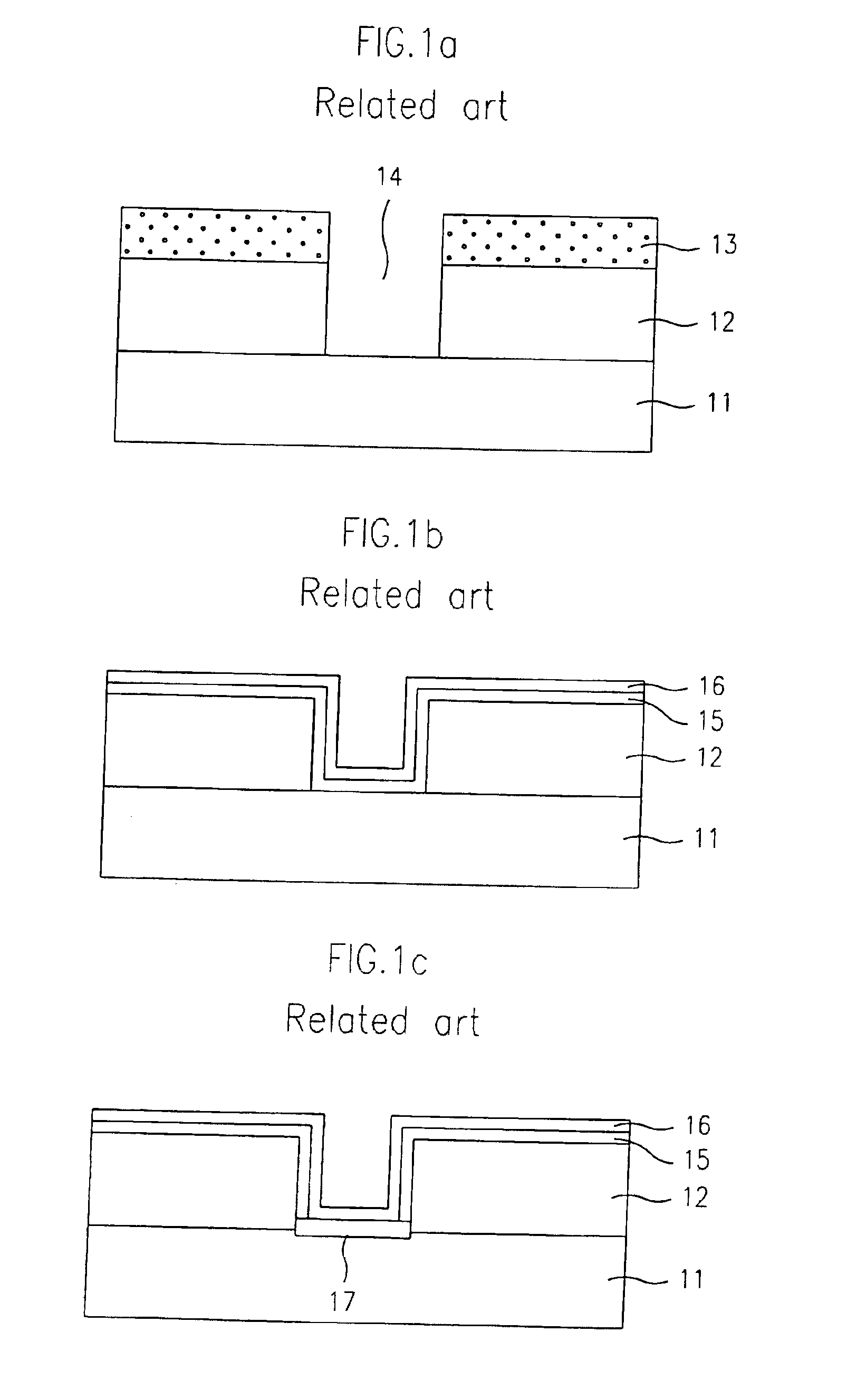

Patents

Literature

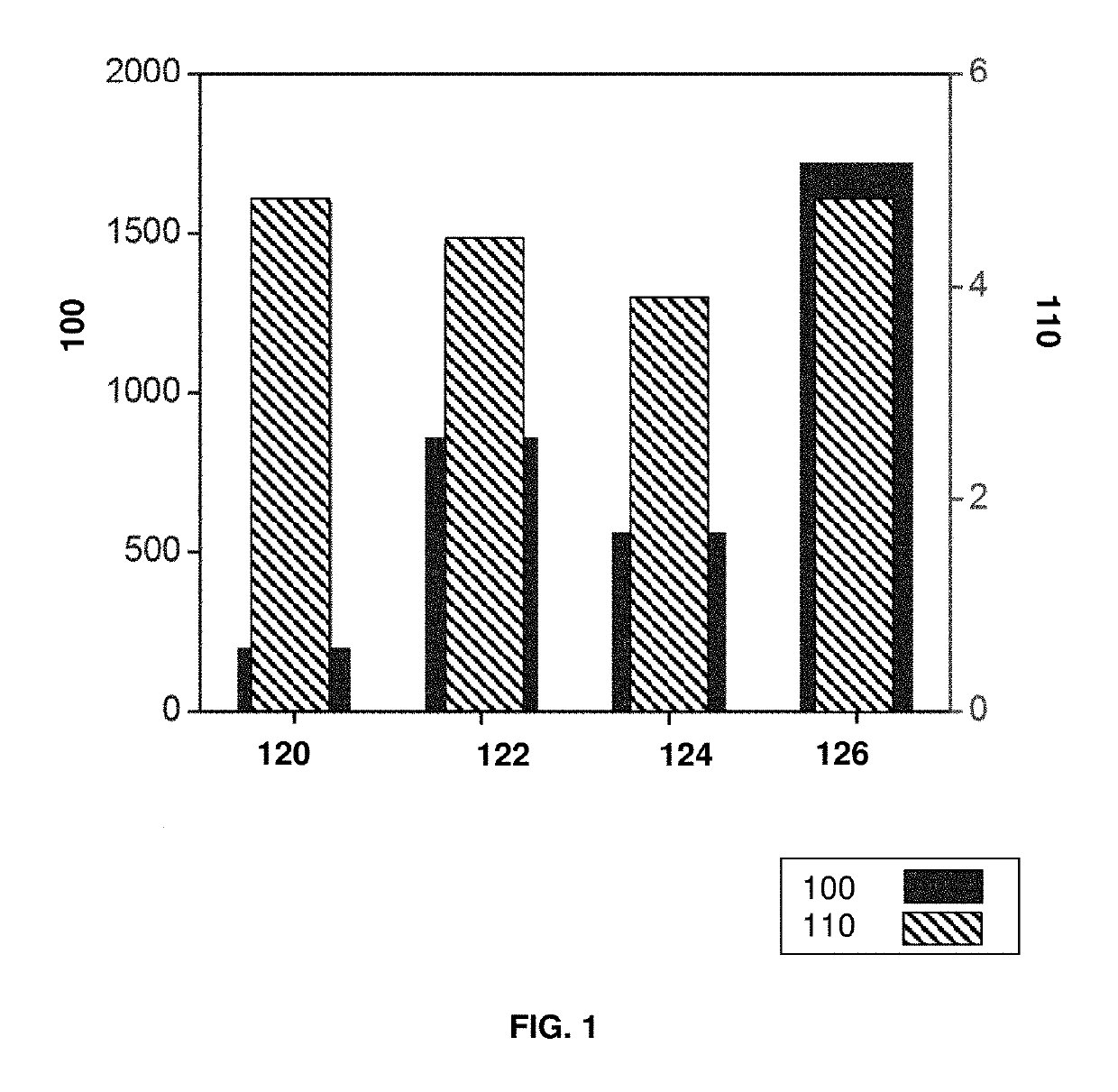

53 results about "Ternary phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials chemistry, a ternary phase is chemical compound containing three different elements. Some ternary phases compounds are molecular, e.g. chloroform (HCCl 3). More typically ternary phases refer to extended solids.

Rapidly solidified high-temperature aluminum iron silicon alloys

InactiveUS10294552B2Large gradientLarge strainAdditive manufacturing apparatusIncreasing energy efficiencySilicon alloyHigh energy

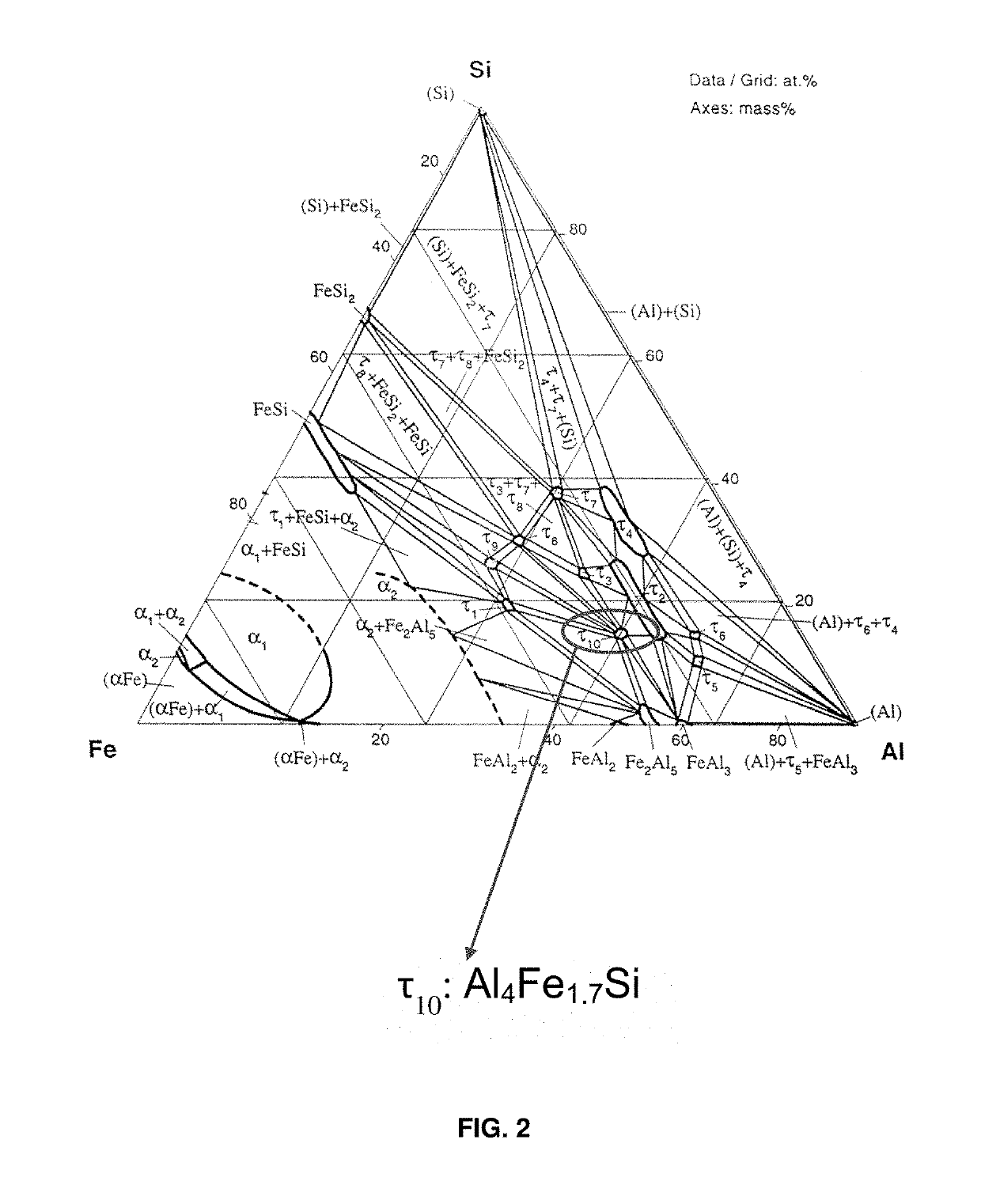

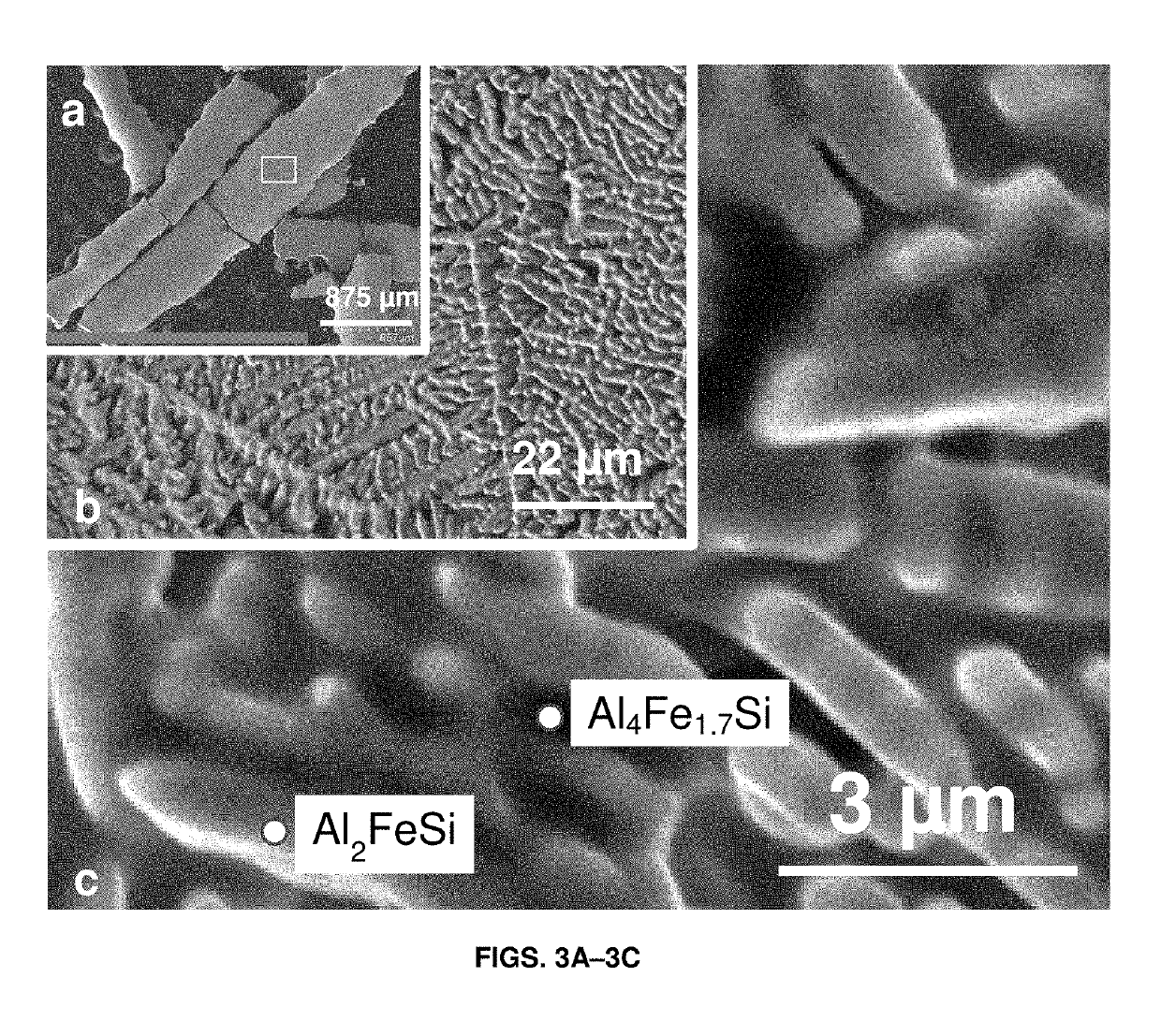

Methods of making high-strength, lightweight alloy components capable of high temperature performance comprising aluminum, silicon, and iron and / or nickel are provided. A high-energy stream, such as a laser or electron beam, may be selectively directed towards a precursor material to melt a portion of the precursor material in a localized region. The molten precursor material is cooled at a rate of greater than or equal to about 1.0×105 K / second to form a solid high-strength, lightweight alloy component comprising a stable ternary cubic phase having high heat resistance and high strength. The stable ternary phase may be AlxFeySiz, where x ranges from about 4 to about 5 or about 7.2 to about 7.6, y is about 1.5 to about 2.2, and z is about 1. The stable ternary phase may also be Al6Ni3Si. Materials and components, such as automotive components, made from such methods are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

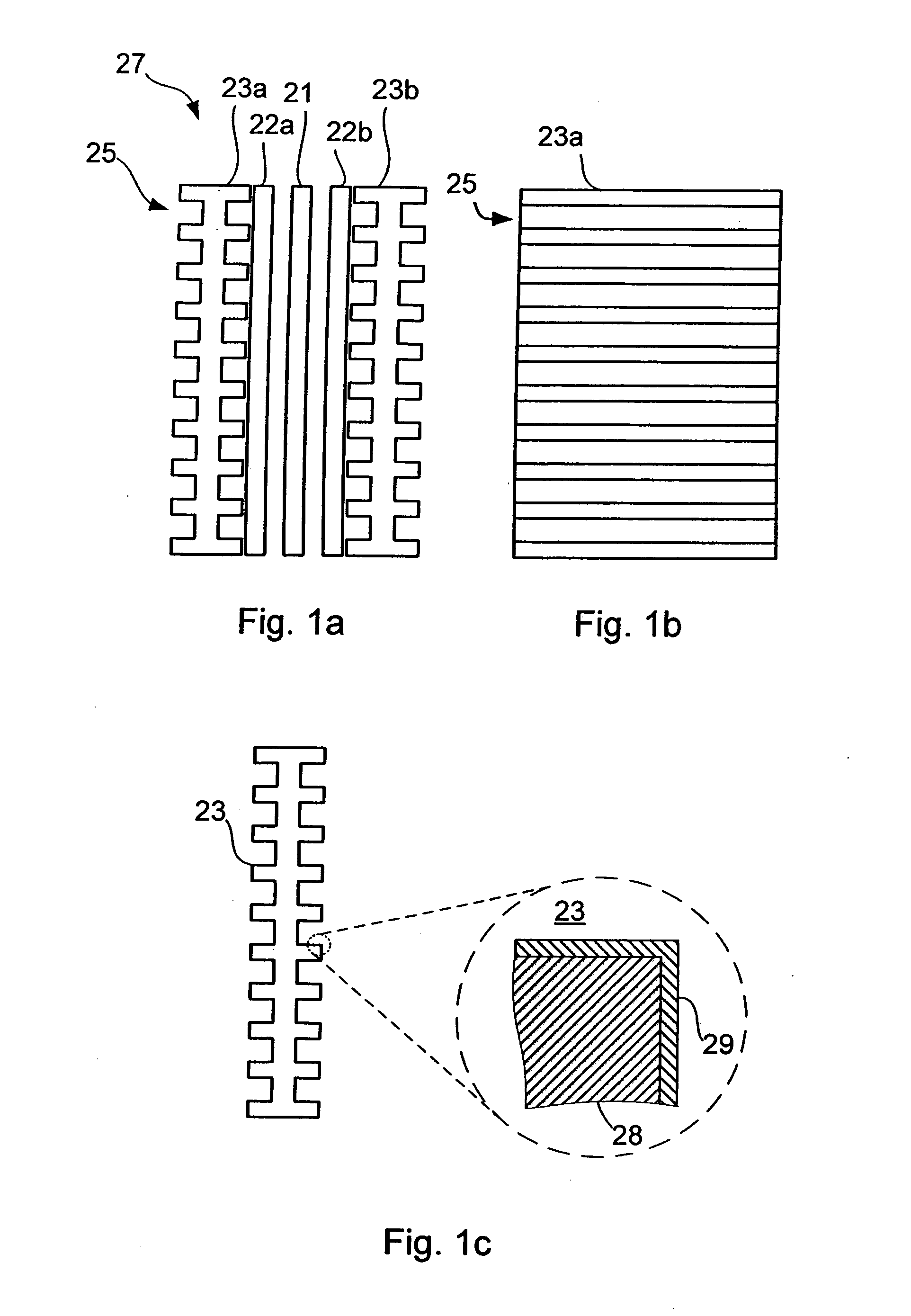

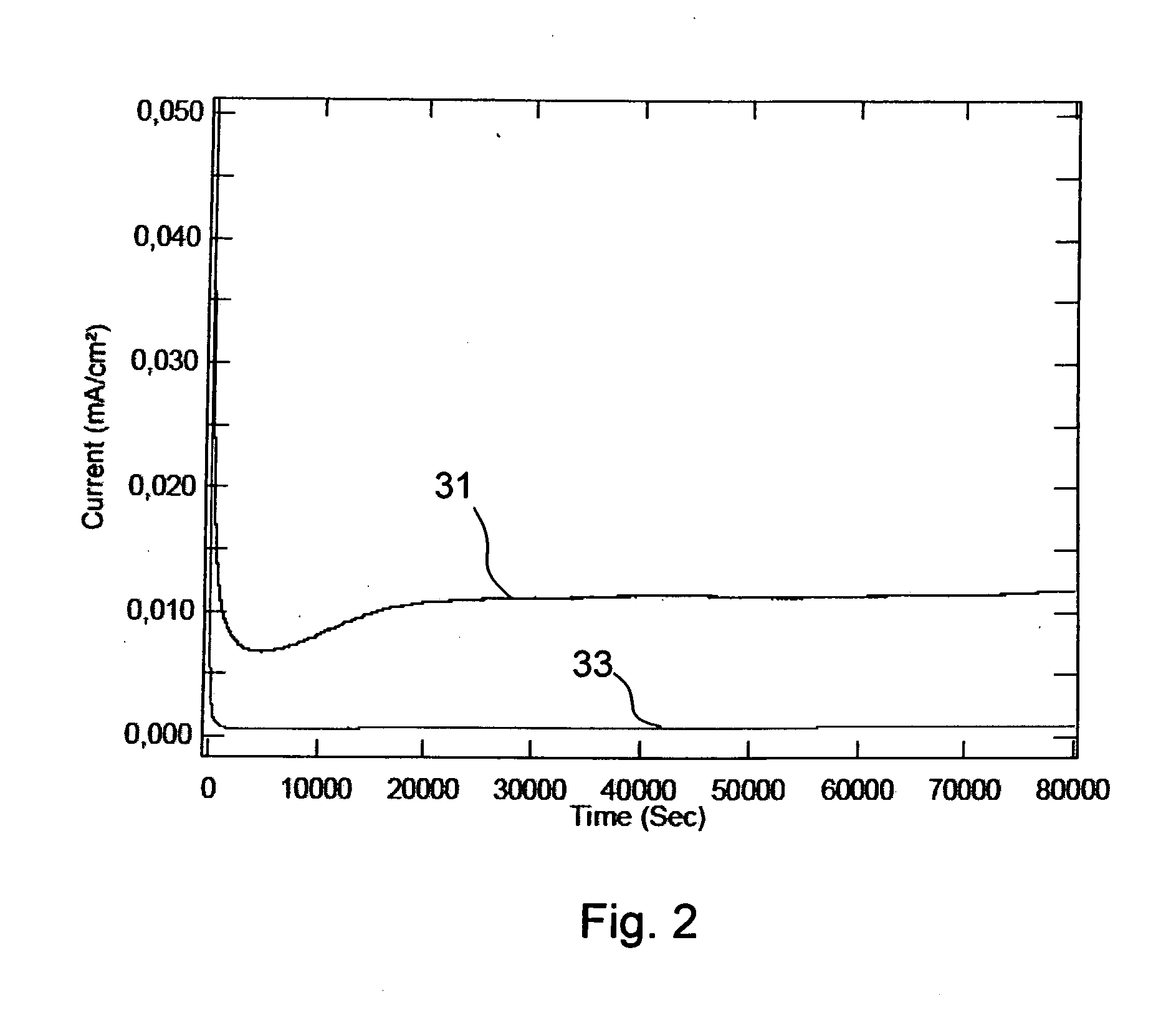

Electrode with a coating, method in production thereof and use of a material

InactiveUS20110033784A1Reduce the impactDecrease risk of weak spotFinal product manufactureVacuum evaporation coatingAtomic elementTernary phase

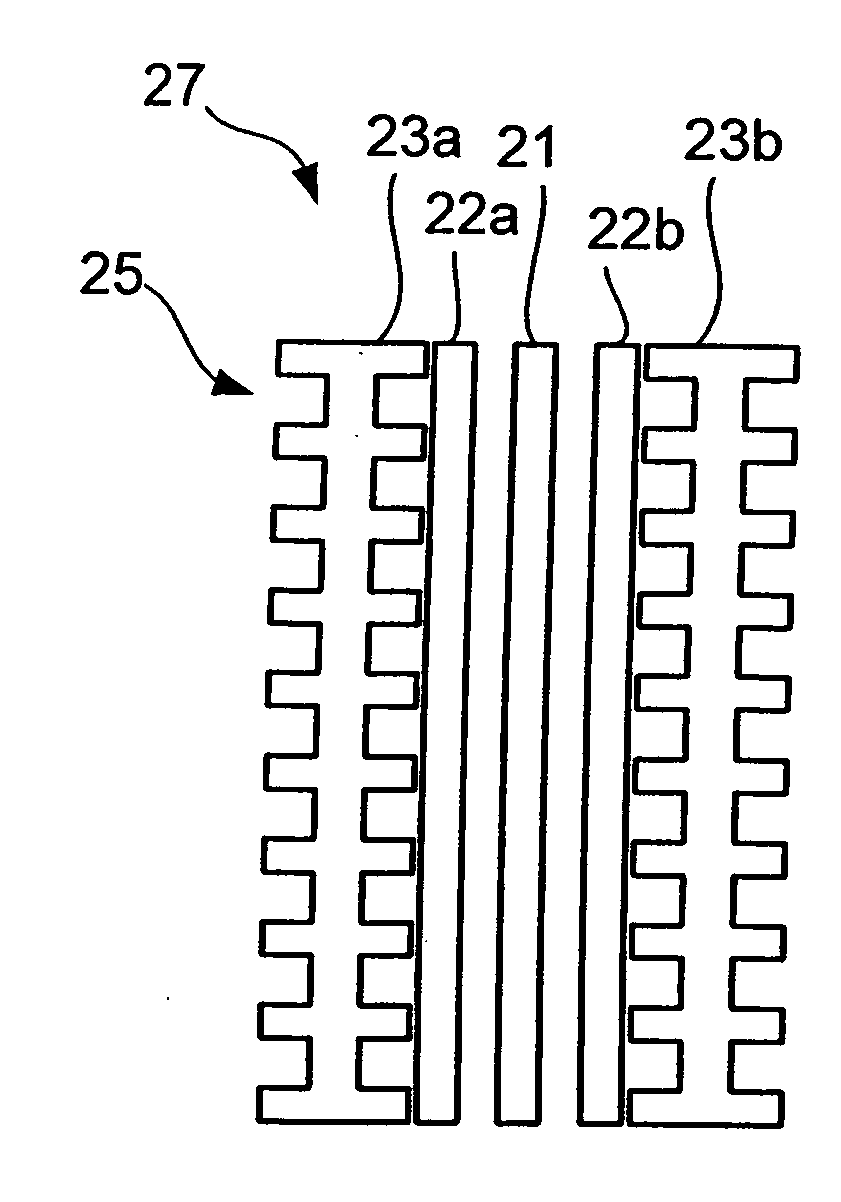

An element being an electrode (23) for an electrochemical cell (27), which comprises an electrically conductive substrate (28) and an electrically conductive corrosion resistant coating (29) comprising a multielement material, which coating is formed on and at least partially covering said conducting substrate, is disclosed. There is also disclosed a method in manufacturing of such electrode and a use of the multielement material for corrosion protection of an electrode for an electrochemical cell. The multielement material has a composition of at least one of a carbide or nitride described by the formula MqAyXz, where M is a transition metal or a combination of transition metals, A is a group A element or a combination of group A elements, X is carbon or nitrogen or both, and z and at least one of q and y are numbers above zero. The multielement material further comprises at least one nanocomposite (4) comprising single elements, binary phases, ternary phases, quaternary phases or higher order phases based on the atomic elements in the corresponding MqAyXz compound.

Owner:IMPACT COATINGS AB

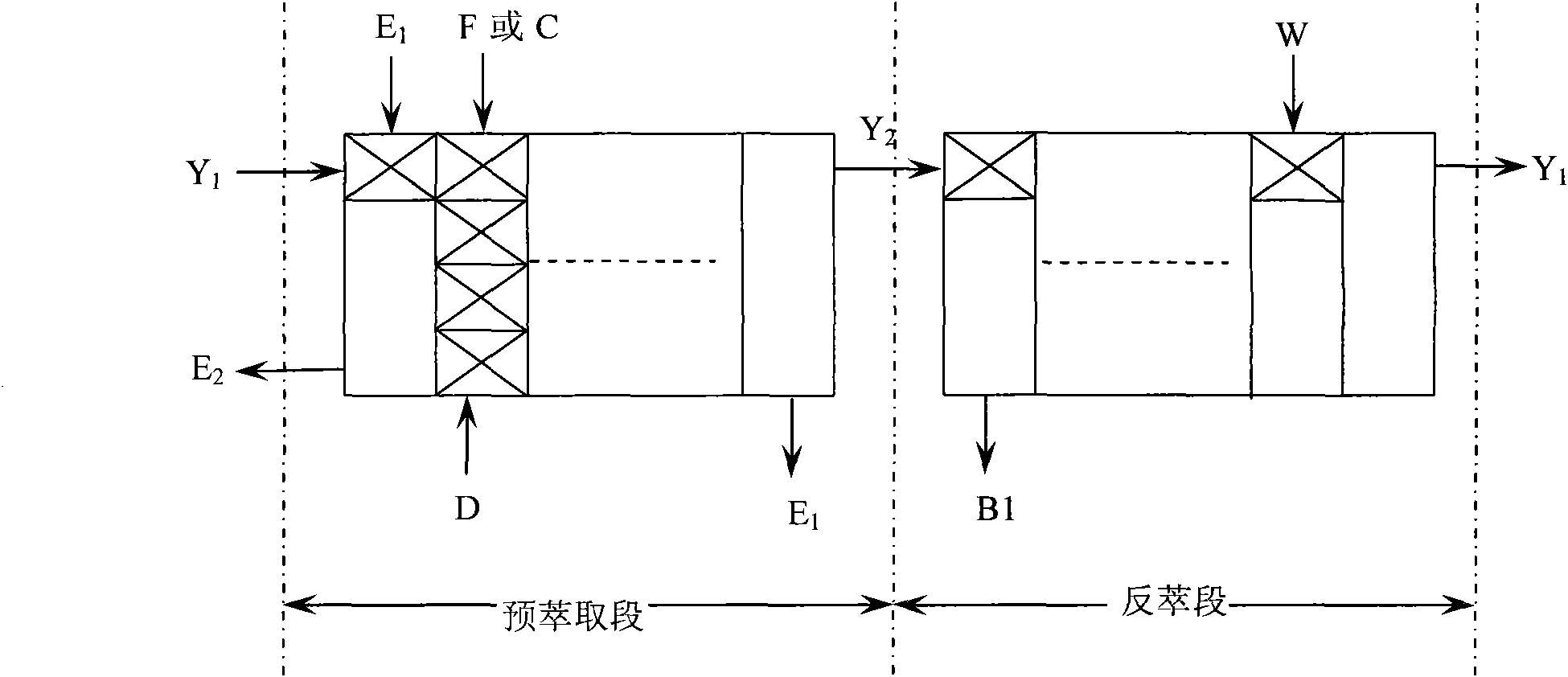

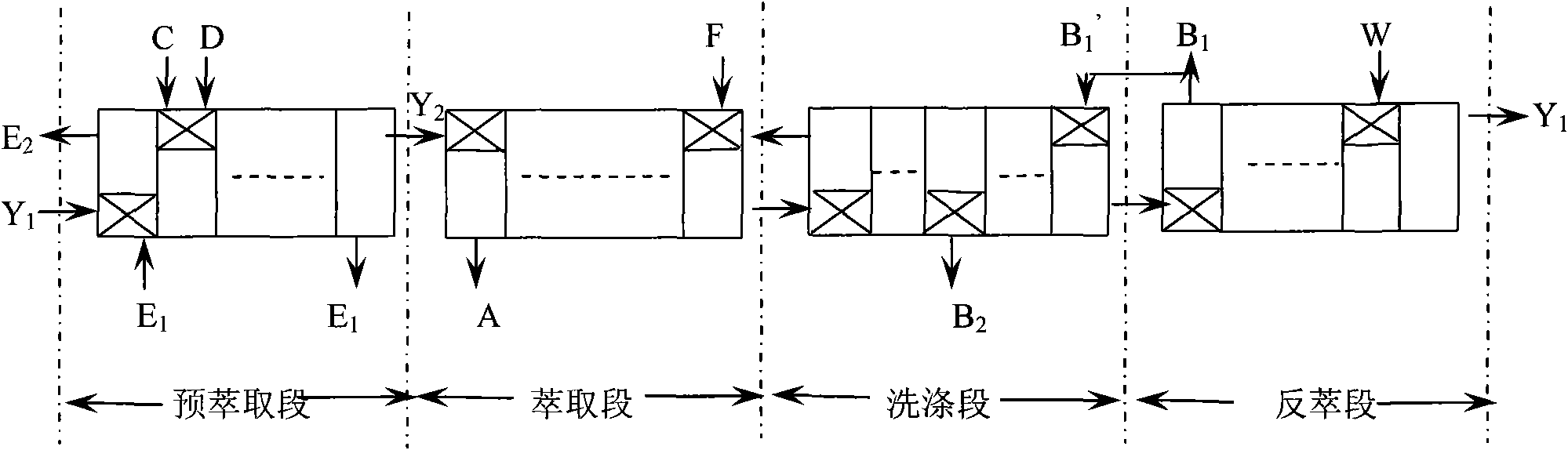

Process for separating rare-earth element by extraction

InactiveCN101781706ALow impurity contentEliminate pollutionProcess efficiency improvementRare-earth elementCalcium bicarbonate

The invention mixes and pre-extracts the mixed solution of acidic organic extractants such as P507, P204, C272, and naphthenic acid with magnesium bicarbonate and / or calcium bicarbonate solution and rare-earth solution. The rare-earth ions are extracted into the organic phase, then the loaded organic phase containing rare-earth ions are obtained through clarification, and can be used for the extract separation of the mixed rare-earth feed liquid. After a plurality of different levels of extraction, washing, stripping, single rare-earth compounds or rare-earth elements-containing enrichments can be obtained. The magnesium bicarbonate and / or calcium bicarbonate solution are prepared by roasting, digesting, carbonizing magnesite, limestone, calcite, dolomite and similar minerals, so that the content of impurities, such as silicon, iron, aluminum is lower. Ternary phase sediment is not produced in the pre-extraction and extraction separation process, so that the purity of the rare-earth products are not affected. The organic phase does not need ammonia saponification and does not produce ammonia-nitrogen wastewater. By adopting the invention, the production cost of rare-earth products is greatly lowered and the cost for three waste disposal is also greatly saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

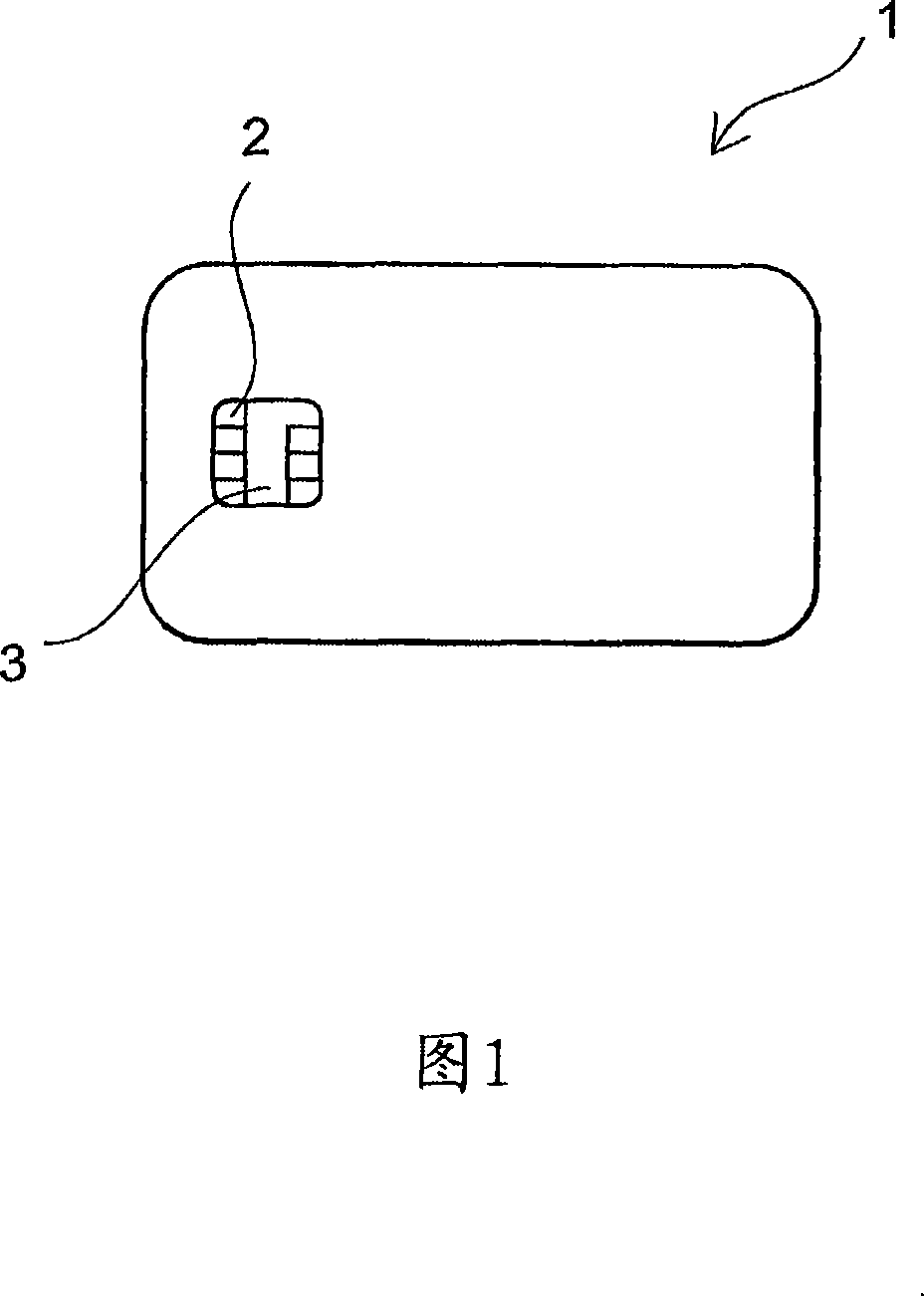

Smart card and smart card reader

InactiveUS20090032593A1Good electrical contactProduced cost-effectivelyCoupling contact membersMetallic material coating processesAtomic elementContact layer

A smart card (1) has a card contact element (2) for establishing an electrical contact with a reader contact element of a smart card reader for reading the smart card (1). The card contact element (2) has a contact surface (3) coated with a contact layer, said contact surface (3) being arranged to be brought into contact with the reader contact element. The contact layer comprises a multiele-ment material that has a composition of at least one of a carbide or nitride described by the formula MqAyXz, where M is a transition metal or a combination of transition metals, A is a group A element or a combination of group A elements, X is carbon or nitrogen or both, and q, y and z are numbers above zero. The multi-element material further comprises at least one nanocomposite comprising single elements, binary phases, ternary phases, quaternary phases or higher order phases based on the atomic elements in the corresponding MqAyXz compound. A reader for reading a smart card (1) is also disclosed.

Owner:IMPACT COATINGS AB

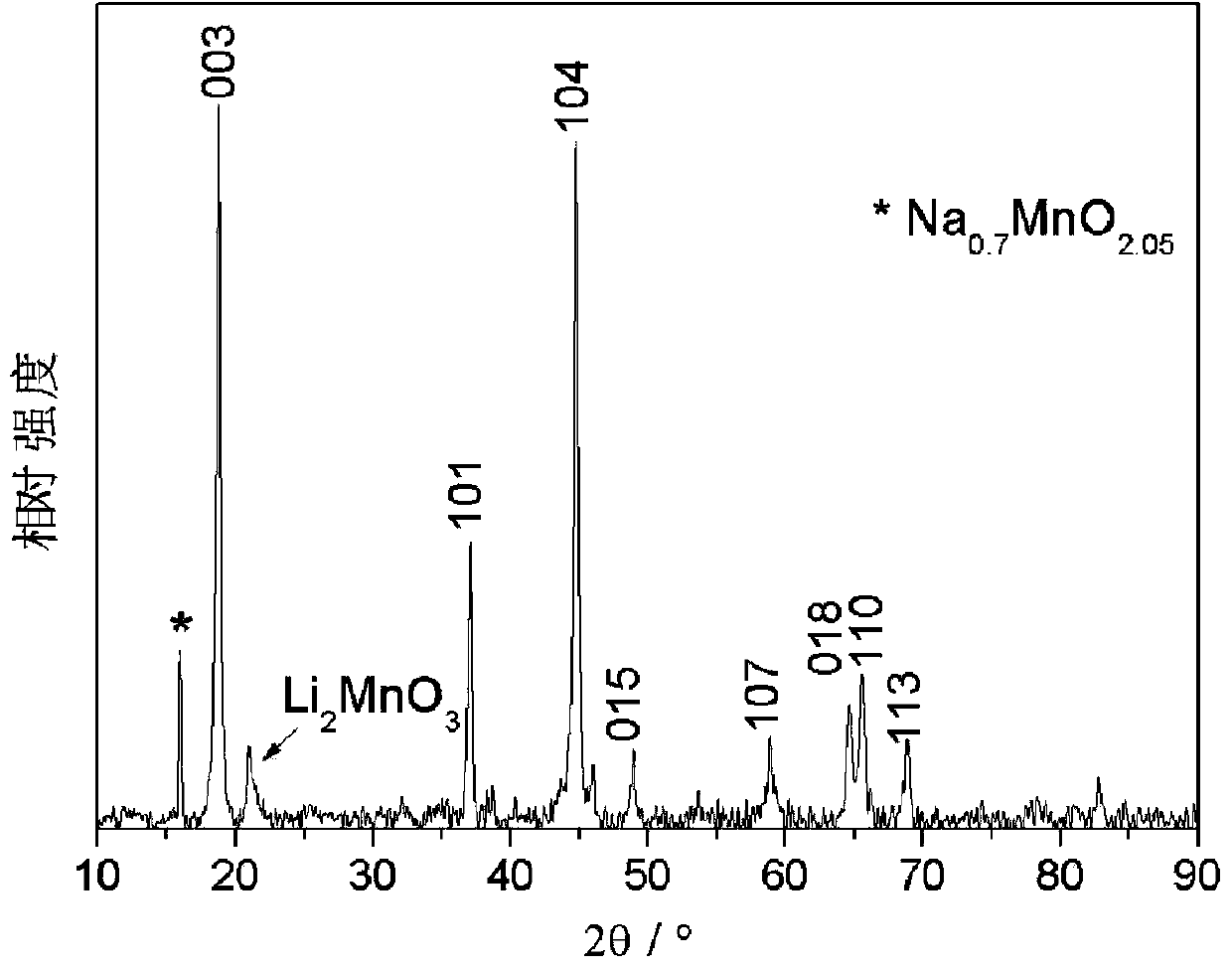

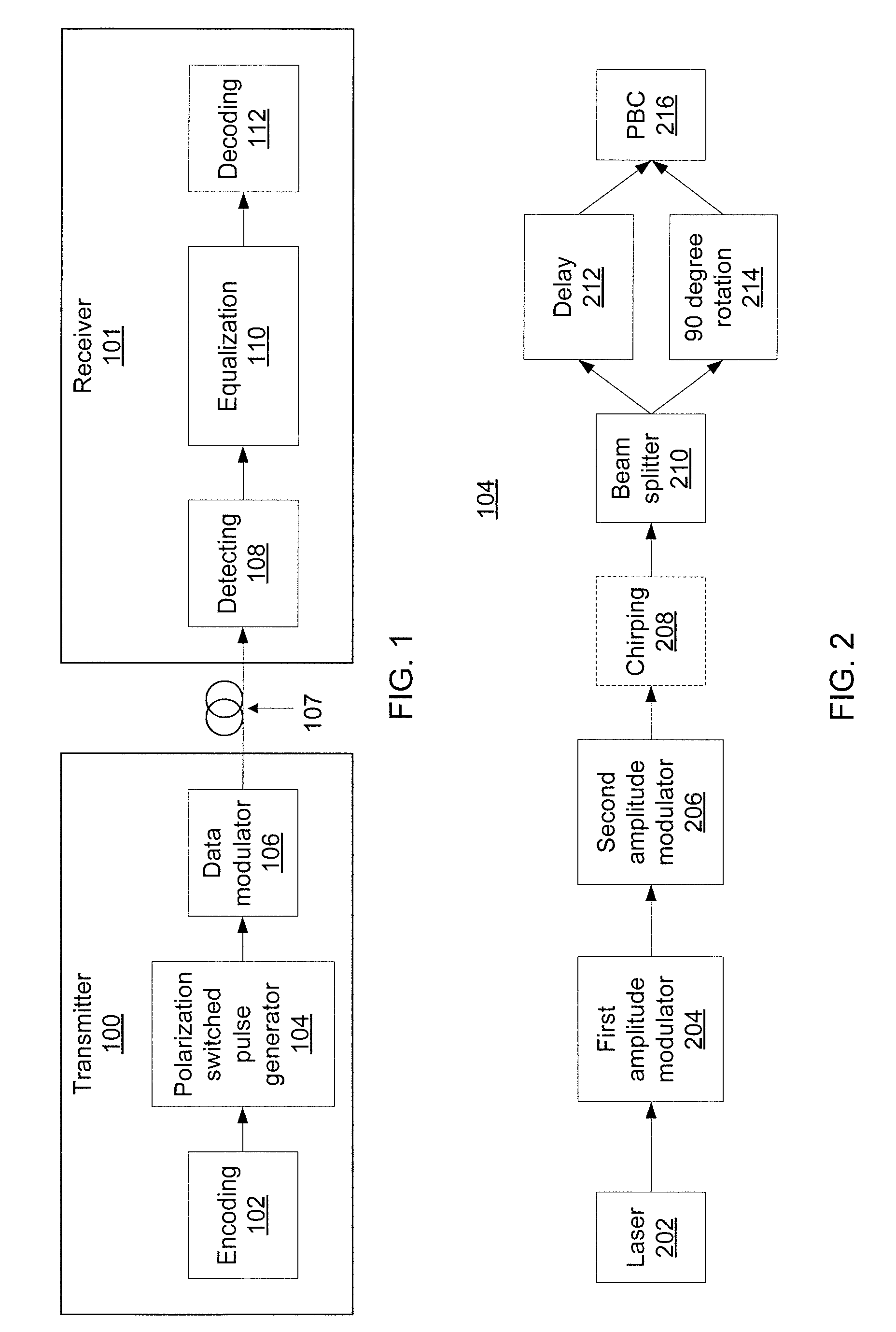

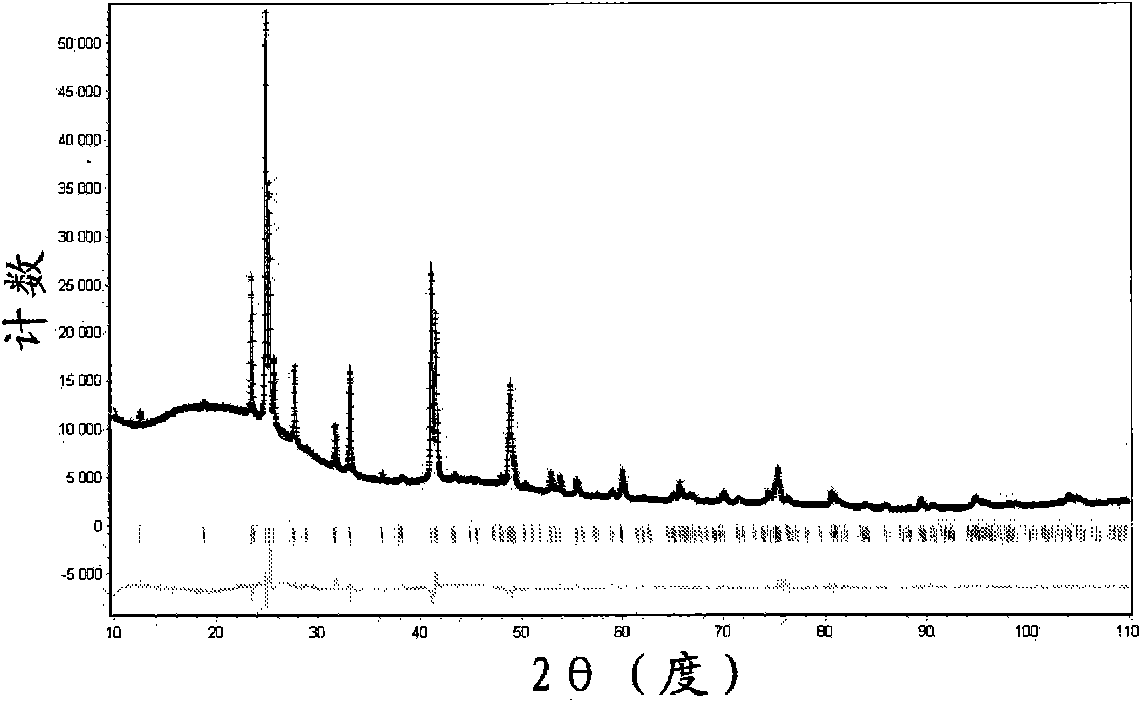

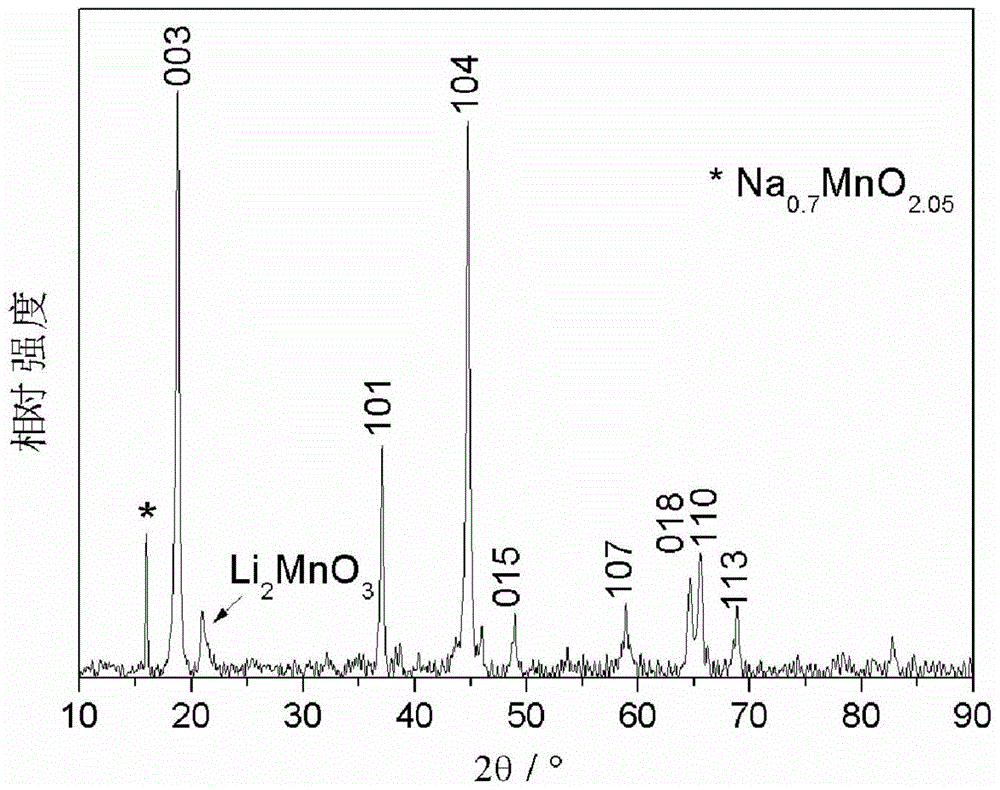

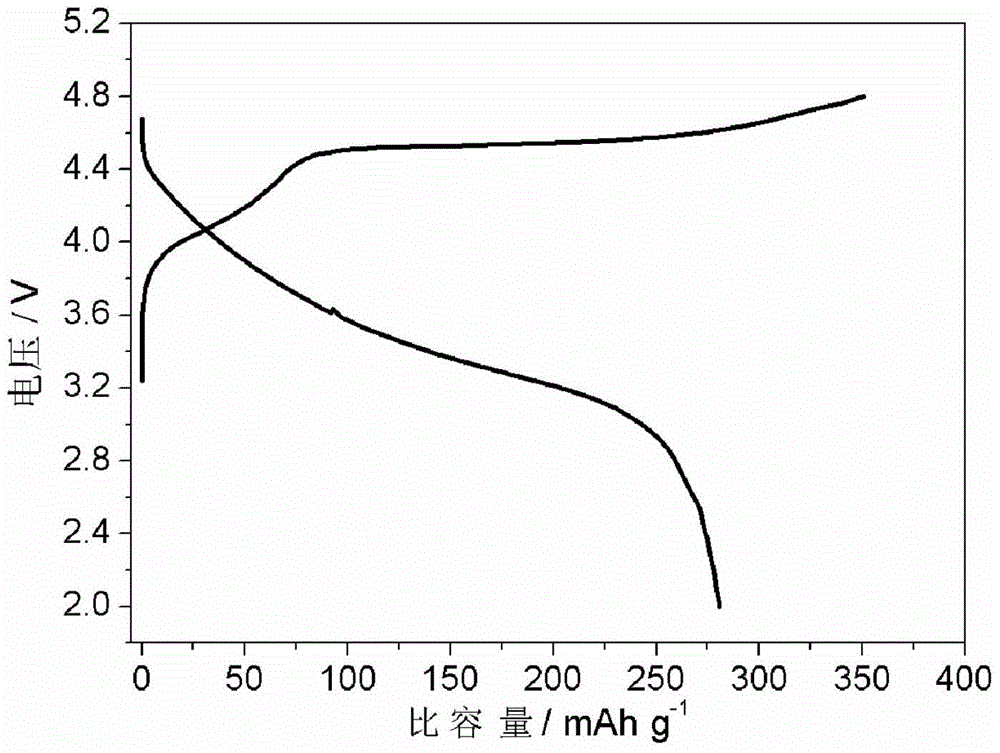

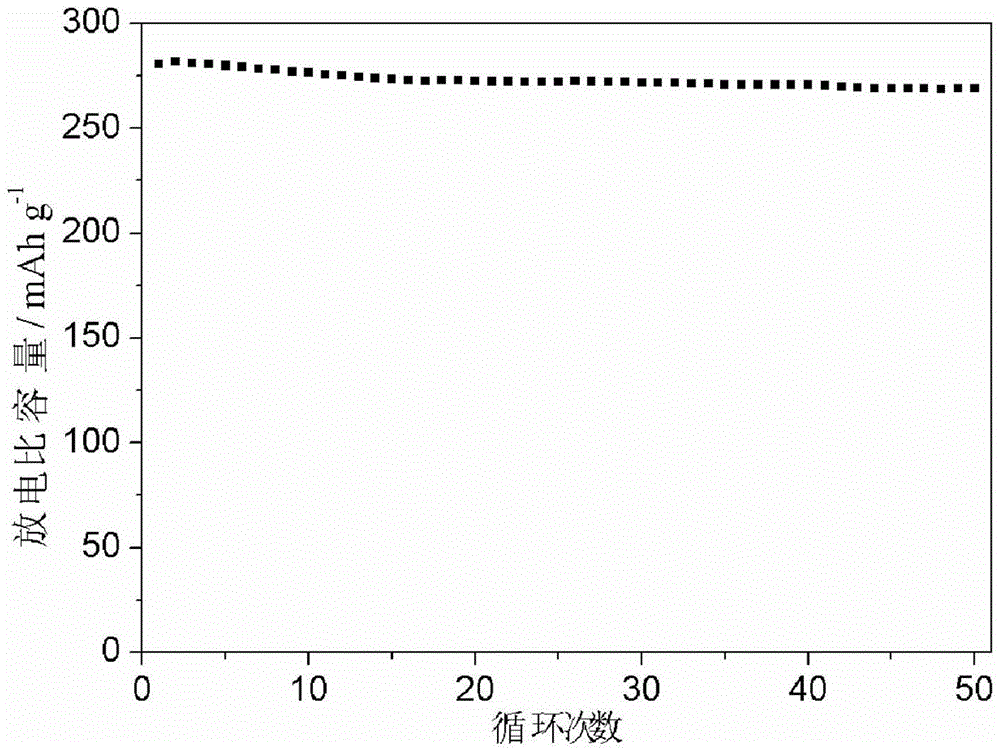

Sodium doped lithium-rich manganese based cathode material for lithium ion battery and preparation method thereof

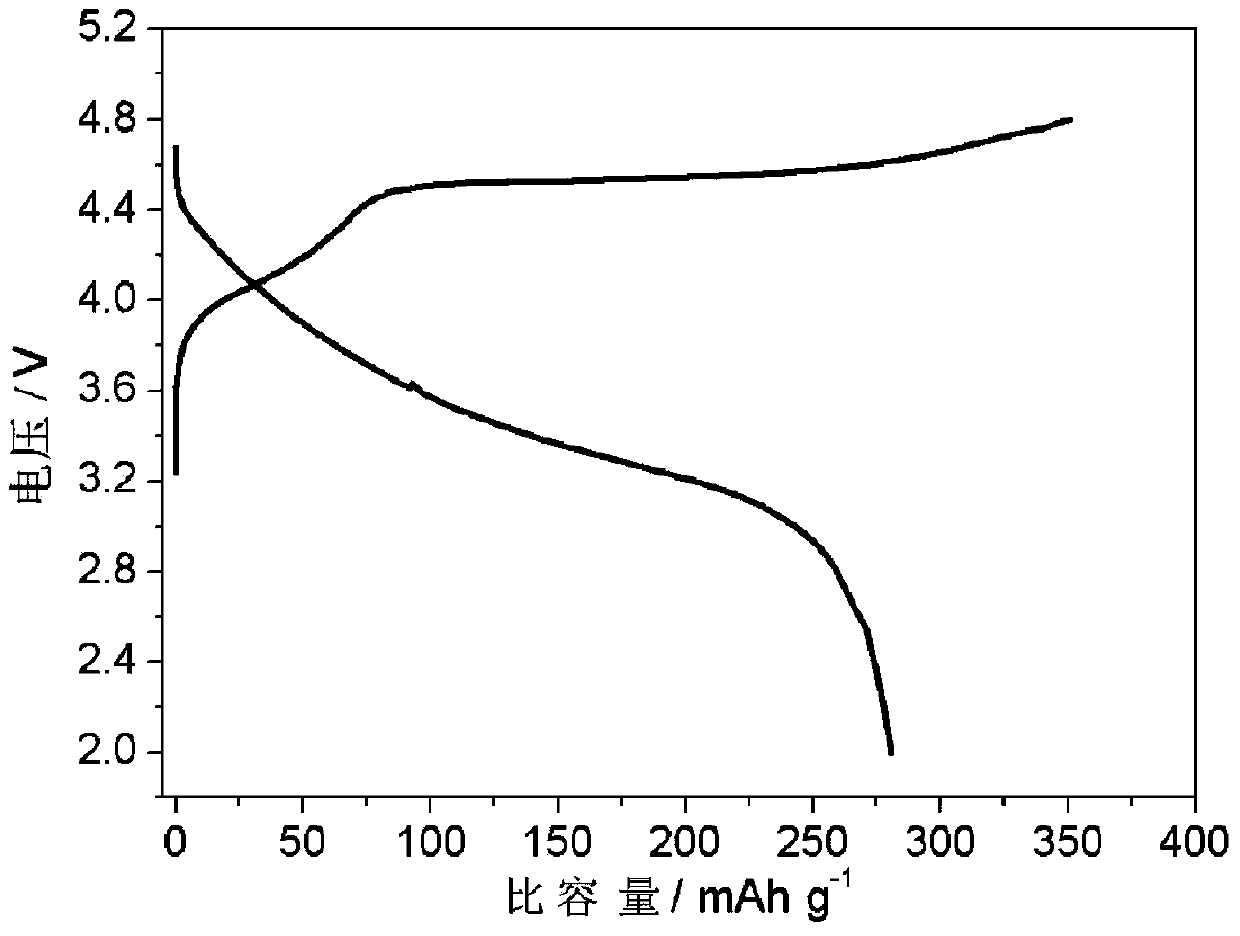

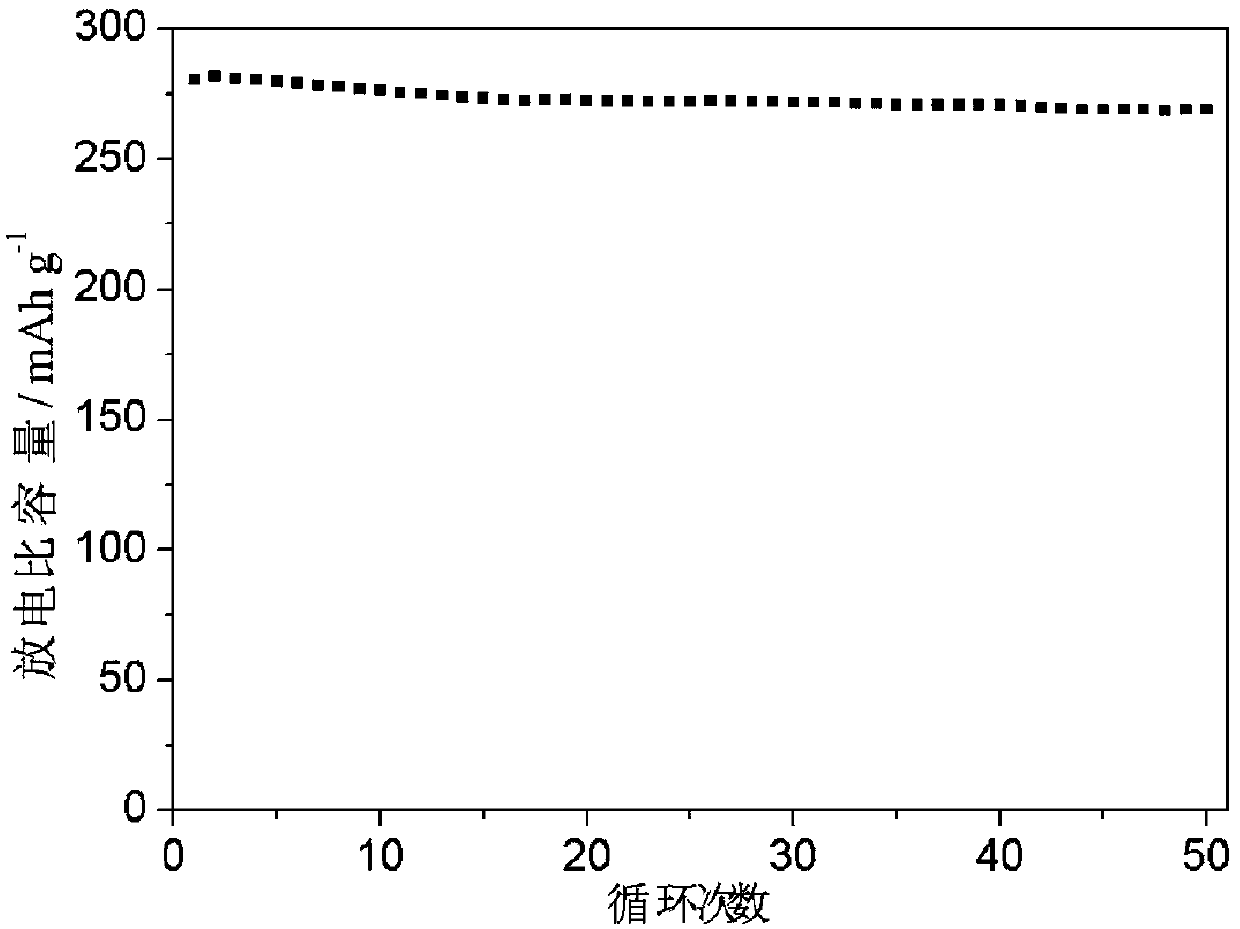

ActiveCN104201337AImprove discharge specific capacityImprove cycle stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a sodium doped lithium-rich manganese based cathode material for a lithium ion battery. The material is a sodium salt doped lithium-rich manganese based solid solution cathode material of which the general formula is xLi[Li1 / 3Mn2 / 3]O2.(1-x)LiNi0.2Co0.2Mn0.6O2, wherein x is equal to or greater than 0.4 and is equal to or less than 0.7, the doped quantity of sodium elements is 1-10% of the mol content of lithium elements, and the sodium salt is one selected from Na2CO3, Na2C2O4 and NaNO3. The mol content of ternary phase manganese of the sodium doped lithium-rich manganese based cathode material for the lithium ion battery is greater than 50%, and the manganese with high reserves and low price is used for replacing cobalt and nickel, so that the application cost can be reduced. Compared with the prior art, the sodium doping provided by the invention can improve the discharging specific capacity and the circulating stability of the rich lithium manganese based cathode material.

Owner:HEBEI UNIV OF TECH

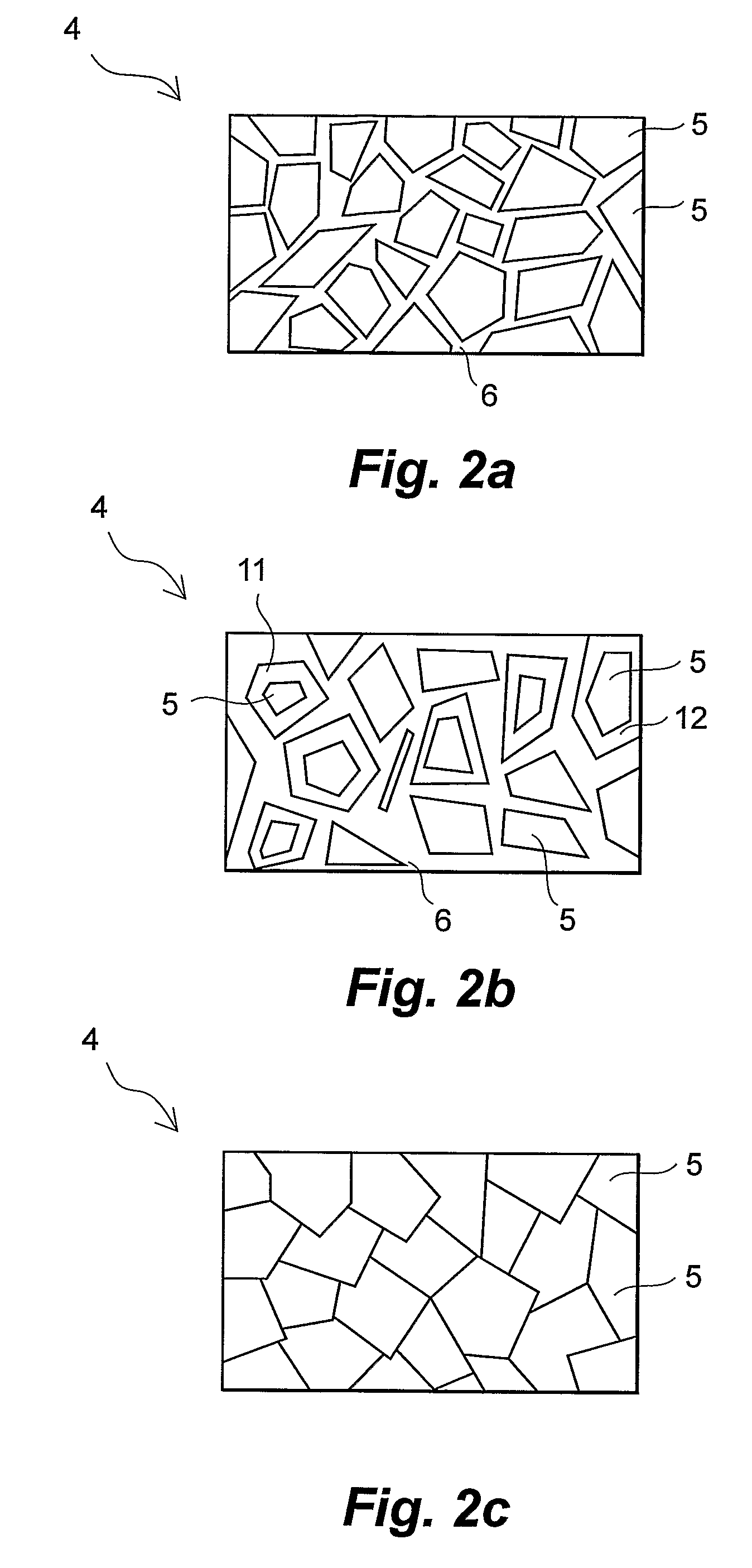

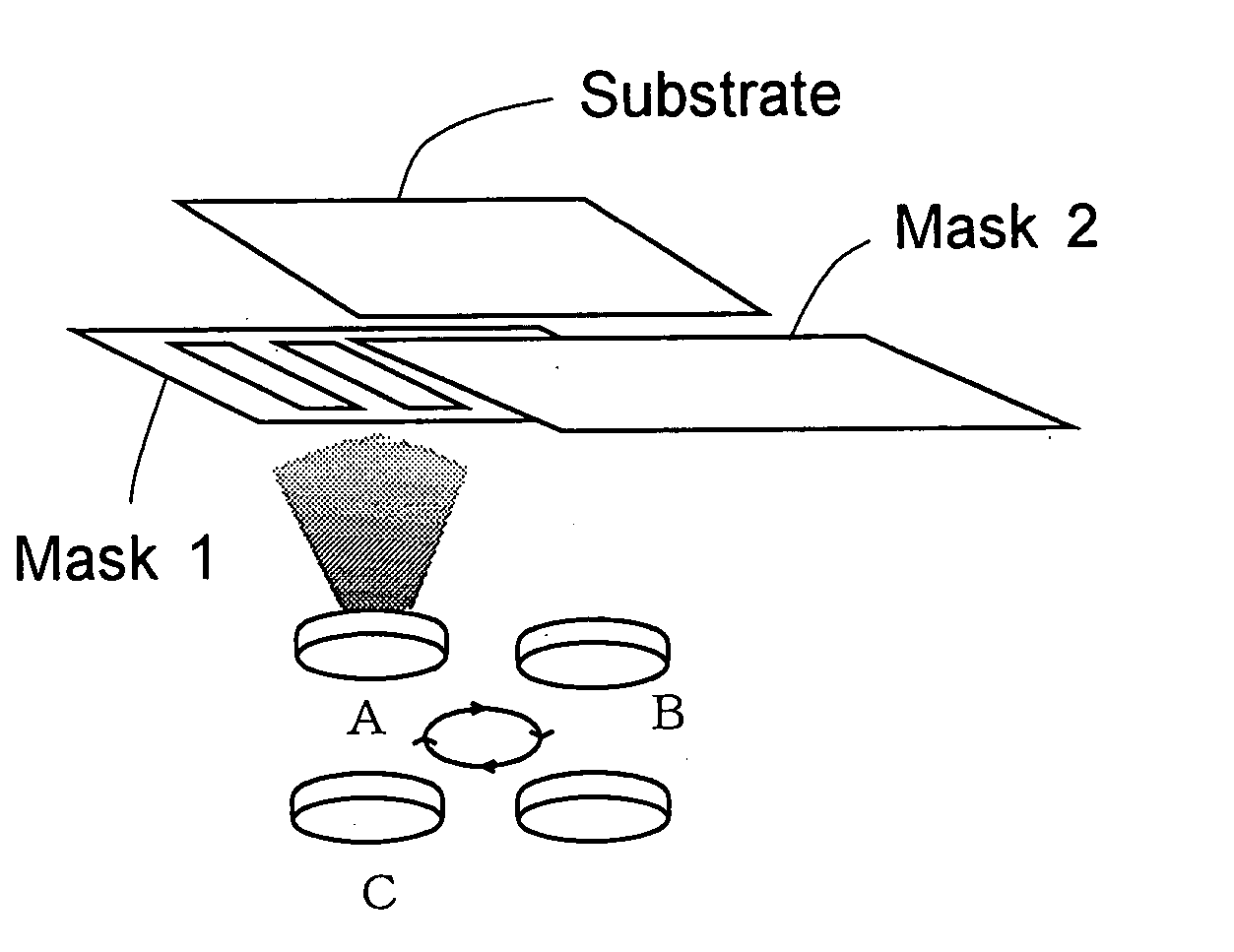

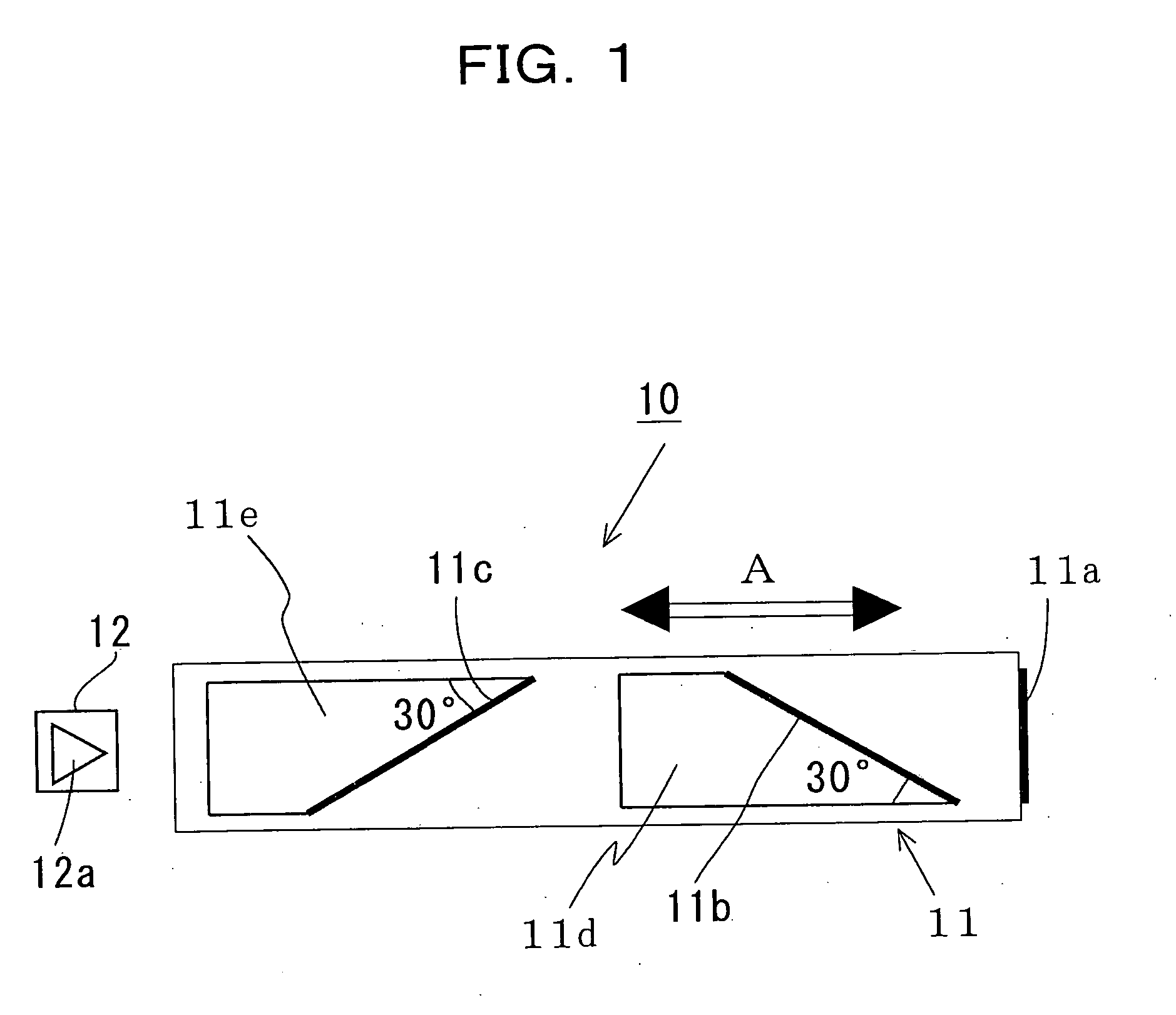

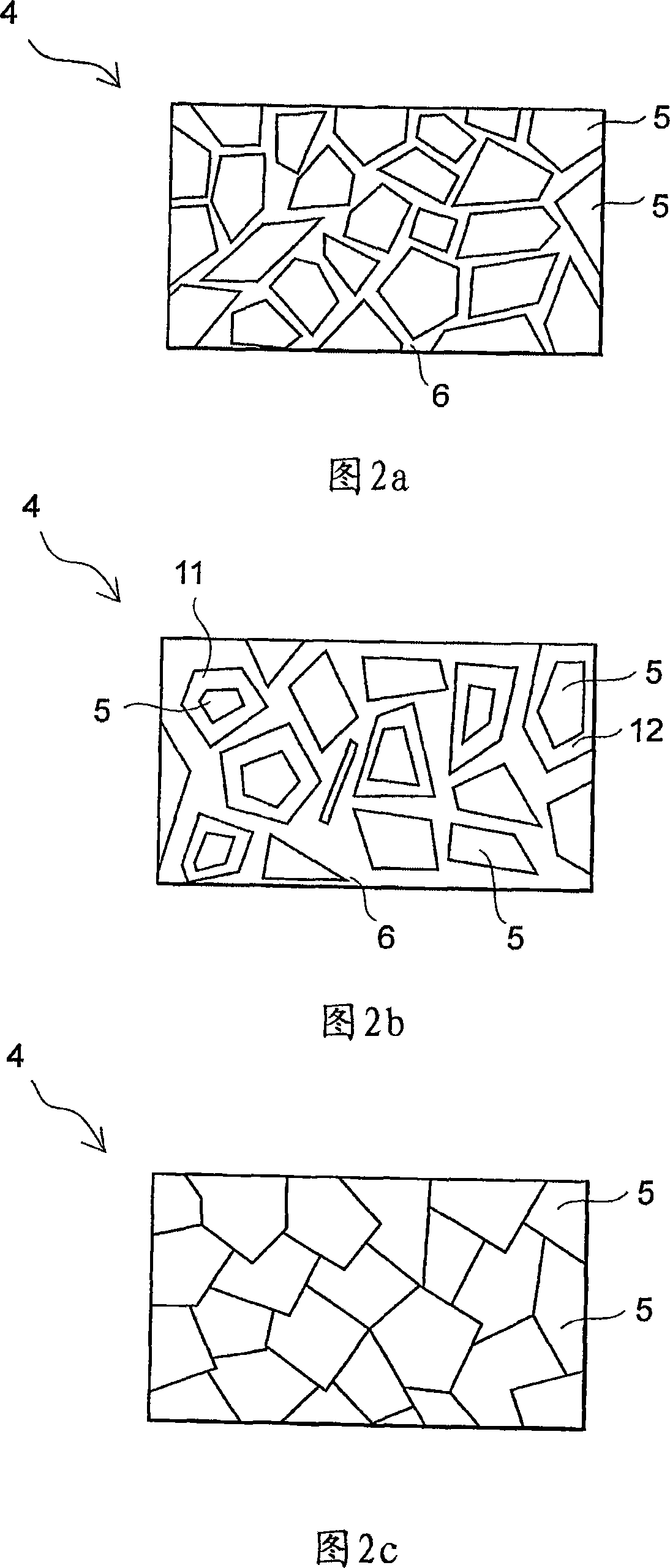

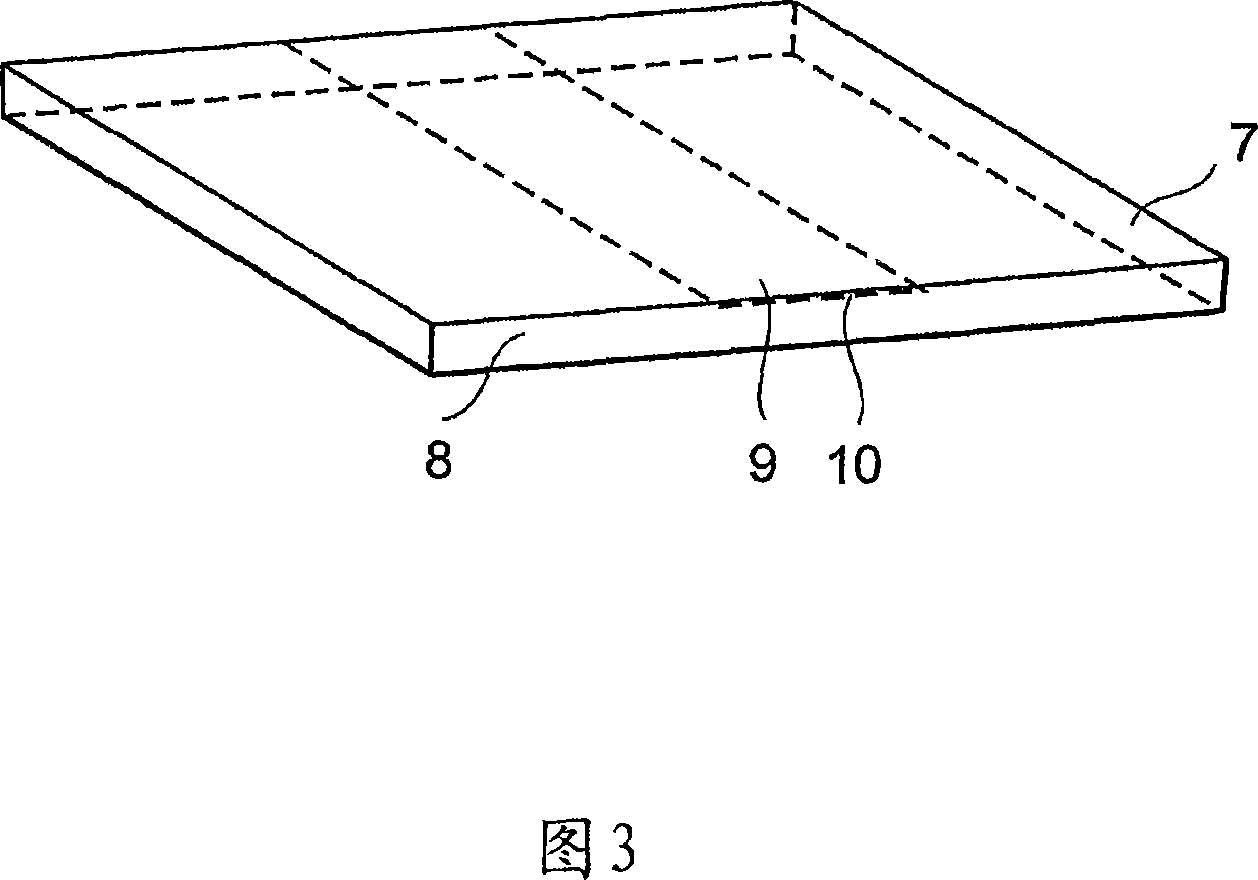

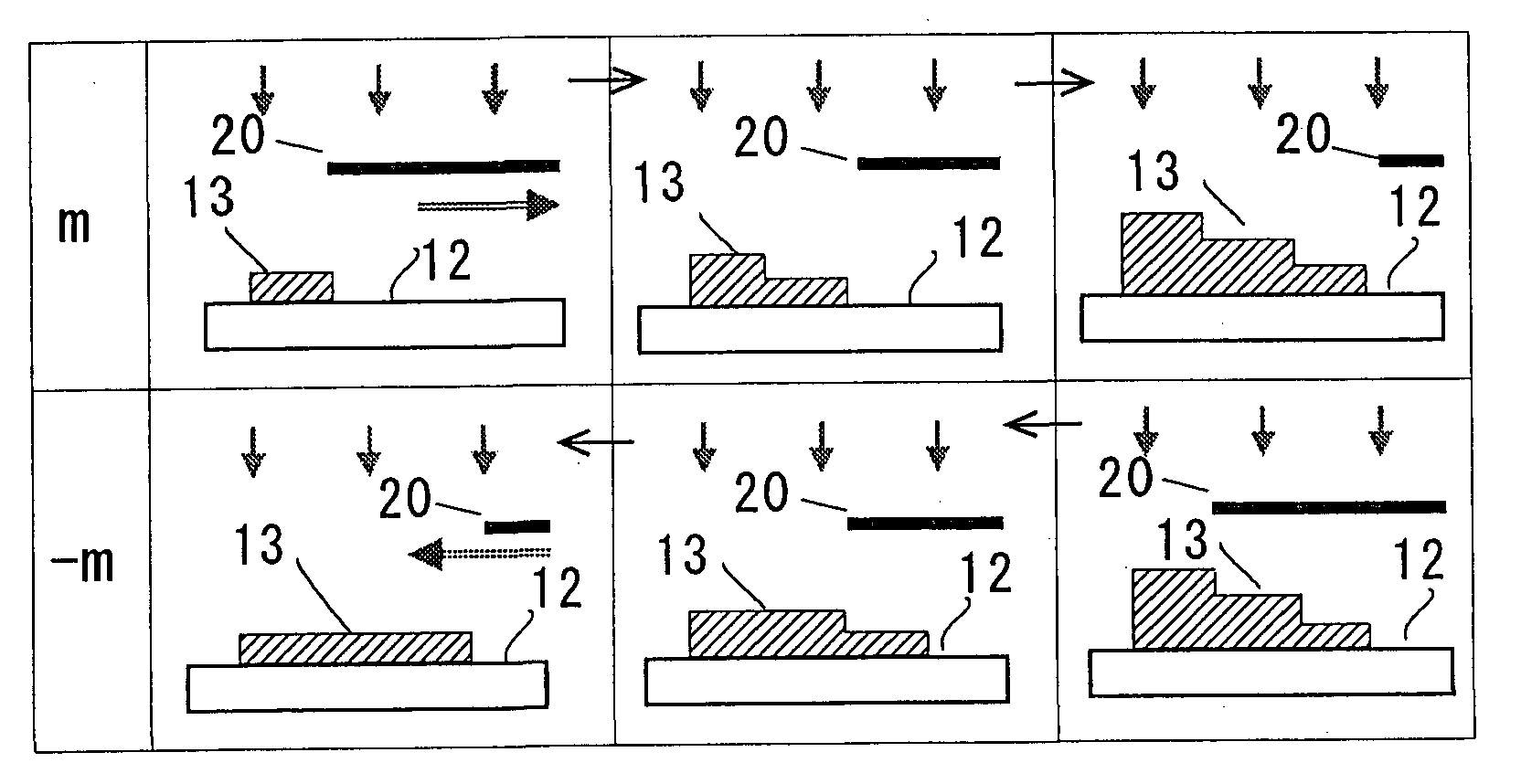

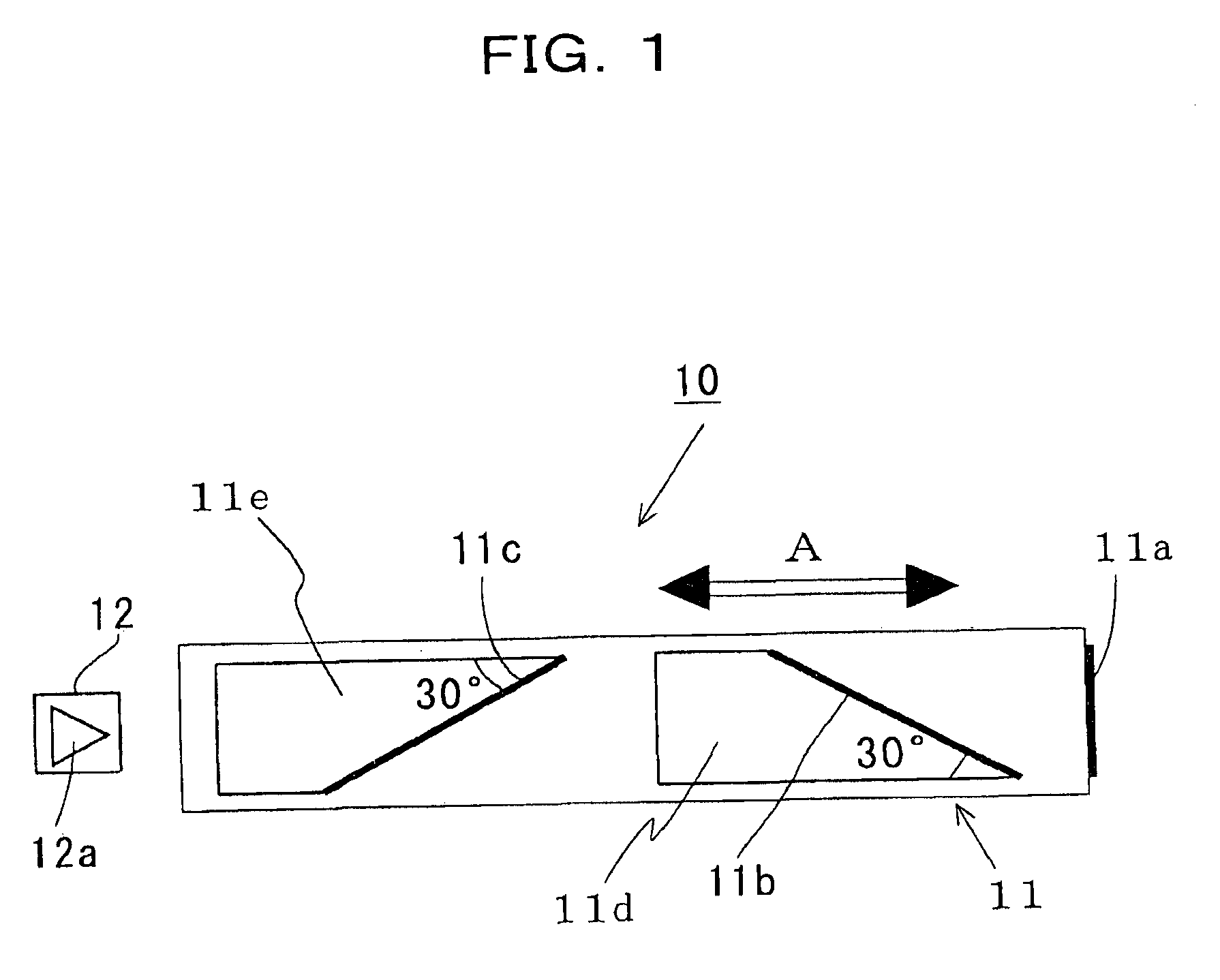

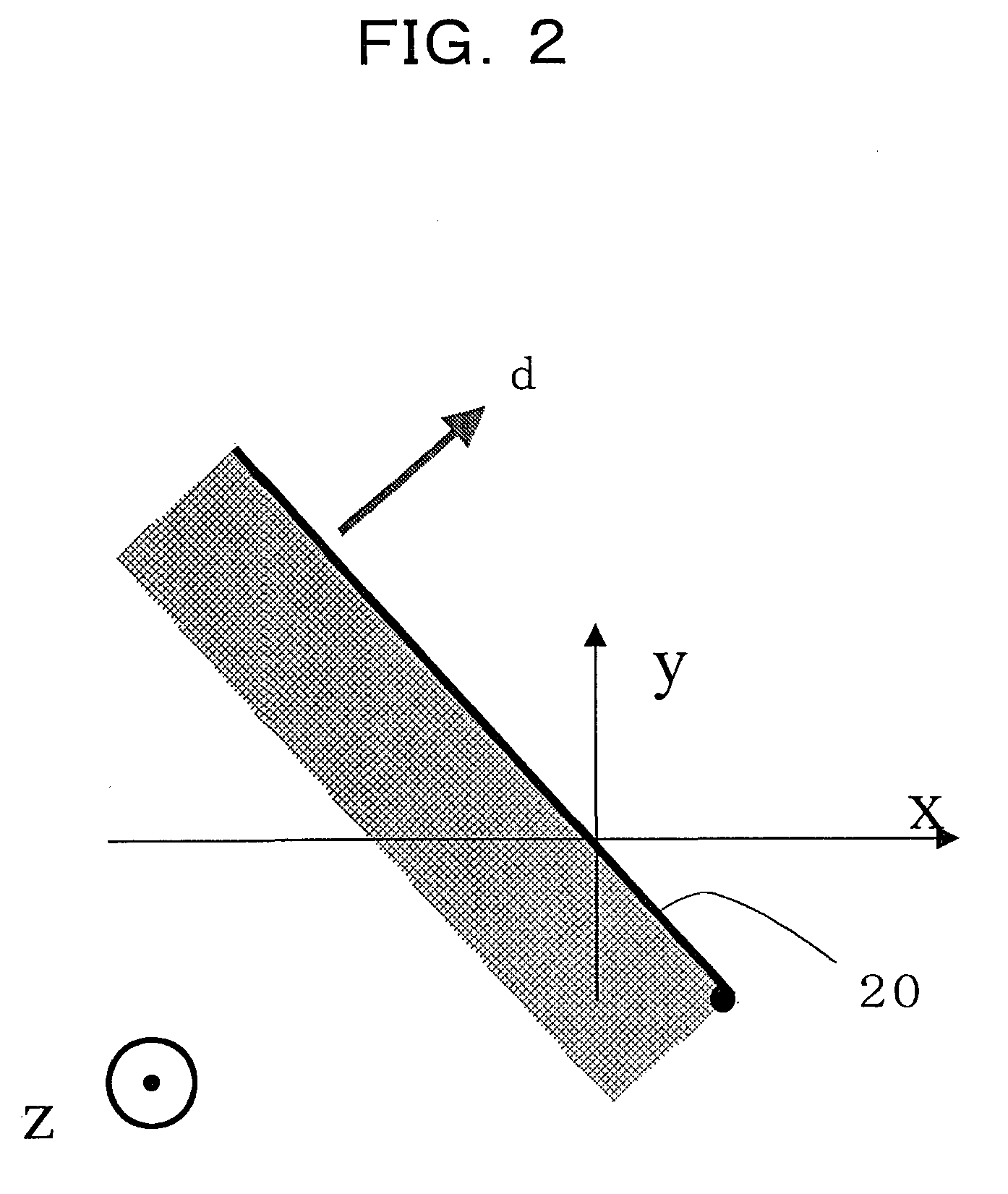

Masking mechanism for film-forming device

InactiveUS20060057240A1Increase equipment costDough-sheeters/rolling-machines/rolling-pinsConfectioneryTernary phaseMechanical engineering

It comprises a mask (11) having a first, a second and a third action edge (11a, 11b, 11c), and a drive means for moving the mask (11) relative to a substrate (12) in a uniaxial direction (A) whereby moving the mask at a fixed rate of movement to cause the edges to successively act on an identical substrate region while successively applying different materials thereto forms thin films of three components successively with respective film thickness gradients oriented in three different directions mutually angularly spaced apart by an angle of 120° to allow these films to overlap, thereby forming a ternary phase diagrammatic thin film 13.

Owner:JAPAN SCI & TECH CORP

Coal ash based composite phase-change thermal storage material and preparation method thereof

InactiveCN107502301ALarge specific surface areaImprove adsorption capacityHeat-exchange elementsDispersityHeat conducting

The invention belongs to the technical field of energy storage materials and relates to a coal ash based composite phase-change thermal storage material and a preparation method thereof. By treatment of expandable graphite, the interlamellar spacing and specific surface area of the expandable graphite are increased, and an ultrasonic stripping method is adopted for stripping into nano flakes; by diluted acid modification after high-temperature expanding treatment of coal ash, the specific surface area of the coal ash is increased, and adsorptivity and dispersity of the coal ash are improved; by expanded graphite flakes forming a heat conducting network in pores of the modified coal ash, energy stored by the phase-change material can be transferred more quickly, and heat transferring effects are improved; myristic acid, stearic acid and polyethylene glycol serve as ternary phase-change base materials and are uniformly embedded into the porous structure of the modified coal ash, and high thermal stability and excellent thermal storage performance are realized. Environmental pollution is reduced due to waste recycling of the coal ash, and the composite phase-change thermal storage material is hopefully and practically applied to fields of building thermal insulation materials, solar energy utilization and the like.

Owner:汪逸凡

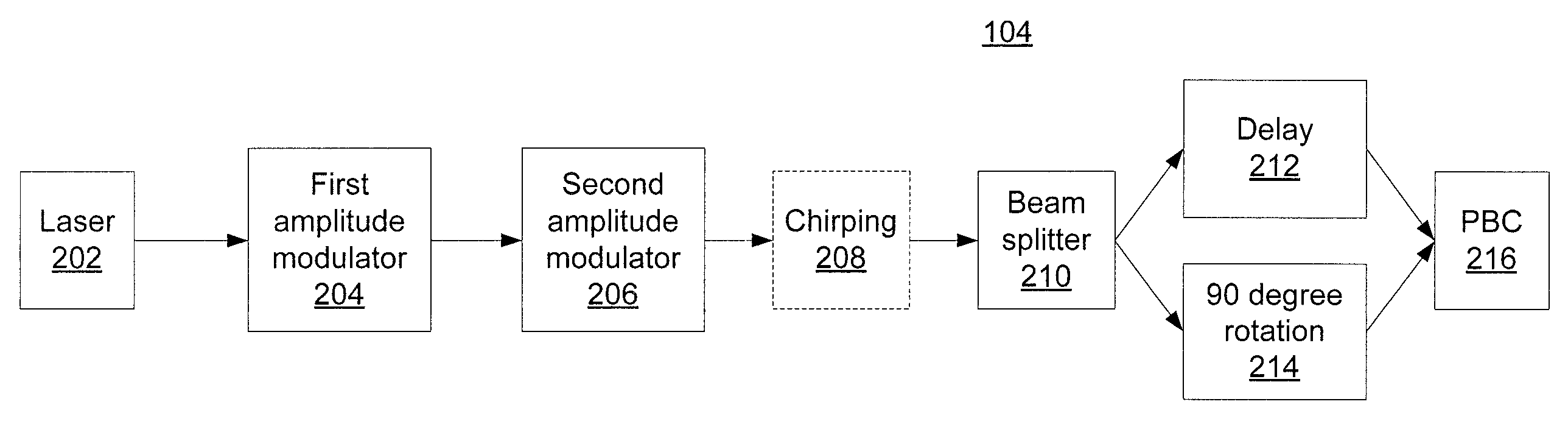

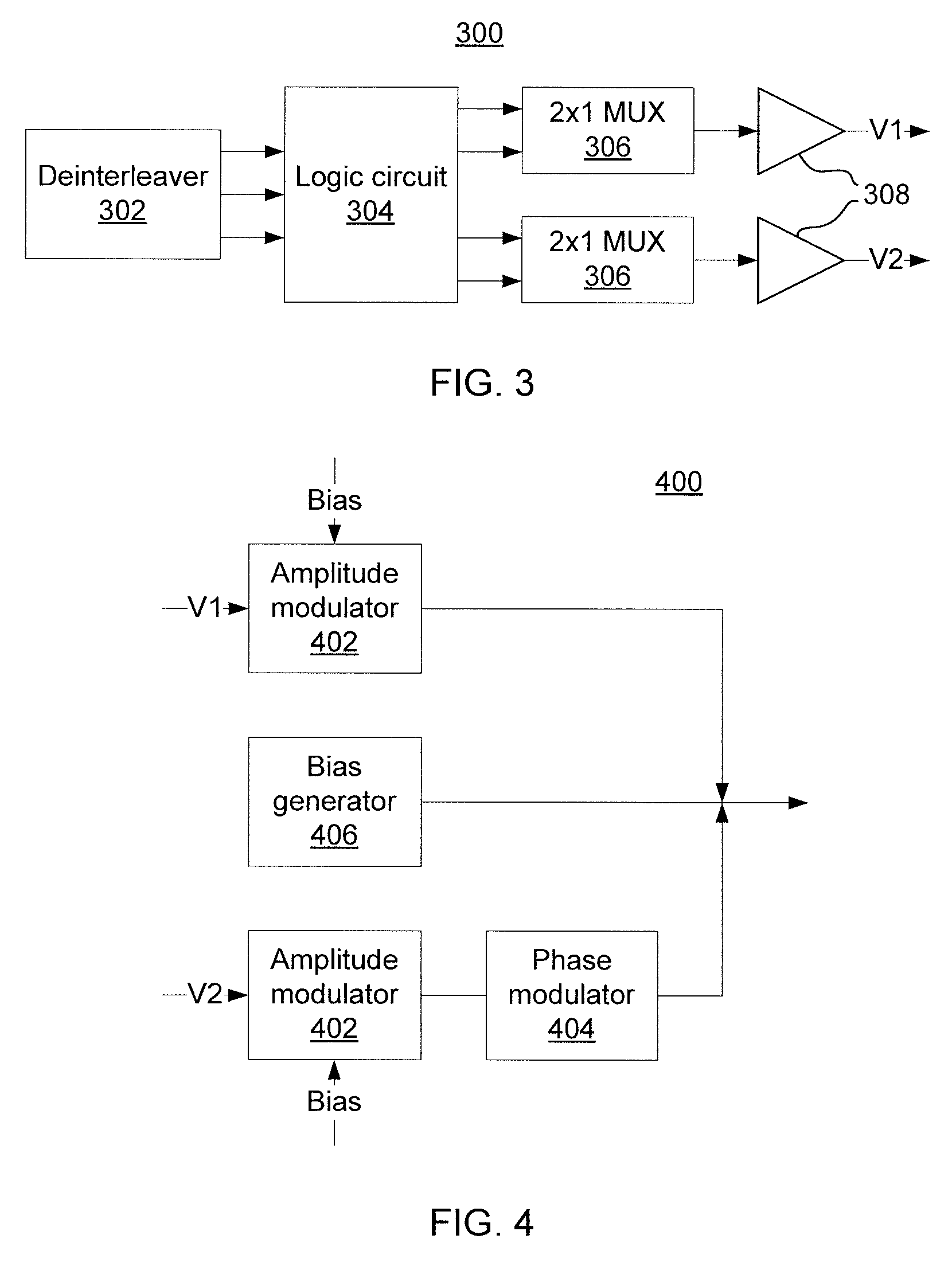

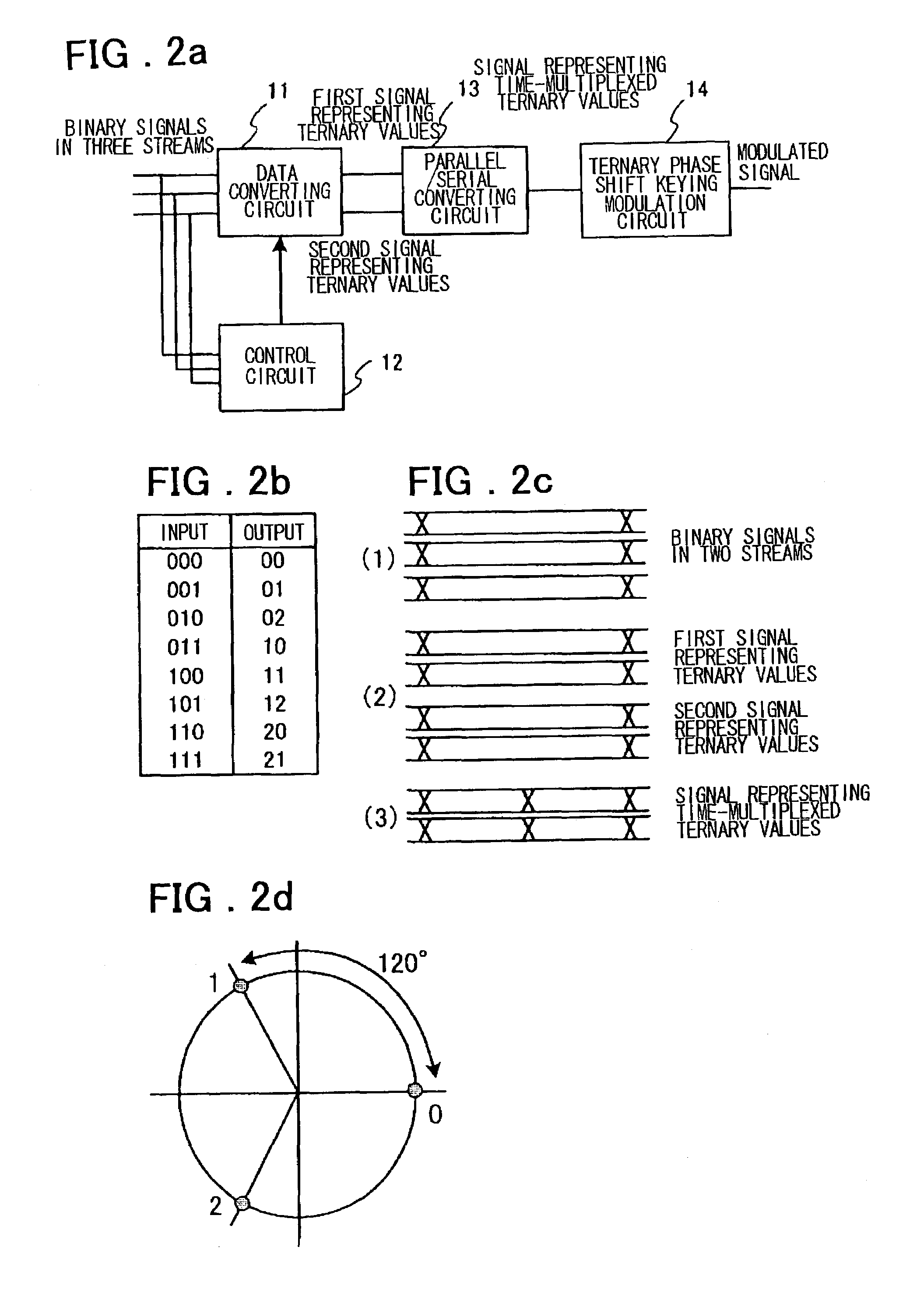

Polarization-switched differential ternary phase-shift keying

ActiveUS9130679B1Phase-modulated carrier systemsElectromagnetic transmissionDifferential phaseCarrier signal

Methods and systems for transmission and reception of ternary phase-shift keyed data that include mapping triplets of binary bits to pairs of ternary symbols, such that three bits of data are encoded across two symbols having three-point constellations; modulating the pairs of ternary symbols onto a carrier; and transmitting the modulated carrier across a transmission medium.

Owner:NEC CORP

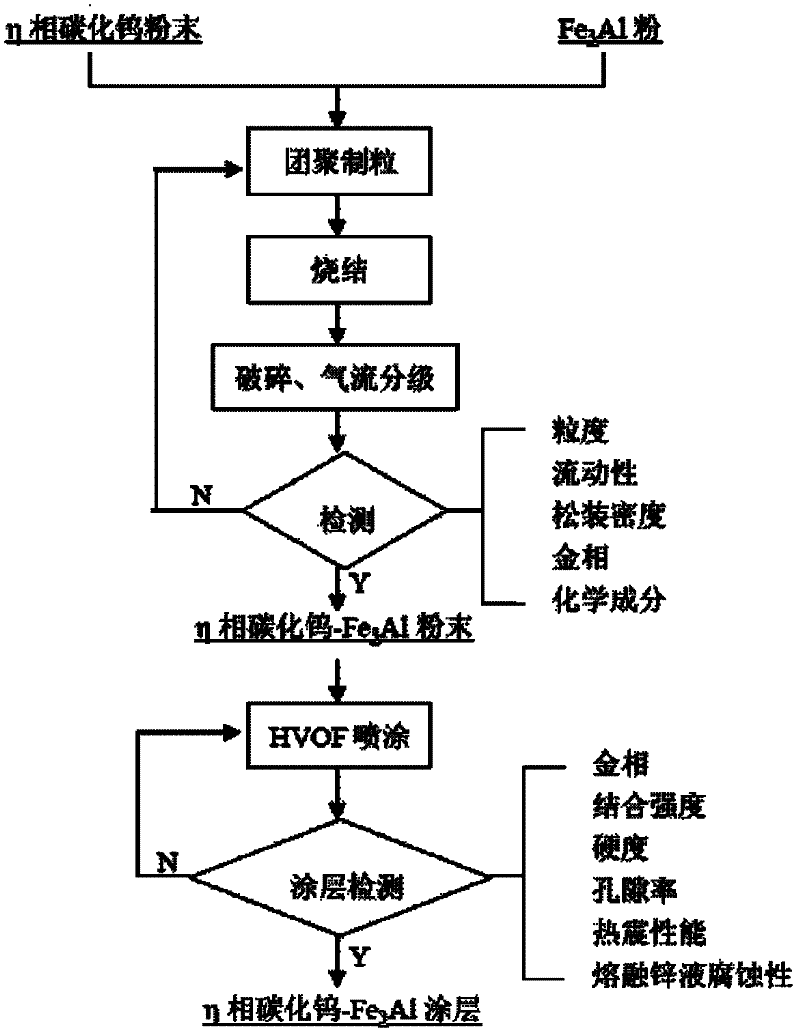

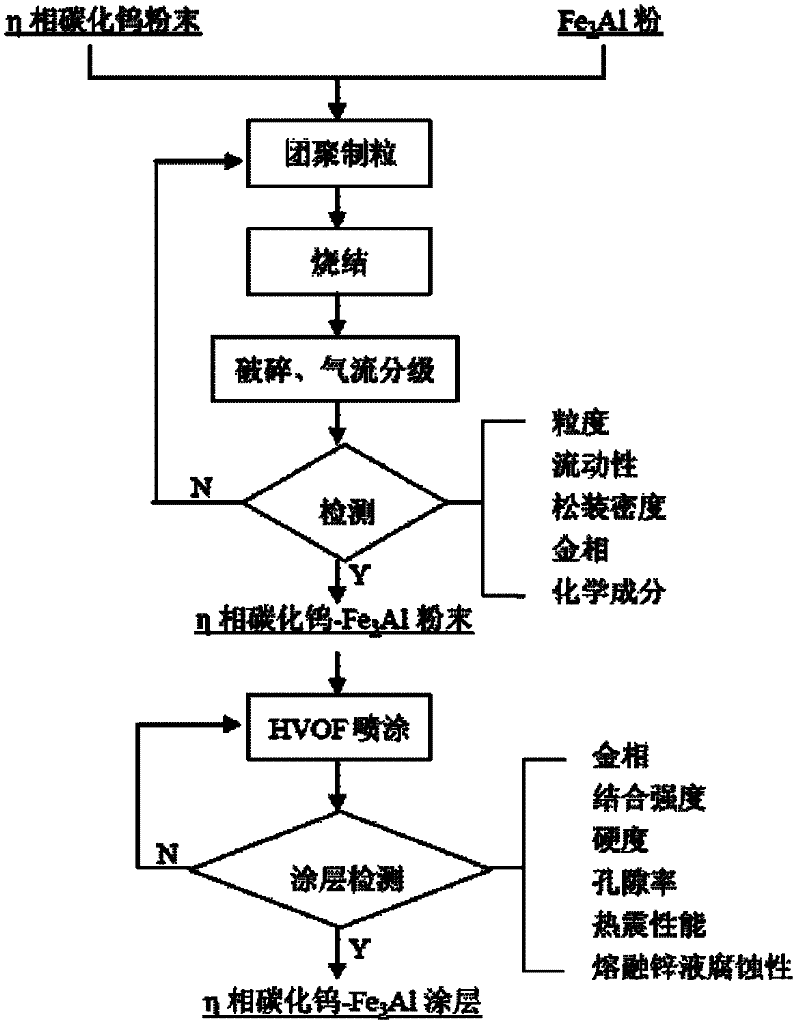

Preparation method of fused zinc erosion resistant coating material for thermal spraying and coating material prepared by the same

The invention provides a fused zinc erosion resistant coating material for thermal spraying and a preparation method of the coating material. The preparation method comprises the steps of: utilizing an eta phase tungsten carbide as a hard phase to replace the WC labile at a high temperature, and utilizing Fe3Al as an adhesion phase to replace Co, preparing an eta phase tungsten carbide-Fe3Al coating on a hot galvanized submerging roller or on the surface of a shaft sleeve of the hot galvanized submerging roller by a thermal spraying method to prepare a target product. The preparation method of the invention has the advantages that the hard phase, eta phase tungsten carbide can effectively prevent the zinc atoms from dispersing inward the alloy to resist against the fused zinc erosion, the eta phase tungsten carbide is high-temperature resistant and indecomposable to perform a good high-temperature wearing resistance function, and the adhesion phase Fe3Al and the Zn can be used for forming a fused zinc erosion resistant Fe-Al-Zn ternary phase, so that the fused zinc erosion resistance is better than that of a sintered WC-Co coating.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Cu-containing high-conductivity and high-electromagnetic-shielding-property wrought magnesium alloy and preparation method thereof

The invention discloses a Cu-containing high-conductivity and high-electromagnetic-shielding-property wrought magnesium alloy which comprises the following components in percentage by weight: 4.90-5.20% of Zn, 0.50-0.80% of Zr, 0.37-2.32% of Cu and the balance of Mg and unavoidable impurities. The preparation method comprises the steps of ingot smelting, homogenization, hot extrusion and the like, because the alloy contains Cu, and Cu, Mg and Zn are combined so as to generate a MgZnCu ternary phase, Zn solute atoms in a matrix are greatly reduced, the lattice distortion of the matrix decreases, and electron scattering is inhibited. Therefore, the alloy subjected to homogenization and extrusion has good conductivity, the electromagnetic shielding property of the alloy is markedly improved, and compared with alloys without containing Cu, the alloy has the advantages that the electromagnetic shielding effectiveness is increased by over 17db. The application scope of high-conductivity, high-electromagnetic-shielding-property and light-weight alloy materials in the fields of aerospace, military industry, microelectronics, and the like is effectively broadened.

Owner:CHONGQING UNIV

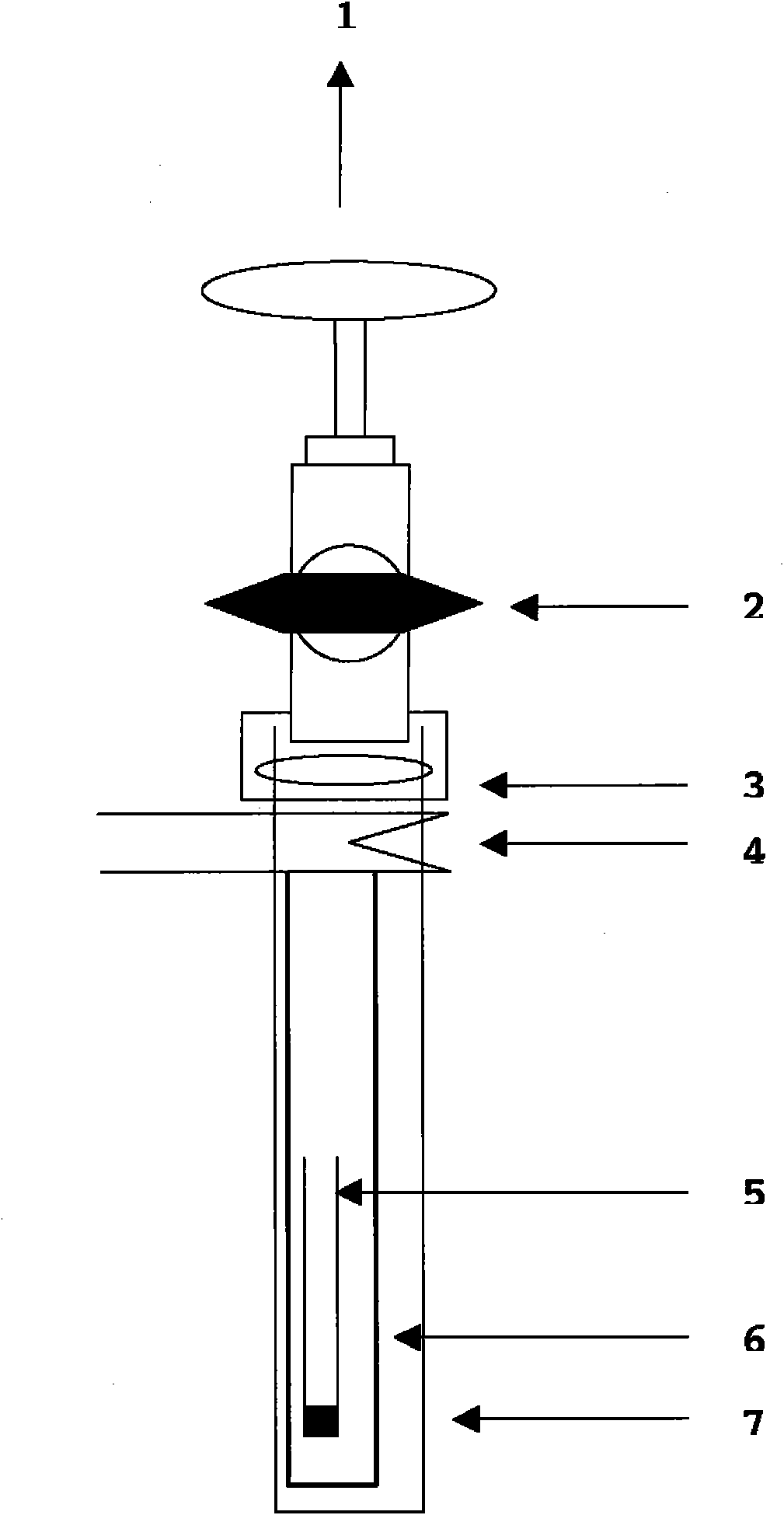

Method for preparing Ge-Sb-Te ternary phase-change material film

InactiveCN102560589AQuality improvementEasy qualityElectrolytic inorganic material coatingDigital storageElectrochemistryTernary phase

The invention provides a method for preparing a Ge-Sb-Te ternary phase-change material film and relates to a phase-change material film. The method comprises the following steps: pre-treating a conductive substrate; preparing a Ge4<+> ion electrolyte solution; preparing a Sb3<+> and Te4<+> ion electrolyte solution; depositing under the condition of constant potential; and depositing under the condition of constant current. The Ge-Sb-Te ternary phase-change material film with stable structure, smoothness, compactness, low impurity content, and strong film layer adhesive force is prepared in a room-temperature water solution according to a simple electric chemical depositing method. The defects of complex technical equipment, high cost and difficulty in large-scale production existing in a magnetic control sputtering method, a chemical vapor deposition method or a traditional electric chemical deposition method are efficiently avoided; the method provided by the invention has the advantages of low cost, short production period, simple preparing technology, stable product quality and the like; and the method has a potential application prospect in the field of the semiconductor, especially the preparation of the phase-change storage material.

Owner:XIAMEN UNIV

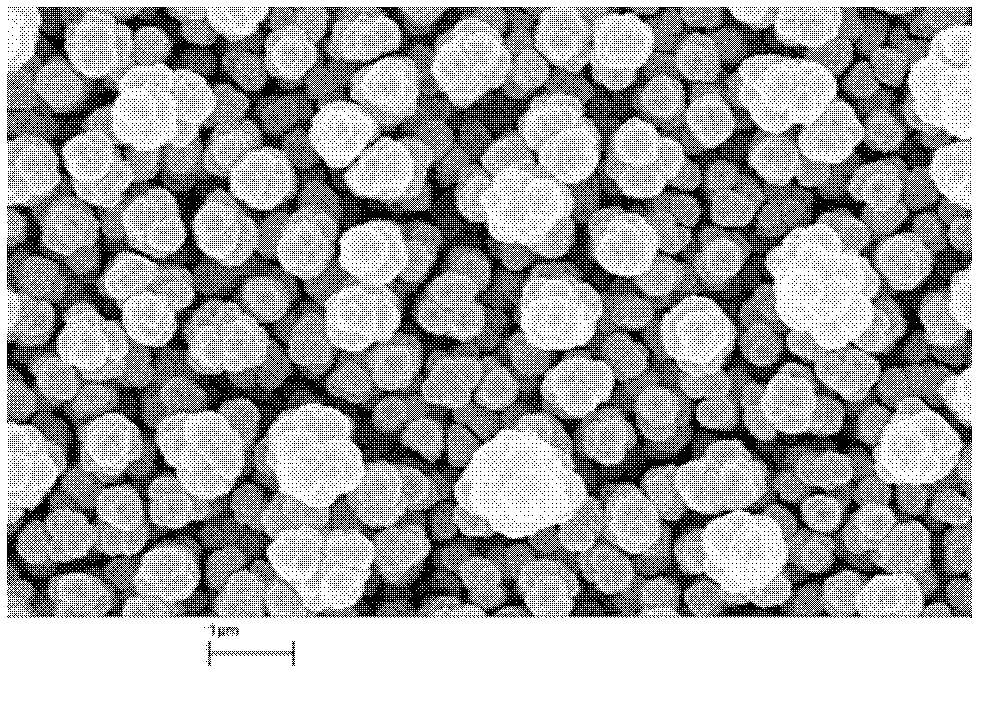

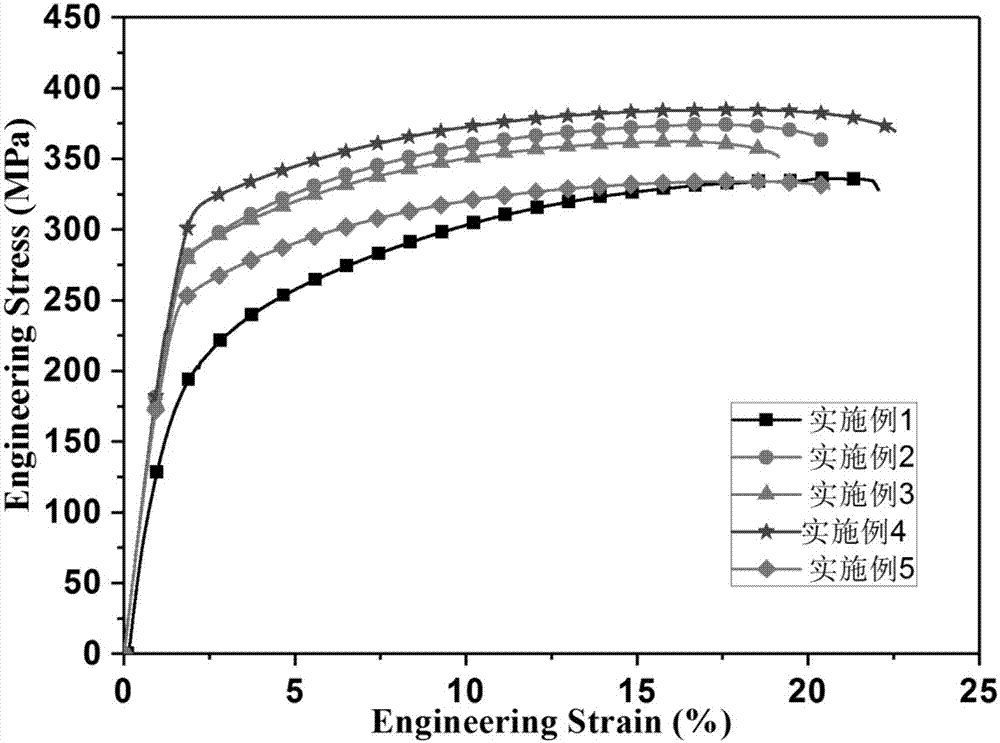

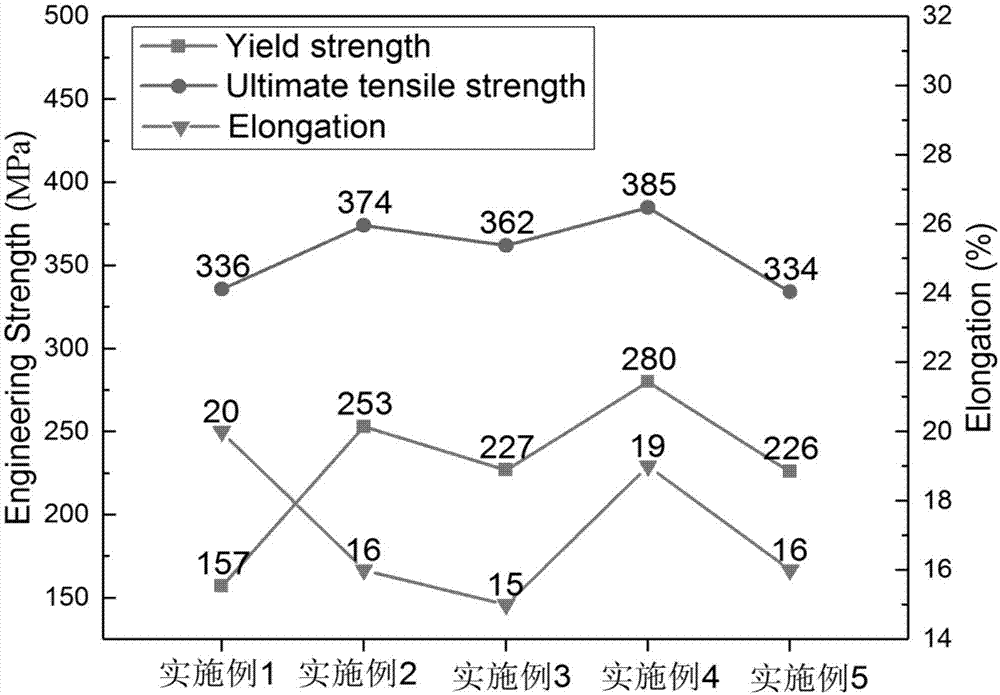

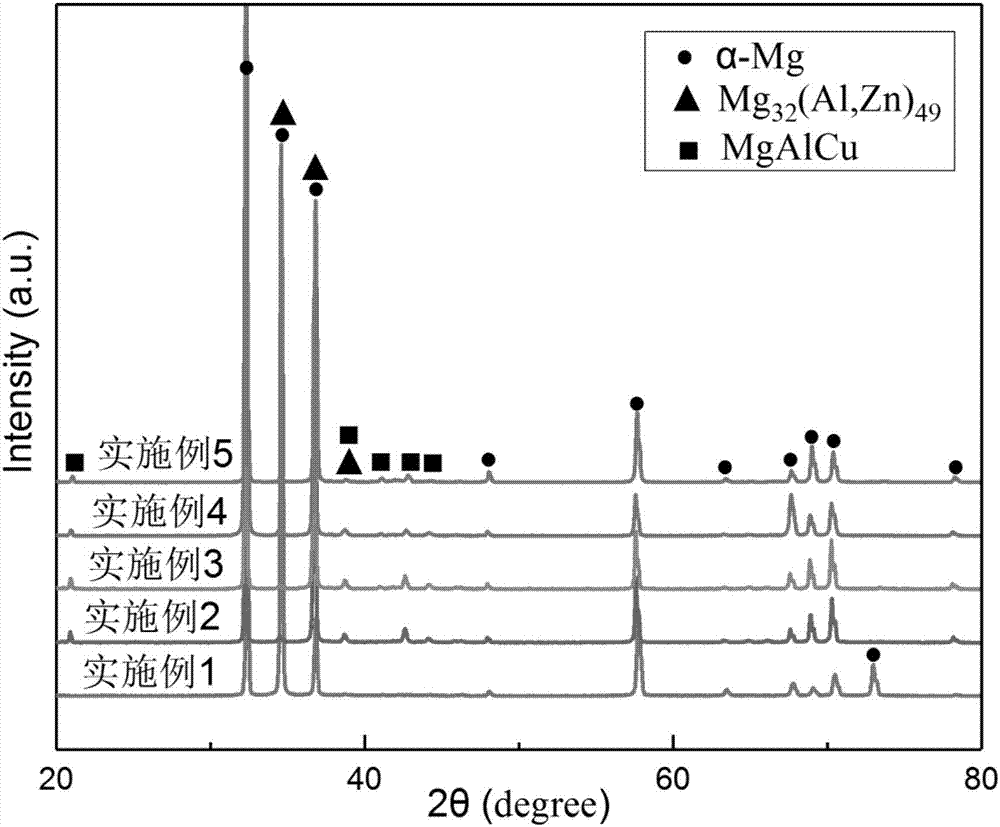

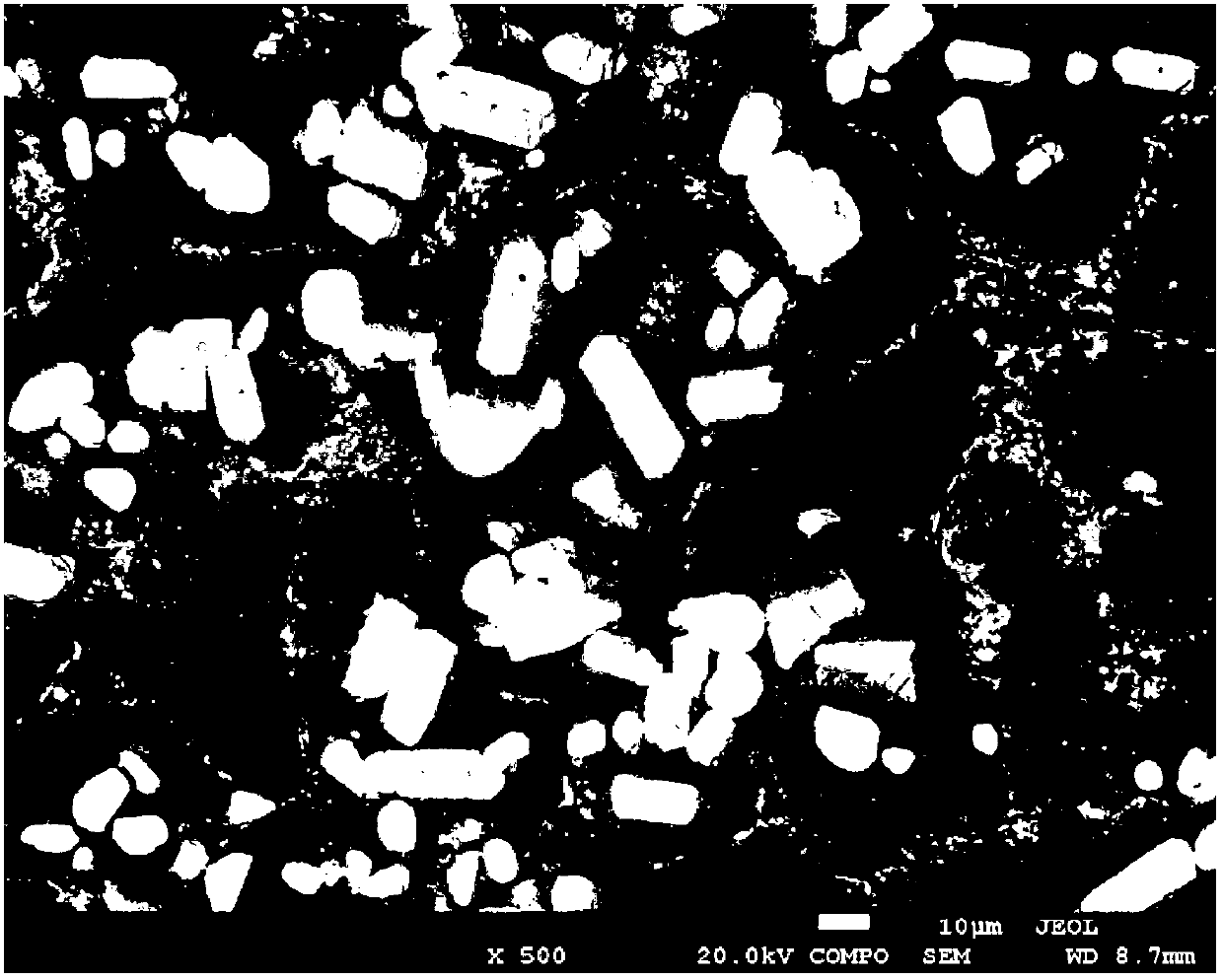

High-strength Mg-Zn-Al deformation magnesium alloy containing Cu and preparation method thereof

The invention relates to a high-strength Mg-Zn-Al deformation magnesium alloy containing Cu and a preparation method thereof, and belongs to the technical field of magnesium alloys. The magnesium alloy consists of the following components in percentage by mass: 5.5-6.5% of Zn, 2.5-3.5% of Al, 0.1-2.1% of Cu, 0.15% or less of inevitable impurities, and the balance of magnesium. 0.1-2.1% of Cu element is added in the magnesium alloy, so that low-melting-point beta-Mg17Al12 phases continuously distributed in a netty form are gradually converted to high-melting-point MgAlCu ternary phases finely scattered, formation of the beta-Mg17Al12 phases is weakened, the mechanical performances of the alloy are improved, and the alloy can serve under higher temperature; the MgAlCu ternary phases can effectively stop growth of grains in dynamic recrystallization process; and the grain size in final extrusion state is about 2 microns. The preparation method of the magnesium alloy is easy to perform, short in time consumption, low in equipment requirements and low in production cost; graphite powder is firstly used for covering when the magnesium alloy is homogenized; and then, an aluminum foil is used for packing to preferably prevent overheating or overburning of the alloy.

Owner:重庆昱华新材料科技有限公司

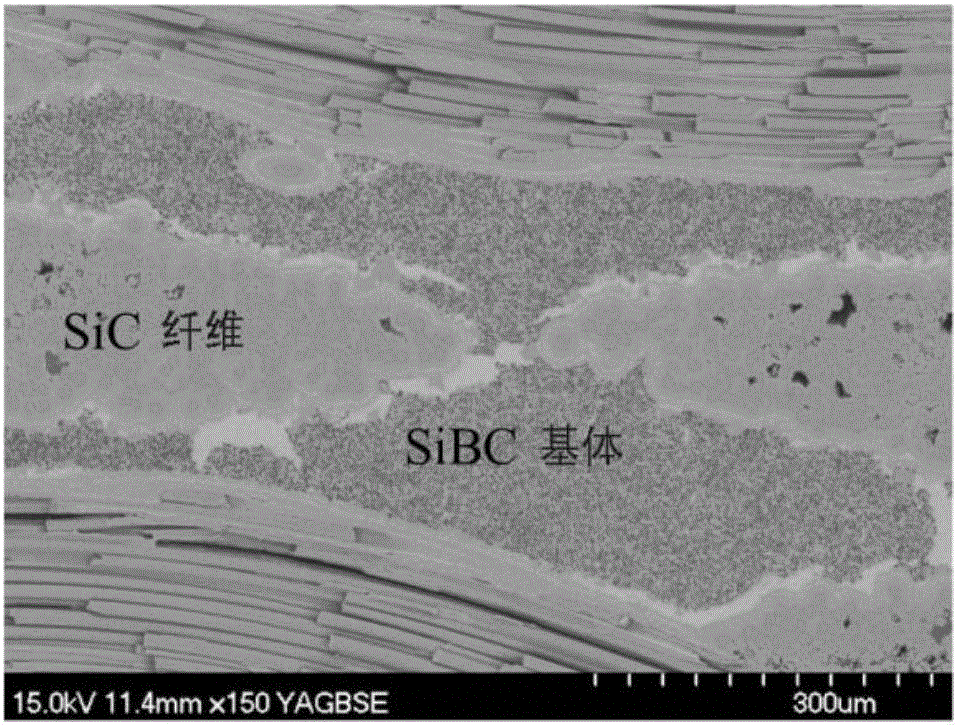

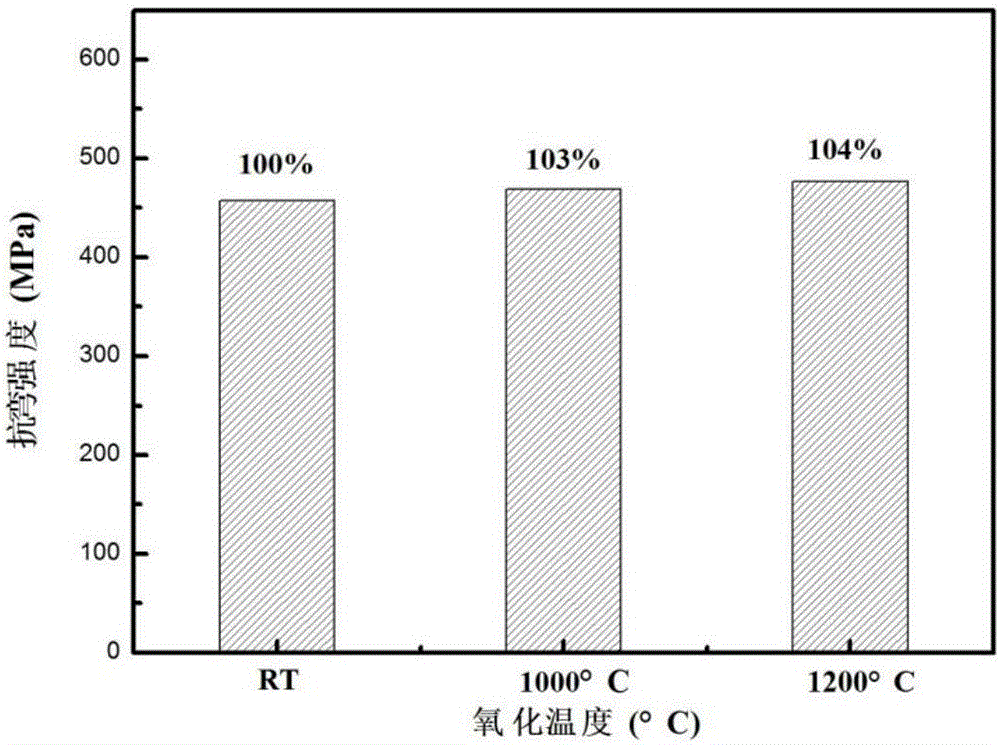

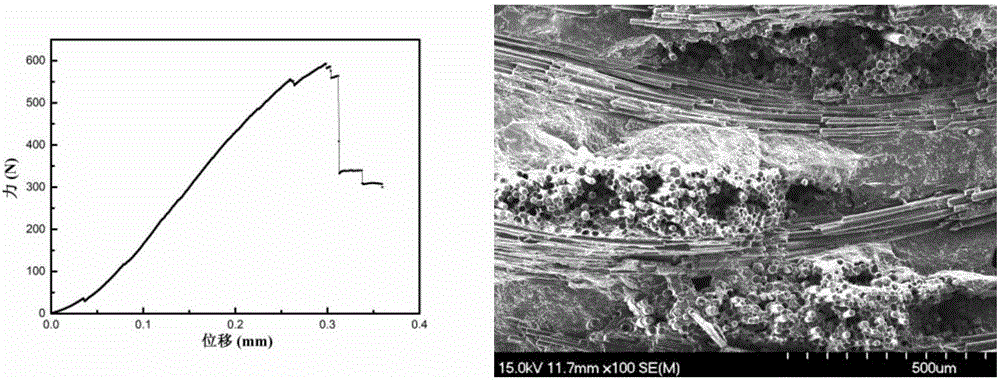

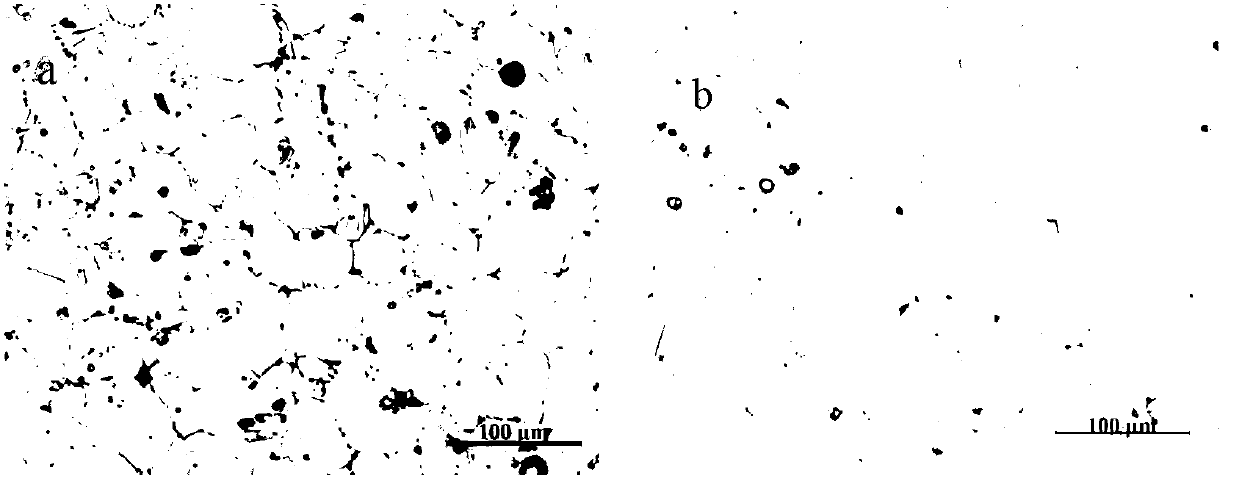

Preparation method for dispersively distributed self-healing phase B12(C,Si,B)3 modified SiC/SiC compound material

The invention discloses a preparation method for a dispersively distributed self-healing phase B12(C,Si,B)3 modified SiC / SiC compound material. The preparation method is adopted for solving the technical problem of poor fracture toughness caused by continuous distribution in the process of introducing a compact self-healing modifying phase according to a present method. According to the technical scheme, the method comprises the following steps: introducing phenolic resin mixed with B4C powder into a porous SiC / SiC compound material by adopting vacuum-pressure dipping; curing, splitting and thermally treating; and performing short-term liquid silicon permeation under a vacuum condition. Fused Si reacts with split C and B4C, thereby generating a ternary phase B12(C,Si,B)3 and SiC which are dispersively distributed in the unreacted Si. According to the invention, a CVI-SiC substrate is capable of effectively protecting SiC fiber and BN interface in the liquid silicon permeation process, the damage to SiC fiber is reduced as far as possible, and the fracture toughness of the compound material is increased to 15-26MPa*ml / 2 from 8MPa*ml / 2 of the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

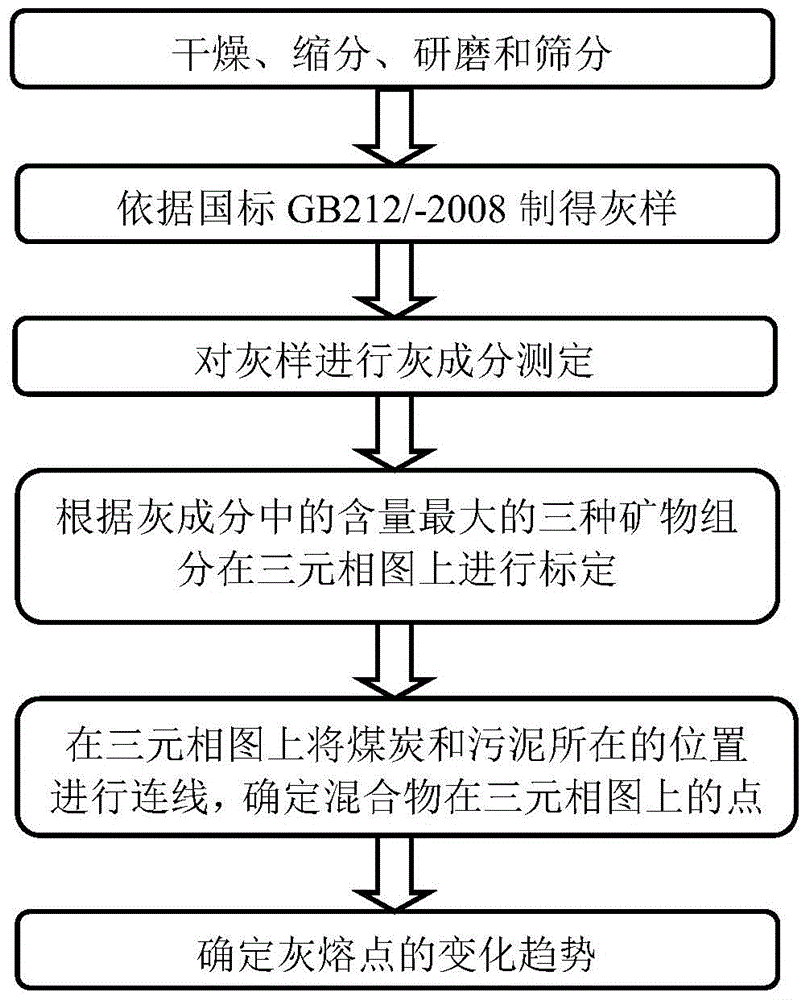

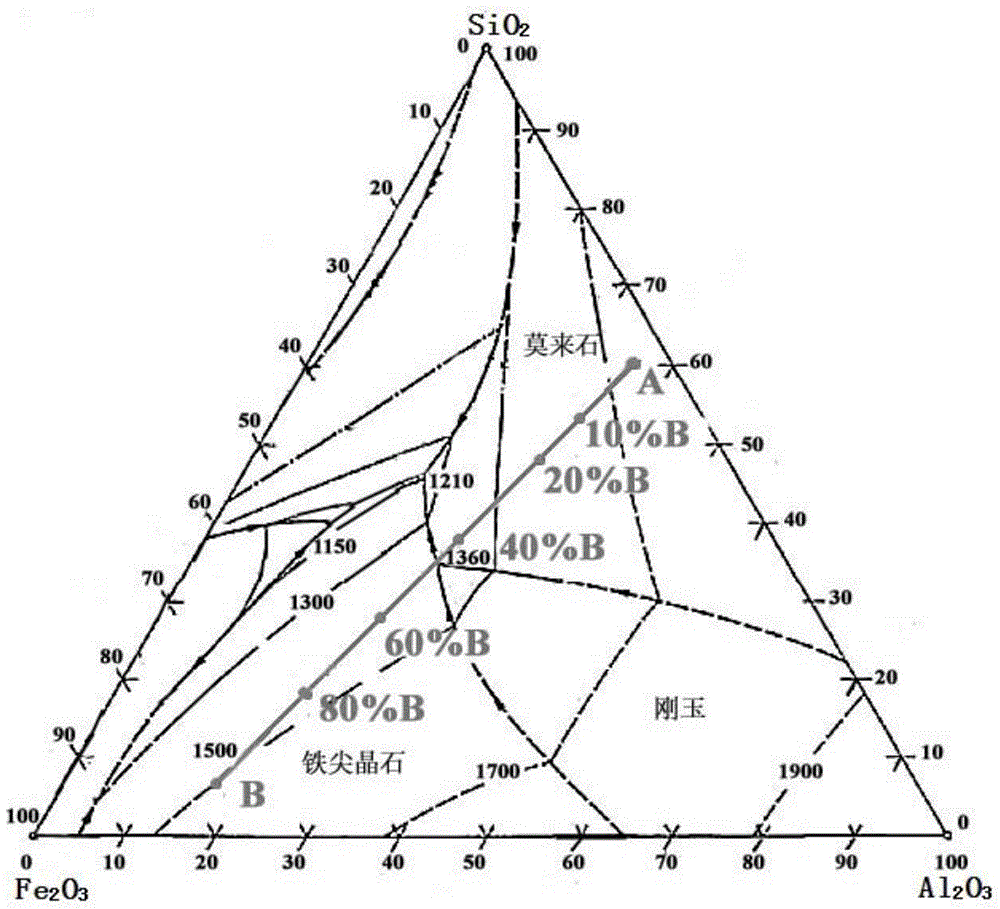

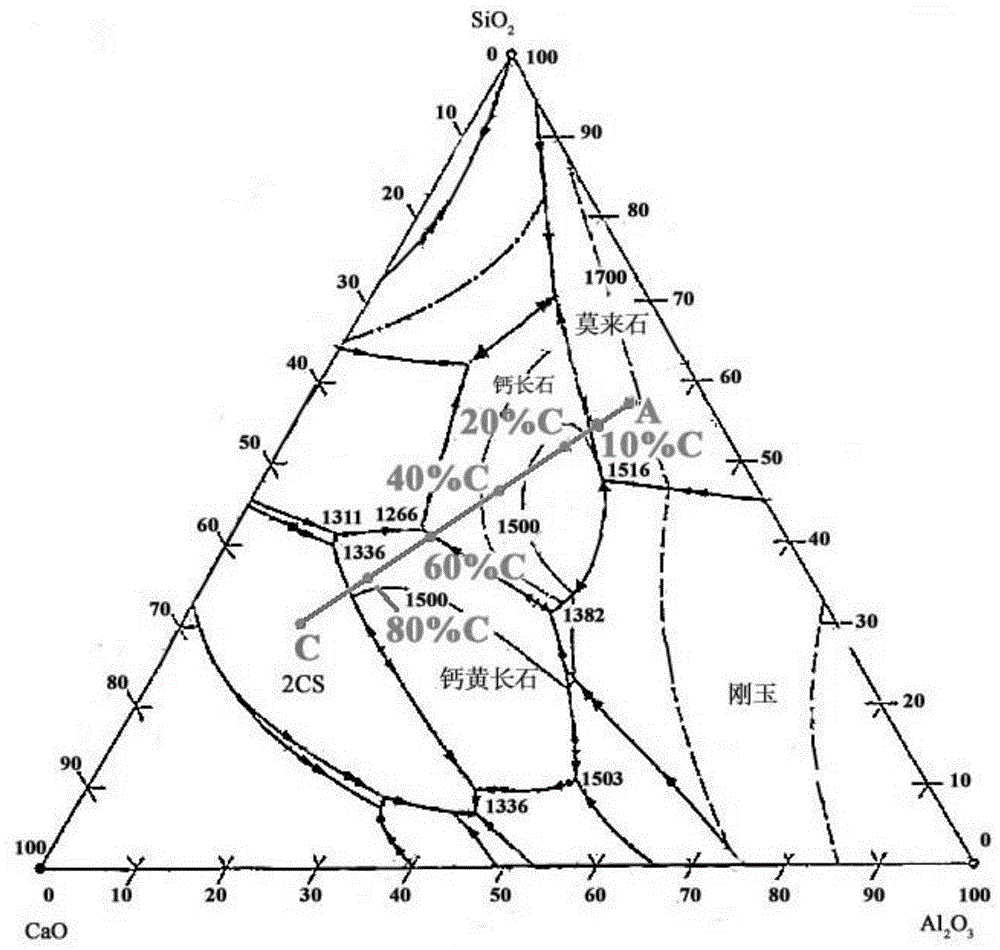

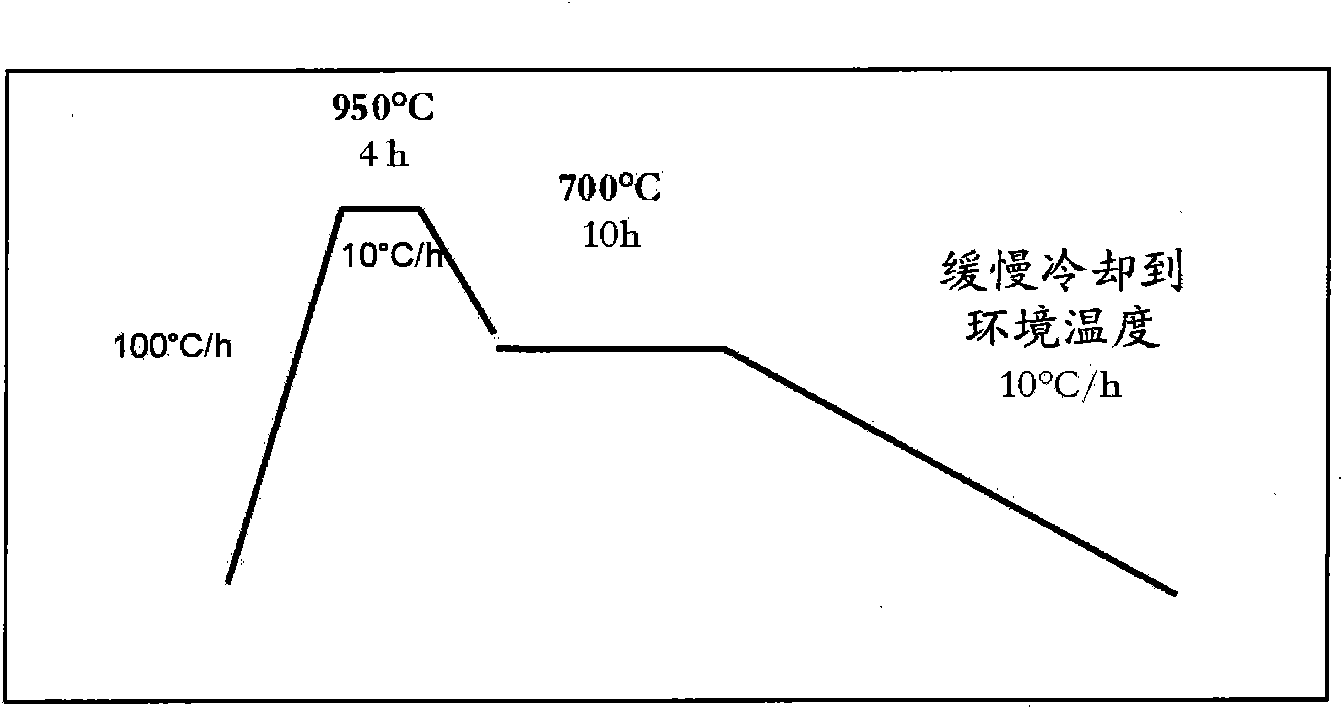

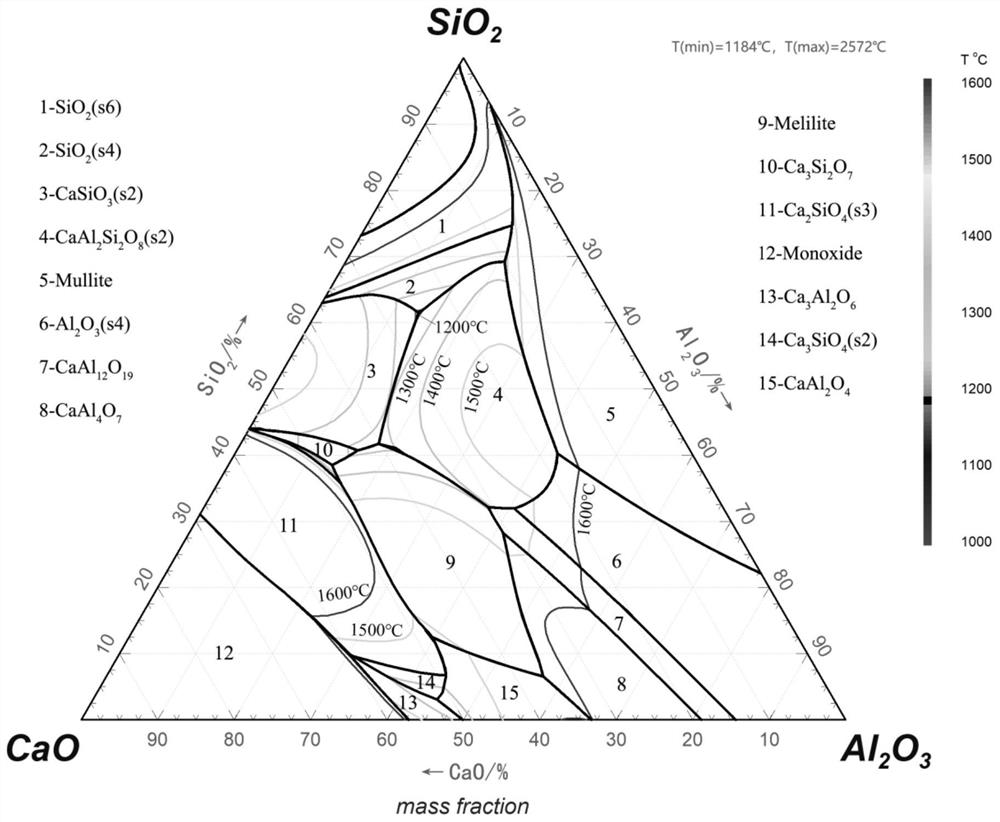

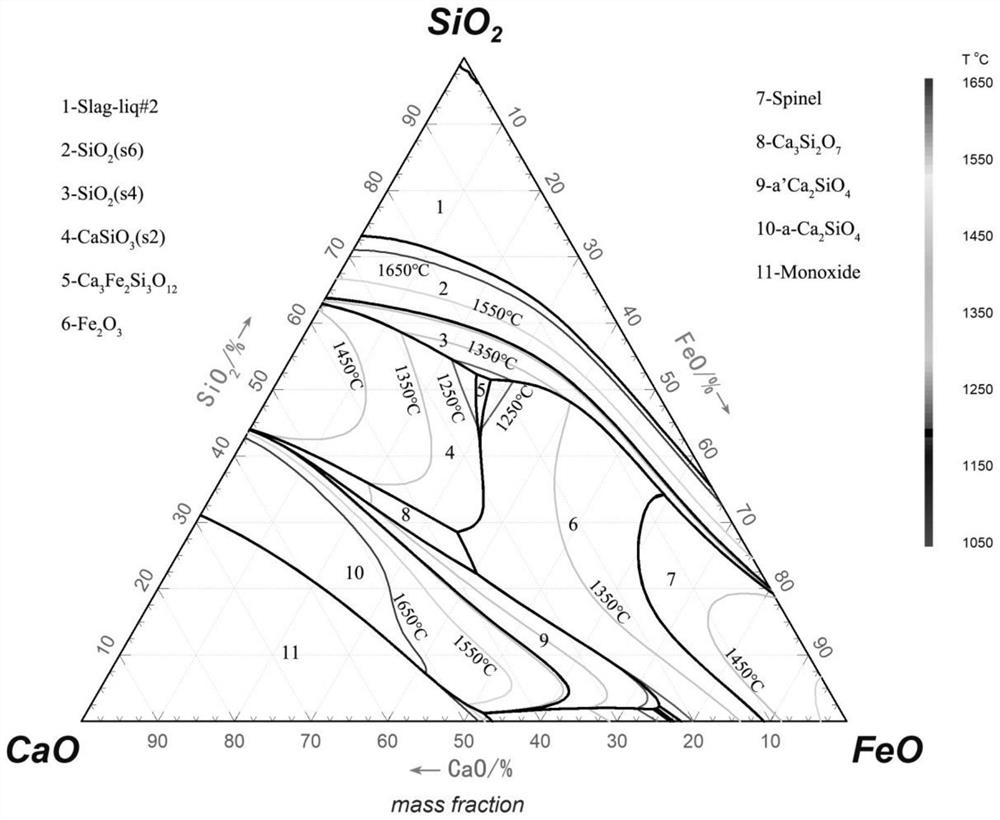

Method for forecasting ash fusion point variation trend after coal and sludge combined firing

InactiveCN104569283AForecasting the change trend of ash melting pointLight in massChemical analysis using combustionSpecial data processing applicationsSludgeComposition analysis

The invention discloses a method for forecasting the ash fusion point variation trend after coal and sludge combined firing. The method comprises the following steps: (1) drying a coal and sludge mixed sample, splitting, grinding, screening the processed mixed sample with a sieve, and drying the mixed sample powder passing through the sieve; (2) preparing an ash sample by adopting a rapid ashing method; (3) performing ash composition analysis on the ash sample, and detecting the species and the contents of mineral constituents; (4) selecting three mineral constituents with the maximum content and selecting corresponding ternary phase diagrams; (5) labeling points on which coal and sludge are located on the ternary phase diagrams and connecting the points on which the coal and the sludge are located into a line; and (6) obtaining the ash fusion point variation trend along with the content of the sludge in the mixed sample. The method can be used for quickly and effectively forecasting the ash fusion point variation trend of the coal and sludge mixed sample along with the content of the sludge to bring convenience for efficiently determining the species of the coal and the sludge in the coal and sludge mixed sample and the ash fusion property variations probably caused after the coal is mixed with the sludge in the initial stage.

Owner:HUAZHONG UNIV OF SCI & TECH

Fe, W and C ternary phase carbide Fe3W3C and preparation method thereof

The invention relates to a preparation method of an Fe, W and C ternary phase carbide Fe3W3C, which comprises the steps of taking reduced iron powder, W powder, and carbon powder as reactor raw materials, preparing Fe-W-C mixed powder according to a stoichiometric ratio (Fe / W / C) of (3-4):(3-4):(1-2), adding a certain amount of raw material mixed powder and a grinding ball into a ball milling jar, after vacuumizing the ball milling jar, charging argon, performing ball milling on the Fe-W-C mixed powder under the argon shield for 30-50h with the steel ball having the diameter of 7-12mm at a ratio of a grinding medium to a material of (7-10):1, allowing the rotating speed of a ball mill to be 400-500r / min, after the ball milling is finished, opening the jar with a glove box to take the powder, performing compaction on the ball-milled powder via a stretcher, selecting a hollow cylinder with the pressure of 400-600MPa and the die dimension of phi 10-30, after the compaction, putting into an SL63-7B vacuum carbon tube furnace for sintering at a heating rate of 10-50 DEG C / min, holding at 1000-1500 DEG C for 0.5-5h, then cooling to the room temperature with the furnace, taking out, and obtaining a block material mainly comprising the ternary carbide Fe3W3C.

Owner:XI AN JIAOTONG UNIV

Novel materials including elements of group 14

The invention relates to a method for preparing a material including at least one member of the Group 14 by thermal degradation of a ternary phase, also known as the Zintl phase, or by reaction therewith with an oxidising solvent. The invention also relates to the material containing at least one element of Group 14 that can be obtained by this method, and to the use thereof mainly in the field ofelectrochemistry, particularly for batteries. The material is more particularly suited for the field of batteries of the alkaline metal and / or alkaline-earth ions type, in particular of the lithium-ion type.

Owner:CENT NAT DE LA RECHERCHE SCI +1

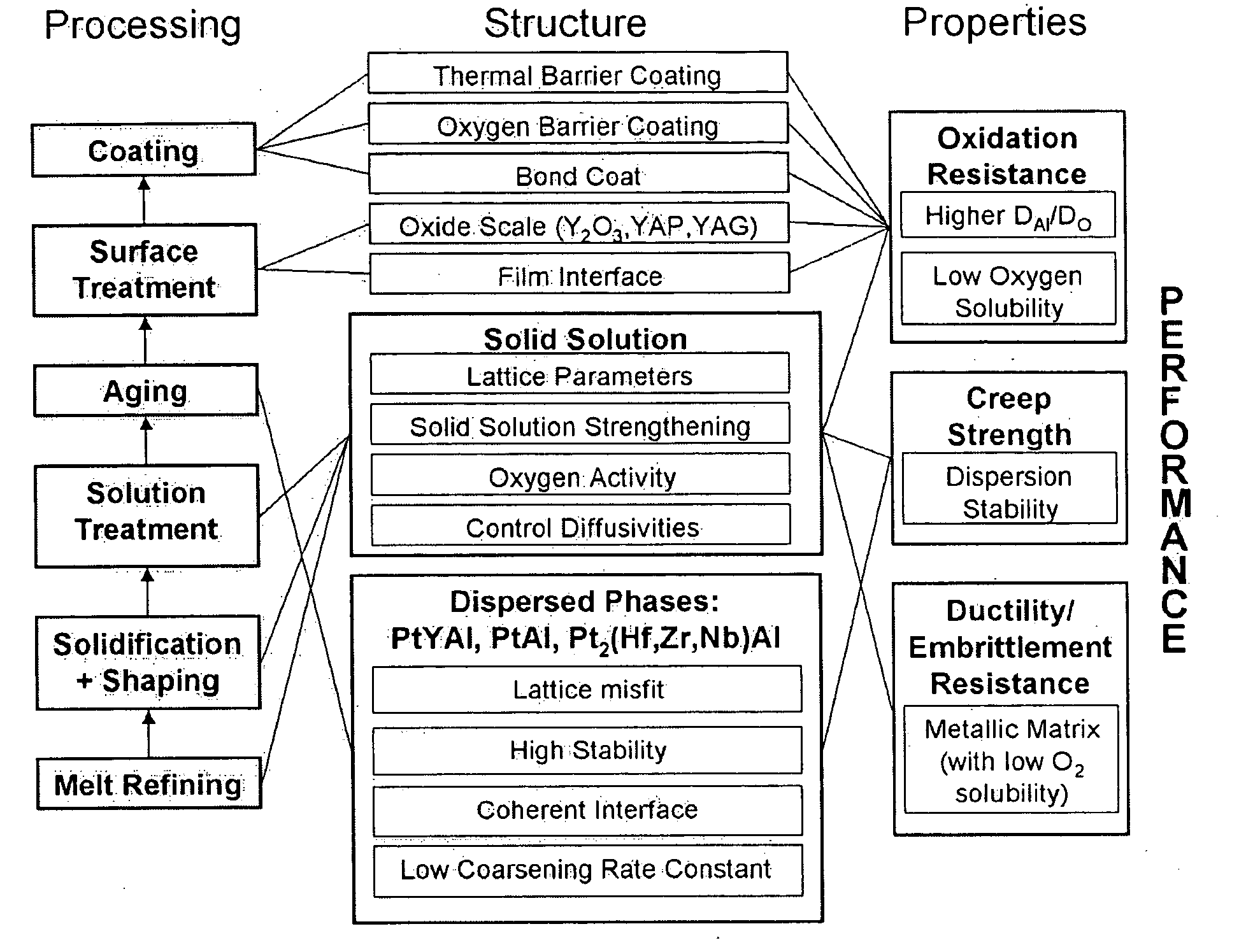

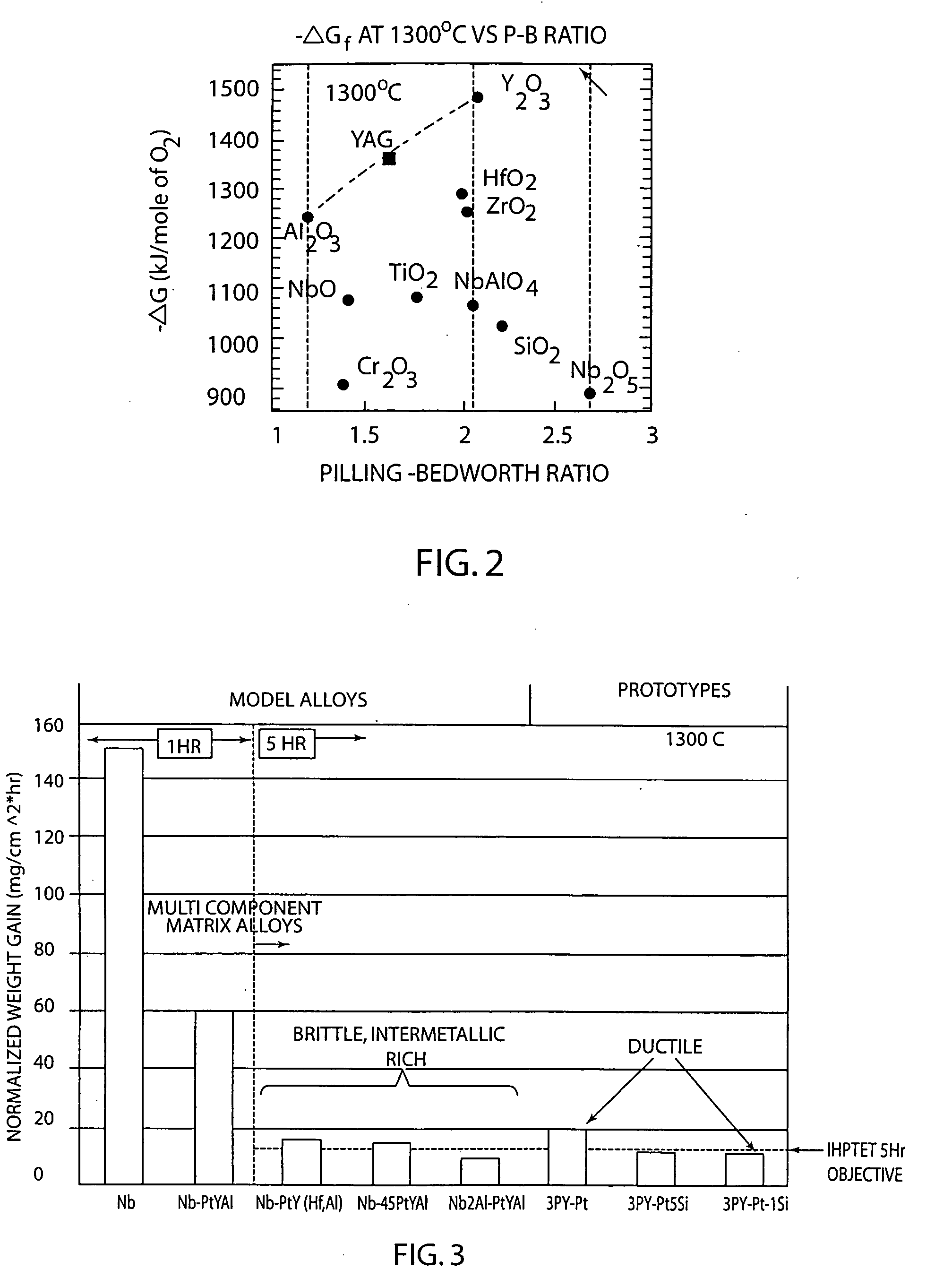

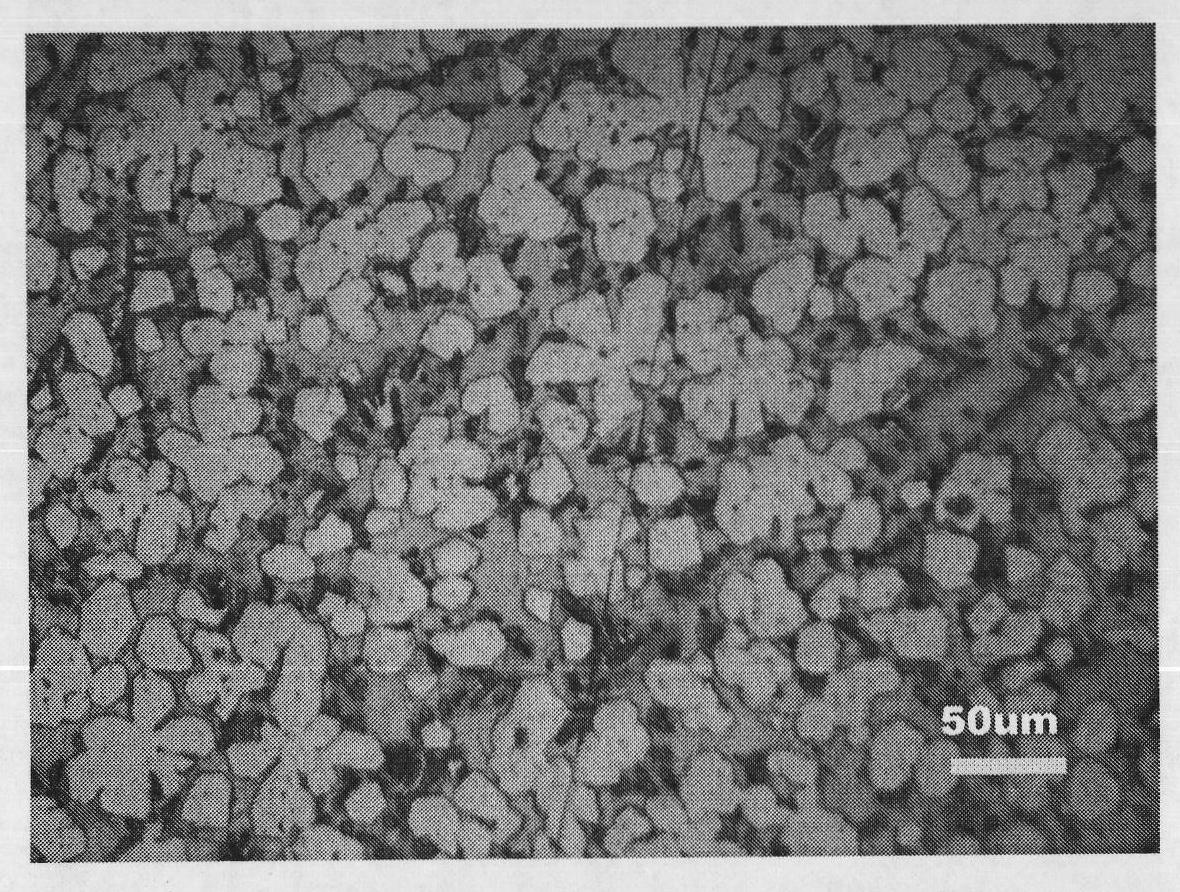

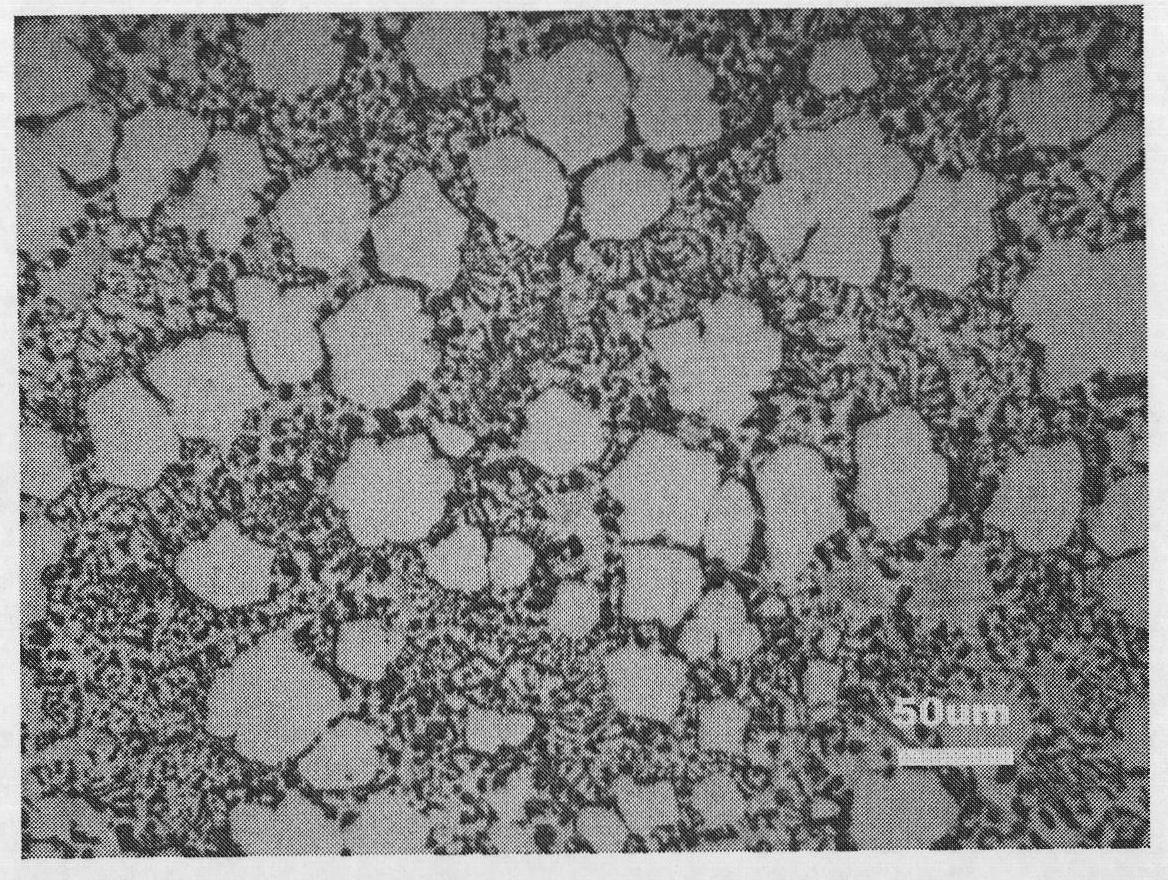

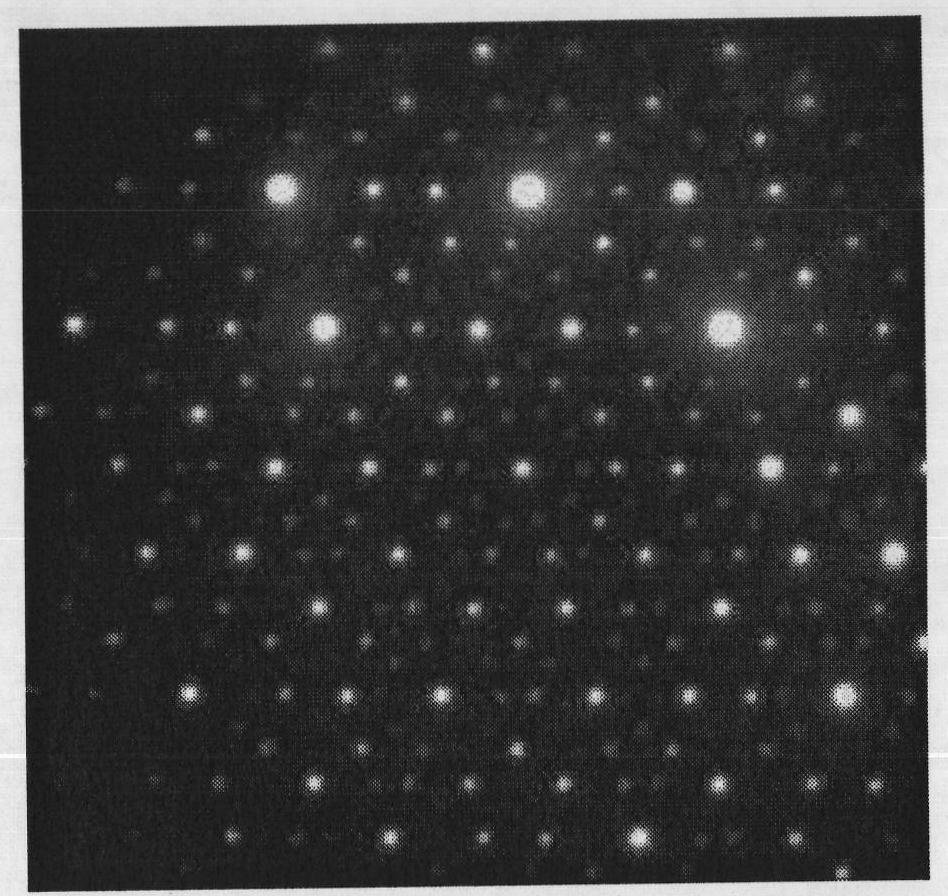

Oxidation resistant niobium based alloys

InactiveUS20060172142A1Improve oxidation resistanceTurbinesEfficient propulsion technologiesOperational costsNiobium

Oxidation resistant niobium based alloys have a composition to provide a stable ternary phase such as PtYAl or PdYAl, which supplies yttrium and aluminum to the system and forms a protective oxide such as Yttria-Aluminum-Garnet (YAG) scale at elevated temperature. These niobium based alloys further achieve an optimal combination of oxidation resistance and creep strength through a fine dispersion of a coherent second phase. The alloys, withstanding higher combustion temperatures, are useful for extreme-environment propulsion and power applications, including hot sections of gas turbine engines, aerospace turbine blades, and chemical and petroleum plants, where higher turbine efficiency and reduction of operating costs, by-products emissions, and global fuel reserves consumption are desired.

Owner:NORTHWESTERN UNIV

Quasicrystal intermediate alloy containing Mg-Zn-Gd radical and preparation method thereof

InactiveCN101787481AImprove mechanical propertiesImprove performanceChemical compositionTernary phase

The invention discloses a quasicrystal intermediate alloy containing Mg-Zn-Gd radical and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 26.9-43.5% of Mg, 43.0-62.0% of Zn and 12.0-13.5% of Gd, the cast structure of the quasicrystal intermediate alloy is characterized by consisting of multi-phase compound structures of icosahedral MgaZnbGdc quasicrystal and Mg7Zn3 divorced eutectic, icosahedral MgaZnbGdc quasicrystaland MgZnGd ternary phase or icosahedral MgaZnbGdc quasicrystal and MgZn, and the volume of the quasicrystal phase can reach 40-70% of the total volumen of the master alloy. In the preparation method, a simple apparatus is utilized to obtain an intermediate alloy material of stable thermal icosahedral quasicrystal containing the Mg-Zn-Gd radical, through controlling the content of alloy elements and the casting process. The preparation process is simple and the production cost is low; the produced alloy has high content of the quasicrystal, wide range of the component, good thermal stability, heat processing performance and good market prospect, and is suitable for industrial production.

Owner:BEIJING UNIV OF TECH

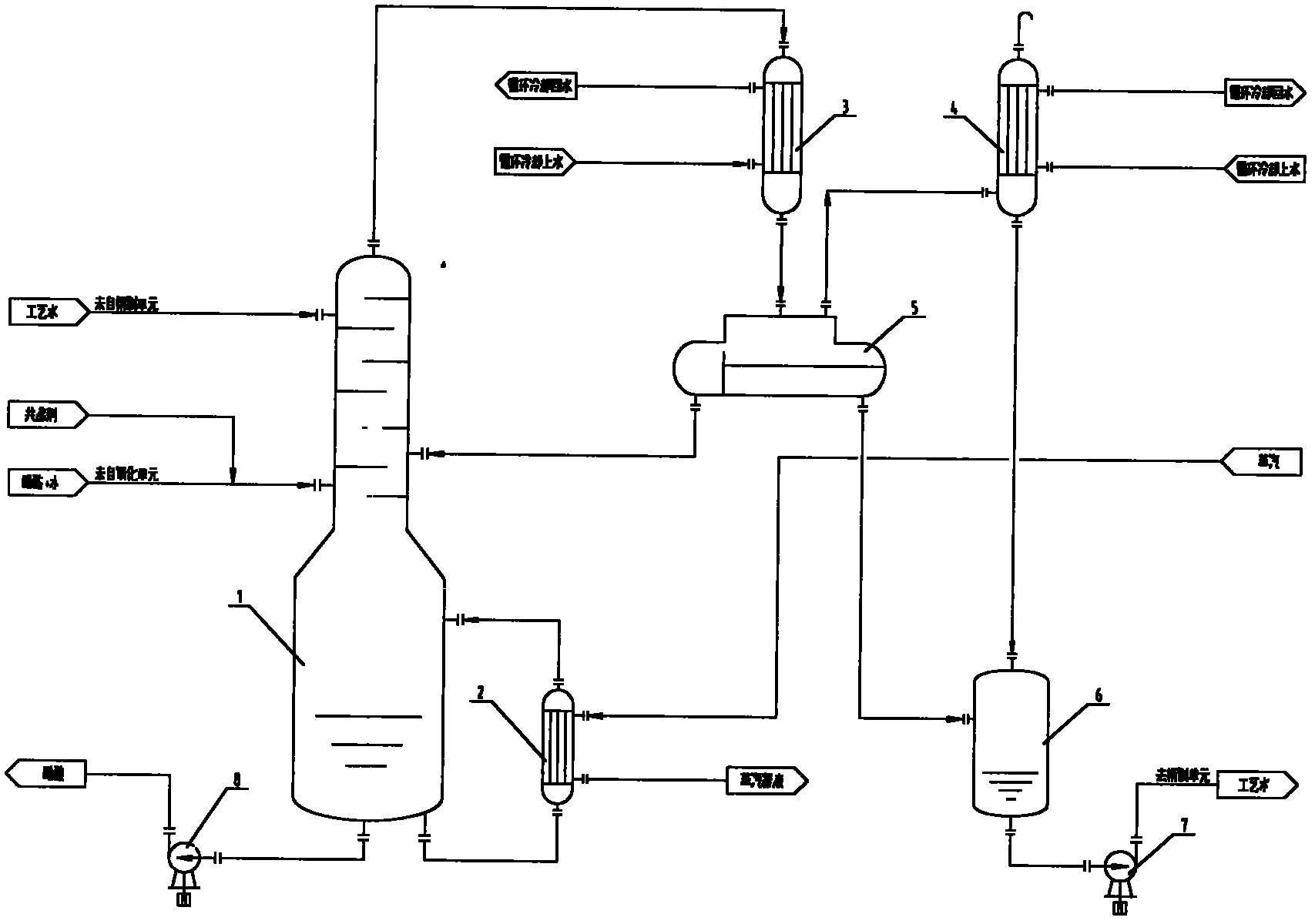

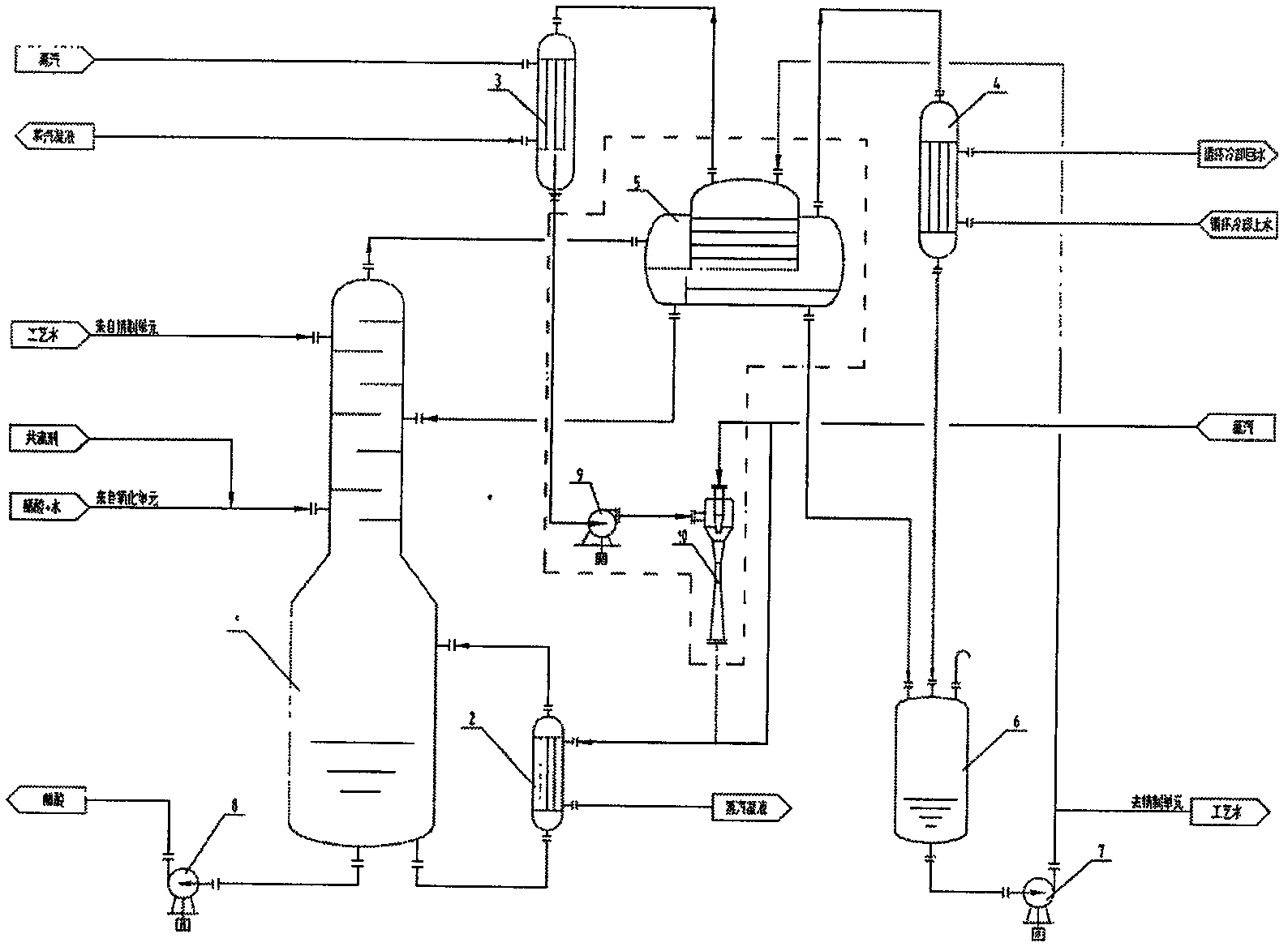

Acetic acid+water azeotropic-rectification energy-saving consumption-reduction method by adding heat pump

ActiveCN102992993AReduce dosageChemical industryCarboxylic compound separation/purificationAcetic acidReboiler

The invention discloses an acetic acid+water azeotropic-rectification energy-saving consumption-reduction method by adding a heat pump, which is characterized by adding a steam blower and a Venturi ejector vacuum pump, which are connected in series through a pipeline, between a steam drum and a tower bottom reboiler in the traditional azeotropic rectification technique. By using the method, the azeotropic point temperature of the steam-azeotrope former in the acetic acid-water-azeotrope former ternary-phase system in the rectification tower is lowered; heat of the steam in the steam drum is extracted and supplied to the tower bottom reboiler, thereby lowering the consumption of the steam; and the process water is cyclically utilized, thereby achieving the goal of saving energy consumption in public works.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

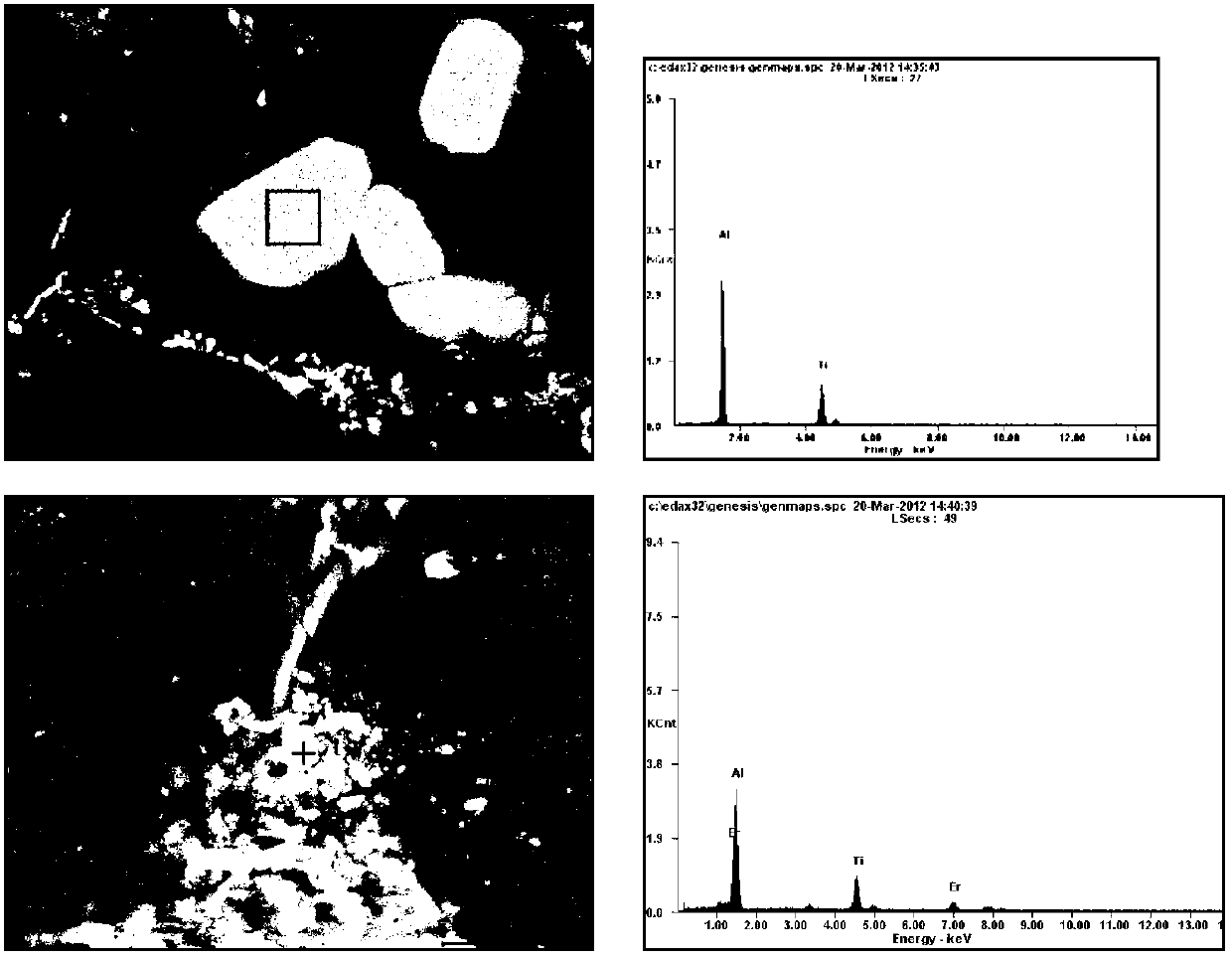

Al-Ti-C-Er refiner and preparation method

The invention relates to an Al-Ti-C-Er refiner and a preparation method and belongs to the technical field of refiners. The Al-Ti-C-Er refiner comprises 3.0-10.0 wt% of Ti, 0.15-0.5 wt% of C, 0.1-0.3 wt% of Er and the balance of Al; the mass ratio of Ti to C is 17 to 22; and the phase of the refiner comprises alpha-Al, TiAl3, TiC, Al3Er, and AlErTi ternary phase. The preparation method comprises the following steps: uniformly mixing Ti, Al and graphite powder, placing the mixture in a mold, and pressing the mixture into blocks; heating and melting an aluminium ingot and covering cryolite; pressing in an Al-Er intermediate alloy and standing; and heating the melt to the required reaction temperature, pressing in the blocks, stirring for reaction, pressing in C2Cl6 for refining, slagging off and pouring. The Al-Ti-C-Er refiner solves the problem of difficult preparation of TiC particles, improves the wettability of C in Al by adding rare earth Er, and also improves the reaction efficiency.

Owner:BEIJING UNIV OF TECH

A kind of sodium-doped lithium-rich manganese-based positive electrode material for lithium ion battery and preparation method thereof

ActiveCN104201337BImprove cycle stabilityLow application costCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a sodium doped lithium-rich manganese based cathode material for a lithium ion battery. The material is a sodium salt doped lithium-rich manganese based solid solution cathode material of which the general formula is xLi[Li1 / 3Mn2 / 3]O2.(1-x)LiNi0.2Co0.2Mn0.6O2, wherein x is equal to or greater than 0.4 and is equal to or less than 0.7, the doped quantity of sodium elements is 1-10% of the mol content of lithium elements, and the sodium salt is one selected from Na2CO3, Na2C2O4 and NaNO3. The mol content of ternary phase manganese of the sodium doped lithium-rich manganese based cathode material for the lithium ion battery is greater than 50%, and the manganese with high reserves and low price is used for replacing cobalt and nickel, so that the application cost can be reduced. Compared with the prior art, the sodium doping provided by the invention can improve the discharging specific capacity and the circulating stability of the rich lithium manganese based cathode material.

Owner:HEBEI UNIV OF TECH

Smart card and smart card reader

InactiveCN101185201AGood electrical contactCost effectiveCoupling contact membersMetallic material coating processesAtomic elementContact layer

A smart card (1) having a card contact element (2) for establishing electrical contact with a reader contact element of a smart card reader for reading the smart card, said card contact element (2) having coated contacts A contact surface (3) of the layer, said contact surface (3) being arranged in contact with a card reader contact element. The contact layer comprises a multi-element material having a composition of at least one carbide or nitride described by the formula MqAyXz, wherein M is a transition metal or a combination of transition metals, A is a group A element or a combination of group A elements, X is carbon or nitrogen or both, and q, y and z are numbers greater than zero. Multi-element materials also include at least one nanocomposite material containing a single element, a binary phase, a ternary phase, a quaternary phase or a higher order phase based on the atomic elements in the corresponding MqAyXz compound. A card reader for reading a smart card (1) is also disclosed.

Owner:IMPACT COATINGS AB

High-yield-ratio wrought magnesium alloy and preparation method thereof

The invention discloses high-yield-ratio wrought magnesium alloy and a preparation method thereof. The high-yield-ratio wrought magnesium alloy comprises, by mass, 3%-4% of Zn, 0.7%-0.95% of Ca, 0.05%-0.33% of Mn, and the balance Mg and inevitable impurities. According to the prepared alloy, a large quantity of Mg-Zn-Ca ternary phases are separated out in the extrusion direction in the extrusion process and evenly distributed in a magnesium matrix, and thus two-phase reinforcement is achieved; a non-recrystallized area in a large proportion has strong texture, and thus the texture reinforcing effect is achieve; a large quantity of nanoscale Mg particles are dispersed and separated out to achieve the dispersion reinforcing effect, growth of recrystallized grains is restrained in the hot extrusion process, and thus the grain refining effect is achieved; and by adding Ca and Mn, the obvious grain refining effect can be achieved, both the strength and toughness of the alloy are improved, the basal texture of the alloy can be weakened through Ca, and thus the plasticity of materials is improved. In this way, the prepared alloy has high strength and a high yield ratio, and high plasticity of the alloy is maintained.

Owner:CHONGQING UNIV

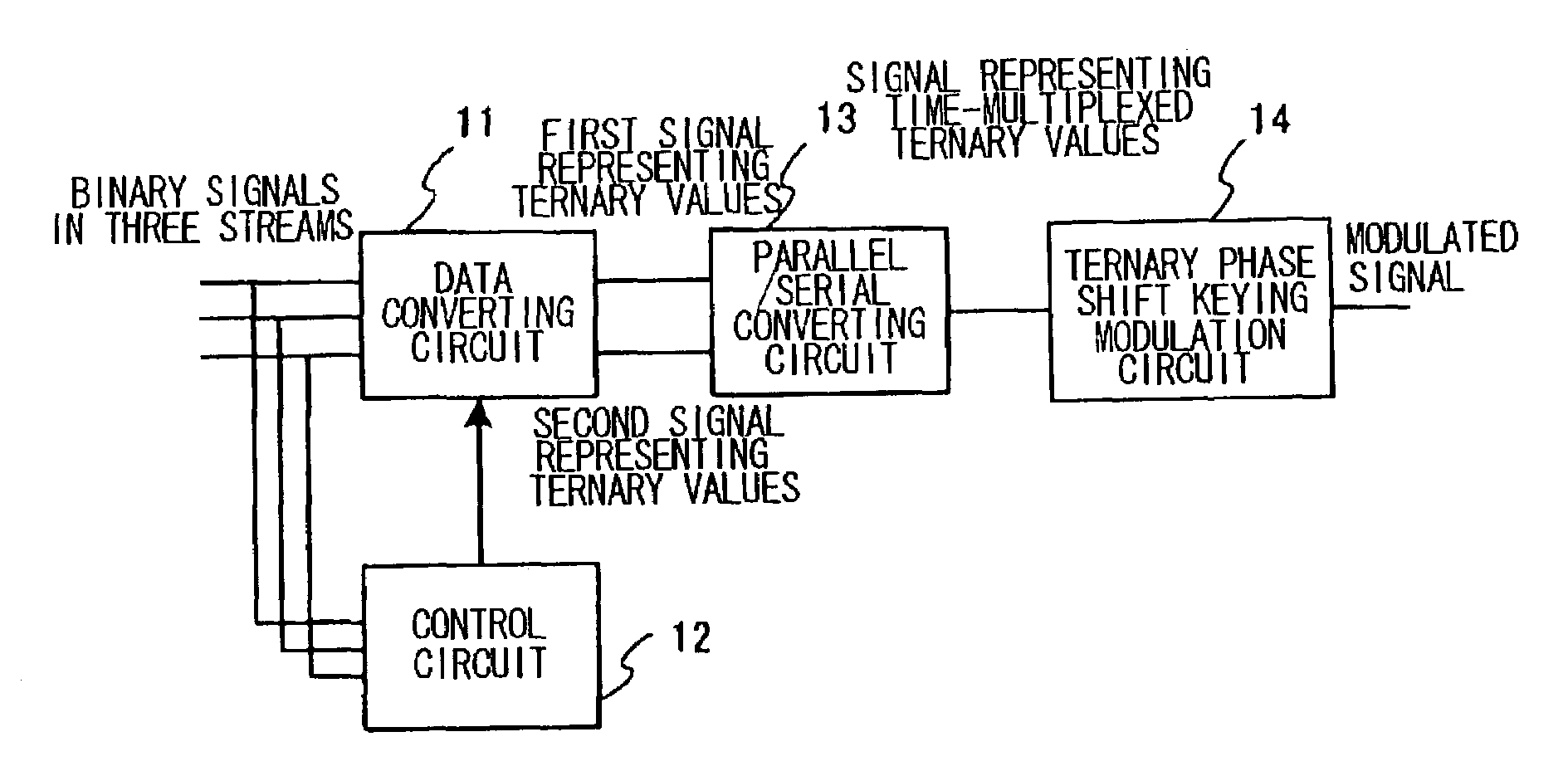

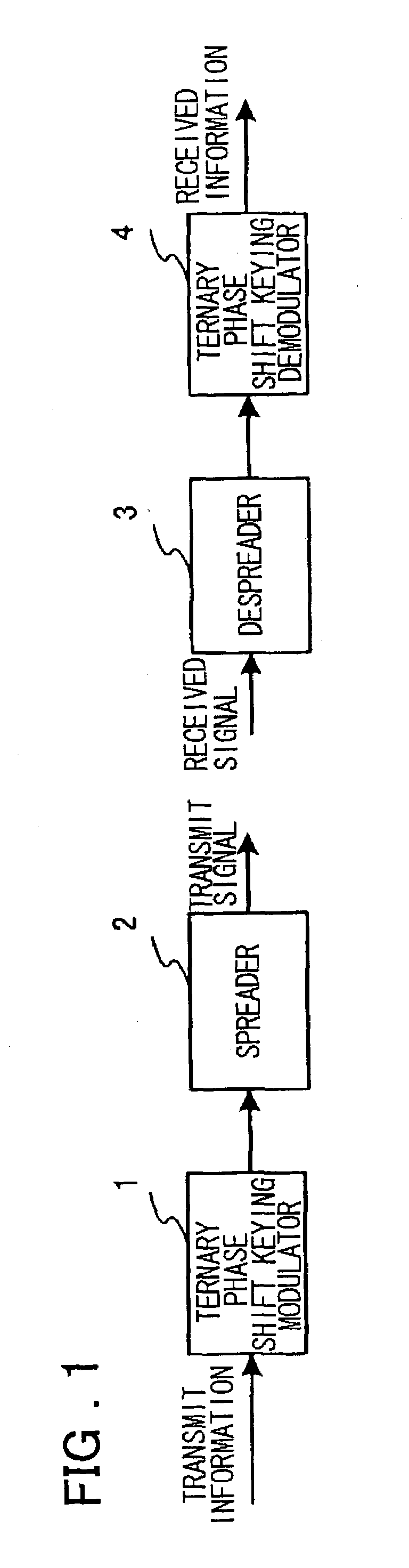

Code division multiple access communication system and method

InactiveUS7330451B2Increase construction costsGreat revenueError preventionCode conversionSignal qualityCommunications system

Disclosed is a CDMA communication system and method that make it possible to accommodate a greater number of user terminals that can be connected per facilities investment. Ternary phase-shift keying (TPSK) modulation is applied as primary modulation in a CDMA communication system. It is possible to deliver far performance in which the Eb / No ratio is improved by about 0.75 dB, in comparison with BPSK and QPSK modulation, in order to obtain the required signal quality. Accordingly, the number of user terminals that can be connected simultaneously in a CDMA system can be increased by about 19%.

Owner:NEC CORP

Masking mechanism for film forming apparatus

ActiveUS20100151128A1Increase equipment costLiquid surface applicatorsVacuum evaporation coatingEngineeringTernary phase

It comprises a mask (11) having a first, a second and a third action edge (11a, 11b, 11c), and a drive means for moving the mask (11) relative to a substrate (12) in a uniaxial direction (A) whereby moving the mask at a fixed rate of movement to cause the edges to successively act on an identical substrate region while successively applying different materials thereto forms thin films of three components successively with respective film thickness gradients oriented in three different directions mutually angularly spaced apart by an angle of 120° to allow these films to overlap, thereby forming a ternary phase diagrammatic thin film 13.

Owner:JAPAN SCI & TECH CORP

Magnesium alloy for negative electrode of battery

InactiveCN105609751AImprove discharge activityIncreased persistenceCell electrodesDischarge efficiencyVacancy defect

The invention discloses a magnesium alloy for a negative electrode of a battery. The magnesium alloy is prepared from the following components: 1.5wt%-2.2wt% of Zn, 1.2wt%-2.0% of Cu, 0.5wt%-1.0wt% of Ce or La, less than 0.2wt% of impurities and the balance of Mg. The Zn element is added to improve the discharge activity and continuity of the magnesium alloy; the Cu element improves a solidus temperature of the material, improves the solid solubility of the Zn, accelerates combination of solute atoms and vacancy defects, eliminates the matrix defect, improves the uniformity of the alloy material and generates an MgZnCu ternary phase; under thermal treatment, ternary phase spheroidizing dispersion distribution is formed on a grain boundary; a product is corroded to smoothly fall off in the discharge process; a magnesium hydroxide passivation layer is destroyed; and further discharge is facilitated. The rare-earth Ce or La element is added to form a few of Mg-Ce or La phases in dot diffuse distribution; balancing of over-high corrosion rate of the magnesium alloy is facilitated; and the discharge efficiency of the negative electrode is improved.

Owner:JIANGSU ZHONGKE YAMEI NEW MATERIAL CO LTD

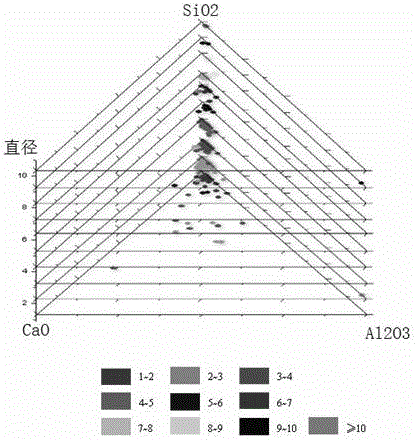

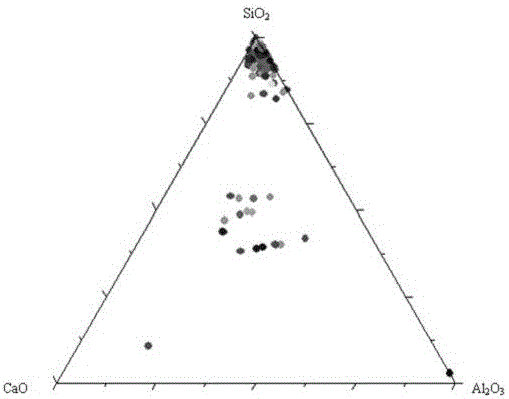

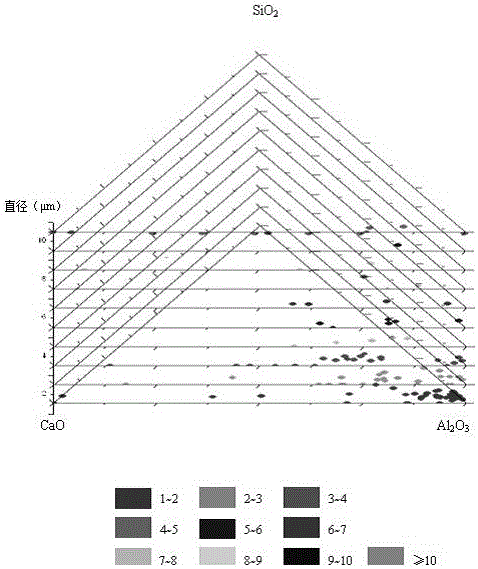

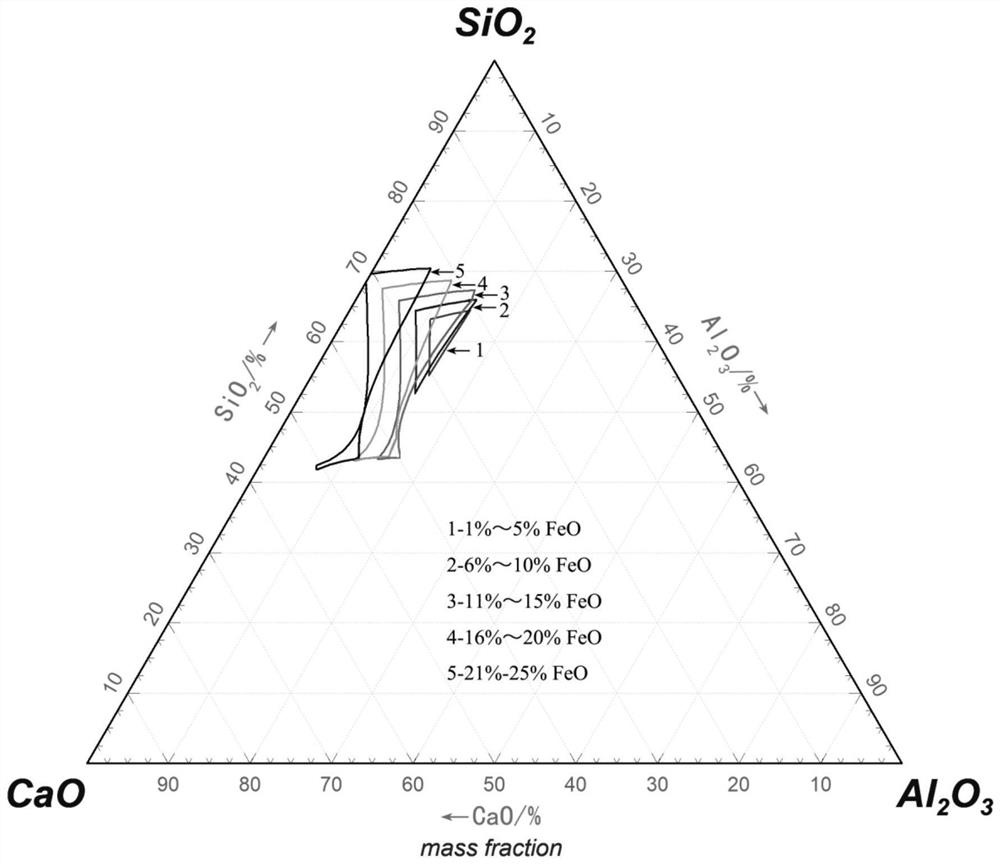

Method for representing inclusions of different sizes, in tire cord steel, in ternary phase diagrams

InactiveCN106204682AIndicates the distribution of different sizesGood deformabilityDrawing from basic elements3D modellingPoint densityTernary phase

The invention relates to a method for representing inclusions of different sizes, in tire cord steel, in ternary phase diagrams. The method comprises the steps of screening data obtained by surface distribution statistics of the inclusions, determining three main components of the inclusions in a sample, and performing normalization processing by weight percentage; then classifying the inclusions by size; and finally projecting the inclusions of the different sizes into the ternary phase diagrams in sequence, filling the ternary phase diagrams with different colors, and superposing the ternary phase diagrams in sequence to form a two-dimensional diagram and a three-dimensional diagram. The ternary phase diagrams of the inclusions of the different sizes are superposed in sequence and filled with the different colors to form a three-dimensional ternary phase diagram, so that distribution situations of the different sizes of the inclusions can be accurately and visually represented, the larger the numerical value of longitudinal coordinates is and the larger the sizes of the inclusions are, and the higher the point density is and the larger the number of the inclusions is; and by observing the ternary phase diagrams, whether the components of the inclusions fall into a region with good deformation capability or not can be known, thereby providing a favorable basis for a production process of the tire cord steel.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

In-Sb-Te ternary phase change nanotube and preparation method of array thereof

InactiveCN103526221AHigh yieldSimple processElectrolysis componentsNanoinformaticsTernary phaseOxygen

The invention discloses an In-Sb-Te ternary phase change nanotube and a preparation method of an array of the In-Sb-Te ternary phase change nanotube. A solution, of which the pH value is equal to 2.2, is prepared and is mixed with antimony chloride, indium chloride and potassium tellurite; one surface of a template is conductive, which is used as a working electrode; a reference electrode and a counter electrode are arranged in an electrolytic tank; electrolyte is transferred into the electrolytic tank; then the electrolytic tank is sealed and inert gas is introduced into the electrolytic tank to remove dissolved oxygen in the electrolyte; differential pulse electrodeposition is carried out. According to the In-Sb-Te nanotube, because a method of combining differential pulse electrodeposition process and a template process is adopted, the In-Sb-Te nanotube has the advantages of high yield, simple process, low synthetic temperature, uniform size, high repeatability and the like. The In-Sb-Te nanotube obtained by using the method has the nanoscale diameter, the length is from a few micrometers to dozens of micrometers, the size is uniform, and the nanotube is smooth and has an array structure; therefore, the nanotube is a good material with phase change property.

Owner:TIANJIN UNIV

Semiconductor device including ternary phase diffusion barrier

InactiveUS6885103B2Reduced ohmic contact resistanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialOhmic contact

A method for manufacturing a semiconductor device can simply form a silicide film for reducing ohmic contact between a metal line and a substrate and a ternary phase thin film as an amorphous diffusion prevention film between a metal line and the silicide film. The method for manufacturing a semiconductor device includes the steps of sequentially forming a first refractory metal and a second refractory metal on a semiconductor substrate, forming a silicide film on an interface between the semiconductor substrate and the first refractory metal, and reacting the semiconductor substrate with the first and second refractory metals on the silicide film to form a ternary phase thin film.

Owner:HYUNDAI ELECTRONICS IND CO LTD

Method for determining slag type of molten pool smelting electronic waste and slag type

ActiveCN113718109AThe method steps are simpleEasy to operateMaterial analysis using wave/particle radiationProcess efficiency improvementSmelting processElectronic waste

The invention relates to a method for determining the slag type of molten pool smelting electronic waste. The method comprises the following steps: (1) determining the content of oxide components forming a slag system in the electronic waste; (2) searching low melting point regions in silicon-calcium-iron and silicon-calcium-aluminum ternary phase diagrams; (3) searching corresponding additives forming the low-melting-point regions of the silicon-calcium-iron and silicon-calcium-aluminum ternary phase diagrams; (4) determining the content of each additive corresponding to the unit electronic waste; (5) carrying out a molten pool smelting test according to the determined content of each additive corresponding to the unit electronic waste, and verifying whether the slag type is an ideal slag type or not; (6) if the slag type is not the ideal slag type, returning to the step (3) and repeating the steps until the ideal slag type is found; and (7) drawing a silicon-calcium-iron or silicon-calcium-aluminum quaternary slag type phase diagram according to the determined ideal slag type. The method is simple in step, high in operability and also suitable for determining the slag type of other novel smelting processes without reference data.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com