Patents

Literature

944 results about "Oily wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oily Waste-water Treatment. Carbtrol offers an Oily Wastewater Treatment System designed to treat a range of oily water applications including floor drain oily waste from maintenance areas, industrial oily process wastewater, parking lot runoffs, and bilge water. The Treatment System is efficient and requires little maintenance.

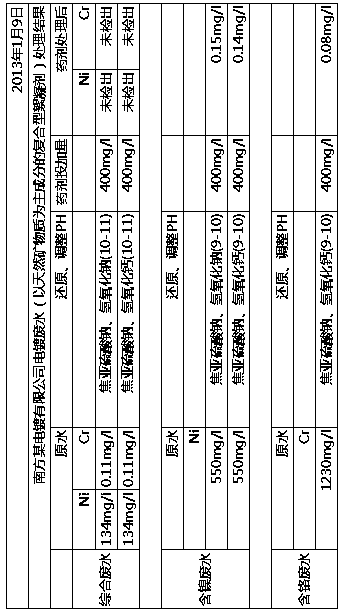

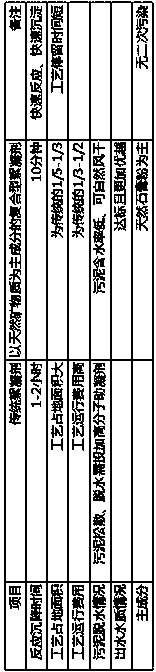

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

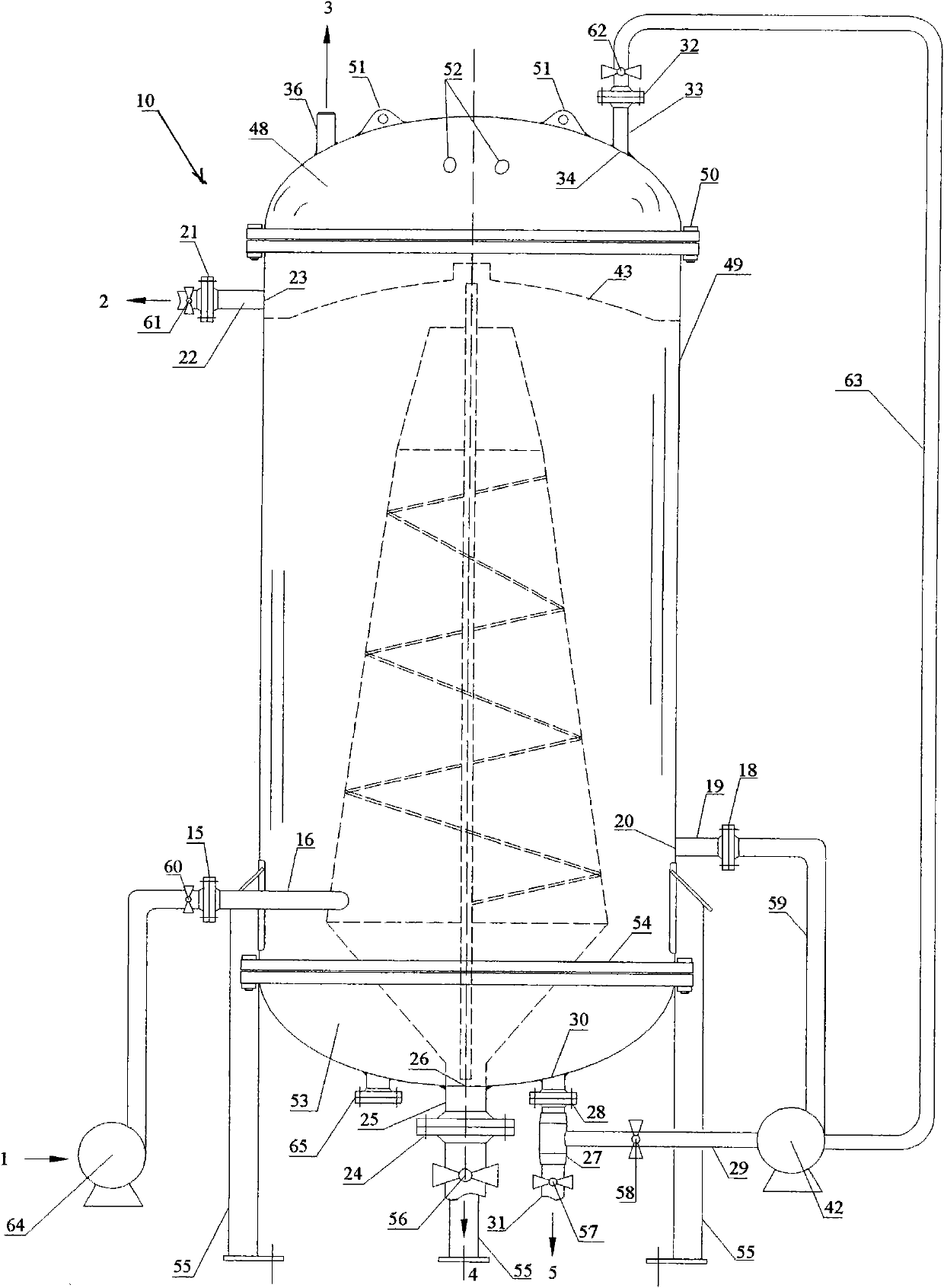

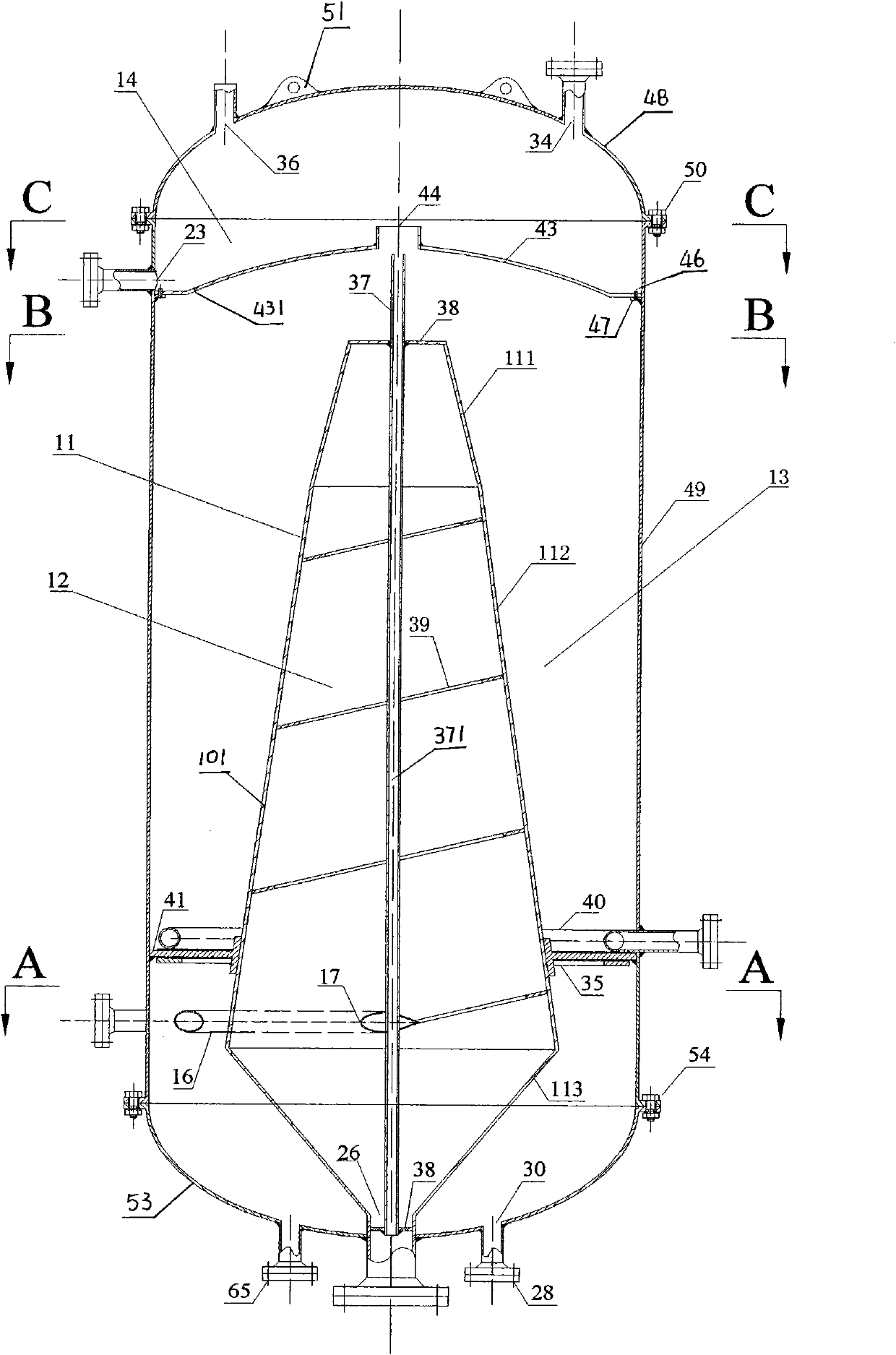

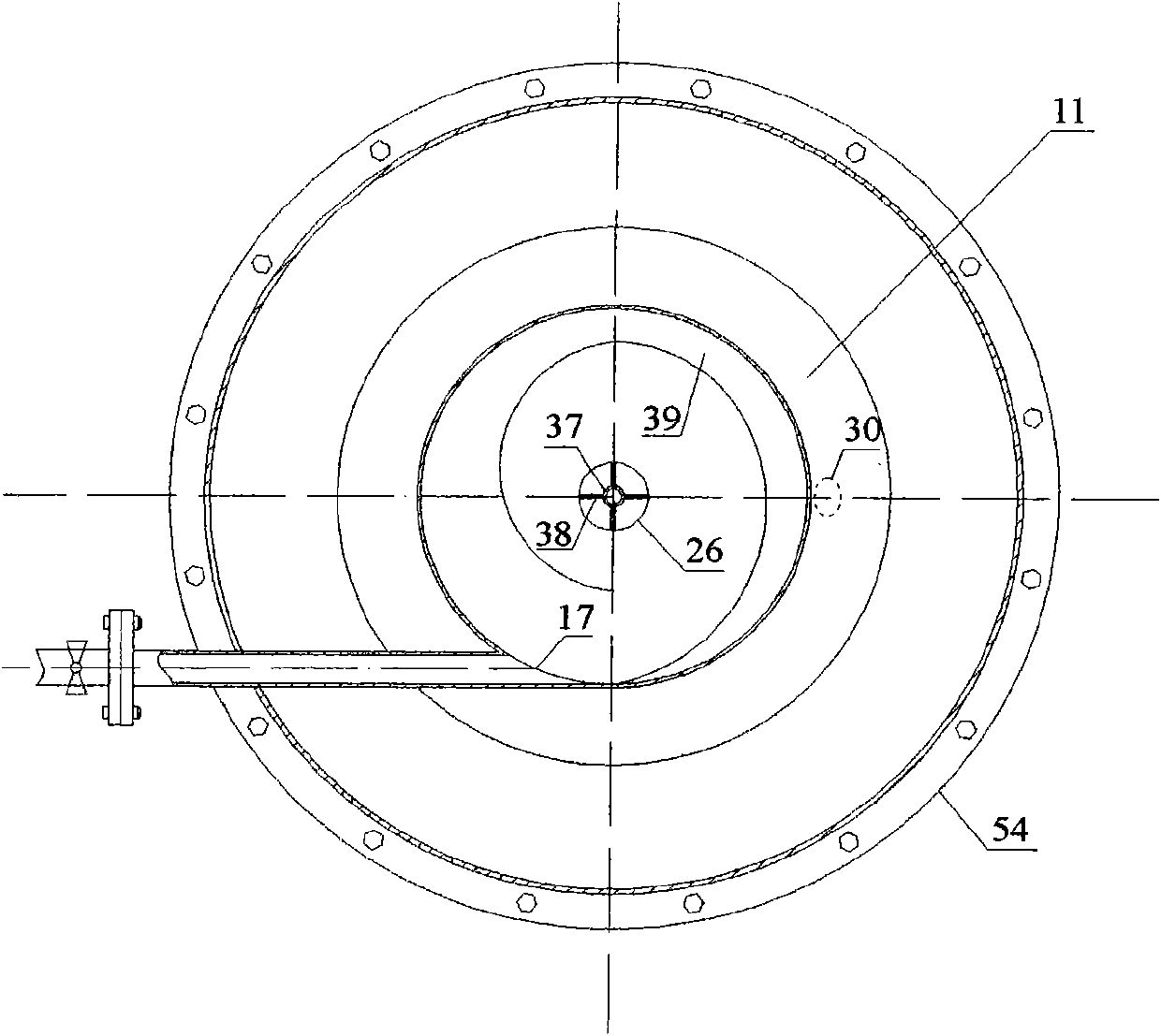

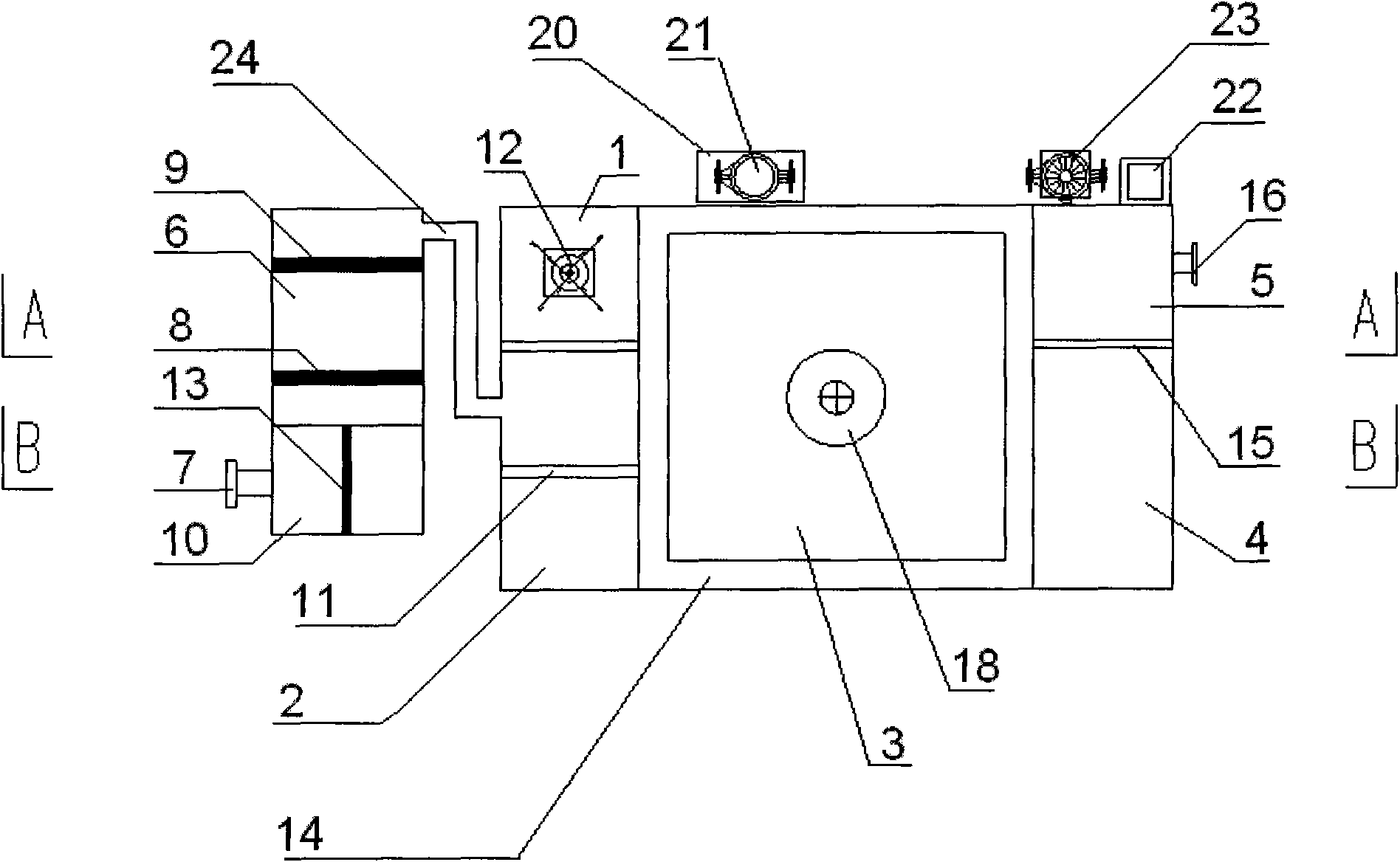

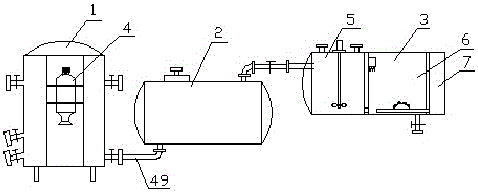

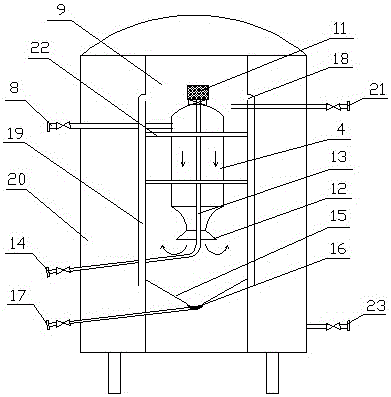

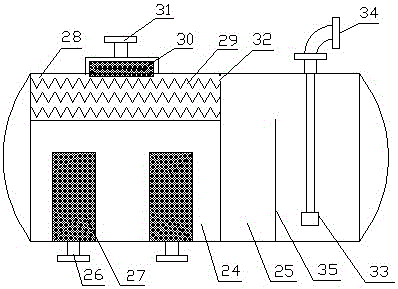

Multiphase separation method and system for processing oily waste water

InactiveCN102198984ACompactSimple appearanceWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentCycloneSolid particle

The invention discloses a multiphase separation method and a system for processing oily waste water. The multiphase separation system comprises a cyclone-air flotation integrated separator, a multiphase pump for mixing gas with liquid arranged at an oily waste water inlet, a multiphase pump for mixing pure water for circulation and backflow with circulation gas and the like. The oily waste water enters from the bottom of a tank body into a cyclone to perform a hydrocyclone separation, tiny bubbles in the waste water are released to perform a first air floatation, light substances such as bubbles with oil particles are moved to the top of the cone-shape cyclone, heavy substances such as solid particles are moved to the bottom of the cone-shape cyclone, the waste water runs over the top of the cone-shape cyclone to enter a secondary air floatation zone, the pure water for circulation and backflow and circulation gas are shear mixed in the multiphase pump, then the oily waste water is subject to a secondary air floatation by using gas-liquid mixture from water distributing apertures on an annular water-locator, and the waste water is subject to a hydrocyclone separation and two air floatation separations in a separator. The invention has the advantages of simple and compact structure, high work efficiency, and is used for the purifying process of oily waste water containing tiny dispersed oil particles.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

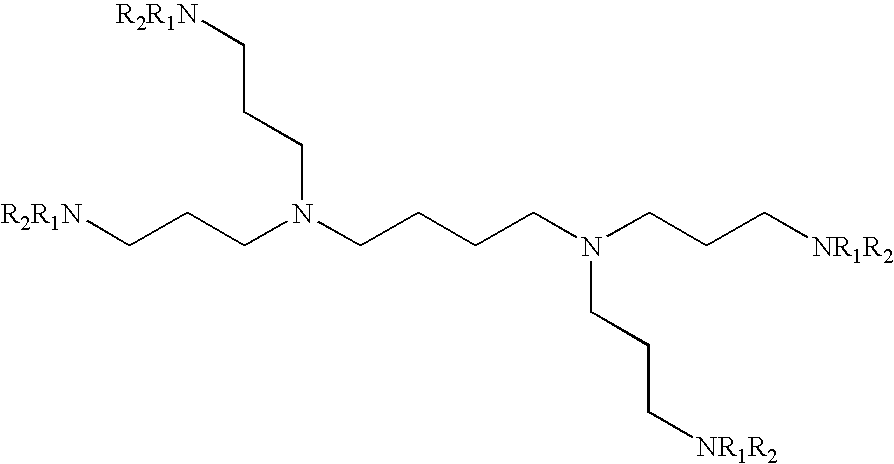

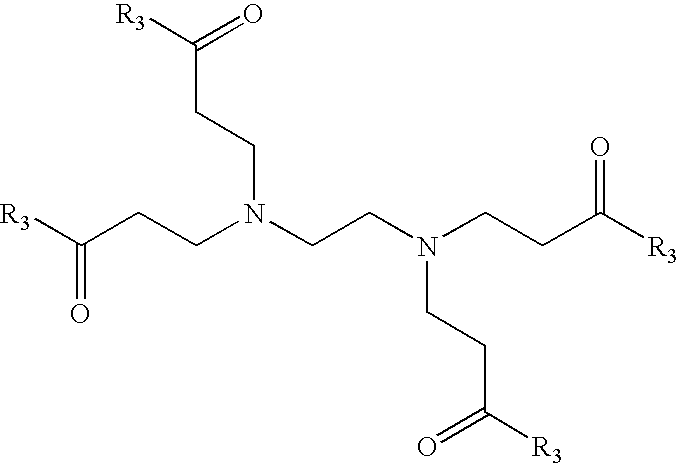

Method of clarifying oily waste water

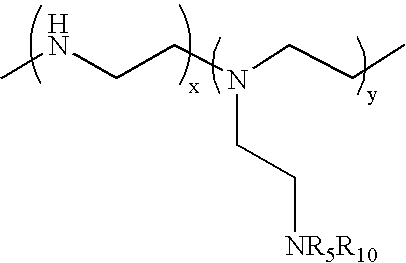

ActiveUS20060289359A1Waste water treatment from quariesTreatment involving filtrationDemulsifierSulfate

A method of clarifying oily waste water comprising adding to the waste water an effective clarifying amount of one or more demulsifiers selected from the group consisting of dendritic polyamines, dendritic polyamidoamines and hyperbranched polyethyleneimines and the reaction products thereof with gluconolactone, alkylene oxides, salts of 3-chloro-2-hydroxypropanesulfonic acid, alkyl halides, benzyl halides and dialkyl sulfates.

Owner:ECOLAB USA INC

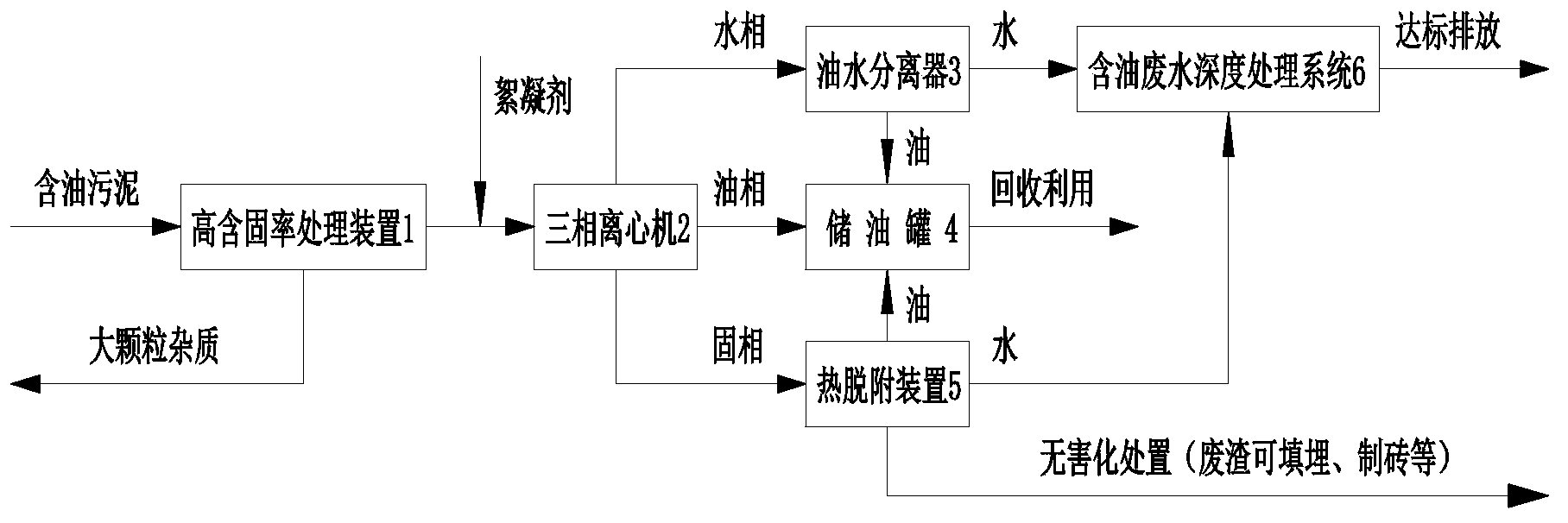

Harmless treatment method for separation and recovery of oily sludge

ActiveCN104341081ALow costEasy maintenance and managementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSludgeOil phase

A harmless treatment technology for separation and recovery of oily sludge comprises the following steps: 1, conveying the oily sludge to a high solid content treatment device, carrying out preliminary screening on large granule impurities in the oily sludge, and conditioning the sludge; 2, conveying pre-conditioned oily sludge to a three-phase centrifuge, and separating oil, water and mud in the oily sludge; 3, conveying the obtained separated liquid to an oil-water separation device, and further carrying out oil and water separation; 4, inputting the obtained oil phase to an oil storage tank, and inputting water to an oily wastewater advanced treatment system; 5, conveying the obtained solid phase sludge transported to a thermal desorption device, and carrying out heating curing separation and condensation oil-water separation in a thermal desorption treatment process; and 6, conveying water output by the oil-water separation device and water output by the thermal desorption device to the oily wastewater advanced treatment system, and carrying out advanced oil-water separation. The method has the advantages of low cost oily sludge treatment cost, convenient maintenance and management, high efficiency and good stability.

Owner:MAIWANG INT BUSINESS SHANGHAI

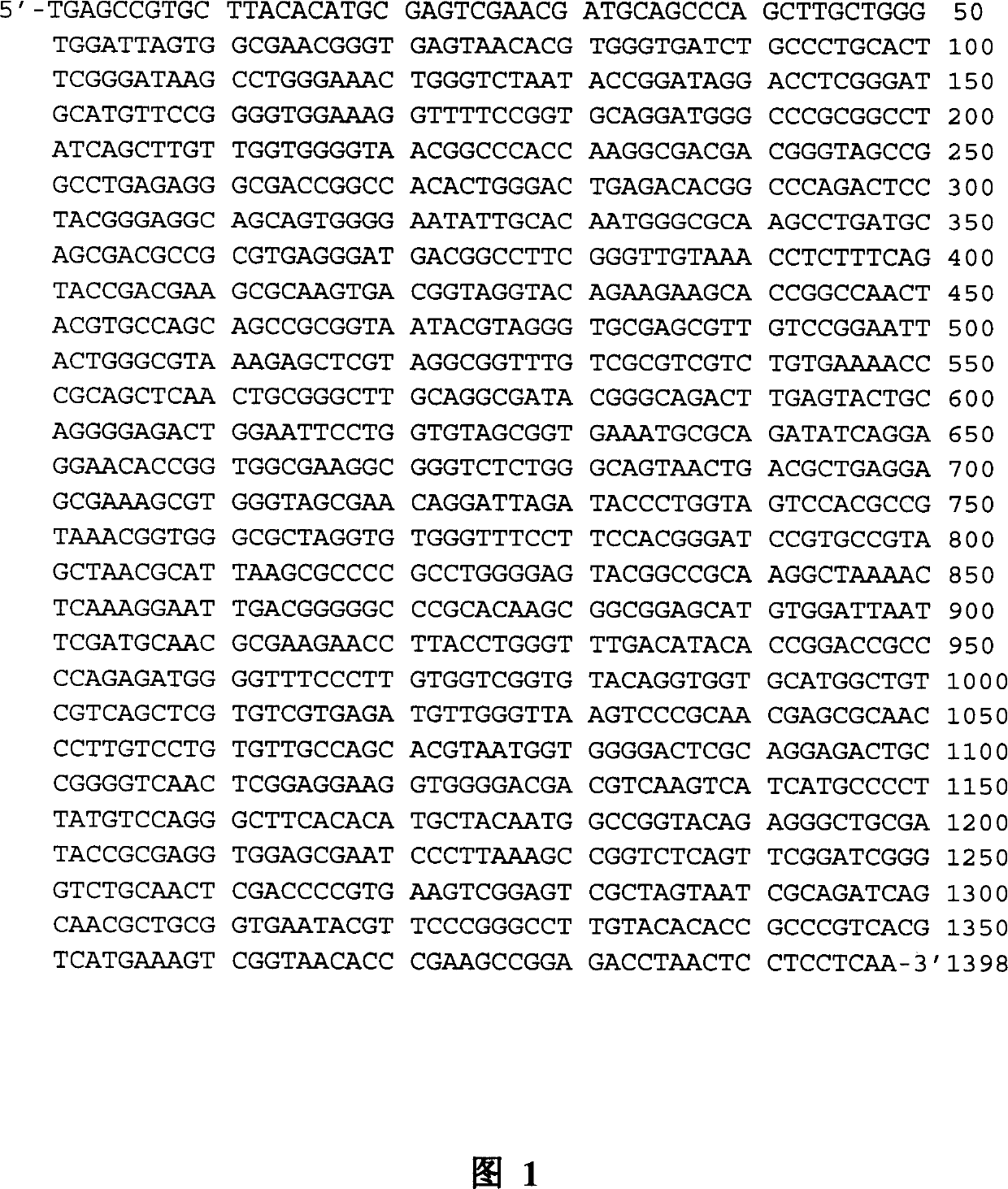

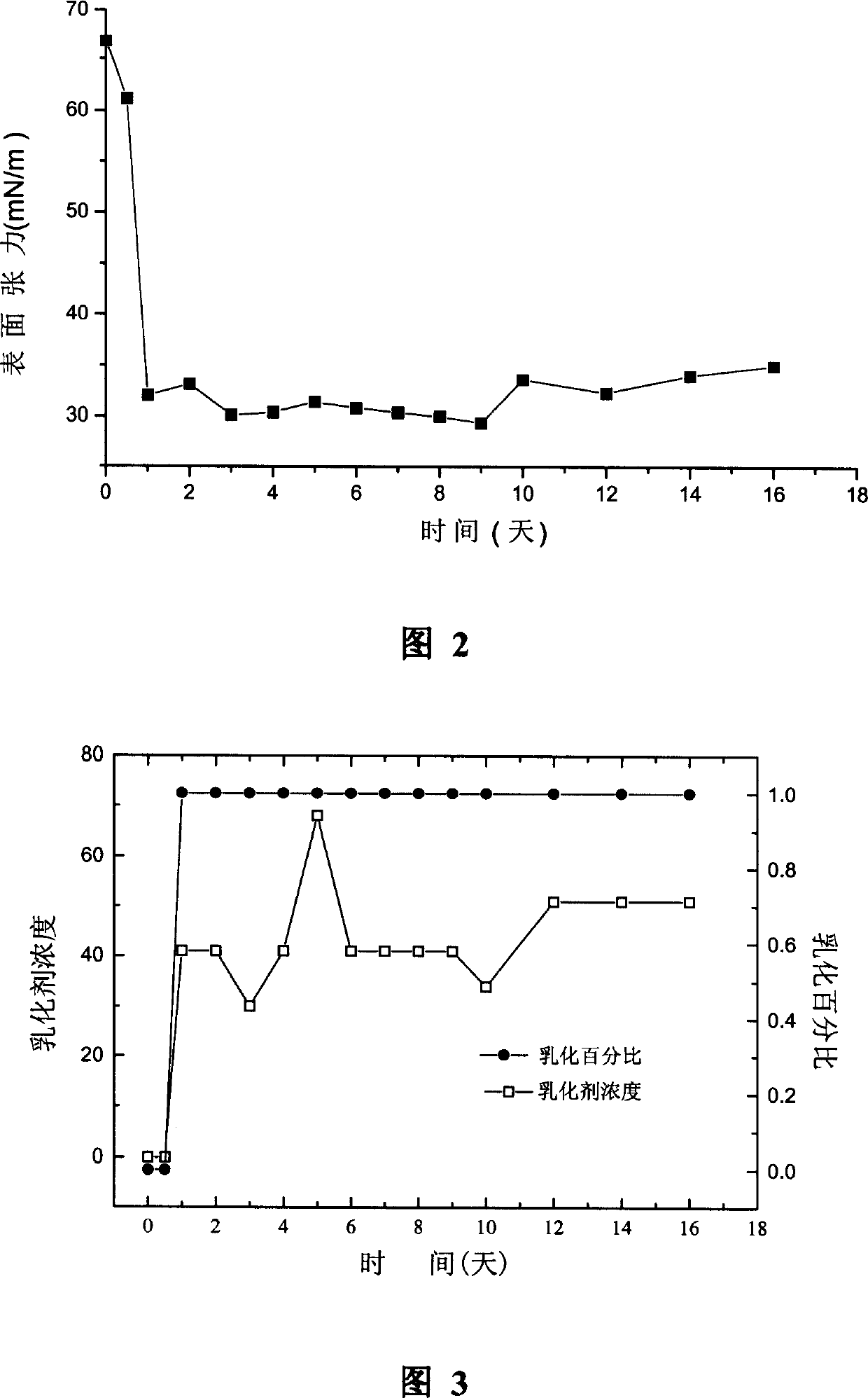

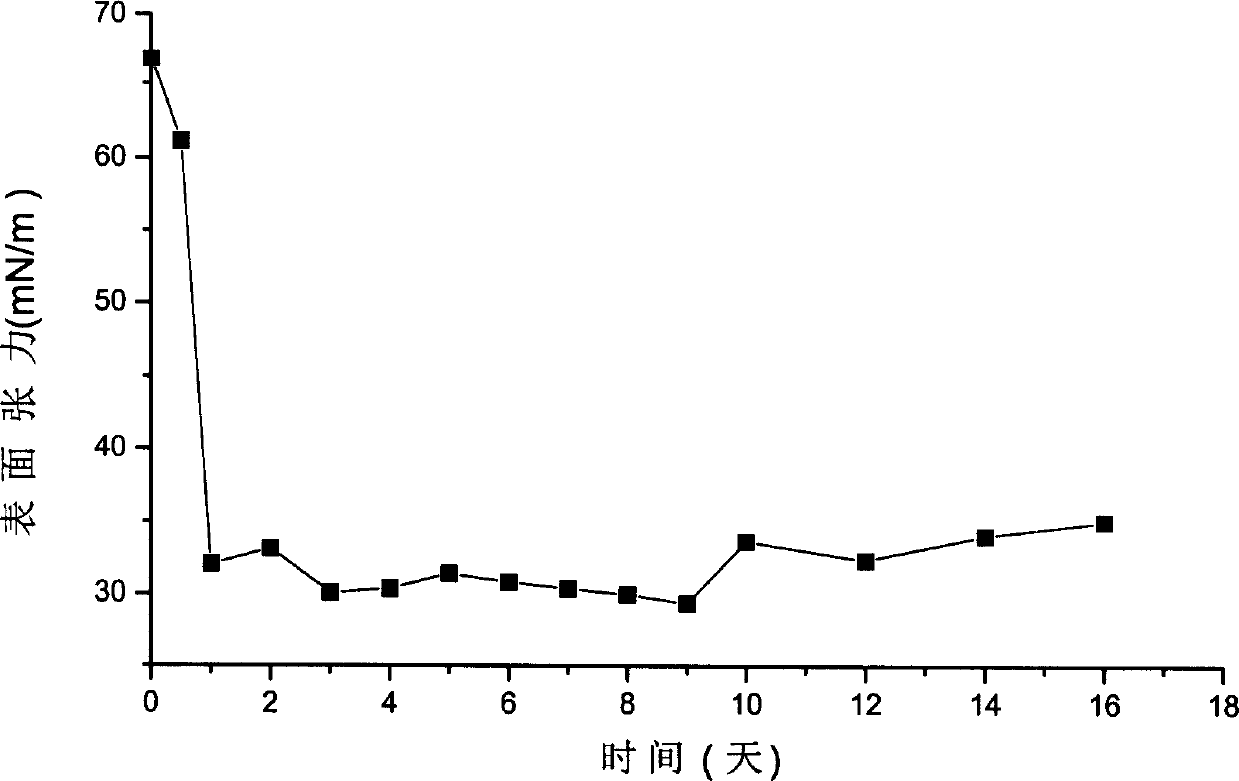

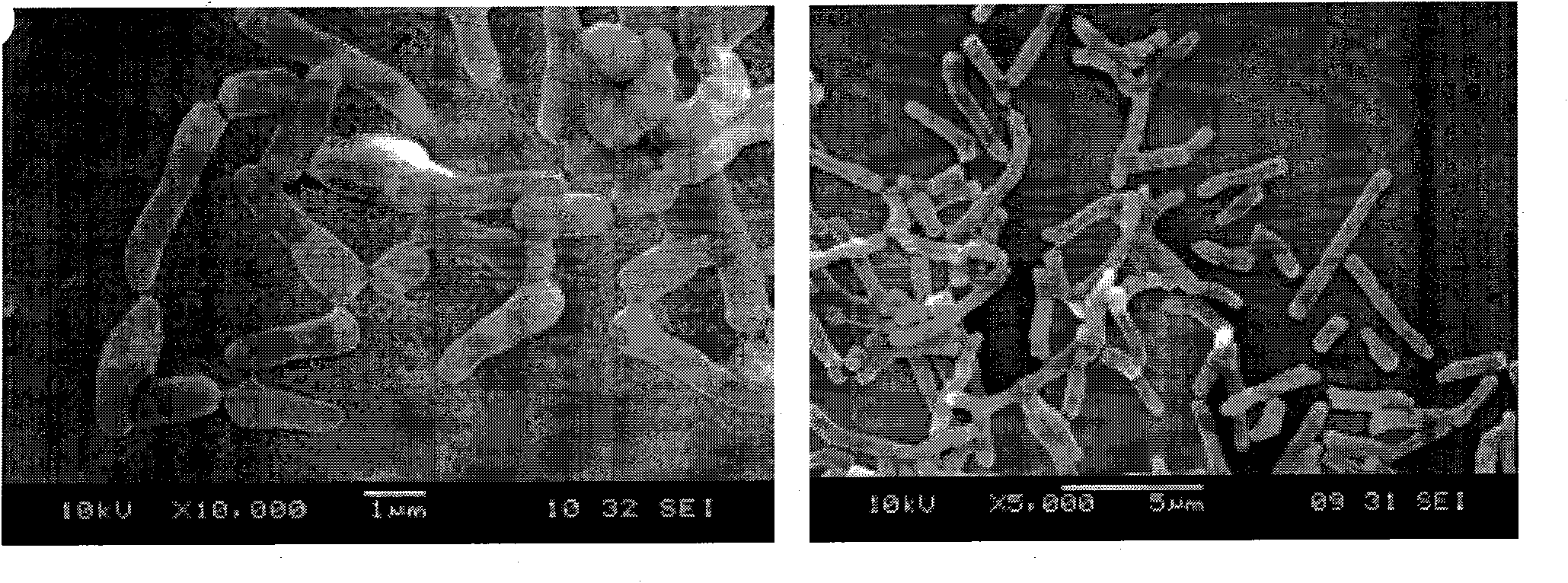

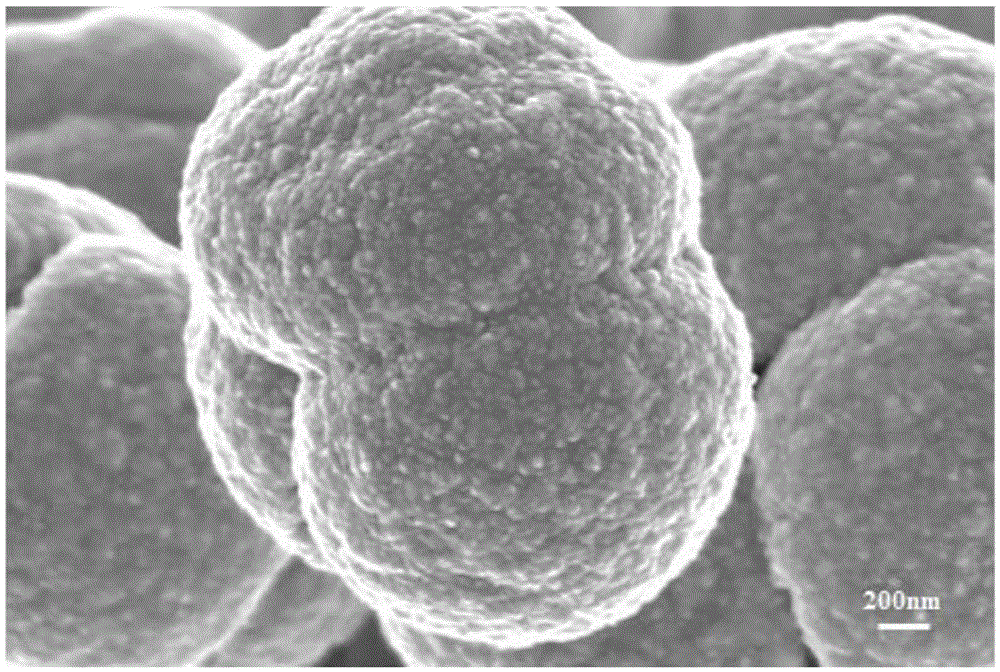

Erythro micrococcus Em and usage for generating biologic emulsifier as well as degrading polycyclic aromatic hydrocarbon

InactiveCN1519312AStrong solubilizationPromotes the degradation of petroleum hydrocarbonsBacteriaFermentationSolubilityAlkane

A Rhodococcus ruber Em (CGMCC No.0868) features that its cells, cell suspension, or immobilized cells can degradate the paraffin and polycyclic arylhydrocarbon because the paraffin and polycyclic arylhydrocarbon are used as its only carbon source and energy source for growing to generate the bioemulsifier of ester. Said emulsifier can obviously decrease the surface tension of aqueous solution, has strong emulsifying power to ester substance, and can increase the solubility of paraffin and polycyclic arylhydrocarbon in water, so it can be used for treating the oil-contained sewage and repairing the petroleum polluted soil.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

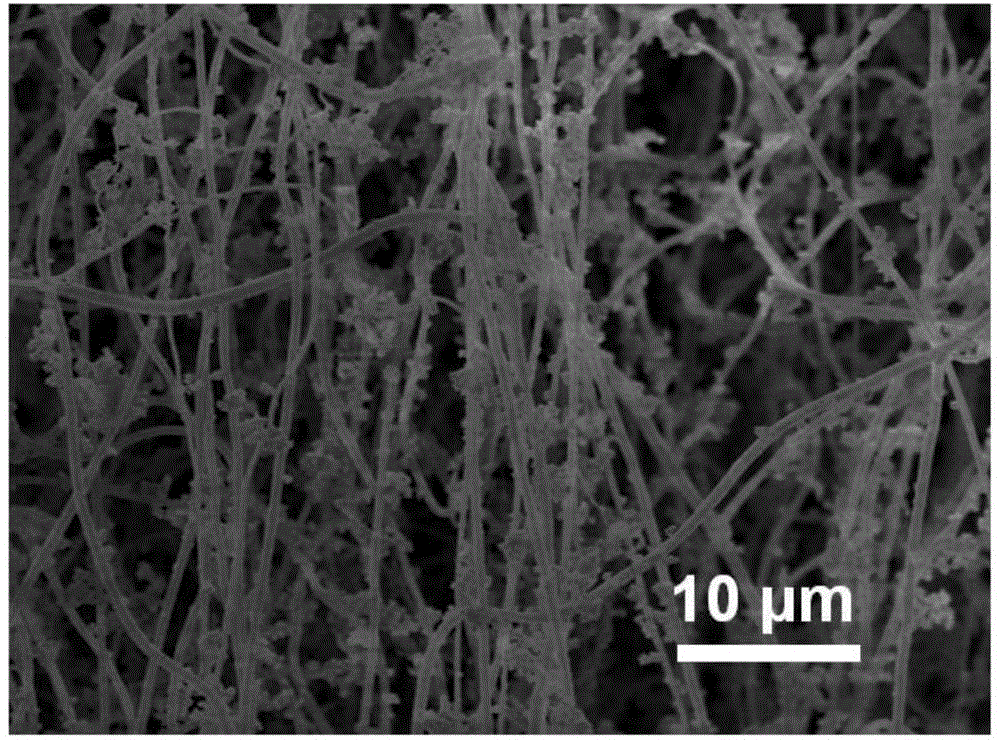

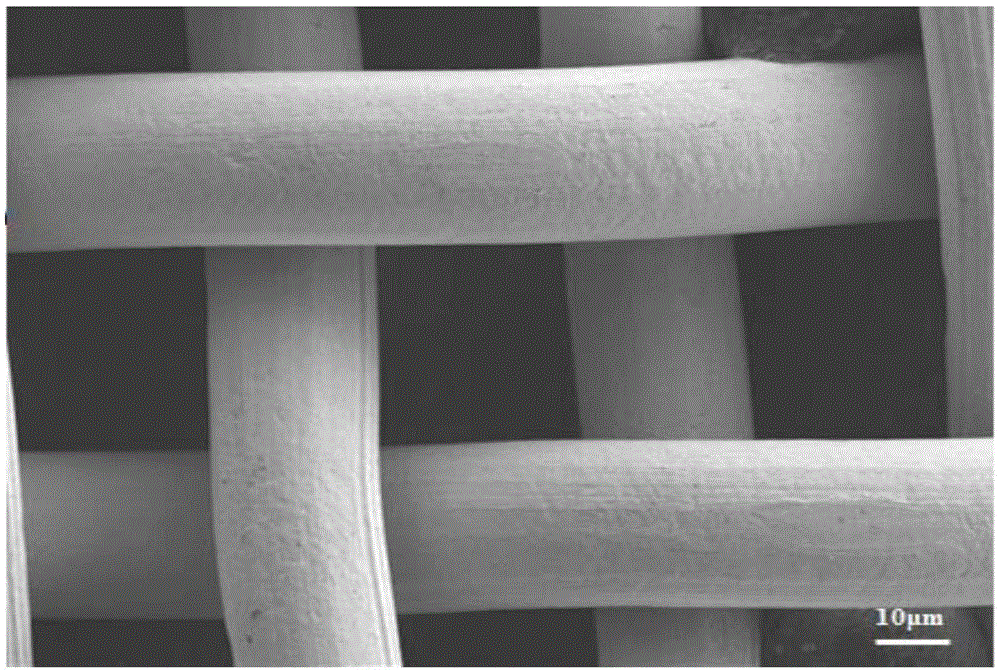

Magnetic response type high-efficiency oil-water separation fiber membrane and preparation method thereof

InactiveCN104436760AResponsiveMagnetic field responsiveLiquid repellent fibresNon-woven fabricsFiberMicro nano

The invention discloses a magnetic response type high-efficiency oil-water separation fiber membrane and a preparation method thereof, and belongs to the field of functional micro-nano fiber materials. The magnetic response type high-efficiency oil-water separation fiber membrane disclosed by the invention is prepared by the following steps: dissolving hydrophobic polymers, such as polyvinylidene fluoride, polyurethane or polycaprolactone, as main raw materials into an organic solvent to form a polymer solution; preparing a non-woven fiber membrane material prepared from micro-nano structure fibers by adopting an electrospinning method; forming a sticky polydopamine membrane through polymerization of polydopamine in an alkaline solution, and firmly attaching magnetic nanoparticles onto the surface of an electrospinning fiber membrane by adopting the sticky polydopamine membrane, so as to prepare the magnetic response type high-efficiency oil-water separation fiber membrane. The fiber membrane disclosed by the invention has a super-hydrophobic / super-oleophilic property in air, and has an excellent adsorptive property on a plurality of common oils; the preparation method of the high-efficiency oil-water separation fiber membrane, disclosed by the invention, is simple, low in energy consumption, and high in efficiency,and can be widely applied to the fields such as remote controllable efficient separation of oily wastewater, and the magnetic responsiveness is realized.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

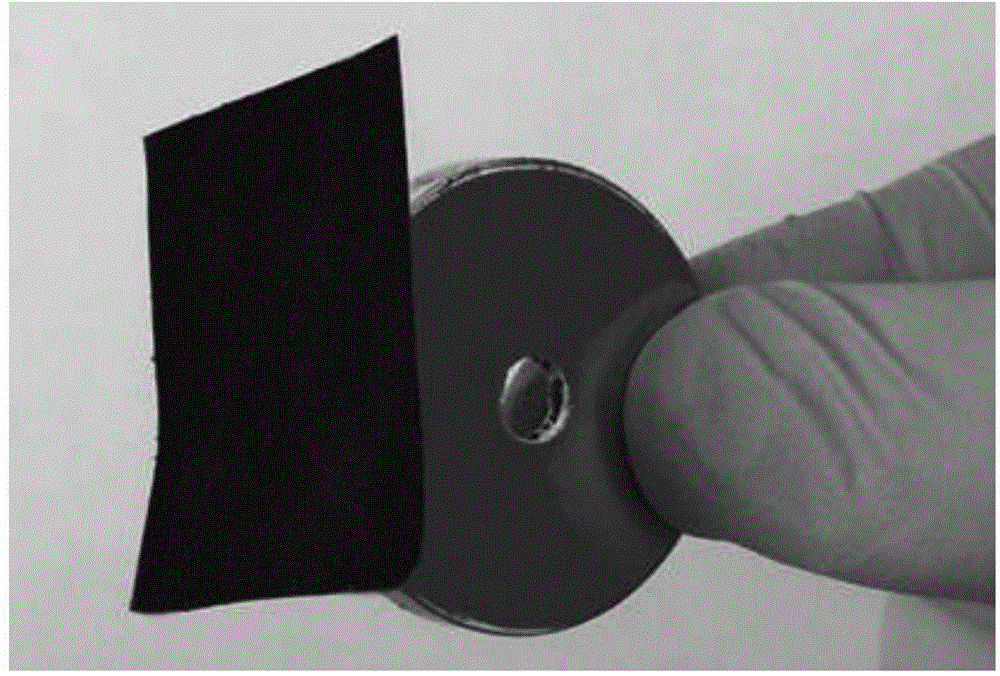

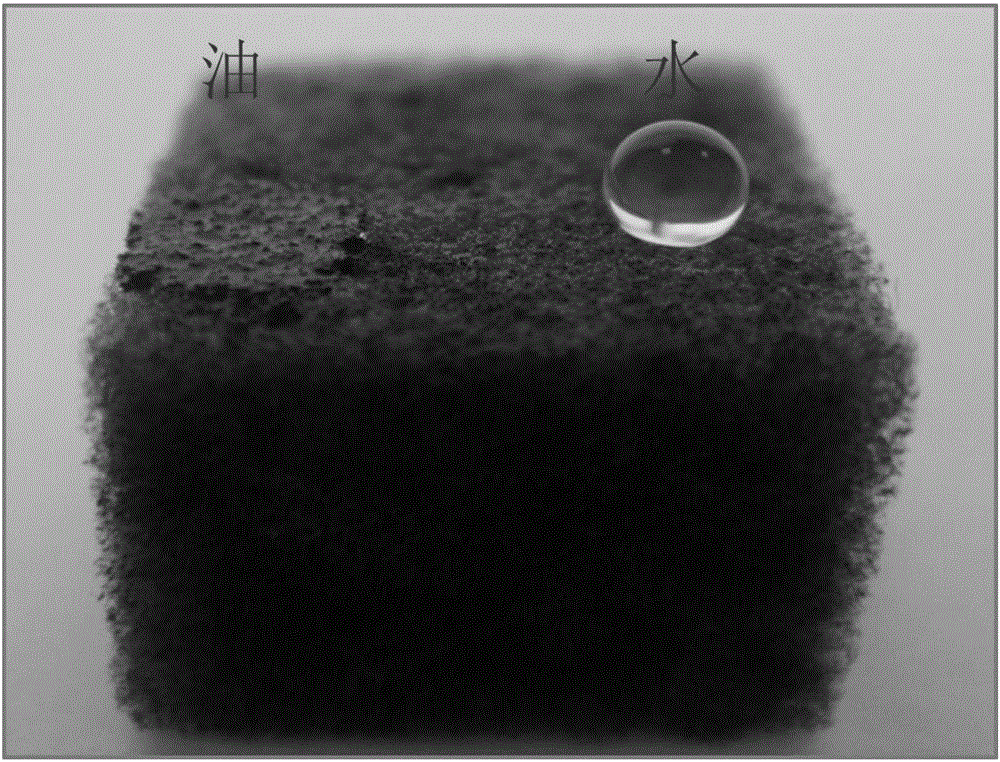

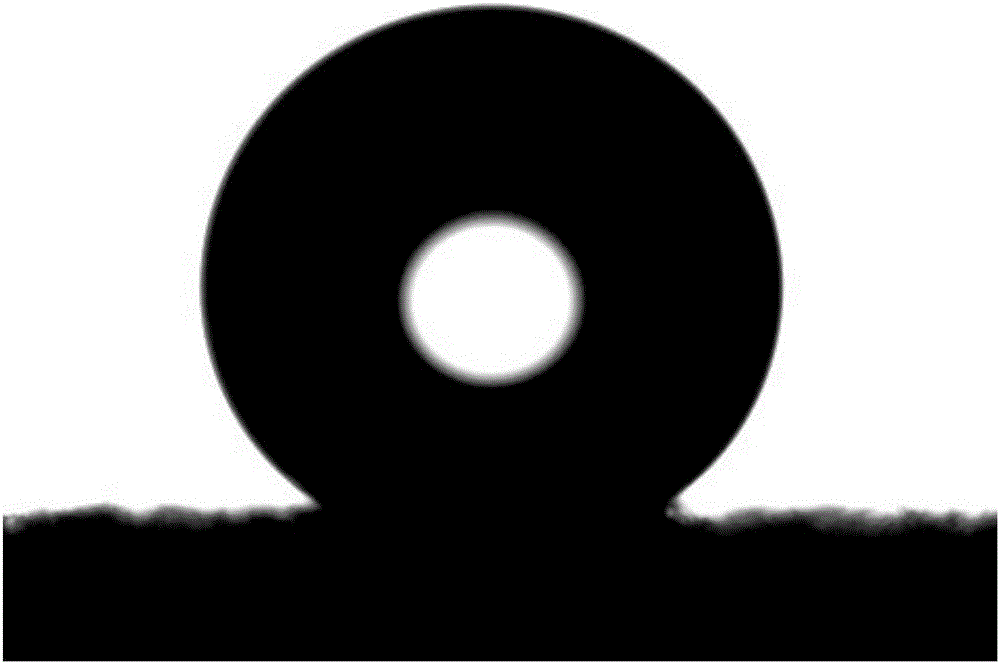

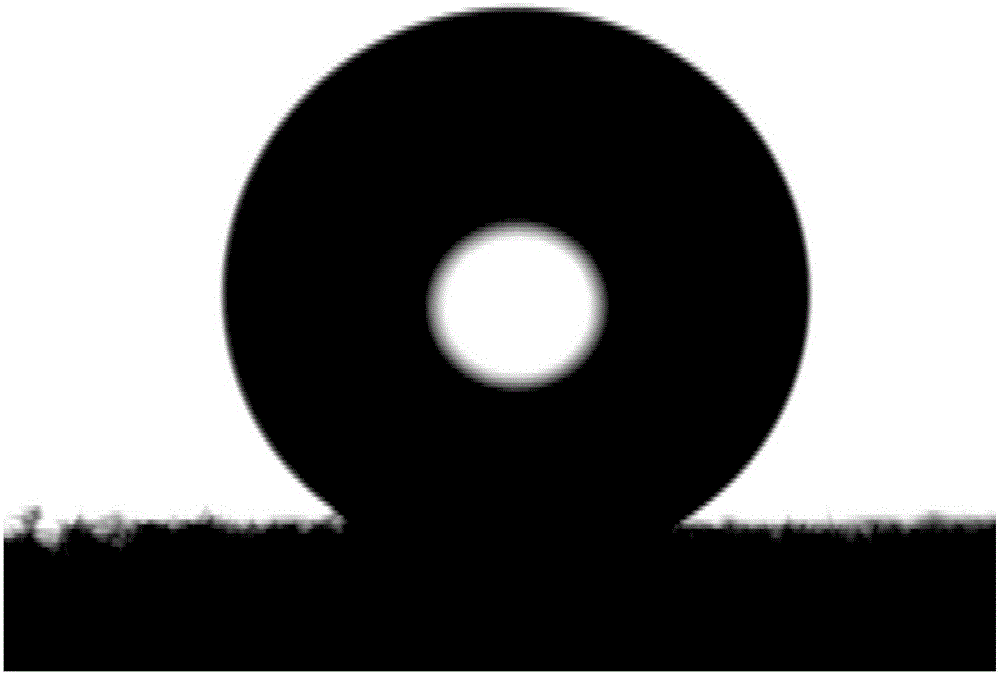

Super-hydrophobic reduced graphene oxide/sponge composite material and preparation method thereof

InactiveCN105754144ASimple preparation processShort response timeOther chemical processesEthylenediamineMicrowave

The invention discloses a super-hydrophobic reduced graphene oxide / sponge composite material and a preparation method thereof. The method includes: employing a microwave-ultrasonic wave method and using ethylenediamine as the reducing agent to reduce graphene oxide into reduced graphene oxide, and under the action of hole and other sound waves, dispersing and attaching the reduced graphene oxide to a commodity sponge, thus obtaining the super-hydrophobic reduced graphene oxide / sponge composite material. The method provided by the invention has the characteristics of simple operation, low cost, short reaction time, high efficiency and low energy consumption, and is beneficial to industrial mass production. The reduced graphene oxide / sponge composite material prepared by the method provided by the invention has excellent hydrophobic and oil absorption properties, large adsorption capacity and good stability, and can be used as a selective adsorbent for oily wastewater treatment.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Rhodococcus ruber and application thereof in degradation of hydrocarbon compounds

InactiveCN101580808ABacteriaContaminated soil reclamationPolycyclic aromatic hydrocarbonPhenanthrene

The invention relates to a bacterial strain of Rhodococcus ruber P14 CGMCC NO.2343. The bacterial strain has the characteristic of floating up from oil matters; the bacterial strain can grow by taking the oil matters as unique carbon source and energy source and degrade the oil matters; and the bacterial strain can grow by taking polycyclic aromatic hydrocarbon as unique carbon source and energy source and degrade hydrocarbon compounds, such as phenanthrene, pyrene, benzopyrene, and the like. The bacterial strain can degrade the oil matters and hydrocarbon compounds, especially the polycyclic aromatic hydrocarbon can be applied in the biological treatment of oily waste water and the biological repair (biological remediation) of oil-contaminated soil.

Owner:SHANTOU UNIV

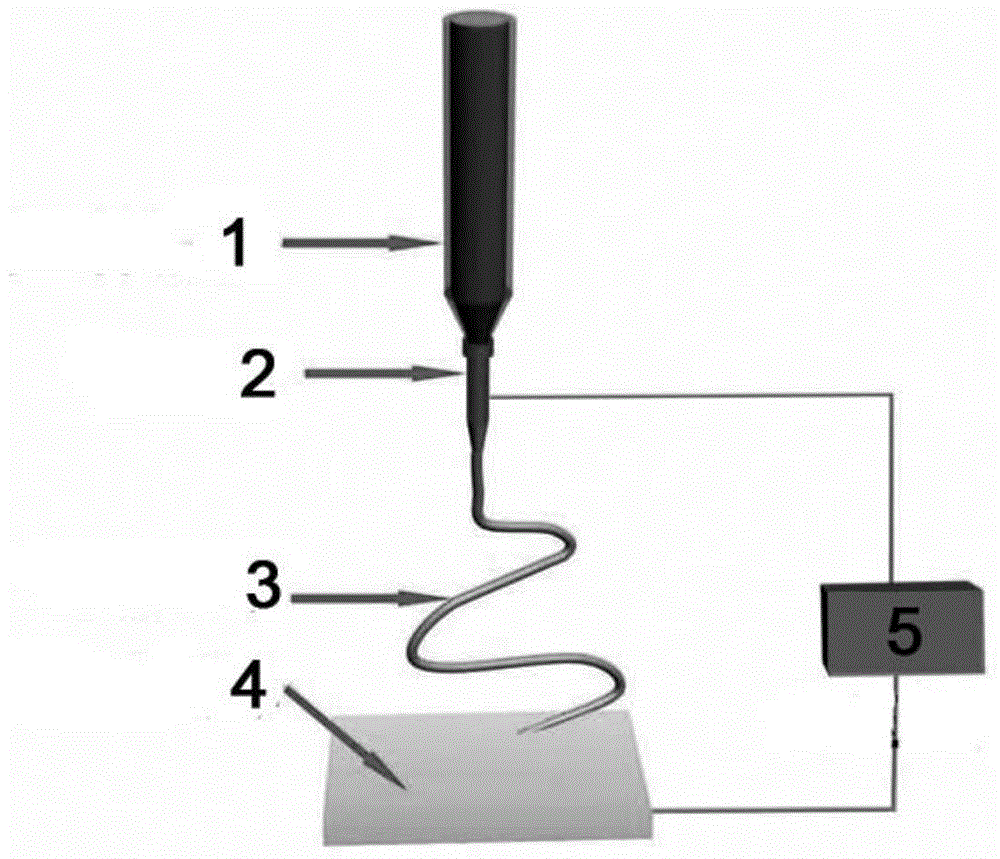

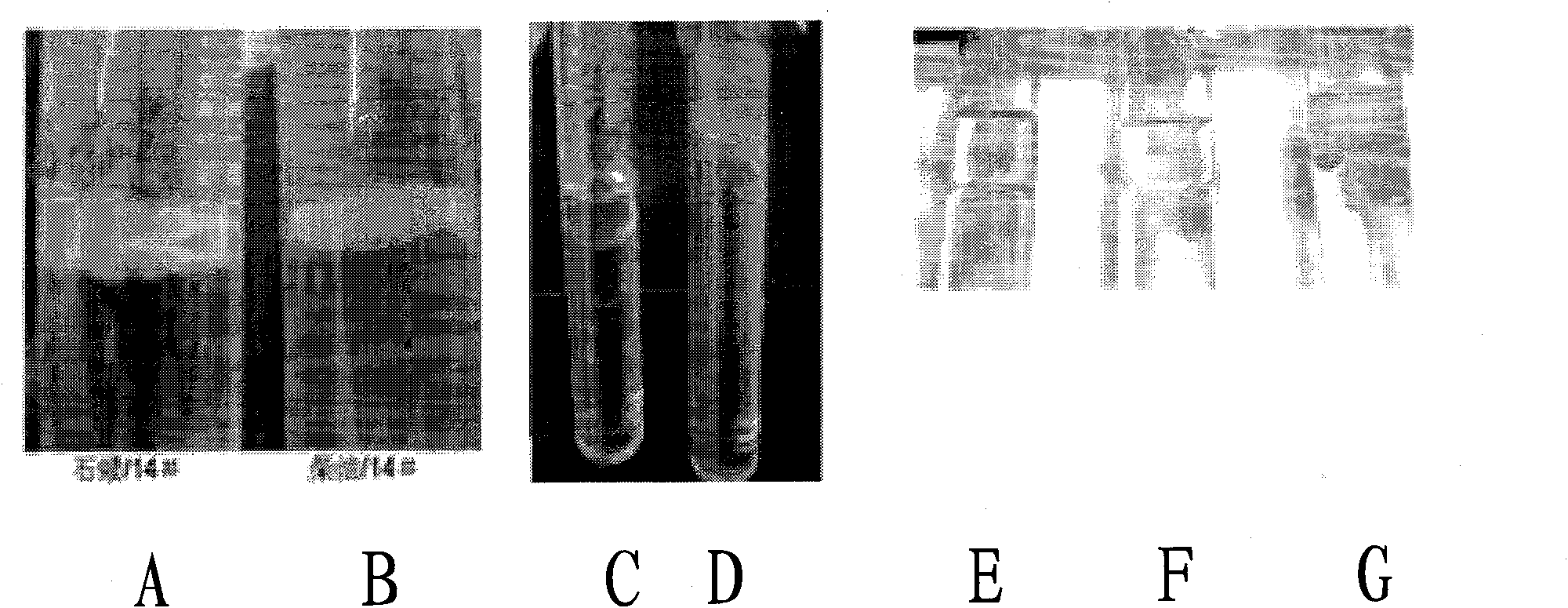

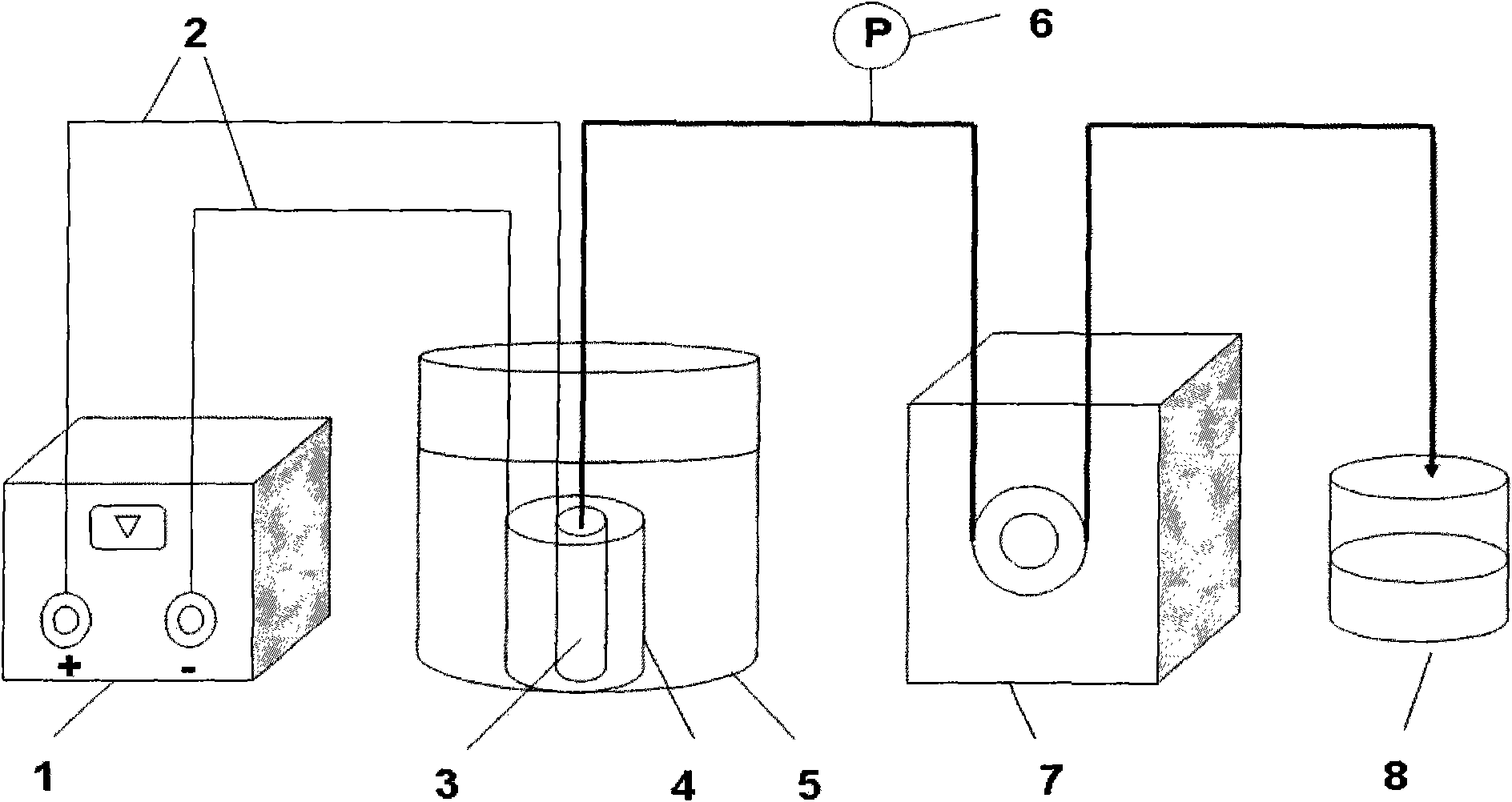

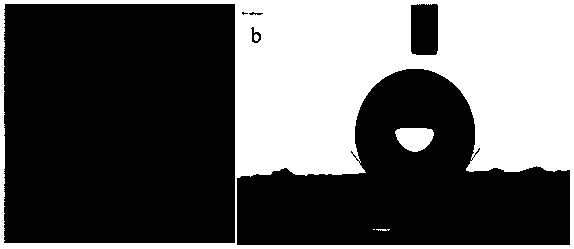

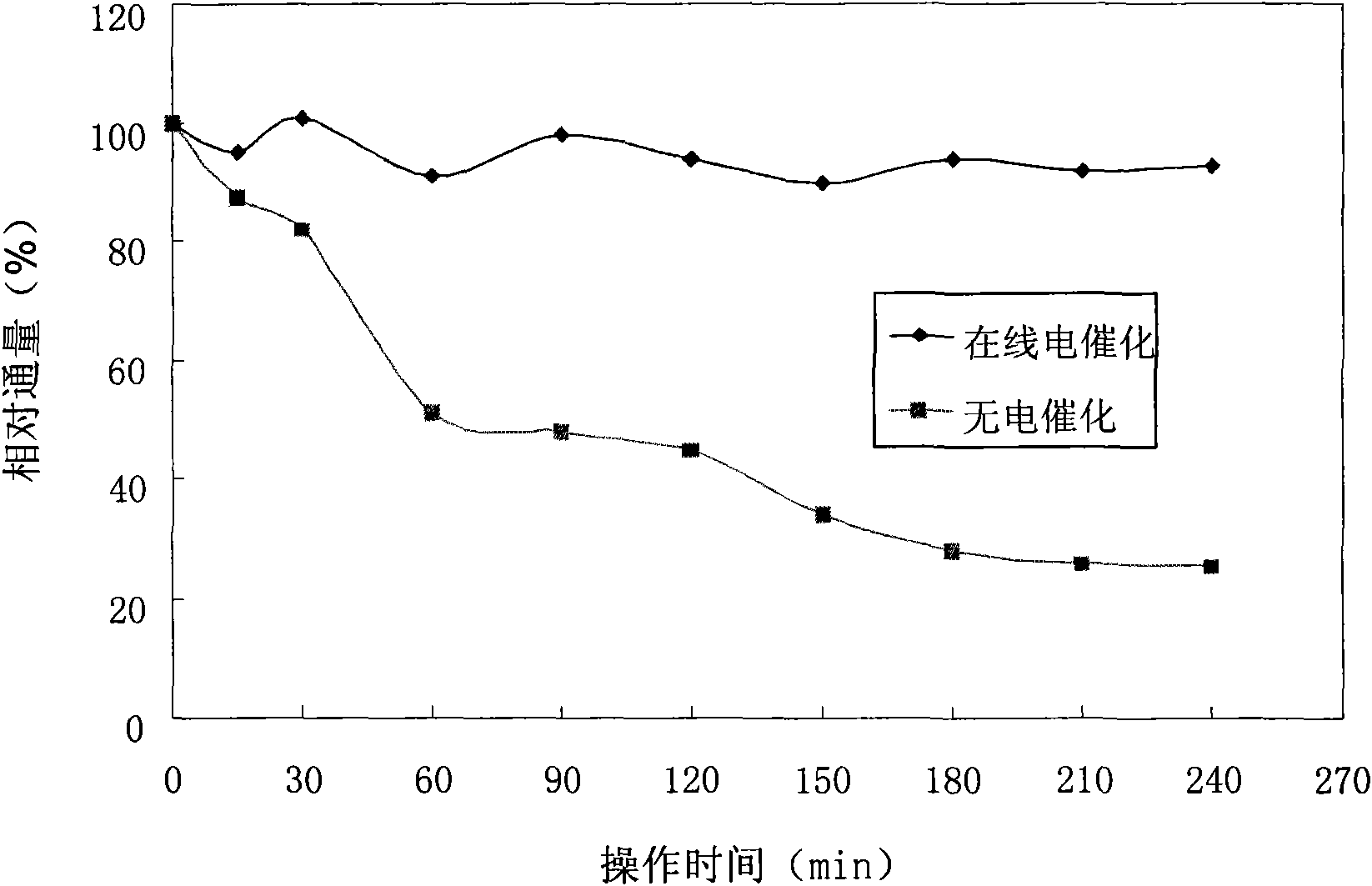

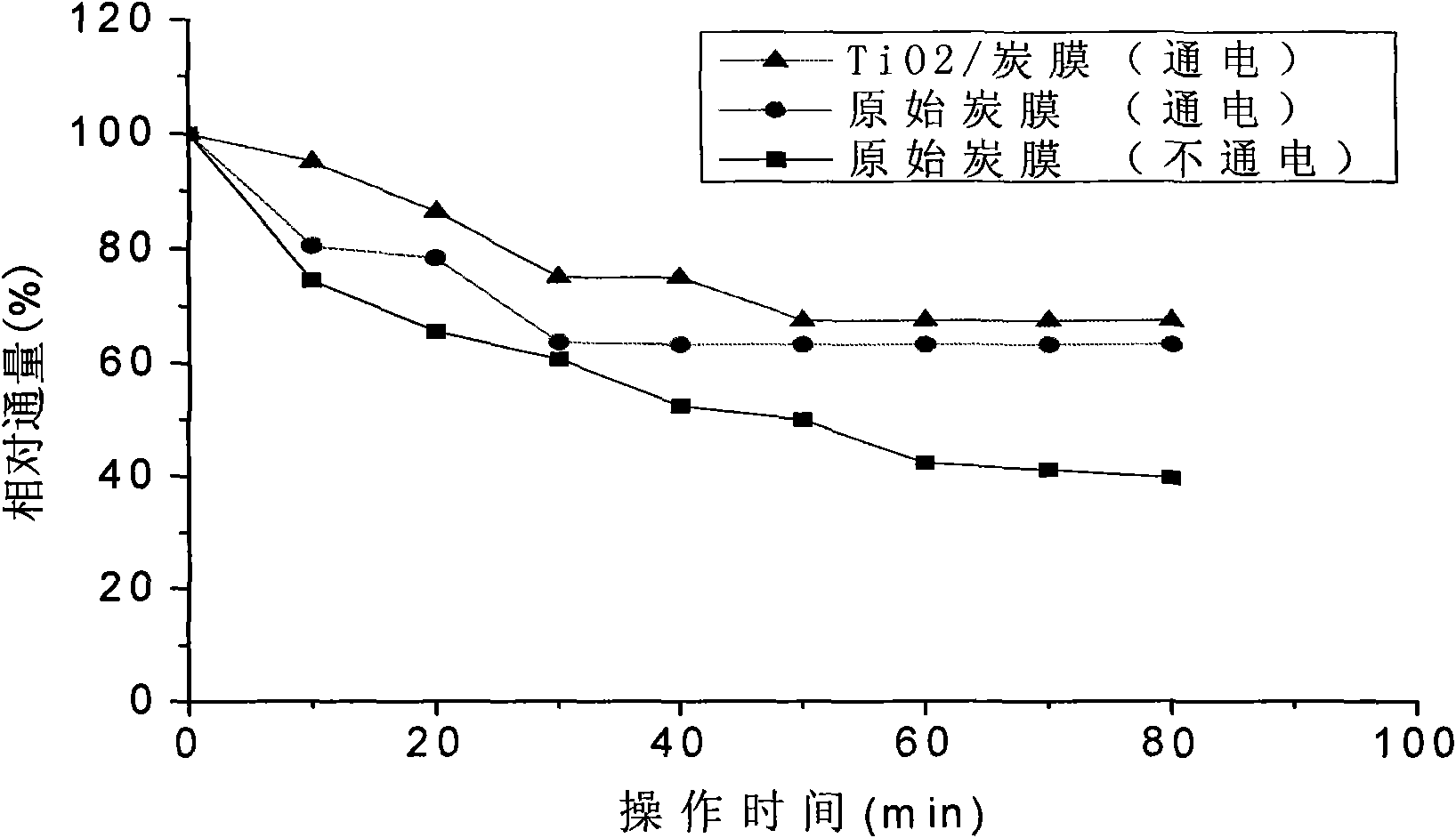

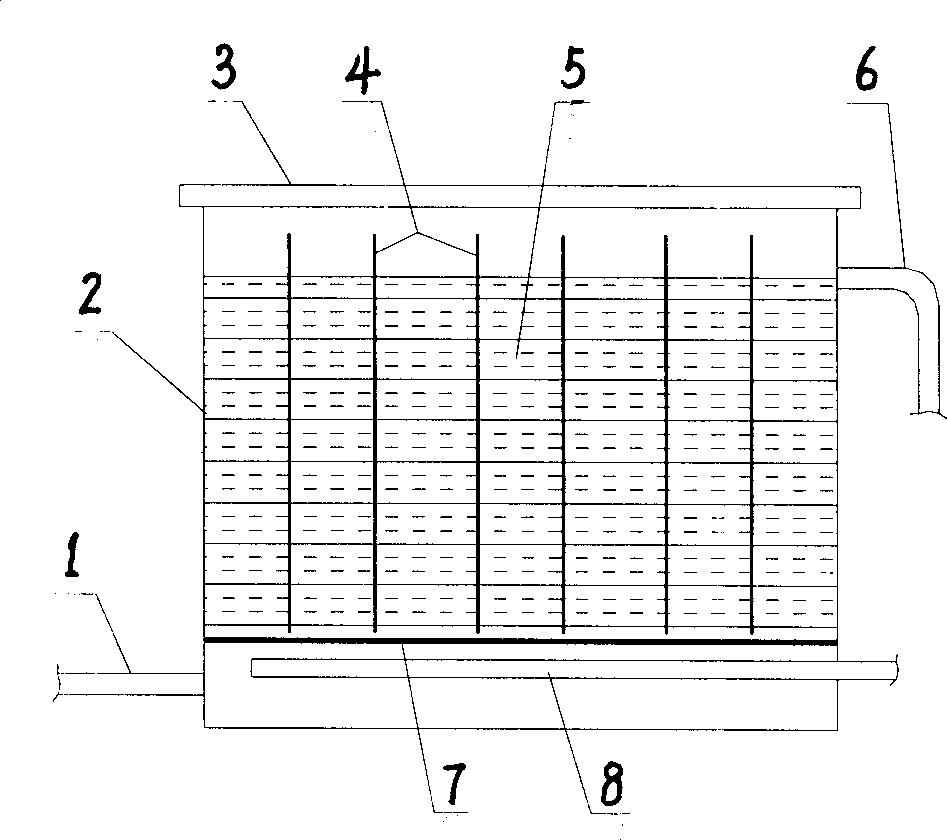

Electro-catalytic membrane reactor device

InactiveCN101597096AImprove electrocatalytic activitySimple processSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPeristaltic pumpElectrolysis

The invention describes an electro-catalytic membrane reactor device, which is characterized in that the device can couple the membrane separation technology and electro-catalysis technology for wastewater treatment, thereby solving the problem of membrane pollution and realizing self-cleaning function of the membrane. The reactor device comprises a feed liquid tank, an electro-catalytic composite membrane, an auxiliary electrode, a regulated power supply, a vacuum gauge, a peristaltic pump and the like; wherein, the electro-catalytic composite membrane is a novel membrane material prepared by taking a microporous carbon membrane as a matrix and a metal or metallic oxide as a catalytic coating layer; one end of the electro-catalytic membrane is closed and the other end thereof is connected with the peristaltic pump through a pipeline; the pump continuously supplies negative pressure so that the feed liquid permeates a separation membrane and seeps from outside to inside along the pipeline; meanwhile, the electro-catalytic composite membrane is taken as the anode and the auxiliary electrode is taken as the cathode; the electro-catalytic composite membrane and the auxiliary electrode are respectively connected with the regulated power supply by leads to form an electrolysis device. By applying voltage to the composite membrane in the process of membrane separation, the organic pollutants deposited on and adhered to the surface and holes of the membrane are electrolytically oxidized to realize antipollution of the membrane. The reactor device has the advantages of simple device, convenient operation, high efficiency, small energy consumption and the like, and can be widely used for treatment and reuse of such industrial wastewater as oily wastewater, dye wastewater, papermaking wastewater and the like.

Owner:大连华鑫源科技发展有限公司

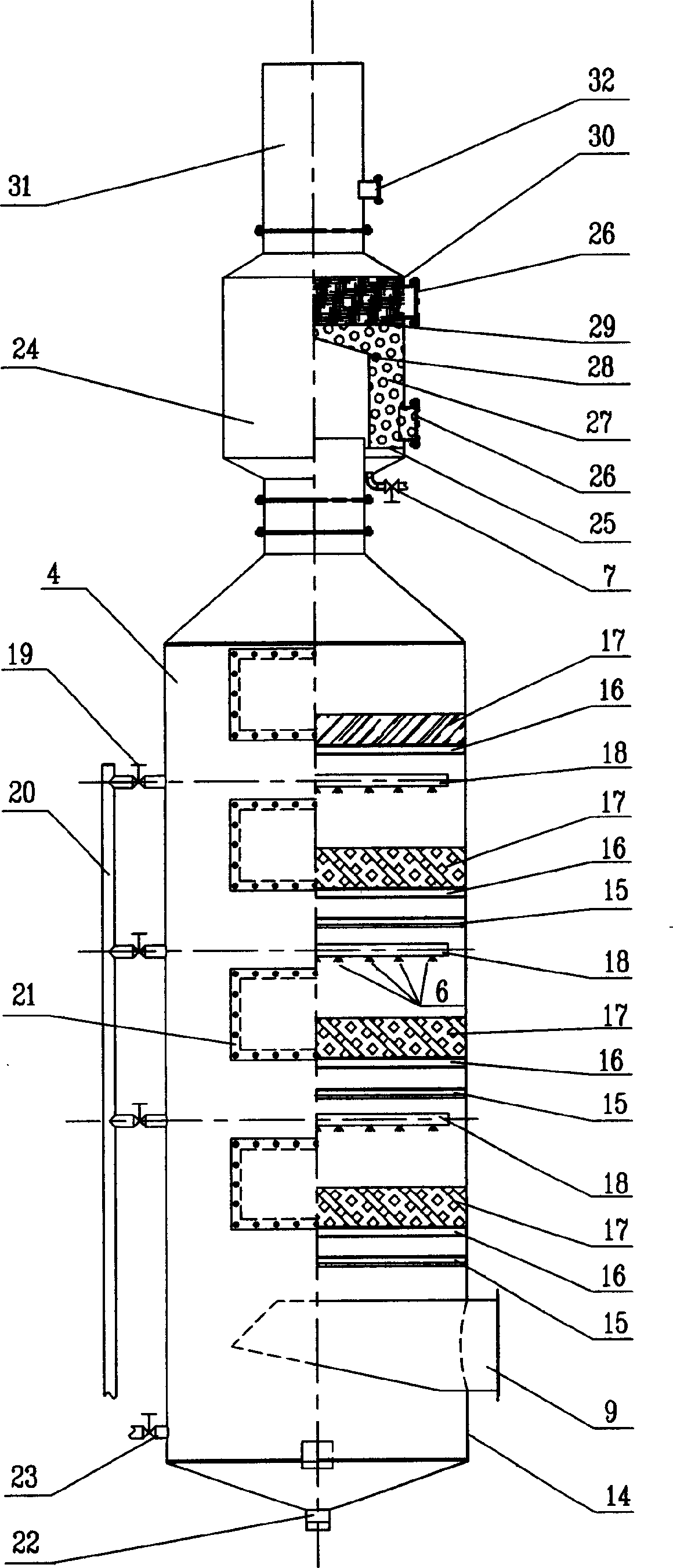

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

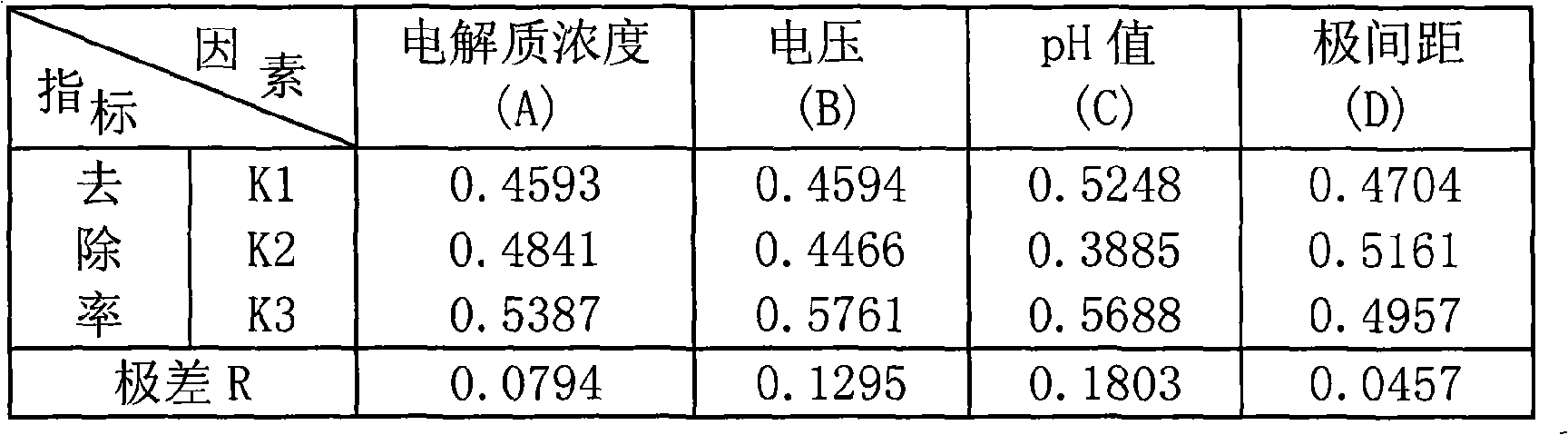

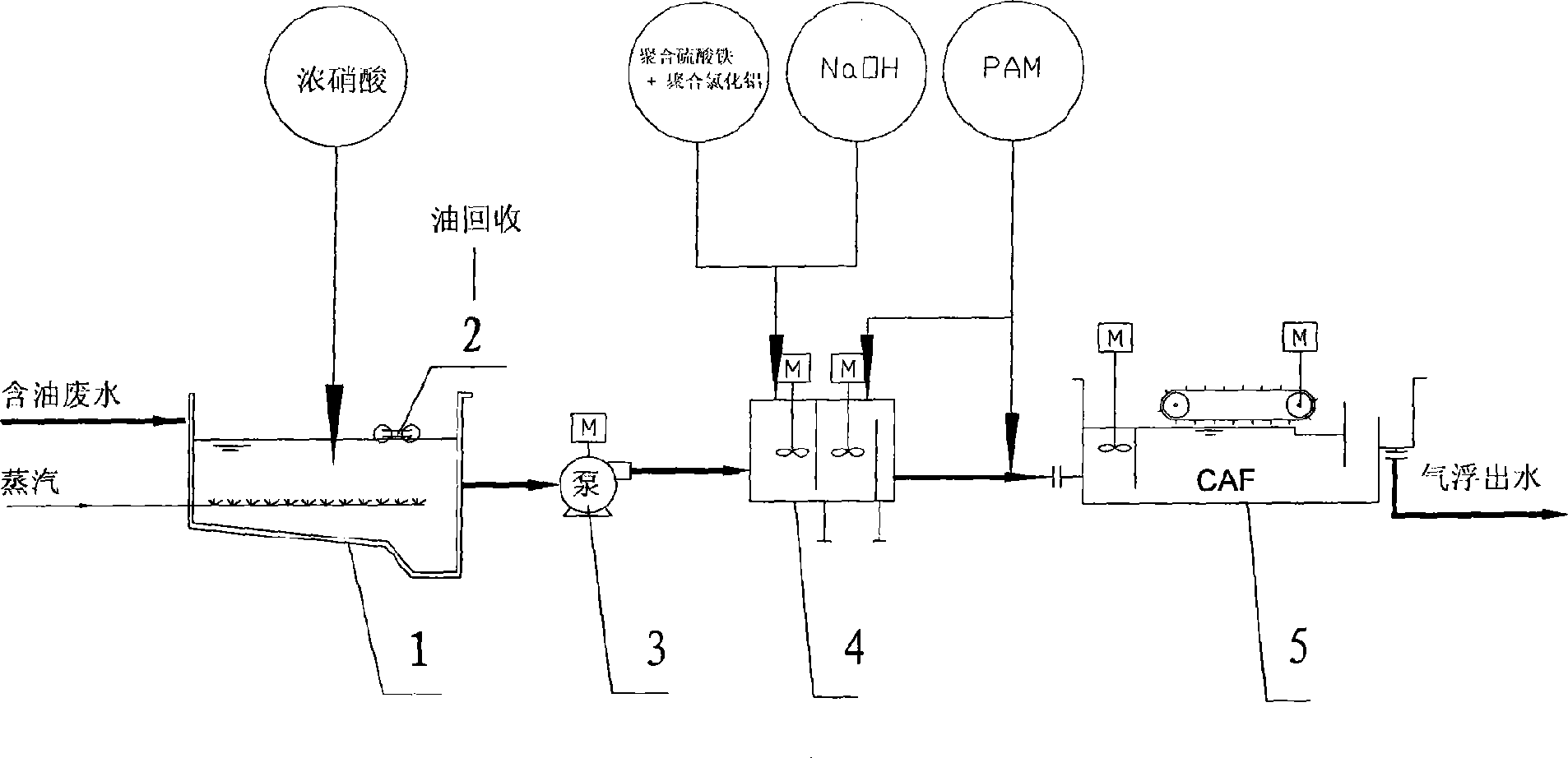

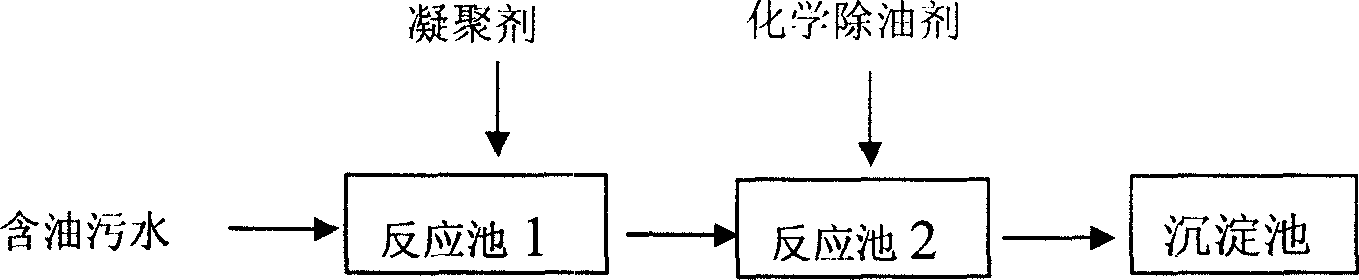

Pretreatment process for oily watewater of cold rolling mill

InactiveCN101475272AHigh recovery rateReduce concentrationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFlocculationHigh energy

The invention relates to a process for pre-treating wastewater containing oil of a cold rolling mill, which solves the problems of poor demulsification effect, high investment, high energy consumption, low recovery rate of waste oil, mass waste residue generation and substandard treated effluent existing in the prior process for pre-treating wastewater containing oil of the cold rolling mill. Recycling of waste oil can be realized through acidification demulsification, oil reclaiming treatment, re-demulsification treatment, flocculation treatment and air floatation separation by steam introduction and the acidification demulsification, so that reclamation rate of the waste oil is improved, energy consumption and investment are reduced, the amount of the waste residue is small, and each index of the pretreated wastewater can be reduced to meet the requirement of secondary treatment so as to greatly reduce the load of the secondary treatment.

Owner:WUHAN IRON & STEEL (GROUP) CORP

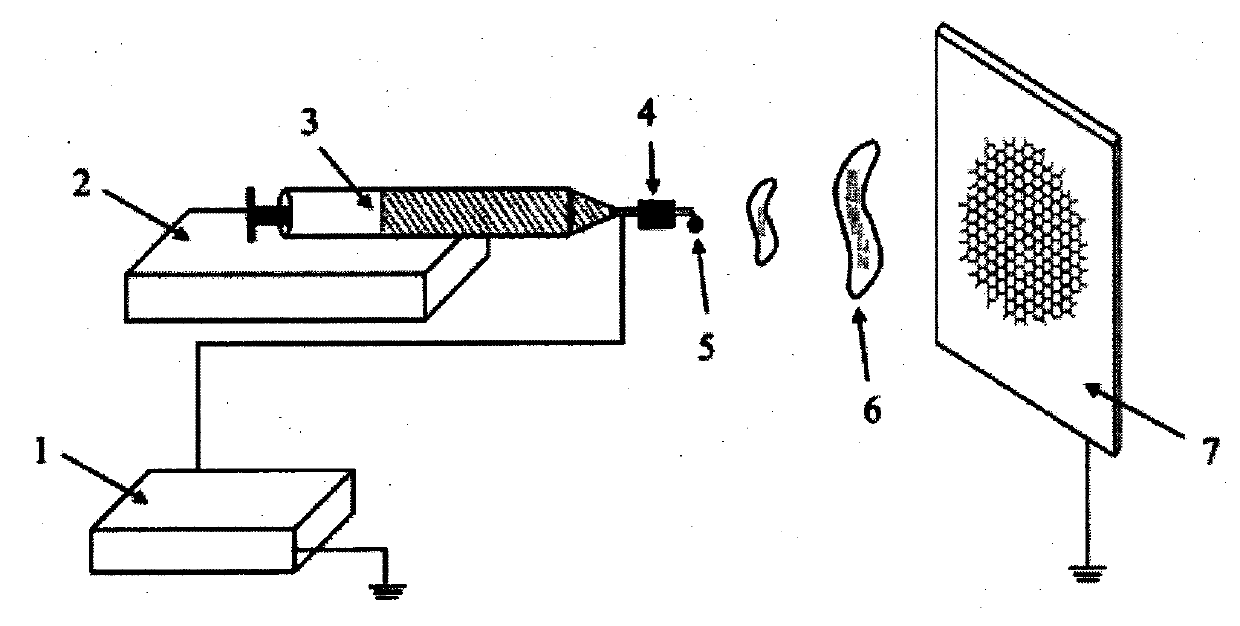

High-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and preparation method thereof

InactiveCN107557894AImprove throughputHigh porosityFatty/oily/floating substances removal devicesUltrasonic/sonic fibre treatmentFiberNanofiber

The invention discloses a high-throughput efficient 2D net-shaped ultrafine nanofiber oil-water separation material and a preparation method thereof. The preparation method comprises the following steps: a polymer solution is prepared from a selected polymer, a net is formed through electrostatic direct injection of the polymer solution, a spinneret vibrates in situ by the aid of external force inan electrostatic direct injection process to promote generation of charged droplets, the droplets are subjected to phase separation, and a uniform 2D net-shaped ultrafine nanofiber material is formedon the surface of a receiving substrate and is in a continuous and seamlessly stacked shape; then the obtained material is subjected to surface modification, and the 2D net-shaped ultrafine nanofiberoil-water separation material with selective surface and interface wetting property is obtained. The preparation process is simple, raw material limitations are few, and the net-shaped ultrafine nanofiber oil-water separation material has tiny meshes and good pore channel connectivity and has great application prospect in the fields of oil purification, oil-containing wastewater treatment and thelike.

Owner:DONGHUA UNIV

Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

ActiveCN105536296AImprove separation efficiencyEfficient separationNon-miscible liquid separationKeroseneCopper sulfate

The invention discloses a super-hydrophobic / super-oleophilicity copper wire mesh for oil and water separation and a preparation method and application thereof. The preparation method comprises the steps that firstly, the copper wire mesh is ultrasonically cleaned through diluted hydrochloric acid, absolute ethyl alcohol and deionized water respectively and dried through nitrogen; chemical deposition liquid of copper sulfate and a sodium thiosulfate solution is prepared; the cleaned copper wire mesh is placed into the chemical deposition liquid for a deposition reaction; the copper wire mesh is taken out and cleaned through the deionized water and dried in the air; the dried copper wire mesh is placed in a solution of a curing agent and polydimethylsiloxane with hydroxyl sealed end, and the copper wire mesh is taken out and heated. No expensive fluorine-containing substance is needed, the copper wire mesh has the advantages that the preparation technology is simple, reaction conditions are mild, no strong acidity or strong basicity or corrosivity reagents are needed, and no harm is caused to the environment, separation of oily wastewater can be achieved rapidly and efficiently, the good separation effect on chloroform, normal hexane, petroleum ether, plant oil, diesel oil, aviation kerosene and the like is achieved, and separation of strong acidity, strong basicity and high salinity oily wastewater can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

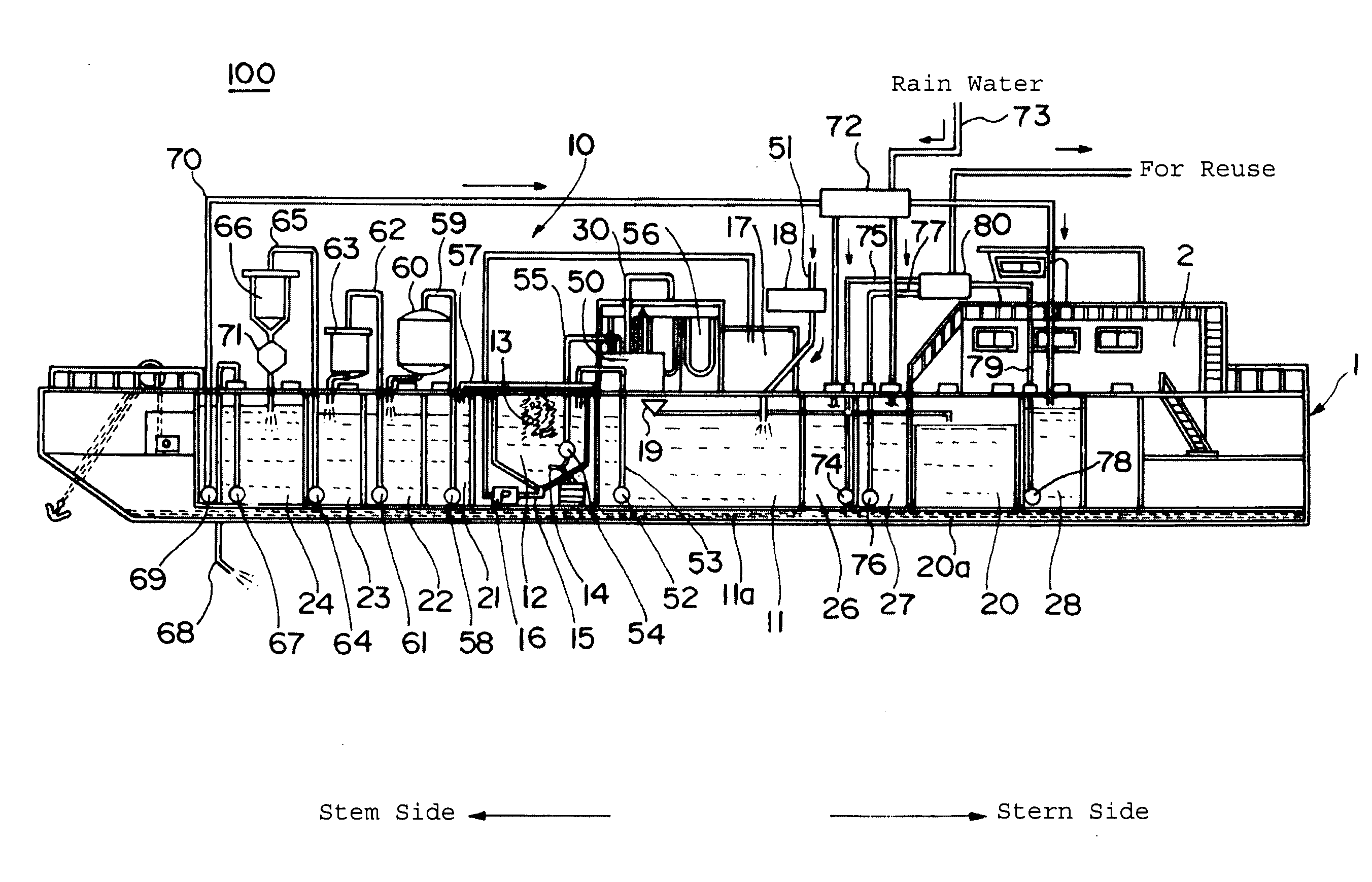

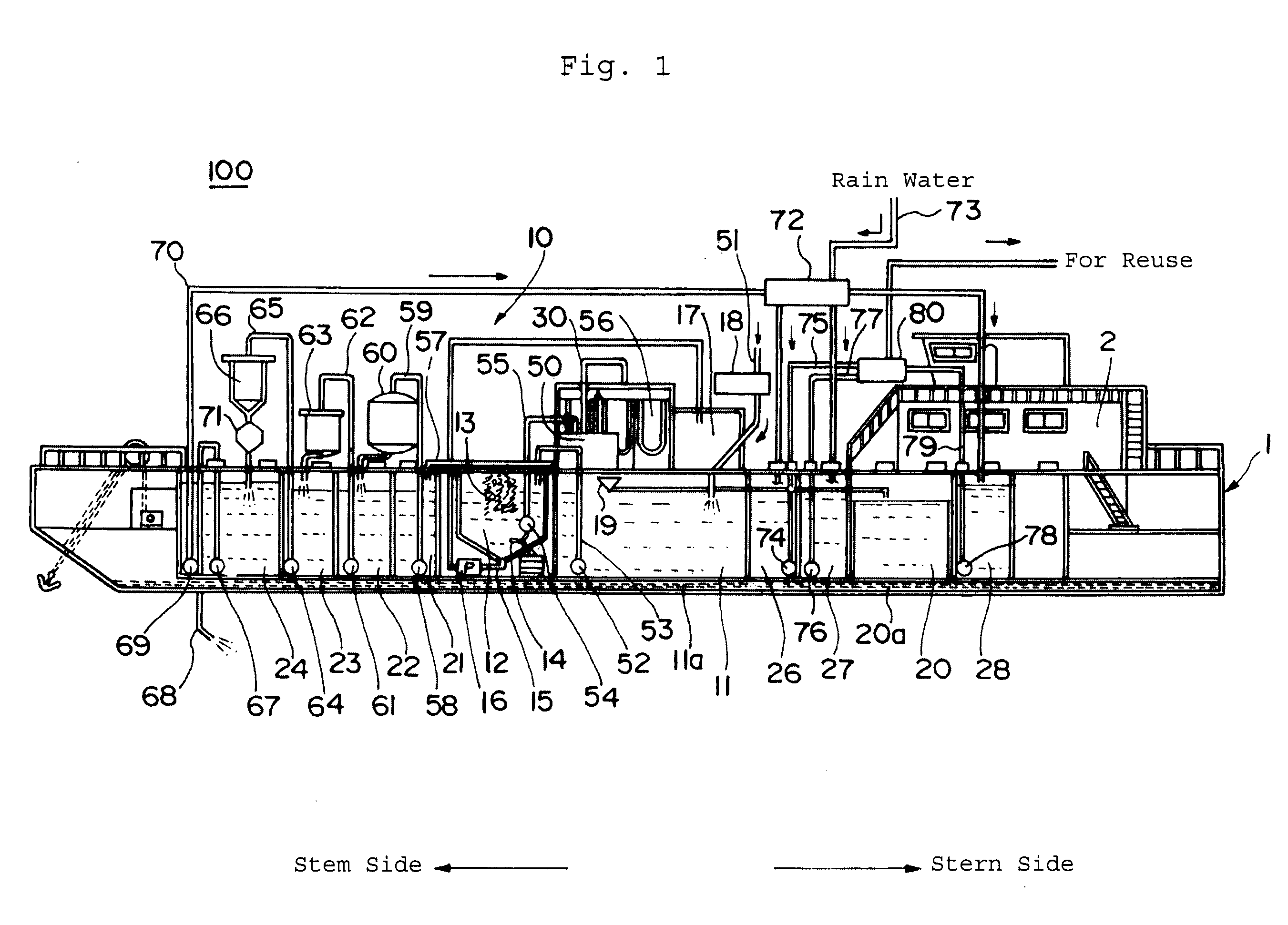

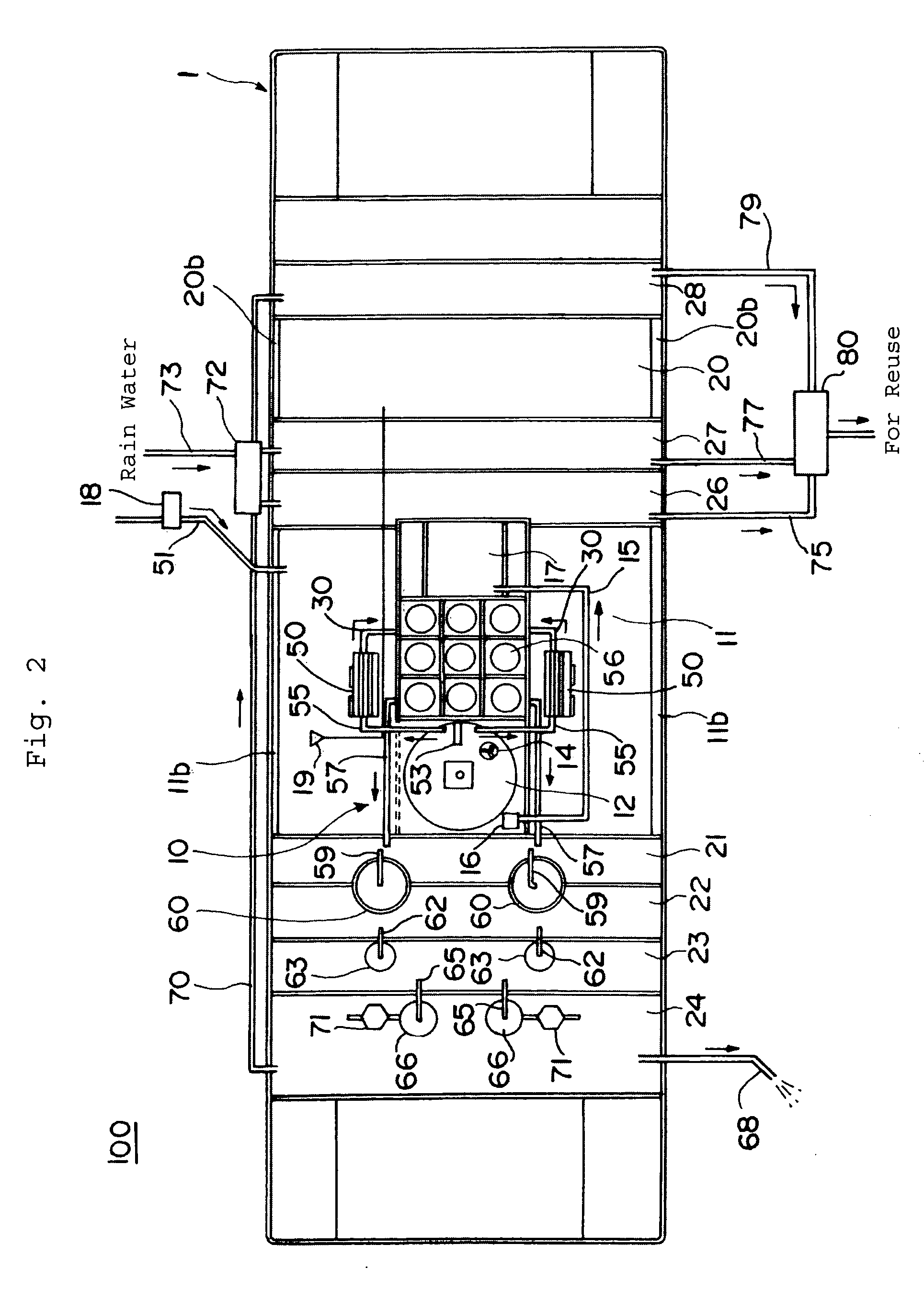

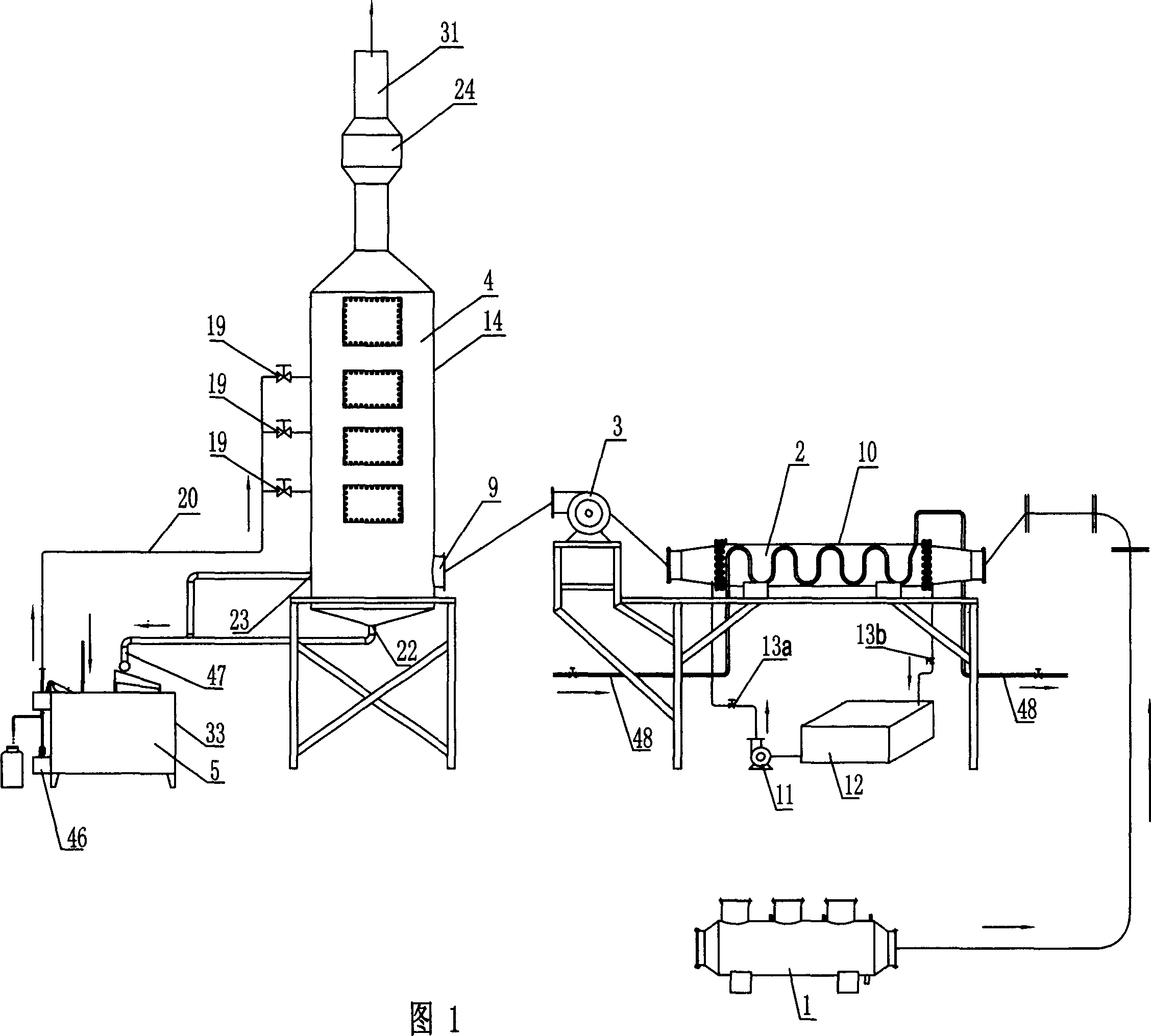

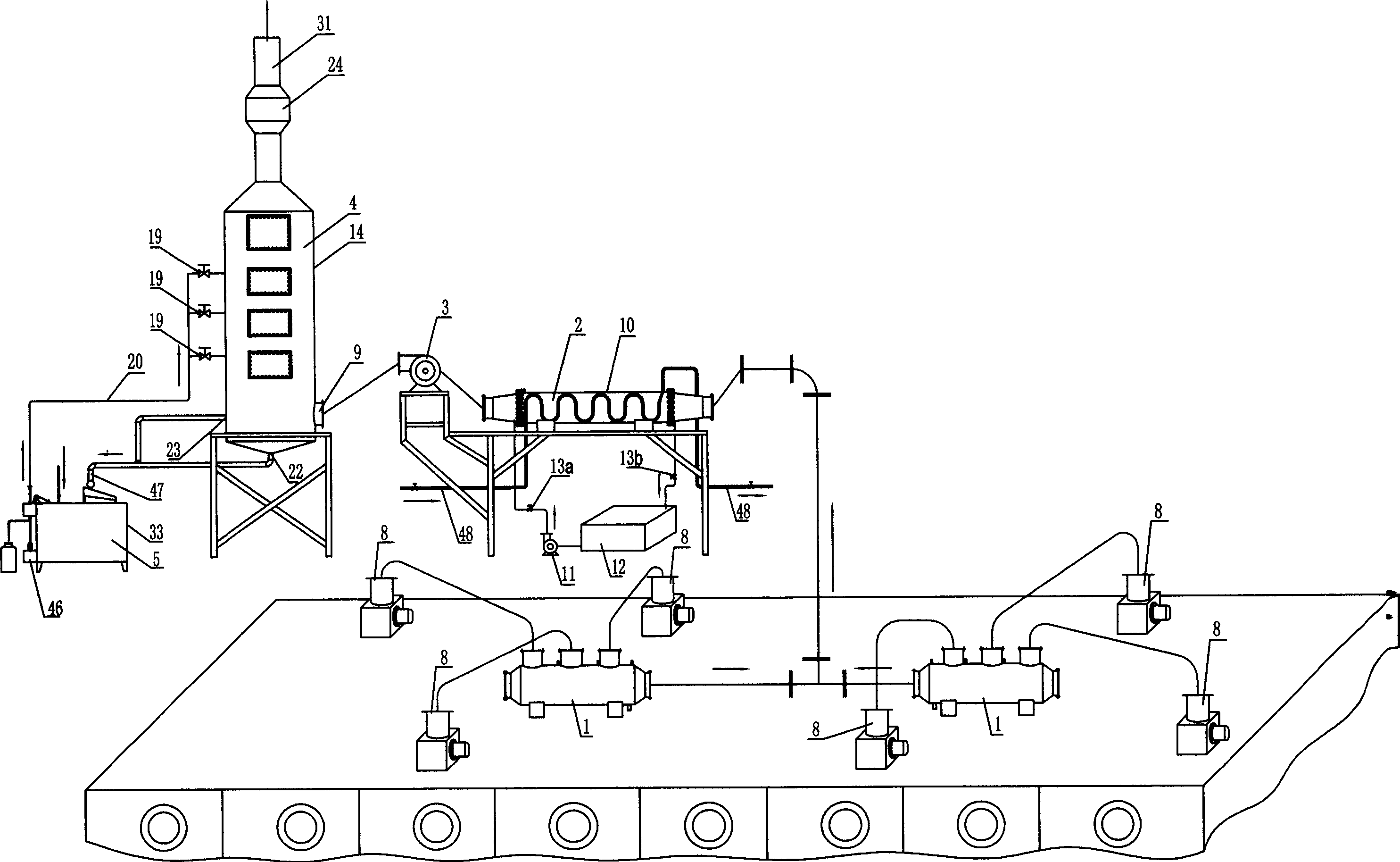

Wastewater treatment ship

ActiveUS20110147293A1Easy dischargeHull interior subdivisionAuxillariesSewage treatmentPurified water

A wastewater treatment ship is provided which is capable of purifying and treating oil bearing wastewater collected from a ship or the sea, wastewater such as domestic water and of reusing the purified water on the ship and easily discharging it. The wastewater treatment ship has a hull able to navigate by being towed or being self-propelled and a purification treatment unit disposed on the hull and configured to collect, purify, and treat wastewater. The purification treatment unit includes a floated oil collecting tank to collect floated oil collected from raw wastewater tank, a stirring tank having a cylindrical straight drum and a funnel-shaped bottom to stir wastewater taken out from the raw wastewater tank together with a coagulant and a collecting path to discharge precipitates, a plurality of filter treatment tanks to be used in multistage filtering treatment of wastewater in the stirring tank, and purified water tanks.

Owner:KANTO KOSAN

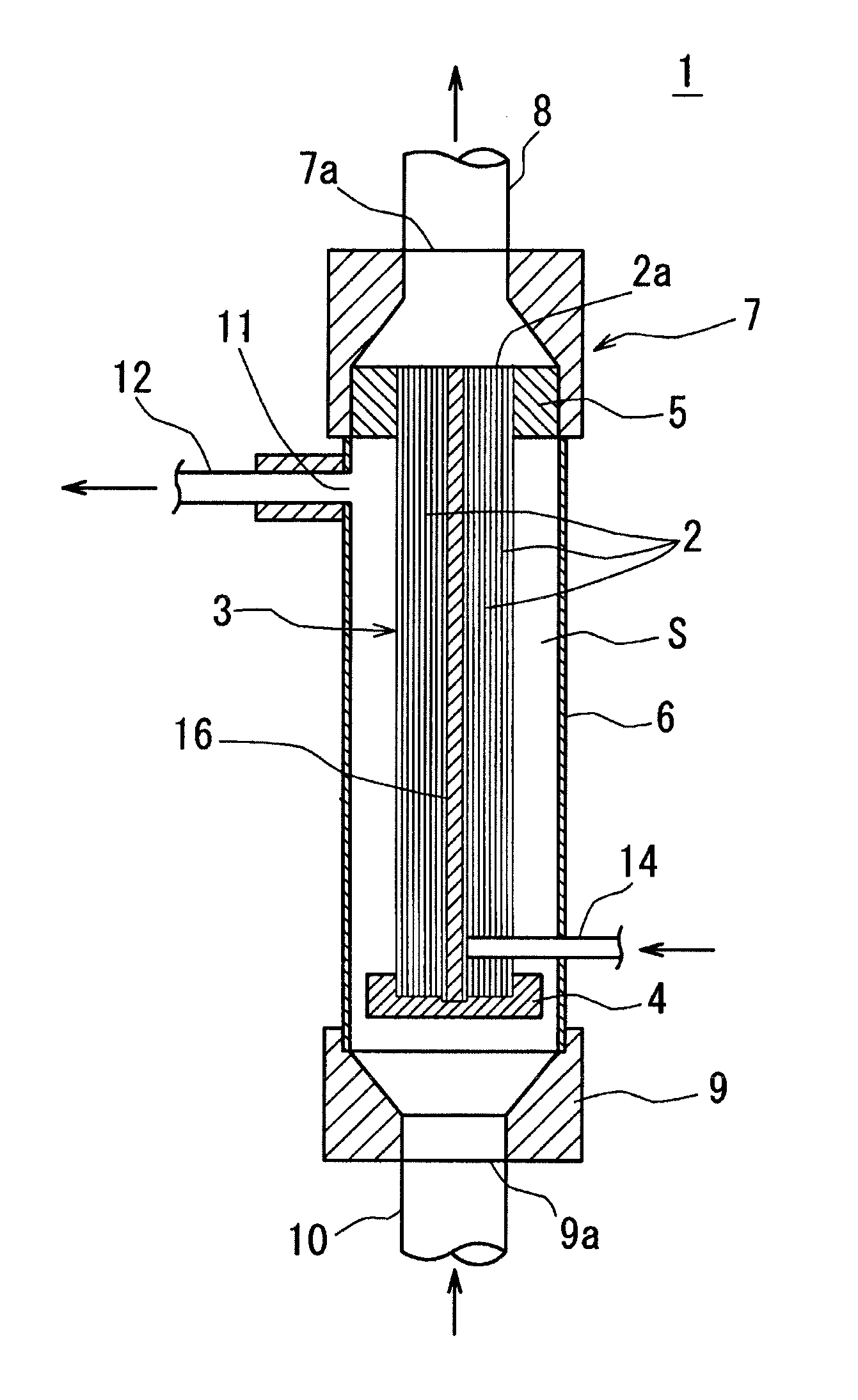

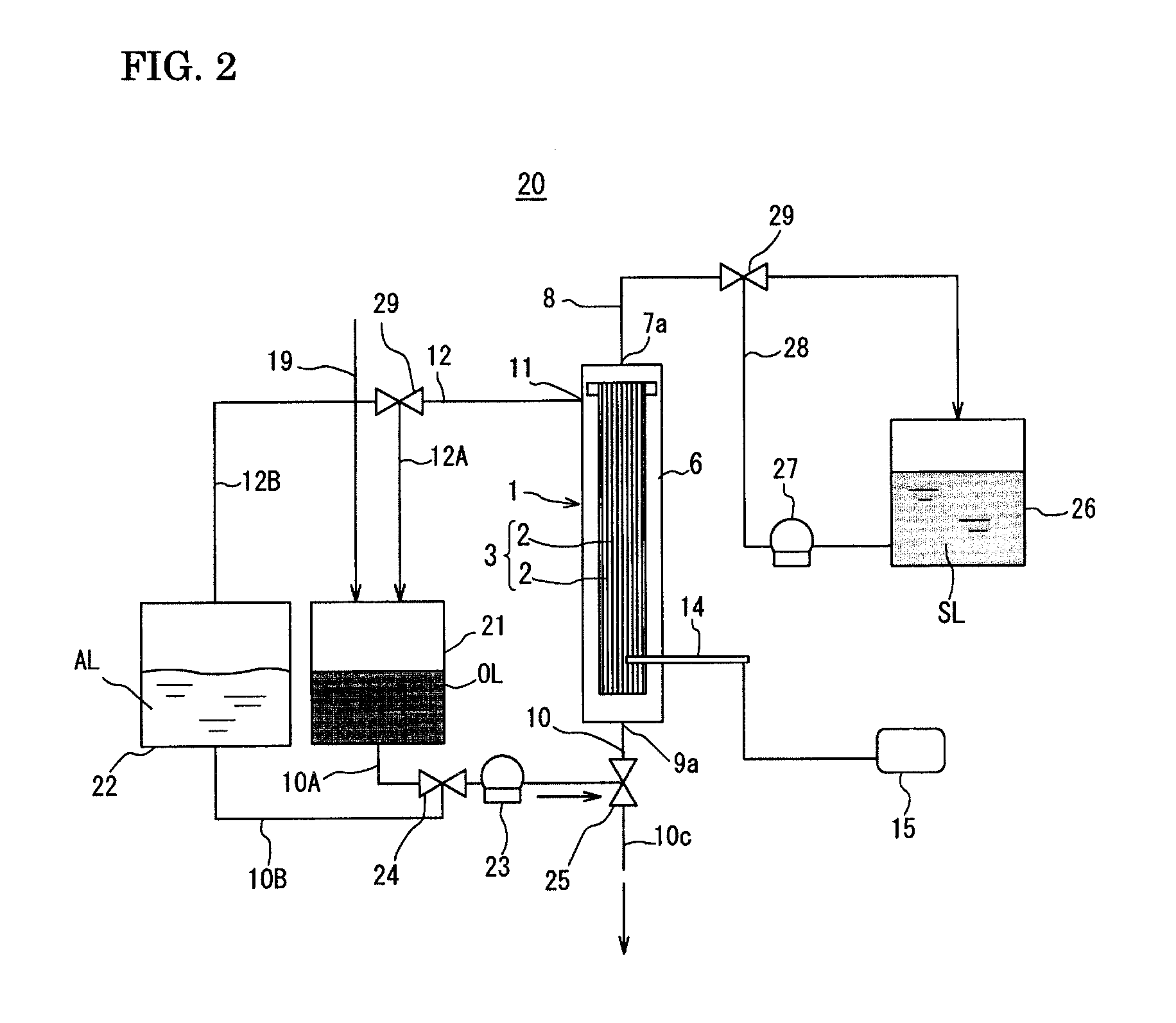

Separation membrane module for oil-containing wastewater treatment, oil-containing wastewater treatment method, and oil-containing wastewater treatment apparatus

InactiveUS20120103904A1Reduce oil contentWithout decreasing amountMembranesWater contaminantsFiberFiltration

Provided is a separation membrane module which is suitable for filtration of oil-containing wastewater. The separation membrane module for oil-containing wastewater treatment separates water-insoluble oil from oil-containing wastewater that has high turbidity and / or high temperature. The separation membrane module for oil-containing wastewater treatment is characterized by using a hollow fiber membrane which is composed of an alkali-resistant porous membrane selected from polytetrafluoroethylene (PTFE), polysulfone (PSF), and polyether sulfone (PES) and which has a tensile strength of 30 N or more, and characterized in that each of the hollow fiber membrane and an end-sealing member of the hollow fiber membrane has a heat distortion temperature of 100° C. or higher.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

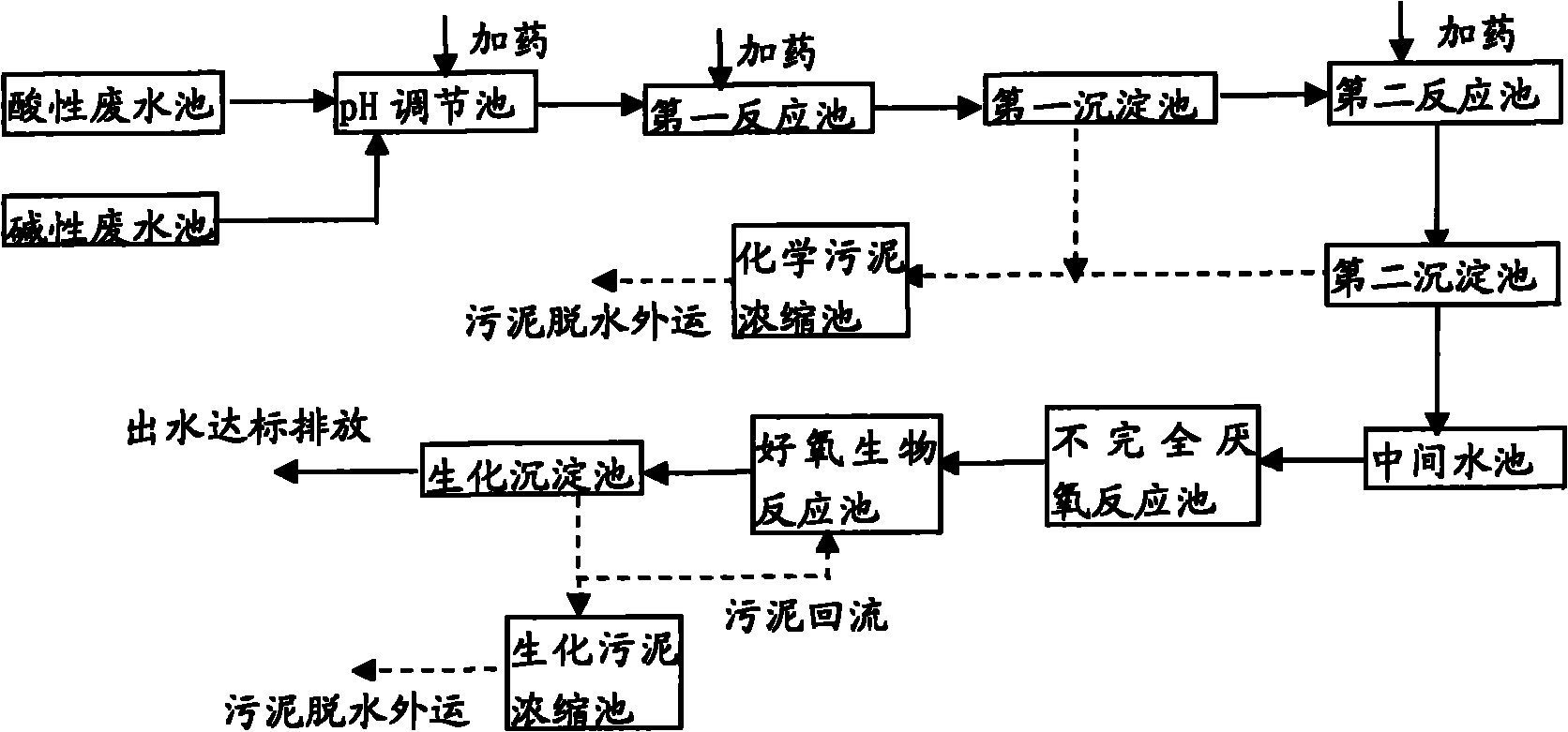

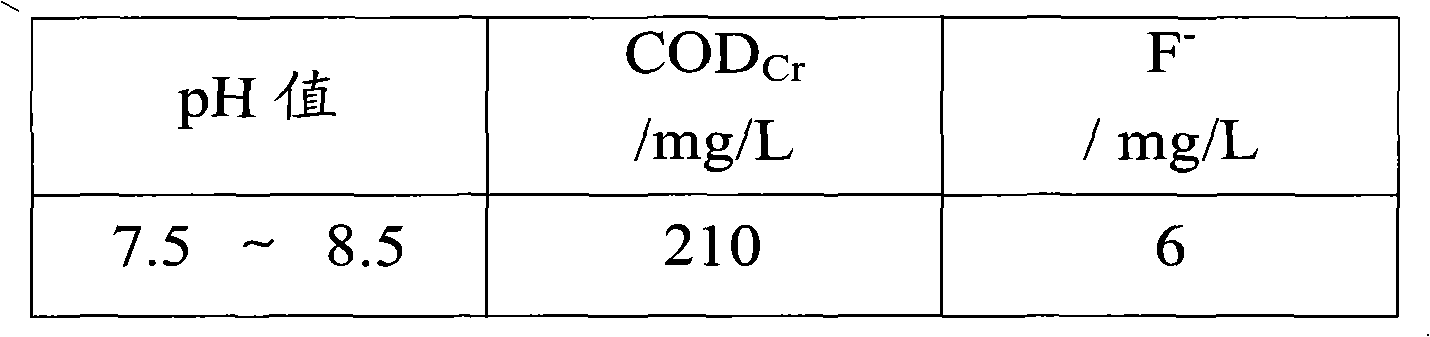

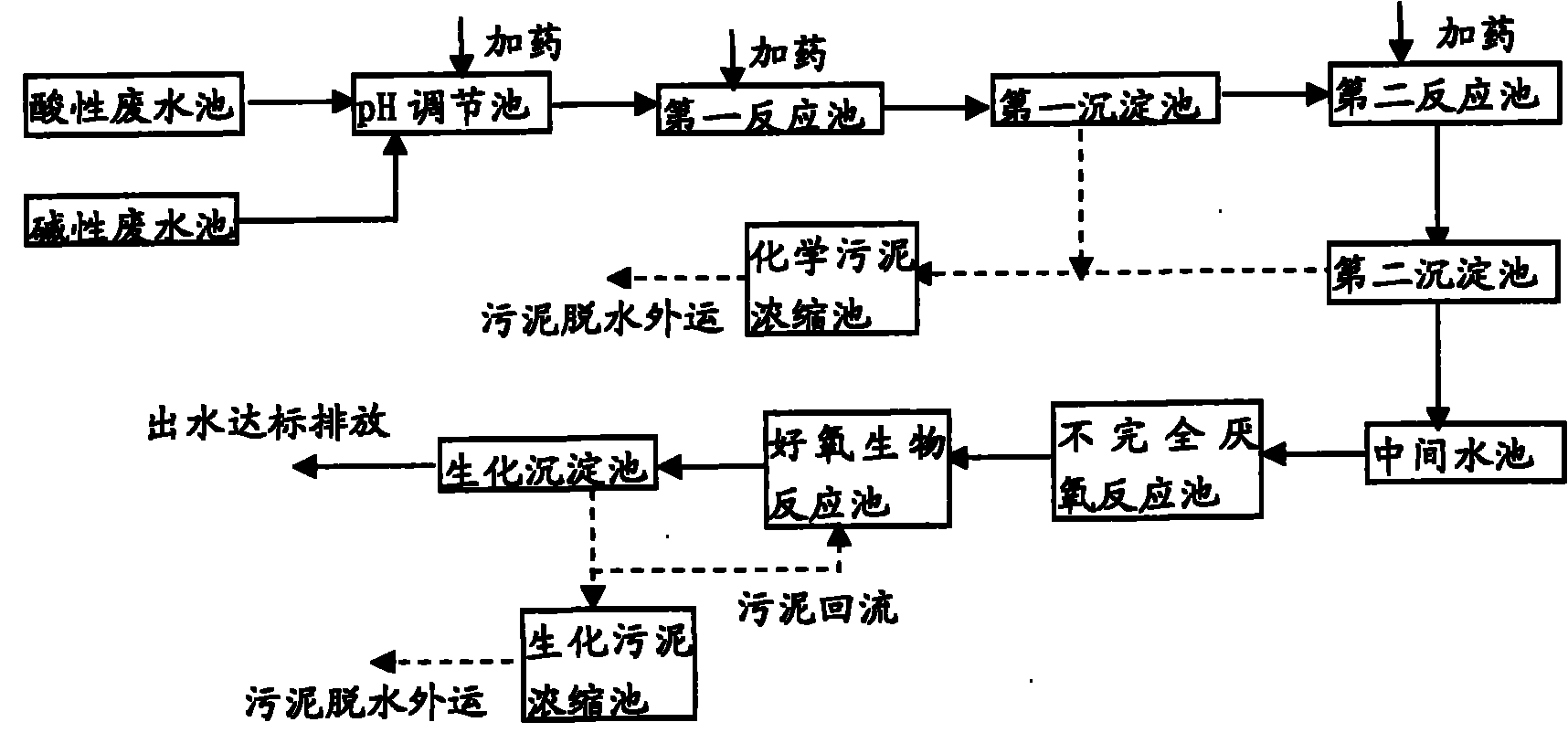

Method and system for treating industrial wastewater of photovoltaic solar cell plates

ActiveCN101973662AEfficient removalReduce concentrationGeneral water supply conservationEnergy based wastewater treatmentChemical oxygen demandStrong acids

The invention discloses a process for treating industrial wastewater of photovoltaic solar cell plates. The process comprises the following steps of: collecting wastewater, namely collecting acid wastewater and alkaline wastewater respectively; regulating pH, namely adding strong acid or strong base into the acid wastewater, alkaline wastewater or acid-alkaline mixed wastewater mixed by the acid wastewater and the alkaline wastewater, and regulating the pH value to be between 8.0 and 8.5 to form conditioning fluid; defluorinating the conditioning fluid and / or removing chemical oxygen demand (COD) from the conditioning fluid, wherein the defluorinating step means throwing calcium salt into the conditioning fluid so as to remove fluorion from the wastewater, and the COD removing step means performing incomplete anaerobic reaction on the conditioning fluid; performing aerobic biological treatment; and sequentially completing the steps to discharge the wastewater meeting the discharge standard. The invention provides a treatment process aiming at the water quality characteristics of the industrial wastewater of the photovoltaic solar cell plates and main design operational parameters.By a treatment system, the fluorion can be effectively removed, the fluorion concentration of effluent can be reduced to be below 10mg / L, and the wastewater CODCr is below 300mg / L and meets the discharge standard. Meanwhile, the invention also provides a system for treating the industrial wastewater of the photovoltaic solar cell plates.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Preparation method of elastic hydrophobic carbon nano tube and graphene compound aerogel

The invention discloses mixed liquor for preparing an elastic hydrophobic carbon nano tube and graphene compound aerogel. The mixed liquor consists of the following components in parts by weight: 0.1to 15 parts of oxidized graphene, 0.01 to 9 parts of carboxyl carbon nano tubes, 0.0001 to 0.1 part of a cross-linking agent, 0.0005 to 0.5 part of an alkaline reducing agent and 2000 parts of deionized water. The method for preparing the carboxyl carbon nano tube and graphene compound aerogel from the components comprises the following steps: (1) preparing a homogeneous water solution of oxidizedgraphene, carboxyl carbon nano tubes, the reducing agent and polymers; (2) preparing a carbon nano tube and graphene hydrogel through one-step hydrothermal reduction; and (3) carrying out dialysis and soaking treatment, and after drying, obtaining the carbon nano tube and graphene aerogel. According to the aerogel prepared in the invention, the mechanical property of the aerogel is improved, thespecific surface area of the aerogel is increased, and the aerogel can be used in the fields of dye absorption, catalytic carriers, variable resistors and the like; the density is just 1.2 to 15.8 mg / cm<3>, the hydrophobic angle is greater than 90 degrees, and the compression rate is 10% to 80%; and due to hydrophobic property and selective adsorption of the aerogel, the aerogel can be widely applied to treatment of oily wastewater and organic matter wastewater.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

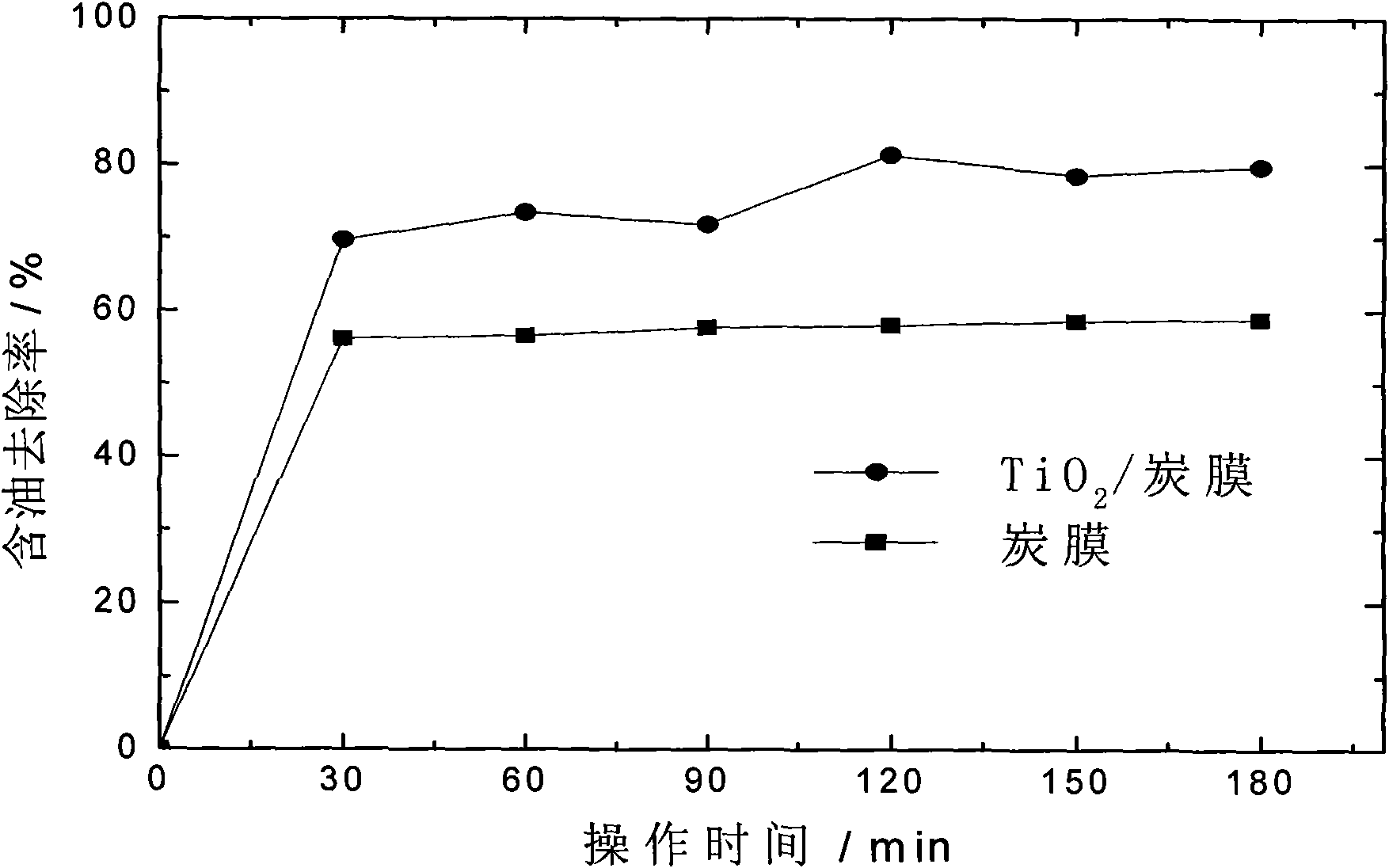

Novel electro-catalytic composite membrane material and preparation method thereof

InactiveCN101559332ATo achieve reinforcementRealize self-cleaningSemi-permeable membranesWater/sewage treatment by electrochemical methodsLow voltageSeparation technology

The invention relates to a novel electro-catalytic composite membrane material and a preparation method thereof. The novel electro-catalytic composite membrane material is characterized in that the material can couple electro-catalytic technology and membrane separation technology. The preparation method comprises the following steps: taking a microporous separation membrane with electric conductivity, namely a carbon membrane, as a substrate, adopting a sol-gel method, mixing a metallic compound, water, a solvent, a catalyst, other additives and the like to be configured into a precursor solution, and obtaining an electro-catalytic composite membrane by sol ageing, film coating, drying and heat treatment; and preparing the composite membrane with superior performances by pretreating a substrate and controlling the mixture ratio of raw materials, the soakage time, the pulling speed, the sintering temperature and the like. The novel electro-catalytic composite membrane material takes the electro-catalytic composite membrane as an anode and a metallic material as a cathode to treat wastewater and realizes the reinforcement of the membrane separation process and the self-cleaning function under the action of a low-voltage electric field. The electro-catalytic membrane material has the advantages of low energy consumption, high separation efficiency, strong antifouling property and the like, and can be widely used for treating and recycling heavily polluted wastewater such as oily wastewater, dye wastewater, paper-making wastewater and the like. The preparation method has the advantages of simple preparation process, cheap equipment, easily-obtained raw materials, convenient operation and suitability for industrialized implementation.

Owner:DALIAN HUAXINYUAN TECHNOLOGY DEVELOPMENT LIMITED COMPANY

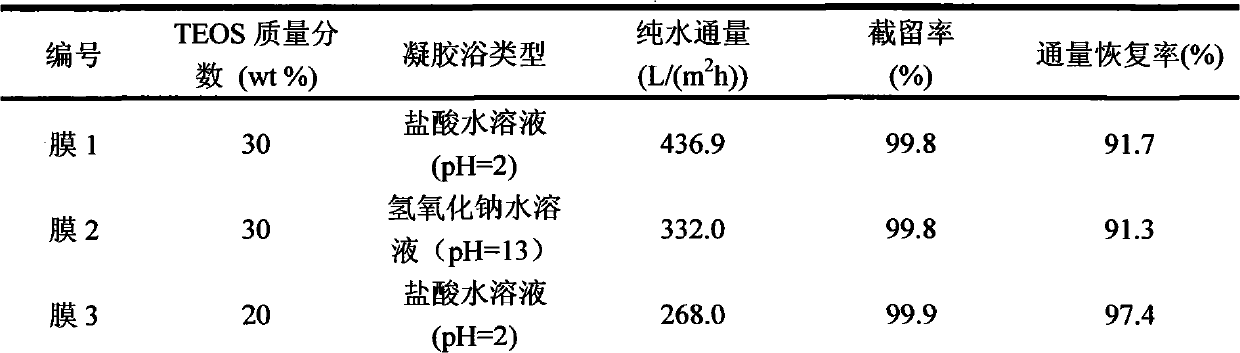

Method for preparing anti-polluting oil-water separation ultra-filtration membrane

ActiveCN102085459AEasy to makeMild conditionsSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneCellulose acetate

The invention discloses a method for preparing an anti-polluting efficient oil-water separation ultra-filtration membrane, which comprises the following steps of: dissolving 16.0 mass percent of cellulose acetate into an N,N-dimethyl formamide solvent based on 100 percent of the mass of membrane casting solution, adding 15.0 to 30.0 mass percent of ethyl orthosilicate, and scraping a nascent state membrane with thickness of 240 microns on a glass plate; placing the nascent state membrane in the air for 10 to 30 seconds, and then soaking the nascent state membrane into gel baths of 25 DEG C, wherein the gel baths are aqueous solution of hydrochloric acid and aqueous solution of sodium hydroxide respectively; and taking out the membrane from the gel bath, placing the membrane into deionizedwater, and changing the water once every 5 hours to obtain the CA(TEOS)-HCl and CA(TEOS)-NaOH modified ultra-filtration membrane. The method is simple in process and mild in conditions; and the flux of the modified membrane is greatly improved, good anti-polluting performance is kept, and the modified membrane has high interception rate and can be used for treating oil-containing wastewater.

Owner:PETROCHINA CO LTD

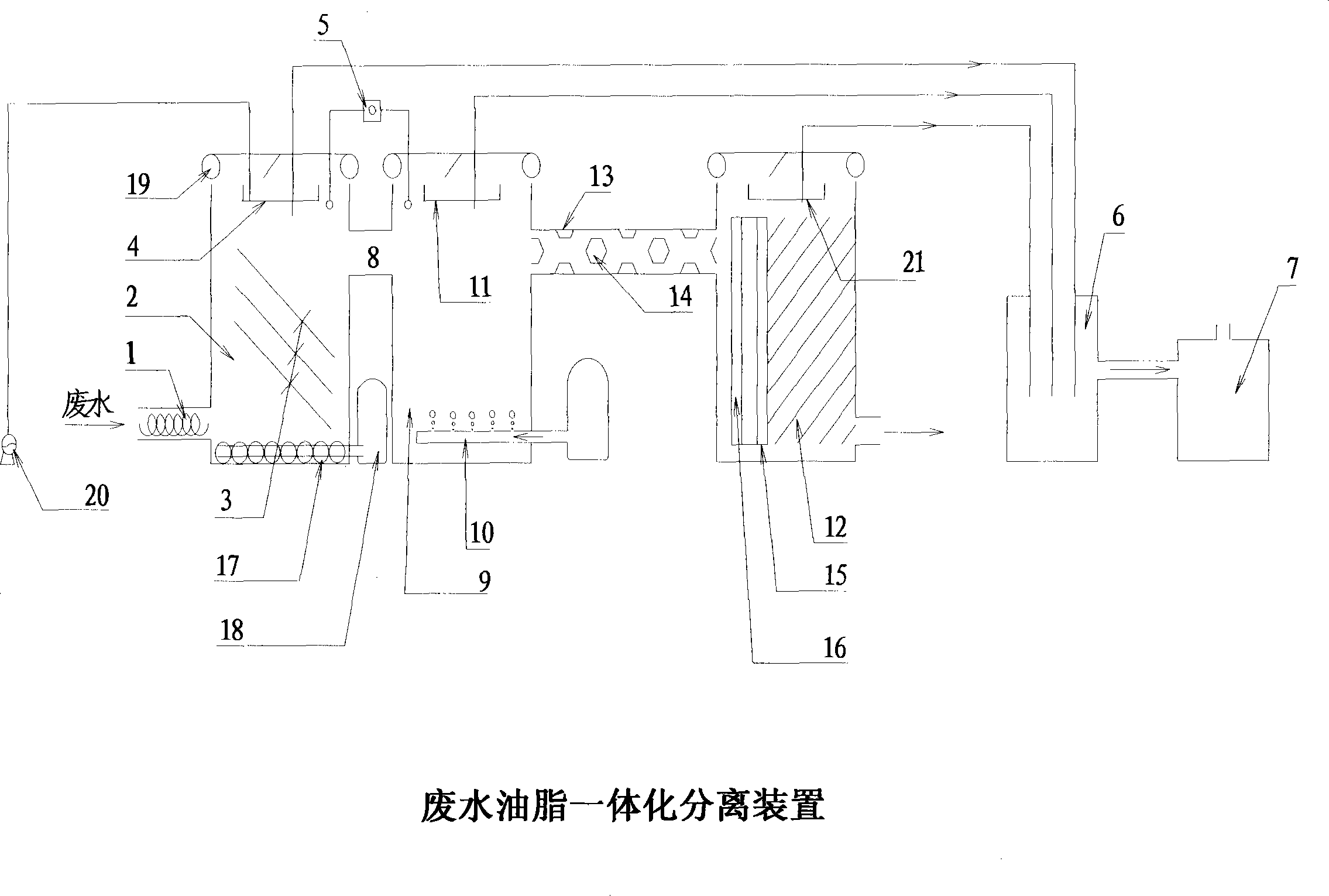

Integral separation device and method for kitchen garbage, waste-water and grease

ActiveCN101215020AEasy to separateLow costFatty/oily/floating substances removal devicesLiquid separationOil and greaseBiodiesel

Disclosed are an oil-water separation facility and a method for refuse waste-water of kitchens, which relate to the field of environment protection. The facility and method are composed of three portions which are respectively gravity oil slick, micro-airfloat oil skimming, thick granulating and the like in accordance with grease distribution shape and character of the refuse waste-water of kitchens, wherein the gravity oil removal section automatically excludes upper oil slick, emulsified oil, dispersed oil and the like float off via the micro-airfloat, thereby achieving separation of oil with smaller particles and water, after handling, oily wastewater left by the treatment of the above two sections further proceeds thick granulating process to lead micro-grease to assemble and form the grease with big particle diameter, then the grease with big particle diameter after floating upward is removed, thereby achieving being separated from water. The facility is capable of separating highly effectively the grease in sewage water, reducing organic loading of subsequent sewage water treatment, simultaneously the separated grease can be prepared into biological diesel fuels, soapstocks and the like, thereby improving resource recycling efficiency. The method has the advantages of feasible technique, cheapness and convenience, automation operation, which is not influenced by seasonal difference in temperature.

Owner:青海洁神环境科技股份有限公司

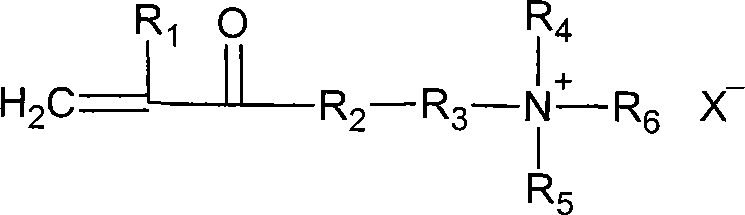

Dispersion polymeric acrylamide emulsion and its application in oil field produced liquid treatment

ActiveCN101161691AEasy to useFast dissolutionWashing/displacing pulp-treating liquorsReinforcing agents additionWater qualityDouble bond

The present invention relates to a waterborne polyacrylamide emulsion, the preparation thereof and the application thereof. The waterborne polyacrylamide emulsion is prepared by the free radical polymerization of the nonionic monomer with the double bond or combined polymerization of the nonionic monomer with the double bond with the cation, using multi inorganic salt solution as the mediums and using polyelectrolyte as the stabilizer. The appearance of the product is cream white, the particle diameter is about 10-100 Mum, the emulsion has high solution rate, and the production process without any organic solvent is innocuous and environmental protection. Compared with the dry powder and the microemulsion of the traditional polyacrylamide, the emulsion of the invention is safe and convenient in use, is capable of being used in the treatment of the oilfield produced liquid combined with the demulsifier to promote the oil-water separation to increase the dehydration of crude oil, wherein the water quality of the dehydrate water. The product can be used as an oil-water separating agent of the oily wastewater in industry and as a water purificant, also be used for sewerage treatment of the oil field and the city as an organic flocculent, and be used in paper making field as a filter aid, a retention aid, a paper strengthening agent, etc.

Owner:HAISO TECH

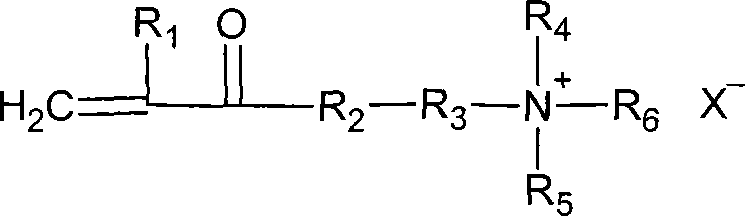

Method for purifying oil-containing waste water of catering and complete equipment thereof

ActiveCN101643301AFacilitate solid-liquid separationImprove production efficiencyFatty/oily/floating substances removal devicesMultistage water/sewage treatmentBio filtrationFiltration

The invention belongs to the technical field of water processing, and in particular relates to a method for purifying oil-containing waste water of catering and complete equipment thereof. The methodcomprises the following steps: mechanical-type oil-dirt separation, coagulation treatment of suspended substances, air floatation biochemical treatment, and biological filtration and sterilization. Compared with the prior art, the method of the invention has the characteristics of high removal efficiency, simple equipment, low running cost, convenient operation, management and maintenance, and caneffectively remove large amount of organic substances and grease in the waste water, the mmonian and chroma of the waste water, and the like, and enables every outlet water index to satisfy the requirement of recycle water.

Owner:上海青溪环保科技有限公司

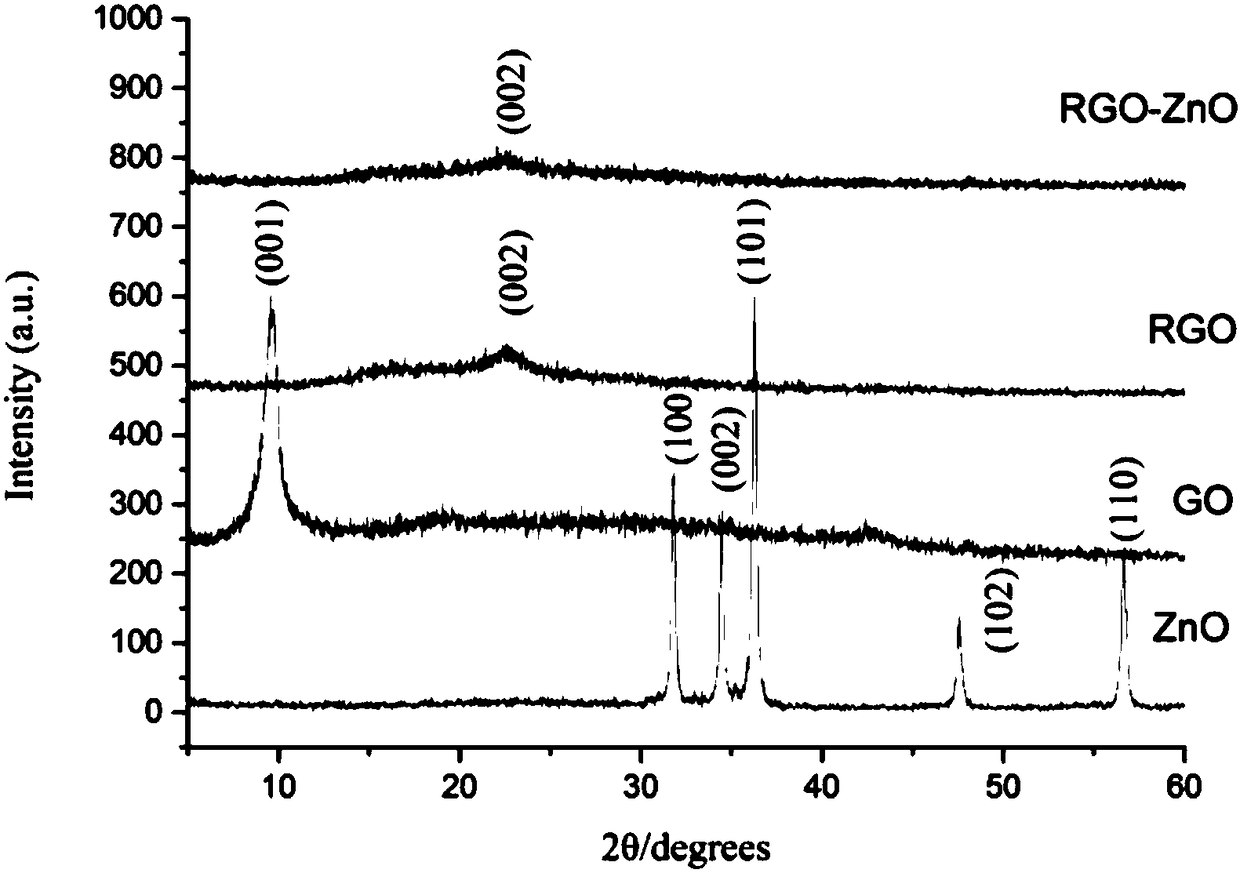

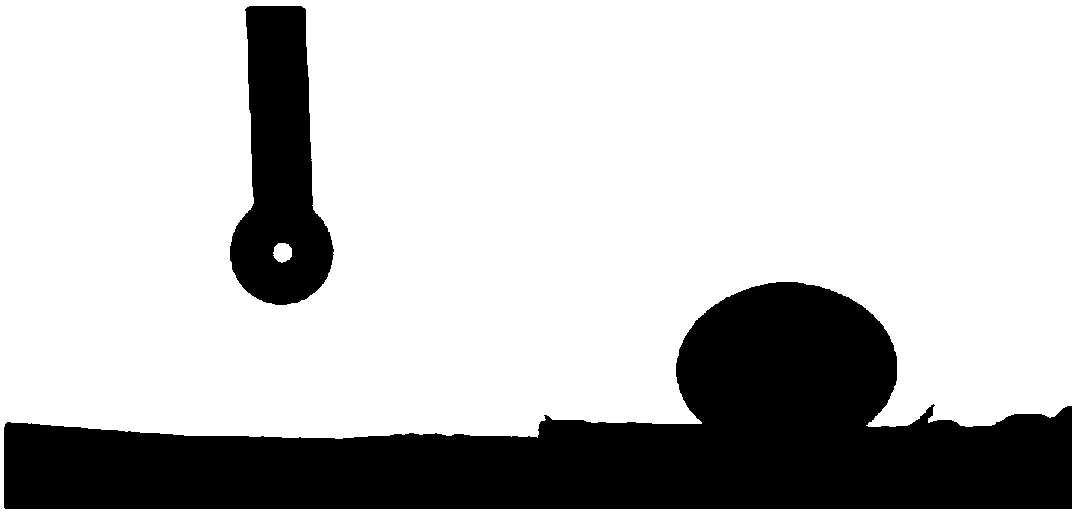

Ultra-hydrophilic-superoleophobic reduced graphene oxide filtering membrane and use

InactiveCN108159889AUndisturbedSimple processMembranesSemi-permeable membranesCellulose ester membraneFiltration

The invention relates to an ultra-hydrophilic-superoleophobic reduced graphene oxide filtering membrane and use, and belongs to the technical field of separation membrane preparation. First, grapheneoxide and nano-zinc oxide are added to distilled water and ultrasonically dispersed; a dopamine solution containing dopamine hydrochloride is added and mechanically stirred; the mixed solution is thensuction-filtered and deposited onto the surface of a mixed cellulose ester membrane by vacuum suction filtration, and the ultra-hydrophilic-underwater superoleophobic unsupported reduced graphene oxide filtering membrane is obtained by drying and self falling. The reduced graphene oxide membrane has the advantages of high water permeation selectivity, flux and stability, and membrane pollution resistance, can effectively separate oily wastewater, provides an efficient, environmentally friendly and economic technical means, and has important practical significance.

Owner:JIANGSU UNIV

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

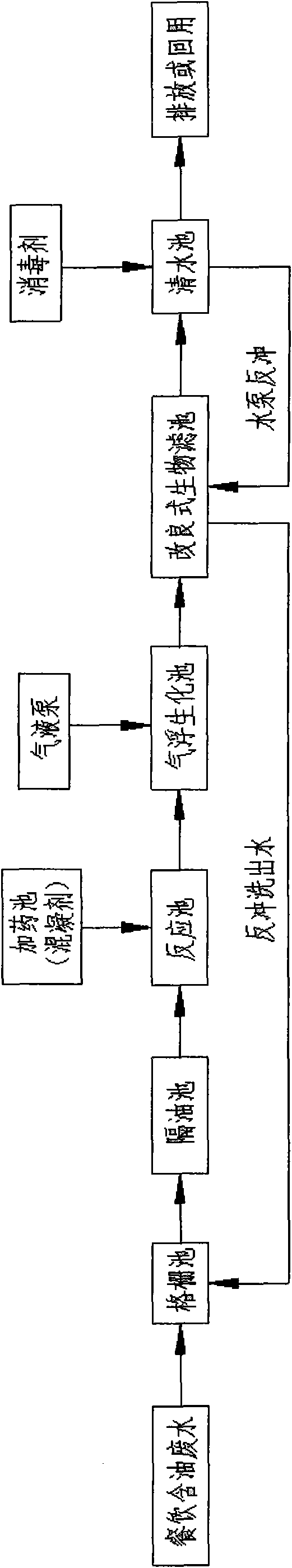

Oil removing pretreatment technology for petroleum oil refining wastewater

ActiveCN106007209AStructural scienceSimple processFatty/oily/floating substances removal devicesTreatment involving filtrationCycloneWater based

The invention discloses an oil removing pretreatment technology for petroleum oil refining wastewater. According to the oil removing pretreatment technology, a water collecting tank with gratings is used for separating sand and sludge; a three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank is used for achieving separation of water, oil and residues; a cyclone oil coarse graining polymerization oil-water separator is used for removing fine oil grains; a dissolved air flotation device is used for demulsification and flocculation reaction, wherein air bubbles and suspended solids in wastewater make contact for adhesion and float upwards, and the standard is met through residue scraping. The technology is simple, the structure is scientific, the three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank, the cyclone liquid coarse graining polymerization oil-water separator and the dissolved air flotation device jointly serve as the core treatment scheme, oily wastewater is pretreated through the density difference of oil and water based on the fluid dynamics principle, a physical method and a chemical method act jointly, and the oil content in the pretreated oily wastewater is smaller than or equal to 20 mg / L and reaches the standard. The oil removing pretreatment technology is large in daily treatment amount, high in oil removing efficiency, remarkable in oil collecting effect and considerable in economic benefit, and the water content of the recycled waste oil is 5% or lower.

Owner:江苏中嘉华新环保科技有限公司

Binary fast porous high-oil-absorption resin and preparation method thereof

The invention discloses a binary fast porous high-oil-absorption resin and a preparation method thereof. The binary fast porous high-oil-absorption resin is synthesized according a suspension polymerization method by taking styrene and methacrylate as monomers in the presence of a pore-forming agent. The binary fast porous high-oil-absorption resin prepared through the method disclosed by the invention has an irregular porous structure on the surface, thereby enlarging the specific area of resin and effectively enhancing the oil absorption velocity and oil absorption magnification of the resin for an oil product. The binary fast porous high-oil-absorption resin prepared through the method disclosed by the invention has good development prospect in the fields of treatment of ocean floating oil and industrial oily wastewater.

Owner:TIANJIN UNIV

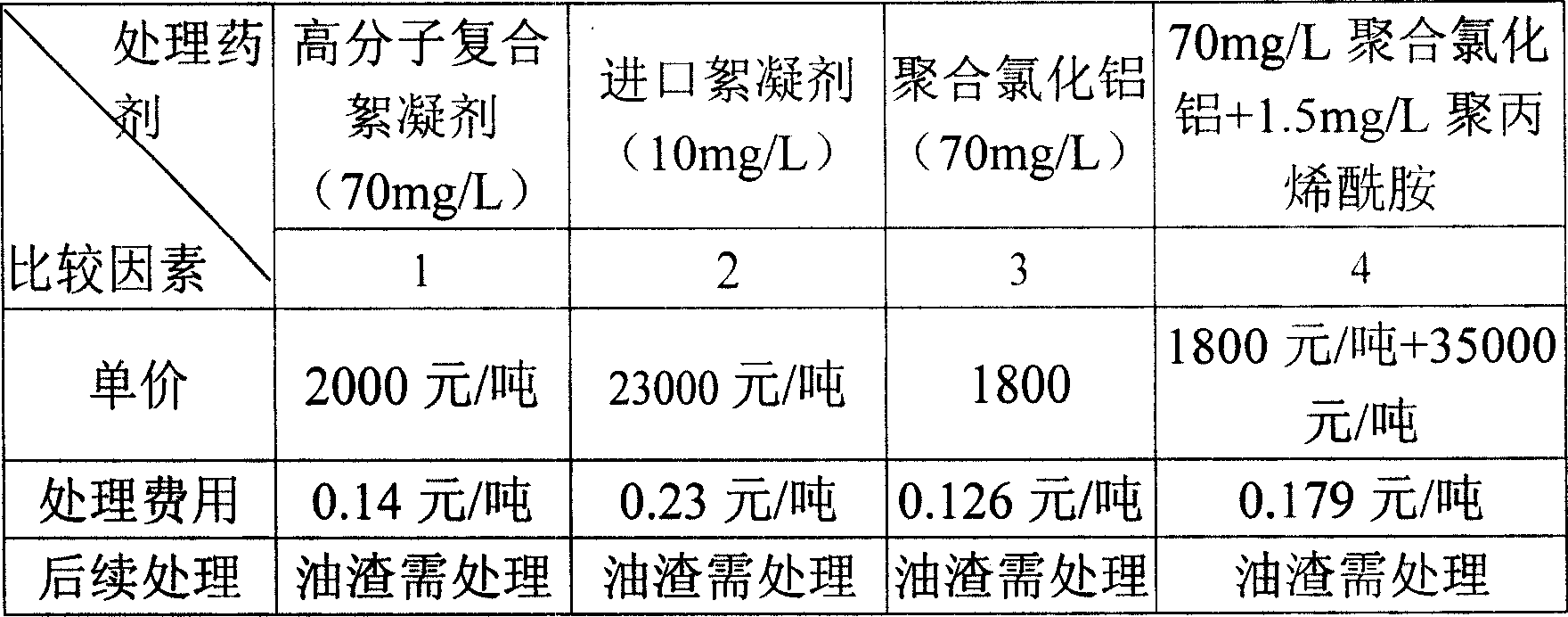

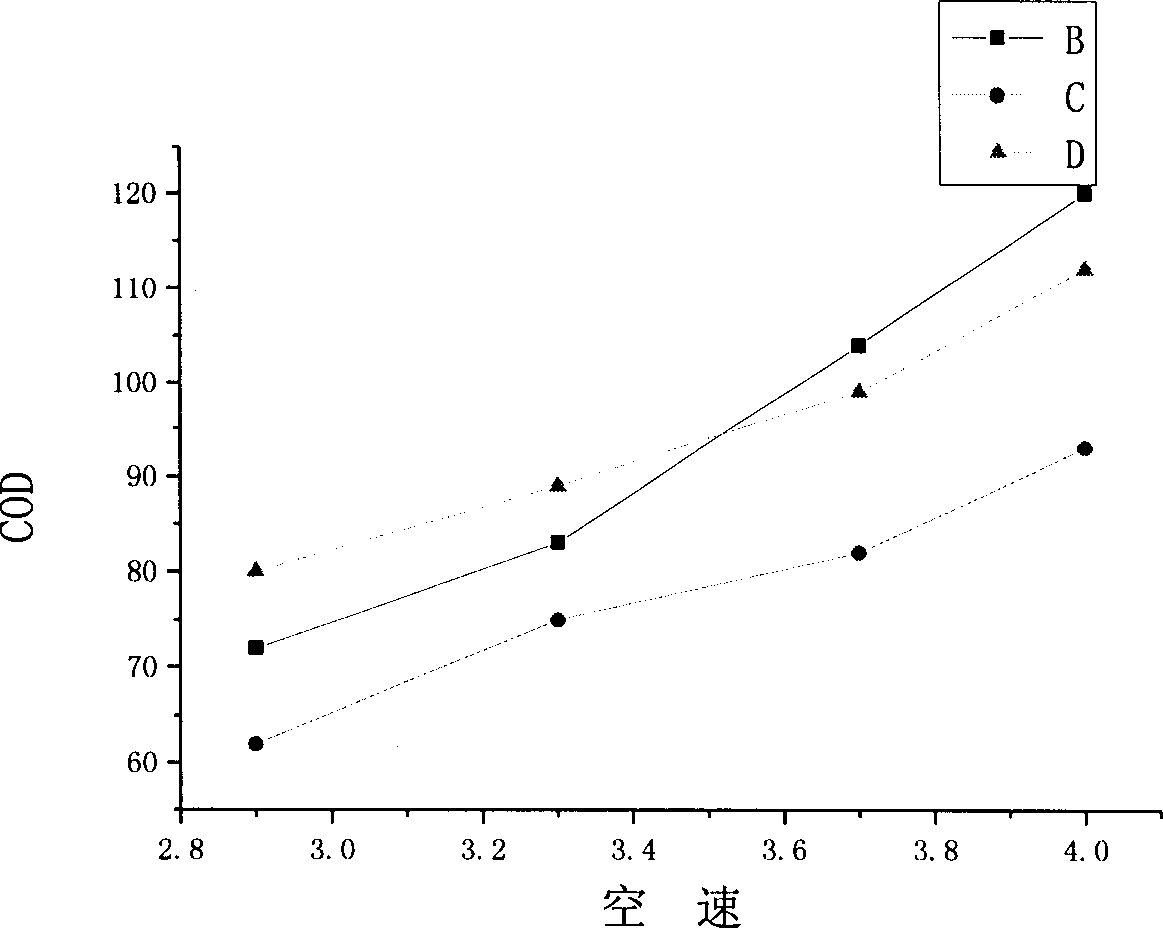

High polymer composite coagulant for treatment of oily waste water and making method thereof

InactiveCN101041495AEasy to handleLess one-time investmentWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chloridePolymer science

The invention discloses a high polymer composite coagulant for disposing oily wastewater and preparing method, which comprises the following steps: setting ingredient and weight ratio of high polymer composite coagulant with polymeric aluminium chloride : polymeric ferric sulfate : soluble glass : polydiene propyl dimethyl amchlor : water = 39.00:(1.90-2.10):(0.26-0.31):(1.04-1.52):(57.80-57.10); setting 0.02% basic ion polyacrylamide in polydiene propyl dimethyl amchlor; preparing finite density water solution with raw material as first step; preparing flocculant intermediate with polyaluminium chloride, polymeric ferric persulfate and sodium silicate as second step; proceeding mixed reaction with flocculating agent intermediate of the second step and polydiene propyl dimethyl amchlor of 0.02% positive ion polyacrylamide; controlling condition as temperature at 70-90 deg.c, pH value at 4-7; stirring intensity at 50-70r / min and ripening time at 6-24h.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Method of treating oil field waste water by electric-multiphase catalytic reaction and its special equipment

InactiveCN1429773ASimple and fast operationMild reaction conditionsWater/sewage treatment by electrochemical methodsMetal/metal-oxides/metal-hydroxide catalystsLiquid wasteFertilizer plant

A process for treating the waste water in oil field by electricity-multi-phase catalytic reaction features that under the existance of external electric field, the organic pollutants in the said waste water are catalytically oxidized by the surface of catalyst. The catalyst is composed of the active components chosen from one or several oxides of Fe, Co, NI, Mn, Cu, Ti, W and Pb and the carrier chosen from SiO2, Al2O3, zeolite molecular sieve and activated carbon. Among the mentioned catalyst, one or several oxides of rare earth metals as auxiliaries may be added. The said catalyst is made upthrough impregnating, oven-drying and sintering; and it can effectively treat oil-contained waste water as well as dinitrophenol waste water, fertilizer plant waste water, cutting liquid waste water,etc.. Its advantages are high effect and low cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Waste gas treatment device

InactiveCN1830522ACreate pollutionEfficient recyclingUsing liquid separation agentPlate heat exchangerTower

A waste gas treating apparatus for atomizing, dusting and absorbing the waste gas coming from the dyeing and finishing industry is composed of fume gathering unit, heat exchanger for recovering heat, sprinkling filler tower and oil-water separator for reclaiming them.

Owner:绍兴永利环保科技有限公司

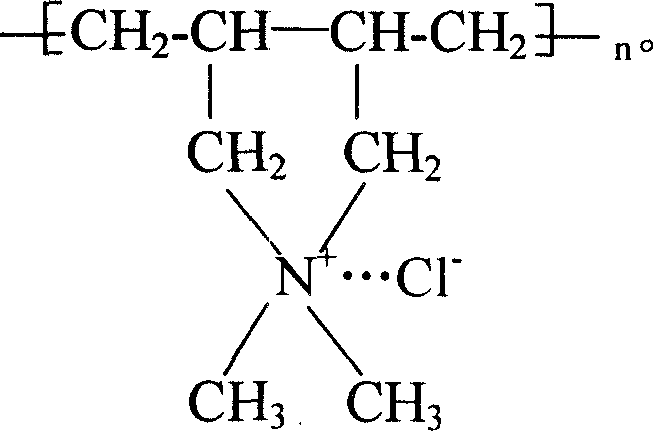

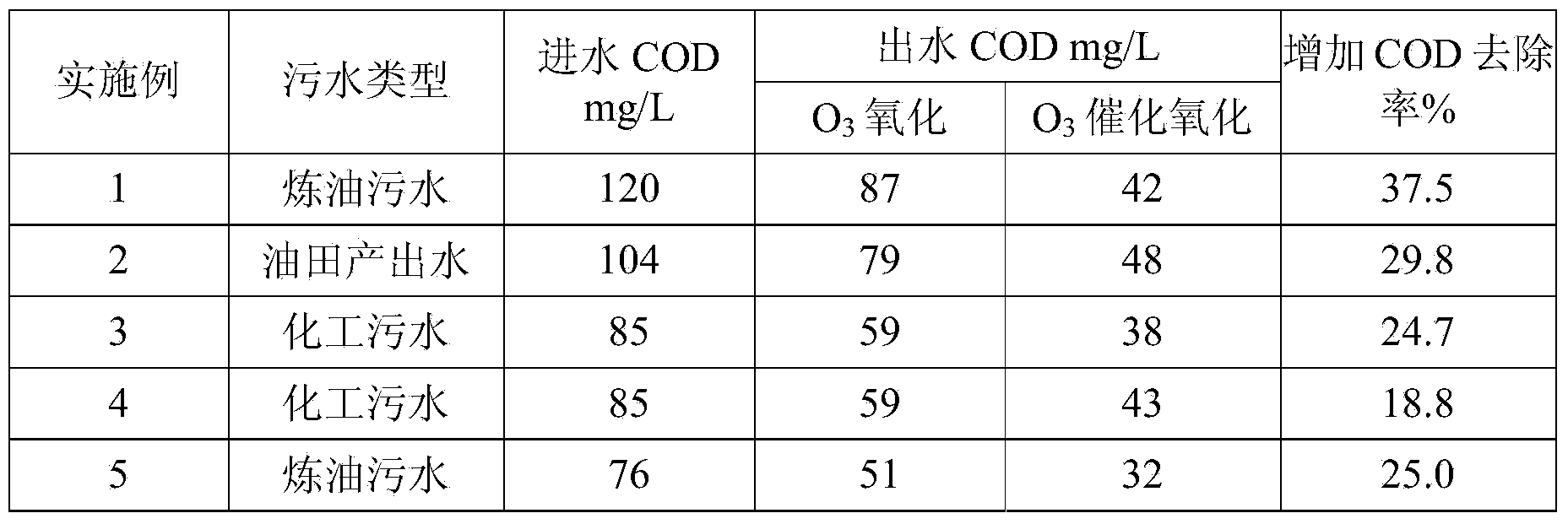

Oily wastewater ozone catalytic oxidation catalyst and preparation method of catalyst

ActiveCN103894202AImprove removal efficiencyReduce upgrade processing costsMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationWater vaporAdhesive

The invention provides an oily wastewater ozone catalytic oxidation catalyst and a preparation method of the catalyst. The method comprises the following steps: pre-activating petroleum coke by using water vapor to obtain a catalyst carrier matrix carbon material; carrying out activation reaction by using the catalyst carrier matrix carbon material and an activating agent to obtain a carbon material carrier; mixing the carbon material carrier and a catalyst precursor nitrate solution, drying and roasting to obtain powder carbon comprising active components of the catalyst; evenly mixing the powder carbon comprising the active components of the catalyst with an adhesive, pressing and forming, releasing pressure, and then drying and crushing to prepare the oily wastewater ozone catalytic oxidation catalyst; or evenly mixing the powder carbon comprising the active components of the catalyst with an adhesive, carrying out extrusion forming, releasing pressure, and then drying and crushing to prepare the catalyst carrier, then mixing the catalyst carrier with the catalyst precursor nitrate solution, drying, roasting and cooling, and then preparing the ozone catalytic oxidation catalyst. The catalyst is capable of reducing the ozone dosage, improving COD removing efficiency and reducing COD upgrading cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com