Efficient full-automatic oil-water separation system

An oil-water separation, fully automatic technology, applied in liquid separation, separation methods, centrifugal separation of water/sewage treatment and other directions, can solve the problems of low separation efficiency, inability to achieve, energy waste, etc., to improve separation accuracy, reduce subsequent blockages, The effect of reducing the loss of waste oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

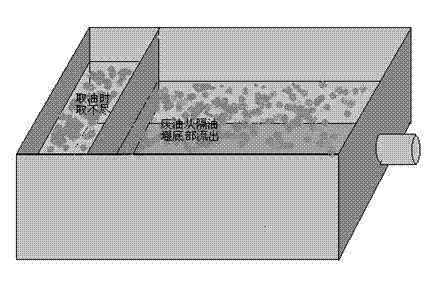

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

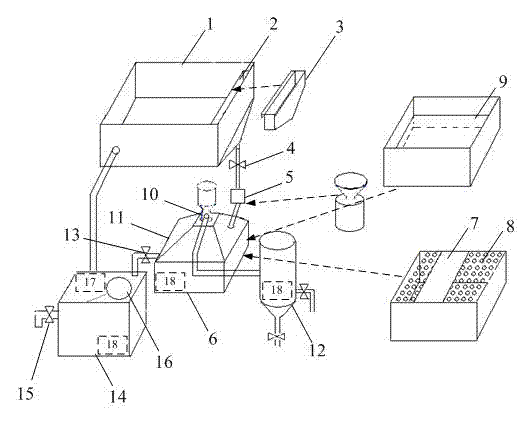

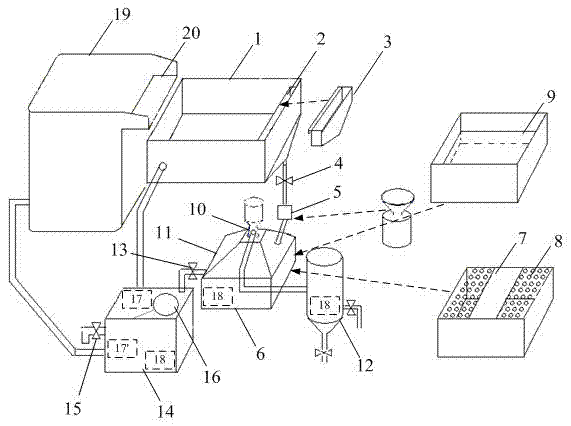

[0044] like figure 2As shown, the present invention has an oil spill pond 1. In actual use, firstly, the oily waste water is pumped into the oil spill pond 1 by using a water pump. Because there is a density difference between water and oil, the oil particles will pass through after a certain period of slow flow. After flowing through the overflow weir 2, the first coarse separation of oil and water is completed, and then the oily wastewater passes through the replaceable stainless steel filter screen 3 (see the enlarged picture for the specific structure) to separate the slag and liquid. Then, the oily wastewater is controlled by the water inlet solenoid valve 4, and the centrifugal rotary slag remover 5 (optional, see the enlarged picture for the specific structure) is deslagging again, and flows into the separation box 6 with a unique structure. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com