Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

A negative electrode material and lithium storage technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of few reports, and achieve the effect of simple process, uniform appearance and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

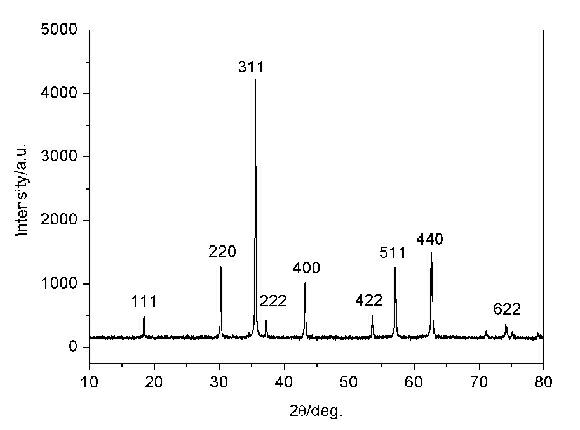

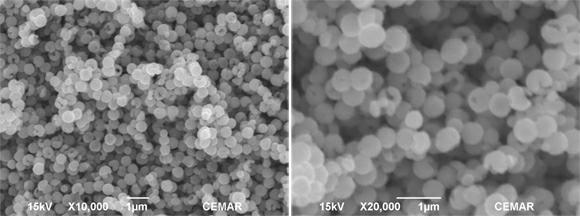

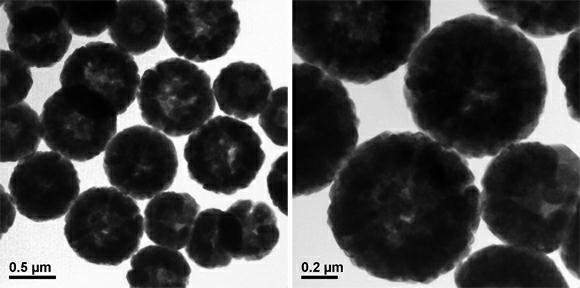

[0032] Weigh 1.35g of ferric chloride hexahydrate, dissolve it in 35 mL of ethylene glycol solution, and then add 1-2 mL of polyethylene glycol 2000 dropwise to 30 o C. Slowly add 2.73g urea and 1.0g glucose (the molar ratio of ferric chloride:urea is 1:9) under magnetic stirring at room temperature, and keep stirring at this temperature for 1 hour. Transfer this mixed solution to a 50 mL polytetrafluoroethylene lined reactor, o React at C for 48 hours. After the reactor is cooled to room temperature, the supernatant is recovered for the next use, the obtained precipitate is separated by filtration and washed with deionized water and absolute ethanol 3 times each, 80 o Vacuum drying at C for 12 hours to obtain a black product. The obtained products were subjected to elemental analysis and XRD analysis, indicating that the product is Fe 3 O 4 / C.

[0033] With ferric chloride: urea molar ratio of 1:9, solvothermal 200 o Hollow sphere structure Fe prepared by C reaction for 48 hour...

Embodiment 2

[0035] Weigh 1.35g of ferric chloride hexahydrate, dissolve it in 35mL of ethylene glycol solution, and then add 1-2mL of polyethylene glycol 2000 dropwise. o Under C water bath heating and magnetic stirring, slowly add 2.73g urea and 1.0g glucose (wherein the molar ratio of ferric chloride:urea is 1:9), maintain this temperature and continue to stir for 1 hour. Transfer this mixed solution to a 50mL polytetrafluoroethylene-lined reactor, at 200 o React at C for 24 hours. After the reaction kettle is cooled to room temperature, the supernatant liquid is recovered for the next use, the obtained precipitate is separated by filtration and washed with deionized water and absolute ethanol 3 times each, 80 o Vacuum drying at C for 12 hours to obtain a black product. The obtained products were subjected to elemental analysis and XRD analysis, indicating that the product is Fe 3 O 4 / C.

[0036] Hollow sphere structure Fe prepared by ferric chloride: urea molar ratio of 1:9, solvothermal...

Embodiment 3

[0038] Weigh 2.70g of ferric chloride hexahydrate and dissolve it in 35mL of ethylene glycol solution, then add 1-2mL of polyethylene glycol 2000 dropwise, and slowly add 6.67g of urea and 1.0g in a water bath at 40°C under magnetic stirring Glucose (wherein the molar ratio of ferric chloride:urea is 1:11), keep this temperature and continue to stir for 1 hour. Transfer this mixed solution to a 50mL polytetrafluoroethylene-lined reactor, at 200 o React at C for 48 hours. After the reaction kettle is cooled to room temperature, the supernatant is recovered for the next use. The precipitate obtained is filtered and separated and washed with deionized water and absolute ethanol 3 times each, 80 o Vacuum drying at C for 12 hours to obtain a black product. The obtained products were subjected to elemental analysis and XRD analysis, indicating that the product is Fe 3 O 4 / C.

[0039] The molar ratio of ferric chloride: urea is 1:11, solvothermal is 200 o Hollow sphere structure Fe pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com