Patents

Literature

167 results about "Fertilizer plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fertilizers or fertilisers are compounds given to plants with the intention of promoting growth; they are usually applied either via the soil, for uptake by plant roots, or by foliar spraying, for uptake through leaves. Fertilizers can be organic (composed of organic matter, i.e. carbon based), or inorganic (containing simple, inorganic chemicals).

Microbial fertilizer-plant synbiotic composition preparation and method for preparing symbiotic preparation

ActiveCN101591199AThe effect of increasing production is obviousStable growthBacteriaMicroorganism based processesContinuous croppingPlant roots

The invention discloses a microbial fertilizer-plant synbiotic composition preparation and a method for preparing the synbiotic preparation. In the composition preparation, the plant synbiotic consists of probiotics, prebiotics and stabilizer; and bacillus forms zymotic fluid. The method for preparing the synbiotic preparation comprises the following steps: fermenting the probiotics; regulating bacteria amount; and preparing and homogenizing to obtain the product. Azotobacter, pralidoxime iodide and potassium bacteria in the preparation can increase soil nutrition, improve the fertilizer utilization rate and soil granule structures, promote the air permeability, water-retaining property and drainage, and overcome the defect of sunlight greenhouse continuous cropping; oligosaccharide prebiotics in the preparation can stimulate crops to improve resistance to pathogenic microorganisms, and promotes permanent planting and proliferation of the probiotics; the preparation can inhibit toxicity generated by bacteria, start self immunity system, eliminate diseases and remove evils, reduce bactericidal pesticide, has cold resistance, heat resistance, drought resistance, waterlogging resistance, saline and alkaline resistance, fertilizer damage resistance, chemical damage resistance and nutrition imbalance resistance, can promote plant root elongation and good development of capillary roots, and promote blooming and fruit yielding.

Owner:渭南德龙生物科技有限公司

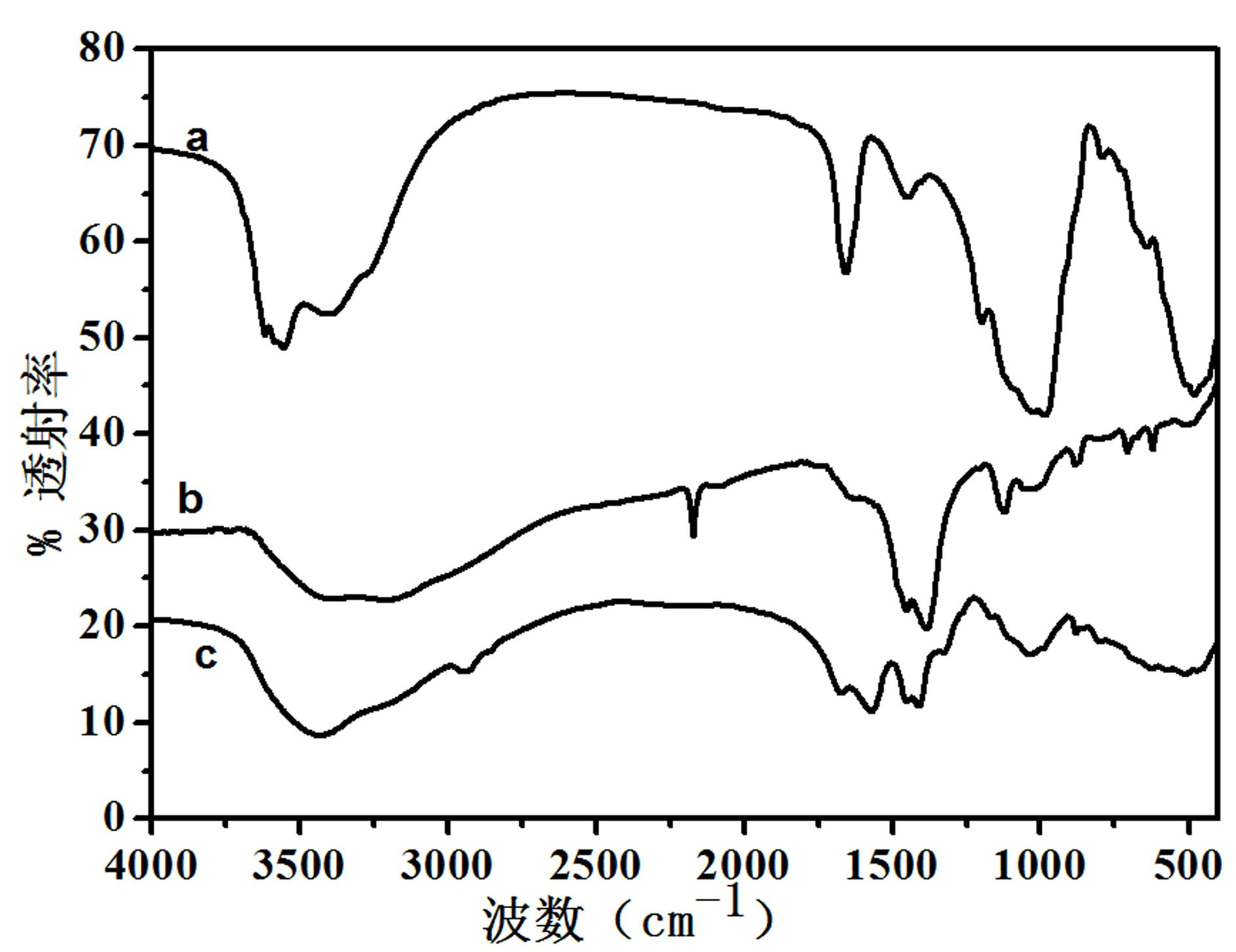

Strain for synthesizing gamma-polyglutamic acid and method for efficiently preparing gamma-polyglutamic acid by using strain

InactiveCN104232504AFast Fermentation ProductionIncrease contentBacteriaMicroorganism based processesInorganic saltsMicroorganism

The invention discloses a strain for synthesizing gamma-polyglutamic acid. The strain is screened from soil around a chemical fertilizer plant and is classified to be named as Bacillus Subtilis NS-9, the collection number of the strain in the China Center for Type Culture Collection (CCTCC NO.) is M2014142, and the collection date of the strain is April 23, 2014. The invention also discloses a method for efficiently preparing gamma-polyglutamic acid by using the strain for synthesizing gamma-polyglutamic acid. Compared with an existing gamma-polyglutamic acid production technique, the adopted bacillus subtilis microbial strain disclosed by the invention can be used for efficiently producing gamma-polyglutamic acid by virtue of fermentation; by optimizing the culture conditions of the bacillus subtilis strain, particularly replenishing a carbon source, inorganic salts and energy substances in a fermentation process, the content of gamma-polyglutamic acid in a fermentation solution can reach 100-200g / L, so that the method for preparing gamma-polyglutamic acid, disclosed by the invention, is high in efficiency and low in cost.

Owner:樟树市狮王生物科技有限公司

Method for improving farmland soil environment capacity

ActiveCN103814649AIncrease environmental capacityIncrease available nutrientsContaminated soil reclamationSoil-working methodsHealth riskFertilizer plant

The invention mainly provides a method for improving the farmland soil environment capacity by combining with the current severe situation of the farmland soil. The method is used for enhancing the self cleaning capacity of the farmland soil, lowering harm on crops by various pollutants (organic matters and heavy metal) in the farmland soil and lowering the adsorption on soil harmful substance by the crops so as to lower the index to the human body health risk by the soil harmful substance. The method is suitable for farmland soils around pollution sources, such as various chemical plants, insecticide factories, electroplate factories and chemical fertilizer plants to prevent various pollutants from invading, the yield of the crop is improved, and the quality of the crop is improved.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

Method of treating oil field waste water by electric-multiphase catalytic reaction and its special equipment

InactiveCN1429773ASimple and fast operationMild reaction conditionsWater/sewage treatment by electrochemical methodsMetal/metal-oxides/metal-hydroxide catalystsLiquid wasteFertilizer plant

A process for treating the waste water in oil field by electricity-multi-phase catalytic reaction features that under the existance of external electric field, the organic pollutants in the said waste water are catalytically oxidized by the surface of catalyst. The catalyst is composed of the active components chosen from one or several oxides of Fe, Co, NI, Mn, Cu, Ti, W and Pb and the carrier chosen from SiO2, Al2O3, zeolite molecular sieve and activated carbon. Among the mentioned catalyst, one or several oxides of rare earth metals as auxiliaries may be added. The said catalyst is made upthrough impregnating, oven-drying and sintering; and it can effectively treat oil-contained waste water as well as dinitrophenol waste water, fertilizer plant waste water, cutting liquid waste water,etc.. Its advantages are high effect and low cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Activated calcium magnesium phosphate fertilizer and preparation method thereof

The invention belongs to the field of chemical production, and relates to an activated calcium magnesium phosphate fertilizer and a preparation method thereof. The activated calcium magnesium phosphate fertilizer is prepared from a calcium magnesium phosphate fertilizer and an organic activating agent. The organic activating agent is one or a mixture of more of lignin, acid lignin, sodium lignin, alcohol waste liquor, monosodium waste liquor, monosodium waste sludge, acid sludge, furfural sludge, beer filter mud, sugar-refinery filter mud and weathered coal. The activated calcium magnesium phosphate fertilizer is prepared by adding the organic activating agent into the calcium magnesium phosphate fertilizer according to a specified ratio, and grinding, placing and drying the mixture. Phosphorus in the activated calcium magnesium phosphate fertilizer is in an activated state, the activated calcium magnesium phosphate fertilizer can be fast and stably released when applied to the soil, can reduce fixation of the soil, and has fast and durable fertilizer effect, so that the utilization rate of the phosphorus is obviously improved. Meanwhile, the activated calcium magnesium phosphate fertilizer has the advantages of simple production process, low production cost, high and stable yield, and contribution to large-scale production and application. Compound fertilizer plants or newly-built phosphate fertilizer plants can produce the activated calcium magnesium phosphate fertilizer under the conditions of small equipment investment.

Owner:SOUTH CHINA AGRI UNIV

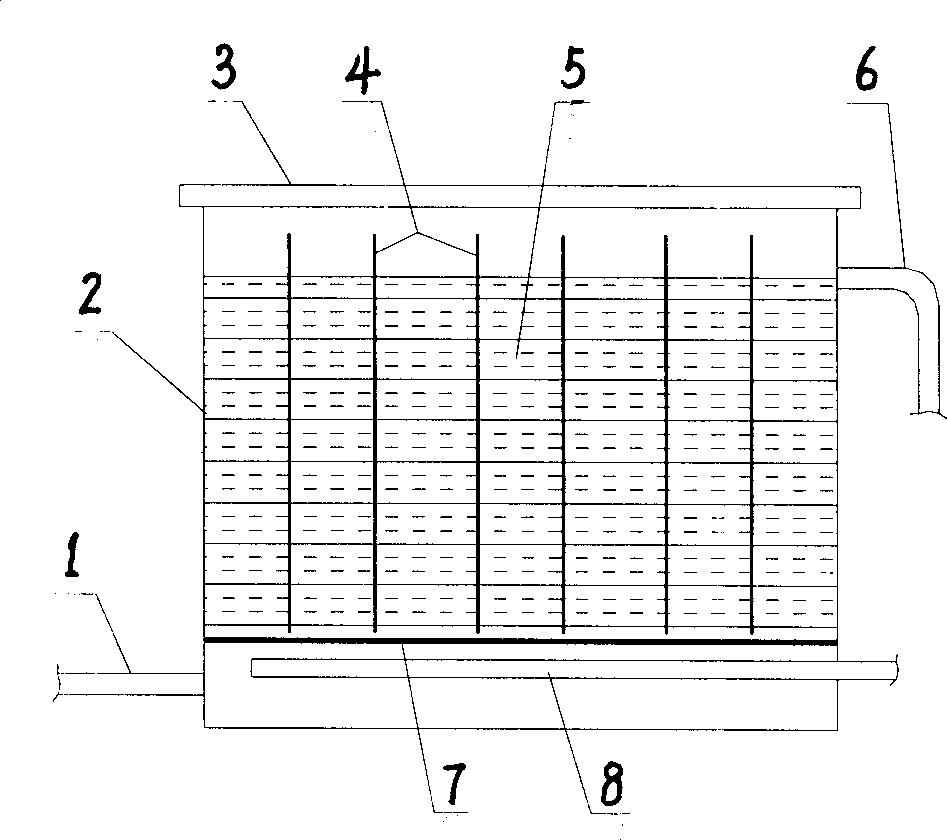

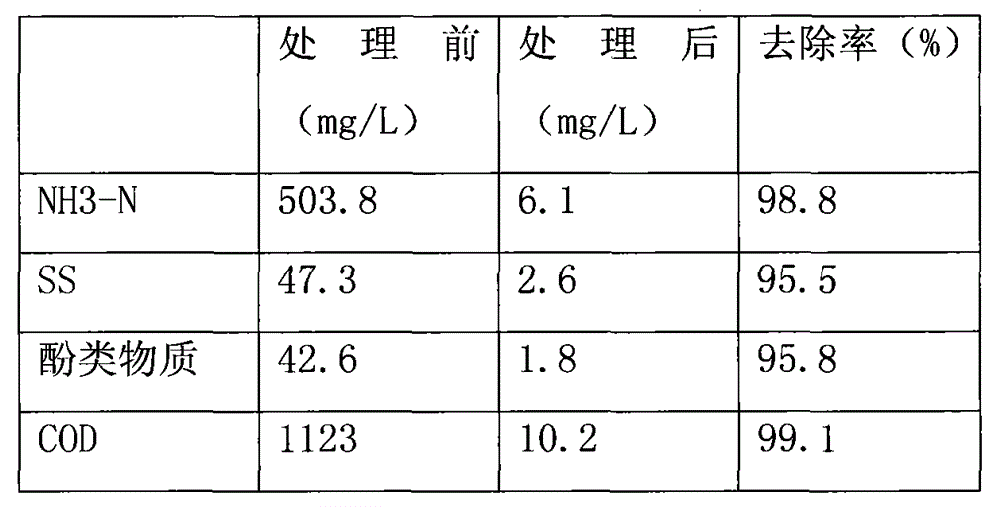

Microbial preparation for restoring fertilizer plant sewage and application thereof

InactiveCN104528955APromote degradationIncrease contact areaBiological water/sewage treatmentSorbentFertilizer plant

The invention belongs to the technical field of microbes, and discloses a microbial preparation for restoring fertilizer plant sewage. The microbial preparation for restoring fertilizer plant sewage is prepared by the following steps: 1) preparing an adsorbent; 2) preparing a microbial carbon source; 3) preparing a microbial carrier; and 4) preparing the microbial preparation. The microbial preparation can effectively remove ammonia nitrogen, SS (suspended sediment) and phenols in the fertilizer plant sewage, has favorable removal effect, and achieves the discharge standard.

Owner:杭州润泽科学器材有限公司

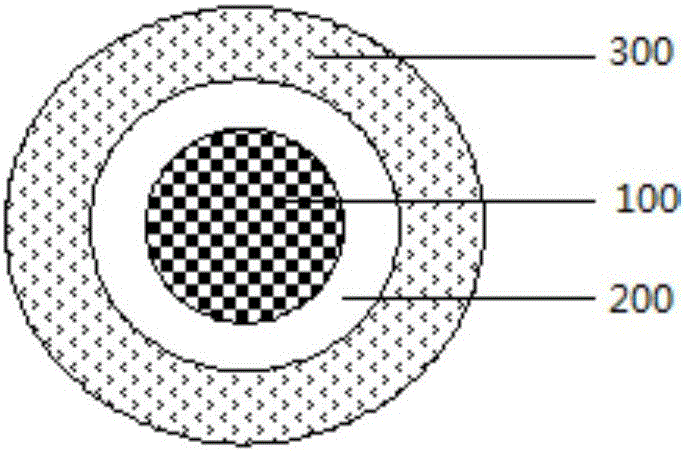

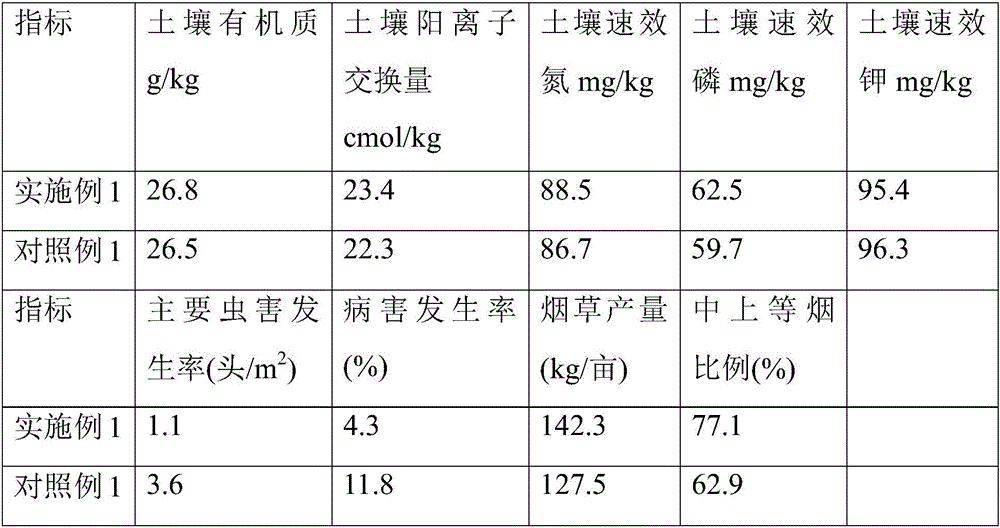

Composite microbial fertilizer for reducing soil pests and diseases of tobacco, and preparation method thereof

InactiveCN106083493AQuick breakdownPromote growthAlkali orthophosphate fertiliserExcrement fertilisersDiseaseCamellia oleifera

The invention provides a composite microbial fertilizer for reducing soil pests and diseases of tobacco, and a preparation method thereof, and belongs to the field of bioorganic fertilizers. The composite microbial fertilizer includes a plurality of fertilizer particles, and every fertilizer particle sequentially comprises a core, a middle layer and an outer layer from inside to outside. The core comprises a nitrogen fertilizer, a phosphorus fertilizer, a potassium fertilizer, mineral powder and a binder. The middle layer comprises fly ash and humic acid. The outer layer comprises animal dung, corn stalks, Camellia oleifera shells, proteins and a first microbial agent. The preparation method comprises the following steps: mixing and granulating first materials to obtain first fertilizer particles; attaching second materials to the surfaces of the first fertilizer particles to obtain second fertilizer particles; fermenting third raw materials to obtain a first mixture; and attaching the first mixture to the surfaces of the second fertilizer particles in order to obtain the composite microbial fertilizer particles. The composite microbial fertilizer prepared in the invention can be applied to reduce the top application frequency, and substantially improve the output and the quality of the tobacco and reduce the soil pests and diseases.

Owner:MUDANJIANG NORMAL UNIV

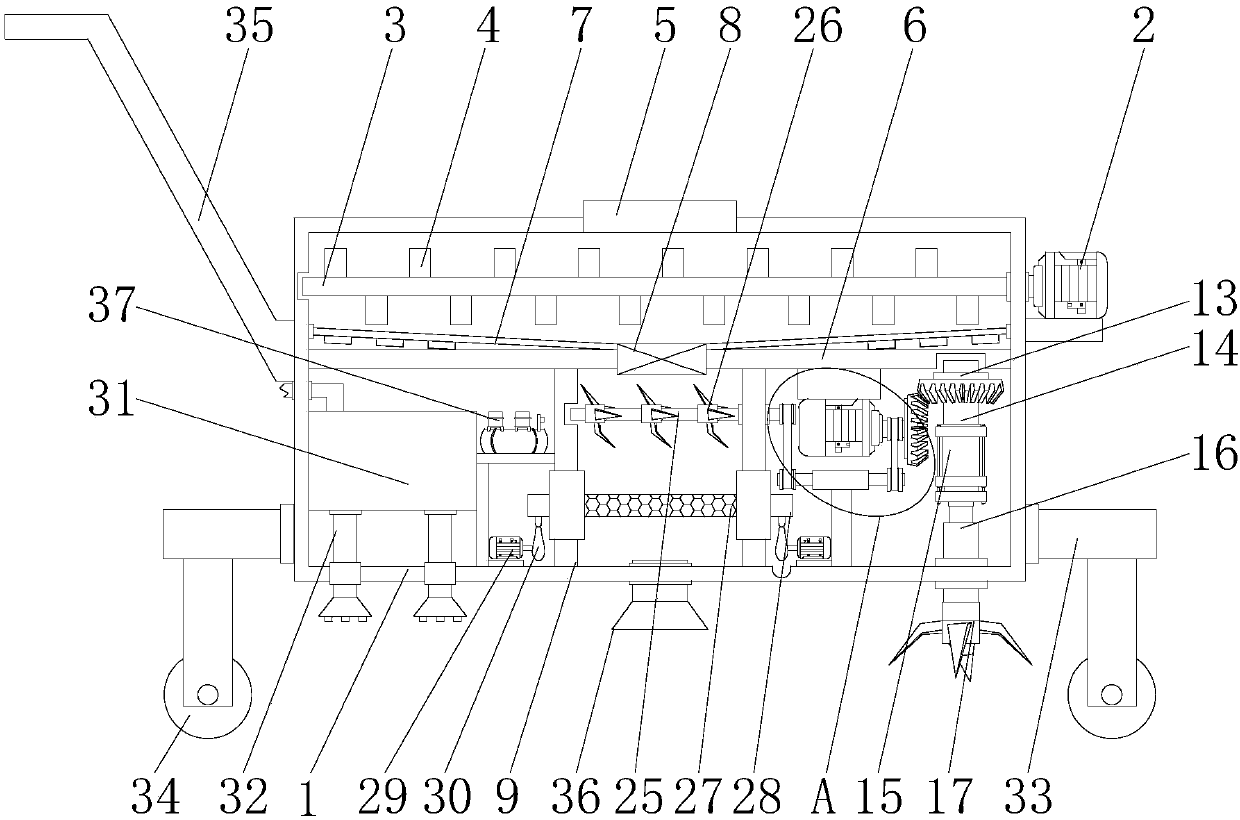

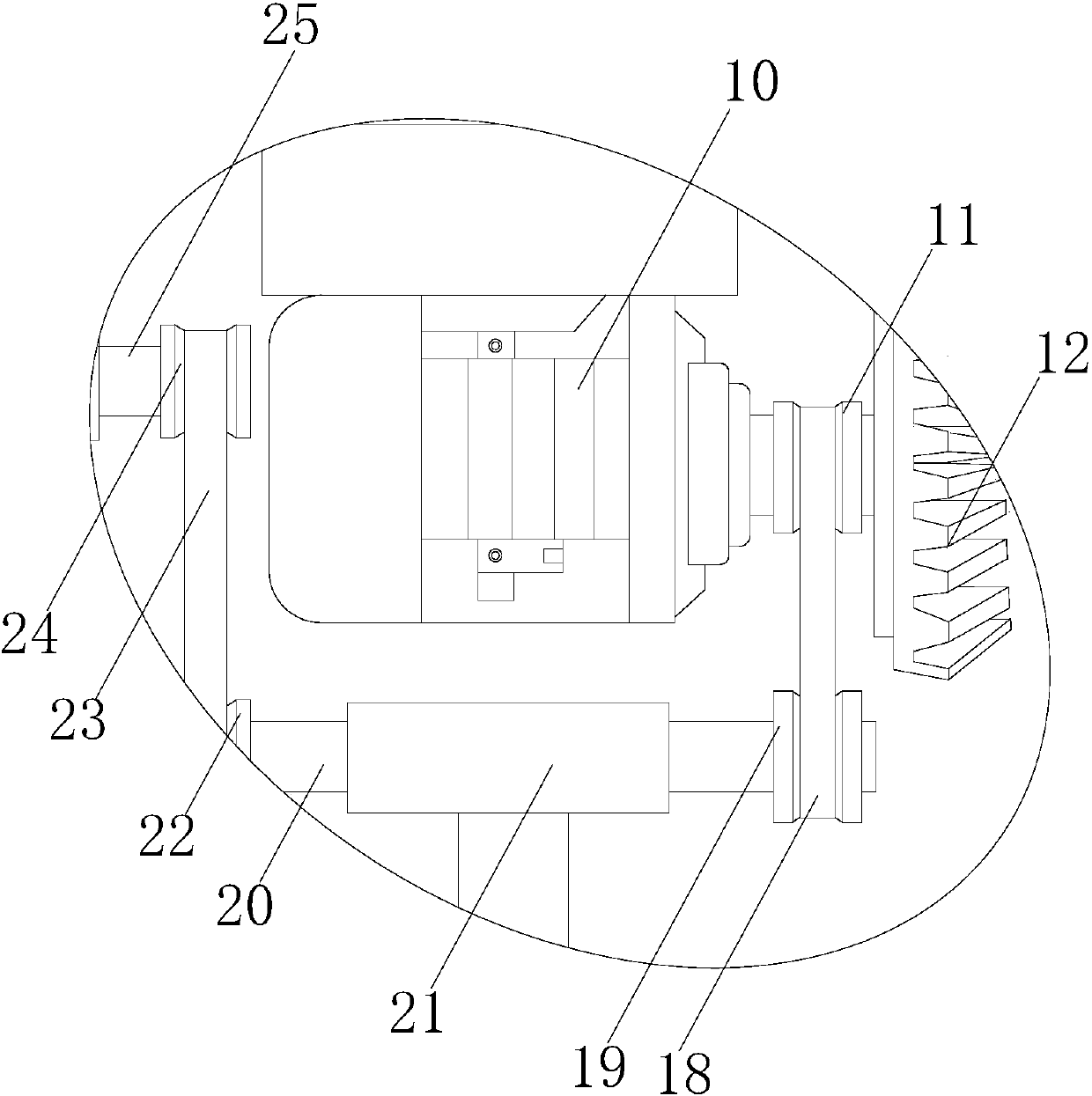

A Repairing Method of Hard Surface Gear

ActiveCN102294566AResolve fault thicknessQuick fixMetallic material coating processesChemical industryFertilizer plant

The invention relates to a technique for repairing a hardened gear, specifically disclosing a method for repairing a hardened gear, which can be applied to industries such as a cement plant, a steel mill, a missile unit, chemical industry, railway, petroleum, mine, a power plant, a sintering plant, a pelletizing plant, a steel rolling mill, a fertilizer plant and the like. The method is capable of solving repair of a fault thickness within a range of 1-300 mm in a cladding manner by employing different materials for a joint layer, a transition layer, a work layer and a processing layer in this order. Therefore, with the method, the hardened gear can be quickly repaired, so that the economic loss caused by the damage of the hardened gear is minimized.

Owner:WUHAN KAIMING HIGH TECH

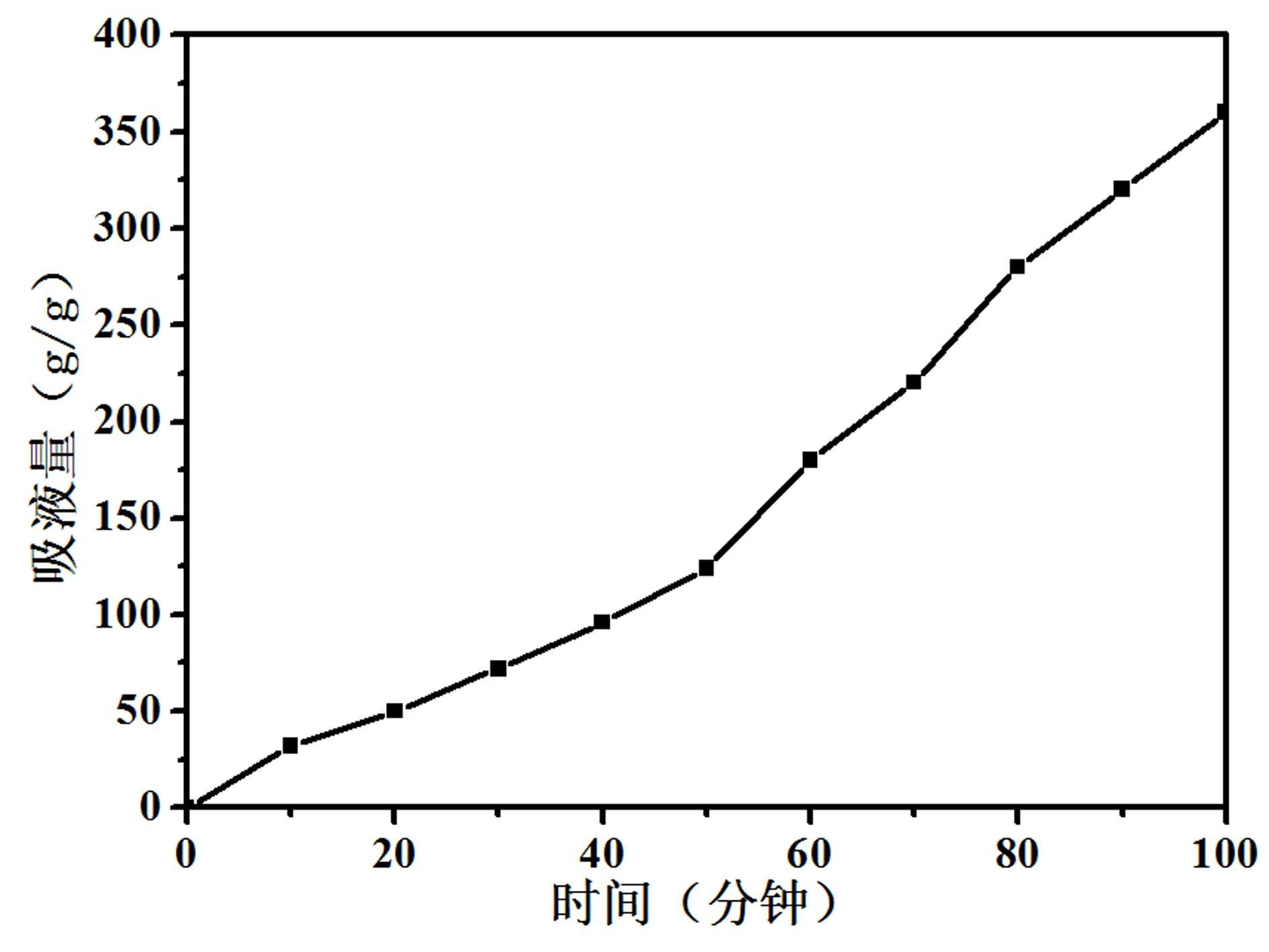

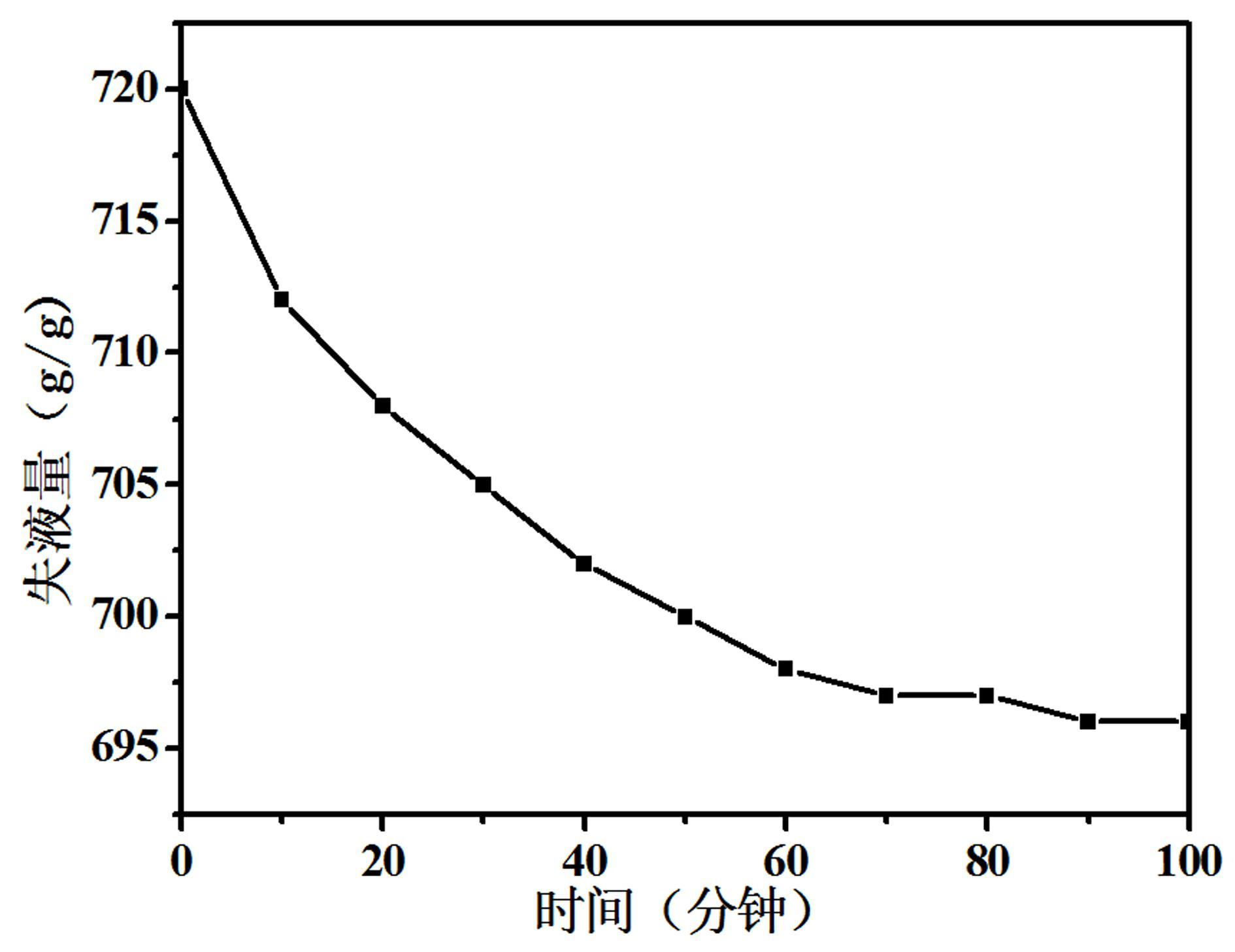

Preparation method for foaming type nutrient composite water-retaining agent

ActiveCN102492070AImprove water absorptionHigh gel strengthOrganic fertilisersSoil conditioning compositionsPotassium persulfateMeth-

The invention provides a preparation method for a foaming type nutrient composite water-retaining agent and belongs to the field of composite materials. Plant ash, acrylamide and palygorskite clay rude ore are adopted as raw materials, potassium persulfate is adopted as an initiating agent, N,N'-methylene-bisacrylamide and the like are adopted as cross-linking agents, ammonium bicarbonate is adopted as a foaming agent, the copolymerization of an aqueous solution is initiated through a free radical to obtain the composite water-retaining agent which has the effects of high water absorption velocity, large water absorption capacity, long water retaining time, good salinity tolerance and high gel strength. Through the addition of the natural fertilizer plant ash, the water-retaining agent isendowed with the advantage of being rich in nutrient elements, thereby being more suitable for the fields of crop planting and desertification environment remediation. The palygorskite clay rude ore is adopted as the main raw material, the addition of inorganic substances is high, so as to greatly reduce the cost of the water-retaining agent; besides, the preparation technology of the composite water-retaining agent is simple, the operation is convenient, and industrialization is facilitated.

Owner:NORTHWEST NORMAL UNIVERSITY

Antiscale scale-remover for industrial water treatment

InactiveCN1666963ANot easy to form clogging phenomenonPrevent secondary scalingScale removal and water softeningFertilizer plantWater cycling

This invention discloses an antiscale and scale remover that used in industrial cycle cooling water disposal. It is composed by humic acid natrium, sodium carbonate, starch, sodium heametaphosphate, the weight percentage is humic acid natrium 15-30%, sodium carbonate 65-75%, starch 2-10%, sodium heametaphosphate 1.2-2%. The compound can improve the water flowability and dispersibility. It belongs to environmental protection product and is no pollution. It has high temperature resistant. Sterilization can be done in working condition. It can be applied to calcium carbide furnace, ferrosilicon furnace, calcium silicon furnace, transformer and cooling water cycling and antiscale and scale remove of carbonization equipment in fertilizer plant.

Owner:翟春生

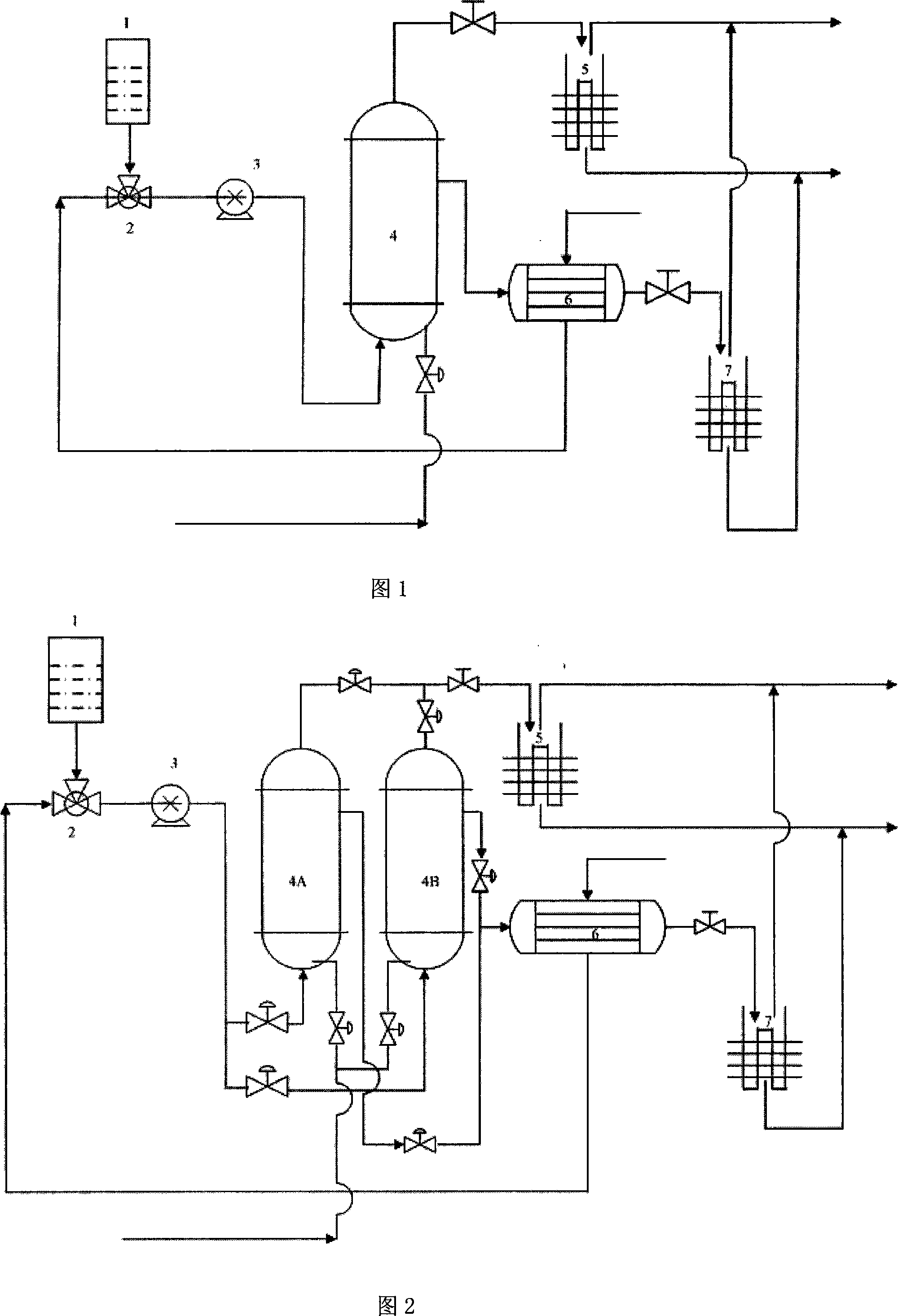

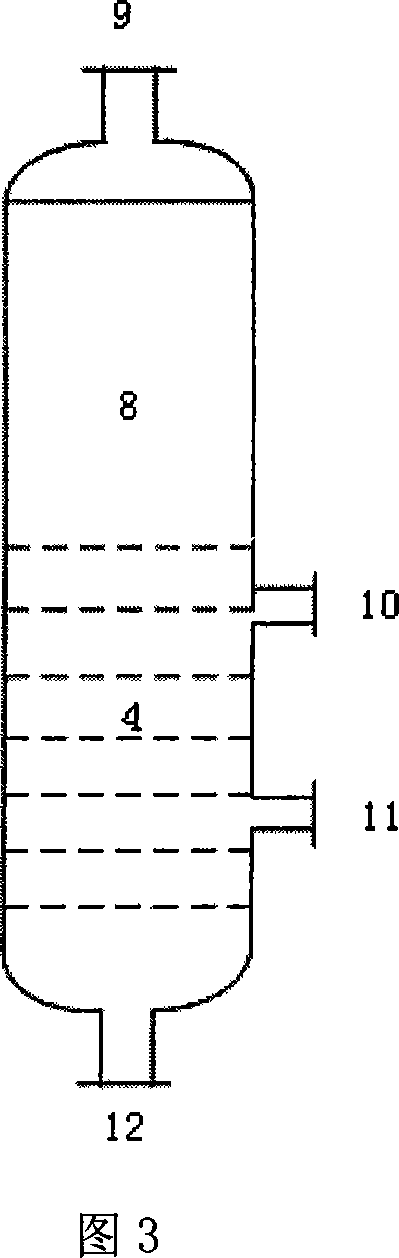

Method for purifying carbamide polluted water

InactiveCN101182063AReduce energy consumptionAchieve the goal of energy saving and emission reductionWater/sewage treatmentBulk chemical productionPurification methodsFertilizer plant

A urea polluted water purification method is a catalytic hydrolysis method of removing urea pollutants from wastewater, which is discharged from chemical fertilizer plants. The hydrolysis catalysts include water-soluble catalysts or supported catalysts. The pH value of wastewater containing the catalysts is generally controlled to be larger than twelve. The purification and hydrolysis technology adopts a multifunctional reactor to realize the gas-liquid separation, the heat exchange and the catalytic hydrolysis, directly mixes steam and wastewater and separates ammonia through the gas stripping. With the heat exchange of treating water and urea desorbing water, the direct mixing and the heat exchanging of the steam and the urea desorbing water, the method lowers the energy consumption, removes the urea desorbing water in the polluted water which is discharged from the chemical fertilizer plant and recovers the ammonia. The national emission standard and the industrial water standard are achieved. The method can be applied to the improvement and the optimization of original hydrolysis technologies and equipments of plants.

Owner:太原海力丰科技发展有限公司

Biomass nanometer gasoline liquid fuel

InactiveCN101955807AFull combustion, non-toxic and smoke-freeNo pollutionLiquid carbonaceous fuelsFertilizer plantNew energy

The invention belongs to the technical field of new energy, in particular relates to a biomass nanometer gasoline liquid fuel which comprises the following raw materials by weight percent: 20-94% of biomass alcohol, 0-50% of gasoline, and 6-35% of combustion-supporting additive. The main raw material, i.e. biomass alcohol used in the invention is leftovers or a secondary product of a chemical plant, a fertilizer plant, a winery, a pharmaceutical factory and a sugar refinery. The invention has advantages that the liquid fuel can not blow up, is relatively safe for storing and transportation, can fully burn, is non-poisonous and smokeless, does not pollute the environment, and can replace the national-standard gasline of 90#, 93#, 97# to be used for motor vehicles.

Owner:东莞市智造生物科技有限公司

Fertilizer application device for garden land

InactiveCN107864707ASolve the problem of digging loose soilPromote growthSpadesWatering devicesFertilizer plantAgricultural engineering

The invention discloses a garden land fertilization device, and the invention relates to the technical field of garden construction. The garden land fertilization device includes a box, the left side of the top of the box is fixedly connected with a first motor through a motor base, the first motor is fixedly connected with a rotating rod, and the left end of the rotating rod runs through the box and extends to the inner cavity of the box , the rotating rod is rotationally connected with the left side wall of the inner cavity of the box, the garden land fertilization device is fixedly connected with the stirring rod through the left side of the second transmission pulley, the left end of the stirring rod penetrates the connecting plate and extends to the left side of the connecting plate, The left end of the stirring rod is rotatably connected with one side of the connecting plate, and the surface of the stirring rod is fixedly connected with a crushing cutter head, which can break up large pieces of fertilizer and spread them evenly into the ground, without causing uneven fertilizer and causing plant death problem, which solves the problem that the existing garden land fertilization device cannot evenly scatter fertilizer into the ground.

Owner:湖州酷趣电子商务有限公司

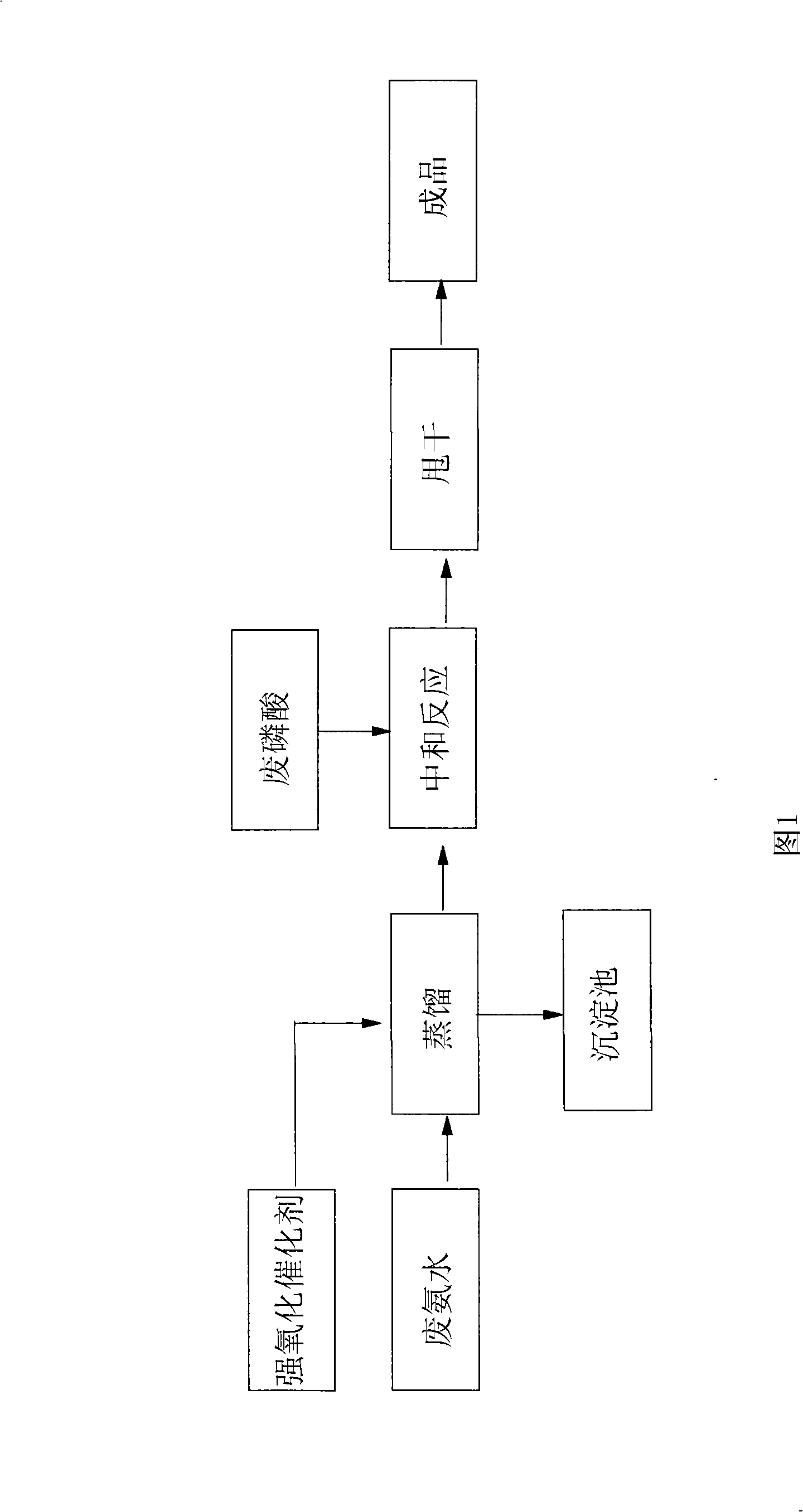

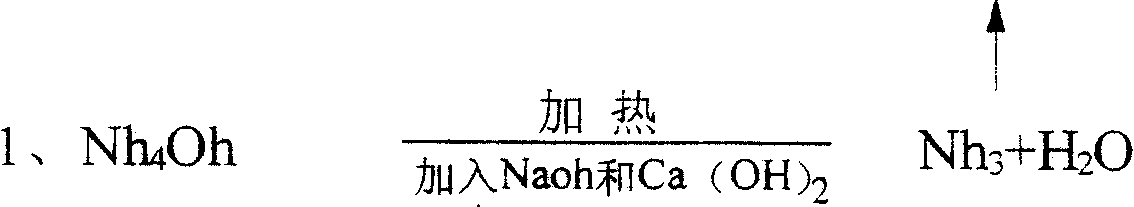

Novel process for producing ammonium tertiary phosphate by using waste ammonia and waste phosphoric acid

The invention belongs to a novel technology for producing ammonium phosphate by utilizing waste ammonia and waste phosphoric acid. The novel process is characterized in that the waste ammonia containing more than 7 percent of ammonium is used for being heated and distillated under the action of a strong oxidative catalyst; the distillated ammonium is then neutralized and reacted with the waste phosphoric acid containing 25 to 92 percent of phosphorus, and finally, the obtained mixture is treated with spin drying to prepare the ammonium phosphate. Compared with the prior art, the novel technology of the invention is simple with low investment and quick returns and also has low production cost by utilizing the waste ammonia and the waste phosphoric acid to make full use of available resources, thus reducing environmental pollution and opening up a new way for the comprehensive utilization of the waste ammonia of chemical plants, coking plants and fertilizer plants as well as the waste phosphoric acid of medicine, electronics and feed processing industries.

Owner:王天伦

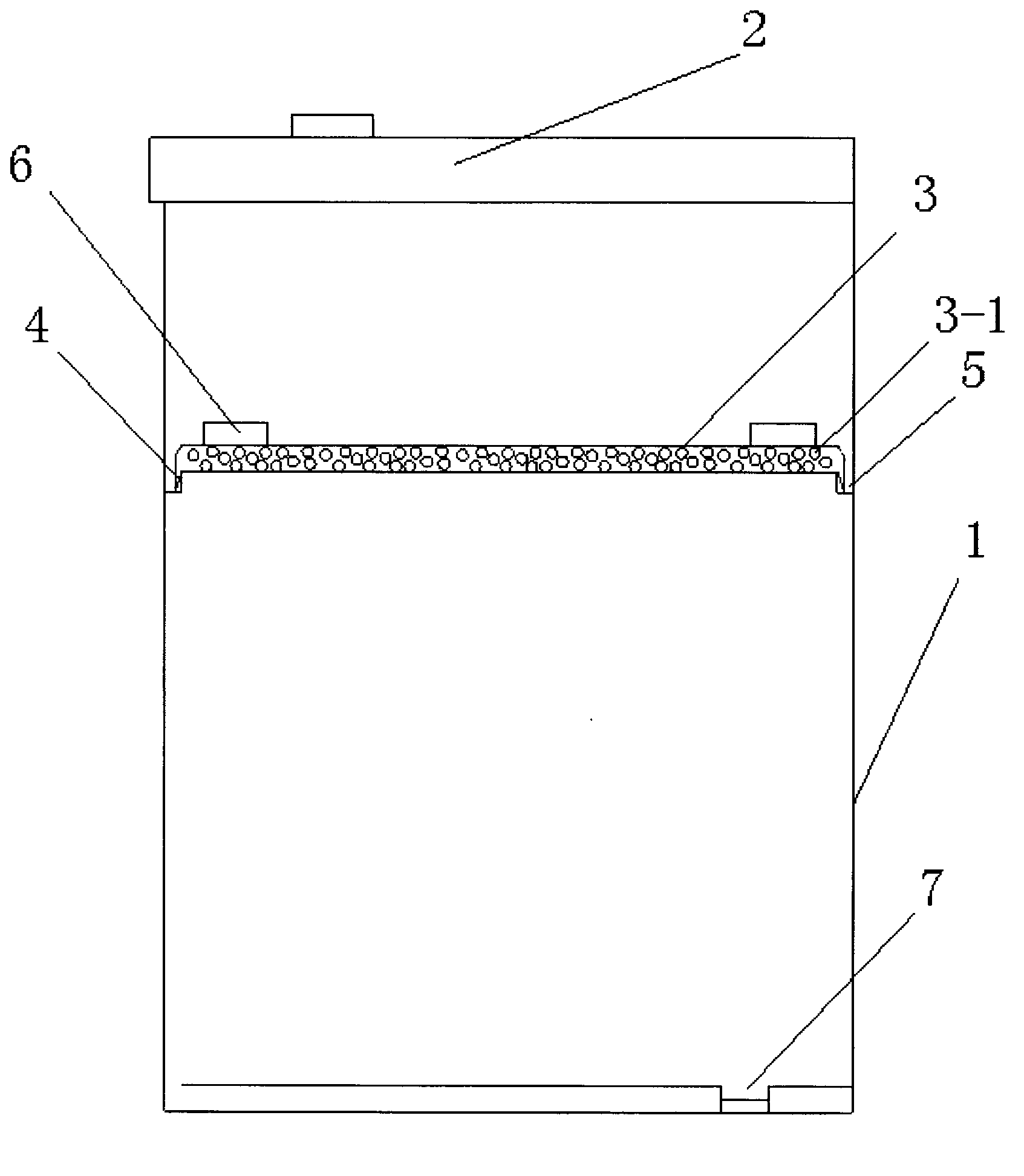

Food waste recovery apparatus

InactiveCN102974144AEasy to shipEasy to placeStationary filtering element filtersEnvironmental resistanceFertilizer plant

The present invention relates to a food waste recovery tank, which comprises a tank body and a cover plate, wherein a filtration plate is arranged inside the tank body, the filtration plate is provided with a snap fitted with a snapping groove inside the tank body, and is further provided with a handle, and the ?bottom of the tank body is provided with an oil outlet hole. According to the present invention, with filtration of the food waste recovery tank, oil water and solid substances in the food waste are separated, wherein the solid substances can be applicable for animal consumption, and can further be directly supplied for environmental protection fertilizer plants to recycle so as to create a certain economic benefit; concurrently the food waste is poured into the food waste recovery tank to avoid mutual pollution due to integrated mixing of the food waste and the domestic waste so as to improve the environment; transportation and placement of the food waste are easily achieved with the food waste recovery tank, such that the food waste can be treated in restaurants on the spot; and the ?bottom end of the food waste recovery tank is provided with the oil outlet hole, such that pouring-out of the oil water is convenient, and then the oil water can be subjected to a unified treatment processing.

Owner:苏州久三智能科技有限公司

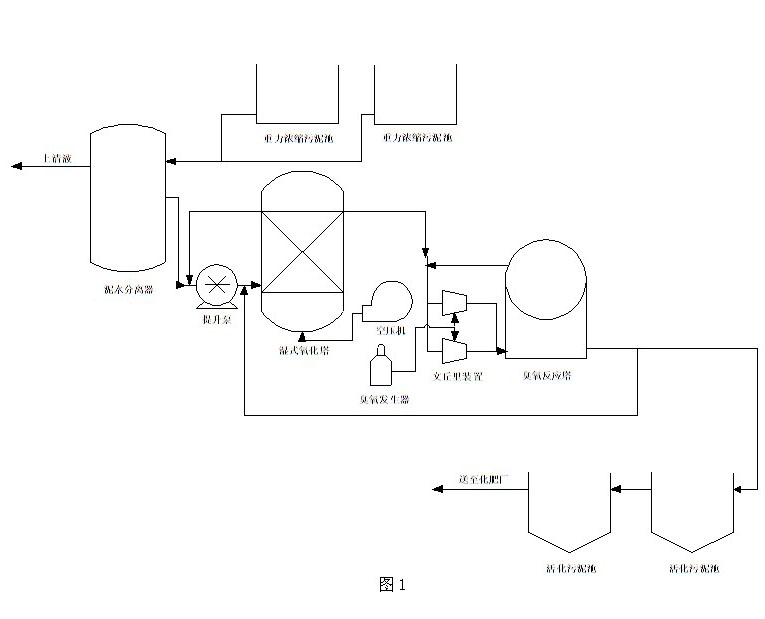

Sludge treatment device and method

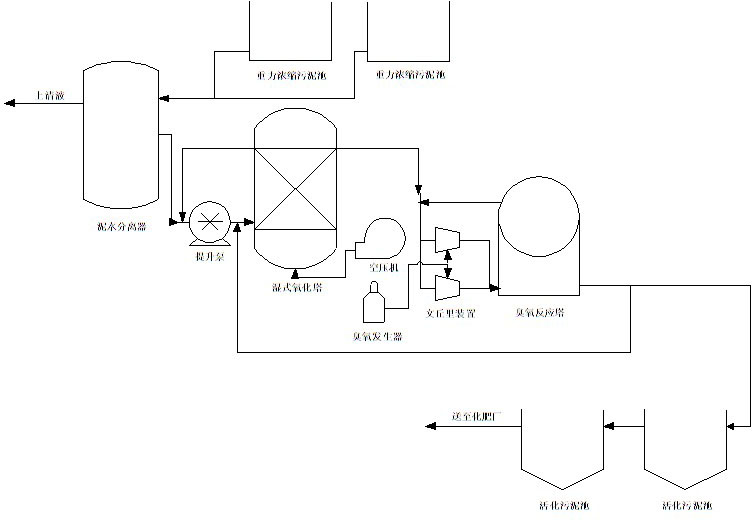

InactiveCN102092914ALow costImprove qualitySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationActivated sludgeTotal solid content

The invention discloses a sludge treatment device and method. The sludge treatment device comprises a gravity concentrated sludge pond, a sludge-water separator, a lift pump, a wet-type oxidization tower, an air compressor, an ozone generator, a Venturi device, an ozone reaction tower and an activated sludge pond. The sludge treatment method comprises the steps of: conveying sludge into the sludge-water separator and then into the wet-type oxidation tower, stirring the sludge, introducing preheated air, and remaining for 1-2h; remaining for 60-80min when the wet-type oxidation tower has the temperature of 150-350 DEG C and the pressure of 1-8Mpa; and conveying the treated sludge into the ozone oxidation tower, introducing ozone with the amount of 0.10kg O3 / kgmlss and reacting for 10-15min. The sludge treated with the method is rich in N, P and K and can be prepared into fertilizers by delivering the sludge to a fertilizer plant and adding a humic acid stock solution so that the quality of fruits and vegetable crops can be obviously improved and the production of melon and fruit can be increased; the treatment cost can be greatly reduced, and the obtained sludge has the moisture content lower than 10% and the total solid content reduced by 50%; and pathogenic bacteria can be inactivated, and the sludge treatment device and method can be better applied to the harmless, decrementing and recycling treatment of the urban sludge.

Owner:东莞市可迪环保科技有限公司

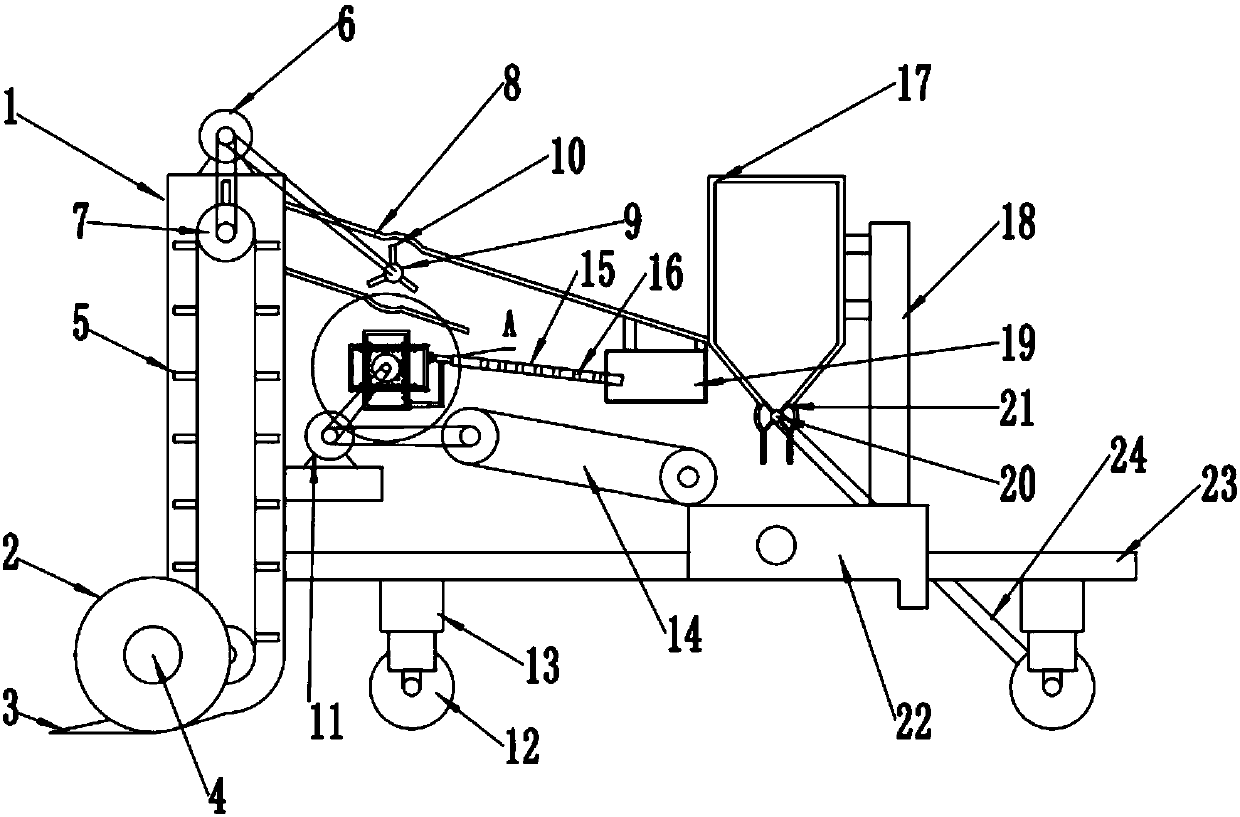

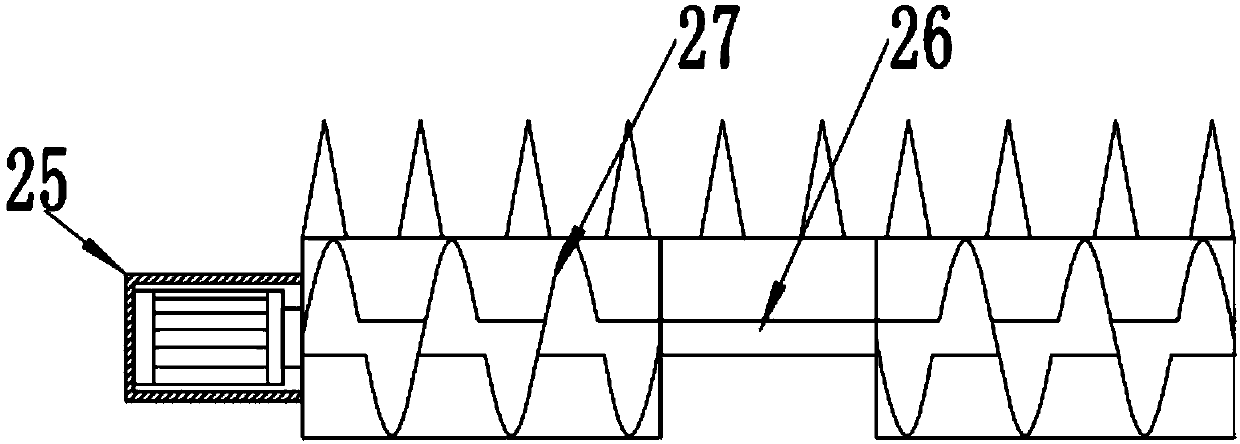

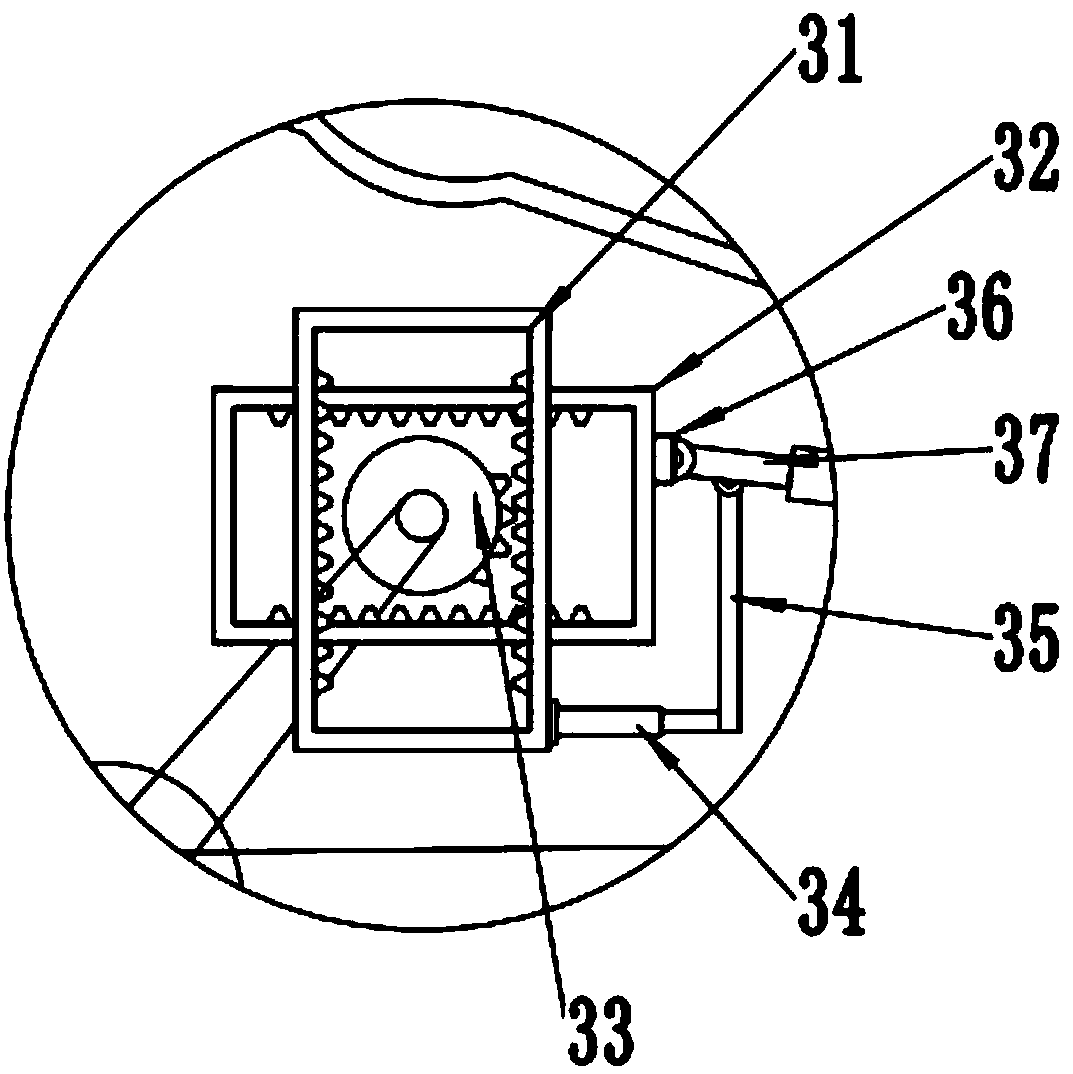

Efficient soil turning and fertilization integrated device

InactiveCN107548582AEffectively break upIncrease the mix rateRotary stirring mixersFertiliser distributersFertilizer plantHelical blade

The invention discloses a high-efficiency soil turning and fertilizing integrated device, which comprises a bottom plate, a turning mechanism, a lifting mechanism, a crushing cavity, a material storage cavity, a sieve plate and a crushing chamber; the turning mechanism is arranged on the left side of the bottom plate, and the turning mechanism The mechanism includes a rotating motor A, a soil gathering cavity, a third rotating shaft, a spiral blade and a soil turning knife; a lifting mechanism is arranged on the right side of the soil turning mechanism, and the lifting mechanism includes a lifting cavity, a rotating motor B, a roller and a lifting blade; A crushing chamber is provided on the right side of the lifting mechanism; a rack frame B is provided at the lower end of the crushing chamber, and a rotating motor C is provided at the lower end of the rack frame B; a soil crushing chamber is provided below the conveyor belt; the soil crushing chamber The upper end is provided with a material storage cavity, and a second rotating shaft is arranged in the material outlet of the material storage cavity, and a toggle plate is fixedly connected to the second rotating shaft. The invention has the advantages of simple structure and convenient operation, which improves the soil turning effect, increases the fertilizer absorption efficiency of plants, and greatly reduces the labor intensity of operators at the same time.

Owner:许乃清

A Method of Improving the Survival Rate of Mountain Afforestation

InactiveCN102283074AGrow fastImprove the survival rate of afforestationClimate change adaptationForestryFertilizer plantPolyvinyl alcohol

The invention discloses a method for improving the survival rate of afforestation in mountainous areas: from late February to early March, tree holes are dug in mountainous areas according to a certain row spacing, and cake fertilizer or compound fertilizer is applied in the tree holes. Select the seedlings suitable for mountain afforestation, add polyvinyl alcohol with water and soil to make mud before planting, dip the roots of the seedlings into the mud and dip the roots, and plant them as you dip, and pour enough water to fix the roots after planting; Place 2 fertilizer bags with organic fertilizers, so that the planting hole can always keep moist, and the plants can continuously absorb the inflowing nutrients, ensuring the rapid growth of the plants under the sufficient supply of fertilizer and water. A method for improving the survival rate of mountain afforestation of the present invention not only increases the survival rate of afforestation to 81-97%, but also overcomes the disadvantages of low afforestation survival rate and slow forest formation caused by the traditional planting mode, and can advance the mountainous area by 3 ~5 years to achieve the expected disaster resistance and landscape effects.

Owner:张冠一

Fertilizer special for reducing cadmium in soil and preparation method of fertilizer

InactiveCN106187402ATo achieve the effect of reducing cadmiumReduce absorptionExcrement fertilisersBioloigcal waste fertilisersFertilizer plantEffective time

The invention provides fertilizer special for reducing cadmium in soil and a preparation method of the fertilizer. Main components of the fertilizer comprise expanded vermiculite powder, vinasse, animal manure, straws, chicken manure, microorganisms and plant ash. The alkaline fertilizer plant ash has a certain passivation effect on cadmium; by the adoption of mutual cooperation of flora such as black aspergilus and saccharomycetes in the vinasse, the fertilizer has a very good cadmium passivation effect; the added expanded vermiculite powder has a certain slow release effect on microbial flora, can prolong the effective time of the fertilizer and also has a certain adsorption effect on the cadmium. The fertilizer and the preparation method of the fertilizer can greatly reduce the content of effective cadmium in the soil and reduce cadmium absorption of plants so as to achieve the effect of reducing the cadmium in the soil.

Owner:郴州市通源生物科技有限公司

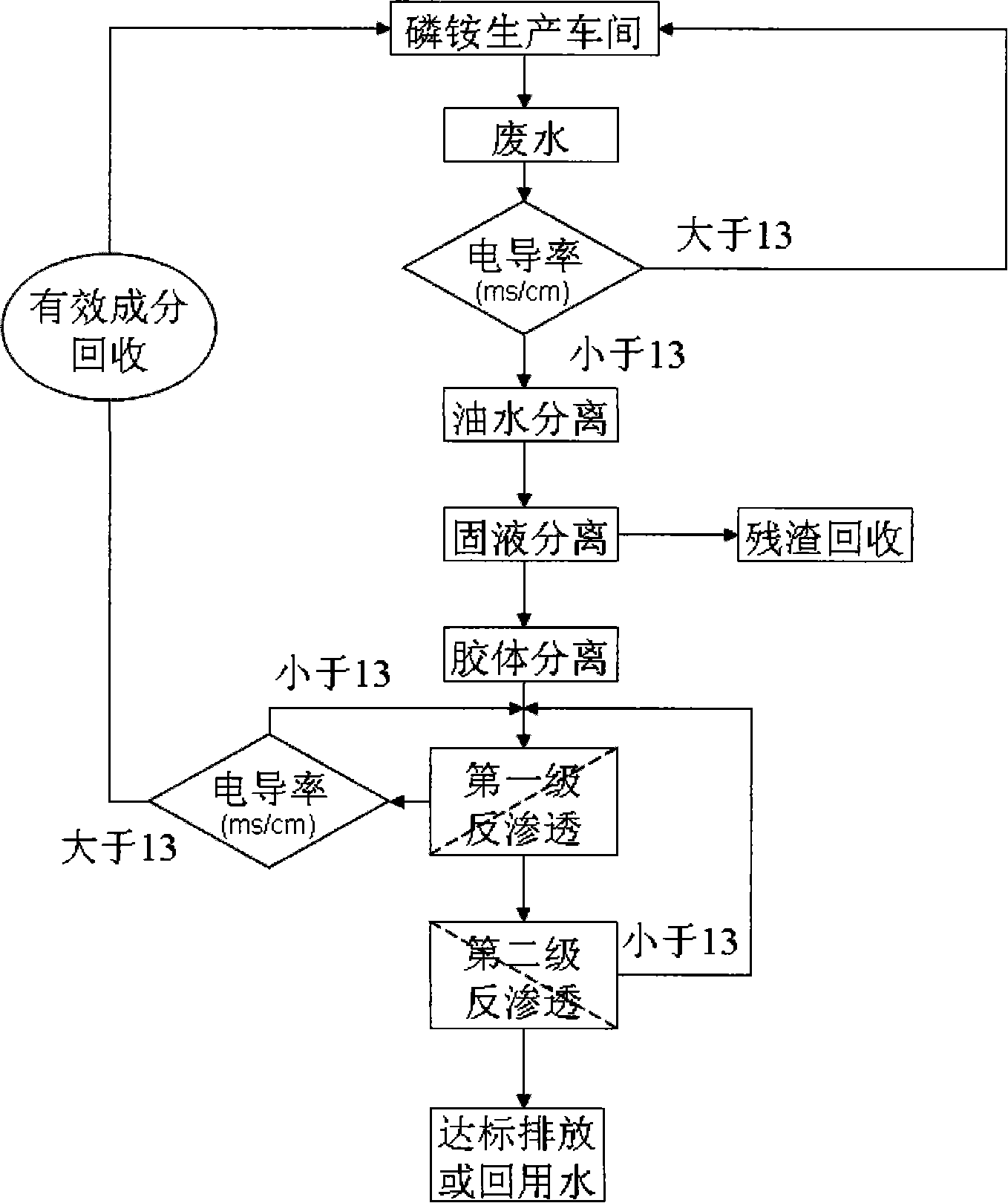

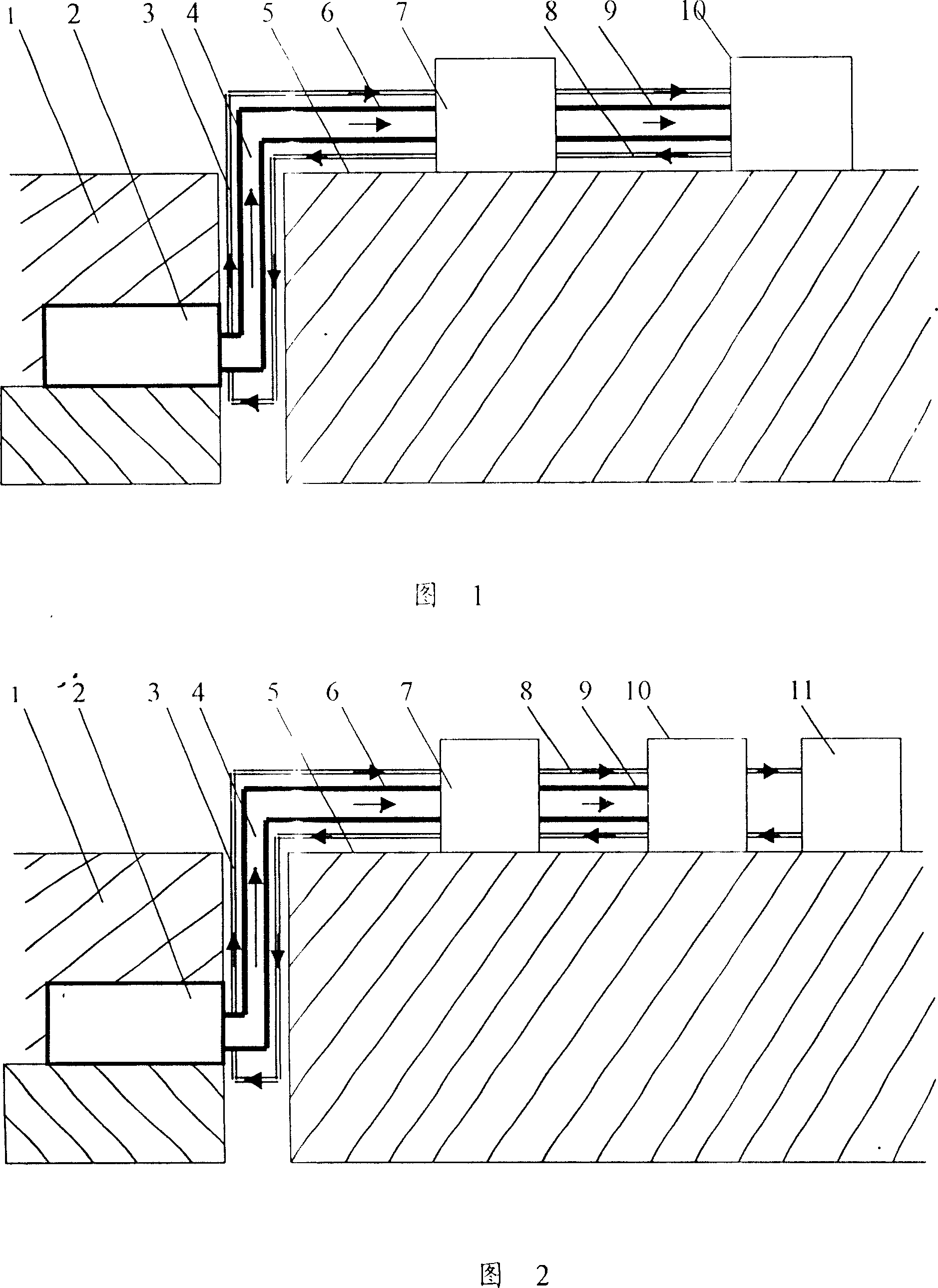

Method for processing acidity ammonium nitrogen wastewater in fertilizer plant by using membrane separation

ActiveCN101139144ARemove available componentsAvoid pollutionFatty/oily/floating substances removal devicesGeneral water supply conservationFertilizer plantReverse osmosis

The present invention discloses a method to treat acidic ammonium and nitrogen wastewater of chemical fertilizer plant by use of membrane separation. The method includes the following methods: a, the wastewater after oil separating is led into a solid-liquor separating device and the solid residue separated out is recycled; the wastewater is let into a colloid separating device to be carried out microfiltration and hyperfiltration treatment; b, the wastewater after being treated is pressed into a first grade reverse osmosis membrane component through pressurization by high pressure pump to carry through concentration, if the electrical conductivity is more than 13ms / cm, then the wastewater is sent back to an ammonium phosphate production department; if the electrical conductivity of the concentrated water is less than 13ms / cm, then the wastewater returns to a second grade reverse osmosis membrane component to carry through desalting. The concentrated water with a electrical conductivity less than 13ms / cm returns to an inlet of the first grade reverse osmosis membrane component to permeate to the freshwater of the second grade reverse osmosis membrane component and discharge. The present invention has the advantages of low energy consumption, low chemical reagent consumption and no secondary pollution. And simultaneously during the wastewater treatment, the present invention realizes the recycling of valuable components like nitrogen and phosphorus, etc.

Owner:WENGFU (GRP) CO LTD

Dry type recovery method for kitchen garbage

InactiveCN101058098ARelieve pressureLow costSolid waste disposalClimate change adaptationRecovery methodFertilizer plant

The invention relates to a garbage waste dry recovery in the following way, using dry and wet separation method, using kitchen self weight to realize garbage partial separation, through centrifugal dehydration, collecting dry storage, packing for transportation. Conducive result is processing the kitchen garbage, reducing the terminal processing pressure, avoiding the generation of the secondary pollution, saving material force, man power and transportation fee, reducing processing cost, conforming to the requirement for economical society, with the processed garbage being able to used by environmental protective fertilizer plant.

Owner:TOPRET IND DESIGN(SHANGHAI) CO LTD

Ammonia nitrogen processing method in processing of waste gas of chemical fertilizer plant

InactiveCN102772996ADecompose thoroughlyAvoid secondary pollutionDispersed particle separationAir quality improvementFertilizer plantPhosphoric acid

The invention discloses an ammonia nitrogen processing method in processing of waste gas of a chemical fertilizer plant. The processing method includes first absorbing waste gas in an absorption tower through orthophosphate, then utilizing a lifting pump to absorb ammonia till diammonium hydrogen phosphate is completely produced, introducing the diammonium hydrogen phosphate into an ammonia still provided with Bi-Be-Ga-Gd-Ho-Tm-Os / alpha-SiO2 through a pipeline, adding an organic denitrification agent, and finally introducing stream into the ammonia still to enable ammonium dihydrogen phosphate and ammonia gas to be decomposed. The ammonia gas is reduced into nitrogen gas under the effect of the catalyst, the ammonium dihydrogen phosphate is delivered to the top of the absorption tower through a circulation pump, and then ammonia gas in waste gas in the pipeline is absorbed again. The ammonia nitrogen processing method of waste gas in the chemical fertilizer plant utilizes phosphoric acid as the absorbent which is continuously absorbed and desorbed in recycle mode, utilizes organic denitrification agent and heavy metal catalyst to completely decompose the ammonia gas and quickly convert the ammonia gas into the nitrogen gas, and avoids secondary pollution to air.

Owner:CHANGZHOU UNIV

Ground steam power station or chemical and fertilizer plant using underground gas

A technical proposal of providing ground fuel electric plant or chemical plant and fertilizer plant with fuel or raw material by using coal gas produced by coal based gasification plant of coal mine. The coal gas produced by coal based gasification plant of coal mine is sent through pipeline or well to ground fuel electric plant as fuel or to ground chemical plant and fertilizer plant as raw material, especially to power plant beside pit mouth or chemical plant and fertilizer plant beside pit mouth as fuel or raw material. A cooling wall composed of cooling water pipes is disposed around the pipeline and well or in the well for transmitting the coal gas produced by coal based gasification plant of coal mine; and the heated cooling water is sent to the ground fuel electric plant or exhaust-heat boiler.

Owner:魏明

Standard brick material prepared by taking phosphogypsum as raw material and preparation method of standard brick

InactiveCN103044007AImprove plasticityImprove low temperature formabilityCeramic materials productionClaywaresMaterials preparationBrick

The invention provides a standard brick material prepared by taking phosphogypsum as a raw material and the preparation method of the standard brick. The weight percentage of the raw materials of the standard brick is as follows: 35% to 55% of slate, 30% to 45% of phosphogypsum and 10% to 20% of powdered coal. The technological process comprises material preparation, primary crushing, fine crushing, screening, storing seasoning, primary refining, secondary refining, extrusion moulding, loading, drying, sinter moulding, grading and boxing. As a result, the final finished standard brick is produced. The preparation method provided by the invention solves the problem about comprehensive utilization of the waste phosphogypsum in the current phosphorous fertilizer plants and the technical problem that the standard brick sample produced through the existing technology and proportioning has low strength and poor sintering performance. The technical raw materials provided by the invention improve low-temperature forming performance and high-temperature sintering performance, and ensures that CaSO4 participates in the sintering reaction to the utmost extent during the high-temperature sintering process.

Owner:徐立萧

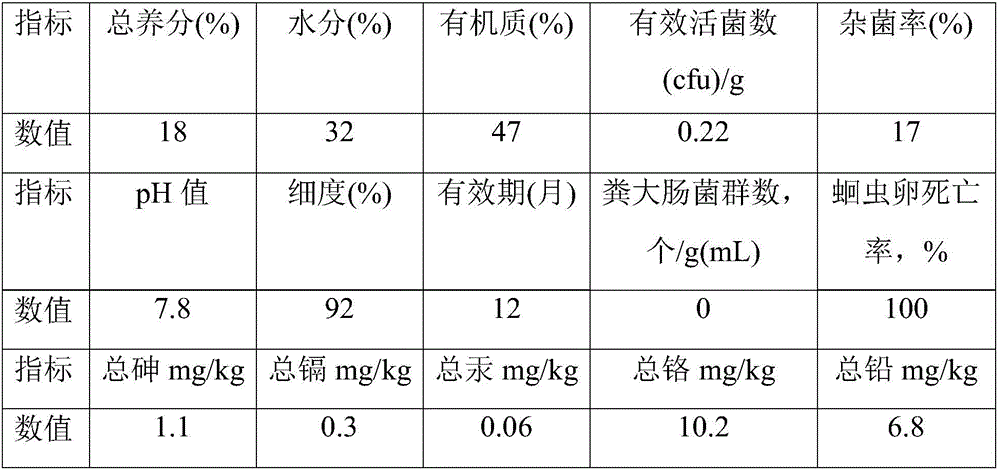

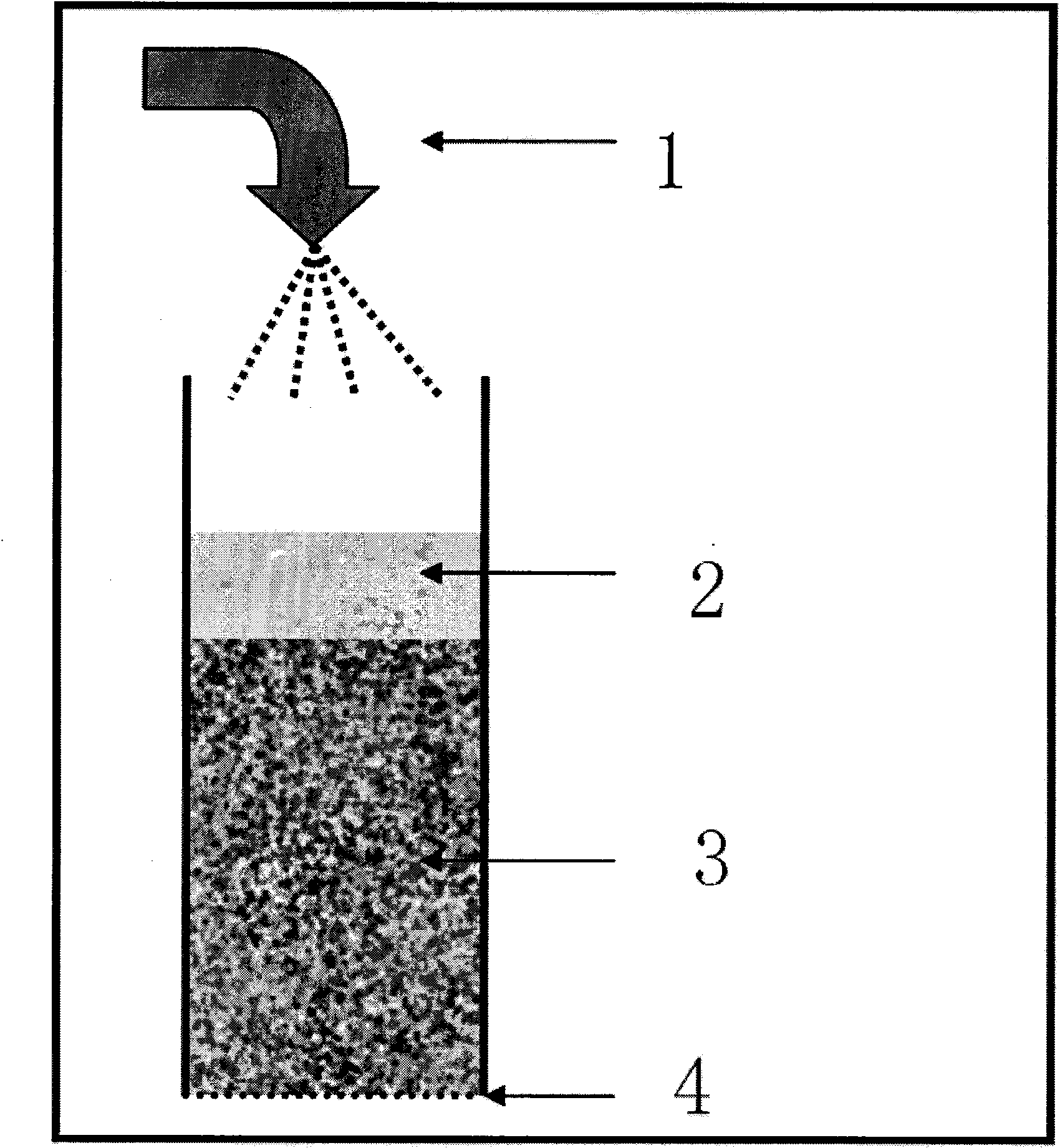

Warehouse type aging preparation method for microbial organic fertilizer

InactiveCN103804040AReach moisture contentReduce moisture contentBio-organic fraction processingOrganic fertiliser preparationPathogenic microorganismFertilizer plant

The invention relates to a preparation method for a microbial organic fertilizer, and particularly relates to a warehouse type aging preparation method for microbial organic fertilizer. The warehouse type aging preparation method comprises an organic material pretreatment step, a primary fermentation step in a fertilizer plant fermentation workshop, as well as a fermentation warehouse aging step, wherein the fermentation warehouse aging step comprises the steps: transferring the fermentation materials with less than 45% of moisture rate, obtained in the primary fermentation step in the fertilizer plant fermentation workshop, into a fermentation warehouse for storage type aging for 8-10 days, stabilizing the aging temperature at 40DEG, completing the storage type aging after the moisture rate of the materials is reduced to 30%, and performing finished product processing and packaging steps to the aged fermentation materials. The fermentation warehouse is utilized for continuing secondary fermentation, namely aging, to the non-entirely thoroughly decomposed materials which are subjected to primary fermentation, volatile substances in organic matters can be decreased, and parasitic ova and pathogenic microorganism can be further killed so as to achieve harmless purpose.

Owner:唐山宏文有机肥料有限公司

Method for preparing potash water glass

ActiveCN103030153AOptimize the way of comprehensive utilizationReduce energy consumptionAlkali metal silicatesFertilizer plantRoom temperature

The invention provides a method for preparing potash water glass. A silica gel byproduct in a phosphatic fertilizer plant is used as one production raw material. In the preparing process, certain quantity of industrial potassium hydroxide solution and wet silica gel are added to a reactor and react at the temperature kept between 80 DEG C and 100 DEG C. After the silica gel is fully dissolved, reacting liquid is in a semitransparent state and is then filtered. A concentration period begins. When the reacting liquid reaches the specified density, concentration stops, and the potash water glass is obtained after the reacting liquid is cooled to the room temperature. Compared with the traditional method that a potash water glass solid is firstly obtained and then reacts to form the liquid at the low temperature, the method for preparing potash water can directly prepare the liquid potash water glass without high temperature and pressurization, thereby being simpler than the traditional method.

Owner:KUNMING DAOERSEN TECH

Compounding method of algae removal bactericide

InactiveCN104621143AStrong penetrating powerStrong killing functionBiocideFungicidesBetaineFertilizer plant

The invention discloses a compounding method of an algae removal bactericide. By adopting the technical scheme, the algae removal bactericide is prepared by compounding the following technical formula (w / %): 3-10% of cetyl trimethyl benzyl betaine, 5-15% isothiazolinone, 5-15% of fatty alcohol polyoxyethylene ether, 10-20% of ethyl alcohol, 3-8% of sodium hypochlorite and the balance of water. The algae removal bactericide adopts a broad spectrum, and is efficient and low in toxicity; the active component-isothiazolinone has very strong penetrating power for the cytomembrane of microorganism; the algae removal bactericide is capable of decomposing and destroying cell tissue and has a very strong killing function for the common bacteria, fungi and algae. The algae removal bactericide can be widely used for sterilizing cooling circulation water of a power plant, a chemical plant, a chemical fertilizer plant, an iron and steel plant, a printing and dyeing mill, an oil refinery and the like.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

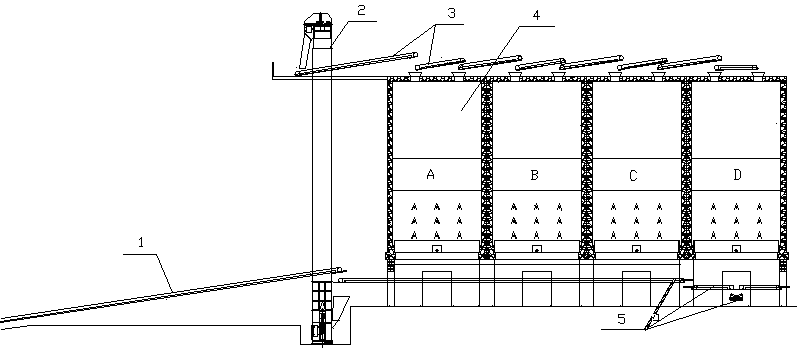

Filtration column for treating phosphorus-containing sewage, and treatment method for phosphorus-containing sewage

InactiveCN103803688AImprove permeabilityHigh utility valueWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionReaction layerFertilizer plant

The invention relates to a filtration column for treating phosphorus-containing sewage. The filtration column comprises a quartz sand layer positioned at an upper layer, and a reaction layer positioned at a lower layer; the reaction layer is a composite material layer which comprises the following components in parts by mass: 10-30 parts of perlite, 10-20 parts of ferric chloride, and 10-20 parts of straw ash. A treatment method for phosphorus-containing sewage comprises the step: treating the phosphorus-containing sewage, introducing the phosphorus-containing sewage in an atomized manner and flowing through the filtration column. The filtration column can make up for the deficiencies of the prior art, has stronger practical values, as well as high permeability, fixation and adsorption performances, and is capable of effectively removing phosphorus in the phosphorus-containing sewage, the filtration column is long in service cycle, low in cost, and environment-friendly, and has higher practical values; and the straw ash in the filtration column comes from a power plant, thus changing wastes into valuables, and relieving the pollution and pressure to the environment as the straw ash in the power plant is piled up.

Owner:江苏晋煤恒盛化工股份有限公司

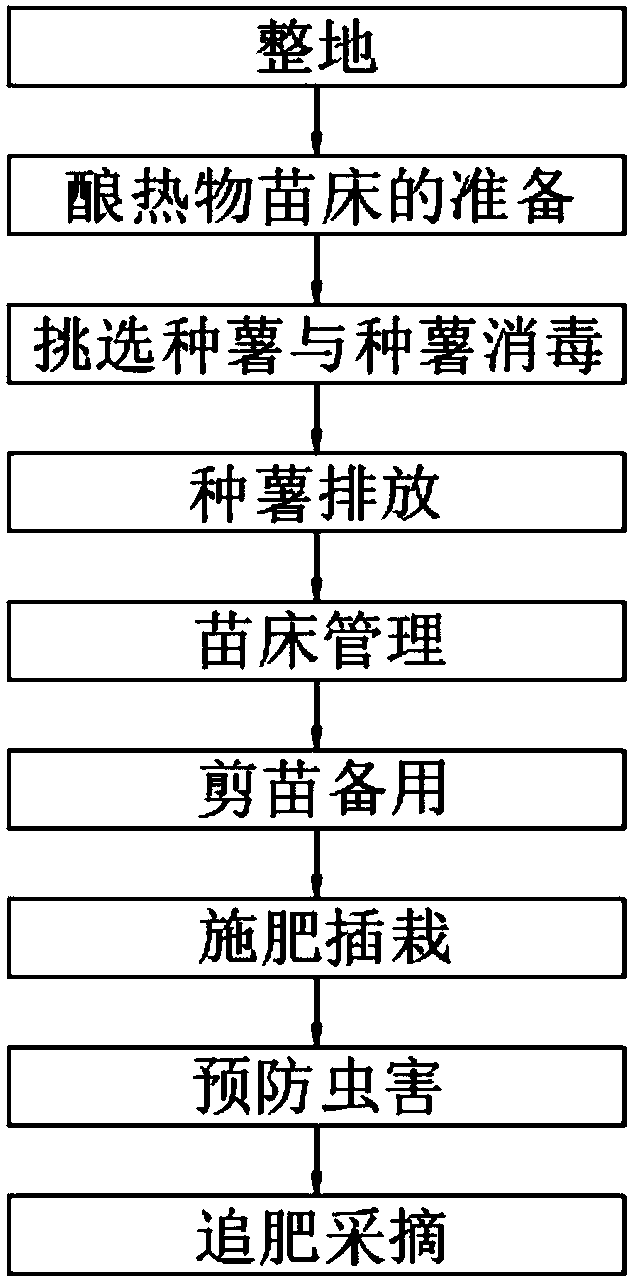

High-yield sweet potato leaf planting method

InactiveCN107896872AIncrease productionShorten the planting periodLeaf crop cultivationFertilizer plantSeedbed

The invention discloses a planting method of high-yield sweet potato leaves, which comprises the following steps: soil preparation, preparation of a seedbed for heating materials, selection of seed potatoes and disinfection of seed potatoes, discharge of seed potatoes, management of seedbeds, seedling cutting for standby, fertilization and planting, Prevention of insect damage and topdressing and picking, the planting method of the step 7) is to dig up the soil obliquely with a small shovel according to the plant spacing of 25 to 30 cm, and insert the potato seedlings. The potato seedlings are about 20 cm long and about 10 cm deep into the soil. Water the furrows immediately after planting. The suitable growth temperature for planting sweet potato leaves in the greenhouse is 22-30°C. The present invention can effectively increase the yield of sweet potato leaves and effectively shorten the planting time of sweet potato leaves through scientific arrangements and reasonable planting methods. cycle, to ensure the rapid growth of sweet potato leaves; at the same time, the present invention can effectively improve and reduce the production cost of enterprises, and improve the economic benefits of enterprises.

Owner:藤县福进大红八角种植专业合作社

Method for synthesizing ammonium sulfate by using recovered ammonia water from chemical fertilizer plant

The invention relates to a method for synthesizing ammonium sulfate by using recovered ammonia water from a chemical fertilizer plant. The method is characterized in that: a catalyst is added into recovered ammonia water; under a heating condition, ammonia in the ammonia water is evaporated, and directly participates in a neutralization reaction with sulfuric acid, such that ammonium sulfate crystals are produced; and spin-drying is carried out, such that an ammonium sulfate finished product is obtained. The method is subjected to simple process, less equipment, and low investment. No water intervention is in the neutralization reaction between ammonia and sulfuric acid, and no evaporation concentration is needed, such that consumption is reduced, and energy is saved. An ammonia recovery rate is higher than 95%. When sulfuric acid is supplemented in mother liquor, the mother liquor can be repeatedly used in continuous production. The method is a good method for comprehensive utilization of recovered ammonia water.

Owner:赵建鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com