Patents

Literature

82results about How to "Effectively break up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

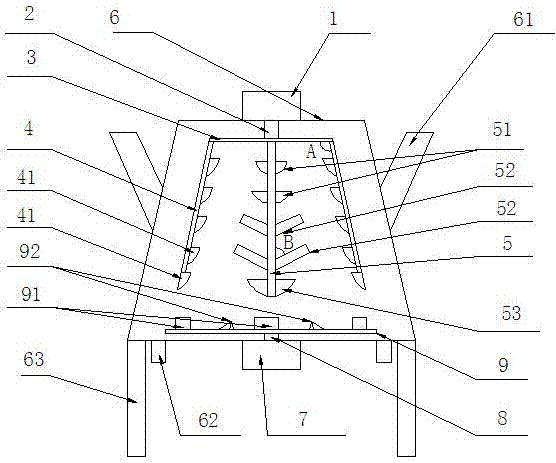

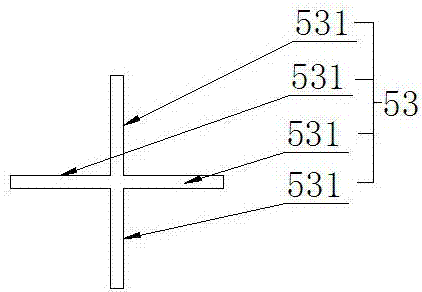

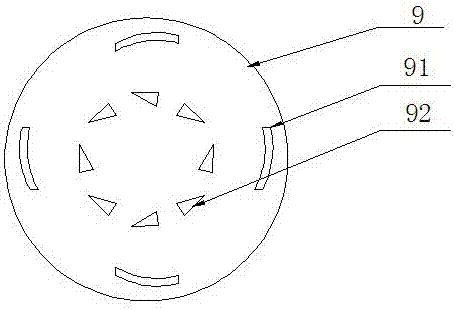

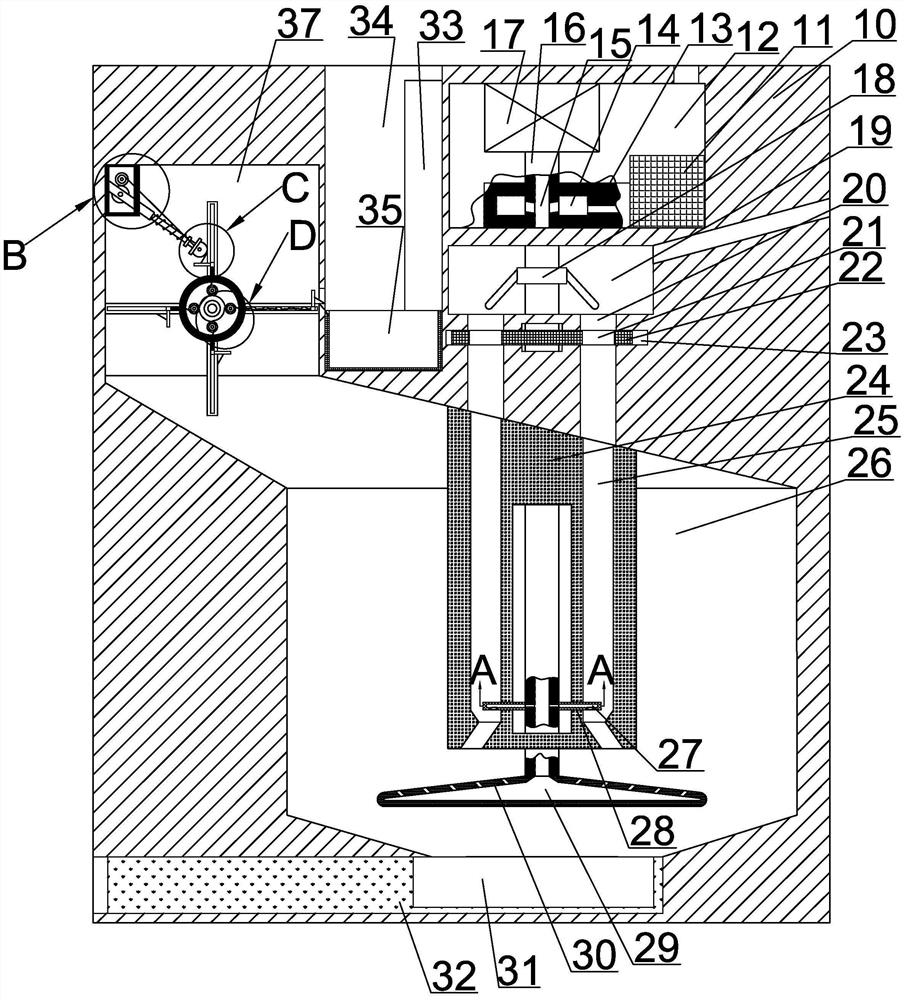

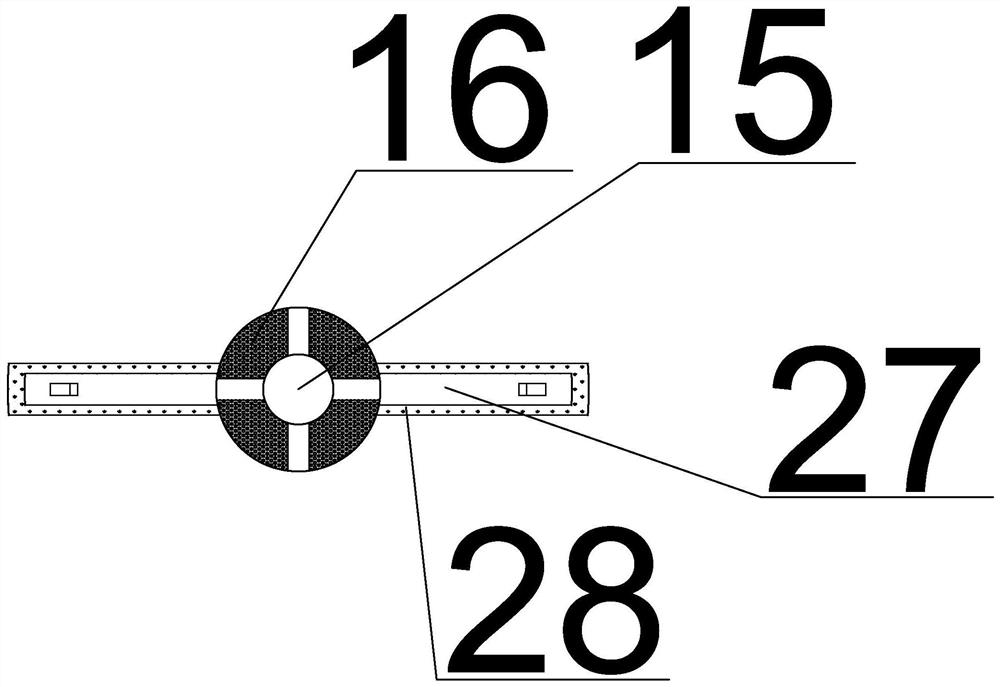

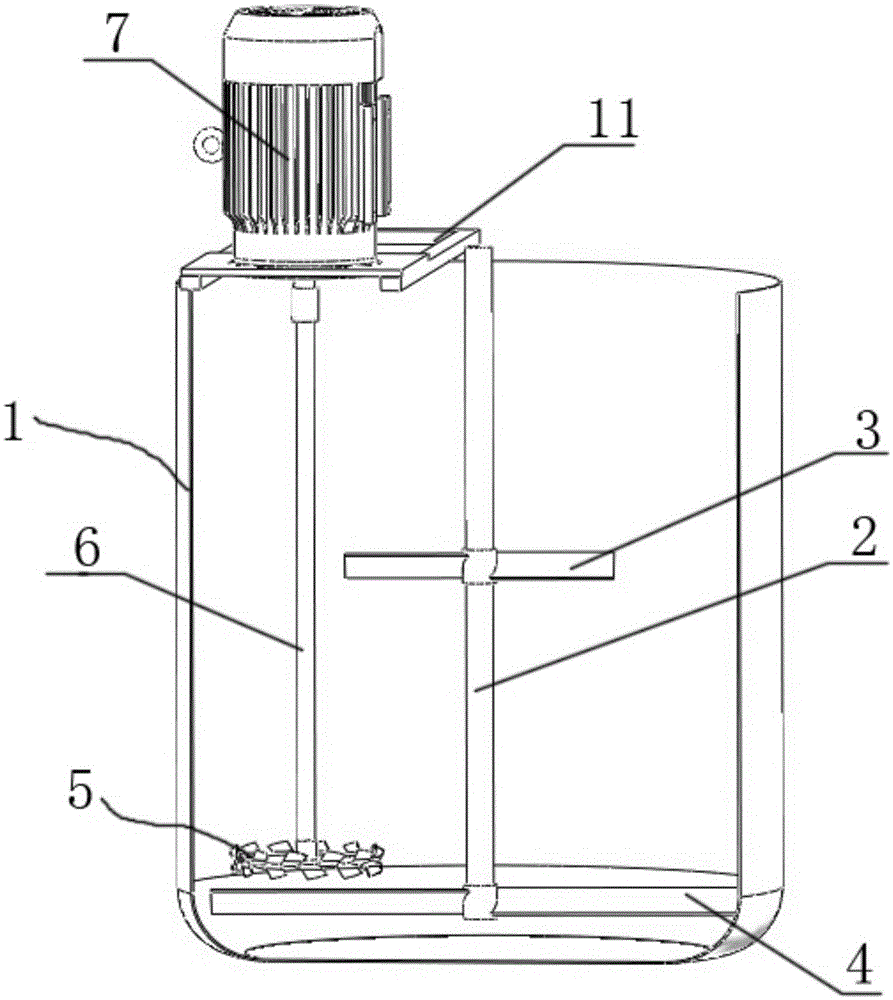

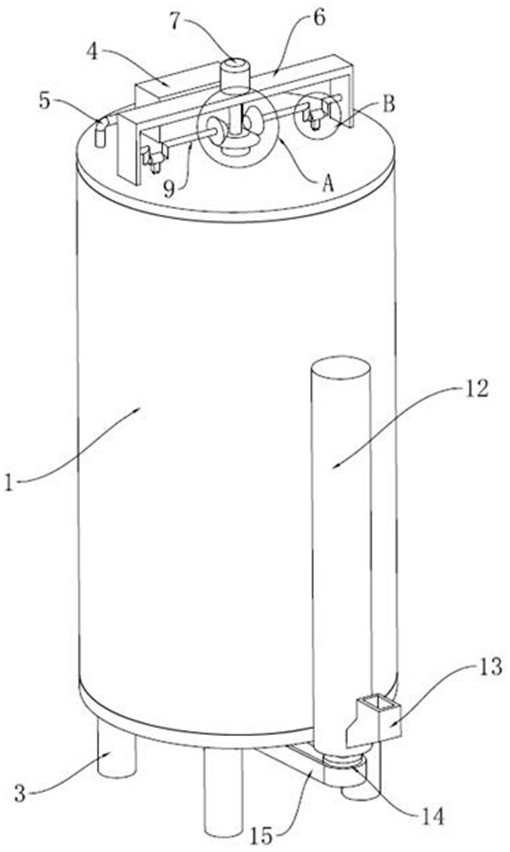

Special high-efficiency stirrer for conductive slurry

InactiveCN106975388AImprove efficiencyLarge cutting areaTransportation and packagingRotary stirring mixersMotor shaftEngineering

A special high-efficiency stirrer for conductive slurry is characterized in that a first motor is arranged in the center of the top of a stirrer shell, and a second motor is arranged in the center of the bottom of the stirrer shell; and a first motor shaft, a transverse stirring rod, tilting stirring rods, a vertical stirring rod, a second motor shaft and a bottom rotating disc are arranged in the stirrer shell. The design of multiple stirring rods is adopted to improve the multi-angle stirring efficiency, various blades are cooperated to effectively scatter large agglomerates in the slurry from all angles, and the bottom rotating disc is especially arranged to effectively prevent the deposition phenomenon in the stirrer body, so the use efficiency is improved.

Owner:江苏昱星科技股份有限公司

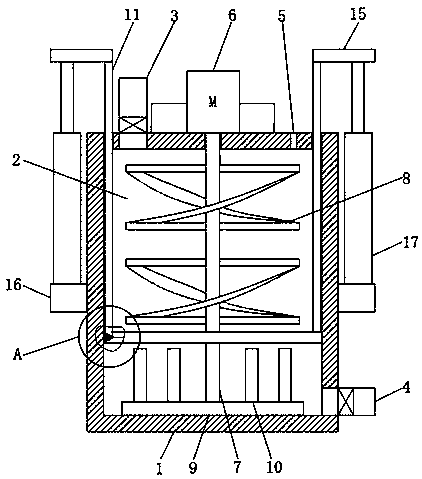

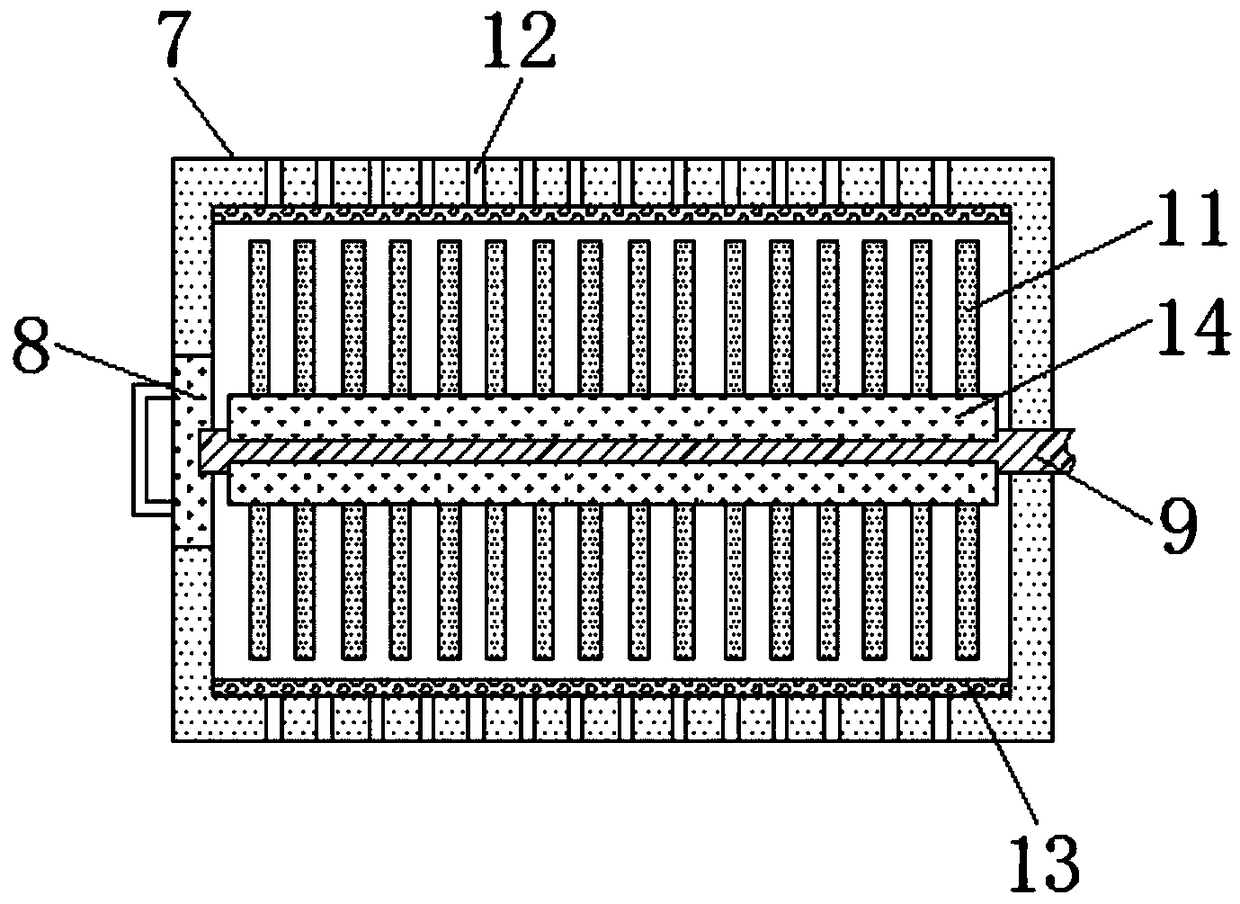

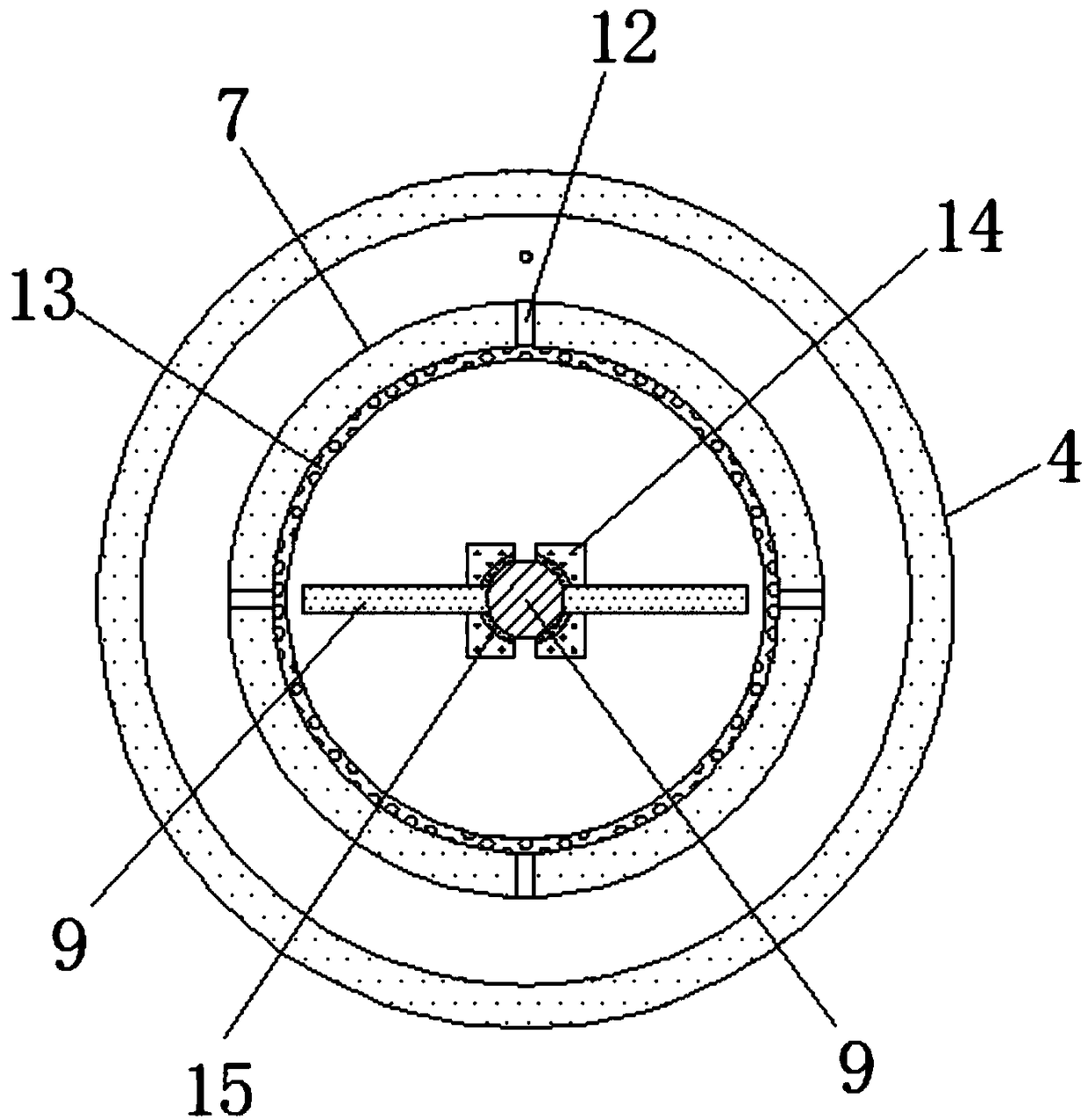

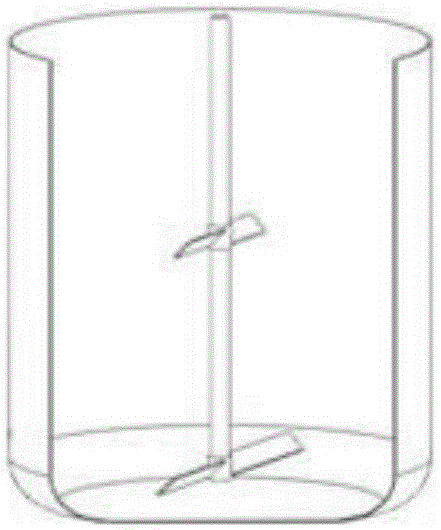

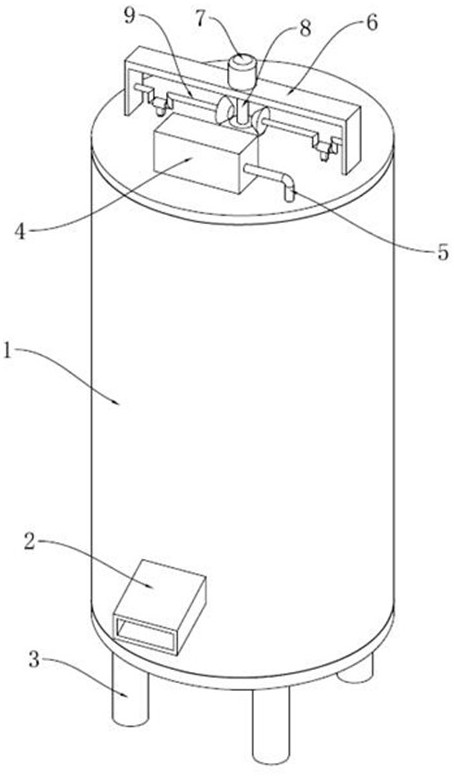

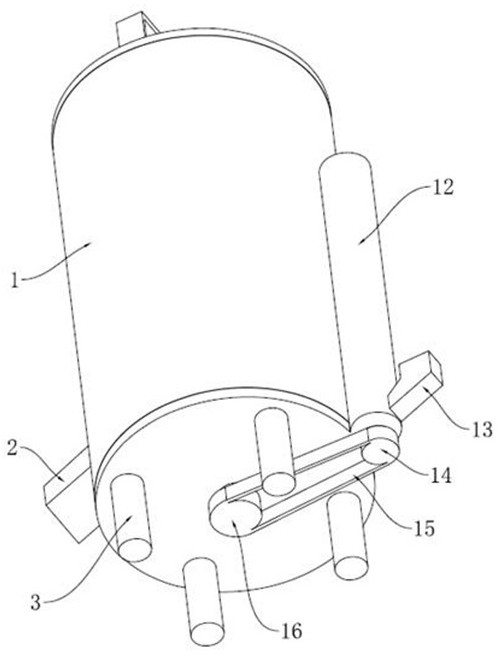

Vertical stirring tank for production of modified asphalt waterproof coiled material

InactiveCN109289643AEffectively break upFacilitates flow mixingShaking/oscillating/vibrating mixersRotary stirring mixersImpellerBituminous waterproofing

The invention discloses a vertical stirring tank for production of a modified asphalt waterproof coiled material. The vertical stirring tank comprises a tank body, the tank body is internally providedwith a stirring chamber, a feed pipe runs through the top side wall of the tank body, a discharge pipe runs through the lower side wall of the tan body, and an air vent runs through the top side wallof the tank body. Through the following two different stirring modes, i.e. double-helix belt impellers and stirring blades, the stirring can be fuller, the double-helix belt impellers can effectivelyscatter the produced agglomerates, promote the flow mixing of materials, roll and stir materials, and achieve a good stirring effect, not only can scrape the materials off the bottom of the stirringchamber, but also can scrape the materials off the inner side wall of the stirring chamber, thus effectively avoiding the high temperature ignition phenomenon caused by accumulation of a large numberof solid or powder modifiers on the stirring chamber inner wall around an asphalt liquid level.

Owner:江苏贝施特防水科技有限公司

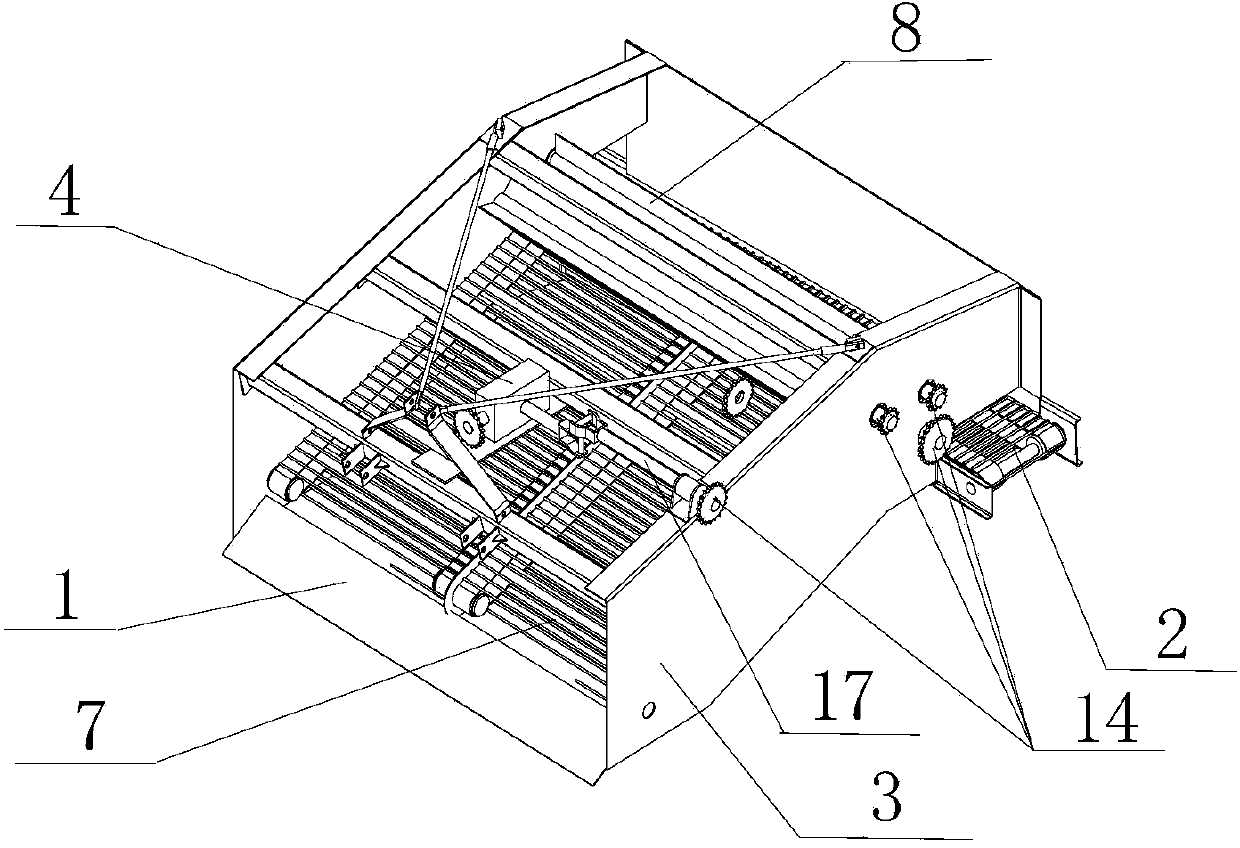

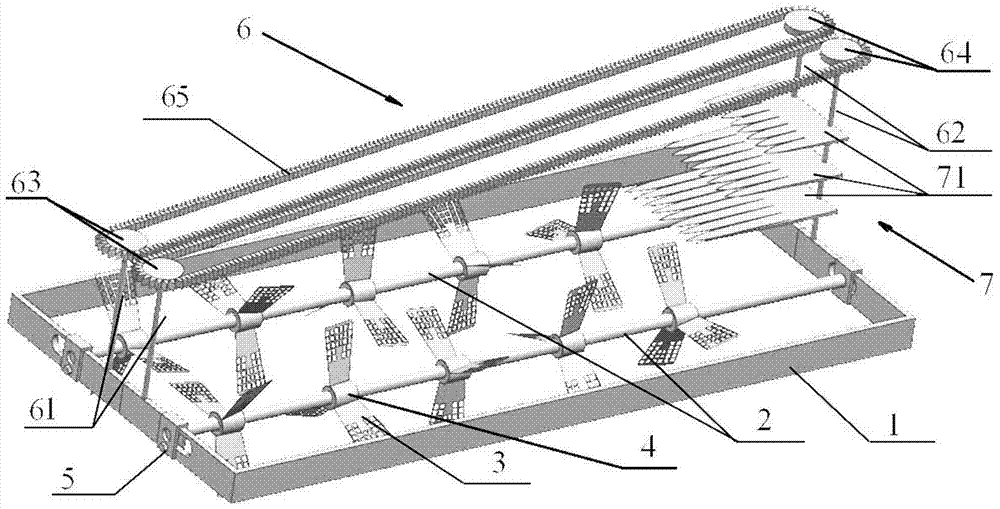

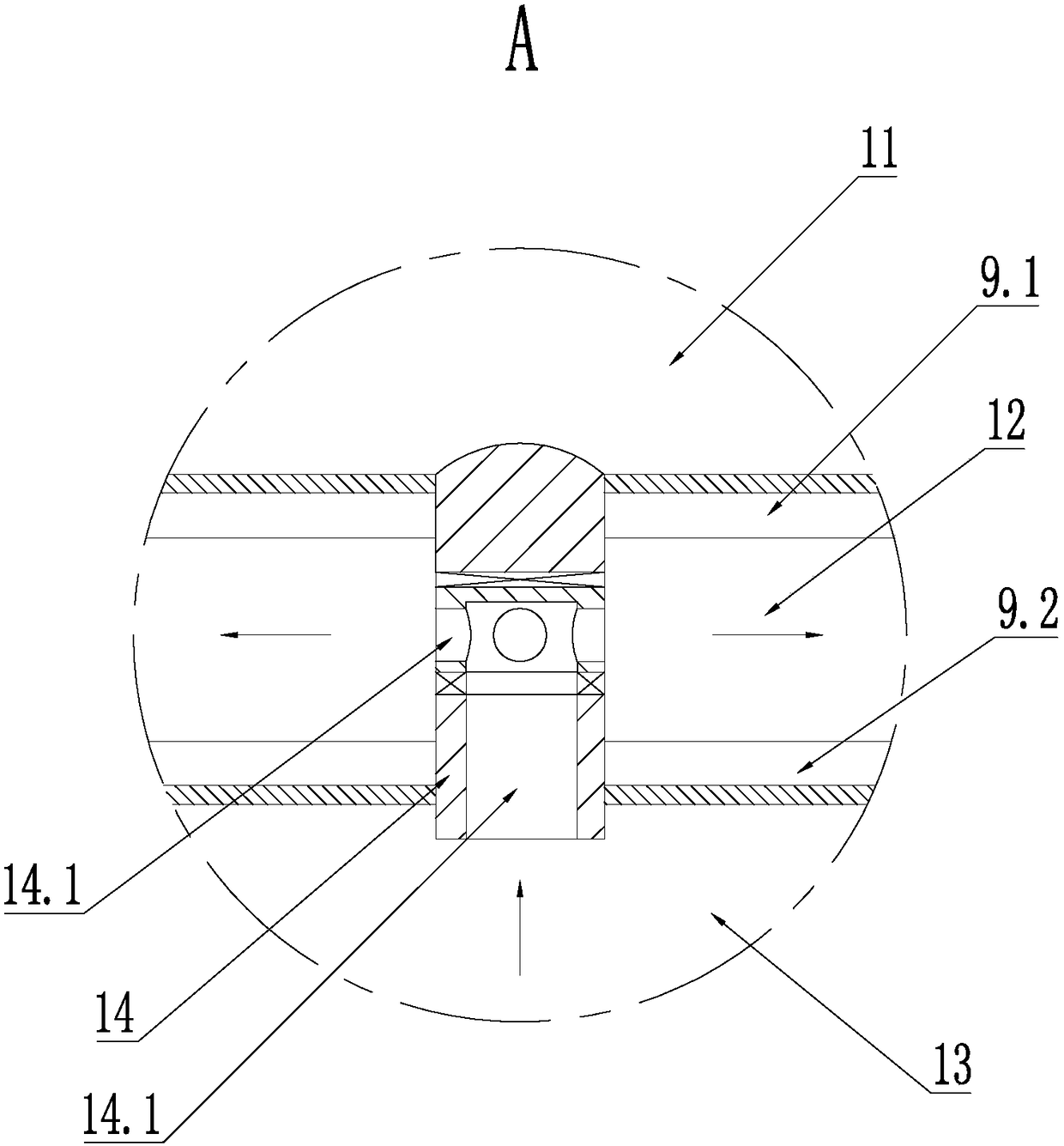

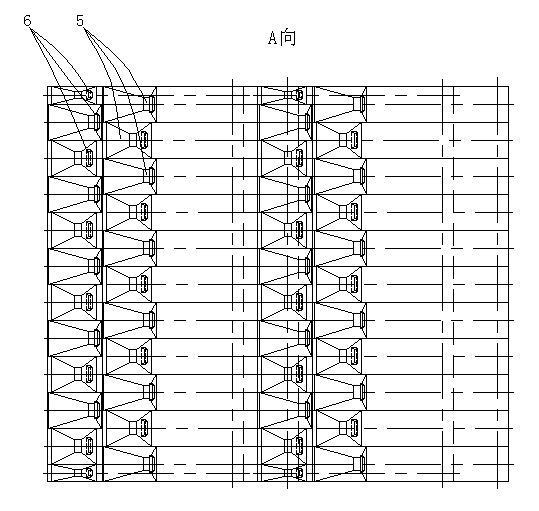

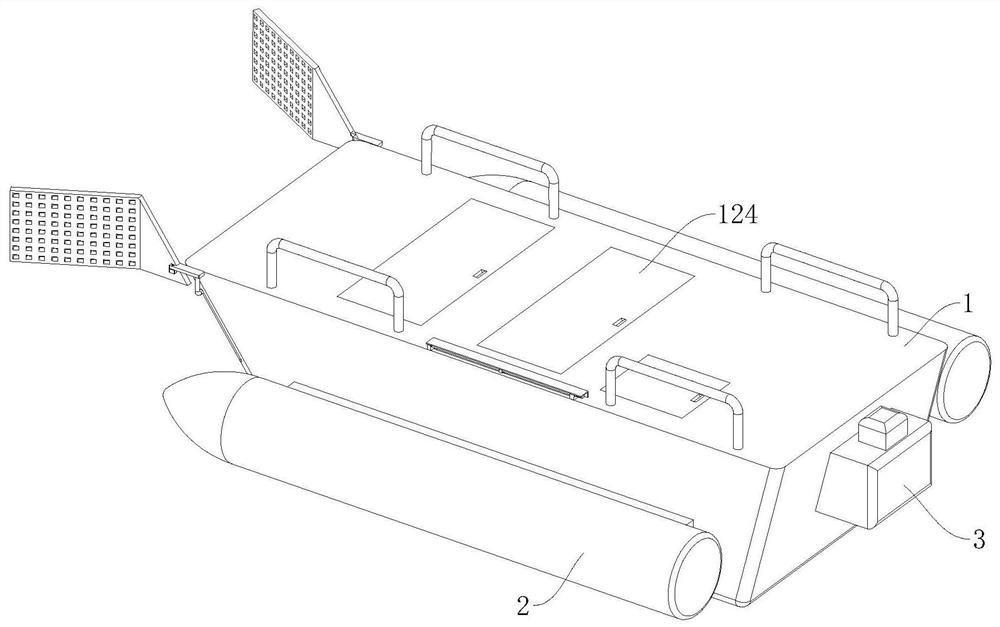

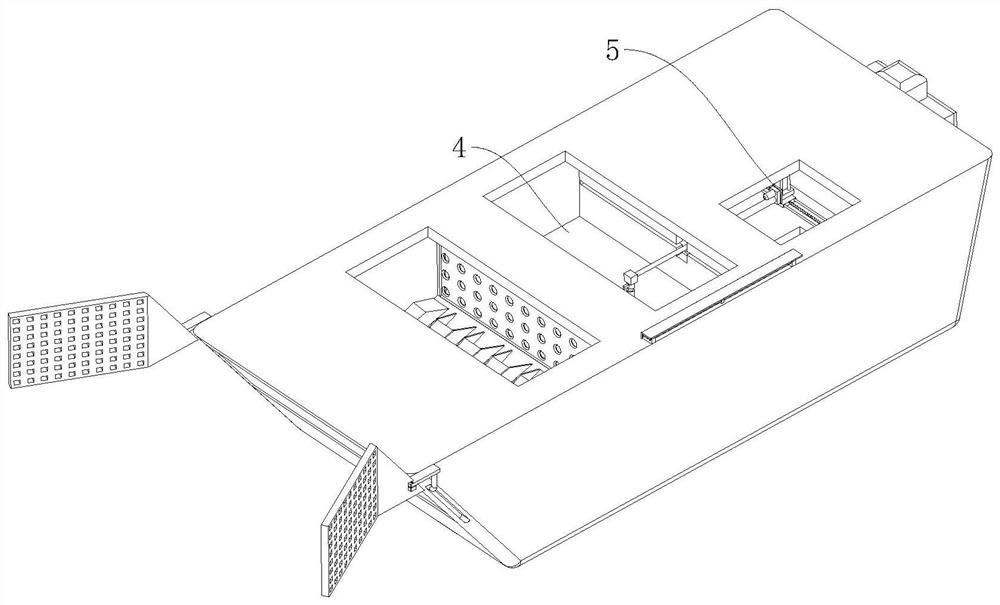

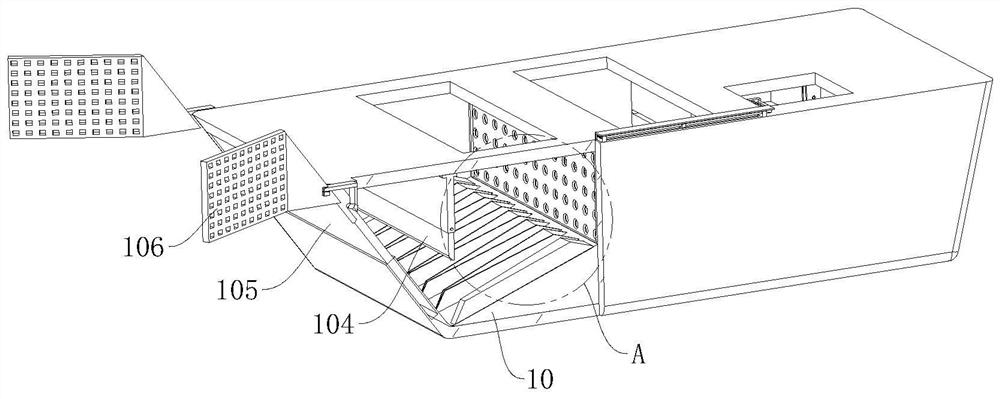

Excavating type one-time recovery residue film recycling machine

InactiveCN103988600AHigh yieldEffectively break upGatherer machinesPulp and paper industrySoil quality

The invention relates to an excavating type one-time recovery residue film recycling machine. The machine comprises an excavating system, a screening system, a breaking system and a separation system, the systems are all fixedly connected with a main box body, the main box body comprises side plates which are symmetrically distributed on the two sides of the excavating system, the two sides of the screening system and the two sides of the breaking system, the separation system is arranged below a gear assembly box, and a gap is arranged between the separation system and the gear assembly box. A transmission system connected with a power system is arranged on the main box body. According to the machine, repeated work does not exist, the adaptability is high, recycling can be completed at a time no matter what kind of soil quality exists, the work efficiency is high, operation is easy, the machine can be suitable for large and small plots, the machine effectively recycles large-area residue films, wastes in the soil can be cleared away at a time, centralized recovery is easily achieved, pollution-free processing is achieved, and the recycling cost is reduced.

Owner:靖边县农业机械管理服务站

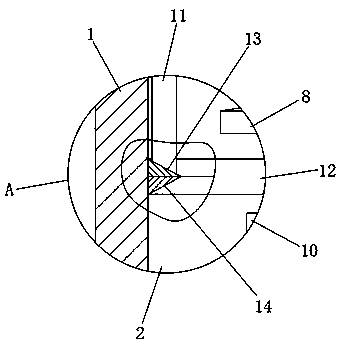

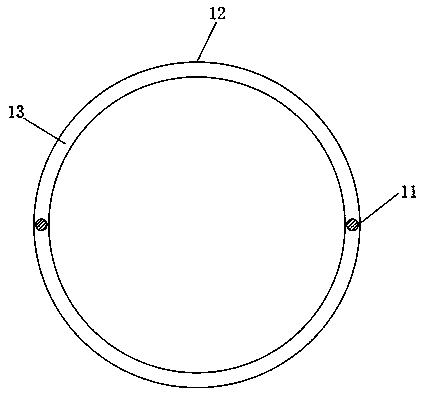

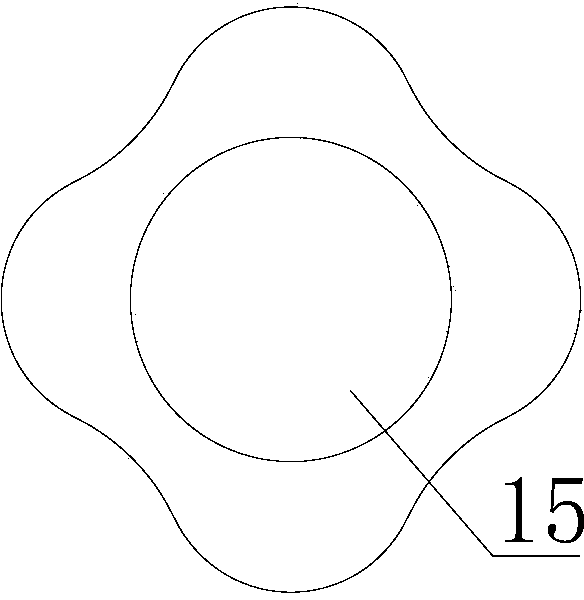

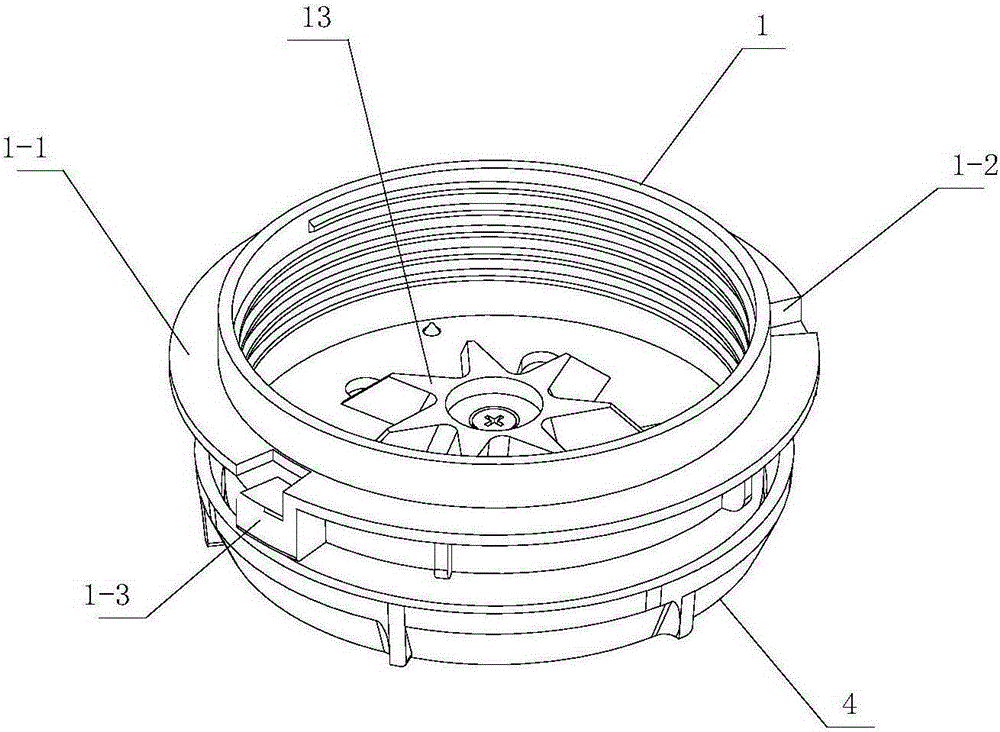

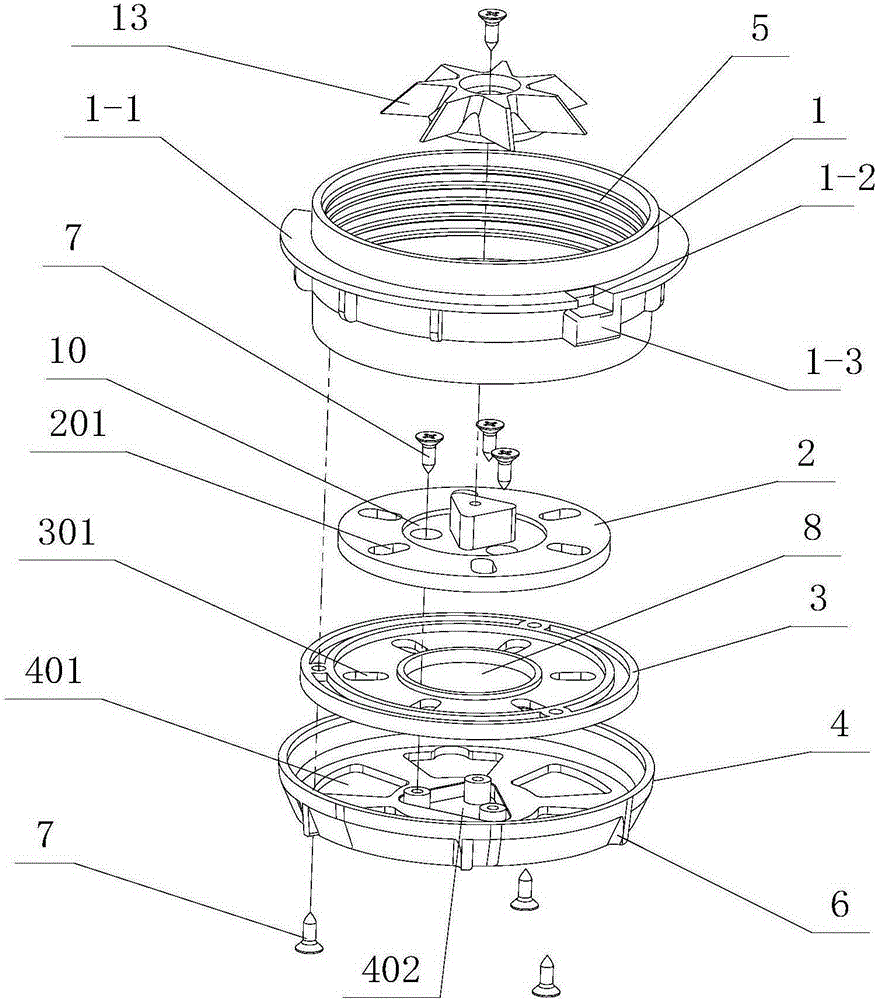

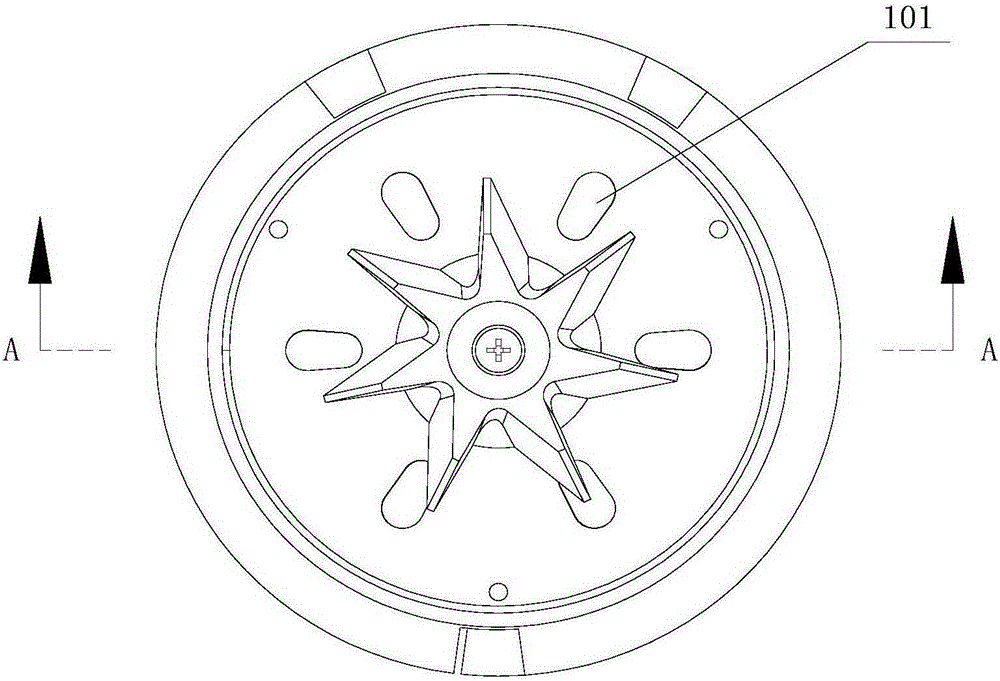

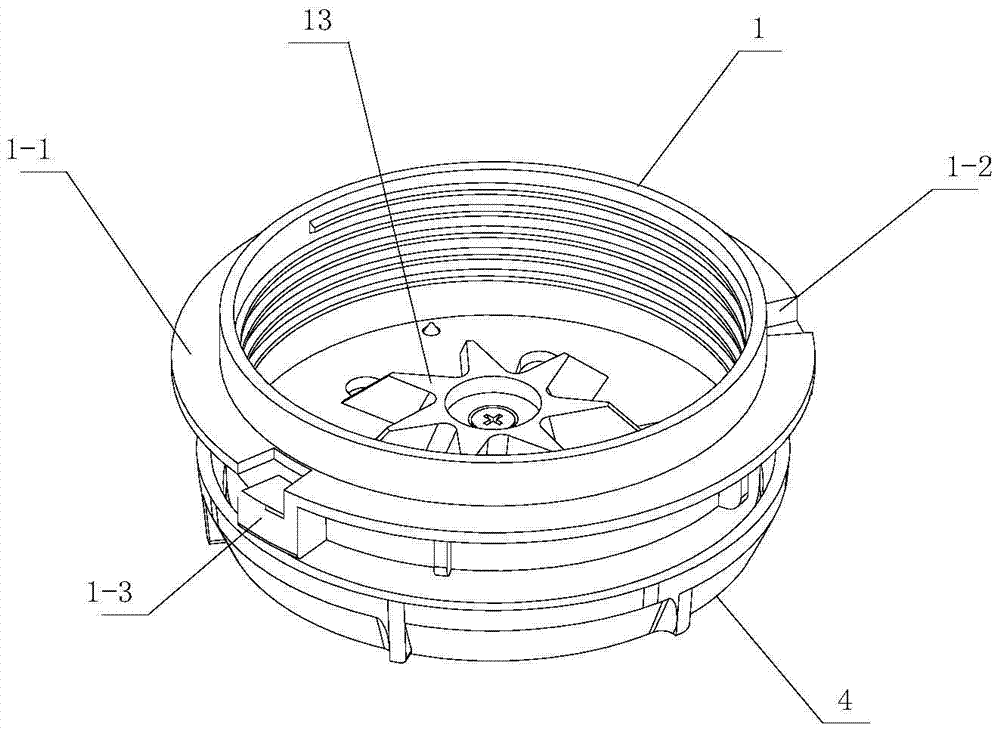

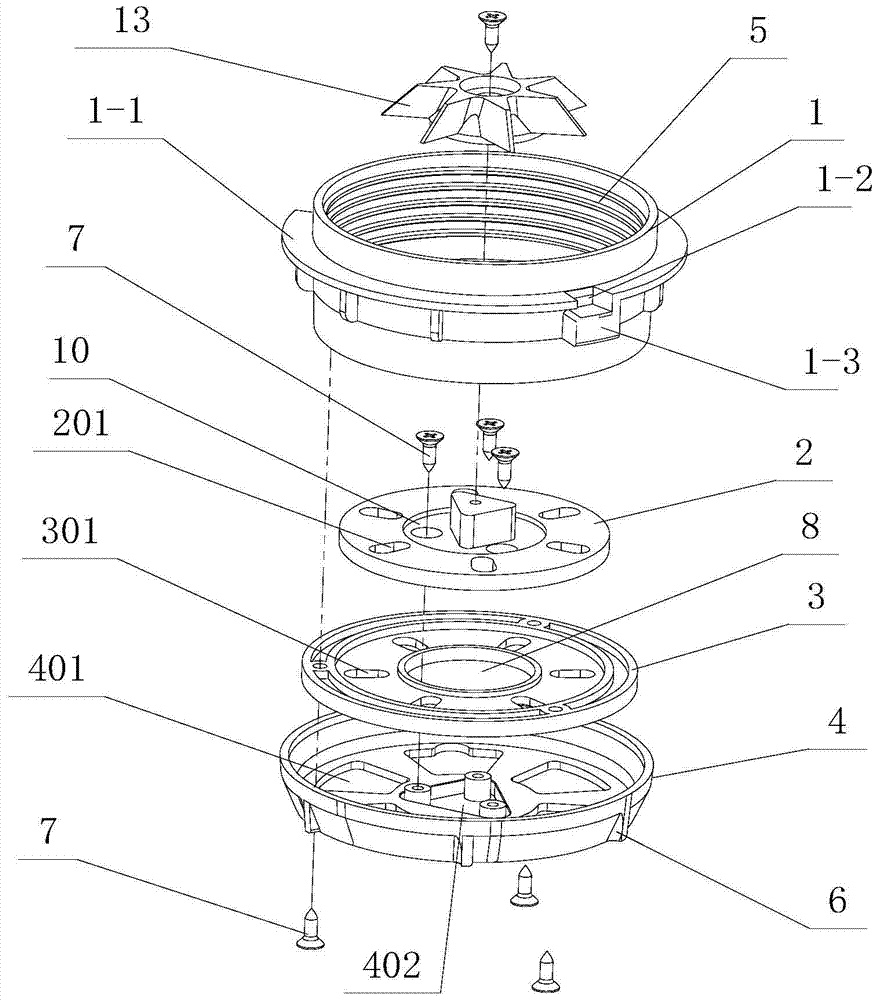

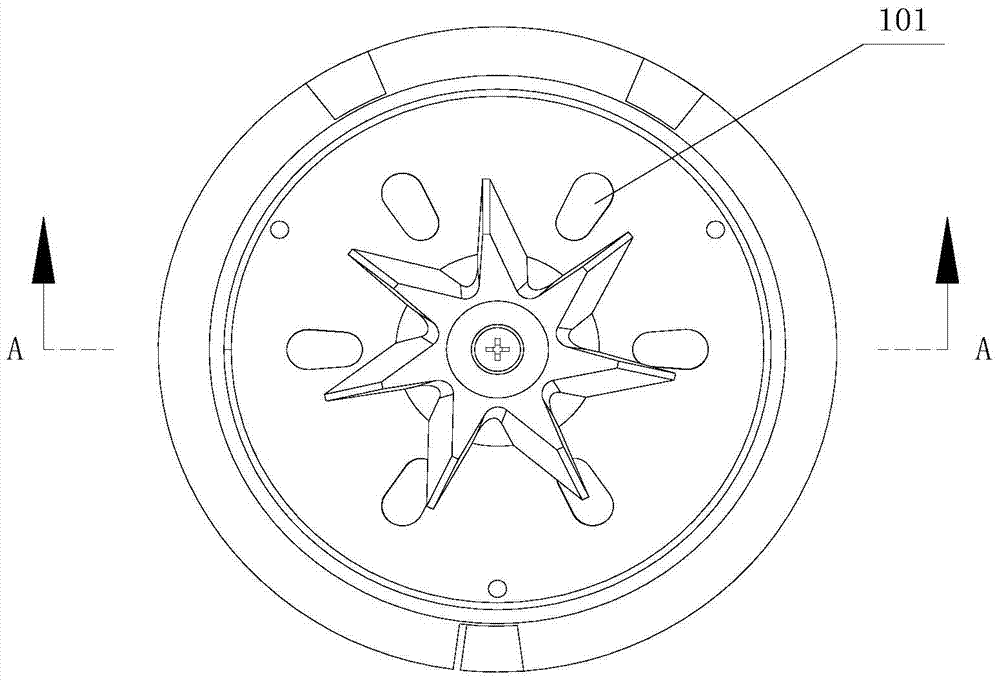

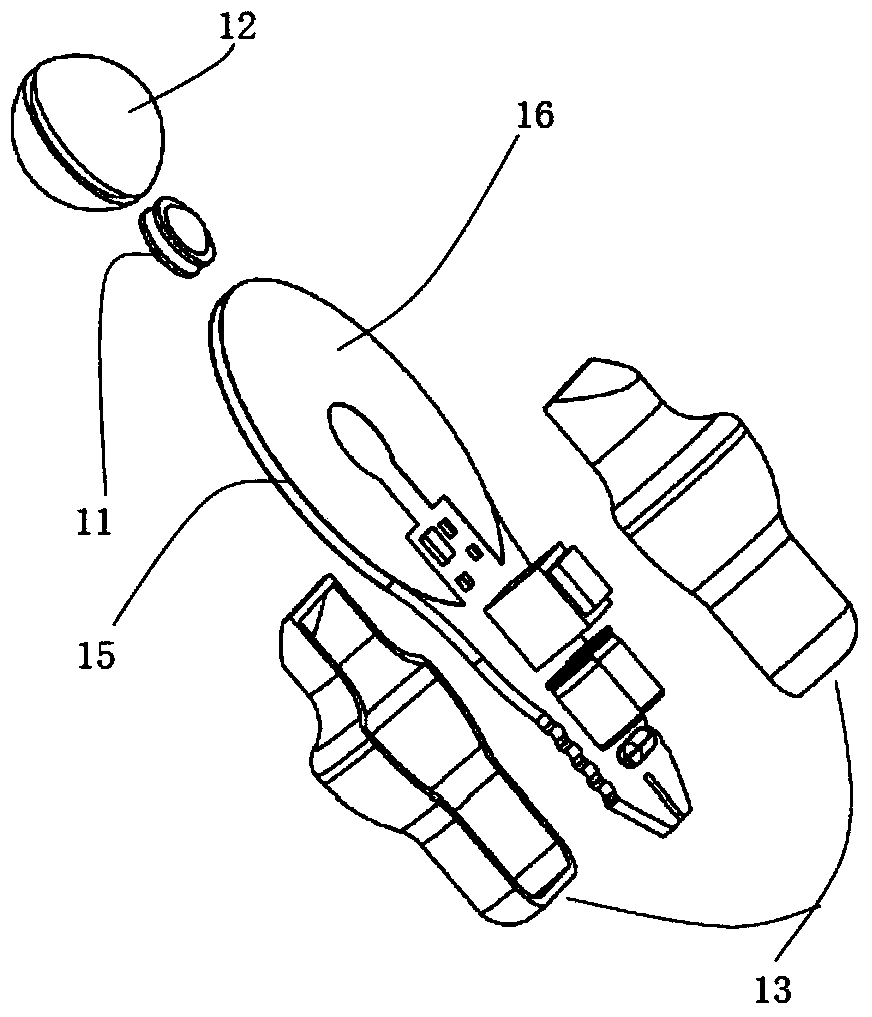

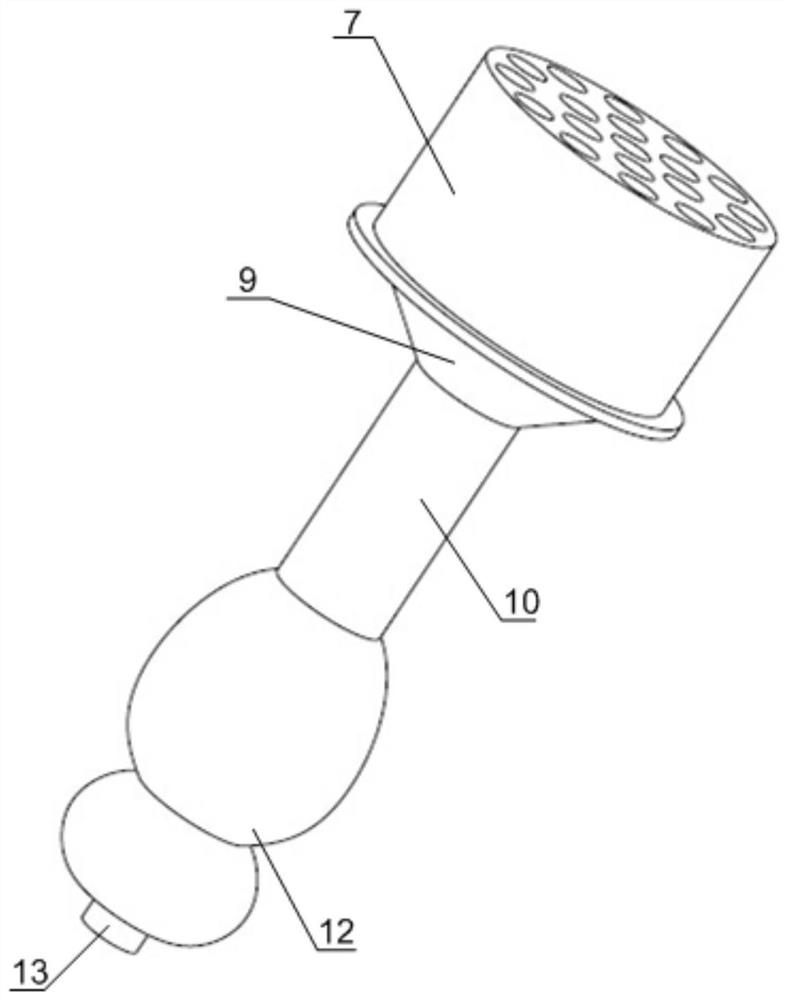

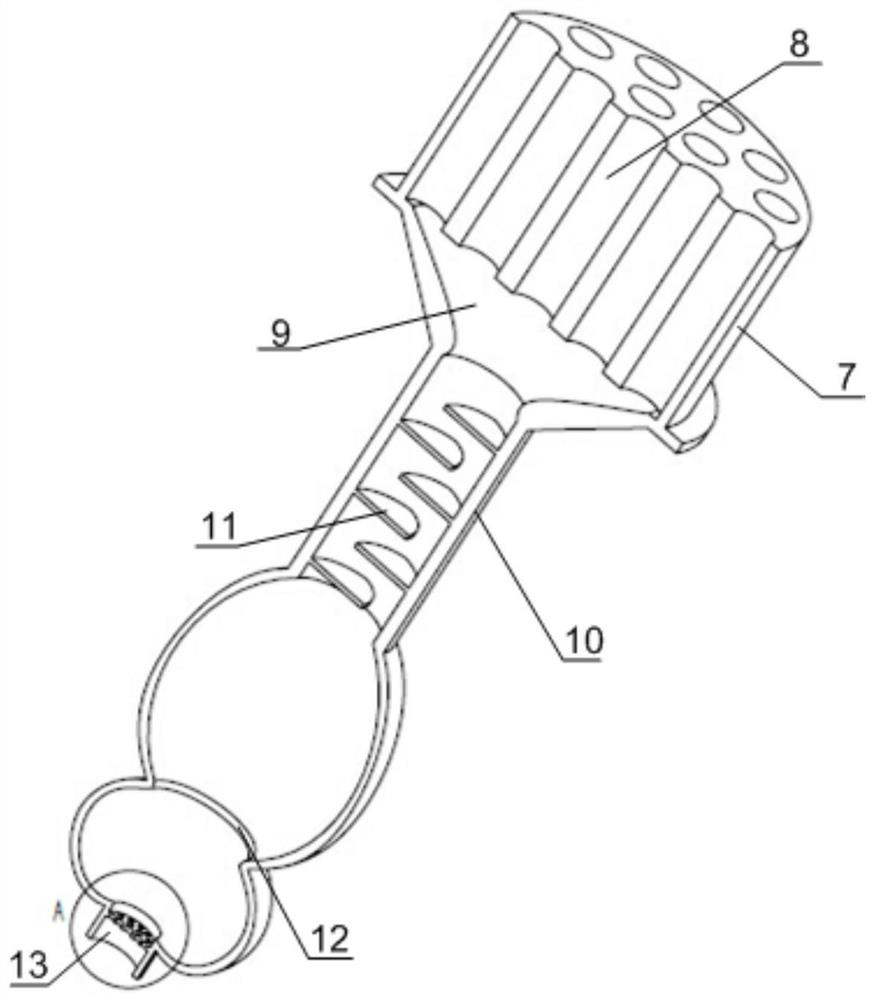

Novel medicine discharging cap and medicine discharging method

ActiveCN105253473ASolve technical problems that are easy to loosen and fallSimple structurePowdered material dispensingMedicine

The invention discloses a novel medicine discharging cap and a medicine discharging method. The novel medicine discharging cap comprises a fixed shell body, a metering plate, a sheltering plate and a rotating shell, wherein the fixed shell body, the metering plate, the sheltering plate and the rotational shell are sequentially overlapped from top to bottom and are coaxially arranged. A round through hole is formed in the middle of the sheltering plate, a downward triangular protrusion is arranged in the middle of the bottom face of the metering plate, and a triangular groove is correspondingly formed in the rotating shell; the triangular protrusion penetrates the round through hole to be arranged in the triangular groove in a matched manner, and screws penetrate the metering plate from top to bottom to enable the metering plate and the rotating shell to be fixedly connected; and the metering plate can freely rotate between the sheltering plate and the fixed shell body, an outer edge is arranged on the outer wall of the fixed shell body in the circumferential direction, gaps are evenly formed in the outer edge, and supporting blocks are arranged under the gaps. When the medicine discharging cap is assembled on a medicine cap mounting opening of a medicine discharging machine, the medicine discharging cap is rotated to enable the fixed shell body to be clamped on a medicine cap mounting opening, and therefore the medicine discharging cap is vertically limited, and is prevented from being jacked up by a transmission component.

Owner:SICHUAN NEO GREEN PHARMA TECH DEV

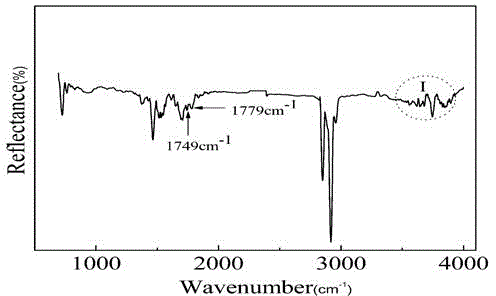

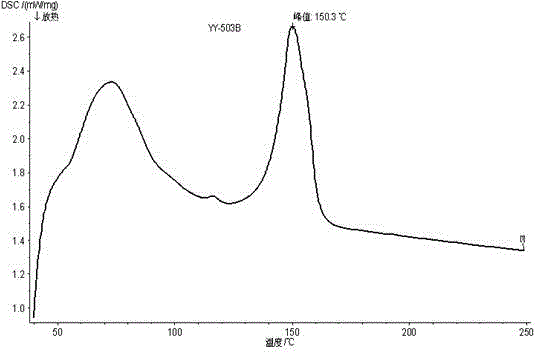

Pretreated pigment and preparation method thereof

ActiveCN103911019AEffectively break upEffective dispersionOrganic dyesPigment treatment with macromolecular organic compoundsPolymer chemistryPhotopigment

The invention relates to a pretreated pigment and a preparation method thereof. The pretreated pigment comprises following components by weight: 8-15 parts of a double-melting-point dispersant, 55-87 parts of a pigment, and 5-30 parts of an assisted dispersant, wherein the number-average molecular weight of the double-melting-point dispersant is 3000-5000, the lower melting point of the double-melting-point dispersant is 75+-5 DEG C and the higher melting point of the double-melting-point dispersant is 150+-10 DEG C. The pretreated pigment is prepared by steps of uniformly mixing in advance, extruding the mixture from a twin-screw extruder, cooling and smashing. By adoption of the double-melting-point dispersant, the agglomerate pigment can be effectively scattered and the pigment can be fully dispersed and be stable. The preparation method has advantages of simple operation, high production efficiency, less dust, and the like, and continuous production can be achieved. The dispersibility of the pretreated pigment can be significantly improved. The pretreated pigment can be used for preparing color master batch with better performances.

Owner:广东波斯科技股份有限公司

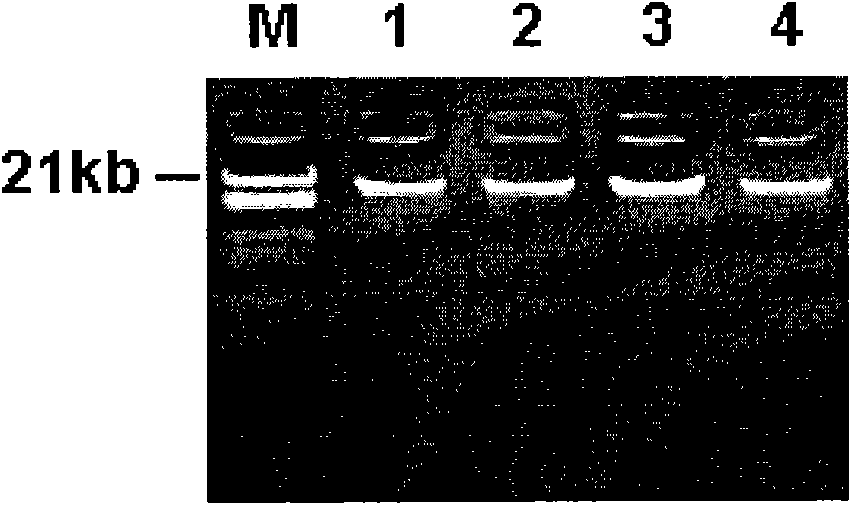

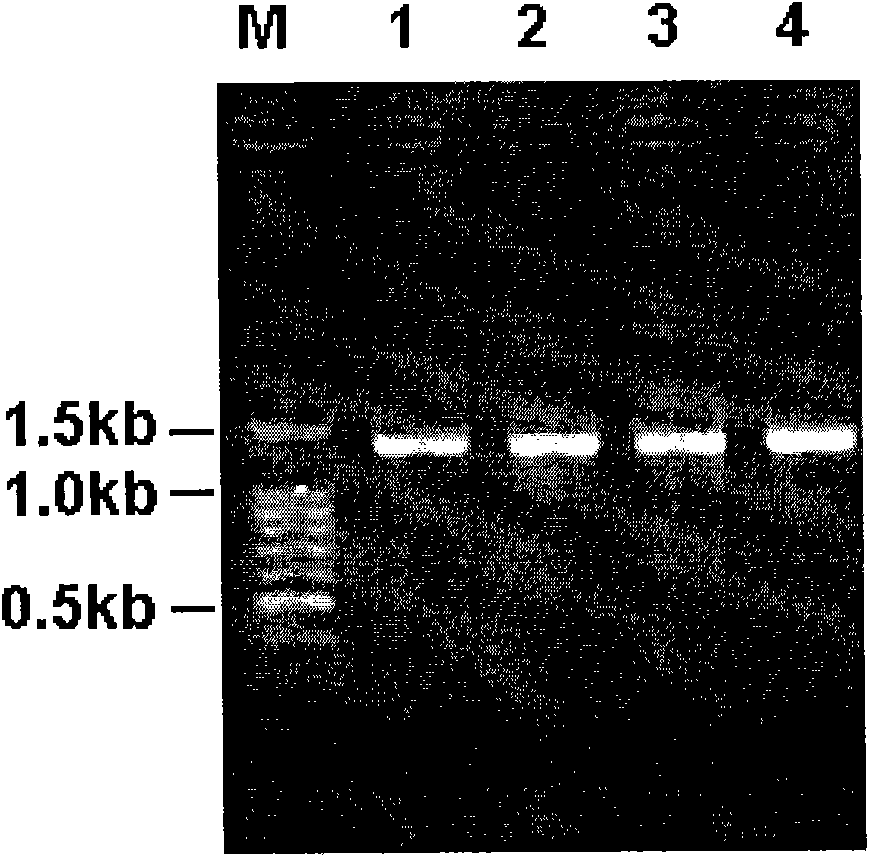

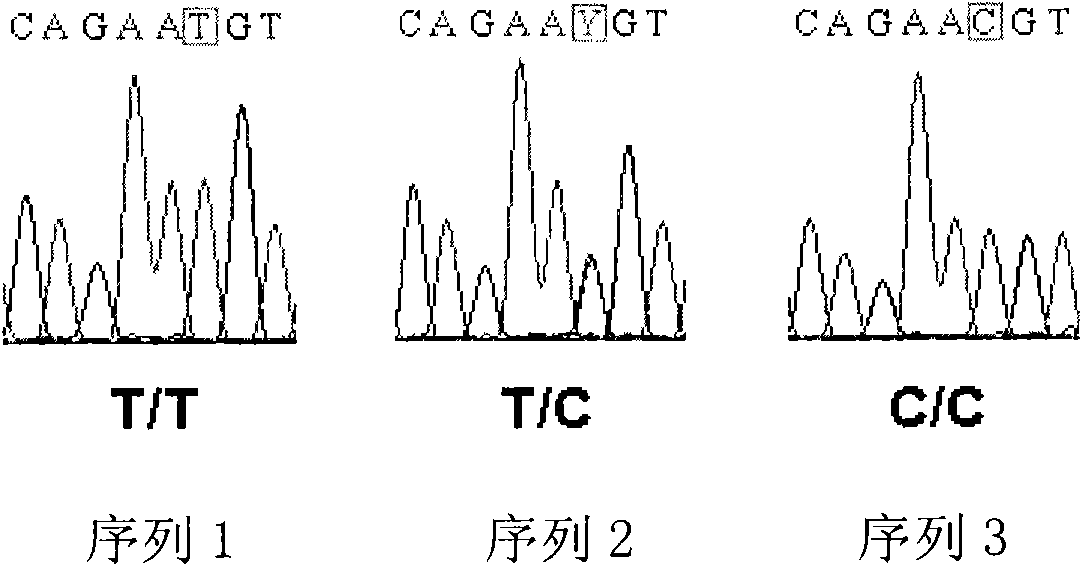

Method for quickly extracting genome DNA from blood clot

The invention discloses a method for quickly extracting a genome DNA from a blood clot. The method comprises the following steps of: (1) filtering the blood clot at a 2 to 20 Newton pressure and collecting filtrate, wherein the filtering pore size is 40 to 130 meshes; (2) uniformly mixing the filtrate with erythrocyte lysate, standing the mixture for 4 to 6 minutes, centrifuging 9,000 to 13,000 grams of the mixture for 0.5 to 1.5 minutes, and taking a deposit; (3) uniformly mixing the deposit with cell lysate, performing water bath on the mixture for 8 to 12 minutes at the temperature of between 63 and 67 DEG C, centrifuging 9,000 to 13,000 grams of the mixture for 0.5 to 1.5 minutes, and taking supernatant; and (4) uniformly mixing the supernatant with isopropanol, and purifying the mixture by using a DNA combination column to obtain the genome DNA. The method has the following advantages that: the DNA extracting content and the purity are significantly improved; purification steps are greatly simplified, a plenty of time is saved; any toxic solvent is not used to ensure the health and the safety of a worker; and a low-cost disposable article is used to ensure that potential crossed contaminations are avoided while reducing the cost. The method is suitable for popularization and application.

Owner:BEIJING TUBERCULOSIS & THORACIC TUMOR RES INST

Incinerator grate with transversely and longitudinally staggered head bosses

ActiveCN101929679AFast dryingImprove the effect of incineration treatmentIncinerator apparatusInstabilityEngineering

The invention discloses an incinerator grate with transversely and longitudinally staggered head bosses. A fixed beam passes through clamping grooves on the tail parts of the same row of fixed grate sheets so as to form fixed grate plates; a movable beam passes through clamping grooves on the tail parts of the same row of movable grate sheets so as to form movable grate plates; the movable grate plates and the fixed grate plates are longitudinally superposed and alternately arranged and gathered to form the grate; a head boss is arranged on the front end of the upper surface of each grate sheet; a primary air hole is formed on the head boss of each grate sheet; the head bosses of two adjacent grate sheets on the same row of grate plates are transversely and longitudinally staggered; and the front ends of each row of grate sheet are flush with one another. Through the incinerator grate with the transversely and longitudinally staggered head bosses, a garbage material layer can be effectively scattered so as to change the garbage height at each position of the incinerator material layer, increase the instability of the garbage material layer and facilitate garbage scattering and loosening; moreover, the incinerator grate realizes all-round scattering, loosening and stirring of the garbage material layer in an incinerator, improves the drying and burning efficiency of garbage, shortens the drying time and contributes to the fast burning of the garbage.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

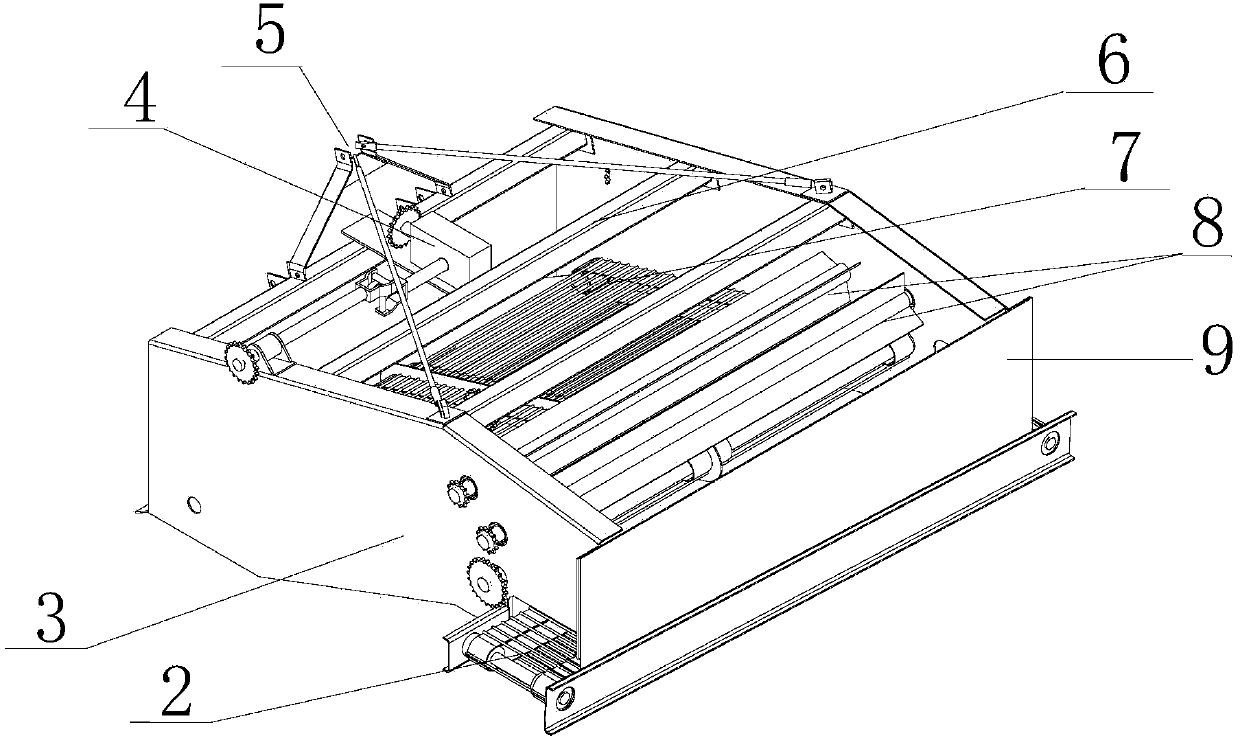

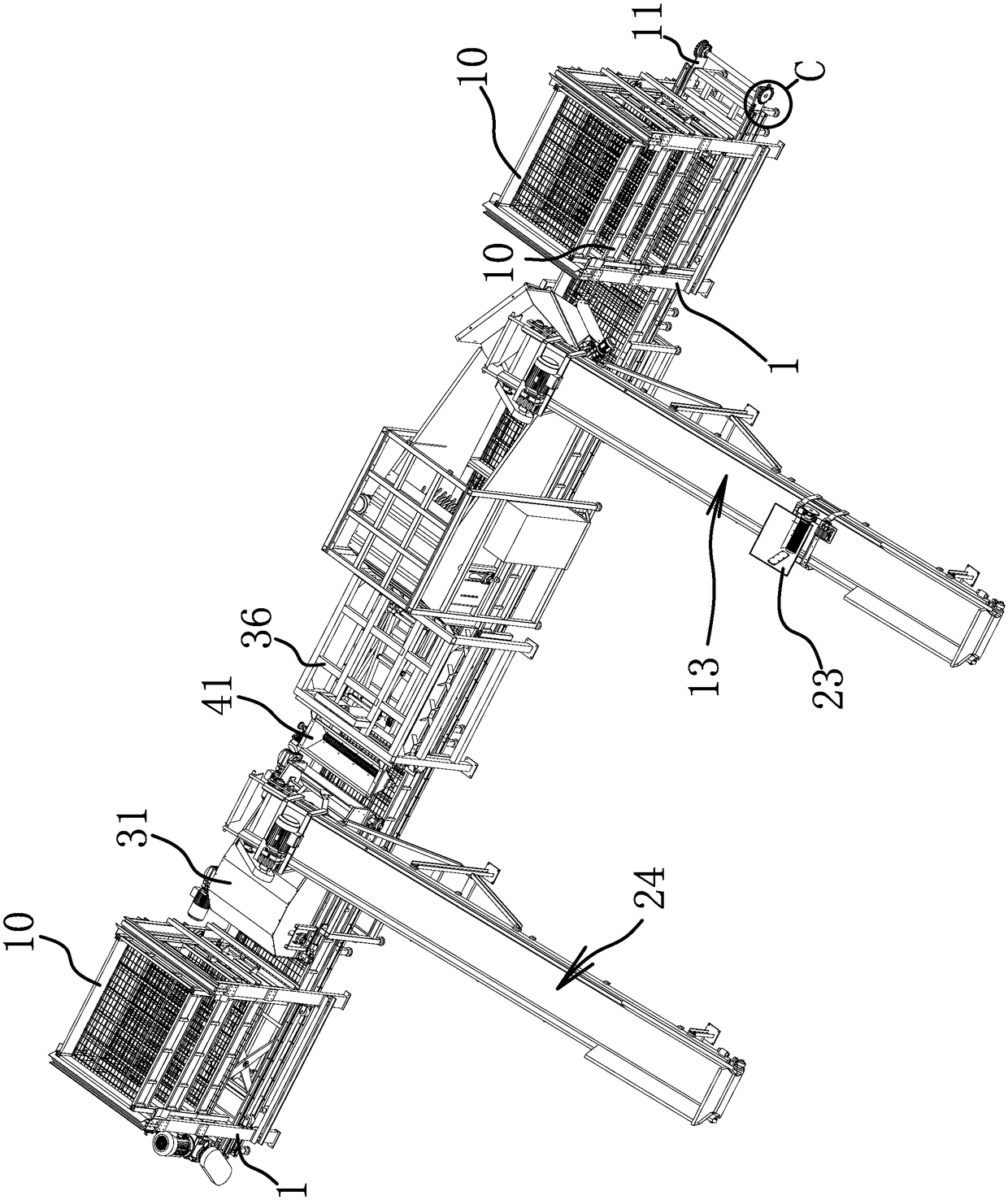

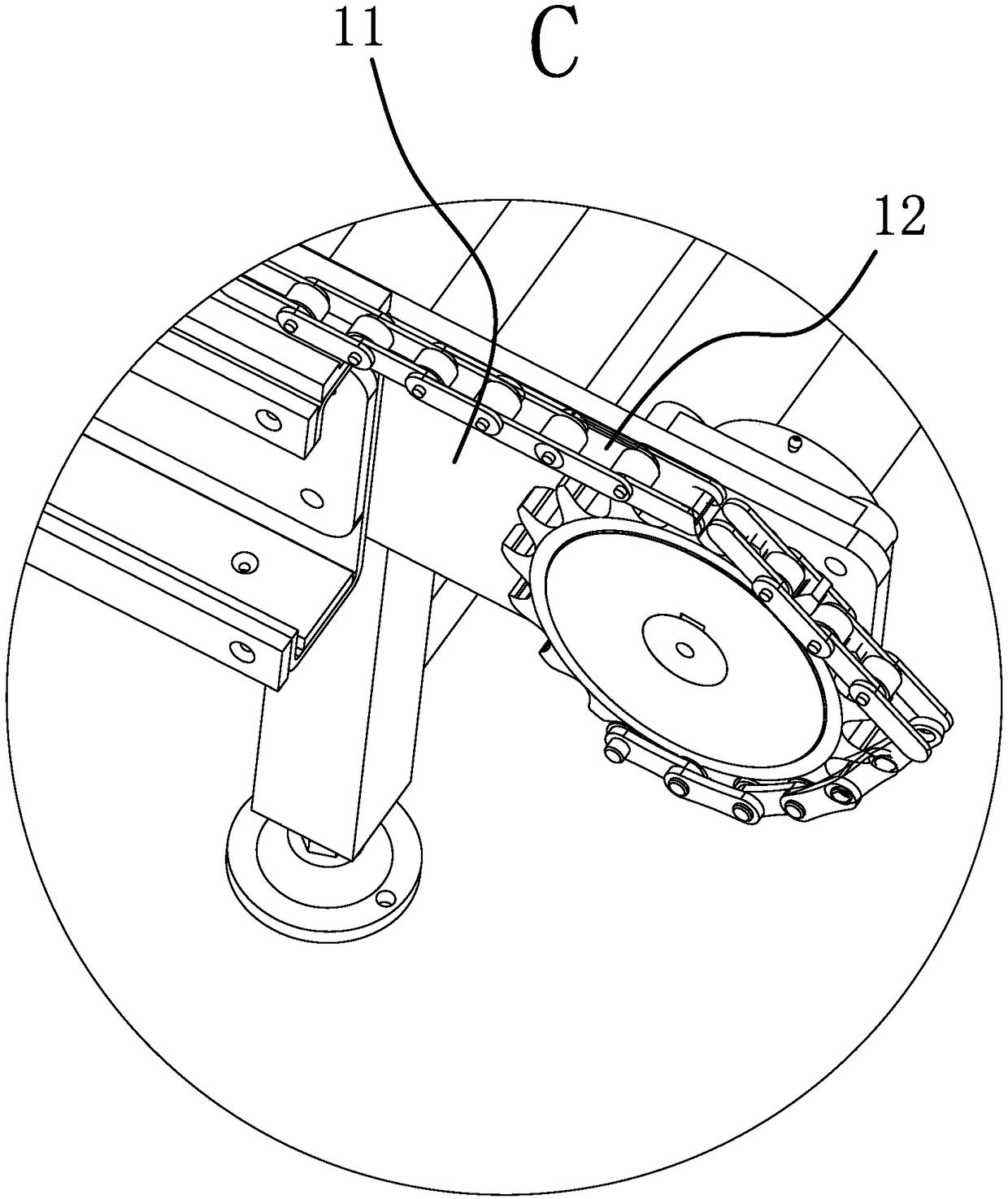

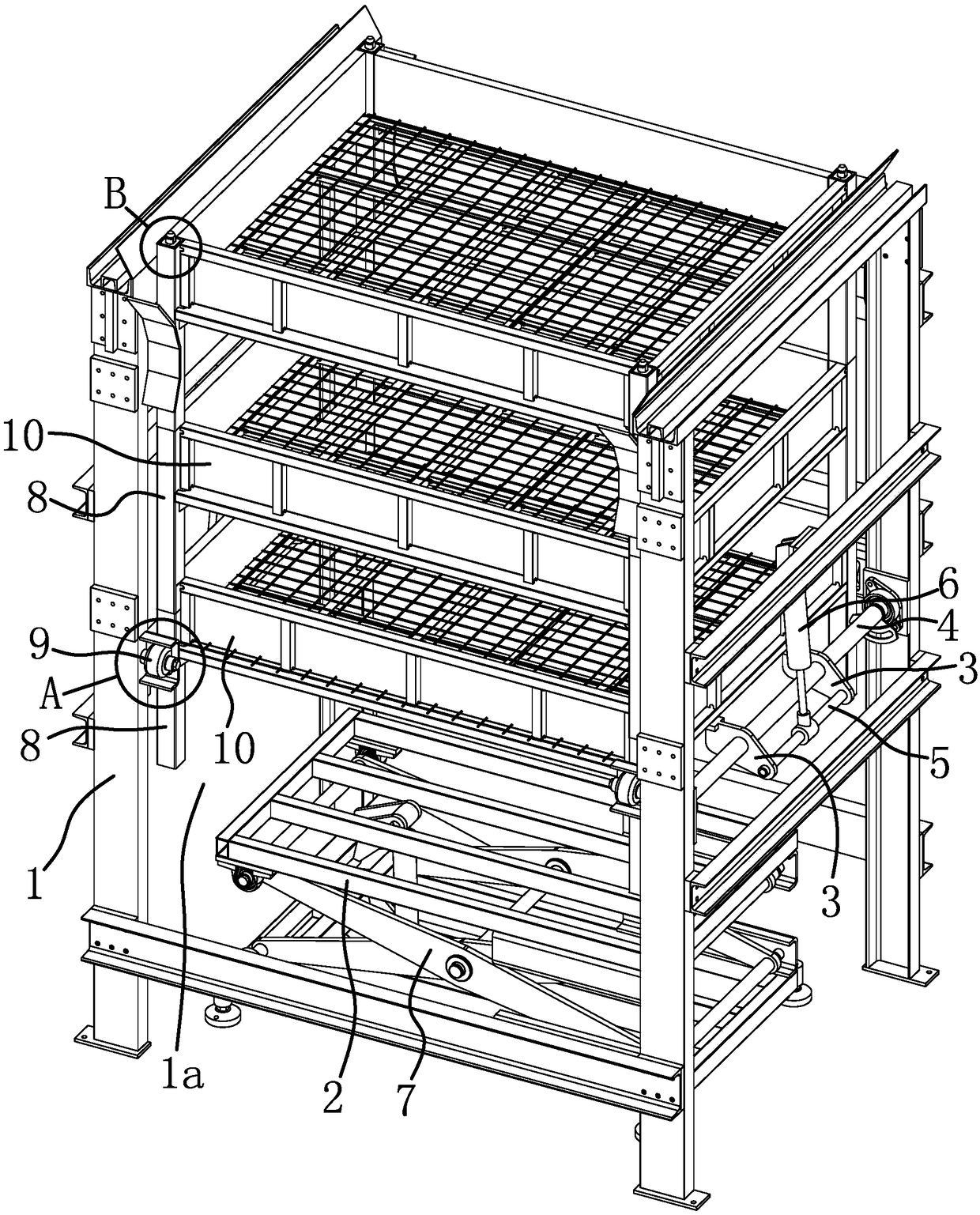

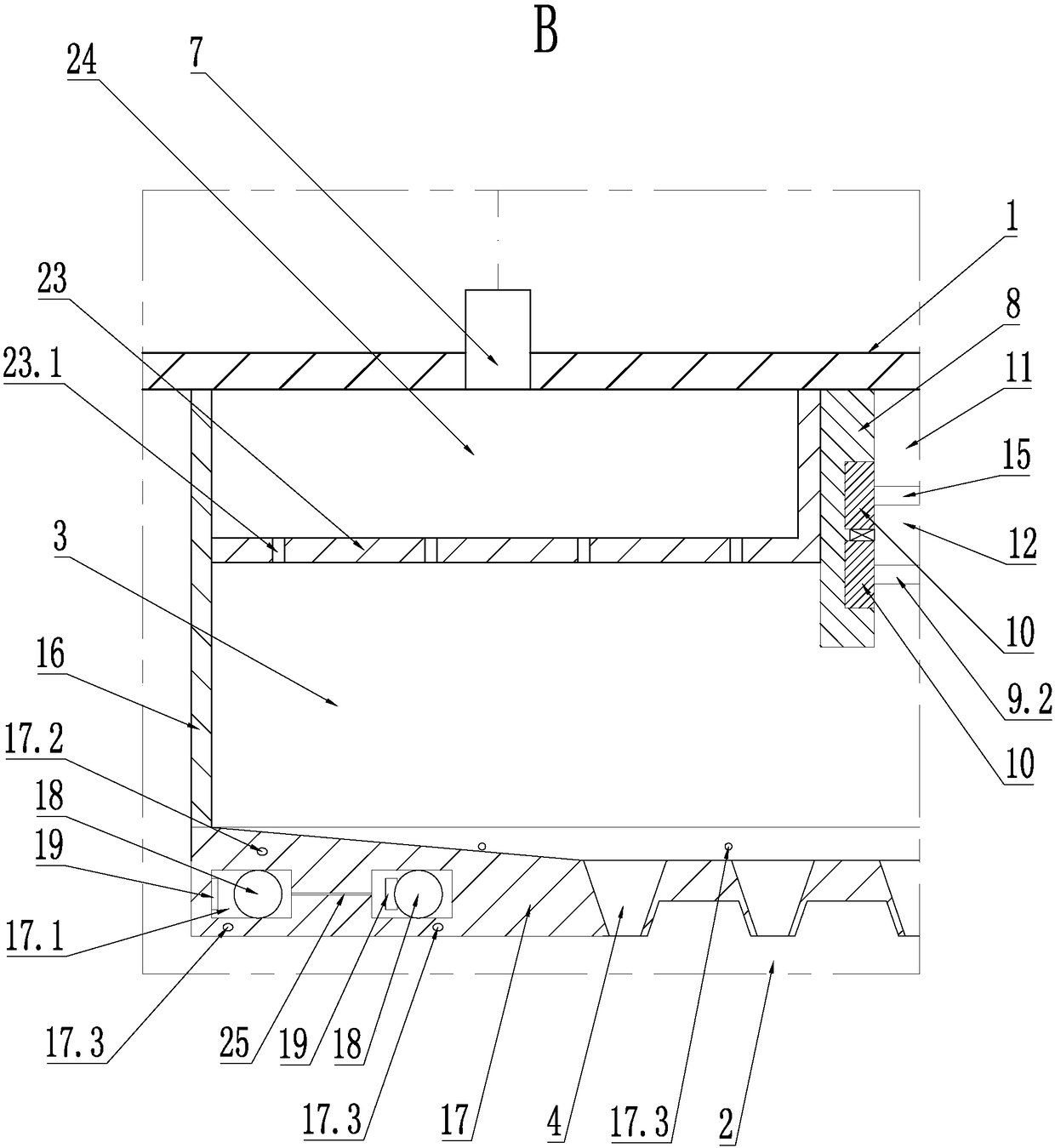

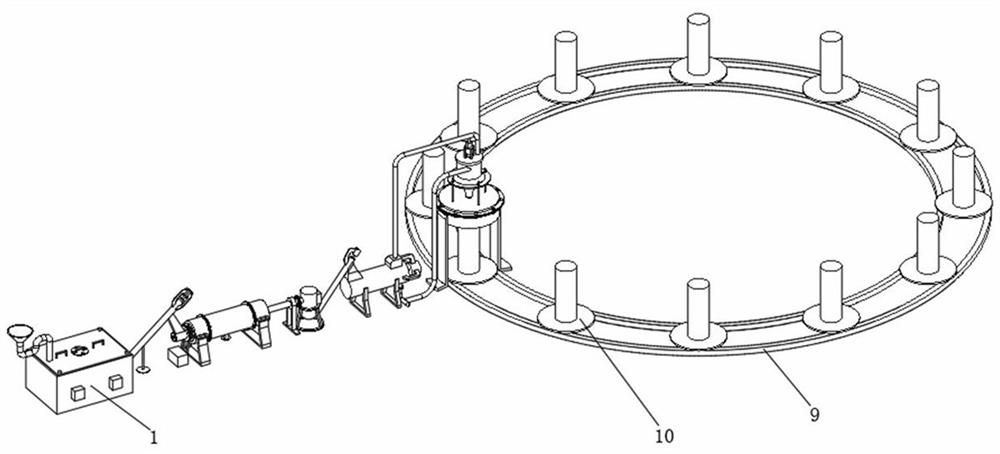

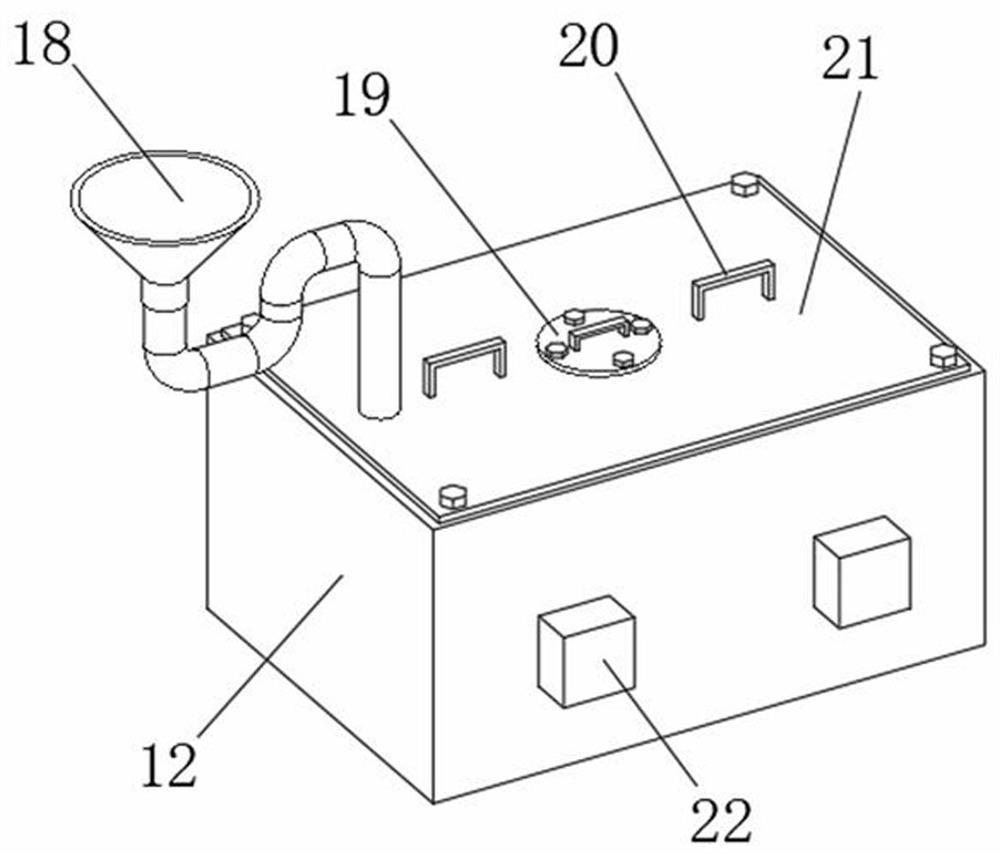

Edible mushroom planting equipment and processing process thereof

PendingCN108782030AEffective release of manpowerImproved ease of processingCultivating equipmentsMushroom cultivationEngineeringEdible mushroom

The invention provides edible mushroom planting equipment and a processing process thereof, belonging to the technical field of machines. The equipment comprises a mounting frame and a conveying chainwhich is horizontally arranged on the mounting frame, wherein a conveying device I, a mixing device, a soil conveying device and a conveying device II are arranged on the mounting frame; the conveying device I is used for conveying a planting frame into a feeding end of the conveying chain, the mixing device is used for conveying strains and fertilizers into the planting frame together, the soilconveying device is used for conveying soil into the planting frame, the conveying device II is used for conveying out the planting frame located at a discharging end of the conveying chain; the conveying device I, the mixing device, the soil conveying device and the conveying device II are sequentially distributed along the conveying direction of the conveying chain; the conveying device I is used for conveying the planting frame from top to bottom, and the conveying device II is used for conveying the planting frame from bottom to top. The processing process comprises the following steps: (A) frame conveying, (B) feeding, (C) flattening, (D) surface wave treatment, (E) soil covering and (F) frame fetching. The edible mushroom planting equipment has the advantage of convenience in use.

Owner:ZHEJIANG HONGYE EQUIP TECH

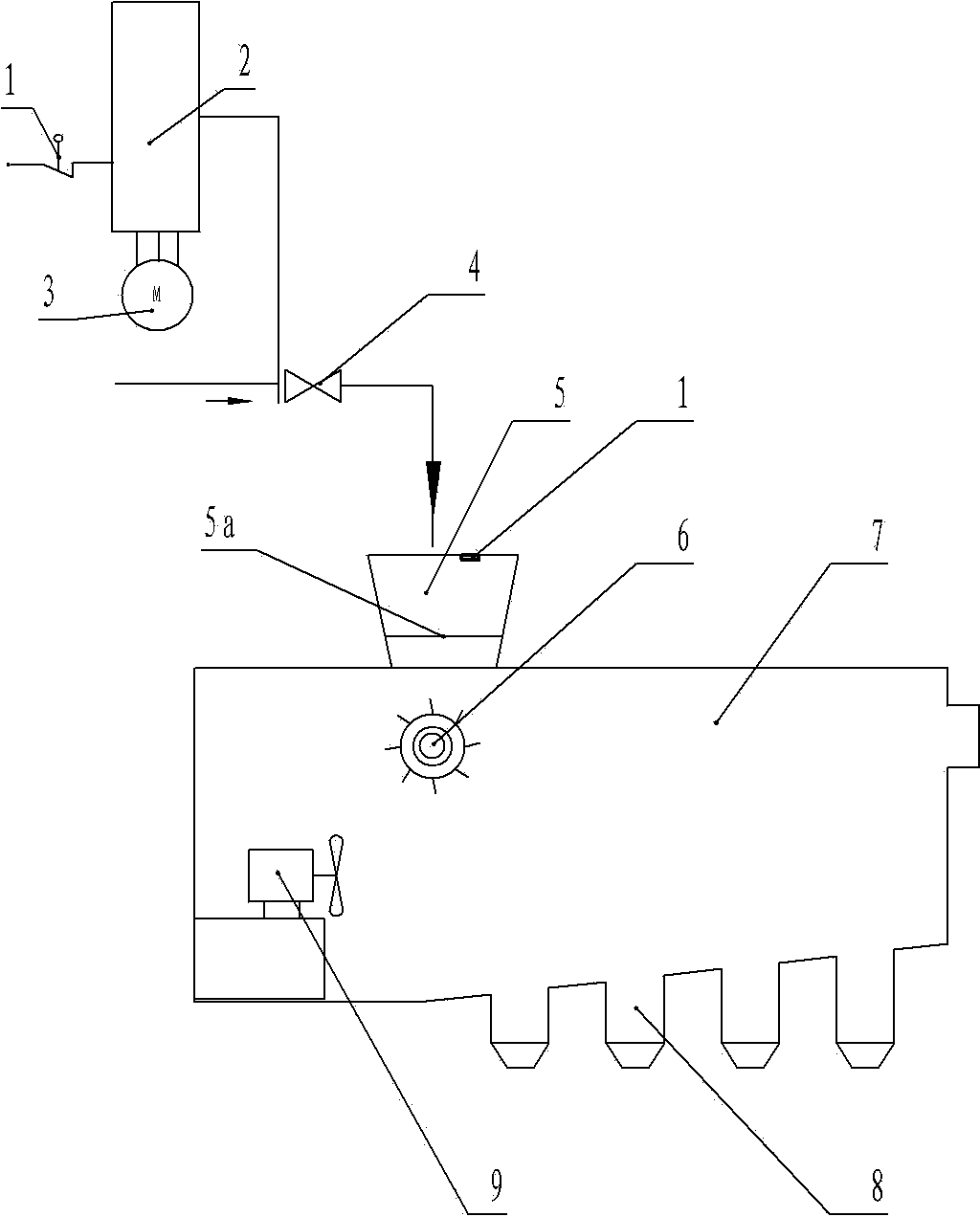

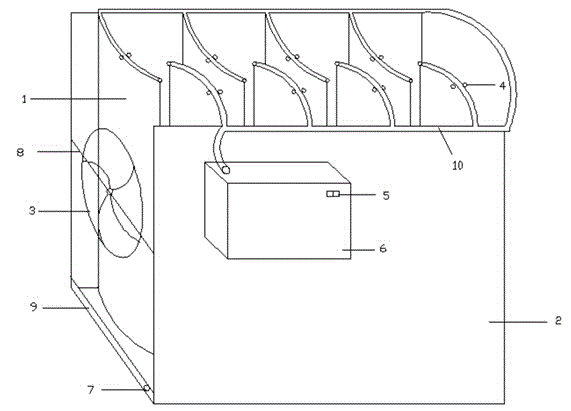

Tea leaf winnower

The invention discloses a tea leaf winnower and belongs to the technical field of tea leaf production equipment. The tea leaf winnower comprises a tank and a blower arranged in the tank, a top plate of the tank is provided with a feed inlet and a feed hopper connected with the feed inlet, a bottom plate of the tank is provided with a plurality of discharge outlets arranged in sequence, the feed hopper is communicated with a feed pipe provided with an electromagnetic valve, a filter screen is arranged in the feed hopper, a separating impeller driven by a motor is arranged below the feed hopper, the bottom plate of the tank is obliquely arranged, and the discharge outlets distant from the blower are higher than the discharge outlets near the blowers. A flow sensor is arranged in the feed hopper, a signal output end of the flow sensor and a signal feedback input end of a frequency converter are respectively serially connected with a power source, a signal output end of the frequency converter is respectively electrically connected with an electric control end of the electromagnetic valve and a motor. The tea leaf winnower is capable of solving the problem that tea leaves stick together so that winnowing effect is affected and impurities are incapable of falling into the corresponding discharge outlets.

Owner:WUZHOU ZHONGMING TEA IND CO LTD

The medicine cap and the method of medicine filling

ActiveCN105253473BSolve technical problems that are easy to loosen and fallSimple structurePowdered material dispensingDrug dispensingAgricultural engineering

The invention discloses a drug-feeding cap and a drug-feeding method, which comprise a fixed shell, a metering plate, a shielding plate and a rotating shell which are overlapped in order from top to bottom and coaxially arranged, a circular through hole is set in the middle of the shielding plate, and the metering There is a downward triangular protrusion in the middle of the bottom surface of the plate, and a triangular groove is correspondingly provided on the rotating shell, and the triangular protrusion passes through the circular through hole to fit in the triangular groove, and uses a screw to pass through the metering plate from top to bottom , the metering plate is connected and fixed with the rotating shell, and the metering plate can rotate freely between the shielding plate and the fixed shell. There are support blocks. When the lower drug cover of the present invention is assembled to the drug cover installation port of the drug dispensing machine, the fixed shell is stuck at the drug cover installation port by rotating the lower drug cover, so that the lower drug cover is vertically limited to prevent it from being lifted by the transmission part .

Owner:SICHUAN NEO GREEN PHARMA TECH DEV

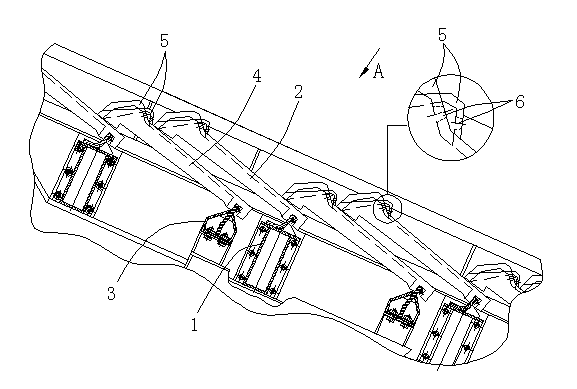

Peanut combine harvester picking mechanism

InactiveCN104770132AImprove fruit picking rateSoil sieving process facilitationDigger harvestersEngineeringVine

The invention relates to a peanut combine harvester picking mechanism, and belongs to the field of agricultural machines. The picking mechanism comprises a base. Two main shafts are rotationally arranged on the base, wherein the axes of the two main shafts are located on the same plane, and the rotating directions of the two main shafts are opposite. The distance between the two main shafts is gradually decreased from one ends of the axes to the other ends of the axes. Fan blades extending in the axial direction are evenly installed and distributed in the peripheral face of each of the two main shafts in the peripheral direction. The number of the fan blades on one main shaft is the same as that of the fan blades on the other main shaft, and the fan blades are staggered. The picking mechanism further comprises a gear and rack transmission device installed on the base. The gear and rack transmission device comprises a front end support, a rear end support, a front end gear, a rear end gear and a transmission rack, wherein the front end support and the rear end support are connected with the base, the front end gear is installed on the front end support, the rear end gear is installed on the rear end support, the transmission rack is meshed with the front end gear and the rear end gear, and the rear end support is higher than the front end support. The picking mechanism can effectively complete the picking procedure after peanut vines are harvested, and the high picking rate is ensured.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

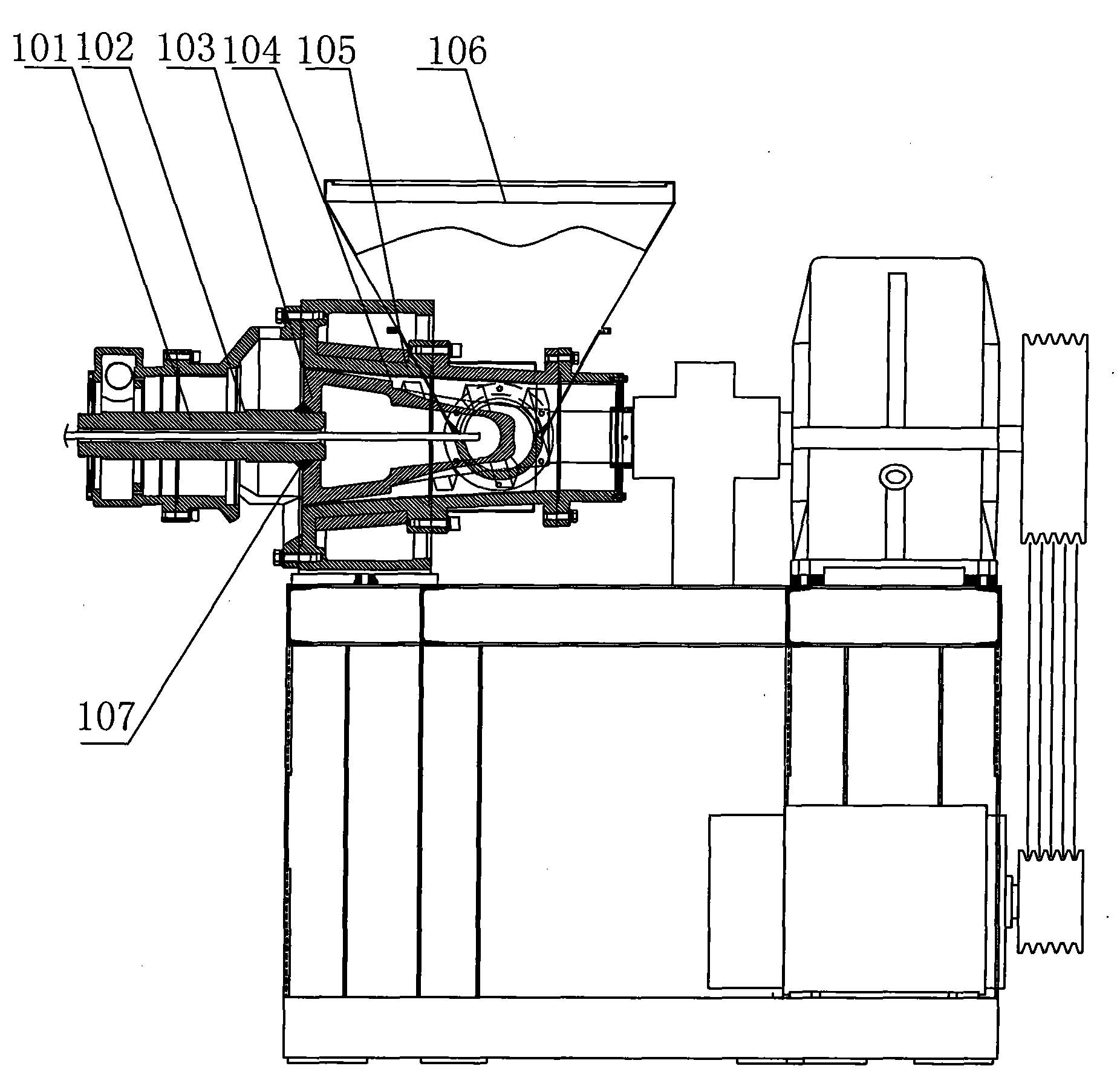

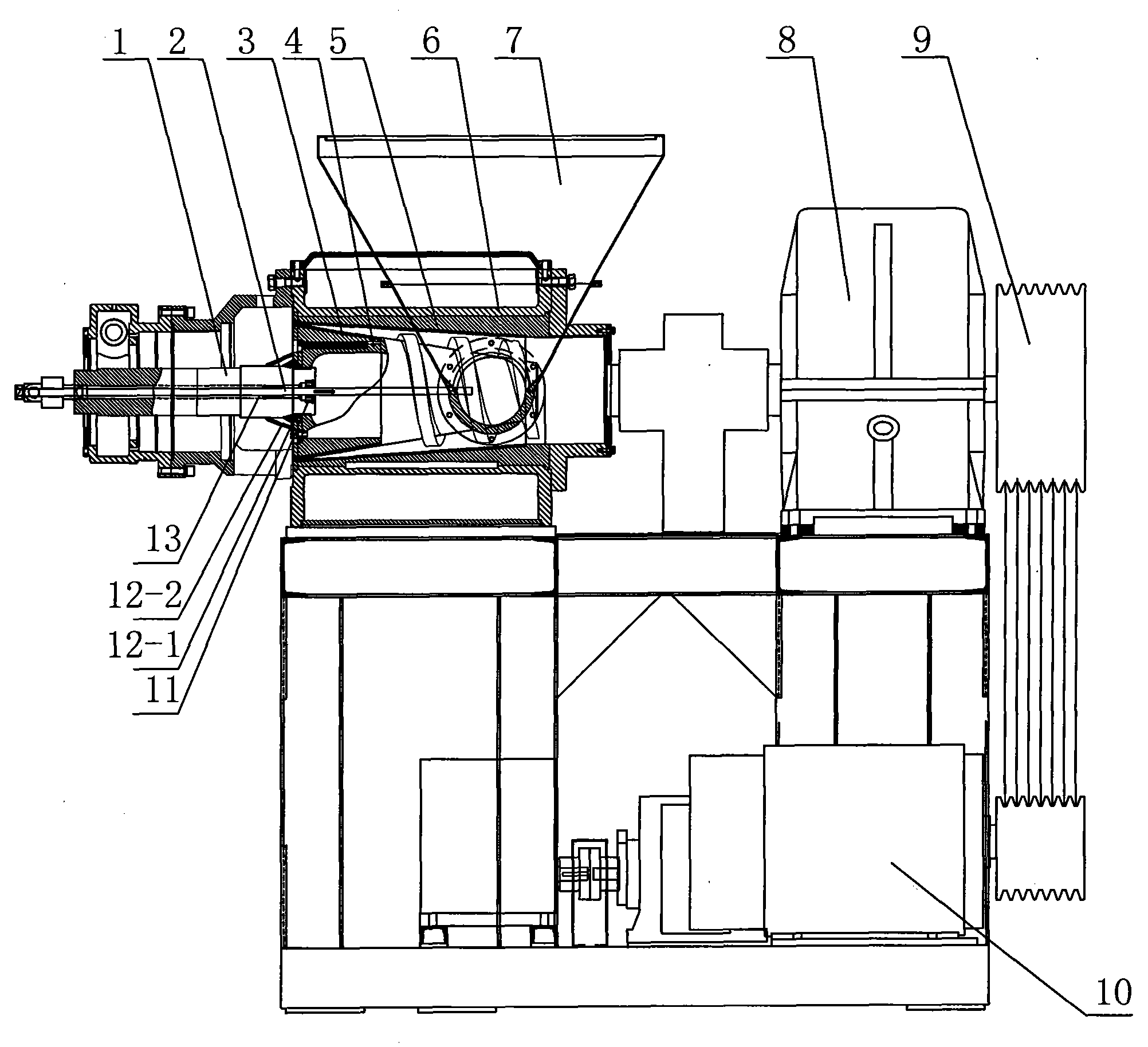

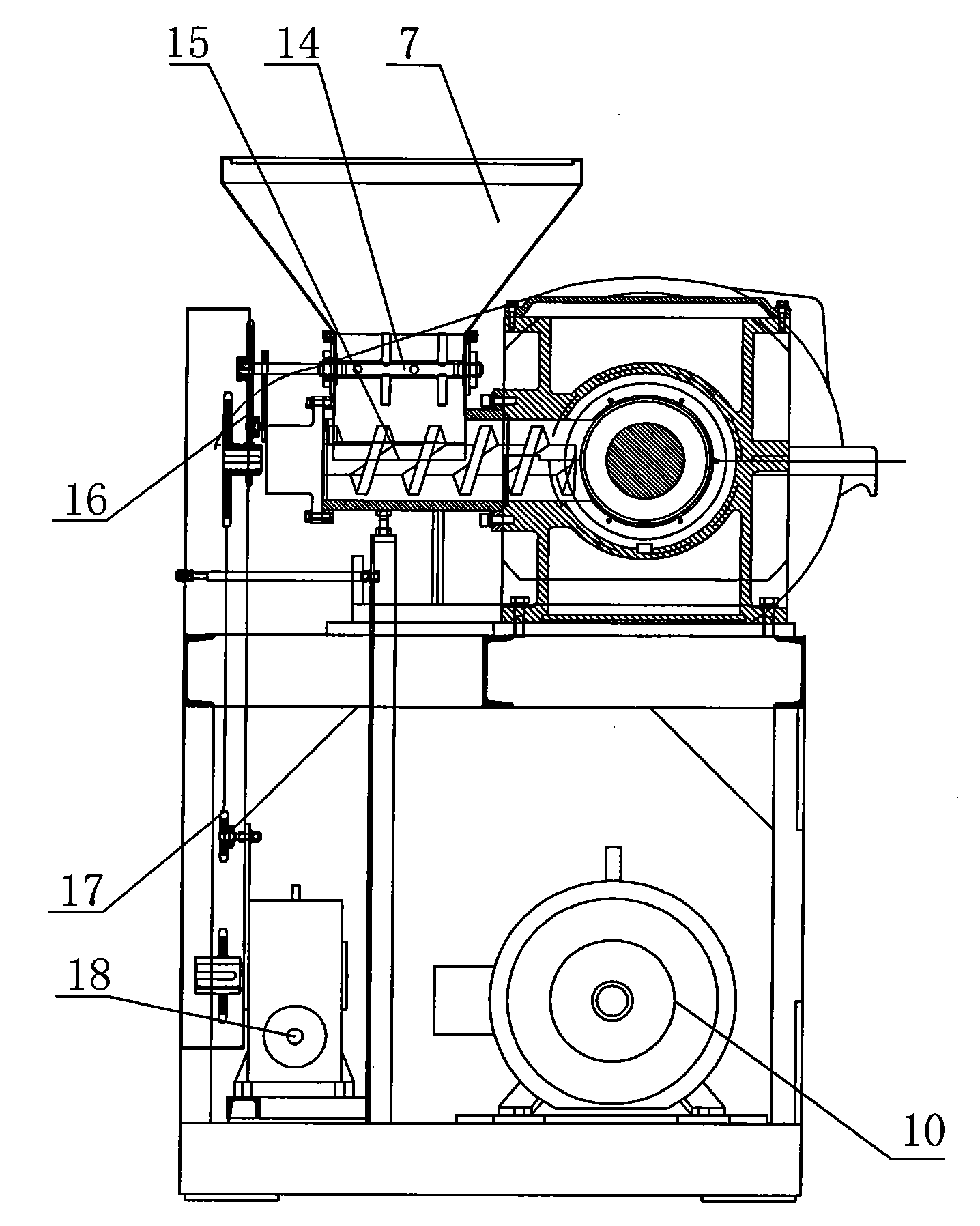

Rubber twisting and cutting machine

InactiveCN101954681AEfficient exchangeAvoid blockingPlastic recyclingGrain treatmentsMotor drivePower transmission

The invention relates to a rubber twisting and cutting machine comprising a feeding device and a twisting and cutting device, wherein the feeding device is composed of a hopper and an auger delivery shaft positioned on the lower part of the hopper; a transmission mechanism drives the auger delivery shaft to transmit materials to a twisting and cutting part; the twisting and cutting device comprises a smashing shaft and a smashing box inner sleeve; a motor drives the smashing shaft to rotate by a power transmission mechanism; the rear part of the smashing shaft is provided with an axial regulating mechanism; the smashing shaft is provided with a separable coat which is fixed on a main shaft by a fixed structure; the smashing box inner sleeve and a smashing box shell are separable; and the inner sleeve is fixed on the smashing box shell by the fixed structure. The invention can prolong the service life of the key parts of the twisting and cutting machine, is convenient to replace and can realize continuous and efficient production.

Owner:江阴市鑫达药化机械制造有限公司

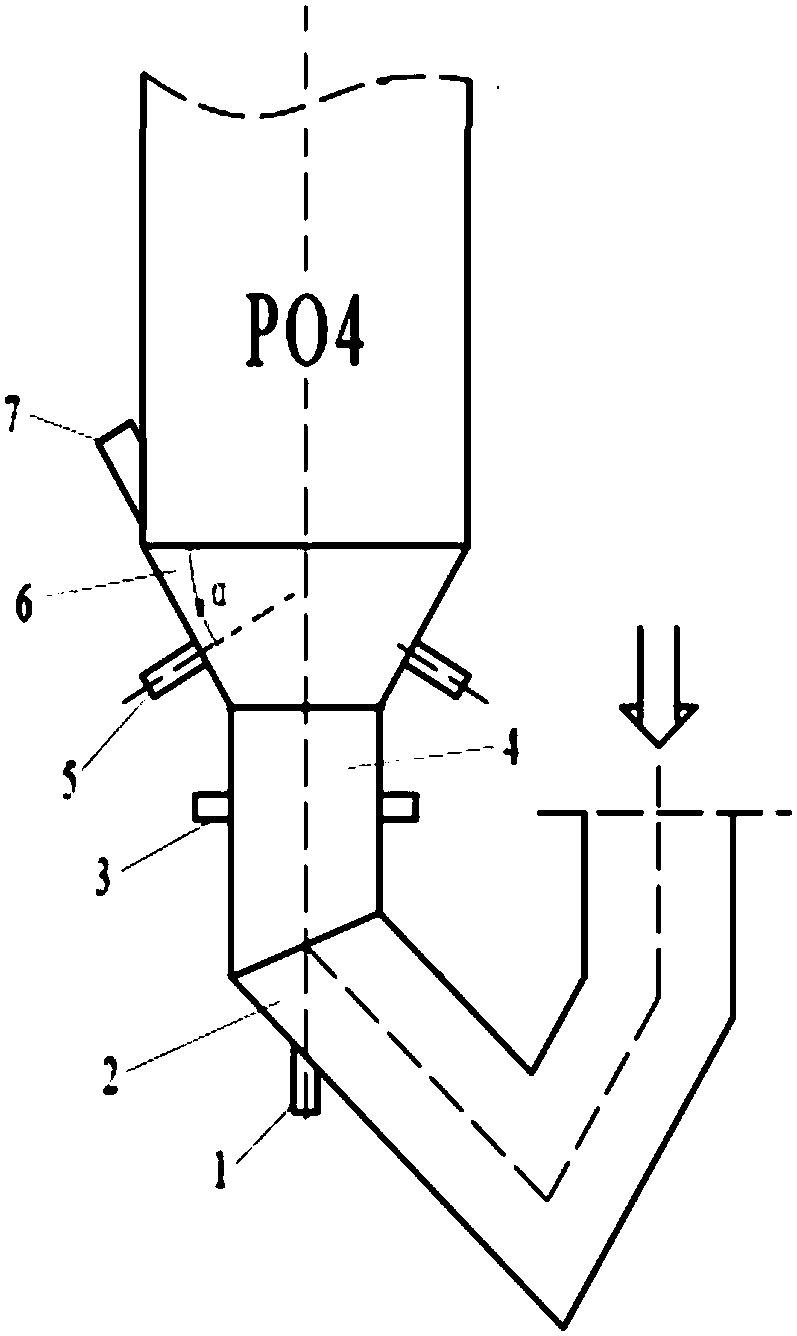

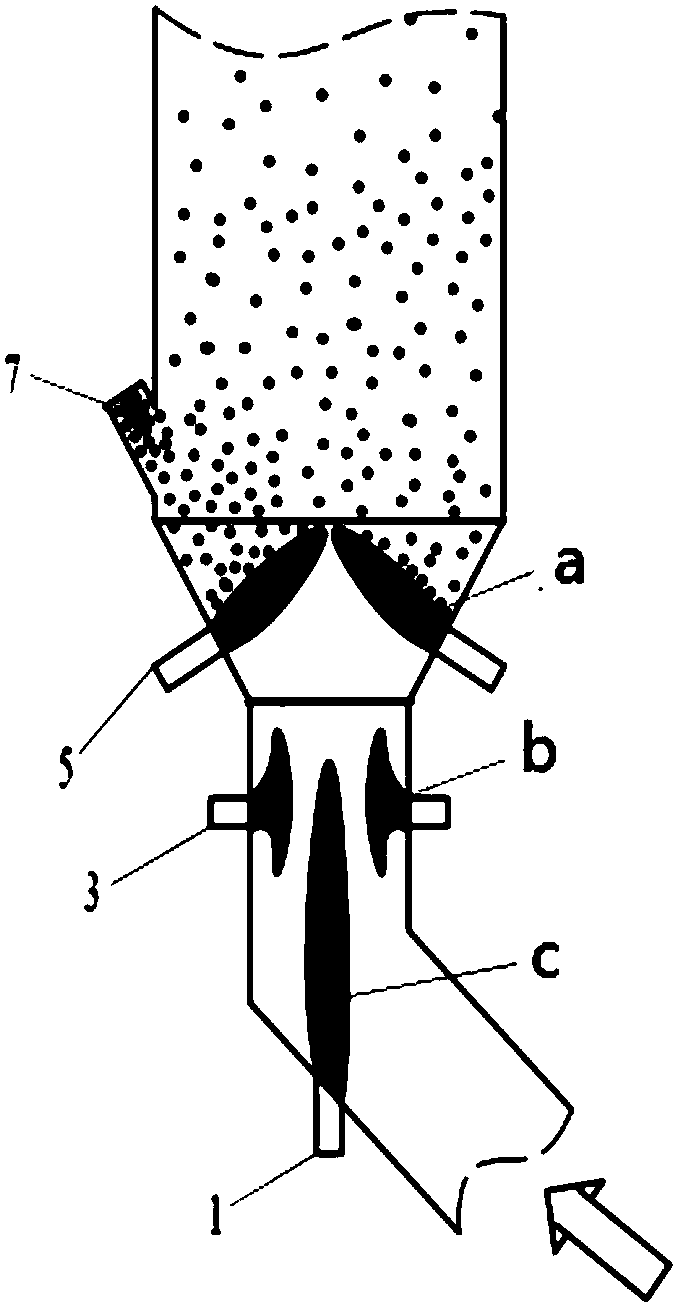

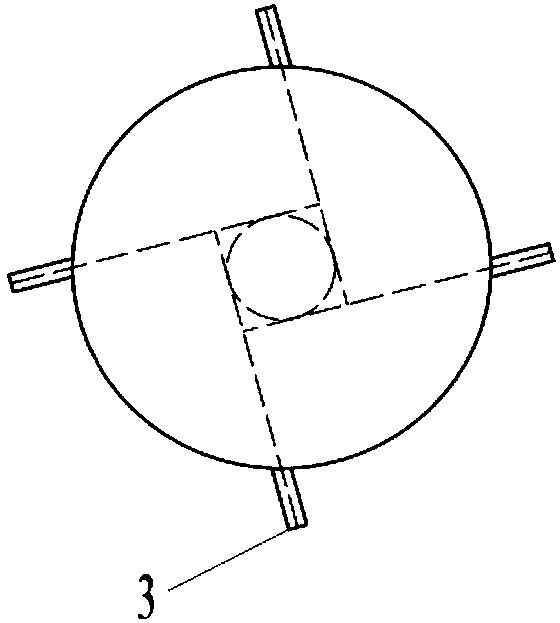

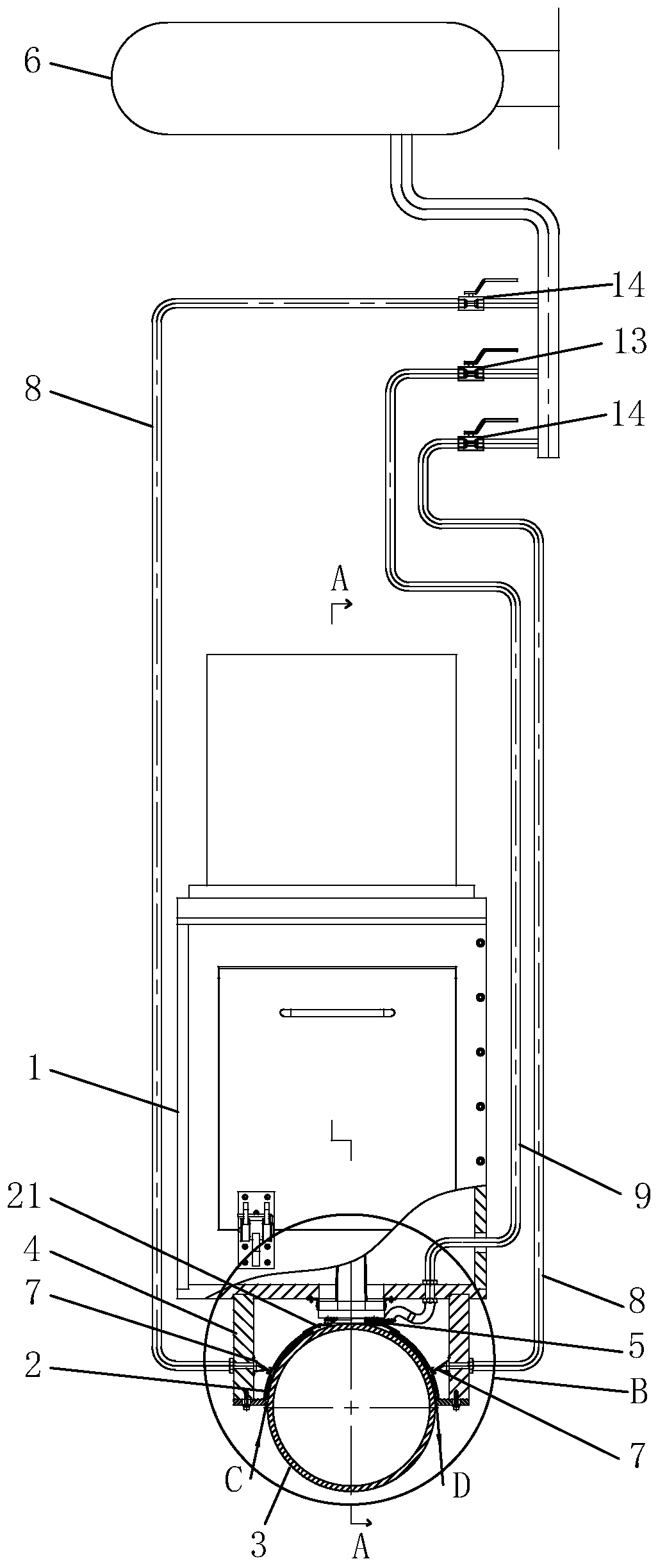

Staged-combustion system of suspension roaster and application thereof

PendingCN107559826AIncrease profitImprove the mixing effectGaseous fuel burnerCombustion systemInstability

The invention discloses a staged-combustion system of a suspension roaster and an application thereof, belonging to the field of roasting. The staged-combustion system comprises a main roaster PO4, amain combustion pipe, an auxiliary gas pipe, a first-stage combustor and a second-stage combustor, wherein the main roaster PO4, the main combustion pipe and the auxiliary gas pipe are connected in sequence; the first-stage combustor is connected to the bottom of the main combustion pipe; the central axis of the first-stage combustor and the central axis of the main combustion pipe coincide; and the second-stage combustor is arranged on the main combustion pipe along a periphery direction and is connected to the main combustion pipe. The staged-combustion system solves the problems existing ina tradition suspension roaster that the insufficient mixing of gas and combustion-supporting gas causes the insufficient combustion of fuel, low utilization rate of fuel and formation of a large amount of high-temperature pollutants, and material dropping causes the flameout of the combustors and the instability of the combustion system. The staged-combustion system has the characteristics of high efficiency, stability and low emission load of pollutants.

Owner:KEDA MAS CLEAN ENERGY +1

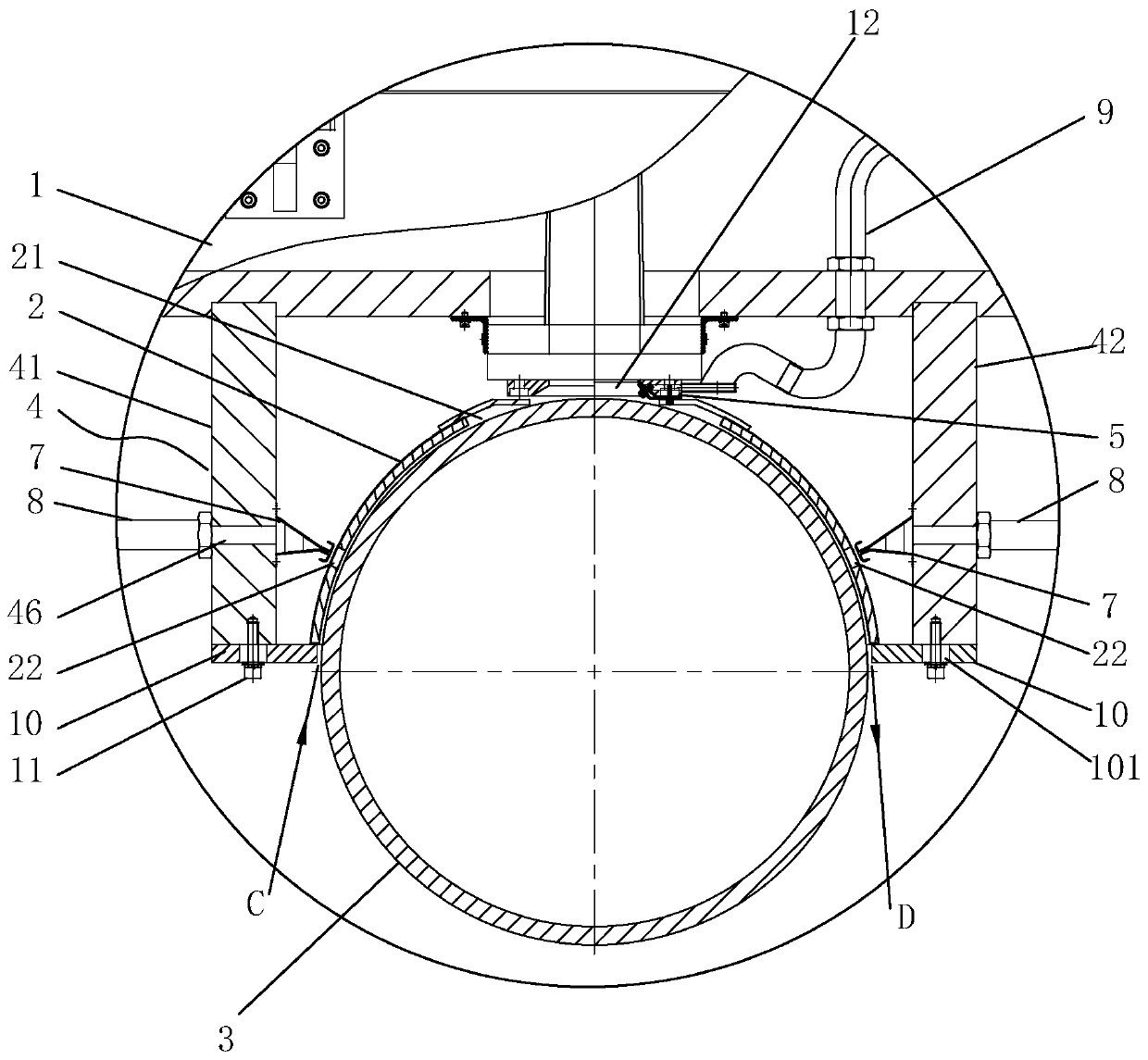

Treatment device for neodymium-iron-boron ultrafine powder waste material

ActiveCN108130416AEffectively break upSimple and reliable discharge processCombustion chamberEngineering

The invention discloses a treatment device for a neodymium-iron-boron ultrafine powder waste material. The treatment device comprises a furnace body. The furnace body is internally provided with a combustion chamber and a material supply chamber, wherein the material supply chamber is formed above the combustion chamber. The material supply chamber communicates with the combustion chamber throughmultiple discharging holes. The furnace body is provided with a feeding opening. The feeding opening communicates with the top of the material supply chamber. The furnace body is provided with first air inlets and a second gas inlet, wherein the first air inlets are used for supplying air to the combustion chamber, and the second gas inlet is used for conveying flame-retardant gas into the material supply chamber so that the material supply chamber can be internally filled with the flame-retardant gas. The material supply chamber is internally provided with a support. One end of the support isfixed to the furnace body. The support is provided with vanes and a motor, wherein the motor is used for driving the vanes to rotate. The vanes are located below the feeding opening in the vertical direction. The treatment device for the neodymium-iron-boron ultrafine powder waste material is high in efficiency and low in cost and can be popularized by production enterprises conveniently.

Owner:江苏启诚磁业有限公司

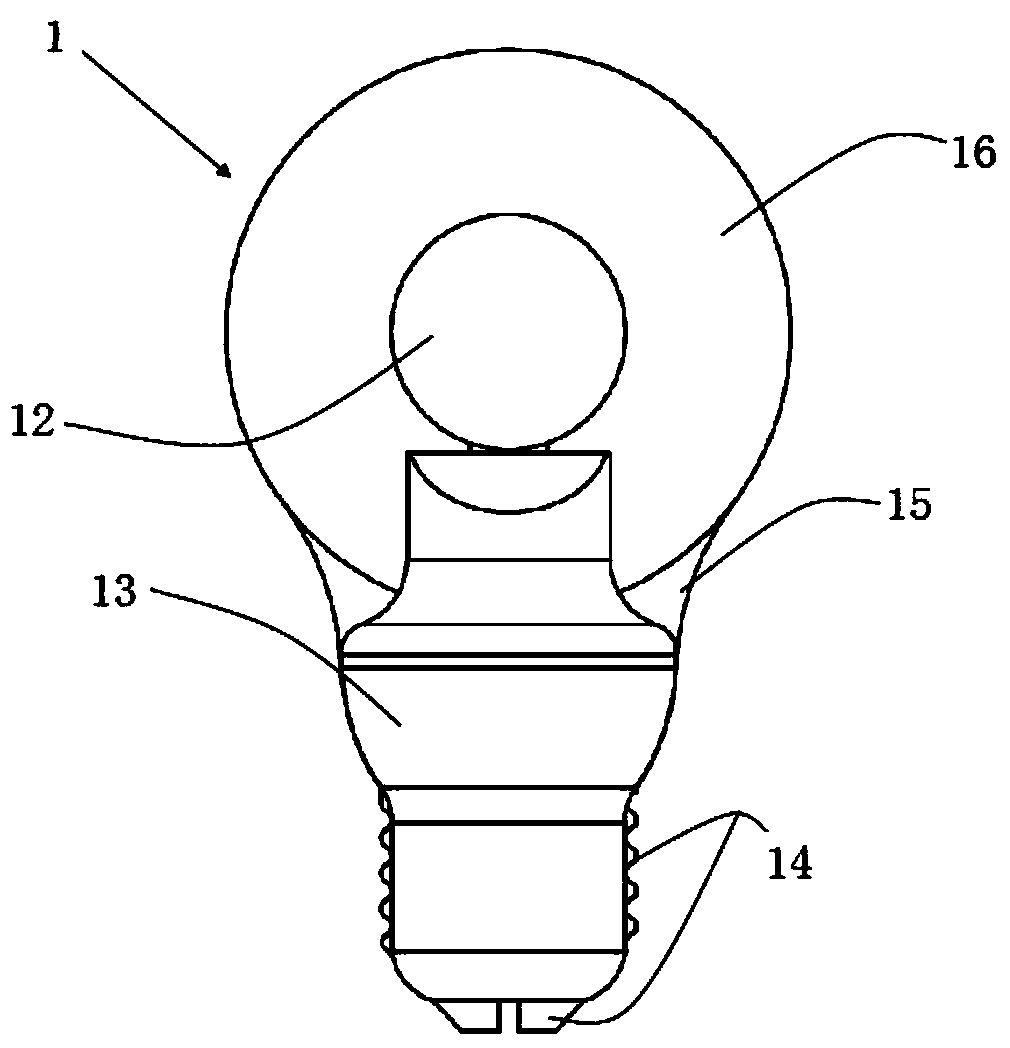

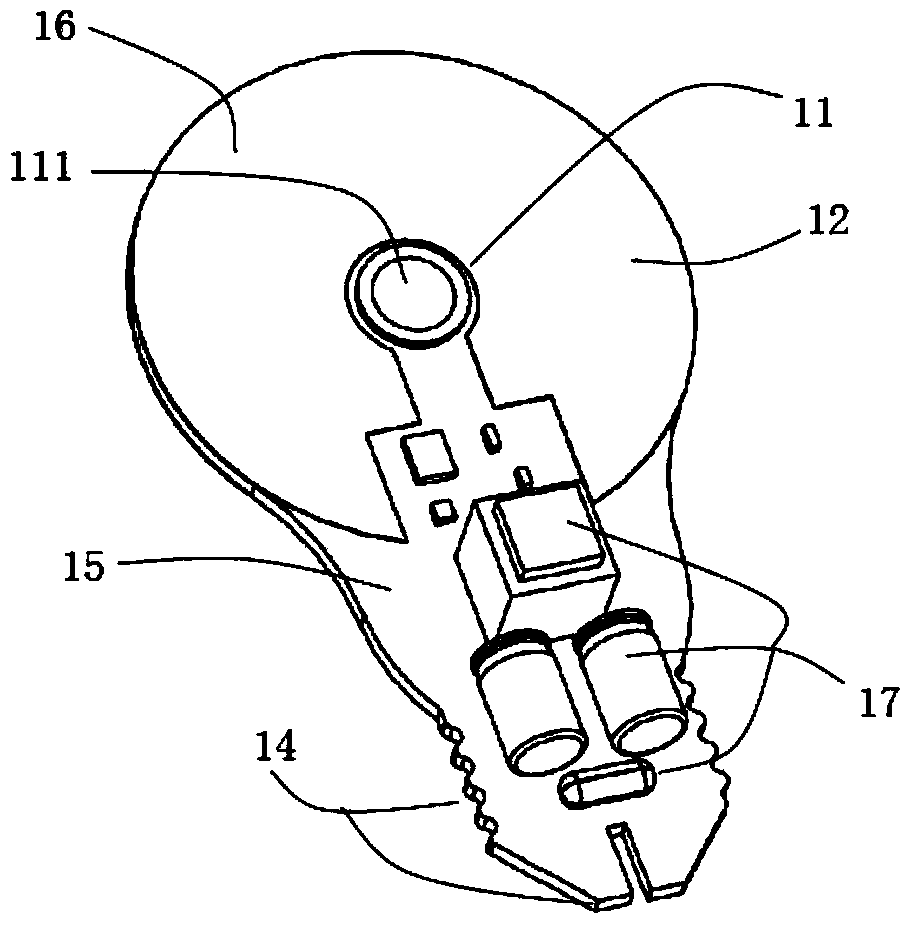

Integrated LED lamp bulb

InactiveCN103994353AEffective full projectionEffectively break upPoint-like light sourceElectric circuit arrangementsDiffusion functionEngineering

The invention discloses an integrated LED lamp bulb. The integrated LED lamp bulb comprises a substrate, a double-faced LED module, an outer shell, transparent covers and a reflecting layer, wherein the LED module is installed at one end of the substrate, the outer shell is buckled at the other end of the substrate, the transparent covers cover the LED module, are installed on the two side faces of the substrate and have the photo-diffusion function, and the reflecting layer is plated between the transparent cover and the substrate. An circuit board integrating reflecting and heat dissipating functions and a drive circuit and an LED lamp made of photo-diffusion transparent resin are integrated, and the circuit board integrates the function of a general screw base, so that the integrated LED lamp bulb is concise in appearance and easy to produce and install, and the integrated LED lamp bulb is similar to a traditional lamp bulb in appearance.

Owner:ZHEJIANG GUANGHUI LIGHTING ELECTRONICS

Flotation system for rare mineral separation

The invention belongs to the field of mineral equipment, and discloses a flotation system for rare mineral separation, which comprises a machine body, a driving space is arranged in the machine body, a driving mechanism for providing energy for the device is arranged in the driving space, and a raw material space is arranged on the lower side of the driving space. A stirring mechanism used for scattering mixed minerals is arranged in the raw material space, through the design of a flotation mechanism, bubbles generated by airflow in flotation liquid are scattered, meanwhile, the bubbles are in hedging contact with the airflow at a discharge port, then the contact between the bubbles and the minerals is fully increased, and therefore the mineral flotation efficiency is greatly improved; through the design of a collecting and scraping mechanism, liquid entangled on a corresponding storage scraping plate can be absorbed, so that water on the collecting and scraping surface of the corresponding storage scraping plate is greatly reduced, next collecting and scraping can be better carried out, meanwhile, the adhesion rate of foam on the storage scraping plate is greatly increased, and the collecting and scraping efficiency is improved.

Owner:嘉兴市汇顺达科技有限公司

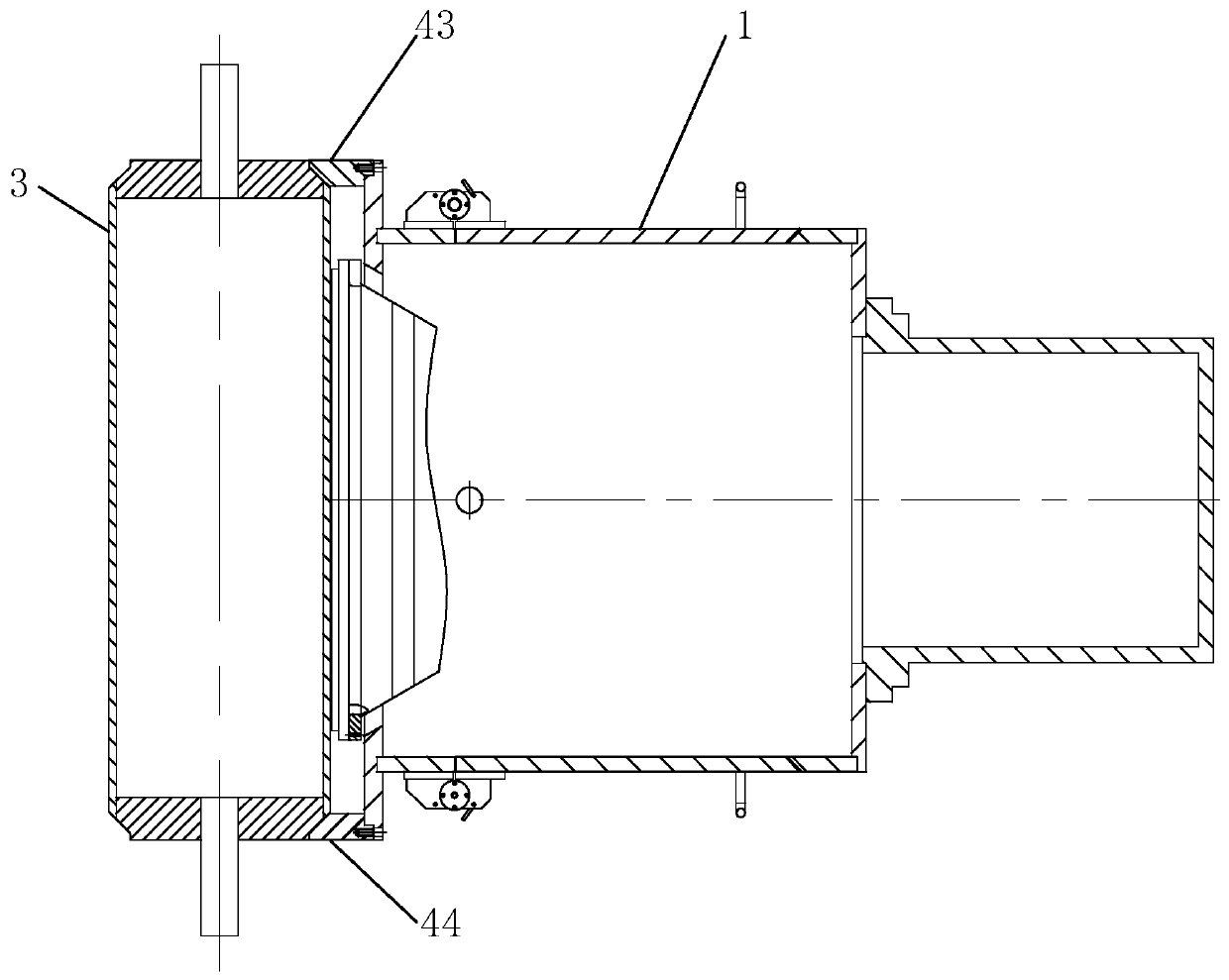

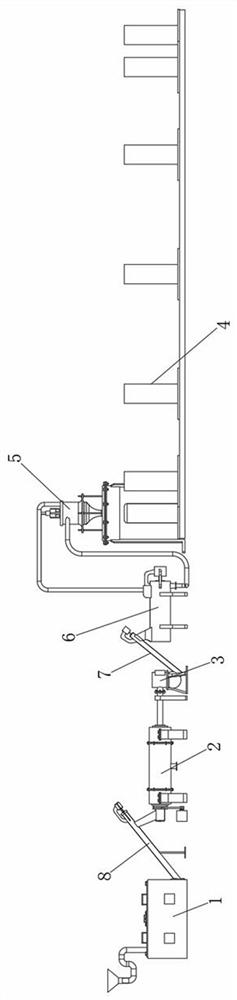

Novel EB curing nitrogen gas protection device

PendingCN110813671AEffectively break upAvoid enteringPretreated surfacesCoatingsPhysical chemistryNitrogen gas

The invention discloses a novel EB curing nitrogen gas protection device. The novel EB curing nitrogen gas protection device comprises an emitting box capable of emitting an electron beam, a coating curing chamber is arranged on the emitting box, a steel roller for feeding a substrate into the coating curing chamber is arranged in the coating curing chamber, an electron beam entry port for allowing the electron beam to be emitted in and to cure the coating on the substrate is arranged on the coating curing chamber, a main nitrogen gas port connected with a nitrogen gas supply device for filling nitrogen gas into the part between the coating curing chamber and the steel roller is arranged at an electron beam inlet, nitrogen gas supplement ports communicating with the coating curing chamberare formed in the parts, close to the end part of the coating curing chamber, of the coating curing chamber, and nozzles for filling the nitrogen gas into the part between the coating curing chamber and the steel roller is arranged on the nitrogen gas supplement ports. The high-pressure and high-flow nitrogen gas forms a high-speed wind blade through the nozzles, and an air layer attached to the surface of the coating substrate or the surface of the printing substrate can be effectively dispersed; and a nitrogen gas curtain formed by the high-speed wind blade can effectively prevent outside air from entering the coating curing chamber, so that the oxygen concentration in the EB curing area is lower than the EB curing requirement.

Owner:中山市优绿智得数码科技有限公司

Incinerator grate with transversely and longitudinally staggered head bosses

ActiveCN101929679BFast dryingImprove the effect of incineration treatmentIncinerator apparatusEngineeringDrying time

The invention discloses an incinerator grate with transversely and longitudinally staggered head bosses. A fixed beam passes through clamping grooves on the tail parts of the same row of fixed grate sheets so as to form fixed grate plates; a movable beam passes through clamping grooves on the tail parts of the same row of movable grate sheets so as to form movable grate plates; the movable grate plates and the fixed grate plates are longitudinally superposed and alternately arranged and gathered to form the grate; a head boss is arranged on the front end of the upper surface of each grate sheet; a primary air hole is formed on the head boss of each grate sheet; the head bosses of two adjacent grate sheets on the same row of grate plates are transversely and longitudinally staggered; and the front ends of each row of grate sheet are flush with one another. Through the incinerator grate with the transversely and longitudinally staggered head bosses, a garbage material layer can be effectively scattered so as to change the garbage height at each position of the incinerator material layer, increase the instability of the garbage material layer and facilitate garbage scattering and loosening; moreover, the incinerator grate realizes all-round scattering, loosening and stirring of the garbage material layer in an incinerator, improves the drying and burning efficiency of garbage, shortens the drying time and contributes to the fast burning of the garbage.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

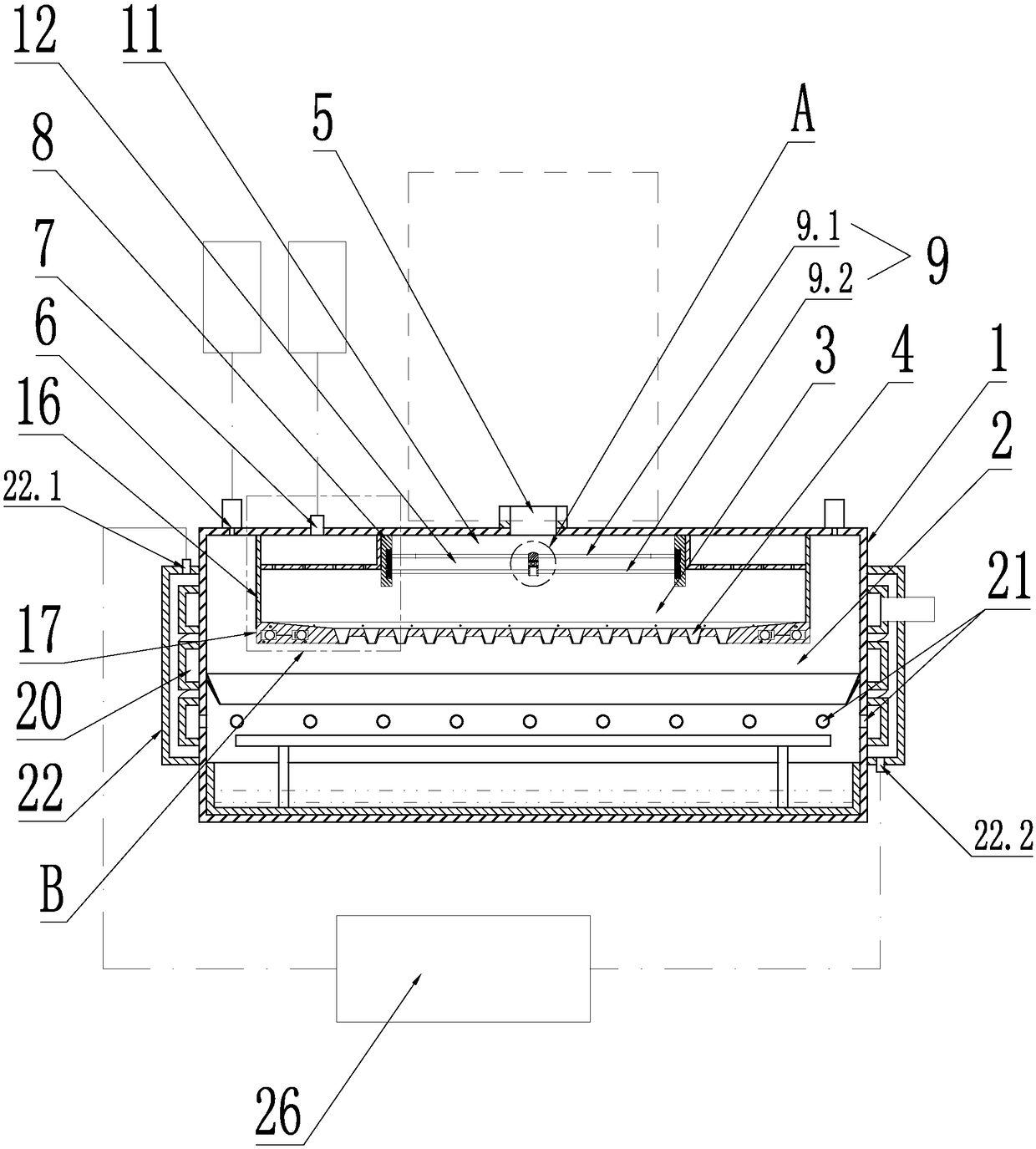

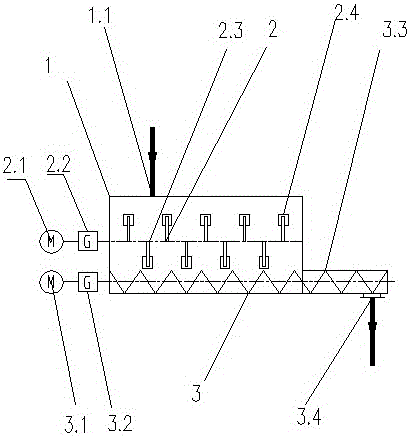

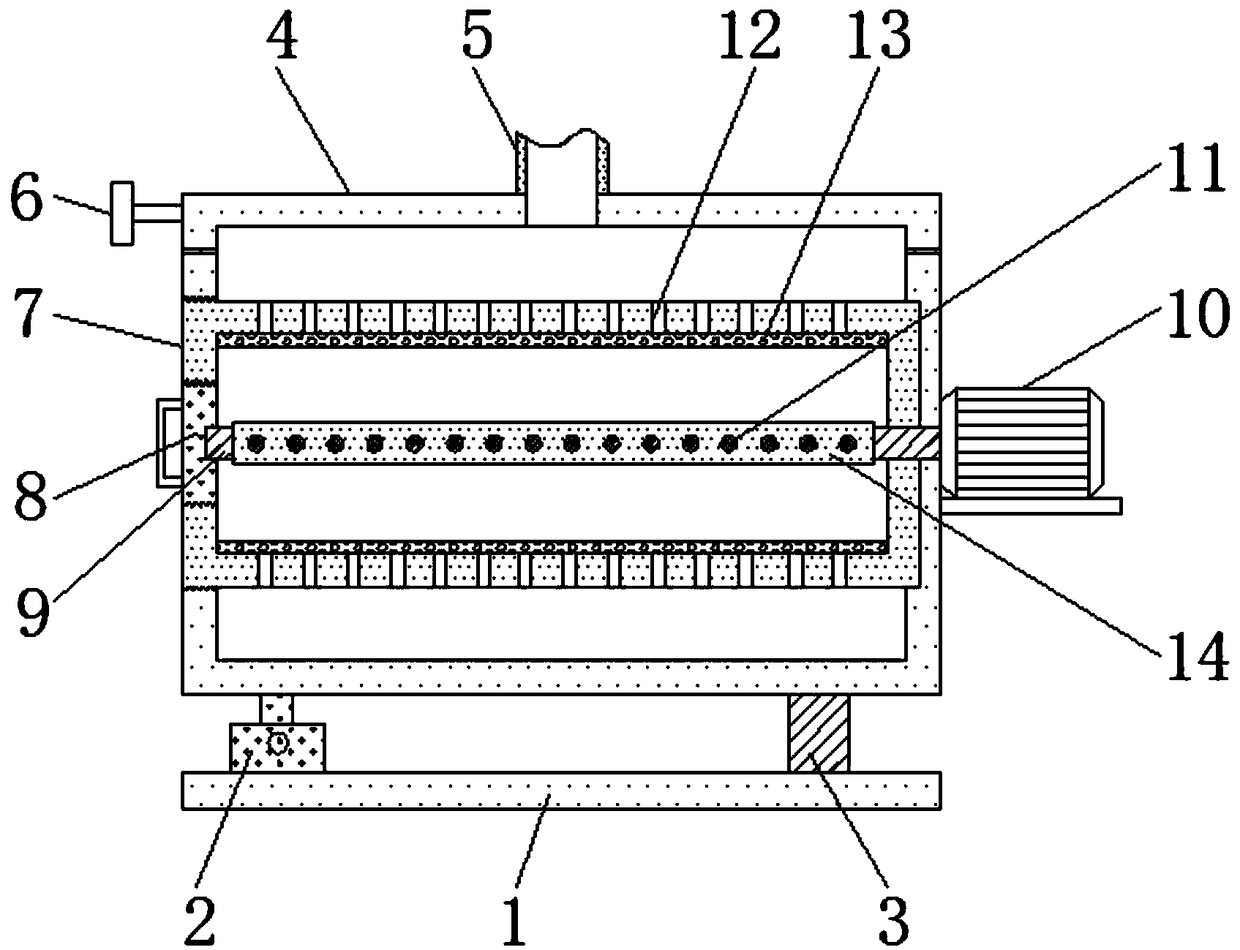

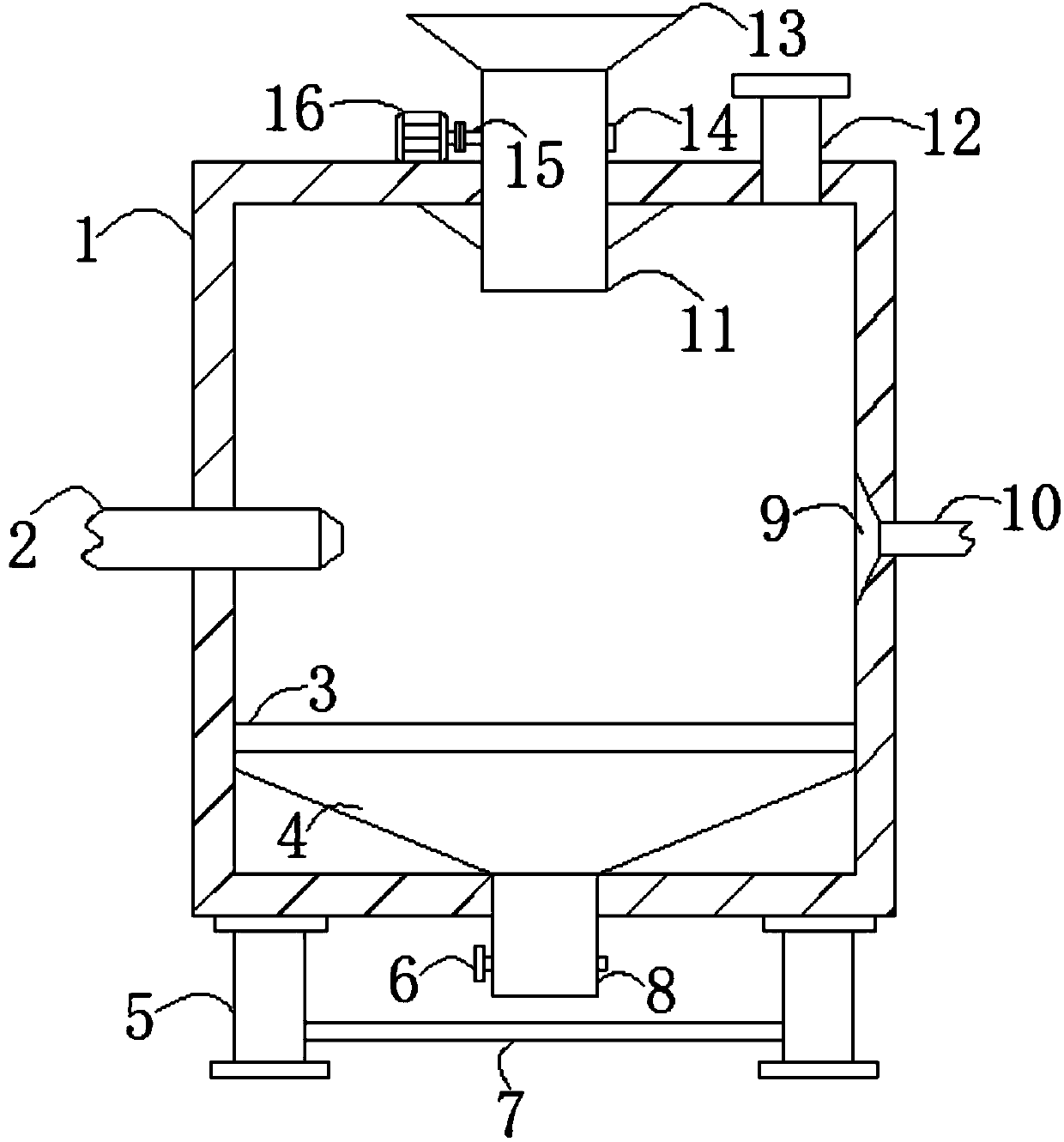

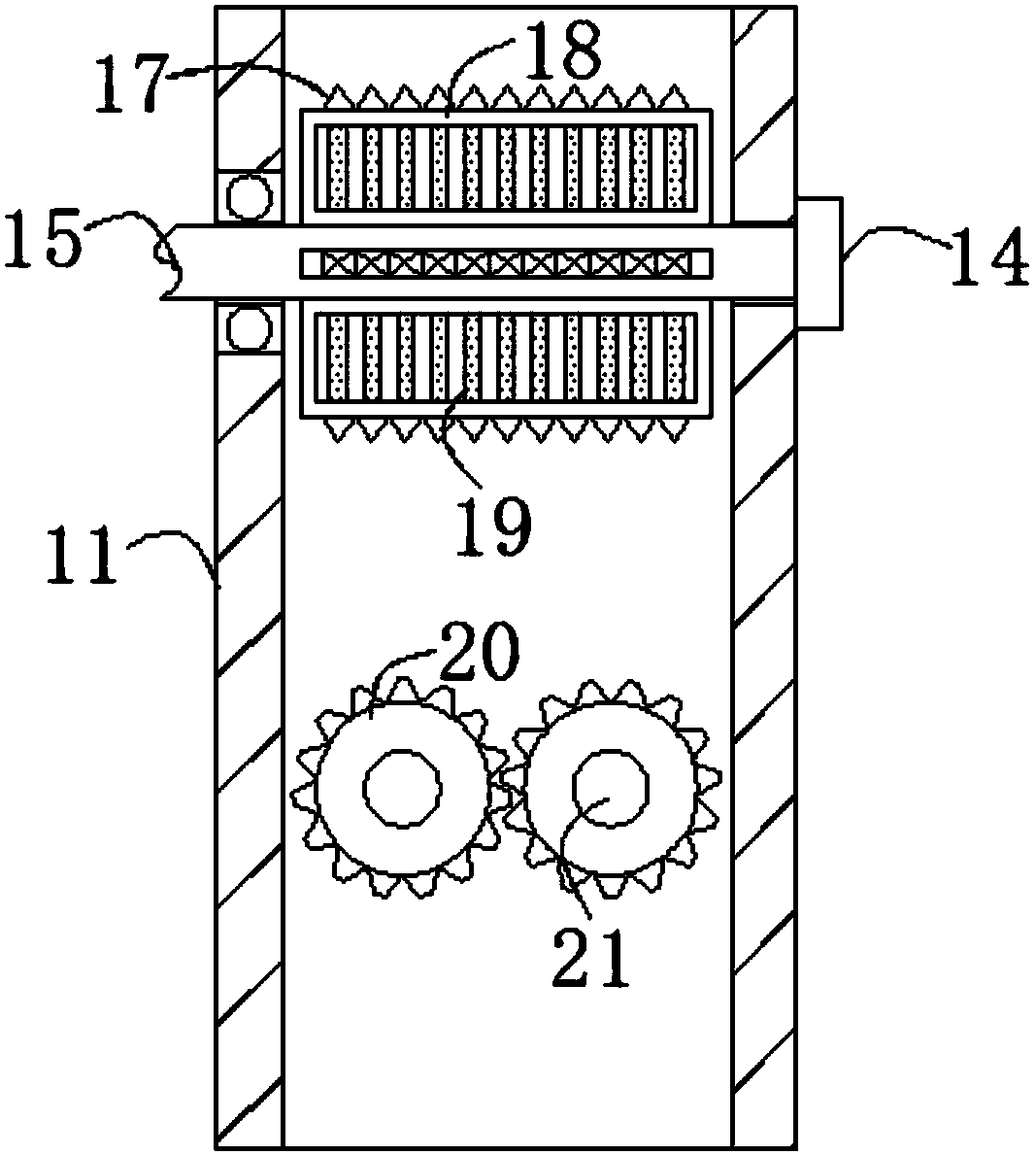

Material feeding device for drier

InactiveCN105972993AEffectively break upReduce contact areaDrying solid materialsDrying goods handlingWaste management

Owner:江苏格兰特干燥浓缩设备有限公司

Pig manure conversion and utilization device with dry-wet separation function

ActiveCN112592014AAccelerateImprove the effectSludge treatment by thermal conditioningSpecific water treatment objectivesBiologyCellulose

The invention discloses a pig manure conversion and utilization device with a dry-wet separation function. The pig manure conversion and utilization device comprises a treatment device, a dehydrationdevice, a dry material box, a fermentation tank, a cyclone separator, a crushing device, a second spiral feeding machine, a first spiral feeding machine, an annular guide rail and an electric trolleybase. According to the pig manure conversion and utilization device with the dry-wet separation function, accurate temperature regulation and control in the anaerobic fermentation tank can be achieved, the anaerobic fermentation speed is effectively increased, pathogenic bacteria in pig manure can be killed through high temperature, and organic matter containing a large amount of cellulose, ligninand other degradation-resistant components in live pig manure can be ground into powder, so that the anaerobic fermentation effect of the live pig manure can be effectively improved, moisture in thelive pig manure can be preliminarily separated through the pretreatment device, clustered live pig manure can be effectively scattered, and the live pig excrement can be effectively dehydrated throughthe dehydration device.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY SCI SHANXI ACAD OF AGRI SCI SAAS

Cleanable demister for oil-gas separator

InactiveCN104826399AFacilitate oil and gas separationSolve not easy to condenseDispersed particle separationPhysicsDemister

The invention provides a cleanable demister for an oil-gas separator. The cleanable demister is composed of an arc demisting plate, a structural plate, a speed-reducing fan, a nozzle, a nozzle control switch, a cleaning solution storing box, a drain outlet, a support bar, an oil collection tank and a solution delivery pipe. The speed-reducing fan reduces the speed of oil mist and can effectively scatter the oil mist, thereby facilitating oil-gas separation. The oil mist coagulates on the arc demisting plate and then can flows into the oil collection tank. The nozzle arranged at the top of the arc demisting plate controls flowing-out of a cleaning solution under the control of the nozzle control switch. The cleanable demister provided by the invention effectively overcomes the problem of uneasy coagulation when the flow velocity of the oil mist is fast, improves the deficiency of uneasy cleaning of the demister, runs based on simple principles and is convenient and practical.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

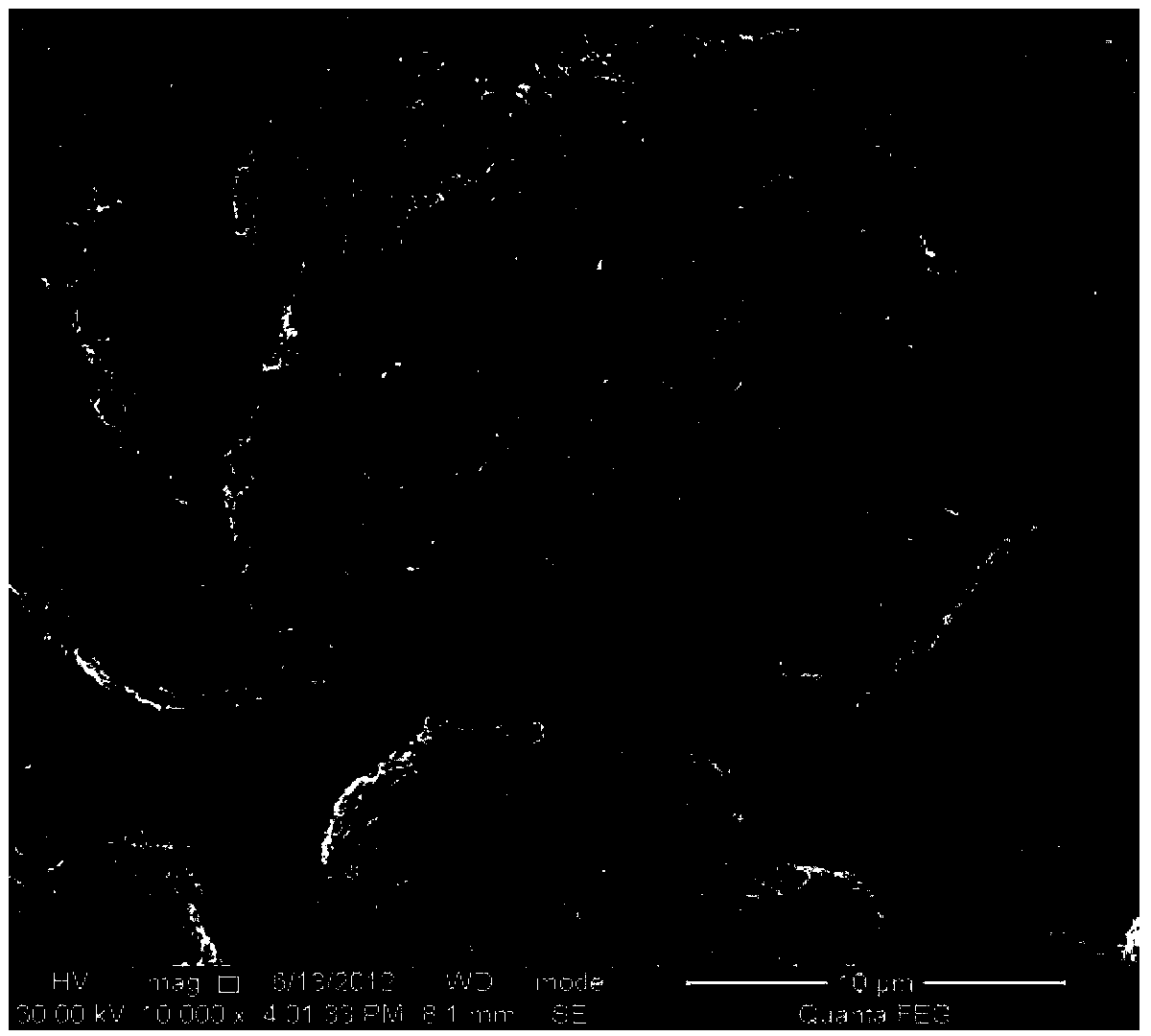

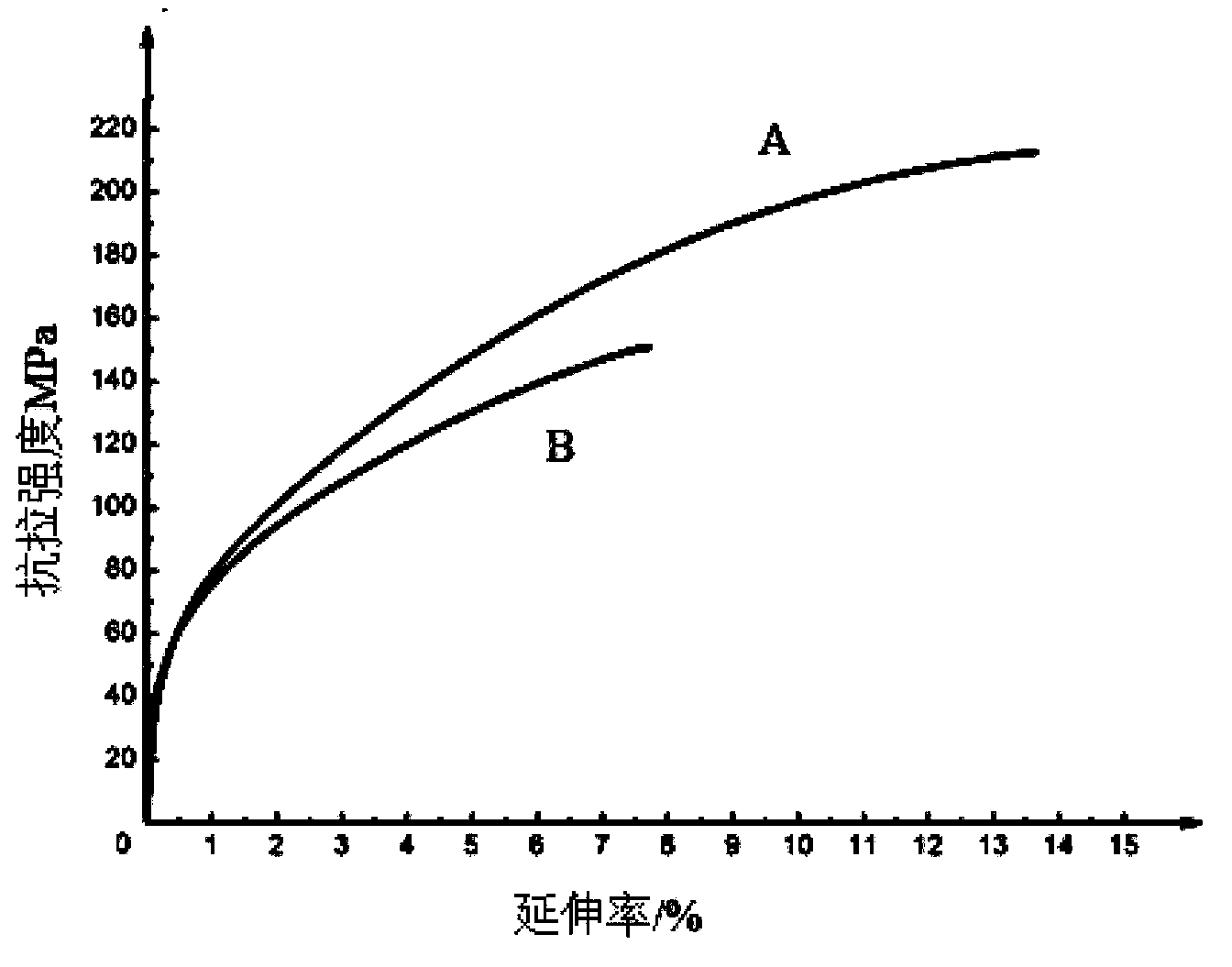

Preparation method of enhanced magnesium-based composite material of carbon nanotubes

The invention relates to a preparation method of an enhanced magnesium-based composite material of carbon nanotubes, relates to a preparation method of a nanometer composite material, and mainly solves the technical problems that the carbon nanotubes are difficultly scattered uniformly in a magnesium alloy matrix and the tensile strength of the enhanced magnesium-based composite material is low. The preparation method comprises the following steps of: firstly, carrying out mixing and ball milling on Zn powder and the carbon nanotubes to obtain composite powder; secondly, pressing the composite powder and magnesium powder into precast blocks after uniformly mixing the composite powder and the magnesium powder; and finally, adding the precast blocks into the molten magnesium powder, heating until obtaining metal solution, and transferring the metal solution into a die to be pressed, thus obtaining the enhanced magnesium-based composite material of the carbon nanotubes, wherein the tensile strength of the enhanced magnesium-based composite material is 195-210 MPa, and the elongation rate of the enhanced magnesium-based composite material is 13-15%. According to the preparation method of the enhanced magnesium-based composite material of the carbon nanotubes, the tensile strength is high, the dispersity is good, and the enhanced magnesium-based composite material of the carbon nanotubes can be applied to the fields of aerospace, automobiles and sports equipments.

Owner:HARBIN INST OF TECH

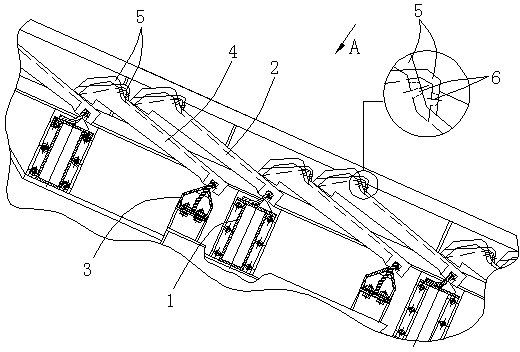

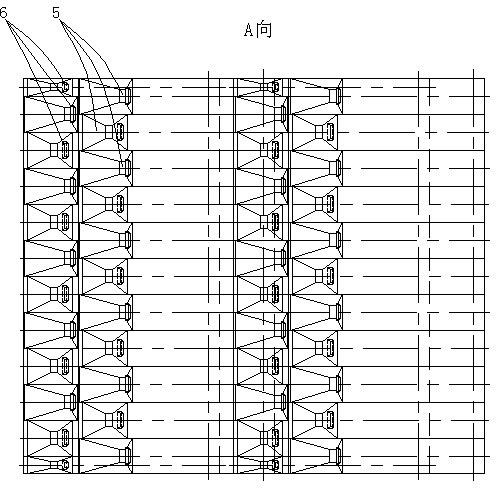

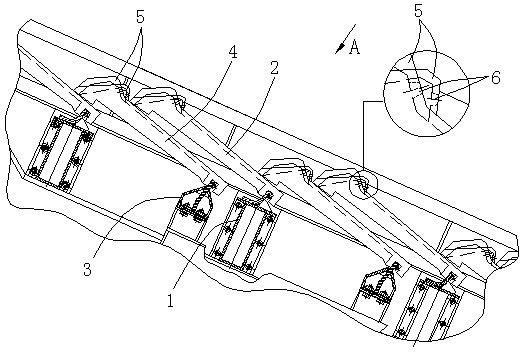

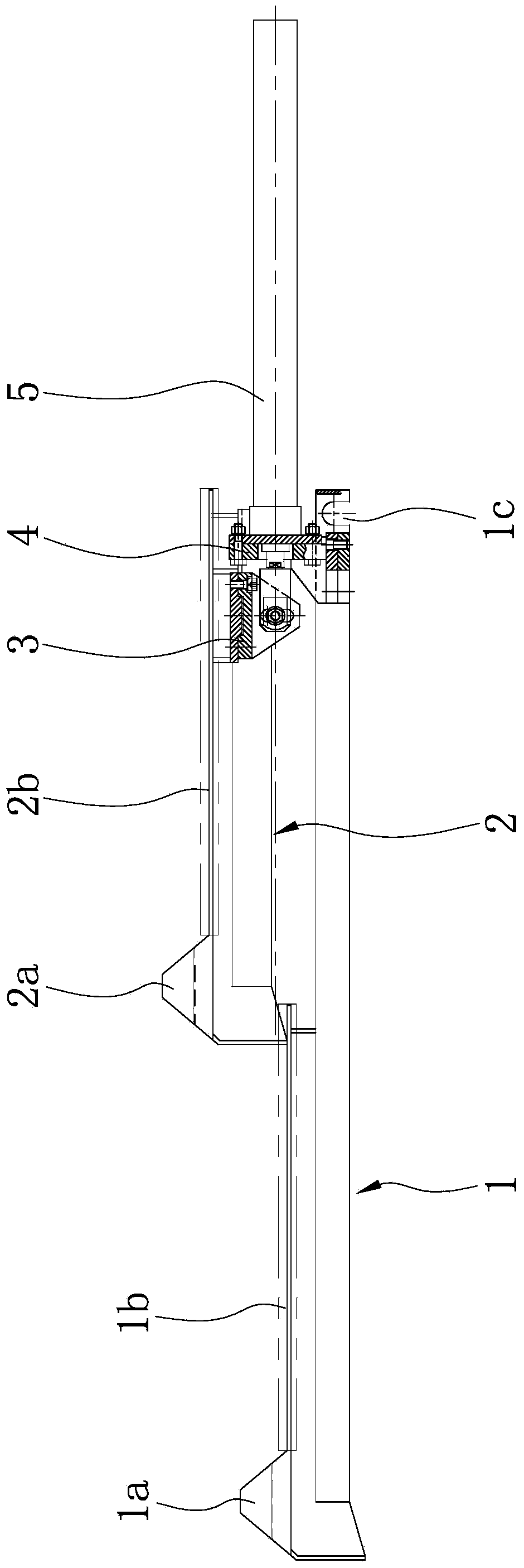

Grate set for garbage incinerator

The invention discloses a grate set for a garbage incinerator. The upper end of the front of a fixed grate segment (1) is provided with a first back movement plane (1b), the front end of the first back movement plane (1b) protrudes upwards to form a first head boss (1a), the upper end of a movable grate segment (2) is provided with a second back movement plane (2b), the top of the front end of the second back movement plane (2b) protrudes upwards to form a second head boss (2a), a driving support (3) is fixed at the bottom of the rear end of the movable grate segment (2), a positioning seat (4) in the rear of the driving support (3) is fixed at the rear end of the fixed grate segment (1), a driving device (5) is mounted on the positioning seat (4), and the front end of the driving device (5) is connected with the driving support (3). The grate set has the advantages that since the fixed grate segment and the movable grate segment are modularized, on one hand, assembly process is simplified, and assembly difficulty is lowered; on the other hand, labor intensity of workers is reduced, and assembly efficiency is improved greatly.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Quick drying device for tea processing

InactiveCN108759400ADry evenlyImprove practicalityPre-extraction tea treatmentTea dryingEngineeringMagnet

The invention discloses a quick drying device for tea processing. The quick drying device comprises a baseplate and a second shell; a first shell is arranged above the baseplate, and the left side ofthe lower end of the first shell is connected to the left side of the upper end of the baseplate through a hinge; the right side of the lower end of the first shell is provided with a support column,and the middle position of the upper end of the first shell is provided with an air inlet; the left upper end of the first shell is provided with a pull rod, and the second shell is located in the first shell; and a sleeve plate is arranged on a connecting rod, and a magnet is arranged between the sleeve plate and a rotating shaft. According to the quick drying device for tea processing, hot air is delivered into device through external equipment, and tea can be quickly dried through cooperation of stir-fry; and in the stir-fry process, small stones or some fragments mixed in the tea can be filtered out, and the practicability is improved.

Owner:福州众点网络技术开发有限公司

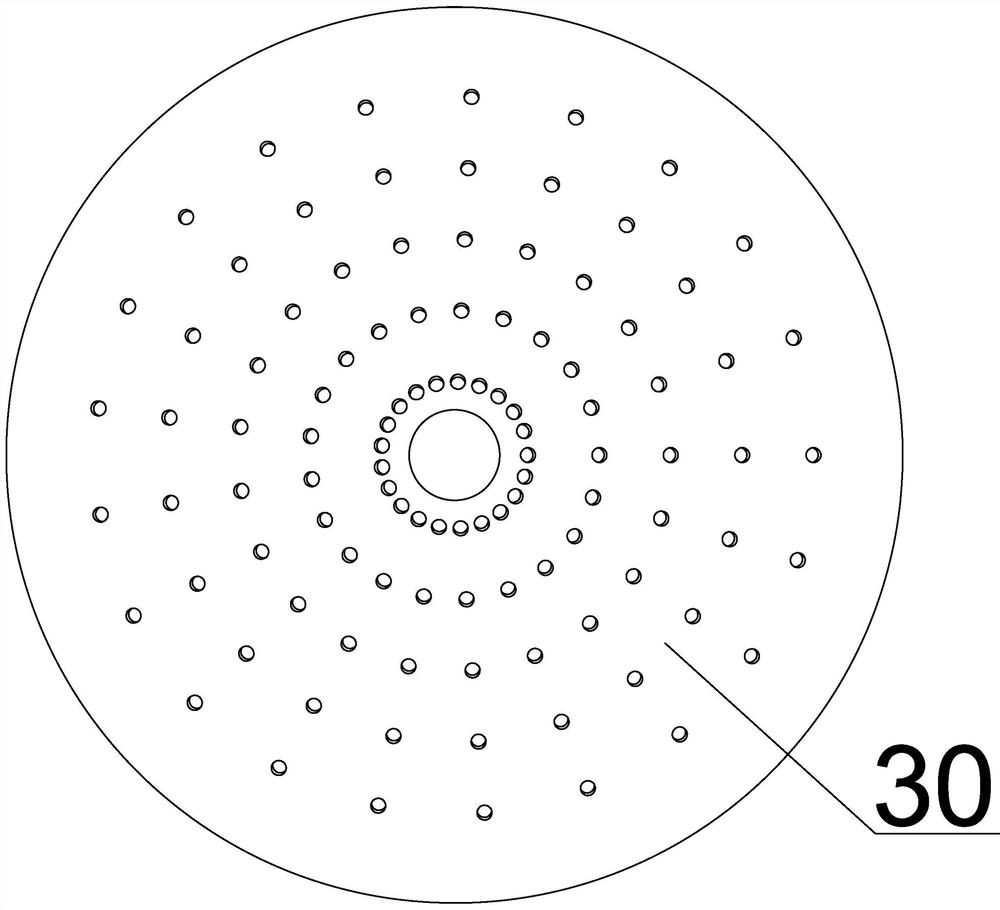

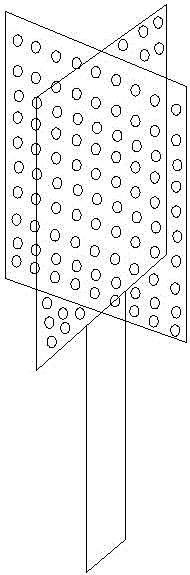

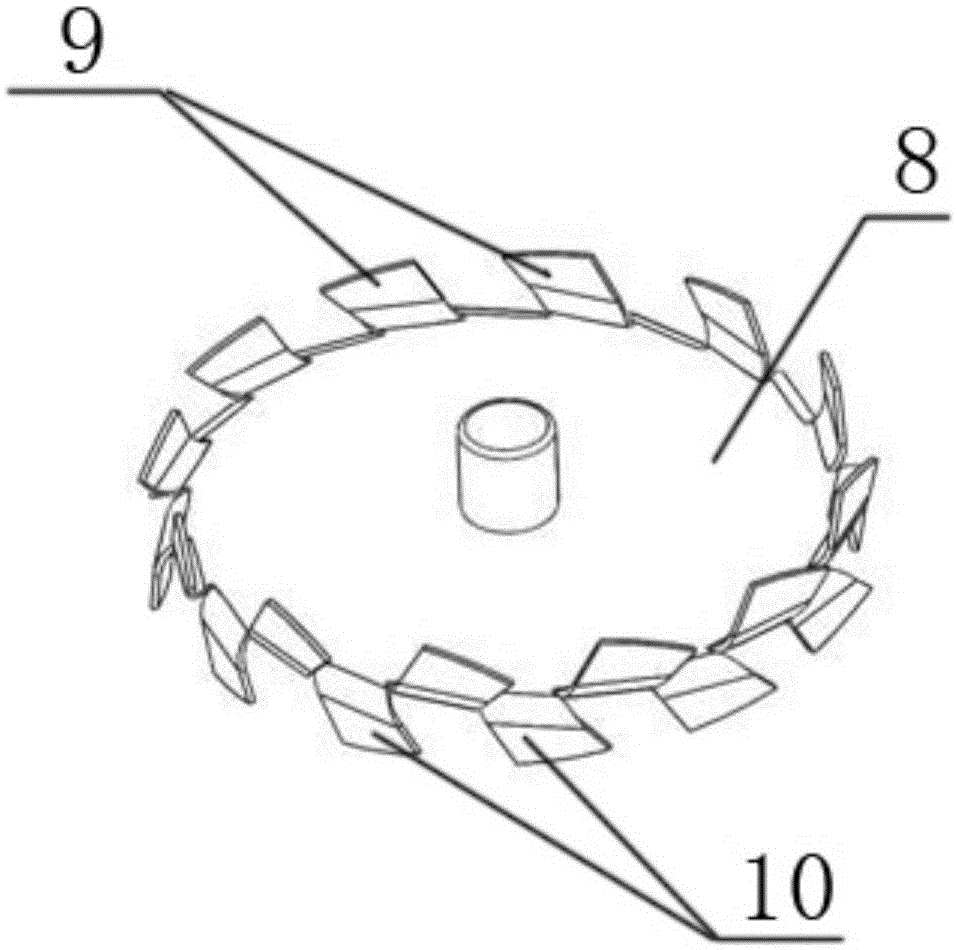

Mortar metalevel particle disperser

InactiveCN105056788AEffectively break upImprove the mixing effectRotary stirring mixersImpellerMaterials science

The invention provides a mortar metalevel particle disperser. The mortar metalevel particle disperser has good stirring effect, good mixing and dispersion effect and higher impact force and shear force, huddle silicon carbide particles can be effectively dispersed, the stirring time is short, and the unit time capacity can be improved. The mortar metalevel particle disperser comprises a stirring container, wherein a central rotating shaft is arranged inside the stirring container, and an upper paddle and a lower paddle are arranged on the central rotating shaft. The mortar metalevel particle disperser is characterized in that a high-speed stirrer is arranged in the stirring container; the high-speed stirrer comprises a disc-type zigzag impeller, a rotary table rotating shaft and a power device; the disc-type zigzag impeller is arranged on the internal side of the stirring container; the disc-type zigzag impeller comprises a rotary table, an upper zigzag plate and a lower zigzag plate; the center of the rotary table is connected with the rotary table rotating shaft; the upper end of the rotary table rotating shaft is externally connected with the power device; and the rotary table rotating shaft is positioned on one side of the central position of the stirring container and is eccentrically arranged.

Owner:HAREON SOLAR TECHNOLOGY CO LTD

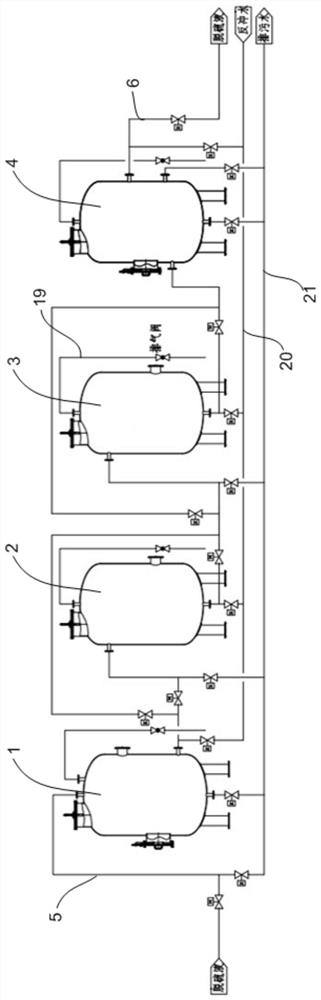

A desulfurization waste liquid purification device

ActiveCN108911041BEffectively break upEffectively disperse and evenly disperseTreatment involving filtrationWaste water treatment from gaseous effluentsActivated carbonProcess engineering

The invention discloses a desulfurization waste liquid purification device, which comprises a first desulfurization tank, a second desulfurization tank, a third desulfurization tank and a fourth desulfurization tank; a porous ceramic filter device and a ceramic membrane are installed in the first desulfurization tank, and a porous ceramic The filter device includes a straight-tube ceramic membrane filter tube. The ceramic membrane filter tube is provided with multiple filter channels. One end of the ceramic membrane filter tube is equipped with a liquid collection bucket, and one end of the liquid collection bucket is connected to one end of the ceramic membrane filter tube. One end of the liquid collection bucket is connected with a collision separation straight pipe, and a plurality of collision plates are arranged at equal intervals in the collision separation straight pipe. One end of the collision separation straight pipe is connected with a gourd-shaped ceramic membrane filter, and one end of the ceramic membrane filter is connected with a There are porous ceramic balls in the liquid outlet pipe and the ceramic membrane filter, and a filter orifice plate is installed at the connection between the liquid outlet pipe and the ceramic membrane filter; ceramic fillers and activated carbon are stacked in the second desulfurization tank, and the third desulfurization tank is equipped with There is activated carbon, and a ceramic membrane is arranged in the fourth desulfurization tank.

Owner:PINGXIANG PANGTAI IND

Lake surface poultry feed identifying and collecting device and method

InactiveCN111891304AEasy to grabEasy Grab Component CaptureSievingHull interior subdivisionShrimpEngineering

The invention relates to the technical field of garbage cleaning, and particularly relates to a lake surface poultry feed identifying and collecting device and method. The ship comprises a ship body and two supporting air bags. The device further comprises a control box, an adsorption mechanism and a catching mechanism. A controller is mounted in the control box; a first storage cabin, a second storage cabin and a third storage cabin are integrally formed in the ship body; a sealed cabin is arranged at the bottom of the second storage cabin; the top of the third storage cabin is communicated with an isolation cabin; the adsorption mechanism comprises a sealing plate and a drainage assembly; the catching mechanism is arranged in the isolation cabin and is used for catching fishes and shrimps; the catching mechanism comprises an elastic rod, a sliding assembly and a grabbing assembly. According to the lake surface poultry feed recognizing and collecting device and method, lake surface garbage and living things can be distinguished, mixing of the lake surface garbage and the living things is prevented, poultry breeding is facilitated, meanwhile, the loading space can be effectively saved, and the garbage treatment efficiency is improved.

Owner:芜湖星之原工业设计有限公司

Metalized slurry of power battery sealing connector and preparation method of metalized slurry

InactiveCN110120275AWell mixedFully brokenNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesiveActive agent

The invention discloses metalized slurry of a power battery sealing connector and a preparation method of the metalized slurry. The metalized slurry comprises a metalized raw material and an organic adhesive, and the mass ratio of the metalized raw material to the organic adhesive is 8-9 : 1-2. The metalized raw material comprises a metal oxide active agent, and the metal oxide active agent comprises the following components in percentage by mass: 10-15% of aluminum oxide powder, 8-15% of silicon dioxide, 1-2% of titanium dioxide and 1-2% of tantalum pentoxide. The organic adhesive comprises ethyl cellulose, terpene alcohol, organic silicon defoamer and an organic silicon flatting agent, and the mass ratio of the ethyl cellulose to the terpene alcohol to the organic silicon defoamer to theorganic silicon flatting agent is 10-15 : 1000-1199 : 3 : 5. The roughness of the metalized surface of the sintered battery sealing connector is reduced to be less than or equal to 1.0 [mu]m, and themetalized sealing strength is improved to be more than or equal to 120Mpa.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

Organic fertilizer rapid drying device

ActiveCN113720122AEffectively break upAvoid lump build-upManure dryingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention relates to the technical field of drying equipment, and discloses an organic fertilizer rapid drying device which comprises a drying box. A U-shaped frame is installed at the top of the drying box, a drying motor is installed in the center position of the upper end of the U-shaped frame, an output shaft of the drying motor is connected with a driving gear, the two sides of the driving gear are engaged with driven gears, a driving shaft is connected to the center position of the lower end of the driving gear, a drying shaft is connected to the bottom of the driving shaft through a flat key, an exhaust box is rotationally arranged at the upper side position of the drying shaft, the interior of the drying shaft is of a hollow structure, multiple drying holes communicating with the exhaust box are connected to the wall of the drying shaft in a penetrating manner, the exhaust box further communicates with an air suction box throw an air blowing pipe, the air suction box is fixed to the top end of the inner wall of the drying box, the air suction box is connected with a hot air box through an air inlet pipe, and the hot air box is fixed to the outer side of the top end of the drying box. According to the organic fertilizer rapid drying device, the drying shaft can rotate while moving up and down, organic fertilizer in the drying box can be effectively scattered, and the caking and stacking phenomena of the organic fertilizer are avoided.

Owner:SHANGDONG TENOV PESTICIDES

Domestic garbage gasification furnace with good gasification effect

InactiveCN107760380AImprove gasification effectImprove work efficiencyGasifier mechanical detailsGasification processes detailsCombustionDrive shaft

The invention discloses a domestic waste gasification furnace with good gasification effect, which comprises a furnace body, a combustion nozzle is arranged at the center of the left side of the furnace body, and the right side of the combustion nozzle penetrates into the inner cavity of the furnace body. The center of the right side of the inner cavity of the furnace is provided with a bell mouth, the right side of the bell mouth is connected with an air inlet pipe, and the right side of the top of the furnace inner cavity is connected with an air outlet pipe. The present invention can effectively disperse domestic garbage by setting bearing housings, transmission shafts, motors, sawtooth, flaps, retaining rods, gears and movable shafts, so that the gasification effect of the domestic garbage gasifier is better , to solve the problem that when the domestic waste gasifier is in use, the domestic waste cannot be effectively broken up before the domestic waste is disposed of, causing the domestic waste to enter the furnace body in a lump, resulting in gasification of the domestic waste. incomplete problem.

Owner:浙江杭胜锅炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com