Edible mushroom planting equipment and processing process thereof

A technology of edible fungi and equipment, which is applied in the field of edible fungi planting equipment and its processing technology, can solve problems such as the impact of efficiency and labor costs, and achieve the effect of ensuring uniformity and improving planting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

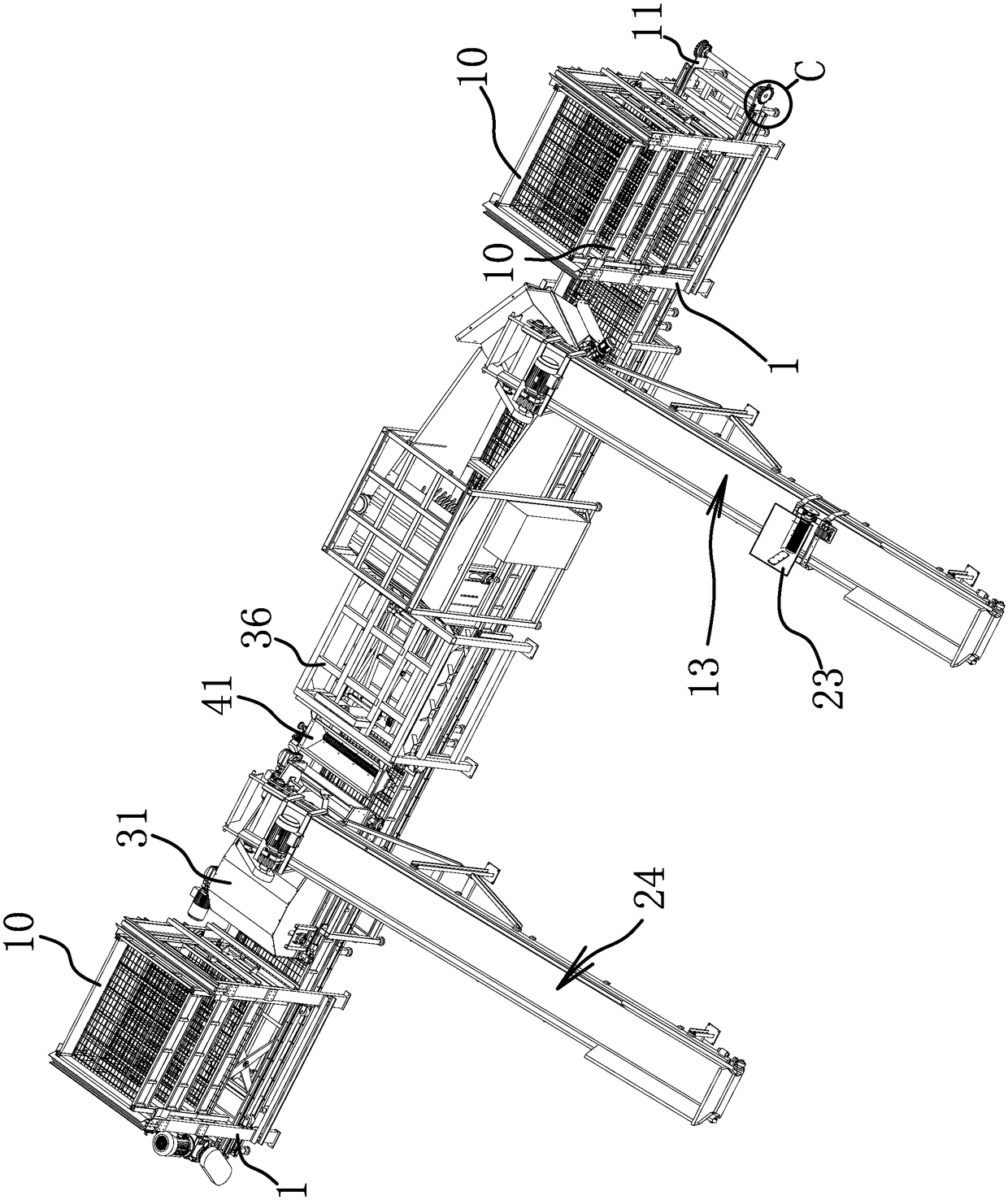

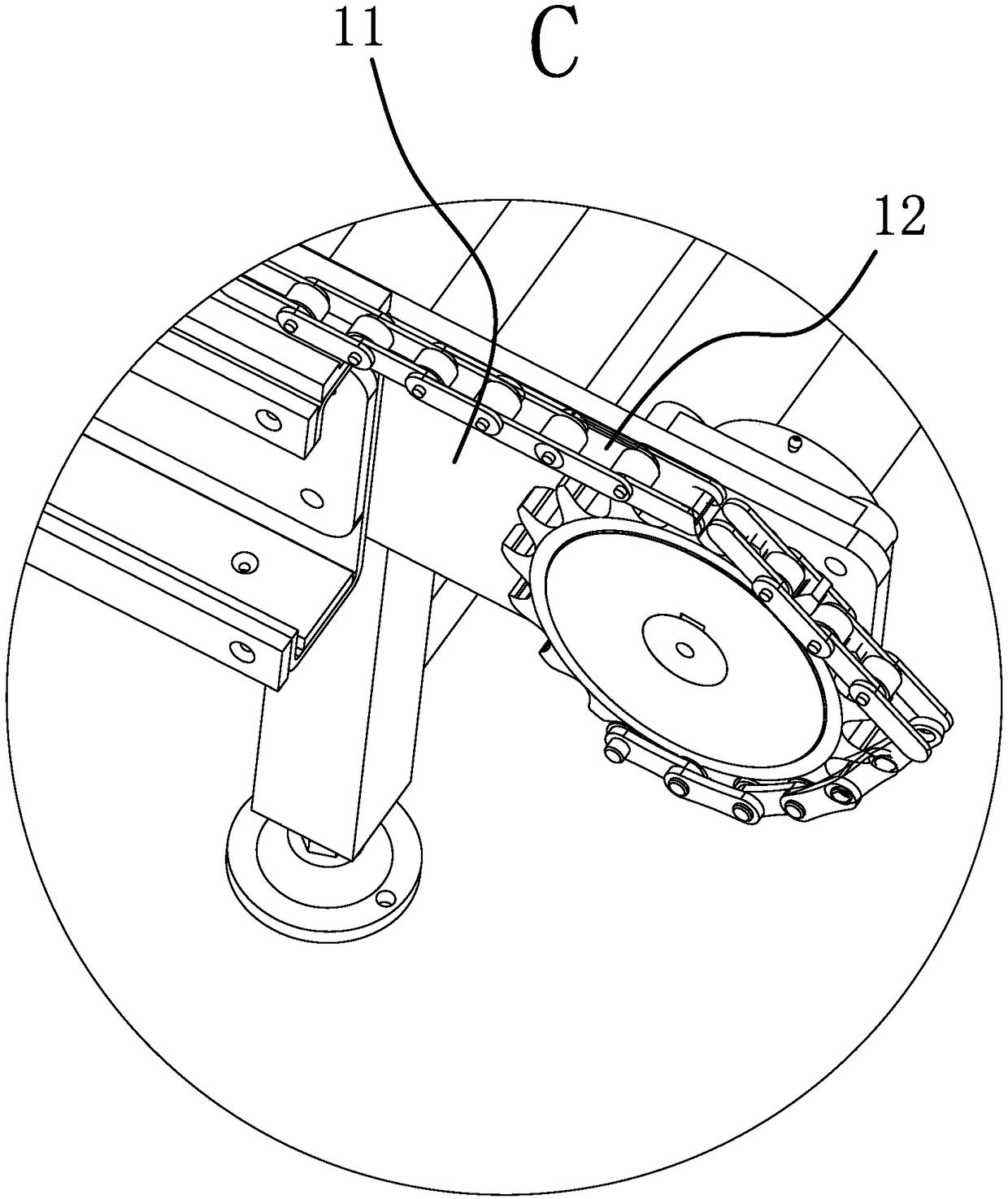

[0075] Such as figure 1 and figure 2 As shown, this edible fungus planting equipment comprises mounting frame 11 and the conveyor chain 12 that is horizontally arranged on the mounting frame 11, and mounting frame 11 is provided with the delivery device that can send planting frame 10 to conveyor chain 12 feeding ends. Bacteria and fertilizer are sent into the mixing device in the planting frame 10 together, the flattening mechanism, the surface wave machine, the soil feeding device that can send the soil into the planting frame 10, and the planting frame that can be at the discharge end of the conveyor chain 12. 10 conveying device two sent out, and conveying device one, mixing device, flattening mechanism, surface wave machine, soil sending device and conveying device two or six are distributed sequentially along the conveying direction of conveying chain 12.

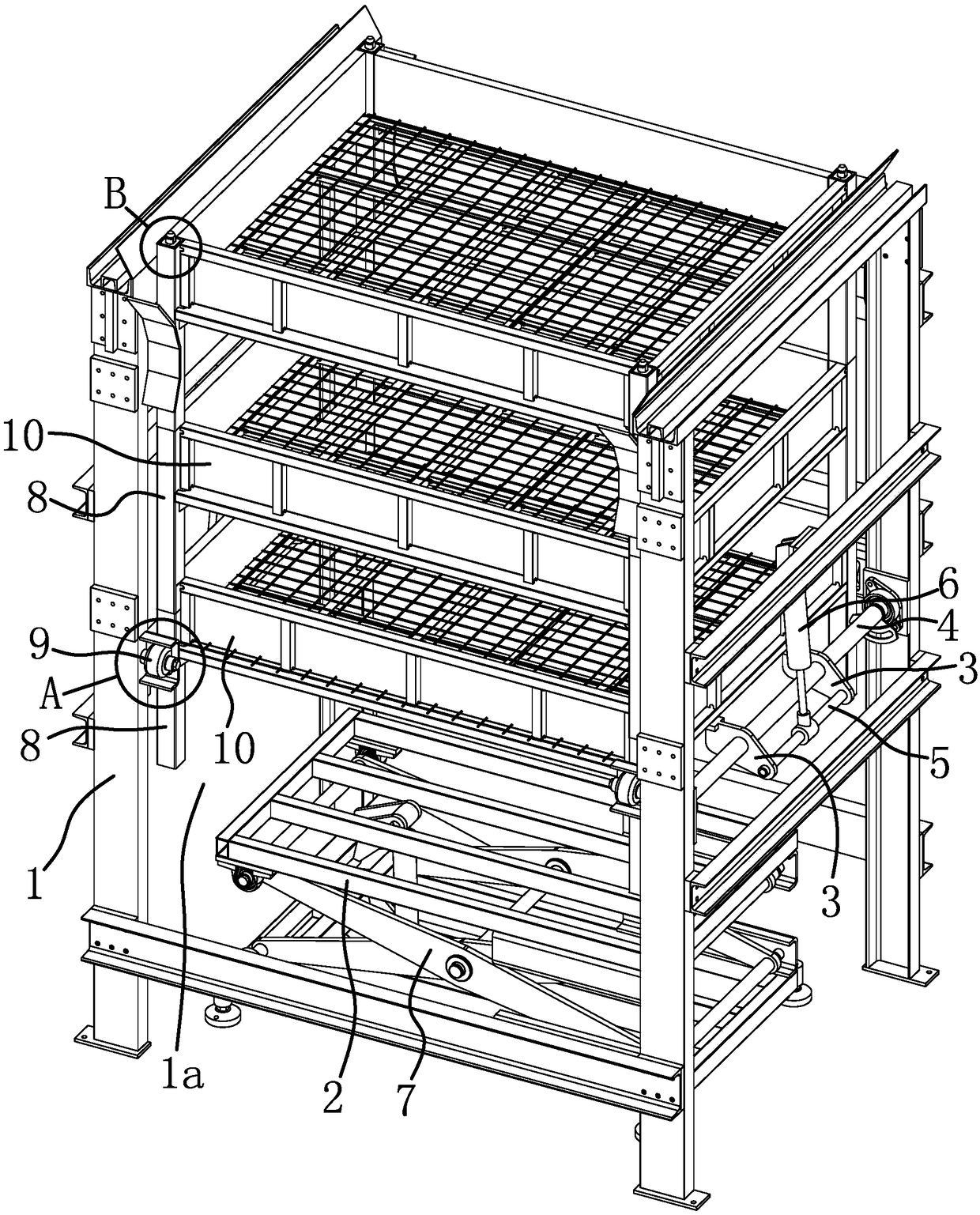

[0076] Among them, such as Figure 3 to Figure 6 As shown, the first conveying device and the second conveying d...

Embodiment 2

[0105] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the rotating shaft 4 is fixedly connected with the bracket 1 , and the support member is a support ring sleeved on the rotating shaft 4 .

Embodiment 3

[0107] The structure and principle of the third embodiment are basically the same as those of the first embodiment, except that the lifting mechanism includes a base and an oil cylinder 2 installed on the base, and the piston rod of the oil cylinder 2 is fixedly connected with the bracket 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com