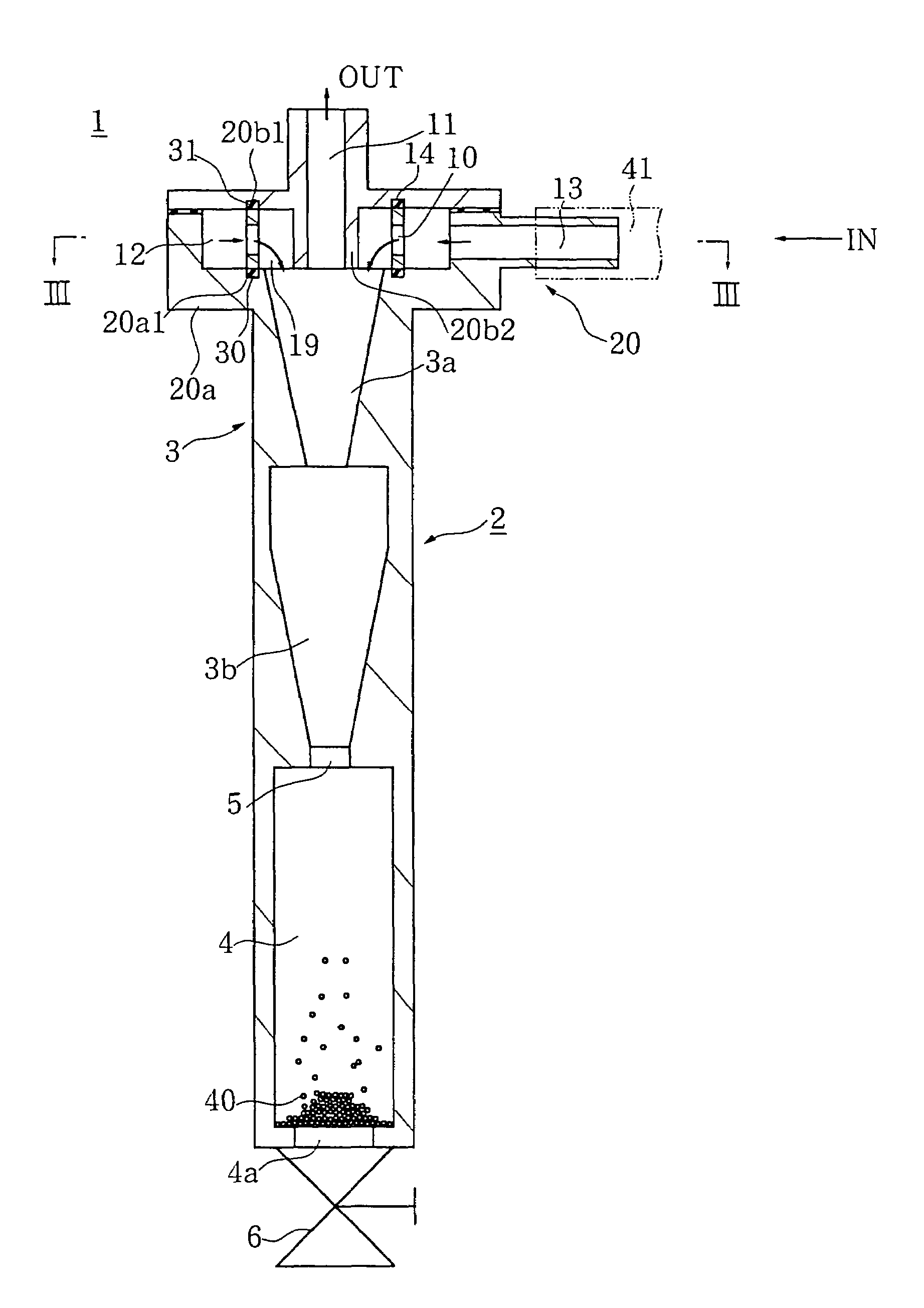

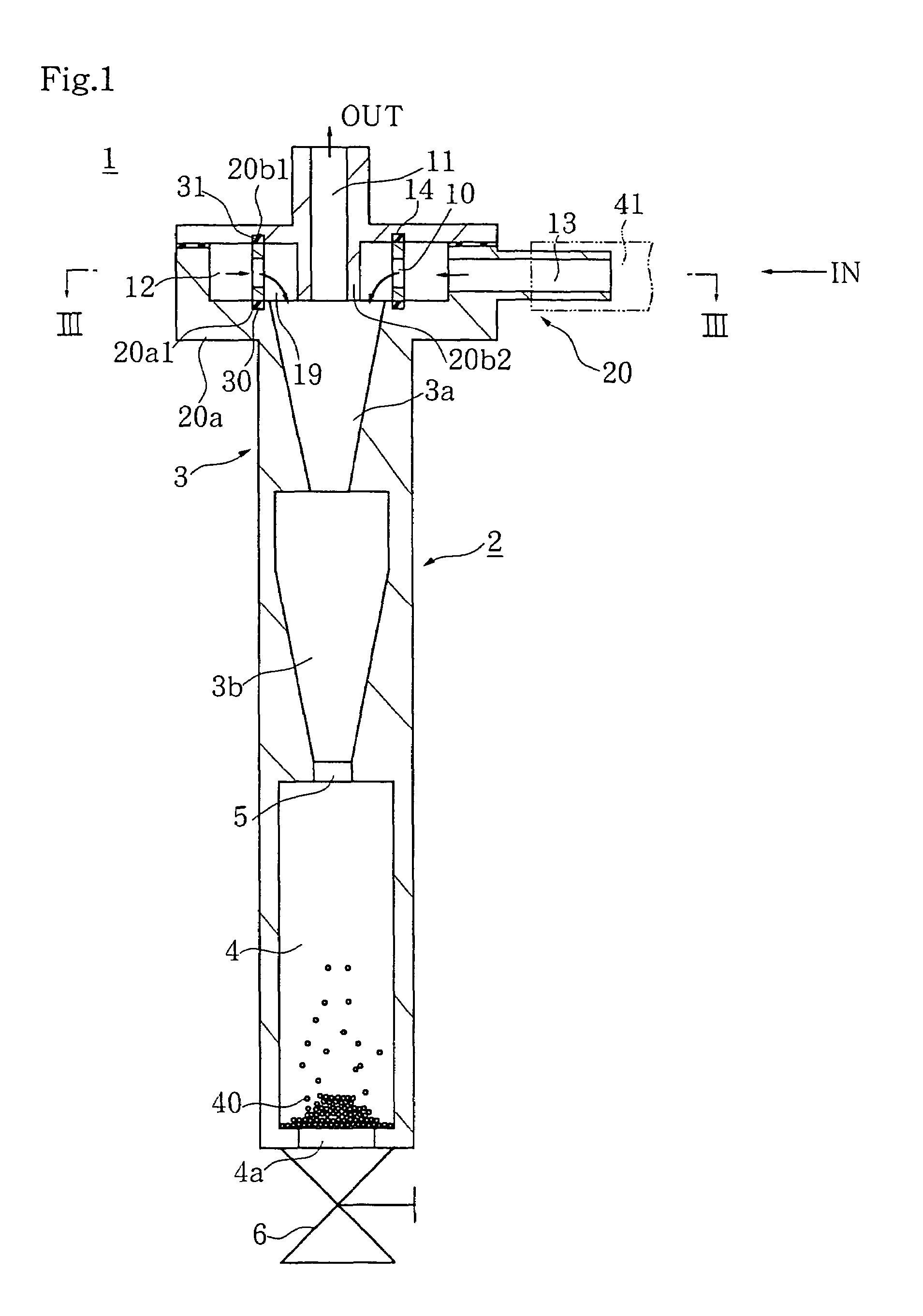

Cyclone separator

ActiveUS7314560B2High separation precisionAccurate particle sizeWater/sewage treatment by centrifugal separationReversed direction vortexCycloneEngineering

The present invention provides a cyclone separator made up of a cyclone portion for generating an eddy flow at a given flow rate by feeding a liquid containing a fine substance from liquid discharge passageways, for transferring the fine substance to an outer circumferential side by applying a centrifugal force to discharge the fine substance-free liquid from a liquid flow-out passageway, and for precipitating the fine substance by decelerating the eddy flow. The liquid discharge passageways are disposed at plural sites and the cyclone separator further contains a liquid pressurizing chamber formed around the plural liquid discharge passageways in communication therewith, and a liquid introduction passageway for introducing the liquid containing the fine substance into the liquid pressurizing chamber.

Owner:INDUSTRIA CO LTD +1

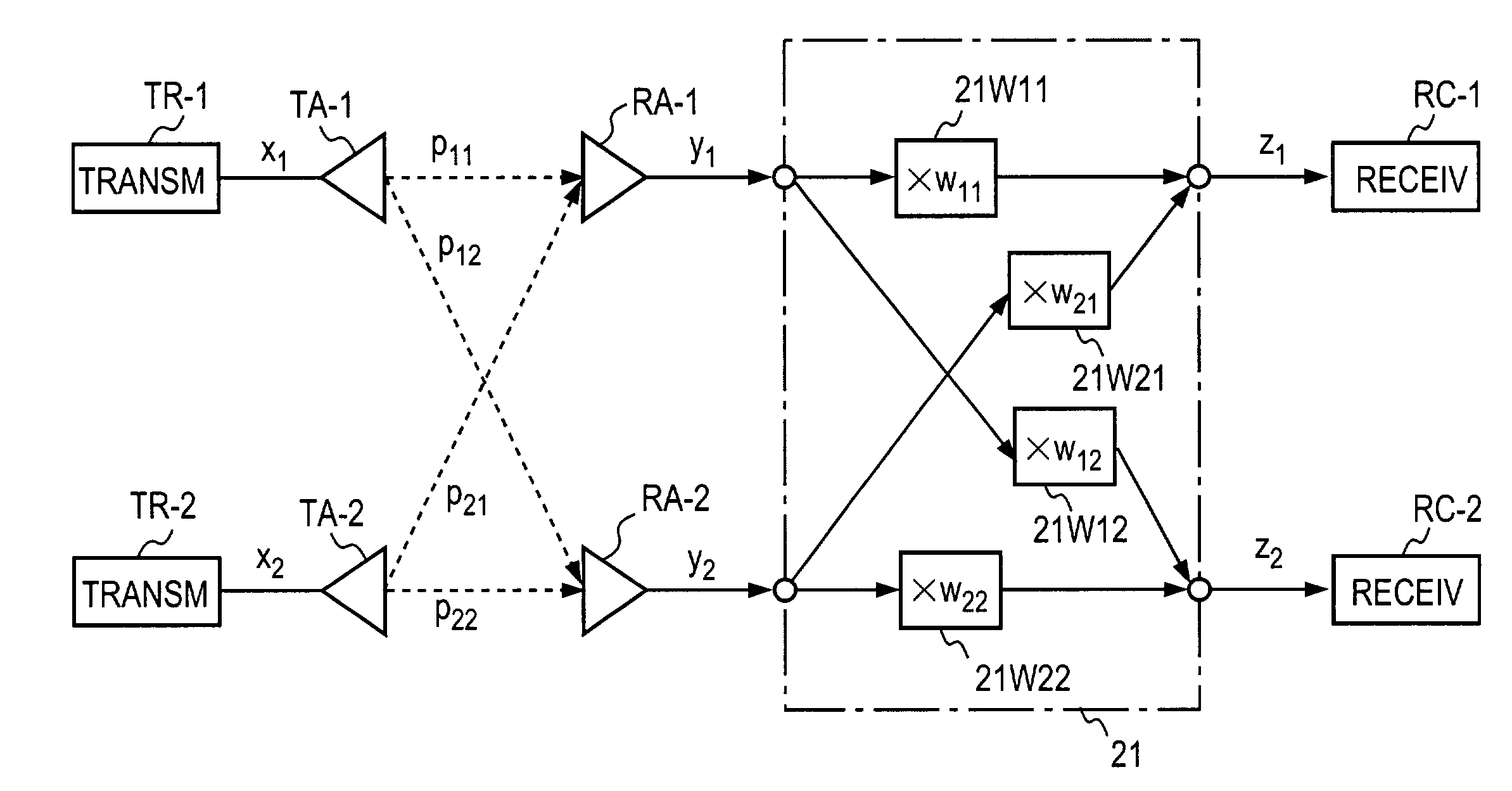

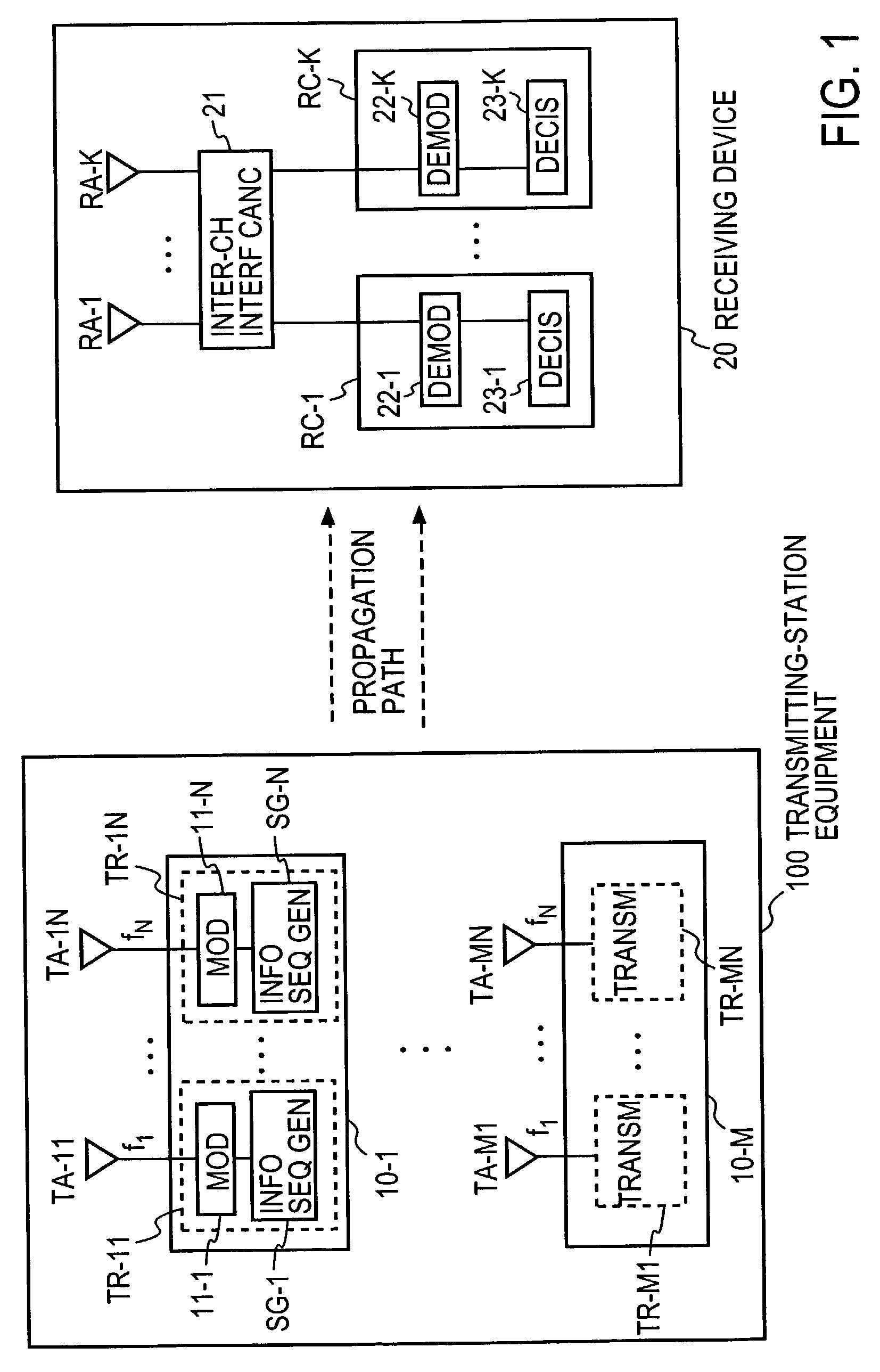

Radio communication method and apparatus for multiplex transmission of plural signals in the same frequency band

ActiveUS7227906B2High separation precisionReduce cross-correlationSpatial transmit diversityFrequency-division multiplex detailsFrequency bandInterference canceller

Different carrier frequencies are chosen for plural transmitters of a transmitting device and signals are transmitted at frequency bands overlapping each other. In the receiving device weighting coefficients are provided in input-to-output paths of an interchannel interference canceller 21 so that the cross correlation between output signals from the interchannel interference canceller is minimized.

Owner:NTT DOCOMO INC

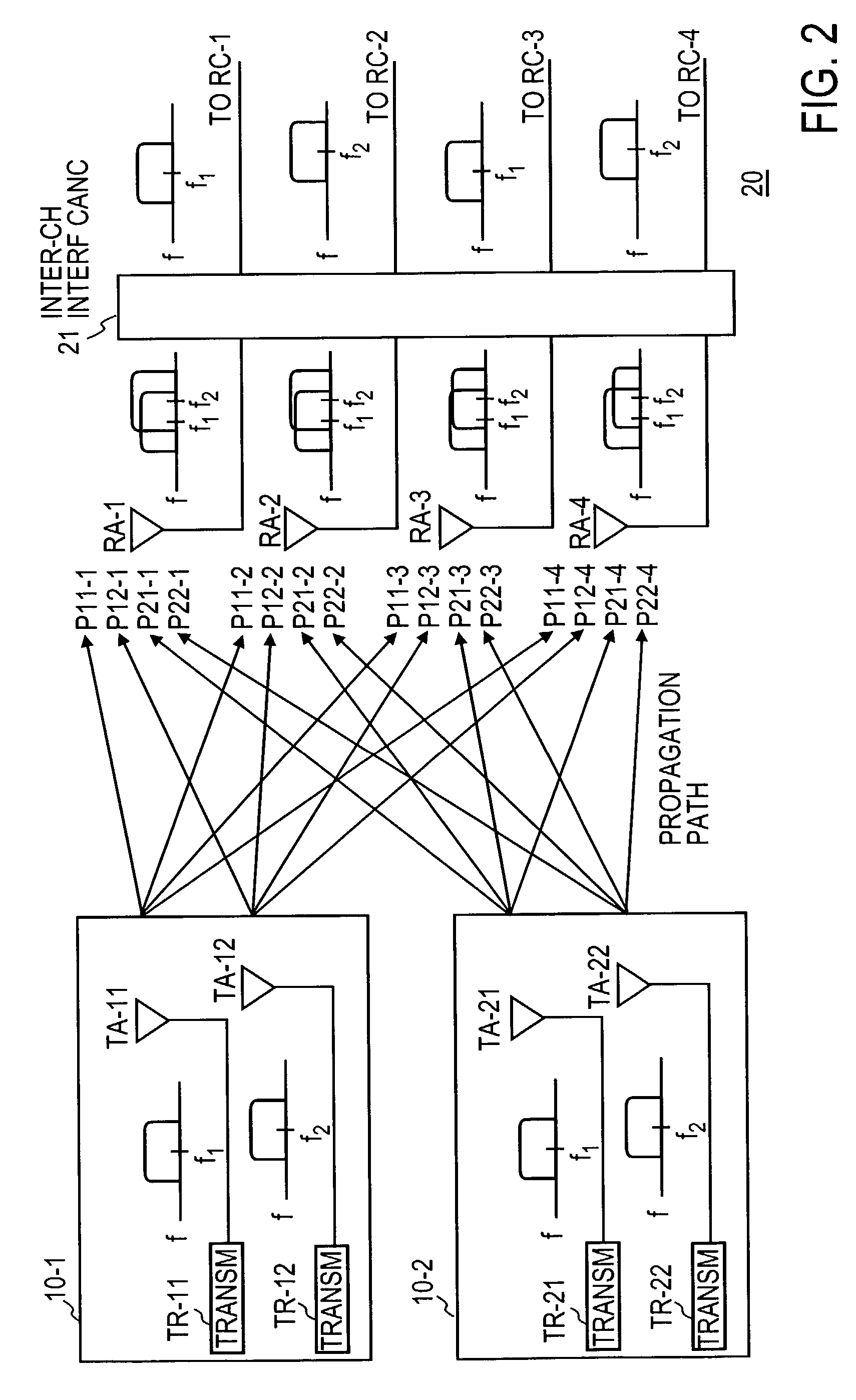

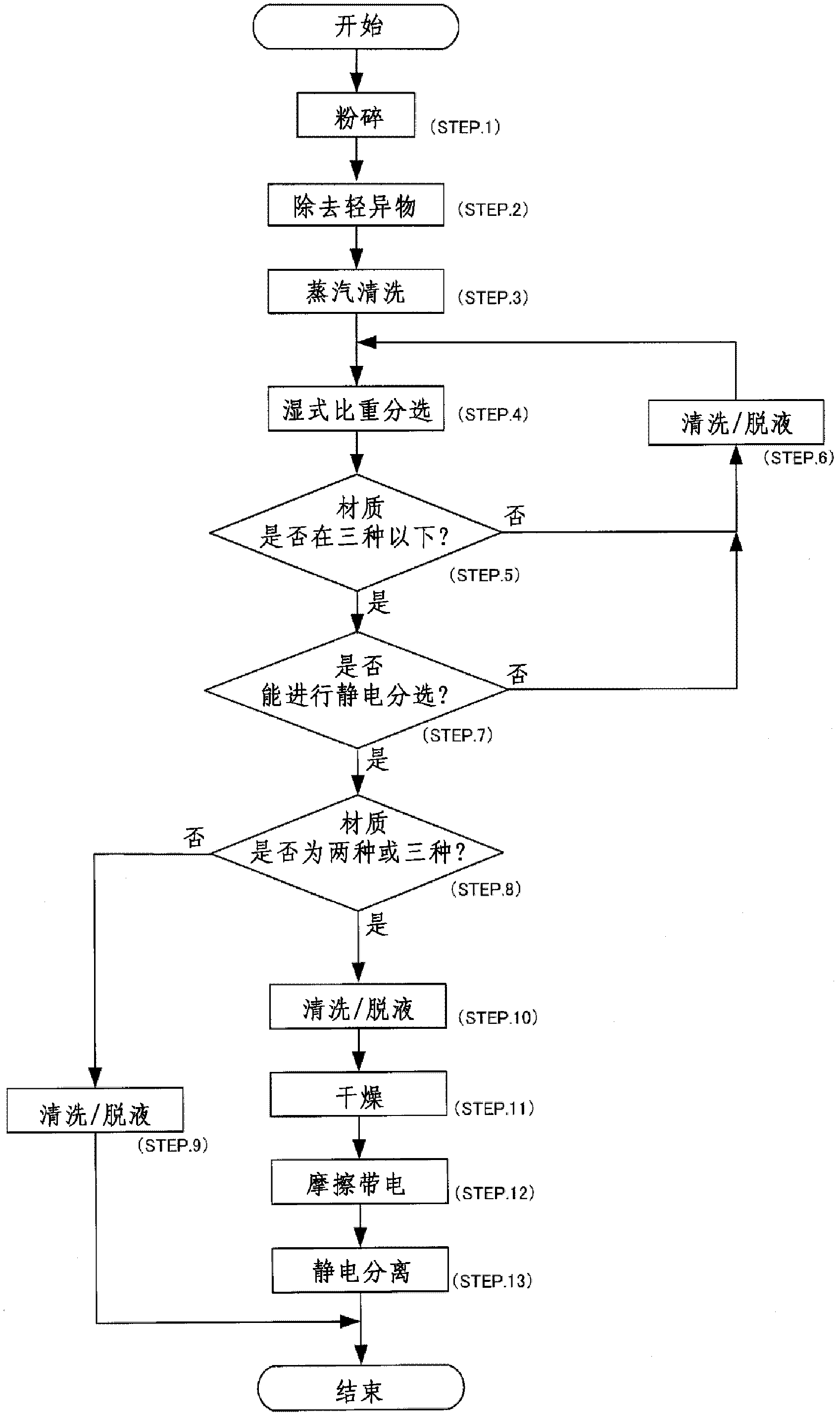

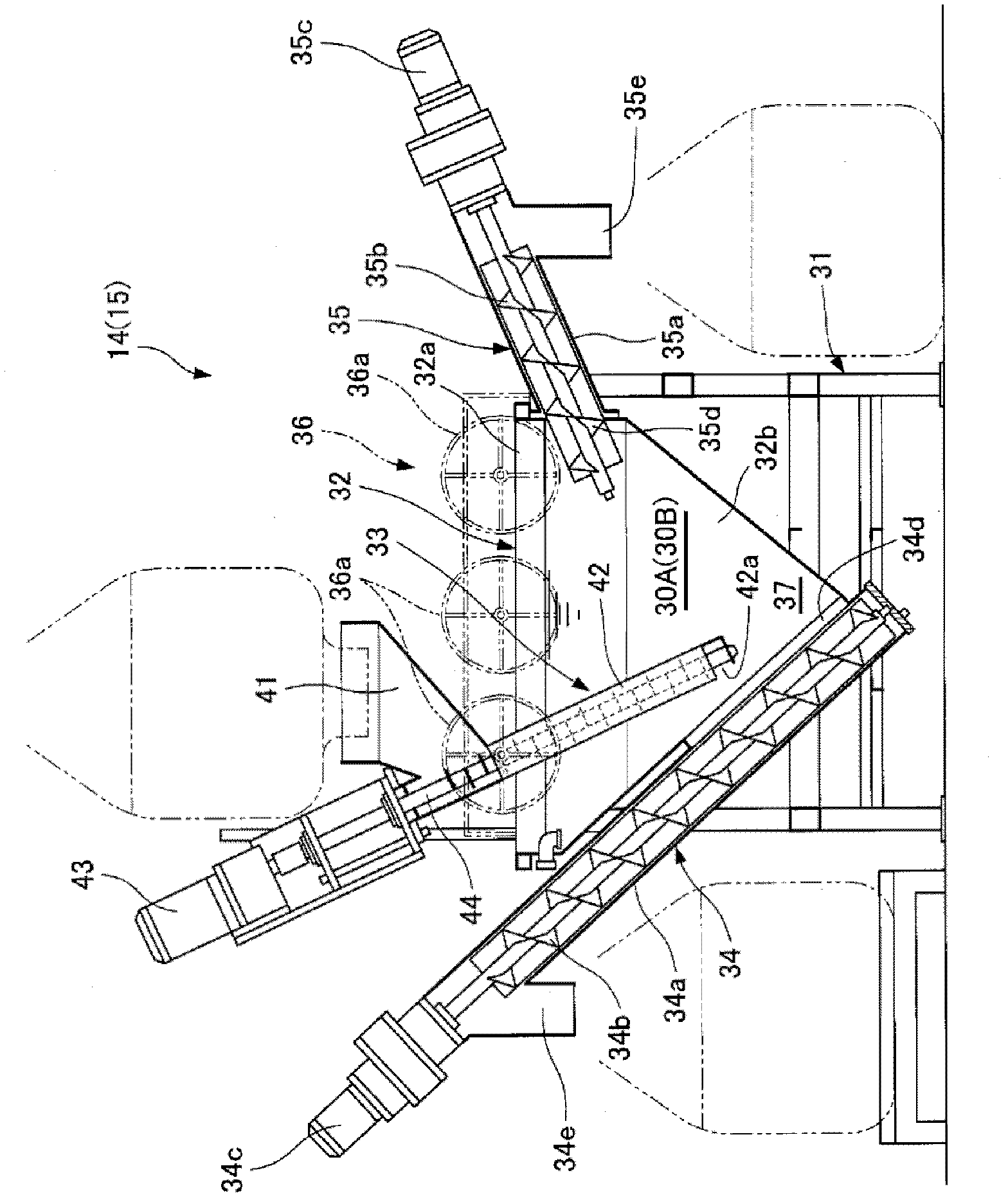

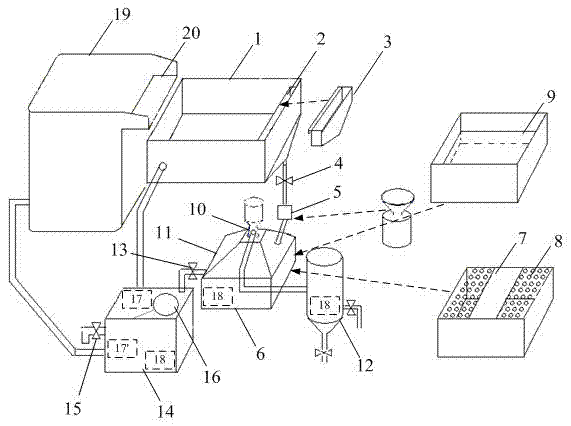

Method and facility for sorting and separating waste plastic

InactiveCN102574304AEfficient implementation of recyclingReliable removalElectrostatic separationPlastic recyclingElectrostatic separationCrusher

Disclosed is a facility for precisely sorting, by material, waste plastic that includes many types of material. Said facility is provided with: a crusher (11) that pulverizes a waste plastic feedstock into waste plastic fragments having a prescribed size; a steam-cleaning device (13) that is disposed downstream from the crusher and that cleans the waste plastic fragments; a primary wet specific-gravity sorter (14) and a secondary wet specific-gravity sorter (15) that are disposed downstream from the steam-cleaning device and that use separation liquids, which have specific gravities in the middle of the specific gravities of the materials included in the waste plastic fragments, to separate out at most three types of floating or sinking specific-gravity-sorted fragments; and first through third electrostatic separation devices (16A-16C), each of which is disposed downstream of the primary and secondary wet specific-gravity sorters and has a frictional charging device, which frictionally charges the specific-gravity-sorted fragments, and an electrostatic sorter that puts the frictionally-charged specific-gravity-sorted fragments in an electrostatic field between a rotating drum electrode to which a high voltage is applied and an opposing electrode, thereby changing the direction the fragments fall and separating said fragments by material.

Owner:HITACHI ZOSEN CORP +1

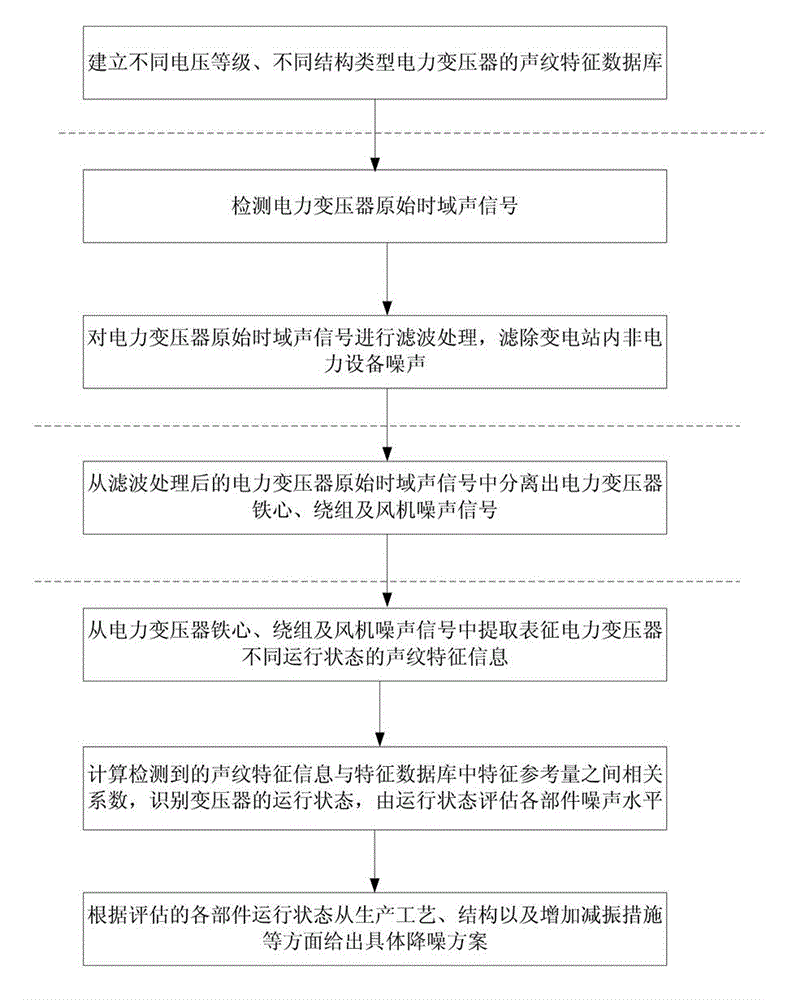

Noise separation-based power transformer noise assessment method

ActiveCN104964738ANoise level is assessed individuallyReduce recognition errorsSubsonic/sonic/ultrasonic wave measurementTransformerNoise level

The invention discloses a noise separation-based power transformer noise assessment method. The steps include: 1) building a voiceprint feature database in advance according to voiceprint feature information corresponding to noise signals generated by a fan component, an iron core component and a winding component when a standard power transformer is in different running states; 2) collecting in real time sound wave signals sent when a transformer to be tested runs, so as to obtain noise signals to be assessed; 3) separating noise signals generated by the fan component, the iron core component and the winding component from the noise signals to be assessed; and 4) extracting voiceprint feature information of each noise signal, identifying the running state of the transformer to be tested, and assessing the noise level of each component according to the running state. The noise separation-based power transformer noise assessment method provided by the invention can realize assessment of the noise level of each component in the power transformer utilizing acoustic characteristics, and has the advantages of easy operation implementation and high assessment precision and efficiency.

Owner:STATE GRID CORP OF CHINA +2

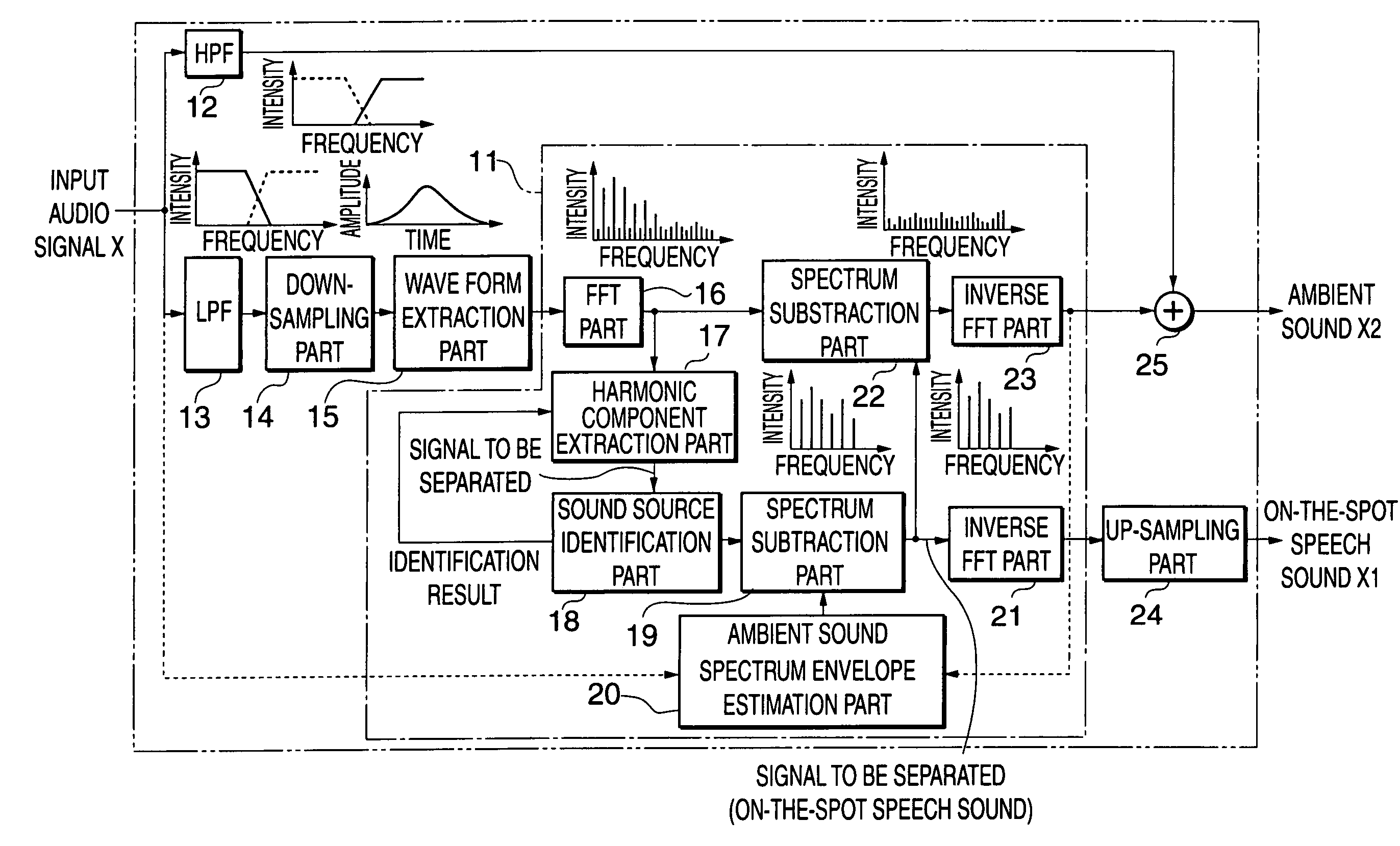

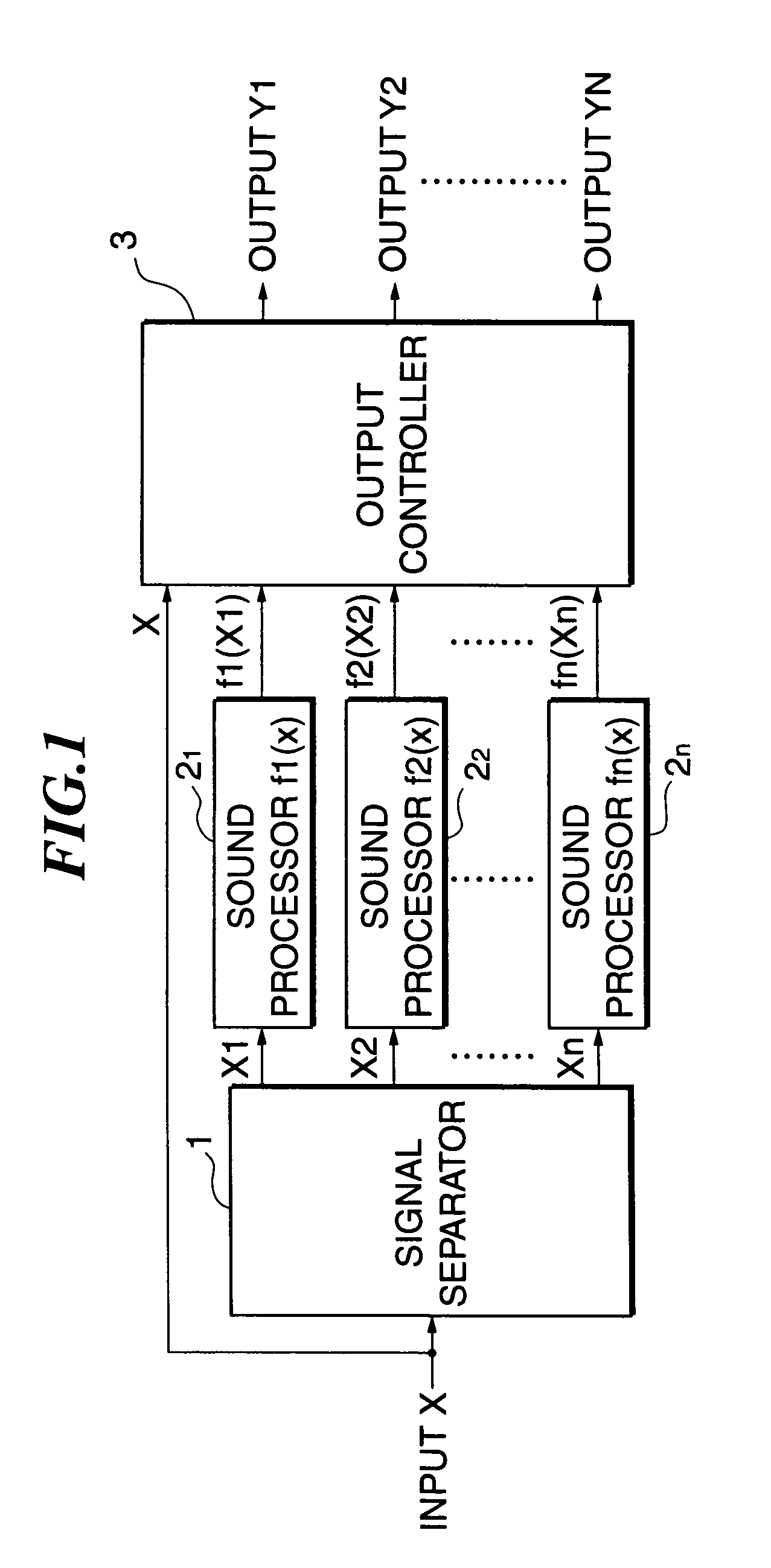

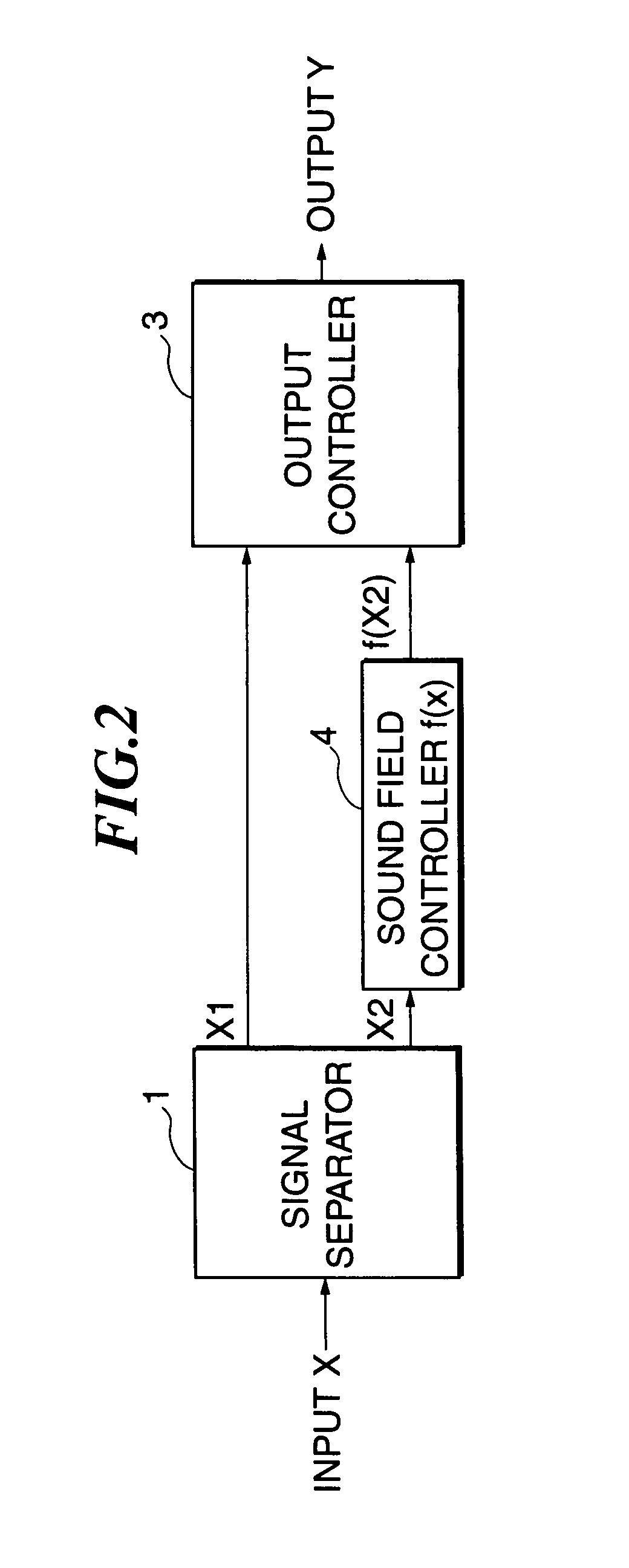

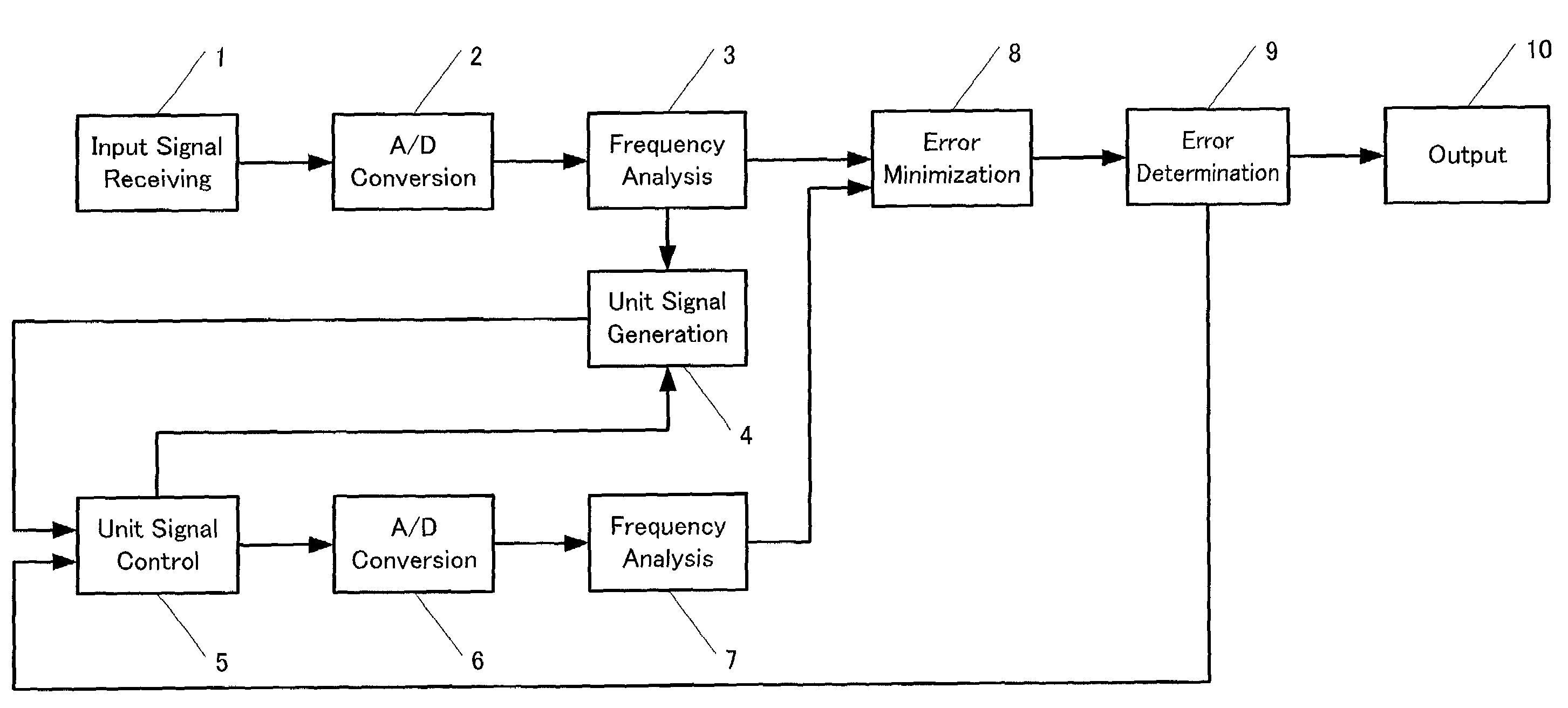

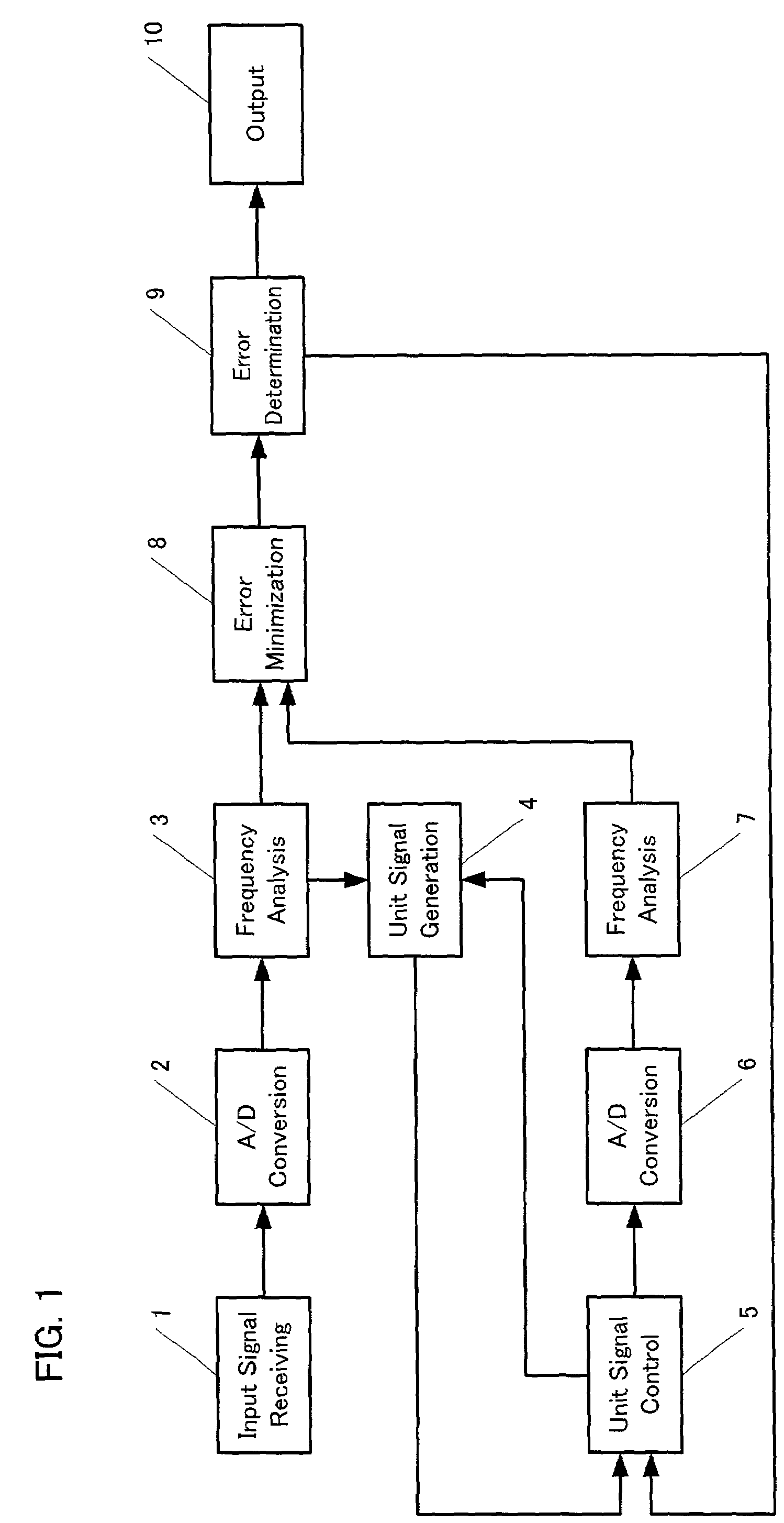

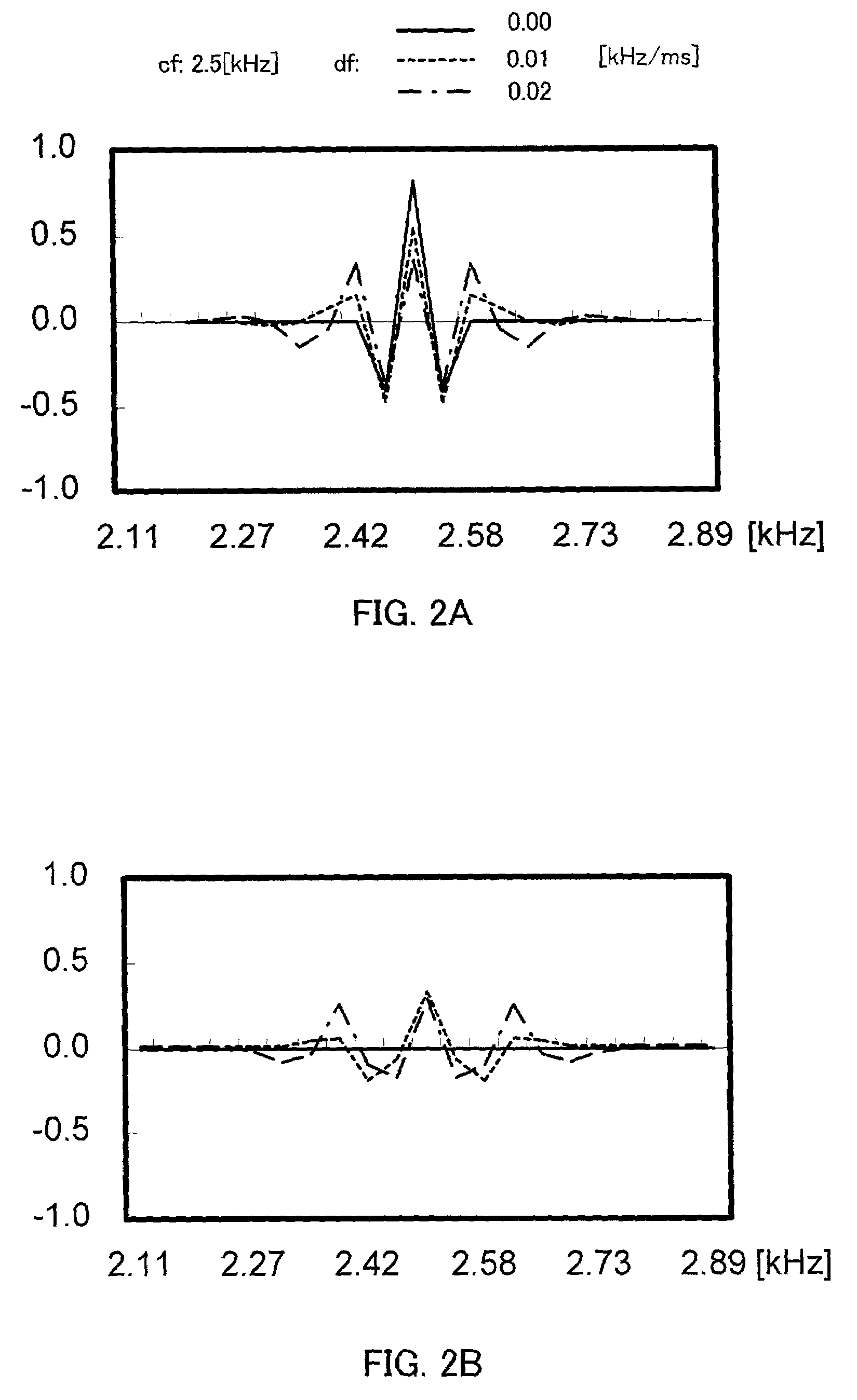

Sound processing method and apparatus

InactiveUS7162045B1High separation precisionSpeech analysisTransmission noise suppressionAudio frequencyComputer science

A sound processing method and apparatus are provided, which are capable of performing sound processing on input audio signals containing a plurality of signal components being different in desired sound processing conditions, in a manner that allows natural sound to be reproduced. An input audio signal of at least one system is separated into a plurality of separated signal components, and each signal component of at least part of the plurality of separated signal components is subjected to individual sound processing according to the signal component, and the plurality of separated signal components are outputted as at least one audio signal after each signal component of the at least part thereof is subjected to the individual sound processing. The plurality of separated signal components are synthesized into a synthesized audio signal, which is then outputted, or alternatively, the plurality of separated signal components are outputted separately as audio signals.

Owner:YAMAHA CORP

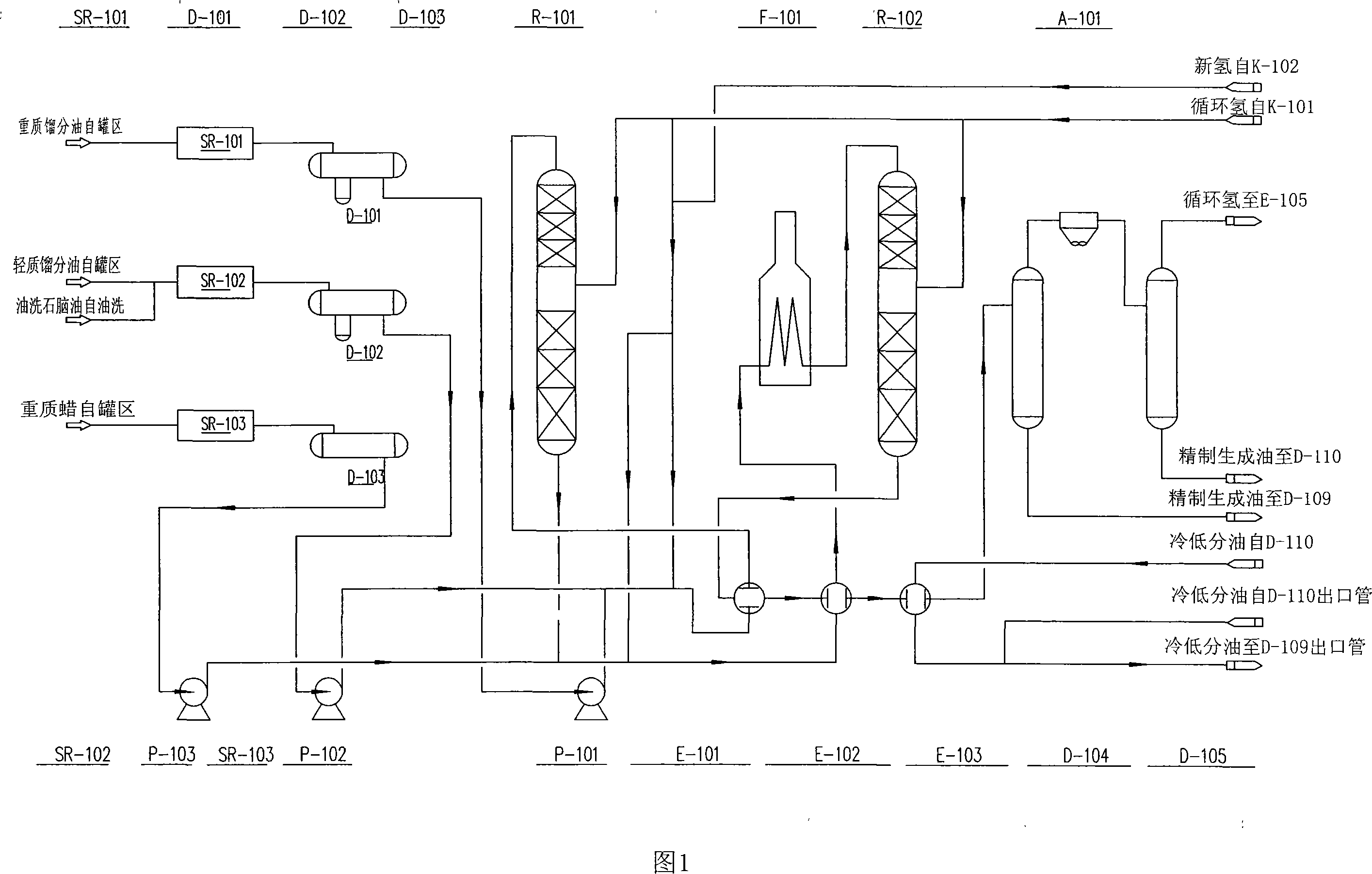

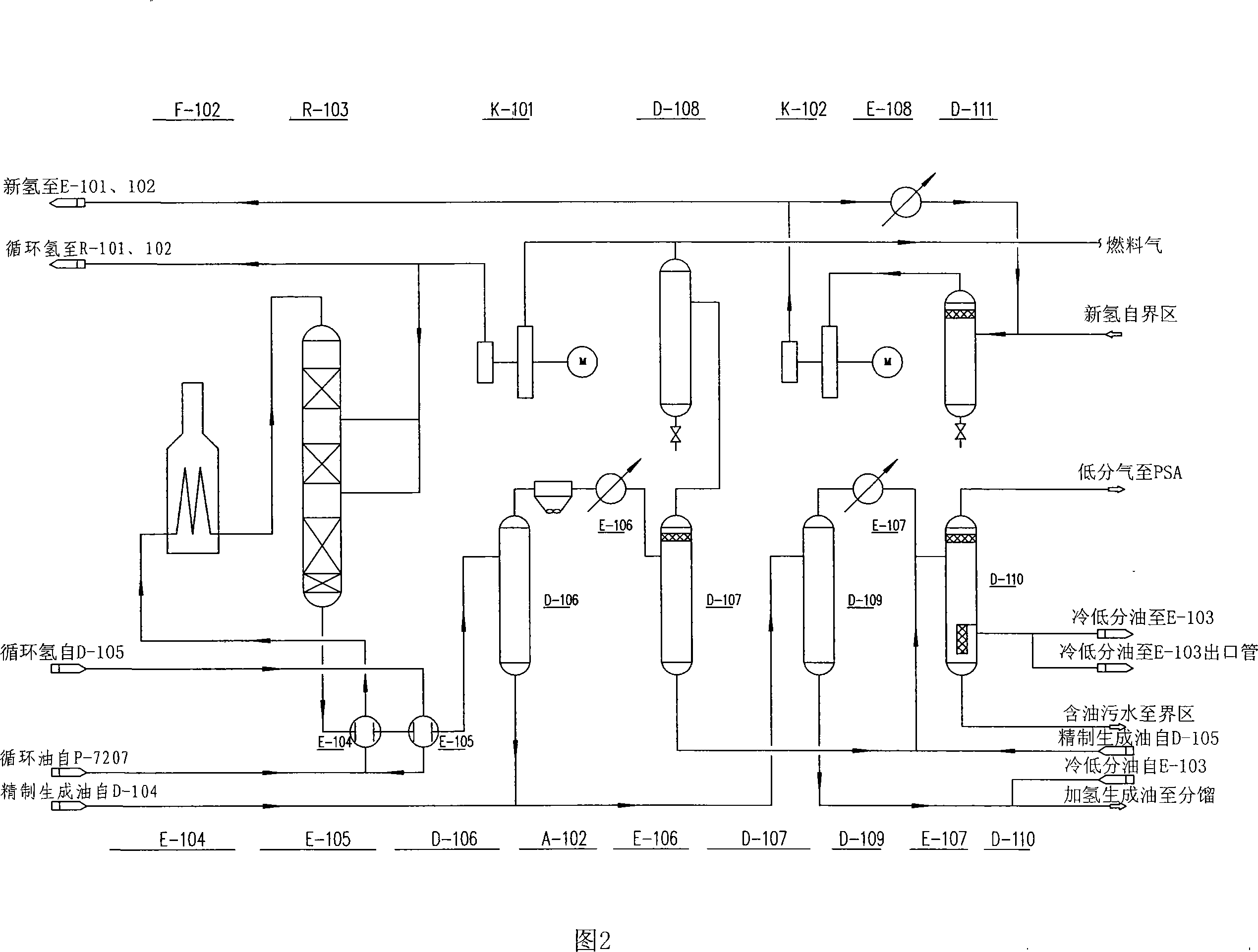

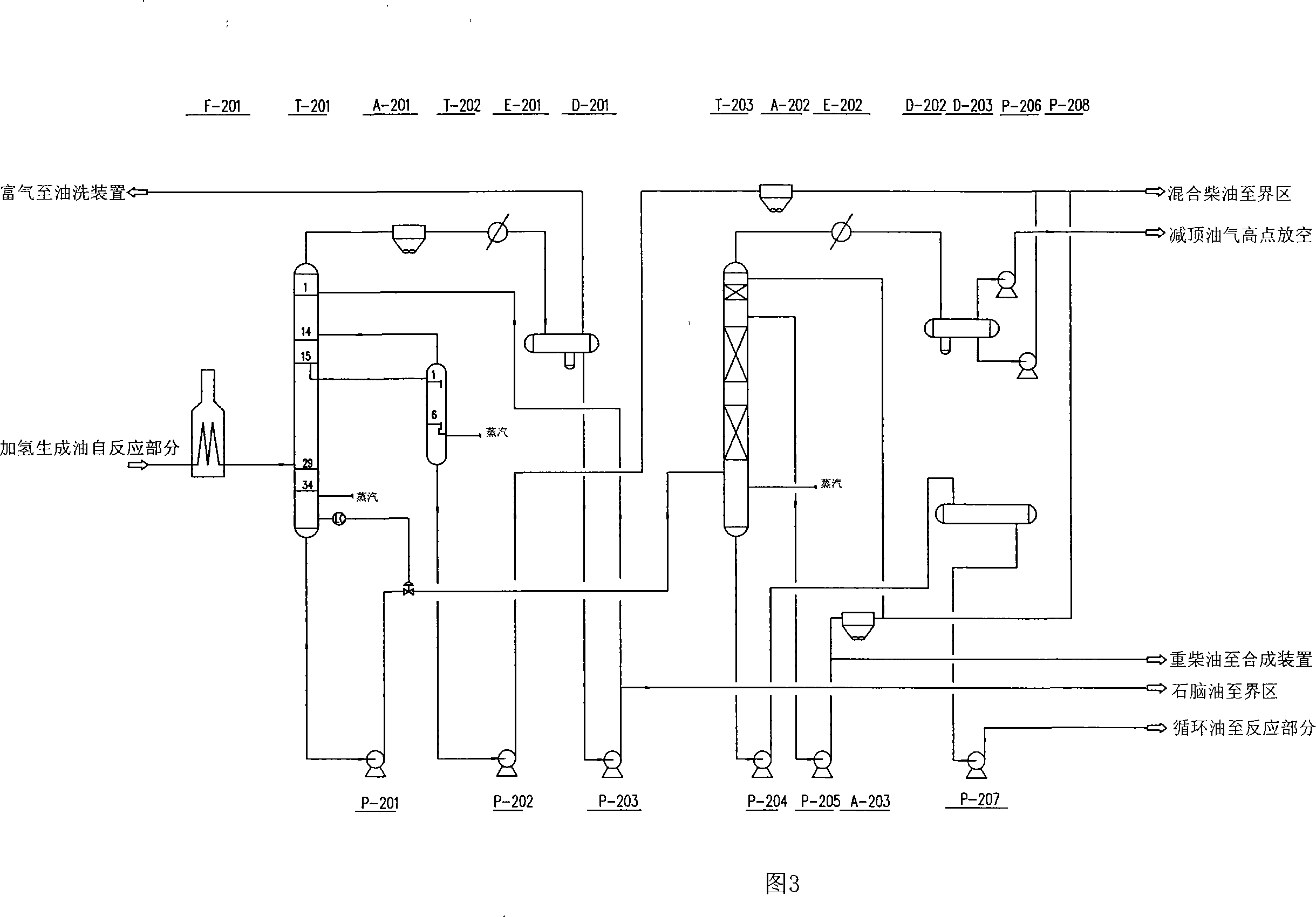

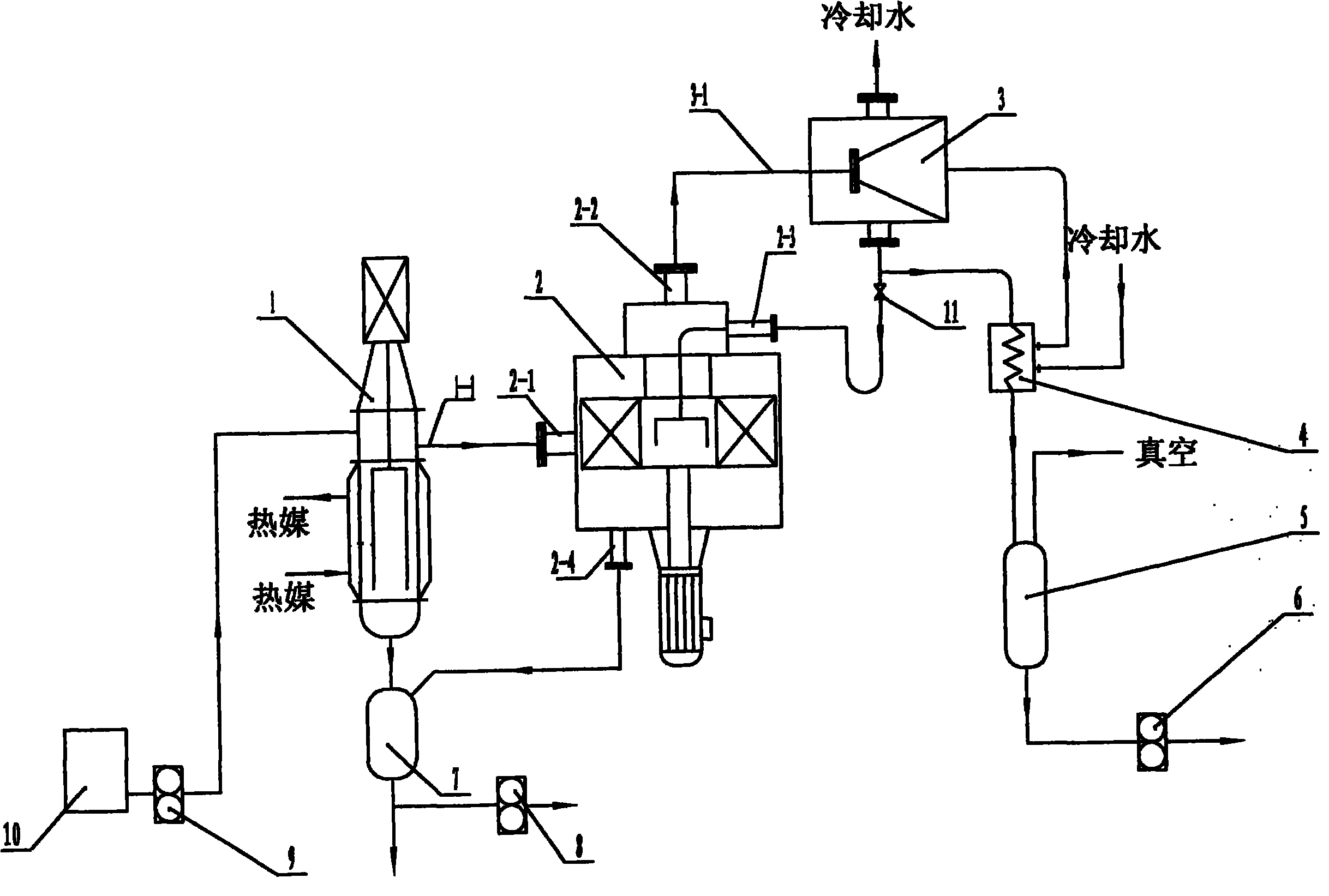

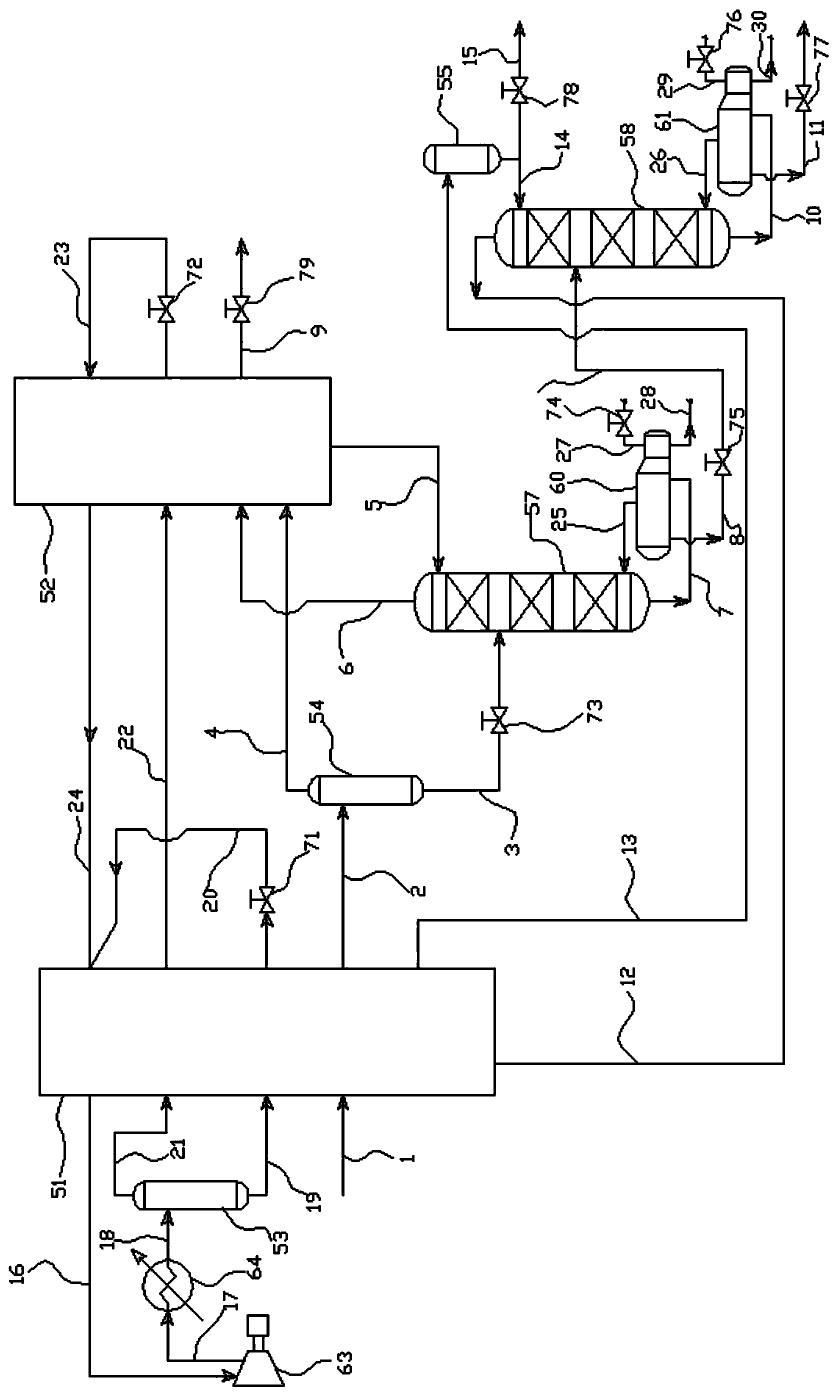

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

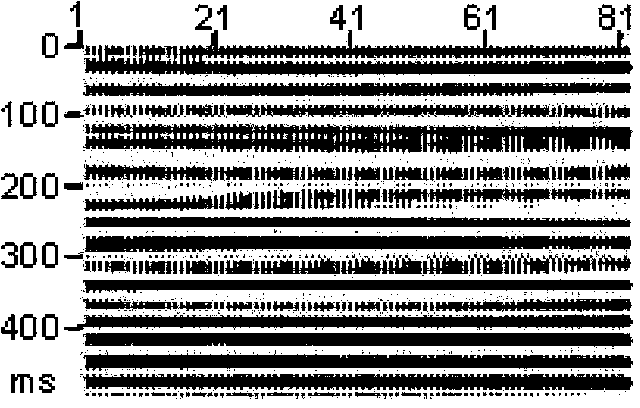

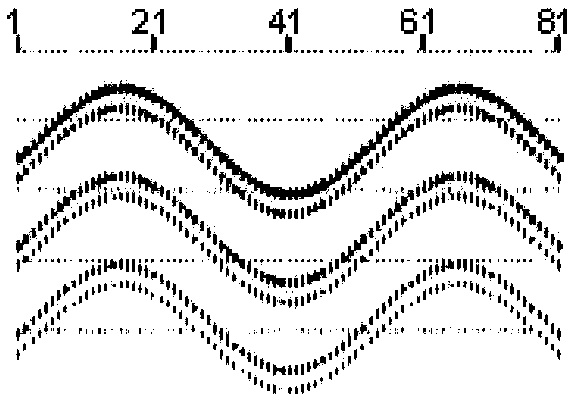

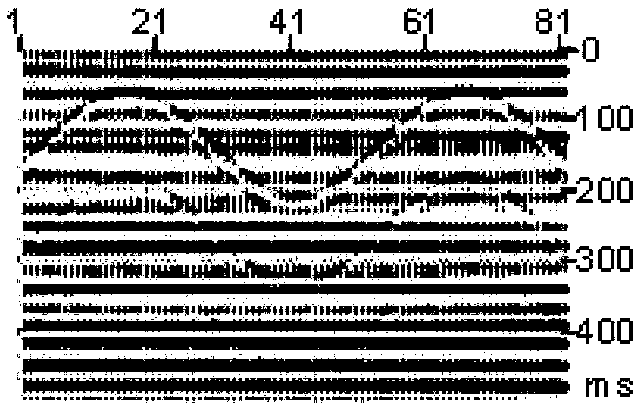

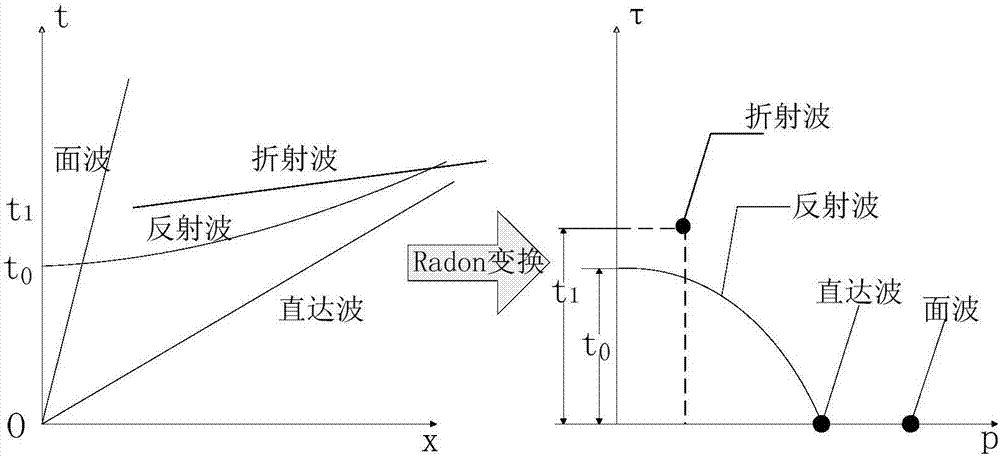

Seismic diffracted wave separating and imaging method

ActiveCN103675897AImprove recognition accuracyImprove forecast accuracySeismic signal processingImaging processingImage resolution

The invention provides a seismic diffracted wave separating and imaging method and belongs to the field of imaging processing and fracture-cave reservoir prediction in geophysical exploration of petroleum. According to the method, diffracted waves are separated from an original seismic record according to the difference between reflected waves and diffracted waves, and the separated diffracted waves are imaged independently. Diffracted wave information obtained through the method provided by the invention is complete, the diffracted wave imaging result has relatively high lateral resolution, and meanwhile, the result of independent imaging of the diffracted waves eliminates an interference effect on the diffracted waves caused by reflected waves, directly reflects the location information of a fracture-cave reservoir body and is conducive to improving the accuracy of identification of the fracture-cave reservoir body.

Owner:CHINA PETROLEUM & CHEM CORP +1

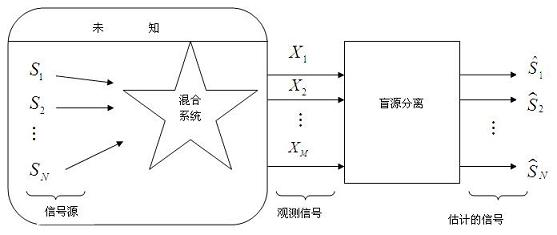

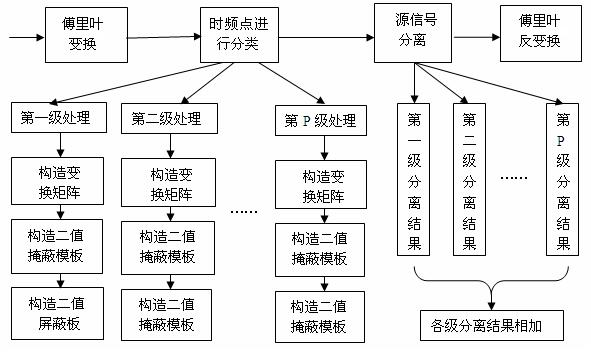

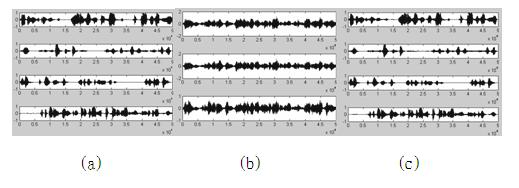

Matrix-transformation-based method for underdetermined blind source separation

The invention discloses a matrix-transformation-based method for underdetermined blind source separation. The method comprises the following steps of: gradually transforming a mixed matrix to obtain a transformed matrix, then acting the transformed matrix on an observation signal to gradually remove each source signal, and constructing multi-stage binary shielding templates by zero points generated in each observation signal to gradually separate the source signal. By the method, the requirement on sparsity of the source signal is reduced; aliasing of at most M-1 paths of source signals is prevented (wherein M is the number of sensors); source signals for forming each time frequency point can be clearly known; the underdetermined separation problem of music signals and noise signals is solved; the statistical property requirement on the source signal is low; the underdetermined separation problem of Gaussian signals and related signals is solved; processing stages are adjusted according to the requirement of separation precision; when the processing level is more, the separation result is better; the separation process is realized by aid of the matrix transformation; and the complexity is relatively low.

Owner:DALIAN UNIV OF TECH

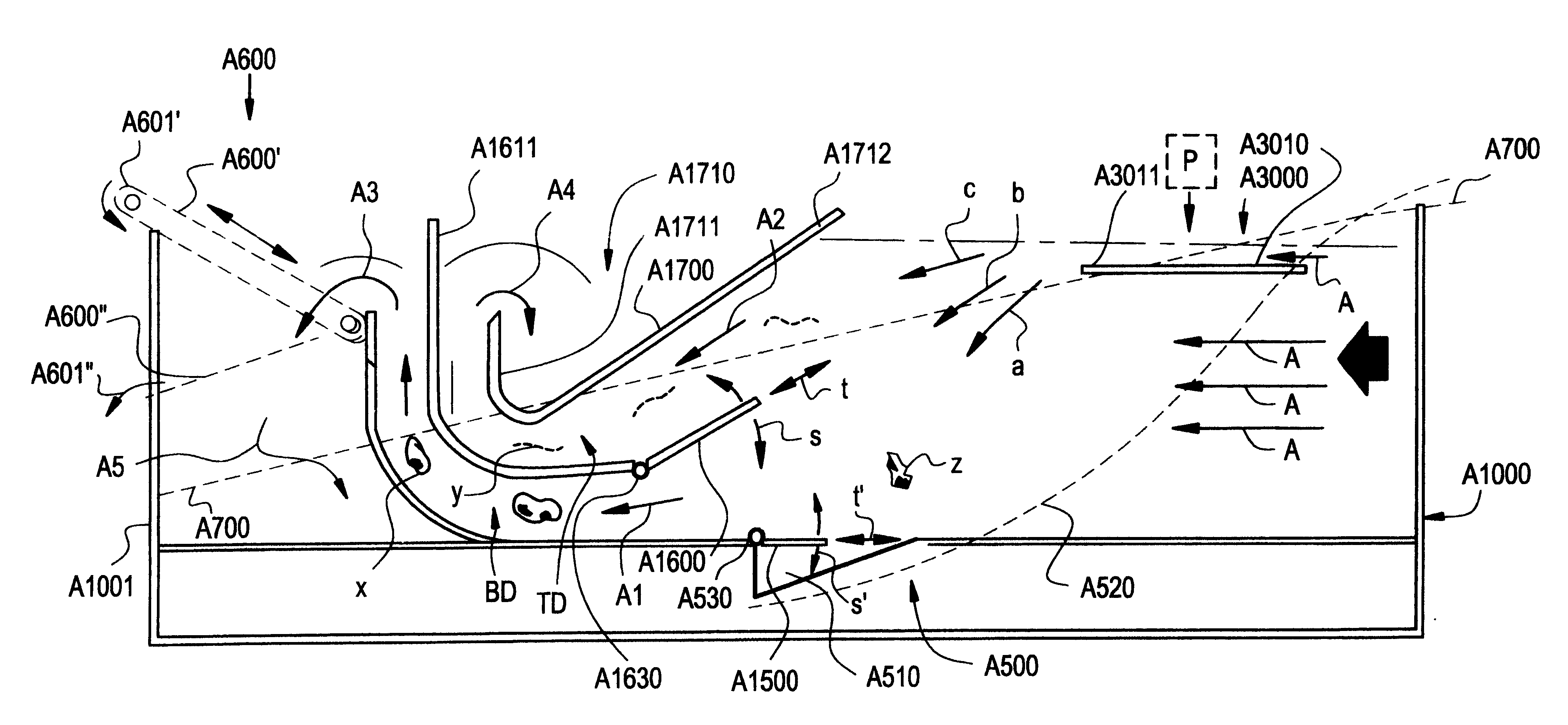

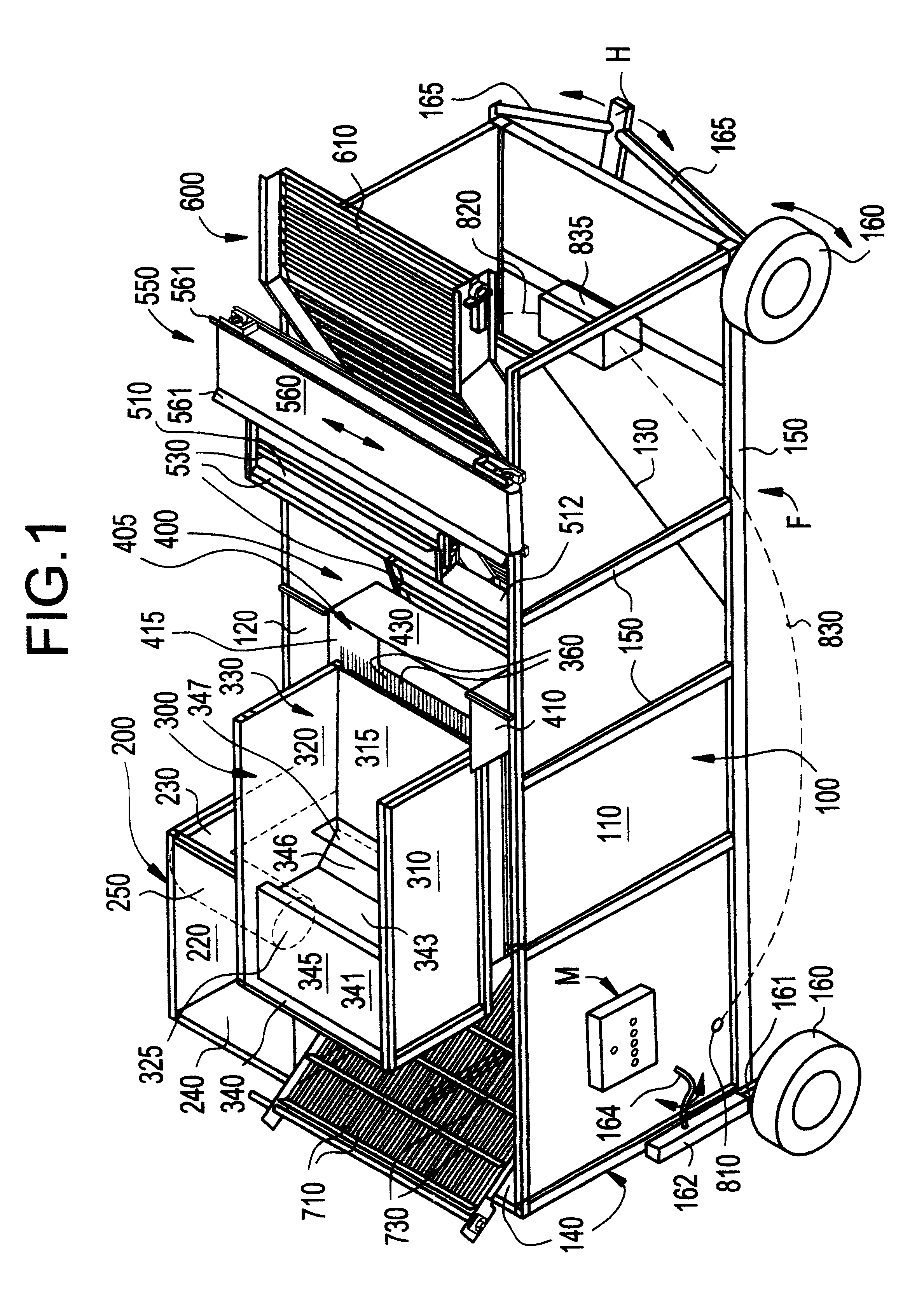

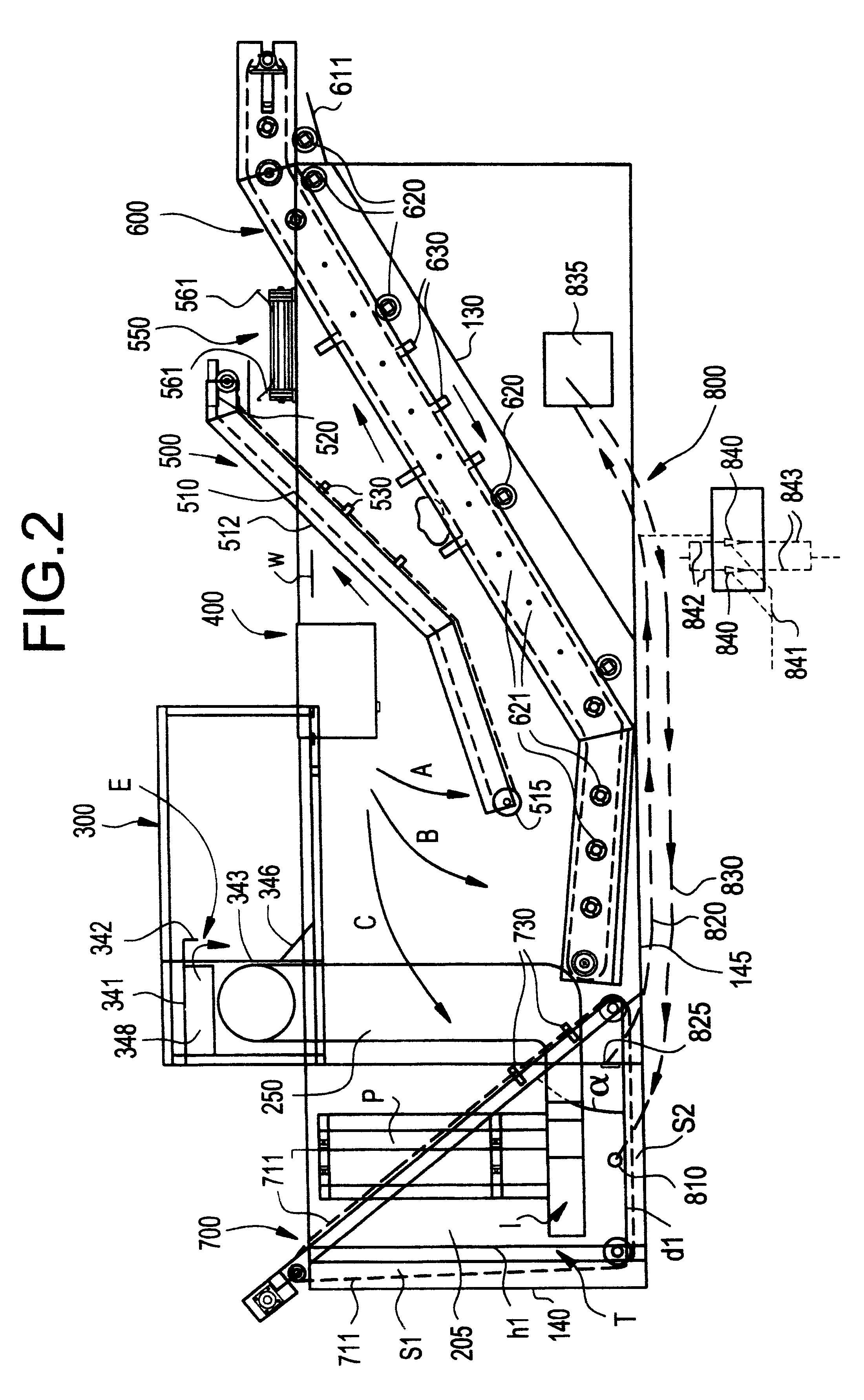

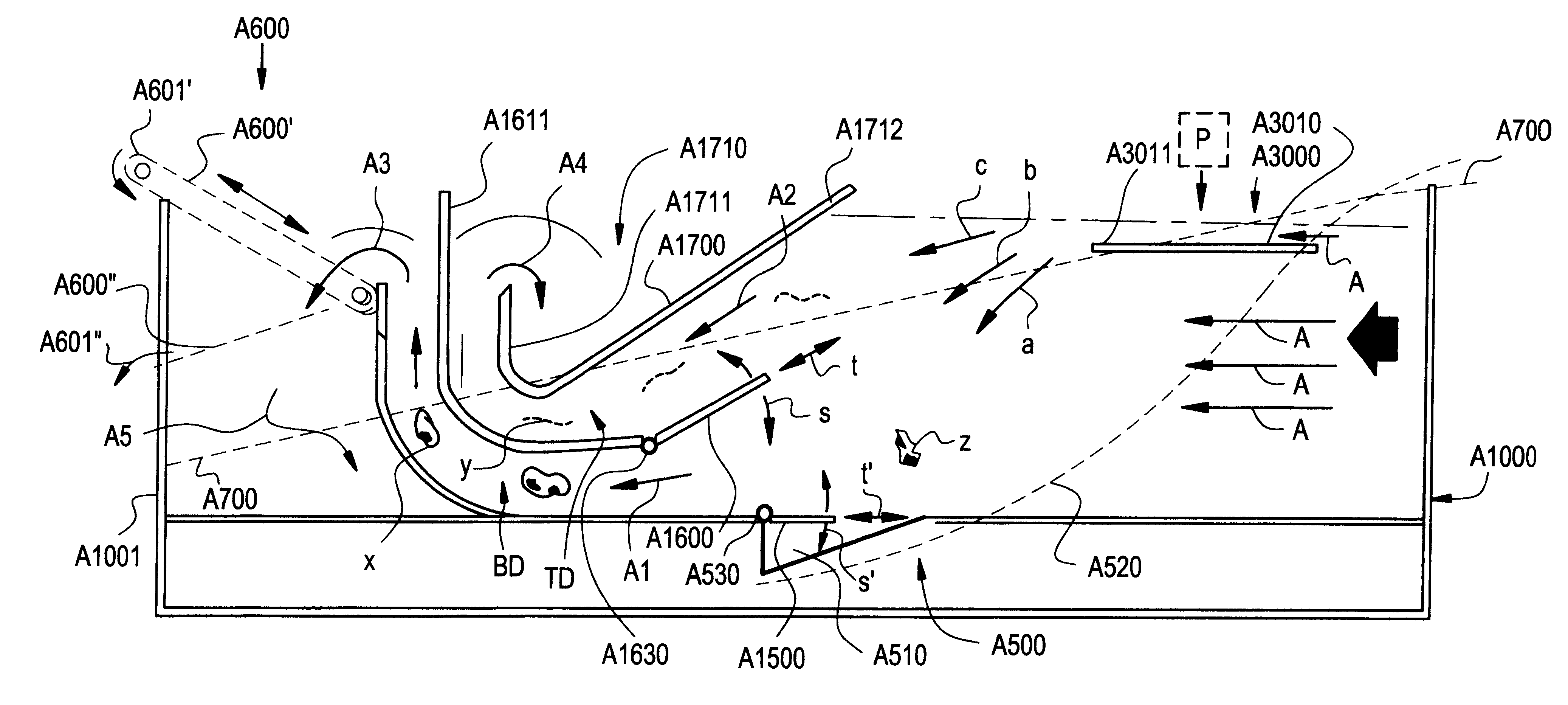

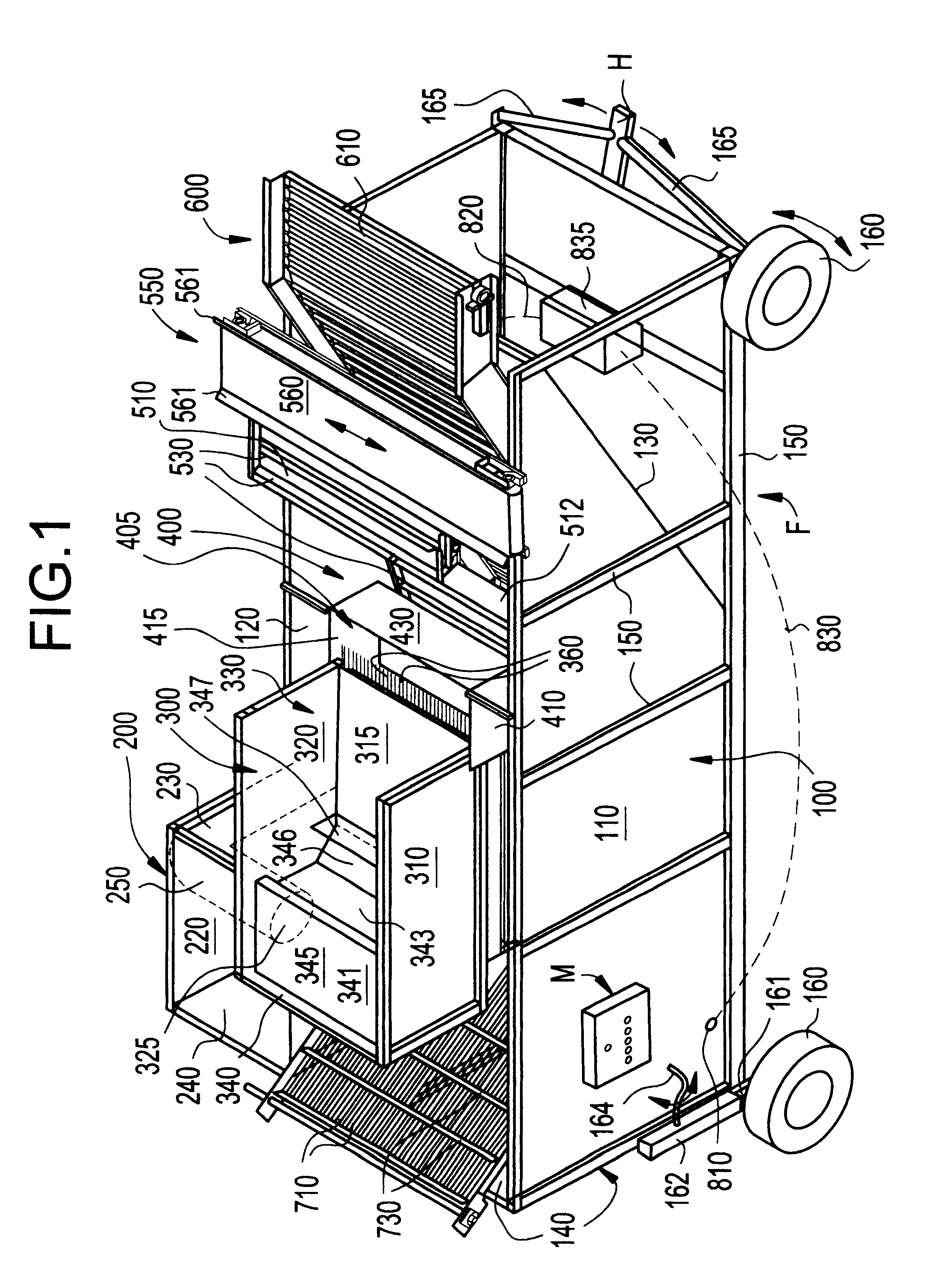

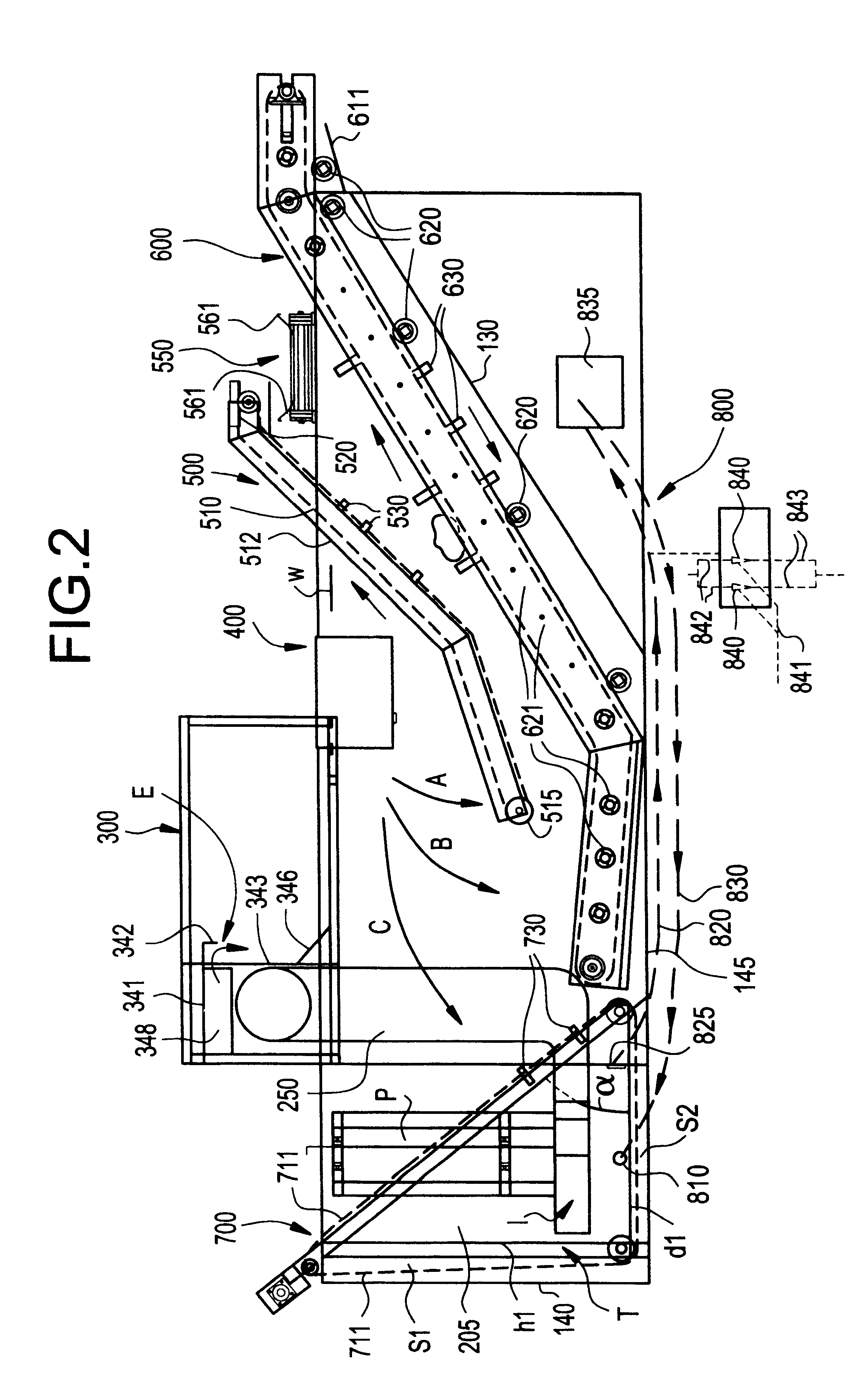

System for debris elimination and item separation and method of use thereof

InactiveUS6293407B1Reduce labor costsReduce water consumptionGas current separationFlotationHigh densityMedium density

A item separating or debris eliminating system includes a tank and a pump for circulating water from one end of the tank around through a duct and back into the opposite end of the tank. A medium density object collector is located within the tank, and a light debris collector is located within the tank. A conveyor filter is included through which substantially all of the water in the tank is circulated. The debris eliminating system preferably also includes a high density object collector within the tank. The system can be used to separate a variety of objects having different densities and terminal velocities in a fluid. Most preferably, the system is utilized for separating debris from potatoes and the like produce.

Owner:FRITO LAY NORTH AMERICA INC

System for debris elimination and item separation and method of use thereof

InactiveUS6213308B1Reduce labor costsReduce water consumptionSievingScreeningHigh densityMedium density

A item separating or debris eliminating system includes a tank and a pump for circulating water from one end of the tank around through a duct and back into the opposite end of the tank. A medium density object collector is located within the tank, and a light debris collector is located within the tank. A conveyor filter is included through which substantially all of the water in the tank is circulated. The debris eliminating system preferably also includes a high density object collector within the tank. The system can be used to separate a variety of objects having different densities and terminal velocities in a fluid. Most preferably, the system is utilized for separating debris from potatoes and the like produce.

Owner:FRITO LAY NORTH AMERICA INC

Manufacturing method of pure natural high-purity stevioside

InactiveCN102199177AReduce extraction timeHigh extraction rateSugar derivativesSugar derivatives preparationFiltration membraneCell wall

The invention relates to a method of using stevia rebaudiana for manufacturing pure natural high-purity stevioside; the method comprises the following steps of: taking the weight of the stevia rebaudiana as the basis of the addition amount of all matters, grinding and sieving after air-drying the stevia rebaudiana, and then collecting the sieved stevia rebaudiana powder; adding pure water, and then adding cellulase for breaking cell walls and simultaneously heating a solution; adopting an ultrasonic wave continuous countercurrent extraction technology for extracting, filtering and separating an extracting solution, adding a solution obtained by squeezing filtered residue into the extracting solution, wherein the filtered residue is used for fermentation so as to obtain biomass, using a membrane device for purifying and removing impurities of filtrate; using an ultrafiltration membrane with the molecular weight cutoff of 6000Da1 for removing macromolecular matters of the filtrate; and using a nano-filtration membrane with the molecular weight cutoff of 1200 Da1 for moving micro-molecular matters of the filtrate and concentrating; using a multifunctional simulating analogue moving bed separation system for absorbing a concentrated solution, using an alcohol solution for elution, using the nano-filtration membrane with the molecular weight cutoff of 600Da1 for filtering the eluted solution so as to remove alcohol or the micro-molecular matters, concentrating by two times, carrying out the spray drying on an obtained concentrated solution so as to obtain the high-purity stevioside.

Owner:武汉普赛特膜技术循环利用有限公司

High-pressure separator and method for high-pressure separation

InactiveCN102380262AOvercoming liquid in gas mixtureOvercome the cycleCombination devicesGaseous fuelsCycloneVapor–liquid separator

The invention discloses a high-pressure separator and a method for high-pressure separation, and is characterized in that: a cyclone gas-liquid separator is disposed on the middle-upper part of a housing of the high-pressure separator; the cyclone gas-liquid separator is connected to the housing of the high-pressure separator through a column tray plate or a gas-collecting pipe; mixed gas entering the high-pressure separator is cyclone-separated by the cyclone gas-liquid separator; after oil, water and few solid particles are removed, the gas is discharged from the high-pressure separator. The invention can reduce the gas phase molecular weight of the high-pressure separator, eliminate physical factors which cause foaming of desulfurizers in a desulfurization tower, and prolong the continuous operation period of the whole device.

Owner:CHINA PETROLEUM & CHEM CORP +2

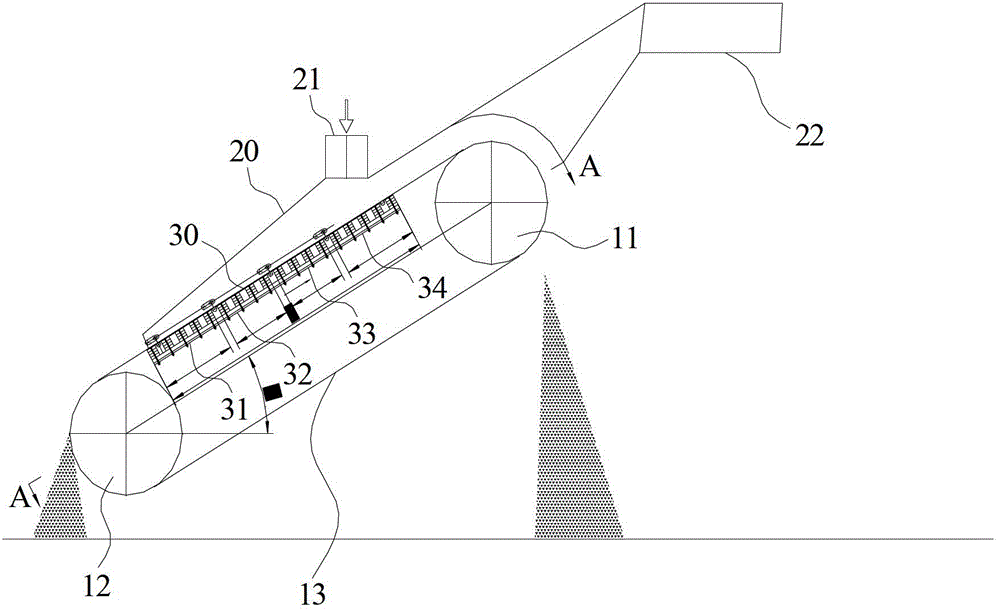

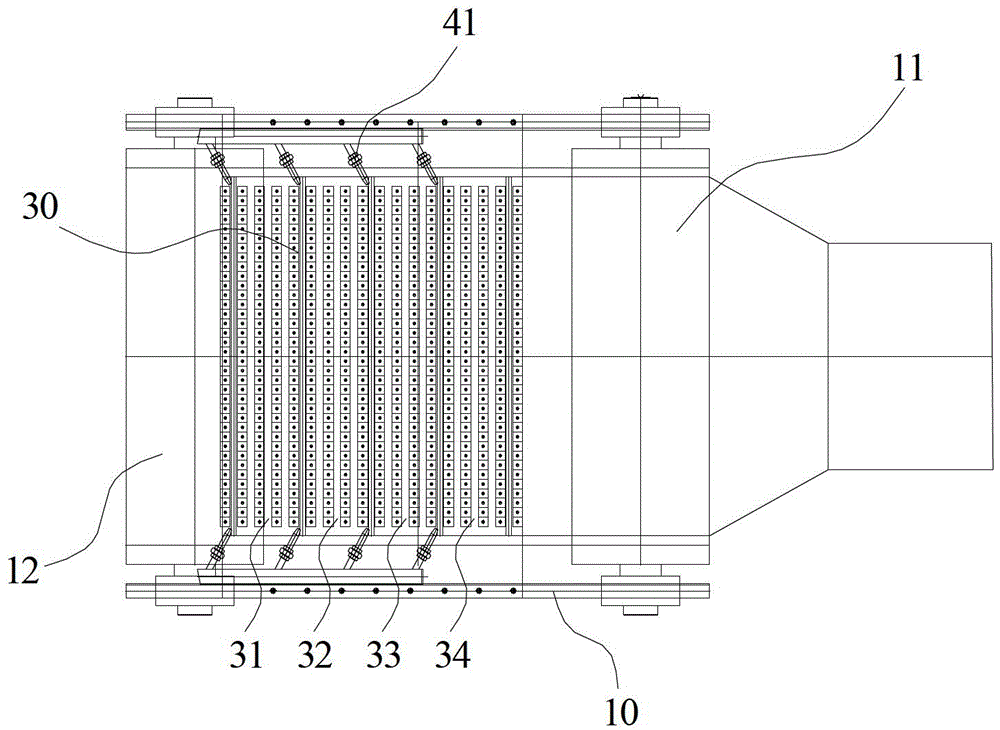

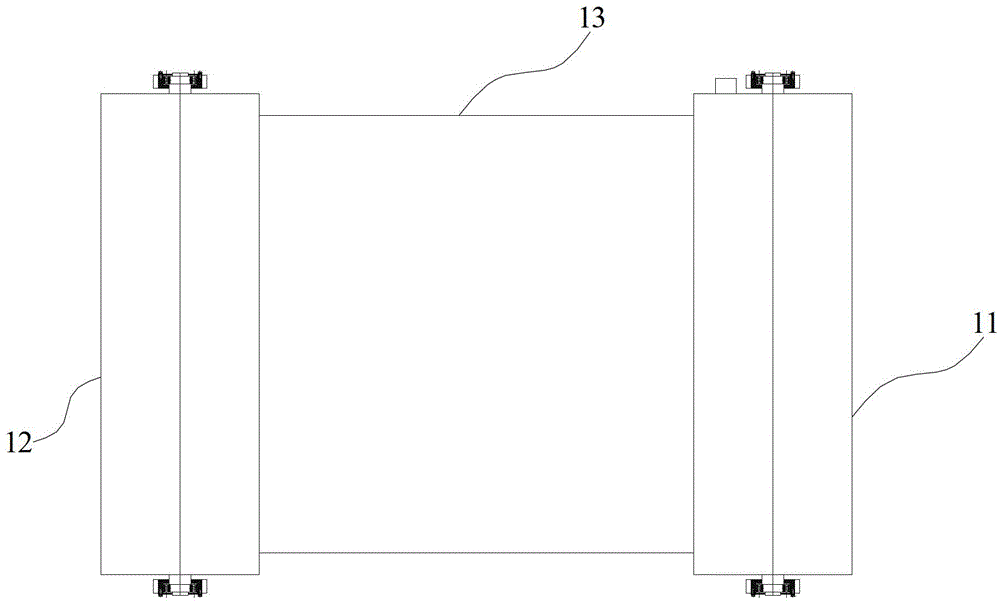

Gravity-magnetic composite dry separator and method utilizing same for mineral separation

InactiveCN103331208AIncrease productivityWide particle size rangeMagnetic separationMagnetic field gradientEngineering

The invention discloses a gravity-magnetic composite dry separator, which comprises an upper roller, a lower roller, a belt, a magnetic system, a guiding cover and a high-pressure gas injection atomization device, wherein the belt is arranged between the upper roller and the lower roller and is driven by the upper roller and the lower roller; the magnetic system is arranged between the upper roller and the lower roller and comprises a plurality of magnetic field areas of which the magnetic field intensity is gradually decreased from bottom to top, and thus the surface of the belt forms a magnetic field gradient; a material conveying space is formed between the guiding cover and the belt; the high-pressure gas injection atomization device is used for atomizing materials entering the guiding cover. The invention also discloses a method utilizing the gravity-magnetic composite dry separator for mineral separation.

Owner:陕西三沅重工发展股份有限公司

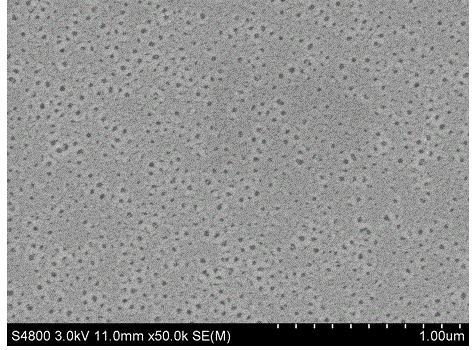

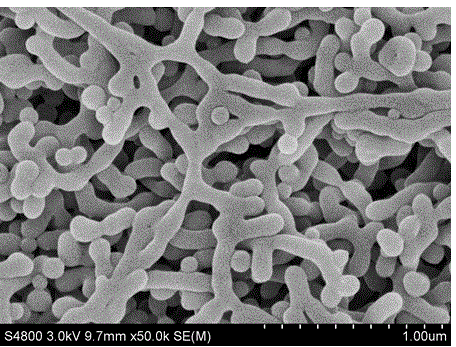

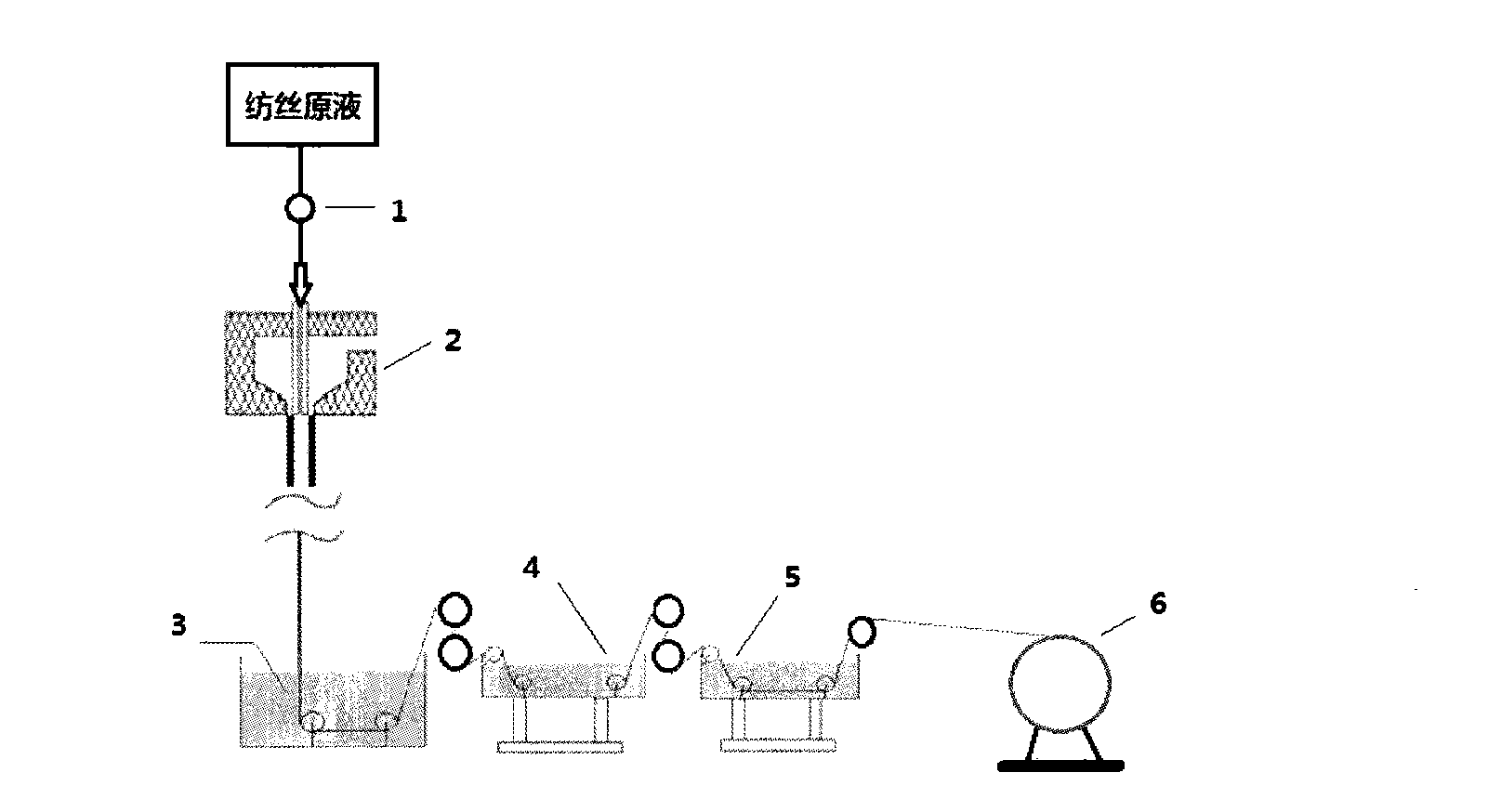

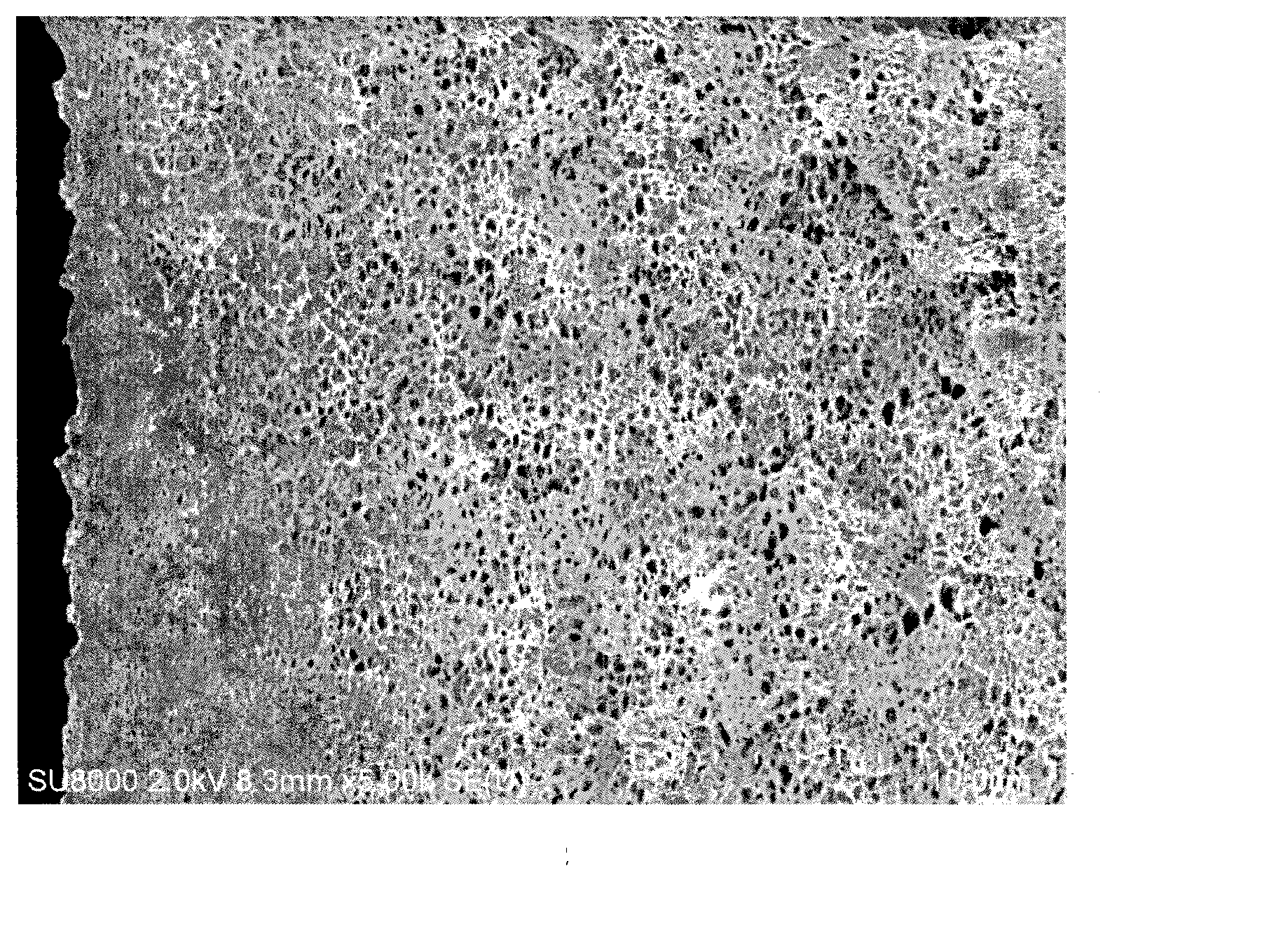

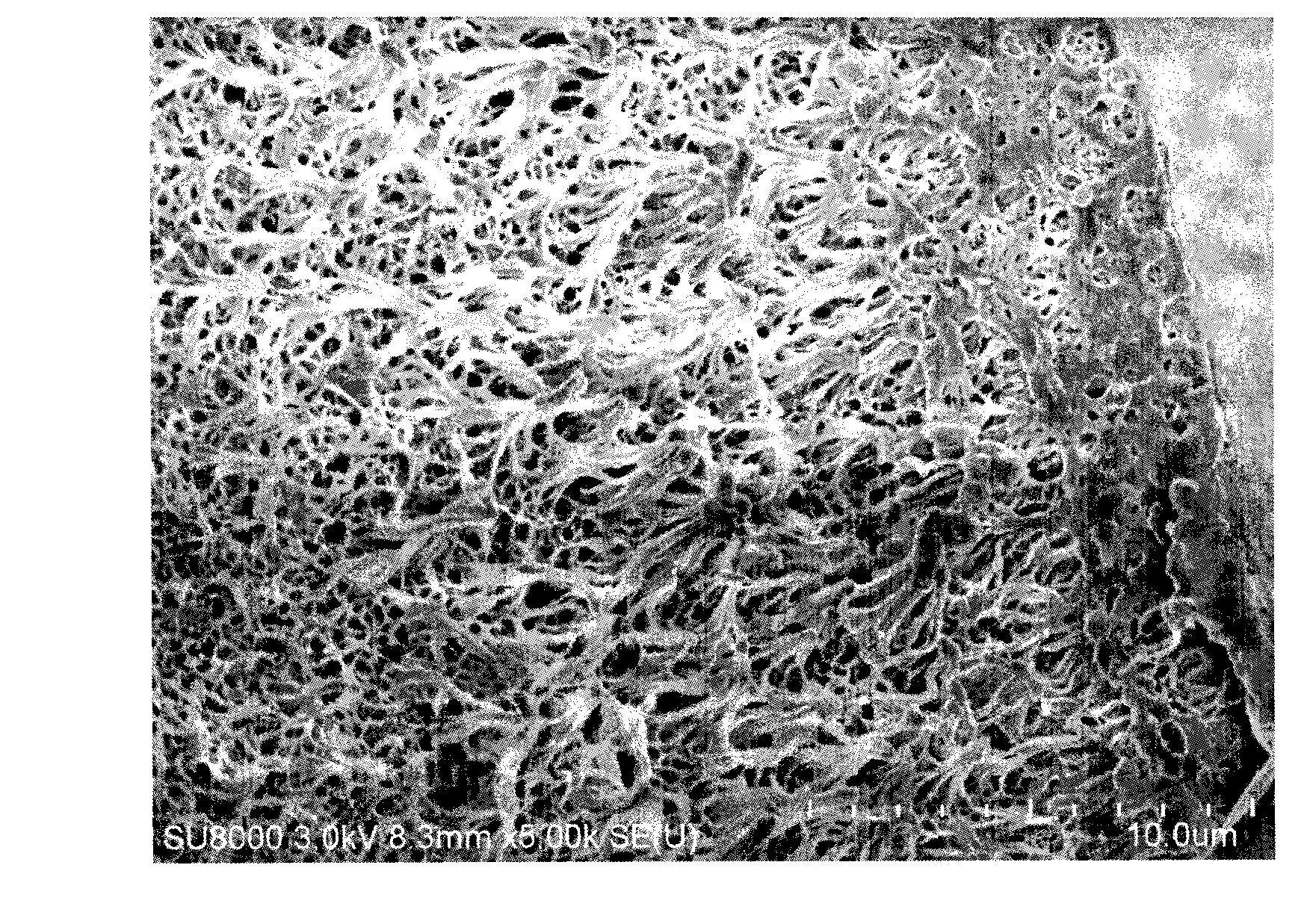

Preparation method of high-toughness equal-hole polymer hollow fiber separating membrane

ActiveCN104056558ANo update requiredNo need to remodelSemi-permeable membranesPolymer scienceSolvent

The invention discloses a preparation method of a high-toughness equal-hole polymer hollow fiber separating membrane. The preparation method comprises the following steps: dissolving a segmented copolymer and an additive or packing into a selective solvent which contains a segmented copolymer, so as to form a casting membrane solution, spinning the casting membrane solution to form hollow fibers, staying in air for appropriate time, and then immerging nascent fibers into a coagulating bath which contains a segmented copolymer, so as to solidify the nascent fibers to form the high-toughness equal-hole polymer hollow fiber separating membrane. According to the high-toughness equal-hole polymer hollow fiber membrane prepared by using the method, the ratio of the maximum hole diameter D to the minimum hole diameter d is less than 2.5, the breaking elongation is 5% to 1000%, and the tensile strength is 5MPa to 500MPa. The prepared high-toughness equal-hole polymer hollow fiber membrane has the relatively high separation accuracy and the relatively good processing and packaging performances.

Owner:ZHEJIANG UNIV

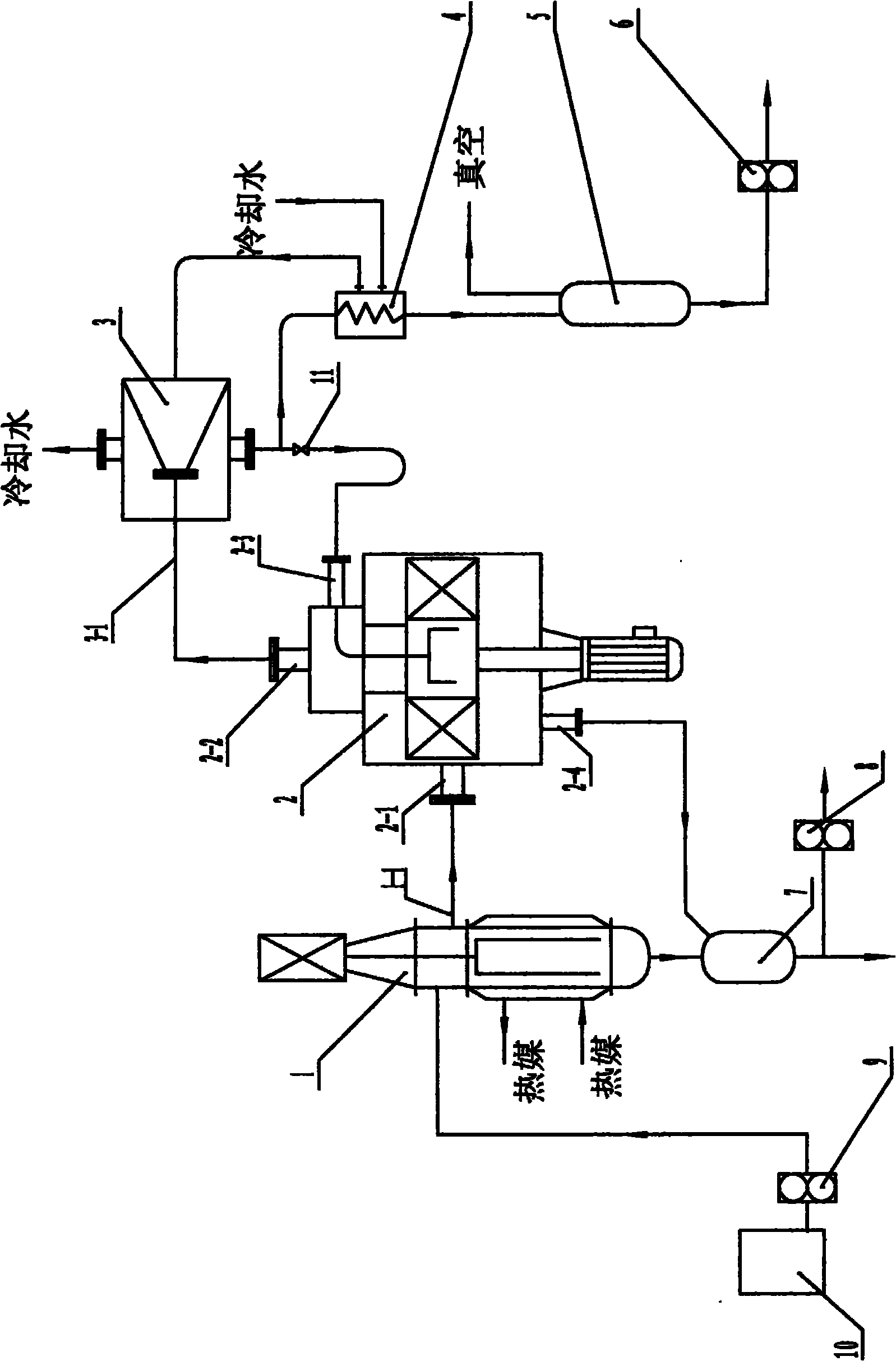

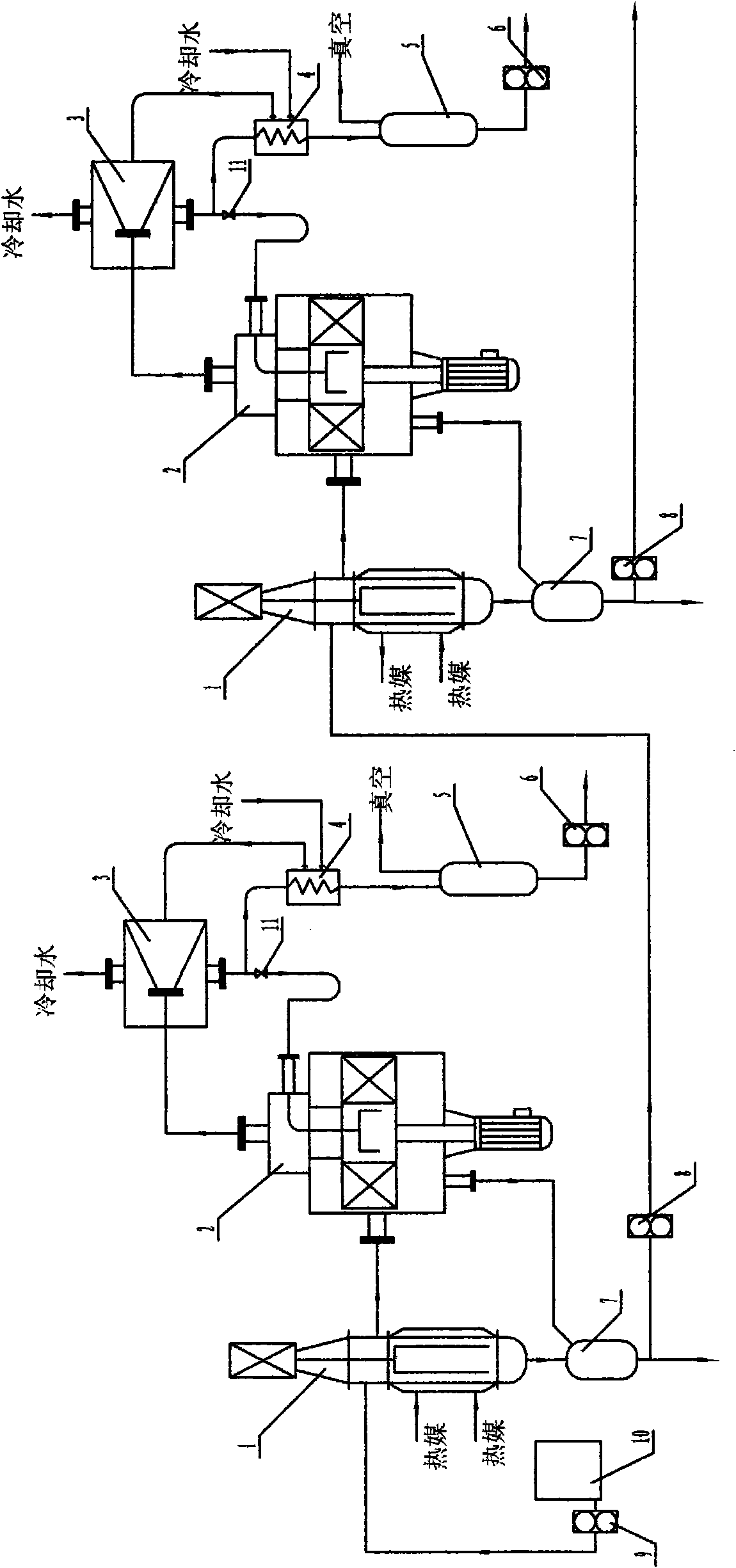

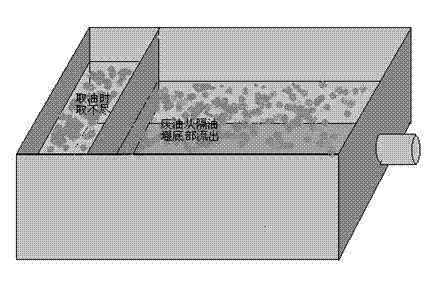

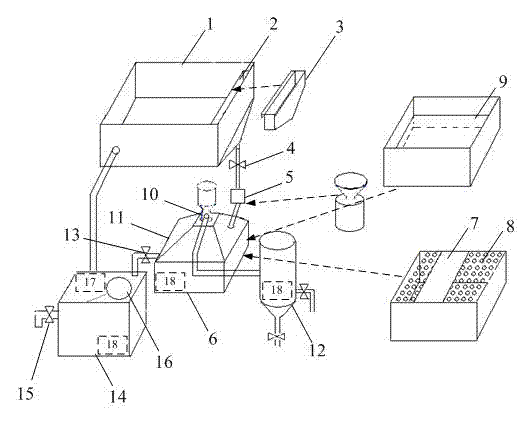

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

Apparatus and program for separating a desired sound from a mixed input sound

A sound separation apparatus for separating a target signal from a mixed input signal, wherein the mixed input signal includes the target signal and one or more sound signals emitted from different sound sources. The sound separation apparatus according comprises a frequency analyzer for performing a frequency analysis on the mixed input signal and calculating spectrum and frequency component candidate points at each time. The apparatus further comprises feature extraction means for extracting feature parameters which are estimated to correspond with the target signal, comprising a local layer for analyzing local feature parameters using the spectrum and the frequency component candidate points and one or more global layers for analyzing global feature parameters using the feature parameters extracted by the local layer. The apparatus further comprises a signal regenerator for regenerating a waveform of the target signal using the feature parameters extracted by the feature extraction means.Since both of local feature parameters and global feature parameters can be processed together in the feature extraction means, the separation accuracy of the target signal is improved without depending on the accuracy for extracting feature parameters from the input signal. Feature parameters to be extracted include frequencies and amplitudes and their variation rates for the frequency component candidate points, harmonic structure, pitch consistency, intonation, on-set / off-set information and / or sound source direction. The number of the layers provided in the feature extraction means may be changed according to the types of the feature parameters to be extracted.

Owner:HONDA MOTOR CO LTD

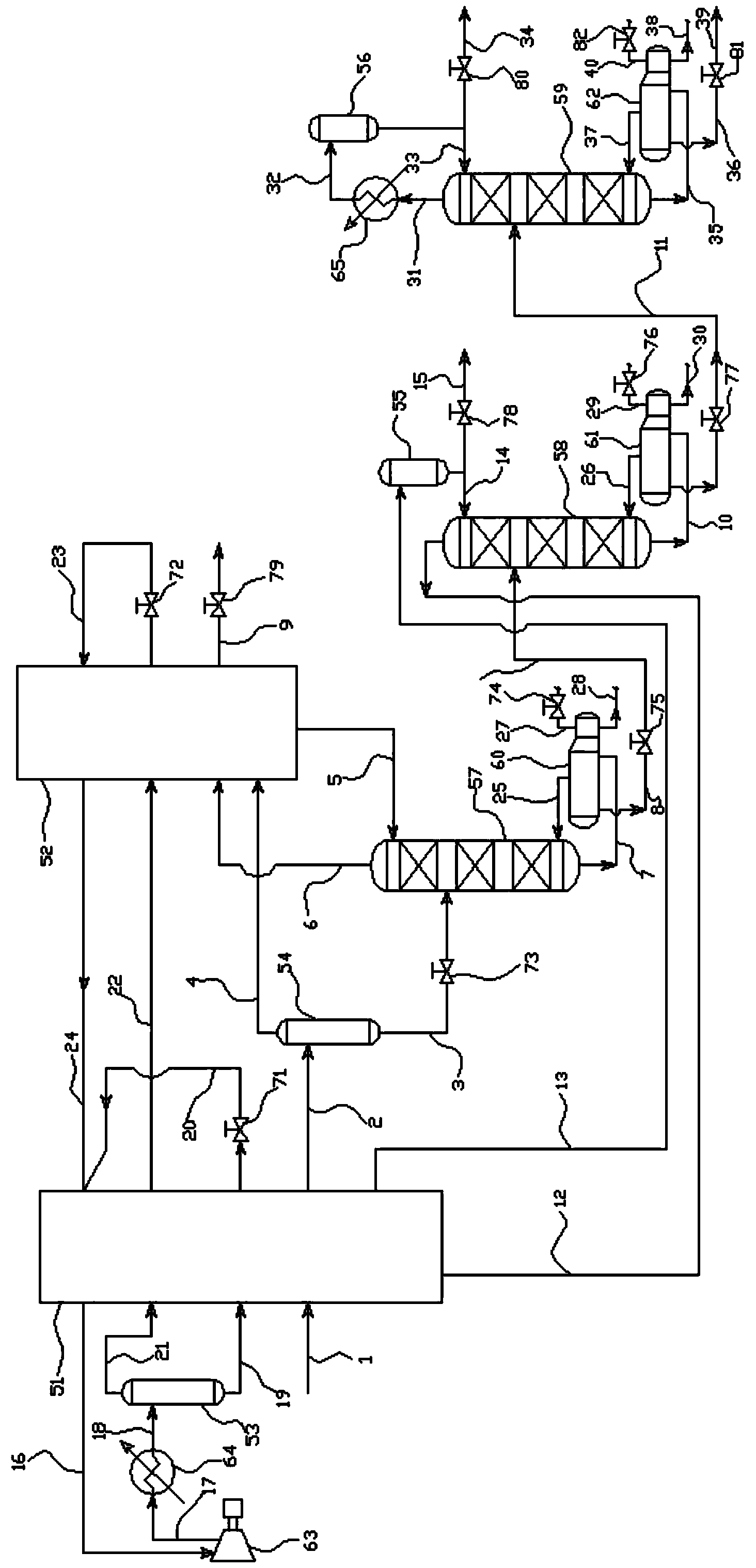

Natural gas liquefying method and device with light hydrocarbon recovery function

InactiveCN103453730AAdjust qualityHigh puritySolidificationLiquefactionPhysical chemistryRefrigerant

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

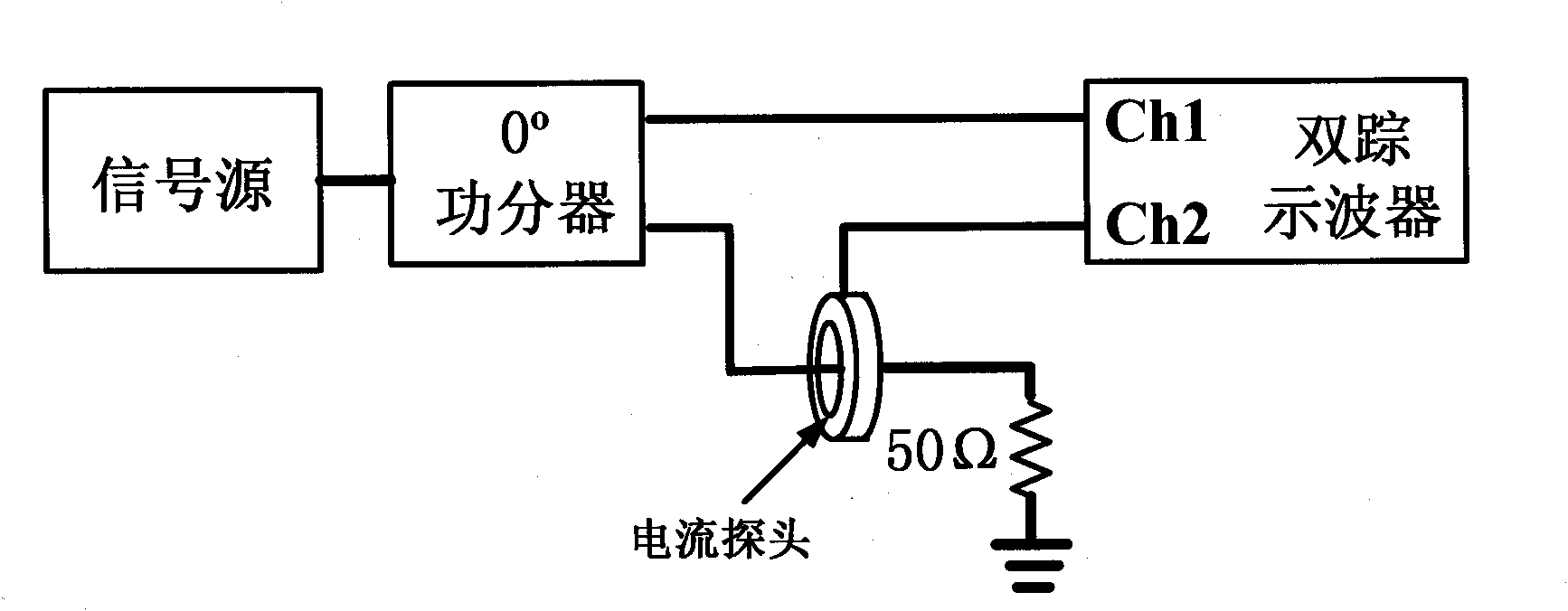

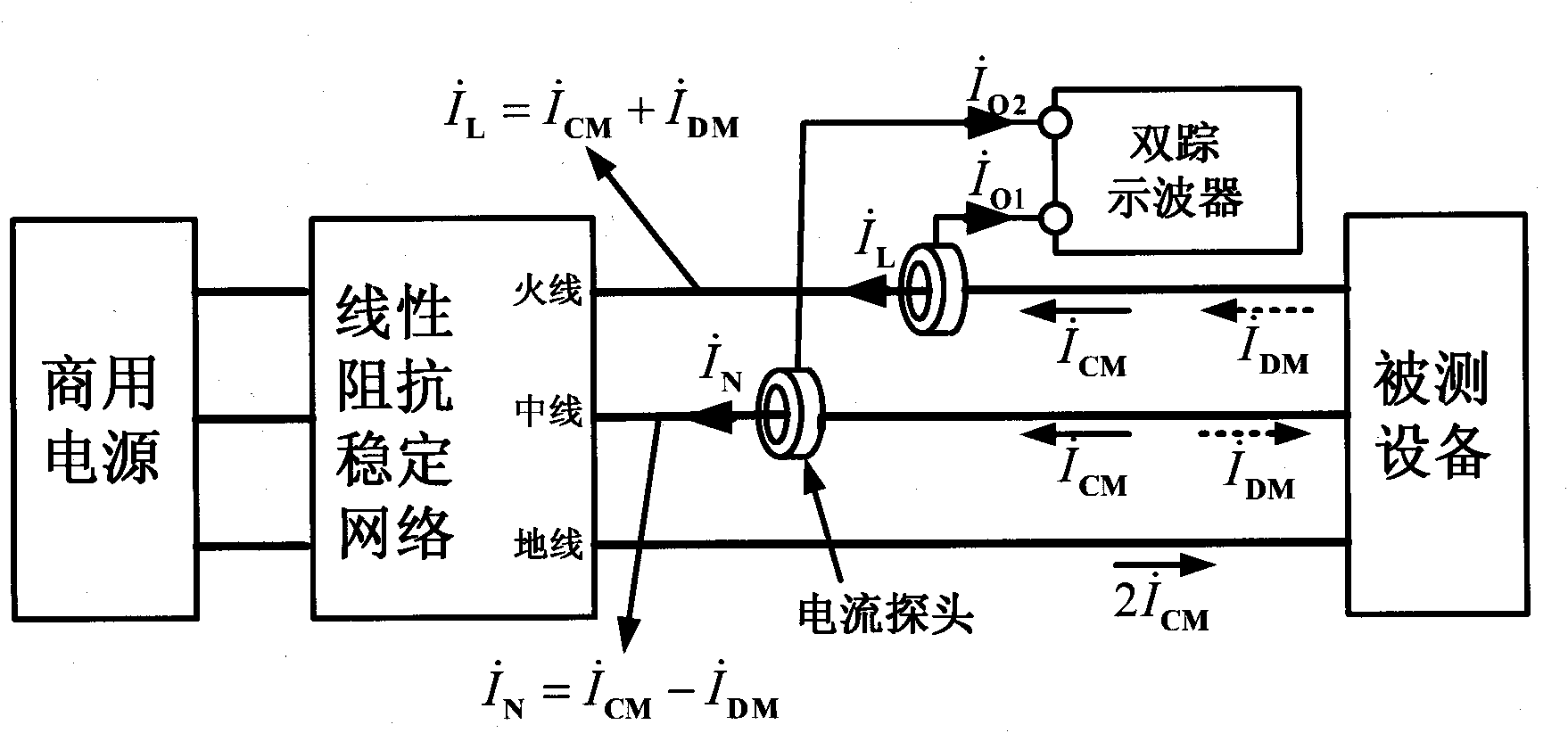

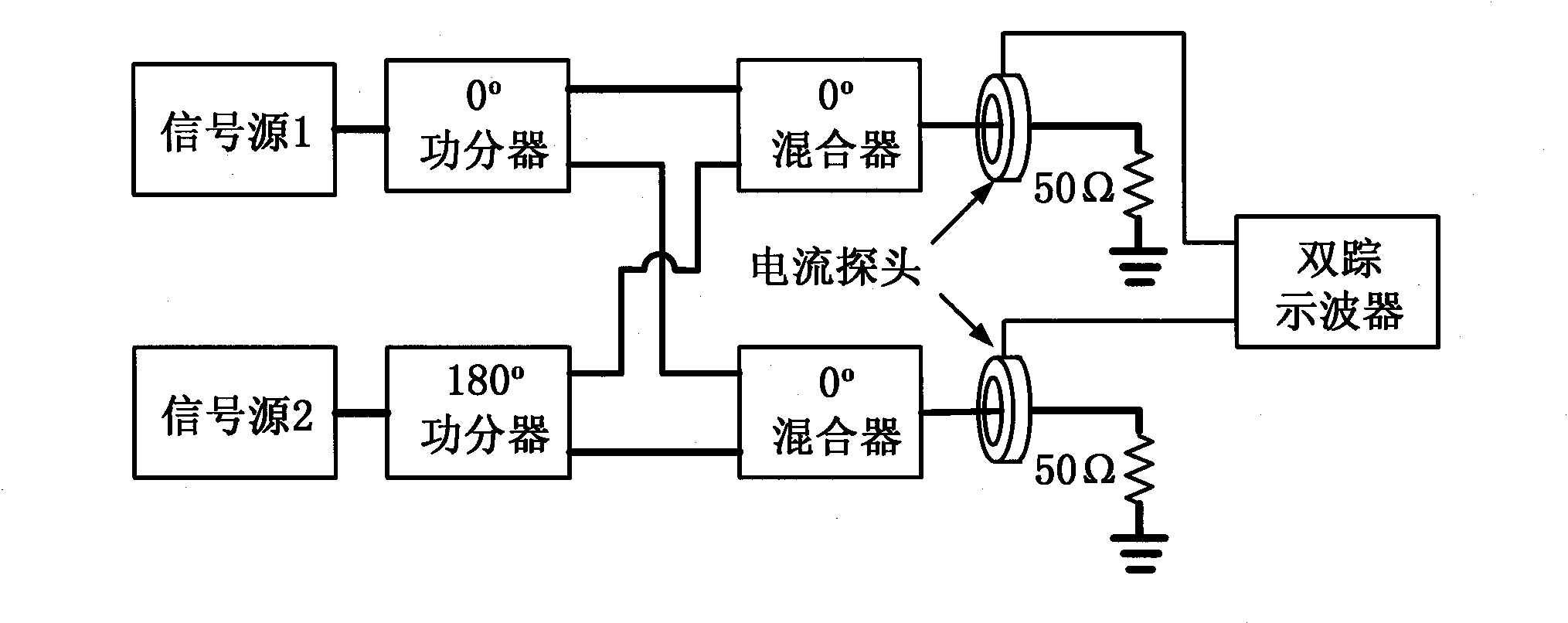

Soft separation method of conducted electromagnetic interference noise based on blind signal processing technology

InactiveCN101799494AAchieve separationHigh separation precisionSpectral/fourier analysisElectrical testingFrequency spectrumSignal on

The invention discloses a soft separation method of conducted electromagnetic interference noise based on a blind signal processing technology, belonging to the field of conducted electromagnetic interference noise inhibition. The method comprises the following steps of: carrying out probe frequency spectrum estimation and compensation on two current probes; simultaneously measuring electromagnetic interference noise time domain signals on a live wire and a middle wire of an electronic system by the two current probes and a double-trace oscilloscope; carrying out blind separation on electromagnetic interference noise by utilizing a Fast ICA (Independent Component Analysis) algorithm in a blind signal processing method to obtain a signal source vector estimation value; and finally, judging the property of separation signals based on the maximum cross correlation coefficient of blind separation signals and common mode or differential mode reference signals. The invention overcomes the defects of using a radiofrequency transformer or a power divider to carry out hard separation on common mode noise and differential mode noise, has the advantages of high separation accuracy and favorable practicability, and lowers the cost.

Owner:NANJING UNIV OF POSTS & TELECOMM

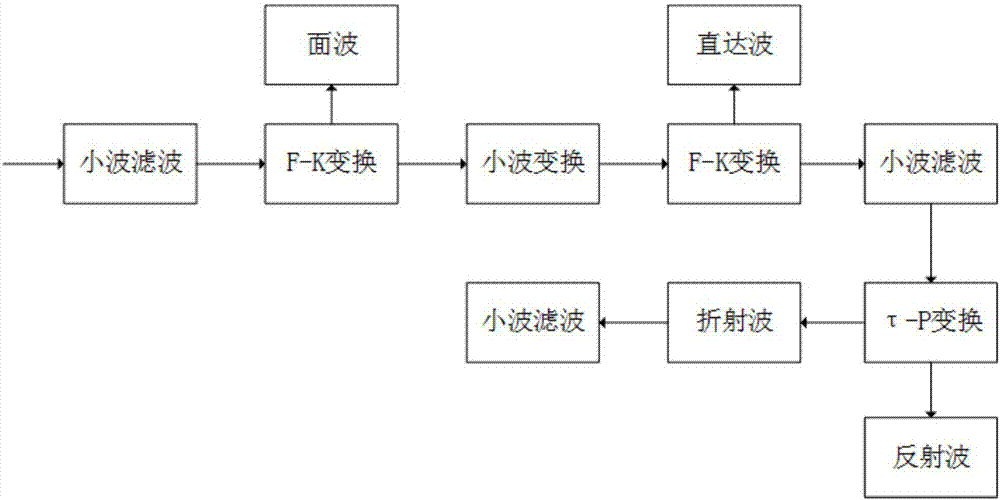

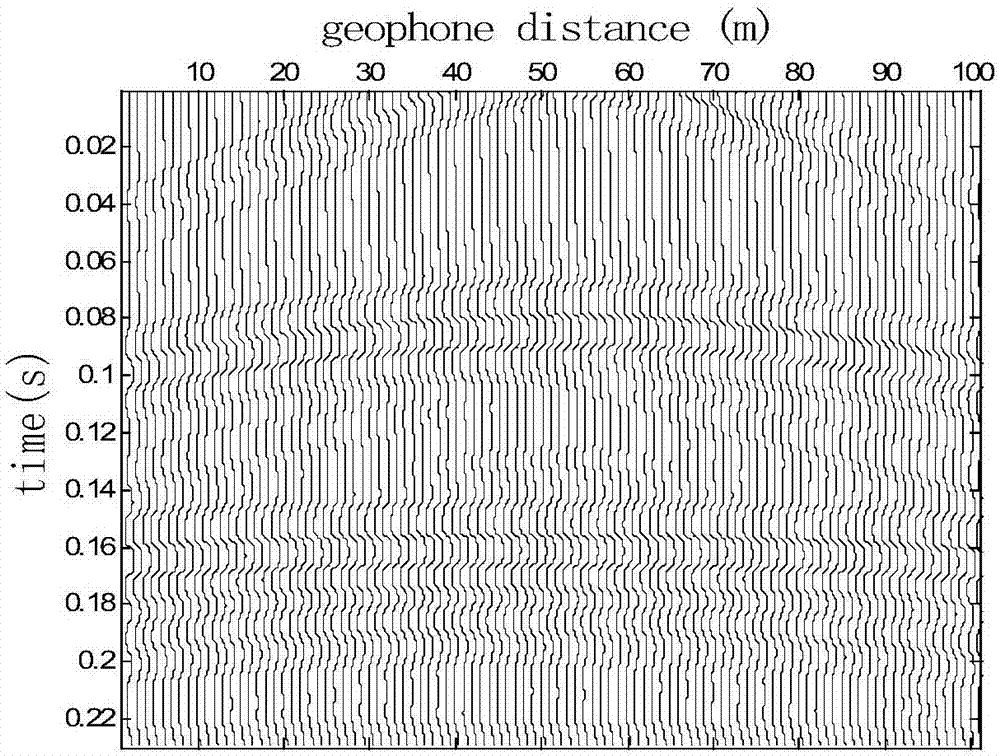

Seismic wave field separation method

ActiveCN107144880AReduce noise signalComprehensive responseSeismic signal processingWave fieldNoise reduction

The invention relates to a seismic wave field separation method. A demodulator, a wavelet filter and engineering seismograph data preprocessing software are utilized for acquiring and analyzing a seismic wave. The method comprises the following steps of acquiring an initial seismic wave signal by means of a demodulator, and performing noise reduction on the initial seismic wave signal through the wavelet filter; performing F-K frequency domain conversion, reverse-F-K frequency domain conversion, linear Radon conversion and reverse Radon conversion on the seismic wave signal after noise reduction, thereby separating out a direct wave, a reflected wave, a refracted wave and a surface wave signal in the seismic wave signal. The seismic wave field separation method effectively improves precision and reliability in wave field separation.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

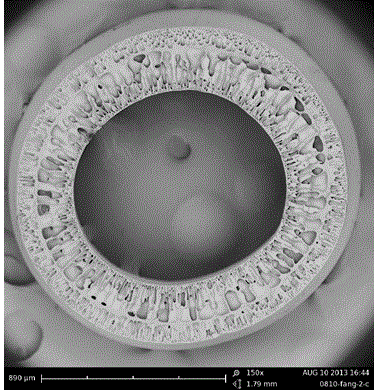

Method for preparing amphiphilic block copolymer modified polyvinylidene fluoride hollow fiber membrane

ActiveCN103055711AImprove hydrophilicityReduce adsorptionSemi-permeable membranesPolymer sciencePolyvinylidene difluoride

The invention provides a method for preparing an amphiphilic block copolymer modified polyvinylidene fluoride hollow fiber membrane, which is characterized by comprising the following specific steps: blending polyvinylidene fluoride, a composite diluent and an amphiphilic block copolymer to prepare film casting liquid; extruding the film casting liquid by a spinning nozzle to form nascent hollow fibers; enabling the formed nascent hollow fibers to enter coagulating bath to carry out coagulation regeneration; placing the obtained hollow fiber membrane into an extraction agent to extract out the diluent; and then placing the obtained product into pure water to soak and wash and processing the obtained product by a pore maintaining agent to obtain the amphiphilic block copolymer modified polyvinylidene fluoride hollow fiber membrane finished product. The method fulfills the aim of hydrophilic modification by blending the amphiphilic polymer so as to finally improve the antifouling property of the membrane.

Owner:苏州富淼膜科技有限公司

Gas, liquid and light-weight oil triphase separating device

ActiveCN105597378ASolving Multiphase Mixing ProblemsSmall pressure lossCombination devicesLiquid degasificationVapor–liquid separatorOil phase

The invention discloses a gas, liquid and light-weight oil triphase separating device which comprises a triphase separator, a gas-liquid separator, an oil-gas separator and an oil supply pump. The gas, liquid and light-weight oil triphase separating device realizes gas, liquid and light-weight oil triphase separation in steps by virtue of centrifugal force generated by whirl and the density difference between light-weight oil and water. The triphase separator is respectively connected with the gas-liquid separator and the oil supply pump by virtue of pipelines, and the oil supply pump is connected with the oil-gas separator by virtue of a pipeline; then gas enters into the gas-liquid separator, so that small liquid drops entrained in the gas are further separated out; and oil enters into the oil-gas separator, so that small gas bubbles entrained in an oil phase are separated out. The device is high in separation precision; according to actual measurement, more than 90% of gas and 90% of light-weight oil can be separated out, so that multi-phase mixing problem in the industries of oil extraction and gas production is solved.

Owner:XI AN JIAOTONG UNIV

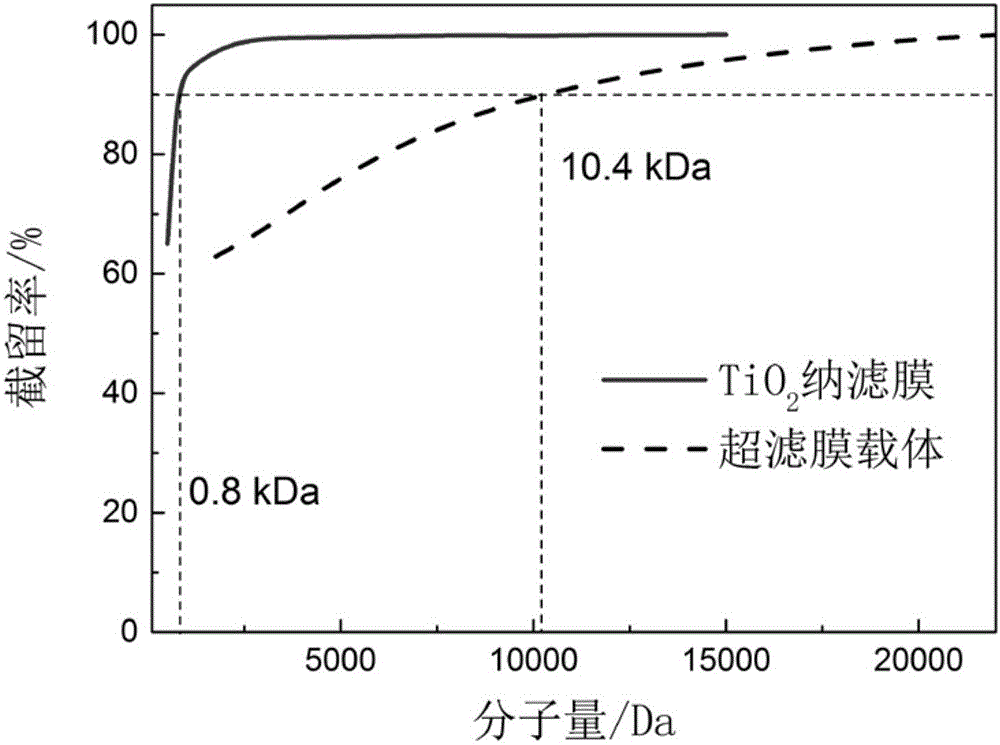

Novel ceramic nanofiltration membrane preparation method

The invention relates to a novel ceramic nanofiltration membrane preparation method. The method includes: dissolving a precursor into an organic solvent to obtain a precursor solution; drying to-be-treated ceramic ultrafiltration membranes; impregnating the dried ceramic ultrafiltration membranes into the precursor solution until complete impregnation is realized, taking out, airing, drying and calcining to obtain ceramic nanofiltration membranes. By addition of active components to pore passages of the ceramic ultrafiltration membranes and in-situ hydrolysis reaction of the active components, ceramic nanoparticles are obtained in the pore passages of the membranes after thermal treatment, and accordingly regulation of membrane pore diameters can be realized; by control of precursor types, precursor concentration, solvents, thermal treatment process and the like, continuous regulation of the pore diameters of the ceramic ultrafiltration membranes can be realized. Due to freeness of new membrane layers formed on the surfaces of the ceramic ultrafiltration membranes, the problem of proneness to cracking of the membrane layers in preparation of the ceramic nanofiltration membranes is avoided, and a series of ceramic nanofiltration membranes different in material and microstructure can be obtained. The novel ceramic nanofiltration membrane preparation method is a novel method for preparing the ceramic nanofiltration membranes.

Owner:NANJING UNIV OF TECH

Method for deacidification of alkylation reaction product

ActiveCN102021016AReduce dosageReduce productionRefining by dialysisCross-flow filtrationElectrostatic precipitation

The invention relates to a method for deacidification of an alkylation reaction product. In the method, after being subject to gravity settling, mixed emulsified liquid of the alkylation reaction product (hydrocarbon oil) and sulfuric acid passes through a component with hydrophobic modified ceramic membrane at a membrane surface speed of 0.01-5m / s for separation, and the deacidification of oil is achieved in a cross current filtration mode under the operation pressure of 0.01-0.3MPa and at the operation temperature of 0-40 DEG C. Under the push of pressure, the oil passes through the ceramic membrane, acid in the oil is trapped, and the acid content in the obtained oil is lower than 100ppm, thereby greatly reducing alkaline usage and waste water generation amount in an acid-base refine system of an alkylation technology and reducing the use of electrostatic precipitation; and the ceramic membrane surface is subject to hydrophobic modification, thus the contact angle of water droplet on the membrane surface is 70 degrees-16 degrees. The method is suitable for removal of polar liquid in various oils, has the advantages of simple process, low energy consumption, high separation precision, no environment pollution and high economic and practical value, and is easy to achieve industrial application.

Owner:NANJING UNIV OF TECH

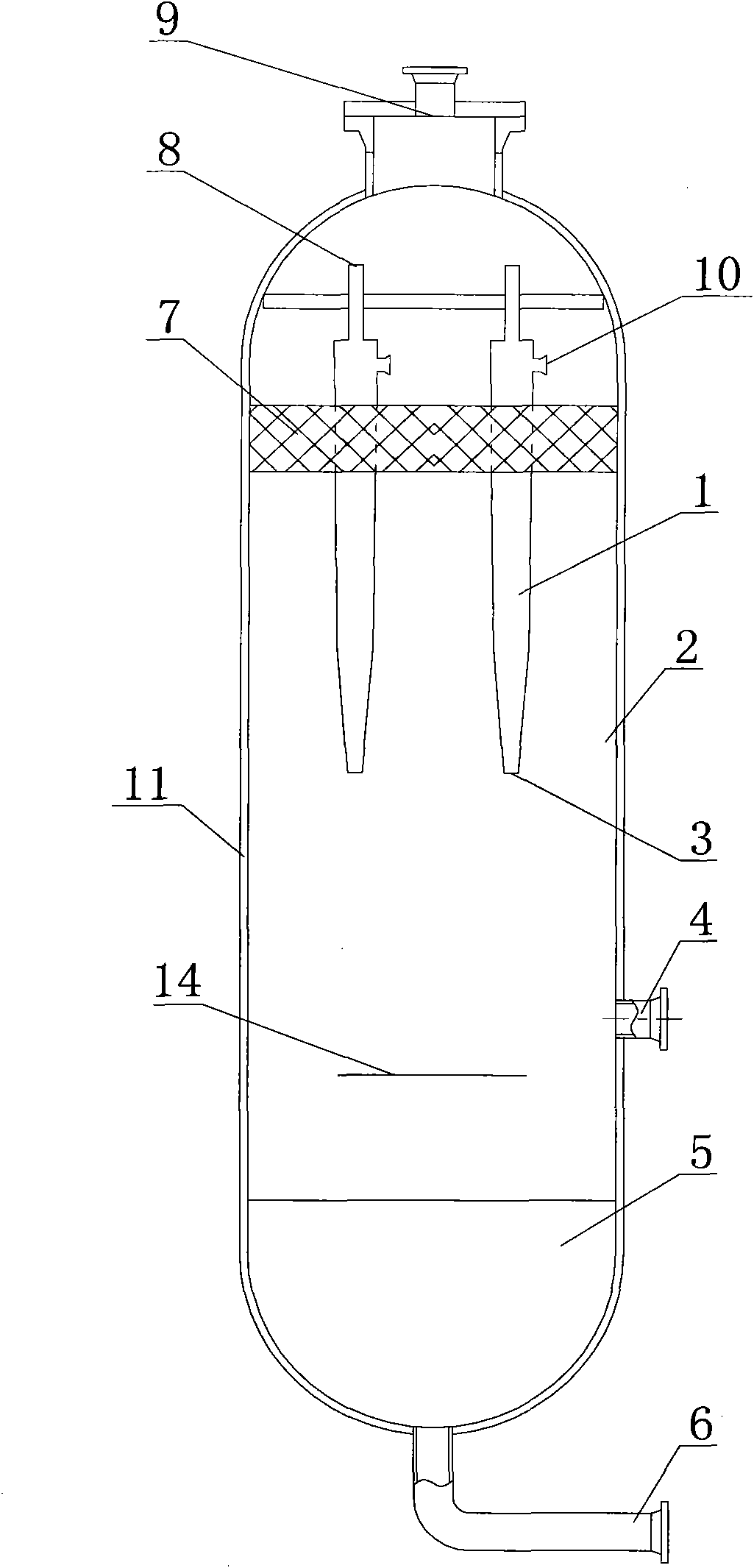

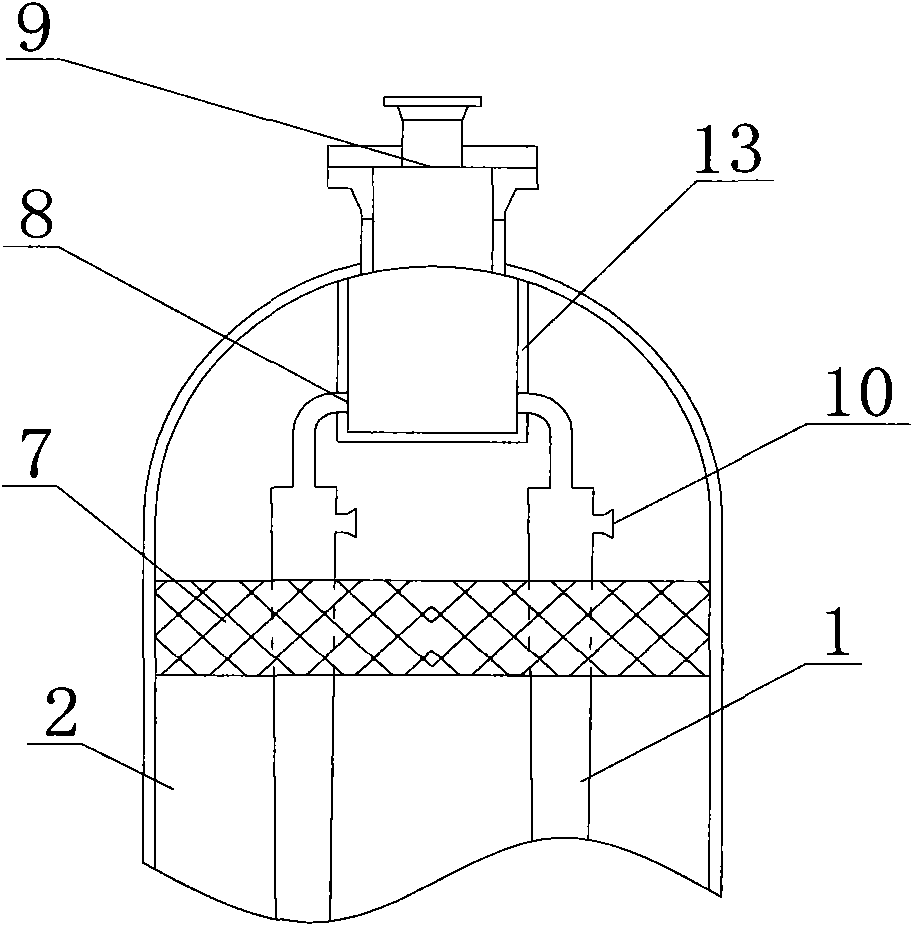

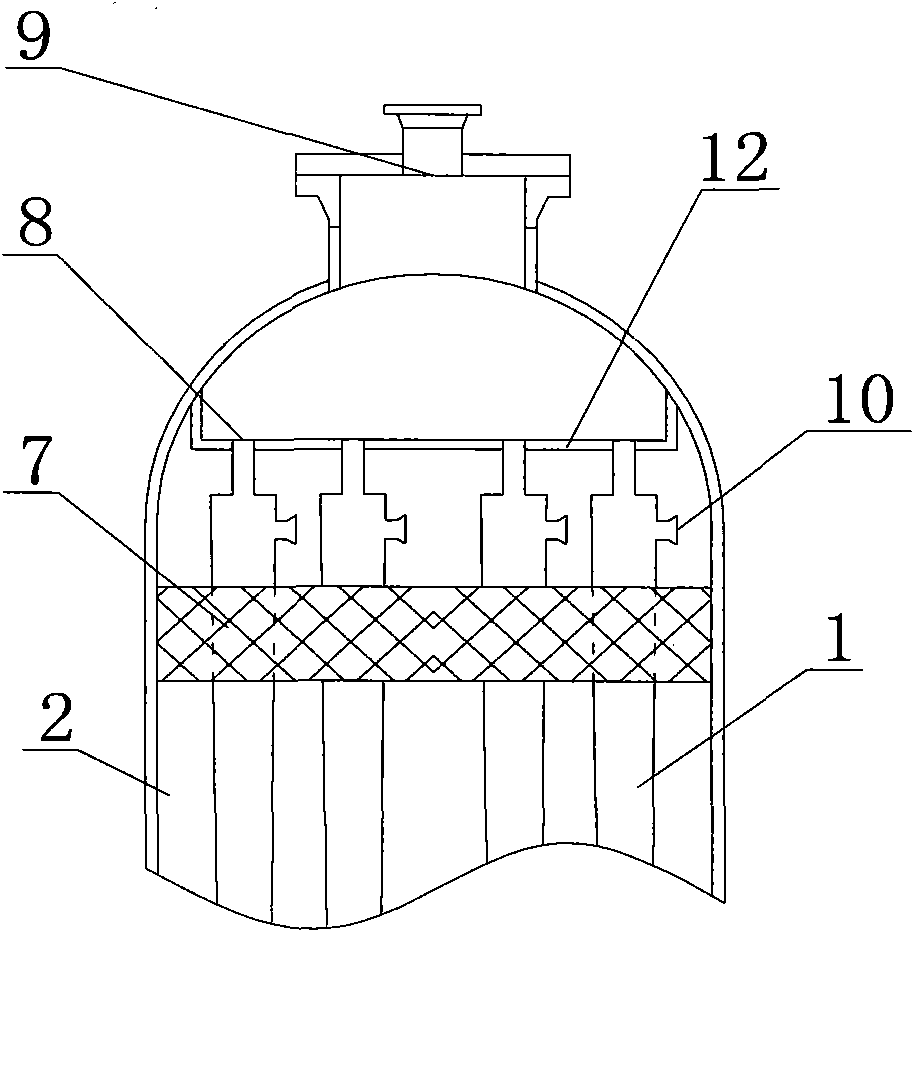

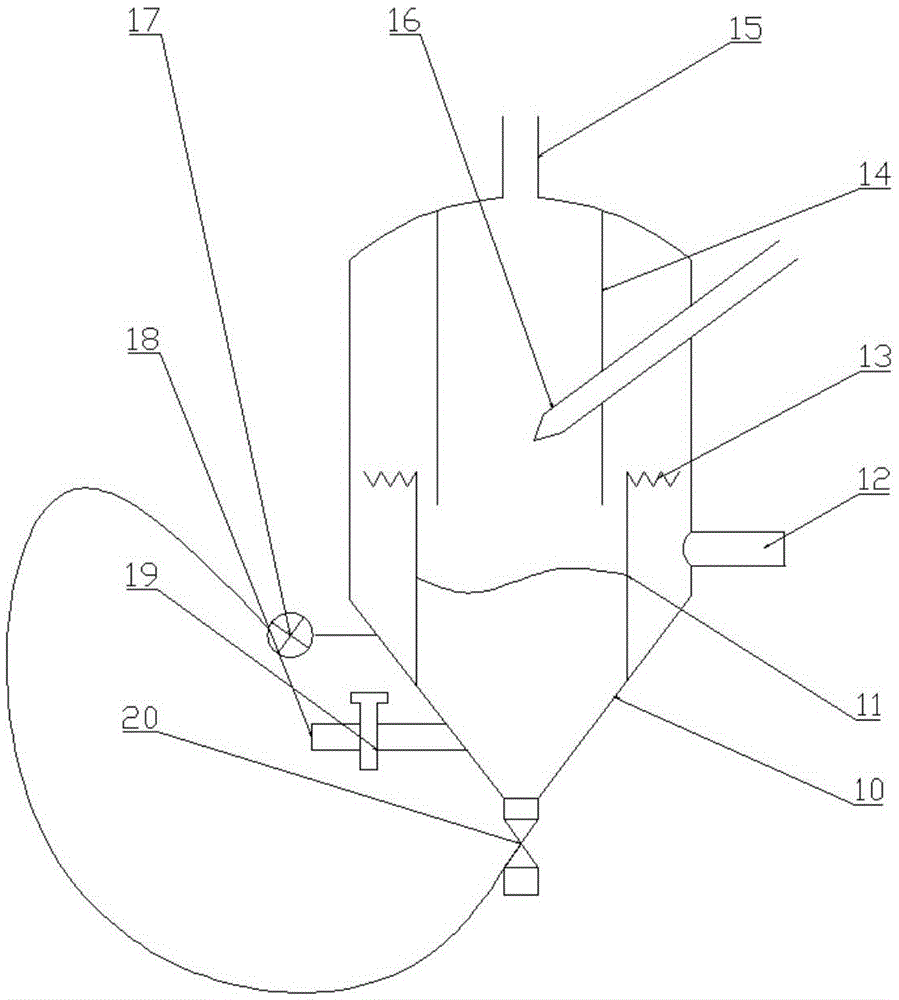

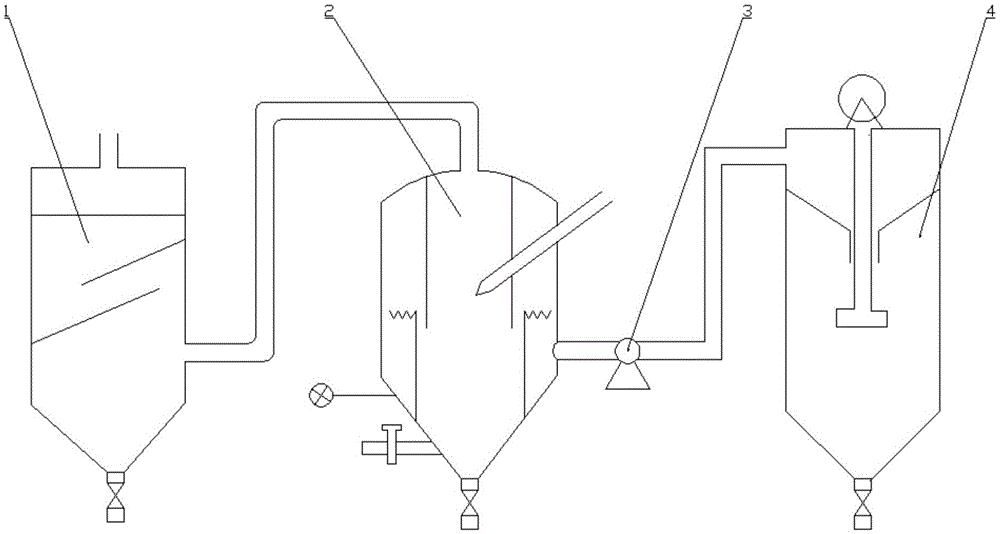

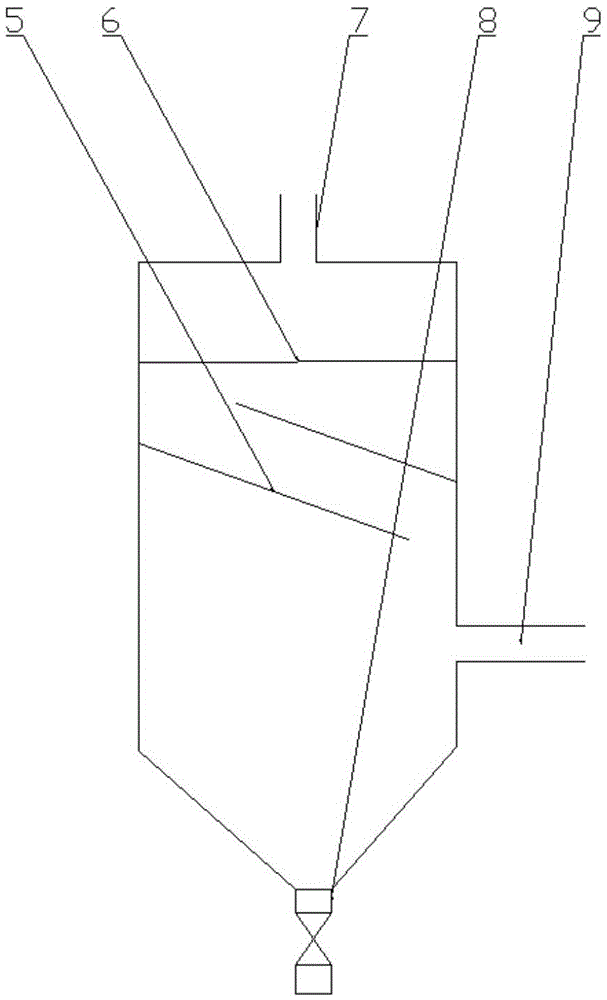

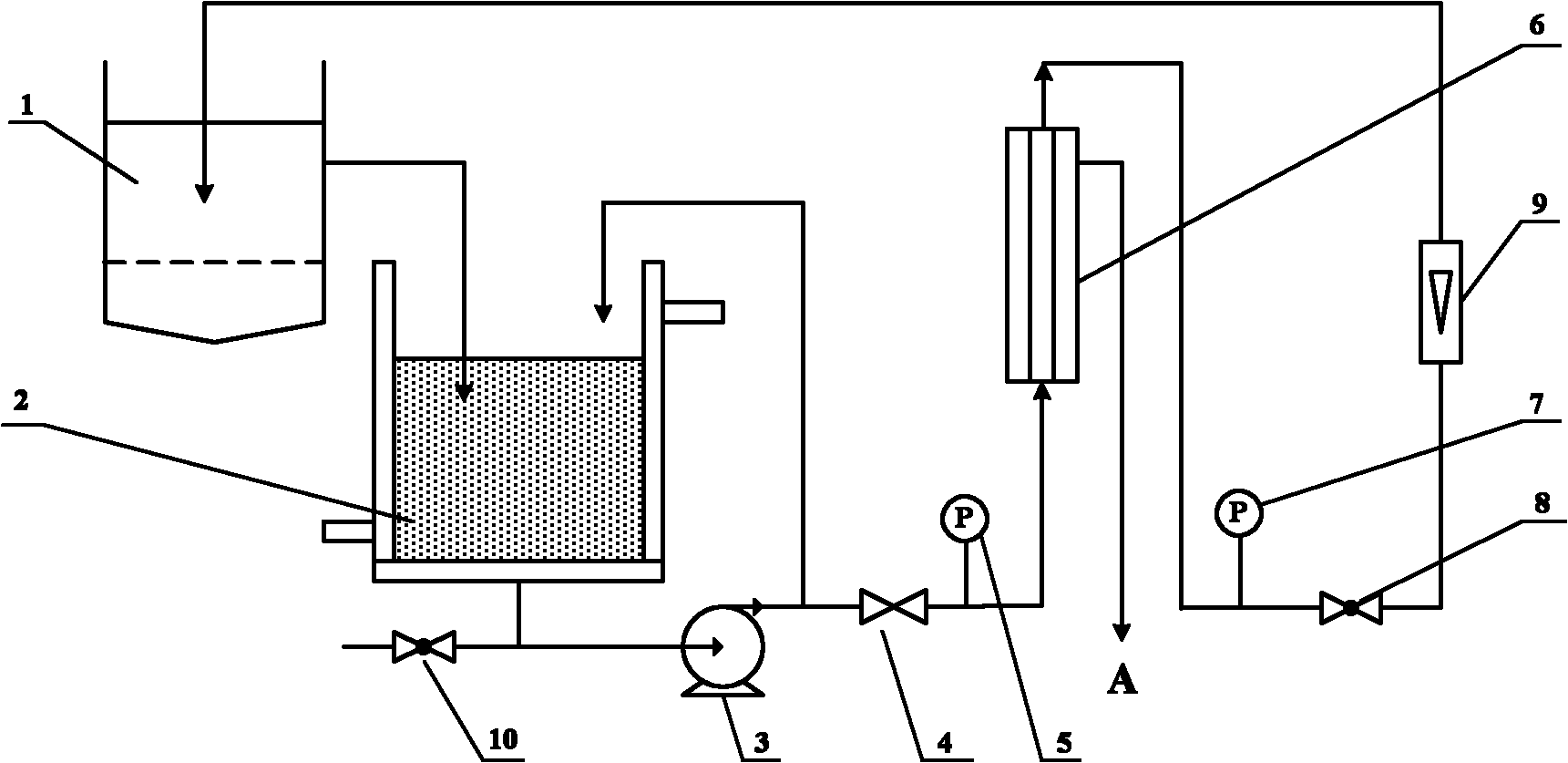

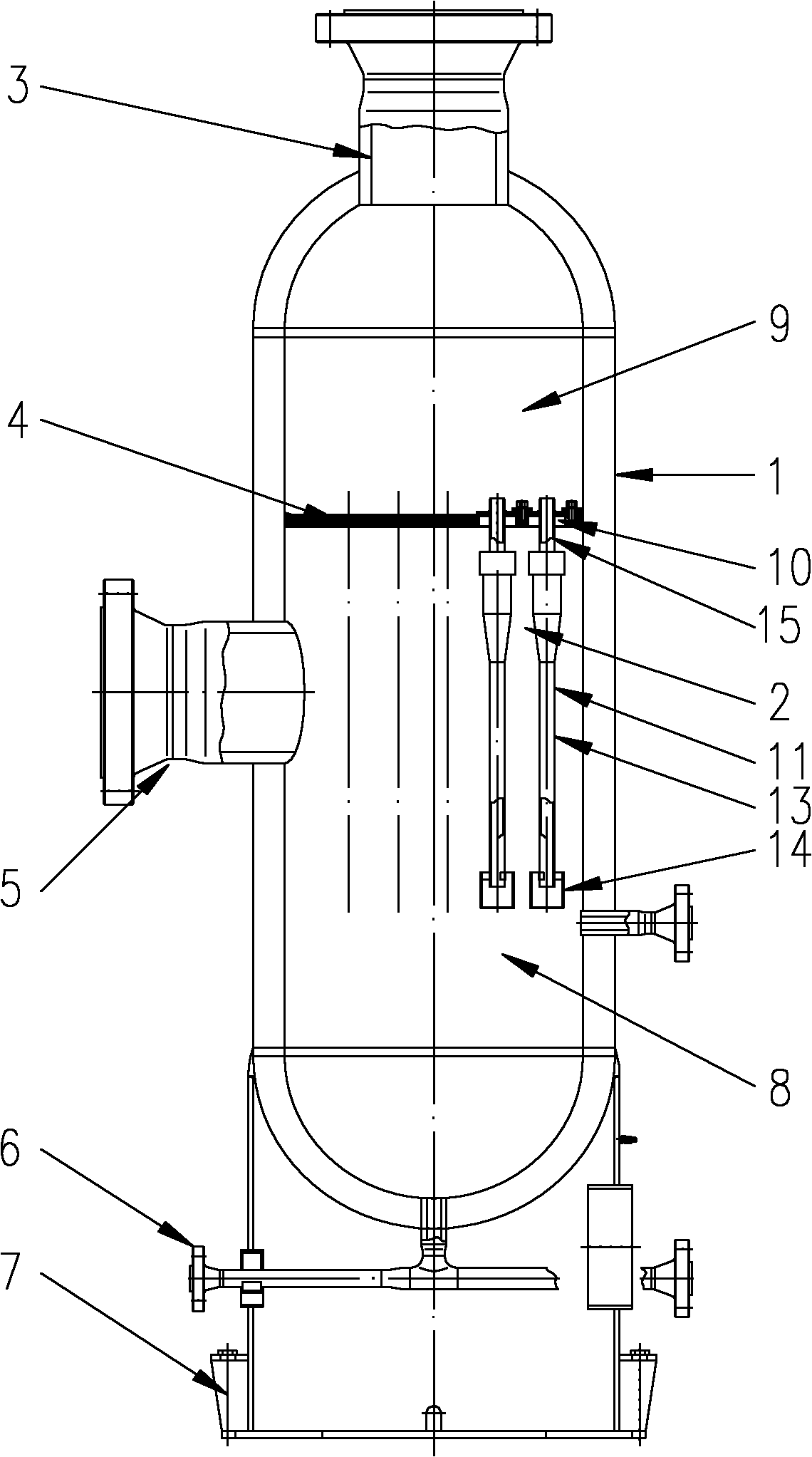

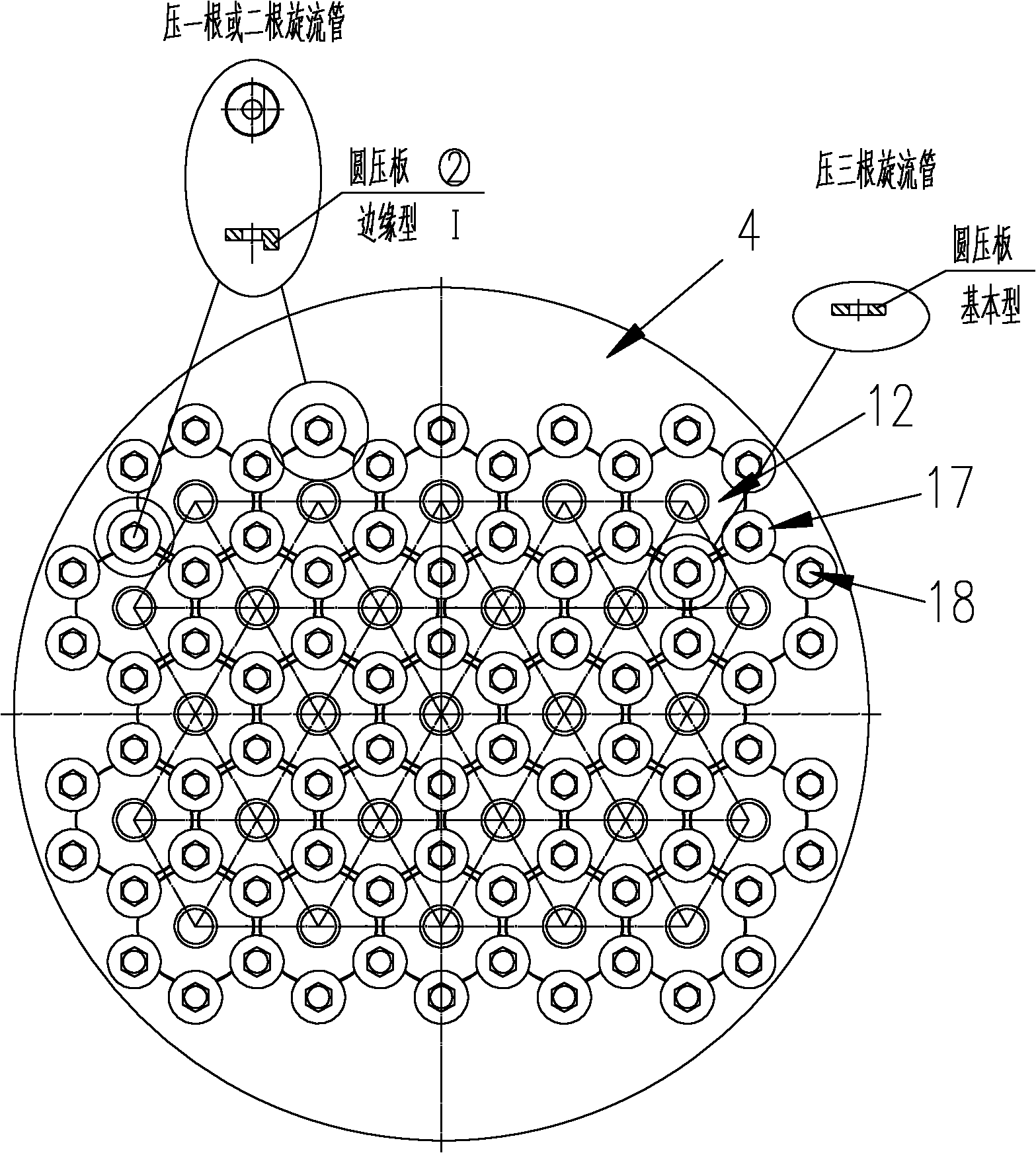

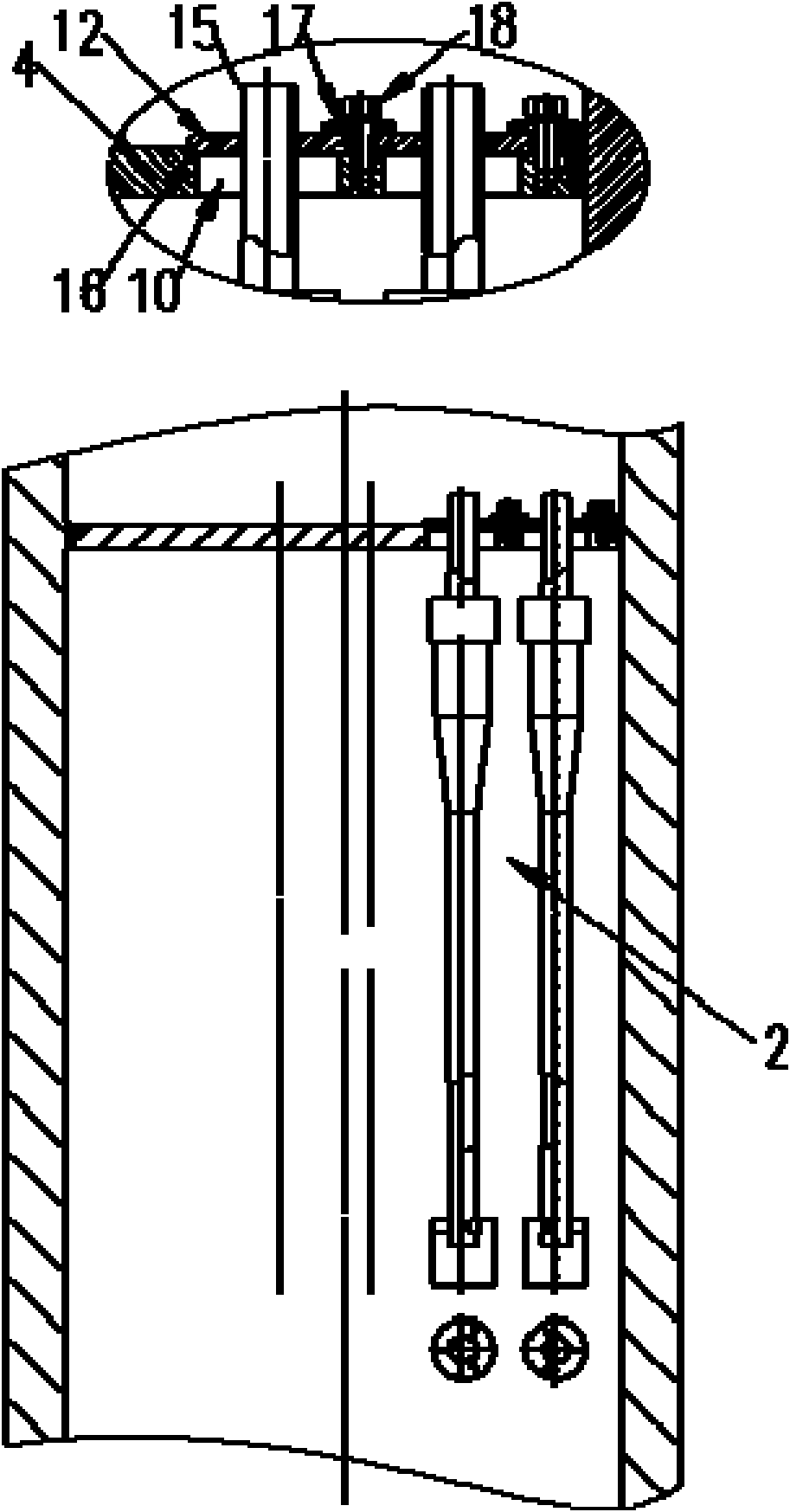

Micro-cyclone reinforced separation device and method for cold-high-pressure separator

ActiveCN102430294AEasy to install and maintainImprove internal space utilizationDispersed particle separationCycloneHydrogenation reaction

The invention discloses a micro-cyclone reinforced separation device and a micro-cyclone reinforced separation method for a cold-high-pressure separator. The micro-cyclone reinforced separation device for the cold-high-pressure separator in a hydrogenation reaction process comprises a cylindrical pressure vessel (1) and a micro-cyclone tube bank (2), wherein the micro-cyclone tube bank consists of one or more micro-cyclone tubes. The device has a simple structure and high separation accuracy; in the high-pressure separator of the hydrogenation reaction process, a high-pressure multi-phase mixture containing liquid particles and gas is subjected to reinforcement of micro-cyclone separation; effective micro-cyclone separation of the liquid particles and the gas in the high-pressure multi-phase mixture is finished under an extremely low pressure; the separation accuracy of the cold-high-pressure separator is improved; the manufacturing cost of the cold-high-pressure separator is reduced; and the device and the method are particularly suitable for operation conditions of high pressure and ultrahigh pressure.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

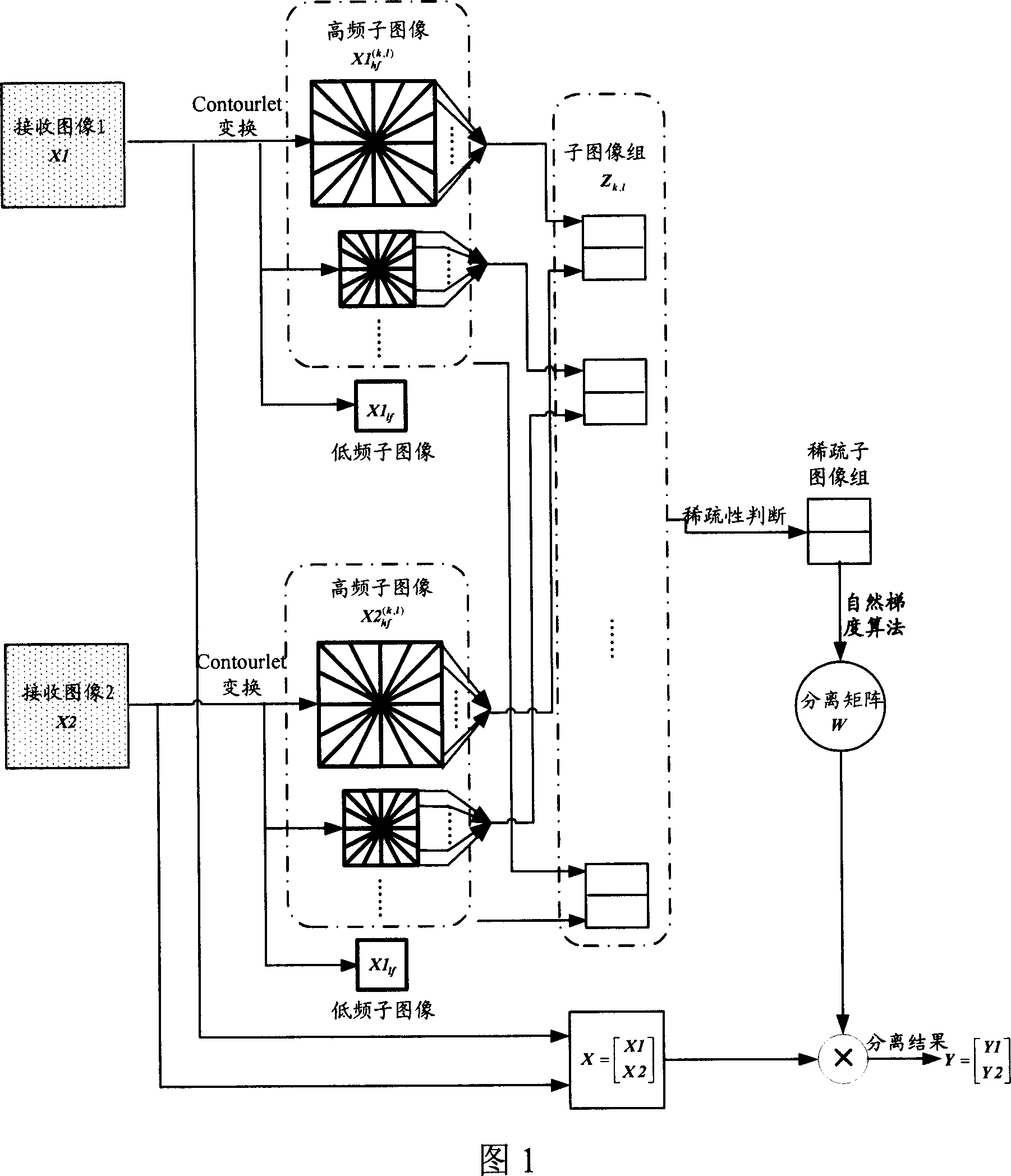

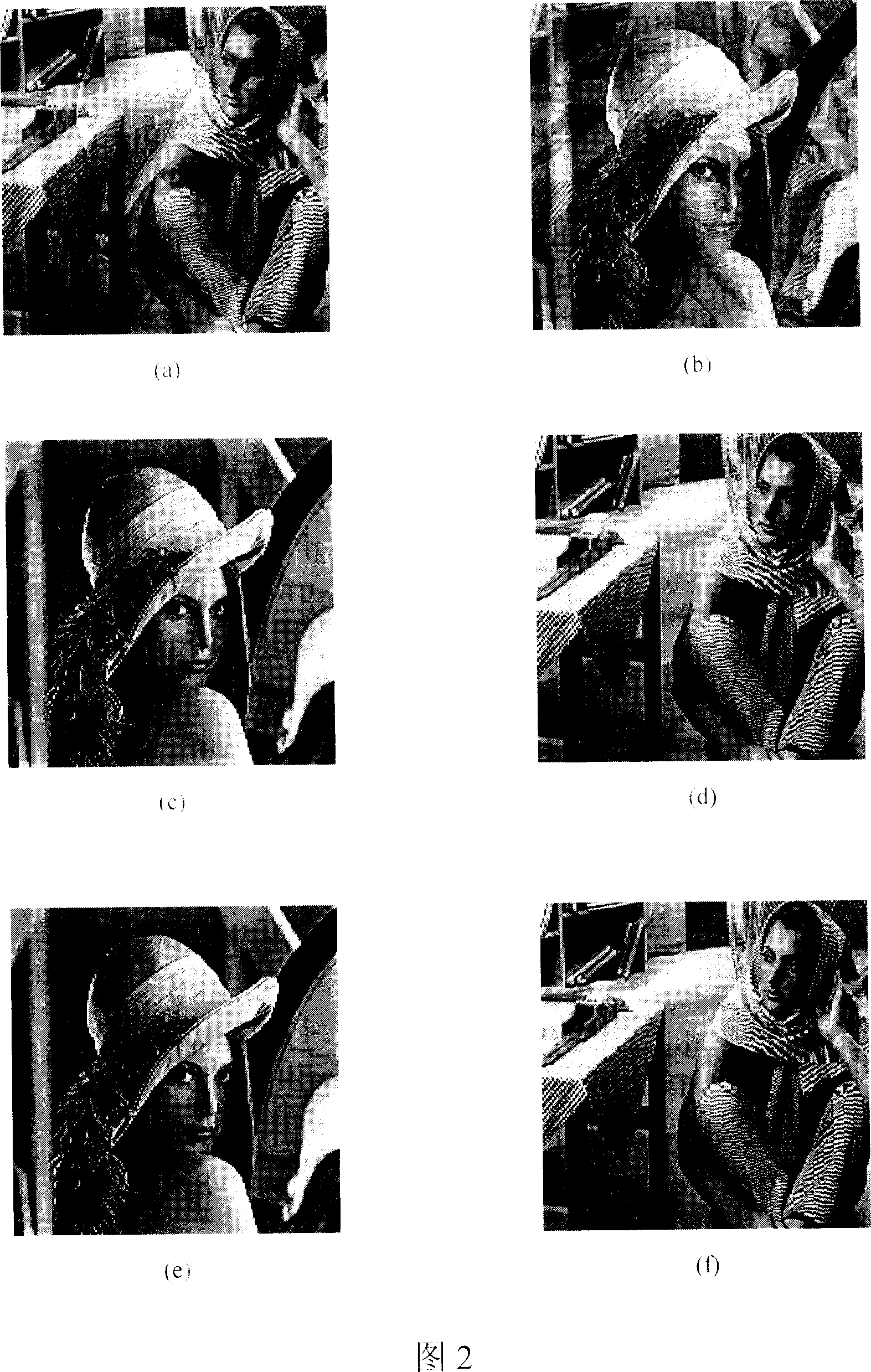

Image blind separation based on sparse change

InactiveCN1936926AHigh separation precisionImprove the performance of separated imagesCharacter and pattern recognitionDecompositionContourlet

First, using Contourlet transform, the method carries out multidirectional multiscale sparse decomposition for received signal of mixed image; in Contourlet transformed domain, using discriminating criterion of sparsity to select group of sub image with best sparsity; then, using traditional quick analysis method of independent components of fixed point to carry out blind separation for selected group of sub image so as to obtain separation matrix; finally, using the separation matrix to carrying out separation for received signal of mixed image, the method picks up each independent components in mixed image so as to reach purpose of separating images from blind sources. Raising precision for separating images from blind sources, the invention is applicable to radio communication system, sonar, and radar system as well as audio, acoustics and medicinal signal processing.

Owner:SHANGHAI UNIV

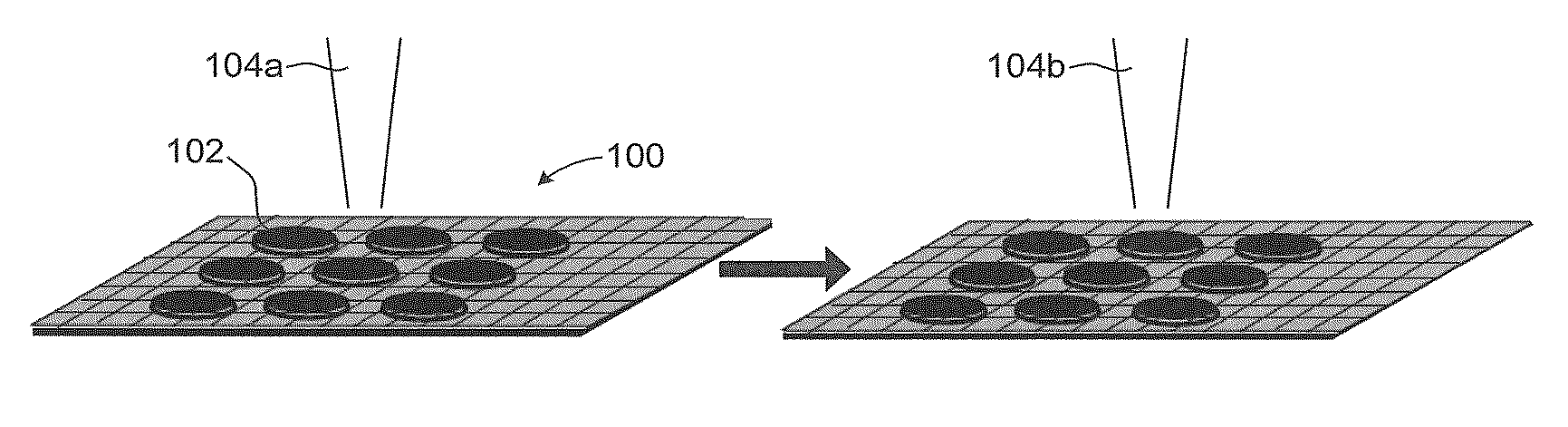

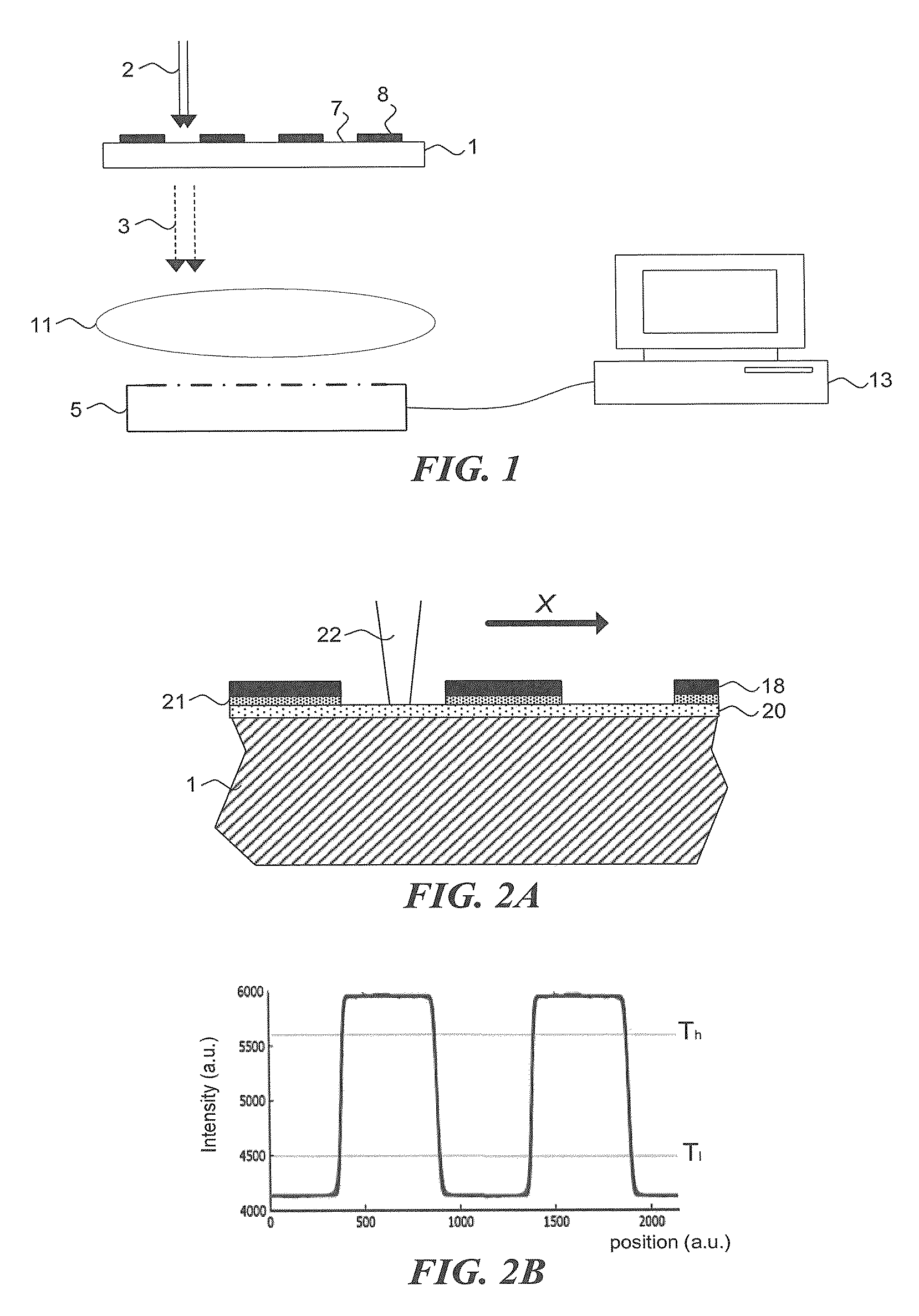

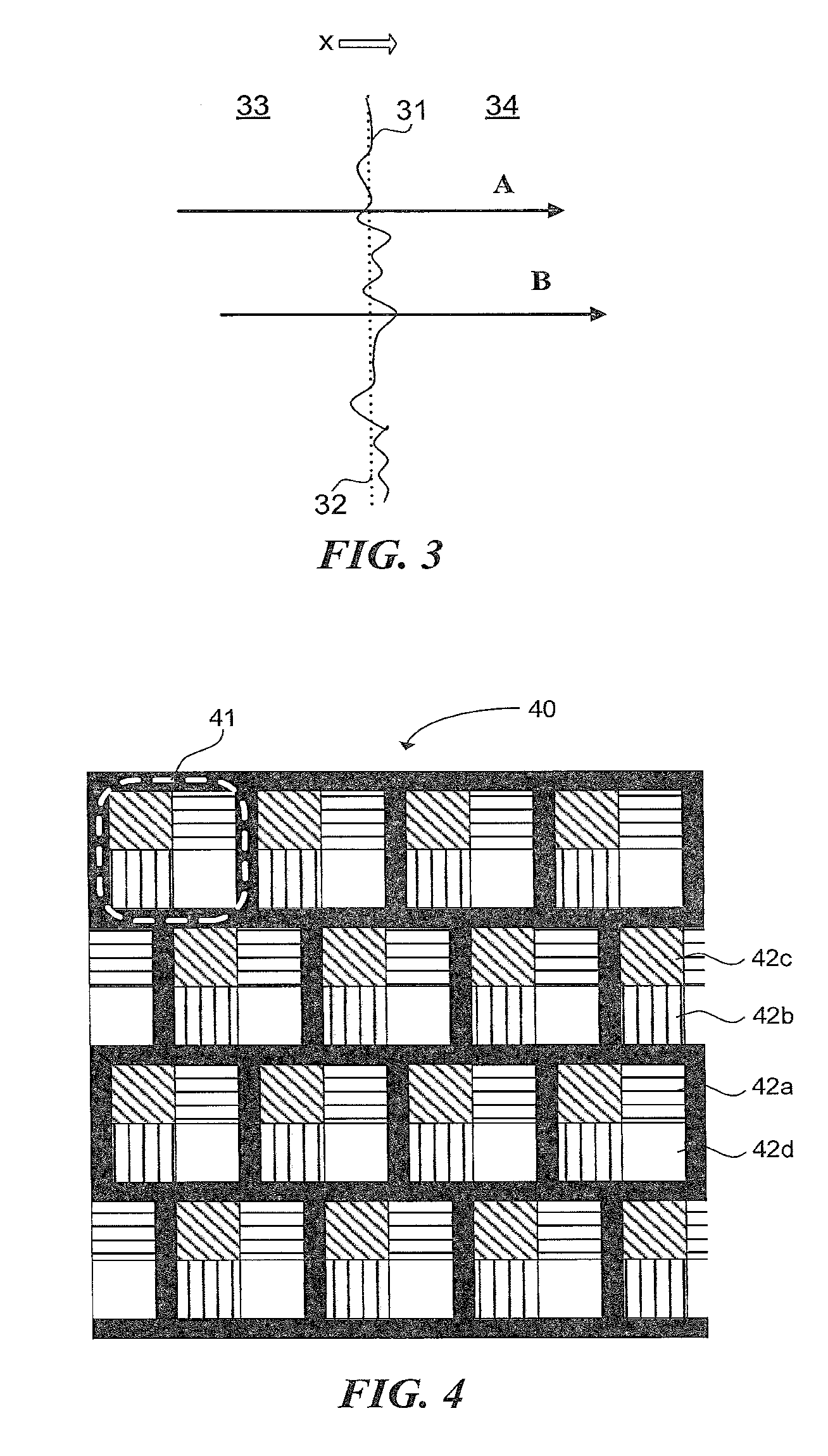

Method for determining a distance between two beamlets in a multi-beamlet exposure apparatus

ActiveUS20120293810A1Improve accuracyLess irregularityElectric discharge tubesNanoinformaticsPhysicsLight beam

The invention relates to a method for determining a distance between charged particle beamlets in a multi-beamlet exposure apparatus. The apparatus is provided with a sensor comprising a converter element for converting charged particle energy into light and a light sensitive detector provided with a two-dimensional pattern of beamlet blocking and non-blocking regions. The method comprises scanning a first beamlet over the pattern, receiving light generated by the converter element, and converting the received light into a first signal. Then the two-dimensional pattern and the first beamlet are moved relatively with respect to each other over a predetermined distance. Subsequently, the method comprises scanning a second beamlet over the pattern, receiving light generated by the converter element, and converting the received light into a second signal. Finally, the distance between the first beamlet and second beamlet is determined based on the first signal, the second signal and the predetermined distance.

Owner:ASML NETHERLANDS BV

Efficient full-automatic oil-water separation system

ActiveCN102583804AEasy to separateHigh separation precisionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesAutomatic controlSlag

The invention provides an efficient full-automatic oil-water separation system which comprises an oil overflow pool, wherein an overflow weir is arranged on one side of the oil overflow pool; a stainless steel slag removal screen is mounted in the overflow weir; a water inlet electromagnetic valve is mounted on a pipeline for connecting the overflow weir and a separation box; a stainless steel filter screen is mounted in the separation box; a buffer plate is arranged above the stainless steel filter screen; a first sensor and a second sensor are mounted in the separation box; the neck part ofthe separation box is connected with an oil storage cup through a pipeline; a water drainage electromagnetic valve is arranged on a pipeline for connecting the separation box and a water storage box;and an automatic water drainage device is mounted in the water storage box. The efficient full-automatic oil-water separation system has the advantages that the separation effect and the separation accuracy can be improved, the use amount of liquid detergent can be reduced and separated wastewater can be reutilized; and besides, the efficient full-automatic oil-water separation system can be controlled intelligently and automatically and butted with the internet of things, so that the labor intensity of workers is reduced.

Owner:孙成胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com