Patents

Literature

6892 results about "Composite oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

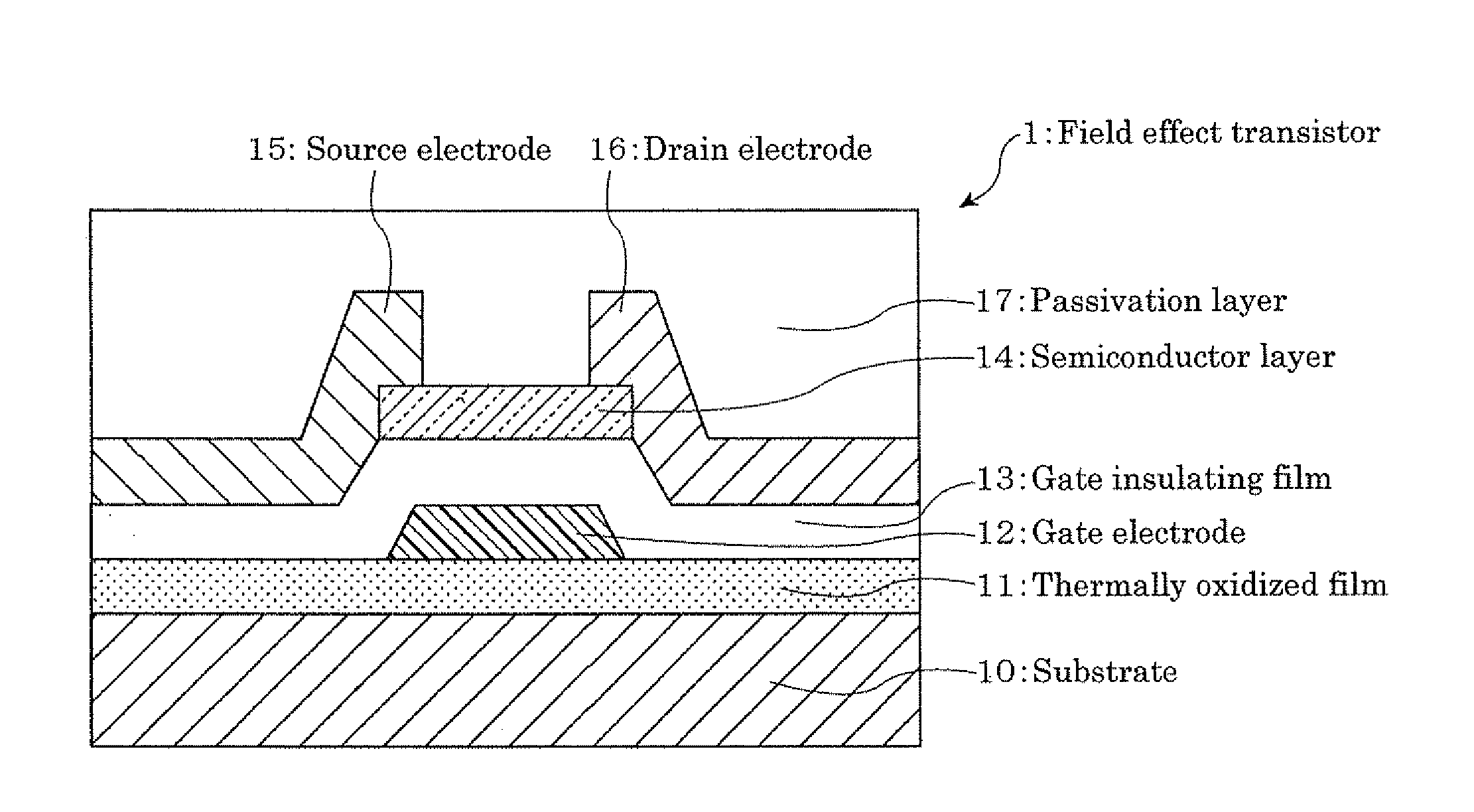

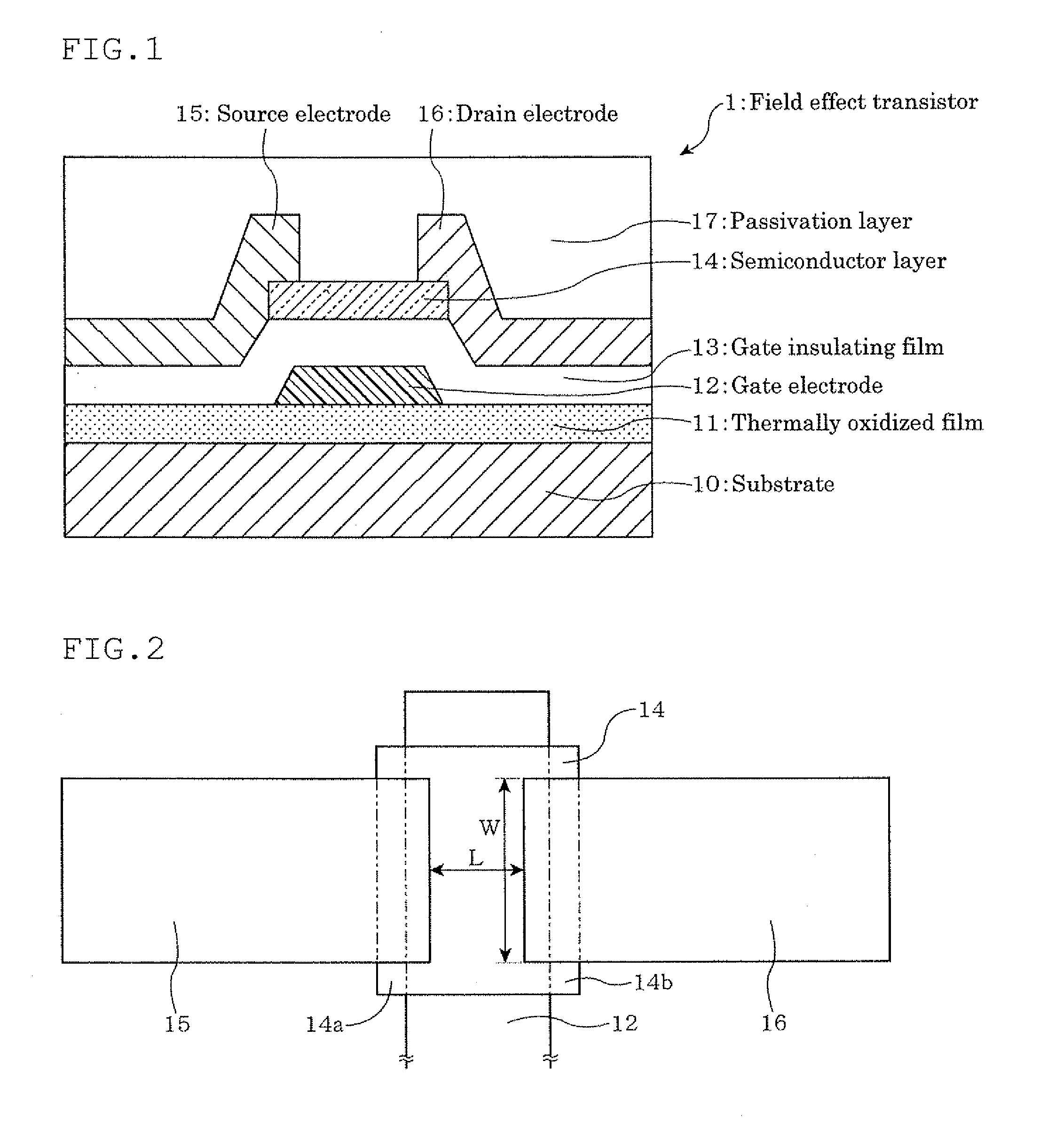

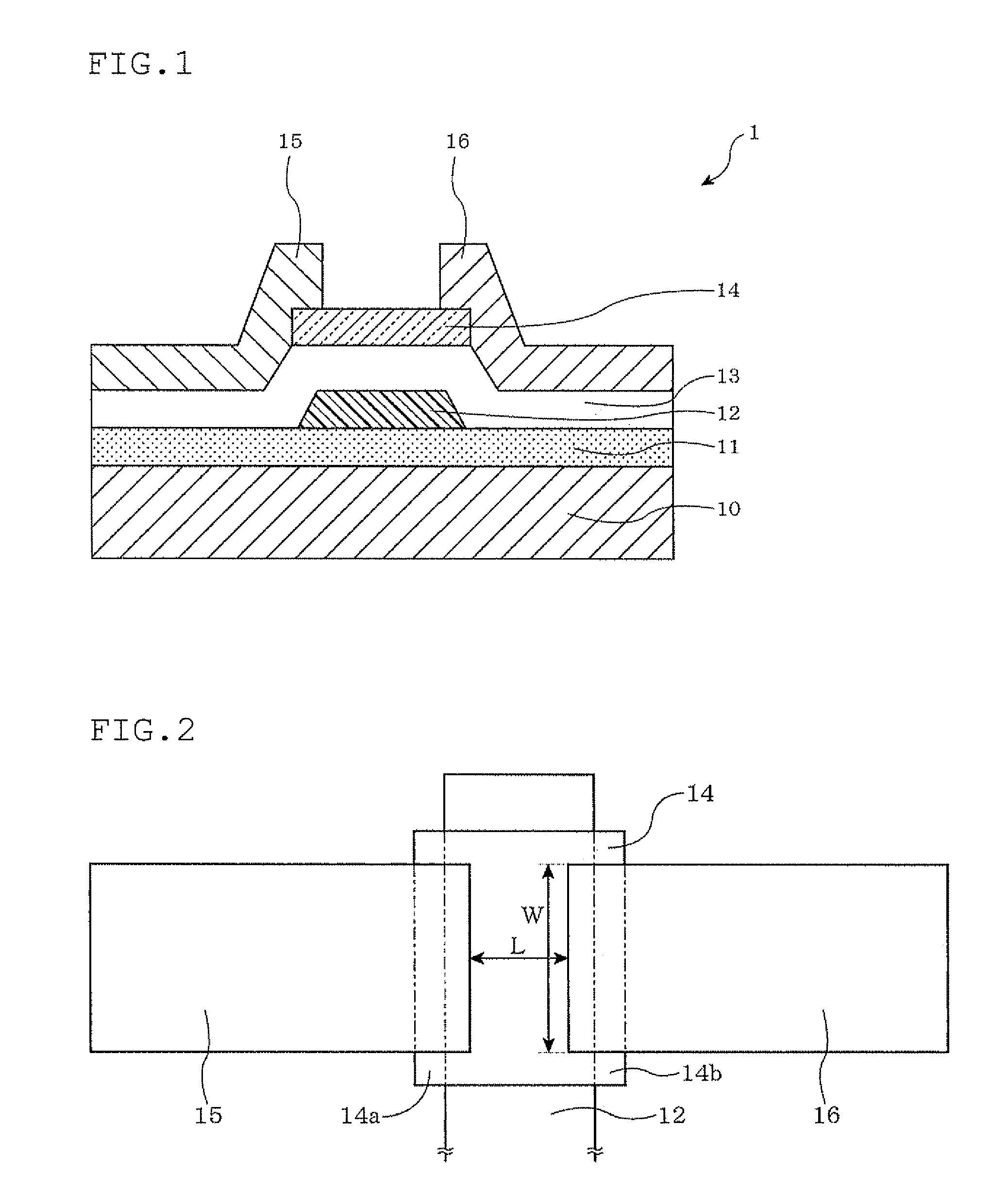

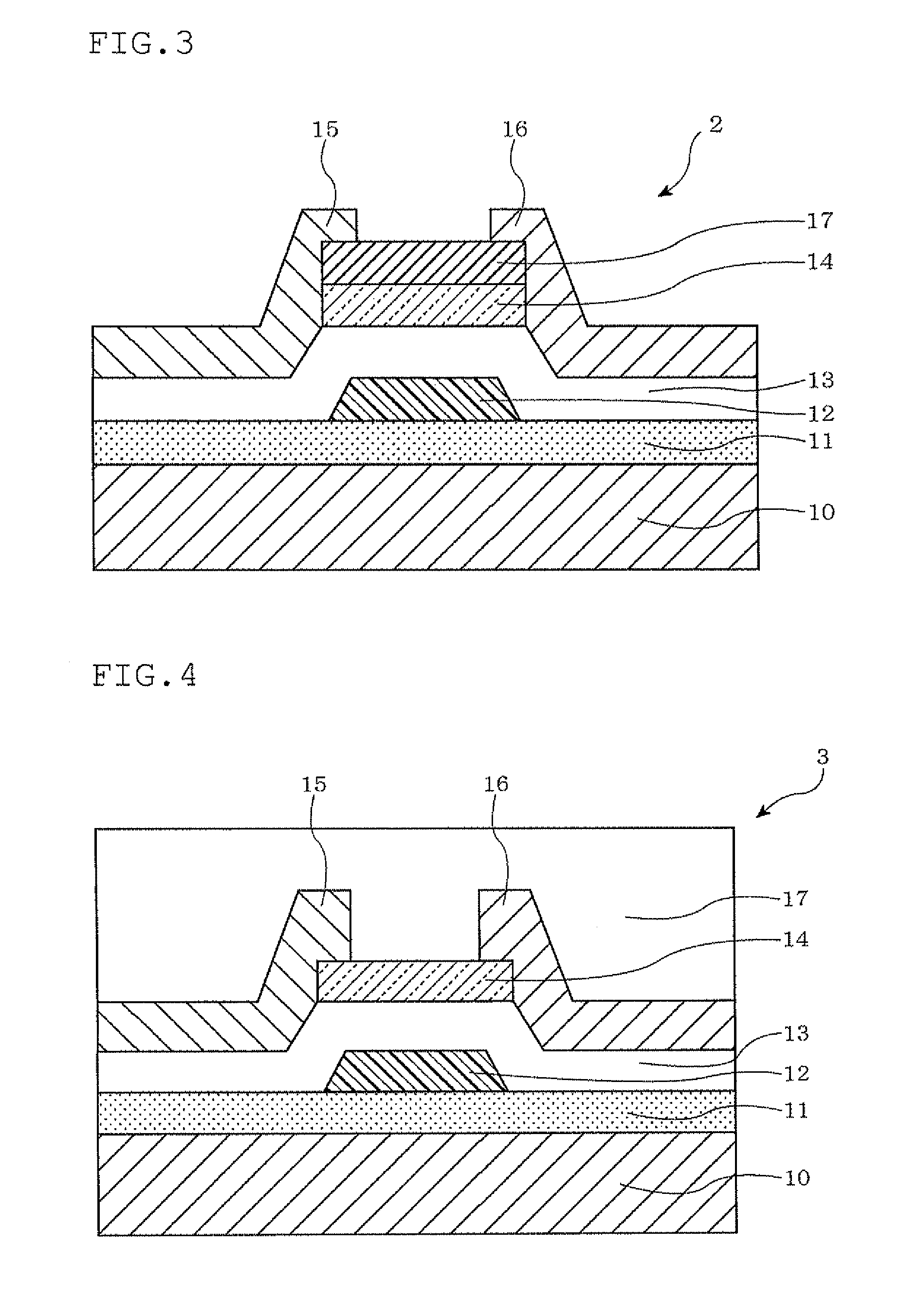

Field effect transistor using oxide semicondutor and method for manufacturing the same

ActiveUS8384077B2Easy to produceLower resistanceSemiconductor/solid-state device manufacturingDiodeIndiumField-effect transistor

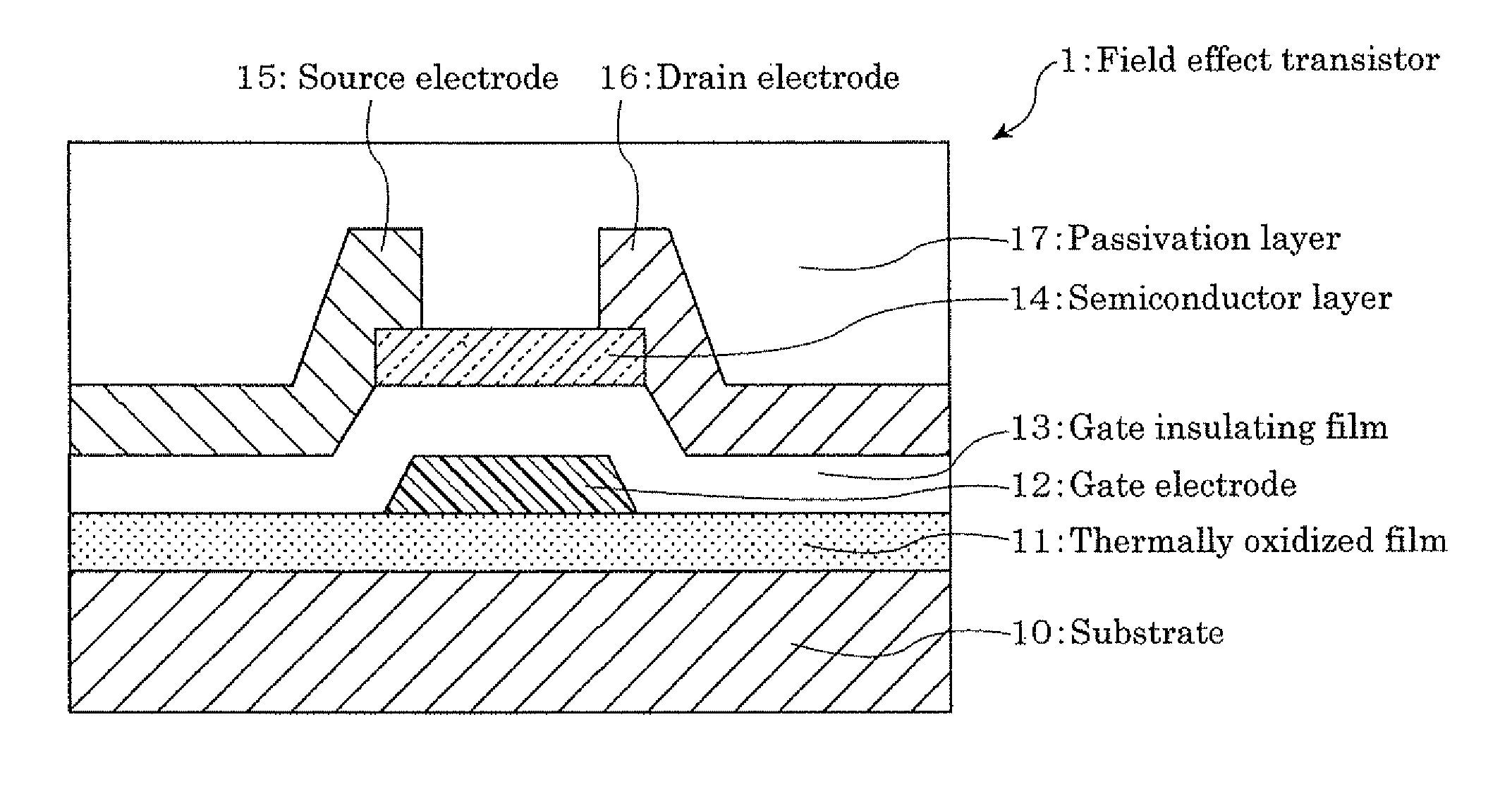

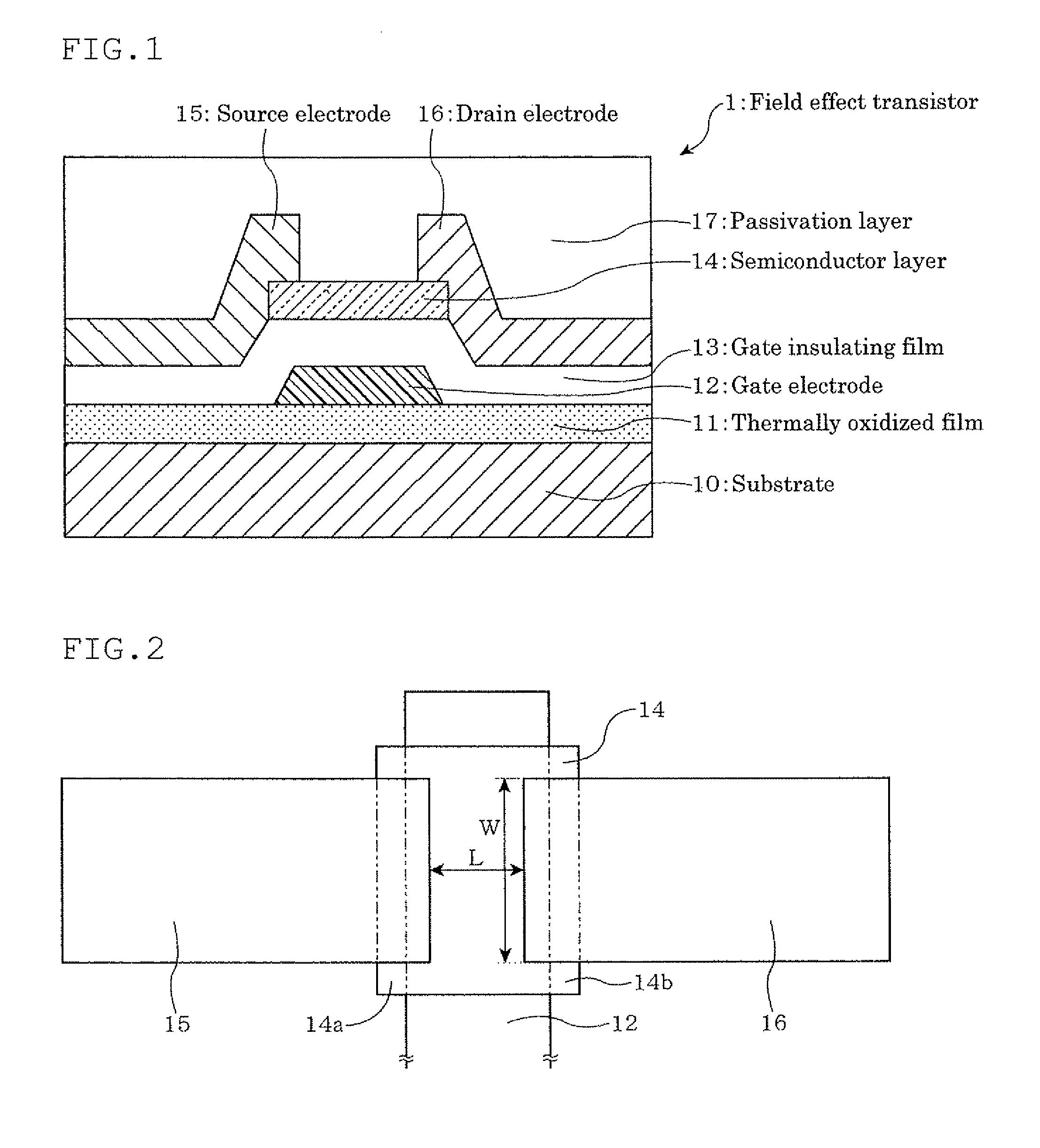

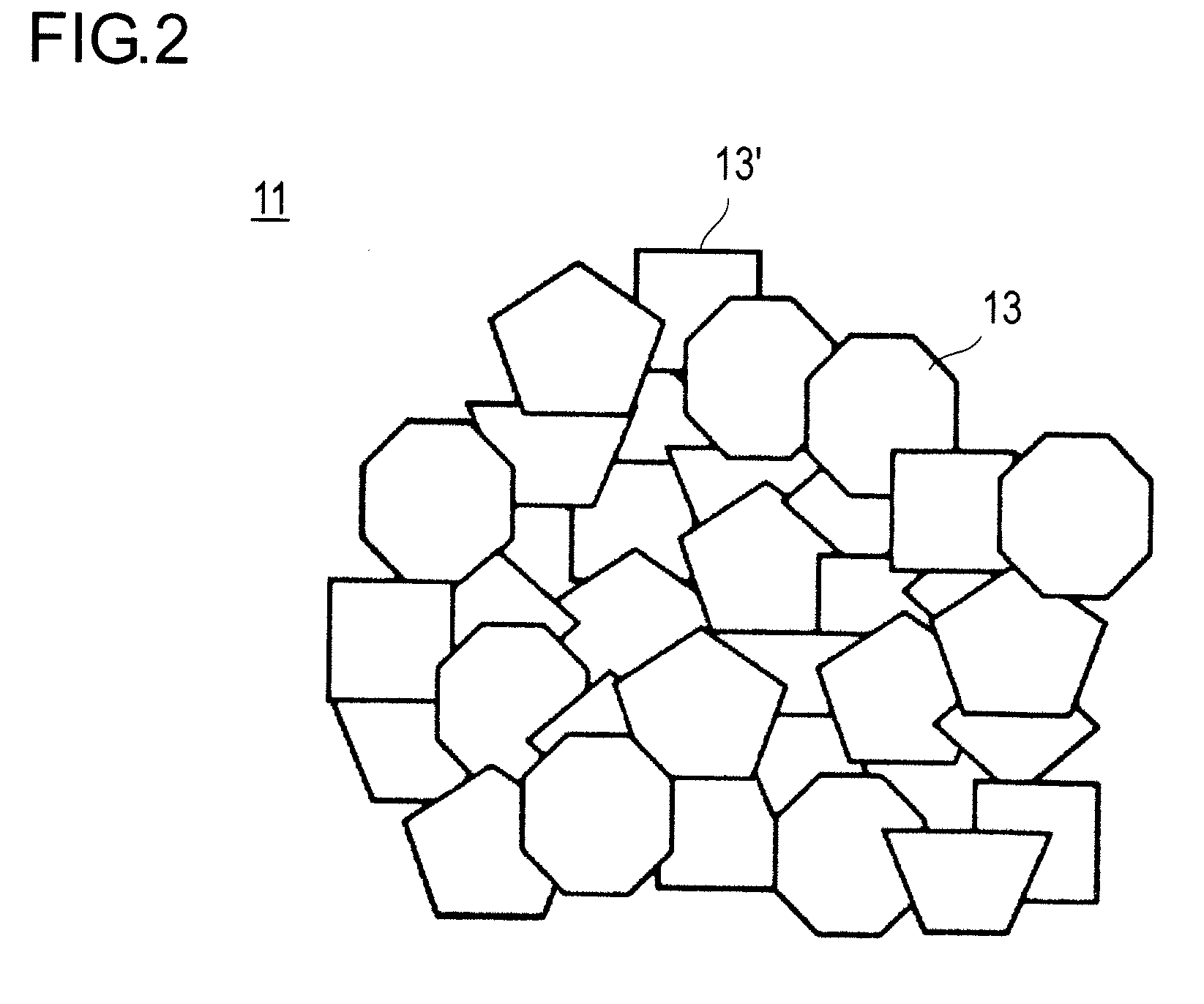

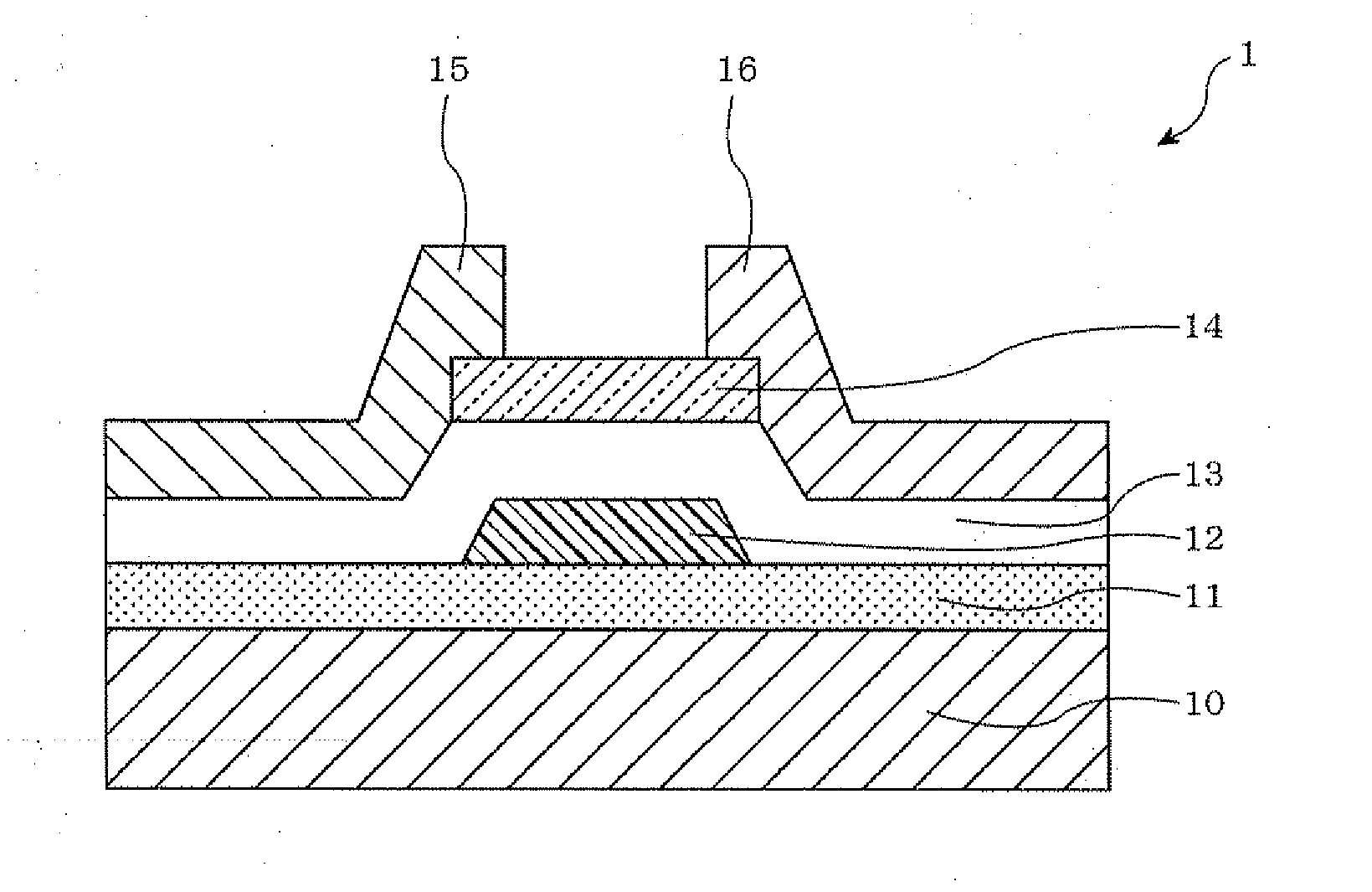

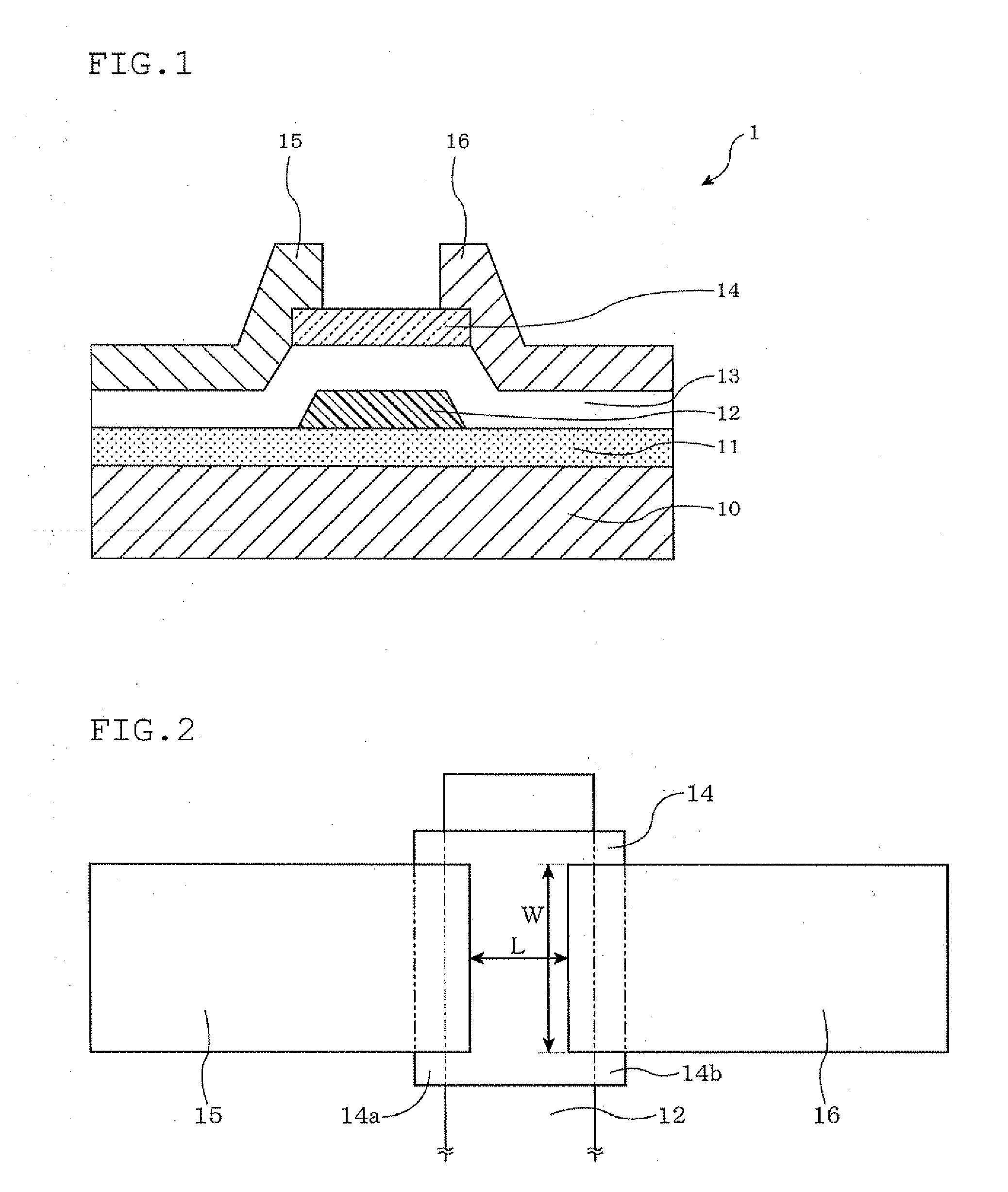

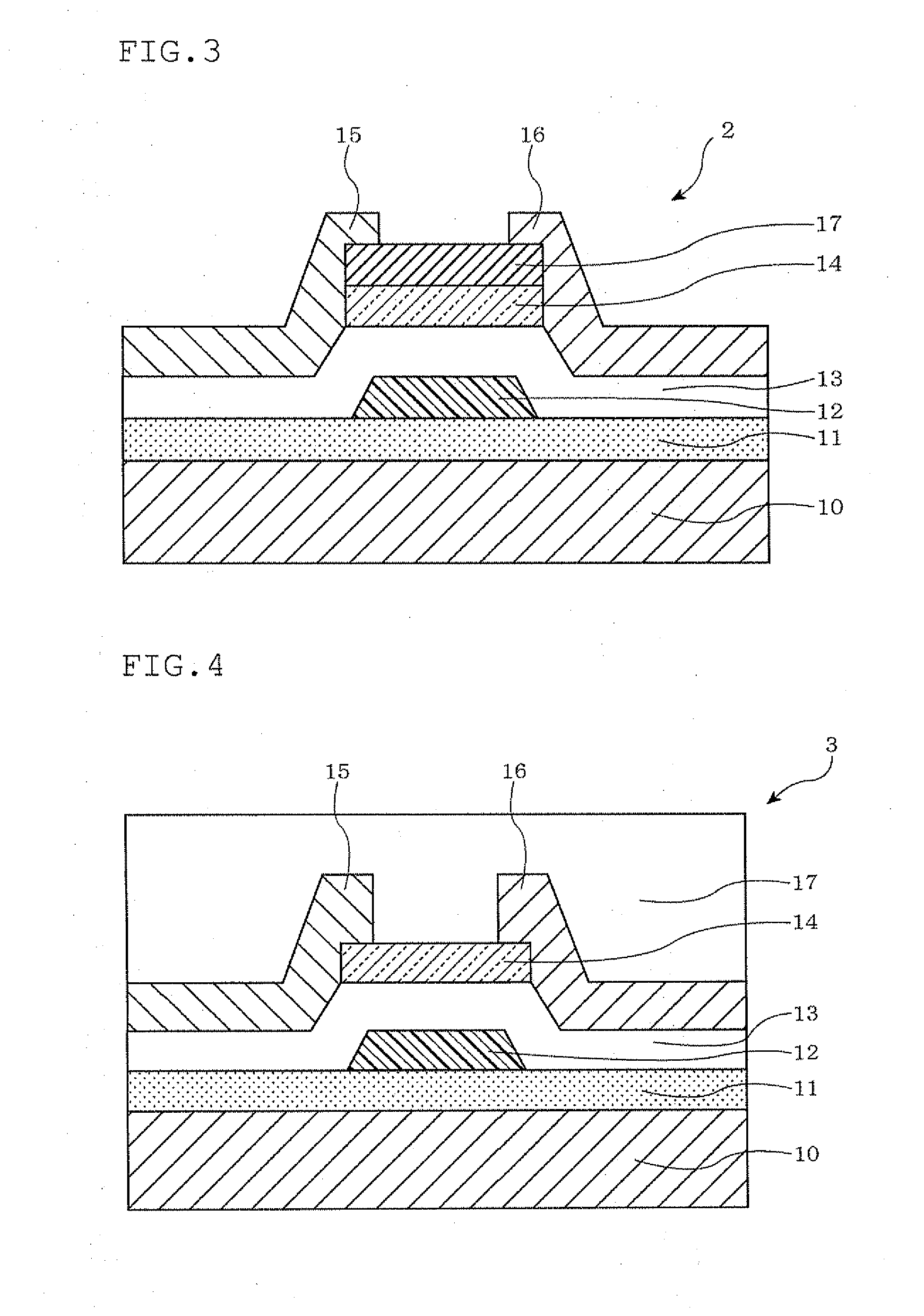

A field effect transistor which includes, on a substrate, at least a semiconductor layer, a passivation layer for the semiconductor layer, a source electrode, a drain electrode, a gate insulating film and a gate electrode, the source electrode and the drain electrode being connected through the semiconductor layer, the gate insulating film being present between the gate electrode and the semiconductor layer, the passivation layer being at least on one surface side of the semiconductor layer, and the semiconductor layer including a composite oxide which comprises In (indium), Zn (zinc) and Ga (gallium) in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+Ga)=0.59 to 0.99 (2)Zn / (Ga+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

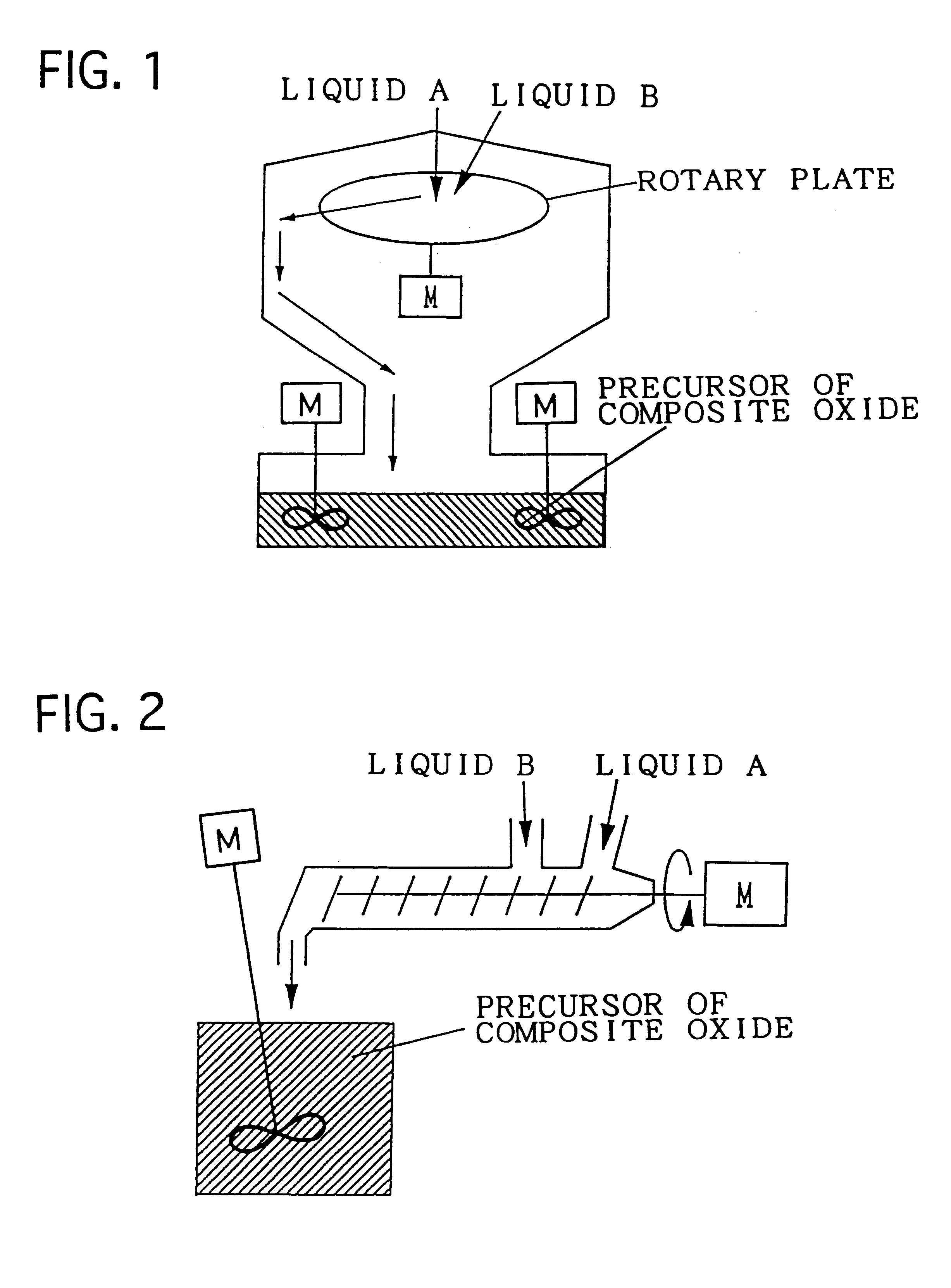

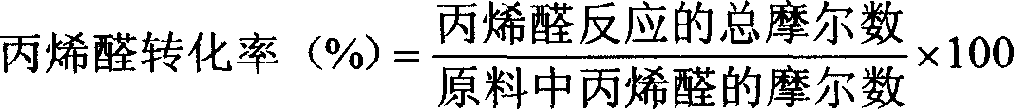

Composite oxide, composite oxide carrier and catalyst

InactiveUS6306794B1Improve heat resistanceImprove homogeneityInternal combustion piston enginesDispersed particle separationHeat resistanceCerium

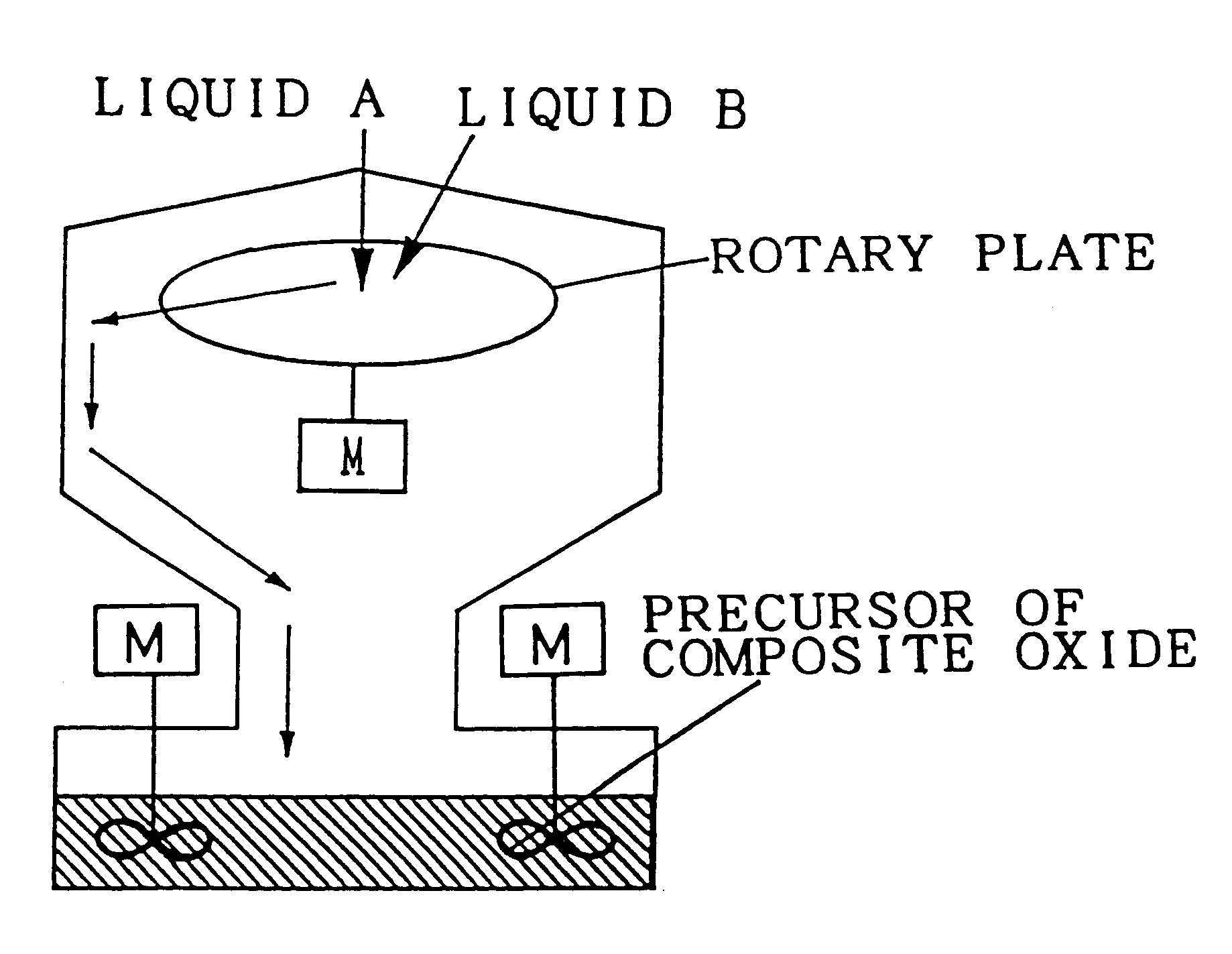

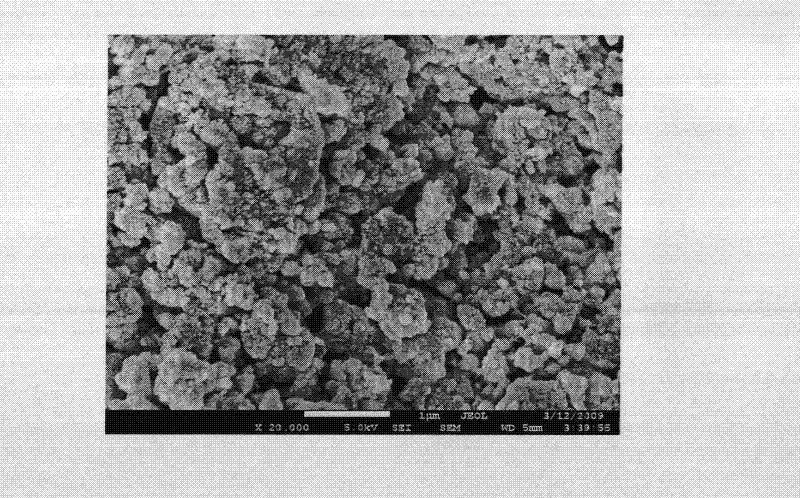

The composite oxide and the composite oxide carrier are manufactured by the precursor forming step and firing step. The composite oxide catalyst is obtained by preparing a composite of catalytic components simultaneously with the formation of the precursor of composite oxide in the step of forming the precursor of composite oxide. The composite oxide and the composite oxide carrier are composed of a composite oxide in which at least one of cerium and zirconium, and aluminium disperse with extremely high homogeneity. With this structure, the heat resistance of the carrier is improved and consequently, enlargement of particles of the composite oxide defining the carrier, and sintering of adjacent particles of the composite oxide can be restrained, whereby the catalyst using the composite oxide carrier in accordance with the present invention is excellent in heat resistance.

Owner:TOYOTA CENT RES & DEV LAB INC

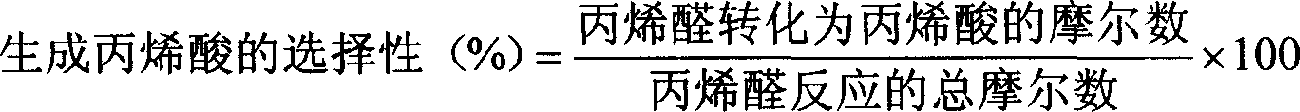

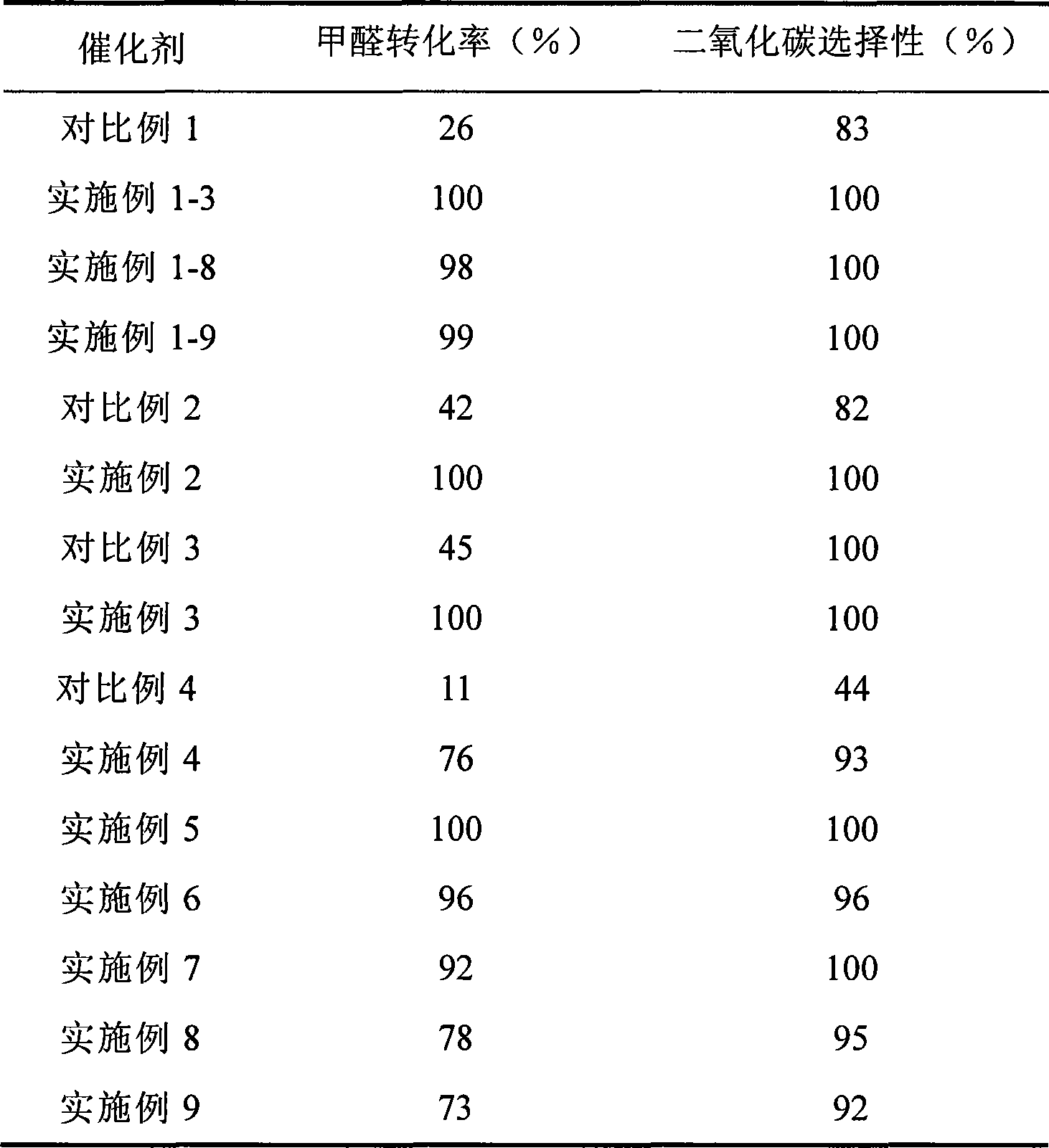

Composite metal oxide for unsaturated aldehyde selective oxidation and preparing method thereof

A composite metallic oxide as catalyst for selective oxidization of unsaturated aldehyde, especially the acrylaldehyde or methyl acrylaldehyde to obtain acrylic acid or methyl acrylic acid, is composed of active components (Mo, V and Cu), stabilizer (at least Sb and Ti) and the composite oxide of Ni, Fe, Si, Al, alkali metal and alkali-earth metal. Its preparing process is also disclosed.

Owner:兰州金润宏成新材料科技有限公司

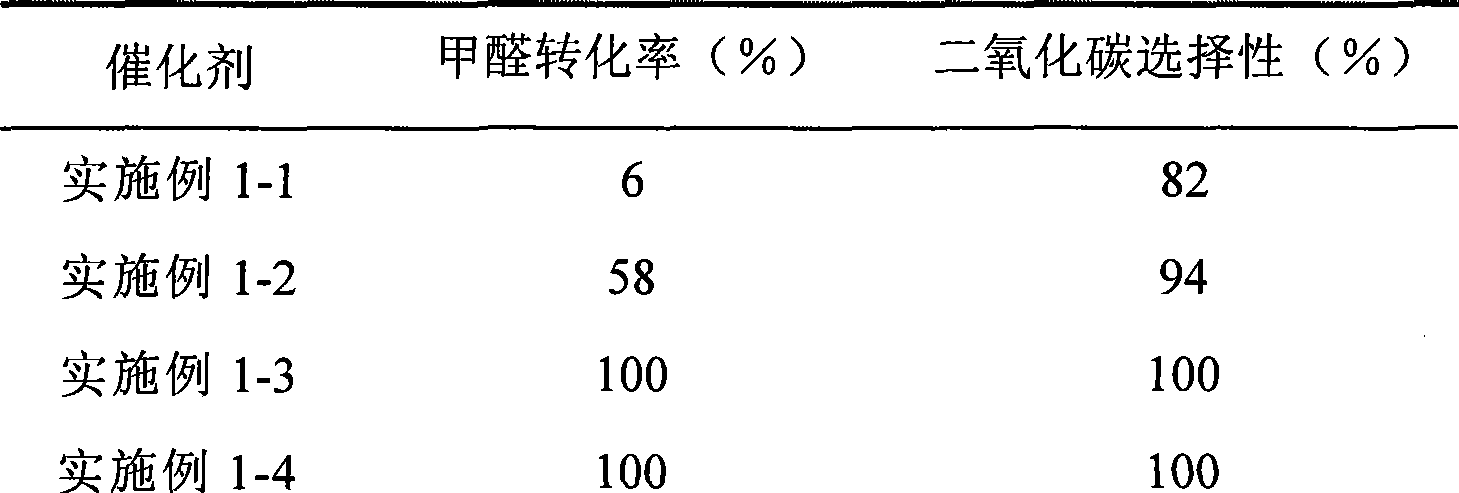

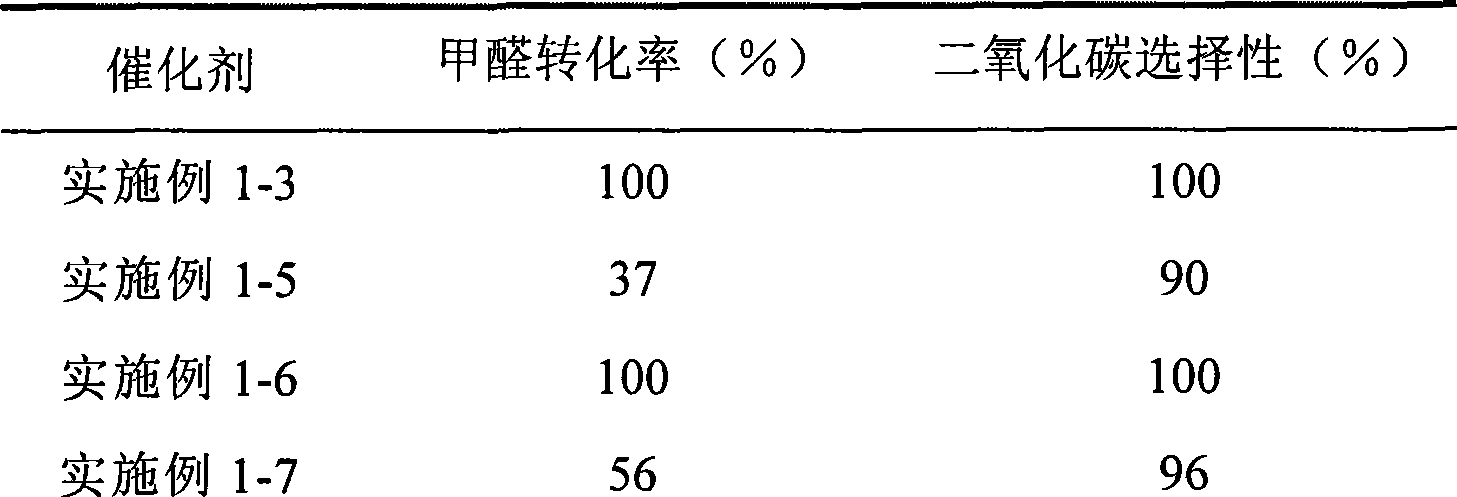

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

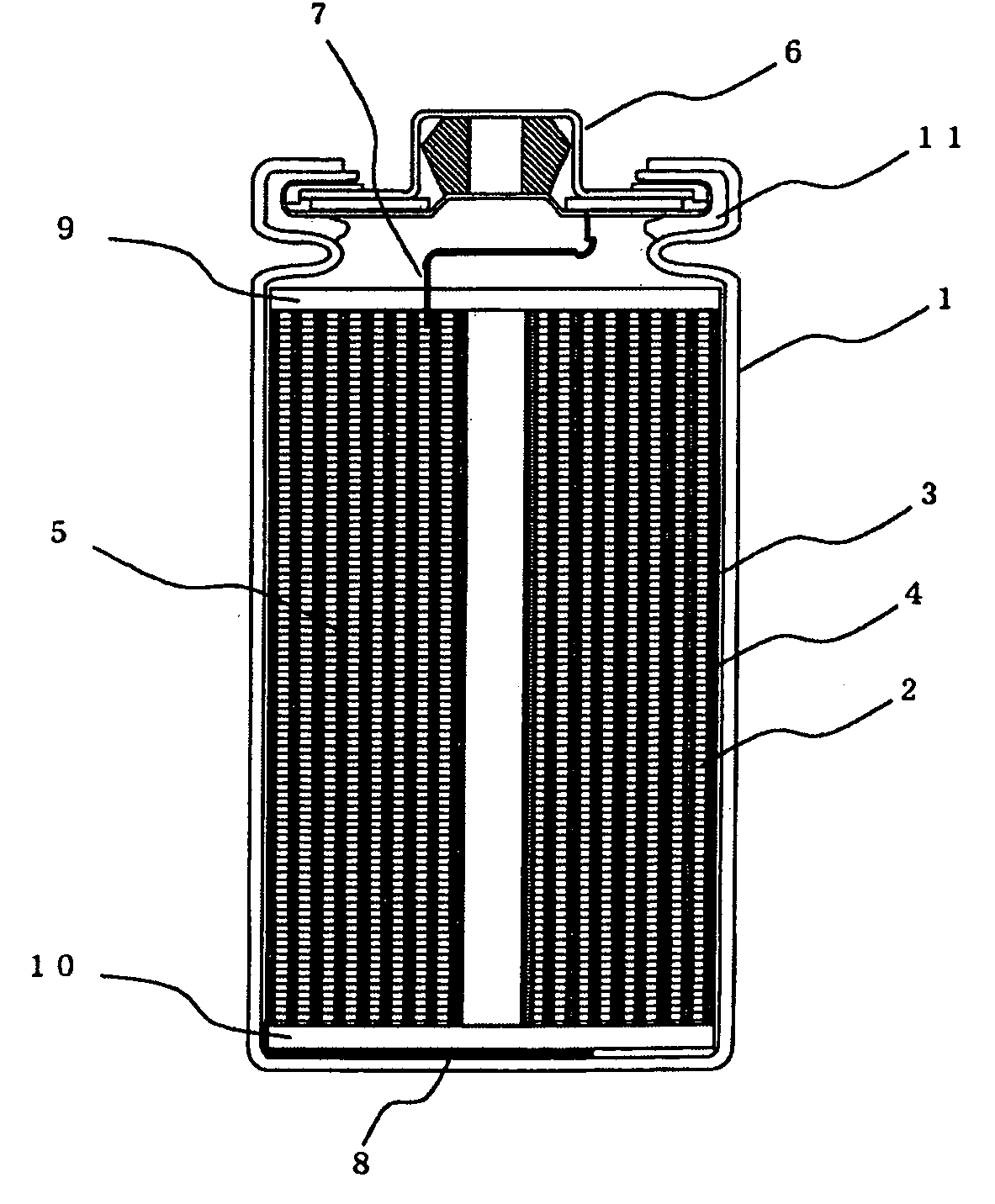

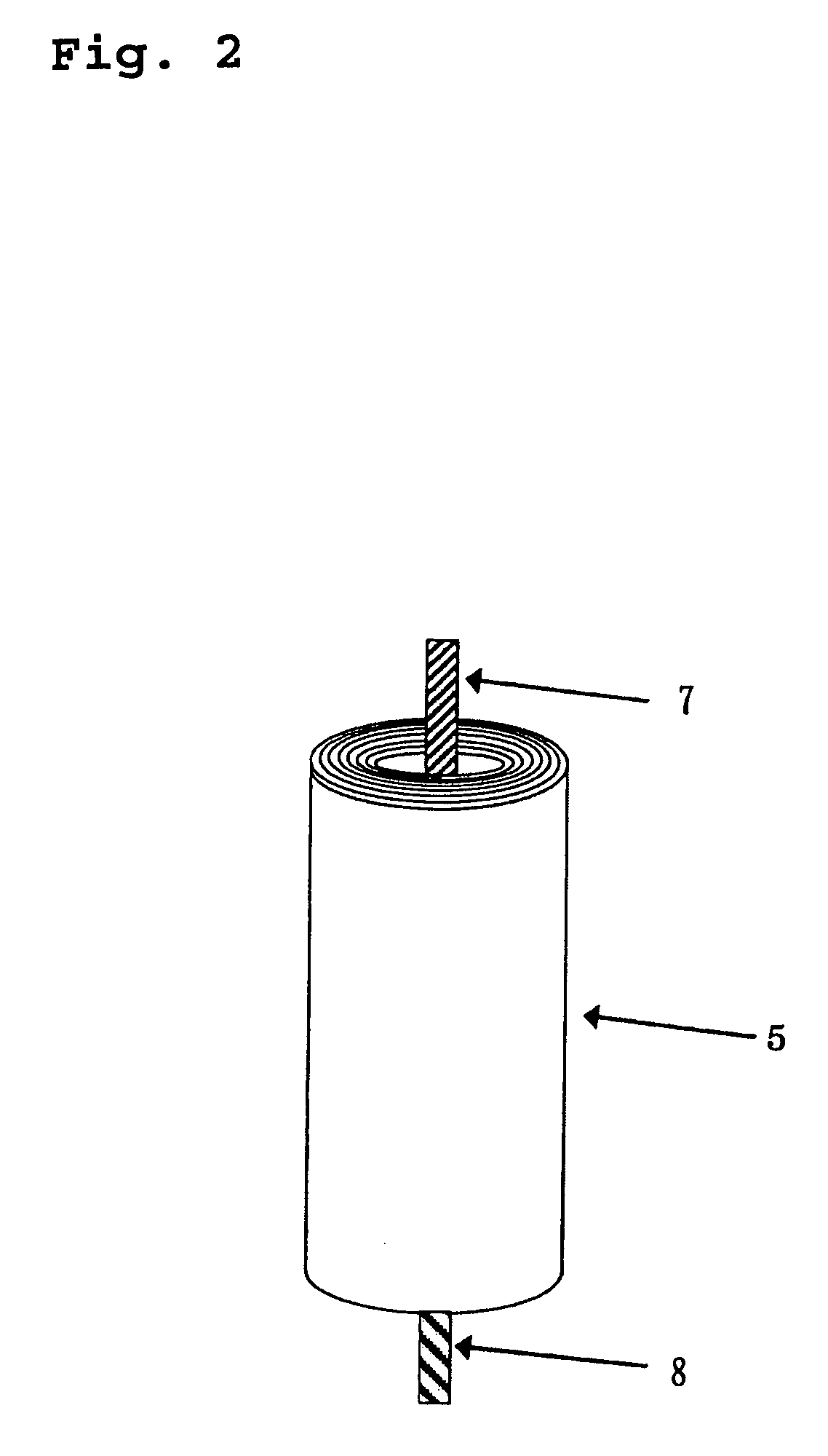

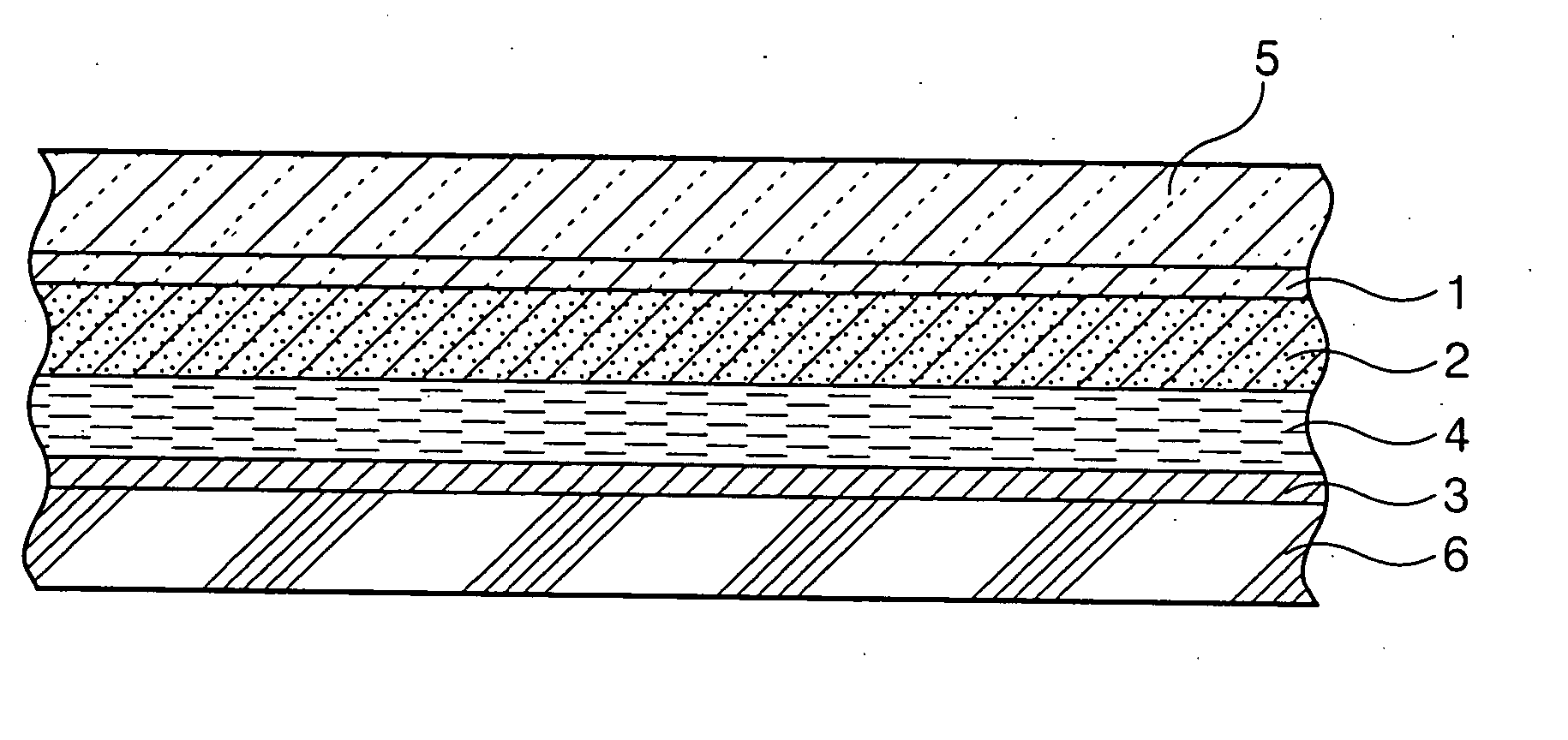

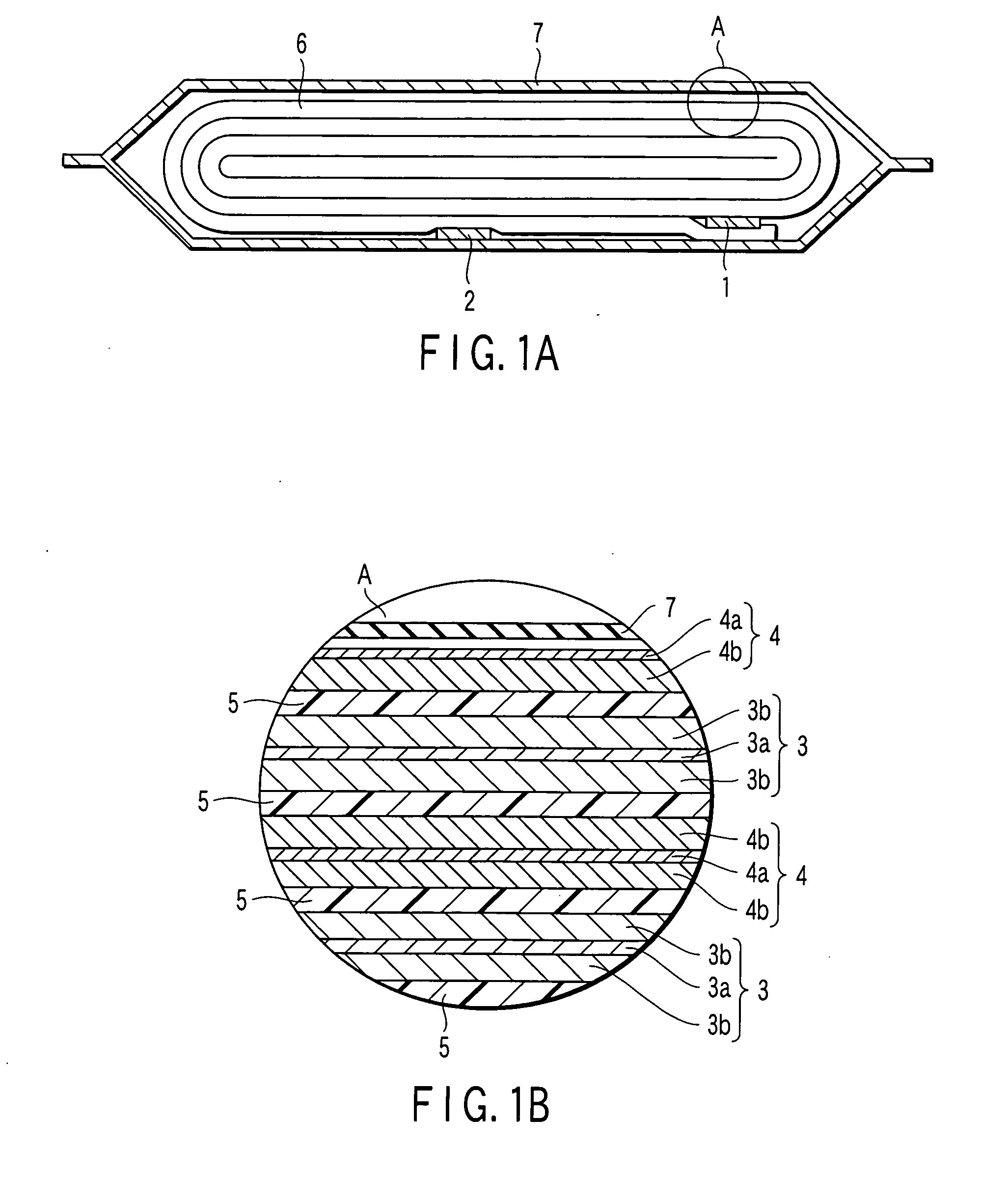

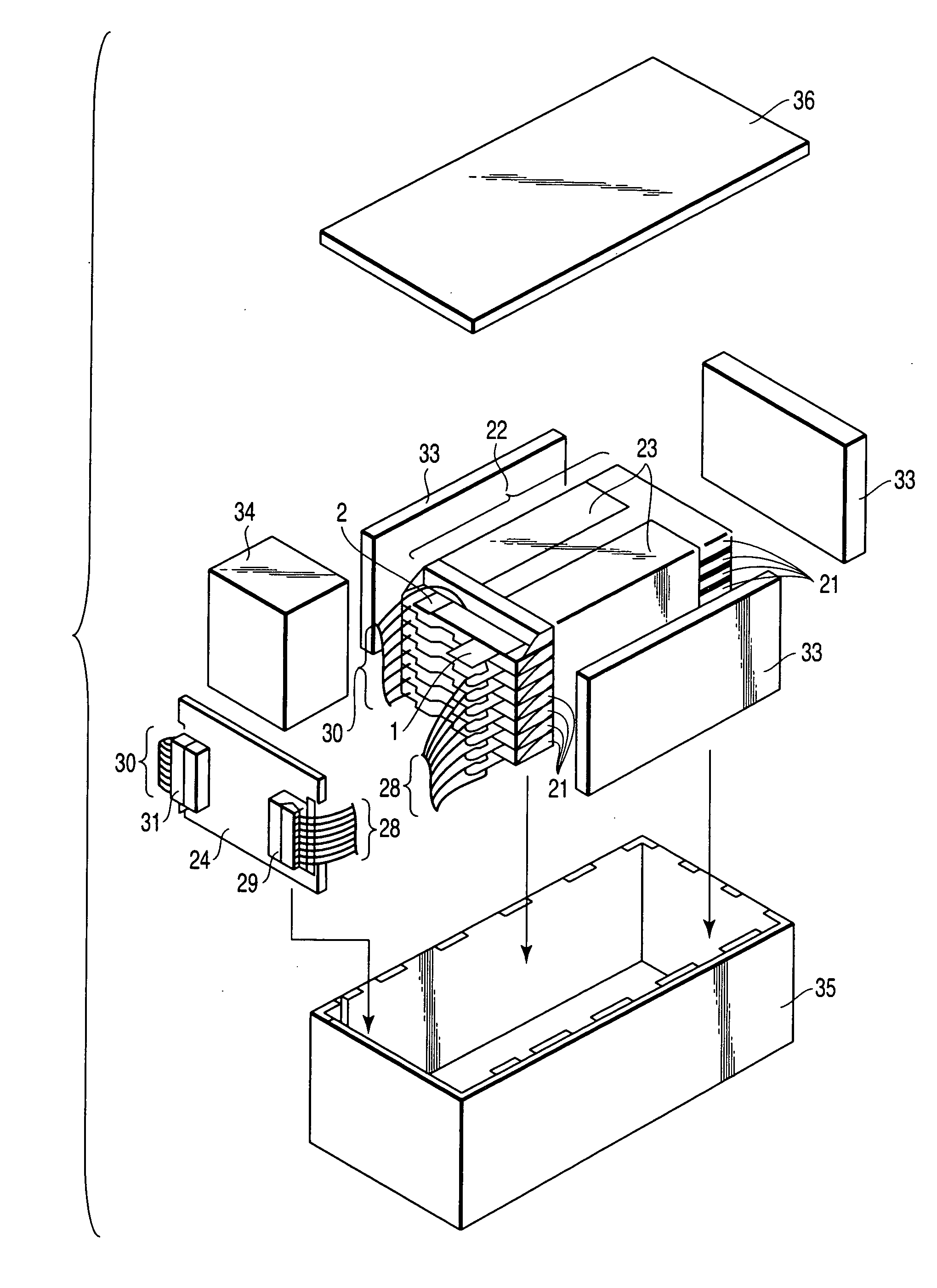

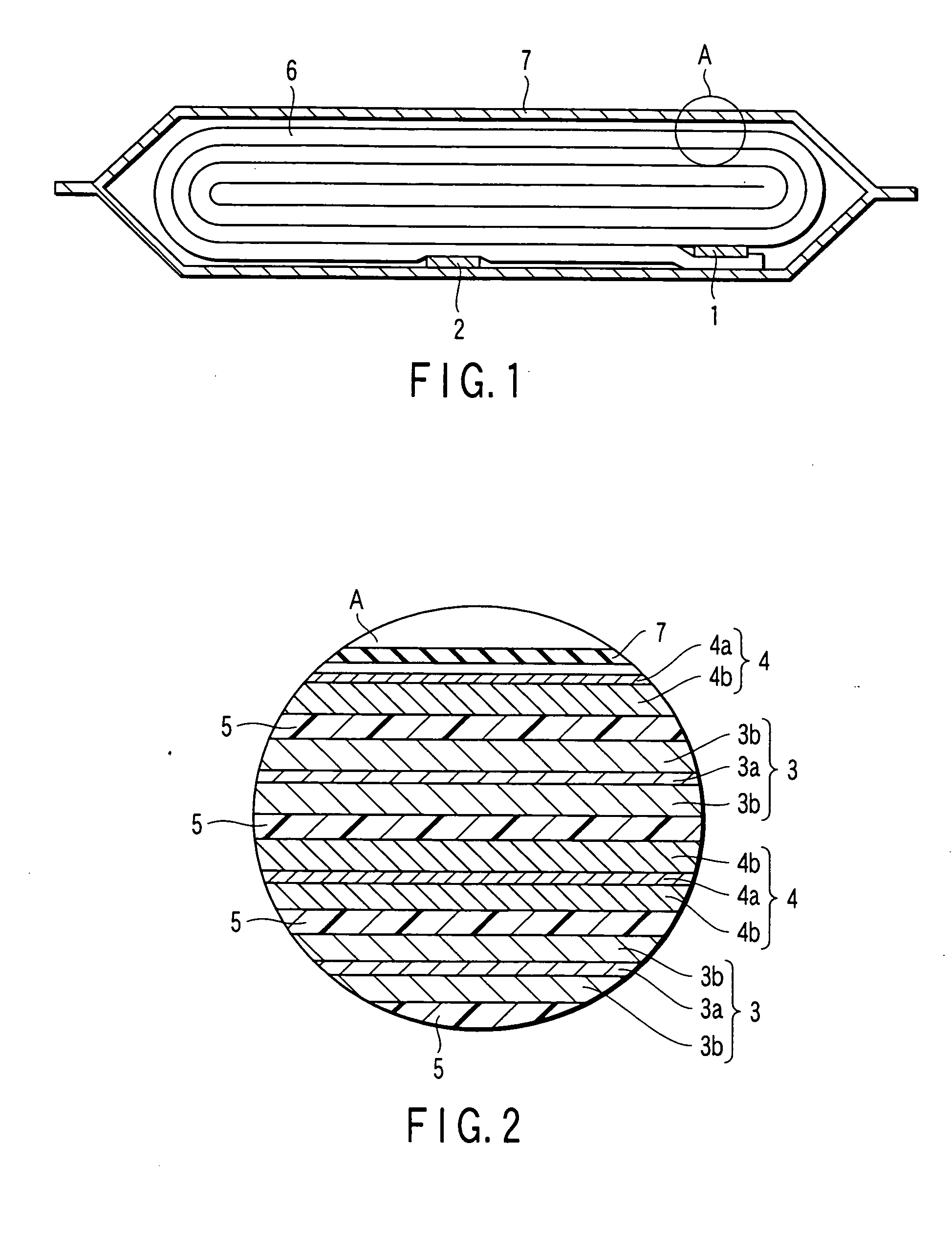

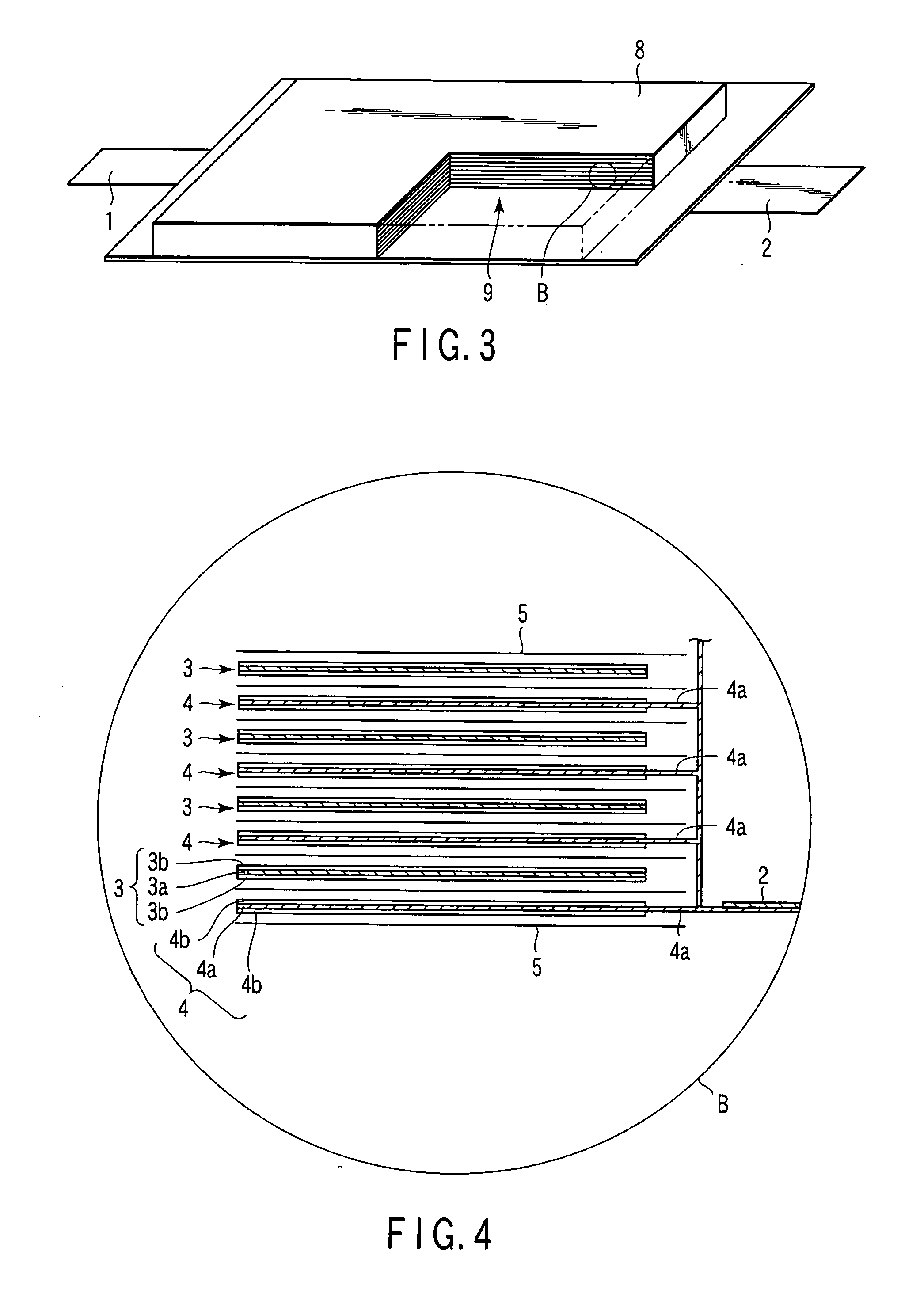

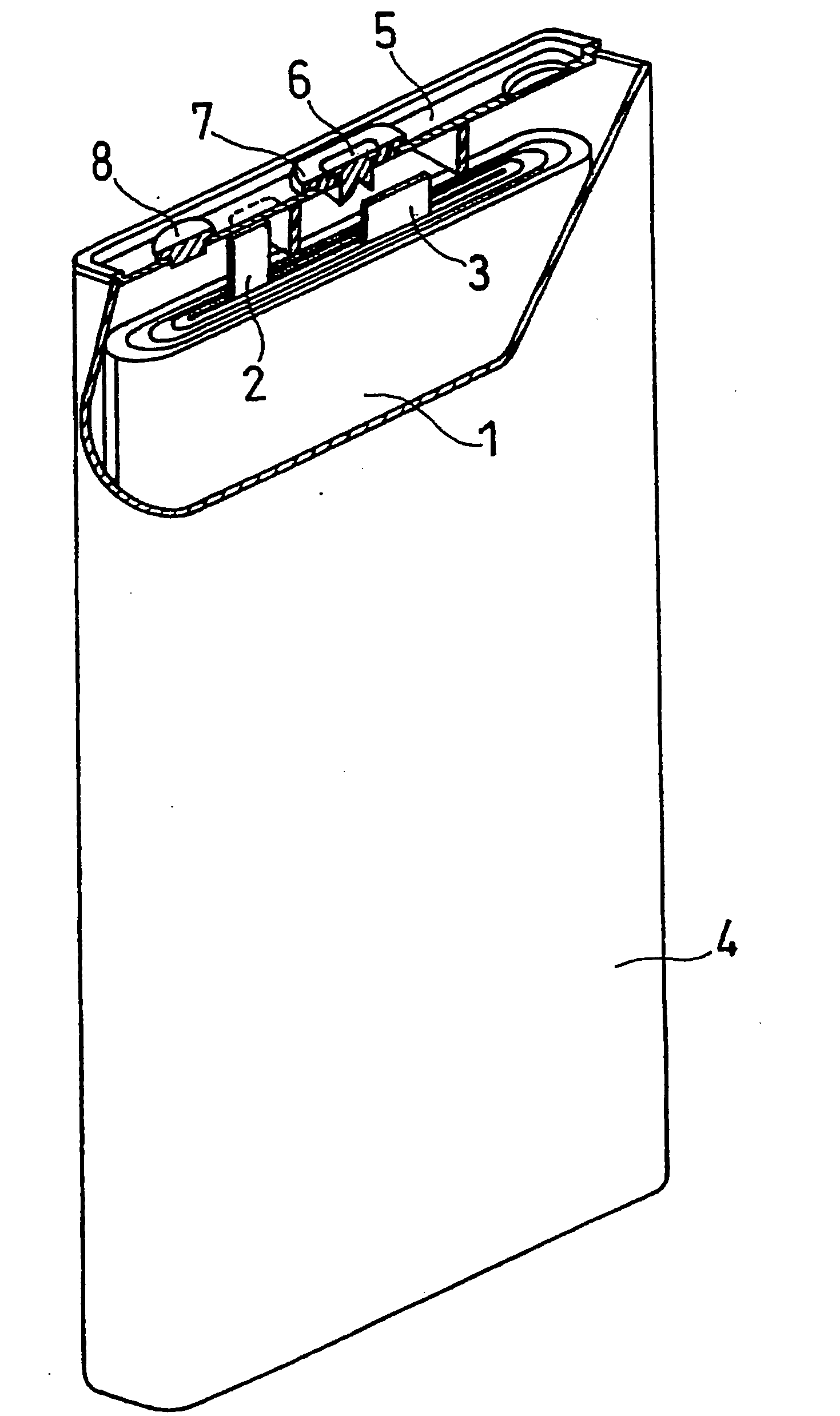

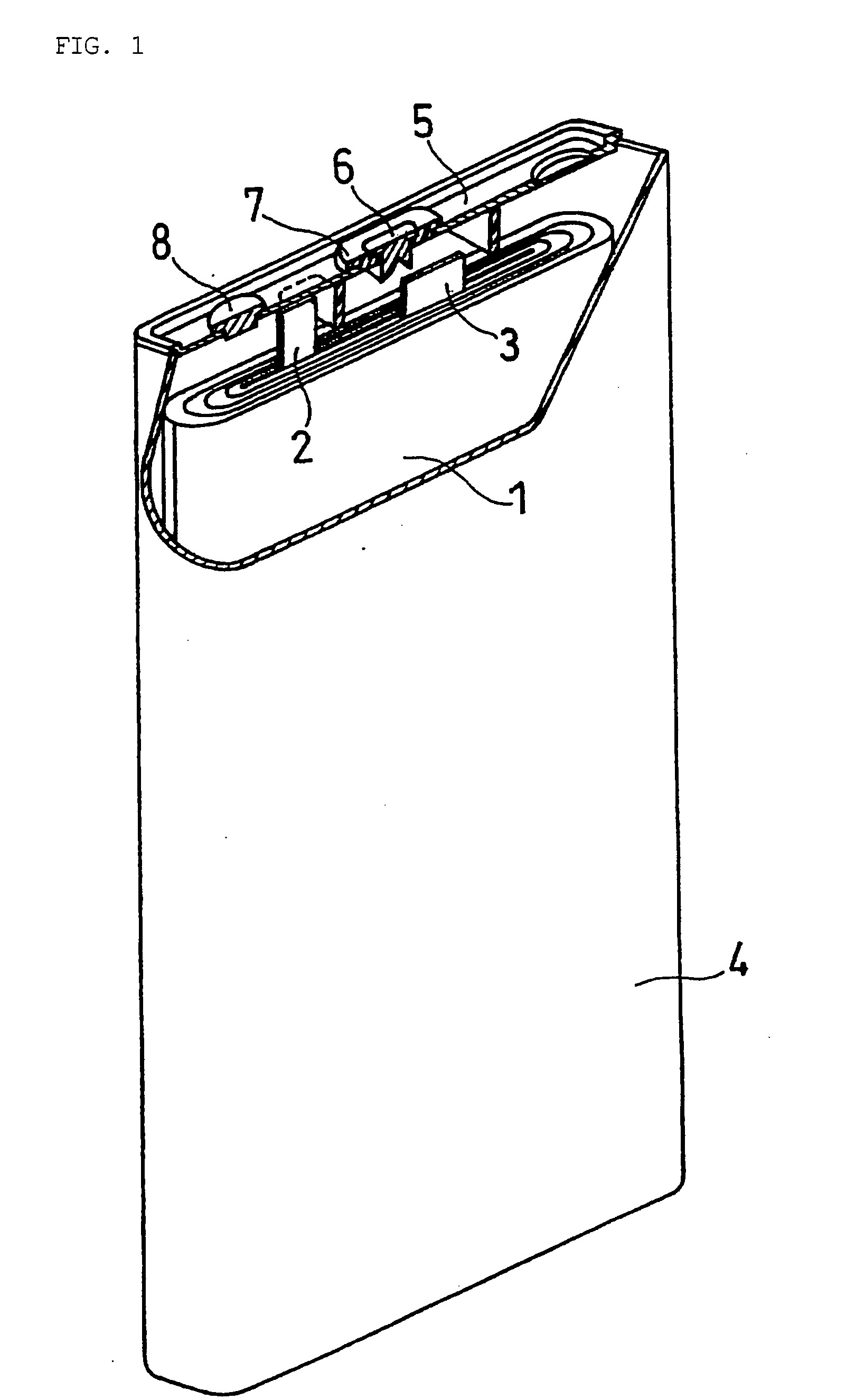

Lithium secondary battery

InactiveUS20090087731A1Improve charge-discharge cycle performanceCell electrodesSecondary cellsSilicon alloyComposite oxide

A lithium secondary battery includes: a positive electrode having a positive electrode active material layer disposed on a positive electrode current collector, the positive electrode active material layer containing a positive electrode binder and a positive electrode active material containing a layered lithium-transition metal composite oxide; a negative electrode having a negative electrode current collector and a negative electrode active material layer disposed on the negative electrode current collector, the negative electrode active material layer containing a negative electrode binder and a negative electrode active material containing particles of silicon and / or a silicon alloy; and a non-aqueous electrolyte. Al2O3 particles are firmly adhered to a surface of the lithium-transition metal composite oxide so that a BET specific surface area of the positive electrode active material after the adherence of the Al2O3 particles is from 1.5 times to 8 times greater than that before the adherence of the Al2O3 particles

Owner:SANYO ELECTRIC CO LTD

Field effect transistor using oxide semicondutor and method for manufacturing the same

ActiveUS20100289020A1Easy to produceReduce contact resistanceTransistorSemiconductor/solid-state device manufacturingIndiumField-effect transistor

A field effect transistor which includes, on a substrate, at least a semiconductor layer, a passivation layer for the semiconductor layer, a source electrode, a drain electrode, a gate insulating film and a gate electrode, the source electrode and the drain electrode being connected through the semiconductor layer, the gate insulating film being present between the gate electrode and the semiconductor layer, the passivation layer being at least on one surface side of the semiconductor layer, and the semiconductor layer including a composite oxide which comprises In (indium), Zn (zinc) and Ga (gallium) in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+Ga)=0.59 to 0.99 (2)Zn / (Ga+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

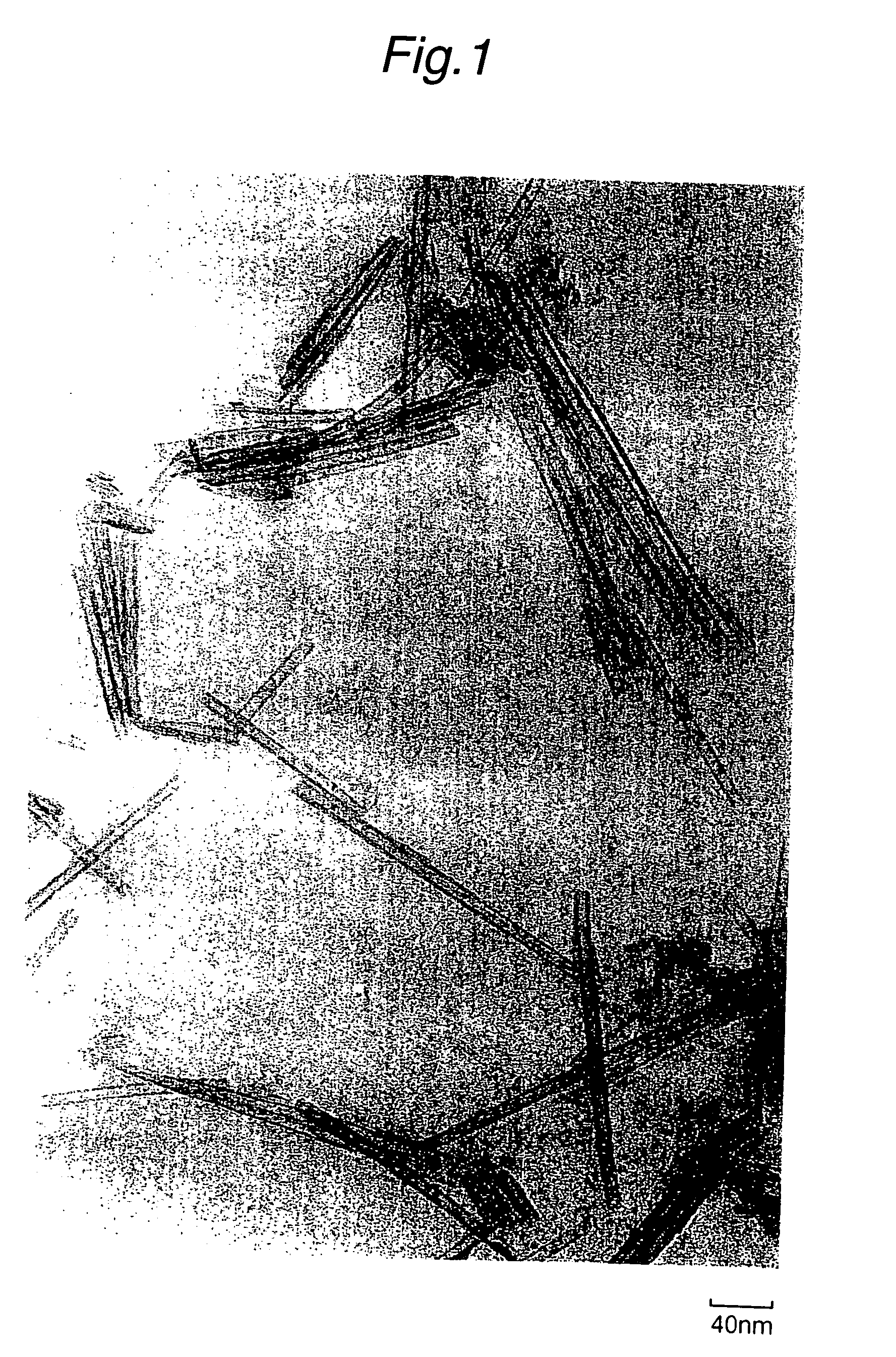

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

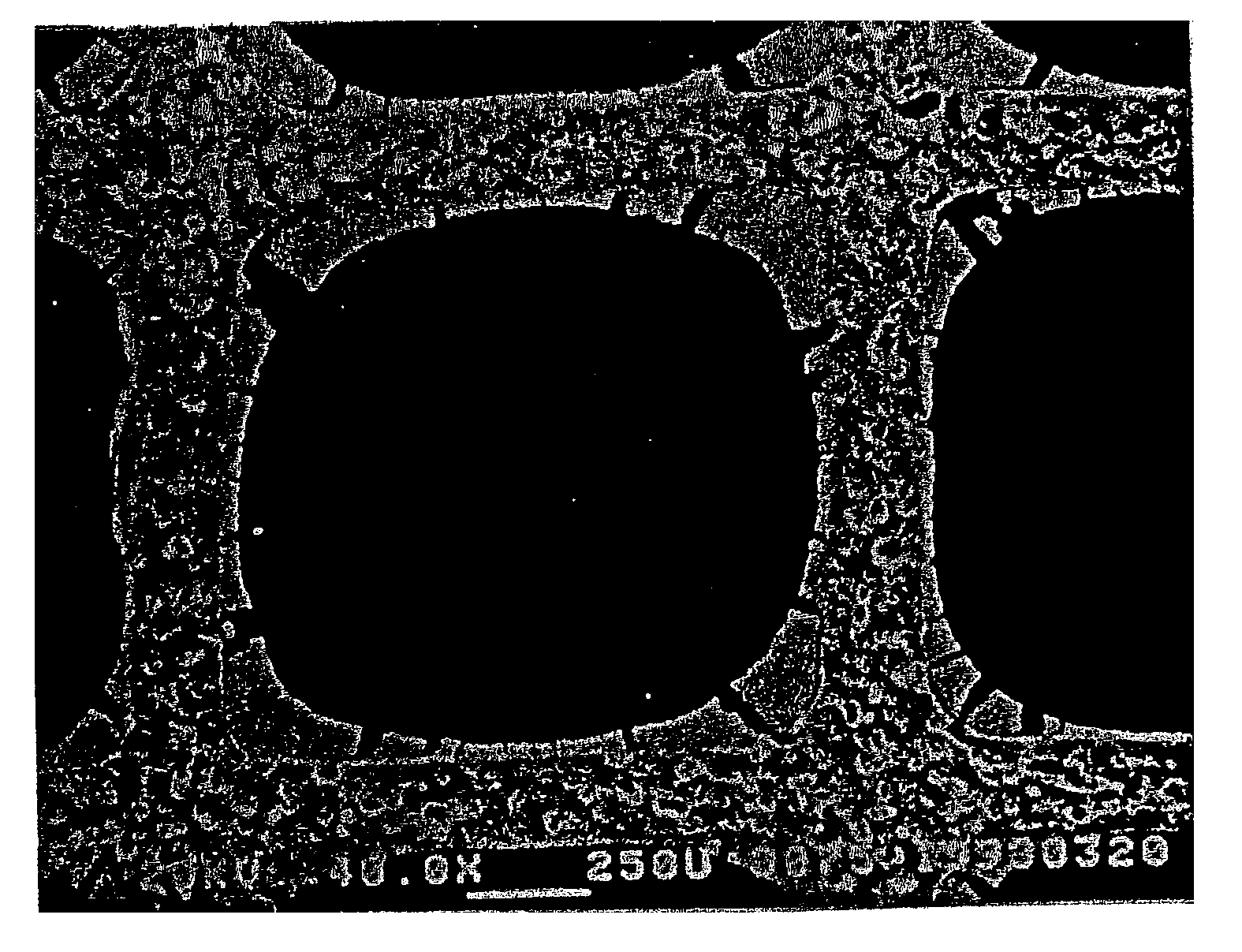

Catalyst for purifying exhaust gas

InactiveUS6335305B1Internal combustion piston enginesDispersed particle separationComposite oxideExhaust gas

A catalyst for purifying an exhaust gas includes a support and a noble metal loaded on the support. The support includes a mixture containing a porous oxide and a composite oxide. The composite oxide is expressed by the following formula:in which the values "a" and "b" are molar ratios and the value "a" falls in a range of from 0.4 to 2.5 and the value "b" falls in a range of from 0.2 to 0.7. The support includes a particle having a particle diameter of 5 mum or more in an amount of 30% by volume or more. With the thus arranged support, even when the catalyst is subjected to such a severe durability test that it is heated at 1,000° C. for 10 to 20 hours, it exhibits a high purifying activity, and its coating layer is inhibited from cracking or coming off.

Owner:TOYOTA CENT RES & DEV LAB INC

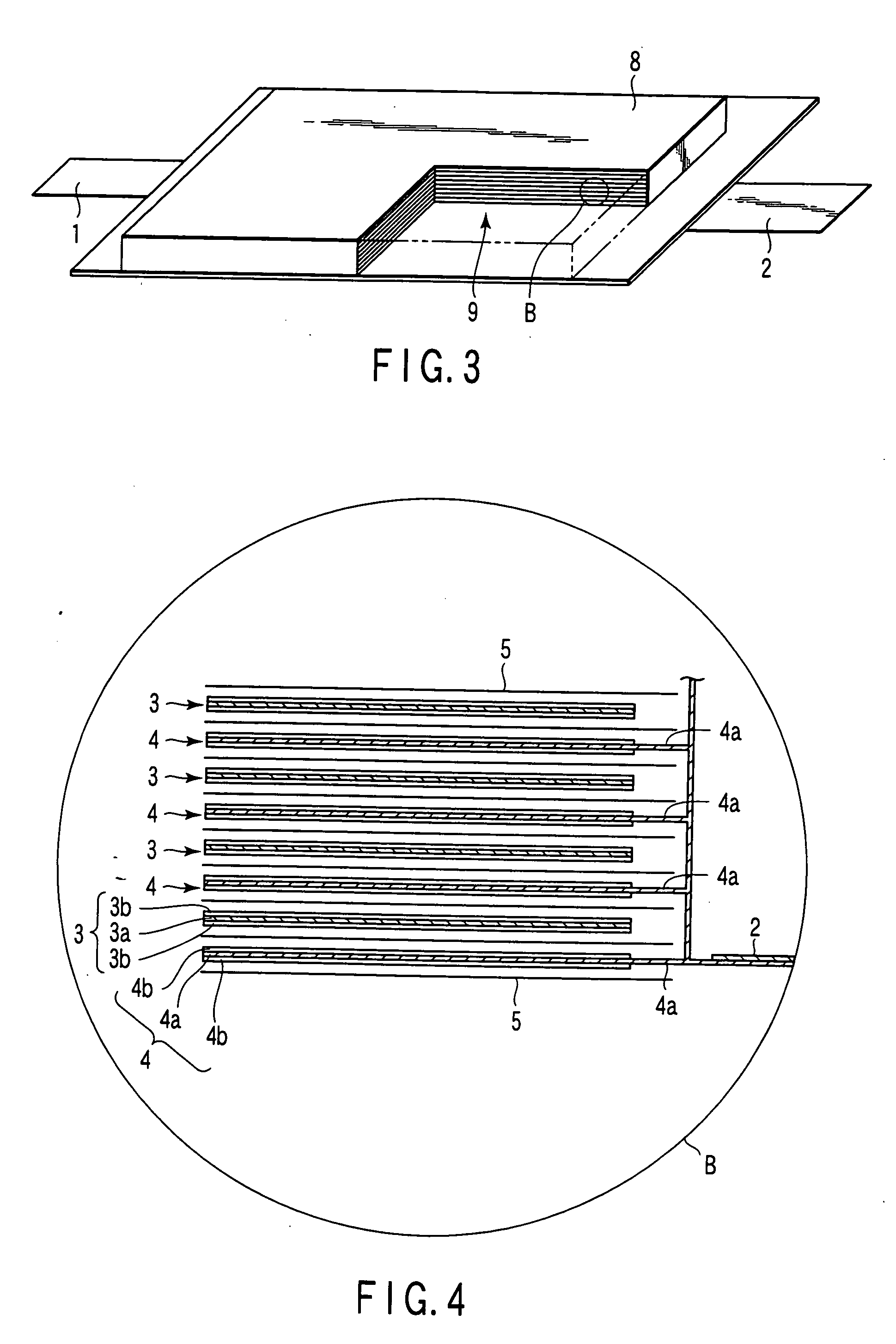

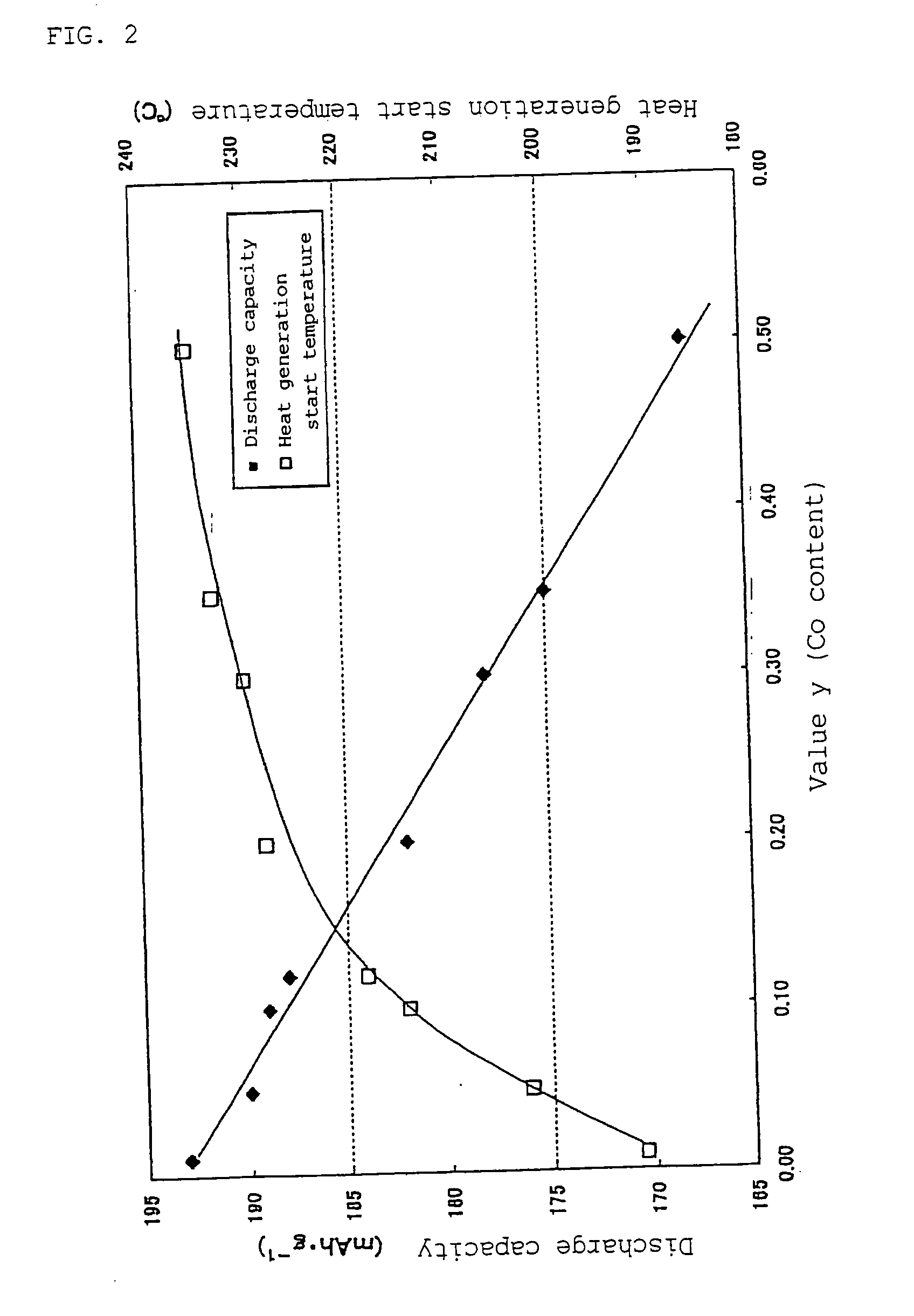

Layered Lithium Nickel Manganese Cobalt Composite Oxide Powder For Material Of Positive Electrode Of Lithium Secondary Battery, Process For Producing The Same, Positive Electrode Of Lithium Secondary Battery Therefrom, And Lithium Secondary Battery

ActiveUS20070202405A1Improve securityImprove battery performanceNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsManganeseCobalt

A powder of a layered lithium-nickel-manganese-cobalt composite oxide for use as a positive-electrode material for lithium secondary battery is provided which, when used as a positive-electrode material for lithium secondary battery, enables a cost reduction and higher safety to be reconciled with improved battery performances. The powder of a layered lithium-nickel-manganese-cobalt composite oxide for use as a positive-electrode material for lithium secondary battery is composed of secondary particles formed by the aggregation of primary particles. It has a composition represented by the following formula (I), has a volume resistivity of 5×105 Ω·cm or lower in the state of being compacted at a pressure of 40 MPa, and has a value of C / S, wherein C is the concentration of carbon contained therein (% by weight) and S is the BET specific surface area thereof (m2 / g), of 0.025 or smaller. The powder has been regulated so as to have a volume resistivity not higher than the specified value and a considerably reduced carbon content while having a composition in a limited range, whereby a cost reduction and higher safety can be reconciled with improved battery performances. Li1+zNixMnyCo1−x−yOδ (I) (0<z≦0.91, 0.1≦x≦0.55, 0.20≦y≦0.90, 0.50≦x+y≦1, 1.9≦δ≦3)

Owner:MITSUBISHI CHEM CORP

Lithium titanate composite electrode material with surface coating layer

InactiveCN101764209AChange physical propertiesChange chemical propertiesCell electrodesMagnesium phosphateMagnesium orthophosphate

The invention relates to a battery electrode material, in particular to a lithium titanate composite electrode material with surface coating layer; in the lithium titanate composite electrode material with surface coating layer, the electrode material is composed of lithium titanate particles and a coating layer coated with the surface of the lithium titanate particles; the particle size of the lithium titanate particles is 100nm-95mum, the average thickness of the surface coating layer is 0.2nm-5m, and the particle diameter of the composite electrode material is 0.1-100mum; the material of the surface coating layer is one or mixture of more than one kind of insulation oxide, insulation composite oxide, aluminium phosphate, magnesium phosphate, lithium fluoride, lithium phosphate or LiMPO4, wherein M is magnesium, ferrum, cobalt, nickel, chromium, titanium or vanadium; in the invention, by carrying out surface coating treatment to the surfaces of the existing lithium titanate particles, a layer of protective film is formed on the surface, so as to change the physical and chemical characteristics of the surface of the lithium titanate active material, the surface can not be reacted with electrolyte even if under overpotential condition, so as to avoid ballooning and ensure the capacity and the circularity of the battery not to be reduced.

Owner:SUZHOU PHYLION BATTERY

Nonaqueous electrolyte battery, battery pack and positive electrode active material

InactiveUS20060134520A1Improve storage characteristicsOrganic electrolyte cellsPositive electrodesLithium oxideLithium hydroxide

A nonaqueous electrolyte battery includes a case, a positive electrode housed in the case and including a positive electrode active material containing a lithium-nickel composite oxide and at least one of lithium hydroxide and lithium oxide, the sum of lithium hydroxide and lithium oxide falling within not less than 0.1% to not more than 0.5% by weight based on the total amount of the positive electrode active material, a negative electrode housed in the case and capable of lithium intercalation-deintercalation, and a separator sandwiched between the positive electrode and the negative electrode and impregnated with a nonaqueous electrolyte containing γ-butyrolactone.

Owner:KK TOSHIBA

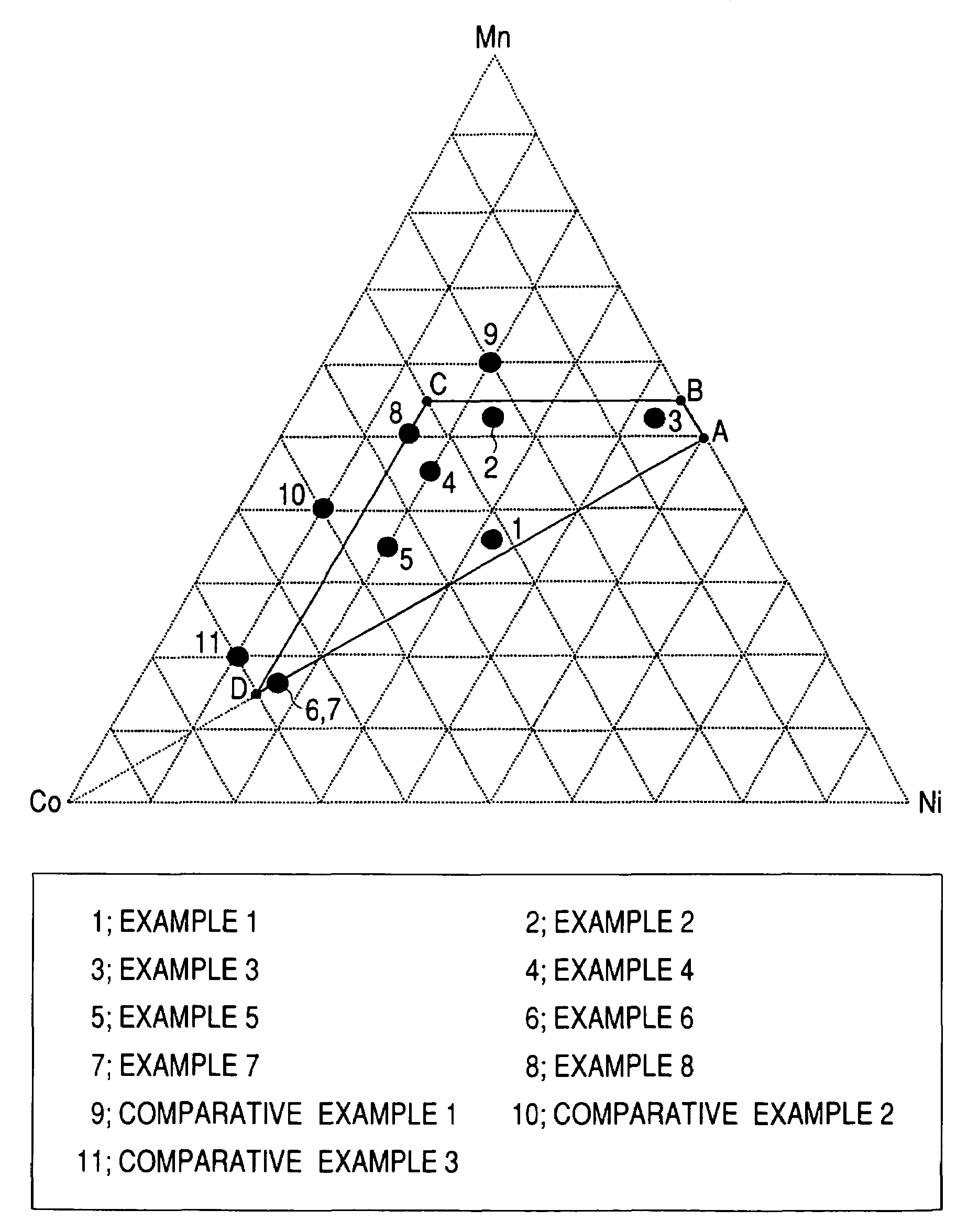

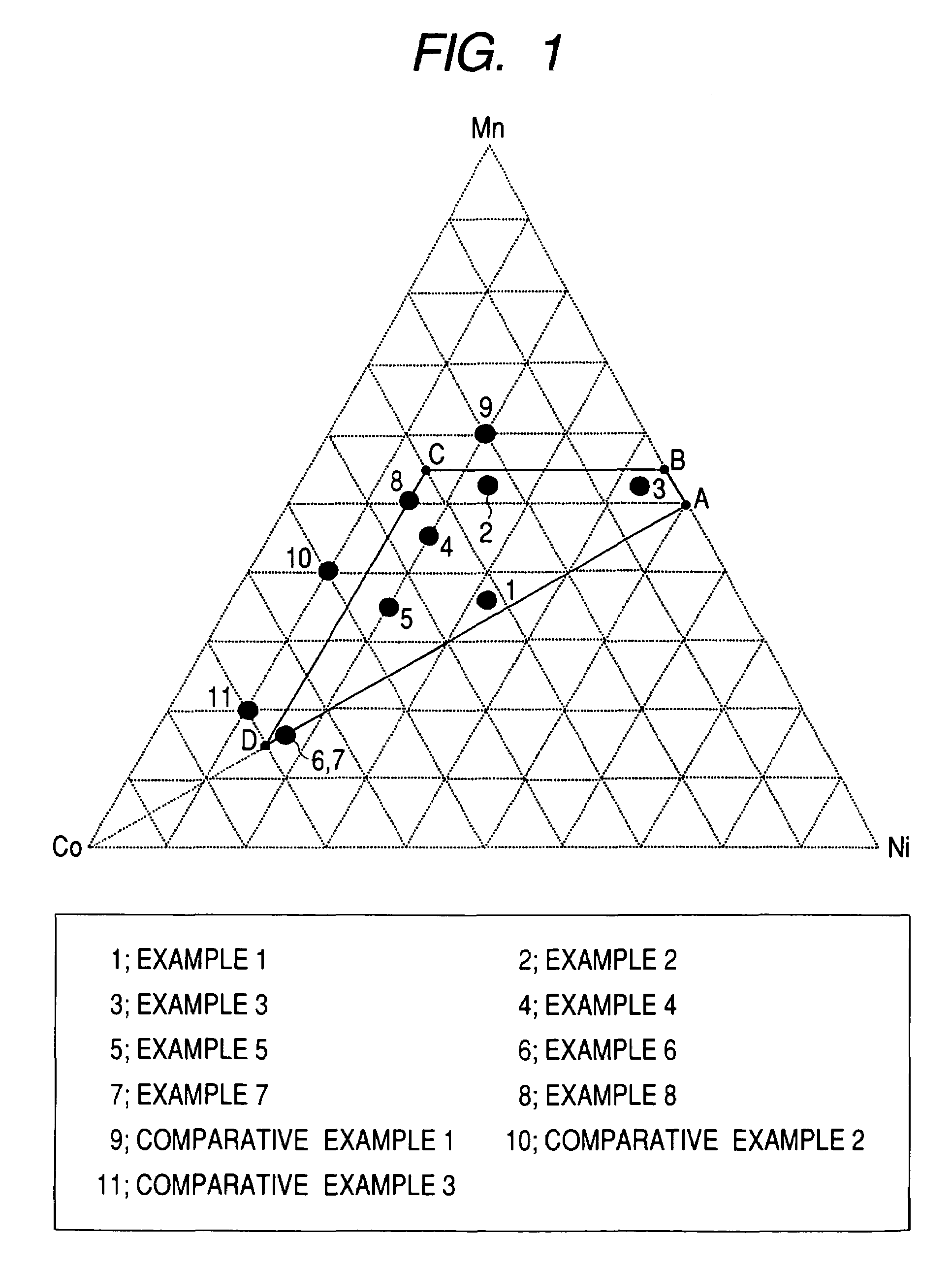

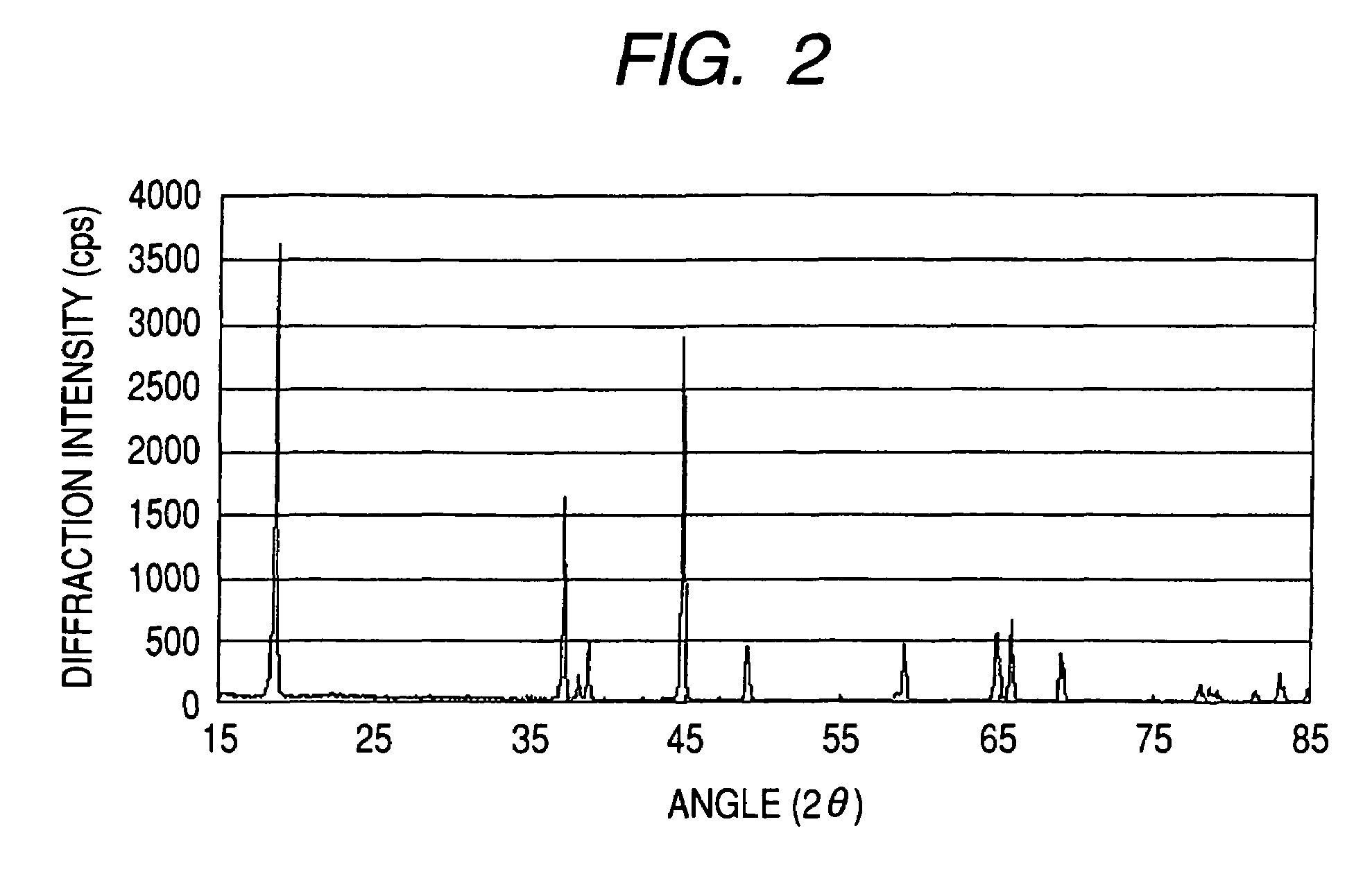

Positive electrode active material for lithium secondary cell and lithium secondary cell

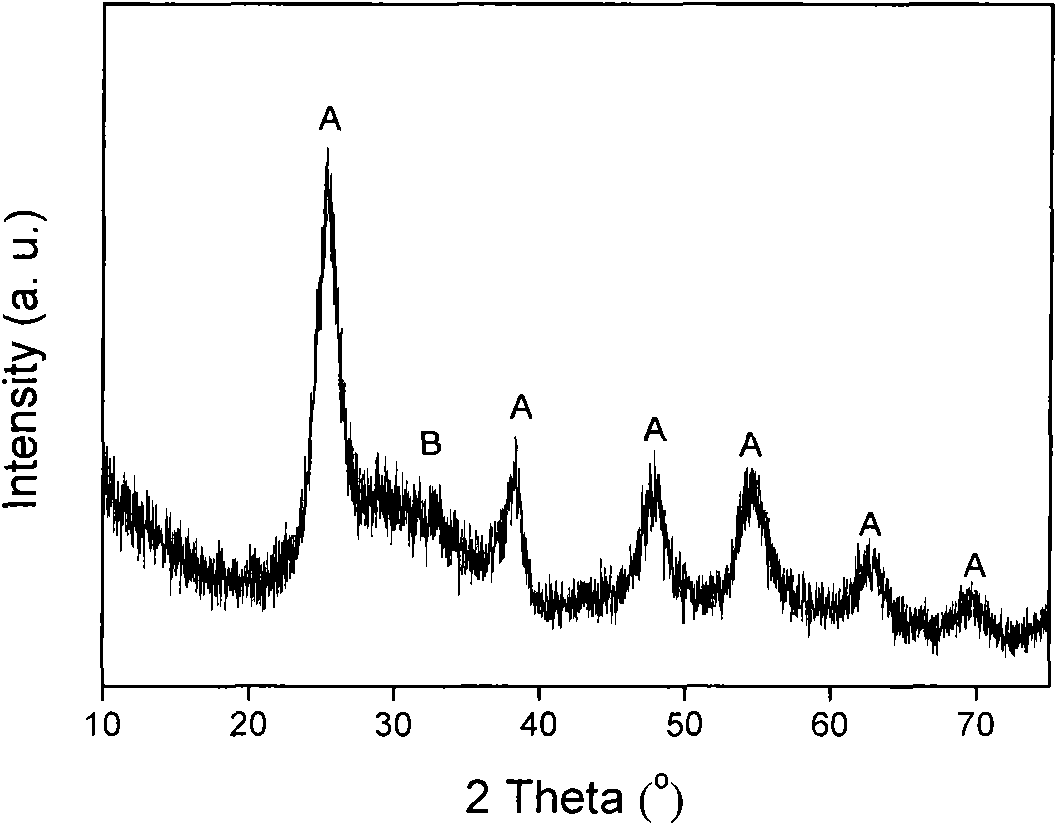

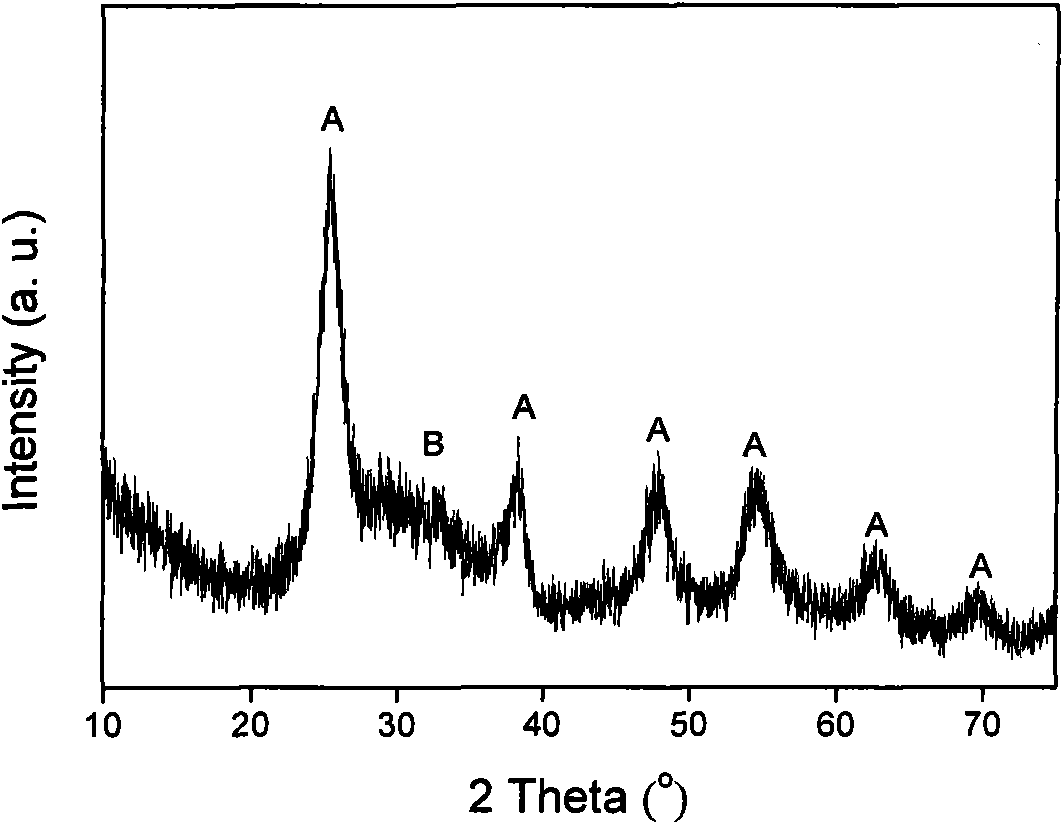

ActiveUS7393476B2Improve cycle performanceIncrease energy densityMaterial nanotechnologyCell temperature controlCrystallographyComposite oxide

A positive active material for lithium secondary batteries, includes a composite oxide including an oxide which is represented by the composite formula LixMnaNibCocO2 and has an α-NaFeO2 structure, and an impurity phase including Li2MnO3. The values a, b, and c are within such a range that in a ternary phase diagram showing the relationship among these, (a, b, c) is present on the perimeter of or inside the quadrilateral ABCD defined by point A (0.5, 0.5, 0), point B (0.55, 0.45, 0), point C (0.55, 0.15, 0.30), and point D (0.15, 0.15, 0.7) as vertexes, and 0.95<x / (a+b+c)<1.35.

Owner:GS YUASA INT LTD

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

Preparation method of low-temperature selective catalytic reduction (SCR) catalyst by removing NOx from flue gas

ActiveCN102008956AIncrease the areaLarge hole volumeNitrous oxide captureDispersed particle separationComposite oxideCoprecipitation

The invention provides a preparation method of a selective catalytic reduction (SCR) catalyst Mn-Ce-M / TiO2 by removing NOx from flue gas, wherein M represents one or more of composite oxides, namely Fe, Co, Cu, Cr, Zr and Al, the molar ratio of the elements is Ti: Mn: Ce: M =1:(0.005-1):(0.005-1):(0-1). In the invention, an improved coprecipitation method is adopted, and an intermediate compound, namely titanium nitrate Ti(NO3)4 is taken as a precursor of TiO2, thus the influence of the other impurities in the precipitation process is overcome; by changing the dispersing homogeneous degree of MnOx and CeO2 on the surface of a carrier TiO2, the activity of the catalyst is improved and the temperature of the SCR reaction is reduced; by adjusting the preparation condition of the TiO2 precursor, the sulfur resistance and water resistance of the catalyst are improved completely; and by adding the elements, such as Fe, Co, Cu, Cr, Zr and Al and the like, the activity and resistance of the catalyst are further modified.

Owner:GUODIAN SCI & TECH RES INST +1

Manganese-based composite oxide catalyst for catalytically decomposing ozone, and preparation method of manganese-based composite oxide catalyst

ActiveCN102600861AAchieve decentralizationAchieve catalytic effectDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureAir treatmentHydrothermal synthesis

The invention relates to a manganese-based composite oxide catalyst for catalytically decomposing ozone, and a preparation method of the catalyst. The catalyst comprises manganese oxide and at least one transition metal oxide. The preparation method is a homogeneous precipitation method or a hydrothermal synthesis method. The manganese-based composite oxide catalyst adopts innocuous and non-poisonous materials, prepares a manganese-based composite oxide catalyst with high catalytic activity, good wet resistance and high catalytic deposition content by the simple and easy method, so that the catalyst is suitable for catalytically decomposing ozone produced in water or air treatment and modern industry and home appliance.

Owner:上海棕晟企业管理合伙企业(有限合伙)

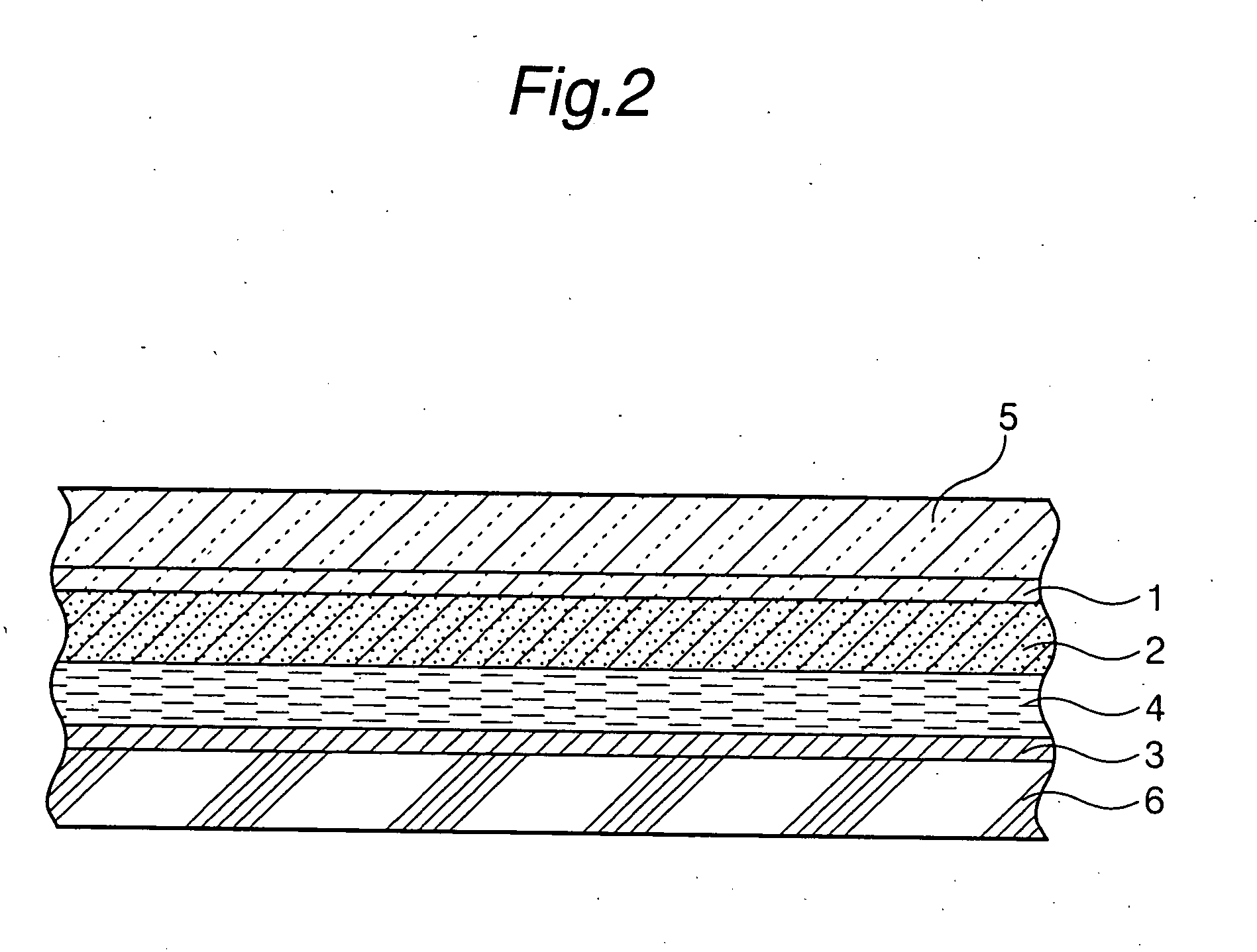

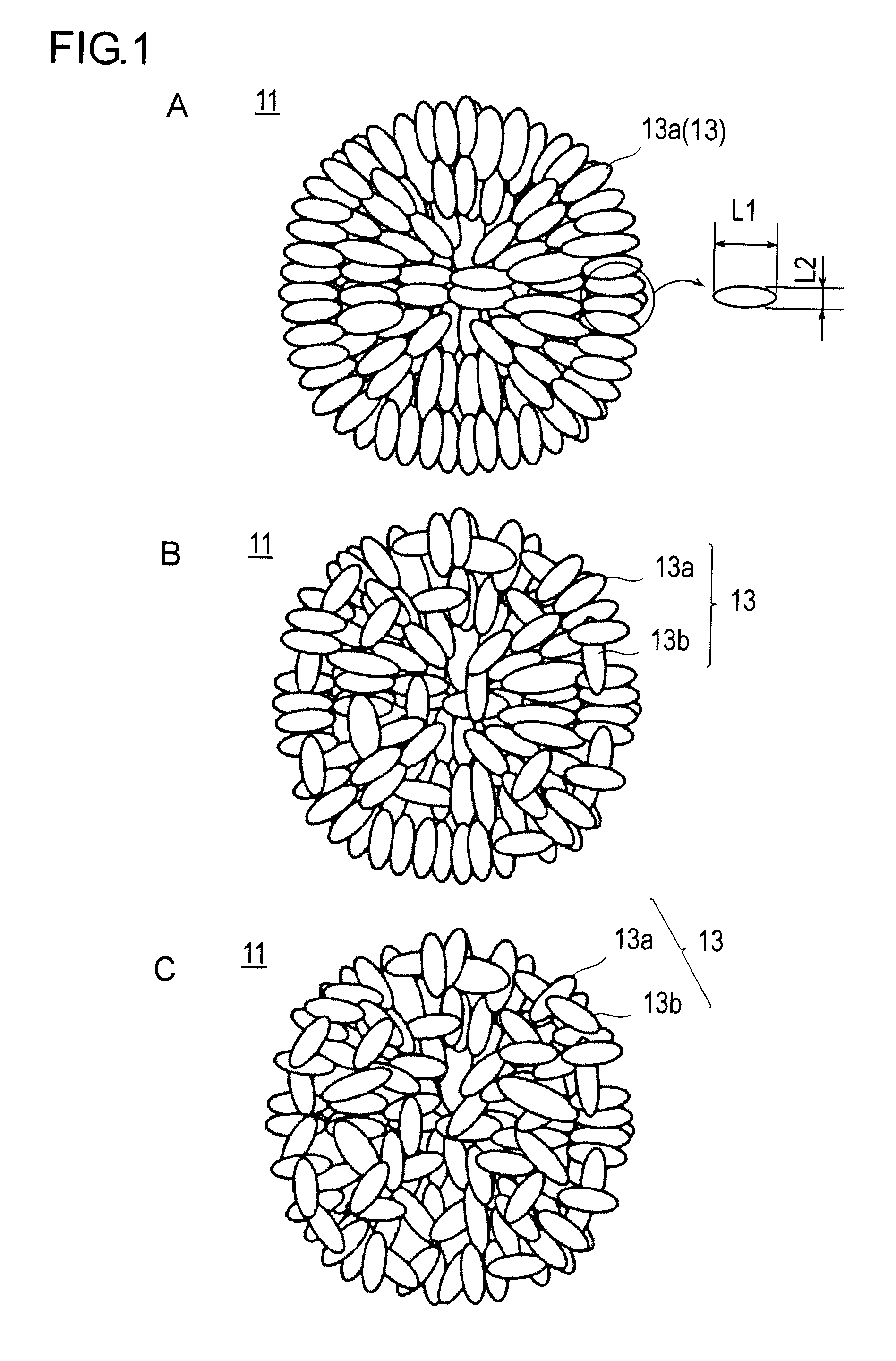

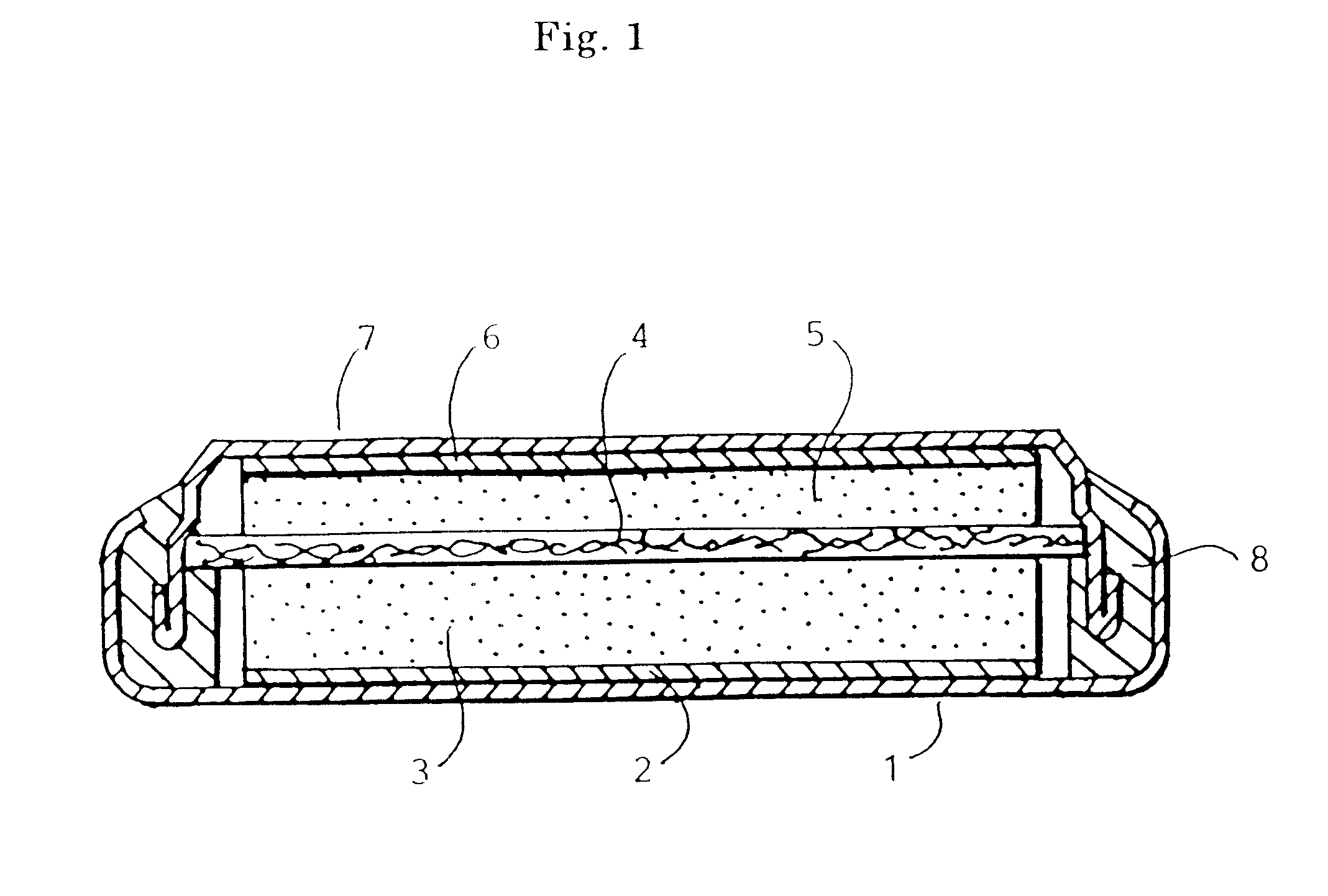

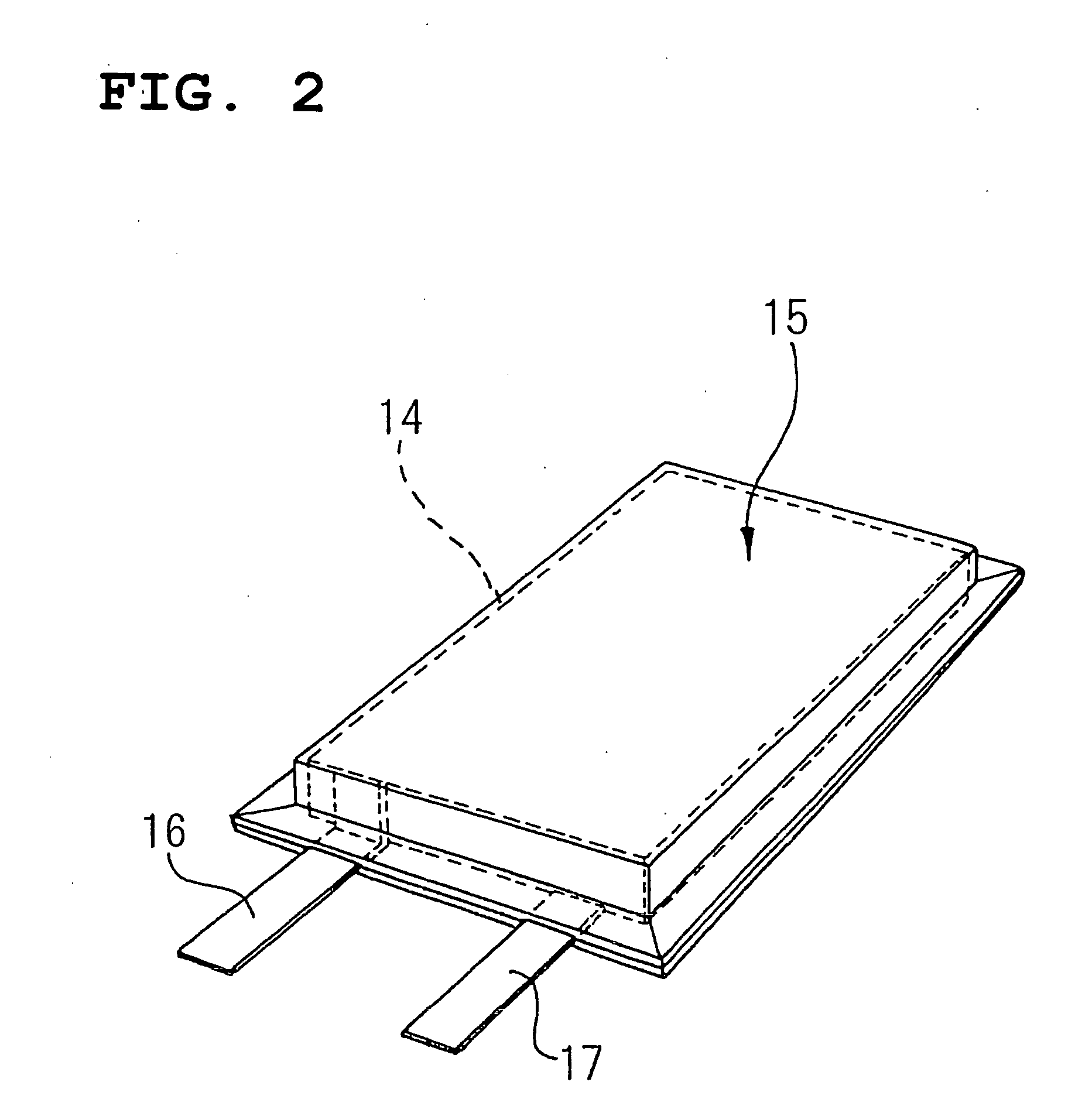

Positive electrode material for lithium ion battery with nonaqueous electrolyte, and battery using the same

ActiveUS20090029253A1Increase output powerAvoid crackingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithium-ion batteryComposite oxide

An object of the present invention is to provide a positive electrode material for non-aqueous electrolyte lithium-ion battery which capable of discharging high output power and inhibiting cracking of secondary particle in the cyclic endurance at a high temperature. The above object can be attained by a positive electrode material for non-aqueous electrolyte lithium-ion battery of the present invention, characterized in that said material comprises secondary particles composed of primary particles of lithium nickel composite oxide containing the primary particles having different aspect ratios, and that at least a part of said primary particles having different aspect ratios are arranged so as to make the longitudinal direction (the long side direction) thereof oriented toward the center of the secondary particle.

Owner:ENVISION AESC JAPAN LTD +1

Composite oxide catalyst for cryogenic selective catalystic reductic oxide nitrogen

InactiveCN101028594AEasy to makeEasy to operateCatalyst carriersDispersed particle separationManganese oxideNitrogen gas

A composite oxide catalyst for removing NOx from the tail gas generated by combustion through low-temp selective catalytic reduction reaction in which ammonia gas or urea is used as reducing agent for reducing the NOx into N2 and H2O is prepared from a composite metallic oxide (whose main component is manganese oxide) and a porous inorganic oxide as carrier through citric acid complexing method.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

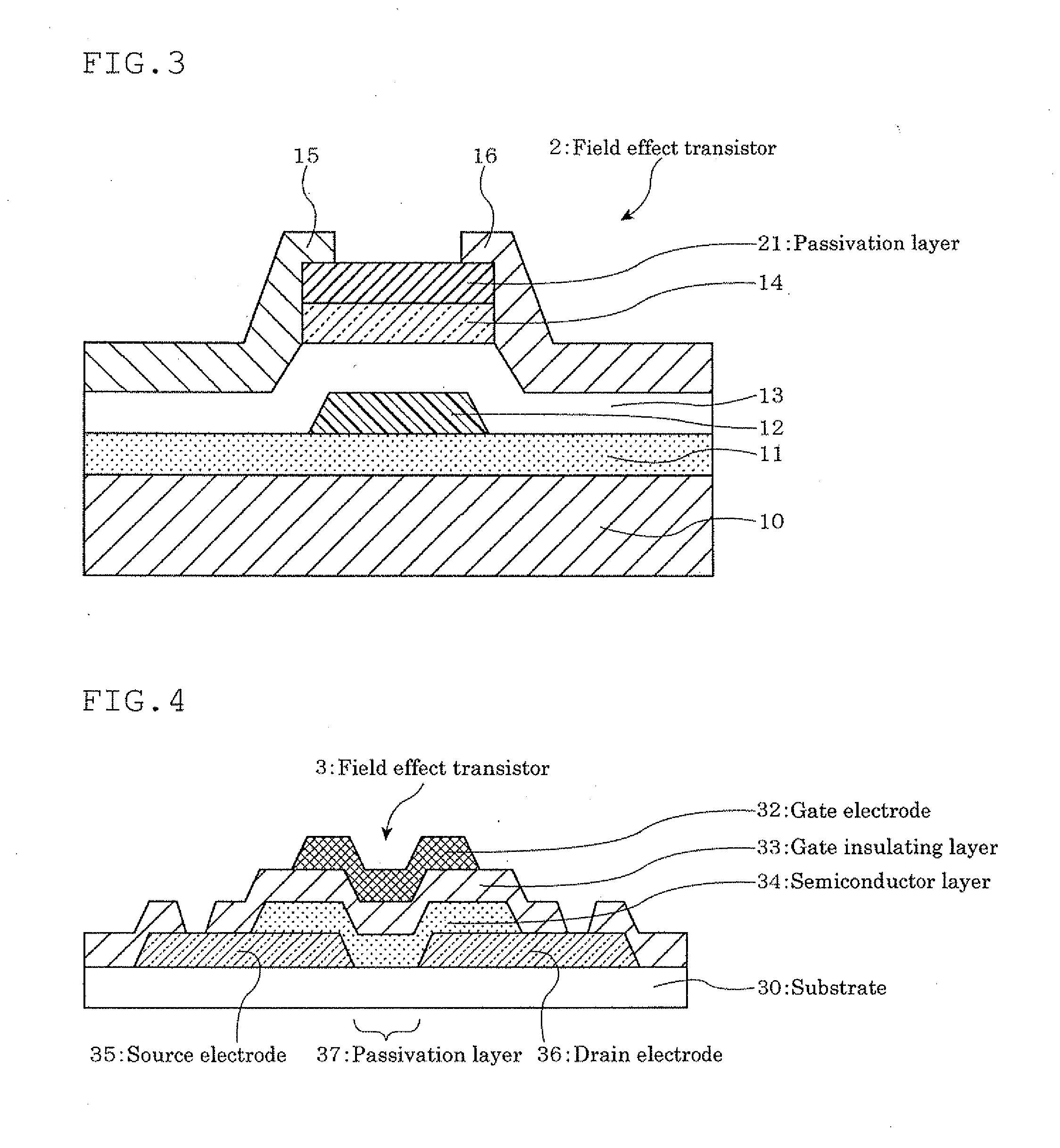

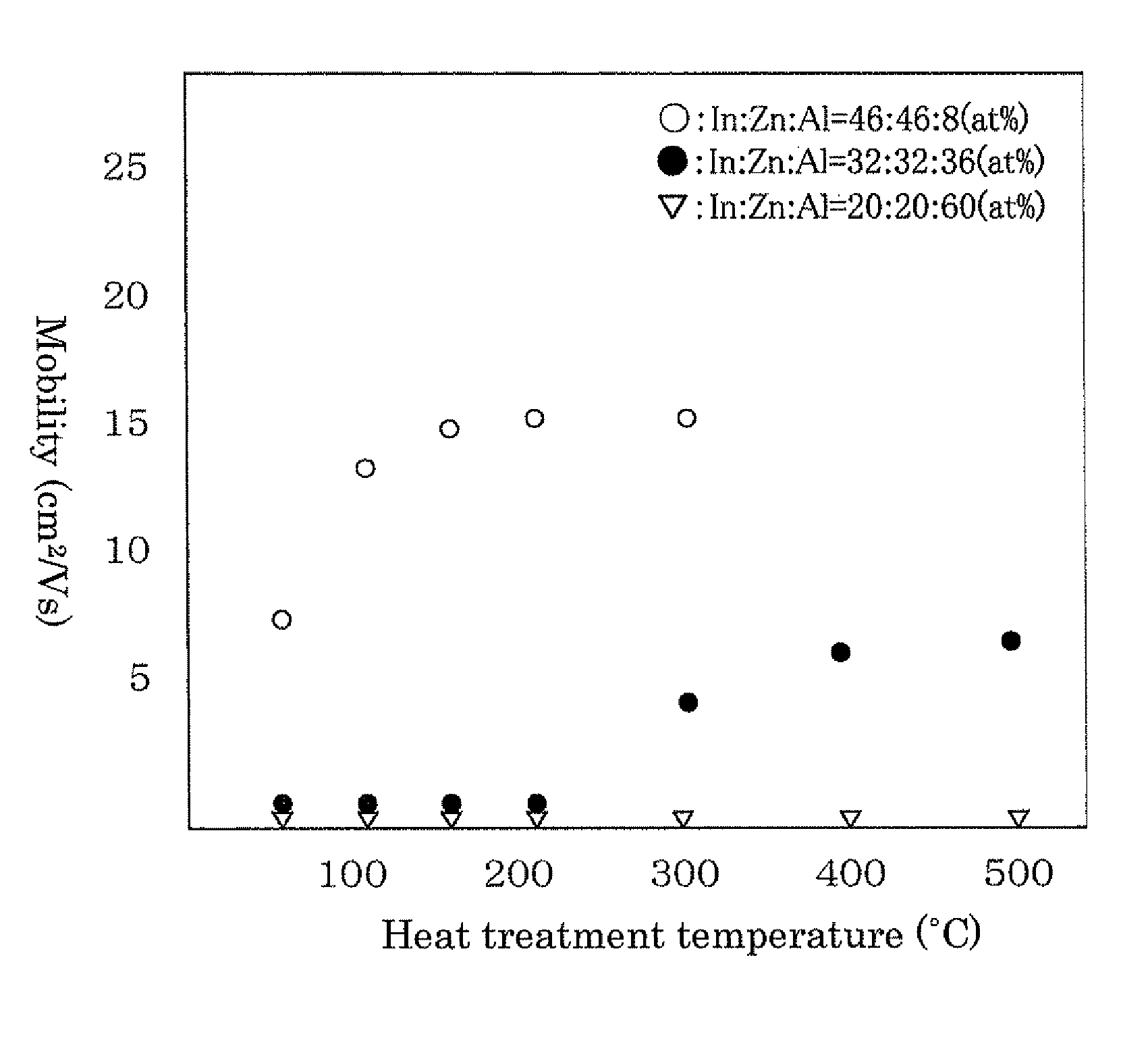

Oxide semiconductor field effect transistor and method for manufacturing the same

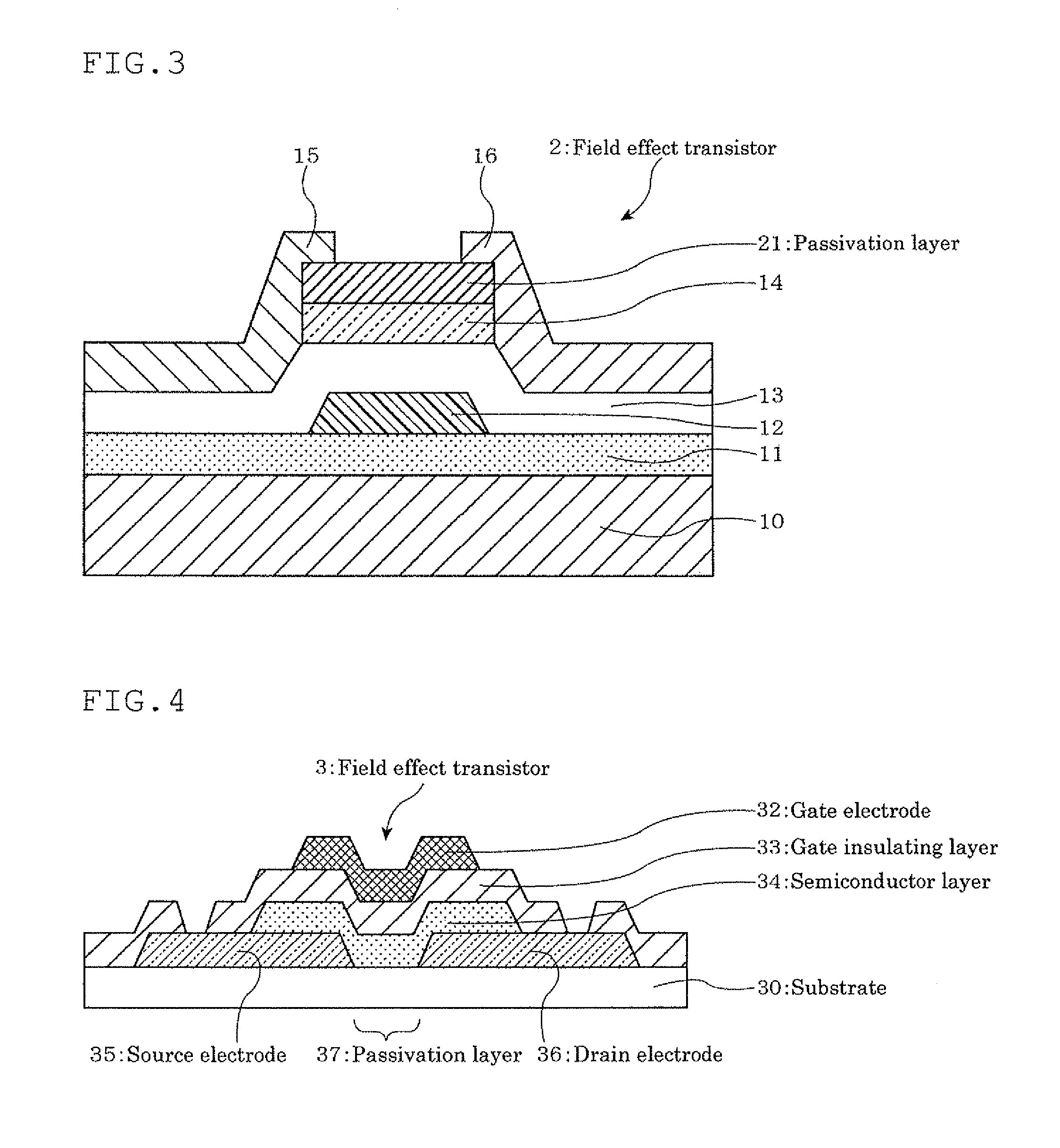

ActiveUS20100276688A1Easy to producePoor smoothnessTransistorVacuum evaporation coatingLanthanideField-effect transistor

A field effect transistor including a semiconductor layer including a composite oxide which contains In, Zn, and one or more elements X selected from the group consisting of Zr, Hf, Ge, Si, Ti, Mn, W, Mo, V, Cu, Ni, Co, Fe, Cr, Nb, Al, B, Sc, Y and lanthanoids in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+X)=0.29 to 0.99 (2)Zn / (X+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

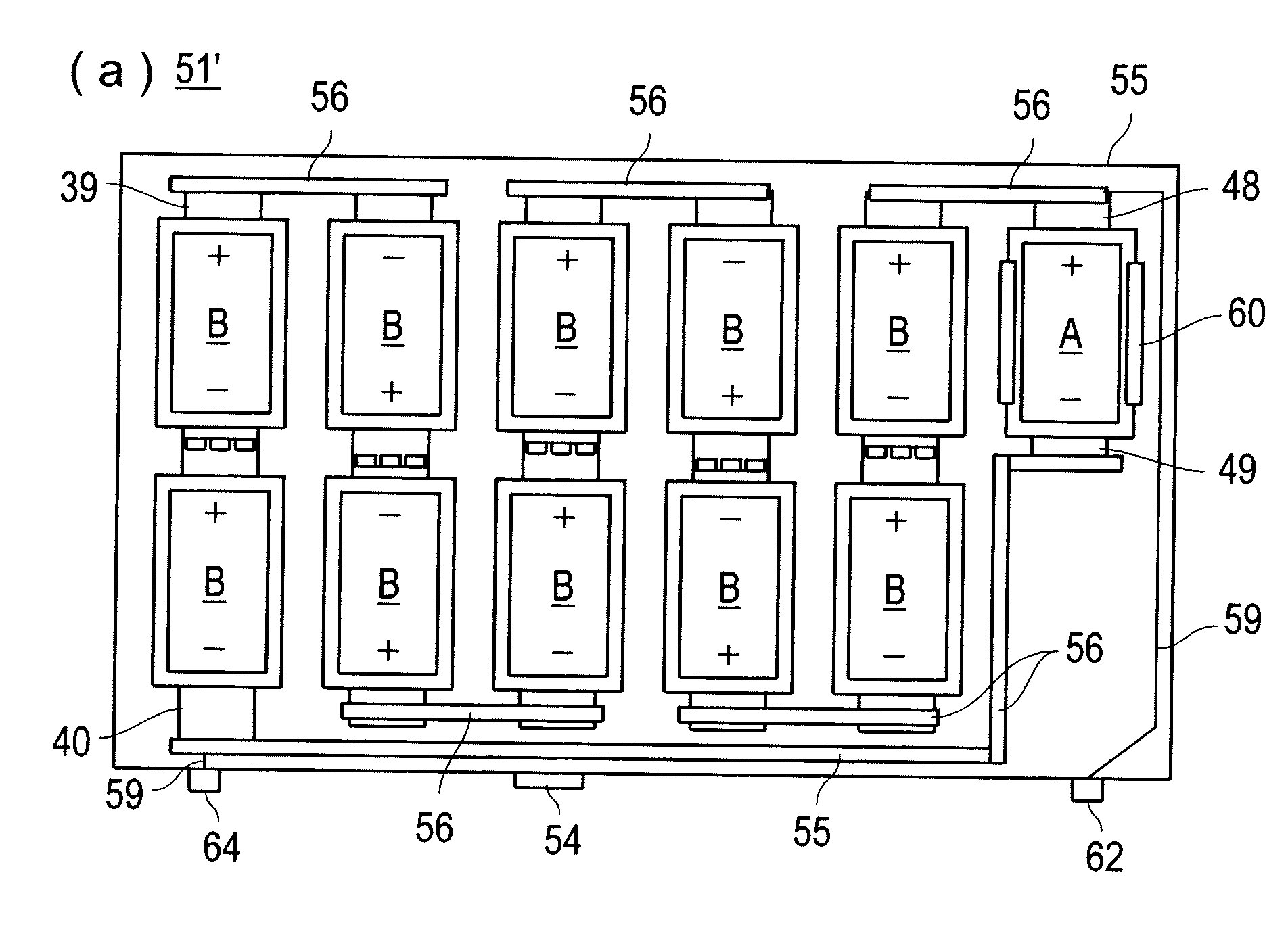

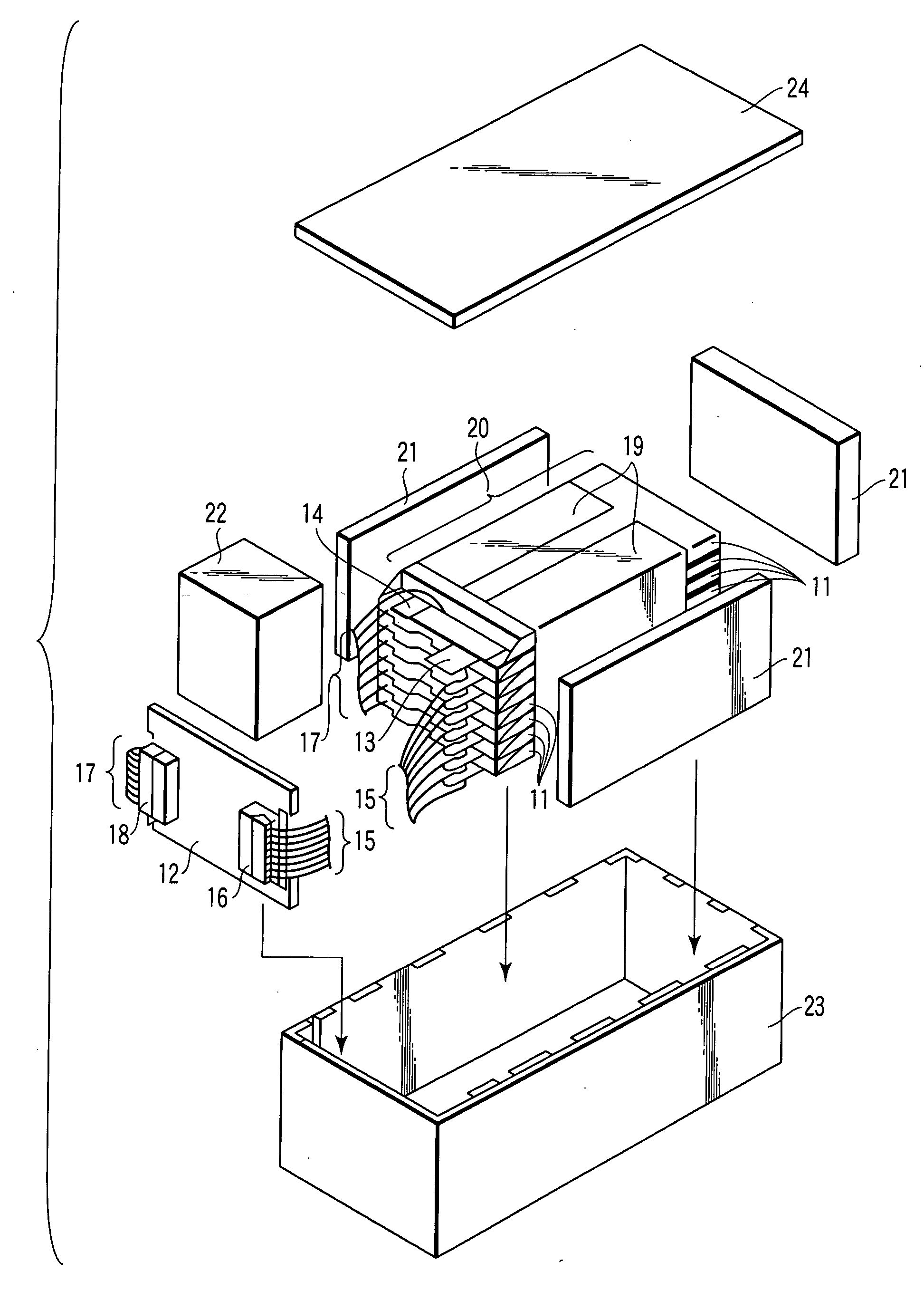

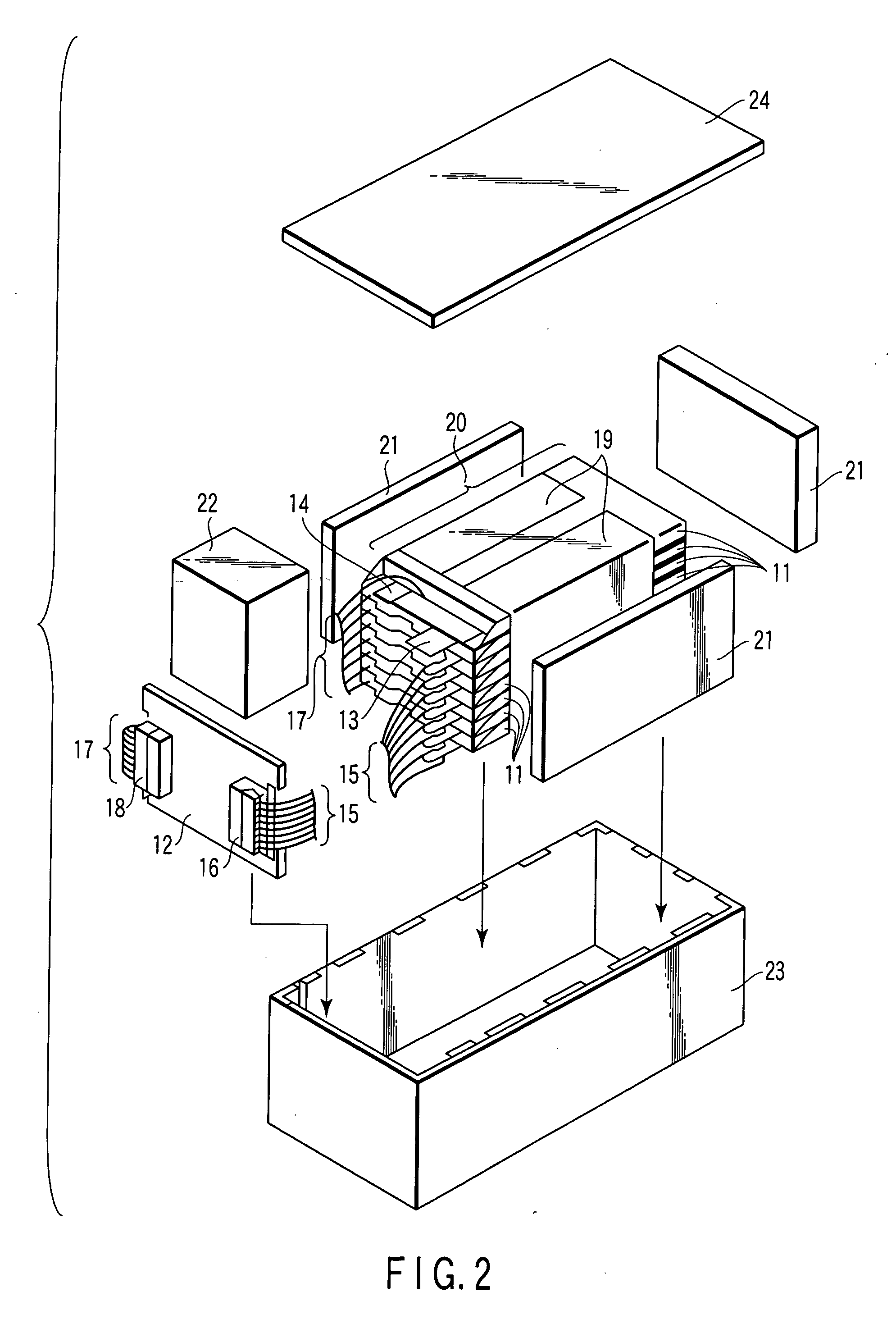

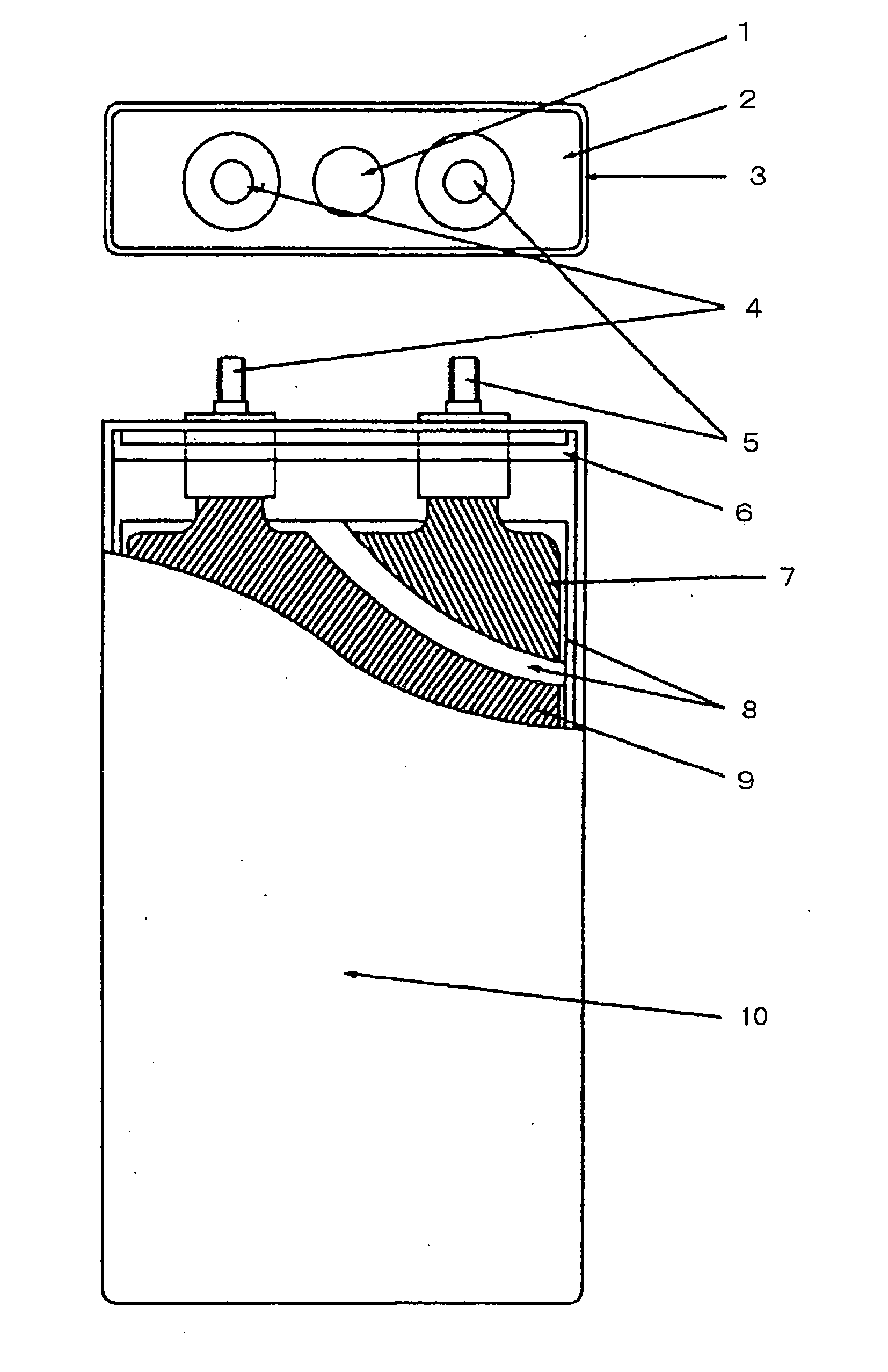

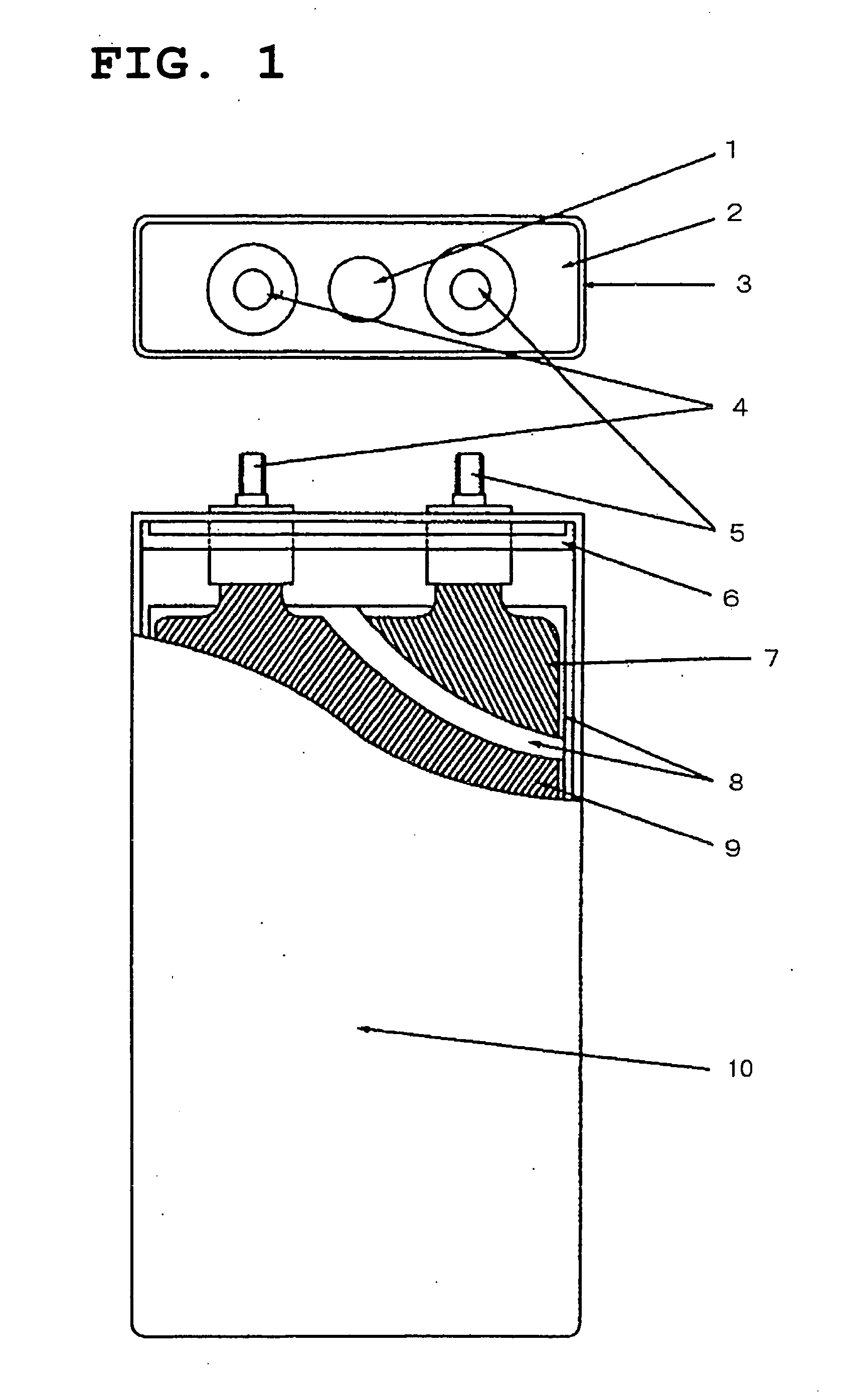

Battery pack and vehicle

ActiveUS20060216600A1Excellent in charge-discharge cycle characteristicFinal product manufactureCell lids/coversElectric capacitySpinel

A battery pack includes nonaqueous electrolyte batteries each comprising a positive electrode and a negative electrode. The positive electrode contains a lithium-transition metal oxide having a layered crystal structure. The negative electrode contains a lithium-titanium composite oxide having a spinel structure. And the positive electrodes and the negative electrodes satisfy the formula (1) given below: 1.02≦X≦2 (1) where X is a ratio of an available electric capacity of each of the negative electrodes at 25° C. to an available electric capacity of each of the positive electrodes at 25° C.

Owner:KK TOSHIBA

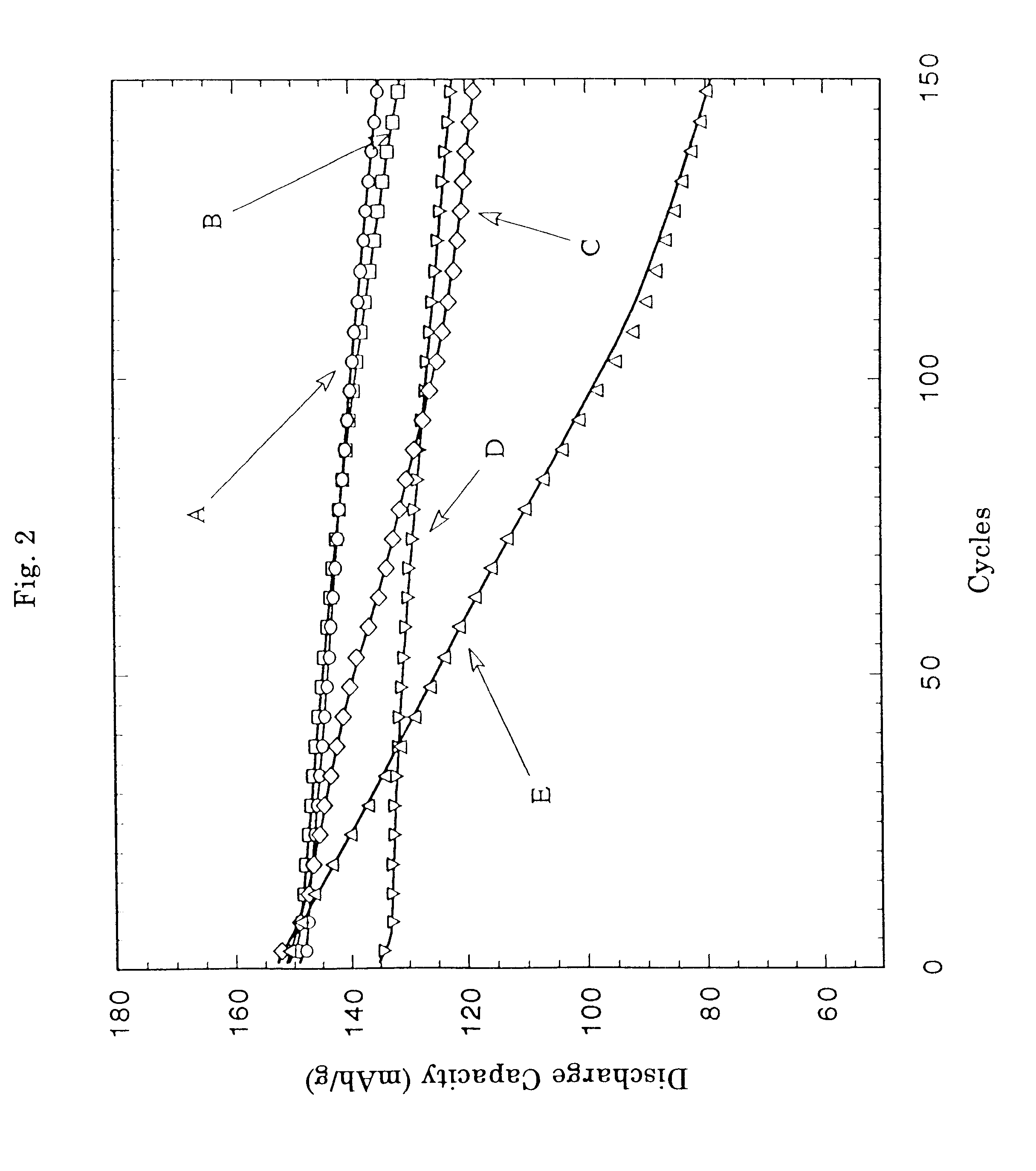

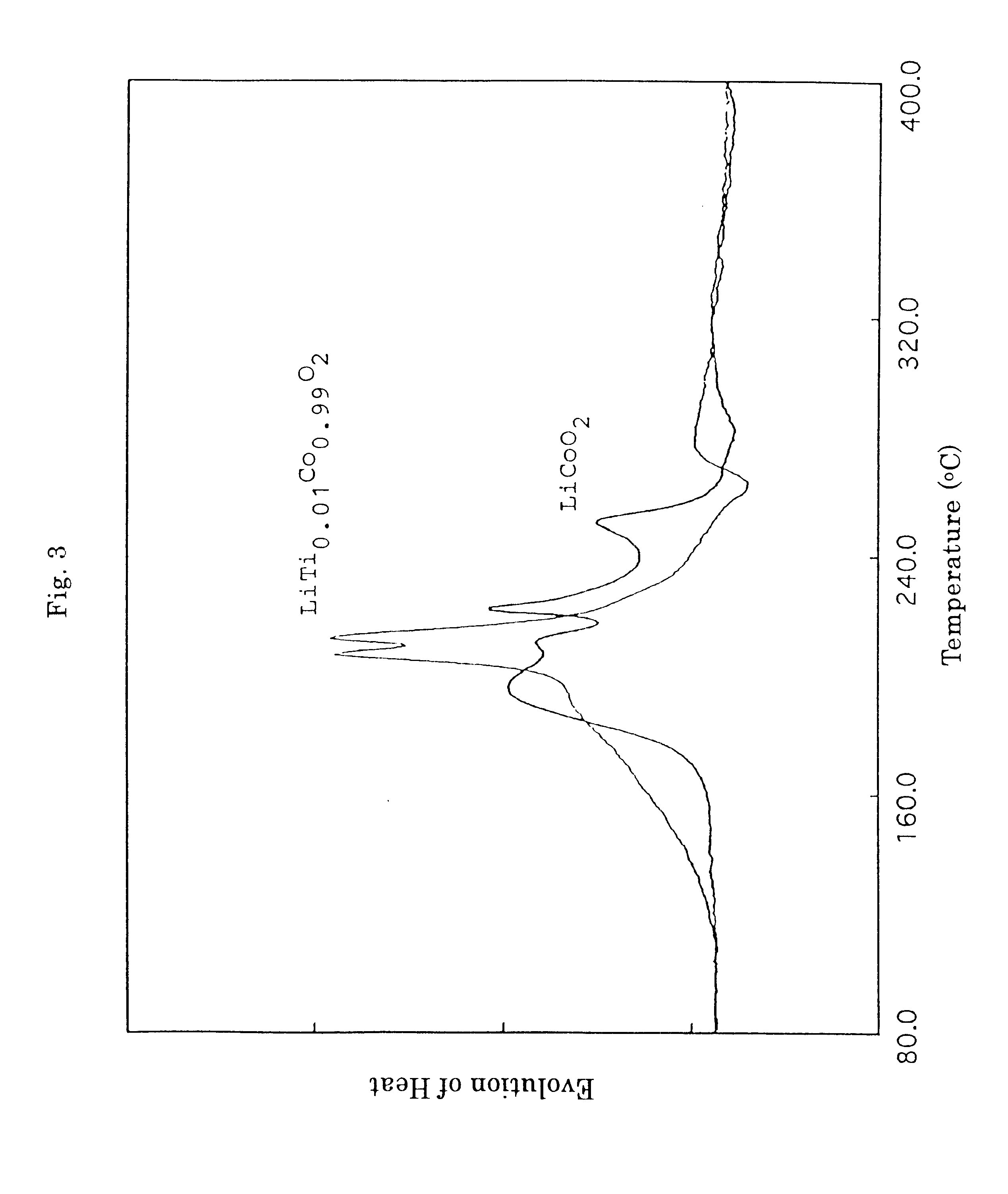

Lithium ion secondary battery, cathode active material therefor and production thereof

A substituted lithium cobalt composite oxide for use as a cathode active material in a lithium ion secondary battery, which has the general formula:in which M represents at least one metallic element selected from the group consisting of Ti, Mo and; x is a numeral in the range of 0.8 to 1.2; and y is a numeral in the range of 0.001 to 0.10.

Owner:HONJIYOU CHEM

Nonaqueous electrolyte battery, battery pack and vehicle

ActiveUS20070072080A1Improving charge-discharge cycle characteristicImprove featuresNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsPhysical chemistryTitanium

A nonaqueous electrolyte battery includes a positive electrode, a negative electrode containing a lithium-titanium composite oxide and a lithium-absorbing material in a weight ratio falling within the range defined in formula (1) given below, and a nonaqueous electrolyte. The lithium-absorbing material has a lithium absorption potential nobler than a lithium absorption potential of the lithium-titanium composite oxide. 3≦(A / B)≦100 (1) Where A denotes the weight (parts by weight) of the lithium-titanium composite oxide, and B denotes the weight (parts by weight) of the lithium-absorbing material.

Owner:KK TOSHIBA

Supported nano gold catalyst for clearing formaldehyde from indoor air and method for preparing the same

InactiveCN1698932ALow costHigh catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHoneycombRare earth

This invention relates to a supported nanometer gold catalyst which is used for cleaning formaldehyde of room air, in addition to its preparing method. The method comprises the following steps: a) using cordierite honeycomb ceramics as the carrier; b) coating a layer of rare earth oxide or composite rare earth oxide in the carrier surface evenly; c) depositing 3-10nm golden grain in the rare earth oxide or composite rare earth oxide, wherein the weight of gold is 1%-3% of the coating. Said catalyst can clean the formaldehyde of the air and the formaldehyde has a high conversion ratio. Meanwhile, the catalytic activity of said catalyst is larger by a magnitude order compared with Mn, Co oxide or rare earth composite oxide catalyst.

Owner:INNER MONGOLIA UNIVERSITY

Active substance of positive electrode and nonaqueous electrolyte battery containing the same

ActiveUS20050019659A1Increase energy densityImprove high rate discharge performanceSecondary cellsAlkali metal oxidesHigh rateHigh energy

A positive active material is provided which can give a battery having a high energy density and excellent high-rate discharge performance and inhibited from decreasing in battery, performance even in the case of high-temperature charge. Also provided is a non-aqueous electrolyte battery employing the positive active material. The positive active material contains a composite oxide which is constituted of at least lithium (Li), manganese (Mn), nickel (Ni), cobalt (Co), and oxygen (O) and is represented by the following chemical composition formula: LiaMnbNicCodOe (wherein 0<a≦1.3, |b−c|≦0.05, 0.6≦d<1, 1.7≦e≦2.3, and b+c+d=1). The non-aqueous electrolyte battery has a positive electrode containing the positive active material, a negative electrode, and a non-aqueous electrolyte.

Owner:GS YUASA INT LTD

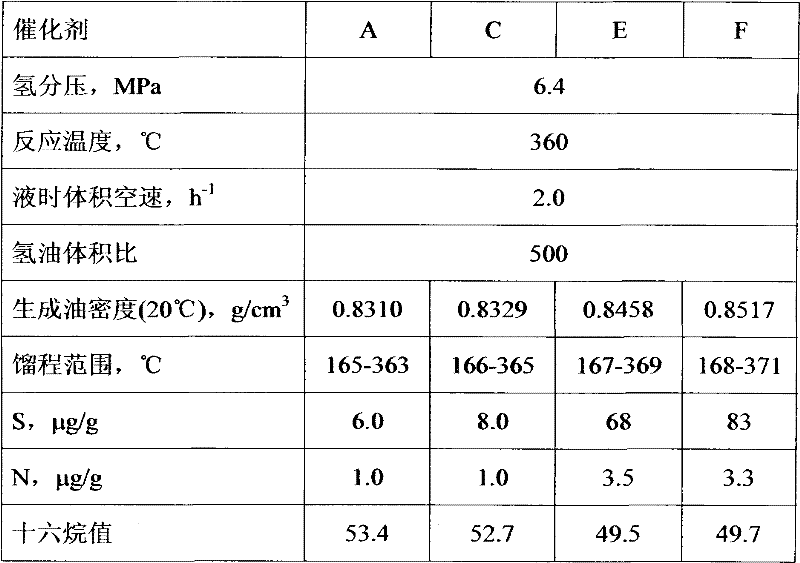

Preparation method of hydrogenation catalyst composition

ActiveCN102451703AImprove adhesionEasy to shapeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminateHigh activity

The invention discloses a preparation method of a hydrogenation catalyst composition. According to the method, sodium meta-aluminate is adopted as an aluminum source in the preparation of a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor through a coprecipitation process, and a proper amount of a CO2 gas is accessed in the colloid forming process, so a difficult shaping problem of a bulk phase catalyst is solved, physicochemical properties of the catalyst are adjusted, and the composition which has the characteristics of large specific surface area and uniform aperture distribution and makes many metal active sites be exposed on the catalyst surface allows the utilization rate of active metals to be improved. The catalyst composition of the invention, which has increased apertures and pore volumes, allows the Ni-W high activity sites to be fully utilized and complex macrostructure molecules to easily contact with the active sites, so the catalyst composition is especially suitable for ultra-deep desulfurization reactions for the production of ultraclean diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxide semiconductor field effect transistor and method for manufacturing the same

ActiveUS8461583B2Easy to produceTransistorVacuum evaporation coatingLanthanideField-effect transistor

A field effect transistor including a semiconductor layer including a composite oxide which contains In, Zn, and one or more elements X selected from the group consisting of Zr, Hf, Ge, Si, Ti, Mn, W, Mo, V, Cu, Ni, Co, Fe, Cr, Nb, Al, B, Sc, Y and lanthanoids in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+X)=0.29 to 0.99 (2)Zn / (X+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

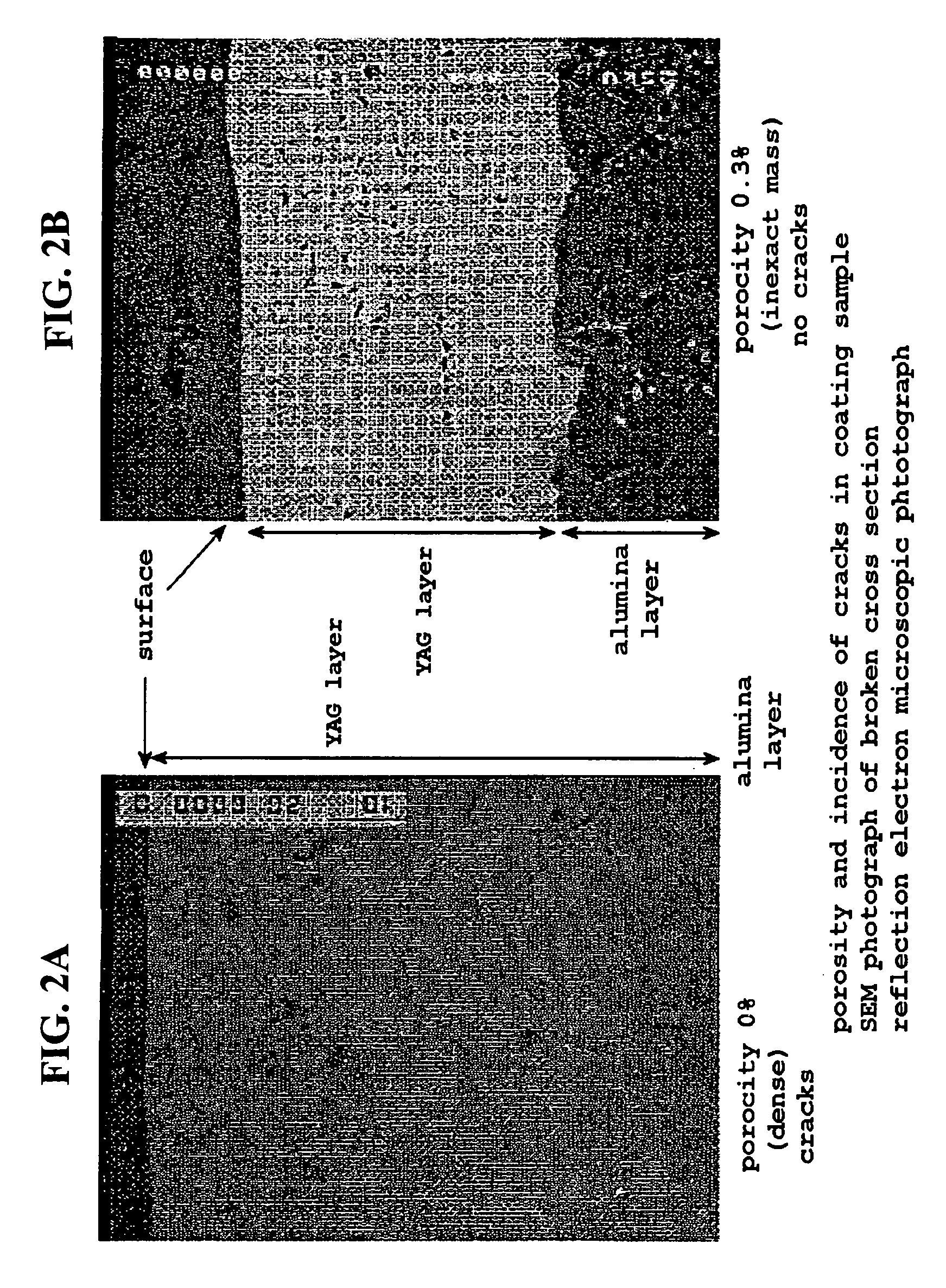

Plasma resistant member

InactiveUS20050227118A1Avoid crackingSufficiently durableElectric discharge tubesVacuum evaporation coatingPorosityHigh density

The present invention provides a plasma resistant member having a reinforced mechanical strength and being sufficiently durable to exposure to a low pressure high density plasma. At least the surface of the alumina based material is formed of an oxide or composite oxide layer of a group IIIA element via an intermediate layer. It is preferable in the construction of the plasma resistant member that the intermediate layer comprises 10 to 80% by weight of the oxide or composite oxide of the group IIIA element in the periodic table and 90 to 20% by weight of alumina. The intermediate layer may also comprise a course ceramic with a porosity of 0.2 to 5%. It is also desirable that at least one of the conditions such as a difference in the thermal shrinkage ratio at 1600 to 1900° C. of 3% or less is provided.

Owner:COVALENT MATERIALS CORP

Lithium composite oxide particle for positive electrode material of lithium secondary battery, and lithium secondary battery positive electrode and lithium secondary battery using the same

InactiveUS20060134521A1Improving low-temperature load characteristicGood paintabilityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsAlkali metal oxidesElectrical batteryComposite oxide

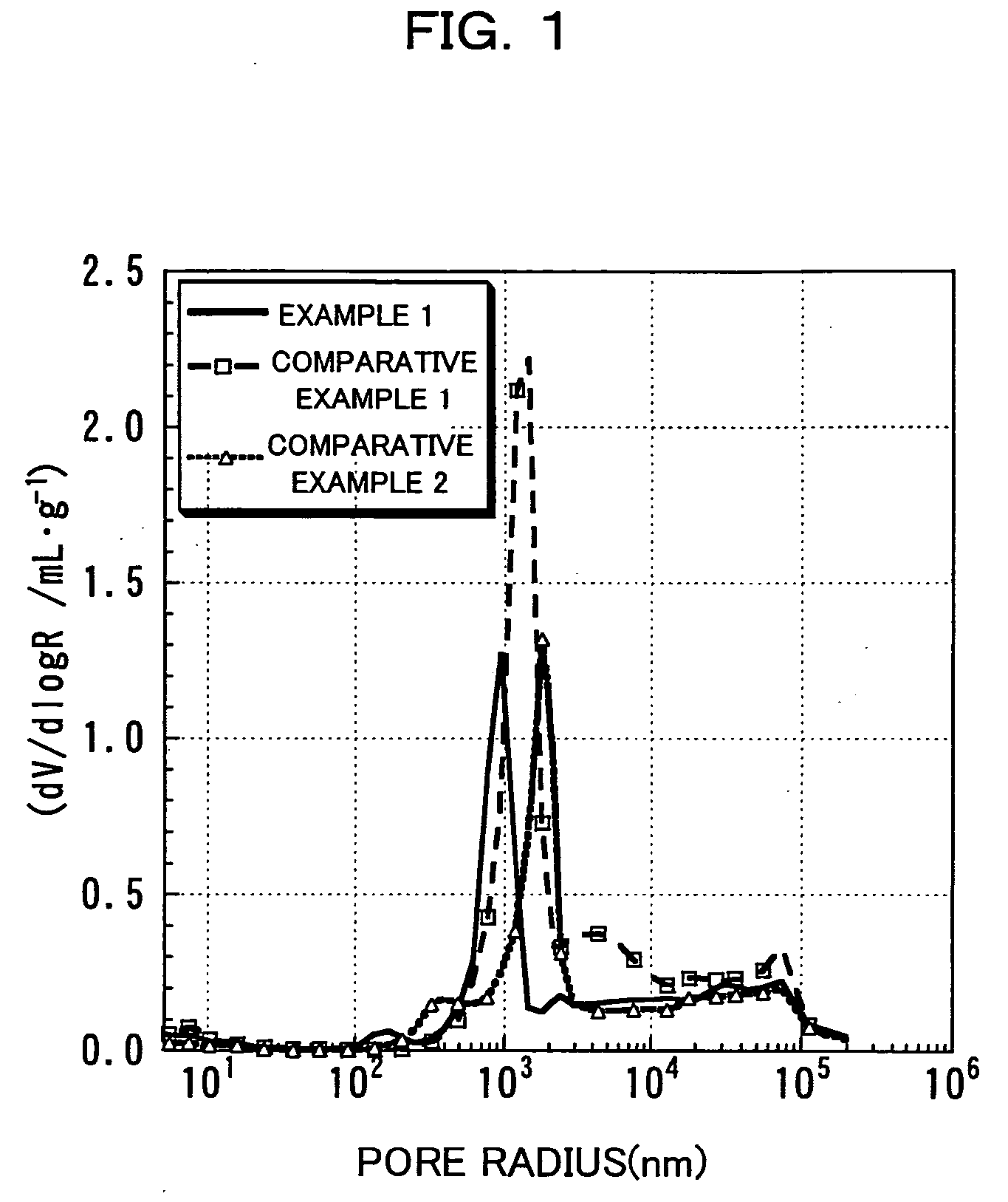

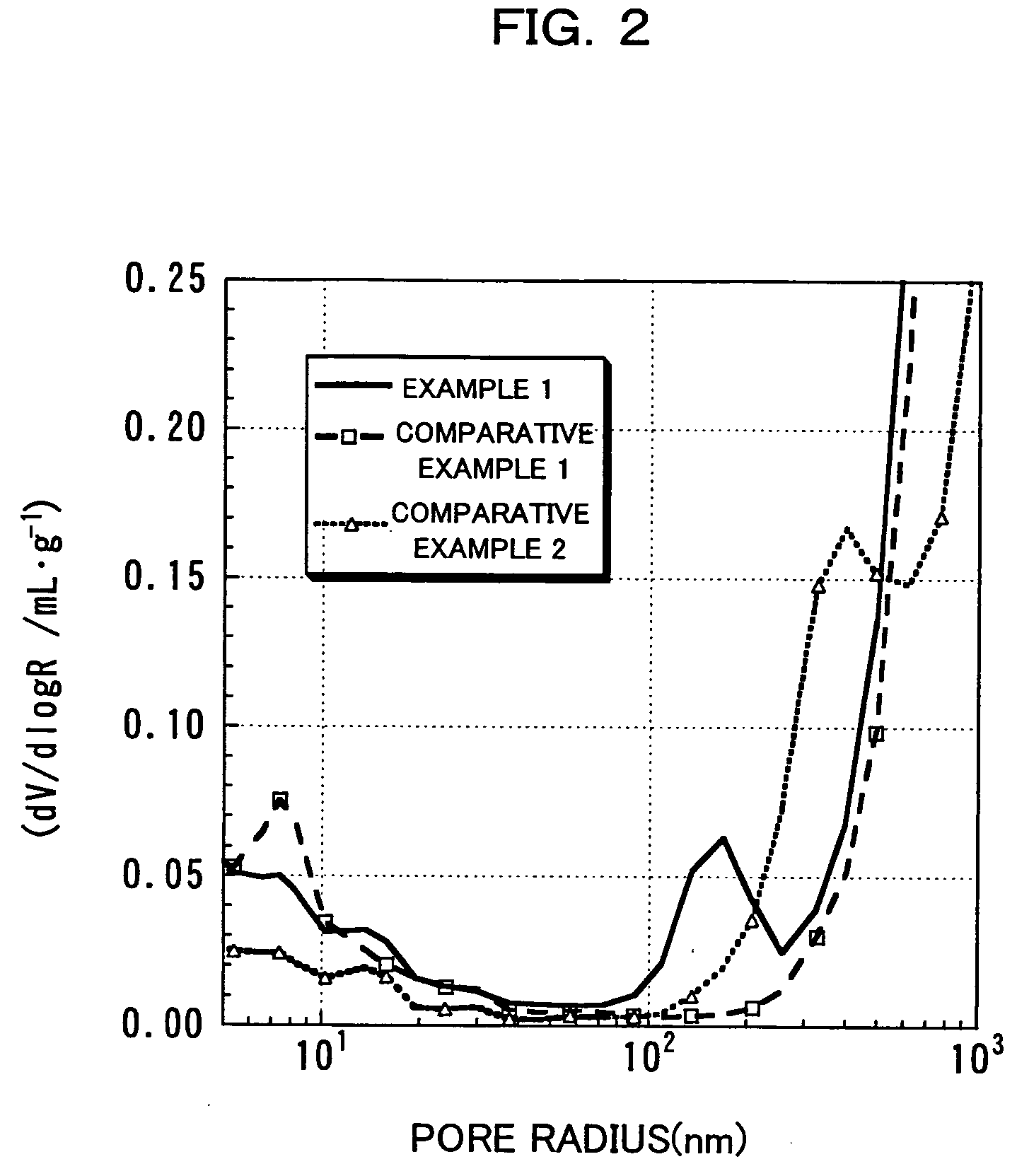

An excellent positive electrode material for a lithium secondary battery is provided that can increase low-temperature load characteristics of the battery as well as improving coatability. When measured by mercury intrusion porosimetry, the material meets Condition (A) and at least either Condition (B) or Condition (C). Condition (A) : on a mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.02 cm3 / g or smaller. Condition (B): on the mercury intrusion curve, the mercury intrusion volume from 50 MPa to 150 MPa is 0.01 cm3 / g or larger. Condition (C): the average pore radius is within 10-100 nm, and the pore-size distribution curve has a main peak (with peak top at a pore radius of within 0.5-50 μm) and a sub peak (with peak top at a pore radius of within 80-300 nm).

Owner:MITSUBISHI CHEM CORP

Normal temperature cured self-assembly composite nano oxide anti-corrosive paint

InactiveCN101481553AReduce defectsImprove anti-corrosion performanceAnti-corrosive paintsSelf-assemblyComposite oxide

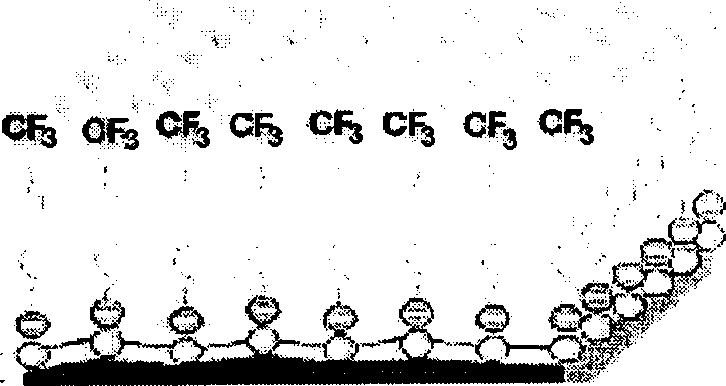

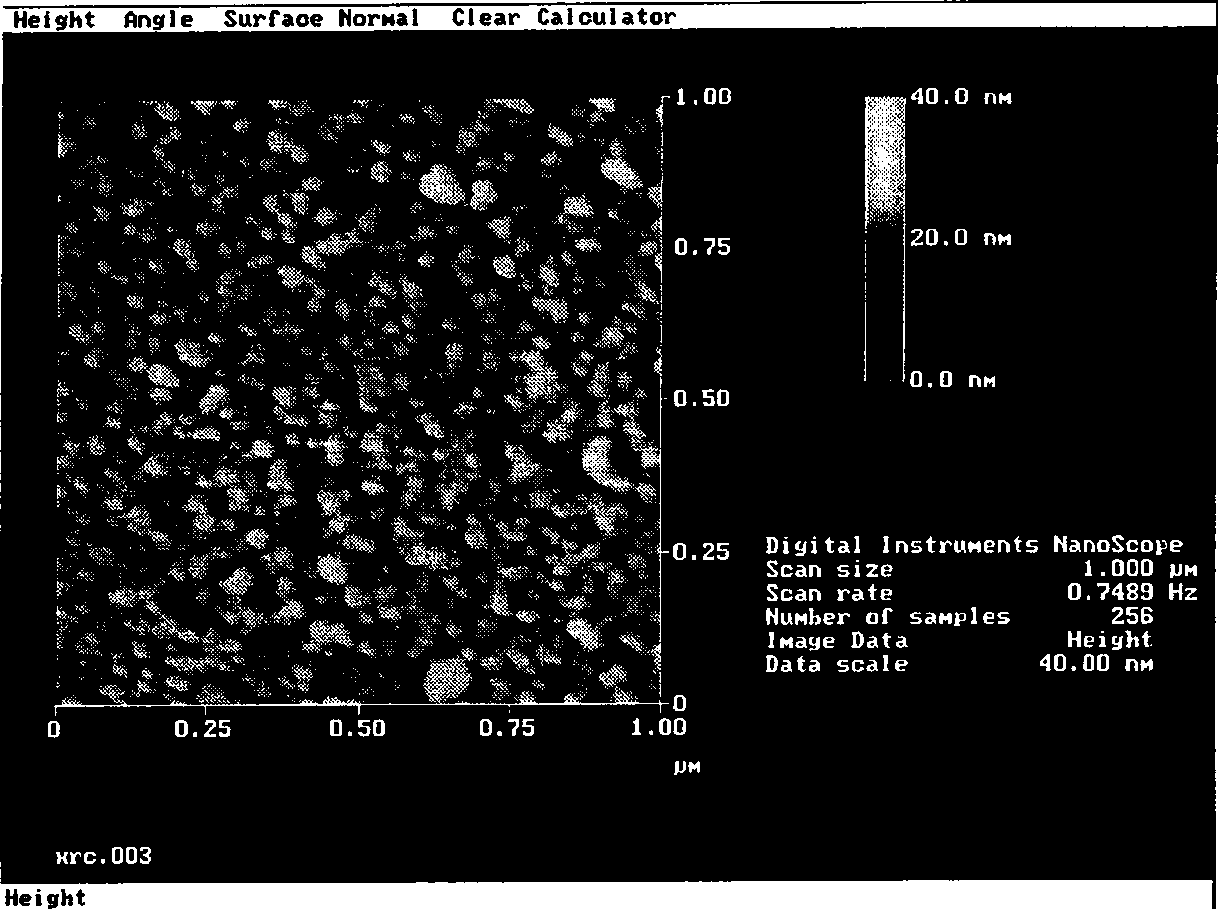

The invention relates to a nanometer antiseptic paint and provides a nanometer composite oxide antiseptic paint for various metal substrates. After the paint is used for treated metal, the coating can be solidified at the normal temperature and has excellent antiseptic property. The composite oxide comprises nanometer silicon dioxide sol and nanometer titanium dioxide sol. After the coating is dried, nanometer particles of the composite oxide subject to the modification of fluorocarbon-type silane coupling agent and other types of organic silane coupling agent undergo self-assembly to form a dense coating with a thickness of 1-5 microns.

Owner:CHANGZHOU NANOCOATING

Non-Aqueous Electrolyte Secondary Battery

ActiveUS20090035659A1Improve featuresGood crystal stabilityElectrode manufacturing processesConductive materialComposite oxideNon aqueous electrolytes

A lithium-containing composite oxide represented by the formula 1: LixNi1-y-z-v-wCoyAlzM1vM2wO2 is used as a positive electrode active material for a non-aqueous electrolyte secondary battery. The element M1 is at least one selected from the group consisting of Mn, Ti, Y, Nb, Mo, and W. The element M2 includes at least two selected from the group consisting of Mg, Ca, Sr, and Ba, and the element M2 includes at least Mg and Ca. The formula 1 satisfies 0.97≦x≦1.1, 0.05≦y≦0.35, 0.005≦z≦0.1, 0.0001≦v≦0.05, and 0.0001≦w≦0.05. The primary particles have a mean particle size of 0.1 μm or more and 3 μm or less, and the secondary particles have a mean particle size of 8 μm or more and 20 μm or less.

Owner:PANASONIC CORP +1

Lithium-nickel-cobalt-maganese containing composite oxide, material for positive electrode active material for lithium secondary battery, and methods for producing these

ActiveUS20060083989A1Large capacityExcels in charge-discharge cycle durabilityElectrode rolling/calenderingFluoride preparationManganeseOxygen

Coagulated particles of nickel-cobalt-manganese hydroxide wherein primary particles are coagulated to form secondary particles are synthesized by allowing an aqueous solution of a nickel-cobalt-manganese salt, an aqueous solution of an alkali-metal hydroxide, and an ammonium-ion donor to react under specific conditions; and a lithium-nickel-cobalt-manganese-containing composite oxide represented by a general formula, LipNixMn1-x-yCoyO2-qFq (where 0.98≦p≦1.07, 0.3≦x≦0.5, 0.1≦y≦0.38, and 0≦q≦0.05), which is a positive electrode active material for a lithium secondary cell having a wide usable voltage range, a charge-discharge cycle durability, a high capacity and high safety, is obtained by dry-blending coagulated particles of nickel-cobalt-manganese composite oxyhydroxide formed by making an oxidant to act on the coagulated particles with a lithium salt, and firing the mixture in an oxygen-containing atmosphere.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com