Oxidation resistant niobium based alloys

a technology of niobium based alloys and niobium based alloys, which is applied in the direction of solid-state diffusion coating, turbines, mechanical equipment, etc., can solve the problems of linear growth kinetics of conventional niobium based alloys, limited room and limited room for nickel based alloys to improve upon the operating efficiency of manufactured components. , to achieve the effect of improving oxidation resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

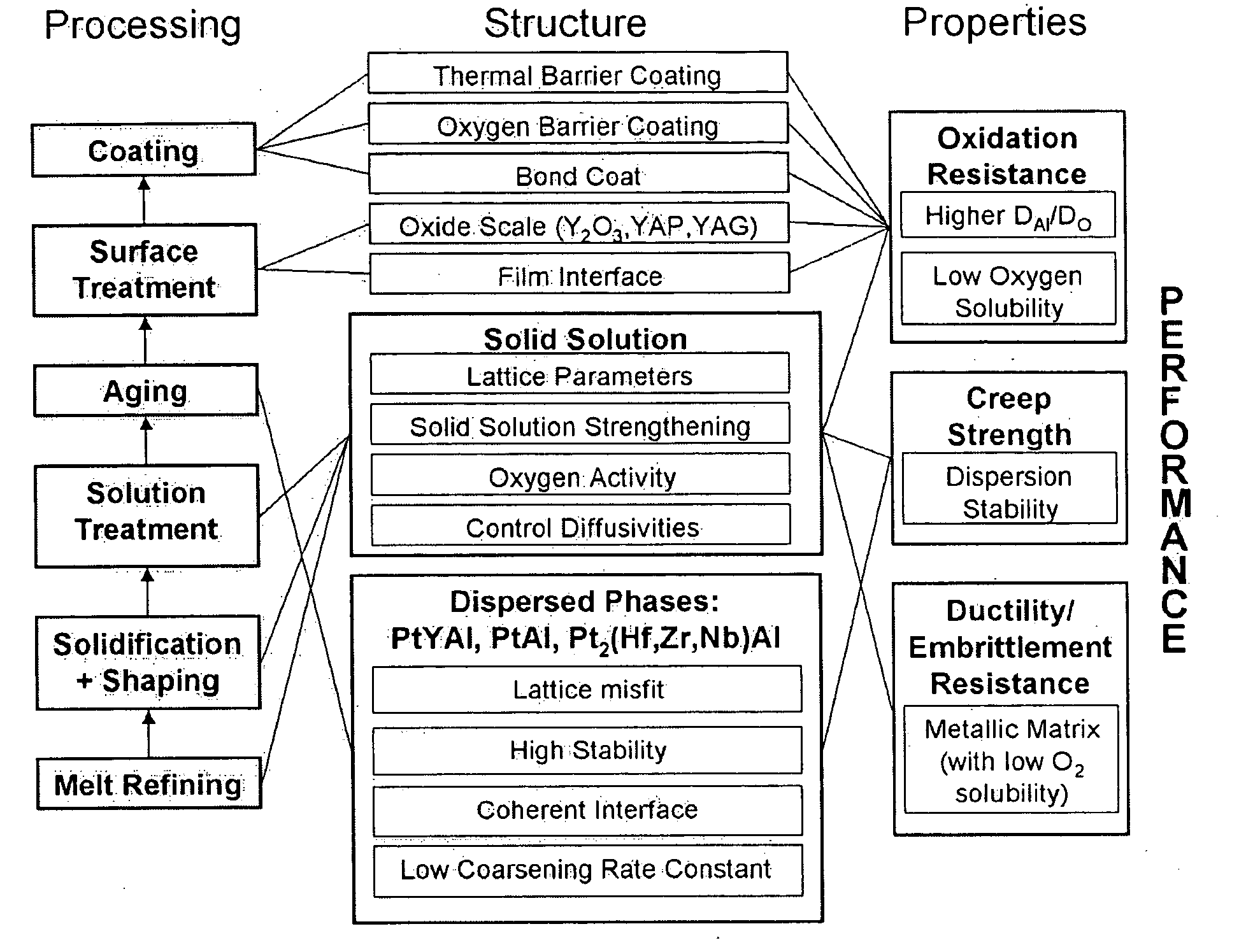

[0022] The present invention provides niobium (Nb) based alloys which have improved oxidation resistance. The alloys can have a multicrystalline microstructure, although the invention is not so limited since the alloys can have a single crystal or directionally solidified microstructure depending on the service application. In an illustrative embodiment of the invention, the Nb based alloy composition comprises at least about 25 preferably about 40 atomic % Nb together with aluminum (Al), platinum (Pt) or palladium (Pd) or a combination thereof, and yttrium (Y). The Nb concentration of the alloy more preferably is at least about 53 atomic % in certain illustrative embodiments described below. The Nb based alloys preferably include from about 10 to about 25 atomic % and more preferably about 10 to about 20 atomic % of Al. The Nb based alloys preferably include from about 5 to about 40 atomic % and more preferably about 5 to about 10 atomic % of Pt or Pd or a combination thereof. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com