Composite type fiber board

A composite, plate technology, applied in the field of materials, can solve the problems of large specific gravity, low strength, unsuitable use, etc., and achieve the effects of reducing weight, improving bending strength, and improving processing convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

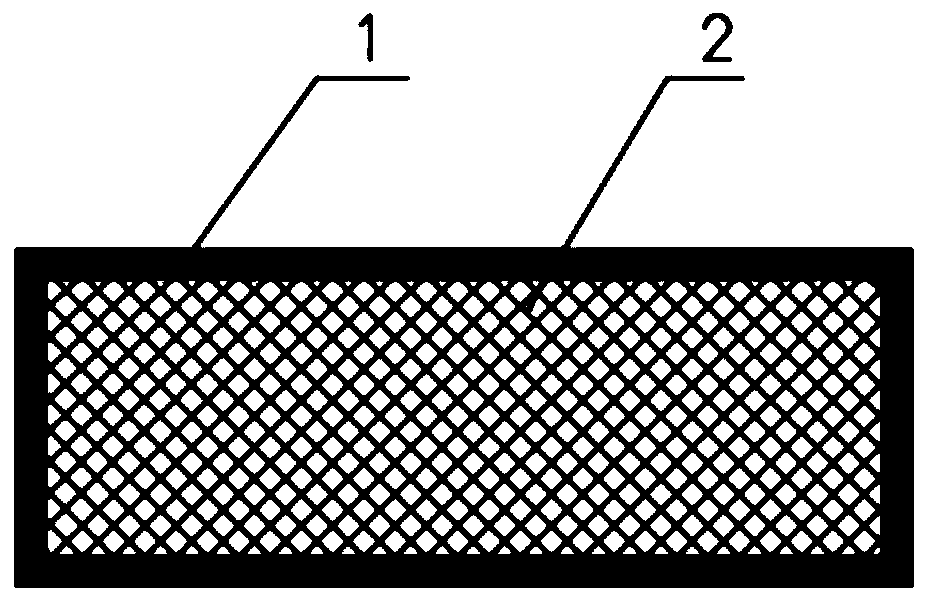

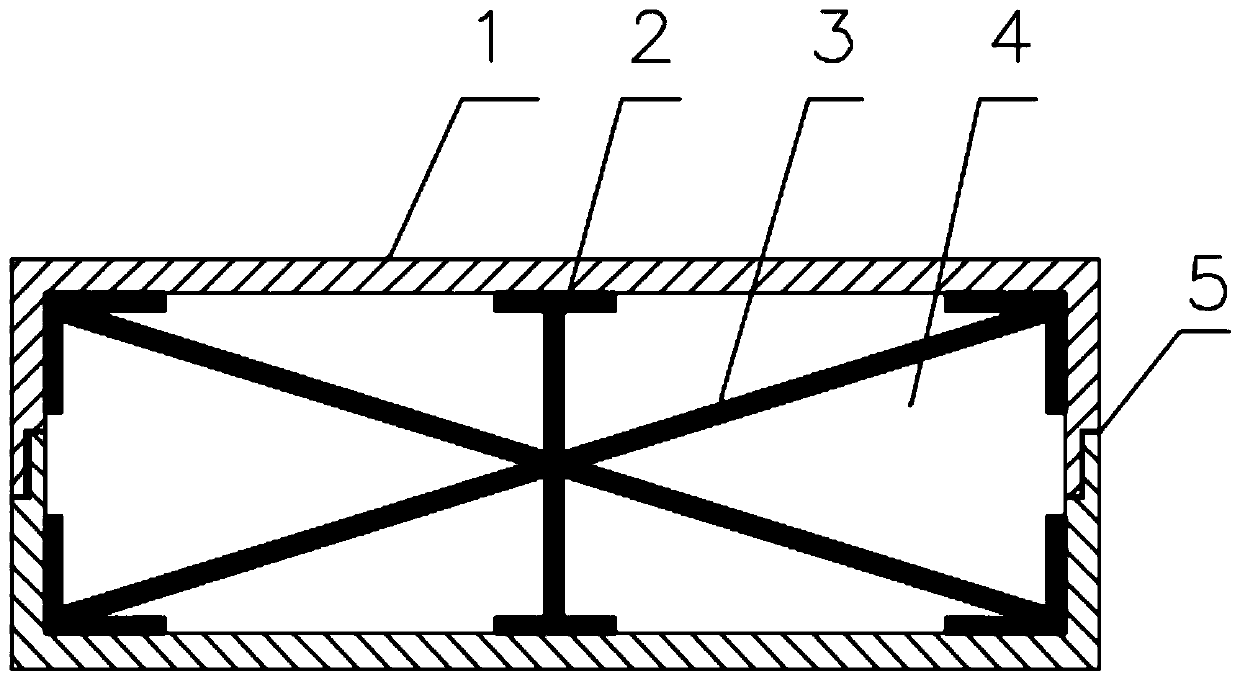

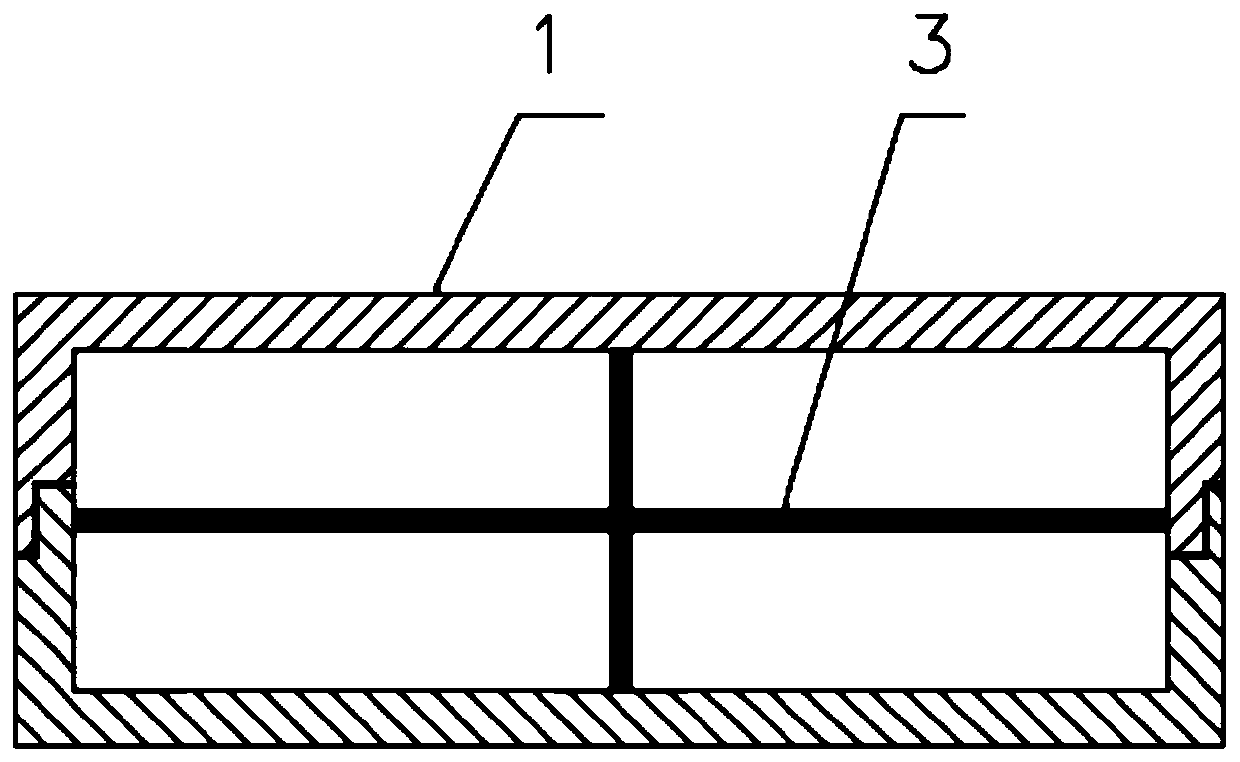

[0026] like figure 2 As shown, a composite fiber plate is hollow, the outer layer is provided with a carbon fiber cortex 1, and the interior is provided with a support 3 to support the carbon fiber cortex 1; the support 3 forms a triangular structure with the plate panel.

Embodiment 2

[0028] Further optimization on the basis of Example 1, a reinforcement beam 2 is provided at the position where the end of the bracket 3 is in contact with the carbon fiber skin 1 .

[0029] Further optimization on the basis of embodiment 2, the reinforcing beam 2 and the carbon fiber skin layer 1 are integrally formed.

[0030] Further optimization on the basis of embodiment 2, the reinforcing beam 2 is connected with the carbon fiber skin layer 1 by riveting or bonding.

[0031] like Figure 2-6 As shown, further optimized on the basis of Example 1, the cross section of the bracket 3 is cross-shaped, star-shaped or triangular. The star here includes the "*" shape. like figure 2 As shown, it is in the shape of "*", such as image 3 As shown, it is in the shape of a cross; Figure 4 As shown, it is a triangle; Figure 5 Shown is a triangular shape.

[0032] Further optimization on the basis of Example 1, the plate cross-section is rectangular, circular or irregular, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com